Xinyang red black tea processing technique

A processing technology, black tea technology, applied in the field of Xinyang black tea processing technology, can solve problems such as difficulty in adapting to the high-quality requirements of black tea, and achieve the effect of tight rope, uniform rolling and uniform fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Xinyang black tea processing technology creation test

[0032] Experimental materials: fresh leaves from Xinyang Group, collected from Shifan Village, Dongjiahe Town, Shihe District, Xinyang.

[0033] Experimental equipment: withering frame, bamboo sieve, 6CRL-65 rolling machine, 6CJ-50 tea deblocking machine, fermentation frame, 30m 2 Fermentation room, 6CH automatic continuous dryer.

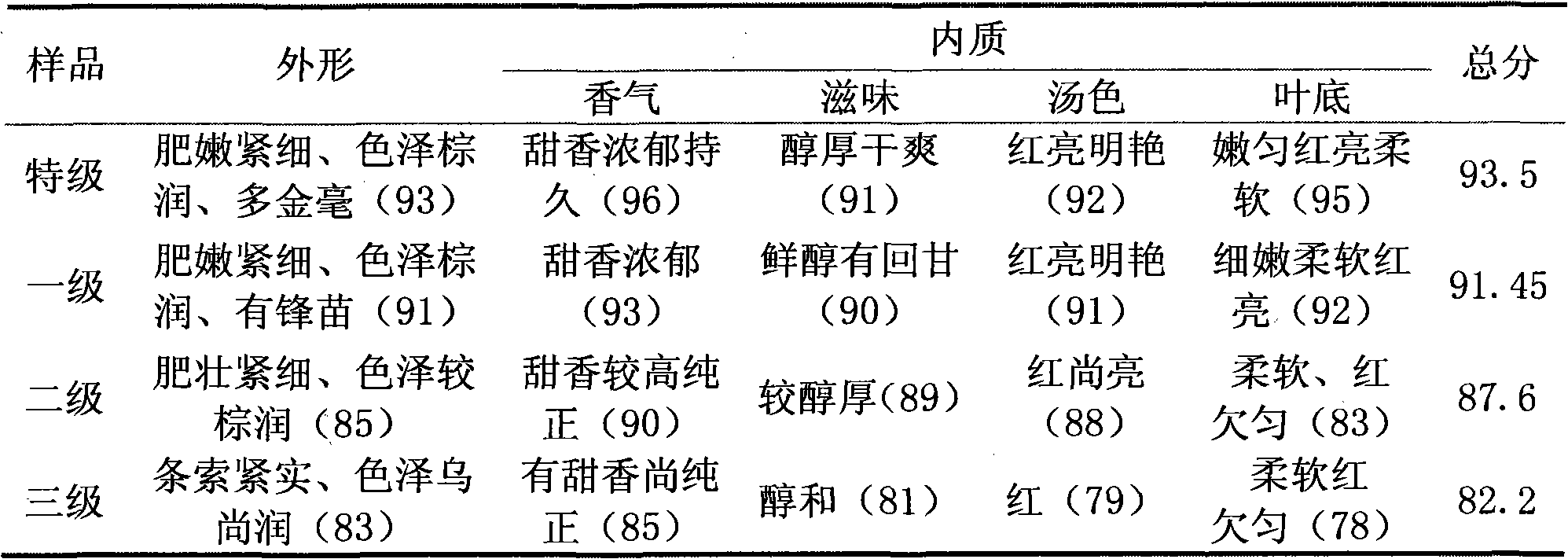

[0034] The tea quality evaluation adopts the sensory evaluation method: the password evaluation is adopted, and the 5-min brewing method is adopted. The quality score of the raw tea in the sensory evaluation is calculated by the weighted average method, and the comprehensive score is calculated according to the following formula:

[0035] Comprehensive score=appearance×25%+taste×30%+aroma×25%+soup color×10%+leaf bottom×10%.

