Patents

Literature

1454 results about "Intake pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intake pressure. inlet pressure. i. The total pressure taken in the engine inlet as a measure of air density. This parameter is sent to the fuel control for fuel scheduling. It is normally known as P 1 pressure. ii.

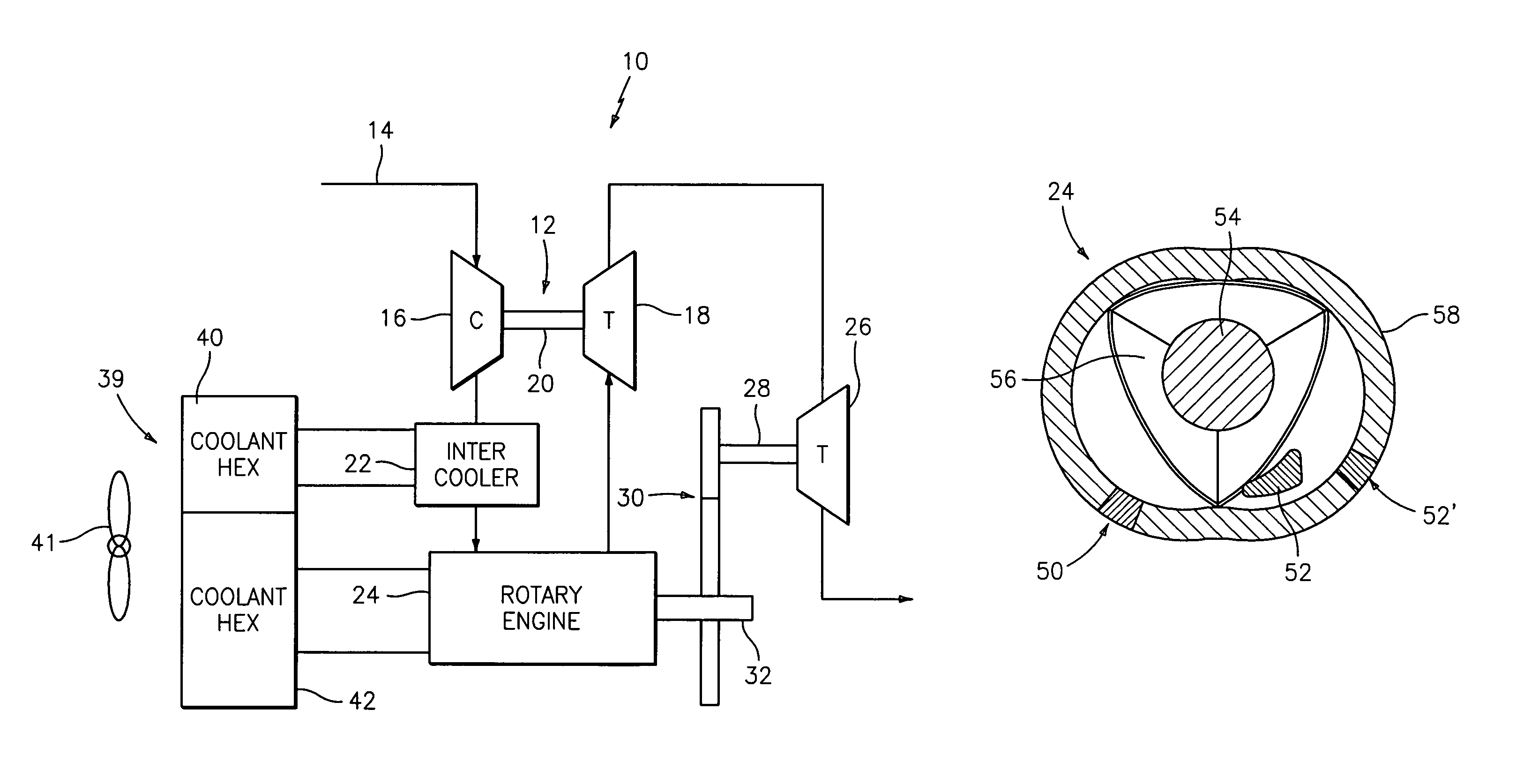

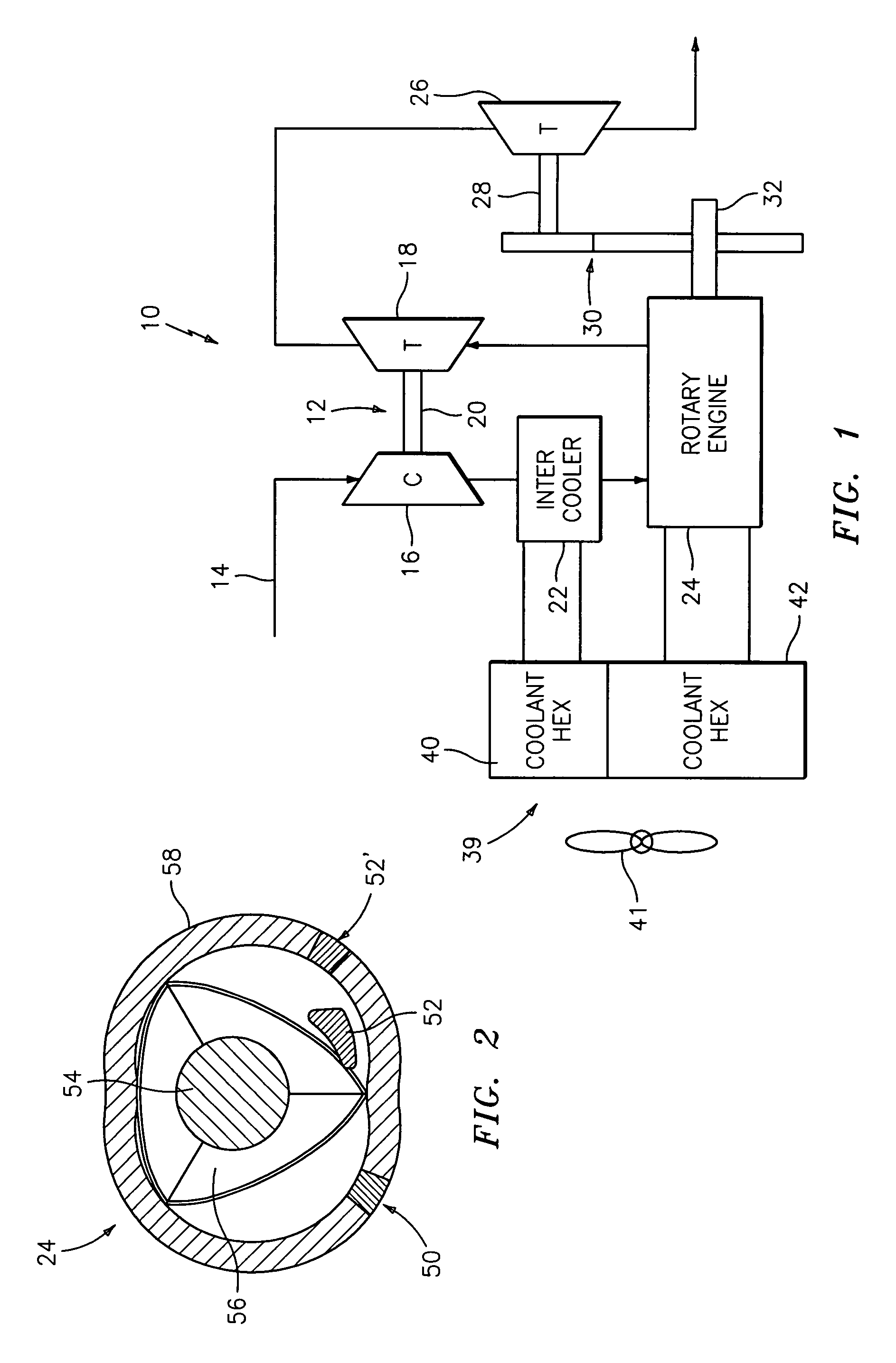

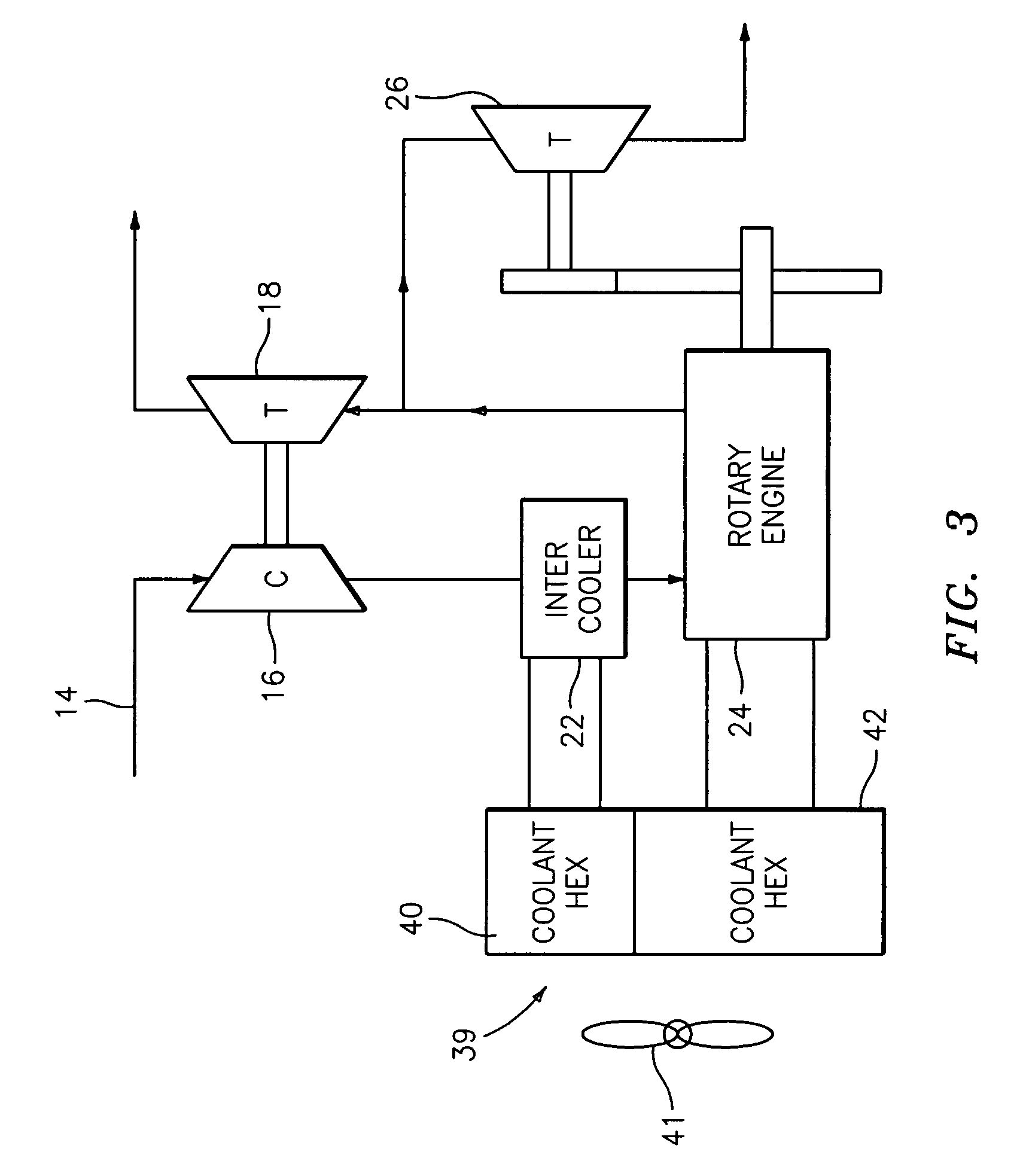

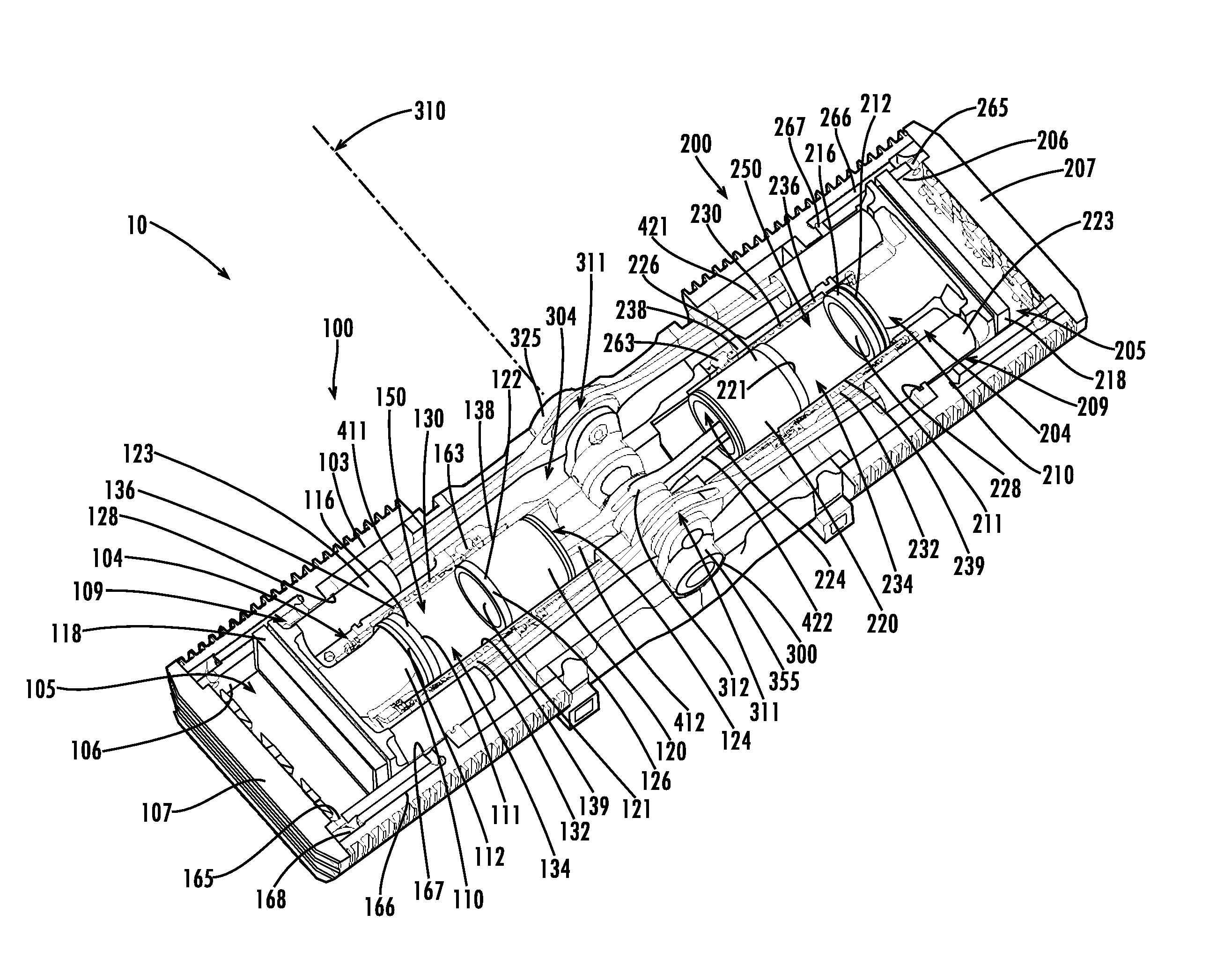

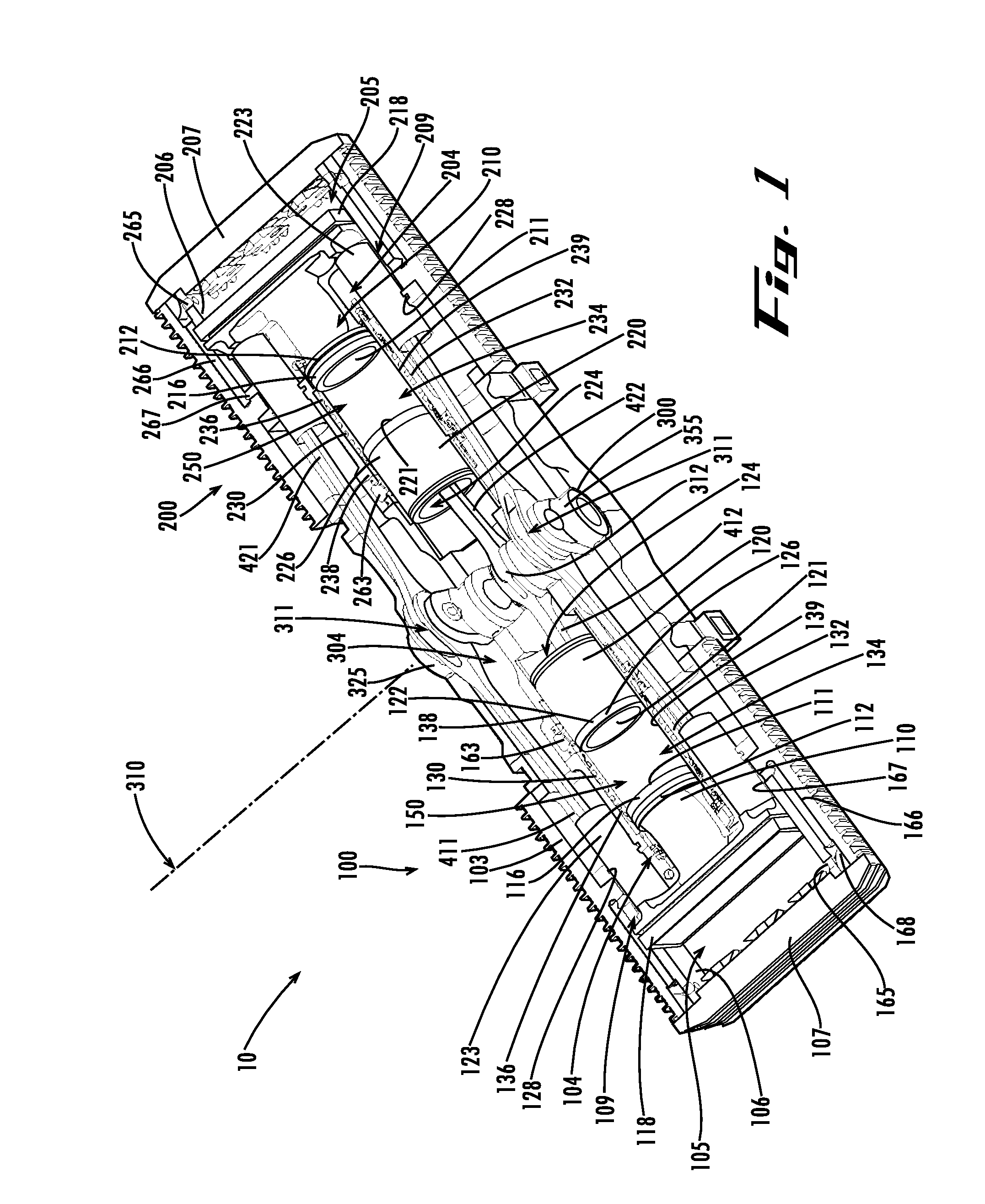

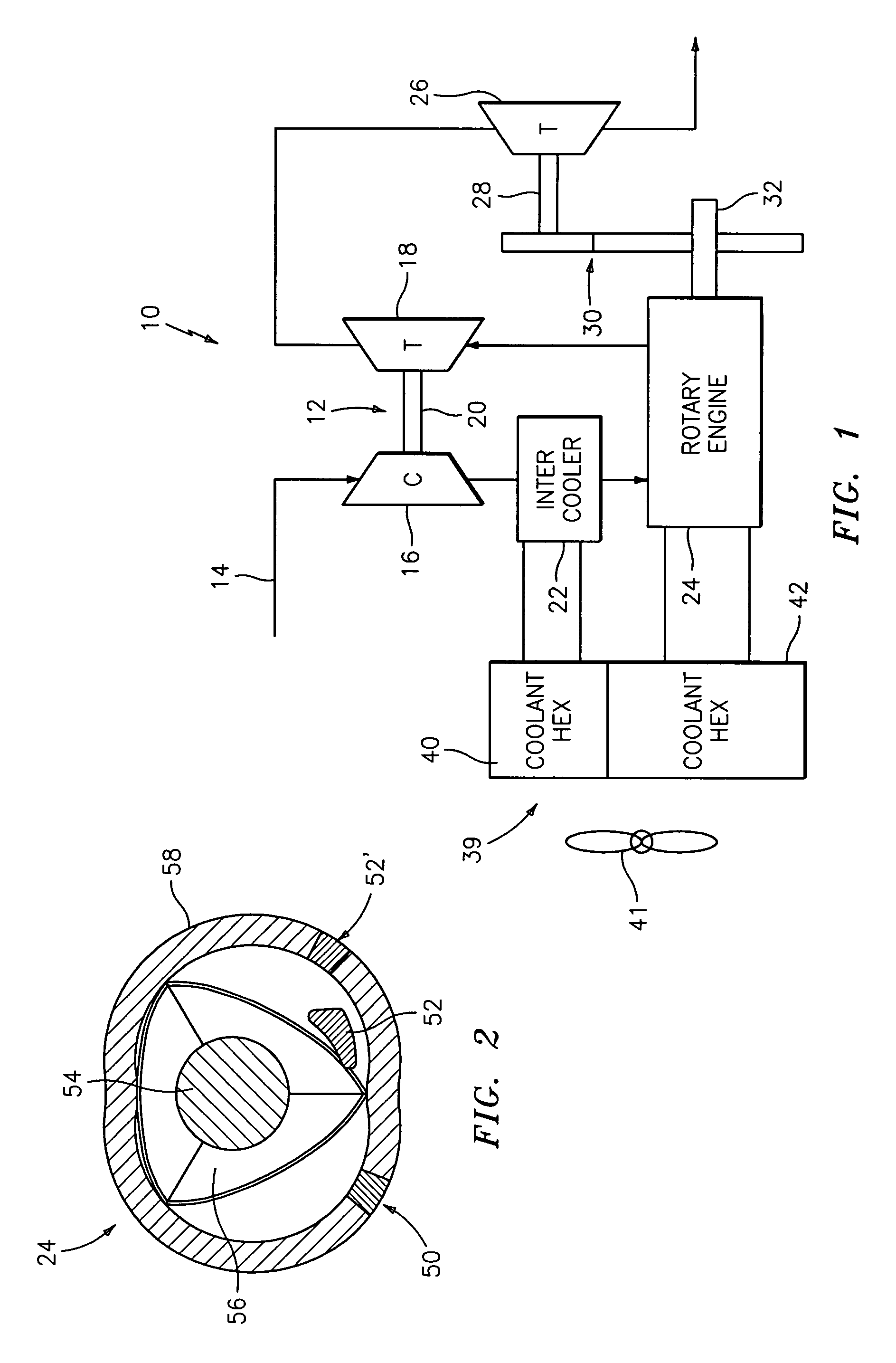

Compound cycle rotary engine

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

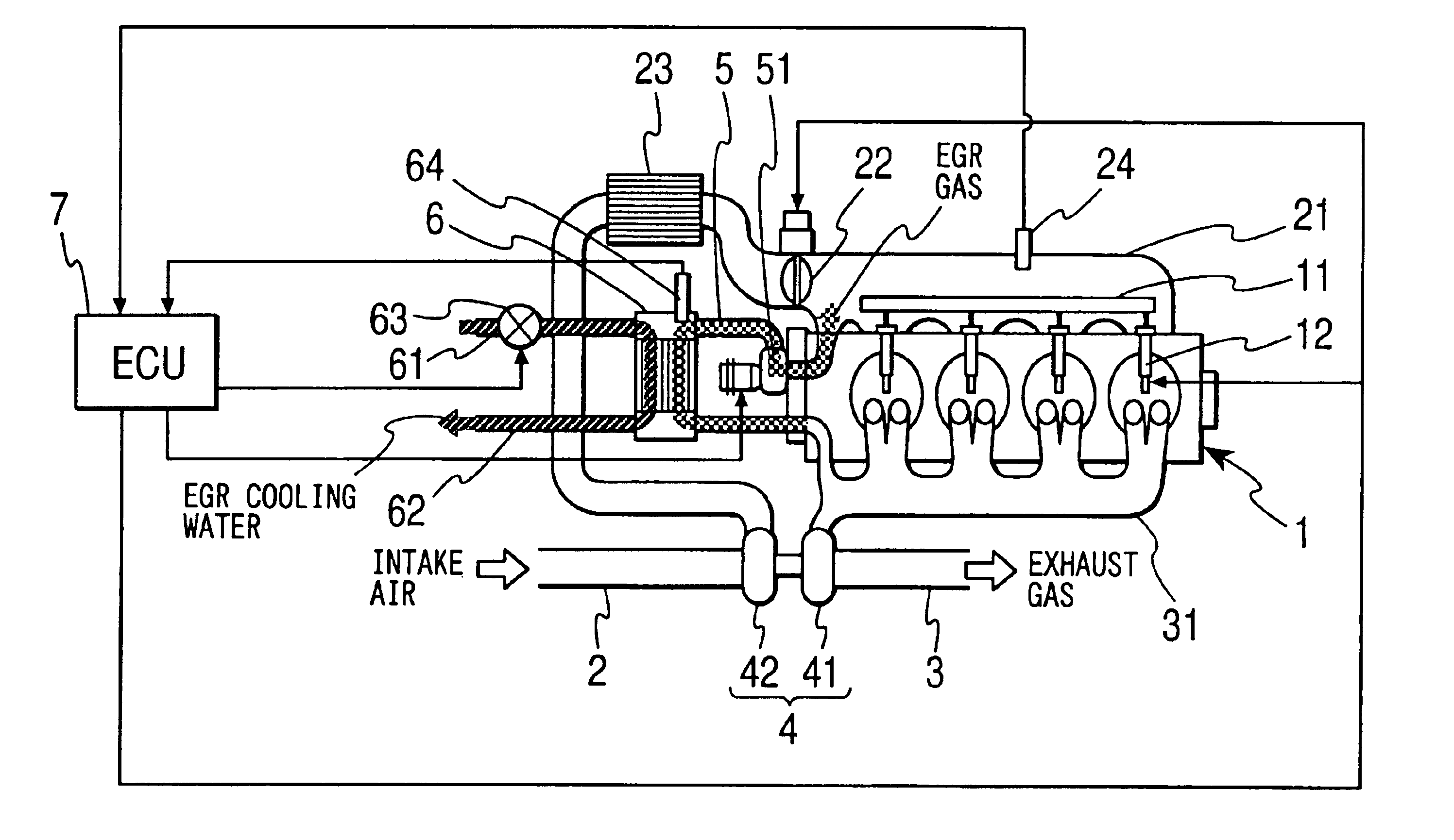

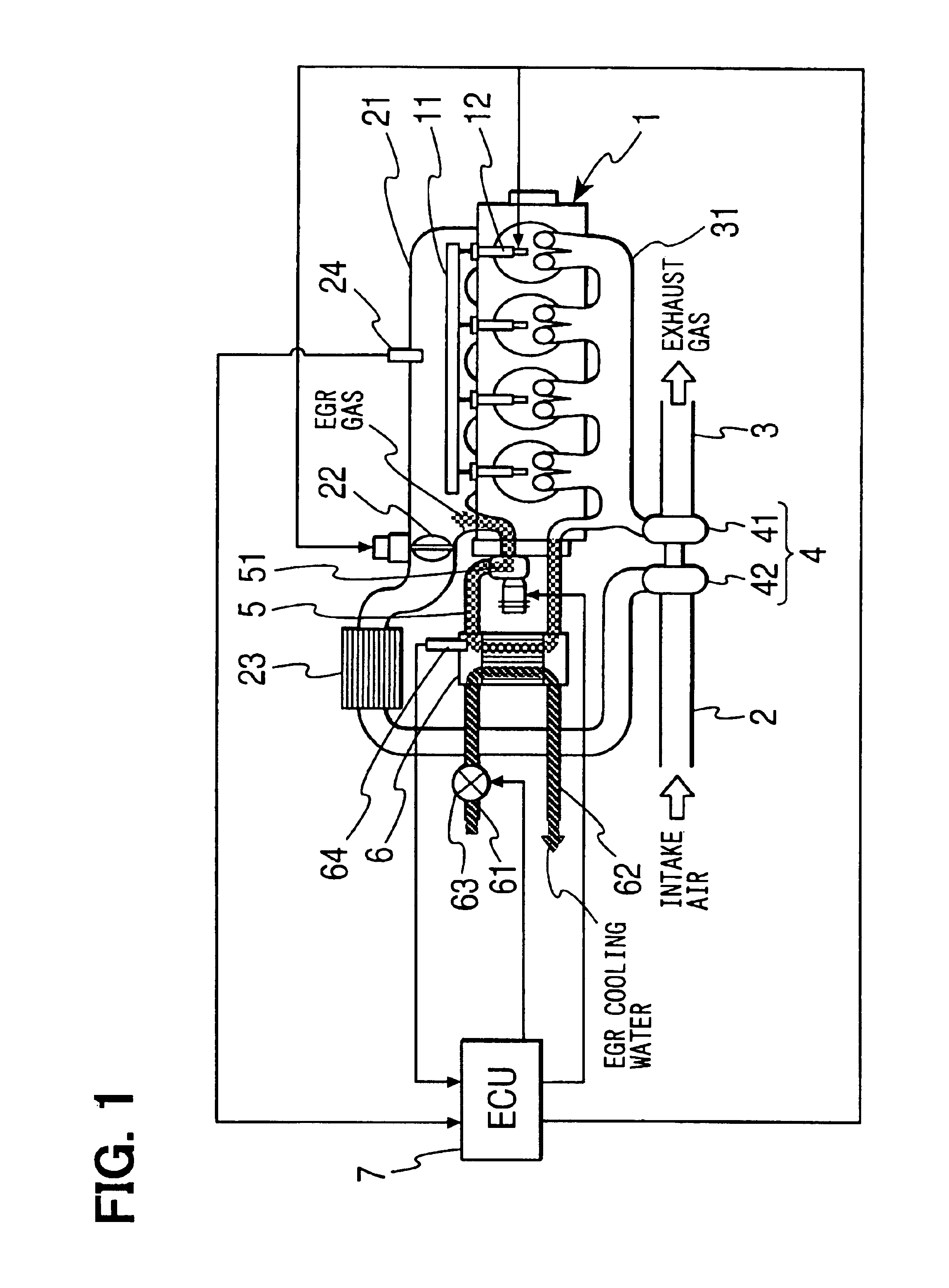

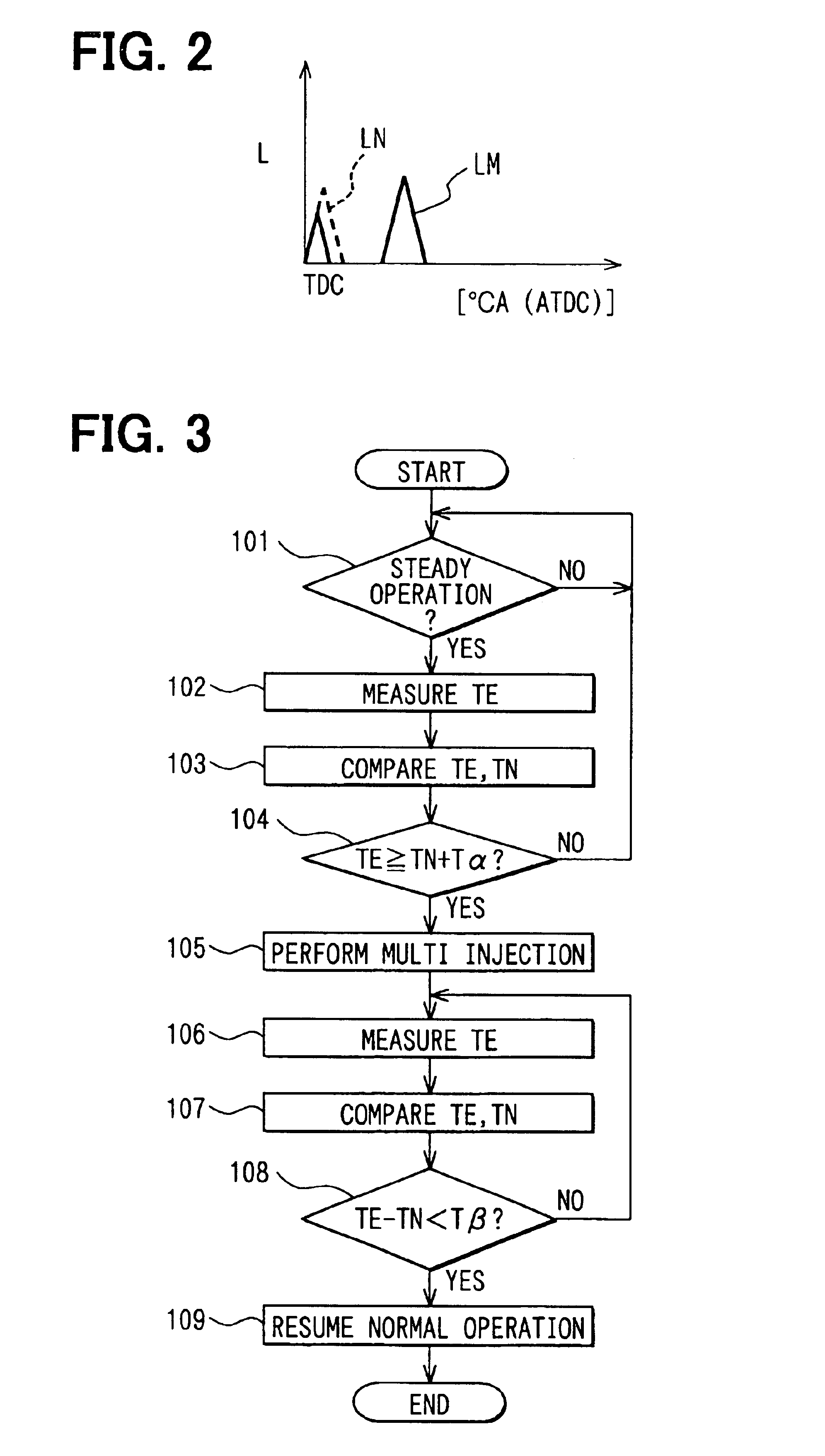

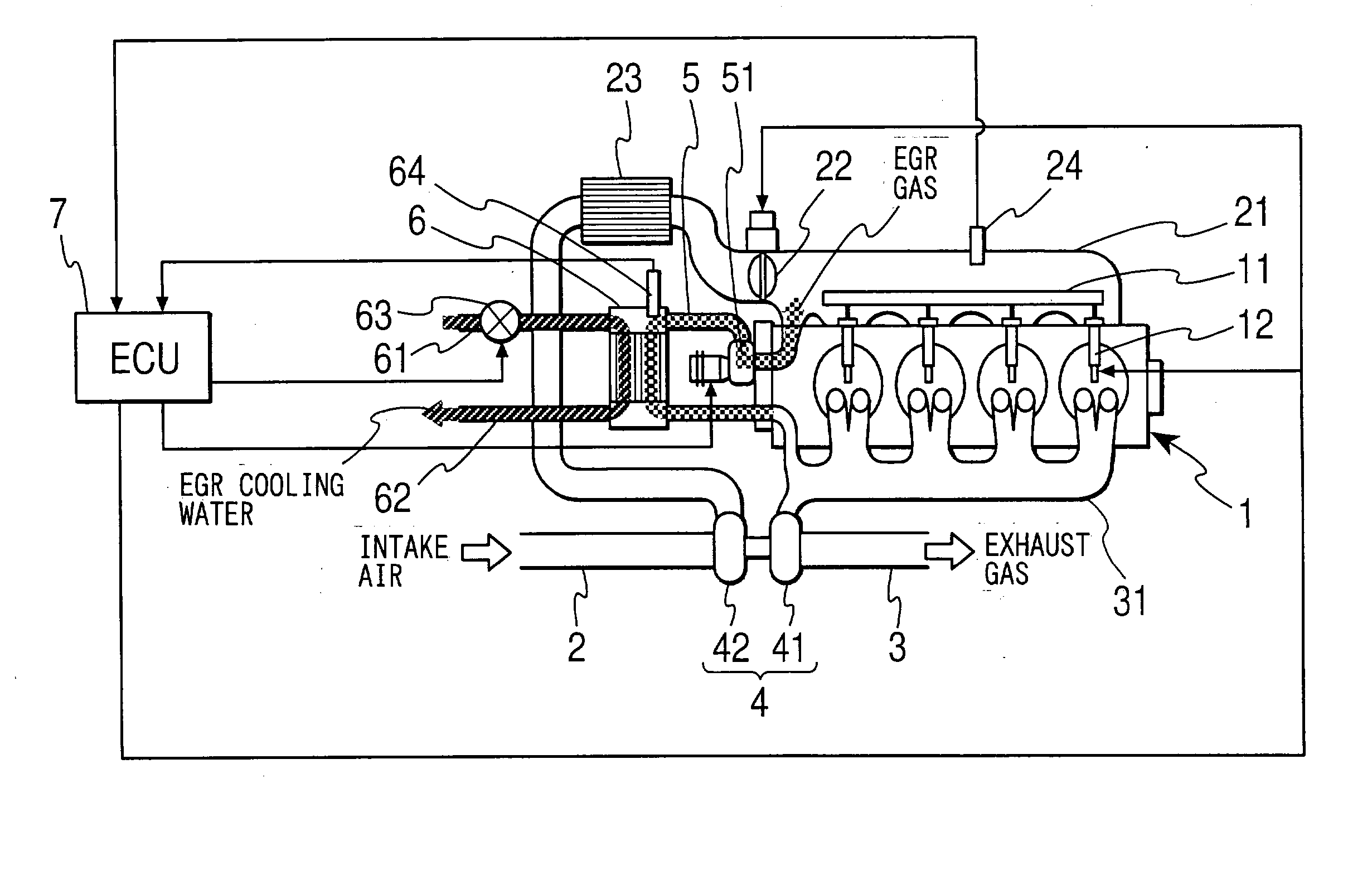

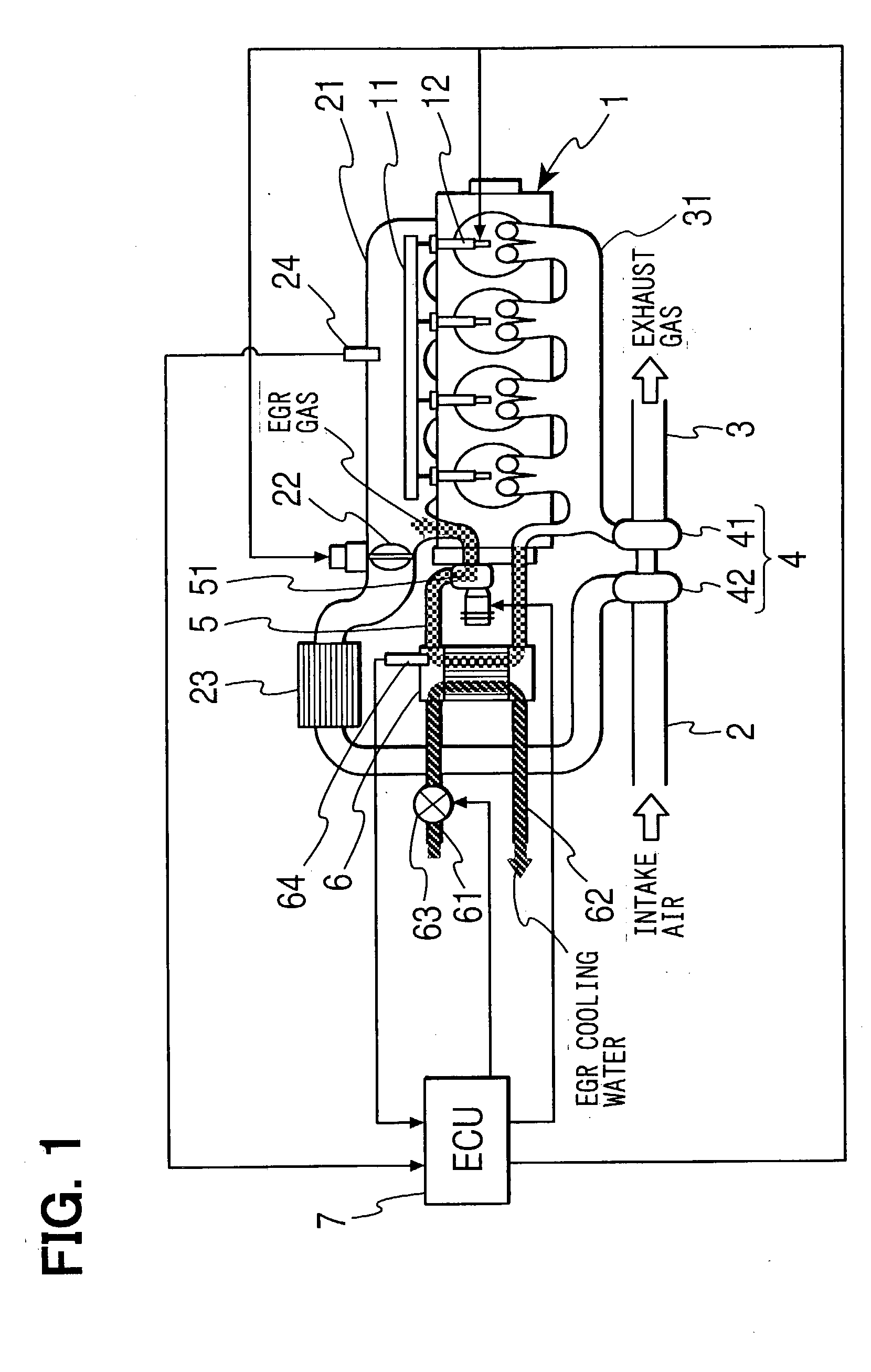

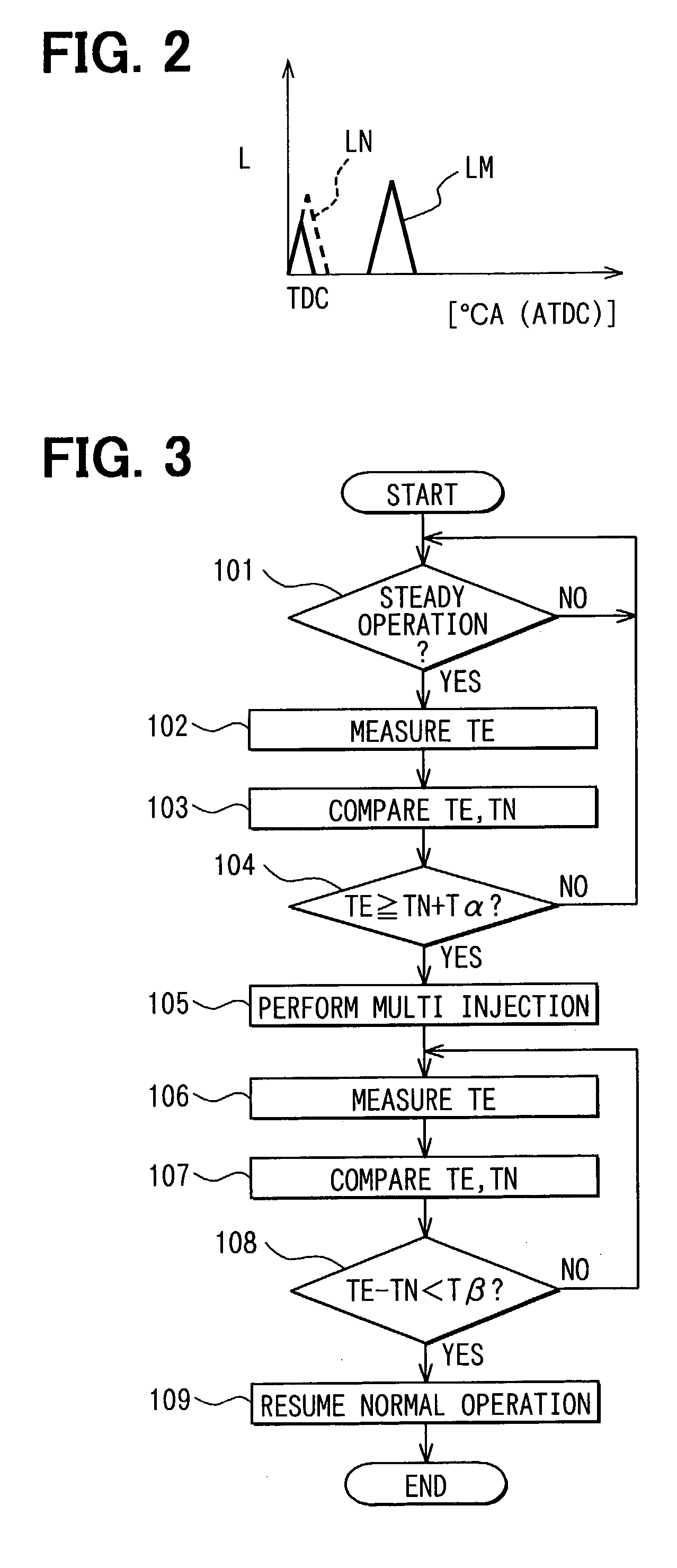

Exhaust gas recirculation system having cooler

InactiveUS6826903B2Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

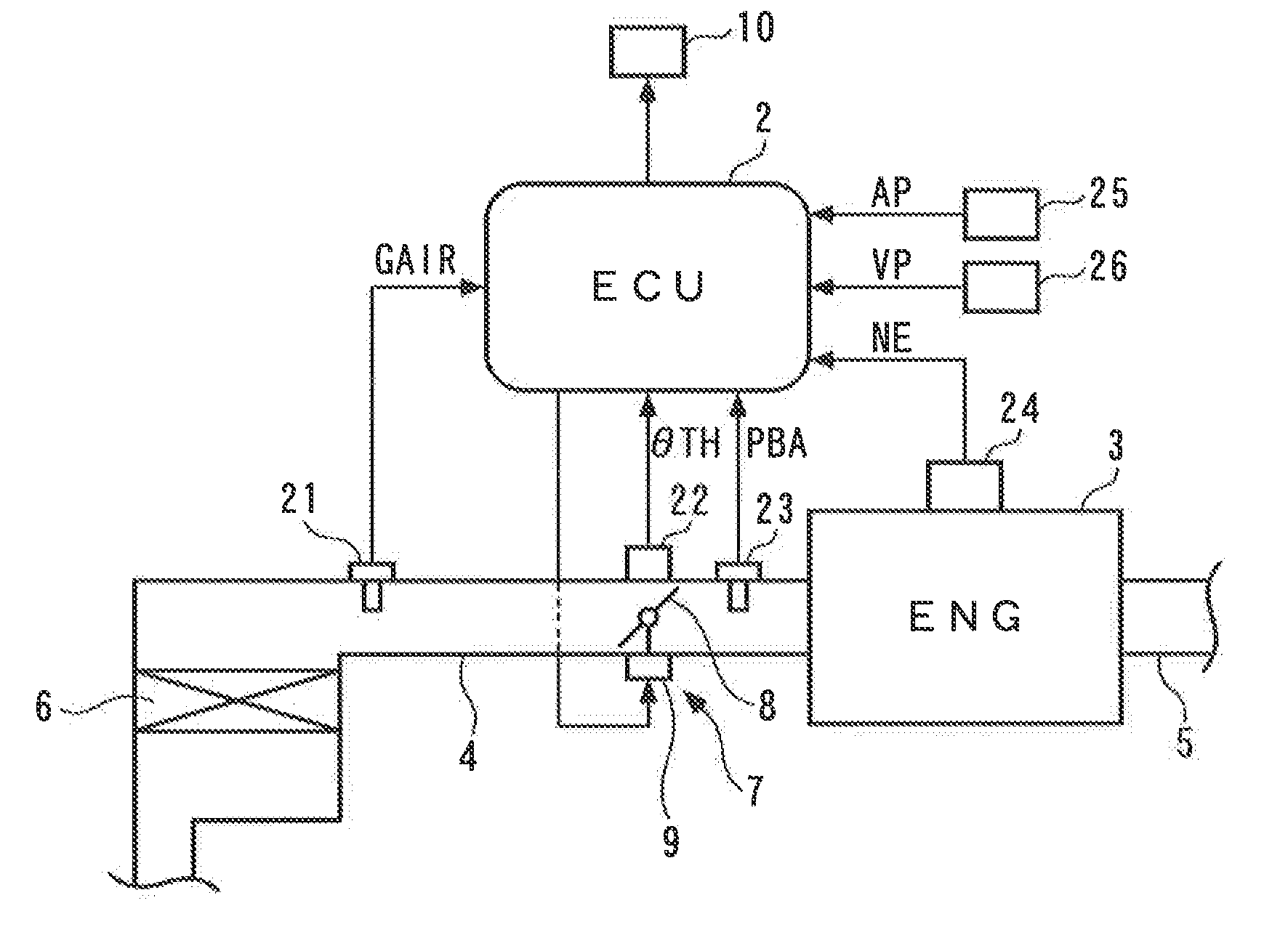

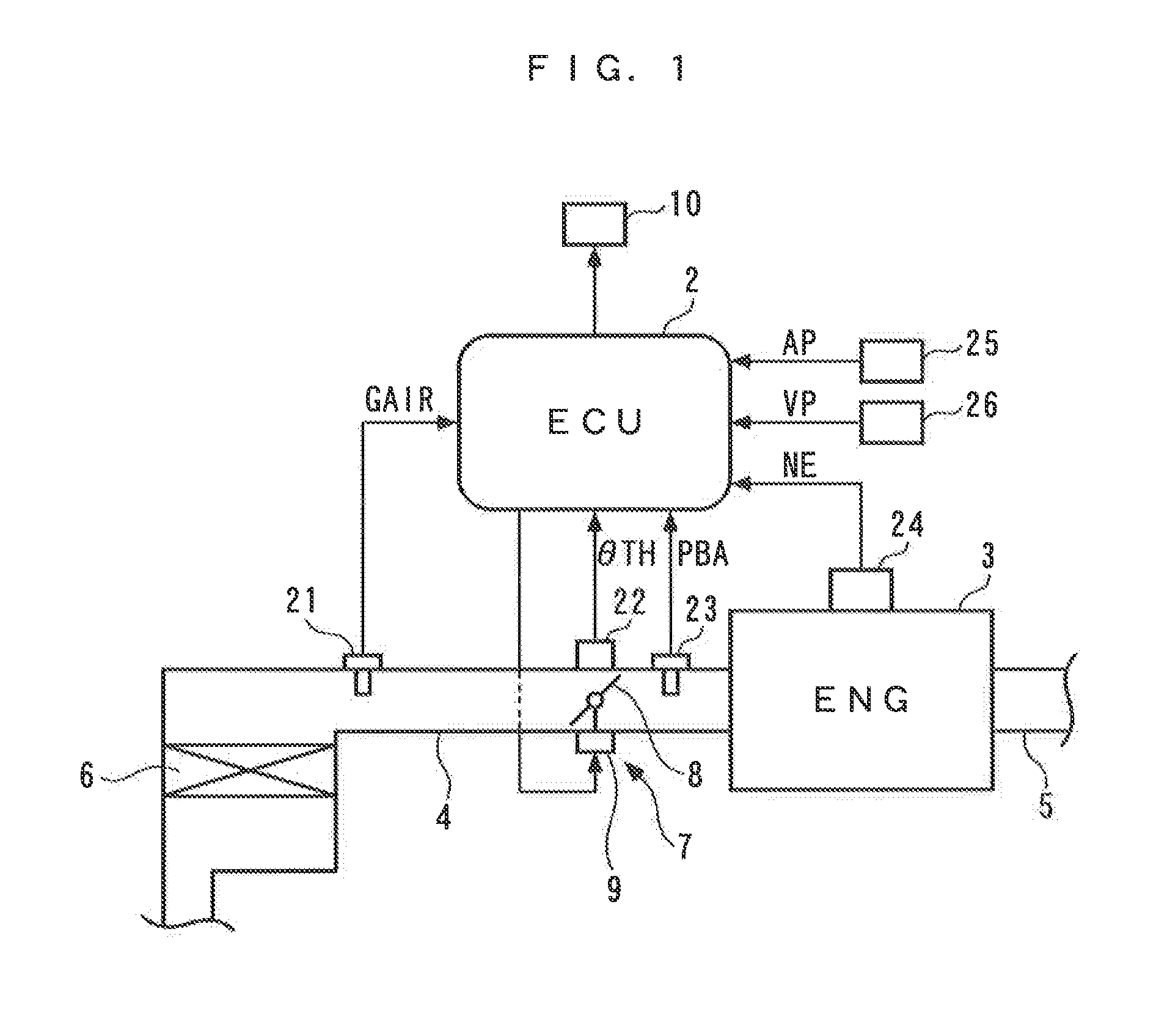

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

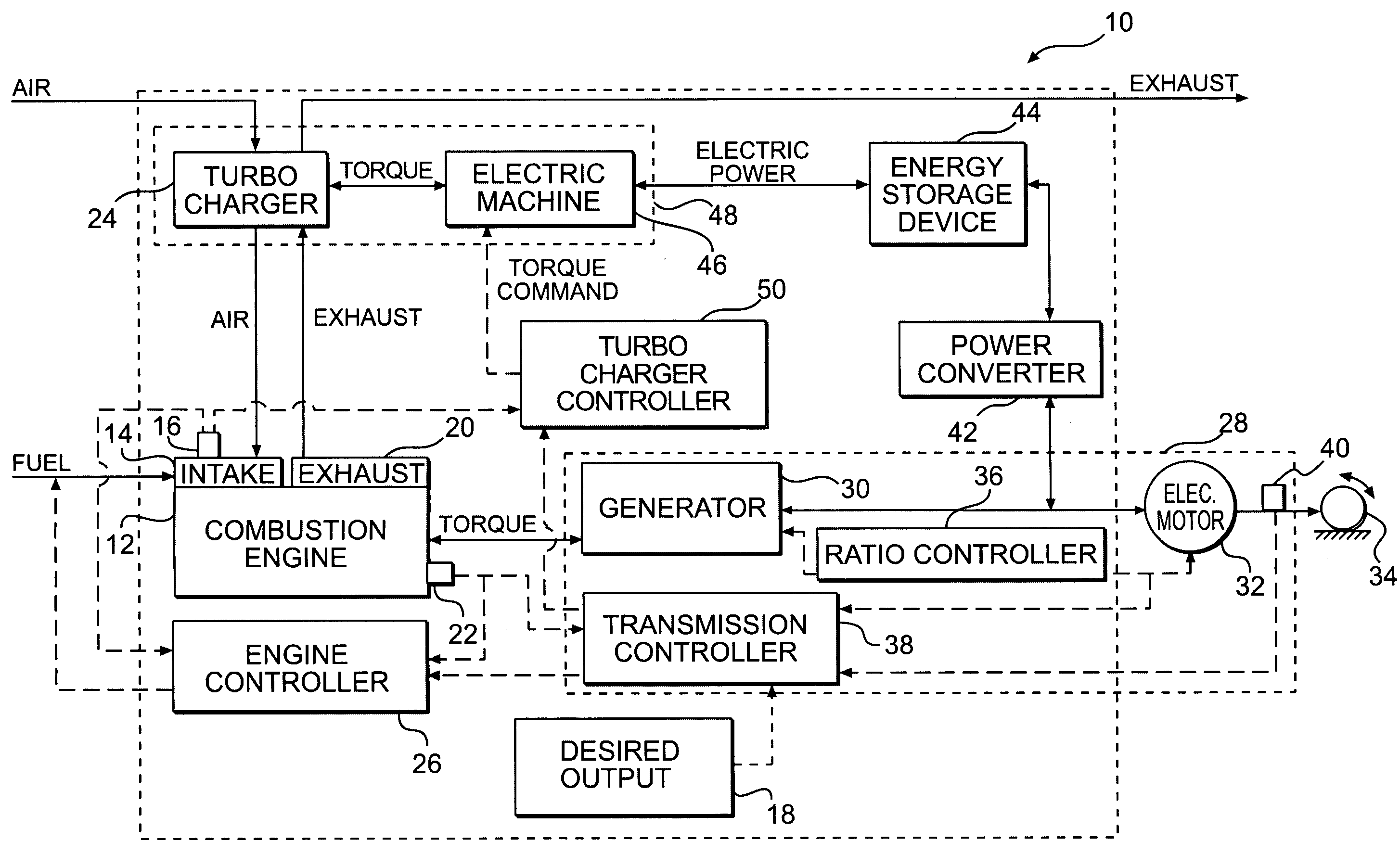

