Patents

Literature

43results about How to "Increase the degree of softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

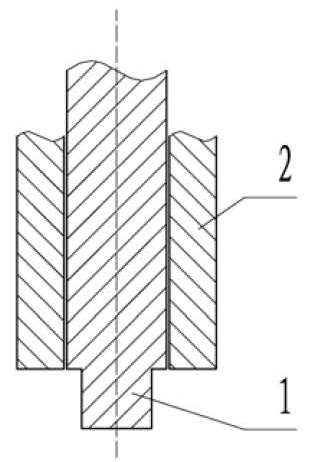

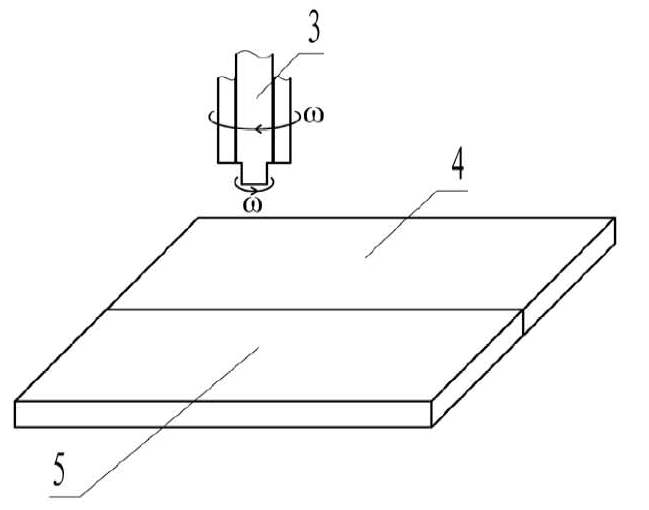

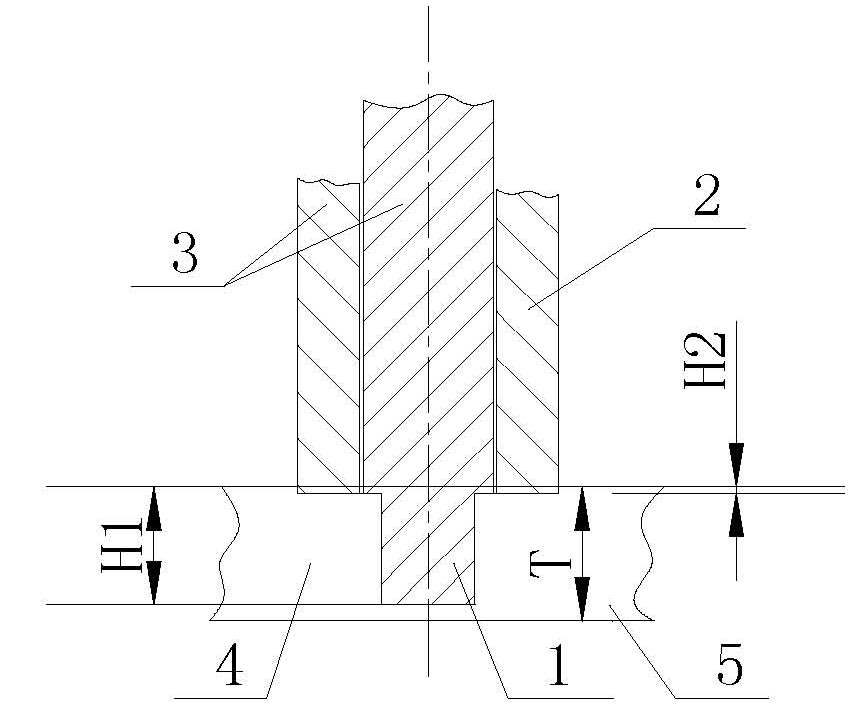

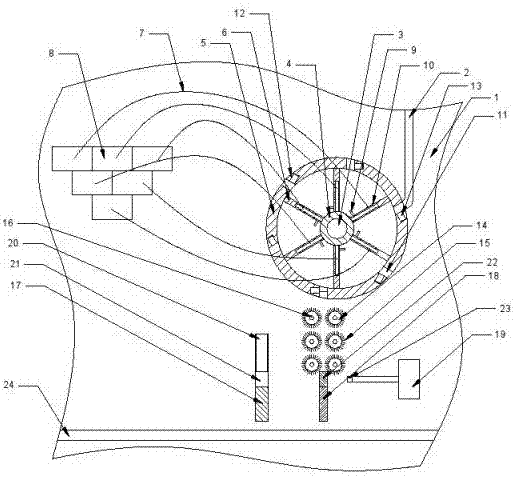

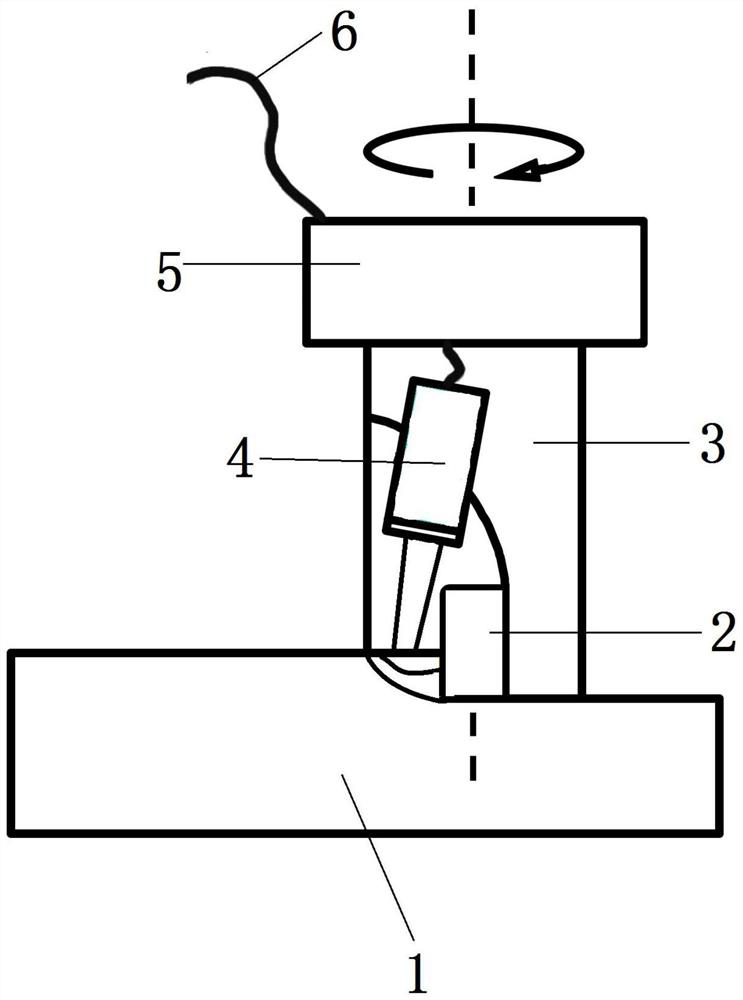

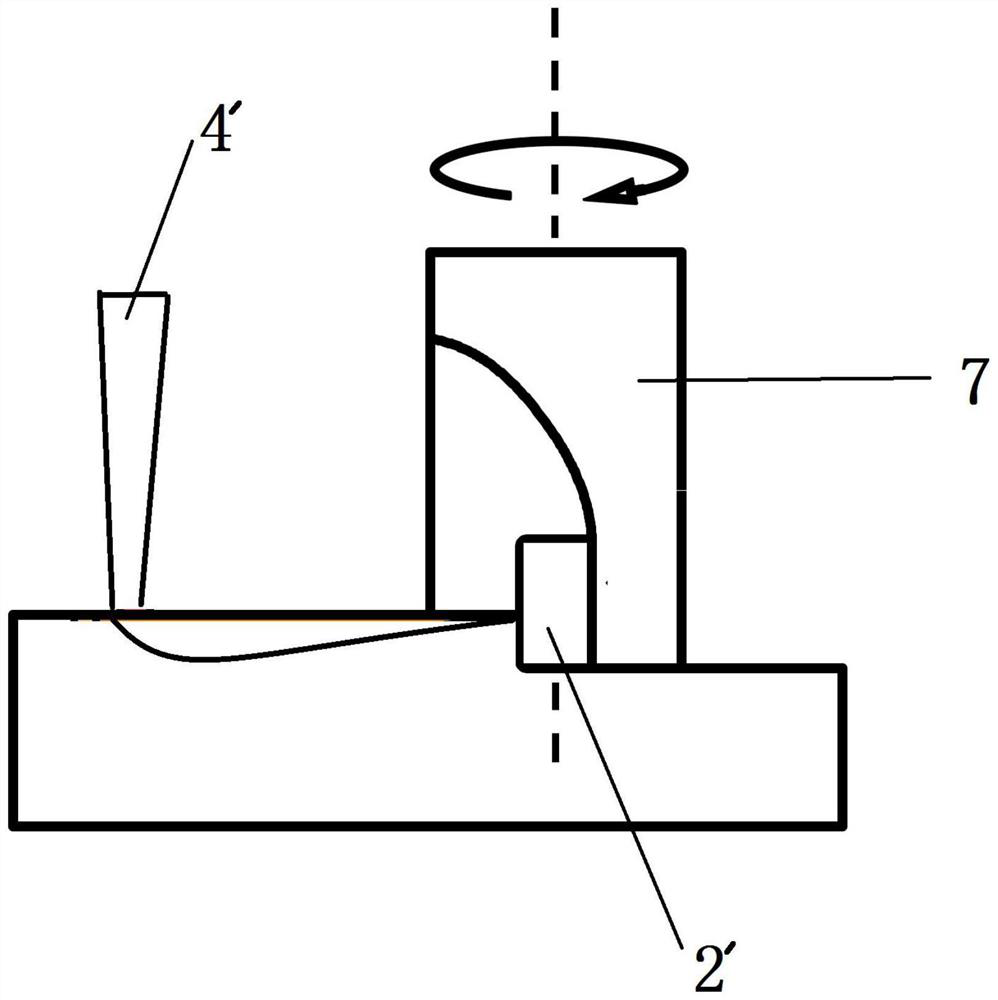

Friction stir welding method for stirring pin and shaft shoulder during differential speed rotation

InactiveCN101890573AReduce stressReduced clamping requirementsNon-electric welding apparatusRotation velocityFriction stir welding

The invention discloses a friction stir welding method for a stirring pin and a shaft shoulder during differential speed rotation, relates to the friction stir welding method and solves the problems of high downward pressure and high forward resistance and various problems caused by overcoming high speed rotation of the stirring pin and high speed rotation of the shaft shoulder in the same direction or non-rotation of the shaft shoulder existing in conventional friction stir welding. The method comprises the following steps of: inserting the stirring pin of a stirring head into a part to be welded at a rotation speed of between 3,000 and 30,000 rpm, wherein the rotation speed of the shaft shoulder of the stirring head is less than that of the stirring pin and the rotation direction of the stirring head is reverse to that of the stirring pin; the rotation speed of the shaft shoulder is 10 to 1,000 rpm; the insertion speed of the stirring head is 1 to 5 millimeter / minute; the depth of the stirring pin inserted into a workpiece is 0 to 0.5mm less than the thickness of the workpiece; and the depth of the shaft shoulder inserted into the workpiece is 0 to 0.5mm; and moving the stirring head along the horizontal direction of a butting surface of a first welded workpiece and a second welded workpiece at a speed of between 100 and 5,000 millimeter / minute. The heat required by the welding does not depend on the friction between the shaft shoulder and the welded material, so high downward pressure is not needed to ensure the friction of the shaft shoulder part to produce heat and the downward pressure is reduced.

