Patents

Literature

1802 results about "Wood panel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for fastening together structural components

Owner:HAYTAYAN HARRY M

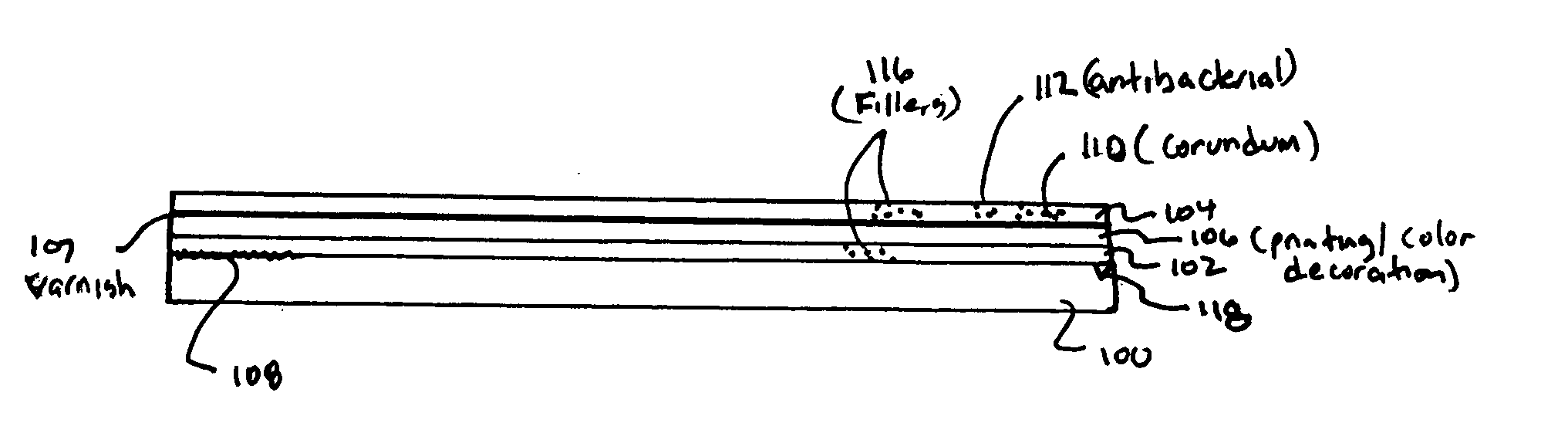

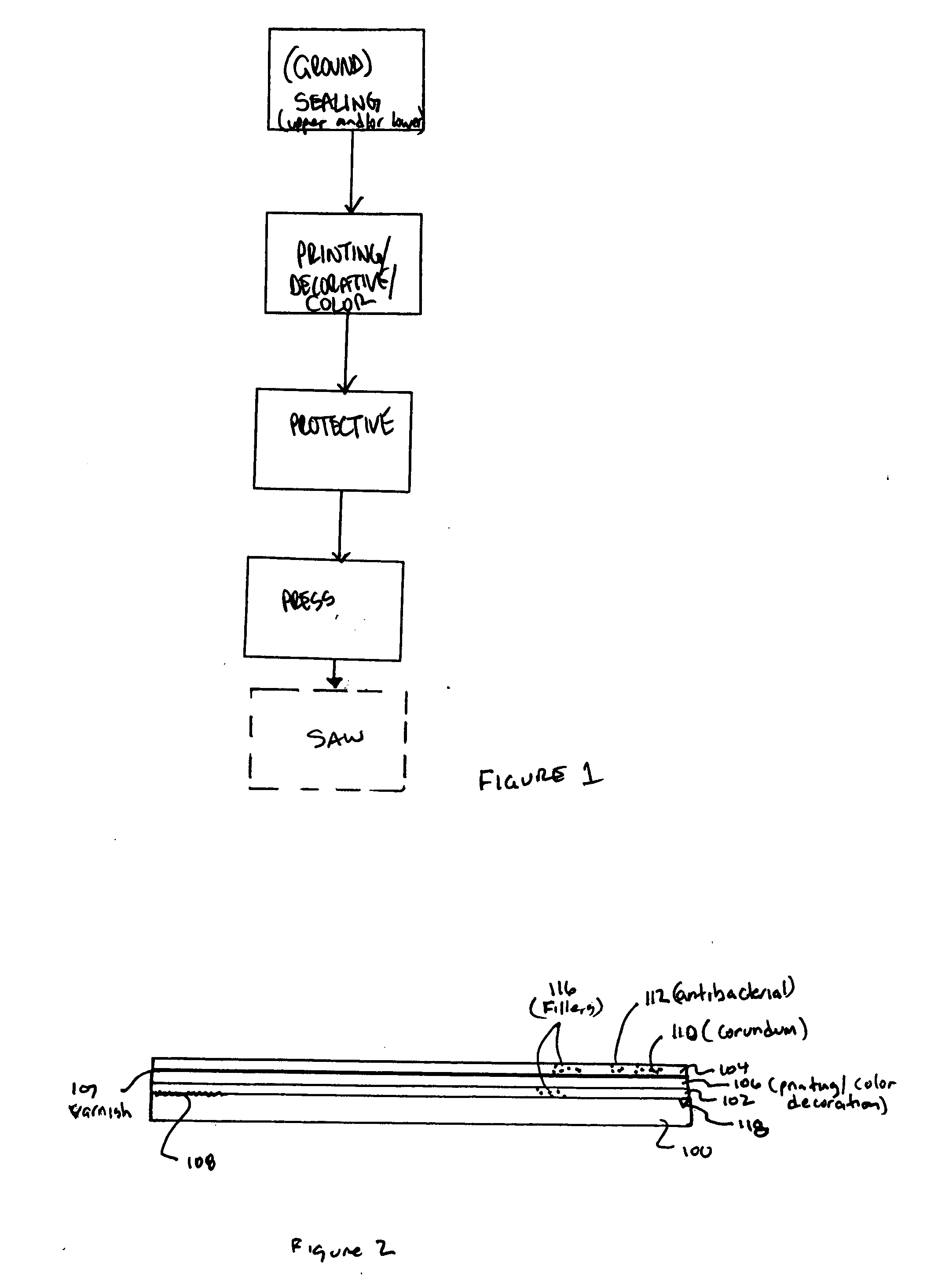

Process for finishing a wooden board and wooden board produced by the process

ActiveUS20040191547A1Avoid absorptionAdjustable levelFibreboardSynthetic resin layered productsMelamine resinEngineering

A process for finishing a wood or wooden board, in particular an MDF or HDF board, with an upper side and an underside. The process includes applying a sealing layer of melamine resin to the upper side of the board and printing a decoration onto the sealing layer. A protective layer is applied of melamine resin to the decoration and the board is pressed under the action of temperature until the protective layer and the sealing layer melt and bond to each other with the inclusion of the decoration printed on.

Owner:FLOORING TECH

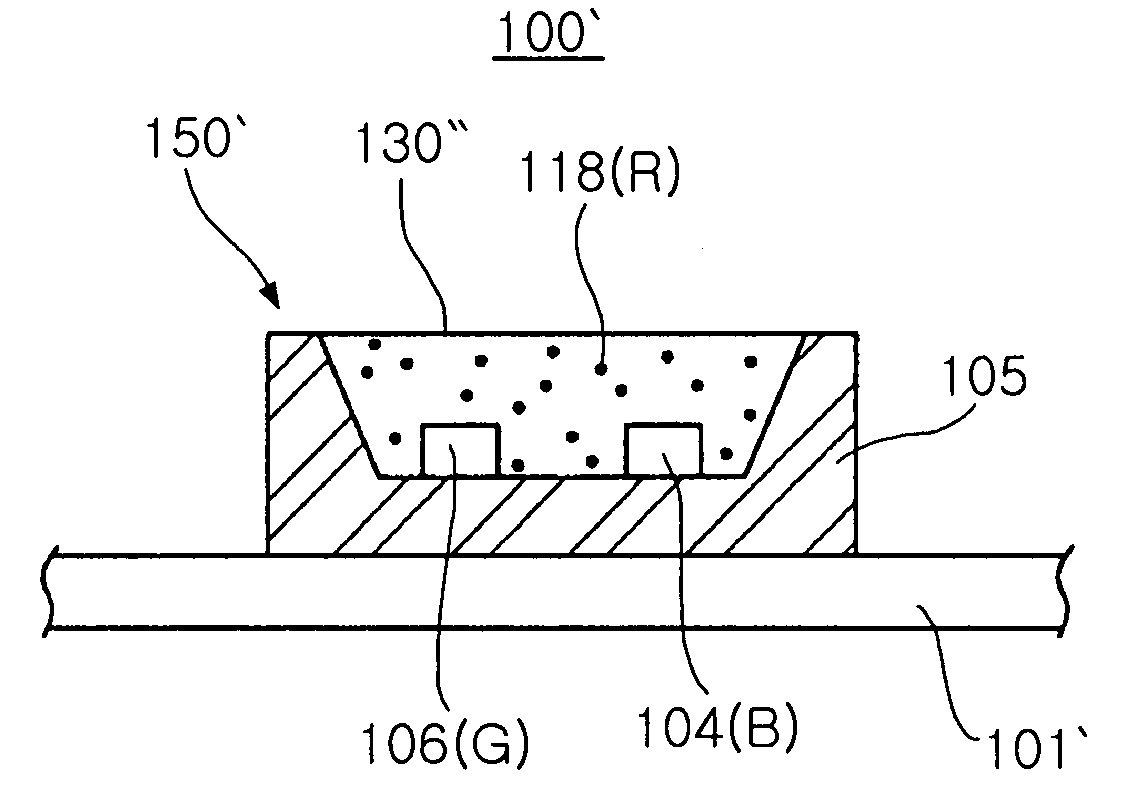

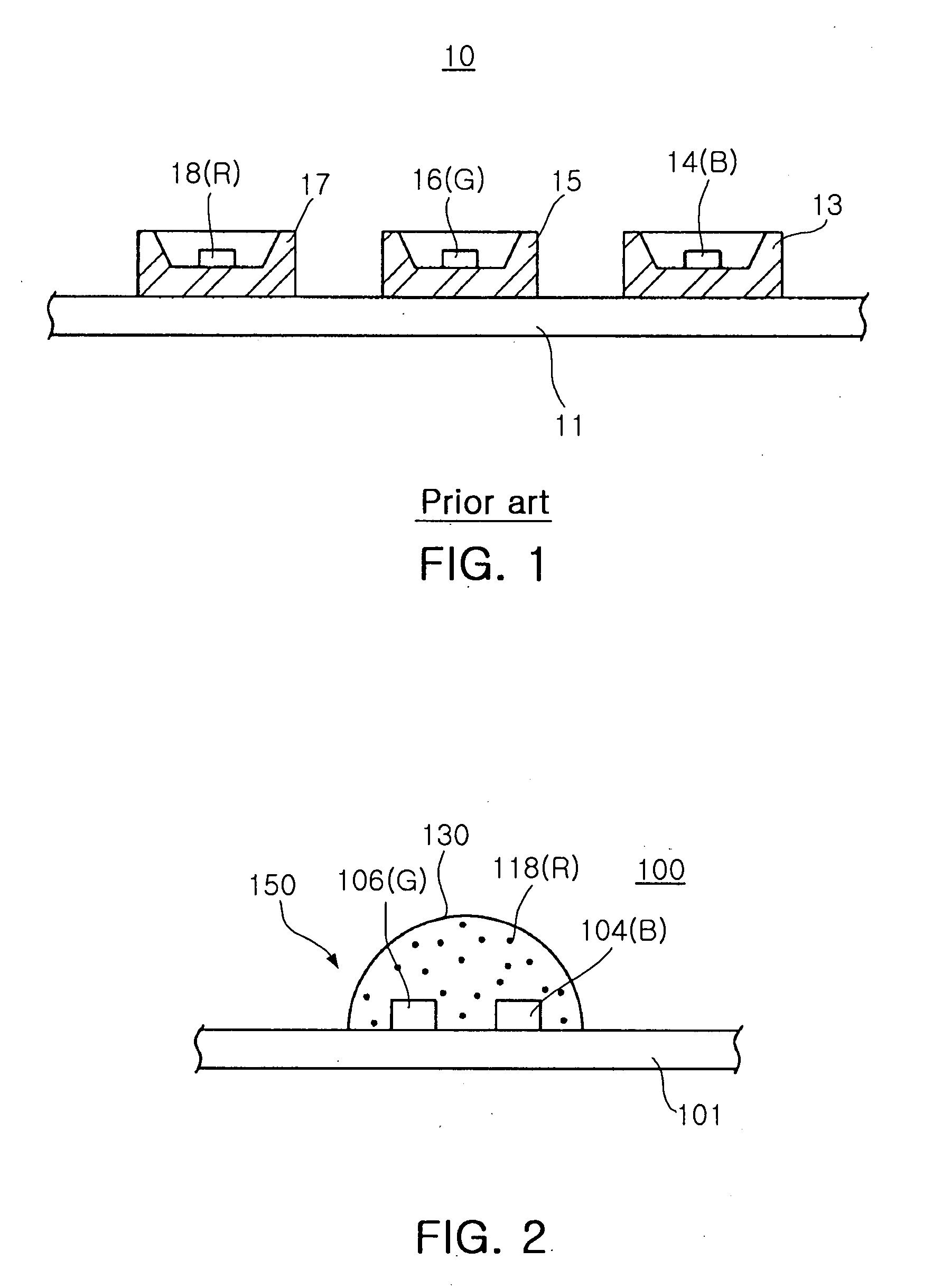

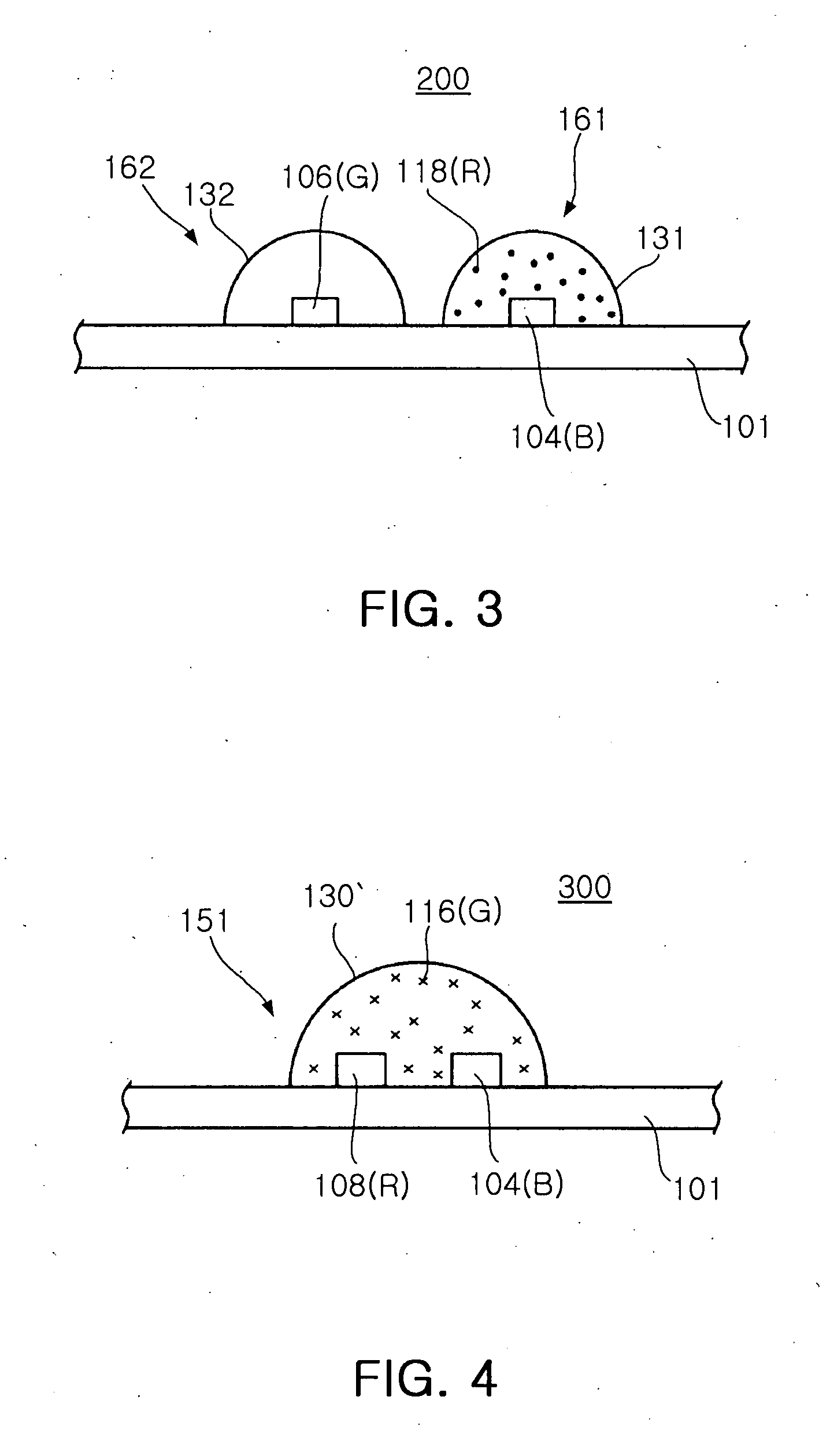

White light emitting diode module

InactiveUS20080048193A1Good reproducibilityImprove uniformitySolid-state devicesLight fasteningsPhosphorGreen-light

A white LED module includes a circuit board, a blue LED chip disposed on the circuit board, a green light source of an LED chip or phosphor disposed on the circuit board, and a red light source of an LED chip or phosphor disposed on the circuit board. At least one of the green and red light sources is a phosphor, which is excited by the blue LED chip to radiate. The blue LED chip emits light in a triangular region defined by color coordinates (0.0123, 0.5346), (0.0676, 0.4633) and (0.17319, 0.0048), the green light source emits light in a triangular region defined by color coordinates (0.025, 0.5203), (0.4479, 0.541) and (0.0722, 0.7894), and the red light source emits light in a triangular region defined by color coordinates (0.556, 0.4408), (0.6253, 0.3741) and (0.7346, 0.2654).

