Patents

Literature

1526results about How to "Reduce bitterness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of enhancing salty taste, salty taste enhancer, salty taste seasoning agent and salty taste-enhanced foods

The present invention relates to a method of enhancing the salty taste of a food or beverage containing salt which comprises adding an acidic peptide or a peptide obtained by subjecting a protein to hydrolysis and deamidation to the food or beverage, a salty taste enhancer comprising the peptide as an active ingredient, a salty taste seasoning agent comprising the peptide and salt, and a food or beverage comprising the salty taste enhancer or the salty taste seasoning agent.

Owner:KYOWA HAKKO FOOD SPECIALTIES +1

Taste masked aqueous liquid pharmaceutical composition

A substantially taste masked liquid pharmaceutical composition containing a pharmaceutically effective amount of an unpleasant tasting drug dissolved or dispersed in an aqueous excipient base, said excipient base comprising polyvinyl pyrrolidone and / or copolyvidone, and high molecular weight polyethylene glycol.

Owner:UNILAB PHARMA TECH

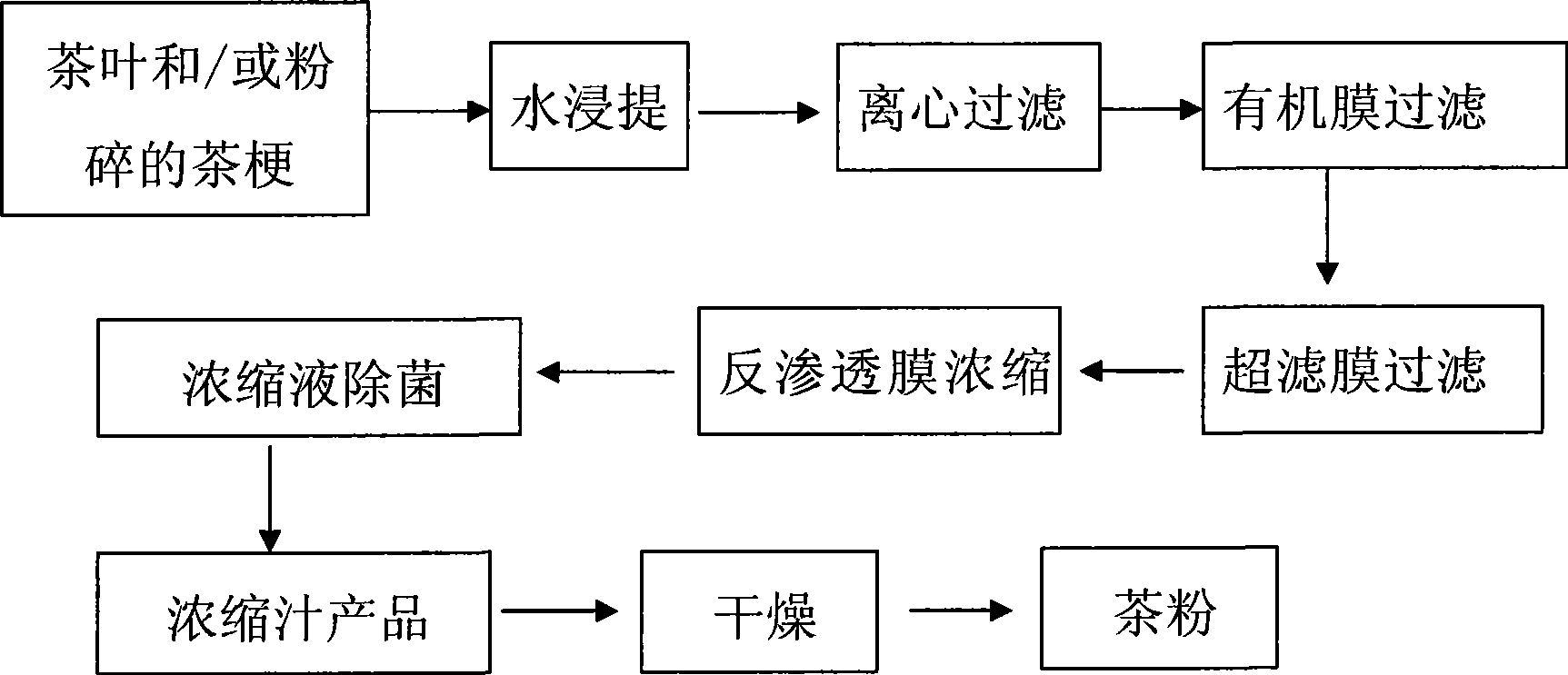

Method for preparing instant tea powder

ActiveCN101164424AReduce bitternessHigh yieldPre-extraction tea treatmentTea extractionBoiling pointFermented tea

The present invention relates to a preparation method of instant tea powder. Said preparation method adopts low-temperature (20-30deg.C), medium-temperature (40-70deg.C) and high-temperature (85-100deg.C) three-stage process to respectively extract fragrance components and taste substances with different boiling points from tea and makes the fragrance components and taste substances in the tea extract be more approached to that of raw material tea, then makes these fragrance components and taste substances be undergone the processes of filtration, enzymolysis, concentration and drying so as to obtain the invented instant tea powder. Said preparation method is applicable to various noble tea, such as dragon well tea, oolong tea, Qimen fermented tea and pekoe silver-needle tea, etc.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Tablets quickly disintegrating in mouth

InactiveUS20030161879A1Quickly disintegrating in mouthEasy to carryOrganic active ingredientsPill deliveryAdditive ingredientPhospholipid

Tablets quickly disintegrating in the mouth which comprise a bitter drug ingredient and a bitterness-reducing ingredient composed of an essential oil, a high sweetness-sweetener and / or an acidic phospholipid or its lyso-derivative. When taken even without water, these tablets exhibit little bitterness. Thus, a bitter drug ingredient can be formulated without coating into tablets quickly disintegrating in the mouth.