Owner:HARBIN INST OF TECH

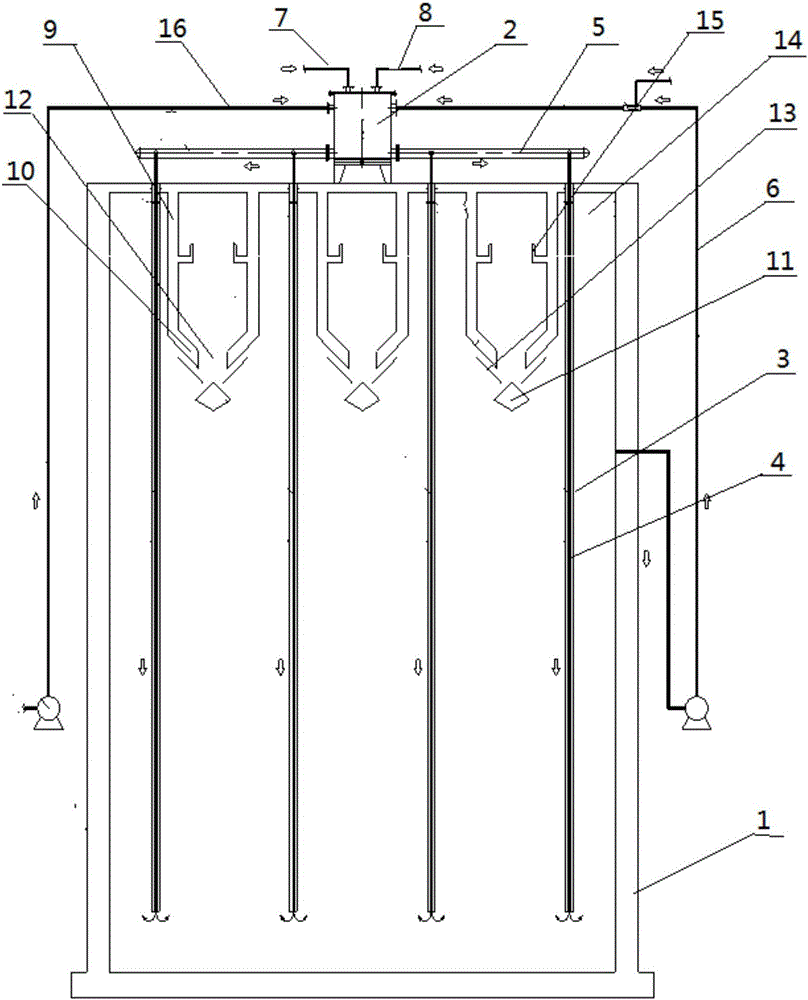

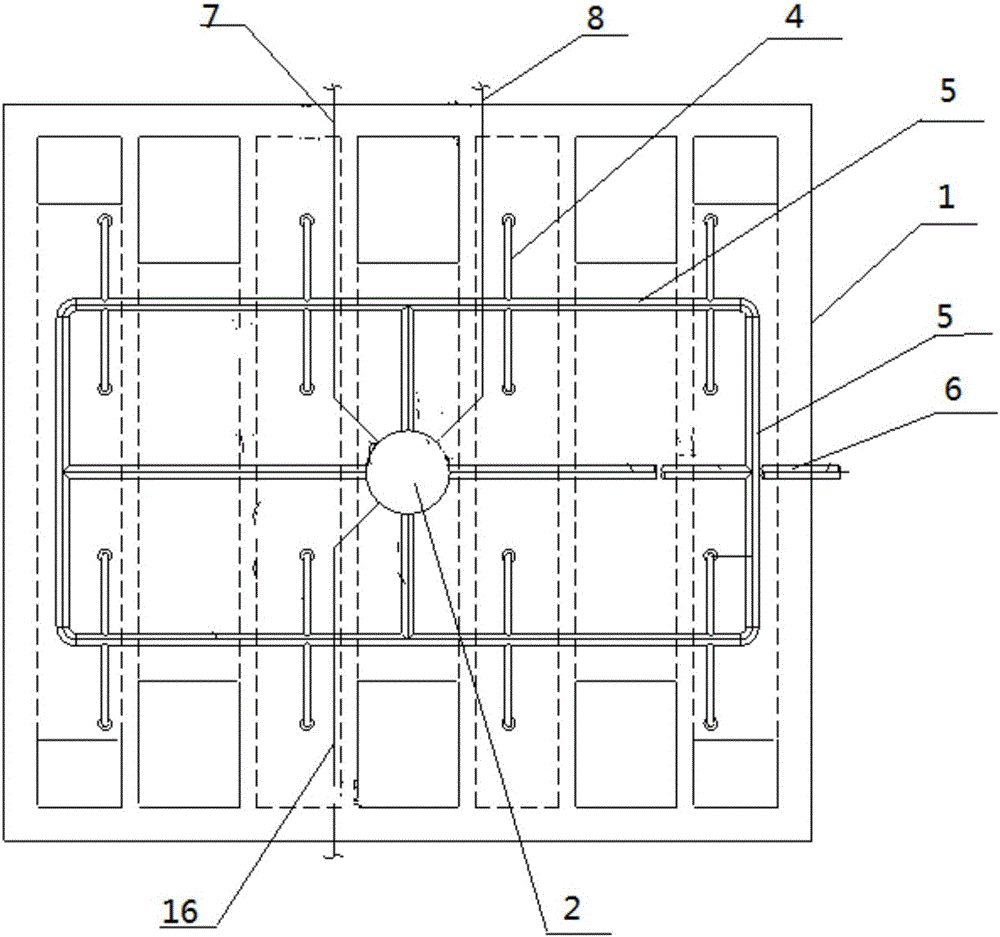

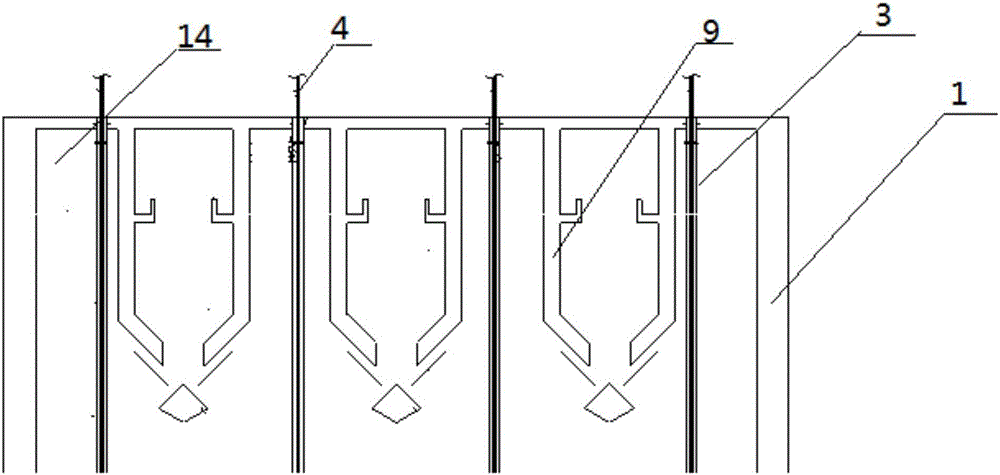

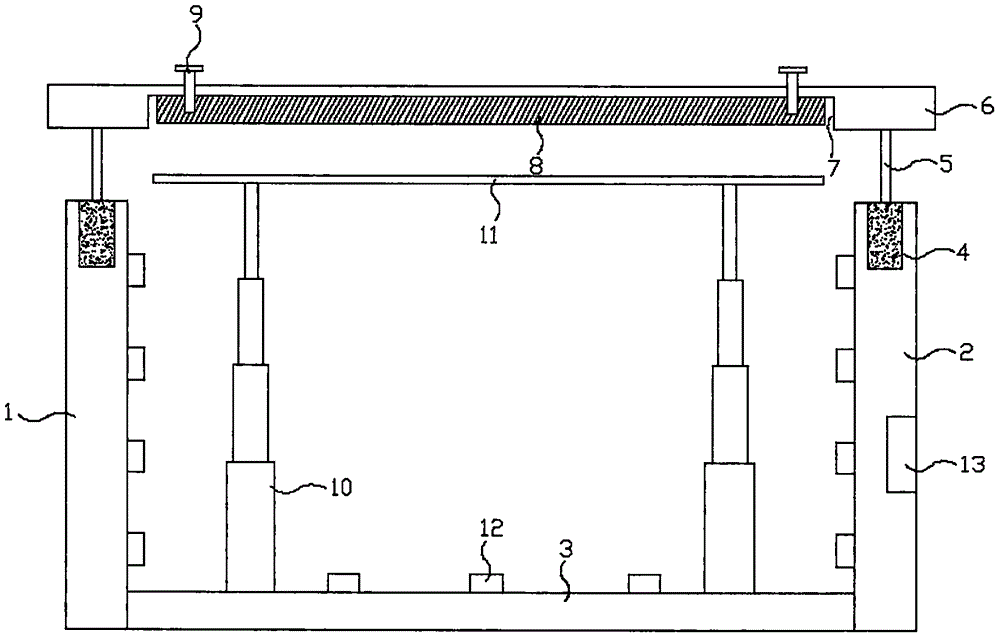

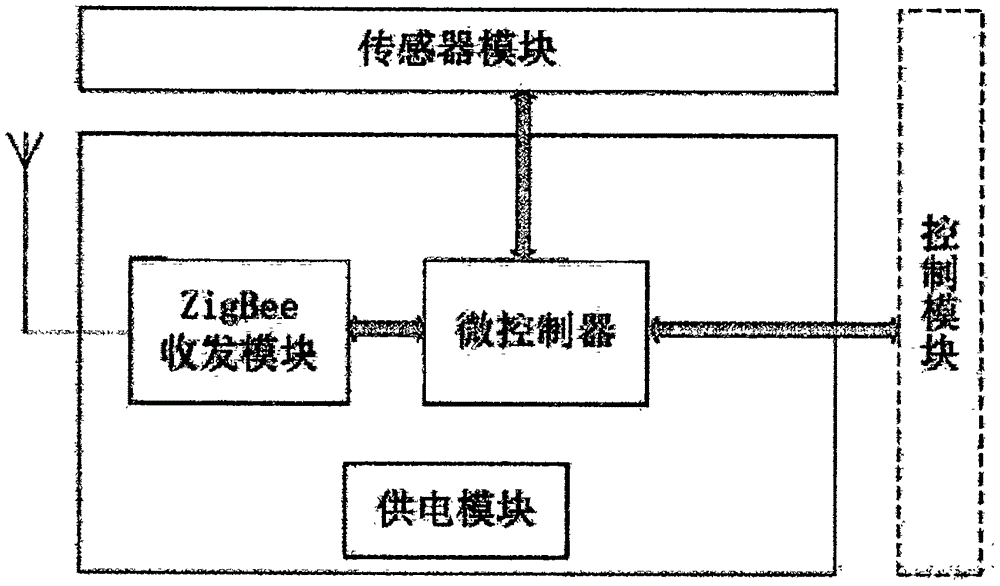

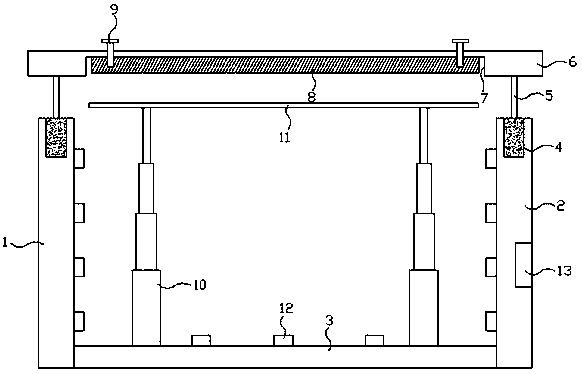

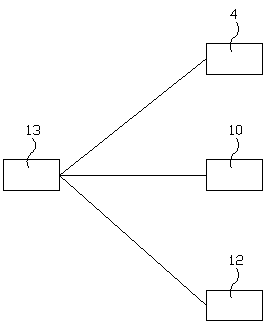

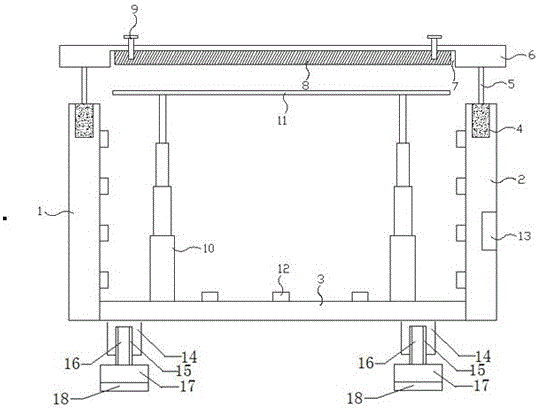

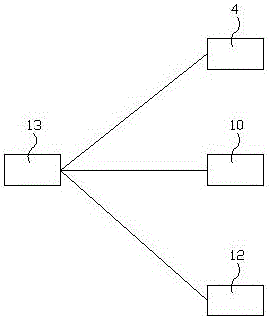

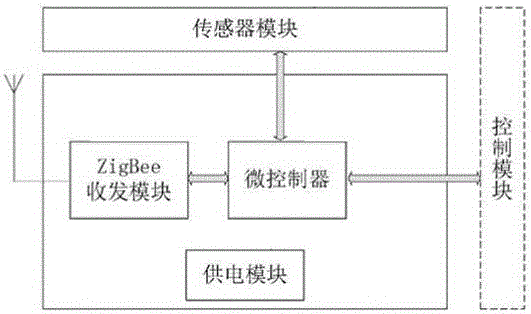

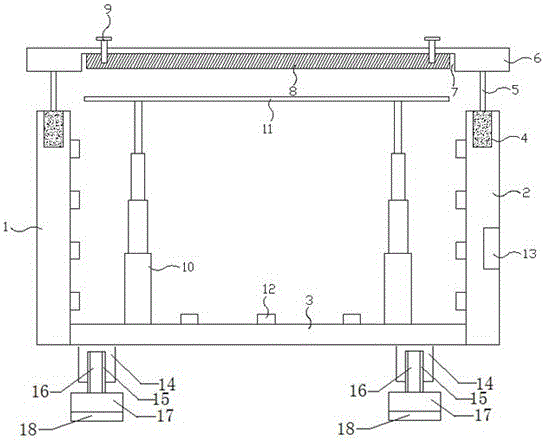

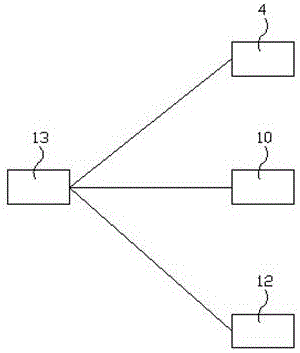

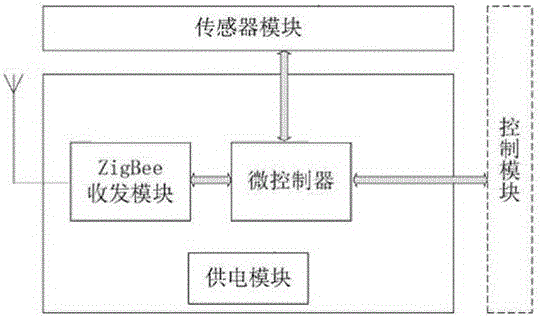

Online-maintenance up-flow anaerobic reactor

ActiveCN105776536AAvoid maintenance difficultiesImprove installation accuracyTreatment with anaerobic digestion processesWater qualityEngineering

The invention discloses an online-maintenance up-flow anaerobic reactor which comprises a reactor body, wherein a three-phase separation unit and a water distribution unit are arranged in the reactor body; the water distribution unit comprises a pressure water distributor and multiple water distribution pipelines extending to the lower part of the reactor body; the water distribution pipeline comprises a sleeve and a detachable water distribution branch pipe arranged in the sleeve; and the water distribution branch pipe is communicated with the pressure water distributor. The aims at providing the online-maintenance up-flow anaerobic reactor which can conveniently and quickly respond to the situation of scale blockage of pipeline, realizes uniform water distribution and low mounting difficulty and improves the effluent quality.

Owner:GUANGZHOU SINOVAST ENERGY ENVIRONMENT GRP

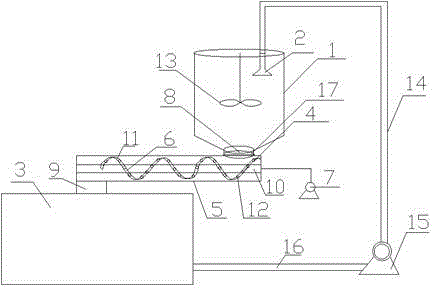

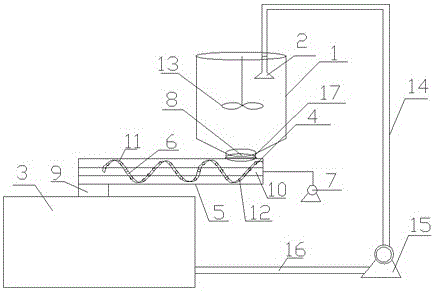

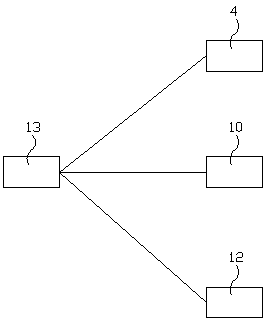

Traditional Chinese medicine soaking device

ActiveCN104857740AImprove wettabilityShorten the soaking timeSolid solvent extractionMechanical engineeringChinese herbology

The invention discloses a traditional Chinese medicine soaking device. The device comprises a material barrel, an extraction device and a screw rod assembly used for conveying materials from the material barrel to the extraction device, wherein the screw rod assembly is arranged between the material barrel and the extraction device; the screw rod assembly comprises a hollow pipe, a