Patents

Literature

1900results about "Fruits/vegetable preservation by dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

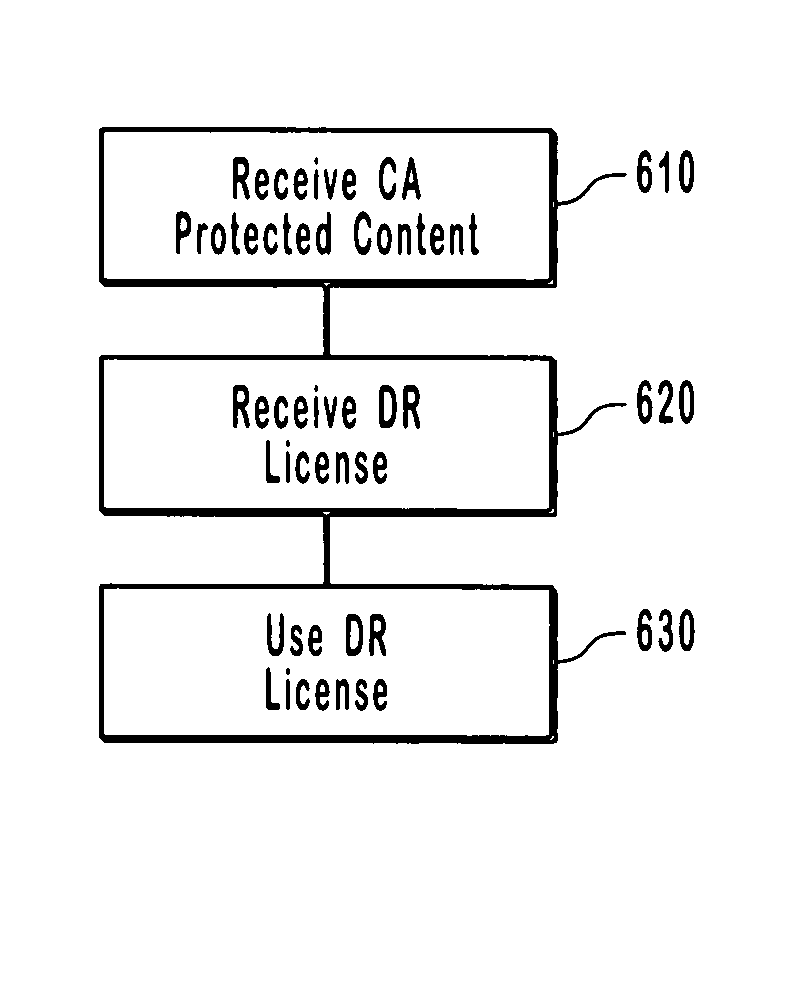

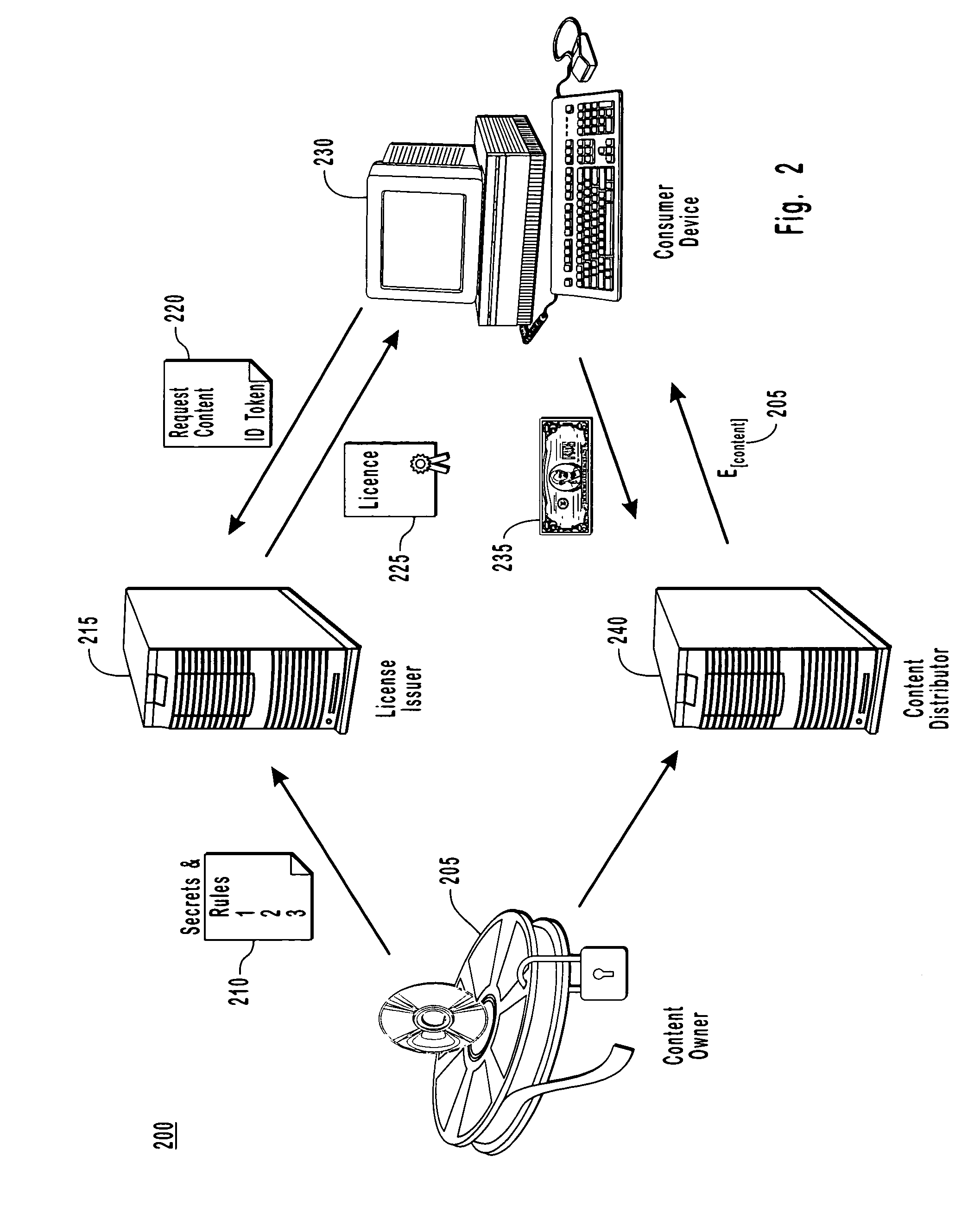

Conditional access to digital rights management conversion

ActiveUS20050182931A1Drying solid materials with heatUser identity/authority verificationSecurity kernelDigital rights management system

The present invention provides for an interface between two seemingly incompatible and different content protection systems. Accordingly, protected content may be transferred between the respective security kernels of a conditional access (CA) and digital rights management (DRM) systems, while maintaining security of the content and any associated protection information. The transfer and consumption of protected content and the associated content protection information may be achieved by temporarily or permanently binding the respective security kernels of the CA and DRM systems, transcribing content protection information, and potentially transcribing the content.

Owner:MICROSOFT TECH LICENSING LLC

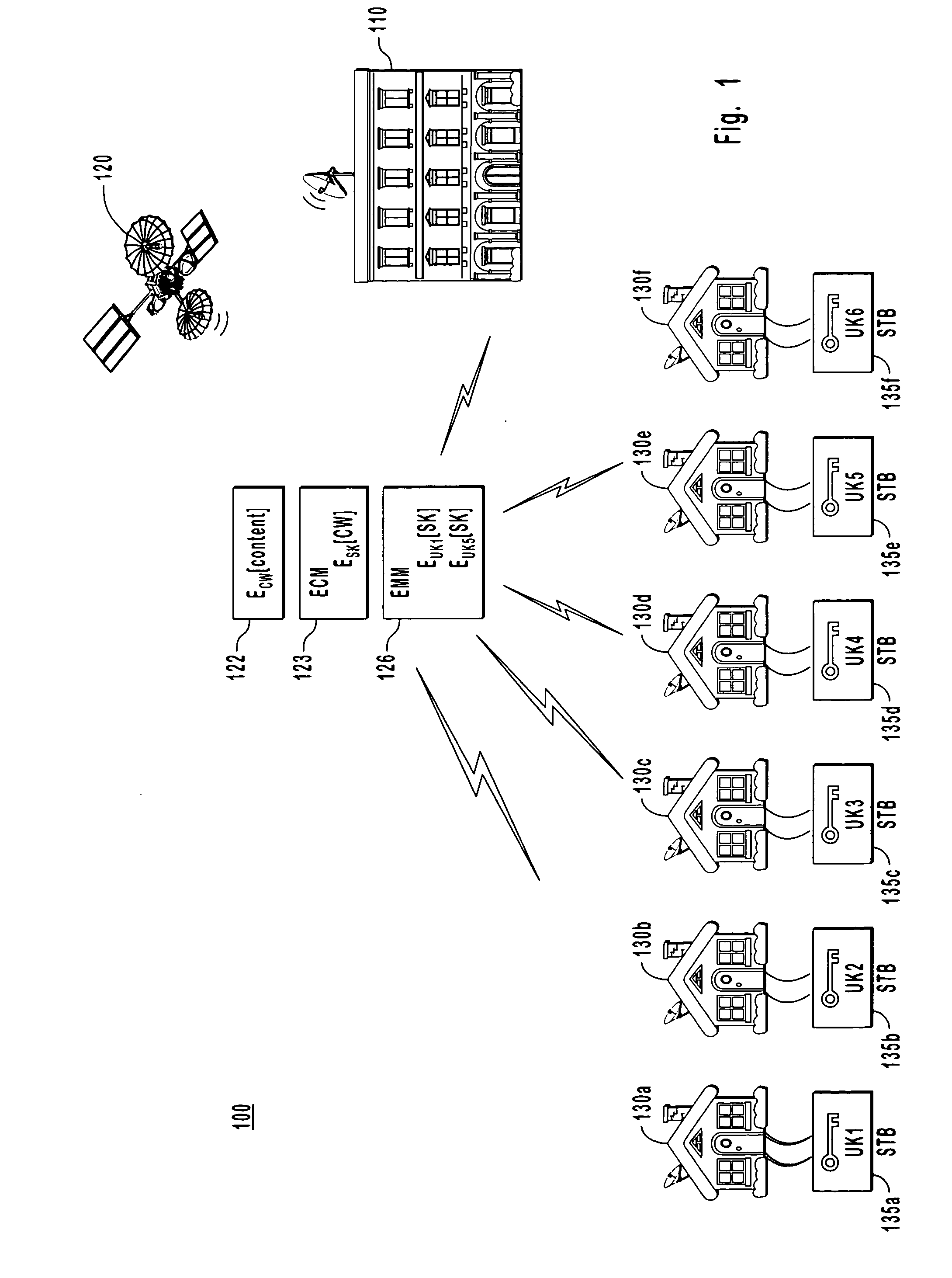

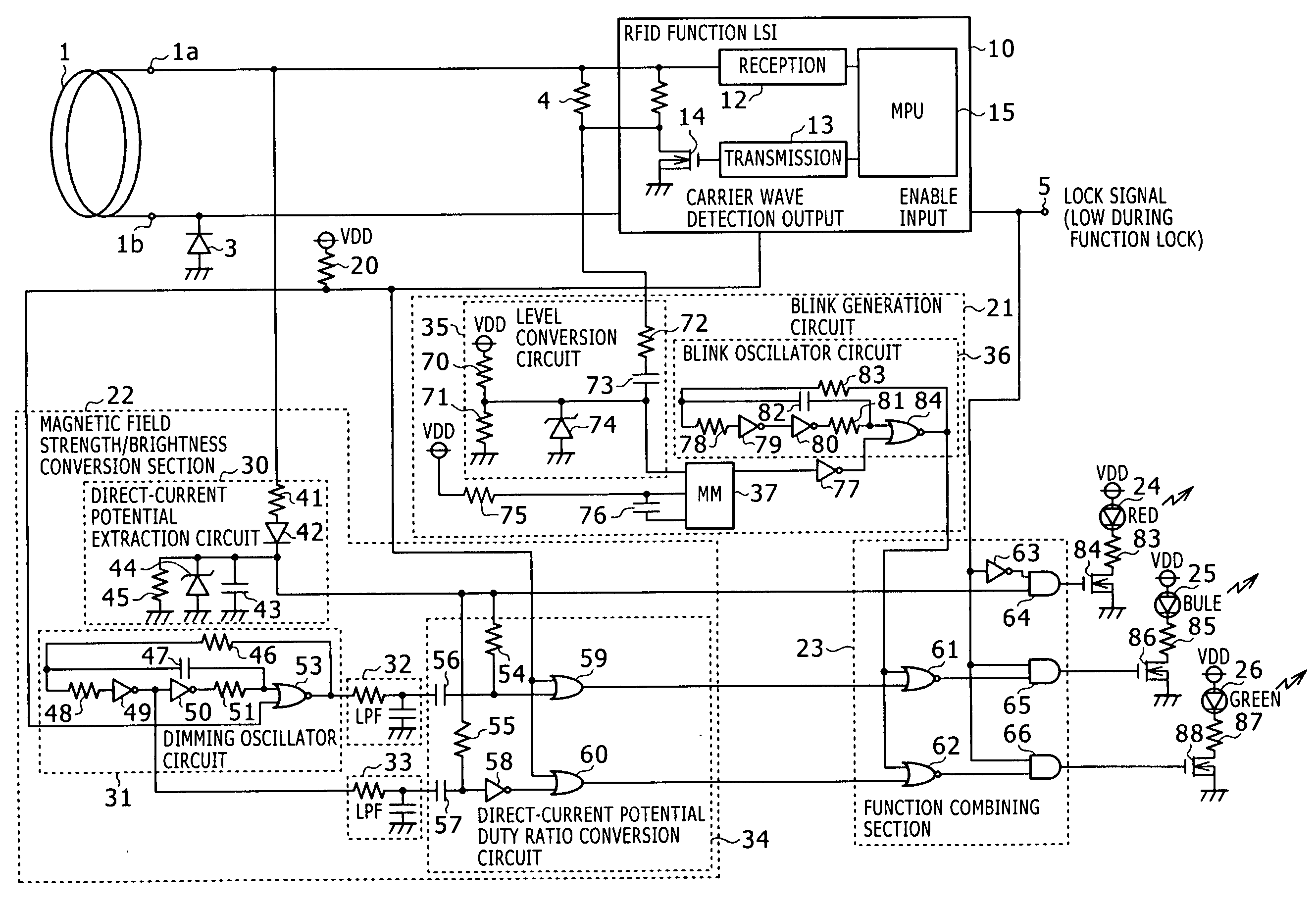

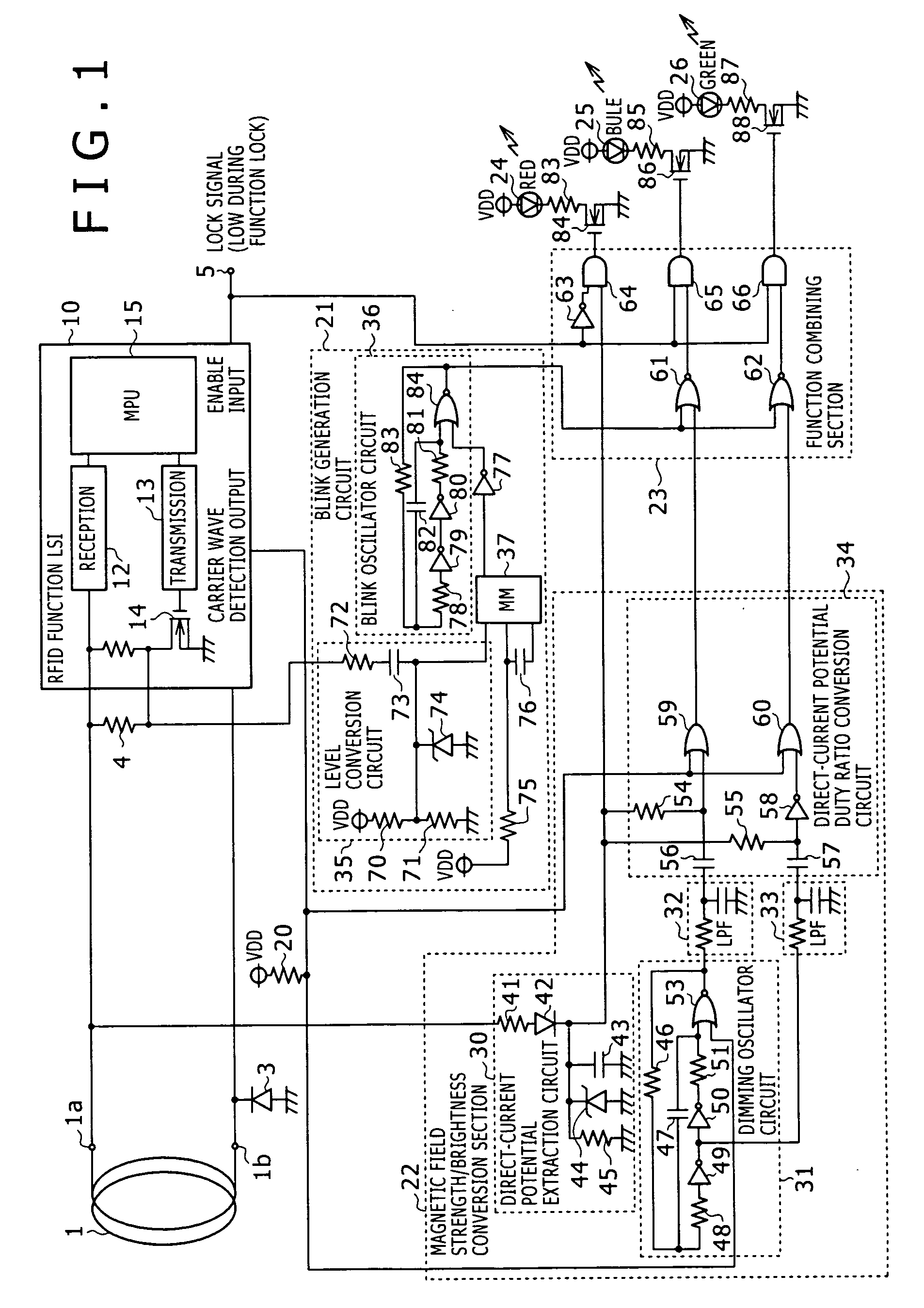

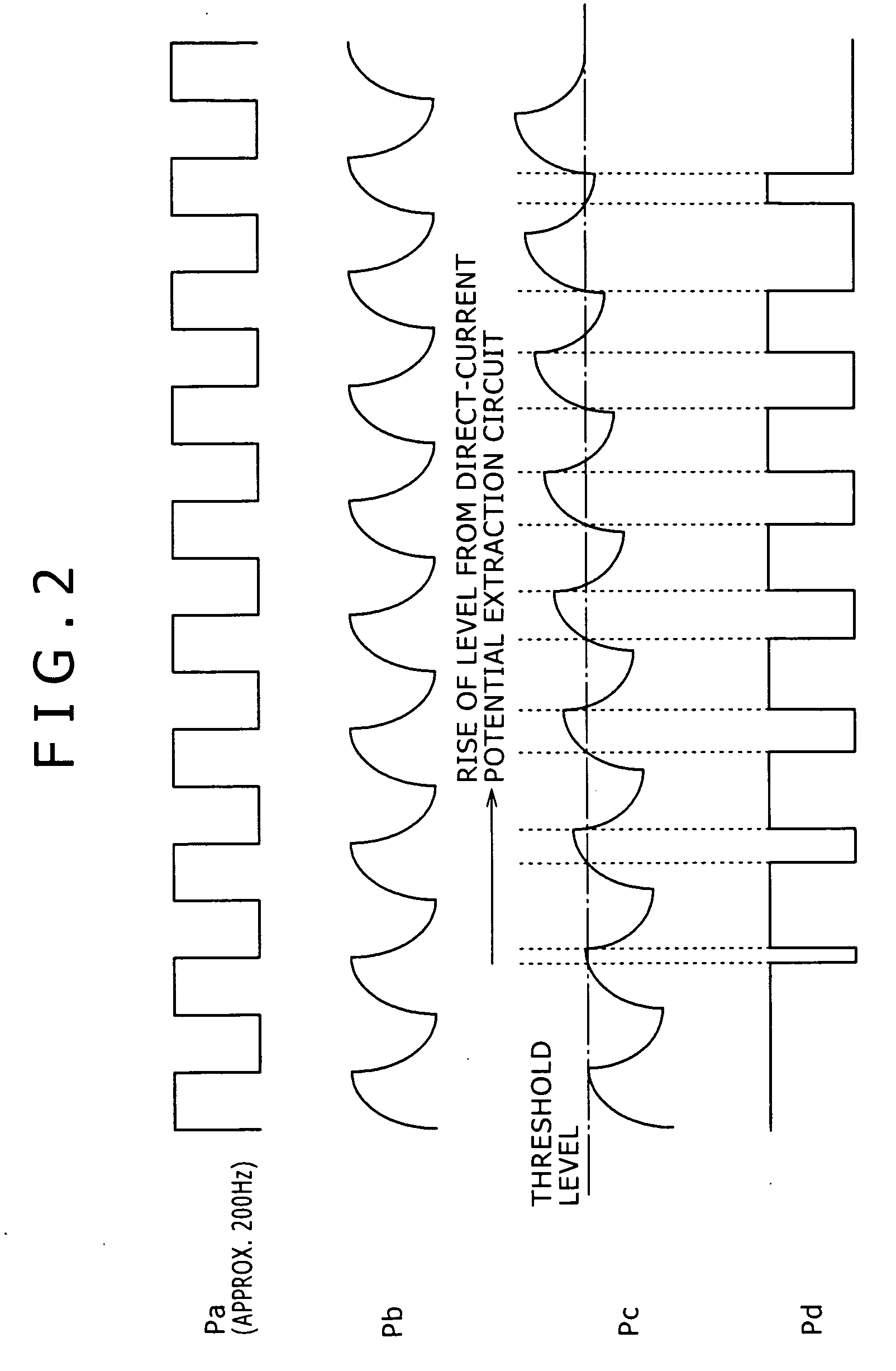

Short-range wireless communication apparatus and cellular phone terminal

InactiveUS20060160488A1User is notifiedAgriculture tools and machinesDrying solid materials with heatCarrier signalEngineering

