Patents

Literature

3891 results about "Black tea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Black tea and production technology

The invention discloses a production technology for black tea with stronger tea fragrance, more mellow taste and darker liquor color. The production technology is characterized by comprising the following steps of: primarily processing raw black tea; removing impurities and screening; humidifying and steaming tea; piling, steaming and shaping; drying or floating and drying; and packaging. The produced brick tea has the advantages of black brown or russet brown color and luster, zero smoke fat pollution, pure and lofty tea perfume, mellow taste, orange red or orange yellow liquor color, red-yellow brightness, eurotium cristatum filled in brick tea, and full grains. The production technology is simple, convenient in implementing, safe and environment-friendly. The produced black tea is smoke-free and harmless, is fragrant and fine-quality and is a real environment-friendly healthy beverage.

Owner:湖北省赵李桥茶厂有限责任公司

A kind of dark tea production process

ActiveCN102273527AReduce time for fermentation processIncrease productionPre-extraction tea treatmentBlack teaAspergillus niger

The invention relates to a production technology of black tea, in particular to the technical field of the black tea. The production technology of the black tea comprises the following working procedures: green removing, twisting, piling, drying at first time, steaming, compacting, fermenting and drying 2, wherein pulp filling is carried out on a tea leaf raw material before the green removing working procedure, and the mass ratio of water to tea leaf is 6-9% in the pulp filling process; and artificially adding inoculated strains between the steaming working procedure and the fermenting working procedure, wherein the artificially inoculated strains are one or more of Eurotium cristatum, candida albican and aspergillus niger. By adopting the production technology provided by the invention,time of a fermentation technology in the production process of the black tea is reduced, production efficiency is improved, and yield of the black tea is increased; meanwhile, the problem that the traditional black tea production technology is controlled by experience and level of a tea making master worker is solved, the time for producing the black tea by utilizing the technology is short, the produced black tea has good consistency, strong taste, pure fragrance, red-yellow soup colour and brown and bright leaf edge.

Owner:HUNAN XIANGFENG TEA

Process for the Manufacture of a Tea Product and Products Obtained Thereby

A process is provided for the manufacture of a tea product which is readily infusible and has improved red colour. The process comprises contacting black tea with ascorbic acid and / or its salts, an oxidizing agent and water for a period of at least 5 minutes followed by drying to prepare a tea product that is infusible in water at 5 to 100° C.

Owner:CONOPCO INC D B A UNILEVER

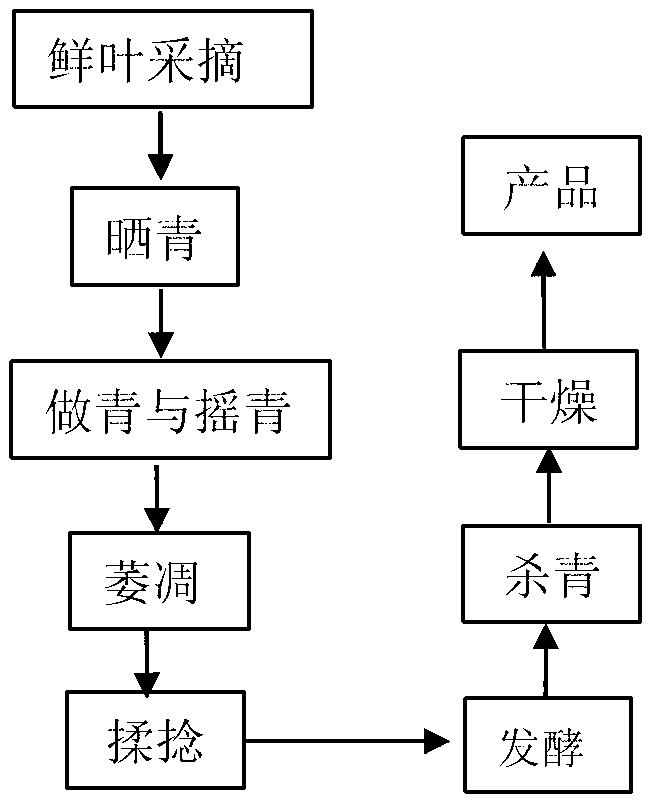

Method for processing fragrant black tea

InactiveCN101791020AReduce bitternessMeet consumer trendsPre-extraction tea treatmentTea consumptionBlack tea

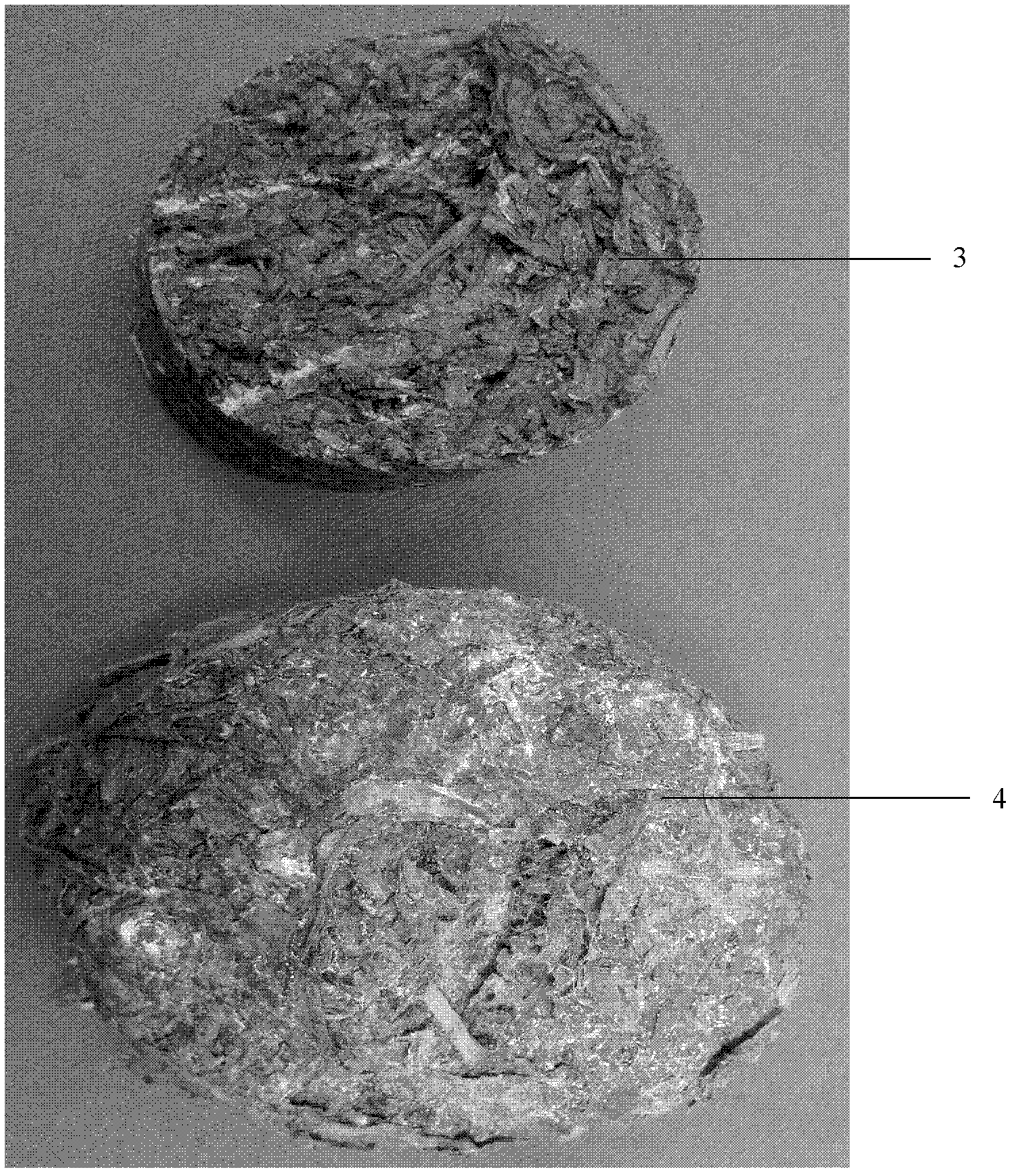

The invention discloses a method for processing fragrant black tea, comprising the following steps: (1) picking the raw materials of tea and airing the raw materials green; (2) airing the tea in the sun at 4-6pm; (3) cooling, rocking green and spreading and airing the tea; (4) rolling the tea after the green colors of the leaves fade away and the fragrance slightly smells; and (5) fermenting the rolled tea until the green color of the tea disappears, the fragrance smells and the leaves become tawny, then curing and spreading and airing the tea until the tea is dry enough. In the method, various types of fresh leaves are used as the raw materials and rich fragrance is gained by introducing part of the processes in oolong tea processing. By the processing method, esterified catechins in thetea are degraded, thereby reducing bitterness of the tea, and the finished tea has aromatic fragrance and pleasant taste through the steps of rolling, fermenting, curing, etc. The tea produced by themethod has no additive, conforms to the safe and healthy tea consumption trend and has broad market prospect.