Owner:TAKEDA PHARMA CO LTD

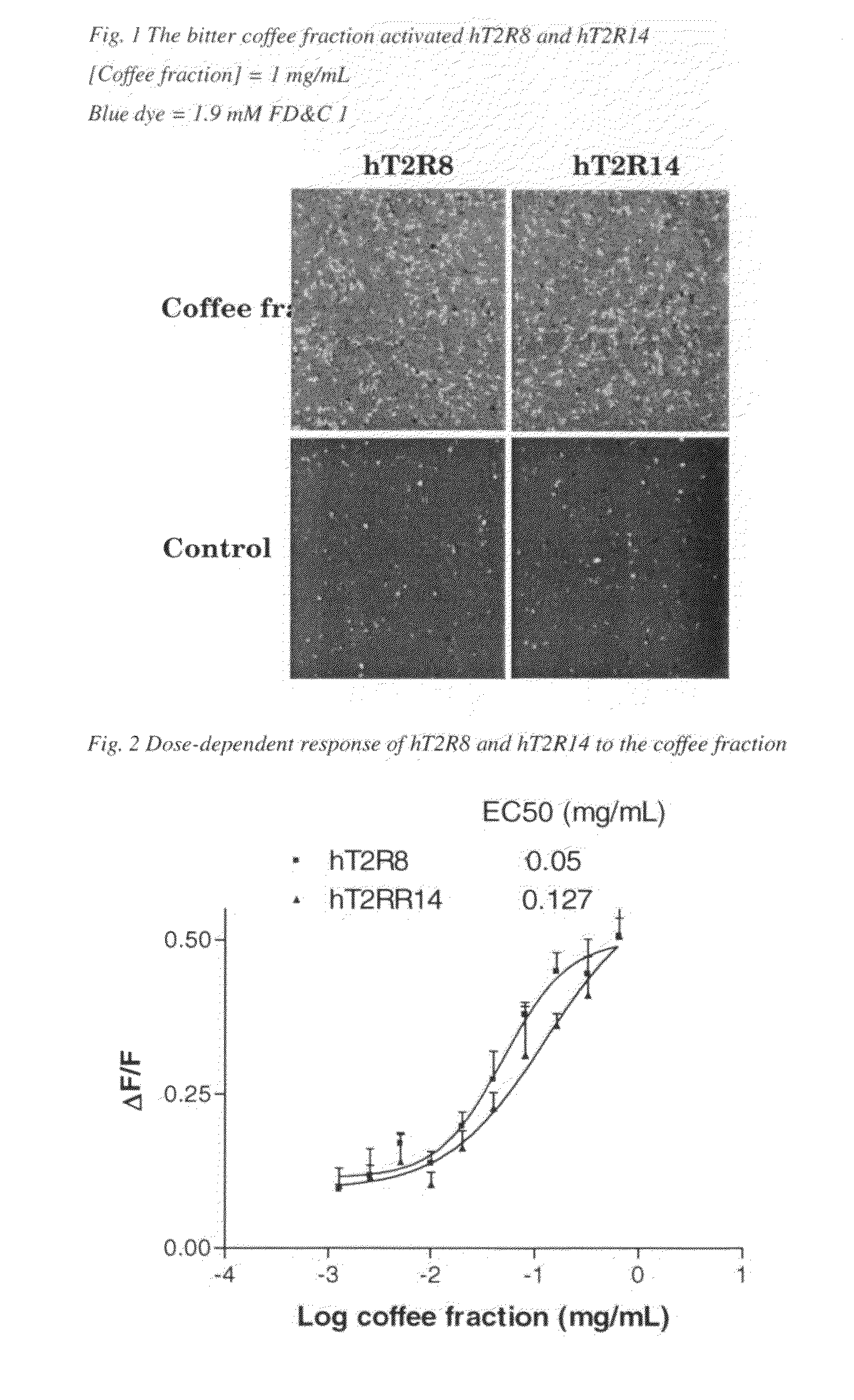

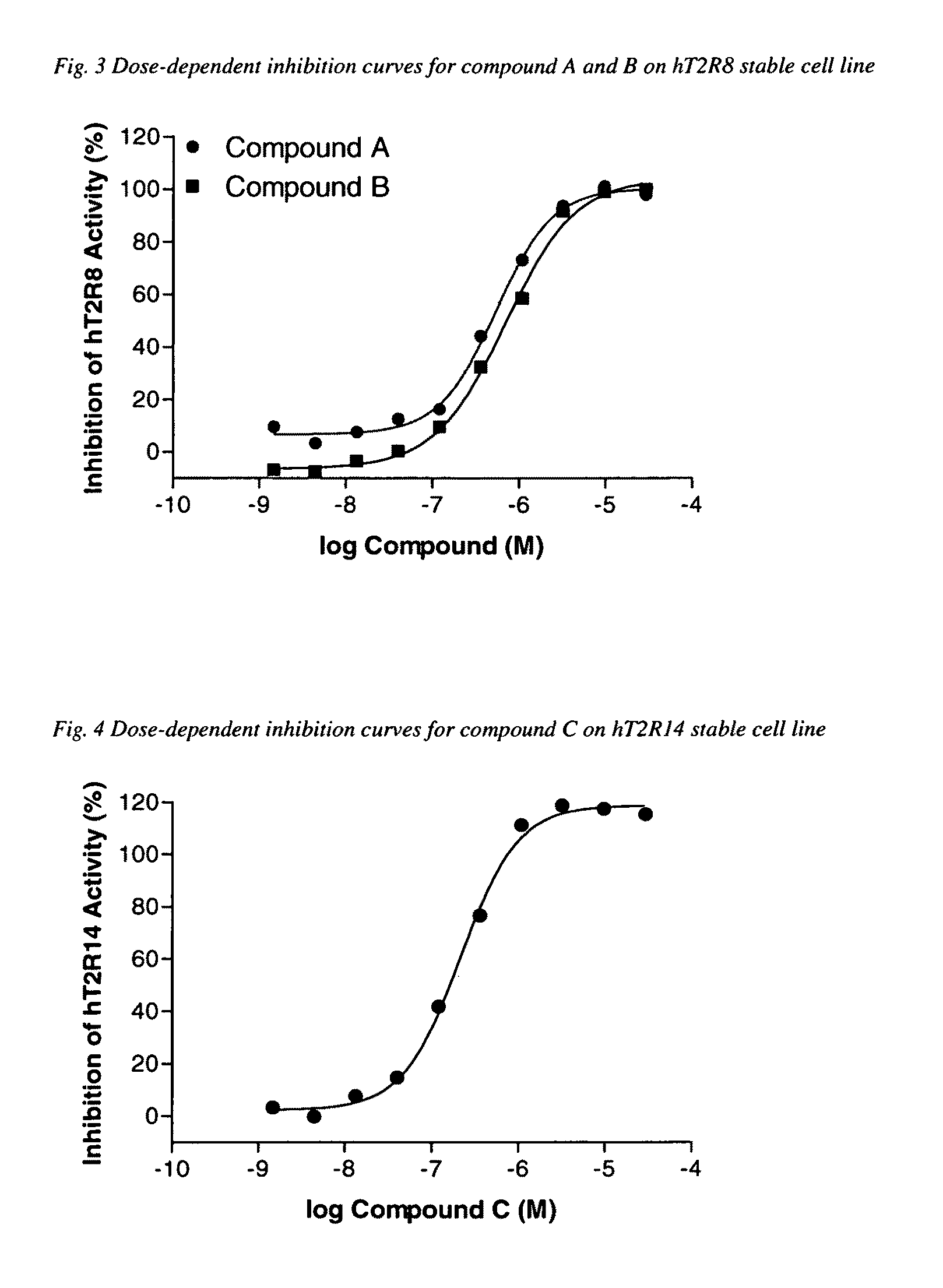

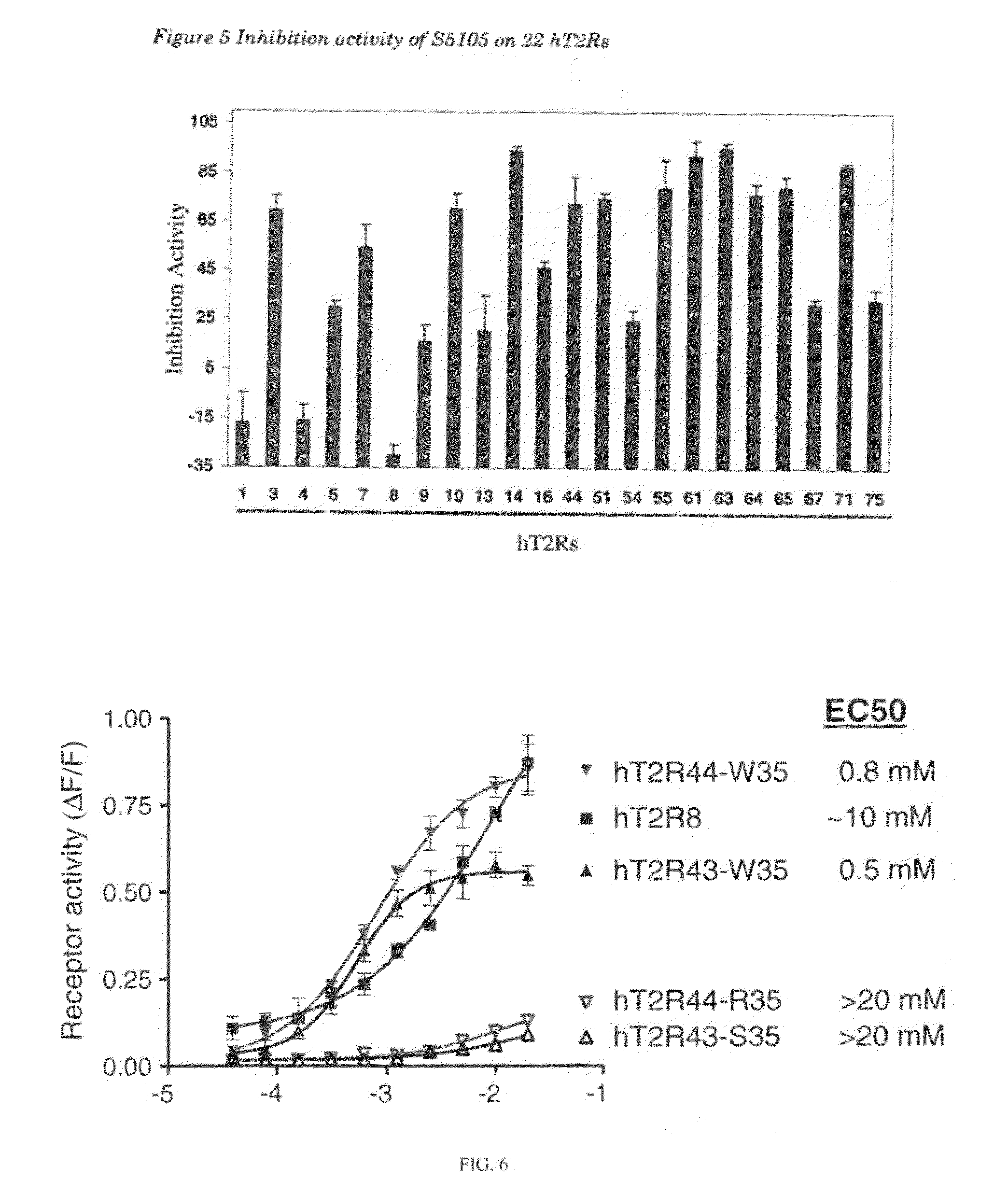

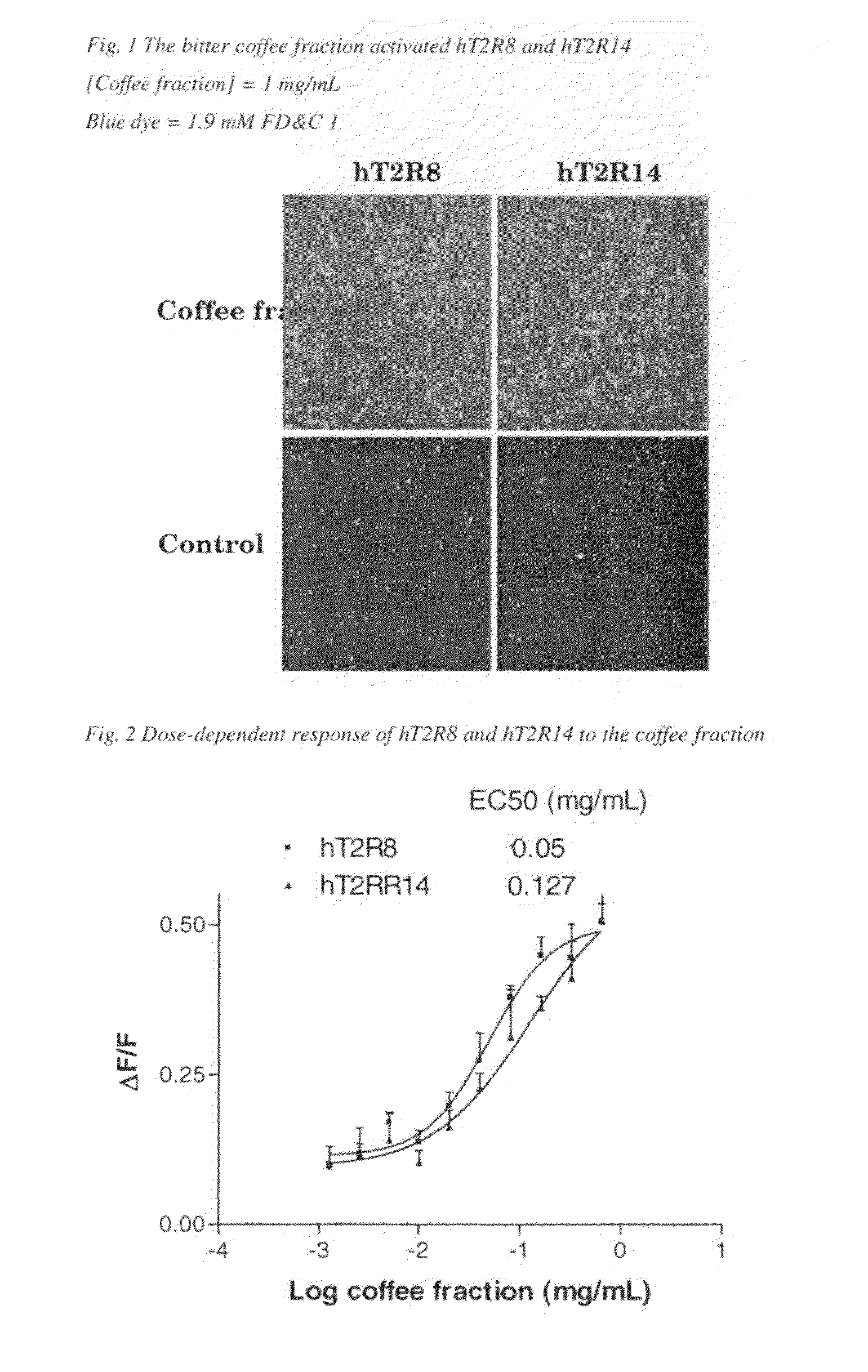

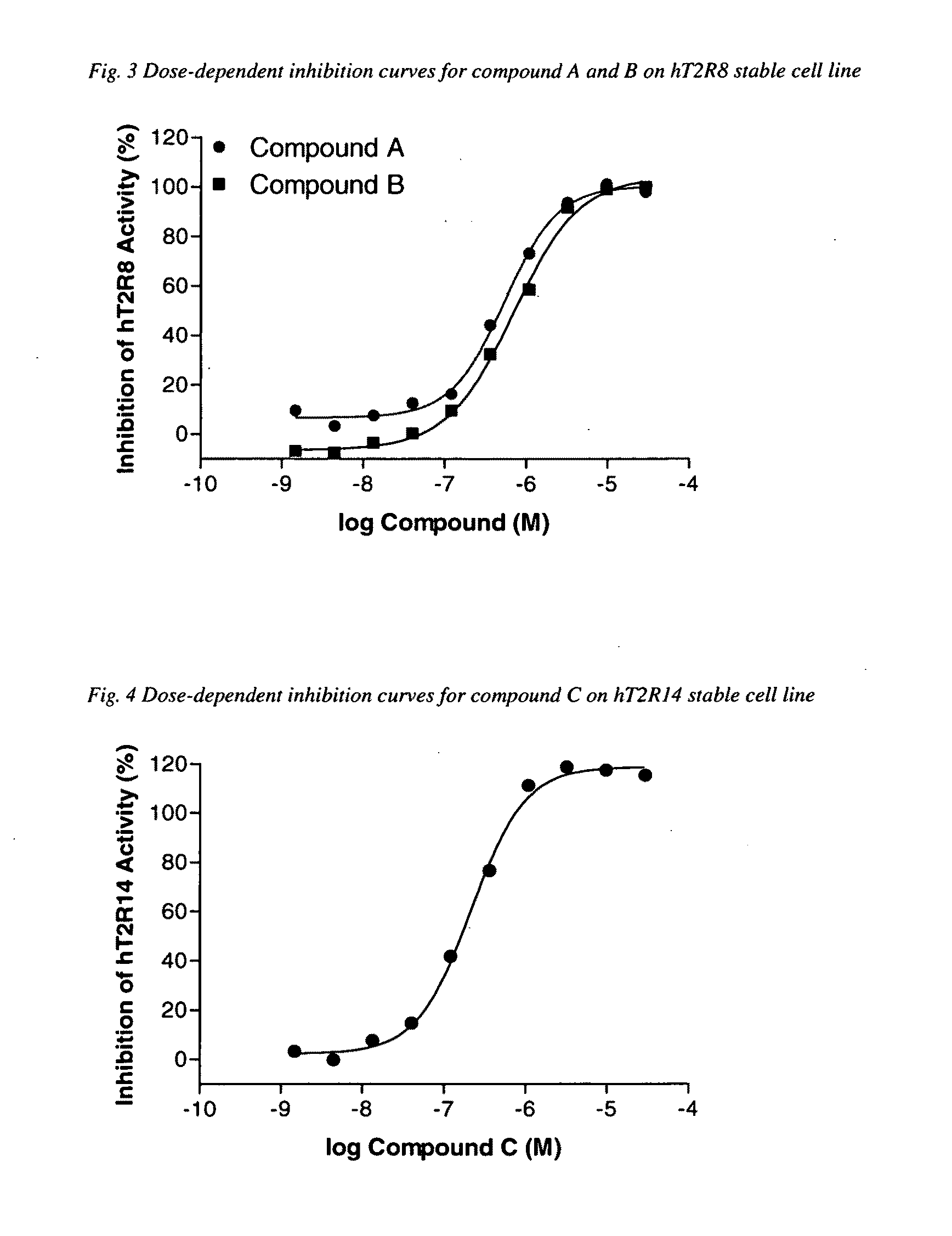

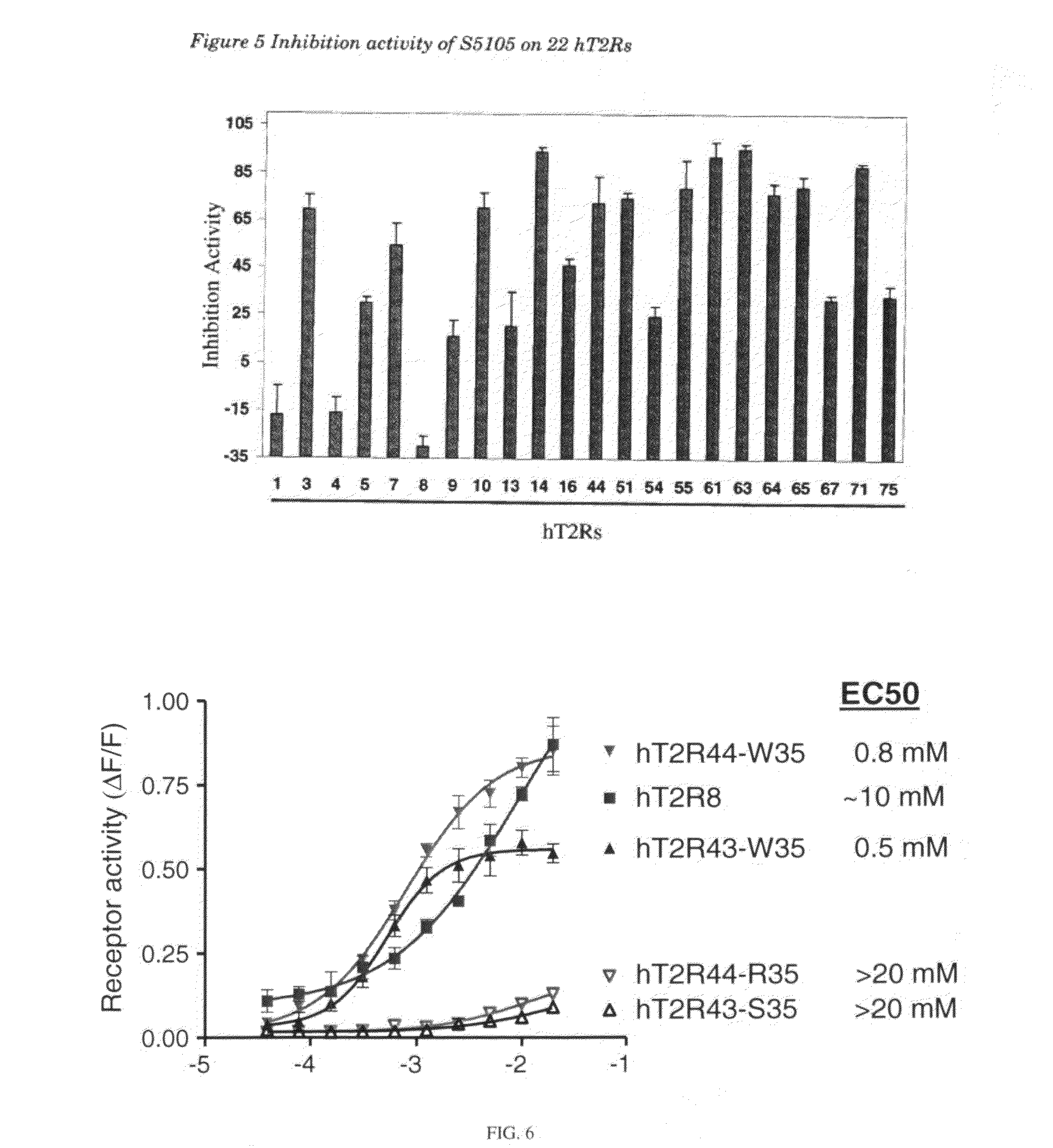

Compounds that inhibit (block) bitter taste in composition and use thereof

The present invention relates to the discovery that specific human taste receptors in the T2R taste receptor family respond to particular bitter compounds present in, e.g., coffee. Also, the invention relates to the discovery of specific compounds and compositions containing that function as bitter taste blockers and the use thereof as bitter taste blockers or flavor modulators in, e.g., coffee and coffee flavored foods, beverages and medicaments. Also, the present invention relates to the discovery of a compound that antagonizes numerous different human T2Rs and the use thereof in assays and as a bitter taste blocker in compositions for ingestion by humans and animals.

Owner:SENOMYX INC

Lhg compositions for reducing lingering bitter taste of steviol glycosides

InactiveUS20080226788A1Reduce odorMask lingering bitter taste(s)Food ingredient as taste affecting agentFood preparationSweetnessMogroside V

Aspects of the invention relate to beverage compositions, including, for example, concentrated and ready-to-drink formulations sweetened with at least a steviol glycoside and further including an LHG juice, extract or combinations thereof in an amount sufficient to reduce the lingering bitter taste of the steviol glycoside and improve the mouthfeel of the beverage. In exemplary embodiments, additional sweeteners are utilized in the beverage in addition to the LHG juice and the steviol glycoside. In other exemplary aspects, LHG powder of mogroside v content from 2 to 99% by weight may be utilized in lieu of or in addition to the LHG juice concentrate. In certain exemplary embodiments having additional non-nutritive sweeteners, the amount of LHG composition is sufficient to reduce one or more off-note tastes of one or more of the additional sweeteners.

