Vacuum microwave production process of meat puffing chips

A production process, a vacuum microwave technology, is applied in the production field of meat puffing to achieve the effects of removing the fishy smell of meat, improving the texture of the meat, and shortening the heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

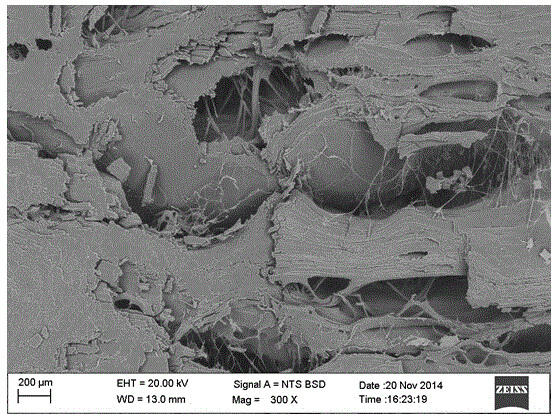

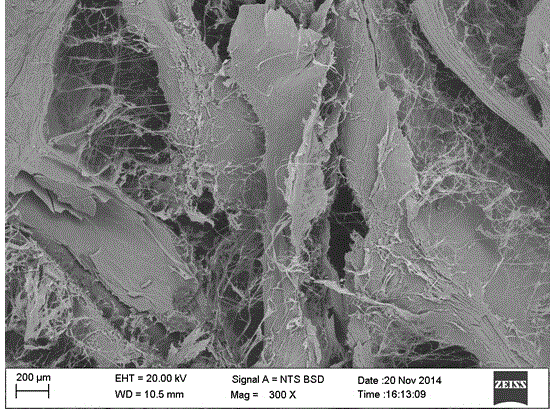

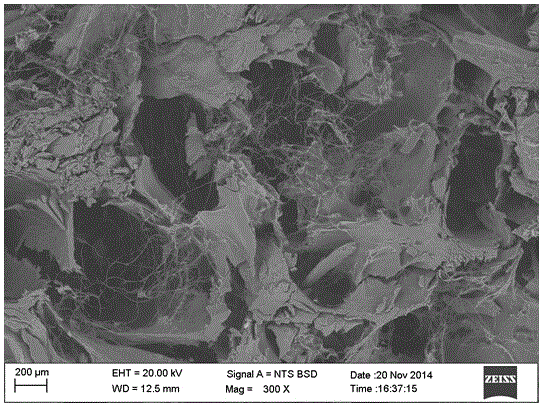

Image

Examples

Embodiment 1

[0031] 1. The preparation process of puffed duck breast meat:

[0032] Preparation of marinade: add 2 kg of ammonium bicarbonate, 2 kg of sodium chloride, 0.5 kg of grass fruit, 0.15 kg of fennel and 0.3 kg of Chinese prickly ash into 995.05 kg of pure water, and mix well to form a 1000 kg marinade.

[0033] Take 5 kg of fresh or thawed duck breast meat that has been washed and drained, and cut it into slices with a length of 5 cm, a width of 3 cm, and a thickness of 0.5 cm.

[0034] Marinate the above meat slices in the marinade, take them out after 4 hours, and put the meat slices in a 55°C oven to pre-dry until the moisture content is 40-55%.

[0035] Take out the meat slices and put them in an airtight container, and store the container at an ambient temperature of 4° C. for 5 to 8 hours for equal humidity treatment.

[0036] Put the meat slices after the wet equalization treatment into the vacuum microwave equipment for puffing and drying. The microwave power during puff...

Embodiment 2

[0059] Embodiment 2: the preparation of puffed pork breast meat:

[0060] Preparation of marinade: Add 2 kg of ammonium bicarbonate, 2.05 kg of sodium chloride, 0.2 kg of grass fruit, 0.15 kg of fennel and 0.3 kg of Chinese prickly ash into 995.3 kg of pure water, and mix well to form a 1000 kg marinade.

[0061] Get 5 kilograms of cleaned fresh or thawed pork breast meat, cut it into slices of length 10cm, width 5cm, and thickness 1cm.

[0062] Marinate the above meat slices in the marinade, take them out after 4 hours, and put the meat slices in a 55°C oven to pre-dry until the moisture content is 67-70%.

[0063] Take out the meat slices and put them in an airtight container, and store the container at an ambient temperature of 4° C. for 10 to 15 hours for equal humidity treatment.

[0064] The meat slices after the wet equalization treatment are put into vacuum microwave equipment for puffing and drying. The microwave power during puffing and drying is 4800W, and the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com