Owner:SOUTH CHINA AGRI UNIV

Technique for producing Jinhuaqianliang tea (flower coil tea)

ActiveCN101352191AQuality improvementUniform qualityPre-extraction tea treatmentCooking & bakingThirst

The technology for producing golden flower Qianliang tea (Hua-juan tea) is characterized in that the technology comprises the process steps as follow: plucking criteria-water removing in high temperature-rolling and shaping-pile-fermentation-dry and adding incense-stems picking and sieving-matching and pile-classificaition and weighting-steam softening-moisture detection-adpressing and sizing-premilary test and baking-cultivating golden flower-aerationagitation. The technology is an improved deep processing technology. The processes of the pile-fermentation and the cultivating golden flower ensure that the appearance of the products is ooiu colour, the interior is brown, and even distributed beneficial organism (namely, golden flower)-eurotium cristatum is clearly saw, the shangse is bright red, the taste is pure and aromatic, and the flower is aromatic, and has the health care functions of promoting sleeping, invigorating stomach and promoting digestion, relaxing bowel, slaking thirst and helping produce saliva, antidiabetics, lowering blood pressure, curing bloated, cuing laxness, etc. The technology fully actives microelements such as vitamins contained in tea, mineral composition, 18 amino acid, protein, glucide, folic acid, catchol which are beneficial to human health and easily absorbed, and the cultivation of golden flower has substantial transformation on tea polyphenols, caffeine, and theophylline that are transferred into elements that are beneficial to human health, all ages, expand market, have high cultural value, provide collection opportunity for black tea lovers.

Owner:湖南省安化县晋丰厚茶行有限公司

Processing process for anhua black raw tea

InactiveCN102972541ASoup color orange redSoup color orange red translucentPre-extraction tea treatmentCooking & bakingBlack tea

The invention relates to a processing process for anhua black raw tea, and in particular relates to the processing process for the anhua black raw tea. The processing process comprises the following steps of: picking fresh leaves, removing water, primarily rubbing, piling, secondarily rubbing, drying, naturally storing and pre-pressing. According to the processing process provided by the invention, the material selecting is particular, and all black tea raw materials adopt the raw materials in the producing area of liudong tea in jiangnan town; in the process of removing water, the firewood is used as fuel, so that air pollution caused by using coal as fuel is avoided and the tea is prevented from absorbing peculiar smell of sulfur dioxide released by coal combustion, and the original flavor of the tea is greatly ensured. The tea can be kept black and oily through the baking of pine firewood, and the tea color is orange red and bright. After being baked, the tea is naturally stored for over one year before being pressed, fermented in an oxidative manner, and primarily processed; no crushing process is needed before the pressing process; as space inside the tea is bigger due to raw tea-leaf pressing, oxygen needed for microbial activities is provided, and so golden flowers can be seen inside the black tea finished product.

