Patents

Literature

3732 results about "Exhaust gas recirculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In internal combustion engines, exhaust gas recirculation (EGR) is a nitrogen oxide (NO x ) emissions reduction technique used in petrol/gasoline and diesel engines. EGR works by recirculating a portion of an engine's exhaust gas back to the engine cylinders. This dilutes the O₂ in the incoming air stream and provides gases inert to combustion to act as absorbents of combustion heat to reduce peak in-cylinder temperatures. NO x is produced in high temperature mixtures of atmospheric nitrogen and oxygen that occur in the combustion cylinder, and this usually occurs at cylinder peak pressure. Another primary benefit of external EGR valves on a spark ignition engine is an increase in efficiency, as charge dilution allows a larger throttle position and reduces associated pumping losses.

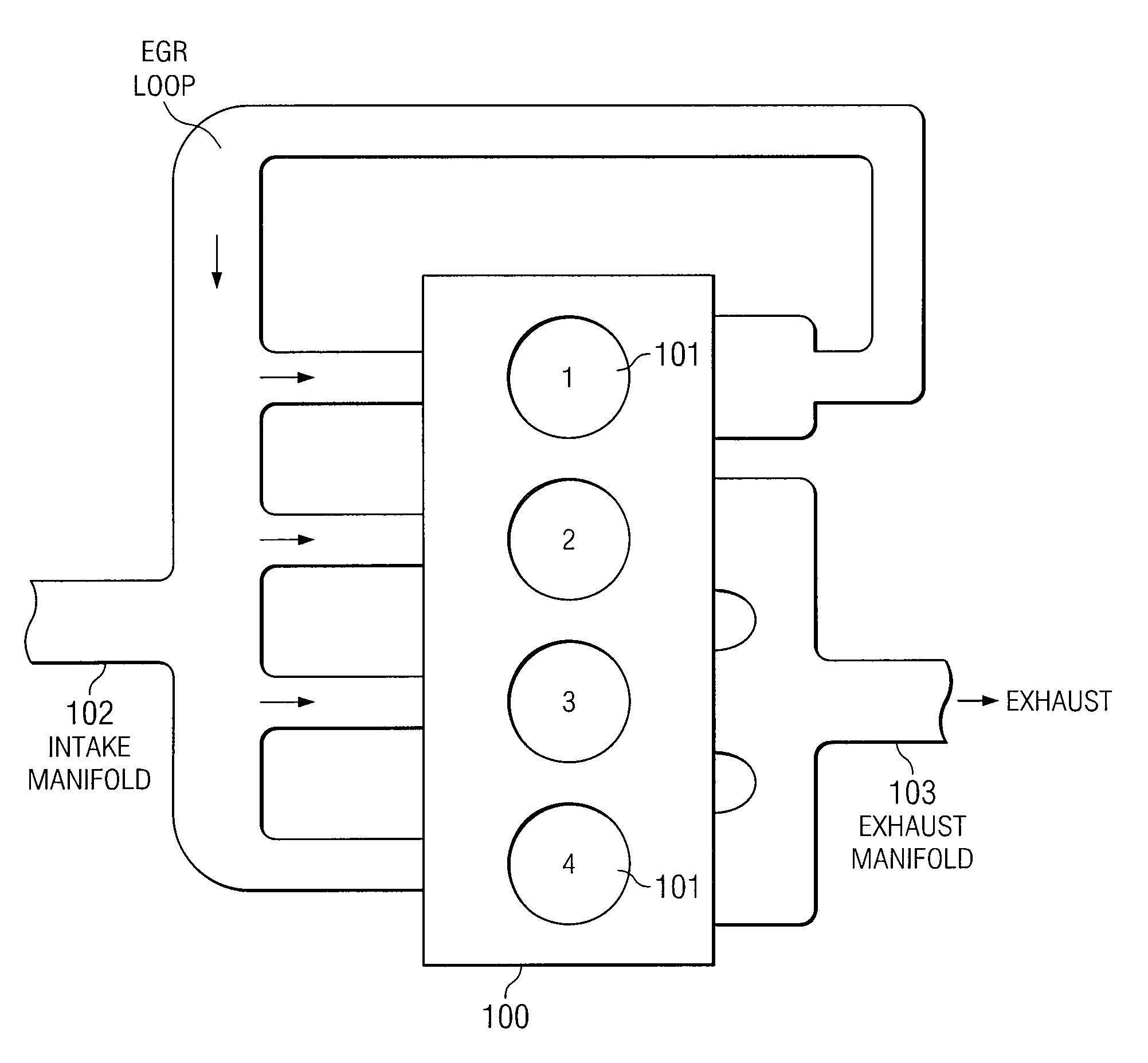

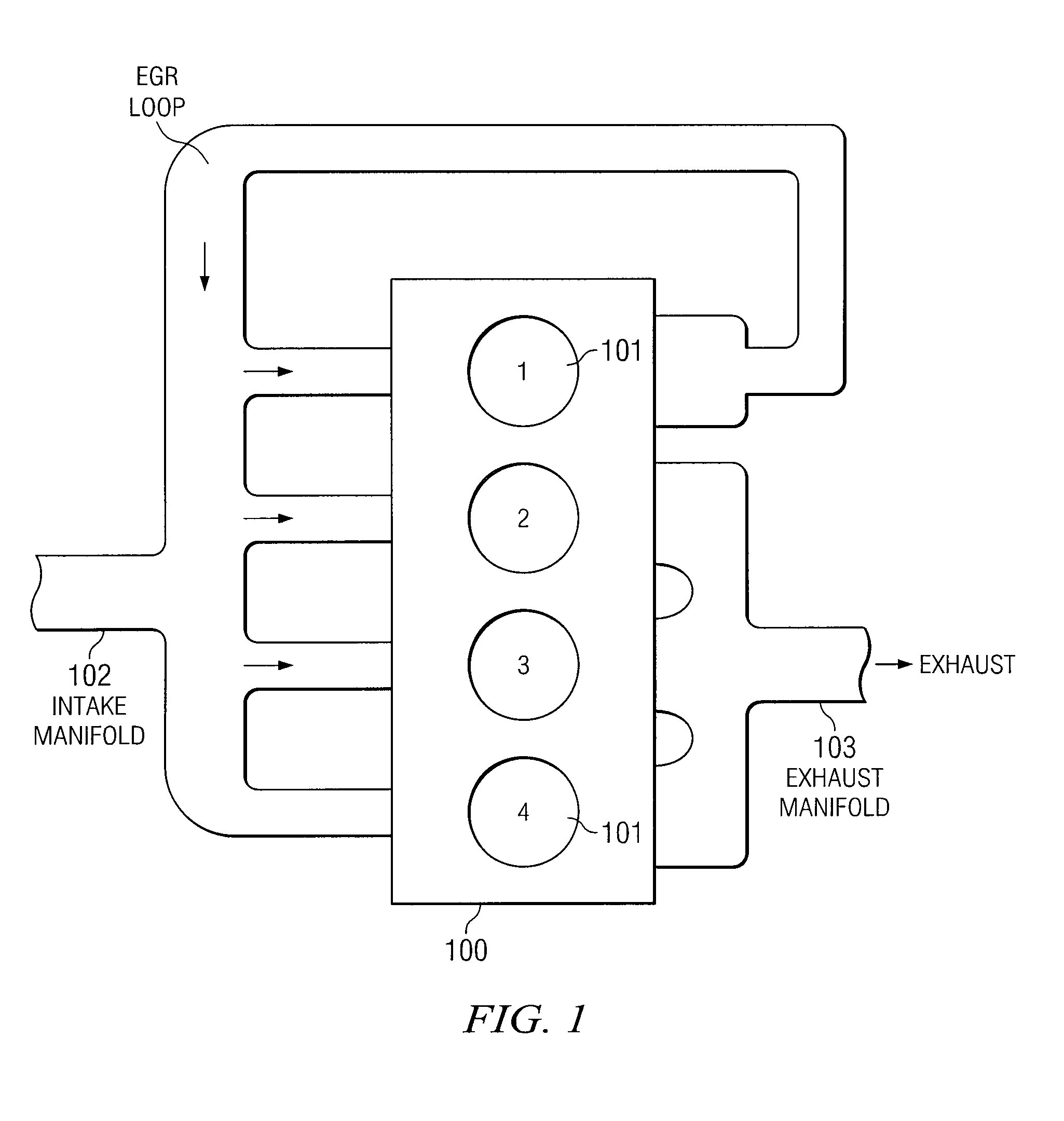

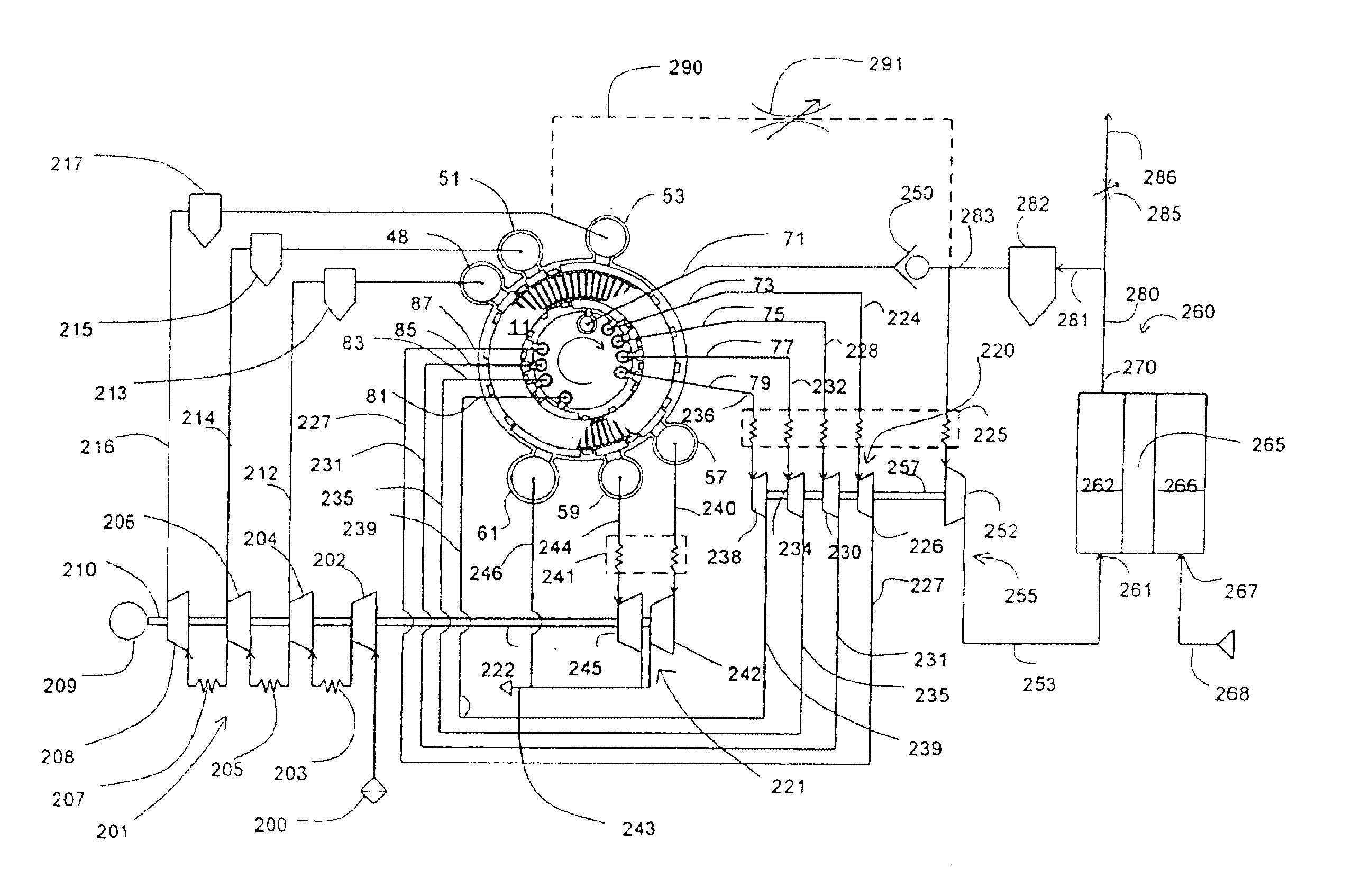

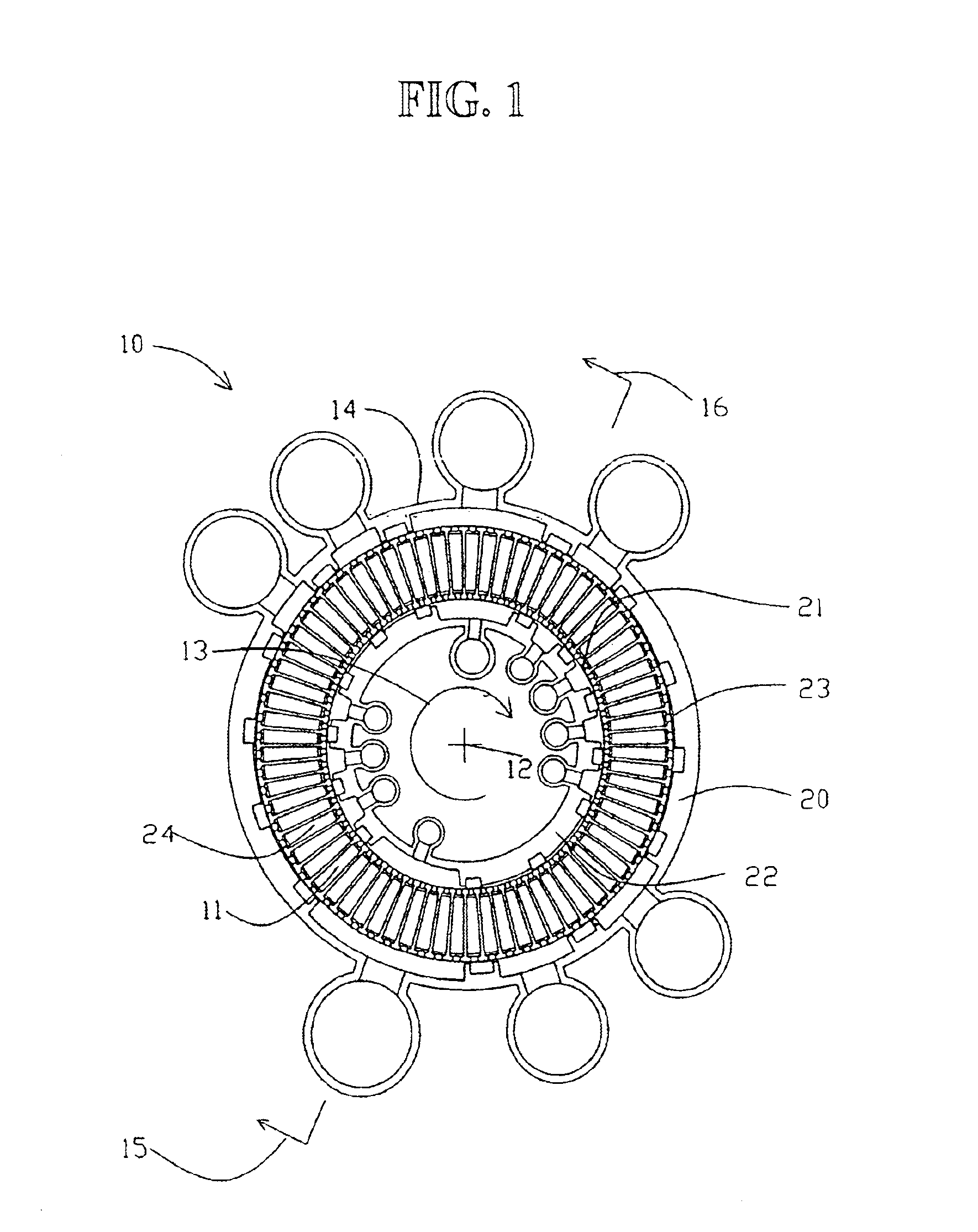

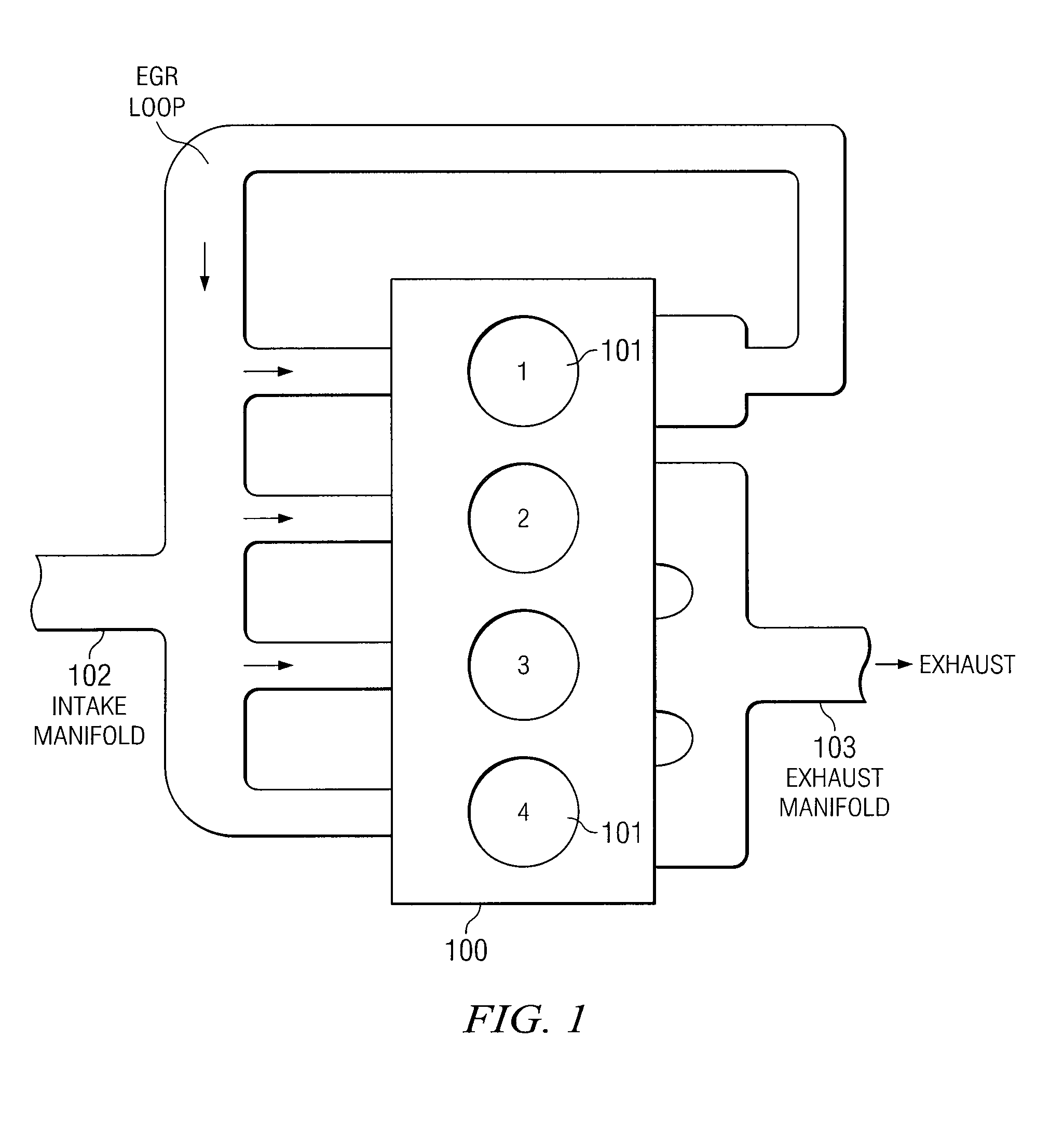

Egr system with dedicated egr cylinders

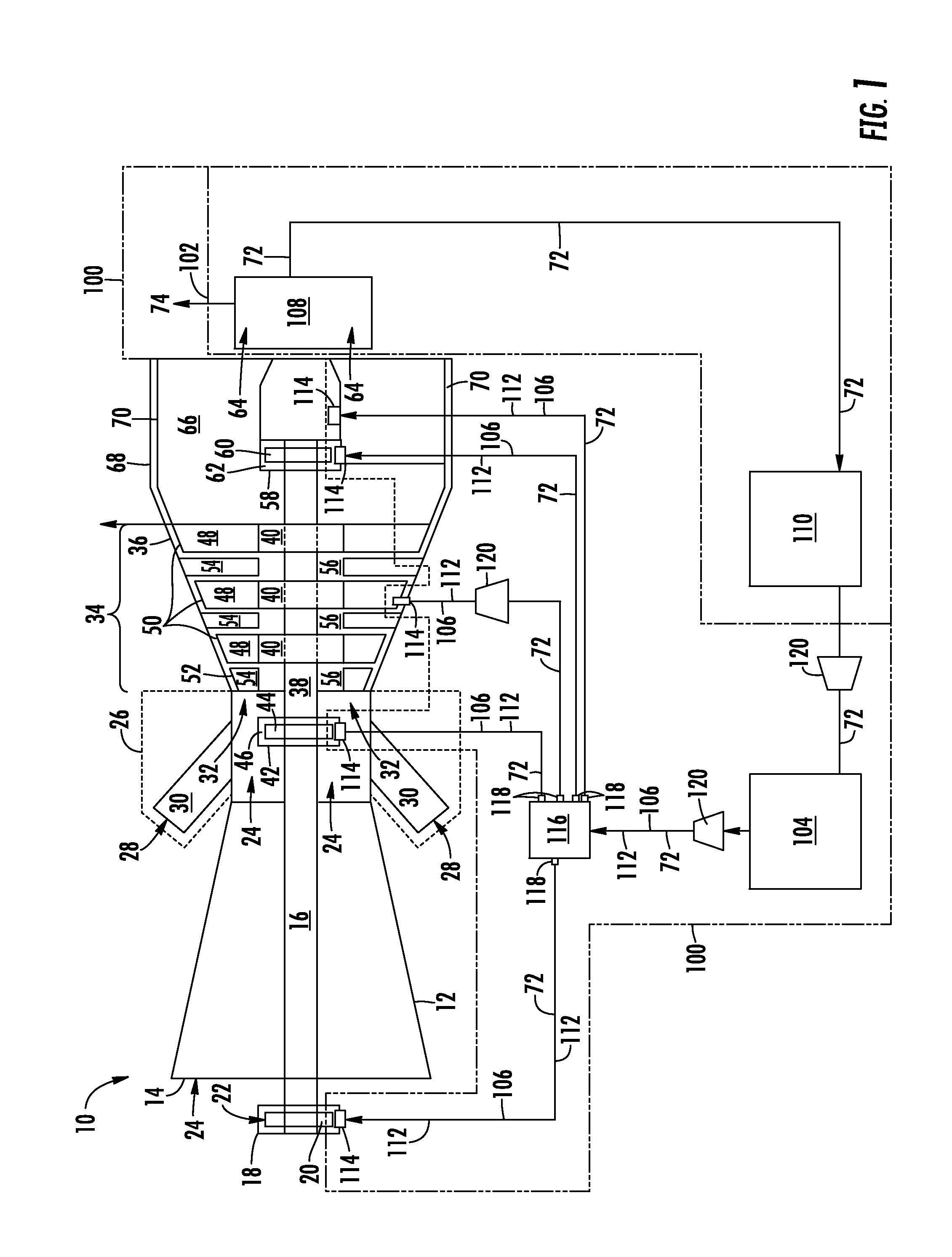

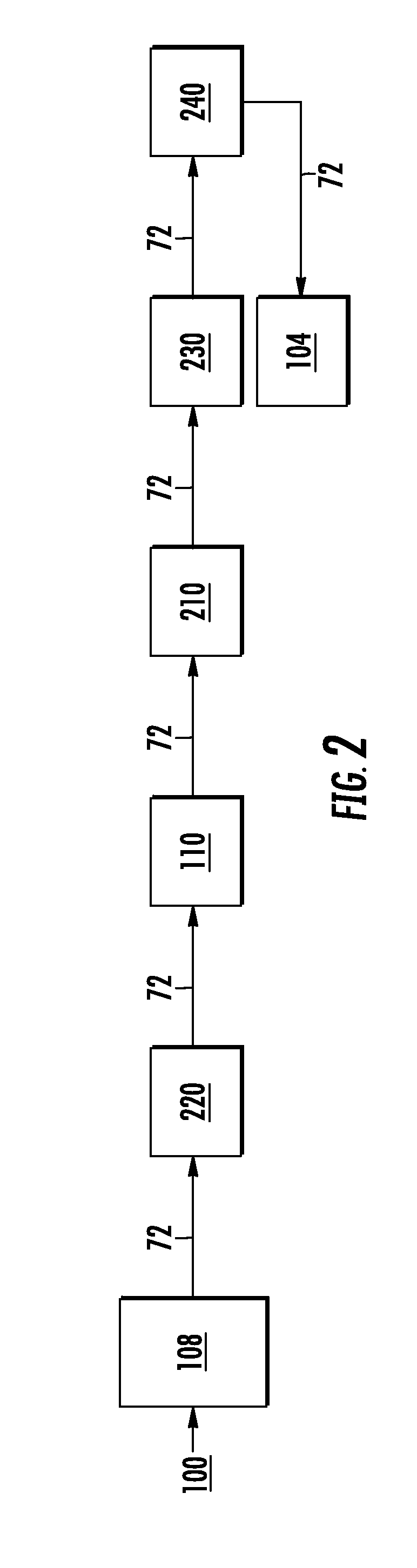

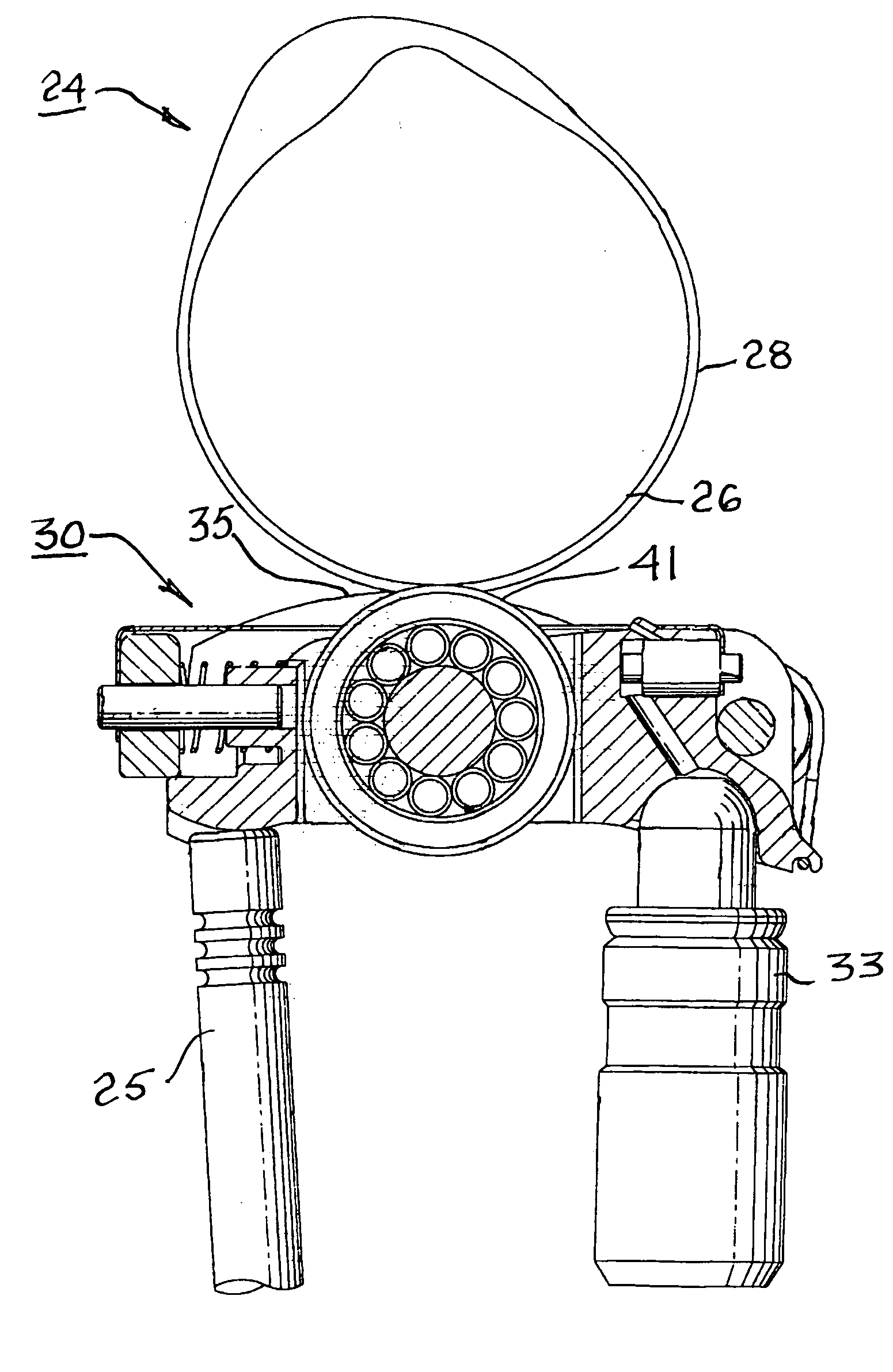

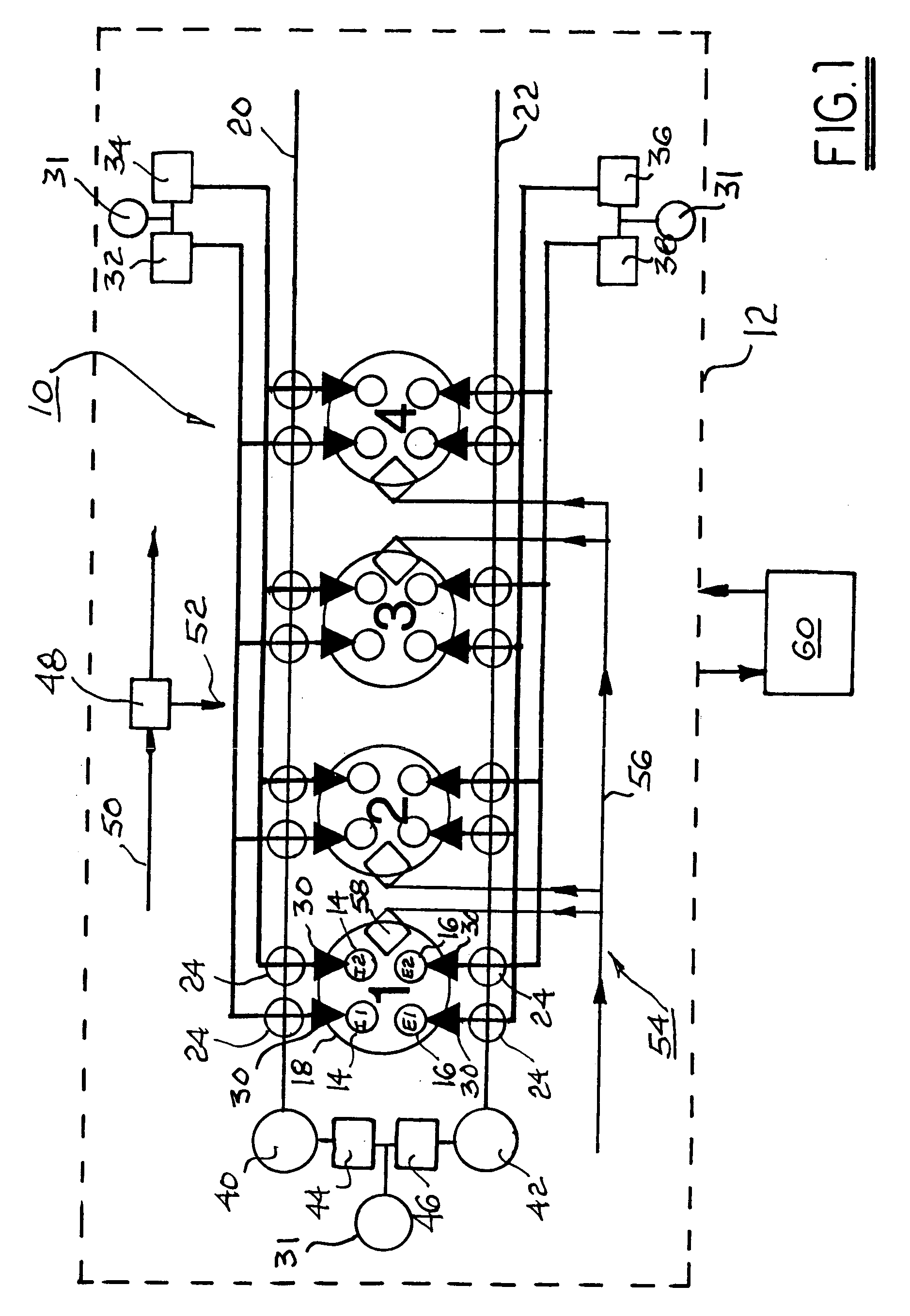

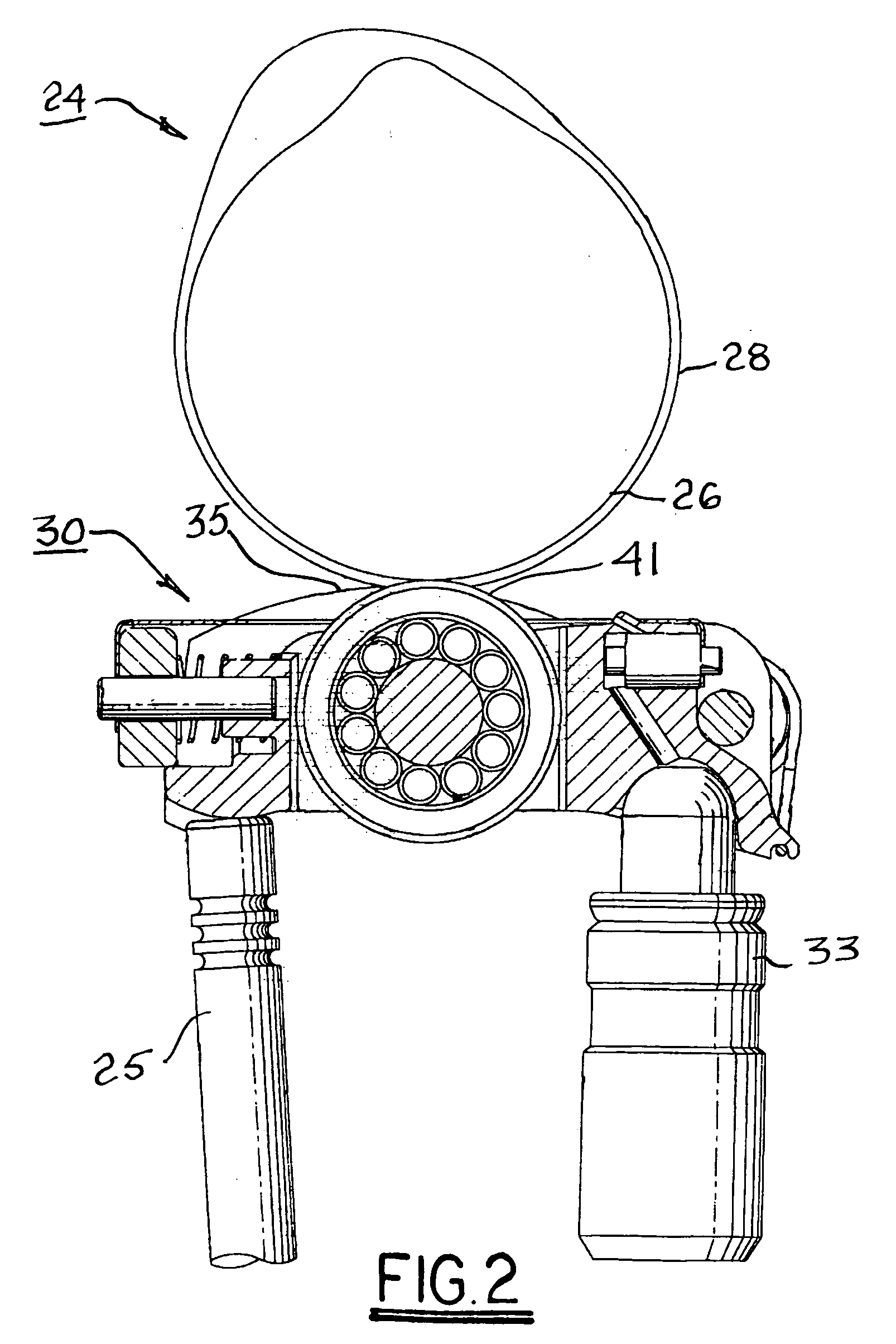

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

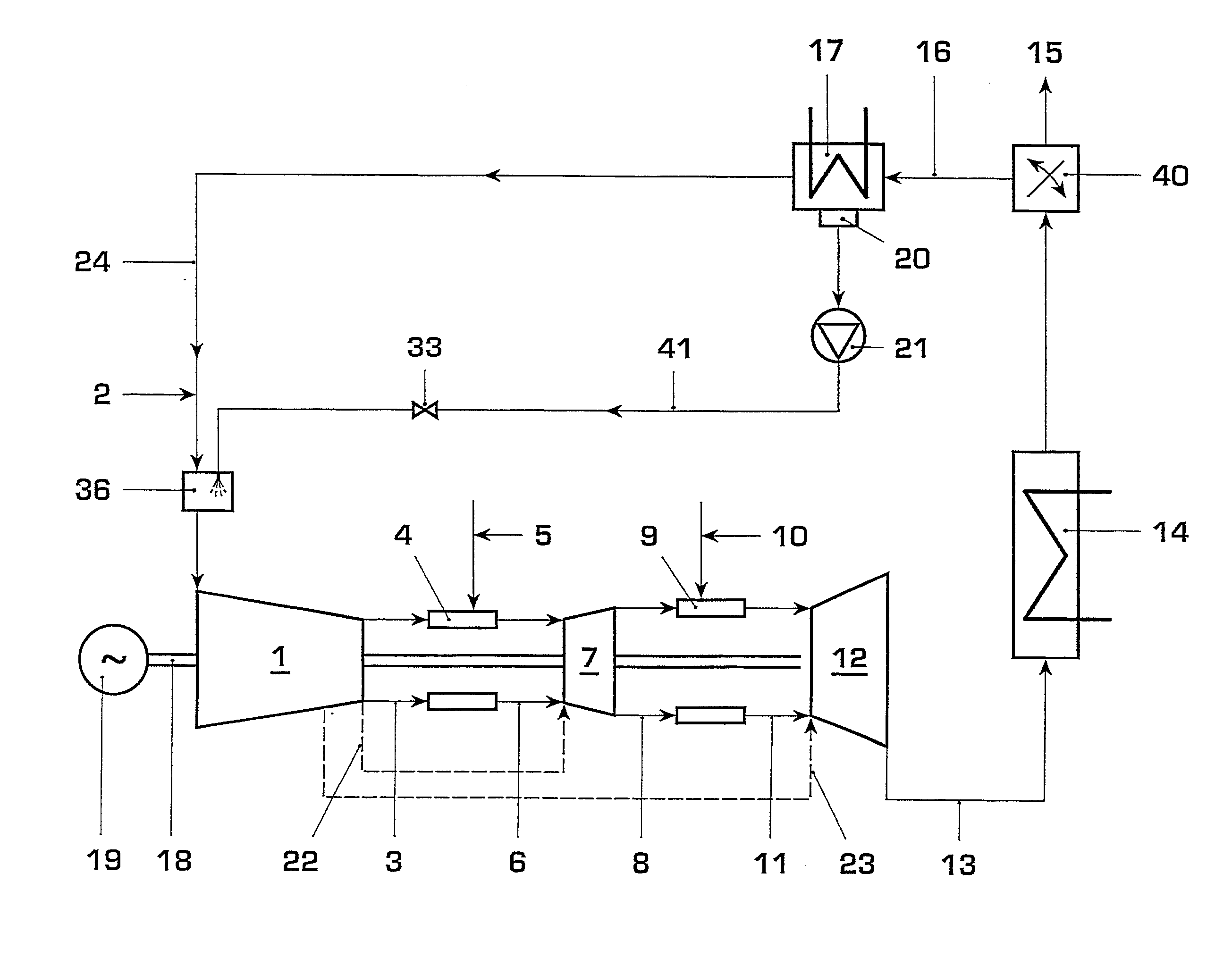

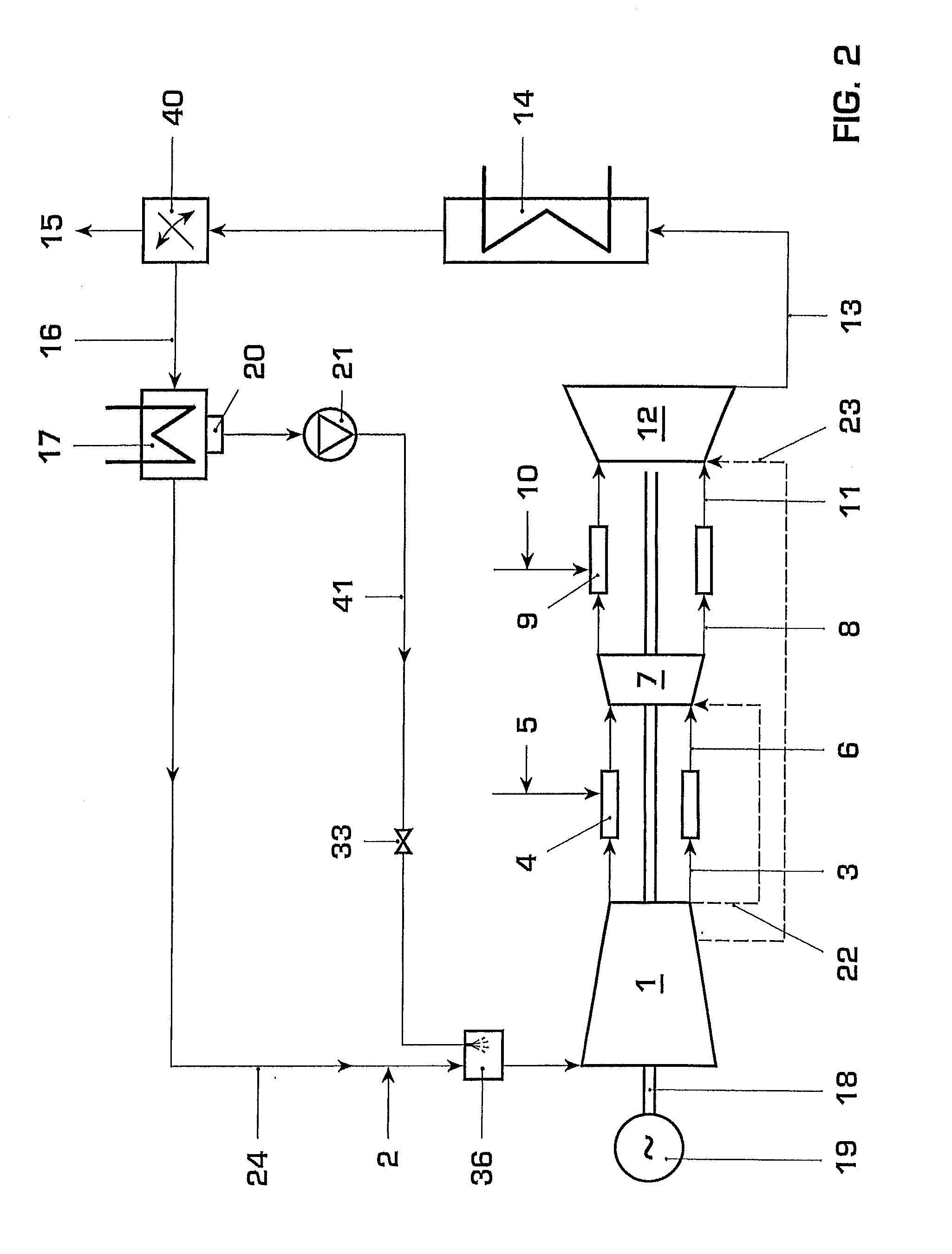

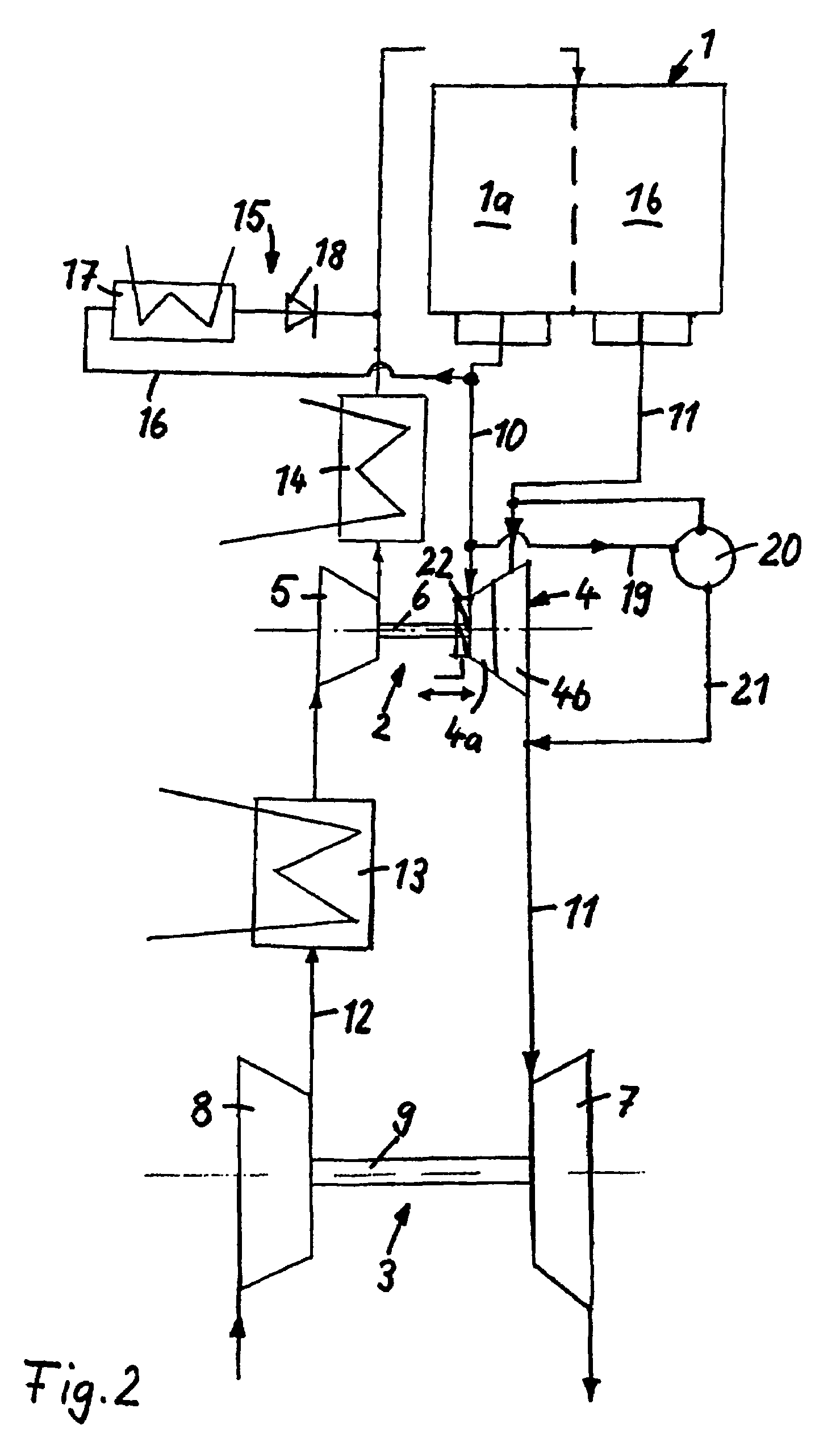

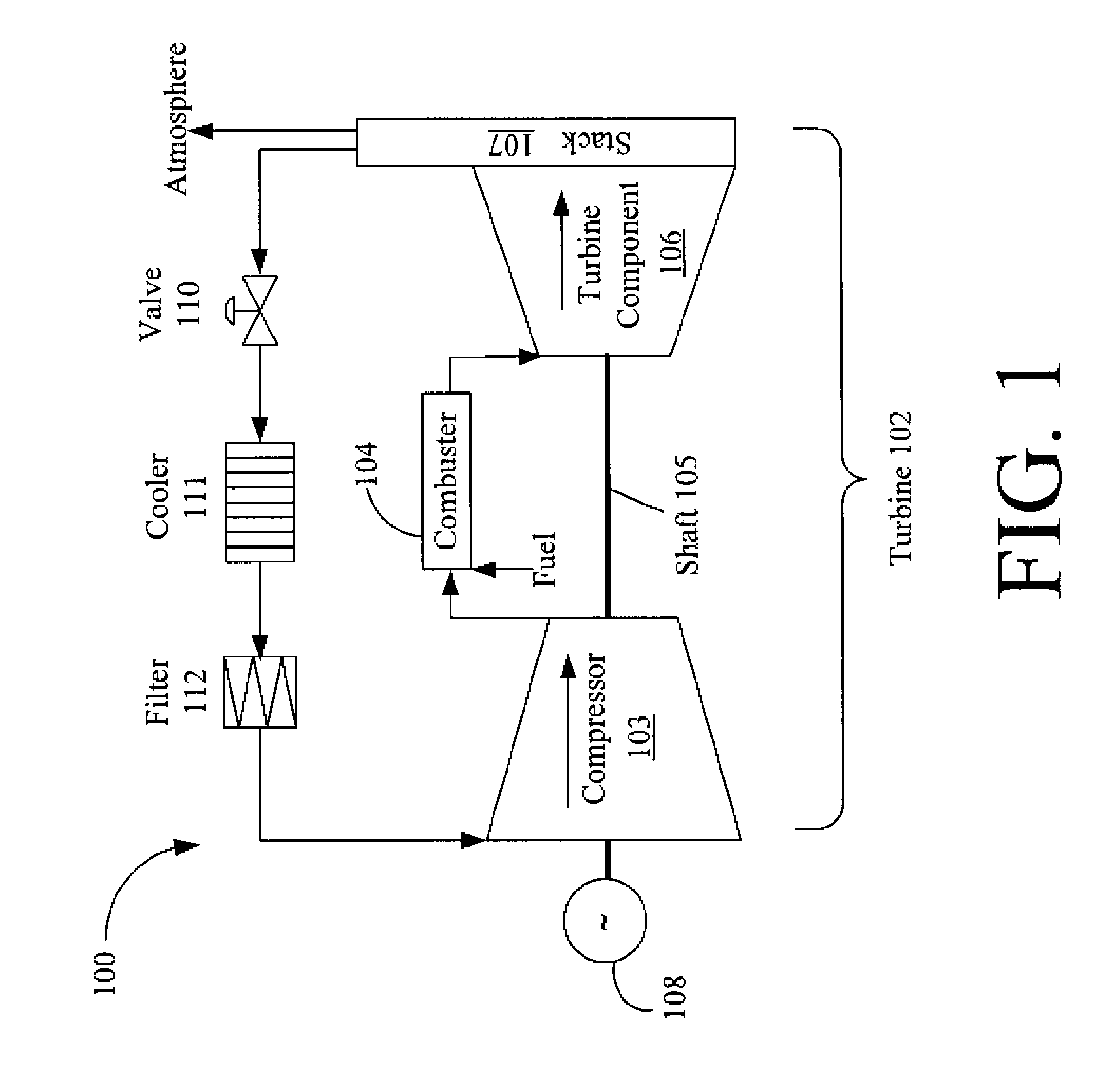

Gas Turbine Installation with Flue Gas Recirculation

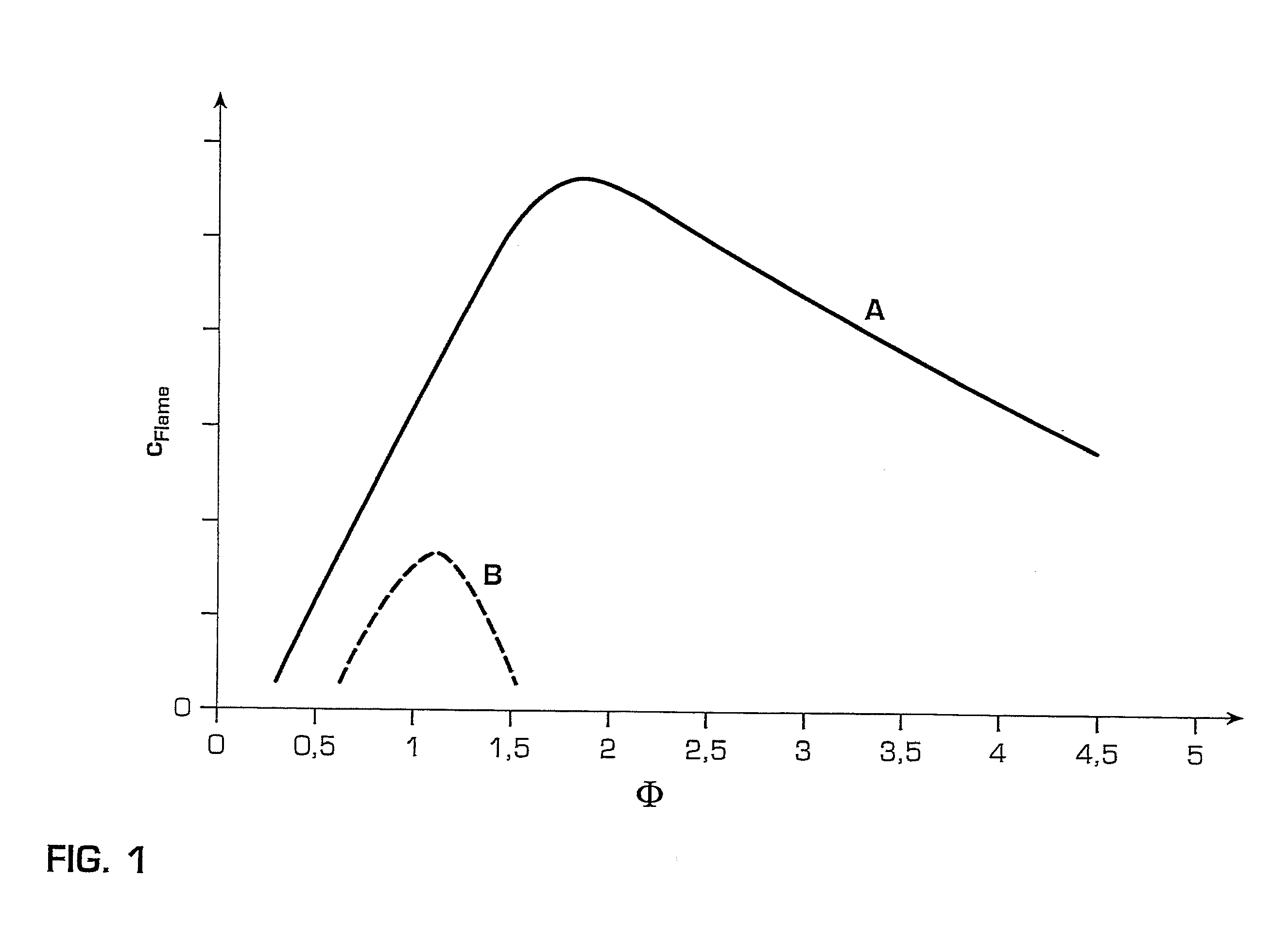

