Patents

Literature

260 results about "Bakelite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bakelite (/ˈbeɪkəlaɪt/ BAY-kəl-eyet; sometimes spelled Baekelite) or polyoxybenzylmethylenglycolanhydride was the first plastic made from synthetic components. It is a thermosetting phenol formaldehyde resin, formed from a condensation reaction of phenol with formaldehyde. It was developed by the Belgian-American chemist Leo Baekeland in Yonkers, New York, in 1907.

Method for preparing bakelite by using nonmetal material in waste printing circuit board

InactiveCN101037527AProtect resourcesReduce secondary environmental pollutionMetallic materialsPrinted circuit board

The invention discloses a method for preparing bakelite, which uses nonmetallic material of waste printed circuit board as raw material to replace wood powder. The method includes steps: mixing 100 quotient of phenolic resin, 25-75 quotient of waster circuit board nonmetallic material particles, 25-55 quotient of wood powder, 15-20 quotient of curing agent, 10-30 quotient of inorganic filler and 2-6 quotient of lubricant under temperature of 90-110 DEG C, cooling, granulating and obtaining the product. The invention can solve problems of treatment and pollution of waste circuit board nonmetallic material, and can reduce production cost of bakelite.

Owner:SHANGHAI JIAO TONG UNIV

Low-temperature curing epoxy polyester powdery paint used on surface of bakelite and preparation method thereof

The invention discloses a low-temperature curing epoxy polyester powdery paint used on the surface of bakelite. The paint comprises, by weight, 20.0 to 40.0% of a polyester resin, 20.0 to 40.0% of an epoxy resin, 1.0 to 3.0% of a curing accelerator, 0.1 to 0.5% of benzoin, 0.5 to 2.0% of a leveling agent, 0.1 to 0.5% of a charge increasing agent, 0.1 to 1.0% of a lustering additive, 0.2 to 1.0% of wax powder, 10.0 to 30.0% of a pigment and 10.0 to 30.0% of a filling material. The powdery paint provided by the invention has good adhesion on the surface of bakelite and undergoes roasting and curing at a temperature of 150 to 160 DEG C for 10 to 20 min, and a coating with excellent performance can be obtained.

Owner:FOSHAN SHUNDE DISTRICT BAILICHI PAINT

Method for preparing high temperature resistant phenol-formaldehyde foam composite thermal-insulating materials

The invention relates to a method for preparation of refractory phenolic cellular syntactic insulant, which consists of adding aluminum hydroxide, pantane and mixed acid curing agent into bakelite A, which is characterized in that: a) adding boride into bakelite A as well, then the boride performing coordination with the bakelite A to produce boron-modified alkyd resin at the indoor temperature; b) selecting inorganic heat-insulating material with thickness of 1-50mm as backing strip, pouring boron-modified alkyd resin onto the backing strip to foam and solidificate with a temperature of 40-90 DEG C for 0.5-1.5 hours, then cooling and demoulding. The invention can resist a high temperature of 250 DEG C and can be used between -190 DEG C and +250 DEG C, which has both champion heat-retaining performance of the phenolic foam plastic and fire resistance of the inorganic heat-insulating material, and has a light weight and is hard to burn, so can be widely used in heat-insulating space.

