Patents

Literature

377results about How to "Uniform fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

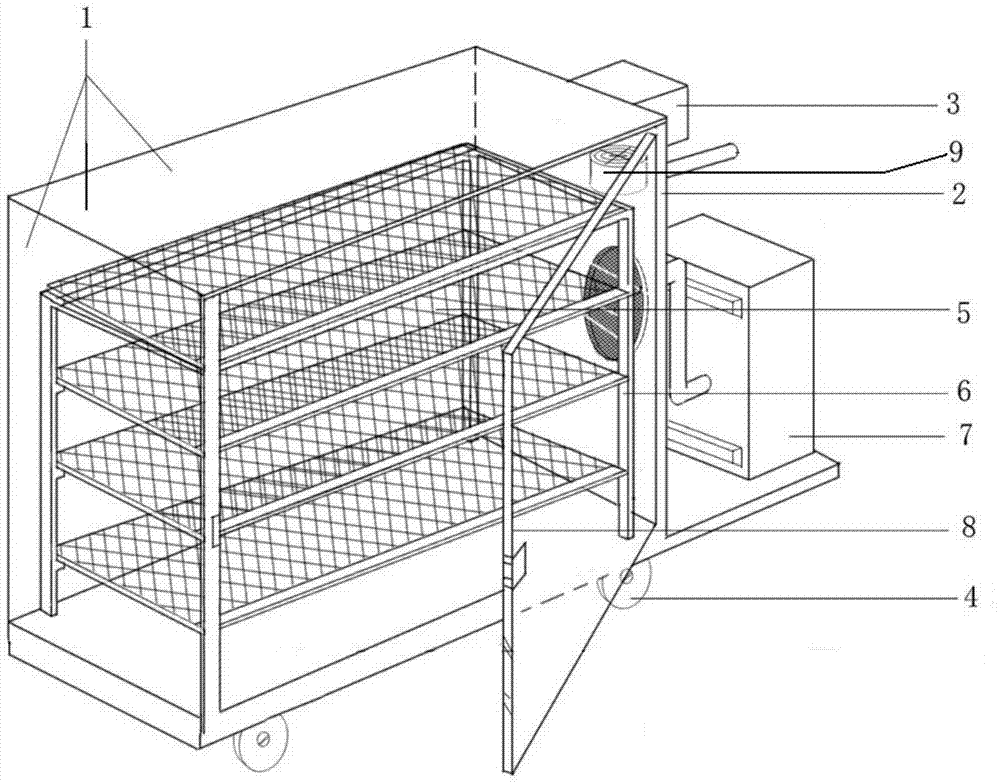

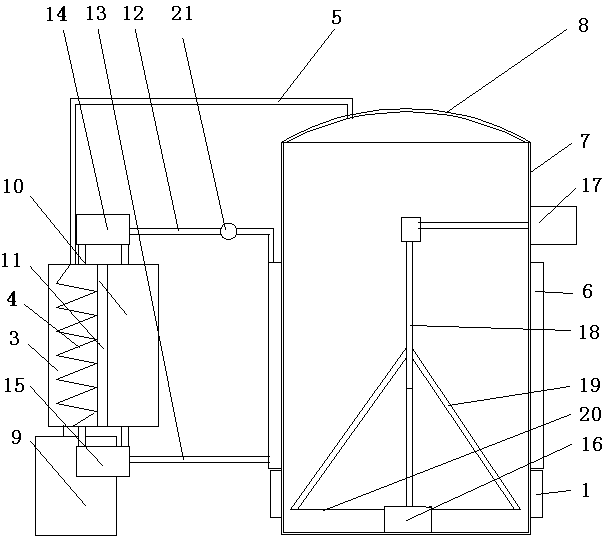

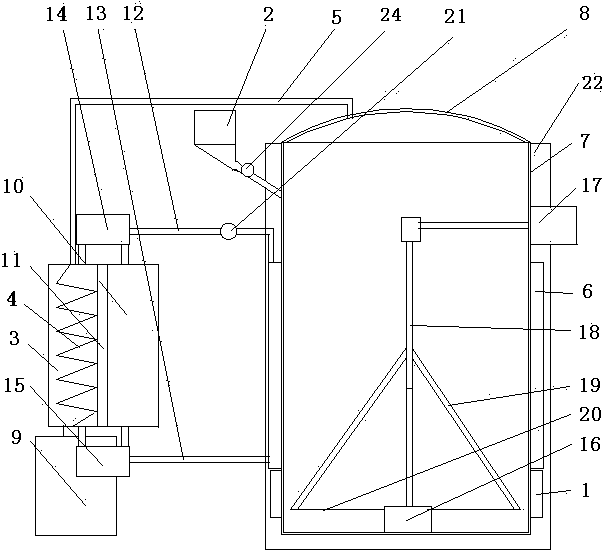

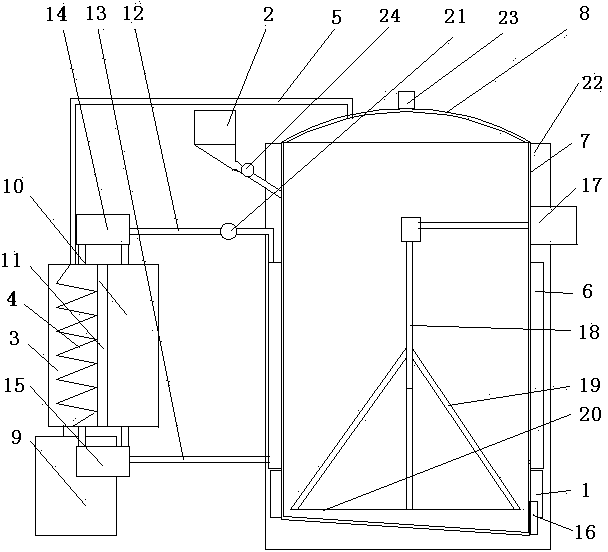

Kitchen waste pretreatment device

ActiveCN103464449ADeodorization up to standardWith automatic sortingSolid waste disposalControl systemOil water

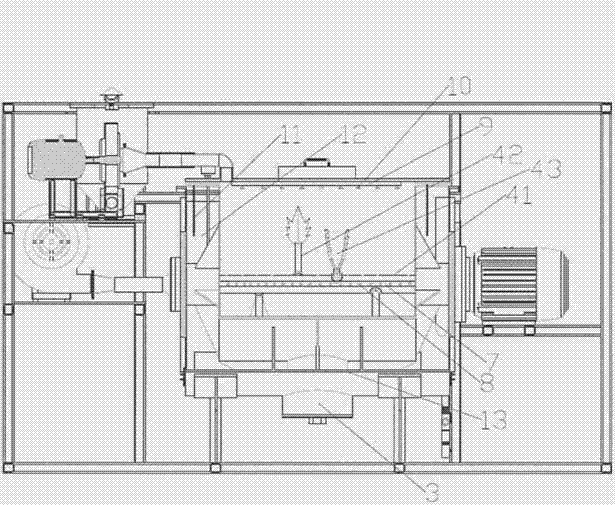

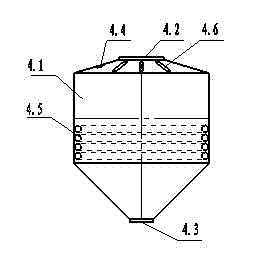

The invention discloses a kitchen waste pretreatment device. The kitchen waste pretreatment device comprises a closed shell and a control system. The kitchen waste pretreatment device is characterized in that the upper end of the shell is provided with a feeding funnel and a feeding motor; the shell is internally provided with an automatic sorting device, a biological fermentation drying device, an oil-water separation device, an ionization deodorization device and a gas condensation device; the feeding funnel is communicated with a kitchen waste charge hole of the automatic sorting device through a discharge hole; the automatic sorting device is communicated with a charge hole of the biological fermentation drying device through a kitchen waste outlet; the automatic sorting device is communicated with the oil-water separation device through a liquid outlet; the biological fermentation drying device is communicated with the gas condensation device through a gas exhaust opening; the gas condensation device is communicated with the ionization deodorization device, so that the effects of automatic sorting, rapid fermentation treatment speed, uniform fermentation, rapid heating speed, capability of oxygenating in fermentation, standard gas deodorization and environment protection and no pollution are achieved.

Owner:SHANDONG MINGLIU KITCHEN WASTE TREATMENT EQUIP CO LTD

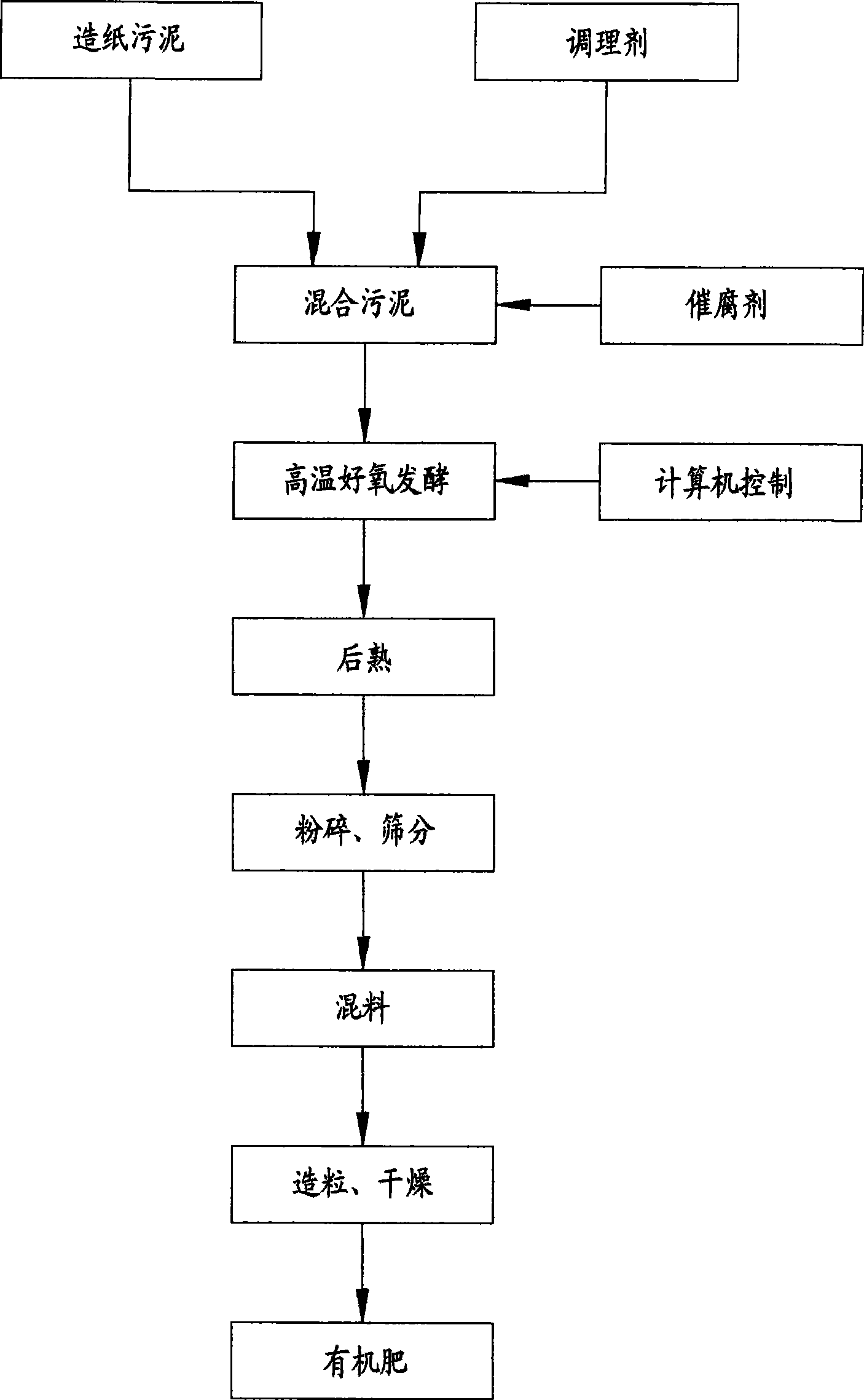

Method for producing fertilizer with papermaking sewage sludge

InactiveCN101429066ARealize comprehensive utilizationSolve processing problemsBio-organic fraction processingOrganic fertiliser preparationSludgePotassium

The invention discloses a method for preparing organic fertilizer from paper-making sludge. The materials such as paper-making sludge, amendment are mixed, subjected to high-temperature aerobic fermentation, post maturation and crushing, screened, and mixed with fertilizer of nitrogen, phosphorus, potassium and the like and medium and micro elements to prepare the organic fertilizer. The method has the advantages of simple process, easy operation, obvious innocuous effect, no environmental pollution and little nutrient loss; and the organic fertilizer prepared by the method is widely applied to industrial crops such as vegetables, fruit trees, Chinese herbal medicines, flowers and field crops such as wheat, corn, paddy rice.

Owner:SHOUGUANG CAILUN ZHONGKE FERTILIZER

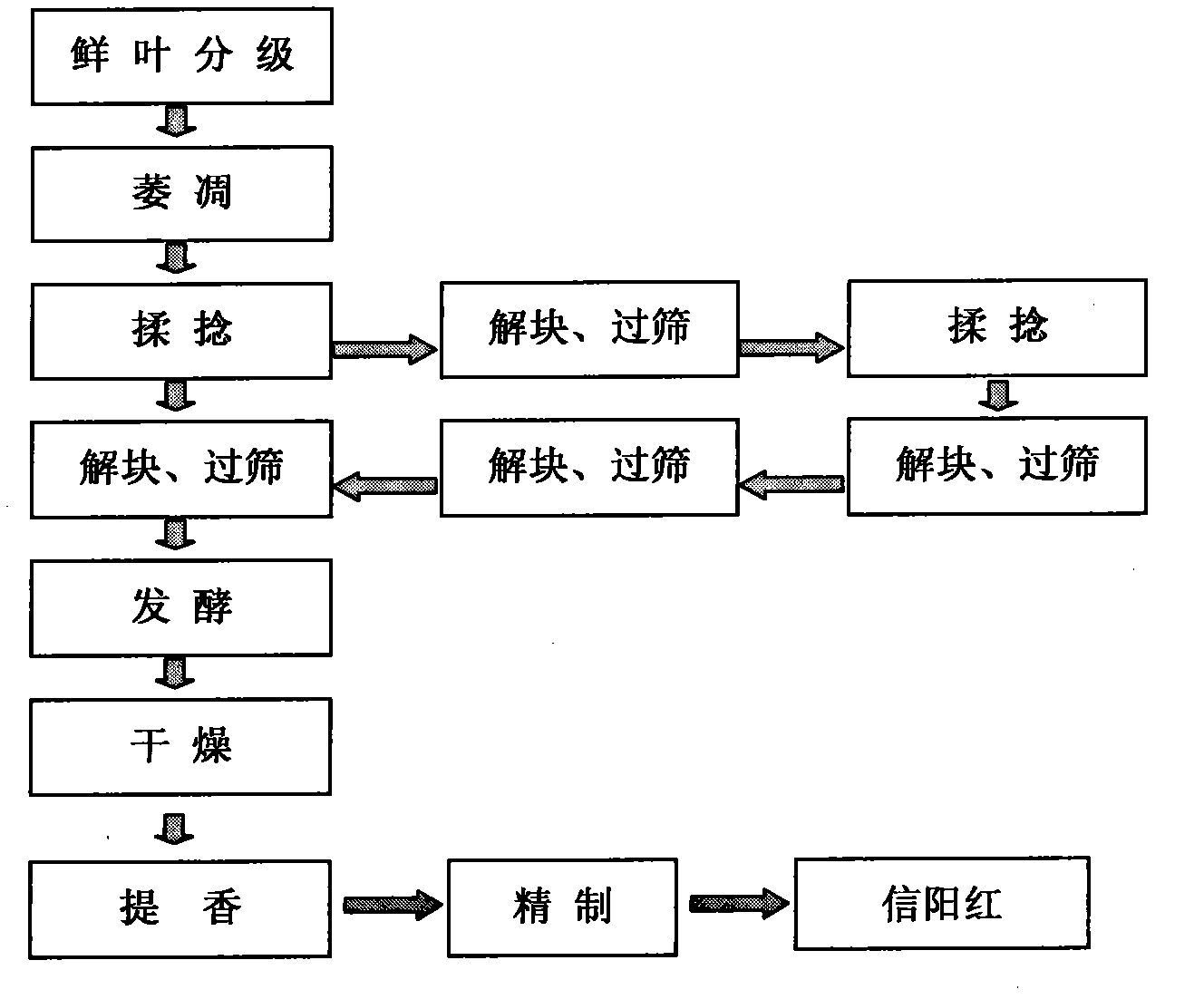

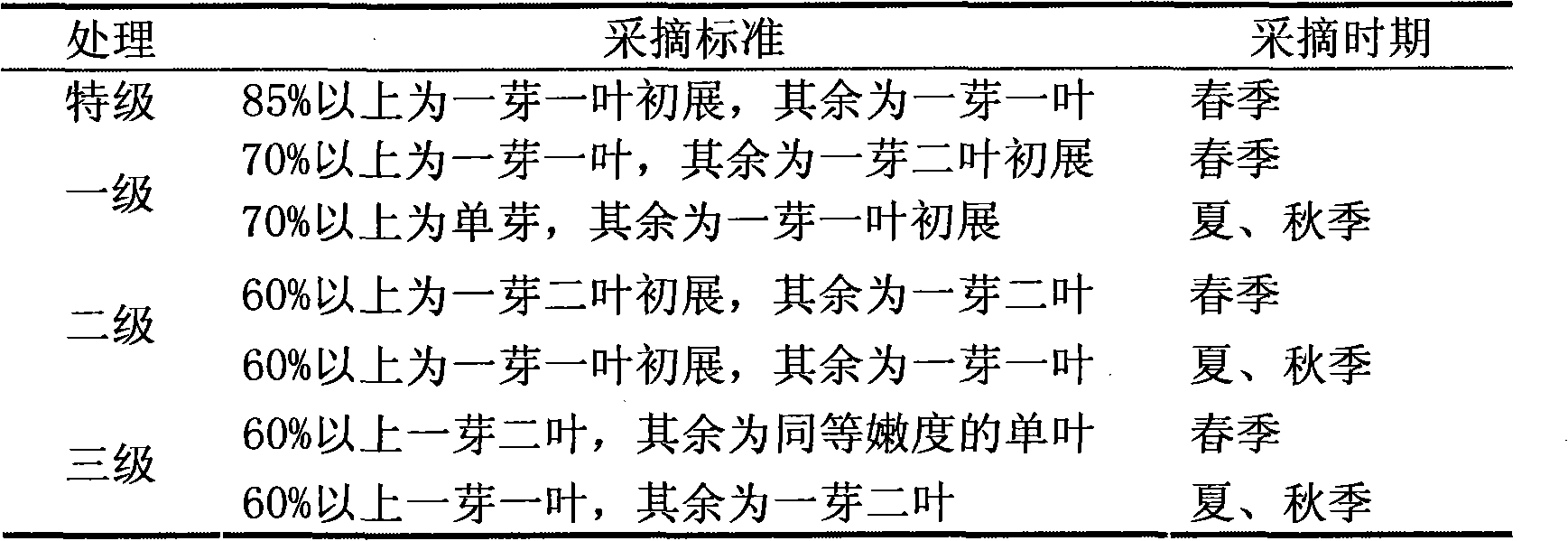

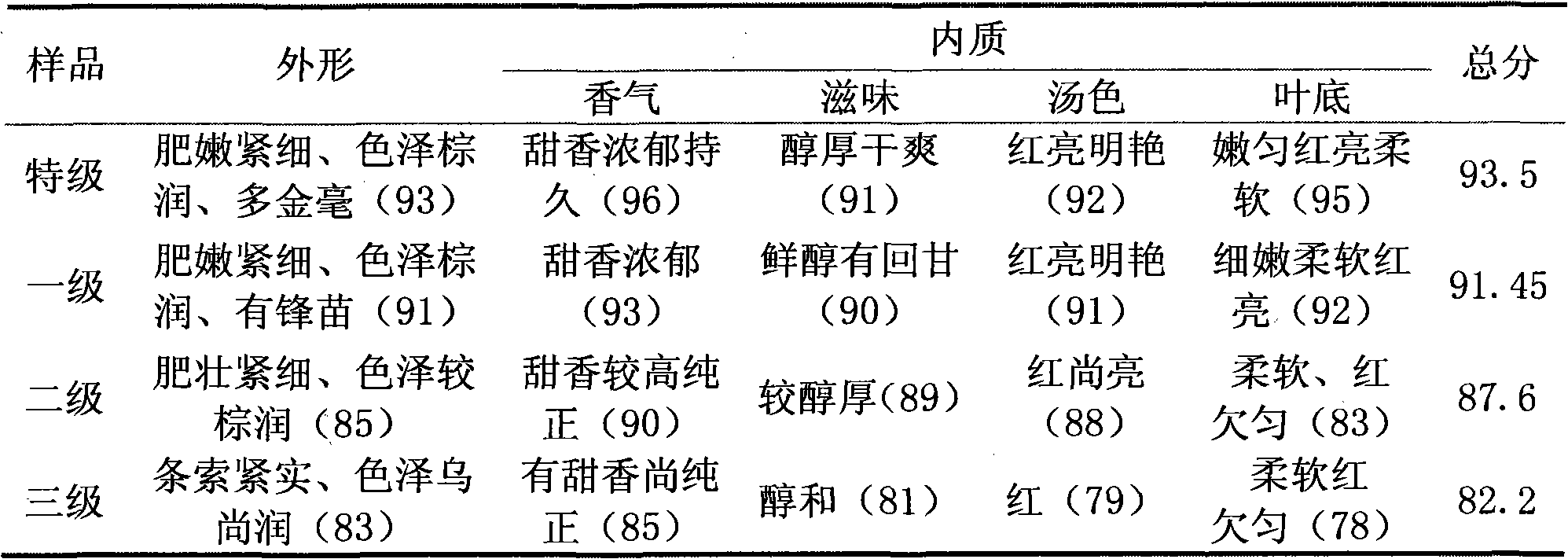

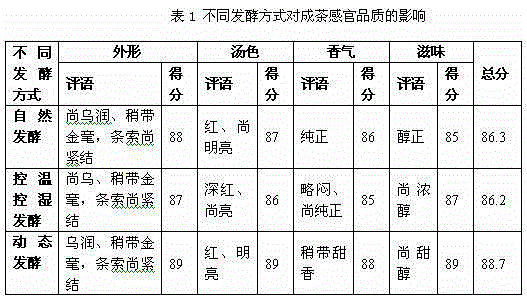

Xinyang red black tea processing technique

The invention relates to a Xingyang red black tea processing technique. The technique comprises the following parameters: wilting temperature: 25-30 DEG C; humidity: 60-70%; wilting time: 6-7 h; twisting machine rotating speed: 55-60 r / min; 2-3 times of twisting, each for 30 min; amount of tea feed: 30-35 kg; unravel machine rotating speed: 35 r / min; sieve pore size: 6#; 2-3 times of unravelling;temperature in a fermentation chamber: 2-7 DEG C; humidity in the fermentation chamber: 96%; tea spread thickness: 10 cm; oxygen supply amount: 5 L / min; fermentation time: 4.5 h; initial drying temperature: 115 DEG C; initial drying time: 20 min; re-drying temperature: 75 DEG C; and re-drying time: 30 min. The processing technique of the invention is unique, and the quality of the made black tea is excellent: the appearance of the product is fat and tender and compact, the peak of the tea is gold and the tea has bright luster; the endoplasm aroma of the tea has rich green flavour; the taste of the tea is mellow and sweet; the tea liquor is brilliantly red; and the root of the tea leaf is soft and green, has many sprouts and a colour of brilliant red.