A method and installation are disclosed which can, for example, provide for reliable, low-Nox-emission operation of a gas turbine installation with hydrogen-rich fuel gas. An exemplary gas turbine installation includes an arrangement for flue gas recirculation into a compressor inlet and for fuel gas dilution. Oxygen content in combustion air can be reduced by recirculation of recooled flue gas, and the fuel gas can be diluted with compressed flue gas. The oxygen reduction in the combustion air can lead to minimum residual oxygen in the flue gas which can be used for fuel gas dilution. As a result of the flue gas recirculation, water content in the combustion air can be increased by feedback of the water which results as a combustion product. The oxygen reduction, increased water content, and fuel dilution can reduce the flame velocity of hydrogen-rich fuel gases and enable a robust, reliable and low-emission combustion.

Owner:GENERAL ELECTRIC TECH GMBH

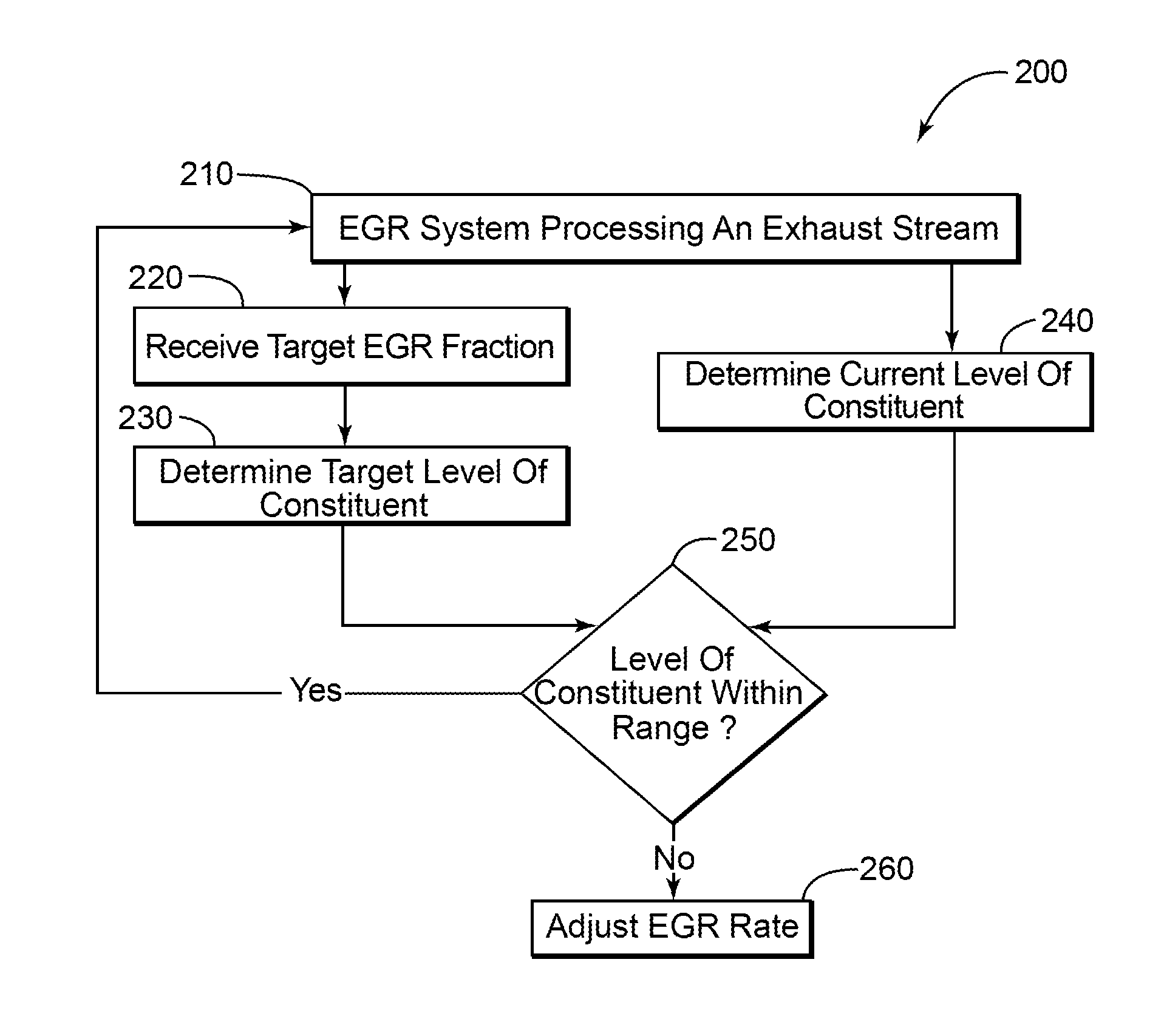

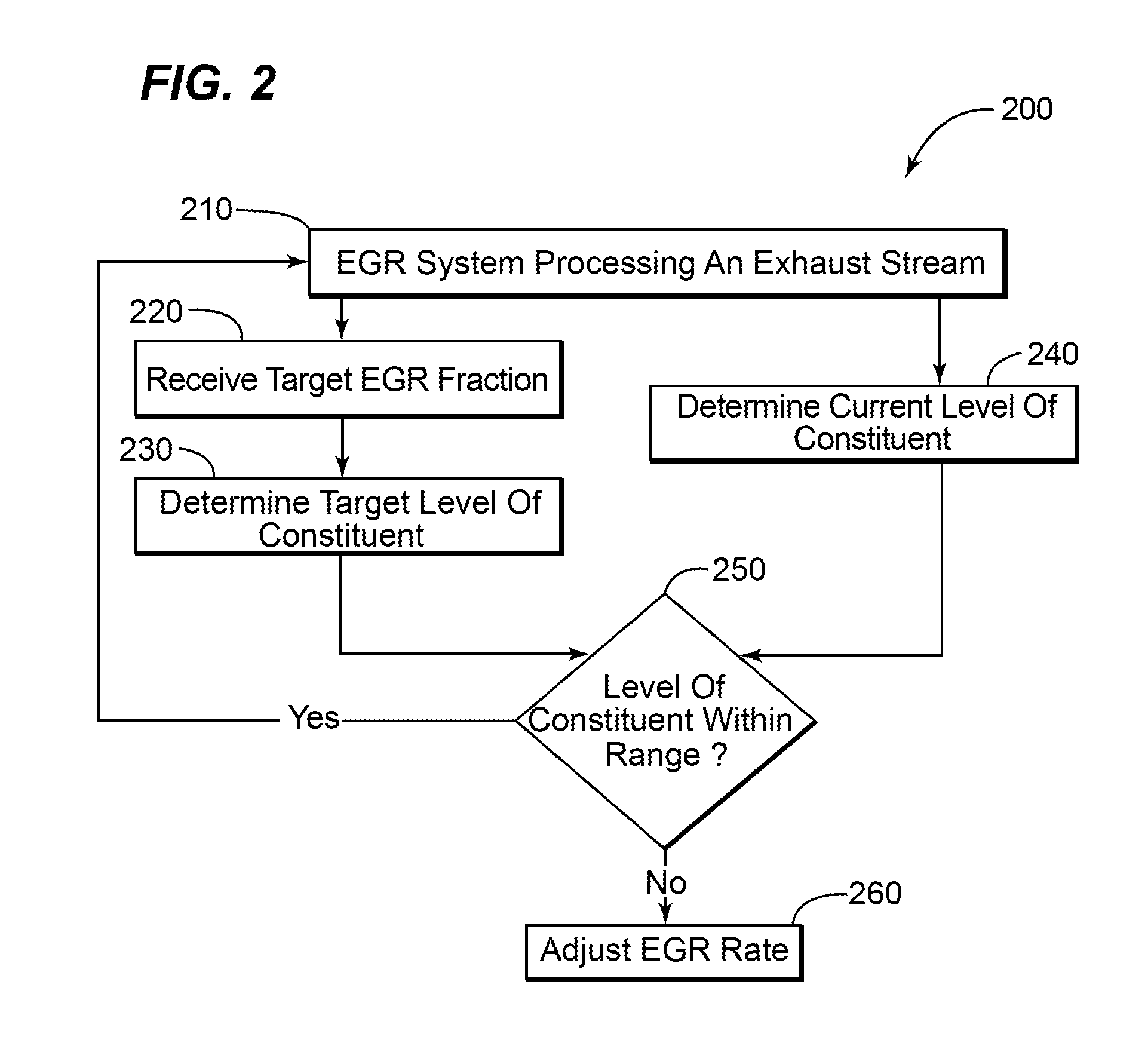

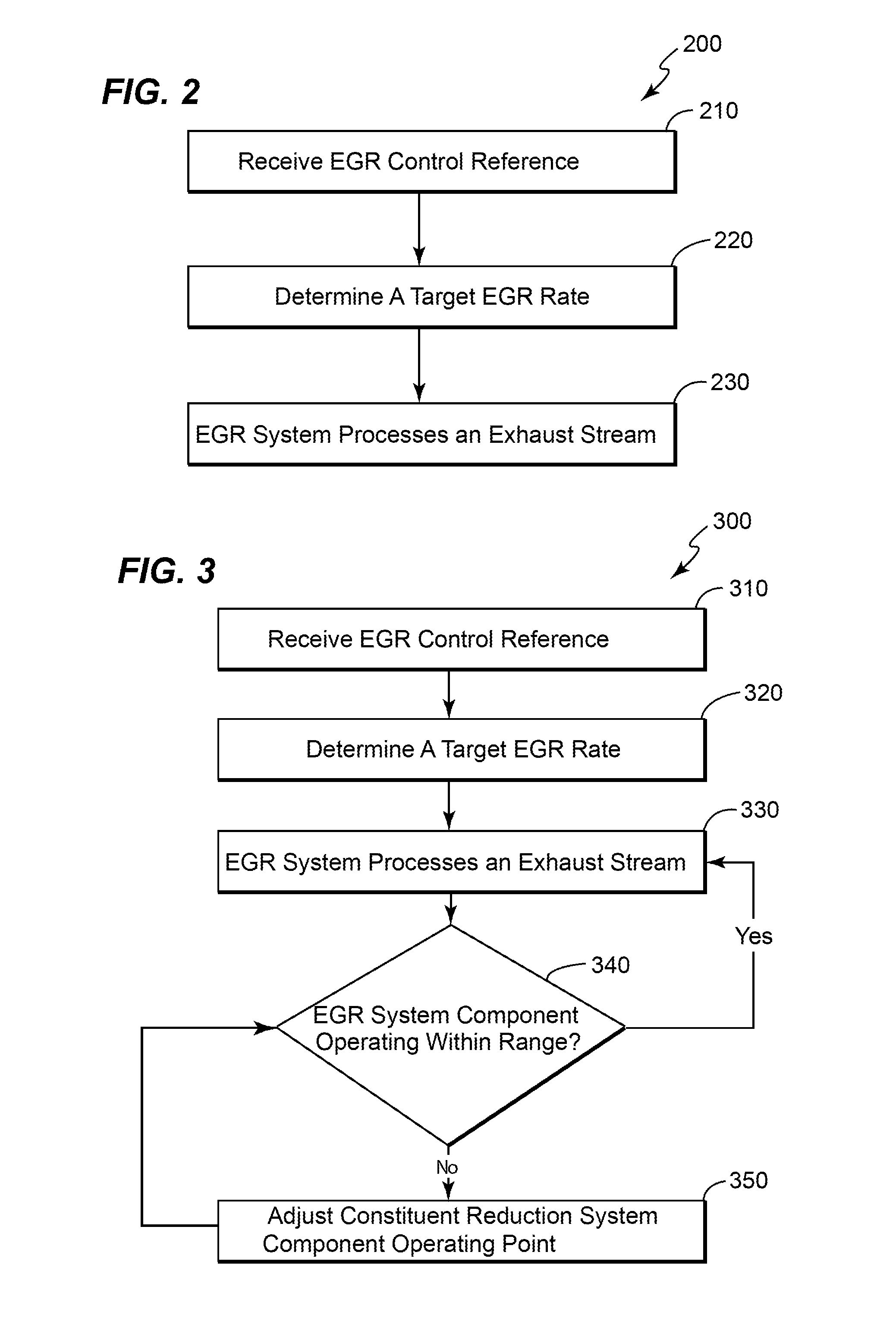

Method and system for controlling a flowrate of a recirculated exhaust gas

ActiveUS7536252B1High trafficAnalogue computers for vehiclesNon-fuel substance addition to fuelStream flowExhaust fumes

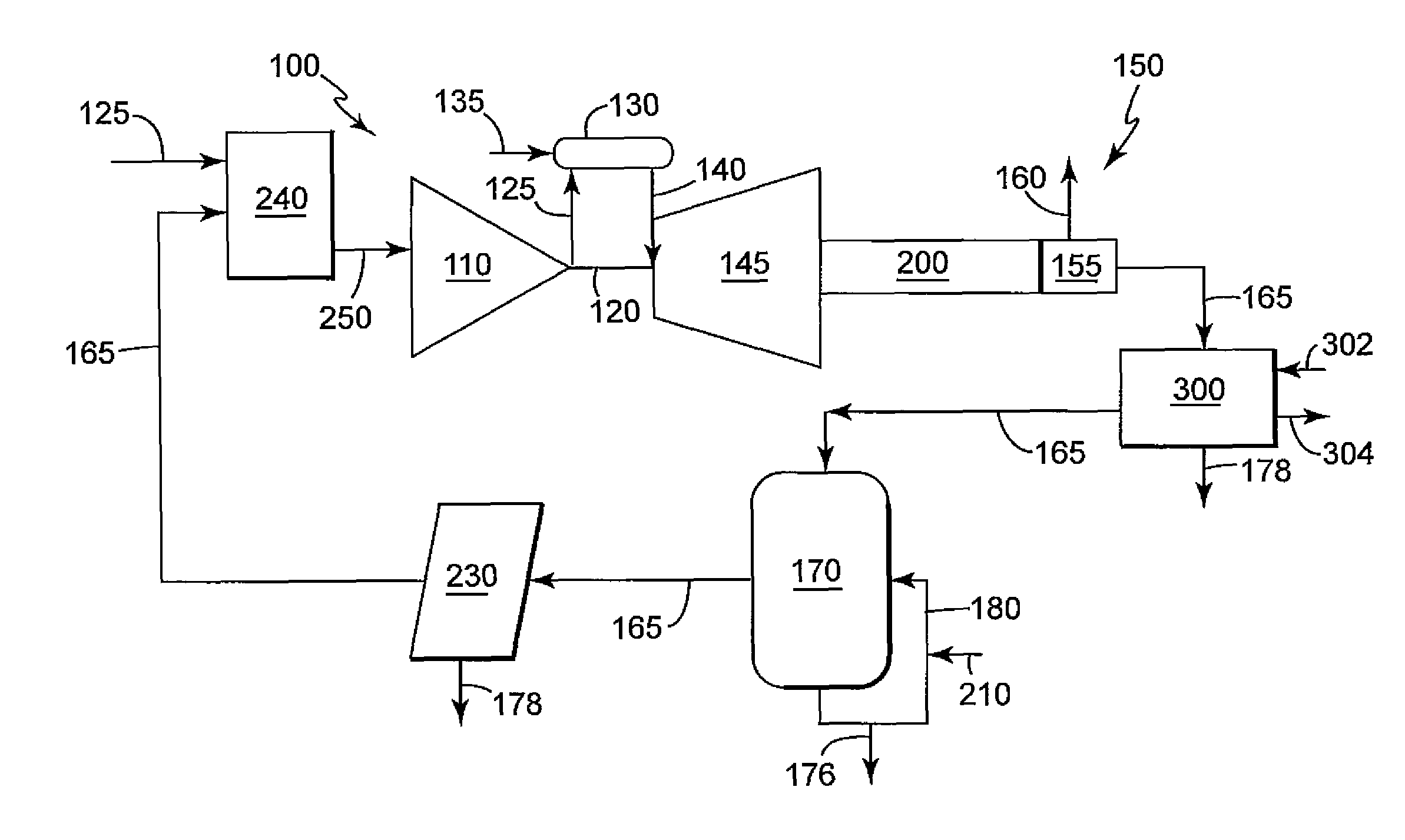

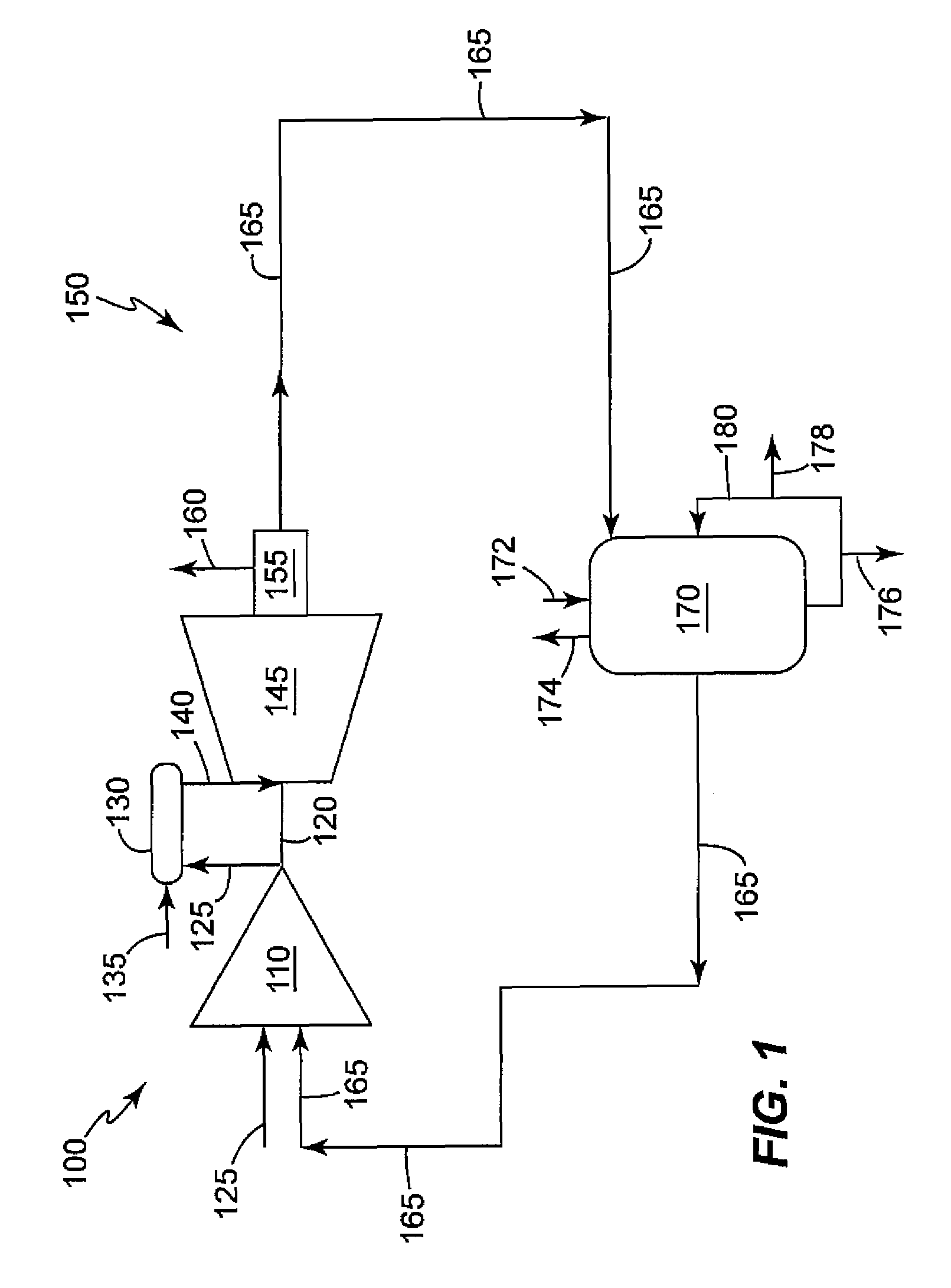

A method and system for controlling an exhaust gas recirculation (EGR) system is provided. The EGR system recirculates a portion of an exhaust through an inlet portion of the turbomachine. The EGR system reduces the level of harmful constituents within the exhaust before the recirculation occurs.

Owner:GENERAL ELECTRIC CO

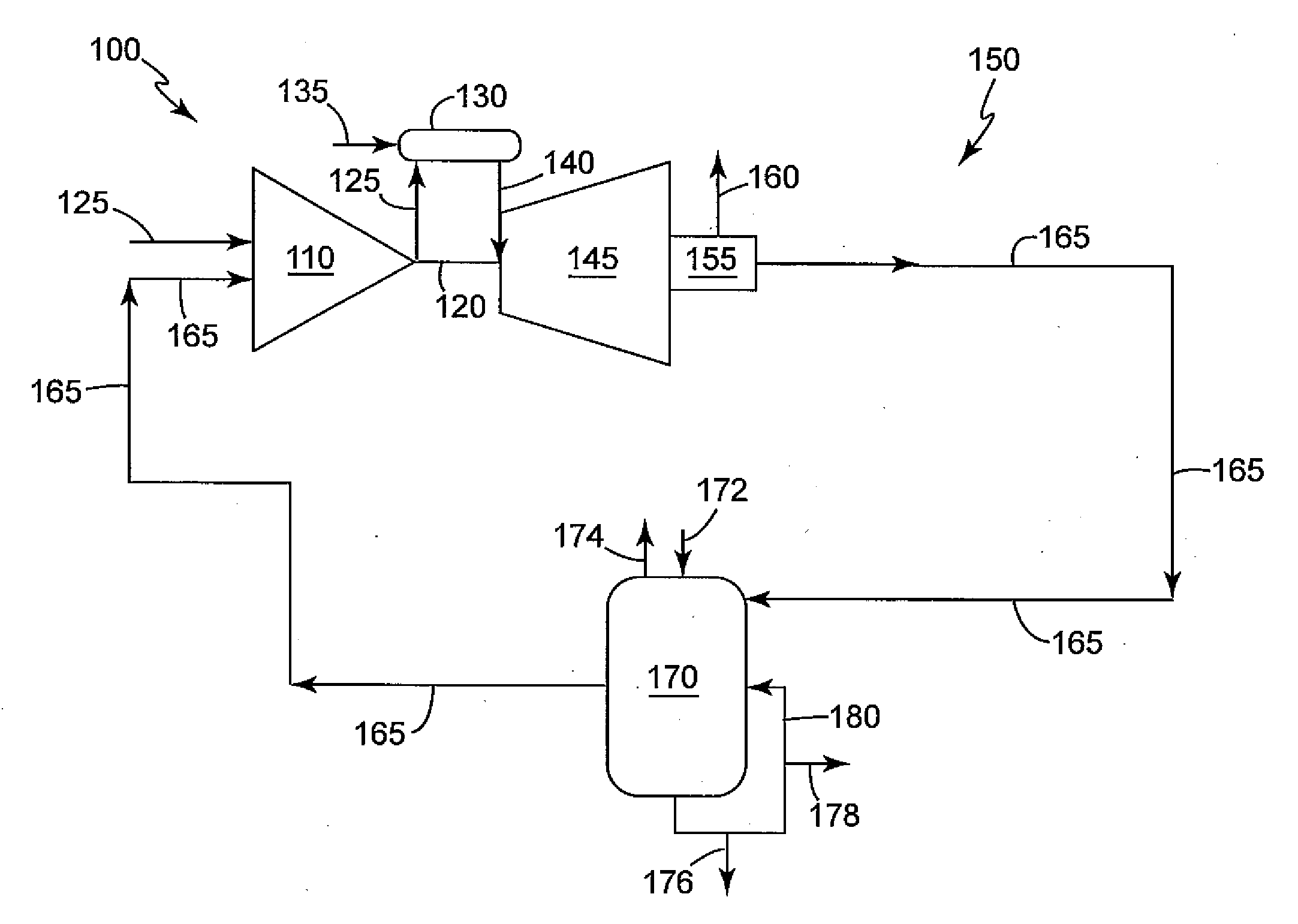

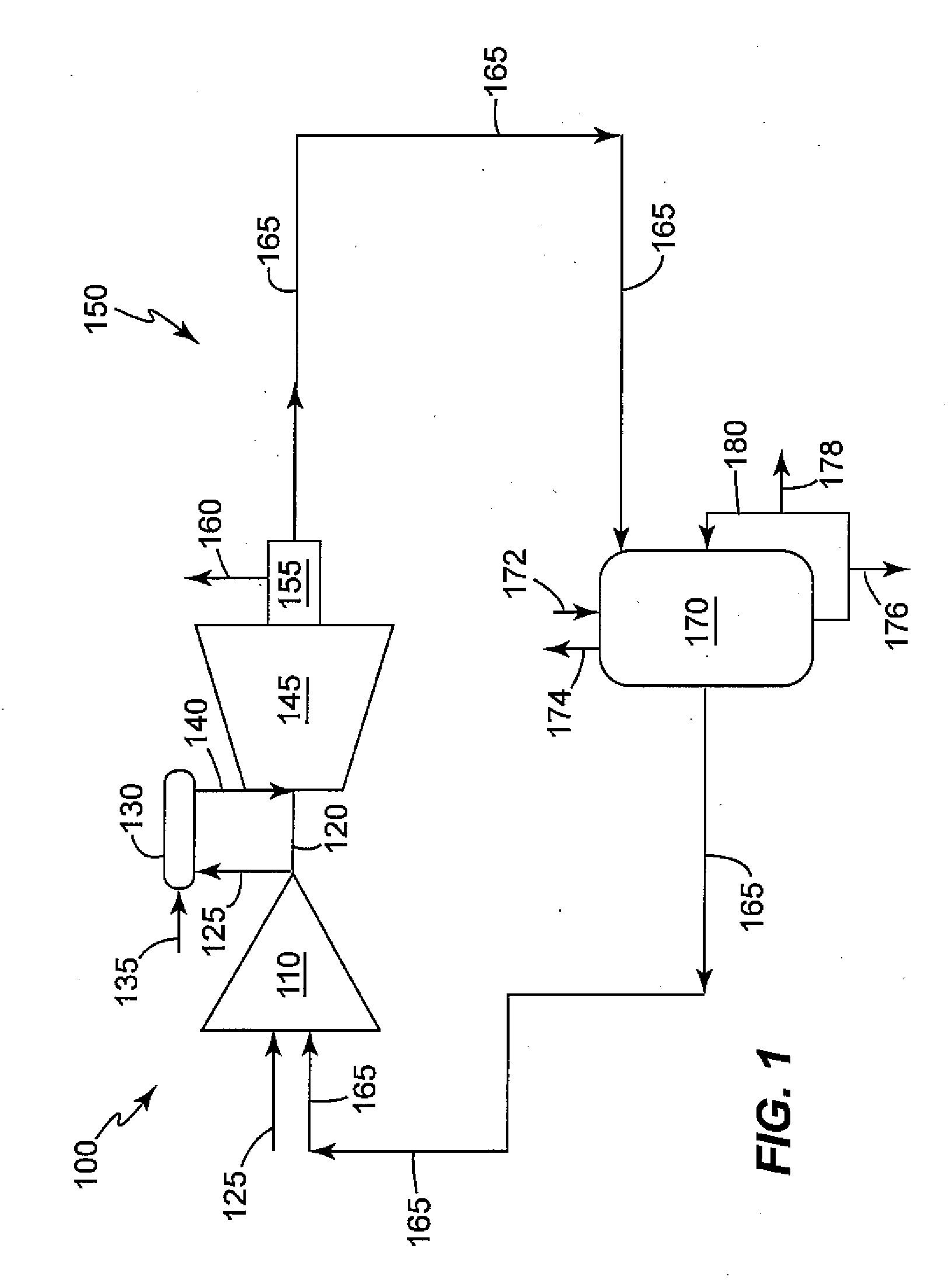

System for recirculating the exhaust of a turbomachine

ActiveUS20090107141A1HydrogenNon-fuel substance addition to fuelExhaust fumesEnvironmental engineering

A portion of the exhaust generated by a turbomachine is recirculated through an inlet portion by an exhaust gas recirculation system. The system reduces the level of harmful constituents within the exhaust before the exhaust is recirculated.

