Patents

Literature

640results about "Radiation/waves wood treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

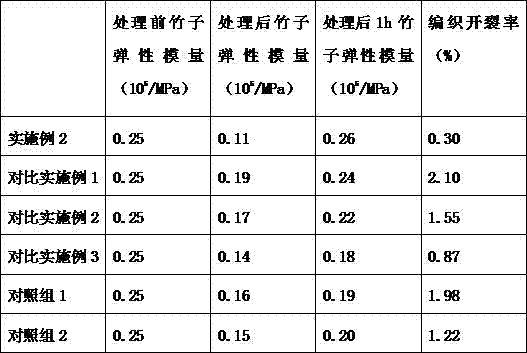

Bamboo softening and modifying technology

ActiveCN104626309AStrengthen the anti-mildew and anti-moth effectPrevent surface discolorationRadiation/waves wood treatmentWood treatment detailsMicrowave ovenEngineering

Owner:福建省奥农竹业开发有限公司

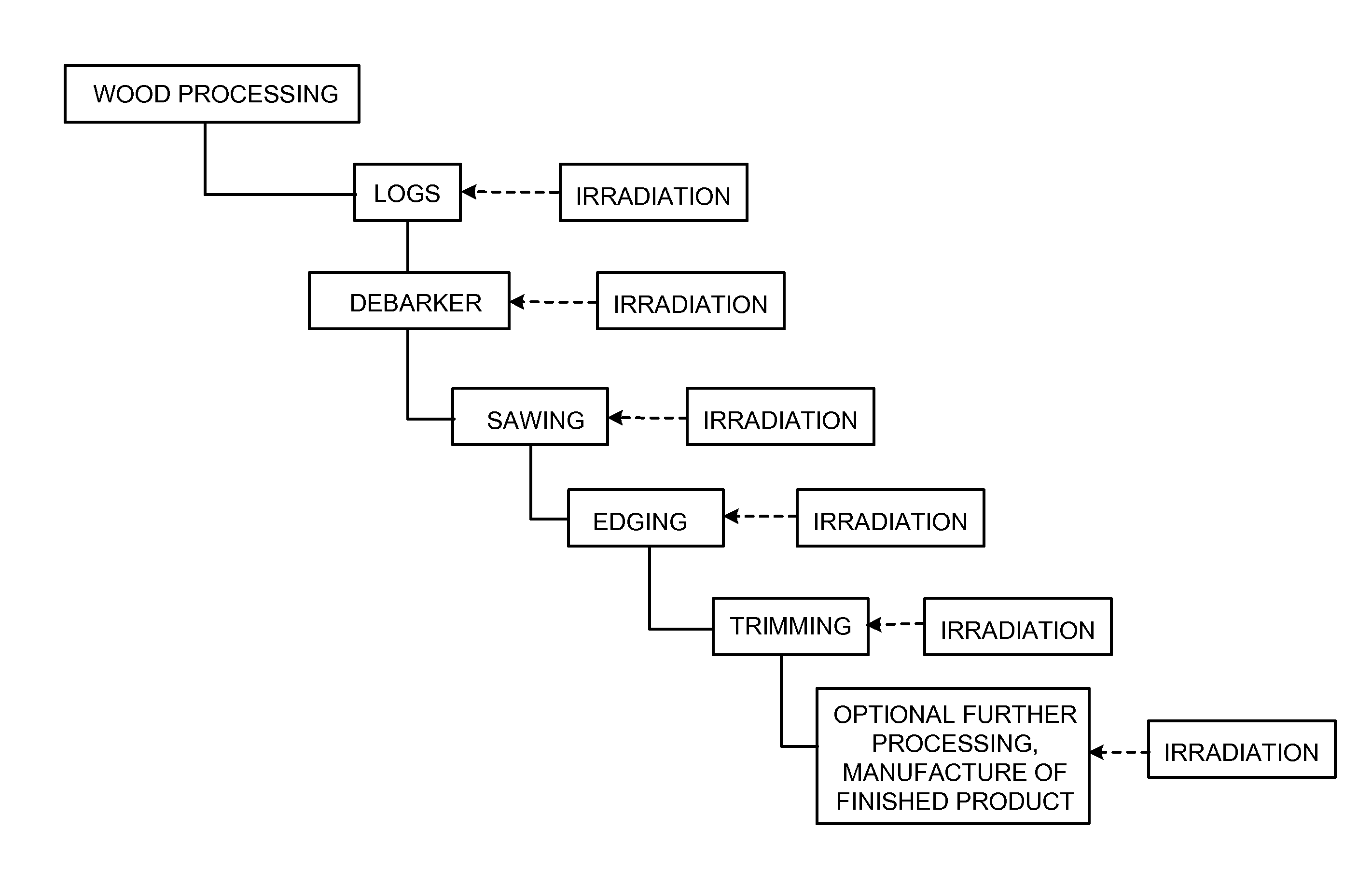