Owner:信阳市浉河区茶叶办公室

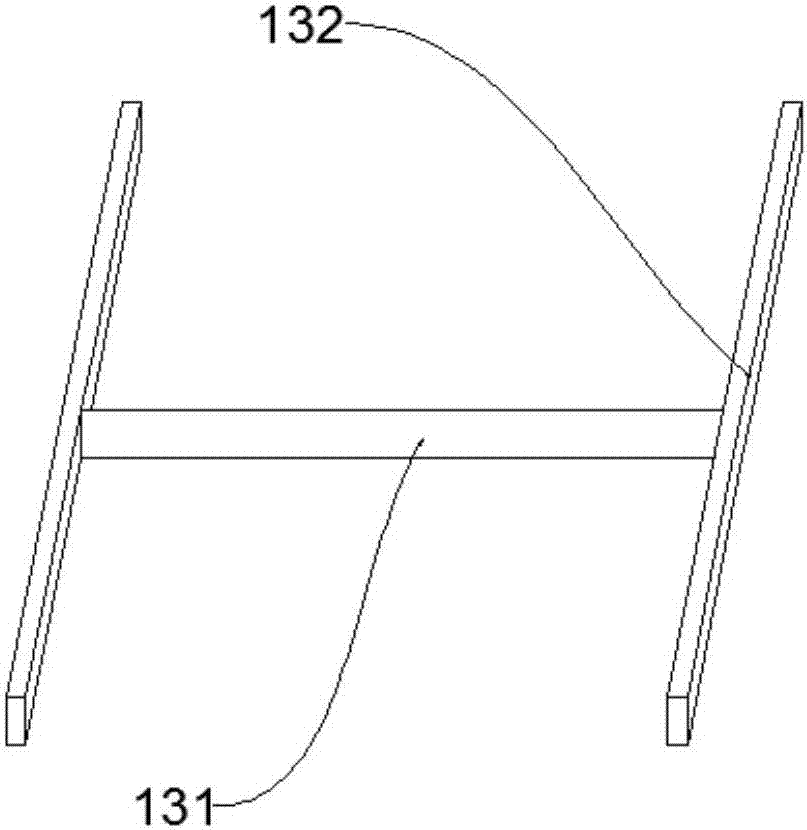

Novel kitchen garbage fermentation device and usage method

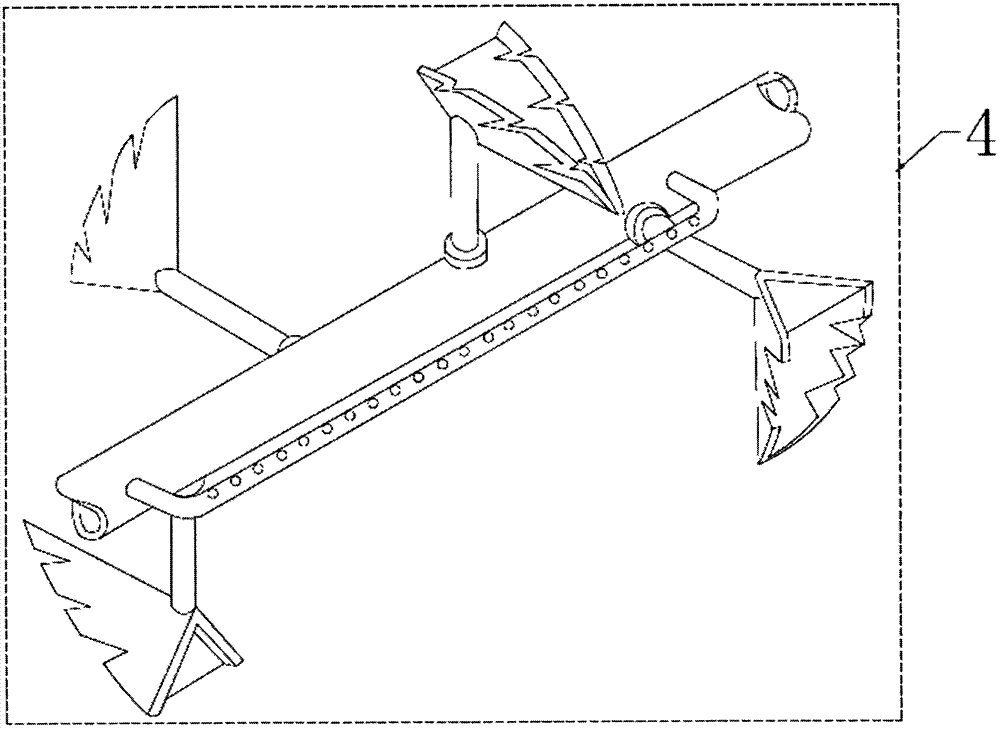

InactiveCN102786363AAvoid circulationLow costClimate change adaptationChemical industryMotor driveEngineering

The invention provides a novel kitchen garbage fermentation device and a usage method, which belongs to the environmental protection device field. The device provided by the invention comprises a U-shaped fermenter, a feed inlet, a discharge port, a fragmentation stirrer, a variable frequency motor, a blower, a ventilation duct, an air vent, a microbe inlet pipe, a charging nozzle, an electric heating pipe, a water interlayer, a protection layer, a deodorizing tower, a support and the like. The fragmentation stirrer is composed of a stirring horizontal shaft, a blade support and a triangle cone blade with arc bottom. Several electric heaters are arranged in the interlayer of a double layer U-shaped fermenter. The variable frequency motor drives the fragmentation stirrer to perform fragmentation stirring on the kitchen garbage. The electric heating pipe heats the water interlayer so that the temperature of the fermenter can be kept between 40-60 DEG C, air is introduced in the ventilation duct through the blower, and a microbe liquid bacteria agent is inoculated in the fermenter through a nozzle on the microbe inlet pipe. The product is discharged out of the fermenter through the discharge port, thereby the minimization of the kitchen garbage can be realized, and the product can be used as a soil organic fertilizer conditioning agent.

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION +1

Method for preparing gold-flower Puer tea by inoculating fungus microorganisms

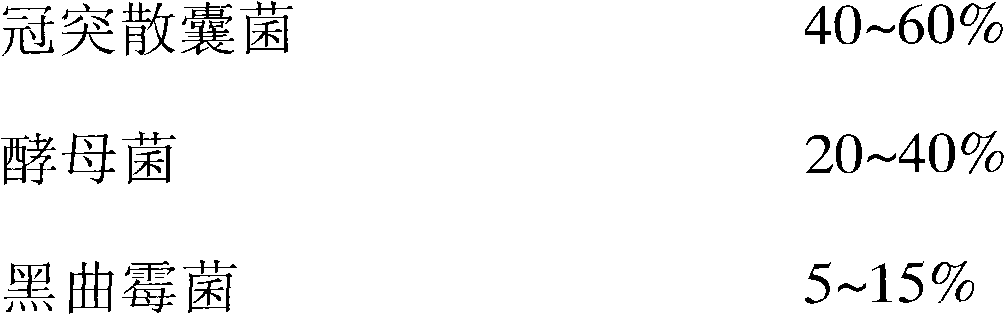

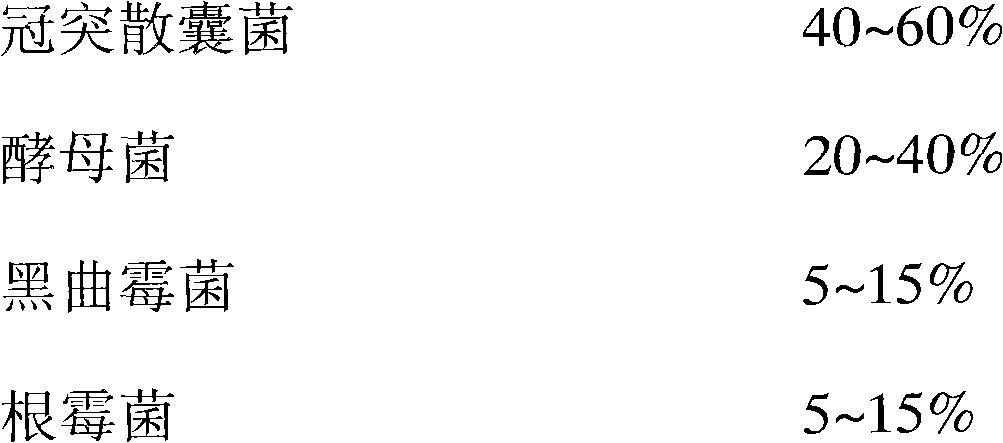

InactiveCN102187920AOutstanding advantagesHighlight positive effectsPre-extraction tea treatmentMicroorganismRhizopus

The invention provides a method for preparing gold-flower Puer tea by inoculating fungus microorganisms. The method is characterized in that: by the means of inoculating mixed fungi which are mainly eurotium cristatum and adding a fermentation promoter, the blooming of the Puer tea is realized, and the gold-flower Puer tea with gold flowers is prepared. In the production process of the Puer tea, besides of the non-dominant bacteria of the eurotium cristatum, the dominant bacteria including the Puer tea such as aspergillus niger, penicillium notatum, rhizopus and microzyme are also inoculated; and in addition, the fermentation promoter is also added, so that not only the bacteria can be quickly bred, but also the operation and control are convenient; and the tea leaves are fermented and uniformly aged and stable in quality. The gold-flower Puer tea prepared by the method has the advantages that: the beneficial effects of the Puer tea and the eurotium cristatum are perfectly combined; the tea is red, thick and bright and has pure aroma and a mellow taste; other health-care effects are further improved; and the quality is improved in essence compared with traditional Puer tea.

Owner:牛乃秀

Enzyme microbial organic fertilizer and preparation method thereof

InactiveCN102010241AWell-developed crop rootsImprove qualityBio-organic fraction processingOrganic fertiliser preparationPhosphateInsect pest

The invention discloses an enzyme microbial organic fertilizer and a preparation method thereof. The enzyme microbial organic fertilizer comprises the following components of 40t of fowl manure, 14t of pig manure, 5t of albumen powder, 5t of Chinese wood oil, 10t of peat, 15t of straw powder, 3t of urea, 5t of monoammonium phosphate, 2t of potassium sulfate, 1t of enzyme element expanding agent, 0.2t of rice bran, 0.2t of red sugar and 0.1t of trace elements. The enzyme microbial organic fertilizer can ensure high natural soil building active bacteria, is used for loosening the soil, forms a crumble structure for achieving the effect of remaining water and fertilizing soil, improves the soil, ensures that the root system of crops is developed, can increase the yield and the income, improves the quality of the crops, and is a prophase guarantee of the sustainable development ecological agriculture. Meanwhile, the enzyme microbial organic fertilizer is suitable for a base fertilizer or additional fertilizer of various crops, fruits and vegetables, has remarkable effects of lowering the plant diseases and insect pests and resisting the droop, and is an ecotype environmental-friendly fertilizer for producing organic foods.

Owner:云南益吉生态肥料有限公司

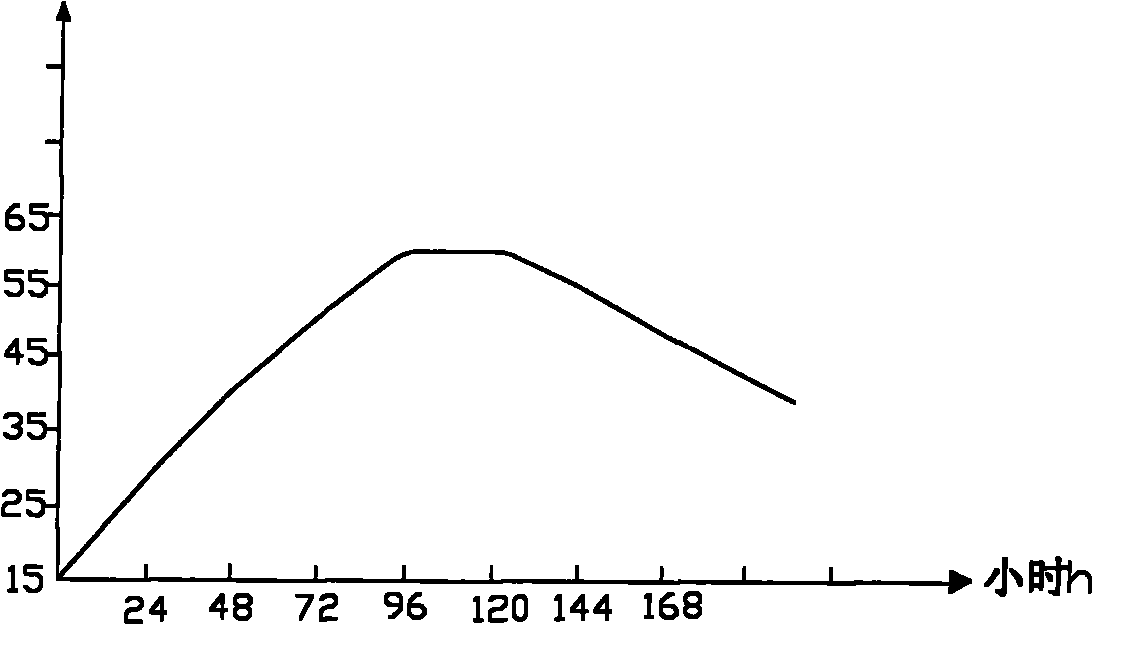

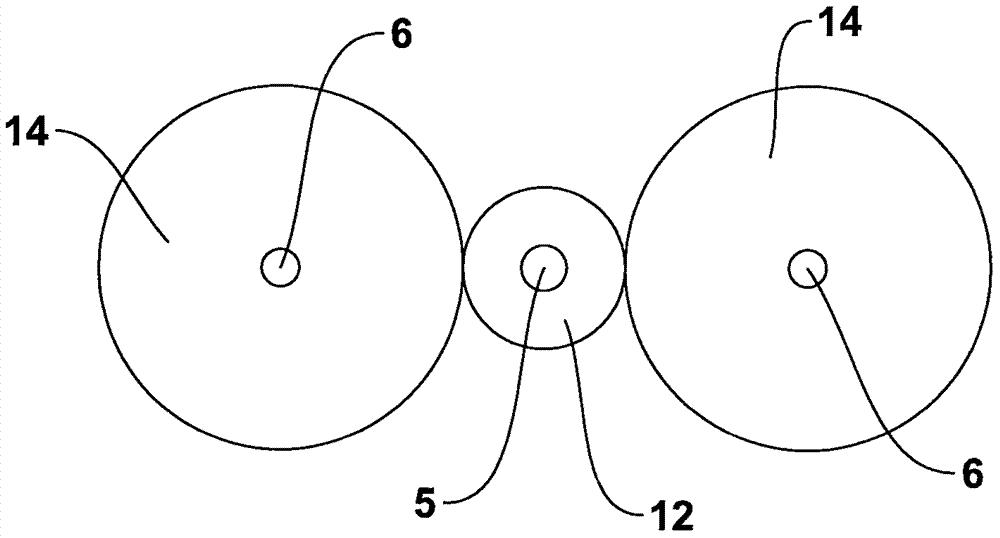

Automated Congou black tea production process

InactiveCN102422910APlay the role of dynamic fermentationUniform fermentationPre-extraction tea treatmentAutomatic controlManufacturing line

The invention discloses an automated Congou black tea production process, which includes a staged dynamic withering technique, a continuous and progressive pressure rolling technique, a high-speed rotational deblocking technique, a variable-temperature dynamic fermentation technique, a microwave tempering and dehydration technique and the like; the staged dynamic withering technique is carried out by four automatic vertical withering machines, the continuous and progressive pressure rolling technique is carried out by six 65 model automatic rolling machines, the high-speed rotational deblocking technique is carried out by a high-speed rotating roller type deblocking machine, the fermentation temperatures of different stages are controlled by an automatic fermentation machine in the variable-temperature dynamic fermentation technique, and on-line tempering is carried out by a microwave tempering machine in the microwave tempering and dehydration technique. The automatic vertical withering machines, the automatic rolling machines, the high-speed rotating roller type deblocking machine, the automatic fermentation machine, the microwave tempering machine, two automatic driers and other equipment are connected through a production line and adopt an automatic control system, consequently, Congou black tea processing realizes automated, continuous and clean production, the quality and sanitary quality of the tea are increased, and the working efficiency is remarkably increased.

