Patents

Literature

582 results about "Lean burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lean-burn refers to the burning of fuel with an excess of air in an internal combustion engine. In lean-burn engines the air:fuel ratio may be as lean as 65:1 (by mass). The air / fuel ratio needed to stoichiometrically combust gasoline, by contrast, is 14.64:1. The excess of air in a lean-burn engine emits far less hydrocarbons. High air–fuel ratios can also be used to reduce losses caused by other engine power management systems such as throttling losses.

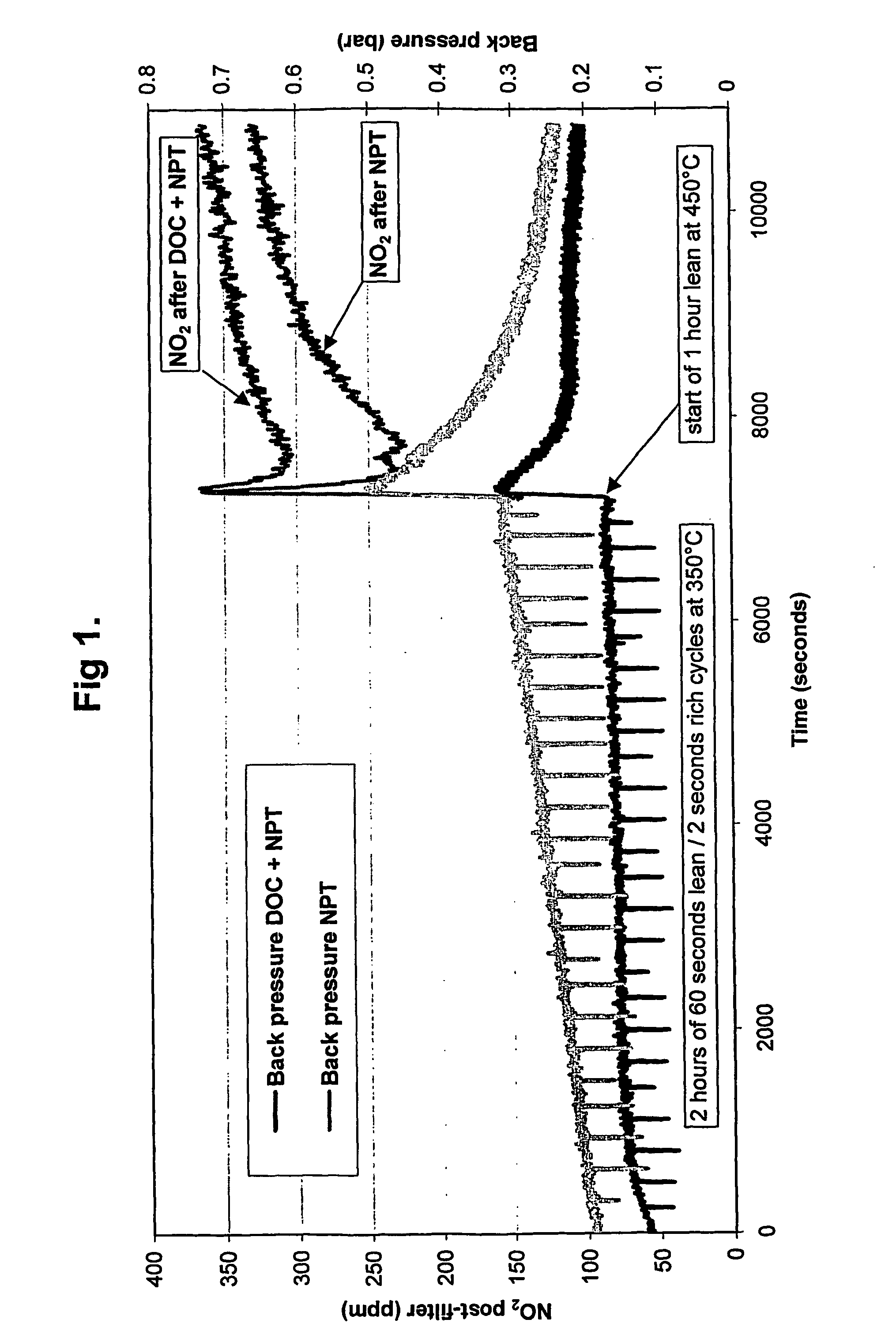

Exhaust gas aftertreatment systems

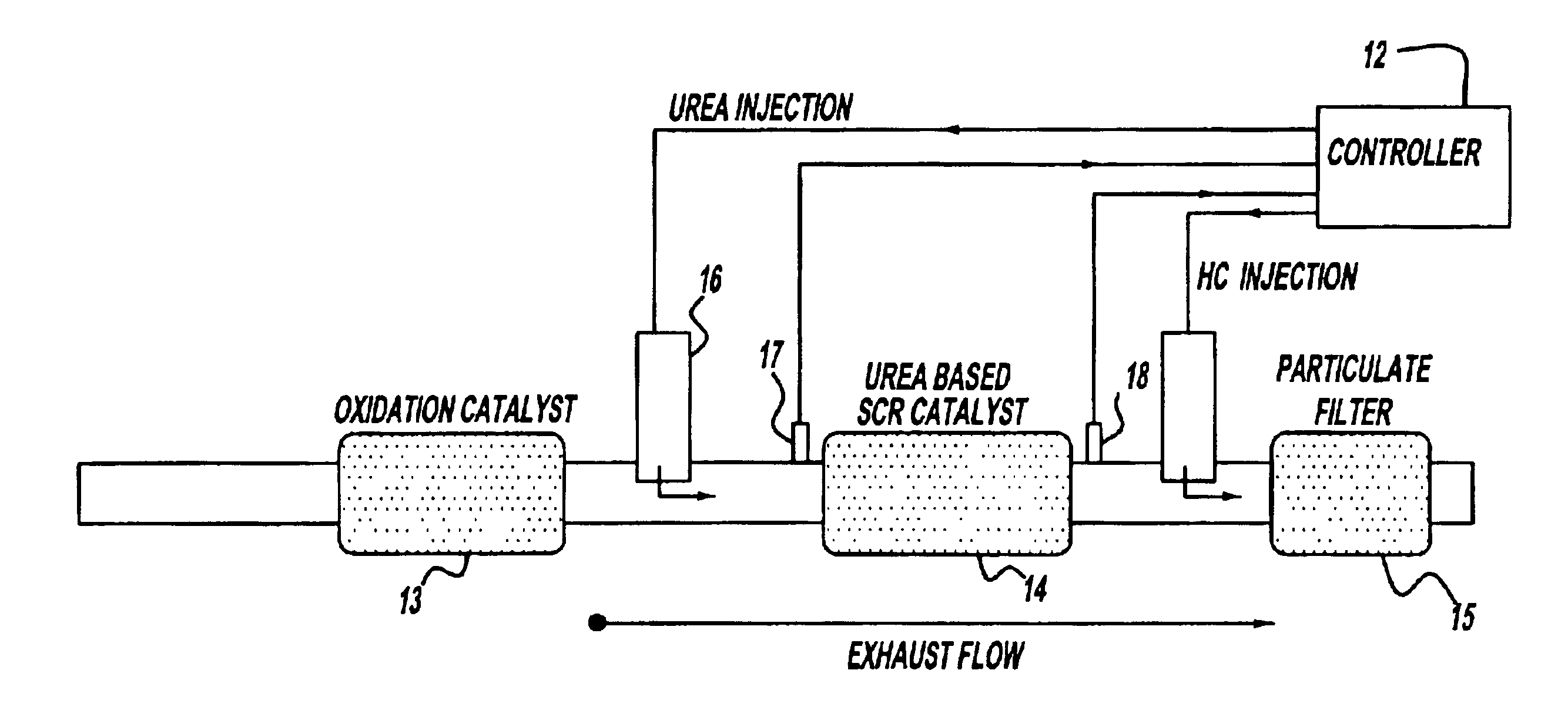

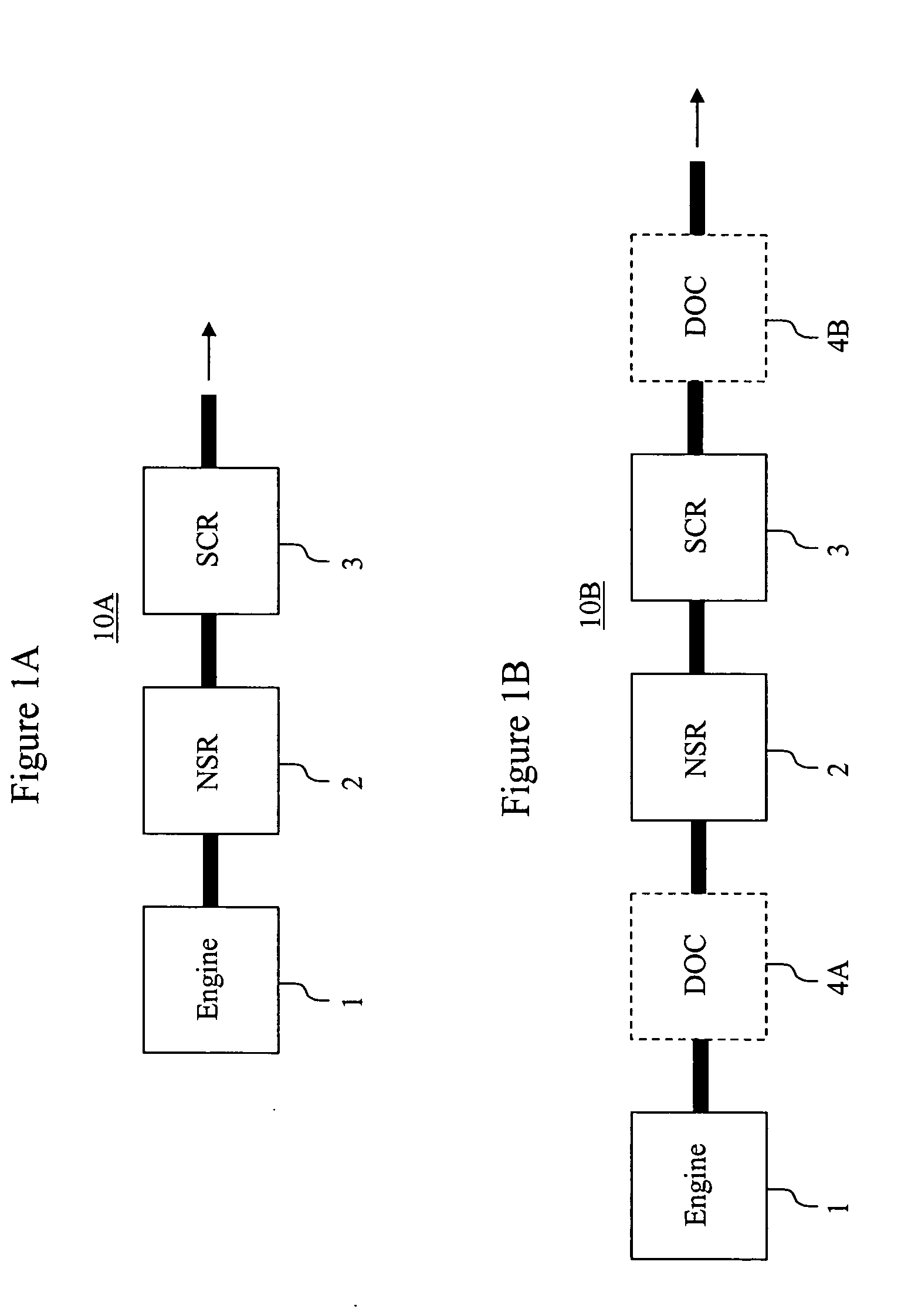

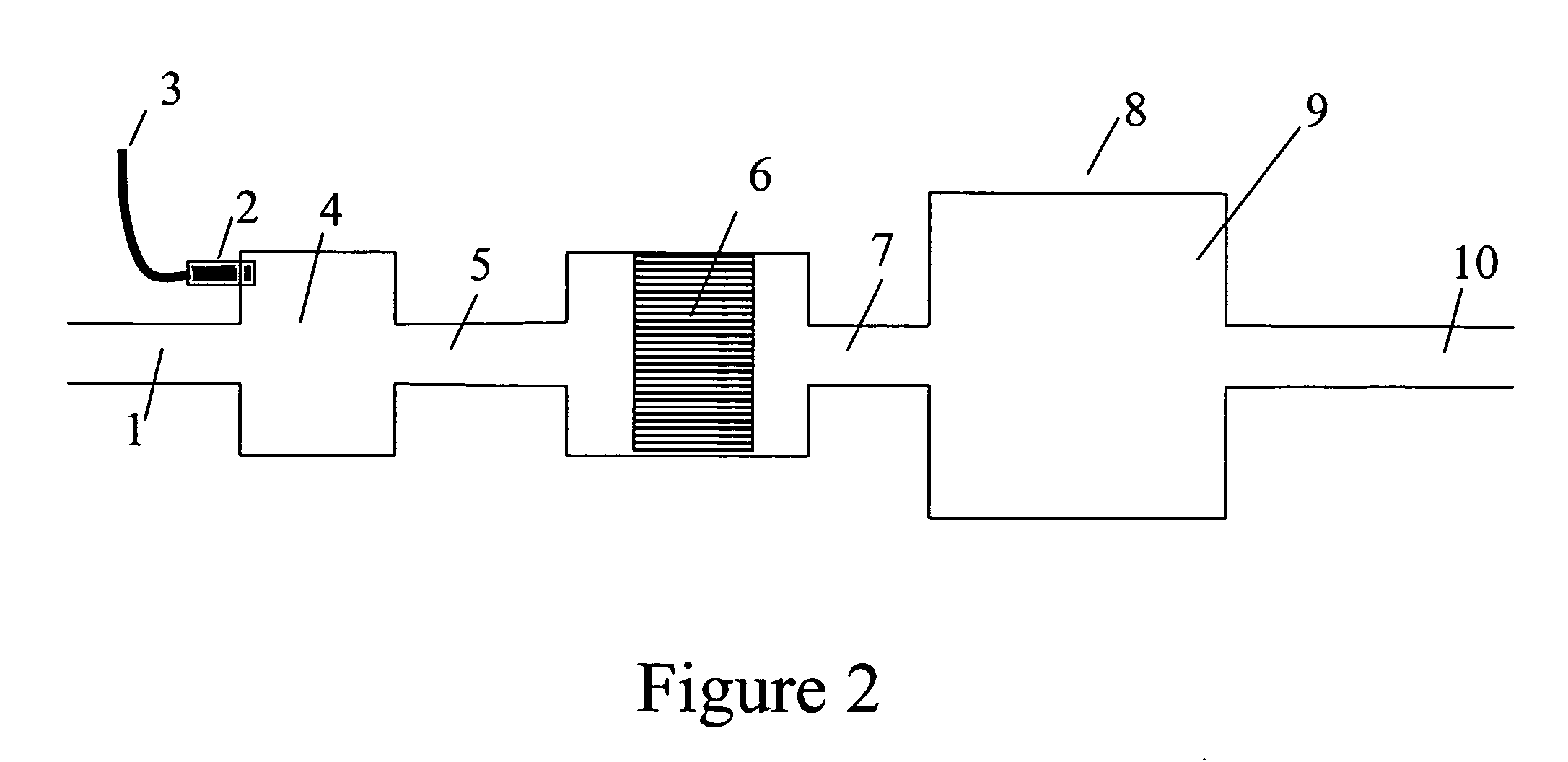

InactiveUS6928806B2Improve NOx conversion efficiencyHigh operating temperatureElectrical controlInternal combustion piston enginesExhaust fumesSystem configuration

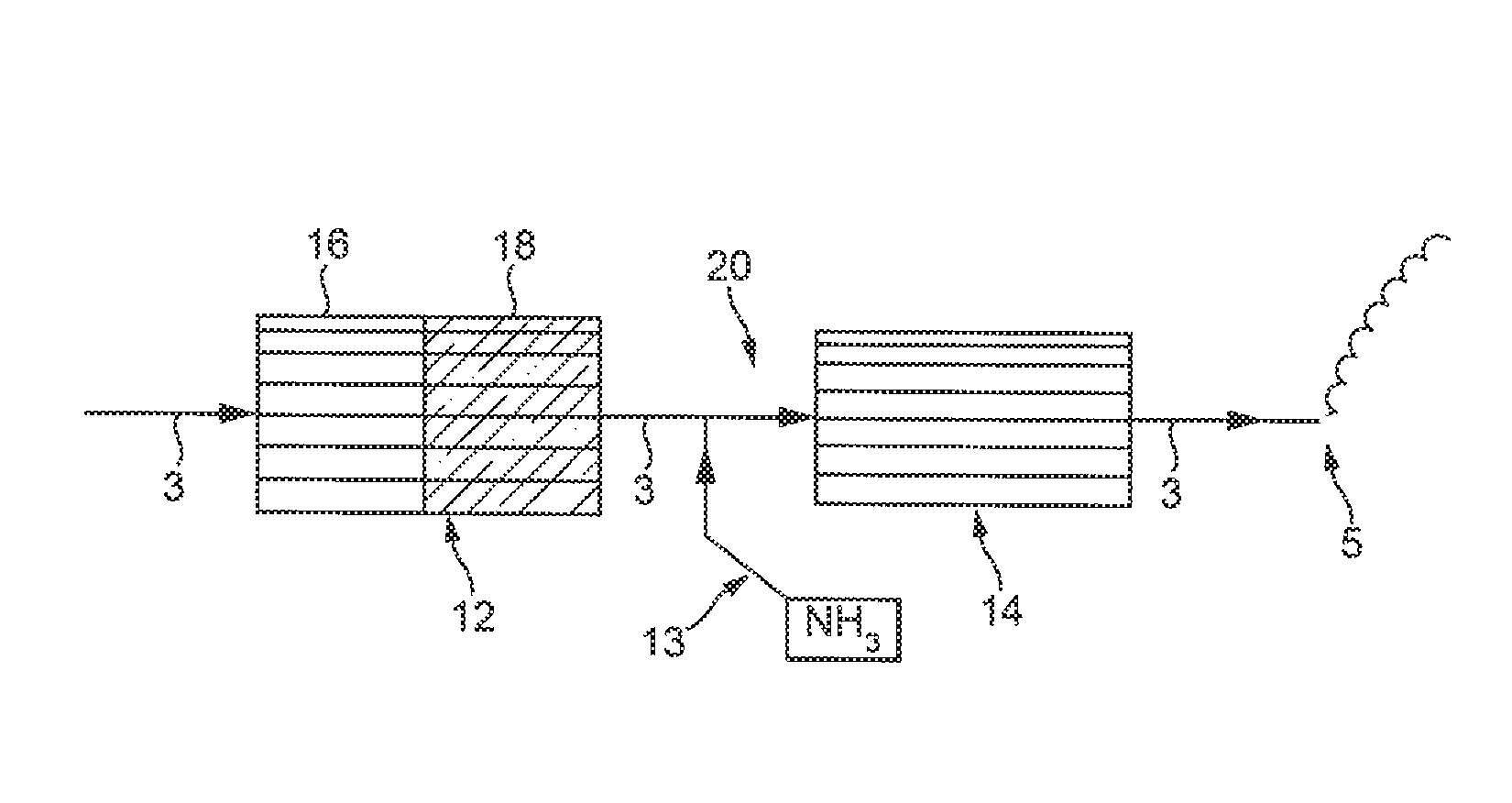

A system for effective NOx and particulate matter control in a diesel or other lean burn internal combustion engine is presented. The system includes a urea-based SCR catalyst having an oxidation catalyst coupled upstream of it and a particulate filter coupled downstream of the SCR catalyst. This system configuration results in improved NOx conversion due to fast SCR catalyst warm-up and higher operating temperatures. Additionally, placing the particulate filter last in this system configuration reduces tailpipe ammonia emissions as well as prevents any thermal damage to the SCR catalyst due to the particulate filter regeneration.

Owner:FORD GLOBAL TECH LLC

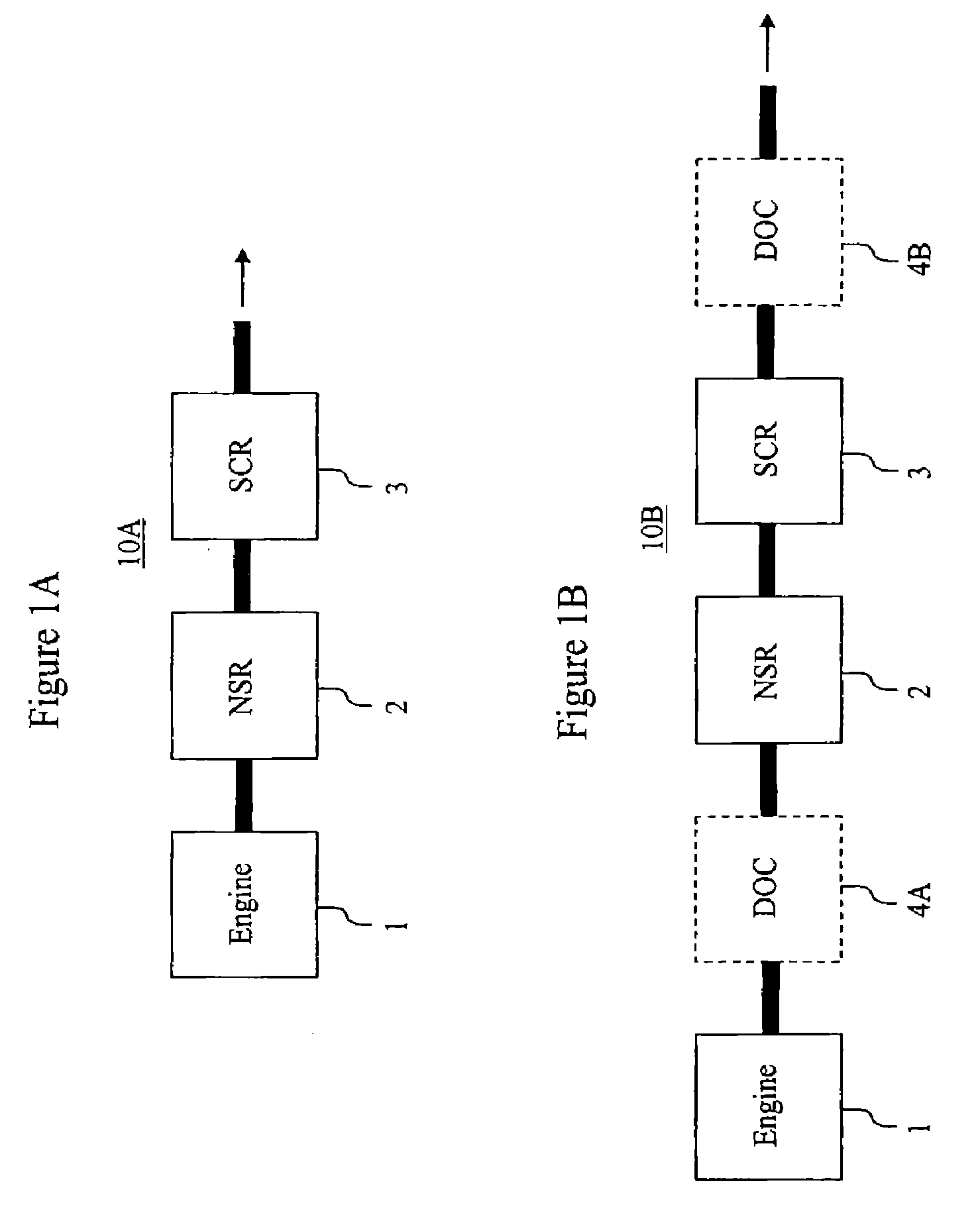

Emissions treatment system with NSR and SCR catalysts

ActiveUS20050129601A1Small sizeReduce amount particulate matterGas treatmentNitrogen compoundsSorbentGasoline

Provided is an emissions treatment system for an exhaust stream, having a NOx storage reduction (NSR) catalyst with a NOx sorbent at a concentration of at least 0.1 g / in3 and a platinum group metal component dispersed on a refractory metal oxide support; and, an SCR catalyst disposed downstream of the NSR catalyst. The emissions treatment system is advantageously used for the treatment of exhaust streams from diesel engines and lean burn gasoline engines.

