Patents

Literature

57results about How to "Reduce free water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

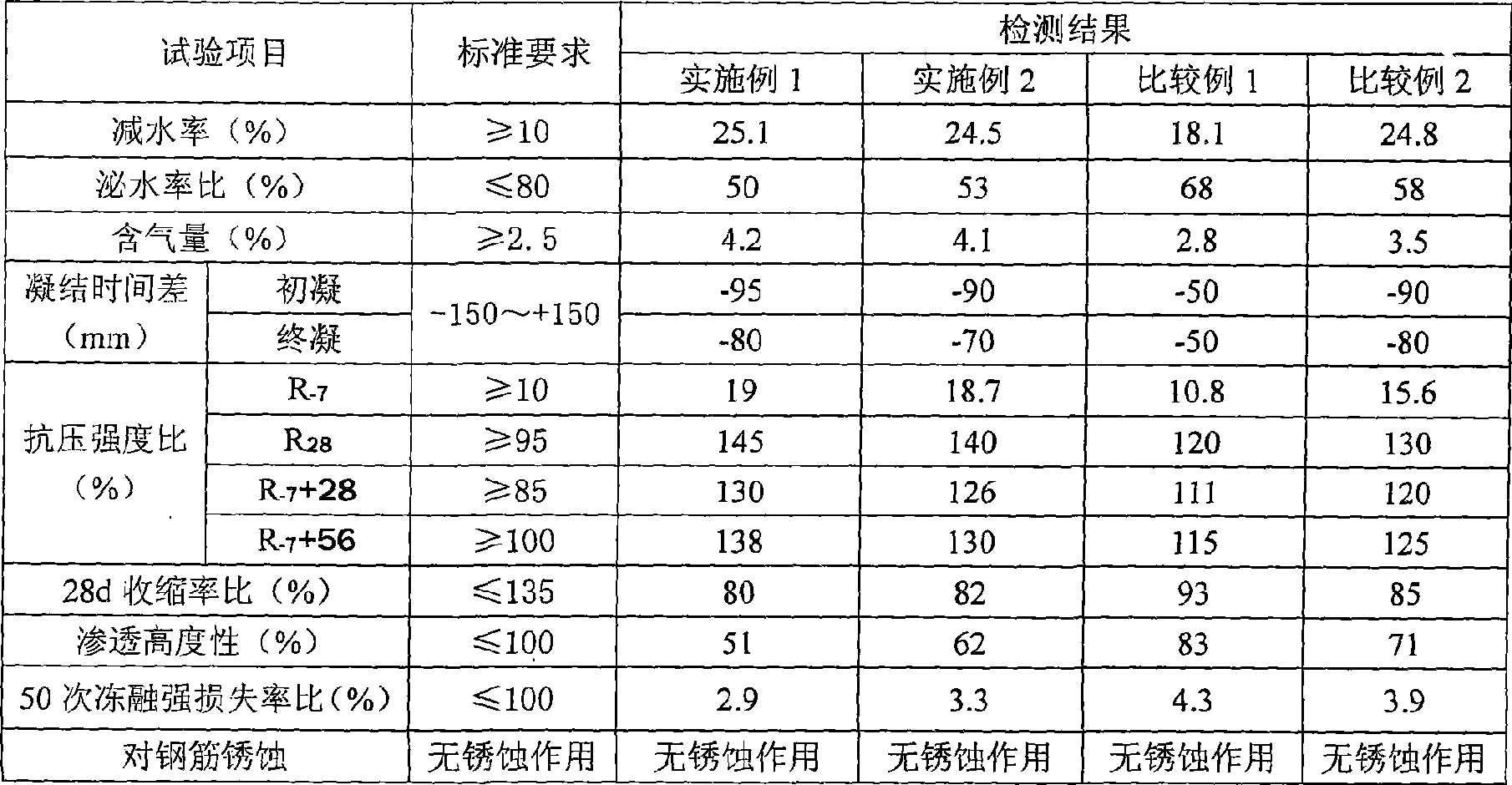

High-early strength antifreezing polycarboxylate high performance water reducing agent and preparation

The invention discloses an early-strength antifreezing polycarboxylate high-performance water reducing agent and a method for preparing the same. The early-strength antifreezing water reducing agent is prepared from a polycarboxylate water reducing agent, an early-strength antifreezing agent, an air entraining agent and water. The method comprises the following steps: A, the synthesis of the polycarboxylate high-performance water reducing agent: (1) esterification reaction; adding methacrylic acid, and the like to a reaction kettle, and (2) polymerization reaction; heating big monomer methoxy polyethyleneglycol methacrylic ester; B, the preparation for the solution of an early-strength antifreezing agent: a, weighing water and adding the same to the reaction kettle, and adding calcium formate to the reaction kettle, and b, adding triethanolamine, and the like to the reaction kettle to prepare the early-strength antifreezing agent solution; C, the preparation of the air entraining agent: weighing water and adding the same to the reaction kettle, and adding powdered three-level colophony to the reaction kettle to obtain the air entraining agent; and D, the preparation of the finished product: weighing the polycarboxylate water reducing agent and adding the same to the reaction kettle, and adding the air entraining agent and the early-strength antifreezing agent solution to the reaction kettle. The early-strength antifreezing polycarboxylate high-performance water reducing agent has higher water reducing rate and remarkable enhancing effect, and is suitable to prepare various common concrete and high-performance concrete at a negative temperature range of between 20 DEG C below zero and 0 DEG C.

Owner:武汉市联合石油化工有限责任公司

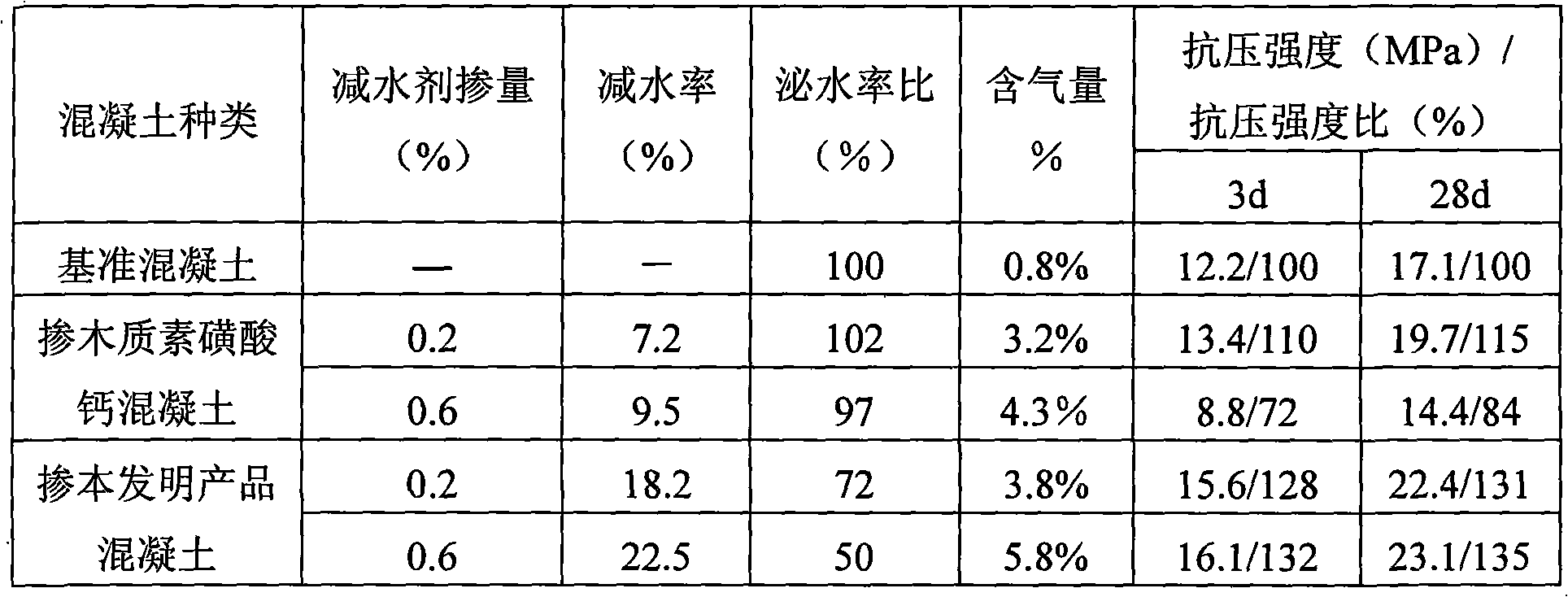

Lignosulfonate series air entraining and water reducing admixture for concrete and its prepn process and application

The present invention relates to preparation process of serial lignosulfonate air entraining and water reducing admixtures for concrete. The preparation process includes the following steps: dissolving solid lignosulfonate in water of the same weight, adding catalyst and oxidant, heating after reaction, adding amine and partial aldehyde to aminate, and dropping the rest aldehyde for condensation reaction to obtain the product; adding surfactant and polymer through stirring, and cooling to obtain liquid phase lignosulfonate as air entraining and water reducing admixture. The present invention is used as the admixture for concrete, and has relatively high water reducing rate, capacity of raising the strength of concrete, and certain setting retarding effect to delay the appearance of cement setting heat peak and reduce crack caused by temperature change.

Owner:SOUTH CHINA UNIV OF TECH

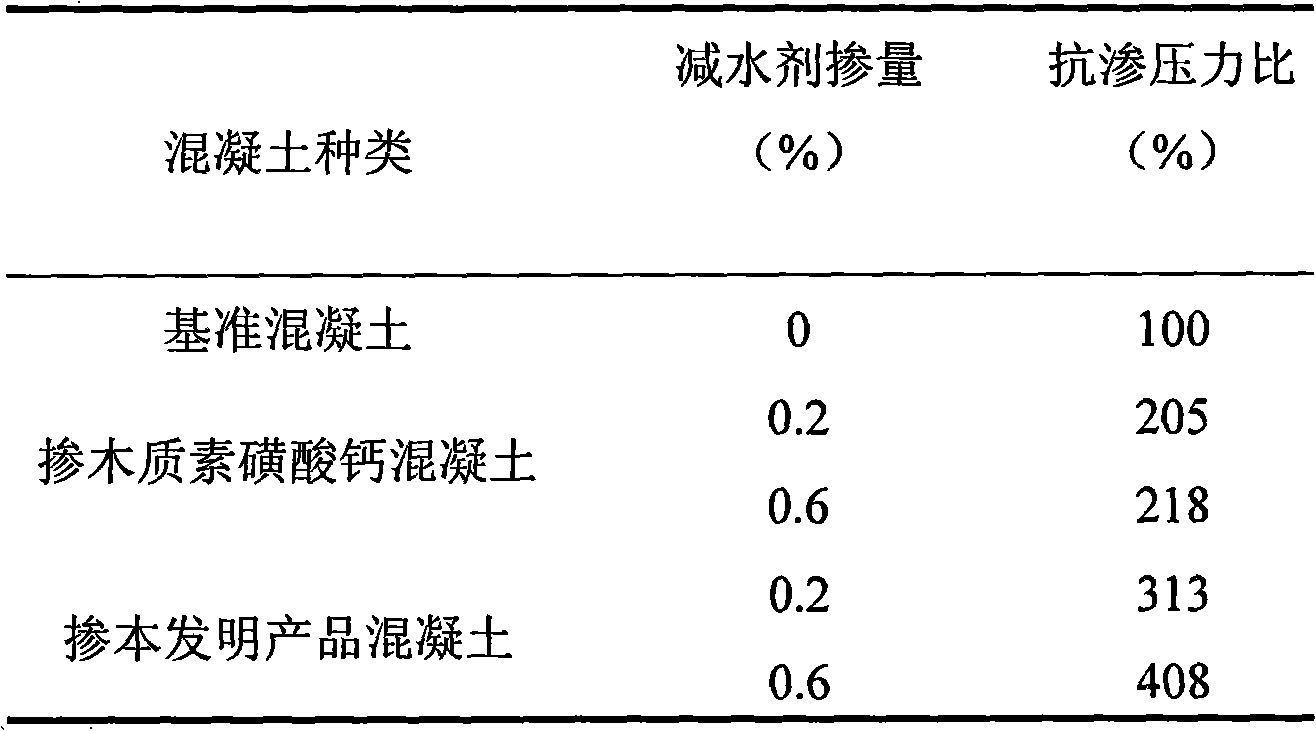

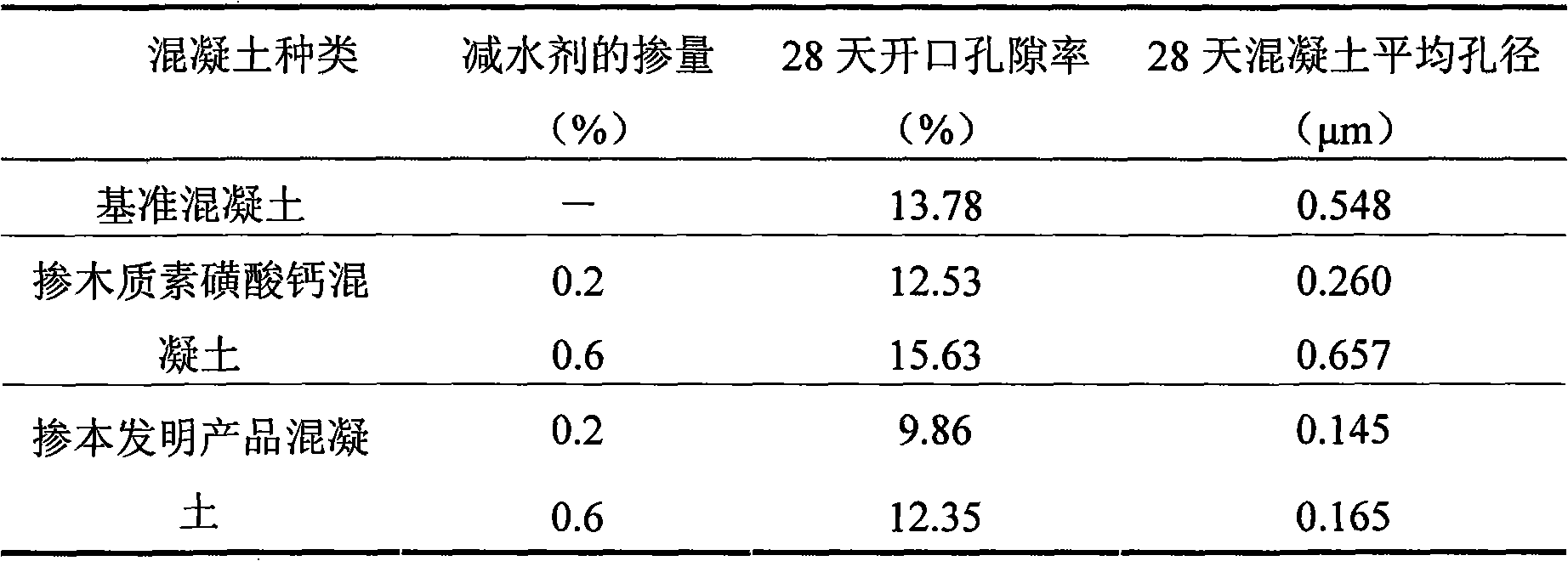

Alkali lignose concrete air-leading water-reducing agent, preparation and use thereof

The invention discloses an alkali lignin concrete water reducing agent, a preparation method and application thereof. The preparation method comprises the following steps: dissolving the alkali lignin in water, adding amines and dropping aldehydes into the mixed solution, reacting the mixed solution to get aminating alkali lignin; adding sulfonating agent into the aldehydes and reacting to get alkane sulfonate compounds; then mixing the aminating alkali lignin and the alkane suflonate compounds to conduct polycondensation, getting alkali lignin concrete water reducing agent, wherein the alkali lignin is 100 parts, amines are 5-20 parts, aldehydes are 20-50 parts, sulfonating agent is 50-100 parts and the surfactant is 2-6 parts(by weight part). The water reducing agent is used for preparing concrete, and the dosage of the water reducing agent according to the weight percentage is 0.2-0.6% of the cement in the concrete. The concrete water reducing agent of the invention has advantages of abundant material source, no toxic, simple production technology and low cost with a water-reducing rate of 22.5%, which significantly increases the fluidity of the concrete and improves the intension of the concrete.

Owner:SOUTH CHINA UNIV OF TECH

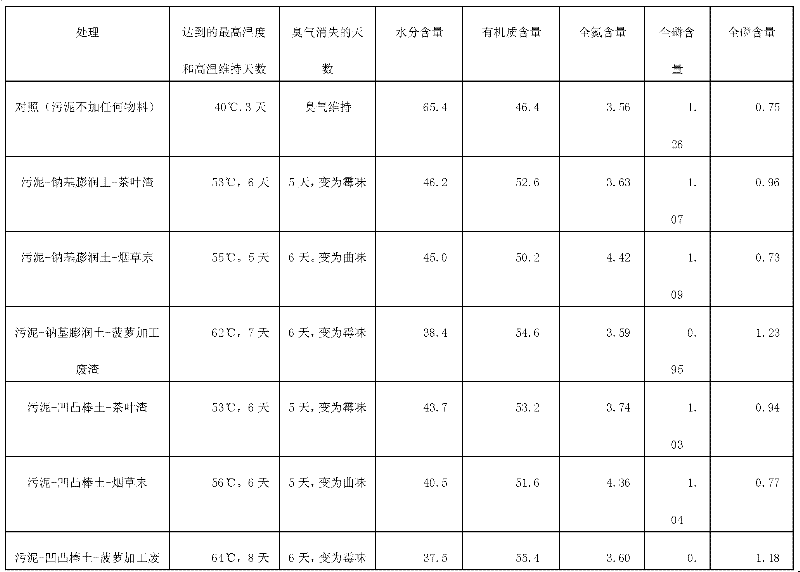

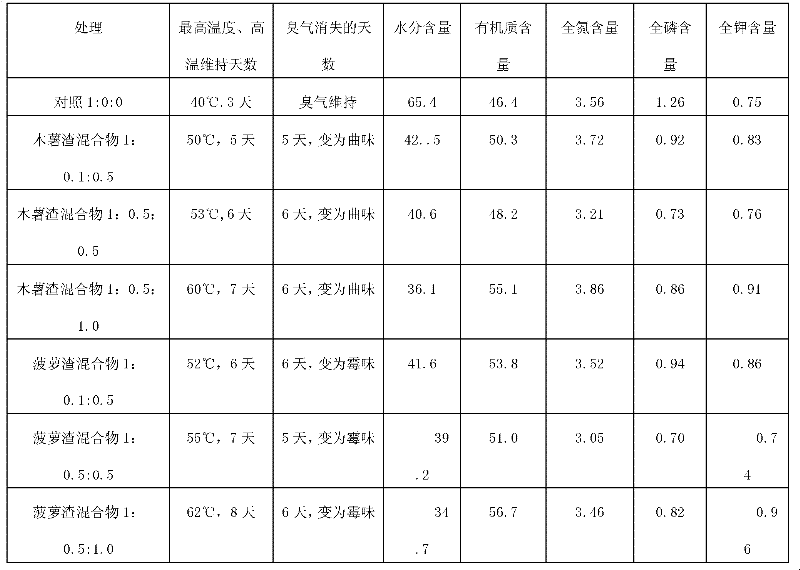

Method for dehydrating and conditioning sludge and preparing raw materials of slow-release fertilizer