Owner:TEA RES INST ANHUI ACAD OF AGRI SCI +1

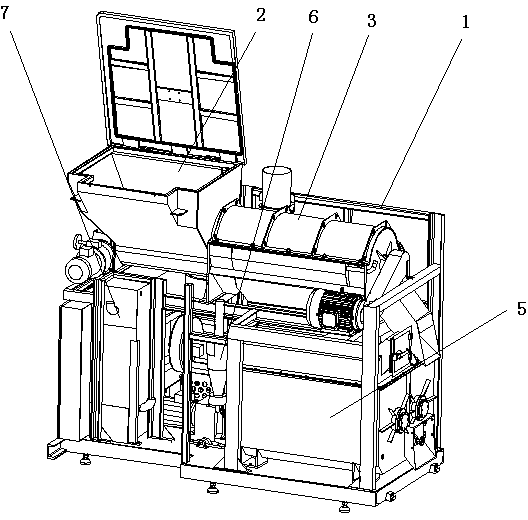

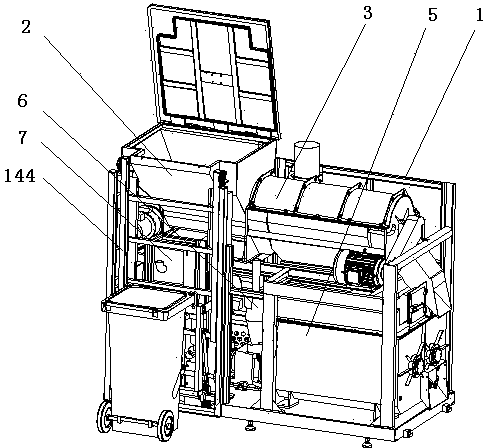

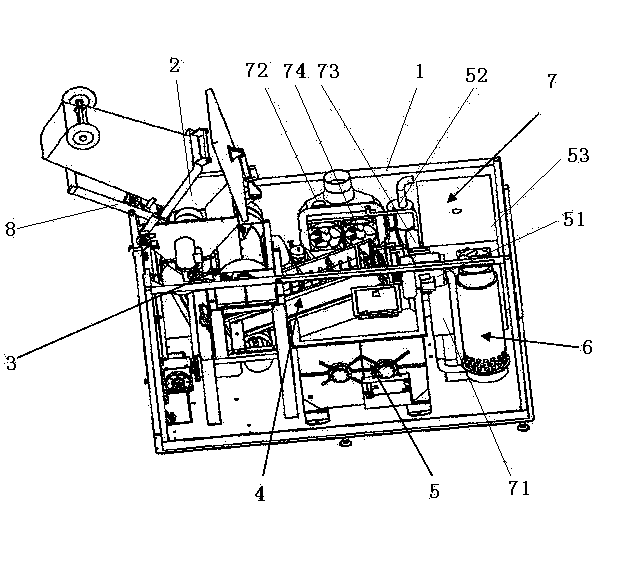

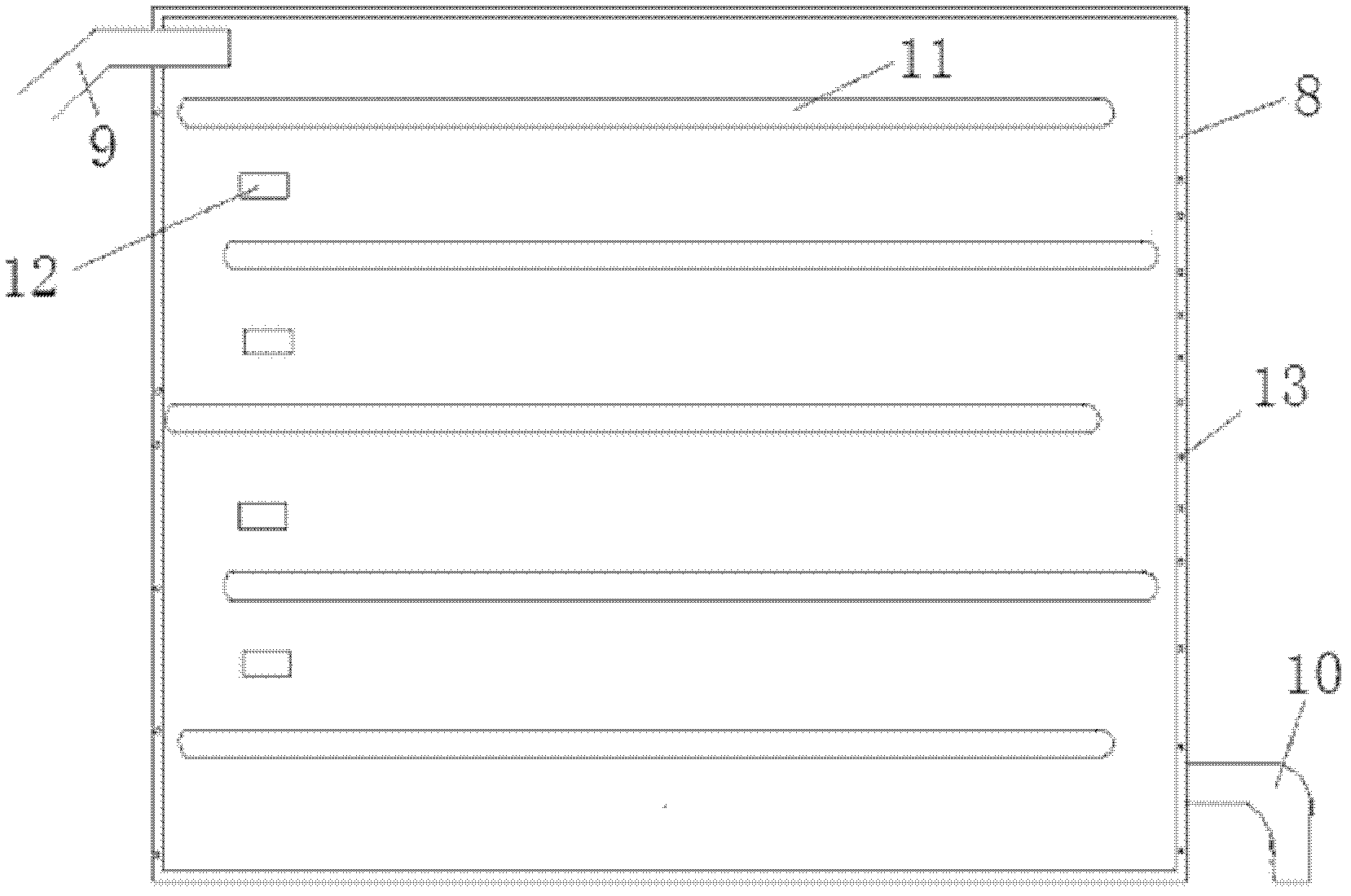

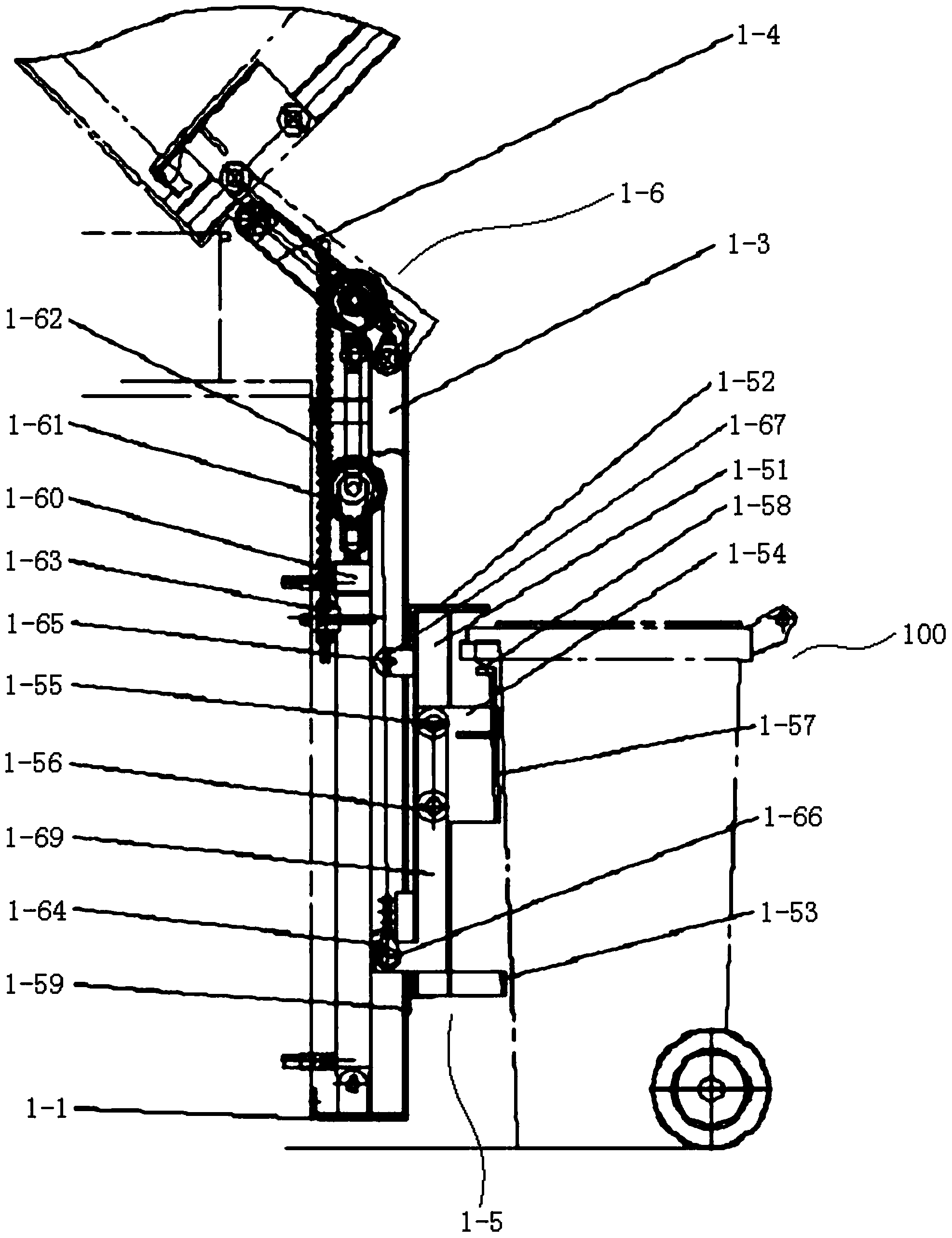

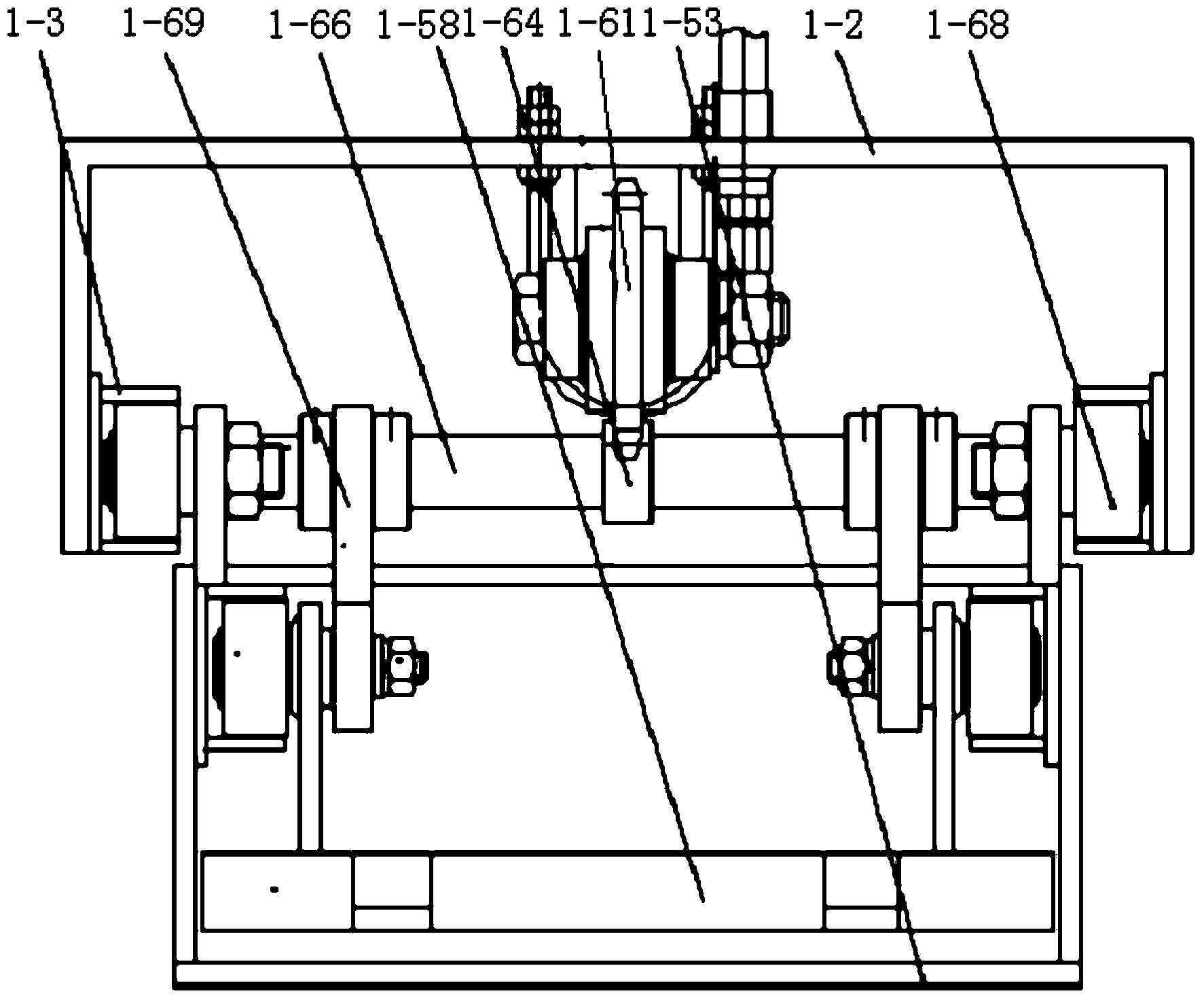

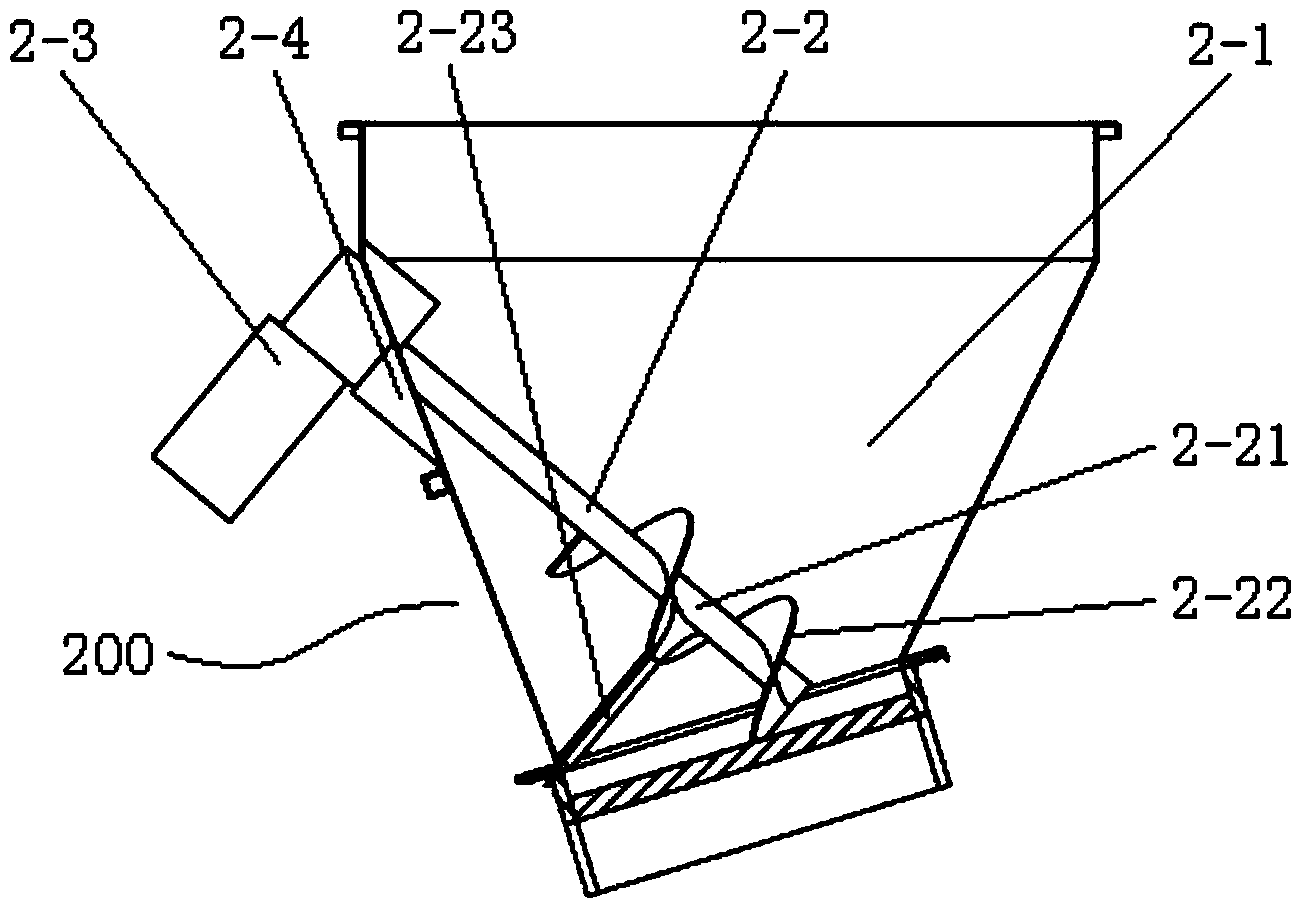

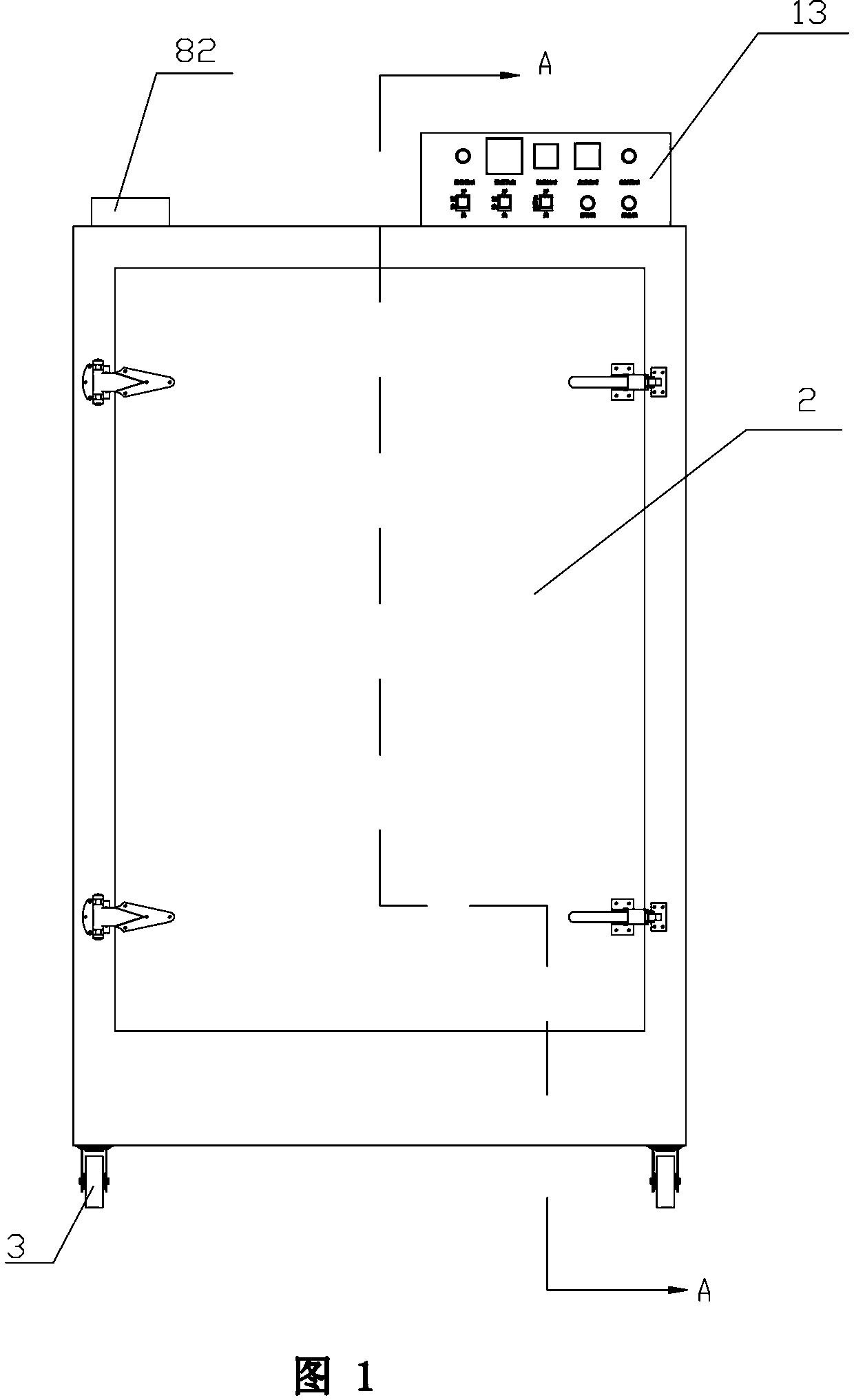

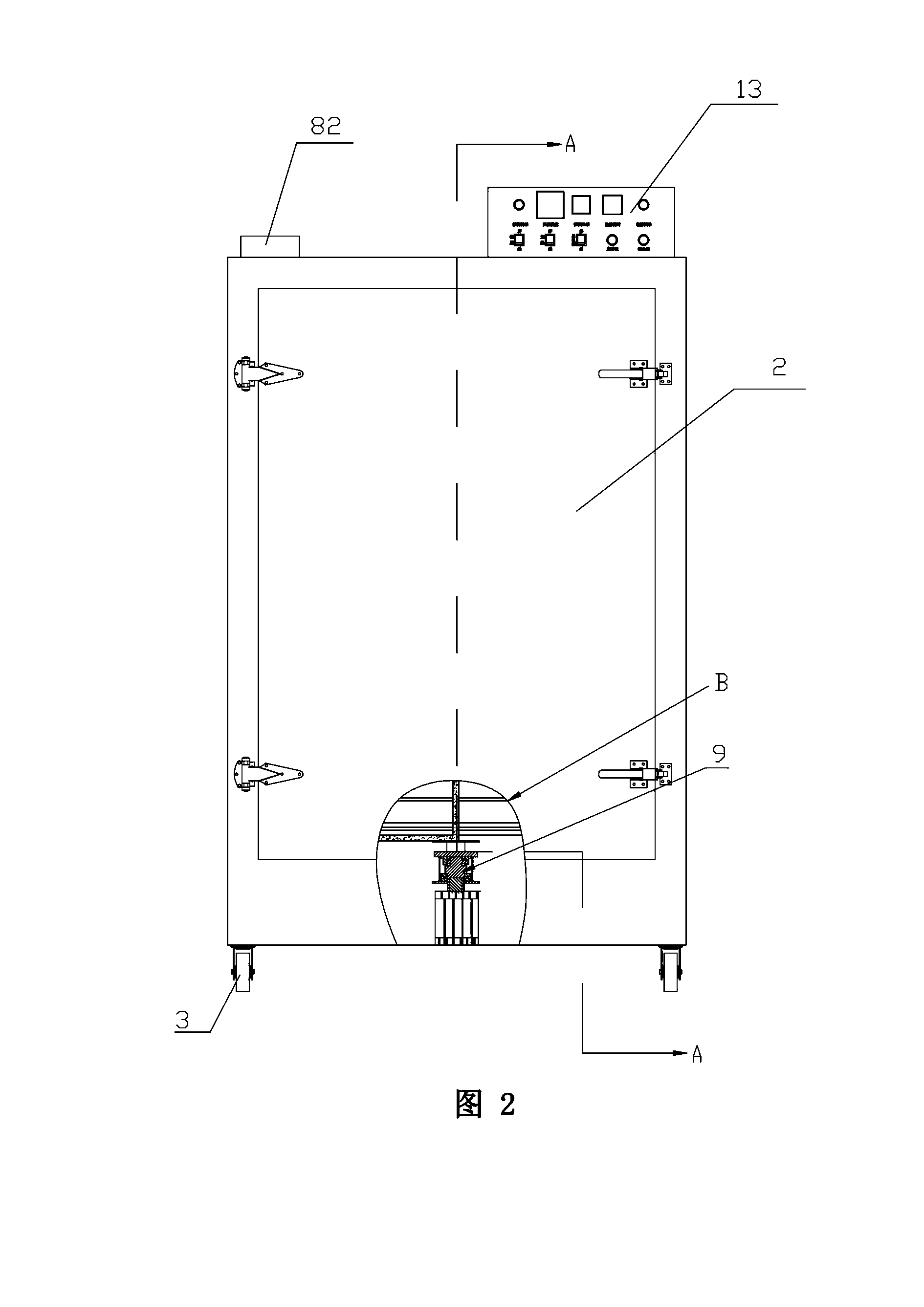

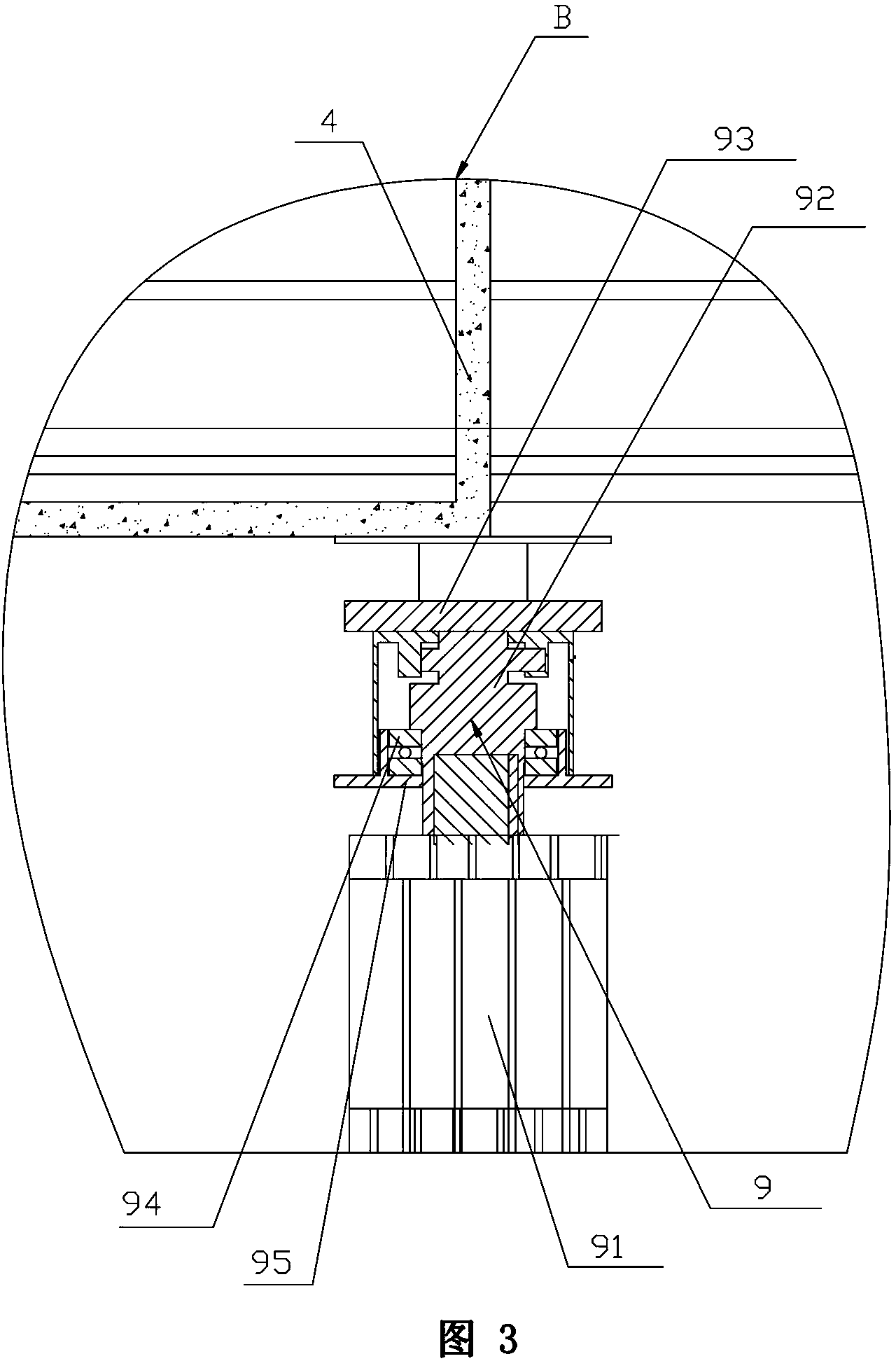

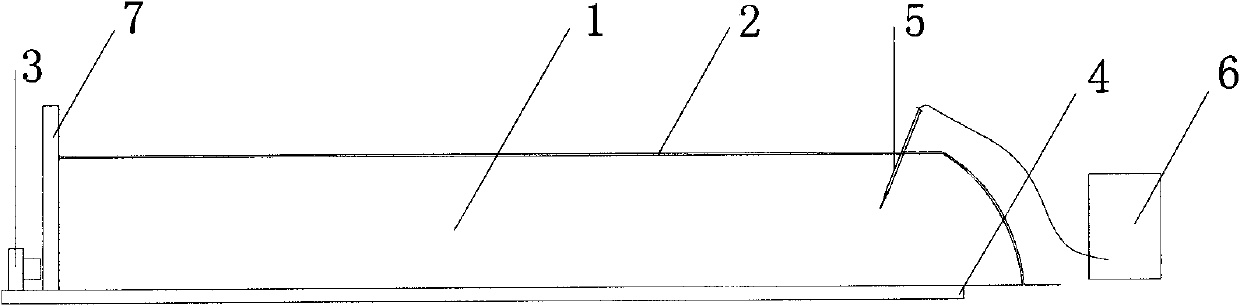

Kitchen waste pretreatment equipment and technology

The invention relates to a kitchen waste pretreatment equipment and technology. The equipment is characterized by comprising a shell body, a garbage can lifting device mounted on one side of the shell body, a feeding device mounted on the upper portion of the shell body, an automatic separation device mounted in the shell body, an extrusion device mounted in the shell body, a smashing device mounted in the shell body, a fermenting and drying device mounted in the shell body and an ionization deodorization device mounted in the shell body. The kitchen waste pretreatment equipment and technology has the advantages of feeding and sorting automatically, being good in solid-liquid separation effect, high in efficiency, high in dehydration rate, high in fermentation treatment speed, even in fermentation, high in heating speed, capable of oxygenating automatically during fermentation, up to standard on gas deodorization, environmentally friendly, free of pollution and convenient to operate, saving manpower and the like, can process the kitchen waste generated by 300 to 500 people in 24 hours, and output 150kg to 200kg organic fertilizer with the moisture content not more than 25%.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

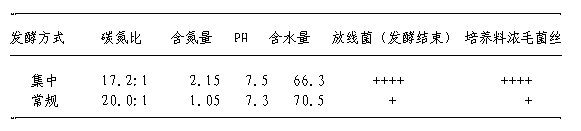

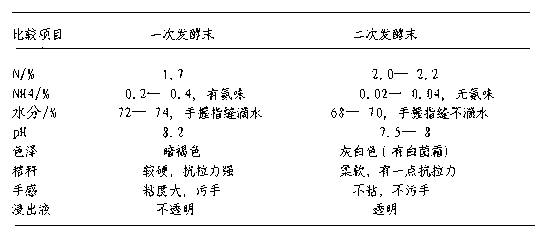

Centralized secondary fermentation method for agaricus bisporus

InactiveCN103319219AQuality productionHigh yield productionBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAnimal Foraging

The invention discloses a centralized secondary fermentation method for agaricus bisporus. The culture medium comprises the following raw materials in parts by weight: 45-60 parts of forage, 35-50 parts of chicken manure, 2-8 parts of gypsum and 3-10 parts of oil cakes. The method comprises the following steps of: uniformly spreading forage in a pre-wetting pool for pre-wetting for 2-5 days; adding chicken manure, gypsum and oil cakes and uniformly and adequately mixing; filling the mixed fermentation material in a ventilating floor in a primary fermentation tunnel, and conveying fresh air to the fermentation material through a fan; fermenting for 4-6 days and transferring the fermentation material to another primary fermentation tunnel. The base material of the primary tunnel fermentation is uniformly stacked on the ventilating floor in a secondary fermentation tunnel, and the temperature of the fermentation material is controlled by operation of the fan. Secondary fermentation comprises the following steps: a balancing stage, a heating stage, pasteurization, cultivation at constant temperature and discharge at low temperature. According to the method, local wheat straw hoods, straws, chicken manure and the like are used as main raw materials to form the culture medium. Centralized scaled production cultivation materials are formed by the technology of pre-treatment of the raw materials, primary fermentation and secondary fermentation.