Owner:GENERAL ELECTRIC CO

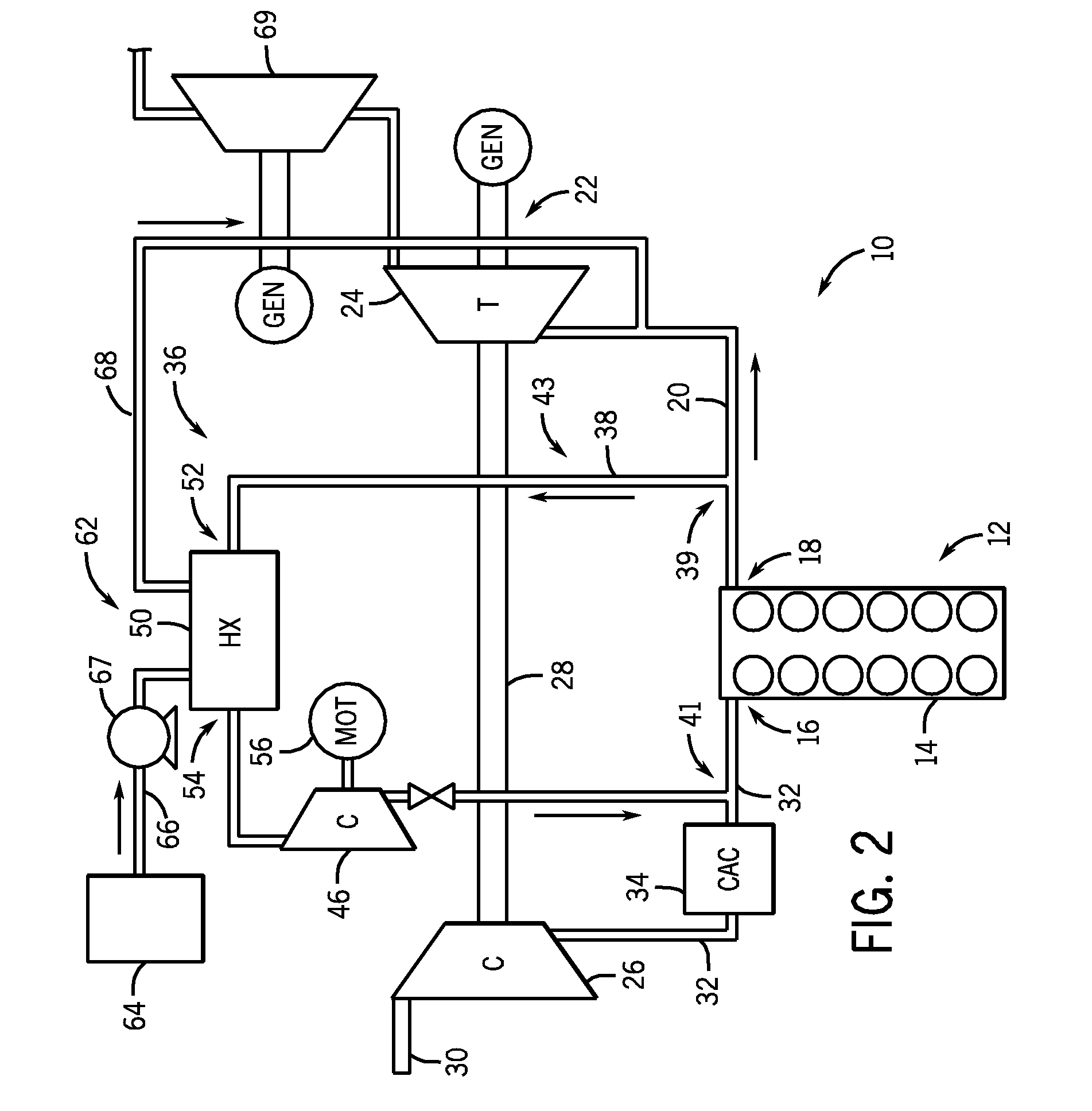

System and method for waste heat recovery in exhaust gas recirculation

InactiveUS20110209473A1Liquid degasificationInternal combustion piston enginesTurbochargerExhaust fumes

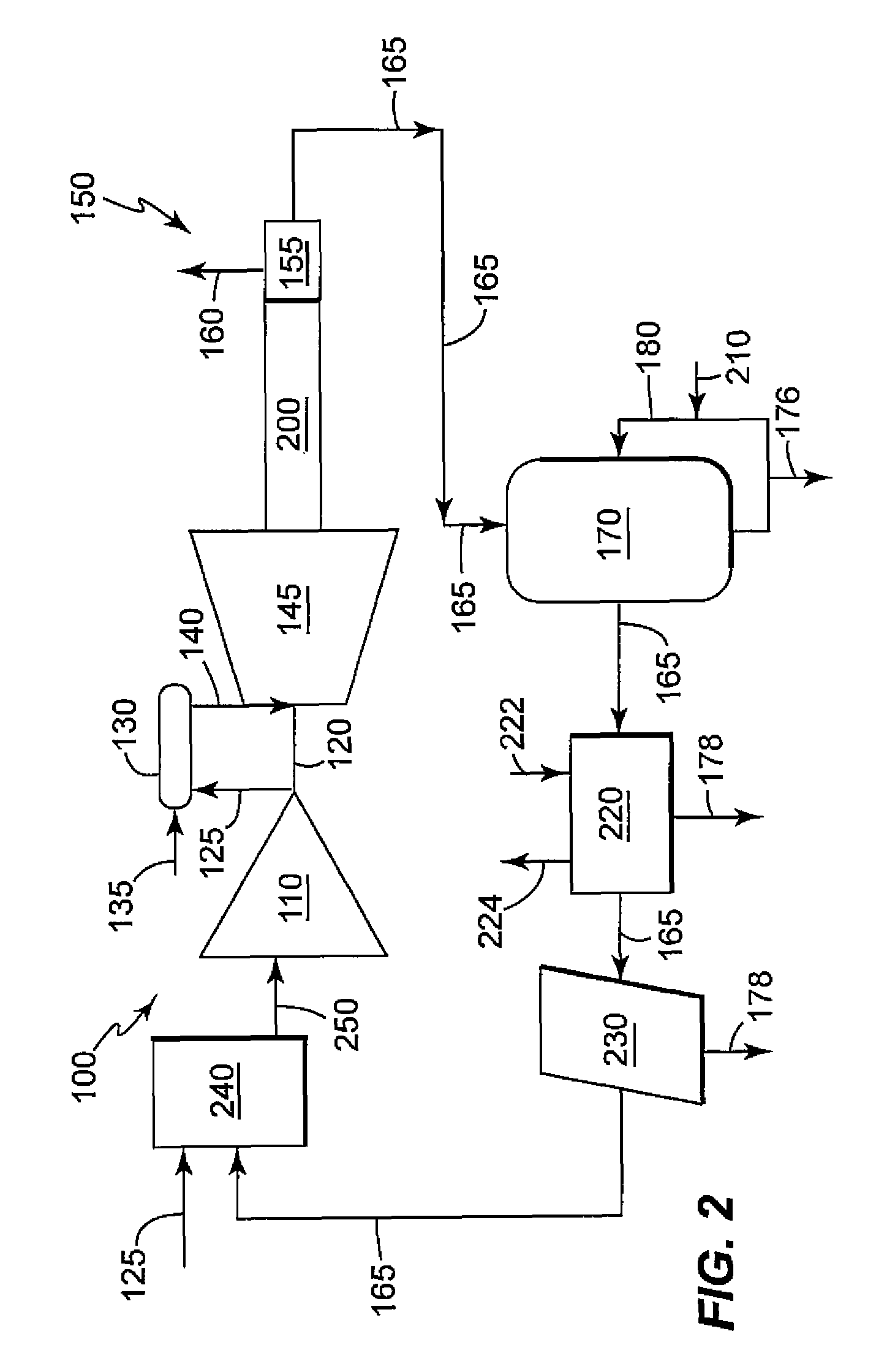

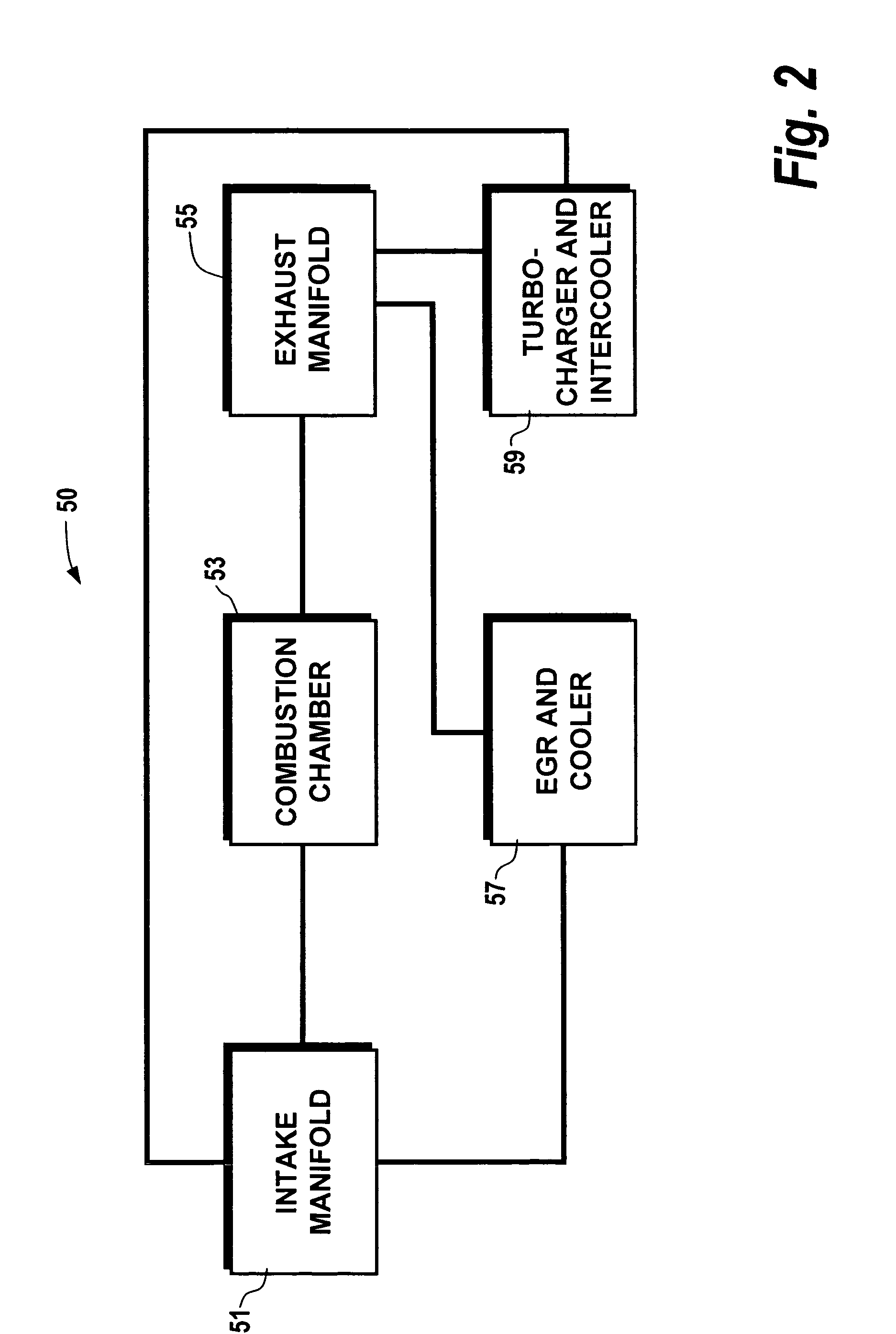

A system and method for waste heat recovery in exhaust gas recirculation is disclosed. The system includes an engine having an intake manifold and an exhaust manifold, an exhaust conduit connected to the exhaust manifold, and a turbocharger having a turbine and a compressor, the turbine being connected to the exhaust conduit to receive a portion of the exhaust gas from the exhaust manifold. The system also includes an EGR system connected to the exhaust conduit to receive a portion of the exhaust gas, with the EGR system including an EGR conduit that is connected to the exhaust conduit to receive a portion of the exhaust gas, a heat exchanger connected to the EGR conduit and being configured to extract heat from the exhaust gas, and a waste heat recovery system connected to the heat exchanger and configured to capture the heat extracted by the heat exchanger.

Owner:GENERAL ELECTRIC CO

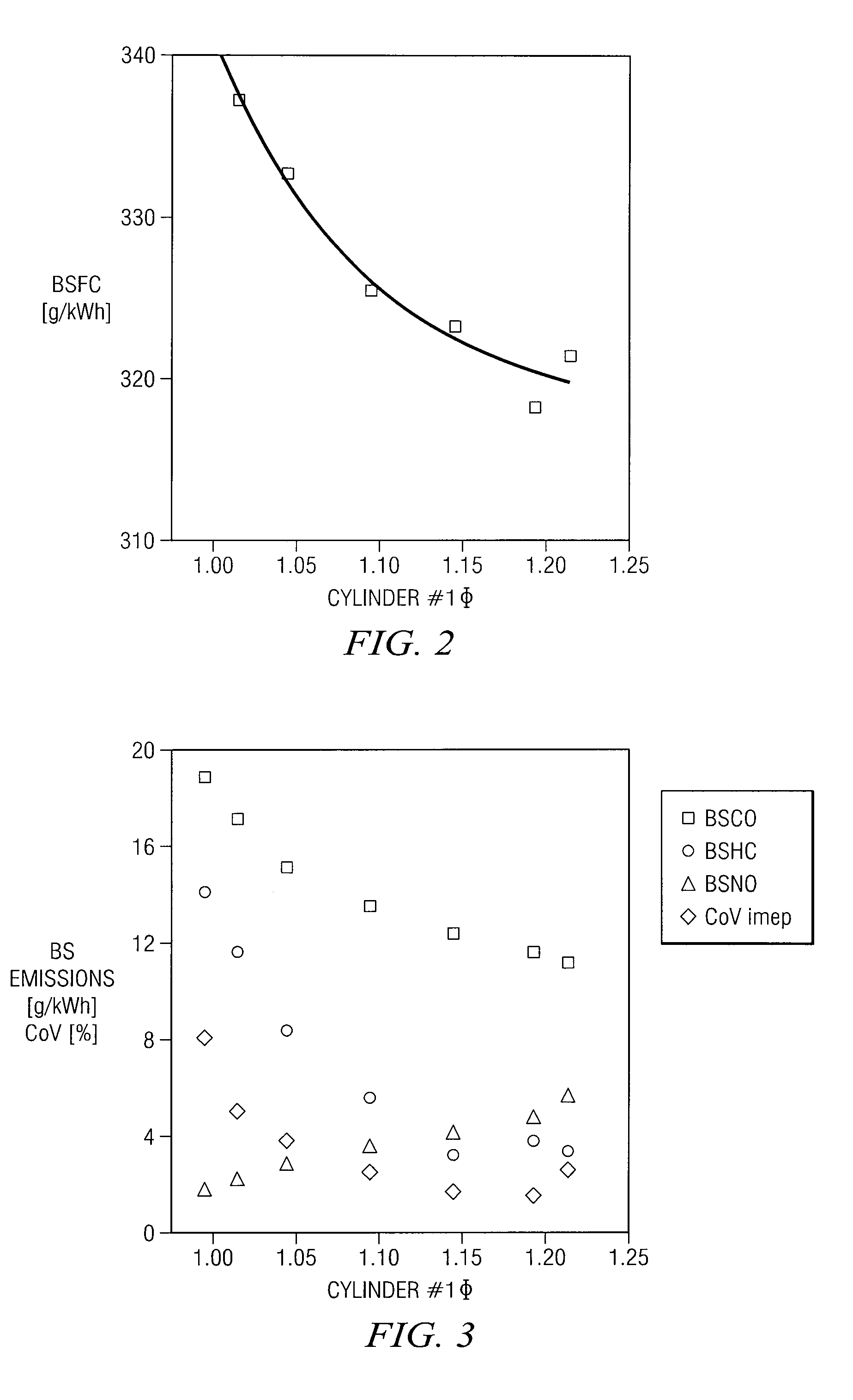

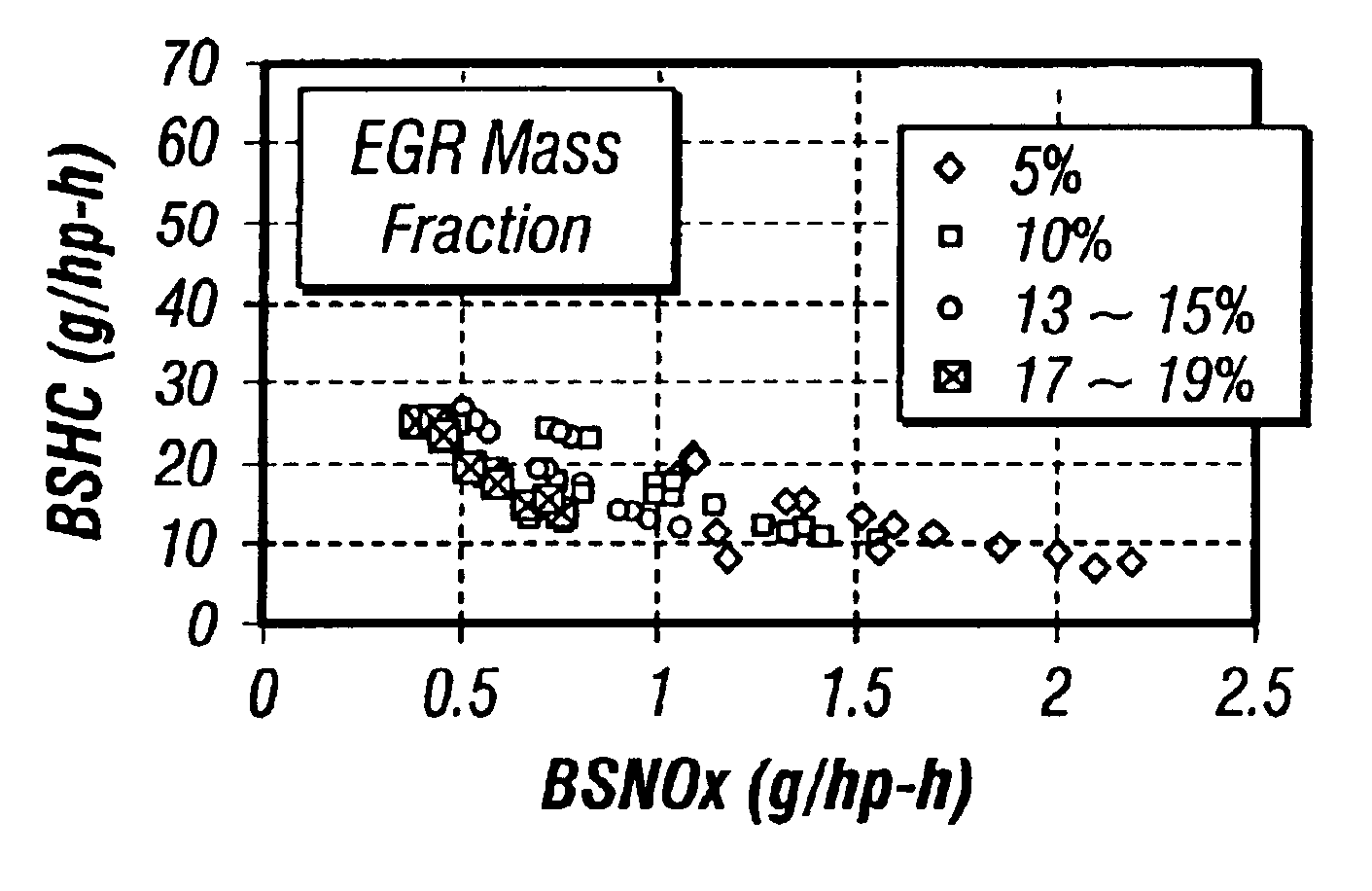

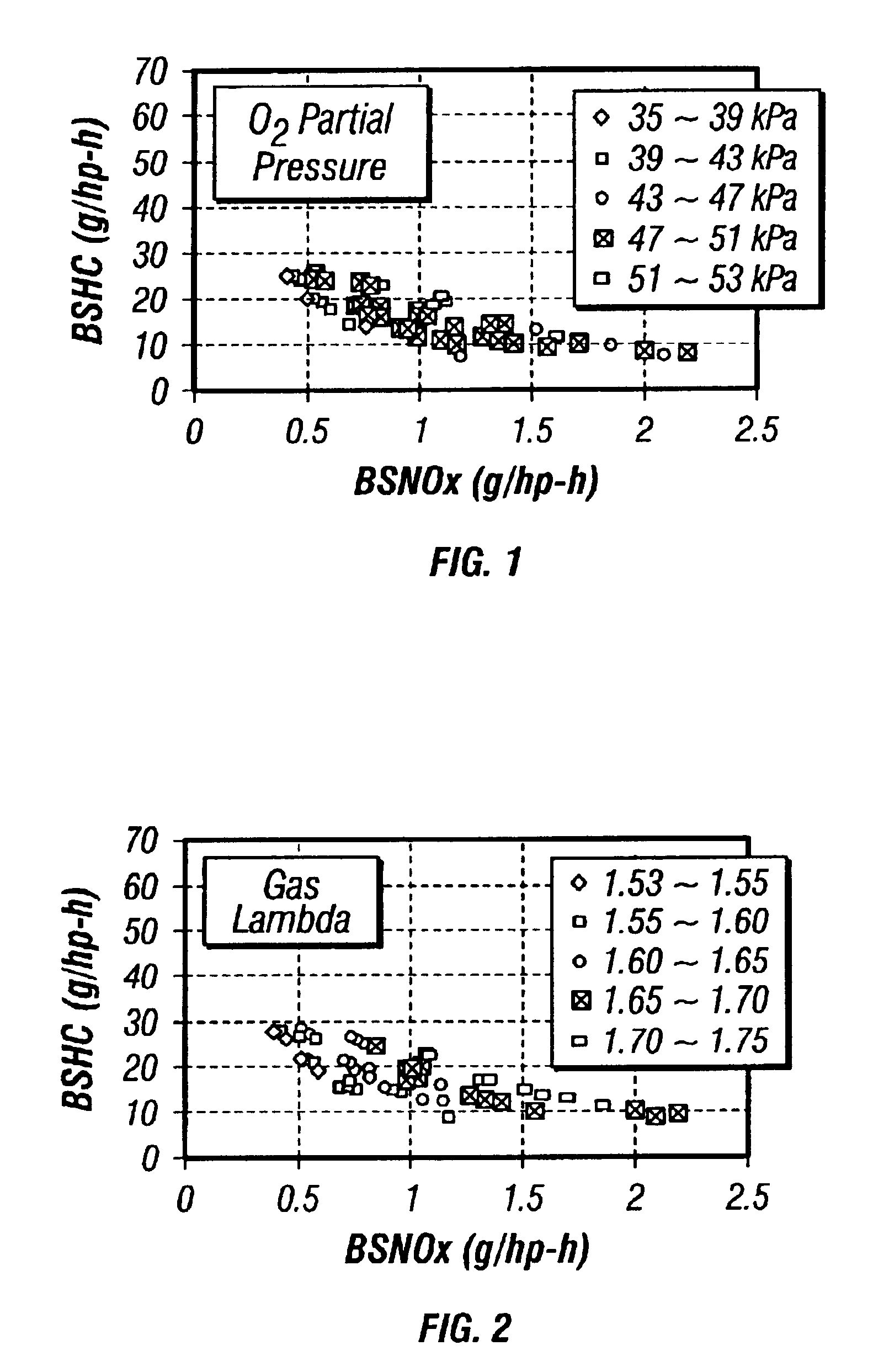

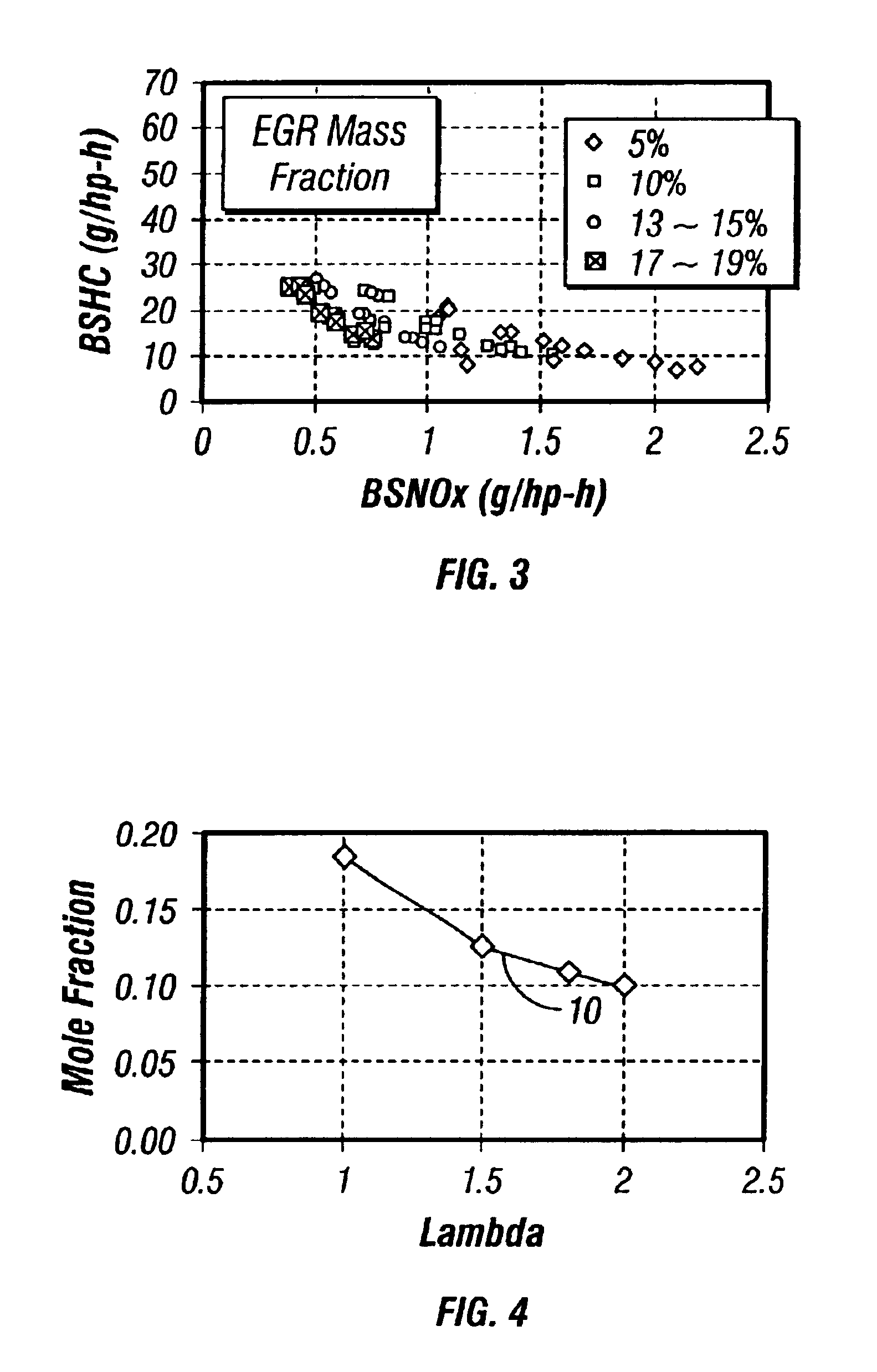

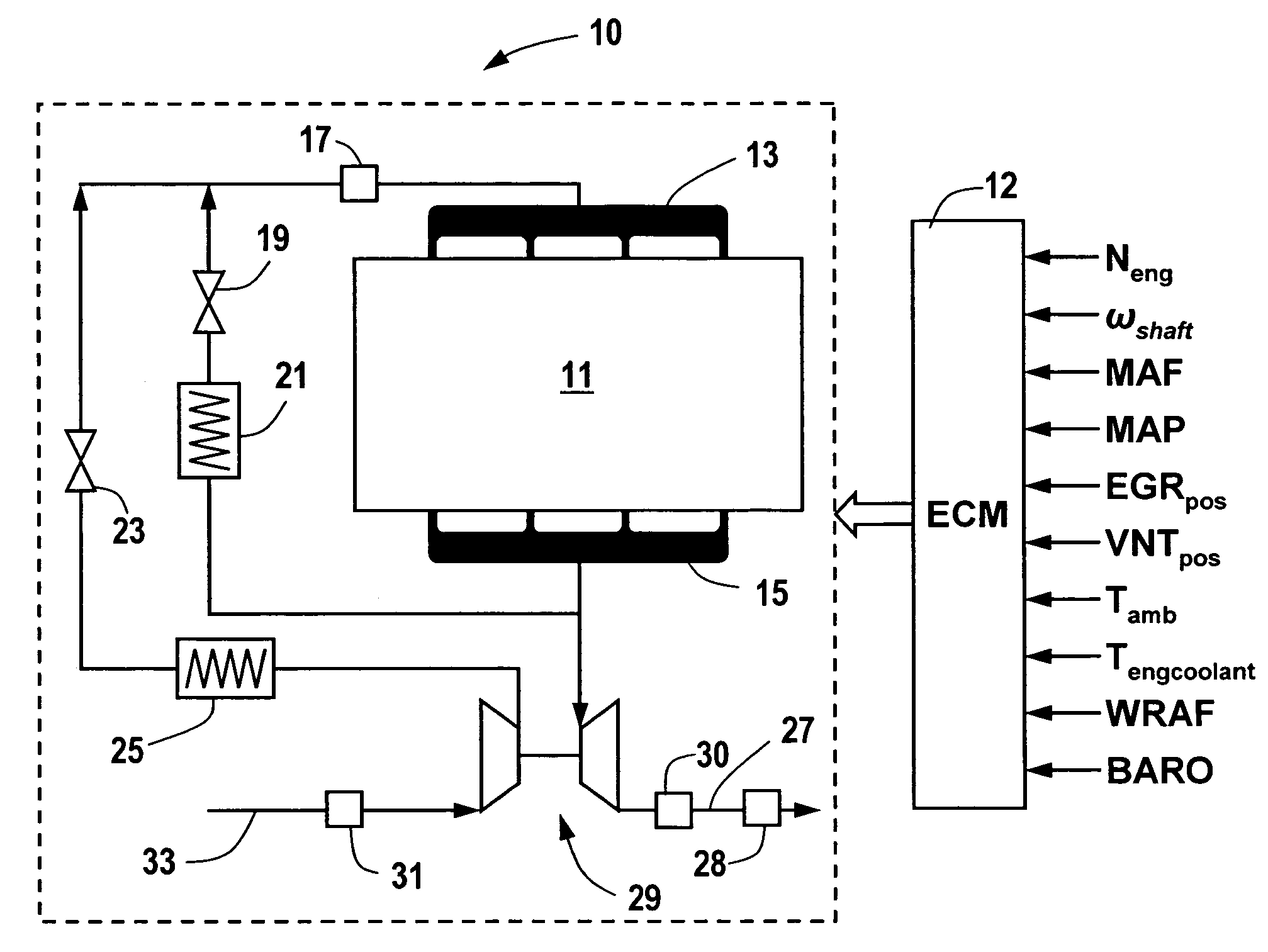

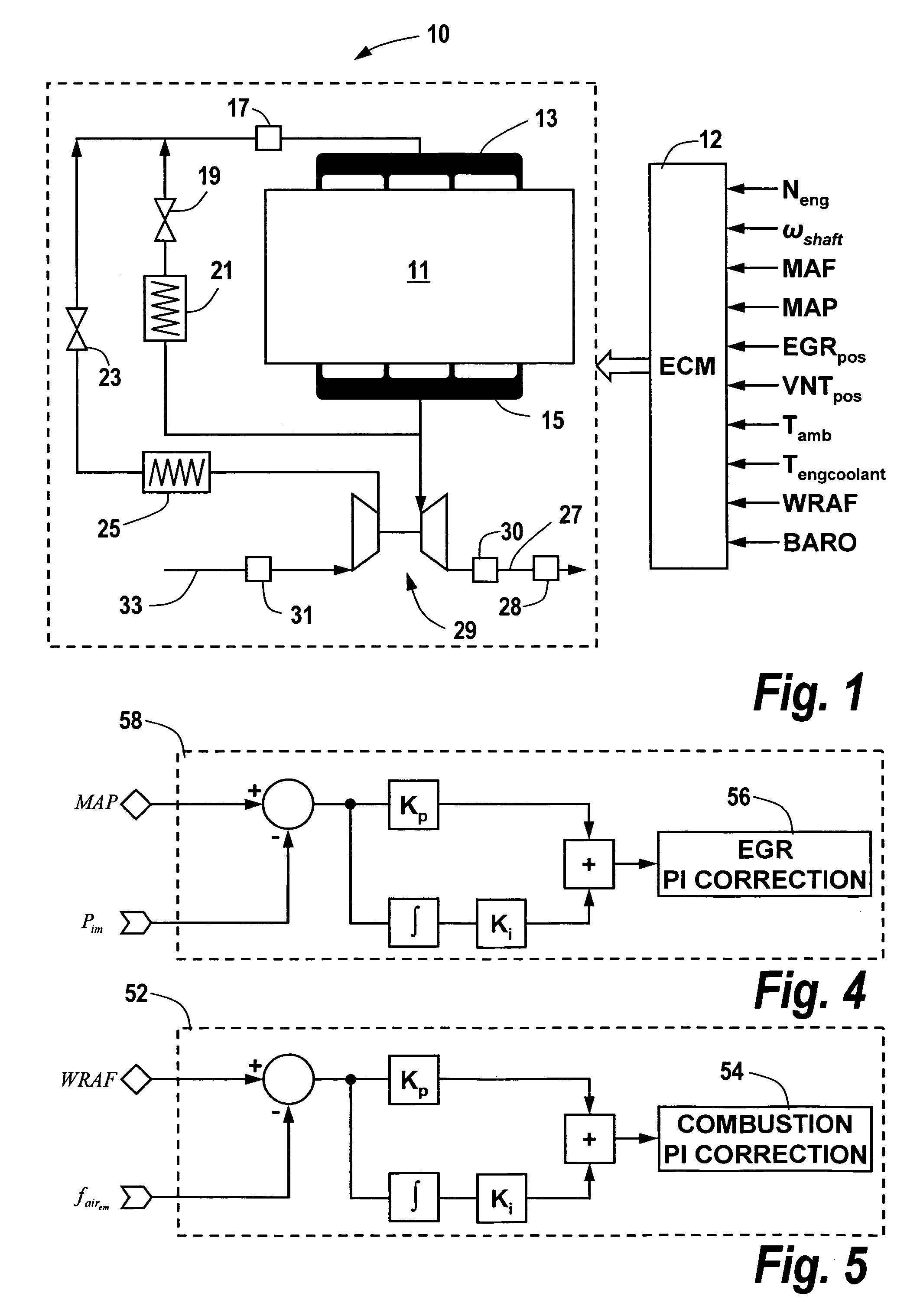

Optimized combustion control of an internal combustion engine equipped with exhaust gas recirculation

InactiveUS6948475B1Avoid condensationImprove concentrationElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An EGR equipped internal combustion engine is controlled to maximize the beneficial effects and minimize the detrimental effects of EGR on engine operation. Specifically, at least one parameter indicative of the O2 concentration in the intake mixture and / or at least one parameter indicative of the H2O concentration in the intake mixture is monitored, and the monitored parameter is relied on to control one or more aspects of engine operation by open loop adjustment of other control strategies and / or by a separate closed loop control strategy. These controls are applicable to virtually any engine, and are particularly beneficial to lean burn engines such as diesel (compression ignition) engines, spark ignited natural gas engines, and dual fuel or other compression ignited natural gas engines. The engine may be equipped with either actively controllable EGR or passive and uncontrolled EGR.

Owner:CLEAN AIR POWER

Electrical current generation system

InactiveUS6921597B2Facilitate pressureFacilitate ion exchangeFuel cell auxillariesHydrogen/synthetic gas productionHydrogenFuel cells

An electrical generating system consists of a fuel cell, and an oxygen gas delivery. The fuel cell includes and anode channel having an anode gas inlet for receiving a supply of hydrogen gas, a cathode channel having a cathode gas inlet and a cathode gas outlet, and an electrolyte in communication with the anode and cathode channel for facilitating ion exchange between the anode and cathode channel. The oxygen gas delivery system is coupled to the cathode gas inlet and delivers oxygen gas to the cathode channel. The electrical current generating system also includes gas recirculation means couple to the cathode gas outlet for recirculating a portion of cathode exhaust gas exhausted from the cathode gas outlet to the cathode gas inlet.