Owner:BASF CATALYSTS LLC

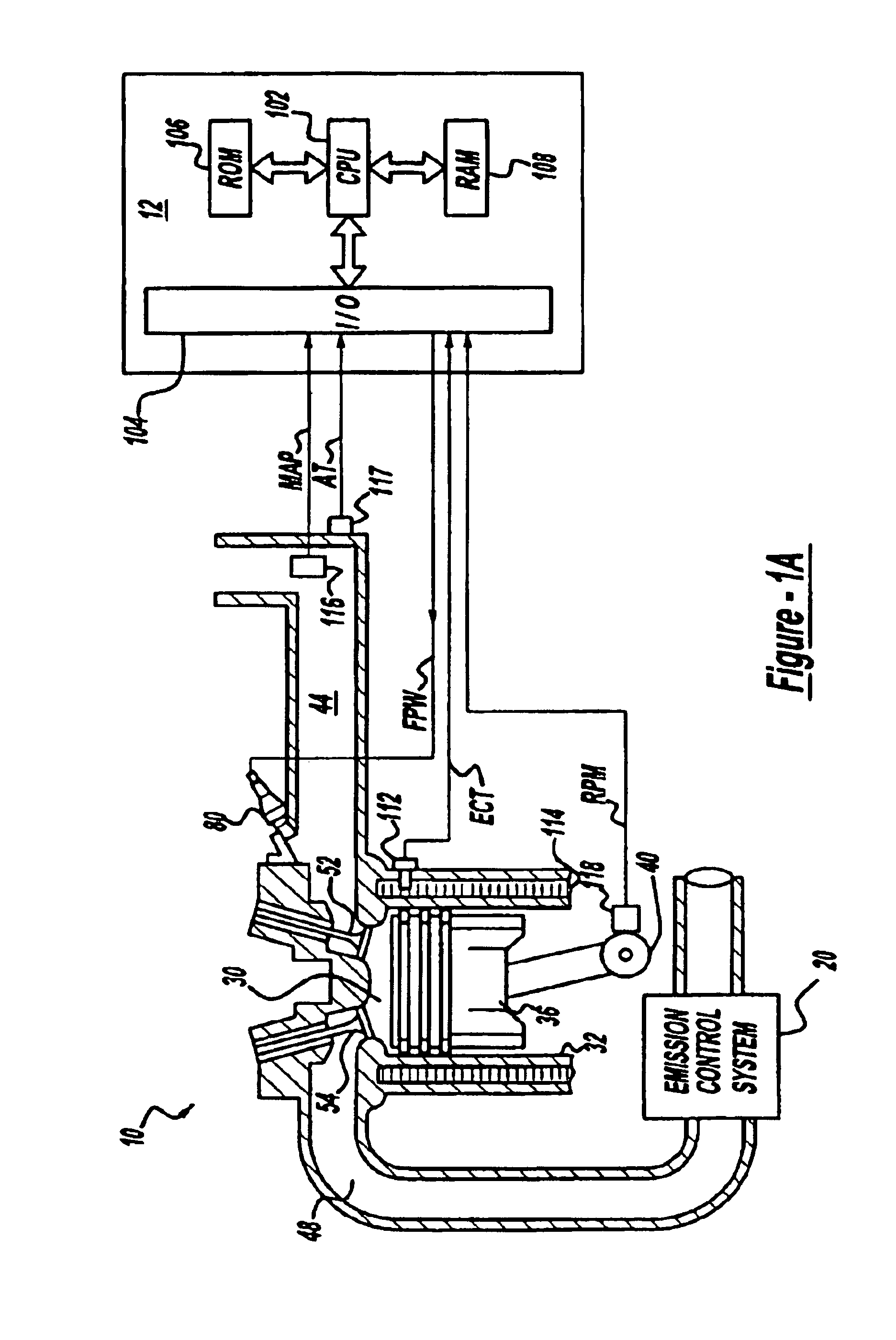

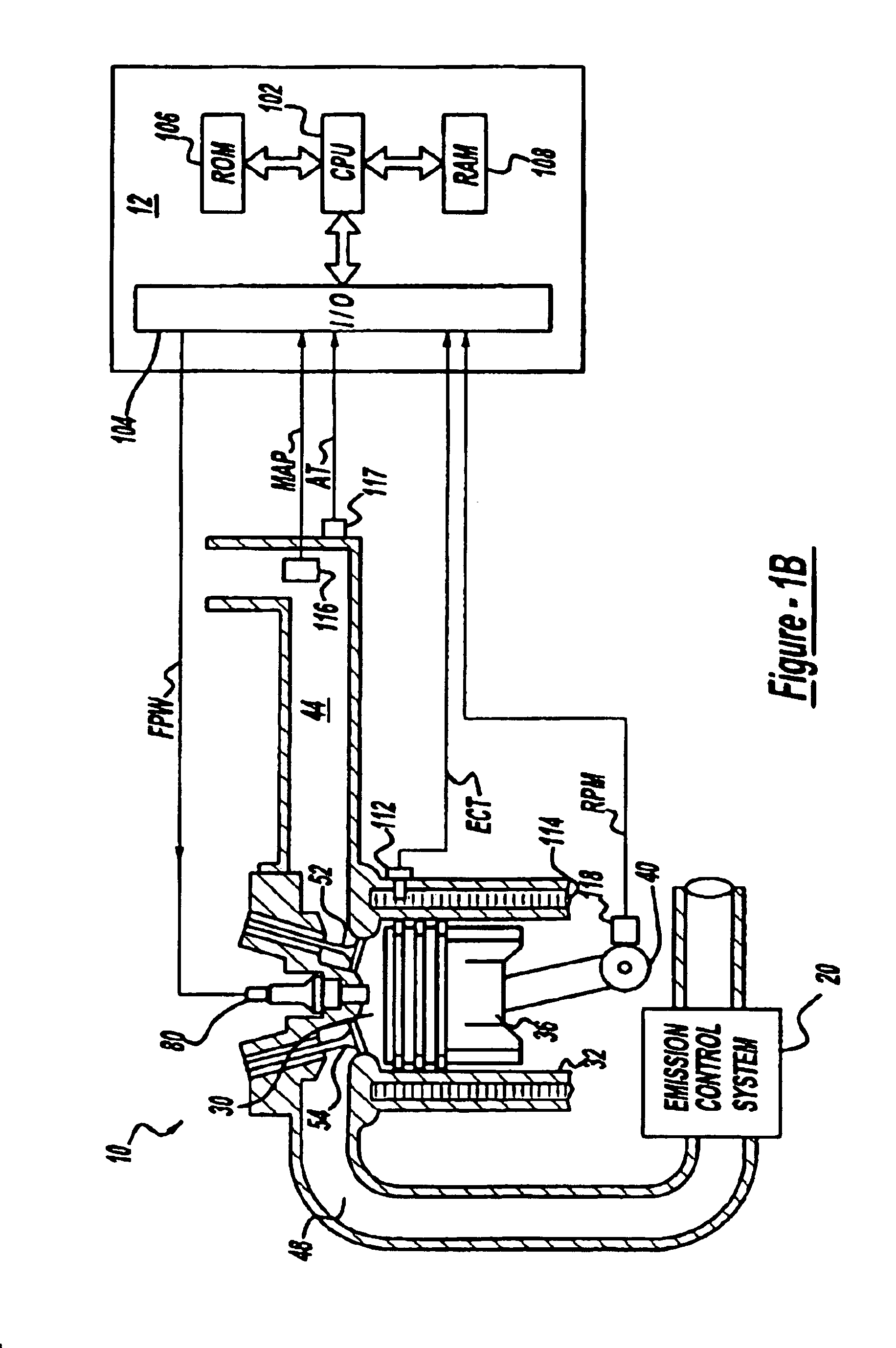

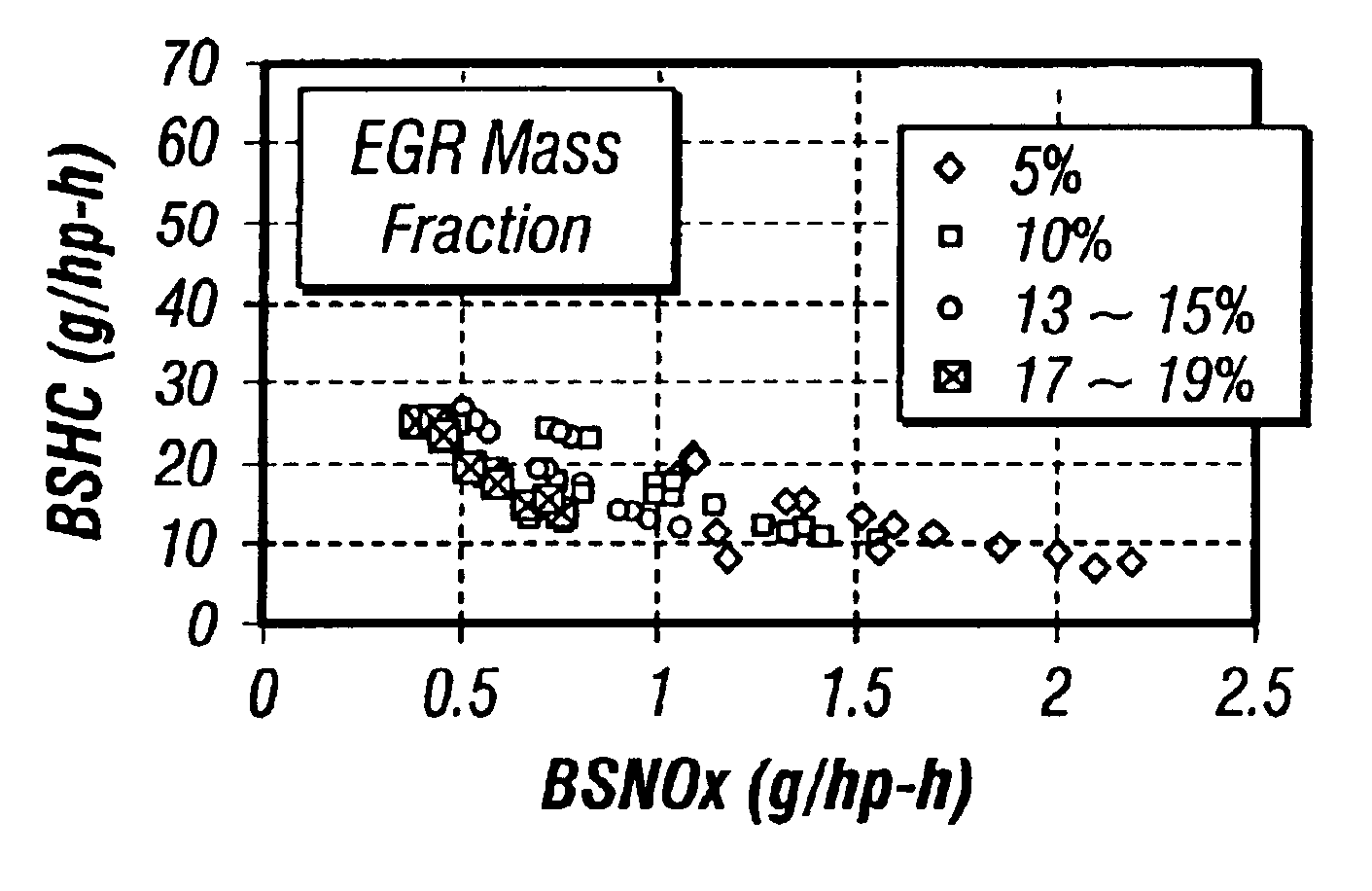

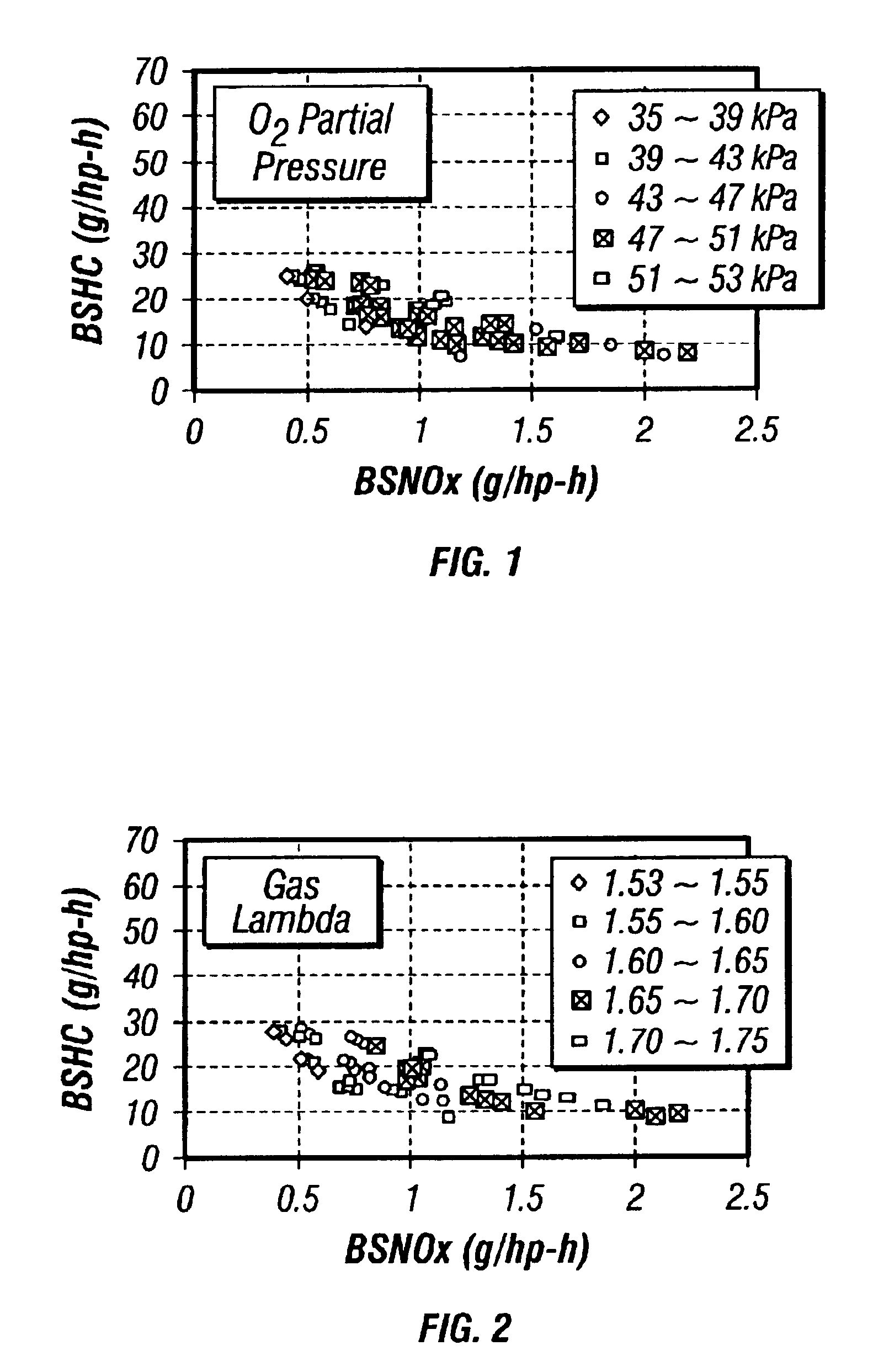

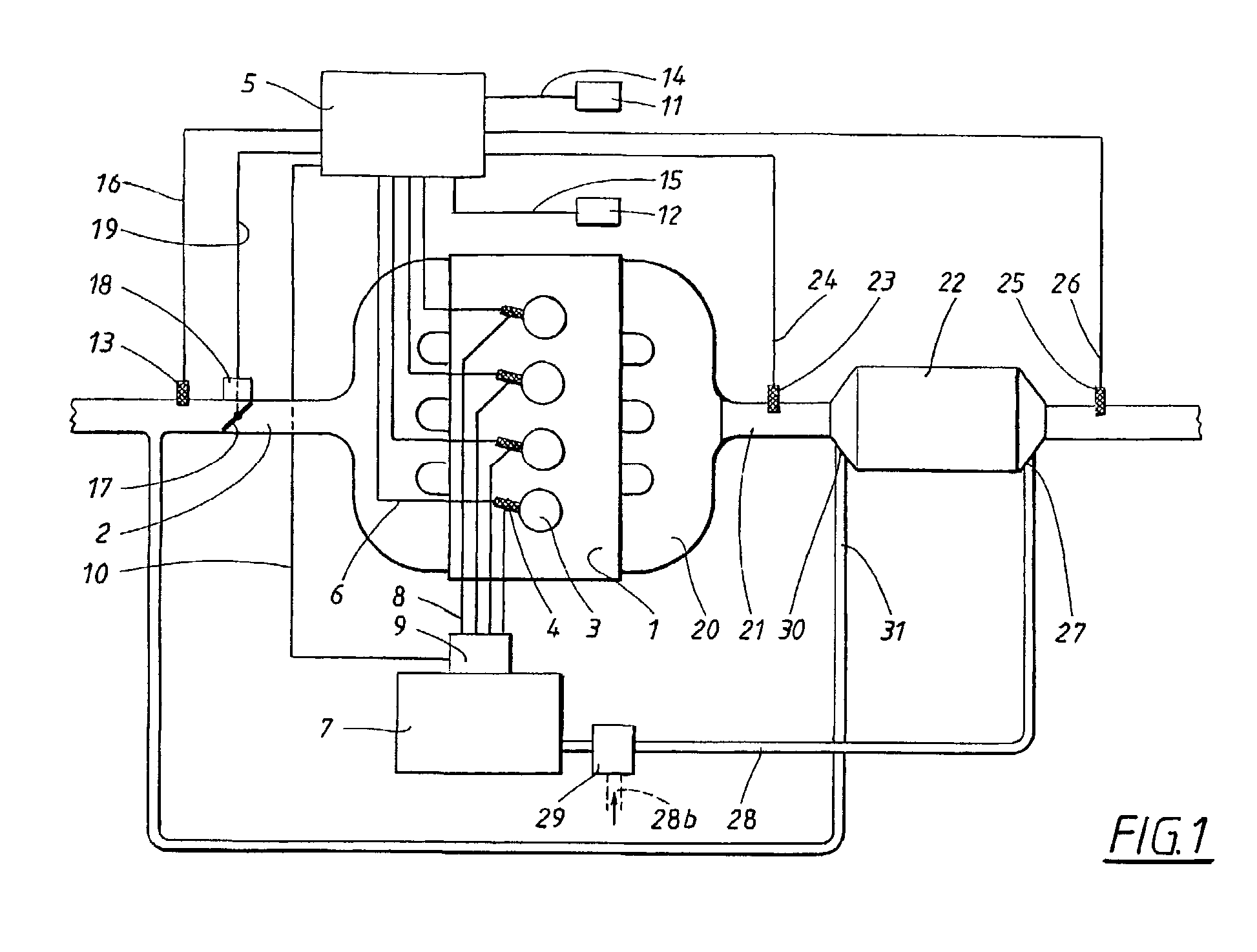

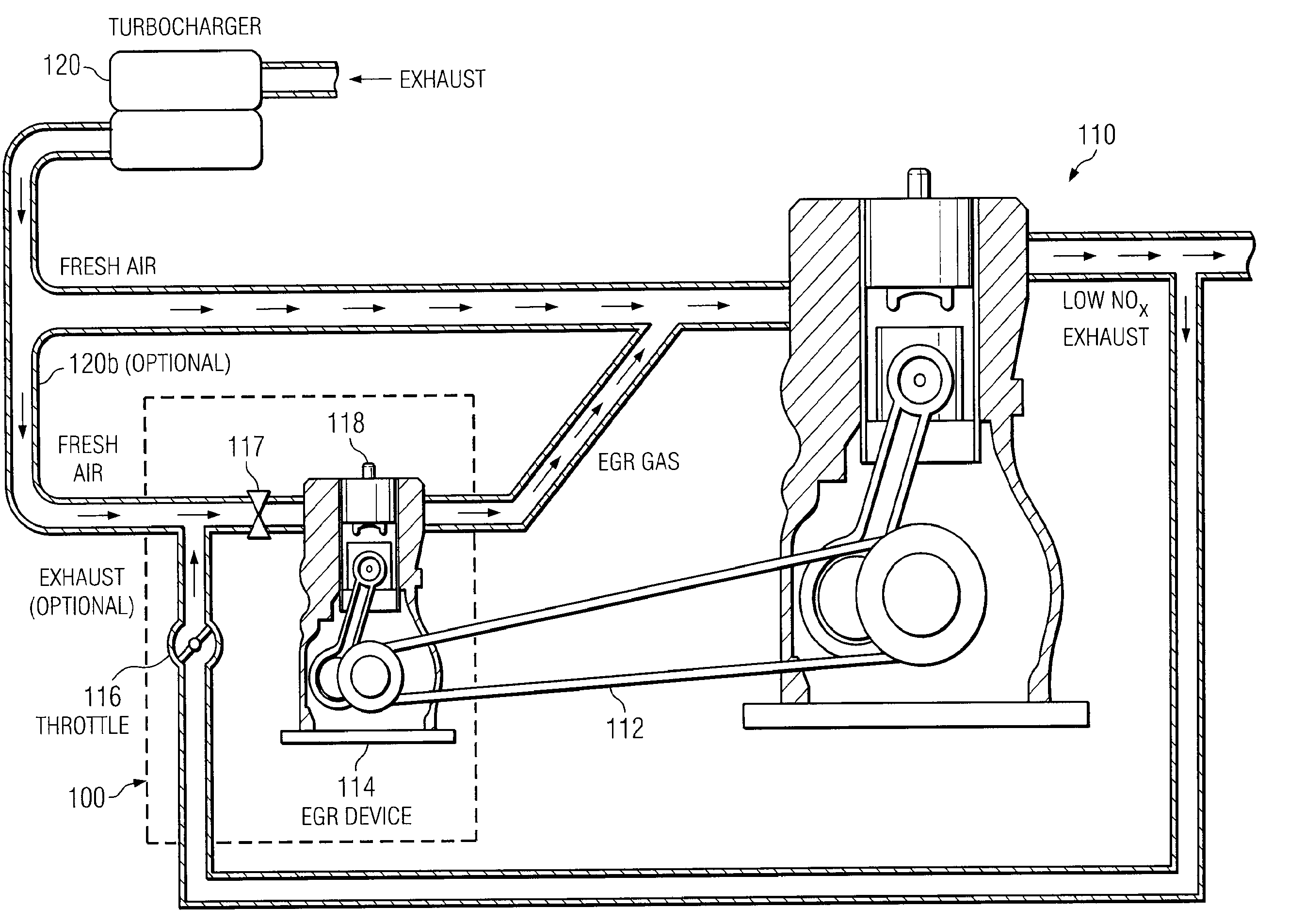

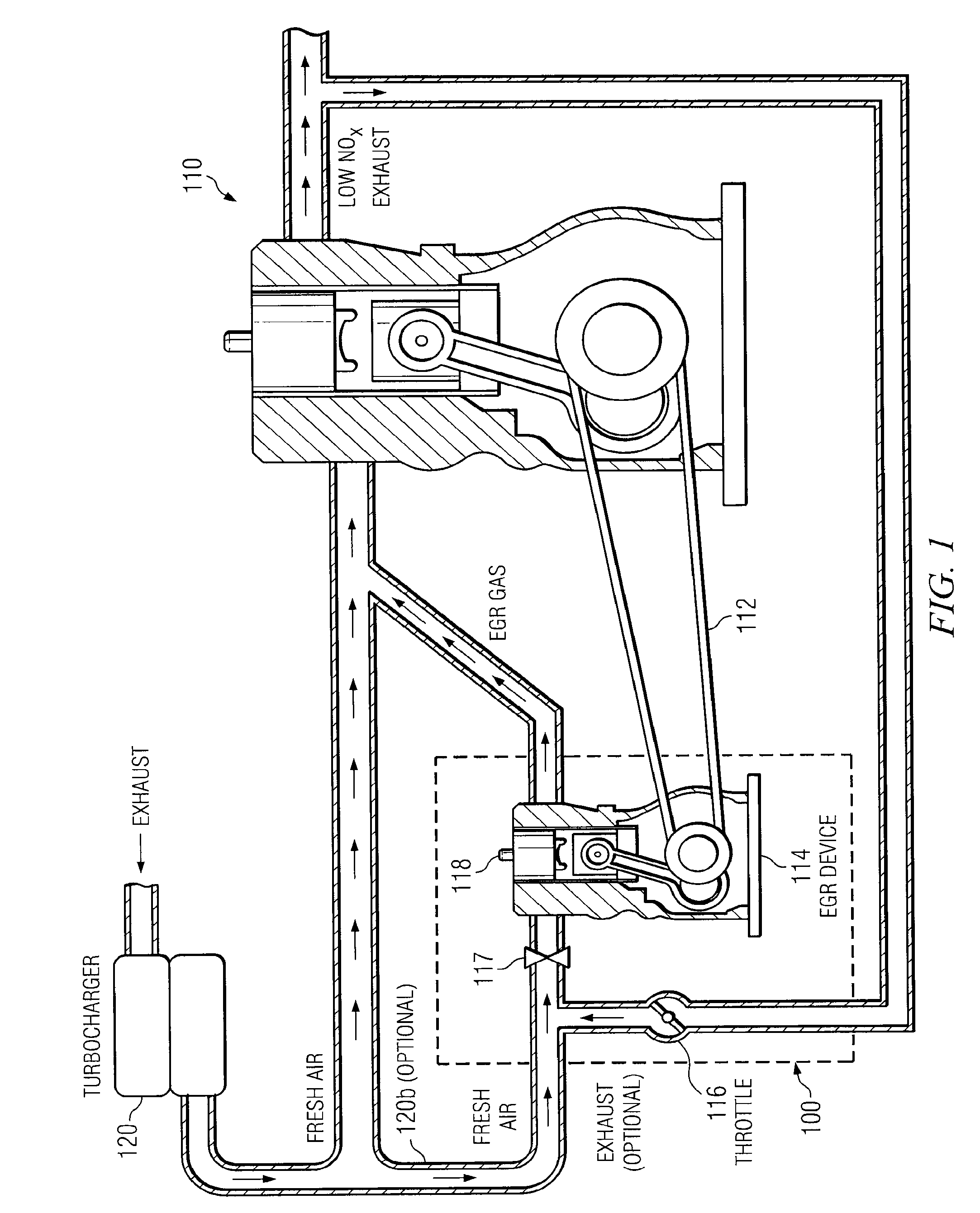

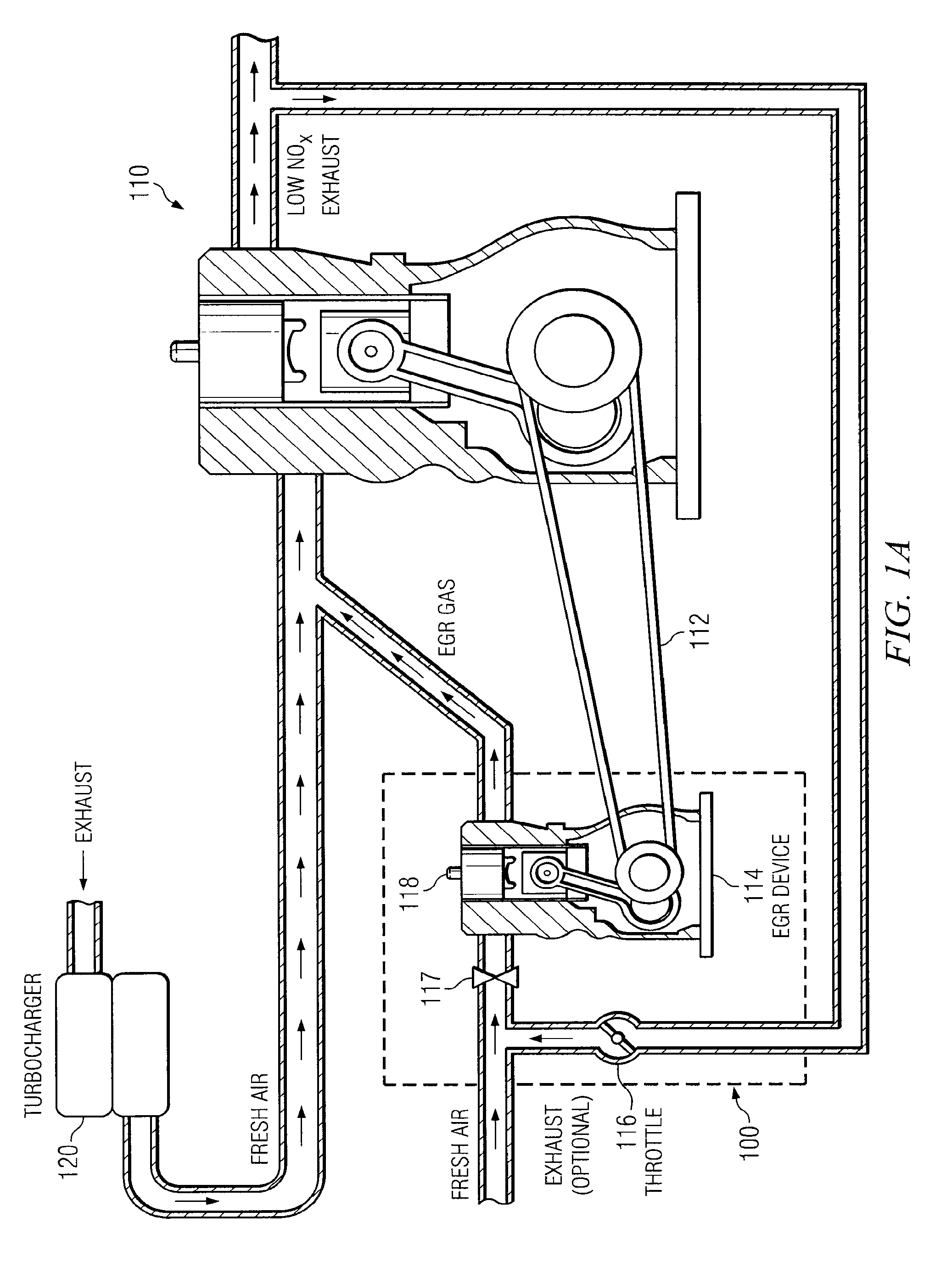

Optimized combustion control of an internal combustion engine equipped with exhaust gas recirculation

InactiveUS6948475B1Avoid condensationImprove concentrationElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

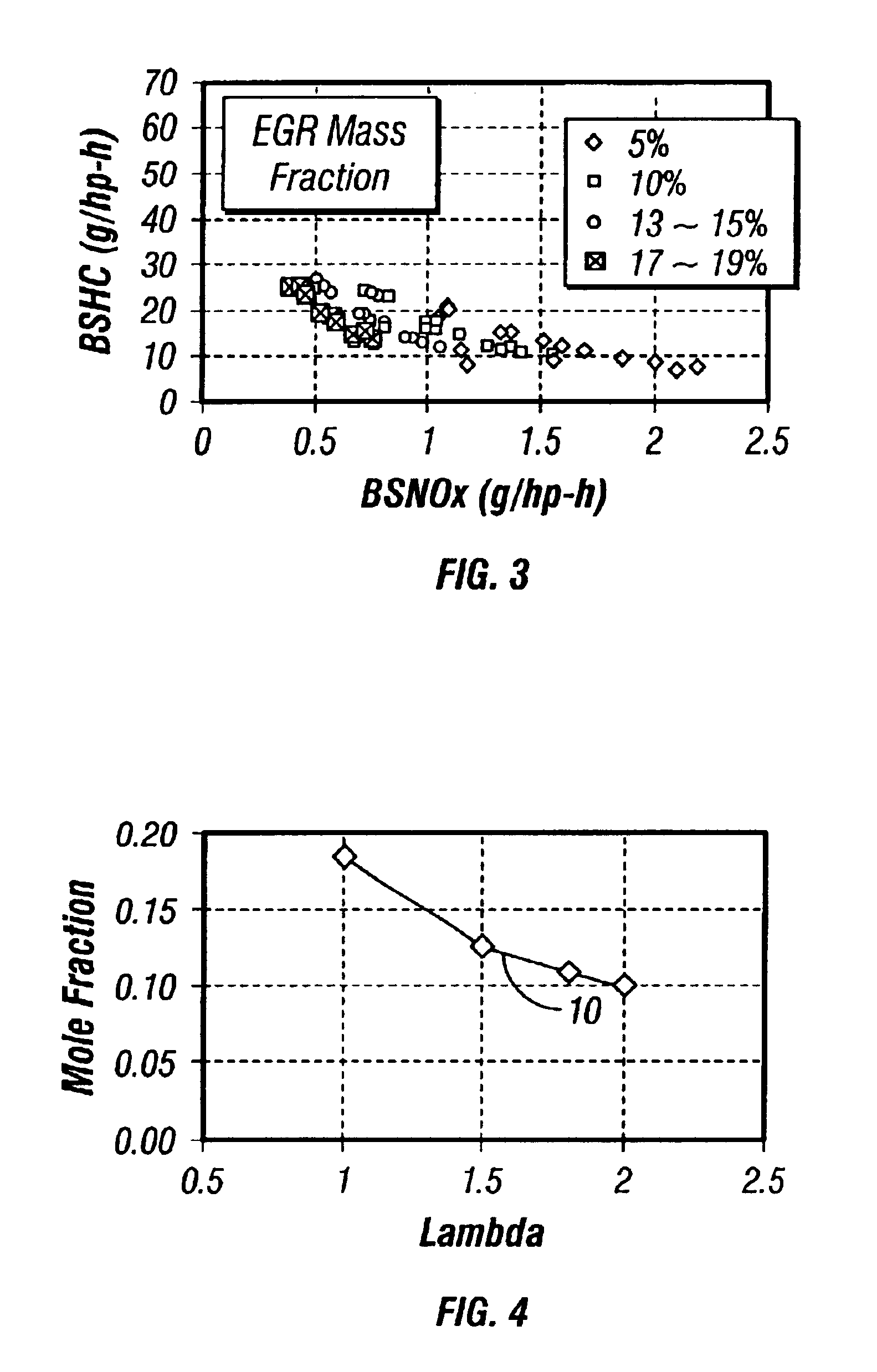

An EGR equipped internal combustion engine is controlled to maximize the beneficial effects and minimize the detrimental effects of EGR on engine operation. Specifically, at least one parameter indicative of the O2 concentration in the intake mixture and / or at least one parameter indicative of the H2O concentration in the intake mixture is monitored, and the monitored parameter is relied on to control one or more aspects of engine operation by open loop adjustment of other control strategies and / or by a separate closed loop control strategy. These controls are applicable to virtually any engine, and are particularly beneficial to lean burn engines such as diesel (compression ignition) engines, spark ignited natural gas engines, and dual fuel or other compression ignited natural gas engines. The engine may be equipped with either actively controllable EGR or passive and uncontrolled EGR.

Owner:CLEAN AIR POWER

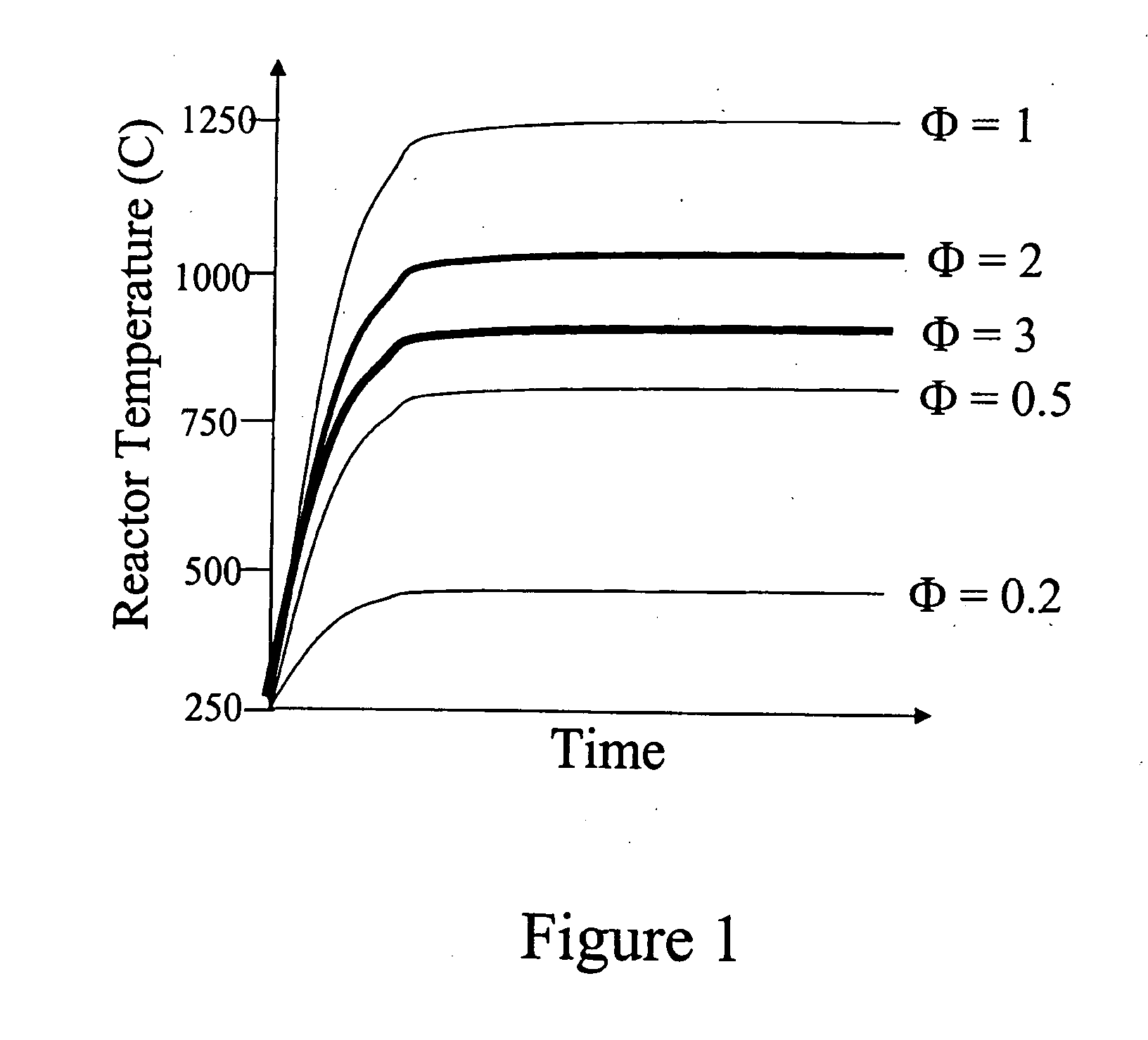

Excess air factor control of diesel engine

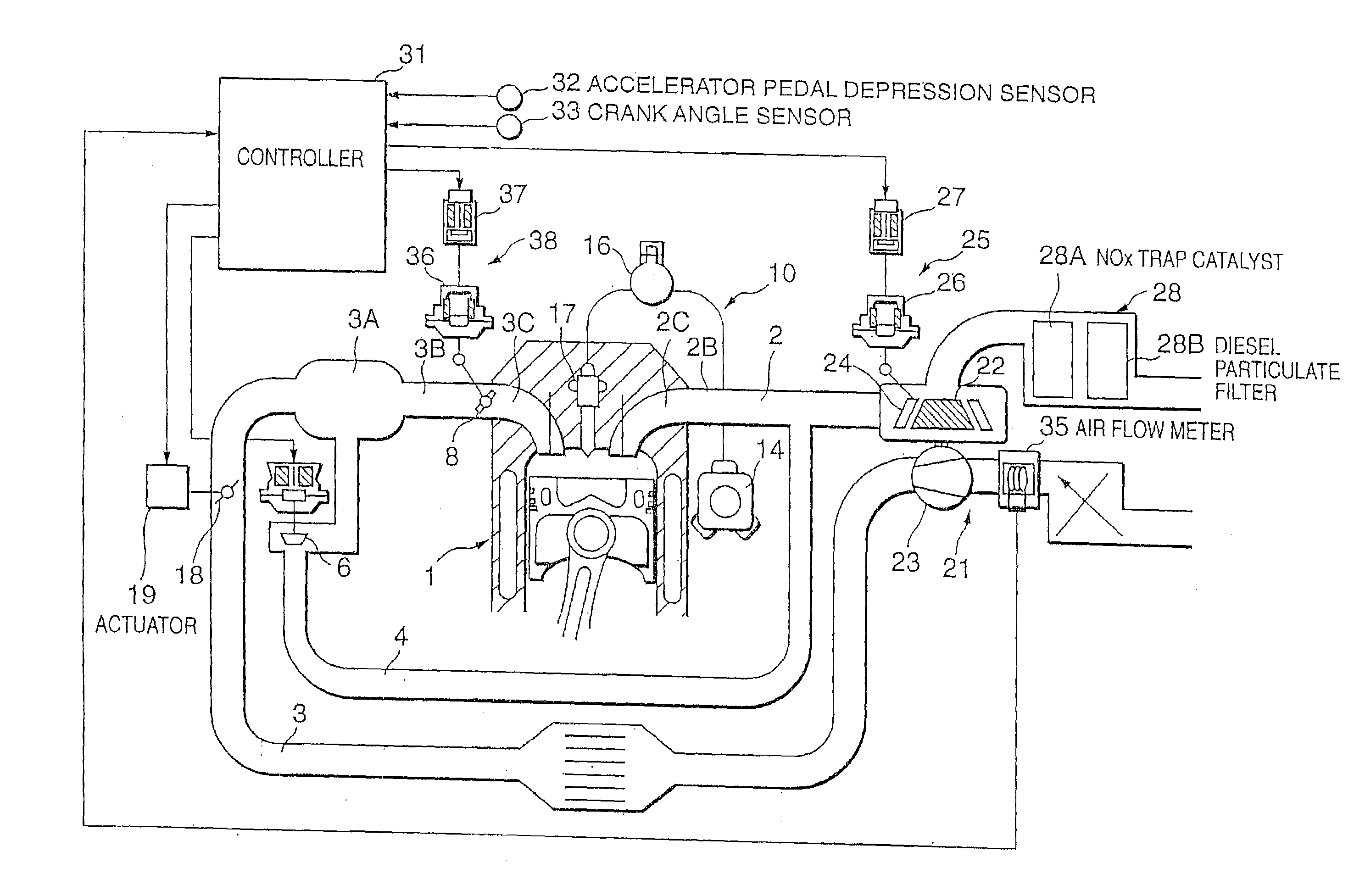

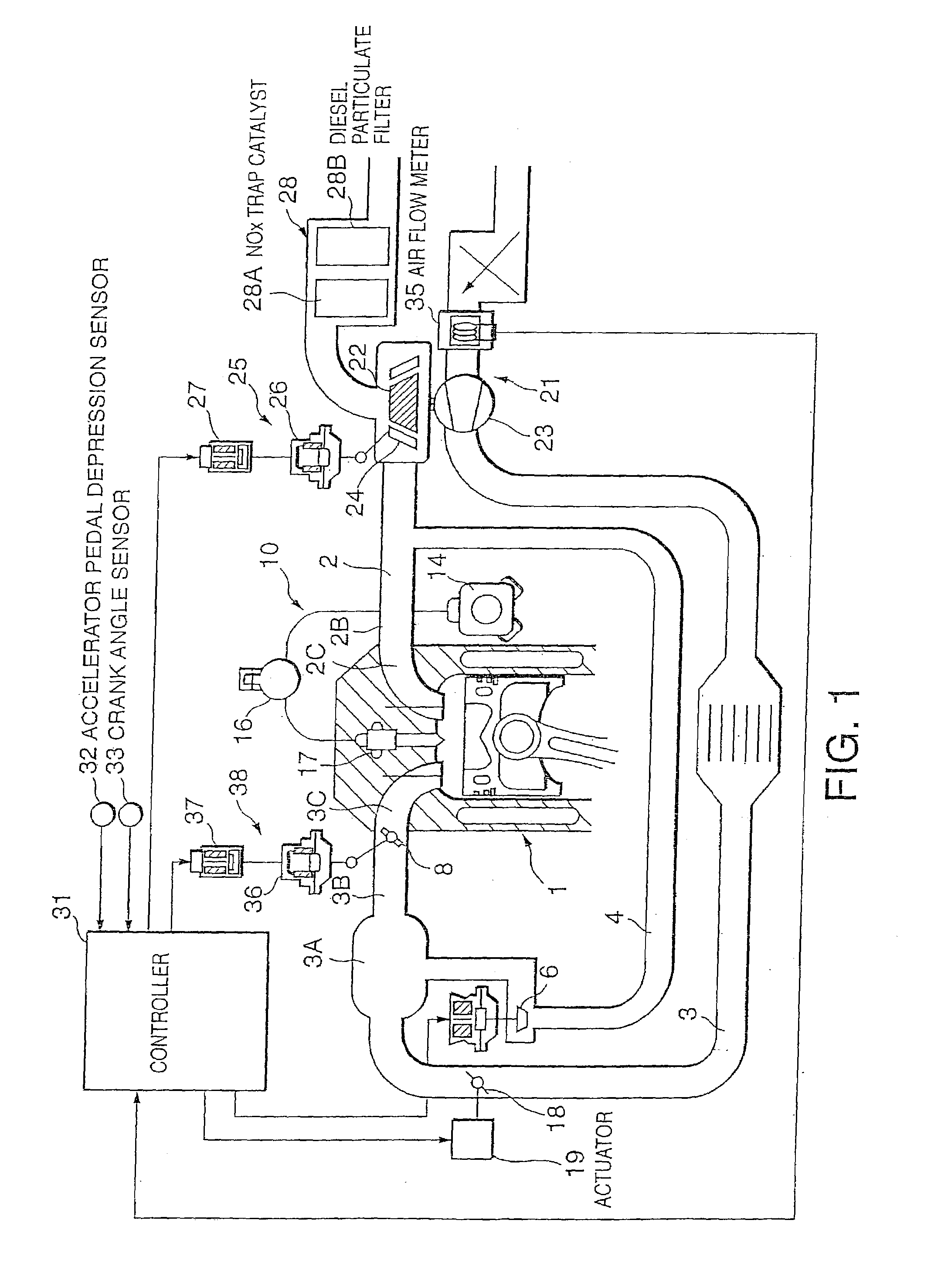

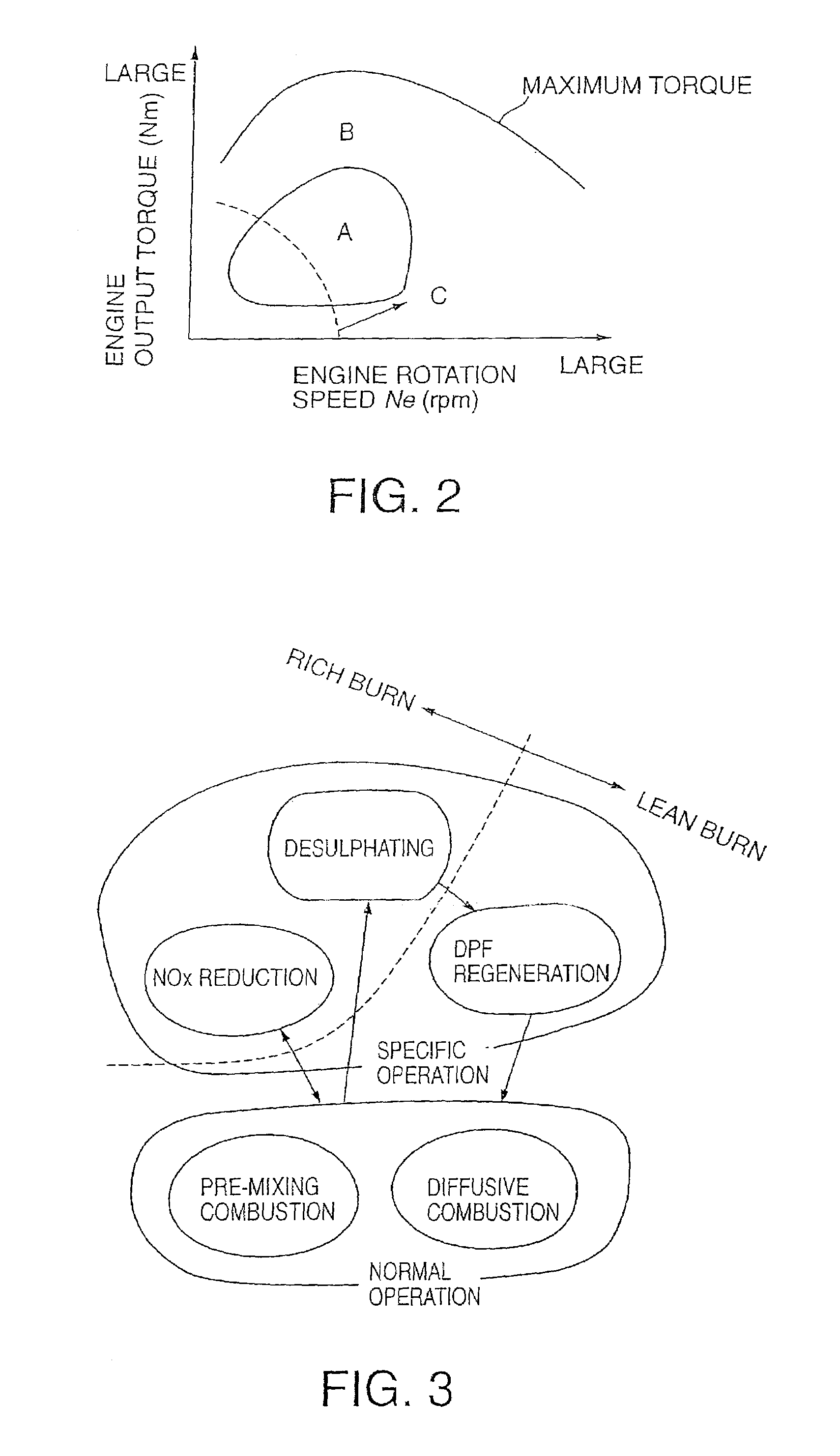

InactiveUS6993901B2Improve accuracyImprove responseElectrical controlNon-fuel substance addition to fuelEngineeringDiesel particulate filter

A diesel engine (1) provided with a NOx catalyst (28A) and a diesel particulate filter (28B) performs lean burn operation during normal running, rich burn operation during regeneration of the NOx catalyst (28A), operation under the stoichiometric air-fuel ratio during desulphating of the NOx catalyst (28A), and operation under a slightly lean air-fuel ratio to regenerate the filter after desulphating of the NOx catalyst (28A). When the lean burn operation is applied, a controller (31) first controls the fuel injection amount, and controls an air supply amount based on the fuel injection amount. When rich burn operation is applied, the controller (31) first controls the air supply amount and controls the fuel injection amount based on the air supply amount. Due to this control, the response of the excess air factor control is enhanced while preventing torque fluctuation accompanying the variation of the target excess air factor.

