Method for improving quality of strong aromatic dry distilled grain

A technology of Luzhou-flavored and dry lees wine, applied in the preparation of alcoholic beverages, etc., can solve the problems of poor quality of pit mud, bacterial infection, easy shedding, etc., achieve less starch loss, prevent bacterial infection, and reduce free water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

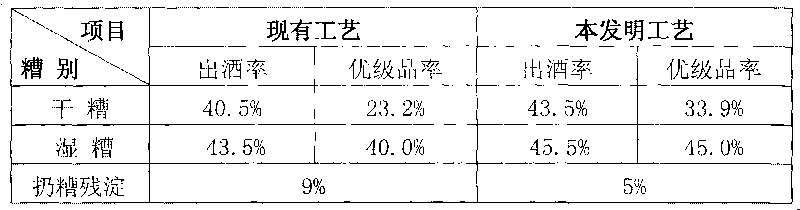

Examples

Embodiment 1

[0044] Example 1 A method for improving the quality of distilled spirits made from five kinds of grains

[0045] The method uses five grains of sorghum, corn, wheat, glutinous rice and rice as raw materials, and the proportioning is carried out according to the weight percentage of sorghum 30%: corn 25%: wheat 17%: glutinous rice 13%: rice 15%.

[0046] The method has the following steps:

[0047] 1. Raw material pretreatment process

[0048] Wash and soak the sorghum in hot water at 95°C for 3 hours, drain the water, and let it dry naturally at room temperature for 4 hours, so that the grains can absorb water sufficiently and evenly, and there is no hard core when pinched by hand. The opening rate reaches 93%, and the water content reaches 55%, then atmospheric pressure dry steaming for 60 minutes;

[0049] Soak the wheat in hot water at 90°C for 3 hours, drain the water, and let it dry naturally at room temperature for 3 hours, so that the grains absorb enough water, the g...

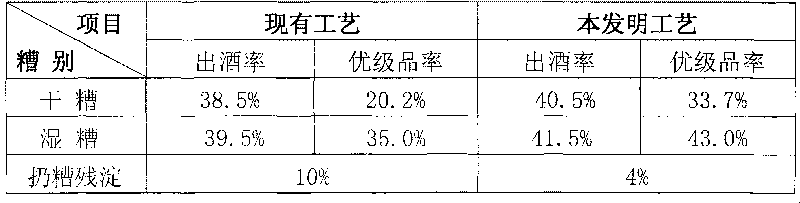

Embodiment 2

[0071] Example 2 Method for Improving the Quality of Dry Distiller's Distillers' Grains Using Sorghum, Wheat, and Corn as Raw Materials

[0072] The method uses sorghum, wheat and corn as raw materials, and the proportioning is carried out according to the weight percentage of 55% sorghum: 25% wheat: 20% corn.

[0073] The method has the following steps:

[0074] 1. Raw material pretreatment process

[0075] Wash and soak the sorghum in hot water at 92°C for 2 hours, drain the water, and let it dry naturally at room temperature for 3 hours, so that the grains can absorb water sufficiently and evenly, without hard core when pinched by hand, with an opening rate of 93% and a water content of 50%, then atmospheric pressure dry steaming for 70 minutes;

[0076] Soak the wheat in hot water at 90°C for 3 hours, drain the water, and let it dry naturally at room temperature for 4 hours, so that the grains absorb enough water, the grains are pinched without hard core, the grains reac...

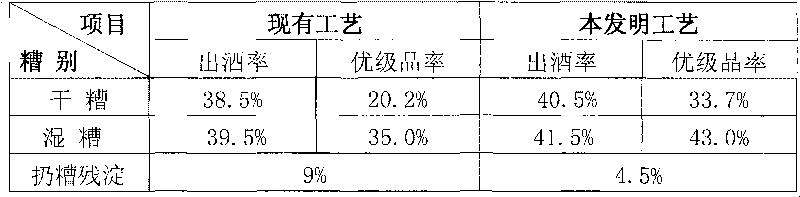

Embodiment 3

[0094] Example 3 The method for improving the quality of distilled spirits made from four kinds of grains

[0095] The method uses four grains of sorghum, wheat, corn and rice as raw materials, and the proportioning is carried out according to the weight percentage of 45% sorghum: 19% wheat: 20% corn: 16% rice.

[0096] The method has the following steps:

[0097] 1. Raw material pretreatment process

[0098] Wash and soak the sorghum in hot water at 94°C for 6 hours, drain the water, and let it dry naturally at room temperature for 1 hour, so that the grains can absorb water sufficiently and evenly, and there is no hard core when pinched by hand. The opening ratio reaches 94%, and the water content reaches 54%, then atmospheric pressure dry steaming for 75 minutes;

[0099] Soak the wheat in hot water at 80°C for 4 hours, drain the water, and let it dry naturally at room temperature for 2 hours, so that the grains can absorb enough water, no hard core when pinched, the grai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com