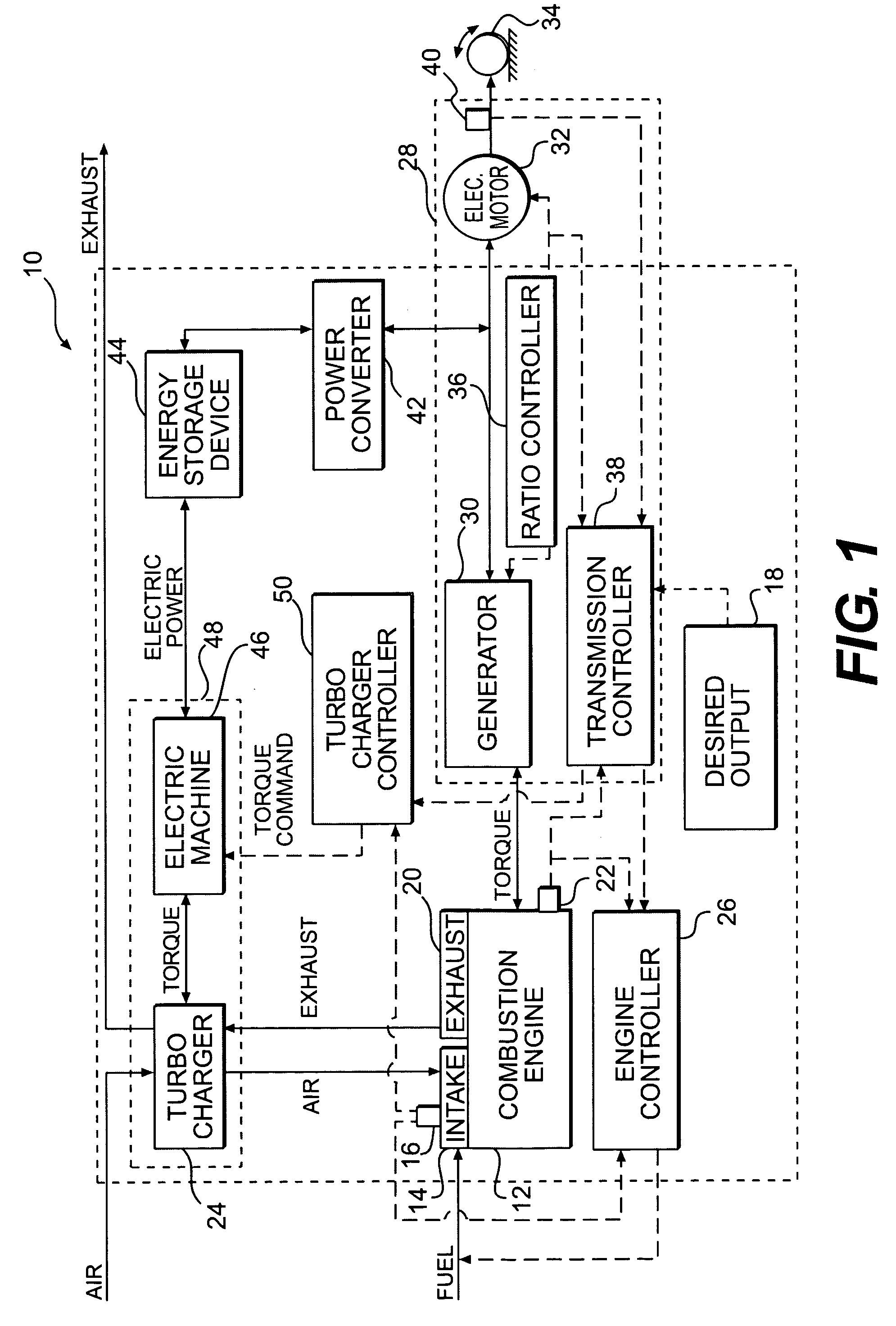

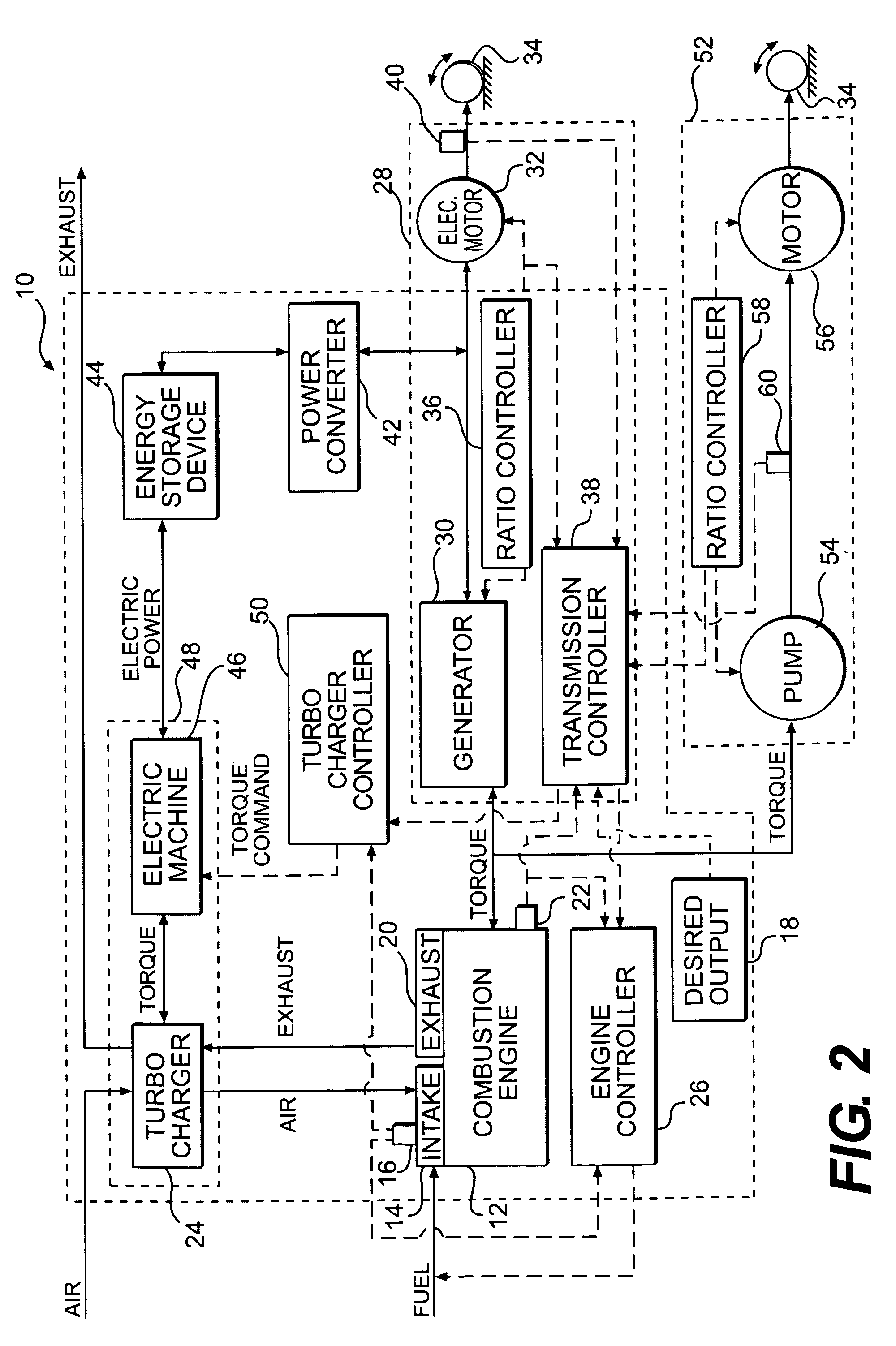

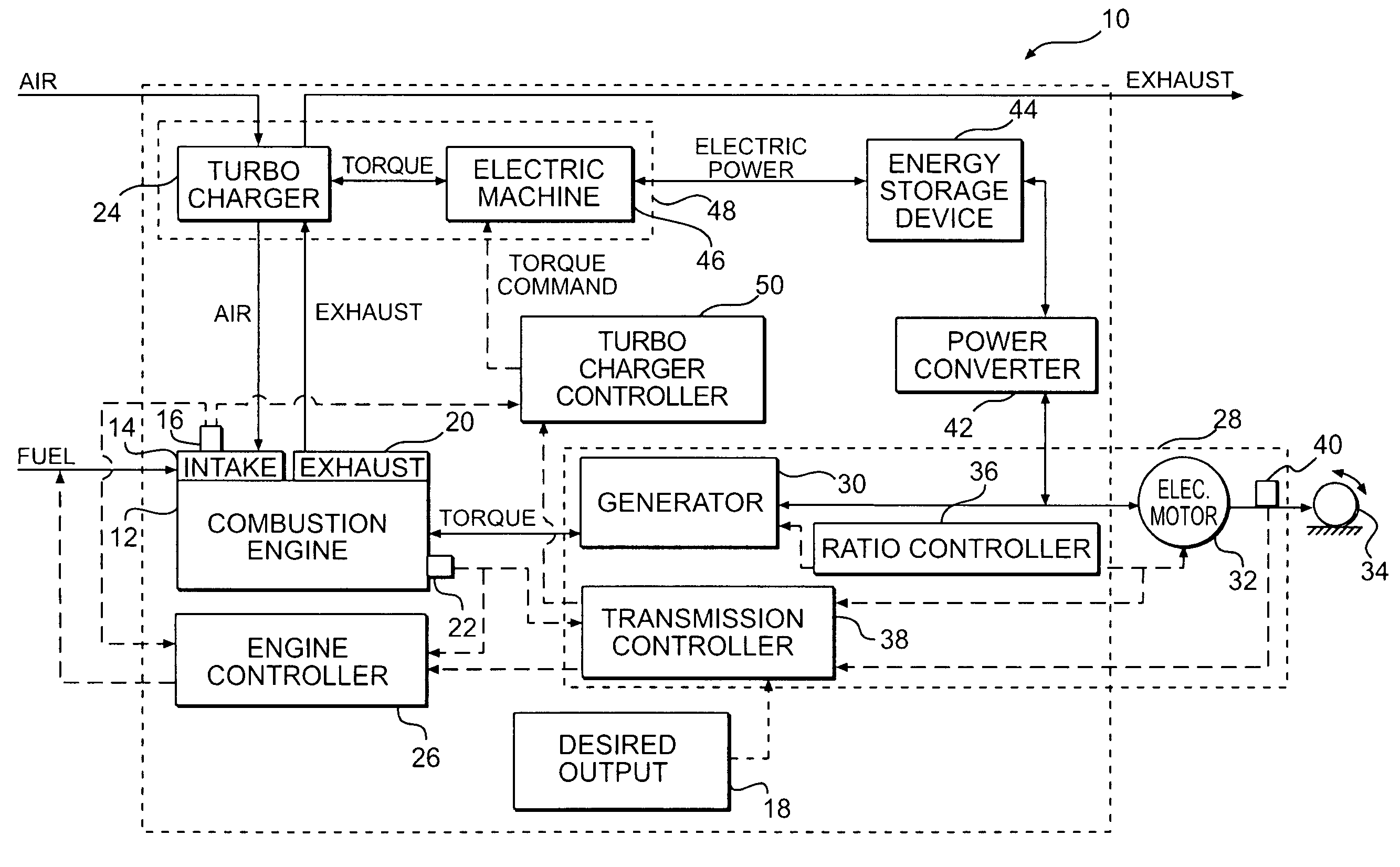

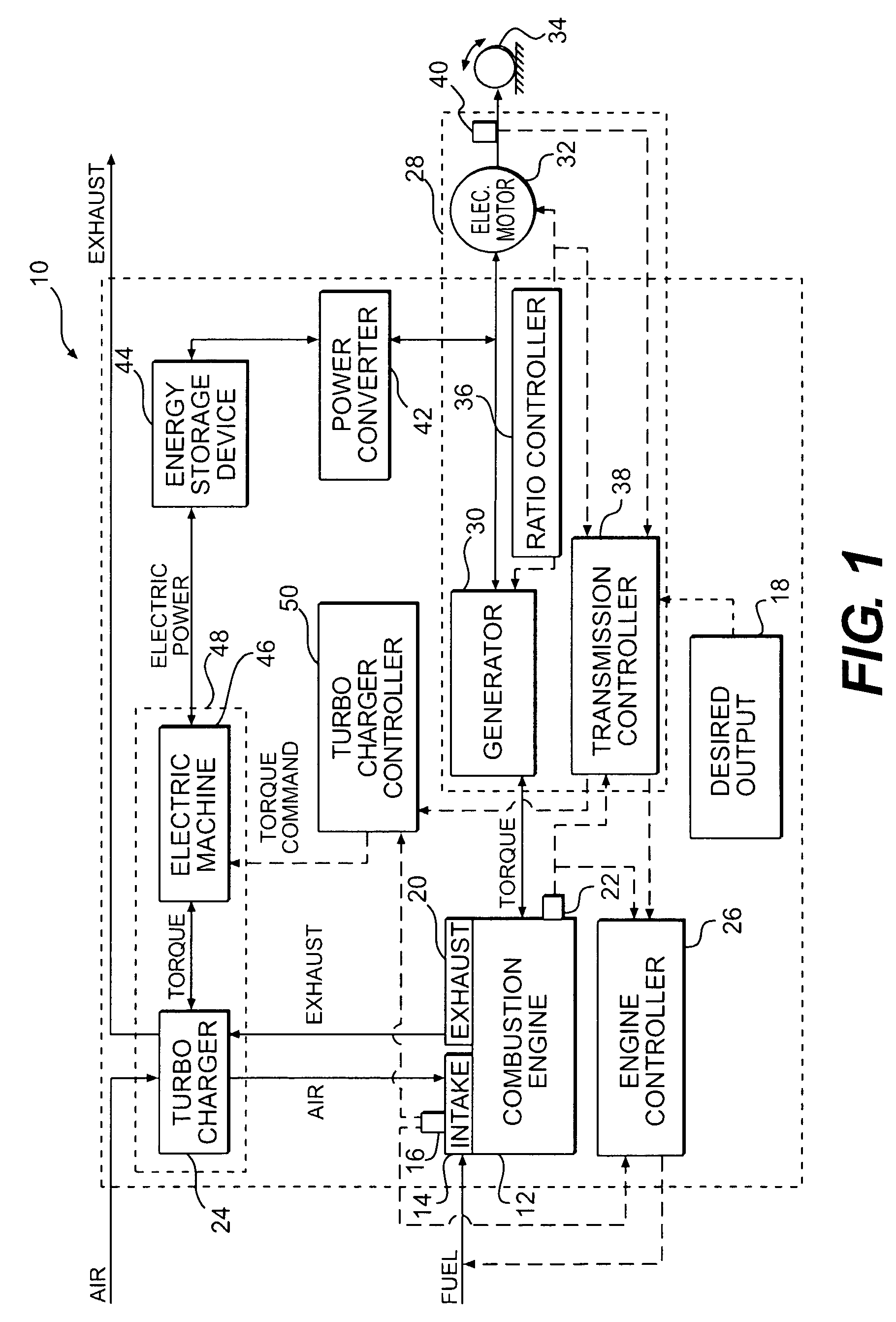

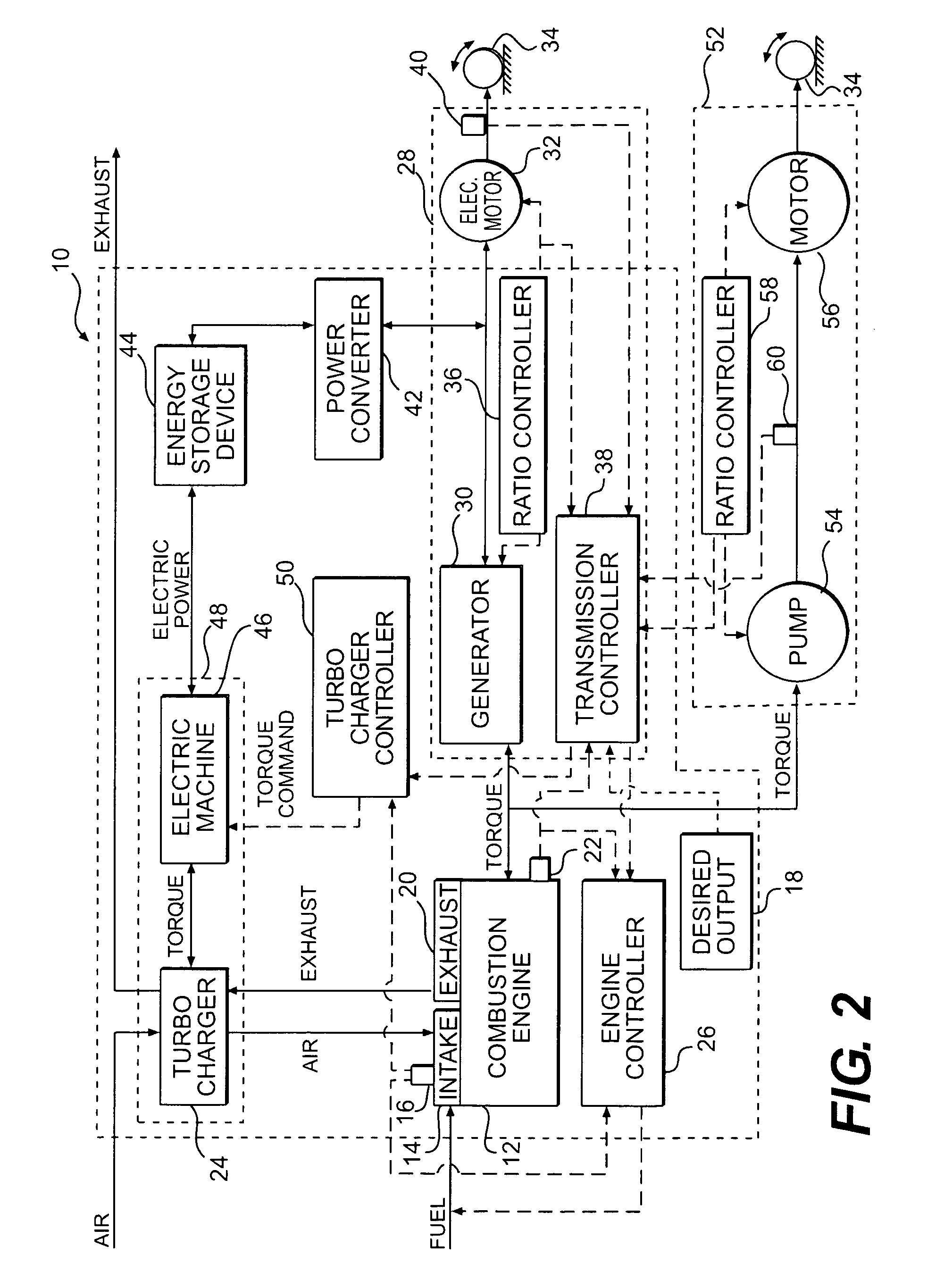

Turbocharger system

A system for controlling intake pressure of a combustion engine operably coupled to a power generation system includes a sensor configured to output a signal indicative of a pressure in an intake system of the combustion engine and a sensor configured to output a signal indicative of a load on the power generation system. The system further includes a turbocharger operably coupled to the intake system. The system also includes an electric machine operably coupled to the turbocharger. The electric machine is configured to supply torque to the turbocharger. The system further includes a turbocharger controller operably coupled to the electric machine. The turbocharger controller is configured to control operation of the electric machine such that the turbocharger supplies a desired intake pressure to the combustion engine based at least partially on the signal indicative of a pressure in the intake system and the signal indicative of a load on the power generation system.