Owner:AIR PROD & CHEM INC

Exhaust gas recirculation system having cooler

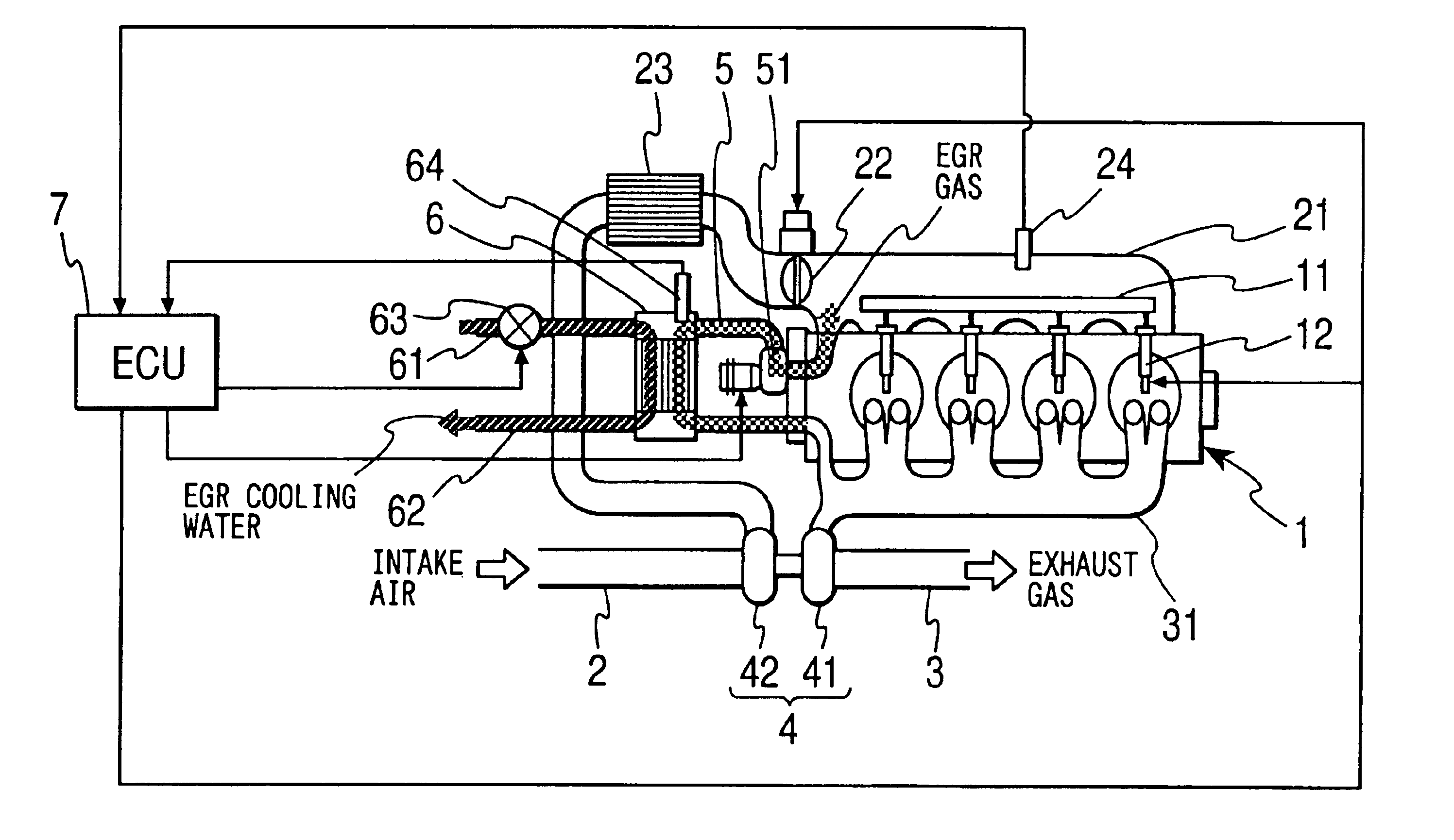

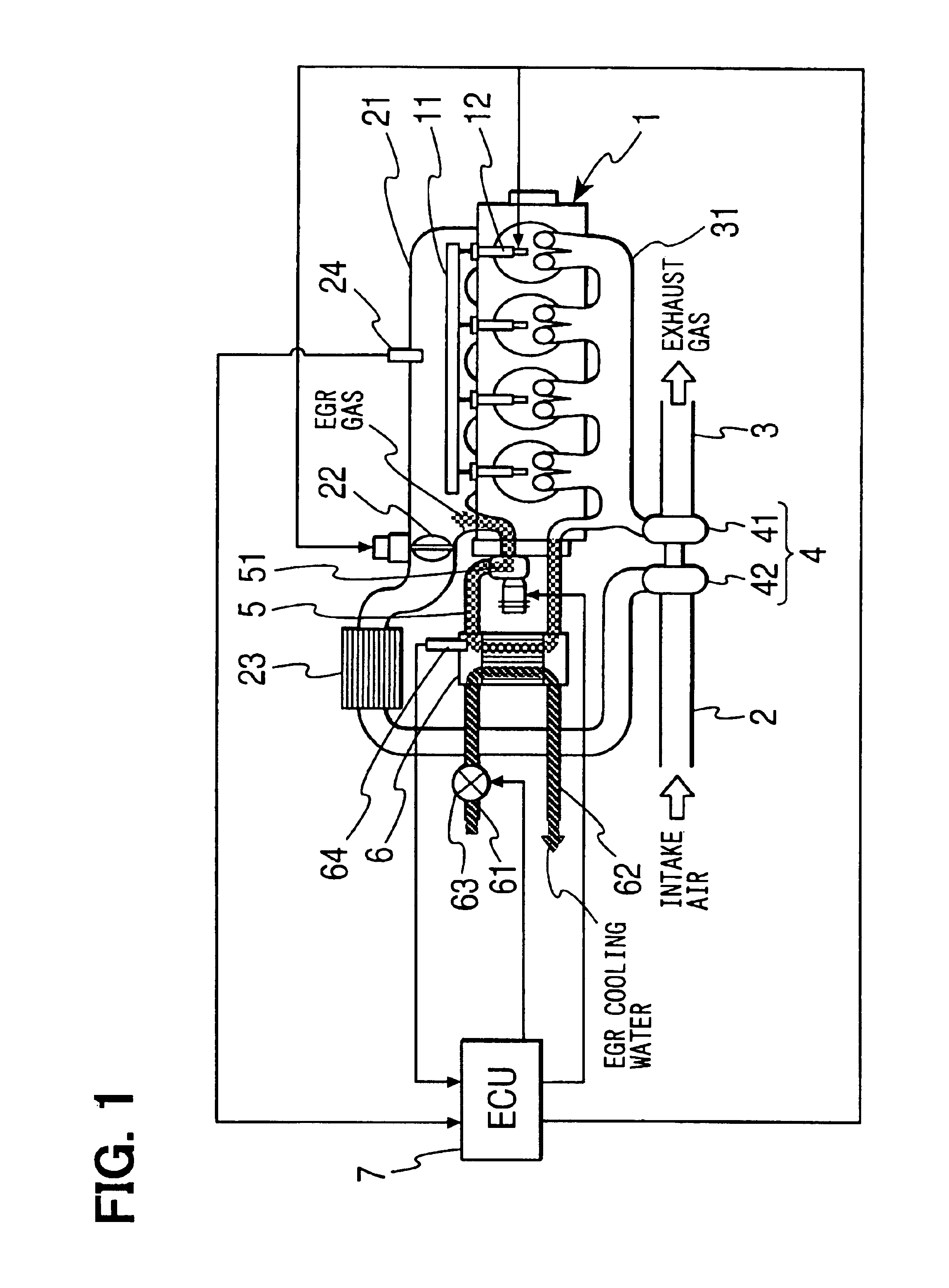

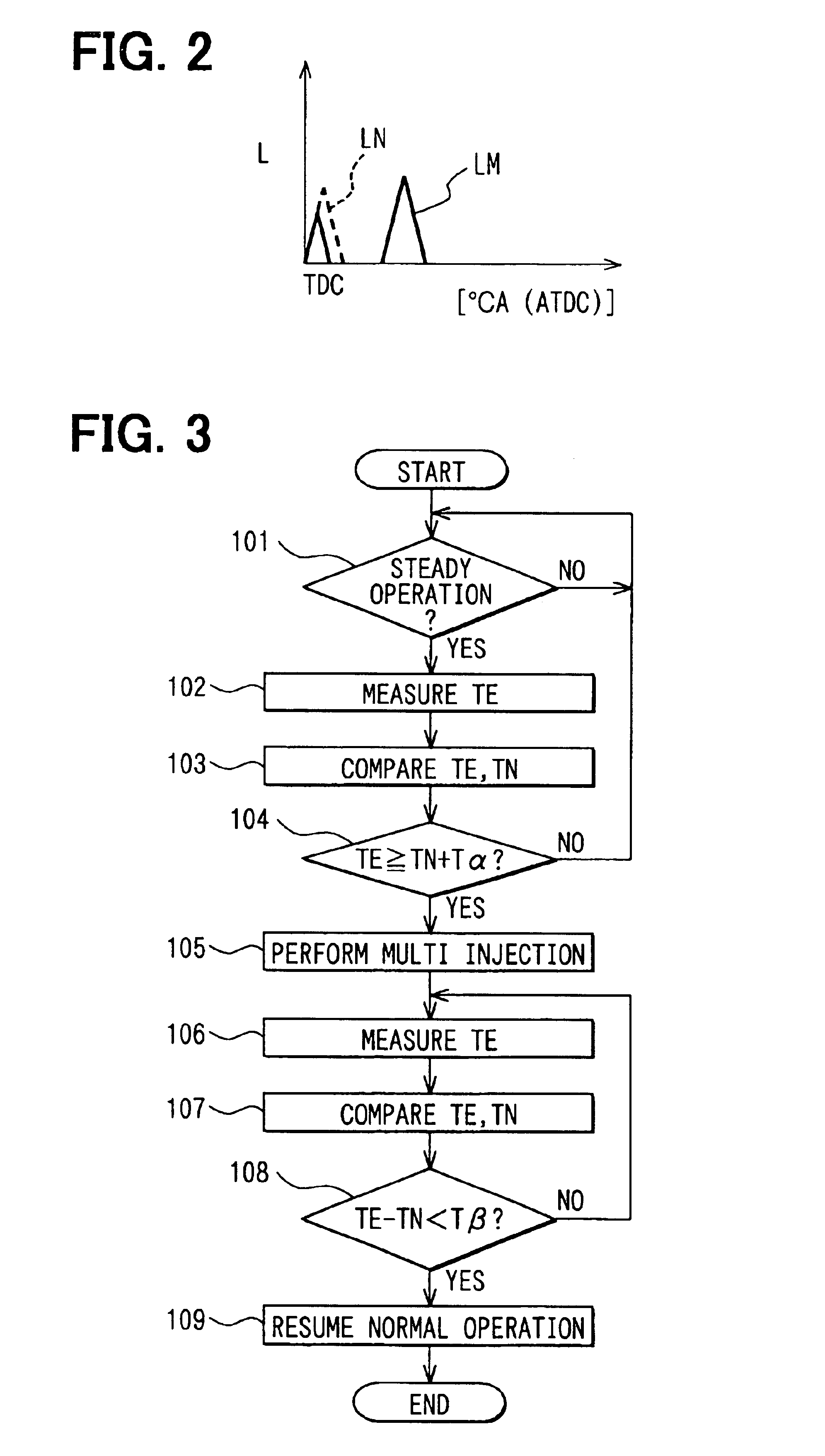

InactiveUS6826903B2Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

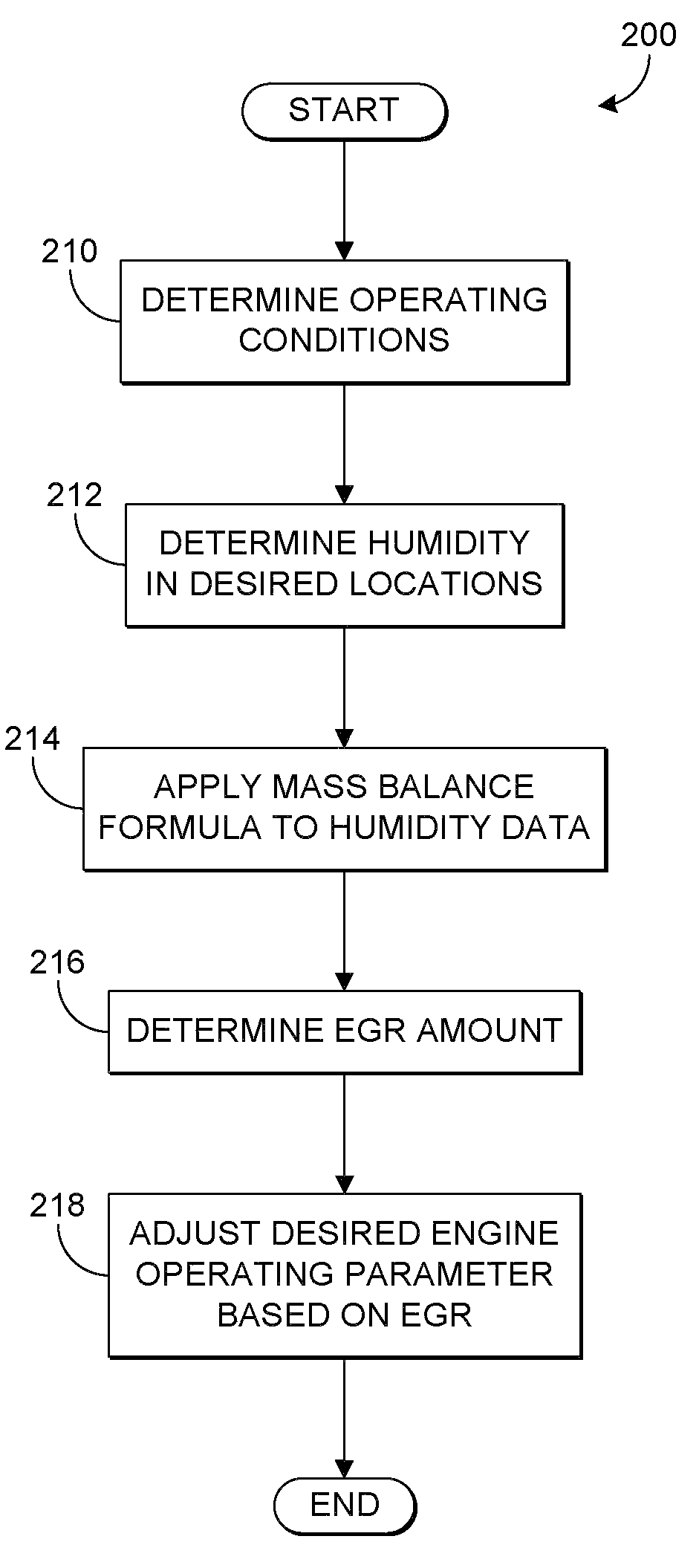

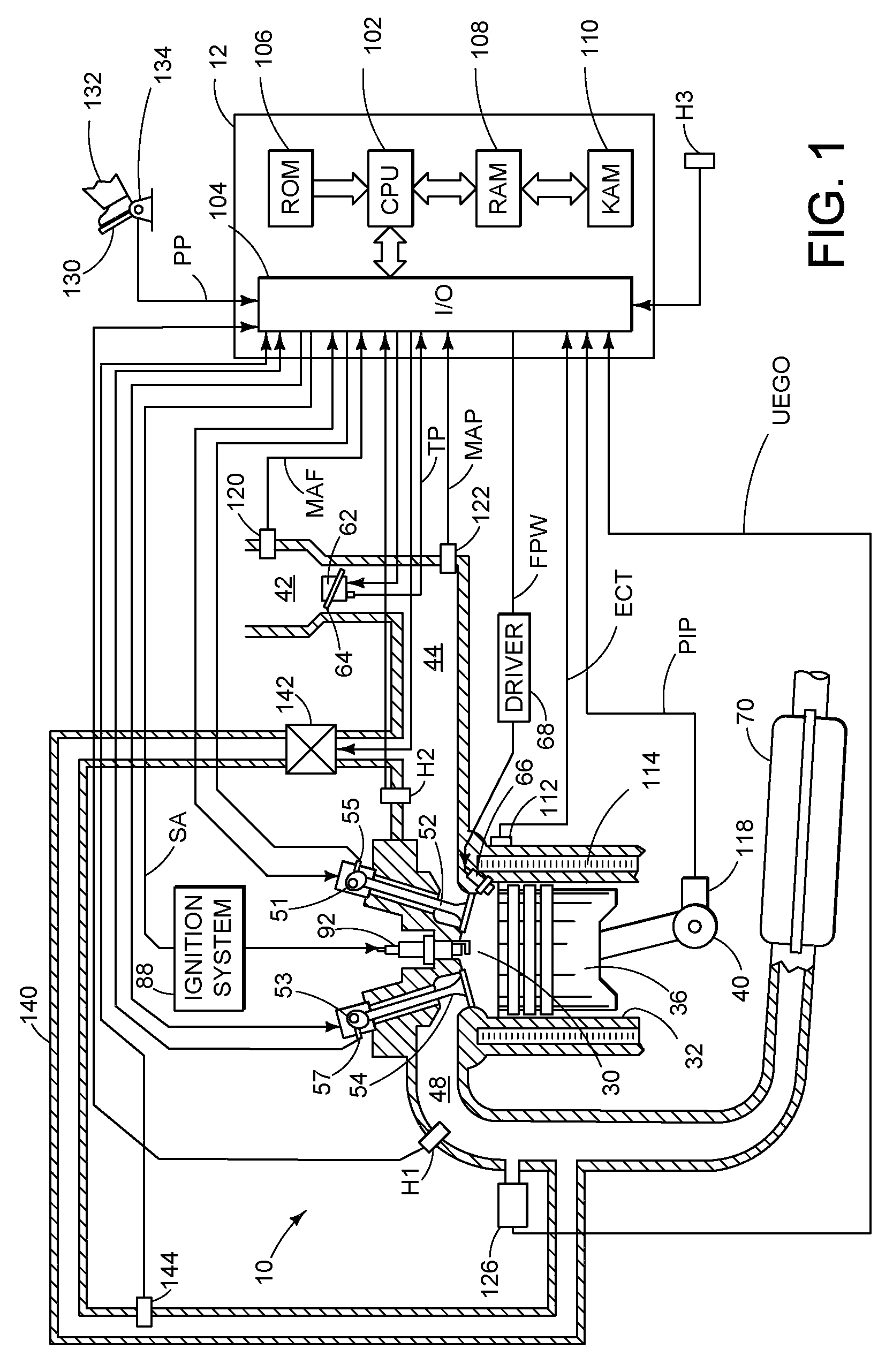

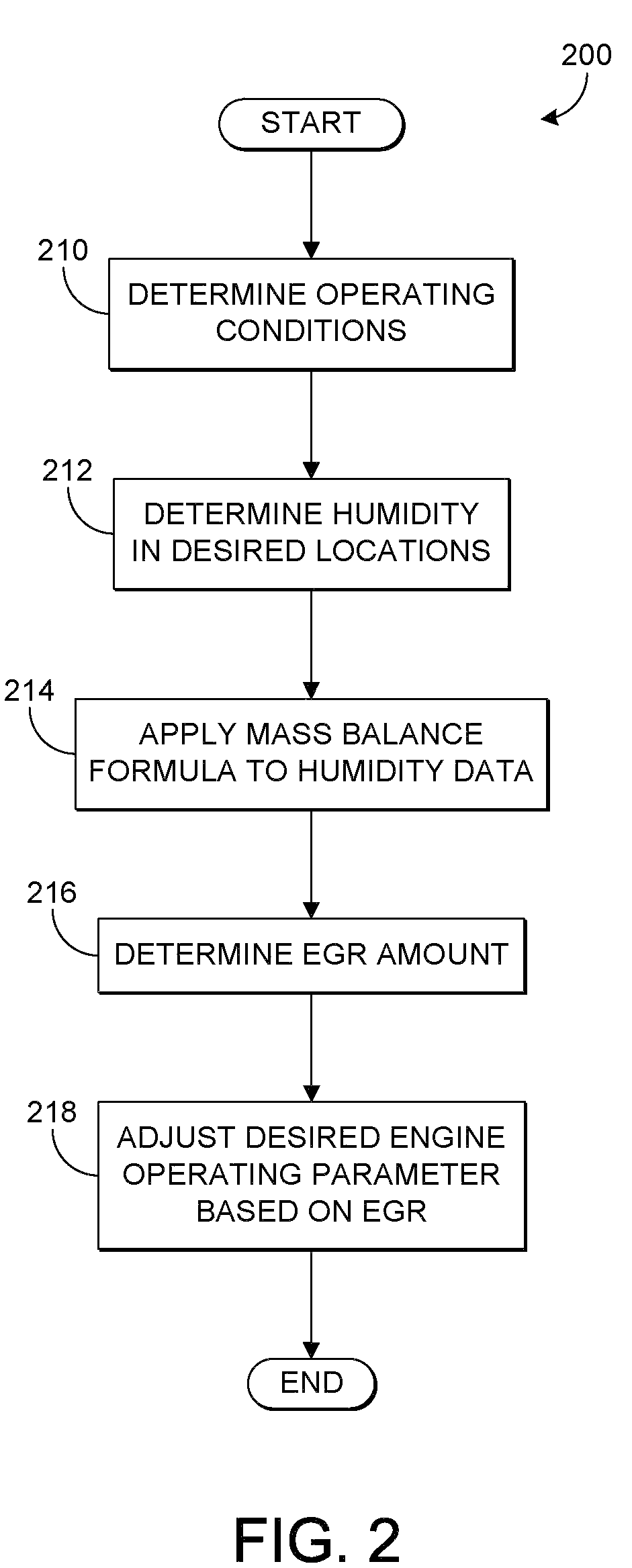

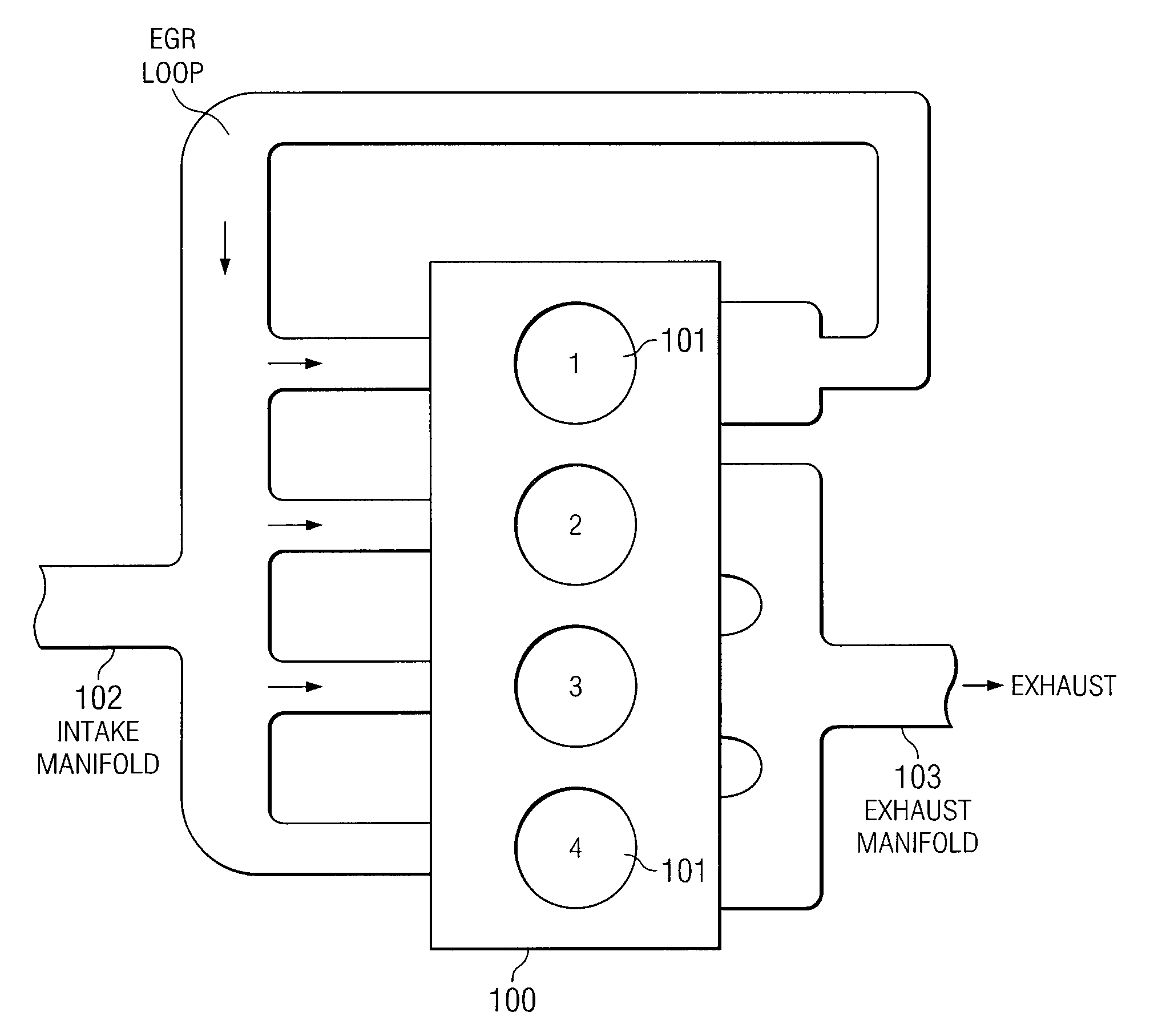

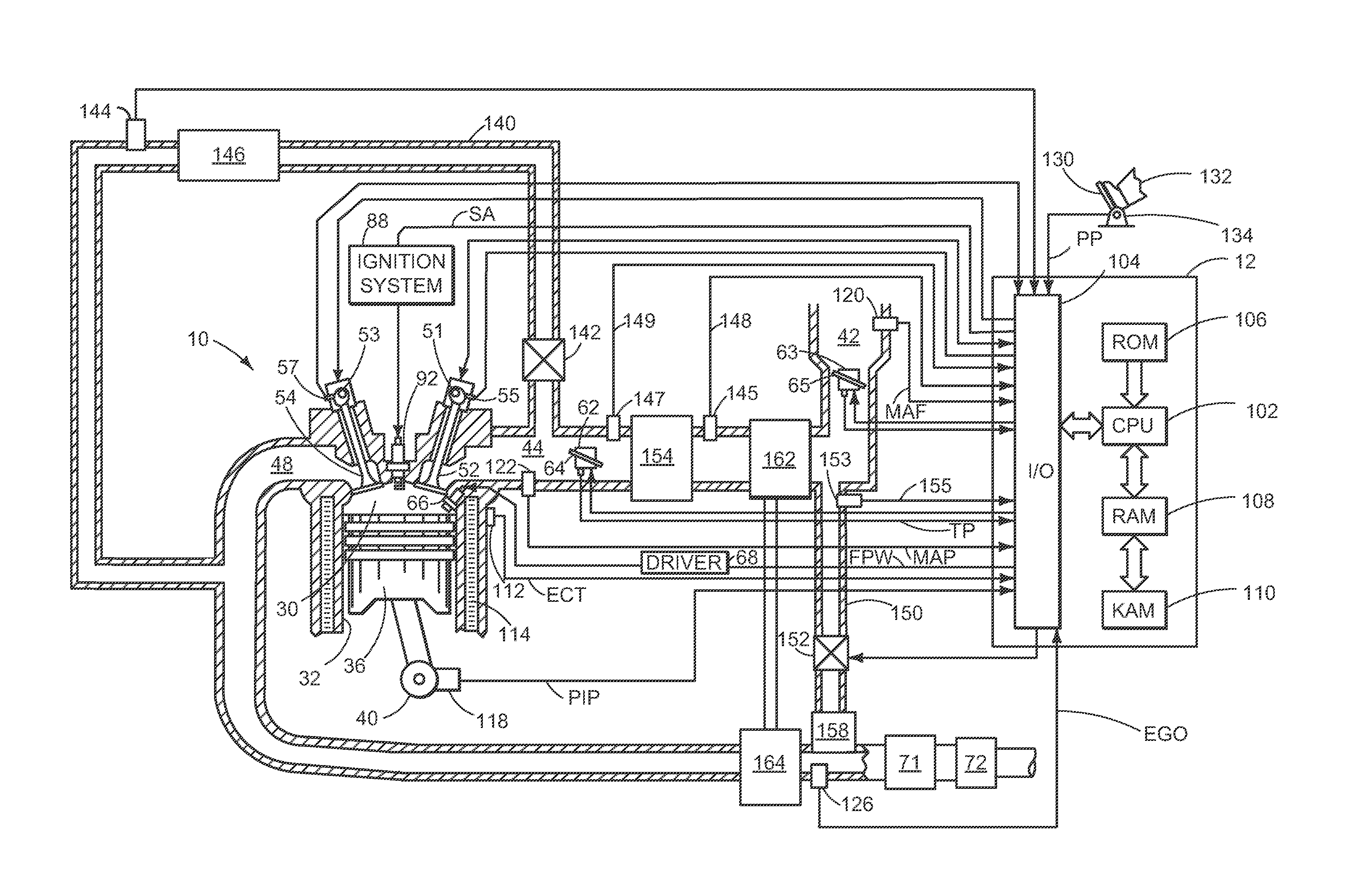

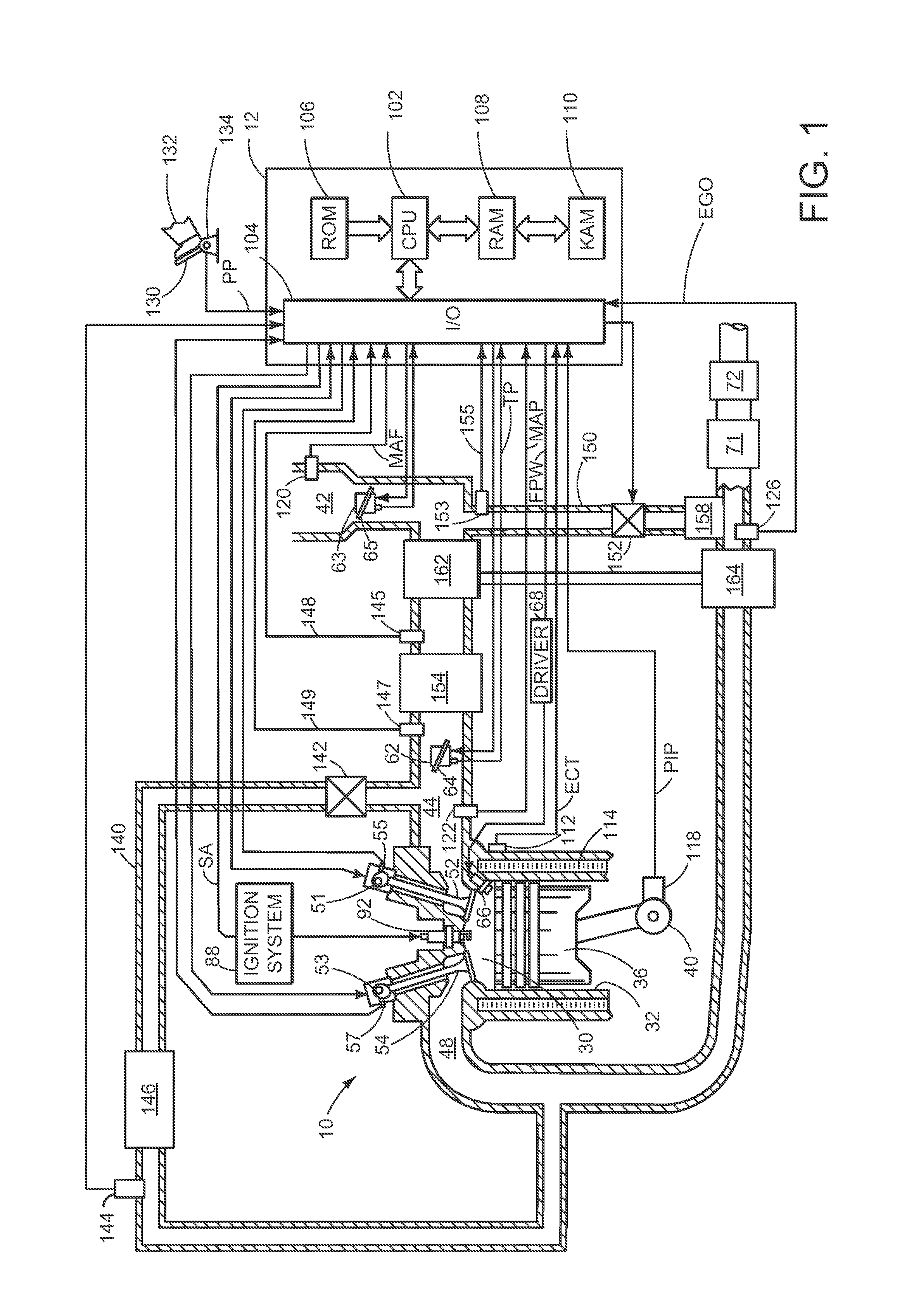

EGR detection via humidity detection

InactiveUS7715976B1Amount of EGRAccurately determineElectrical controlInternal combustion piston enginesExhaust gas recirculationMoisture sensor

Various systems and methods are described for controlling an engine in a vehicle which includes an exhaust passage and an exhaust gas recirculation system. One example method comprises adjusting an engine operating parameter based on an exhaust gas recirculation amount, the exhaust gas recirculation amount based on a first humidity and a second humidity, the first humidity generated from a first humidity sensor at a first location and the second humidity generated from a second humidity sensor located in the exhaust passage of the engine.

Owner:FORD GLOBAL TECH LLC

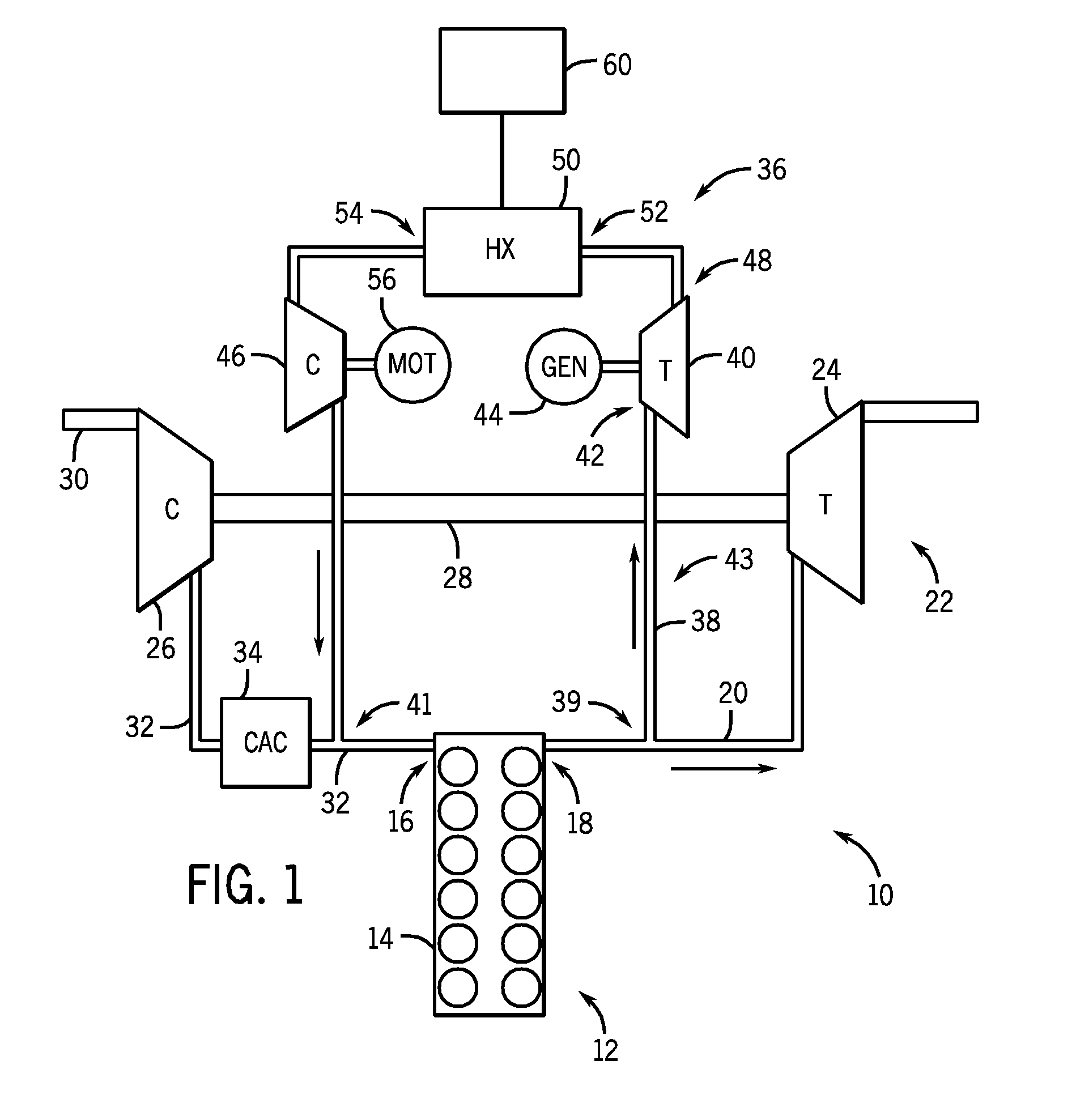

EGR system with dedicated EGR cylinders

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

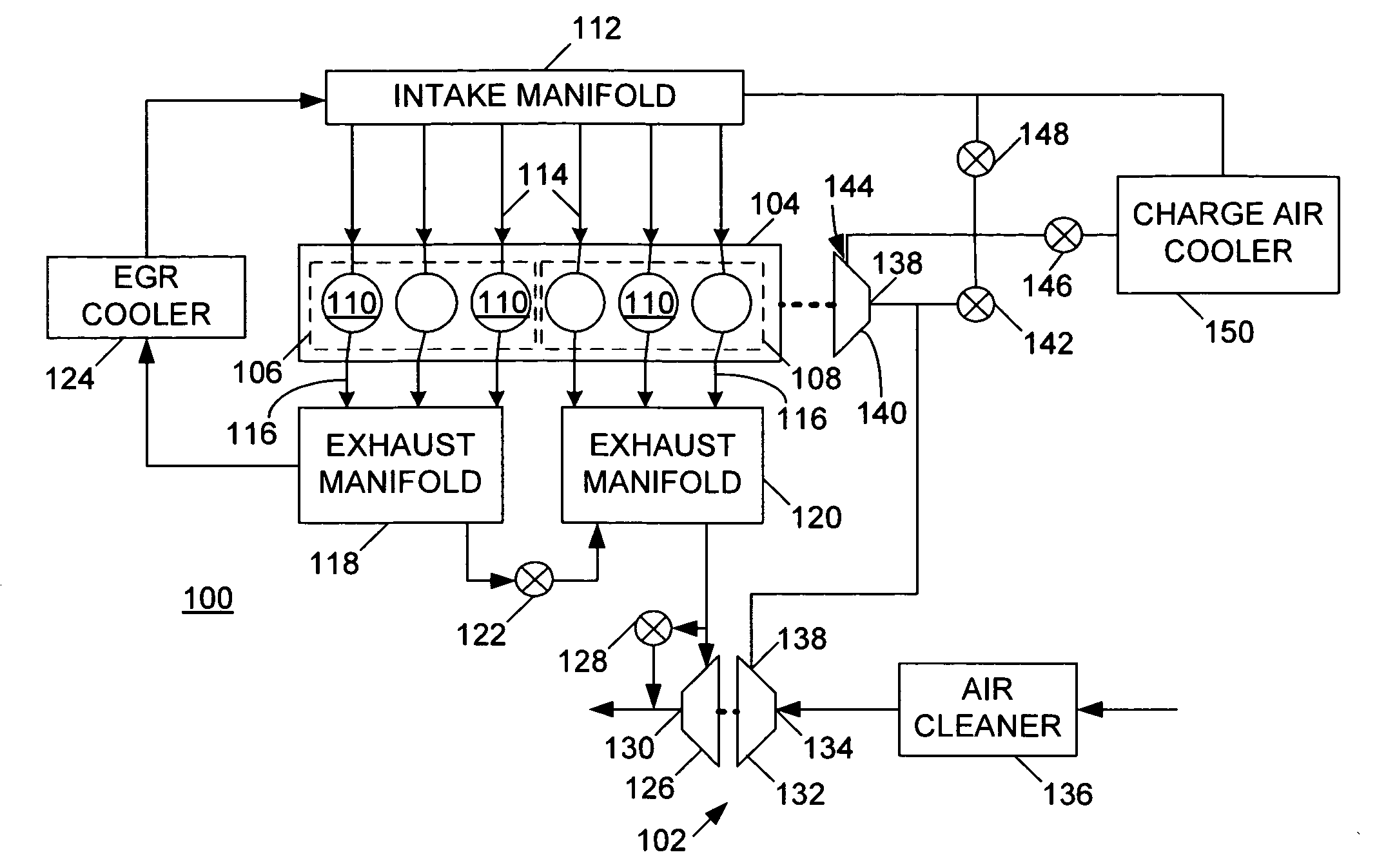

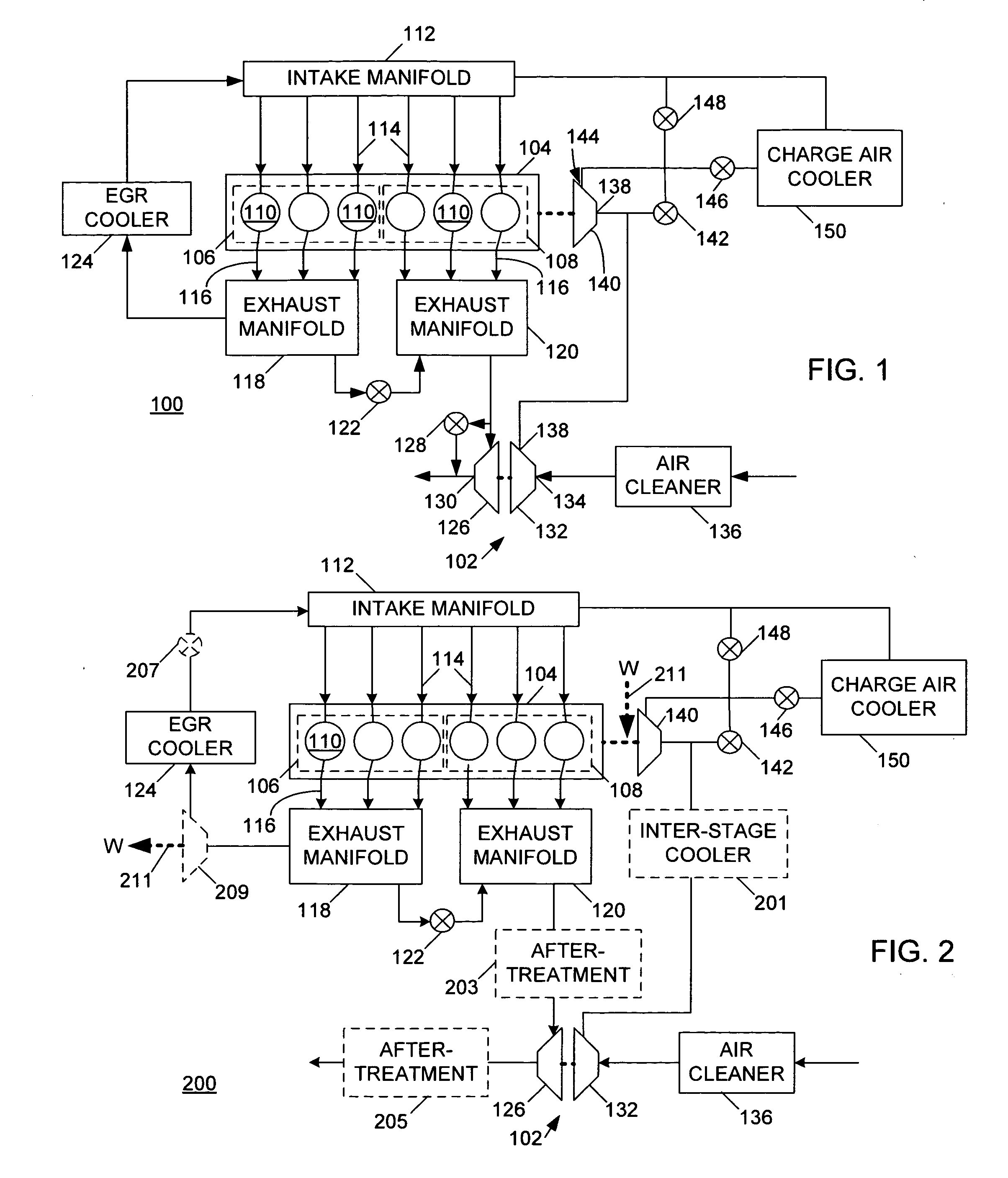

Constant EGR rate engine and method

ActiveUS20070175215A1Non-fuel substance addition to fuelInternal combustion piston enginesExhaust valveTurbocharger

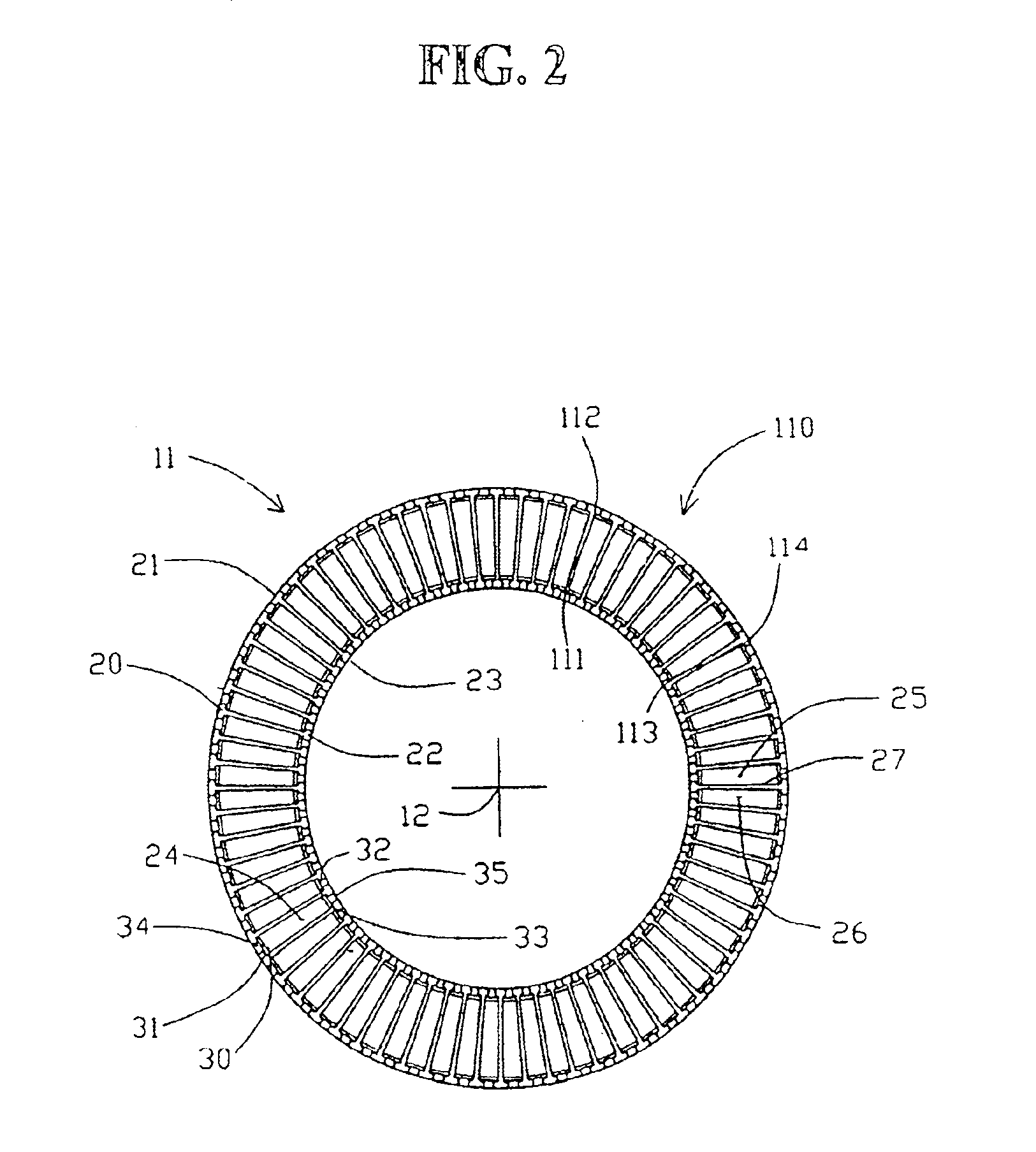

An internal combustion engine (100) includes a first exhaust manifold (120), and a second exhaust manifold (118) fluidly connected to the first exhaust manifold (120) through an exhaust valve (122). An exhaust gas recirculation (EGR) cooler (124) constantly fluidly connects the second exhaust manifold (118) with an intake manifold (112). A turbocharger (102) has a turbine (126) in fluid communication with the first exhaust manifold (120), and a compressor (132) in fluid communication with a supercharger (140). A charge air cooler (150) fluidly connects the supercharger (140) with the intake manifold (112).