Owner:湖南三十九铺茶业有限公司 +1

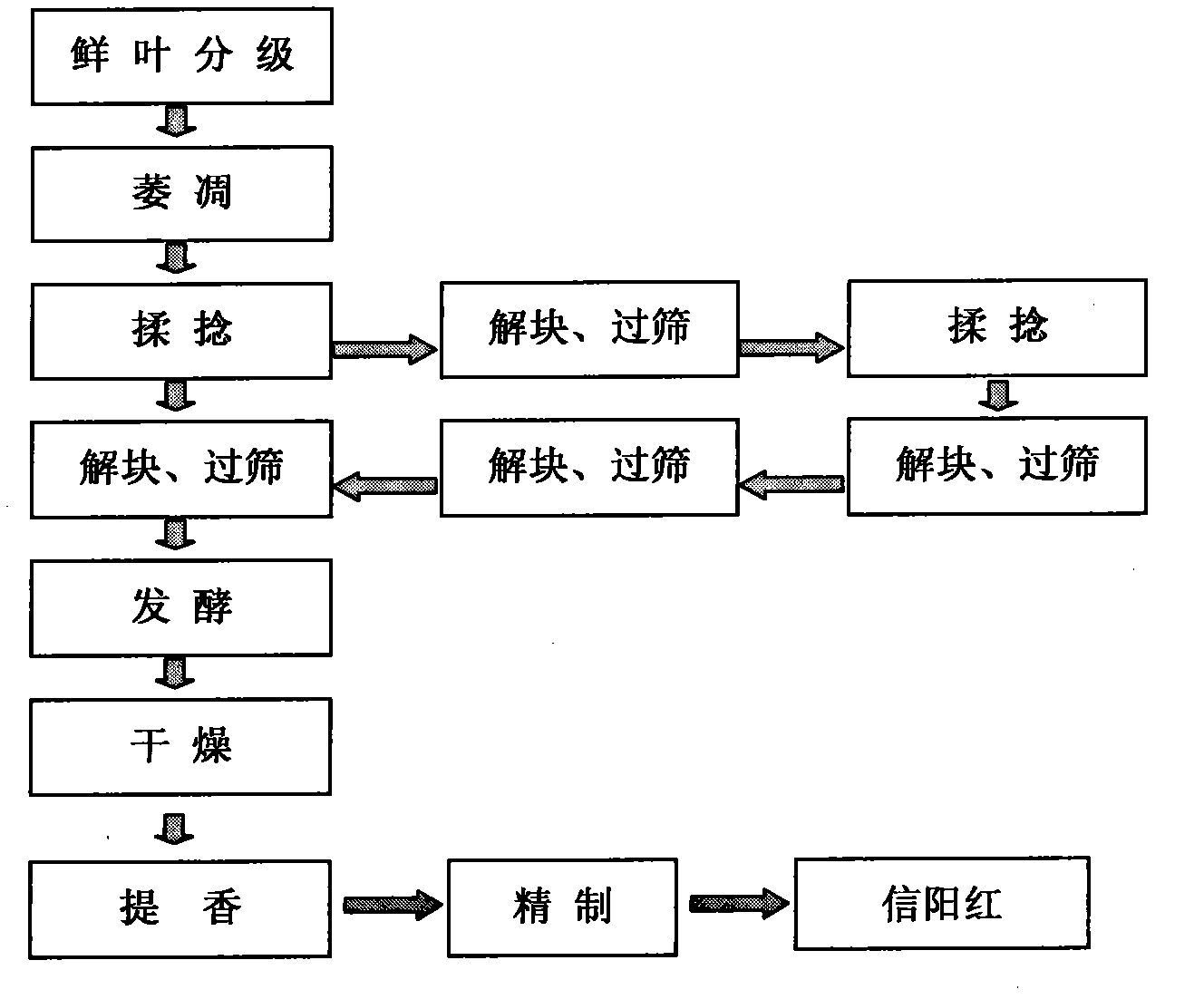

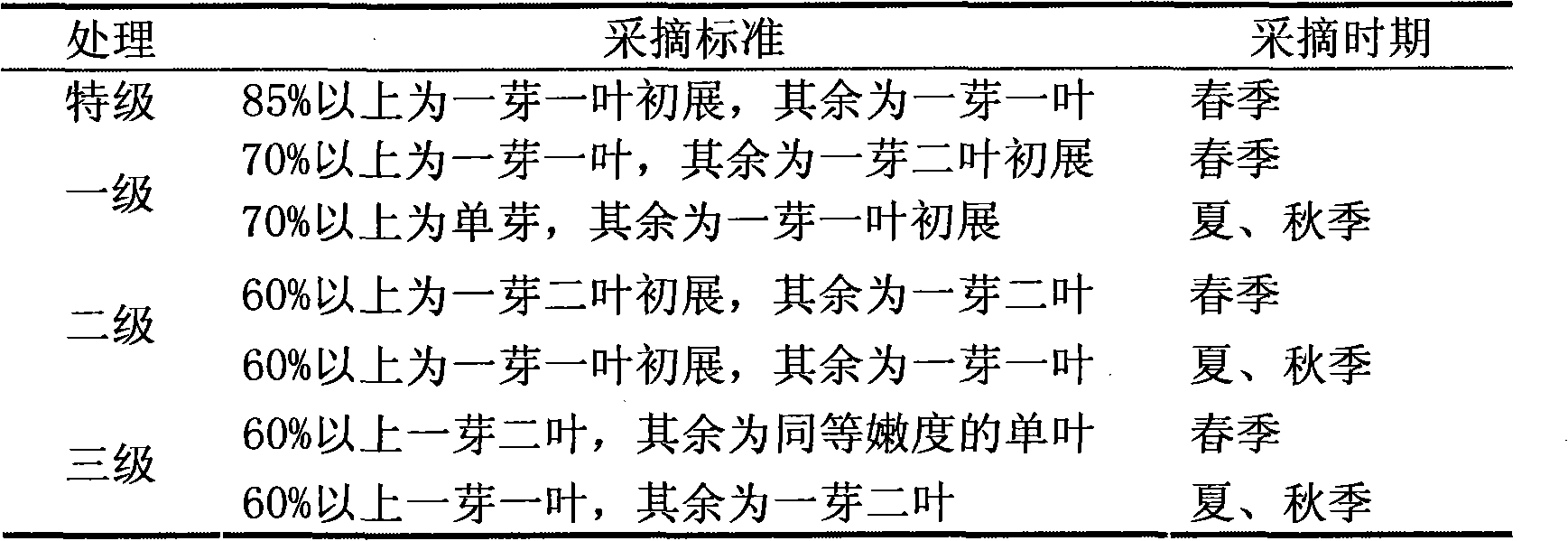

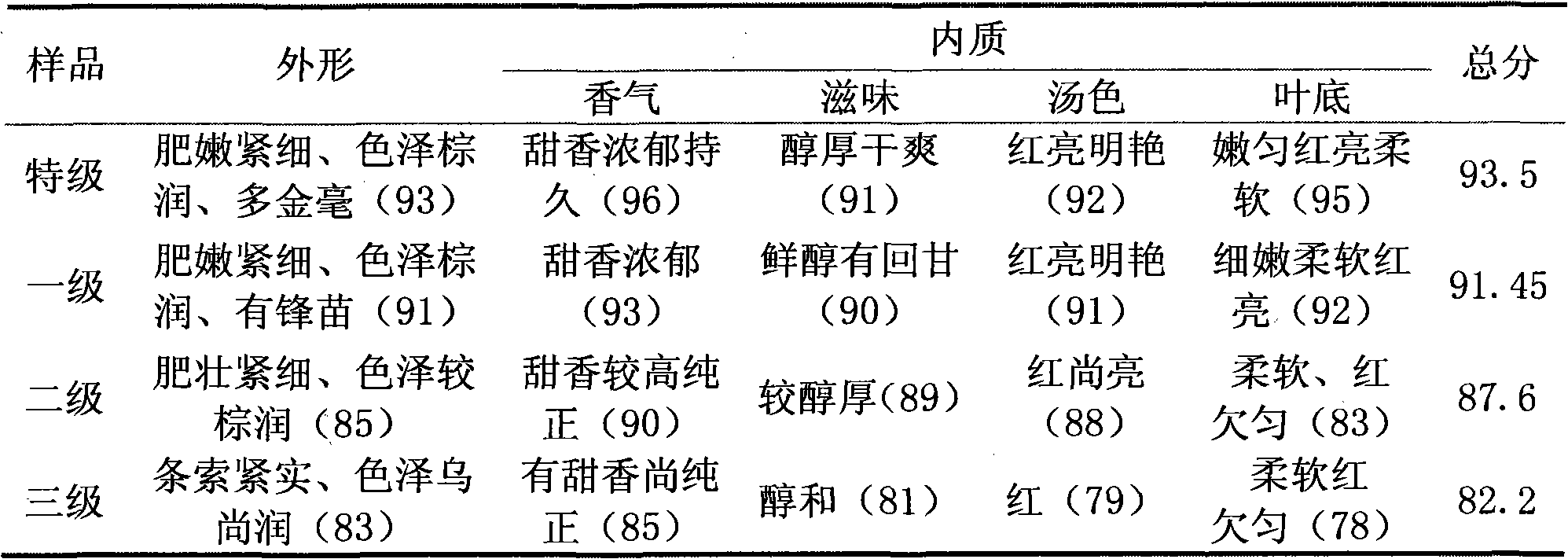

Xinyang red black tea processing technique

The invention relates to a Xingyang red black tea processing technique. The technique comprises the following parameters: wilting temperature: 25-30 DEG C; humidity: 60-70%; wilting time: 6-7 h; twisting machine rotating speed: 55-60 r / min; 2-3 times of twisting, each for 30 min; amount of tea feed: 30-35 kg; unravel machine rotating speed: 35 r / min; sieve pore size: 6#; 2-3 times of unravelling;temperature in a fermentation chamber: 2-7 DEG C; humidity in the fermentation chamber: 96%; tea spread thickness: 10 cm; oxygen supply amount: 5 L / min; fermentation time: 4.5 h; initial drying temperature: 115 DEG C; initial drying time: 20 min; re-drying temperature: 75 DEG C; and re-drying time: 30 min. The processing technique of the invention is unique, and the quality of the made black tea is excellent: the appearance of the product is fat and tender and compact, the peak of the tea is gold and the tea has bright luster; the endoplasm aroma of the tea has rich green flavour; the taste of the tea is mellow and sweet; the tea liquor is brilliantly red; and the root of the tea leaf is soft and green, has many sprouts and a colour of brilliant red.