Owner:CATERPILLAR INC

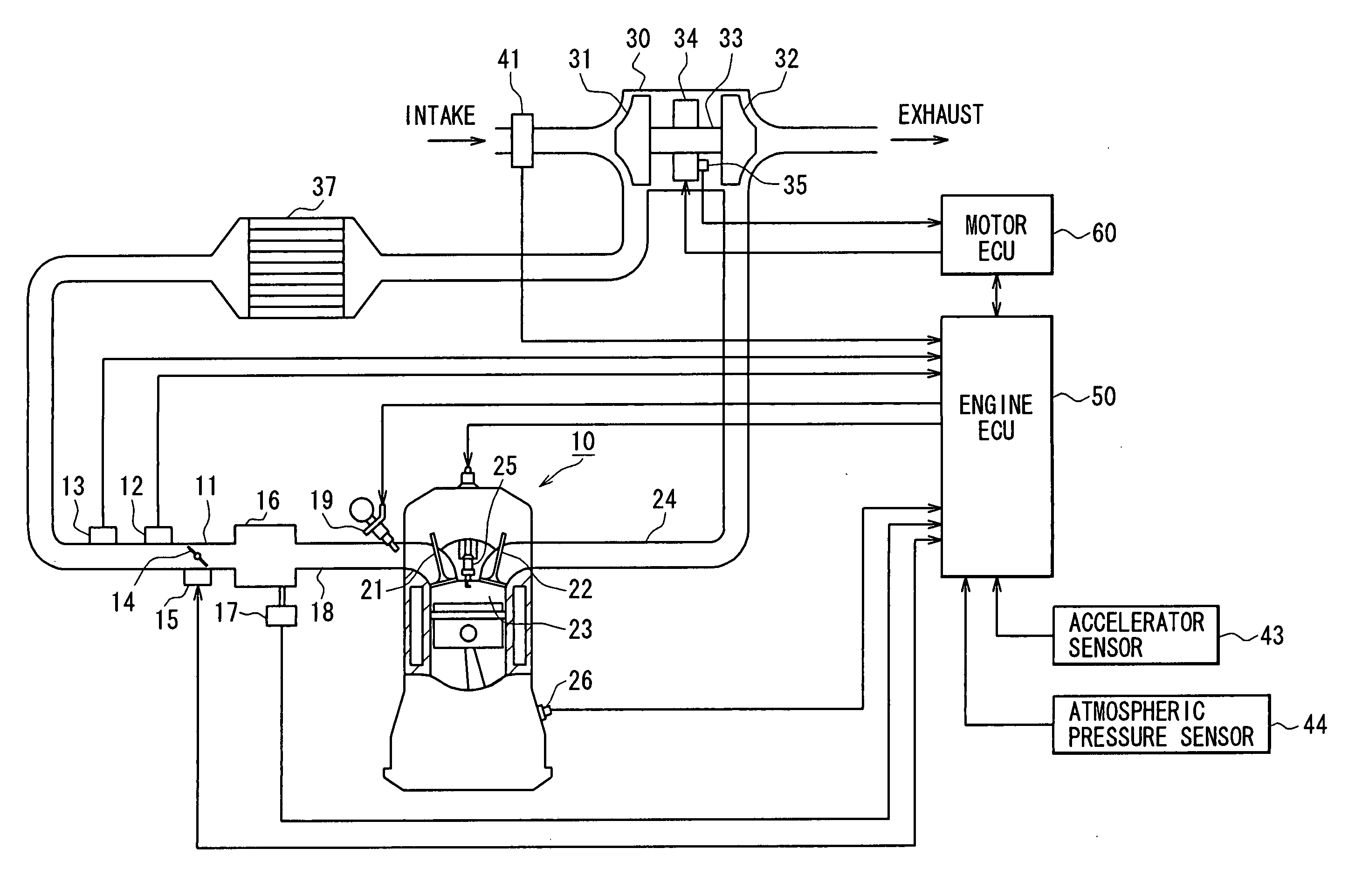

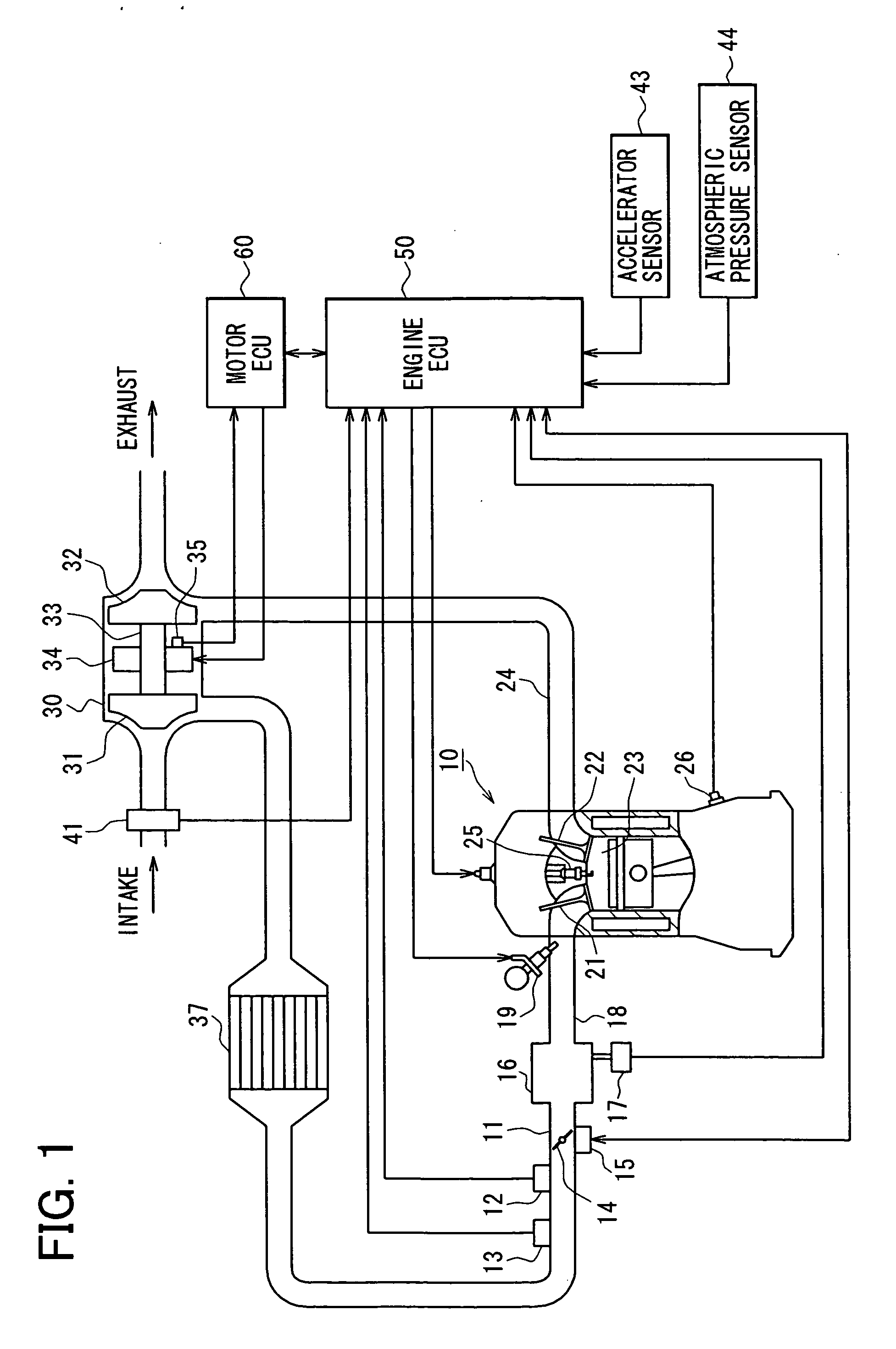

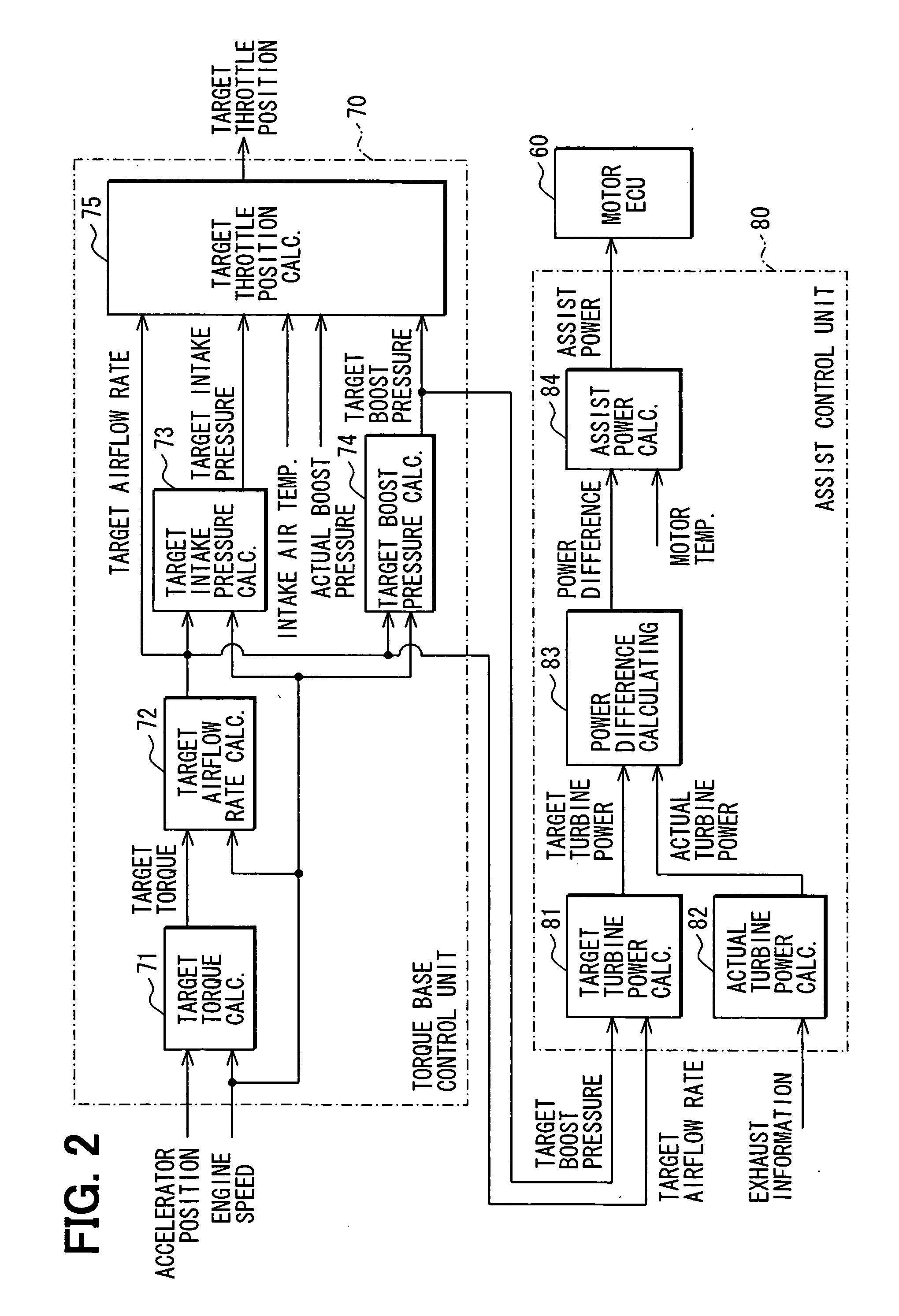

Controller for internal combustion engine with supercharger

InactiveUS20060196182A1Efficient powerIncrease consumptionElectrical controlInternal combustion piston enginesTurbochargerElectric machinery

A torque base control unit calculates target torque based on an accelerator position and engine speed. The control unit further executes calculation of target airflow rate, calculation of target intake pressure, and calculation of target boost pressure based on the target torque. Target throttle position is calculated based on the target airflow rate, target intake pressure, target boost pressure, actual boost pressure, and throttle passed intake temperature. An assist control unit calculates target turbine power based on the target airflow rate and the target boost pressure calculated by the torque base control unit and calculates actual turbine power based on exhaust information. Assist power of a motor attached to a turbocharger is calculated based on the power difference between the target turbine power and the actual turbine power.

Owner:DENSO CORP

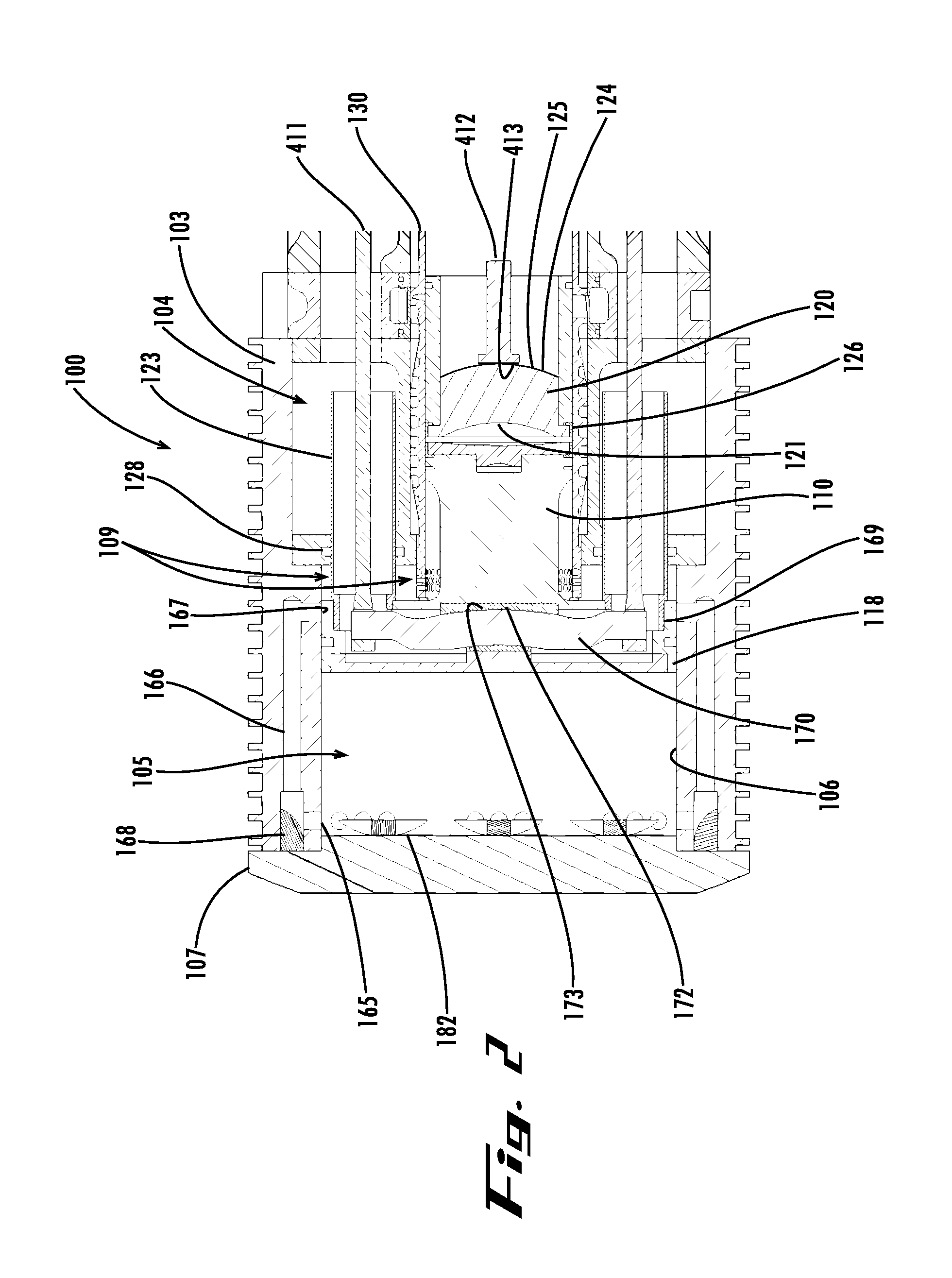

Internal combustion engine

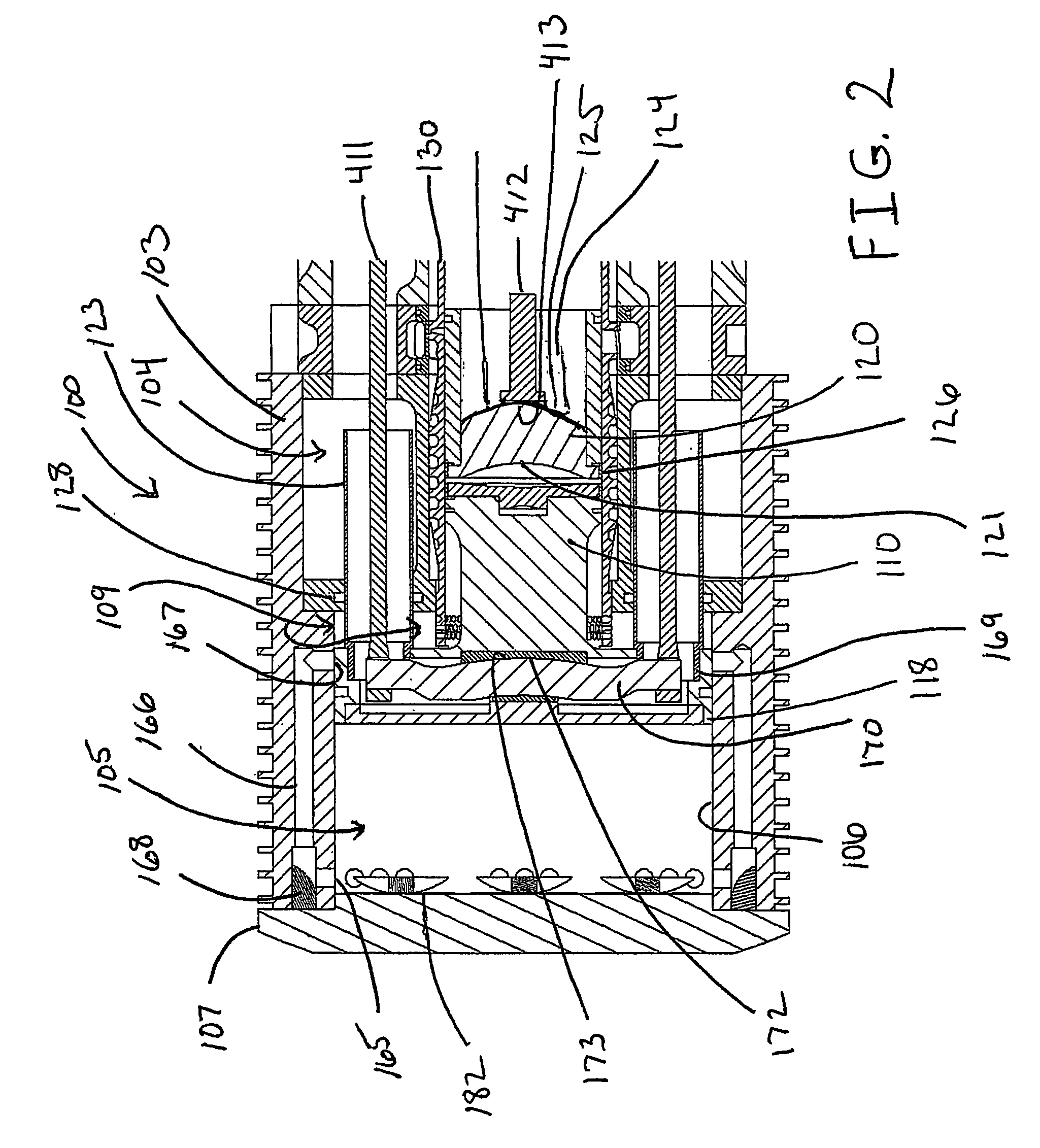

InactiveUS7469664B2Reduce weightImprove efficiencyInternal combustion piston enginesOutput powerExternal combustion engineEngineering

An internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons. All the pistons may be connected to a common central crankshaft. The inboard pistons of each cylinder may be connected to a common joint on the crankshaft with pushrods and the outboard pistons may be connected to a common joint on the crankshaft with pullrods. Each opposed cylinder may include an integrated scavenge pump for providing positive intake pressure. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through angular positioning of the journals on the crankshaft.

Owner:ADVANCED PROPULSION TECH

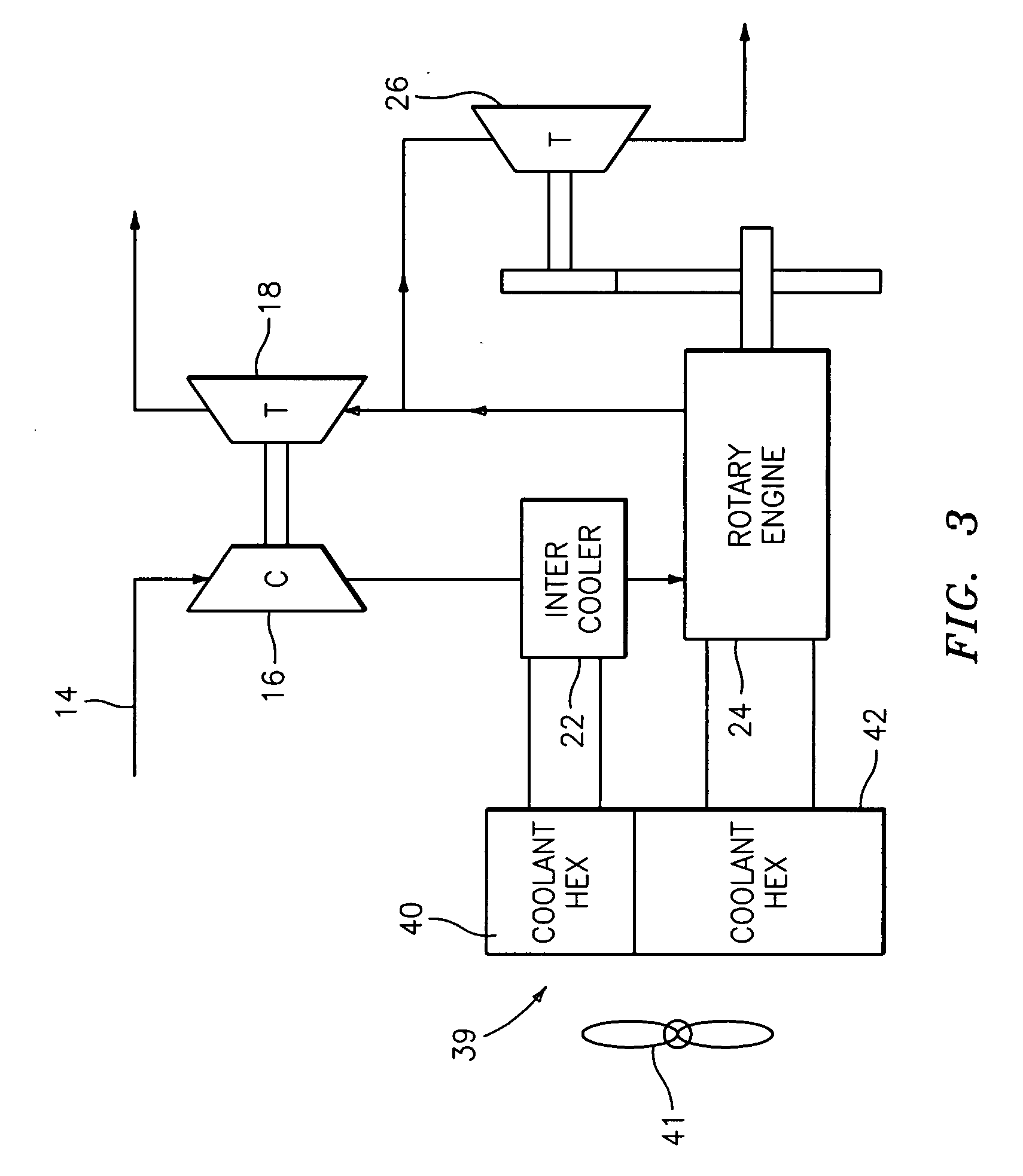

Compound cycle rotary engine

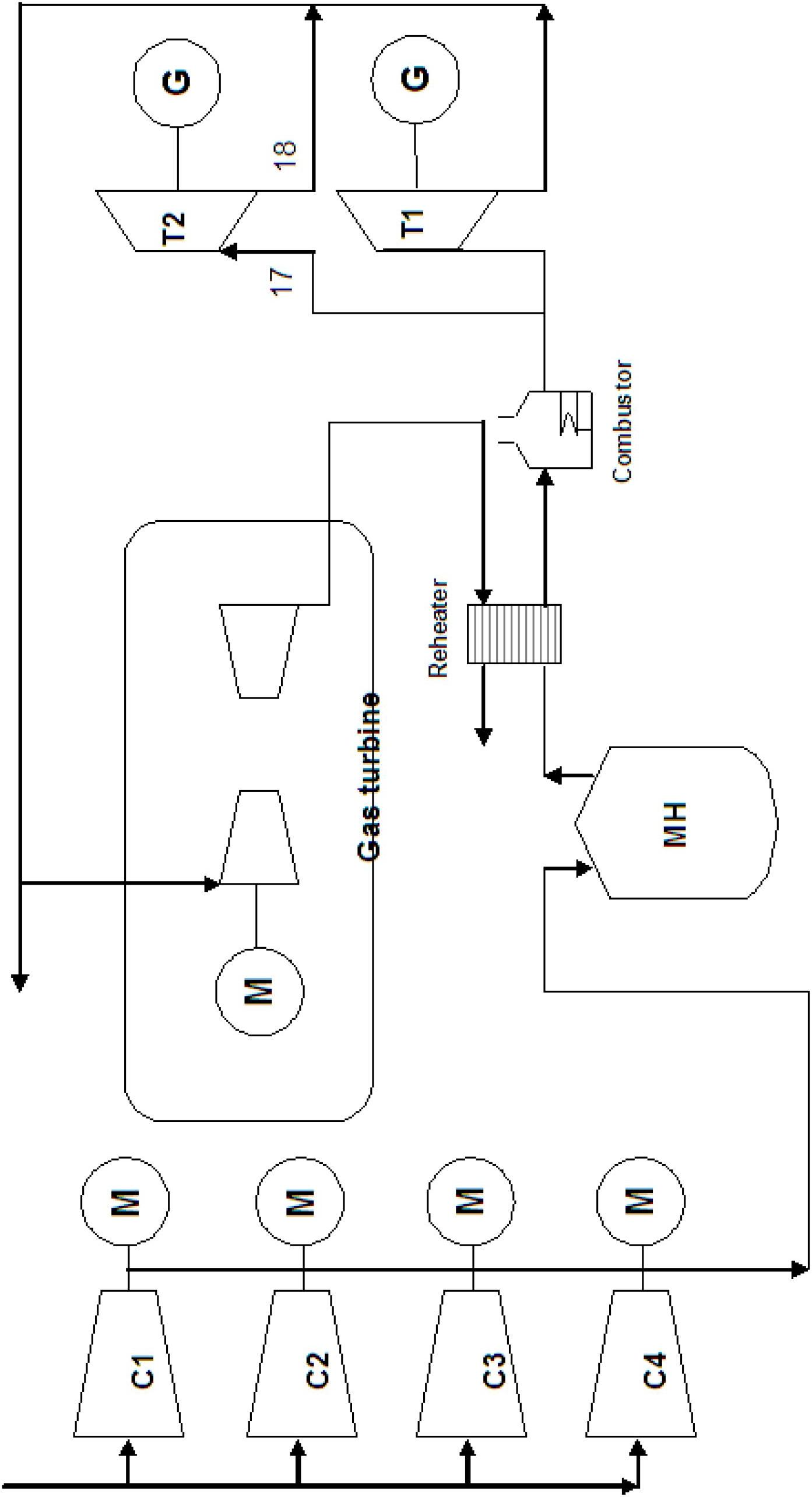

ActiveUS20090007882A1Reduce fuel consumptionHigh power to weightInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