Owner:SAMSUNG ELECTRONICS CO LTD

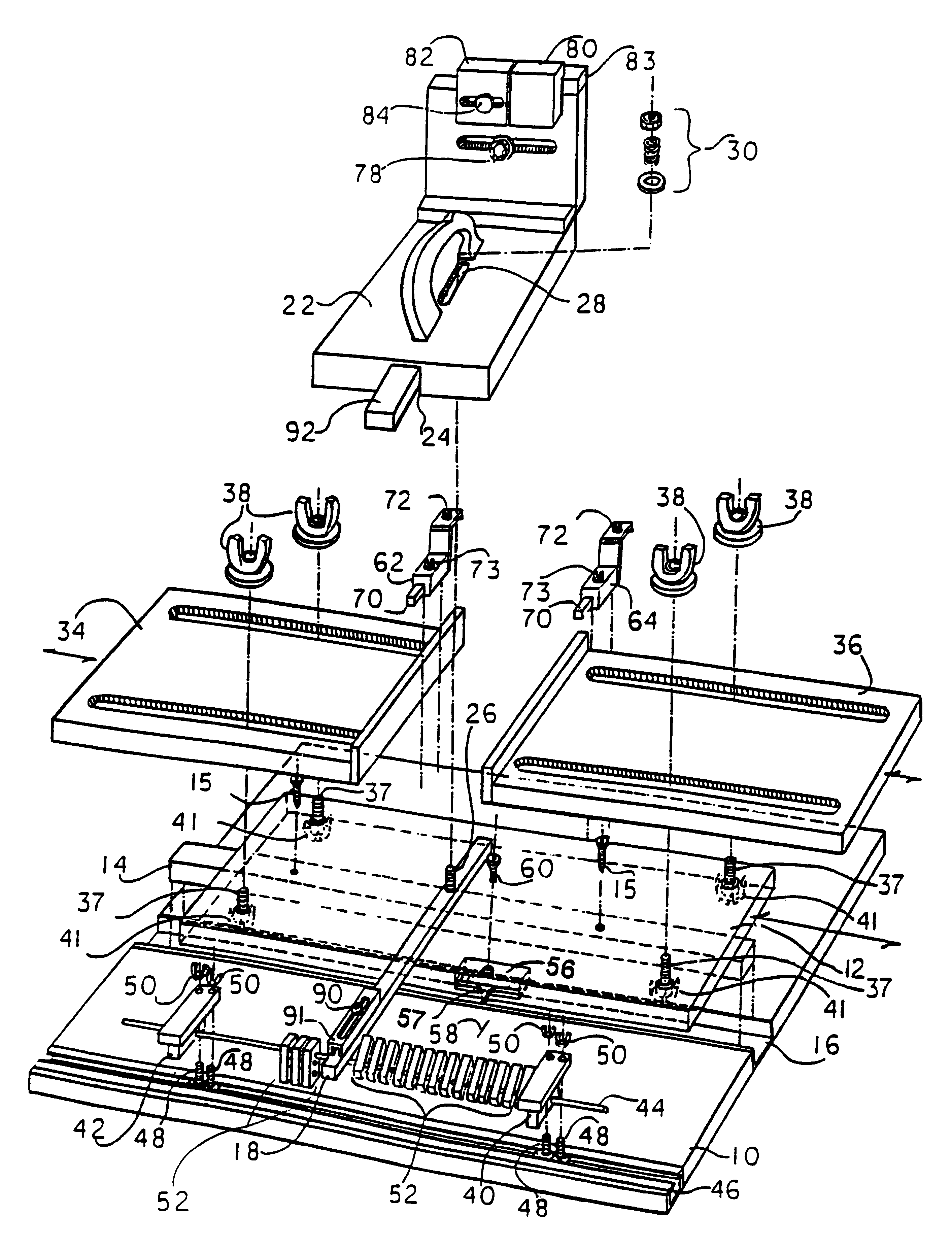

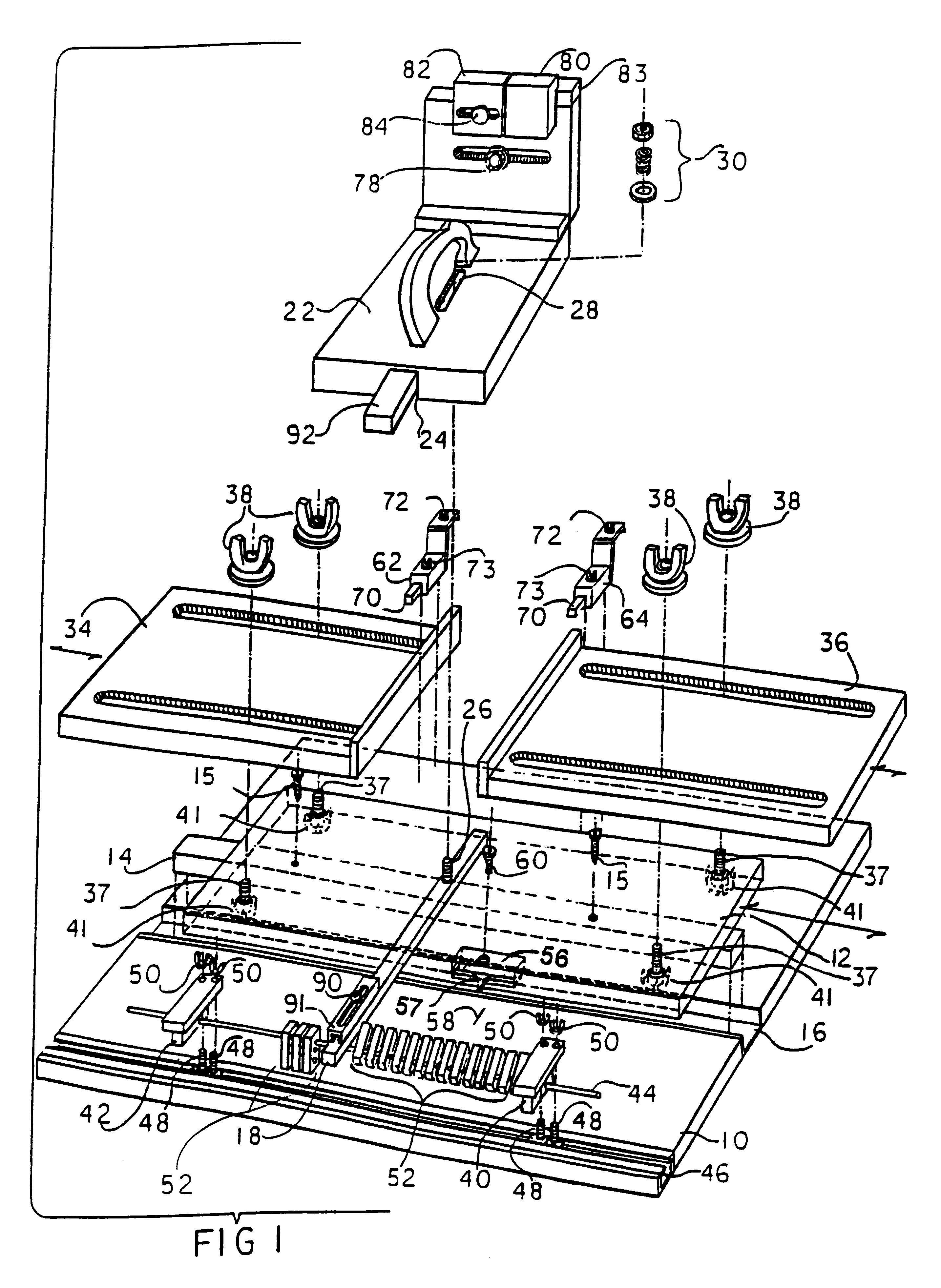

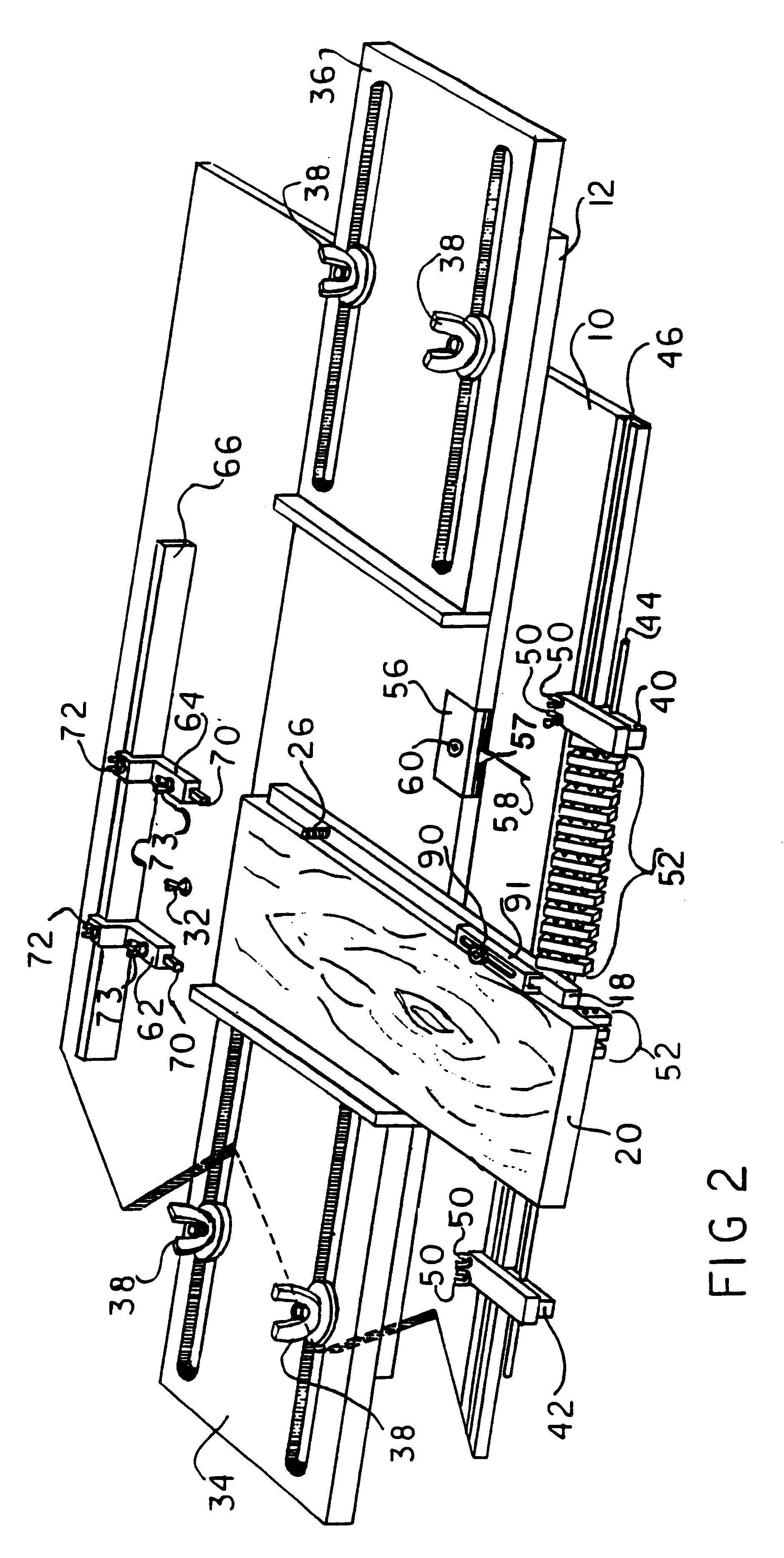

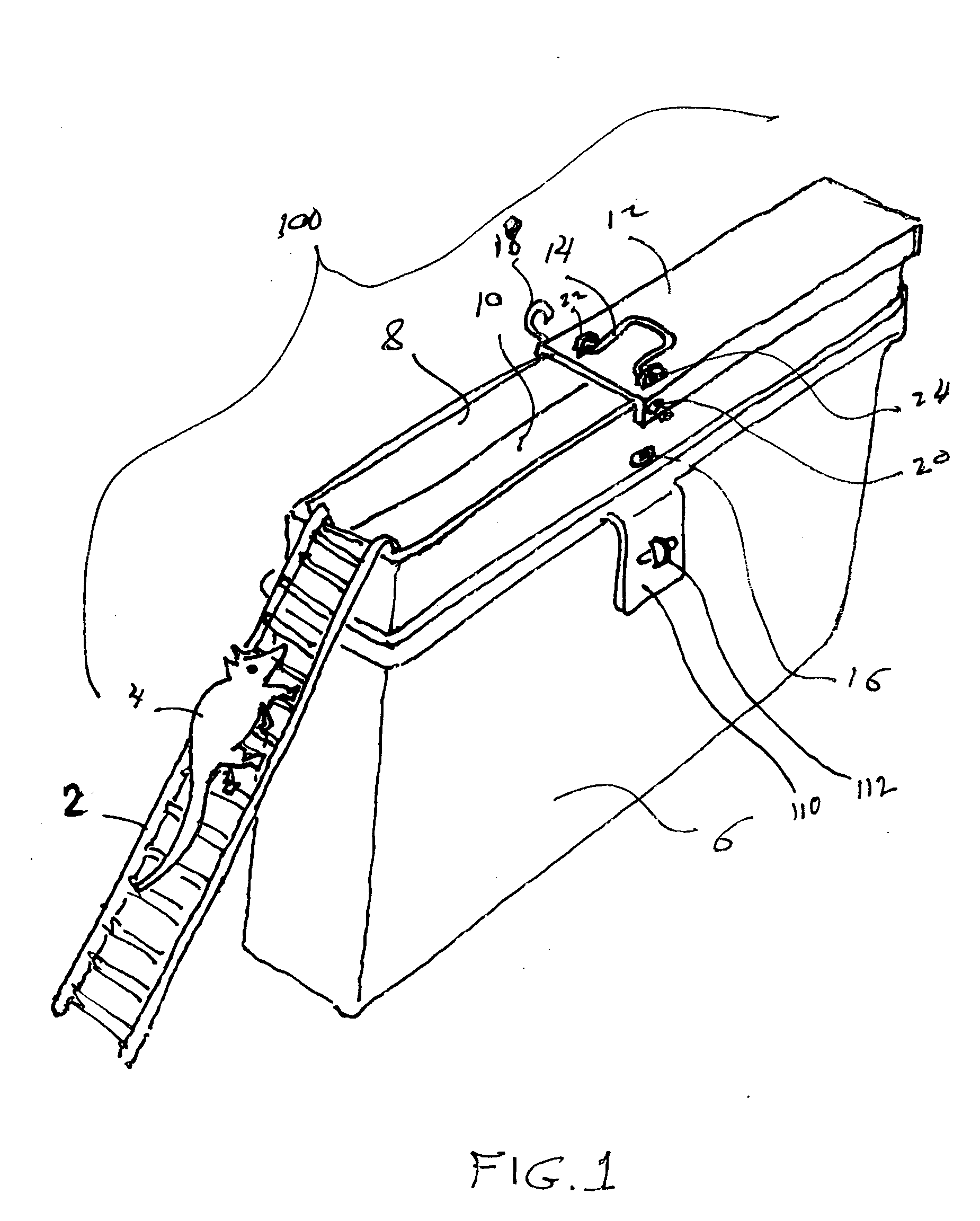

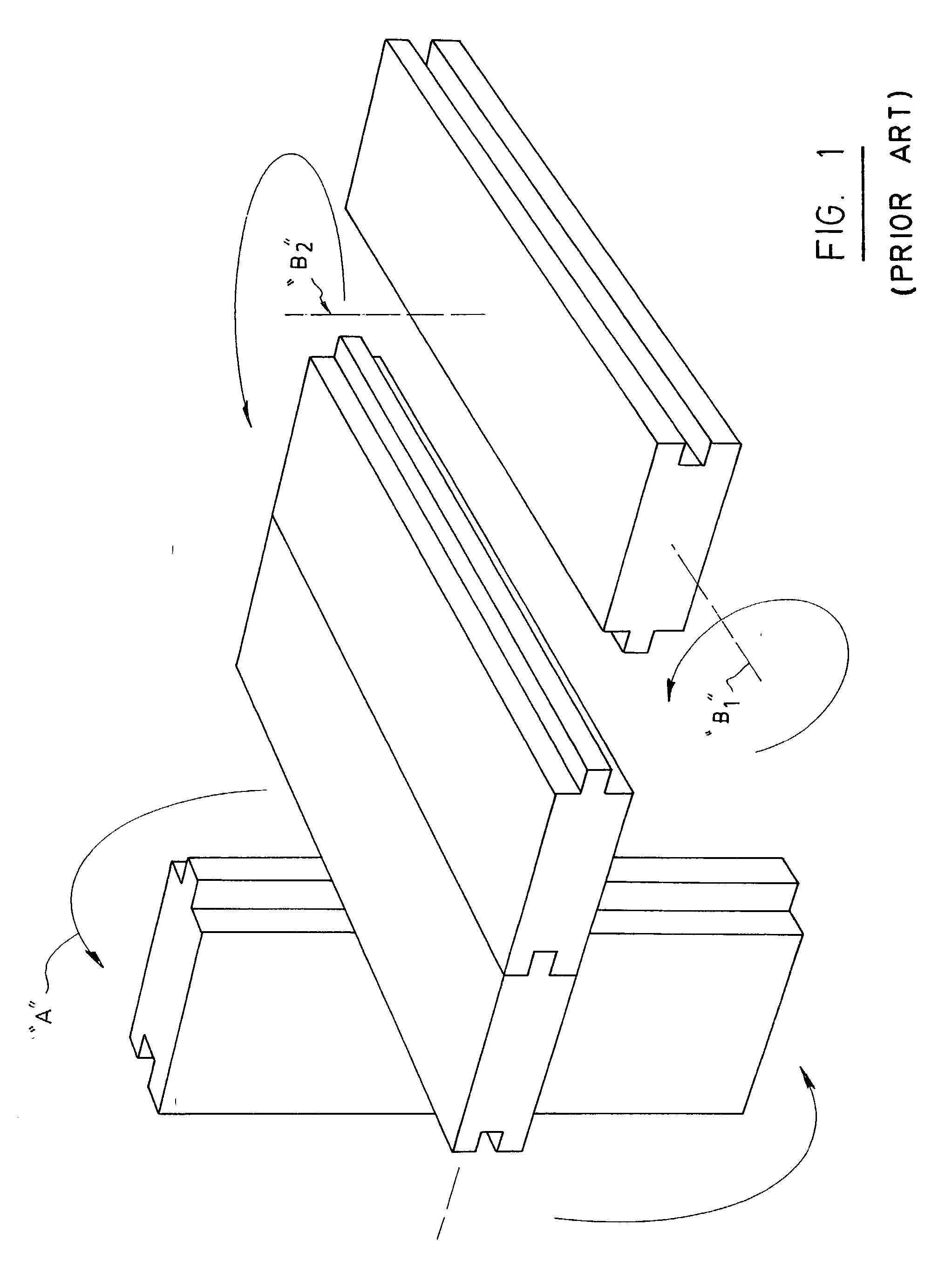

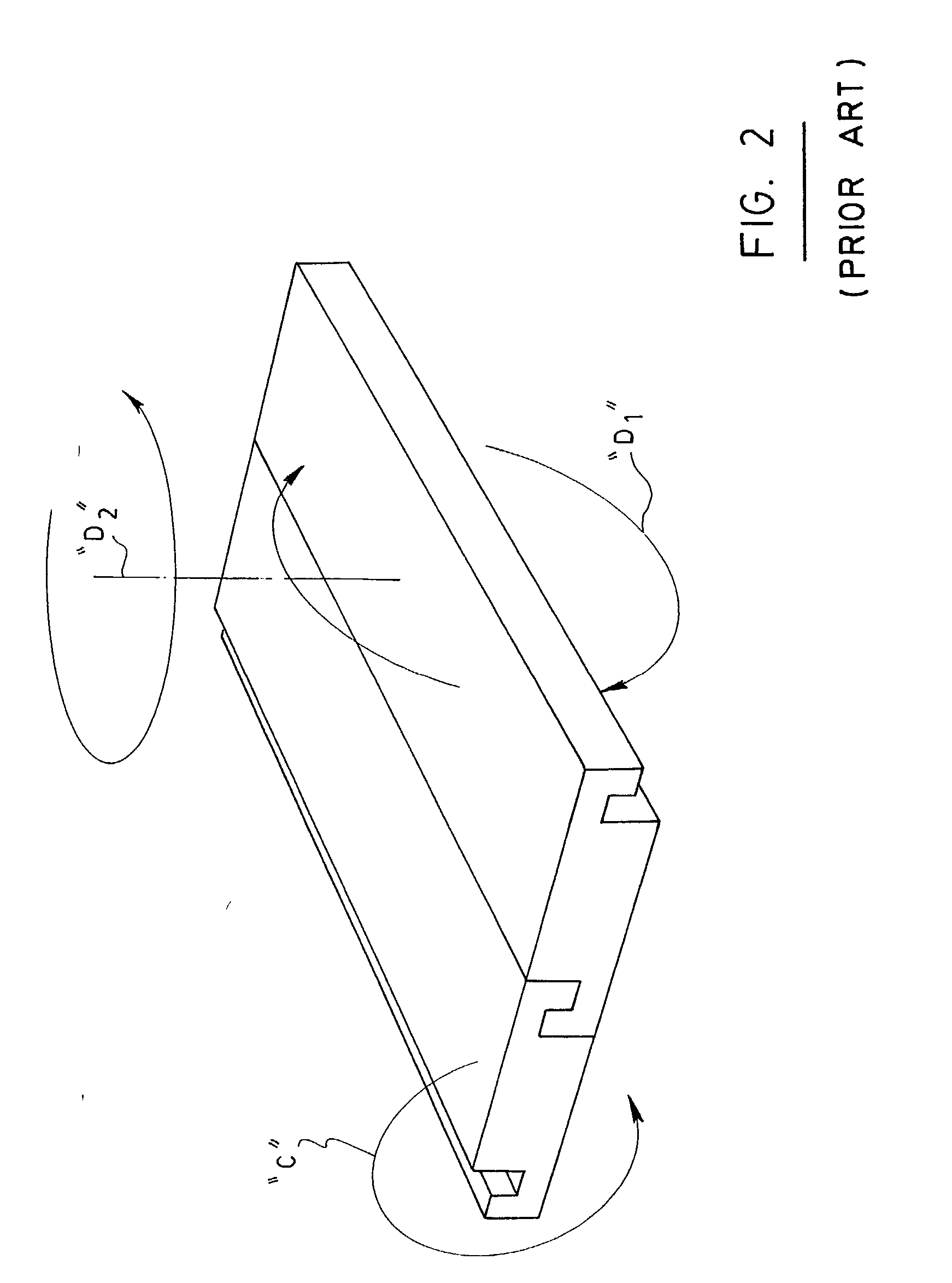

Jig system for positioning the placement of multiple cuts in a workpiece

InactiveUS6206060B1Reduce lateral movementGreat accuracy positioningDrilling/boring measurement devicesTongue/grooves making apparatusEngineeringDovetail joint

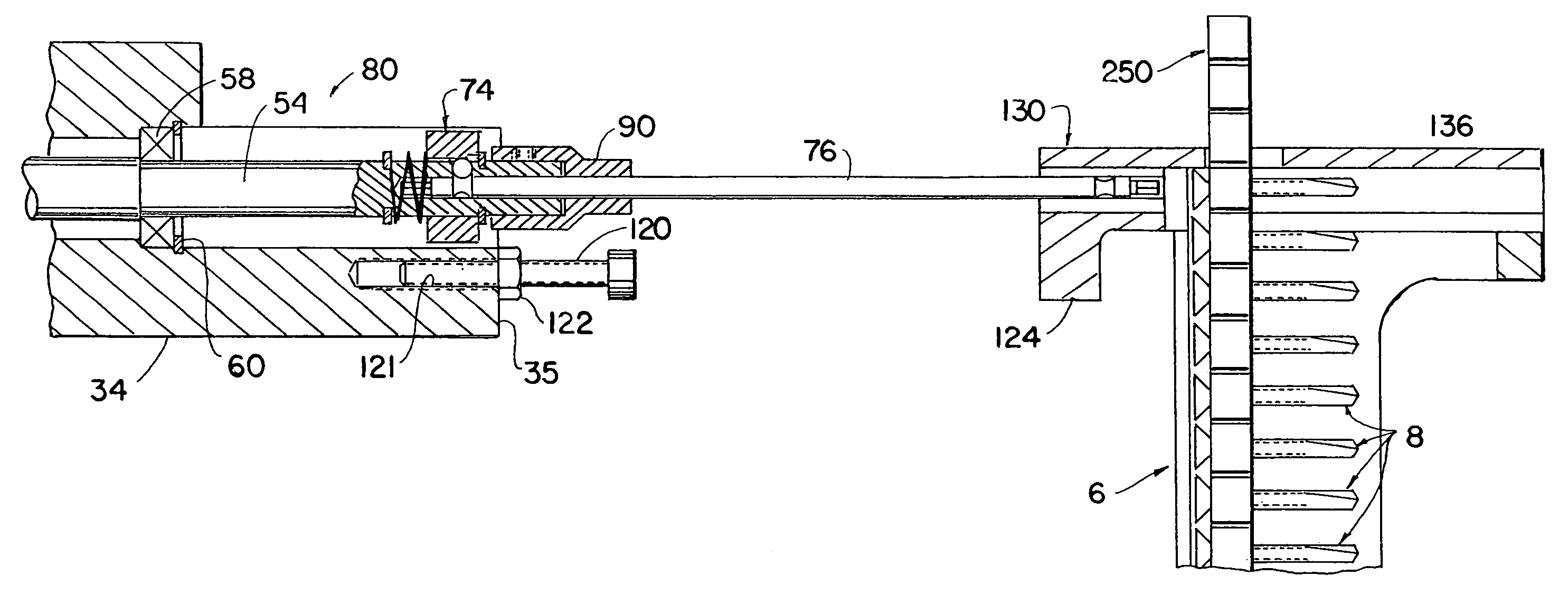

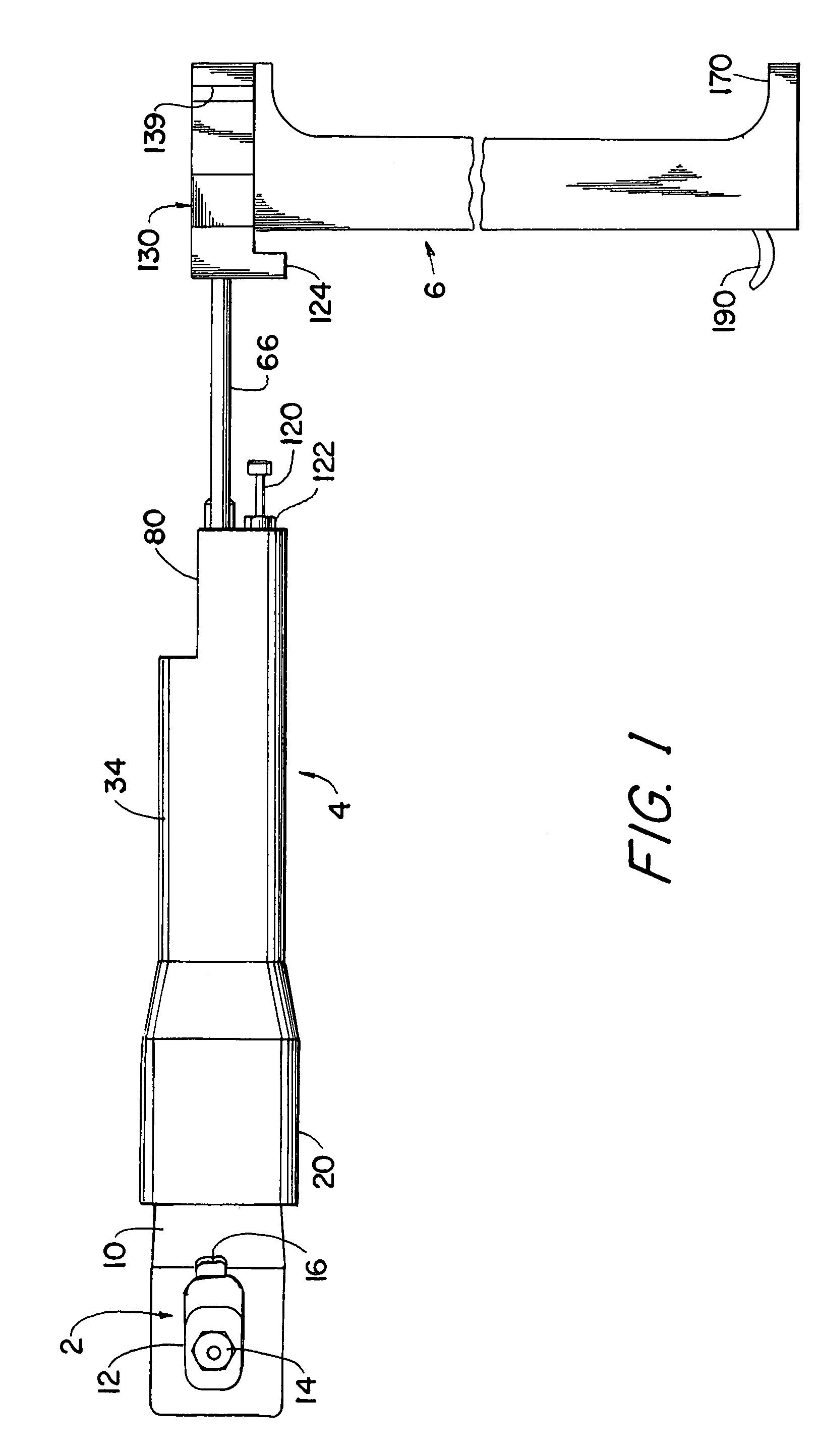

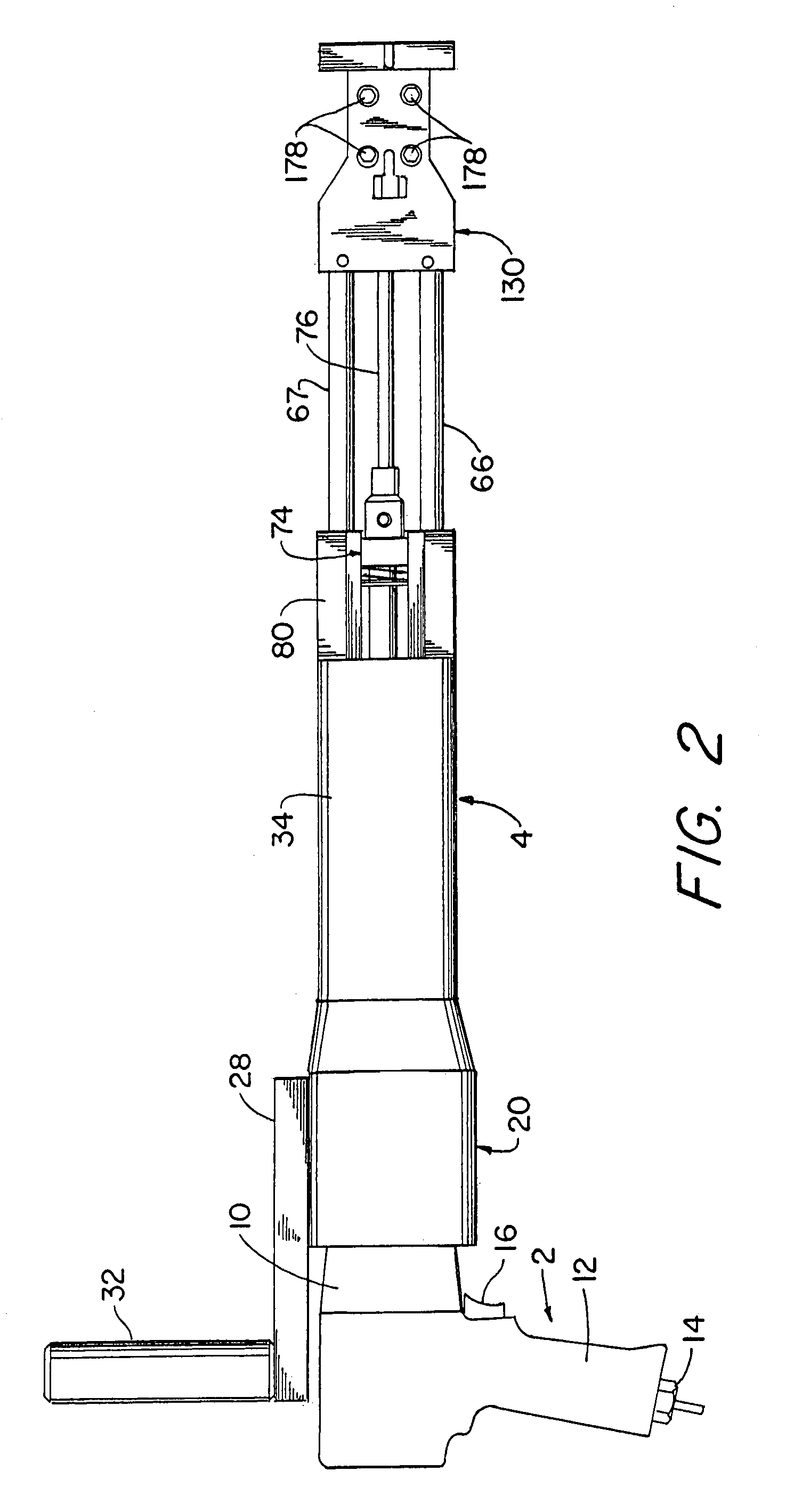

The present invention is a jig system for precisely positioning the placement of multiple cuts such as in the placement of dovetail or box joints cut in a wood panel. A row of multi-use adjustable spacers controls the indexing of a workpiece and can be used with a stationary and / or a portable cutting tool. The movability of the spacers permits a workpiece to be cut on both sides of a guide bar fence thereby assuring that the first cut will always be made on the same side of a drawer and will be esthetically pleasing regardless of the width of the workpiece. Additionally, the adjustability of the spacers accommodates any desired cutting tool height, angle and / or size. The jig system comprises: a stationary fixture; a spacer bar; a plurality of spacers engaged with the spacer bar, the spacers are adapted for lateral and rotational movement along the spacer bar thereby providing an engaged and non-engaged working mode; a sliding member adapted for lateral movement on the stationary fixture and for engaging at least one of the spacers in the engaged working mode; and means for holding the spacer bar and connecting the spacer bar to the stationary fixture while engaging with at least one of the spacers during the engaged working mode.

Owner:BLAKE F RICHARD

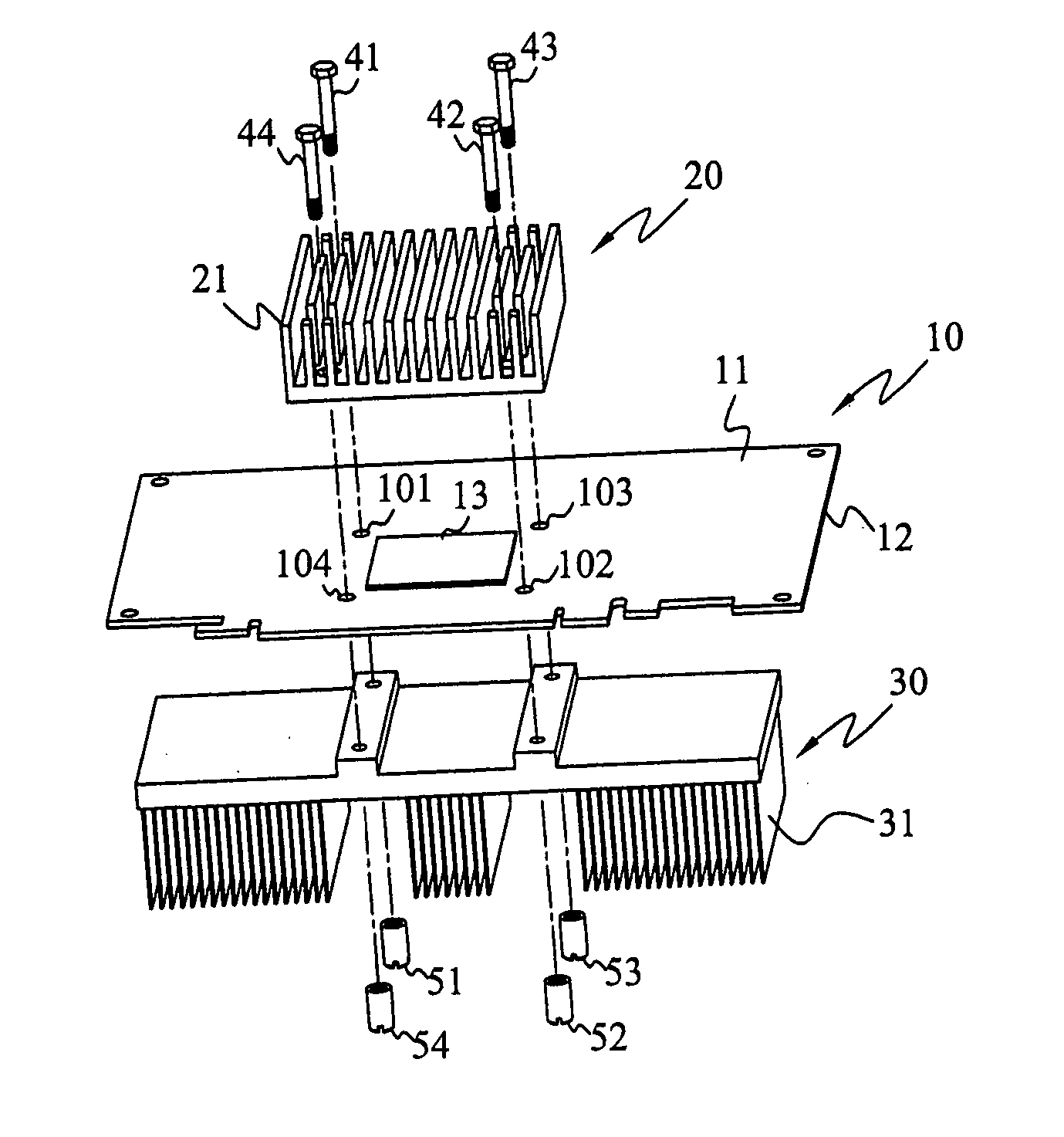

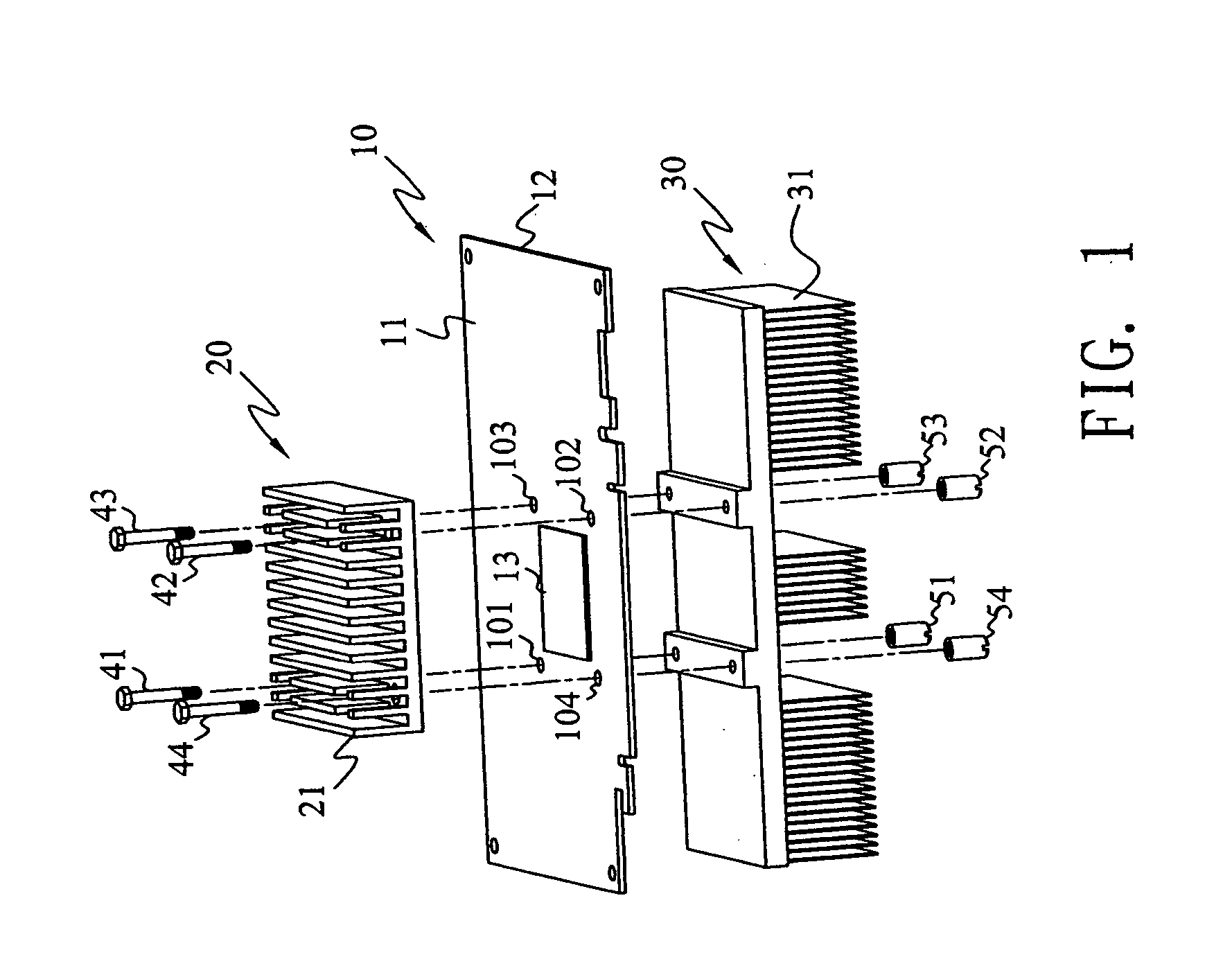

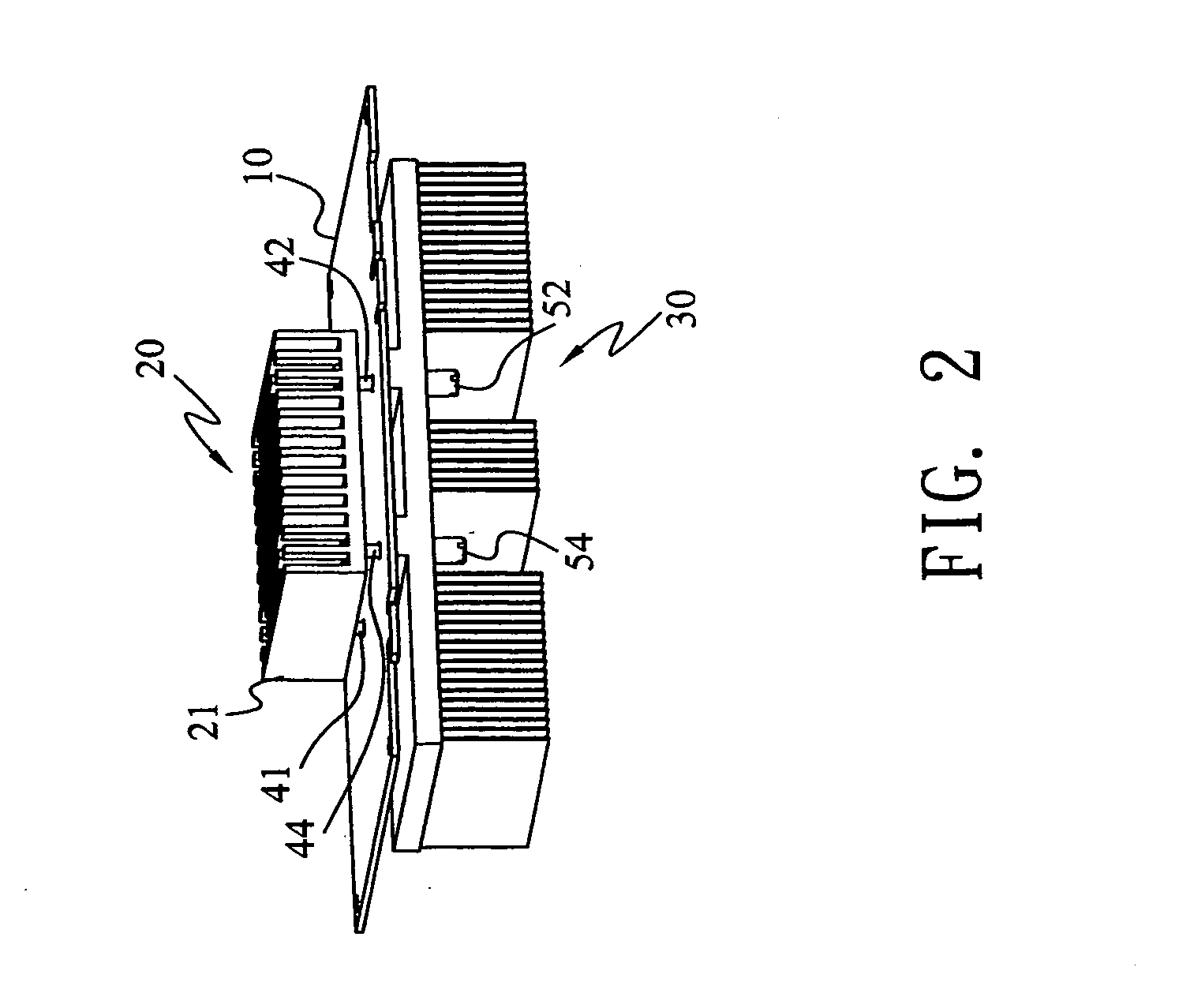

Circuit board having heat dissipation through holes

InactiveUS20070091578A1Improve cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesShortest distanceEngineering

A circuit board having heat dissipation through holes, wherein a plurality of through holes are provided in the perimeter of the chip on the circuit board, and heat conduction elements are utilized to connect the heat dissipater and auxiliary heat dissipater provided on two sides of the circuit board. The heat conduction element may be the heat conduction column or heat pipe made of copper or aluminum, and is used to connect the heat dissipater and auxiliary heat dissipater with the shortest distance, thus achieving the speedy transfer of heat generated by the chips and raising the heat dissipation efficiency significantly.