screw rod body arranged in the hollow pipe and a power device for providing power control for the screw rod body, the hollow pipe is transversely arranged, two ends of the hollow pipe are in a sealed state, an upper material conveying port connected with the material barrel is formed in one end of the upper side of the pipe wall of the hollow pipe, a lower material conveying port connected with the extraction device is formed in the other end of the lower side of the pipe wall of the hollow pipe, and a stirring device and a spray head are arranged in the material barrel. The traditional Chinese medicine soaking device has the benefit of capability of increasing the extraction efficiency and the extraction degree of medicines.

Owner:JIANGSU HUATAI HEAVY IND EQUIP

Sand-preventing method of artificial borehole wall, and material for sand prevention

ActiveCN107163926AImprove salt toleranceCalcium resistantFluid removalDrilling compositionAlkylphenolSURFACTANT BLEND

The invention discloses a sand-preventing method of an artificial borehole wall, and a material for sand prevention. The material for sand prevention comprises guide liquid, sand carrying liquid and promoting liquid which are prepared separately, wherein the guide liquid comprises the following components in percentage by weight: 0.5 to 20 percent of sodium chloride, 0.2 to 2 percent of calcium chloride, 0.1 to 1 percent of magnesium chloride, 0.2 to 4 percent of alkylphenol polyoxyethylene, 0.3 to 8 percent of an anionic surfactant capable of resisting calcium and magnesium ions and 0.01 to 6 percent of a dimethyl diallyl ammonium chloride-acrylamide-acrylic acid copolymer; the sand carrying liquid comprises the following components in percentage by weight: 0.01 to 5 percent of a dimethyl diallyl ammonium chloride-acrylamide copolymer and 0.5 to 20 percent of ammonium chloride; and the promoting liquid comprises the following components in percentage by weight: 8 to 22 percent of a penetrating agent and 18 to 35 percent of a dehydroxylation catalyst. The material for sand prevention performs sand prevention, can protect the stratum, has high sand carrying capability, reduces friction and enhances the consolidation strength, and the penetration ratio of the artificial borehole wall formed after sand prevention is more than 12 <mu>m<2>.