Owner:CONCENTRATE MFG OF IRELAND

Method for processing fragrant black tea

InactiveCN101791020AReduce bitternessMeet consumer trendsPre-extraction tea treatmentTea consumptionBlack tea

The invention discloses a method for processing fragrant black tea, comprising the following steps: (1) picking the raw materials of tea and airing the raw materials green; (2) airing the tea in the sun at 4-6pm; (3) cooling, rocking green and spreading and airing the tea; (4) rolling the tea after the green colors of the leaves fade away and the fragrance slightly smells; and (5) fermenting the rolled tea until the green color of the tea disappears, the fragrance smells and the leaves become tawny, then curing and spreading and airing the tea until the tea is dry enough. In the method, various types of fresh leaves are used as the raw materials and rich fragrance is gained by introducing part of the processes in oolong tea processing. By the processing method, esterified catechins in thetea are degraded, thereby reducing bitterness of the tea, and the finished tea has aromatic fragrance and pleasant taste through the steps of rolling, fermenting, curing, etc. The tea produced by themethod has no additive, conforms to the safe and healthy tea consumption trend and has broad market prospect.

Owner:SOUTH CHINA AGRI UNIV

Taste masked aqueous liquid pharmaceutical composition

Owner:UNILAB PHARMA TECH

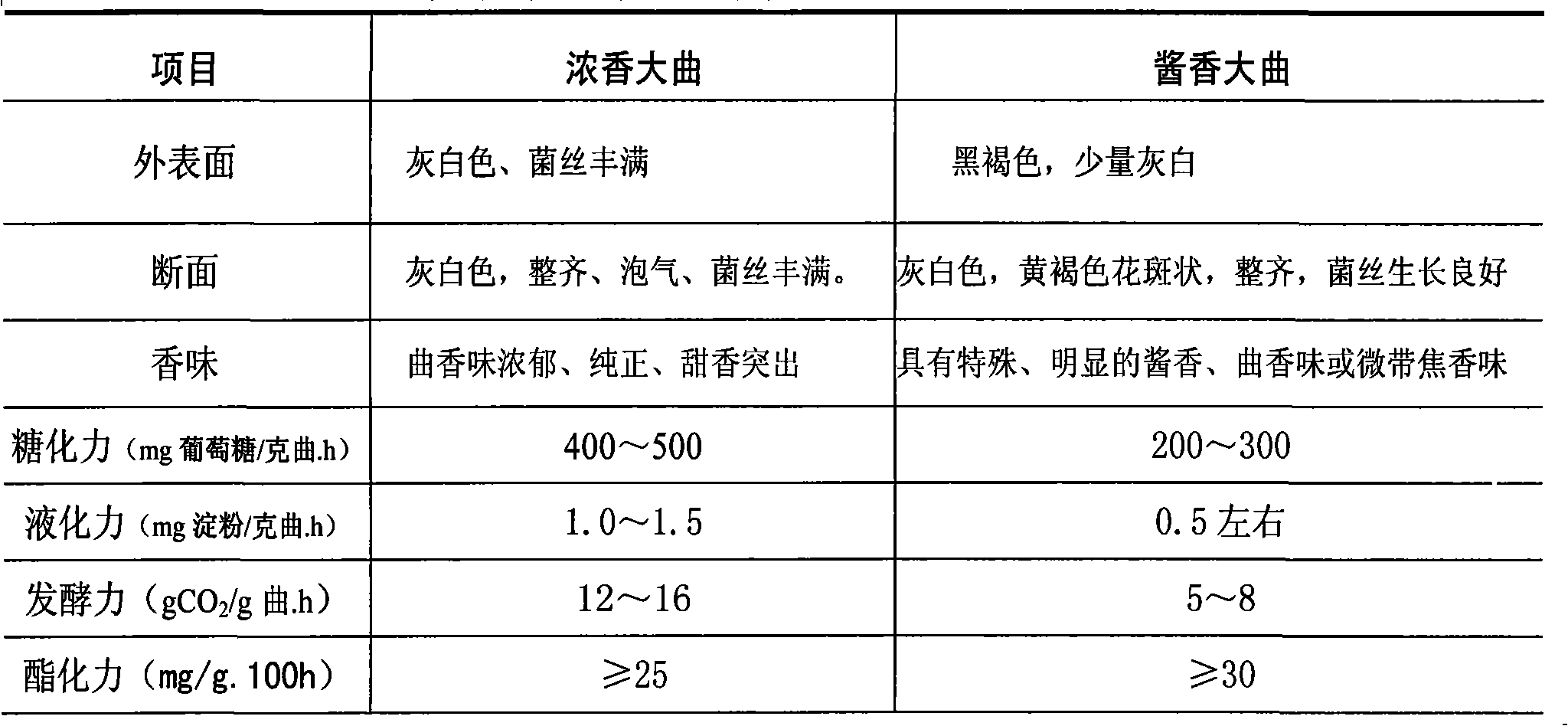

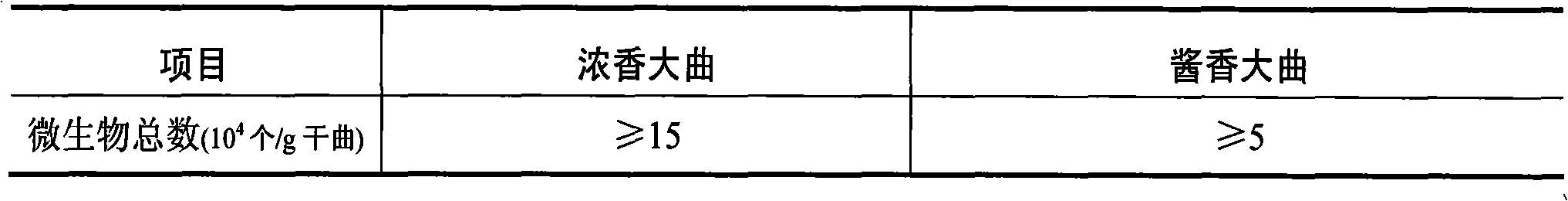

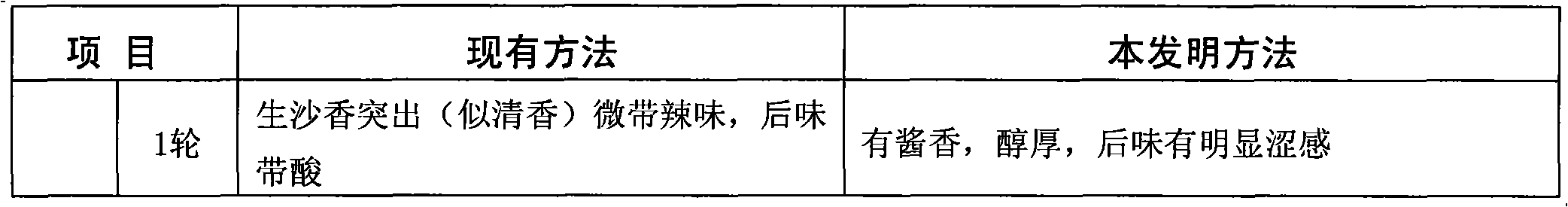

Production method of Maotai-flavor liquor

ActiveCN101602991ARemove Lao ChenEliminate pesticide residuesAlcoholic beverage preparationBiologyBrewing

