Patents

Literature

215results about How to "Good puffing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stage method for improving uniform expansion effect of granular fruits and vegetables during microwave spouted drying

The invention discloses a stage method for improving the uniform expansion effect of granular fruits and vegetables during microwave spouted drying, which belongs to the technical field of the processing of fruit and vegetable foods. The method mainly comprises the steps of: performing selection, washing, dicing, enzyme killing by blanching, and color protection treatment on fruit and vegetable raw materials; placing the pretreated fruit and vegetable cubes into a microwave spouted drying bed; setting the microwave power and the air inlet heating temperature; then performing the combined drying of stage hot air drying and microwave drying; and controlling different spouted air intakes at different drying stages, wherein the uniform expansion effect of products is improved during the quick microwave drying. The method has the advantages that the method ensures that the granular fruits and vegetables are evenly heated in a microwave field through a hot air and microwave spouted drying stage method, has quick moisture evaporation, ensures that the fruits and vegetables have porous structures after the drying, effectively improves the expansion degree of the products, also improves the expansion effect of the products and ensures the uniform expansion of the products while the granular fruits and vegetables are quickly dried, and has the characteristics of good preservation of nutrient content and good qualities of color luster, sense and the like.

Owner:JIANGNAN UNIV +1

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

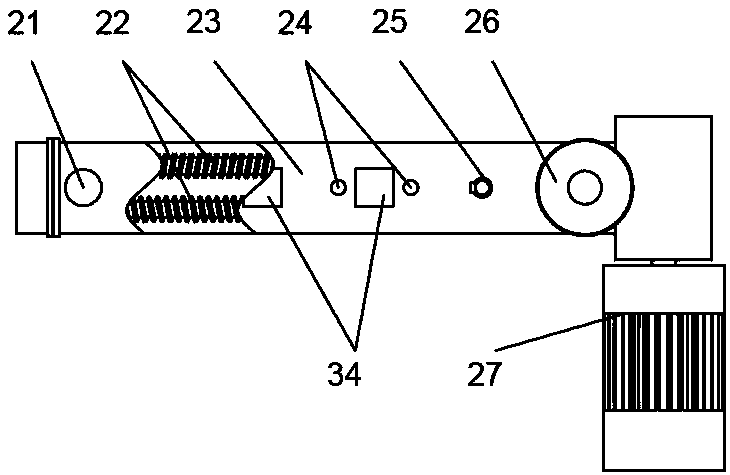

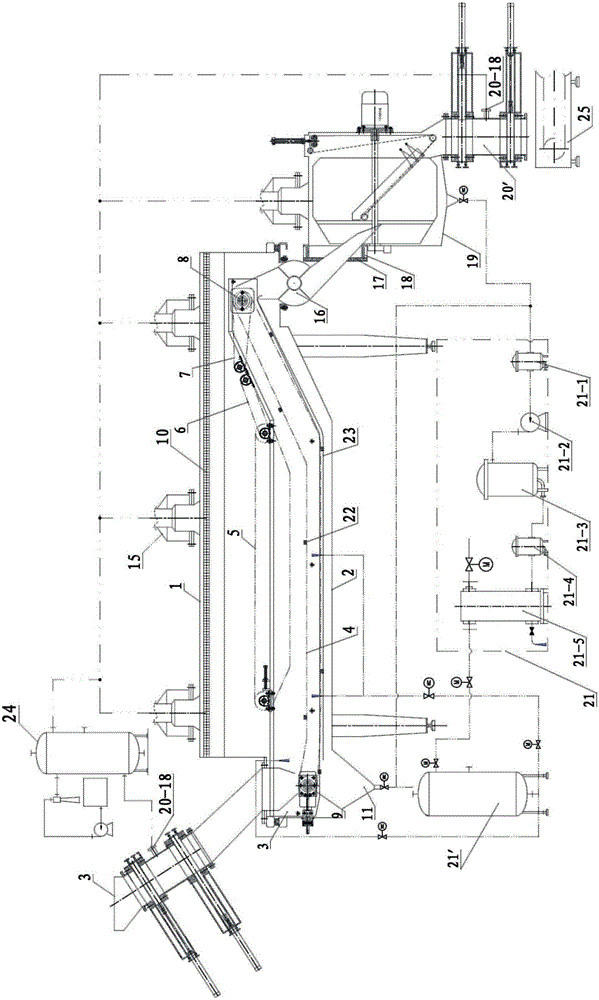

Oil spraying instant noodle production line and production technology thereof

InactiveCN101720890AFragrant and delicious tasteReduce oil contentFood preparationDough processingAlkaline waterHigh volume manufacturing

The invention relates to oil spraying instant noodle production line and production technology thereof. The production line is sequentially provided with an alkaline water bucket, a quantitative water adding bucket, a vibrating screen, a double shaft flour-mixing machine, a curing feeder, a composite tablet machine, a continuous tablet machine, a three-layer vaporizer, a cutting folder, a spraying flavouring machine, an oil spraying noodle frying machine, a microwave drying machine, an air cooling machine and an output packaging device. The equipment is full automatic, production efficiency is high, thus being applicable to mass production; in the production equipment, oil spraying device is adopted to carry out oil spraying treatment on noodle block, the noodle block has the flavour of common instant noodles while the oil content thereof is only about 5%, thus the noodle block is a good low oil content healthy food.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

Coffee carbon fiber plush printed blanket and preparation method thereof

InactiveCN102162170AIncrease weaving densityReduce stretch deformationCarbon fibresWarp knittingEngineeringAcrylic fiber

The invention discloses a coffee carbon fiber plush printed blanket and a preparation method thereof. The blanket is knitted by a double-needle-bed warp knitting machine; and the plush yarn of the blanket is a yarn obtained by blended knitting of coffee carbon fibers and acrylic fibers, wherein the double-yarn specification of the yarn obtained by the blended knitting is 28-36s; the base material terylene is warped, and then the coiled head is used as the knitting yarn and weft insertion yarn of the blanket. The preparation method comprises the following steps: starching and high-temperature setting of a white grey cloth, fuzzing, lustering, shearing, flat screen printing, aging and fixation, washing, dehydrating and drying, carding, fuzzing, lustering, shearing, binding and packaging and warehousing. The coffee carbon fiber plush printed blanket disclosed by the invention has the characteristics of bright color, soft handfeel, heat accumulation, warm keeping and the like, special healthcare functions of dehumidification, anion release, antibacterium and the like, and advantages of economy and environmental protection.

Owner:JIANGSU QIYING HOME TEXTILE

Expanded pellet feed for trionyx sinensis and preparation method thereof

The invention discloses an expanded pellet feed for the trionyx sinensis. The curing degree of the expanded pellet feed is 100 percent. The expanded pellet feed is prepared from domestic white fish meal, America white fish meal, imported eel-grade red fish meat, flour, cassava pieces, soy beans, non-transgenic soybean meal, fermented soybean meal, pregelatinization starch, milk powders, mineral premix, vitamin premix, monocalcium phosphate, calcium propionate and phosphatide oil by using a twin-screw extruding fully-curing expansion machine to firstly carry out quenching and tempering on the materials for 160 to 200 seconds under the conditions that a vapour pressure is between 0.4 and 0.5MPa, a humidity is between 19 and 23 percent, and a temperature is between 85 and 90 DEG C, and then carry out curing on obtained product under the conditions that a curing temperature is 180 DEG C, a cavity pressure is between 22 and 28atm and a curing time is between 25 and 30 seconds. Each kilogram of mineral premix comprises Mg, Na, K, Fe, Cu, Mn, Zn, Se, Co and I. The expanded pellet feed for the trionyx sinensis has the advantages of reasonable configuration of various elements required by nutrition and growth, complete curing, resistance to cause damage to all nutritional factors, low cost, higher stability in water and higher digestibility.

Owner:NINGBO TECH BANK

Preparation method for puffed sandwich crispy date

InactiveCN103621933AReduce oil contentAvoid greasy tasteFood shapingFood ingredient functionsDietary fiberDeep frying

The invention discloses a preparation method for a puffed sandwich crispy date. A differential-pressure puffing technique is adopted, the method is simple and safe, any additive is not required to be added, the product effect is good, the appearance of the red date is better kept, the Vc, polysaccharide and dietary fiber of the red date and rich protein and unsaturated fatty acid of almond are combined to enable the snack food to have more comprehensive nutrients, most importantly, the problems of high oil and fat content, oily taste, serious destroy of nutritional ingredients and short expiration date in the deep-frying and puffing are avoided, and as a result, the snack food is green, safe and nutritious.

Owner:GUANGXI UNIV

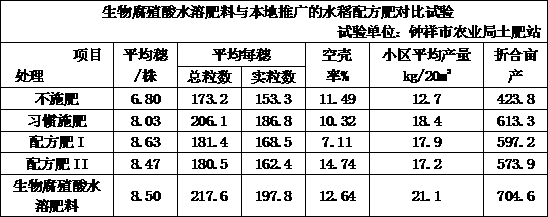

Biological humic acid water soluble fertilizer

InactiveCN108218588AIncrease profitImprove disease resistanceMagnesium fertilisersAlkali orthophosphate fertiliserMicrobial agentPhosphate

The invention discloses a biological humic acid water soluble fertilizer. The biological humic acid water soluble fertilizer is composed of, by weight, 7 to 10 parts of potassium nitrate, 8 to 12 parts of ammonium nitrate, 8 to 11 parts of monoammonium phosphate, 12 to 16 parts of urea, 18 to 23 parts of humic acid, 0.04 to 0.08 part of amino acid chelated trace element, 11 to 15 parts of a composite microbial agent, 20 to 25 parts of organic matter, 6 to 9 parts of sodium sulfafe decahydrate, 3 to 5 parts of boric acid, 5 to 8 parts of magnesium sulfate monohydrate, 0.5 to 0.9 part of a biogenic stimulant, and 2 to 4 parts of an anti-caking agent. The biological humic acid water soluble fertilizer is comprehensive in nutrient composition, and reasonable in formula; mutual cooperation of the elements in the biological humic acid water soluble fertilizer is achieved; fertilizer utilization rate is increased; and the biological humic acid water soluble fertilizer is capable of improvingcrop disease resistance and stress resistance, and increasing crop yield and product quality.

