Patents

Literature

1050results about "Wood compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

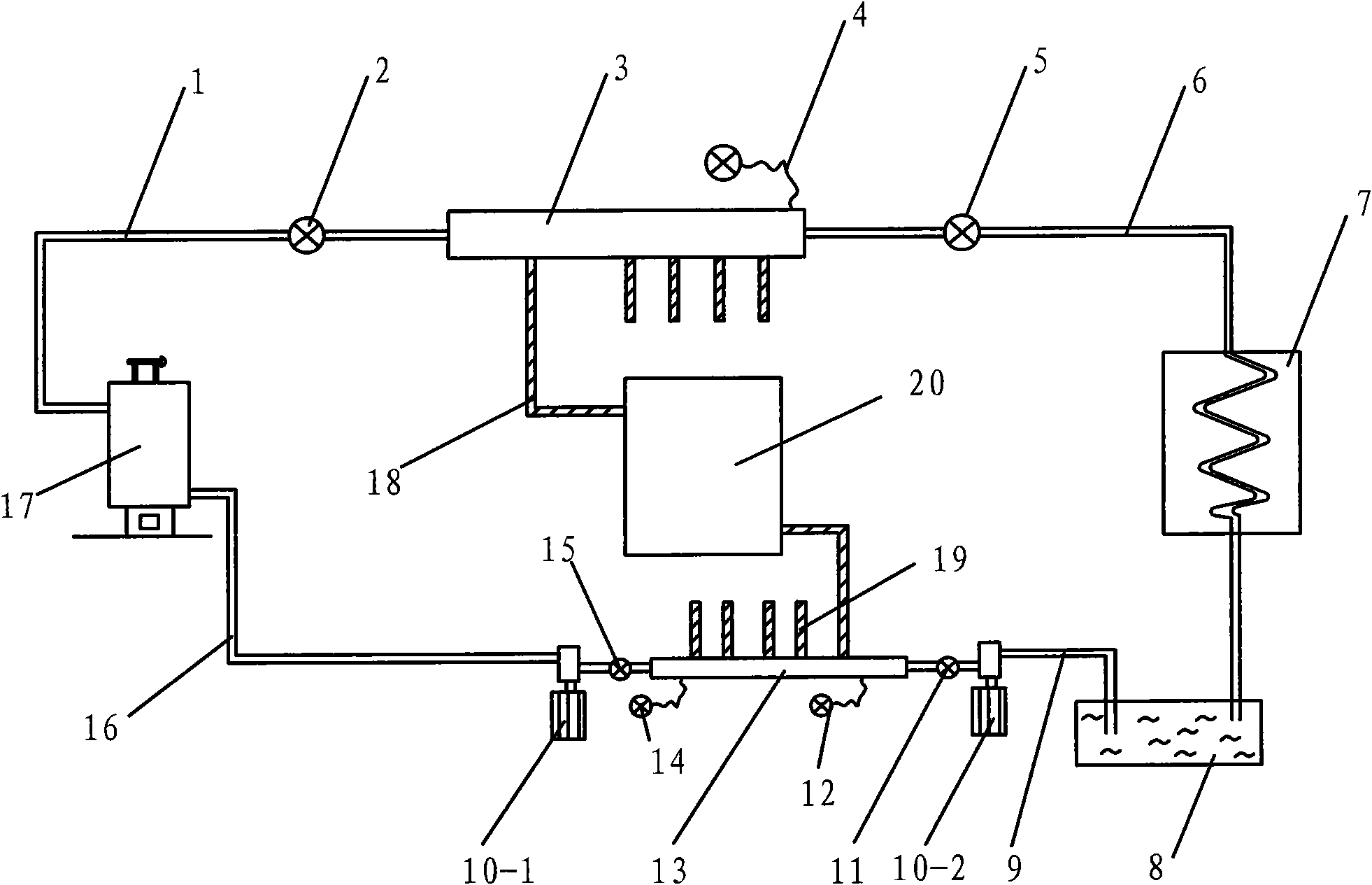

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

Method and apparatus for separating sheet glass

InactiveUS20060191970A1Heating evenlyQuality improvementWood compressionGlass severing apparatusFlat glassInitiation point

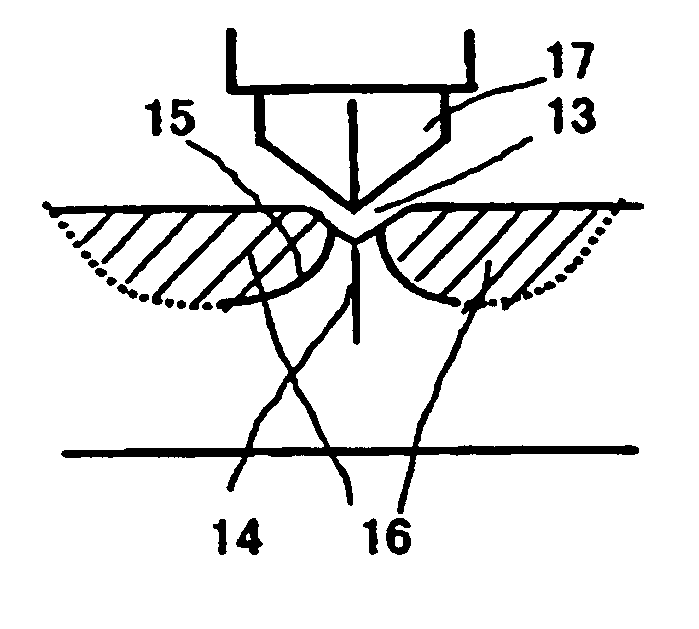

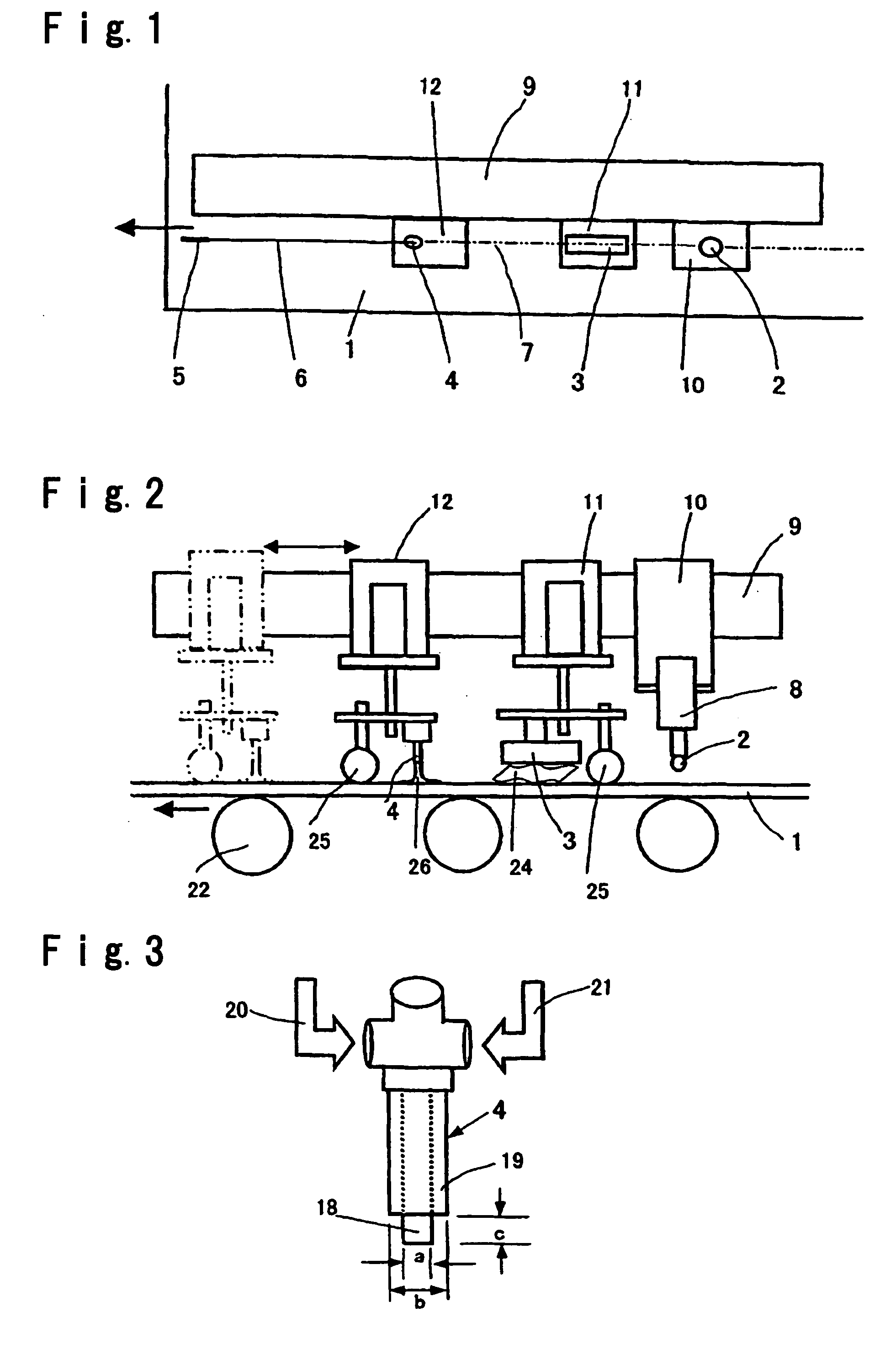

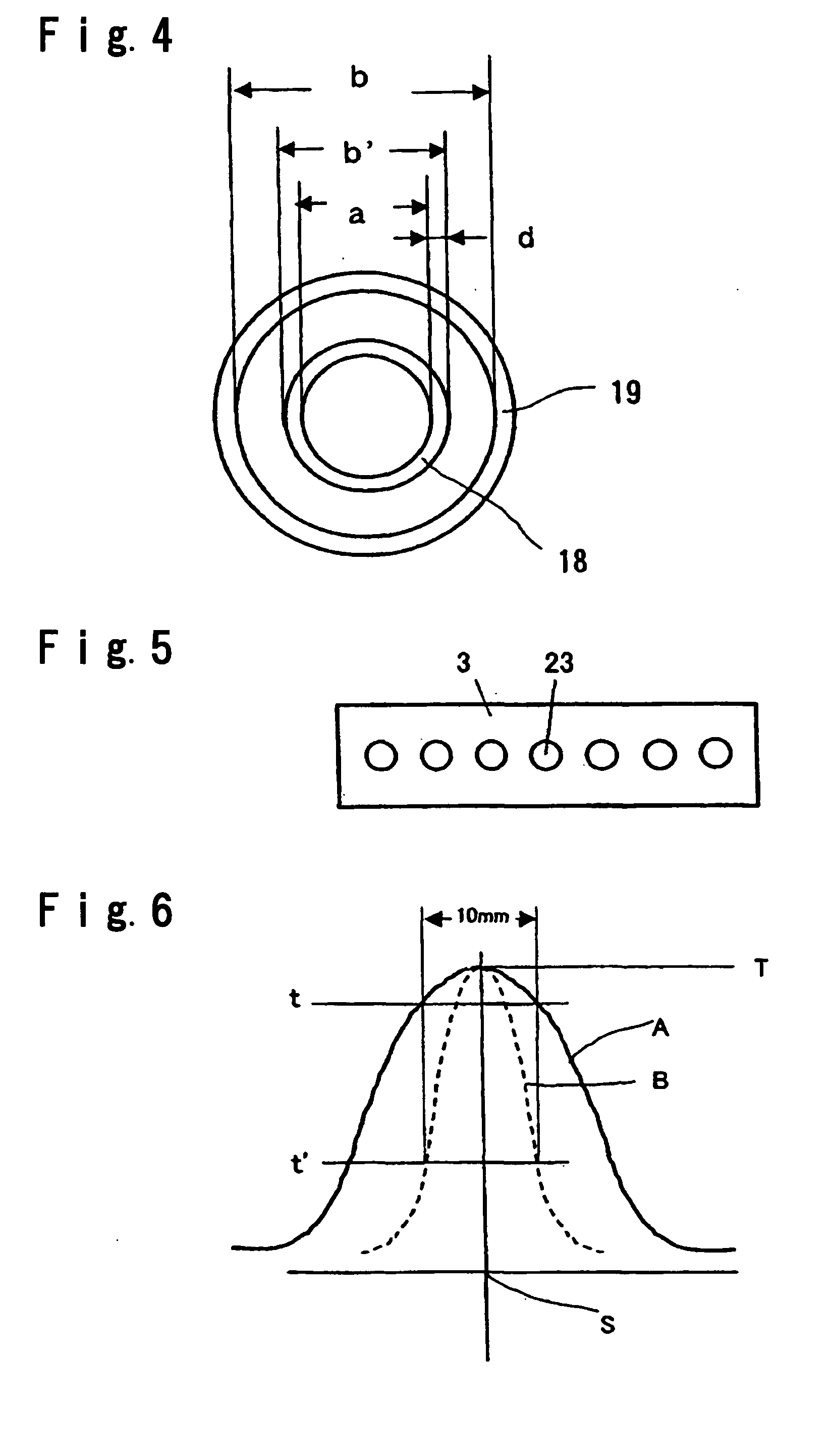

In separation of sheet glass by making use of thermal strain, separated surfaces can be obtained to avoid the occurrence of glass chips and to have excellent linearity even in relatively thick sheet glass. After a score, which serves as a crack initiation point is engraved at a separation initiation point in sheet glass, the sheet glass is heated along an imaginary line of by a heating burner; the heated portion of the sheet glass with the imaginary line of separation set therein is locally cooled by a mist, which is produced by a cooling nozzle comprising a liquid-ejecting port disposed at a central portion thereof and a gas-ejecting port disposed around an outer periphery of the liquid-ejecting port, the liquid-ejecting port projecting farther than the gas-ejecting port; and a minute crack of the score is caused to propagate along the imaginary line of separation to form a crack required for separation of the sheet glass.

Owner:ASAHI GLASS CO LTD

Technical wood and manufacture method thereof

ActiveCN103171014AImprove the utilization rate of solid woodHigh densityWood compressionWood impregnation detailsHot pressHot pressing

The invention relates to technical wood and a manufacture method thereof. The manufacture method comprises the steps of dying and drying eucalyptus and poplar veneers, conducting gum dipping and thickening on the wood veneers by using an ultrasonic vibration method, assembling gum dipping boards, conducting semi-solidification hot-pressing maintaining by using a curve die high-frequency press, conducting square slicing on the technical wood or cutting the technical wood into wood veneers, assembling the wood veneers in the same direction according to needed thickness, and conducting hot pressing and thickening. The thickness of the technical wood veneers or wood square produced by using the manufacture method is as high as 0.8-1.8kg / cm<3>, the thickness of the technical wood is more than 1.5 times of that of common technical wood, a plurality of items of physical and mechanical properties are improved by more than 1.5 times, the technical wood is not easy to crack, product durability improves to more than one time, service life of products is prolonged, and using fields of the products are extended.