There is provided a short-range wireless communication apparatus and a cellular phone terminal that can surely and immediately notify a user of the optimum distance between a contactless IC card reader / writer and a contactless IC card not through an MPU or a CPU and if the contactless IC card function is locked, surely notify the user as such. In an RFID card, a magnetic field strength / brightness conversion section adjusts the brightness of two LEDs in accordance with the detected magnetic field strength of a carrier wave. A blink generation circuit detects whether the RFID card is in a communication state and blinks the LEDs if so. A function combining section combines the functions to indicate the magnetic field strength and the communication state with the brightness and blinking of the LEDs. An LED with another color illuminates only when an RFID function LSI is in a lock state.

Owner:SONY CORP

Dried product and a drying process

InactiveUS6268012B1Minimize impactNot to damageFruits/vegetable preservation by dehydrationMeat/fish preservation by dryingWater activityFresh air

A dried fruit or vegetable has a water content in the range 4% to 7%, and has a water activity of 0.4. Substantially all of the cells of the dried product are undamaged. An air drying process is gentle and contains four phases, during which the temperature of the drying air is maintained at 60° C. In a first phase the relative humidity of the drying air is allowed to rise to between 50% and 55%, and is maintained substantially constant at this value during a second phase by maintaining exchange of the drying air with fresh air substantially constant. In a third phase of the process, the relative humidity of the drying medium is permitted to decrease relatively rapidly until the fourth phase commences, at which stage the relative humidity is permitted to asymptotically approach a predetermined relative humidity value. During the drying process, excessive temperature differences and relative humidity differences between the temperature and relative humidity, respectively of the drying medium and the product are avoided in order to minimize damage to the cellular structure of the product.