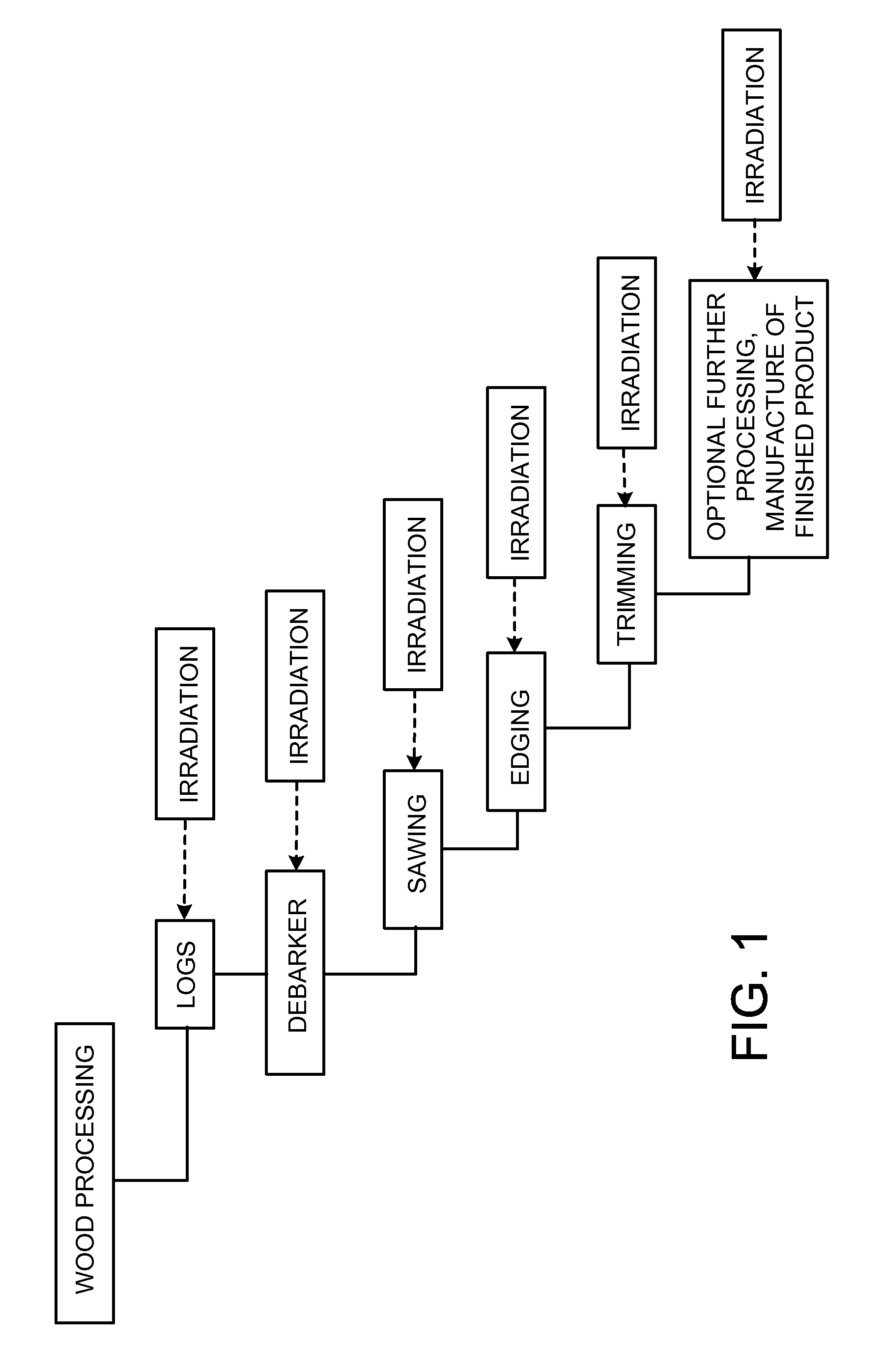

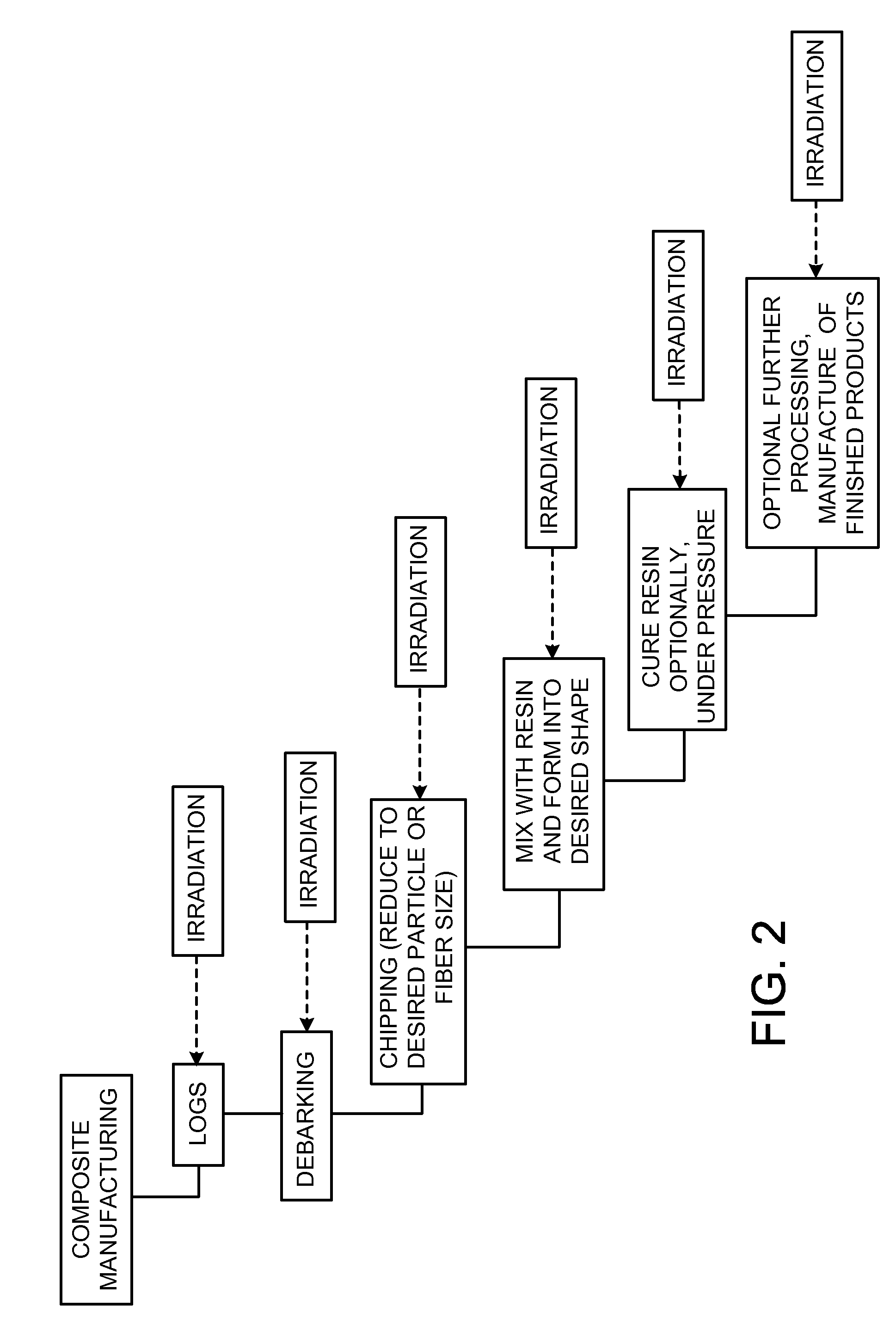

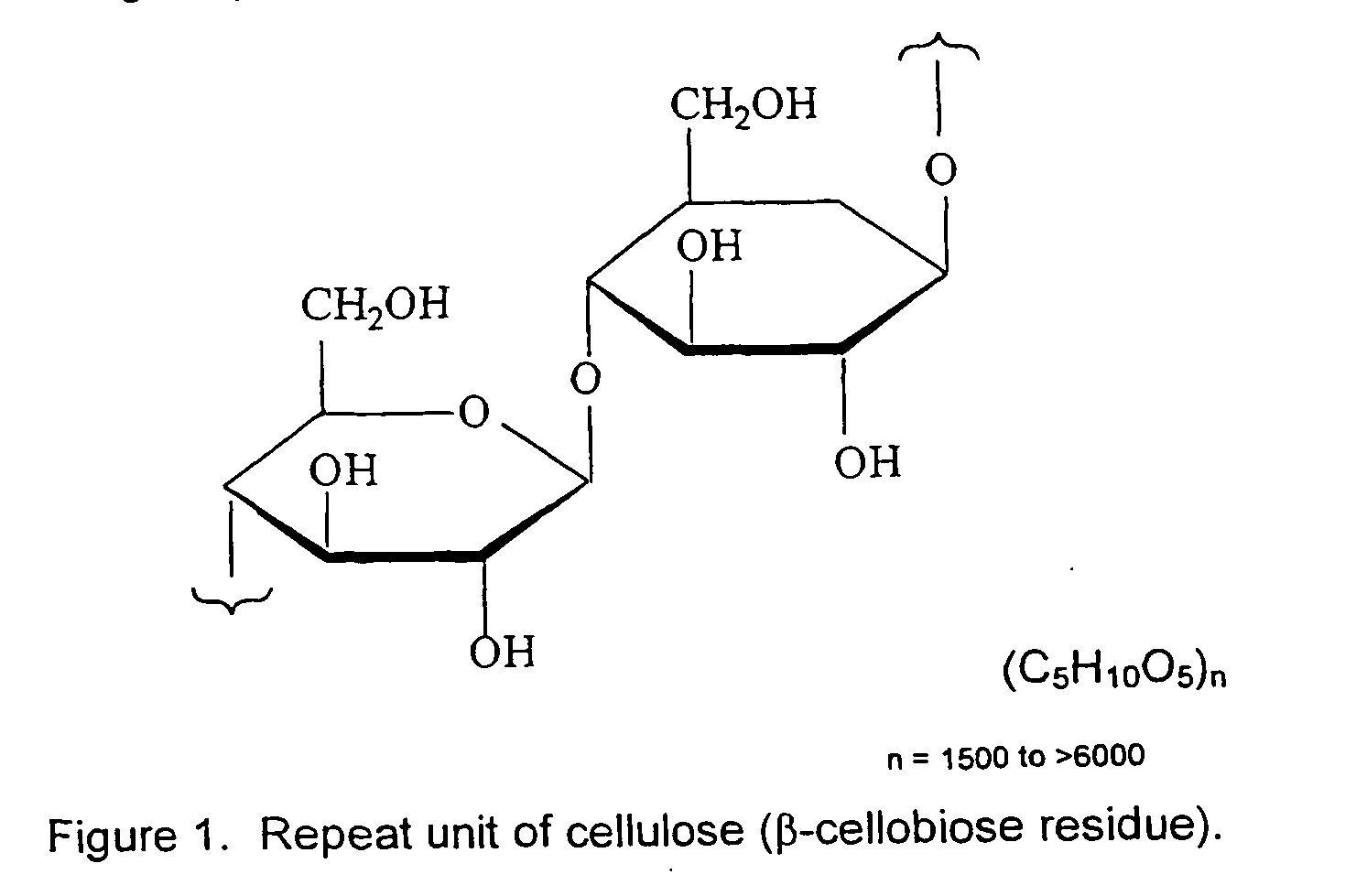

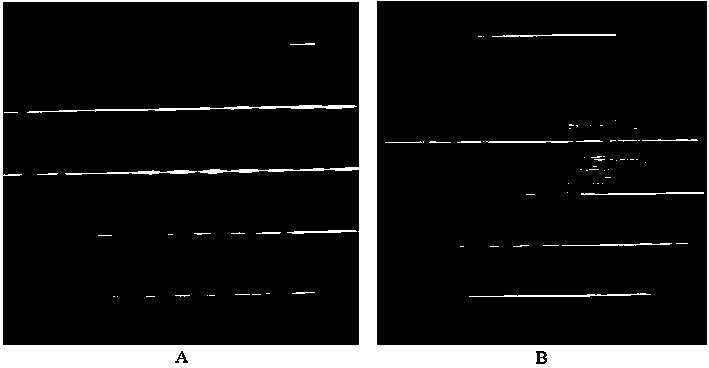

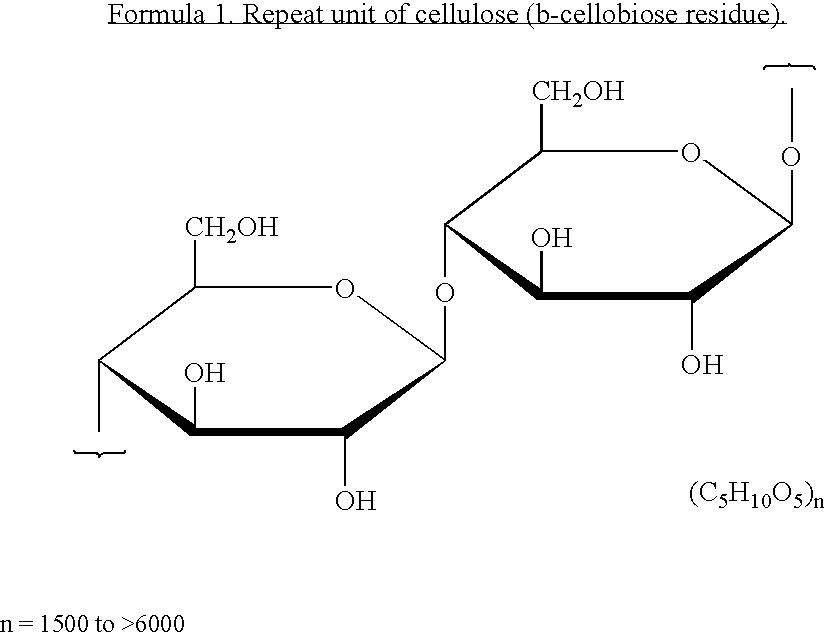

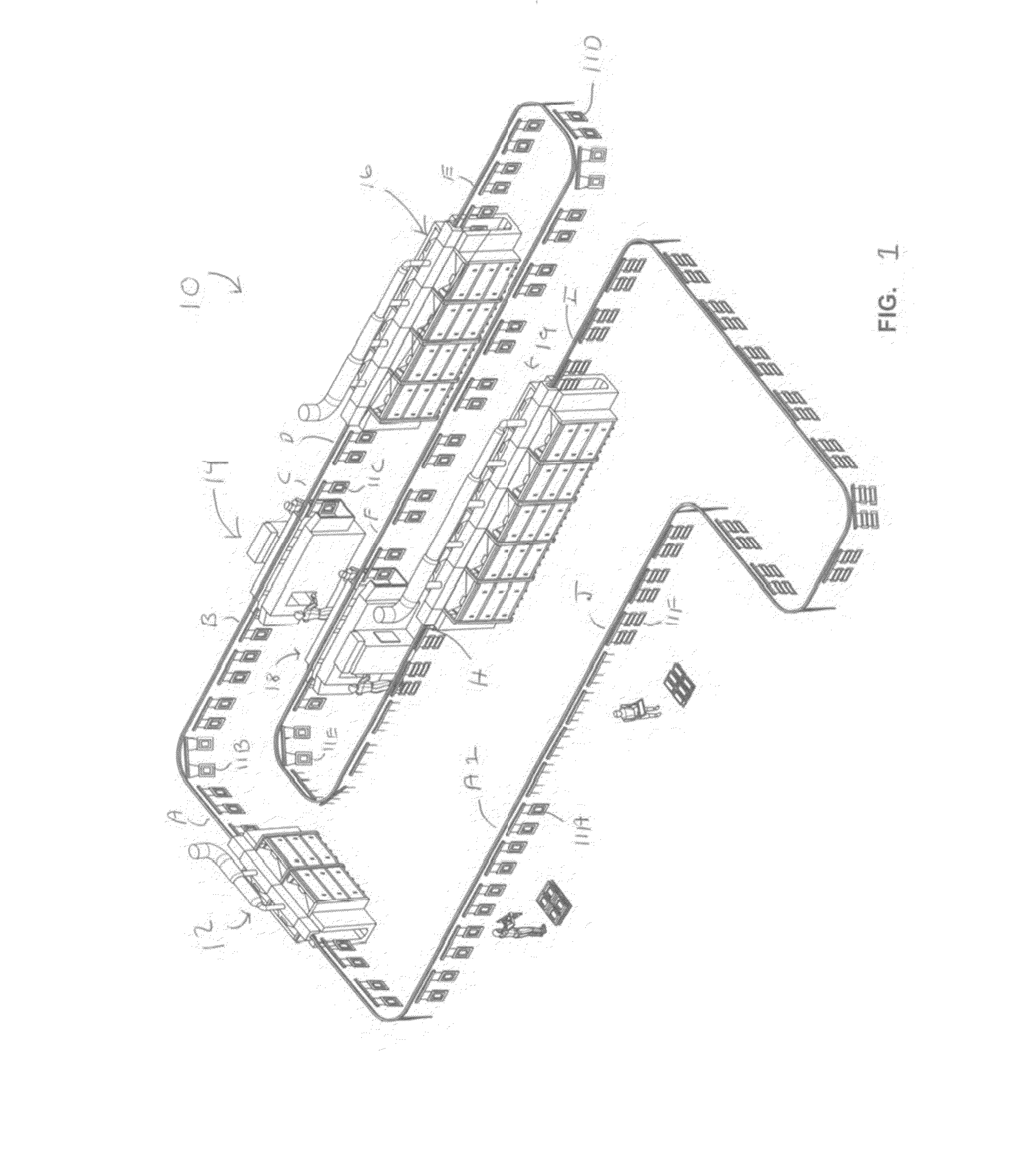

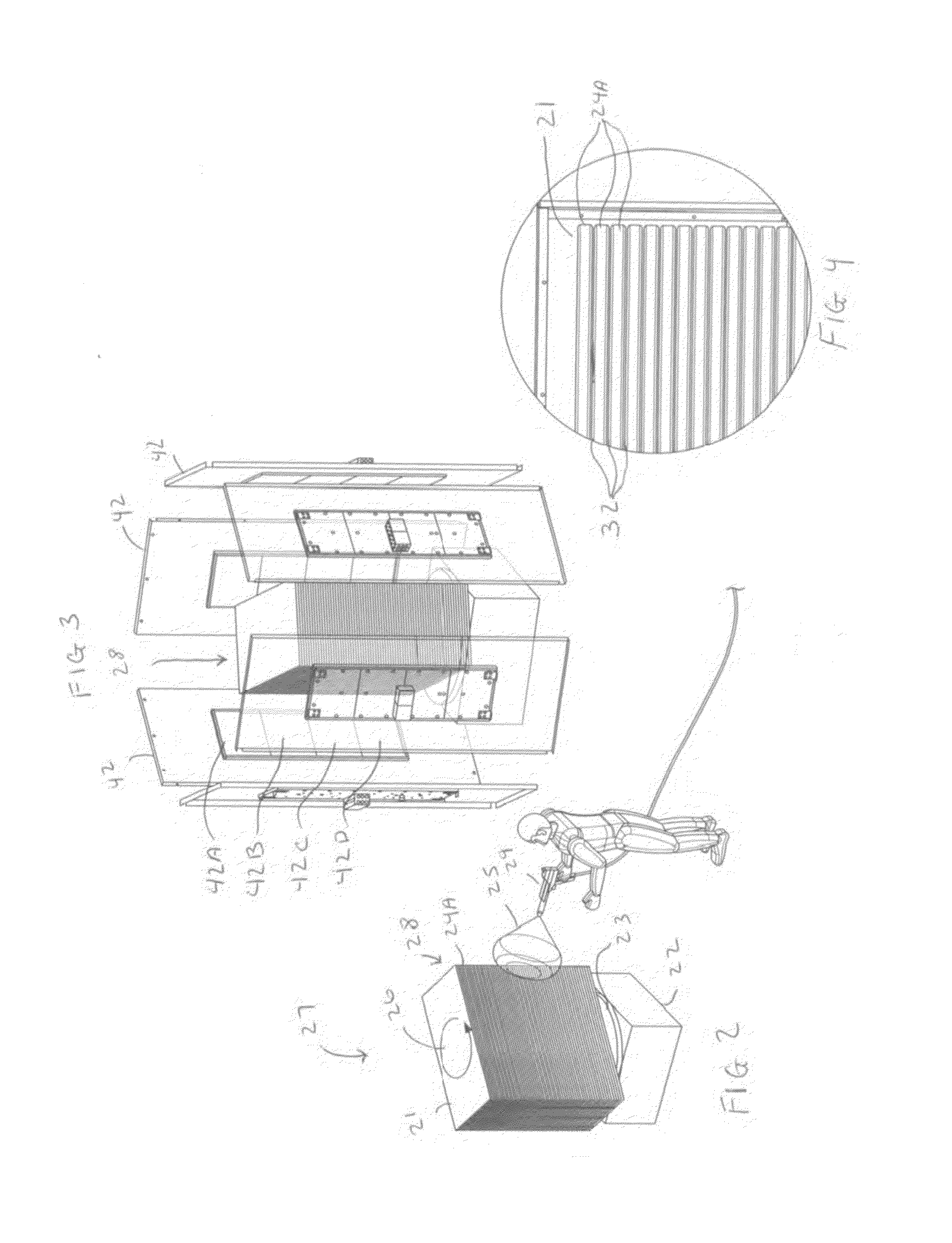

Cellulosic and lignocellulosic structural materials and methods and systems for manufacturing such materials

ActiveUS20120074337A1Raise the ratioImprove the level ofCellulosic pulp after-treatmentRadiation/waves wood treatmentCelluloseStructural material

Methods of treating wood and wood products include irradiating untreated wood having a first molecular weight with ionizing radiation to cause an increase in the molecular weight of a cellulosic component of the wood to a second, relatively higher molecular weight.