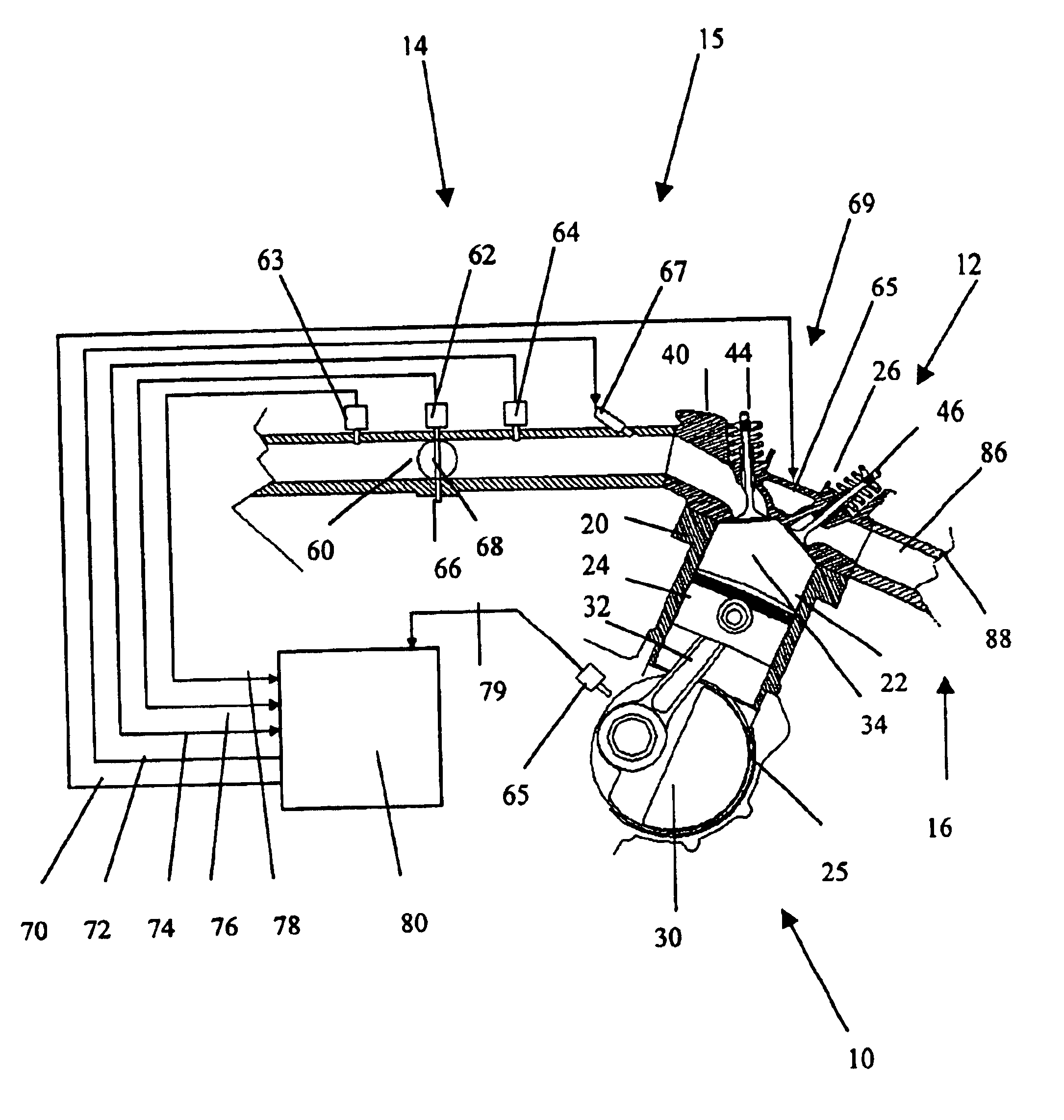

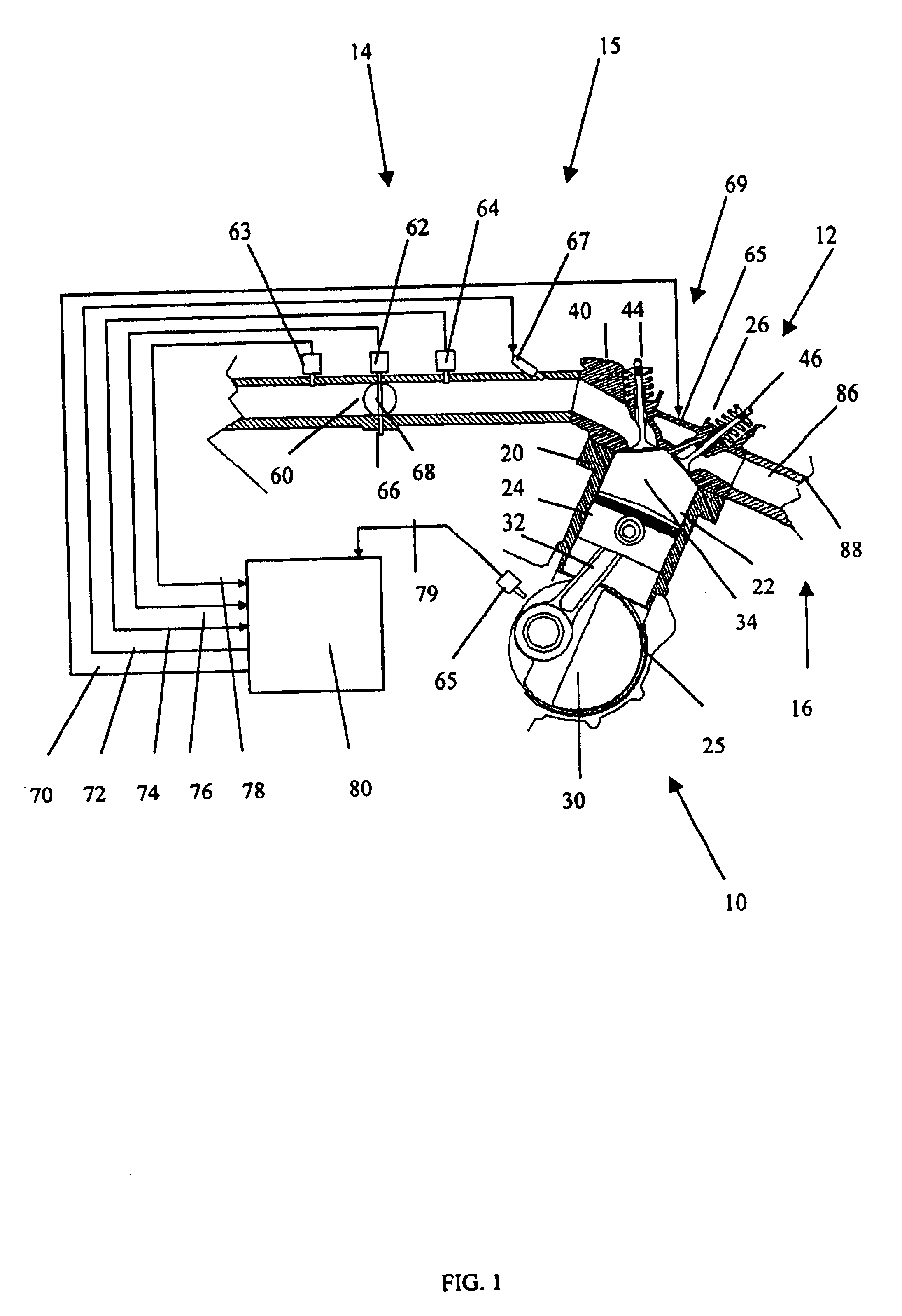

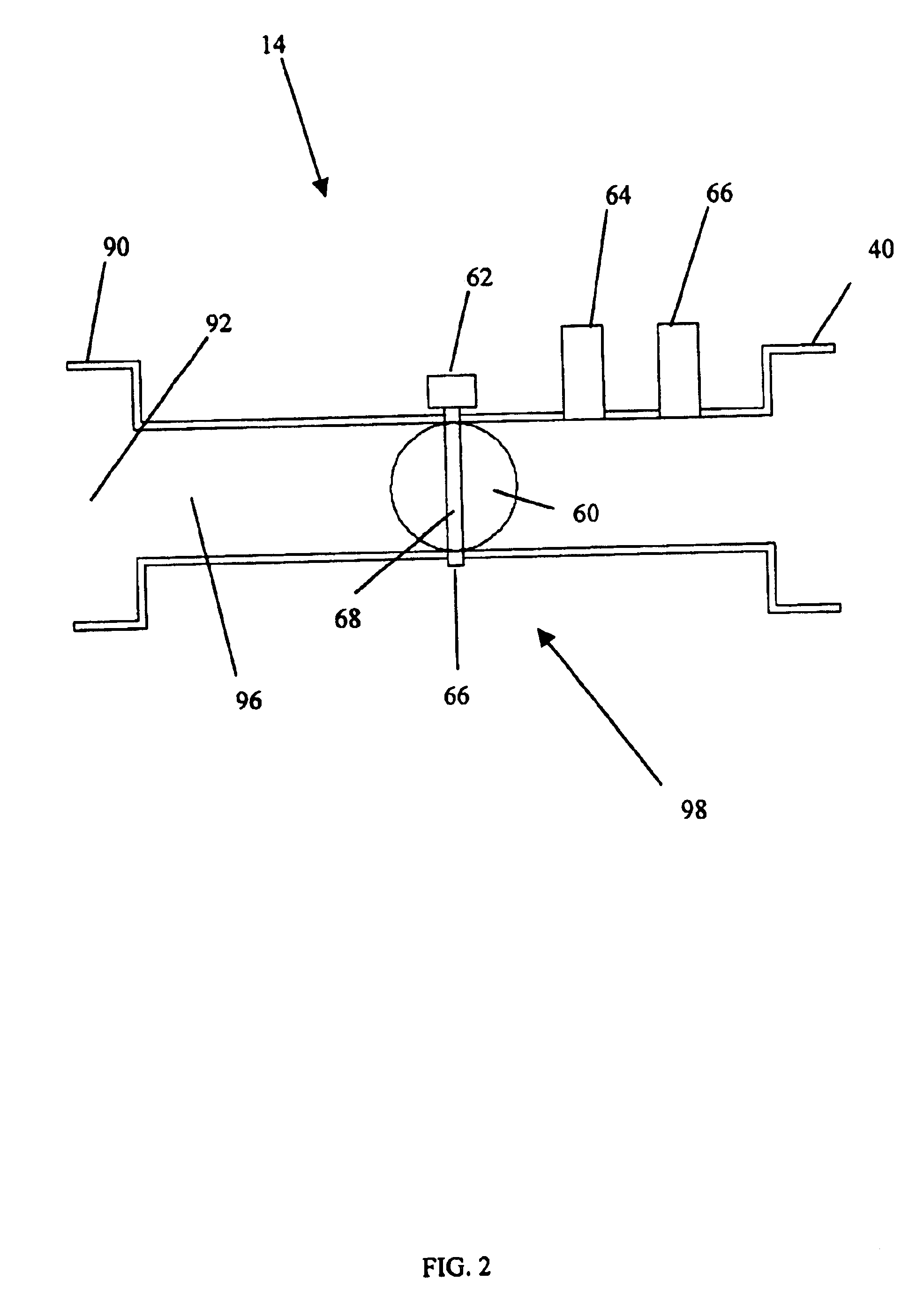

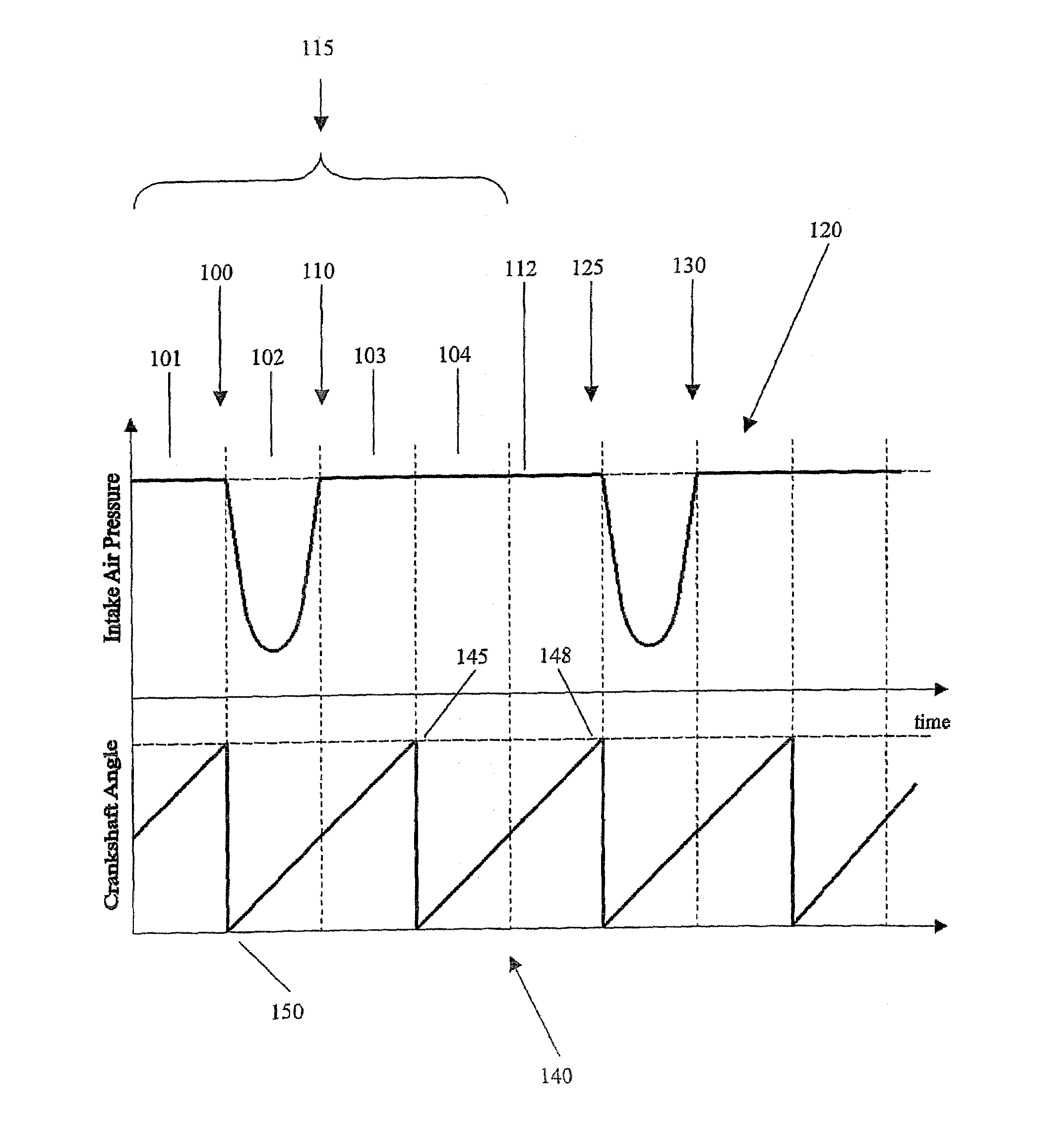

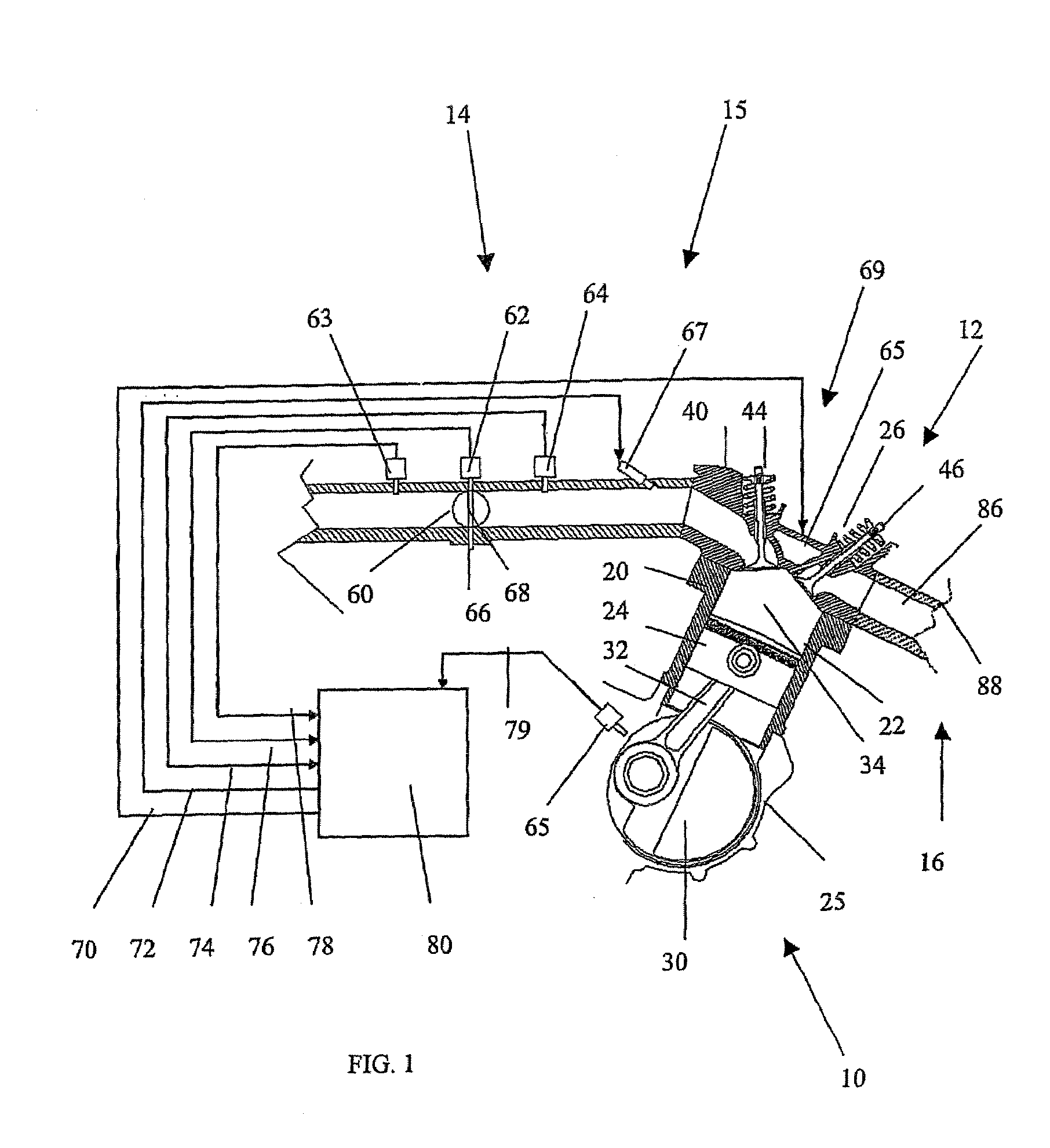

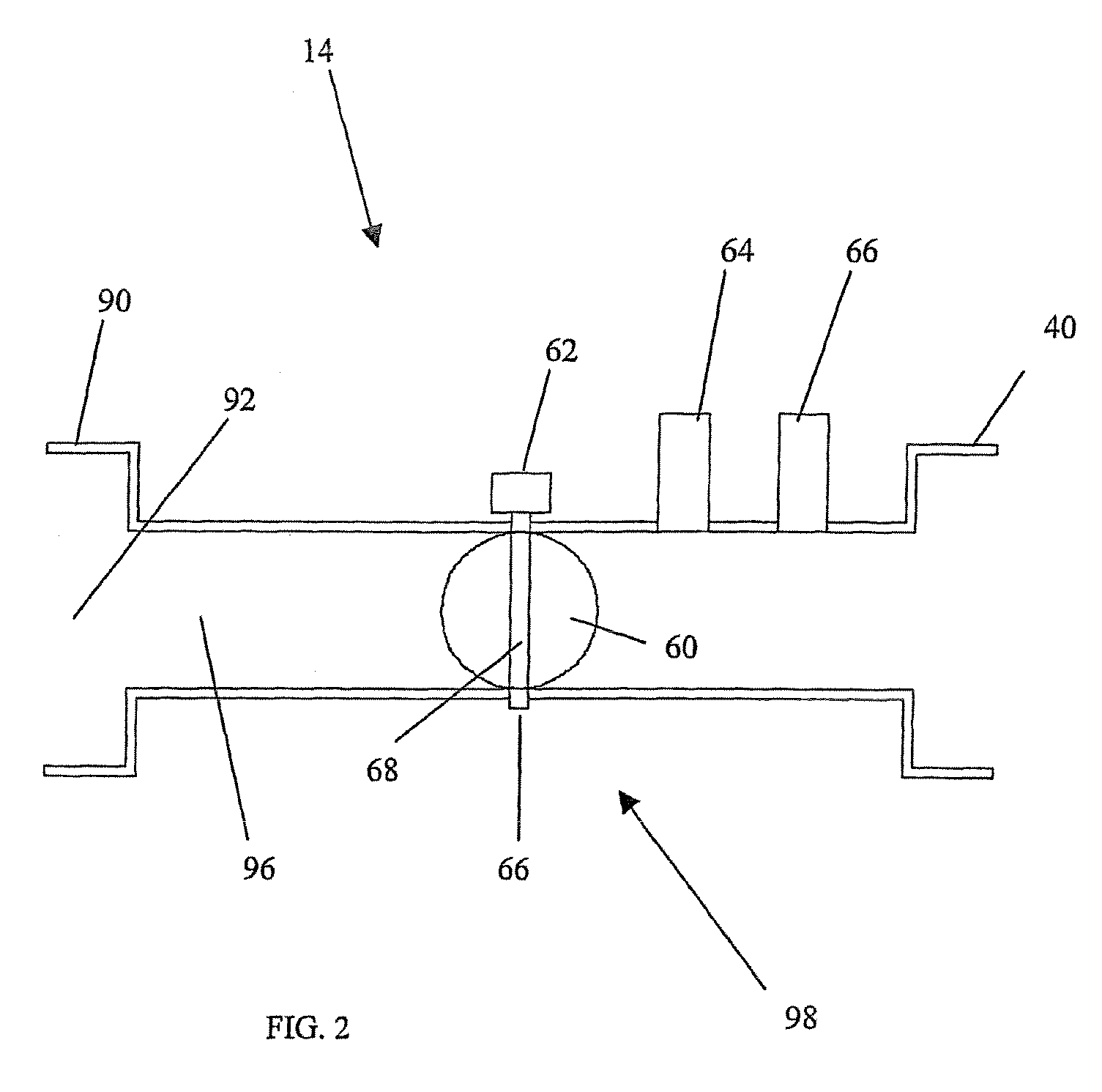

Engine timing control with intake air pressure sensor

InactiveUS6804997B1Reduce in quantityRobust implementationElectrical controlEngine testingExternal combustion engineInlet valve

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine (10) through monitoring intake air pressure fluctuations (120). The opening of the intake valve (44) is mechanically linked to the crankshaft position of an engine. When the intake valve (44) opens it creates air pressure fluctuations in the air induction system (14) of the engine (10). The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event (100 to 110) and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position.

Owner:ELECTROJET TECH INC

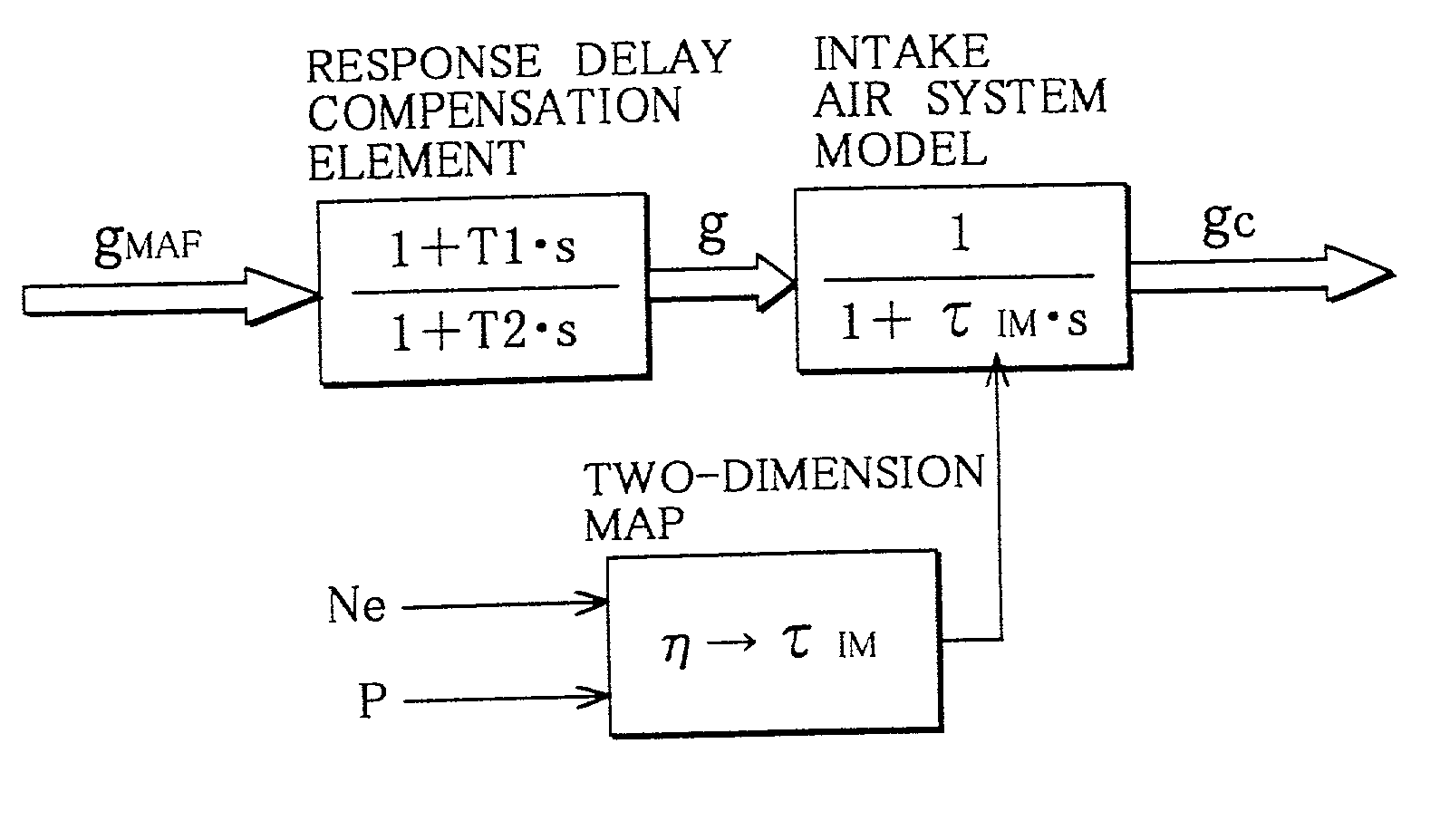

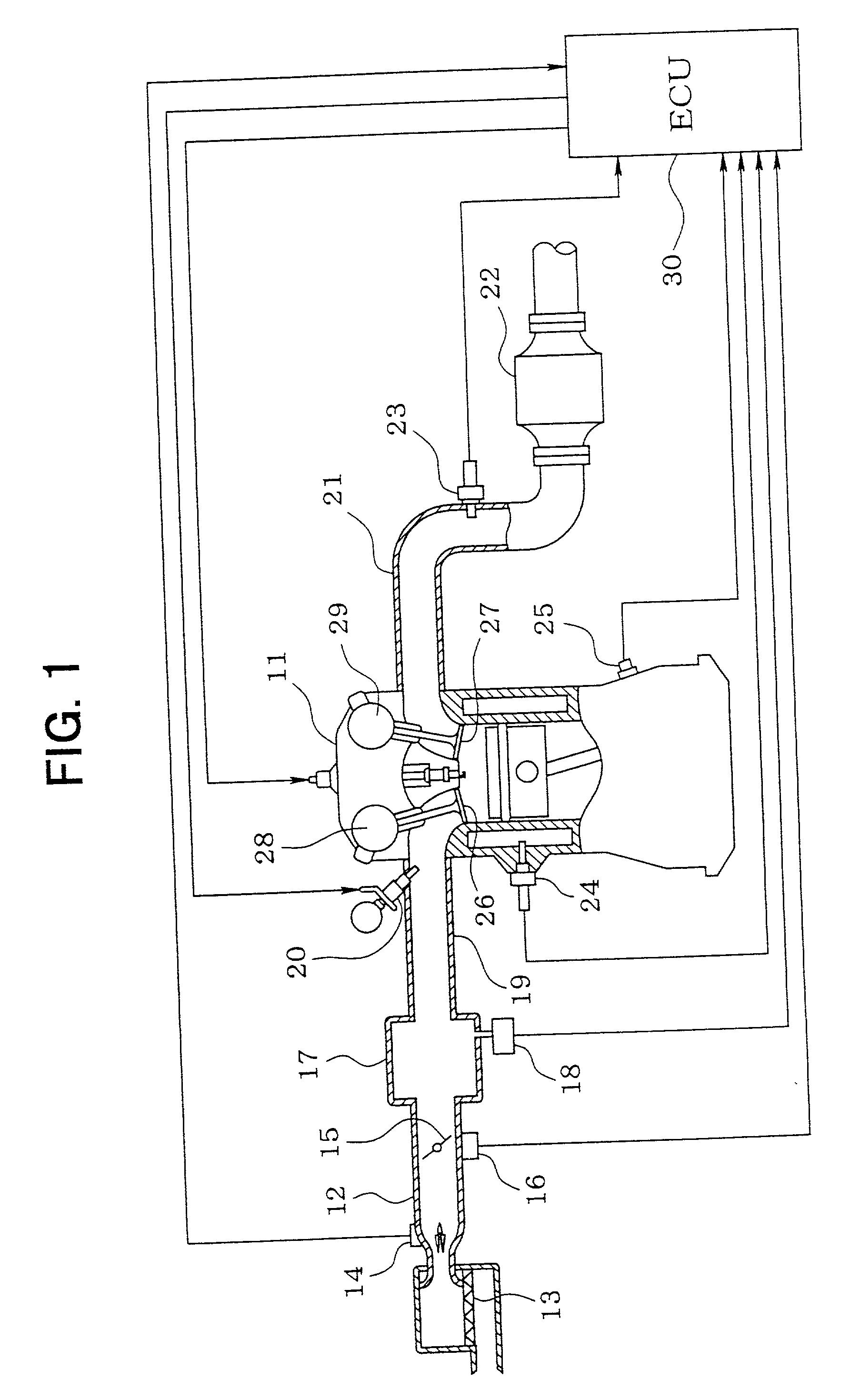

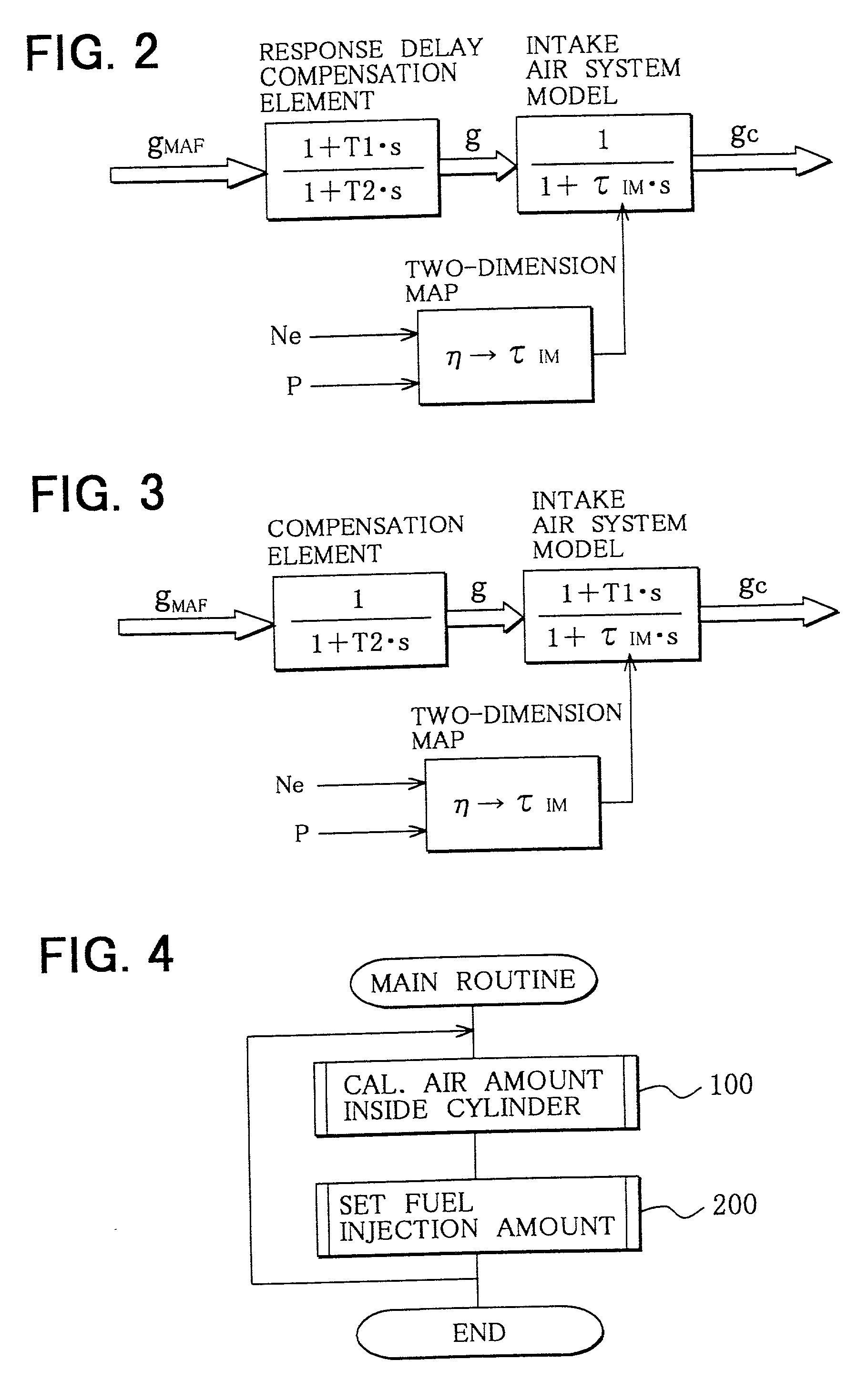

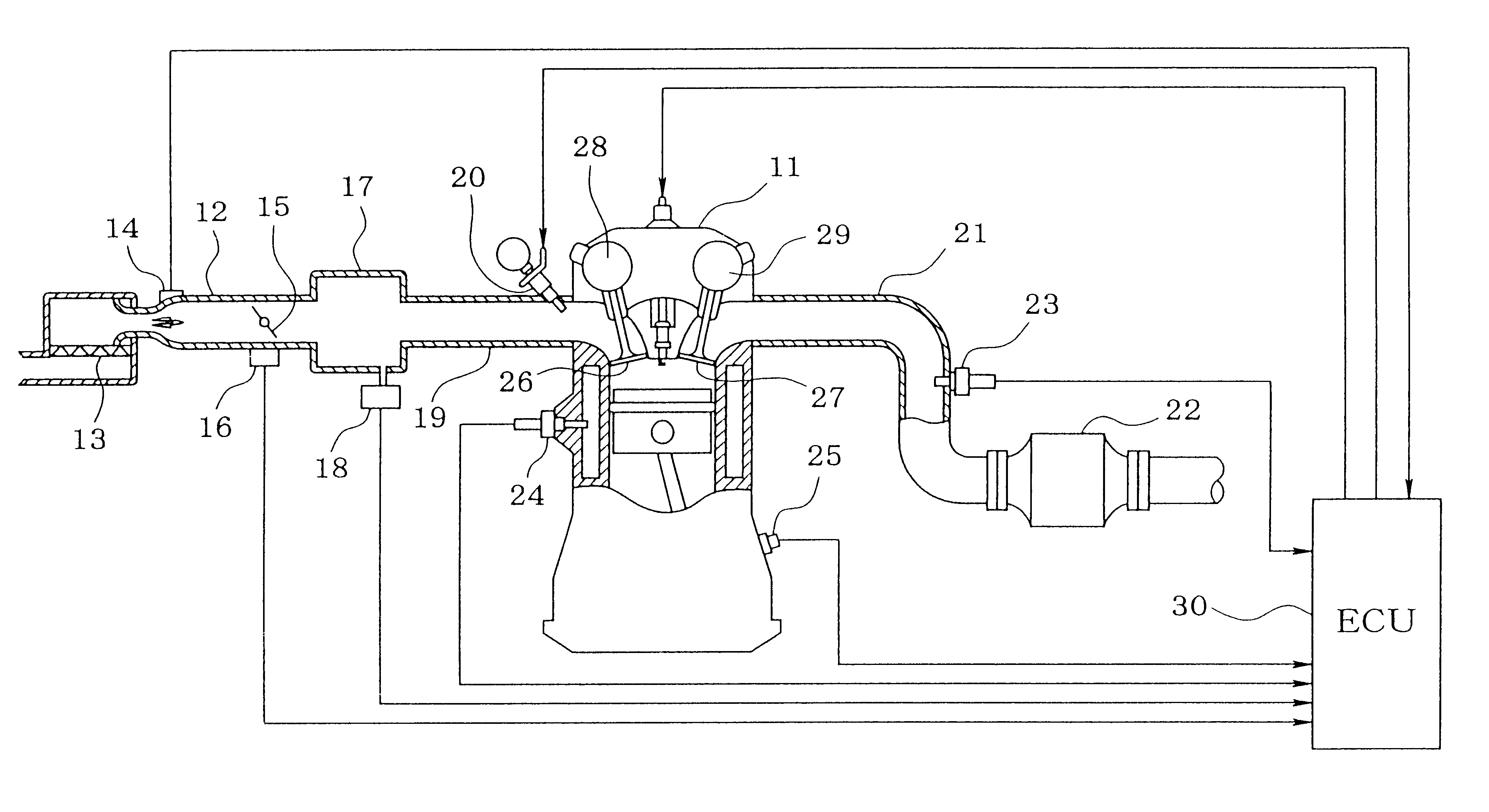

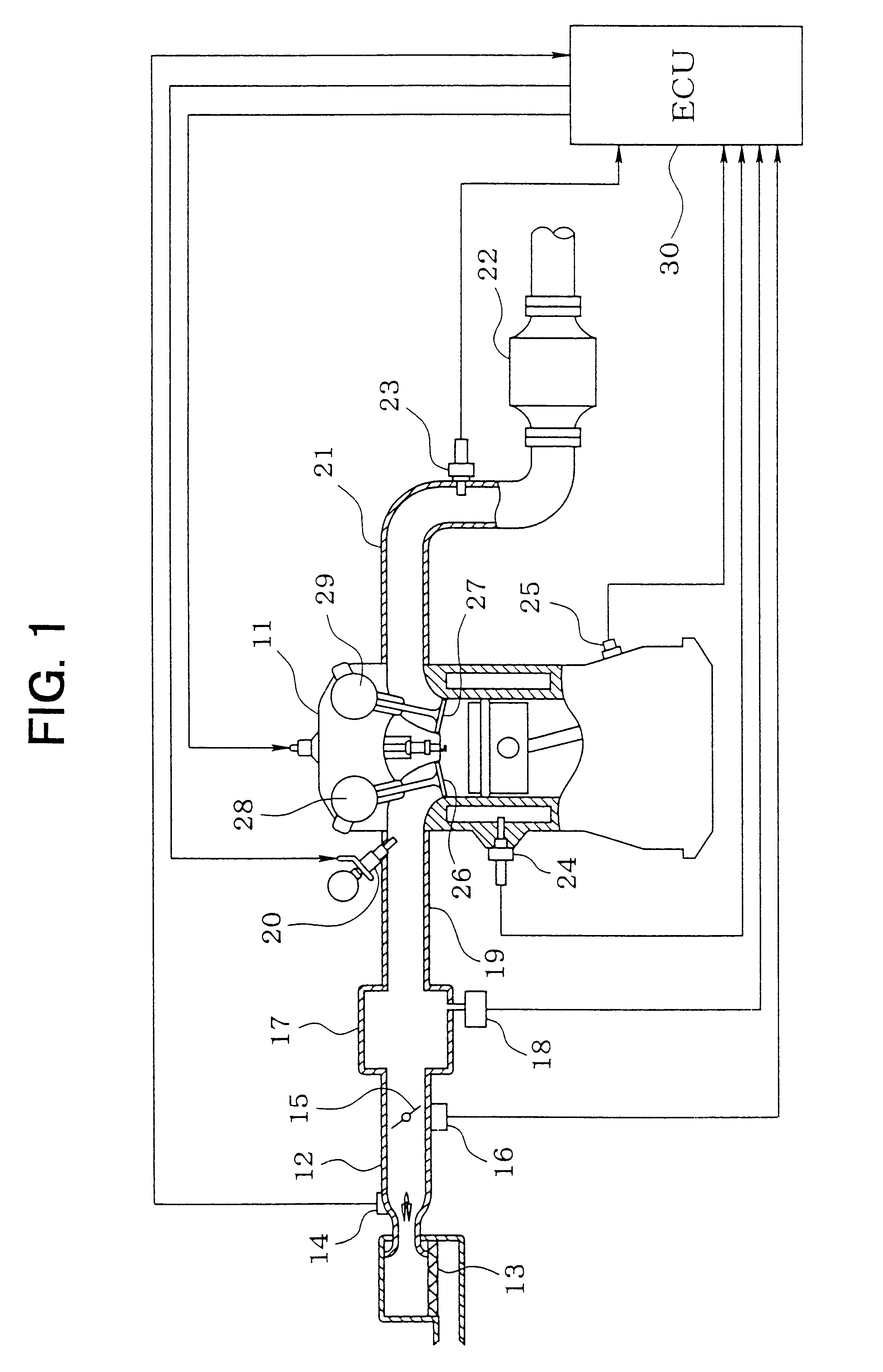

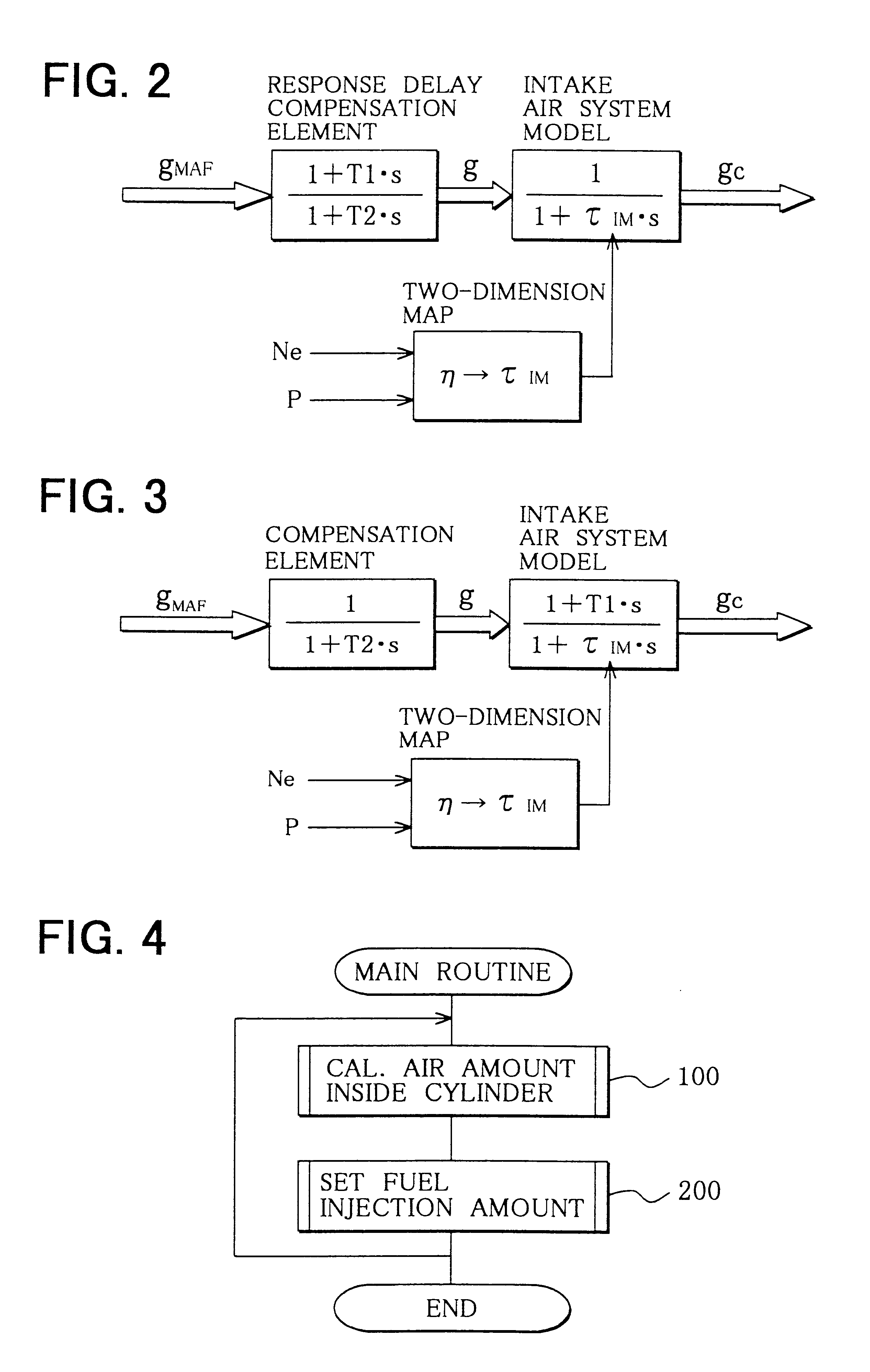

Air amount detector for internal combustion engine

InactiveUS20020107630A1Improve calculation accuracyAnalogue computers for vehiclesElectrical controlResponse delayPhase advance

A response delay compensation element for compensating a response delay of an output gMAF of an airflow meter by a phase advance compensation is provided so that an output g of the response delay compensation element is input to the intake air system model. A transfer function of the phase advance compensation is <paragraph lvl="0"><in-line-formula>g=(1+T1.s) / (1+T2s).gMAF< / in-line-formula>where T1 and T2 are time constant of the phase advance compensation, which is set based on at least one of the output gMAF of the airflow meter, engine speed, an intake air pressure, and a throttle angle. The model time constant τIM of the intake air system model is calculated by variables including volumetric efficiency and the engine speed. The volumetric efficiency is calculated by two-dimensional map having the engine speed and the intake air pressure as parameters thereof.