Owner:湖北吾尔利生物工程股份有限公司

Yoghourt ice-cream and preparation method thereof

The invention discloses a sour milk ice cream. After being added with white granulated sugar, pure milk is carried out lactobacillus zymotechnics, and added with ice cream powder and sour milk base powder, then frozen, finally, the ice cream is produced; wherein, the percentage of the weight of each ingredient in the gross weight of the raw materials is as follows: the pure milk 62-72%, the white granulated sugar 2-6%, the lactobacillus 0.06-0.12%, ice cream powder 24-33%, and the sour milk base powder 0.5-1.2%. The sour milk ice cream not only keeps the taste and the flavor of the sour milk, but also keeps the original nutrition of milk due to the direct freezing preparation by carrying out lactobacillus zymotechnics on the pure milk and the white granulated sugar, what is more, protein, milk sugar and the like in the milk that are not easy to be absorbed by human body are decomposed into lactic acid and amino acid that are easy to be absorbed, and the absorptivities of calcium, phosphorus and iron are higher.

Owner:甜蜜风情饮食文化传播(北京)有限公司

Preparation method for expansion jujube crisp slices

The invention relates to a preparation method for expansion jujube crisp slices. Non-fried expansion fruit and vegetable is a novel fruit and vegetable dried product subsequent to a traditional fruit and vegetable dried product, a vacuum frozen and dried product and a vacuum low-temperature fried fruit and vegetable crisp slice. The expansion fruit and vegetable crisp slice has the advantages of low fat, low calorie, high fiber, rich vitamins and minerals, and the like, and the prior flavor of the fruit and vegetable is concentrated. At present, a method for directly expanding fresh jujubes is not reported at home and aboard. The invention adopts the technological process of producing the expansion jujube crisp slice taking the fresh jujube as the raw material: the fresh jujubes-washing-enucleation-section-expansion-cooling-sorting-packaging-expansion jujube crisp slices. The invention has the advantages as followings: firstly, the materials are not needed to carry out sugar permeability treatment or pre-drying treatment, so that the processing procedure is simplified; secondly, pressure-difference expansion is adopted, and the defects of high oil content and short shelf life of the prior production of jujube expansion by vacuum frying are overcome; and thirdly, pressure difference is increased, thereby the expansion effect of the jujube crisp slices is favorable.

Owner:SHAANXI UNIV OF SCI & TECH

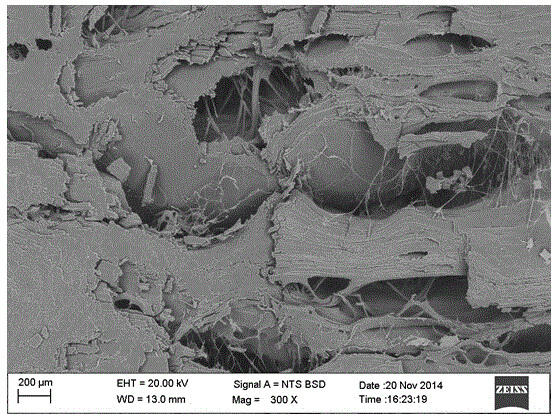

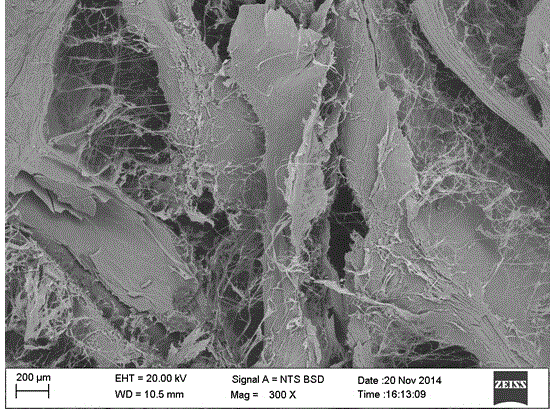

Vacuum microwave segmented combined drying manufacturing method of instant crisp dehydrated fish ball

InactiveCN102423087APromote circulationEffective use of volumeFood preparationNutritive valuesAdditive ingredient

A vacuum microwave segmented combined drying manufacturing method of an instant crisp dehydrated fish ball belongs to the technical field of aquatic food processing. The invention comprises the following steps: processing fresh or frozen fresh fish to obtain pure fish flesh, performing deodorization of the pure fish flesh by a composite rinsing solution, grinding the fish flesh, adding ingredients, immediately performing ball forming, gelation, heating and curing of the ground raw material, finally performing vacuum microwave segmented combined drying of the cured fish balls so as to obtain the high-quality instant crisp dehydrated fish ball product. Vacuum microwave segmented combined drying allows the materials to be dehydrated in vacuum environment, prevents the materials from contacting oxygen, and maintains the original color, profile, flavor, and nutrients of the raw material to a maximum extent; with the vacuum environment, the boiling point of water is decreased, and with the microwave volume heating, the heat efficiency is significantly improved; the drying time is greatly reduced; after drying, the product has a porous structure, good crispness, excellent color, flavor, taste, and shape, low water content, high nutritive value, and is high-protein healthy leisure food suitable for people of all ages.

Owner:JIANGNAN UNIV +1

Health-care dried banana and preparation method thereof

The invention discloses a health-care dried banana and a preparation method thereof. The health-care dried banana consists of the following materials in parts by weight: 80-120 parts of bananas, 45-70 parts of starch, 2-8 parts of skim milk powder, 4-10 parts of Chinese herbal medicine powder, 1-5 parts of salt and 65-90 parts of water. The health-care dried banana is prepared by the following process steps of performing microwave enzyme deactivation, cooking, curing, slicing, drying, bulking and the like. The health-care dried banana is treated by employing the microwave and radiation, the adverse influence caused by long-time high temperature is avoi8ded, the nutrient loss is reduced, and the natural flavor is kept. According to addition of the Chinese herbal medicine powder, the nutritional ingredients of the dried banana are increased, the dried banana has the effects of clearing heat and reducing pathogenic fire, and the phenomenon that the pathogenic fire is caused by polyphagia is avoided. The step of color protecting is avoided in the preparation process, and due to the addition of starch, the production cost is reduced, and the taste of the dried banana is improved.

Owner:浦北县共和香蕉专业合作社

Flavored agaricus bisporus puffed food

InactiveCN102657325AImprove crispnessHigh expansion rateFood preparationNutritive valuesMicrowave method

The invention relates to a flavored agaricus bisporus puffed food which is prepared by taking fresh agaricus bisporus as a raw material and adding corresponding minor ingredients. The preparation method comprises the steps of color protection processing, stoving, pulverizing, mixing main and auxiliary materials in a certain proportion, adding water, blending, microwave puffing, drying, cooling, obtaining finished product and packaging. The flavored agaricus bisporus puffed food is prepared by adopting a microwave method, makes use of nutrition value of agaricus bisporus and people's love of fungi food, retains nutrition value of agaricus bisporus to the maximum, and opens up a new approach for the use of agaricus bisporus. Diversity of agaricus bisporus foods is increased and economic value of a lot of unqualified mushroom, mushroom root and chipping in processing and grading edible fungi products is improved. Furthermore, the flavored agaricus bisporus puffed food has the advantages of long shelf life and unique taste.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