Owner:上海胜星树脂涂料有限公司 +1

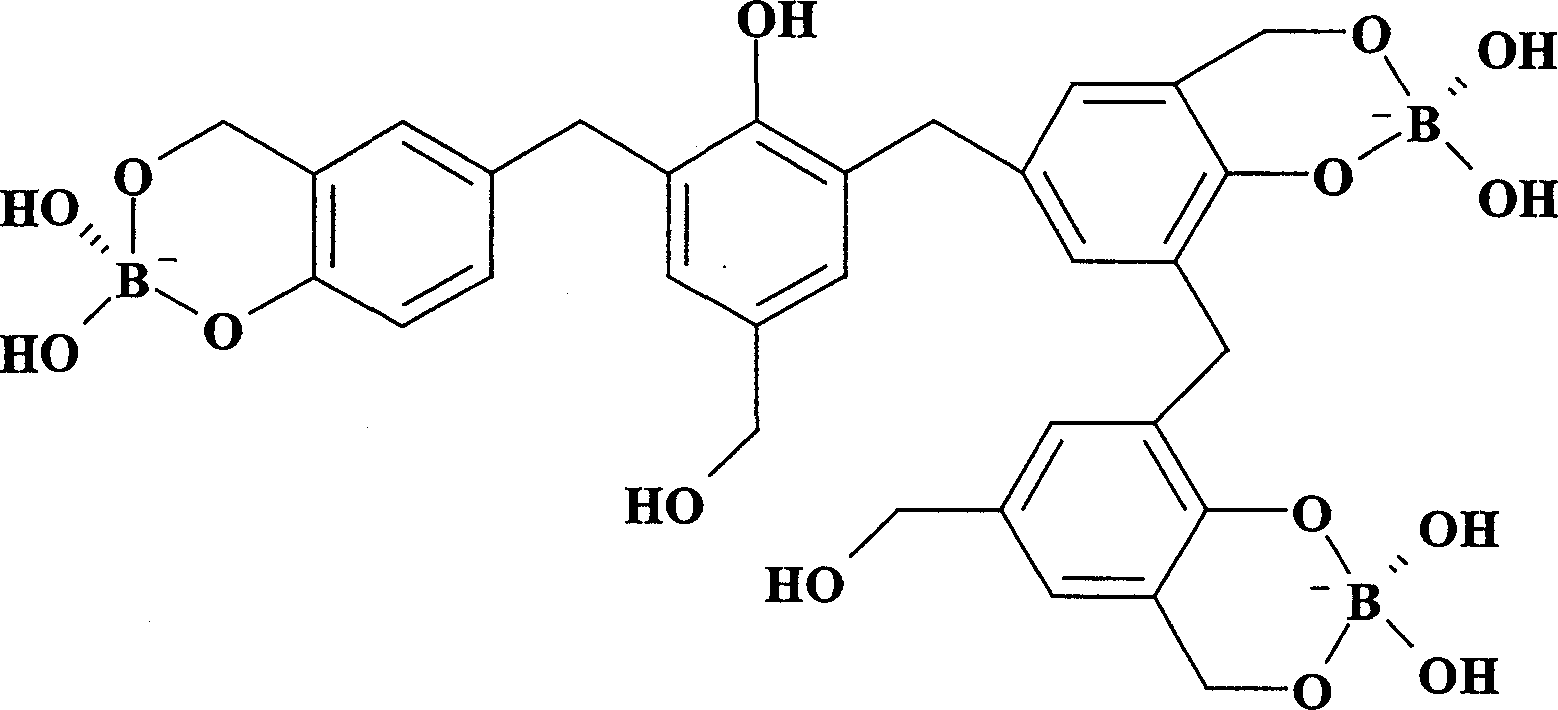

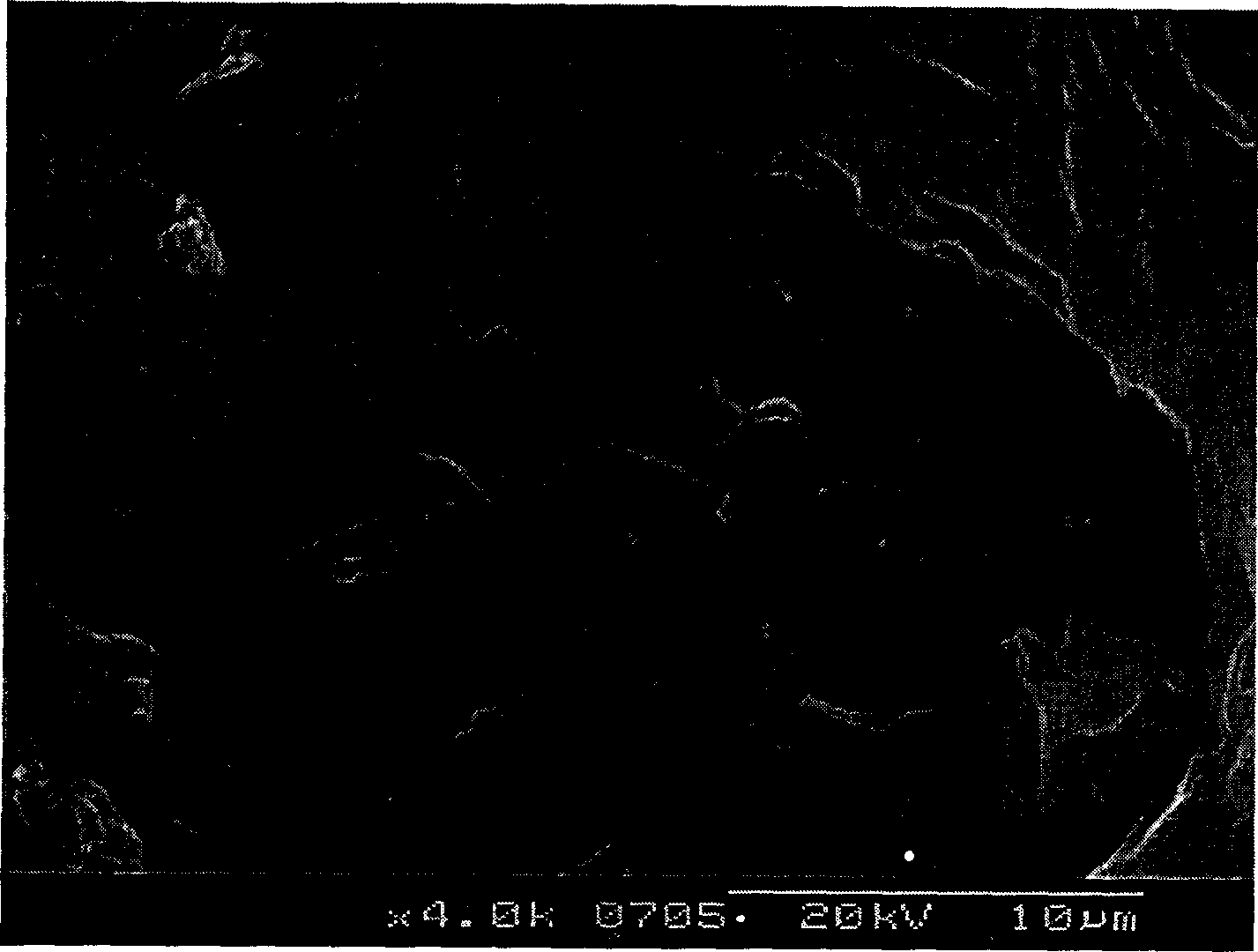

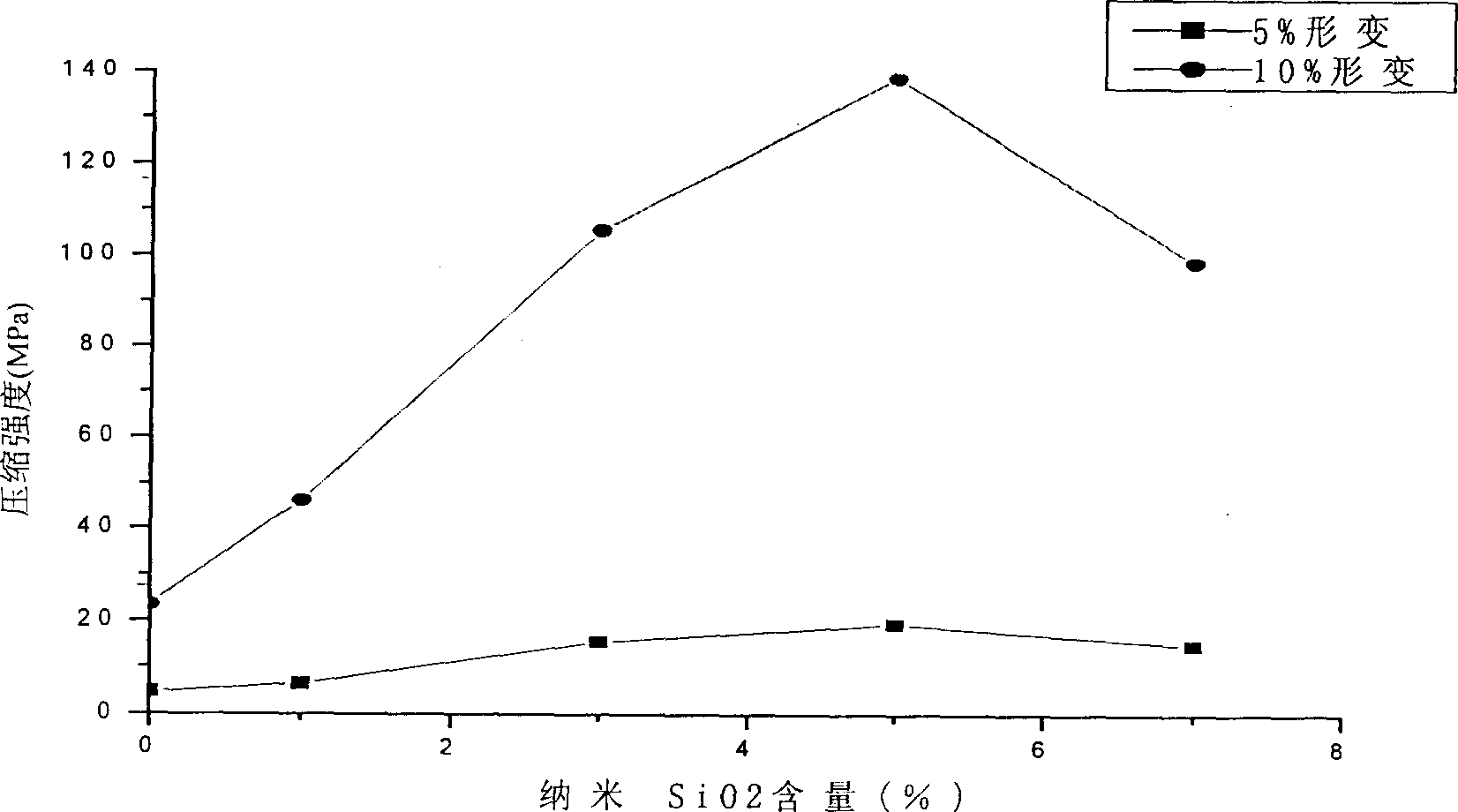

Prepn. process of nano SiO2/boron bakelite resin nano composite material

InactiveCN1834151AImprove heat resistanceImproves ablation resistanceFireproof paintsNano compositesResin matrix

This invention is attributed to the technology of nano-composite materials and specifically relates to a method to prepare nano-sized silicon dioxide / boron phenolic resin nano-composite materials. In this method, solution blending and ultrasonic wave-aided dispersion are combined so as to ensure nano-sized dispersion of the nano-particles in composite materials. The nano-sized silicon dioxide is surface treated so as form good interfaces with boron phenolic resin matrix and to adequately take advantages of nano-sized silicon dioxide and boron phenolic resin. This invention aims at preparing boron phenolic resin nano-composites with different nano-sized silicon dioxide content by reasonable technique control. The rigidity, wear resistance and thermo-chemical stability of nano-sized silicon dioxide and good mechanical properties, thermo resistance and ablation resistance of boron-modified phenolic resin are utilized, and therefore the prepared nano-sized silicon dioxide / boron phenolic resin nano-composite materials can be widely used in high-temperature abrasion materials, ablation resistant materials, special structural materials and thermo resistant materials.