Owner:ASUSTEK COMPUTER INC

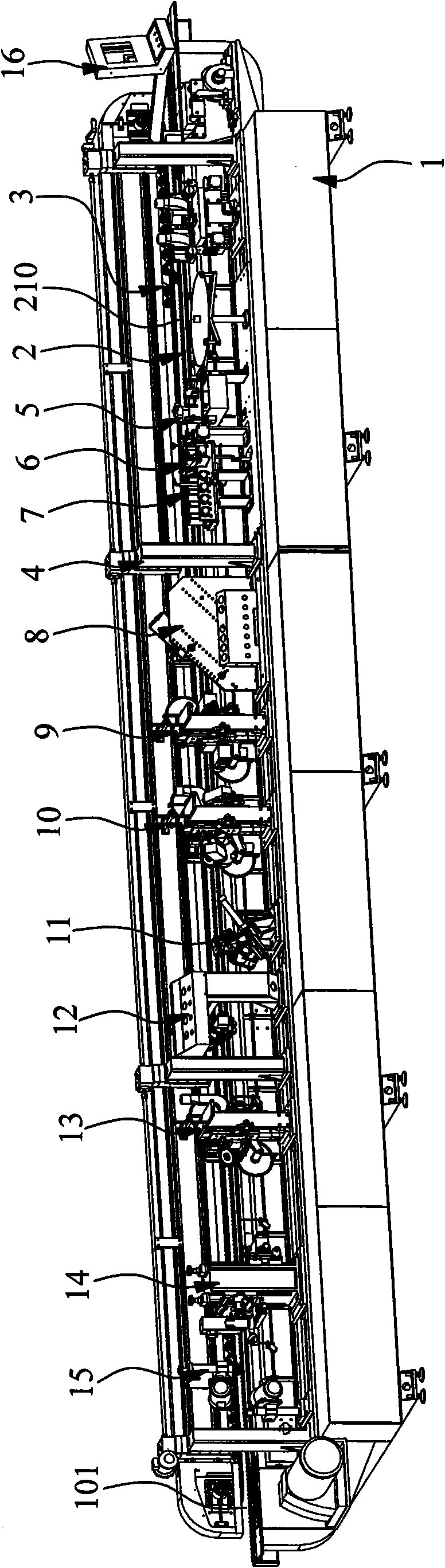

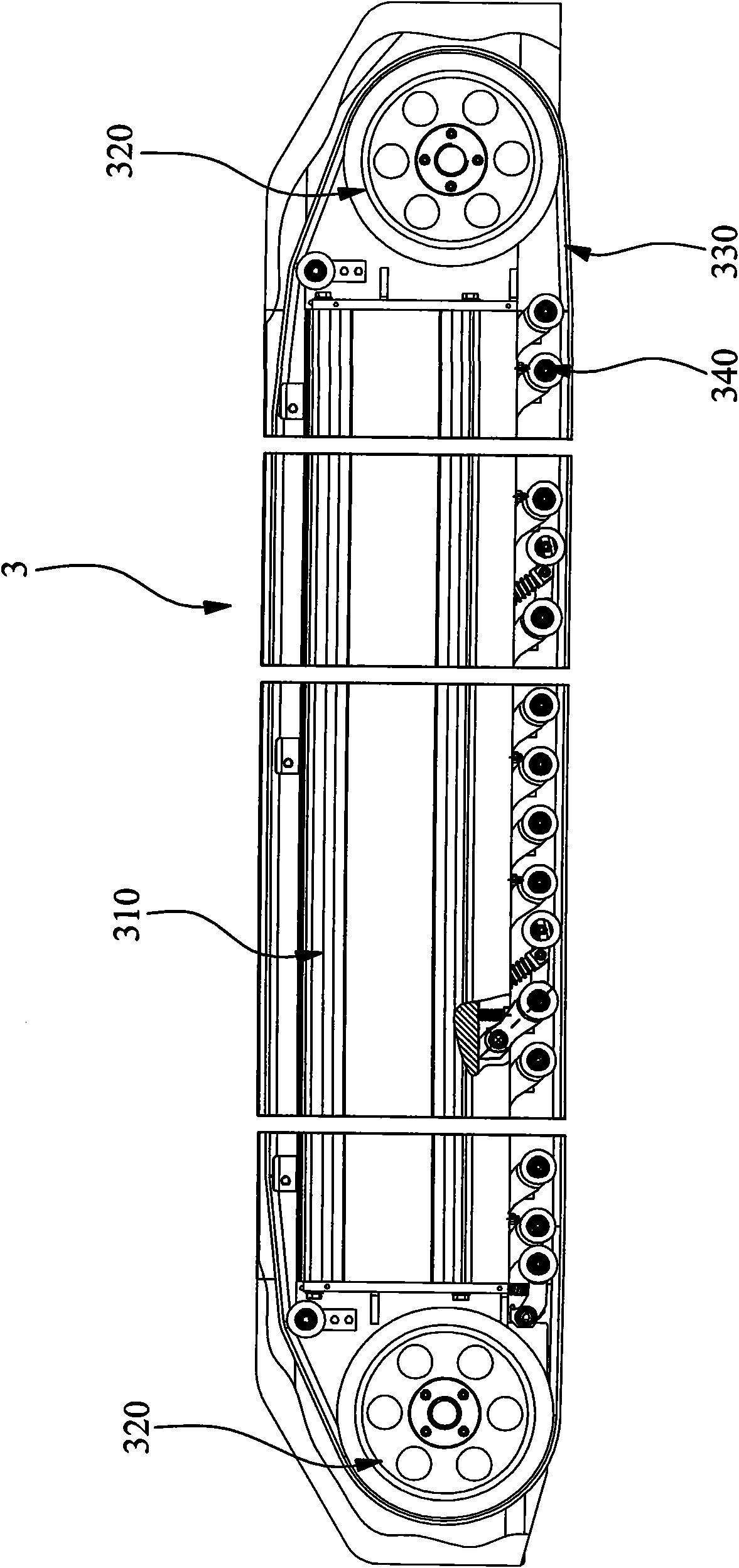

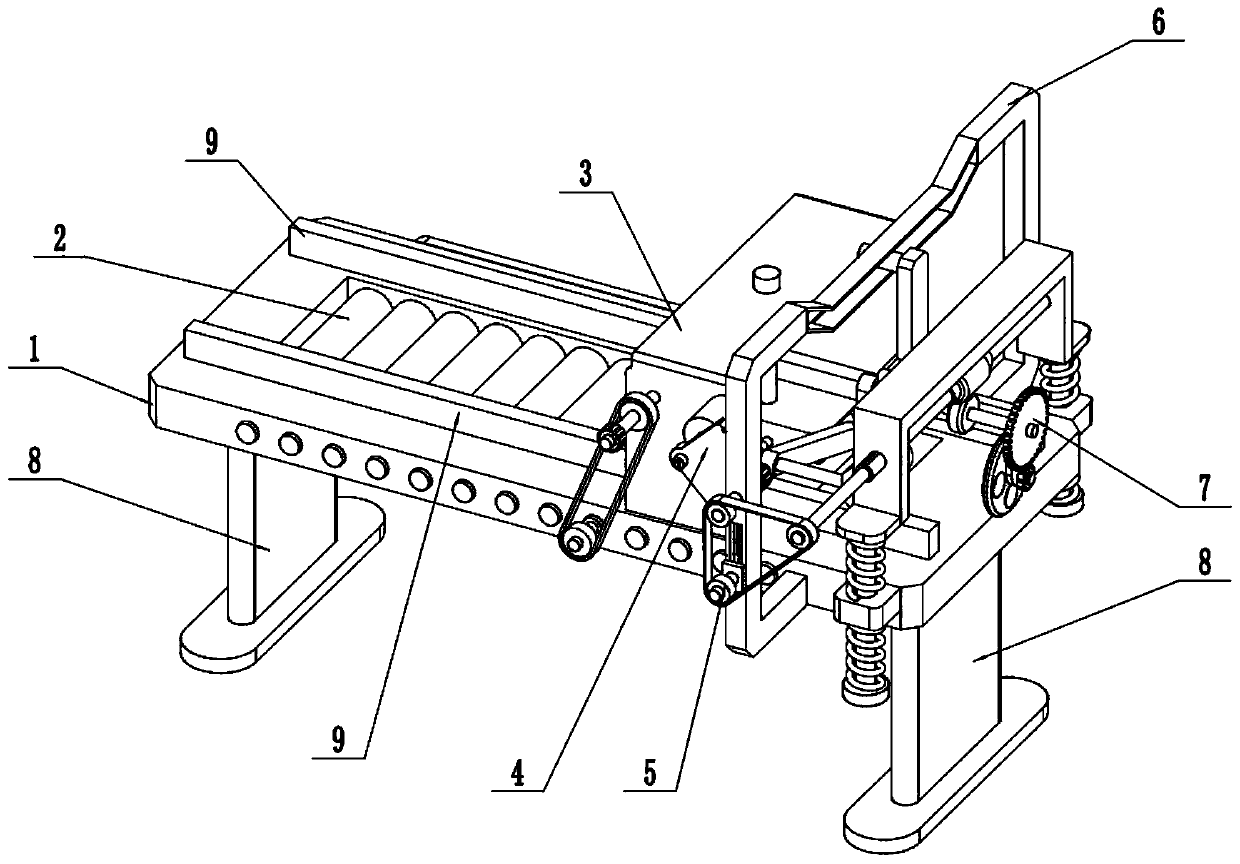

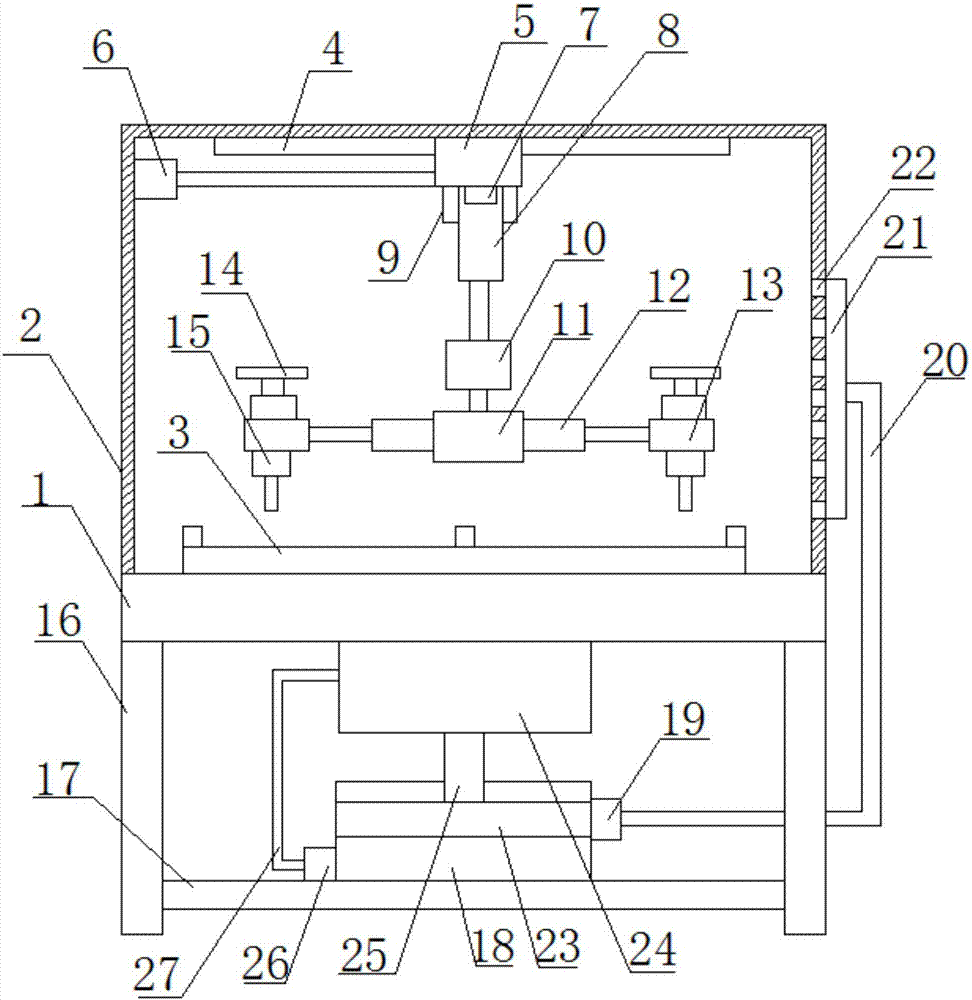

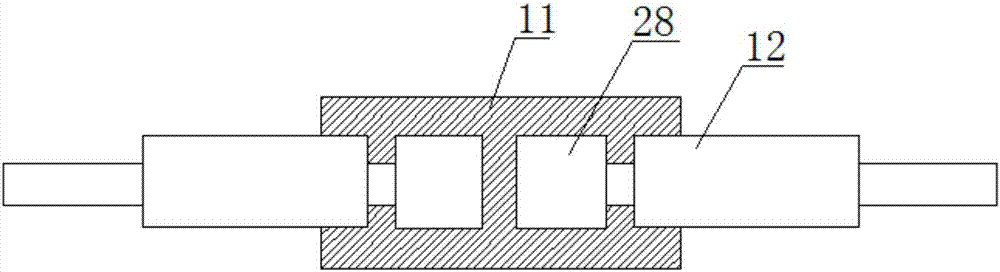

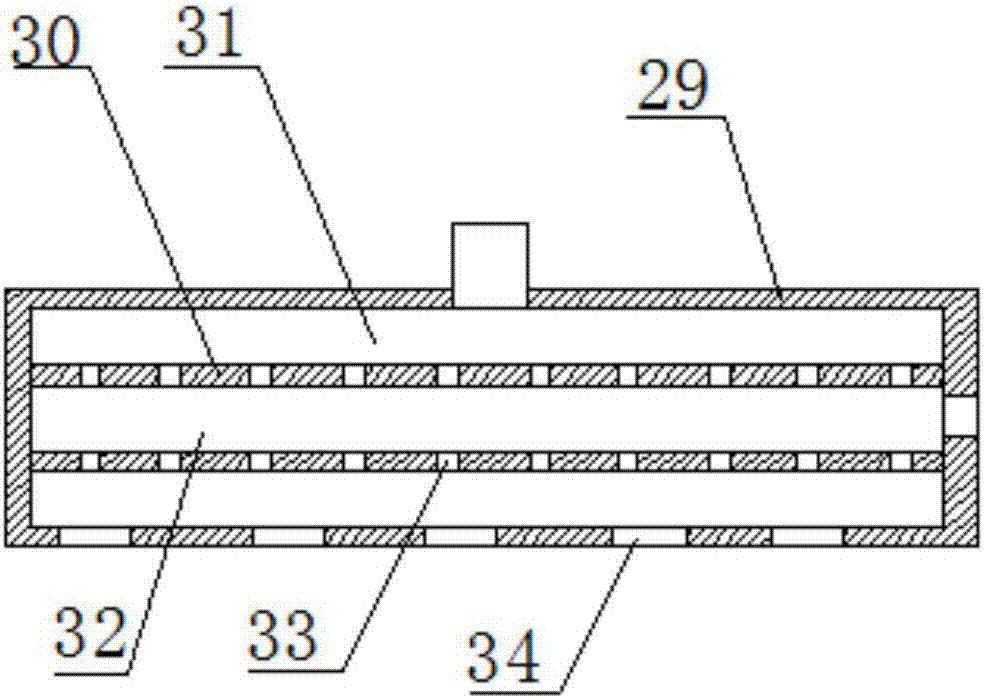

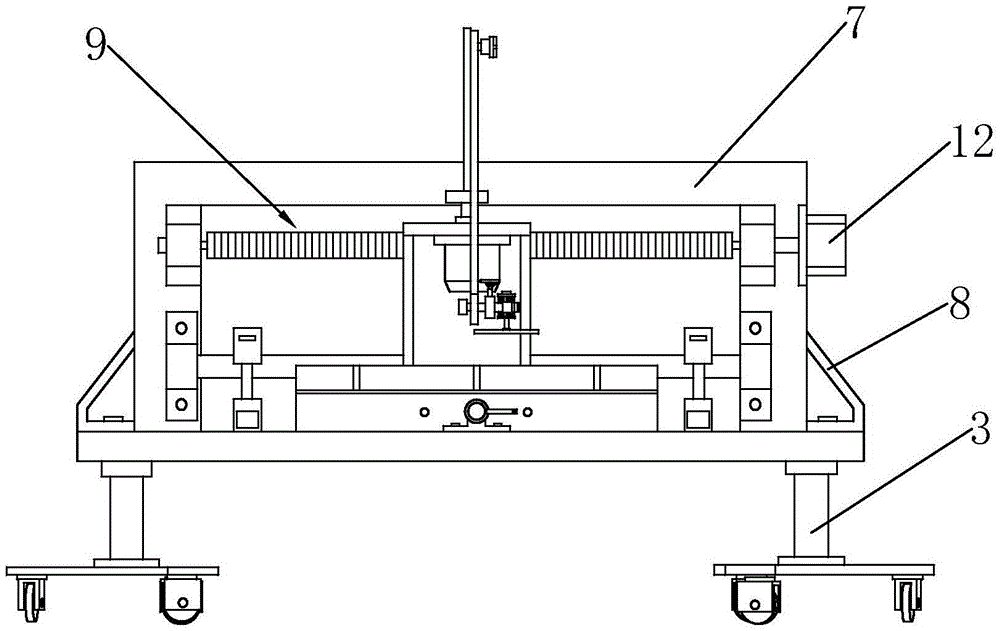

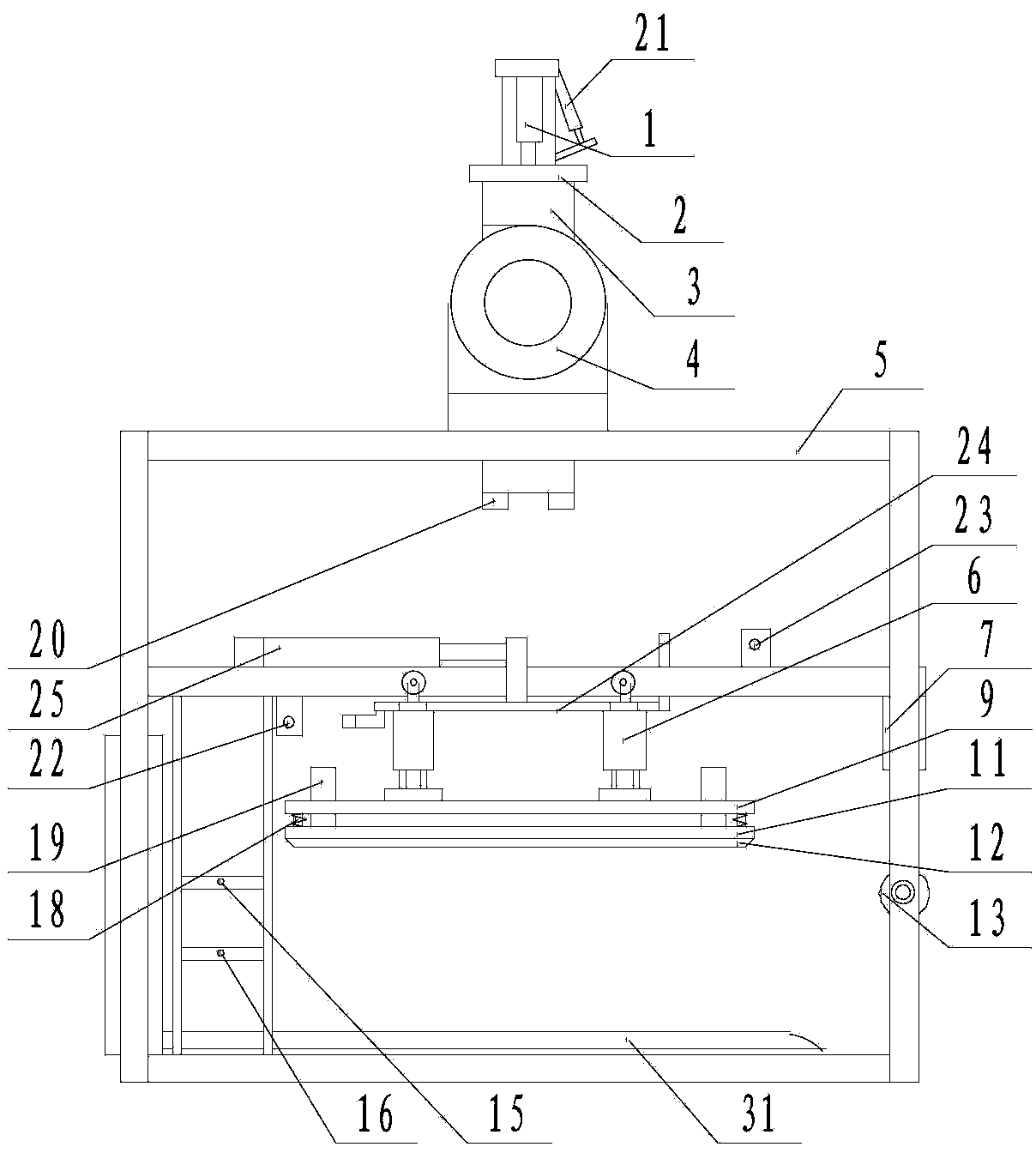

Heavy type automatic edge banding machine controlled by encoder

ActiveCN102114662ARealize the purpose of one machine with multiple functionsLow costWood working apparatusDomestic articlesMachine controlEngineering

The invention discloses a heavy type automatic edge banding machine controlled by an encoder, comprising a stand, a chain conveying device, a crawler-type pressing device, a glue supplying and belt pressing device, a belt cutting device, an up / down roughing device, an up / down finishing device, an up / down edge scraping device and an up / down polishing device; wherein the crawler type pressing device is arranged on the stand through a stand column assembly to ensure that the crawler type pressing device can ascend or descend relative to each stand column of the stand column assembly, and an upper roughing assembly of the up / down roughing device, an upper finishing assembly of the up / down finishing device, an upper edge scraping assembly of the up / down edge scraping device and an upper polishing assembly of the up / down polishing device are connected on a cross beam of the crawler type pressing device so as to ascend or descend synchronously along with the crawler type pressing device. The heavy type automatic edge banding machine can be used for carrying out edge banding operation on wood boards with higher specification in thickness, is free from the limit of the thickness of the wood boards, has a wide application range, is multipurpose and is beneficial to reduction of equipment cost for enterprises when edge banding operation and production are carried out on the wood boards.

Owner:NANXING MACHINERY CO LTD

Ultraviolet (UV) digital jet printing manufacturing method of plate-type components of floor boards and furniture

The invention relates to an ultraviolet (UV) digital jet printing manufacturing method of plate-type components of floor boards and furniture, which comprises the following process steps of 1 manufacturing digital jet printing pattern decoration picture; 2 preparing a base material; 3 coating aqueous back cover putty; 4 digitally printing a UV decoration layer in a jetting mode; 5 coating a UV primer layer; and 6 coating UV finish. The manufacturing method has the advantages of (1) directly printing on the surfaces of plate-type base materials of a density board, a multi-layer plywood, a laminated wood, a common board, a wood model and the like; (2) using electromagnetic radiation of ultraviolet light to enable UV printing ink jetted from a sprayer to be rapidly solidified on the plate-type base materials; (3) reducing scrappage of material pieces, effectively improving work efficiency and reducing cost; and (4) being free of volatile odor and environment-friendly in production processes due to the fact that the UV printing ink is solidified in a short time. In addition, during UV digital jet printing manufacture of the plate-type components of the floor boards and the furniture, production quantity can be flexibly set according to requirements, material categories, colors and pictures can be changed at random, one-piece cost and effect same regardless of the batch size.

Owner:南京雷励数码科技有限公司

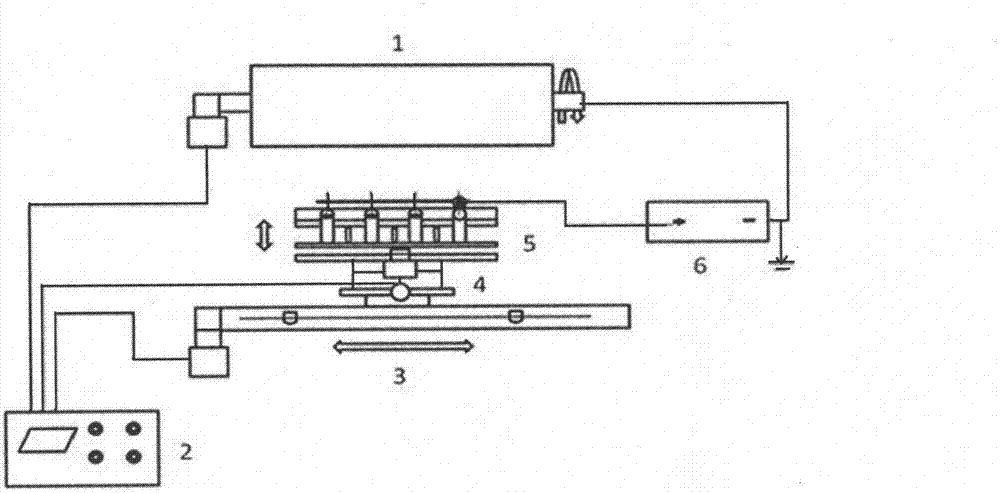

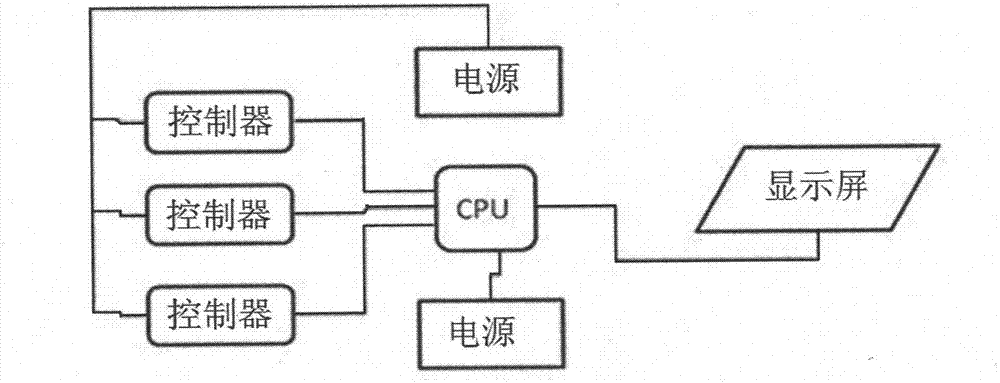

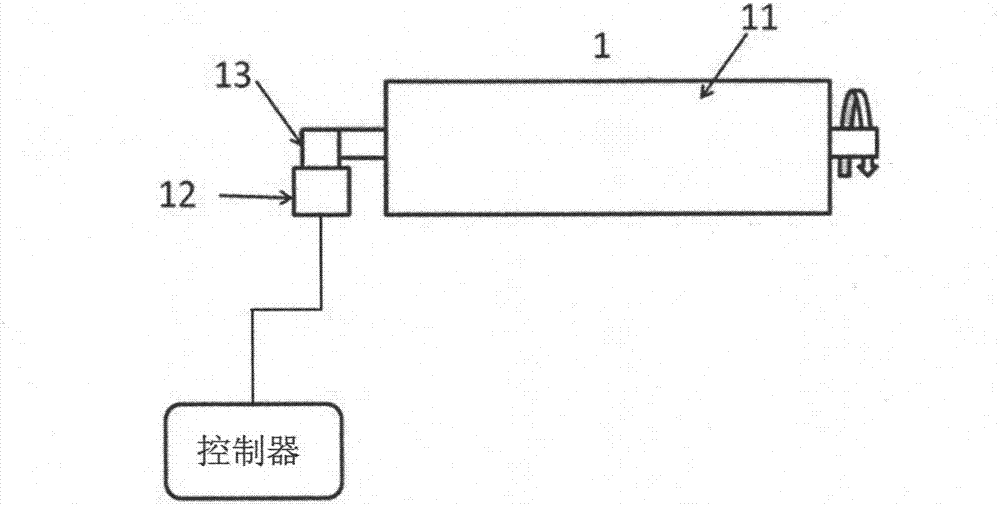

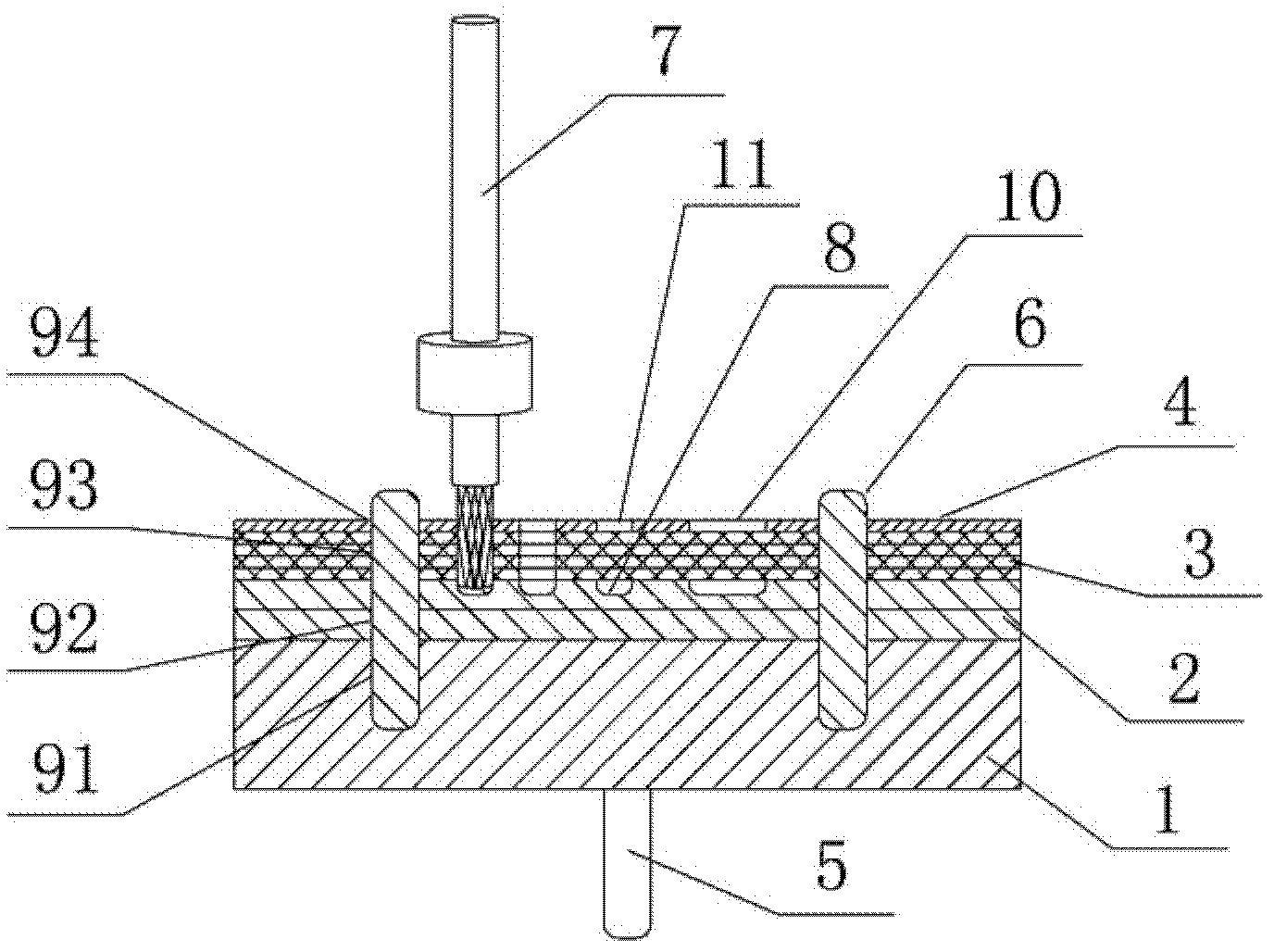

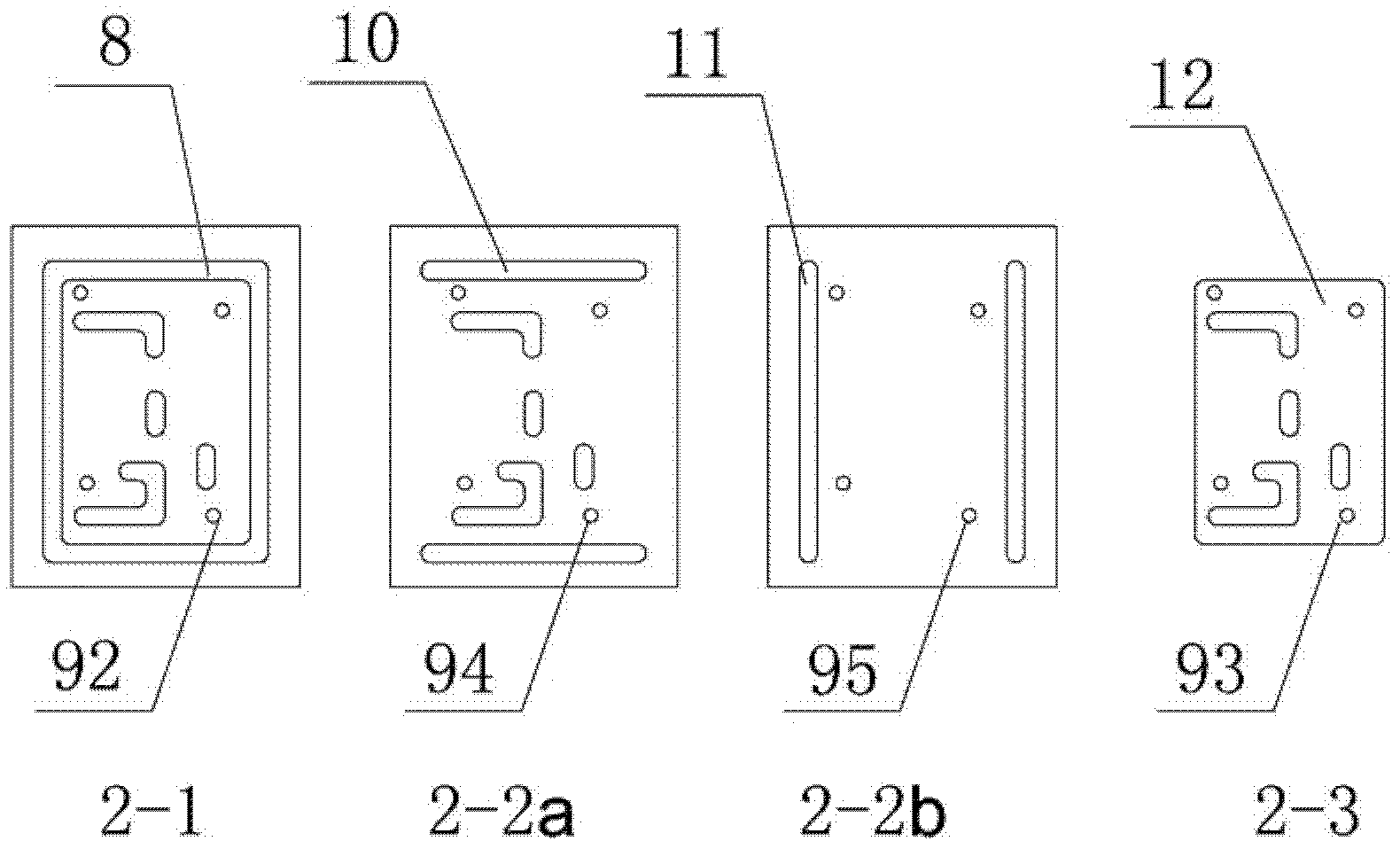

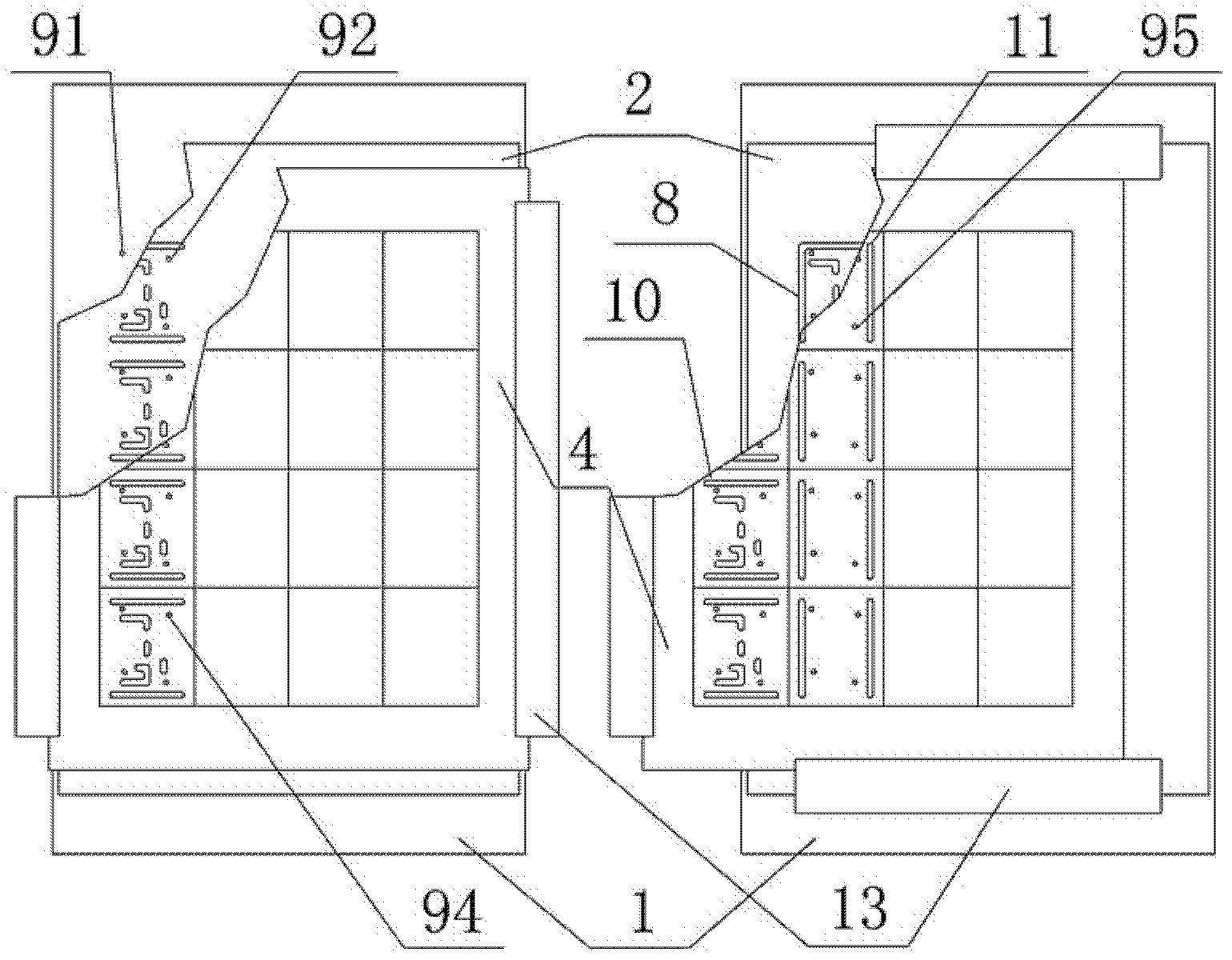

Automatic control multi-spray-head electrostatic spinning equipment

InactiveCN102776582AEasy to adjustAffect qualitySpinnerette packsFilament/thread formingFiberAutomatic control

The invention provides automatic control multi-spray-head electrostatic spinning equipment, which comprises a high-voltage electrostatic generator, a receiving device and a lifting device and is characterized by also comprising an automatic control box, a dustproof transverse moving slide table, a multi-passage precise liquid supply pump and a self-cleaning type multi-spray-head device, wherein data interfaces of multi-passage precise liquid supply pump, the dustproof transverse moving slide table and the receiving device are respectively connected with the automatic control box, an injector is fixedly arranged at the multi-passage precise liquid supply pump, the self-cleaning type multi-spray-head device is connected with the front end of the injector, a bakelite plate covered with a conducting wire is fixedly arranged on a spinning head, a conducting clamp post is fixedly arranged on the bakelite plate covered with the conducting wire, and the high-voltage electrostatic generator is connected with the conducting clamp post. The automatic control multi-spray-head electrostatic spinning equipment has the advantages that the precision, integration and automation degree is high, the operation is simple, convenient, safe and fast, the production efficiency is high, and wide application prospects are realized in the industrial aspect of nanometer fibers.

