Processing method of circuit board and circuit board with contour tolerance of +/-0.05mm

A processing method and technology for circuit boards, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of axial offset of milling cutters, affecting the accuracy of circuit board dimensions, and inability to meet circuit board shape tolerances, etc. Extended service life, guaranteed continuity and consistency, and easy access to materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

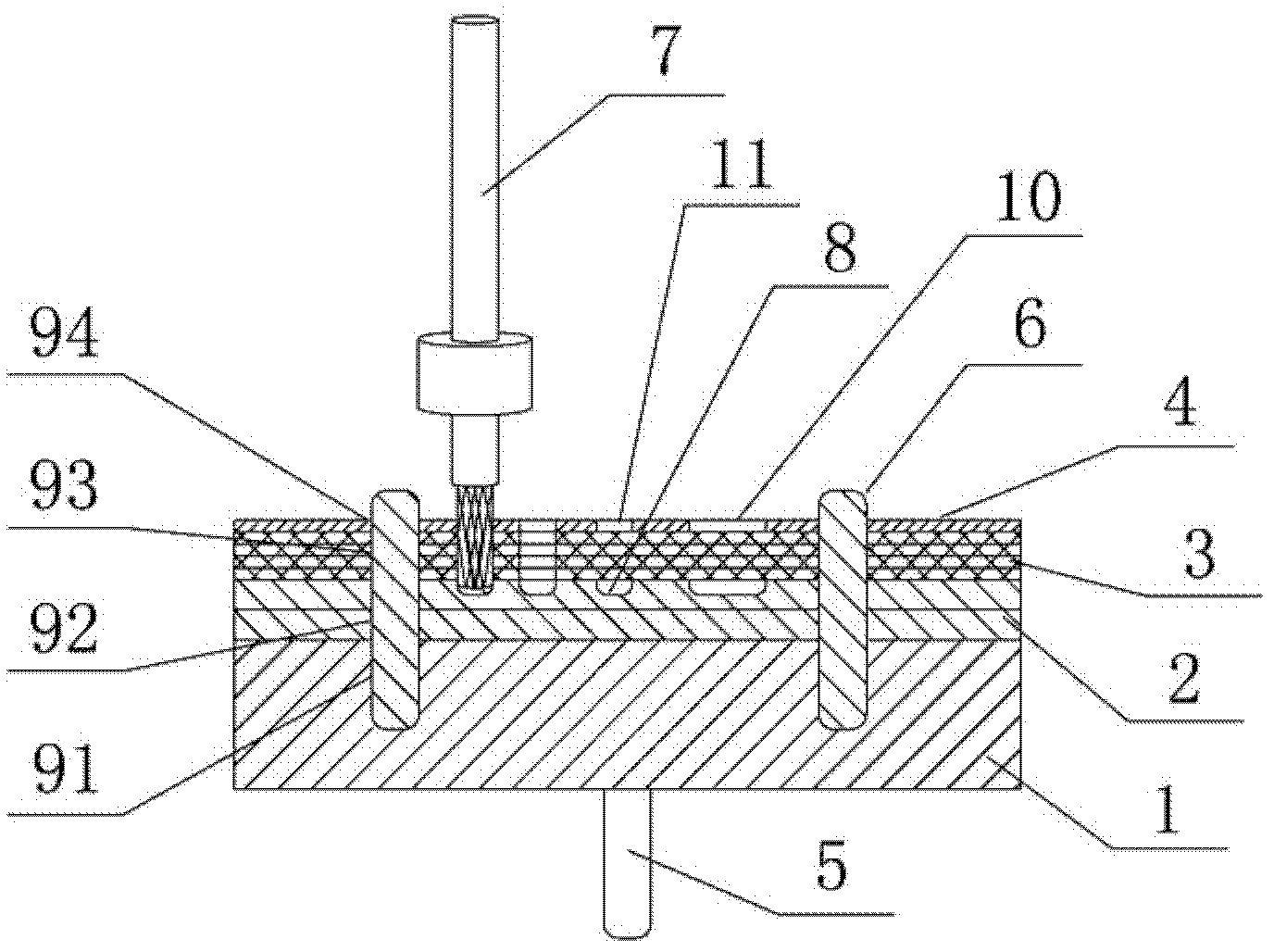

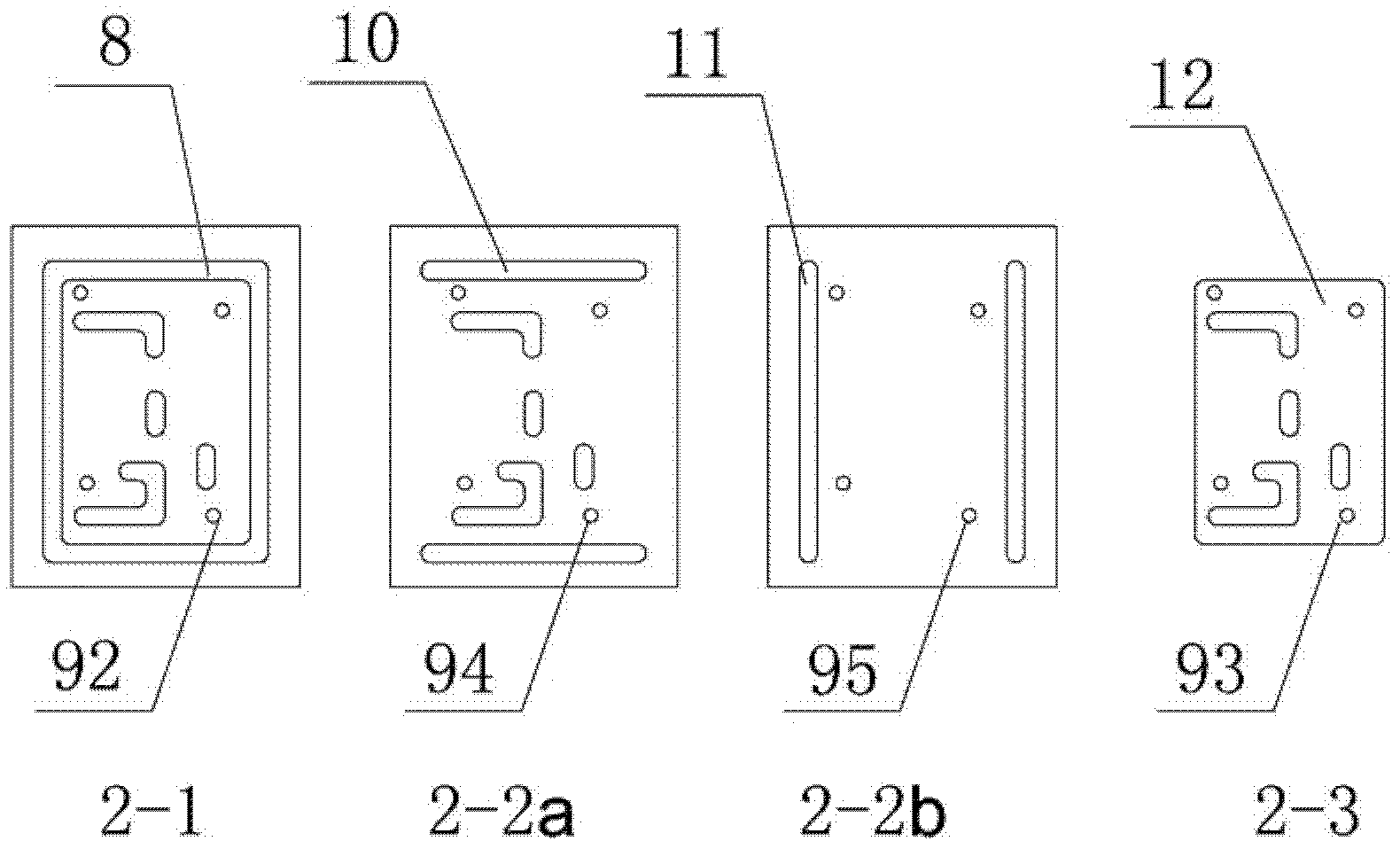

