Patents

Literature

64results about How to "Evenly distributed moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fermentation technology of tea leaves

ActiveCN107455501AImprove processing efficiencyMellow tastePre-extraction tea treatmentChemistryRelative humidity

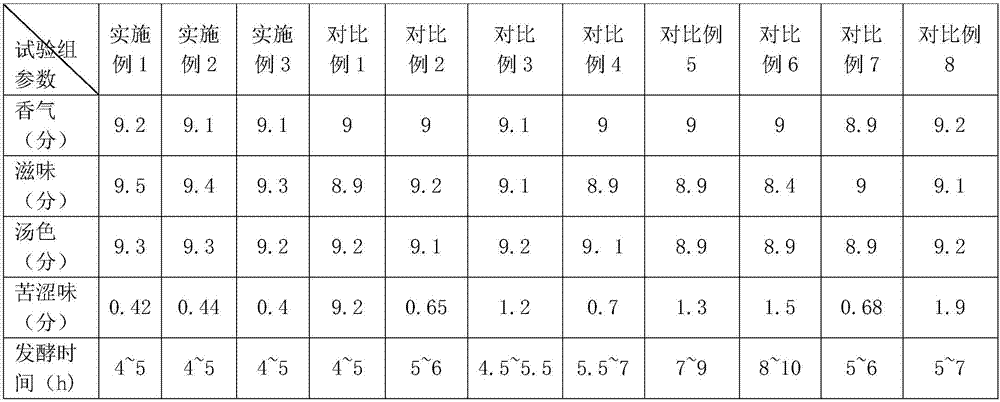

The invention belongs to the technical field of processing of tea leaves, and particularly discloses a fermentation technology of tea leaves. The fermentation technology comprises the following steps of (1) performing pretreatment; (2) performing rolling: adding starch of which the weight is 2-3% of that of the tea leaves to the tea leaves obtained in the step (1), twisting and rolling the tea leaves, after the tea leaves are rolled for 0.2-0.3h, adding starch of which the weight is 2-3% of that of the tea leaves, and continuing rolling for the time being 0.6-0.9h; (3) performing steaming; (4) performing inoculation; (5) performing pressurizing; and (6) performing fermentation: placing the pressurized tea leaves into a fermentation room with temperature being 25-28 DEG C and relative humidity being 92-96%, performing fermentation, and in the process of fermentation, stirring the tea leaves for 1-2 times. When the tea leaves are fermented through the fermentation technology, negative influence of harmful microorganisms on the quality of the tea leaves in the fermentation process can be restrained; and besides, the tea leaves obtained through the fermentation technology are unique in taste, the bitter taste is greatly reduced, the mouth feel is greatly improved, and after the tea leaves are drunk for a long term, the health of bodies is facilitated.

Owner:GUIZHOU YANGCHUNBAIXUE TEA IND

Processing method for balancing moisture in wood

InactiveCN101387471AEvenly distributed moistureReduce distortionDrying solid materials with heatHearth type furnacesEngineeringTherapeutic effect

The invention provides a method for balancing moisture in wood by microwave, which belongs to the field of wood processing. Currently, in order to solve the problem of uneven water ratio, the prior mode is to put wood which is generally dried in a health preserving room, control temperature and humidity in space, and process the product after at least 10 days of temperature and humility control to ensure the evenness of the water ratio inside the wood. Thicker wood requires more time, even requires about a month. With the prior treatment mode, the materials not only occupy mass fields and storage capacity, but also use great capital, and have low efficiency. The method comprises the following steps: a sawed timber or a wood part which is subjected to the prior drying or air drying with water ratio of between 8 and 15 percent is treated by microwave for 3 to 30 seconds with power density of microwave radiation of between 0.5 and 5 watt / centimeter<3>, the gradient and the stress of water ratio of treated wood are obviously reduced. The method has the advantages of simple process, good treatment effect, capability of continuous treatment and the like.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

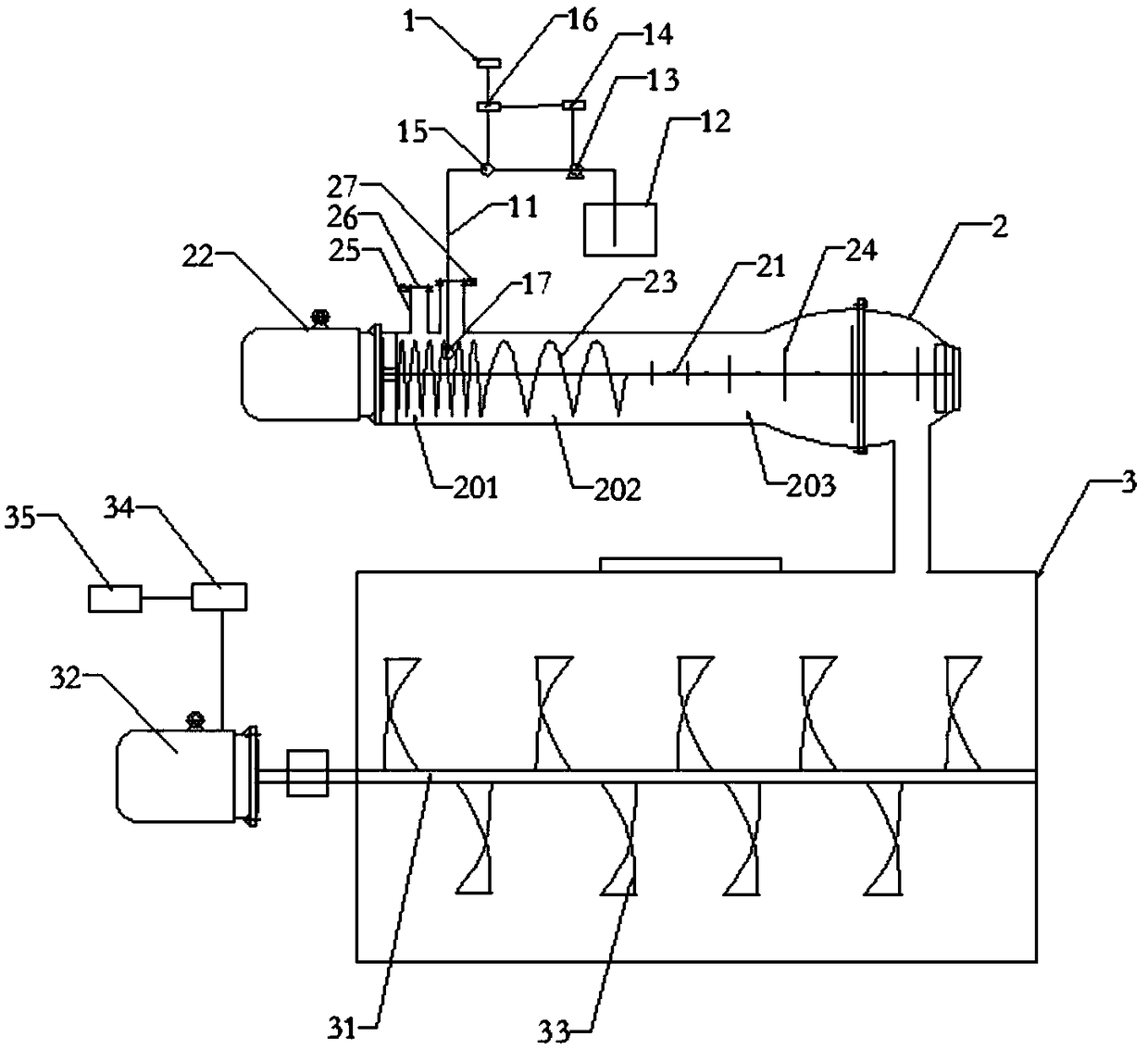

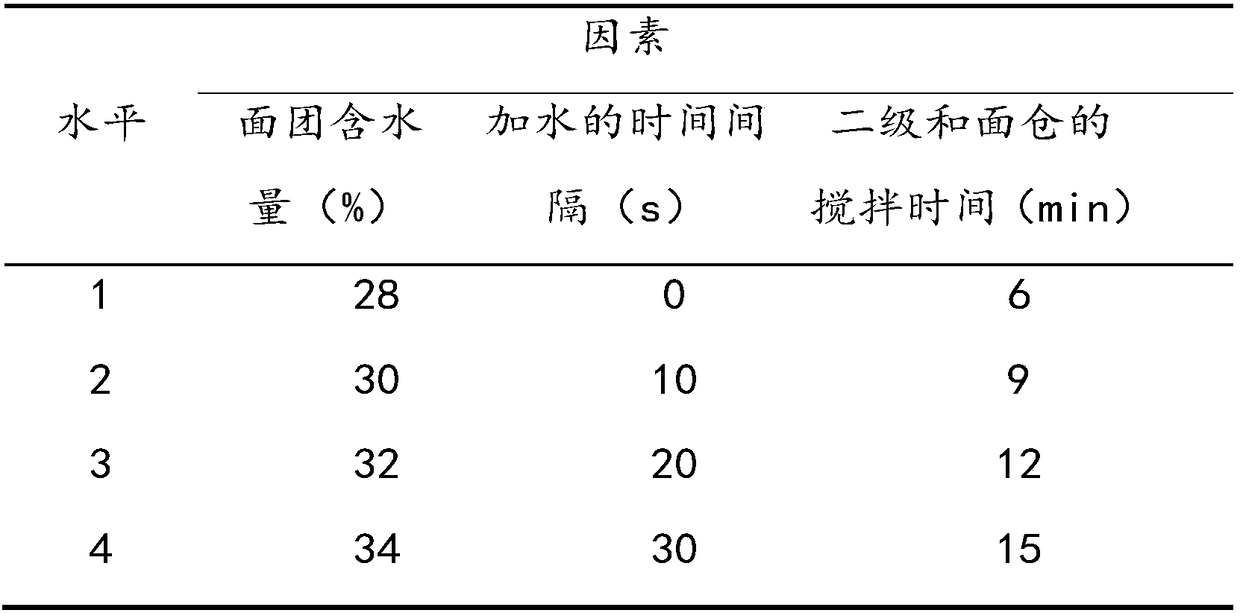

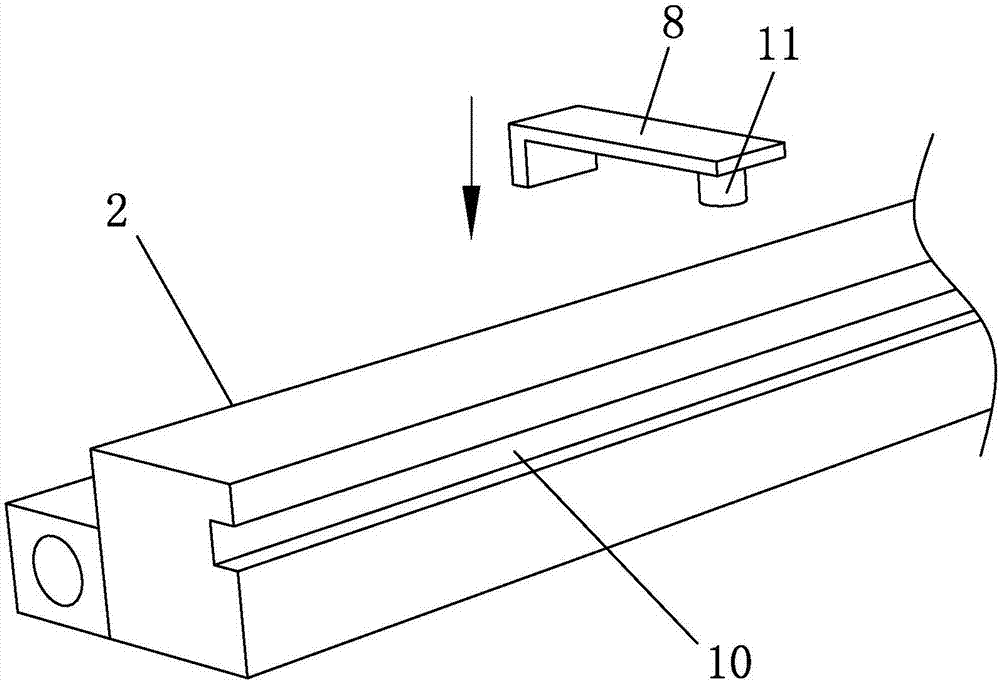

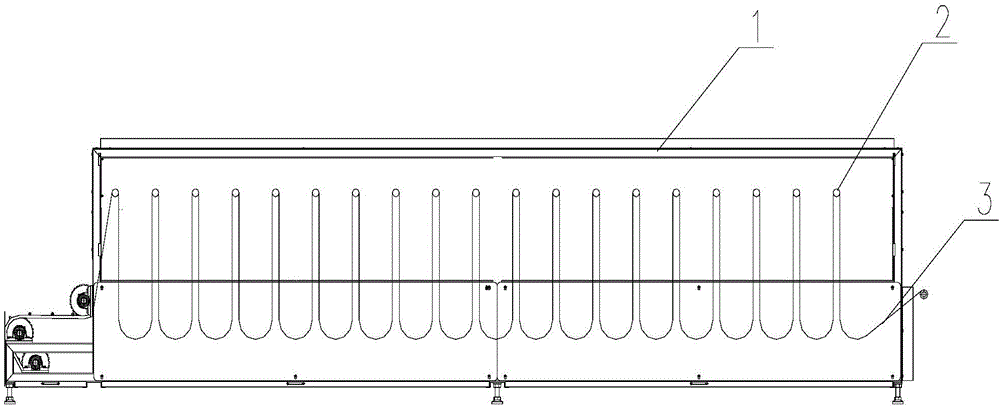

Dough kneading device, dough kneading method and noodle making machine

ActiveCN108260615AIncrease contact areaStir wellMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsGlutenPulp and paper industry

The invention belongs to the technical field of mechanical dough kneading and relates to a dough kneading device, a dough kneading method and a noodle making machine. The dough kneading device provided by the invention comprises a water supply mechanism, a primary dough kneading chamber and a secondary dough kneading chamber, wherein a first stirring shaft is arranged in the primary dough kneadingchamber, and one end of the first stirring shaft is connected with a first power mechanism; the interior of the primary dough kneading chamber is divided into three mutually communicating stirring areas, namely a first stirring area, a second stirring area and a third stirring area sequentially, paddles are arranged in the first stirring area and the second stirring area, and a stirring rod is arranged in the third stirring area; at least one material inlet is formed in the primary dough kneading chamber and the material inlet communicates with the first stirring area; and the water supply mechanism comprises a water pipe, one end of the water pipe extends into the first stirring area by virtue of the material inlet, and the water pipe at the end is connected with a water atomization device. The dough kneading device can enable wheat flour to quickly absorb water and be thoroughly mixed with water and is helpful to form dough with proper expansion of gluten, loos particles and uniformcolor for high quality fine dried noodles.

Owner:想念食品股份有限公司

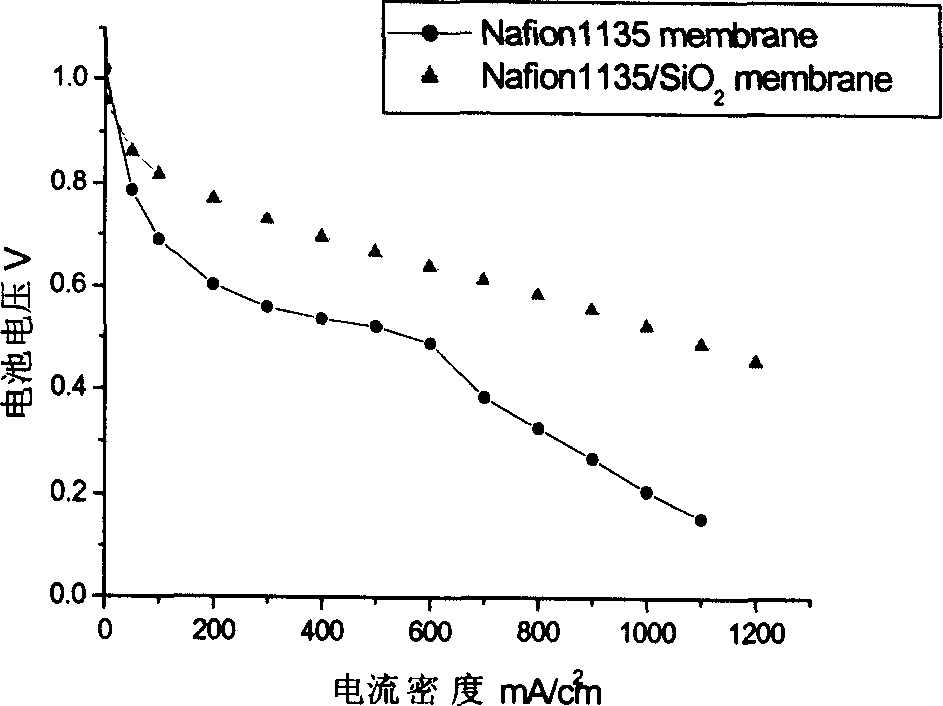

Process for preparing proton composite exchange membrane for high temperature proton exchange membrane fuel battery

InactiveCN1545156AImprove water absorptionImprove water retentionCell electrodesCell component detailsAlcoholProton

The invention relates to a method of preparing proton exchange compound film used for a fuel cell, a preparing method of proton exchange compound film used for a high temperature proton exchange film fuel cell, and the preparing method as follows: (1) immersing the proton exchange film into a mixed solution of oxide precursor and alcohol in a bulk ratio of 1 to 5-3 to 2, and sealing and placing at normal temperature for 10-14 hours; (2) taking the film out of the mixed solution, and blotting the solution on the film surface with filter paper; (3) immersing the film into a mixed solution of alcohol and water in a bulk ratio of 1 to 1-5 to 1 and blending for 1-30 minutes; (4) taking the film out, firstly airing at room temperature and then drying at 100 deg.C in vacuum for 6-48 hours. The product prepared has the characters of being able to effectively working at 80deg.C-140deg.C, and higher water -absorbing and -preserving abilities.