Owner:XYLECO INC

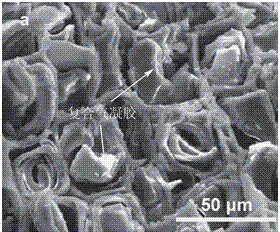

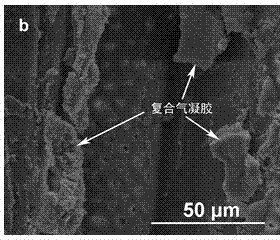

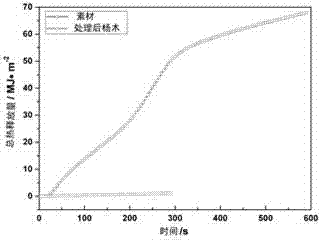

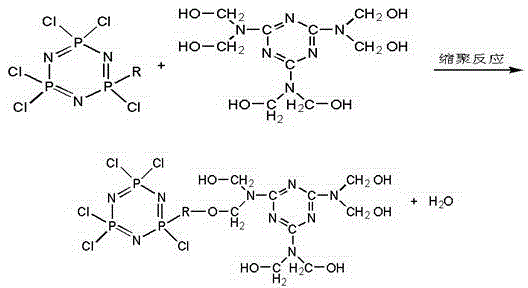

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

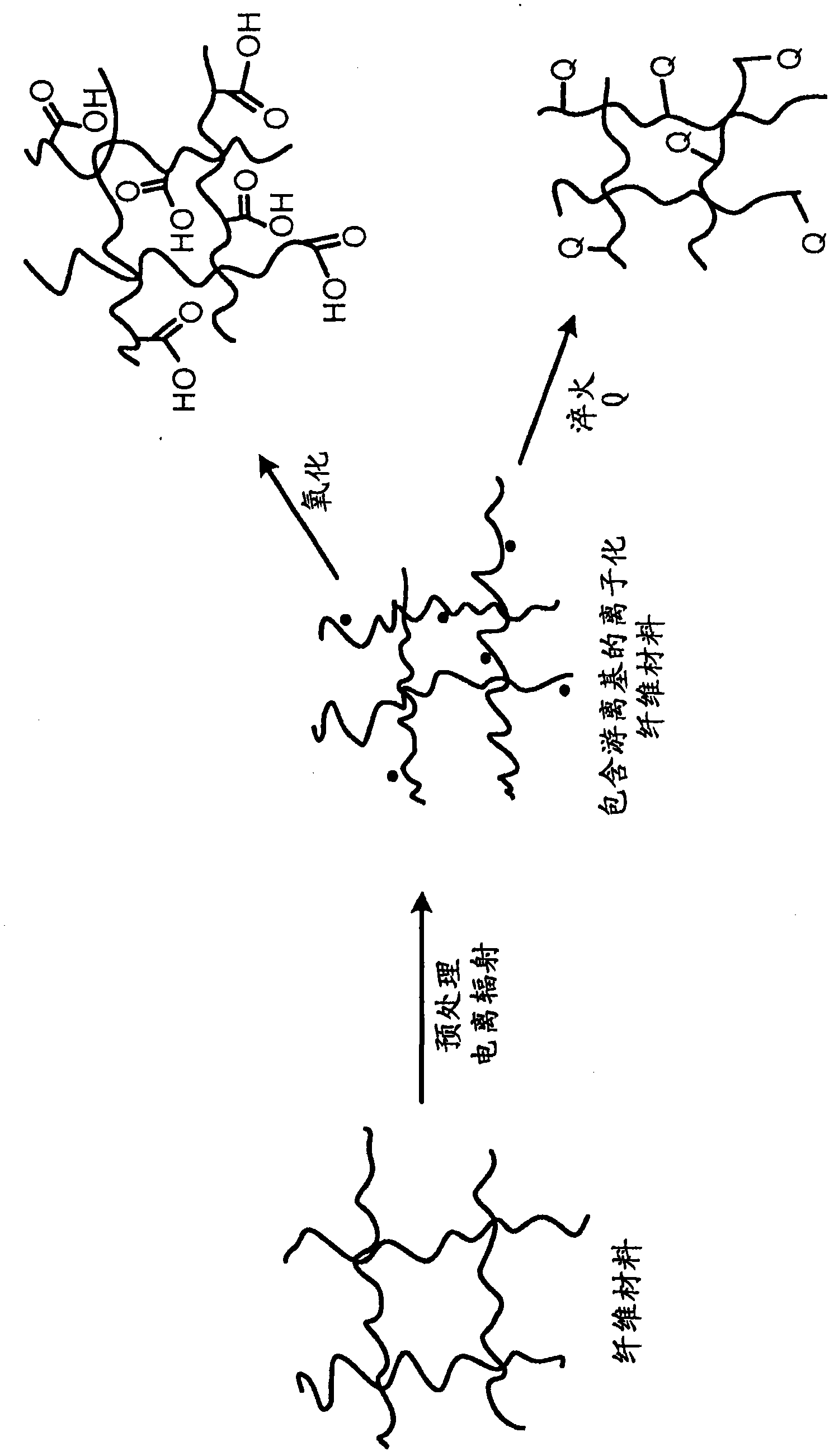

Treatment of natural polymer based materials and the products based thereon

InactiveUS20050048207A1Enhanced interactionLower extractable contentRadiation/waves wood treatmentNon-macromolecular organic additionSimple Organic CompoundsAfter treatment

A method for modifying a substrate containing a natural polymeric material to improve its interaction with other materials, the method comprising: A) Treating the substrate containing the natural polymeric material with a modifying agent selected from the group consisting of organo-functional coupling agents and multi-functional amine containing organic compounds; and B) optionally exposing the substrate containing natural polymeric material with one or more treatments selected from the group consisting of: i) subjecting the substrate to extraction with a solvent to reduce the content of extractable materials associated with the natural polymeric material prior to or during treatment with the modifying agent; ii) treatment with a physical field selected from static physical fields, high-frequency alternating physical fields and combinations of two or more thereof either prior to, during or after treatment with the modifying agent; and iii) oxidation of at least part of the natural polymeric material prior to or during treatment with the modifying agent.