Owner:INT ENGINE INTPROP CO LLC

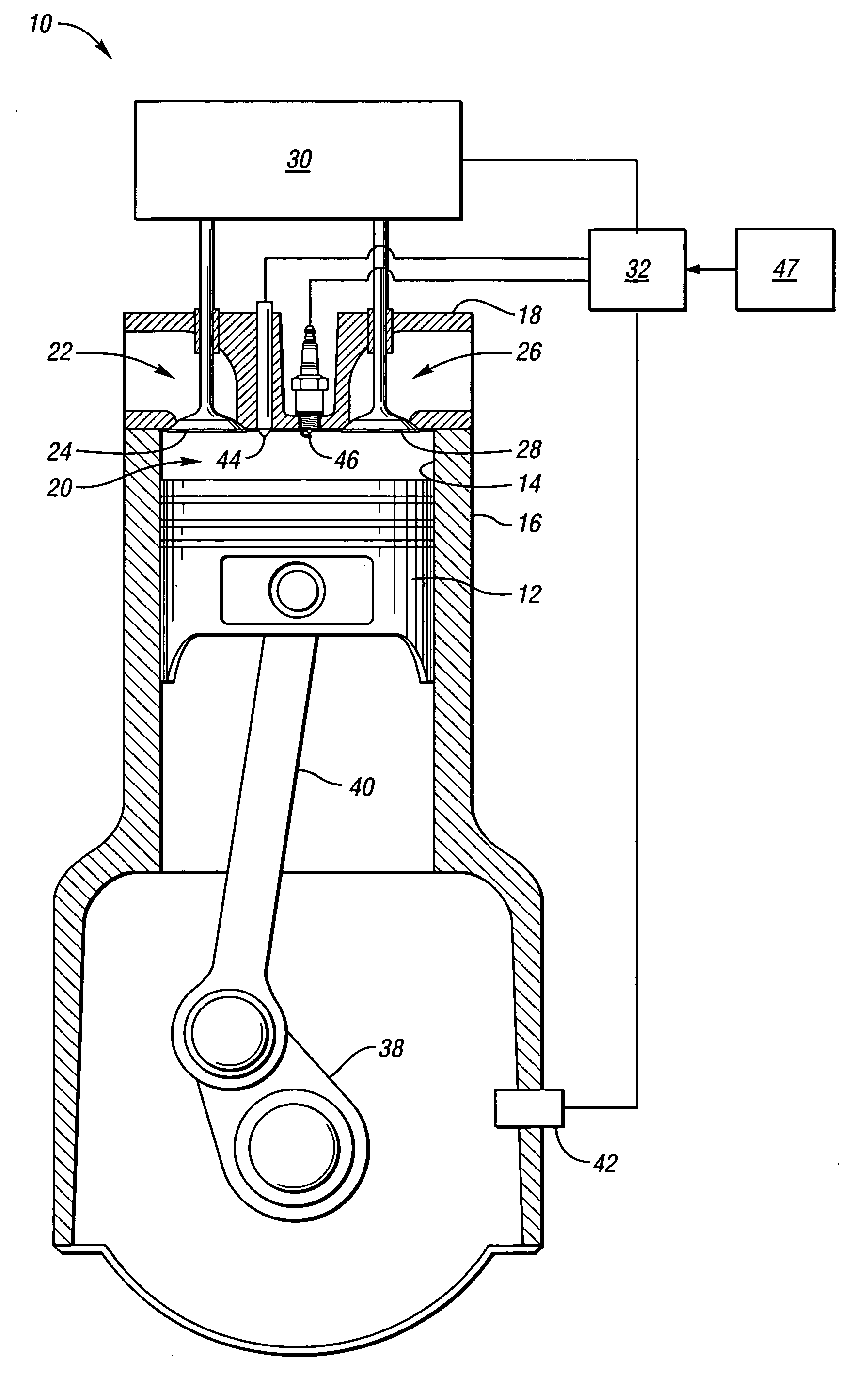

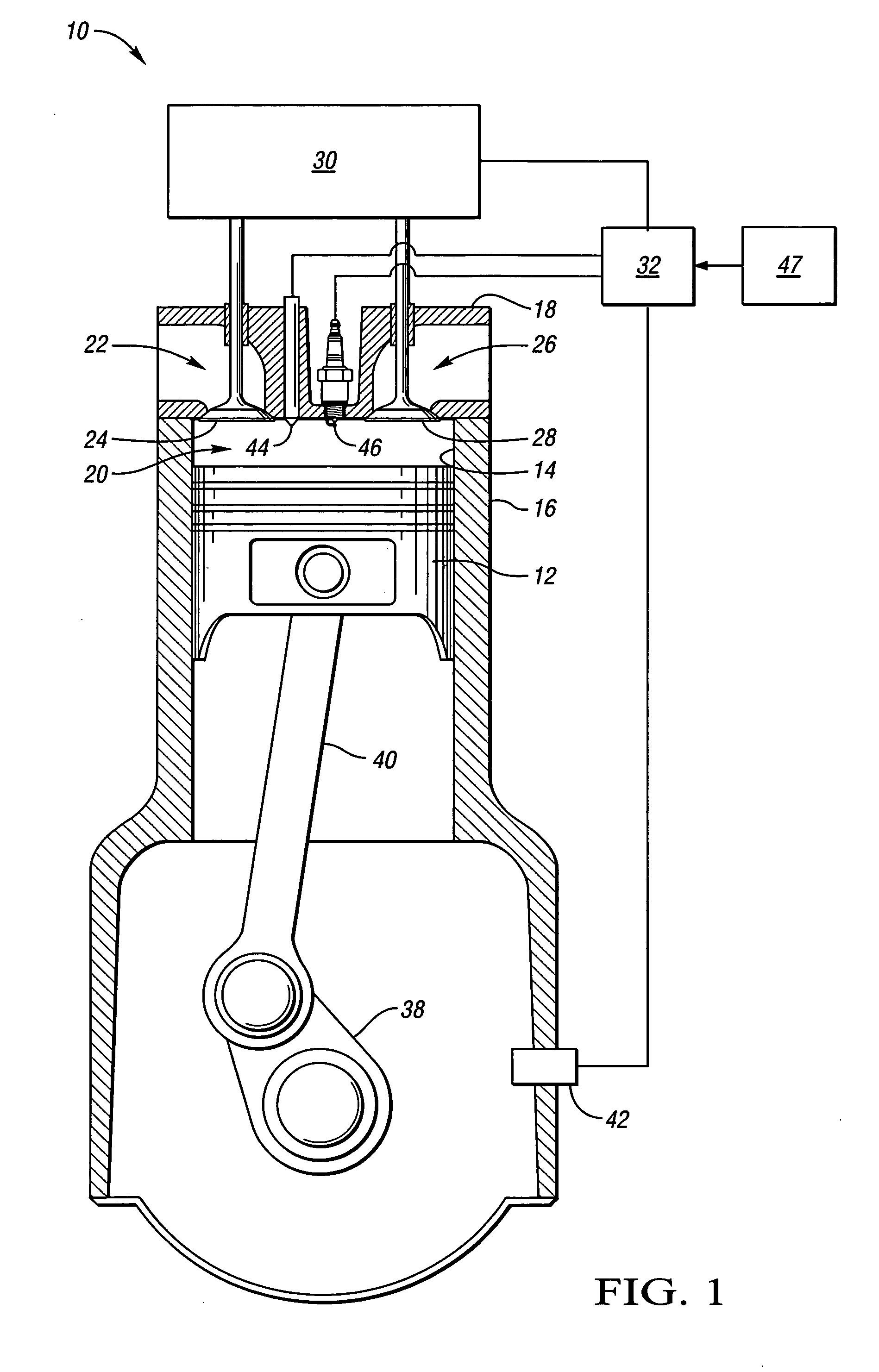

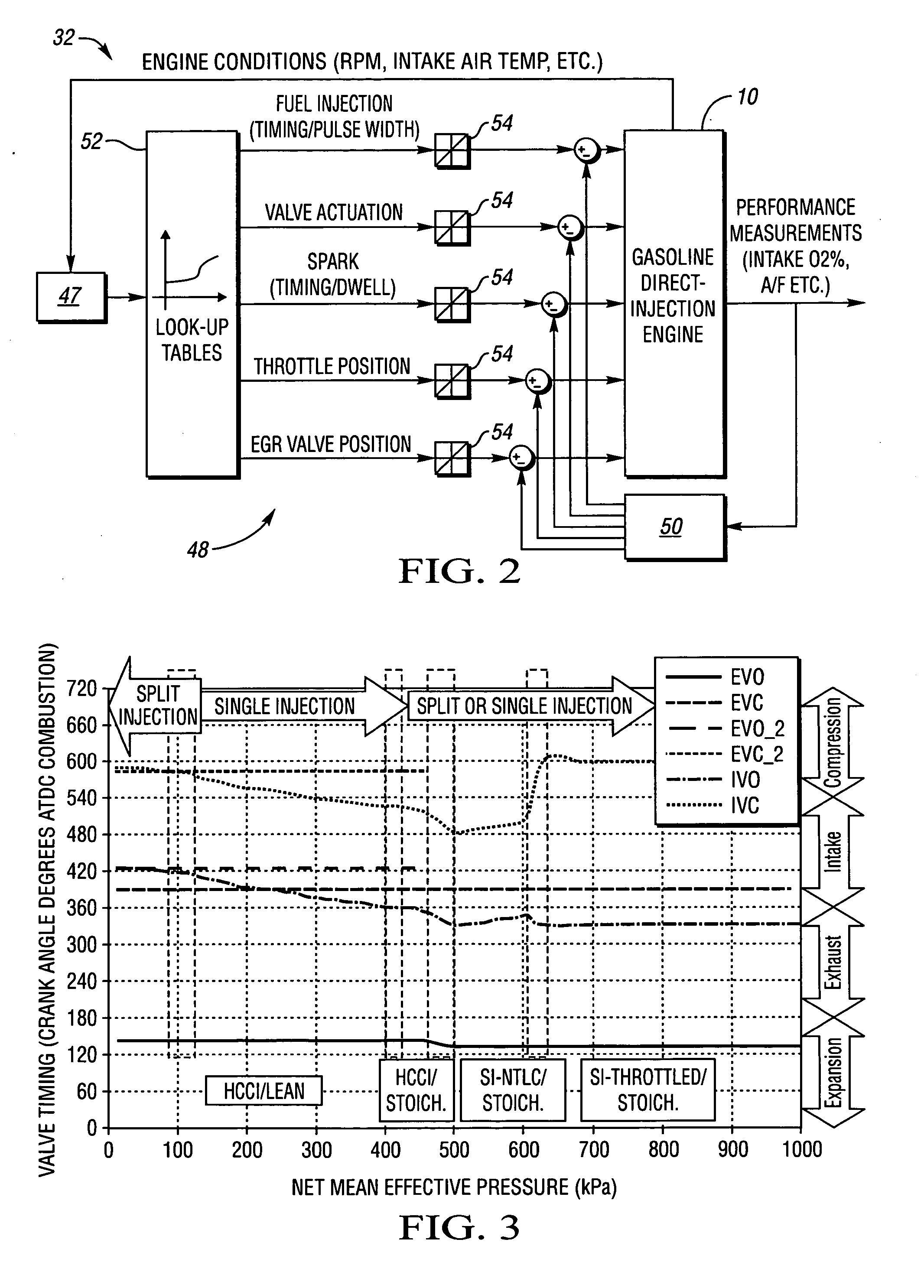

Method of HCCI and SI combustion control for a direct injection internal combustion engine

InactiveUS20060243241A1Improve fuel economyRobust controlValve arrangementsElectrical controlHomogeneous charge compression ignitionGasoline direct injection

The present invention relates to methods for robust controlled auto-ignition and spark ignited combustion controls in gasoline direct-injection engines, including transients, using either exhaust re-breathing or a combination of exhaust re-compression and re-breathing valve strategy. These methods are capable of enabling engine operation with either lean of stoichiometric or stoichiometric air / fuel ratio for oxides of nitrogen (NOx) control, with varying exhaust gas recirculation (EGR) rates and throttle valve positions for knock control, and with a combination of homogeneous charge compression ignition (HCCI) and spark ignition (SI) combustion modes to optimize fuel economy over a wide range of engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

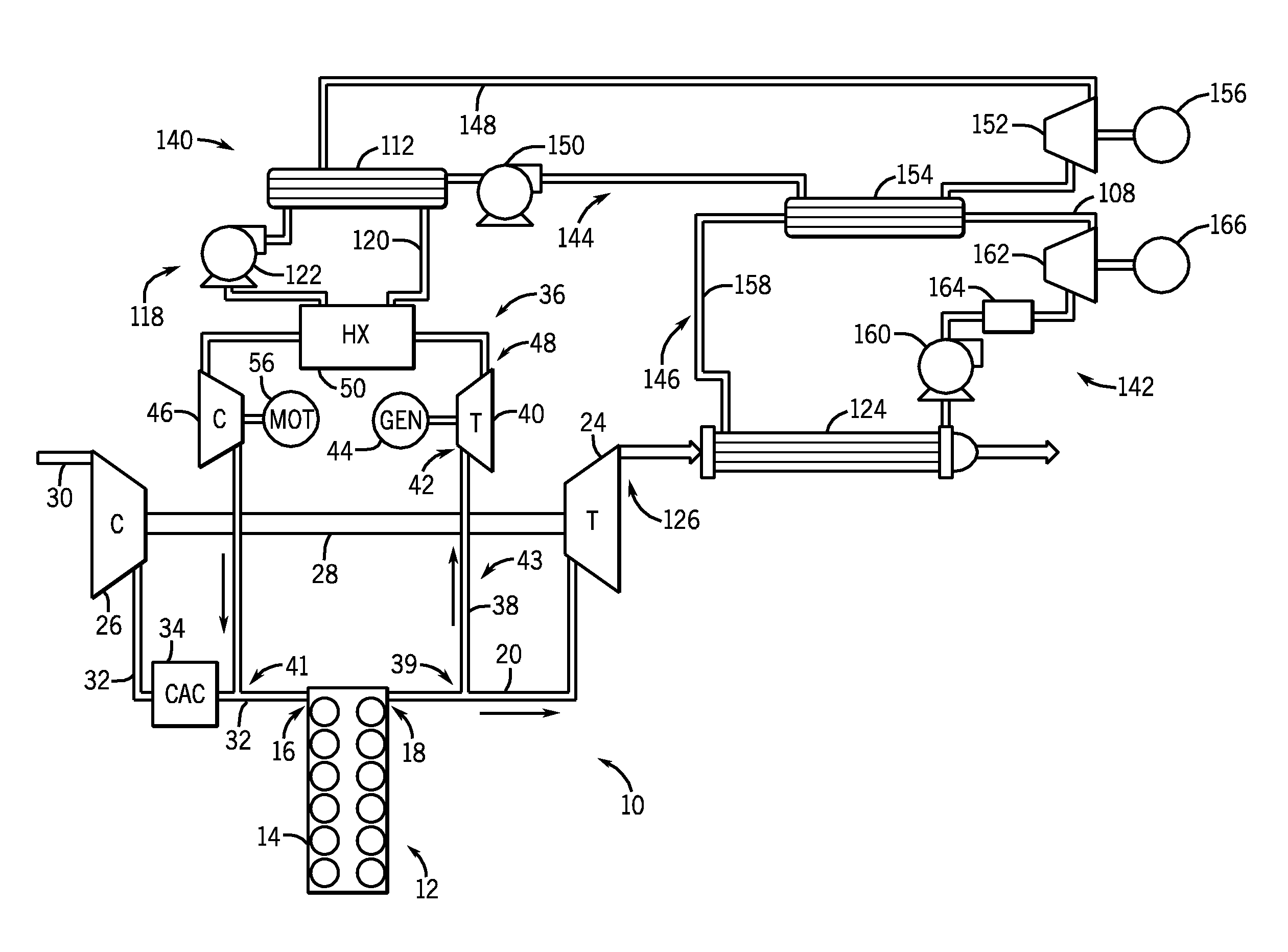

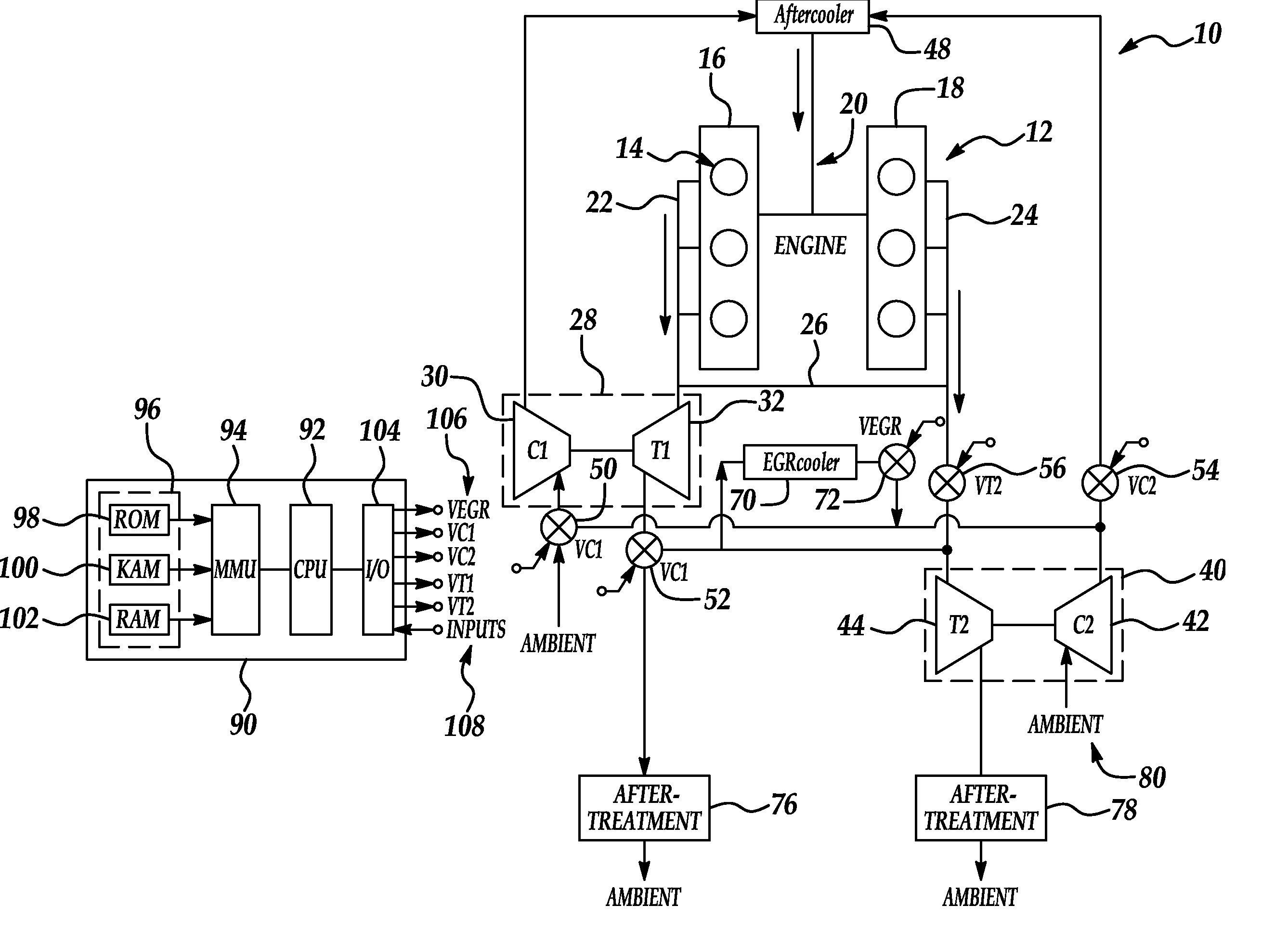

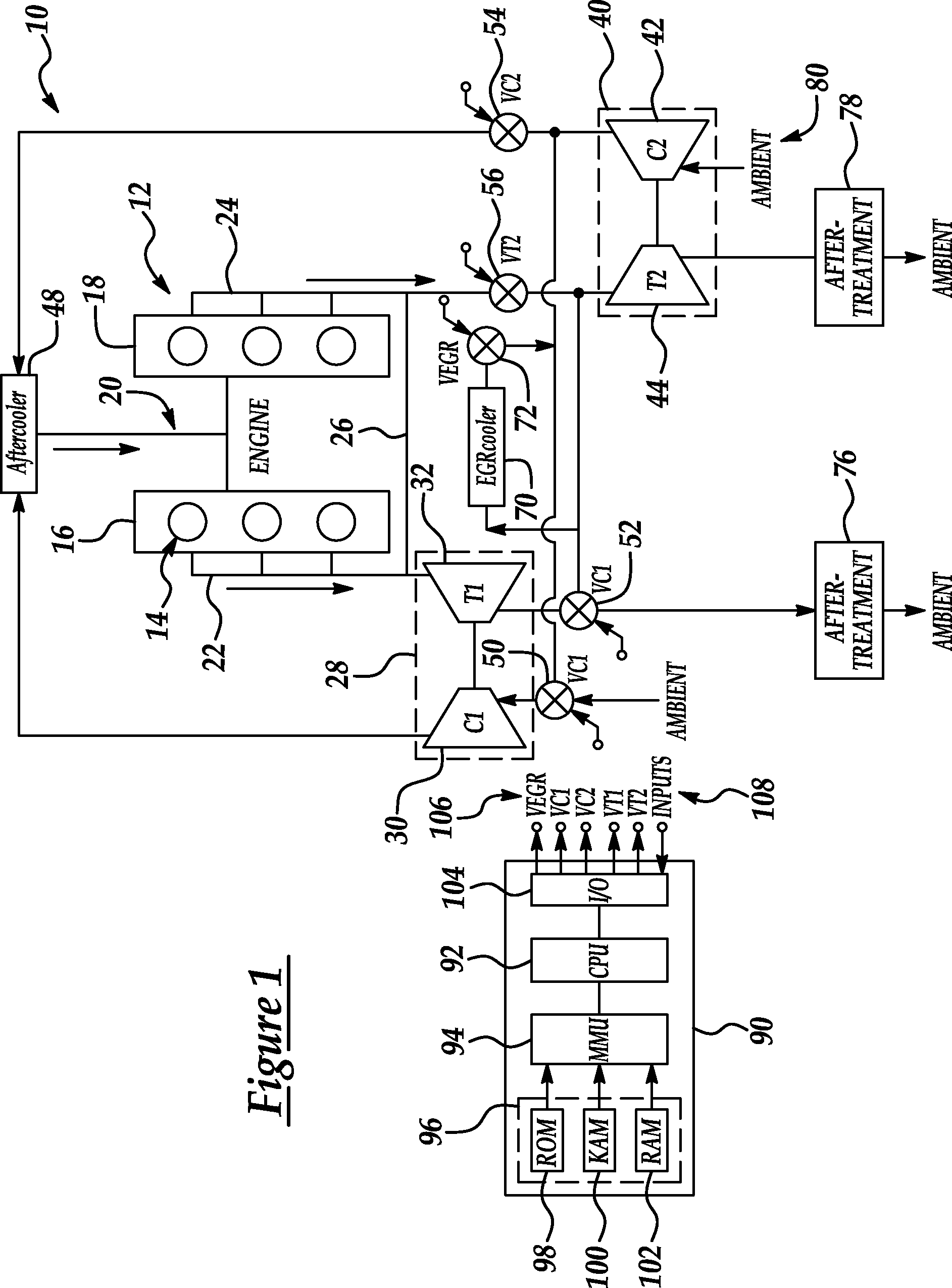

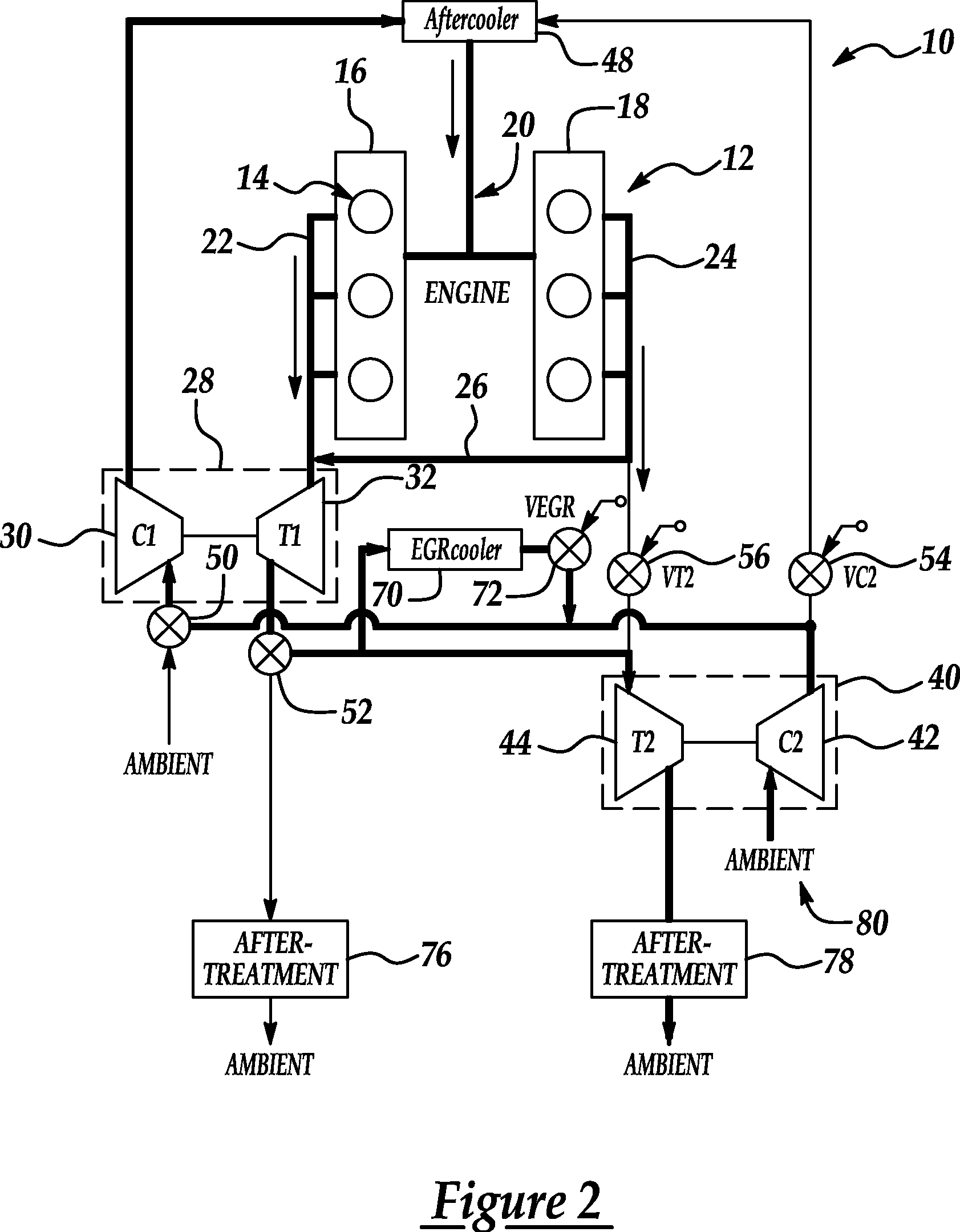

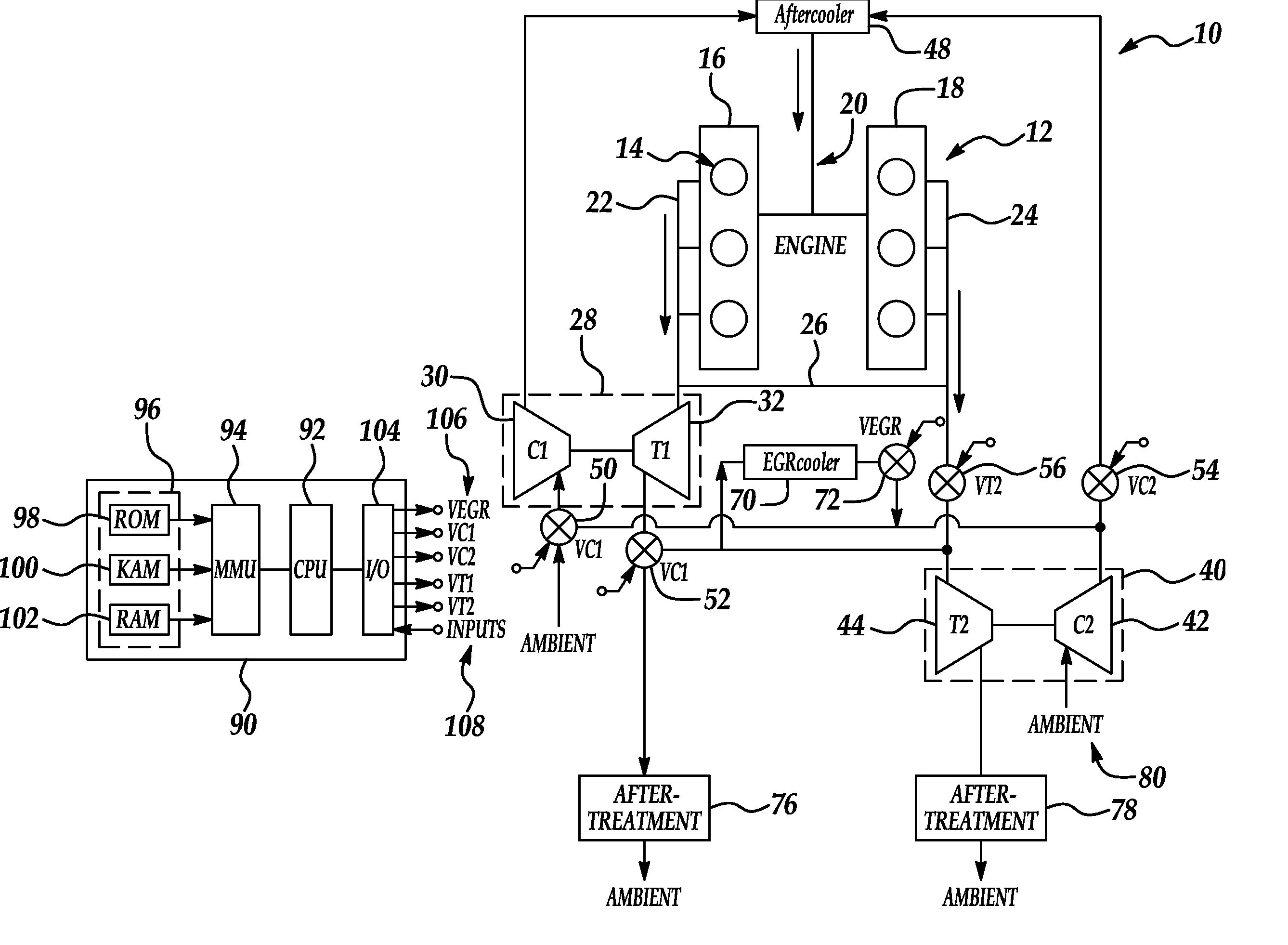

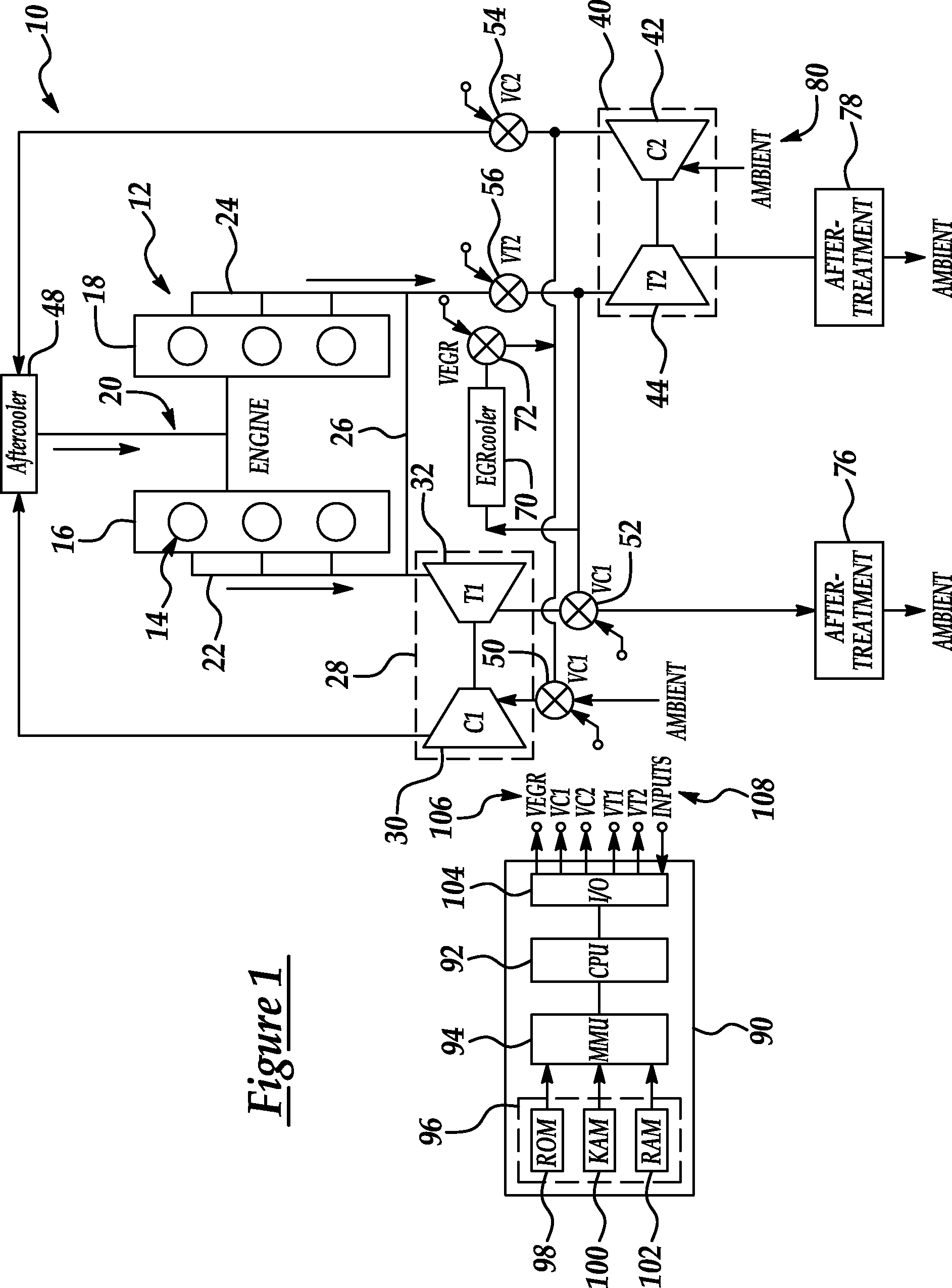

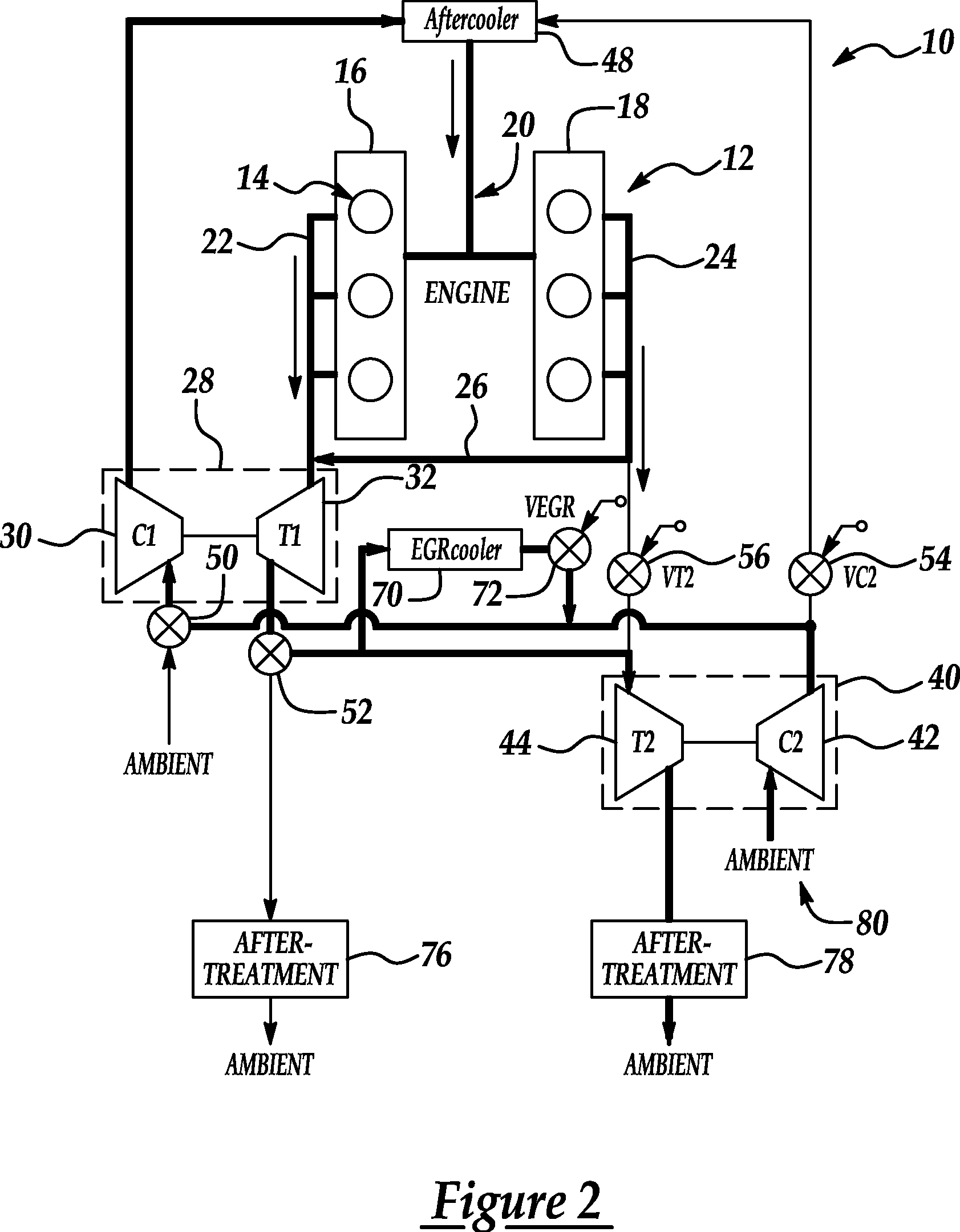

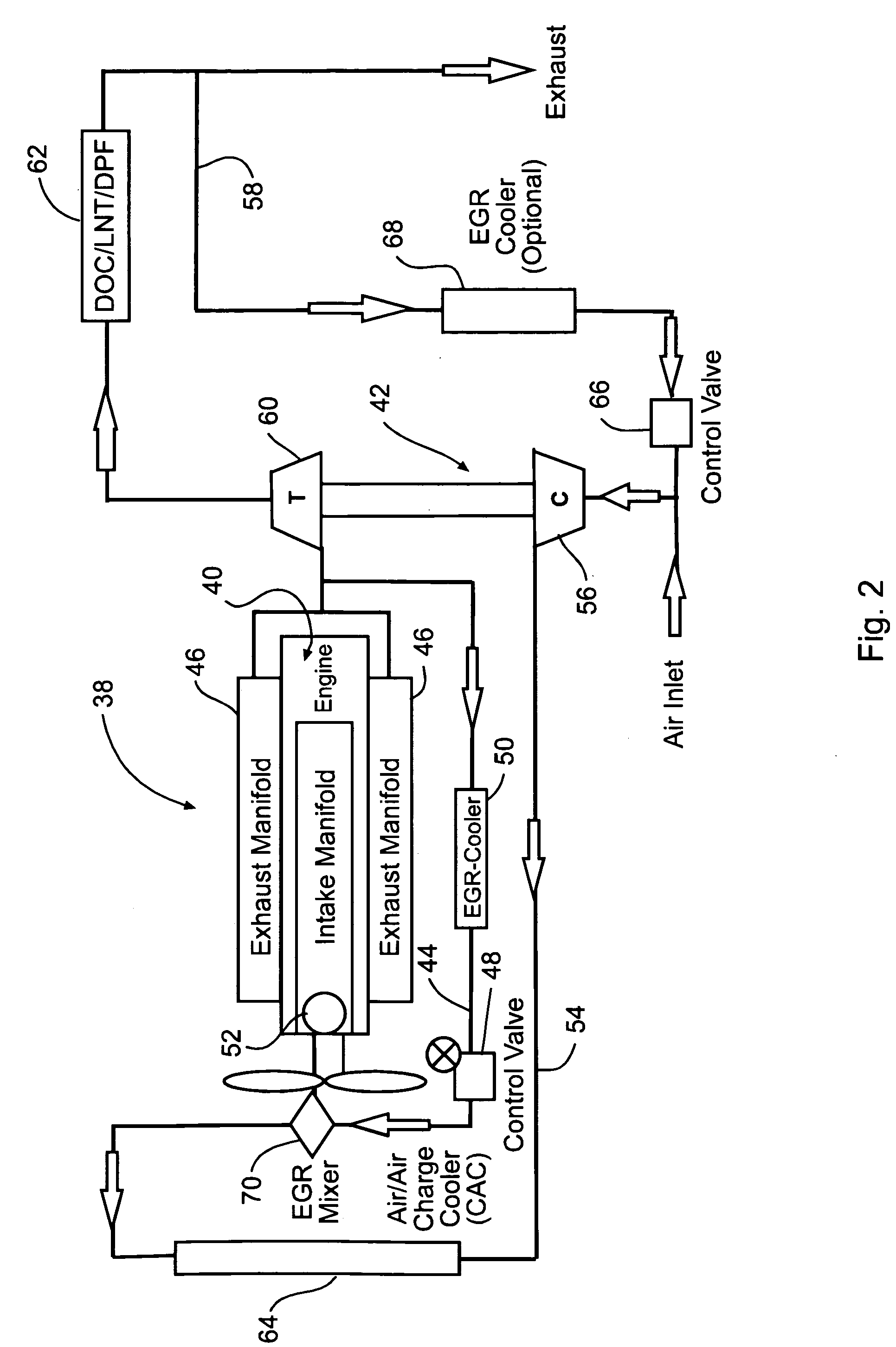

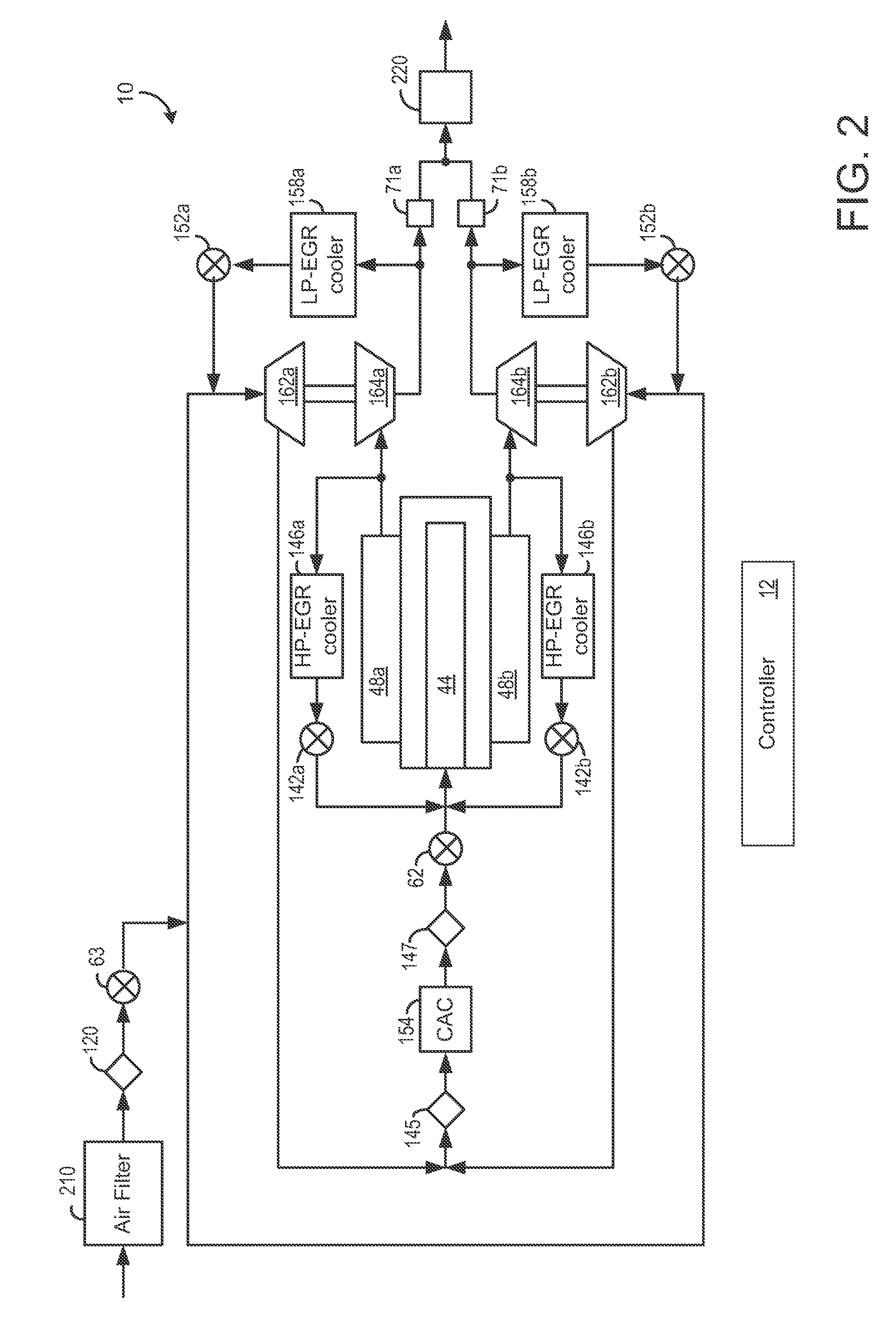

Series/parallel turbochargers and switchable high/low pressure EGR for internal combustion engines

InactiveUS20060021347A1Promote generationSufficient handling capacityElectrical controlInternal combustion piston enginesTurbochargerHigh pressure

Systems and methods for turbocharging an internal combustion engine include operating two turbochargers in a series configuration for a first operating region and a parallel configuration for a second operating region. Systems and methods for controlling exhaust gas recirculation (EGR) in a turbocharged internal combustion engine provide low pressure EGR upstream of a compressor inlet for a first operating region and high pressure EGR downstream of a compressor outlet for a second operating range to further improve turbocharger operating margin and overall efficiency.

Owner:FORD GLOBAL TECH LLC

Series/parallel turbochargers and switchable high/low pressure EGR for internal combustion engines

InactiveUS7165403B2Promote generationImproved vehicle launchElectrical controlNon-fuel substance addition to fuelTurbochargerExternal combustion engine

Systems and methods for turbocharging an internal combustion engine include operating two turbochargers in a series configuration for a first operating region and a parallel configuration for a second operating region. Systems and methods for controlling exhaust gas recirculation (EGR) in a turbocharged internal combustion engine provide low pressure EGR upstream of a compressor inlet for a first operating region and high pressure EGR downstream of a compressor outlet for a second operating range to further improve turbocharger operating margin and overall efficiency.