Owner:东营市科诺石油技术有限责任公司

Old-fashioned visual effect jean cloth

ActiveCN105568658AEven by forceIncrease the degree of softeningDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsPolymer scienceDenim

Old-fashioned visual effect jean cloth is characterized in that a preparing method comprises the following steps: (1) desizing and softening jean cloth; (2) dehydrating the jean cloth and taking out, and then placing in a water washing machine; (3) performing water washing enzymes treatment on the jean cloth; (4) cleaning the jean cloth after the water washing enzymes treatment; (5) performing cat's whisker treatment on the jean cloth after the cleaning; (6) needling and wearing the jean cloth after the cat's whisker treatment; (7) after the wearing treatment, cleaning, dehydrating, drying, ironing and sizing, and hanging and baking the jean cloth in sequence in order to obtain the finished product jean cloth.

Owner:佛山市杰德纺织有限公司

Bamboo arc sheet spreading method

InactiveCN100443274CNot easy to reboundIncrease the degree of softeningWood compressionProduction rateAgricultural engineering

Owner:NANJING FORESTRY UNIV

Splitting preventing peeling method of broad beans

ActiveCN106942765AIntegrity guaranteedImprove work efficiencyFood treatmentAgricultural scienceElectric machinery

The present invention discloses a splitting preventing peeling method of broad beans. The peeling method comprises the following steps: preparing: a peeling device of the broad beans is used; selecting: the broad beans with uniform granules are selected; broad bean soaking: the broad beans are soaked in clean water; circle preparing: pig tails are prepared into pig tail circles; starting: the broad beans are put into a material feeding channel, a rotating motor is started to drive an inner sleeve tube and an outer sleeve tube to rotate together, and the broad beans fall to support plates; auxiliary motors are started and drive circular shafts to rotate; softening: the broad beans on the support plates press and trigger switches, and steam produced by steam engine working is sprayed out from spraying nozzles to soften the outer shells of the broad beans; peeling: brushing hairs on the circular shafts are used to remove outer shells of the broad beans; limiting: brushing hairs push the broad beans to be limited on a clamping part of a second pillar; and sleeving: a piston rod of an air cylinder is used to push the broad beans to move at a high speed to the direction of the pig tail circles, so that the pig tail circles in through-holes sleeve the broad beans. The scheme mainly solves the problems that the traditional broad bean peeling technology is low in efficiency and likely to cause splitting of the broad beans.

Owner:CHONGQING ZHOUYI FOOD CO LTD

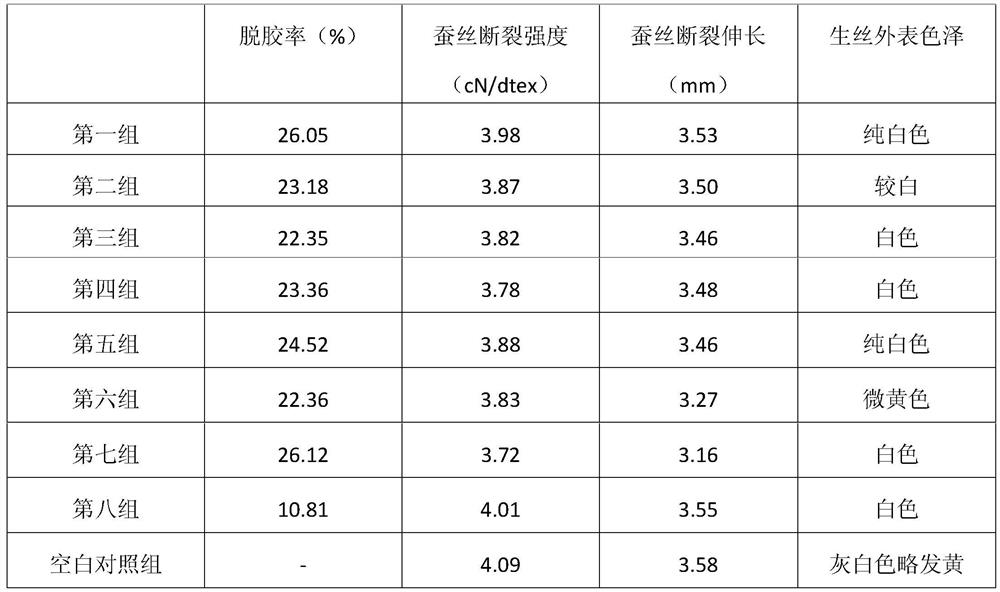

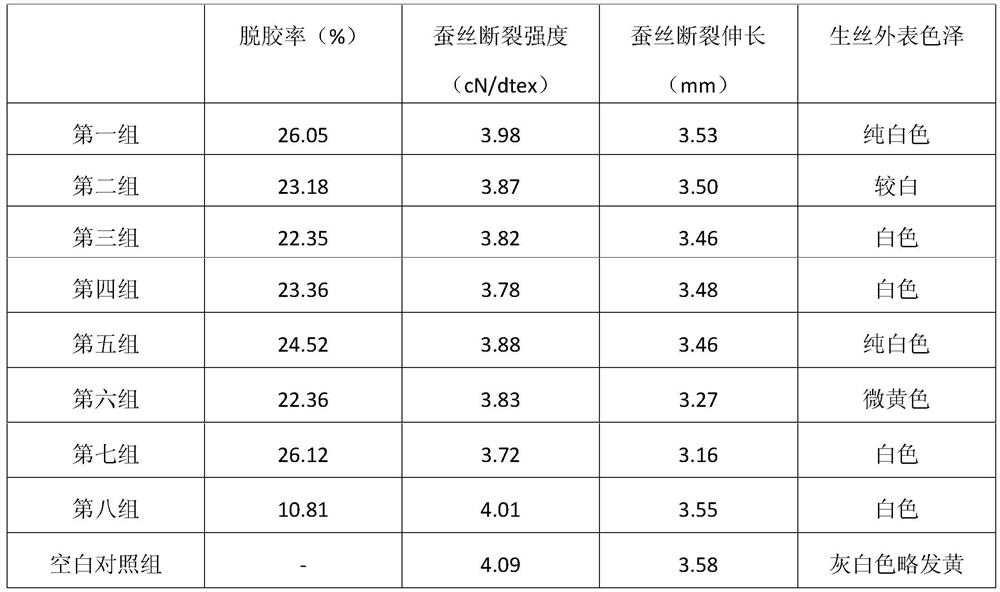

Preparation method of silk quilt

ActiveCN112401598AIncrease productivityExcellent and stable qualityBlanketBiochemical fibre treatmentAntibiosisEngineering

The invention relates to the technical field of home textiles, in particular to a preparation method of a silk quilt. The preparation method of the silk quilt comprises the following steps of (1) silkpreparation, (2) refining, (3) rinsing, (4) modification, (5) drying and (6) silk quilt preparation. The silk quilt prepared through the method is high in production efficiency, excellent and stablein quality, safe in operation process, easy and convenient to operate and capable of saving resources, compared with a traditional preparation process, the preparation process time is shortened, the production cost is reduced, the prepared silk is fragrant, pleasant, good in cotton bulkiness and tension and good in whiteness. Meanwhile, the health-care functions of antibiosis, mite prevention, insect prevention and the like are realized.

Owner:广西农投时宜农业科技有限公司 +2

Wood veneer softening process

InactiveCN109318326AAccelerateAvoid wrinklingRadiation/waves wood treatmentWood treatment detailsChemistryPolyethylene glycol

The invention discloses a wood veneer softening process. The process comprises the following steps: a, spraying a softening solution on a wood veneer, standing for 3-5h, and thus obtaining a product A, wherein the softening solution comprises the following components in part by weight: 20-30 parts of polyethylene glycol, 3-5 parts of glacial acetic acid, 1-3 parts of sodium dodecyl benzene sulfonate, 0.5-1 part of fatty alcohol polyoxyethylene ether sodium sulfate, 0.5-1.5 parts of boric acid and 30-40 parts of deionized water; b, conducting microwave irradiation for the product A for 5-9min by a microwave generator, and thus obtaining a product B, wherein the microfiltration frequency is 80-90KHz, and the power is 1-3W / cm2; c, putting the product B into a steam box, heating for 0.5-2h with steam, and thus obtaining a product C; d, clamping the product C by two pore plates to keep the product C smooth, and thus obtaining a product D; e, drying the product D, and thus obtaining a product E; f, painting boiled tung oil on the two sides of the product E, and thus obtaining a product F; and g, heating the product F to 80-120 DEG C to enable the tung oil to completely penetrate into theproduct F, and thus obtaining a finished product. The wood veneer handled by the process has the advantage of fitting to furniture with the surface with a large curvature.

Owner:湖州南浔登越家居有限公司

Processing process for forming vintage visual effect of denim

InactiveCN105803756AEven by forceIncrease the degree of softeningDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsDenimMedicine

The invention provides a processing process for forming a vintage visual effect of denim. The processing process is characterized by comprising the following steps of: (1) carrying out desizing and softening treatment on the denim; (2) dehydrating the denim and taking out and putting the denim into a water washing machine; (3) carrying out water-washing ferment treatment on the denim; (4) washing the denim subjected to the water-washing ferment treatment; (5) carrying out whiskering treatment on the washed denim; (6) after whiskering treatment, carrying out stitching treatment and wearing-out treatment on the denim; and (7) sequentially carrying out washing, dehydration, drying, ironing and sizing, hanging and drying on the denim after the wearing-out treatment to obtain finished-product denim.

Owner:耿云花

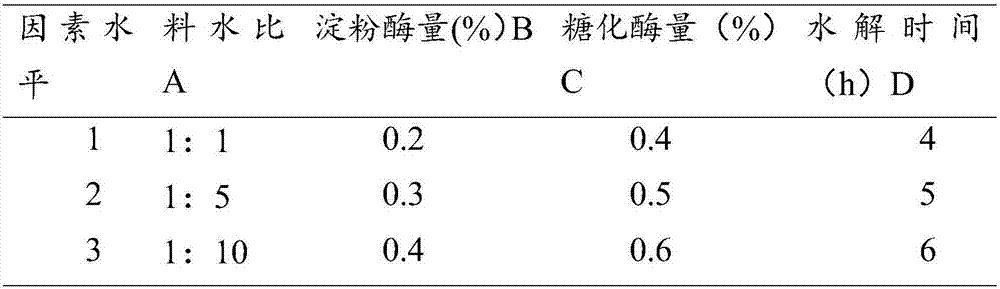

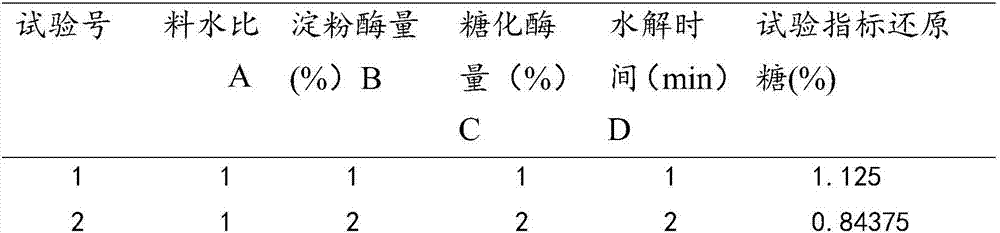

Compound beverage made from cordyceps militaris, corn and peanuts

ActiveCN107258915AShorten the soaking timeIncrease the degree of softeningMilk substitutesFood scienceFlavorCordyceps

The invention provides a compound beverage made from cordyceps militaris, corn and peanuts. The beverage product is obtained by the following steps: preparing a cordyceps militaris residue hydrolysate, conducting early-stage treatment on the corn, conducting early-stage treatment on the peanuts, conducting pulping, conducting gelatinization and liquefaction on the corn pulp, conducting blending, conducting homogenization, and conducting sterilization and checking. According to the invention, the beverage has a unique flavor compounding flavors of the cordyceps militaris, the corn and the peanuts. The beverage is milk yellow, fragrant, sweet and tasty, and is homogeneous in texture. The beverage has an emulsion appearance, has no deposition or delamination phenomena but a small amount of deposition is allowed after a long-time preservation, and a small amount of fat floats on bottle walls. For the compound beverage, protein content is more than 1%, and content of soluble solid is 10% or above, and fat content is 1% or above, and content of total sugar (on glucose basis) is 6-12%.