Owner:DONGHUA UNIV

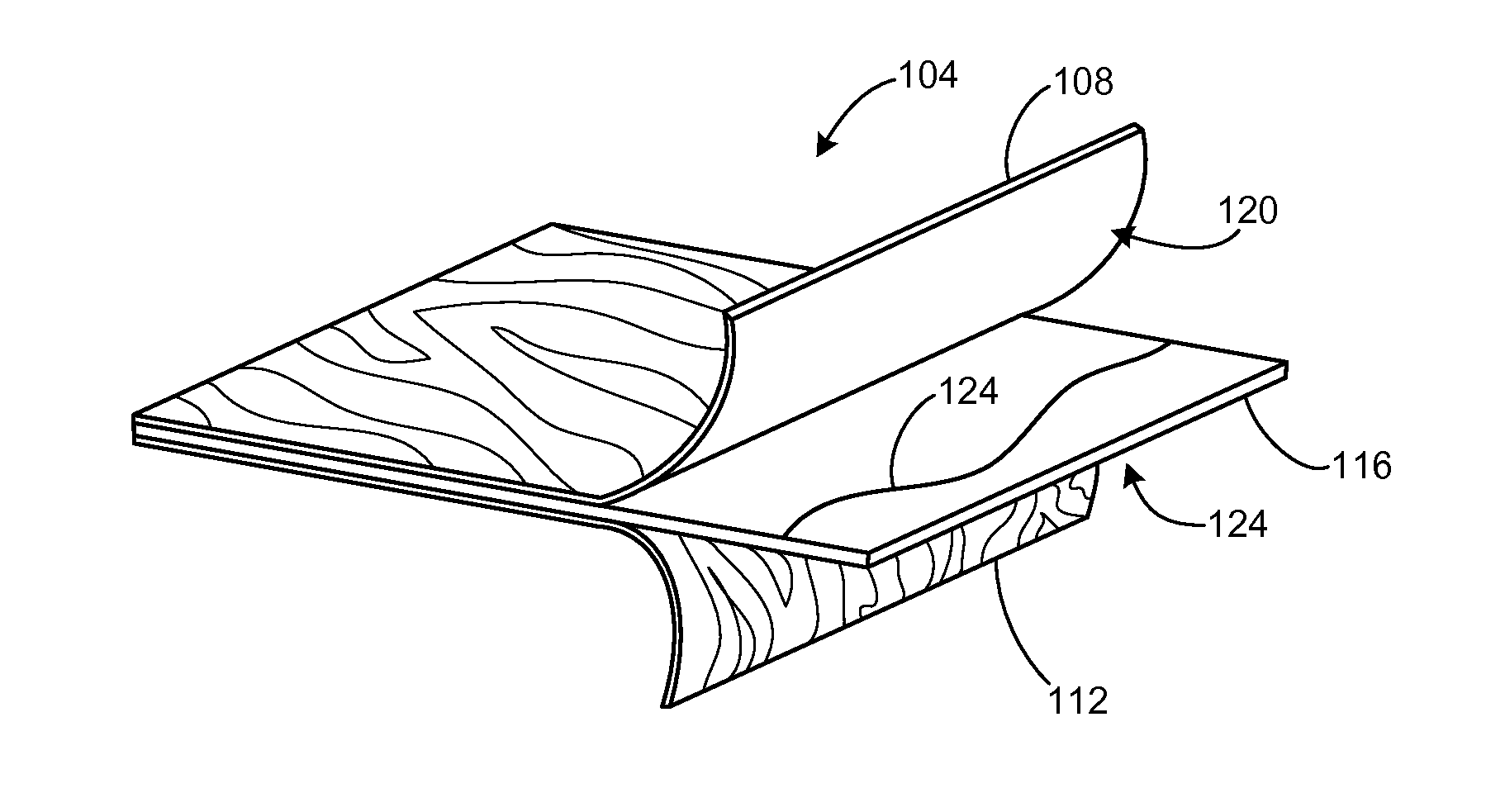

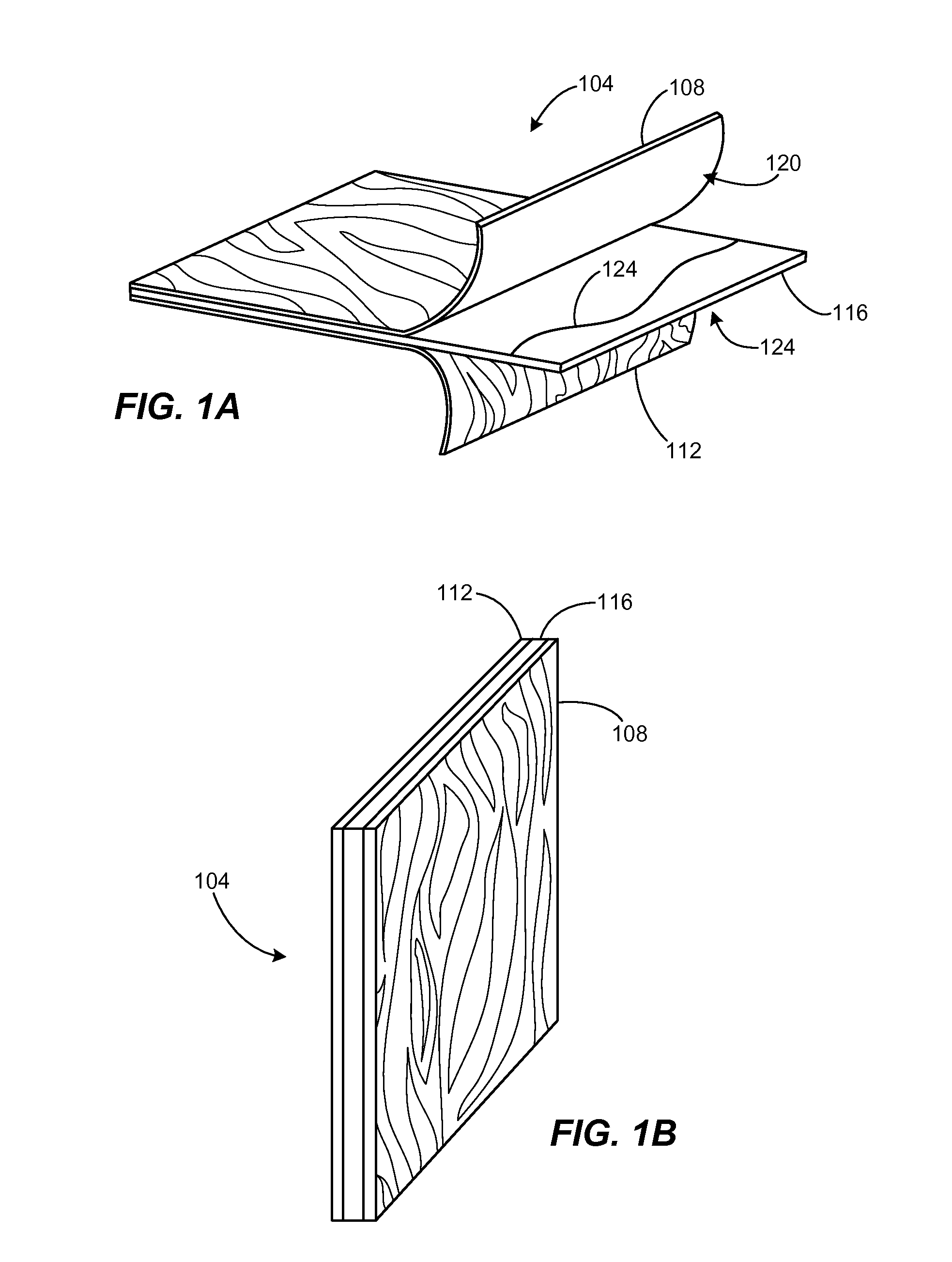

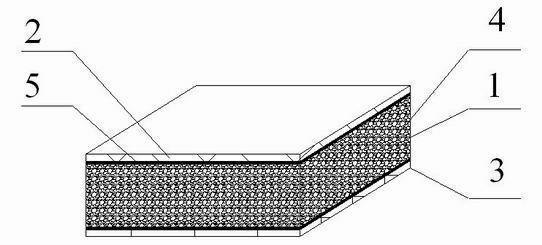

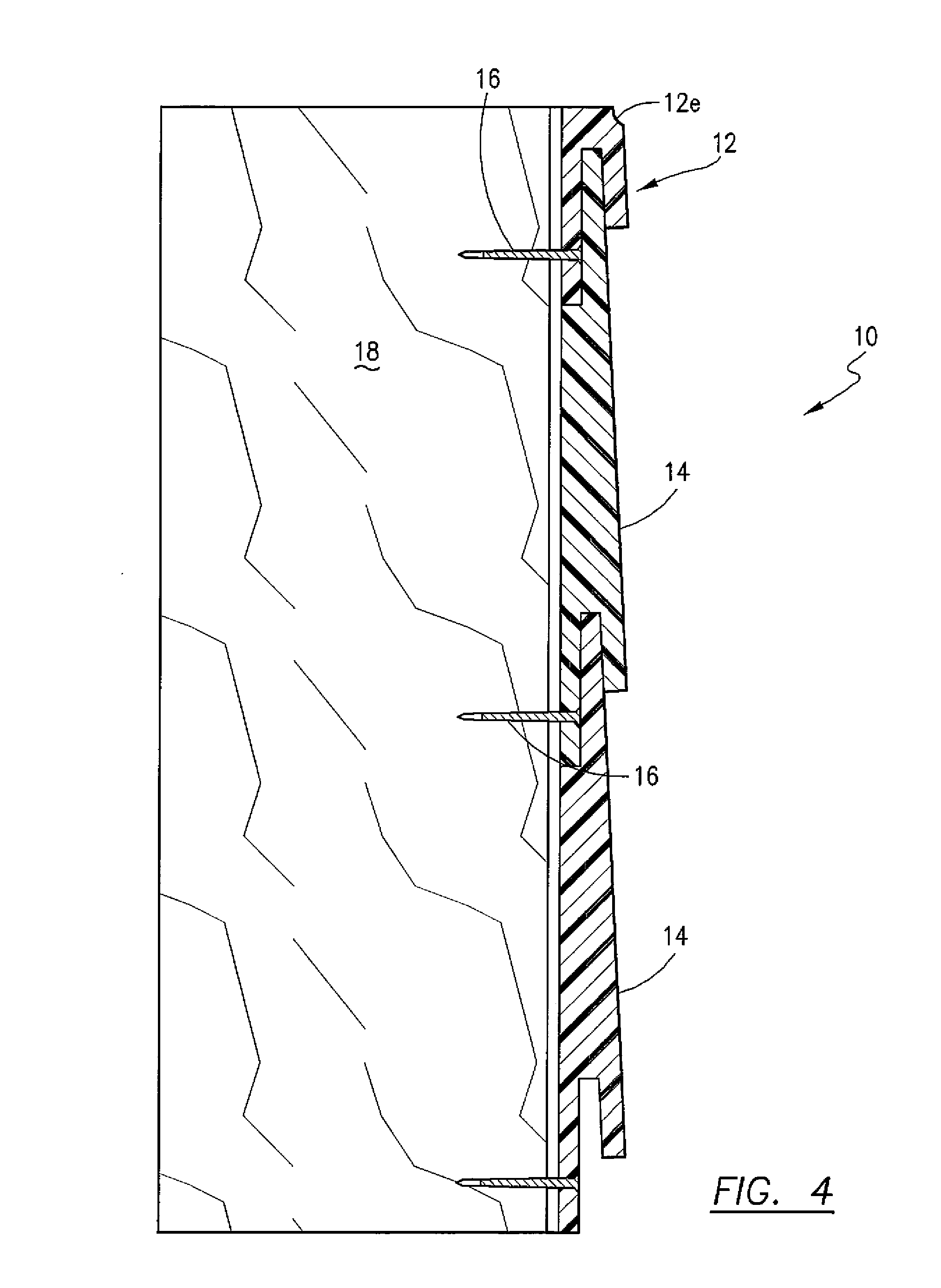

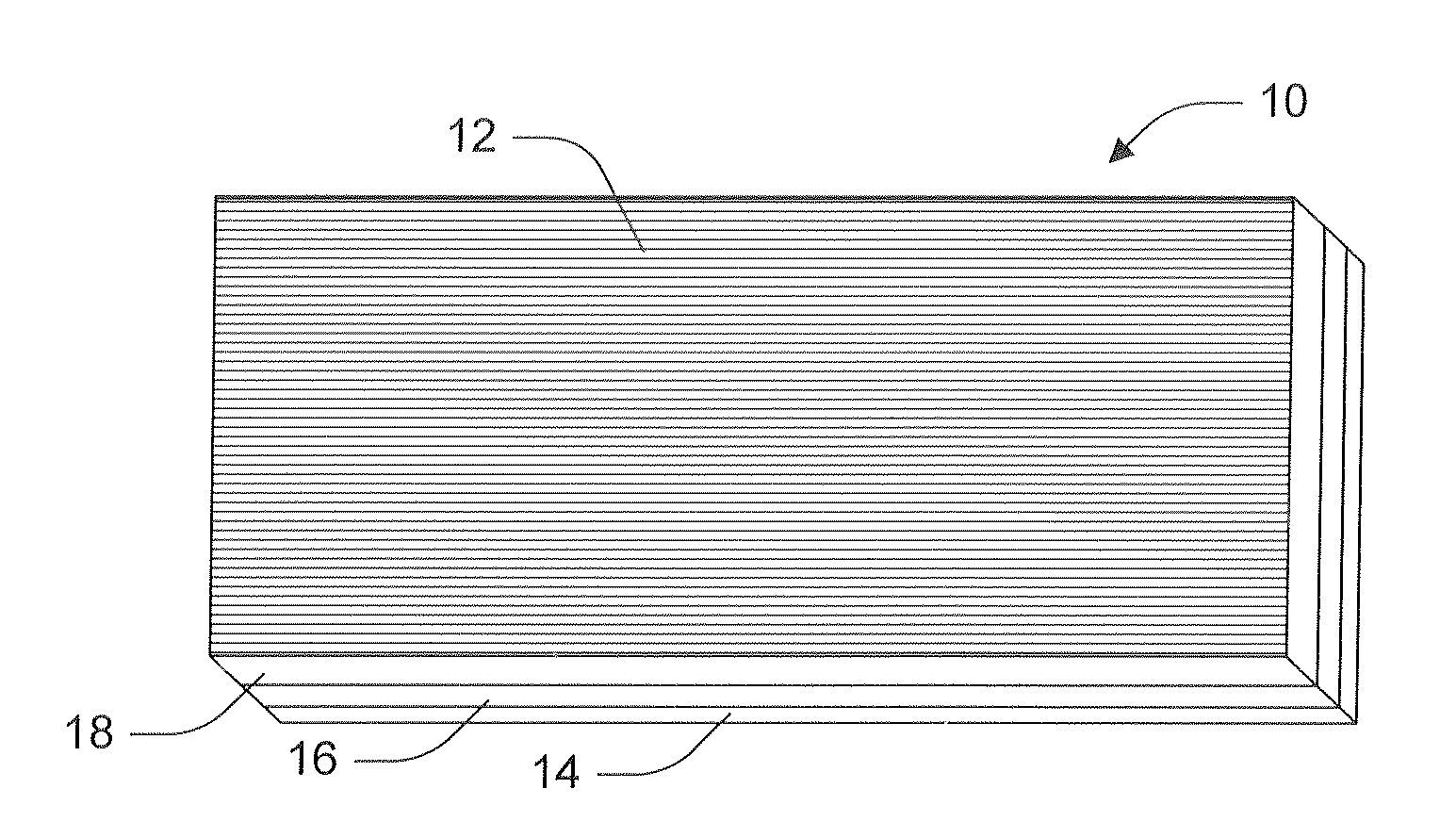

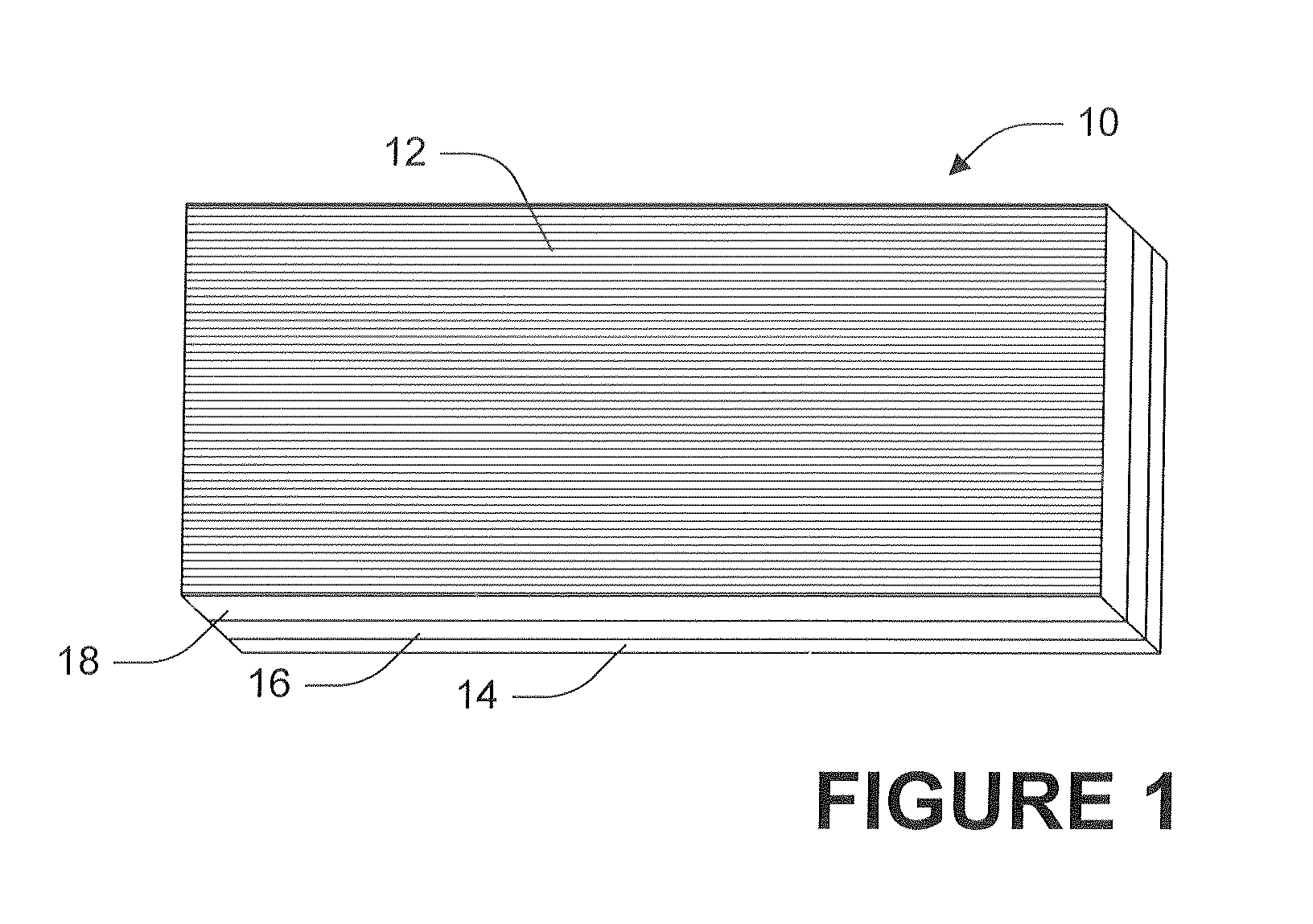

Light transmissive bendable wood panel

ActiveUS20130196119A1Prevent movementLow costDecorative surface effectsDuplicating/marking methodsEngineeringWood panel

A light transmissive bendable wood panel provides a wood panel that may be finished in a similar manner to traditional wood panels, but is light transmissive to allow the light transmissive bendable wood panel to be illuminated. The light transmissive bendable wood panel may be formed with a bendable substrate to allow various curves or other shapes to be formed. The light transmissive bendable wood panel may comprise a face layer having a permeable backing to ensure full adhesion with the substrate. A back layer may be provided to stabilize the light transmissive bendable wood panel and prevent curling, cupping, and delaminating. The light transmissive bendable wood panel may be backlit or edge lit. One or more illuminated designs may be formed in a face layer of the light transmissive bendable wood panel.

Owner:DOBECZ GILBERT +1

Bamboo-made wallboard

InactiveCN1743598AReduce weightEasy constructionConstruction materialLayered productsFiberWood shavings

A bamboo wall board is composed of bamboo tubes with adhesive peripheral faces, in which, the outer shapes of multiple bamboo tubes are the same, they are orthohexagonal post, die-square or cylindrical and an adhesive agent for connecting bamboo tubes is set at the contact places of the peripheral faces, the tubes are filled with fillers of bamboo bits, wood flour, wood shavings, fibers, crushed plant stovers, cement slurry, gypsum powder or foamed plastics, all of which are doped with adhesives. The bamboo wallboard is adhered with coats of bamboo boards, wood plywood, fiberboard, plastics, metallic board, gypsum boards or asbestos boards.