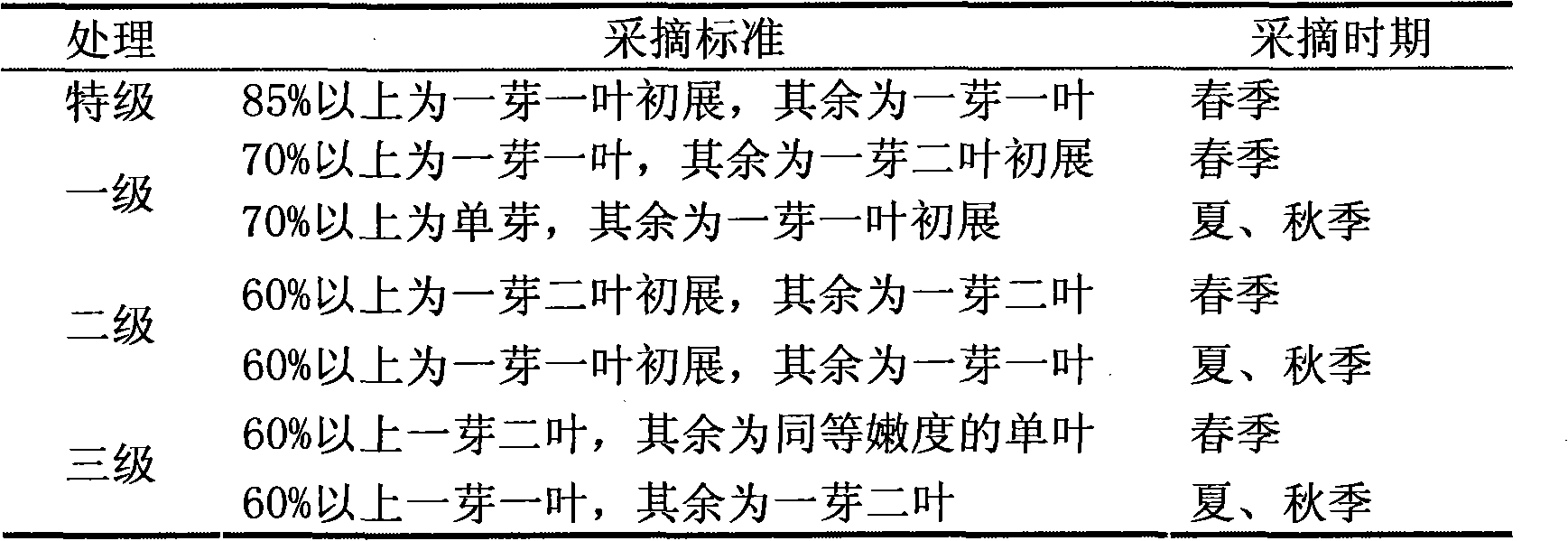

[0036] (1) Effects of different picking standards on the sensory quality of Xinyang black tea

[0037] The fresh leaves were picked in spring, summer...