Owner:COMMONWEALTH SCI & IND RES ORG

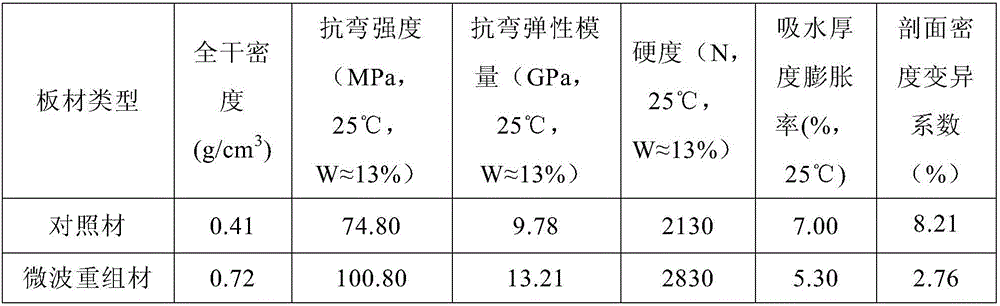

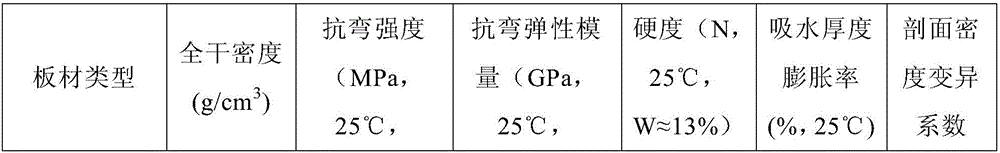

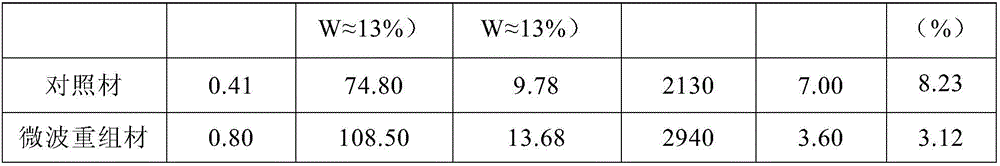

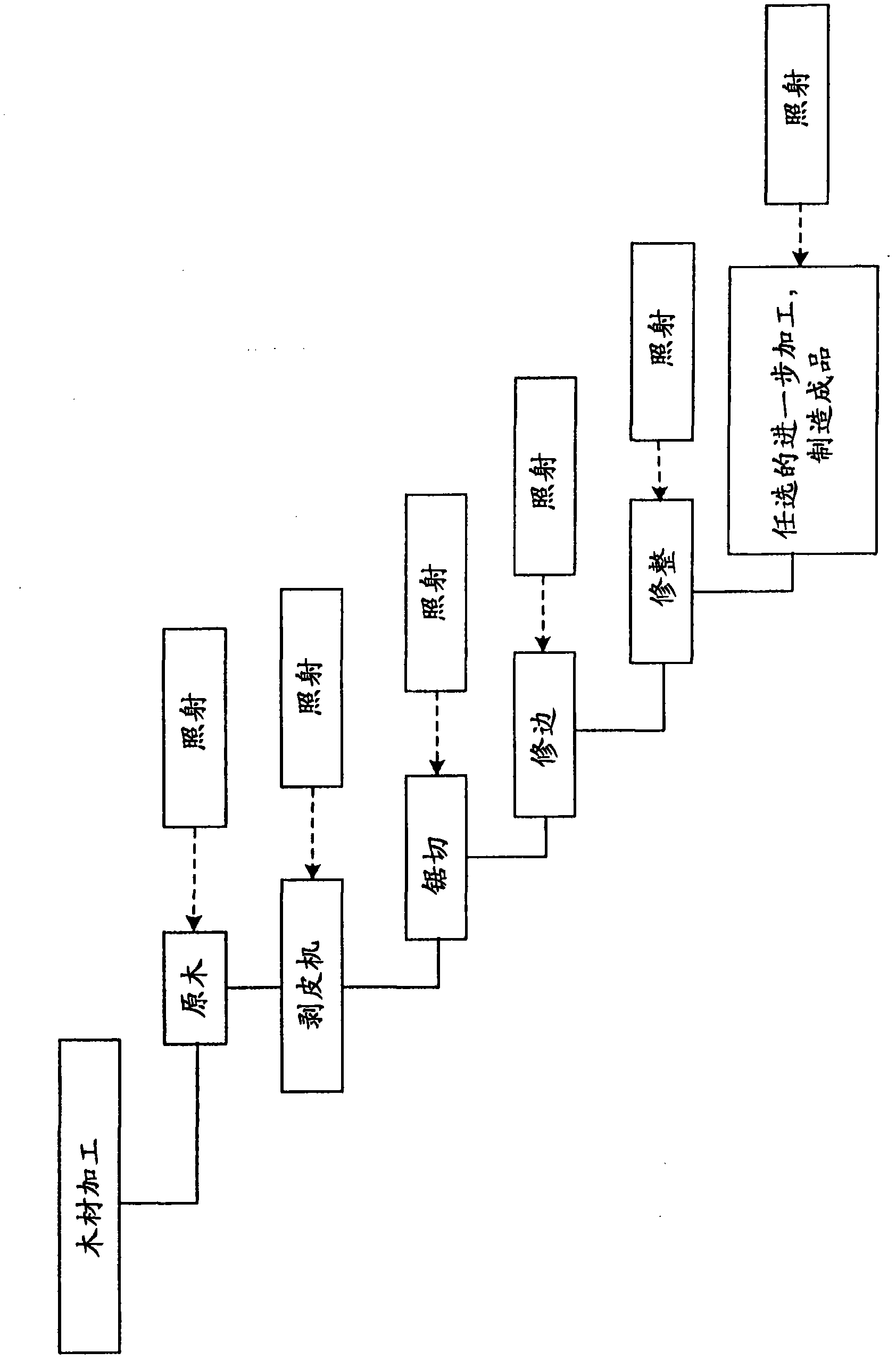

Microwave treatment reconstructed material and preparing methods thereof

InactiveCN105965638AImprove permeabilityEase of industrial productionRadiation/waves wood treatmentWood treatment detailsMicrowaveVolumetric Mass Density

The invention discloses a microwave treatment reconstructed material and preparing methods thereof. A raw material of the microwave treatment reconstructed material comprises sawn timber. The microwave treatment reconstructed material is obtained through the sawn timber via the preparing method 1 or the preparing method 2. According to the preparing method 1, the sawn timber is subjected to high-strength microwave treatment firstly, and then direct hot press is conducted. According to the preparing method 2, the sawn timber is subjected to high-strength microwave treatment firstly, then the sawn timber is immersed in a resin-based bonding agent or a biology-based bonding agent, and then the microwave treatment reconstructed material is formed through hot press or cold press. According to the microwave treatment reconstructed material and the preparing methods thereof, the problems that the density of the timber is not even, the mechanical performance is not high, the size stability of the immersed reconstructed material is poor, the immersing depth is not enough, and uniformity is poor are solved. The microwave treatment reconstructed material prepared through the methods can be used in the furniture field, the indoor decoration field and the wood structure building field.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

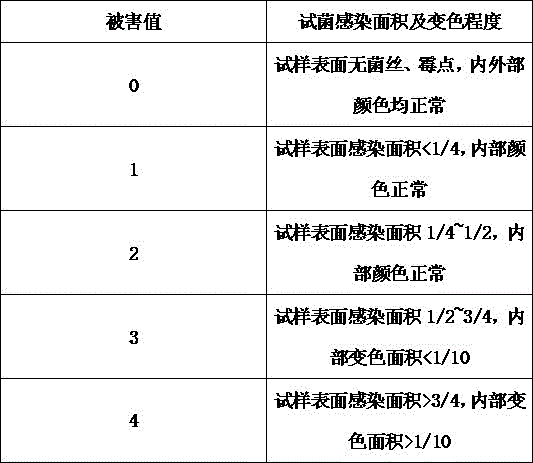

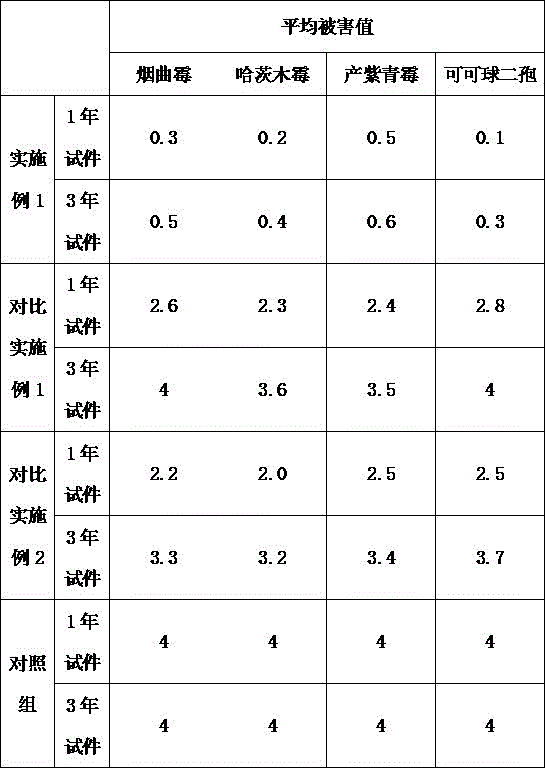

Mildew and worm preventive treatment method for wicker

InactiveCN106182271AHigh content of active ingredientsImprove mildew resistanceRadiation/waves wood treatmentPressure wood treatmentMedicineMildew

The invention discloses a wicker anti-mold and insect-proof treatment method, comprising the following steps: (1) raw material treatment, (2) air-drying treatment, (3) bacterial liquid treatment, (4) water steaming treatment, (5) drying treatment, (6) Anti-mold and insect-proof treatment, (7) Secondary drying treatment. The mildew-proof and insect-proof properties of the treated wicker in the invention are well improved, no mold and insect-eaten phenomena will occur within 12 years under normal use conditions, and the wicker has good moisture-proof, crack-proof and wear-resistant properties.

Owner:阜南县永盛工艺品有限公司

Cellulosic and lignocellulosic structural materials and methods and systems for manufacturing such materials

Methods of treating wood and wood products include irradiating untreated wood having a first molecular weight with ionizing radiation to cause an increase in the molecular weight of a cellulosic component of the wood to a second, relatively higher molecular weight.

Owner:XYLECO INC

Methods of conferring fire retardancy to wood and fire-retardant wood products

ActiveUS20150352744A1Radiation/waves wood treatmentVacuum evaporation coatingFire retardantEngineered wood

A process is provided for treating wood products including lumber, plywood and other engineered wood products comprising the steps of applying an aqueous fire-retardant impregnate and applying a coating to the surface of the wood product. In one embodiment, said process confers fire-retardant properties to the wood products sufficient to pass the extended burn test of ASTM E-84. The present invention also provides fire retardant wood products.

Owner:KOPPERS PERFORMANCE CHEM

Manufacturing method of solid wood furniture bent parts

InactiveCN105599096ASolve the technical problems of large amount of sewage and long softening cycleImprove bending qualityRadiation/waves wood treatmentWood treatment detailsSolid woodProcess engineering

The invention provides a manufacturing method of solid wood furniture bent parts. The method includes the following steps that firstly, material varieties are selected, and raw materials are machined; secondly, microwave heating softening treatment is performed; thirdly, bending and forming are performed; fourthly, drying and shaping are performed; fifthly, cooling is performed. The manufacturing method can replace a common cooking softening technology and a kiln drying shaping technology, production technology time is shortened, and production efficiency is improved; the springback rate of bend wood is reduced through a microwave heating softening method, and the bending quality of manufactured products is improved; no waste liquid is generated in the production process, and environmental friendliness is facilitated in the production process; the production period is short, production cost is low, and economic benefits can be increased easily.