The invention discloses a production method of Maotai-flavor liquor. Compared with conventional process, the invention replaces sorghum and wheat with rice, sticky rice, corn, wheat and sorghum which serve as brewing materials, replaces the process of only taking Maotai-flavor daqu as a ferment with the fermentation process of combining two daqu: Luzhou-flavor daqu and Maotai-flavor daqu for preparation, and replaces the convenient process of twice of grain addition, eight rounds of fermentation and seven rounds of liquor taking with the process of one-time grain addition, nine times of fermentation and eight times of liquor taking. The invention has the following advantages: the quality of each round of liquor and combined mixed body of each round of liquor is superior the quality of the existing method, thus obviously reducing the yield of liquor of inferior quality rounds, obviously improving the yield of liquor of superior quality rounds and improving the total yield, and the Maotai-flavor style of the product and aftertaste thereof are both superior to Maotai-flavor style and aftertaste of the Maotai-flavor liquor prepared by the existing method, and the product has elegant multi-grain compound flavor.

Owner:SICHUAN TUOPAI SHEDE WINE

Production method for improving summer green tea quality

A production method for improving quality of summer green tea comprises picking summer fresh tea, spreading at 18-22deg.C for 20-25h, evaporation deenzyming under 0.03kg / m2-0.05kg / m2 for 40-60s, cooling to normal temperature, sprinkling tannase and / or cellulase aqueous solution 0.5-1.5wt. parts for per 45 fresh tea, twisting, unblocking, oven drying, and parching, wherein the enzyme liquid contains tannase and cellulase equal to 15000 u / g tannase powder and cellulase powder 50mg.The method is suitable for improving quality of summer tea with two or three leaves and a bud. The method reduces the content of ester-catechin in summer tea, increases the content of amino acid and soluble sugar, reduces astringency of the tea, and improves the taste of tea, thereby making full use of material of summer tea and improving effectiveness of operations of tea garden.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Roasted famous high-quality green tea and production process thereof

InactiveCN102669313AGuaranteed qualityPromote hydrolysisPre-extraction tea treatmentTemperature controlGreen tea

The invention relates to roasted famous high-quality green tea and a production process thereof, belongs to the technical field of tea processing, and provides a production process of roasted famous high-quality green tea to effectively improve quality of the green tea. The production process includes steps of fresh tea leaf fixation, shaping and drying. Fresh tea leaves are further cured before fixation by placing the fresh tea leaves in a precision temperature control device at the set temperature of 35DEG C to 36 DEG C for 2-4 hours of curing.

Owner:中国测试技术研究院生物研究所

Green tea processing method for reducing bitterness of autumn tea and summer tea

ActiveCN102940053AReduce bitternessFull-bodied taste qualityPre-extraction tea treatmentGreen teaTea leaf

The invention discloses a green tea processing method for reducing bitterness of autumn tea and summer tea, comprising the following steps:1) selecting tea leaves: selecting fresh tea leaves of autumn and summer and grading; 2) withering: spreading the fresh tea leaves for withering, wherein the water content of the withered leaves is 70-75%; 3) conducting fine manipulation: carrying out fine manipulation on the withered leaves to obtain fine-manipulated leaves, wherein fine manipulation comprises rotating and cooling which are alternately and repeatedly; 4) de-enzyming: de-enzyming the fine-manipulated leaves to obtain de-enzymed leaves; 5) dampening: dampening the de-enzymed leaves; 6) rolling: rolling the dampened leaves; 7) drying: using a gross fire to dry the rolled leaves until the water content is 10-20%, then using a complete fire to dry, wherein the water content of the dried leaves is 4-6%. According to the invention, by using the fresh tea leaves and optimizing the processing method, the produced green tea can reduce the bitterness of tea, thus fragrance of green tea with natural fragrance of flower is formed, and the taste quality is thick and mellow.

Owner:婺源县聚芳永茶业有限公司

Identification of human T2R receptors that respond to bitter compounds that elicit the bitter taste in compositions, and the use thereof in assays to identify compounds that inhibit (block) bitter taste in compositions and use thereof

ActiveUS20100254916A1Reduce bitternessSuppress bitternessBiocideCosmetic preparationsTaste receptor ligandBitter tastes

The present invention relates to the discovery that specific human taste receptors in the T2R taste receptor family respond to particular bitter compounds present in, e.g., coffee. Also, the invention relates to the discovery of specific compounds and compositions containing that function as bitter taste blockers and the use thereof as bitter taste blockers or flavor modulators in, e.g., coffee and coffee flavored foods, beverages and medicaments. Also, the present invention relates to the discovery of a compound that antagonizes numerous different human T2Rs and the use thereof in assays and as a bitter taste blocker in compositions for ingestion by humans and animals.