Owner:天津市朗明通信科技有限公司

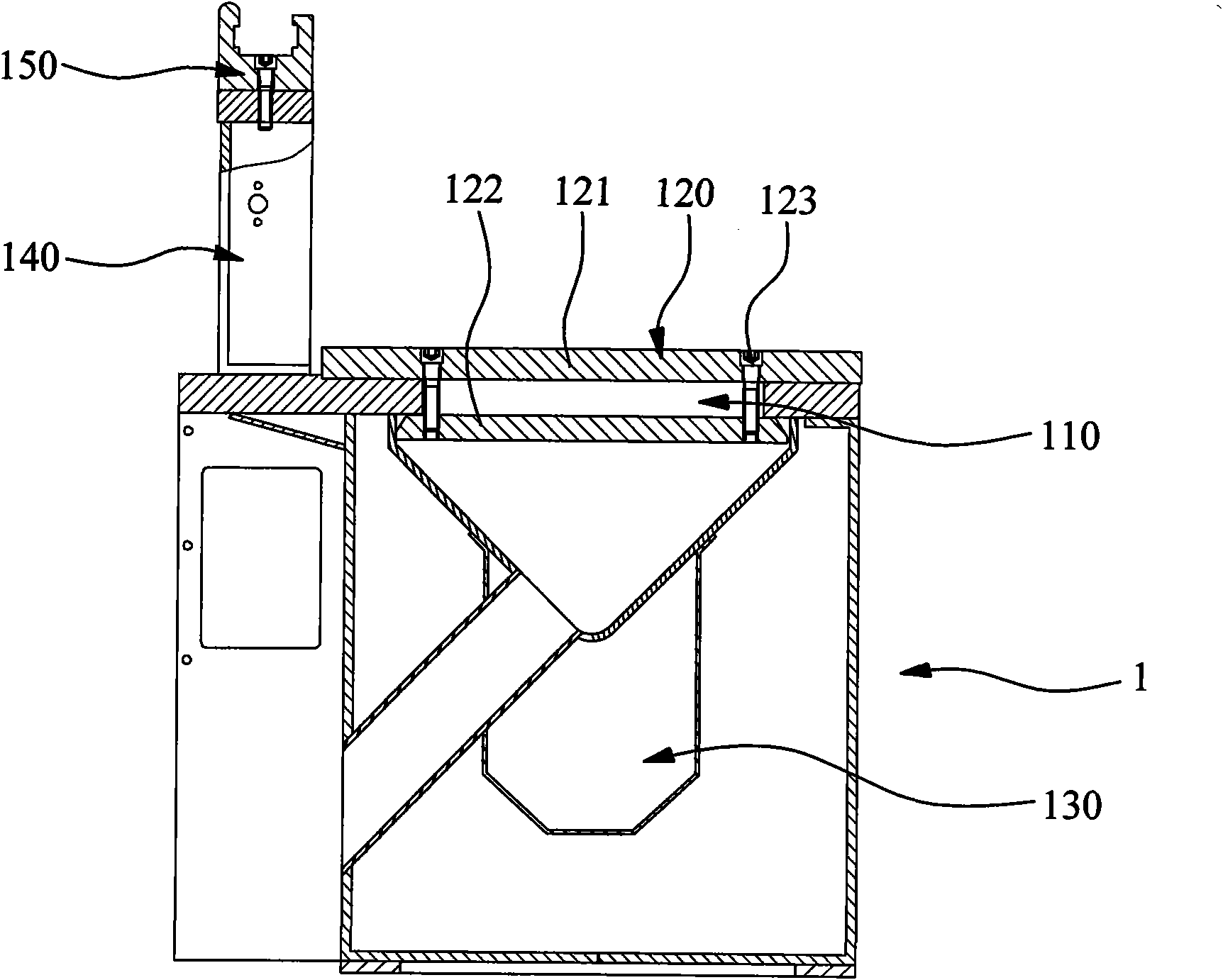

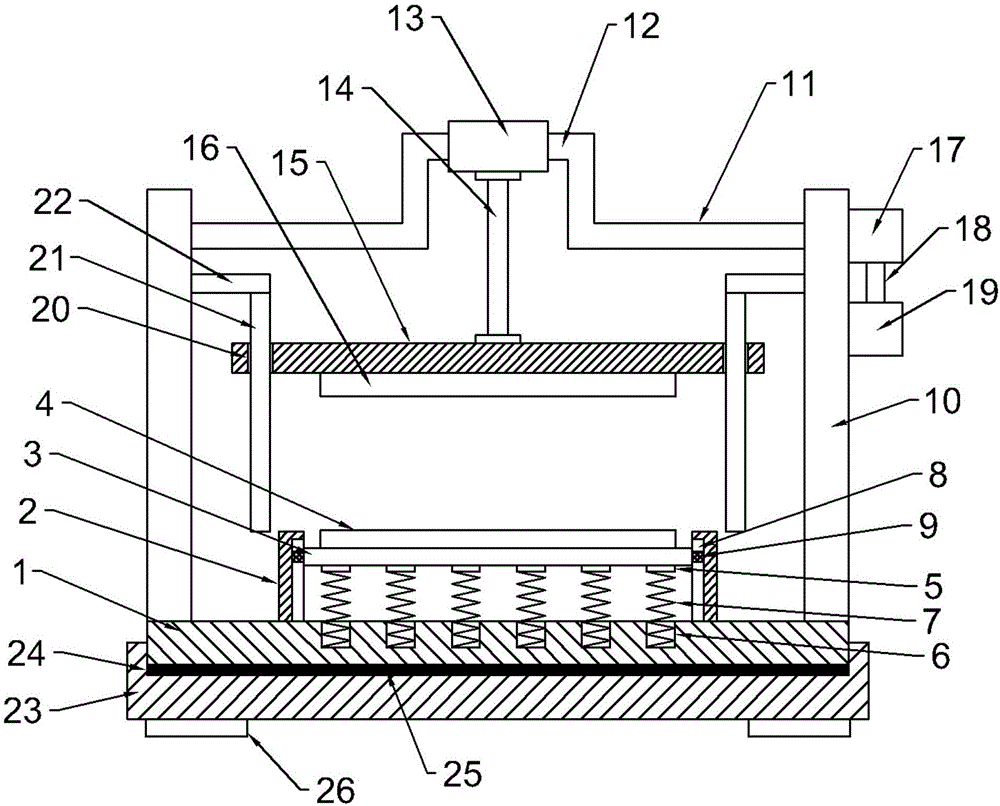

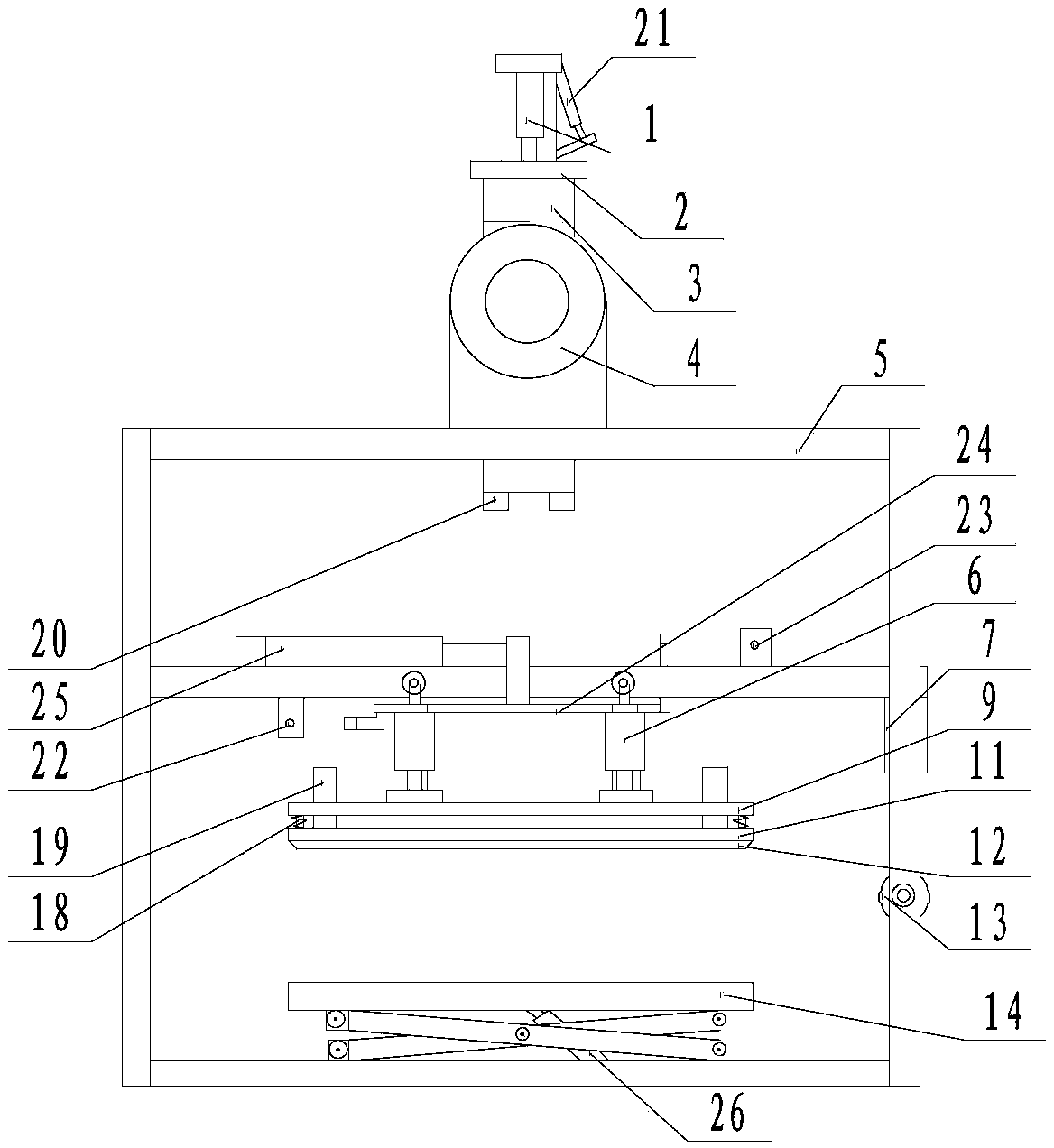

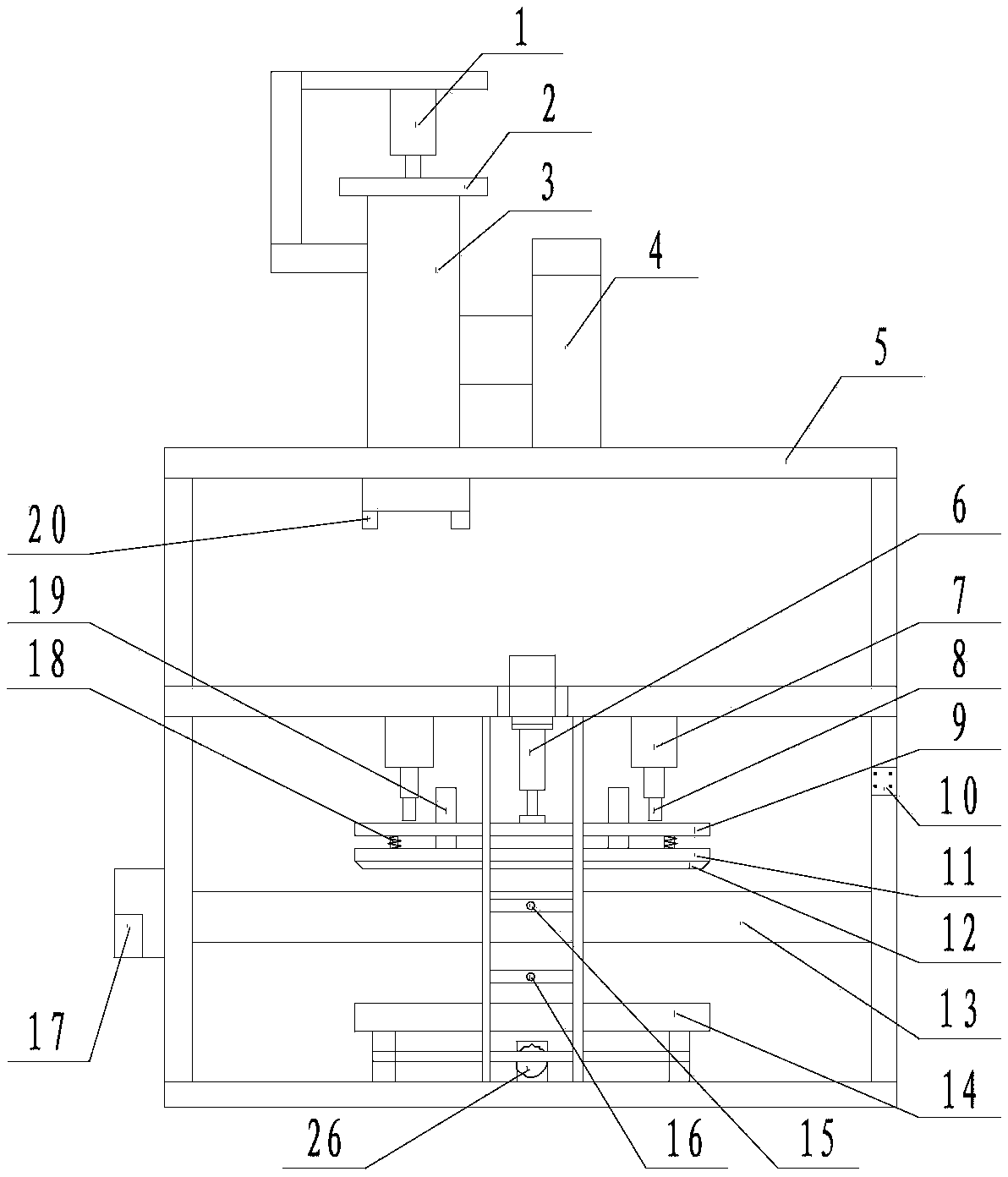

Continuous and stable hot-pressing equipment for furniture boards

InactiveCN106493806AEnsure safetyQuality assurancePlywood pressesVeneer pressesEngineeringWood panel

The invention discloses continuous and stable hot-pressing equipment for furniture boards. The equipment comprises a bottom plate, limiting plates, a supporting plate, a work table, connectors, grooves, buffering springs, sliding grooves and sliding blocks; supporting columns are installed at the upper end of the bottom plate, a crank shaft is arranged between the two supporting columns, a rod journal is arranged in the middle of the crank shaft and is provided with a shaft sleeve in a sleeved mode, the lower end of the shaft sleeve is connected to a lifting plate through a connecting rod, and a hot-pressing plate is arranged on the lower surface of the lifting plate; and guide holes are formed in the left end and the right end of the lifting plate, and guide rods penetrate into the guide holes. According to the equipment, the boards placed on the work table can be hot-pressed continuously, and the hot-pressing is higher relative to traditional hot-pressing; the supporting plate under the work table has the buffering function, the safety of the boards can be guaranteed in the process of continuous hot-pressing, damage caused by excessive hot-pressing force can be avoided, and the hot-pressing quality is guaranteed; and the overall base has the buffering performance, and therefore the hot-pressing equipment can be stable and safe and is suitable for being popularized and used.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

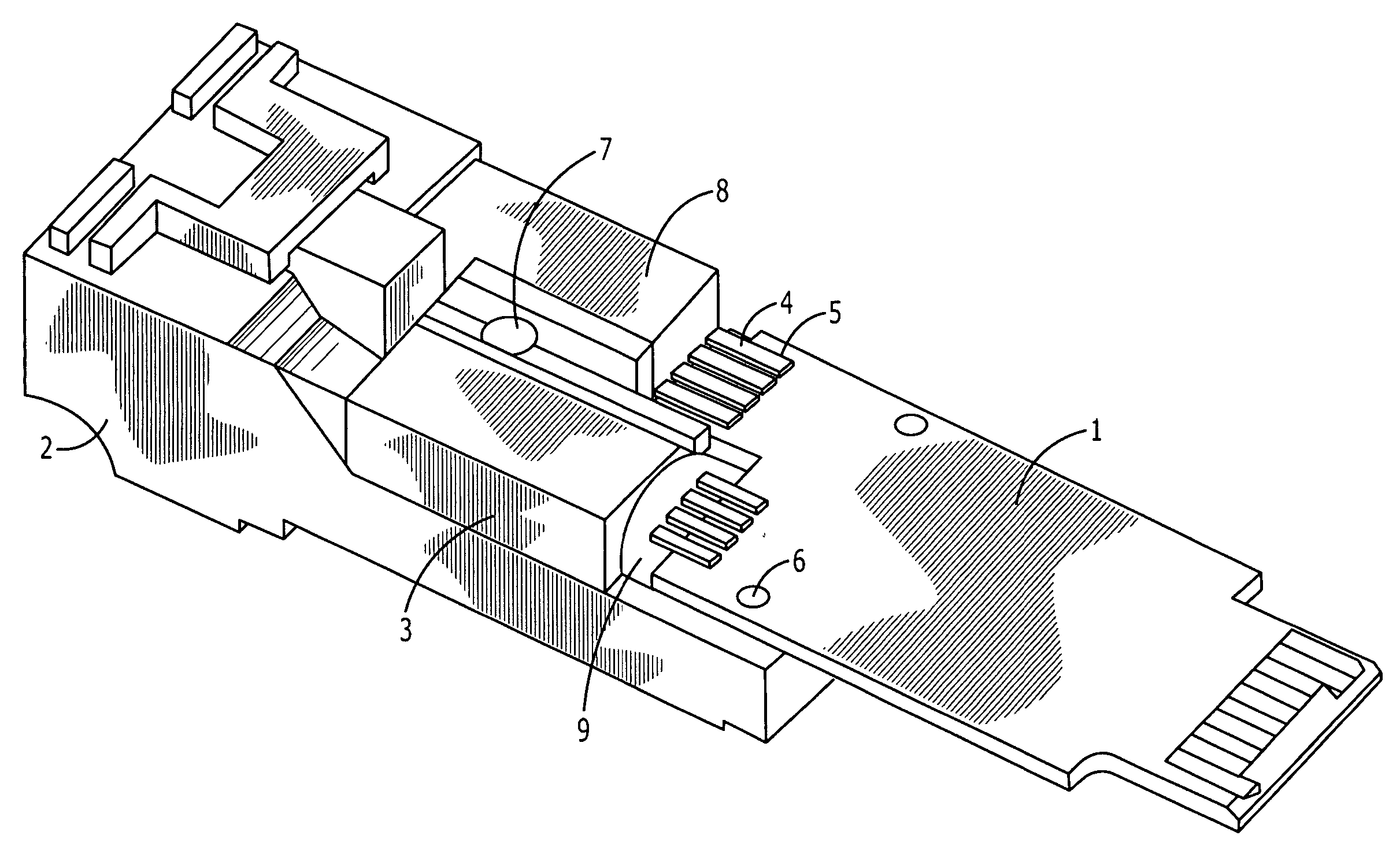

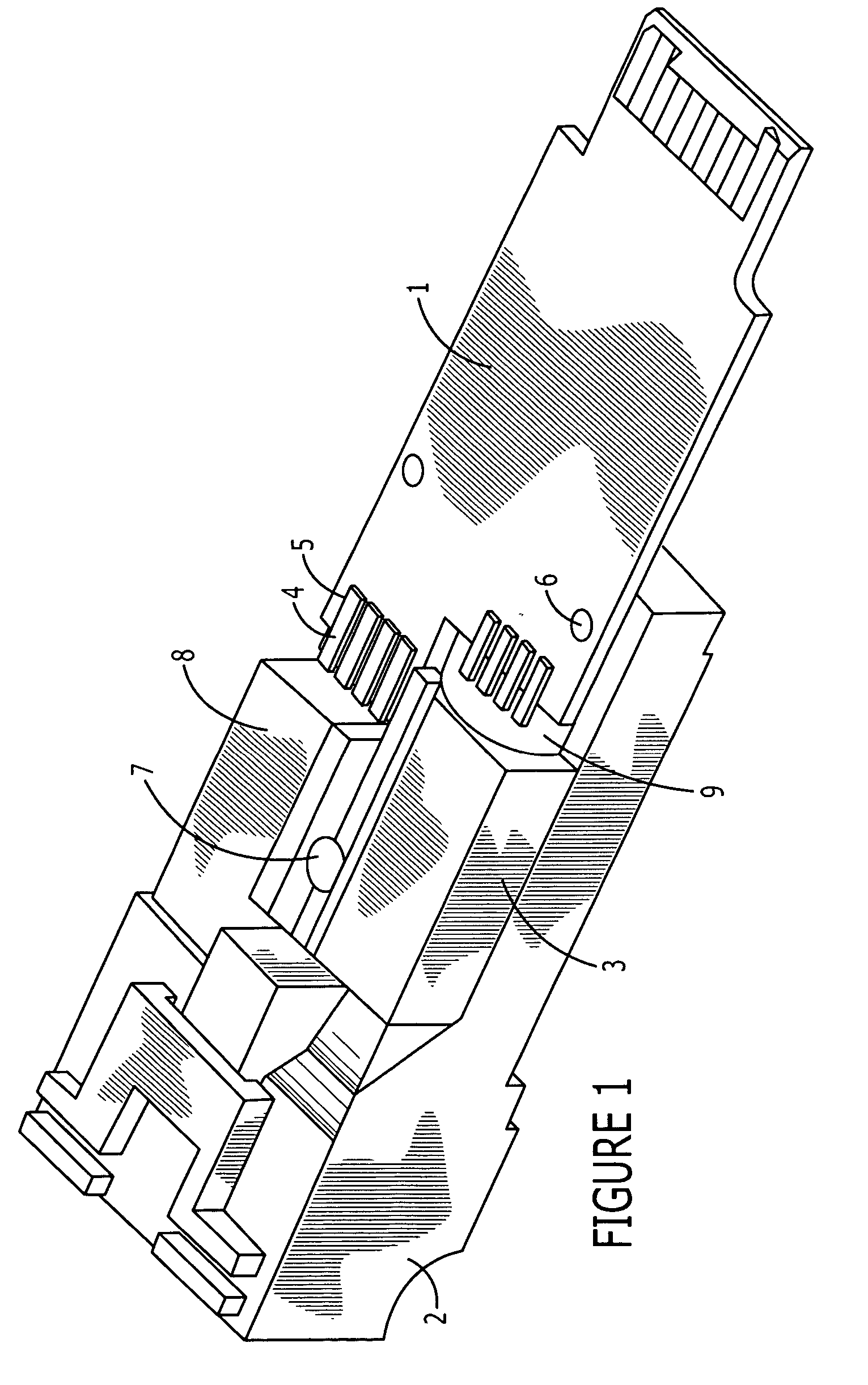

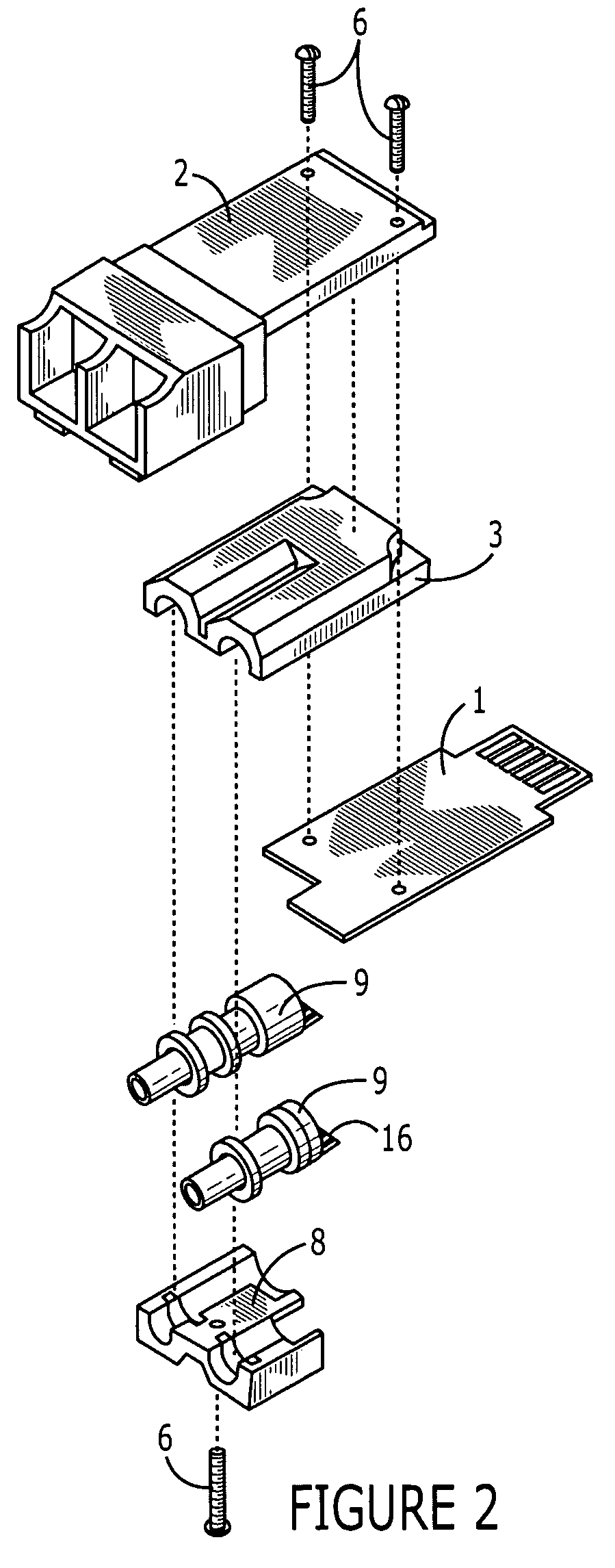

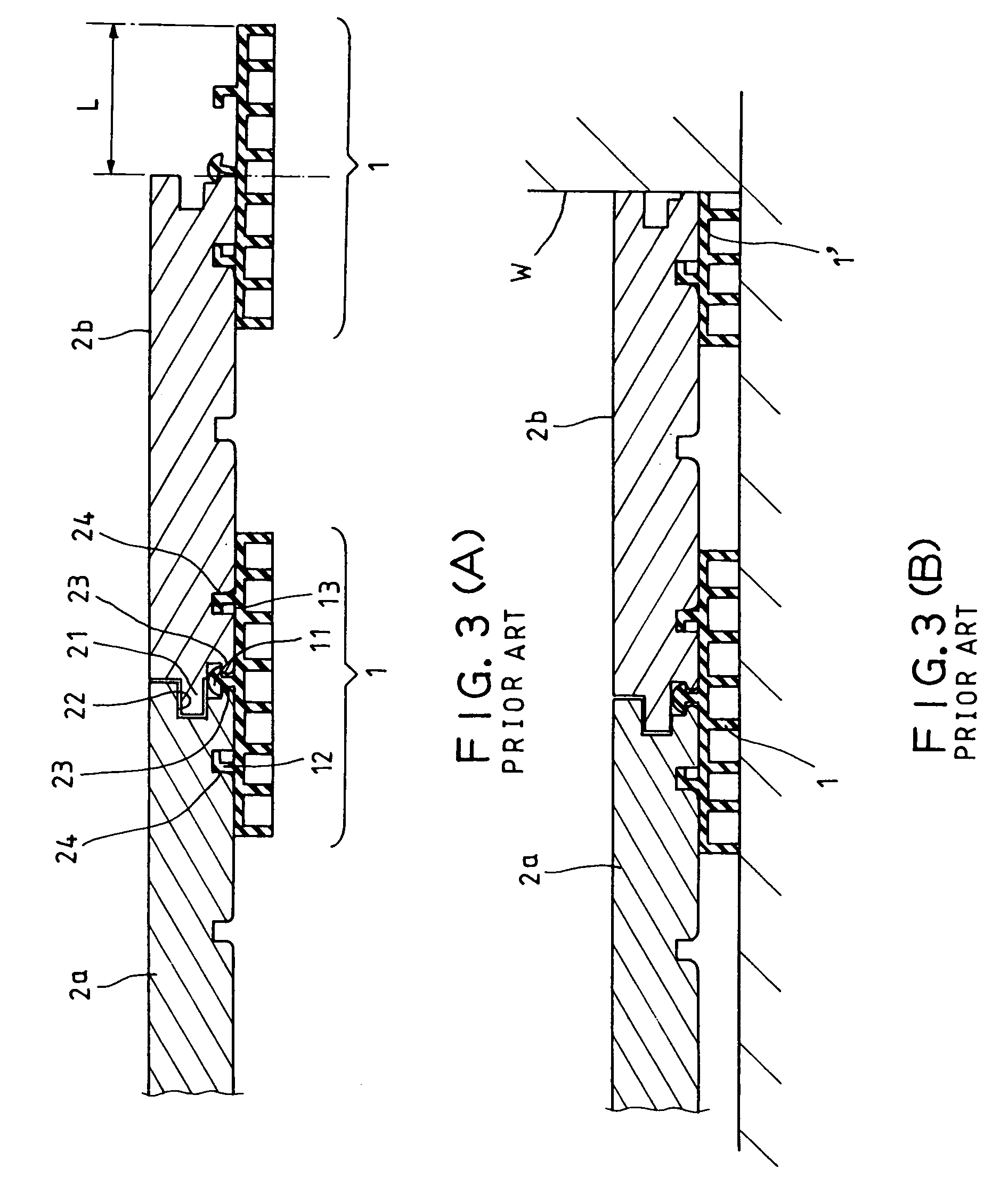

Opto-electric module and method of assembling

InactiveUS20050018978A1Maintain structural integrityMaintain integrityCoupling light guidesElectricityElectrical conductor

An opto-electric module comprising: (a) an OSA having an optical axis, and optical end, an electrical end; (b) a planar circuit board having top and bottom surfaces and one or more electrical contacts on at least one of the surfaces of the circuit board; (c) a connector interface for receiving a mating connector; (d) a substrate connected to the connector interface, the OSA and the circuit board, the substrate holding the circuit board parallel to the optical axis of the OSA; and (e) an electrical interface between the electrical end of the OSA and the electrical contacts of the circuit board, the electrical interface comprising a flexible conductor extending orthogonally from the optical axis of the OSA and bending around to overlay the electrical contacts on the circuit board.

Owner:TE CONNECTIVITY CORP

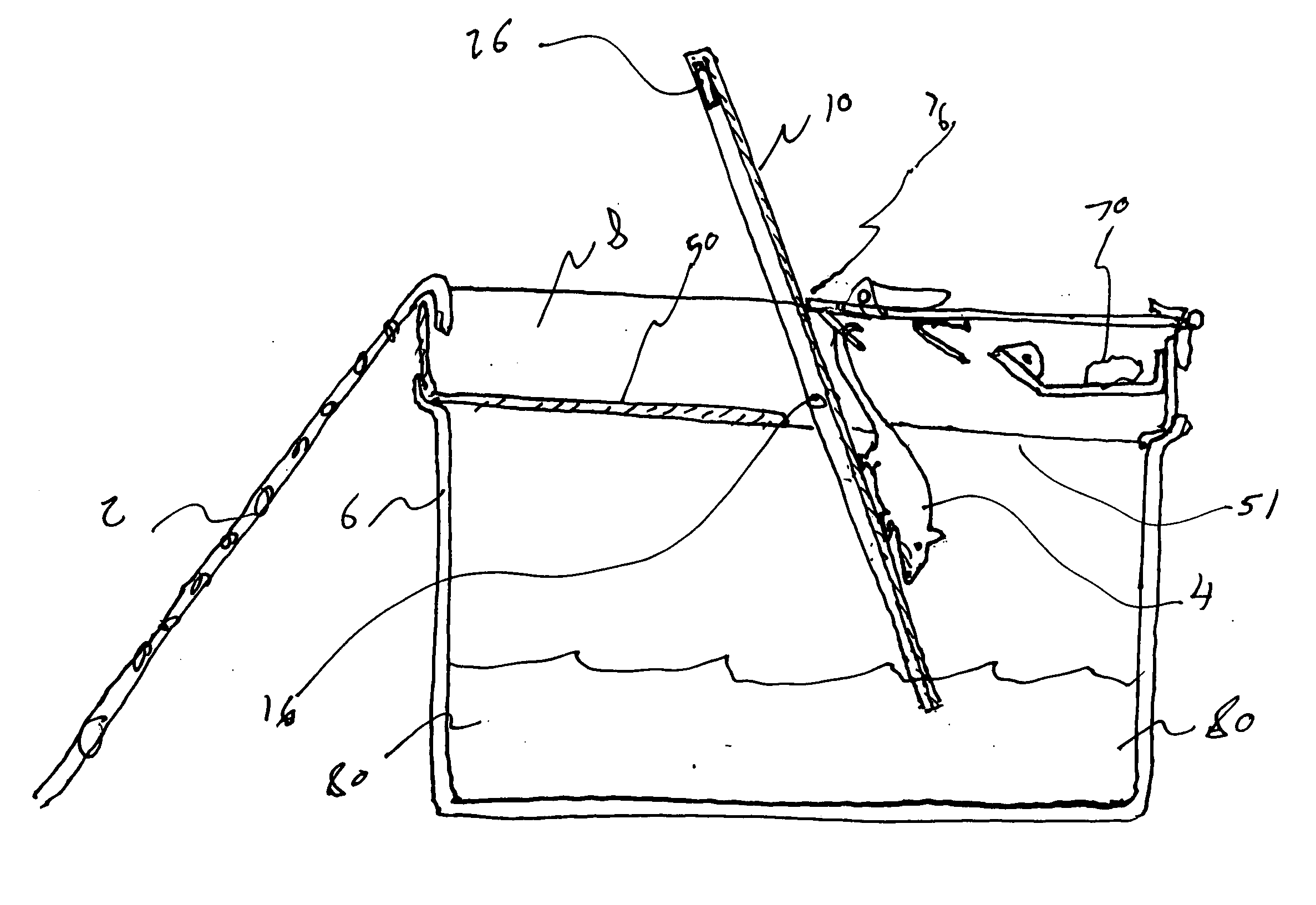

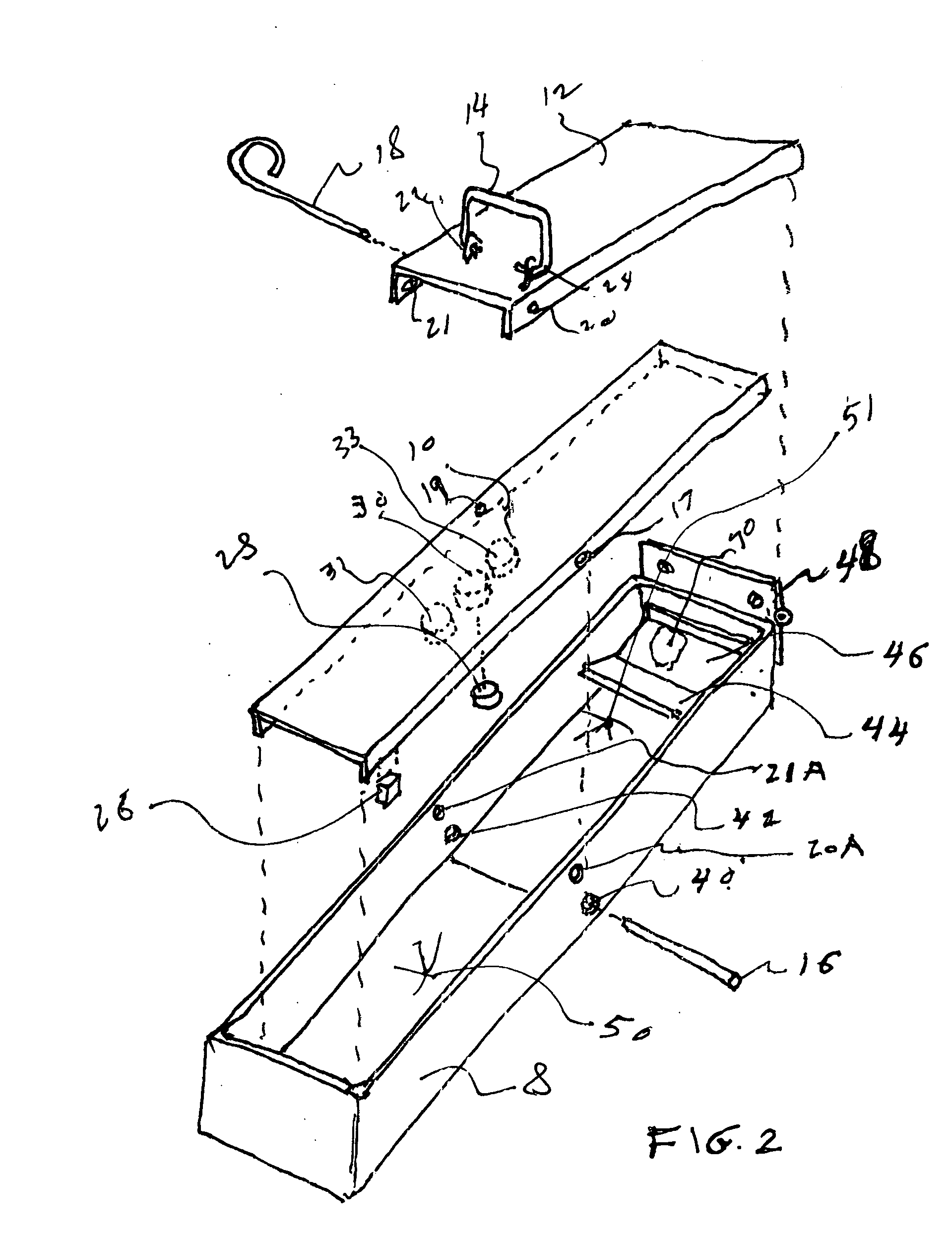

Rodent trap

Rodent Trap with a lid, a pivot plank, a ferrous metal rectangular open topped box, a magnet, a pivot point, a food holding platform, a guide panel, a climbing ramp or rope and a rodent receptacle. The guide panel and the bait tray are fixed at one end of the rectangular box. The box has half of the floor removed. The pivot point holds the plank so that it can rotate. The pivot plank includes a magnet on its underside. The magnet is attracted to the ferrous metal portion of the floor of the box so that a rodent can climb up the ramp, travel along the pivot plank, wedge itself between the pivot plank and the guide panel in the pursuit of bait causing the magnetic attraction to break and the pivot plank to rotate down causing the rodent to drop into the receptacle below the rectangular box.