Owner:SICHUAN MAOSEN BIOLOGICAL SCI & TECH

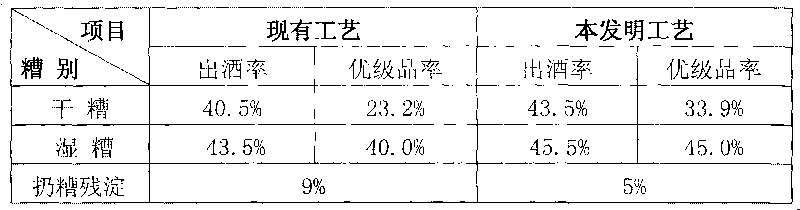

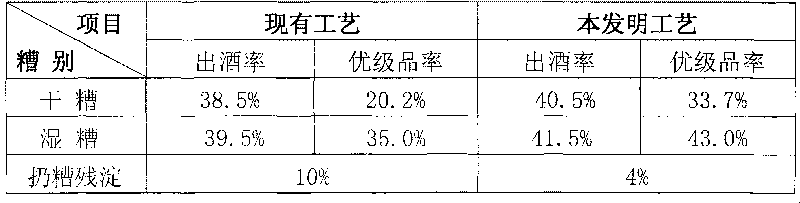

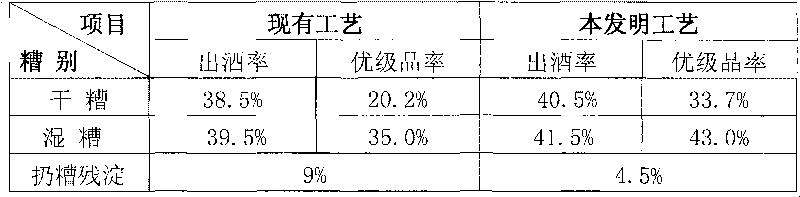

Method for improving quality of strong aromatic dry distilled grain

ActiveCN101705167AIncrease the acidity in the cellarQuality improvementAlcoholic beverage preparationChemistryPre treatment

The invention discloses a method for improving quality of strong aromatic dry distilled grain, comprising the steps of pretreating the materials, piling and fermenting, taking out of a pit, stirring the mixed grains, getting wine and steaming grains, getting out of a steamer and proportioning water, reducing temperature and mixing the rice flour, entering the pit and sealing the pit. The method is characterized in that new measures about a pit mud maintenance in contact with the dry grains and about a prevention of mixed bacteria infection are carried out by not crushing part of the materials for wine making, increasing the mixed grain amount and reducing the use quantity of bran shells, thereby improving acidity of fermented grain for pit entry and water retention property of the fermented grain, and greatly improving the quality of the dry distilled grain. The method improves the quality of dry grains, improves the high-quality yield of the dry distilled grain by about 35%, improves the high-quality yield of the wet grain by above 10% and improves wine yield by above 3% so that the whole pit can brew high-quality wine. The invention has simple technology, easy operation, low production cost, good wine quality and easy implementation, thereby providing reliable guarantee for large-area application of technical reform in strong aromatic wine production enterprise.

Owner:SICHUAN TUOPAI SHEDE WINE

Method for pu'er tea fermented by biological enzyme

A method for fermenting Puí»er tea by biologic enzyme includes such steps as mixing raw tea, water and nutritive liquid containing biologic enzyme in mass ratio of 1: (0.4-0.6): (0.1-0.3), stacking on shelves layer by layer which controlling the layer height to be 40-70 cm, and fermenting at 40-65 deg.C for 20-25 days. Its advantages are short time, and high quality of tea.

Owner:王乐观

Method for preparing organic fertilizer by utilizing kitchen garbage

InactiveCN109053283ASolve the pollution of the environmentEfficient removalFatty oils/acids recovery from wasteBio-organic fraction processingVegetable oilAdditive ingredient

The invention discloses a method for preparing organic fertilizer by utilizing kitchen garbage. The method comprises the following steps: (1) separating and crushing; (2) filtering to remove floatingoil; (3) performing the enzymolysis treatment; (4) separating oil; (5) performing the primary fermentation; (6) performing the secondary fermentation; and (7) granulating. The method for preparing theorganic fertilizer by utilizing the kitchen garbage is simple in process, and low in cost; and moreover, the vegetable oil and animal fat in the kitchen garbage can be effectively removed, the nutrition ingredients in the kitchen garbage can be effectively recycled and made into the organic fertilizer with good fertility, and the environmental pollution problem of the kitchen garbage can be solved.