Owner:WUHAN UNIV OF TECH

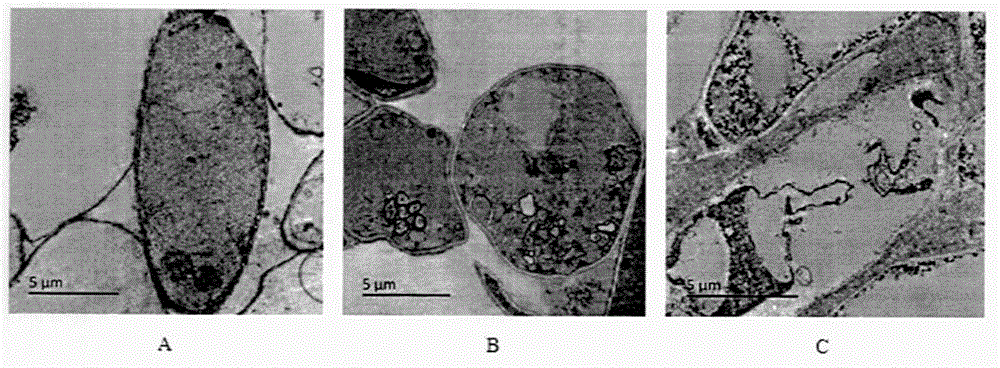

Method for uniformly drying agaricus bisporus slices through variable-frequency ultrasound-assisted impregnation pretreatment and vacuum microwaves

ActiveCN104304426AImprove uniformity of vacuum microwave dryingUniform colorFruits/vegetable preservation by dehydrationDielectricAgaricus

The invention relates to a method for uniformly drying agaricus bisporus slices through variable-frequency ultrasound-assisted impregnation pretreatment and vacuum microwaves, and belongs to the field of deep processing of agricultural products. The method comprises the following steps: cleaning agaricus bisporus and cutting into 5-8mm thick slices, protecting color by using a mixed solution of vitamin C, citric acid and calcium chloride, and carrying out variable-frequency staged ultrasound impregnation treatment on the color-protected agaricus bisporus slices: a first stage: putting the agaricus bisporus slices in clear water according to a ratio of agaricus bisporus slice to water of 1:5, and setting the water temperature to 45-50 DEG C, the ultrasonic frequency to 45KHz, the ultrasonic power to 120-150W, and the treatment time to 30-40min; a second stage: taking out the agaricus bisporus slices and putting into a mixed solution of 50-60% by mass fraction of sucrose and 5% by mass fraction of salt according to a ratio of agaricus bisporus slice to mixed solution of 1:10, and setting the water temperature to 35-40 DEG C, the ultrasonic frequency to 100KHz, the ultrasonic power to 210-240W and the treatment time to 40-50min; finally, carrying out vacuum microwave drying, and setting the microwave transmitting power to 15-20W / g, the degree of vacuum to 70-80kPa and the drying time to 15-25min. The agaricus bisporus slices subjected to variable-frequency ultrasound-assisted impregnation treatment has uniformly distributed dielectrics; when the vacuum microwave drying is carried out, a material is uniformly heated in a microwave field, and moisture is rapidly evaporated, so that the dried agaricus bisporus slice is uniformly distributed in color and luster, and is uniform in shape and better in rehydration.

Owner:JIANGSU ACAD OF AGRI SCI

Special type sludge dewatering extrusion granulator

InactiveCN101121107AReduce energy consumptionSave energySludge treatment by de-watering/drying/thickeningGranulation by material expressionWater vaporScrew thread

The present invention provides a novel technical device of sludge dehydration and belongs to the solid waste disposal field. The device is applicable to the dehydration and granulation requirements of sludge with various components. A single screw and reverse screw threads and a peculiar structure arrangement are adopted to make the water of the sludge (a moisture content of which is about 80 percent) is dehydrated as a form of liquid, and make the sludge form a sludge dehydration and granulation process, the moisture content of which is 30 percent to 35 percent. A special sludge dehydration and granulation machine fills a blank that the sludge dehydration has to be dehydrated as the form of water vapor, which greatly reduces the energy cost of the sludge dehydration. With small size, low operation cost, high production efficiency, high mechanization degree and wide scope of application, the present invention is a novel and most energy-saving and cleanly-produced sludge dehydration device.

Owner:朱清海

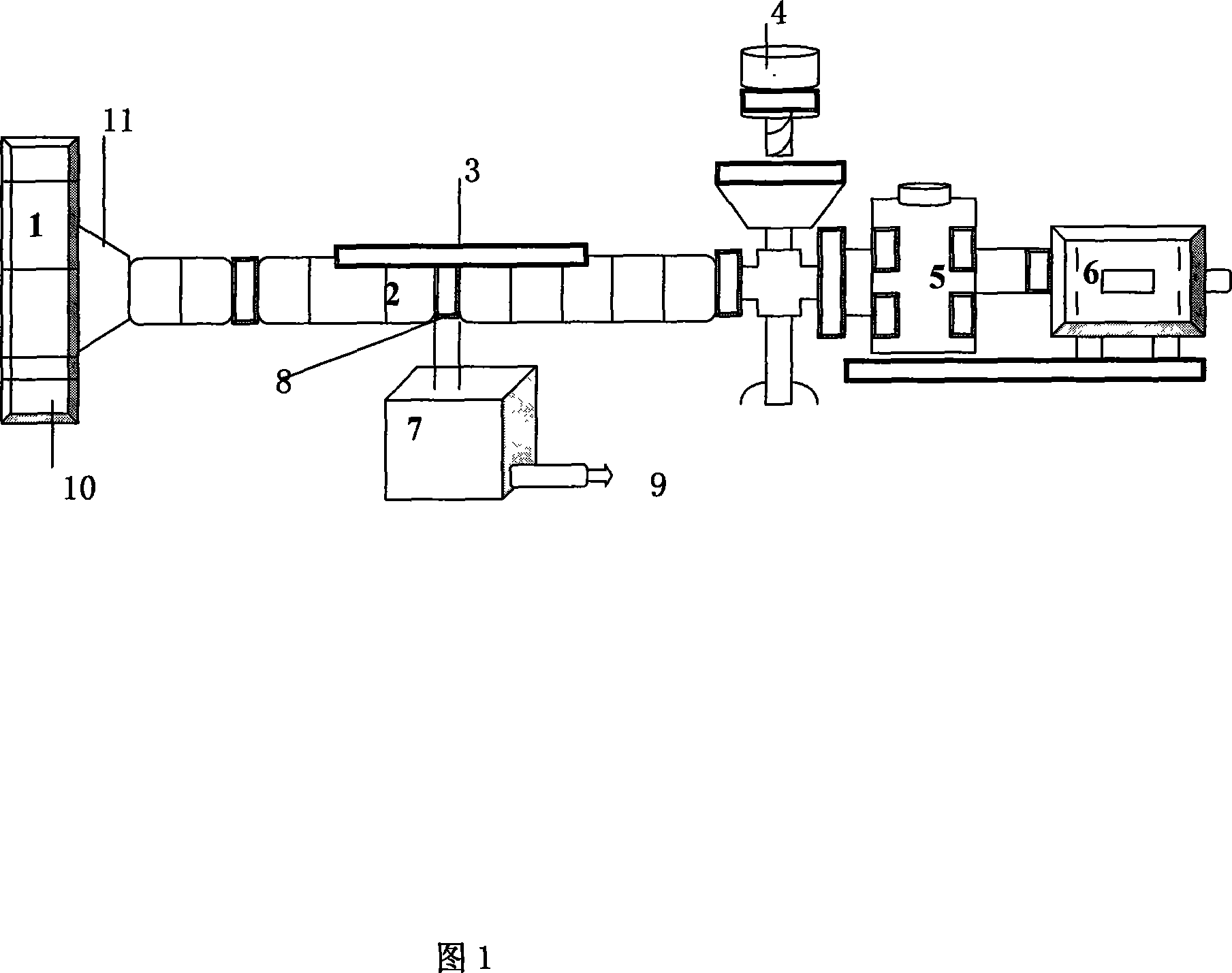

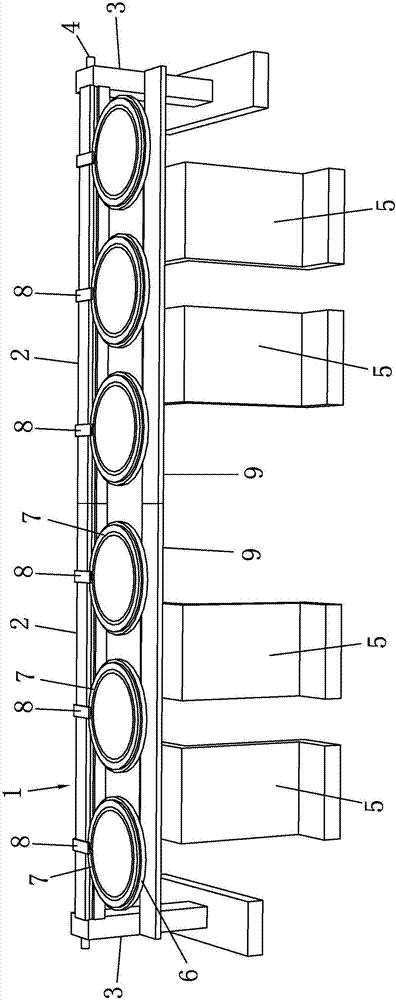

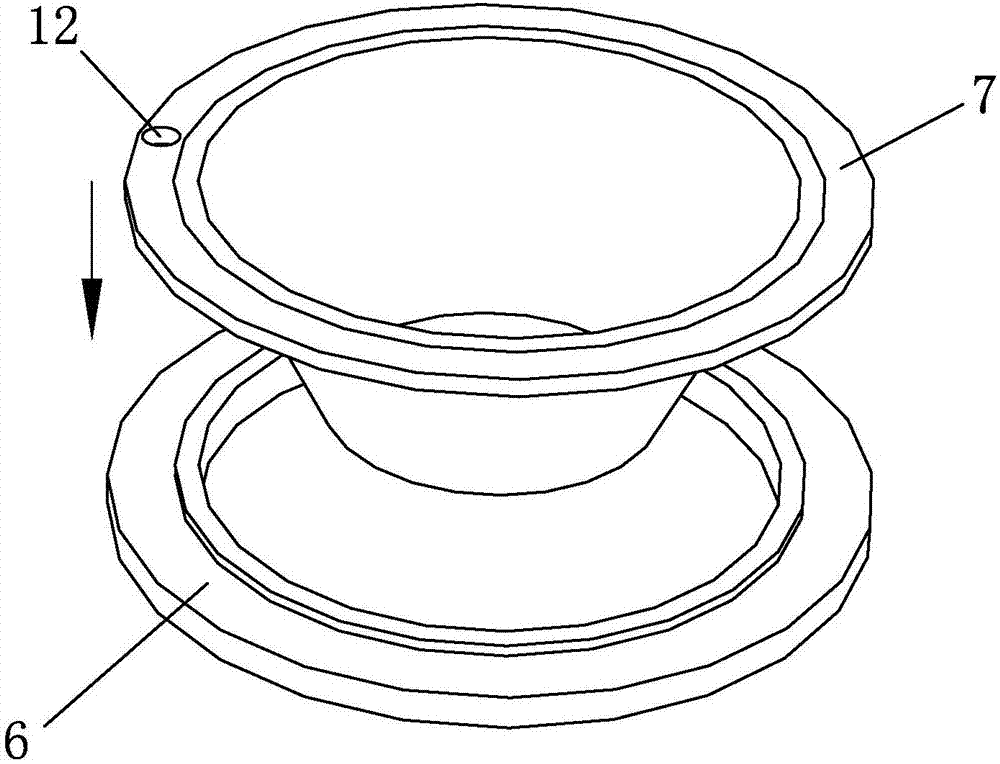

Vacuum type yarn steaming forming equipment and application method thereof

ActiveCN104278455ALow boiling pointEvenly distributed moistureTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnThermal insulation

The invention discloses vacuum type yarn steaming forming equipment which mainly comprises a box, a water ring vacuum pump, a box door and a water tank. A water level meter and a heating pipe are arranged in the water tank. A water inlet pipe and a water outlet pipe are arranged on the lateral wall of the box. A suction pipe is arranged in the box. A filter cover is disposed on the suction pipe. A pressure gauge and a surface temperature meter are further disposed on the surface of the top end of the box. The invention further provides an application method of the vacuum type yarn steaming forming equipment. The method includes: sequentially performing preheating, vacuumizing, heating, standing thermal insulation, secondary vacuumizing, heating and thermal insulation on the box. The vacuum type yarn steaming forming equipment has the advantages that the equipment is simple in structure, low in manufacturing cost, low in energy consumption, high in controllability and good in thermal insulation performance, water inlet amount, humidity and temperature change can be well adjusted, mildew and off-shade of the yarn processed by the equipment are avoided, yarn damage is avoided, condensing spots are avoided, processing time is short, yarn weight loss is compensated, and yarn quality is improved.

Owner:JIANGSU JINDA TEXTILE IND

Vacuum microwave production process of meat puffing chips

ActiveCN104351819AImprove meat structureInternal tissue swellingFood shapingFood dryingFlavorMicrowave

The invention relates to a vacuum microwave production process of meat puffing chips, belonging to the technical field of deep processing of agricultural products. The production process comprises the steps of cleaning raw material meat, cutting the cleaned meat into pieces, pickling the meat pieces by pickling seasonings, pre-drying by hot air, carrying out samming treatment, and puffing and drying by vacuum microwave; finally, sterilizing by irradiation to obtain the meat puffing leisure product which is high in crispness and good in flavor. After the preparation technology is adopted, the nutritional ingredients of the raw material are maintained to the utmost extent; the meat puffing chips are crisp in mouth feel and convenient to eat. After the preparation method and the practical technology of the meat puffing chips are used, a practical and feasible new way is provided for deep processing and utilization of meat products.