Owner:SEARS RICHARD B

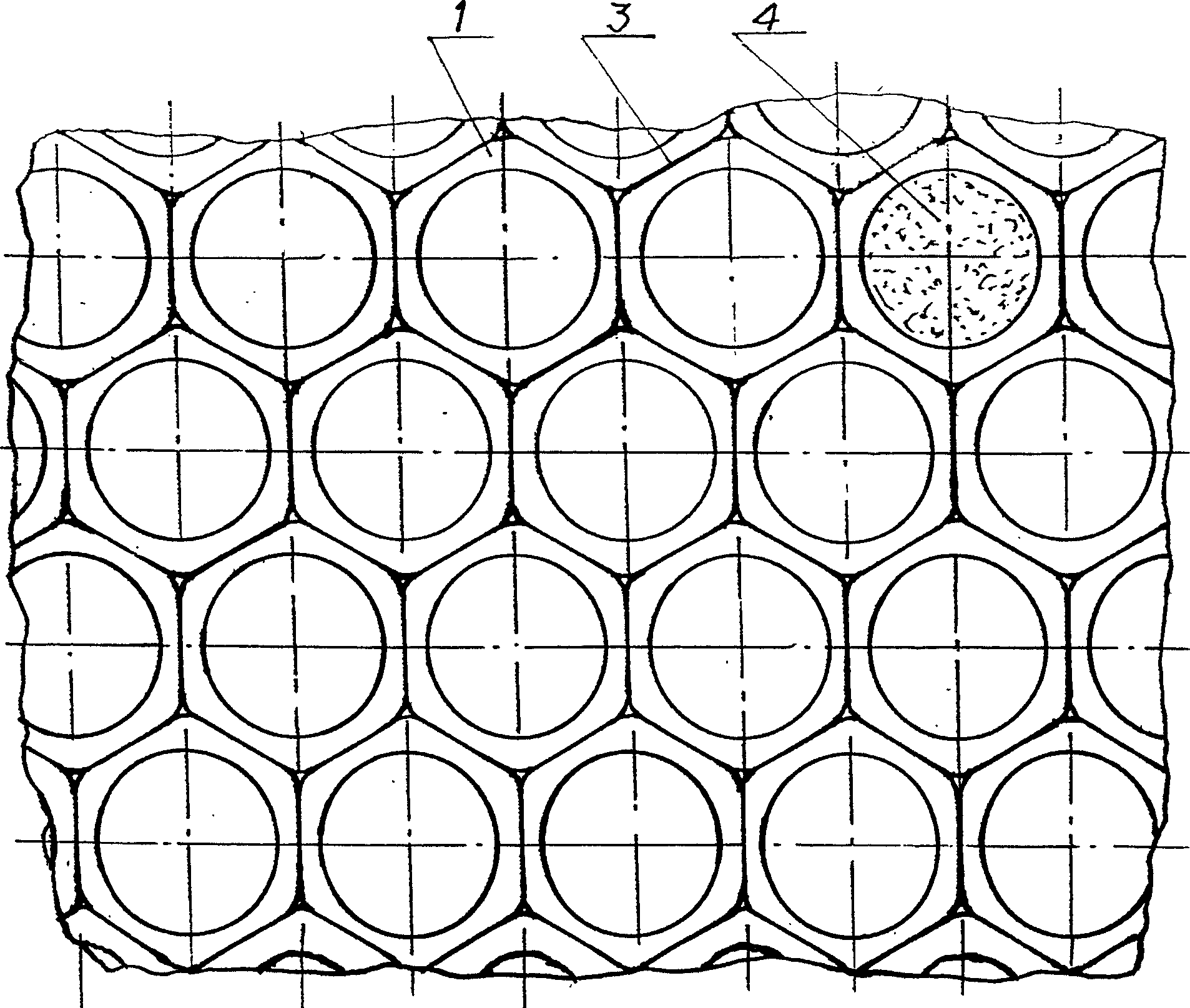

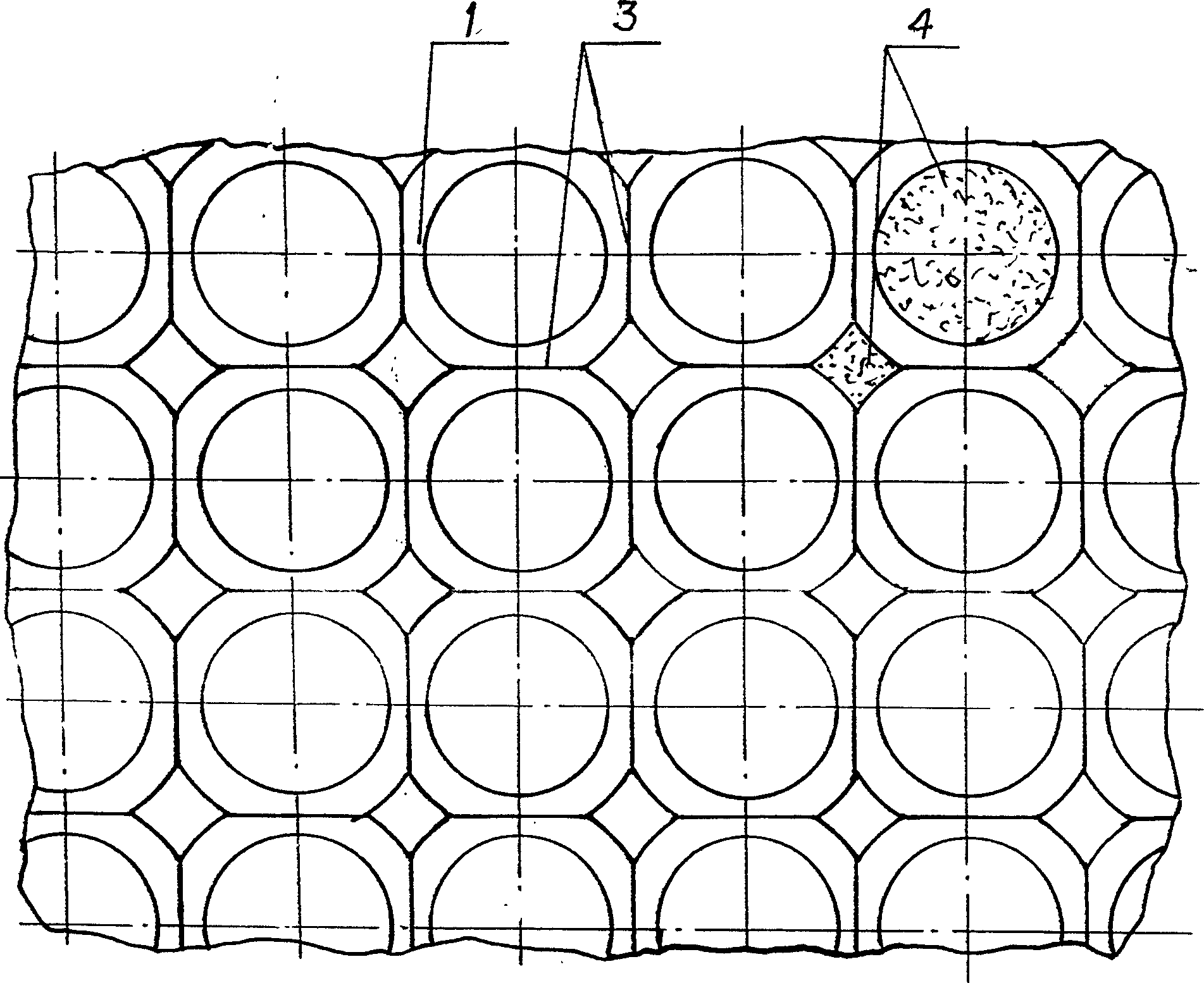

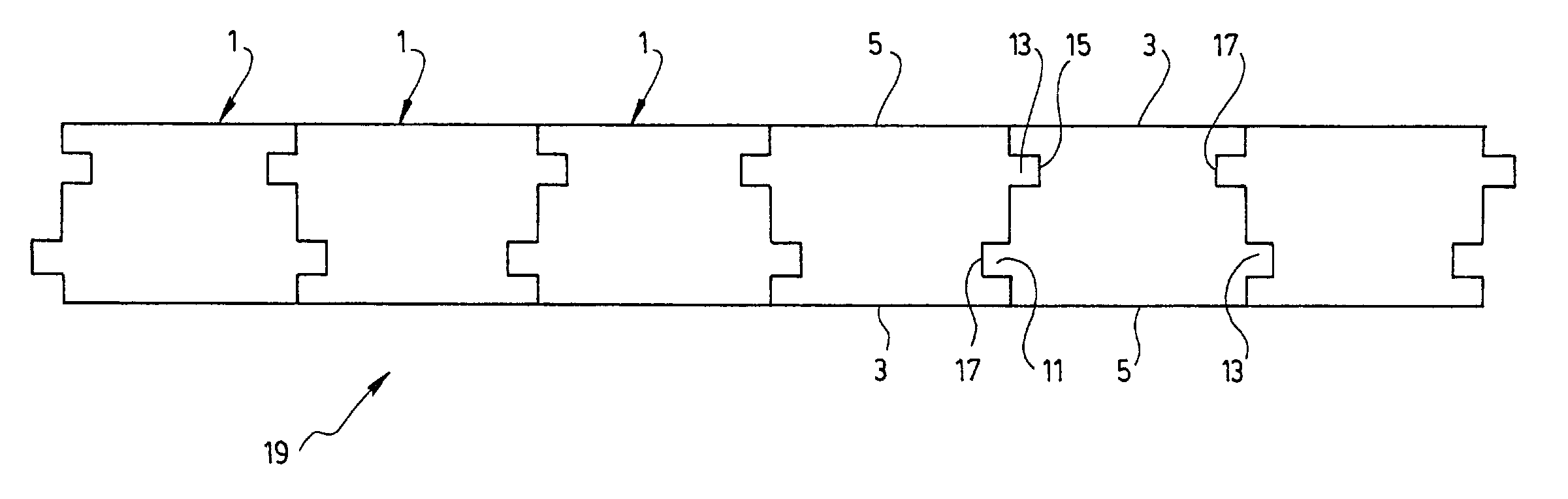

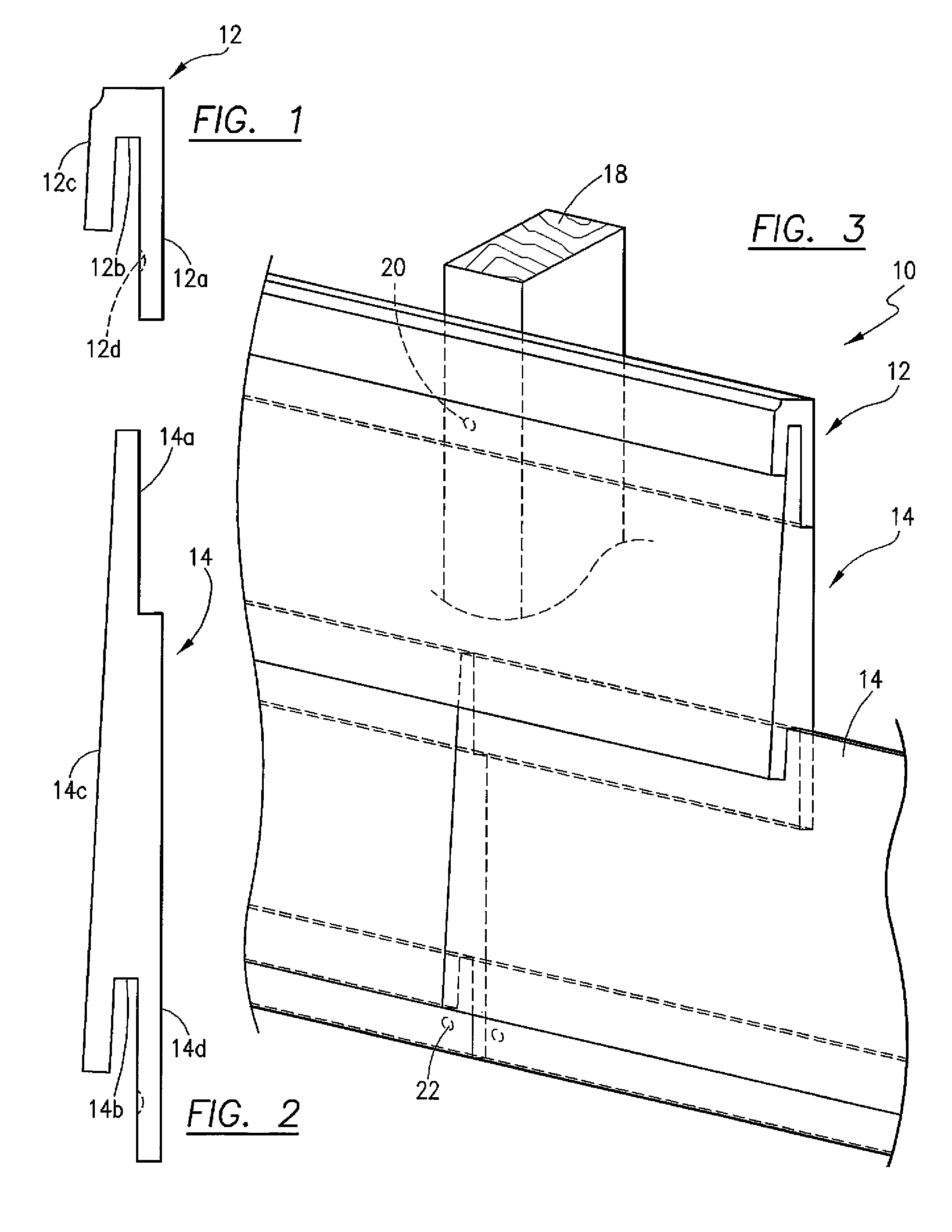

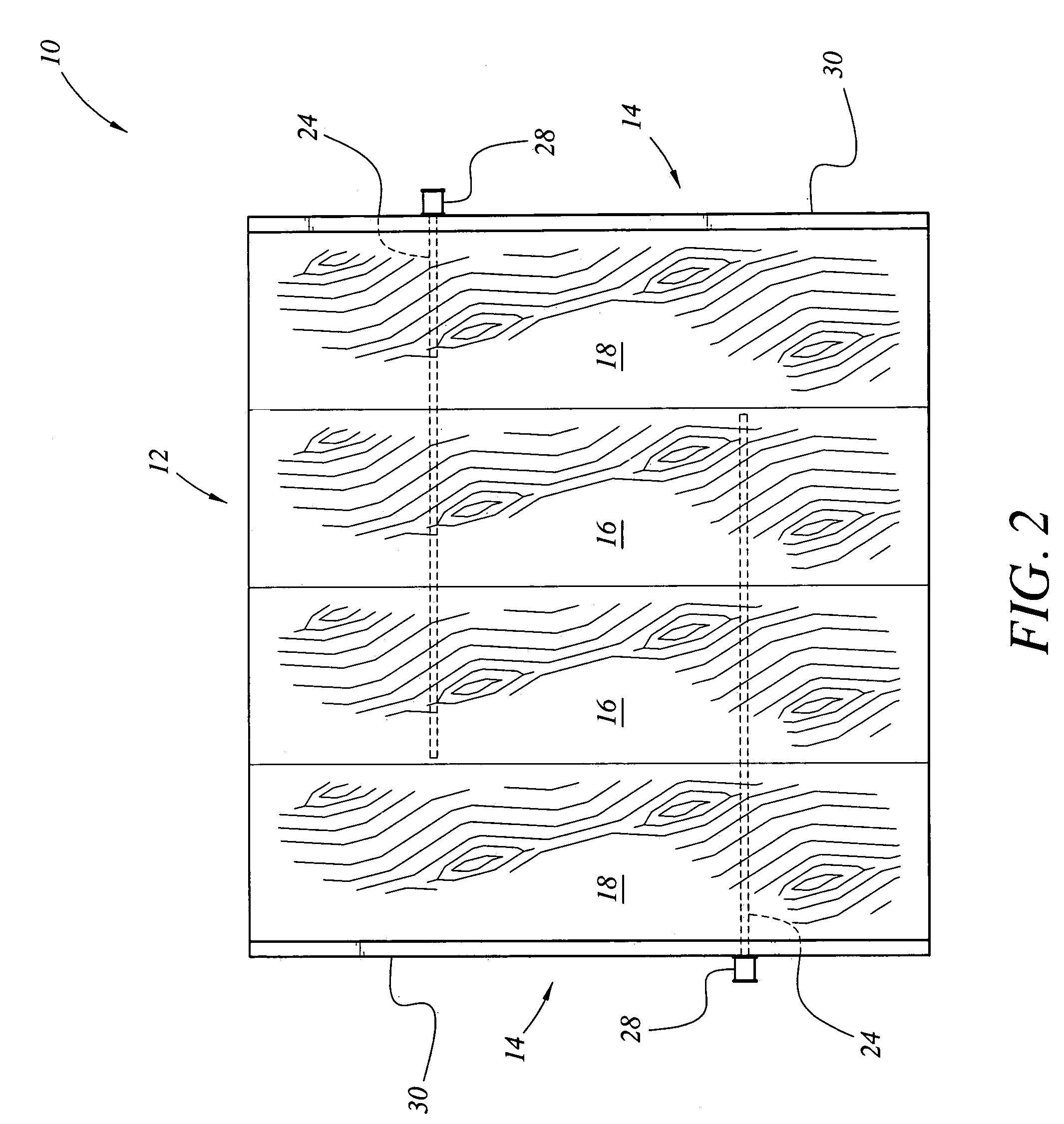

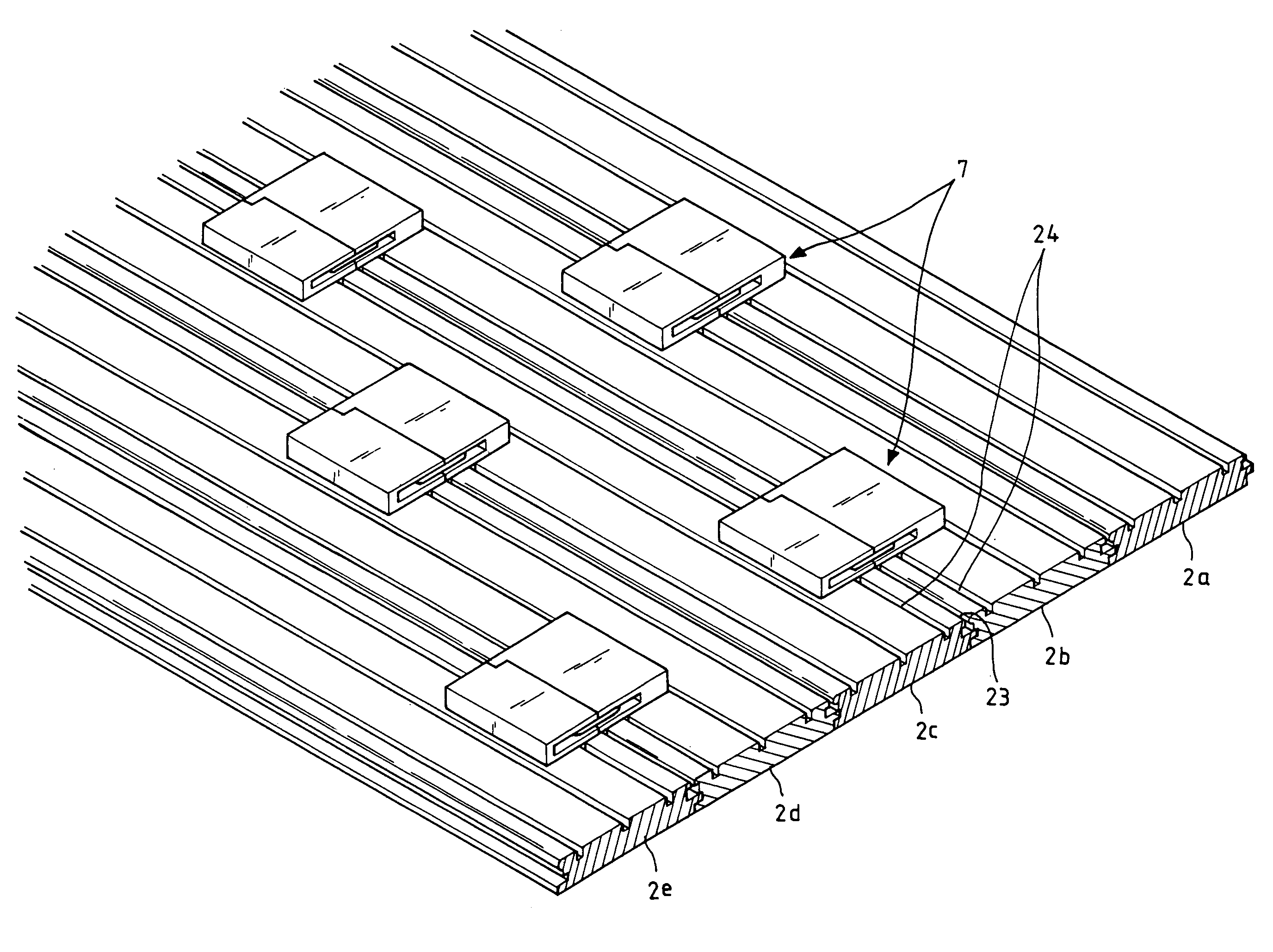

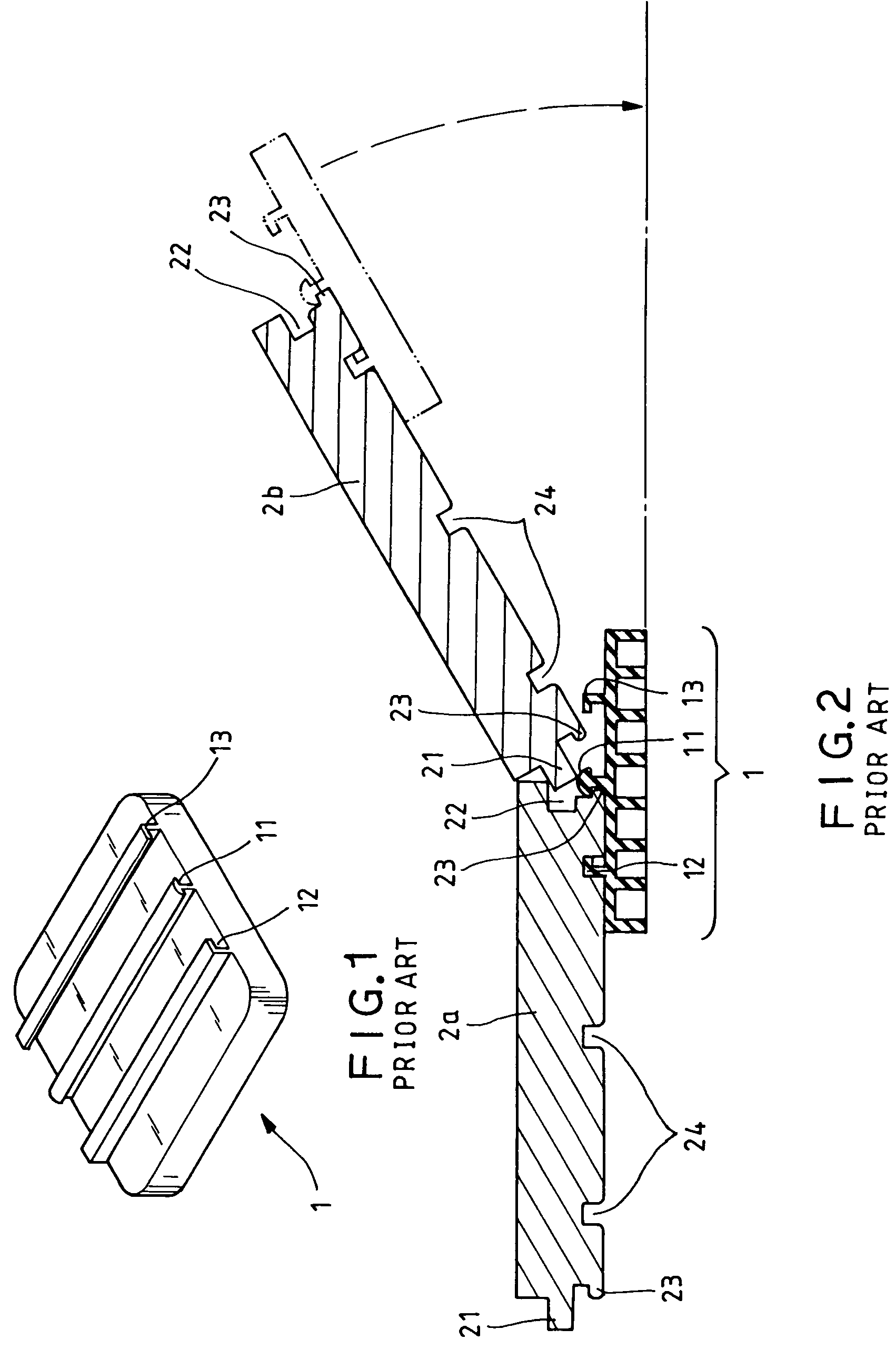

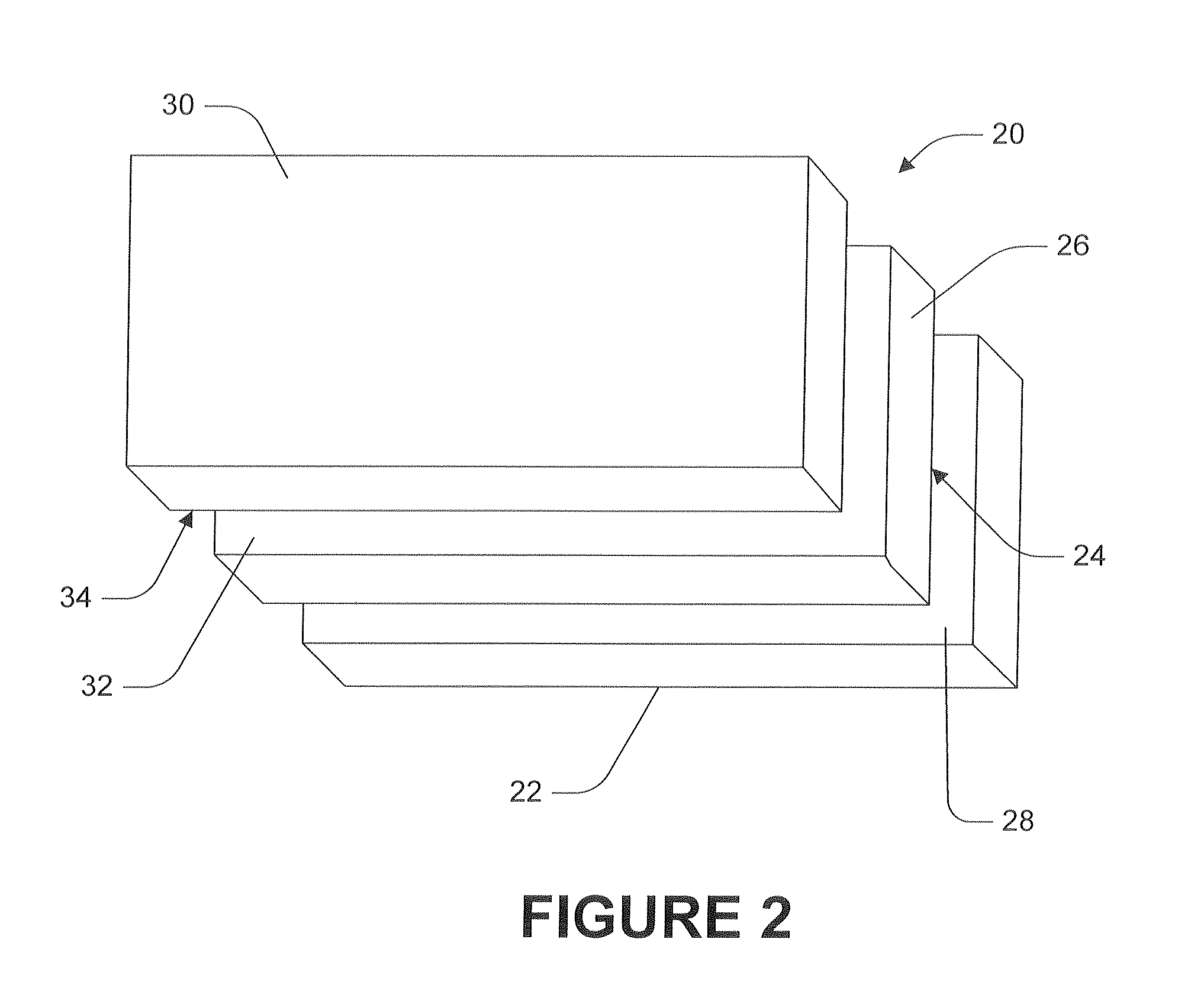

Panels made of interlocked wood pieces

Disclosed are wood pieces for use to manufacture wood panels. Each of these wood pieces has an upper surface, a lower surface and two opposite sidewalls. Tongues and grooves or hooks and notches are provided on the opposite sidewalls of each of the wood pieces in such a way that (1) there is at least one tongue or hook on each sidewall and at least one corresponding groove or notch on the other sidewall and (2) the tongues or hooks on the tongues or hooks on the opposite sidewalls are positioned at a same height between the upper and lower surfaces of each wood piece, and the grooves or notches are positioned at another same height selected as a function of the one where stand the tongues or hooks. When the wood pieces are cut in such a way that their tongues and grooves or hooks and notches are positioned as indicated hereinabove, it is then requested that, after one wood piece has been positioned in a given flat position with an upper surface and a bottom surface, the adjacent wood piece be then positioned in a reverse position, with its bottom surfaces on top and its upper surface at the bottom. The wood pieces of similar shape are then interlocked with each other by alternatively locating one wood piece upside down and another piece upside up. Due to their configuration, each of the wood pieces is longitudinally orientable in one direction or the other, upon request. This is particularly interesting in the case where the wood pieces are cut from logs or branches that are of conical shape, since it is then possible to position them "head to tail" in an alternate manner in order to manufacture a straight panel.

Owner:DESCHENES GUILDO

Method for preparing mulberry leaf tea

InactiveCN101632406ASweet tastePlay a health effectTea substituesFood preparationCooking & bakingBlood sugar

The invention relates to tea leaves, in particular to mulberry leaf tea prepared by taking mulberry leaves as a raw material. The preparation method of the mulberry leaf tea comprises the following steps: putting 2kg of aired mulberry leaves into a kettle by picking leaves, washing, cleaning and airing for 4-5 hours after heating the kettle to 130-180 DEG C, continuously stir-frying for 5-6 minutes continuously, removing 10-30% of water in the leaves, stir-frying until the leaves are flexible and then taking out of the kettle; putting on a wood board, twisting for 3-5 minutes, twisting until the leaves are in a cord shape, and spilling leaf juice; then, putting the leaves into a kettle of 70-80 DEG C for baking, heating evenly, stir-frying until tea strips form powder when being pinched by hands, taking out of the kettle and cooling in a spread way; and afterwards, removing fine crushed powder impurities by using a fine sieve, then grading according to colors, shapes and tastes, packaging, putting into a dry sealed container after sealing, and storing. The invention has the advantages of lowering blood sugar, reducing the weight, clearing up fat, promoting metabolism, eliminating fatigue, being beneficial for health preserving, health care and life prolonging and the like.

Owner:山西析城山土特产开发股份有限公司

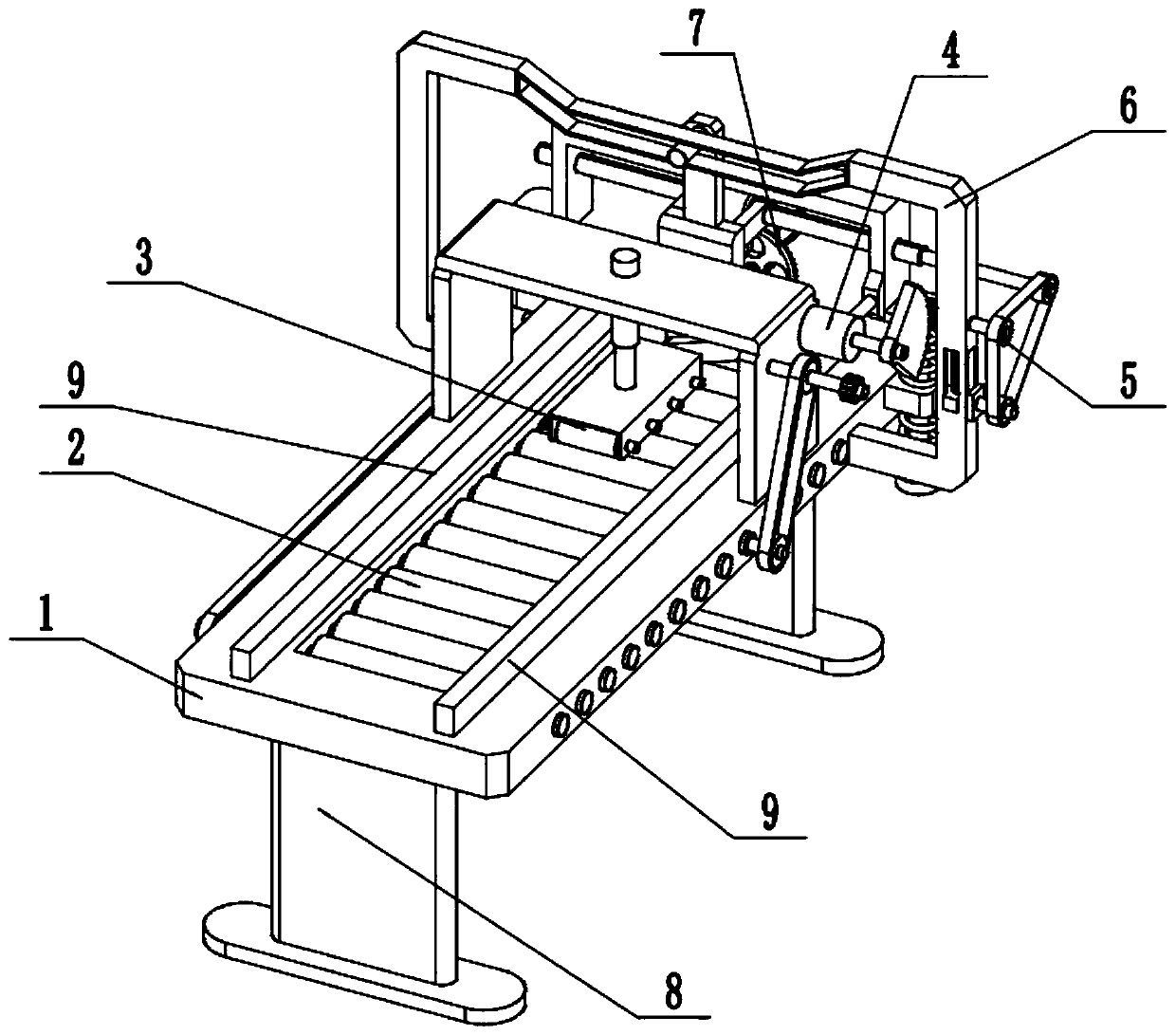

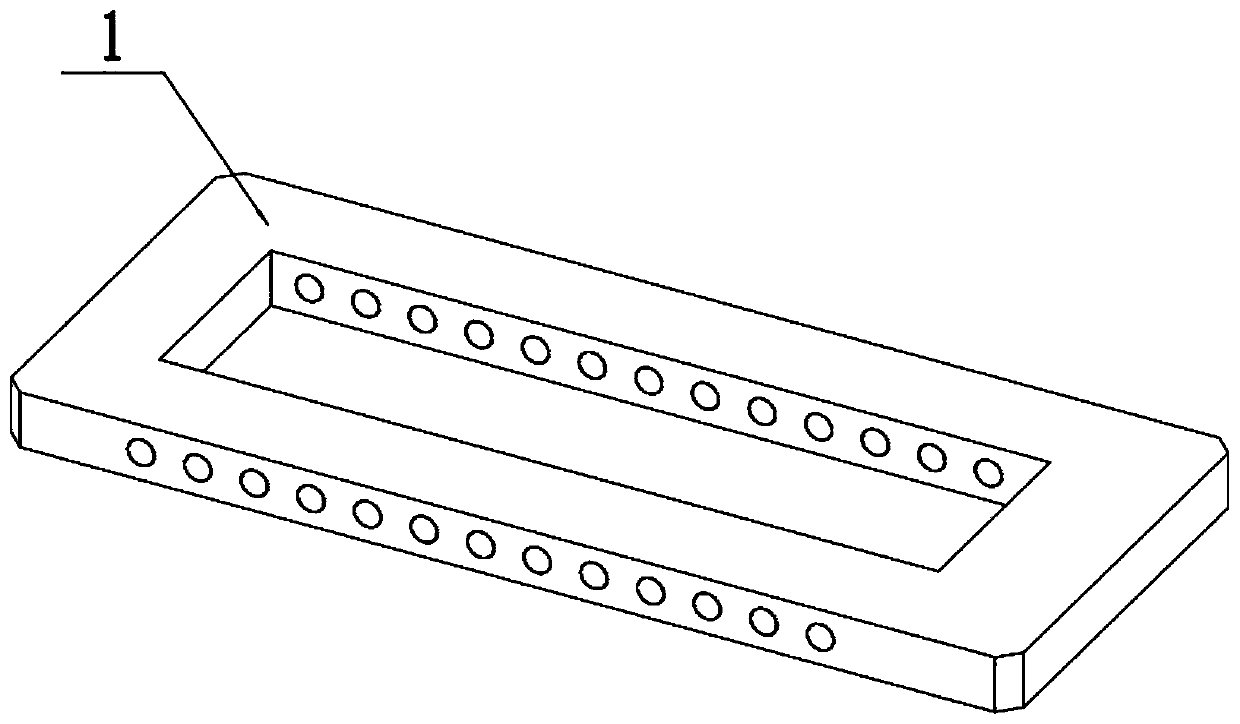

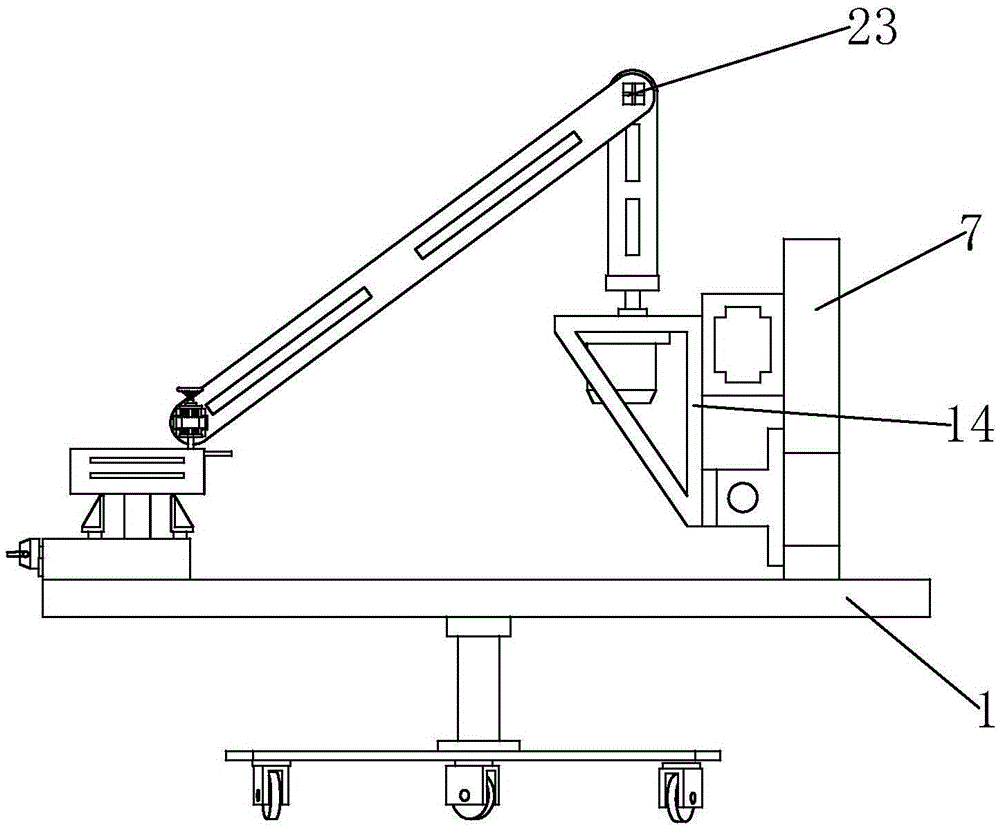

Wood board fixed-length cutting device

InactiveCN110238914AImprove cutting efficiencyImprove stabilityFeeding devicesGripping devicesEngineeringFixed length

The invention relates to the field of wood processing, in particular to a wood board fixed-length cutting device. The wood board fixed-length cutting device comprises a rack, a board conveying roller assembly, a pressure roller, a driving mechanism, a tensioning linkage wheel, a guide frame, a cutting mechanism, supporting legs and side baffles; the supporting legs are fixed at the front end and the rear end of the bottom face of the rack separately; the side baffles are fixed at the left end and the right end of the top face of the rack separately; the board conveying roller assembly is connected in an installation groove in the top face of the rack; the board conveying roller assembly is located between the two side baffles; the pressure roller is arranged at the front end of the top face of the rack; and the board conveying roller assembly is connected to the side end of the pressure roller. According to the wood board fixed-length cutting device, continuous fixed-length cutting is carried out on a wood board by adopting an automatic feeding and fixed length cutting mode, the cutting efficiency is high, and the labor force is low.