Owner:广西中创农业集团有限公司

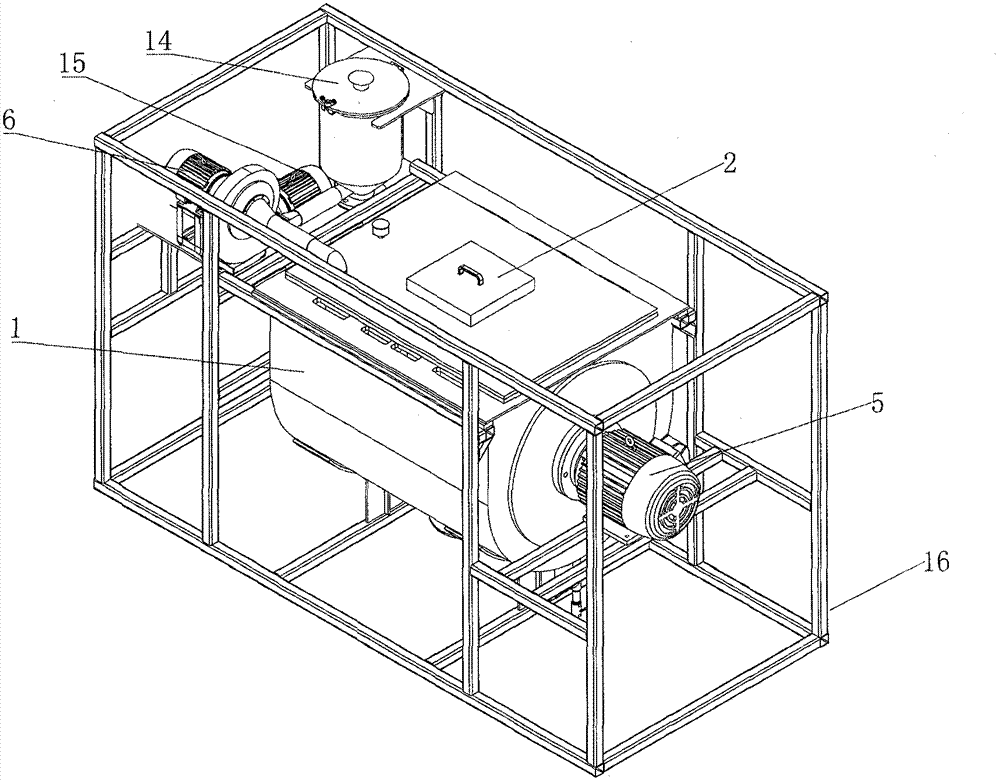

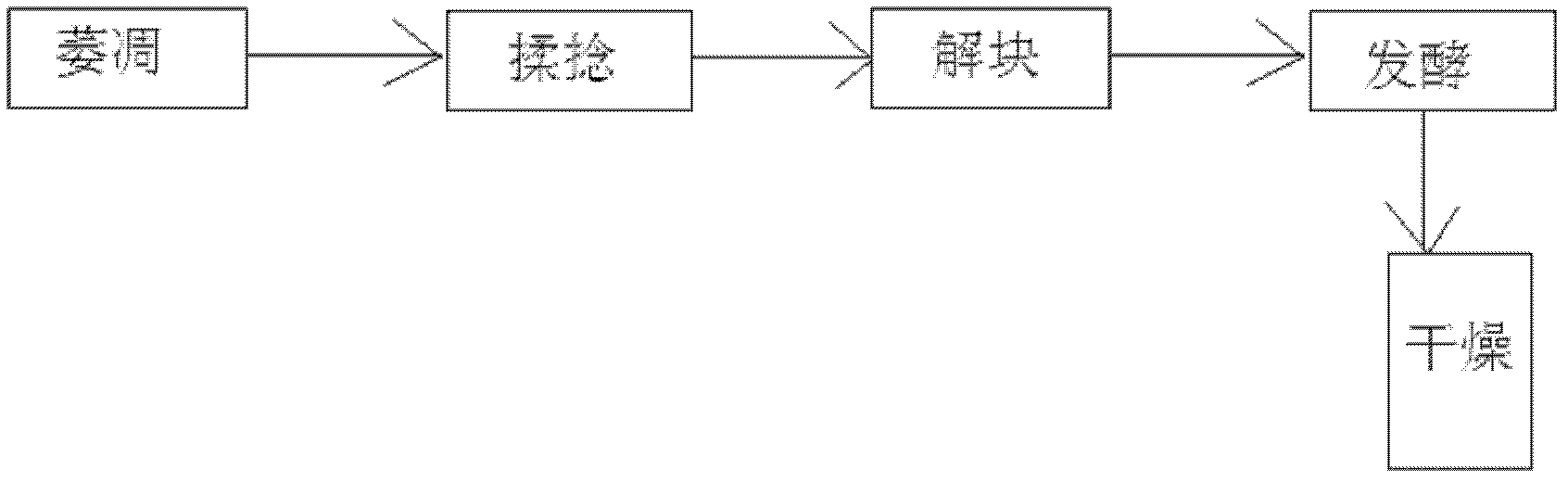

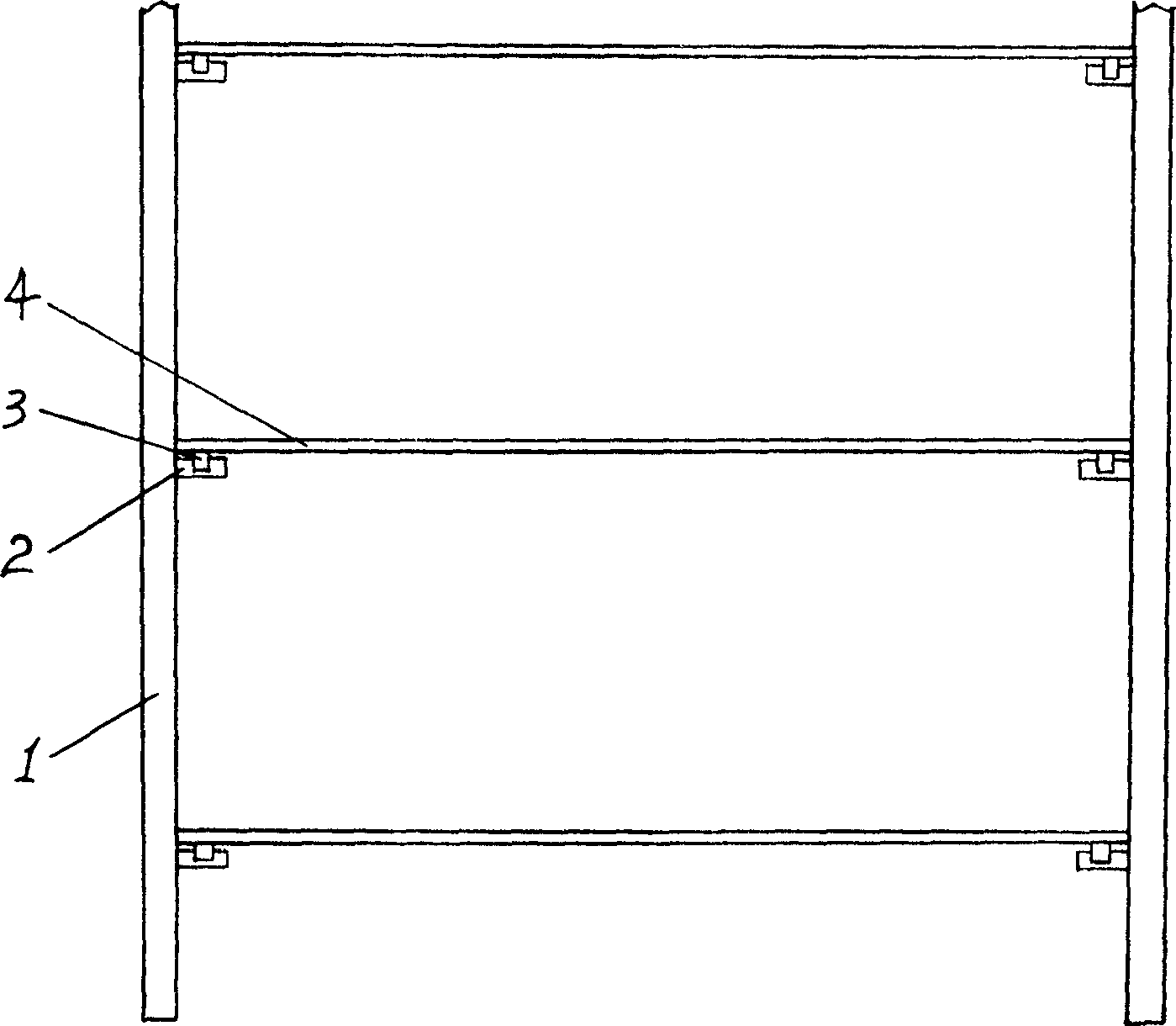

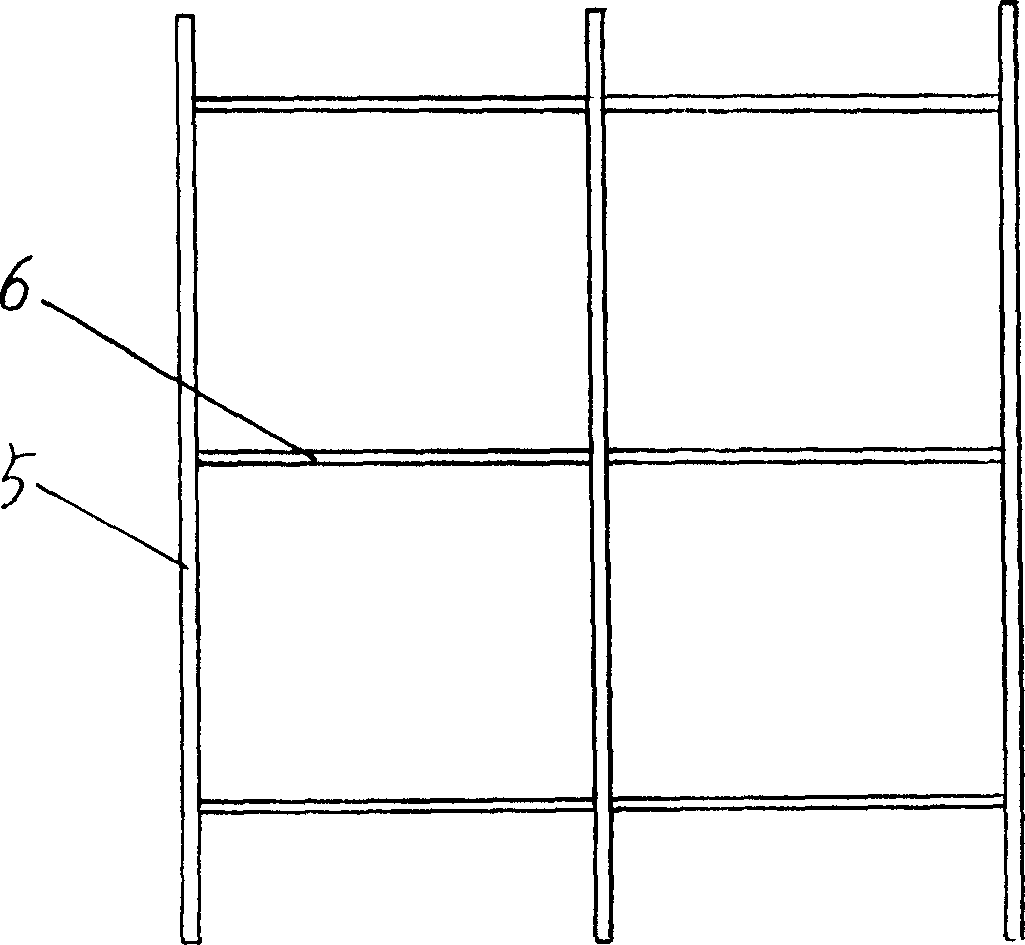

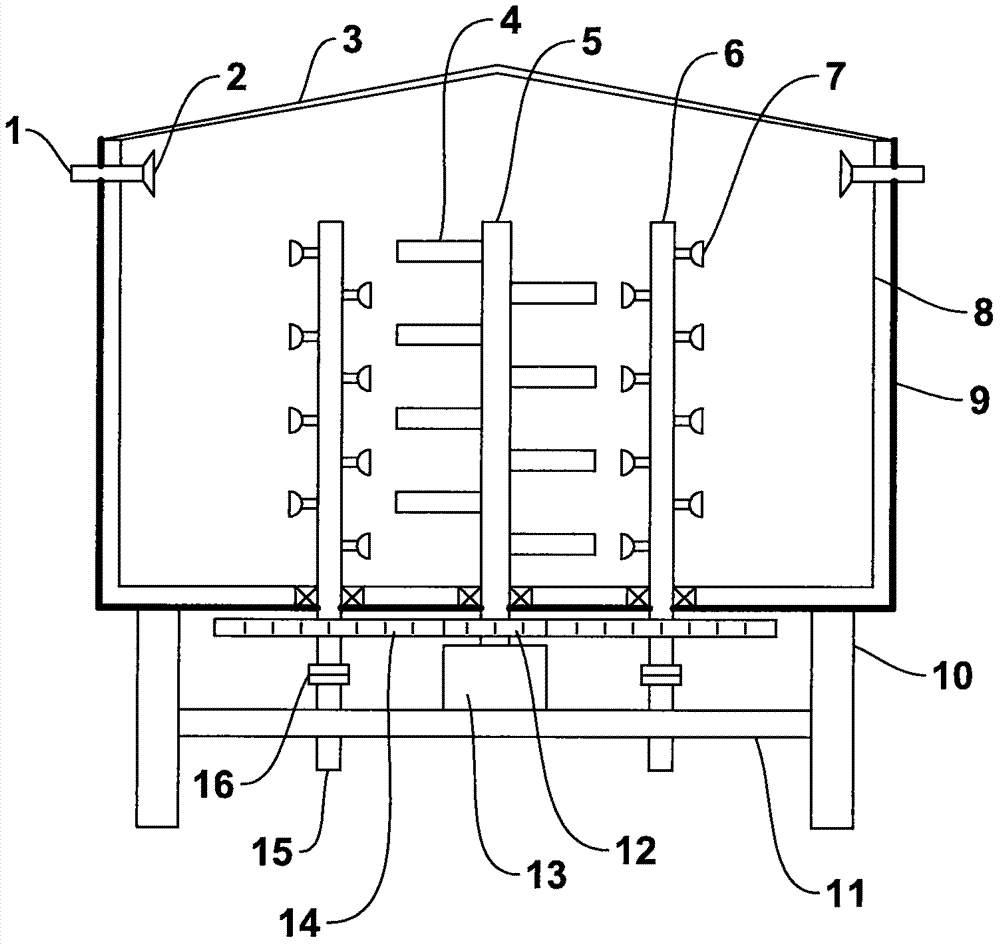

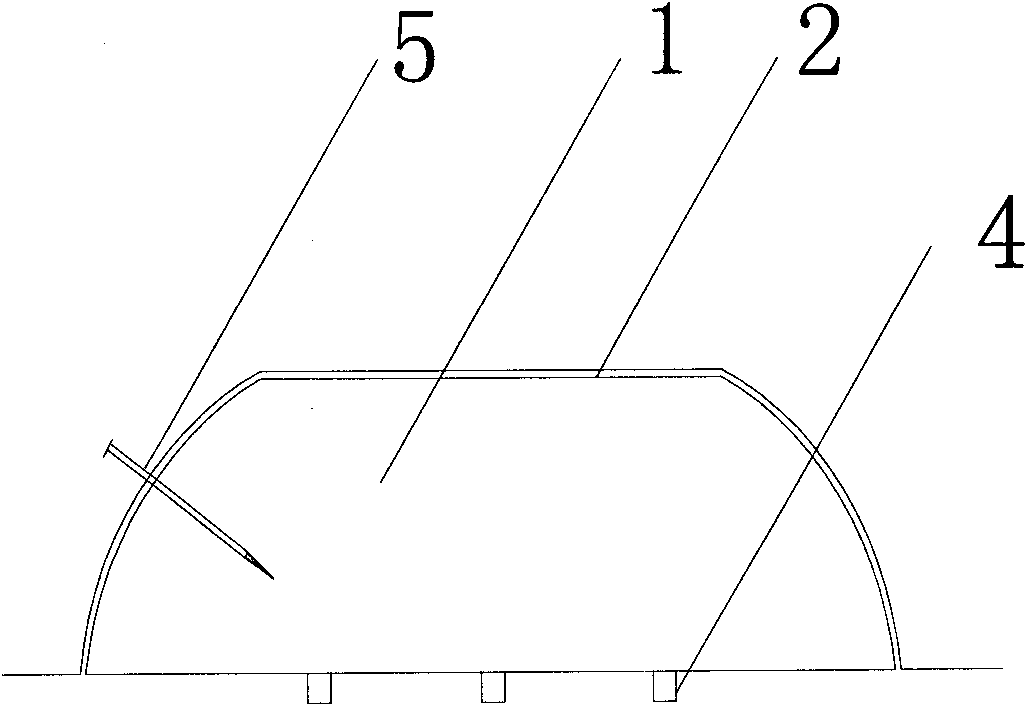

Black tea fermentation machine

ActiveCN103181427AMaintain humidityUniform fermentationPre-extraction tea treatmentBlack teaAgricultural engineering

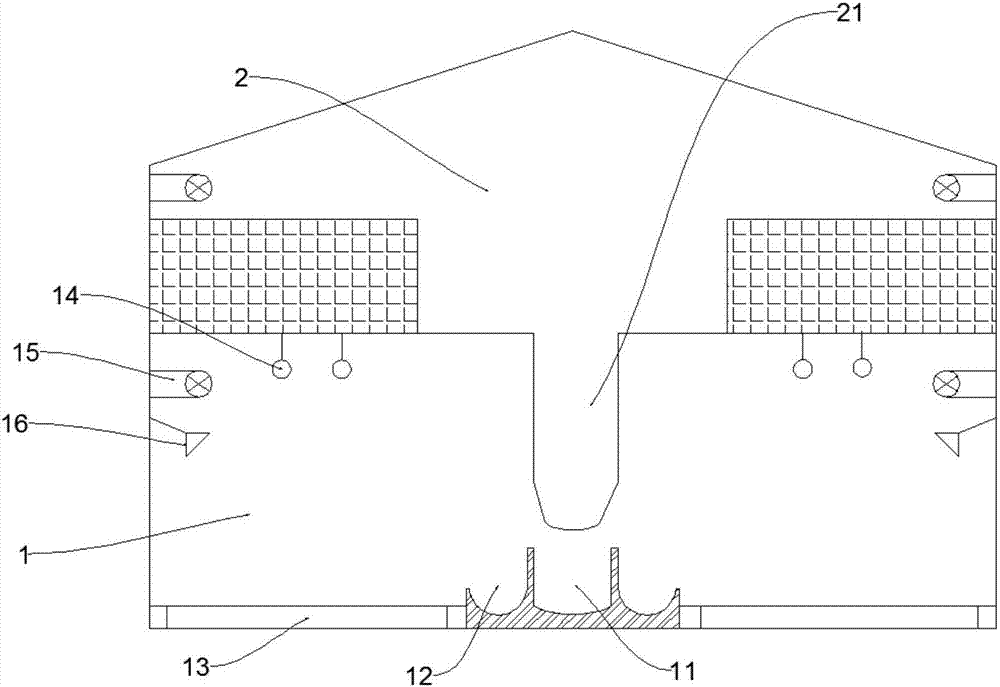

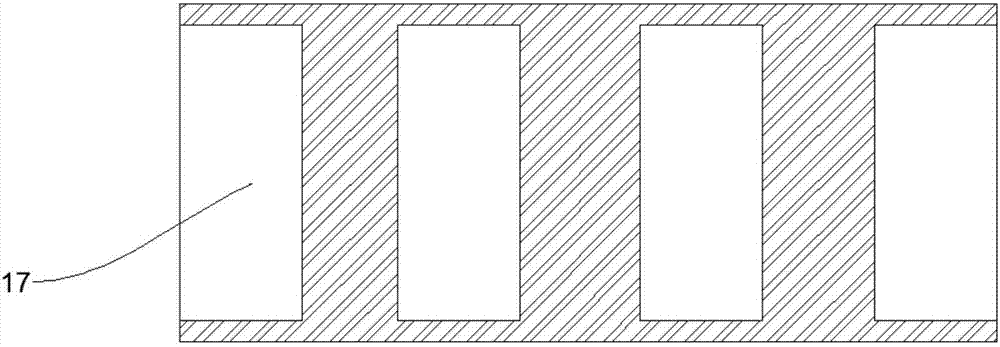

The invention relates to a black tea fermentation machine which comprises a fermentation box, wherein a screen frame is arranged in the fermentation box; at least one fermentation screen is arranged on the screen frame; a hot moisture device used for regulating the humidity, a hot air device used for regulating the temperature, and a control device used for controlling the operation of the fermentation machine are assembled in the fermentation box; and the control device is respectively connected with the hot moisture device and the hot air device. Heat is transmitted into the fermentation box through the hot air device, so that the temperature in the fermentation box is guaranteed; moreover, water is heated through an electric heating tube of the hot moisture device, so that the water is evaporated, and the temperature in the fermentation box is guaranteed; and therefore, the fermentation temperature and humidity can be met at each position on the screen frame, and tea leaves arranged on the screen frame are uniformly fermented, so that the color, aroma and taste of black tea are guaranteed, and the fermentation quality of the black tea is improved.

Owner:FUJIAN JIAYOU TEA MACHINERY INTELLIGENT TECH

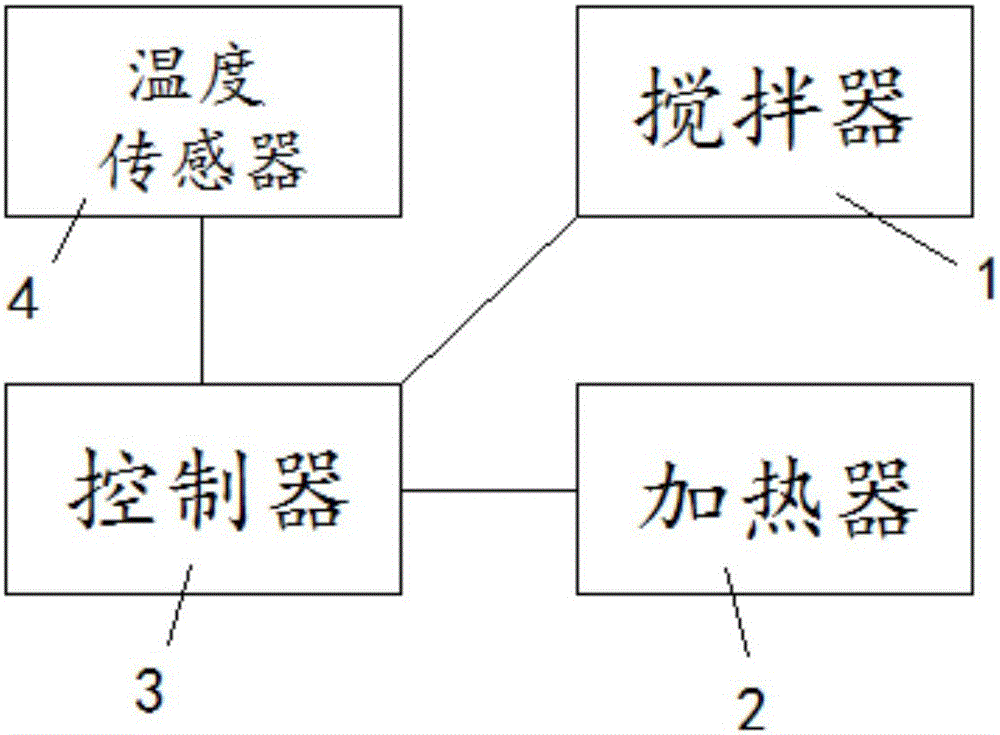

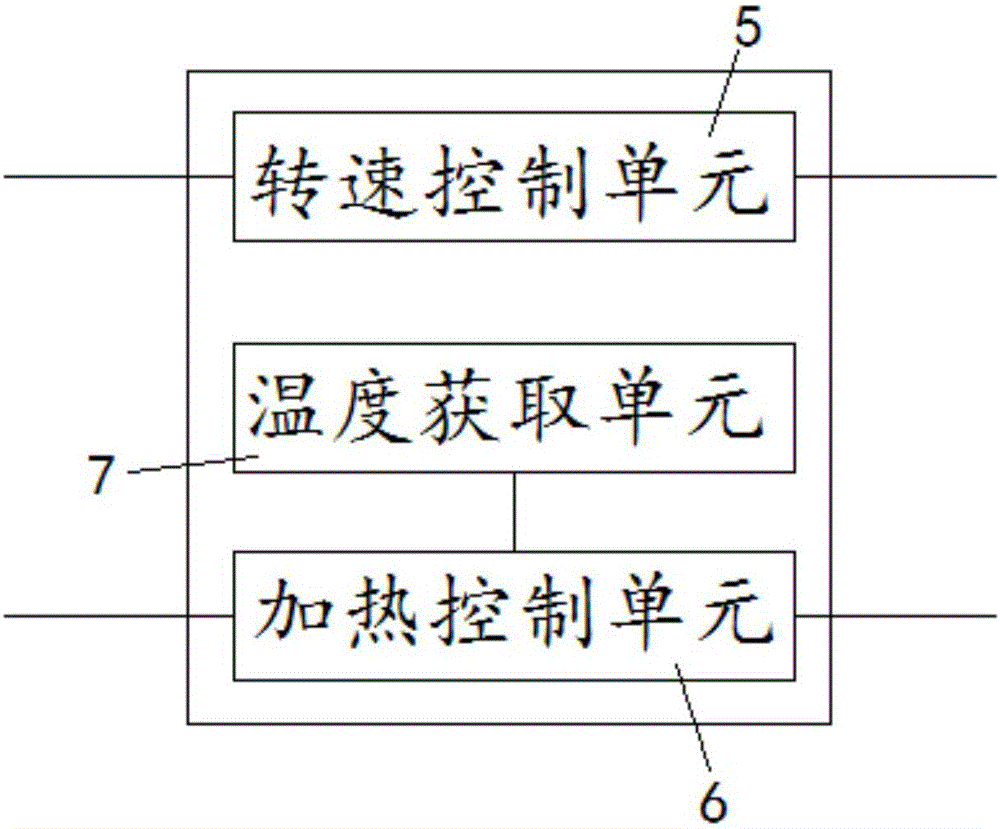

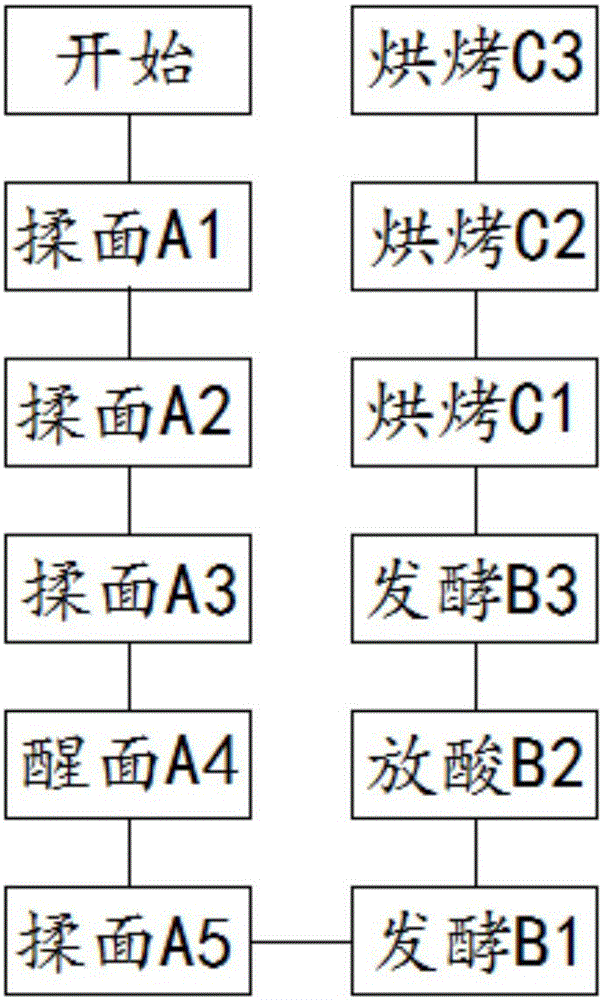

Bread maker control system, device and method

InactiveCN106308566AImprove production efficiencyImprove qualityBread-toastersCooking & bakingControl system