ActiveCN102180581AReduce moisture contentReduce free waterSludge treatment by de-watering/drying/thickeningBio-organic fraction processingClay mineralsPhosphoric acid

The invention relates to a method for preparing a slow-release fertilizer, in particular provides a method for dehydrating and conditioning sludge and preparing raw materials of the slow-release fertilizer. The method particularly comprises the following steps of: adding water-absorbing clay minerals, a mixture of water-absorbing macromolecular compounds and plant residues to dehydrated sludge ineach cubic meter, composting and fermenting for 10-15 days according to a conventional method, sequentially adding compounds formed by phosphoric acid radicals and ammonium ions and magnesium-containing alkaline substances in fermentation products, and mixing uniformly to obtain the raw materials for producing a slow-release type organic-inorganic compound fertilizer. The method for dehydrating and conditioning the sludge and preparing raw materials of the slow-release fertilizer, disclosed by the invention, is suitable for large-scale sludge dehydration treatment and also provides high-nutrient raw materials for the manufacturing of the slow-release fertilizer.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

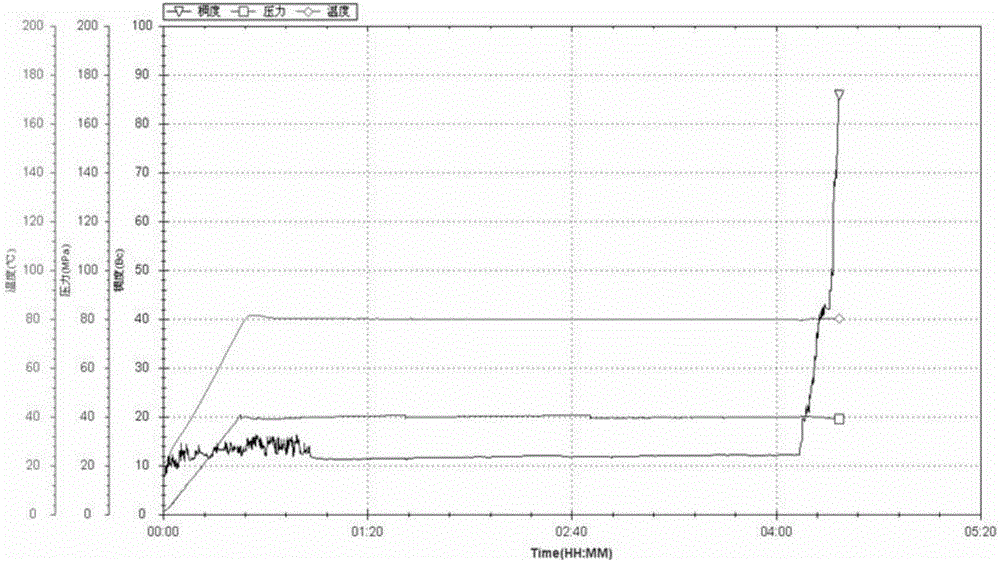

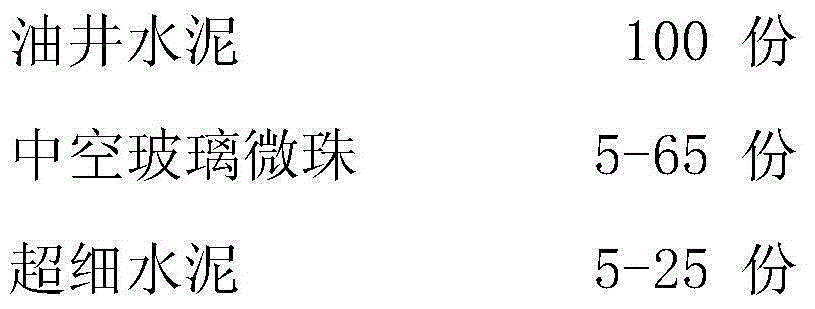

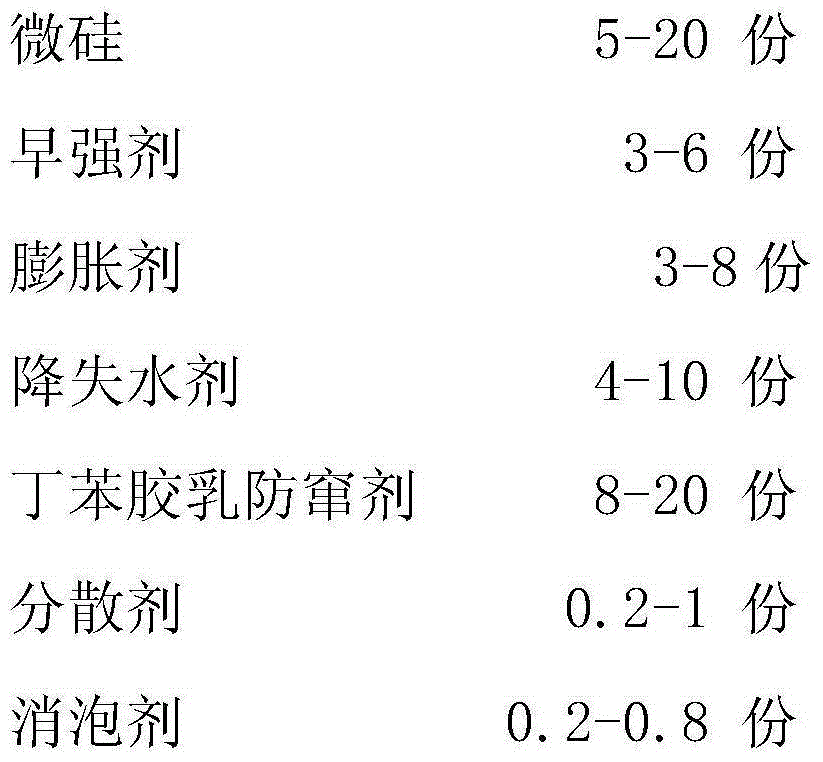

Low-density micro-expansion early-strength channeling-preventive oil well cement slurry and preparation method thereof

InactiveCN105062441AImprove performanceReduce free waterDrilling compositionVolumetric Mass DensityCement slurry

The invention discloses low-density micro-expansion early-strength channeling-preventive oil well cement slurry and a preparation method thereof. The density of the cement slurry is 1.05-1.55g / cm<3> and can be adjusted. The cement slurry is composed of oil well cement, lightening agents, stabilizing agents, early-strength agents, expansion agents, styrene-butadiene latex channeling-preventive agents, fluid loss agents, dispersing agents, defoaming agents and water, wherein the lightening agents are hollow glass micro beads, the stabilizing agent are superfine cement and micro silicone. The cement slurry is little in system free water, small in fluid loss amount, high in channeling-preventive performance, micro-expansion performance and mobility, good in slurry stability and adjustable in thickening time, has the advantages of being fast in low-temperature strength development, capable of preventing gas channeling and the like, and can be used for low-pressure leakage zones and low-pressure oil and gas reservoirs, and medium and low temperature region well cementation construction.

Owner:CNPC BOHAI DRILLING ENG

Composition for inhibiting concrete alkali aggregate reaction and preparation thereof

The invention belongs to the technical field of concrete engineering, and in particular relates to a composition for inhibiting concrete alkali-aggregate reaction and a preparation method thereof. The composition for inhibiting the concrete alkali-aggregate reaction comprises the following compositions: 10 to 50 percent of plasticizing agent, 10 to 70 percent of aluminate and 10 to 30 percent of alkali metal salt or alkaline-earth metal salt, wherein the alkali metal salt or the alkaline-earth metal salt is selected from at least one group of lithium compounds, barium compounds or calcium-magnesium compounds, and the total content of various compositions is 100 percent. The composition can cover or coat active elements of aggregate, prevent or isolate contact reaction between alkali metal ions such as K<+> and Na<+> and the active elements of the aggregate, prevent generation of soluble swelled gel and generation of insoluble compounds, and further eliminate alkali-aggregate reaction and improve the durability of concrete.

Owner:苏笮斌

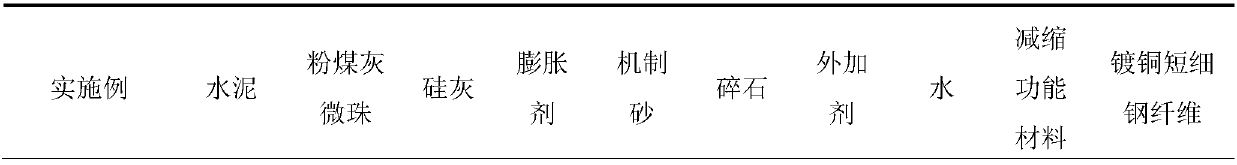

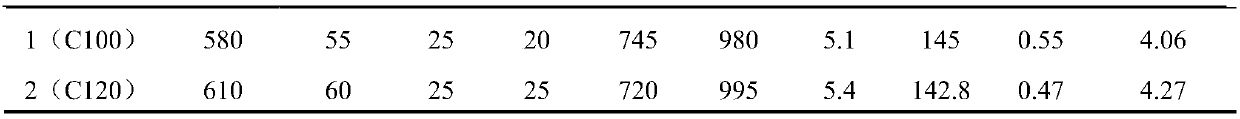

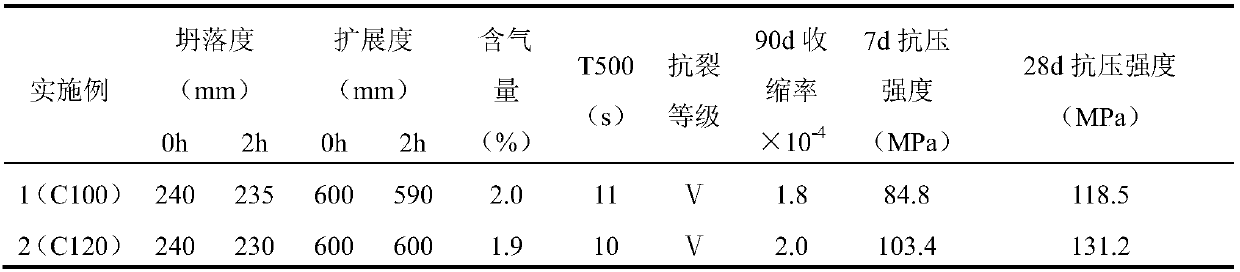

Ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete and preparation method thereof

The invention discloses ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete and a preparation method of the ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete. The steel pipe-encased concrete comprises the following raw materials in parts by weight: 580-680 parts of cement, 30-60 parts of pulverized fuel ash microbeads, 25-50 parts of silica fume, 20-35 parts of an expanding agent, 700-750 parts of manufactured sand, 800-1050 parts of macadam, 0.4-1.2 parts of a shrinkage reducing functional material, 3.5-7 parts of an additive, 120-160 parts of water and 4-5.5 parts of copper plated short and fine steel fibers. The manufactured sand with a high stone powder content is used for replacing natural river sand; the stone powder serves as an inert admixture; the high activity pulverized fuel ash microbeads and silica fume are adopted; and workability, compactness, and homogeneity of the concrete are improved by using a ball effect and amicro-aggregate effect of the high activity pulverized fuel ash microbeads and the silica fume. A novel expanding agent is prepared from the pulverized fuel ash and phosphogypsum; the strength is improved; moreover, an air content is further reduced by using the additive to improve the compactness. The obtained manufactured sand concrete with the high stone powder content is excellent in serviceability, mechanical property, volume stability and crack resistance.

Owner:WUHAN UNIV OF TECH

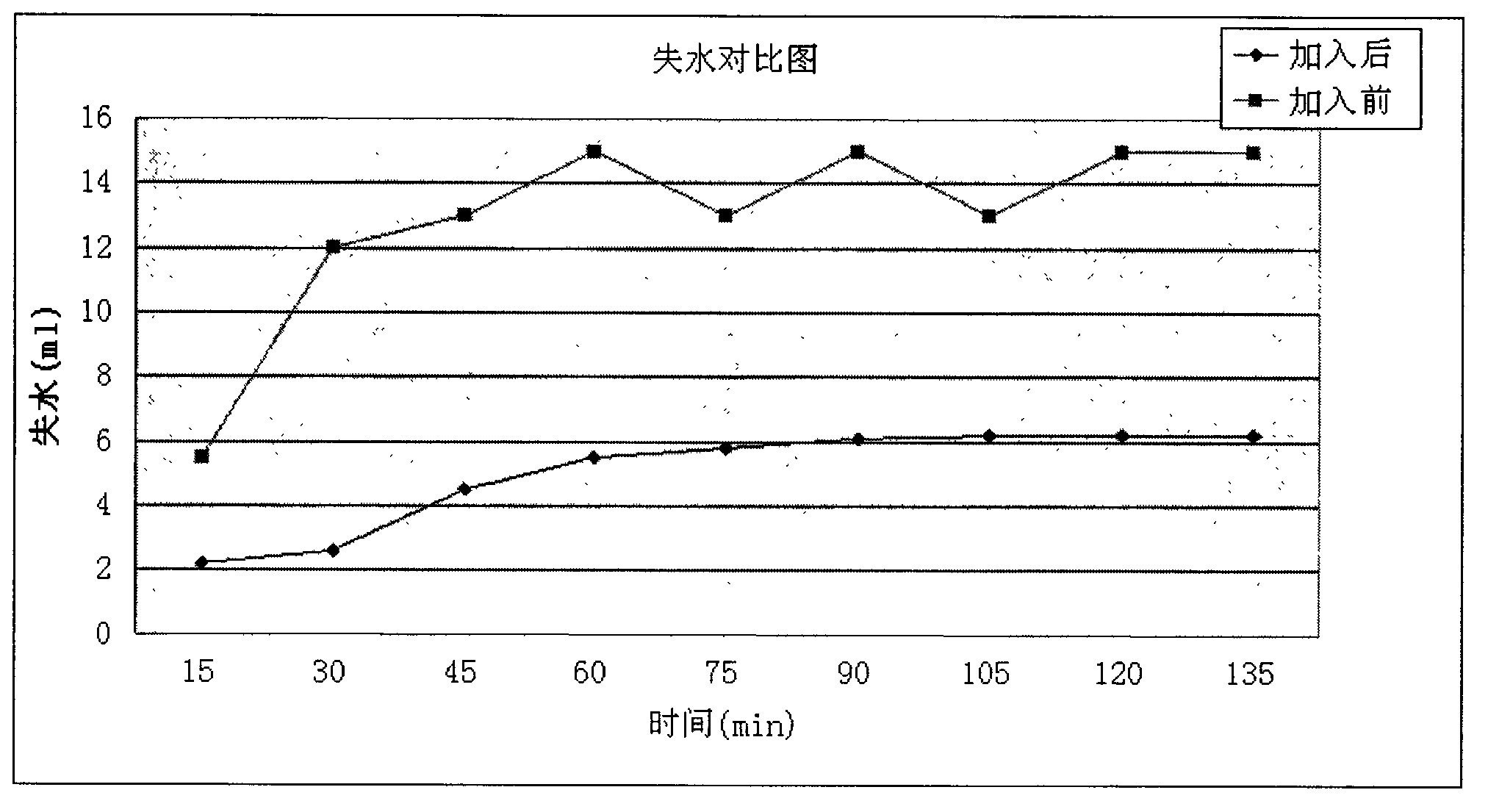

High-water-retaining-property shield construction premixed synchronous grout material

The invention discloses a high-water-retaining-property shield construction premixed synchronous grout material which comprises cement, coal ash, admixture, bentonite, fine sand, additives and water. The additives mainly comprise non-ionic cellulose ether, carbohydrate, polycarboxylic acid slump retaining agents, starch ether and magnetic hydrotalcite. The high-water-retaining-property shield construction premixed synchronous grout material has the advantages that the optimized admixture, the bentonite, the fine sand with the fineness modulus being 1.6 and the additives special for mortar are jointly used in the shield construction premixed synchronous grout material, the fluidity loss of the adjusted grout material is less than or equal to 30mm in 6 hours, bleeding rate is reduced to be lower than or equal to 3.0%, and sedimentation after a vibration test is less than or equal to 20mm; due to the fact that the magnetic hydrotalcite is added, the grout material can reduce construction noise during stirring and absorb heavy metal ions to prevent heavy metal in the mortar from causing secondary pollution on the basis that the original physical properties are kept.