Owner:SINO MAPLE JIANGSU CO LTD

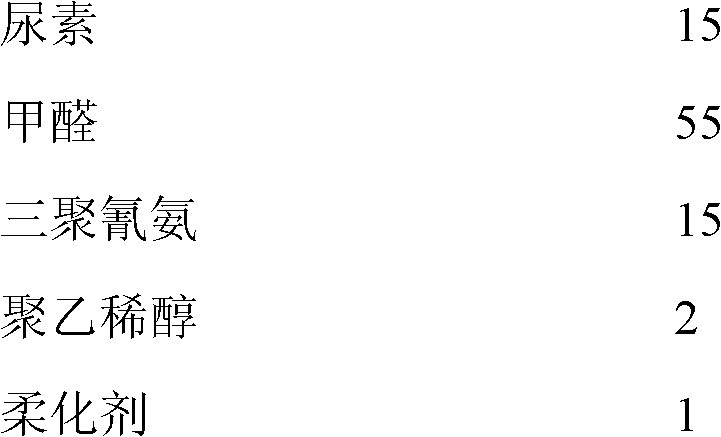

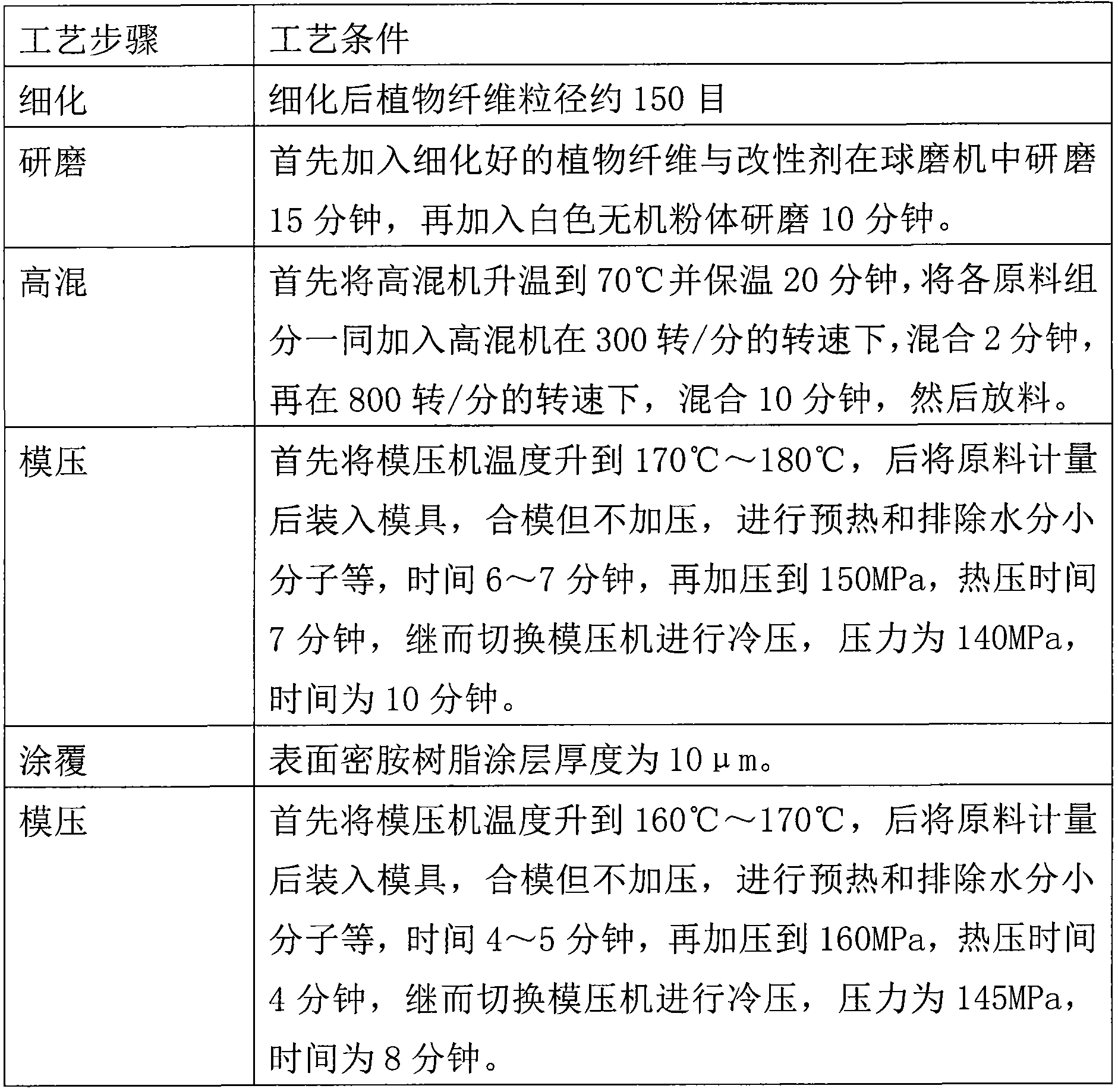

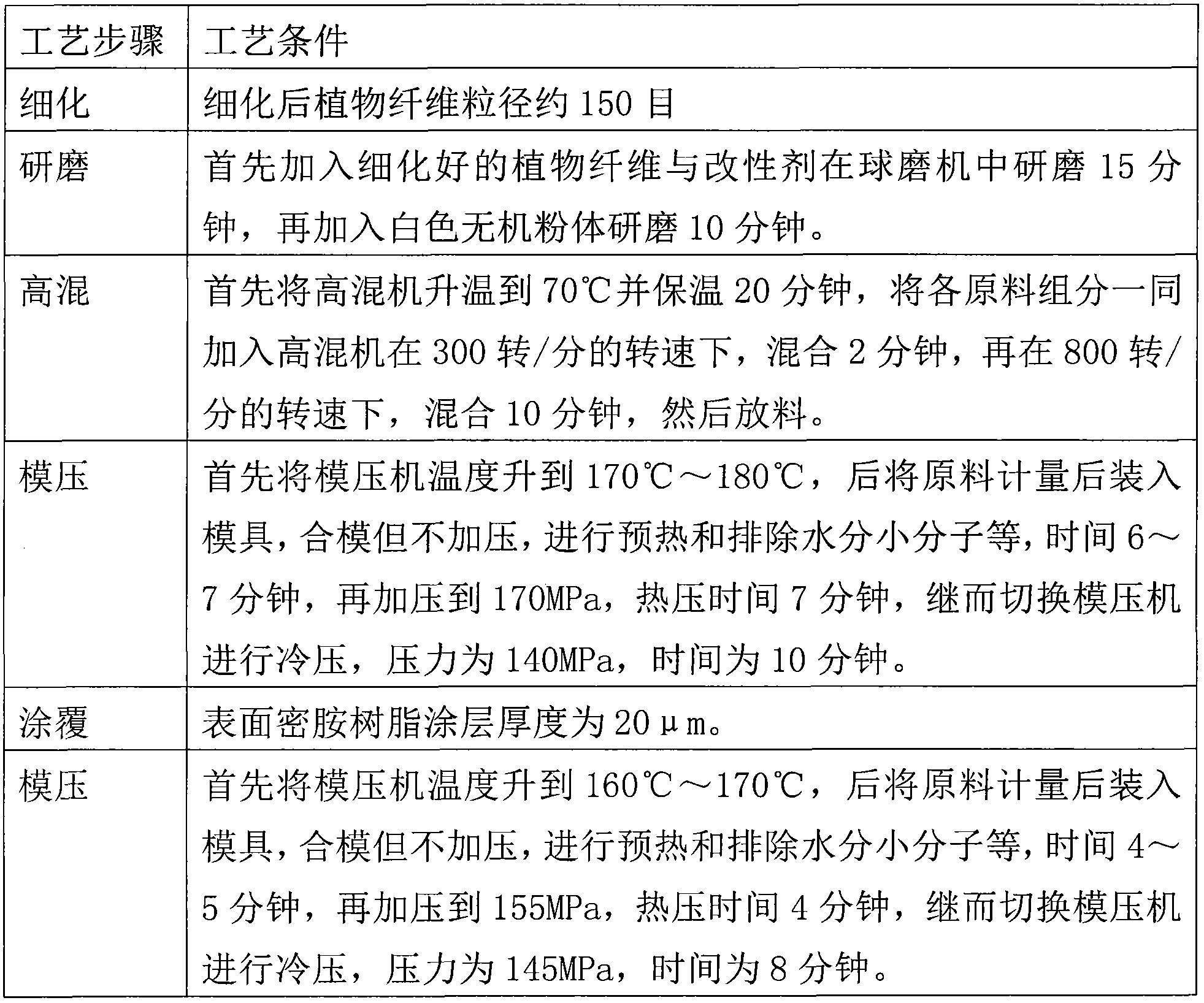

Manufacturing method for vegetable fiber compound tableware

ActiveCN102794803AControlled high temperature oxidative degradationControllable DurabilityWood compressionAviationHusk

The invention belongs to the technical field of vegetable fiber compound tableware and specifically relates to a manufacturing method for the vegetable fiber compound tableware. The manufacturing method specifically comprises seven steps. The production cost of the vegetable fiber compound tableware is obviously lower than that of the traditional metal, ceramic and melamine tableware; the traditional metal, ceramic and melamine tableware can be replaced by the vegetable fiber compound tableware; a large quantity of vegetable fibers, such as, crop straws, rice husks, cobs, sawdust, and the like, are effectively utilized; the atmospheric pollution caused by vegetable fiber burning is effectively prevented and the waste is turned into the wealth; the main products are as follows: basins, bowls, cups, dishes, trays, snack boxes, soup ladles, soup spoons, chopsticks, aviation meal boxes, and the like; and the products have the characteristics of high ceramic simulating strength, good natural texture, clear and gorgeous grains, and the like.

Owner:安徽绿之态秸秆制品有限公司

Method for blending and setting wood

ActiveCN101596730AAlleviate the prominent contradiction between supply and demandExpand the scope of useWood compressionWood treatment detailsPulp and paper industryDistortion

The invention relates to the technique field of wood processing treatment, in particular to a method for blending and setting wood. The method for blending and setting wood comprises steps of sorting treatment, softening process, blending and deforming, setting, temperature reduction and humidifying, and cooling and health preserving. The method solves the problems existing in the existing traditional wood blending and distortion technique that wood utilization ratio is low, obtained products have poor size stability and high recovery rate of radius of curvature and is easy to crack, deform, decay and go moldy, etc.

Owner:ZHEJIANG SHIYOU TIMBER

Surface reinforced solid wood section material, floor board and manufacturing method thereof

ActiveCN101603623AReduce pollutionStable moisture contentWood compressionFurniture partsSolid woodVolumetric Mass Density

Owner:ZHEJIANG SHIYOU TIMBER +1

Manufacturing method of surface compressed plate

InactiveCN101664948AHigh densityHigh strengthWood compressionWood treatment detailsPolymer scienceVolumetric Mass Density

The invention relates to a manufacturing method of a surface compressed plate, in particular to solving the technical problem of providing a manufacturing method of a surface compressed plate featuring high surface layer density, high strength, low probability of deformation, simple technology, strong operability and lighter color. The technical scheme for solving the problem is as follows: the method comprises the following steps: (1) drying and controlling the water content between 20% and 30%; (2) rolling and controlling the compression ratio between 10% and 30%; (3) impregnating surface layer, namely soaking one or two sides of the plate into light-color water-soluble low molecular weight phenolic resin adhesives at a concentration of 10-25%; (4) softening by steam and controlling thesoftening temperature between 120 DEG C and 140 DEG C and time between 20min and 60min; and (5) compressing surface layer and controlling the compression ratio between 15% and 50%, the hot pressing temperature between 160 DEG C and 180 DEG C and the unit pressure between 1.5MPa and 4.5MPa. The method is suitable for such fields as furniture manufacturing, indoor decoration and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY

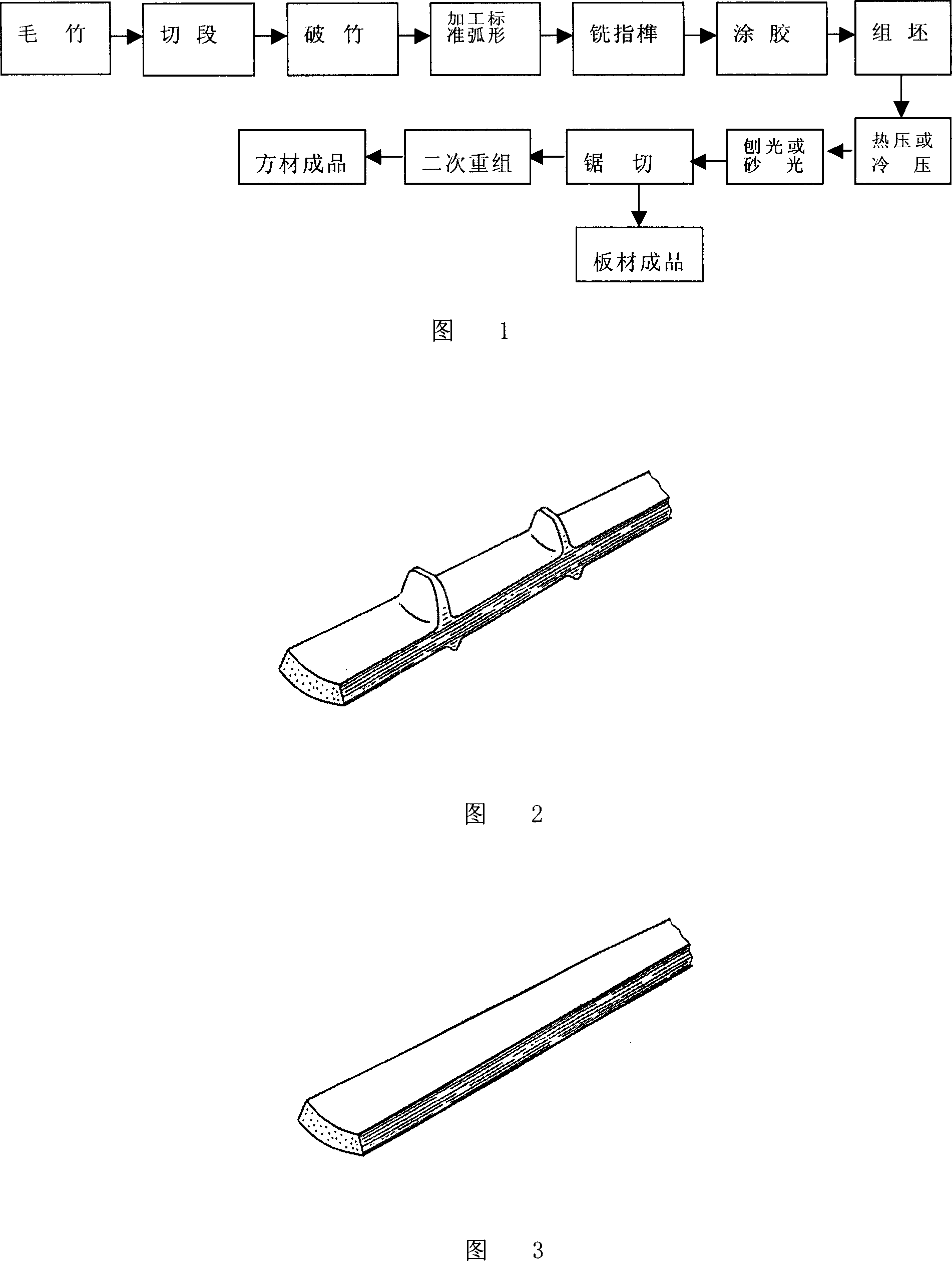

Original bamboo inner-dissecting outer-linked softening unfolding recombining technology

ActiveCN102225564AFew slicesHigh yieldWood compressionWood treatment detailsSingle plateCarbonization

The invention discloses original bamboo inner-dissecting outer-linked softening unfolding recombining technology. The technology comprises the following steps: sawing an original bamboo into bamboo tubes with a specified length, dissecting the bamboo tubes into several arc shaped bamboo sheets, removing inner bamboo joints, performing high-temperature softening and plasticizing treatment of the bamboo sheets, performing inner-dissecting outer-linked unfolding of the arc shaped bamboo sheets by a bamboo filament-linked unfolding milling machine, removing the inner of the bamboo with a fixed width and milling, performing boiling or carbonization, drying, dipping, drying, prepressing into single plates, drying, cutting core layers, dipping, performing blank assembling and plate alignment, performing hot pressing and stratification, trimming, and finally performing hot pressing and recombination according to the purposes. The invention overcomes the disadvantages of existing excessive processing procedures for bamboo, large equipment investment, high labor expense consumption, low raw material utilization rate, and high processing cost, and the prepared bamboo sheet material is applicable to industry such as architecture, decoration, furniture, etc.

Owner:HUNAN ACAD OF FORESTRY

Flame-retardant anti-corrosive fiber bamboo base material and preparation technology thereof

ActiveCN102794801AIncrease profitCarbonization pyrolysis effect is remarkableWood compressionLayered productsFiberCarbonization

The invention discloses a flame-retardant anti-corrosive fiber bamboo base material and a preparation technology thereof. The method comprises the following steps of: 1) cutting raw bamboo into bamboo filament; 2) flame-retardant treatment: soaking the bamboo filament prepared in the step 1) in a flame retardant aqueous solution; 3) drying: after the flame-retardant treatment, drying the bamboo filament at 55-65 DEG C until the absolute water content does not exceed 12%; 4) carbonization pyrolysis: feeding the dried bamboo filament into a carbonization pyrolysis kiln, and performing high-temperature treatment according to the pyrolysis gradient; and 5) sequentially performing gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain the bamboo base material. The bamboo base material has strong stability, the product surface does not crack, the corrosion resistance is enhanced, good flame retardance is realized, and the bamboo base material can be used in various weathers and environments.

Owner:WUXI BODA BAMBOO & WOOD INDAL

Solid wood bending technological method for curve-shaped structural member of redwood furniture

ActiveCN104802247AImprove the level of production technologyHigh strengthWood compressionWood treatment detailsSolid woodColor effect

The invention discloses a solid wood bending technological method for a curve-shaped structural member of redwood furniture. The solid wood bending technological method comprises the following steps: (1) wood type selection and lumber processing; (2) boiling or steaming for thermal treatment for softening; (3) longitudinal compression; (4) die bending forming; (5) drying sizing; (6) aging for life nourishing; (7) later processing and bending to manufacture the curve-shaped structural member of the redwood furniture. The solid wood bending technological method has the advantages that the generally conventional lineation sawing processing method can be replaced; a redwood type solid wood lumber can be directly bent into a curve-shaped part; the production technological level for the curve-shaped part of the redwood furniture can be increased, and the production technological steps can be simplified; the utilization rate of redwood type woods can be increased, the intensity of the curve-shaped part is enhanced, and the texture and color effect and the paint decoration quality on the surface of a product are guaranteed.