Owner:NANYANG INST OF TECH

Preparation technique of compressed dark tea crafts and product

InactiveCN105379862AGood qualityIncrease the degree of softeningPre-extraction tea treatmentComposite materialEngineering

Owner:吴旺华

Automatic heating device for diesel oil

InactiveCN106527529AEasy to useIncrease the degree of softeningTemperatue controlHydraulic cylinderOil processing

The invention discloses an automatic heating device for diesel oil. The automatic heating device comprises a first supporting plate and a second heating plate. One end of the first heating board and one end of the second heating board are respectively provided with a hydraulic cylinder internally, and one end of each hydraulic cylinder is provided with a hydraulic supporting rod. One end of the hydraulic supporting rod is provided with a mounting plate, and furthermore one side of the mounting plate is provided with a mounting trough in which a template is arranged. A base plate is arranged between one end of the first supporting plate and one end of the second supporting plate. One side of the base plate is provided with an electric telescopic rod, and one side of the electric telescopic rod is provided with a supporting plate. One side of the first supporting plate, one side of the second supporting plate and one side of the base plate are respectively provided with a plurality of heaters. The other side of the second supporting plate is provided with a controller. The automatic heating device can heat the diesel oil on the supporting plates through the heaters and further has advantages of improving softening degree, increasing efficiency in printing a pattern by the diesel oil, facilitating diesel oil processing, and improving diesel oil processing efficiency.

Owner:WUXI CHUANGNENG POWER TECH CO LTD

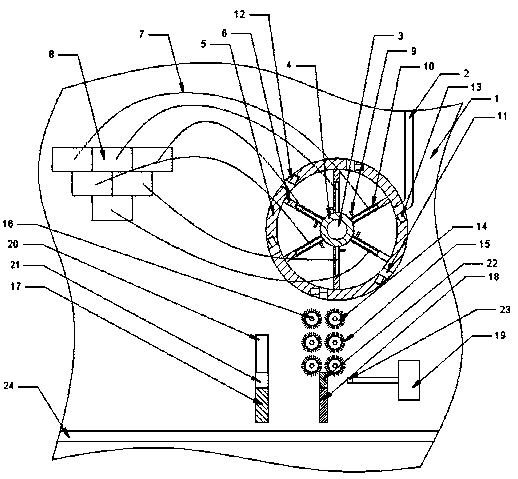

Broad bean peeling device

ActiveCN107041562BIntegrity guaranteedImprove work efficiencyFood treatmentElectric machineryAgricultural engineering

The invention discloses a peeling device for broad beans. The peeling device comprises a rack. The rack is provided with a feeding path, a rotary mechanism, a peeling mechanism and a sleeving mechanism, wherein the rotary mechanism is formed by a rotary motor, an internal casing pipe and an external casing pipe; a rotating shaft of the rotary motor is fixedly connected with the internal casing pipe; supporting plates with a cavity are formed between the internal casing pipe and the external casing pipe; each supporting plate is connected with a steam pipe; each steam pipe is connected with a steam machine; a trigger switch is mounted on each supporting plate; a plurality of spray holes are formed in each supporting plate; a plurality of feeding ports are arranged on the periphery of the external casing pipe; a groove is formed in the inner wall of the each feeding port; the groove is in a slideable connection with a baffle plate; the peeling mechanism has a plurality sets of round shafts; a plurality of brush hairs are arranged on the periphery of the outer wall of each round shaft; the round shafts are fixedly connected with an auxiliary motor; the sleeving mechanism includes a first supporting column, a second supporting column and an air cylinder; the first supporting column is provided with a through hole and a storage groove; and the top of the second supporting column is provided with a clamping part. By the use of the peeling device, problems of low broad bean peeling efficiency and broad bean crack during the use of a traditional peeling technology can be solved.

Owner:CHONGQING ZHOUYI FOOD CO LTD

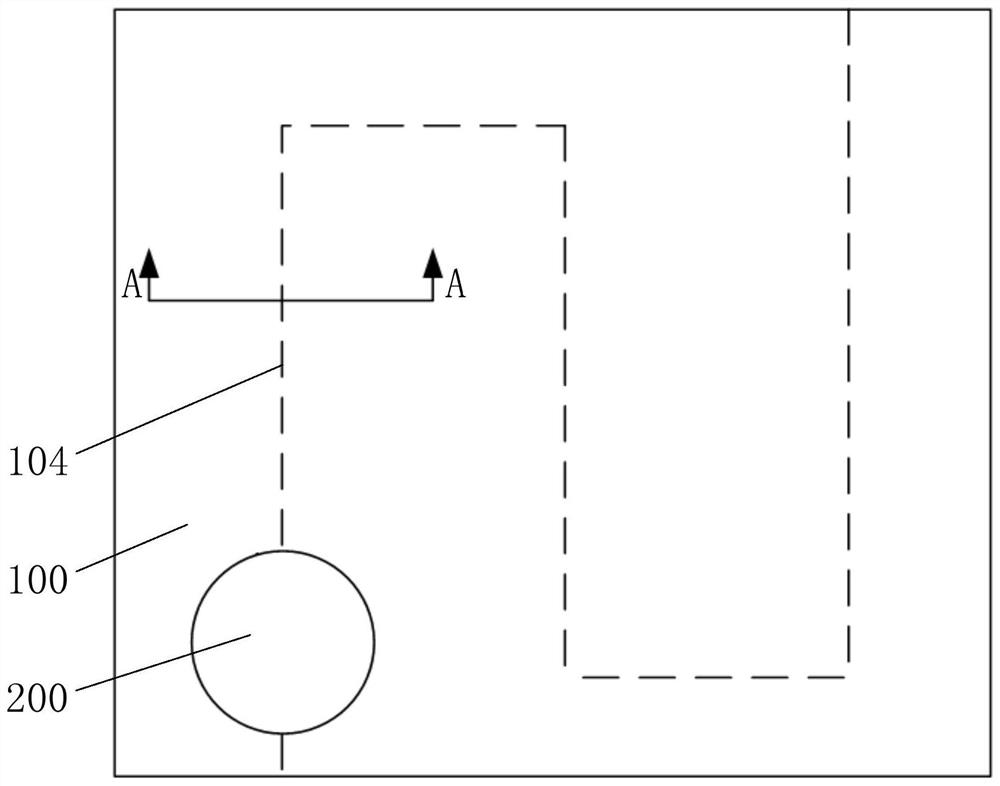

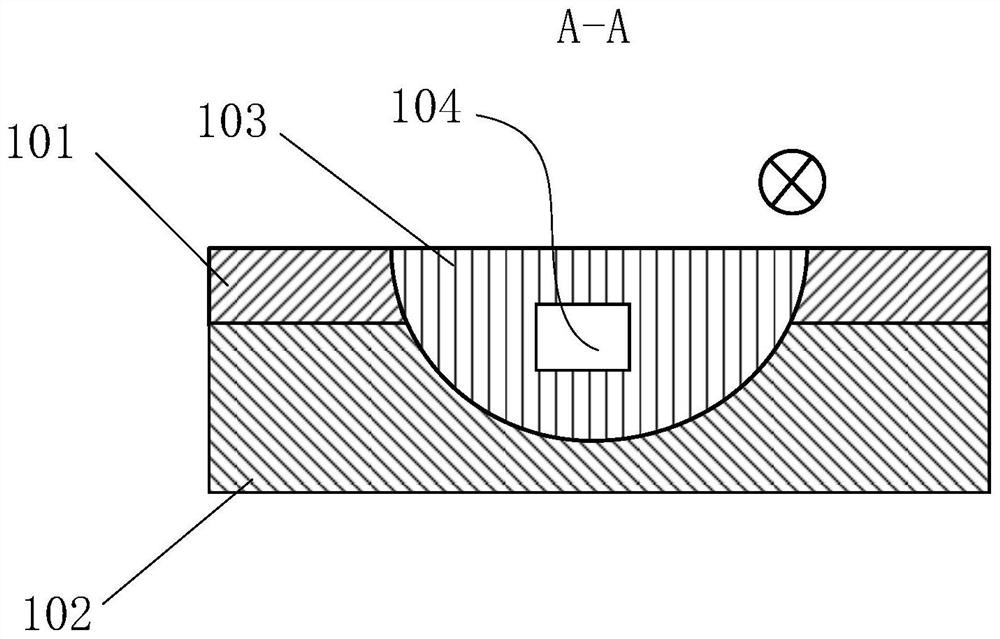

Copper-aluminum different-material cooling plate friction stir tunnel forming method and cooling plate

InactiveCN112719567AHigh melting pointPromote softeningNon-electric welding apparatusFriction weldingFriction stir welding

The invention discloses a copper-aluminum different-material cooling plate friction stir tunnel forming method and a cooling plate. The copper-aluminum different-material cooling plate friction stir tunnel forming method comprises the following steps of selecting a copper alloy plate and an aluminum alloy plate as base materials, and removing oxide layers on the surfaces of the copper alloy plate and the aluminum alloy plate; stacking, clamping and fixing the copper alloy plate and the aluminum alloy plate, taking the copper alloy plate as an upper copper plate of the cooling plate, and taking the aluminum alloy plate as a lower aluminum plate of the cooling plate; starting a main shaft of friction stir welding equipment to drive a stirring head to rotate, so that the stirring head is inserted into the upper copper plate and the lower aluminum plate by a preset depth, and the stirring head keeps rotating; driving the stirring head to horizontally move along a designated welding path to weld the upper copper plate and the lower aluminum plate, so that the cooling plate is obtained; and meanwhile, enabling the stirring head to rotate to enable materials in a weld joint to flow upwards, overflow and deposit on the surface of the weld joint, so that a tunnel is formed in the cooling plate.