Owner:TONGJI UNIV

Halogenless fire retarded epoxy resin composition

This invention relates to a composition used in printed circuit board domain, mainly used for making cohesive body and copper clad, and specially mean a composition of a halogen-free flame recardant epoxy resin. Accounting weight it includes 60-80 portions phosphorated ether resin, 5-11 portions carboxyl terminated acrylenitrile-buta-diene rubber, 13-27 portions composite curing agent which composed by azotic bakelite, phenol-azotic bakelite and DOS at EQU of 2:4:1, 0.01-0.3 portions iminazo curing accelerator. This invention has no any addition type flame recardant and the cohesive is very smooth. It has good ion migration resistance, thermal insulating and general property, fit for making circuit board.

Owner:GUANGDONG SHENGYI SCI TECH

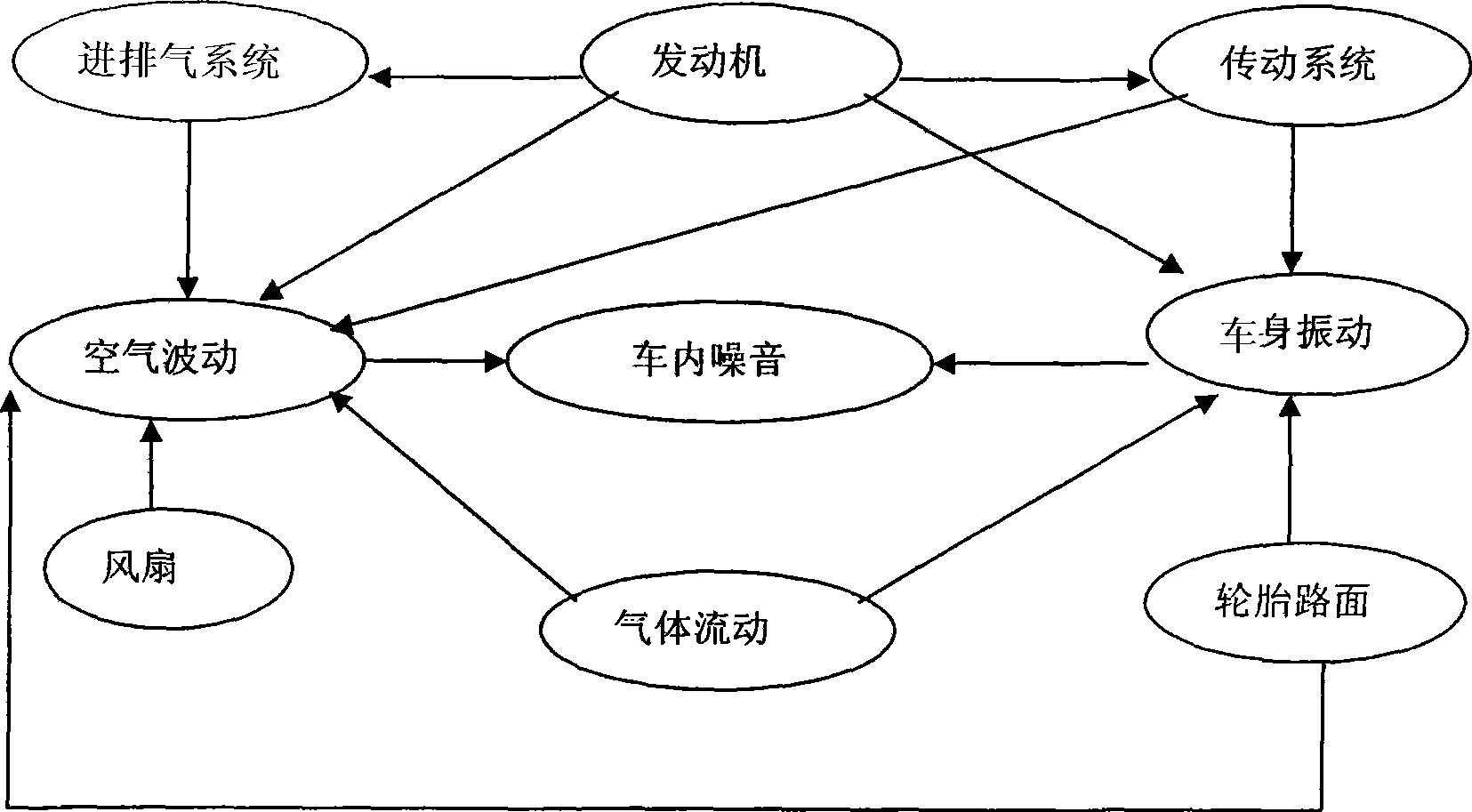

Passenger car floor with sound insulation and decrease of noise functions

ActiveCN101450642AInhibit sheddingPrevent water absorptionSuperstructure subunitsMetal layered productsHigh densityAcoustic absorption

The invention discloses a bus floor with acoustic insulation and damping functions, which is arranged at the back of a carriage, and comprises the following layers from the top down: a floor leather layer, a damping slab rubber layer, a bakelite board interlayer, a multilayer compound acoustic damping cotton layer, a steel plate layer and a self-crusting rubber-plastic sponge layer. A cavity is also arranged between the bakelite board interlayer and the multilayer compound acoustic