Owner:ZHONGSHAN TAIXING FURNITURE CO LTD

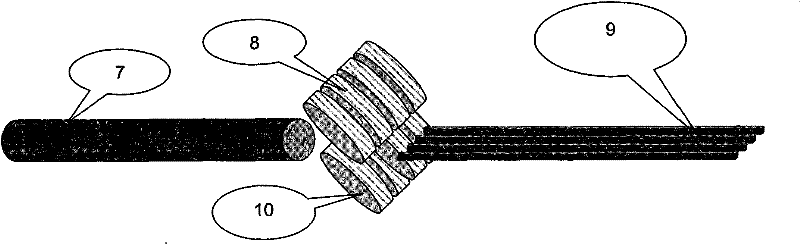

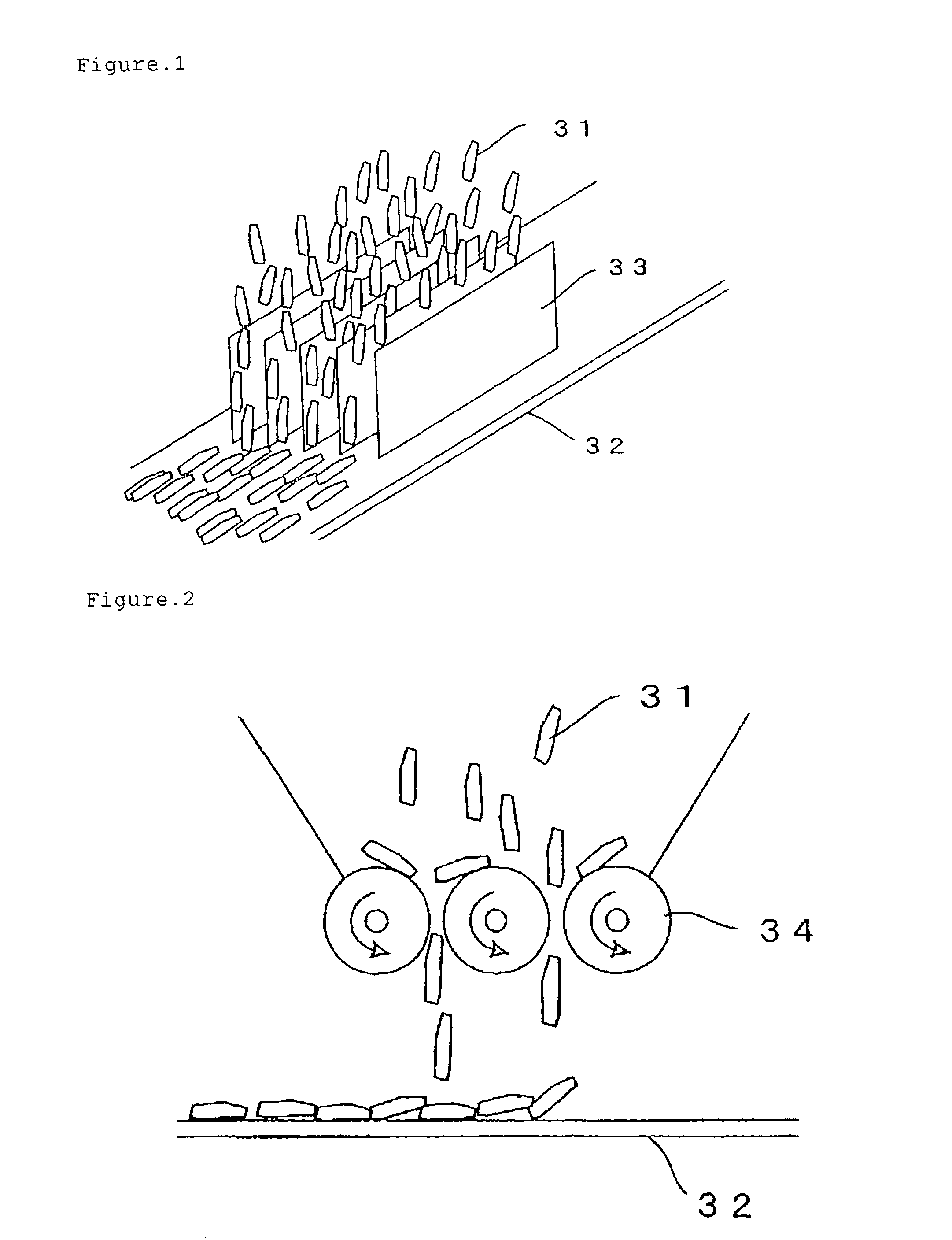

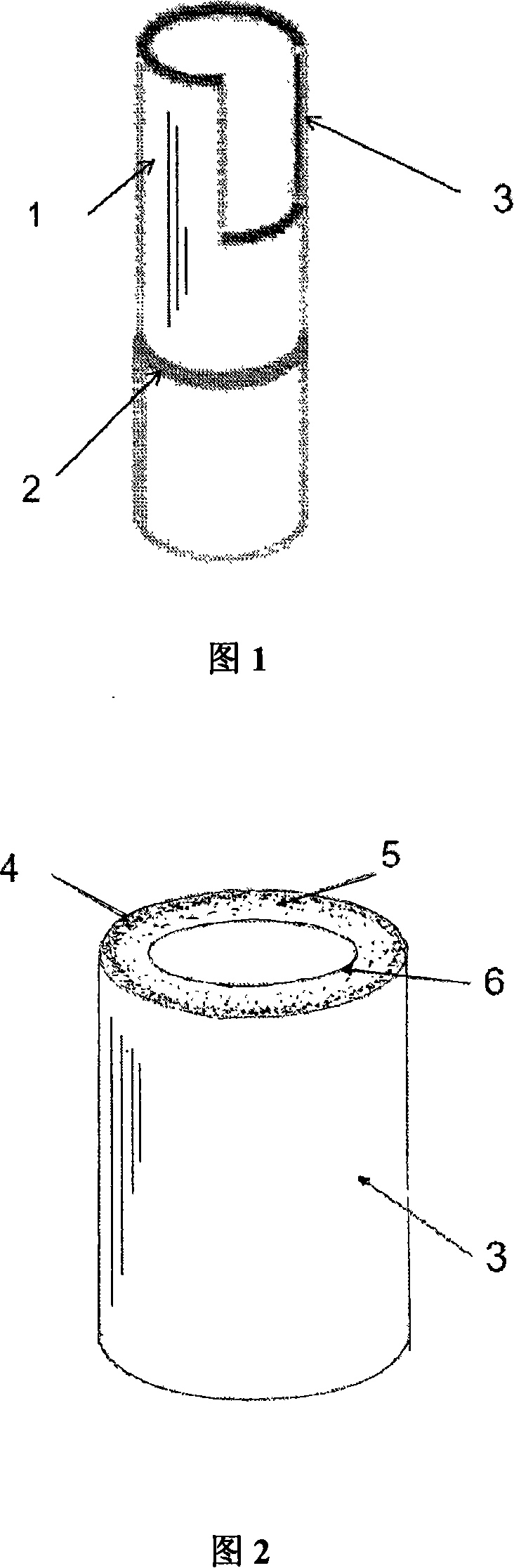

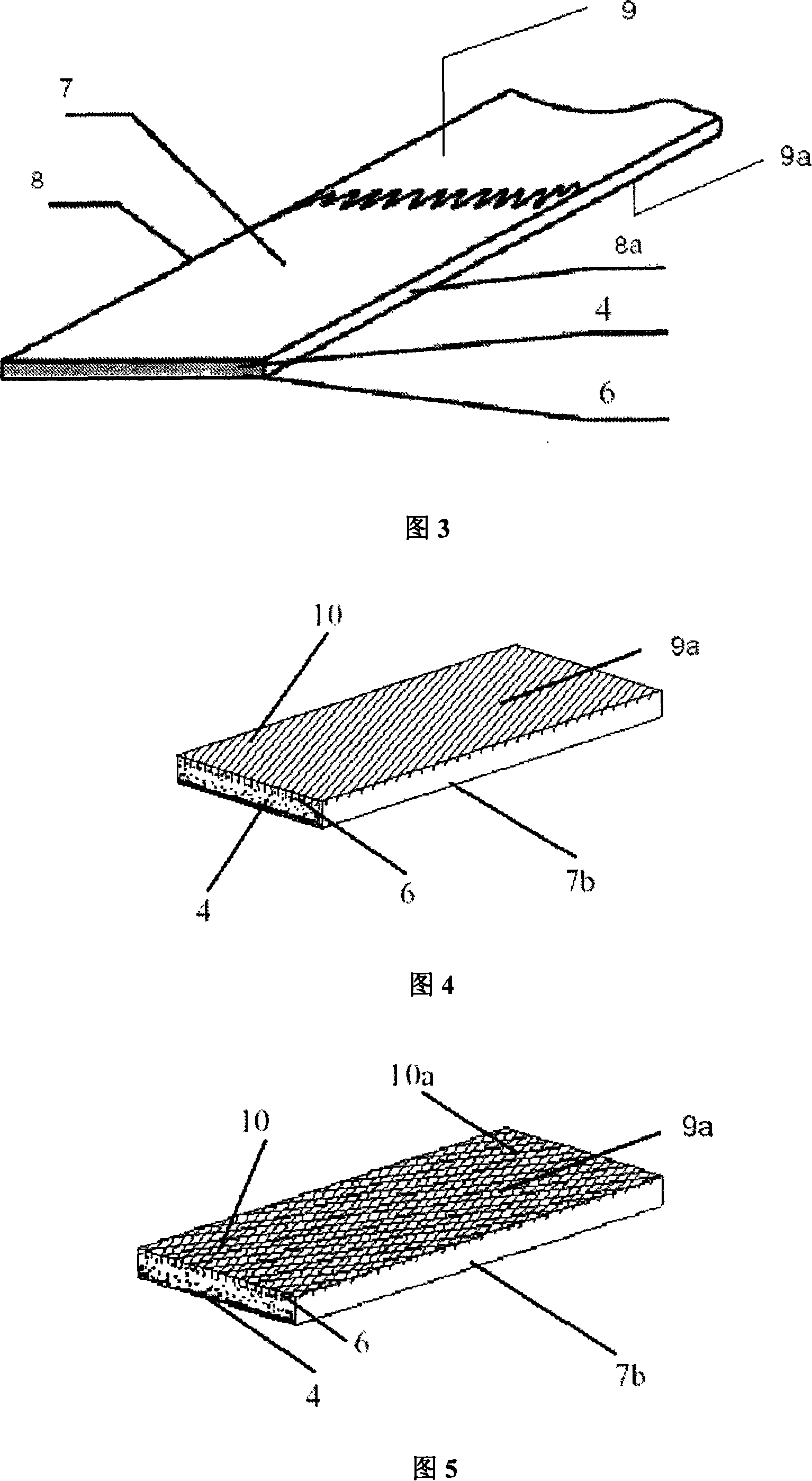

Step for flattening arc-shaped bamboo remaining bamboo outer and inner surface layer, flattening method using the same step and flattening device

The present invention discloses process and apparatus for flattening arc bamboo sheet. During flattening arc bamboo sheet, radial force is applied while dispersed crack-preventing holes are formed in the yellow layer of the arc bamboo sheet. The process of flattening arc bamboo sheet includes the first heating to soften bamboo material, and the subsequent flattening. The apparatus for flattening arc bamboo sheet includes one or several pairs of axially parallel rolls, and each roll pair includes one smooth roll and one nailed roll with dispersed lugs in the surface. The present invention has the advantages of less reduction of the strength of bamboo material, high utilization rate of bamboo resource and no cracking caused by flattening.

Owner:杭州新竹文化创意有限公司

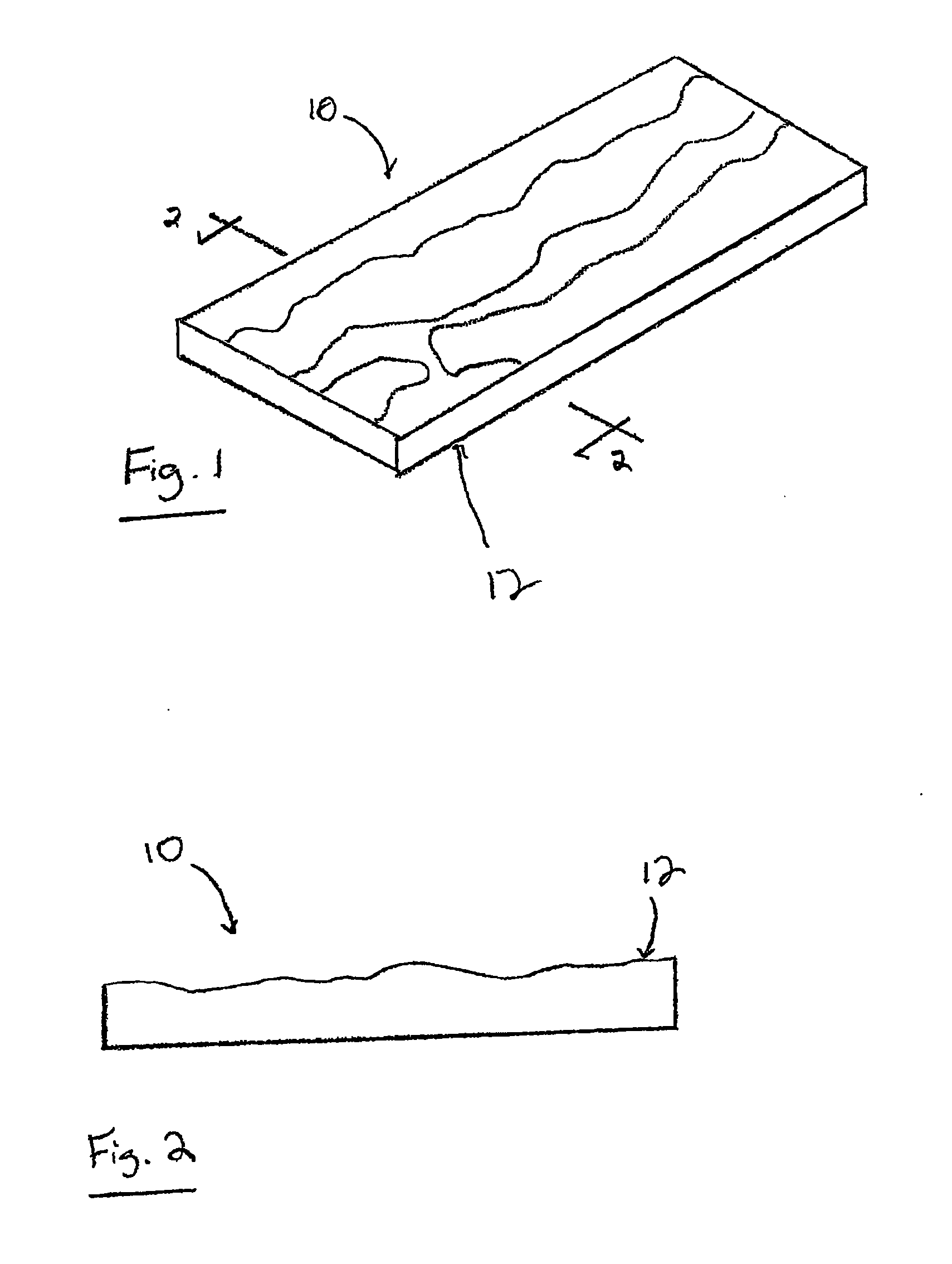

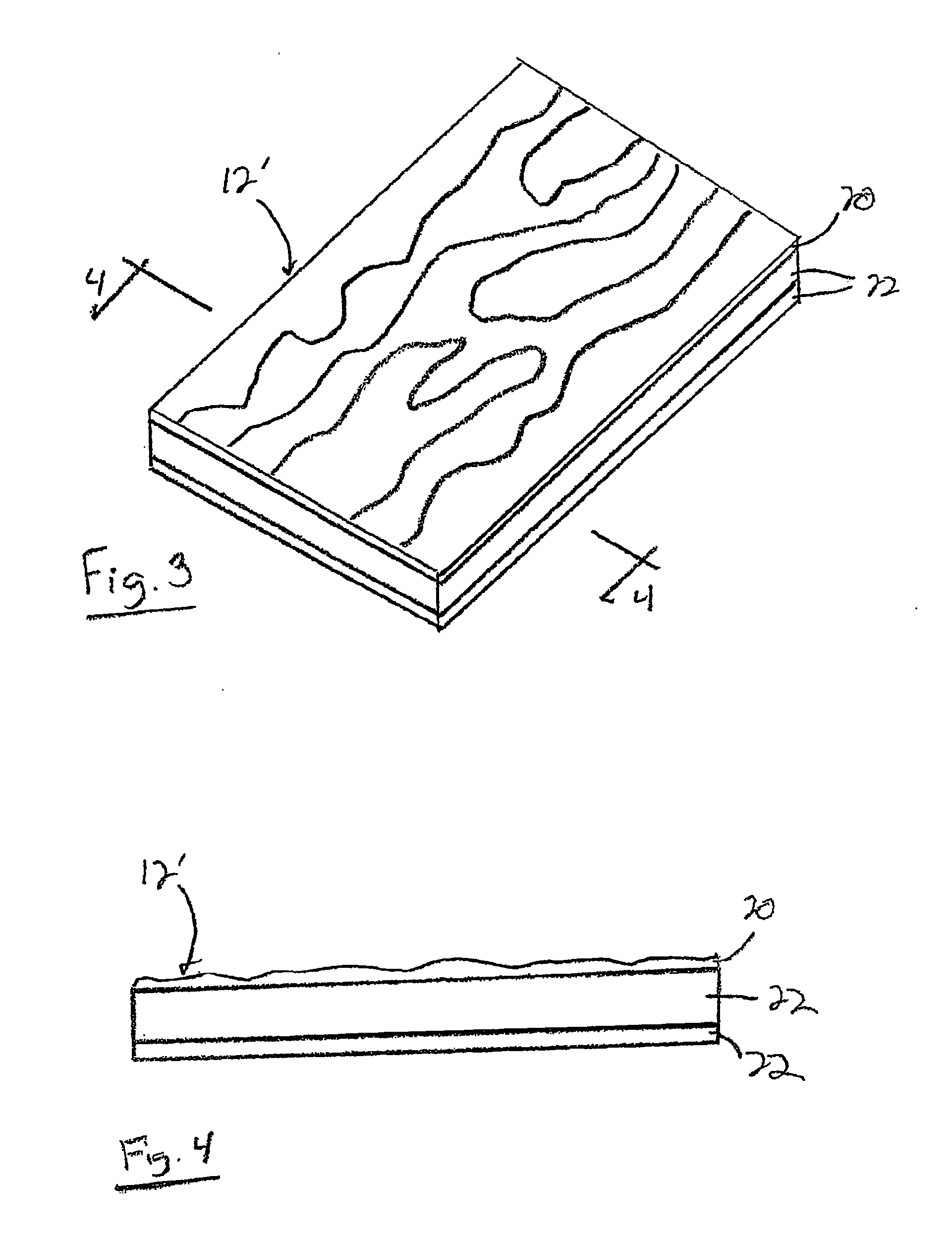

Manufactured Wood Boards Having a Distressed Appearance

InactiveUS20100304089A1Natural appearanceWood compressionMechanical surface treatmentPulp and paper industryWood plank

The present invention is a wood-based product utilized in forming various structures and other items. The product includes a piece of wood disposed on the exposed surface of the product that has been embossed with a desired pattern to give the product a desired appearance, such as a distressed or weathered appearance. The wood piece used in the product is embossed at a sufficient temperature and pressure to create the desired appearance in the wood piece. Additionally the product can be formed completely or only partially from the wood piece.