Owner:南京欧旺食品科技有限公司

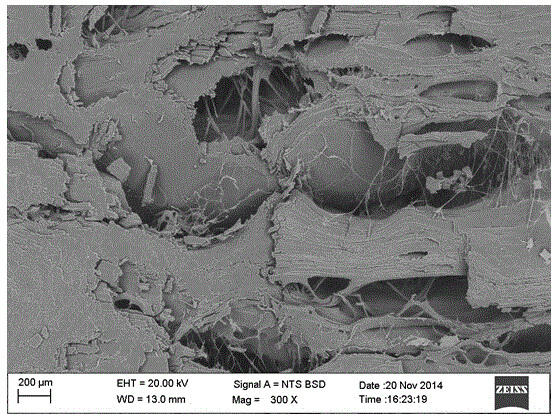

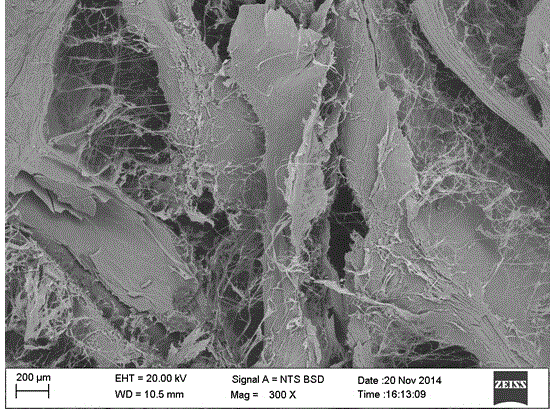

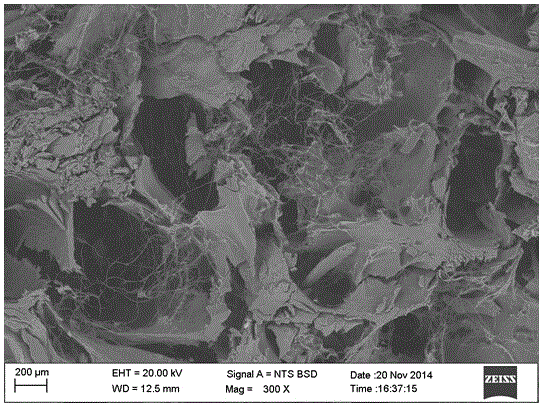

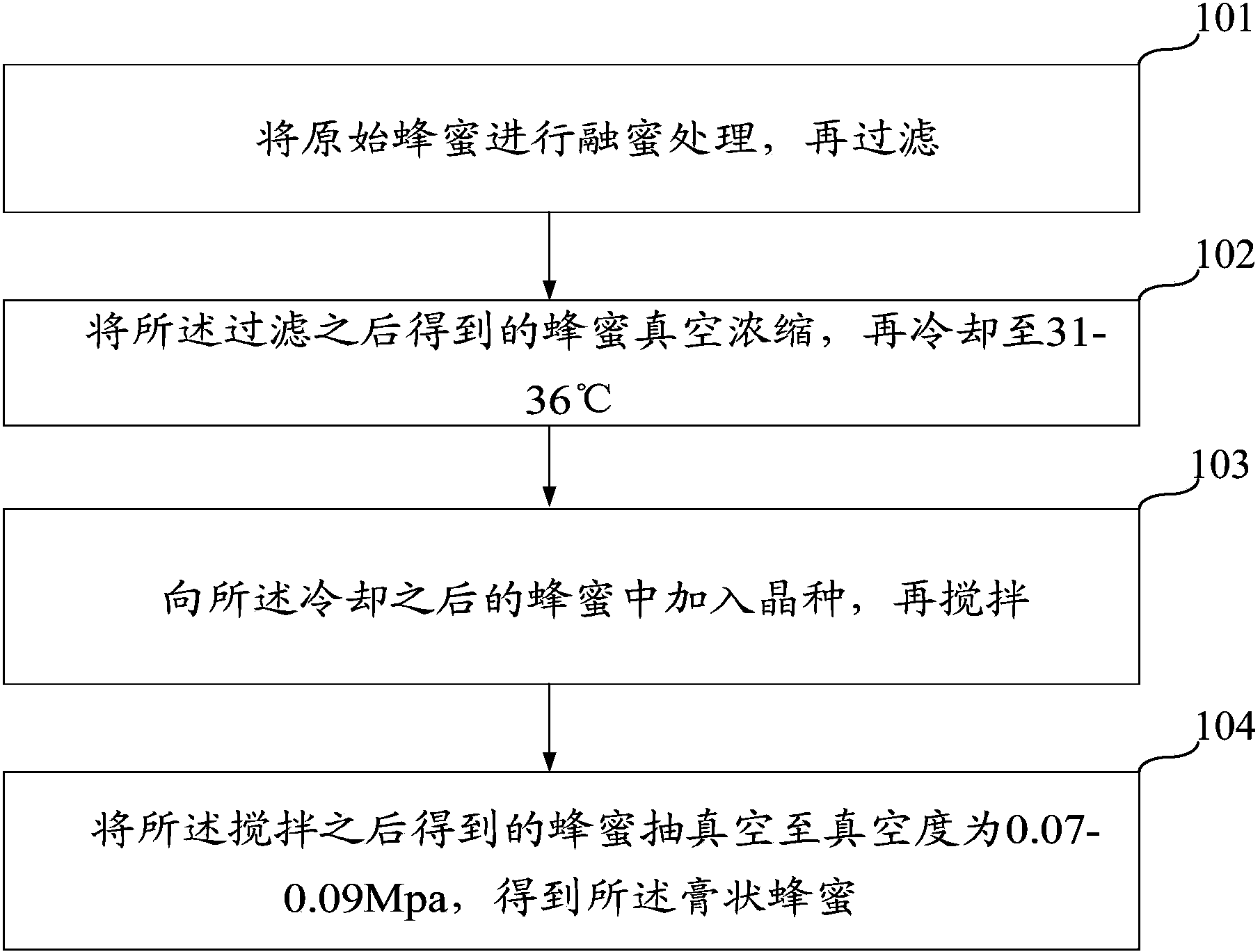

Paste honey and processing technique thereof

The invention relates to the food field, in particular to paste honey and a processing technique thereof. The processing technique of the paste honey comprises the following steps: raw honey is fused, and then is filtered; the filtered honey is concentrated in vacuum, and then is cooled to 31-36 DEG C; the cooled honey is added with seed crystals, and then is stirred, wherein the seed crystals are natural crystals of the raw honey, and have the particle sizes of 20-40 microns, and the weight ratio of the added seed crystals to the cooled honey is 10-15: 100; the stirred honey is vacuumized until the vacuum degree is 0.07-0.07 Mpa to obtain the paste honey. The processing technique avoids the problem of easy deterioration due to uneven natural crystals of the liquid honey; and the paste honey prepared by the processing technique has the advantages of bright color, mellow and normal taste and easy coating.

Owner:TIANSHUI XILIAN BEE IND

Planting method for cane shoots

InactiveCN107125011AGuaranteed normal growthSufficient operating spaceCultivating equipmentsHorticultureShootNormal growth

The invention discloses a planting method for cane shoots. The method comprises the following steps: (a) selecting a cane shoot field and a cane shoot variety; (b) fertilizing the cane shoot field and breeding seed plants; (c) transplanting the seedlings; (d) erecting a positioning frame in the cane shoot field; (e) erecting a support frame in the cane shoot field; (f) putting in planting pots; (g) digging planting holes; (h) moving the planting pots into the planting holes; and (i) managing the field. According to the invention, seedlings are planted into the planting pots, and the planting pots are lifted away from the cane shoot field for a certain altitude; the distance between two adjacent planting pots is adjusted according the size of the seedlings, and then the positions of the planting pots are fixed; the planting holes are formed in the corresponding positions of the cane shoot field according to the placement positions of the planting pots; the seedling planting space is adjusted according to the size of the seedlings; the planting space of the cane shoot field is fully utilized; the normal growth of the seedlings is guaranteed; and in the transplanting process, a plurality of planting pots are simultaneously planted into the corresponding planting holes, so that the labor is saved, the transplanting time is shortened and the survival rate of the seedlings is increased.

Owner:湖州桑农生态农业有限公司

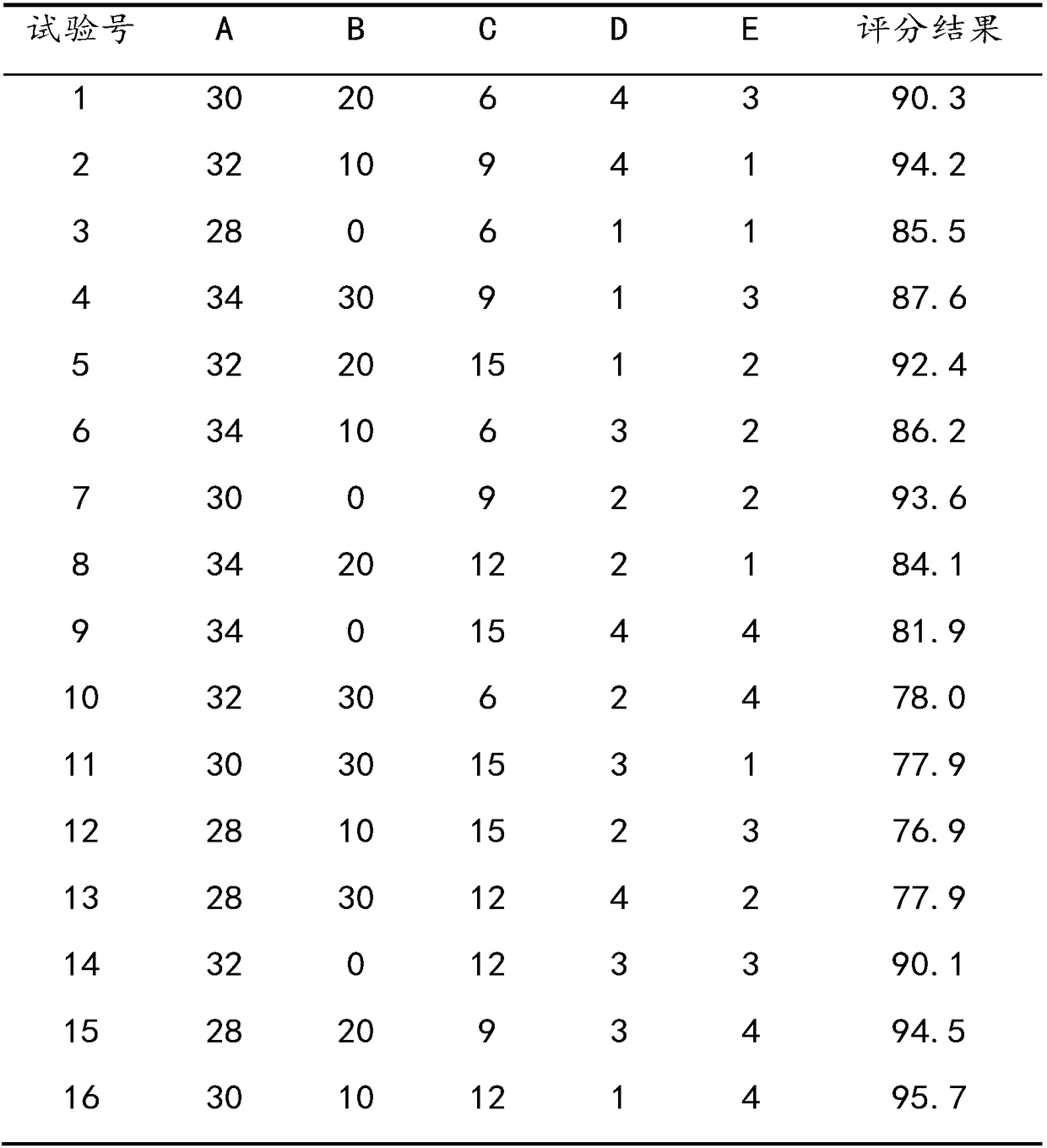

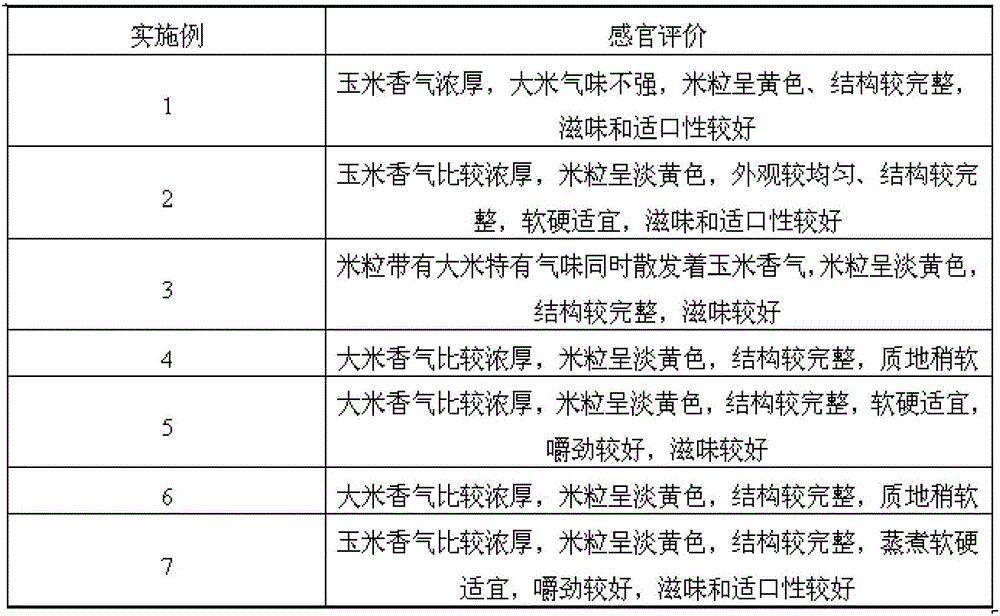

Ultrahigh-pressure artificial miscellaneous grains and making method thereof

InactiveCN105707679APromote absorptionRich and long tasteFood ingredient as taste affecting agentFood ingredient as flavour affecting agentPhosphatePotato starch

The invention discloses ultrahigh-pressure artificial miscellaneous grains. Rice and corn are used as raw materials, the raw materials are firstly smashed and are separated through a 60-mesh sieve, then the separated raw material powder is mixed in proportion, soybean separation protein powder and sweet potato starch phosphate ester are added and are evenly mixed, then water is added, the mixture is kneaded into dough, the dough is subjected to double-layer vacuum packaging and then is put into an ultrahigh-pressure container, deionized water is poured into the container, processing is performed under the pressure of 100-600 MPa for 5-30 minutes, then the dough is pressed into dough strips, the dough strips are made into rice grains, and the rice grains are cooked, dried and cooled to produce the finished product artificial miscellaneous grains. The made artificial miscellaneous grains are high in boiling fastness, high in sensory evaluation, good in taste, complete in structure, rich in fragrance and good in palatability.