Owner:DENSO CORP

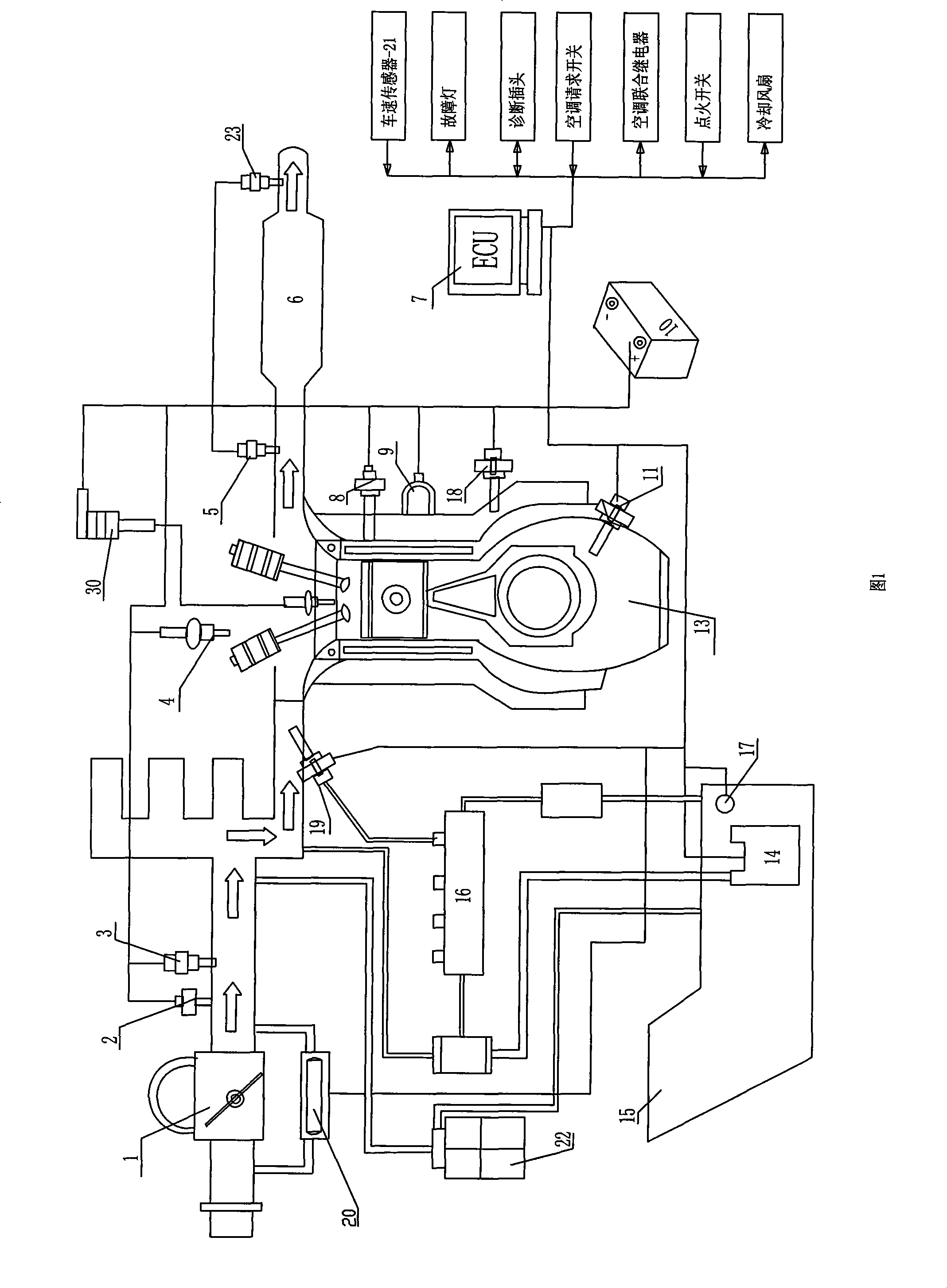

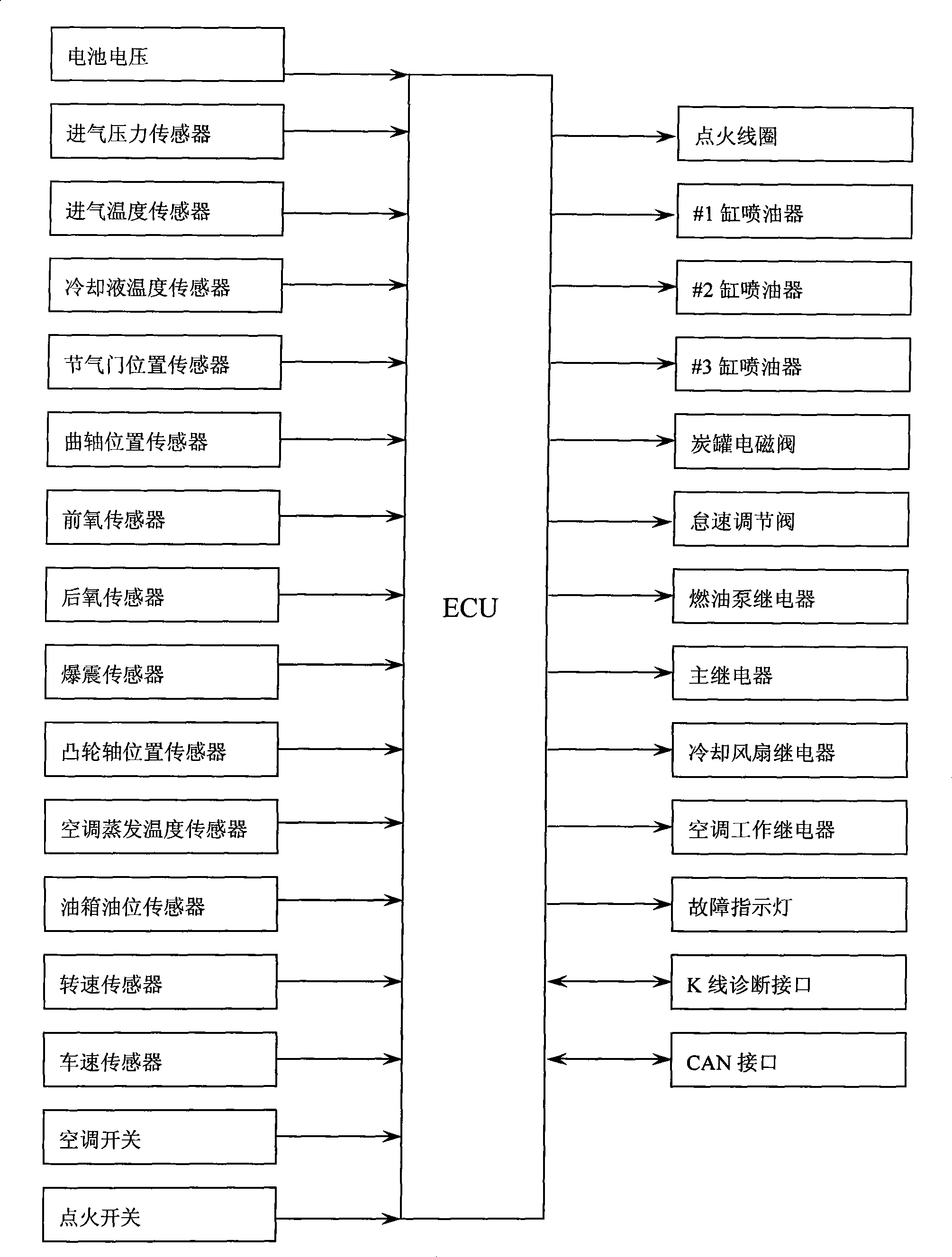

Electric-controlled petrol engine work system

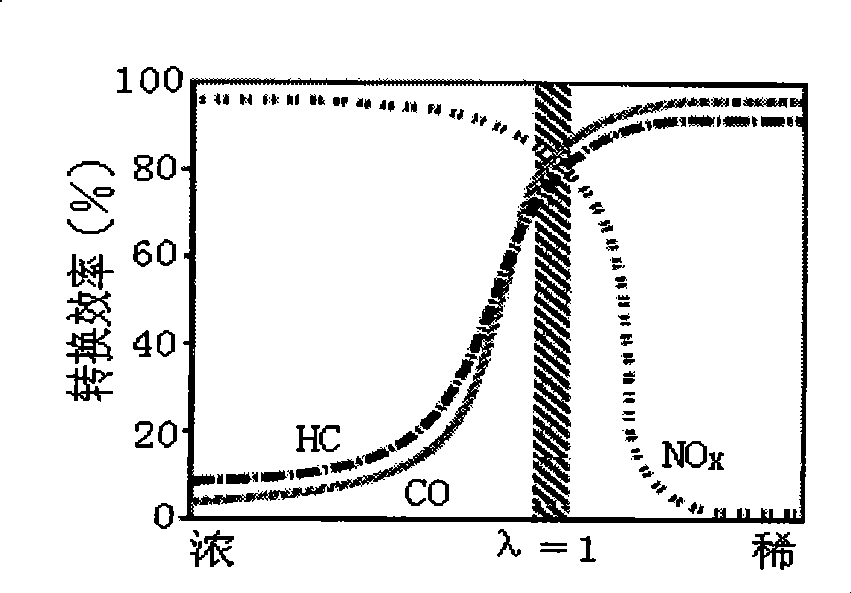

InactiveCN101363380ARich control functionsGood control function integration performanceElectrical controlMachines/enginesIdle speed controlIgnition coil

The invention provides a work system of an electronically controlled gasoline engine, comprising an air intake system, a fuel oil supply system, an ignition system as well as an electronic control system; the electronic control system consists of a sensor section, an electronic control unit ECU and an actuator section, wherein, the sensor section includes a throttle position sensor, an intake pressure and temperature sensor and an intake temperature sensor which are arranged on an intake pipe of an intake system, a camshaft position sensor, a coolant temperature sensor and a crankshaft position sensor which are arranged on the engine, a front oxygen sensor arranged in front of a three-way catalyst converter on an exhaust pipe of the engine, and the components of the sensor section are all connected with the ECU, and the actuator section consists of an electric fuel pump, an oil sprayer, an idle speed regulating valve and an ignition coil; the components of the actuator section are all connected with the ECU, and the ECU includes a fuel injection control program, an ignition control program and an idle speed control program; the system adopts reasonable control strategy and has comprehensive control function, good integrated performance of control function and fine system portability.

Owner:张和君 +1

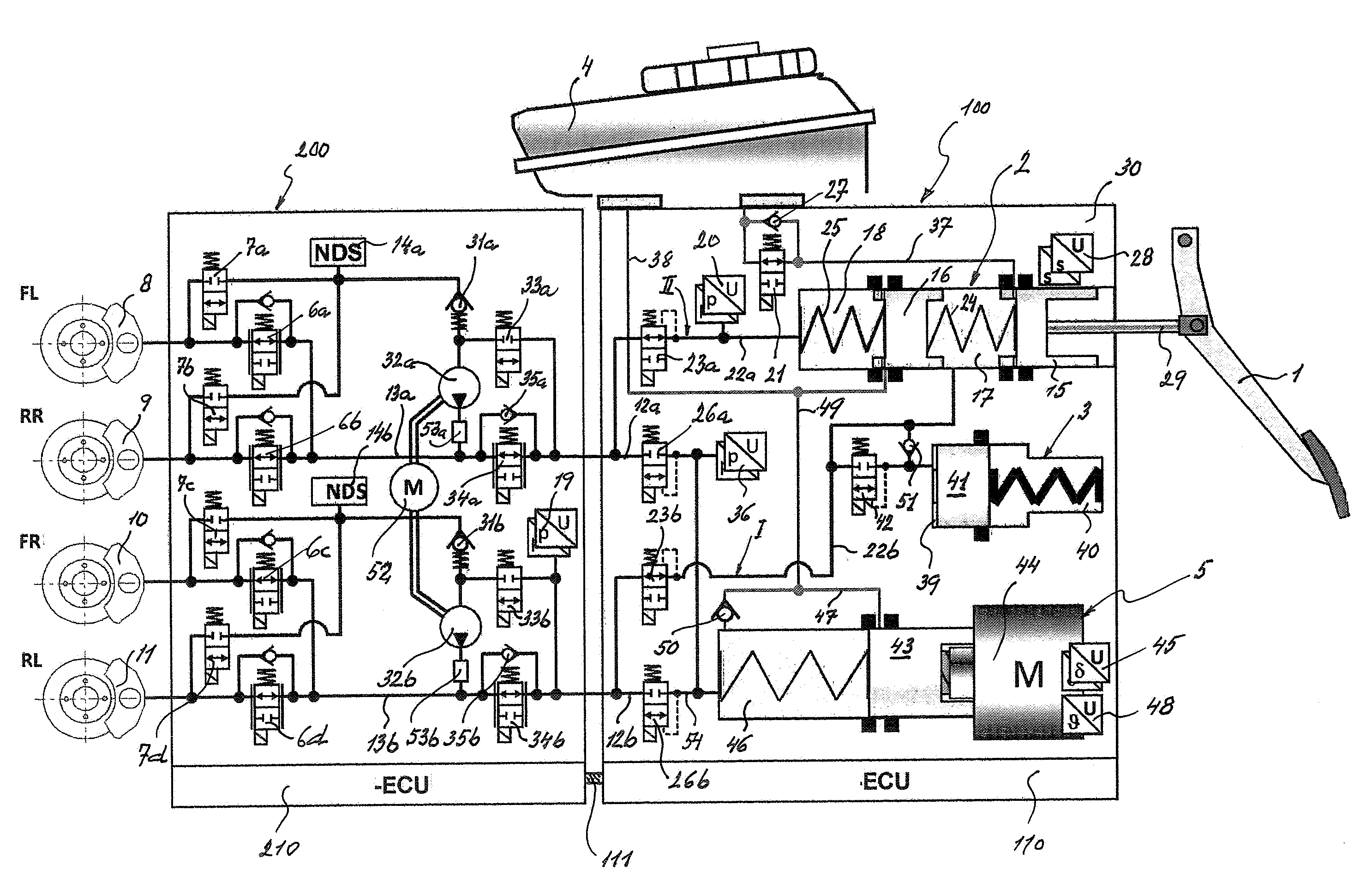

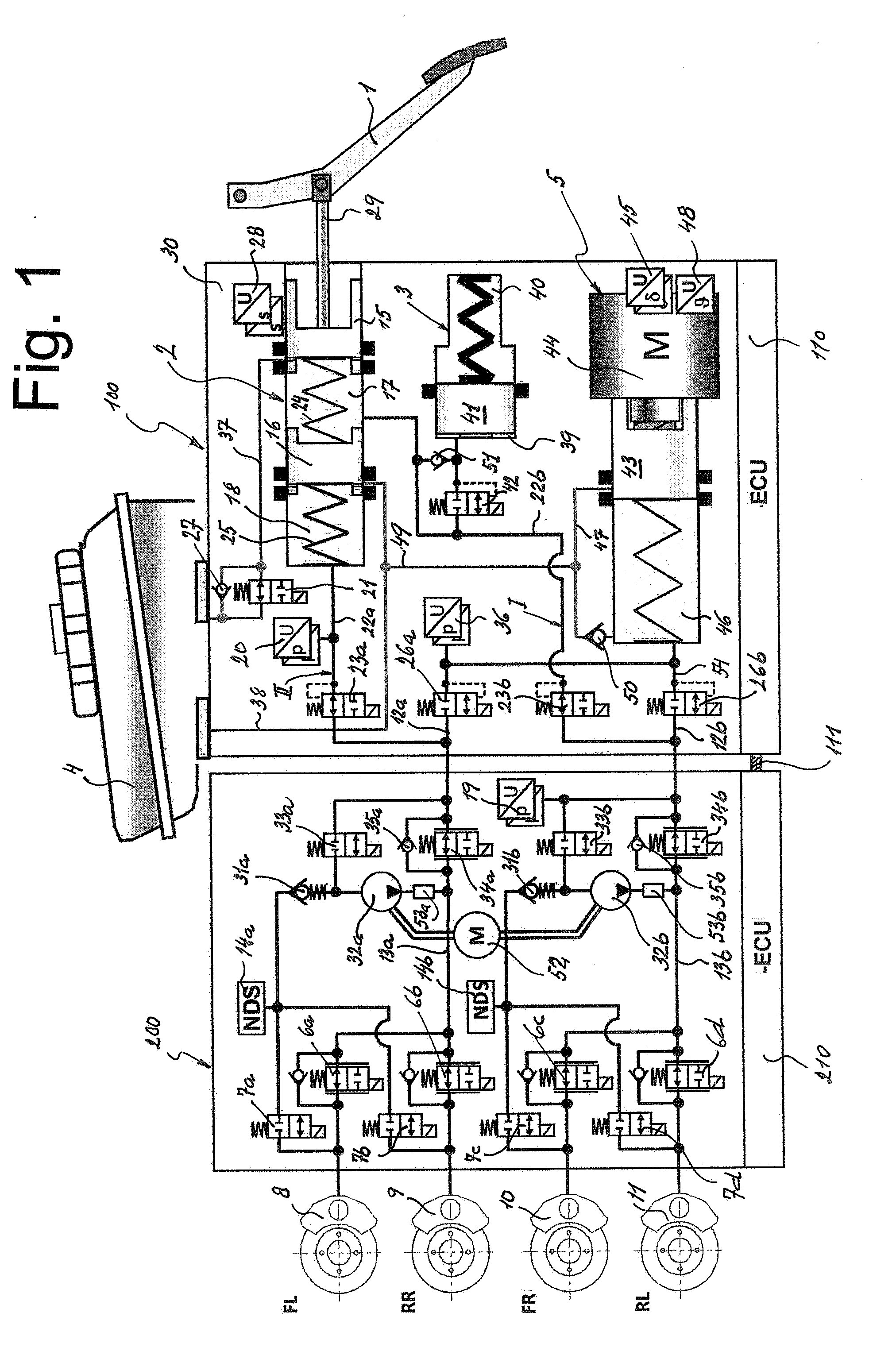

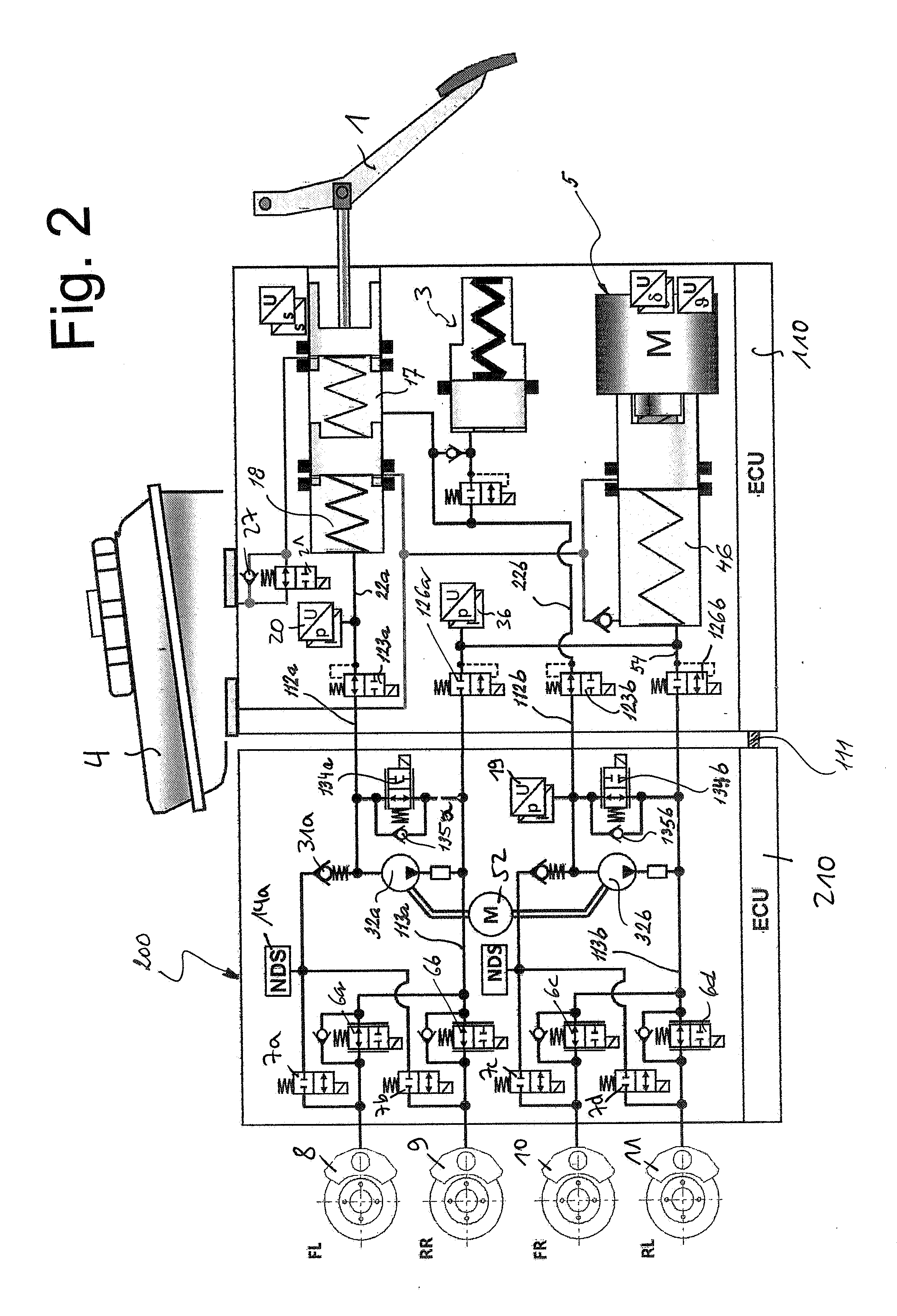

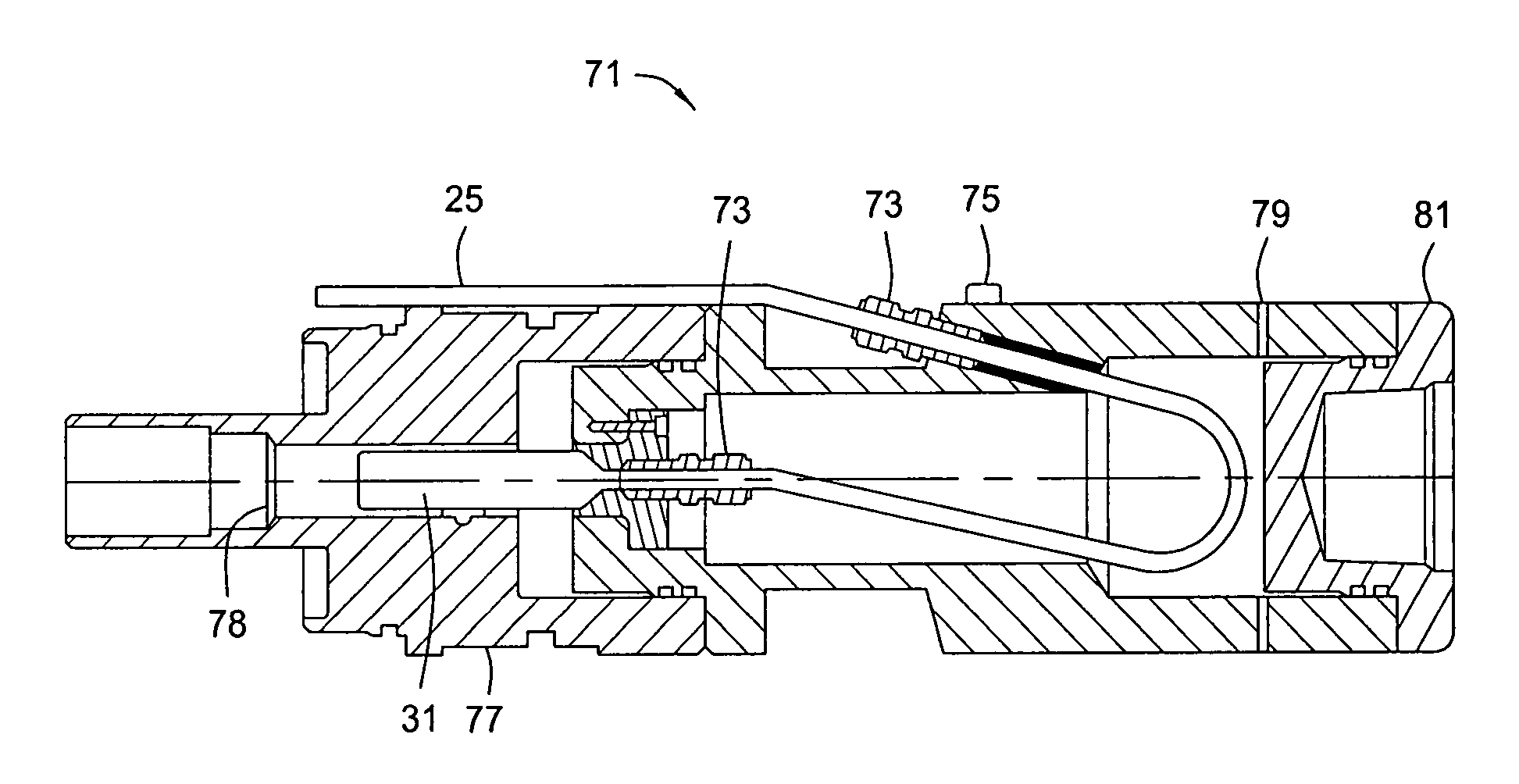

Brake System for Motor Vehicles

A motor vehicle brake system operable in a brake-by-wire and fallback modes. The system includes a brake pedal (1), a master cylinder (2), a reservoir (4), a travel simulator (3), an electrically controllable pressure source (5), isolation valves (23a, 23b) pumps (32a, 32b) and a low-pressure accumulator (14a, 14b), an inlet valve (6a-6d) and an outlet valve (7a-7d) for each wheel brake (8, 9, 10, 11), valves (34a, 34b; 134a, 134b) connected to the pumps (32a, 32b), and a control and regulation unit (110, 210). A valve arrangement (23a, 23b) establishes for each brake circuit (I, II) a connection from the pressure chamber (17, 18) of the master cylinder (2) to the modulator admission pressure line (13a, 13b; 113a, 113b) and disconnects the connection when unenergized, the valve arrangement (23a, 23b) preventing the pressure source (5) from being subjected to pressure from the pressure chambers (17, 18).

Owner:CONTINENTAL TEVES AG & CO OHG

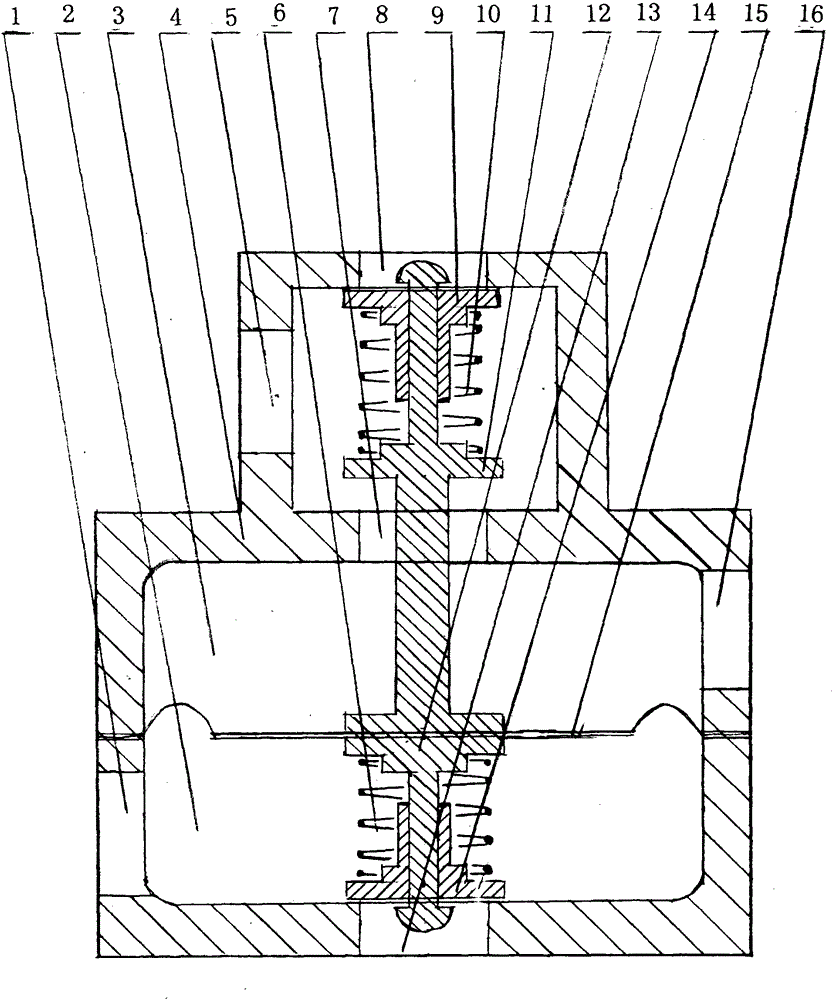

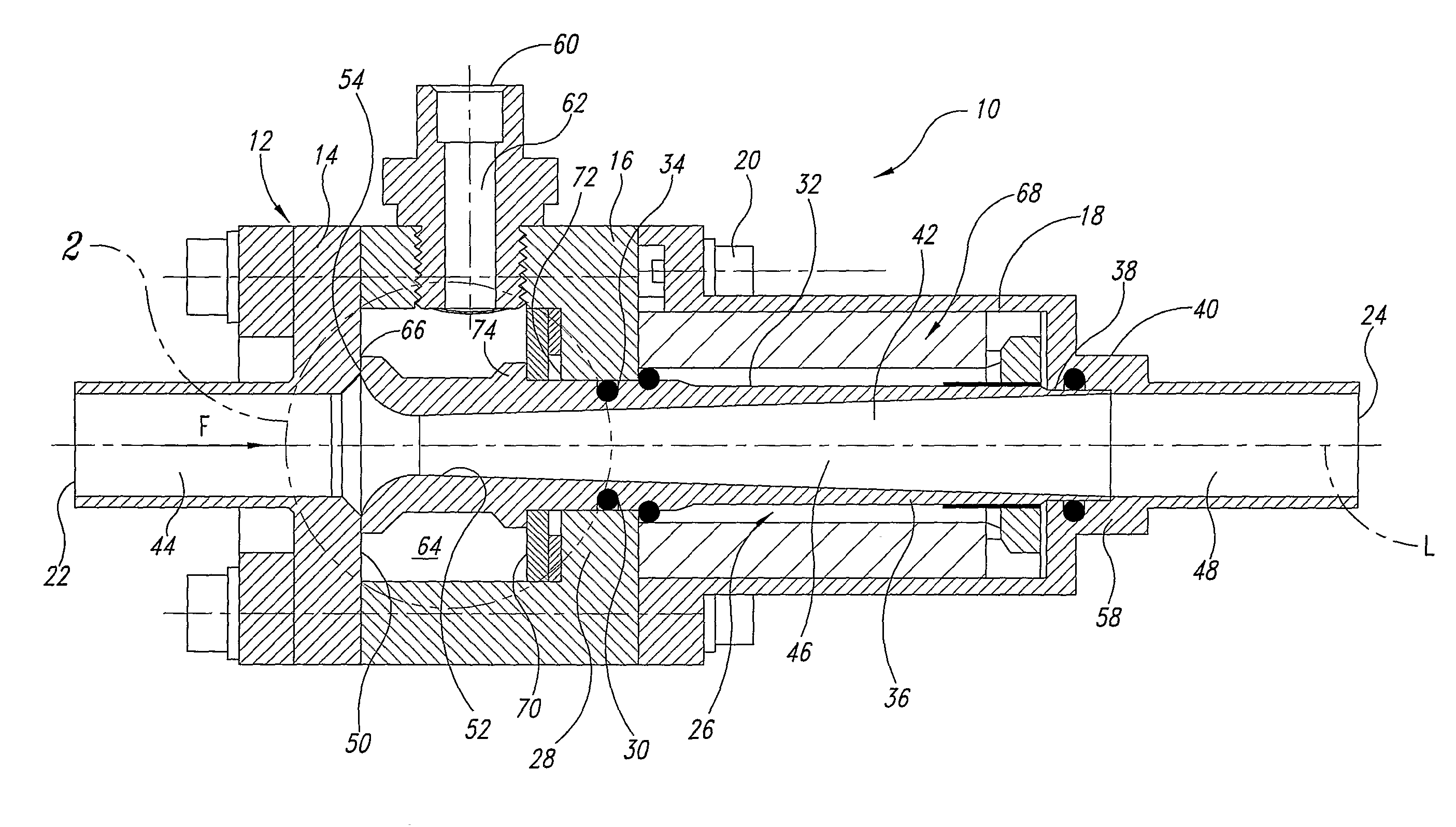

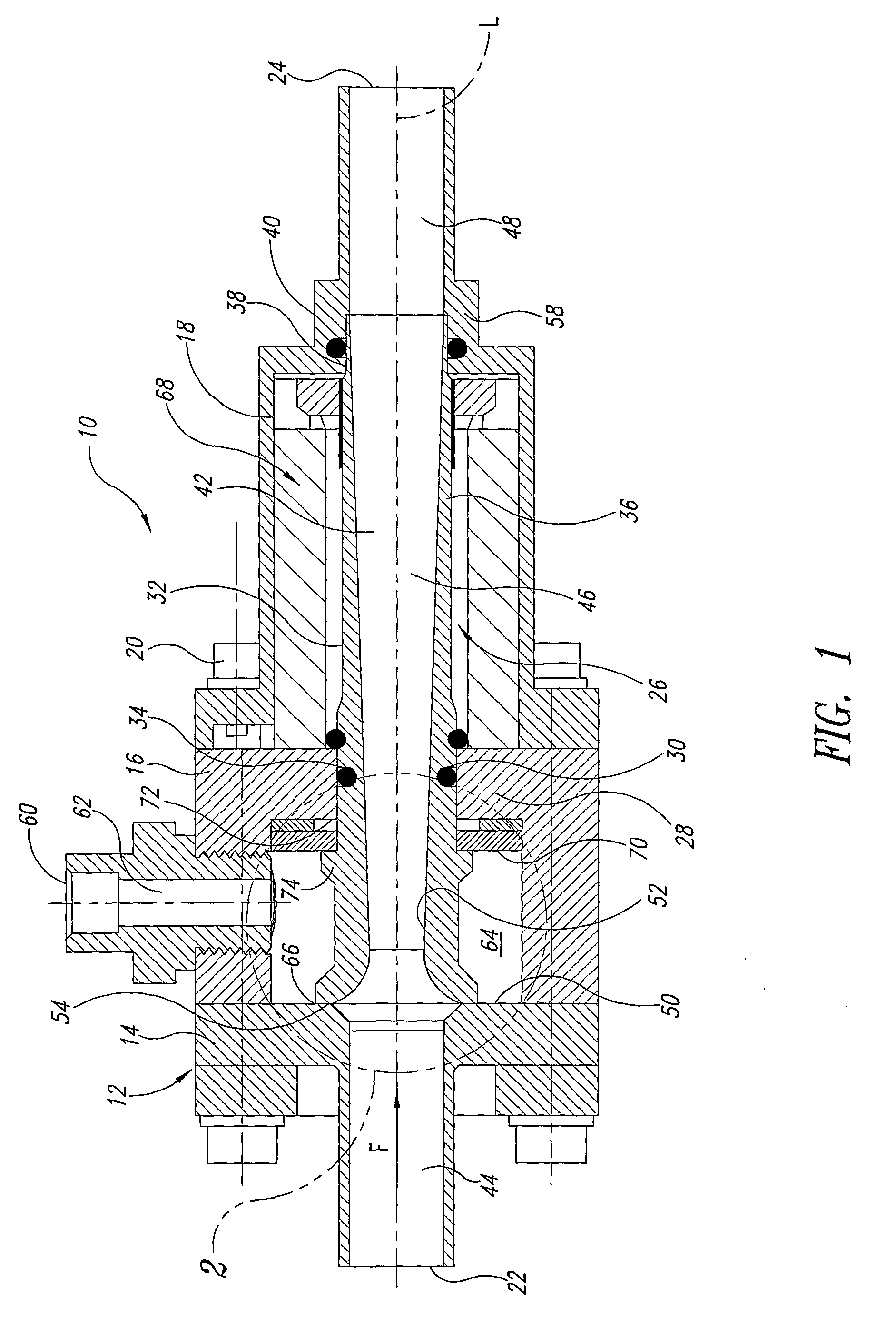

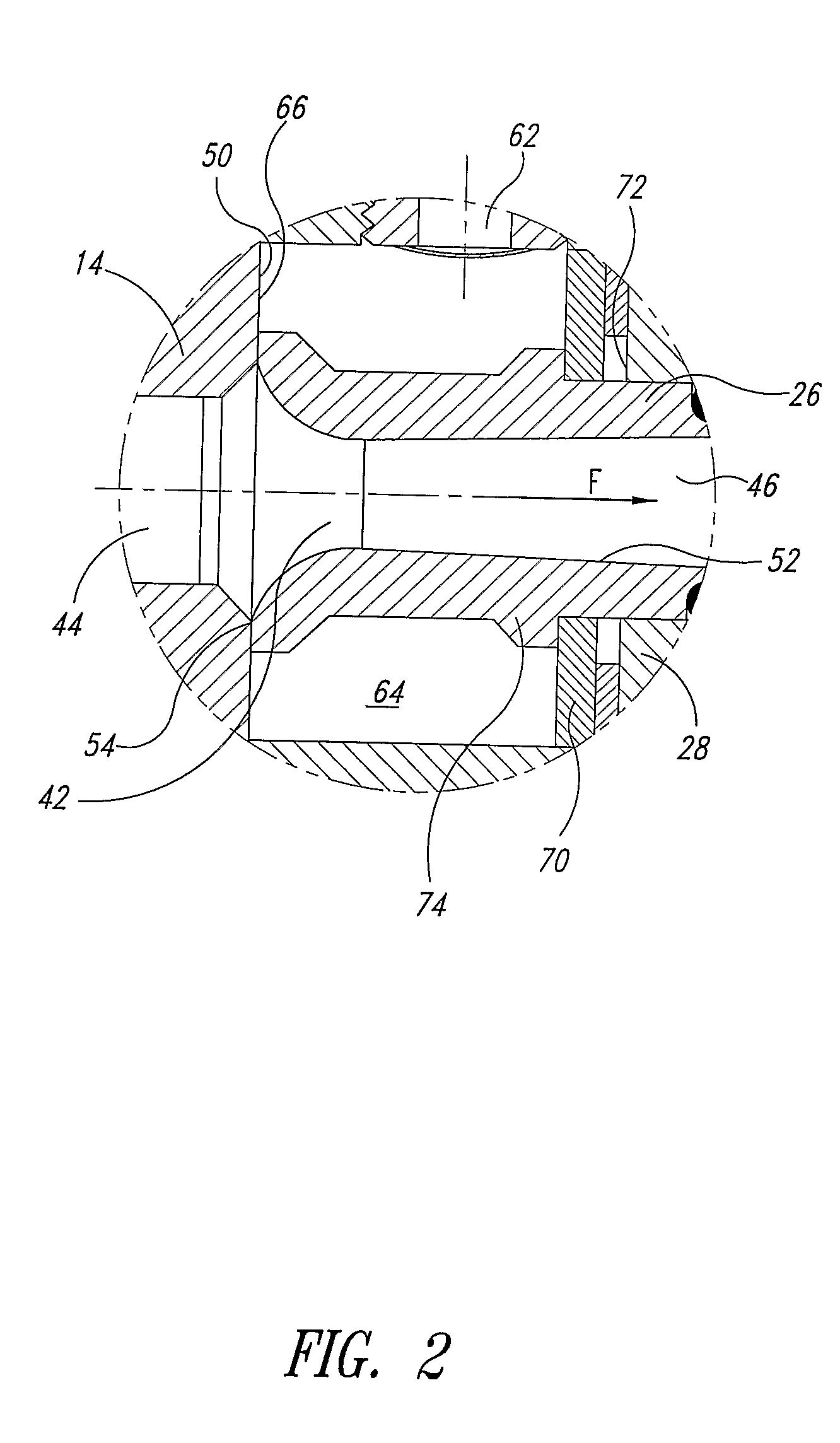

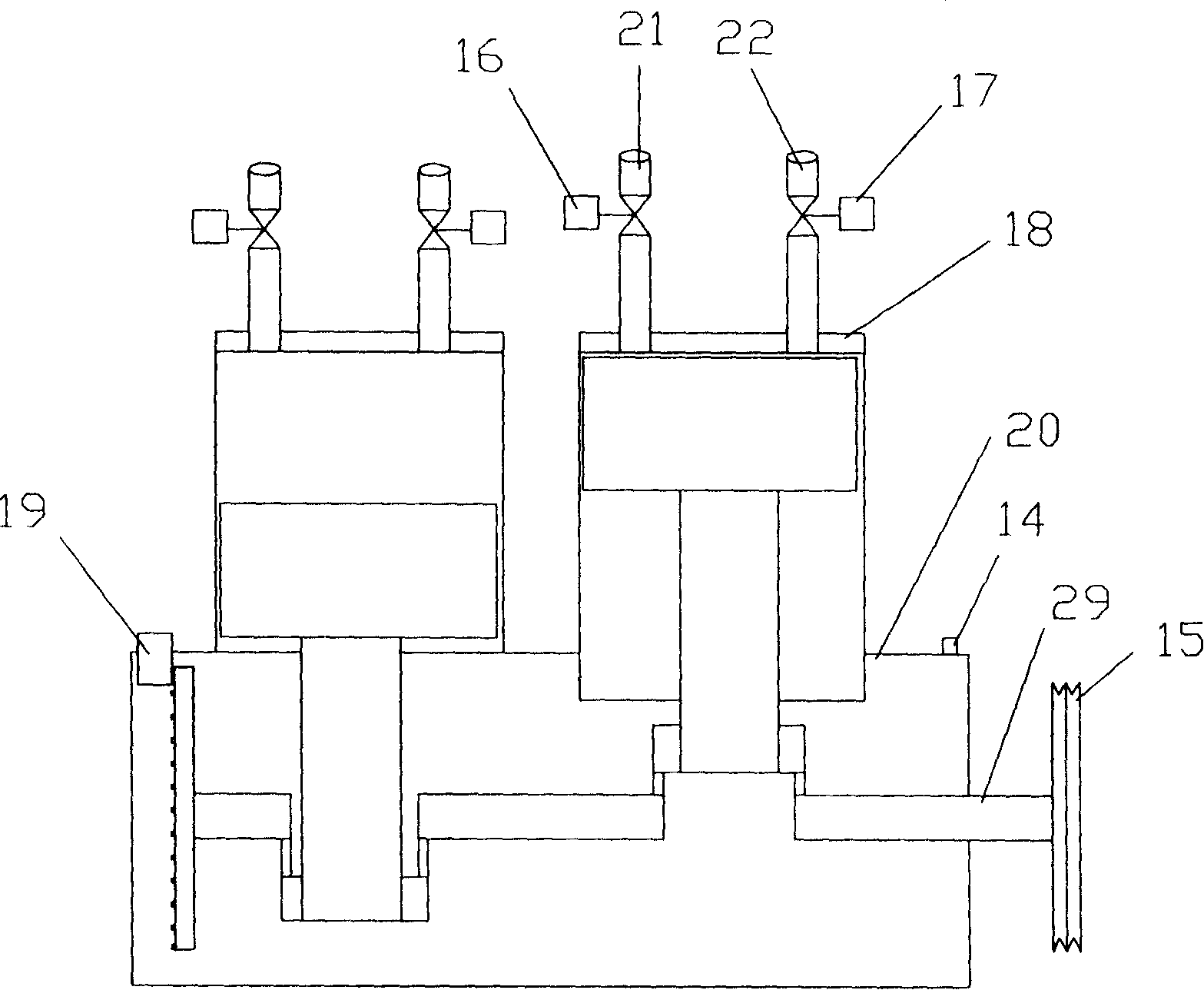

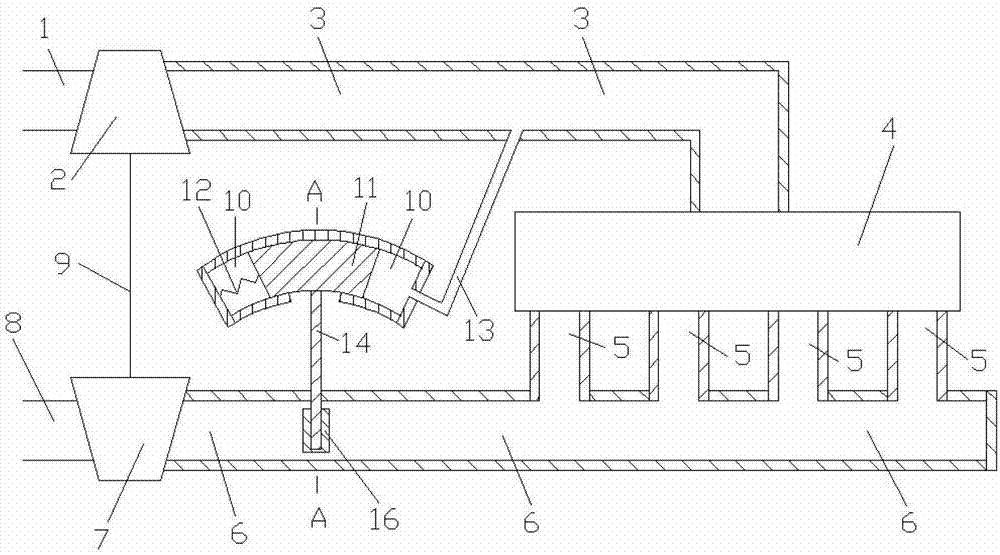

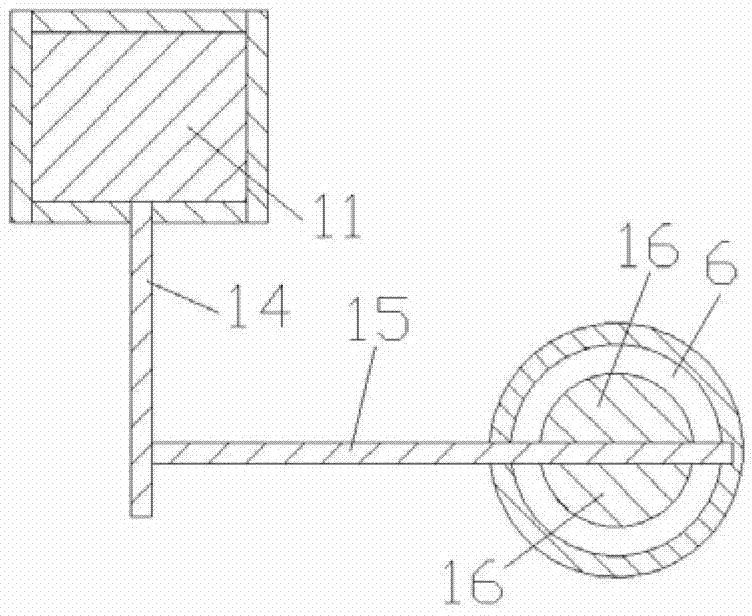

Intake pressure balancing adjuster for supercharged and intercooled gas engine

ActiveCN103603747ASimple structureIncrease the maximum output powerInternal combustion piston enginesFuel supply apparatusIntake pressureStreamflow