Owner:SENOMYX INC

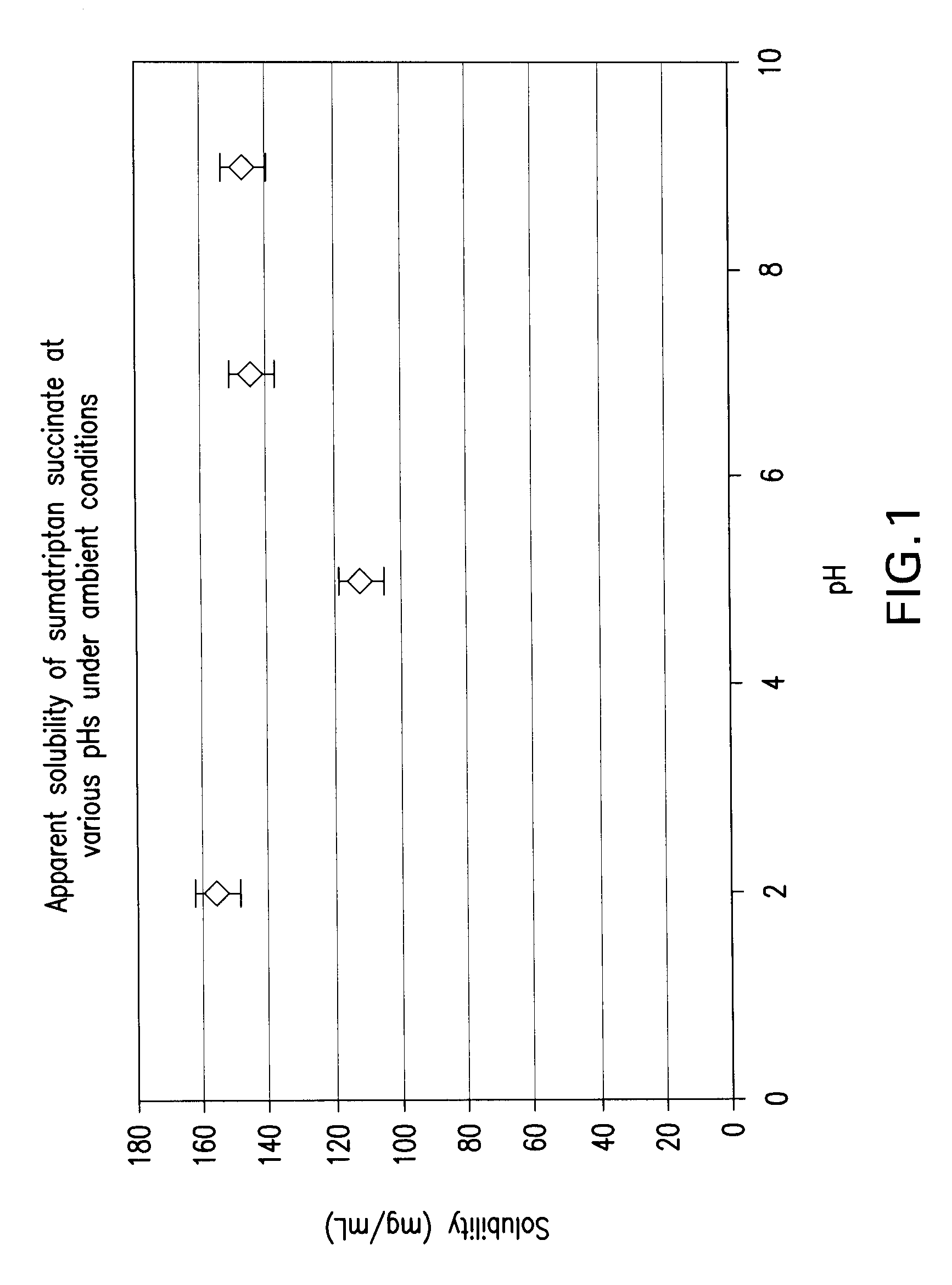

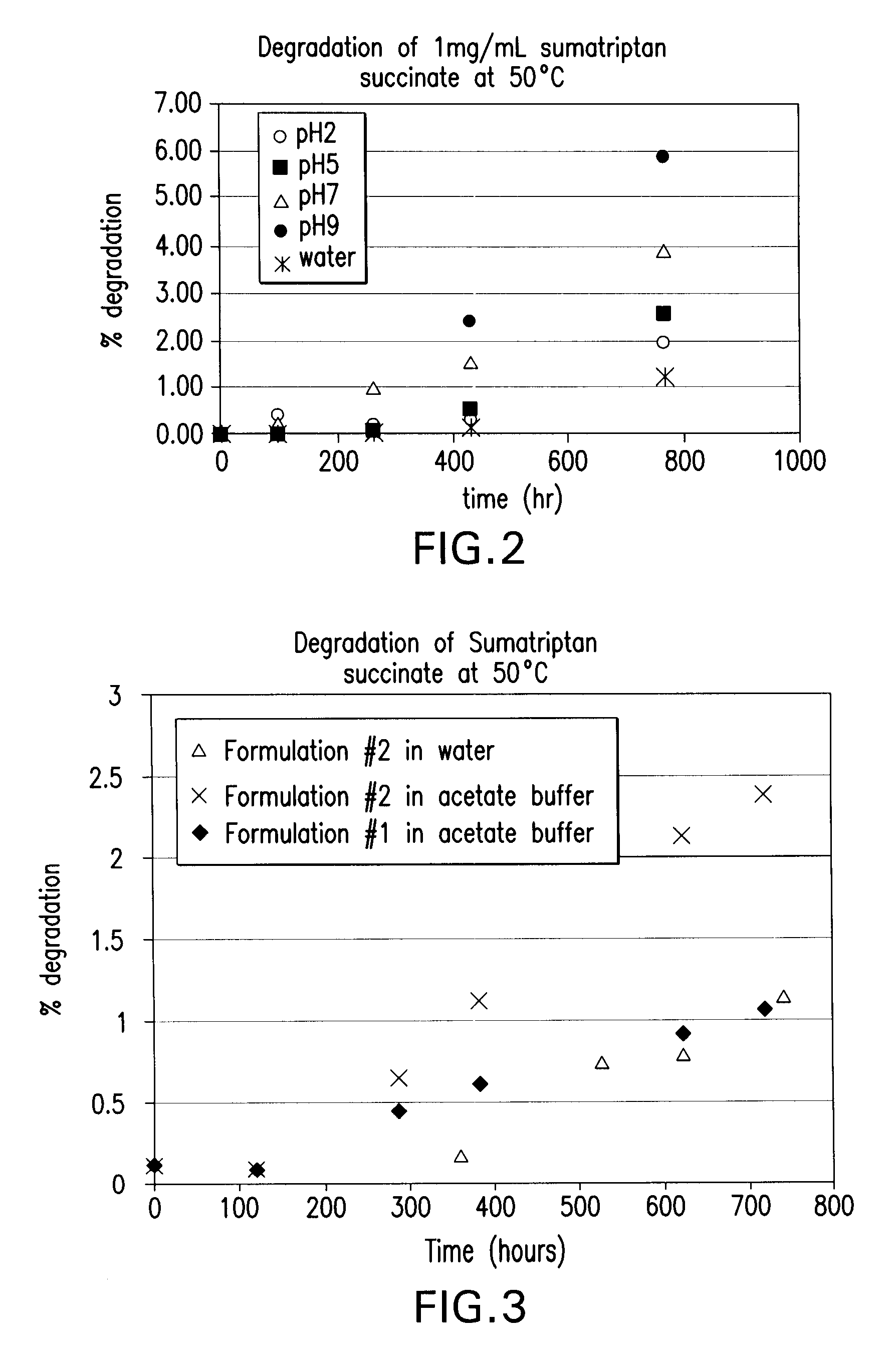

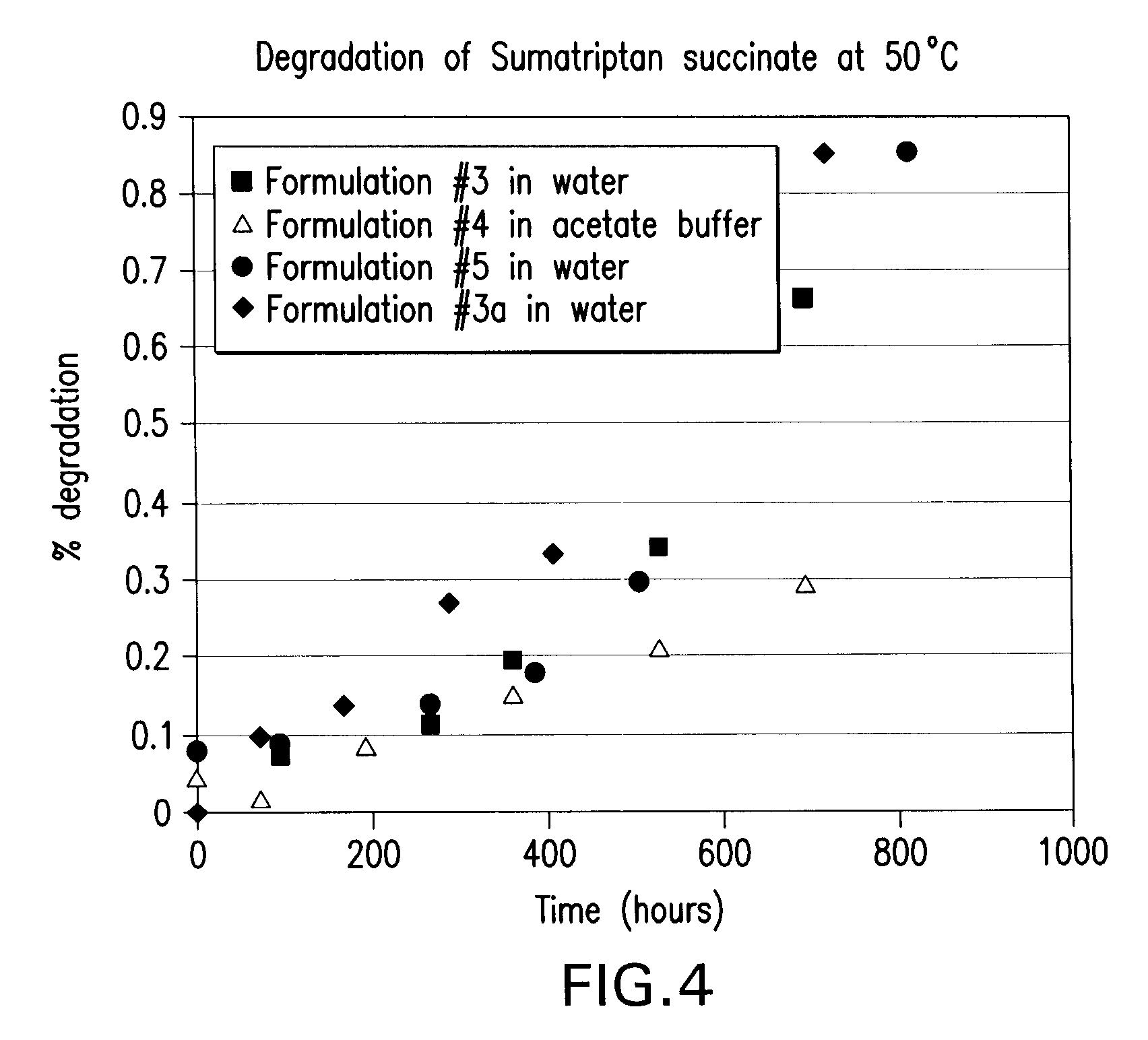

Stable and palatable oral liquid sumatriptan compositions

InactiveUS20070166336A1Minimize and mask bitternessReduce bitternessBiocideNervous disorderMetaboliteSumatriptan

The present invention is directed to improved oral liquid compositions that include sumatriptan, or a pharmaceutically acceptable salt or metabolite thereof, and a pharmaceutically acceptable carrier that includes a liquid portion of the composition. The compositions are substantially free of oxidation impurities. Typically, the compositions include a sweetening agent and a flavoring agent, or a bitterness-reducing agent and flavoring agent. Processes of preparing such compositions and methods of administering such compositions are also included.