Owner:NISSAN MOTOR CO LTD

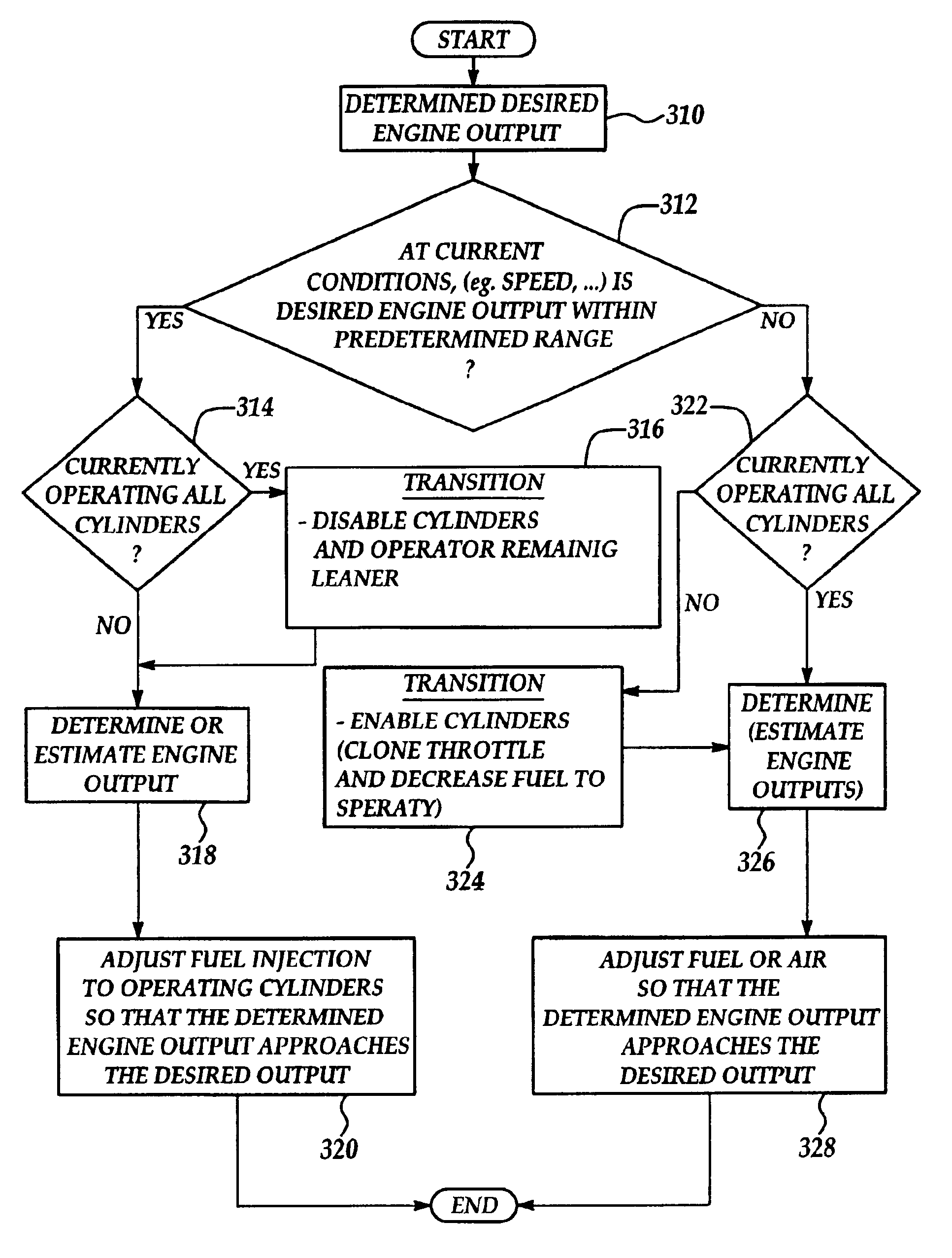

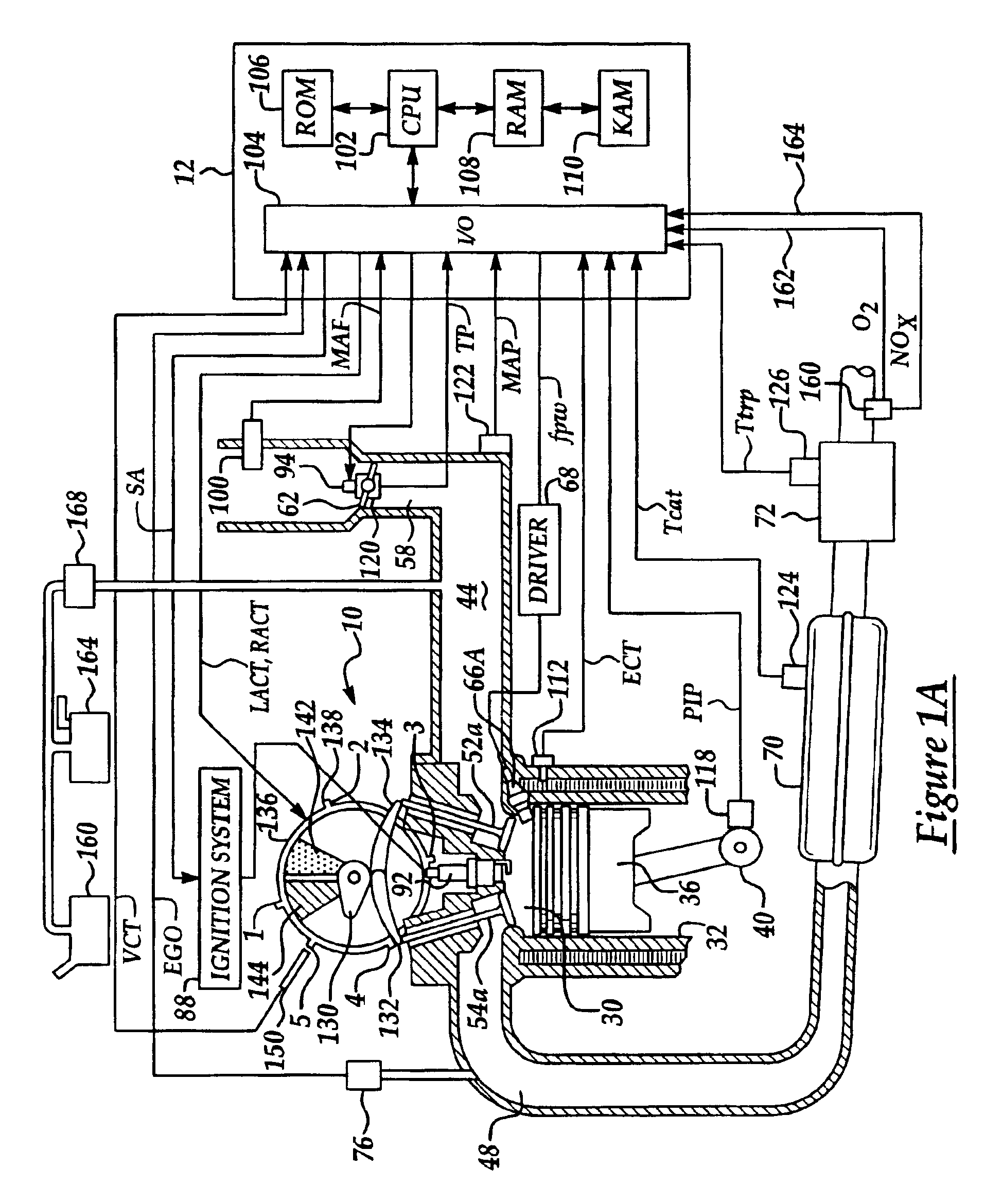

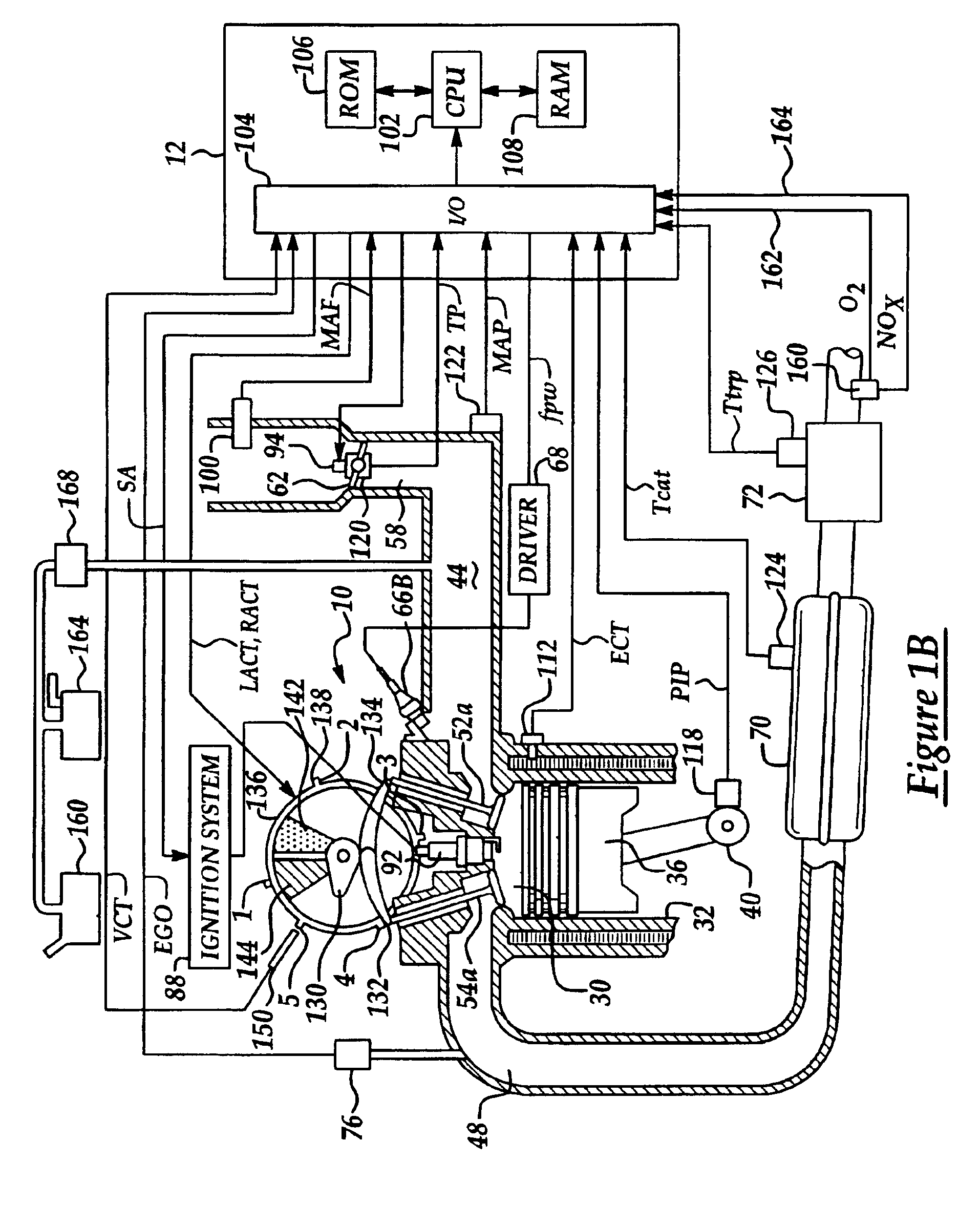

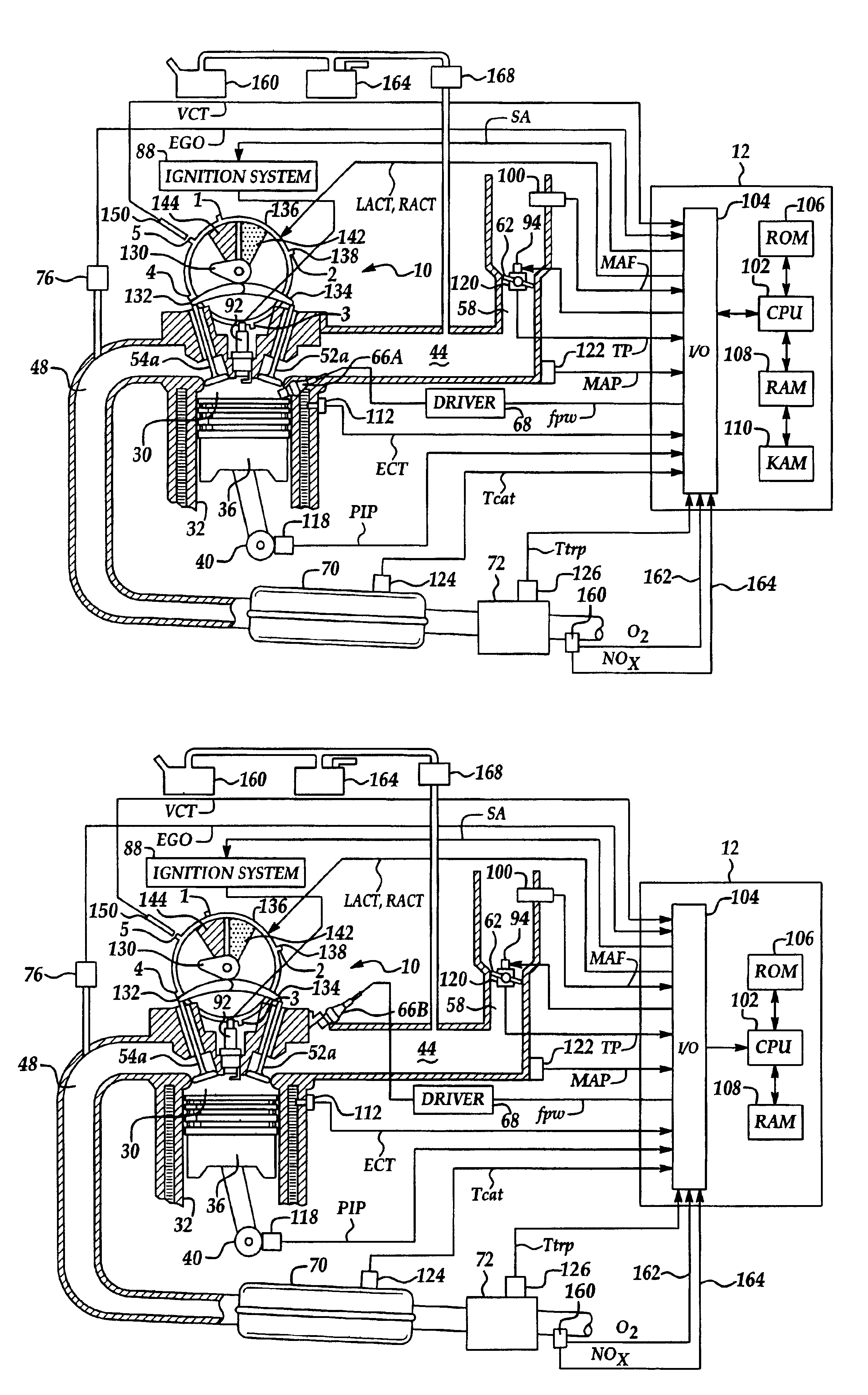

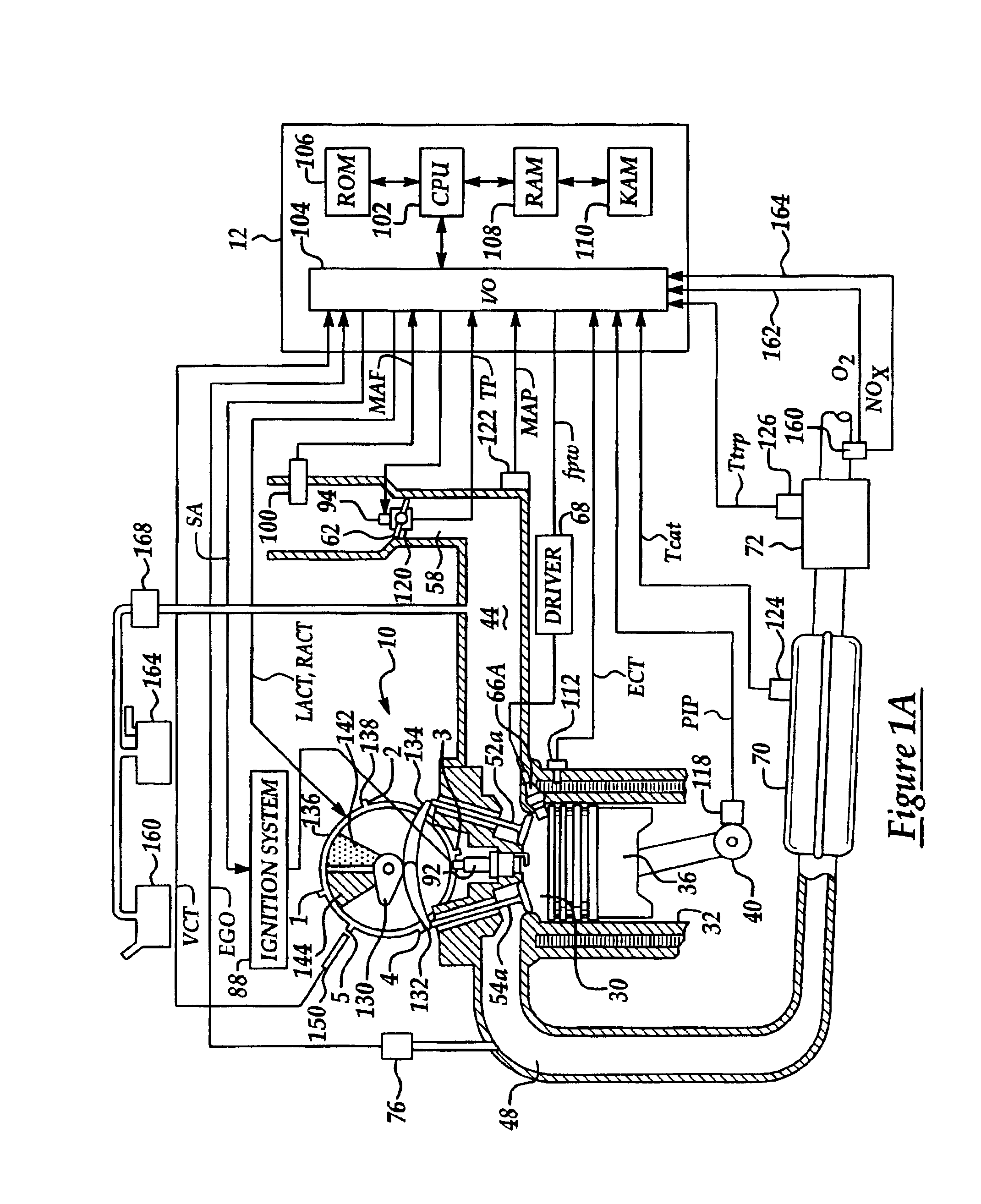

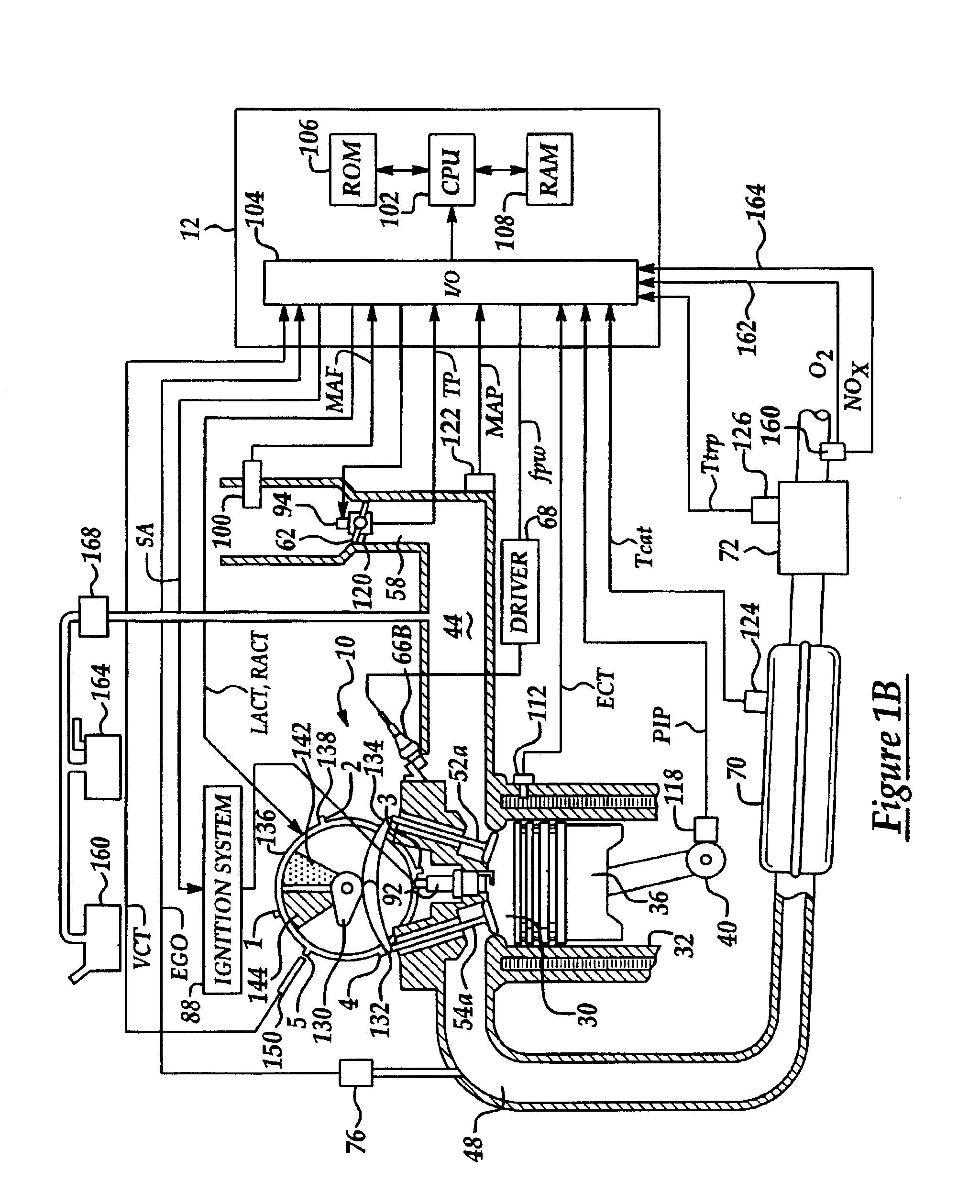

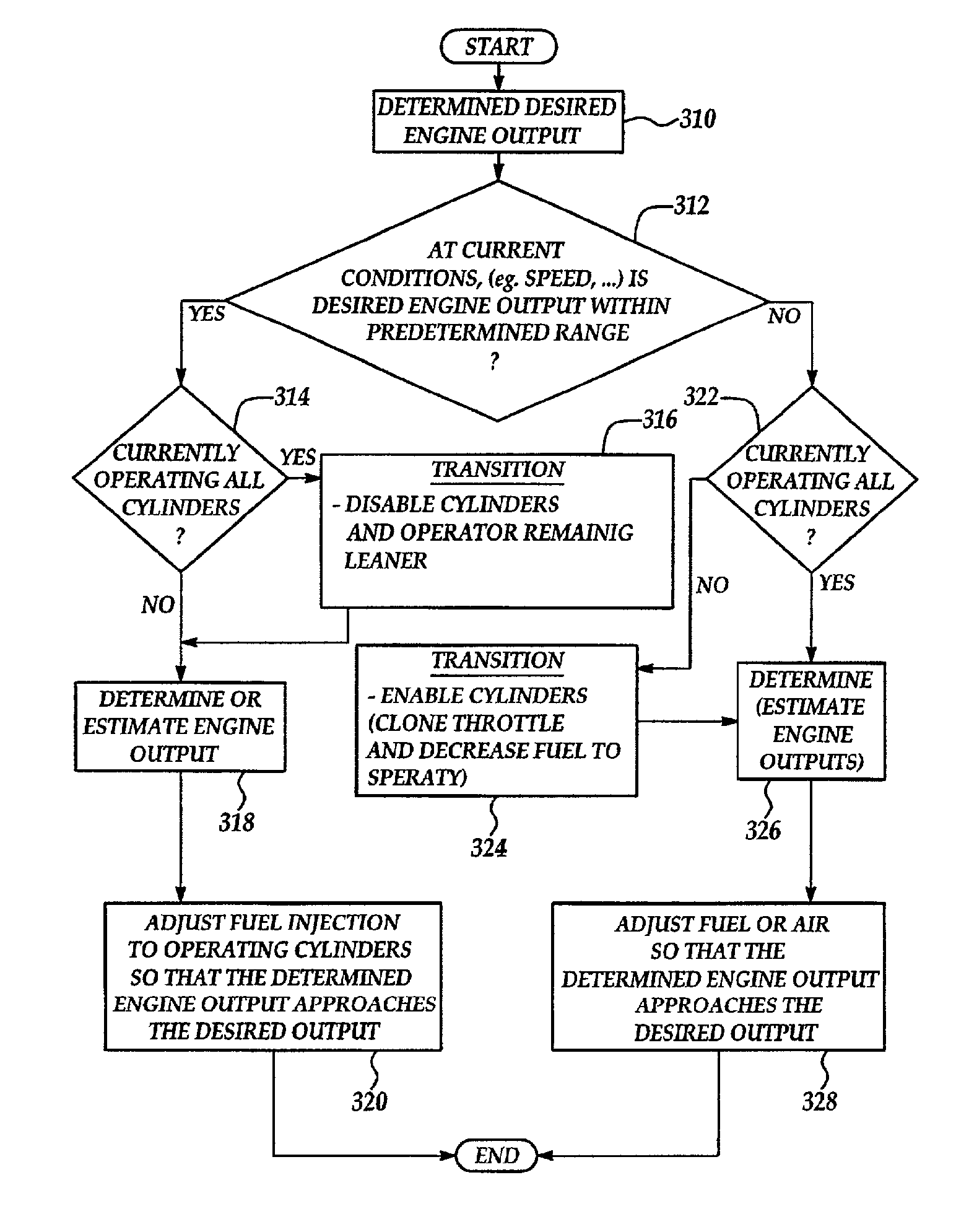

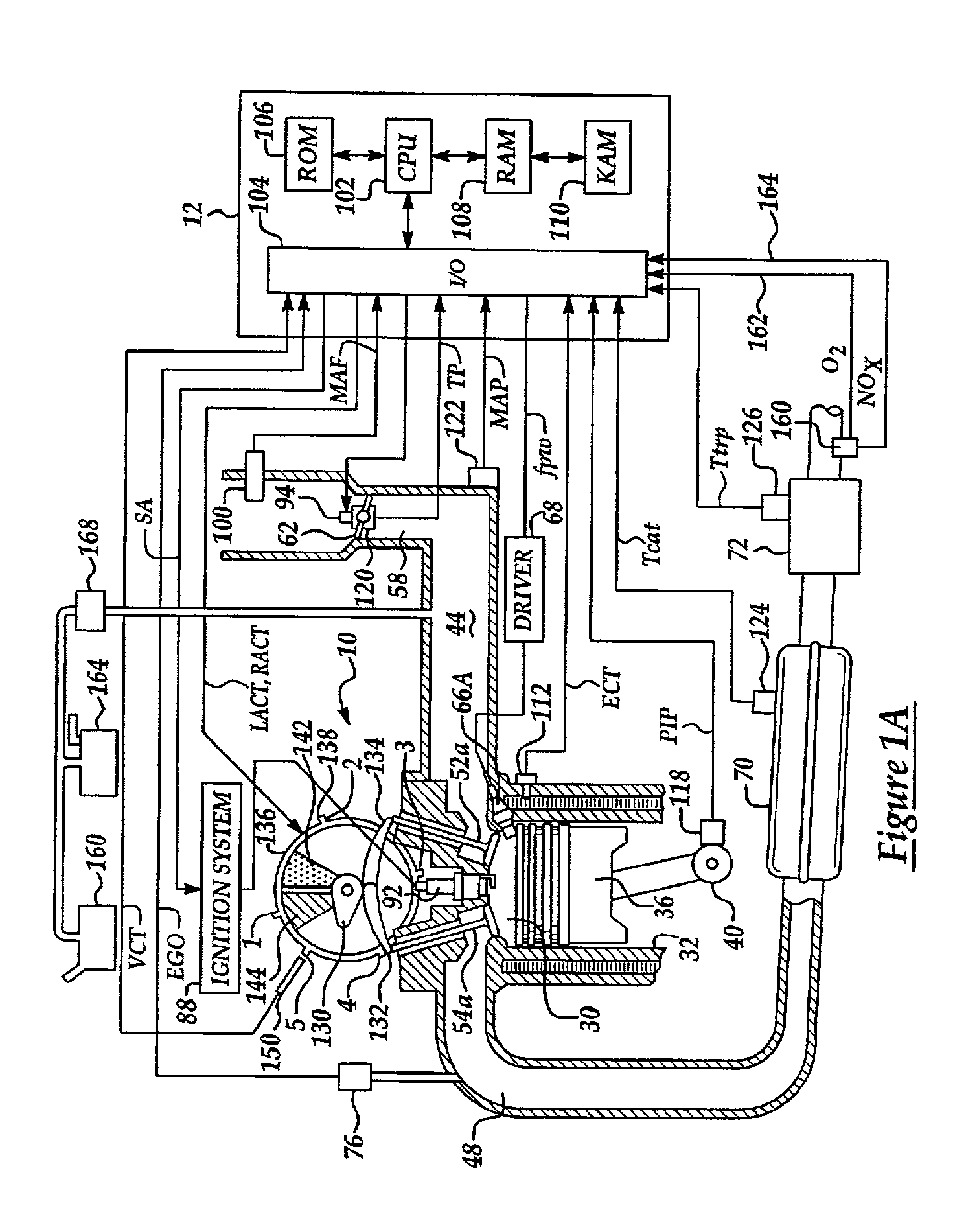

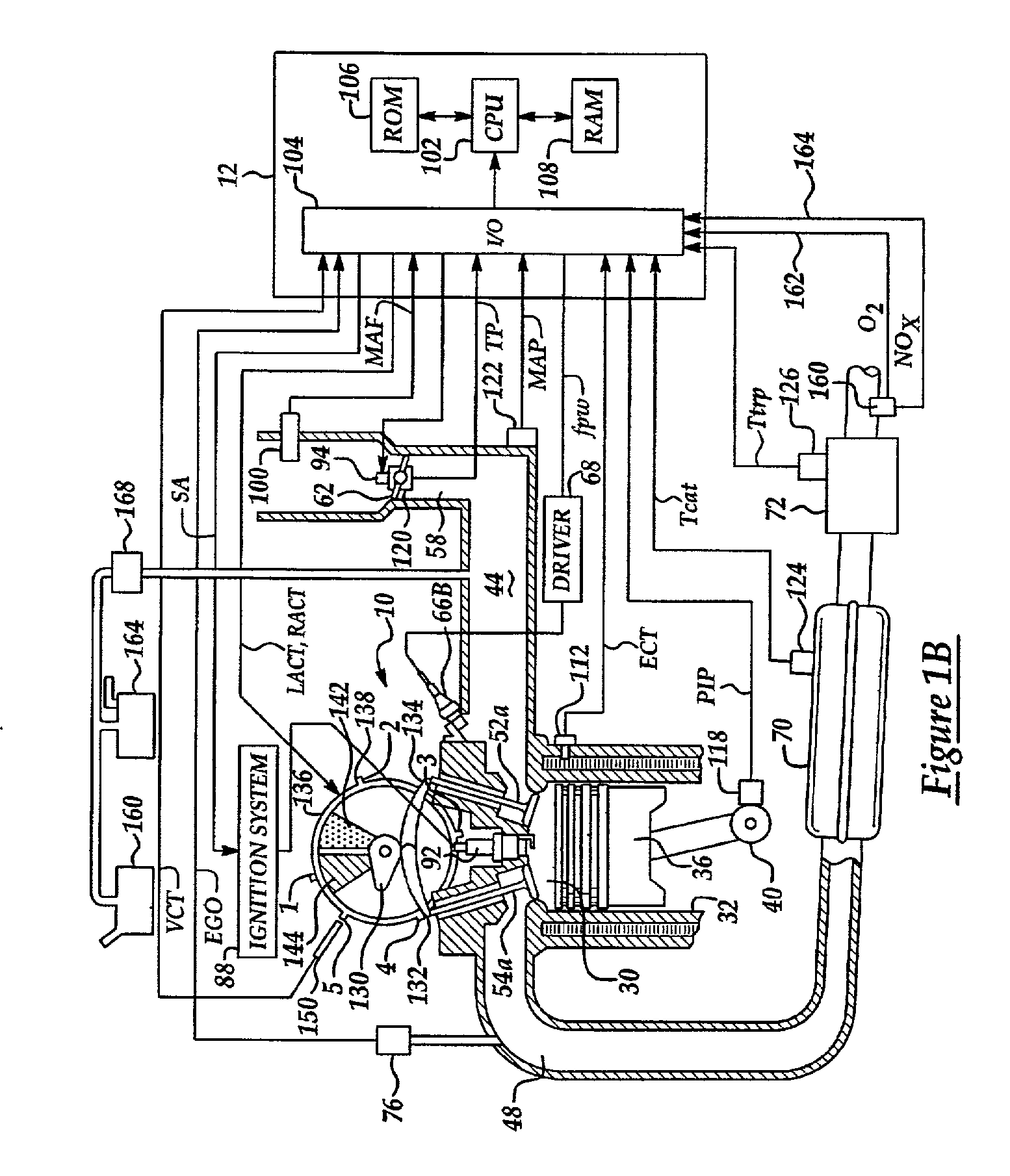

Idle speed control for lean burn engine with variable-displacement-like characteristic

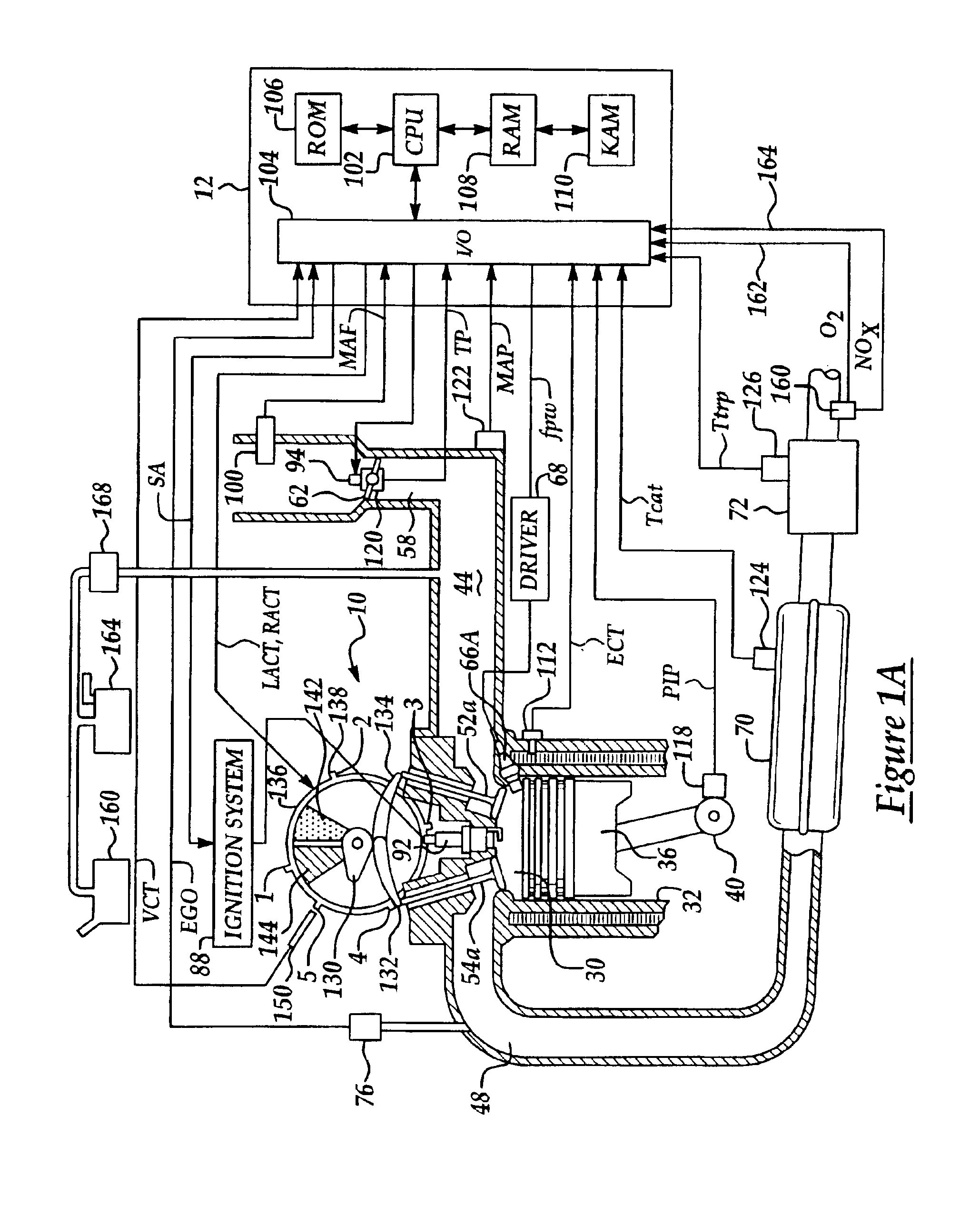

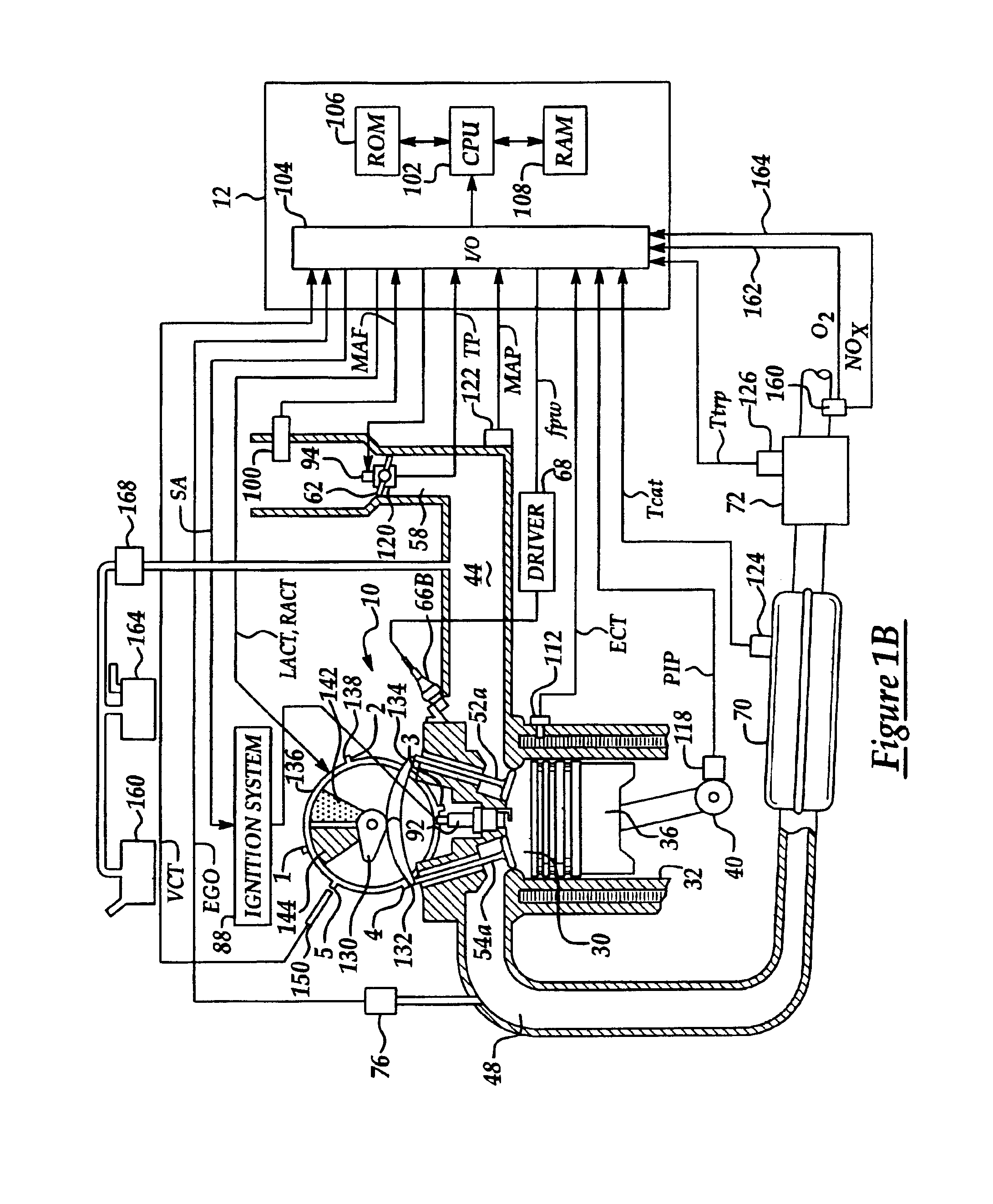

InactiveUS6769398B2Easy to operateDegradation of combustionElectrical controlIdling devicesAdaptive learningIdle speed control

A method is disclosed for controlling operation of a engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air-fuel mixture and a second group of cylinders pumping air only (i.e. without fuel injection.) In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: auto speed control, sensor diagnostics, air-fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, and default operation. In addition, the engine control method also disables the split air / lean operating mode under preselected operating conditions.

Owner:FORD GLOBAL TECH LLC

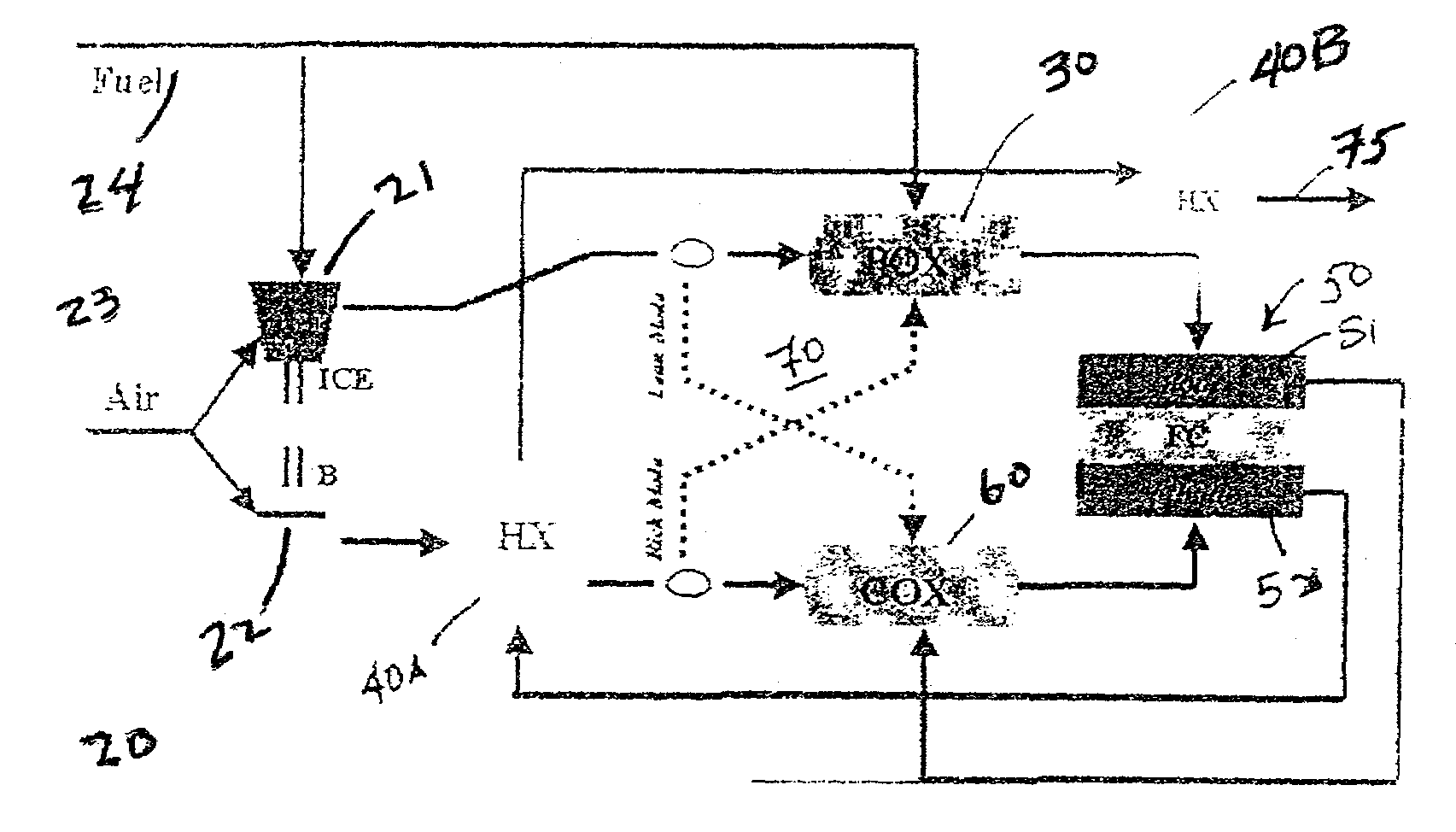

Devices and methods for reduction of NOx emissions from lean burn engines

The invention provides devices and methods for generating H2 and CO in an O2 containing gas stream. The invention also provides devices and methods for removal of NOX from an O2 containing gas stream, particularly the oxygen-rich exhaust stream from a lean-burning engine, such as a diesel engine. The invention includes a fuel processor that efficiently converts added hydrocarbon fuel to a reducing mixture of H2 and CO. The added fuel may be a portion of the onboard fuel on a vehicle. The H2 and CO are incorporated into the exhaust stream and reacted over a selective lean NOX catalyst to convert NOX to N2. thereby providing an efficient means of NOX emission control.