Owner:河北三楷展创建材有限公司

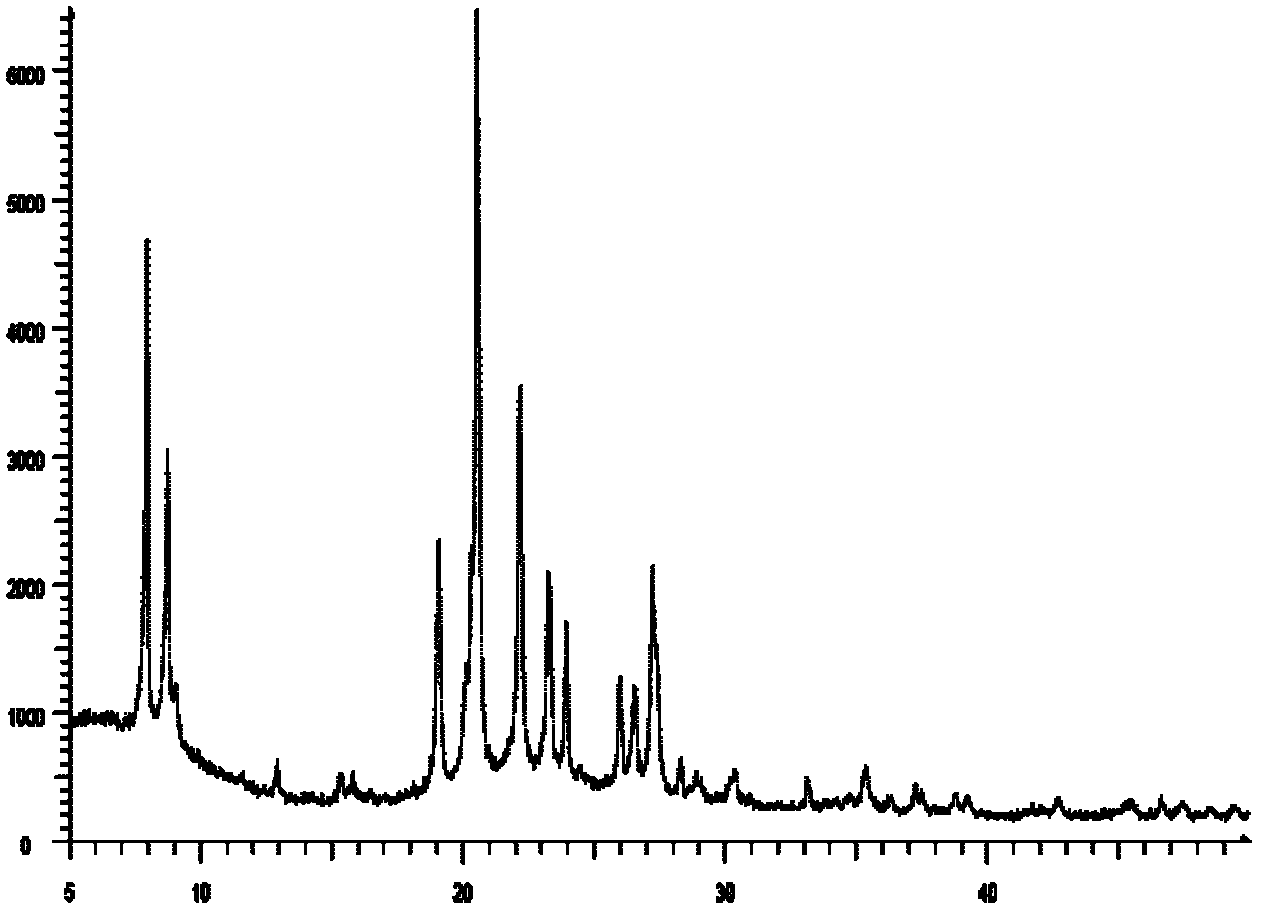

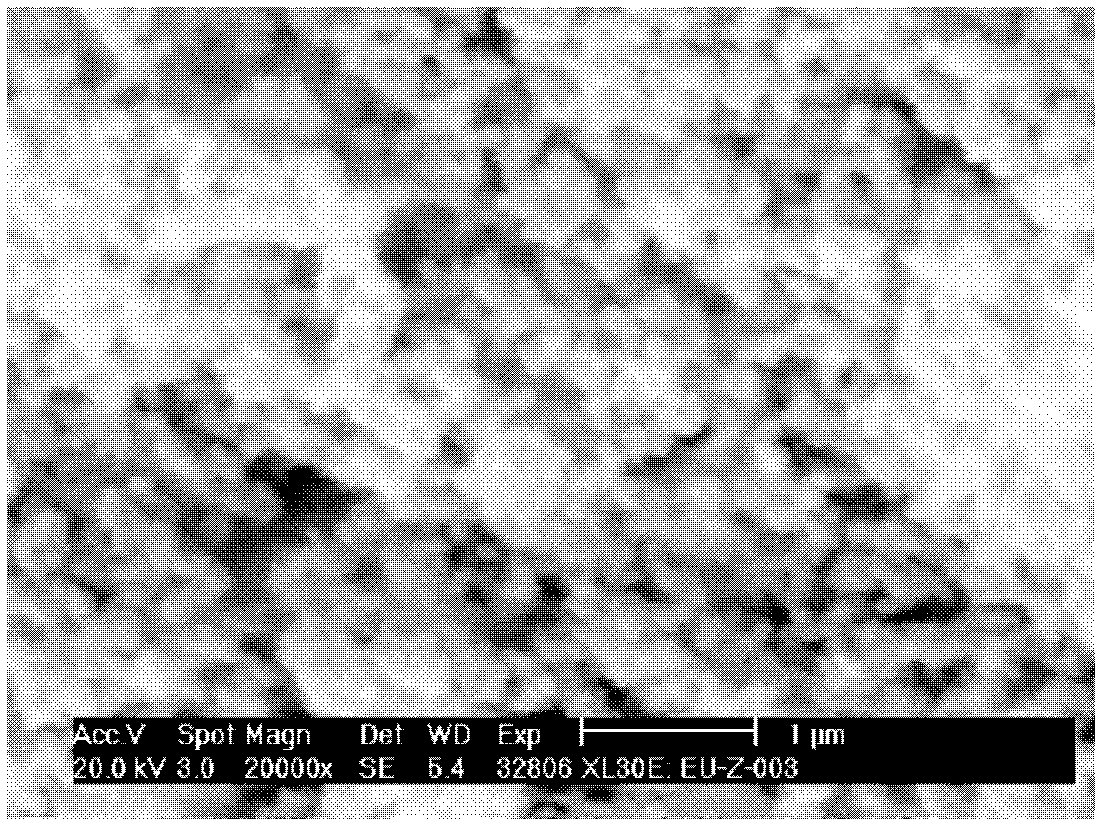

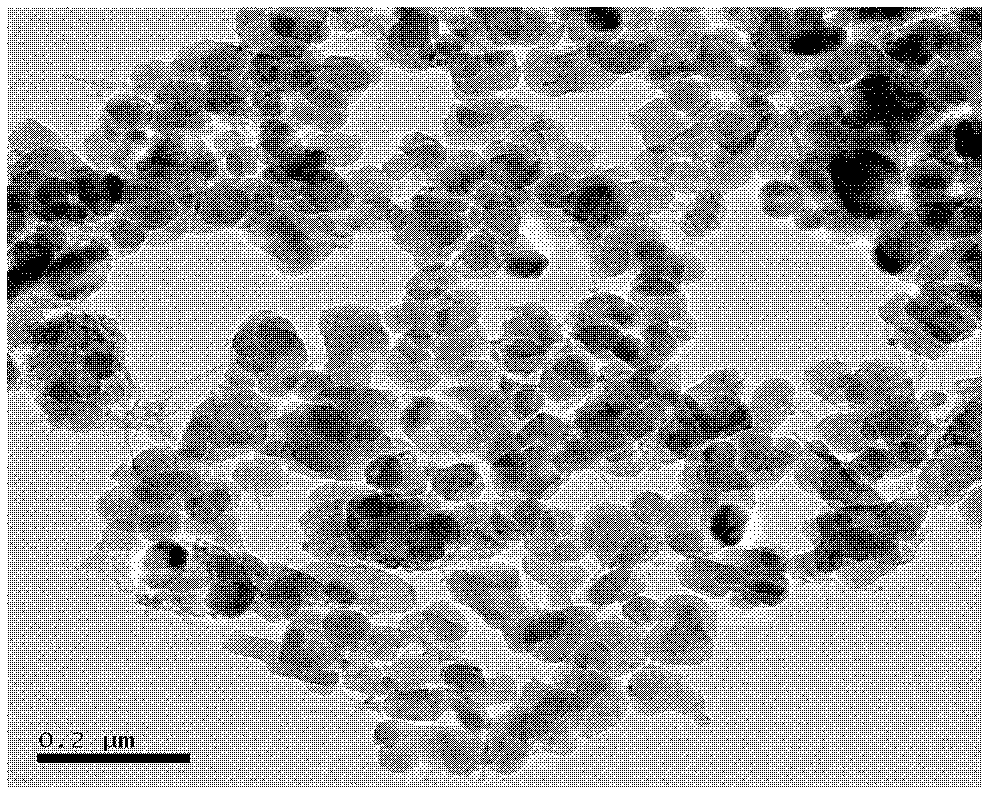

Preparation method of EUO structural nano silica-alumina molecular sieves

InactiveCN103121691ASimple processShort synthesis timeCrystalline aluminosilicate zeolitesMolecular sieveHydrogen

The invention relates to a preparation method of EUO structural nano silica-alumina molecular sieves, and mainly solves problems of large particle size, low yield, and impure crystalline phase of EUO structural sial zeolites prepared by existing technology. The preparation method includes evenly mixing an aluminum source, an silicon source, a template R, seed crystals and water to obtain an initial gel mixture with a molar ratio of (1 - 150) Na2O: (15 - 300) SiO2: Al2O3: (1 - 20) R: (200 - 3500) H2O; adjusting the hydrogen by inorganic acid or inorganic base, placing the mixture in a reactor to crystallize for 12 hours to 7 days on a condition of 140-200 DEG C temperature, and recycling solid productions to prepare so as to obtain pure phase EUO structural nano silica-alumina molecular sieves. According to the technical scheme, the preparation method solves the problems effectively and can be used in industrial production of the EUO structural nano silica-alumina molecular sieves.

Owner:CHINA PETROLEUM & CHEM CORP +1

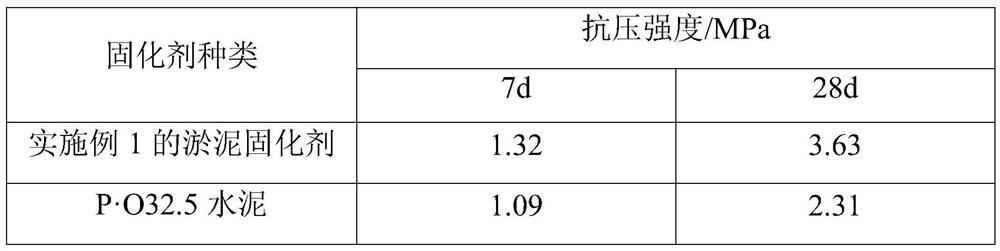

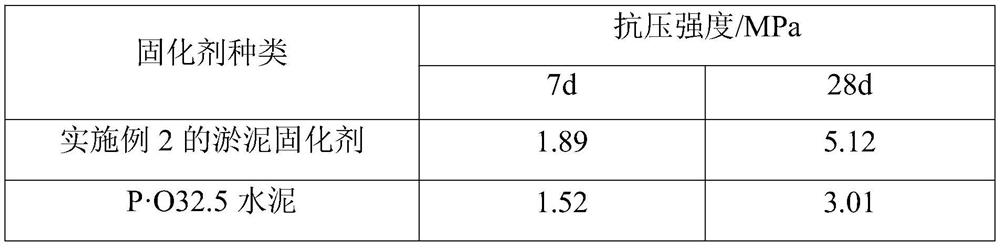

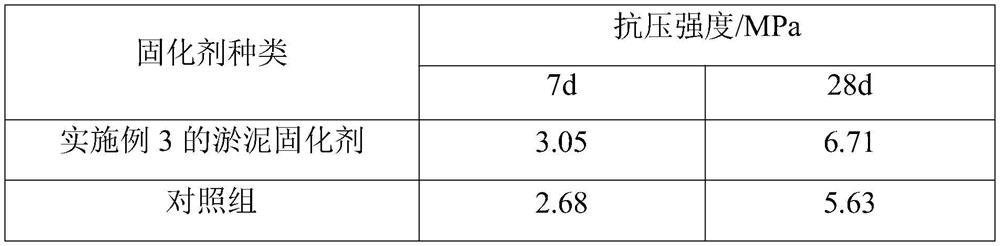

High-strength solidifying agent for sludge solidified soil and preparation method thereof

InactiveCN109305785AImprove cracksReduce microscopic crack defectsFixation/solidifcation sludge treatmentSludgeMaterials science

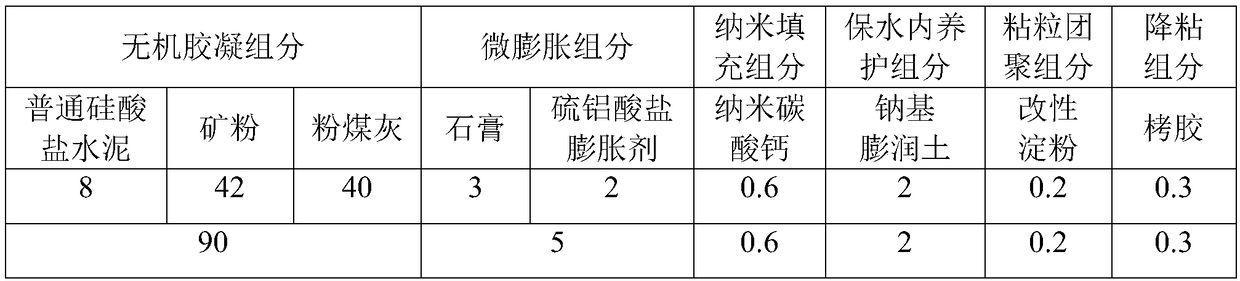

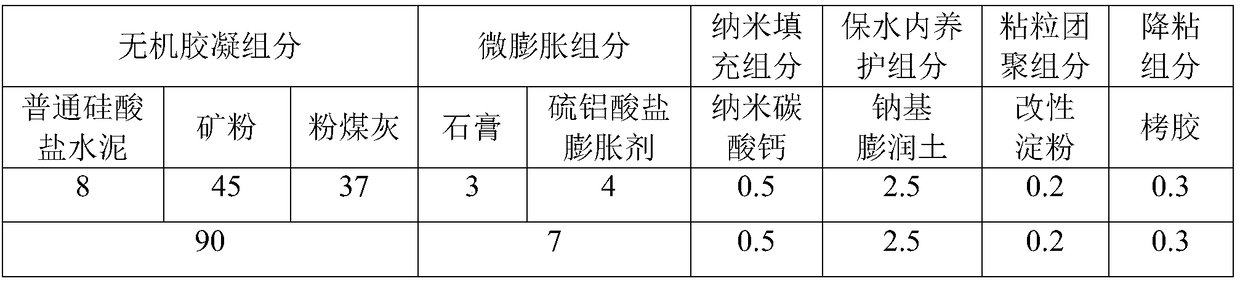

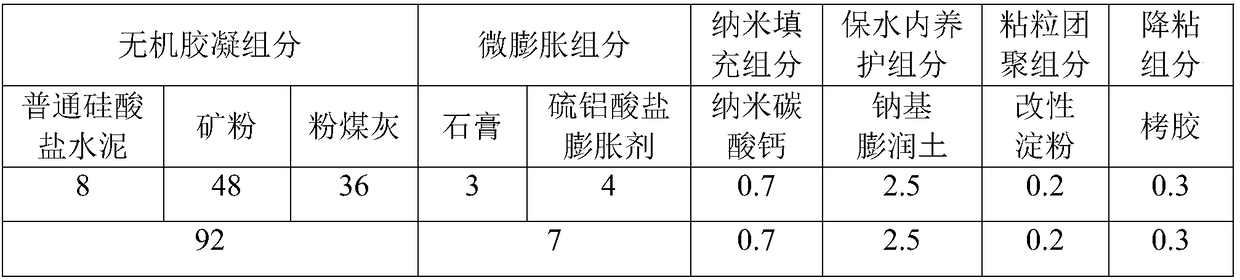

The invention discloses a high-strength solidifying agent for sludge solidified soil and a preparation method thereof. The solidifying agent is prepared by compounding the following components in parts by weight: 90-95 parts of inorganic gel component, 5-10 parts of slight-expansion component, 0.5-1 part of nano filling component, 2-4 parts of water retention and internal maintenance component, 0.2-0.4 part of cosmid aggregate component and 0.1-0.3 part of viscosity reducing component. The solidifying agent for sludge solidified soil disclosed by the invention has the advantages of moderate dosage, high solidifying strength, fast strength increase, good solidifying effect on sludge with high water content, strong environmental friendliness and the like; the unconfined compressive strengthof the prepared solidified soil reaches 1.5 MPa or more, and the cohesion C exceeds 100 kPa. The technical problem of low compressive strength and low cohesion of the sludge solidified soil is solved,and the application range of the sludge solidified soil is expanded.