Owner:DTL

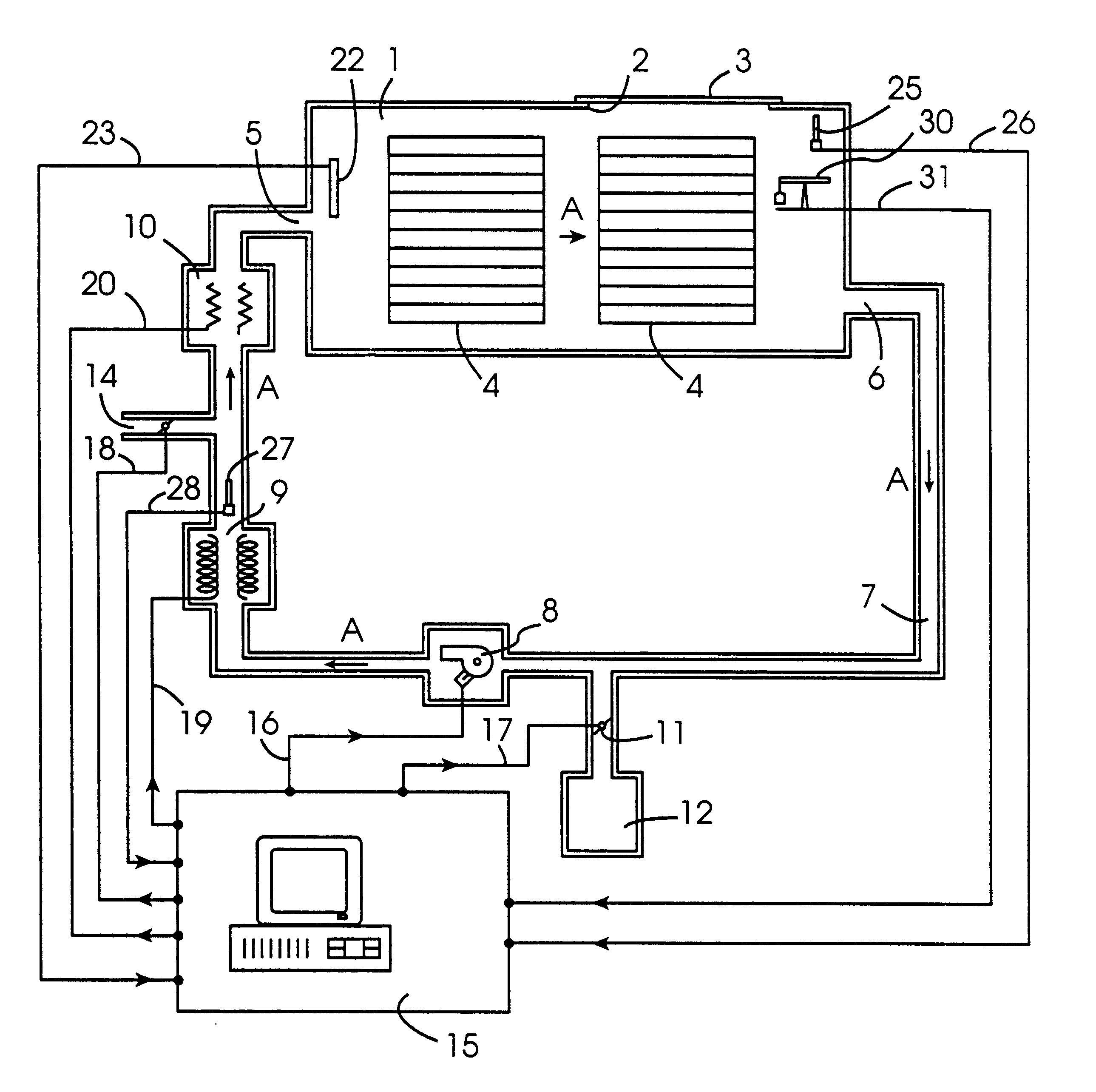

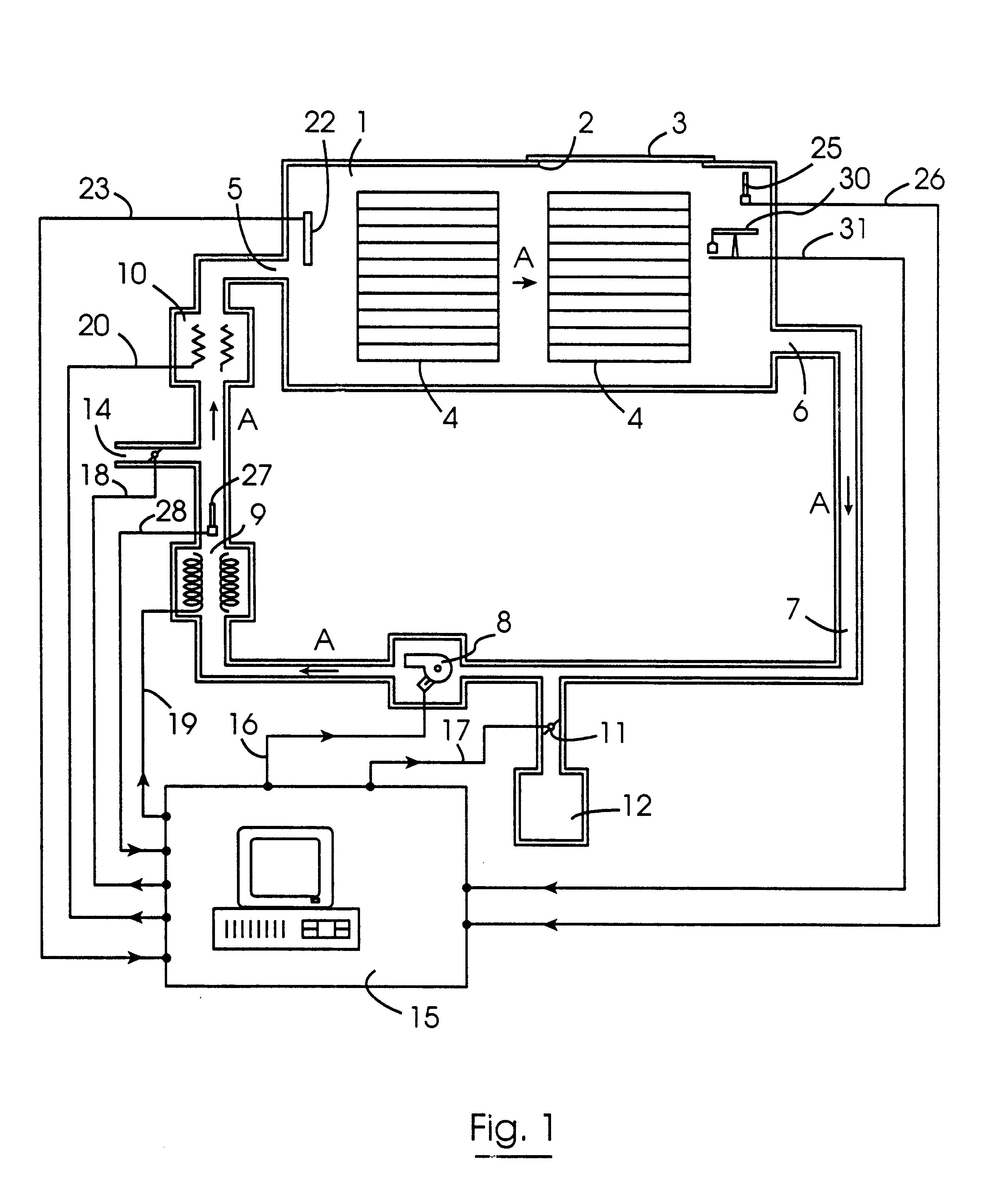

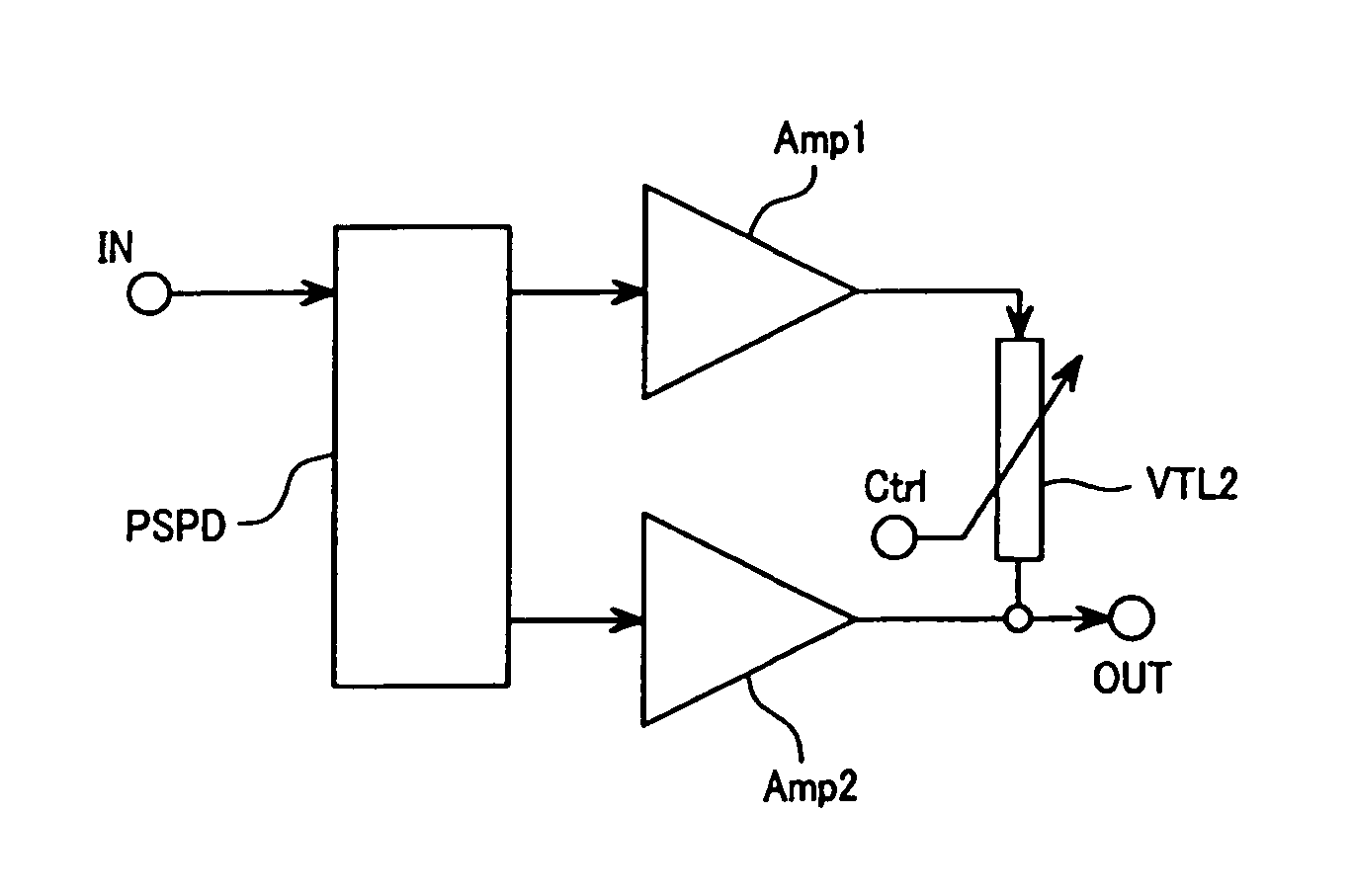

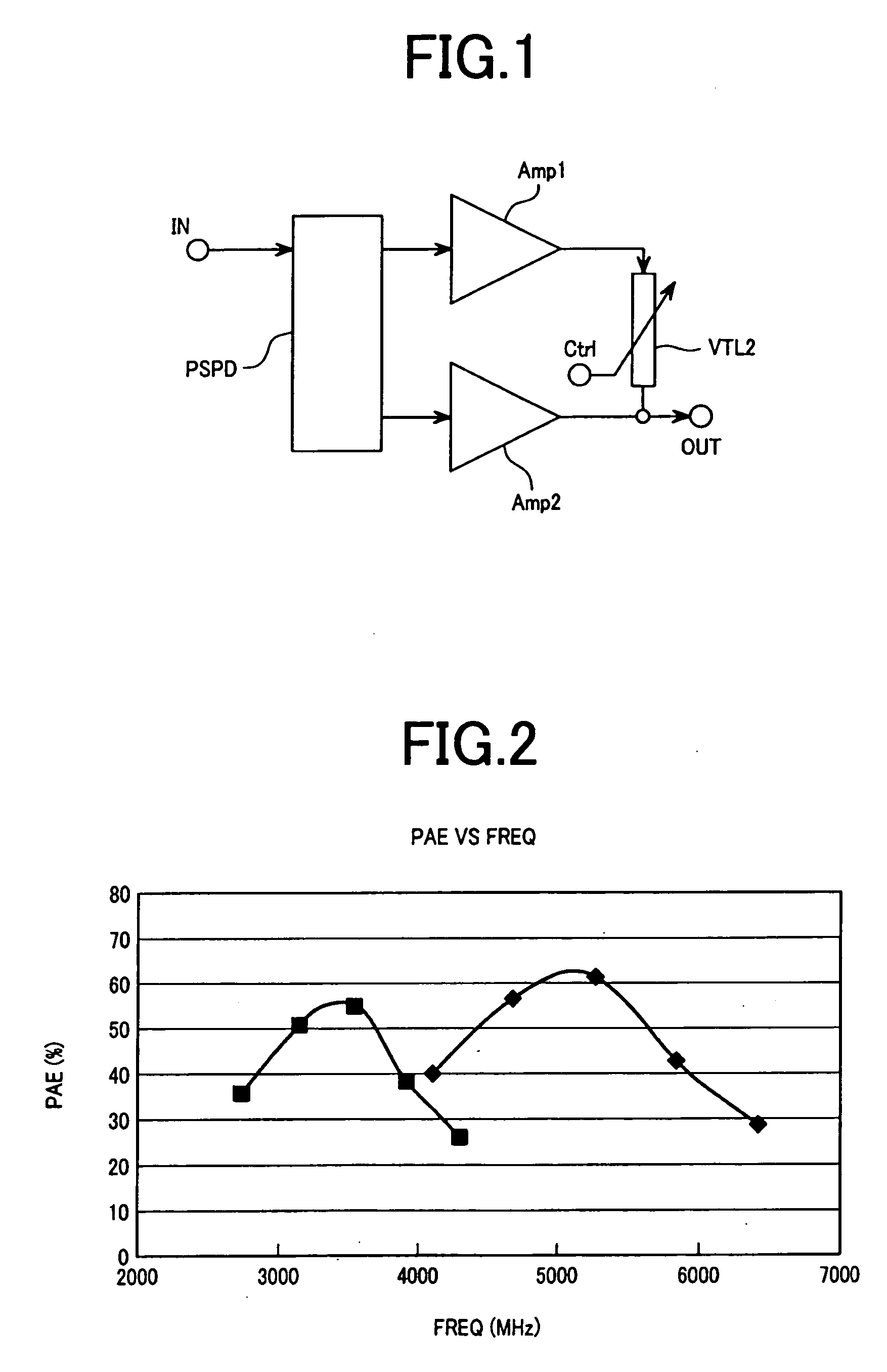

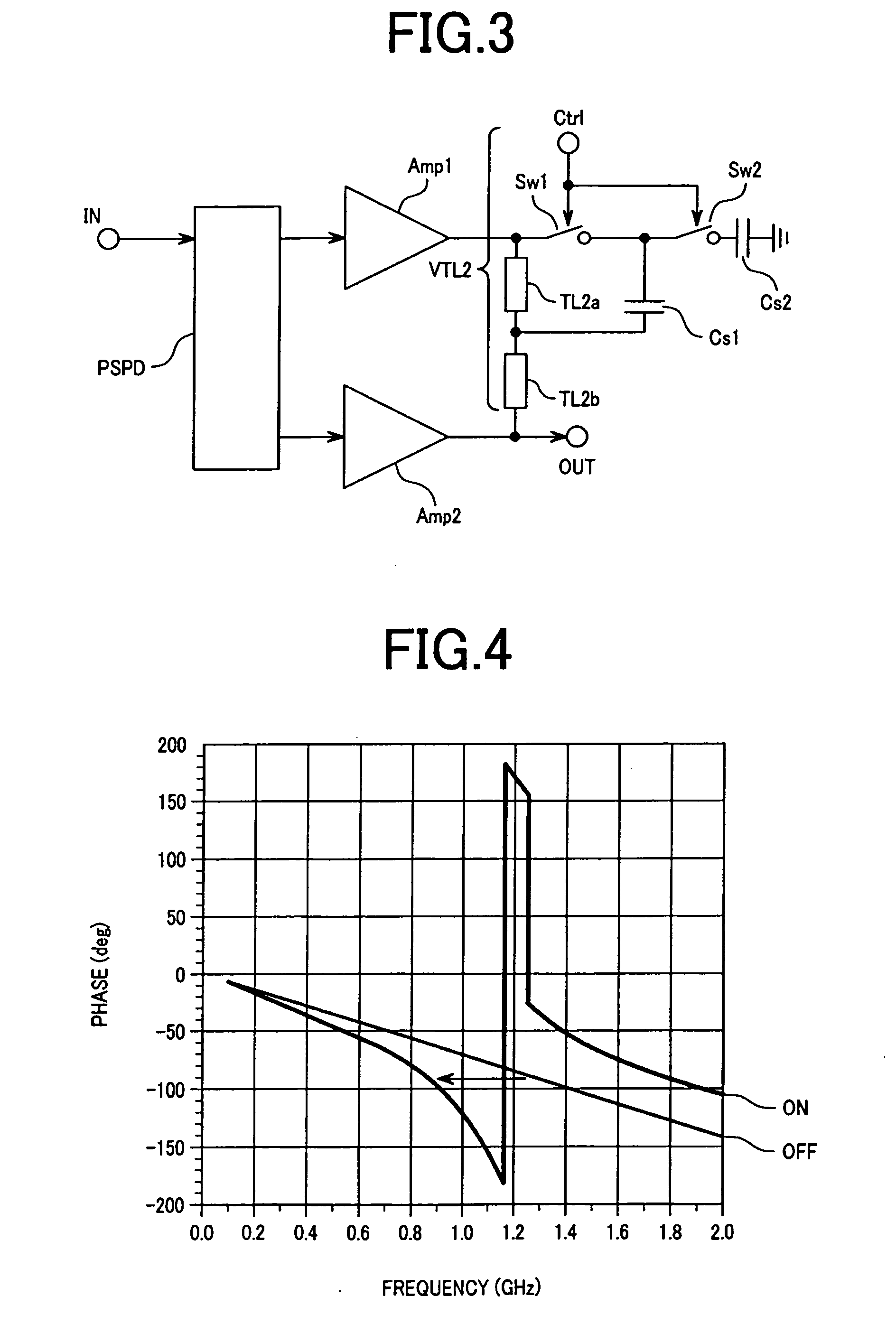

Power amplifier and transmitter

InactiveUS20070008032A1Simple structureImprove power efficiencyAgriculture tools and machinesDrying solid materials with heatMulti bandPower-added efficiency

A 90-degree phase delay power divider part PSPD is connected to an input side of a carrier amplifier Amp1 and a peak amplifier Amp2, and a variable electric length power combiner VTL2 is connected to an output side thereof. A control signal Sig is applied through a control terminal Ctrl of the variable electric length power combiner VTL2, and adjustment is performed in correspondence to a carrier frequency band of a carrier signal RFs so that an electric length of the variable electric length power combiner VTL2 becomes nearly 90 degrees. As a result, an electric length of an output power combining circuit of a Doherty type amplifier can be made variable, and a power-added efficiency can be enhanced for a multi-band or broad band.

Owner:HITACHI LTD

Method of combining freeze-dry and vacuum microwave drying to preparing fruits, vegetables and aquatic leisure food

InactiveCN101228896ARetain shapeRetain nutrientsFruits/vegetable preservation by irradiation/electric treatmentMeat/fish preservation by irradiation/electric treatmentFreeze-dryingDrying time

The invention relates to a method for preparing fruit-and-vegetable or aquatic leisure foods by freeze-drying and subsequent vacuum microwave combination, which belongs to a field of leisure food processing technique. The main process of the invention is that: after handpicking, blanching for extinguishing enzyme or blanching curing, then cooling soaking and quick freezing in a flavor liquid, the fruit and vegetable or aquatic raw material is freeze-dried to reduce the water content to 60-30 percent and then is vacuum-microwave dried to lead the final water content of fruit and vegetable to be less than 5 percent. The invention adopts a novel combined drying technique of freeze-drying before and subsequent vacuum microwave which is carried out by stages. The technique can not only maintain the nutrition and the form of the product in the maximal degree, but also remarkably shorten the drying time, reduce the drying energy consumption, save the cost and can have remarkable expansion effect at the same time, which improves the comprehensive quality of leisure foods.

Owner:JIANGNAN UNIV +1

Process for preparing dehydrated vegetable products

Owner:ROCKSTROM ERIK I

Sulfurless preserved fruit confect and its producing method

The invention relates to preserved fruit without additive and a production method, which comprises that the raw material of the preserved fruit undergoes low-temperature refrigeration drying. The method realizes the production method of the preserved fruit without additive, in particular the sulfur-free production method, and meanwhile, the color of the raw material is maintained.