Owner:WOCKHARDT EU OPERATIONS SWISS

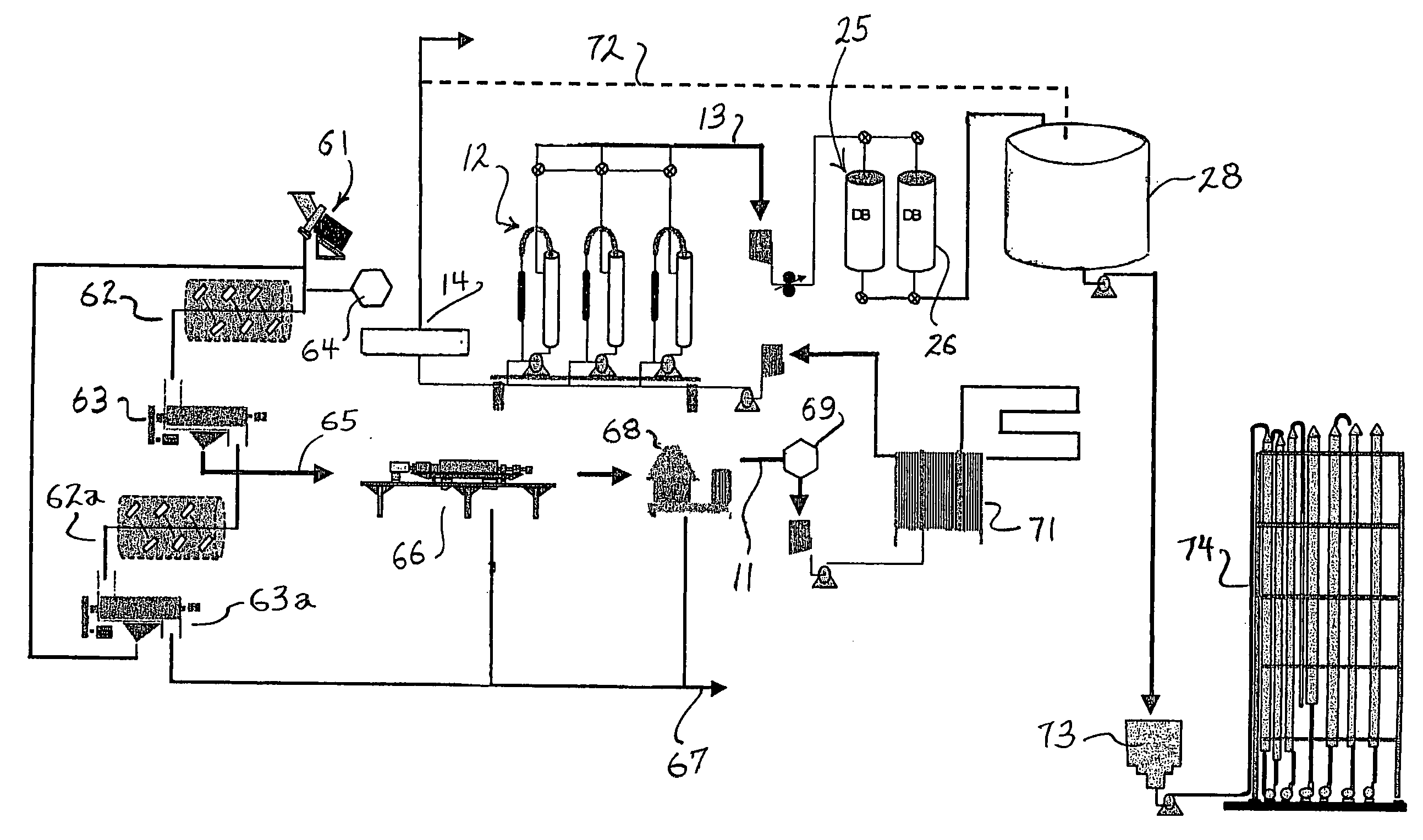

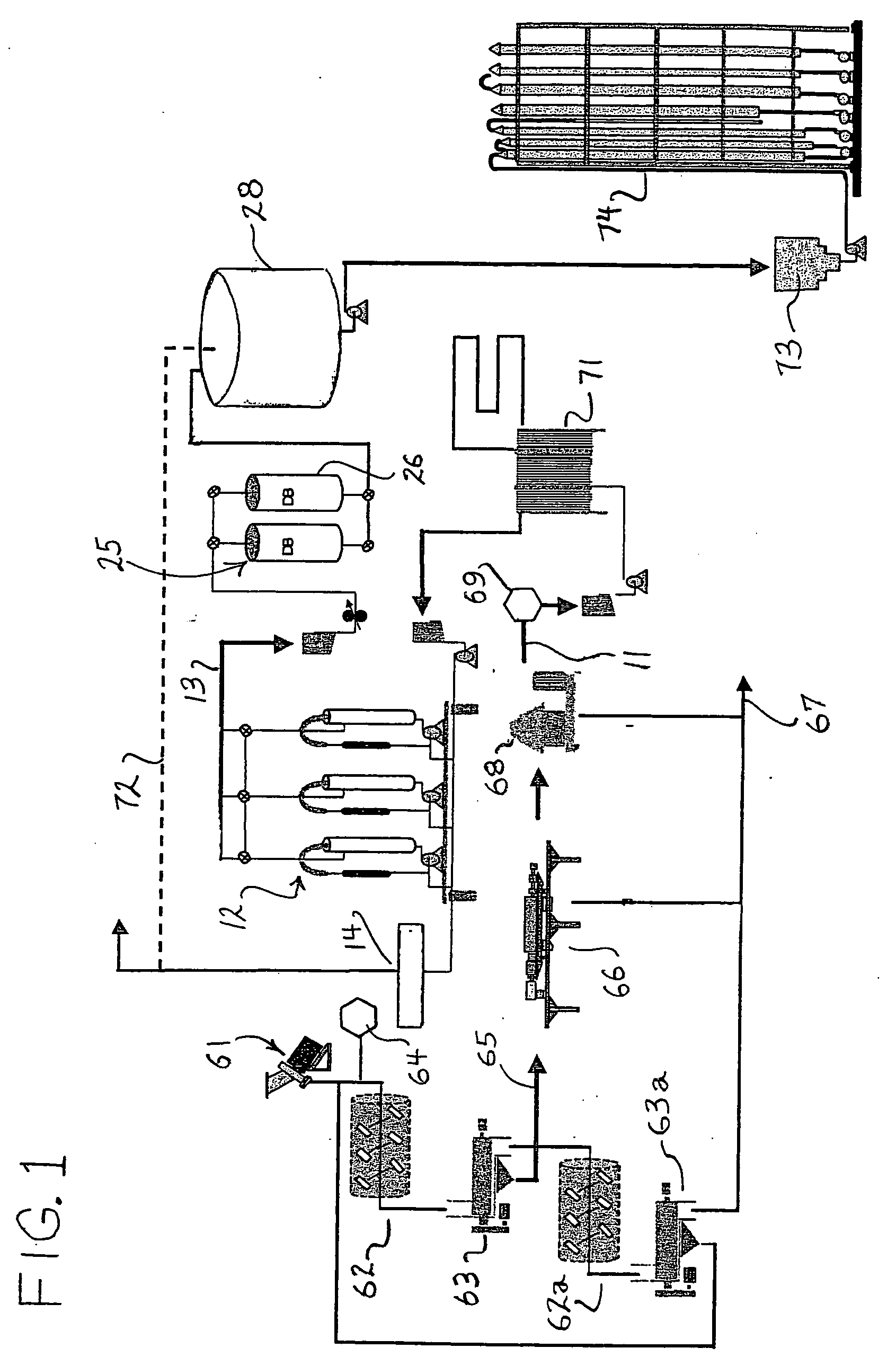

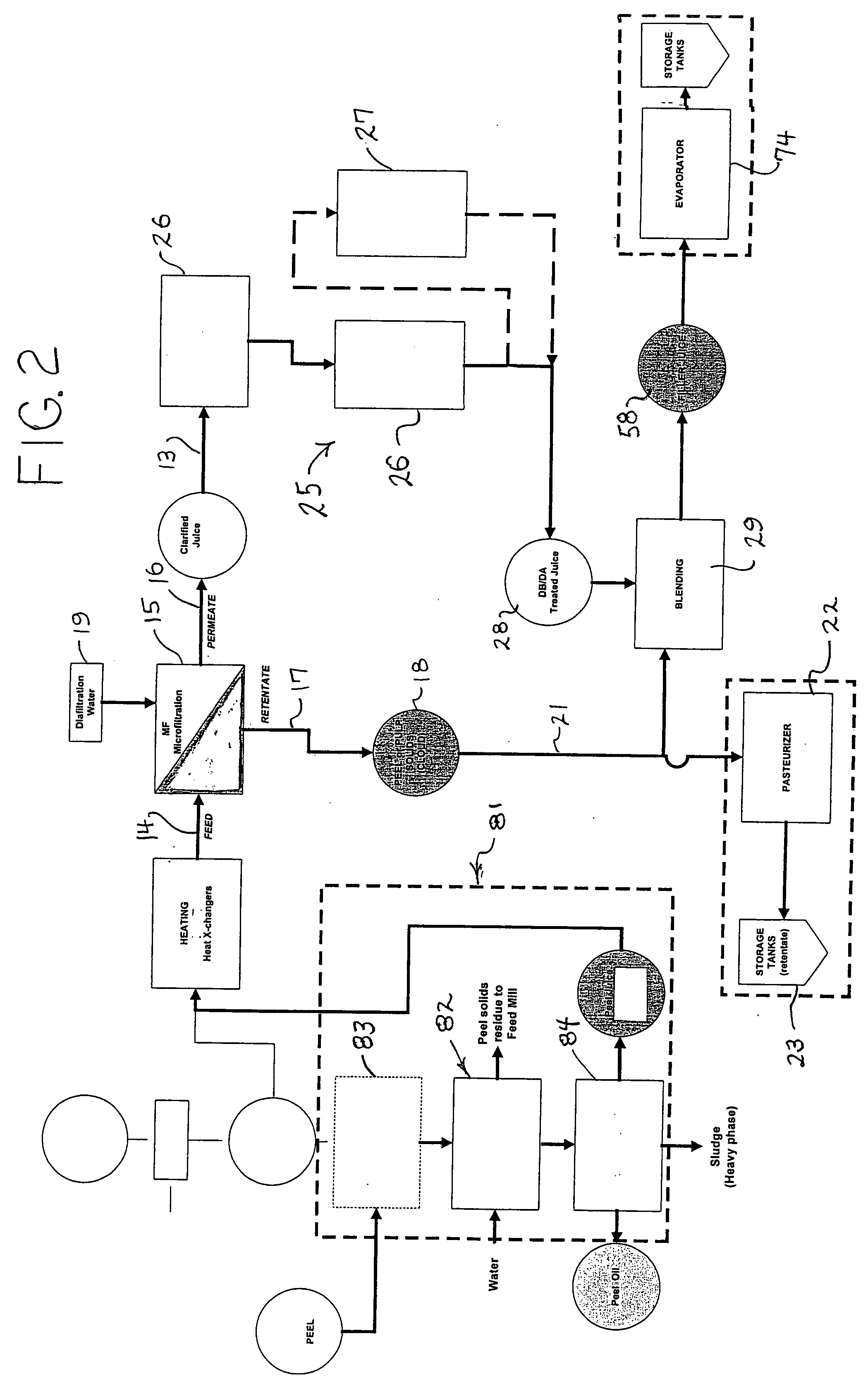

Citrus peel juice

InactiveUS20060105089A1Improve utilizationHigh yieldFruit and vegetables preservationCheese manufactureFruit juiceSlurry

Byproduct from extracting citrus juice from whole fruit is made into a slurry and extracted to provide a rudimentary peel juice. This is processed into a raw peel juice and microfiltered to prepare a clarified raw peel juice. The peel juice is processed to remove naturally occurring components which detract from the quality of the fruit juice. Such components are removed by contacting the peel juice with an adsorptive rein in order to provide an enhanced peel citrus juice, which can be blended with other juices.

Owner:TROPICANA PROD INC

Compositions and methods for producing flavored seasonings that contain reduced quantities of common salt

ActiveUS20060286275A1Decrease sodium intakeIncrease potassium intakeAnimal feeding stuffCheese manufactureInosinic acidSalt substitute

The present invention provides flavored seasoning compositions containing low-salt substitutes that reduce the quantify of common salt used to flavor foods. More specifically, the compositions contain (a) a flavored seasoning mixture comprising flavoring agents, and flow agents, bulking agents, binding agents and / or preservatives, and (b) a salt substitute containing potassium chloride and bitterness inhibitors taurine and 5′-adenosinic acid, 5′-inosinic acid and / or 5′-guanylic acid. Furthermore, the present invention provides foods containing these compositions, methods of using these compositions and methods for preparing them.

Owner:S & P INGREDIENT DEV

Holothurian peptide functional food and preparation method thereof

InactiveCN101341978AAvoid residueSave the hassleProtein composition from fishAnimal proteins working-upDiseaseAdditive ingredient

The invention discloses a sea cucumber polypeptide functional food and a preparation method thereof which not only remarkably improves the content of polypeptide, but also has no chemical residues; the contents of salt and arsenic are low; the food is healthier and safer to eat; simultaneously the food is simply operated, easily controlled, is effective and saves energies. The key technical scheme includes: selecting a compound protease of Protamex and needing not to adjust the pH value of materials; carrying out processes of desalting and arsenic removing on an enzymolysis liquid; more than 80 percent of the molecular weight of the product is between 100 to 6000Dalt; wherein, the small polypeptide of 100 to 2100Dalt is more than 70 percent; the product components and the content weight percentages are as follows: 50 to 60 percent of polypeptide, 5 to 10 percent of free amino acids, 2.5 to 7.5 percent of mucoitin as well as containing the inherent nutrition components of a plurality of minerals and vitamins of the sea cucumber. The product has the effects of resisting knub, reducing blood pressure, preventing cardio-cerebrovascular diseases, resisting fatigue, delaying senescence, improving the immunity. The food can be used as a healthy food to eat and can also be used as a food and a medicine additive.

Owner:DALIAN FEIDE BIOIND

Oral pharmaceutical composition

InactiveUS20060198885A1Reduce bitternessOrganic active ingredientsPill deliveryAlkaline earth oxidesCetirizine

An oral pharmaceutical composition having reduced bitterness comprising therapeutically effective amounts of cetirizine or its pharmaceutically acceptable salts, alkaline earth oxide and a pharmaceutically acceptable carrier comprising a disintegrant wherein the composition disintegrates rapidly in the oral cavity.