damping cotton layer. The multilayer compound acoustic damping cotton layer comprises three layers from the top down, namely a porous sponge acoustic absorption layer, a high-density rubber-plastic sponge acoustic insulation layer and a self-adhesion damping acoustic insulation layer. The bus floor adopts sealing, acoustic absorption, acoustic insulation and vibration reduction to achieve the acoustic insulation and damping functions. After the floor is adopted, noise in a bus can be reduced, and environment in the carriage becomes more comfortable.

Owner:ZHONGTONG BUS HLDG

Pure epoxy powder coating for coating bakelite board and preparation method thereof

The invention discloses a pure epoxy powder coating for coating a bakelite board, which comprises the following components in part by weight: 100 to 200 parts of epoxy resin, 1 to 50 parts of epoxy hardener, 0 to 200 parts of inorganic filler and 0 to 10 parts of auxiliary agent. That the bakelite board is coated by the pure epoxy powder coating is an ideal method, which has the advantages that: (1) when the powder coating is sprayed and baked, no solvent is generated, and over-sprayed powder can be recycled; (2) the coating process is simple and has few procedures; (3) compared with paint, the powder coating has superior adhesion, hardness, impact resistance, wear resistance and chemical resistance, and a coat is difficult to damage; and (4) through formula adjustment, surface coats with any grains, colors and glosses can be obtained, and have excellent decorative effect.