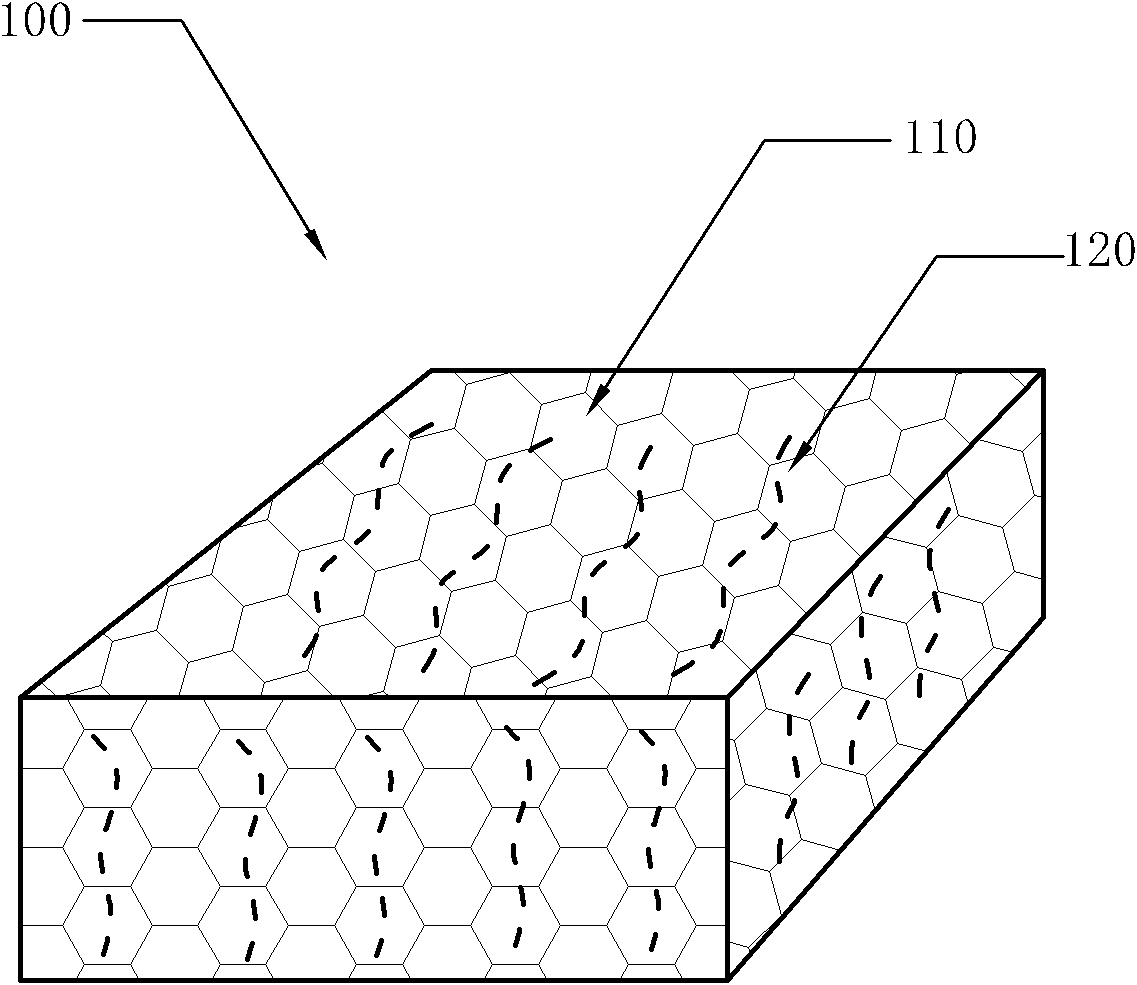

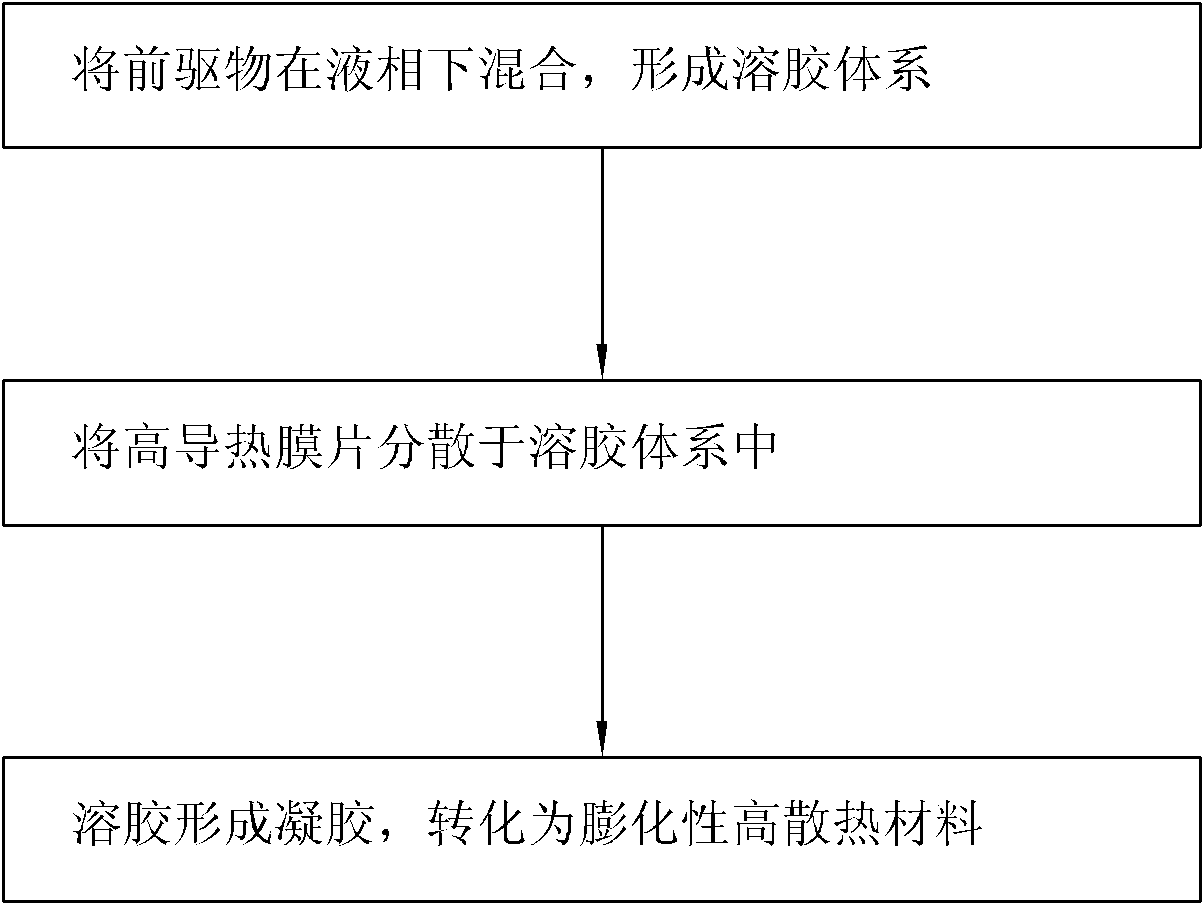

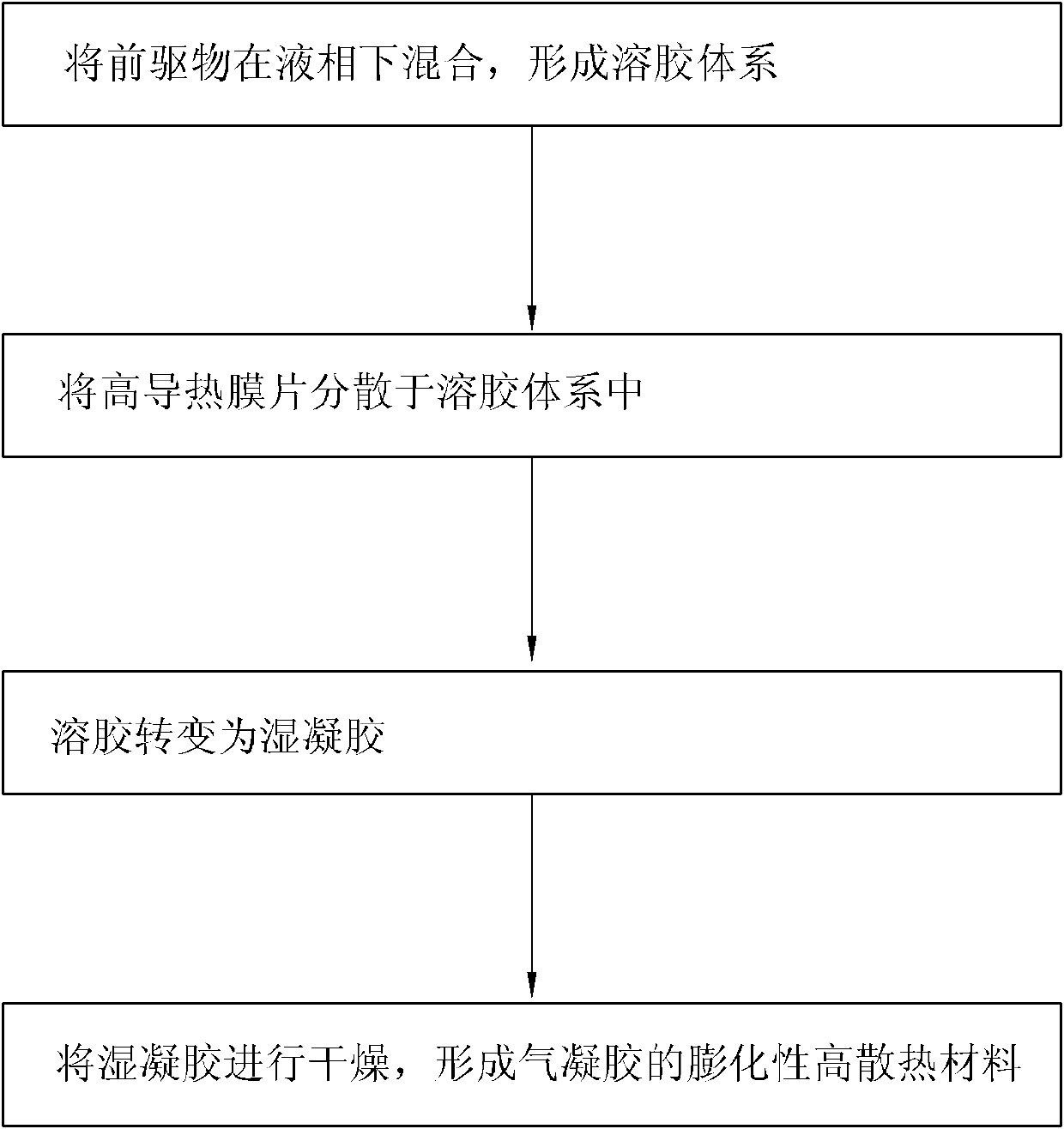

Expanding and high heat dissipation material and preparing method thereof

The invention provides an expanding high heat dissipation material and a preparing method thereof, and belongs to the technical field of heat dissipation. The heat dissipation material consists of gels and a high heat conduction membrane distributed in the gels, wherein the gels are liquogels, aerogels and carbon aerogels, the high heat conduction membrane is a graphite membrane or a graphene membrane with a width ranging from 0.001-10 millimeters and a length ranging from 0.1-300 millimeters, the high heat conduction membrane is, by mass, 0.1% to 0.3% of the total heat dissipation material. According to the expanding high heat dissipation material and the preparing method thereof, the expanding high heat dissipation material is obtained by applying the high heat conduction materials to gel products, therefore a novel and light high heat dissipation material is achieved.

Owner:SHANGHAI JIEYUAN ENVIRONMENTAL SCI & TECH

Industrial process of producing parched rice

The industrial process of producing parched rice includes the steps of: soaking, washing, dripdrying and steaming of Indica rice or glutinous rice; freezing of the steamed rice at temperature of minus 5 deg.c and humidity lower than 30 % inside a refrigerator; low temperature drying at 0-5 deg.c temperature and 10 % below humidity inside a drying equipment; and parching. The parched rice is crisp. The process is independent of weather condition and suitable for production all the year around. The parched rice has long guarantee period and may be packed together with seasoning packet inside degradable package to form instant food.

Owner:叶键

Method for producing fruit and vegetable crisps by combination of vacuum low-temperature frying and vacuum microwave drying

The invention relates to a process for producing fruit and vegetable crisps by combination of vacuum low-temperature frying and vacuum microwave drying. The method mainly comprises the following steps of performing selecting, finishing, cleaning, blanching for enzyme deactivation or pretreatment such as precooking, cooling, steeping and quick-freezing on fruit and vegetable raw materials, and concretely comprises the steps: firstly processing the raw materials into a semi-product with a water content of 50%-35% and an oil content of 3%-10% through a vacuum low-temperature frying process, and then drying and dewatering the semi-product through a vacuum microwave drying process, wherein the water content of a finished product is controlled to be below 5%, the oil content is controlled to be below 10%, and the expansion ratio is 1.5-2.0. According to the process, the nutrients and shape of the product are ensured to the greatest extent, the dehydration time can be obviously shortened, the energy consumption is lowered, the cost is reduced, and meanwhile, the oil content of the product can be effectively controlled, so that the process is particularly suitable for application to processing of the fruit and vegetable crisps.