Owner:INT ENGINE INTPROP CO LLC

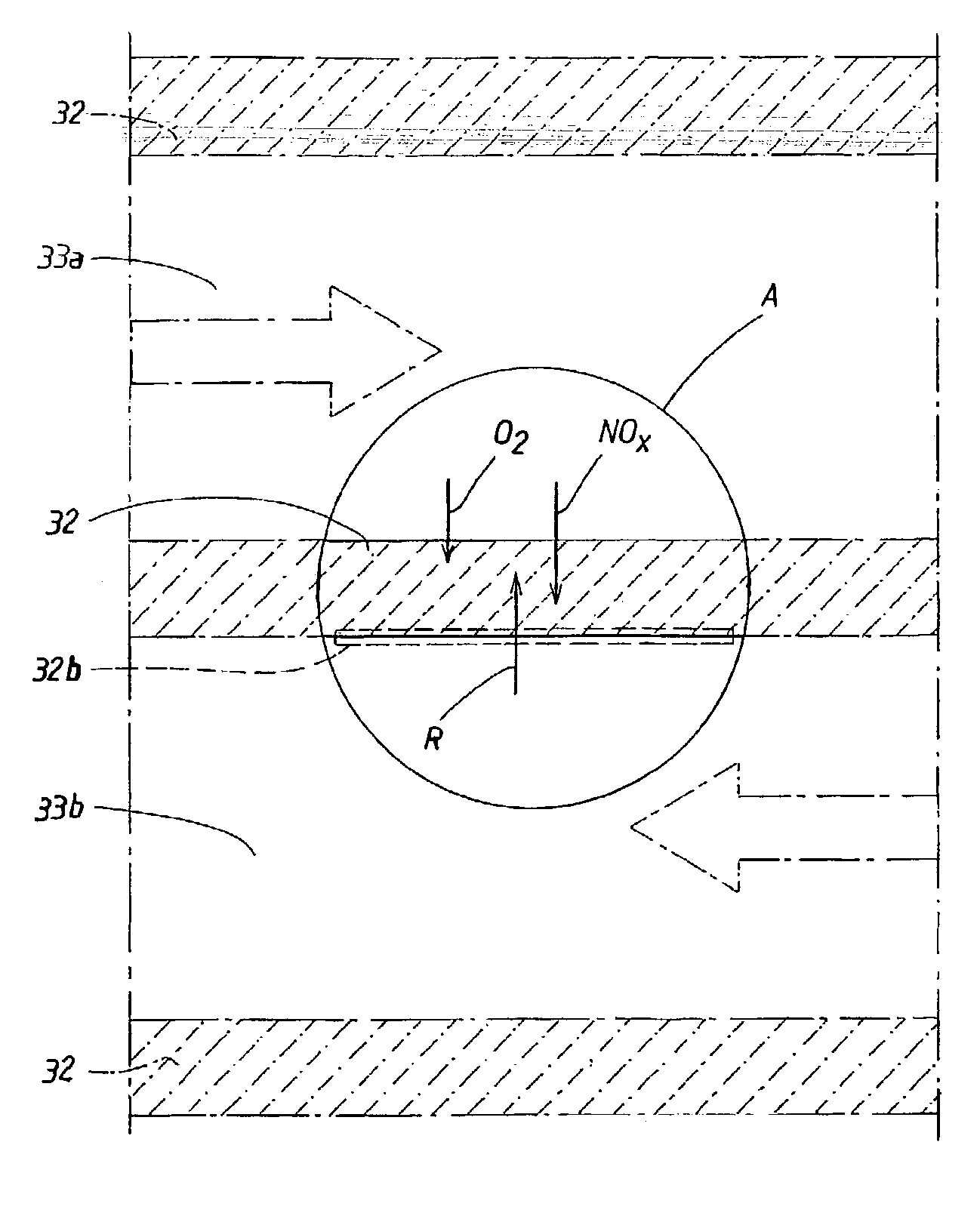

Device and method for reduction of a gas component in an exhaust gas flow of a combustion engine

InactiveUS8065870B2Reduce the amount requiredEasy dischargeCombination devicesElectrical controlCombustionProcess engineering

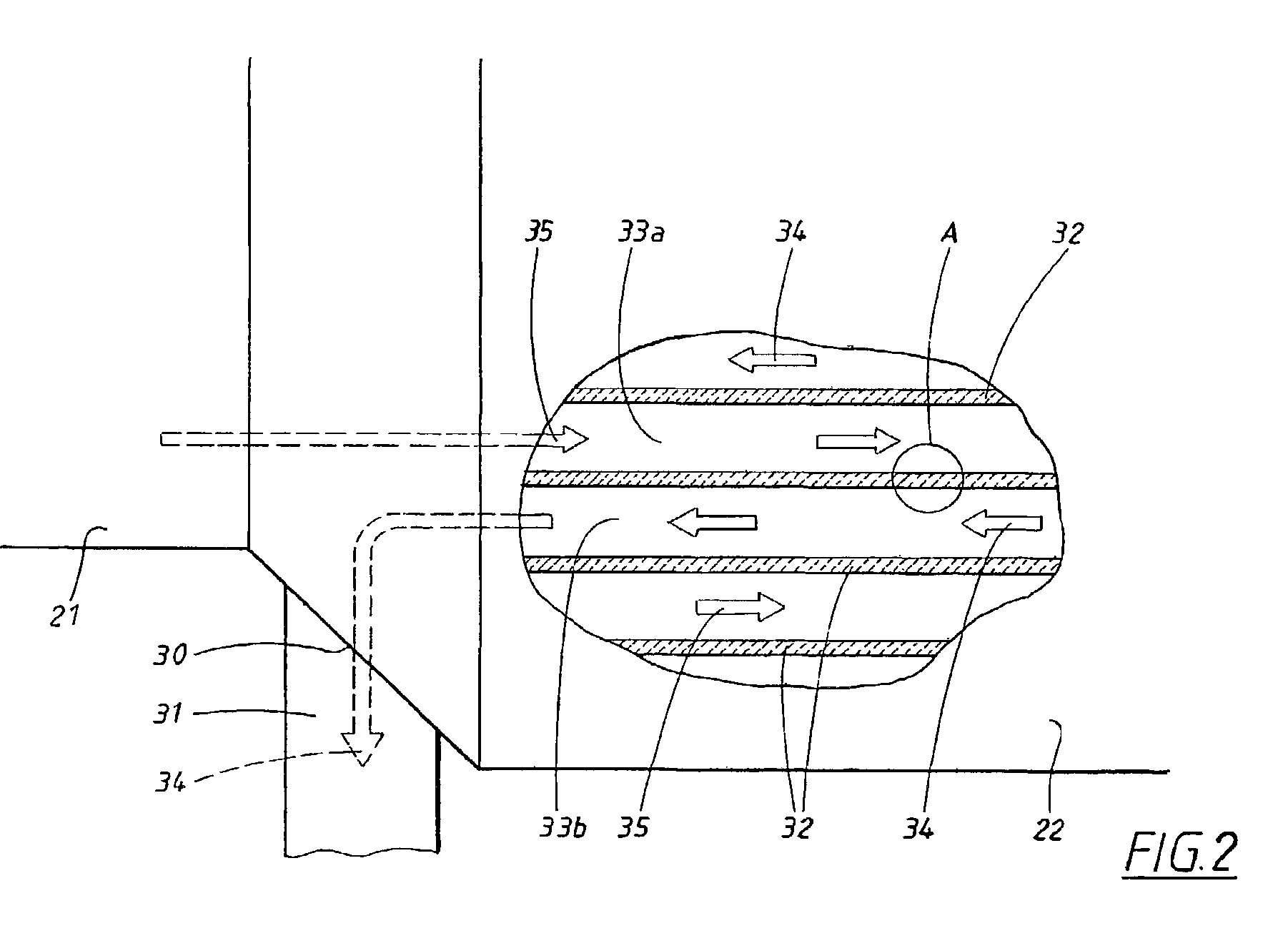

Method and device for reduction of a gas component in an exhaust gas flow of a combustion engine (1) that is adapted for operation by a lean air / fuel mixture. An exhaust pipe (21) is included for transport of the exhaust gas flow from the engine (1). A separation unit (22) is also included that is arranged along the exhaust pipe (21), which separation unit (22) has a wall structure (32) of a material which provides separation of the gas component from the exhaust gas flow by means of a selective passage of the gas component before other gas components in the exhaust gas flow. The method provides for a reduction and a separation unit that is intended to be utilized during such a reduction. An improved reduction of in particular NOx compounds from a so-called “lean-burn” engine is also provided.

Owner:VOLVO TECH

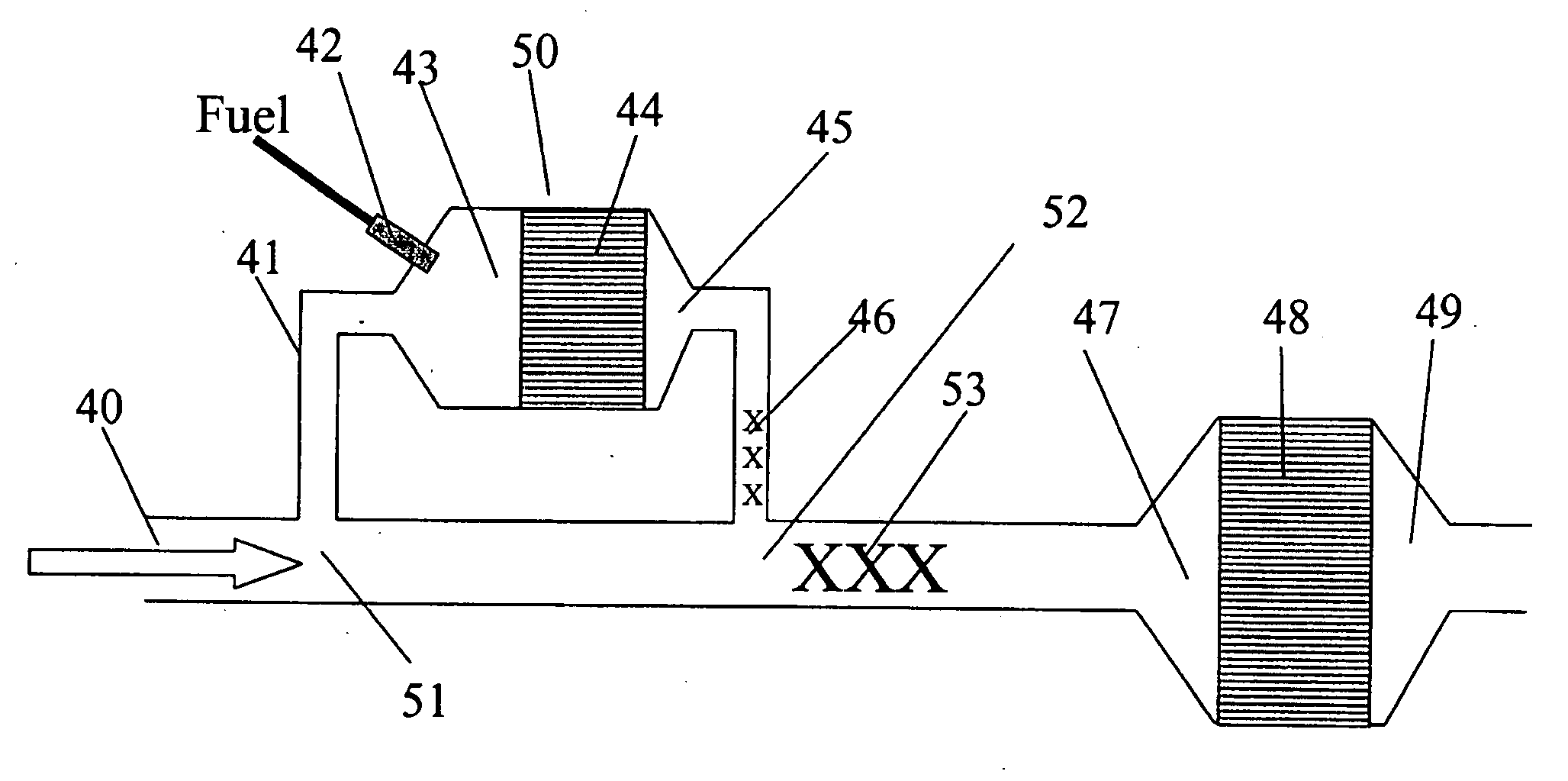

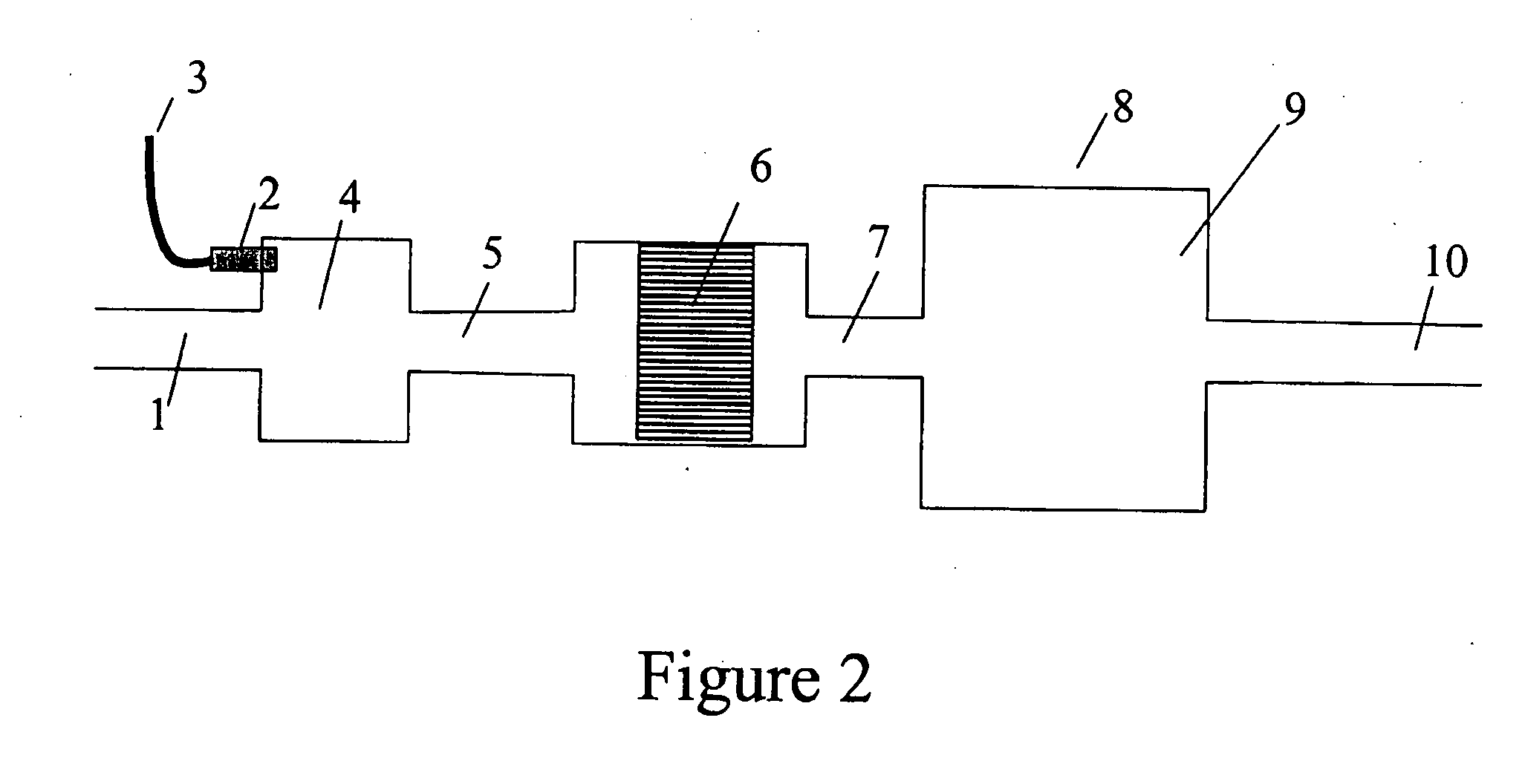

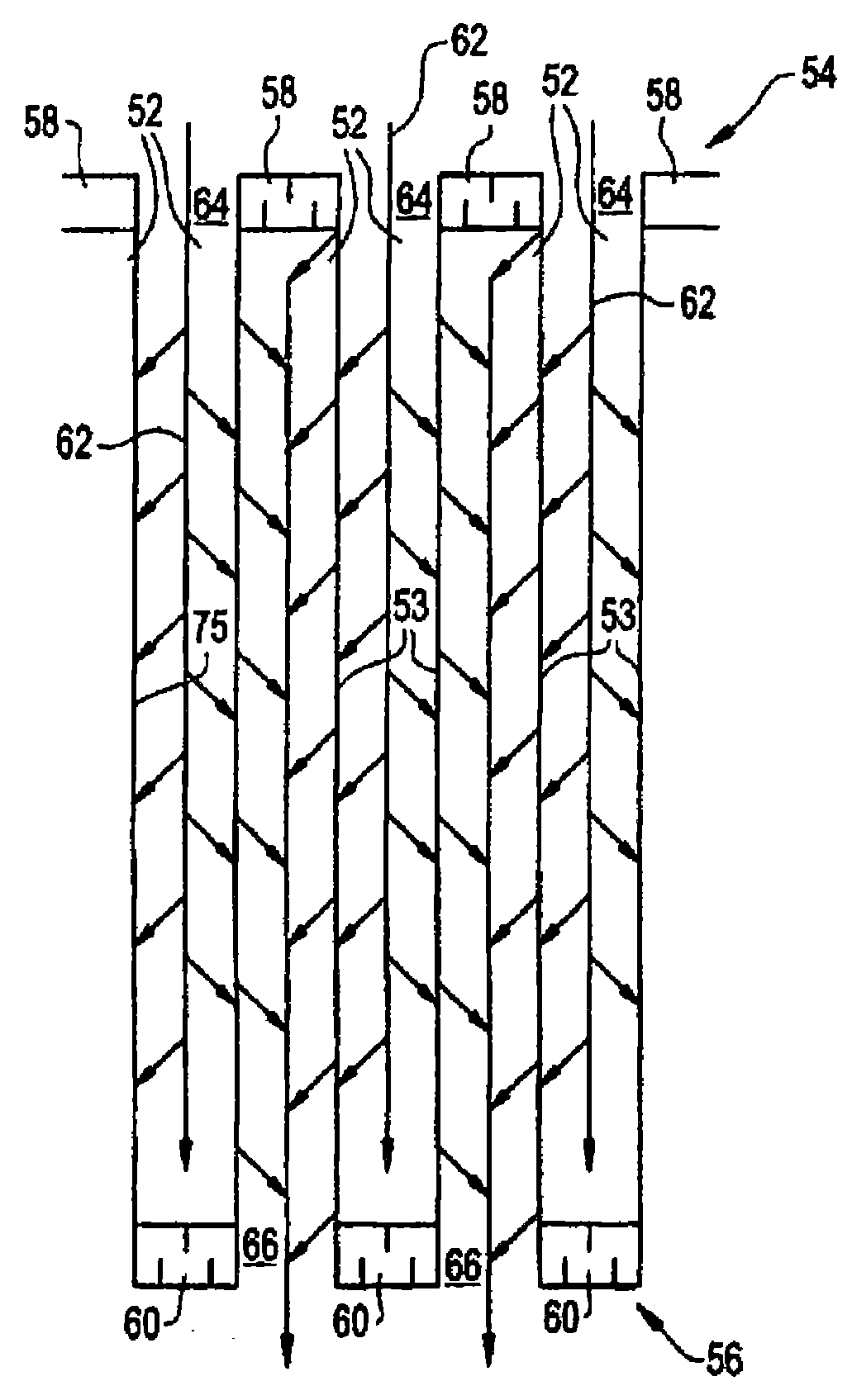

Diesel fuel burner for diesel emissions control system

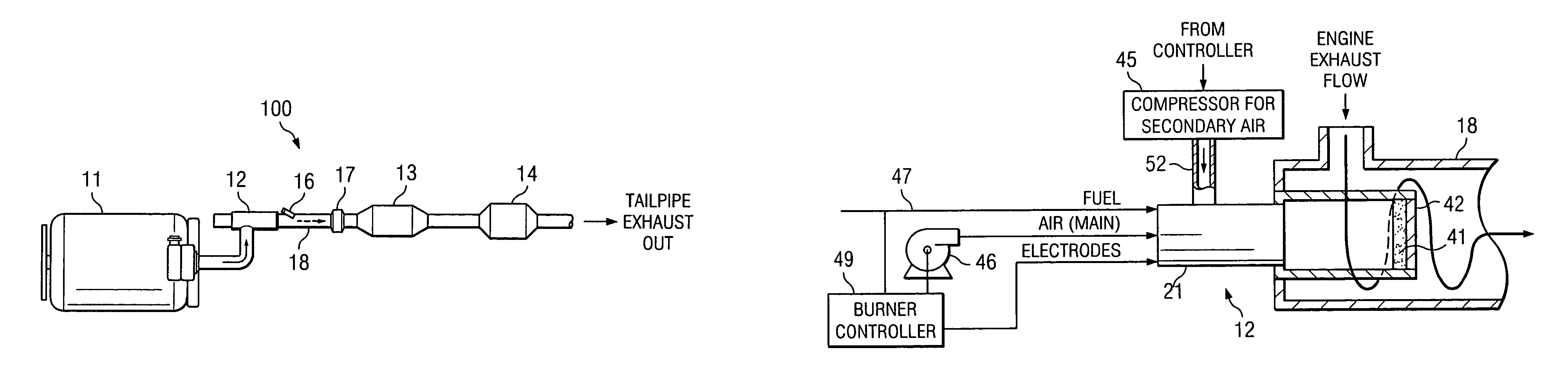

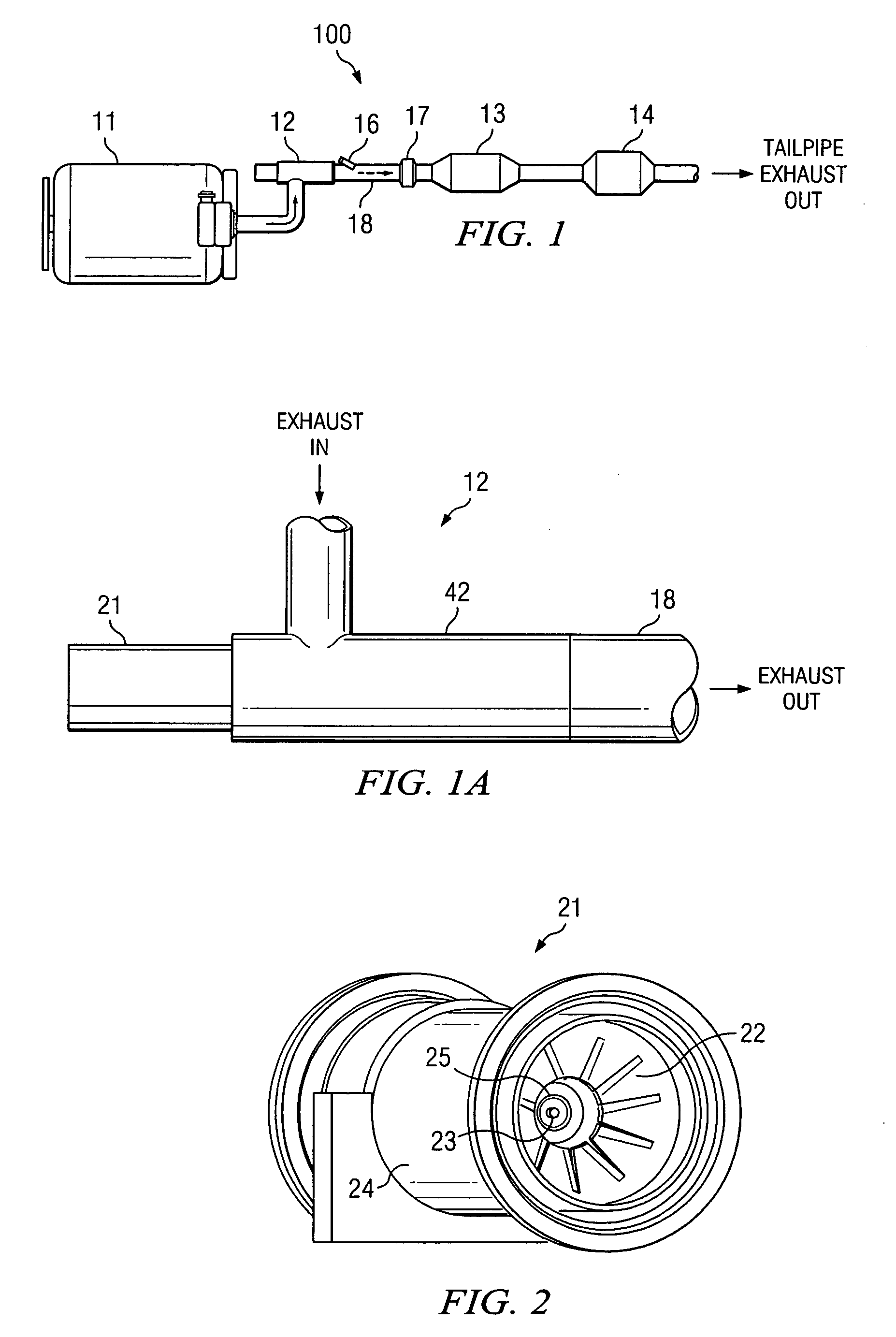

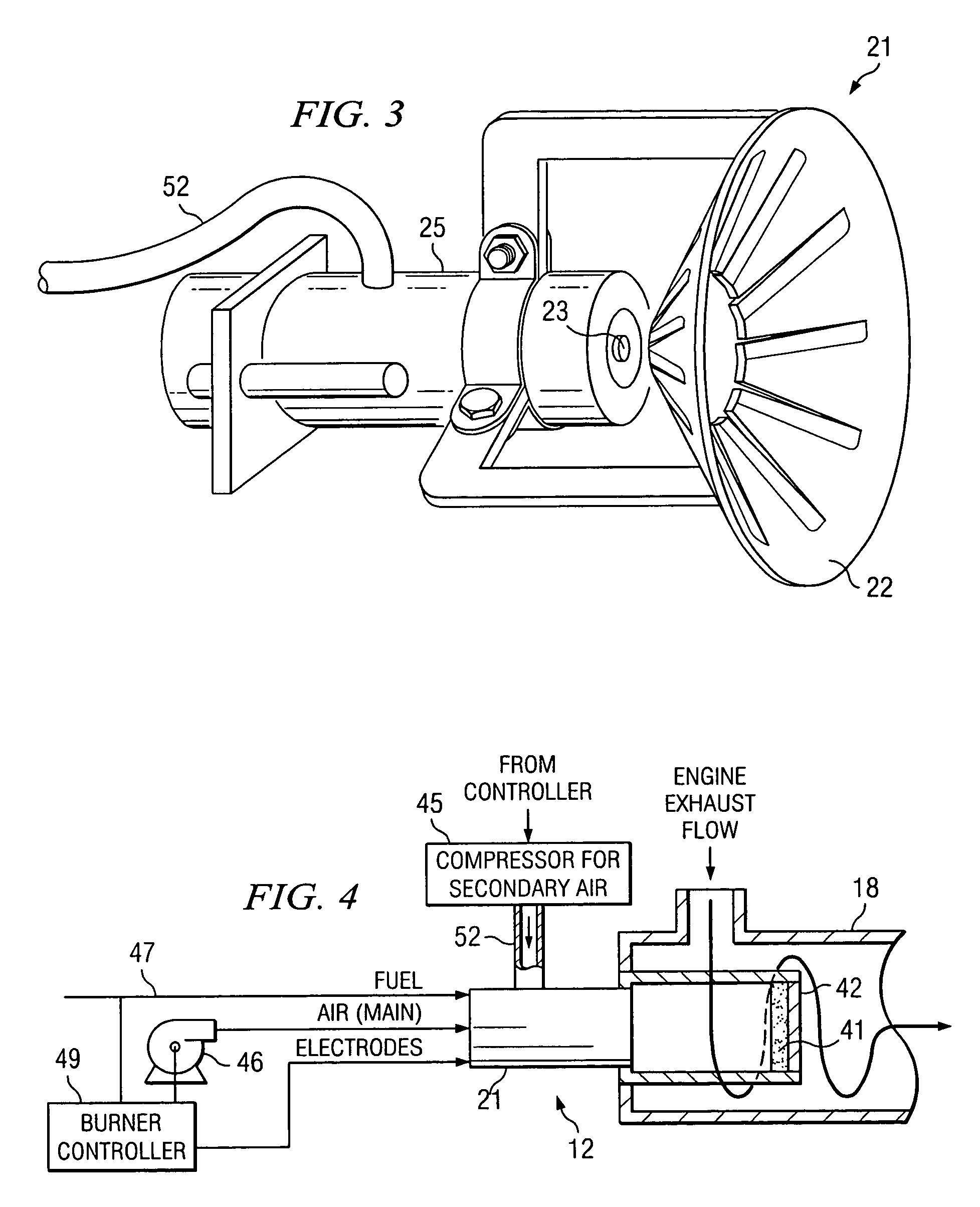

ActiveUS7032376B1Small sizePromote regenerationInternal combustion piston enginesExhaust apparatusCombustorExternal combustion engine

A burner for use in the emissions system of a lean burn internal combustion engine. The burner has a special burner head that enhances atomization of the burner fuel. Its combustion chamber is designed to be submersed in the engine exhaust line so that engine exhaust flows over the outer surface of the combustion chamber, thereby providing efficient heat transfer.

Owner:SOUTHWEST RES INST

Method to improve fuel economy in lean burn engines with variable-displacement-like characteristics

InactiveUS6758185B2Easy to operateOverall engine torque fallsElectrical controlNon-fuel substance addition to fuelTemperature controlAdaptive learning

Owner:FORD GLOBAL TECH LLC

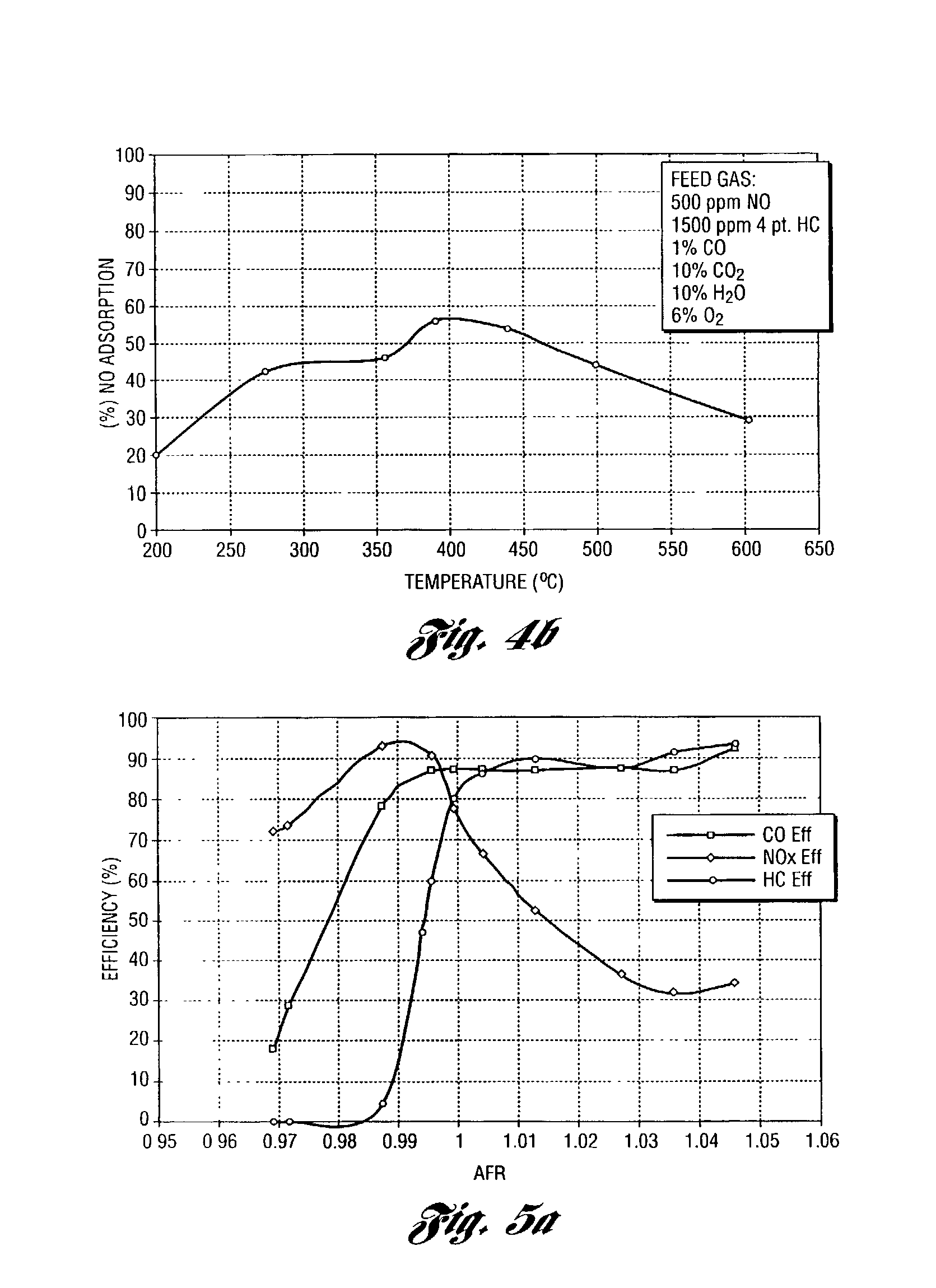

Exhaust system for a lean burn internal combustion engine

An exhaust system for an internal combustion engine has a catalysed ceramic wall flow particulate filter coated with a washcoat composition. The washcoat composition includes an oxidation catalyst of at least one platinum group metal and a NOx absorbent. The washcoat composition has a D50 of less than or equal to 8 μm. The NOx absorbent absorbs NOx contained in an exhaust gas when the composition of the exhaust gas is lambda >1, and releases the NOx absorbed in the NOx absorbent when the exhaust gas composition is 1≦lambda. The exhaust system has a platinum group metal catalyst upstream of the filter for oxidising NO to NO2 at least when the composition of the exhaust gas is lambda >1. The uncoated portions of the ceramic wall flow particulate filter have a porosity of >40% and a mean pore size of 8-25 μm.