Owner:张斌

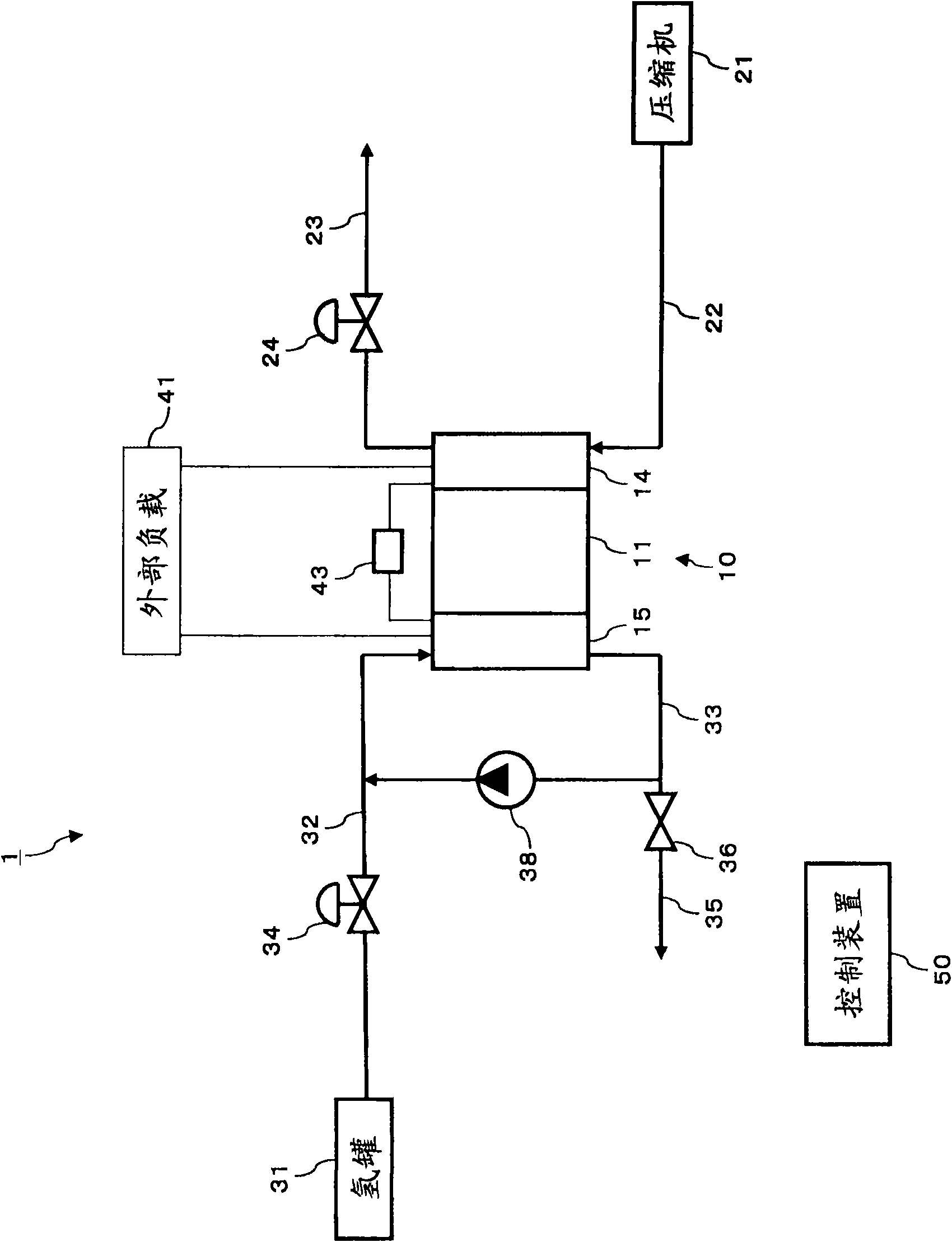

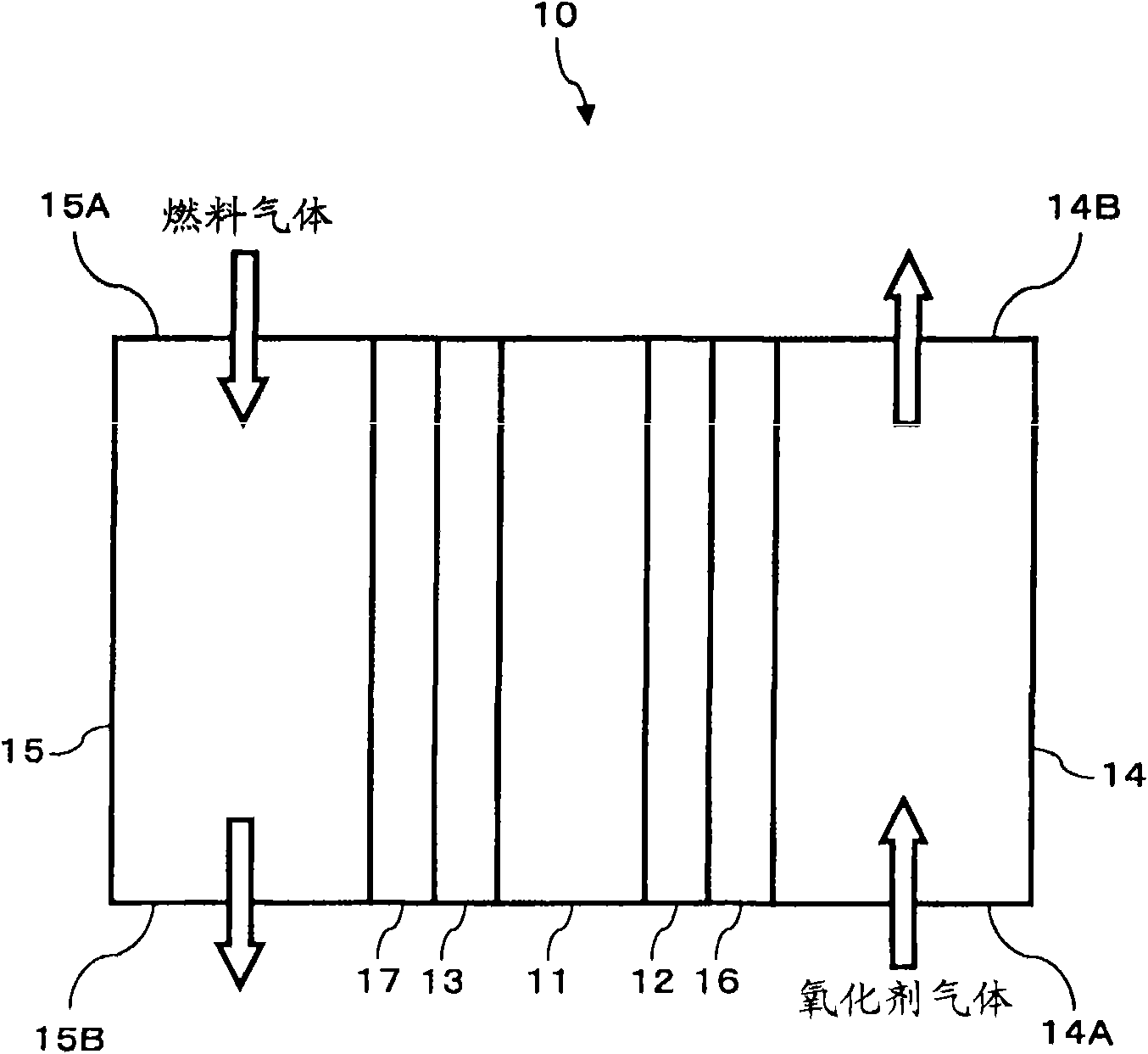

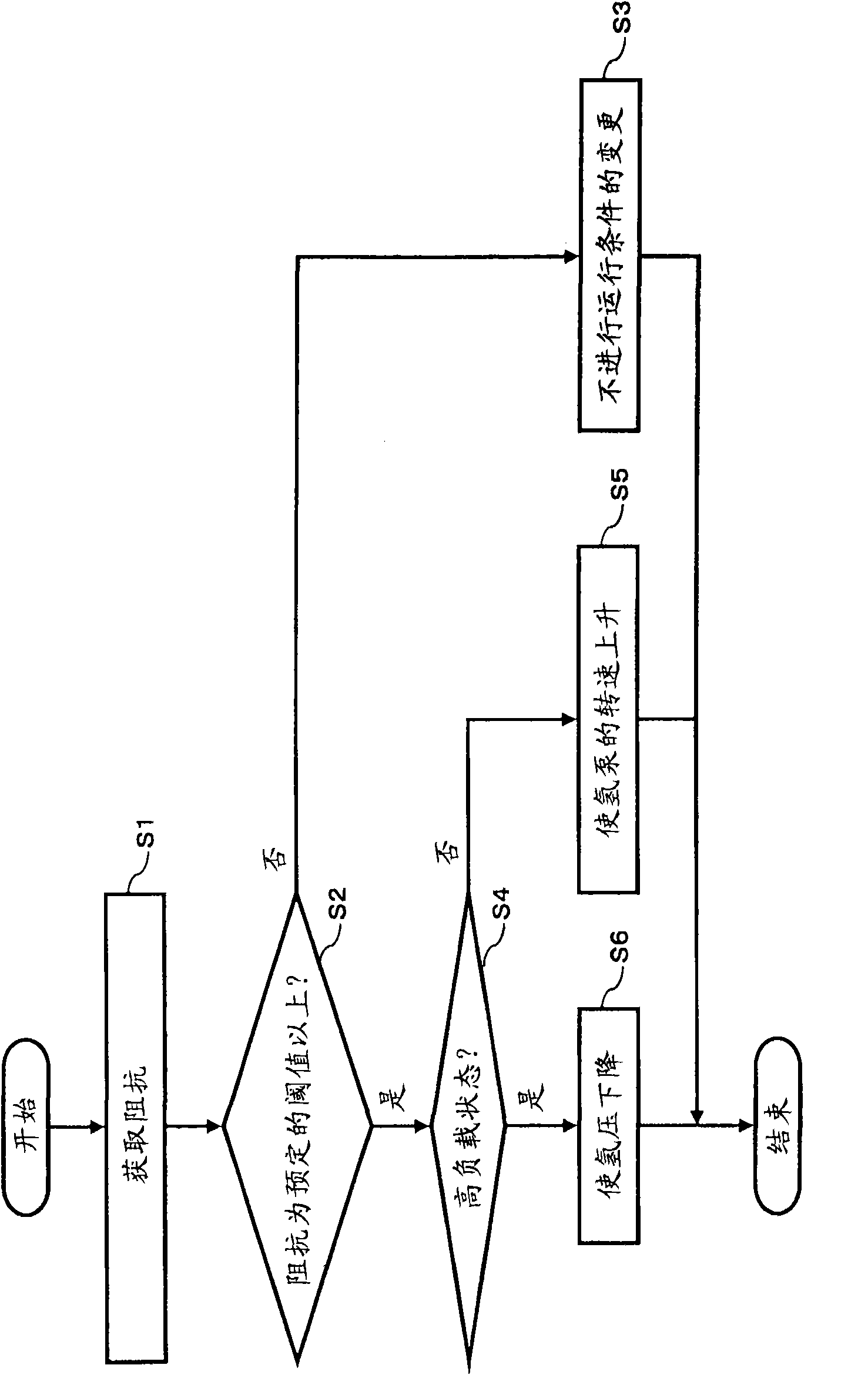

Fuel cell system and control unit for fuel cell system

ActiveCN101689665AEvenly distributed moistureWater management in fuel cellsSolid electrolyte fuel cellsFuel cellsEngineering

This invention provides a fuel cell system which can render the distribution of water in an electrolyte membrane even without lowering the pressure of a fuel gas. A fuel cell system (1) comprises an electrolyte membrane (11), an oxidant electrode provided on one side of the electrolyte membrane (11), and a fuel electrode provided on the other side of the electrolyte membrane (11). An oxidant gas flow passage (14) for supplying an oxidant gas along the face of the oxidant electrode and a fuel gas flow passage (15) for supplying a fuel gas along the face of the fuel electrode are provided so that the flow direction of the oxidant gas faces the flow direction of the fuel gas. A control unit (50) conducts control so that, when the electrolyte membrane (11) is dry, the flow rate of the fuel gaswhich flows through the fuel gas flow passage (15) is increased.

Owner:TOYOTA JIDOSHA KK

Macadamia nut microwave vacuum drying process

InactiveCN102499397AReduced nutrient contentRetain nutrientsFood processingFood preparationMicrowaveProcess engineering

The invention discloses a macadamia nut microwave vacuum drying process, belonging to the technical field of food processing. The macadamia nut microwave vacuum drying process comprises the steps of sorting, microwave vacuum drying, vacuum packaging and storing. A microwave vacuum drying technology is applied to drying of macadamia nut, thus a drying period of the macadamia nut is reduced to 40-90 minutes from the original 2-5 days, energy consumption is greatly reduced, and production efficiency is improved, quality of the nut is improved, product taste is more crisp, colour and lustre are obviously improved, and storage period of the macadamia nut is prolonged; besides, the microwave vacuum drying technology is introduced, thus drying of the macadamia nut is easier to control in real time and automatic production is realized.

Owner:KUNMING UNIV OF SCI & TECH

Curtain wall terra-cotta and method for producing the same

The invention belongs to the technical field of construction materials, in particular to a curtain wall ceramic board and a preparing method thereof. The main ingredient of the curtain wall ceramic board is shale, and the auxiliary ingredient is argil. The invention uses the shale as the main raw material for producing the curtain wall ceramic board, saves a great amount of clay and kaolin resources, and effectively uses the shale with sufficient resources. The invention also uses a wet ball milling method to uniformly mix the raw materials, the finished product rate is high, the finished products can reach the requirement of the relative standards of the national standard GB / T21086-2007 and the like, the color difference is reduced, the cost is lowered, and the dust pollution is reduced.

Owner:ZHEJIANG ANKE NEW MATERIAL

Quhao green tea processing technology

InactiveCN106857899AOvercome bitternessOvercoming the disadvantage of darkening the colorPre-extraction tea treatmentFlavorEconomic benefits

The invention discloses a Quhao green tea processing technology. The processing technology comprises the following processing steps: fresh leaf spreading, fixation, cool sharing and moisture regaining, rolling, baking for the first time, cool sharing and moisture regaining, processing by frying in a small pot, processing by frying in a big pot, cool sharing and sieving, sufficient drying and cooling for sub-packaging. According to the Quhao green tea processing technology provided by the invention, organic combination is effectively performed on existing processing equipment, technological process and the like; by adopting a segmented and coarse-fine combined processing method, the defects existing widely in current processing technology that the bitter taste of tea soup is strong and the fragrance is easy to mix up with old soup are effectively overcome; the tea soup quality is effectively improved; the taste and flavor of Quhao green tea are guaranteed; the economic benefit of tea peasants is conducive to being improved; therefore, the Quhao green tea processing technology has a relatively strong promotional value and market.

Owner:宁波市奉化区雪窦山茶叶专业合作社

Preparation method of culture medium for edible fungi

InactiveCN104892067AImprove nutrient utilizationIncrease productionFertilizer mixturesBiotechnologySucrose

The invention discloses a preparation method of a culture medium for edible fungi, belongs to the technical field of edible fungus production and aims at providing a preparation method of a culture medium for edible fungi, which is simple and feasible as well as capable of ensuring that the water of the whole culture medium is uniformly distributed. In order to solve the technical problem, the invention adopts the technical scheme as follows: the culture medium comprises the following raw materials in parts by weight: 60-70 parts of cotton seed hulls, 10-20 parts of corn cobs, 10-30 parts of wheat bran, 3-5 parts of lime powder, 5-15 parts of soybean straws and 0.5-1 part of cane sugar; and the preparation method comprises the steps of watering to pre-wet the cotton seed hulls and the corn cobs, uniformly mixing, stacking the pre-wet cotton seed hulls and corn cobs, covering the cotton seed hulls and the corn cobs by using a plastic film soaked with 5% lime water, and overturning after 2-5 days; then, covering to further ferment, and repeating in such a way for 2-3 times, and keeping the temperature of the mixed fermentation material not higher than 75 DEG C in the mixed fermentation process of the cotton seed hulls and the corn cobs to obtain fermented clinker; and after weighing the mixed fermentation clinker and other ingredients according to a certain ratio, spreading layer by layer, stirring by using a stirrer for 2-3 times, and uniformly mixing.

Owner:山西奥格姆农业科技有限公司

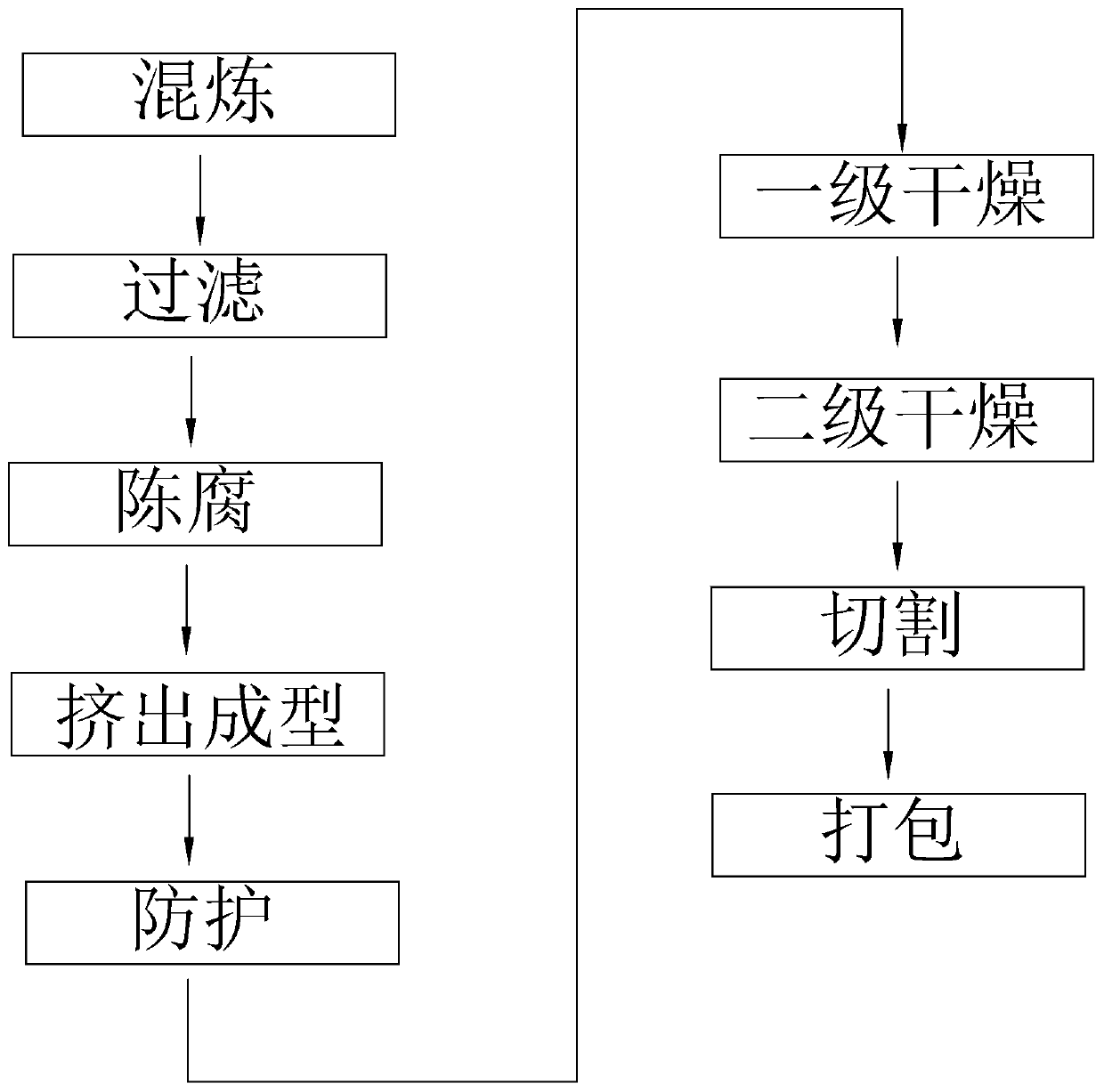

Denitration catalyst production process

PendingCN110743533AAffects structural strengthAvoid crackingDispersed particle separationCatalyst activation/preparationPtru catalystHoneycomb like

The invention discloses a denitration catalyst production process, which comprises: A1, mixing; A2, filtering; A3, ageing; S4, extrusion molding: putting the aged raw material into an extruder, and extruding the raw material from an extruder mold to form a honeycomb-like catalyst crude product; A5, protection: packaging and sealing the catalyst crude product by using a protection paper shell; A6,primary drying: placing the protected catalyst crude product on a cart, pushing into a drying chamber, and drying; A7, secondary drying; A8, roasting; A9, cutting; and A10, packaging, wherein the stepA6 is divided into four stages, the first stage is a heating constant-humidity stage, the second stage is a constant-temperature constant-humidity stage, the third stage is a constant-temperature dehumidification stage, and the fourth stage is a gentle cooling stage. According to the invention, with the production process, cracks are prevented from being generated on the surface of the catalyst product, and the structural strength of the catalyst product is guaranteed.

Owner:SHANDONG BOLIN ENVIRONMENTAL PROTECTION TECH DEV

Eurotium cristatum tea automatic fermentation process

ActiveCN105230827ARealize automatic controlEasy to operatePre-extraction tea treatmentHigh pressureMoisture regain

The invention relates to a fermented tea automatic processing method, in particular to a eurotium cristatum tea processing method. The processing steps include: spraying to loose tea, moisture regain, microwave sterilization, inoculation, fungus-growing, and drying. The process provided by the invention realizes automatic fermentation of eurotium cristatum tea, has simple and automatic procedure, and solves the problem that the tea prepared by high pressure steam sterilization has moisture flavor. Also, the air introduced in the fermentation process is subjected to filtering treatment, the sundry bacteria contamination problem is effectively solved, the temperature is controlled at a temperature suitable for eurotium cristatum growth, thus being in favor of rapid growth of eurotium cristatum and effectively shortening the production cycle. Through fermentation for 3-5 days, eurotium cristatum tea covered with eurotium cristatum can be obtained.