The invention relates to a bread maker controller system, device and method. By means of variable-speed control over stirring rotation speed and duration and precise control over heating temperature and duration in different stage of bread making, combined dough kneading is conducted at different rotation speeds and durations, the manual dough kneading process is simulated, quick film output can be achieved, dough quality is high, time for fermentation and baking in later stages is greatly shortened, and bread making time is greatly shortened. After bread is cut, the bread is uniform in bread pore density, and the bread sends out strong wheat aroma, can be tore into slices and is better in taste.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

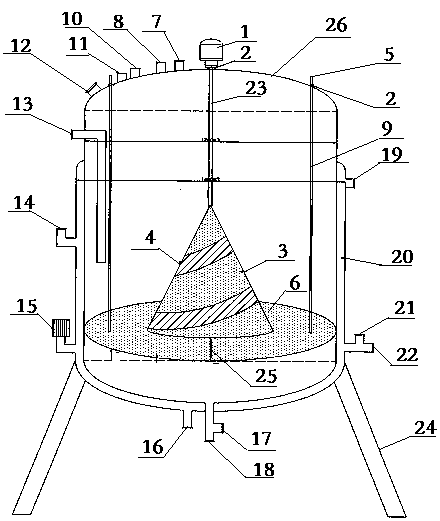

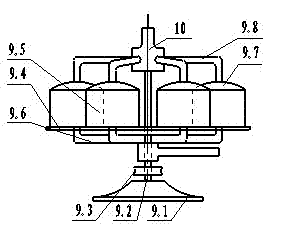

Multifunctional rice wind fermentation tank and process method thereof

InactiveCN108130256AReduce security risksLabor savingAlcoholic beverage preparationEngineeringEnergy consumption

The invention provides a multifunctional rice wind fermentation tank and a process method thereof. Semi-solid rice wine is prepared from sticky rice as a primary raw material. A cone-shaped stirrer and a round partition plate are arranged in the tank body, the round partition plate is arranged below the cone-shaped stirrer, spiral stirring blades are mounted on the cone-shaped surface of the cone-shaped stirrer, a connecting rod is mounted on the cone-shaped stirrer, penetrates through the top of the tank body and is driven by a motor, the round partition plate is composed of two semi-circularpartition plates which can turn around, and any one of the semi-circular partition plates can go up and down along with a tensile rod thereon to be horizontal or vertical to the other semi-circular partition plate. The multifunctional fermentation tank which integrates sticky rice soaking, steaming and cooling and separating steps before rice wine fermentation can finish all the work in th same container by a single person, so that the labor cost is lowered, the resources are saved, the work efficiency is improved, and the product quality is ensured. Multiple tanks are connected in series, sothat hot air and waste water are fully utilized, and the energy consumption cost is lowered.

Owner:湖北晶聚利精密组件有限公司

Method for fermenting old leaves of Kongfu black tea

InactiveCN102246867APromote redistributionSatisfy reassignmentPre-extraction tea treatmentBlack teasHorticulture

The invention discloses a method for fermenting old leaves of Kongfu black tea, which comprises the steps of: taking middle and small-leaf dark brownish green, i.e. one bud has 3-4 leaves; thinly tedding the dark brownish green in an environment with a temperature of 20-30 DEG C and humidity of 70-90%, wherein 2-3 times of flipping is carried out during the process of tedding; fully filling withered leaves in a rolling bucket, rolling at a revolution speed of 35-45 r / min for 50-60 minutes without pressing, then lightly pressing to 1 / 4-1 / 3 of the rolling bucket, and alternating for 10-20 minutes, wherein the time for whole rolling is 75-100 minutes until 85-95% of the rolled leaves become orange and yellow, and the rope-forming rate is 80-90%; and putting the rolled leaves in a fermenting disc, wherein the thickness of piled leaves is 10-12 cm, the environment has a temperature of 20-30 DEG C and humidity of 90-95%, 3-6 times of flipping is carried out during the process until 90-95% of the rolled leaves become yellowish red, have brightly colored luster, and are fragrant and sweet or fruity. The method for fermenting the old leaves of the Kongfu black tea lowers breaking and crushing rate and improves completeness of bud leaves, and the even fermentation is guaranteed.

Owner:GUIYANG CHUNQIU INDAL

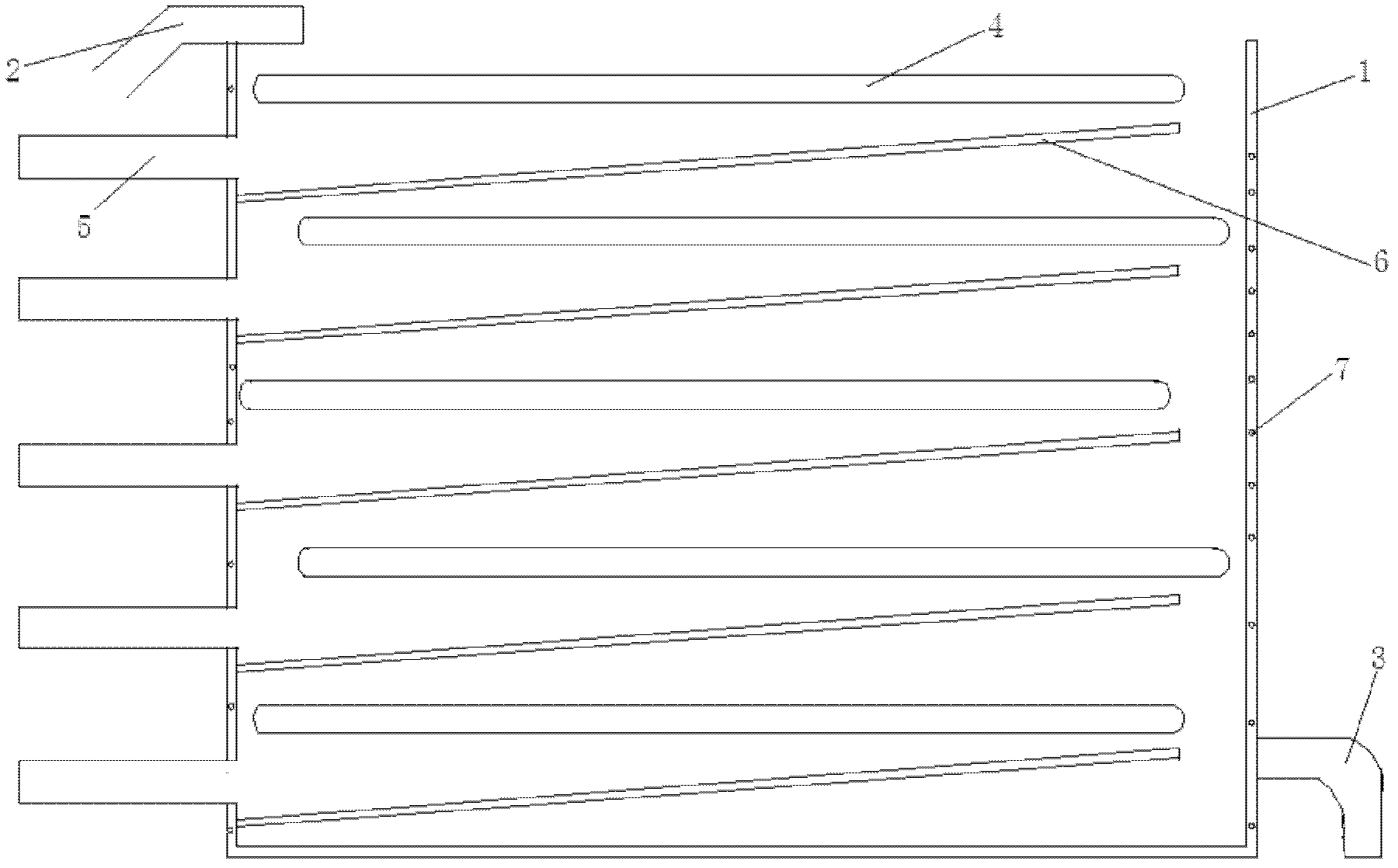

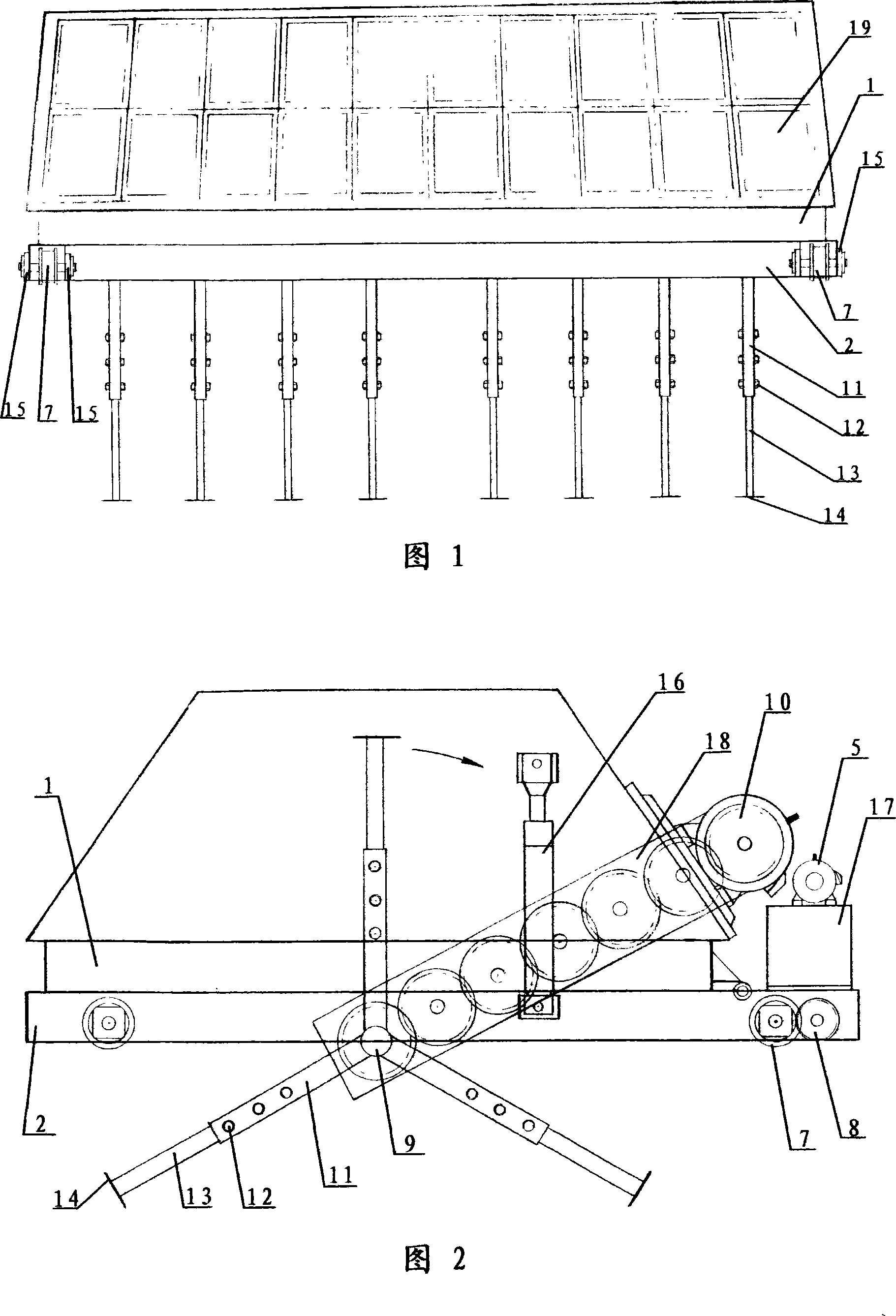

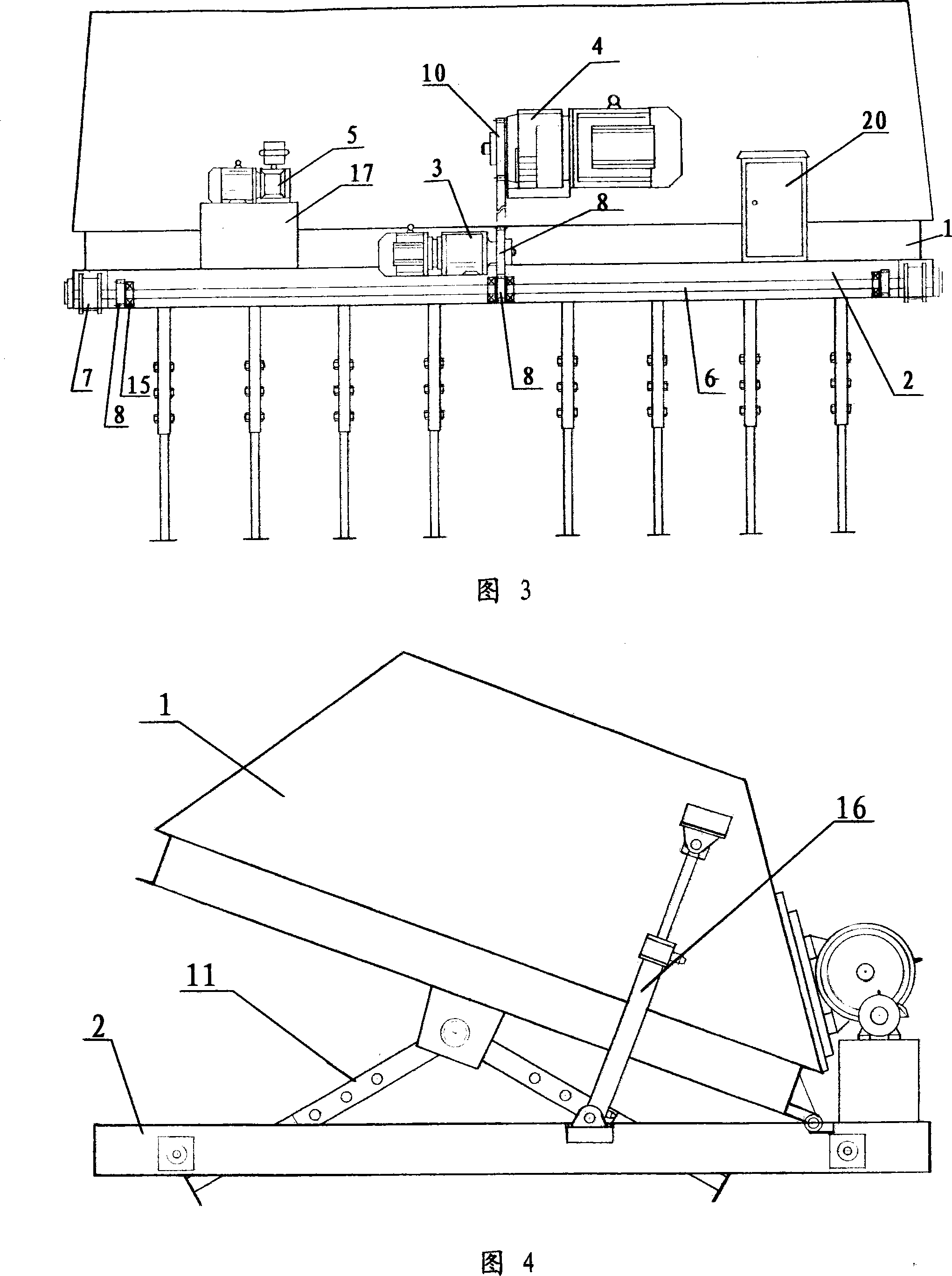

Groove type turning machine for sludge

InactiveCN101168490AUniform fermentationSave energyChemical industryOrganic fertiliser preparationSludgeControl theory

The invention discloses a chute-type sludge turner, which comprise an upper base and a lower base, and a hydraulic lifter between the upper and lower bases, wherein the upper base is horizontally arranged with a turning element connected with a regulating speed motor, the front and back sides of the lower base are provided with running mechanisms connected with the regulating speed motor. The invention has strong turning ability as 120m3 / h, and large turning depth more than 1.2m, breaking and mixing functions on material, firm rake teeth, hydraulic automatic lifting, and full-gear operation, with energy-saving and high efficiency.

Owner:张锦华

Mixed aeration type organic fertilizer fermenting equipment

InactiveCN106927877AIncreased fermentation activityFully fermentedBio-organic fraction processingIrradiation based treatmentOrganic manurePulp and paper industry

The invention discloses mixed aeration type organic fertilizer fermenting equipment, which comprises a fermenting tank. A sun shed is fixedly installed at the top of the fermenting tank. The upper part of the sidewall of the fermenting tank is provided with multiple water supplement pipes. Water spray heads are arranged at the ends of the water supplement pipes at the inner side of the fermenting tank. A mixer shaft is arranged in the middle of the inner side of the fermenting tank, and aerator pipes are arranged at left and right sides of the mixer shaft. Multiple stirring paddles are arranged on the mixer shaft at the inner side of the fermenting tank. Multiple jet heads are arranged on the aerator pipes at the inner side of the fermenting tank. A driving gear is arranged on the mixer shaft at the lower side of the fermenting tank. The lower end of the mixer shaft is provided with a motor. A driven gear is arranged on each aerator pipe at the lower side of the fermenting tank. The lower end of each aerator pipe is connected to an oxygen pipe through a rotating joint. By the use of the equipment, organic fertilizers can be enshrined, fermentation activity is enhanced, fermentation period is shortened, and fermentation quality is guaranteed.