Owner:信阳市浉河区茶叶办公室

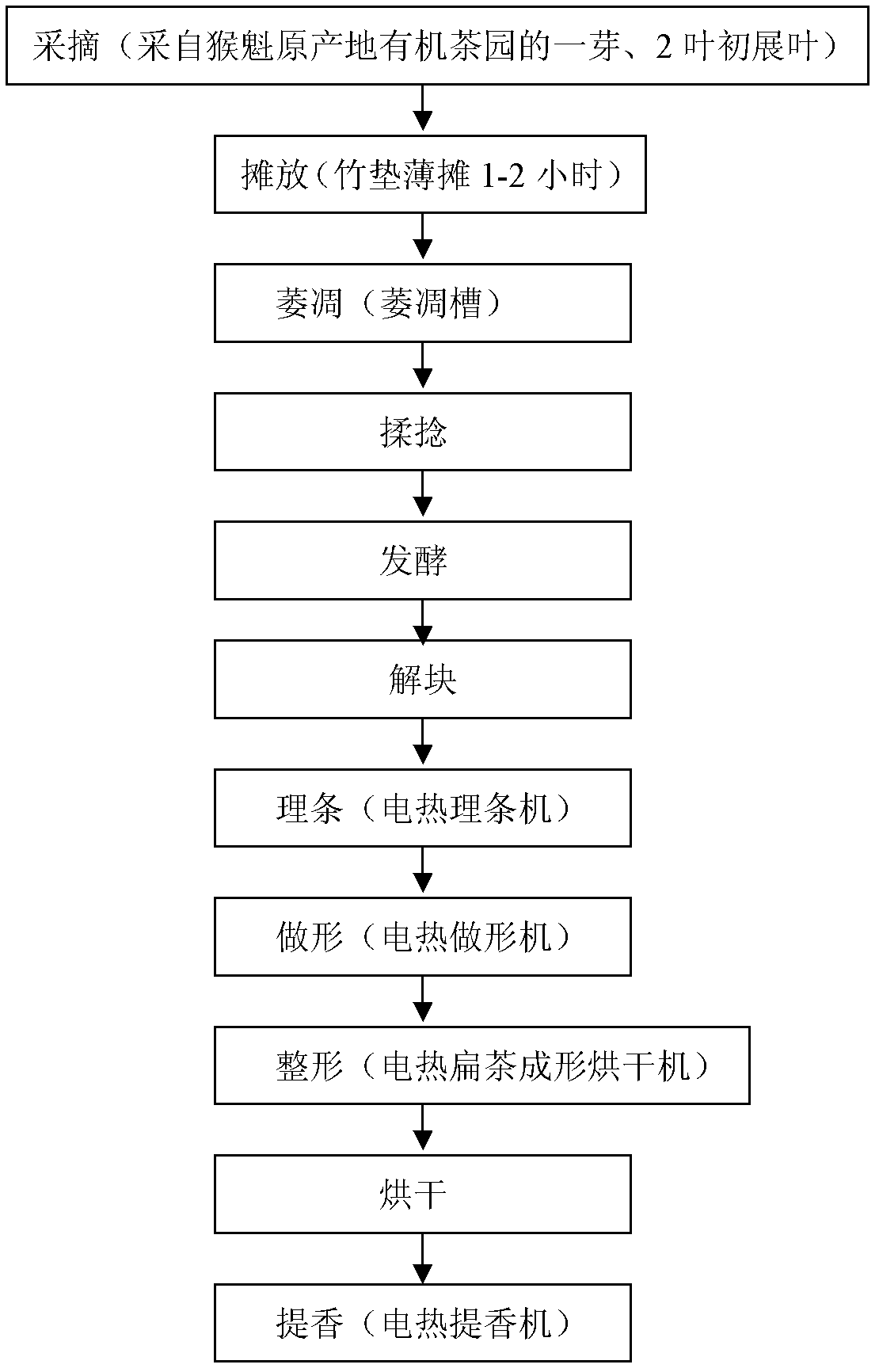

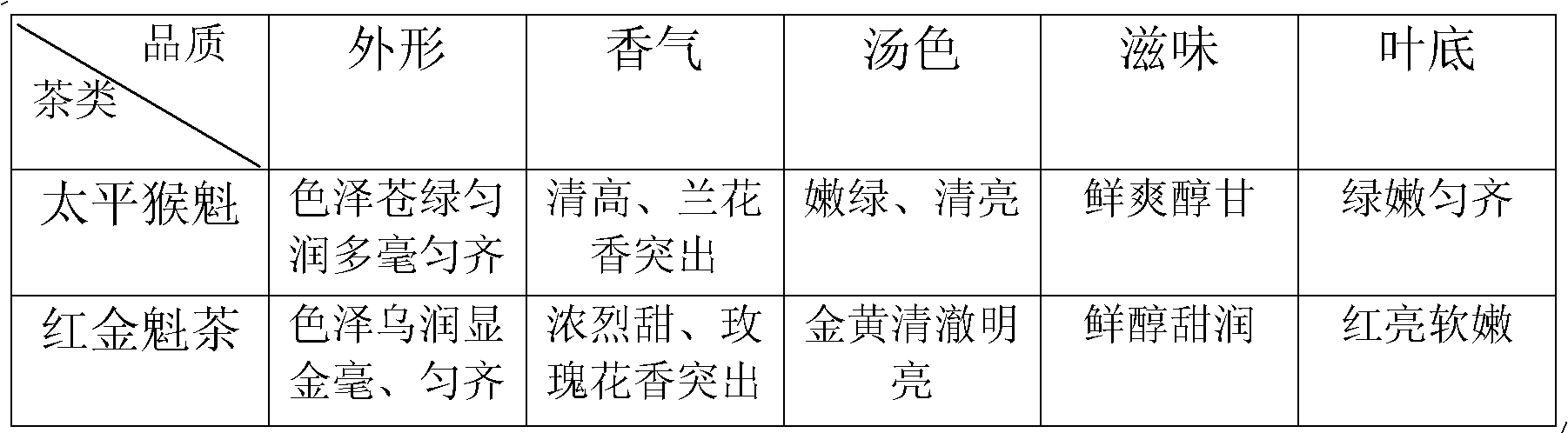

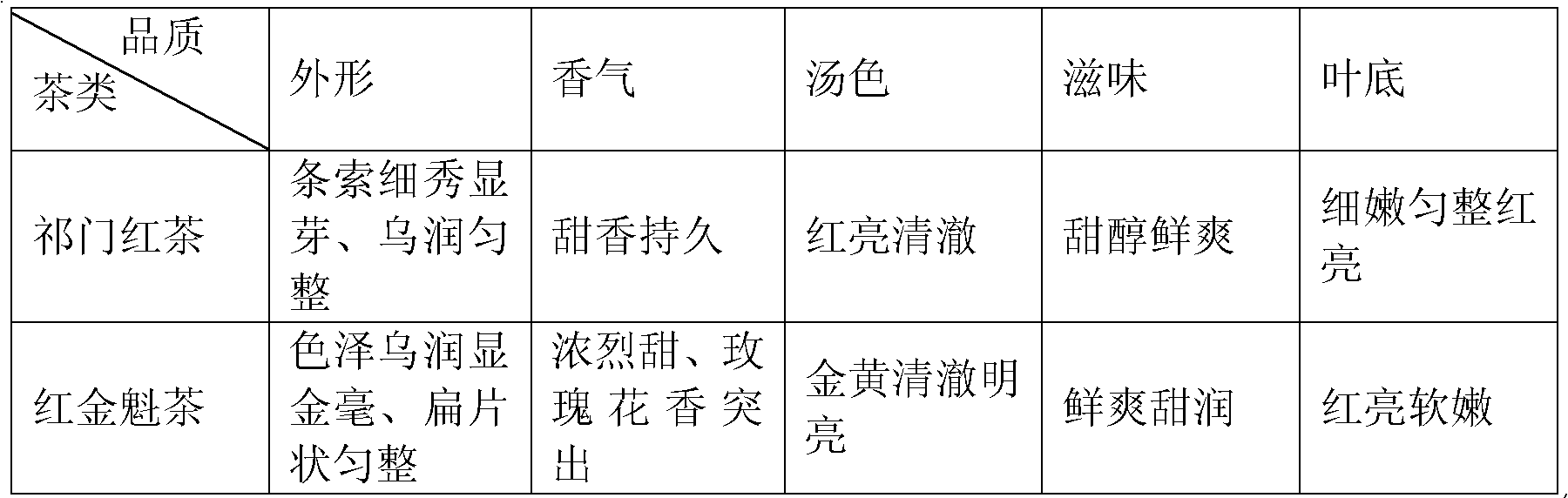

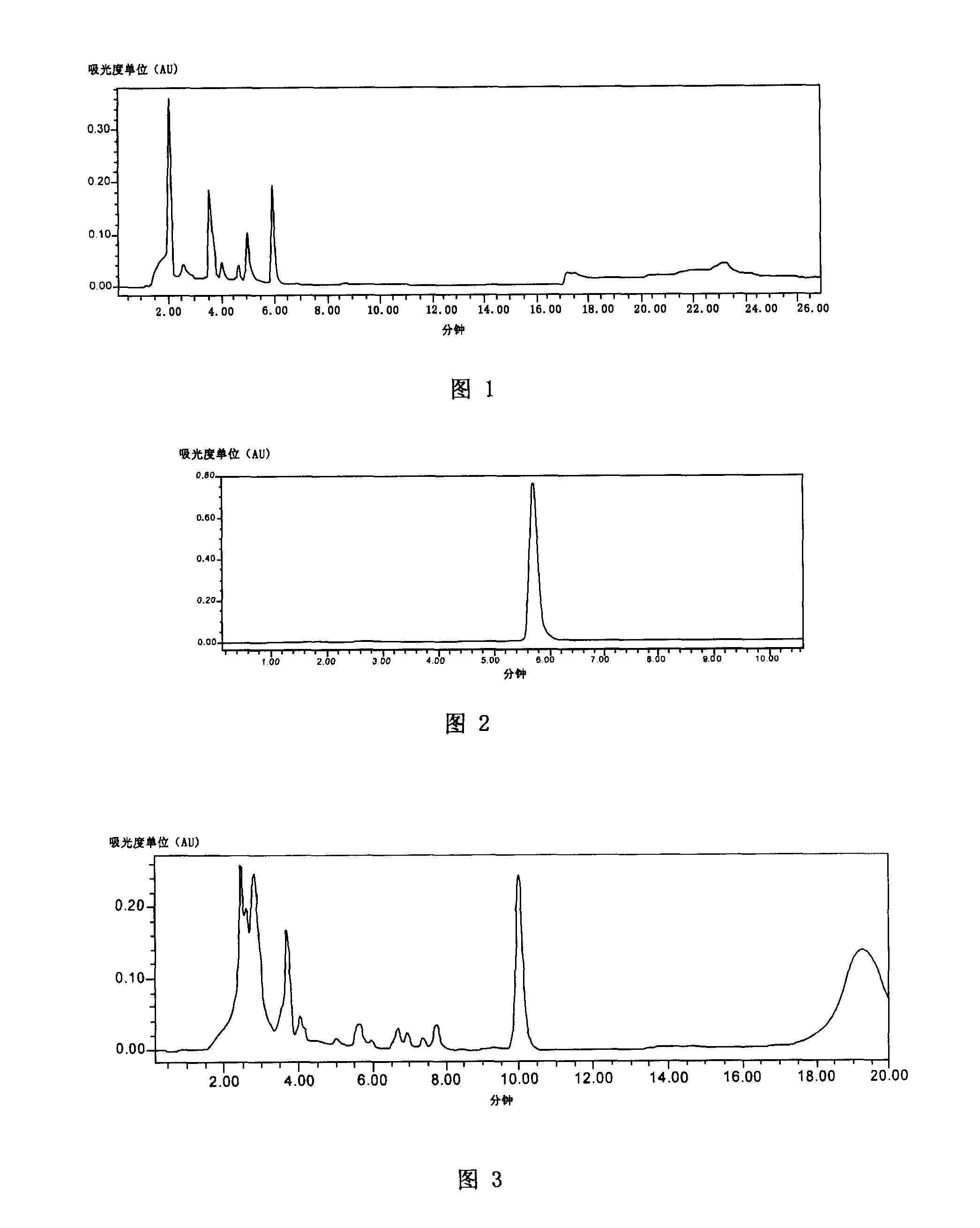

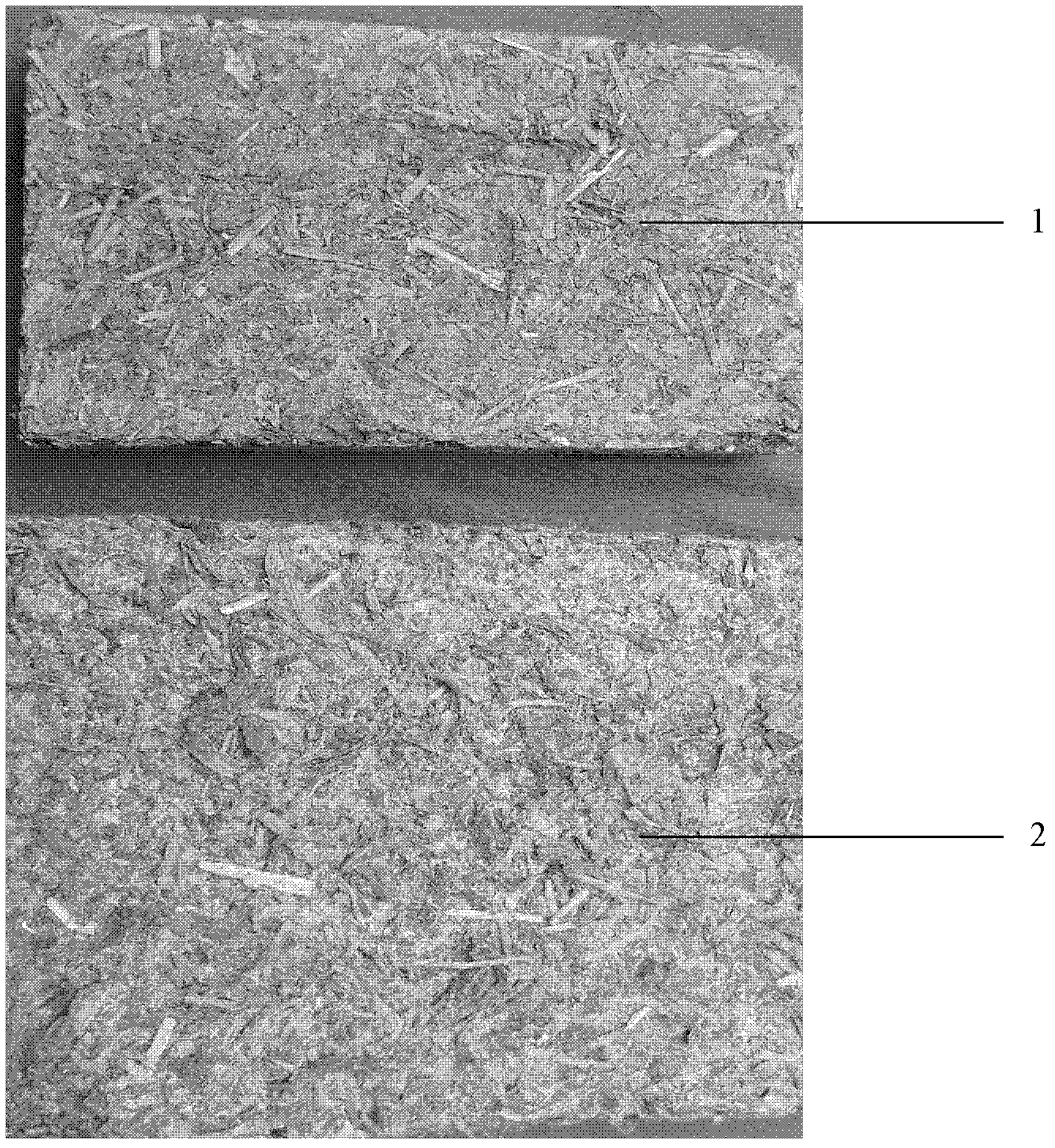

Flat black tea (Black Jinkui) and making process thereof

A making process for a flat black tea includes the following steps: shoots are picked at the beginning of the emergence of a bud and two leaves; the shoots are spread for 1 to 2 hours, the thickness of the spread shoots is 1cm to 2cm, and the shoots are turned for just one time every half an hour; the fresh shoots are put into a withering trough, spread by 1.5cm to 2.0cm and then withered by 36 DEG C to 40 DEG C of hot air for 4 to 6 hours; the withered shoots are first gently rolled for 2 minutes, pressurized for 1 to 2 minutes and loosened for 2 minutes; the shoots are then fermented, the temperature is 40 DEG C to 50 DEG C for spring tea and 35 DEG C to 40 DEG C for summer tea, and the fermentation time is 4 to 5 hours; after being deblocked, the shoots are put into a trough type electric heater and carded, the carding temperature is 130 DEG C to 150 DEG C, and the time is 10 to 15 minutes; after being carded, the shoots are pressed to become flat under 130 DEG C to 150 DEG C, and the time is 10 to 15 minutes; the shoots are then put into a flat tea-shaping dryer and shaped, the shaping temperature is 110 DEG C to 130 DEG C, and the time is 5 to 10 minutes; after shaping, the drying temperature is 90 DEG C to 100 DEG C, and the time is 4 to 5 minutes; finally, the shoots