Owner:FORD GLOBAL TECH LLC

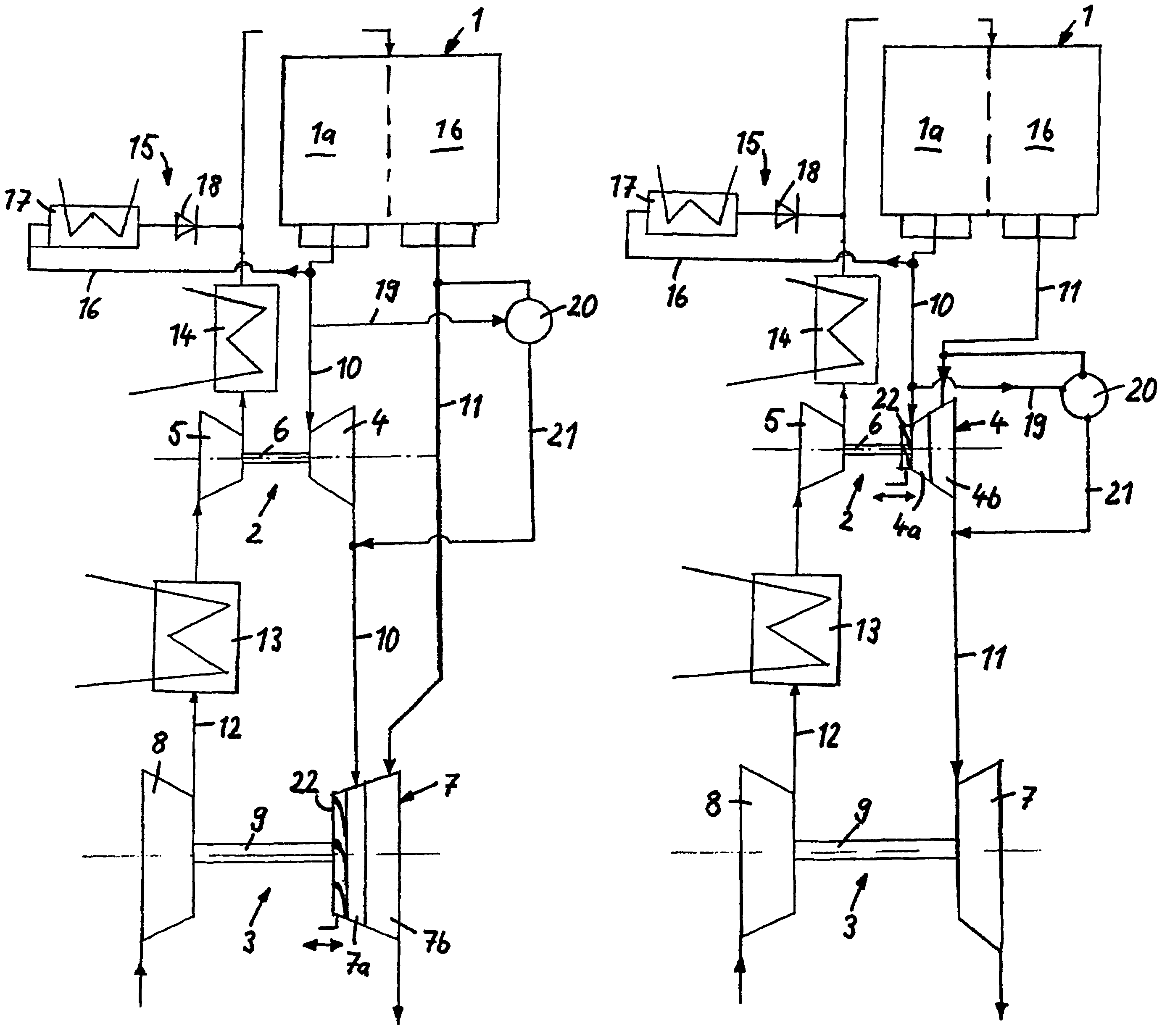

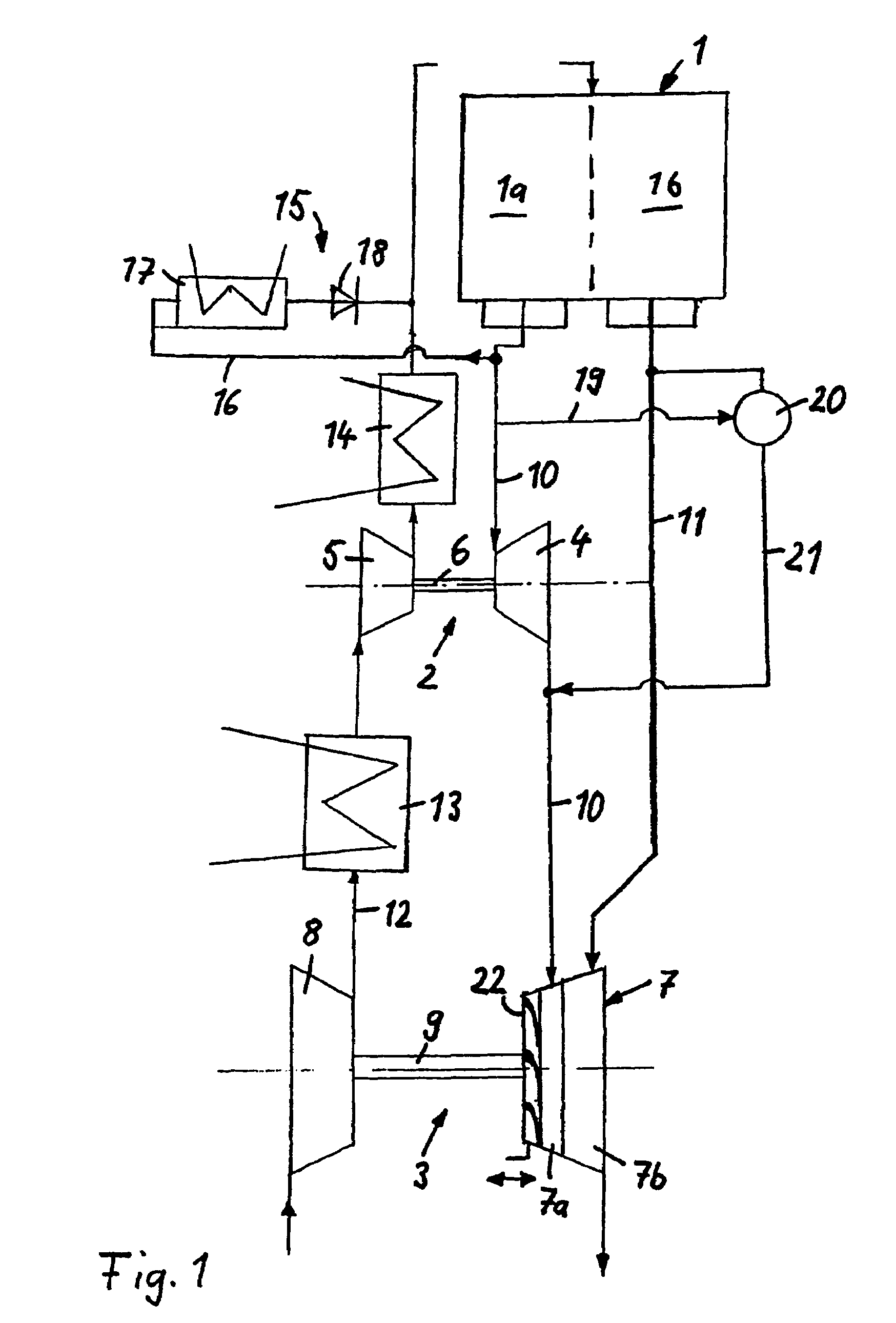

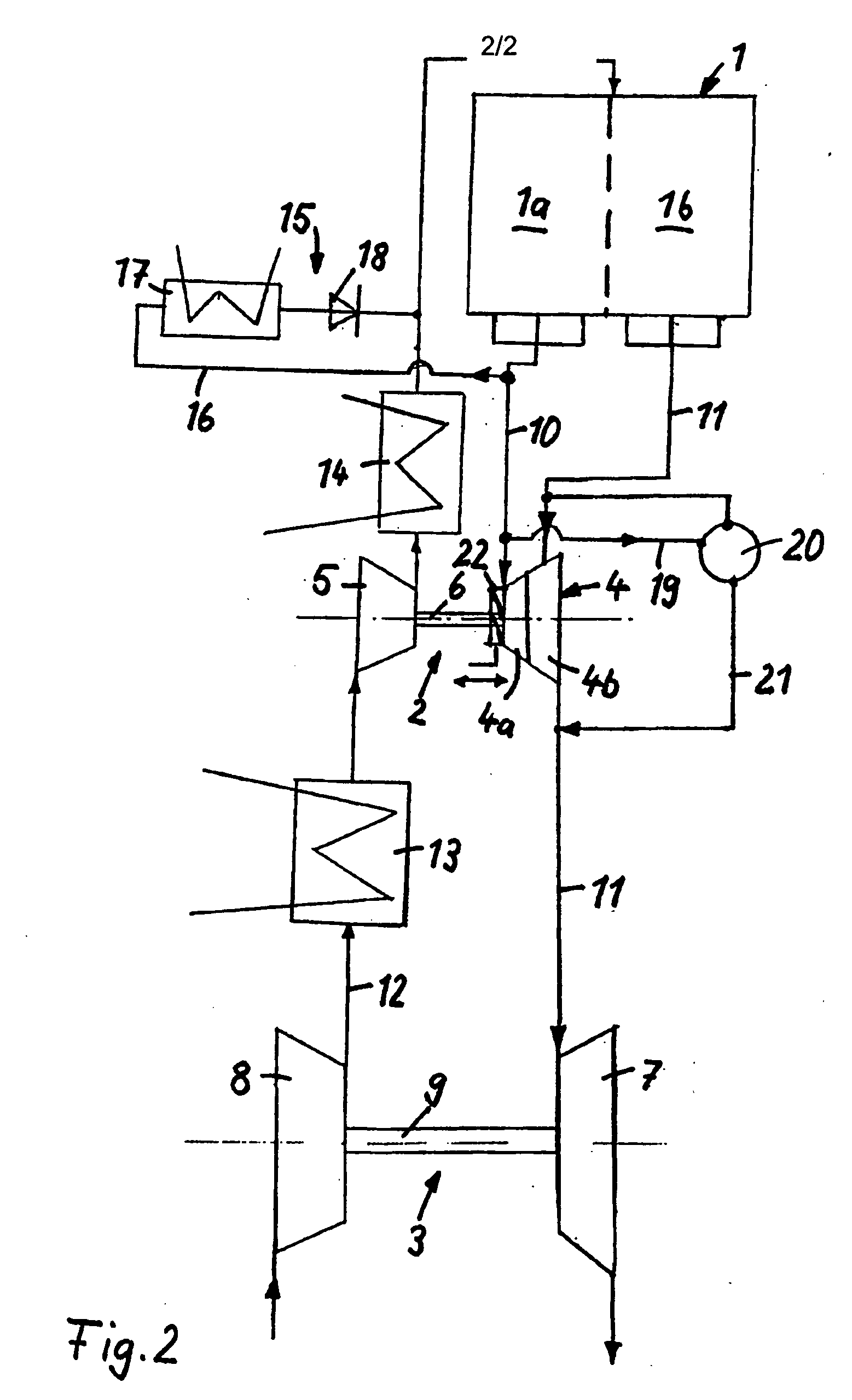

Internal combustion engine having two exhaust gas turbocharger

InactiveUS7540150B2Simple meansNon-fuel substance addition to fuelInternal combustion piston enginesExhaust valveTurbocharger

In an internal combustion engine provided with two exhaust gas turbochargers which each comprise a turbine in an exhaust line and one compressor in an intake section of the engine, two exhaust lines are provided which are each assigned to at least one of the exhaust gas turbines, an exhaust gas recirculation device being arranged between an exhaust line upstream of an exhaust gas turbine and the intake section downstream of a compressor and the two exhaust lines including bypass lines with a control valve for selectively permitting the exhaust gas to bypass the turbine closer to the engine.

Owner:DAIMLER AG

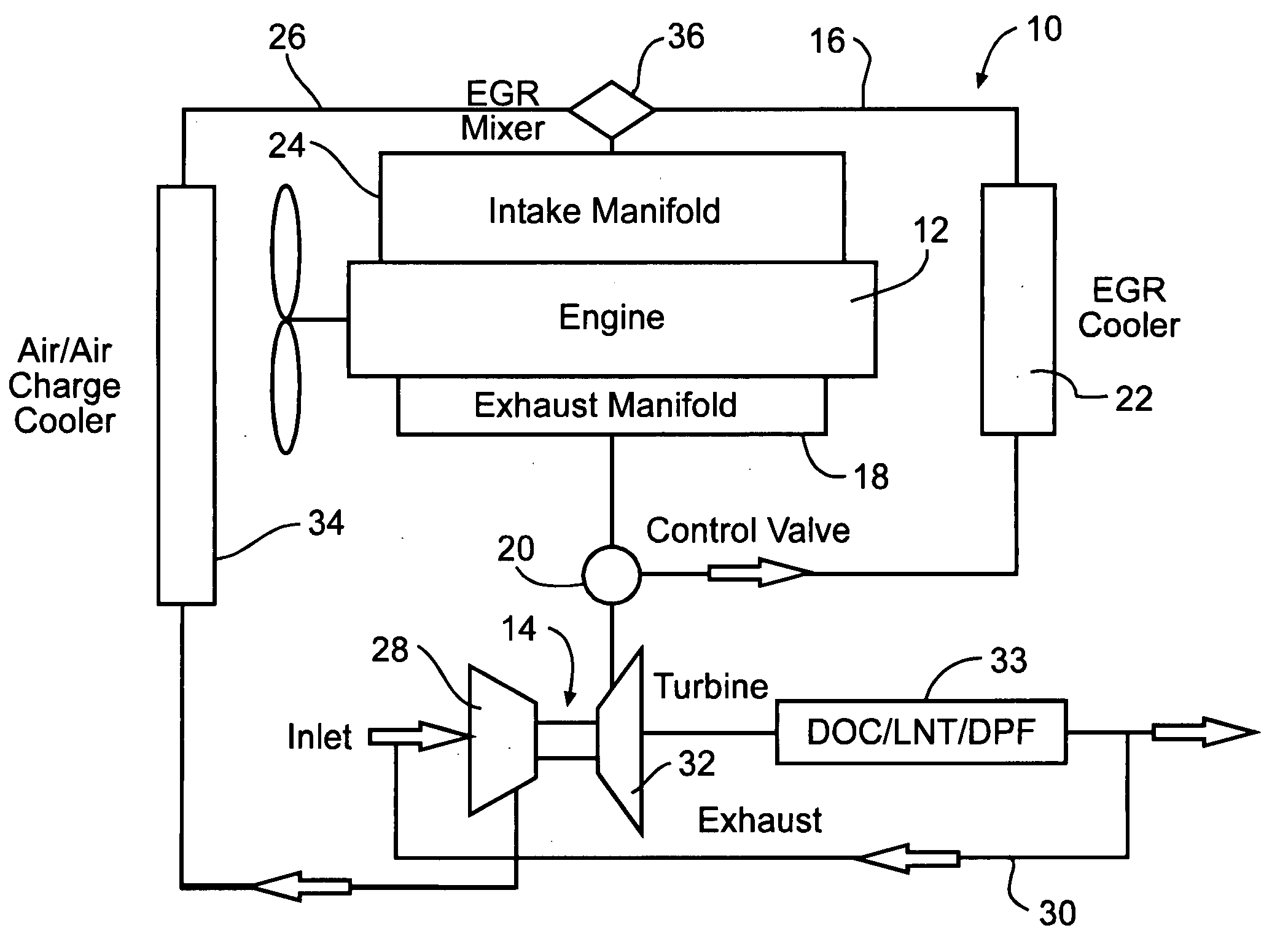

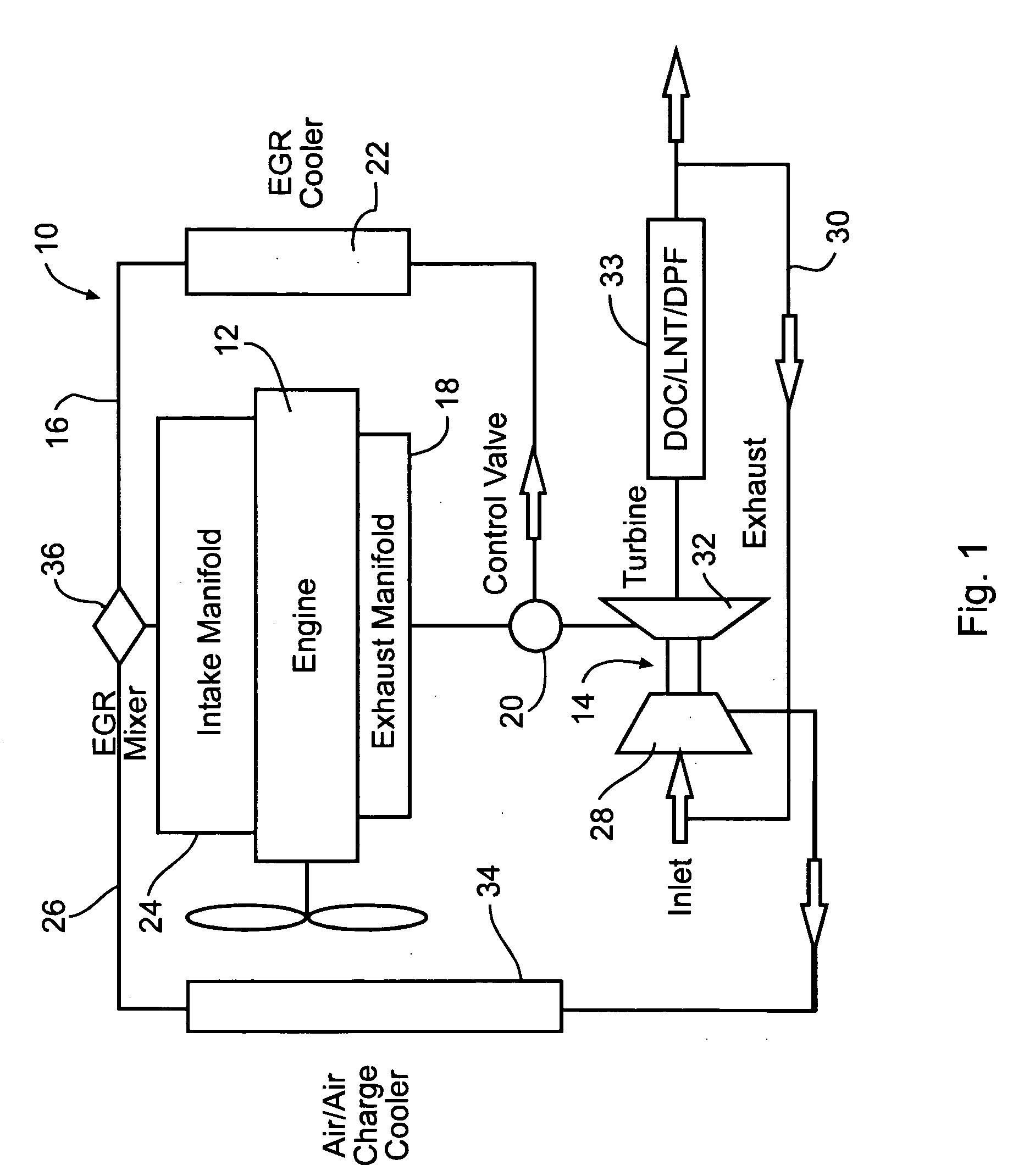

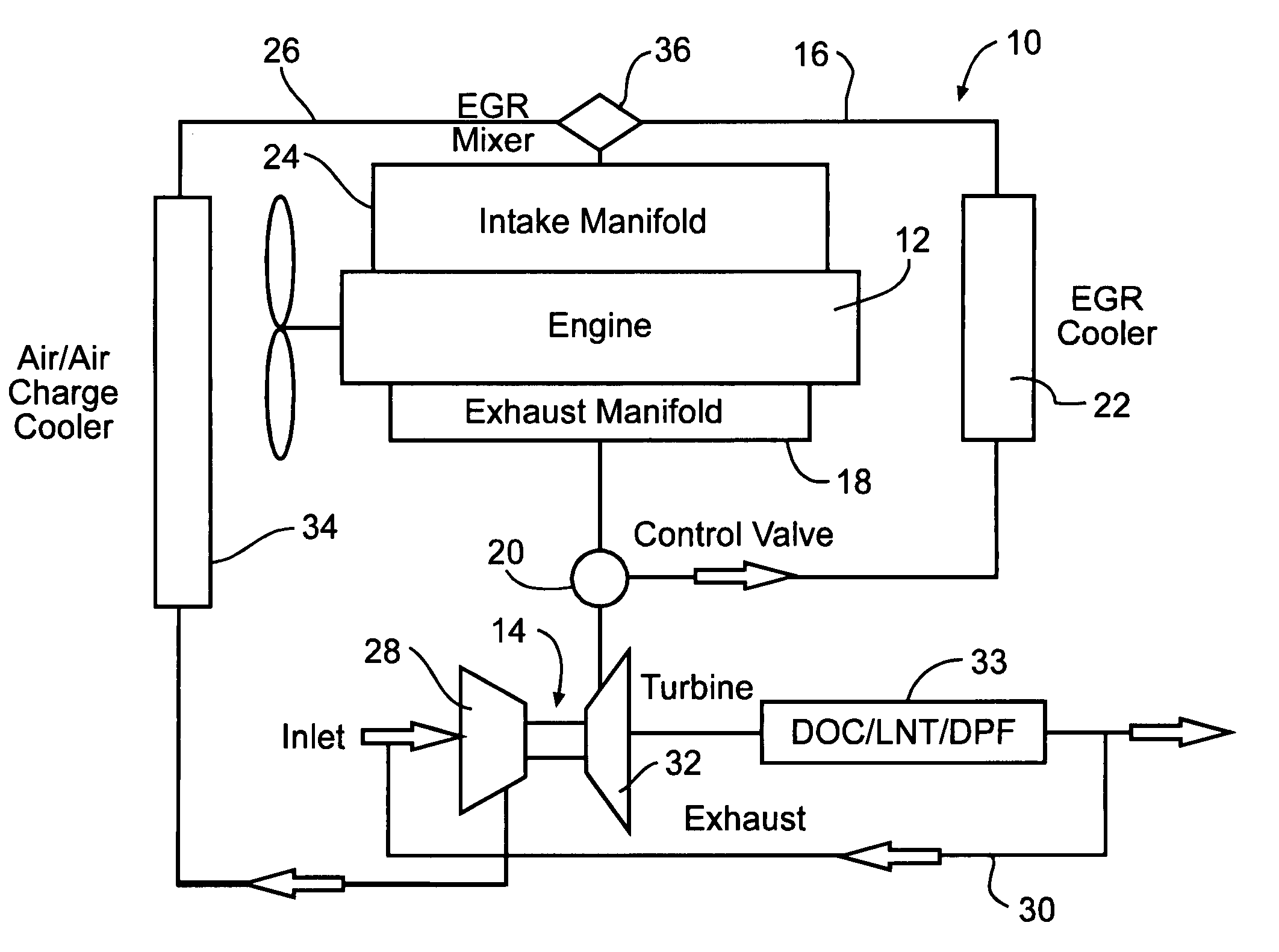

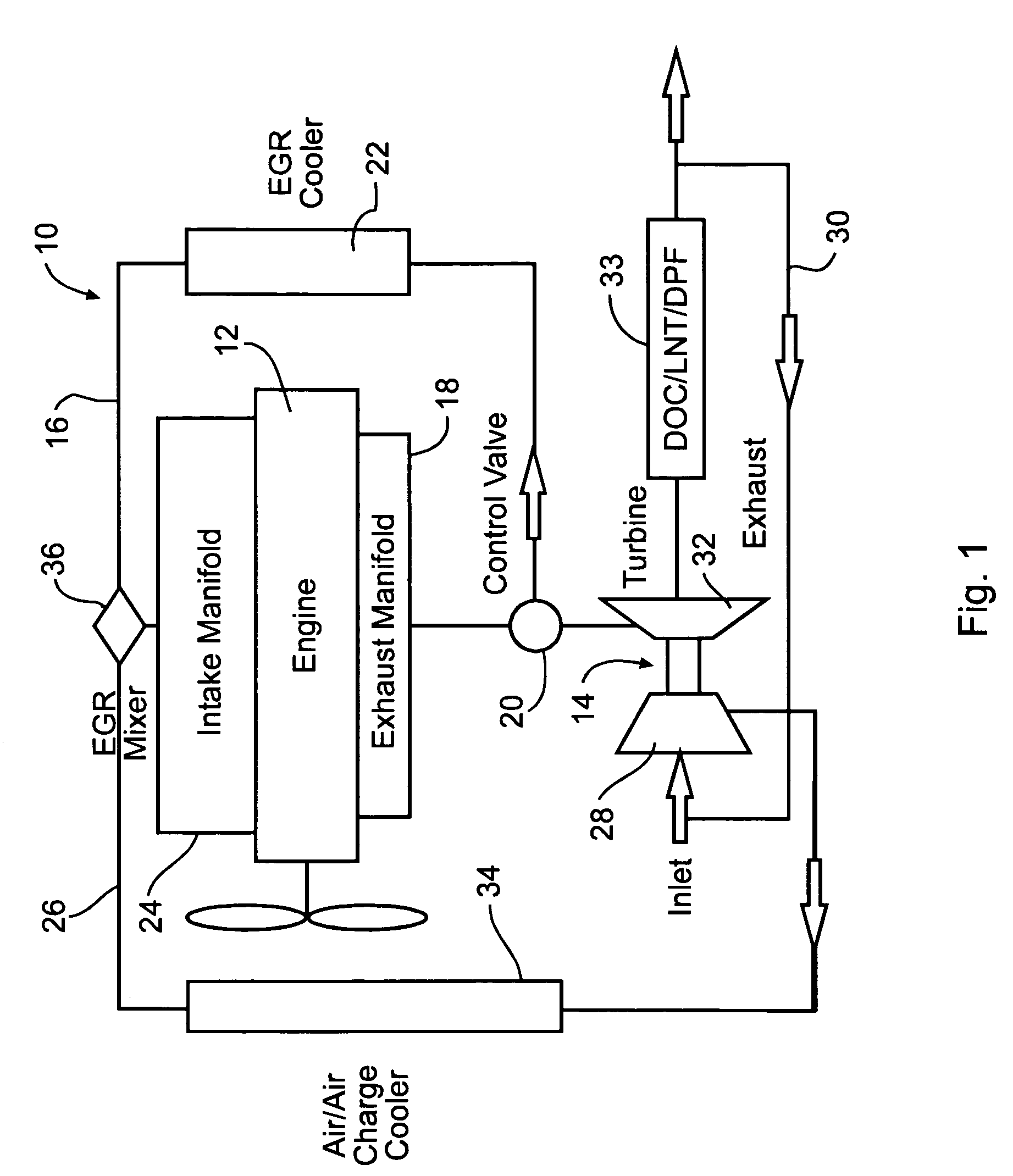

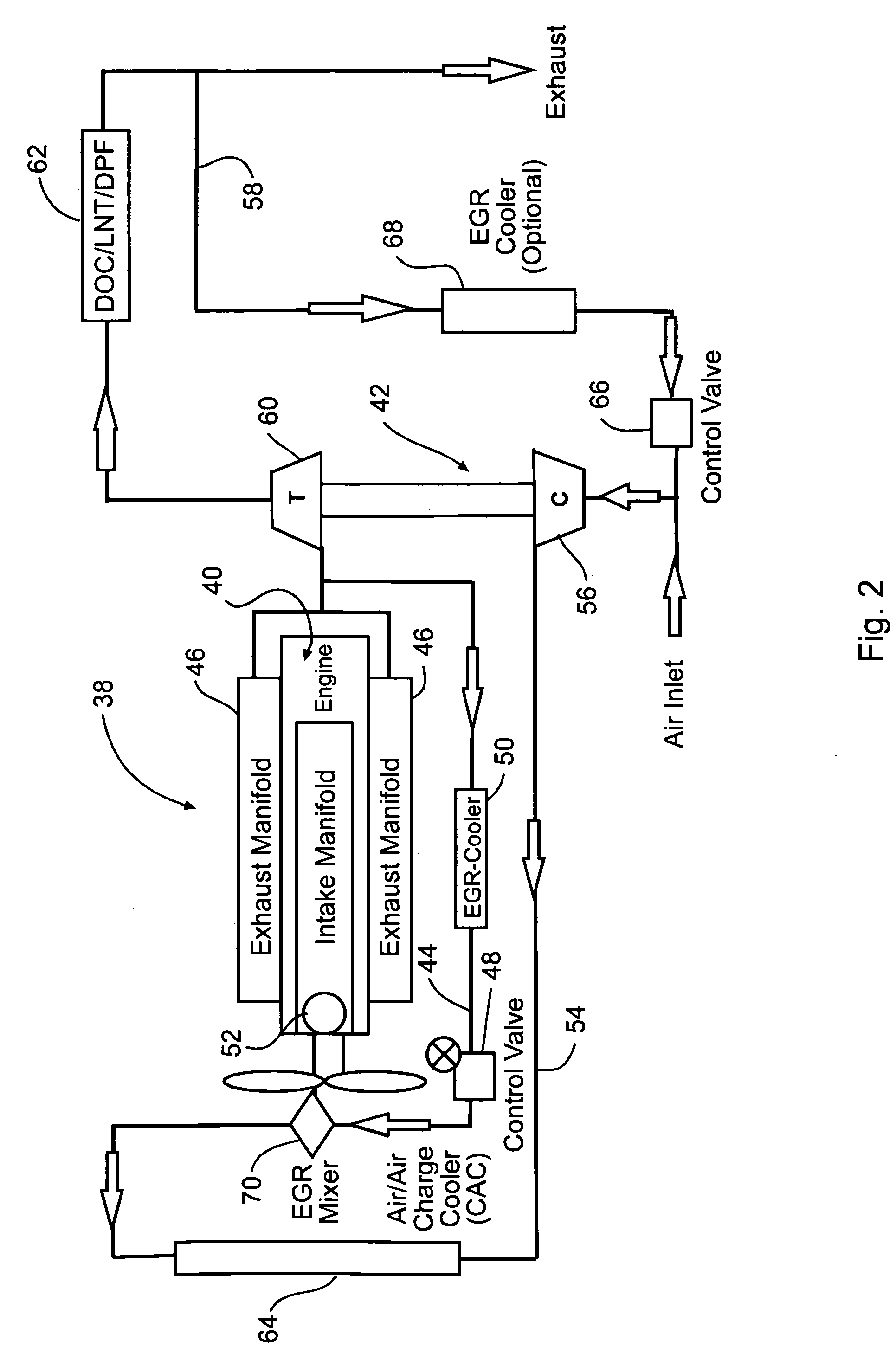

Dual and hybrid EGR systems for use with turbocharged engine

ActiveUS20050103013A1Non-fuel substance addition to fuelInternal combustion piston enginesSingle stageTurbocharger

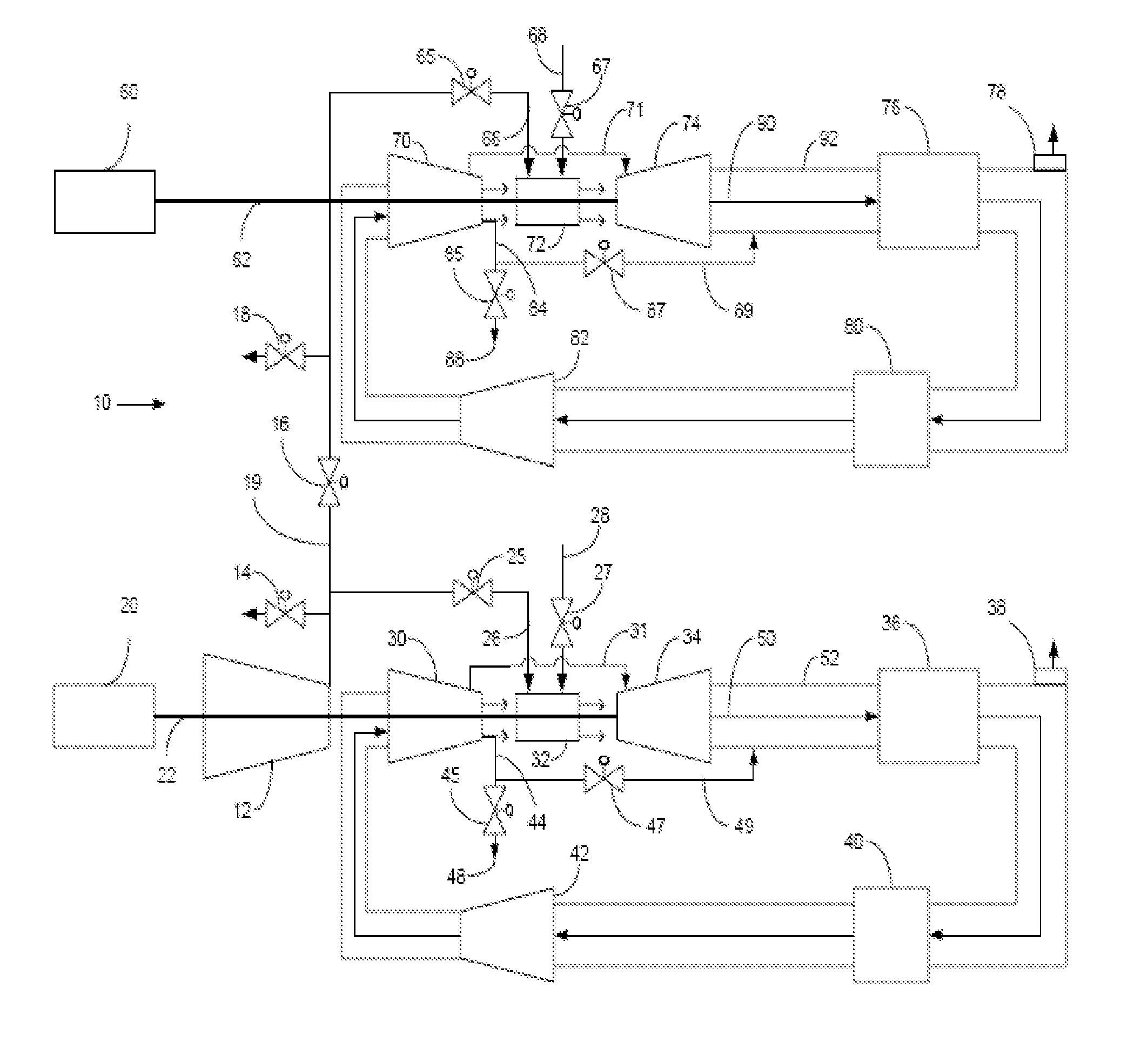

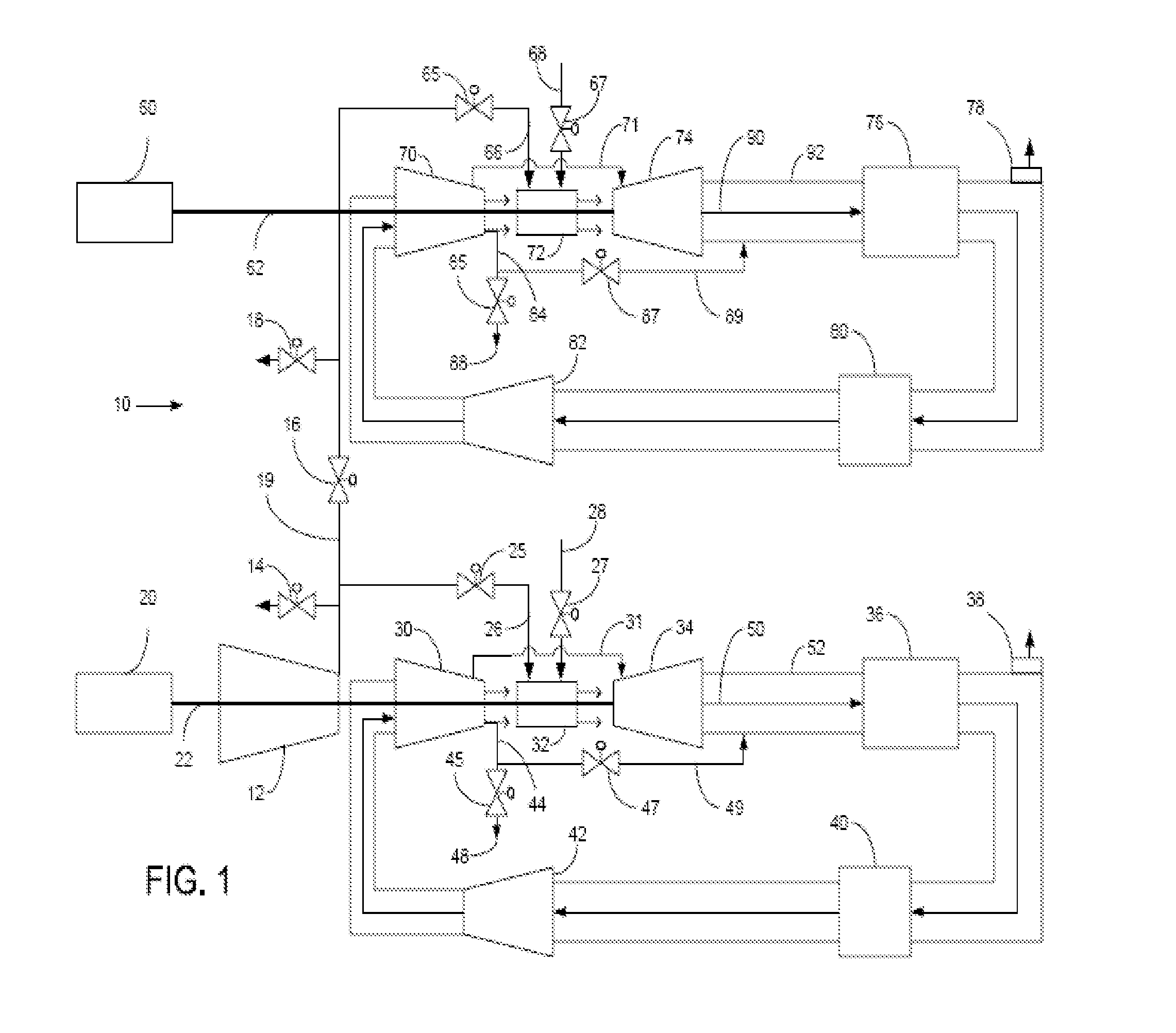

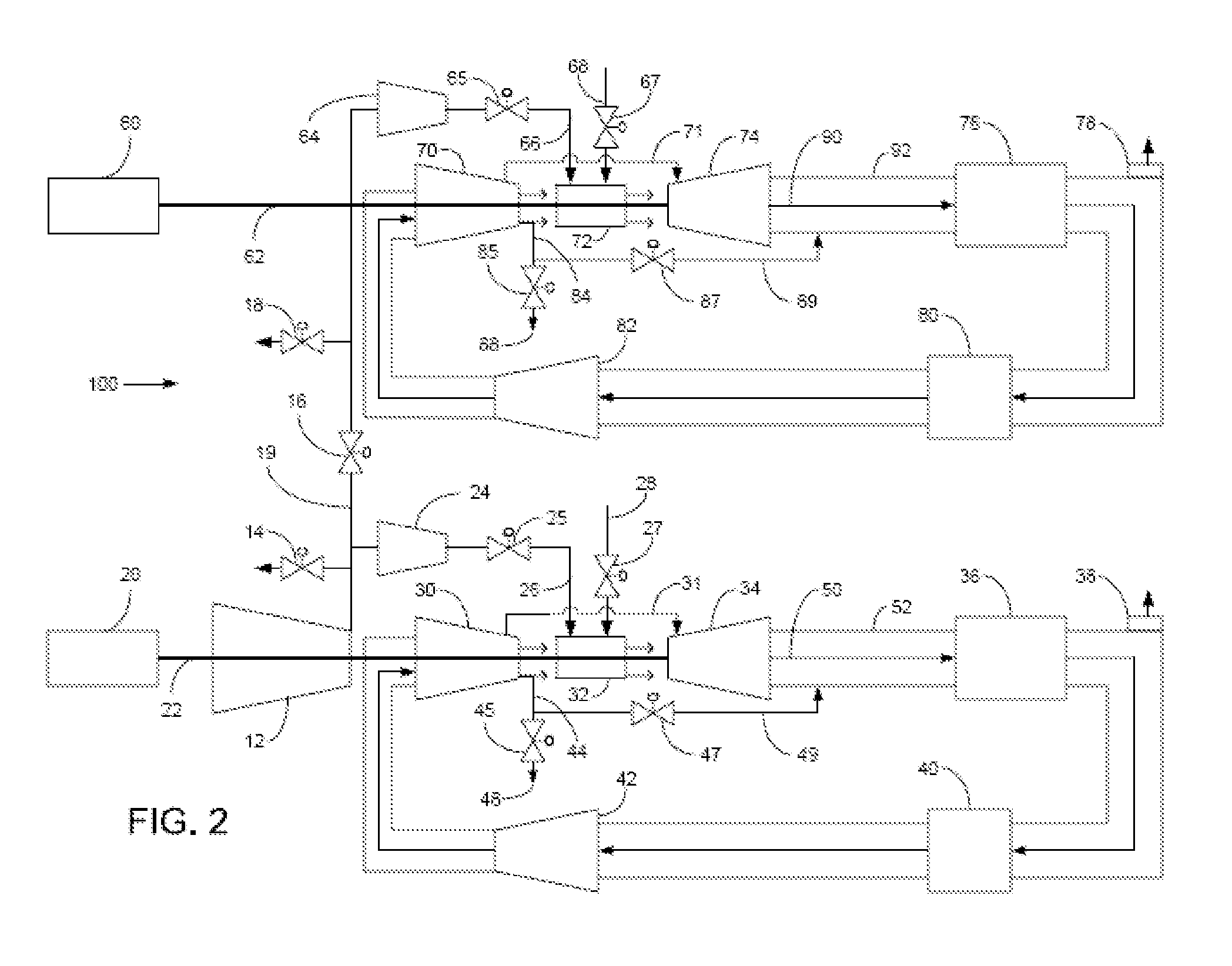

EGR systems for an internal combustion engine configured to operate using multiple-staged turbochargers, or a pair of single stage turbochargers, to provide exhaust gas recirculation to meet emissions requirements while not affecting engine performance. One or two EGR loops operating at low, intermediate, or high pressures may be employed. EGR exhaust gases may be taken directly from the exhaust manifold, or after the exhaust stream has passed through a turbocharger turbine. EGR exhaust gases may be injected at an intermediate pressure between stages of a multiple stage turbocharger, or alternatively between a low pressure turbocharger compressor and high pressure turbocharger compressor, before being boosted to a pressure high enough to ensure the desired mass flow to the engine and delivered to the intake manifold. Intake air may be pressurized prior to mixing with the EGR exhaust gases.

Owner:GARRETT TRANSPORATION I INC

System for recirculating the exhaust of a turbomachine

ActiveUS7861511B2HydrogenInternal combustion piston enginesEnvironmental engineeringExhaust gas recirculation

A portion of the exhaust generated by a turbomachine is recirculated through an inlet portion by an exhaust gas recirculation system. The system reduces the level of harmful constituents within the exhaust before the exhaust is recirculated.