Owner:刘海明

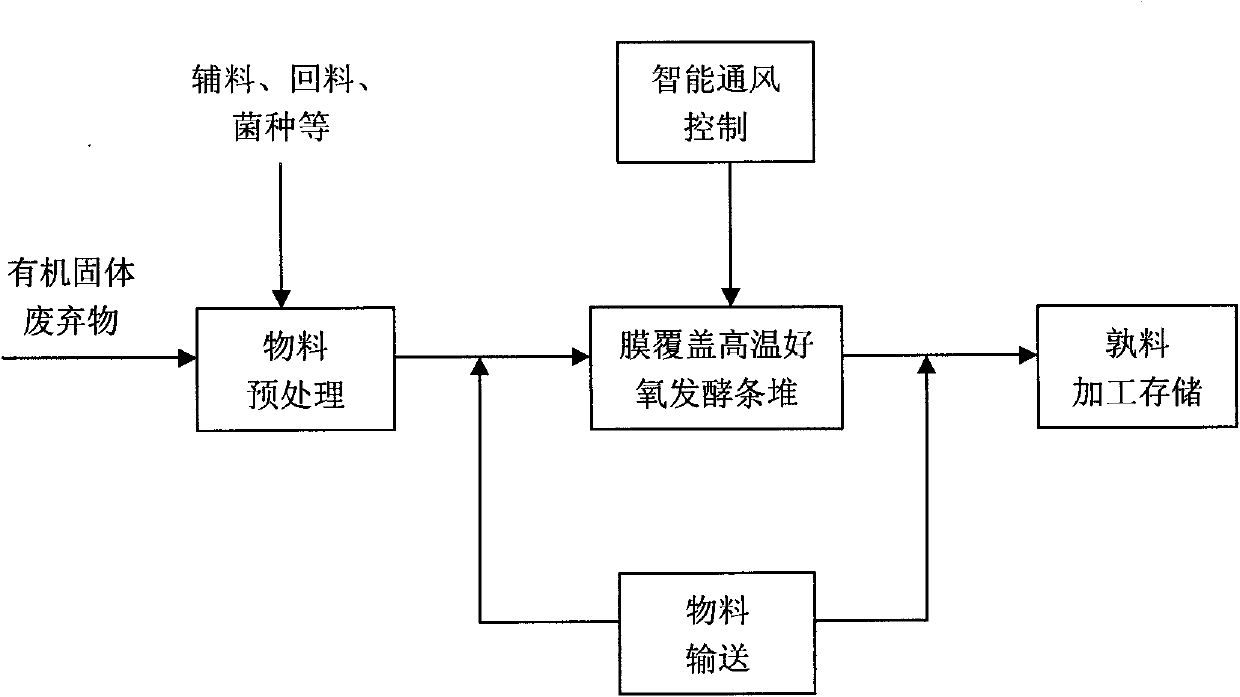

Organic solid waste film covering high-temperature aerobic fermentation method

InactiveCN101792339AThermal insulationReduce the impactBio-organic fraction processingClimate change adaptationControl systemAgricultural engineering

The invention relates to the technical field of organic solid waste processing, in particular to an organic solid waste film covering high-temperature aerobic fermentation method. The fermentation method is characterized in that the organic solid waste is pretreated; the pretreated material is piled in strip pile; the material strip pile is provided with a sensor and covered with a waterproof breathable film; a blower and an air-pipe under the material are used for supplying oxygen to the material; an intelligent ventilating control system is used for optimizing the fermentation process; after the material is fully decomposed, the waterproof breathable film on the material strip pile is removed, and then the material strip pile is transported into a clinker storing or processing area. Compared with the prior art, the fermentation method has short building period, few disposable investment, flexible construction, low operating cost, small odor influence, rain-proof, wind prevention and heat preservation effect and can protect the material from being affected by outside weathers.

Owner:SHANGHAI YUANJUN ENVIRONMENTAL PROTECTION TECH CO LTD

Gas-phase double-dynamic tobacco alcoholization fermentation method

The gas-phase double-dynamic alcoholization fermentation method of tobacco is characterized by that it can make the tobacco raw material placed in fermentation tank implement fermentation under the following conditions; introducing compressed air into fermentation tank and making periodic pulsed pressurization and decompression process, the pressure pressurized into the fermentation tank every time is up to 0.10-0.25 MPa, and retained in 1-50 min., then the pressure is released, and decompressed to 0.0-0.5 Mpa, and retained in 1-60 min., and the periodic pulsed circulation time from pressurization to decompression is 1-120 min., its fermentation temp. is 26-46 deg.C, humidity is 80%-95%, and the fermentation time is 20-30 day so as to implement gas-phase double-dynamic fermentation of tobacco alcoholization, and can raise colour and taste of tabacco.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Intelligent black tea fermentation device

InactiveCN103564073AImprove fermentation qualityReduce consumptionPre-extraction tea treatmentInfraredMicrocomputer

The invention discloses an intelligent black tea fermentation device which comprises a fermentation box, wherein the housing of the fermentation box is mainly made of toughened glass, and a temperature and humidity control device is arranged at the fermentation box. The toughened glass can absorb a large number of infrared radiation energy and can also keep good visible light transmittance. The toughened glass is applied to four surfaces of the housing of the fermentation box and can absorb solar radiation to ferment black tea, so that electric energy consumption is reduced, and low-carbon environment-friendly production is realized. The toughened glass is a transparent material, so that the fermentation conditions of the black tea in the fermentation box can be conveniently observed from different directions at any time. The temperature and humidity control device is controlled by a microcomputer and regulates and controls the temperature and humidity needed by fermentation through a fan and a mist spray faucet, so that each position of each layer of gauze screen on a fermentation frame can achieve the temperature and humidity condition needed by fermentation so as to ensure that the tea fermentation is more uniformly, therefore the color, the fragrance and the taste of black tea are ensured, and the fermentation quality of the black tea is increased. The intelligent black tea fermentation device has the advantages of convenience in operation, energy conservation, environmental friendliness and easiness in promotion and application.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Soybean meal fermentation process

InactiveCN103829031AShort fermentation timeReduce manufacturing costAnimal feeding stuffBiotechnologyBiological activation

The invention provides a soybean meal fermentation process. The soybean meal fermentation process mainly comprises the following steps: raw material clearing, strain activation, strain culture and domestication, mixed inoculation, fermentation, low-temperature drying, cooling, crushing, screening and packaging. The soybean meal fermentation process provided by the invention has the main characteristics that a compound bacterium solution obtained by reasonable matching of various bacterium solutions is adopted for the mixed inoculation, and through the synergy of multiple strains, the fermentation time is shortened, and the production cost is reduced. In addition, temperature and humidity environments for material fermentation are guaranteed during fermentation, and materials are stirred at regular time in a fermentation process to ensure uniform fermentation of the materials. The fermented materials are uniform in quality and high in nutritional value, and the absorption rate of animals to feed is improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

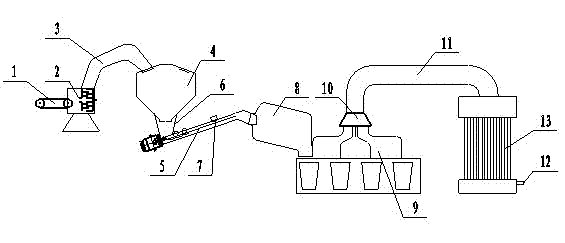

Brewing device by taking sweet sorghum stalks as raw materials

InactiveCN102586081AAvoid pollutionEvenly mixedBioreactor/fermenter combinationsBiological substance pretreatmentsCooling towerEngineering

The invention relates to the field of preparation of alcohol from sweet sorghum stalks, in particular to a brewing device by taking the sweet sorghum stalks as raw materials. According to the brewing device, the problems of more dust, difficulty in degerming, incapable of realizing continuous production, long fermentation time, low alcohol yield by crushing and conveying raw materials in open airin the prior art are solved. The sweet sorghum stalks are fed into a crushing machine through a raw material conveyor, are crushed and then are fed into a sterilizing and collecting tank through an airtight pipeline; the sterilized materials are fed into the conveyor and are simultaneously inoculated by an inoculated spraying pipe; the materials are mixed with bacteria and stirred and then are fed into a rotary drum type solid state fermentation tank in a closed form for fermenting; the fermented materials are fed into an alcohol distiller for continuously distilling in a closed form; and steam containing alcohol enters a cooling tower for separating. The brewing device has the advantages that the fermenting time is short, various indexes are easily controlled, the mixing degree is of thestrain is uniform and the fermenting materials are balanced in fermentation; the pollution to the environment is avoided, so that the fermentation is cleaner; and the quality of products is improved,continuous operation can be ensured and the production efficiency is improved.

Owner:山西鼎圣精工机械制造股份有限公司

A production method for chicken manure fermented feed

InactiveCN104642767AIncrease contentImprove palatabilityFood processingAnimal feeding stuffBiotechnologyHazardous substance

The present invention discloses a production method for chicken manure fermented feed, and relates to the technical field of feed processing. The feed is compounded from the following raw materials by weight percent: 60% to 70% of fresh chicken manure, 10% to 15% of corn flour, 10% to 15% of wheat bran, White lees of 5% to 10% of white distiller's grains and 0.2% to 0.3% of microbial fermentation agents. The production steps are as follows: a, taking materials; b, compounding materials, c, adjusting water content; d, sealing; and e, fermentation. According to the invention, microbial fermentation agents are added to the raw materials to carry out sealed fermentation, so that the raw materials are decomposed and transformed, parasite eggs and pathogenic bacteria are killed, harmful substances are degraded and removed, content of absorbable proteins, sugars, amino acids is increased, and palatability of the feed is greatly improved.

Owner:南丹县水产畜牧兽医局

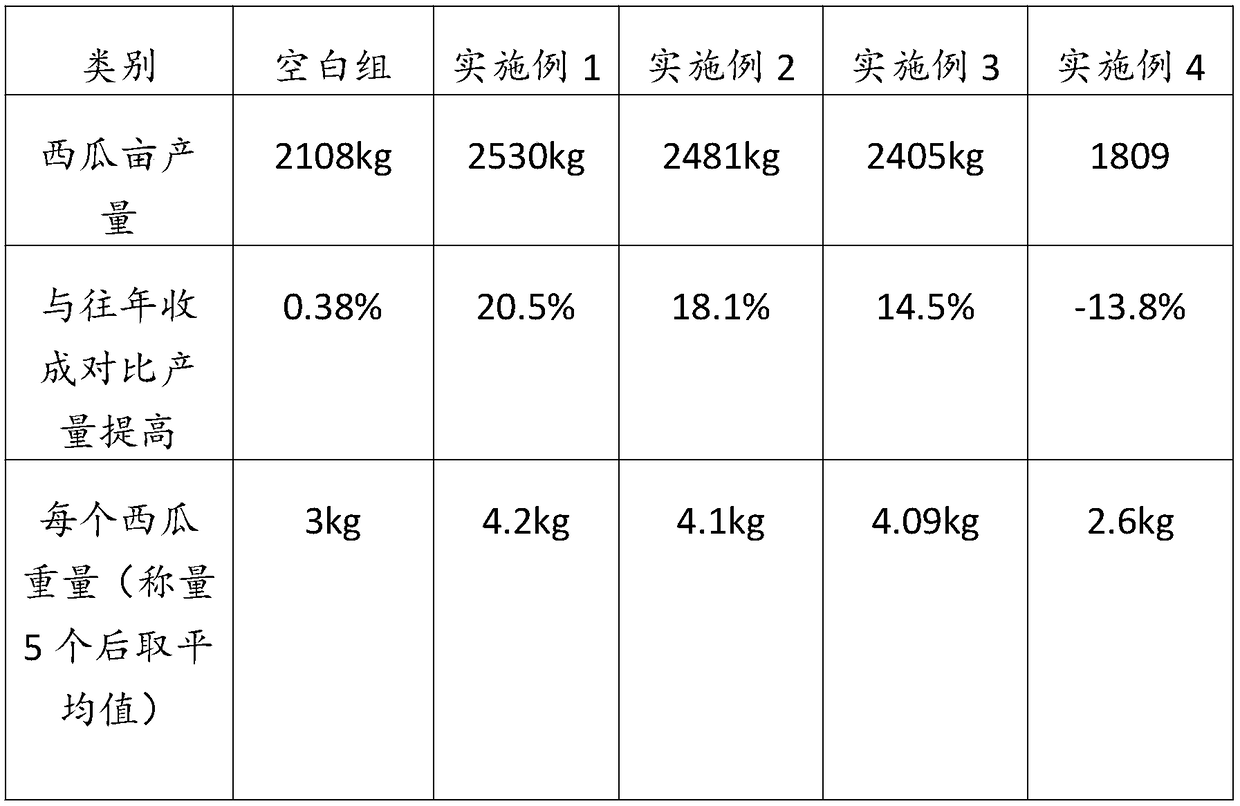

Selenium-rich beef breeding method

InactiveCN107148942AImprove nutritional statusPromote growthFood processingAnimal feeding stuffAnimal scienceFarmyard manure

The invention discloses a selenium-rich beef breeding method. The selenium-rich beef breeding method comprises the following steps: planting and processing selenium-rich forage: applying selenium-containing farmyard manure to a grassland, sowing ryegrass and Chinese trumpet creeper in a mixed manner, and spraying a selenium-containing leaf fertilizer to obtain a selenium-rich feed; providing an oxtall for selenium-rich beefs: stacking the feed on an upper-layer oxtall, and breeding the beefs on a lower-layer oxtall; fattening the selenium-rich beefs: feeding the beefs with the selenium-rich feed; and slaughtering the selenium-rich beefs. As the selenium-rich forage is planted on the grassland and then prepared into the selenium-rich feed to feed the beefs, direct ingestion of sodium selenite is avoided, and an accident of selenosis cannot occur; and meanwhile, as the forage converts selenium absorption into the existence form easily absorbed by the beefs, selenium absorbed by the beefs is safe and reliable, the selenium content of the beefs reaches high indexes, and accordingly, the nutrition value of the beefs is effectively improved.

Owner:农元荣

Full-automatic intelligent wine brewing machine

ActiveCN104342354AGuaranteed pressureNovel structureAlcoholic beverage preparationAutomatic controlProcess engineering

The present invention discloses a full-automatic intelligent wine brewing machine, which comprises a sealed housing, a heater, a cooling condensing device and an automatic control device, and is characterized in that the middle of a cooling tank is divided into a condensing tank and a heating tank through two separation plates, a semiconductor refrigeration system is arranged between the two separation plates, the semiconductor refrigeration sheet of the semiconductor refrigeration system is fixedly connected with the condensing tank, the semiconductor heat elimination sheet is fixedly connected with the heating tank, a water jacket sleeves on the outer wall of the cylinder, the upper portion of the water jacket is provided with a liquid inlet, the lower portion is provided with a liquid outlet, the liquid inlet on the lower end of the heating tank is communicated with the liquid outlet of the water jacket through a liquid inlet pipe, the liquid outlet on the upper end of the heating tank is communicated with the liquid inlet of the water jacket through a liquid outlet pipe, the upper end of the condensing tank is communicated with the liquid outlet of the water jacket through the upper control valve on the liquid inlet pipe, and the lower end is communicated with the liquid inlet of the water jacket through the lower control valve on the liquid outlet pipe. The full-automatic intelligent brewing machine has advantages of complete fermentation, easy cleaning, automatic slag discharge, energy source saving and the like.