are put into an aroma-increasing machine to increase aroma, the aroma-increasing temperature is 90 DEG Cto 110 DEG C, and the aroma-increasing time is 5 to 10 minutes. The invention solves the problem on how to cleanly, mechanically and continuously produce black flat Houkui tea.

Owner:黄山毛峰茶业集团有限公司

Hubei Chinese flowering crabapple tea and preparation method and application of extractive thereof

ActiveCN101199301ATake advantage ofPre-extraction tea treatmentMetabolism disorderAntioxidantChinese flowering crabapple

The invention discloses a preparation method and the application of Hubei crabapple tea and the extract, which comprises the preparation method of Hubei crabapple black tea, green tea, brick tea, concentrated slices and pigment as well as the processing method of bottled Hubei crabapple beverage and the application of the Hubei crabapple tea in blood sugar and blood fat lowering drugs. The invention gets a plurality of Hubei crabapple products and fully utilizes the characteristics of the Hubei crabapple of itself, so the invention is also well applied in the blood sugar and blood fat lowering drugs as well as in antioxidant.

Owner:YICHANG HUMANWELL PHARMA +1

Technology for mechanical and clean processing of black tea in different shapes

InactiveCN1792200ARich shapeIncrease color varietiesPre-extraction tea treatmentBlack teaEngineering

A technology for mechanically preparing to black tea with different shapes including needle shape, spiral shape, flat shape and particles is disclosed.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