Owner:SPECTRUM TOWERS

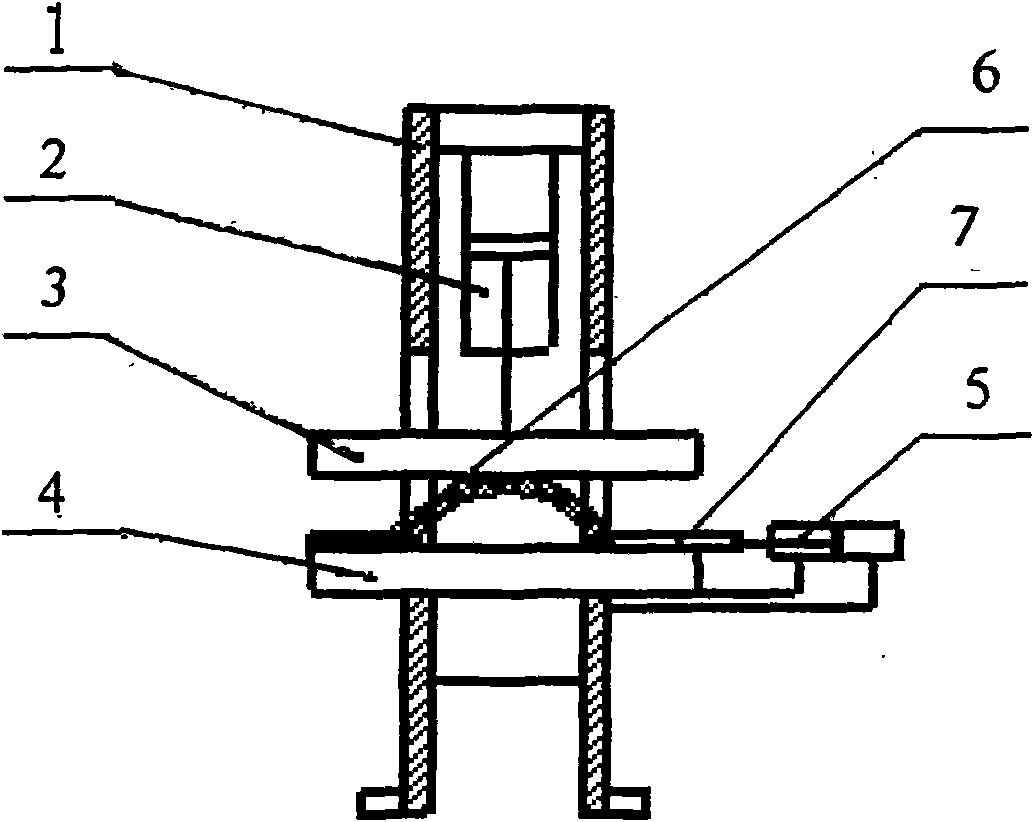

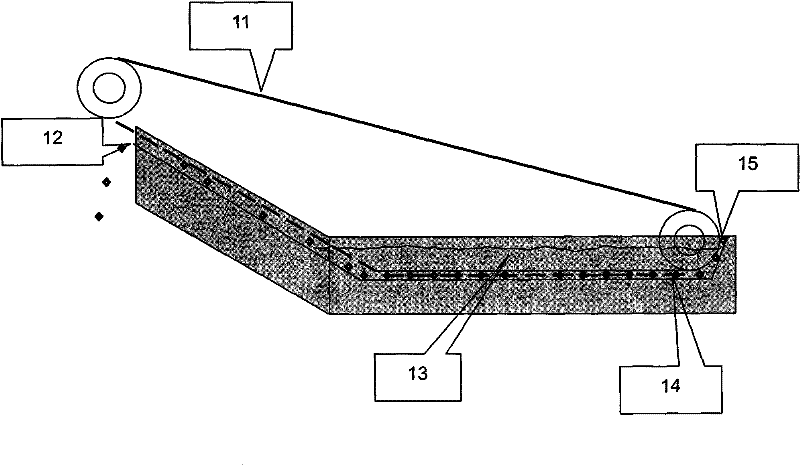

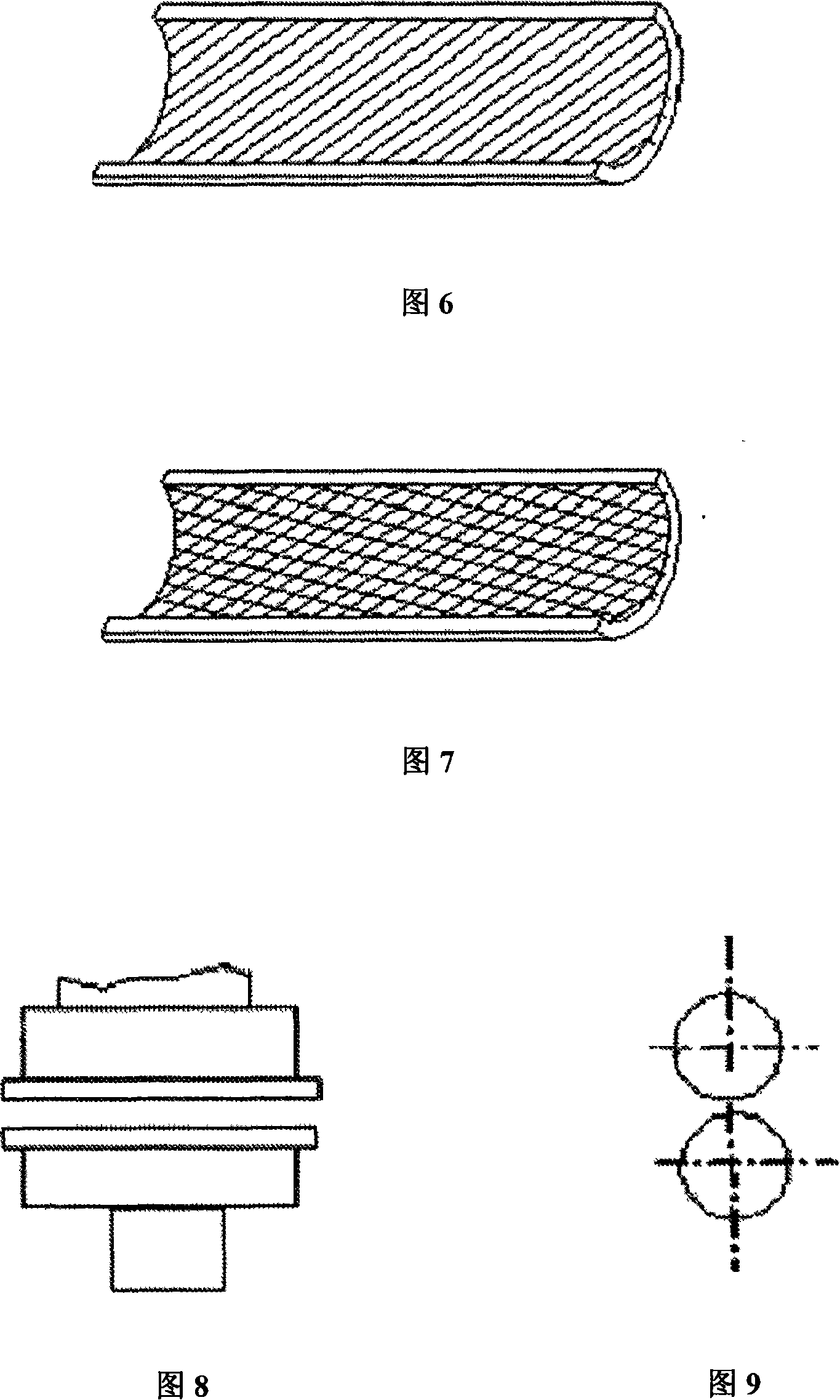

Arc-shaped bamboo wood expanding device

The invention relates to an arc-shaped bamboo wood expanding device which is characterized by comprising a stand (1), a positive pressure cylinder (2), an upper hot pressure plate (3), a lower hot pressure plate (4), a lateral pressure cylinder (5), a fixed baffle plate (6) and a lateral pressure push plate mechanism (7), wherein the positive pressure cylinder (2), the upper hot pressure plate (3), the lateral pressure push plate mechanism (7) and the fixed baffle plate (6) are fixed on the stand (1); and the upper hot pressure plate (3) is arranged corresponding and perpendicular to the lower hot pressure plate (4), and the upper hot pressure plate (3) is connected with the positive pressure cylinder (2). The invention has the advantages that arc-shaped bamboo wood is expanded to a plane-shaped bamboo chip, width of the bamboo chip can be increased, and the use ratio of the bamboo wood is improved.

Owner:NANJING FORESTRY UNIV

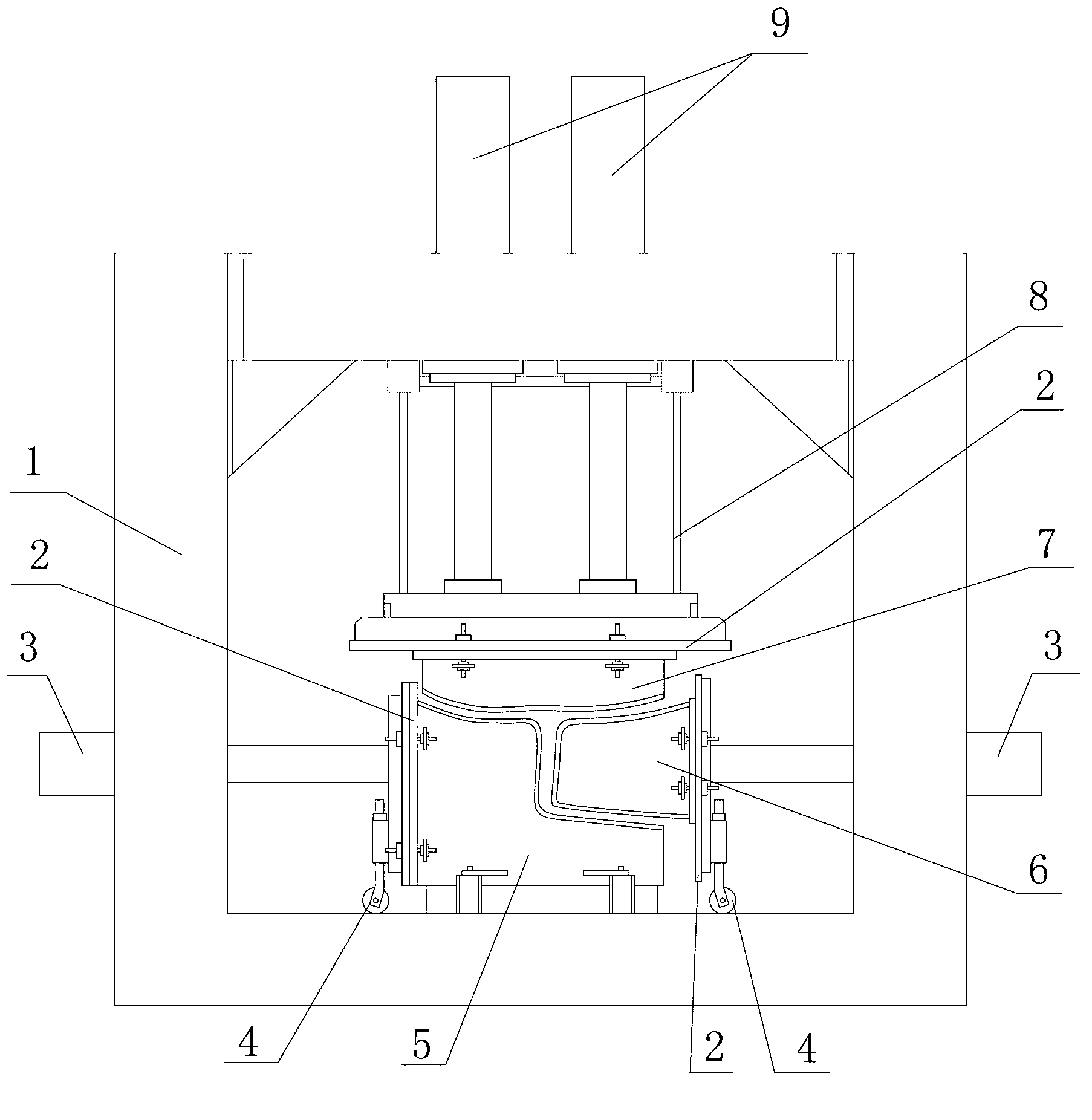

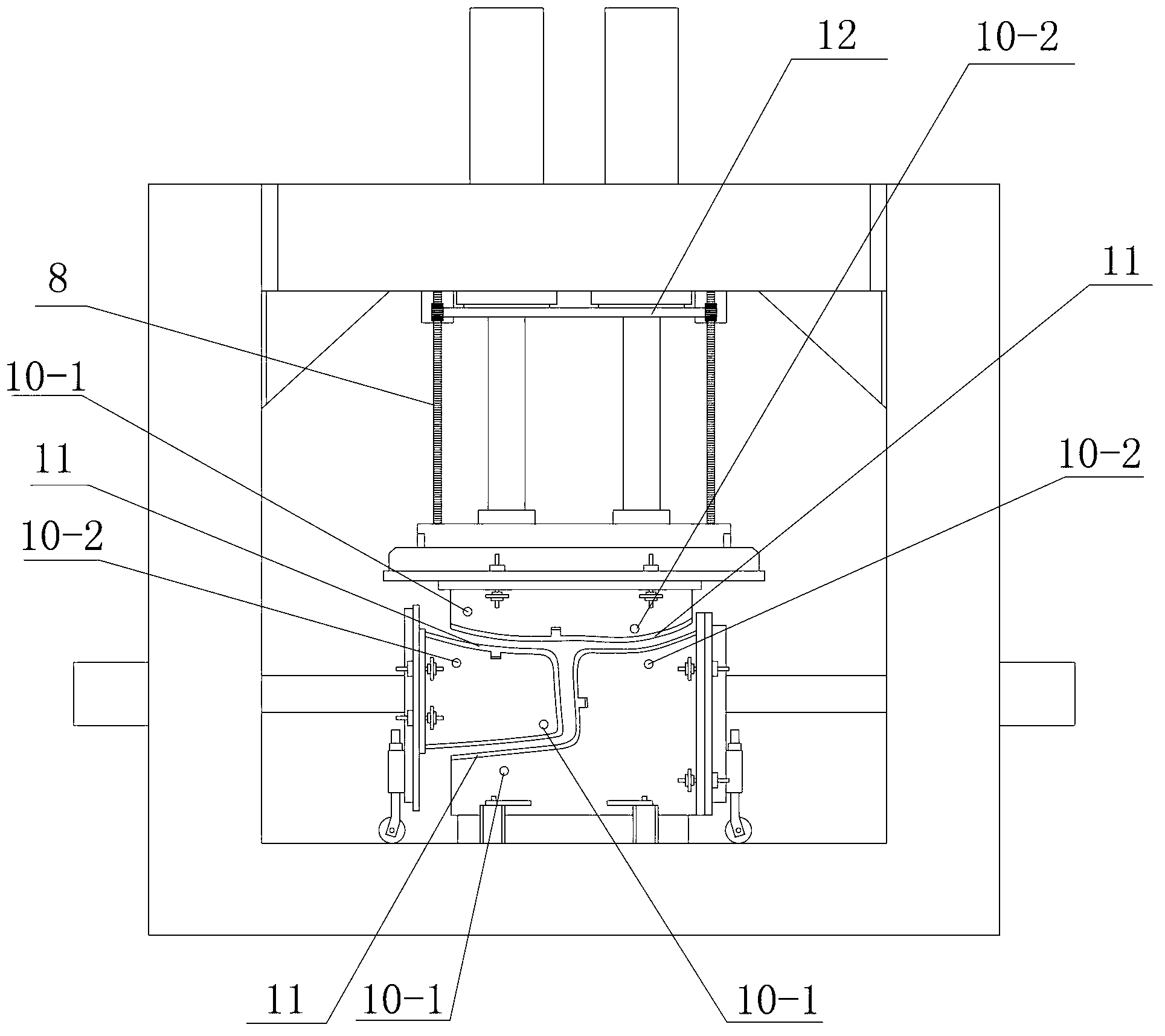

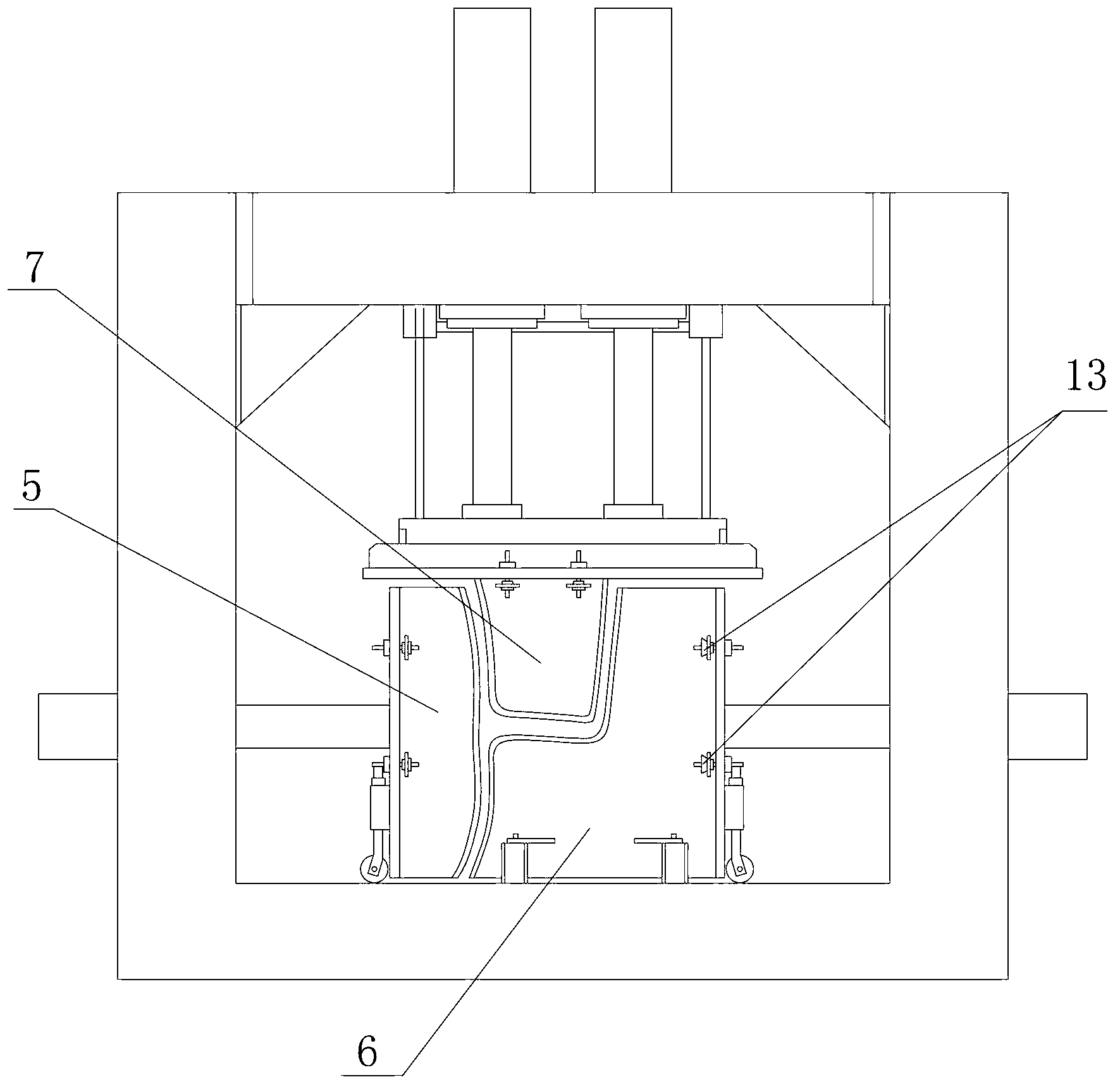

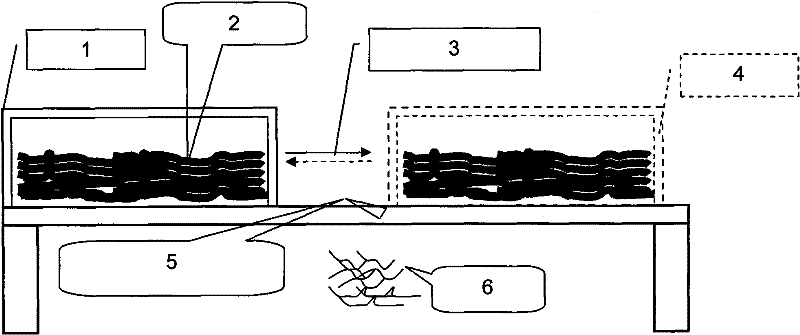

Manufacture method of multi-layer gluing bentwood chair and bentwood foot blank pressing machine

ActiveCN102848445AHigh strengthHigh compressive strengthWood compressionMetal sheetHigh Frequency Waves

The invention relates to a manufacture method of a multi-layer gluing bentwood chair and a bentwood foot blank pressing machine, aiming to provide the manufacture method with a characteristic of a high utilization rate of woods. The bentwood foot blank pressing machine has the advantage of high production efficiency. The technical scheme is that the manufacture method of the multi-layer gluing bentwood chair comprises the following steps of: I, manufacturing a foot blank; step 1, manufacturing a thin wooden sheet; step 2, manufacturing a wooden sheet set; step 3, pressing the foot blank; step 4, obtaining the foot blank; step 5, drillinga hole in the foot blank, modifying, sanding, and painting; and II, assembling. The bentwood foot blank pressing machine is characterized by comprising a machine frame, an upper die, a left die and a right side, wherein a guide rail mechanism is arranged between bottoms of the left die and the right die and a bottom plate of the machine frame; horizontal oil cylinders are arranged on a vertical post at the left side of the machine frame and a vertical post at the right side of the machine frame; a pair of rod oil cylinders are fixed to a cross beam at the top of the machine frame; pressing faces of three dies are wrapped with a layer of metal sheets; and every two metal sheets are connected with a power supply of a high-frequency heater.

Owner:陈传根

Production method for high-temperature heat treatment of bamboo bunch

ActiveCN105690512ASimple production processProduction process is environmentally friendlyWood compressionCane mechanical workingHigh pressureMechanical property

The invention discloses a production method for high-temperature heat treatment of a bamboo bunch. The production method comprises the following steps: (1) preparation of bamboo chips; (2) softening treatment; (3) rolling compaction; (4) a heat treatment process; and (5) cooling and humidifying treatment. The production method is simple in production process, high in production efficiency, short in processing period, free of heat-source equipment cooling, and low in energy consumption and waste; heat transfer oil is adopted as a heat source; compared with high-temperature and high-pressure saturated steam, the heat transfer oil has the advantages that not much waste gas is generated during bamboo bunch preparation, and the production process is environmentally friendly; and meanwhile, when the bamboo bunch is subjected to high-temperature heat treatment in an atmosphere of ammonia gas, the prepared bamboo bunch is uniform is defibering effect, high in permeability and uniform in bamboo color, the difference between physical and mechanical properties is relatively small, and the anti-distortion and anti-cracking properties of reconstituted bamboo timber can be improved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for producing high-density recombined wood

InactiveCN102172940AHigh static bending strengthHigh surface hardnessWood compressionVeneer manufactureHigh densityEngineering

The invention relates to a method for producing high-density recombined wood, which is used for manufacturing plates and recombined module timber by the following steps of planning, processing by high-temperature steam, drying, dipping glue, draining glue, drying after draining glue, tidying or weaving, balancing for nourishing, pressing to shape, solidifying at a high temperature and the like. The density of the high-density recombined wood can reach 0.7-1.2kg / cm<3>; the high-density recombined wood has the characteristics of peculiar texture, fine grain, excellent performance, small possibility of cracking and deforming and the like, does not need to prevent insects, prevent mildew, prevent corrosion, prevent from cracking and the like, and can be directly used for the fields of floor, furniture, building and the like. The method disclosed by the invention has simple working procedures, and abandoned secondarily secondary small fuel wood and secondary small wood are utilized to produce plates and module wood, thereby changing waste materials into things of value, and greatly saving forest resource. The wood is an ideal log substitute.