Owner:BEIJING YUSHIYUAN FOOD

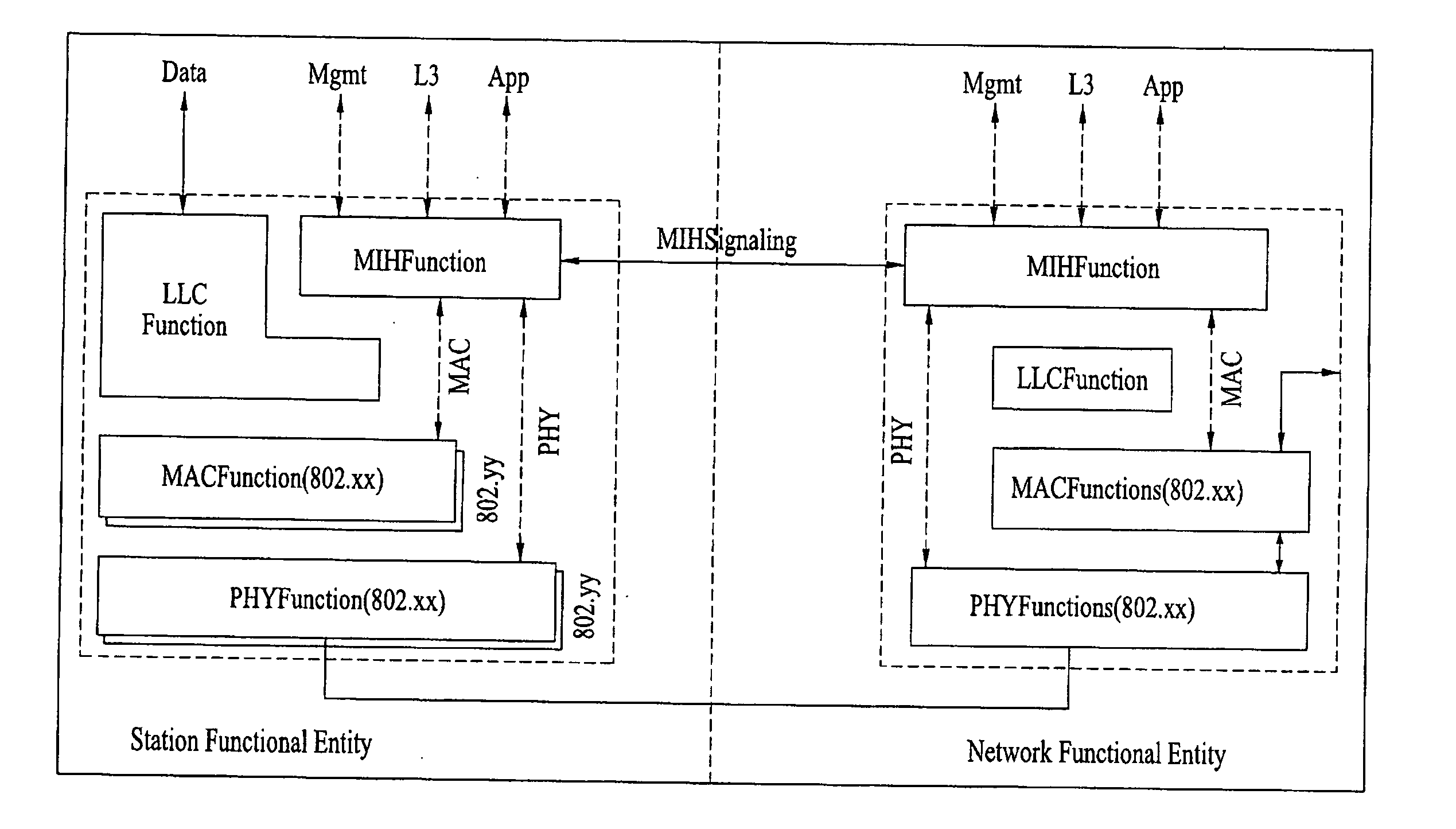

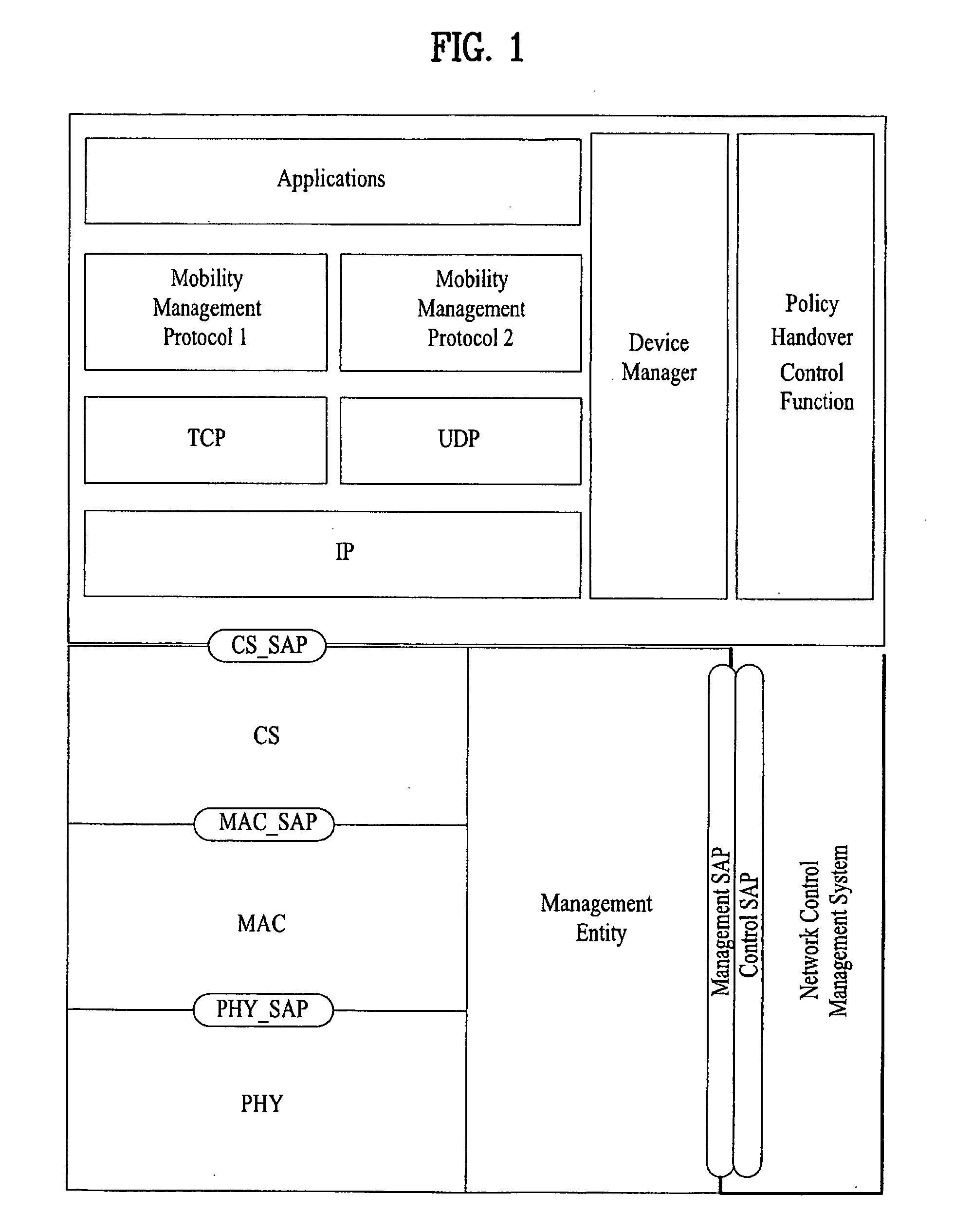

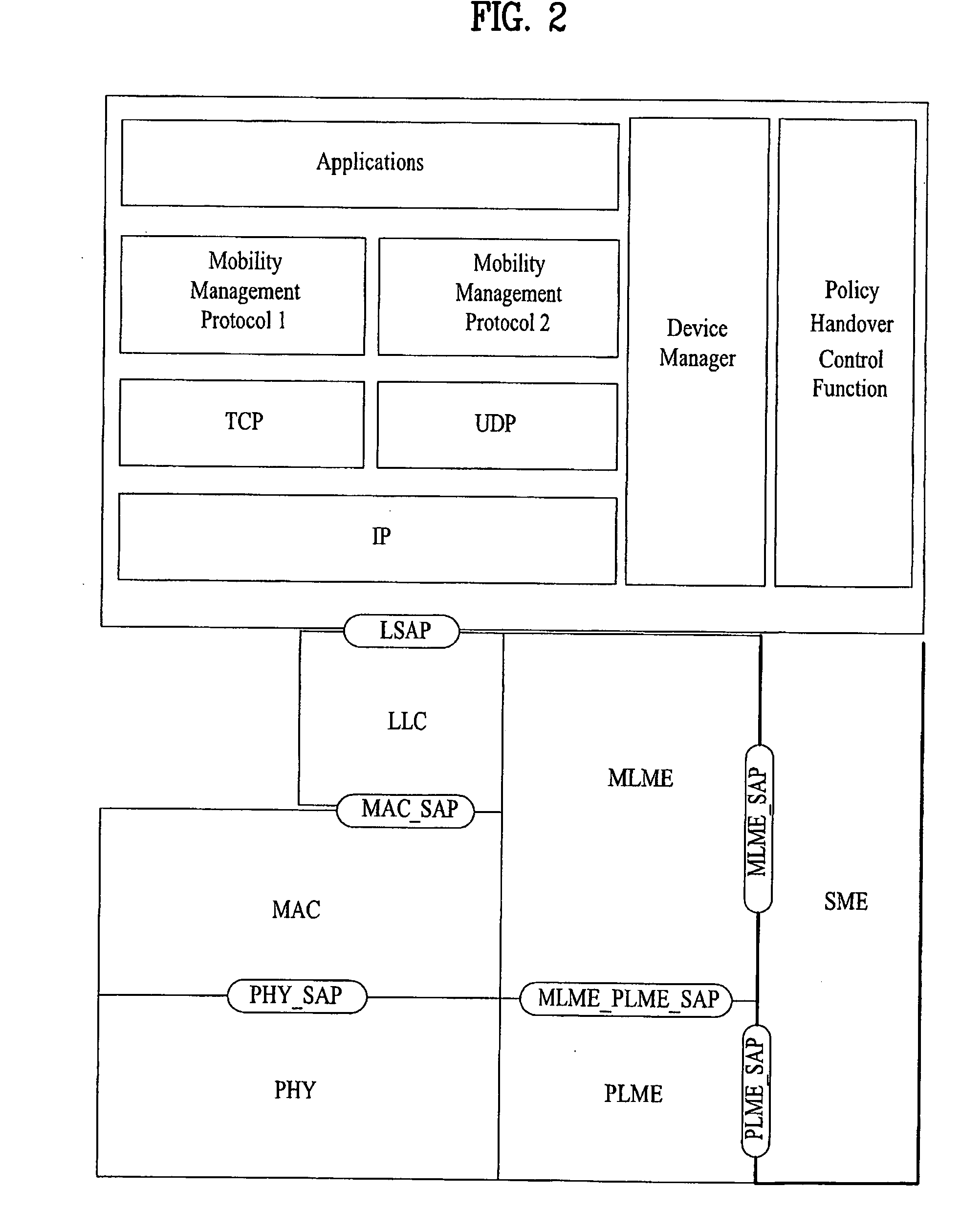

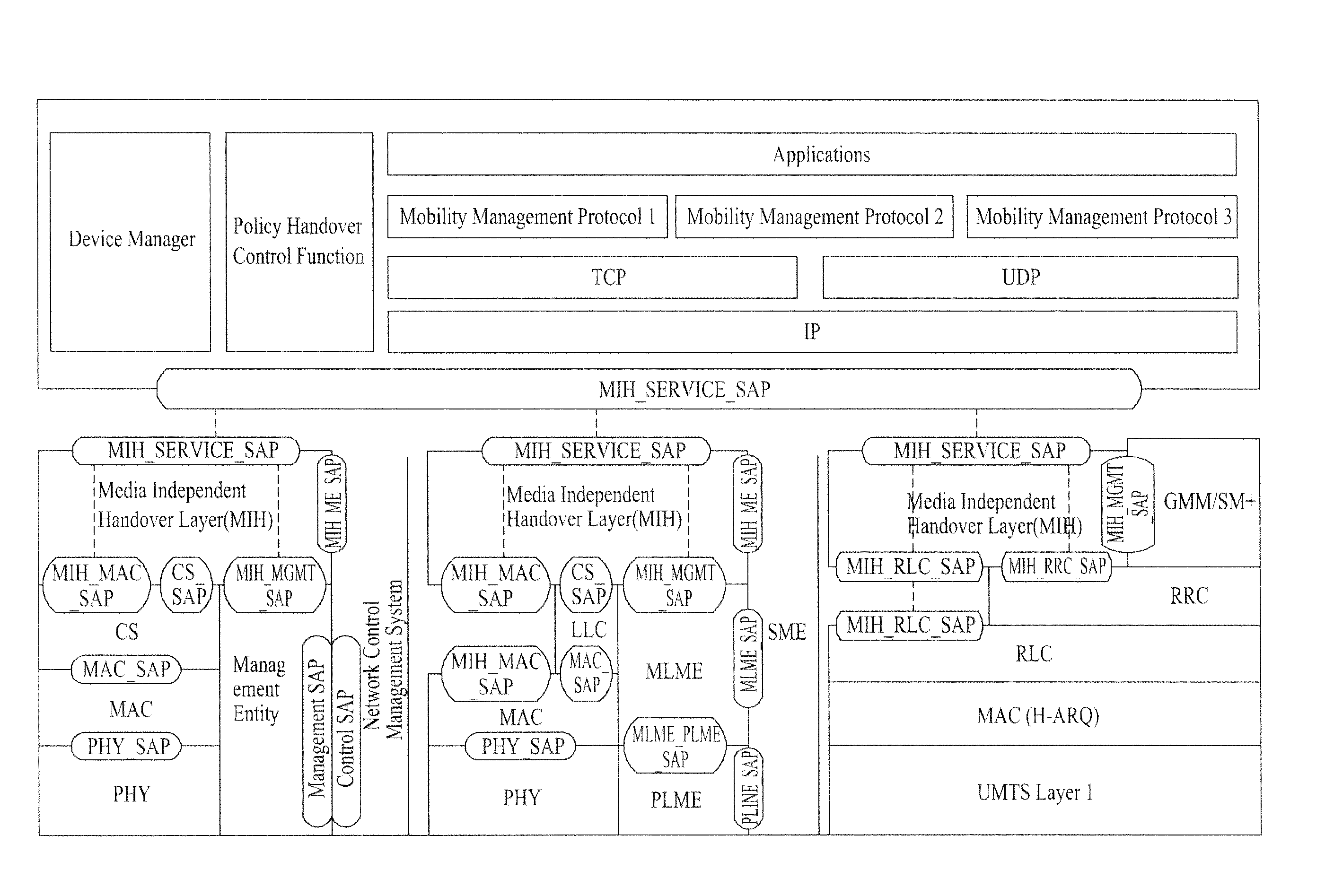

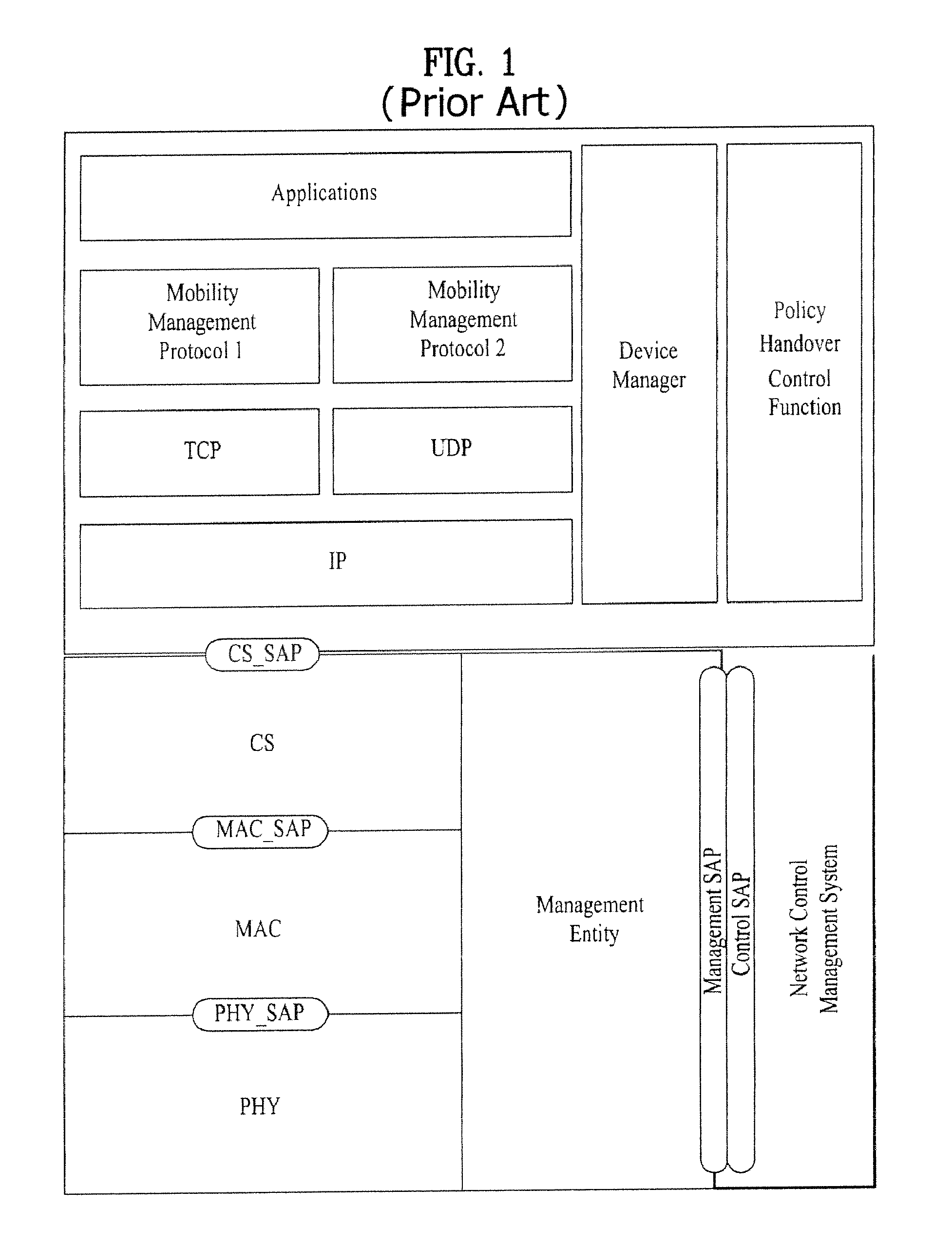

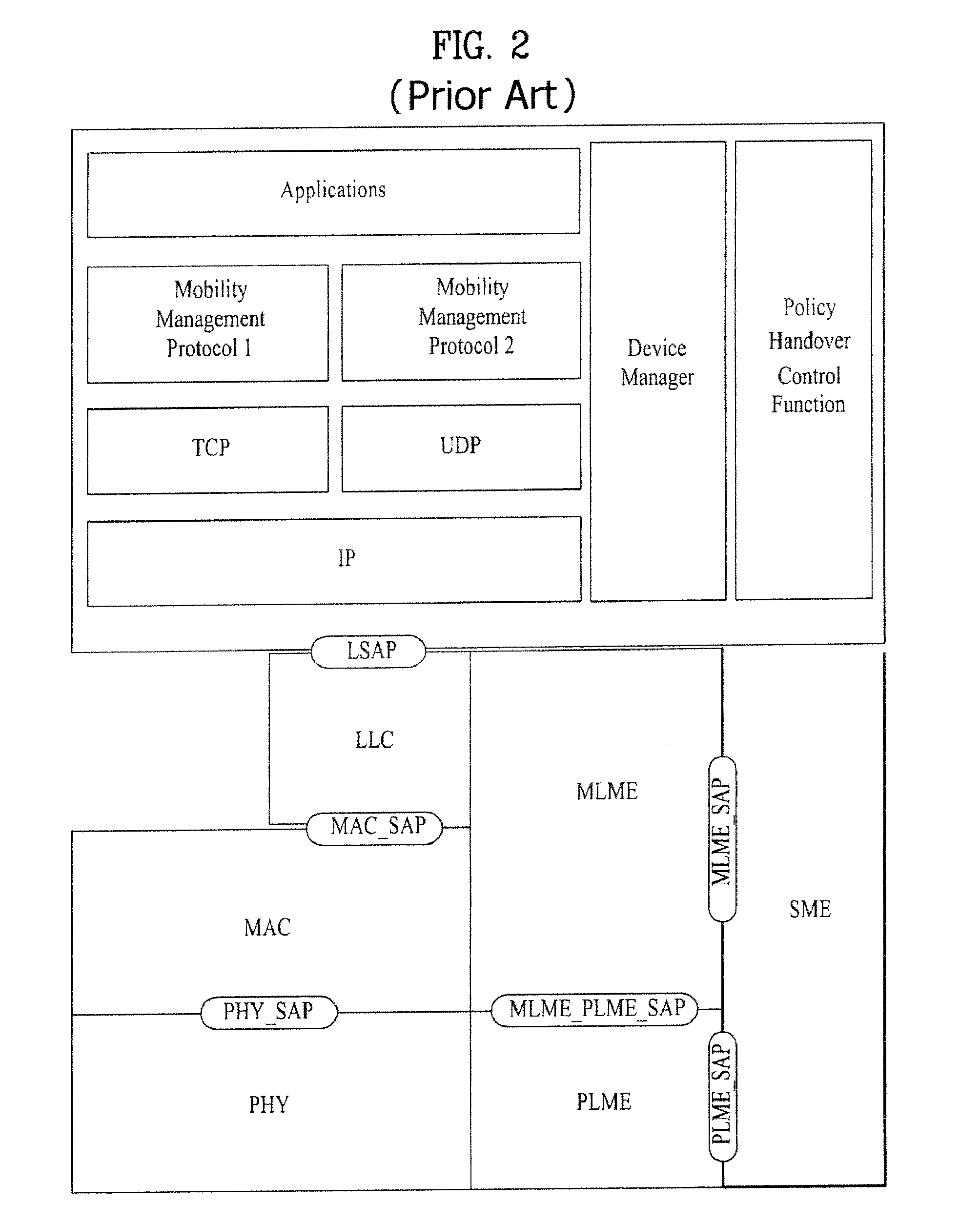

Method of initializing and establising links in a multi-mode mobile terminal

InactiveUS20060259598A1Eliminate the problemAgriculture tools and machinesDrying solid materials with heatHeterogeneous networkHandover

A method of performing a handover with at least one of a homogeneous and heterogeneous network is disclosed. More specifically, the method comprises establishing a heterogeneous network handover module for converging information from the at least one network interface module associated with the at least one of a homogeneous and heterogeneous network into a unified presentation and receiving a message for powering on at least one network interface module in a mobile terminal from the heterogeneous network handover module. The method further comprises performing a power on operation for activating the at least one network interface module and transmitting a confirmation message for indicating a power on operation status to the heterogeneous network handover module.

Owner:LG ELECTRONICS INC

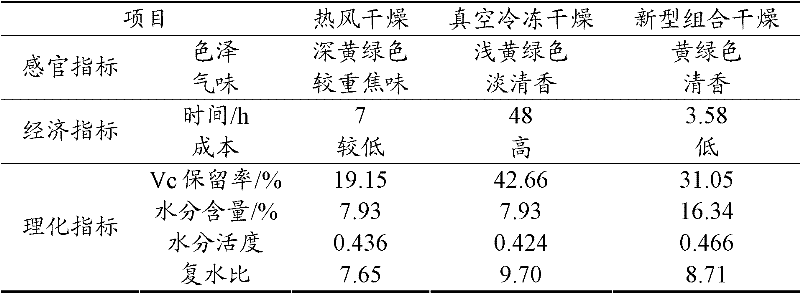

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

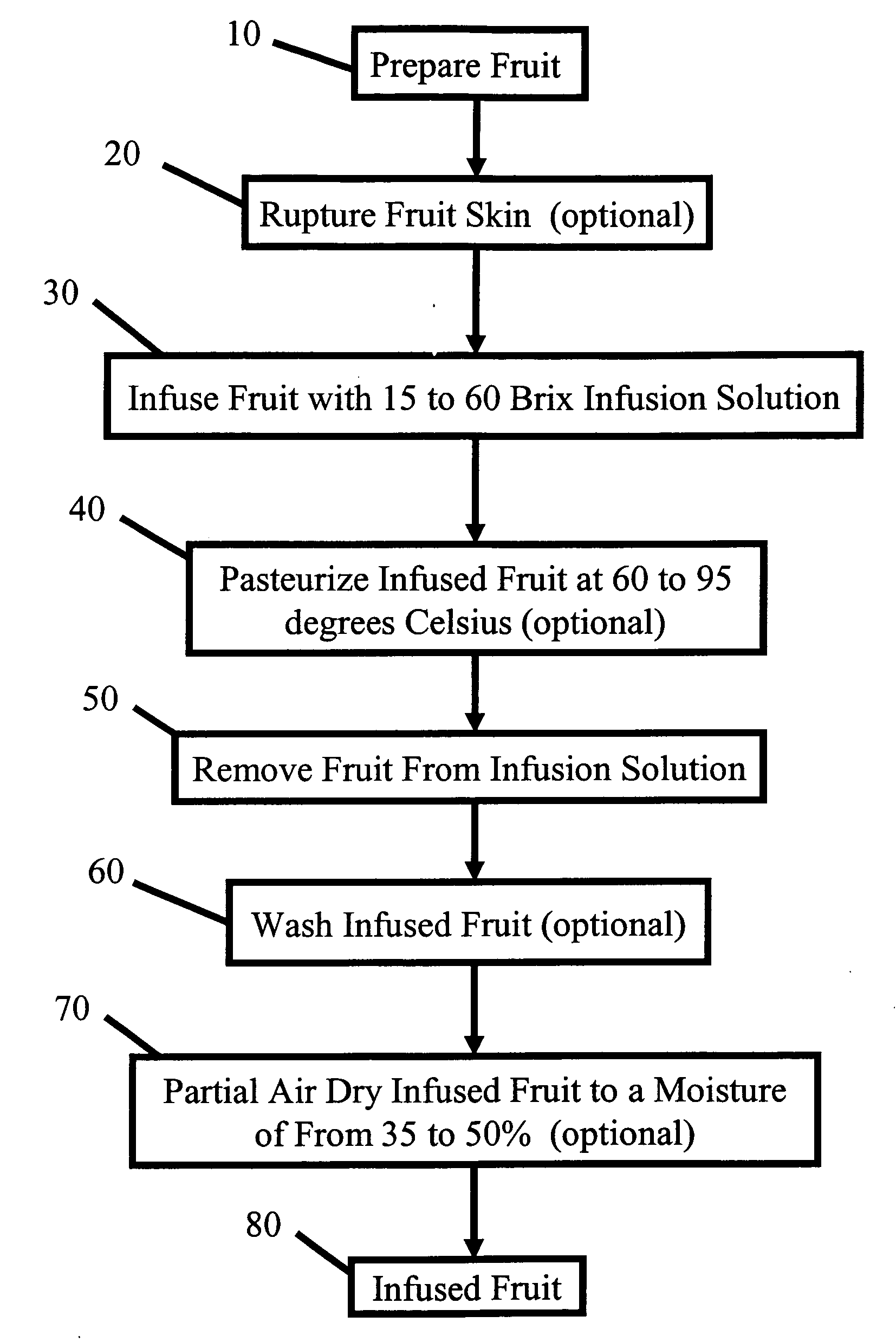

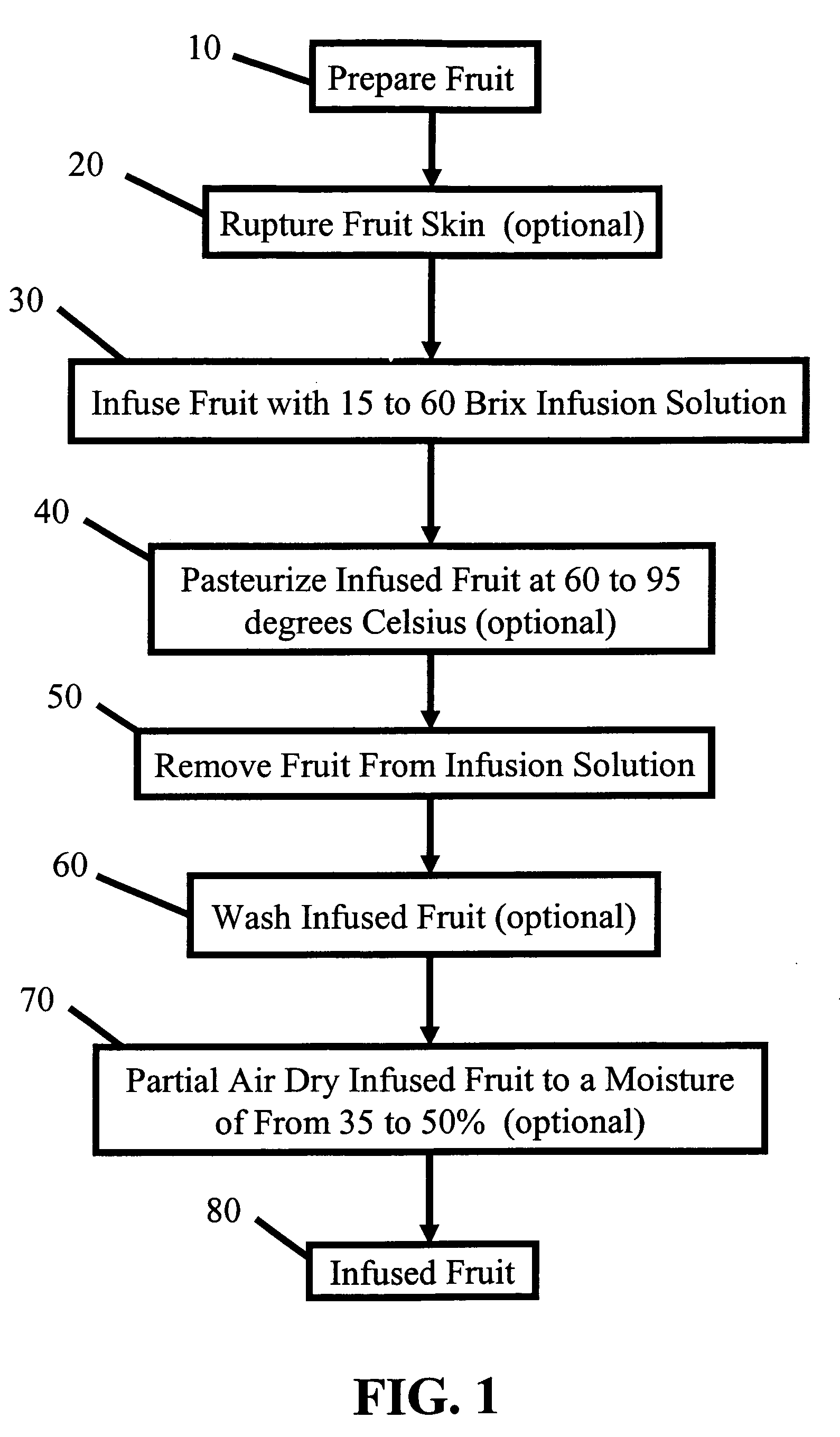

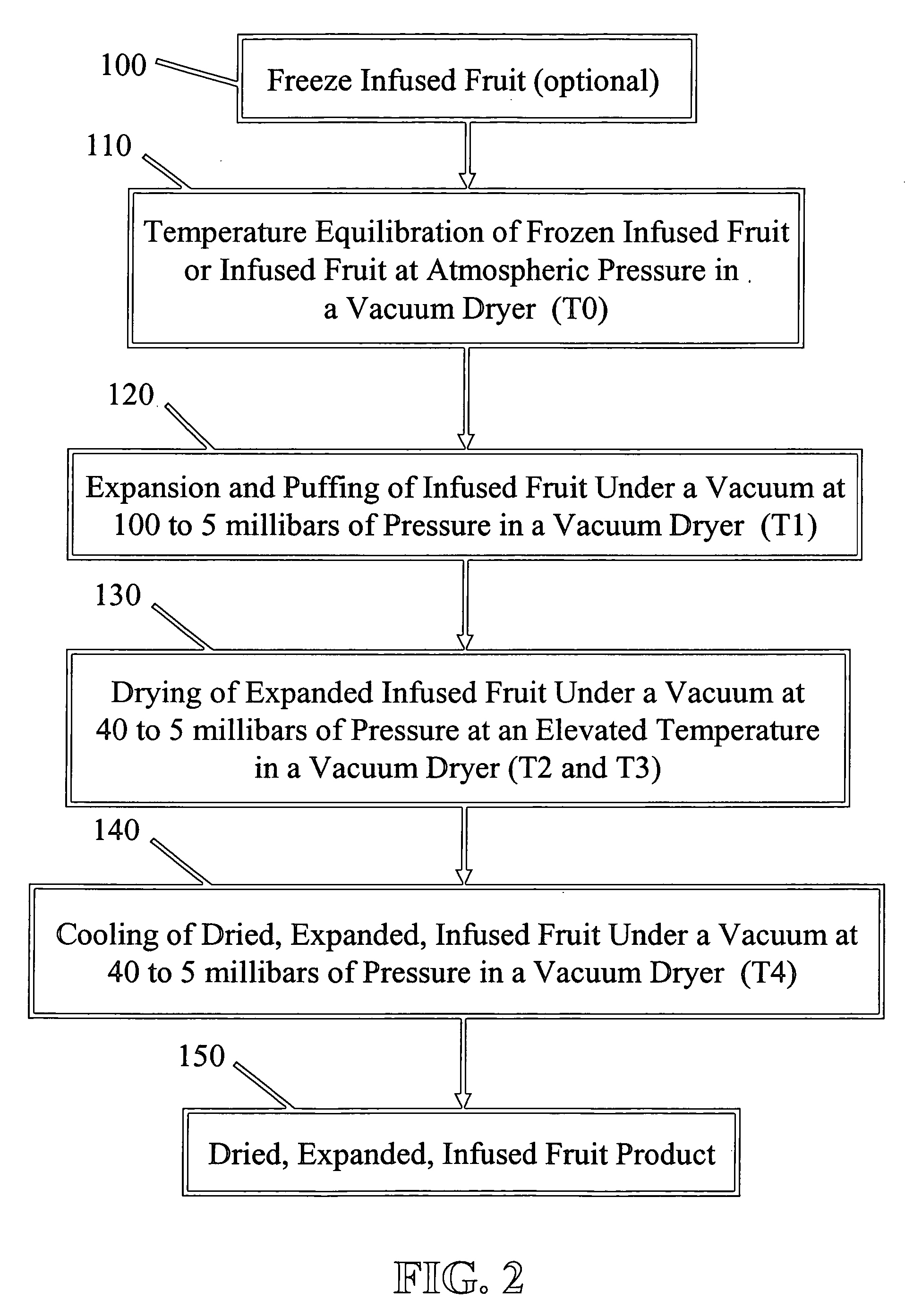

Vacuum puffed and expanded fruit

InactiveUS20060013925A1Light and crisp tasteLow buoyant densityFood shapingFruits/vegetable preservation by coatingWater activityDried fruit

A method is disclosed for preparing an expanded, vacuum puffed, dried fruit product. The method includes infusing the fruit with a low Brix infusion solution and then expanding the fruit by subjecting it to a vacuum at elevated temperature followed by drying of the fruit under a vacuum at elevated temperature and finally cooling of the fruit under lowered temperature while maintaining the vacuum. The product produced by the method is light, crisp, and has a low water activity and a low buoyant density.