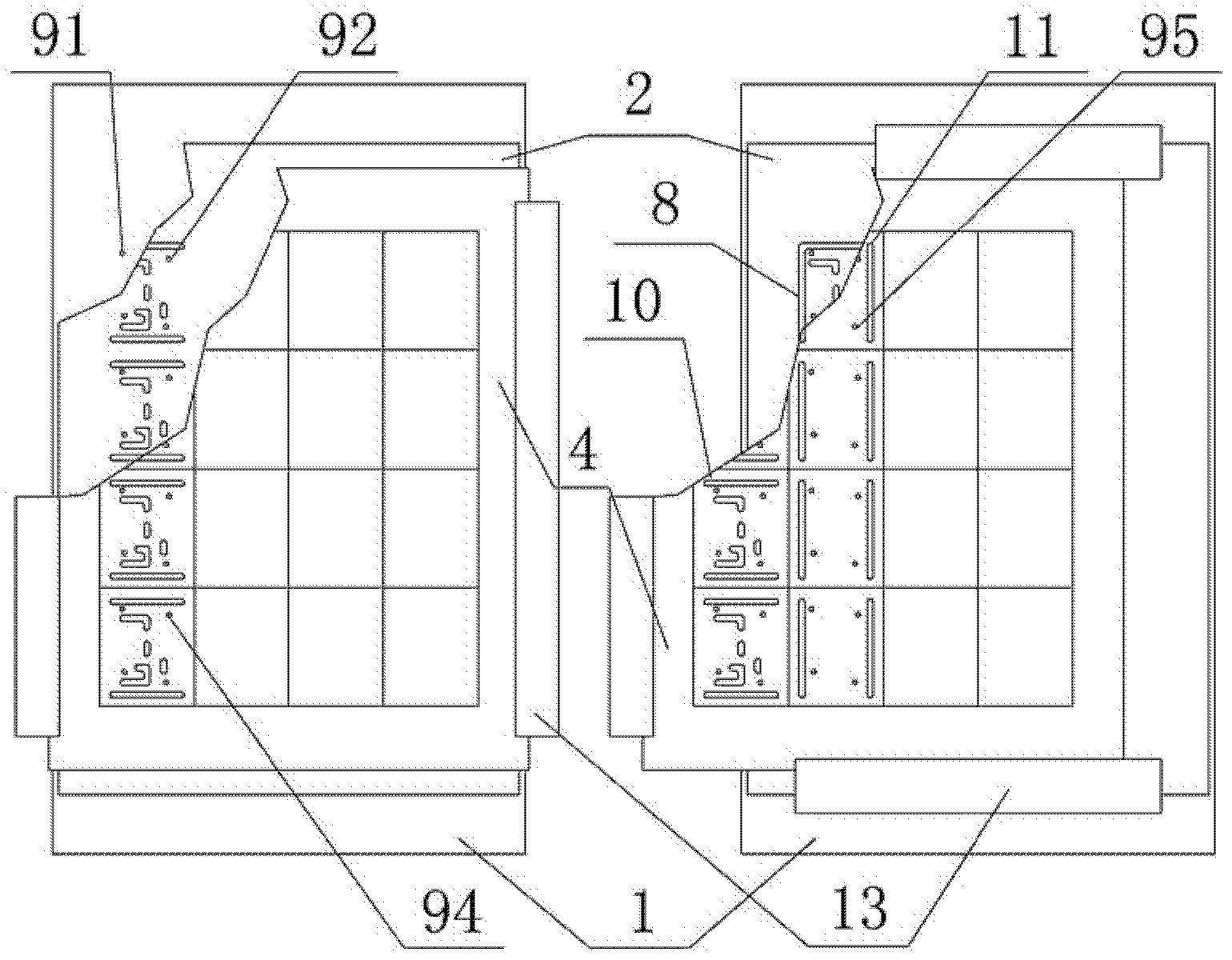

[0036] Such as Figure 1 to Figure 6 A processing method of a circuit board and a circuit board with a shape tolerance of ±0.05mm are shown. Paste an epoxy resin board with a vacuum channel on a special bakelite board as a backing board. The circuit board is placed on the pins that meet the tolerance requirements. There are at least three pins in the finished SET of each circuit board. Cover the circuit board with tape For the cover plate with milling slots, use a fixed row of pins on the bakelite board, and use a new milling cutter to perform two cycles of milling in the horizontal direction and the vertical direction for each row of the circuit board. Bakelite board: choose the bakelite board made of phenolic resin commonly used in the current circuit board production process, with a thickness of 10mm, and use two pins to fix it in the "one hole and one slot" positioning device on the milling machine table. Epoxy resin board: The ordinary prepreg used in circuit board manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com