Owner:哈工万联智能装备(苏州)有限公司

Manufacturing method of flower compressed tea and flower compressed tea prepared by same

InactiveCN105230864AImprove qualityIncrease the degree of softeningTea substituesSpecial ornamental structuresEngineeringTea leaf

The invention discloses a manufacturing method of flower compressed tea and flower compressed tea prepared by the same. The manufacturing method comprises the following steps: (1) wetting and softening loose flower tea; (2) transferring the wetted and softened loose flower tea into a mould press, and pressing loose flower tea into moulds with a predetermined shape so as to obtain handicrafts of flower compressed tea; (3) drying the obtained handicrafts of flower compressed tea. The technology is characterized in that in the wetting and softening step, the loose flower tea is wetted and softened by high temperature steam until the flower tea becomes soft and is not broken after being bended. The moulds in the mould press can give off heat. A heating device is horizontally or vertically arranged on the external surface of the mould, or is arranged on the internal wall of the mould.

Owner:吴旺华

An environment-friendly asphalt automatic heating device

ActiveCN106192677BEasy to useIncrease the degree of softeningRoads maintainenceHydraulic cylinderControl engineering

The invention discloses an automatic environment-friendly asphalt heating device which comprises a first supporting plate and a second supporting plate. Hydraulic cylinders are arranged in one end of the first supporting plate and one end of the second supporting plate. A hydraulic strut is arranged at one end of each hydraulic cylinder. An installation plate is arranged at one ends of the hydraulic struts, an installation groove is formed in one side of the installation plate, and a template is arranged in the installation groove. A bottom plate is arranged between one end of the first supporting plate and one end of the second supporting plate, an electric telescopic rod is arranged on each side of the bottom plate, and a supporting plate is arranged at one ends of the electric telescopic rods. Multiple heaters are arranged on each of the first supporting plate, the second supporting plate and one side of the bottom plate. A controller is arranged on the other side of the second supporting plate. By the adoption of the automatic environment-friendly asphalt heating device, asphalt on the supporting plate can be heated through the heaters, the softening degree is increased, and the pattern printing efficiency of the asphalt is improved; convenience is brought for machining of the asphalt; and the machining efficiency of the asphalt is improved.

Owner:振林建设集团股份有限公司

A processing method for making denim present an old visual effect

ActiveCN104372599BEven by forceIncrease the degree of softeningDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsDenimMedicine

A processing method for making denim show an old visual effect, which is characterized by comprising the following steps: (1) desizing and softening the denim; (2) dehydrating the denim, and then placing it in a washing machine; (3) ) Washing and enzyme treatment of denim; (3) Cleaning of denim after washing and enzyme treatment; (4) Whiskering of denim after washing; (5) Stitching of denim after whiskering (6) After the abrasion treatment, the denim is washed, dehydrated, dried, ironed and shaped, and rack-baked to obtain the finished denim. The resulting denim has a real sense of aging and little damage to the overall fabric.

Owner:ZHEJIANG TENGMA TEXTILE CO LTD

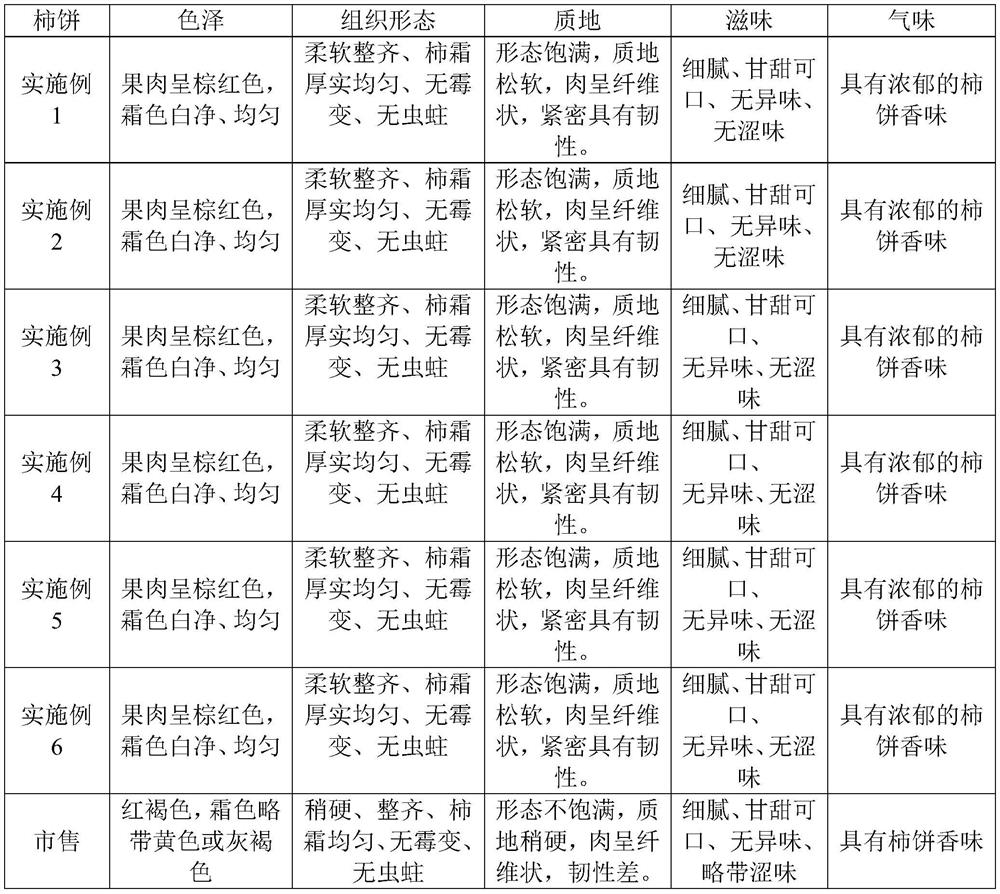

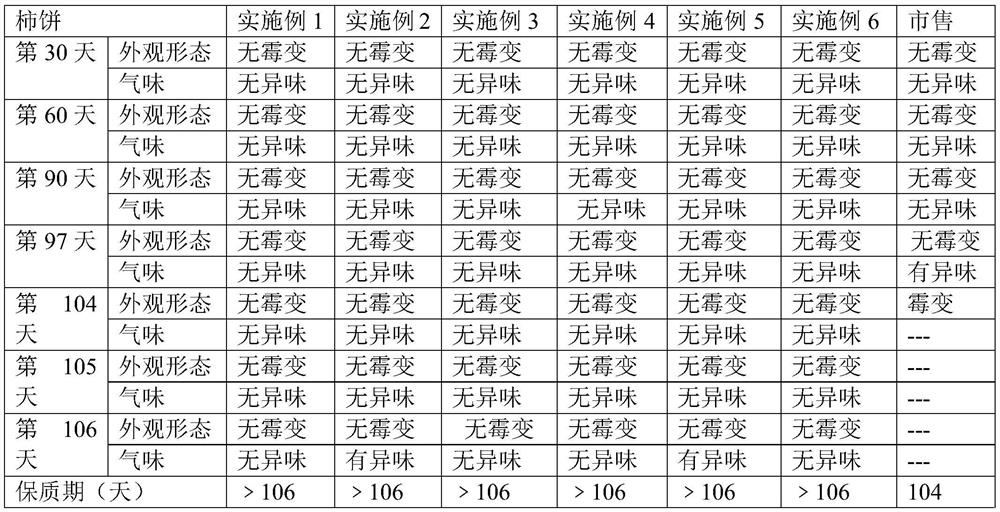

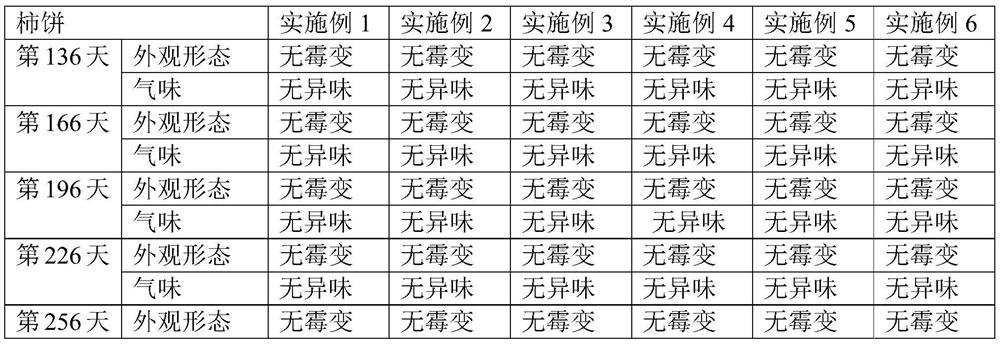

A kind of persimmon cake processing method

ActiveCN108713706BReduce adhesionGuaranteed respirationFruits/vegetable preservation by coatingRipeningProcess engineering

The invention discloses a persimmon processing method. The persimmons are air-dried, peeled, kneaded and decolorized, and then ripened for the first time, softened for the first time, ripened for the second time, softened for the second time, and finally stored for frosting to obtain the dried persimmons. In this method, konjac glucomannan solutions with different mass contents are used to dip-coat persimmon pulp in the peeling, ripening and frosting stages of persimmon processing, and the film-forming and antibacterial properties of konjac glucomannan solution are used to combine two steps at the same time. The high-temperature short-time treatment method and medium-temperature baking accelerate the deastringency and ripening of persimmon pulp, promote the formation of persimmon frost, improve the quality and flavor of persimmon, prolong the shelf life of persimmon, and realize the clean production of persimmon; The process of the method is reasonable, each process index is complete and feasible, and is suitable for industrial production.