Owner:JIANGSU NATURE WAY TECH

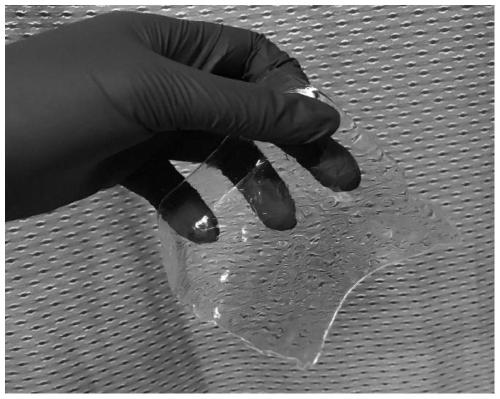

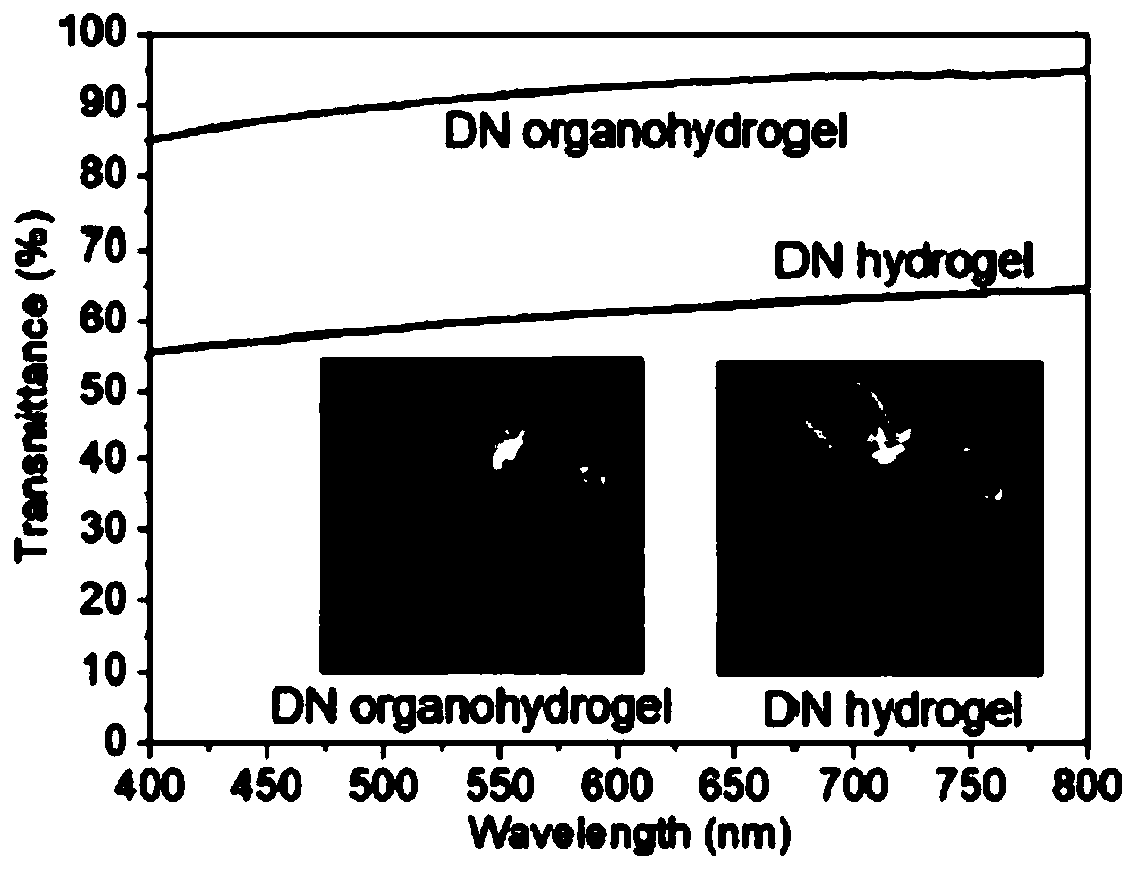

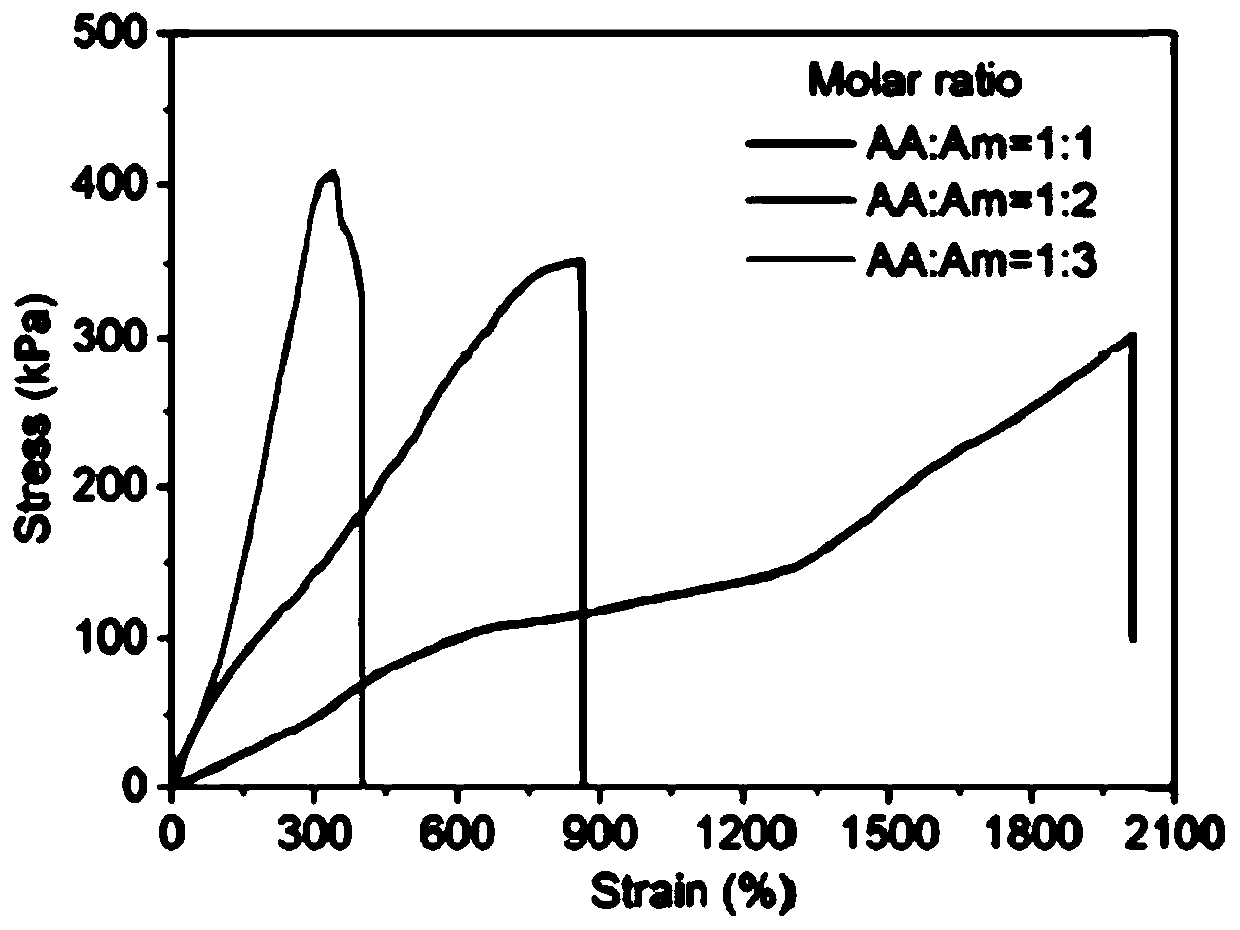

Preparation method of anti-freezing organic-hydrogel with reversible adhesion and self-healing properties

ActiveCN111333872ANot easily oxidizedStable and reversible adhesion propertiesPolyvinyl alcoholSupercapacitor

The invention discloses a preparation method of an anti-freezing organic-hydrogel with reversible adhesion and self-healing properties. The prepared organic hydrogel has the properties of reversible adhesion, high stretchability, self-healing, high moisture retention, freezing resistance, transparency and the like, and the preparation process is simple, the raw material cost is low, the preparation efficiency is high, and the method is suitable for industrial production. The anti-freezing organic-hydrogel has potential application prospects in the aspects of reversible adhesion devices, flexible electronic devices, supercapacitors, transparent electrodes and the like. The preparation process adopted by the invention comprises the following steps: (1) preparing a polyvinyl alcohol (PVA) solution; (2) preparing a PVA / monomer pre-gel solution; and (3) carrying out ultraviolet irradiation gelatinization on the pre-gel solution.

Owner:XIAN TECH UNIV

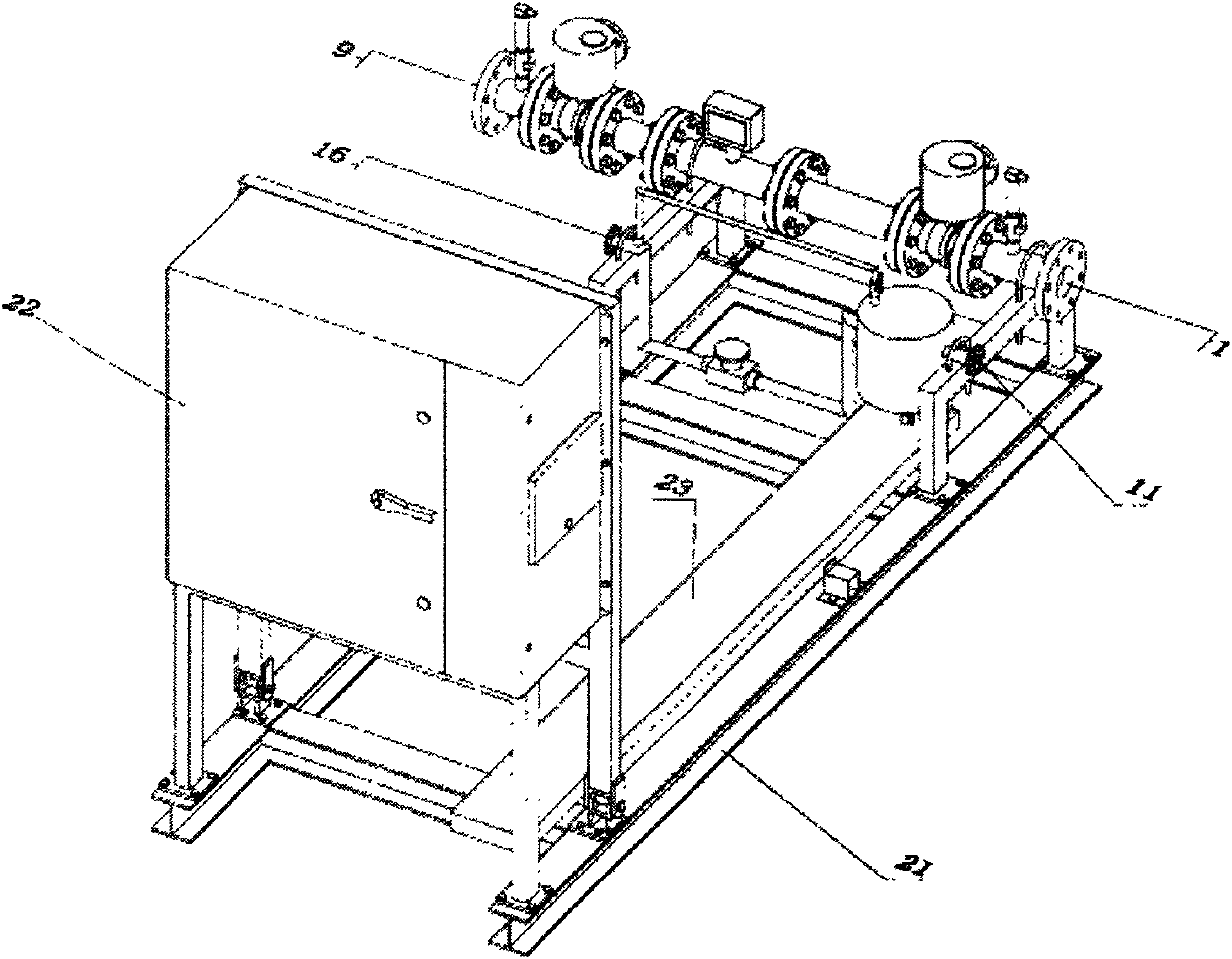

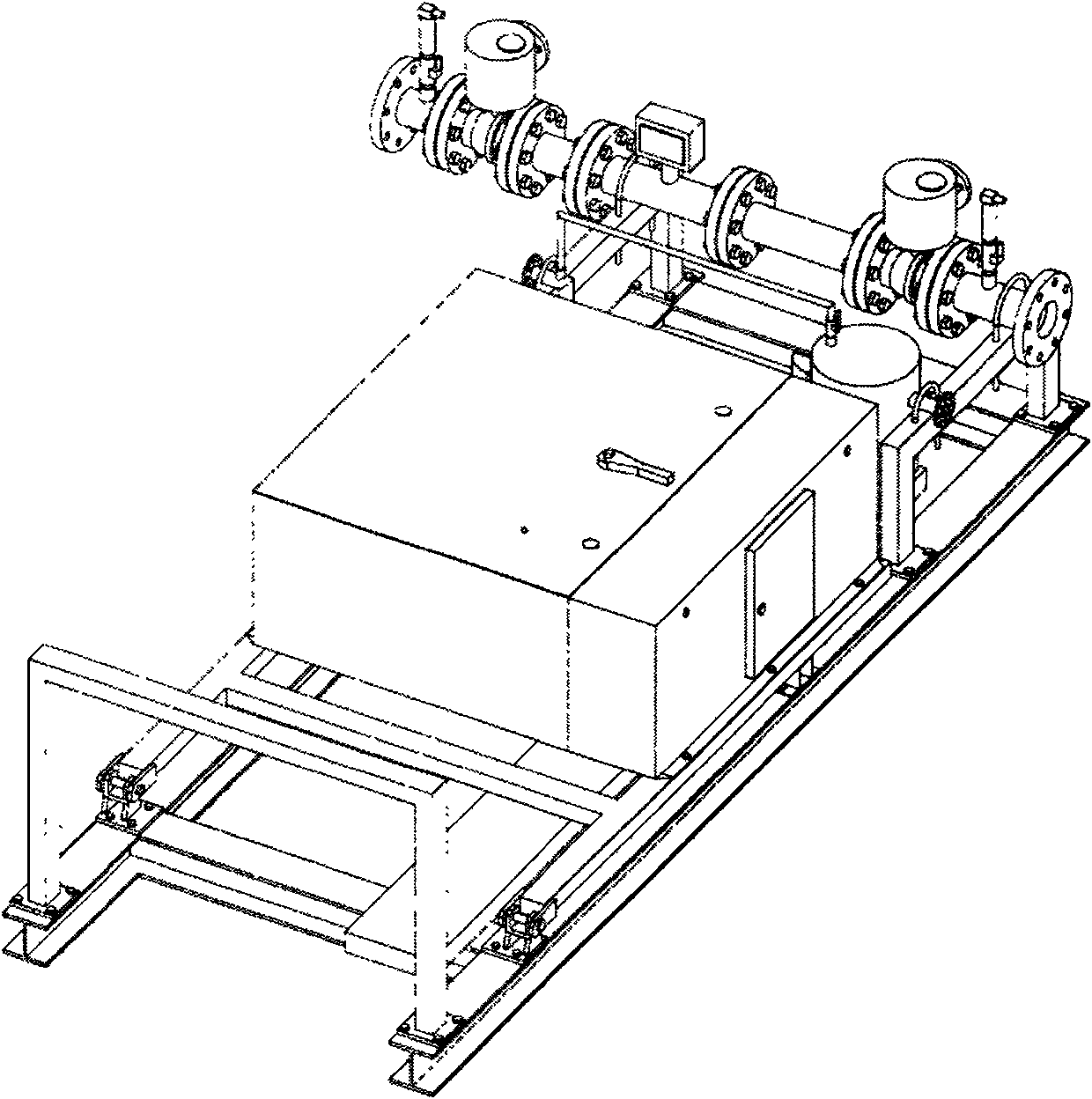

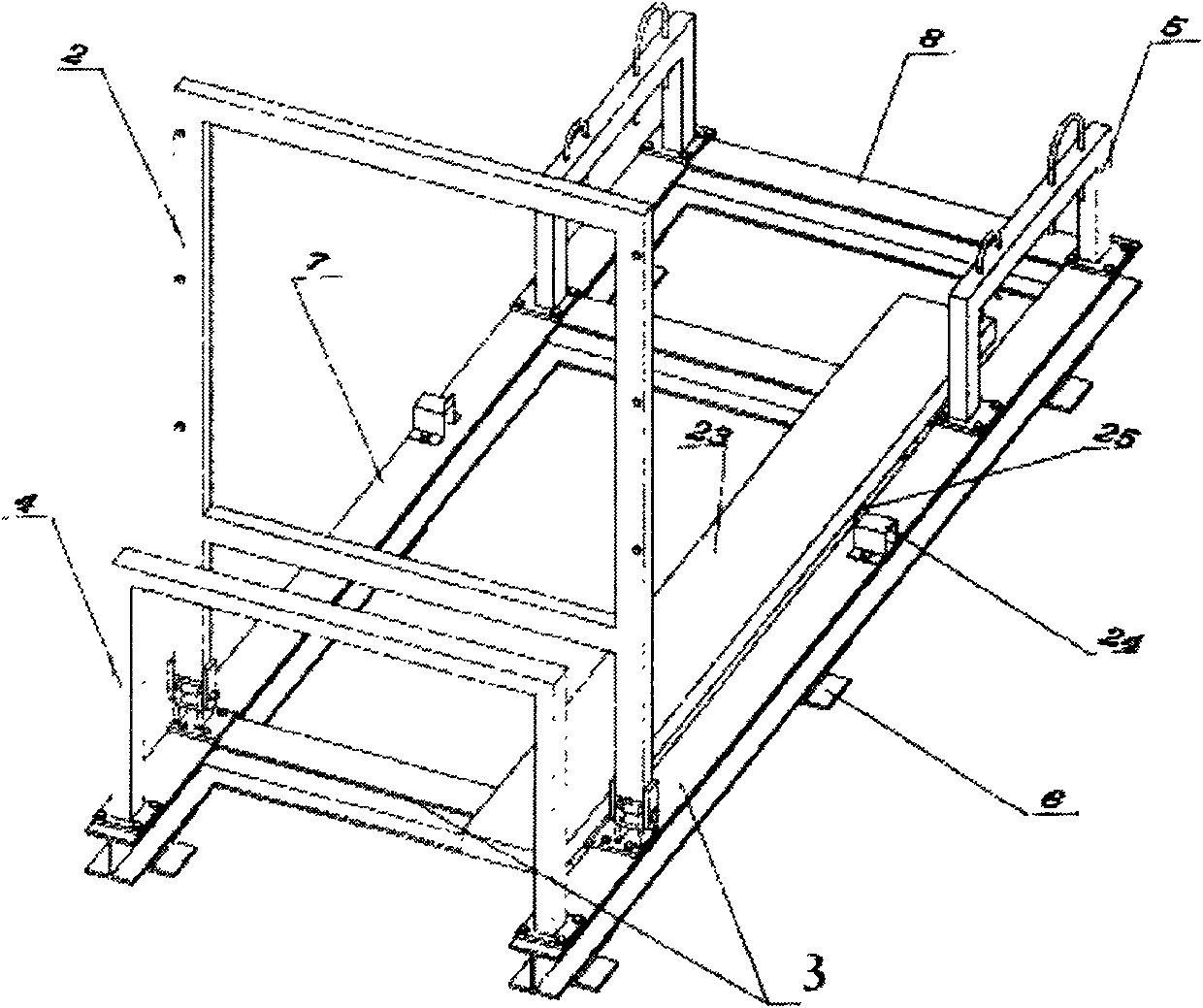

Exploitation measuring device and method of coal bed gas well

ActiveCN102168548AConvenient automatic separationImprove pump efficiencySurveyFluid removalProduction rateVapor–liquid separator

The invention provides an automatic exploitation measuring device and control method of a coal bed gas well. The measuring and control method is used for controlling a working fluid level by controlling the casing pressure of the coal bed gas well so as to stop the using of a traditional gas-liquid separator on the gas well field; requirements on gas production rate measurement can be satisfied by using a gas flowmeter; meanwhile, the liquid is separated from solid-phase coal powder and a gas after produced to the ground and before passing through a liquid flowmeter, thus the measuring accuracy is improved; the measurement is realized and the measuring accuracy is also increased while the liquid production rate is very small. A produced liquid measuring device, a produced gas measuring device and a control box provided by the invention are respectively mounted on a base bracket to form a highly integrated automatic exploitation measuring and control system of the coal bed gas well; therefore, the parameters are measured and field equipments on the well field are also simplified; the device is very simple and convenient to move, mount, operate, use and maintain; moreover, the invention also provides an optimized exploitation control method of a coal bed gas well.