Owner:JOHNSON MATTHEY PLC

Catalysed substrate monolith

ActiveUS8667785B2Avoids and reduces problemReduce and prevent poisoningCombination devicesNitrogen compoundsInternal combustion enginePlatinum group

Owner:JOHNSON MATTHEY PLC

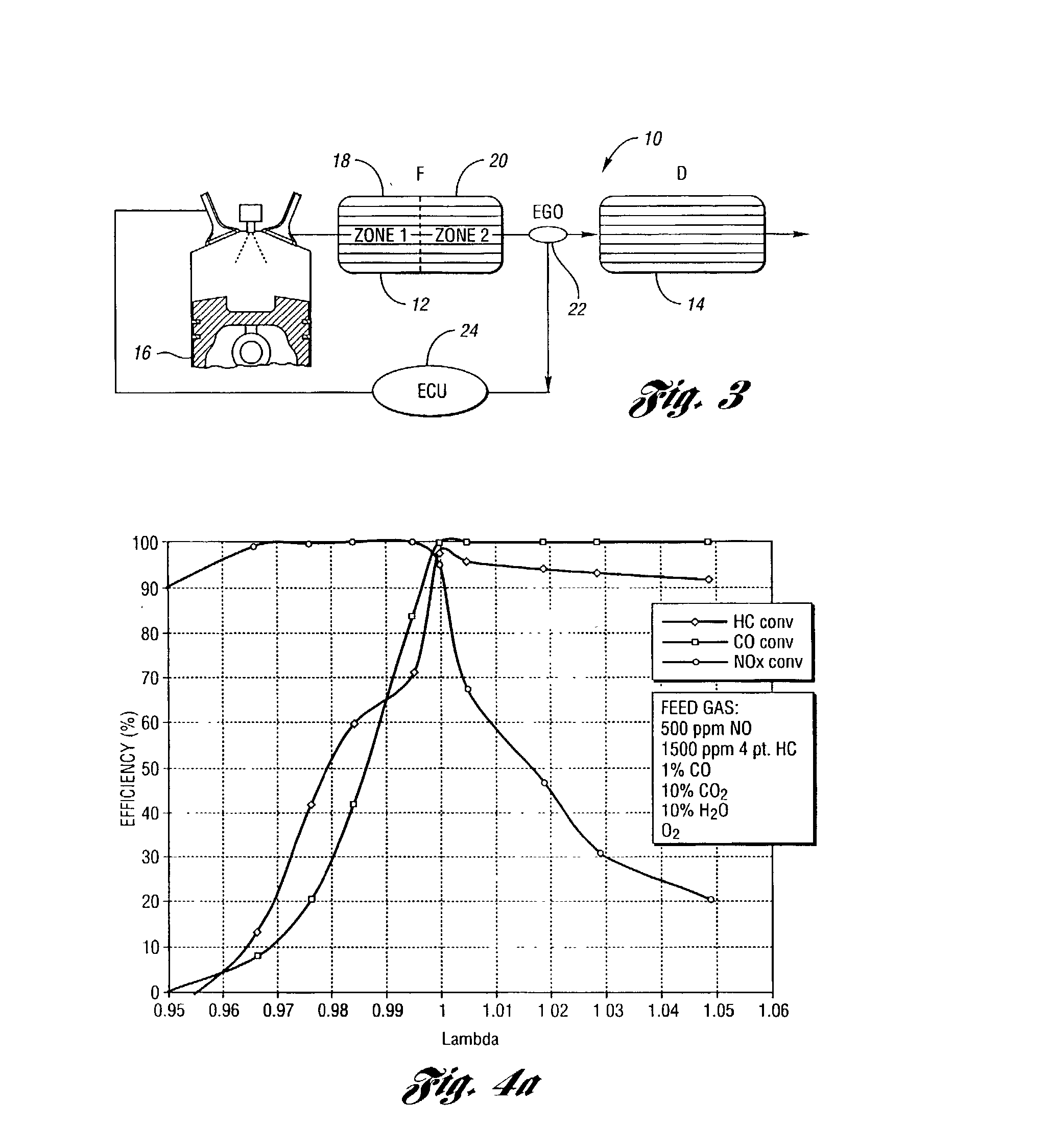

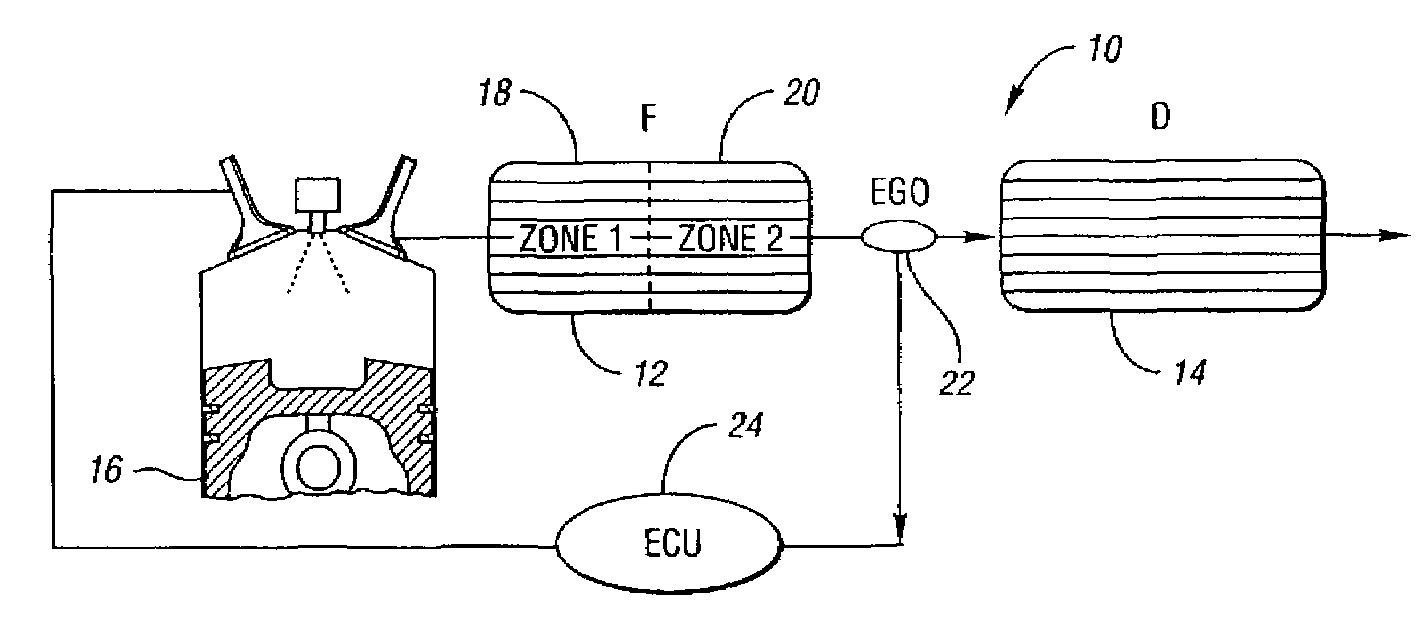

Catalyst system for lean burn engines

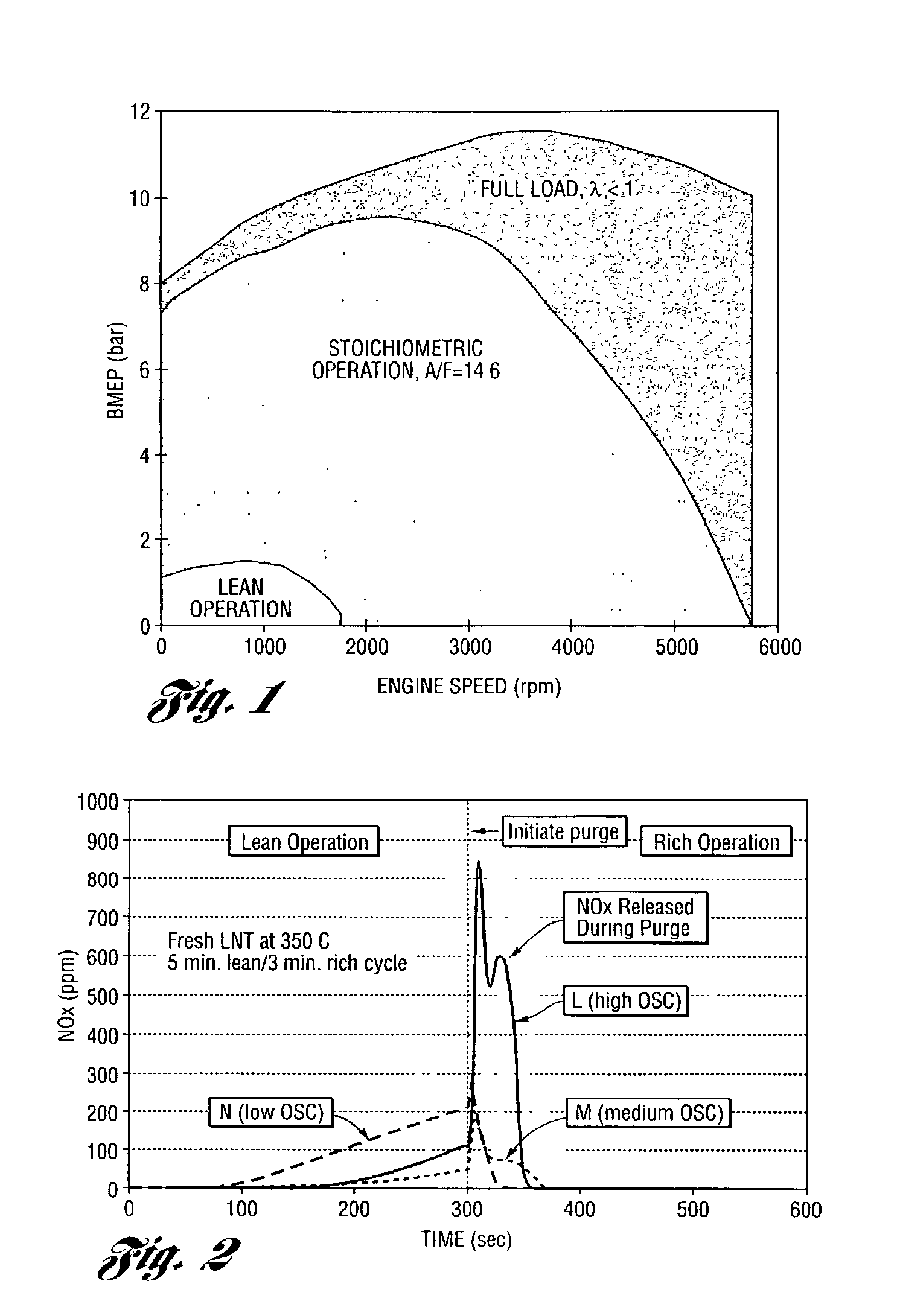

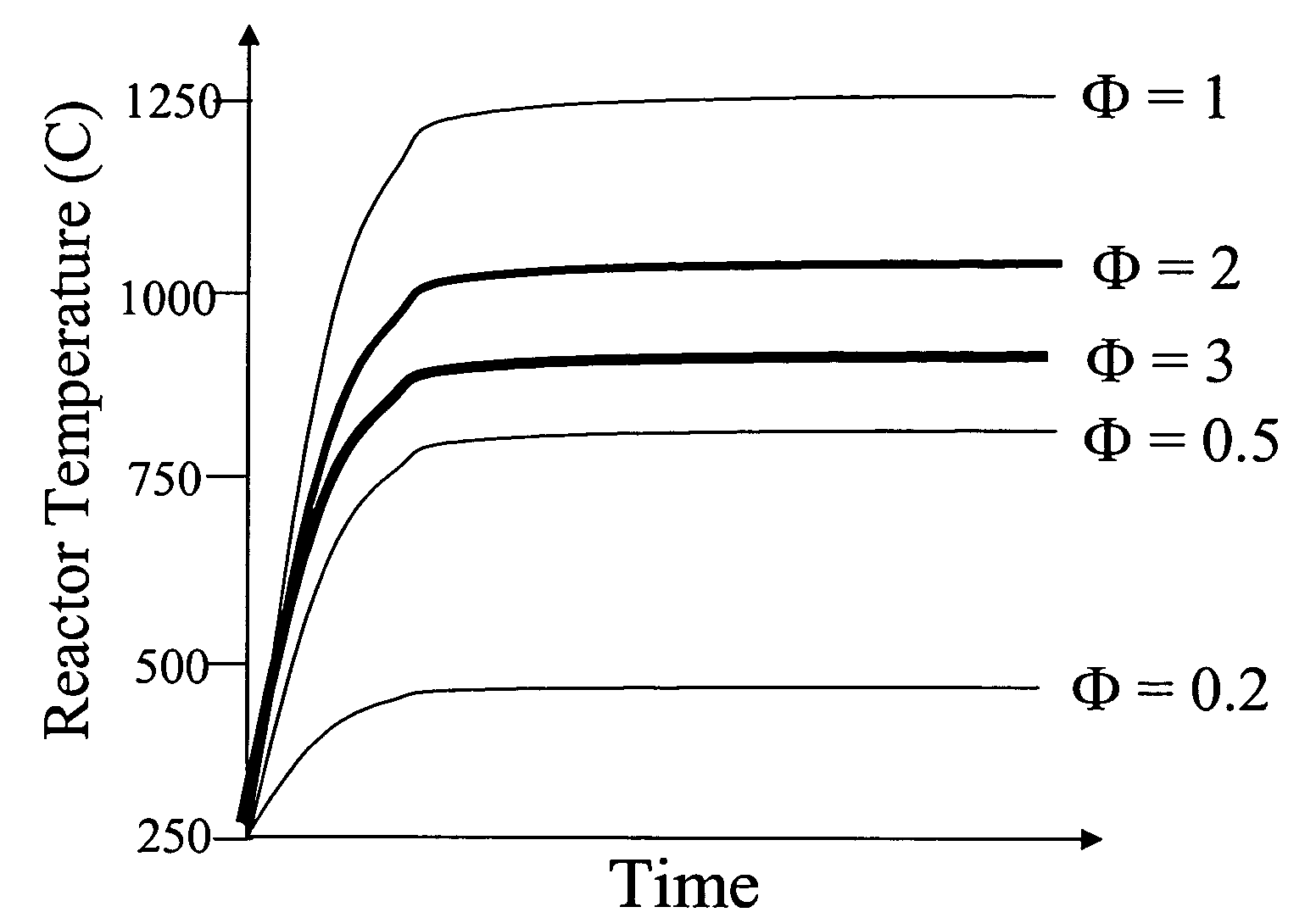

InactiveUS20040082470A1Minimizes oxygen storage functionMinimize releaseInternal combustion piston enginesDispersed particle separationFree zoneAlkaline earth metal

A catalyst system to provide emission reductions under lean and stoichiometric conditions. The catalyst system comprises a forward catalyst having a first cerium-free zone including oxides of aluminum, alkali metals and alkaline earth metals and precious metals and a second zone with a lower loading of precious metals, oxides of aluminum, alkali metals or alkaline earth metals. This forward catalyst stores NOx emissions under lean conditions for subsequent reduction and converts HC, CO and NOx during stoichiometric operation. The second downstream catalyst includes precious metals, reduces emissions under stoichiometric conditions, and stores any residual NOx emitted from the first catalyst for subsequent reduction. In another embodiment, a forward catalyst has top and bottom layers designed to reduce emissions under lean conditions. In this embodiment, a second downstream catalyst is used to reduce emissions under stoichiometric conditions. In yet another catalyst, multiple zones are created within a single catalyst.

Owner:FORD GLOBAL TECH LLC

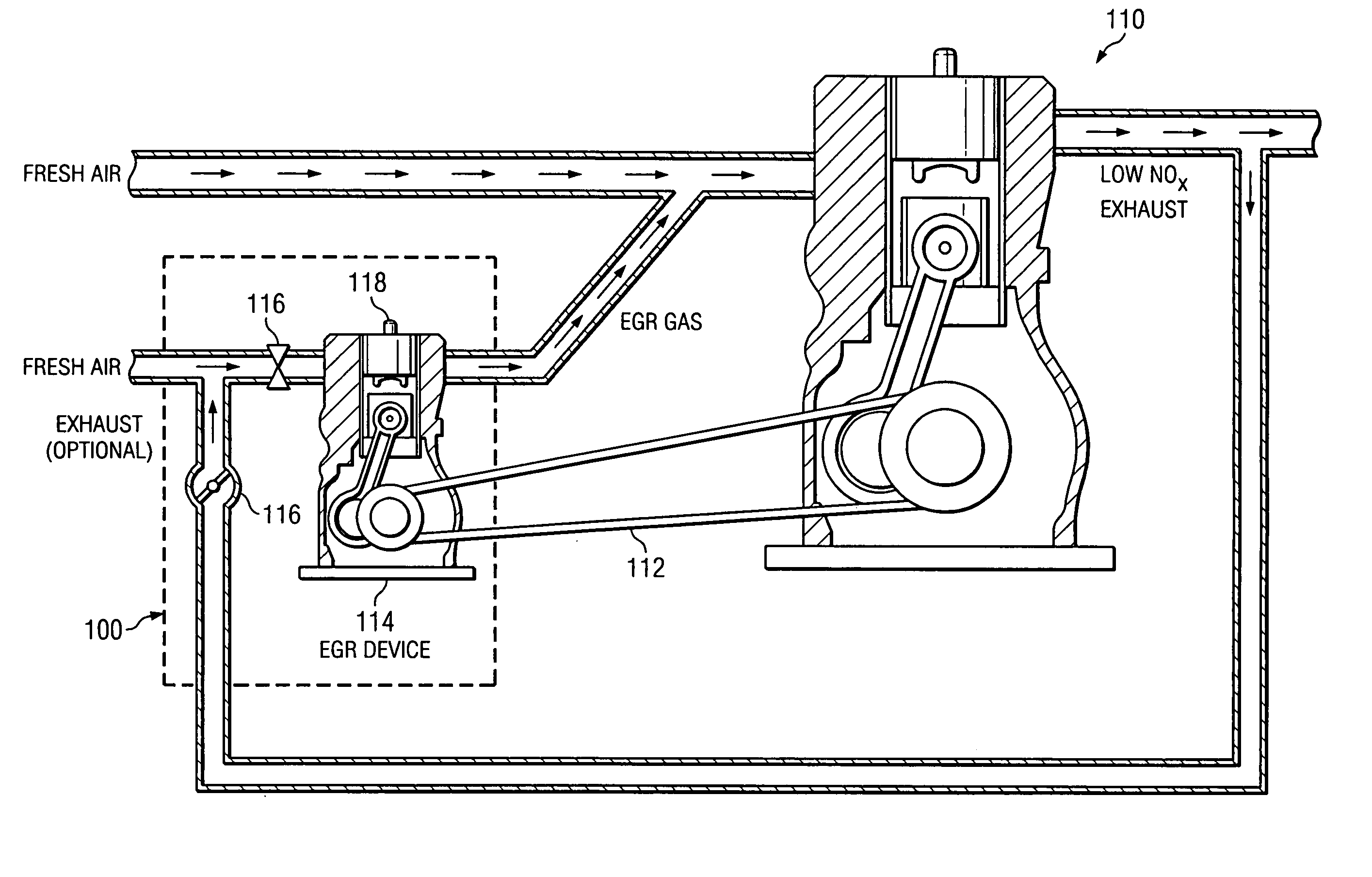

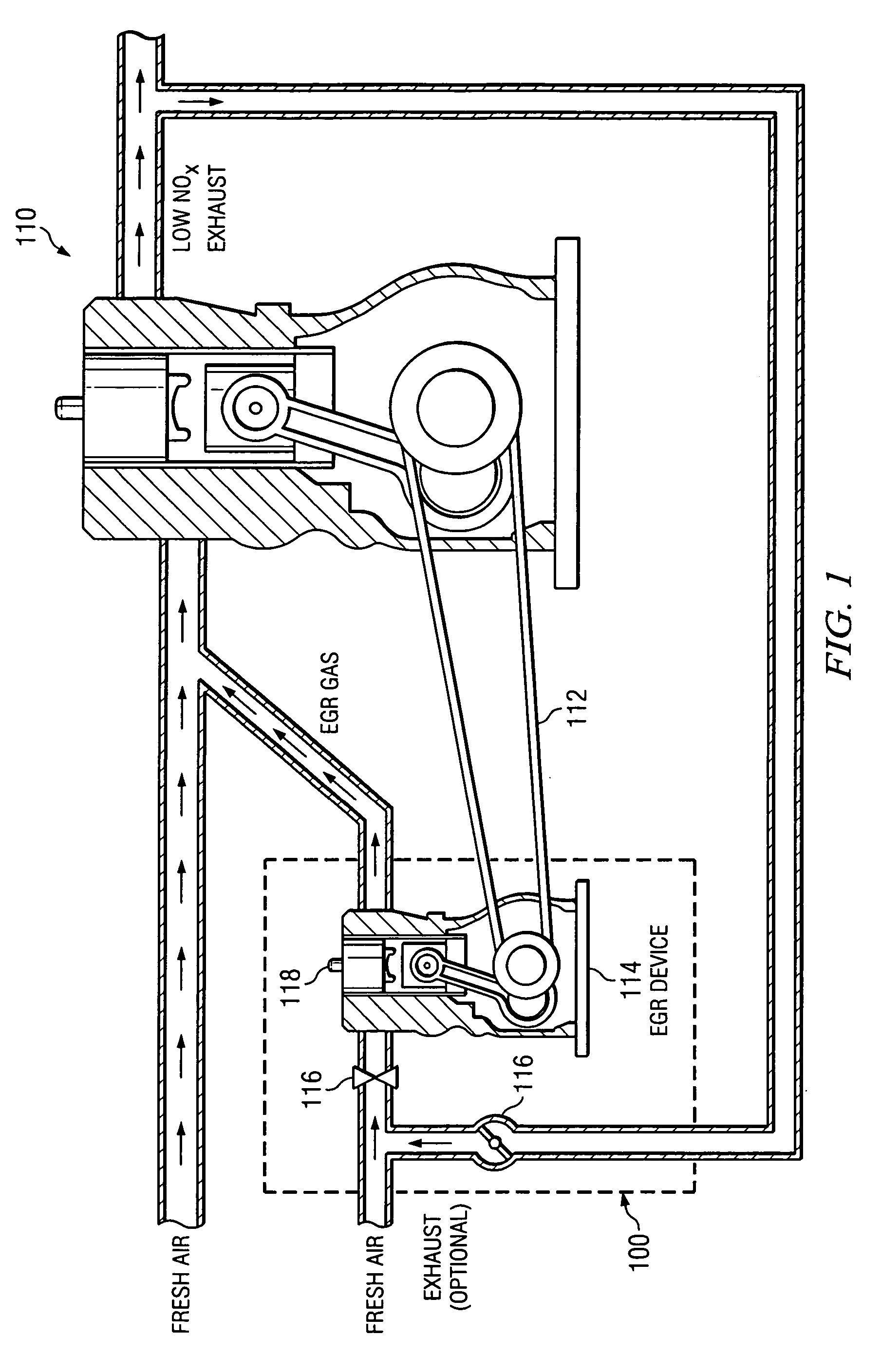

Secondary internal combustion device for providing exhaust gas to EGR-equipped engine

ActiveUS7721541B2Alleviate challengeReduce nitrogen oxide emissionsInternal combustion piston enginesNon-fuel substance addition to fuelCombustionEngineering

A system and method for providing exhaust gas to an EGR-equipped lean burn diesel engine (the primary engine). The exhaust gas is provided by a secondary internal combustion device, whose configuration, thermal cycle, and operating conditions may be different from that of the primary engine. The secondary internal combustion device may receive recirculated exhaust gas, fresh air, or some combination of both.

Owner:SOUTHWEST RES INST

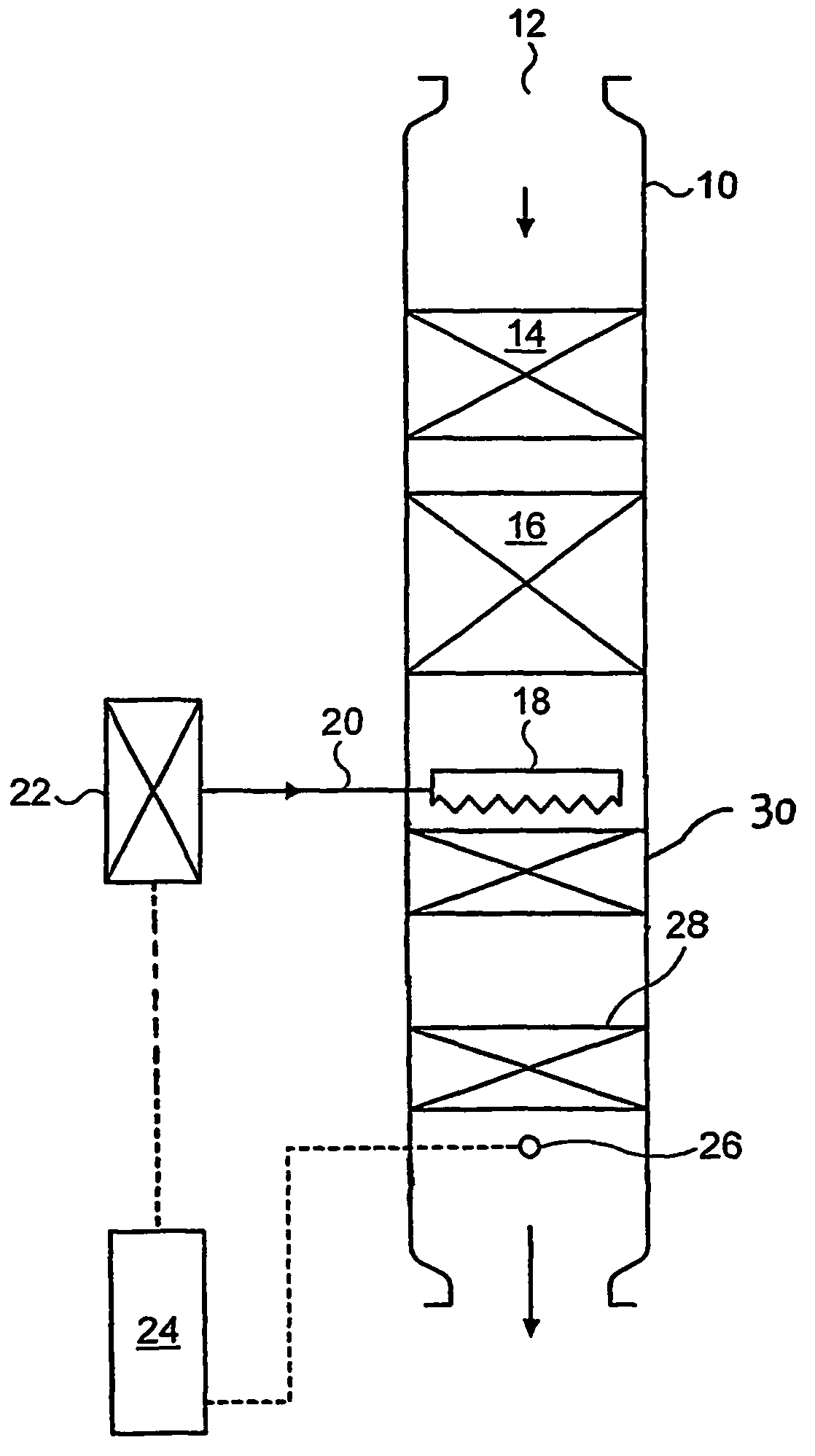

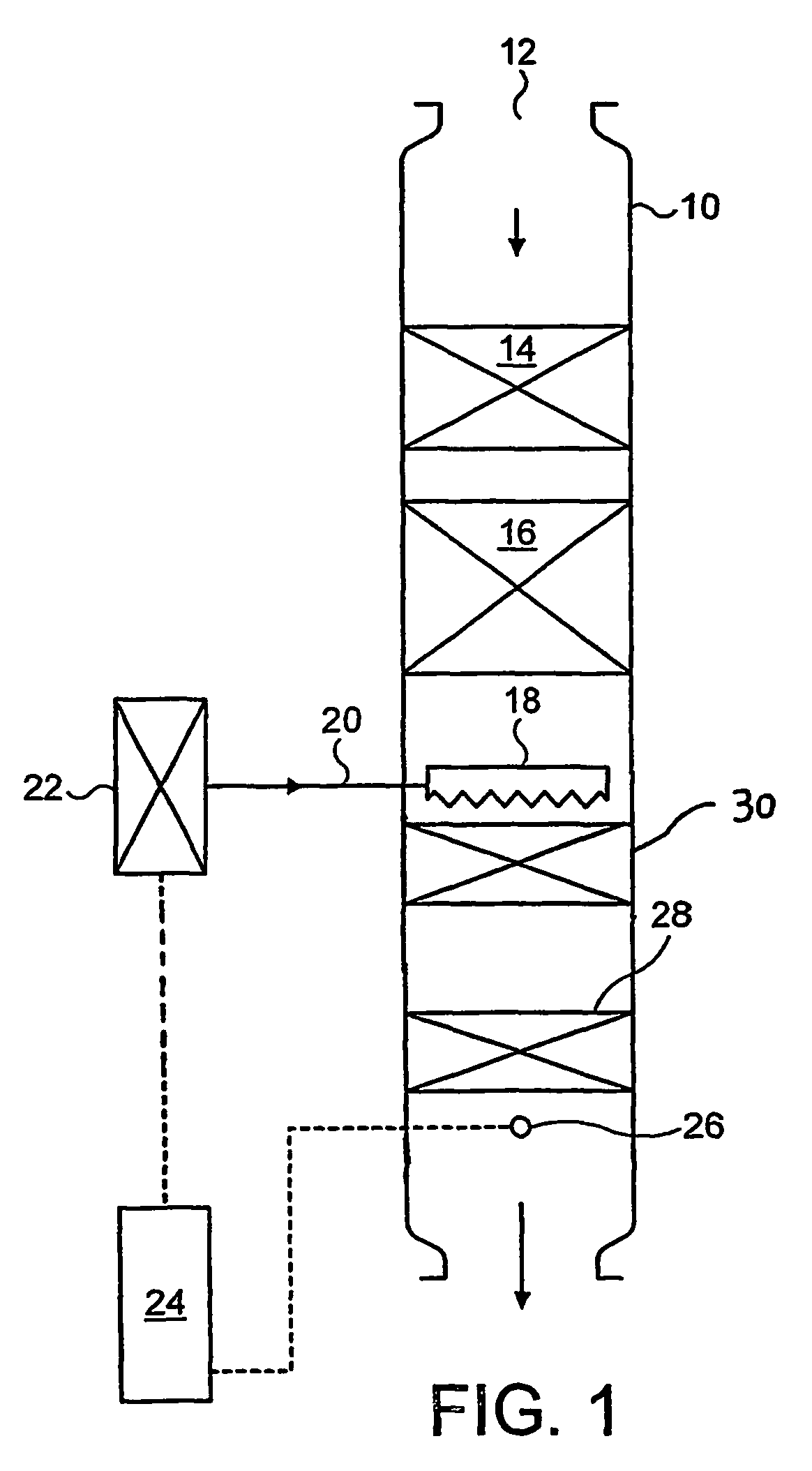

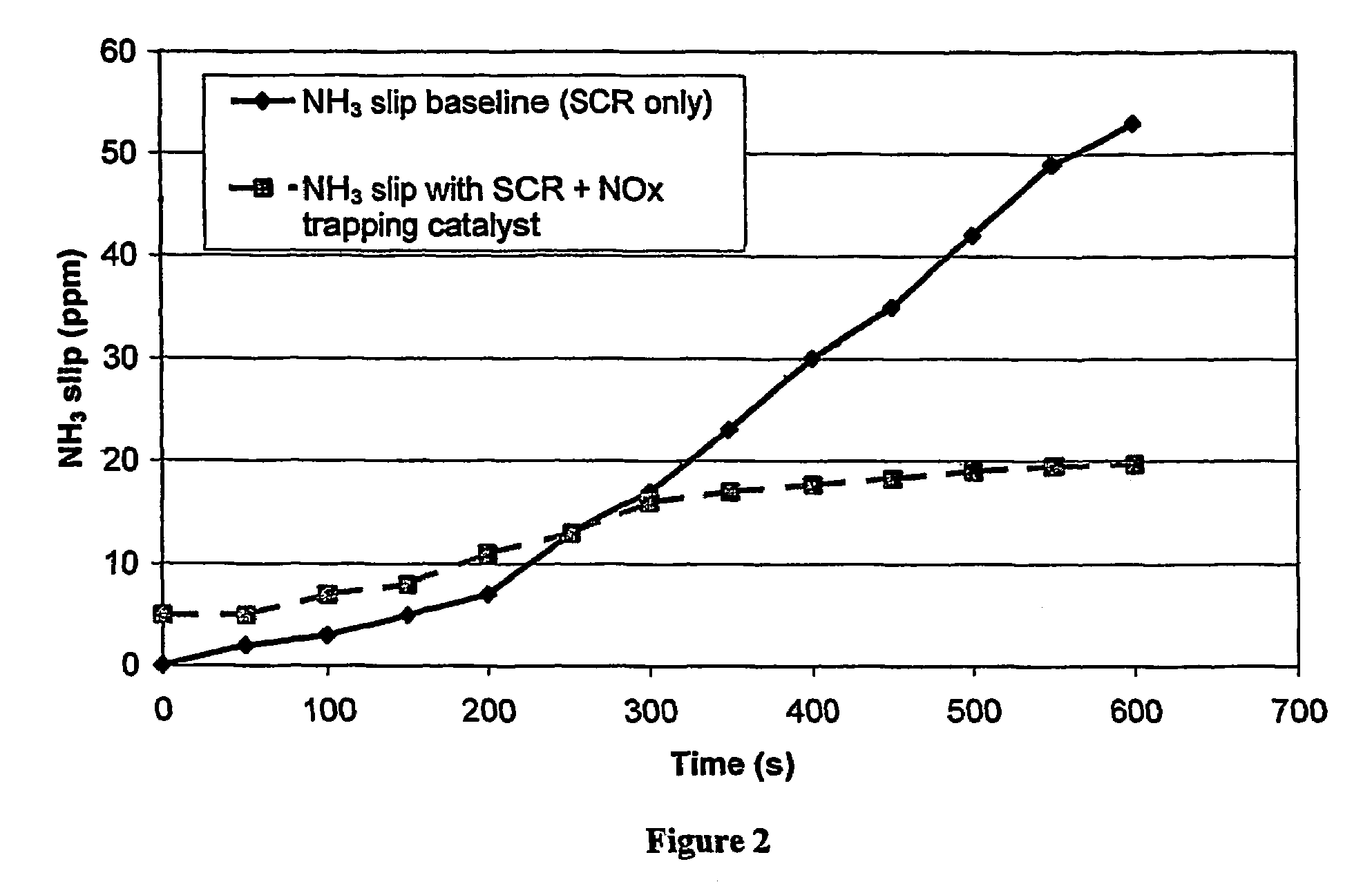

Exhaust system for lean burn IC engines

An exhaust system (10) for a lean-burn internal combustion engine comprises a nitrogen oxide (NOx) absorbent (28), a catalyst (30) for catalyzing the selective catalytic reduction (SCR) of a NOx with a NOx specific reactant, first means (18, 22) for introducing a NOx specific reactant or a precursor thereof into an exhaust gas upstream of the SCR catalyst (30) and means (24) for controlling the introduction of the NOx-specific reactant or precursor thereof into the exhaust gas via the first introducing means (18, 22), wherein the SCR catalyst (30) is disposed upstream of the NOx absorbent (28) and optionally with the NOx absorbent, wherein the control means (24) is arranged to introduce the NOx-specific reactant or the precursor thereof to exhaust gas via the first introducing means (18, 22) only when the SCR catalyst (30) is active, whereby exhaustion of NOx-specific reactant to atmosphere is substantially prevented.

Owner:JOHNSON MATTHEY PLC

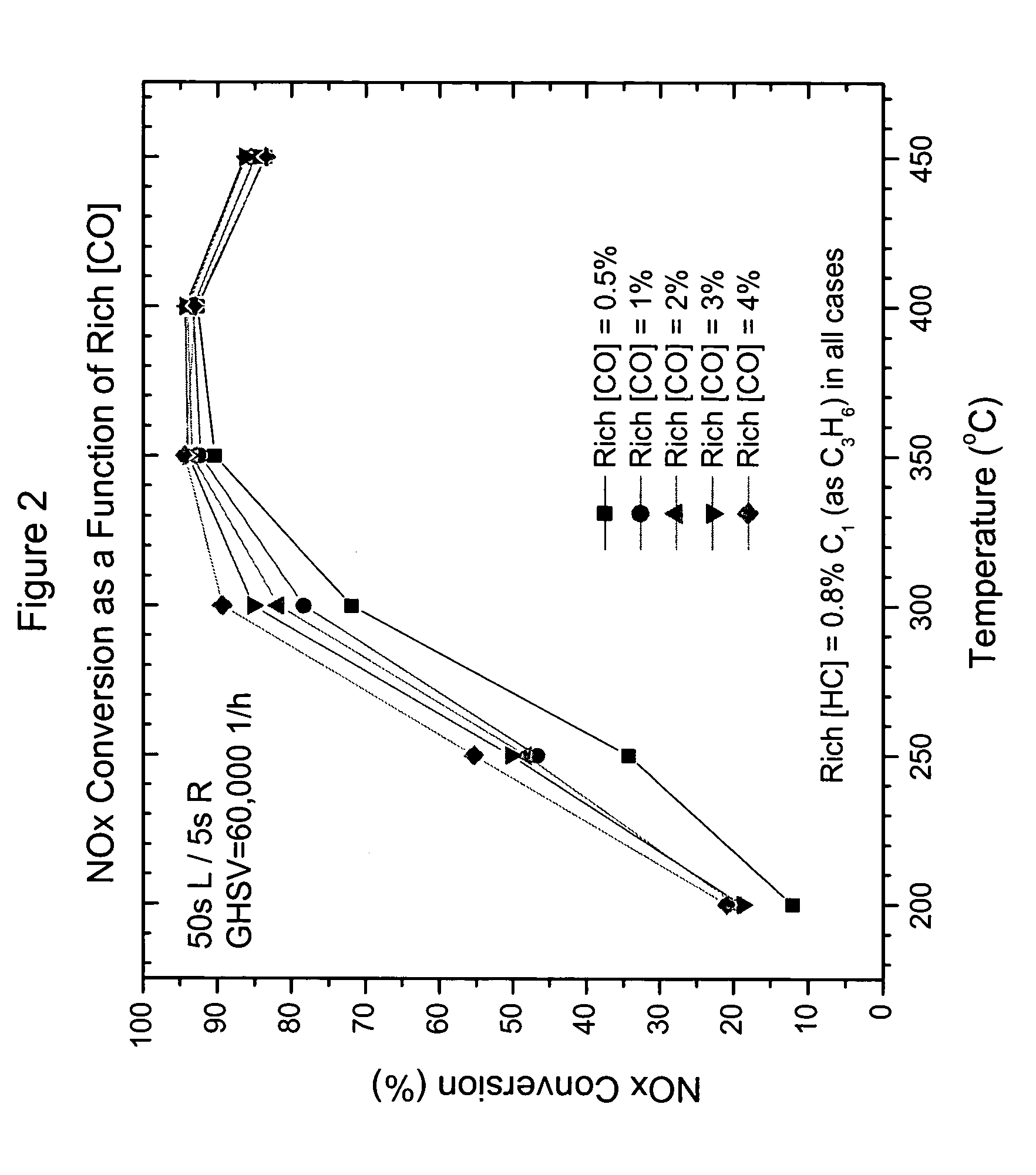

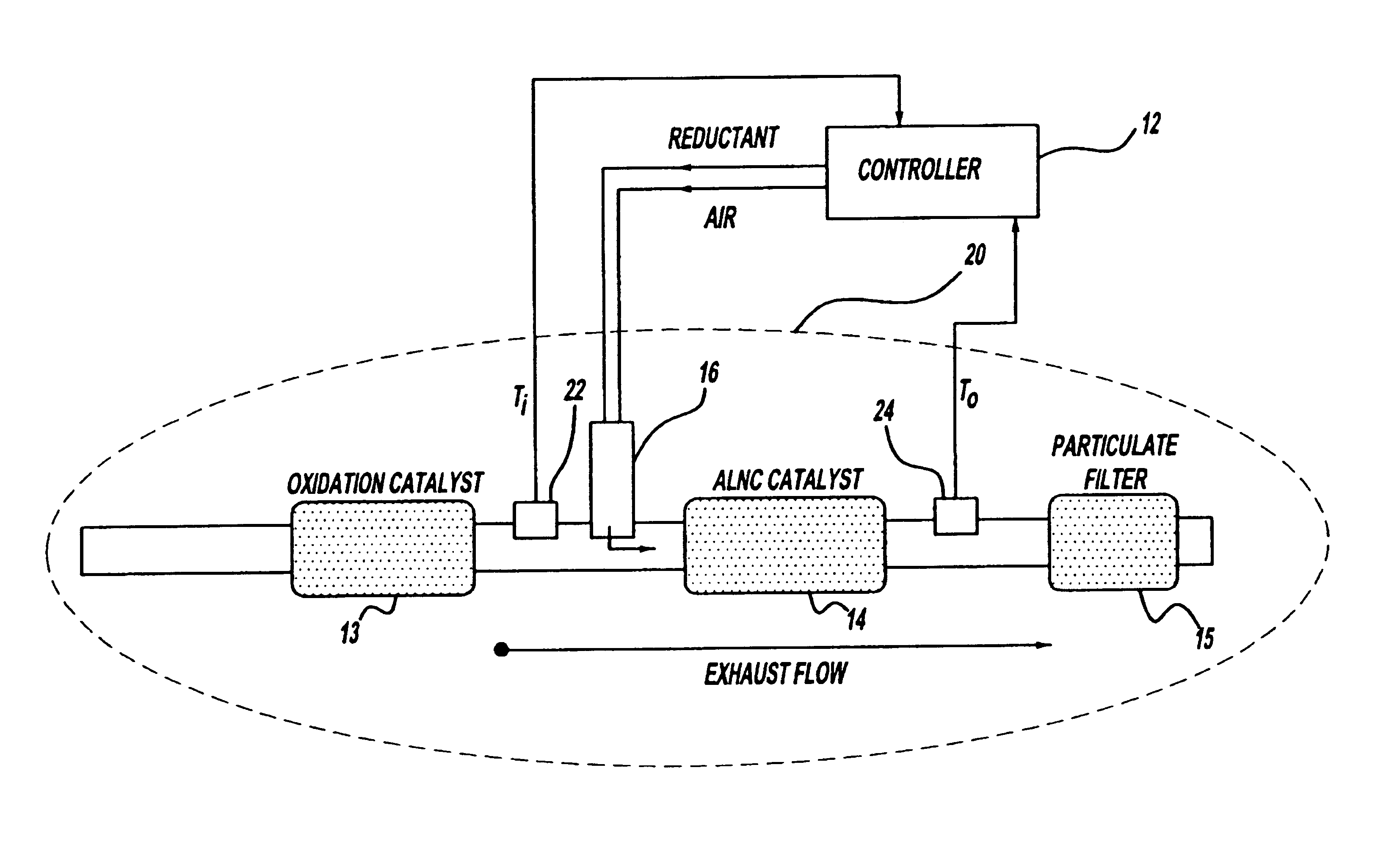

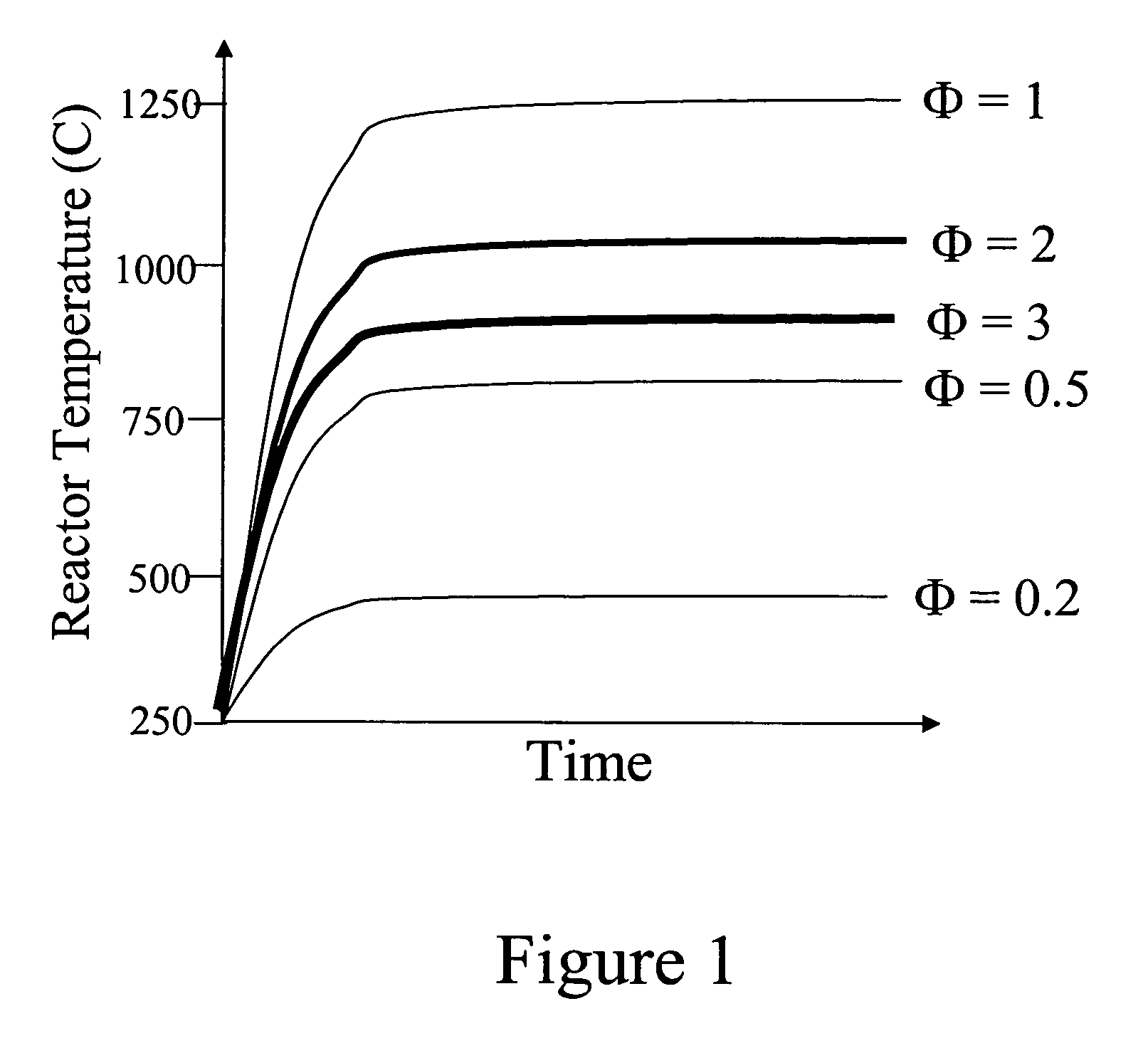

Diesel aftertreatment systems

InactiveUS6983589B2Easy to controlImprove economyInternal combustion piston enginesExhaust apparatusControl systemInternal combustion engine

A method for accurately diagnosing deterioration in an emission control system for a lean burn internal combustion engine is presented. The emission control system includes an Active Lean NOx (ALNC) Catalyst and a system for injecting a hydrocarbon-based reductant into the ALNC thereby improving its NOx conversion efficiency. The method teaches calculating a rate of change of exotherm across the ALNC and differentiating between deterioration of the ALNC and deterioration of the reductant injection system based on the magnitude and the sign of the rate of change of the exotherm. Once the diagnosis of deterioration is made, and the deteriorated component is identified, appropriate corrective measures, such as adjusting or discontinuing the reductant injection amount, and setting diagnostic codes, are taken.