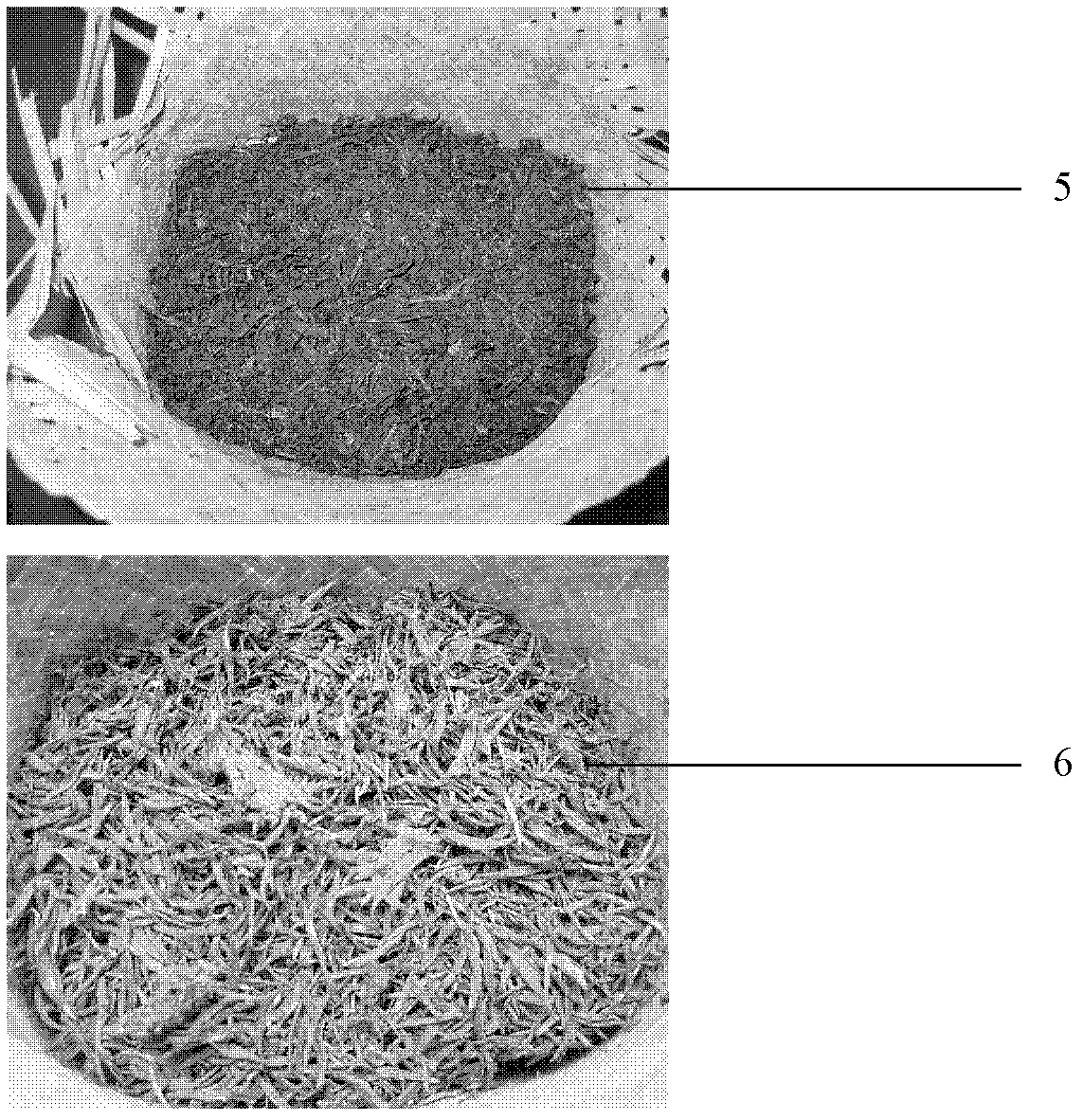

Fungus growing process for black tea

InactiveCN102524442APromote growthDoes not cause mildew problemsPre-extraction tea treatmentSporeBrick

The invention mainly relates to a processing method for fungus growing of the black tea. The method comprises the following steps: the black tea raw material is pile-fermented, steamed, and sprayed with spore powder of eurotium cristatum; the tea leaves are formed by pressing, and sealed and disinfected at high temperature; and the tea leaves are cooled, and after a period of time of fungus growing, the tea leaves are fixed and dried. The method has the advantages that the fermentation time can be shortened; thalluses inside and outside the brick tea can grow uniformly and luxuriantly; the color of the golden flower can retain for a long time; and the golden flower can also stay all the time.

Owner:安化道然茶业有限公司

Processing technology of congou black tea

The invention relates to a processing method of a tea, in particular to a manufacturing method of a congou black tea. A bud with a leaf or a bud with two leaves serves as a raw material and undergoes selection, leaf cooling, withering, leaf rotation, rolling, fermentation, drying, stalk sorting, packing and the like so that the congou black tea is manufactured. The congou black tea is compact, even and orderly in appearance, liquid color is orange red and bright, the flowery fragrance is durable, the taste is strong and sweet, and the congou black tea is a boutique in black teas. The congou black tea is simple in manufacturing method and low in production cost, has the effects of clearing heat, quenching thirst, moistening spleen and being tasty, also has the effects of tasting and sight enjoying, has good color, fragrance and taste, is good for physical and mental health, meets the physical and mental requirements of consumers and enhances the tea culture of China.

Owner:宁德市茶产业研究开发中心

Instant pu'er tea and its preparation method

The invention discloses a rapid-soluble Pu'er tea and preparing method to accelerate body to release energy, which comprises the following steps: blending Pu'er tea and ripe tea ( or black tea and green tea) according to certain proportion; grinding roughly; extracting through water; condensing; drying; adding beta-cyclodextrin; recycling aged perfume benzine ingredient through steam distilling method or super-critical extracting method; packing the benzine and rapid-soluble tea powder together; adding isomaltose hypgather, degrading factor and flavoring factor.

Owner:YUNNAN LONGRUN TEA TECH

Method for preparing black tea fungus juice beverage by using fermentation method

InactiveCN101843346ACompliance with securityGood Flavor Taste ColorFood preparationNutritive valuesFruit juice

The invention belongs to the field of light industrial food and relates to a method for preparing a black tea fungus juice beverage by using a fermentation method. The method is characterized in that the black tea fungus juice comprises the following raw materials: 100-300ml of black tea fungus mother liquor, 3-10g of tea leaf, 1,000ml of water, 15-50g of sugar and 100-200ml of fruit juice. The method comprises the following steps of: dissolving the sugar in tea water to prepare sweet tea water; then adding the fruit juice and the black tea fungus juice; and fermenting according to two different fermentation stages of early ventilating, stirring and fermenting and later standing and fermenting. The method overcomes the defects of a traditional domestic workshop type natural and single fermentation mode and the defects of unstable quality, no output guarantee, poor product taste, and the like, improves the product nutritional value, the taste and the flavor and the product quality and provides a technological base for the industrial development and the scale production of black tea funguses and the comprehensive utilization of tea resources.

Owner:FUJIAN NORMAL UNIV

Artificial inoculation production method of camellia nitidissima

ActiveCN101579024ASolve the defects of hair flower qualityRealize manual inoculationPre-extraction tea treatmentFood preparationCamellia chrysanthaBlack tea

The invention provides an artificial inoculation production method, which relates to an artificial inoculation method of Jinhua fungus of tea and a processing method of camellia nitidissima. The invention is characterized in that the artificial inoculation production method comprises the following steps of preparation of Jinhua fungus culture solution, preparation of inculating tea, artificial inoculation of Jinhua fungus, culture of Jinhua fungus, drying of products and the like. The invention has high flowering rate of the tea, uniform flowering, coarse grain of eurotium cristatum and golden color, can bring the flowering stage forward by about 3 days, can obviously improve the quality and production efficiency of the camellia nitidissima, is applicable to flowering of all teas (compressed tea and loose tea) and provides reliable guarantee for improving flowering quality of black tea.

Owner:湖南省安化县晋丰厚茶行有限公司

Process for processing black tea of golden camellia

InactiveCN102987034ASignificant comprehensive benefitsFully fermentedTea substituesMicrowaveBlack tea

The invention relates to a process for processing black tea of golden camellia. The processing process comprises the steps of (1) picking, wherein fresh leaves of the golden camellia, which just change from purple to green, are picked; (2) sunning, wherein the water loss of fresh leaves reach 3-8% through sunning treatment; (3) shaking and rocking, wherein leaves are subjected to shaking treatment in an air-conditioning room, and rocking is conducted twice to five times; (4) withering, wherein tea leaves are cut into sections and withered, and the water content in tea leaves after withering is within a range of 55%-65%; (5) rolling, wherein the rolling procedure comprises vacuum rolling, slight pressing, compressing, loosening and deblocking; (6) fermenting, wherein fermentation is conducted for 8-10 hours at a temperature within a range of 24-25 DEG C; (7) removing water, wherein microwave water-removing is conducted for 2-7min at a temperature within a range of 100-110 DEG C; and (8) drying, wherein drying is conducted in a perfuming machine to obtain the black tea of the golden camellia. According to the process for processing the black tea of the golden camellia, the black tea of the golden camellia has the fragrance of flowers, the fragrance is evident, the liquor color is red, the taste is mellow, fresh and sweet, and the quality is unique.

Owner:GUANGXI FUXIN SCI & TECH

Production process for red tea

ActiveCN103404618APromotes enzymatic oxidationThe taste is mellow and refreshingPre-extraction tea treatmentBlack teaFood flavor

The invention discloses a production process for red tea. The production process comprises the following steps of: (1) fresh leaf withering; (2) freezing; (3) thawing; (4) rolling; (5) fermenting; (6) drying. According to the production process for the red tea, the withering process normally only needs 1-2 hours, and the rolling process needs 15-30 minutes; by carrying out the thawing process, the cell membrane permeability can be increased, the enzymatic oxidation of polyphenol materials can be accelerated, and the withering time and the rolling time are greatly shortened by at least 6 hours than a traditional method, so that the production efficiency is improved; the red tea produced by utilizing the production process has the advantages that the flavor is mellow and tasty, the liquor color and leaves are red and bright, and the quality is high.