Owner:浙江仕强竹业有限公司

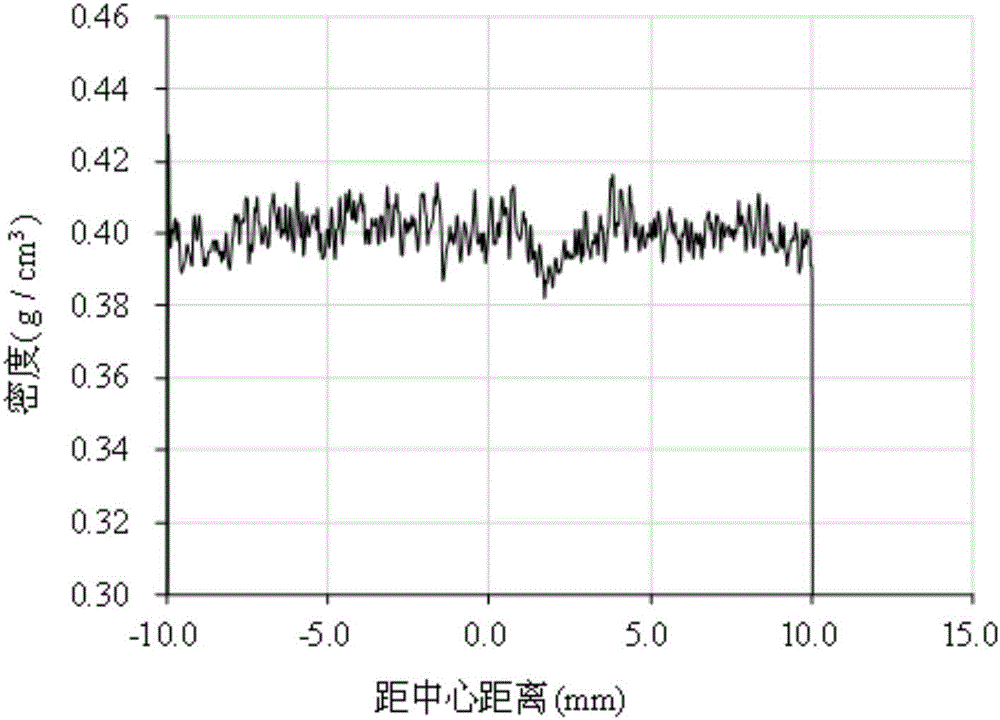

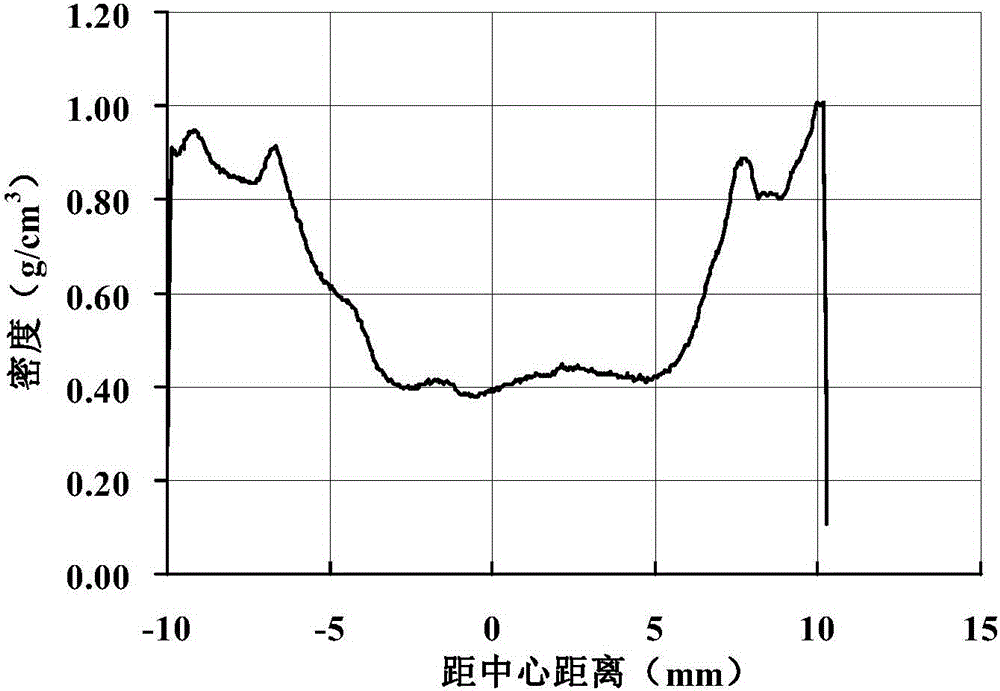

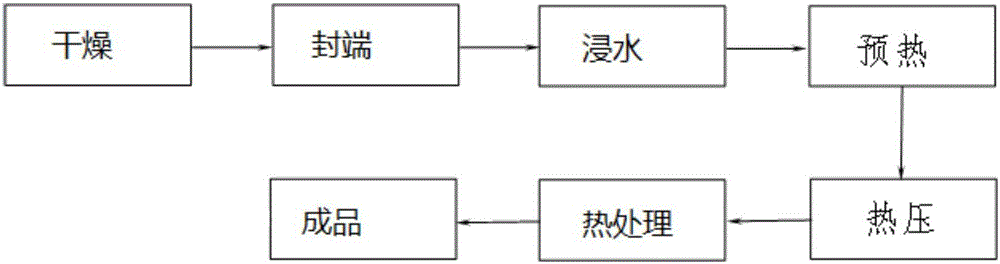

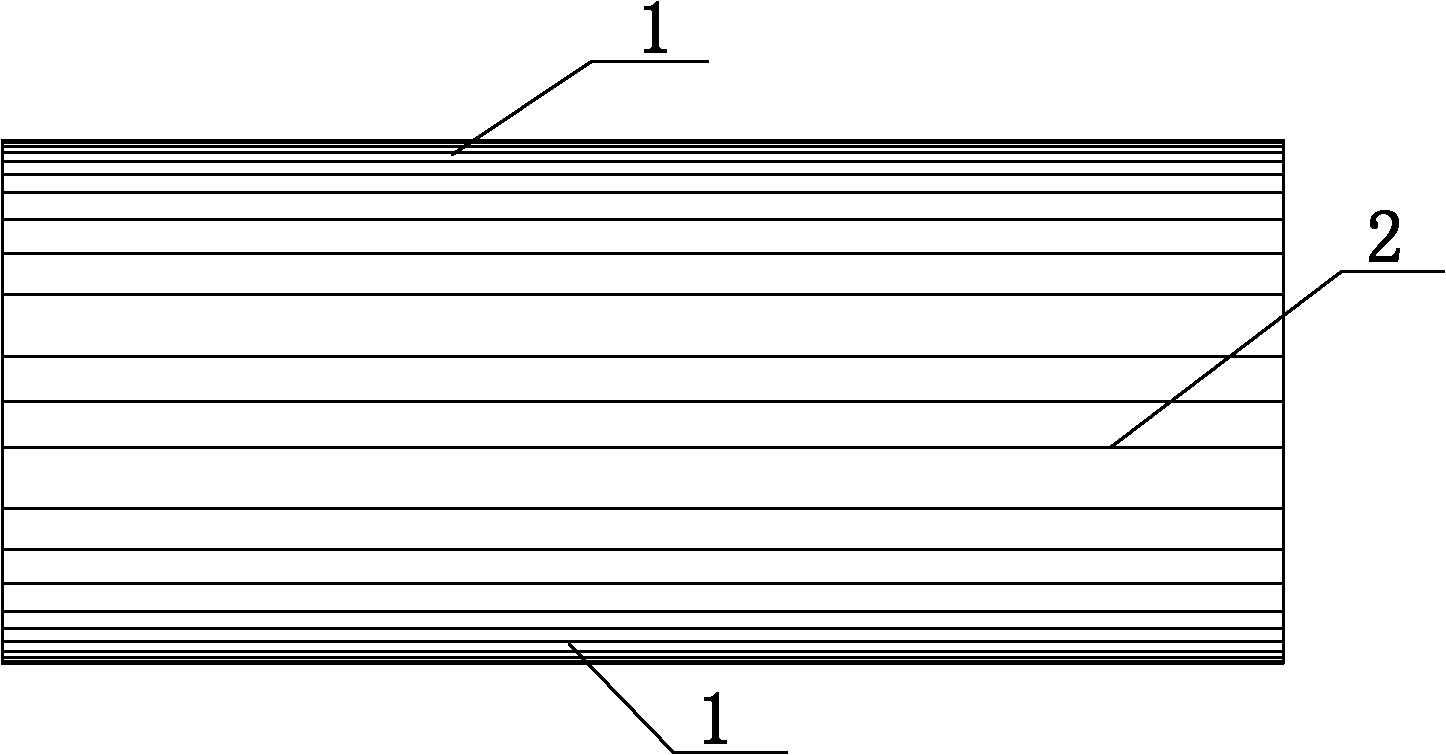

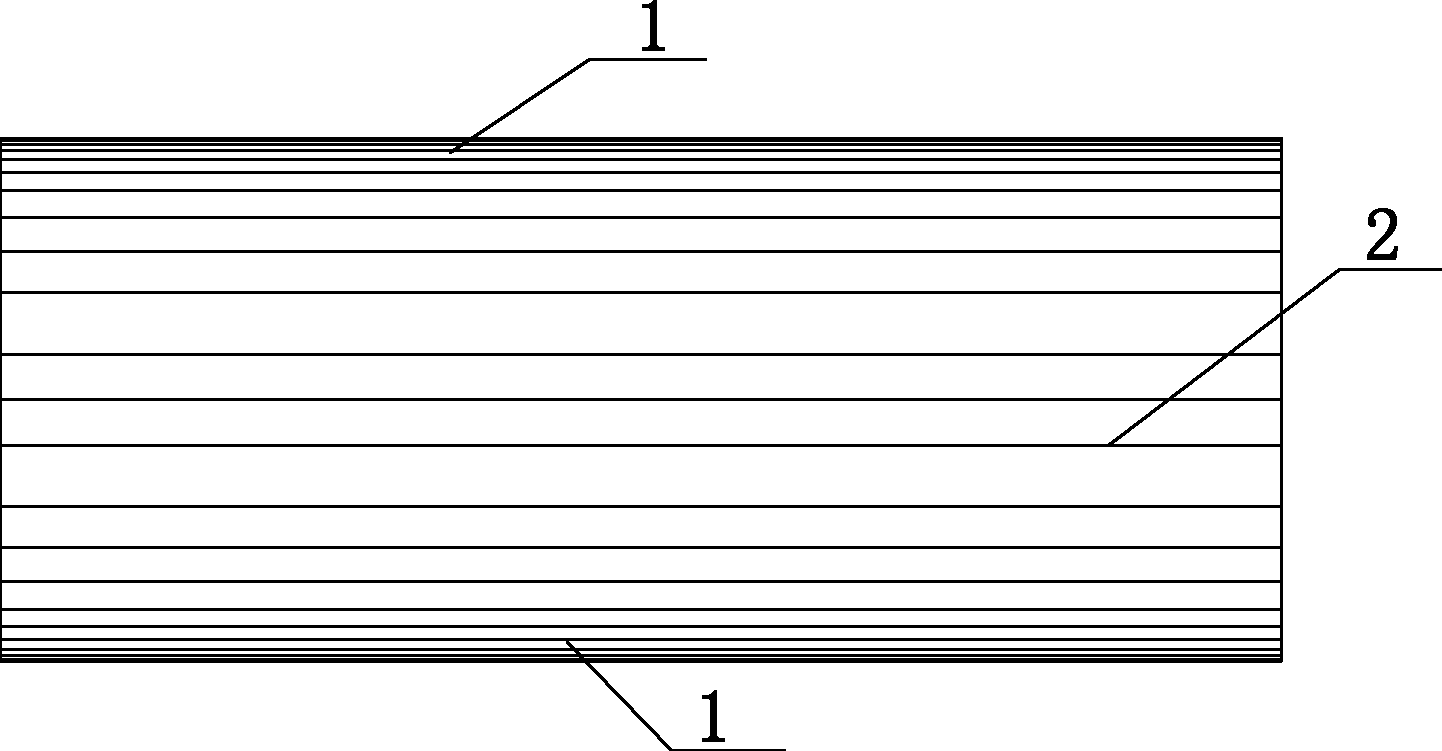

Production method for gradually thickening compression layer of surface layer of wood

ActiveCN106217566ACause quantityImprove compression performanceWood compressionWood treatment detailsSurface layerHardness

The invention discloses a production method for gradually thickening a compression layer of a surface layer of wood. The method specifically comprises the steps of drying, end sealing, immersion, preheating, hot pressing, thermal treatment and finished product obtaining. According to the production method, the controllable range of the thickness of the compression layer is extended, the accuracy of compression processing is improved, the rate of finished products is increased, and the compression layers has excellent surface density, hardness, bending strength and elasticity modulus.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