Owner:FORD GLOBAL TECH LLC

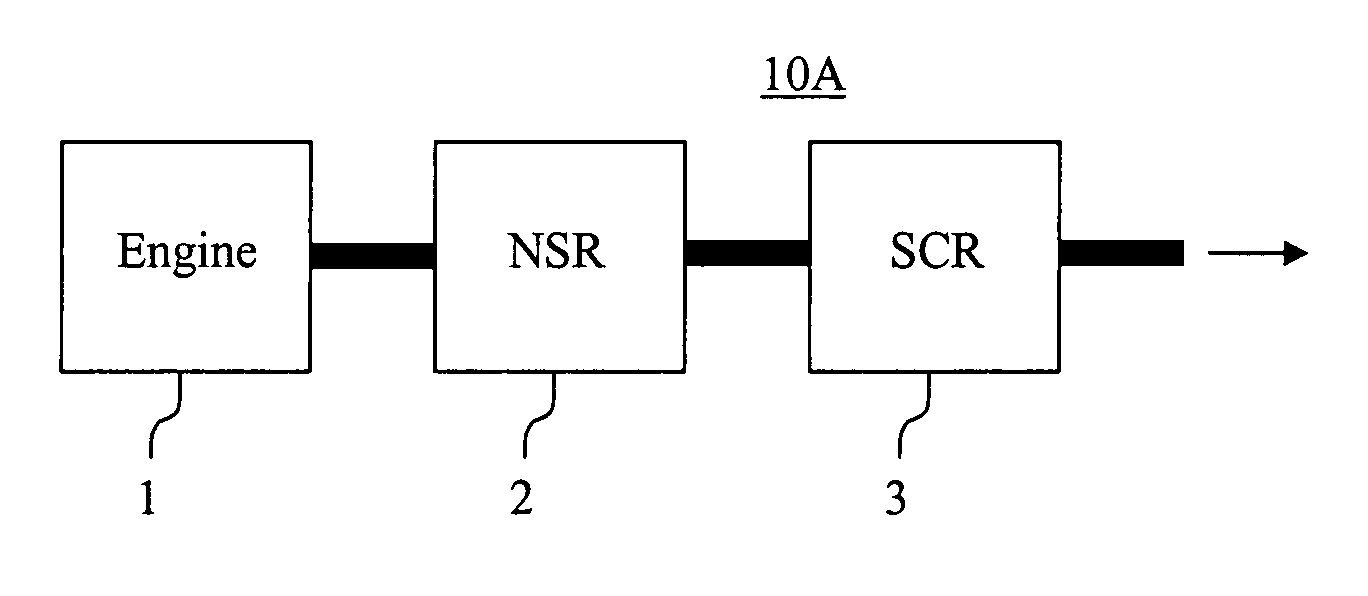

Emission Treatment System with NSR and SCR Catalysts

ActiveUS20070269353A1Improve economyEmission reductionCombination devicesGas treatmentSorbentGasoline

Provided is an emissions treatment system for an exhaust stream, having a NOx storage reduction (NSR) catalyst with a NOx sorbent at a concentration of at least 0.1 g / in3 and a platinum group metal component dispersed on a refractory metal oxide support; and, an SCR catalyst disposed downstream of the NSR catalyst. The emissions treatment system is advantageously used for the treatment of exhaust streams from diesel engines and lean burn gasoline engines.

Owner:BASF CORP

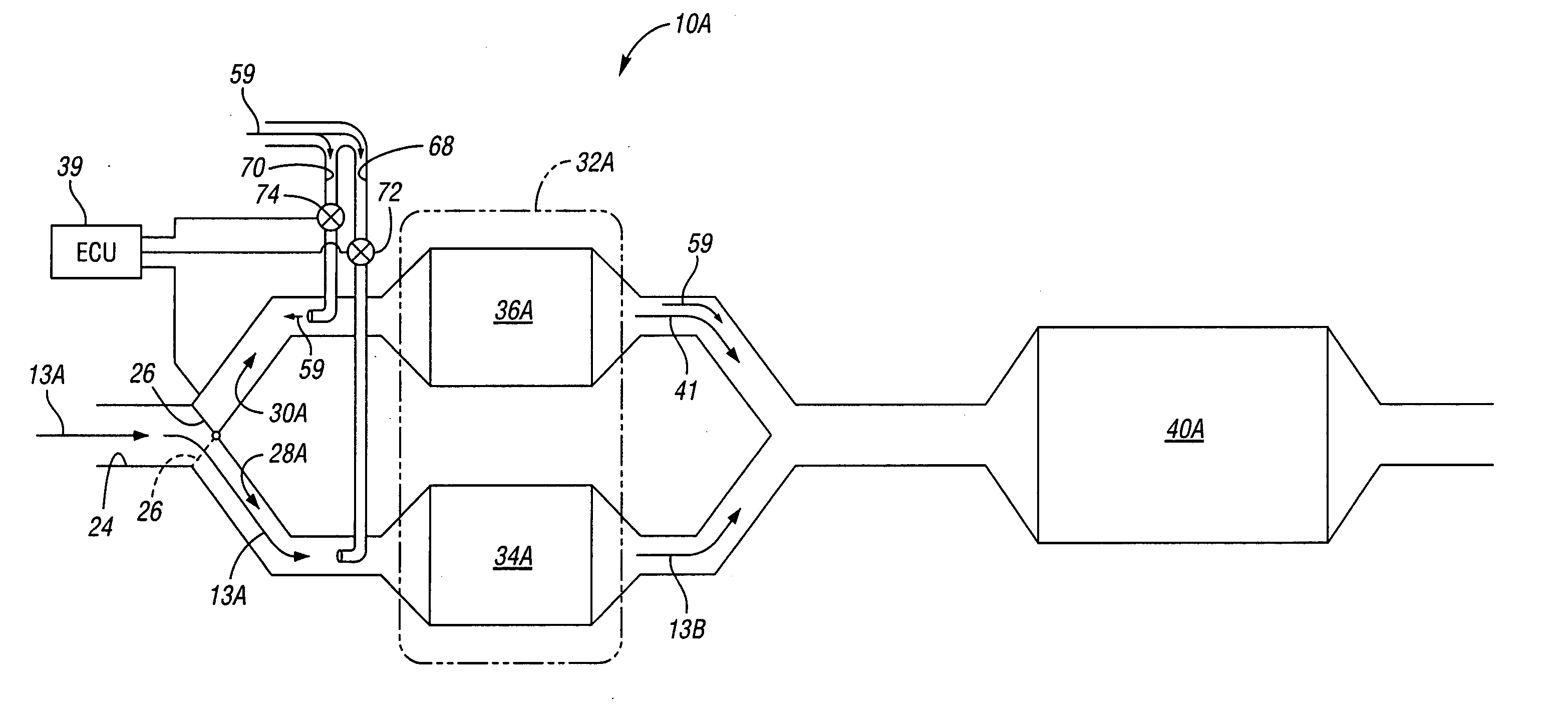

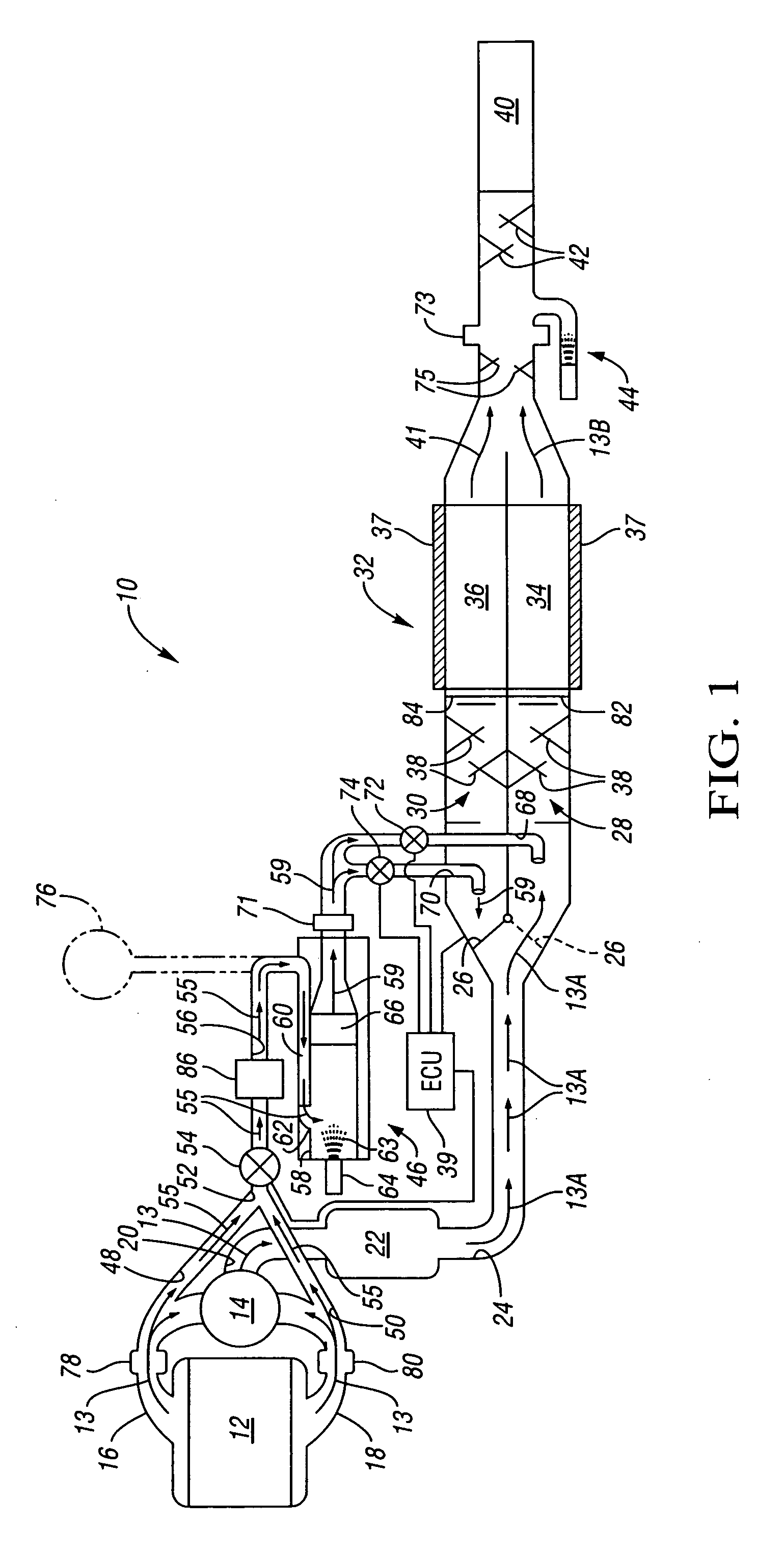

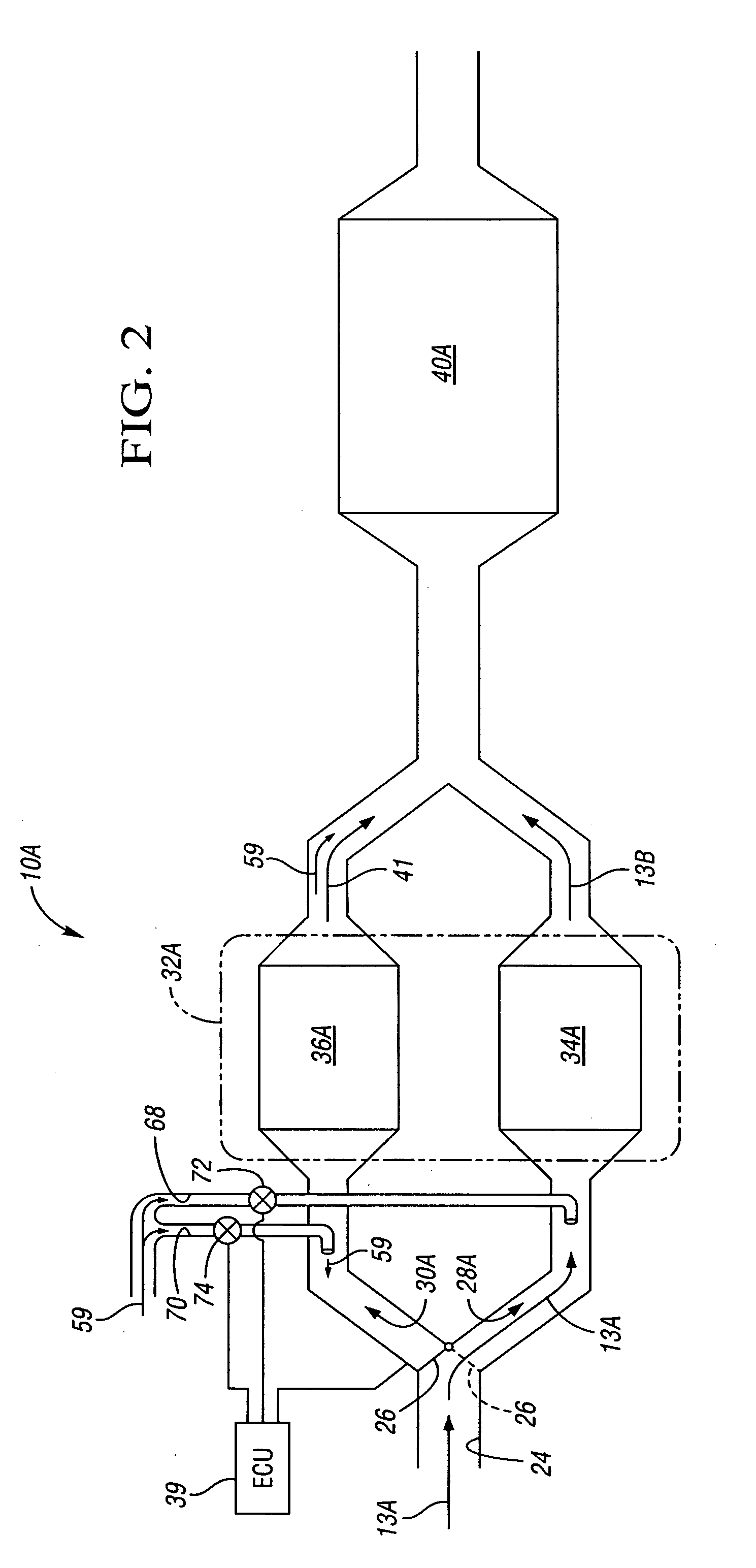

Exhaust aftertreatment system and method of use for lean burn internal combustion engines

The present invention is an aftertreatment system for lean burn internal combustion engines. The present invention provides a multiple branch lean NOx trap, or LNT, with a diverter valve operable to selectively direct lean exhaust flow to one portion of the LNT while another portion of the LNT regenerates in a low oxygen environment. Additionally, the present invention employees a continuously operating side stream exhaust fuel reformer that delivers a reductant, such as partially oxidized (POx) gas or reformate, to the LNT for regeneration. The present invention also provides a method of exhaust aftertreatment of a lean burn internal combustion engine utilizing the system provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

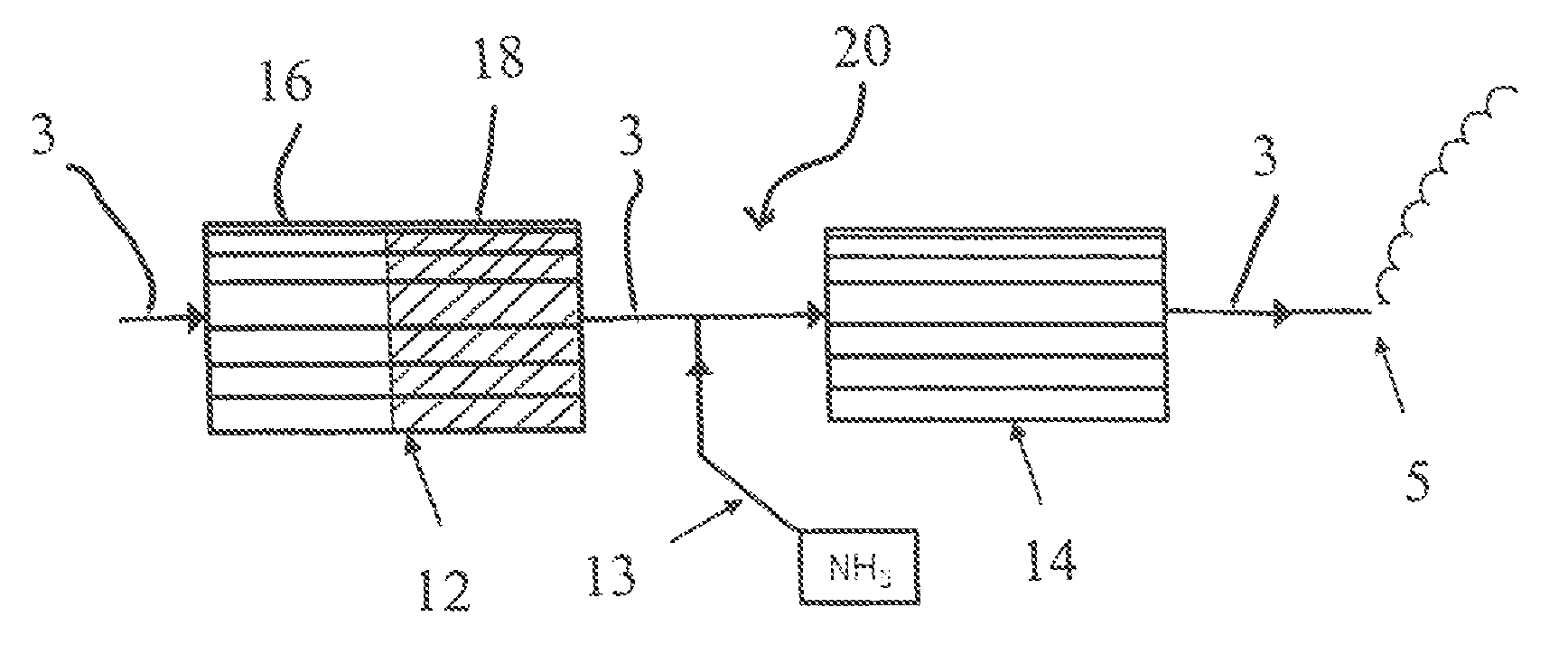

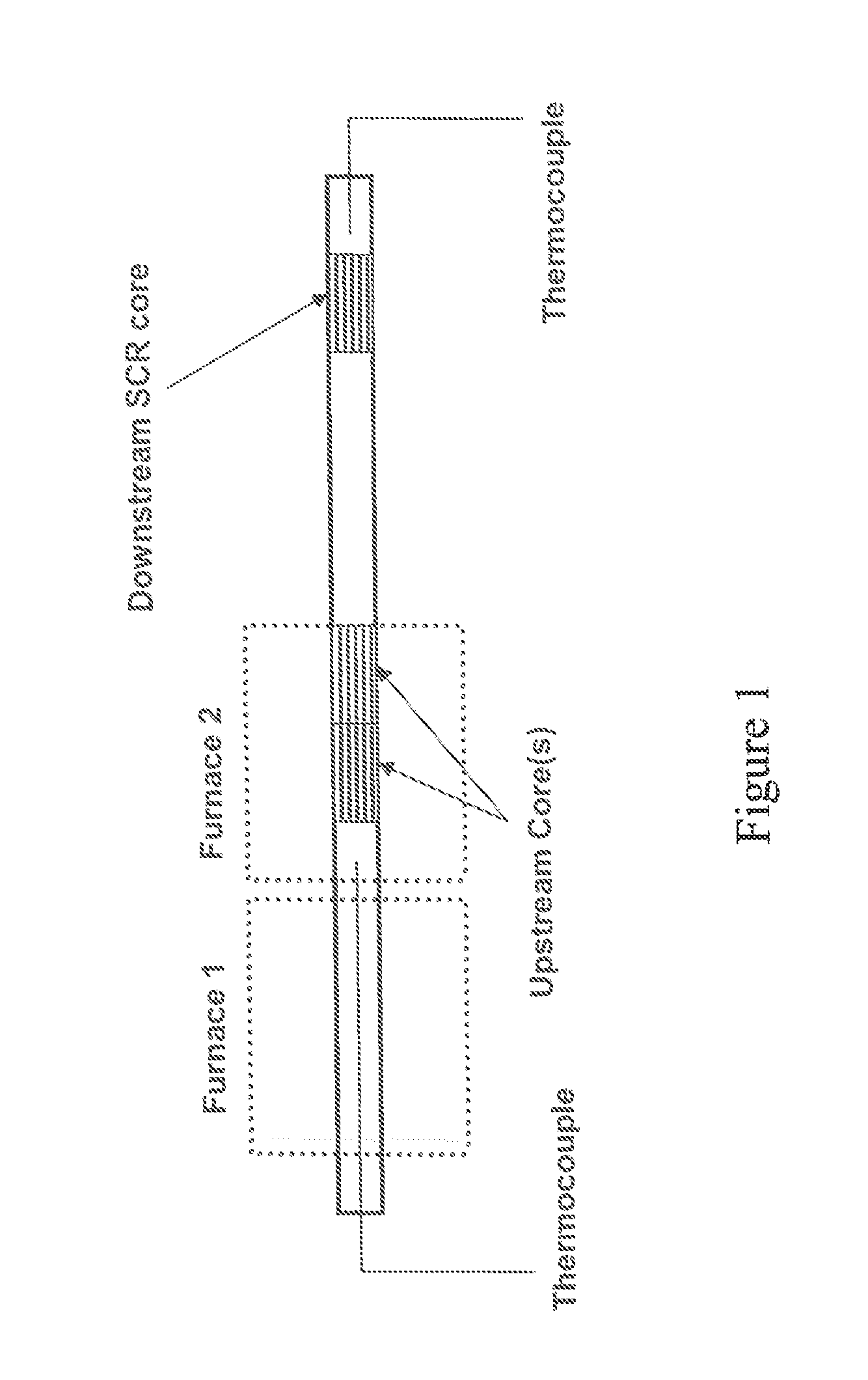

Exhaust system for a lean-burn internal combustion engine including scr catalyst

InactiveUS20130149223A1Reducing and preventing selective catalytic reduction catalystReduce and prevent poisoningCombination devicesNitrogen compoundsExternal combustion engineEngineering

An exhaust system 20 for an internal combustion engine comprises a) a first catalysed substrate monolith 12 comprising a first washcoat coating disposed in a first washcoat zone 16 of the substrate monolith and a second washcoat coating disposed in a second washcoat zone 18 of the substrate monolith, wherein the first washcoat coating comprises a catalyst composition comprising at least one platinum group metal (PGM) and at least one support material, wherein at least one PGM in the first washcoat coating is liable to volatilise when the first washcoat coating is exposed to relatively extreme conditions including relatively high temperatures, wherein the second washcoat coating comprises at least one material supporting copper for trapping volatilised PGM and wherein the second washcoat coating is oriented to contact exhaust gas that has contacted the first washcoat; and b) a second catalysed substrate monolith 14 comprising a catalyst for selectively catalysing the reduction of oxides of nitrogen to dinitrogen with a nitrogenous reductant disposed downstream from the first catalysed substrate monolith.

Owner:JOHNSON MATTHEY PLC

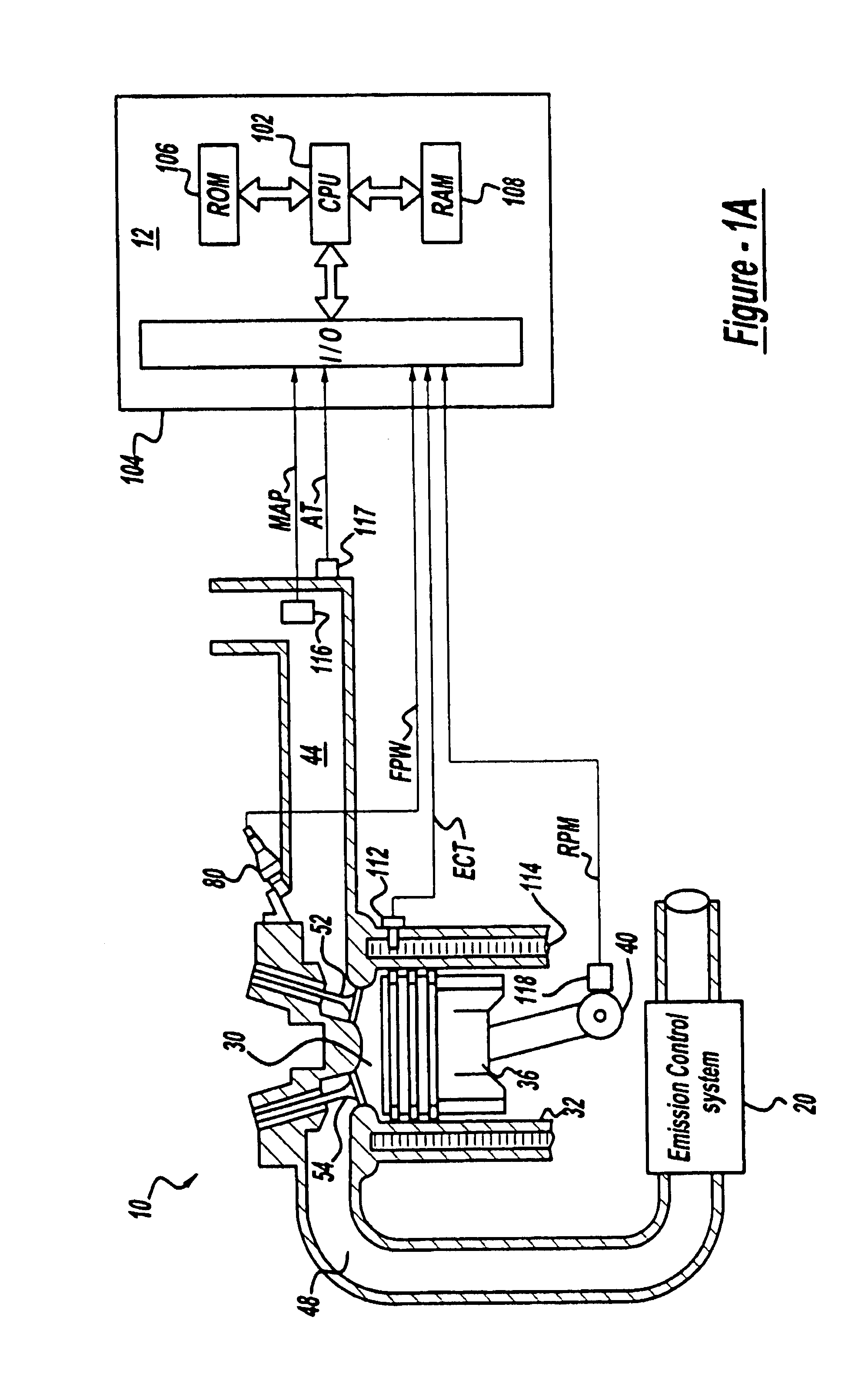

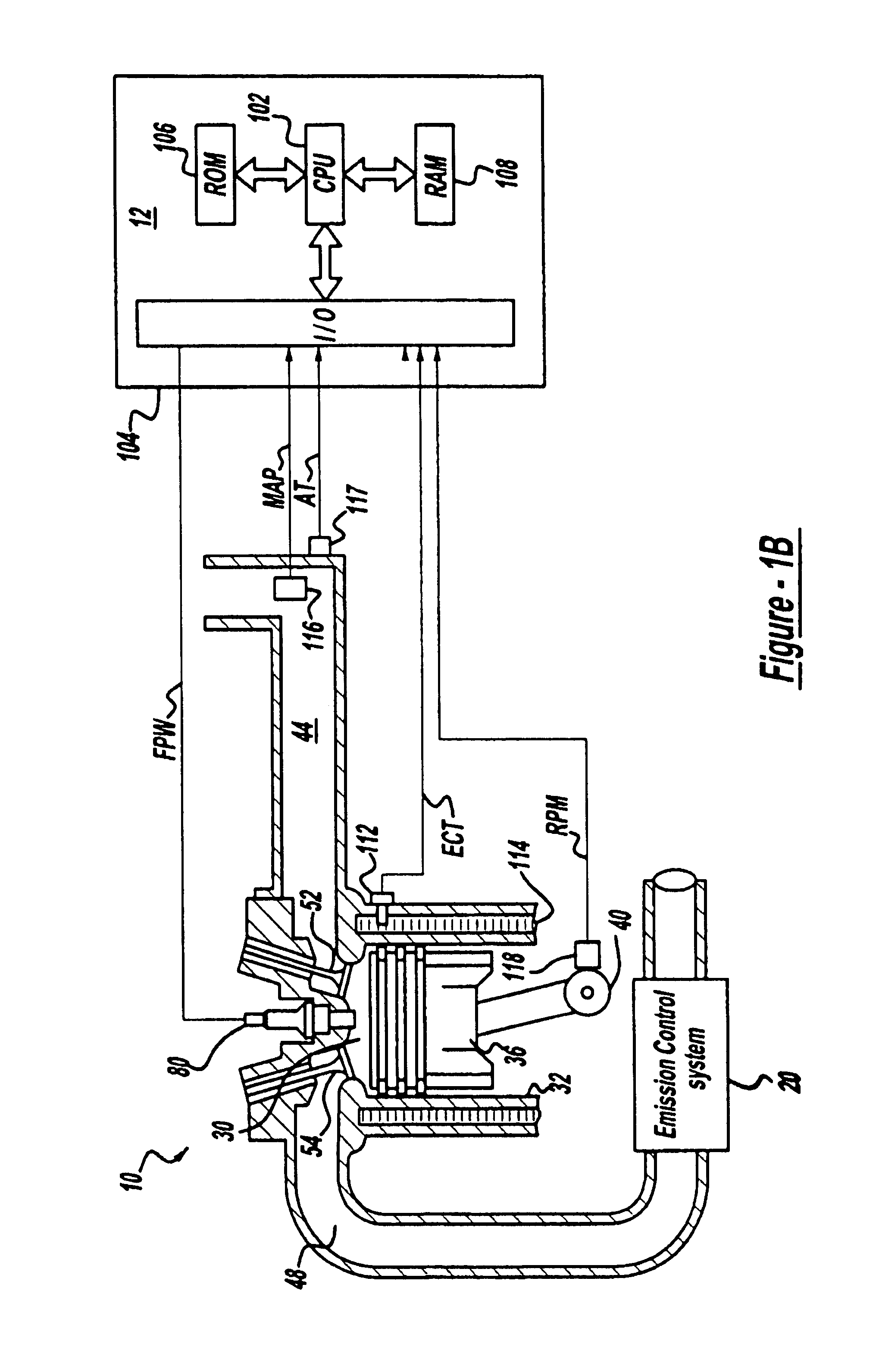

Overall scheduling of a lean burn engine system

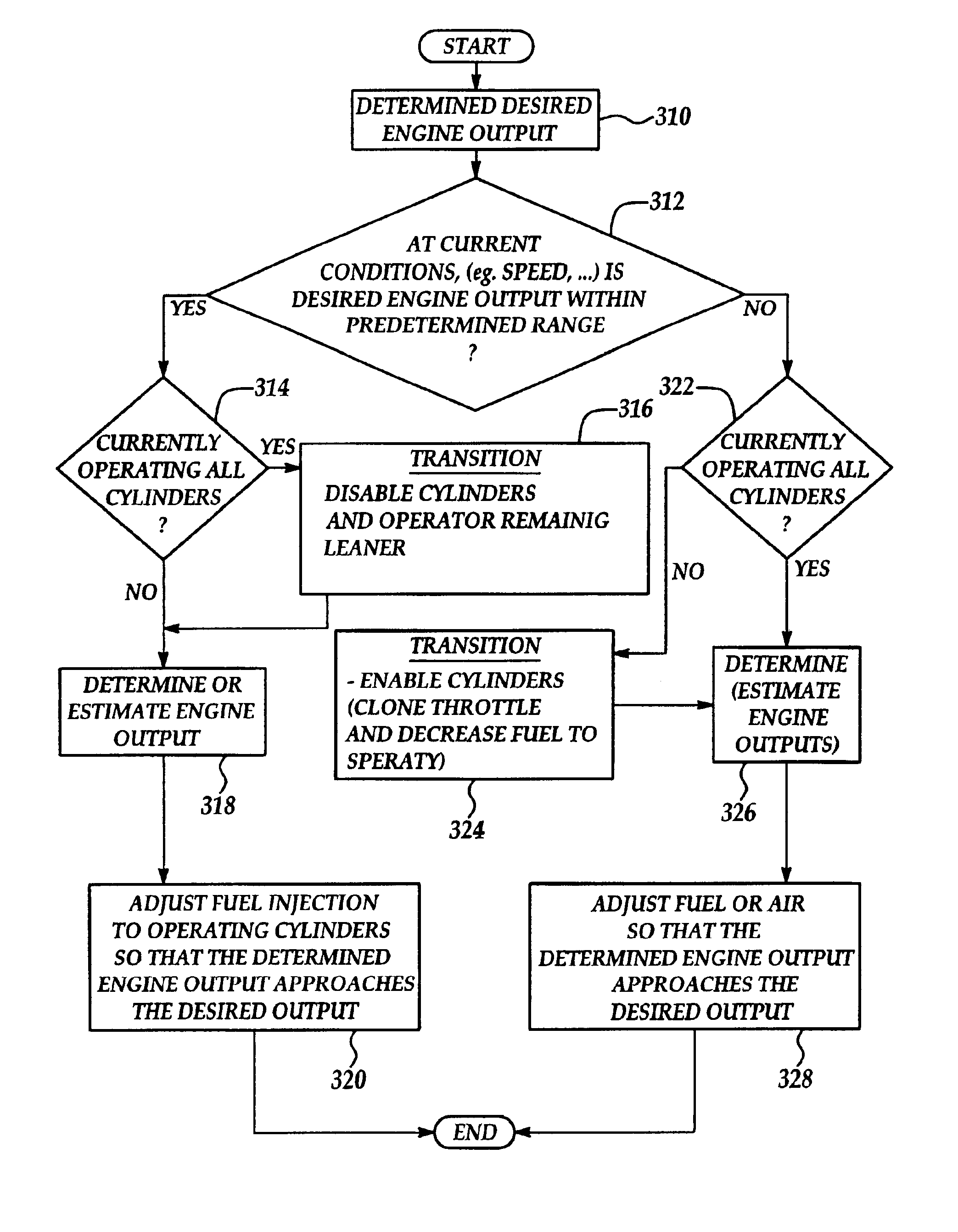

InactiveUS6691669B2Improve carrying capacityFuel to the remaining cylinders is rapidly increasedElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Catalyst system for lean burn engines

InactiveUS7329629B2Increased thermal stability and light-offEliminates NOx releaseInternal combustion piston enginesDispersed particle separationAlkaline earth metalPtru catalyst

A catalyst system to provide emission reductions under lean and stoichiometric conditions. The catalyst system comprises a forward catalyst having a first cerium-free zone including oxides of aluminum, alkali metals and alkaline earth metals and precious metals and a second zone with a lower loading of precious metals, oxides of aluminum, alkali metals or alkaline earth metals. This forward catalyst stores NOx emissions under lean conditions for subsequent reduction and converts HC, CO and NOx during stoichiometric operation. The second downstream catalyst includes precious metals, reduces emissions under stoichiometric conditions, and stores any residual NOx emitted from the first catalyst for subsequent reduction. In another embodiment, a forward catalyst has top and bottom layers designed to reduce emissions under lean conditions. In this embodiment, a second downstream catalyst is used to reduce emissions under stoichiometric conditions. In yet another catalyst, multiple zones are created within a single catalyst.

Owner:FORD GLOBAL TECH LLC

Devices and methods for reduction of NOx emissions from lean burn engines

ActiveUS7181906B2Reduce nitrogen oxide emissionsHydrogenInternal combustion piston enginesDiesel engineOxygen rich

The invention provides devices and methods for generating H2 and CO in an O2 containing gas stream. The invention also provides devices and methods for removal of NOX from an O2 containing gas stream, particularly the oxygen-rich exhaust stream from a lean-burning engine, such as a diesel engine. The invention includes a fuel processor that efficiently converts added hydrocarbon fuel to a reducing mixture of H2 and CO. The added fuel may be a portion of the onboard fuel on a vehicle. The H2 and CO are incorporated into the exhaust stream and reacted over a selective lean NOX catalyst to convert NOX to N2. thereby providing an efficient means of NOX emission control.