Owner:陕西怡萱农业科技有限公司

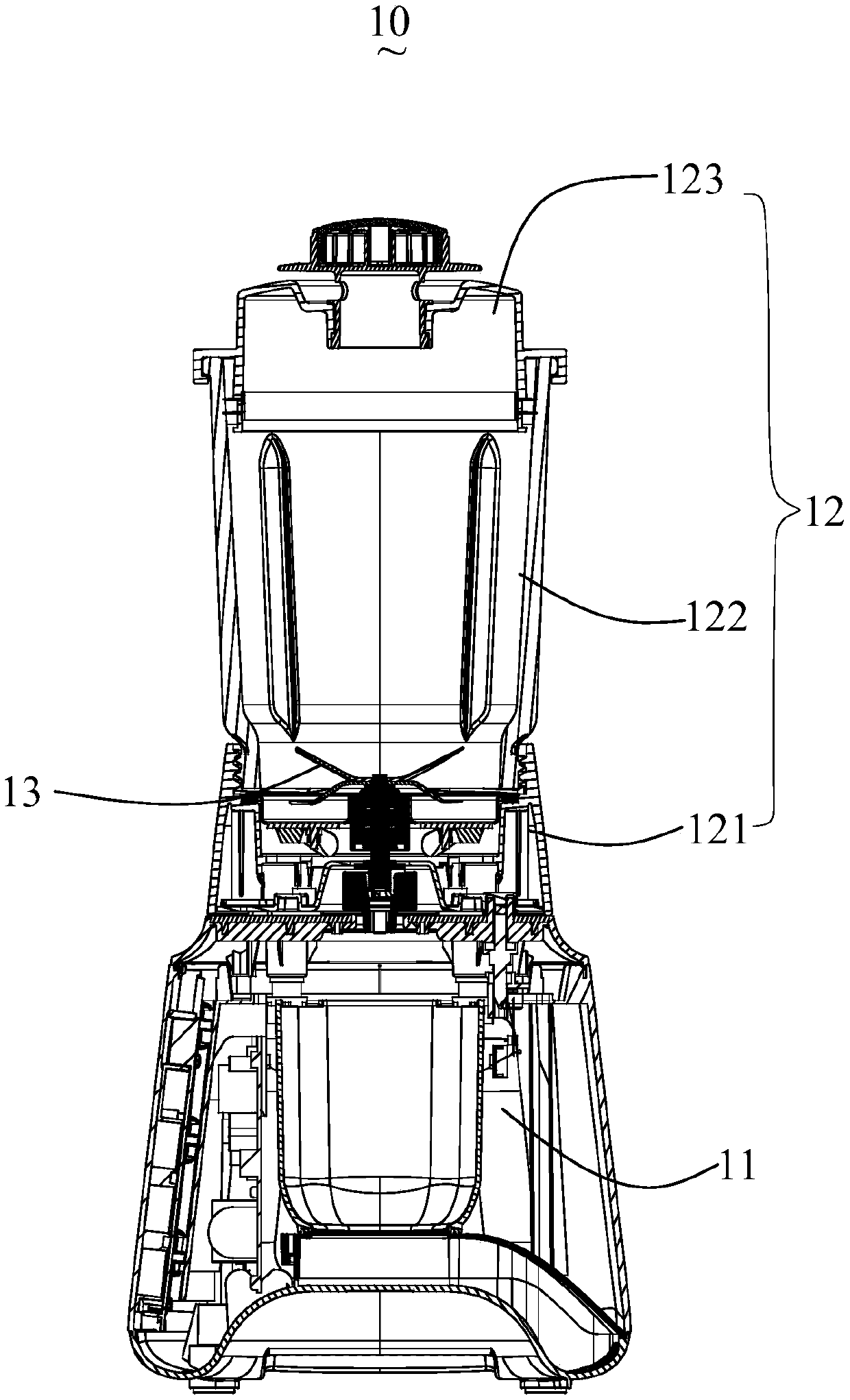

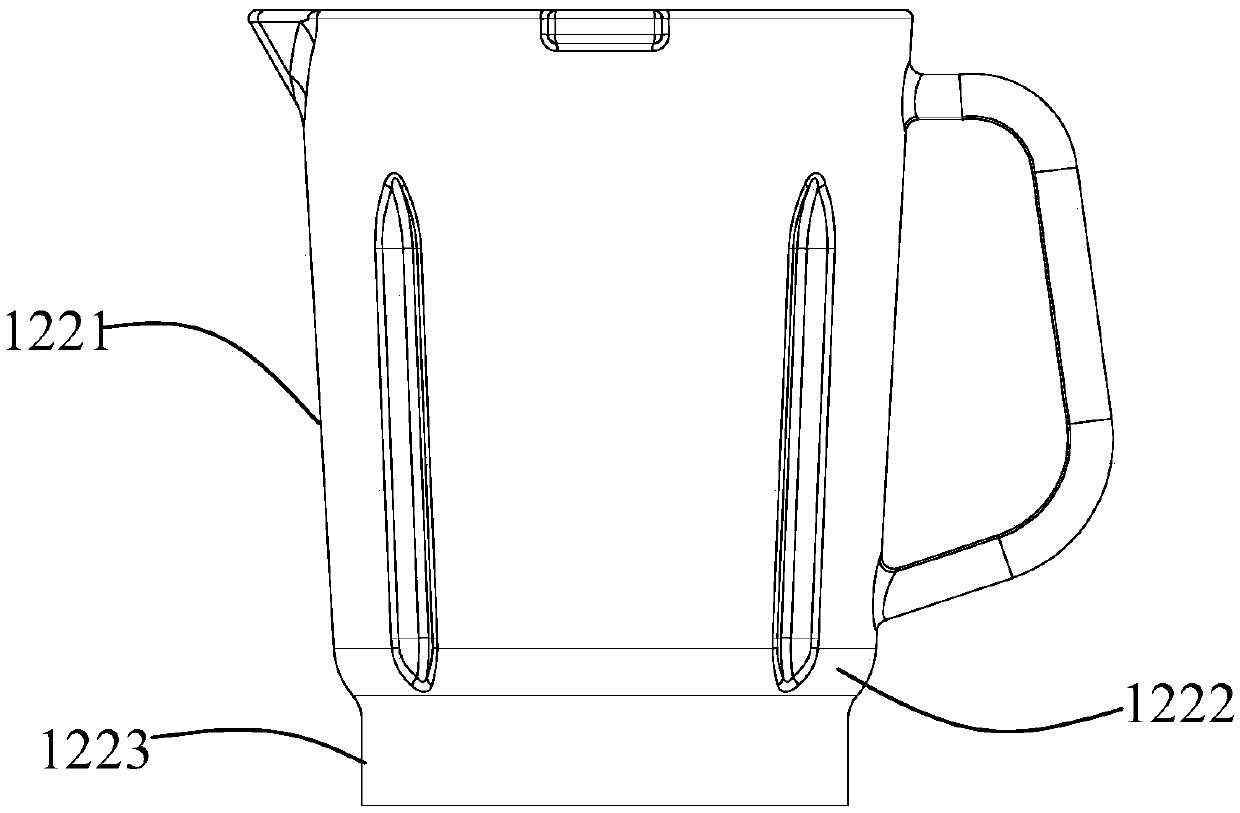

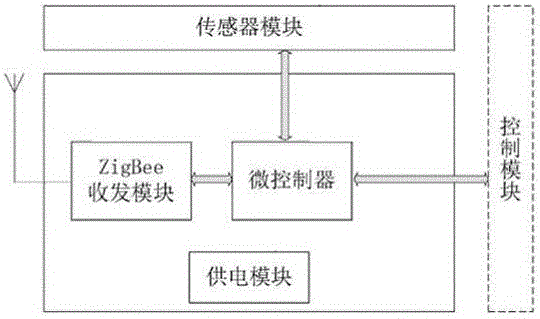

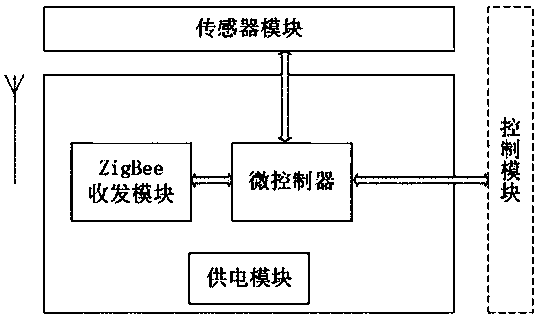

Food processor

ActiveCN111358313AGuaranteed StrengthExtended service lifeKitchen equipmentElectric machineryEngineering

The invention relates to a food processor including a main machine, a motor arranged in the main machine, a stirring cup arranged above the main machine, and a crushing knife arranged in the stirringcup; the crushing knife is connected with a motor shaft of the motor through a connector; the stirring cup comprises a cup base, a glass cup body and a cup cover. The cup cover covers an upper openingof the glass cup body; the cup base is mounted at a lower opening of the cup body, the glass cup body comprises a heat gathering section with the wall thickness larger than that of other positions, the ratio of the wall thickness of the heat gathering section to the wall thickness of the upper opening ranges from 1.1 to 1.5, and the highest position of the crushing knife is located below the highest position of the heat gathering section. Compared with the prior art, the glass cup body is light, the crushing strength of the glass cup body can be met, the service life of the glass cup body isprolonged, and user operation is facilitated.

Owner:JOYOUNG CO LTD

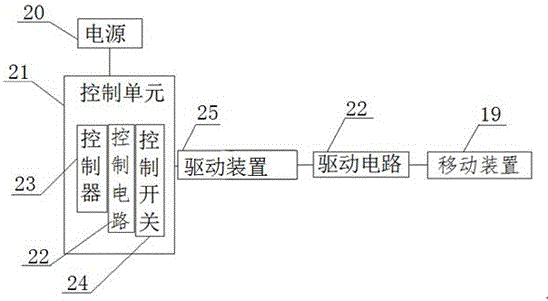

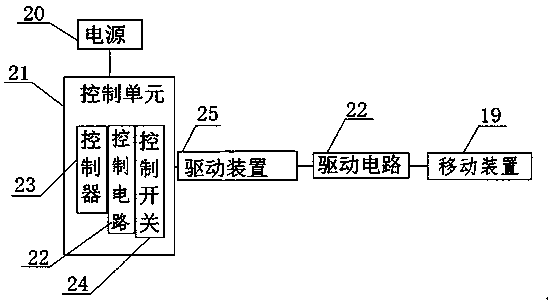

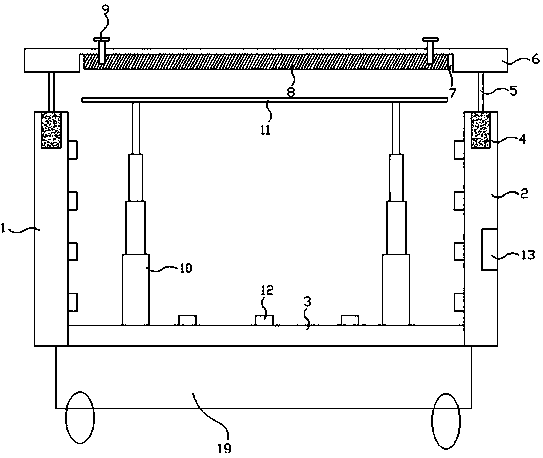

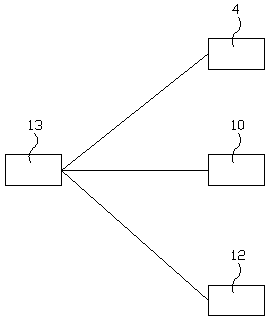

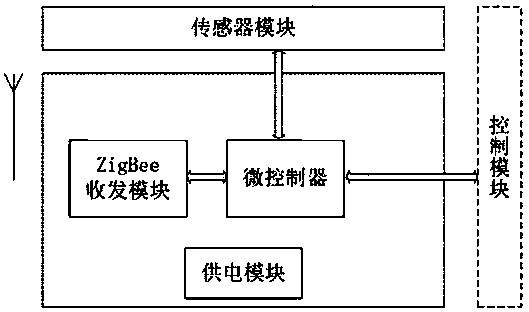

Mobile automatic pitch heating device

The invention discloses a mobile automatic pitch heating device which comprises a first support plate and a second support plate, wherein a hydraulic cylinder is arranged in one end of each of the first support plate and the second support plate; a hydraulic strut is arranged at one end of each hydraulic cylinder; a mounting plate is arranged at one end of each hydraulic strut; a mounting groove is formed on one side of each mounting plate; each mounting groove is internally provided with a template; a bottom plate is arranged between one end of the first support plate and one end of the second support plate; an electric expansion rod is arranged on one side of the bottom plate; a support plate is arranged at one end of the electric expansion rod; a plurality of heaters are arranged on one side of each of the first support plate, the second support plate and the bottom plate; and a controller is arranged on the other side of the second support plate. According to the device, the heaters can heat pitch on the support plates, the device increases a softening degree, accelerates softening of the pitch, brings convenience to pitch processing and improves processing efficiency of the pitch.