Owner:威海品诚贸易有限公司

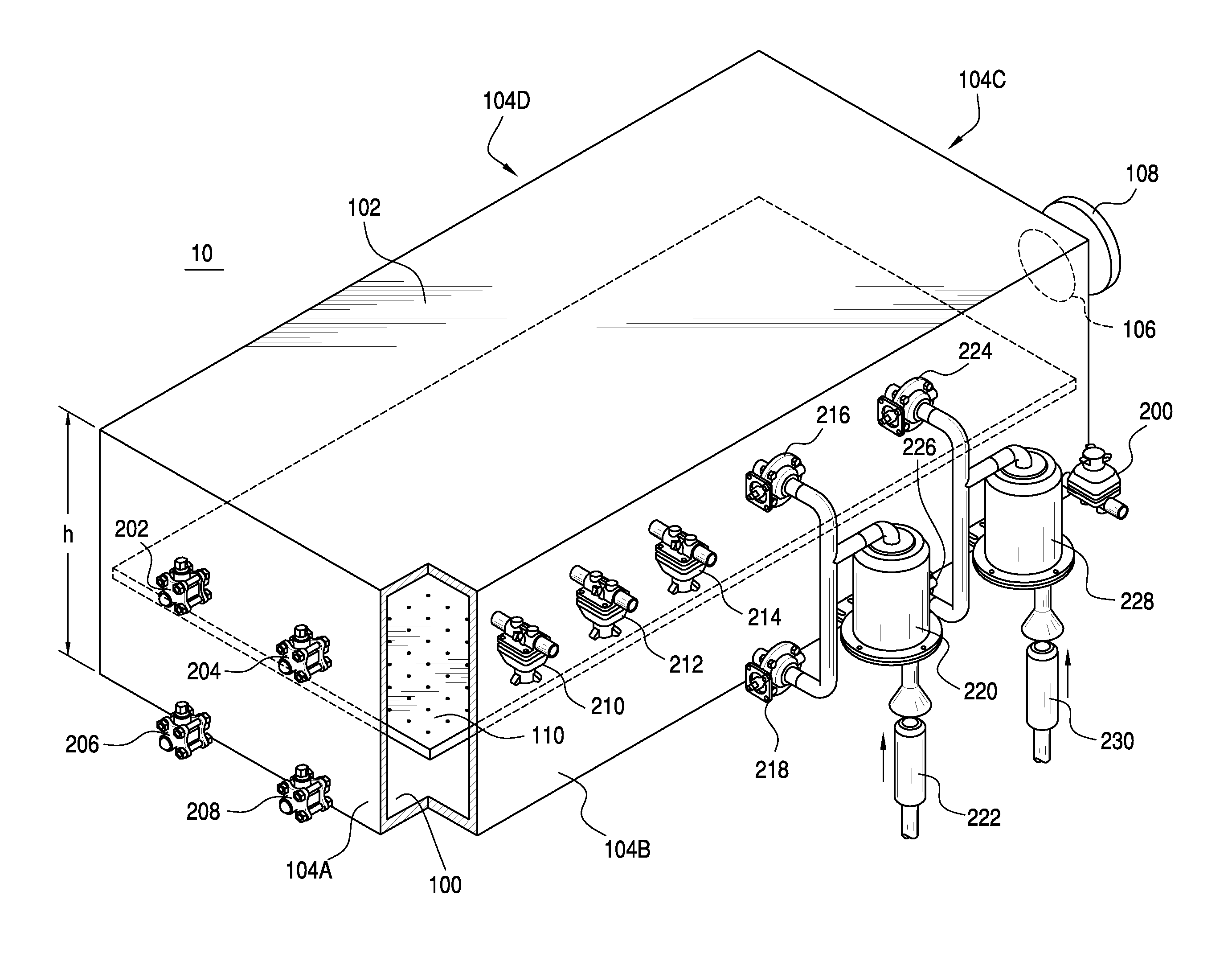

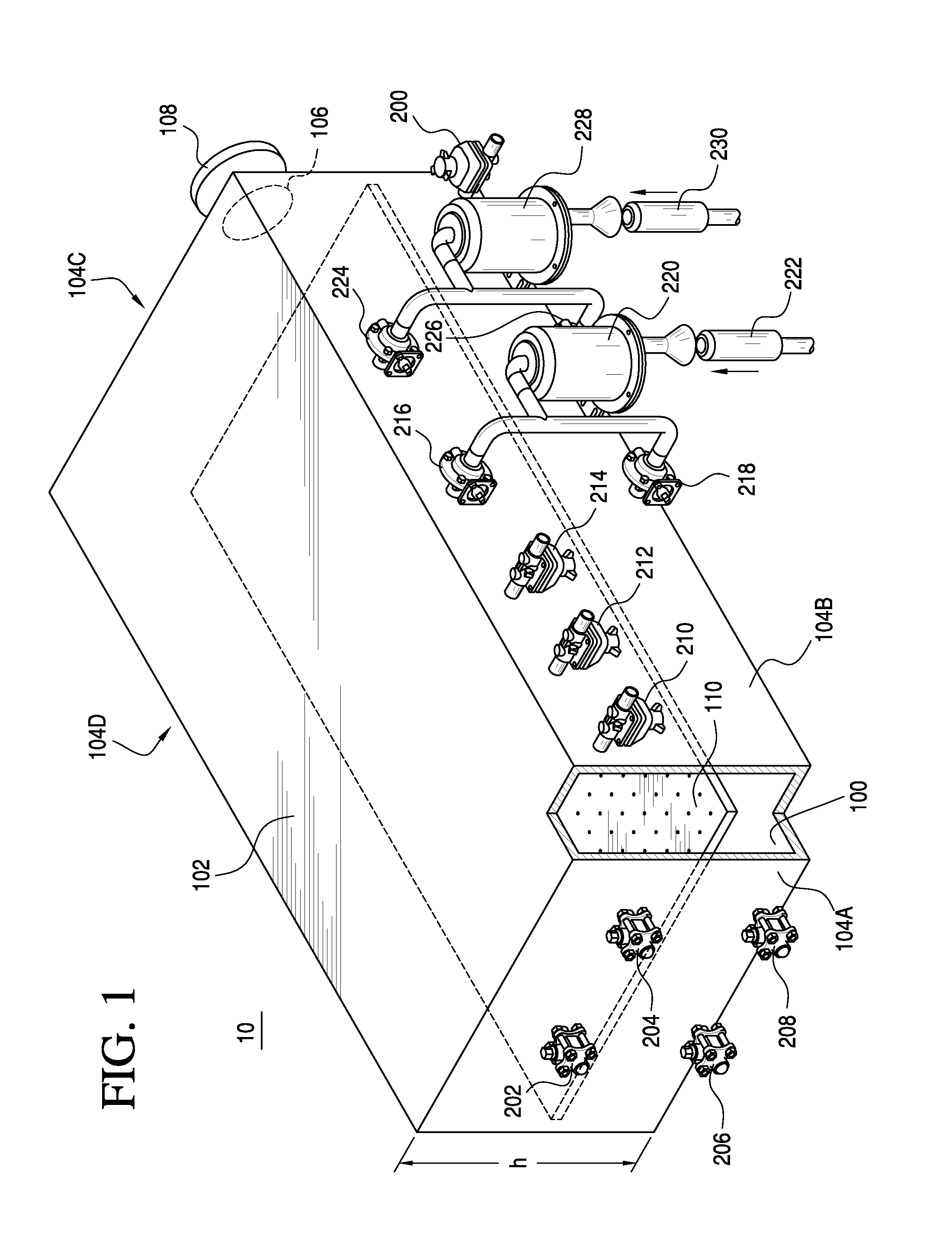

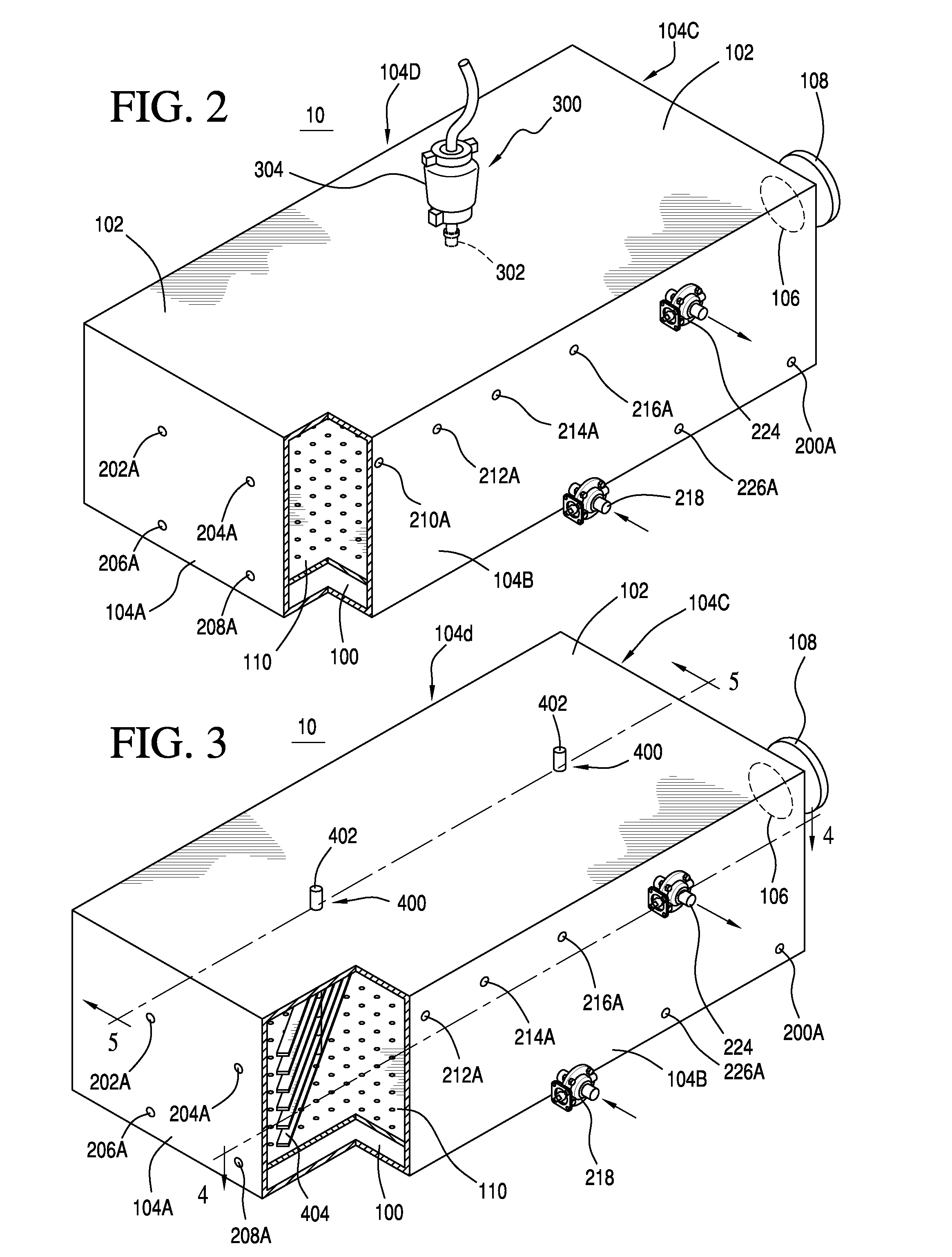

Solid state bioreactor adapted for automation

InactiveUS20150166945A1Uniform fermentationReduce operating costsBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBioreactor

Production-scale solid state bioreactors designed to facilitate and maximize the automation of solid-state fermentation processes while maintaining sterile transfer of materials. The invention also provides automated solid-state fermentation systems that include the bioreactors and related methods of solid state fermentation utilizing the bioreactors.

Owner:NOVOZYMES BIOAG AS

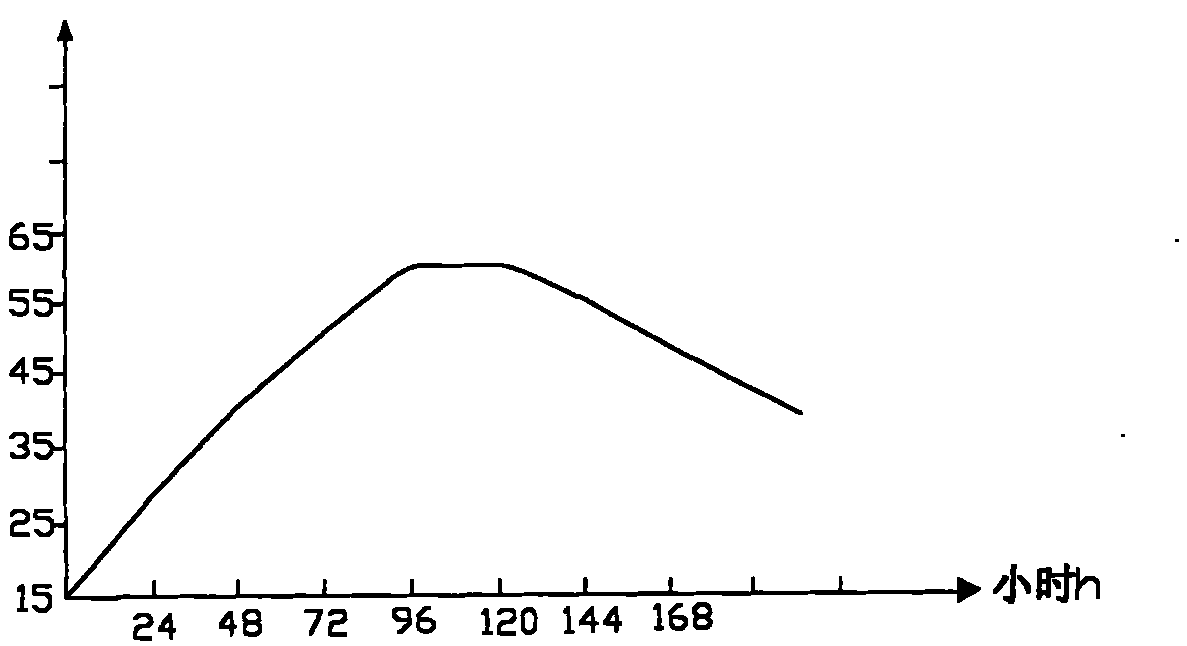

Congou black tea dynamic fermentation method

InactiveCN104543068AUniform fermentationFermentation is not regulated evenlyPre-extraction tea treatmentBiotechnologyPolyphenol

The invention provides a Congou black tea dynamic fermentation method. The method comprises the following steps: selecting Fuding white fresh leaf raw materials in the tenderness from one-bud-one-leaf to one-bud-two-leaf, conducting withering and twisting processes according to traditional Congou black tea processing, deblocking the twisted leaf, regulating and controlling temperature, relative humidity, oxygen concentration and the like of the fermentation environment at the beginning of fermentation, placing the twisted leaf in a dynamic fermentation cylinder of a detachable fermentation device, driving a rotary cylinder to uniformly rotate through a linked motor, and enabling the fresh leaf in the rotary cylinder to slowly slide in the fermentation process so as to realize dynamic fermentation. The inherent ideas of the conventional fermentation that the oxygen concentration of the fermentation environment is not regulated and controlled, and the temperature humidity of the fermentation is roughly regulated and controlled are broken through, the fermentation temperature, relative humidity, oxygen concentration and the like can be precisely regulated and controlled through the detachable fermentation device, uniform fermentation of the leaf is realized, parts of the fermented leaf can be uniformly regulated and controlled through outside parameters, polyphenol oxidative polymerization reaction of the leaf is uniformly conducted, and the black tea product with excellent sensing quality is obtained.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

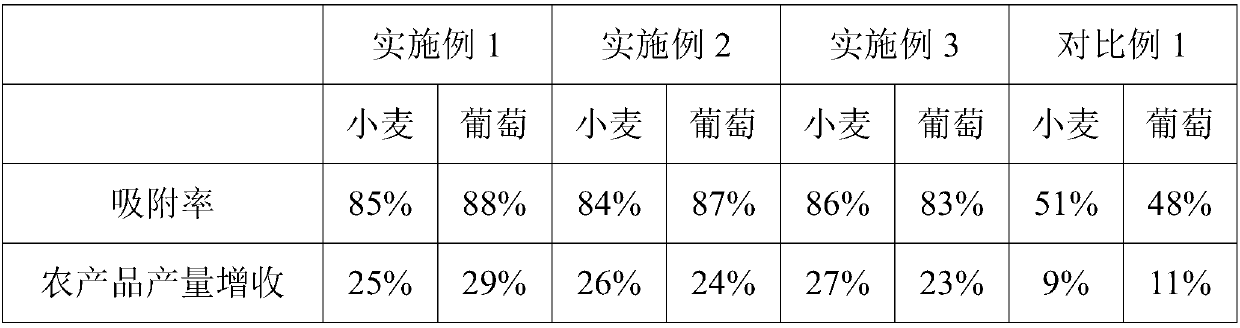

Bio-organic fertilizer for absorbing heavy metals and preparation technology thereof

InactiveCN109534897AReduce contentQuality improvementMagnesium fertilisersExcrement fertilisersDiseasePlant disease

The invention discloses a bio-organic fertilizer for absorbing heavy metals. The bio-organic fertilizer is characterized by comprising the following components in parts by weight: 33-45 parts of substrate, 12-18 parts of microbial flora and 19-27 parts of inorganic heavy metal absorbing material, wherein the substrate comprises the following components in parts by weight: 30-42 parts of animal waste, 26-38 parts of plant straw, 12-19 parts of rice hull and 11-20 parts of wheat bran. The microbial flora and the inorganic heavy metal absorbing material in the bio-organic fertilizer can effectively absorb heavy metal ions in soil, can mutually boost, are capable of promoting soil quality while removing heavy metals and are beneficial to growth of crops; fermenting raw materials are placed into a plug flow type fermentation cabin for fermenting, and meanwhile, a stirrer is adopted for continuously stirring, so that fermentation is more sufficient and uniform, quality and use ratio of bio-organic fertilizer can be promoted and the bio-organic fertilizer can be more fully decomposed and utilized to improve soil and reduce diseases.

Owner:南京国龙生物科技有限公司

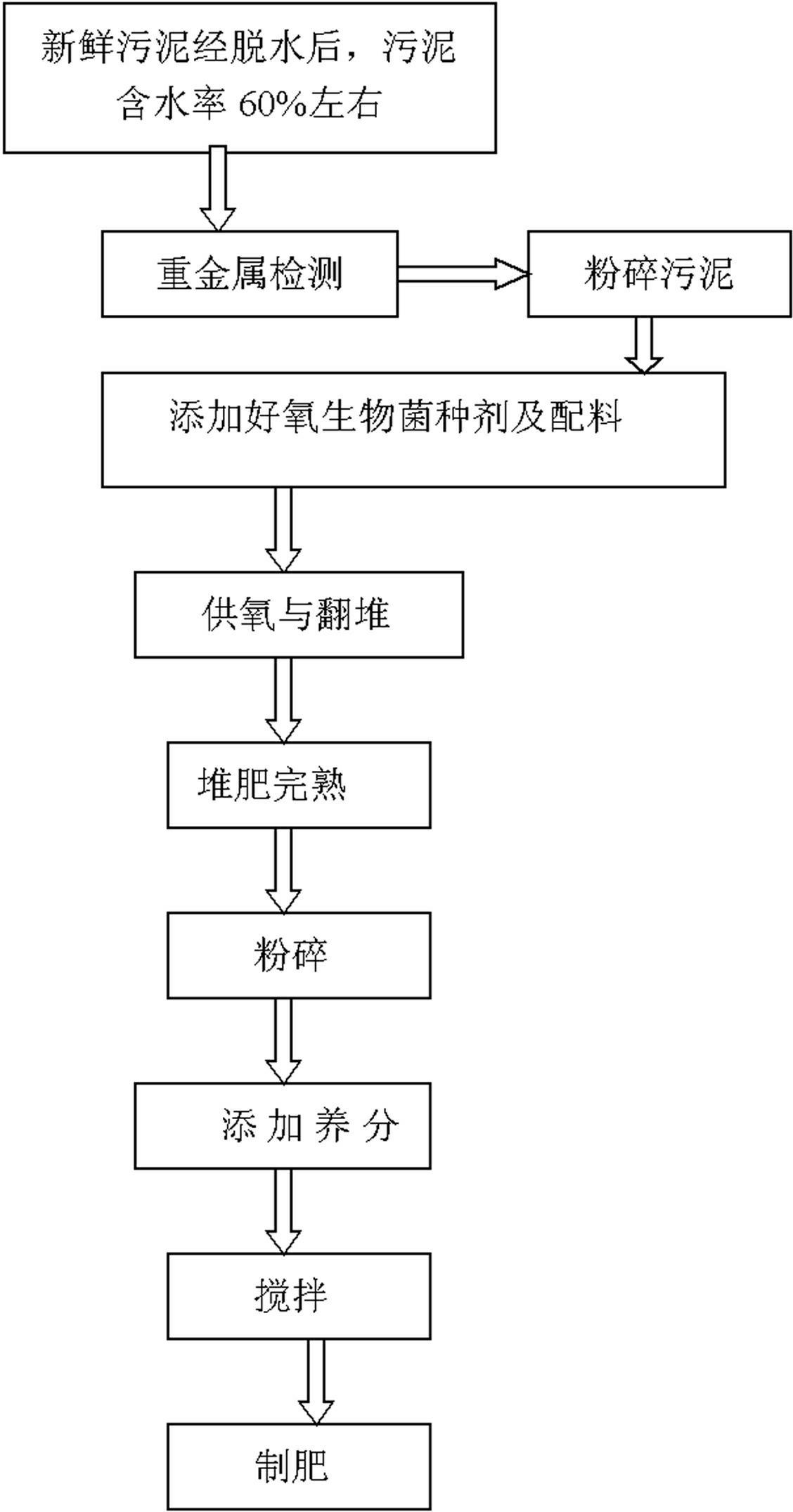

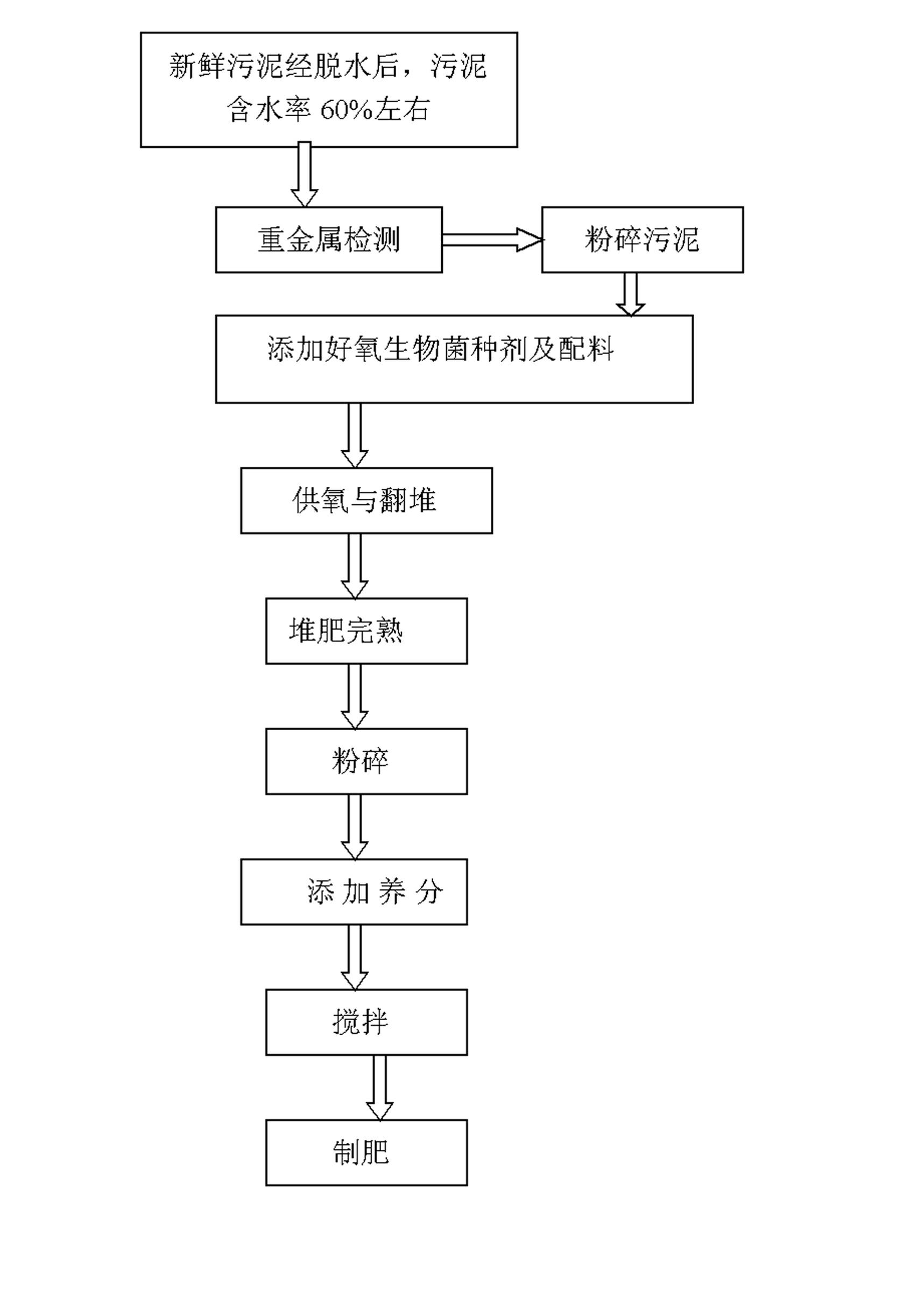

Method for preparing fertilizer by using domestic sludge

InactiveCN102093098AAvoid pollutionAchieve recyclingBio-organic fraction processingClimate change adaptationSludgeDecomposition

The invention discloses a method for preparing a fertilizer by using domestic sludge, which comprises the following steps of: (1) reducing the water content of the domestic sludge to be less than 60 percent; (2) crushing; (3) adding aerobic biological strains and accessories to perform high-temperature fermentation on the domestic sludge till thorough decomposition; (4) supplying oxygen to the domestic sludge and turning; (5) after the compost is thoroughly decomposed, crushing the blocky sludge; (6) adding nutrients; (7) stirring; and (8) preparing a granular or powdery organic fertilizer. The method realizes sterilization, ova killing, uniform fermentation and stable quality; and the prepared fertilizer is used for agricultural and forest production, and fulfills the purpose of recycling resources.

Owner:中山市祥源环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com