Owner:INT ENGINE INTPROP CO LLC

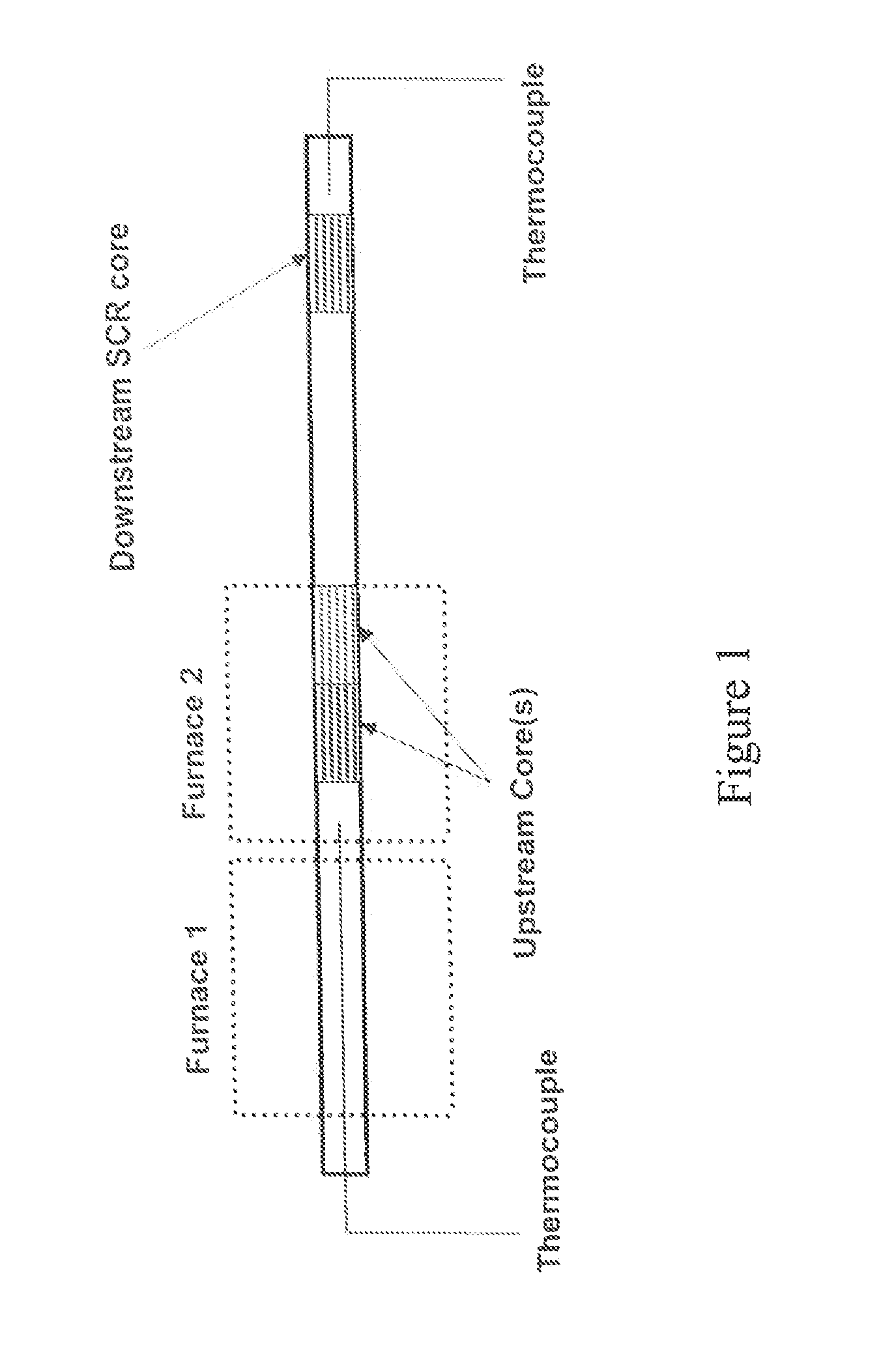

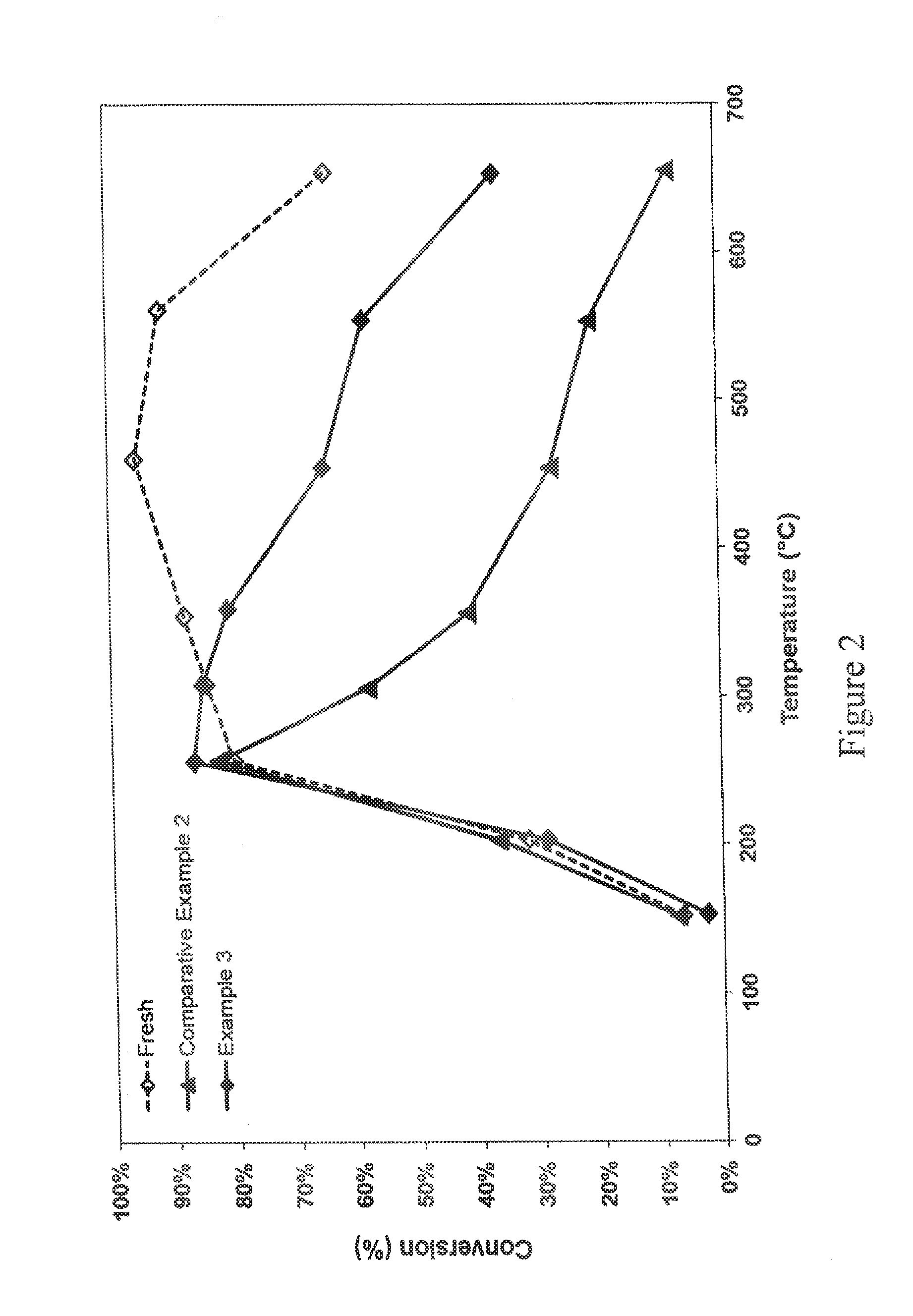

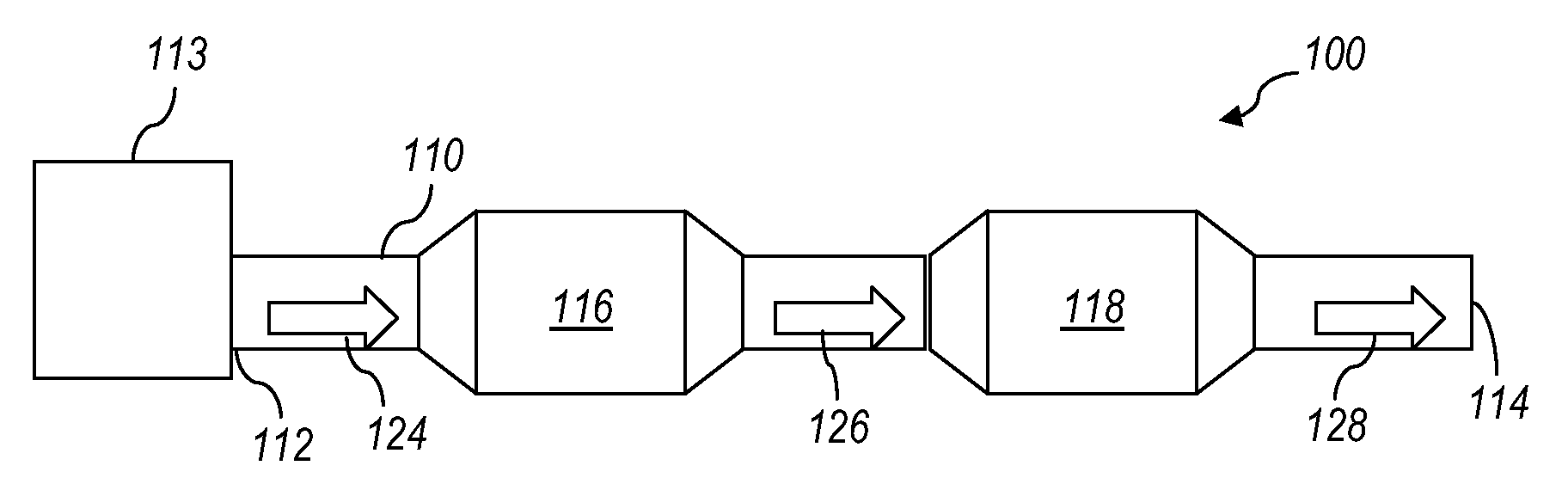

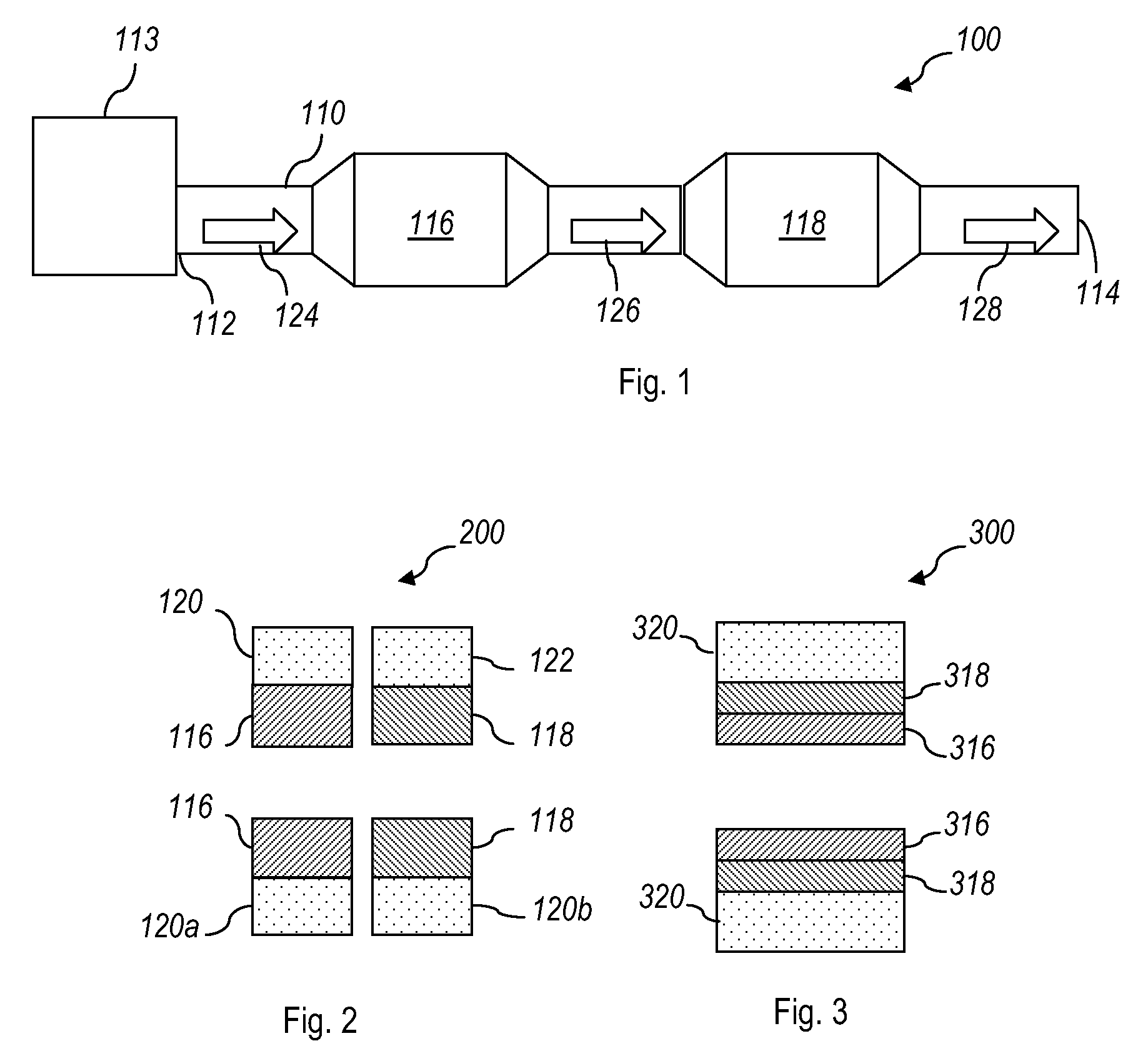

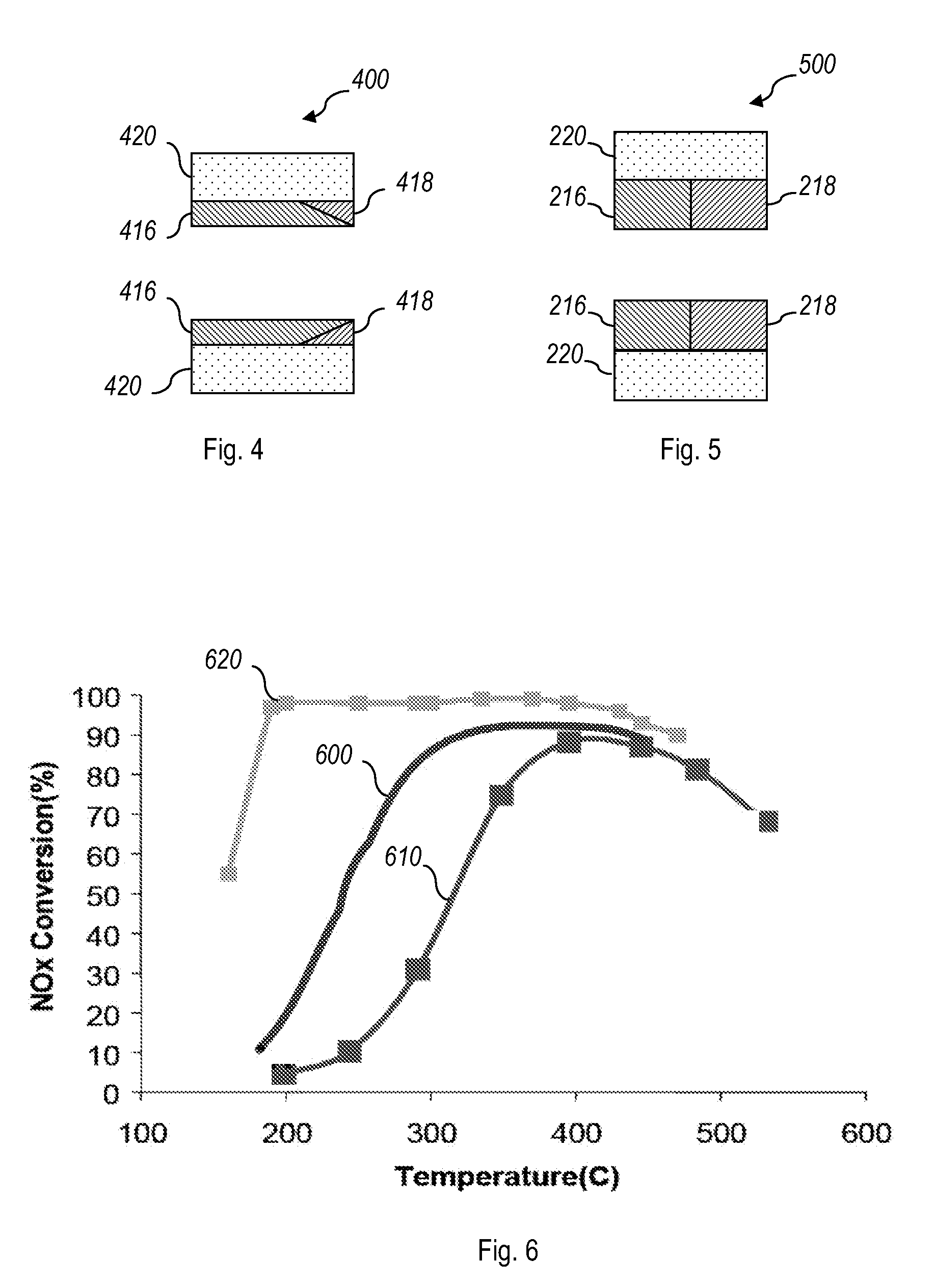

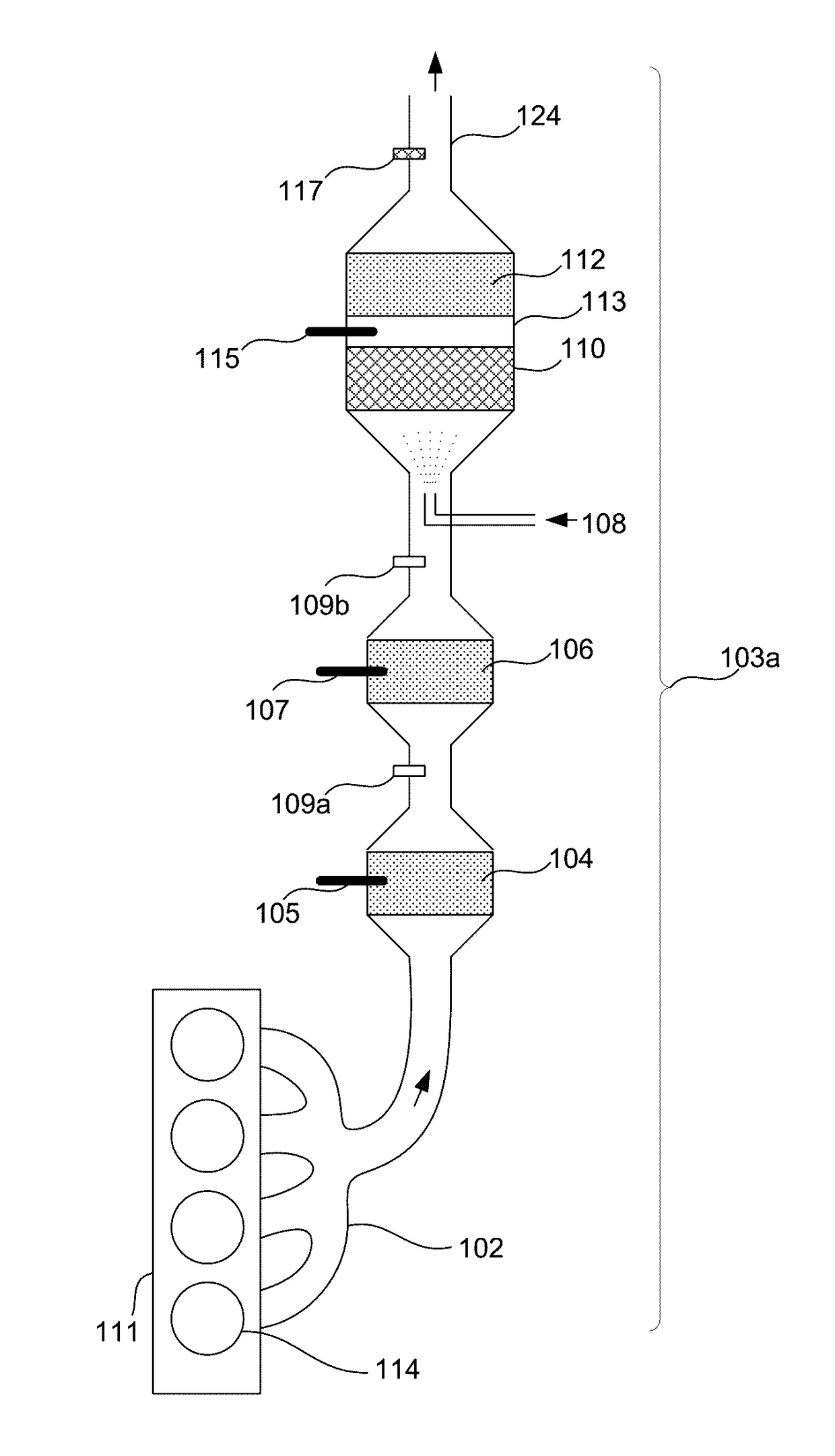

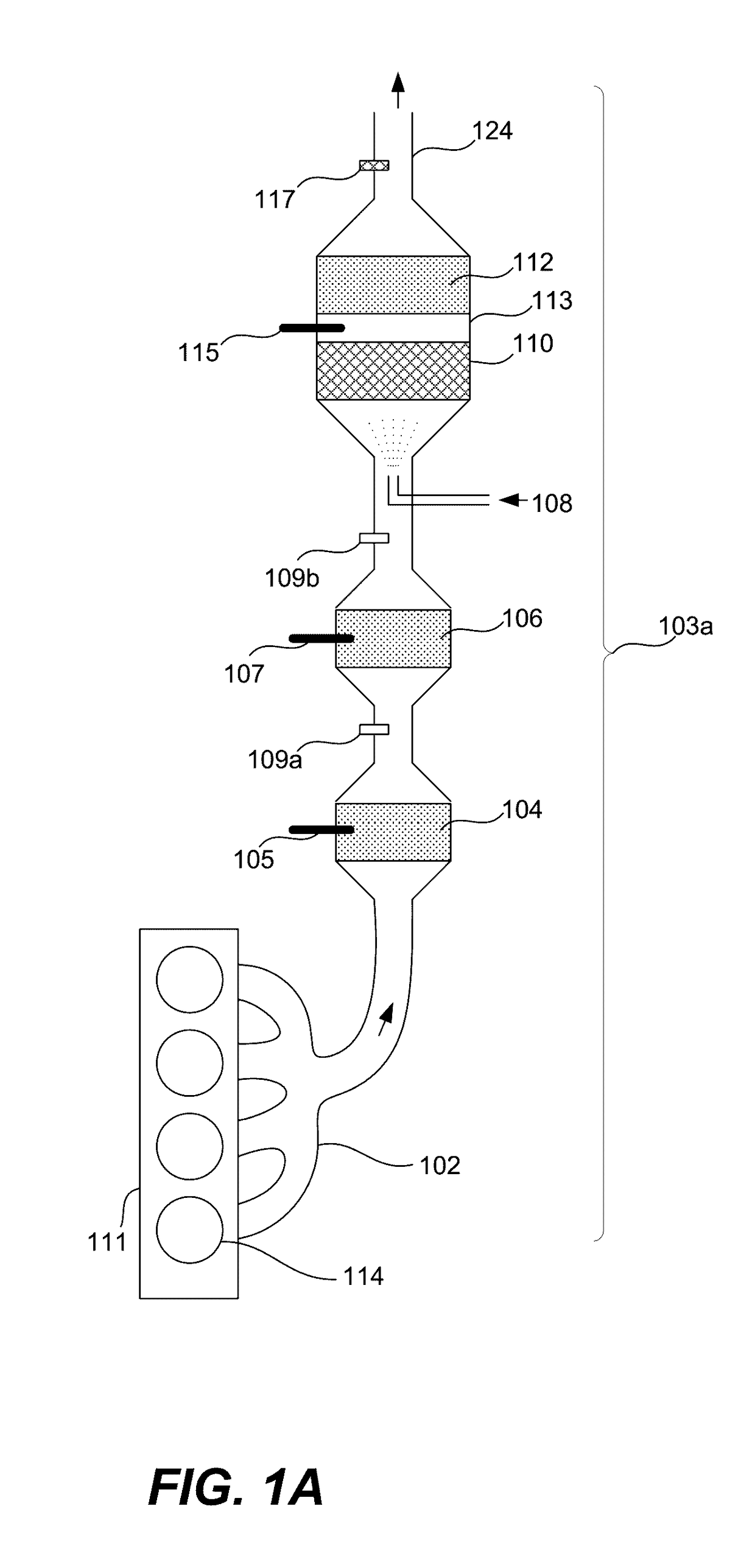

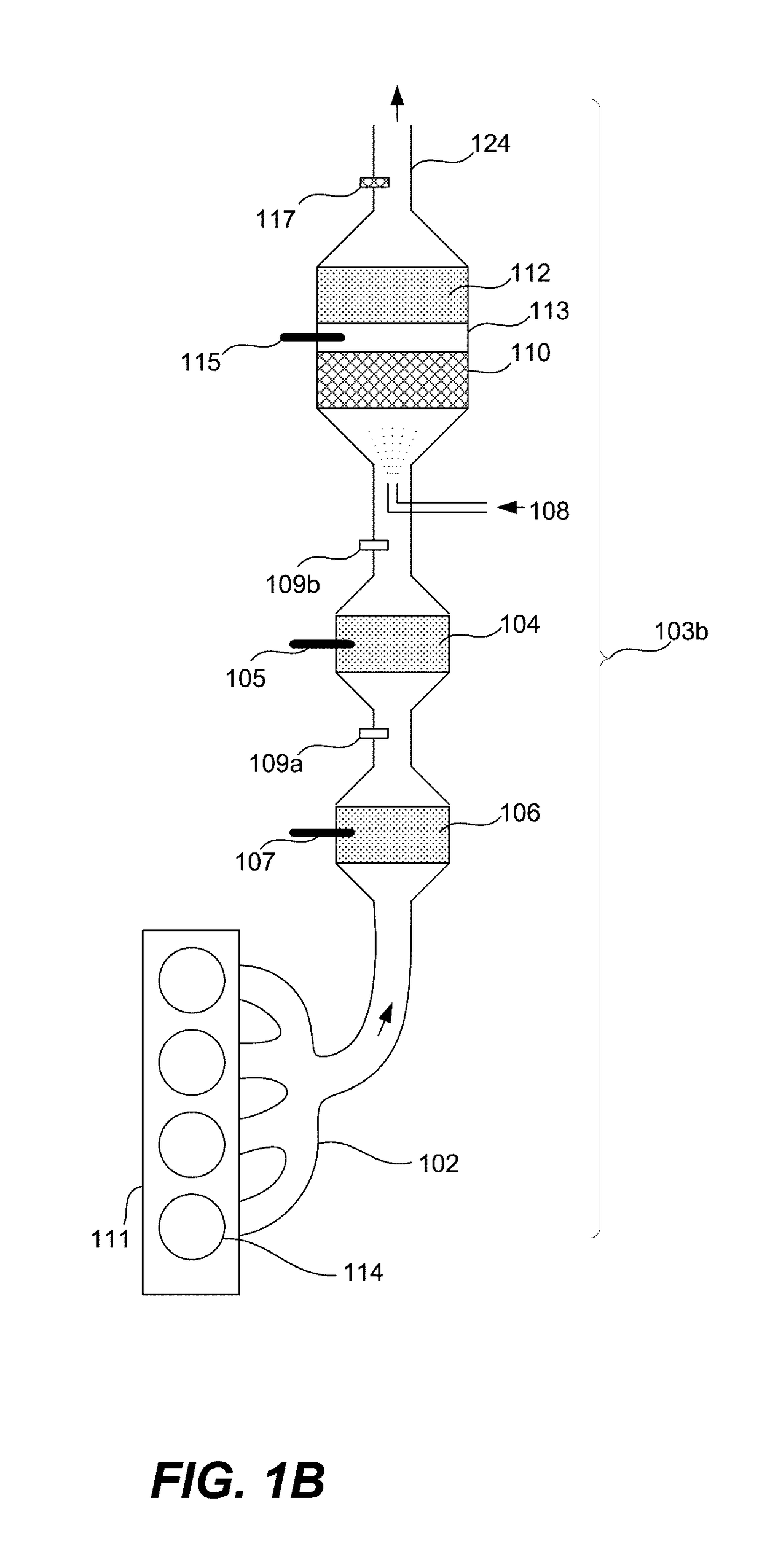

CATALYSTS, SYSTEMS, AND METHODS FOR REDUCING NOx IN AN EXHAUST GAS

InactiveUS20100101221A1Reduce nitrogen oxide emissionsReduce NOxGas treatmentMolecular sieve catalystsExhaust fumesAmmonia

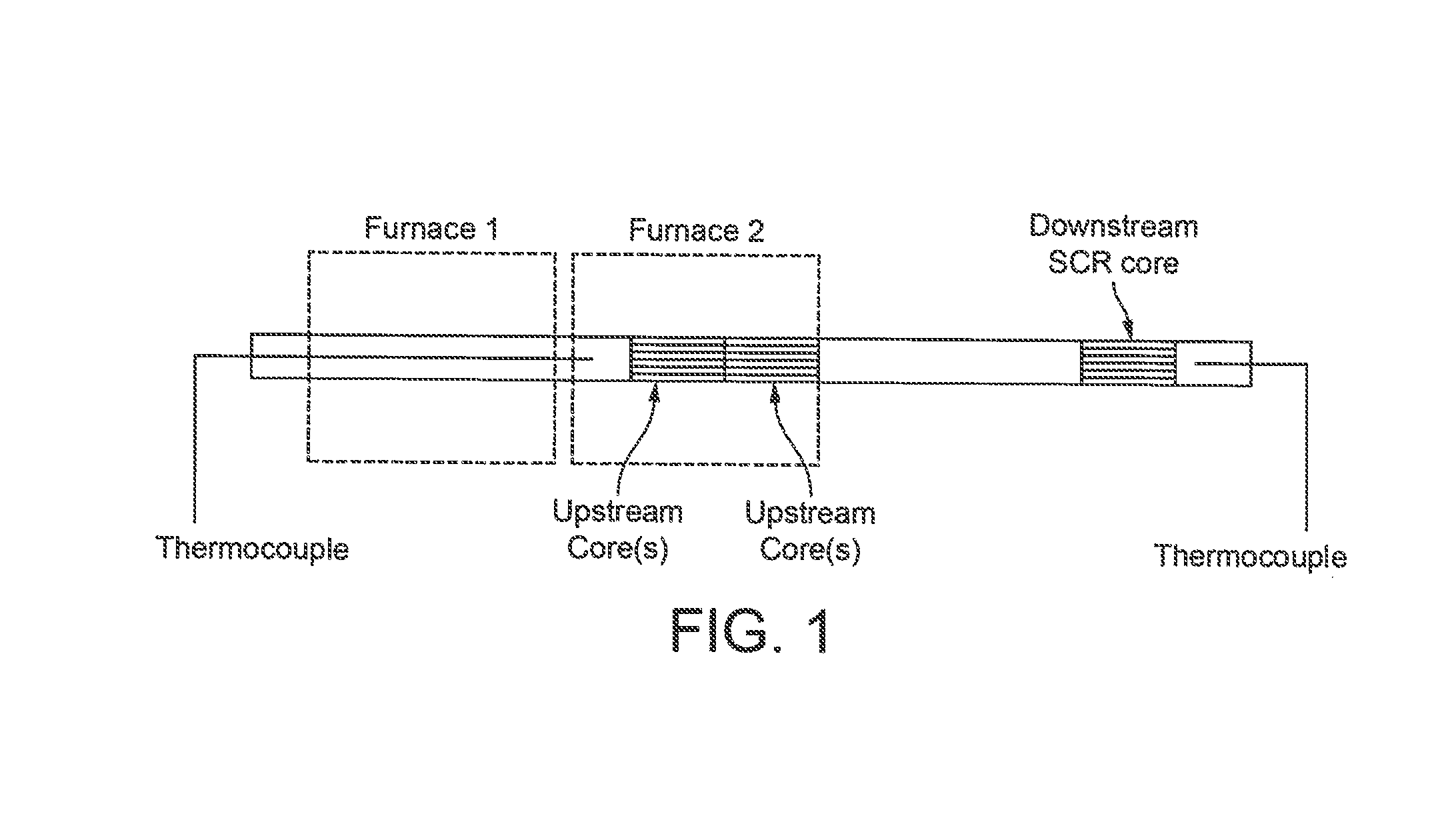

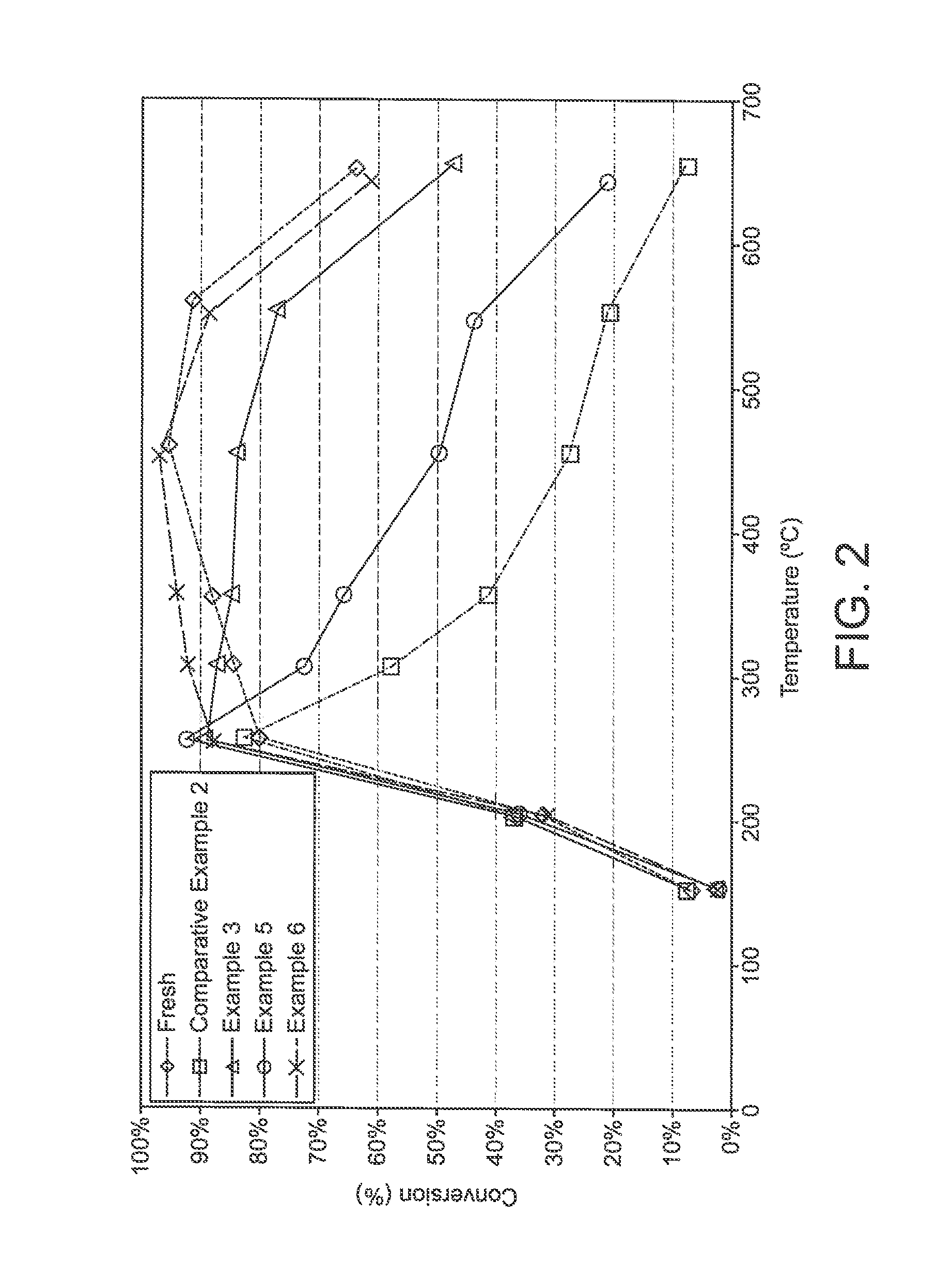

Catalysts, systems, and methods disclosed herein provide for reduced NOx emissions in the exhaust stream of a lean burning engine. The catalysts include two different types of selective catalytic reduction (SCR) catalysts (i.e., two different types of catalysts that may catalytically reduce NOx using a reductant). The first SCR catalyst (116) is an SCR catalyst having a composition that produces a reductant (e.g., an HC-SCR catalyst that produces ammonia) and the second catalyst (118) is an SCR catalyst (e.g., NH3-SCR) having a composition that reduces NOx using the reductant produced by the first SCR catalyst (116).

Owner:CATERPILLAR INC

Method to improve fuel economy in lean burn engines with variable-displacement-like characteristics

InactiveUS20030221655A1Accurate air-fuel ratioIncrease in temperature of catalystElectrical controlNon-fuel substance addition to fuelTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

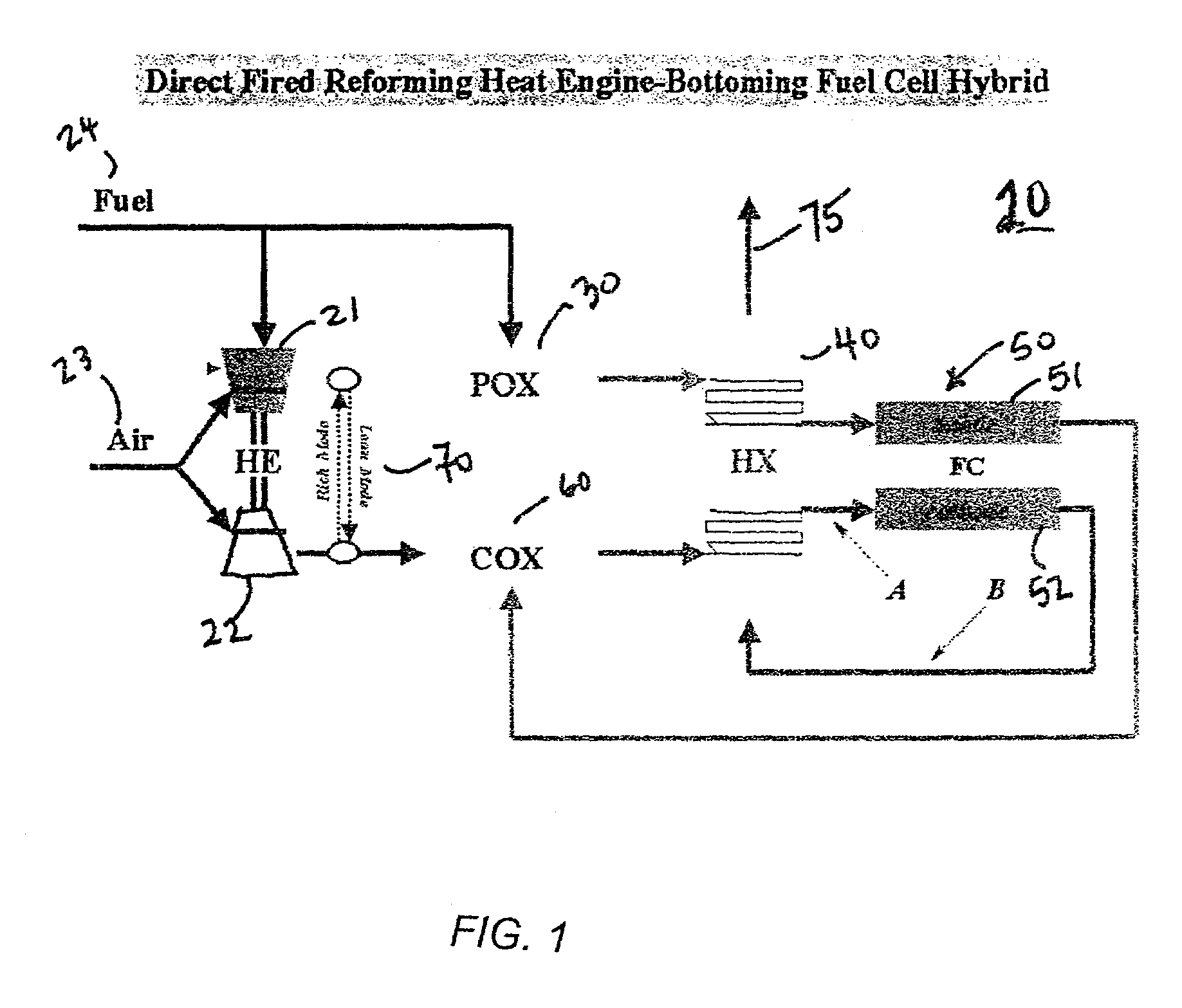

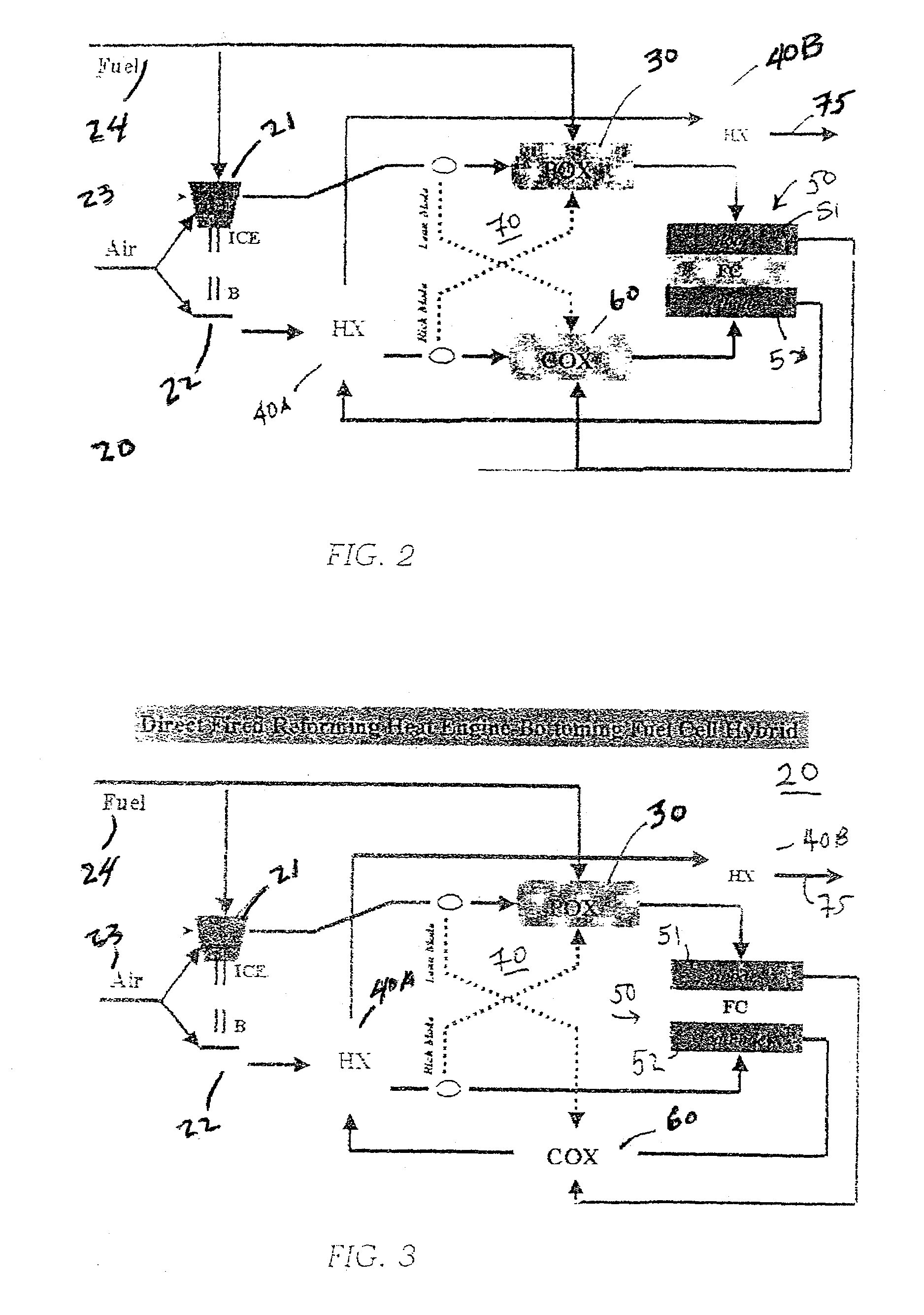

Direct fired reciprocating engine and bottoming high temperature fuel cell hybrid

InactiveUS6994930B1High densityImprove efficiencyFuel cell heat exchangeExhaust apparatusHigh concentrationFuel cells

A system of a fuel cell bottoming an internal combustion engine. The engine exhaust gas may be combined in varying degrees with air and fed as input to a fuel cell. Reformer and oxidizers may be combined with heat exchangers to accommodate rich and lean burn conditions in the engine in peaking and base load conditions without producing high concentrations of harmful emissions.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Secondary internal combustion device for providing exhaust gas to EGR-equipped engine

ActiveUS20060112940A1Eliminating primary efficiency reduction challengeReduce nitrogen oxide emissionsNon-fuel substance addition to fuelInternal combustion piston enginesCombustionDiesel engine

A system and method for providing exhaust gas to an EGR-equipped lean burn diesel engine (the primary engine). The exhaust gas is provided by a secondary internal combustion device, whose configuration, thermal cycle, and operating conditions may be different from that of the primary engine. The secondary internal combustion device may receive recirculated exhaust gas, fresh air, or some combination of both.