Owner:CHONGQING OPRO ENERGY TECH CO LTD

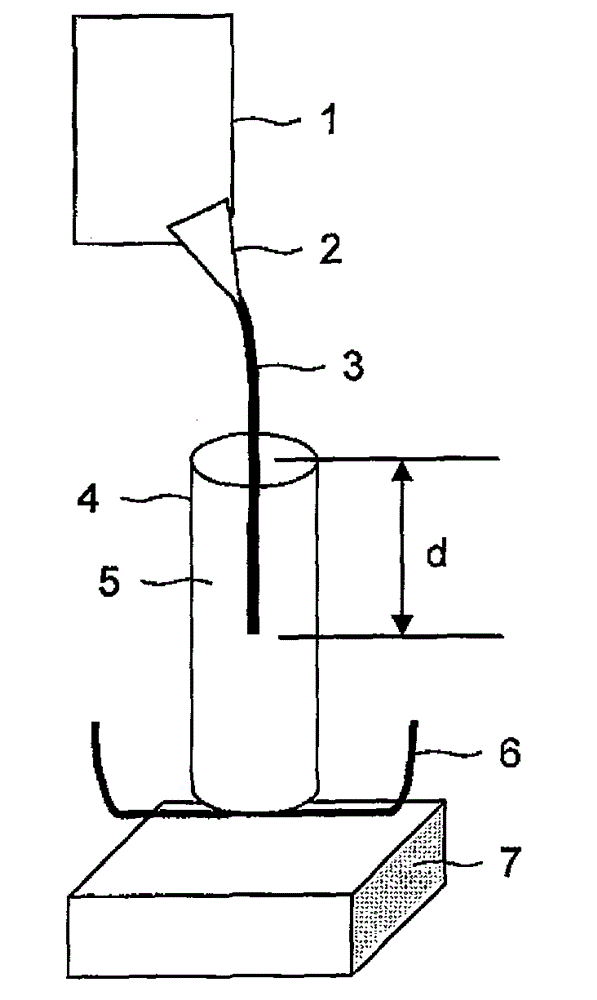

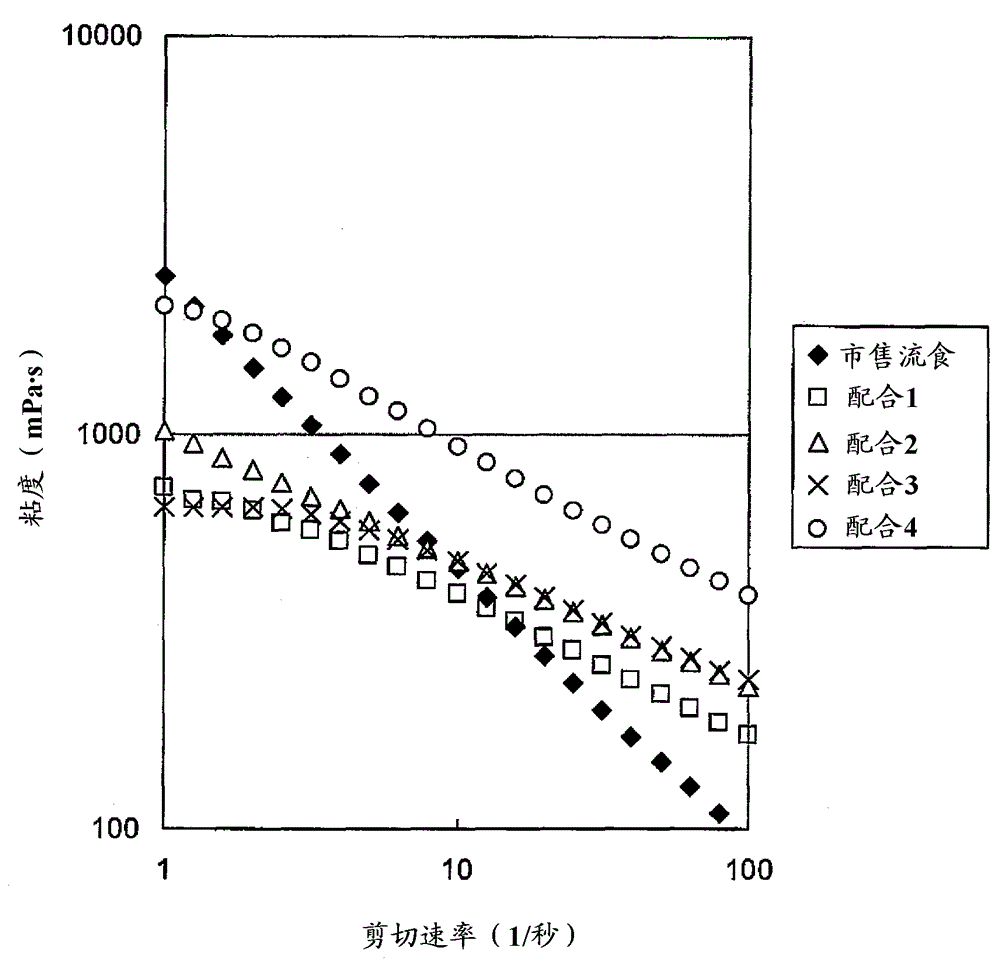

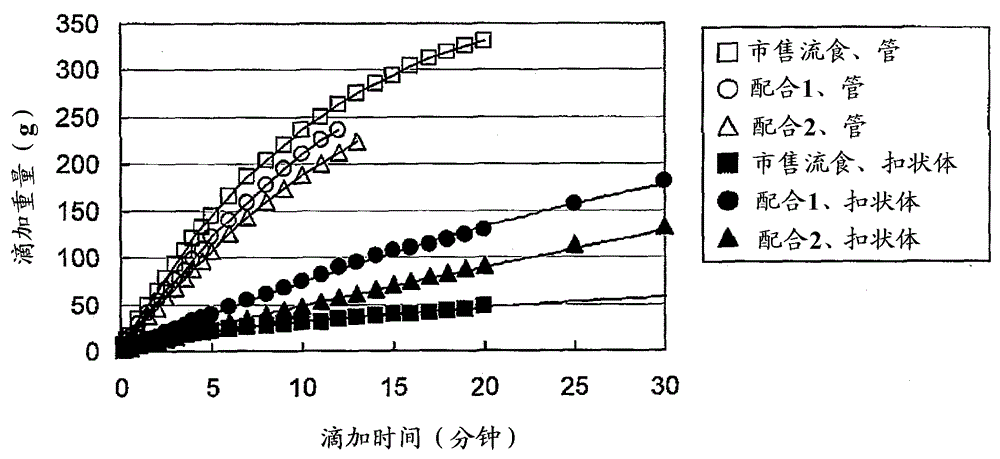

Viscous nutritional composition

ActiveCN103561591AEasy to manufactureReduce free waterFood ingredient as viscosity modification agentFood preparationNutritionEngineering

Provided is a liquid food which can be fed through free fall and has a physiologically preferable viscous property compared to a liquid food having an extremely low viscosity. With the use of an adjuvant that imparts a viscous property but not shear fluidization, a nutritional composition which sustains a viscosity facilitating the production thereof in processes from the blending of starting materials to the filling of containers, and which, after heating, has a viscosity suitable for tube feeding through free fall, can be provided.

Owner:MEIJI CO LTD

Green high-strength and high-toughness concrete and preparation process thereof

ActiveCN114230289AClosely connectedHigh structural densitySolid waste managementFiberAggregate (composite)

The invention relates to the field of concrete, and particularly discloses green high-strength and high-toughness concrete and a preparation process thereof. The green high-strength and high-toughness concrete is prepared from the following raw materials in parts by weight: cement, fly ash, mineral powder, natural aggregate, modified regenerated aggregate, water, an additive and composite fibers, a preparation method of the modified regenerated aggregate comprises the following steps: weighing waste concrete blocks, pretreating to obtain regenerated aggregate, putting the regenerated aggregate into a sodium gluconate solution, stirring and soaking, then taking out the regenerated aggregate, and performing drying post-treatment to obtain the modified regenerated aggregate; the preparation method comprises the following steps: weighing the cement, the fly ash and the mineral powder, mixing and stirring to obtain a premix; weighing the natural aggregate, the modified regenerated aggregate and the composite fiber, stirring and mixing to obtain a mixture; weighing the water, the additive, the premix and the mixture, mixing and stirring to obtain a mixture, and pouring and curing to obtain the concrete, the concrete has the advantages of greenness, high strength and high toughness.

Owner:深圳市深建混凝土有限公司

High-temperature-resistant and salt-tolerant spacer fluid with high density and preparation method of spacer fluid

The invention discloses a high-temperature-resistant and salt-tolerant spacer fluid with high density and a preparation method of the spacer fluid. The spacer fluid is prepared from solvent water, a suspension stabilizer, a cleaning agent, a fluid loss agent, a retarder, a defoamer, a weighting agent and sodium chloride, wherein the suspension stabilizer is prepared from natural mineral, modified diutan gum, a polymer, inorganic salt and white carbon black; the weighting agent is prepared from iron ore powder and micro-Mn in a weight ratio being 1:(0.05-0.20). The preparation method of the spacer fluid is simple, the suspension stabilizer is added to water slowly, hydration is performed for 5-10 min after high-speed stirring is performed for 1-2 min, then the weighting agent, the fluid loss agent, the cleaning agent and the retarder are added slowly in sequence, the mixed solution is stirred rapidly for 1-2 min, finally, the defoamer is added and uniformly stirred, and preparation is completed. The application temperature range of the high-temperature-resistant and salt-tolerant spacer fluid with high density is 30-190 DEG C, the density is adjustable in a range of 2.00-2.80 g / cm<3>, and the spacer fluid reaches saturation for salt tolerance; the spacer fluid has the advantages of little free water in a system, small fluid loss amount, high fluidity, good slurry stability and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

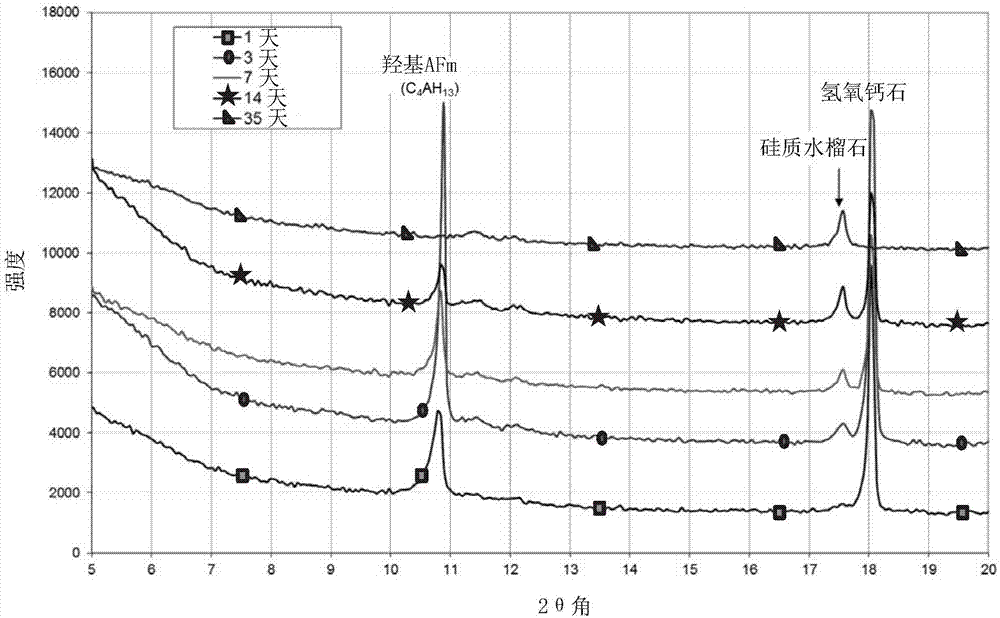

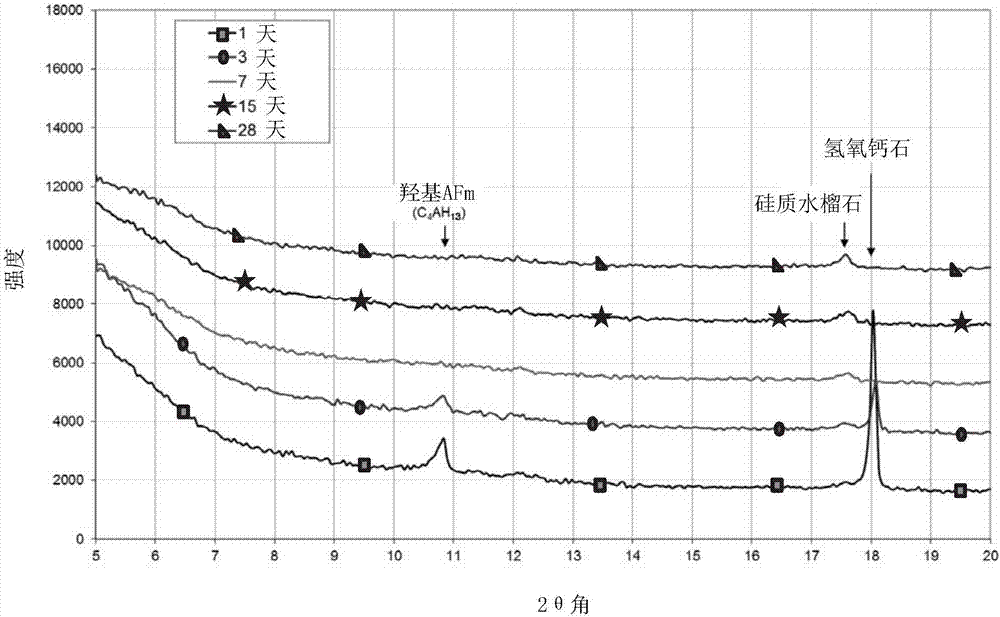

Silt curing agent prepared from steel slag modified phosphogypsum and use method thereof

InactiveCN111825408AIncreases hydration activityImprove cementing performanceFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentCalcium biphosphateO-Phosphoric Acid

The invention provides a silt curing agent prepared from steel slag modified phosphogypsum and a use method thereof. The silt curing agent comprises the following components: 40-70% of steel slag modified phosphogypsum powder, 30-60% of a cementing agent and 1-10% of a reinforcing agent, wherein the steel slag modified phosphogypsum powder is formed by mixing and modifying 5-25% of steel slag and75-95% of phosphogypsum by mass percentage. According to the invention, phosphogypsum is firstly modified by steel slag, alkaline substances of the steel slag react with soluble phosphoric acid, calcium phosphate and fluoride impurities contained in the phosphogypsum to be converted into insoluble precipitate substances, the adhesion among crystals in increased, so that the bonding performance ofphosphogypsum is improved, and meanwhile, acidic substances like sulfuric acid and phosphoric acid in the phosphogypsum are mixed with the steel slag to destroy the vitreous structure in the steel slag, so that the compact silicate vitreous structure in the steel slag is dissociated, the hydration activity of the steel slag is improved, and the strength of silt cured by the curing agent is furtherimproved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