Owner:振林建设集团股份有限公司

A traditional Chinese medicine infiltration device

ActiveCN104857740BTo achieve the infiltration effectImprove wettabilitySolid solvent extractionMedicinal herbsEngineering

Owner:JIANGSU HUATAI HEAVY IND EQUIP

Manufacturing method of yellow compressed tea and yellow compressed tea prepared by same

InactiveCN105230824AGood qualityIncrease the degree of softeningPre-extraction tea treatmentComposite materialTea leaf

The invention discloses a manufacturing method of yellow compressed tea and yellow compressed tea prepared by the same. The manufacturing method comprises the following steps: (1) wetting and softening loose yellow tea; (2) transferring the wetted and softened loose yellow tea into a mould press, and pressing loose yellow tea into moulds with a predetermined shape so as to obtain handicrafts of yellow compressed tea; (3) drying the obtained handicrafts of yellow compressed tea. The technology is characterized in that in the wetting and softening step, the loose yellow tea is wetted and softened by high temperature steam until the yellow tea becomes soft and is not broken after being bended. The moulds in the mould press can give off heat. A heating device is horizontally or vertically arranged on the external surface of the mould, or is arranged on the internal wall of the mould.

Owner:吴旺华

A mobile asphalt automatic heating device

The invention discloses a mobile automatic pitch heating device which comprises a first support plate and a second support plate, wherein a hydraulic cylinder is arranged in one end of each of the first support plate and the second support plate; a hydraulic strut is arranged at one end of each hydraulic cylinder; a mounting plate is arranged at one end of each hydraulic strut; a mounting groove is formed on one side of each mounting plate; each mounting groove is internally provided with a template; a bottom plate is arranged between one end of the first support plate and one end of the second support plate; an electric expansion rod is arranged on one side of the bottom plate; a support plate is arranged at one end of the electric expansion rod; a plurality of heaters are arranged on one side of each of the first support plate, the second support plate and the bottom plate; and a controller is arranged on the other side of the second support plate. According to the device, the heaters can heat pitch on the support plates, the device increases a softening degree, accelerates softening of the pitch, brings convenience to pitch processing and improves processing efficiency of the pitch.

Owner:振林建设集团股份有限公司

An environmentally friendly mobile asphalt automatic heating device

ActiveCN106094929BEasy to useIncrease the degree of softeningTemperatue controlHydraulic cylinderEngineering

The invention discloses an environment protection-type movable asphalt automatic heating device, which comprises a first supporting plate and a second supporting plate, wherein one end of the first supporting plate and one end of the second supporting plate are internally provided with hydraulic cylinders; one end of each hydraulic cylinder is provided with a hydraulic support rod; one end of the hydraulic support rod is provided with a mounting plate; one side of the mounting plate is provided with a mounting groove; the mounting groove is internally provided with a template; a bottom plate is arranged between one end of the first supporting plate and one end of the second supporting plate; one side of the bottom plate is provided with an electric telescopic rod; one end of the electric telescopic rod is provided with a supporting plate; one side of the first supporting plate, one side of the second supporting plate and one side of the bottom plate are all provided with a plurality of heaters; and the other side of the second supporting plate is provided with a controller. Asphalt on the supporting plate is heated via the heaters, the softening degree is improved, the asphalt softening efficiency is quickened, convenience is brought to processing of the asphalt, and the asphalt processing efficiency is improved.

Owner:吉林省博远环保科技有限公司

Sand control method and sand control material for artificial well wall

ActiveCN107163926BImprove salt toleranceReduce interfacial tensionFluid removalDrilling compositionActive agentAlkylphenol

The invention discloses a sand-preventing method of an artificial borehole wall, and a material for sand prevention. The material for sand prevention comprises guide liquid, sand carrying liquid and promoting liquid which are prepared separately, wherein the guide liquid comprises the following components in percentage by weight: 0.5 to 20 percent of sodium chloride, 0.2 to 2 percent of calcium chloride, 0.1 to 1 percent of magnesium chloride, 0.2 to 4 percent of alkylphenol polyoxyethylene, 0.3 to 8 percent of an anionic surfactant capable of resisting calcium and magnesium ions and 0.01 to 6 percent of a dimethyl diallyl ammonium chloride-acrylamide-acrylic acid copolymer; the sand carrying liquid comprises the following components in percentage by weight: 0.01 to 5 percent of a dimethyl diallyl ammonium chloride-acrylamide copolymer and 0.5 to 20 percent of ammonium chloride; and the promoting liquid comprises the following components in percentage by weight: 8 to 22 percent of a penetrating agent and 18 to 35 percent of a dehydroxylation catalyst. The material for sand prevention performs sand prevention, can protect the stratum, has high sand carrying capability, reduces friction and enhances the consolidation strength, and the penetration ratio of the artificial borehole wall formed after sand prevention is more than 12 <mu>m<2>.

Owner:东营市科诺石油技术有限责任公司

Environment-friendly lift type asphalt automatic heating device

InactiveCN106192675AEasy to useHeight adjustableRoads maintainenceHydraulic cylinderControl engineering

The invention discloses an environment-friendly lift type asphalt automatic heating device. The environment-friendly lift type asphalt automatic heating device comprises a first supporting plate and a second supporting plate. One end of the first supporting plate and one end of the second supporting plate are each internally provided with a hydraulic cylinder, and one end of each hydraulic cylinder is provided with a hydraulic supporting rod. A mounting plate is arranged at one ends of the hydraulic supporting rods. A mounting groove is formed in one side of the mounting plate. A template is arranged in the mounting groove. A bottom plate is arranged between one end of the first supporting plate and one end of the second supporting plate. Electric telescopic rods are arranged on one side of the bottom plate. A supporting plate is arranged at one ends of the electric telescopic rods. One side of the first supporting plate, one side of the second supporting plate and one side of the bottom plate are each provided with a plurality of heaters. A controller is arranged on the other side of the second supporting plate. According to the environment-friendly lift type asphalt automatic heating device, heaters can be used for heating asphalt on the supporting plate, the softening degree is improved, the efficiency of printing patterns through asphalt is improved, convenience is brought for asphalt machining, and the asphalt machining efficiency is improved.

Owner:LIUZHOU SHOUGUANG TECH

A kind of preparation method of silk quilt

ActiveCN112401598BIncrease productivityExcellent and stable qualityBiochemical fibre treatmentBlanketPolymer scienceEngineering

The invention relates to the technical field of home textiles, in particular to a method for preparing a silk quilt. The preparation method of the silk quilt of the present invention comprises the following steps: (1) preparation of silk, (2) refining, (3) rinsing, (4) modification, (5) drying and (6) preparation of silk quilt. The silk quilt prepared by the method of the present invention has high production efficiency, excellent and stable quality, safe operation process, easy operation, and resource saving. Compared with the traditional preparation process, the preparation process time is shortened and the production cost is reduced. Silk has a pleasant fragrance, good bulkiness and tension, and good whiteness. It also has health functions such as antibacterial, anti-mite, and insect-proof.

Owner:广西农投时宜农业科技有限公司 +2

Liftable automatic asphalt heating device

The invention discloses a liftable automatic asphalt heating device. The liftable automatic asphalt heating device comprises a first supporting plate and a second supporting plate, wherein a hydraulic cylinder is arranged inside one end of each of the first supporting plate and the second supporting plate, and a hydraulic supporting rod is arranged at one end of each hydraulic cylinder; a mounting plate is arranged at one ends of the hydraulic supporting rods; a mounting groove is formed in one side of the mounting plate; a moulding plate is arranged inside the mounting groove; a bottom plate is arranged between one end of the first supporting plate and one end of the second supporting plate; electric telescopic rods are arranged on one side of the bottom plate, and a supporting plate is arranged at one ends of the electric telescopic rods; a plurality of heaters are arranged on one side of each of the first supporting plate, the second supporting plate and the bottom plate; a controller is arranged on the other side of the second supporting plate. The liftable automatic asphalt heating device can heat asphalt on the supporting plate through the heaters to enhance the softening degree of the asphalt, so that the efficiency for printing a pattern by using the asphalt is improved; and the liftable automatic asphalt heating device brings convenience to asphalt processing and improves the asphalt processing efficiency.

Owner:LIUZHOU SHOUGUANG TECH

Heat-assisted milling device

PendingCN113333840AReduce lossesIncrease the degree of softeningMilling equipment detailsMetal working apparatusTool bitMilling cutter

The invention discloses a heat-assisted milling device, and relates to the technical field of machining equipment. The heat-assisted milling device comprises a milling cutter and a heating device, wherein the heating device is connected to a cutter handle of the milling cutter, and the heating device is used for heating a workpiece. The distance between a heating area formed on the workpiece by the heating end of the heating device and a machining area formed on the workpiece by the cutter bit of the milling cutter of the machine tool is 0.05-10 mm. Compared with a traditional heat-assisted milling machine tool, the heat-assisted milling device has the advantages that the time difference between a heating procedure and a milling procedure at the same position of the workpiece is shortened, so that the heat loss between the two procedures is reduced, the utilization efficiency of a heat source is improved, the softening degree of the machining area part of the workpiece is enhanced, and the machining quality is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com