Owner:GE INFRASTRUCTURE TECH INT LLC

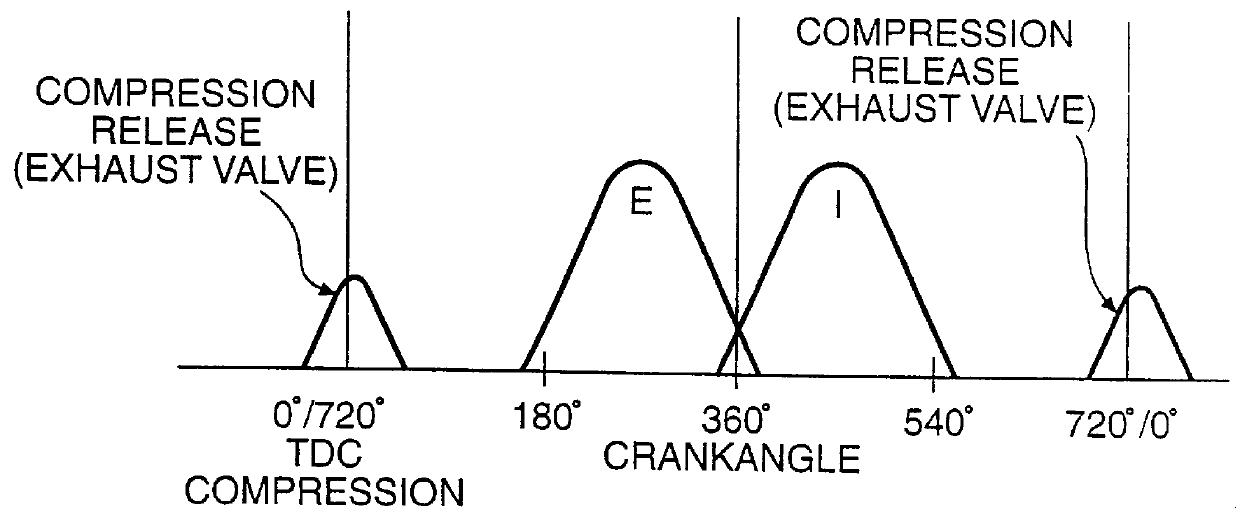

Method and apparatus to accomplish exhaust air recirculation during engine braking and/or exhaust gas recirculation during positive power operation of an internal combustion engine

InactiveUS6082328AHigh retarding powerEasy to operateValve arrangementsNon-fuel substance addition to fuelStored energyExternal combustion engine

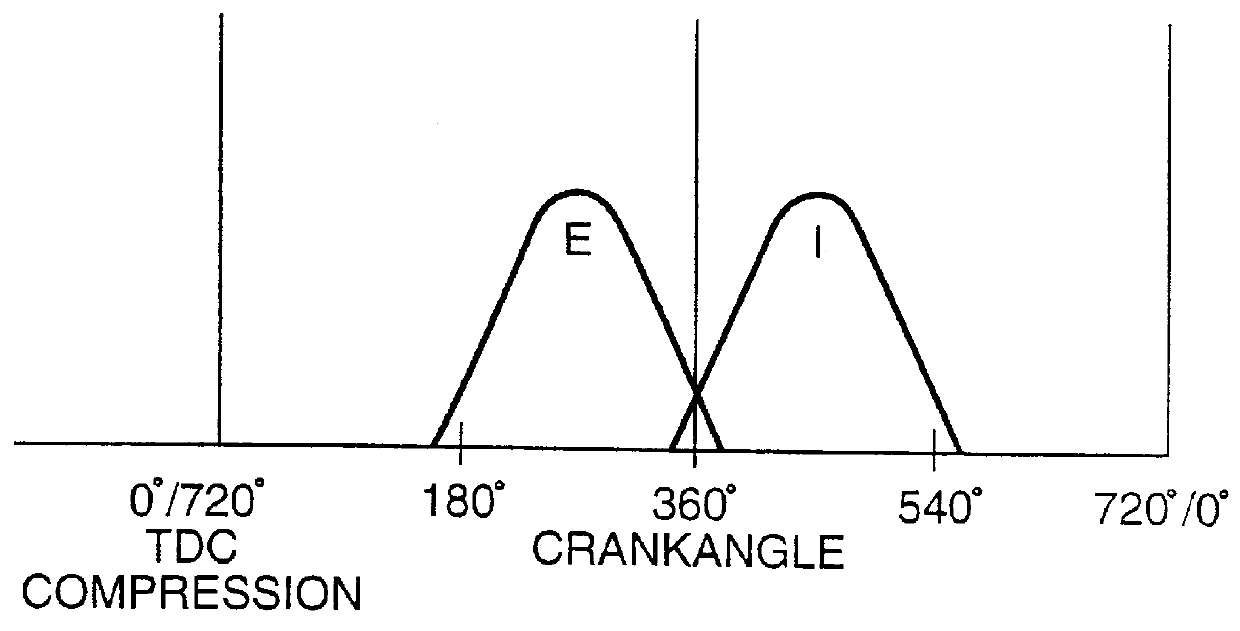

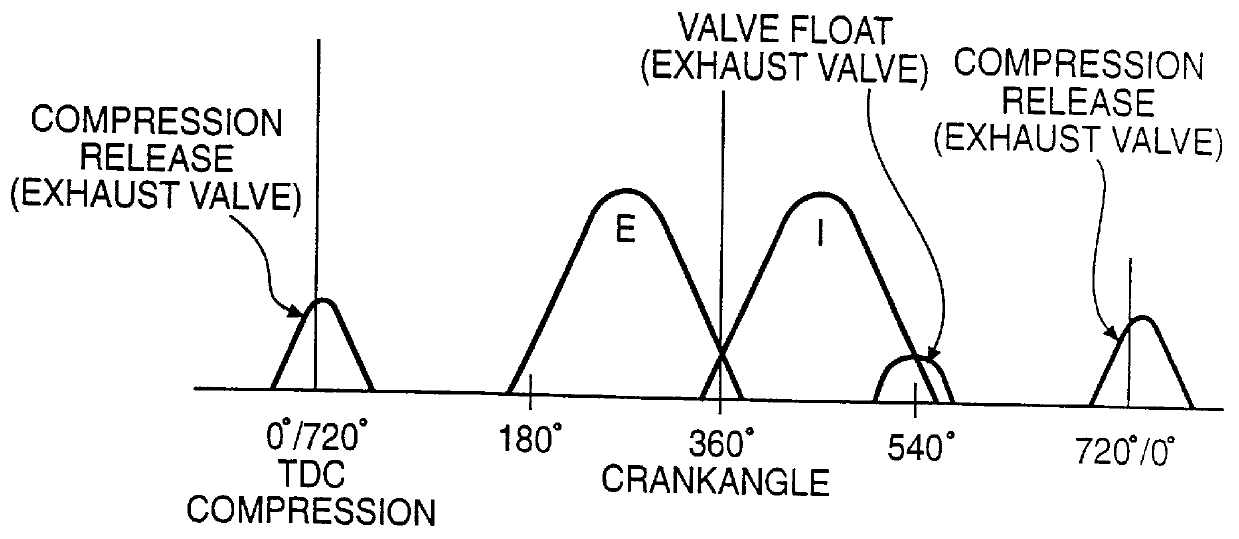

A method and apparatus for carrying out variable timing exhaust gas recirculation is disclosed for use during both positive power and retarding operation of an internal combustion engine. Motion or energy is derived from an engine component and stored as potential energy. The stored energy is selectively applied to a valve actuator to carry out exhaust gas recirculation in an engine cylinder. The energy derived from the engine may be stored and selectively applied to the valve actuator with an electronically controlled trigger valve. The valve actuator may be a slave piston having an inner core and an outer sleeve capable of opening the valve of the cylinder in response to independent exhaust gas recirculation and compression release hydraulic systems.

Owner:DIESEL ENGINE RETARDERS

Internal combustion engine having two exhaust gas turbocharger

InactiveUS20070107430A1Simple meansIncreased recirculationNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerExhaust fumes

In an internal combustion engine provided with two exhaust gas turbochargers which each comprise a turbine in an exhaust line and one compressor in an intake section of the engine, two exhaust lines are provided which are each assigned to at least one of the exhaust gas turbines, an exhaust gas recirculation device being arranged between an exhaust line upstream of an exhaust gas turbine and the intake section downstream of a compressor and the two exhaust lines including bypass lines with a control valve for selectively permitting the exhaust gas to bypass the turbine closer to the engine.

Owner:DAIMLER AG

Dual and hybrid EGR systems for use with turbocharged engine

InactiveUS7013879B2Non-fuel substance addition to fuelInternal combustion piston enginesSingle stageTurbocharger

EGR systems for an internal combustion engine configured to operate using multiple-staged turbochargers, or a pair of single stage turbochargers, to provide exhaust gas recirculation to meet emissions requirements while not affecting engine performance. One or two EGR loops operating at low, intermediate, or high pressures may be employed. EGR exhaust gases may be taken directly from the exhaust manifold, or after the exhaust stream has passed through a turbocharger turbine. EGR exhaust gases may be injected at an intermediate pressure between stages of a multiple stage turbocharger, or alternatively between a low pressure turbocharger compressor and high pressure turbocharger compressor, before being boosted to a pressure high enough to ensure the desired mass flow to the engine and delivered to the intake manifold. Intake air may be pressurized prior to mixing with the EGR exhaust gases.

Owner:GARRETT TRANSPORATION I INC

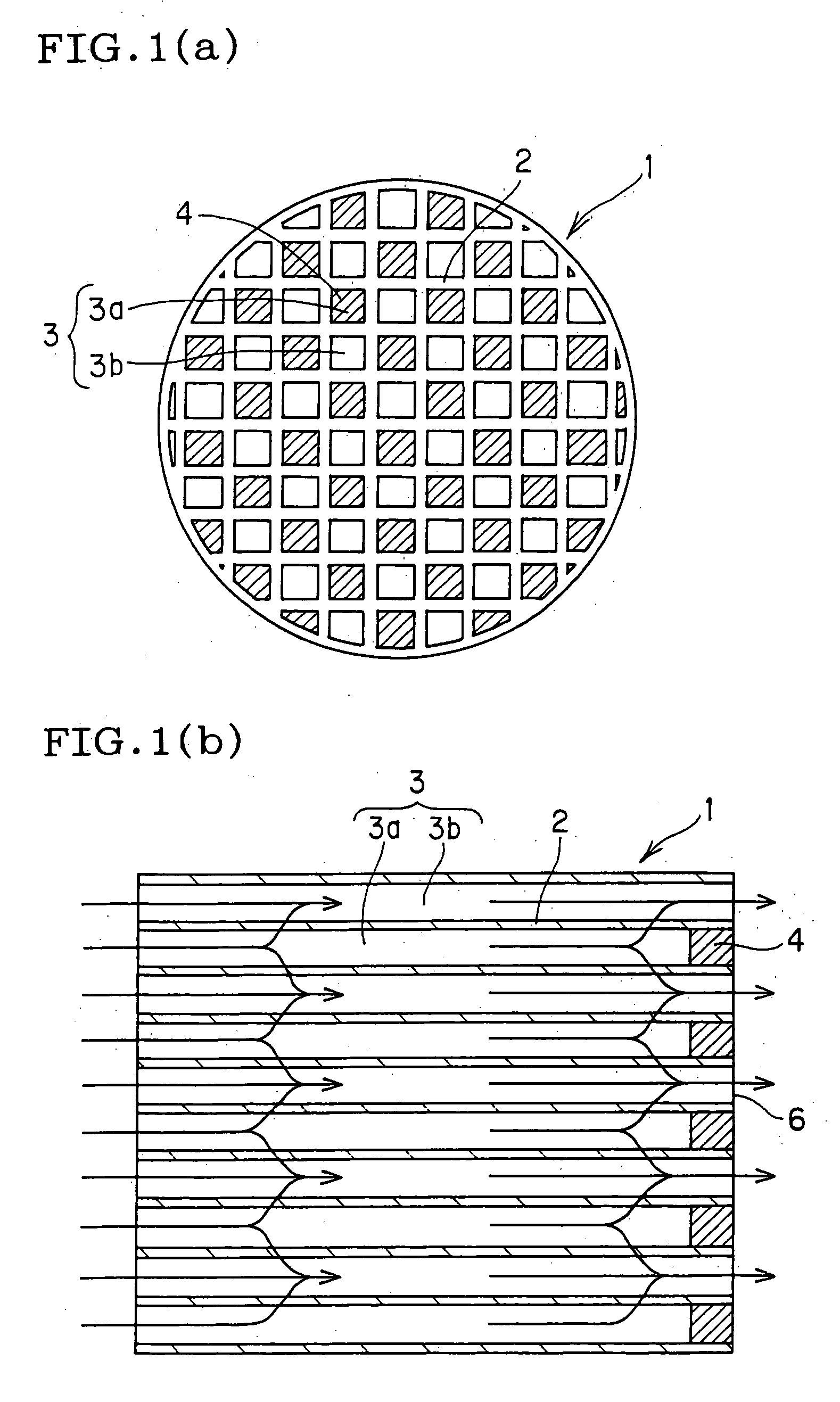

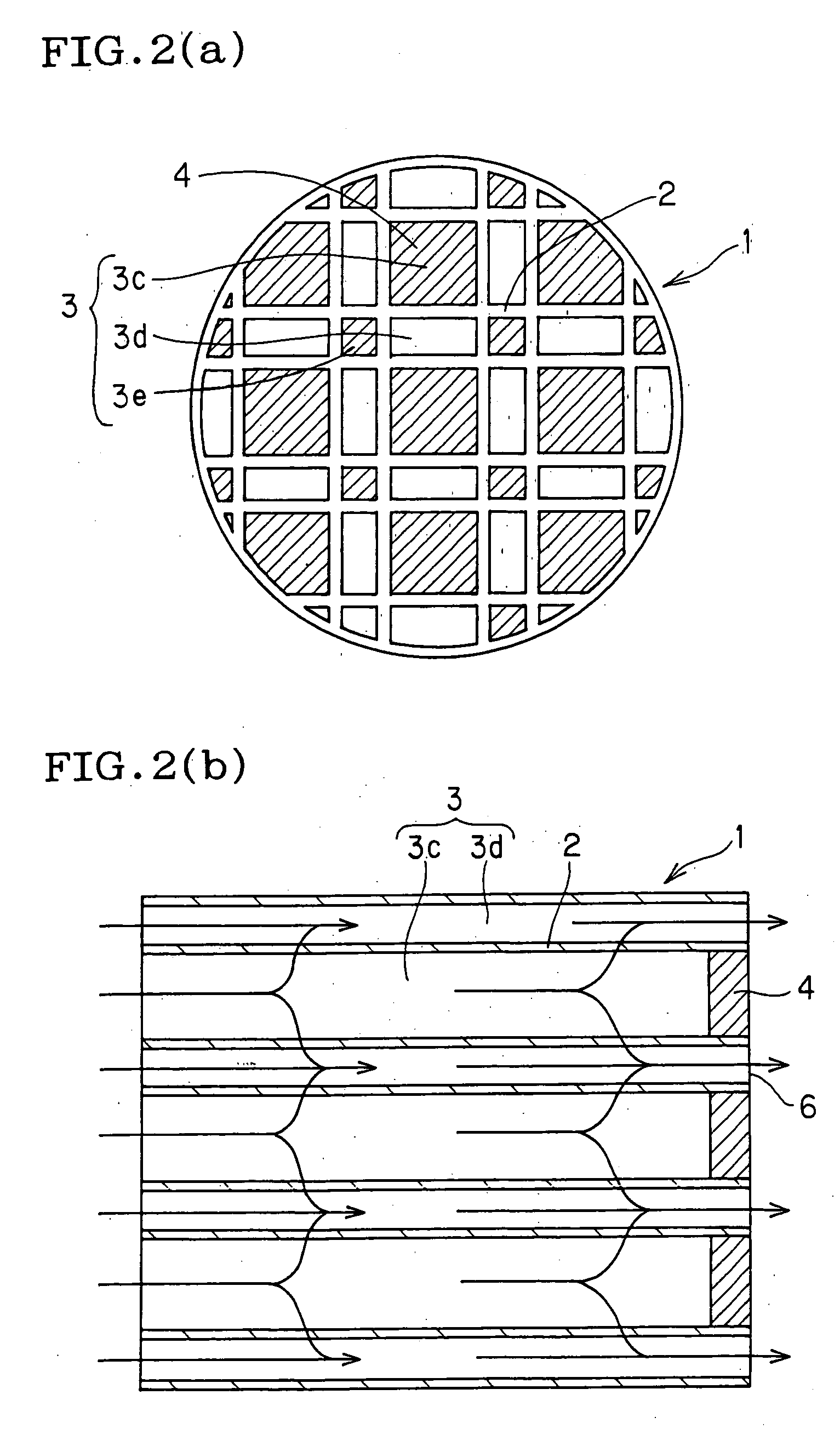

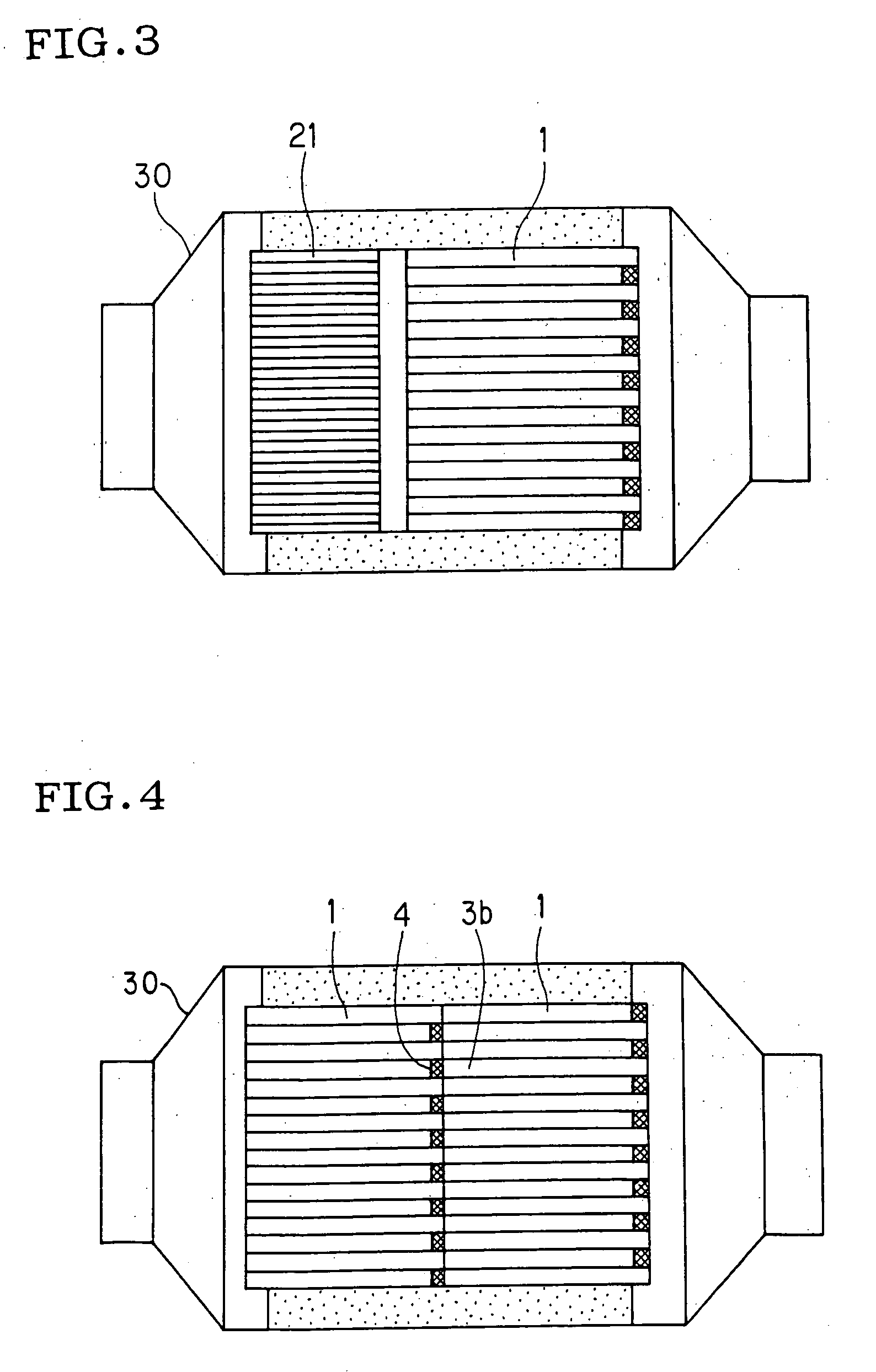

Honeycomb filter and exhaust gas purification system

A honeycomb filter comprises a honeycomb structure having a large number of through channels formed in the axial direction and partitioned by porous partition walls, wherein specified through channels are plugged only on one end face at the same side out of two end faces. This honeycomb filter shows less pressure loss, and is hardly clogged with solids that cannot be extinguished by combustion such as ash, iron oxide, and the like. Furthermore, an unwanted discharge of particulates deposited in through channels of the filter in a larger amount due to pulsation even under conditions that the exhaust gas from an engine greatly pulsates can be effectively suppressed. This filter is also usable as an element for exhaust gas purification system, or a part of composite filter in addition to the use for an exhaust gas purification filter for gasoline engines. The production method therefor is also disclosed.