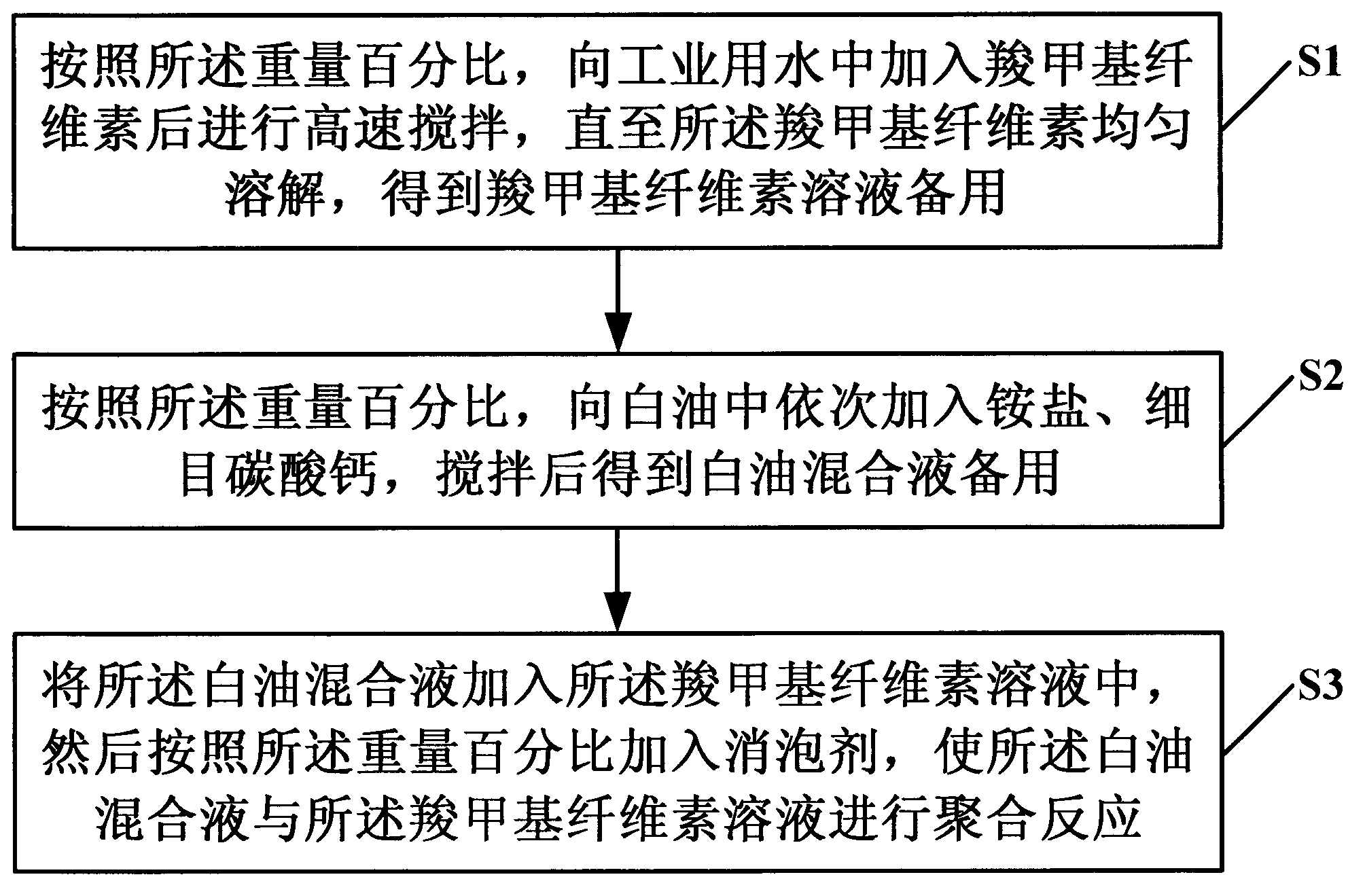

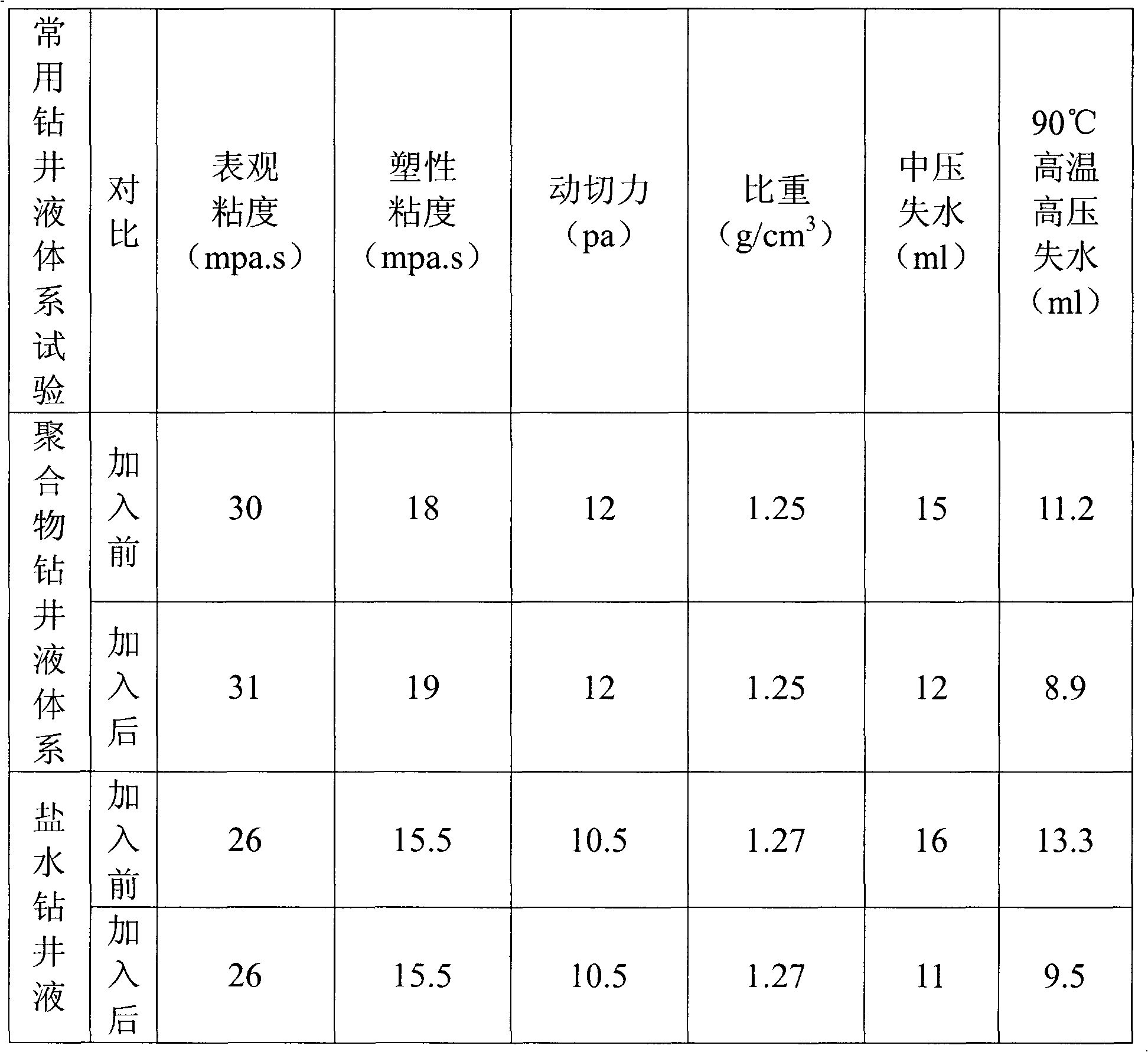

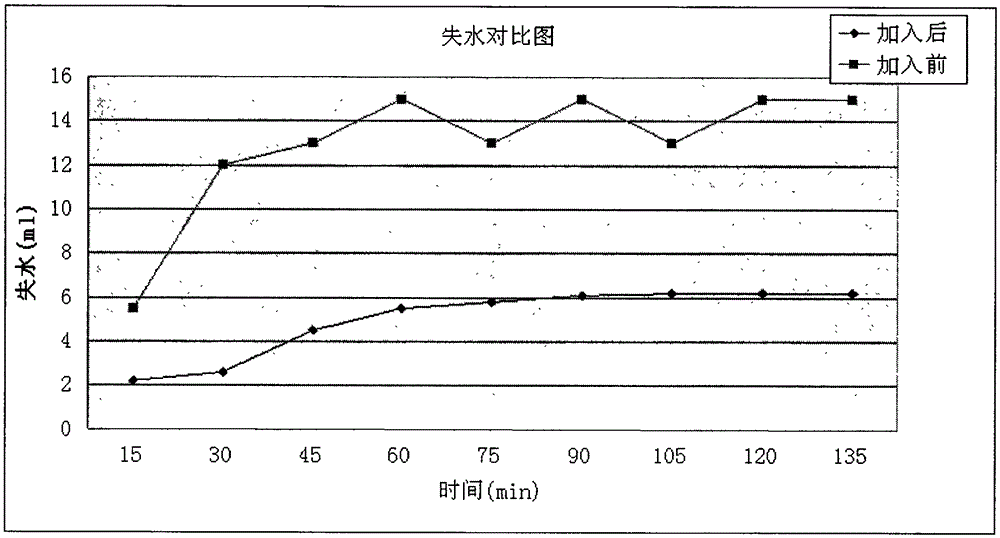

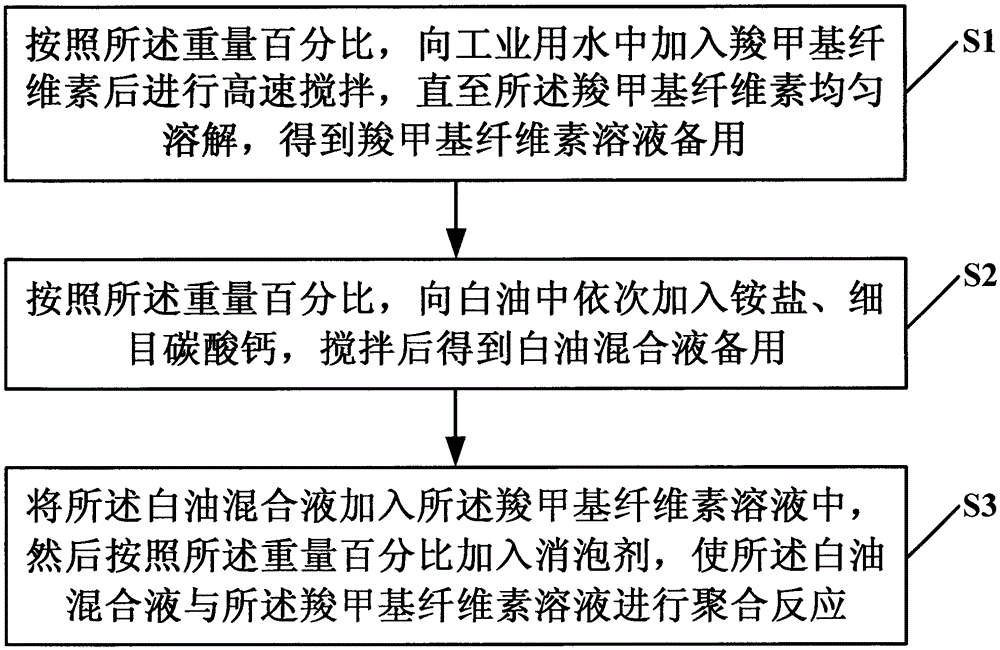

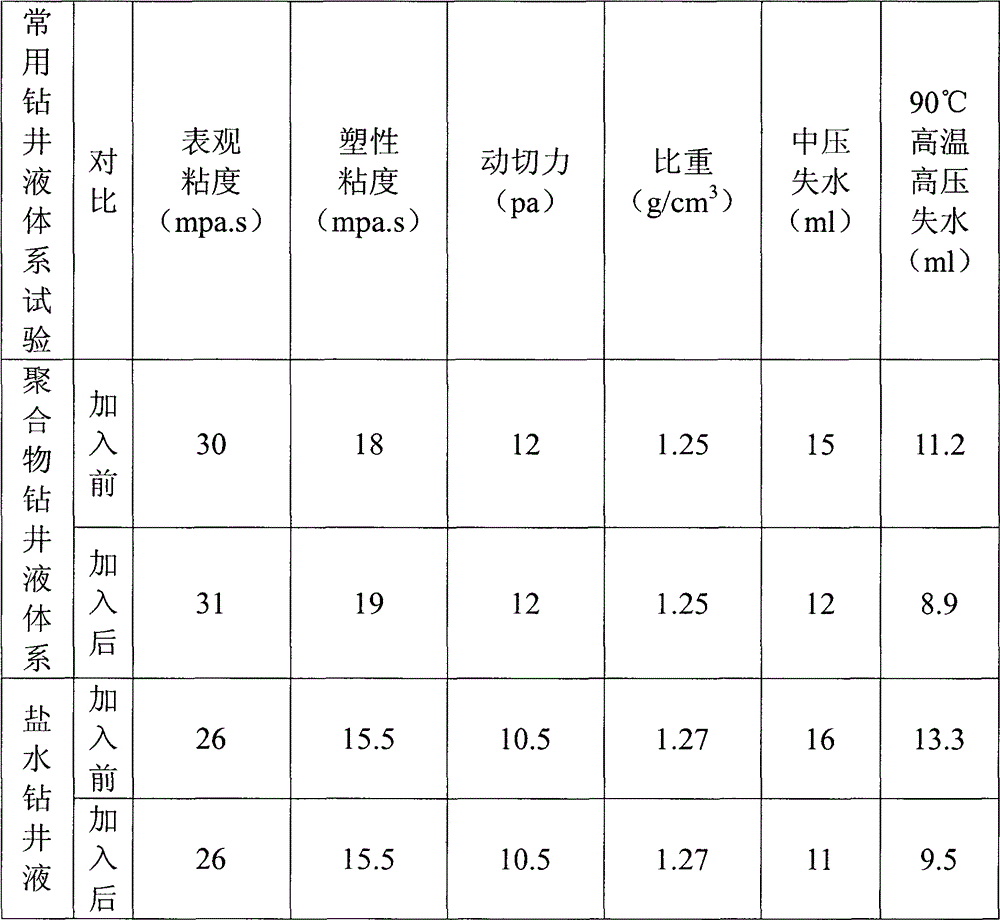

Oil layer protective agent for drilling fluid and production method thereof

ActiveCN103820085APerformance is not affectedReduce free waterDrilling compositionWorking fluidOil phase

The invention provides an oil layer protective agent for drilling fluid and a production method thereof, which is used for solving the problems of high requirement on solid control equipment in site because of high configuration cost, incompatibility of working fluid and formation fluid and narrow use because of the constraint of service conditions such as poor rock incompatibility of oil and gas layers in the oil layer protective agent in the prior art. The oil layer protective agent for drilling fluid is prepared from the following components in percentage by weight: 27-35% of industrial water, 1-1.5% of carboxymethylcellulose, 53-60% of white oil, 5-10% of ammonium salt, 5-10% of fine calcium carbonate and 1-1.5% of defoamer. The oil layer protective agent for drilling fluid disclosed by the invention takes subsidiary function in reducing water loss so as to further reduce free water permeate into the stratum without influencing the performance of the drilling fluid; the matching degree of the particle size of the oil layer protective agent can be maximized according to the pore throat characteristics of different stratum oil and gas layers so as to effectively realize plugging; the proper oil-phase proportion can more effectively avoid the damage to oil and gas layers; the preparation cost is low.

Owner:BEIJING BAOWO PETROLEUM TECH

Low density cementitious compositions for use at low and high temperatures

InactiveCN107531570AReduce churnReduce free waterSolid waste managementDrilling compositionLow densitySilicon dioxide

A cementitious binder, includes a hydraulic binder in an amount in the range from 50 to 80% by weight of the cementitious binder; a first siliceous based material in an amount in the range from 0.5 to35% by weight of the cementitious binder, the first siliceous based material having a (SiO2) / (AI2O3) ratio by weight greater than 2.5; a second siliceous based material in an amount in the range from10 to 25% by weight of the cementitious binder, the second siliceous based material being different from the first siliceous based material and having (a) a (SiO2) / (AI2O3) ratio by weight greater than 10 and (b) a BET specific surface area greater than 5m2 / g; and an aluminum based material in the range from 0 to 10% by weight of the cementitious binder and having a (SiO2) / (AI2O3) ratio by weightlower than 2.5, wherein 0.09 < AIEFF / ( AIEFF+SiEFF) < 0.28, where AIEFF = molar content of alumina in the hydraulic binder, and SiEFF = molar content of silica in the first siliceous based material for particles having a size lower than 3 mu m + molar content of silica in the second siliceous based material.

Owner:HOLCIM

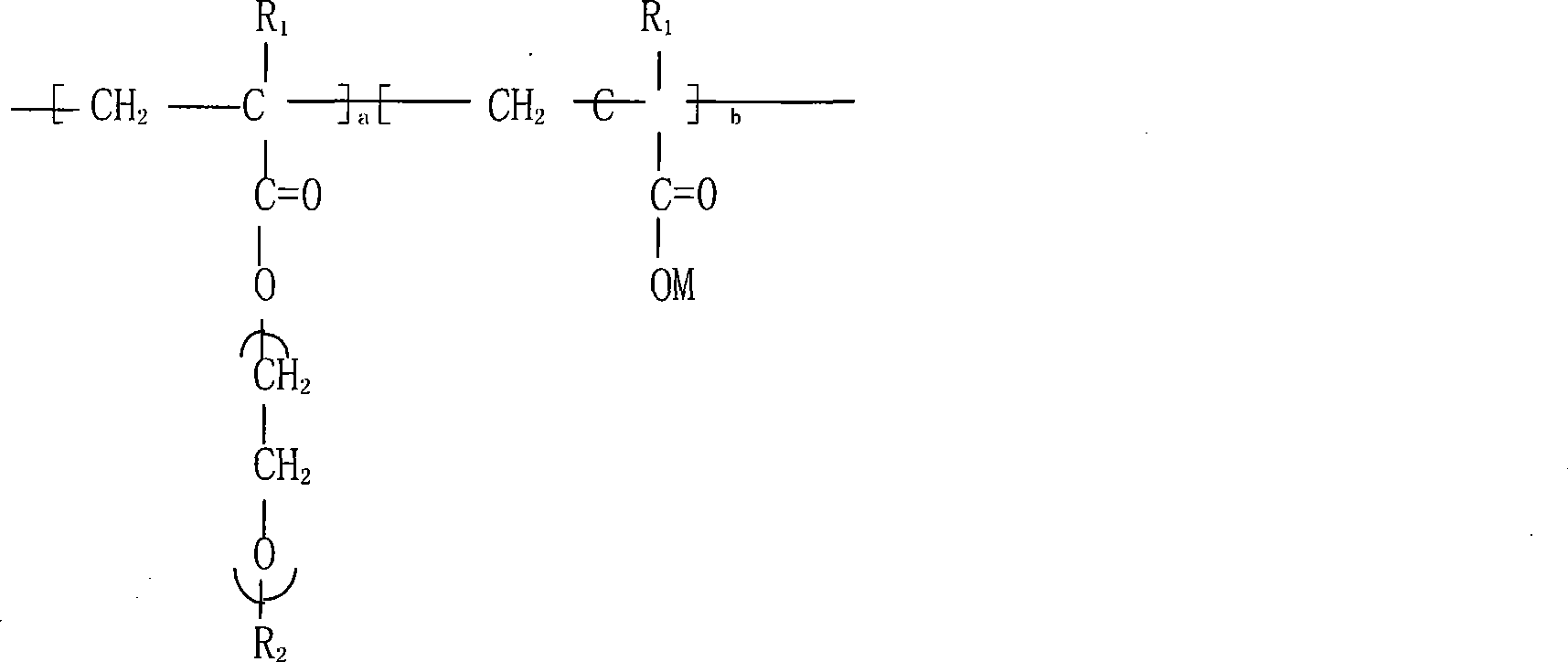

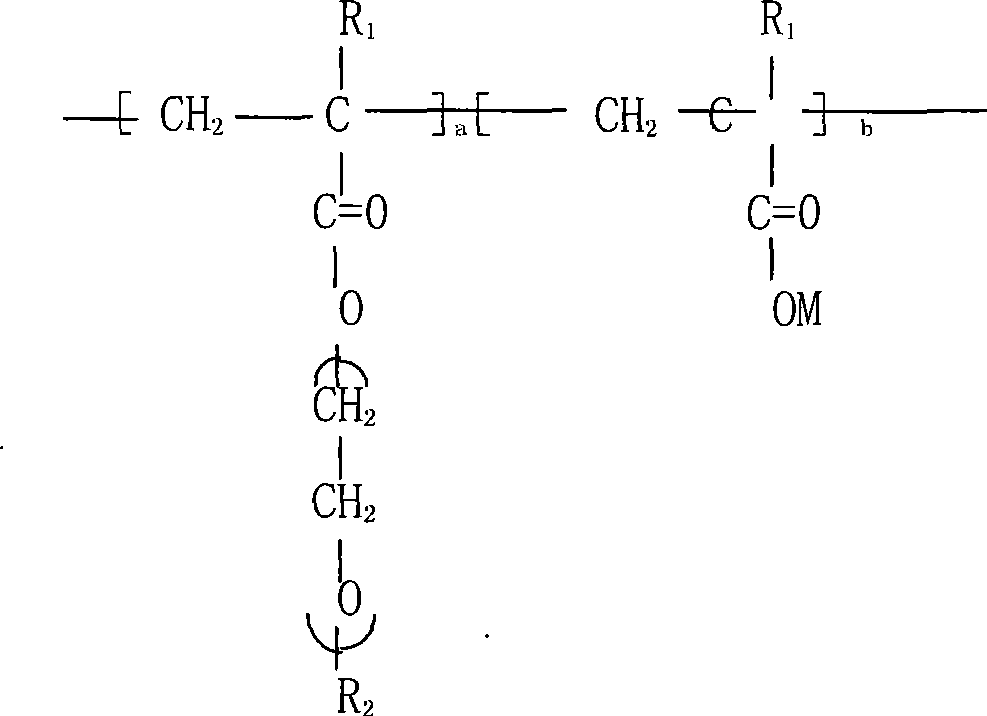

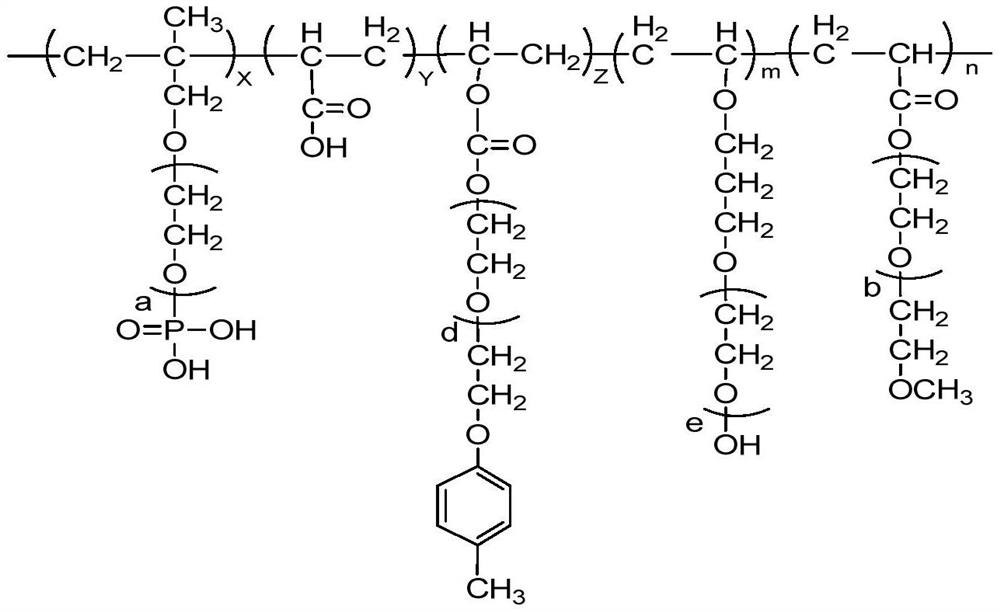

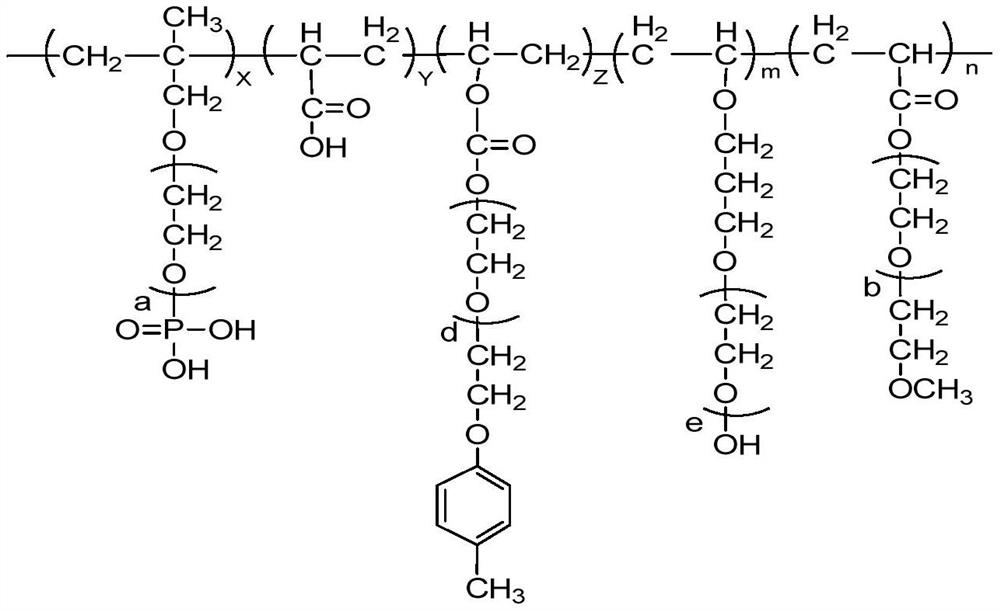

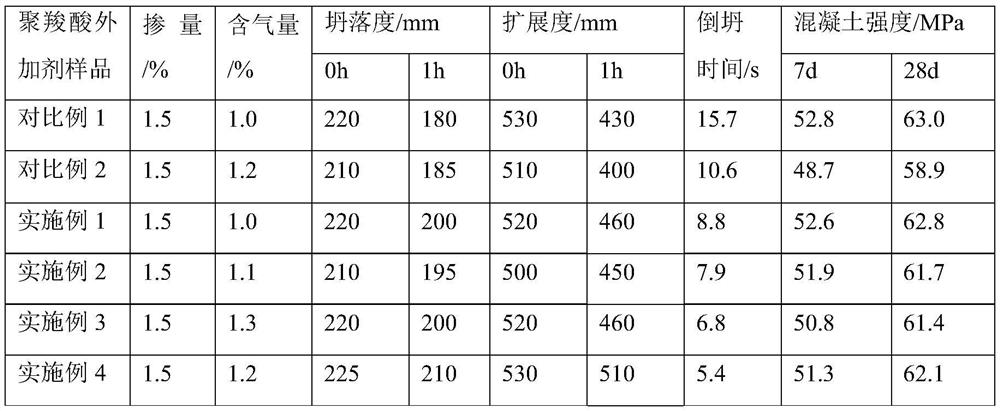

Preparation method of viscosity-reducing mud-resistant polycarboxylate superplasticizer

ActiveCN112608423AReduce viscosityReduce packageSolid waste managementPolymer scienceFunctional monomer

The invention discloses a preparation method of a viscosity-reducing mud-resistant polycarboxylate superplasticizer. The preparation method comprises the following steps: esterifying and grafting a rigid structure end group functional monomer with strong hydrophobicity, and copolymerizing 3-hydroxypropyl vinyl polyoxyethylene ether, unsaturated acid and other small monomers to obtain the polycarboxylate superplasticizer. Under the synergistic effect of various groups, the polycarboxylate superplasticizer prepared by the preparation method has the effects of remarkable viscosity reduction function, excellent mud resistance and low doping amount sensitivity.