Owner:GRACELAND FRUIT +1

Composite vegetable powder products and method for preparing the same

InactiveCN101095493ACompatibility is reasonablePreserve nutritional valueFruits/vegetable preservation by freezing/coolingFood preparationFlavorPre cooling

The invention relates to a kind of compound vegetable powder and the production method. The comprised components and their weight proportion are as follows: cabbage powder 20-85%, west orchid powder 0-50%, and other vegetable powder of cruciferae 0-30%. The method comprises following steps: picking raw material, selecting, pre-cooling, washing, blanching, cooling, cutting to sheet or block, freezing, subliming drying, hydrolyzing drying, grinding, matching, vacuum packing. The product is characterized by reasonable matching, flavor for absorption, health-care effect. The process is reasonable and the nutrition and biological activity in vegetable are retained at maximum degree because of the vacuum freezing technique.

Owner:SHANGHAI RIYI AGRI TECH

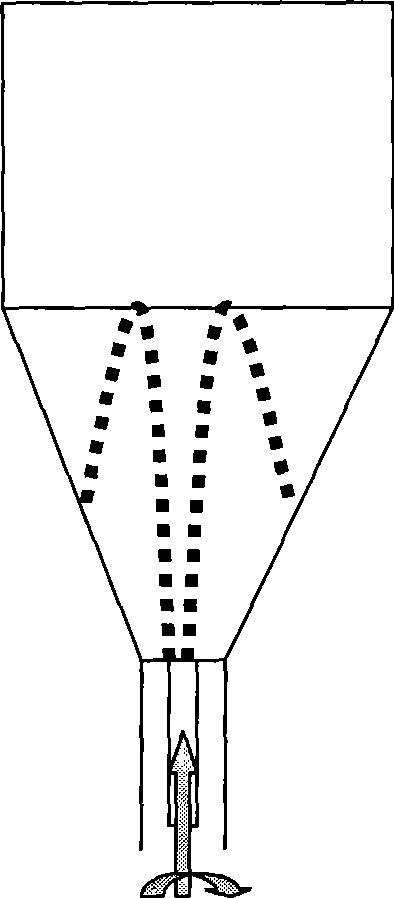

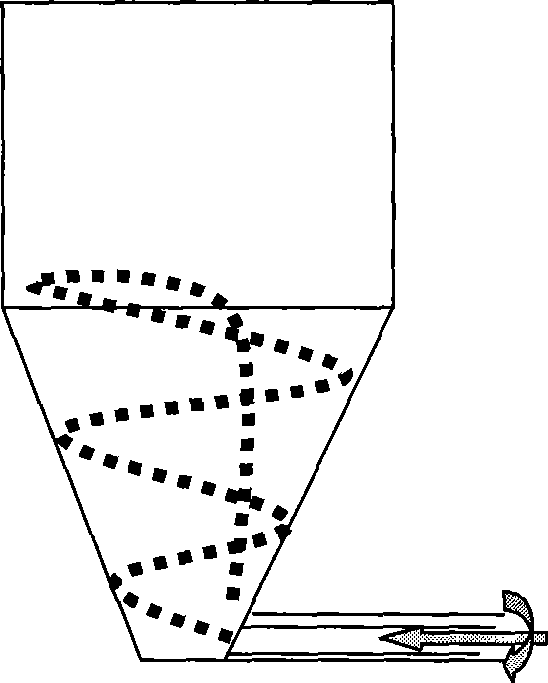

Sprouted auxiliary means for improving microwave desiccation homogeneity of granular garden stuff

InactiveCN101433233ASpray evenlyImprove uniformityFruits/vegetable preservation by dehydrationFood treatmentAir volumeAgricultural engineering

The invention discloses an auxiliary spouting method for improving the uniformity of microwave drying of granular fruits and vegetables, which belongs to the technical field of the processing of fruit and vegetable food. Pretreated fruits and vegetables are placed into a microwave spouting drying bed, the microwave power and the air intake heating temperature are preset, then the central air intake volume and the air intake angle of the spouting bed are adjusted to ensure that a dried material spouts in the spouting bed in different forms, the air intake pressure and the air intake angle are adjusted according to different drying stages of the material at the same time, and the microwave energy received by the material is more uniform than that of the prior fixation or fluidization mode; and the microwave adopts internal heating, so the moisture of the dried fruits and vegetables is effectively and quickly evaporated to achieve the aim of uniform drying. Through the auxiliary spouting method, the material is uniformly heated in a microwave field, the moisture is evaporated quickly, the drying time is greatly shortened, the prior color and luster, shape and nutrient substances of the dried fruits and vegetables can be furthest retained, and the dried fruits and vegetables have porous structures and good rehydration property, thereby obtaining a high-quality dehydrated fruit and vegetable product.

Owner:JIANGNAN UNIV +1

Productive technology for preserving and processing fruits and vegetables

InactiveCN101766209AMaintain nutritional qualityImprove food safetyFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingNutrition qualityNutritional quality

The invention belongs to productive technology for preserving and processing fruits and vegetables, mainly comprising the processes of grading selection, cleaning, arranging and splitting, preserving, dewatering and sterilizing, packing and refrigerating and the like. The technology is mainly characterized in that after two times of sterilizing by ozone and ultraviolet rays in sequence, the fruits and vegetables are soaked by an natural edible antistaling agent to form a film so as to carry out atmosphere packaging by mixed gas, thereby maximally maintaining nutritional quality of the fruits and vegetables, improving edible safety of the fruits and vegetables and prolonging sale and preservation period.

Owner:乔维汉 +2

Far infrared unit for dewatering vegetable

InactiveCN1689416AImprove qualityImprove quality, drying speedDrying solid materials with heatFood processingPulp and paper industryHeat transfer efficiency

The far infrared vegetable dewatering apparatus includes drying cabinet, transmission mechanical,, conveying mechanism and heater. The drying cabinet has material feeding port and induced draft port in the top and discharge port and air intake in the bottom. The present invention features that the drying cabinet is separated with partition boards into several layers with separated conveying mechanism, transmission mechanism, heating unit and guide board. The present invention has small size, convenient operation, fast drying speed, high heat efficiency and low power consumption, and the dried vegetable product has bright color and high quality.

Owner:SHANDONG UNIV OF TECH

Method of initializing and establishing links in a multi-mode mobile terminal

InactiveUS20100261475A1Agriculture tools and machinesDrying solid materials with heatEngineeringHeterogeneous network

A method of performing a handover with at least one of a homogeneous and heterogeneous network is disclosed. More specifically, the method comprises establishing a heterogeneous network handover module for converging information from the at least one network interface module associated with the at least one of a homogeneous and heterogeneous network into a unified presentation and receiving a message for powering on at least one network interface module in a mobile terminal from the heterogeneous network handover module. The method further comprises performing a power on operation for activating the at least one network interface module and transmitting a confirmation message for indicating a power on operation status to the heterogeneous network handover module.

Owner:LG ELECTRONICS INC

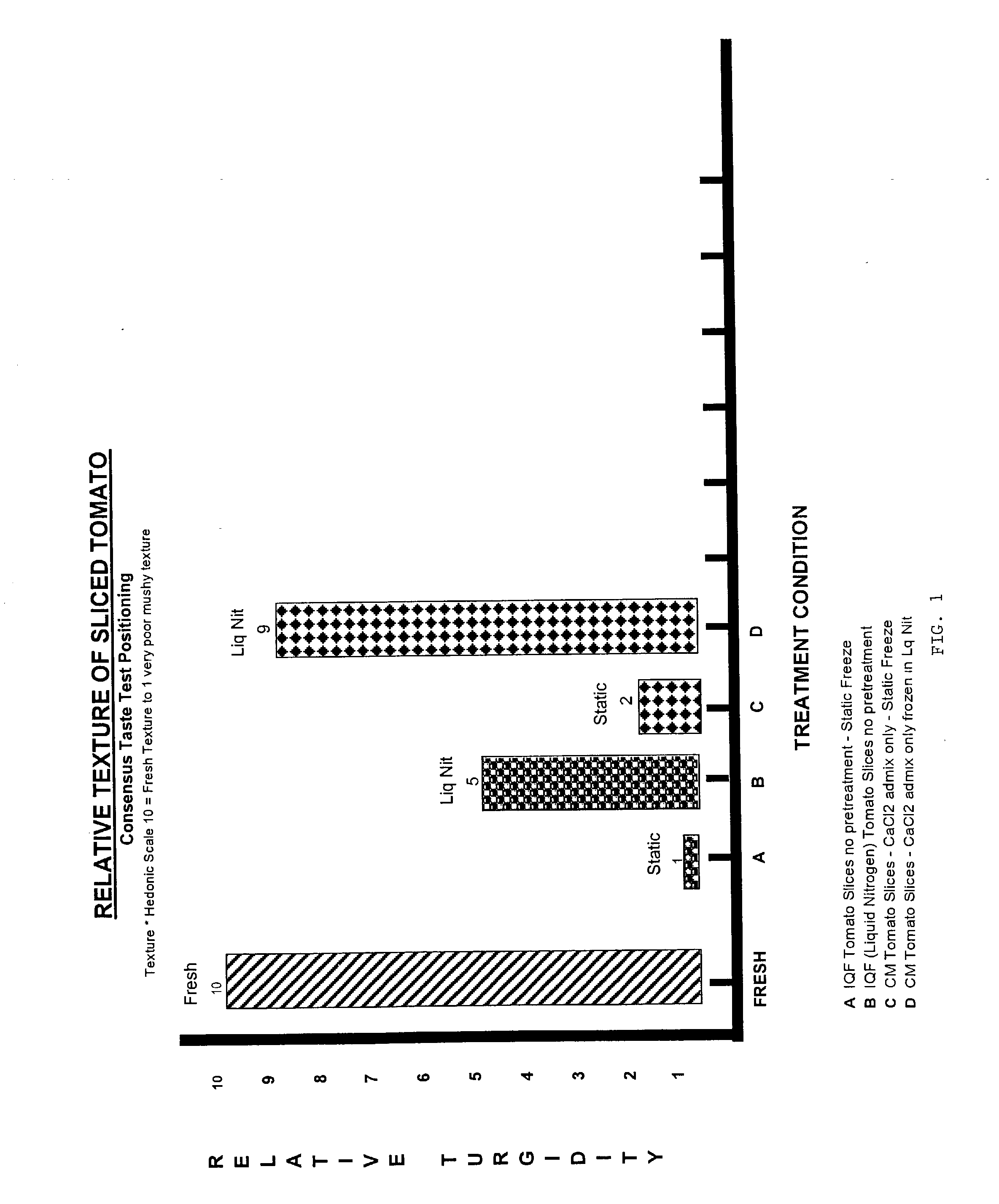

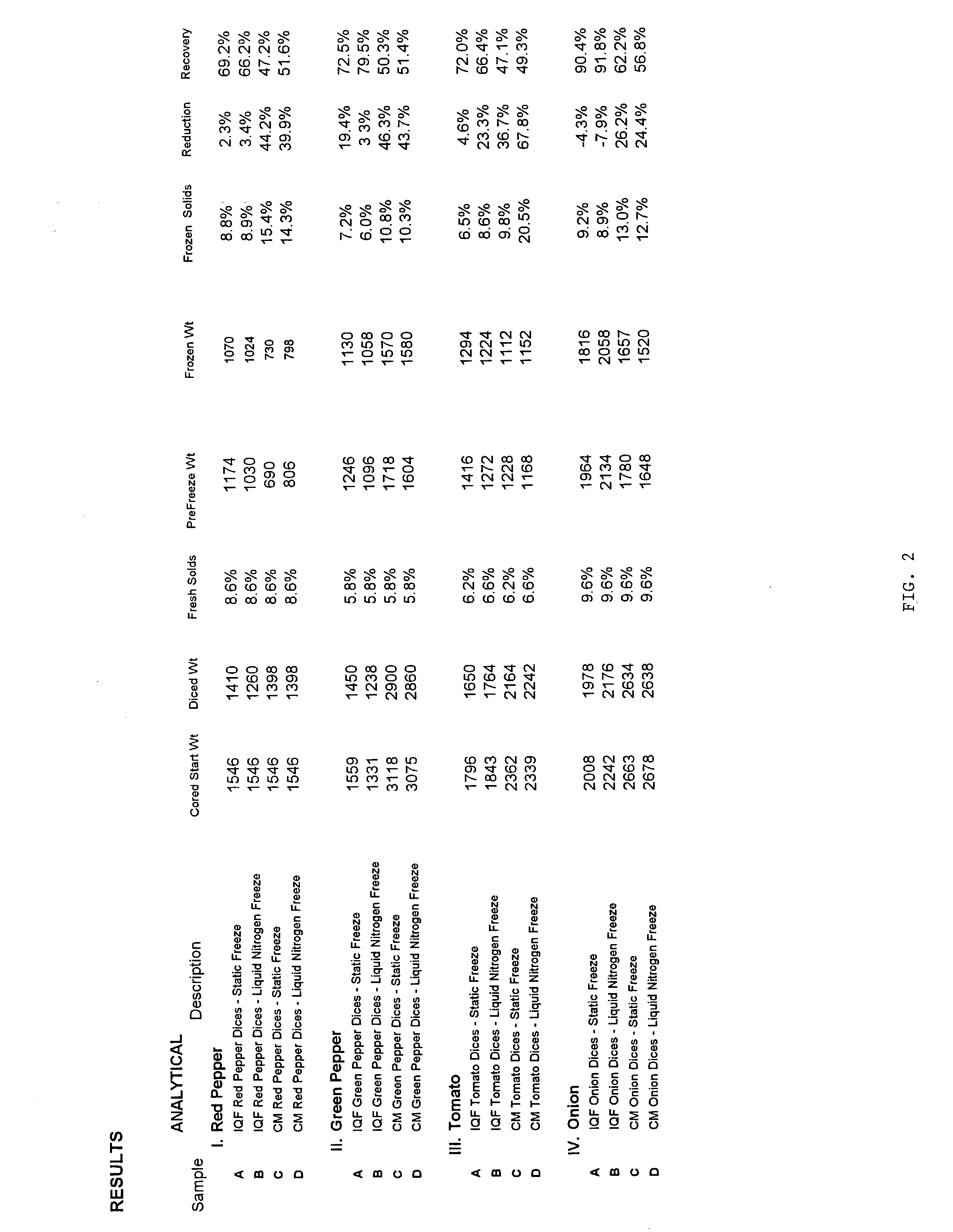

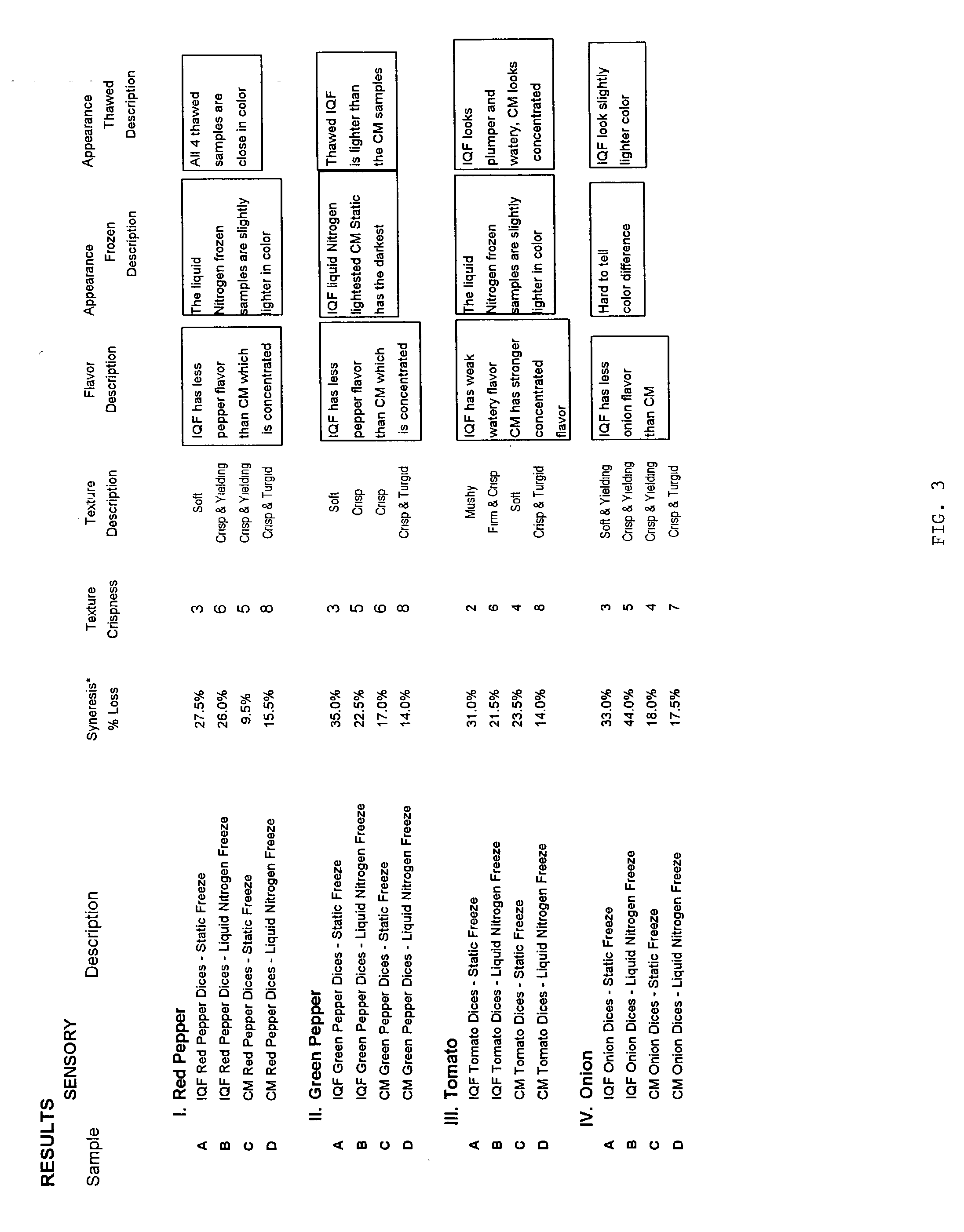

Method for production of frozen vegetables or fruits

InactiveUS20040096559A1Improve featuresLess leachingMilk preservationWort preparationFrozen vegetablesChemistry

The present invention relates to a method for producing frozen and dehydro-frozen vegetables and fruits, wherein the method includes the method of cryogenically freezing the fruits or vegetables.