Disclosed is an intake control device for a supercharged and intercooled gas engine. By coaxial control bidirectional pressure relief means, the output pressure of two superchargers is simultaneously controlled by the aid of one device, the technical problem of unbalanced output pressure of the two superchargers is solved, a complicated structure respectively controlling the output pressure of the two superchargers is simplified, functional cost is reduced, reliability is improved, the influence of a balancer on maximum intake flow of the engine is thoroughly eliminated, and the maximum output power of the engine is improved. The device is applicable to the gas engine with air and gas respectively supercharged and intercooled.

Owner:陕西中唐电力能源科技有限公司

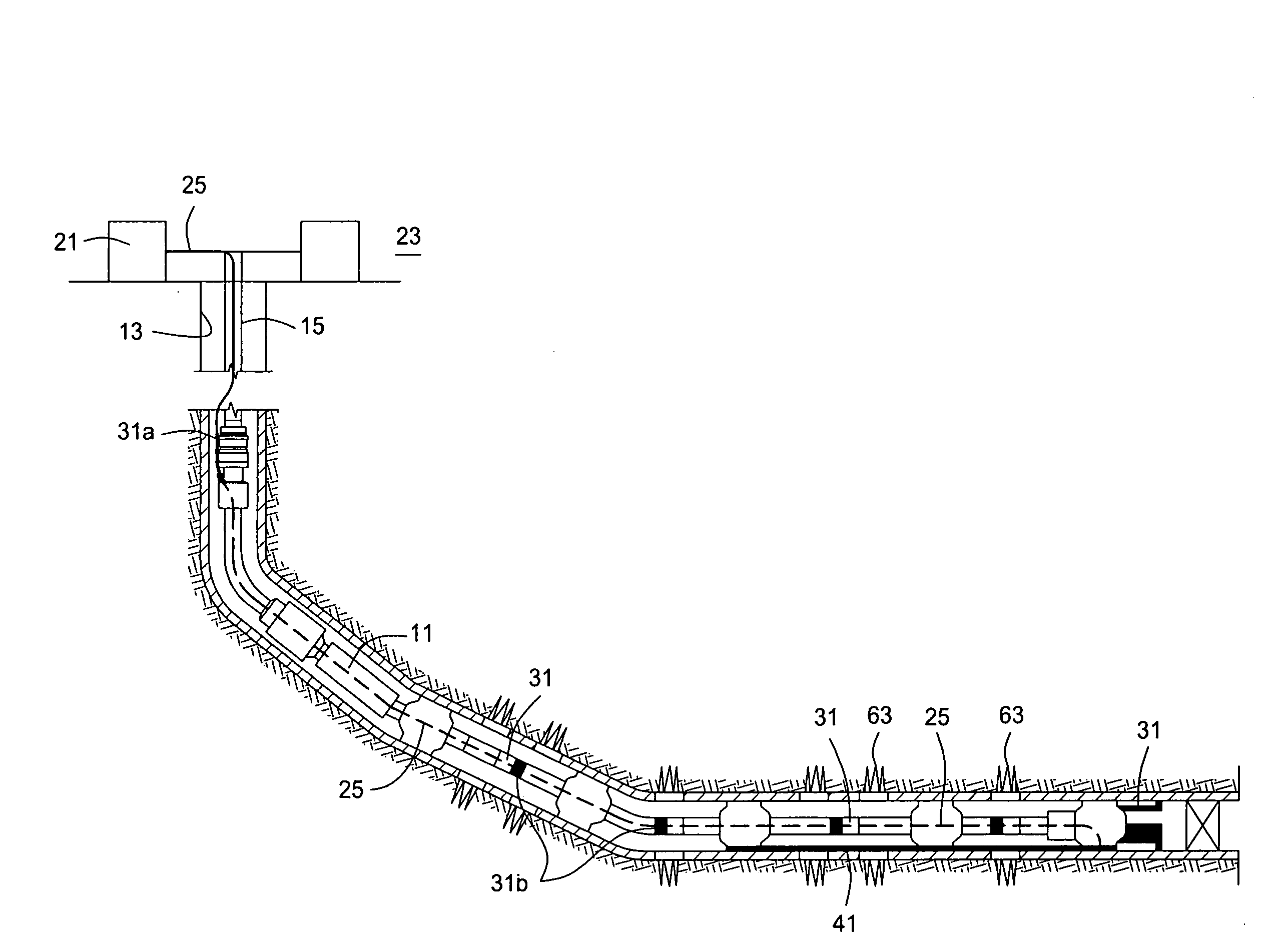

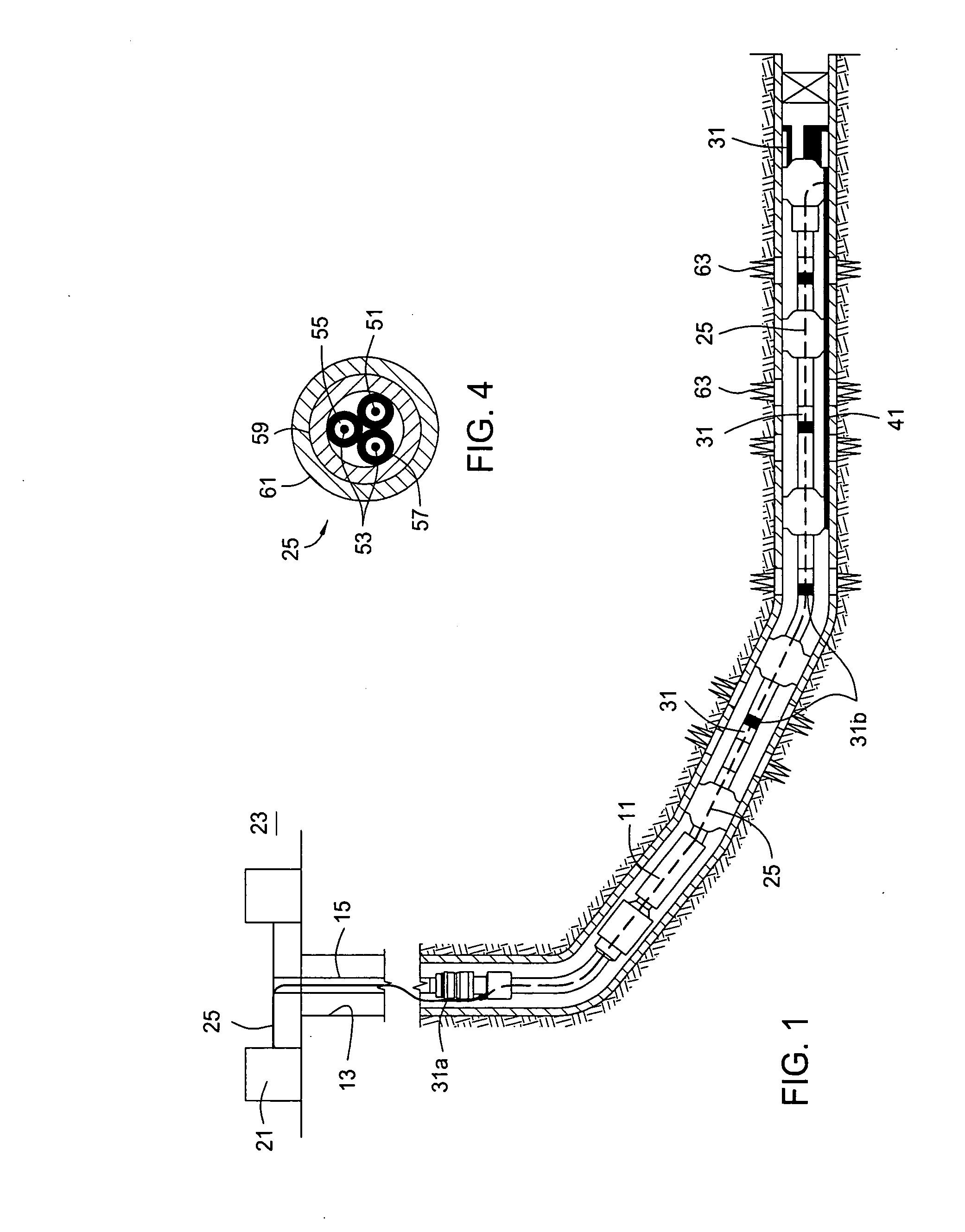

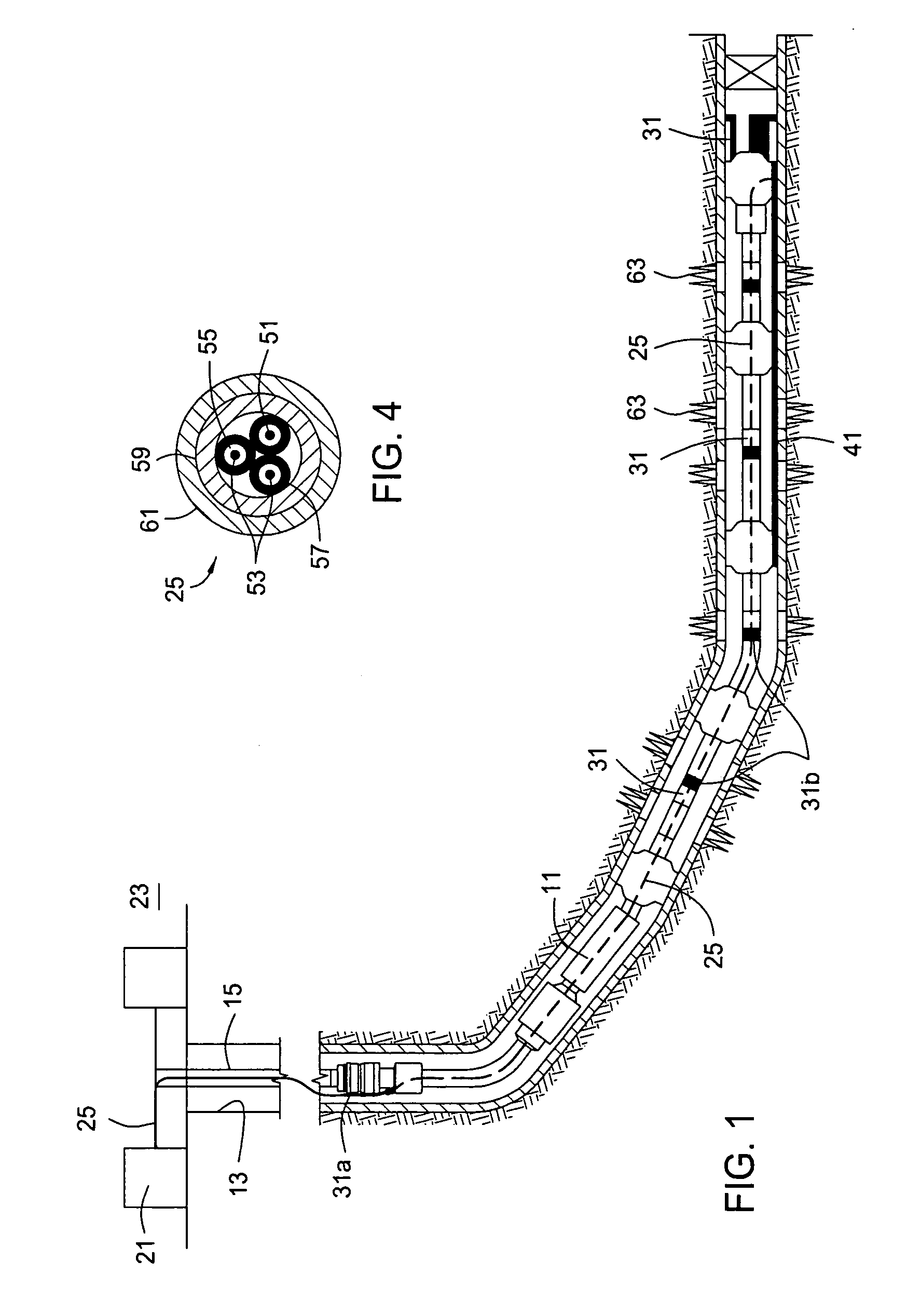

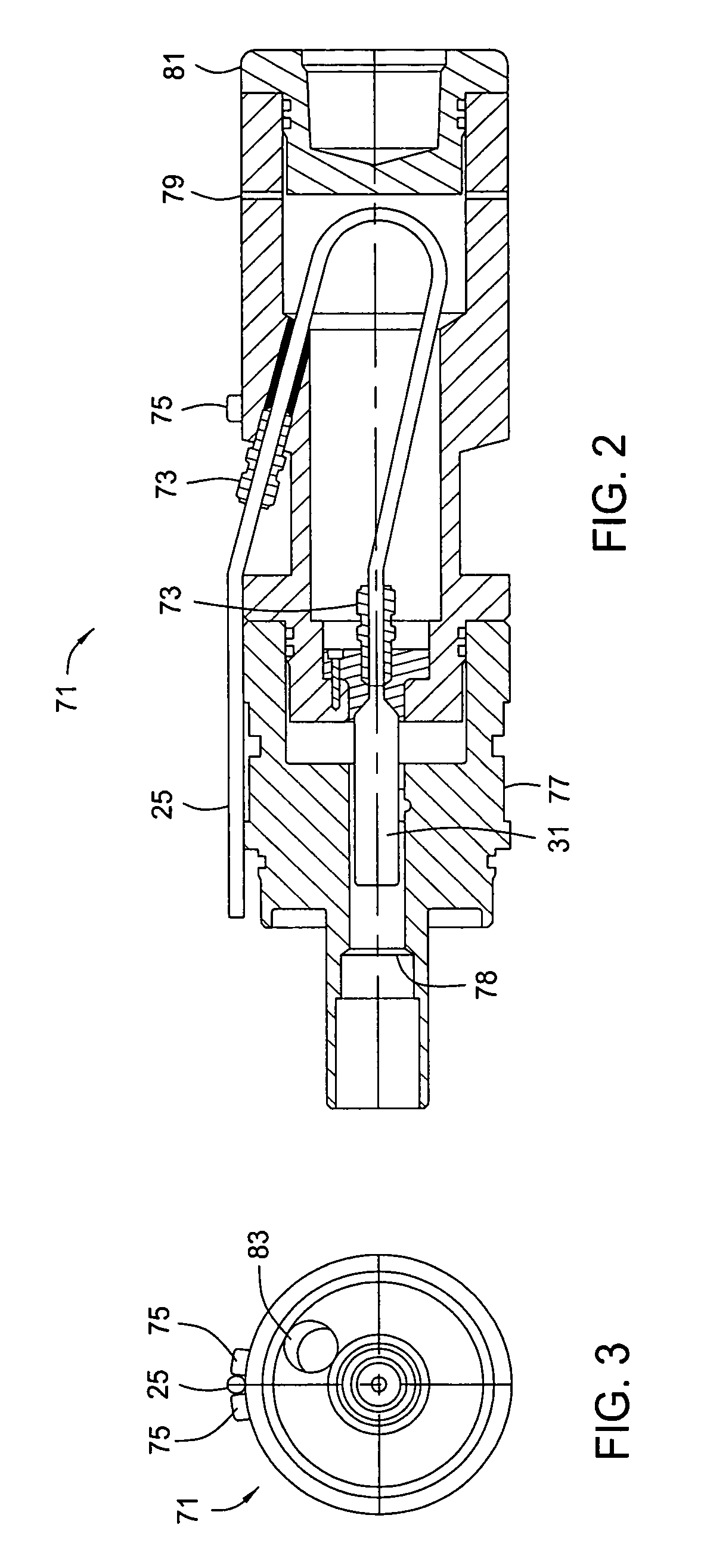

System, method, and apparatus for downhole submersible pump having fiber optic communications

A downhole submersible pump system, method, and apparatus utilizes fiber optic sensors and distributed temperature sensors below the submersible pump to monitor pump discharge pressure and temperature, intake pressure and temperature, and motor temperature. In addition, distributed temperature sensors are used below the pump to monitor the perforations within the well bore.

Owner:BAKER HUGHES INC

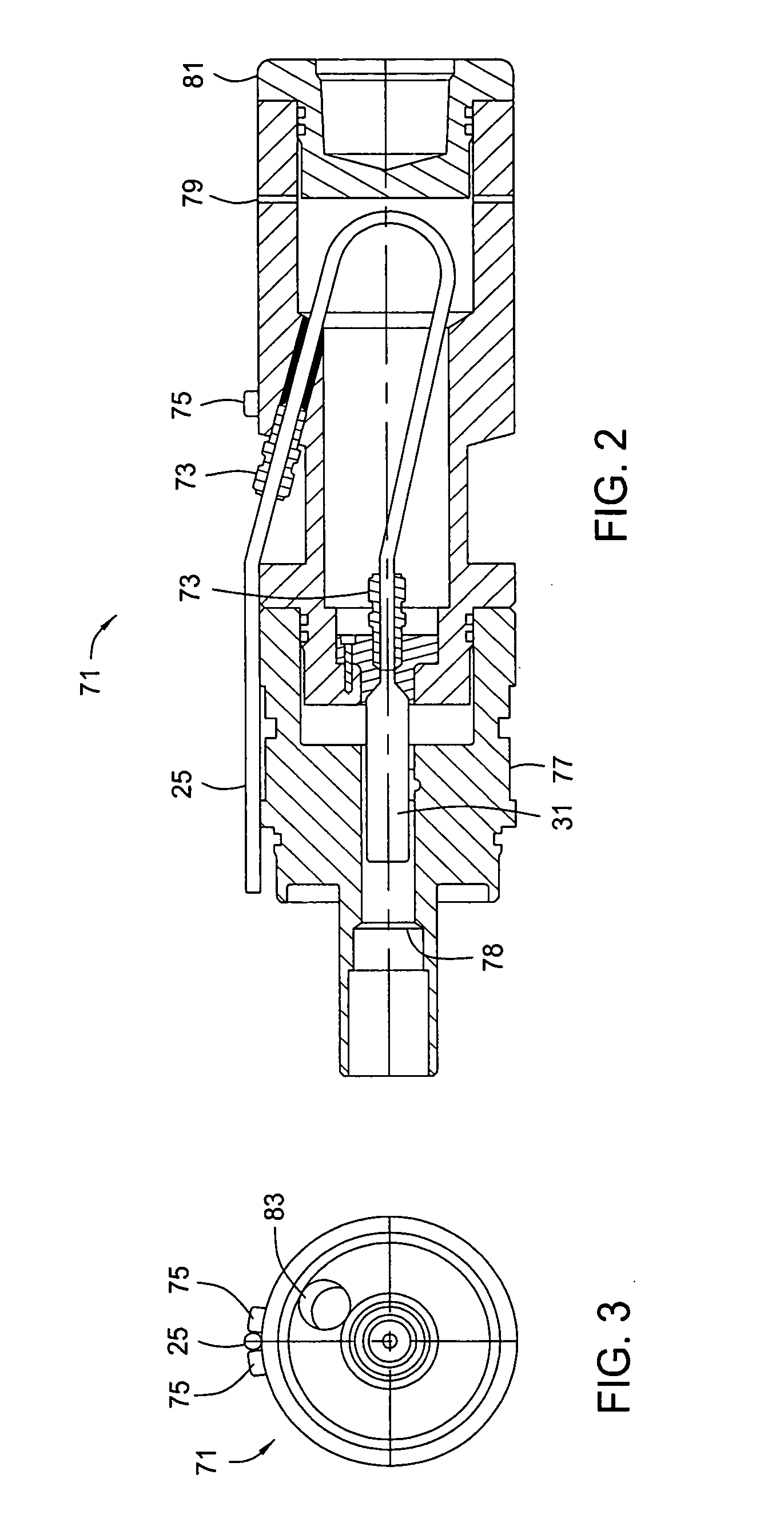

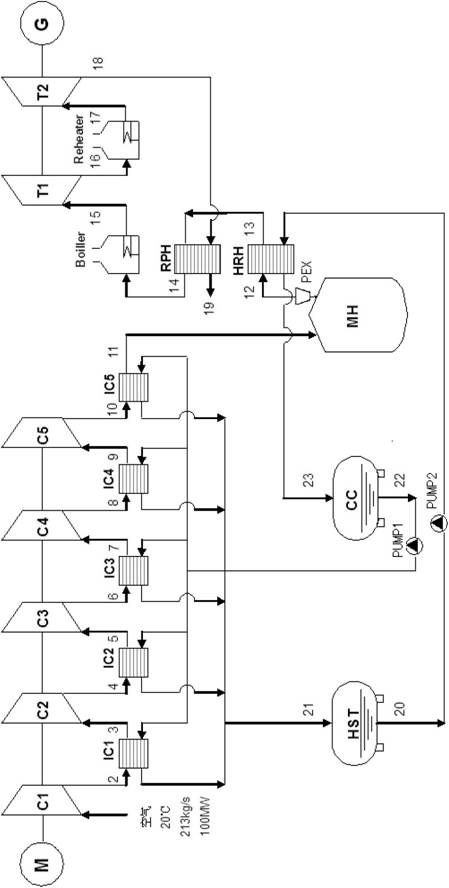

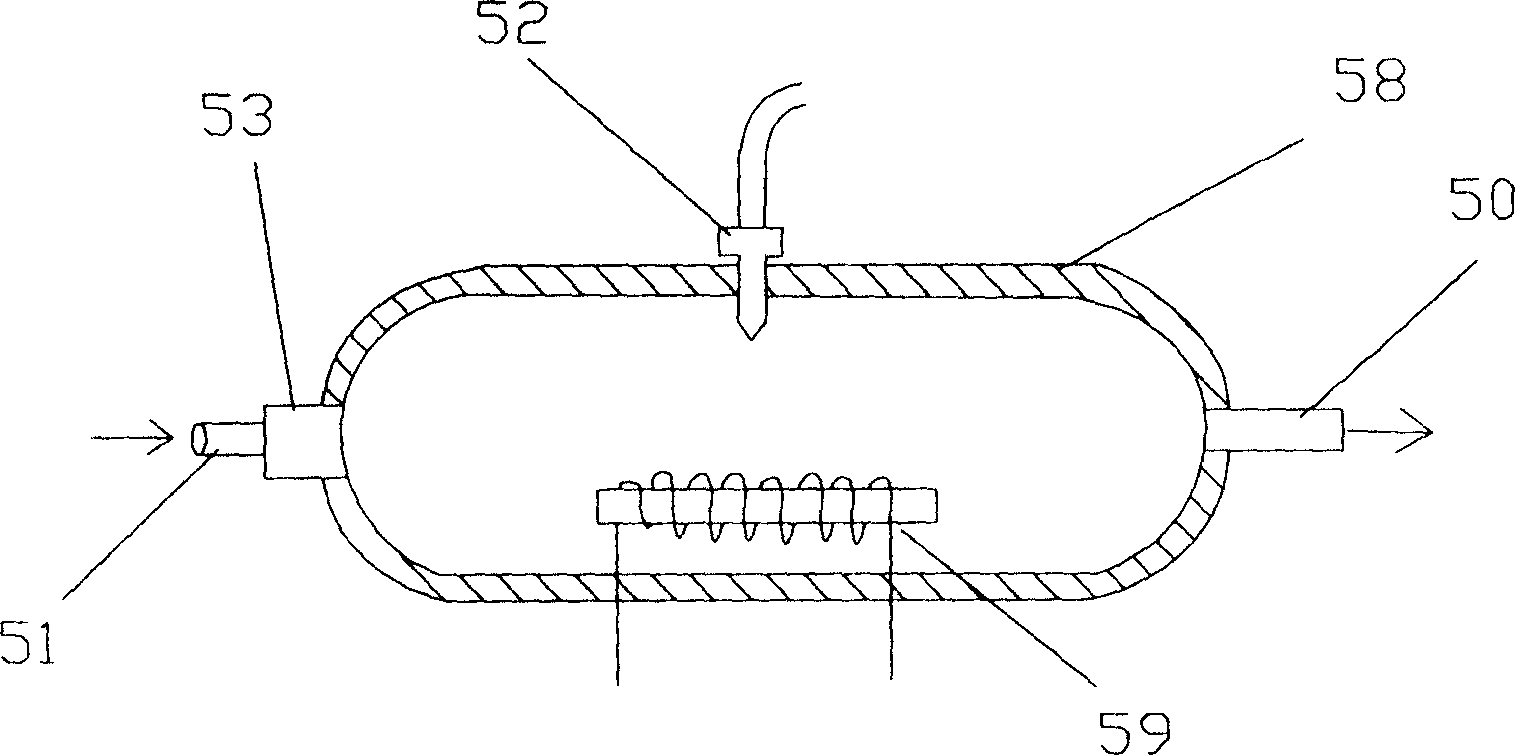

Compressed air energy storage system

InactiveCN102661175ATake advantage ofImprove energy conversion efficiencyPump componentsEngine componentsPre expansionThermal energy storage

The invention discloses a compressed air energy storage system, which comprises a compressor unit, a pre-expansion device, a turbine expansion machine, an intermediate cooler, an electric motor, a power generator, a hot water storage tank and a cold water storage tank, wherein the system utilizes electric energy which is not used up in the user electricity consumption valley period or wind power station power generation peak period for driving the compressor unit to work, the air at the normal pressure is compressed to high pressure, in addition, the part of air with rich pressure energy is stored into a high-pressure-resistance hole, in addition, the stored high-pressure air is released in the user electric consumption peak period or the wind power field generation valley period, an expansion unit is pushed to apply work, and the electric energy is output. The air pre-expansion device is additionally arranged at an outlet of an air storage chamber, so the air inlet pressure of the air turbine expansion machine is stable, the work stability of a power generation system is enhanced, low-temperature air at an outlet of the pre-expansion device is utilized for cooling hot water from the hot water storage tank, the temperature of the low-temperature air is raised through absorption of heat from the hot water, and the cooled water enters the cold water storage tank. The compressed air energy storage system is provided with the hot water storage tank and the cold water storage tank, the water is cyclically utilized in a closed loop, the water is not consumed, in addition, the heat discharged by the compressor is fully utilized and conveyed back to the high-pressure air at the outlet of the pre-expansion device. The high-pressure air at the outlet of the pre-expansion device is recovered through a heat recovering device (HRH).

Owner:XI AN JIAOTONG UNIV

Air amount detector for internal combustion engine

InactiveUS6662640B2Improve calculation accuracyAnalogue computers for vehiclesElectrical controlResponse delayPhase advance

A response delay compensation element for compensating a response delay of an output gMAF of an airflow meter by a phase advance compensation is provided so that an output g of the response delay compensation element is input to the intake air system model. A transfer function of the phase advance compensation iswhere T1 and T2 are time constant of the phase advance compensation, which is set based on at least one of the output gMAF of the airflow meter, engine speed, an intake air pressure, and a throttle angle. The model time constant tauIM of the intake air system model is calculated by variables including volumetric efficiency and the engine speed. The volumetric efficiency is calculated by two-dimensional map having the engine speed and the intake air pressure as parameters thereof.

Owner:DENSO CORP

Turbocharger system

A system for controlling intake pressure of a combustion engine operably coupled to a power generation system includes at least one turbocharger operably coupled to the intake system of the combustion engine. The at least one turbocharger is configured to increase the intake pressure in the intake system of the combustion engine. A turbocharger controller is configured to compare actual and desired intake pressures and control operation of the at least one turbocharger based on the comparison such that the turbocharger supplies a desired intake pressure to the combustion engine.

Owner:CATERPILLAR INC

Fuel Cell System with Variable Coanda Amplifiers for Gas Recirculation and System Pressure Regulation

InactiveUS20070259226A1Easy to controlLarge flow cross sectionNon-fuel substance addition to fuelInternal combustion piston enginesFuel cellsAudio power amplifier

A Coanda flow amplifier has a suction intake, an outlet, a fluid channel extending between the suction intake and the outlet, and a drive-flow inlet, which is fluidly connected to the fluid channel via a drive-flow discharge slit, whereby the flow cross section of the drive-flow discharge slit is variably adjustable. In a method to operate the Coanda flow amplifier, the variably adjustable flow cross section of the drive-flow discharge slit is chosen such that a pressure ratio between an output pressure of the drive flow when it leaves the drive-flow discharge slit, and an intake pressure of the drive flow when it enters the drive-flow discharge slit, does not exceed a critical pressure ratio. A fuel cell system comprises at least one fuel cell, a fluid source, a fluid line, and a Coanda flow amplifier arranged in the fluid line, whereby the Coanda flow amplifier is equipped with a drive-flow discharge slit with a variably adjustable flow cross section.

Owner:NUCELLSYS GMBH

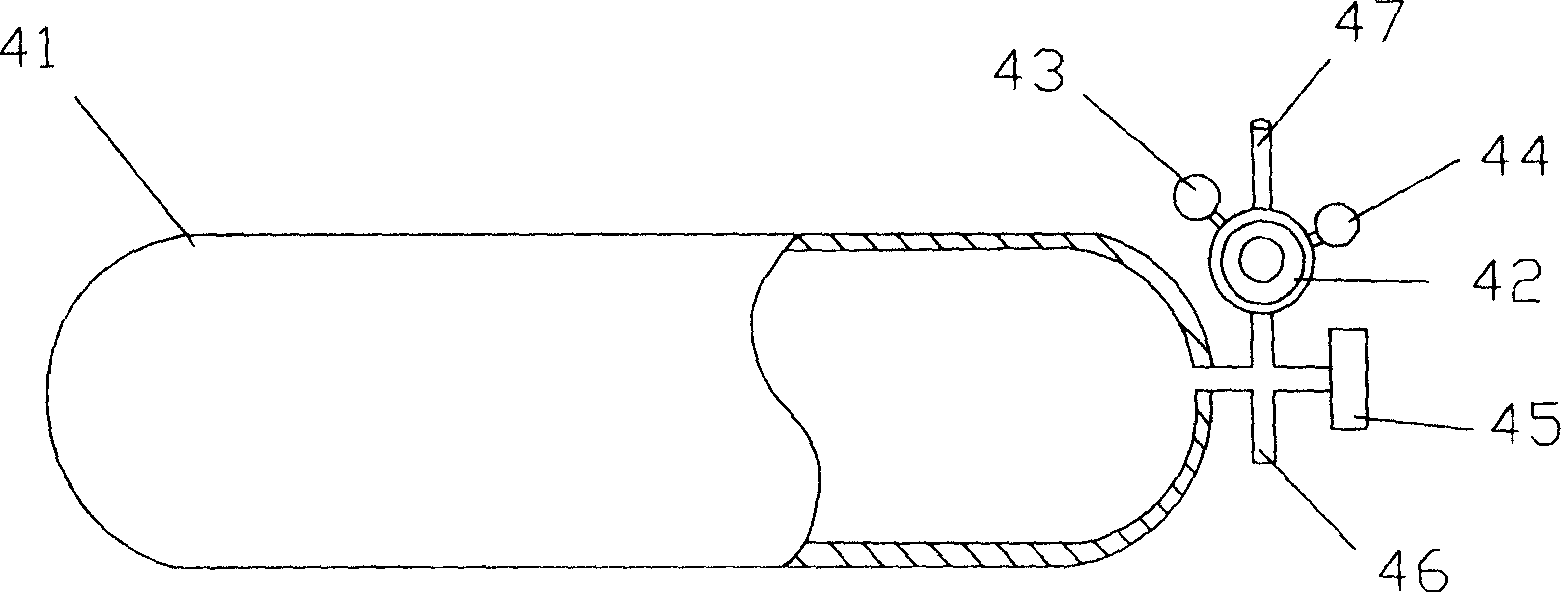

On-board engine using compressed air as power

InactiveCN1851260ASimple structureSafety/regulatory devicesReciprocating piston enginesOn boardElectric machinery

The invention relates to car carried engine used compressed air as power. It includes engine body, crank shaft, gear box, and belt sheave. The end of the crank shaft is connected with piston in cylinder. The cylinder cover is set intake pressure pipe and exhaust pipe. The engine body is set engine speed, dead point-distinguishing signal generator, and engine crank shaft dish rotating electric machinery. The crank shaft is set one way overrunning clutch. Compared with the existing technique, it has the advantages of environmental protection and simple structure.

Owner:陈志新

Engine timing control with intake air pressure sensor

InactiveUS7225793B2Reduce complexityLow costElectrical controlVolume/mass flow by thermal effectsExternal combustion engineInlet valve

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine through monitoring intake air pressure fluctuations. The opening of the intake valve is mechanically linked to the crankshaft position of an engine. When the intake valve opens it creates air pressure fluctuations in the air induction system of the engine. The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position. A circuit is provided for simultaneously measuring intake temperature using a single bridge type pressure sensor in order to calculate air mass flow rate.