Owner:NGK INSULATORS LTD

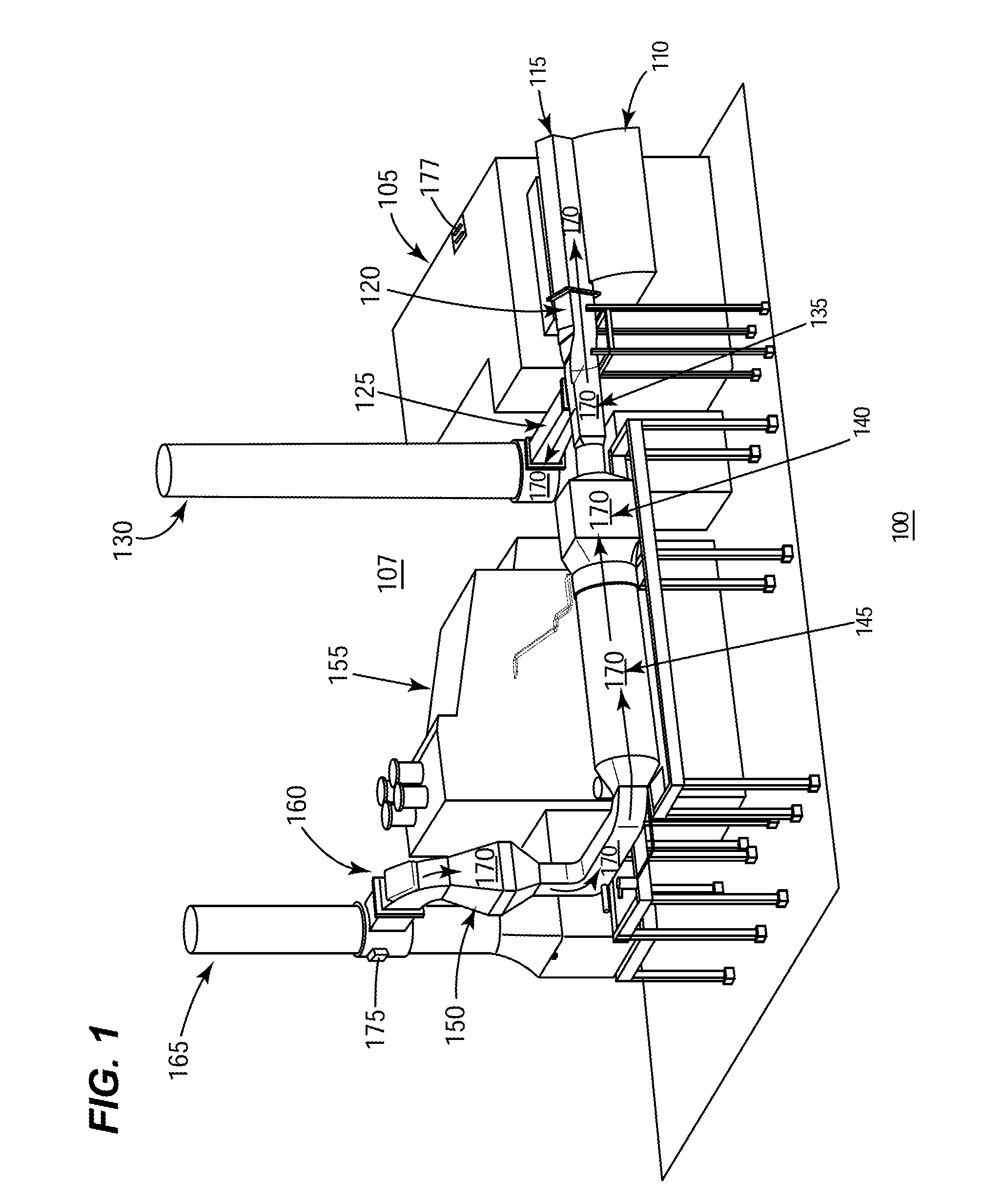

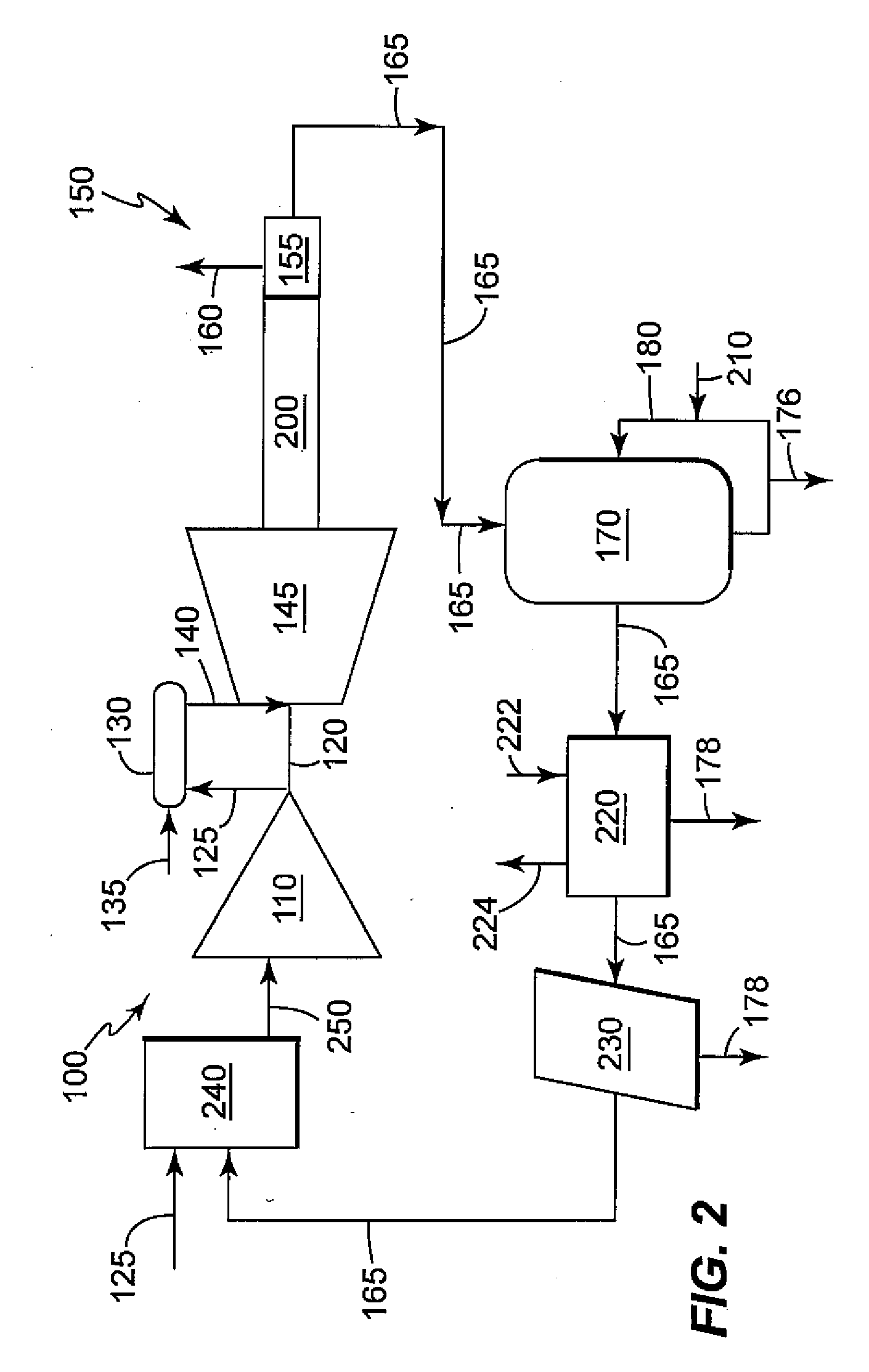

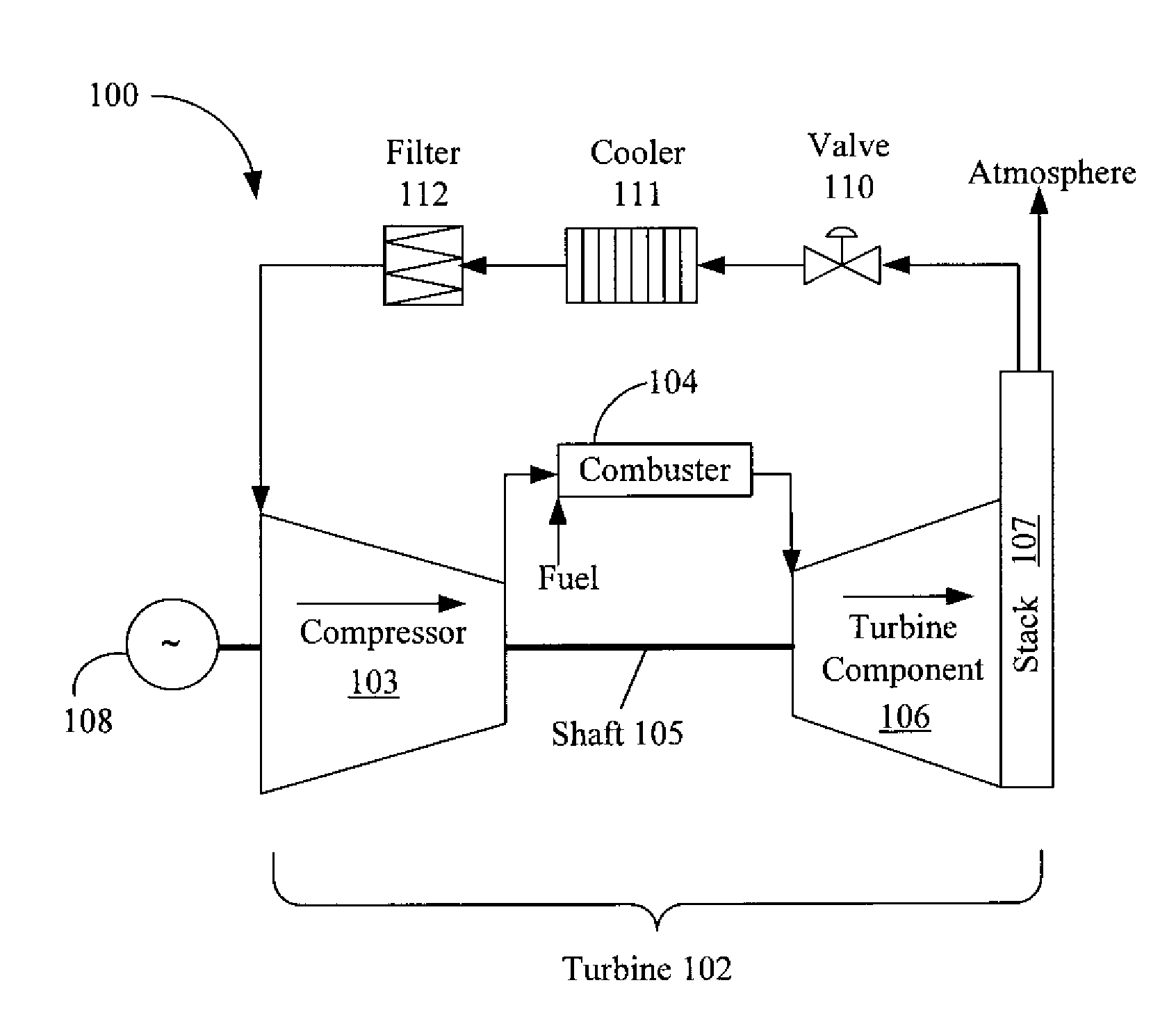

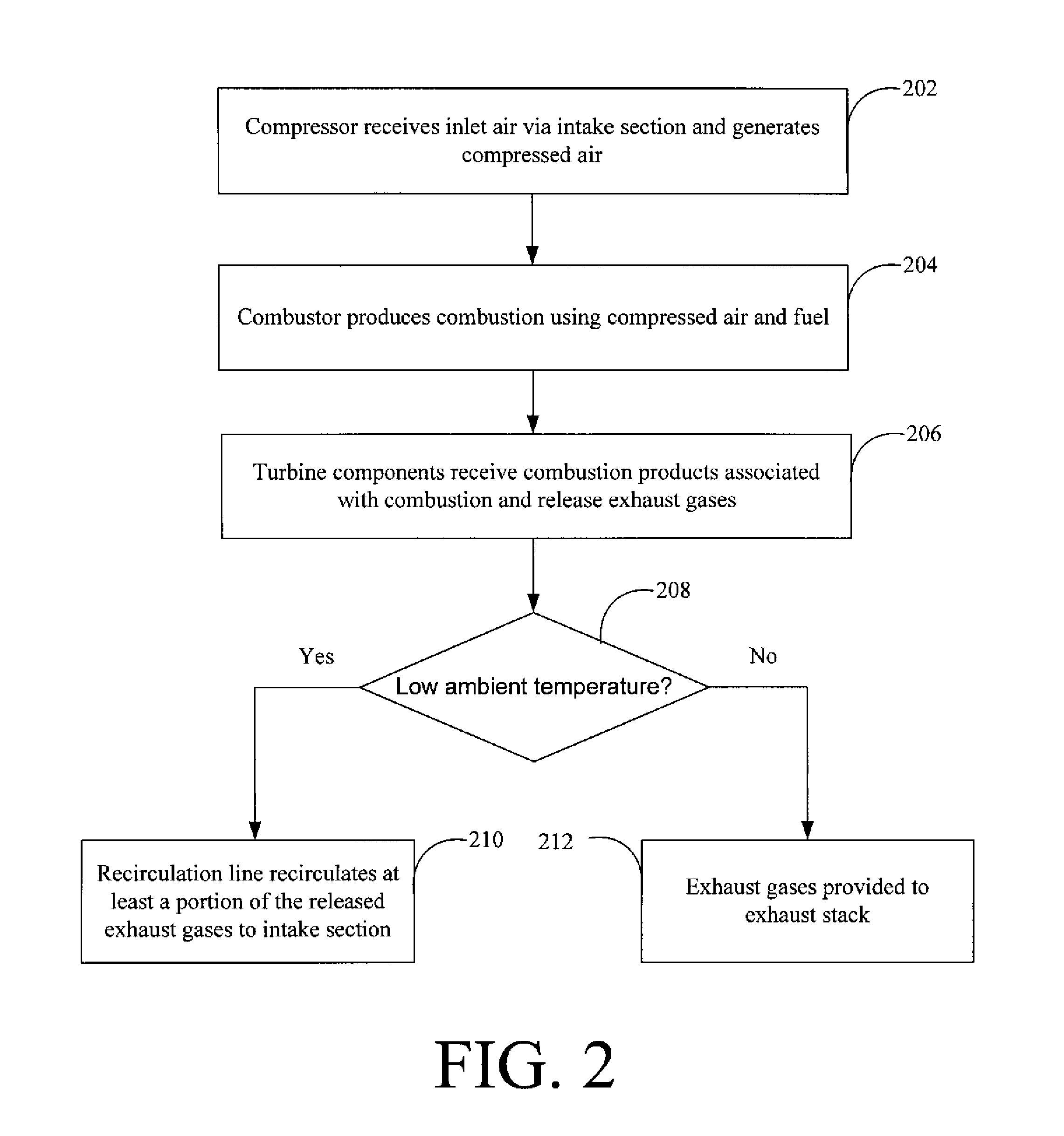

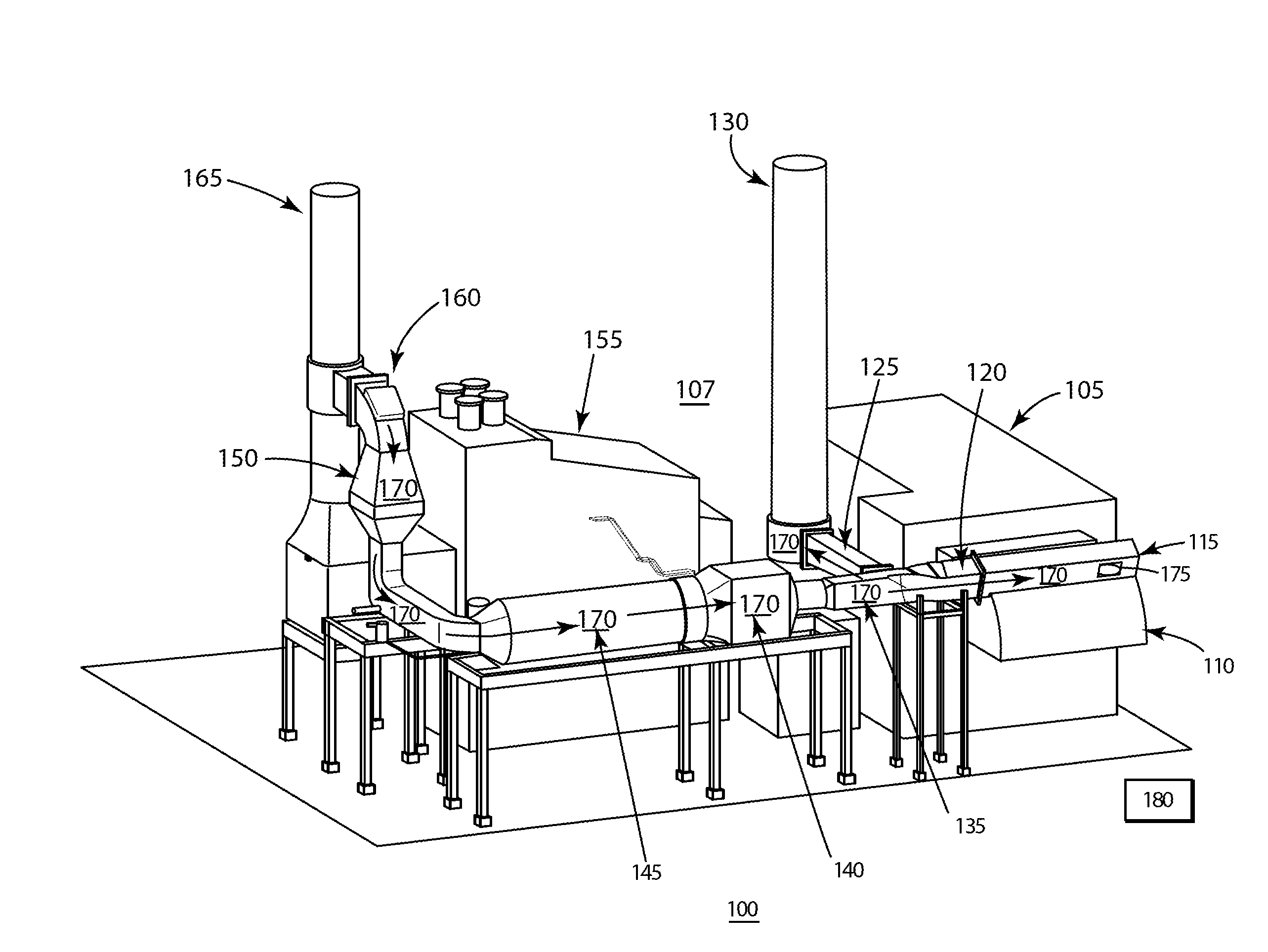

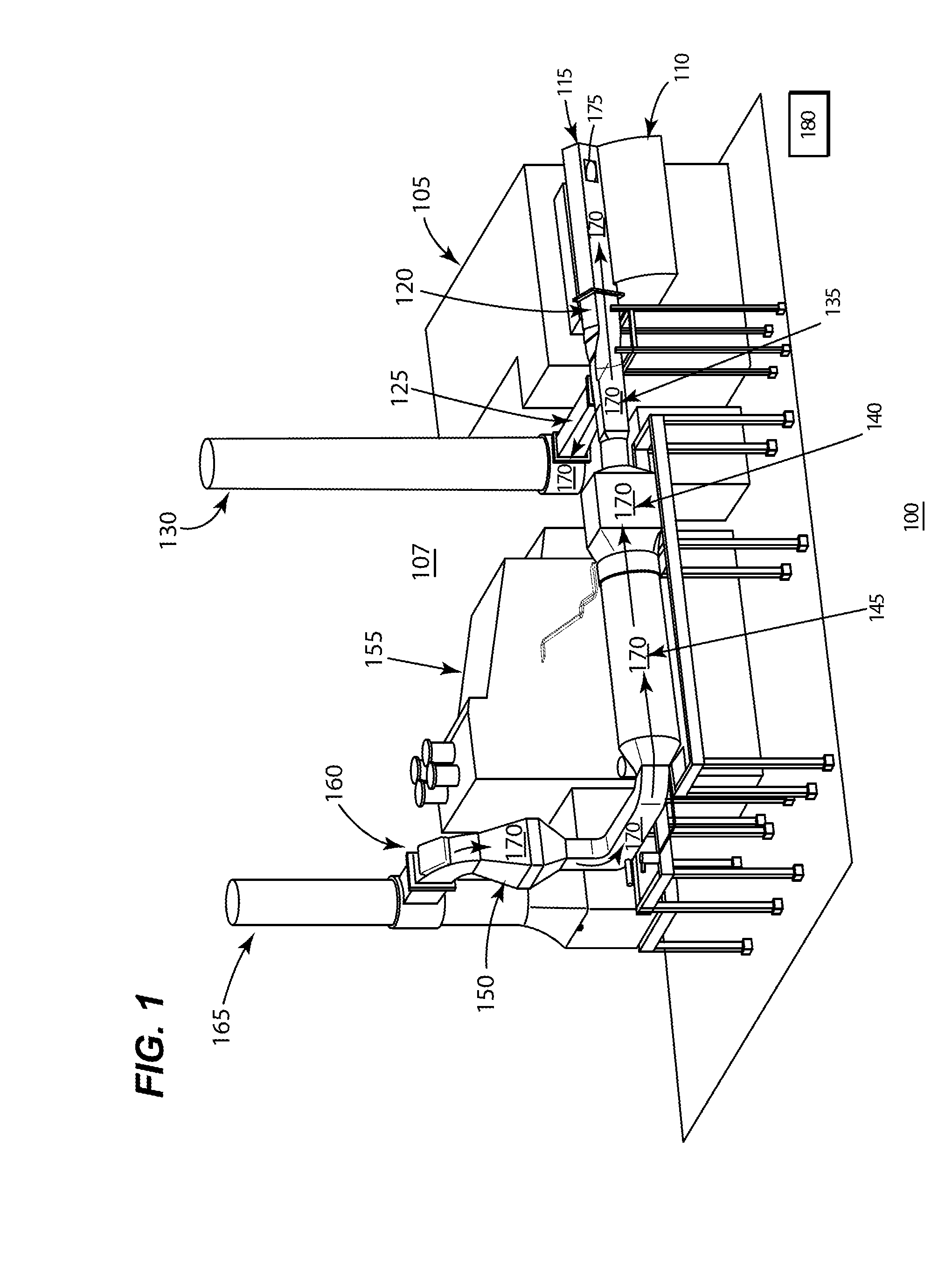

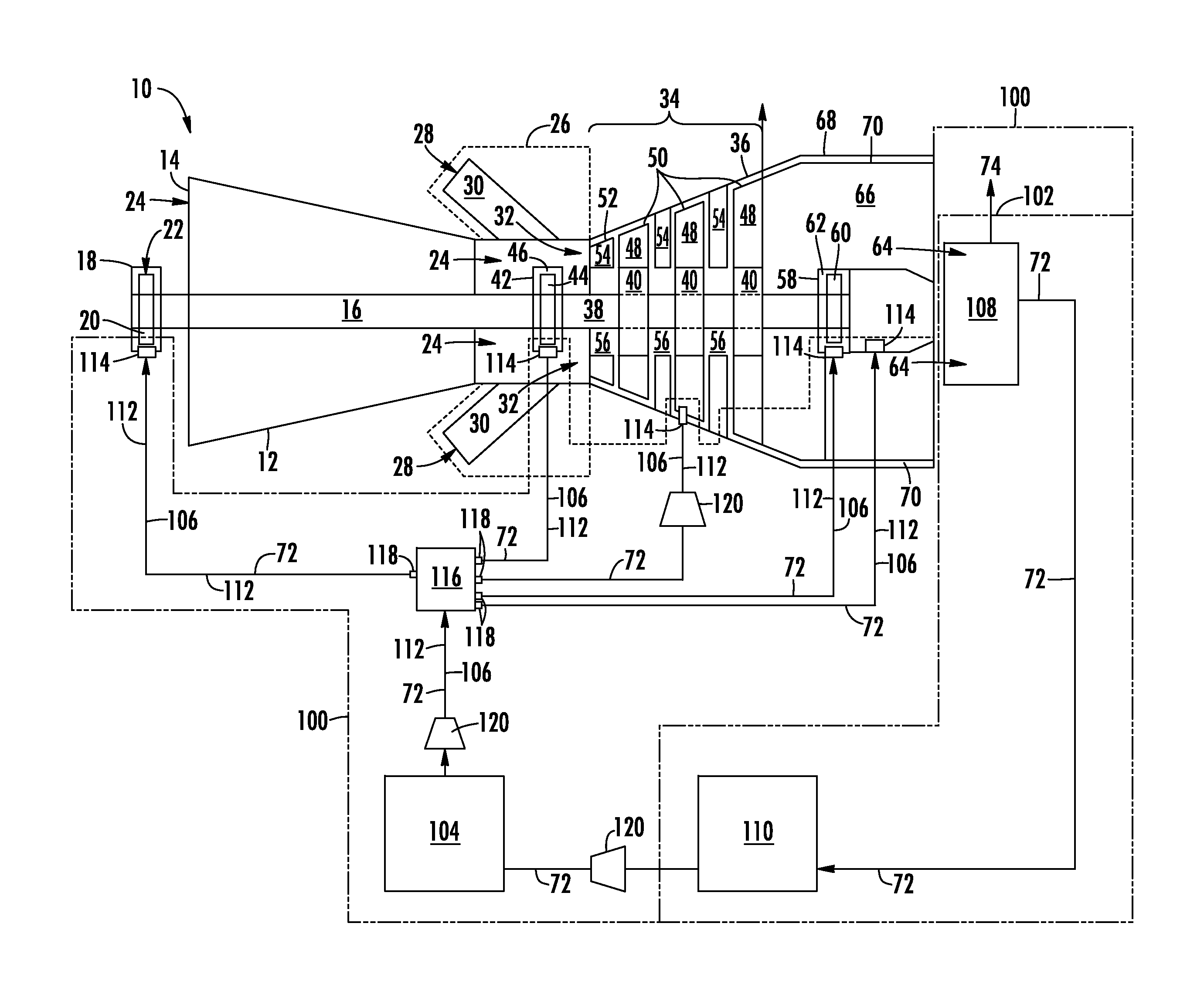

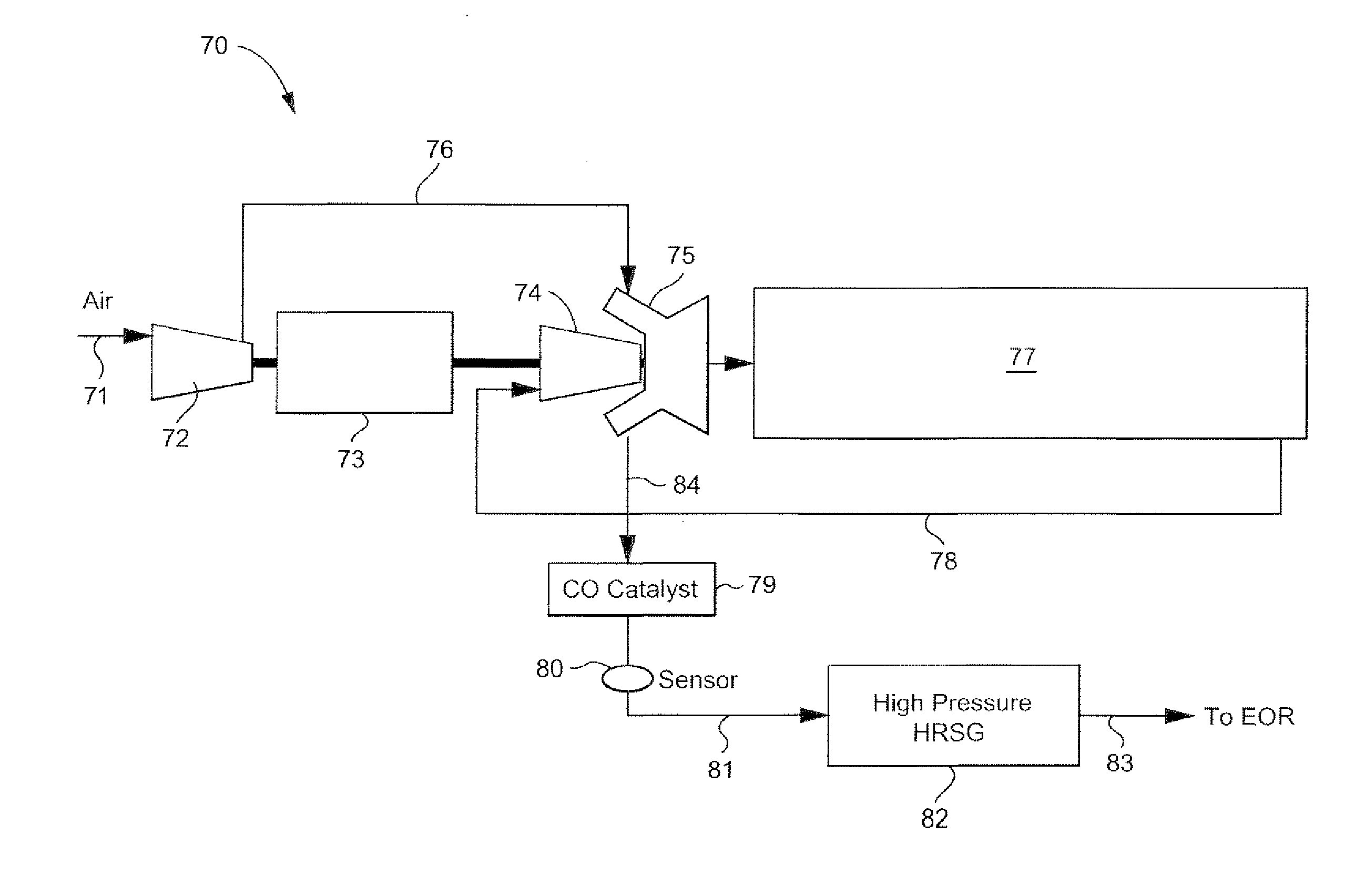

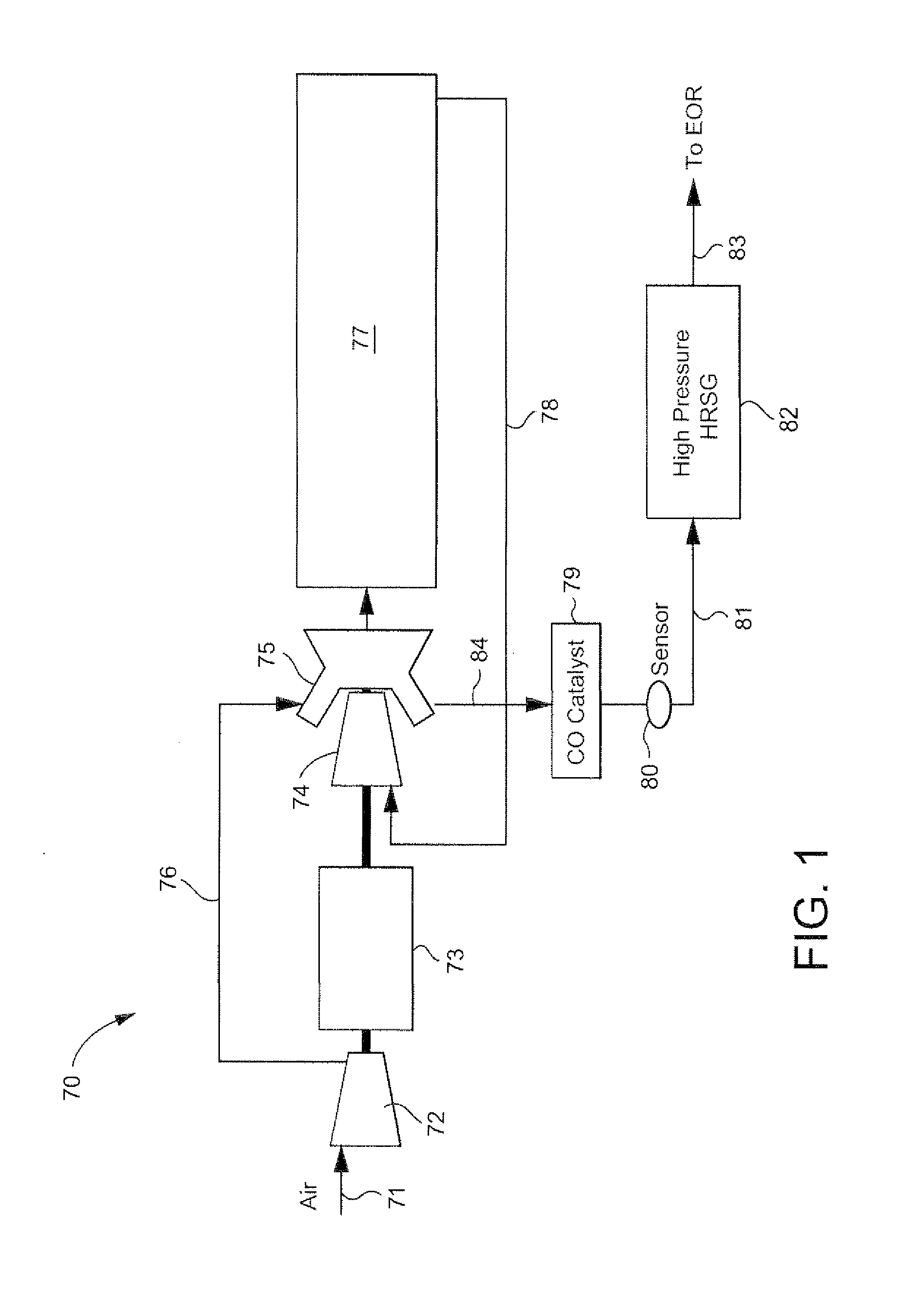

Systems and Methods for Exhaust Gas Recirculation (EGR) for Turbine Engines

InactiveUS20090205334A1Reduction of operational variationReduce the impactNon-fuel substance addition to fuelExhaust apparatusCombustorExhaust fumes

Systems and methods may be provided for exhaust gas recirculation. The systems and methods may include receiving, via an intake section, inlet air at an input of a compressor, generating compressed air at the compressor using the received inlet air, and providing the compressed air from the compressor to a combustor, where the combustor produces combustion involving the compressed air and fuel. The systems and methods may also include receiving combustion products associated with the combustion at a turbine component, where the turbine component releases exhaust gases, and recirculating at least a portion of the exhaust gases to the intake section via a recirculation line, where the recirculated exhaust gases raise a temperature of the inlet air.

Owner:GENERAL ELECTRIC CO

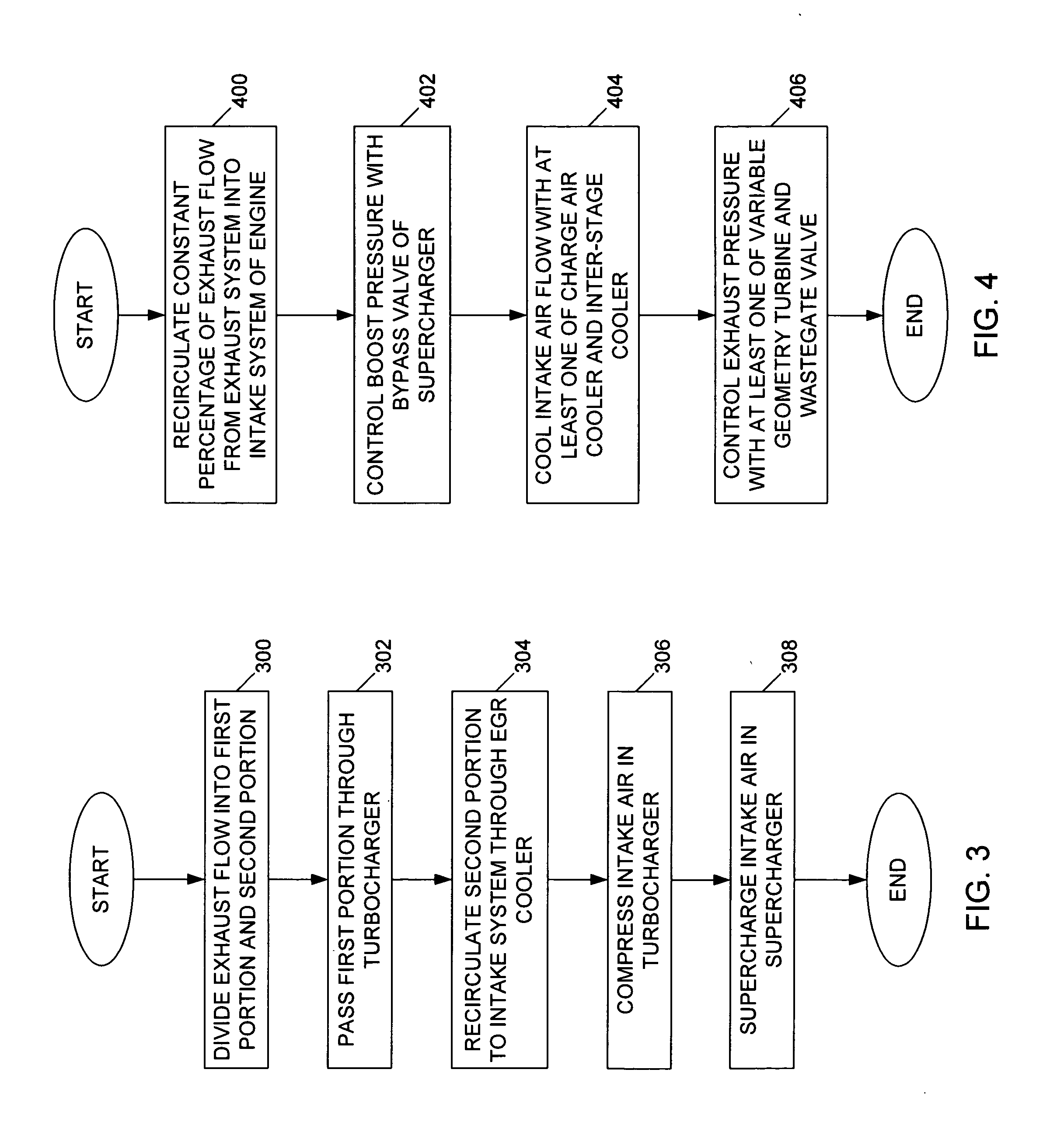

Fixed rate egr system

InactiveUS20120023937A1Maintain desirable combustion stabilityReduce throttling lossesElectrical controlInternal combustion piston enginesEngineeringExhaust gas recirculation

A method is provided for controlling EGR flow in turbocharged engine. The method comprises operating a low-pressure exhaust gas recirculation (LP-EGR) system at a fixed EGR percentage rate of fresh airflow from mid-load down to a minimum engine load, even as load changes. In this way, errors in the delivered LP-EGR rate during transient conditions may be alleviated by providing a fixed EGR percentage of fresh airflow at all engine loads within a fixed mode range.

Owner:FORD GLOBAL TECH LLC

Method for controlling a flowrate of a recirculated exhaust gas

A method for controlling a turbomachine exhaust gas recirculation (EGR) system is provided. The EGR system may allow for the removal and sequestration of at least one constituent within the exhaust before the recirculation occurs.

Owner:GENERAL ELECTRIC CO

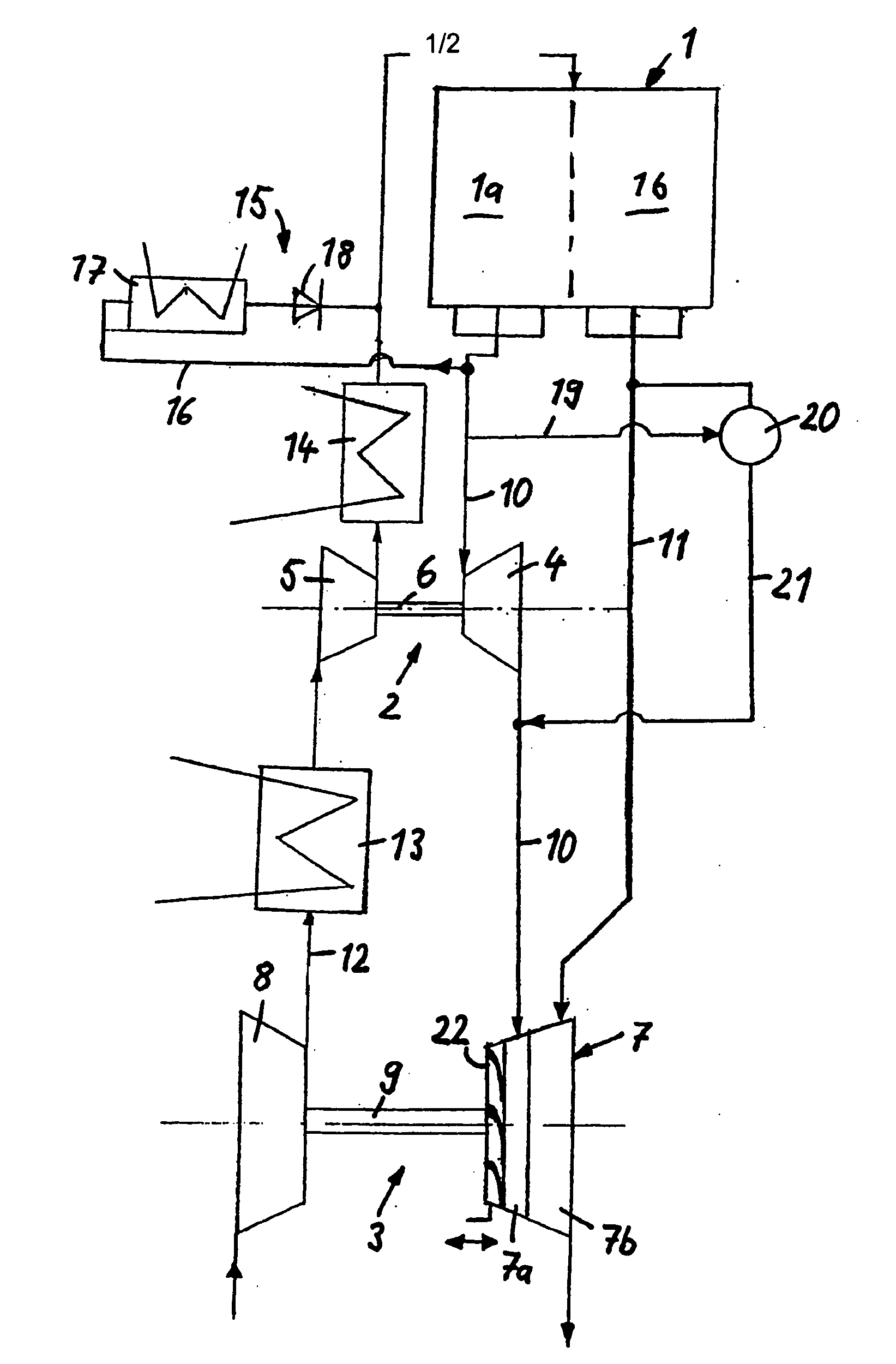

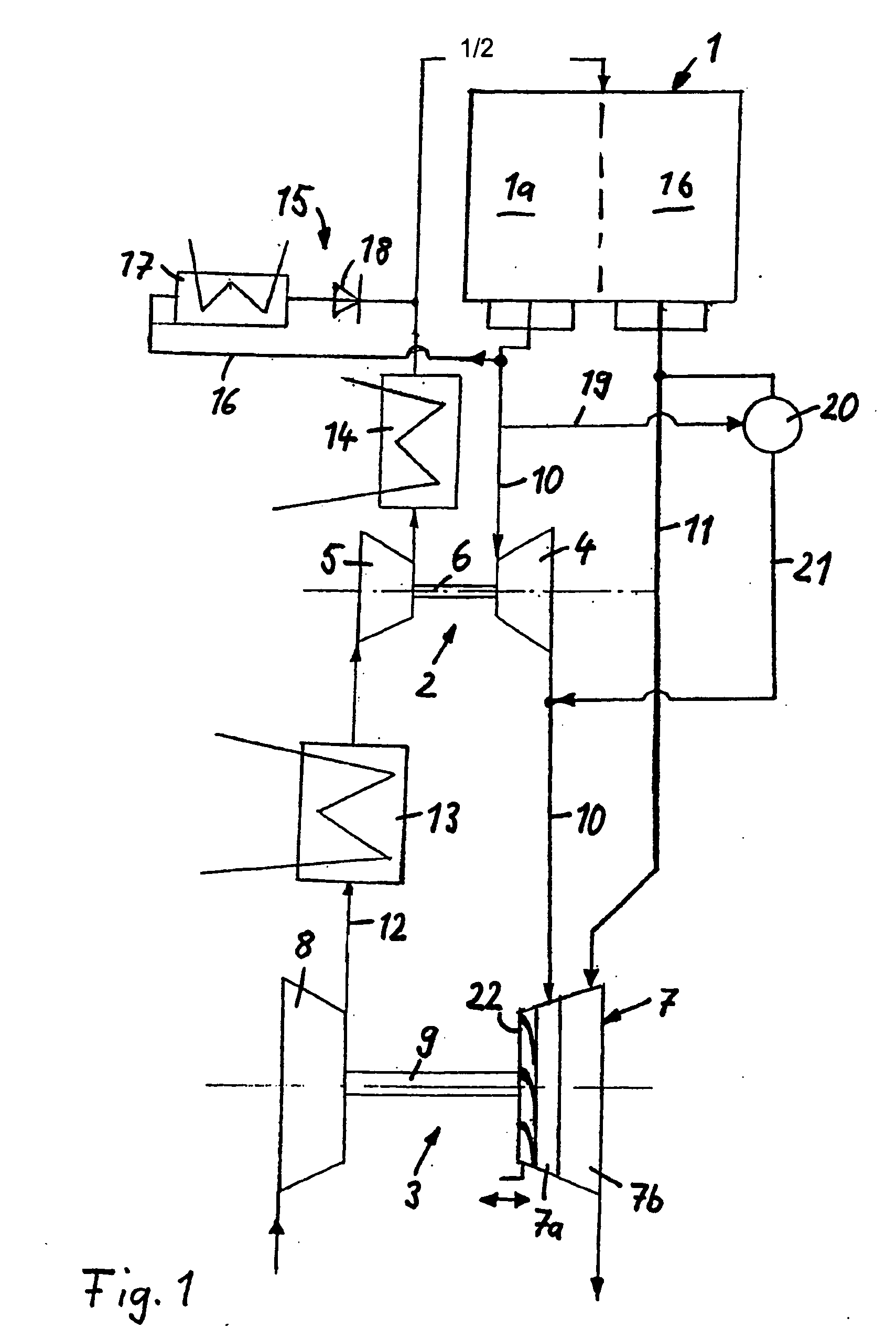

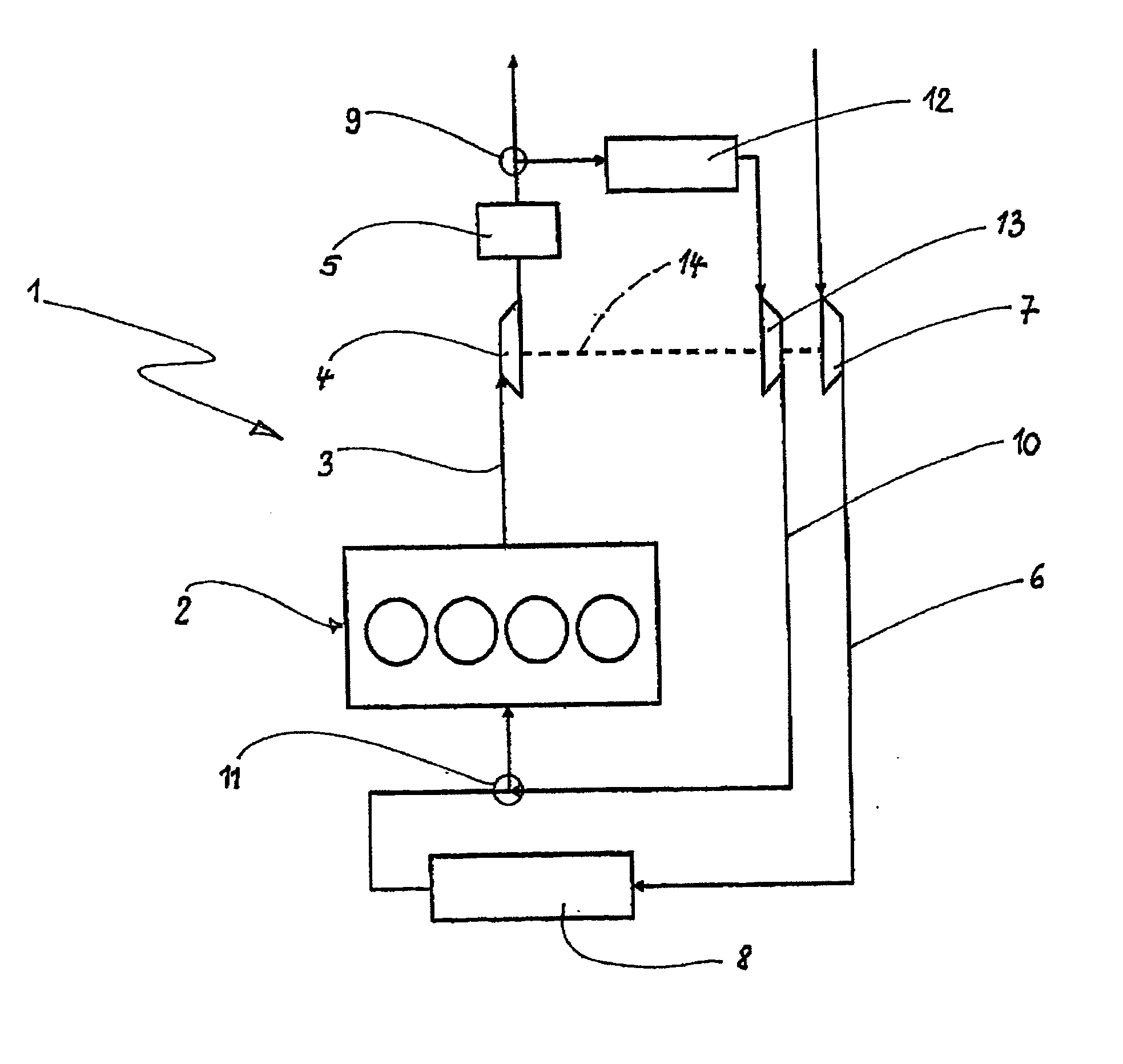

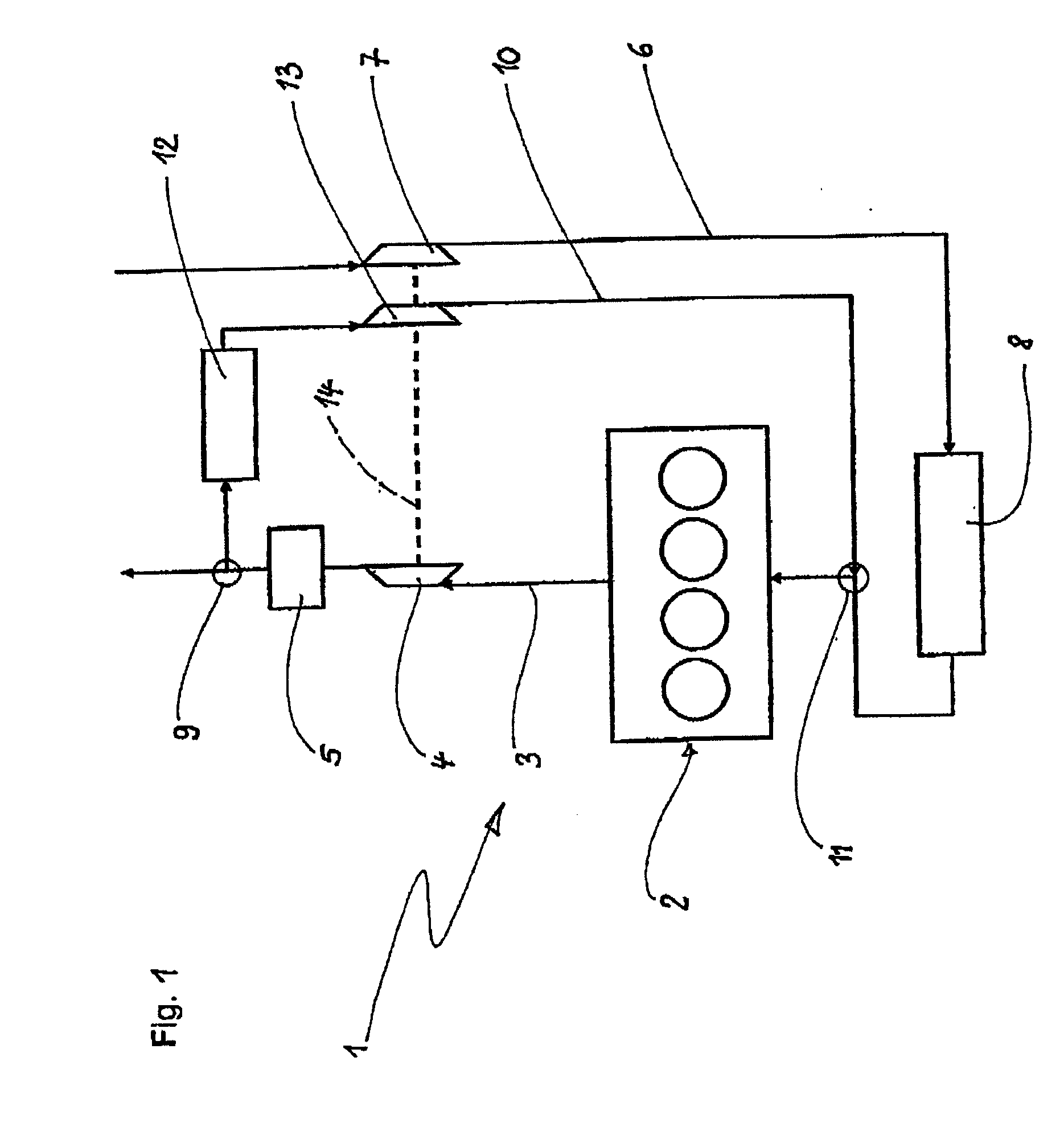

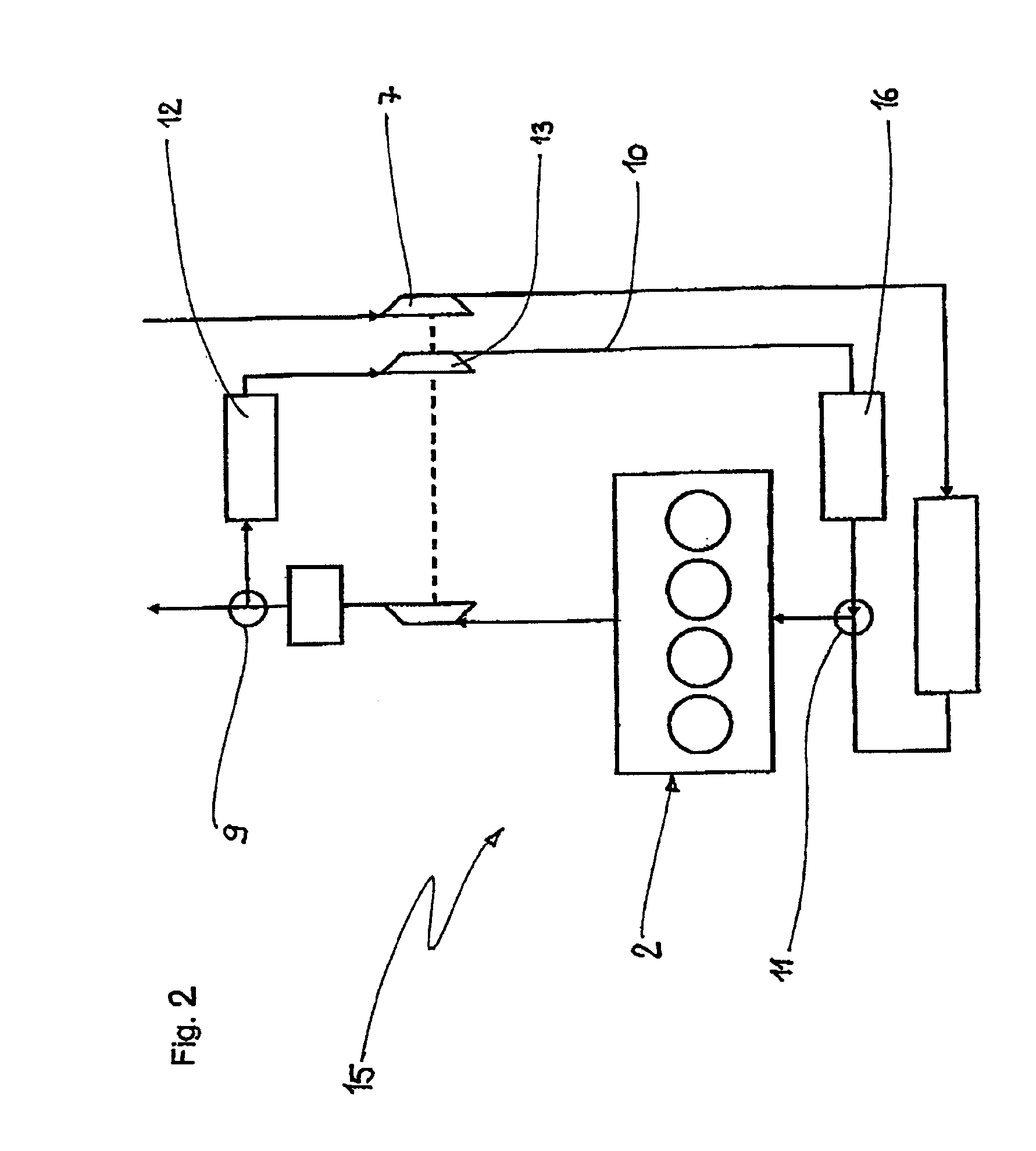

System for exhaust gas recirculation in a motor vehicle

InactiveUS20060248888A1Reduce corrosion damageInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesAir compressor

A system for recirculation of cooled exhaust gas from a vehicle internal combustion engine includes an internal combustion engine (2) having an intake system (6) and an exhaust gas system (3), an exhaust gas recirculation (EGR) line (10) that contains an exhaust gas cooler (12), an exhaust gas turbine (4) arranged in the exhaust gas system, (3) and a charge air compressor (7) and a charge air cooler (8) arranged in the intake system (6). The exhaust gas stream is extracted at the low pressure side (9) of the exhaust gas turbine (4). An exhaust gas compressor (13) is arranged in the EGR line (10), and the recirculated exhaust gas stream can be fed to the intake system downstream of the charge air cooler (8).

Owner:BEHR GMBH & CO KG

System and method for cooling a gas turbine with an exhaust gas provided by the gas turbine

ActiveUS20130283808A1Turbine/propulsion engine coolingGas turbine plantsExhaust fumesExhaust gas recirculation

A system for cooling a gas turbine with an exhaust gas provided by the gas turbine generally includes an exhaust gas recirculation system including an exhaust gas scrubber. The exhaust gas recirculation system is disposed downstream from the gas turbine and may receive at least a portion of the exhaust gas provided by the gas turbine. The system may also include a moisture separator located downstream from the exhaust gas recirculation system, and a cooling circuit configured to connect to one or more cooling circuit inlets. The one or more cooling circuit inlets may provide fluid communication between the cooling circuit and the gas turbine.

Owner:EXXONMOBIL UPSTREAM RES CO +1

Intake oxygen estimator for internal combustion engine

ActiveUS7117078B1Electrical controlDigital data processing detailsExternal combustion engineExhaust gas recirculation

An internal combustion engine system includes an intake manifold, a combustion chamber, an exhaust manifold and exhaust gas recirculation apparatus for recirculating a portion of the exhausted gases from the exhaust manifold to the intake manifold. An estimate intake manifold oxygen concentration is determined from the air fraction within the intake manifold which is determined from an engine system model that provides interdependent air mass fractions at various locations within the engine system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method of operating a stoichiometric exhaust gas recirculation power plant

At least one main air compressor makes a compressed ambient gas flow. The compressed ambient gas flow is delivered to a turbine combustor at a pressure that is greater than or substantially equal to an output pressure delivered to the turbine combustor from a turbine compressor as at least a first portion of a recirculated gas flow. A fuel stream is delivered to the turbine combustor, and a combustible mixture is formed and burned, forming the recirculated gas flow. A turbine power is produced that is substantially equal to at least a power required to rotate the turbine compressor. At least a portion of the recirculated gas flow is recirculated through a recirculation loop. An excess portion of the recirculated gas flow is vented or a portion of the recirculated gas flow bypasses the turbine combustor or both.

Owner:GENERAL ELECTRIC CO

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS20060144356A1Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

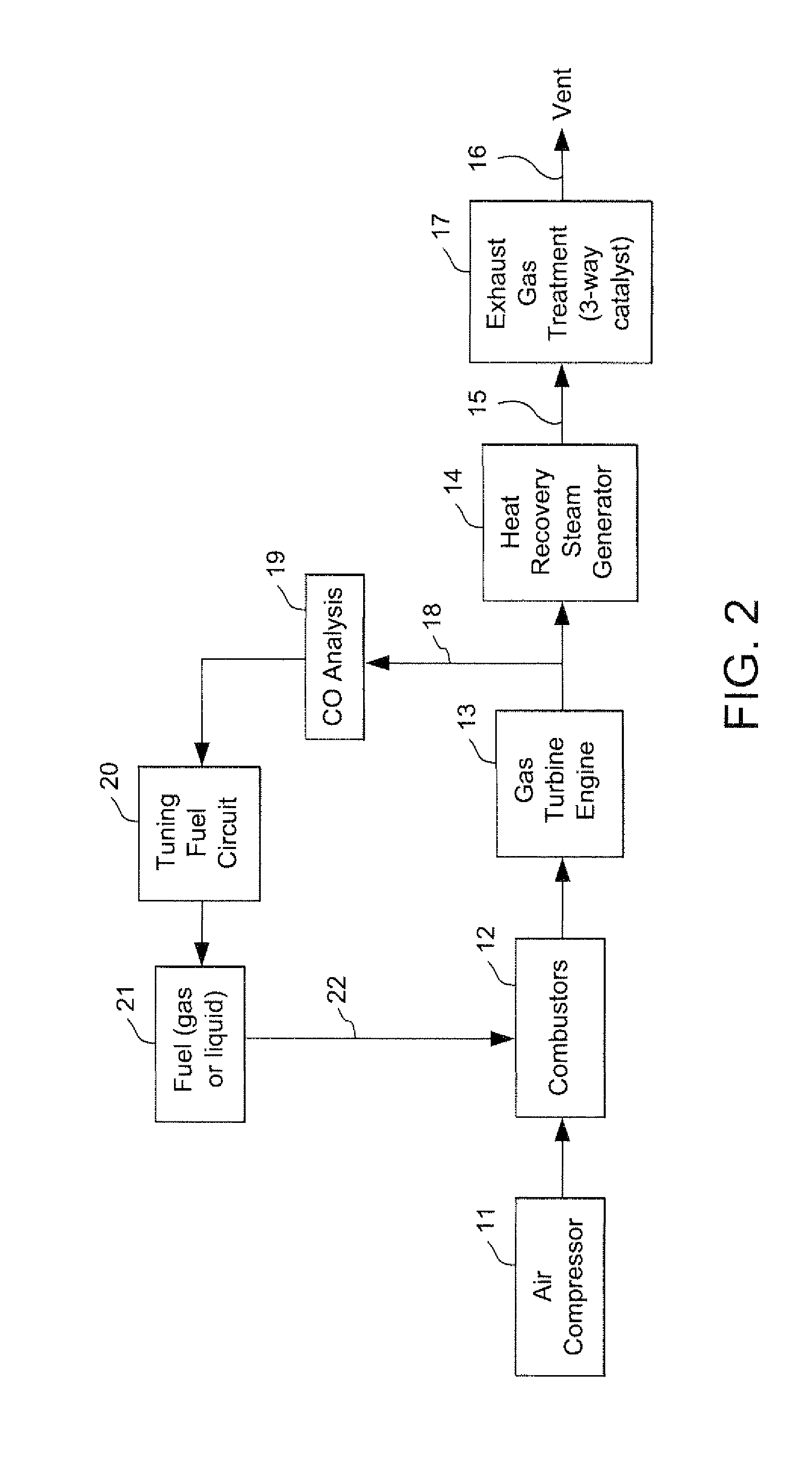

Stoichiometric exhaust gas recirculation and related combustion control

ActiveUS20120185144A1Analogue computers for vehiclesExhaust apparatusOxygenExhaust gas recirculation

A fuel control system for a gas turbine engine that includes a primary fuel circuit, a fuel tuning circuit, a plurality of combustors connected to the fuel tuning circuit, oxygen and carbon dioxide sensors in the exhaust stream and a feedback control loop operatively connected to the fuel tuning circuit and to the oxygen and carbon monoxide sensors which serve to control the precise amount of fuel and air being fed to each one of the plurality of combustors in the engine. A parallel array of control valves in a tuning fuel circuit connect to corresponding ones of the plurality of combustors in the gas turbine engine. The fuel control system thereby “fine tunes” the amount of fuel and air being fed to each combustor using data regarding the detected oxygen and carbon monoxide concentrations in the exhaust gas as provided through a feedback control loop.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com