Owner:SUN PHARMA INDS

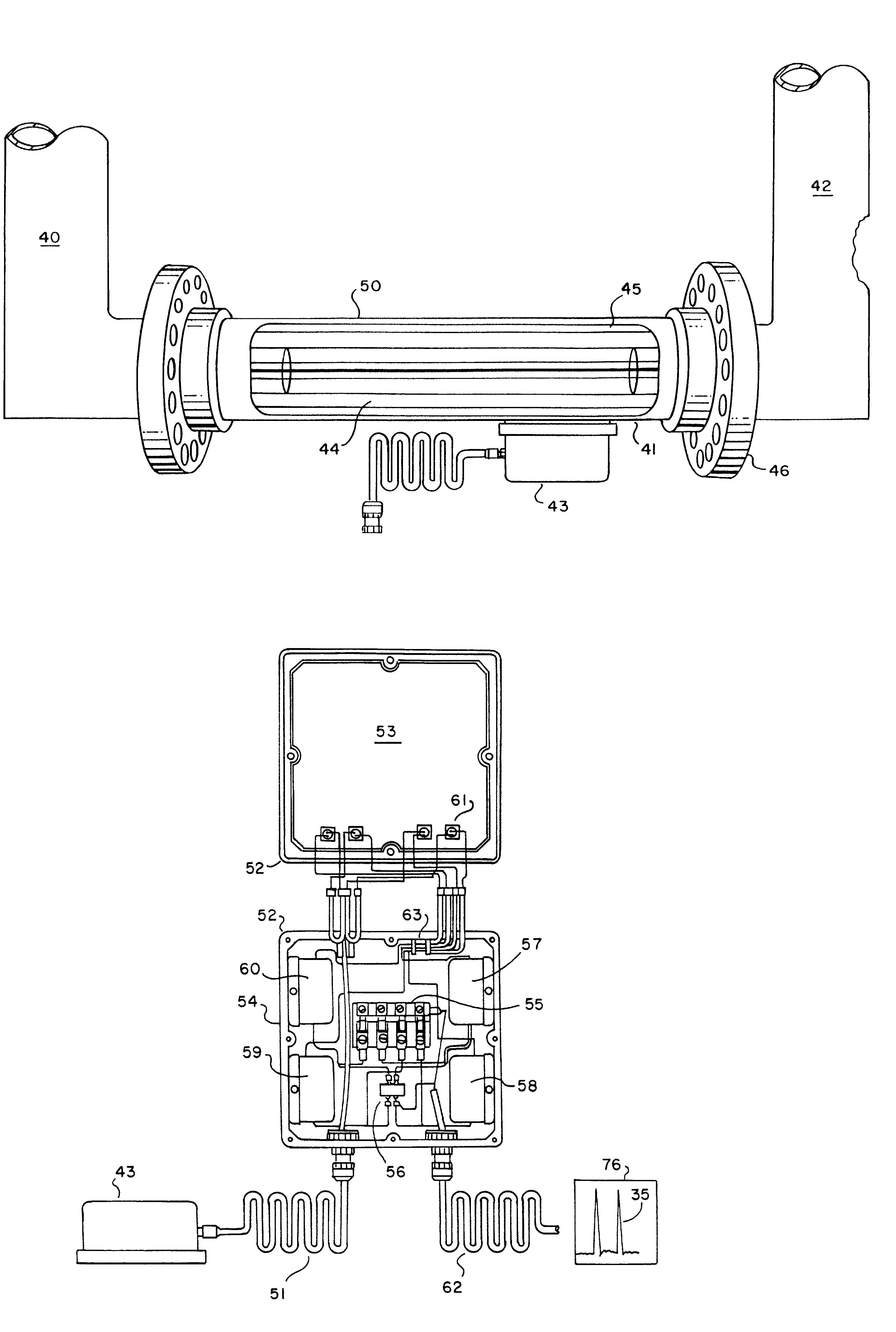

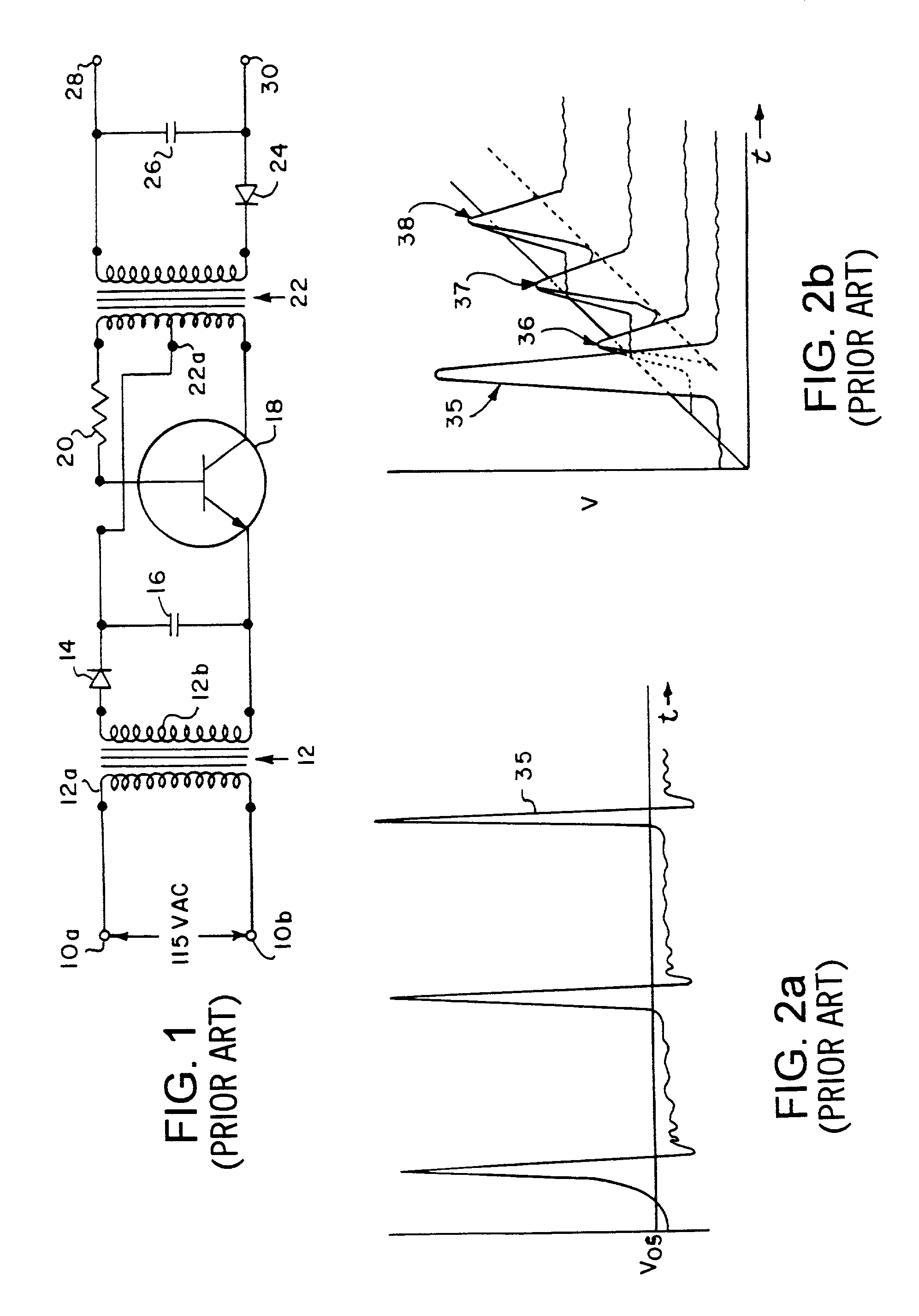

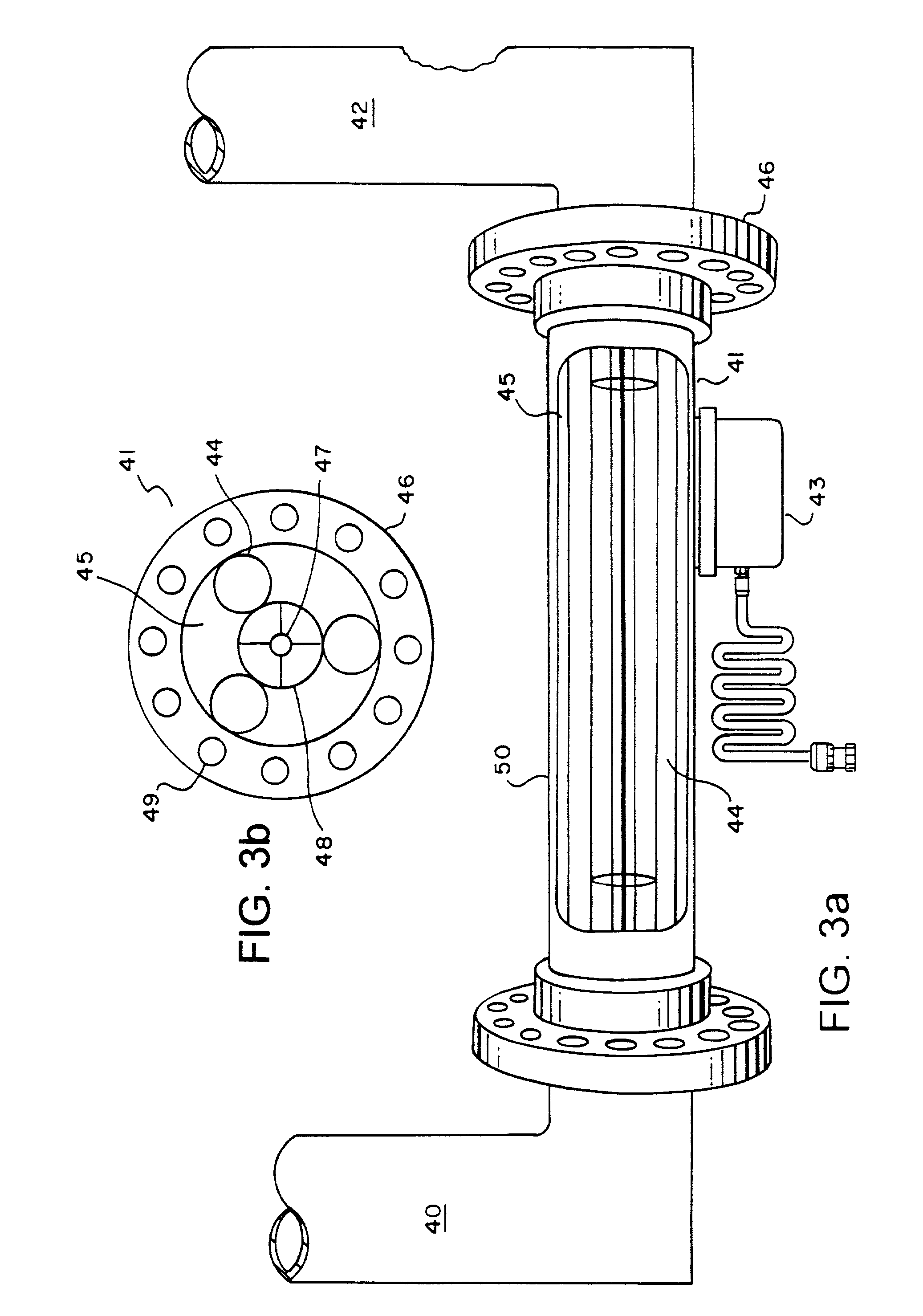

Methods of preparing and using electrostatically treated fluids

InactiveUS6974561B1Measurably betterIncrease crop yieldElectrolysis componentsLiquid separation by electricityWater basedVoltage spike

The present invention includes an improved electrostatic device for energizing fluids, in particular water based fluids, which will be used to provide a benefit to living organisms, machinery, processes and substances. The improved device of the invention will include an electrostatic voltage spike signal generator, two or more radio frequency signal generators, one or more antennas, optional one or more signal boosters and a fluid conduit. When fluid is treated with the improved device of the invention, the fluid will become energized and can be used to provide significant benefits in applications such as milk production, flower production, fruit production, crop production, vegetable production, shrimp production, egg production, meat production, gasoline combustion, waste fluid combustion, scale removal, water purification, fluid tracking, fluid sterilization and more.

Owner:COMPLETE WATER SYST L L C

Method for processing instant tea powder

ActiveCN101189990AAvoid lostInhibit deteriorationPre-extraction tea treatmentTea extractionInstant teaFlavor

The invention provides a method that takes fresh tea leaves as raw materials to process instant tea powder, which can prevent loss and deterioration of nutrition substance when in the tea manufacturing process. The technique is that: when the raw material is extracted, pectinase is added to enhance extraction rate of the tea leaves and to extract solid substance from solution after the processes of extracting, enzymatic hydrolysis, filtration, condensation and drying, etc. of the raw materials; then tannase is added for enzymatic hydrolysis, so as to resolve the deposition problem of the tea soup and to reduce the bitterness of the instant tea powder and improve the dissolution ability of the tea powder in cold water. The technologies of membrane separation and condensation are adopted in filtration and condensation process; and spray drying or vacuum freeze drying is adopted in drying process; therefore, the whole production process is carried out at relatively low temperature, which maximally preserves the nutrition substances and flavor substances, and the produced instant tea powder is abundant in nutrition and has fresh and soft taste.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Method for extracting proteins and chitin from heads and shells of prawns

ActiveCN101579132AProlong autolysis timeHigh extraction rateAnimal proteins working-upFood preparationFlavorCalcium EDTA

The invention discloses a method for extracting proteins and chitin from heads and shells of prawns, which uses fermentation with lactic acid bacteria to liquefy and separate the proteins in the heads and shells of the prawns and obtains the proteins by drying. Lactic acid produced in fermentation can dissolve inorganic calcium salts in the heads and shells of the prawns and transfer the inorganic calcium salts to fermentation liquor, and residue can be decolorized to give the chitin. The method comprises the following steps: (1) crushing the heads and shells of the prawns and adding water into the crushed heads and shells of the prawns; (2) adding glucose or sucrose into the crushed heads and shells of the prawns; (3) inoculating with the lactic acid bacteria; (4) keeping temperature for fermentation; and (5) after the fermentation is finished, separating the fermentation liquor from the fermentation residue, neutralizing and drying the fermentation liquor to obtain proteins, and subjecting the fermentation residual to soaking in a diluted acid and decolorization to obtain the chitin. The proteins obtained by the method has the characteristics of light fishy smell and bit flavor, excellent flavor and rich calcium lactate content and can be used in food.