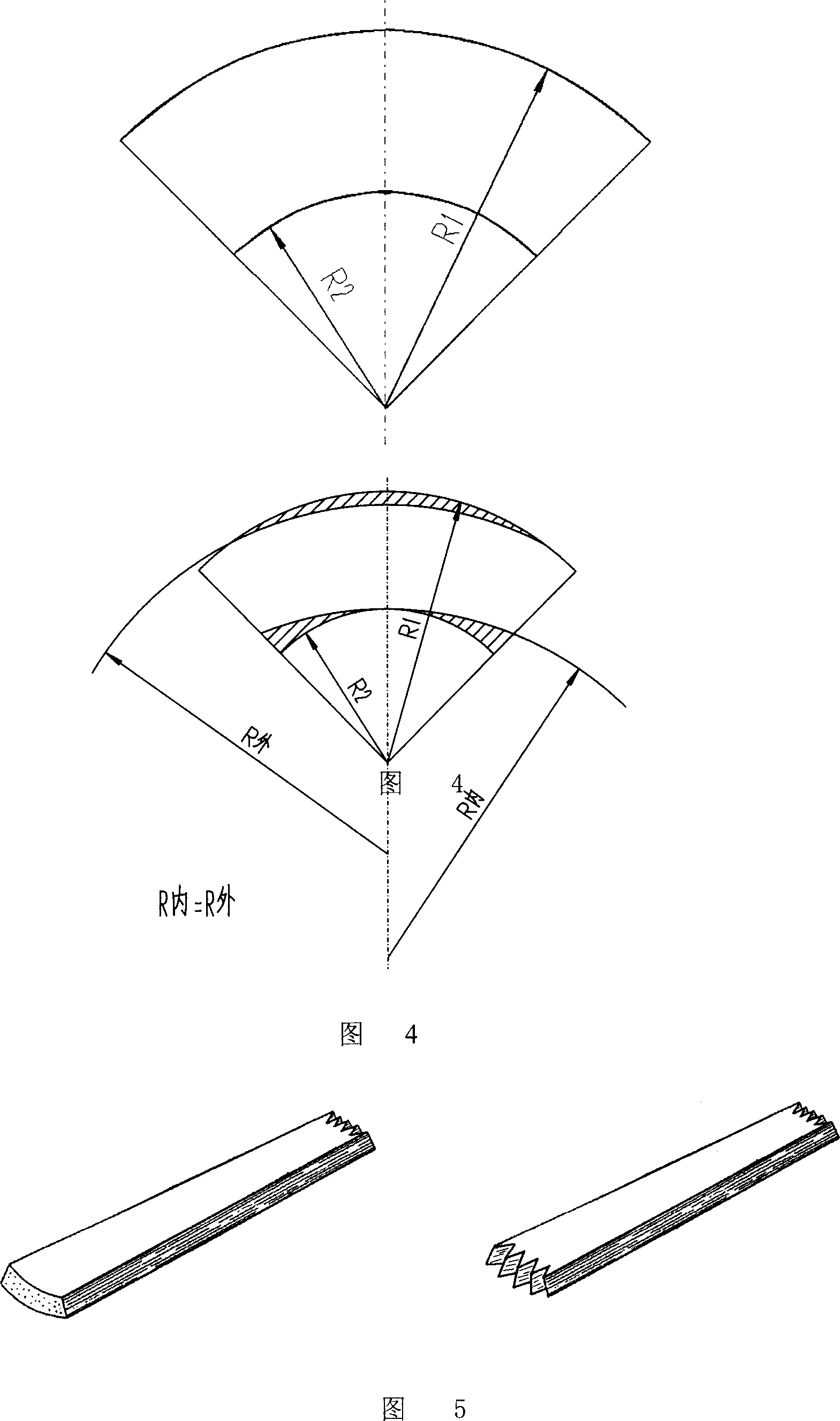

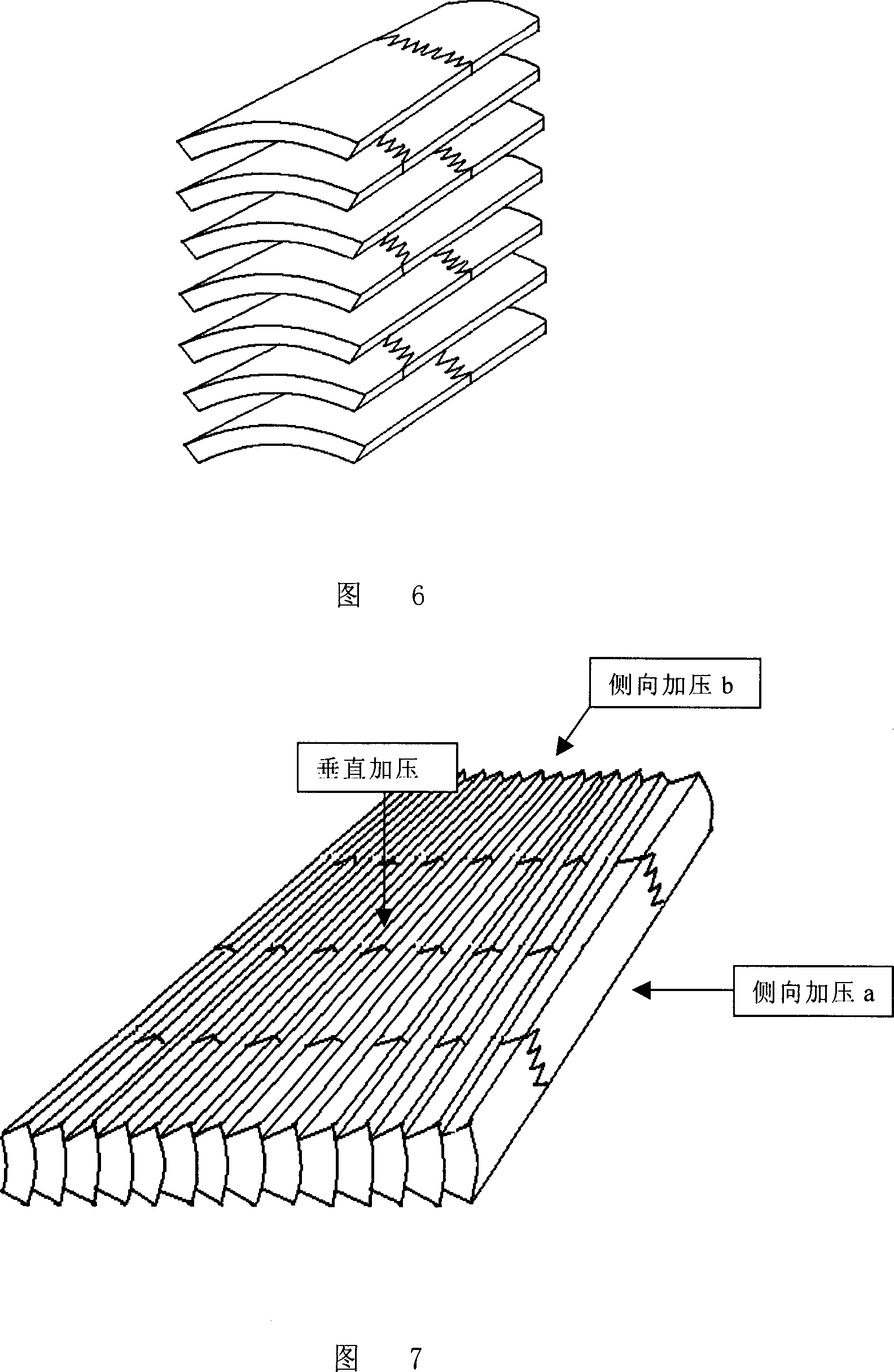

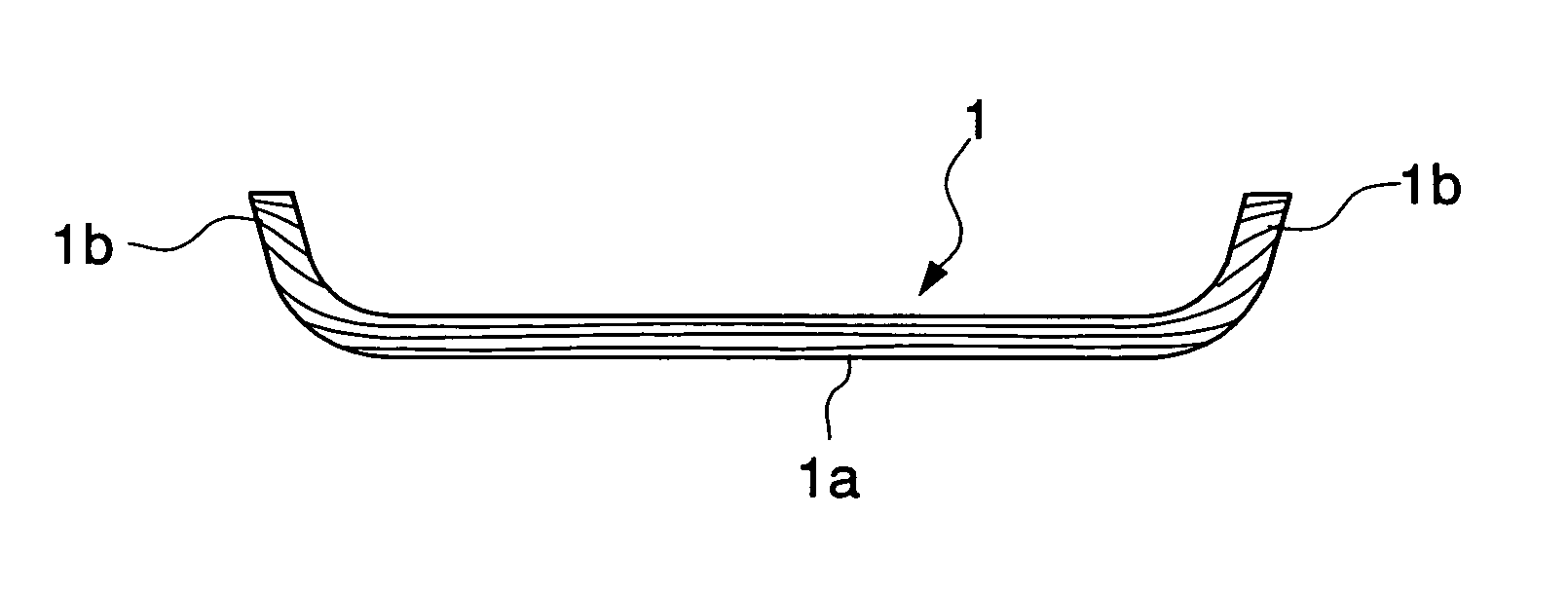

Curved bamboo material original state regroup method and its making method

InactiveCN1970254AMaintain natural structureHigh strengthWood compressionWood veneer joiningHigh intensityEngineering

It relates to the arc shape bamboo wood original status restructuring material. It is made by arc bamboo plates with smooth inside and outside compressing and sticking along the same direction. It maintains the natural structure of the bamboo wood with high strength restructured material. It can replace many precious wood and all kinds of artificial board. It improves bamboo wood utilization rate and saves this particular resource.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

Wax sizing and resin bonding of a lignocellulosic composite

InactiveUS6113729AReduce thickness swellReduces caul plate stickingFibreboardBaby linensCelluloseWax

There is provided a method for producing lignocellulosic composites. This method is useful in reducing the thickness swell of these composites on their exposure to water. This method also is useful in reducing the hot-press times required to make lignocellulosic composites. Furthermore, there is provided a method by which wax sizing may be used without the previously expected reduction in physical properties. Also, there is provided a method by which caul plate sticking may be reduced when hydrogen peroxide is used as a furnish add-on.

Owner:BORDEN CHEMCIAL INC

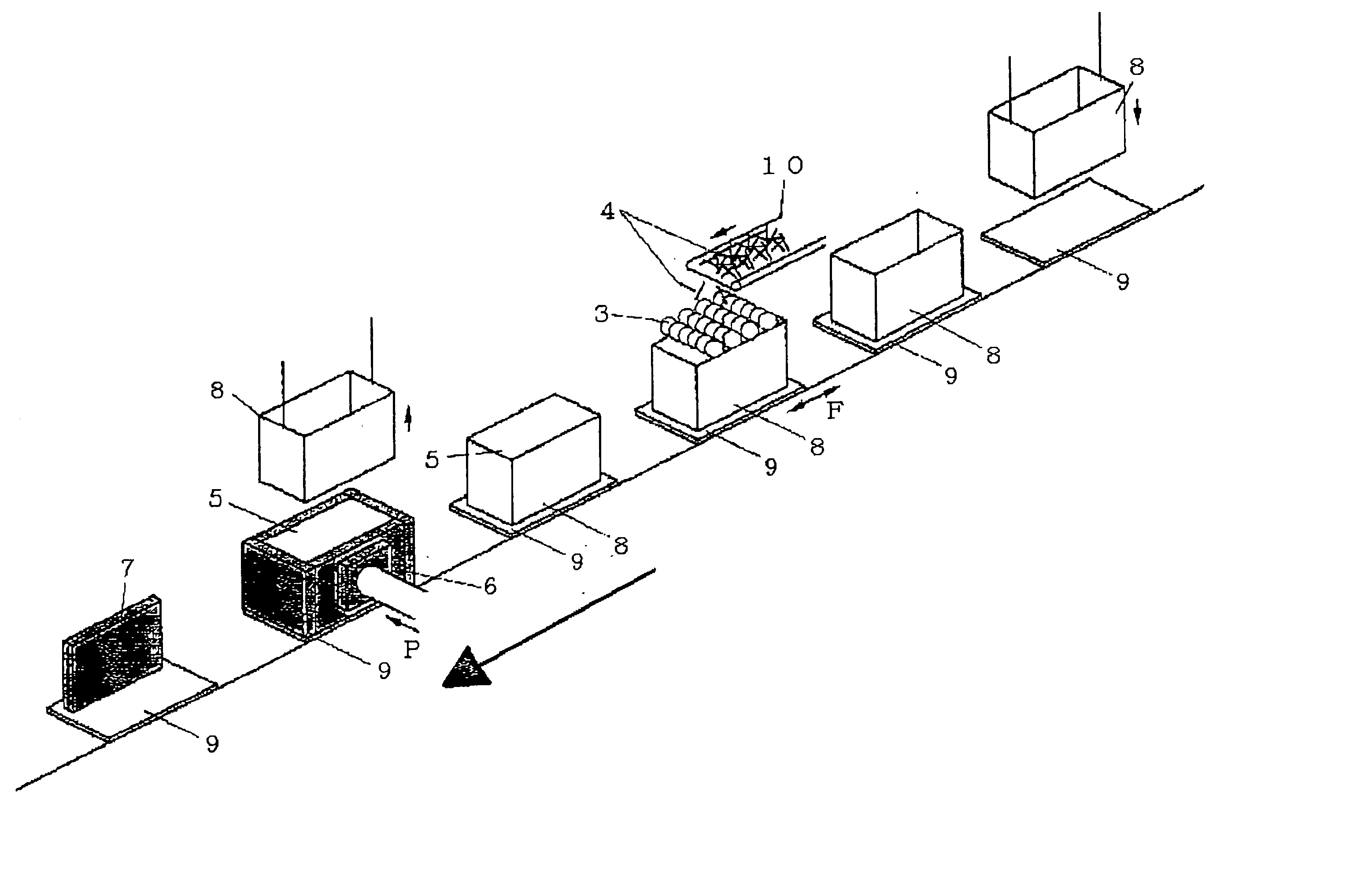

Process for producing woody composite material

Owner:SEKISUI CHEM CO LTD

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804655AReduce energy consumptionTake advantage ofLiquid surface applicatorsWood compressionSolid woodWear resistant

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: forming a solid wood flooring block, sanding the block, removing dust, coloring, coating UV putty coat I, solidifying I, sanding I, coating UV putty coat II, solidifying II, sanding II, coating wear resistant base coat, semi-solidifying I, coating transparent UV base coat, solidifying III, sanding III, coating UV finishing coat, semi-solidifying II, coating formaldehyde-removing UV wear resistant finishing coat, solidifying IV, and forming the finished product. The solid wood flooring produced by the process has the advantages of good colour and lustre, clear texture, high anti-bending static bending strength, good surface abrasion resistance, stable size, small deformation and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

Bamboo arc sheet spreading method

InactiveCN1966223AIncrease the degree of softeningIncrease the degree of stereotypingWood compressionProduction rateAgricultural engineering

Owner:NANJING FORESTRY UNIV

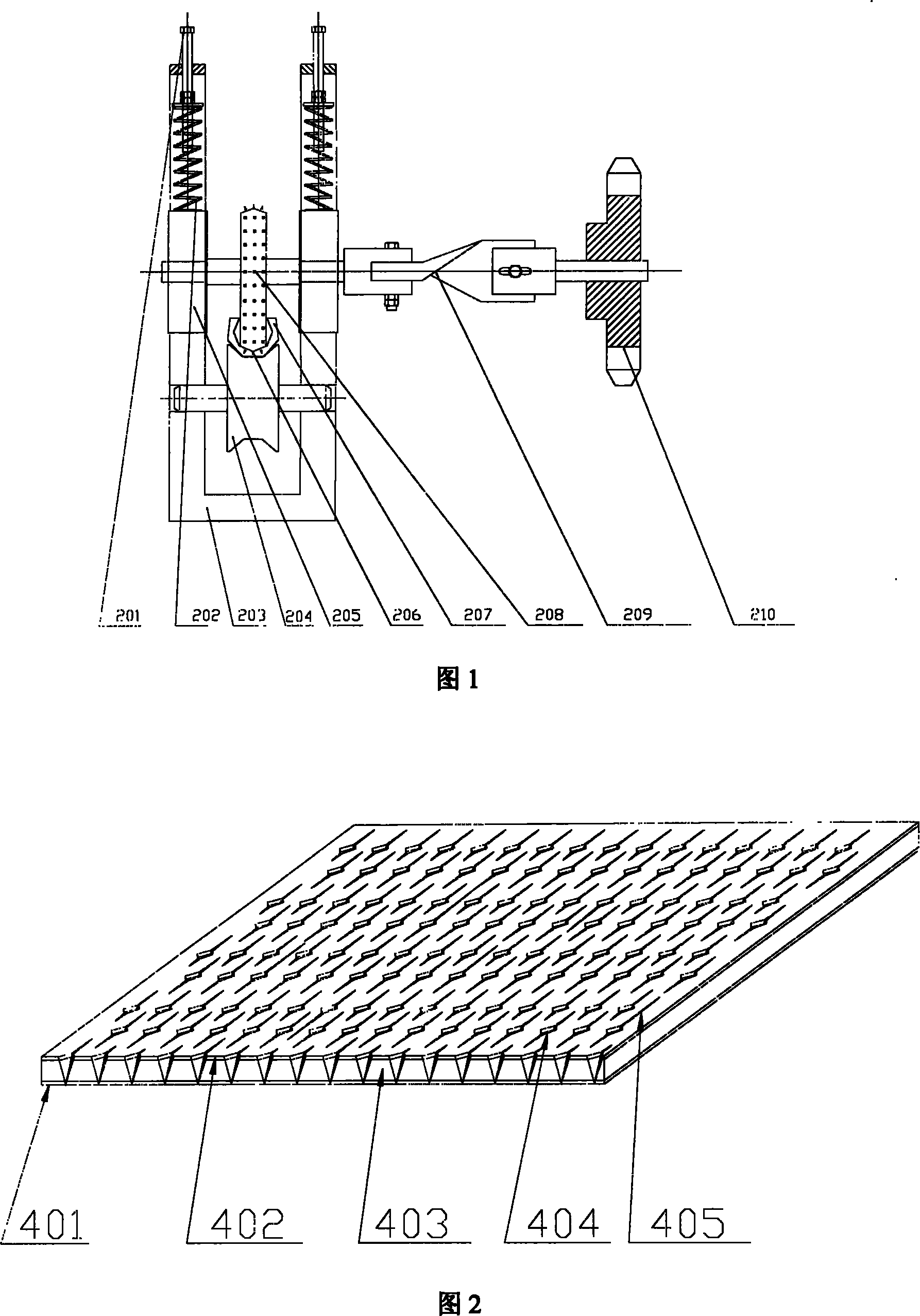

Fast-growing wood surface reinforcing manufacturing method and sections manufactured thereby

ActiveCN102626941AImprove permeabilityNo burstDrying using combination processesWood compressionPulp and paper industryMoisture

The invention relates to a fast-growing wood surface reinforcing manufacturing method and sections manufactured thereby, belonging to the field of functional improvement on wood and wood processing. The technical scheme comprises the following steps of (1) drying step: drying fast-growing wood till a moisture content of 5-12%; (2) carbonizing step: carbonizing the fast-growing wood; (3) surface reinforcing step: compacting and reinforcing the surface of the fast-growing wood; and (4) thermally processing and fixing step: thermally processing and fixing the fast-growing wood at the temperature of 180-220 DEG C. The problems are solved that in the conventional technical scheme, the production process is complicated, the production cost is high, the wood yield is low, obtained sections are poor in texture and color and luster and poor in product stability, and the like; compared with the prior art, the fast-growing wood surface reinforcing manufacturing method has the advantages of simple process, no addition of any chemical in the production process, environment-friendly production, high production efficiency, capability of realizing large-scale flow-line production, low wood loss, high wood yield, low production cost and the like; and the obtained fast-growing wood surface-reinforced sections have the advantages of hard surfaces and soft middle parts or bottoms, high size stability, high corrosion resistance, clear texture, plump color and luster, good decorative effect and the like.

Owner:福建秦朝木业科技有限公司

Method for manufacturing compressed carbonized poplar board

InactiveCN101733805AReduce stressGood dimensional stabilityWood compressionWood charring/burningCarbonizationHardness

The invention relates to a method for manufacturing fast-growing wood sheet, in particular to a manufacturing method for modifying a fast-growing poplar board, belonging to the technical field of sheet manufacture. The invention has the advantages of small internal stress of a compressed carbonized poplar board manufactured by the method and good stability of the size of the board, thereby ensuring the quality of a compressed carbonized wood. The invention overcomes the defects of a fast-growing poplar sheet, such as low density, low hardness, low strength, easy corrosion, difficult direct use and the like, improves the density of the sheet by carrying out compression and densification for the poplar sheet, carries out carbonization on the compressed poplar sheet on the condition of pressurization, and eliminates the compression stress inside the sheet so as to prevent springback of the sheet and improve the size stability, density and strength. The poplar board manufactured by the method can be directly used as a sheet. The compressed carbonized poplar board can be partially or entirely used to replace high-quality precious wood, thereby relieving the contradiction between continuously reduced precious wood resources and increasing demand for wood.