Owner:NANJING INST FOR THE COMPREHENSIVE UTILIZATION OF WILD PLANTS CHINA COOP

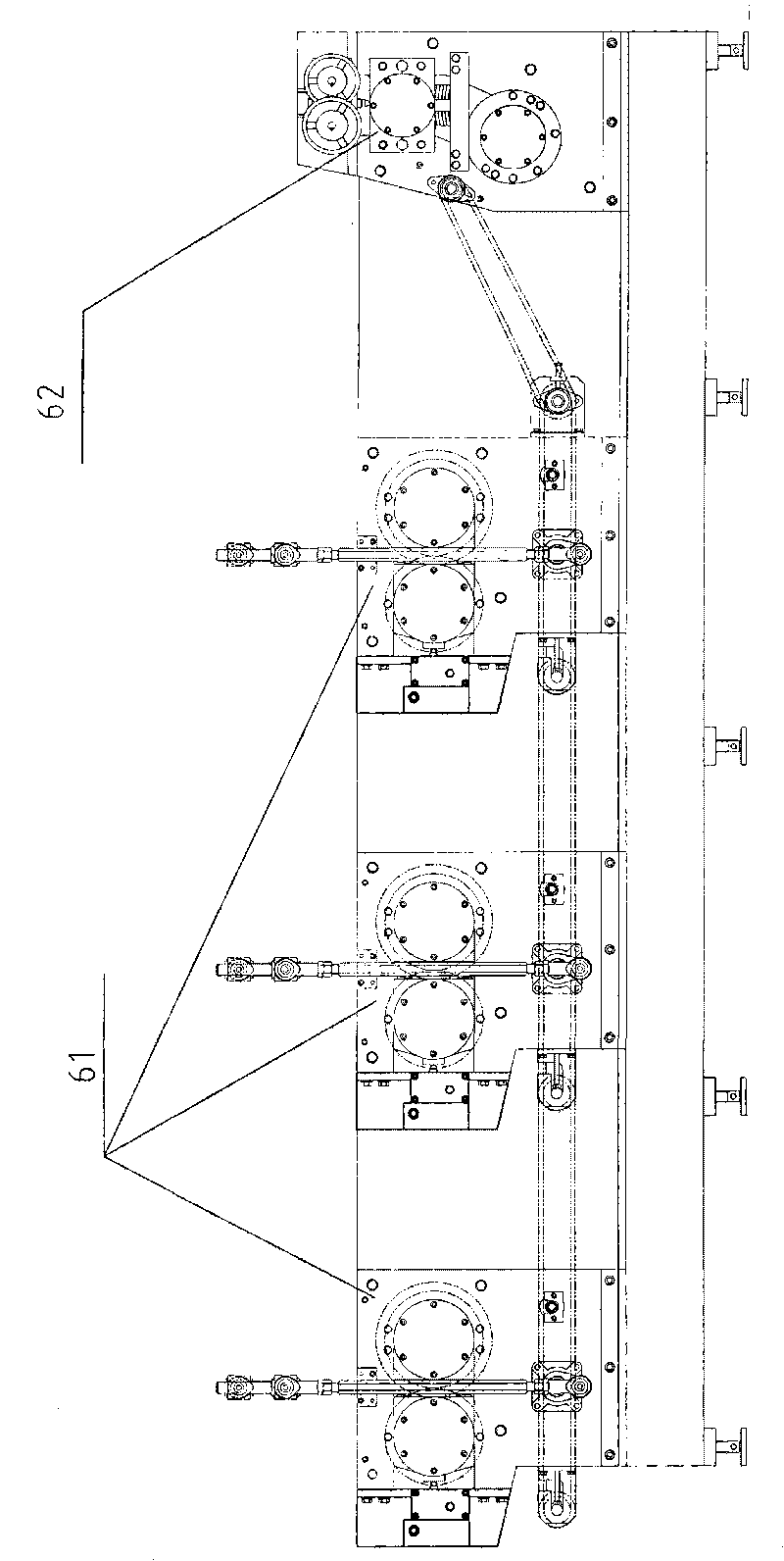

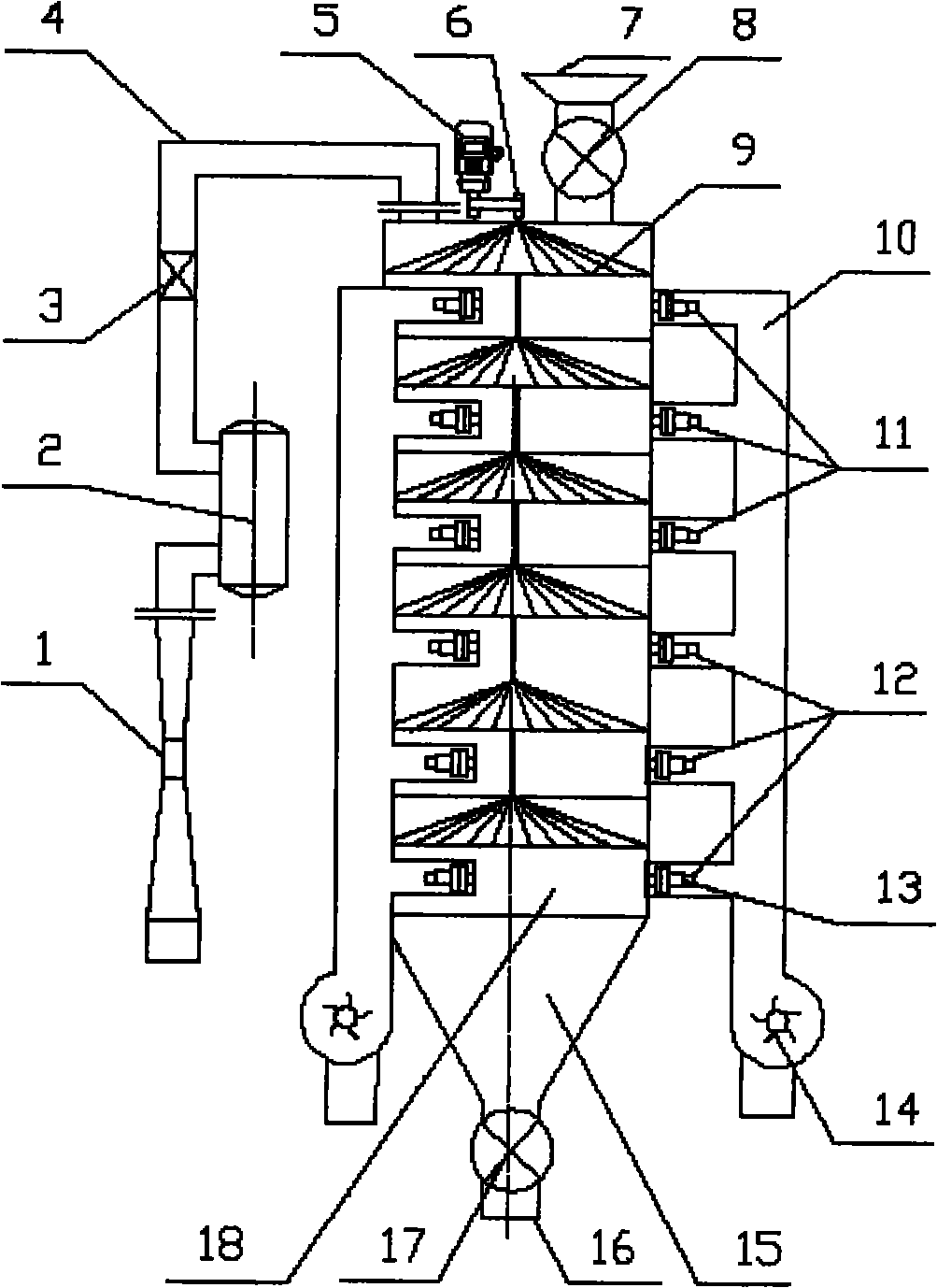

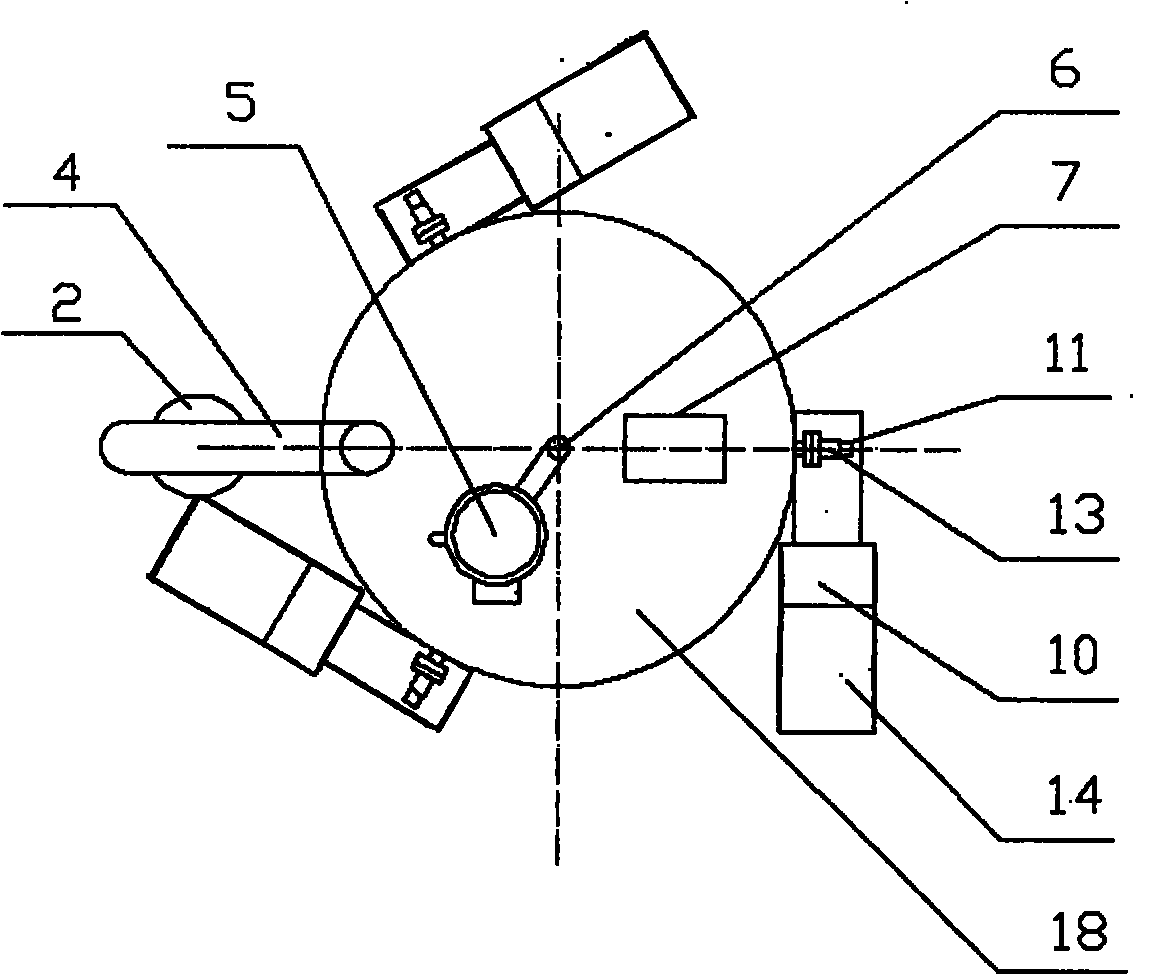

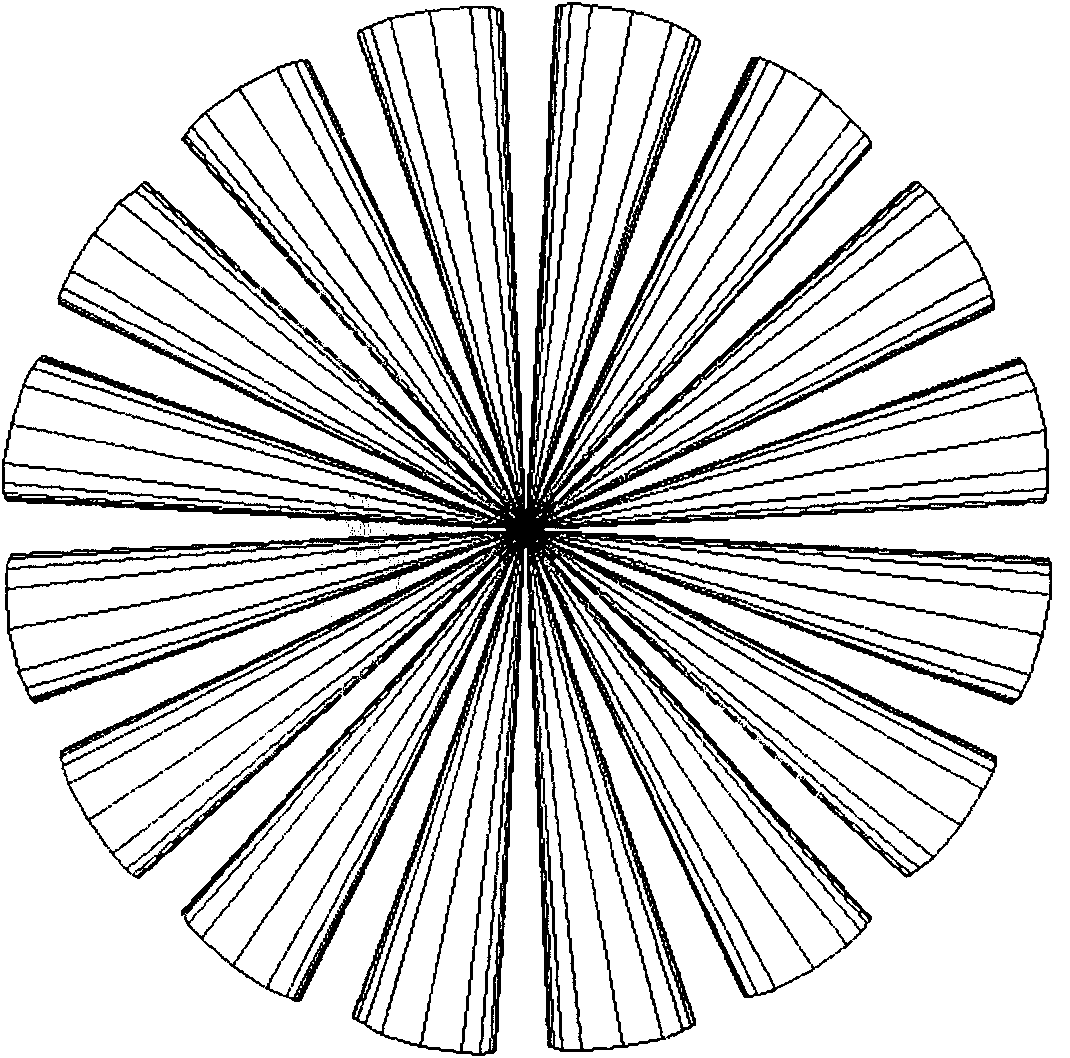

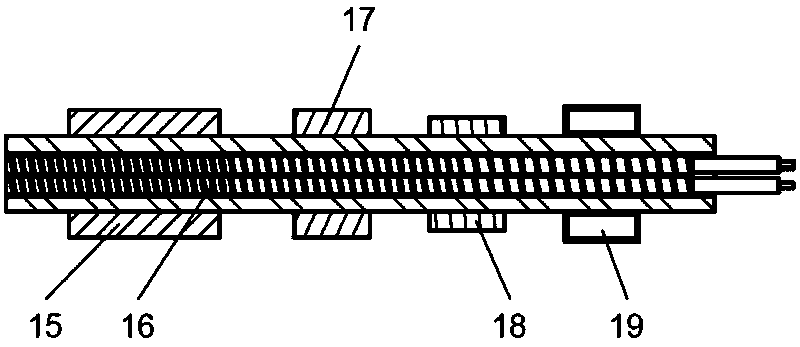

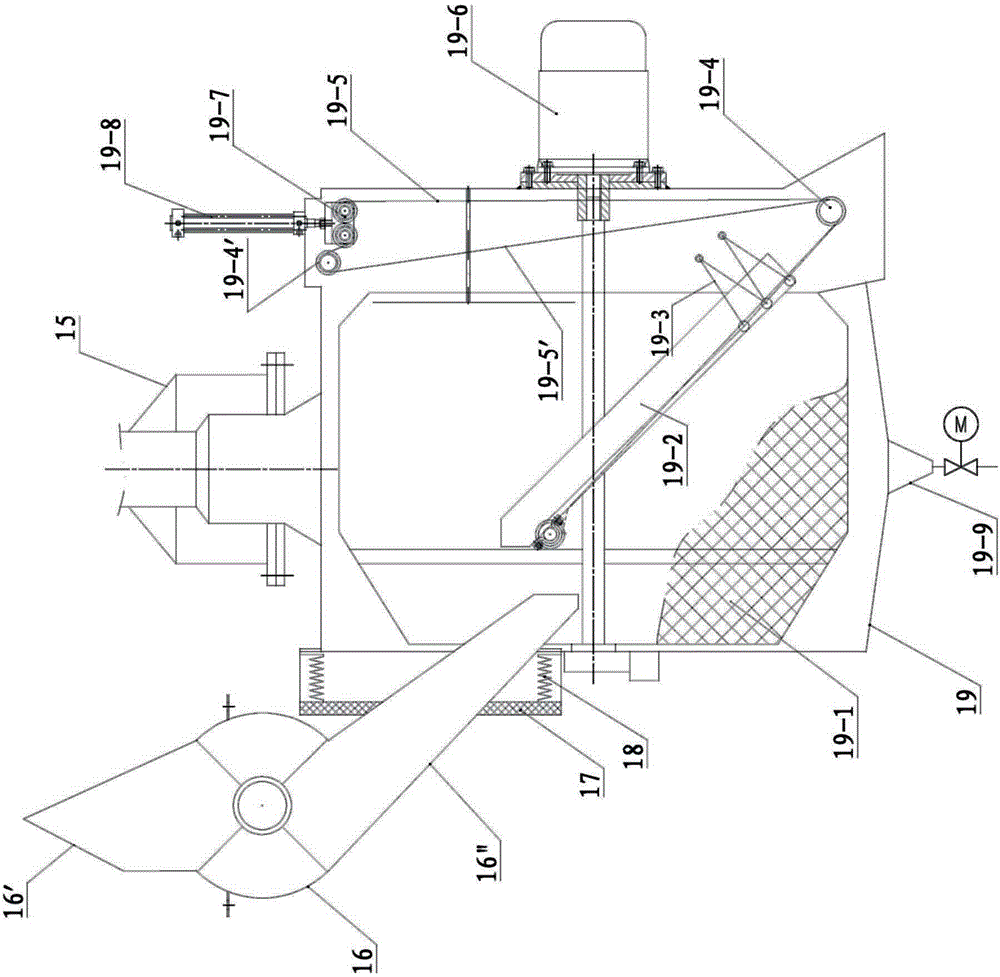

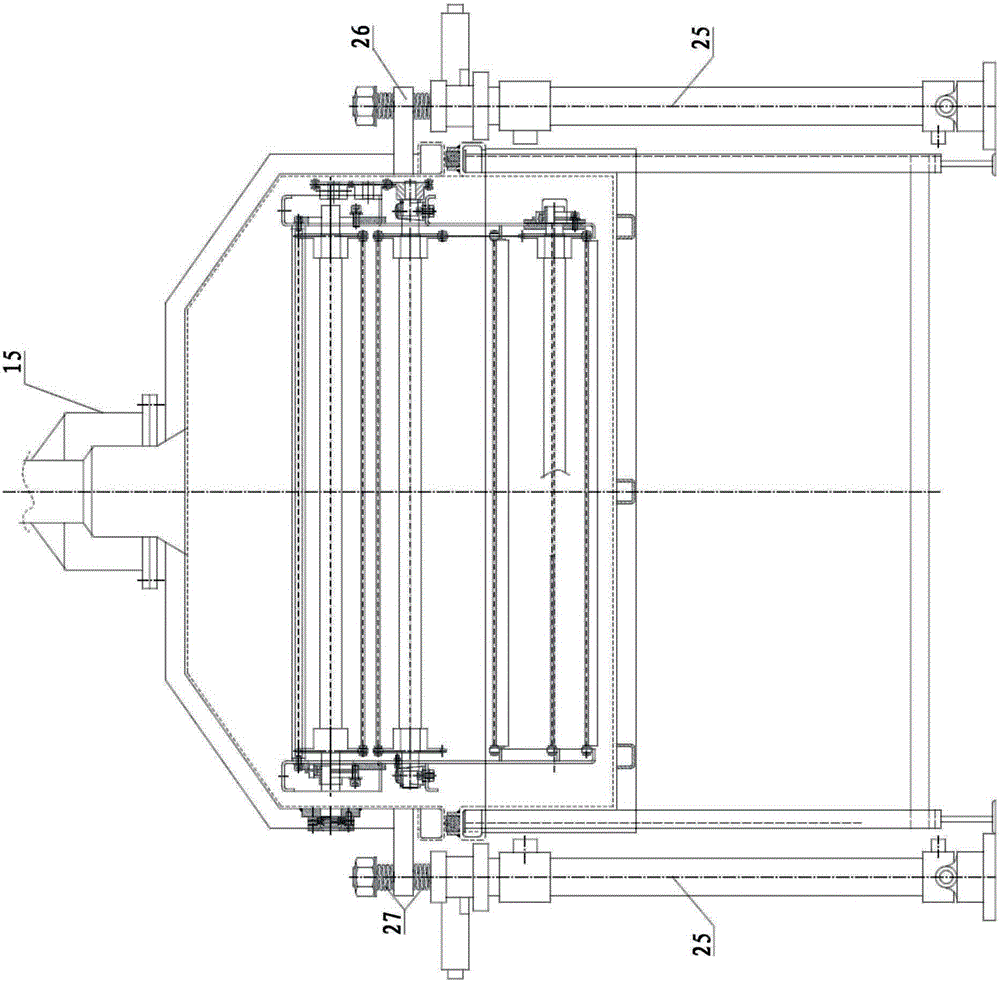

Cut leaf tobacco microwave vacuum drying equipment

ActiveCN101822415AImprove sensory qualityKeep the aromaTobacco preparationVacuum pumpingElectric machinery

Cut leaf tobacco microwave vacuum drying equipment is characterized by comprising a vertical cylinder-shaped drying cavity, a vacuum-pumping system communicated with the drying cavity, and a microwave heating system, wherein the top part and the bottom part of the drying cavity are respectively provided with a feed port and a discharge port, the drying cavity is internally provided with a material dispersion mechanism, the material dispersion mechanism comprises a spindle arranged on the axle center of the drying cavity, and multi-layer material dispersion plates arranged on the spindle, the spindle is driven to rotate by a motor, the microwave heating system is divided into a continuous microwave heating unit arranged on the upper part of the drying cavity and a pulsed microwave heating unit arranged on the lower part of