Owner:ZHEJIANG KZJ NEW MATERIALS CO LTD

Preparation method of high-viscosity starch-based paper tube adhesive

InactiveCN107459945AIncrease stickinessIncrease layer spacingNon-macromolecular adhesive additivesStarch adhesivesAdhesivePotato starch

The invention relates to the technical field of preparation of adhesive, in particular to a preparation method of high-viscosity starch-based paper tube adhesive. According to the preparation method, potato starch is extracted from potatoes, the potato starch, polyvinyl alcohol and oxalaldehyde are subjected to crosslinked polymerization, and the viscosity of the starch-based adhesive is improved, so that the adhesion viscosity of the traditional starch adhesive is improved; fermenting liquid enriched amino acid and organic carboxylic acid and imvite for expanding the interlayer spacing are mixed, the amino acid and the organic carboxylic acid in the fermenting liquid are further degraded under the action of microorganisms, the generated amino groups and carboxylic groups are grafted and attached to the interlayer and the surface of the imvite, the number of the hydrophilic amino groups and the carboxylic groups on the interlayer and the surface of the imvite is increased, and the hydrophilic imvite is obtained; and the obtained hydrophilic imvite and the starch-based adhesive are mixed to obtain the piper tube adhesive, wherein the hydrophilic imvite has extremely high hydrophilic water-absorbility, free water at the periphery of the base adhesive is reduced and the base adhesive particles are sticky to form films easily, so that the initial adhesion time of the paper tube adhesive is reduced.

Owner:常州聚盛节能工程有限公司

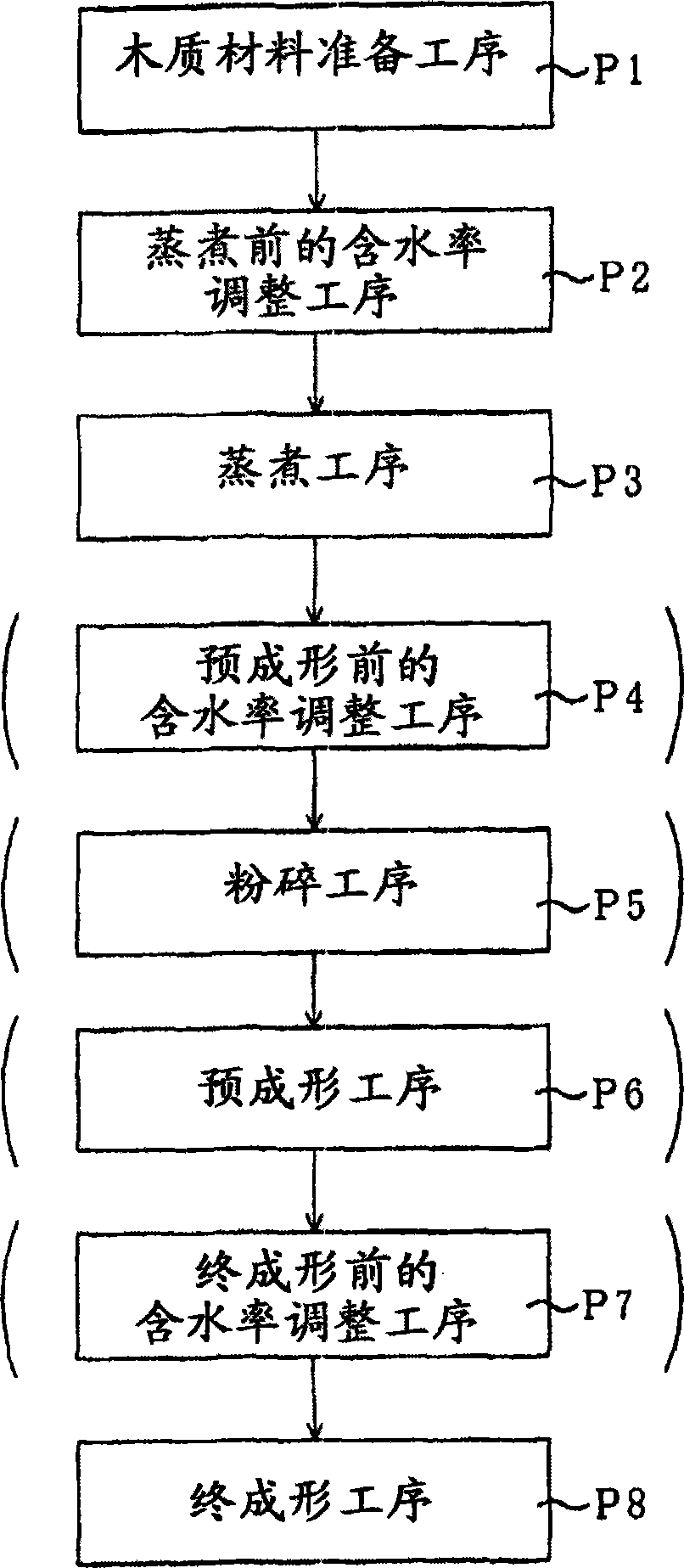

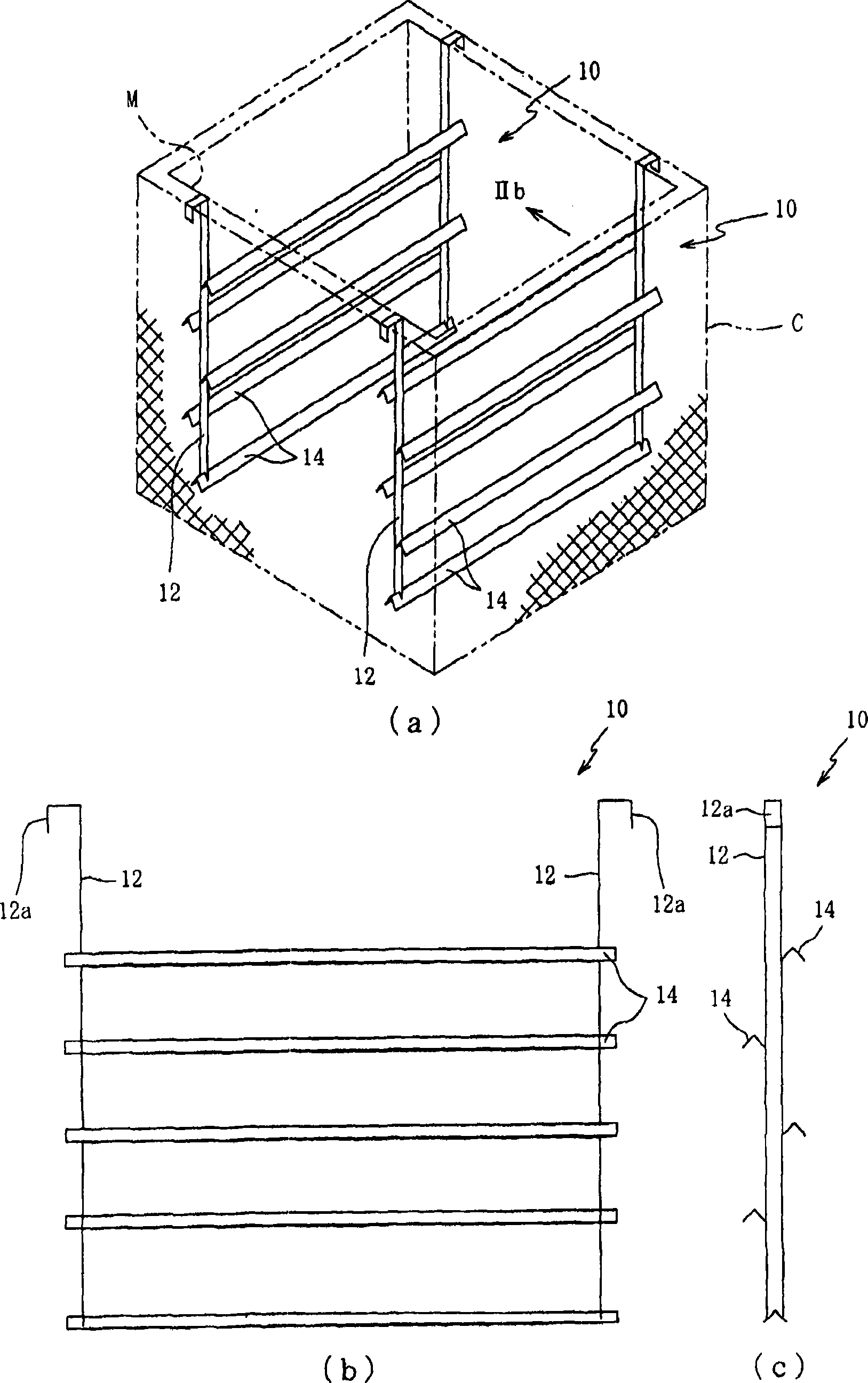

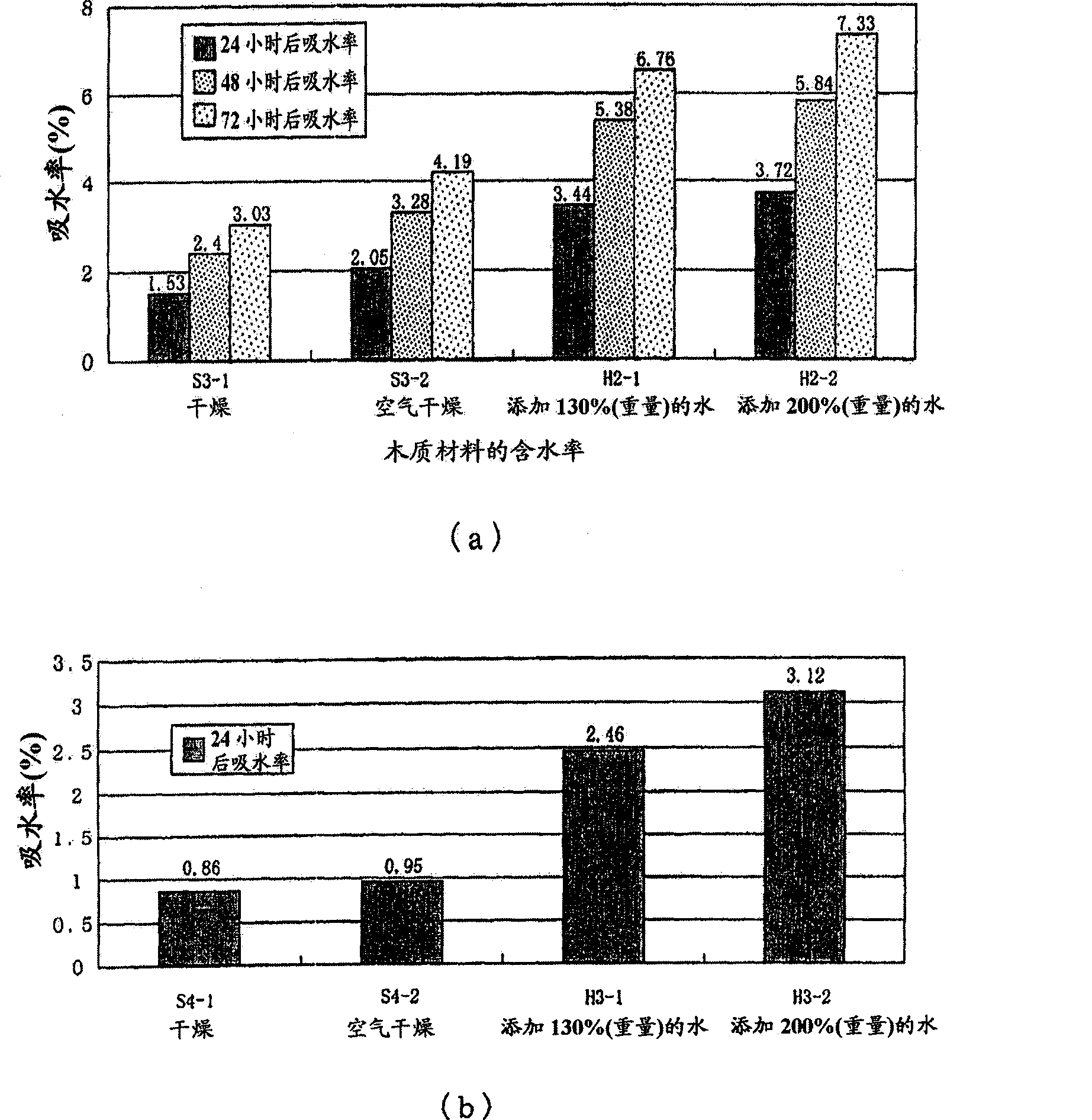

Method for producing xylon molded body and xylon molded body

InactiveCN101428431AShorten the timeLow thermal conductivityWood compressionWood dampingFormic acidMoisture

The invention relates to a woody material resinification, especially to a method for manufacturing a woody formed article and the woody formed article which is characterized by a reduced odor and a low water absorption ratio of a woody material resinification topic. The invention relates to the method for manufacturing the woody formed article which shows an adhesivity or a thermal flow property in the woody article and the woody formed article. After the moisture percentage of the woody material is regulated, the cooking treatment to a woody tissue by contacting a heated aqueous vapor can reduce the water absorption ratio and the odor from a formic acid or an acetic acid to minimum.

Owner:中日精工株式会社

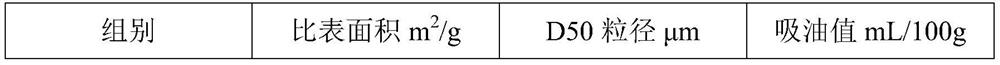

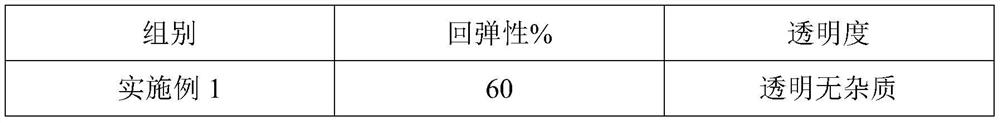

Preparation method of precipitated silicon dioxide for high-resilience transparent silicon rubber

InactiveCN113213495AReduce free waterEasy to disperseSilicon compoundsPrecipitated silicaOrganosilicon

The invention belongs to the technical field of silicon dioxide, and particularly relates to a preparation method of precipitated silicon dioxide for high-resilience transparent silicon rubber. The precipitated silicon dioxide for the high-resilience silicon rubber, provided by the invention, is prepared by a two-step method by taking water as a reaction base solution, taking a sodium silicate solution and a sulfuric acid solution with modulus of 1.5-3.5 as reaction raw materials and taking an organosilicon compound with mass fraction of 0.01-0.1% as an auxiliary agent. The specific surface area of the precipitated silicon dioxide for the high-resilience silicon rubber is 150-210 m < 2 > / g, the oil absorption value is 150-210 mL / 100 g, the precipitated silicon dioxide is applied to the silicon rubber, the resilience of the silicon rubber is 60-75%, and the silicon rubber is transparent and free of impurities. In addition, the preparation process of the precipitated silicon dioxide for the high-resilience silicon rubber is simple and environment-friendly, the production cost is relatively low, and industrial production is easy to realize.

Owner:GUANGZHOU FEIXUE MATERIAL TECH +1

A ready-mixed synchronous grouting material for shield tunneling construction with high water retention

The invention discloses a high-water-retaining-property shield construction premixed synchronous grout material which comprises cement, coal ash, admixture, bentonite, fine sand, additives and water. The additives mainly comprise non-ionic cellulose ether, carbohydrate, polycarboxylic acid slump retaining agents, starch ether and magnetic hydrotalcite. The high-water-retaining-property shield construction premixed synchronous grout material has the advantages that the optimized admixture, the bentonite, the fine sand with the fineness modulus being 1.6 and the additives special for mortar are jointly used in the shield construction premixed synchronous grout material, the fluidity loss of the adjusted grout material is less than or equal to 30mm in 6 hours, bleeding rate is reduced to be lower than or equal to 3.0%, and sedimentation after a vibration test is less than or equal to 20mm; due to the fact that the magnetic hydrotalcite is added, the grout material can reduce construction noise during stirring and absorb heavy metal ions to prevent heavy metal in the mortar from causing secondary pollution on the basis that the original physical properties are kept.