Owner:NANJING FORESTRY UNIV

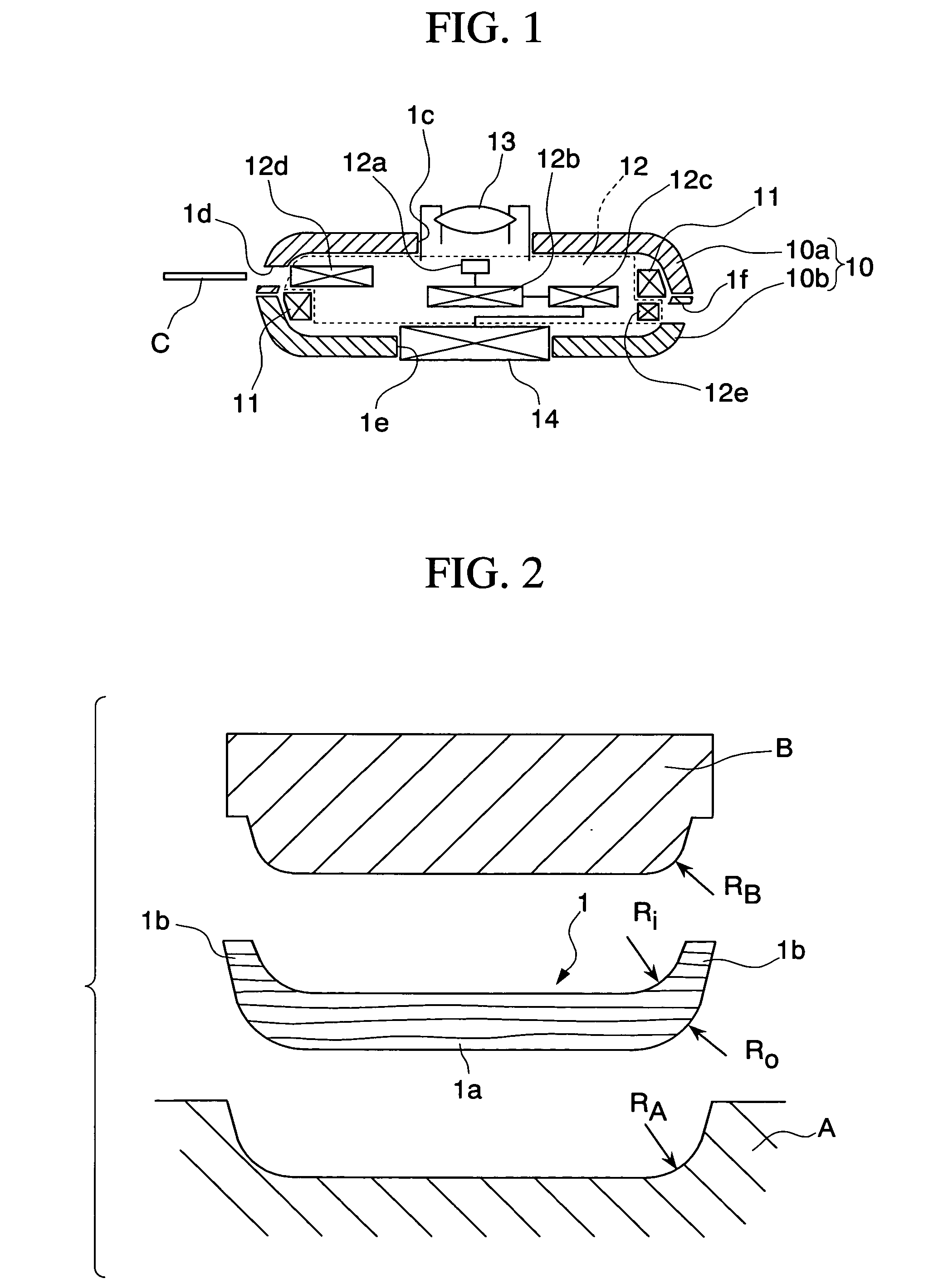

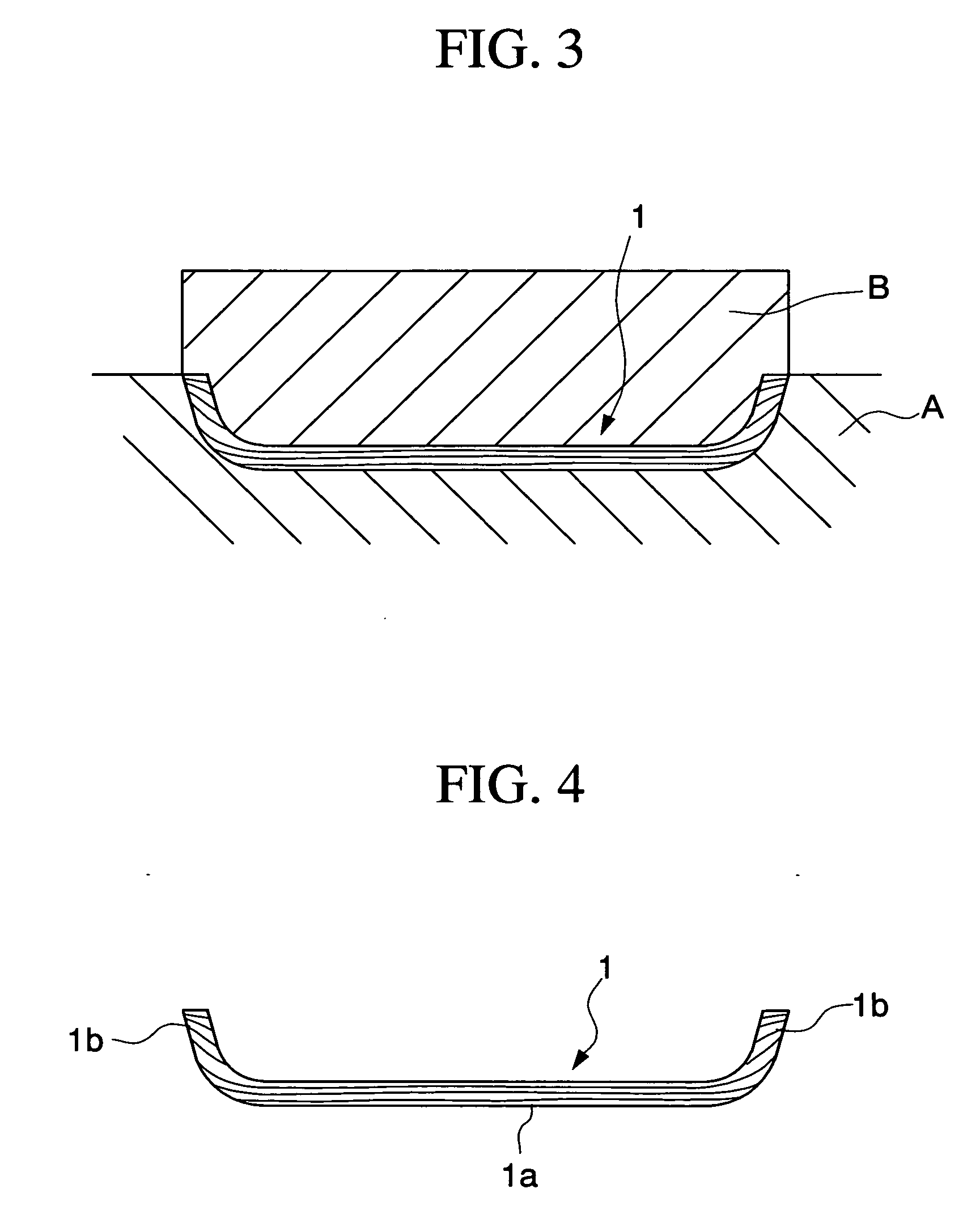

Electronic device

Owner:OLYMPUS CORP

Flattened bamboo plate material and making method thereof

The present invention provides a flattened bamboo possessing a single-layered, solid and pressed bamboo plate with a majority of outer and inner bamboos on. The processed bamboo board possesses at least a seamless longitudinal surface and two parallel longitudinal sections, which are perpendicular to the longitudinal surface. In addition, the present invention also provides a method for manufacturing the flattened bamboo board.

Owner:杭州庄宜家具有限公司

Wood floor carbonizing processing method

InactiveCN101570031AEasy to operateQuality improvementWood compressionWood charring/burningEngineeringWood plank

The invention refers to the field of wood floor processing, in particular to a wood floor carbonizing processing method. The method comprises the following steps: (1) pretreatment: cutting wood into the shape of floor to obtain floor planks; (2) heat pressing carbonizing: putting the floor plank into a heat pressing machine for high temperature carbonizing to obtain carbonized wood planks; (3) cooling: putting the carbonized wood planks into the heat pressing machine to be cooled to lower than 160 DEG. C by the cold oil device of the heat pressing machine; (4) finish product producing: withdrawing the cooled carbonized wood plank from the heat pressing machine and executing post-treatment to obtained finished carbonized wood floor product. This method finishes carbonizing and cooling directly in the same heat pressing machine, thus causing the operation to be simple and convenient and the whole carbonizing process to be safe and controllable with higher yielding rate and higher quality of the finished floor product.