Owner:SOUTH CHINA AGRI UNIV

Processing method for reducing bitter taste of green tea and product

The invention provides a processing method for reducing bitter taste of green tea and a product. The method comprises the following steps: 1), grading fresh tea leaves, removing non-tea impurities, and spreading the tea leaves to cool the tea leaves under a certain temperature and humidity conditions or a natural condition till the water content of the fresh tea leaves is about 70 percent; 2) subjecting graded fresh tea leaves to deactivation of enzymes to fully destruct the activity of enzymes and reduce the water content in the fresh leaves; 3) subjecting the tea leaves subjected to primarydeactivation of enzymes to secondary deactivation of enzymes, and re-softening the leaves; 4) re-moisturizing the leaves subjected to secondary deactivation of enzymes or sealing the tea leaves till the tea leaves turning yellow; 5) twisting at controlled temperature and humidity; 6) drying the twisted leaves, drying the twisted leaves over gross fire till the water content is 20 to 30 percent, and drying the twisted leaves over a high fire till the water content is about 5 percent; and 7) packaging. In the invention, the deactivation of enzymes is performed twice, the re-moisturizing and sealed yellowing are performed under certain temperature and humidity conditions, and twisting at controlled temperature and humidity is performed. Compared with the conventional processing technique, the method obviously relieves the bitter taste of green tea and makes the flavor of the product more mellow.

Owner:SHENZHEN SHENBAO HUACHENG TECH

Fermentation tea and preparation method thereof

ActiveCN101189994AMinimize quality variationQuality improvementPre-extraction tea treatmentDry weightCatechin

The invention relates to a fermented tea. Accounting by the dry weight of the tea, the content of the tea polyphenol of the tea is less than 19 percent, and the total content of the catechin ECG and EGCG is less than 5 percent, and the content of the abrownins is relatively low. The manufacturing method of the fermented tea can be used for producing tea drink or mixed tea.

Owner:李新敏

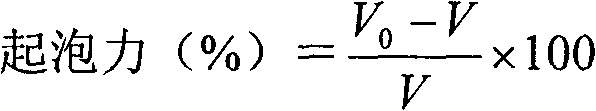

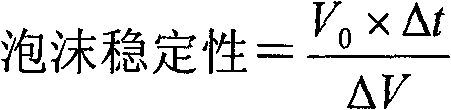

Egg white powder with high foamability and preparation method thereof

The invention provides egg white powder with high foamability and a preparation method thereof and relates to reconstruction of whey protein structure and functional properties, belonging to the technical field of biological processing of foodstuffs. According to the invention, on the basis of preliminary work, enzymatic hydrolysis of lipase in advance and cooperative enzymatic hydrolysis of composite protease are utilized for treatment of egg white; total usage amount of lipase and composite protease is less than usage amount of individually used lipase or protease, and however, foamability and foam stability of egg white powder obtained by combined utilization of lipase and composite protease are higher than those of egg white powder obtained by individual utilization of lipase or composite protease; the egg white powder obtained in the invention can meet demands for high-grade products on the market, and the advantages of a simple process and high cost performance are achieved in the invention. According to the invention, the ratio of active usage amount of Aspergillus oryzae protease, papain and trypsin is determined to be 1:1:1; the usage amount and other technological parameters cooperatively allow egg white powder with high foamability to be obtained; egg white powder with high foamability provided in the invention enables the additional output value of eggs to be increased, lays a technical foundation for development and industrial production of special-purpose egg white powder products and increases economic benefits for enterprises.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Novel processing method for green tea

The invention discloses a novel processing method for green tea. The method comprises the following steps: picking fresh leaves; spreading; sunning; dewatering; cooling by spreading; rolling; pre-drying for shaping; cooling by spreading; re-drying; cooling by spreading; and refining. According to the finished green tea prepared by the method, the bitter taste in the tea leaves are reduced, the freshness, the aroma and the refreshingness of the tea leaves are enhanced, ester catechins in the tea leaves are reduced, and the content of effective ingredients such as amino acids, soluble polysaccharides and caffeine in the tea leaves is increased.

Owner:JIANGSU MINGYUAN TEA TECH SCI

Hawthorn fruit and glutinous rice wine

The invention discloses a hawthorn fruit and glutinous rice wine.The hawthorn fruit and glutinous rice wine is prepared from, by weight, 55 parts of glutinous rice, 25 parts of hawthorn fruits and 20 parts of sorghum rice, wherein the sum of parts by weight is 100.A brewing method of the hawthorn fruit and glutinous rice wine comprises the following steps that 1, peel and pits of hawthorn fruits are removed after the hawthorn fruits are cleaned, hawthorn fruit pulp, hawthorn fruit peel and hawthorn fruit pits are obtained, the hawthorn fruit pulp is beaten to obtain hawthorn fruit paste, the hawthorn fruit pits are ground to obtain hawthorn pit powder, the hawthorn fruit paste and the hawthorn pit powder are mixed and stirred to be uniform, a squeezer is used for squeezing juice, and hawthorn juice is obtained.The hawthorn fruit and glutinous rice wine is fragrant, sweet and delicious, has the sour taste and is good in taste.

Owner:陕西百贤酒业有限公司

Preparation method for taste base peptide for steamed savory flavoring

The invention discloses a preparation method for taste base peptide for steamed savory flavoring, and belongs to the field of food additives. The method comprises the following steps: performing enzymolysis on defatty grouts to prepare raw material peptide; performing maillard reaction on the raw material peptide and sugar to prepare the taste base peptide; taking the raw material peptide and reducing sugar as raw materials, common salt and / or cysteine as accessories, and 6 to 16g / 100ml raw material peptide, 0.5 to 4.5g / 100ml reducing sugar, 2 to 10g / 100ml common salt, and 1 to 5g / 100ml cysteine as ingredients of the maillard reaction, controlling the temperature to 80 to 130 DEG C, and reacting for 0.5 to 3.5 hours; and cooling a reaction solution by ice water, and spray drying the reaction solution to obtain the taste base peptide. The taste base peptide is a light yellow powder base, and the content of taste potentiating peptide with 1,000-5,000 Da is as high as 20 to 30 percent; compared with a product prepared by the conventional method, the content of amino acid with bitterness of a product prepared by the method is decreased by 10 to 60 percent, and the browning rate is decreased by 40 to 80 percent; and the taste base peptide can be taken as an additive, applied to the steamed savory flavoring, and effectively overcomes the disadvantages of dark color, strong and pungent top note, inadequate mouthfeel, and the like of national savory flavoring products.

Owner:JIANGNAN UNIV

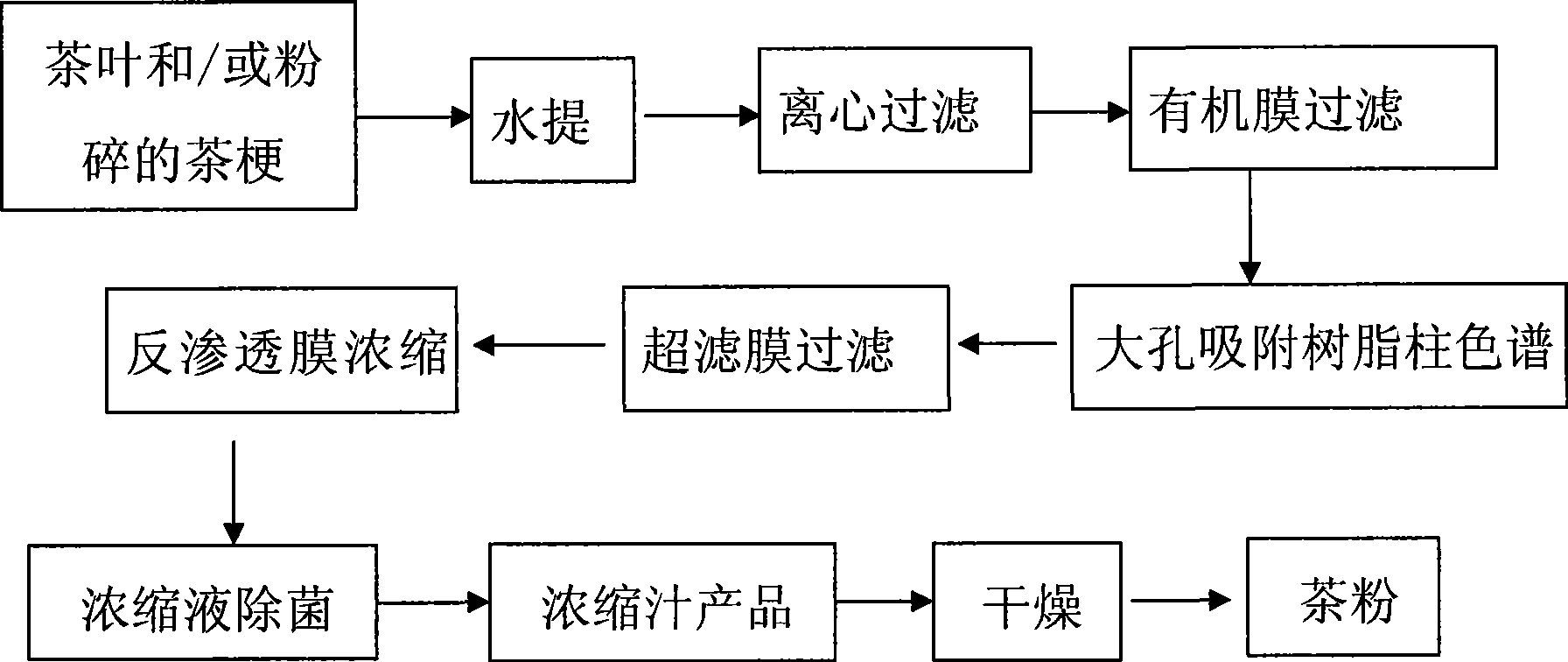

Tea extract and preparation method thereof

InactiveCN101461433AGood for lowering blood pressureHigh in theanineTea extractionFood preparationSolubilityDry weight

The invention discloses a tea extract containing theanine and catechin, in which, the theanine content is 3-4wt% of the tea extract by dry weight. The invention further discloses the preparation method: lixiviating the tea and / or crushed tea stems by the water of 0-70 degrees centigrade; filtering by centrifugation; filtering by organic membrane; and filtering by the Dalton ultra-filter with molecular weight retaining range of 1000-5000; concentrating by counter permeable membrane; where, all the filtering and concentrating by counter permeable membrane are under the temperature of 10-35 degrees centigrade; degerming, and obtaining concentrated juice state tea extract; and further drying to obtain tea powder state tea extract. The tea extract of the present invention has substantial health caring effects of enhancing immunity, soothing nerves, restoring consciousness and improving attentiveness and memory; and achieves the advantages of good cold water dissolvability, clear tea water,fresh taste and fragrant smell. The preparation of the invention can use tea stems as raw material, uses resource effectively, reduces cost, has simple processes, low energy consumption and no pollution.

Owner:健士星生物技术研发(上海)有限公司

Processing method for cheese suitable for taste of Chinese people

The invention relates to the technical field of dairy product processing, in particular to a processing method for natural cheese suitable for the taste of Chinese people. In the method, fresh milk is pasteurized after being filtered, purified and standardized, and is then cooled to the curding temperature, compound starter is first added for preacidification, the acidity is then regulated, calcium chloride and compound rennin are then added, curds are formed by heat preservation and then cut into curd blocks, whey is discharged after the curd blocks are stirred and heated and the temperature is preserved, and the curd blocks are taken out, added with salt and Chinese ham powder, molded, vacuumized and fermented to ripen under the constant temperature. The curding speed is high, the period of fermentation is short, the production cost is low, proteolysis and lipolysis are moderate, the bitterness is light, and since the tastes of the cheese, the acidophilus milk and the Chinese ham are mixed together, the taste of the produced natural cheese is more suitable for the taste of Chinese people.

Owner:ZHEJIANG UNIV +1

Sweetener blend compositions

InactiveUS20130136838A1Improve taste qualityIncreased sugar-like taste qualityConfectionerySweetmeatsSweetnessTaste quality

Natural sweetener blends and sweetened compositions having an improved, sugar-like taste quality are provided herein. Also provided are methods of improving the sugar-like taste quality of sweetened compositions comprising such natural sweetener blends.

Owner:THE COCA-COLA CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com