the drying cavity, and the two heating units can respectively hierarchically arranged in multi groups along the shell of the drying cavity. Compared with the prior art, the invention has the advantages that the cut leaf tobacco microwave vacuum drying equipment can carry out the microwave drying in stages to the cut leaf tobacco under the a vacuum status, reduces the drying temperature of the cut leaf tobacco, keeps the fragrant of the cut leaf tobacco, improves the aesthetic quality of the cut leaf tobacco, at the same time, can realize the rapid dehydration and drying of the cut leaf tobacco, and improves the filling value of the cut leaf tobacco.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for preparing marsh gas by using lignocellulose

InactiveCN101775412AImprove utilization efficiencyShorten fermentation timeWaste based fuelFermentationCellulosePretreatment method

The invention discloses a method for preparing marsh gas by using lignocellulose, which comprises the following steps: first pre-treating a lignocellulose raw material by an extrusion bulking method, then uniformly mixing the pre-treated lignocellulose raw material and nutrient substances for producing marsh gas bacteria by anaerobic fermentation, and feeding the mixture into an anaerobic fermentation bioreactor to perform anaerobic fermentation to produce the marsh gas. The pre-treating method for the lignocellulose raw material is characterized in that the operation is simple, the method can continuously treat the materials in batch, the biodegradability and the fermentation speed of the treated raw materials are improved, the conversion rate of biomass is greatly improved, and the fermentation residues can be used as agricultural efficient organic fertilizers.

Owner:NANJING UNIV OF TECH

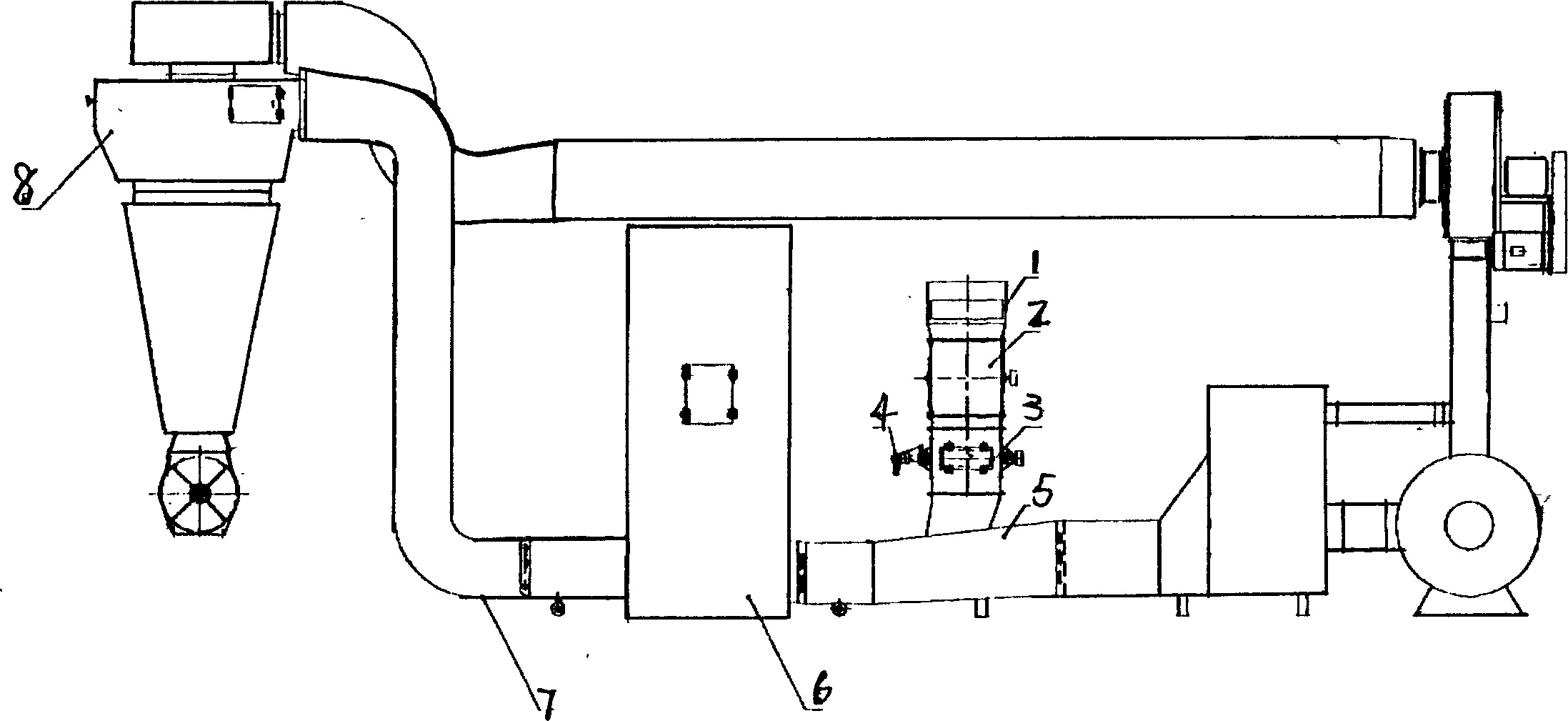

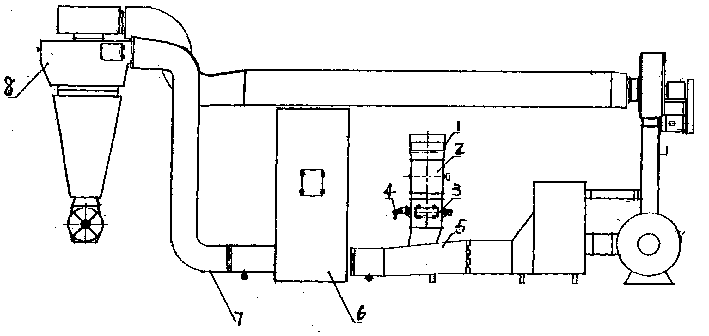

Cut tobacco fast puffing and drying process

InactiveCN1436495AReduce green miscellaneous gasHigh expansion rateTobacco preparationTarLower grade

The present invention relates to the tobacco processing process and is especially the puffing and drying process of cut tobacco. The tobacco process includes feeding material, heating cut tobacco, puffing and discharge. The beneficial effects of the present invention includes reserving tobacco fragrance in cut tobacco, reducing the green and sundry smell in cut tobacco, converting the color of low-grade cut tobacco, raising the puffing rate of cut tobacco, reducing cost of cigarette, raising filled tobacco amount, decreasing tar content in cigarette, making cut tobacco soft, loose elastic and no oxidation and browning, killing bacteria and other toxic microbes and producing no environmental pollution.