Owner:HANGZHOU EFUTON TEA

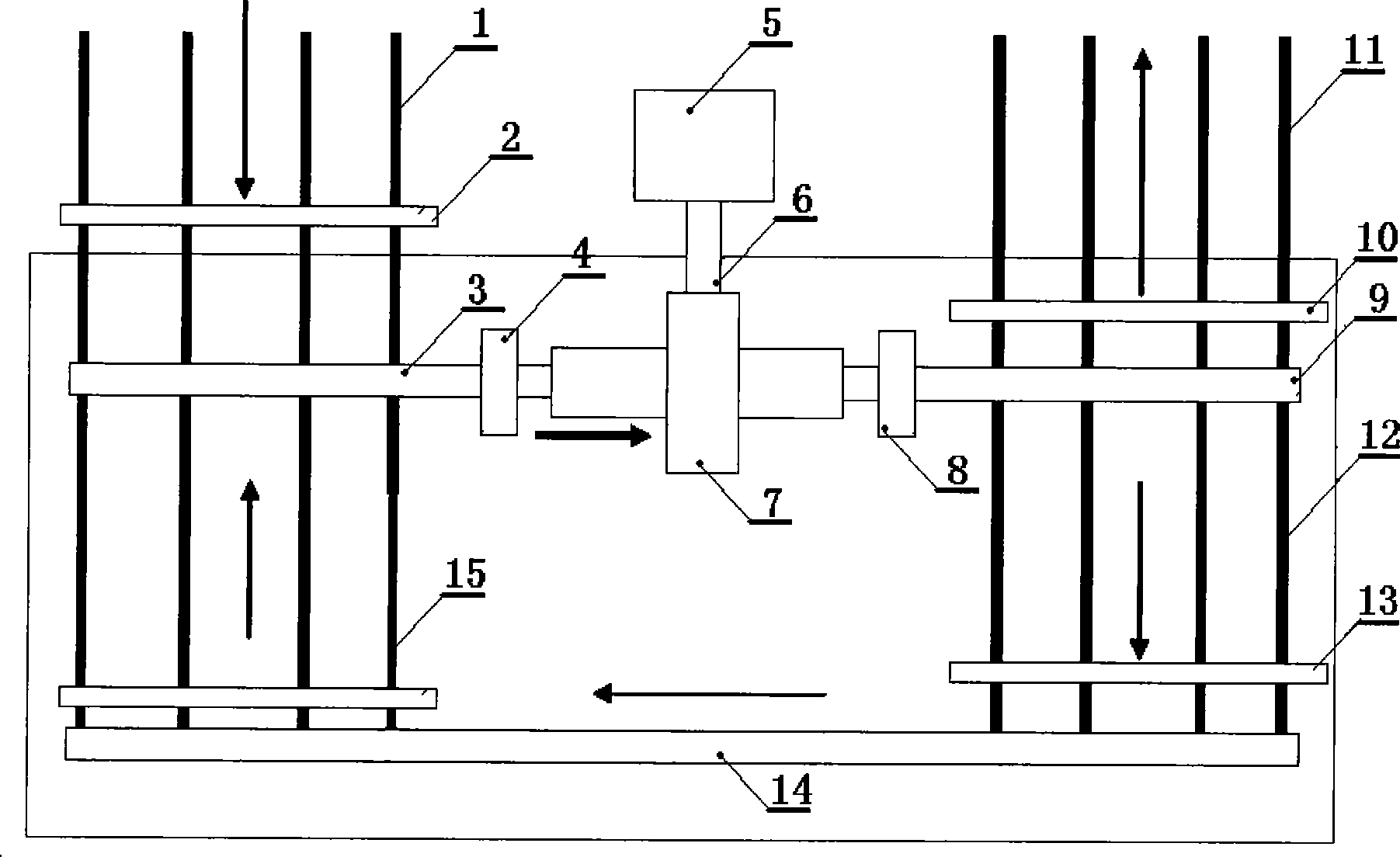

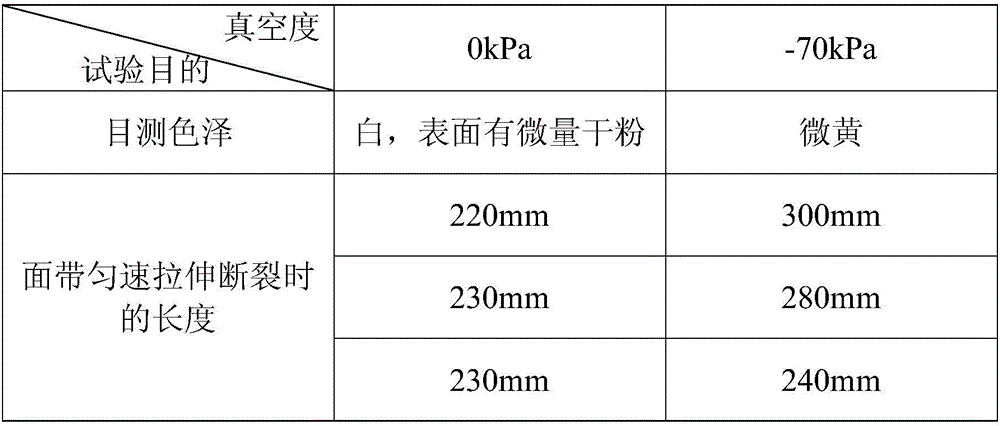

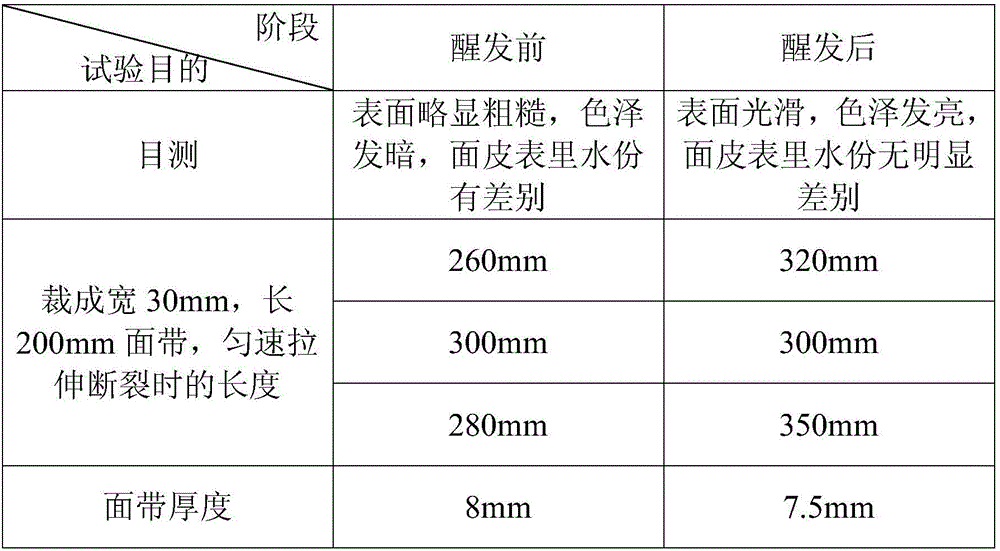

Fully automatic production technology of handmade noodles and fermented noodles

InactiveCN105851843AIncreased degree of formationImprove ductilityFood scienceEngineeringFully automatic

The invention provides a fully automatic production technology of handmade noodles and fermented noodles. The handmade noodles and the fermented noodles are made according to the following technological steps of performing vacuum dough mixing; performing dough fermentation; performing dough sheet shaping; performing dough sheet fermentation and stretching; performing dough sheet pressing; performing secondary dough sheet fermentation and stretching; performing secondary dough sheet pressing; performing dough sheet fermentation and stretching for the third time; performing strip cutting; performing dough thread stretching; performing cutting off of dough threads with fixed lengths; performing dough thread drying; and performing packaging. According to the fully automatic production technology of the handmade noodles and fermented noodles, provided by the invention, dough sheet fermentation and stretching are performed for at least three times, so that the mouth feel of products can be effectively improved, and the fully automatic production technology has the characteristics of being high in production efficiency and low in defective rate.

Owner:河北玉桥食品有限公司

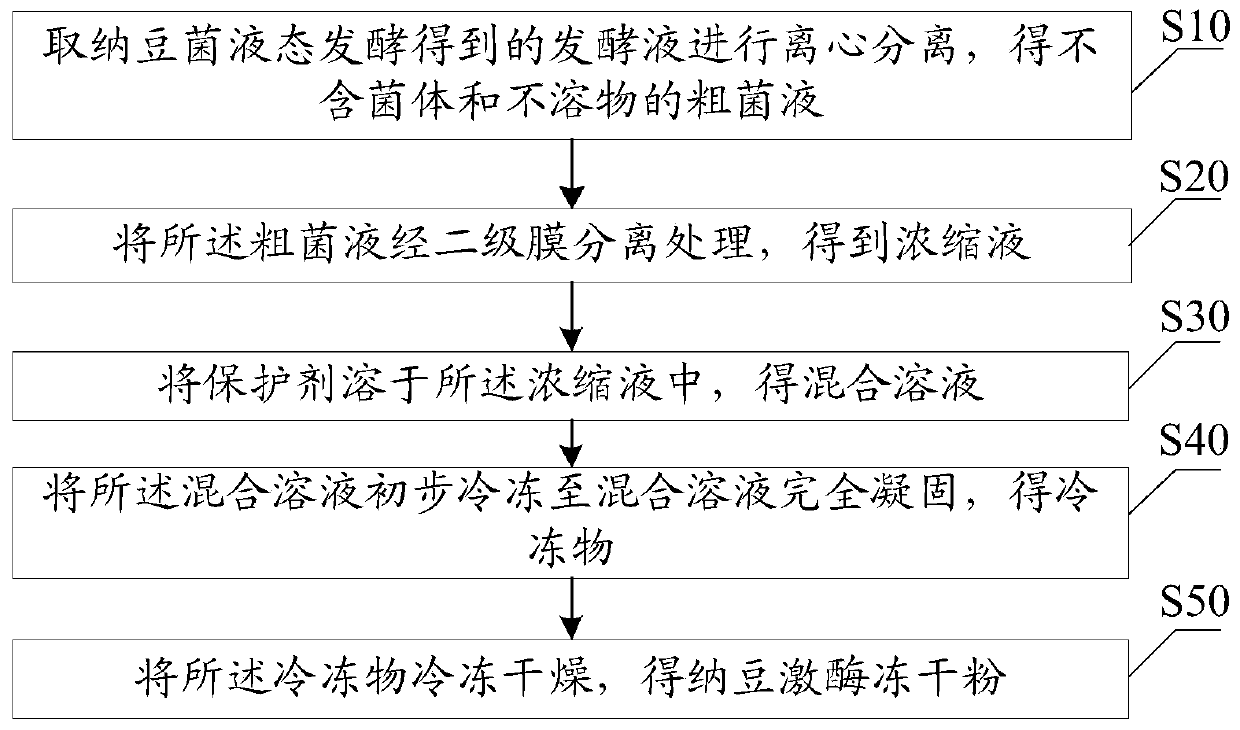

Preparation method for nattokinase lyophilized powder

ActiveCN109722427AEvenly distributed moistureHigh purityChemical industryMicroorganism based processesMoisture distributionFreeze-drying

The invention discloses a preparation method for nattokinase lyophilized powder, and relates to the technical field of fermentation. The preparation method includes the following steps: taking a fermentation broth obtained through the liquid fermentation of bacillus natto to perform centrifugal separation so that a crude bacterium solution without containing bacteria and insoluble substances can be obtained; performing secondary membrane separation treatment on the crude bacterium solution so that a concentrated liquid can be obtained; dissolving a protective agent into the concentrated liquidso that a mixed solution can be obtained; performing preliminary freezing on the mixed solution until the mixed solution is completely solidified so that a frozen object can be obtained; and performing freeze drying on the frozen object so that nattokinase lyophilized powder can be obtained. The provided preparation method is simple and easy to operate; and the prepared nattokinase lyophilized powder is uniform in moisture distribution, low in water content and easy to effectively preserve for a long time, and has high purity and enzyme vitality.