Owner:河北三楷展创建材有限公司

Grout material for subsea tunnel

The invention discloses a grout material for subsea tunnel. The grout material contains compound additives; the effective component of the compound additives includes aluminum sulfate, sodium sulfate, sodium fluoride, water reducer and allowance of matrix, and the matrix is one or mixture of polyving akohol water solution and polyacrylamide solution. After combining with the matrix formed by the polyving akohol or polyacrylamide, the water reducing agent in the compound additive can be evenly dispersed in a cement paste system, the surface of the cement grain is covered, the cement grain surface energy is reduced, the cement granular aggregation is decreased, and massive free moistures are released; under the condition of using low water ash ratio, the grout fluid also can keep big fluidity, thus the paste fluid has good injecting property; meanwhile, the water reducing agent and the matrix also have the retarding effect; the grout fluid has good fluidity at the early period, and a certain pumping period, thereby facilitating the construction operation.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

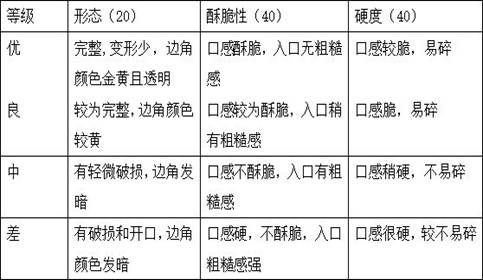

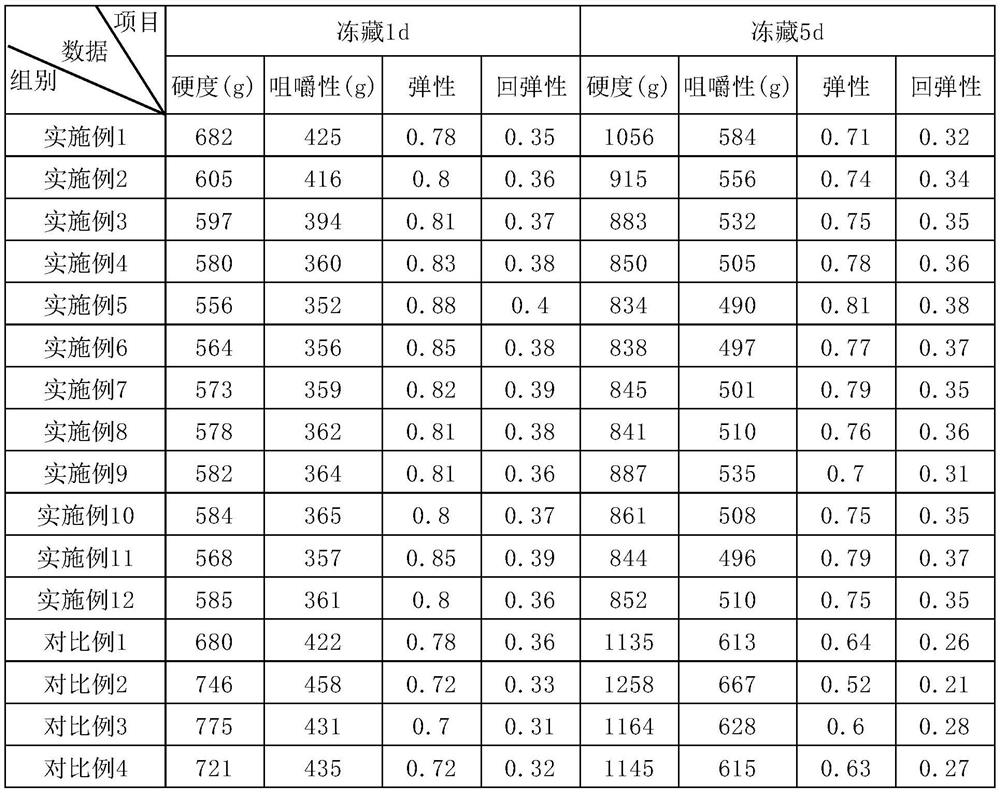

Improved crisping agent, application thereof in pot stickers and preparation method of pot stickers

PendingCN111990433AImprove microstructureGreat tasteDough treatmentBakery productsDisulfide bondingPotato starch

The invention provides an improved crisping agent, application thereof in pot stickers and a preparation method of the pot stickers. The improved crisping agent comprises the following raw materials in parts by weight: 20-30 parts of potato starch, 30-40 parts of soluble soybean polysaccharide, 15-20 parts of diacetyl tartrate mono / diglycerides, 10-15 parts of propylene glycol alginate, 10-15 parts of konjac powder and 10-15 parts of sodium hexametaphosphate. The improved crisping agent aims to solve the technical problem that in mass-produced pot stickers, sulfhydryl groups of protein in cooked flour are deoxidized to form disulfide bonds, which causes too high wrapper toughness, hard and tough taste cannot be changed by frying and baking again and the palatability is poor.

Owner:郑州康晖食品科技有限公司

Hot-processed sandwich biscuit and preparation method thereof

InactiveCN110915849AImprove food safetyKeep the mouth moistDough treatmentBakery productsBiotechnologySodium metabisulfite

The invention discloses a hot-processed sandwich biscuit and a preparation method thereof, and belongs to the field of food processing. The preparation method comprises the following steps: step 1, flour blending: preparing flour, green juice powder, white granulated sugar powder, fresh milk, paste soup and palm oil as a first group for later use; using ammonium bicarbonate, baking soda and pre-gelatinized starch as a second group for later use; preparing an enzyme preparation, dissolving the enzyme preparation with water to serve as a dissolving solution for later use, as a third group for later use, and adding water into sodium pyrosulfite for dissolving for later use; step 2, dough kneading: putting the first group of flour into a dough kneading machine to be stirred, then adding the second group of flour to be stirred, and then pumping the dissolved solution into the dough kneading machine to be stirred; finally, adding a sodium pyrosulfite dissolving solution, and stirring; repeating the step 2 to prepare at least two dough; step 3, calendering; step 4, roll cutting and forming; step 5, drying: transferring the shaped biscuit semi-finished product into a drying machine for drying; subjecting the stuffing and the blank synchronously to a drying process of hot processing, so that the purpose of fusing the tastes of the stuffing and the blank is achieved; step 6, packaging.

Owner:CHACHA FOOD CO LTD +1

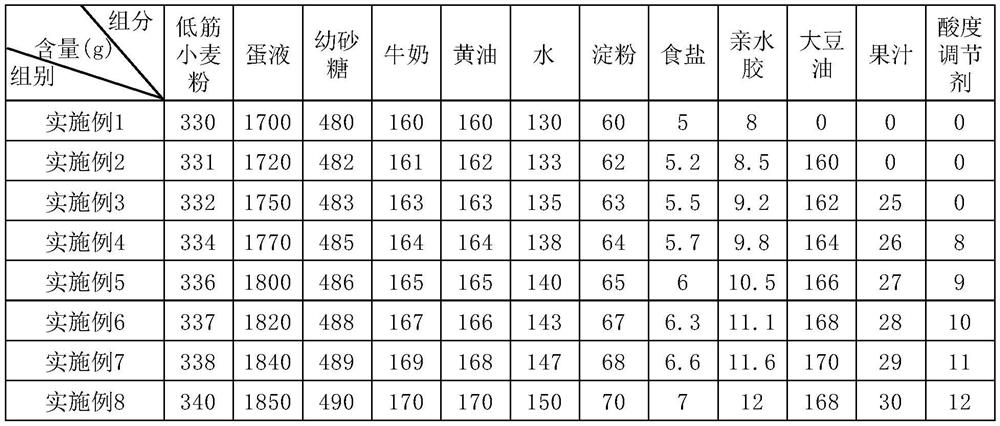

Frozen boiled dough chiffon cake base and preparation method thereof

ActiveCN111670932APrevent agingNot easy to ageClimate change adaptationBakery productsBiotechnologySugar

The invention discloses a frozen boiled dough chiffon cake base and a preparation method thereof, and relates to the technical field of cake processing. The frozen boiled dough chiffon cake base comprises the following components in parts by weight: 330 to 340 parts of low-gluten wheat flour, 1700-1850 parts of egg liquid, 480-490 parts of caster sugar, 160-170 parts of milk, 160-170 parts of butter, 130-150 parts of water, 60-70 parts of starch, 5-7 parts of salt, 8-12 parts of hydrophilic glue. The preparation method of the frozen boiled dough chiffon cake base comprises the following steps:S1. pre-stirring of the egg white, S2. liquid material preheating, S3. boiled dough mixing, S4. inflation and stirring, S5. Baking and S6. cooling and packaging. The frozen boiled dough chiffon cakebase has the technical effects of being high in water content, good in moisturizing performance, soft in taste and not prone to aging, thereby prolonging the preservation period.

Owner:武汉市仟吉食品有限公司

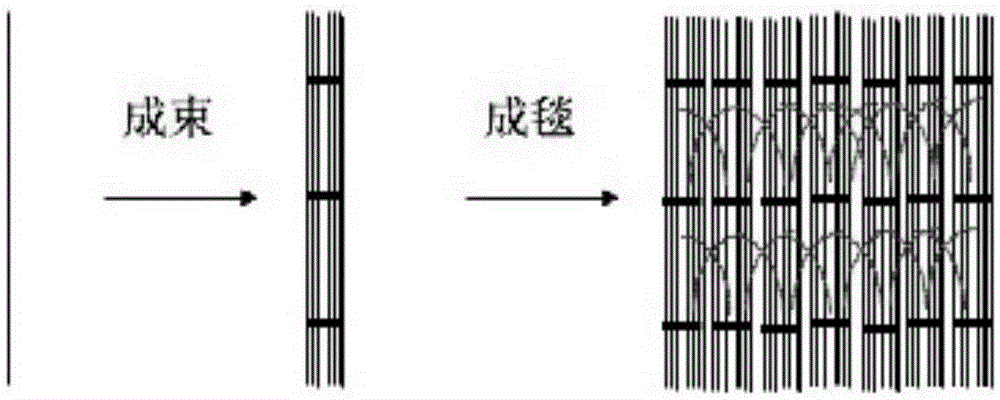

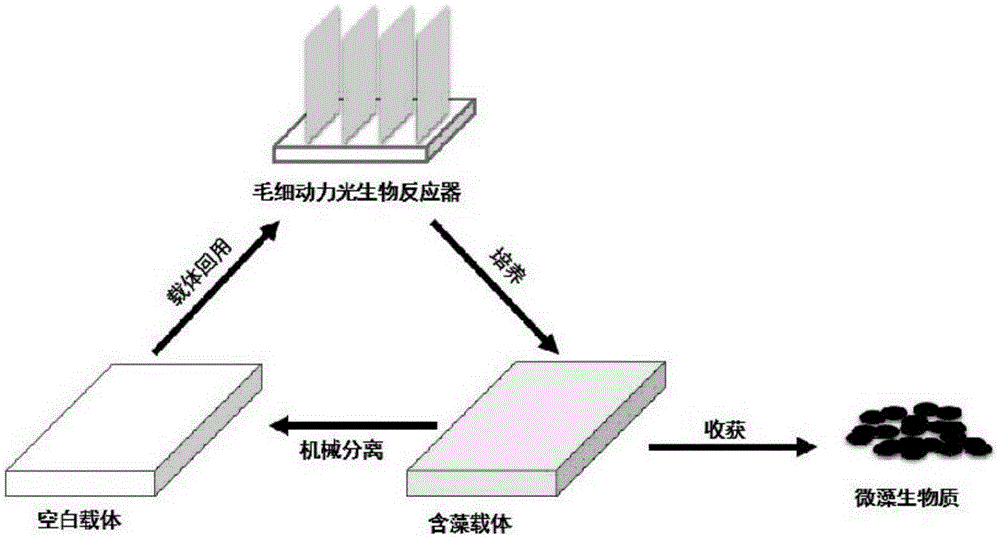

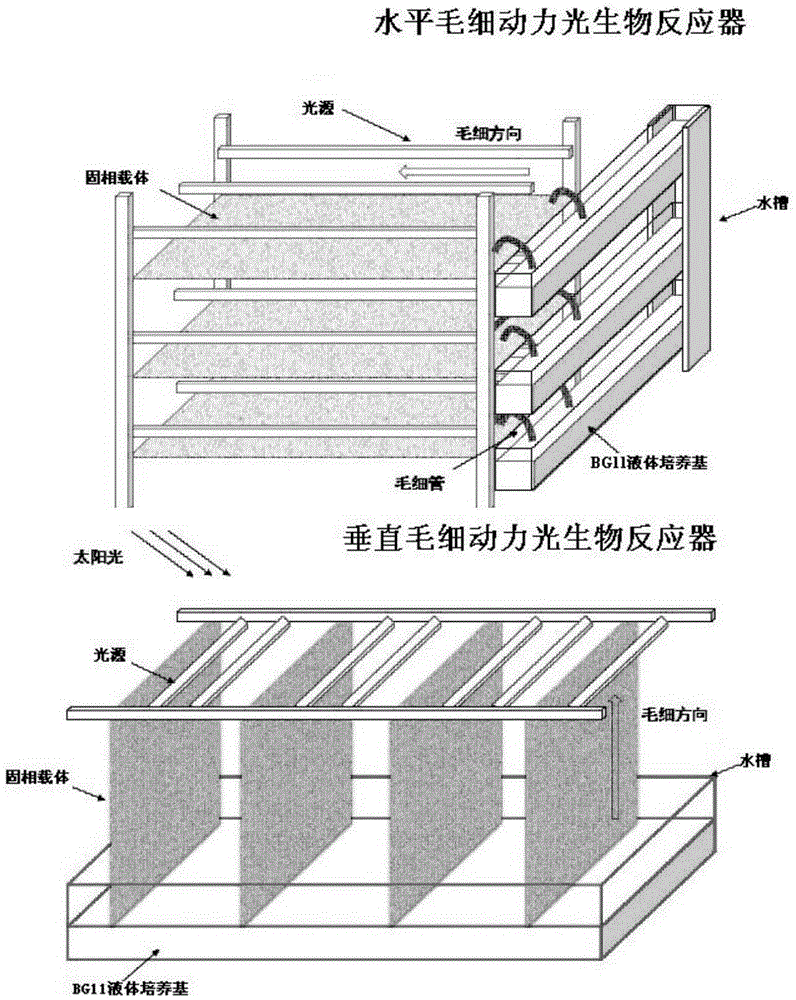

Microalgae solid-phase attached growth culture method with water and nutrition supplied based on capillary power

ActiveCN105420113AEliminate the enrichment and concentration processSave energyUnicellular algaeMicroorganism based processesSupporting systemSelenastrum

The invention discloses a microalgae solid-phase attached growth culture method with water and nutrition supplied based on capillary power, and belongs to the technical fields of production and harvesting of microalgae. The culture method comprises the following steps: inoculating an algae solution on a solid-phase vector, and keeping the solid-phase vector on a transparent supporting system; and then on the basis of the capillary performance of the solid-phase vector, automatically sucking a BG11 liquid culture medium and storing in the solid-phase vector, and supplying water and nutrition to microalgae on the solid-phase vector, so that the growth of the microalgae is achieved, wherein the microalgae is scenedesmus, chlorella or selenastrum capricornutum. The culture method disclosed by the invention, when used for culturing the microalgae, can simplify culture and harvesting processes and save energy; and the culture method is applied to the industrial production of energy microalgae, edible fungi, microalgae bio-products and like products.

Owner:TSINGHUA UNIV

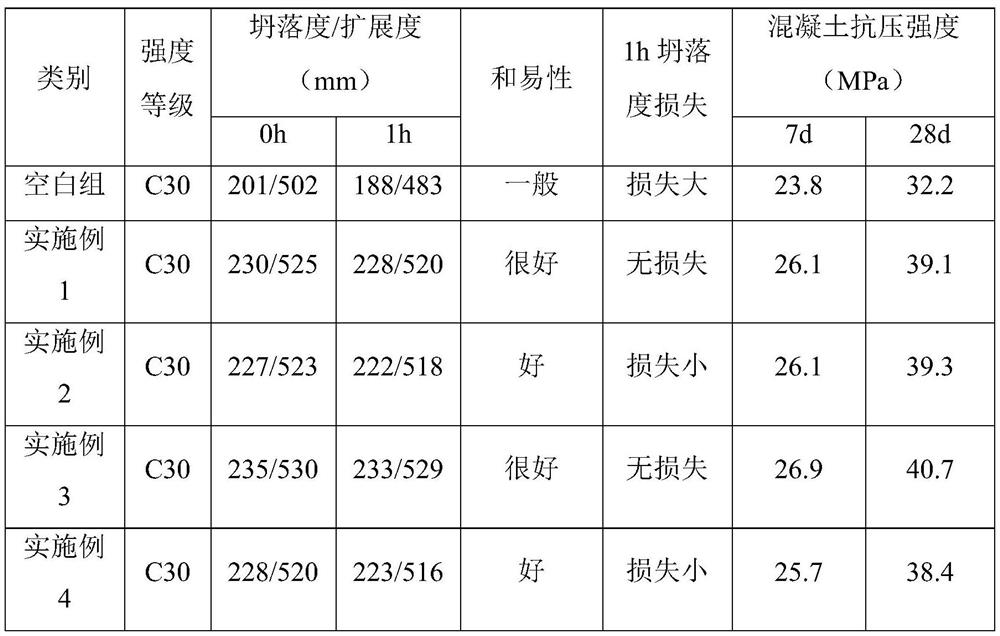

Slump retaining type concrete synergist and preparation method thereof

The invention discloses a slump retaining type concrete synergist and a preparation method thereof. The concrete synergist is prepared from the following substances in parts by weight: 12-20 parts ofa reinforcing agent, 8-15 parts of a regulator, 5-10 parts of an alkanol acrylate copolymer, 3-8 parts of maleic anhydride, 4-8 parts of a retarder, 2-5 parts of a lubricant and the balance of water.According to the invention, the polyol can make the cement fully hydrated; after the active sodium salt is doped into the concrete to promote the generation of low-sulfur calcium sulphoaluminate and hexagonal plate solid solution, the hexagonal plate solid solution fills internal pores and capillary channels of the concrete, so that the compactness of the concrete is improved, and the strength ofthe concrete is promoted to be improved. The alkanol acrylate copolymer can control the slump loss of concrete over time, so that the [xi] potential of the surface layer of cement particles is kept unchanged, and the cement particles are uniformly dispersed. Under the synergistic effect of the components, the synergist can obviously improve the early strength and later strength of concrete.

Owner:浙江鑫月新材料科技有限公司

Oil layer protective agent for drilling fluid and production method thereof

ActiveCN103820085BPerformance is not affectedReduce free waterDrilling compositionWorking fluidOil phase

The invention provides an oil layer protective agent for drilling fluid and a production method thereof, which is used for solving the problems of high requirement on solid control equipment in site because of high configuration cost, incompatibility of working fluid and formation fluid and narrow use because of the constraint of service conditions such as poor rock incompatibility of oil and gas layers in the oil layer protective agent in the prior art. The oil layer protective agent for drilling fluid is prepared from the following components in percentage by weight: 27-35% of industrial water, 1-1.5% of carboxymethylcellulose, 53-60% of white oil, 5-10% of ammonium salt, 5-10% of fine calcium carbonate and 1-1.5% of defoamer. The oil layer protective agent for drilling fluid disclosed by the invention takes subsidiary function in reducing water loss so as to further reduce free water permeate into the stratum without influencing the performance of the drilling fluid; the matching degree of the particle size of the oil layer protective agent can be maximized according to the pore throat characteristics of different stratum oil and gas layers so as to effectively realize plugging; the proper oil-phase proportion can more effectively avoid the damage to oil and gas layers; the preparation cost is low.

Owner:BEIJING BAOWO PETROLEUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com