Owner:李锋

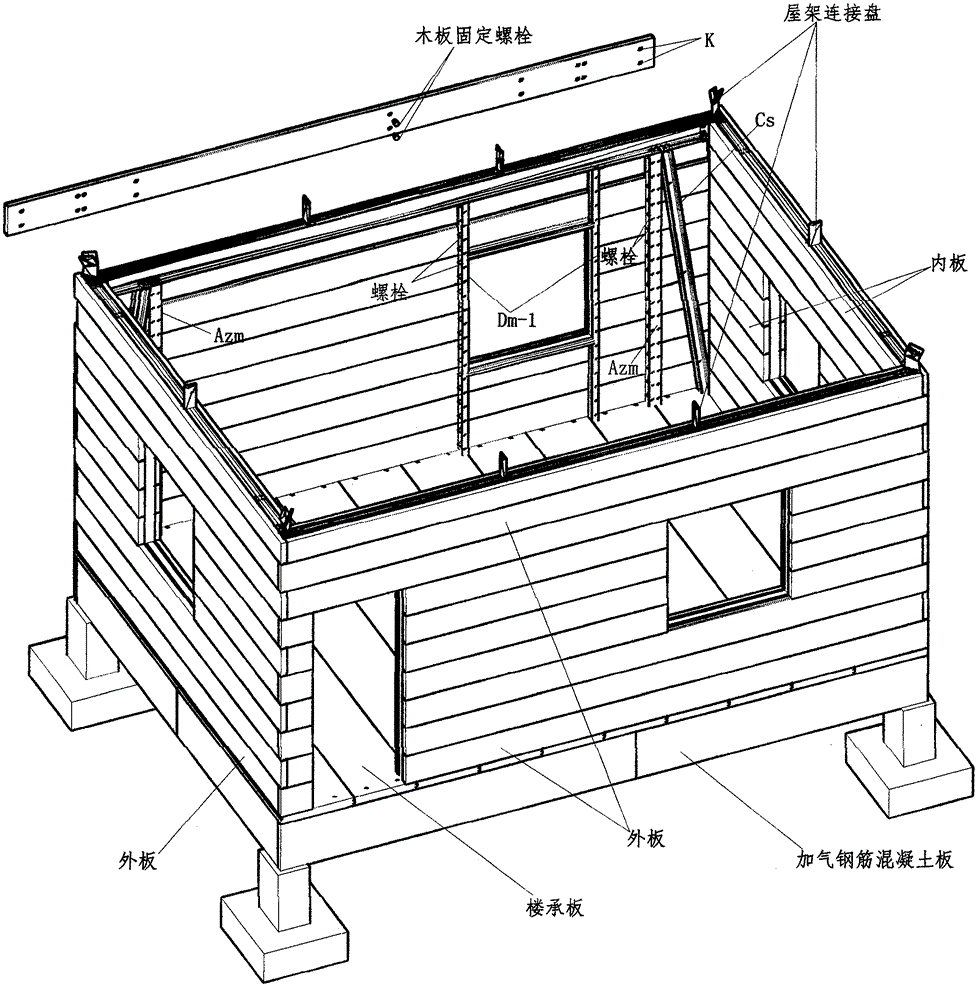

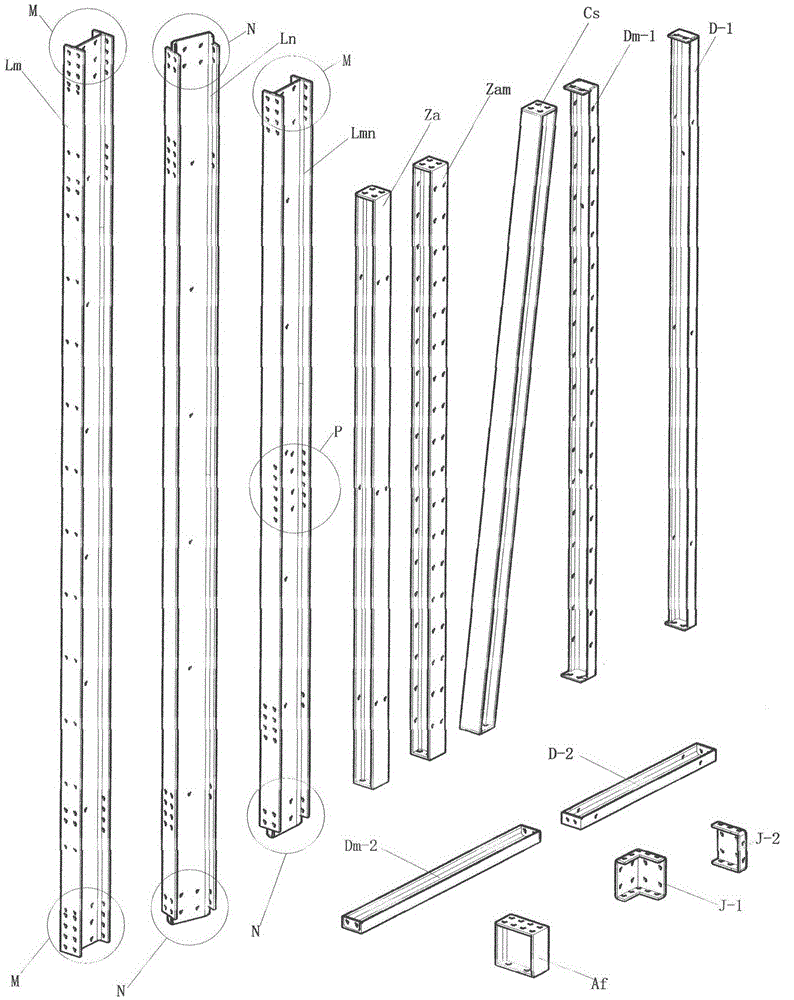

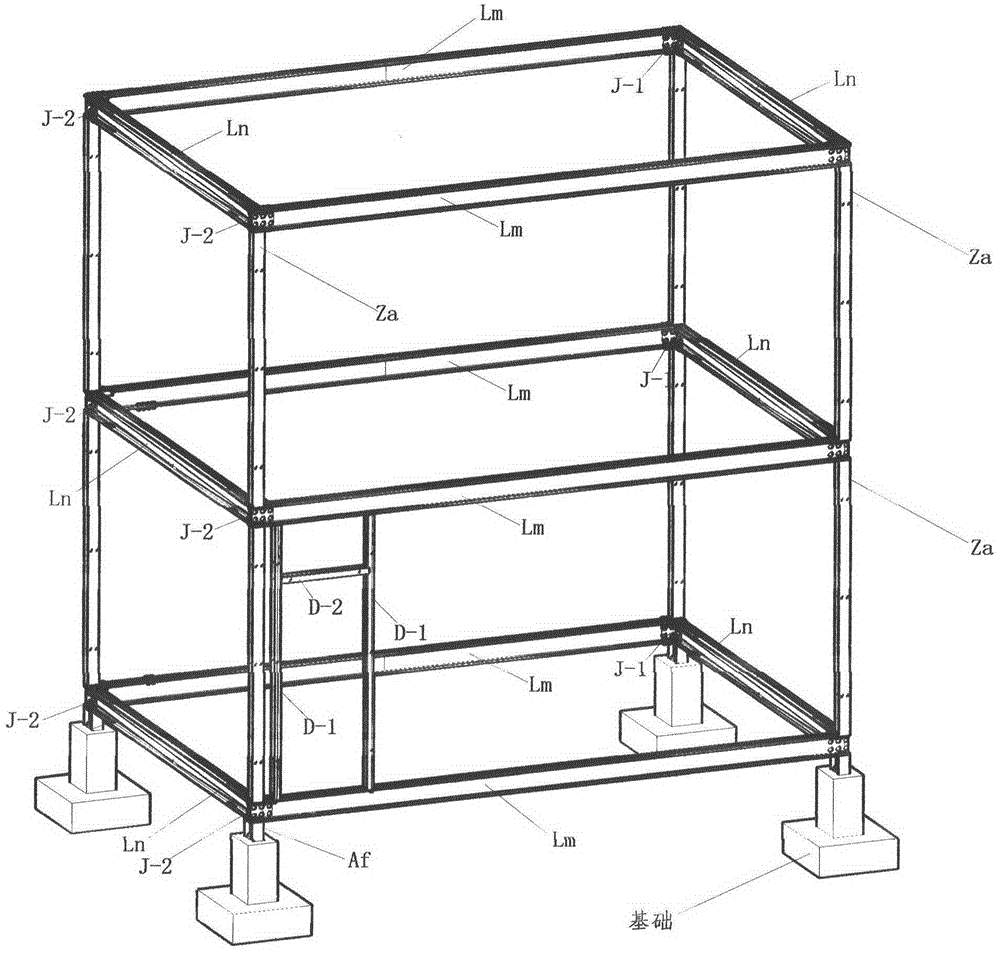

Assembled house adopting new structural system

The invention discloses a novel technique capable of ensuring industrialized production of all components of a house and building the house through assembly completely. Specifically, the technique is implemented in the way that heavy metal components are connected to form a stress framework, and aerated concrete plates or planks are installed on the framework to achieve house building. The technique has the advantages that construction is achieved through assembly, and high-quality house building can be achieved quickly; the components to be assembled are simple and can be provided by existing factories; materials are environment-friendly and long in service life, and the house is durable; the components are simple in structure, and large-scale production can be achieved conveniently; installation is easy and convenient, and requirements for the skill of constructors are low; house performance is excellent, and the house is resistant to wind and earthquake, capable of achieving heat insulation and sound insulation and long in service life; as soon as the house is built, all basic work of refined decoration is finished; the components of limited varieties can meet the requirement for building different types of houses, so that component factories can provide the components efficiently at low cost; house building cost is low, no assembly mark is left on the house, and the house can be easily accepted in the market; materials can be recycled.

Owner:深圳市华煜建工科技有限公司

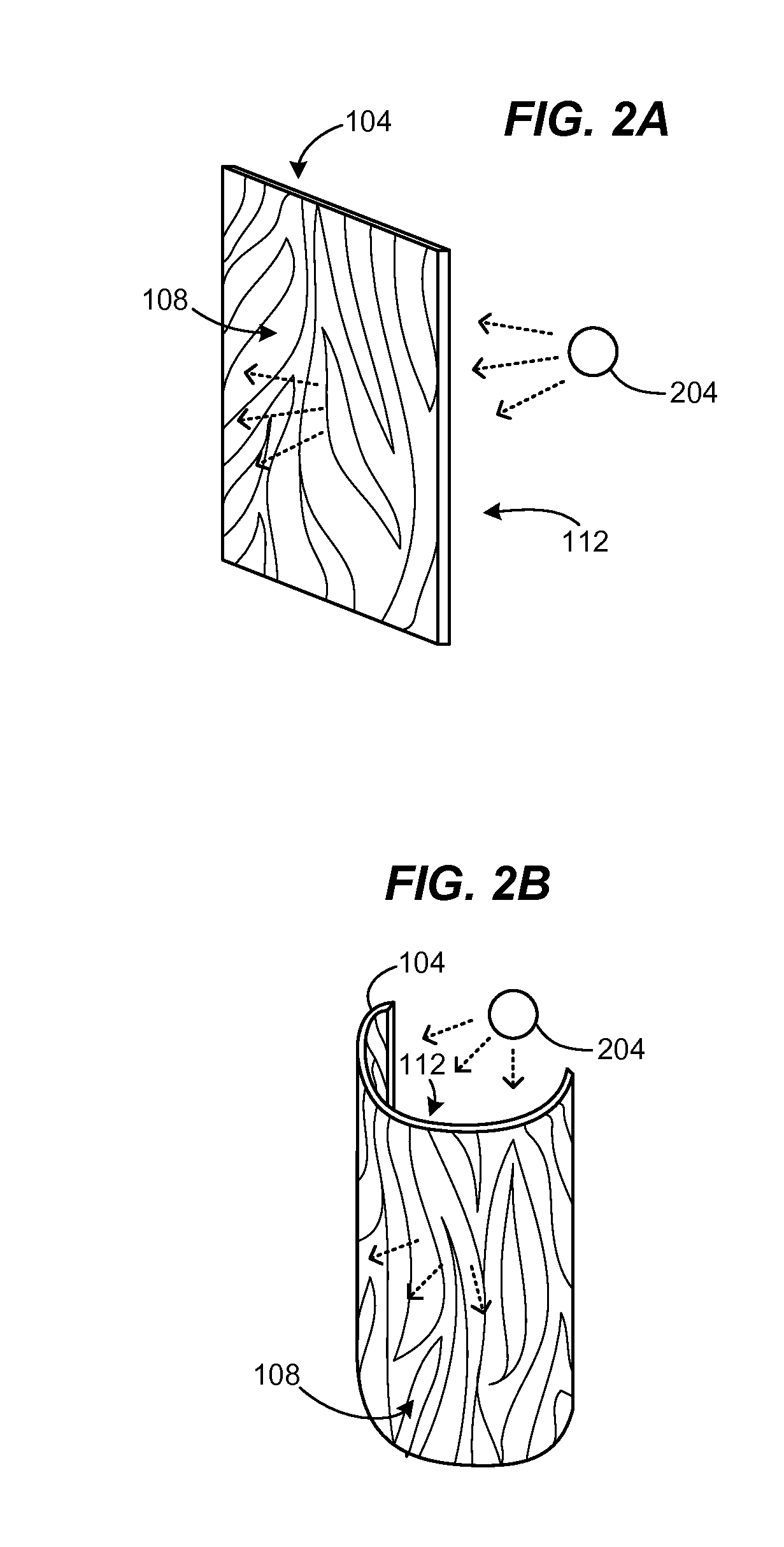

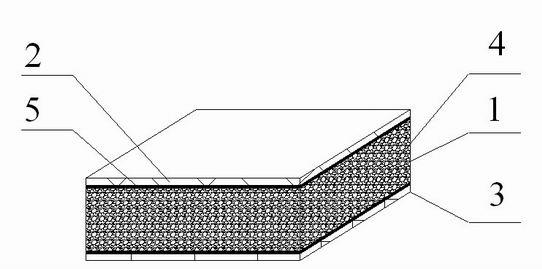

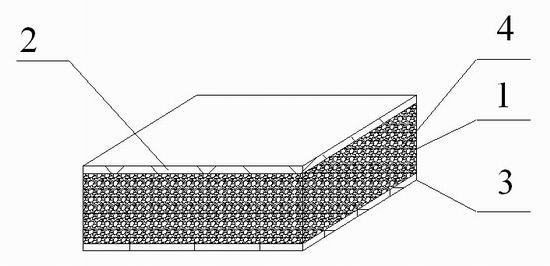

Wood fiber reinforced flame retardant foam composite plate and manufacturing method thereof

InactiveCN102114659AImprove use valueSolve the "Three Rural Issues"Wood working apparatusDomestic articlesAdhesive cementPhenolformaldehyde foam

The invention relates to a wood fiber reinforced flame retardant foam composite plate and a preparation method thereof. The external layer of the composite plate is a wood panel, and the foam core plate in the internal layer is a wood fiber reinforced phenol formaldehyde foam material or a melamine modified formaldehyde foam material. The wood fiber is treated by a coupling agent. The invention further relates to a manufacturing method of the plate. The wood panel is adhered to the external layer panel of the foam core plate. The plate can be manufactured by performing lamination thermal composition on the materials by using an adhesive, and also can be manufactured by directly foaming between fixed dual-layer panels. The foam core plate uses wood fiber reinforced phenol formaldehyde foam or melamine modified formaldehyde foam material. The flame retardant performance can accord with the specified standard. The foam core plate is flame retardant and small in smoke amount, generates no harmful gas, and meets requirement of environmental friendliness, so that the composite plate has excellent sound absorption and heat insulation properties. The fiber reinforced foam base material has an excellent mechanical property.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Efficient wood plate processing equipment

InactiveCN107336292AReduce difficultyReduce pollutionProfiling/shaping machinesBark-zones/chip/dust/waste removalArchitectural engineeringSlide plate

The invention discloses a high-efficiency wood board processing equipment, which comprises a workbench. A protective cover is arranged on the upper side of the workbench. A horizontal first sliding rail is arranged on the inner upper end of the protective cover, and a longitudinally arranged sliding plate is arranged on the first sliding rail. , the lower side of the skateboard is provided with a longitudinal second slide rail, the second slide rail is provided with a second electric telescopic rod, the lower end of the second electric telescopic rod is provided with a first motor, and the output end of the first motor is provided with a mounting seat , the inside of the mounting seat is left and right symmetrically provided with a second motor, the output ends of the two second motors are provided with a fourth electric telescopic rod, the outer end of the fourth electric telescopic rod is provided with a mounting plate, and the upper side of the mounting plate is provided There is a grinding device, a cutting device is arranged on the lower side of the mounting plate, a supporting plate is arranged on the lower part of the legs, and a dust collection box is arranged on the upper side of the supporting plate. The invention has the advantages of simple structure, convenient use, high processing efficiency, reduced work intensity and reduced dust pollution.

Owner:侯添有

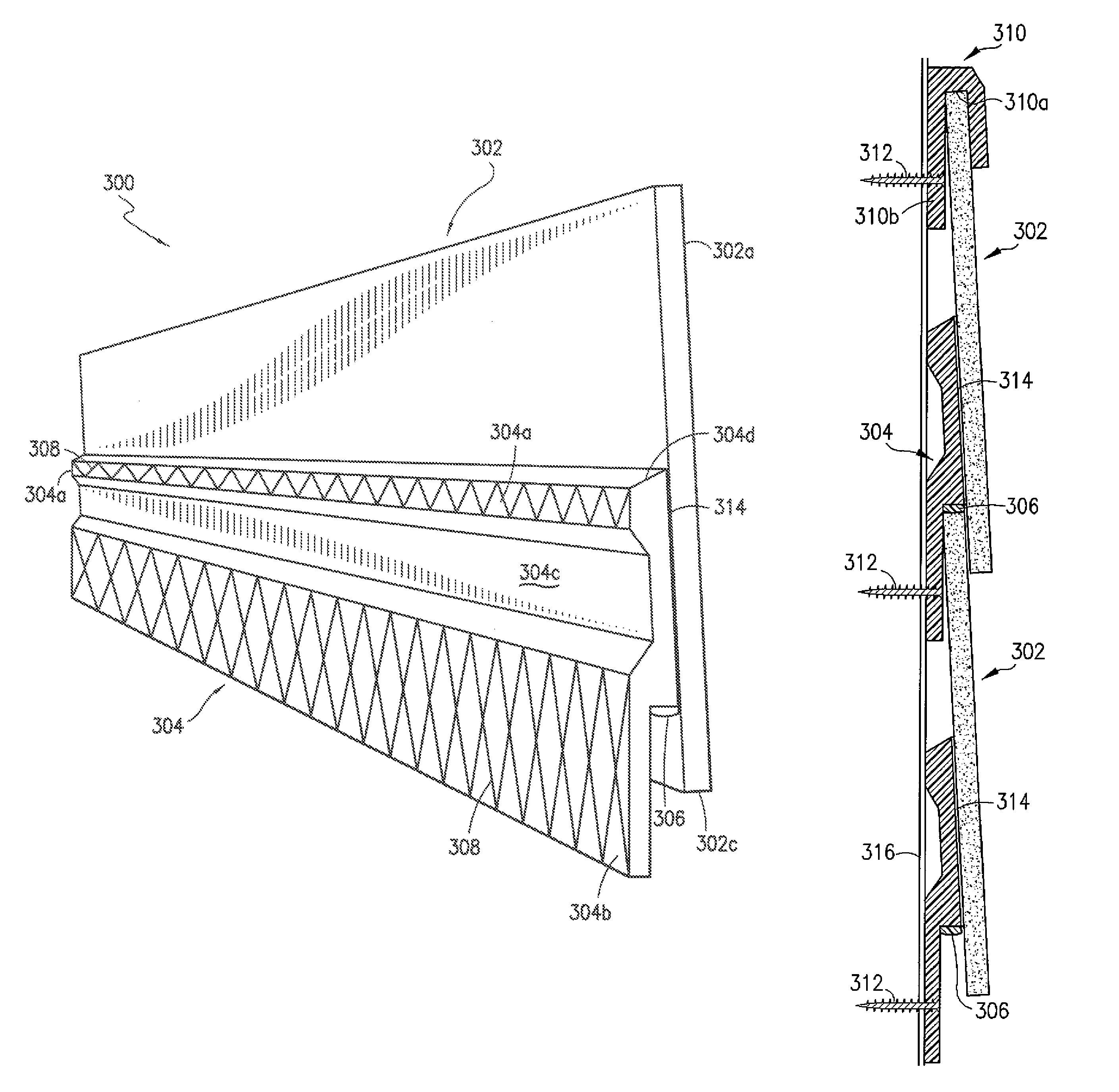

Panels including trap lock adaptor strips

InactiveUS8695303B2Increased durabilityHigh strengthRoof covering using slabs/sheetsCeilingsEngineeringUltimate tensile strength

Exterior building siding for aesthetic and protection of the building against wind, rain and solar energy by attaching each horizontal plank from the top of the wall downwardly that includes a starting strip where each plank is interlocked to the plank above it. Each of the horizontal planks includes a top wall portion that fits snuggly into an “L-shaped” groove above it so that the panels can be firmly locked together vertically in a downwardly fashion to prevent any wind uplift against the siding or moisture intrusion. In the preferred embodiment, an adaptor strip is bonded to a conventional siding plank for trap lock engagement. Each adaptor strip has a longitudinal recess to reduce mass and volume and a mid panel support for strength.

Owner:TOP DOWN SIDING

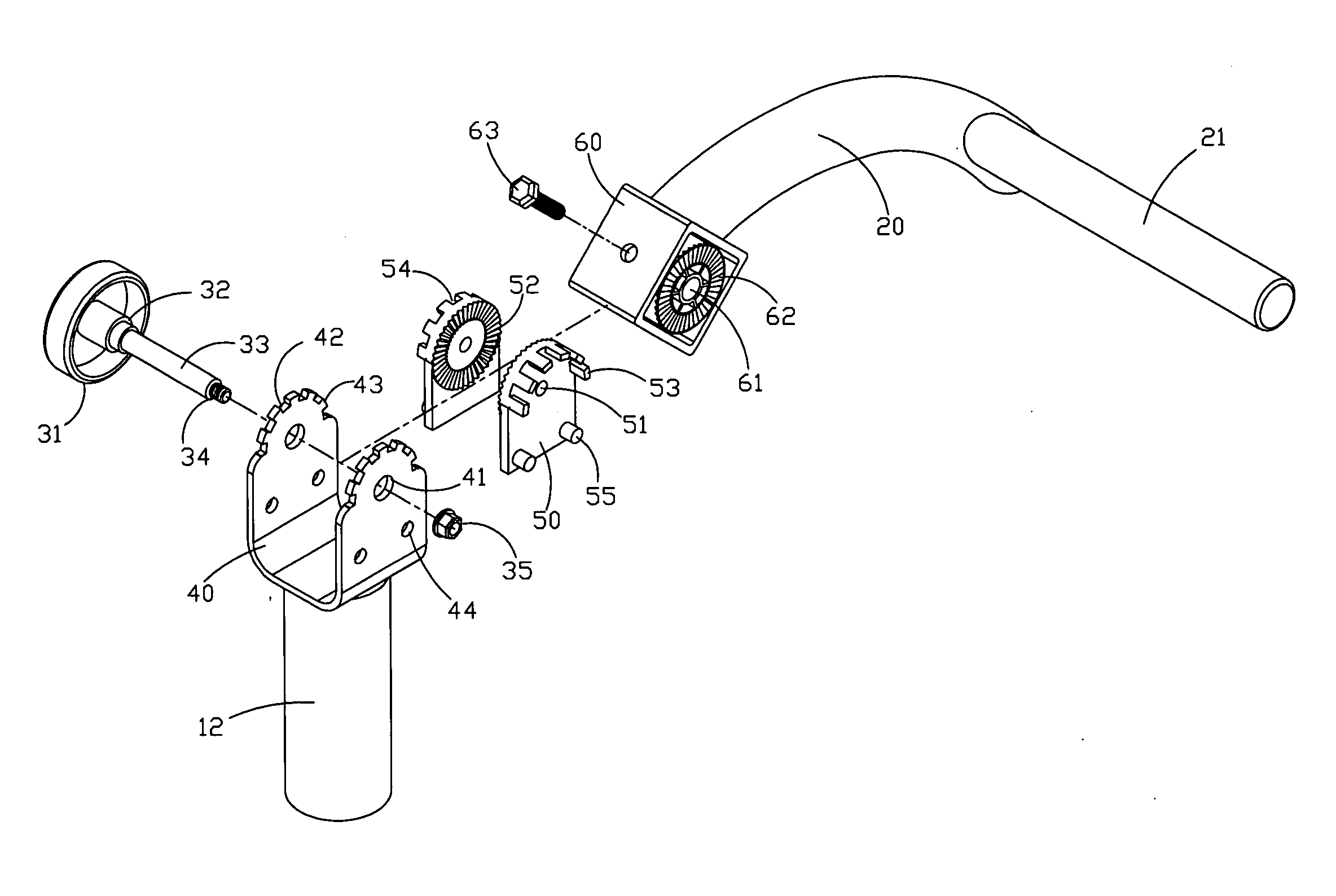

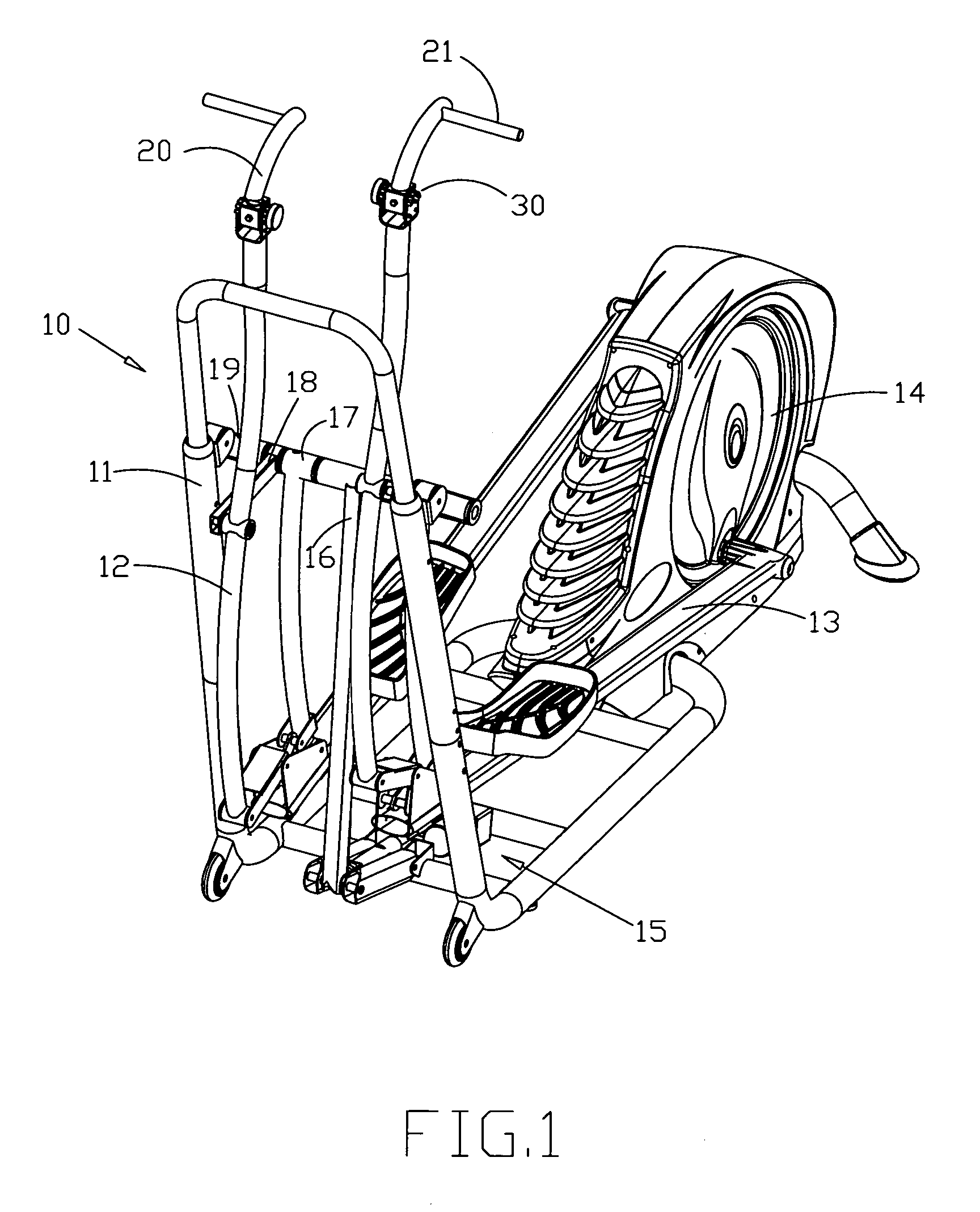

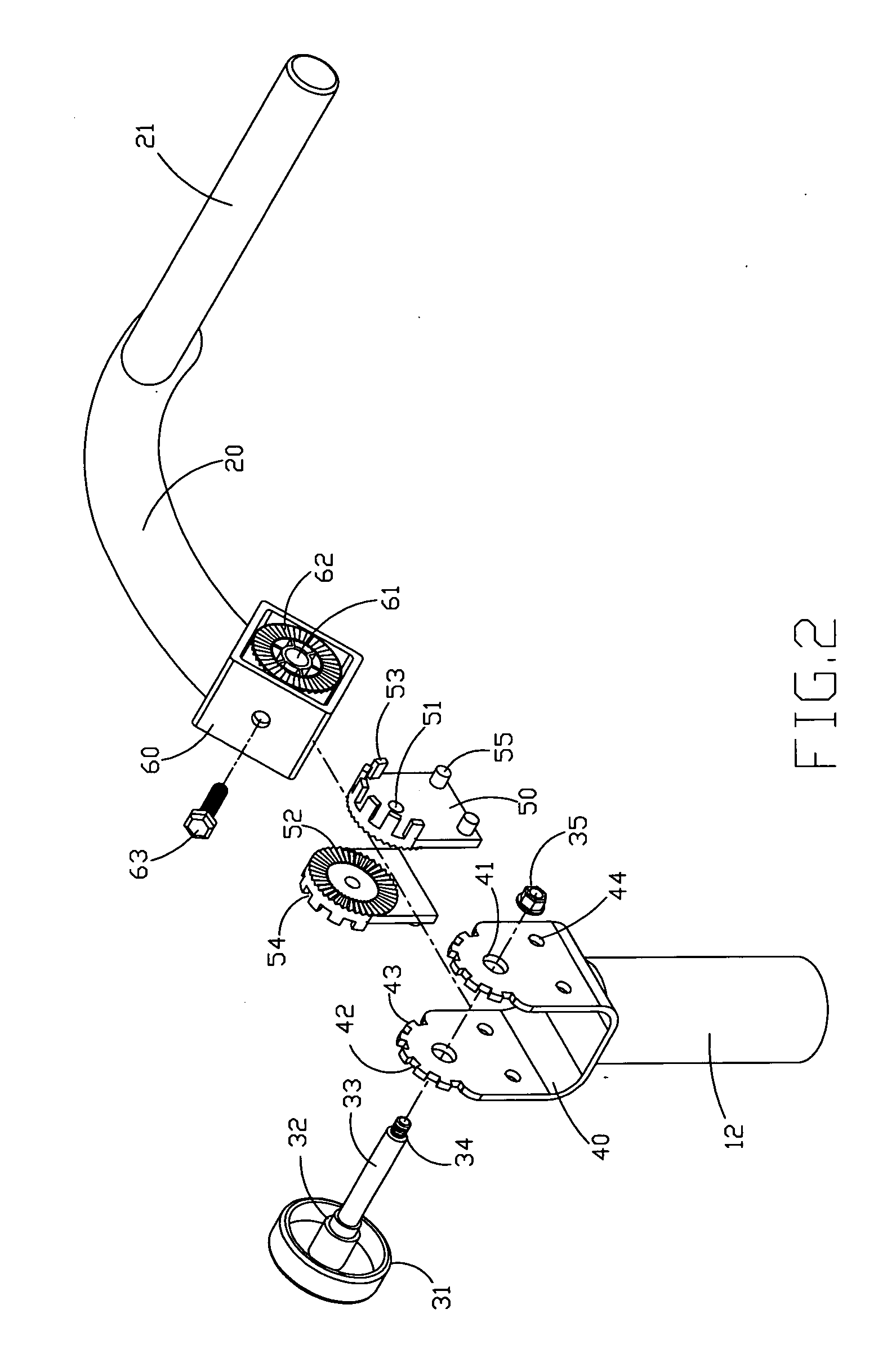

Adjustable handle support of an exercise apparatus

InactiveUS20050227824A1Improve disadvantagesMovement coordination devicesCardiovascular exercising devicesHydraulic cylinderEngineering

The invention relates to an adjustable handle support of an exercise apparatus having a main frame, two rocker arms on the main frame and two planks in connection with power source (e.g. motor, flywheel, hydraulic cylinder, etc.). The rocker arms are individually movable in a swing motion or jointly movable with the planks. An adjusting mechanism is interposed between the handle support and the rocker arm for adjusting the handle support to suitable angles for different operators.