Owner:WUHAN POLYTECHNIC UNIVERSITY

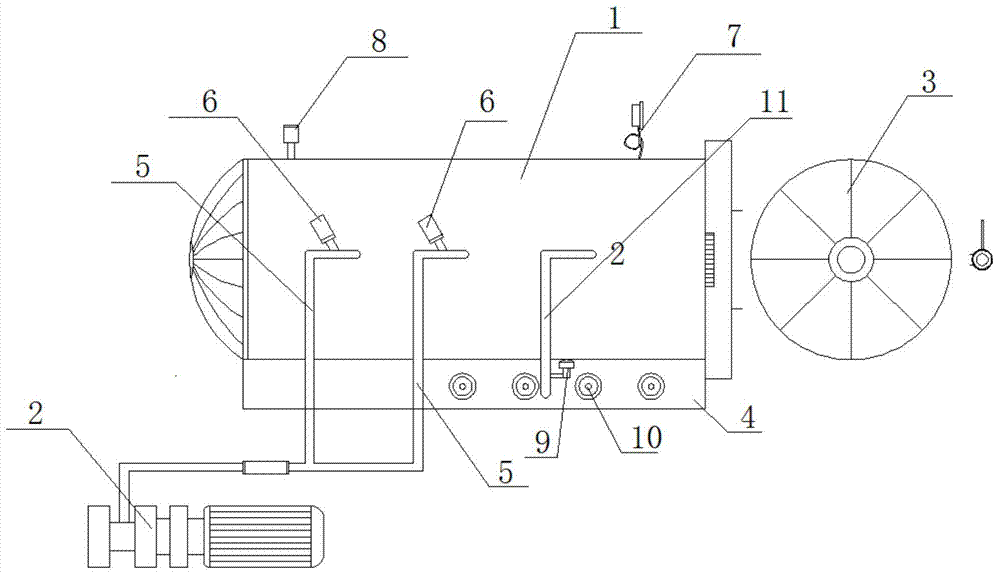

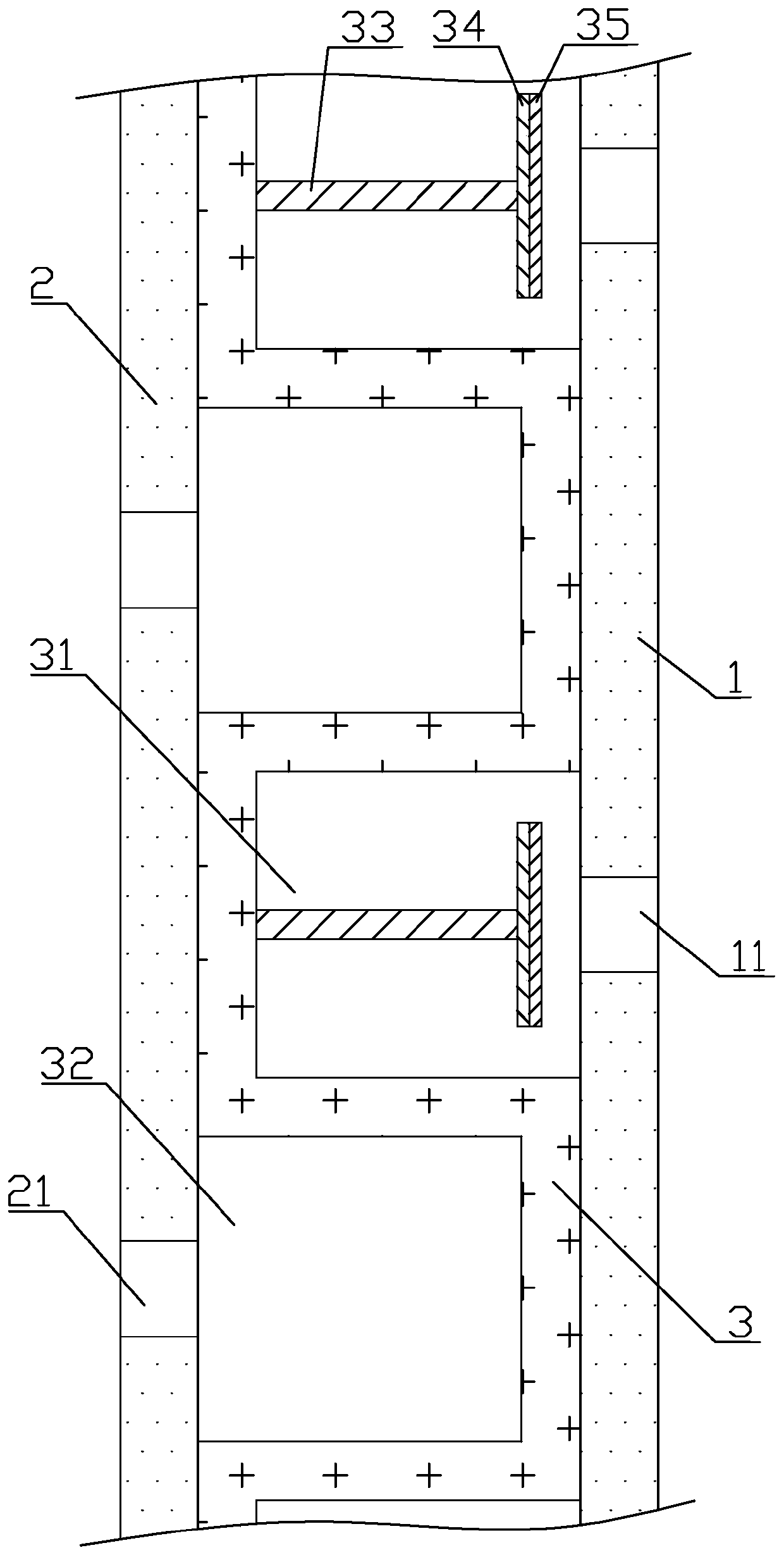

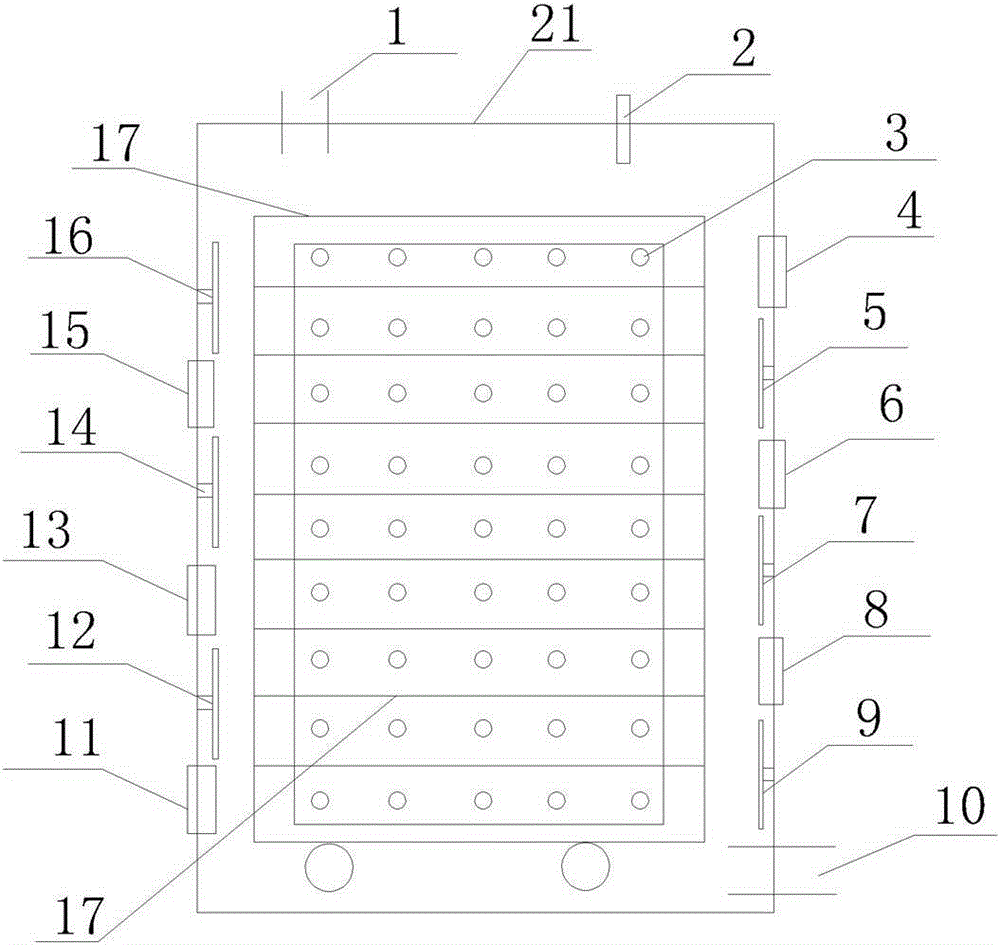

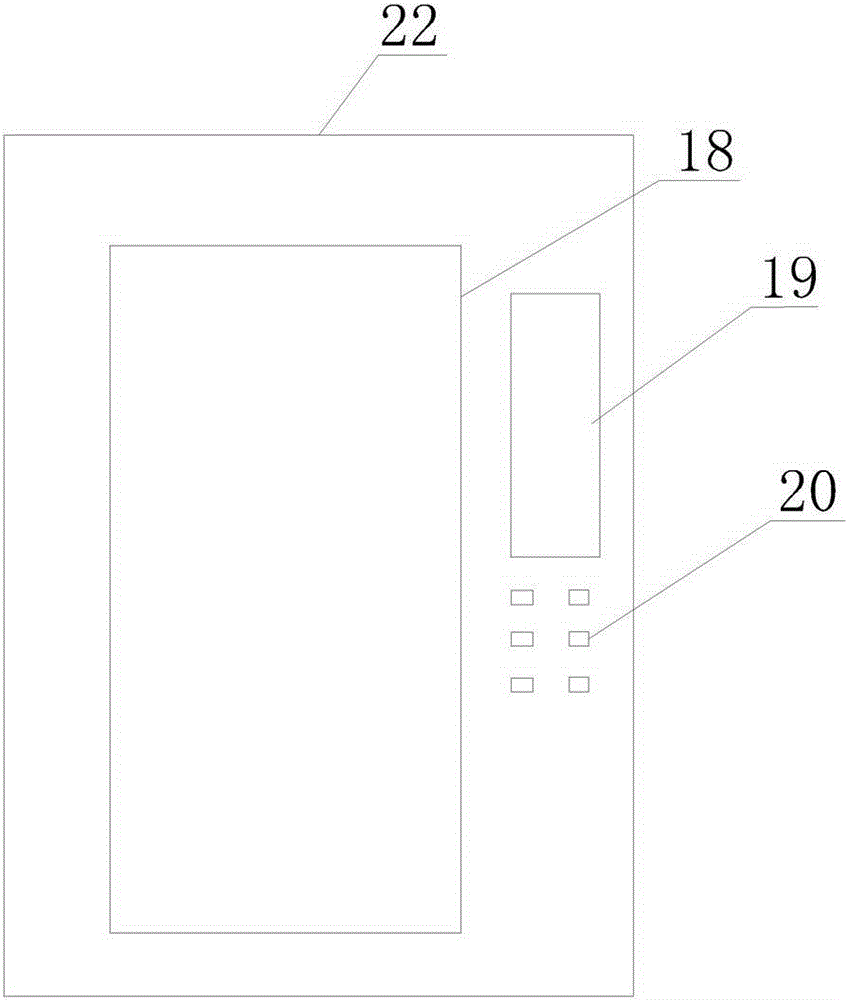

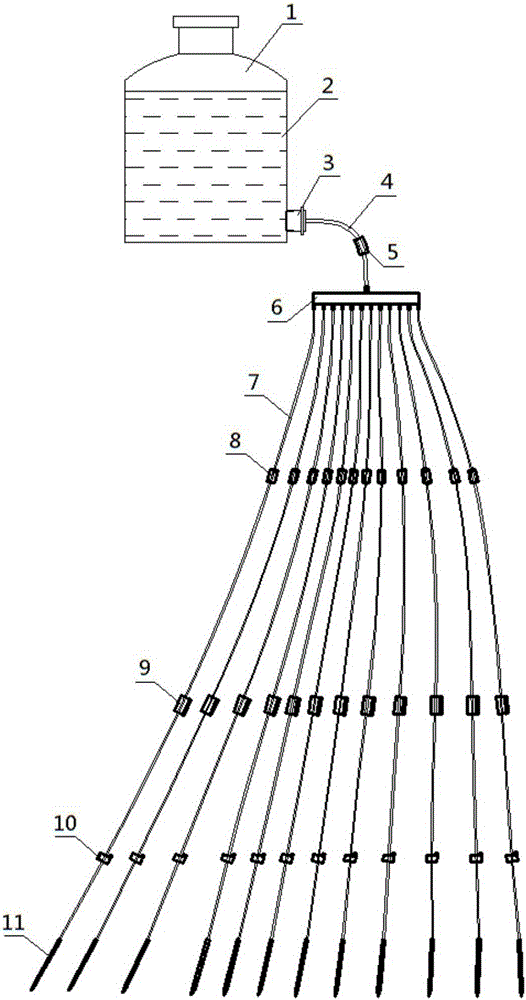

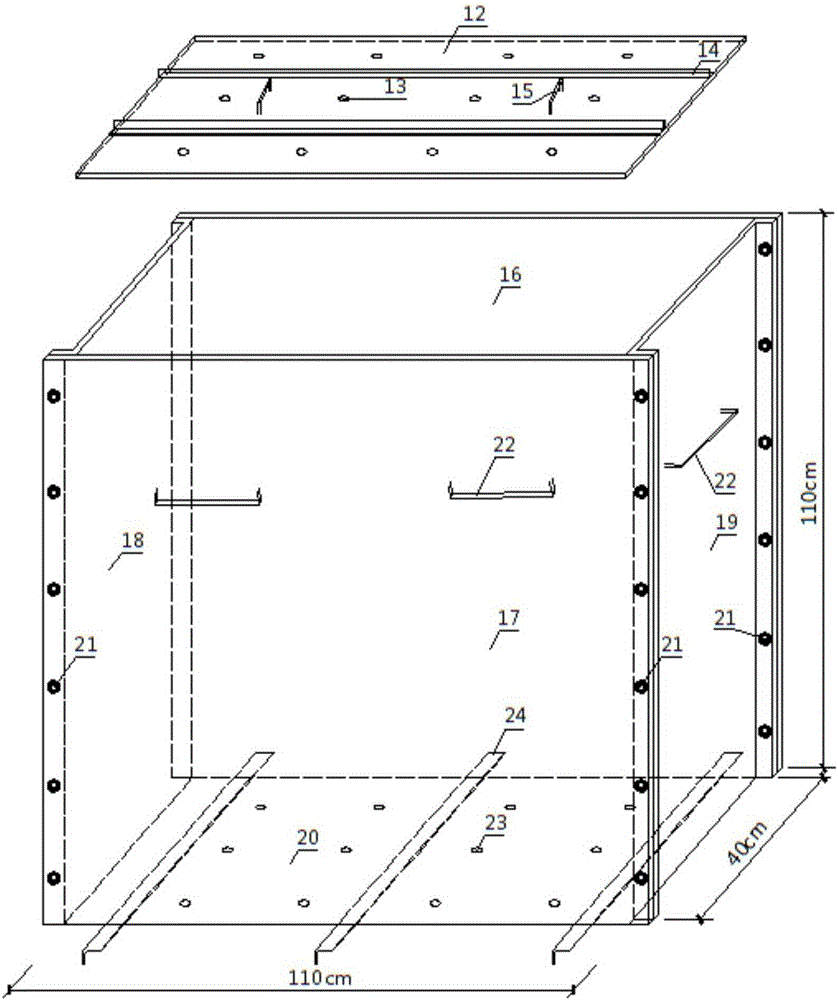

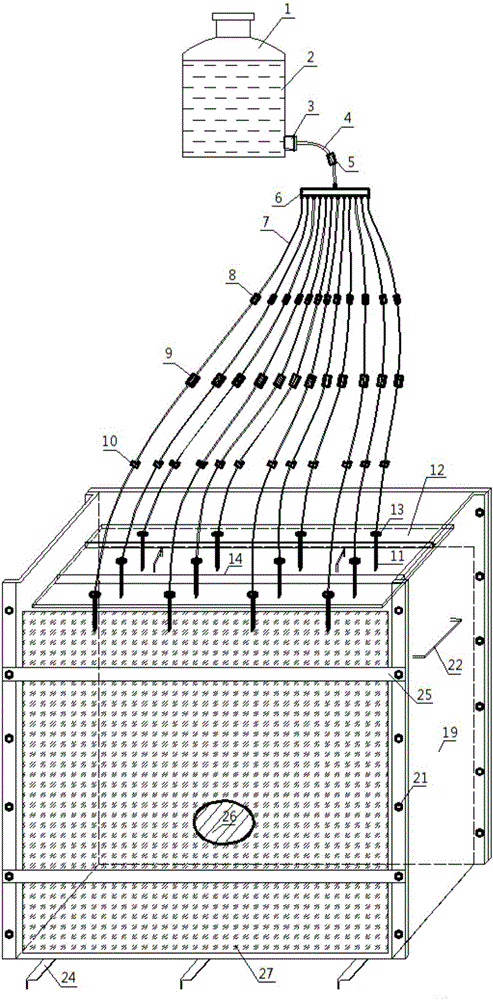

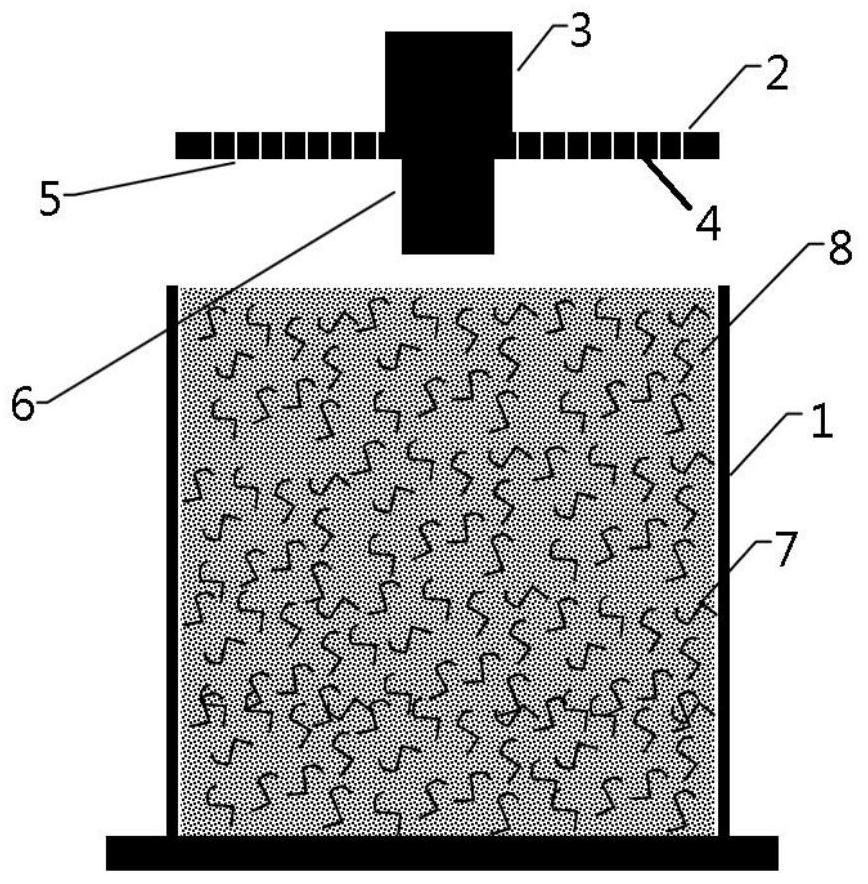

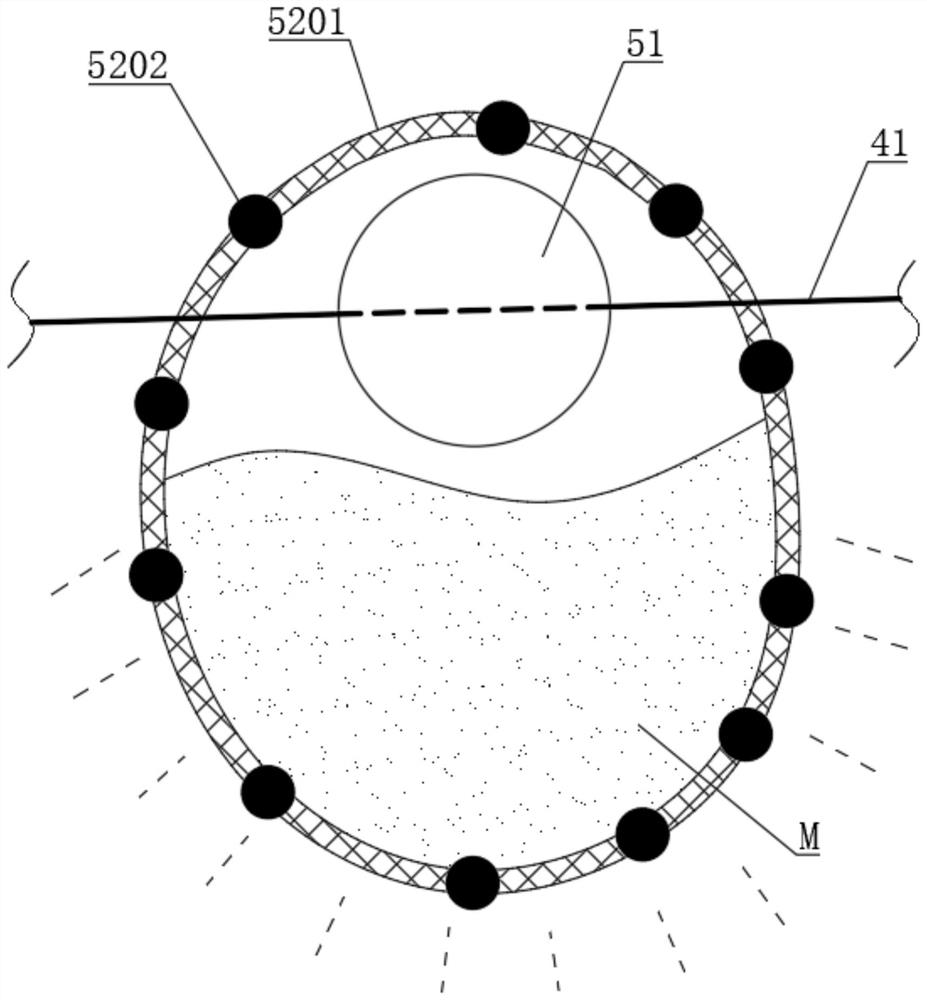

Test method for simulating expansive surrounding rock tunnel rainfall infiltration

InactiveCN105223121AEvenly distributed moisturePermeability/surface area analysisWater useExhaust valve

The invention discloses a test method for simulating expansive surrounding rock tunnel rainfall infiltration. The test method includes the steps that step1, a test device for simulating expansive surrounding rock tunnel physical model rainfall infiltration is established, wherein the test device comprises a water diversion flow-guiding system portion and a model casing portion, the water diversion flow-guiding system portion is installed on the upper portion of the model casing portion, and the water diversion flow-guiding system portion and the model casing port are connected through metal pipes with small holes in pipe walls; step2, a water-containing bottle contains water used for simulating rainfall, the water flows into a flow-distributing device from the water-containing bottle through a master flow-guiding pipe and is divided into 12 branches of water through the flow-distributing device, all the branches of water flow into the metal pipes with the small holes in the pipe walls through flow-guiding water-distributing pipes, and the points of the metal pipes are inserted into rock mass by 10 cm-15 cm; because the water inside the pipes has certain head pressure, the water inside the metal pipes is pressed into the rock mass through the pressure, and when air enters the flow-guiding water-distributing pipes and causes unsmooth water flowing, the air inside the pipes is exhausted through exhaust valves to keep smooth water flowing. The device is simple in structure, and the effects that the water is guided into the rock mass, water of surrounding rock is distributed evenly, and the rainfall per unit time can be effectively controlled can be achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