Owner:ELECTROJET TECH INC

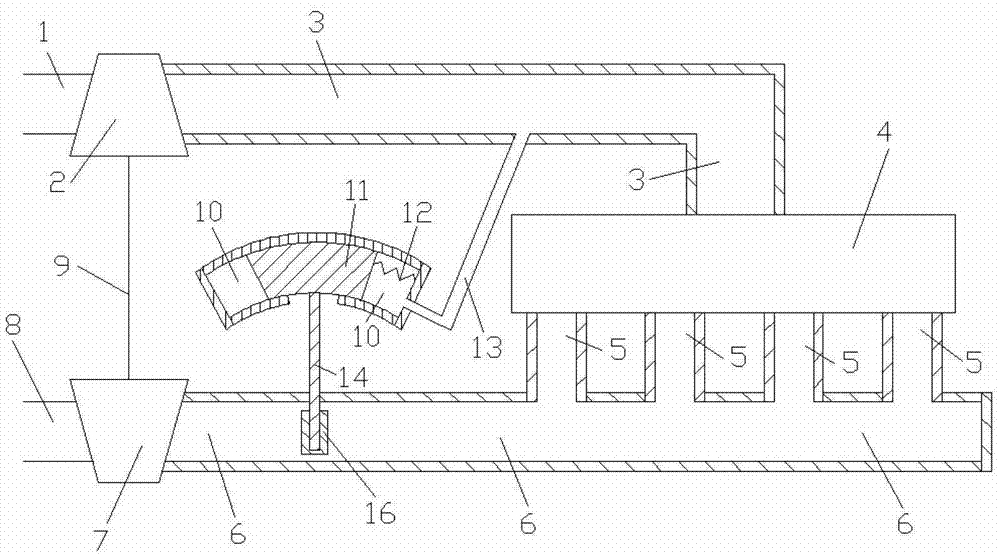

Variable air exhaust through flow area air inlet pressure control type adjusting device for turbocharged engine

InactiveCN103089409AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesInlet pressureAir compressor

A variable air exhaust through flow area air inlet pressure control type adjusting device for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and an air inlet pipe of the engine. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air inlet pressure control type adjusting device for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

System, method, and apparatus for downhole submersible pump having fiber optic communications

A downhole submersible pump system, method, and apparatus utilizes fiber optic sensors and distributed temperature sensors below the submersible pump to monitor pump discharge pressure and temperature, intake pressure and temperature, and motor temperature. In addition, distributed temperature sensors are used below the pump to monitor the perforations within the well bore.

Owner:BAKER HUGHES INC

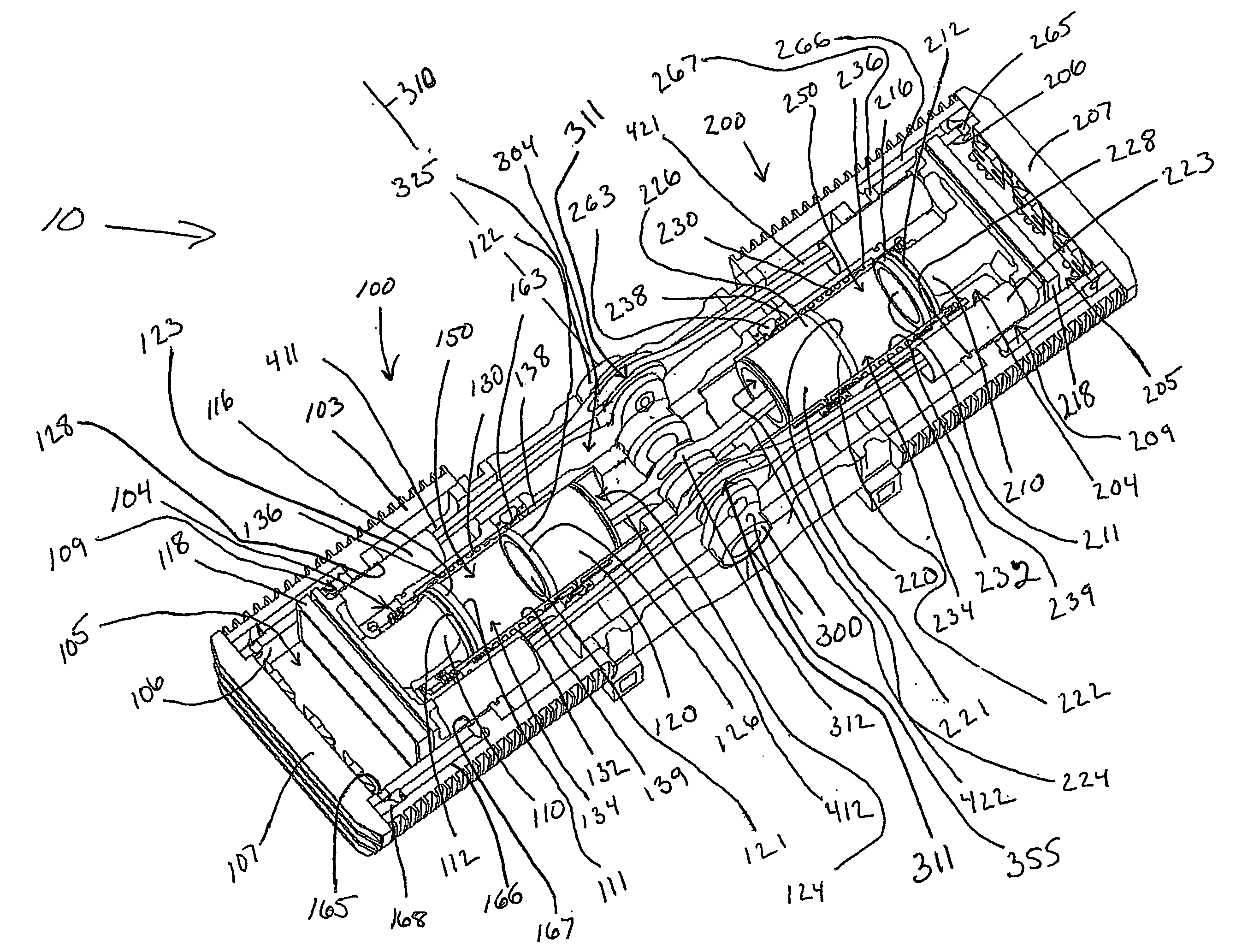

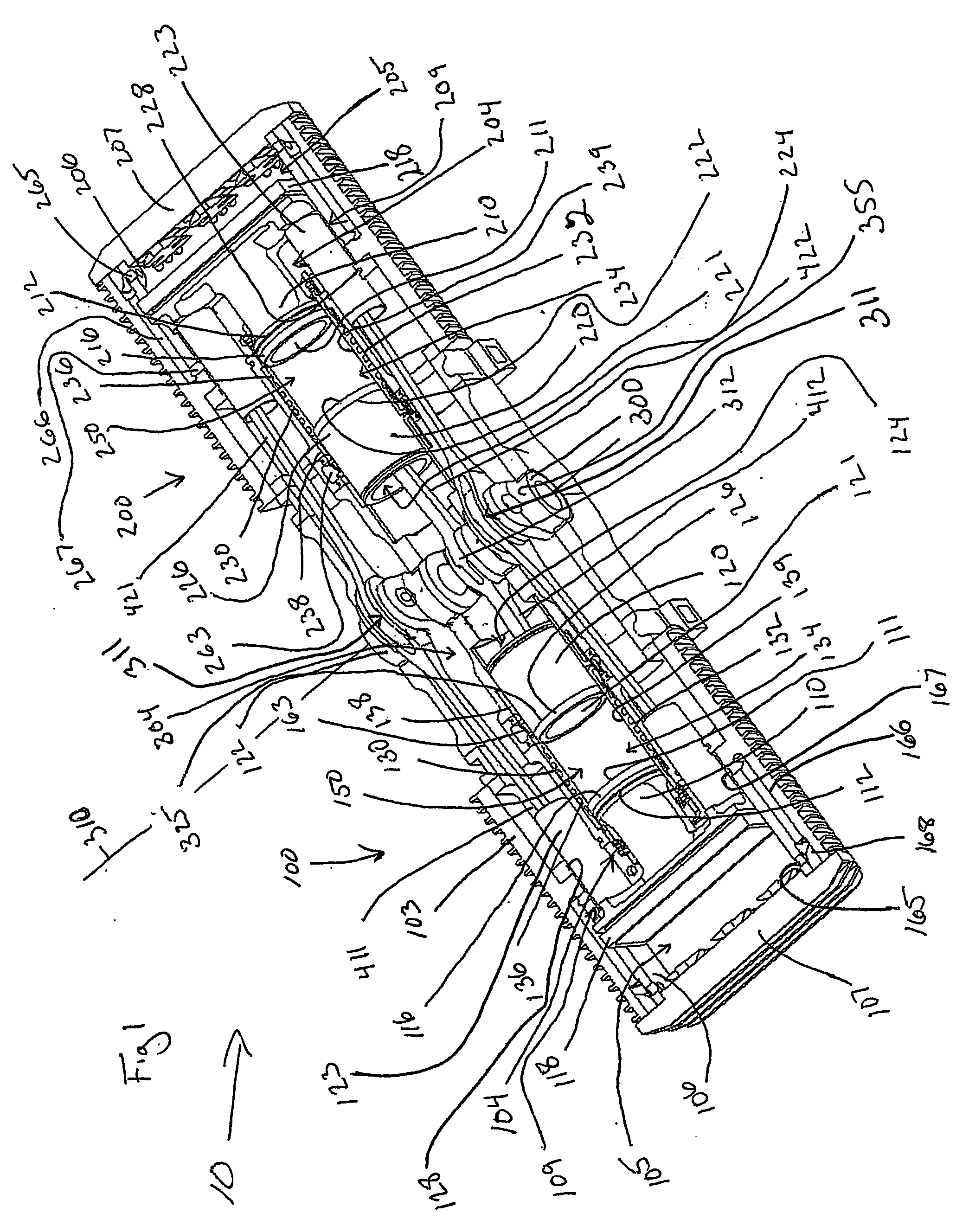

Internal combustion engine

InactiveUS20060124084A1Improve efficiencyHeight profile of has been reducedInternal combustion piston enginesOutput powerControl theoryMechanical engineering

A two-stroke internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons, with all the pistons connected to a common central crankshaft. The inboard pistons of each cylinder are connected to the crankshaft with pushrods and the outboard pistons are connected to the crankshaft with pullrods. Each opposed cylinder further comprises an integrated scavenge pump for providing positive intake pressure. This configuration results in a compact engine with a very low profile, in which the free mass forces can be substantially balanced. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through angular positioning of the journals on the crankshaft.

Owner:ADVANCED PROPULSION TECH

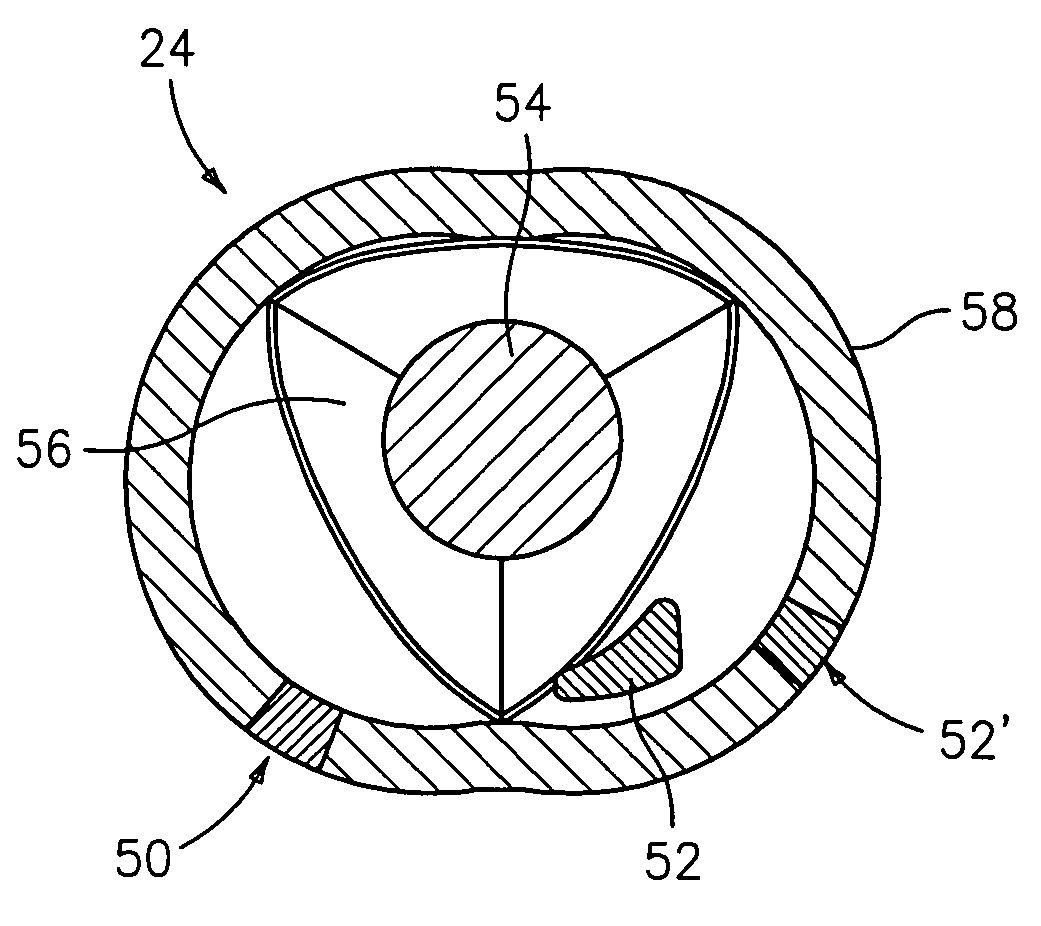

CO2 compressor

InactiveUS6129532ASmall sizeStable, reliable lubricant supply unitRotary/oscillating piston combinations for elastic fluidsCompressorForeign matterDifferential pressure

A CO2 compressor is disclosed for forcing and moving a lubricant under discharge pressure. If the oil path is reduced in size or a pressure reducing part is inserted to handle the large differential pressure caused between the discharge pressure and the intake pressure, the oil path would become liable to be easily clogged by foreign matter. In view of this, an intermittent oil supply mechanism is formed in the oil path using the sliding contact portion between a fixed member of the compressor body and a movable member. Thus, the substantial lubrication time period is shortened and the amount of oil supplied is limited.

Owner:DENSO CORP

Exhaust gas recirculation system having cooler

InactiveUS20030213230A1Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

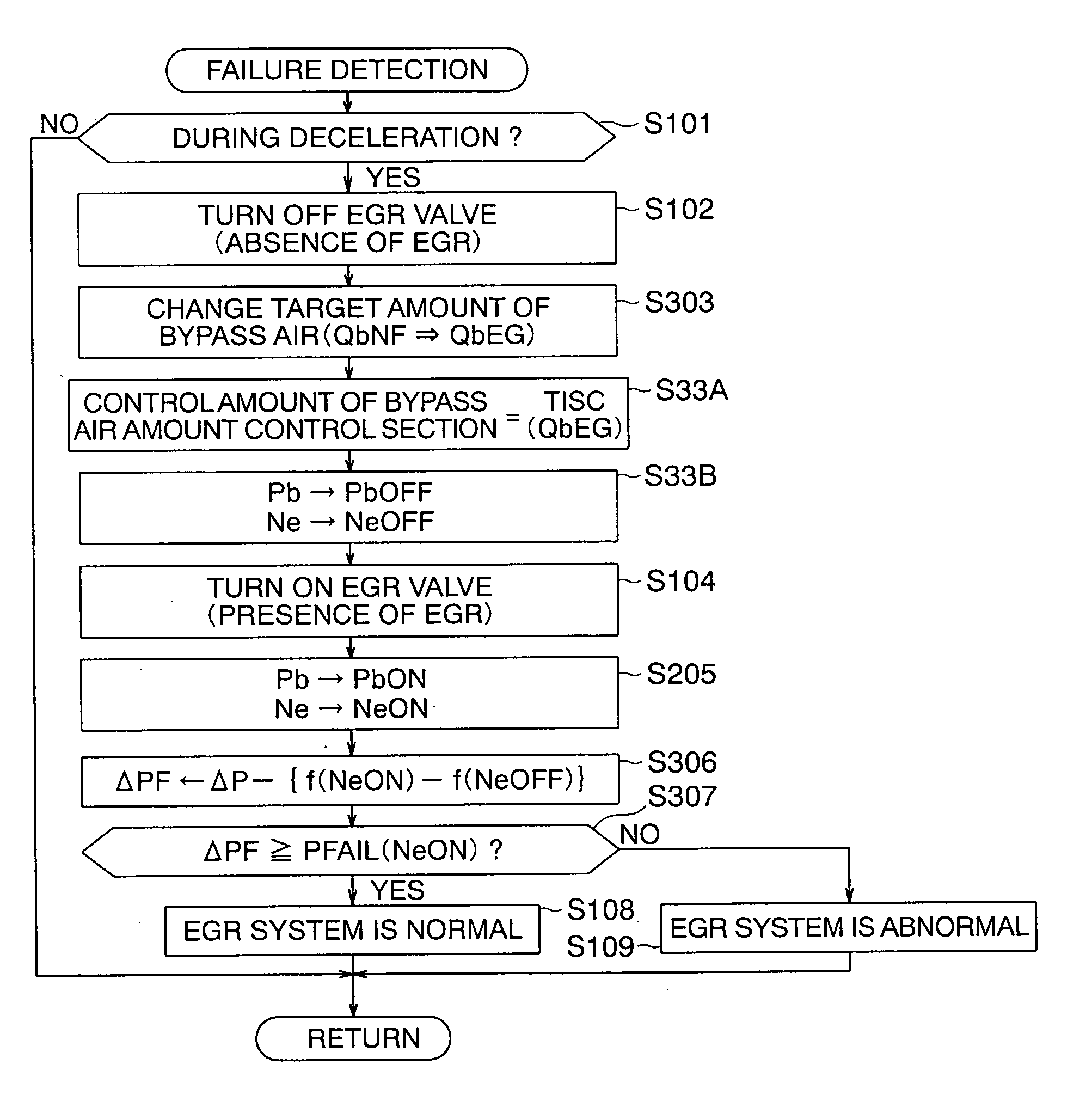

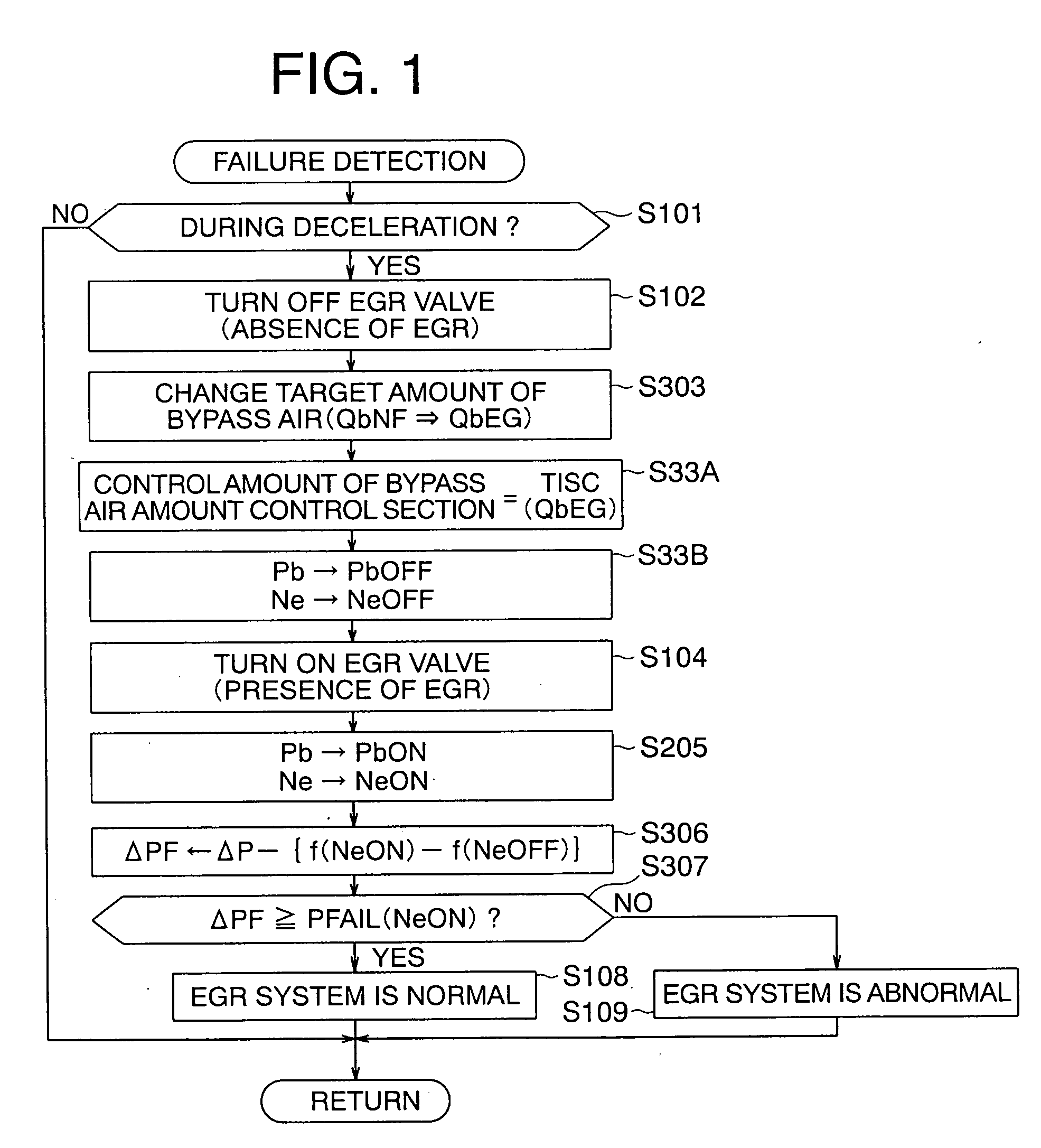

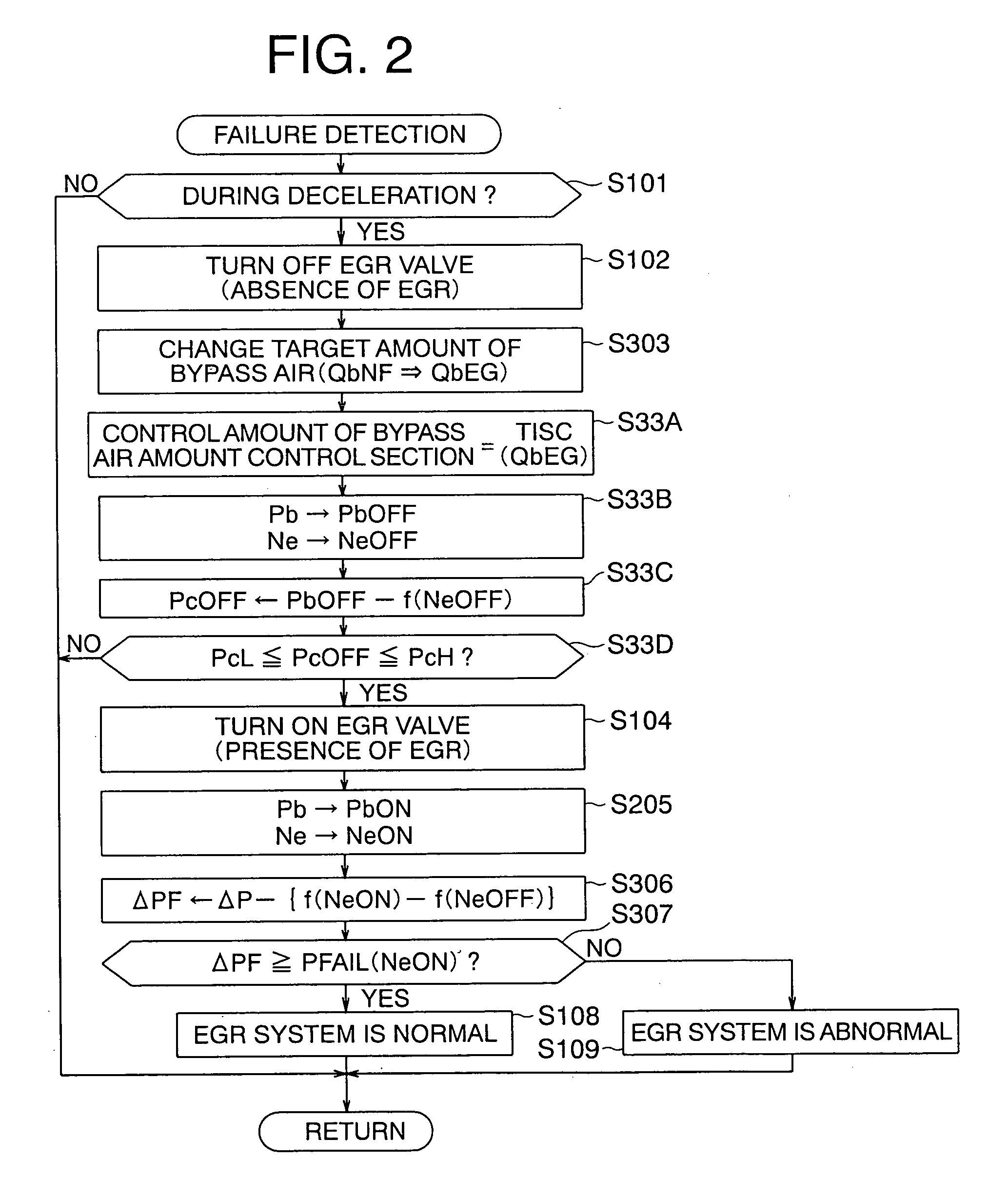

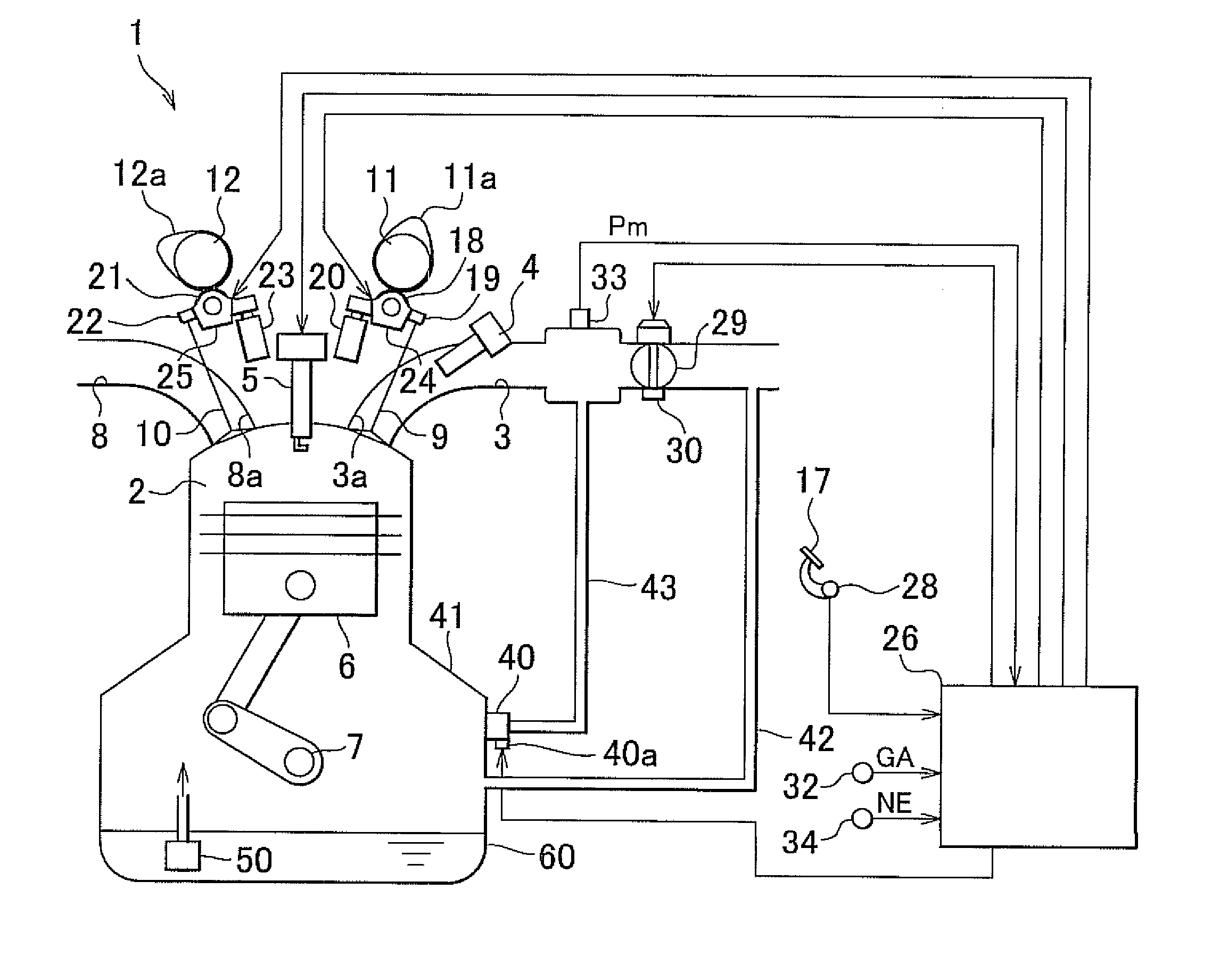

Control apparatus for an internal combustion engine

InactiveUS20070062499A1Highly reliable failure determinationDetermination failsElectrical controlNon-fuel substance addition to fuelIntake pressureRevolutions per minute

A control apparatus for an internal combustion engine can compensate for a variation of intake pressure resulting from various factors whereby a failure detection area can be expanded, and false detection can be prevented to enable failure determination for an EGR system with high reliability. The apparatus determines whether a vehicle is decelerating, forcedly opens and closes an EGR valve, and determines whether an EGR control device is in failure by comparing a pressure change index value based on intake pressures upon the forced opening and closing of the EGR valve with a failure determination value. The apparatus adjusts the intake pressure to a predetermined state before the EGR valve is forcedly opened and closed, whereby a failure determination can be always made based on the intake pressure whose variation was compensated for with the intake pressure becoming a predetermined characteristic to the number of revolutions per minute of the engine.

Owner:MITSUBISHI ELECTRIC CORP

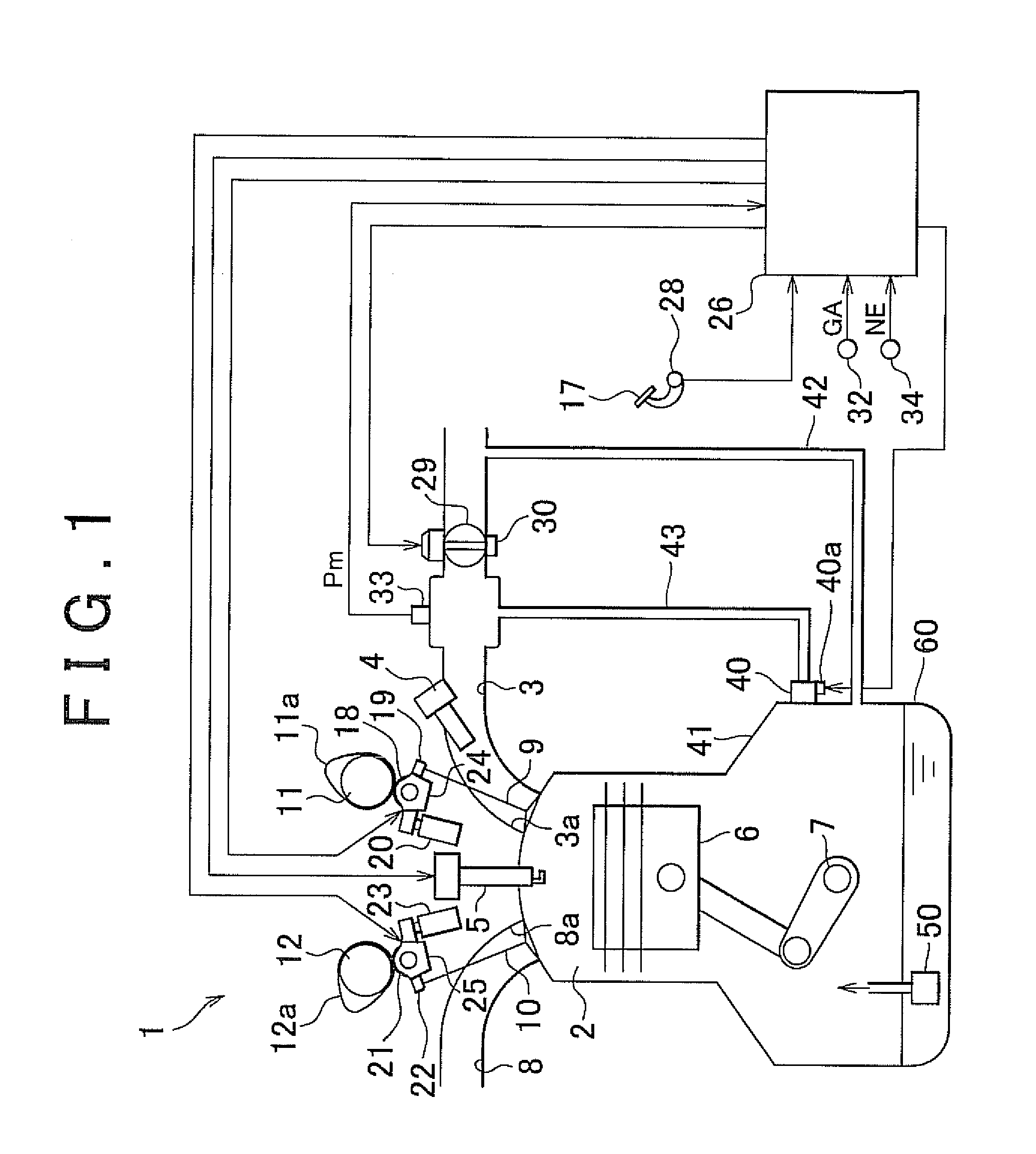

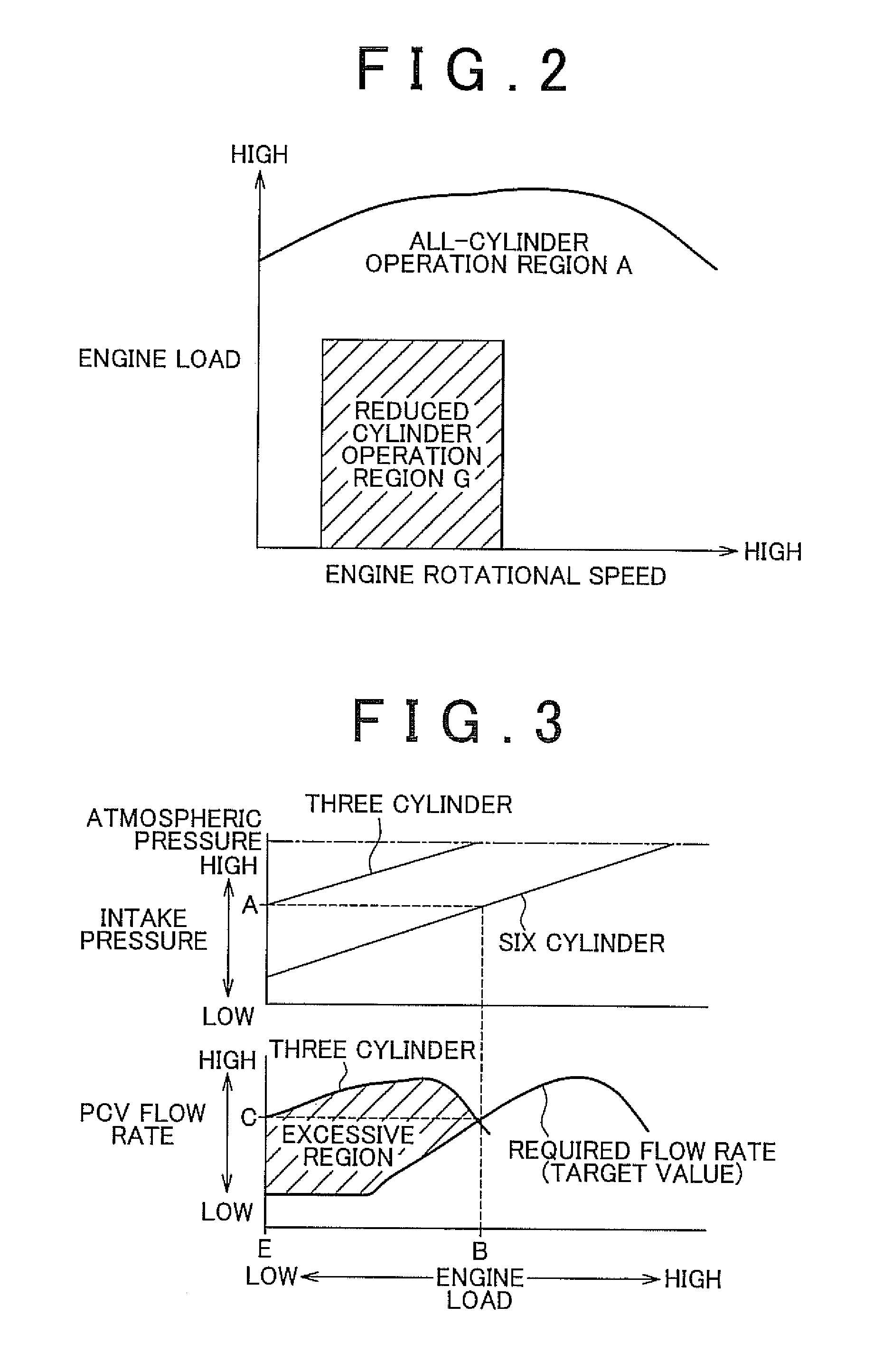

Control device for internal combustion engine and control method for internal combustion engine

ActiveUS20100192925A1Easy to controlReduce in quantityValve arrangementsInternal combustion piston enginesExternal combustion engineCrankcase

An engine includes: a valve stop mechanism that varies the number of operating cylinders as a cylinder cut-off mechanism; and a blow-by gas recirculation system that has a blow-by gas passage that returns blow-by gas, flowing from a combustion chamber to a crankcase, to an intake passage and a PCV valve that is equipped with an electric motor and that adjusts the flow rate of gas returned to the blow-by gas passage. A control device variably sets the opening degree, corresponding to a target value of the flow rate of gas, of the PCV valve on the basis of an intake pressure in an intake passage to adjust the opening degree of the PCV valve so that the flow rate of gas becomes the target value.