Owner:CONAGRA FOODS +2

Composition heating type vegetable dewatering device

InactiveCN101053339ASolve the yellowingSolve the characteristicsFruits/vegetable preservation by dehydrationStraight tubeEngineering

The present invention provides a composition heating type vegetable dewatering device comprising a drying box, transmission device, conveying device and irradiating device, wherein the drying box constituted by the multi-layer, each layer set a set of conveying device driven by transmission device, and forming groove type material channel, above each channel set far infrared irradiating device, at the top of drying box has a feed inlet, at the bottom of drying box has a material outlet, there is air inducing vent at the upper wall of each layer, it sealing connects with fan by air inducing tube. Its characteristics are that each layer of the lower lateral wall of box is equipped with air inlet, wind supply tube sealing connects with heating device, the wind supply tube comprising flange and unequal-diameter straight tube, connecting tube connected with each layer, variable diameter tube and elbow, connecting tube diameters are reduced from top to bottom. The present invention adopts far infrared and hot wind composition heating method, solving the problem only when using far infrared heating surface materials roast will be easier yellow, and improving the quality of dried vegetables.

Owner:SHANDONG UNIV OF TECH

Technique for cultivating high-quality and high-yield toadstool

InactiveCN101743852ABig shapeBroaden employment opportunitiesFruits/vegetable preservation by dehydrationHorticultureAgricultural sciencePest control

The invention discloses a technique for cultivating high-quality and high-yield toadstool, which comprises cultivation material formula, clinker cultivation without bags, management after cultivation, pest control, picking, processing and preservation. The invention has the advantages that the toadstool product has a bigger lobe shape, thick cover and fat flesh and fresh and tender encarpium, thereby being welcomed by markets. The invention not only widens the job opportunities for people but also provides a healthy food for people.

Owner:陈宝建

High composite aquosity fruit vegetables and edible fungi non-sulphur drying technics

InactiveCN101156622AGood color protectionImprove crispnessFood preparationFruits/vegetable preservation by dehydrationSulfurSolvent

The invention relates to a high-rehydration and high-safety fruit vegetable or edible fungus non-sulfur drying technique, and is characterized in that the tidied and cleaned fruit vegetable or edible fungus is blanched and scalded, and then is positioned in solvent containing 0.1-0.5 percent of citric acid and 0.02-0.1 percent of cysteine, and through the ultrasonic process which is favorable to protect the color and the drying, the finished product is made. The invention takes comprehensive researches on the blanching and scalding technique, the compositions of the blanching and scalding fluid, the color protecting technique, and the drying technique of the fruit vegetable or edible fungus non-sulfur drying technique; the invention does not adopt the noxious and harmful process methods such as sulphur fumigating, and charcoal-fire firing and drying; the invention can get better color protecting effect by combining organically the advanced ultrasonic process and compound color protecting fluid; and ensures that the finished products can keep fine color, fragrant, taste, and shape after being rehydrated; the invention has high rehydration and high safety. In the case of the bamboo shoot drying, the obtained product is white, the residual value of SO2 is less than or equal to 0.05g / Kg, the rehydration rate reaches more than 5-10, the crispness after rehydration is good, and the invention possesses the characteristic faint scent and the characteristic fresh taste of the fresh bamboo shoot.

Owner:YIBIN UNIV

Production method of evaporated vegetables

InactiveCN102308869AAvoid damageGood puffing effectFruits/vegetable preservation by dehydrationMicrowaveWater activity

The invention relates to a production method of evaporated vegetables. The method comprises the following steps: pretreating a vegetable raw material, performing a first hot air drying for reducing the moisture content of the vegetable to 60%-70%, carrying out a microwave drying for reducing the moisture content of the vegetable to 30%-40%; then carrying out an osmotic treatment, and performing a second hot air hot air drying for reducing the moisture content of the vegetable to 10%-20%, wherein the water activity is 0.64-0.44, the rehydration rate is 3.1-7.6. According to the invention, when the vegetable is dried to low moisture content, the vegetable can be performed an infiltration process by penetrating fluid, therefore the penetrating fluid can be absorbed by vegetable, the penetrating fluid is evenly distributed which makes the vegetable possessing special nutrition characteristics and makes the final product possessing the high-moisture content and the low moisture activity. The production method of the invention is capable of effectively raising the organoleptic quality and rewatering performance, raising the preservability of the product and simultaneously reducing the production cost.

Owner:JIANGNAN UNIV

Curable resin composition for sealing LED element

InactiveUS20060229408A1Improve adhesionExcellent level of heatDrying solid materials with heatMeat/fish preservation by heatingOptical transparencyHeat resistance

A curable resin composition for sealing an LED element is provided. The composition includes (i) an organopolysiloxane with a polystyrene equivalent weight average molecular weight of at least 5×103, (ii) a condensation catalyst, (iii) a solvent, and (iv) a finely powdered inorganic filler. It is suited to formation of a coating film or the like with excellent heat resistance, ultraviolet light resistance, optical transparency, toughness and adhesion, and is ideal for applications such as the sealing of LED elements.

Owner:SHIN ETSU CHEM IND CO LTD

Microwave vacuum stage drying method for high moisture vegetables and fruits

InactiveCN102511542AGood value for moneyReduce energy consumptionFruits/vegetable preservation by dehydrationFreeze-dryingMicrowave power

The invention relates to a microwave vacuum stage drying method for high moisture vegetables and fruits, which comprises the following steps pretreating high moisture vegetables and fruits and putting in a microwave vacuum drying oven, under the conditions that the vacuum degree is 0.06-0.07MPa and the microwave power is 1000-2000W, drying to wet basis moisture content of 40-50%; and then regulating the vacuum degree of 0.08MPa, regulating the microwave power of 800W, heating for every 1min and powering off the microwave vacuum drying oven to stop heating for 1min and drying until the wet basis moisture content is lower than 7%. The stage drying adopted by the invention is characterized in that a material is subjected to microwave vacuum continuous drying to a certain water content, then a process of microwave vacuum intermittent drying is carried out until the material safely stores the moisture, and surface hardening generated by continuous high temperature can be effectively avoided at later period of drying the high moisture vegetables and fruits, and even the local high temperature coking phenomenon can be avoided, thereby the quality of the product is improved, the quality of the dry products is close to that of the vacuum freeze-drying products, and the energy consumption is reduced as well as production period is shortened.

Owner:HENAN UNIV OF SCI & TECH

Method for quickly preparing non-puffing low sugar fruit freeze-dry crisp pieces

ActiveCN101433300AShorten freeze-drying timeLow costFruits/vegetable preservation by freezing/coolingFood preparationFreeze-dryingVacuum drying

The invention discloses a method for quickly preparing non-puffed low-sugar fruit jelly crispy chips and belongs to the technical field of fruit and vegetable food processing. Fruit chips are mainly prepared by the following steps: fruit washing, peeling, pit removal, slicing, pretreatment, freezing, freezing and drying, microwave vacuum drying, hot air drying and packaging. The method adopts freezing and drying in a sublimation drying stage of the fruit chips and controls the water content of products to be 37 percent. The method adopts microwave vacuum drying till the water content of the fruit chips is 10 percent in a resolving drying stage, and then adopts hot air dying to make the terminal water content of the fruit chips less than 5 percent. Low-sugar fruits are apples, pears or peaches which have a sugar degree of between 8 and 10. As post treatment of the freezing and drying, microwave vacuum drying and hot air drying greatly reduce energy consumption. Meanwhile, compared with lyophilized products, products dried by the method have no obvious change in quality and appearance.