Owner:江苏智思机械制造有限公司

Preparation method of vacuum low-temperature deep-fried edible mushrooms

ActiveCN108378270AMaintain nutrientsAvoid lostFood freezingFood ingredientsDeep fryingEdible mushroom

The invention discloses a preparation method of vacuum low-temperature deep-fried edible mushrooms, and belongs to the technical field of processing of leisure foods. The preparation method comprisesthe following steps of firstly, performing ultrasonic wave-light wave united treatment on edible mushrooms with a salt solution, then performing ultrasonic wave-vacuum-ultrasonic wave multi-stage immersing, performing quick freezing, performing vacuum low-temperature deep-frying, and performing deoiling to make edible mushroom crisps of which the oil content is only 5-7%. Conventional blanching with hot water and fixation are not adopted, so that the nutrient components of the materials can be maintained to the maximum extent; and a multi-stage immersing technology is adopted, so that the immersing efficiency is improved, and the oil content of products can be notably reduced. The vacuum low-temperature deep-fried edible mushrooms is low in preparation cost, high in puffing rate of products and good in sense organ quality.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Preparation method of pleurotus ostreatus-yam compound crisp chips with the addition of black onions

ActiveCN105077071AShort processing timeGood puffing effectFood ingredient functionsFood preparationRice flourFlavor

The present invention discloses a preparation method of pleurotus ostreatus-yam compound crisp chips with the addition of black onions, and the method comprises the following steps that selected pleurotus ostreatus is subjected to washing, blanching, cooling, draining and other pretreatments for later usage; selected purple yams are subjected to washing, peeling, color protecting, blanching, cooling, draining and other pretreatments for later usage; black onion powder is prepared for later usage; then the pleurotus ostreatus, the purple yams and the black onion powder are mixed for beating into pulp, glutinous rice flour is added for molding, and then vacuum drying, water balancing, microwave puffing and packaging are carried out. Microwave puffing technology is adopted, the pleurotus ostreatus is used as the main raw material, and the purple yam and the black onion powder with health-care effects are added so that the method is capable of maximizing the preservation of original nutritional ingredients of food, enabling the processing time to be short and the puffing effect to be good, improving the product taste and saving the cost; the prepared compound crisp chips are crisp in texture, are non-fried, natural, green, healthy and are long in storage period; the original color and flavor of the compound crisp chips are furthest maintained; and the compound crisp chips can make consumes get a variety of function complementary nutritional ingredients.

Owner:XUZHOU UNIV OF TECH

Method for enhancing water binding capacity of plant wiredrawing protein

PendingCN111838399AImprove water retentionSimple preparation processProteins working-up by texturisingVegetable proteins working-upBiotechnologyVegetable oil

The invention discloses a method for enhancing a water binding capacity of a plant wiredrawing protein, and belongs to the technical field of food processing technologies. The preparation process is simple and comprises that vegetable protein powder, vegetable fat, a food coloring agent, water, glutamine transaminase and polydextrose / polyphosphate are weighed in proportion and mixed evenly, the mixture is put into a stirrer to be stirred for 15-20 min at a constant speed and reacts for 2 hours at 37-42 DEG C, and the product after the reaction is put into a co-rotating meshing twin-screw extruder and is extruded to form the plant drawing protein. The preparation process is simple, and the prepared plant wiredrawing protein is high in water-holding capacity, has chewing feeling similar to meat when being eaten, and is low in cost.

Owner:浙江远江生物科技有限公司

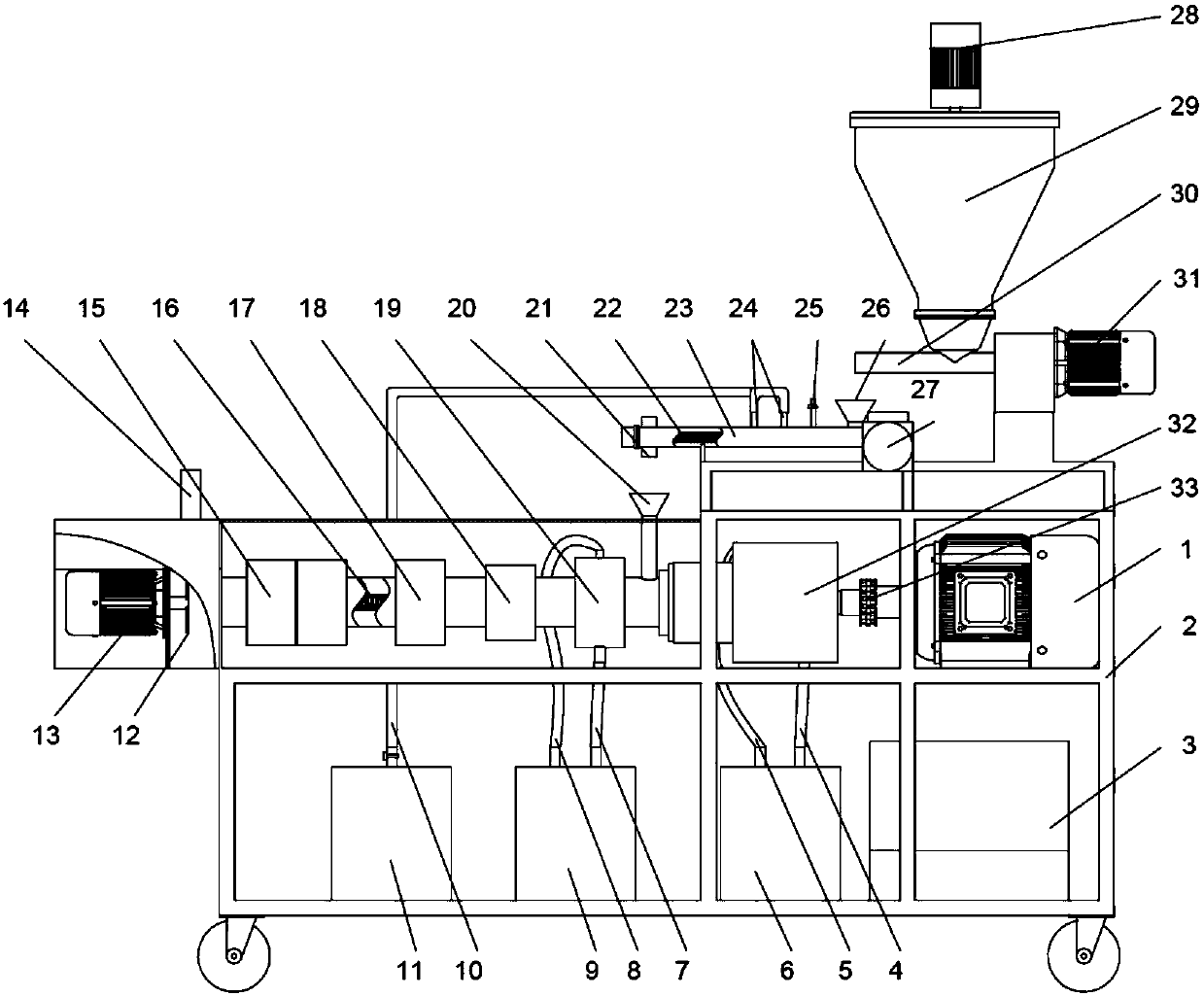

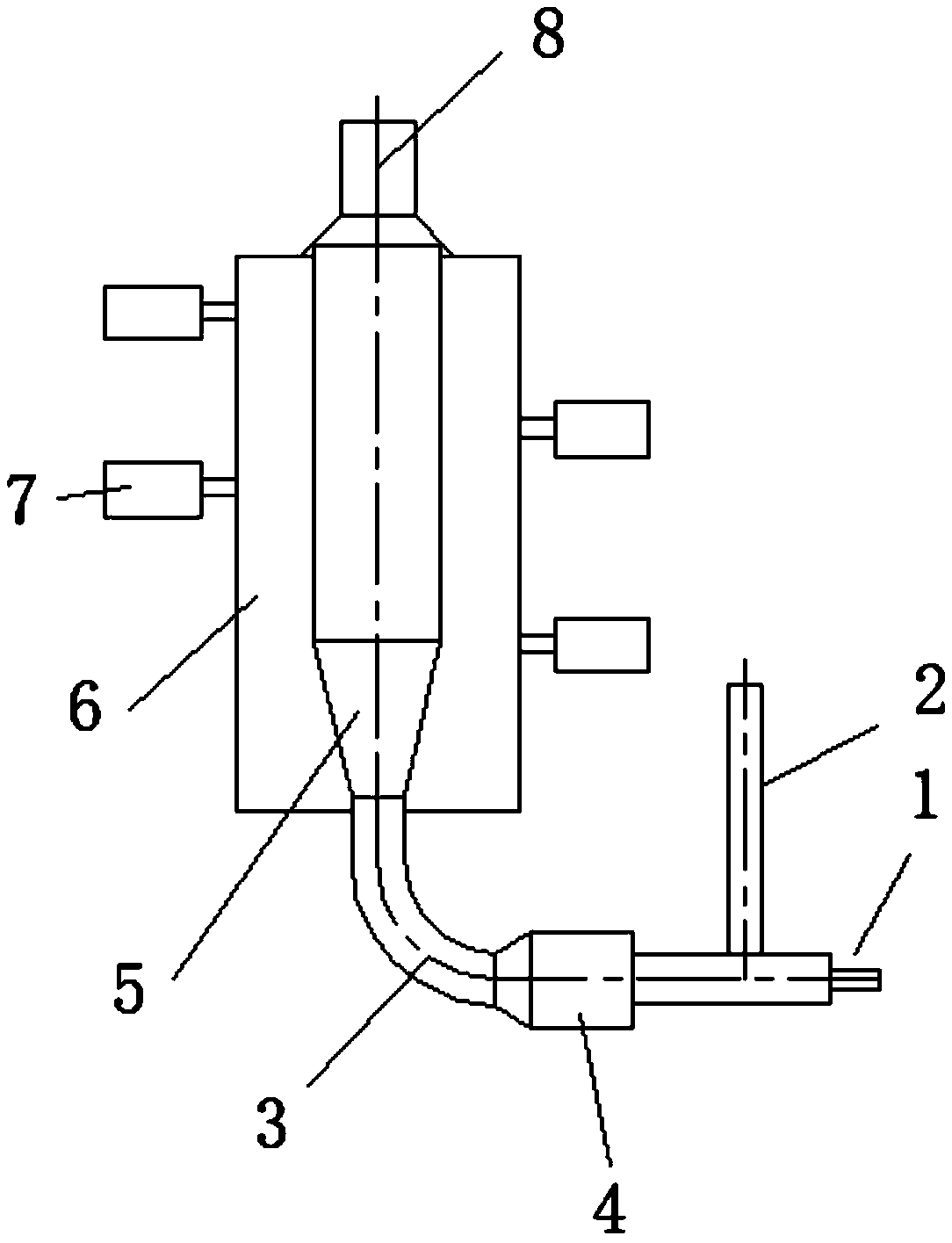

Shiitake mushroom powder extruding, puffing and processing method and processing equipment