Owner:JURONG RONGBEI TEA CULTURE CO LTD

Cold-resisting ginger jujube tea and preparation method thereof

The present invention relates to a cold-resisting ginger jujube tea for building up body and its preparation method. It is made up by using fresh ginger, jujube, black tea, honey and white sugar as raw material through the processes of decoction, filtration, concentration and drying.

Owner:HUBEI DUANYAO PHARMA

Method for preparing Hongluochun tea

InactiveCN101731377ATight shapeImprove the technical problems that cannot be vacuum packedPre-extraction tea treatmentVacuum packBlack tea

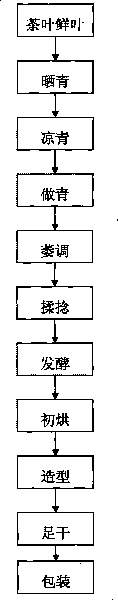

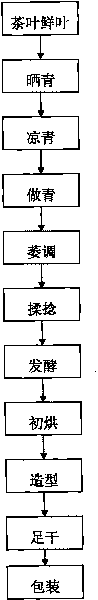

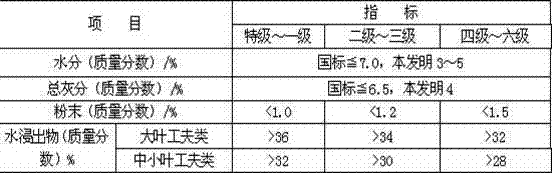

The invention discloses a method for preparing Hongluochun tea. Fresh leaves of black tea varieties or oolong varieties are taken as raw materials, and are subjected to green drying, green curing, fixing, withering, kneading, fermenting, primary drying, modeling and sufficient drying to prepare the required Hongluochun tea. The preparation process combines processing technology for black tea, green tea and oolong, so that the prepared Hongluochun tea has the characteristics of having the liquor color of the black tea, appearance of the green tea, flower fragrance of the oolong and the like. The spiral form of the Hongluochun tea solves the technical problem that the conventional strip black tea cannot be vacuum-packed so as to effectively solve the problems of fresh keeping and quality keeping of the black tea; and the Hongluochun tea fills up a blank that flower fragrance black tea does not exist in the market. The fresh leaves of black tea varieties or oolong varieties are taken as raw materials and are prepared into the flower fragrance Hongluochun tea by optimizing the processing technology. The fresh leaves in summer time are processed into the Hongluochun tea, so a problem that summer tea is thick bitter can be effectively solved, the quality of the summer tea can be improved, and the economic benefit of the summer tea can be increased.

Owner:TEA RES INST GUANGDONG ACAD OF AGRI SCI

Method for prepn. beverage contg. black tea

InactiveCN1947533ATea pigment (high in theaflavinThearubigin) high contentPre-extraction tea treatmentTea extractionBlack teaGreen tea

A process for preparing the brown tea beverage from dried green tea includes such steps as high-temp extracting in water to obtain liquid tea extract, cooling, loading it in reactor or fermentor, adding fresh tea leaf's juice, filling O2 or air, stirring while reactive fermenting until its color can meet the requirement, filtering, removing impurities, membrane filtering, proportionally mixing it with auxiliaries, stirring, and loading in cans. It can also be further processed to obtain concentrated brown tea or instant powder.

Owner:海南群力药业有限公司

Foam-holding agent and utilization thereof

InactiveUS20060051483A1Dense and smooth-textured foamFood ingredient as foaming agentFood shapingCoix lacrymaBlack tea

The present invention provides a foam-holding agent which has a sufficient foam-holding property and is satisfactory with regard to safety, taste, aroma and other properties required for foods, as well as providing effervescent drinks or forming beverage comprising the foam-holding agent. More specifically, the present invention is directed to a foam-holding agent for effervescent drinks or forming beverage, which comprises a tea leaf extract obtained by preparing tea in a standard manner from leaves of black tea, green tea, oolong tea, Gynostemma pentaphyllum tea, Mate tea, Pu-erh tea, barley tea, Coix lacryma-jobi var. ma-yuen tea, brown rice tea, Houttuynia cordata tea or other tea leaves, and then extracting catechin-rich components using a solvent such as water and / or ethanol. The present invention is also directed to effervescent drinks or forming beverage characterized by comprising the above foam-holding agent, which have excellent foam-producing and foam-holding properties and also provide dense and smooth-textured foam.

Owner:SUNTORY HLDG LTD

High-aroma black tea preparation method

ActiveCN102919406AQuality improvementLong lasting aromaPre-extraction tea treatmentBlack teaFermentation

The invention relates to a high-aroma black tea preparation method which can solve the problems that the current black tea is insufficient in essence aroma, short in storage time, poor in color, and unsatisfactory in taste, and the drink effect is affected. The preparation method comprises the following steps: withering picked fresh tea leaves to an extent that the tissues of the fresh tea leaves with 70-80 percent of moisture content are in a brittle and hard state, and allowing the aroma to be sent forth; kneading withered and aroma-lost tea leaves to tight and straight strips, and reducing size to achieve attractive appearance; utilizing oxygen supply fermentation equipment to realize ventilation and oxygen supply of the kneaded leaves, wherein the leaf color is subjected to the changes of dark green, yellowish green, yellow, reddish yellow, yellowish red, red and marroon in sequence, and the aroma is subjected to the changes of no aroma, faint scent and flowery flavour; and drying two times, wherein the second drying is carried out after the leaves are subjected to the first drying and cooling, and separated bagging and metering are carried out when the leaves are hot. The method is unique, advanced and scientific and is easy to operate; the black tea is good in quality, black and glossy in strip shape, and is slightly golden; the aroma is lasting and similar to the aromas of Narcissus and rose; the liquor color is red bright; the taste is sweet; the leaf tea is bright and red in color; and the black tea is delicious.

Owner:刘文新

Red tea processing method

ActiveCN102630769APromote oxidationPromote transformation formationPre-extraction tea treatmentFlavorBlack tea

The invention discloses a red tea processing method, which comprises the following steps of: withering: placing fresh tealeaves into a blowing-type withering groove to be withered; green rolling: guiding withered tealeaves into a green rolling machine to be rolled until the tealeaves turn from green to dark, the edge of each tealeaf turns red, the tealeaves are moisturized when being touched by hand, the greenness disappears and the floral fragrance spreads; kneading: guiding the green-rolled fresh tealeaves into a kneading machine to be kneaded; fermenting: filling the kneaded tealeaves after be de-blocked into a fermenting disc or a clean bamboo basket, and stopping the fermentation until floral and fruity flavor radiates; primary drying: pouring the fermented tealeaves into a single-layer drying machine to be primarily dried; re-kneading: guiding hot tealeaves into the kneading machine to be re-kneaded; re-drying: guiding the re-kneaded tealeaves after being de-blocked into the drying machine to be re-dried; sufficient drying: placing the tealeaves into a tea fragrance enhancer to be slowly dried at a low temperature; spreading for cooling: placing the dried tealeaves into a bamboo disc to be spread and cooled to the normal temperature; and screening: screening the cooled tealeaves to remove broken pieces.

Owner:桂东县玲珑王茶叶开发有限公司

Snow pear, banana and corn jam and preparation method thereof

The invention discloses a snow pear, banana and corn jam which is prepared from the following raw materials by weight parts: 198-215 parts of the snow pear, 66-75 parts of the banana, 55-64 parts of the corn powder, 13-16 parts of peach blossoms, 6-9 parts of Radix Ranunculi Ternati, 4-6 parts of Codonopsis Lanceolata, 5-7 parts of Cornus officinalis, 6-8 parts of pseudo-ginseng, 3-4 parts of pawpaw kernels, 4-5 parts of Epimedium davidii franch, 55-58 parts of white sugar, 26-32 parts of chocolate powder, 3-6 parts of black tea powder, 12-15 parts of sesame oil, 28-33 parts of jujube flower honey, and a proper amount of purified water. The jam provided by the invention, during preparation, is added with the corn powder with healthcare effects; the Cornus officinalis which can tonify the liver and kidney, induce astringency, control nocturnal emission and reduce urination, and help produce saliva and slake thirst; the Radix Ranunculi Ternati which can reduce phlegm and resolving masses and reduce swelling and detoxify; the Codonopsis Lanceolata which can enrich the blood, promote lactation, clear away heat and toxic materials, reduce swelling and eliminate pus; the pawpaw kernels which can remove evil and relieve restlessness; the pseudo-ginseng which can clear away the liver-fire and dispell stagnation; and, Epimedium davidii franch which can tonify the kidney and yang, dry damp and dispell pathogenic wind. The jam provided by the invention is bright in color, sour and sweet, fine and soft in mouthfeel, unique in fruit and corn fragrance, high in nutrition and health value, and thus is wide in market prospect.