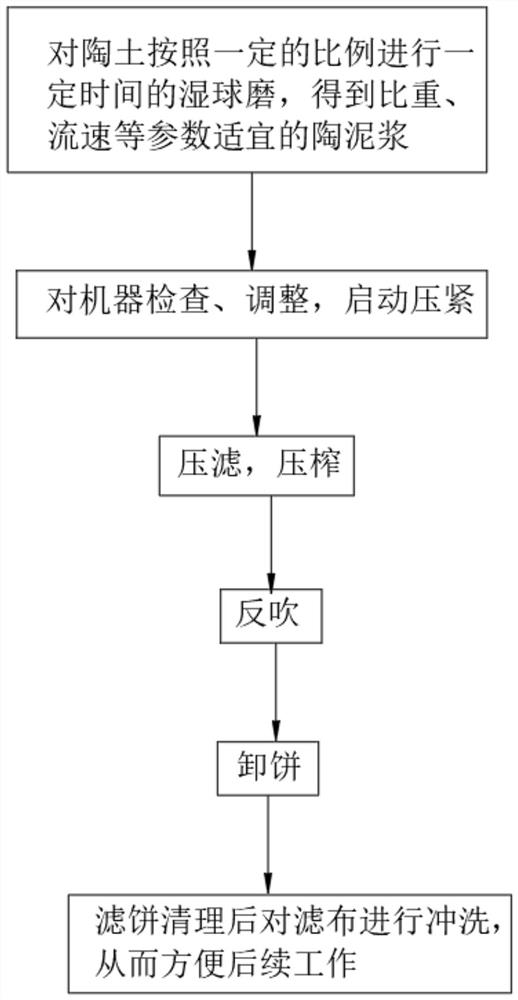

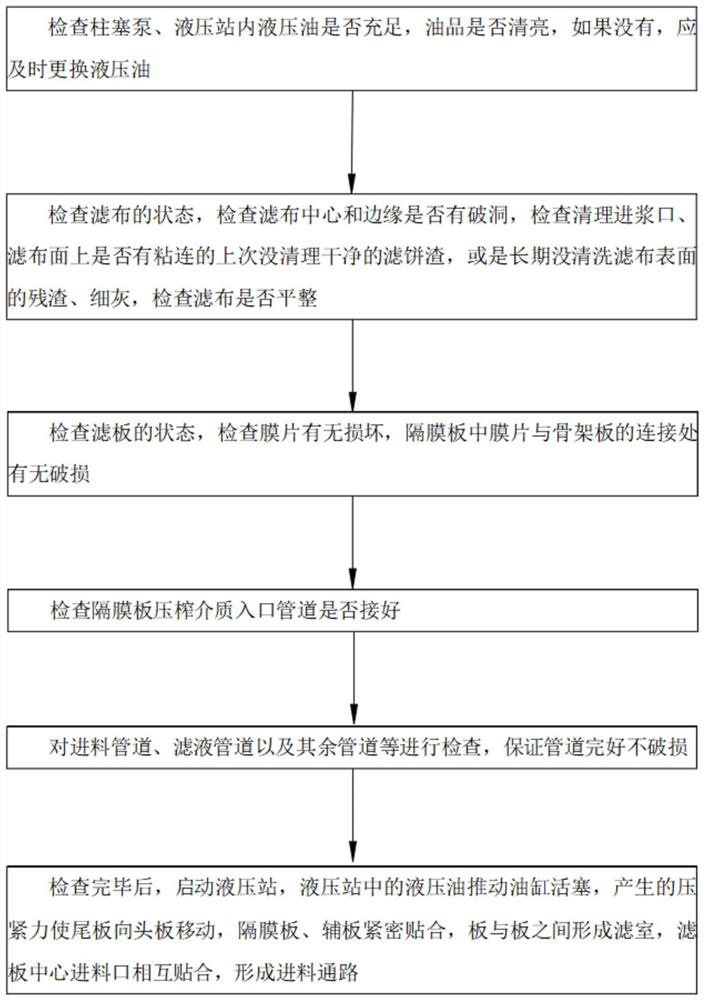

Diaphragm squeezing process for processing tile ceramic plate raw materials

The invention discloses a diaphragm squeezing process for processing brick ceramic plate raw materials, which comprises the following steps: preparing raw materials: performing wet ball milling on argil according to a certain proportion to obtain ceramic slurry with proper parameters such as specific gravity and flow velocity, and adjusting a machine; in the first step of filter pressing, hydraulic oil pushes an oil cylinder piston to tightly press filter cloth, a filter plate and a plunger pump in a filter press to pump ceramic slurry into the filter press, the ceramic slurry enters a filter chamber composed of the filter cloth and a diaphragm filter plate, the ceramic slurry flowing in the filter chamber is blocked by the filter cloth, after squeezing is finished, high-pressure air is blown into a slurry inlet, a filter cake is discharged, and the filter cake is filtered out; after the filter cake is cleaned, the membrane filter plate is flushed, so that subsequent work is facilitated. The diaphragm squeezing process for processing the brick, tile and ceramic plate raw materials is reasonable in design, the obtained filter cake is low in moisture content and uniform in moisture distribution, the diaphragm squeezing process is suitable for forming and processing brick, tile and ceramic plates, damage to filter cloth and filter plates can be reduced, the service life of a filter press rack is prolonged, and the diaphragm squeezing process is suitable for application and popularization.

Owner:FUJIAN LOPO TERRACOTTA PANELS MFG

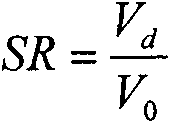

Preparation method of preboiled rice

InactiveCN109730251AHigh nutritional valueHigh meal rateSeed preservation by heatingUltra high pressureHigh pressure

The invention relates to a preparation method of preboiled rice, and belongs to the technical field of food processing technologies. The preparation method comprises the following steps of cleaning and grading, segmented soaking, ultra-high-pressure treatment, steaming and gelatinization, drying and rice husking and milling; wherein segmented soaking comprises the steps that firstly, rice after cleaning and grading is soaked for 0.5-1 h at 80-90 DEG C and then soaked for 1-2 h at 50-70 DEG C until the moisture content of the rice reaches 32-35%. The preparation method of the preboiled rice hasthe advantages that adopted temperature varying soaking can greatly shorten the soaking time of the preboiled rice; the combination of the ultra-high-pressure treatment can make the distribution of the moisture in the rice more uniform, thereby improving the gelatinization degree of the preboiled rice, and shortening the steaming time, so that the gelatinization of the preboiled rice is more uniform, the white heart grains of the preboiled rice is eliminated, the rice color also becomes light, the appearance of the preboiled rice is more uniform, and the acceptability of customers can be greatly improved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Putty paste used for building exterior wall and preparation method thereof

InactiveCN106752243AImprove crack resistanceImprove insulation effectFilling pastesEmulsion paintsCrack resistanceEmulsion

The invention provides putty paste used for a building exterior wall and a preparation method thereof. The putty paste is prepared from white cement, salt gypsum powder, ash-calcium powder, rubber powder, an elastic polypropylene emulsion, a leveling agent, a shrinkage compensating agent, an insulating agent, ionized water and additive according to the weight ratio. When the putty paste is prepared, the conventional materials are added, the insulating agent and the additive prepared in the special method are added, and the crack resistance and the heat preservation property of the putty paste are improved.

Owner:河南同伟建材有限公司

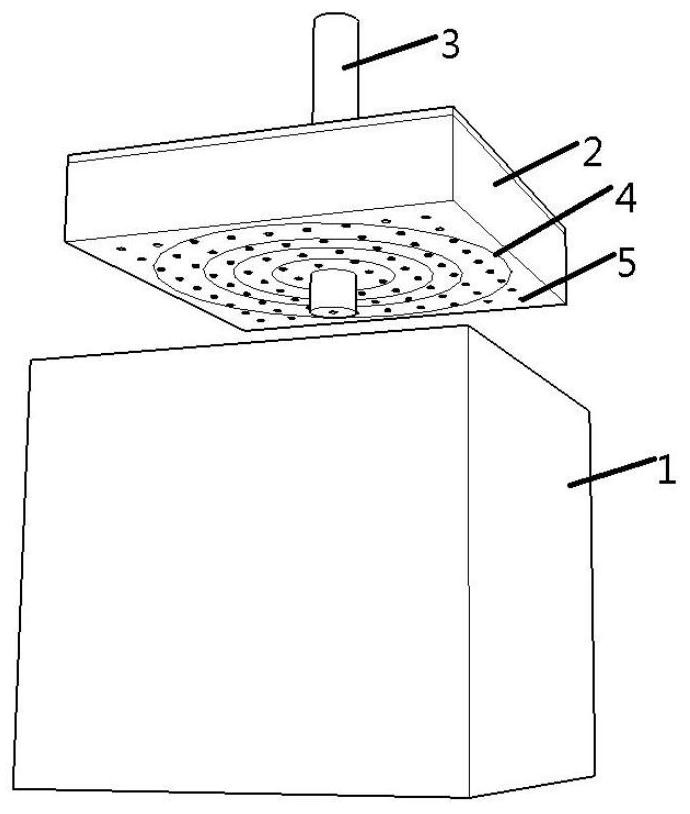

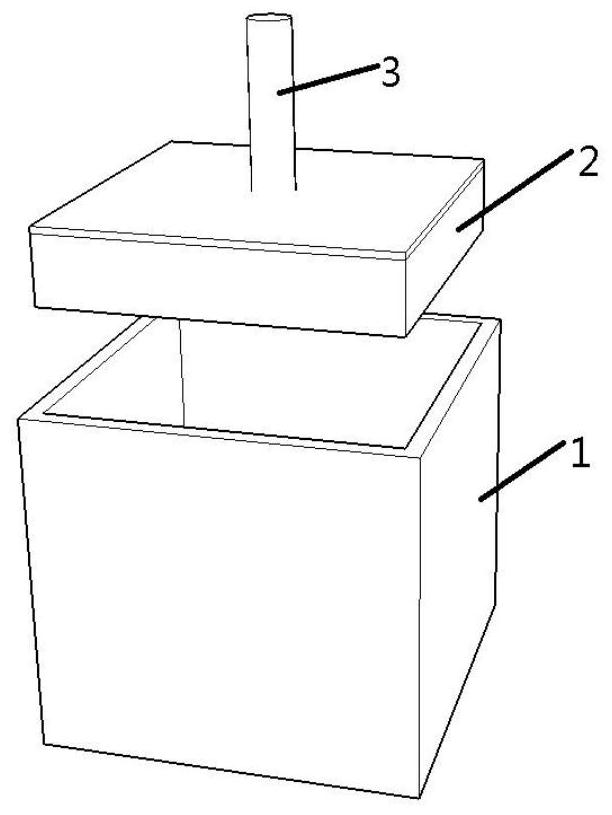

Microwave heating curing device and process and cured substrate manufactured through process

ActiveCN112314391AStable structureMicrostructural stabilityGrowth substratesCulture mediaFiberMoisture distribution

The invention provides a microwave heating curing device and process and a cured substrate manufactured through the process, and belongs to the field of plant cultivation. The process comprises the following steps of preparing raw materials; performing charging; heating and curing, starting a water seepage system and a microwave generation device to enable water to uniformly wet the substrate rawmaterials from top to bottom, sharply increasing the temperature of the wetted substrate raw materials under the action of a microwave field, controllably melting hot-melt cured fibers in the substrate raw materials, and starting a pressure mechanism to control a pressing block to move and compress the substrate raw materials to enable the substrate raw materials to be bonded with each other; andcooling and forming, closing the water seepage system, the microwave generation device and the pressure mechanism after the pressing block moves to a certain degree, stopping heating the raw materialsand moving the pressing block, cooling and demolding to form a cured substrate block. According to the process for producing the cured substrate, the distribution of moisture at the upper part and the lower part of the cured substrate is relatively uniform, and the substrate block with improved moisture distribution produced on the basis of the process is produced on the basis of specific raw materials and processes and has a specific structure.

Owner:INST OF URBAN AGRI CHINESE ACADEMY OF AGRI SCI

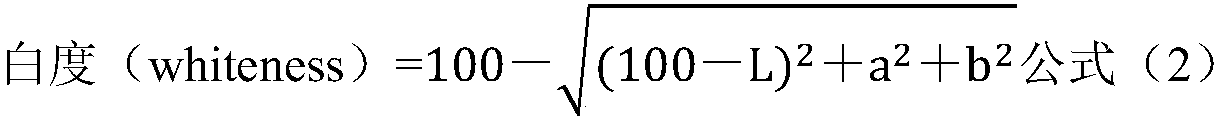

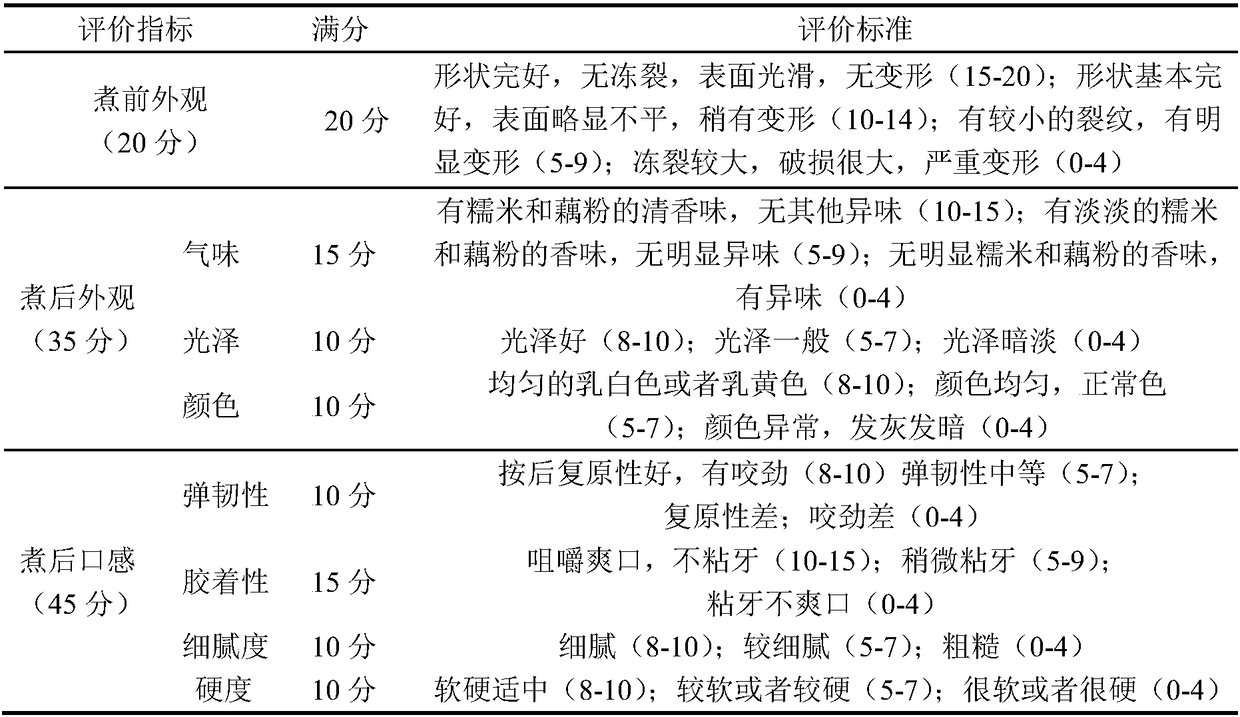

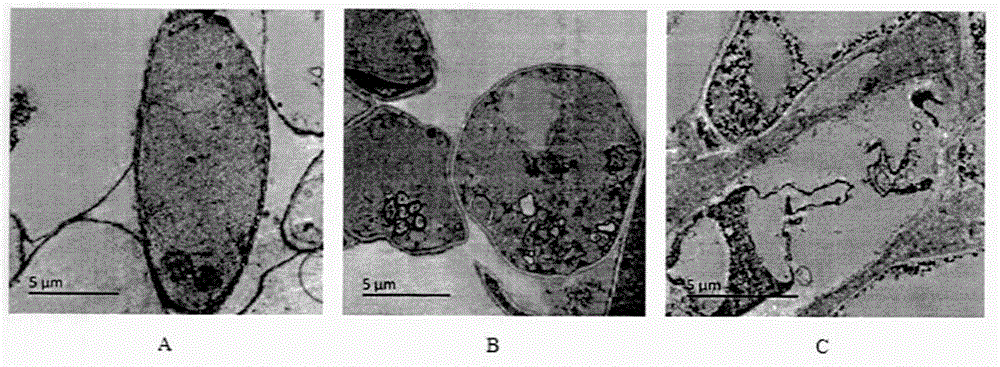

Highly digestible sweet soup balls and preparation method thereof

The invention belongs to the field of food processing and relates to highly digestible sweet soup balls and a preparation method thereof. The highly digestible sweet soup balls are characterized by being prepared from components by weight as follows: 40-70 parts of glutinous rice flour, 28-35 parts of wheat starch, 7-12 parts of lotus root starch, 3-8 parts of sucrose, 60-75 parts of water, 0.15-0.25 parts of hydroxypropyl distarch phosphate starch, 0.01-0.02 parts of monoglyceride, 0.03-0.05 parts of sucrose ester, 0.1-0.25 parts of ascorbic acid and 0.05-0.2 parts of composite phosphate. A traditional technology is adopted and tightly combined with a modern production technology, and production cost can be reduced substantially. The sweet soup balls prepared with the formula are easy toform and are full, besides, frost cracking rate and water loss rate of the quick-frozen sweet soup balls are greatly reduced, time for cooking is shortened, soup obtained after cooking cannot be turbid, and the digestive rate is increased by 10.5%.