PendingCN107692189ASufficient water absorptionIdeal material formFood shapingDeep fryingSupersaturation

The invention relates to a shiitake mushroom powder extruding, bulking puffing and processing method and processing equipment, and belongs to the technical field of food processing. The method comprises the following steps of performing drying and crushing, performing mixing and stirring, performing steam conditioning, performing extruding and puffing, and performing potary outputting. According to the method disclosed by the invention, the situation that water absorption is sufficiently performed by materials at high temperature is guaranteed by the steam preheating; and ideal material shapesare also provided for the subsequent extrusion and puffing; after the steam conditioning , heating and pressure boosting are reasonably controlled by the extrusion and puffing , so that the situations that the conditioned materials achieve the state of "supersaturation" of moisture content and pressure can be released instantly are guaranteed, subsequent working procedures of deep-frying and thelike are not needed, and under the premise that nutrient components are not damaged, the ideal puffing effect can be achieved, and crisp and exquisite mouth feels are further guaranteed; and besides,continuous mechanization for realizing the method disclosed by the invention is realized by the equipment disclosed by the invention, so that the method and equipment can be practically applied to industrial production and processing.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Rice food and production method thereof

The invention discloses a rice food and a production method thereof. The rice food comprises the following raw material components in part by weight: rice, soy sauce, disodium ribonucleotide, white sugar, garlic powder and the like. The production method comprises the following steps: rinsing, soaking, steaming and refrigerating the rice to form a rice cake; cutting the rice cake, drying, baking,sorting, and seasoning with seasoning liquid; and drying, sorting, metering and packaging finished products, and storing in a finished product warehouse. The puffing degree and mouthfeel of the rice food are greatly improved, so the rice food is more crispy and delicious; and the rice food is particularly added with nutrition elements of calcium, iron and zinc, so the applicable users of the ricefood are widened to the old with weak chewing capacity from the main users of children and the youth, and the leisure food has the function of supplementing the nutrition elements.

Owner:安徽阿幸食品有限公司

Expanded graphite expansion device through microwave gas diffusion

The method relates to the technical field of graphite expansion devices and in particular relates to an expanded graphite expansion device through microwave gas diffusion. The expanded graphite expansion device comprises a vertically arranged microwave excited cavity, wherein a plurality of microwave sources surround the outer part of the microwave excited cavity; a furnace tube is arranged insidethe microwave excited cavity; an expanded graphite output pipeline is arranged on the top of the furnace tube; the bottom end of the furnace tube is connected with an expansible graphite powder and airflow vortex mixing device by virtue of an expansible graphite gas delivery pipeline; a three-way pipe is connected to the feeding hole of the expansible graphite powder and airflow vortex mixing device; another two ports of the three-way pipe are respectively connected with an expansible graphite feed pipeline and an air inlet pipeline; and the air inlet pipeline is connected with an air blowingdevice. According to the device, the temperature rise time is short, the graphite intercalation compound is decomposed and exploded in a very short time, the formed expanded graphite has an excellentexpansion effect, the temperature rise process is avoided before production, the cooling process also does not exist when the production is stopped, the production can be optionally started or stopped, the energy consumption is low, the furnace surface temperature is low, and the operating environment is good.

Owner:深圳市弘玮微波技术有限公司

Globefish floating puffed feed

InactiveCN104970219ASolve the problem of poor puffing effectImprove immunityAnimal feeding stuffBiotechnologyHerbal preparations

The present invention relates to a globefish floating puffed feed and belongs to the technical field of aquaculture. The feed includes the following raw materials: steam fish meal, peeled soybean meal, chicken meat meal, insect protein powder, hemoglobin powder, corn protein powder, high-gluten flour, spirulina powder, calcium dihydrogen phosphate, soybean lecithin, fish oil, complex vitamins, complex mineral salts, coated methionine, coated lysine, Chinese herbal medicine preparations, ethoxyquin, choline chloride and bentonite. The globefish floating puffed feed has excellent stability in water, low dissolve-loss rates, less feed waste, and low pollution of water bodies. The use of the coated amino acids decreases the use amount of fish meal and reduces the pollution of the aquaculture water quality caused by phosphorus, and the globefish floating puffed feed can be prepared by the existing mainstream production equipment and is easy for mass production. The feed can also significantly improve the immunity, disease resistance and survival rate, promote the growth and enhance the homogeneity of the globefishes.

Owner:TONGWEI

Full-automatic continuous type vacuum frying oil removing machine

The invention relates to a full-automatic continuous type vacuum frying oil removing machine which is capable of maintaining high-vacuum-degree stability under the situation of continuous feeding and discharging. The machine is provided with an upper frying bin body, a lower frying bin body, a wedge disc type feeding and discharging sealing device, a centrifugal oil removing machine device, a vacuum system, an oil filtering device, a cleaning system and an upper frying bin pressurizing device. The wedge disc type feeding and discharging sealing device serves as a feeding and discharging sealing device, or the feeding and discharging sealing device is formed by combining two vacuum valves. The simple high-speed centrifugal oil removing machine device is adopted. The machine is simple in structure, low in manufacturing cost, convenient to press and maintain, high in applicability, suitable for continuous vacuum frying processing of fruits, vegetables, dried fruits, cooked wheaten food, aquatic products, livestock and poultry meat and other food, applicable to frying processing equipment in large, medium and small food processing enterprises and large collective canteens, also applicable to continuous vacuum impregnation, and capable of being wholly and automatically controlled.

Owner:陈长清

Method for manufacturing insole with jute fiber

ActiveCN101167606AEfficient removalWeaken joint forceInsolesFibre treatment to obtain bast fibreFiberPectinase

A method for manufacturing insoles by jute fibers comprises treating jute fibers with the complex enzyme de-gelatinizing, wherein, the complex enzyme de-gelatinizing treatment uses complex enzyme aqueous solution which is formulated by pectase and laccase to provide the de-gelatinizing treatment to jutes, adjusting the pH value of the complex enzyme aqueous solution to be more than or equal to 4.0 but less than 5.0 when the complex enzyme de-gelatinizing treatment is carried out, elevating the temperature to 35 DEG C to 65 DEG C for 20-120 minutes, and then adjusting the pH value of the solution to be 7.5 to 9.5, keeping the temperature under 40 DEG C to 70 DEG C for 20-120 minutes, enzyme-devitalizating the jutes which are treated by the complex enzyme, mixing the de-gelatinized jute fibers with the chemical fibers, carding, net-spreading, and needling the mixed fibers, hot-pressing the needled mixed fibers and molding. The insole manufactured by the method of the invention is very comfortable when in use, and is not urticant in feeling when in use, good in bacteria repellency, not easily wormy, and strong in air permeability, hygroscopicity, and moisture character.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Vacuum microwave production process of meat puffing chips

ActiveCN104351819AImprove meat structureInternal tissue swellingFood shapingFood dryingFlavorMicrowave

The invention relates to a vacuum microwave production process of meat puffing chips, belonging to the technical field of deep processing of agricultural products. The production process comprises the steps of cleaning raw material meat, cutting the cleaned meat into pieces, pickling the meat pieces by pickling seasonings, pre-drying by hot air, carrying out samming treatment, and puffing and drying by vacuum microwave; finally, sterilizing by irradiation to obtain the meat puffing leisure product which is high in crispness and good in flavor. After the preparation technology is adopted, the nutritional ingredients of the raw material are maintained to the utmost extent; the meat puffing chips are crisp in mouth feel and convenient to eat. After the preparation method and the practical technology of the meat puffing chips are used, a practical and feasible new way is provided for deep processing and utilization of meat products.

Owner:南京欧旺食品科技有限公司

Method for degumming jute by using complex enzyme

InactiveCN101130887AReduce usageImprove spinnabilityBiochemical fibre treatmentVegetable materialPectinaseLacquer

The present invention relates to a method for degumming jute by utilizing composite enzyme. The described composite enzyme includes pectase and laccase, and said method includes the following steps: utilizing pectase and laccase to make them into composite enzyme aqueous solution, and impregnating jute with said composite enzyme aqueous solution, the weight ratio of the described composite enzyme aqueous solution and jute is 15:1, and the weight ratio of described composite enzyme and jute is greater than or equal to 0.5:100 and less than 1:100: regulating pH value of said composite enzyme aqueous solution to 5.0-5.5, heating to 55deg.C-60deg.C, retaining for 25-50min, then regulating pH value of said solution to 7.5-8.0, and retaining for 25-50min at 60deg.C-70deg.C, finally, making the jute after which is treated by composite enzyme undergo the process of enzyme deactivation treatment.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Expansion method for shaping jujubes

InactiveCN101543277AOvercoming oiliness and short shelf lifeEasy to processFood shapingFood preparationWater contentZiziphus jujuba

The invention relates to an expansion method for shaping jujubes. In the prior art, before a fruit and vegetable expansion product is expanded, complex treatment is needed to be carried out on processed materials, such as pre-drying of materials (water content of raw materials is lowered to a certain degree), sugar permeability treatment, moisture equilibrium treatment, pre-expansion treatment, and the like. A method of directly expanding fresh jujubes is not reported at home and aboard. The invention adopts the technological process of producing shaping expansion jujubes taking the fresh jujubes as the raw material as follows the fresh jujubes-washing-enucleation-expansion-cooling-sorting-packaging-crisp slice of expansion jujube. The method is characterized in that firstly, the jujube expansion raw materials are only washed and enucleated without any other treatment, and processing procedures are simplified; secondly, pressure-difference expansion is adopted, and the defects of high oil content and short shelf life of the prior production of jujube expansion by vacuum frying are overcome; and thirdly, external pressure is adopted, thereby the pressure difference is increased, and the expansion effect of the shaping jujubes is favorable.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com