Embodiment 2

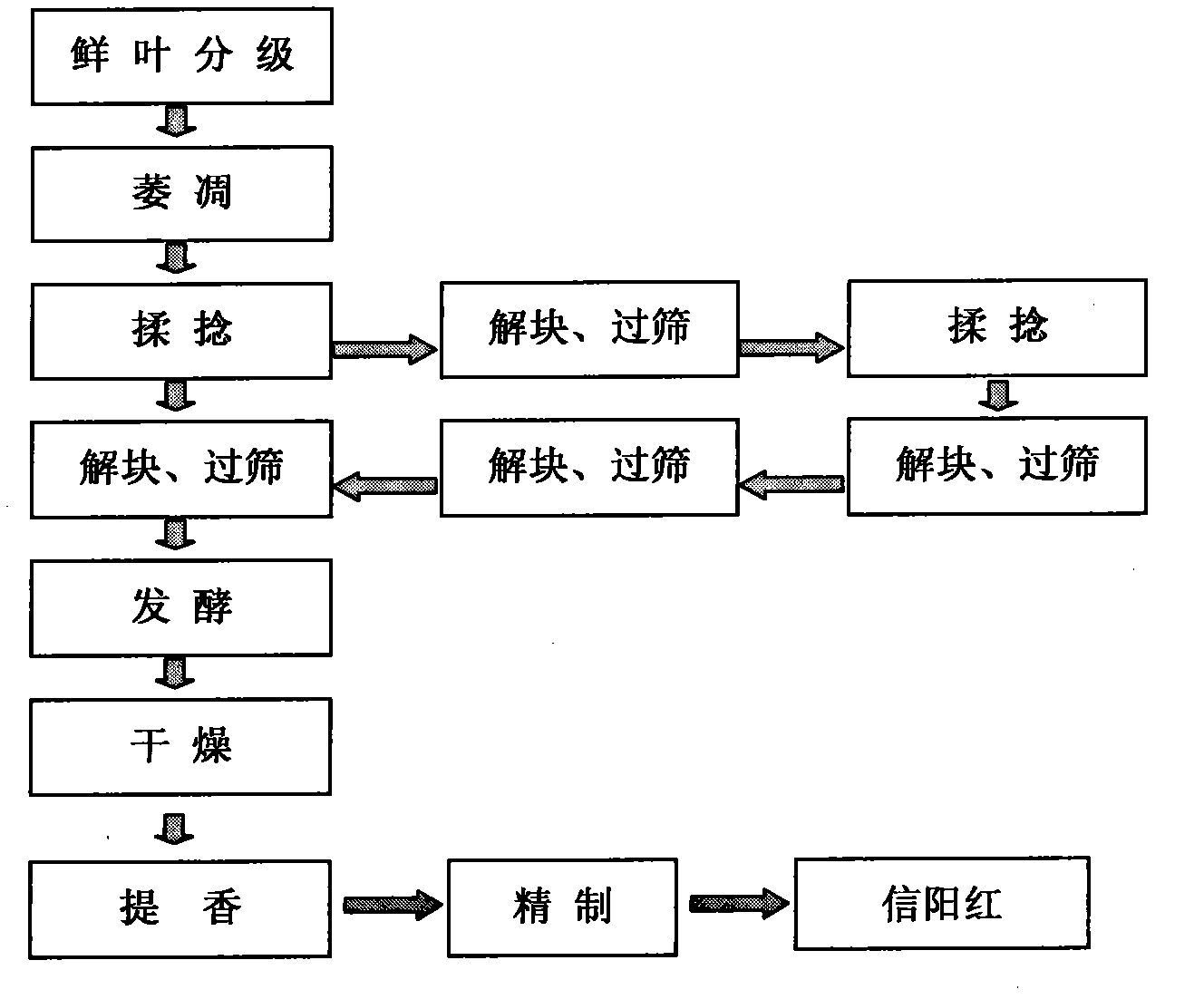

[0079] Embodiment 2 A kind of processing technology of Xinyang black tea, see figure 1 , including the following steps:

[0080] (1) Picking and grading of fresh leaves: The fresh leaves of local tea tree varieties in Xinyang (suitable for making Xinyang Maojian) are used as raw materials for black tea processing. Generally choose to pick on sunny days, fresh leaves require fat buds and leaves, no fish leaves and scales, no damage from diseases and insect pests, no foreign matter, no damage, and maintain the freshness of fresh leaves. The fresh leaves are strictly graded in batches, divided into varieties, and produced in time. Process of the present invention has carried out grading to fresh leaf (seeing table 1).

[0081] (2) Withering: The withering room requires good ventilation. The indoor temperature is generally controlled at about 25-30°C. The temperature is regulated by air conditioners and hot air fans. High and then low"; the thickness of the spread leaves is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com