Owner:WU PETER +1

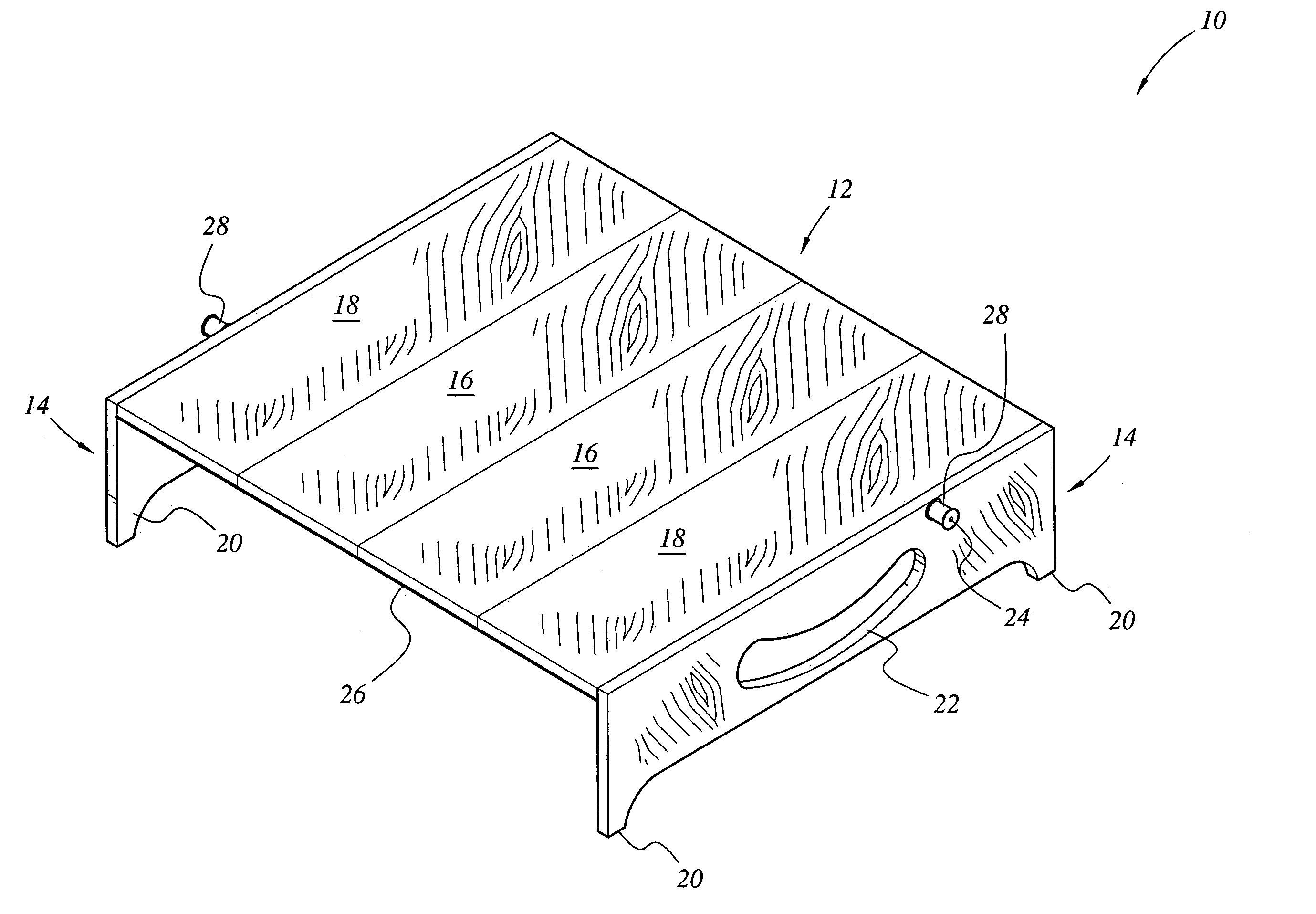

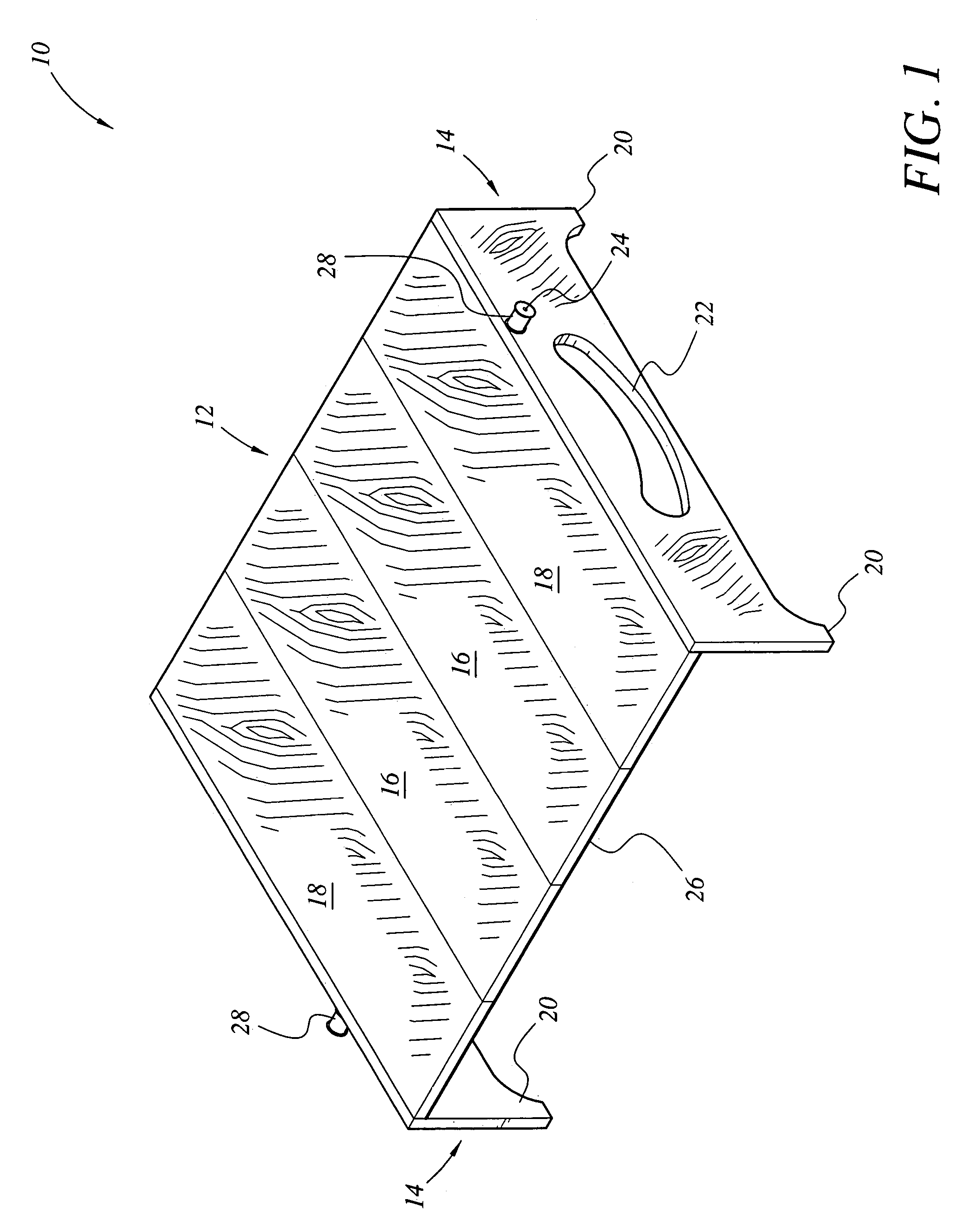

Portable collapsible table and game board

A portable collapsible table or tray having multiple wooden panels hinged to each other from underneath by a piece of fabric. The panels fold in a zigzag manner into a compact, folded form which is easily carried in a bag. The panels are secured to form a rigid table surface by inserting removable support rods laterally and crosswise through the wooden panels. The end panels each receive a locking rod at its respective outer side. Support panels having handle cutouts and legs are attached at each end of the table by hinges. These support panels have bores therethrough for inserting the support pins, and are thus locked in place, along with the wooden surface panels when the rods are inserted. The support panels fold with the surface panels when the support rods are removed forming a compact configuration. A game board version without support panels is provided.

Owner:SHARPE MELANIE A +1

Processing method of circuit board and circuit board with contour tolerance of +/-0.05mm

InactiveCN102196671ASolve the influence of axial precisionExtended service lifePrinted circuit manufactureFluteEpoxy

The invention discloses a processing method of a circuit board and a circuit board with a contour tolerance of + / -0.05mm. The processing method comprises the following steps: 1) fixing a special carte on a milling machine table top; 2) aligning and overlaying an epoxy resin board and a cover board on the special carte; 3) drilling a special carte dowel hole on the special carte, an epoxy resin board dowel hole on the epoxy resin board and the first row of dowel hole of the cover board; 4) processing the circulation milling path of the cover board and the epoxy resin board, which corresponds to the circuit board; 5) drilling the second row of dowel hole of the cover board; 6) putting a circuit board dowel on the epoxy resin board dowel hole on the epoxy resin board; 7) processing a millingcutter according to the first circulation milling flute and the second circulation milling flute of the cover board; and 8) processing the other rows of the circuit board according to the technology of step 7 to form the circuit board with contour tolerance of + / -0.05mm. The method is characterized in that precision can not be affected by external factors, the circuit board can be reused, and thecontinuity and the consistency of contour dimensional accuracy can be guaranteed.

Owner:大连亚太电子有限公司

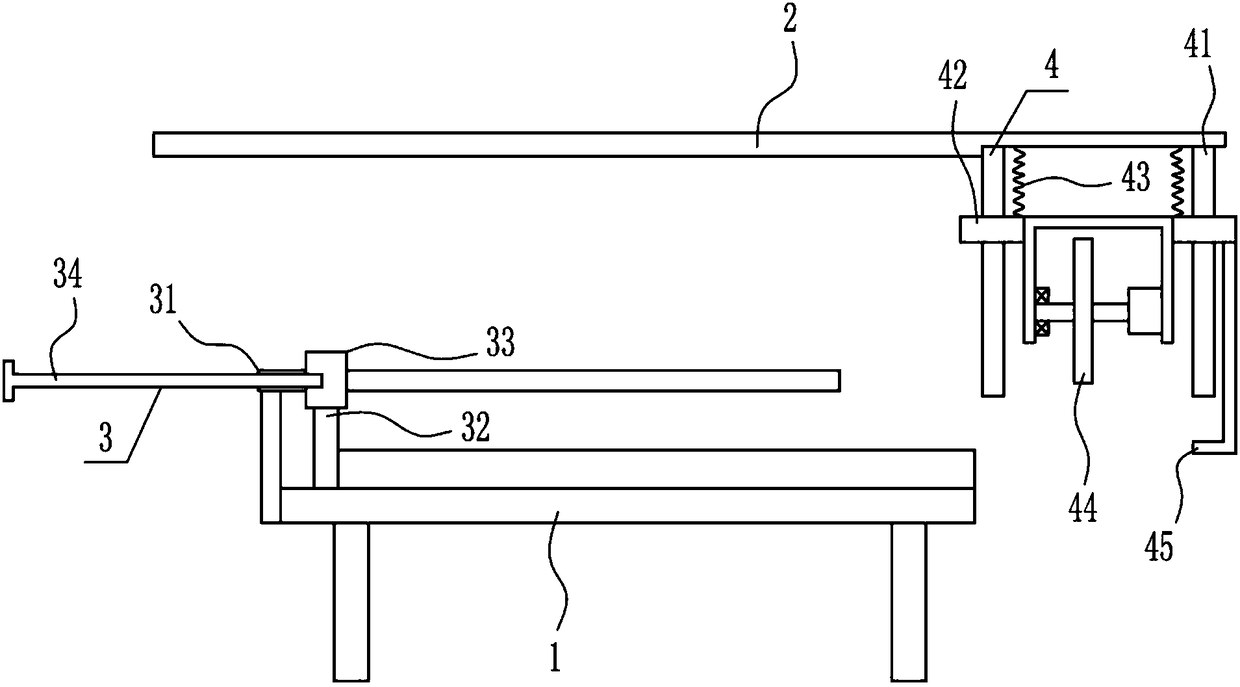

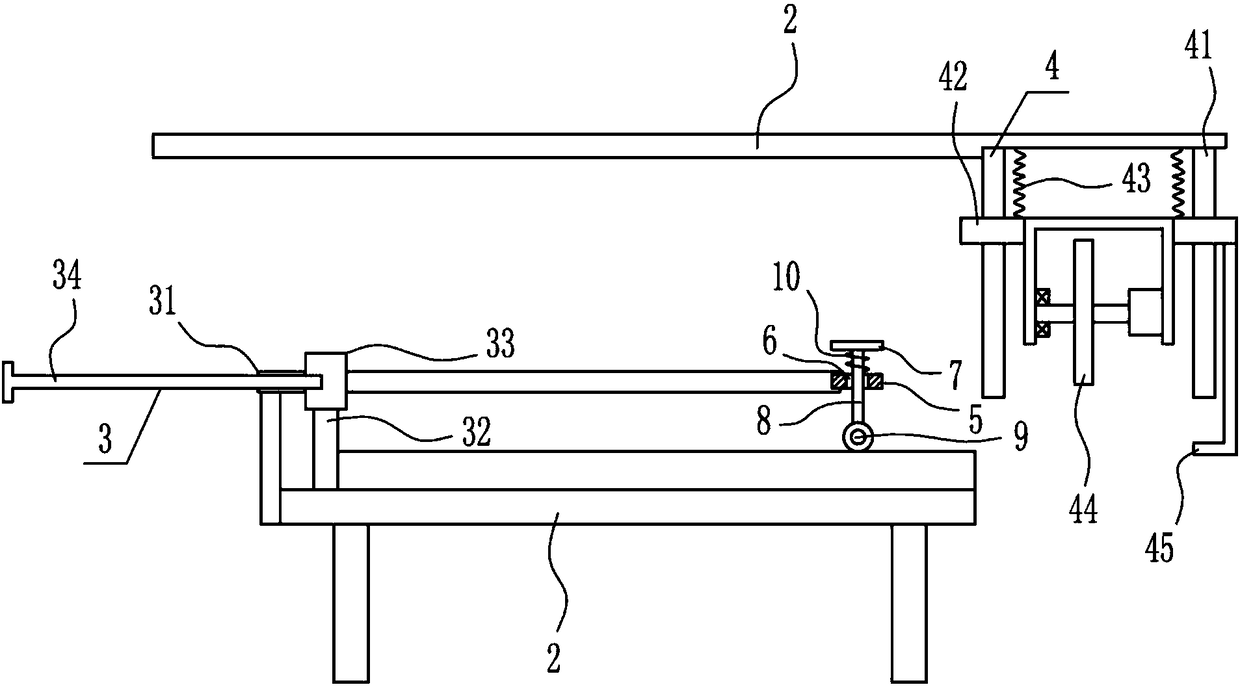

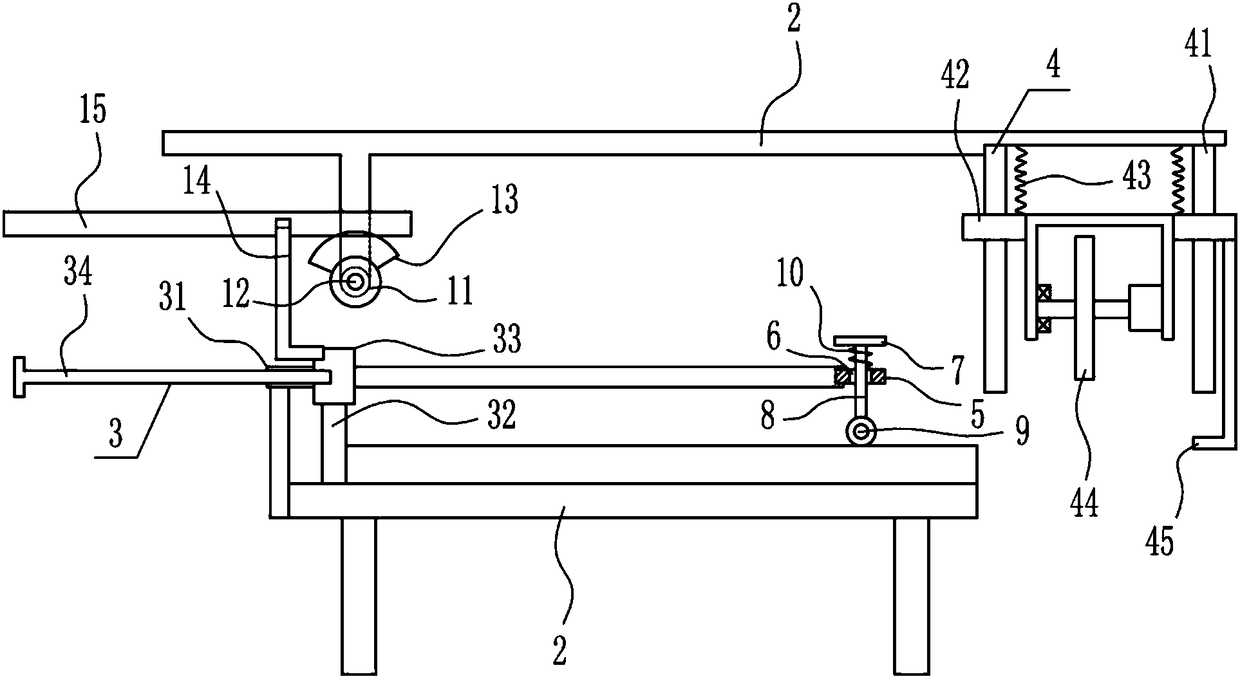

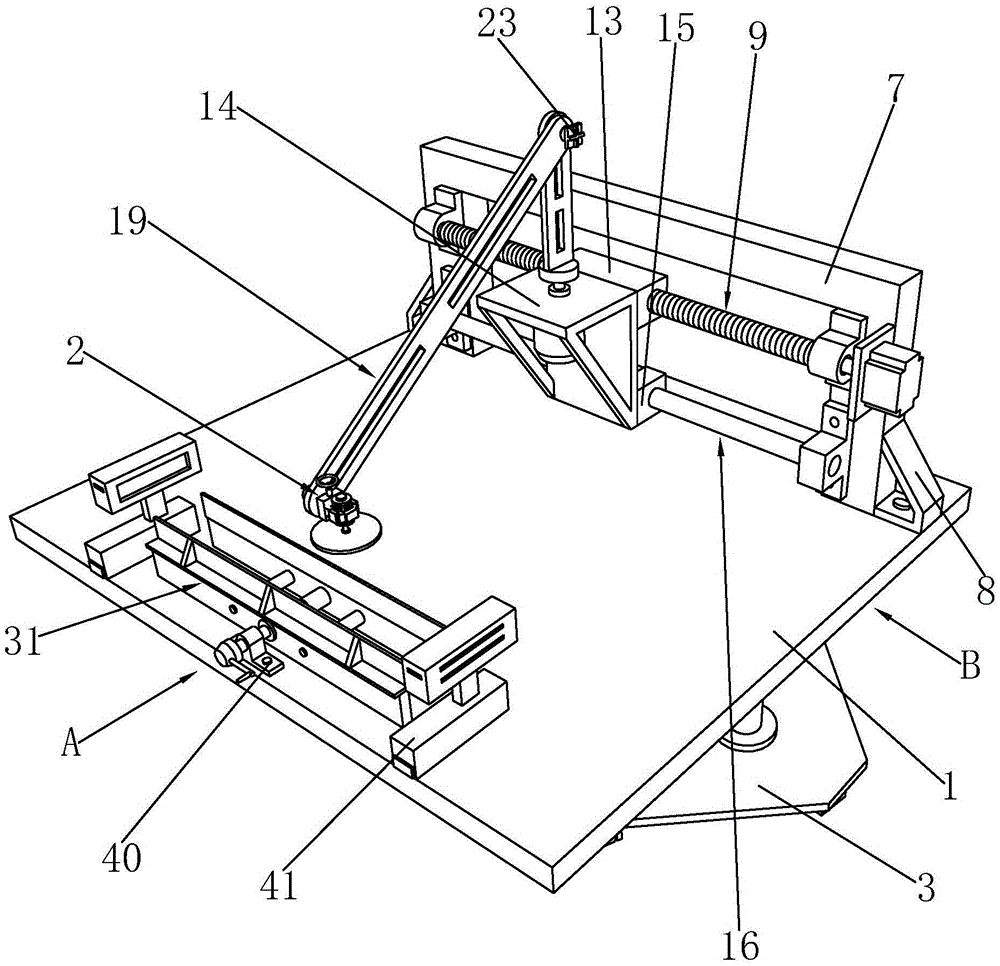

Automatic conveying and cutting device for building wood board

InactiveCN108177200ARealize cut-to-lengthAvoid cutsProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringIdler-wheel

The invention relates to a cutting device, in particular to an automatic conveying and cutting device for a building wood board. The technical problem to be solved by the invention is to provide the automatic conveying and cutting device for the building wood board, wherein the automatic conveying and cutting device can be used for automatically pushing the wood board and can realize fixed-lengthcutting. The automatic conveying and cutting device for the building wood board comprises a worktable and the like; the top of the worktable is connected with a moving mechanism; a top plate is arranged above the worktable; and the right side of the top plate is connected with a cutting mechanism. The automatic conveying and cutting device for the building wood board, provided by the invention, isprovided with the moving mechanism, a first guide rail, a push plate, a first guide sleeve, a push rod and the cutting mechanism, so an electric saw wheel can be moved without manpower, and efforts of a worker can be saved; by arranging a fixing block, a check block, a lifting rod, an idler wheel and a second spring, the wood board is prevented from being warped when the wood board is cut, so steady cutting of the electric saw wheel is not affected.

Owner:周远桂

Polishing device for wooden decorative board

InactiveCN105538077AImprove stabilitySimple structureEdge grinding machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses a polishing device for a wooden decorative board. The polishing device comprises a mounting platform and a polishing mechanism. A supporting base frame is arranged on the mounting platform. A screw mechanism is transversely arranged on the supporting base frame. A sliding seat is connected onto the screw mechanism in a sliding manner. A polishing worktable is fixed on the sliding seat. A rotating mechanism is rotationally connected onto the polishing worktable, and comprises a rotating base, a first rotating arm and a second rotating arm. The first rotating arm is arranged on the rotating base, and is rotationally connected with the second rotating arm. The polishing mechanism is fixed at one end of the second rotating arm. A clamping mechanism is arranged on the mounting platform. A dust absorption treatment unit is arranged on the mounting platform. A moving support is arranged below the mounting platform. Through the adoption of the characteristics of the screw mechanism and the rotating mechanism, the polishing device can extend and rotate, the polishing range is adjusted flexibly, the effect of smoothly polishing the wooden decorative board and high polishing efficiency are achieved, and the polishing device is simple in structure, high in practicability and remarkable in economic benefit.

Owner:嵊州市古艺木雕装饰有限公司

Clamp unit for Do-It-Yourself (DIY) solid wood flooring

Owner:MEI TZU CHIANG

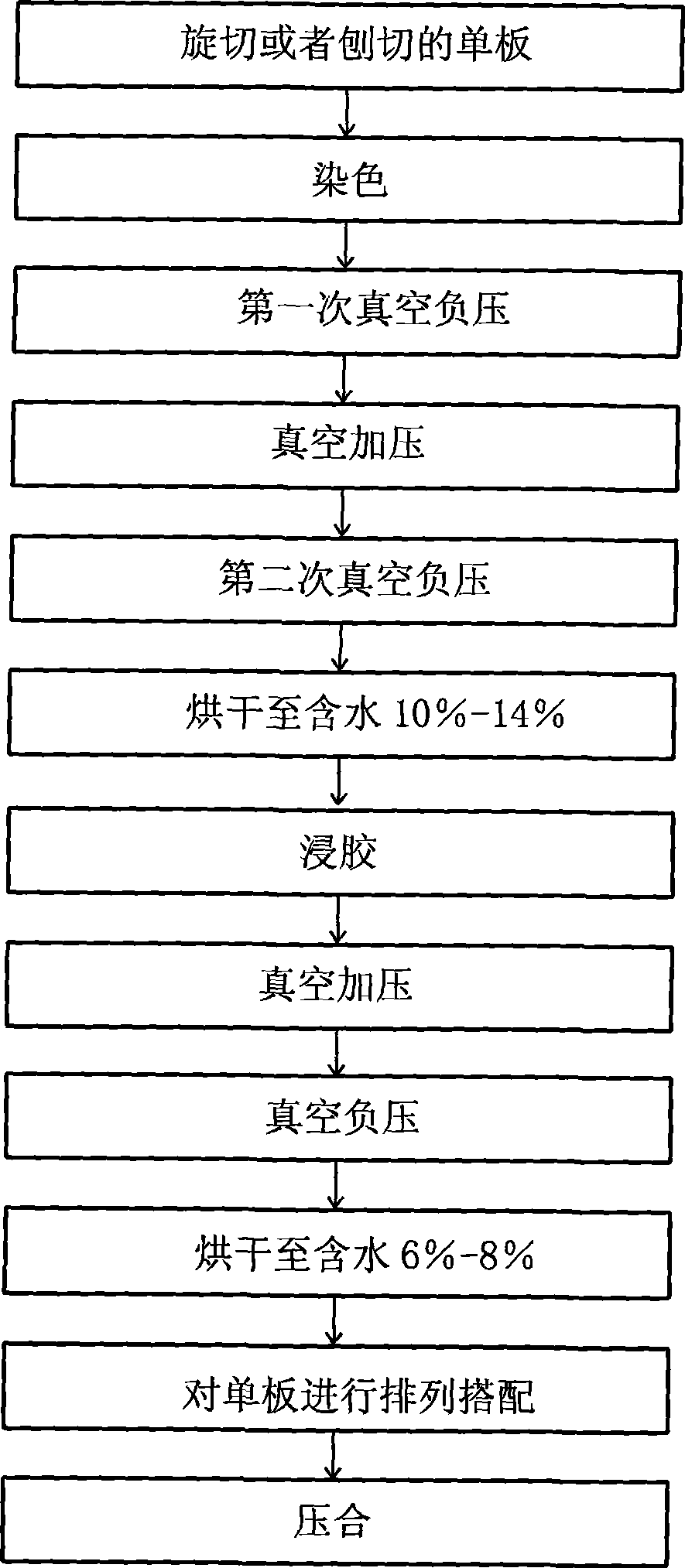

Color solid plate manufacture method

InactiveCN101508123AEnvironmentally friendlyFlame retardantOther plywood/veneer working apparatusWood treatment detailsSolid woodPulp and paper industry

The invention provides a method for manufacturing a colored solid wood panel, belongs to a processing method for wood utilization, and in particular relates to a method for manufacturing a multi-layer colored panel. The invention aims to provide a method for manufacturing a multi-layer colored panel which overcomes the defects of natural wood and effectively solves the problems of looseness and softness, susceptibility to corrosion, flammability, and the like of fast growing wood. The multi-layer colored panel has the characteristics of environmental protection, inflame retarding, moisture resistance, corrosion resistance, wearing resistance, difficult deformation and strong plasticity.

Owner:王殿国

Automatic single plate feeding machine

InactiveCN103420158AReduce intensityAvoid operational accidentsControl devices for conveyorsRotary conveyorsHydraulic cylinderControl system

The invention discloses an automatic single plate feeding machine, and belongs to the field of wood processing equipment. The automatic single plate feeding machine is mainly used for raw material transport in the wood processing process, and solves the problems that manual feeding is high in manpower cost and labor intensity, and long-time operation can easily lead to fatigue and further lead to operation accidents in the prior art. According to the technical scheme, the automatic single plate feeding machine comprises a machine frame, a lifting device and a control system; the lifting device comprises a hydraulic pump station and a jacking hydraulic cylinder, the machine frame is provided with a feeding roller, a third lifting sensing device, a fourth limiting sensing device, more than one material absorbing and feeding device and an air supply system, the feeding roller is connected with a first power device, a fourth power device is arranged in the position, above the feeding roller, on the machine frame, and the control system comprises a PLC, a control circuit, a frequency converter and an electromagnetic valve, wherein the control circuit, the frequency converter and the electromagnetic valve are connected with the PLC.

Owner:阎育华

Wood panel with water vapor-permeable polyester layer

Disclosed is a panel comprising a nonwoven polyester water vapor-permeable layer having a moisture vapor transmission rate of less than 5 perms attached to an underlying engineered wood board.

Owner:HUBER ENGINEERED WOODS

Panel containing bamboo

InactiveUS20090263617A1Synthetic resin layered productsWood working apparatusSurface layerEngineering

A multi-layered composite wood panel including a core layer, a first surface layer and a second surface layer. The core layer is formed from wood flakes and has a top surface and a bottom surface. The first surface layer is adhered to the top surface of the core layer and includes strands of woven bamboo. The second surface layer is adhered to the bottom surface of the core layer and includes strands of woven bamboo. The core layer, first surface layer and second surface layer are bound together to form a substantially rectangular plane having a thickness of between about 0.25 inches and about 2.0 inches.

Owner:HUBER ENGINEERED WOODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com