Owner:中山市大涌镇生产力促进中心

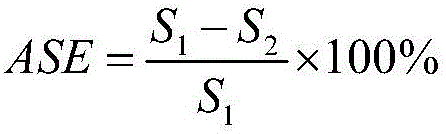

Processing method for improving mould prevention and moth prevention of bamboos

InactiveCN107351206AImprove crack resistanceImprove performance such as insect resistanceRadiation/waves wood treatmentWood treatment detailsMicrowaveHeat treated

The invention discloses a processing method for improving mould prevention and moth prevention of bamboos. The processing method is characterized by comprising the following steps: (S1) the bamboos are sectioned to obtain bamboo blanks; and the bamboo blanks are put in lime water for dipping, are taken out for cleaning, and are aired; (S2) the materials obtained in the step (S1) are processed by microwaves; (S3) the materials obtained in the step (S2) are put in mould prevention and moth prevention liquid for dipping, and are taken out for drying to obtain materials A; and (S4) the materials A are heated, cleaned and aired. In the processing method for improving mould prevention and moth prevention of the bamboos, through optimization of the processing process, the treated bamboos achieve excellent mould prevention, damp prevention and moth prevention effects, and are excellent in size stability and durability; the appearance of bamboo products can be effectively improved; and the service life of the bamboo products is prolonged.

Owner:宿松县先盛竹业有限公司

Softening method for osier wood

InactiveCN106272811AGood softening effectFeatures have little effectRadiation/waves wood treatmentWood treatment detailsMicrowaveEngineering

The invention discloses a softening method for osier wood, and belongs to the technical field of osier processing. The softening method specifically comprises the following steps of (1) pretreatment of osier; (2) steam explosion treatment; (3) immersing and drying treatment; (4) microwave treatment; and (5) drying and weaving. By adoption of the softening method for the osier wood, a remarkable softening effect on the osier wood is achieved, and the weaving time can be shortened by 30-50%; in addition, the softening method has little influence on the original characteristics of the osier wood, the cracking rate in softening treatment and the cracking rate in weaving processing are decreased by 15-20% and 20-30% correspondingly compared with existing methods; and the finally treated osier wood is good in strength and stability, excellent in corrosion resistance and worm prevention and not prone to being roughed when used, and better use value is achieved.

Owner:阜南县环宇柳木工艺制品有限公司

Preparation method of antibacterial mould-proof plywood for decoration

ActiveCN107351197AInhibit residual mold activityGood flexibilityRadiation/waves wood treatmentNon-macromolecular adhesive additivesCelluloseHuman health

The invention mainly relates to the technical field of machining of artificial boards, and discloses a preparation method of antibacterial mould-proof plywood for decoration. The preparation method comprises drying, dipping, freezing, gluing, hot pressing and arrangement; the method is simple, safe and nontoxic; the obtained plywood for decoration reaches the mould inhibition rate of 76.3%, and contains no poisonous chemical reagent; the human health is guaranteed in the preparation and use process of the plywood; a veneer is firstly dried at low temperature, so that the water content is lower than the water content of a conventional veneer, the activity of the mould remained in the veneer is inhibited, the moulding is inhibited, the absorption of treatment solution in later treatment process is promoted, and the production efficiency is improved; and the dried veneer is put in sodium selenite solution for ultrasonic dipping, so that the sodium selenite solution is fully infiltrated in the veneer to inhibit growth of infectious microbes, the binding force of lignin to cellulose is reduced, the softness of the veneer is improved, breakage is prevented, and the machining performance and the use performance of the plywood are improved.

Owner:徐州市嘉翔木业有限公司

Method for willow artwork dyeing through natural indigo pigment

ActiveCN107253249AGood colorGood spotlightRadiation/waves wood treatmentWood treatment detailsSteepingDistillation

The invention discloses a method for willow artwork dyeing through a natural indigo pigment. The method comprises the following aspects that (1) indigo extraction is conducted, specifically, a plant raw material is subjected to crushing, fermentation, water soluble extraction and low-temperature drying, and the indigo pigment is prepared; (2) acid-alkali steeping is conducted, specifically, a hydrochlric solution with the concentration being 0.3-0.4% and a sodium hydroxide solution with the concentration being 0.25-0.3% are used to steep a willow artwork correspondingly; (3) cooking for impurity removal is conducted, specifically, impurities in the willow artwork is removed through cooking; (4) steaming for dyeing is conducted, specifically, the indigo pigment with the mass being 11-13% that of distillation boiler water is added, and steam dyeing is conducted; (5) low-temperature drying is conducted, specifically, the dyed willow artwork is dried; (6) infrared color fixing is conducted, specifically, the willow artwork is wrapped through mixed slurry and placed under infrared lamplight with the illumination intensity being 470-520 lux for color fixing; (7) ultraviolet inspection is conducted, specifically, the willow artwork subjected to color fixing is placed under an ultraviolet lamp, and the color fixing condition is inspected; and (8) tung oil layer coating is conducted, specifically, the willow artwork qualified after inspection is coated with tung oil, and after drying, the willow artwork with the natural indigo pigment is prepared.

Owner:阜南县宏达工艺品厂

Board softening and mould proofing method

InactiveCN106182286AGuaranteed flexibilityNatural colorRadiation/waves wood treatmentWood treatment detailsSodium bicarbonateFiber

The invention discloses a board softening and mould proofing method. Softening and mould proofing are carried out at the same time, the treatment period is short, the method is simple, the working efficiency is improved by 15.3%, batch treatment can be carried out, softening and mould proofing are carried out through three steps, the effect is durable, traces are not left, and the cost is saved by 14.2%. A board is soaked with fermentation liquor, generated micromolecule matter can change the organization structure, fibers are initially softened, restraining on growth of infectious microbes is achieved, and deep pigments are dissolved; the board is soaked with a Chinese drug solution, rapid permeability is achieved, outside-to-inside even antibiosis is achieved, the using amount is small, antibacterial treatment can be carried out after diluting with water, safety and high efficiency are achieved, the cost is low, and the effect is durable; the board is subject to ultrasonic soaking with a sodium bicarbonate solution, antibiosis and disinfection are carried out, blots are removed, mould proofing and moth proofing are carried out, and the fibers are softened; and the board is dried in a low-temperature and low-humidity room, so that the pliability of the board is kept, preparation is facilitated, the fracture rate is reduced by 6%, the color and luster of the board can be kept natural, even and new, and color and luster treatment in the later period is facilitated.

Owner:阜南县创发工艺品有限公司

Method for dyeing rattans with plant-based black dye

ActiveCN107336314AImprove permeabilityImprove surface activityRadiation/waves wood treatmentElectric wood treatmentActive agentWarm water

The invention discloses a method for dyeing rattans with plant-based black dye. The method is characterized by comprising the steps that (1), softening is performed, wherein the rattans are soaked in warm water firstly and then soaked in a softener solution to be subjected to ionization treatment; (2), dyeing is performed, wherein the rattans are soaked in an active agent solution for 2-3 h, and then dyeing and drying are performed and repeated for 3-4 times; (3), color protection treatment is performed, wherein the rattans are subjected to atomization treatment with a color fixative; (4), fixation is performed, wherein the fixation treatment is conducted on the rattans needing color protection by ultraviolet light and mixed mud; and (5), air-drying is performed, wherein the dye-fixed rattans are dried to the moisture content of 7%-10%, and then the rattans are coated with paraffin oil and air-dried. Compared the rattans produced through the method with a control group, the content of the dye in the rattans is increased by 61.5 mg / 100 g, the discoloration test time is prolonged by 55 h, and the bending rate is increased by 7.8%.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Preparation method of light transmission bamboo sheet

ActiveCN107825551AKeep swollenTranslucentRadiation/waves wood treatmentWood treatment detailsFiberAlcohol

The invention discloses a preparation method of a light transmission bamboo sheet. The preparation method of the light transmission bamboo sheet includes the steps that after the outer green and the yellow of a bamboo material are removed and the bamboo material is made into the bamboo sheet, a chemical agent is adopted for processing so that part of lignin, cell inclusion and other substances inthe bamboo sheet are removed; and then after cleaning by clean water, the bamboo sheet is sequentially soaked in absolute ethyl alcohol and dipped in tung oil, and the light transmission bamboo sheetis obtained. The light transmission bamboo sheet obtained through the method has good light transmission performance, the fiber texture of the bamboo material is reserved, a unique decoration effect is achieved, and the light transmission bamboo sheet can be used for manufacturing a bamboo lampshade, a bamboo fan, a bamboo curtain and other indoor decorative articles.

Owner:FUJIAN AGRI & FORESTRY UNIV

Drying method for wood

InactiveCN106393342AFast dryingStable Quantitative ProductionRadiation/waves wood treatmentWood treatment detailsMicrowaveWood plank

The invention discloses a drying method for wood. The drying method comprises the following steps that A, the wood is pre-planed, and the wood is cut into boards with the same size; B, the pre-planed wood is soaked with brine; C, the wood soaked with the brine is wrapped with tin foil paper and baked; D, the baked wood is coated with a wood anti-cracking agent, and then the wood is subjected to microwave and ultrasonic drying; and E, the wood obtained after microwave and ultrasonic drying is performed is subjected to thermal convection drying. By the adoption of the drying method for the wood, the moisture in the wood can be dried effectively, and the moisture content of the wood is less than 8.5% and meets the dry standard; the phenomena of cracking, deformation, bending and warping of the wood and the like can be avoided; the drying speed of the wood can be increased effectively, the time is shortened, the cost is lowered, and the stable mass production of the wood is achieved; and the quality of the obtained wood is stable, and the error between the moisture content and the target moisture content of dried products is small.