Owner:SOUTHWEST RES INST

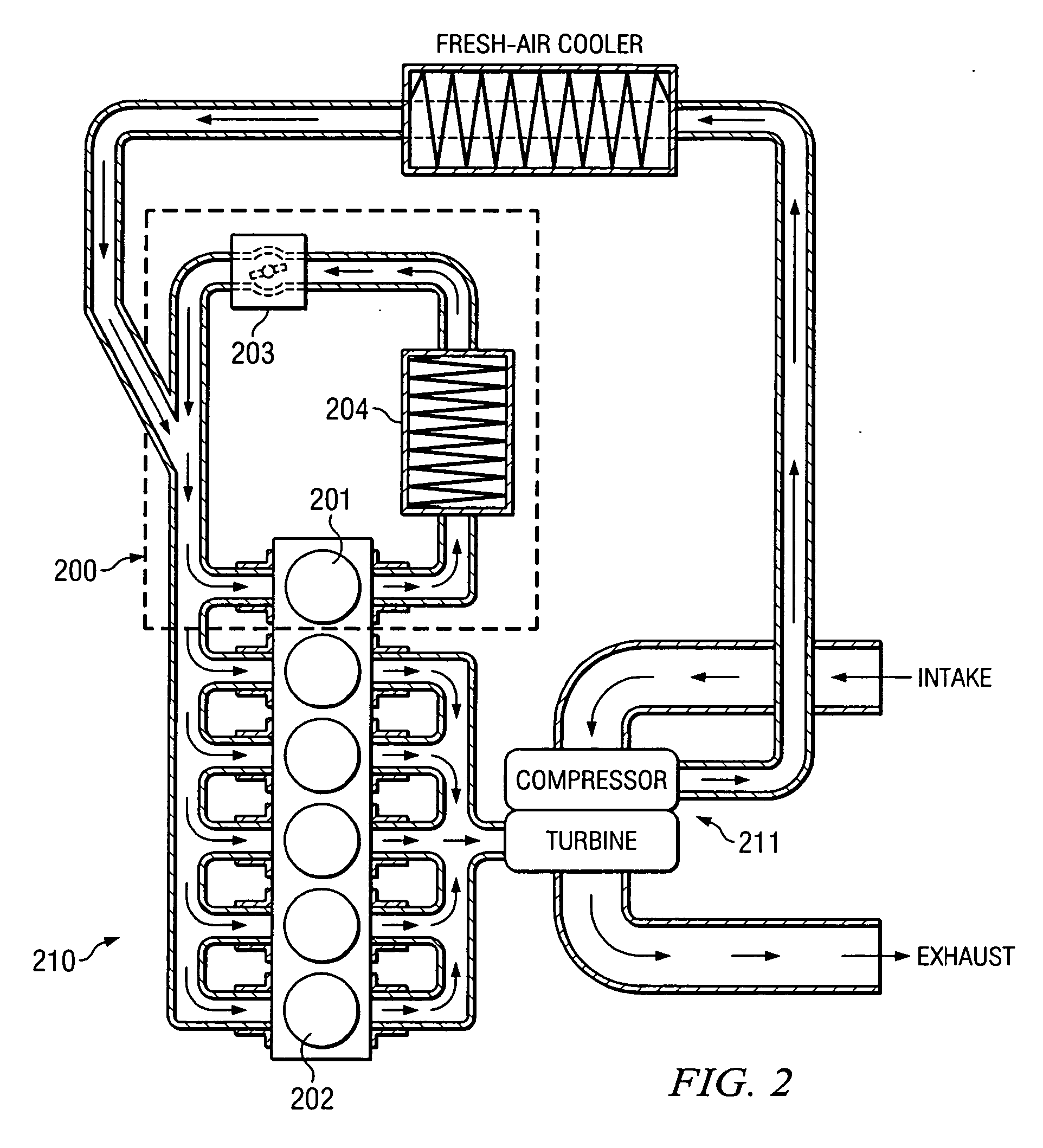

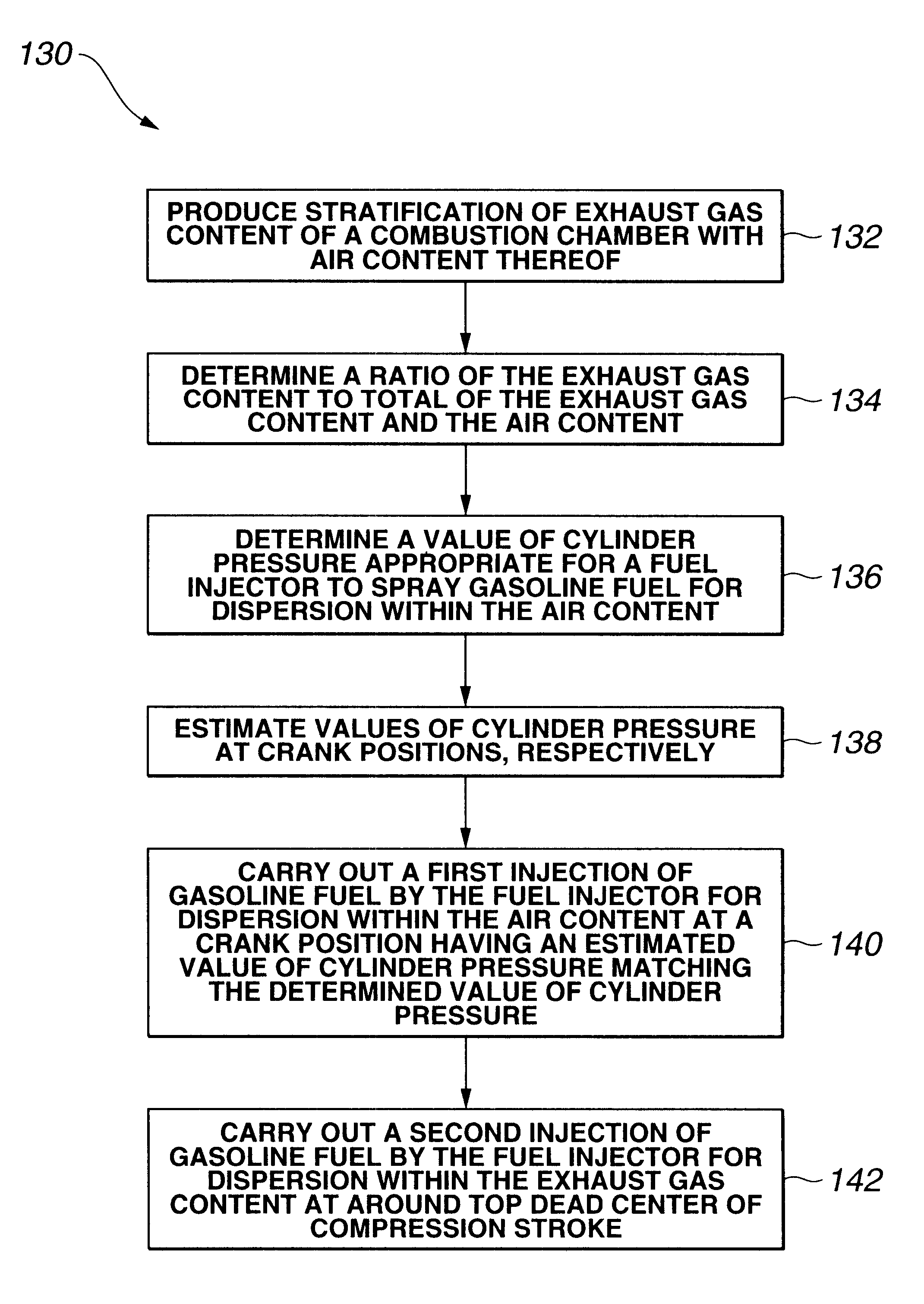

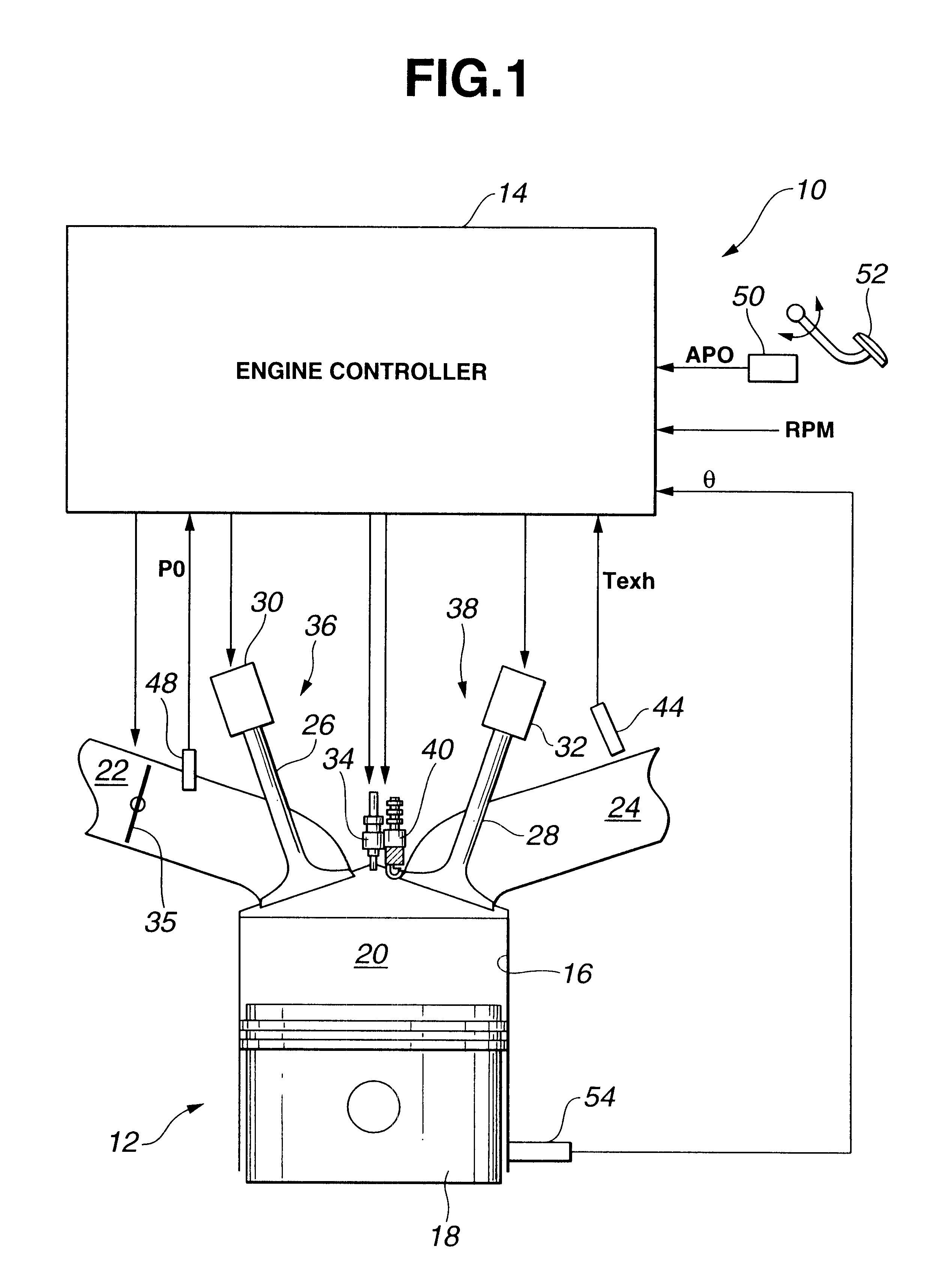

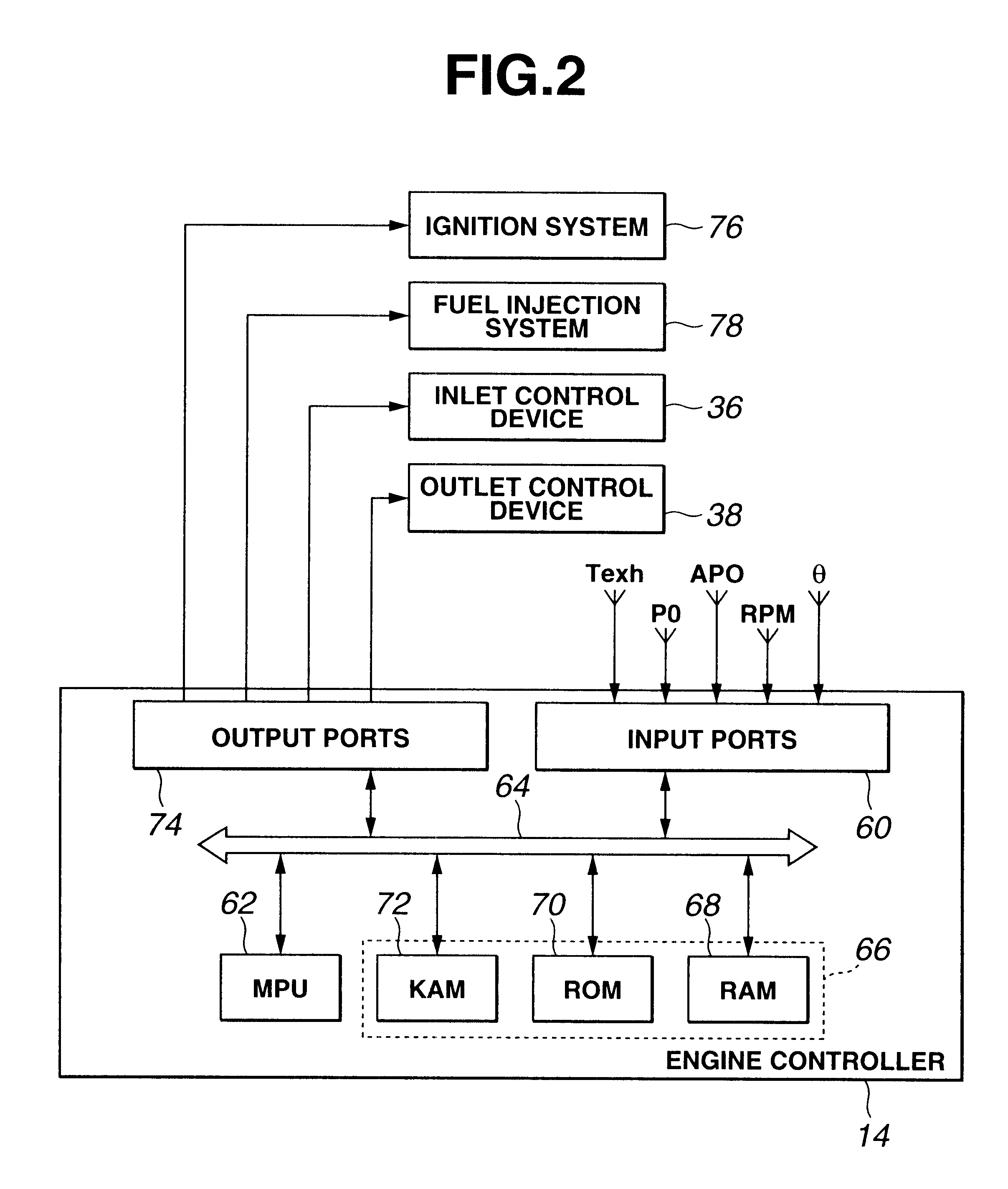

Controlled auto-ignition lean burn stratified engine by intelligent injection

A system and method for widening auto-ignition range of a lean burn internal combustion engine employs stratified charge of exhaust gas content and air content. A fuel injection system carries out a first injection of gasoline fuel for dispersion within the air content, and a second injection of gasoline fuel for dispersion within the exhaust gas content. This intelligent injection of gasoline fuel accomplishes auto-ignition of gasoline fuel within the exhaust gas content over extended range of engine speed and load.

Owner:NISSAN MOTOR CO LTD

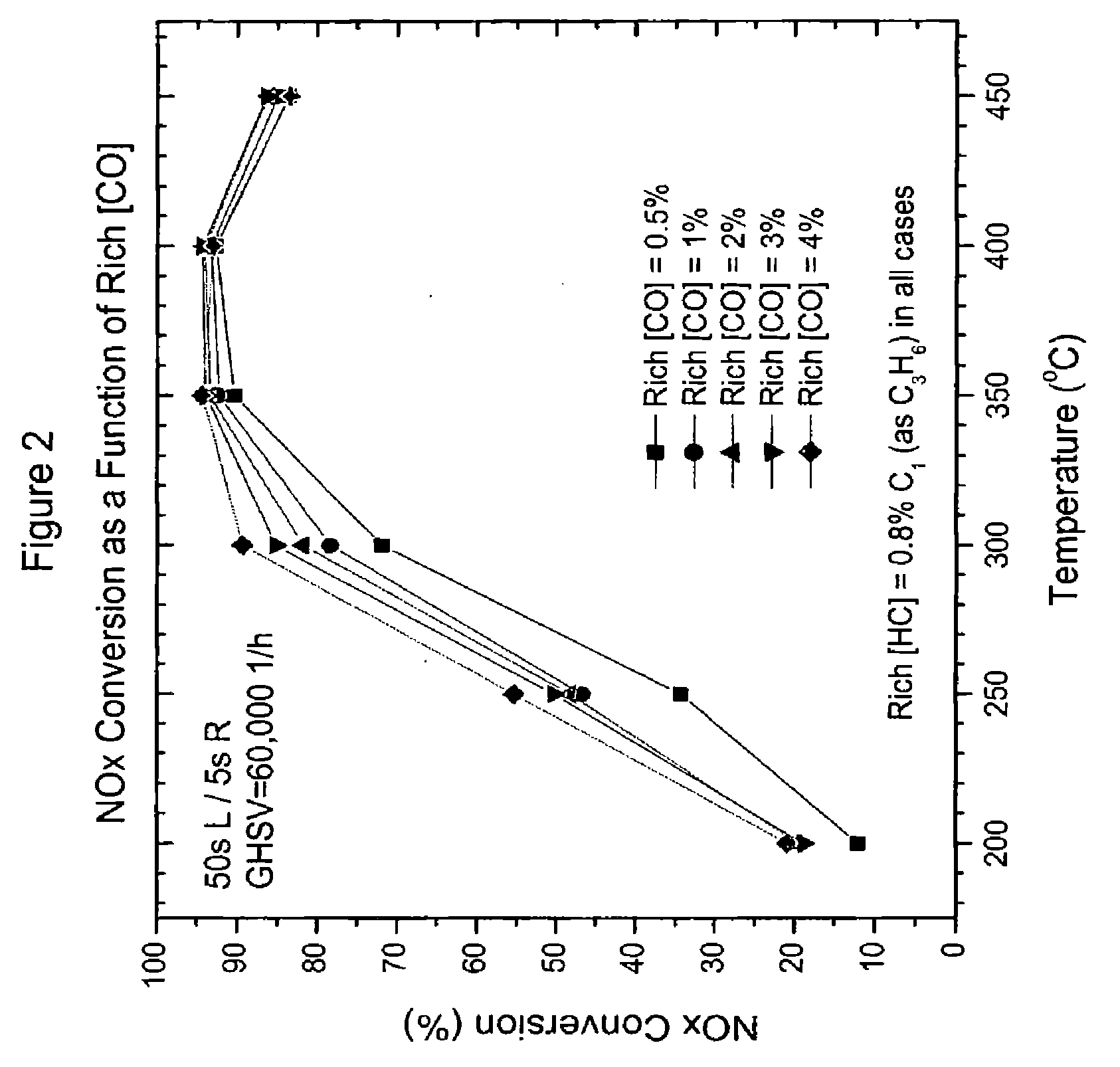

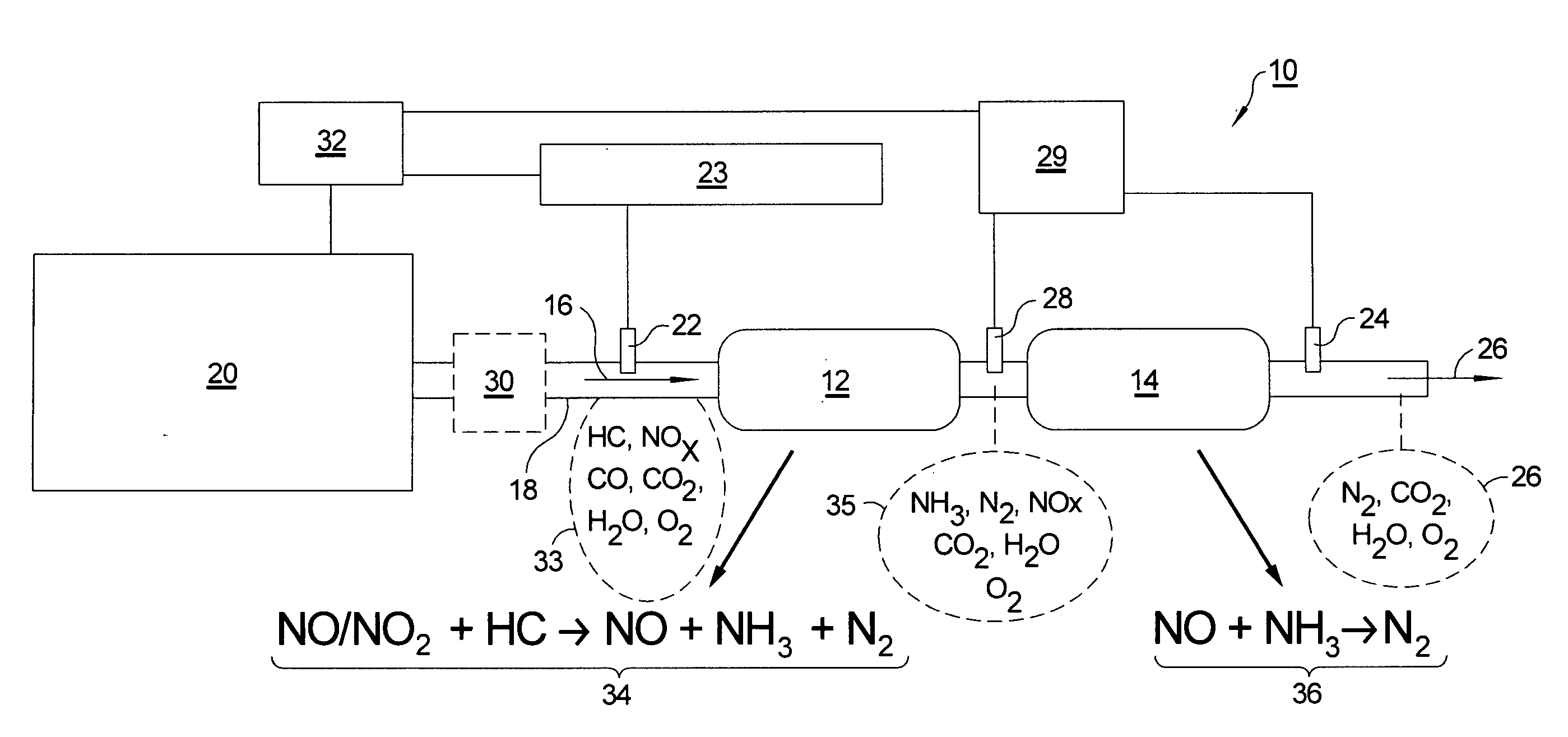

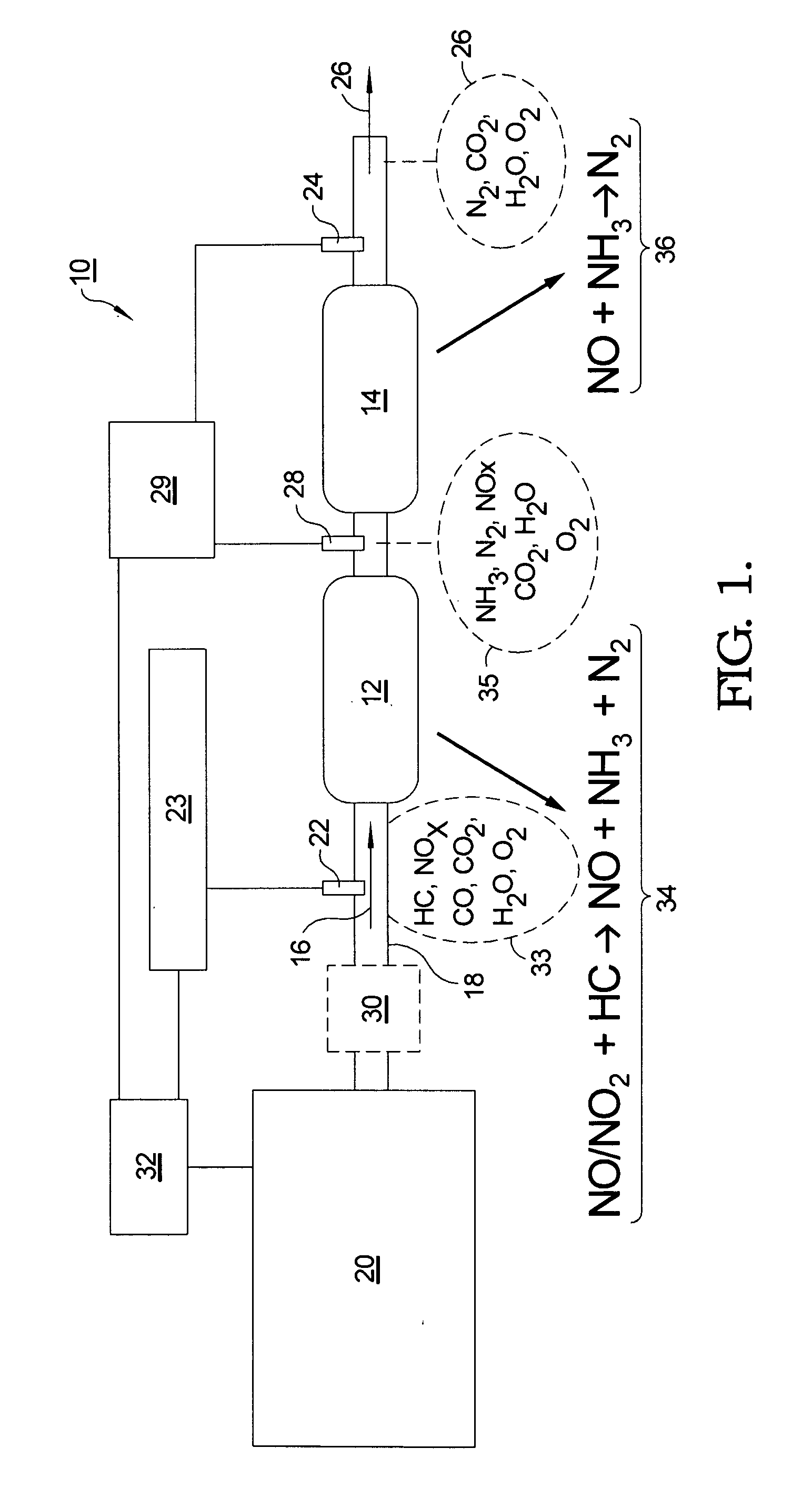

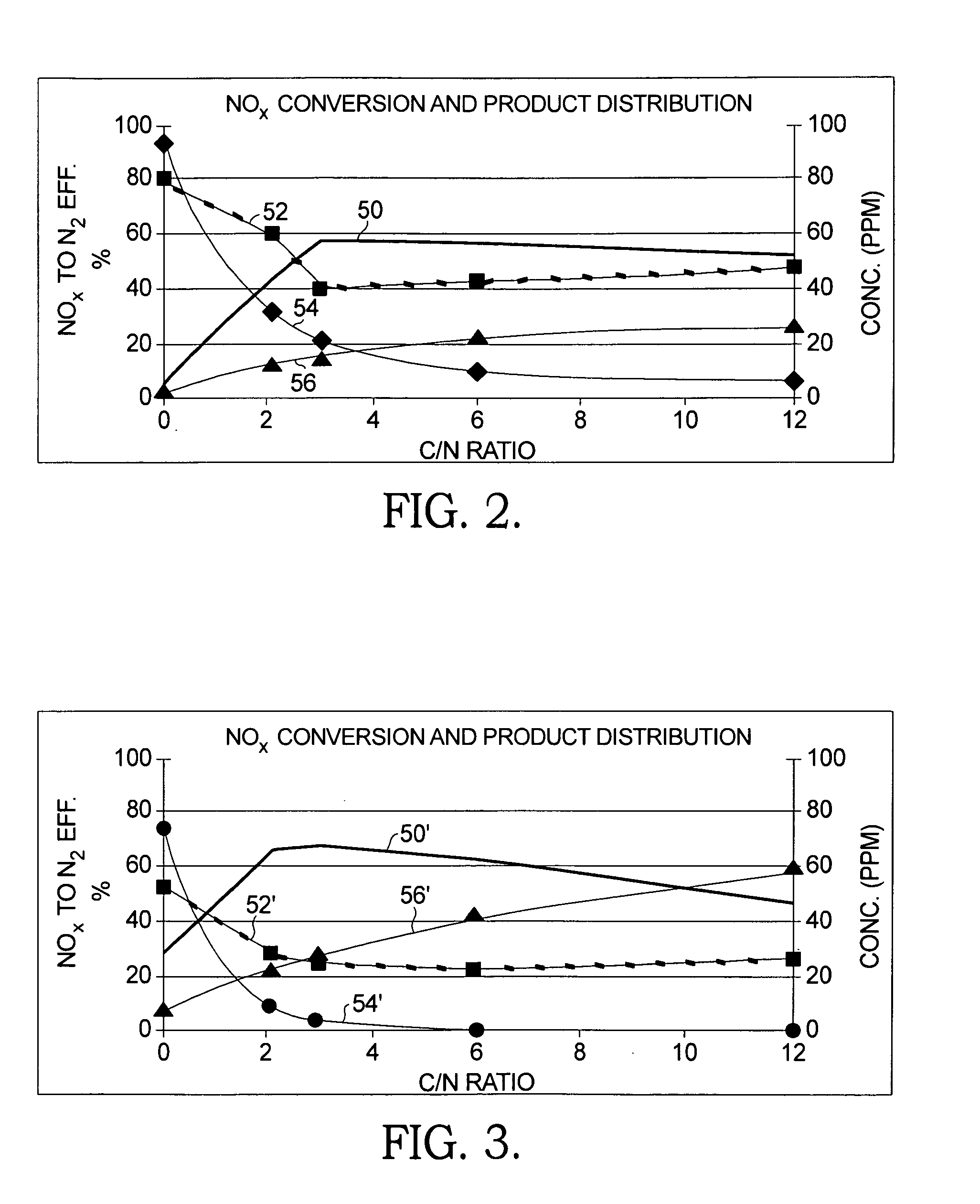

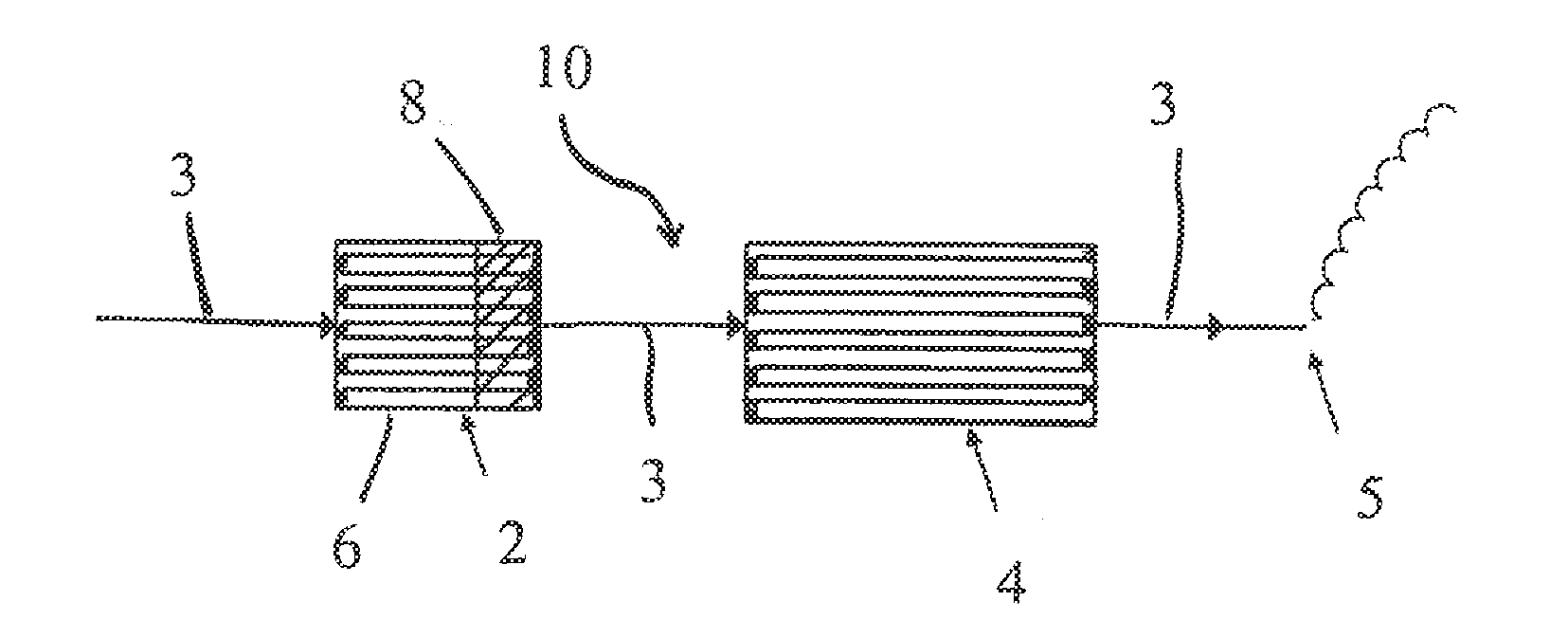

Dual catalyst NOx reduction system for exhaust from lean burn internal combustion engines

ActiveUS20100000202A1Remove loadGas treatmentInternal combustion piston enginesMolecular nitrogenInternal combustion engine

A method and apparatus for reducing the percentage of nitrogen dioxide and nitrogen monoxide in an exhaust gas stream of an internal combustion engine, comprising the steps of injecting a hydrocarbon compound and optionally hydrogen into the exhaust gas stream; passing the exhaust gas through a first catalyst for selective reduction of a portion of the nitrogen oxides to nitrogen, ammonia, and N-containing species; passing the exhaust gas through a second catalyst for selective reduction of a portion of the nitrogen oxides with ammonia to molecular nitrogen; sensing ammonia concentration in the exhaust gas stream after passage through either or both of the first and second catalysts; and controlling by a controller in a feedback loop the injecting to an amount of hydrocarbon that will produce a predetermined concentration of ammonia and nitrogen oxides at the sensor that will lead to high NOx conversion.

Owner:DELPHI TECH IP LTD

Lean burn internal combustion engine exhaust gas temperature control

ActiveUS20170130630A1Electrical controlInternal combustion piston enginesTemperature controlExternal combustion engine

A variety of methods and arrangements for controlling the exhaust gas temperature of a lean burn, skip fire controlled internal combustion engine are described. In one aspect, an engine controller includes an aftertreatment system monitor and a firing timing determination unit. The aftertreatment monitor obtains data relating to a temperature of one or more aftertreatment elements, such as a catalytic converter. Based at least partly on this data, the firing timing determination unit generates a firing sequence for operating the engine in a skip fire manner such that the temperature of the aftertreatment element is controlled within its effective operating range.

Owner:TULA TECH INC

Catalysed substrate monolith

ActiveUS20130149221A1Avoids and reduces problemReduce and prevent poisoningCombination devicesNitrogen compoundsInternal combustion engineMetal

A catalysed substrate monolith 12 for use in treating exhaust gas emitted from a lean-burn internal combustion engine, which catalysed substrate monolith 12 comprising a first washcoat coating 16 and a second washcoat coating 18, wherein the first washcoat coating comprises a catalyst composition comprising at least one platinum group metal (PGM) and at least one support material for the at least one PGM, wherein at least one PGM in the first washcoat coating is liable to volatilise when the first washcoat coating is exposed to relatively extreme conditions including relatively high temperatures, wherein the second washcoat coating comprises at least one metal oxide for trapping volatilised PGM and wherein the second washcoat coating is oriented to contact exhaust gas that has contacted the first washcoat coating.

Owner:JOHNSON MATTHEY PLC

Oxidation catalyst for internal combustion engine exhaust gas treatment

ActiveUS8652429B2Continuous and effective cleaningReduce the amount requiredNitrogen compoundsInternal combustion piston enginesCombustionExternal combustion engine

The invention provides an exhaust gas cleaning oxidation catalyst and in particular to an oxidation catalyst for cleaning the exhaust gas discharged from internal combustion engines of compression ignition type (particularly diesel engines). The invention further relates to a catalysed substrate monolith comprising an oxidizing catalyst on a substrate monolith for use in treating exhaust gas emitted from a lean-burn internal combustion engine. In particular, the invention relates to a catalysed substrate monolith comprising a first washcoat coating and a second washcoat coating, wherein the second washcoat coating is disposed in a layer above the first washcoat coating.

Owner:JOHNSON MATTHEY PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com