Owner:SHANDONG LUHUA GROUP +1

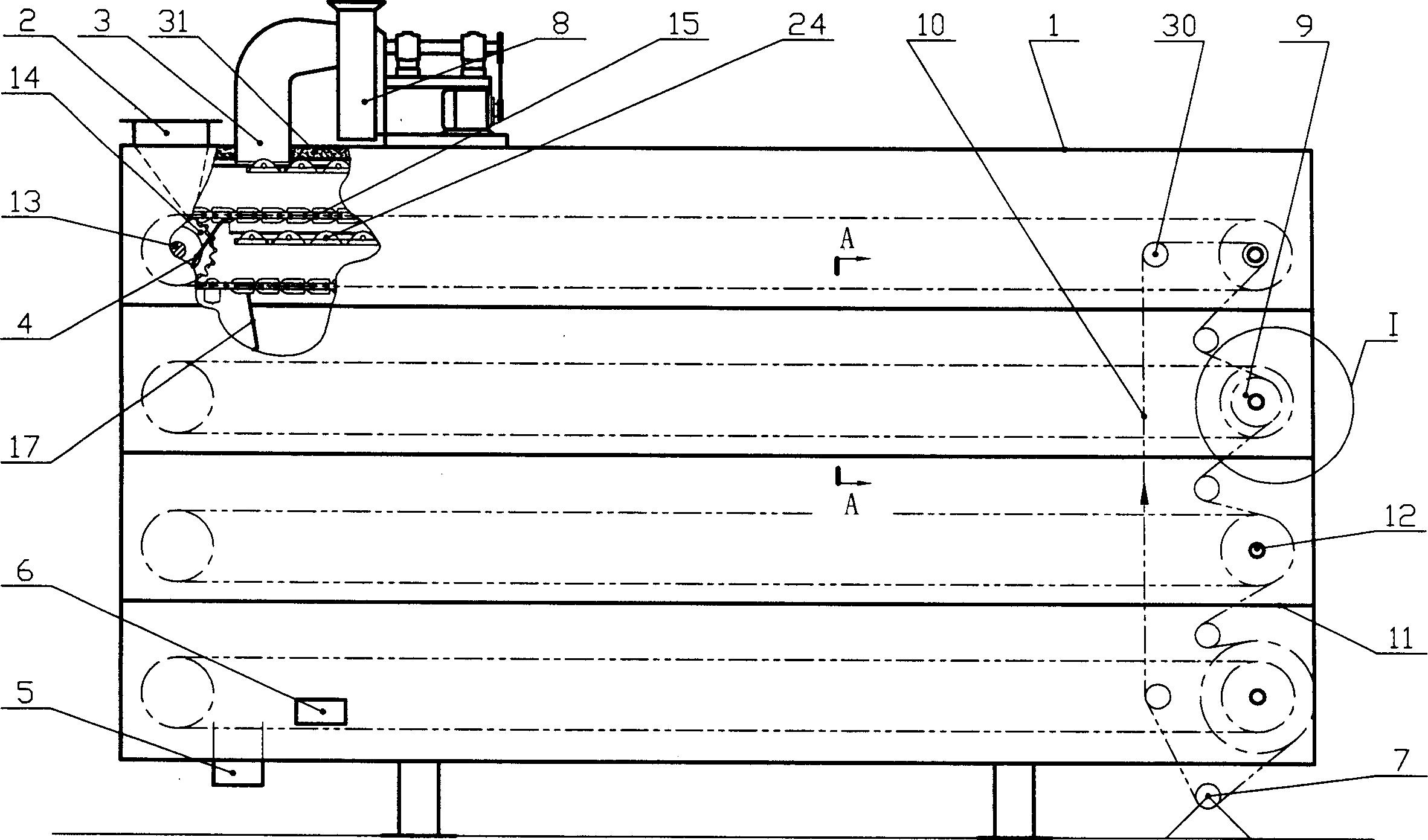

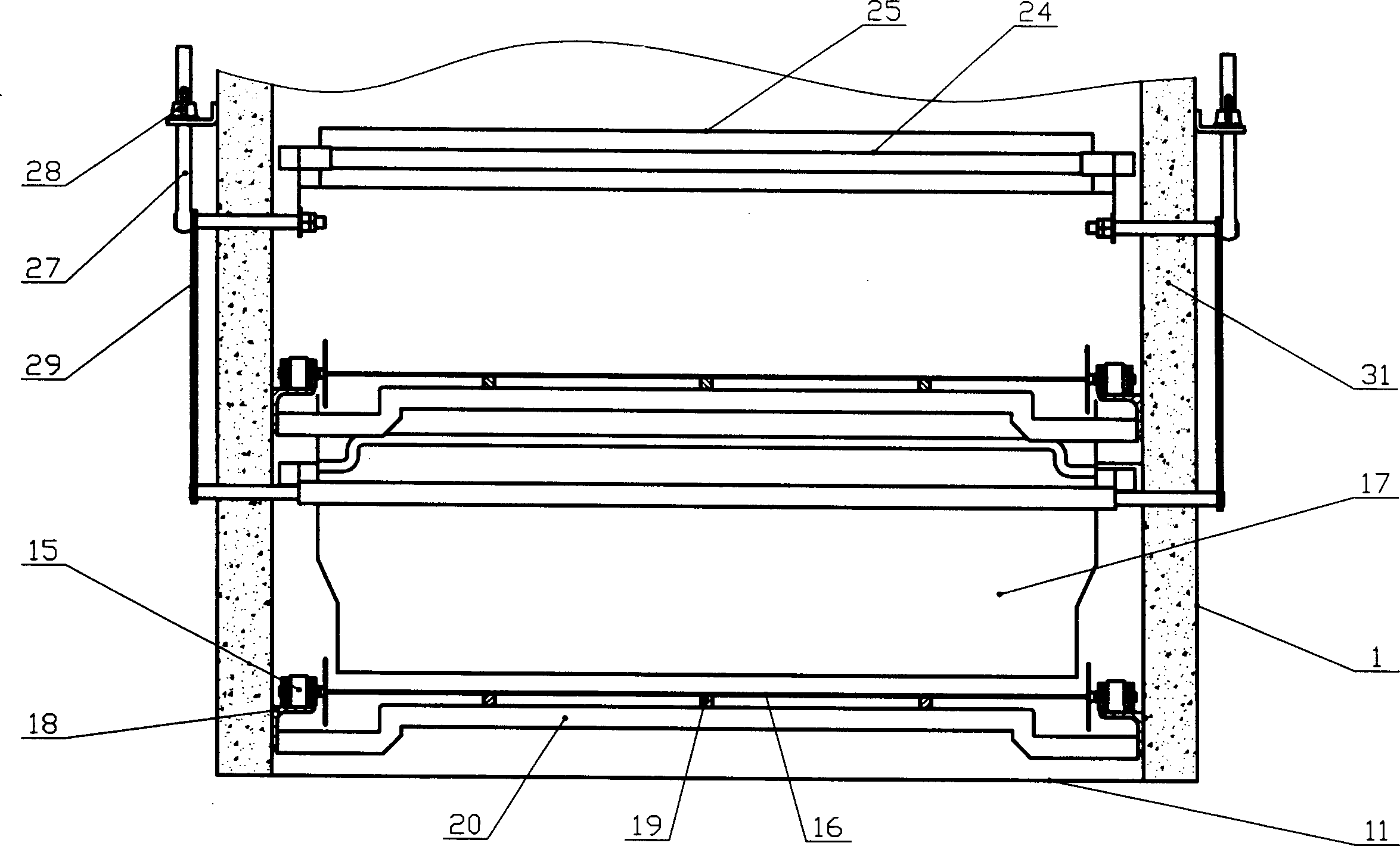

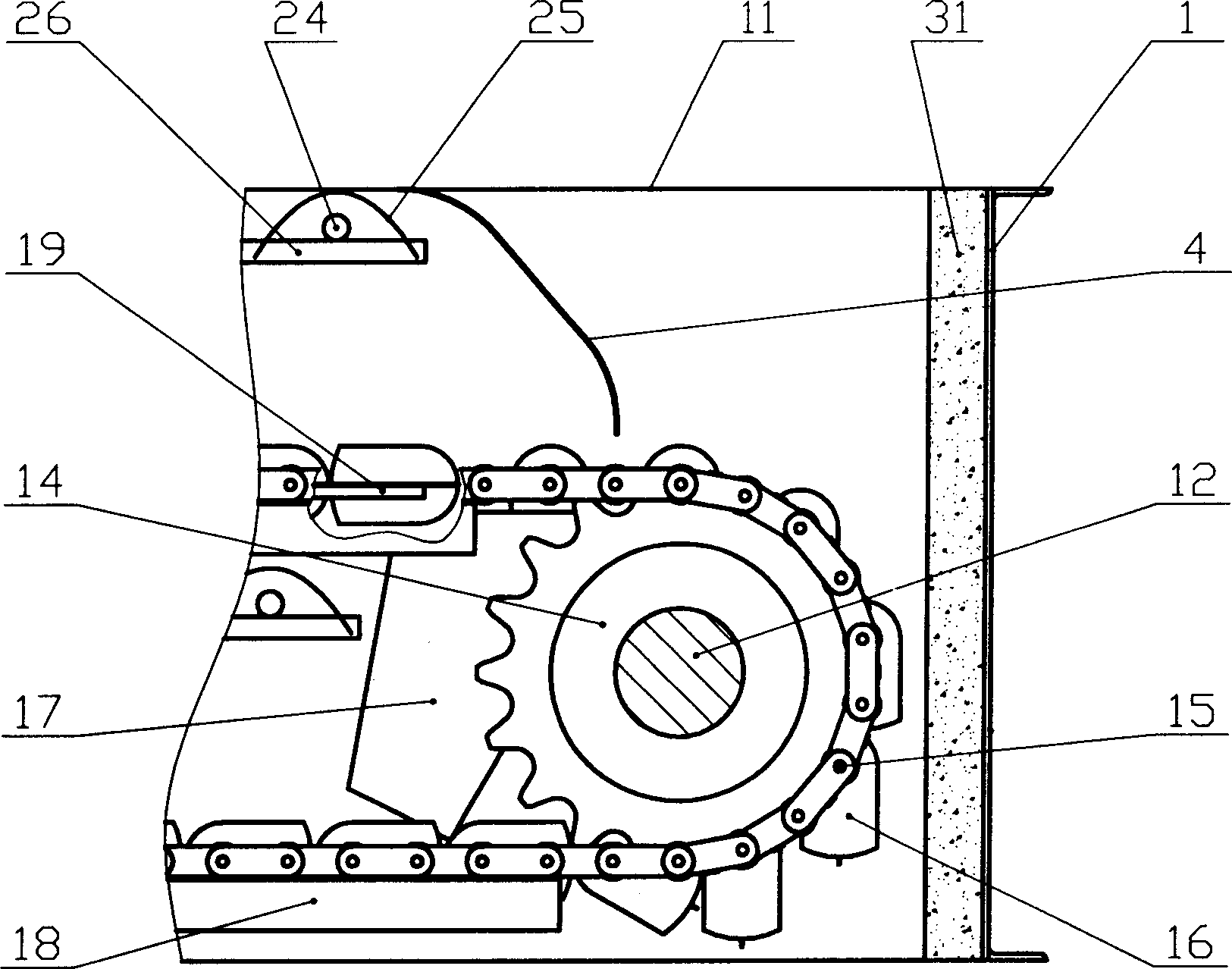

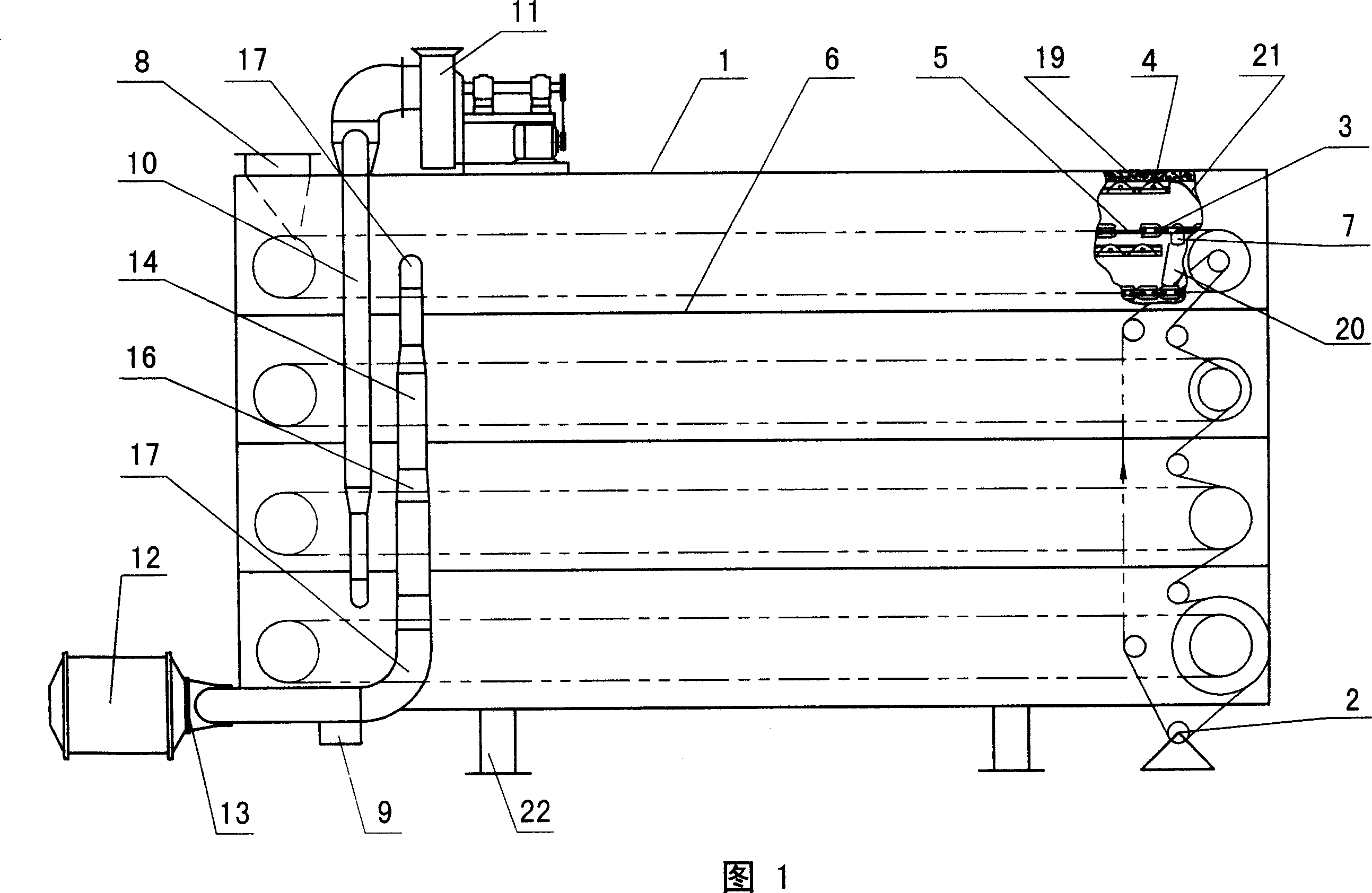

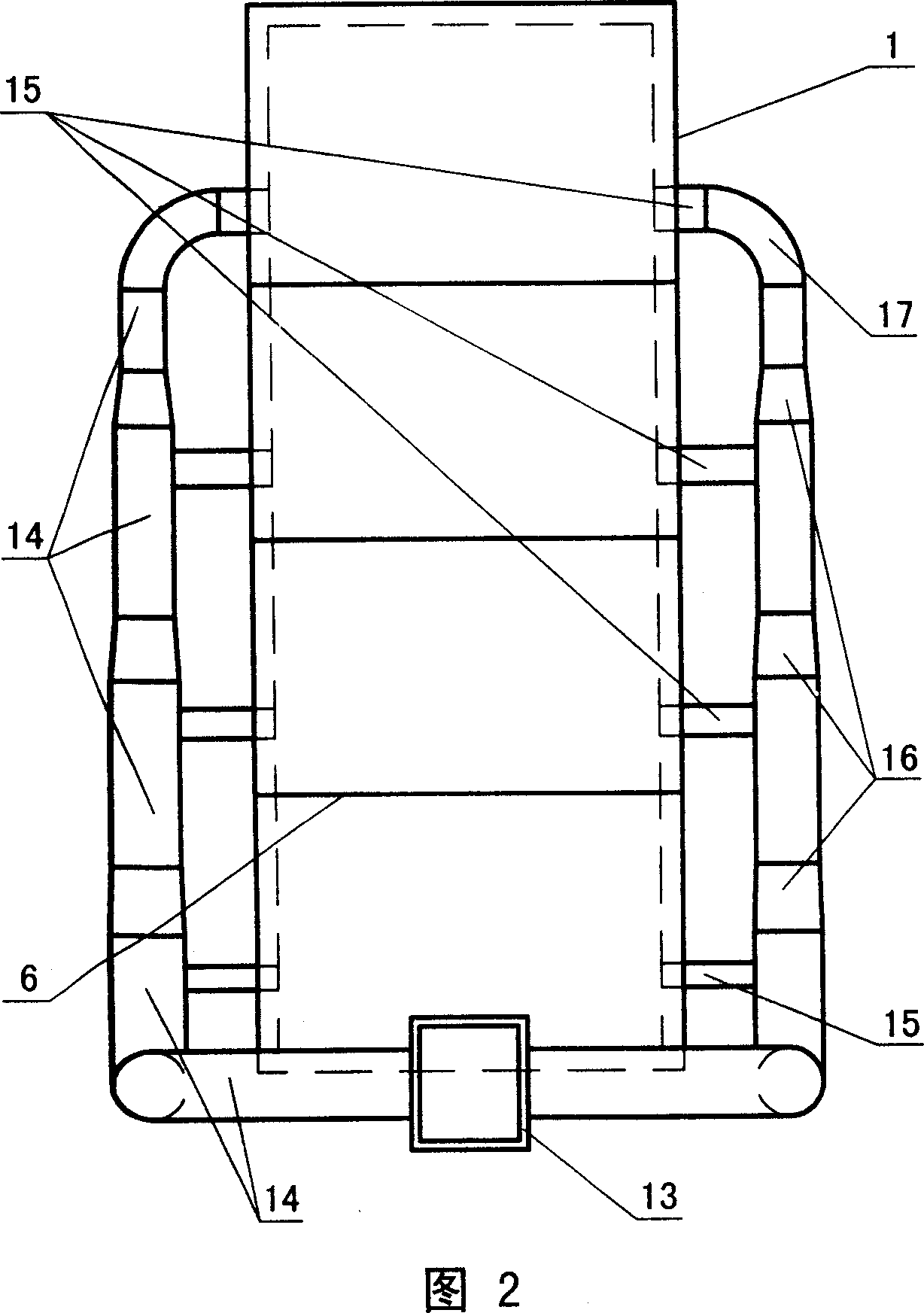

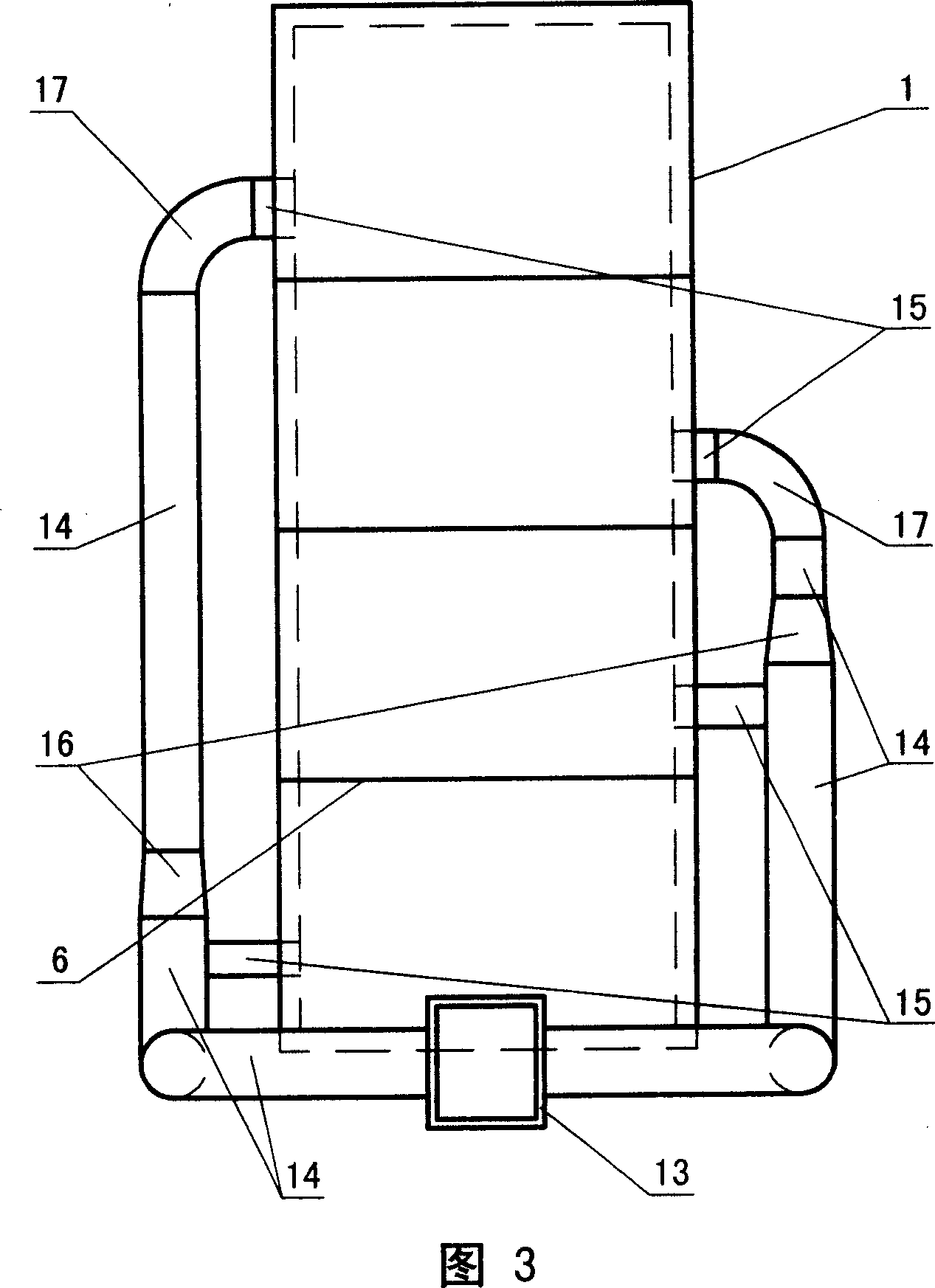

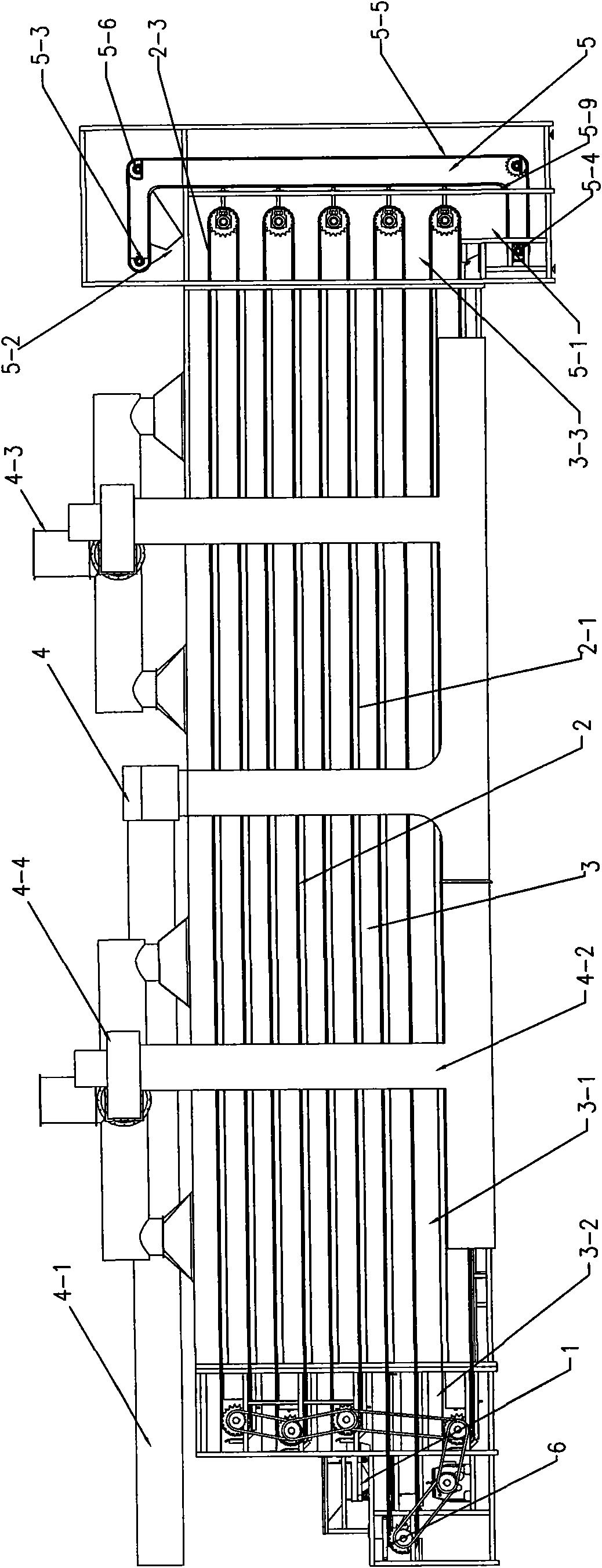

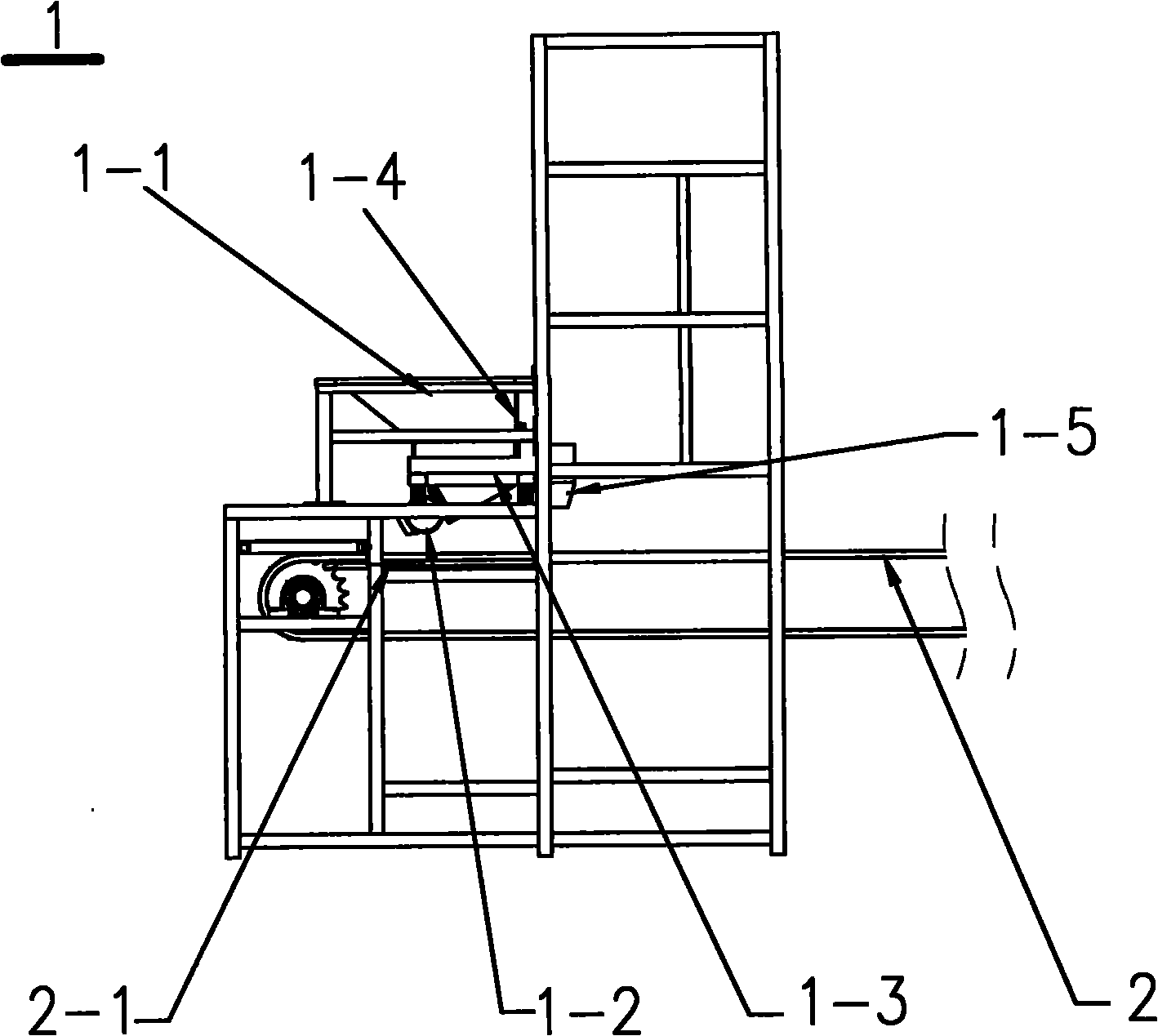

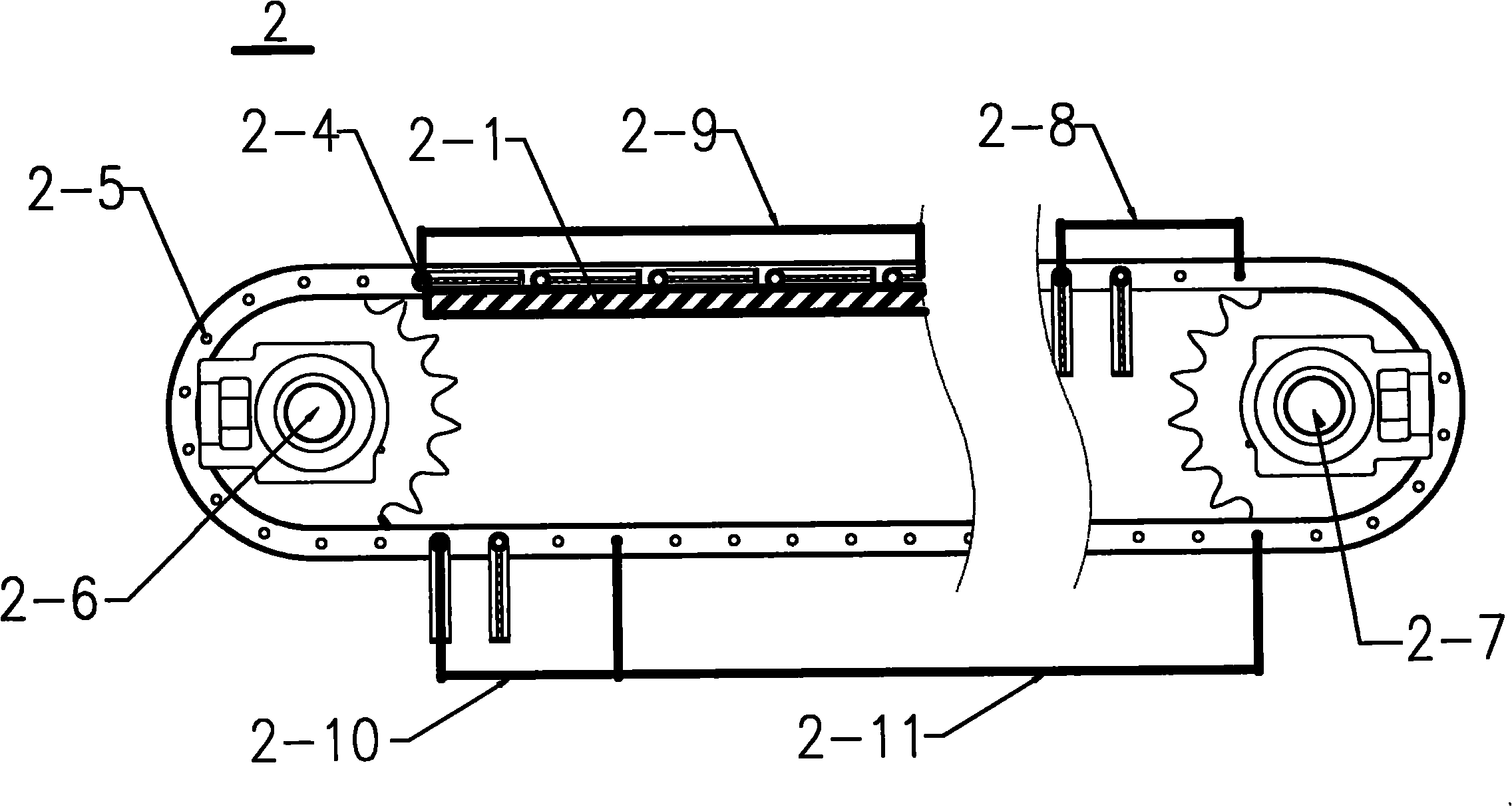

Self-circulation multi-layer slat dryer and self-circulation segmented drying method