Owner:玉溪万德能源技术有限公司

Preparation method of functional wood material with photocatalytic activity

ActiveCN107803900AWide variety of sourcesReduce manufacturing costRadiation/waves wood treatmentPhysical/chemical process catalystsProtonationUltraviolet lights

The invention provides a preparation method of a functional wood material with a photocatalytic degradation function. The preparation method solves the problems that a wood material is easily polluted, color change under ultraviolet light is large, and the catalyzing efficiency of photocatalytic degradation of organic dyestuff through a single catalyst is low. The preparation method comprises thesteps that first, surface activation is conducted on the wood material through a sodium hydroxide solution; g-C3N4 after being subjected to protonated treatment is loaded on the surface of the wood material through a vacuum impregnation method; and taking ammonium fluorotitanate and urea as raw materials, TiO2 is grown on the surface of the wood material which is loaded with the g-C3N4, and the functional wood material with the photocatalytic activity is obtained through the steps of heat preservation, cleaning and the like. The degradation rate of rhodamine B and a methylene blue solution with the mass concentration being 2 mg / L and under ultraviolet illumination within four hours can reach to 95% or above through the functional wood material, change in color difference of the surface ofthe wood material after being subjected to ultraviolet light aging can be effectively reduced, color stability of the surface of the wood material is greatly improved, and the preparation technology has the advantages that the technology is simple, operation is easy, the cost is low, and the environment-friendly effect is achieved.

Owner:NORTHEAST FORESTRY UNIVERSITY

Softening treatment method for bamboo

ActiveCN107042562AGood flexibilityRigid recovery and liftingRadiation/waves wood treatmentPressure wood treatmentMedicineMegasonic cleaning

The invention discloses a softening treatment method for bamboo and belongs to the technical field of wicker processing. The softening treatment method comprises the following steps of (1) bamboo pretreatment, (2) high temperature and high pressure treatment, (3) ultrasonic cleaning treatment, (4) softening treatment fluid preparation, (5) soaking treatment and (6) dry weaving treatment. The method mainly improves softness during bamboo weaving, increases the weaving yield, also can effectively realize recovery and promotion of bamboo rigidity, improves the usage quality of a weaved product and prolongs the service life of the weaved product. Besides, bamboo after being treated in this way can be subjected to high temperature softening treatment and then deserve secondary plastic weaving, the problem that existing wickerwork cannot be effectively reused is solved, and the method has good popularization and use value.

Owner:阜南佳利工艺品股份有限公司

Aging method of cattail

InactiveCN105965646AImprove smoothnessGood flexibilityRadiation/waves wood treatmentWood treatment detailsAge methodMicrowave

The invention discloses an aging method of cattail. The aging method particularly comprises the steps of arrangement, fermentation, aging and drying. The aging method of cattail is simple, and is low in cost; the cost is saved by 13.4%; cattail is subjected to yeast fermentation treatment, so that a fiber structure is softened, a smoothness sense of cattail is improved, the soaking of an aging treatment agent is accelerated, and the weaving speed is increased; the aging treatment agent is extracted from all natural raw material, two times of extraction are conducted after lactobacillus fermentation, and the aging treatment agent is safe and nontoxic, so that the mildewproof and mothproof effects are improved significantly, the color and luster of the aged cattail are pure and natural, and an extraction yield is increased by 8.4%; the aging treatment is conducted through microwave ultrasound, so that the painting is quick and uniform, the flexibility of cattail is improved, the grade of a woven product is raised, the drying is facilitated, and the working efficiency is improved.

Owner:阜南县大喜柳编工艺品有限公司

Method for improving corrosion resistance of wicker products

ActiveCN106182248AImprove organizational structureImprove insect and mildew resistanceRadiation/waves wood treatmentWood treatment detailsHigh humidityHardness

The invention discloses a method for improving corrosion resistance of wicker products. The method comprises the following steps: (1) skin removal of wickers, (2) softening treatment, (3) wicker weaving, and (4) anti-corrosion treatment. Various steps of the method are matched scientifically and reasonably, and the manufactured wicker products are good in insect prevention, mildew prevention and corrosion resisting effects and are high in surface hardness. Compared with the prior art, the method has the characteristics that the surface hardness of the wicker products can be improved by about 25%, the wicker products are used under the condition of high acid and alkali, the anti-corrosion time of the wicker products can be 4-5 times longer than the original anti-corrosion time, the service life can be prolonged by about 30% under the conventional using conditions, and can be prolonged by 40% or above under the condition of high humidity, use stability is good, anti-deformation ability is high, corrosion resistance is good, and use value is high.

Owner:阜南县猛发工艺品有限公司

Mould preventing treatment method for straw plaited articles

InactiveCN106182265AEnhance the effect of anti-mildew treatmentGood for protecting flexibilityRadiation/waves wood treatmentWood treatment detailsSecondary radiationMedicine

The invention discloses a mould preventing treatment method for straw plaited articles. The method comprises the first step of raw material treatment, the second step of drying treatment, the third step of radiation treatment, the fourth step of mould preventing treatment liquid preparing, the fifth step of immersing treatment, the sixth step of secondary drying treatment, the seventh step of secondary radiation treatment, the eighth step of secondary immersing treatment and the ninth step of airing weaving. Straw plaited article raw materials treated through the method have high mould preventing performance and are safe, harmless, good in flexibility and high in tensile strength and folding strength, and weaving is better facilitated.

Owner:FUNAN YONGXING ARTS & CRAFTS

Softening and mildew proofing method of willow rattan used for weaving

InactiveCN106217561AGuaranteed flexibilityBright whiteRadiation/waves wood treatmentWood treatment detailsCelluloseStaining

The invention discloses a softening and mildew proofing method of willow rattan used for weaving. According to the softening and mildew proofing method of the willow rattan used for weaving, the softening treatment and the mildew proofing treatment can be performed at the same time, the treatment cycle is short, the method is simple and practicable and the working efficiency can be improved by 16.8%; the batch treatment can be realized, the effect is lasting through three-step bleaching and the cost can be saved by 13.2%. After the willow rattan is soaked in fermentation liquor, the produced small molecule substances are capable of softening cellulose preliminarily, inhibiting the growth of infectious microbe and decomposing darker pigments; after the willow rattan is ultrasonic soaked in a borax solution, the antibiotic, disinfectant, anti-mildew and anti-moth effects can be realized and the structure of epidermal cellulose can be destroyed; after the willow rattan is bleached in a traditional Chinese medicine solution, the permeation can be rapid, the antibiotic treatment can be uniform from outside to inside, the usage amount of traditional Chinese medicine extract is less and the antibiotic treatment can be performed after the traditional Chinese medicine extract is diluted by water, so that the safety and the efficiency are good, the cost is low and the effect is lasting. The willow rattan is dried in room at low temperature and low humidity, so that the flexibility of the willow rattan can be kept and the broken rate of weaving can be reduced by 8%. The epidermis of the willow rattan can be removed after the treatment, so that the colour and lustre of the willow rattan can be kept naturally bright and white and the later-stage staining can be pure.

Owner:阜南县创发工艺品有限公司

Molding and color changing preventing treatment method for rubber wood panel

InactiveCN106182275AImprove mildew resistanceEnhanced anti-tarnish propertiesRadiation/waves wood treatmentWood treatment detailsEngineeringColor changes

The invention discloses a molding and color changing preventing treatment method for a rubber wood panel. The method comprises the first step of treating fluid preparing and the second step of molding and color changing preventing treatment. Various steps in the method are matched scientifically and reasonably, the molding and color changing preventing performance of the rubber wood panel is excellent, and under the normal usage condition, the phenomena of molding and color changing of the rubber wood panel cannot happen in ten years. The rubber wood panel has the light traditional Chinese medicine scent, the immunity of the human body can be improved when the rubber wood panel is used in living homes, and the using value is high.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Modification method applicable to eucalyptus timbers

ActiveCN106426474AGood filling effectHigh strengthRadiation/waves wood treatmentWood treatment detailsPolyethylene glycolWood machining

The invention relates to the technical field of timber treatment, and in particular to a modification method applicable to eucalyptus timbers. The timber treatment method disclosed by the invention mainly utilizes sodium silicate and ethanol to carry out hydrolysis and condensation polymerization reactions under the effect of polyethylene glycol as a catalyst, so that nano-sized particles are aggregated and a sol system is formed; moreover, before timbers are treated by being soaked in a treating solution, an acid-deficient solution is first utilized to treat the eucalyptus timbers, an escin solution is also used for soaking the eucalyptus timbers, and thereby the wall breakability and wettability of timber cell walls are increased; after treatment in the treating solution, gel molecules can be further regularly arranged by treatment methods of fumigation and microwave drying, and thereby the purpose of modifying the eucalyptus timbers and increasing the stability of the timbers is achieved.