Owner:周发荣

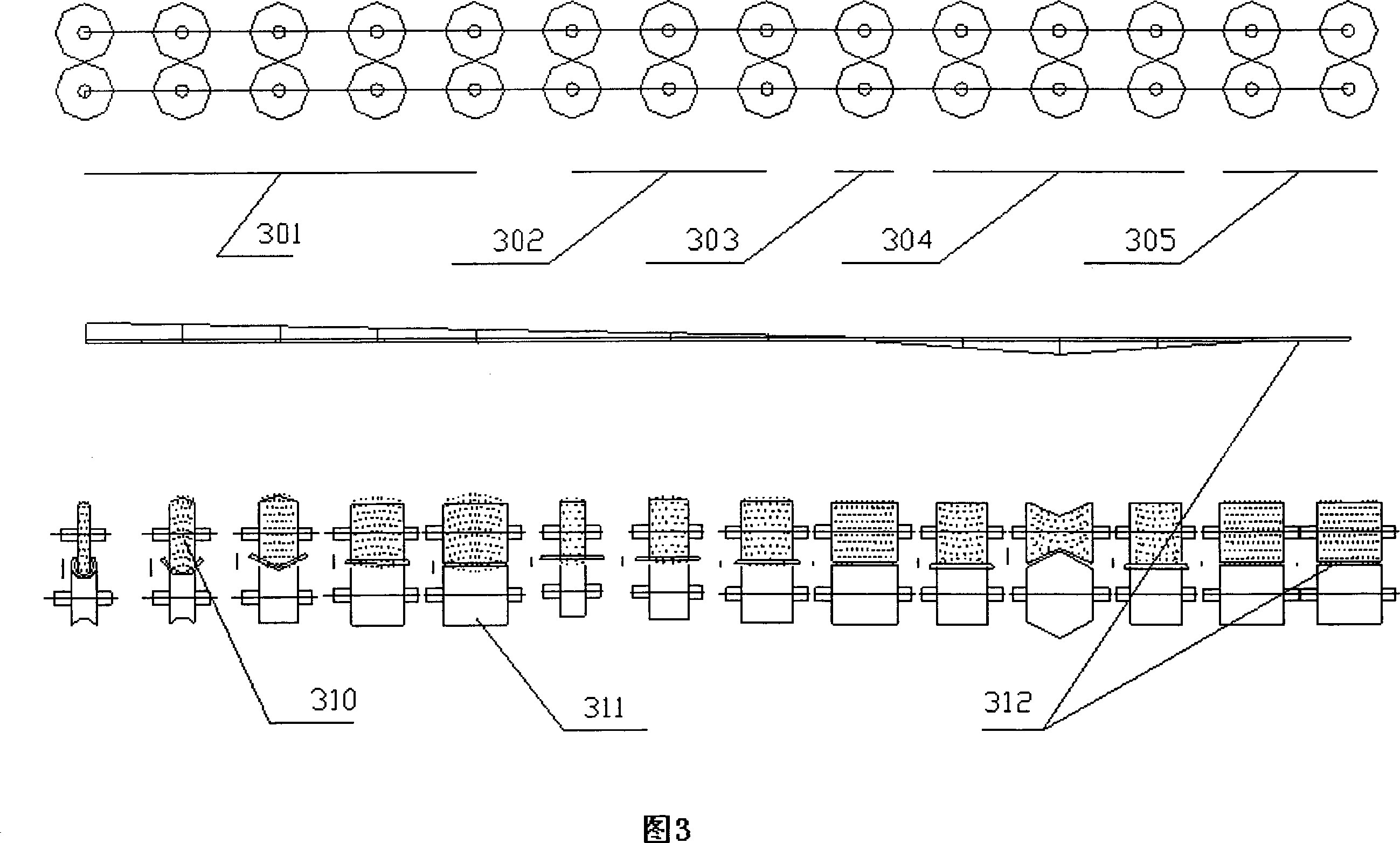

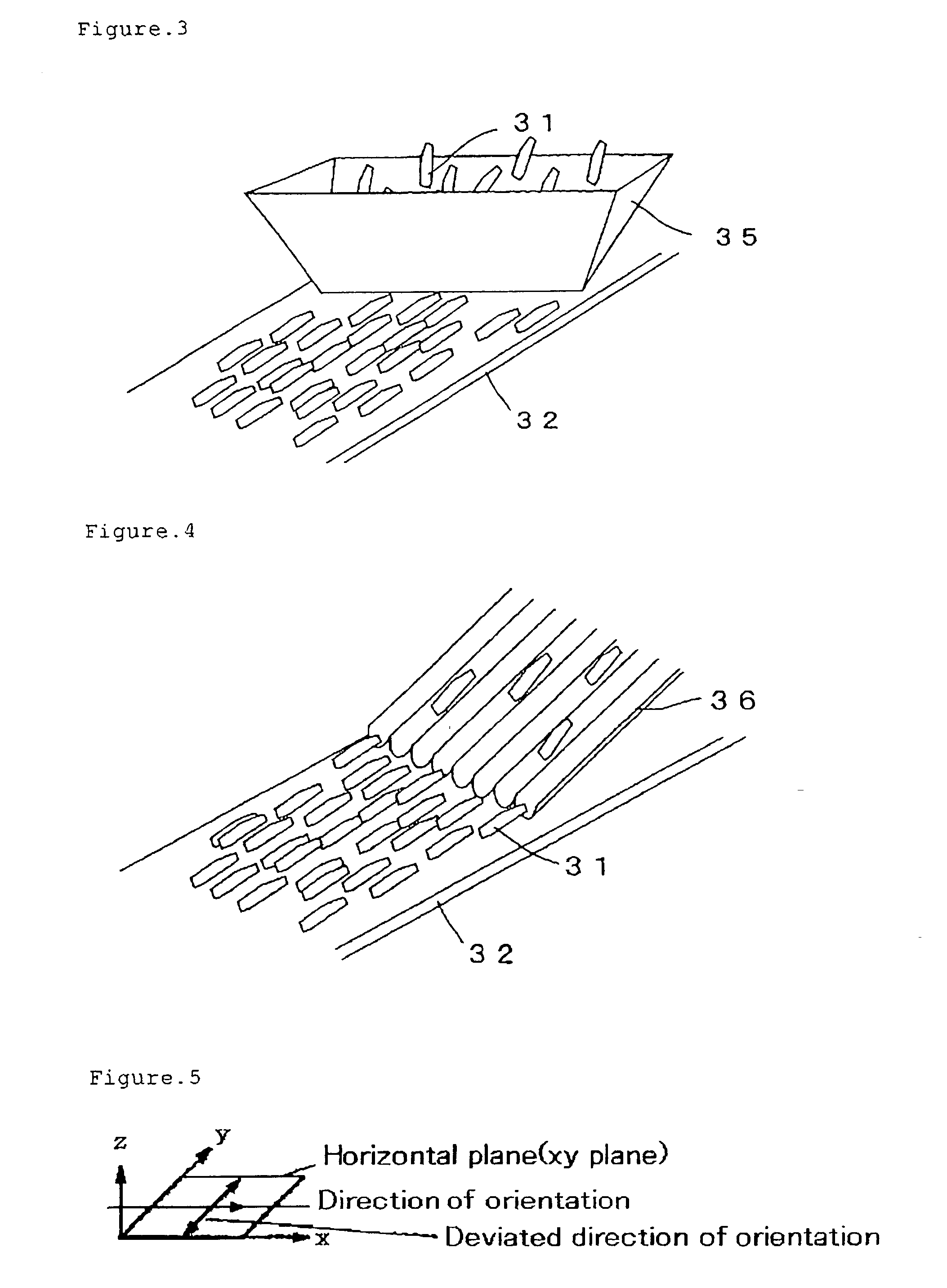

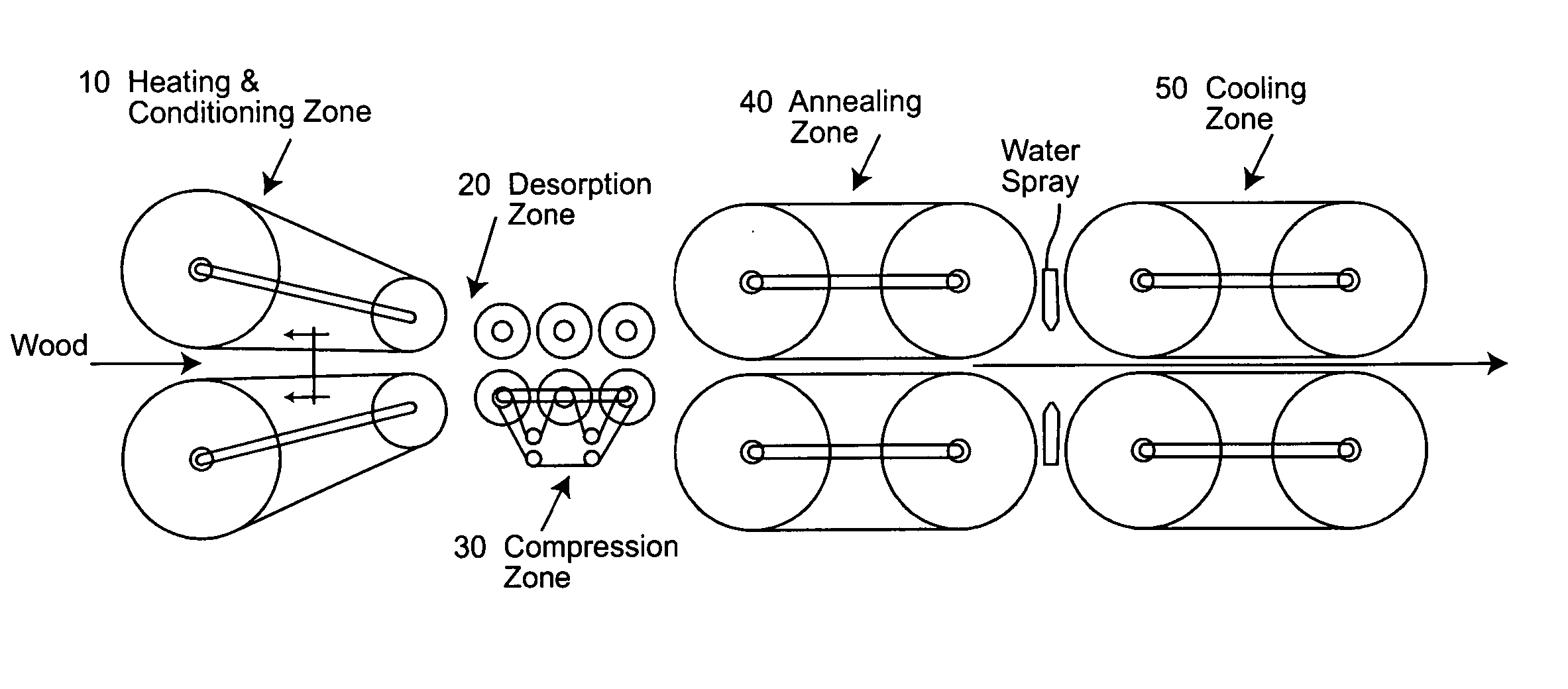

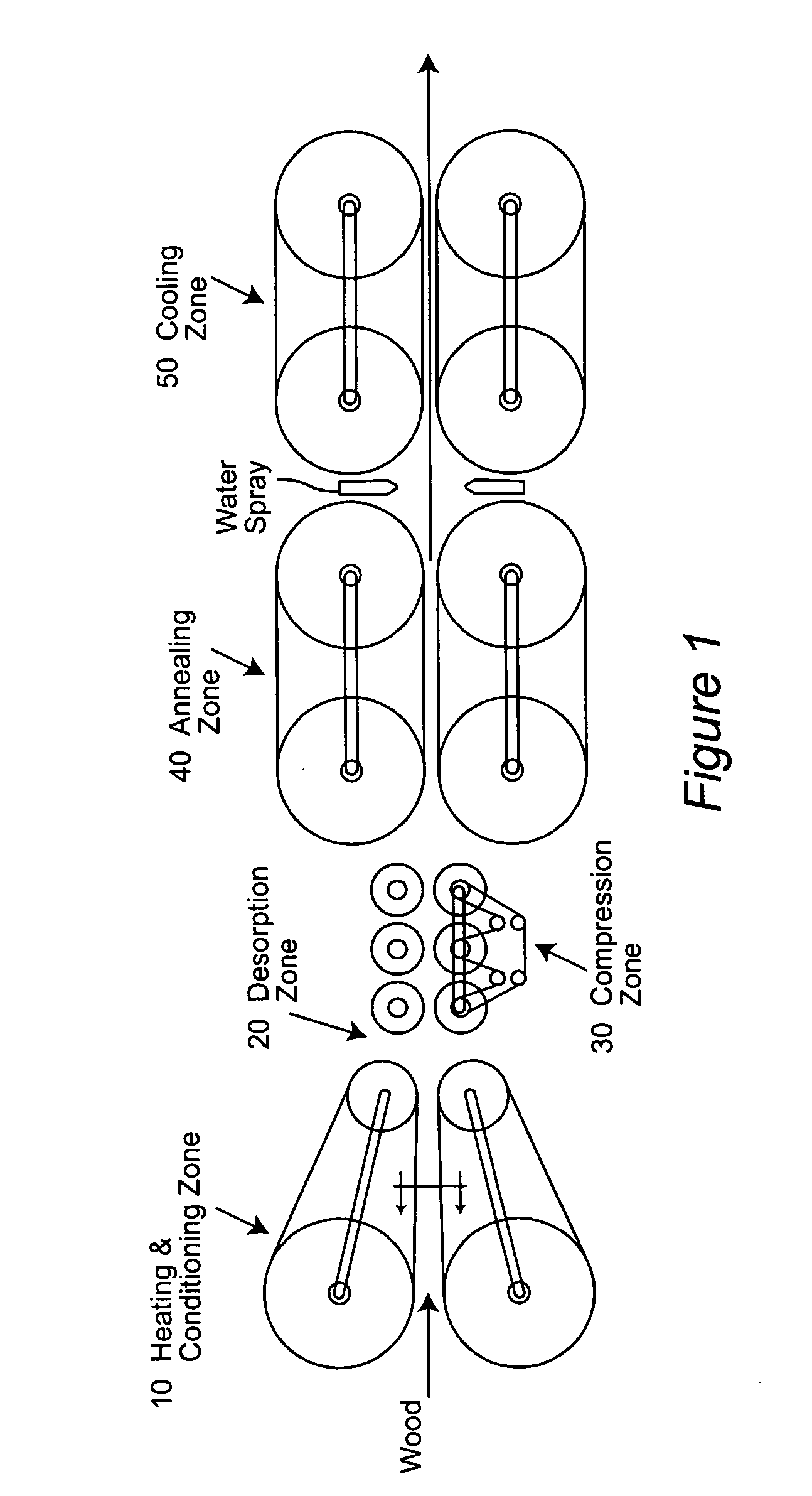

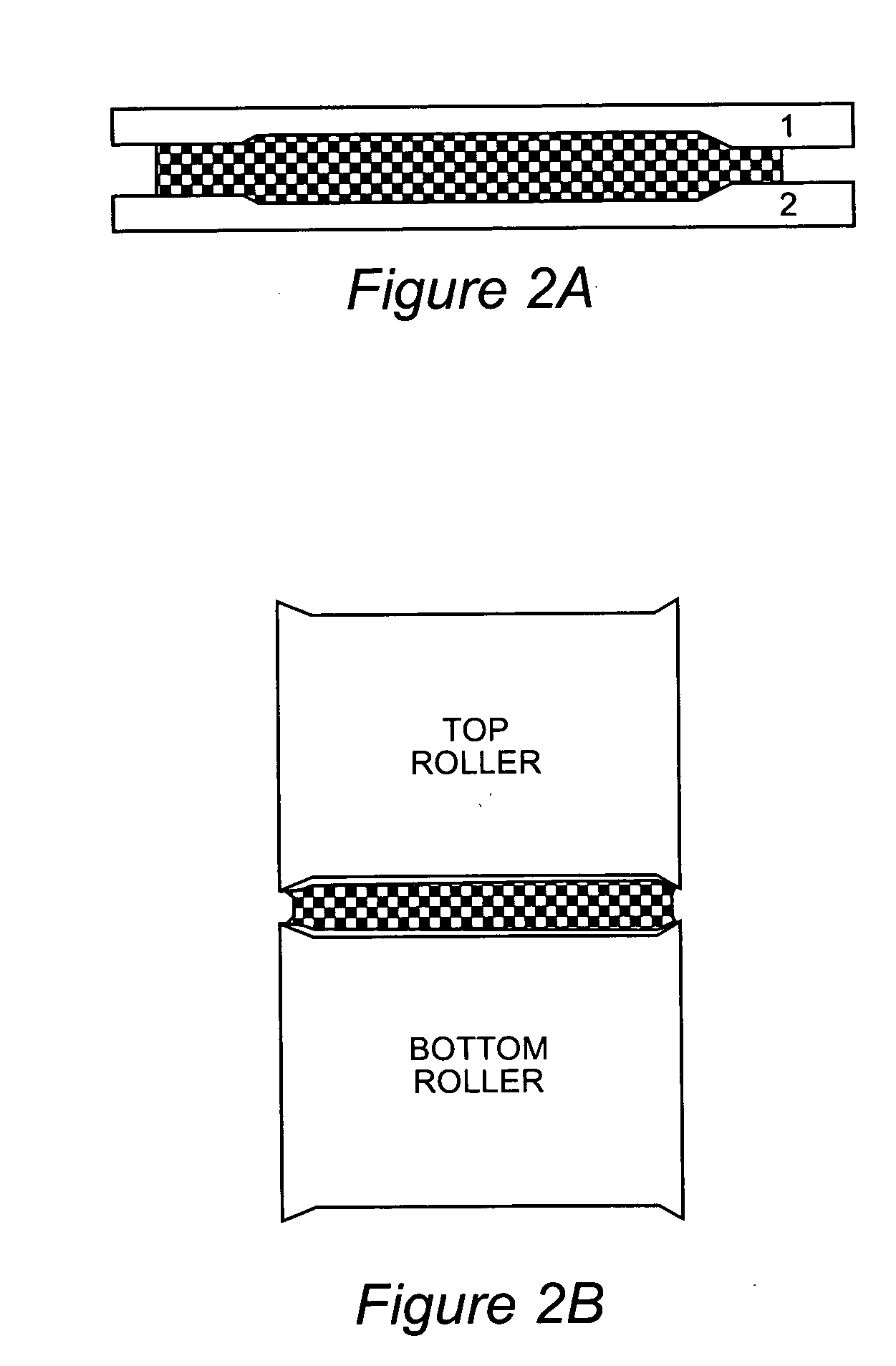

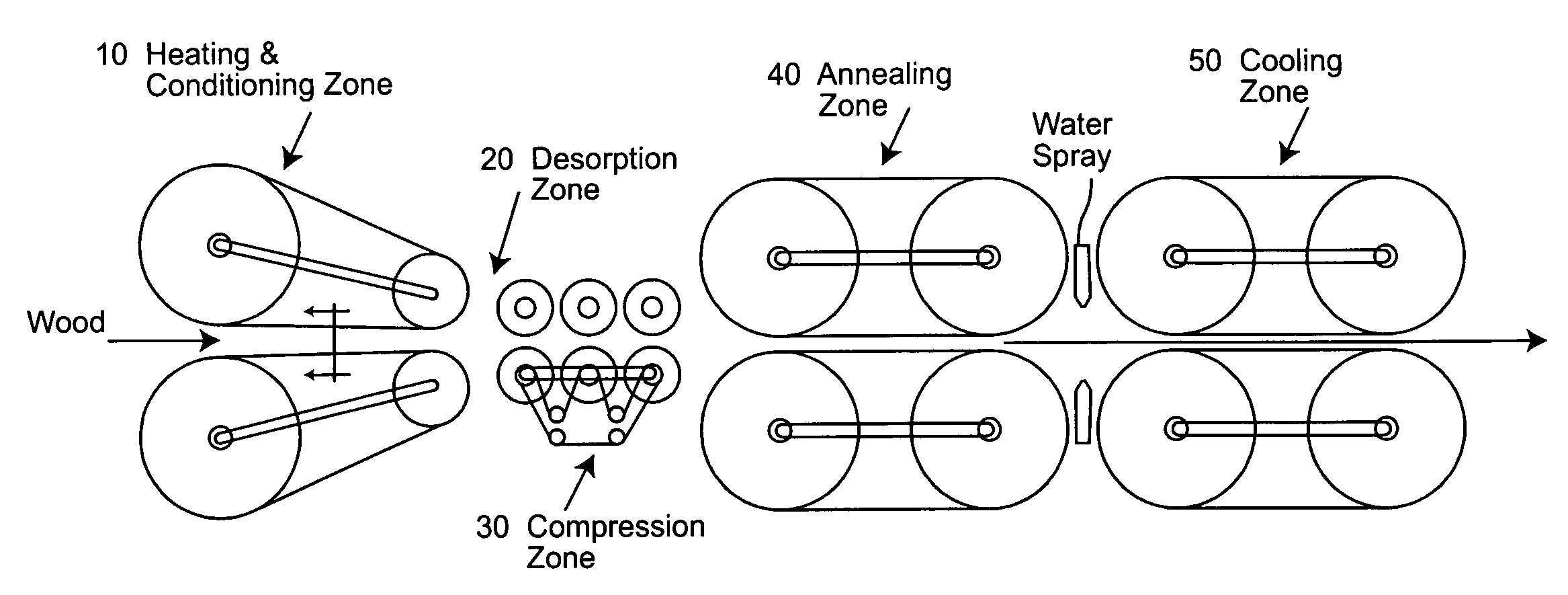

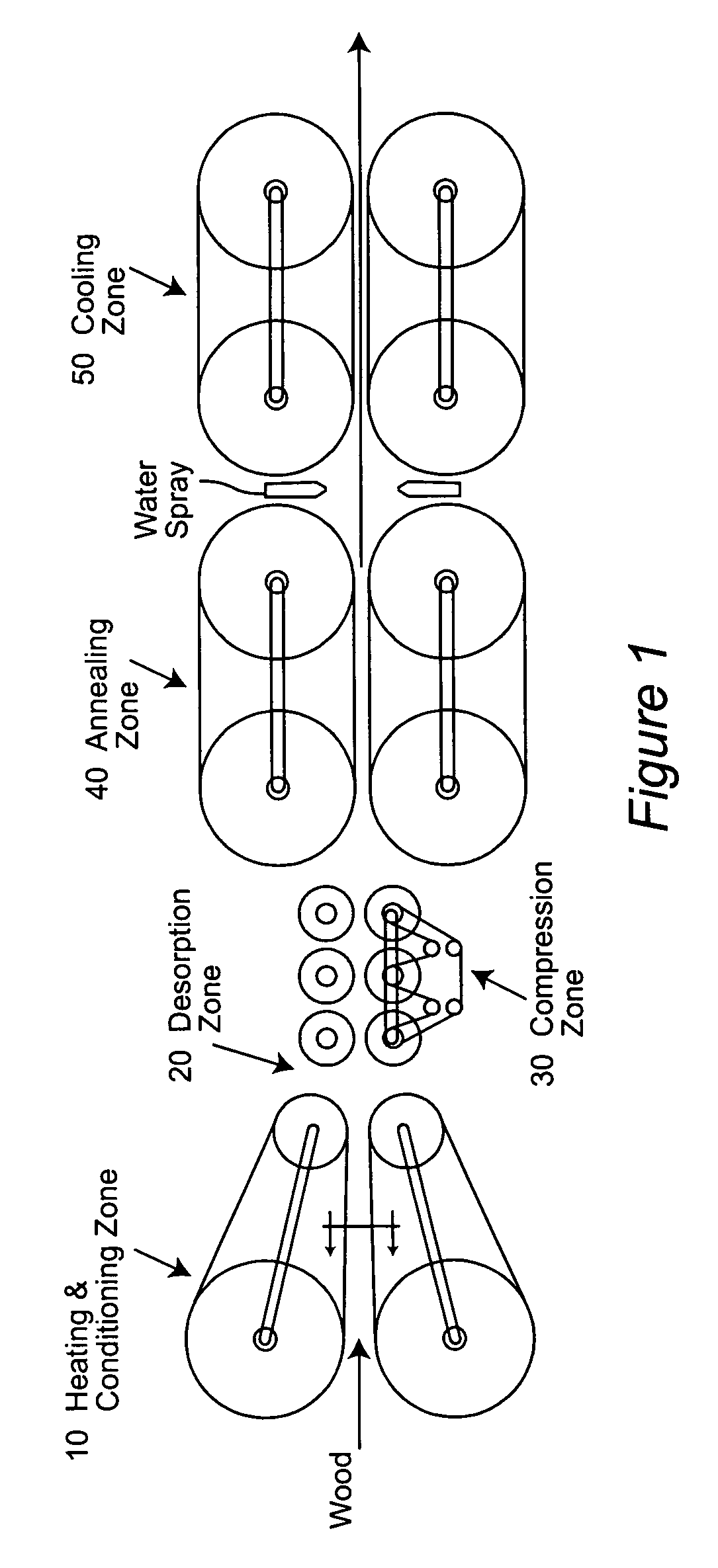

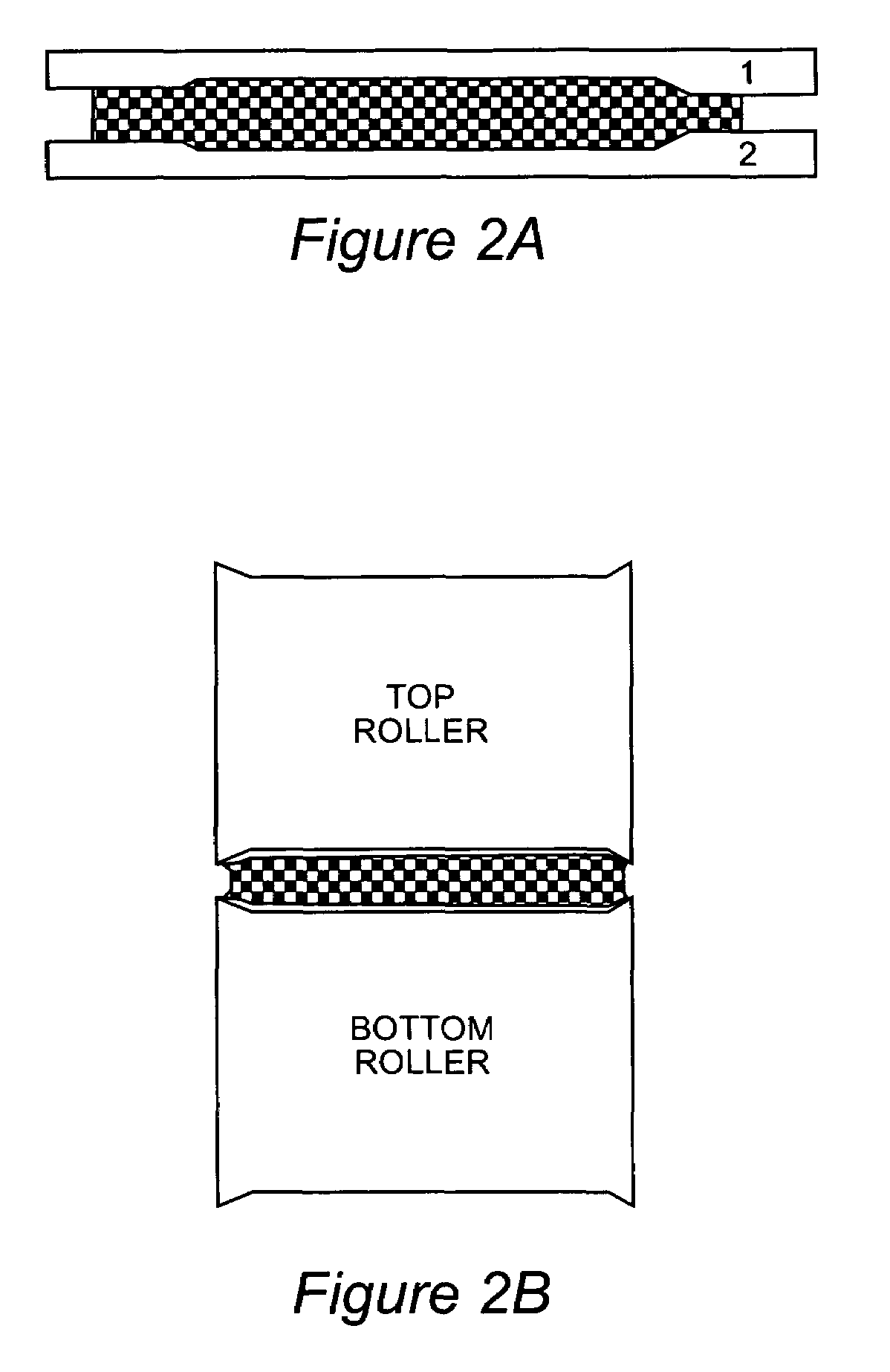

Viscoelastic thermal compression of wood

ActiveUS20050006004A1High density and strength and dimensional stabilityHigh stiffnessWood compressionWood treatment detailsHigh densityThermal compression

A high density wood product that is made from low-density wood is provided. The wood product is made using a continuous viscoelastic thermal compression (VTC) process and exhibits high density, strength and dimensional stability, compared to the lower density starting material (typically composite panels such as strand board) from which it is made.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Viscoelastic thermal compression of wood

ActiveUS7404422B2High density and strength and dimensional stabilityHigh stiffnessWood compressionWood treatment detailsHigh densityThermal compression

A high density wood product that is made from low-density wood is provided. The wood product is made using a continuous viscoelastic thermal compression (VTC) process and exhibits high density, strength and dimensional stability, compared to the lower density starting material (typically composite panels such as strand board) from which it is made.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Super-hydrophobic timber and preparation thereof

InactiveCN101234498AStable in natureSimple operation processWood compressionWood layered productsChemical treatmentRoom temperature

The invention discloses a super-hydrophobic wood with the pores of a wood body filled with super-hydrophobic substances. The preparation steps comprise: (1) the wood is put into a die; (2) certain amount of super-hydrophobic substance powder is added into the die to submerge the wood; the pressure in the die is lifted to 1-50MPa on a press; the temperature rises to 80-100 DEG C and is maintained for 0.5-20h; then the pressure is lowered to 0MPa; the material is taken out when the temperature rises to 105-110 DEG C; (3) the taken-out wood is cooled to the room temperature and scraped the super-hydrophobic substance on the surface to derive the super-hydrophobic wood. The contact angle between the super-hydrophobic wood and the water is 150 degrees and the roll angle is less than 10 degrees. The layer is tasteless and nontoxic, thereby having a broad application prospect in the fields such as lossless transportation of liquid, self-cleaning, water and damp resistance, etc. The method for preparing super-hydrophobic wood provided by the invention has the advantages of simple operation technology, good controllability, low cost, no complicated chemical treatment, no expensive equipment and industrialization facilitating.

Owner:成都新红鹰家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com