Owner:BENGBU JINWANG FOOD

Collateral-dredging antihyperlipidemic product containing dark tea active substance and preparing method thereof

InactiveCN101229279ABalance metabolismPromote excretionMetabolism disorderPill deliveryBlack teaSugar

The invention provides a collateral-dredging lipid reduction product comprising active materials of black tea and a preparation method; the product consists of extracts of Anhua Red Tea and drug-food homologous substances; the preparation method of the invention produces a special and brand-new preparation method resulting from the formula specialty; the invention has the comprehensive functions of collateral dredging, lipid reduction, sugar reduction, decompression and weight reduction.

Owner:贺志弘

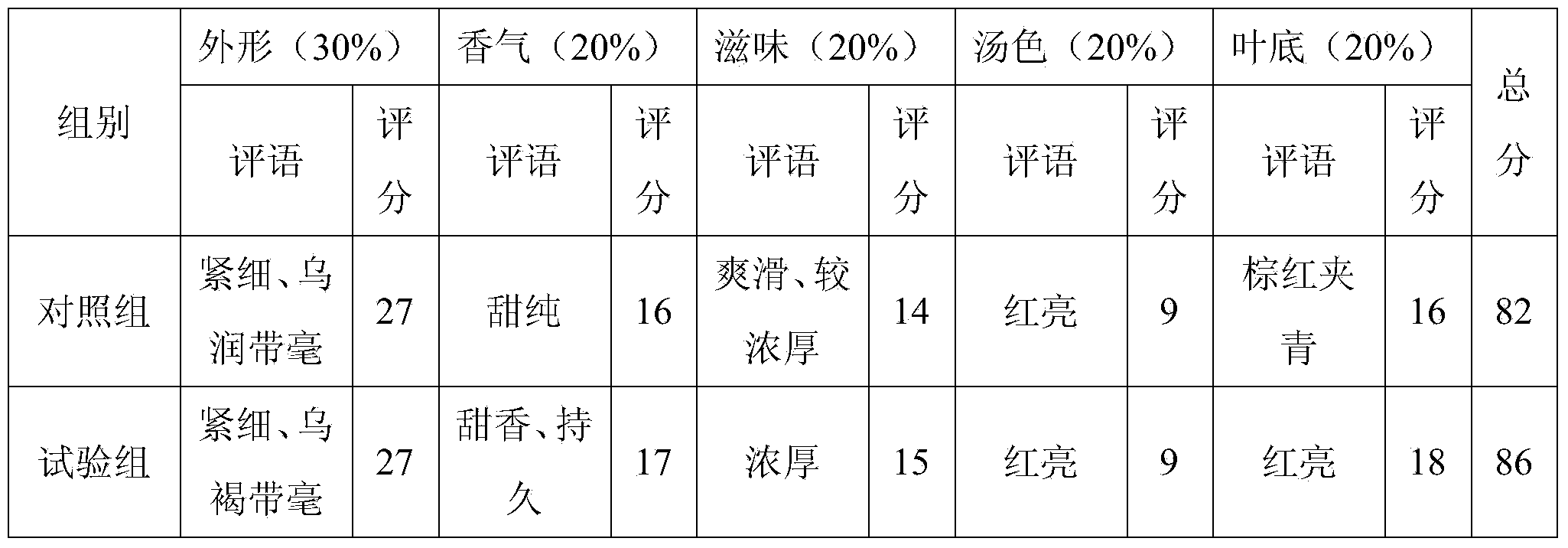

Huangguanyin black tea processing technology

InactiveCN103392849AGolden colorSimple processing technologyPre-extraction tea treatmentGeraniolPhenethyl alcohol

The invention discloses a Huangguanyin black tea processing technology. The Huangguanyin black tea processing technology utilizes Huangguanyin which is a Tieguanyin-Huangjingui hybrid as a raw material. The Huangguanyin black tea has effects of generating body fluid and clearing heat, inducing dieresis, diminishing inflammation and killing bacteria, removing toxins, and nourishing stomach. The Huangguanyin black tea processing technology improves the existing processing technology, reduces volatilization of aromatic alcohol, geraniol, benzyl alcohol, alpha-phenethyl alcohol, cis-3-vinyl ester and methyl salicylate, and reduces harmful substances such as trans-2-hexenal. Through the Huangguanyin black tea processing technology, the Huangguanyin black tea has a good fragrance, a mellow taste and a golden color.

Owner:贵州省湄潭县黔茗茶业有限责任公司

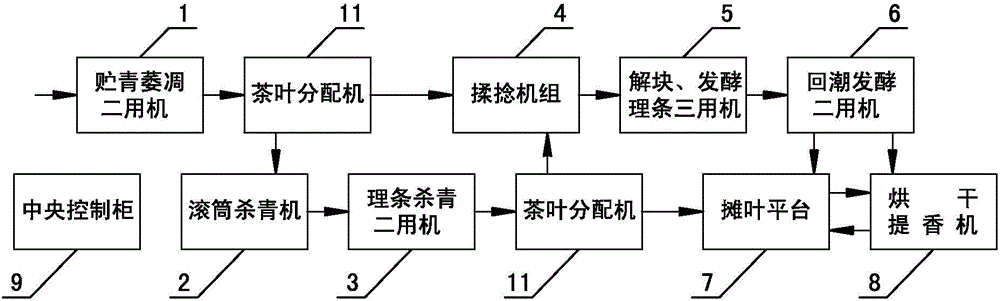

Continuous production line based on processing of black tea, green tea, yellow tea and white tea, and method thereof

ActiveCN104814170AReduce equipmentImprove versatilityPre-extraction tea treatmentCooking & bakingProduction line

The present invention discloses a continuous production line based on the processing of black tea, green tea, yellow tea and white tea and a method thereof. The continuous production line includes tea leaf frying devices, tea leaf transporting devices connected between the tea leaf frying devices, a green leaf storage and withering double function machine connected with a rotary drum enzyme deactivating machine and a tea leaf rolling assembling unit through a tea leaf dispenser, a carding and enzyme deactivating double function machine connected with the rotary drum enzyme deactivating machine and connected with the tea leaf rolling assembling unit and a tea leaf spreading platform through the tea leaf dispenser, a deblocking, fermenting and carding triple function machine connected with the tea leaf rolling assembling unit, a moisture regaining and fermenting double function machine connected to the deblocking, fermenting and carding triple function machine, and connected with the tea leaf spreading platform and a baking and fragrance improving machine. The continuous production line effectively solves the problem that the current tea leaf production line and tea leaf processing technology can only process a single tea variety, but cannot meet the requirement of tea leaf processing of many varieties of tea leaves of tea farmers, has high device versatility and good product quality, and is of high practical value.

Owner:浙江丰凯机械股份有限公司

Processing technique of Qihong Huang tea

ActiveCN101455247AFully fermentedPromote the degradation of substancesPre-extraction tea treatmentBlack teaEngineering

The invention discloses a processing technique of novel Qimen black tea, including: picking process, sorting process, sorting and cooling process, indoor wilt processes, manual kneading and twisting process, fermentation process, fermentation cooling process, primary drying process, primary frying cooling process, baking adjusting process, adjusting cooling process, frying drying process, drying cooling process, color selection process, and packaging process. Compared with the prior technology, the invention reserves the integral tea leaves that the other black teas do not have and overcomes the problem that the traditional process Qimen black tea taste bitter; resolves the problem of black color and luster, boring, not fresh, fine problem of the black tea in traditional mechanism process; overcomes the stifling perfume and low perfume of the prior black tea through a perfume improving process, improves the appearance evenness after classification about 50% and improving the classification accuracy by a color selecting process; the invention does not contain chopping, screen shaking, air classification, stalk-sorting, and stacking processes, holds the integral appearance of tea leaves and has some ornamental.

Owner:安徽省祁门红茶发展有限公司

Lotus Fuzhuan brick tea and preparation method thereof

The invention relates to lotus Fuzhuan brick tea and a preparation method thereof, in particular to a polymorphic and novel black tea preparation method by optimally combining genuine big leaf tea raw materials in Anhua (China) with medicinal and edible plants. The lotus Fuzhuan brick tea has the characteristics of black tea raw materials in local Anhua, ensures that the original ecological attributes of black tea products, has the obviously functions of nourishing yin to replenish the kidney, generating liquid to moisten dryness, nourishing yin to enrich fluid, regulating immune system, and has the obvious effects of tonifying the spleen to dispel wetness, smoothing qi for digesting and reducing blood lipid.

Owner:贺志弘 +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com