Owner:兴业县金达木材有限公司

Preparation method of functional type engineered wood

ActiveCN105563586AWear-resistantWeather-resistantRadiation/waves wood treatmentWood treatment detailsStainingManufacturing technology

The invention relates to a furniture plate and in particular to a preparation method of a functional type engineered wood. The preparation method comprises the following steps: rotary cutting or slicing to prepare a blank veneer, and shearing the blank veneer into a needed size to obtain an A veneer; soaking the A veneer in a ternary compound solution prepared from a biomass nano cellulose solubilizer, a flame retardant and acid dyes, and carrying out treatments including toughening, flame retarding and dyeing to obtain a B veneer, wherein the ternary compound solution is prepared from the biomass nano cellulose solubilizer, the flame retardant and the acid dyes of a bis-azo compound according to the mass ratio to be 1:(25-40):(100-300) in a compounding manner; and adding a formaldehyde decomposition powder in a modified MUF adhesive, uniformly stirring, and carrying out dispensing, assembling, cold pressing and sawing on the B veneer to obtain a finished product. With the interface controlling design, the biomass nanotechnology and the synergistic compounding technology, the preparation method effectively solves the diversified matching problem of the flame retardant, a staining reagent and the adhesive, and realizes one material with multiple functions of the reconstituted decorative lumber manufacturing technology.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

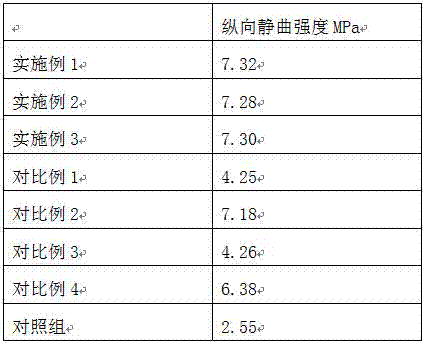

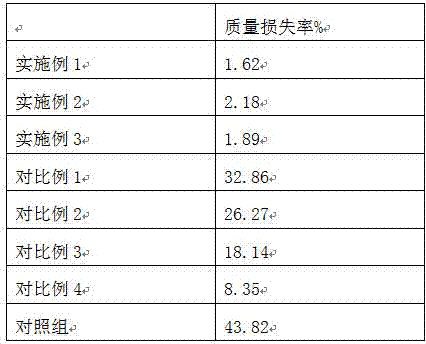

Antiseptic treatment technology for woodware

InactiveCN107398971AImprove anti-corrosion performanceImprove longitudinal static bending strengthRadiation/waves wood treatmentWood treatment detailsCancer researchStatic bending

The invention discloses an antiseptic treatment technology for woodware, and relates to the technical field of woodware treatment. The technology comprises the first step of surface treatment, the second step of pre-preg treatment and the third step of resin impregnation. According to the provided antiseptic treatment technology for woodware, the antiseptic performance of the woodware is effectively improved, meanwhile, the longitudinal static bending intensity of the woodware can be effectively improved, and accordingly the mechanical performance of the woodware is improved.

Owner:FUNAN NATURE ARTS & CRAFTS

Treatment of natural polymer based materials and the products based thereon

InactiveUS7459185B2Reduce contentRadiation/waves wood treatmentNon-macromolecular organic additionSimple Organic CompoundsAfter treatment

A method for modifying a substrate containing a natural polymeric material to improve its interaction with other materials, the method comprising: A) Treating the substrate containing the natural polymeric material with a modifying agent selected from the group consisting of organo-functional coupling agents and multi-functional amine containing organic compounds; and B) optionally exposing the substrate containing natural polymeric material with one or more treatments selected from the group consisting of: i) subjecting the substrate to extraction with a solvent to reduce the content of extractable materials associated with the natural polymeric material prior to or during treatment with the modifying agent; ii) treatment with a physical field selected from static physical fields, high-frequency alternating physical fields and combinations of two or more thereof either prior to, during or after treatment with the modifying agent; and iii) oxidation of at least part of the natural polymeric material prior to or during treatment with the modifying agent.

Owner:COMMONWEALTH SCI & IND RES ORG

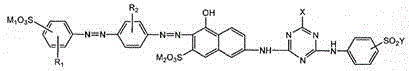

Dyeing method for improving color fastness to light of osier

InactiveCN107486908AImprove color fastness to lightEnhanced photooxidative stabilityRadiation/waves wood treatmentWood treatment detailsVolumetric Mass DensityBinding force

The invention belongs to the technical field of osier dyeing, in particular to a dyeing method for improving color fastness to light of osier. The method specifically comprises the following steps of (1) osier pretreatment and (2) osier dyeing. The permeation of a coloring agent is effectively improved, the degree of aggregation of dye molecules is higher, crosslinking binding between the dye molecules and the ingredients of osier is prompted, the binding force is high, leachability resistance is good, the electronic cloud density of azo group hydrogen atoms is reduced, the shielding effect on azo groups is achieved, the photooxidation resistance stability of the azo groups in the structure of the dye molecules is improved, and finally, the color fastness to light of a dye is improved; and furthermore, osier is evenly dyed and has good color fastness to water, the difference between the color of the interior and the color of the exterior of osier is small, osier is evenly dyed without stains, and is bright and glossy, and the quality of the wickerwork made of osier is effectively improved.

Owner:安徽阜南县万家和工艺品有限公司

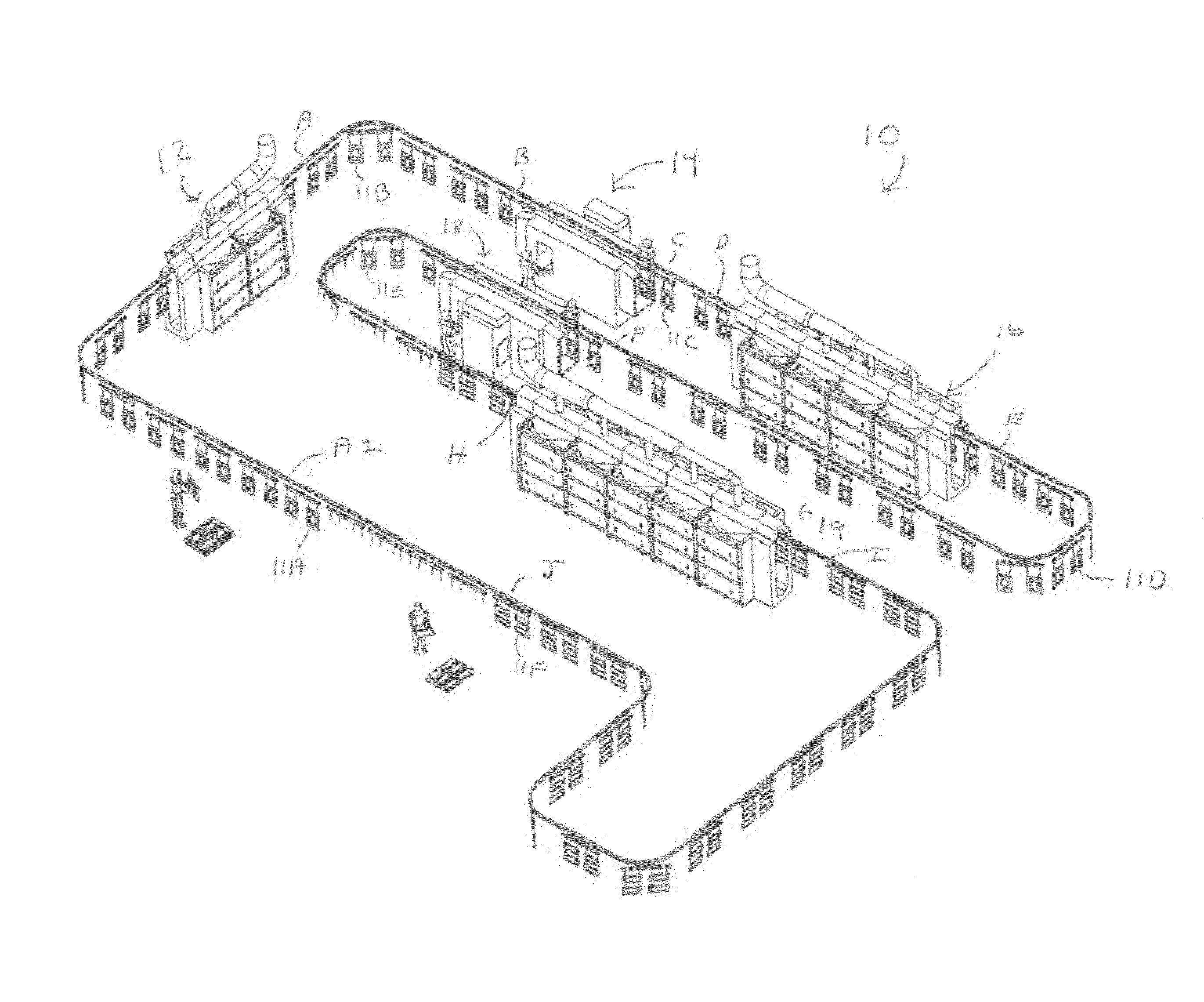

System and Methods for Edge Sealing Medium Density Fiberboard (MDF) and Other Engineered Wood Laminates Using Powder and Liquid Coatings

InactiveUS20140127417A1Radiation/waves wood treatmentElectric shock equipmentsMedium density fiberboardEngineered wood

The present invention has to do with a method and system for coating and curing engineered wood products (EWP) in general, and the edges of EWPs in particular. One method for coating and curing medium density fiberboard (MDF) and other engineered wood laminates using coatings is provided.

Owner:HERAEUS NOBLELIGHT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com