Owner:TOYOTA JIDOSHA KK

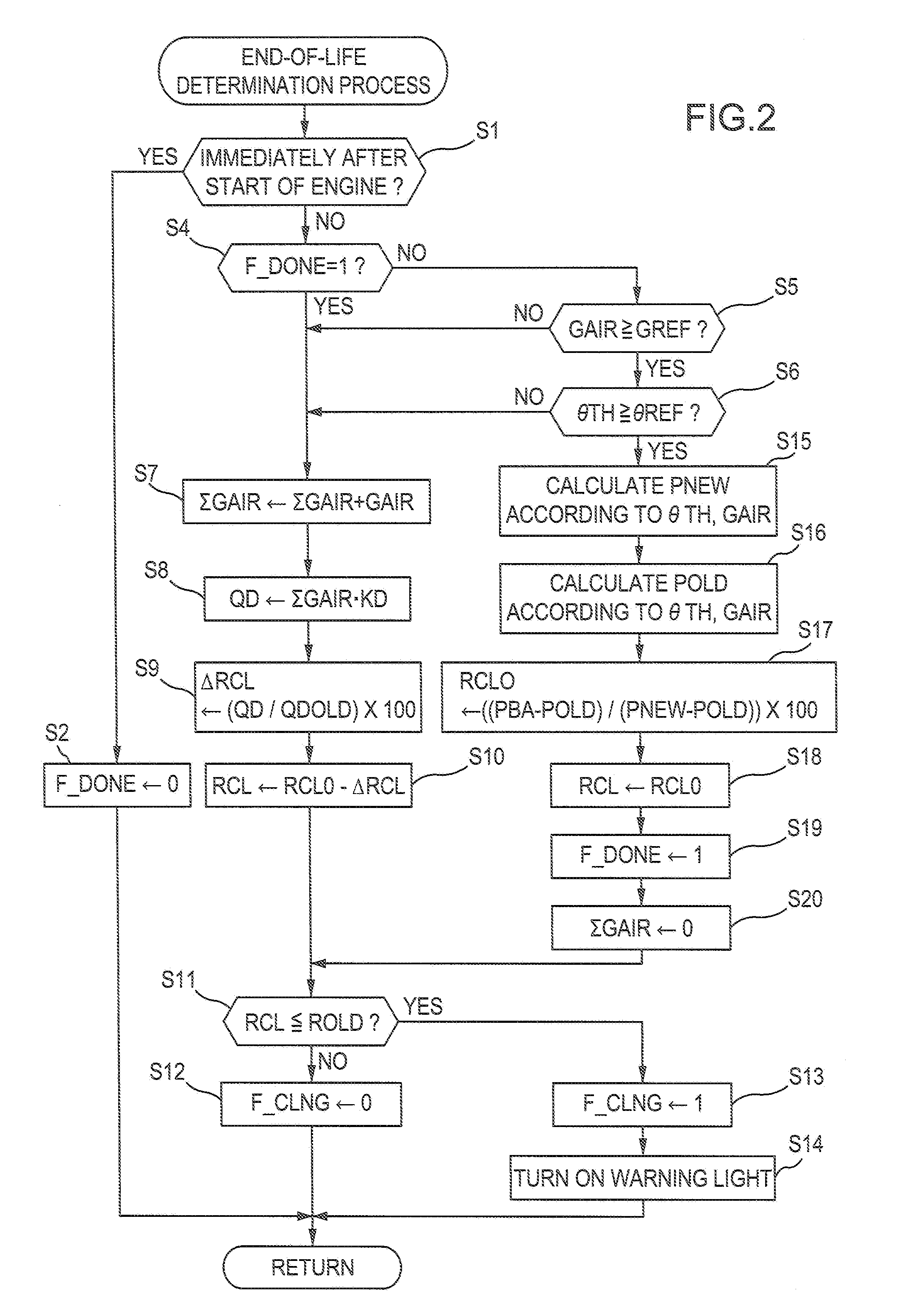

End-of-life estimation device for air cleaner

InactiveUS20130036804A1Accurate estimateCheap constructionInternal-combustion engine testingElectrical controlEngineeringLife time

An end-of-life estimation device for an air cleaner, which is capable of always accurately estimating an end of a service life of the air cleaner with an inexpensive construction, thereby enabling the air cleaner to be efficiently used until the service life comes close to the end. The end-of-life estimation device calculates a life parameter indicative of remaining service life of the air cleaner during running of an engine, on an as needed basis, and stores a relationship between the degree of clogging of the air cleaner, an intake air amount, and an intake parameter (an intake pressure on a downstream side of the air cleaner and / or a throttle valve opening). Further, the end-of-life estimation device calculates and updates a reference value with reference to which the life parameter is calculated, based on the stored relationship, according to the detected intake air amount and intake parameter.

Owner:HONDA MOTOR CO LTD

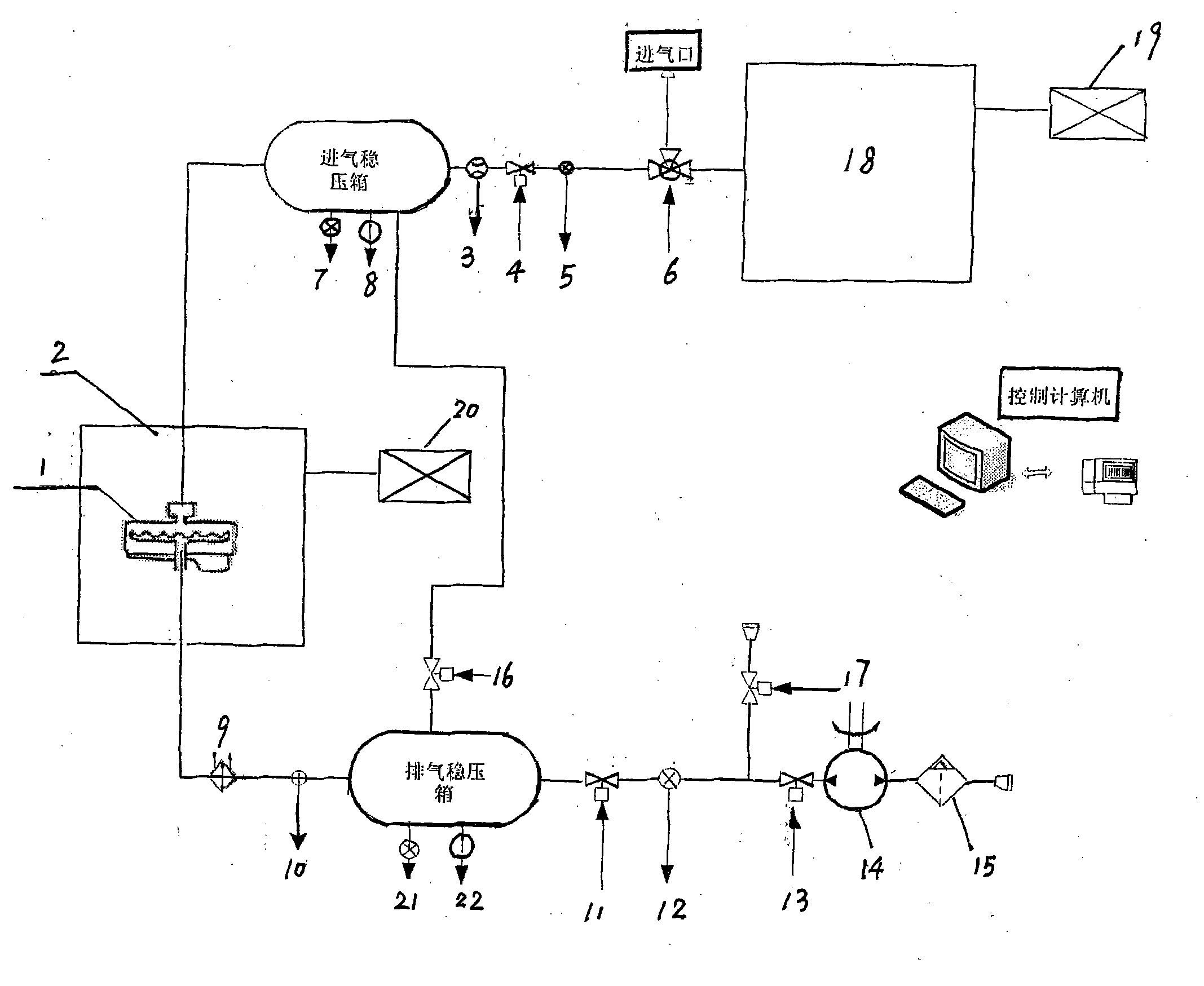

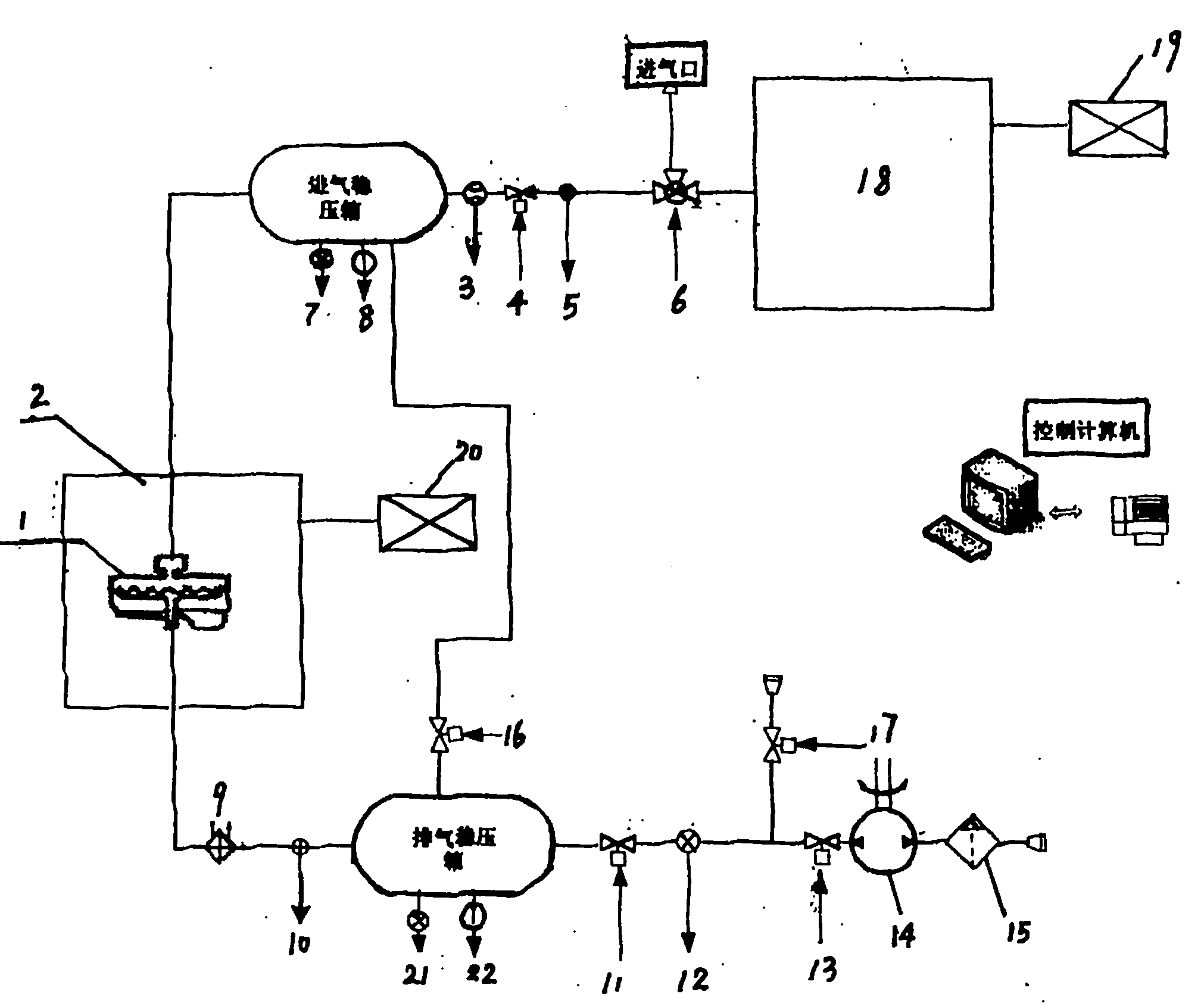

Engine plateau environment laboratory

The invention relates to an engine plateau environment laboratory which comprises an intake pressure simulation system, an exhaust pressure simulation system, a high and low temperature control chamber and a control system. The high and low temperature control chamber is used for placing an engine, the intake pressure simulation system is formed by sequentially connecting an intake pressurizer tank, a low-temperature box body and a refrigeration unit, and the exhaust pressure simulation system comprises an exhaust heat exchanger, an exhaust pressurizer tank, an exhaust electric control valve, a vacuum pump and a gas-water separator. Dispersive high-altitude natural environmental conditions (pressure, temperature and moisture) are intensively simulated in the laboratory, thereby improving the precision and the efficiency of the engine high-altitude environmental experiments.

Owner:MILITARY TRANSPORTATION UNIV PLA

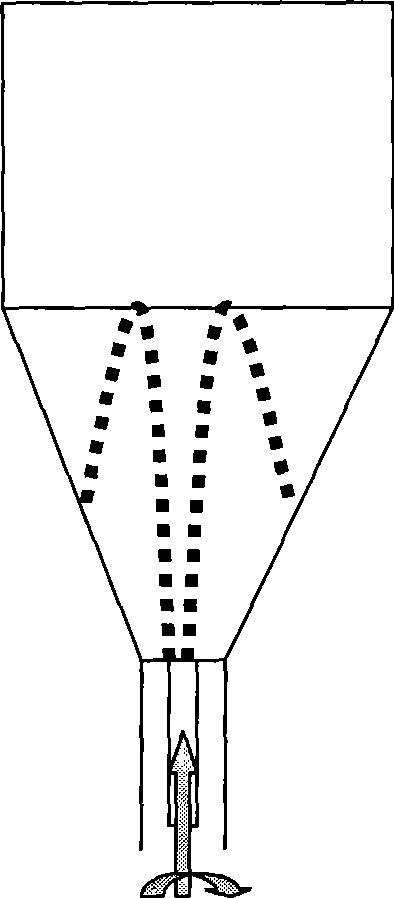

Sprouted auxiliary means for improving microwave desiccation homogeneity of granular garden stuff

InactiveCN101433233ASpray evenlyImprove uniformityFruits/vegetable preservation by dehydrationFood treatmentAir volumeAgricultural engineering

The invention discloses an auxiliary spouting method for improving the uniformity of microwave drying of granular fruits and vegetables, which belongs to the technical field of the processing of fruit and vegetable food. Pretreated fruits and vegetables are placed into a microwave spouting drying bed, the microwave power and the air intake heating temperature are preset, then the central air intake volume and the air intake angle of the spouting bed are adjusted to ensure that a dried material spouts in the spouting bed in different forms, the air intake pressure and the air intake angle are adjusted according to different drying stages of the material at the same time, and the microwave energy received by the material is more uniform than that of the prior fixation or fluidization mode; and the microwave adopts internal heating, so the moisture of the dried fruits and vegetables is effectively and quickly evaporated to achieve the aim of uniform drying. Through the auxiliary spouting method, the material is uniformly heated in a microwave field, the moisture is evaporated quickly, the drying time is greatly shortened, the prior color and luster, shape and nutrient substances of the dried fruits and vegetables can be furthest retained, and the dried fruits and vegetables have porous structures and good rehydration property, thereby obtaining a high-quality dehydrated fruit and vegetable product.

Owner:JIANGNAN UNIV +1

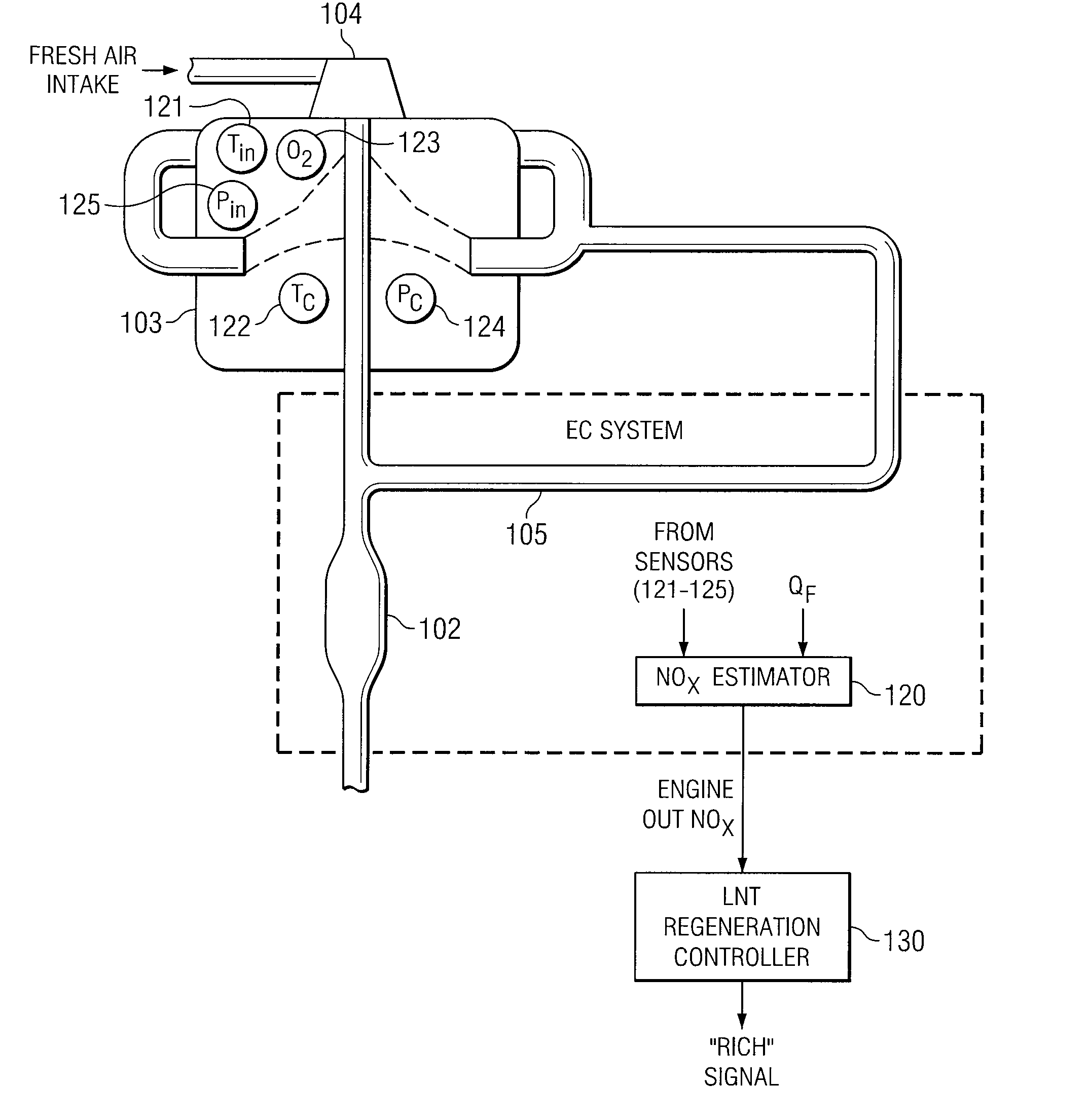

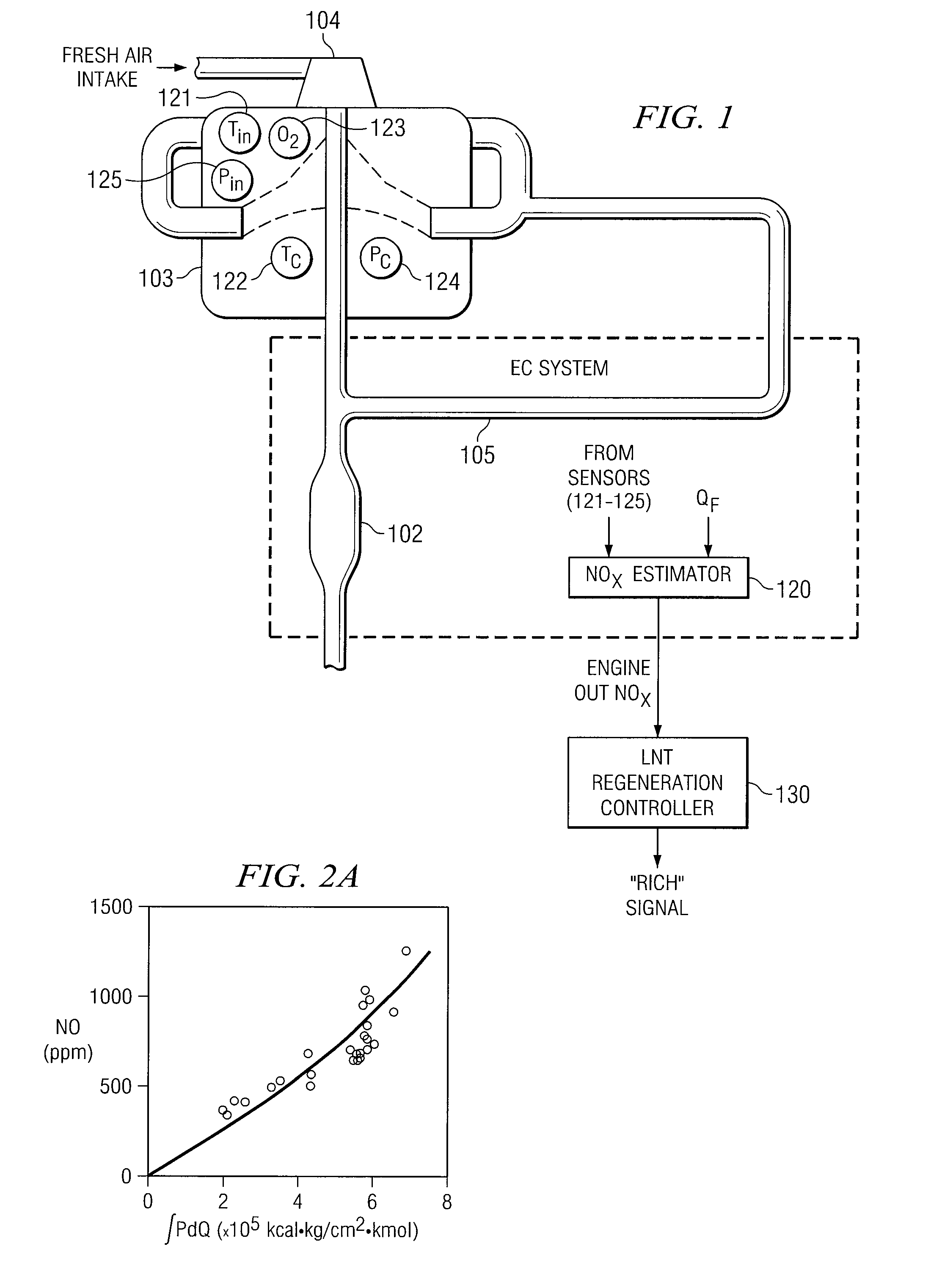

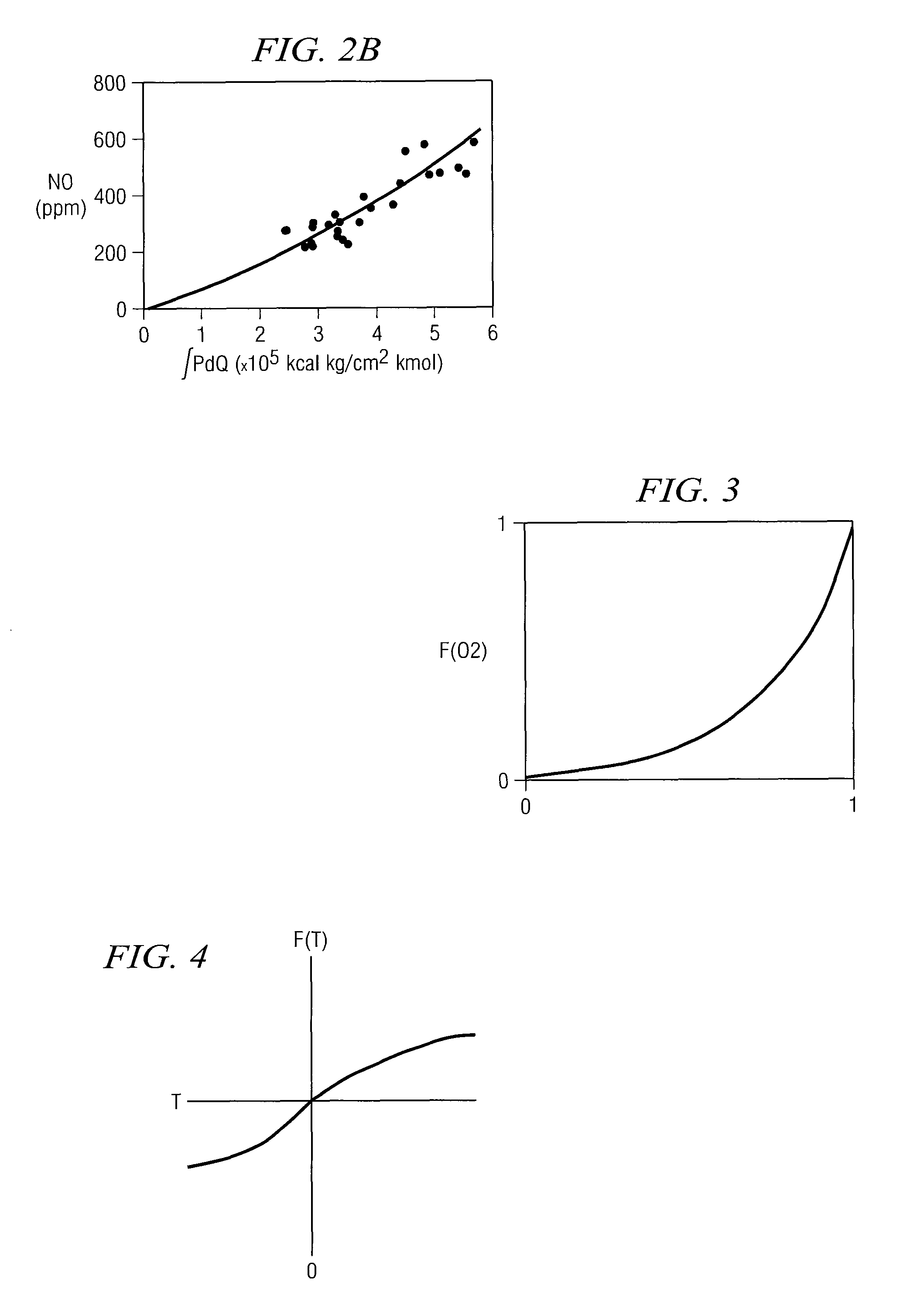

Estimation of engine-out NOx for real time input to exhaust aftertreatment controller

A method and system for estimating engine-out NOx from a diesel engine. The estimation is calculated from a mathematical model that expresses engine-out NOx as functions of cylinder pressure, intake oxygen, and effective temperature, respectively. Input data for each of these functions may be obtained from fuel quantity data and from measured data, the latter including intake pressure, cylinder pressure, intake oxygen concentration, coolant temperature, and intake manifold temperature.

Owner:SOUTHWEST RES INST

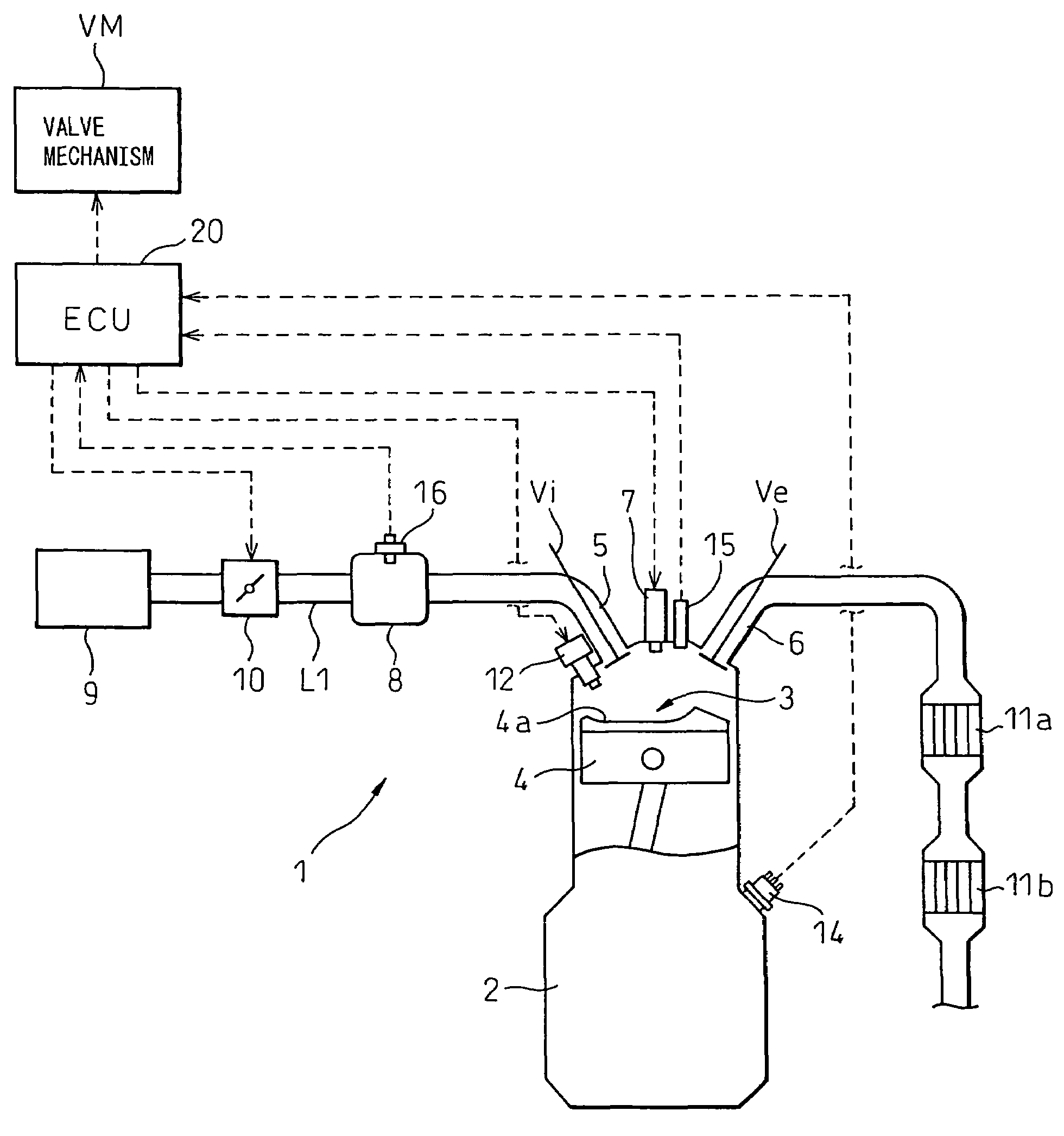

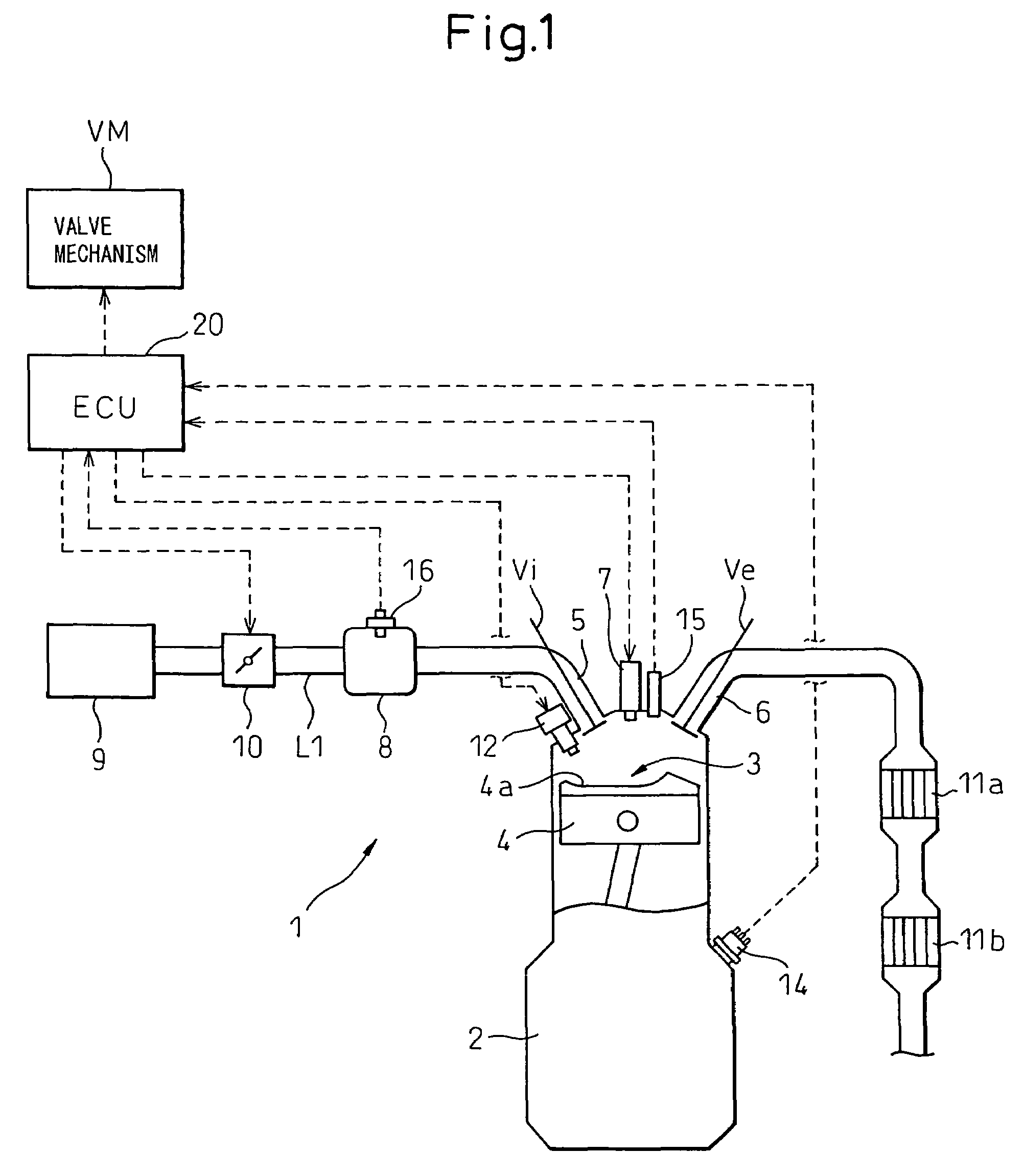

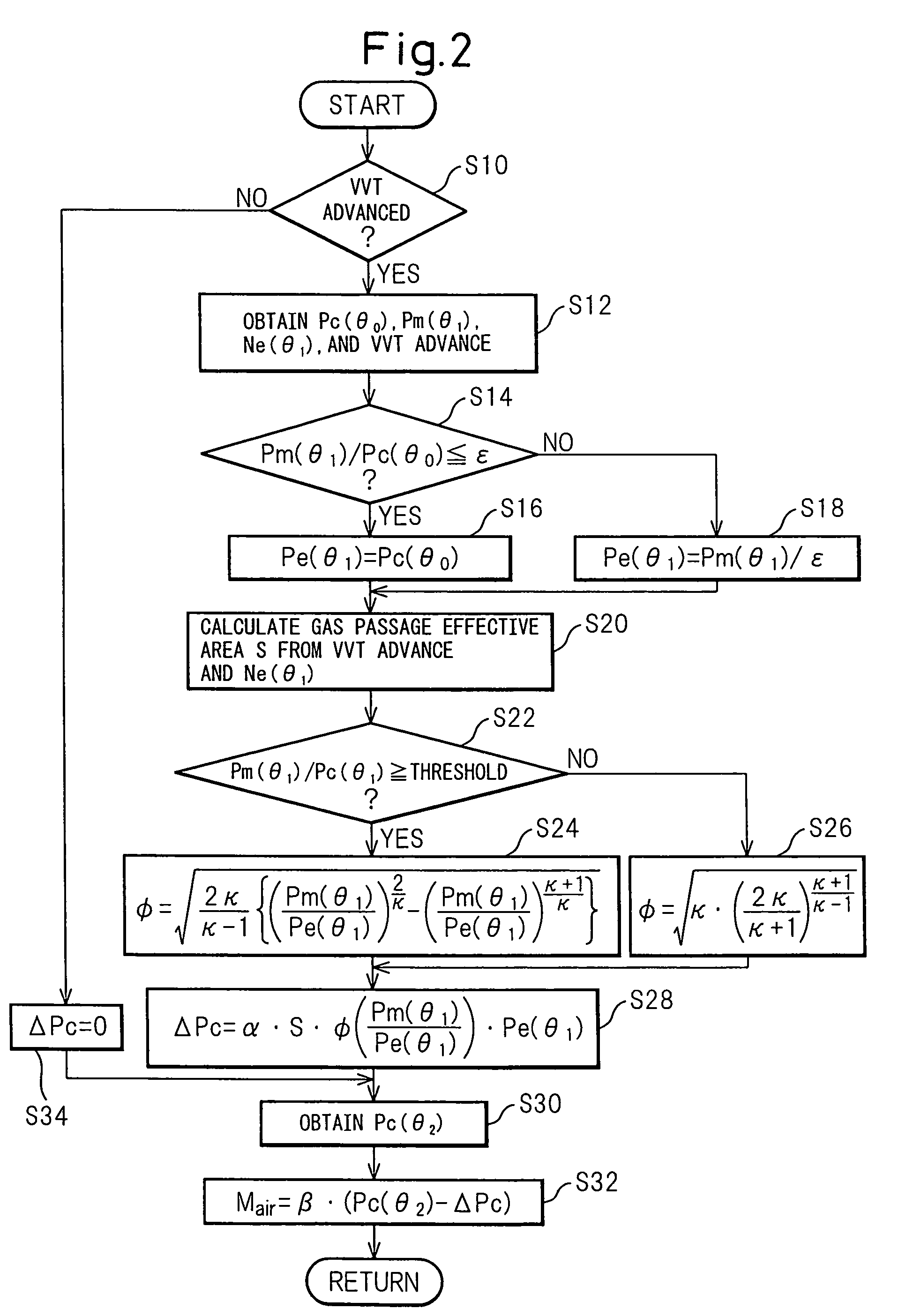

Control system and control method of internal combustion engine

ActiveUS7367318B2Low costValve arrangementsElectrical controlExhaust valveExternal combustion engine

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com