ActiveCN101972032AGuaranteed dehydrationQuality assuranceFood treatmentFruits/vegetable preservation by dehydrationCyclic processControl system

The invention discloses a self-circulation multi-layer slat dryer, which comprises a feeding and discharge device (1), a drying chamber (3) and a wind network system (4), wherein the wind network system (4) is used for supplying hot wind to the drying chamber (3) to heat materials. The self-circulation multi-layer slat dryer is characterized by further comprising a multi-layer flat conveyor device (2), a lifter (5) and a control system for controlling the dryer. In addition, the invention also discloses a self-circulation segmented drying method. The self-circulation multi-layer slat dryer and the self-circulation stepwise drying method have the advantages of realizing segmented temperature and humidity control, ensuring dehydration is performed according to the laws of a baking curve in a material drying process, ensuring the quality of dried products, ensuring the materials are uniformly heated because the multi-layer slat conveyor device is used in combination with the lifter to function in turning the materials over in the self-circulation process of the materials, meeting the materials of different characteristics, setting the temperature, humidity and time of each segment according to the characteristics of the materials and realizing discharge at any time, along with wide application range, high drying quality and capability of realizing automatic production.

Owner:扬州福尔喜果蔬汁机械有限公司

Method for processing non-sulfur Chinese yam

ActiveCN101028134ASimple processShorten the processing cycleFood preparationFruits/vegetable preservation by dehydrationSulfurAqueous solution

A process for processing Chinese yam without sulfur includes such steps as screening raw materials, washing, peeling, cutting to become blocks or slices, immersing in the aqueous solution of sodium chloride, washing, drying in the air, microwave drying while sterilizing, and packing in sealed mode.

Owner:HUAISHANTANG BIOTECH

Slow cooker compositions and methods of making and using same

InactiveUS20050208182A1Good cooking timeMeat/sausages markingSausage casingsVegetable ProductClosed cell

Shelf stable meal kits for slow cooker applications, the meal kits including a dehydrated vegetable product characterized by having an exterior surface composed of a hardened, closed cell structure. The invention further provides shelf stable meal kits for slow cooker applications, the meal kits including a dehydrated vegetable product having a vitreous like material on 25% or more of the surface area of the vegetable product. Further provided are shelf stable meal kits for slow cooker applications that include a dehydrated vegetable product having a stabilizing amount of a stabilizer. Methods for rehydrating dehydrated vegetables, as well as methods for preparing meal kits for slow cooker applications are also provided.

Owner:GENERAL MILLS INC

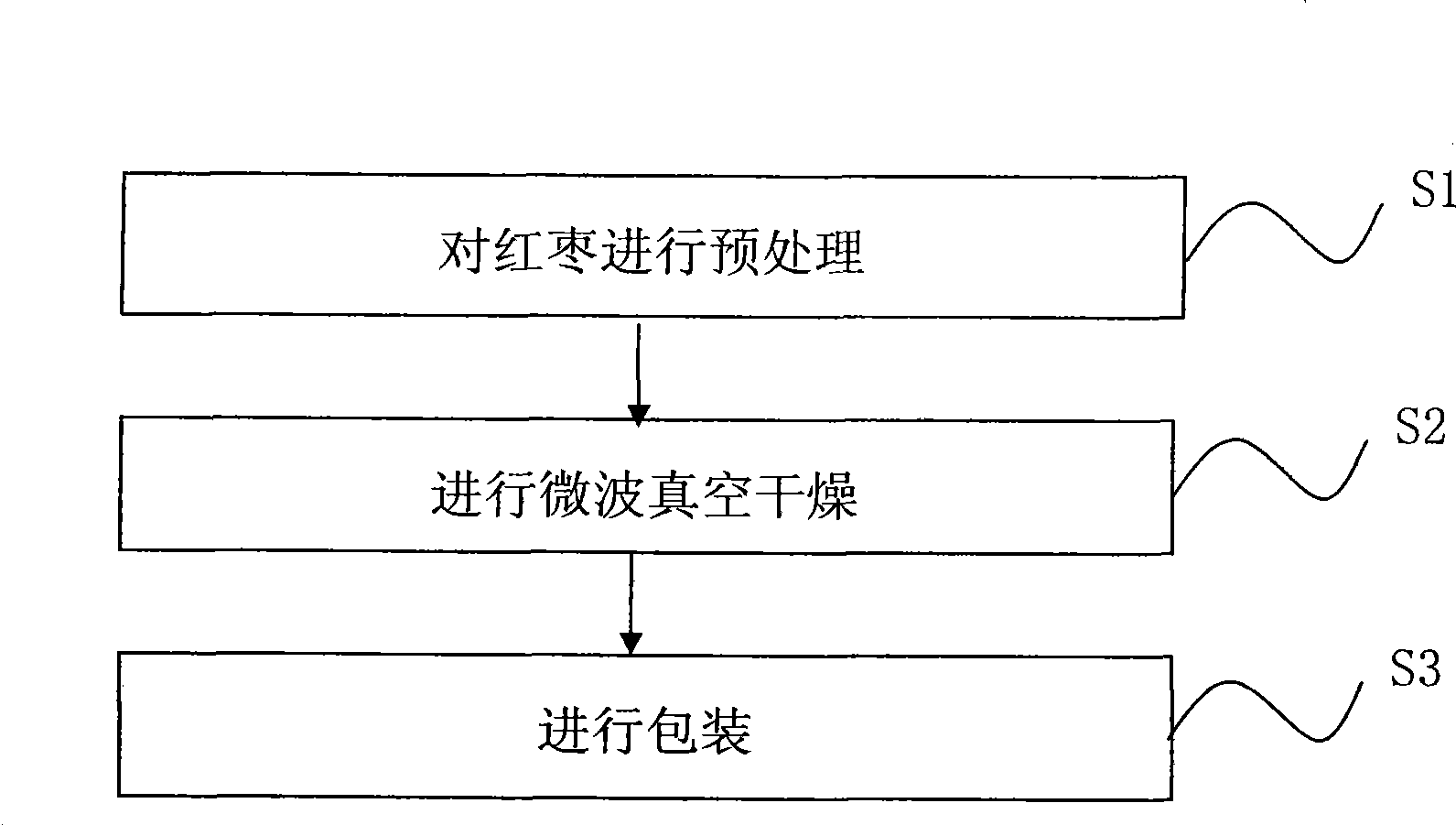

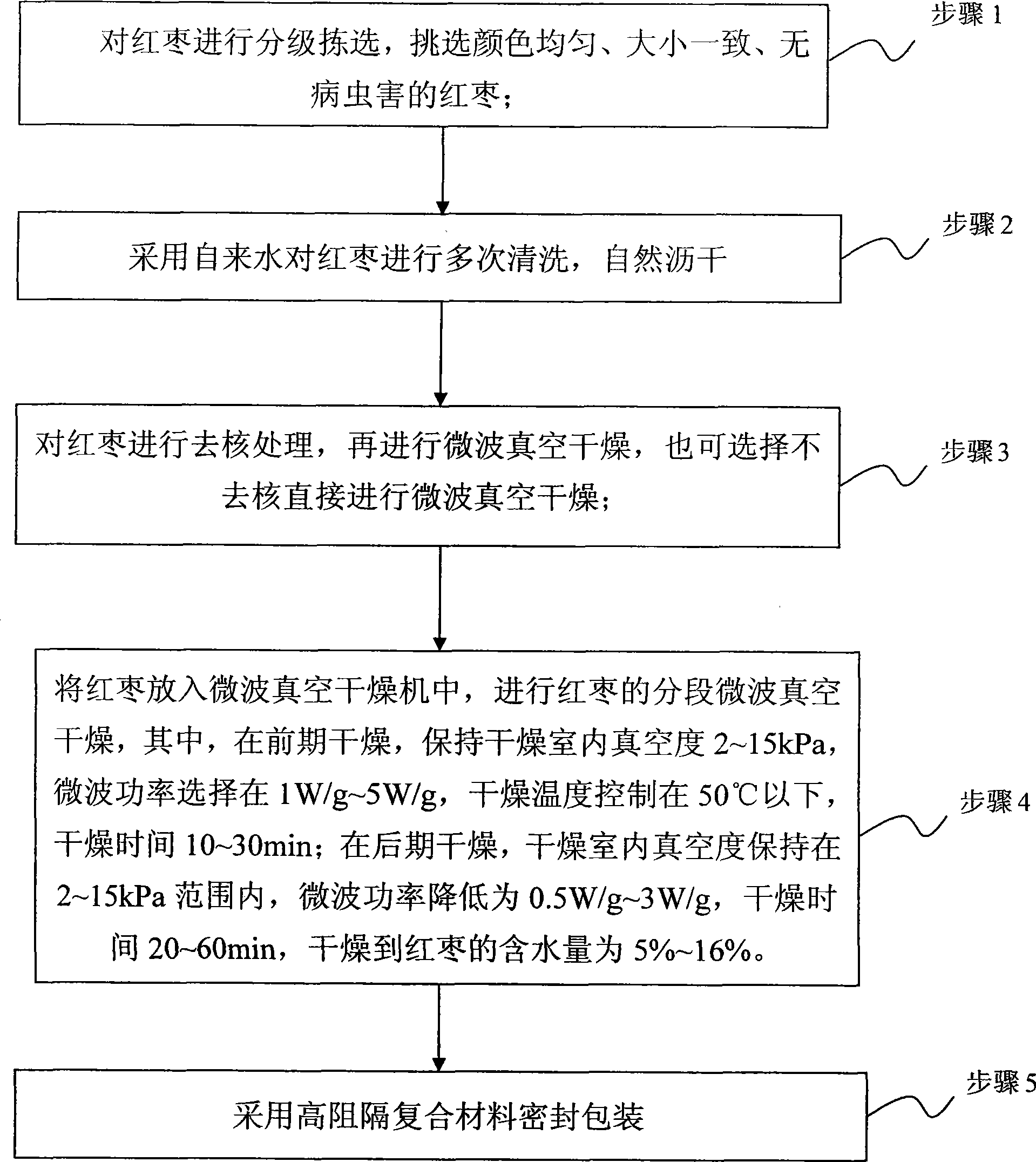

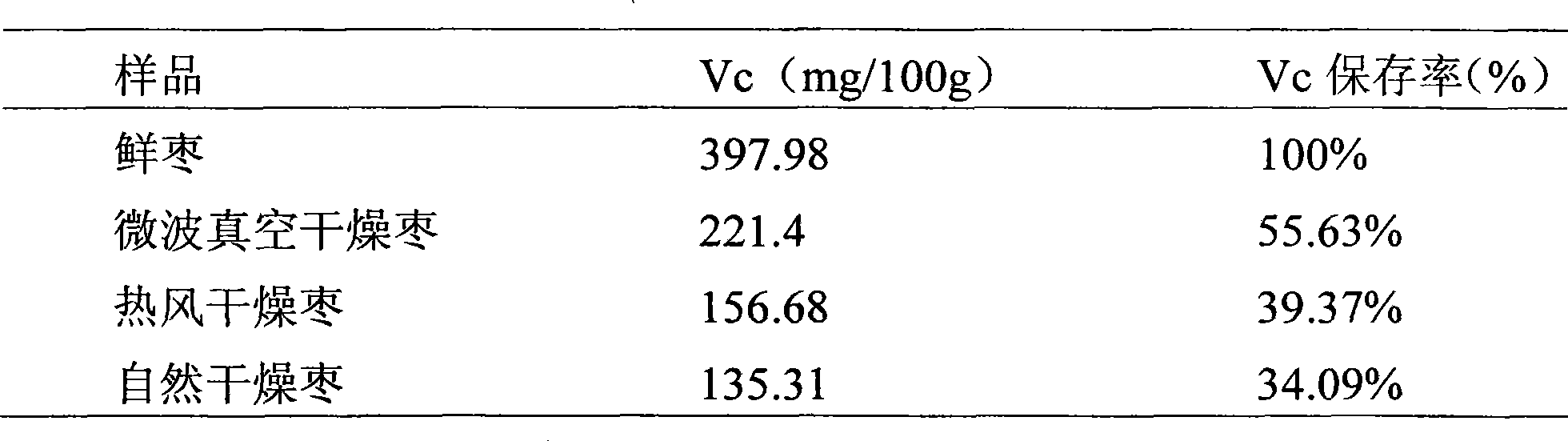

Method for preparing dry red date and red date produced thereby

InactiveCN101438730ALow drying temperatureAvoid damageFruits/vegetable preservation by dehydrationDate RangeMicrowave power

The invention discloses a preparation method for red dates by microwave vacuum drying, and red dates prepared thereof. The method comprises the following steps: pretreatment of the red dates, microwave vacuum drying of the pre-treated red dates and packing the red dates which undergoes microwave vacuum drying. The step of microwave vacuum drying to the red dates is as follows: the red dates are put in a microwave vacuum dryer, and the sectional microwave vacuum drying is carried out on the red dates; in the early stage of drying, the degree of vacuum in the drying chamber is maintained between 2 kPa to 15 kPa, the microwave power is selected between 1W / g to 5W / g, the drying temperature is controlled below 50 DEG C, and the drying time ranges from 10 min to 30 min; and in the later stage of drying, the degree of vacuum in the drying chamber is maintained between 2 kPa to 15 kPa, the microwave power is reduced to a magnitude of 0.5W / g to 3W / g, the drying time lasts for 20 min to 60 min, and the water content of the dried red dates ranges from 5 percent to 16 percent. The preparation method has rapid drying, is highly effective, energy-saving, environment-friendly and sanitary, can effectively maintain the original color, aroma, taste, active ingredients and the nutrient content of the red dates and provides the high-quality microwave-vacuum-dried red dates.

Owner:XIAMEN JIAQI BIOLOGICAL FOOD

Method for preparing dry day-lily buds

InactiveCN101911963AIncrease powerIncrease productionFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationFlavorFood additive

The invention discloses a method for preparing dry day-lily buds. The method comprises the following steps of: fixing day-lily buds; removing green from the day-lily buds, roasting and / or airing the day-lily buds; inspecting the dry day-lily buds; packaging the inspected dry day-lily buds; and putting the packaged dry day-lily buds in storage. The method is characterized in that: the fixing step comprises the following specific steps of: scattering picked fresh day-lily buds on a steaming sieve, wherein scattering thickness is between 150 and 200 millimeters; racking the steaming sieve; pushing the steaming sieve into a steam box; introducing steam into the steam box; controlling temperature in the steam box to be between 50 and 65 DEG C; steaming for 5 to 8 minutes; and opening the door of the steam box to take the steaming sieve out. Compared with the prior art, the method has the advantages that: 1) any food additive does not need to be added in a fixing process and the dry day-lily buds have a natural color, natural taste, natural flavor and sweet taste; 2) day-lily bud drying rate is increased by 2 percent by steam fixation and the growth rate of market prices is increased by 13 percent; and 3) the day-lily buds processed by the steam fixation are accordant with food quality standard, do not cause any pollution, are truly green food and are well appreciated by customers.

Owner:湖南吉祥食品有限公司

Intermediate wave infrared and radio frequency combined drying method suitable for dehydration of large-scale seasoning edible mushrooms

ActiveCN102986838AHeating up fastLittle impact on qualityFruits/vegetable preservation by dehydrationNutritionDrying time

The invention relates to an intermediate wave infrared and radio frequency combined drying method suitable for dehydration of large-scale seasoning edible mushrooms, and belongs to the field of edible mushroom foodstuff processing technology. The method comprises the steps of pre-treating the edible mushrooms (carefully chosen, cleaning, sorting and sharding, blanching for enzyme deactivation at a temperature of 90-100 DEG C), cooling in a seasoning liquid, immersing and draining, pre-dehydrating with the intermediate wave infrared at a temperature of 60-70 DEG C with a wind speed of 1-3 m / s and a radiation distance of 10-18 cm to make moisture content reduced to 30%-60%; then performing radio frequency drying to make the moisture content of the edible mushroom reduced to 8%, wherein plate distance is 20.5 cm; frequency is 27 MHz; power is 6 KW; a material temperature is 50-60 DEG C; and material plates can be arranged in three layers. Problems of difficulty for removing the moisture in a later stage of the intermediate wave infrared drying by employing the intermediate wave infrared and radio frequency combined drying method, because the radio frequency has strong penetrability. The materials during the radio frequency drying process can be placed in a plurality of layers, so that nutrition and shapes of the product can be retained to a large extent; at the same time, drying time is shortened significantly; drying energy consumption is lowered; and cost is reduced.

Owner:JIANGNAN UNIV

Preparation method of dried mangoes

InactiveCN104082694AHigh nutritional valueIncrease productivityFood freezingClimate change adaptationNutritive valuesFreeze-drying

The invention discloses a preparation method of dried mangoes. The preparation method comprises the steps of removing rotten mangoes and impurities from mangoes, cleaning the mangoes with saline water, removing skins and kernels of the mangoes, slicing regularly, performing color protection on the sliced mangoes, pickling with sugar, putting in a tray in a microwave drying device for microwave drying to remove 55-60% of moisture in the sliced mangoes, quickly freezing with liquid nitrogen, lyophilizing in a tray of a vacuum freezing-drying device for reducing the moisture of the mangoes to be 5-6%, and performing vacuum drying to obtain the dried mangoes. The dried mangoes prepared by adopting the method have the high nutritive value and the good quality.

Owner:莆田市川佰投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com