Owner:HUAZHONG AGRI UNIV

Tea leaf fermentation process formula

InactiveCN109258847AImprove processing efficiencyMellow tastePre-extraction tea treatmentMicroorganismBitter taste

The invention belongs to the technical field of tea leaf processing, and particularly discloses a tea leaf fermentation process. The tea leaf fermentation process formula comprises the following steps: (1) pretreatment; (2) twisting: adding starch of which the weight accounts for 2-3% of the weight of tea leaves in the tea leaves added in step (1), rubbing and twisting the tea leaves, after twisting the tea leaves for 0.2-0.3 h, adding starch of which the weight accounts for 2-3% of the weight of the tea leaves, and keeping twisting for 0.6-0.9 h; (3) steaming; (4) inoculation; (5) pressurization; and (6) fermentation: fermenting the tea leaves for 4-5 h in a fermentation chamber of which the temperature is 25-28 DEG C and the relative humidity is 92-96%, and stirring the tea leaves once or twice in a fermentation process. When the tea leaves are fermented by the tea leaf fermenting process, negative effects of harmful microorganisms to the quality of the tea leaves in a fermentation process can be inhibited, moreover, the tea leaves fermented by the process is unique in taste, the bitter taste is greatly reduced, the taste is greatly improved, and if a person drinks the tea for along time, health of the user is facilitated.

Owner:夏邦德

A method of uniformly drying Agaricus bisporus slices combined with frequency conversion ultrasonic assisted dipping pretreatment and vacuum microwave

ActiveCN104304426BImprove uniformity of vacuum microwave dryingUniform colorFruits/vegetable preservation by dehydrationBiotechnologyAgaricus

Owner:JIANGSU ACAD OF AGRI SCI

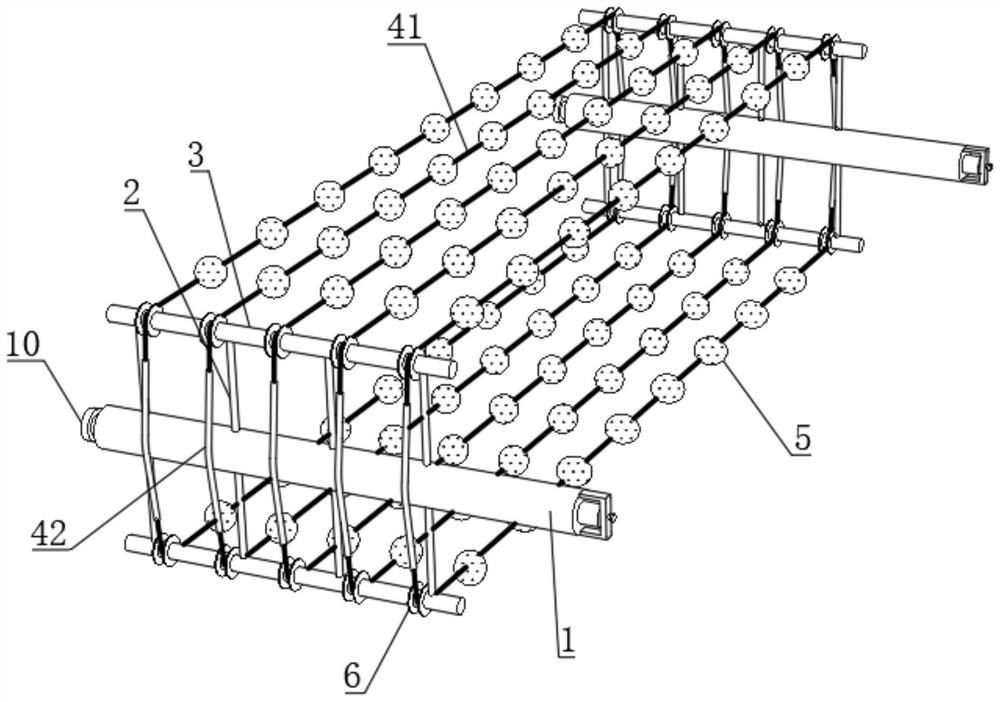

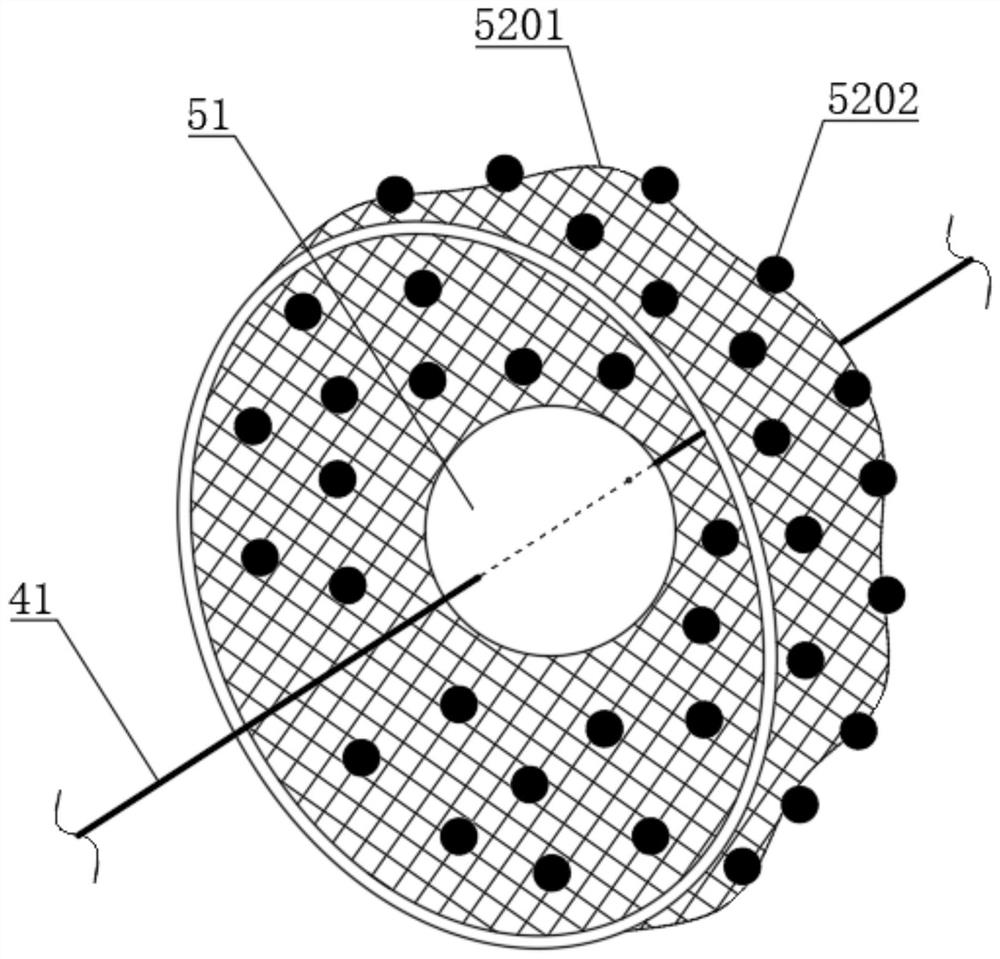

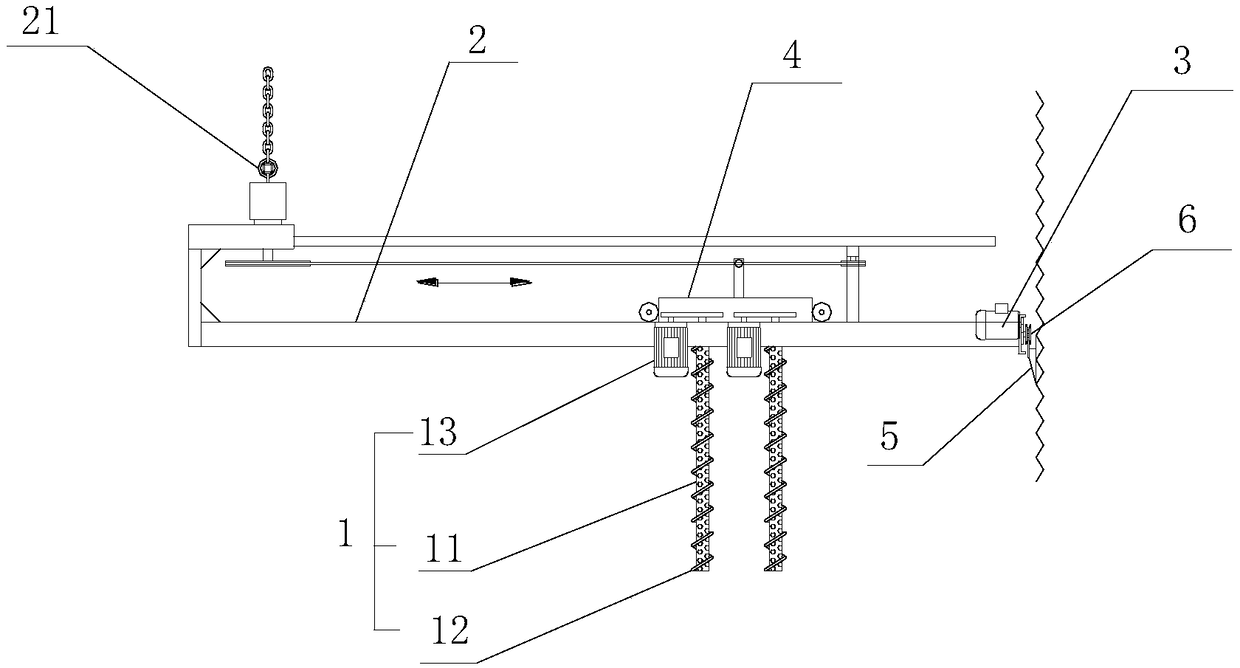

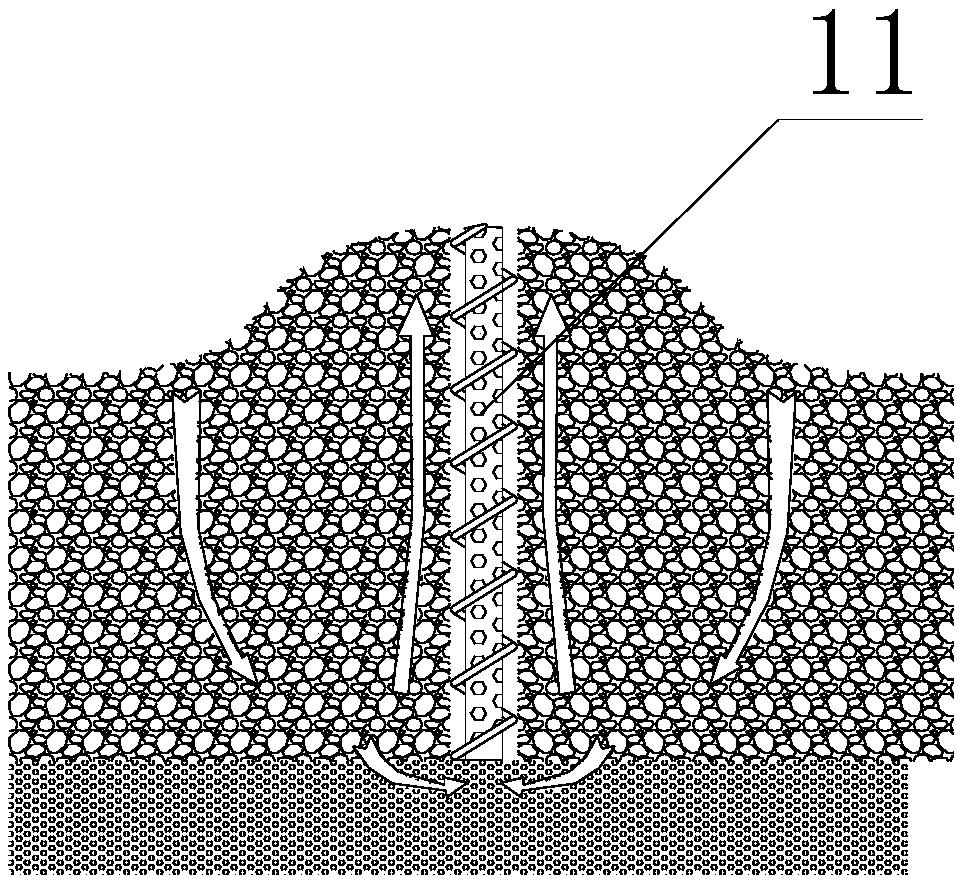

Embedded auxiliary fermentation migration net for harmless treatment of organic fertilizer

InactiveCN112759439AReduces incomplete fermentationImprove fermentation qualityBio-organic fraction processingOrganic fertiliser apparatusWater storageAgricultural science

The invention discloses an embedded auxiliary fermentation migration net for harmless treatment of an organic fertilizer, and belongs to the field of organic fertilizers. The embedded auxiliary fermentation migration net is embedded in a fertilizer pile in advance, and in the process that the fertilizers need to be turned over, a pair of rotary drums are rotated to drive closed ball chains on the outer sides of the rotary drums to move in multiple directions; the net can loosen and turn the fertilizer, can absorb excessive moisture from the fertilizer in a wet area, transfers the moisture to the fertilizer in a dry area, promotes uniform distribution of the moisture of the fertilizer, and has a storage effect on surrounding moisture after the moisture is transferred. The condition that moisture in the fertilizer is lost again under the action of self weight is greatly reduced, water storage and moisture preservation are performed on surrounding fertilizer, and sufficient fermentation of the fertilizer is ensured, so that the condition that in the prior art, due to the fact that a large amount of moisture is accumulated at the bottom of the fertilizer, fermentation of the fertilizer above is incomplete is reduced, and the fermentation quality of the fertilizer pile is greatly improved.

Owner:苏鹏

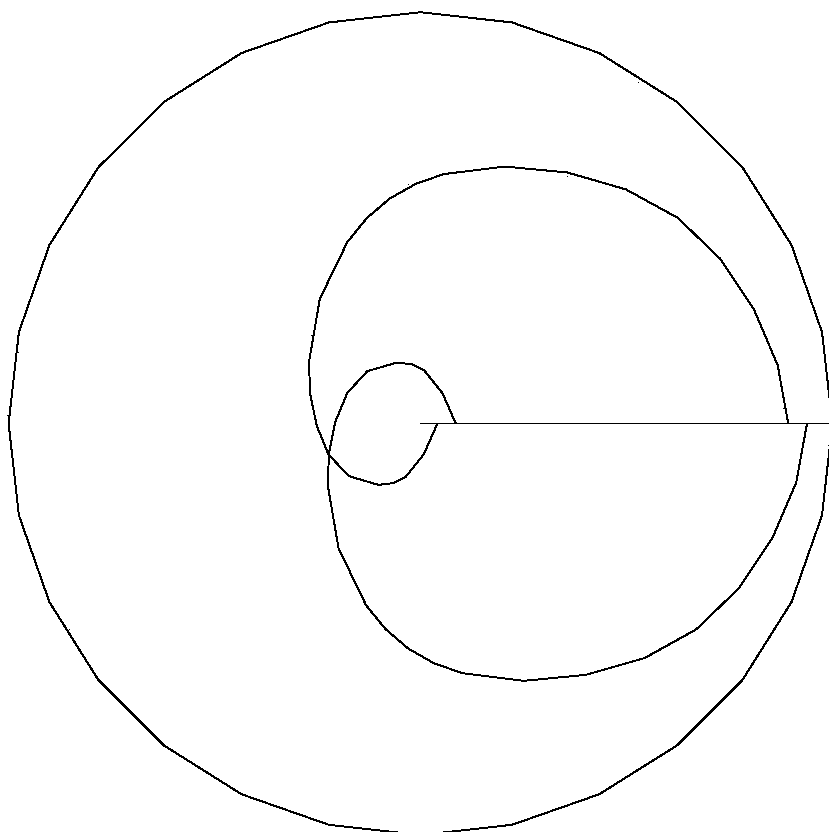

Silo material stirring device

PendingCN109186210AShorten drying timeImprove drying efficiencyDrying gas arrangementsSeed preservation by dryingPower unitSpiral blade

The invention discloses a silo material stirring device. The silo material stirring device comprises a stirrer and an air feeding mechanism, wherein the stirrer comprises a stirring shaft, spiral blades and a power unit, wherein the stirring shaft is vertically inserted into a material silo; the spiral blades are mounted on the stirring shaft; and the power unit is used for driving the stirring shaft to rotate; a central cavity extending in the axial direction is formed in the stirring shaft; a plurality of air holes communicating with the central cavity are formed in the side wall of the stirring shaft; and the air feeding mechanism is movably connected with the stirring shaft to feed air into a central hole. According to the silo material stirring device, a problem of moisture gradient during drying materials in the silo is solved, the drying speed of the materials can be effectively increased while uniform drying and stable quality of the materials in the silo are realized, the drying time is shortened, and the drying efficiency is enhanced.

Owner:合肥弘恩机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com