Owner:GUANGZHOU QINGTIAN INDAL

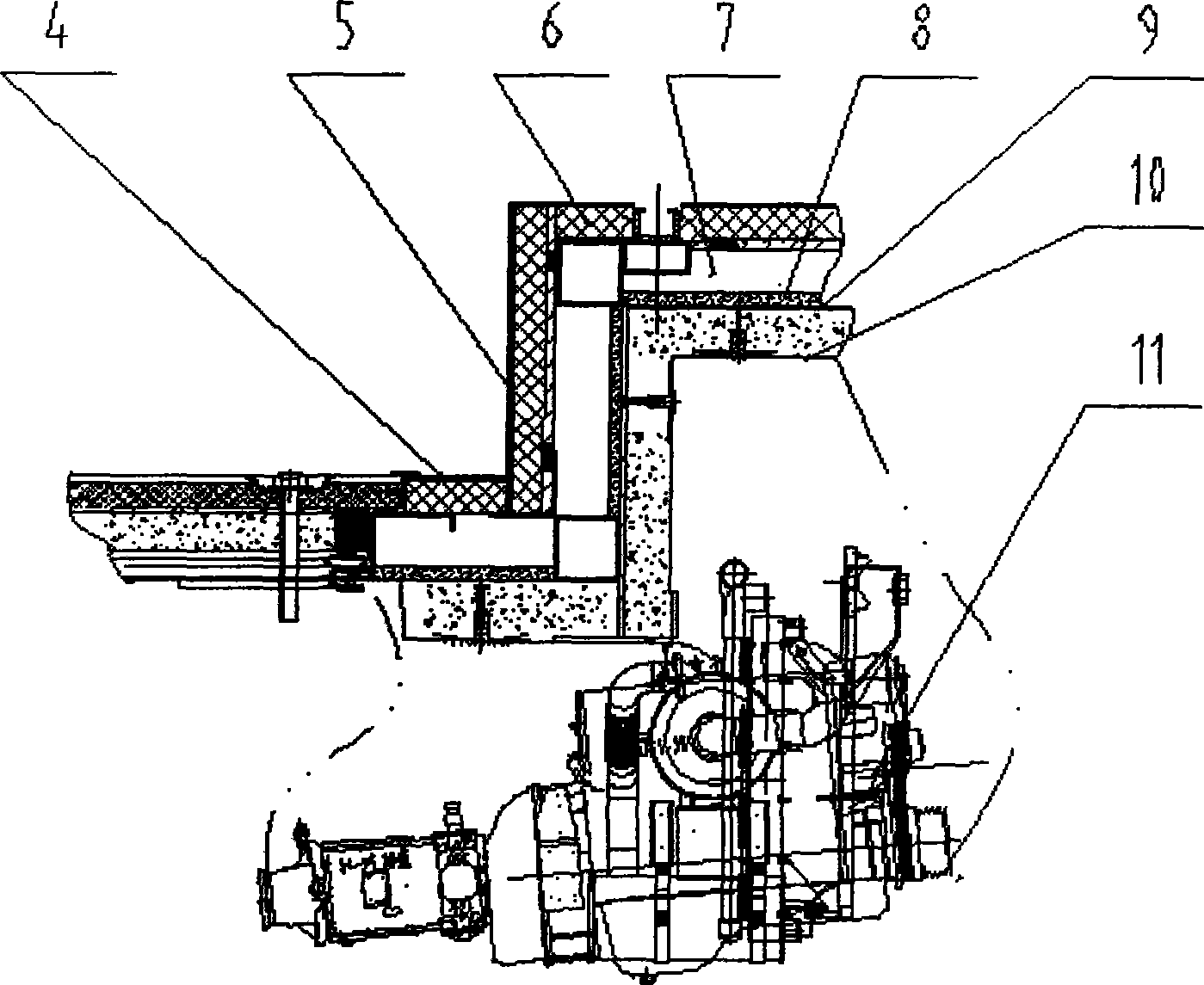

Plasma cutting gun displacement colliding-proof device

InactiveCN101134261ASimple structureCompact structurePlasma welding apparatusProximity sensorControl system

The present invention relates to welding and cutting equipment technology, and is especially one plasma cutting torch collision preventing device for numerically controlled plasma cutting machine. The plasma welding torch collision preventing device includes one turning plate and one bottom ring connected together, one lower clamping ring with permanent magnet and inductor type approach sensor, one blocking iron set between the bottom ring and the lower clamping ring, one electrically insulating bakelite sleeve inside the conic hole of the lower clamping ring, and one upper clamping ring set around the upper end of the bakelite sleeve and connected to the lower clamping ring; and the plasma cutting torch is set inside the upper clamping ring and the bakelite sleeve. The present invention protect the plasma cutting torch by means of the inductor type approach sensor to send out signal, the control system to perform corresponding commands, and detection coil and the lower clamping ring to separate or displace.

Owner:WUXI FENGHUA WELDING EQUIP

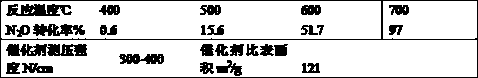

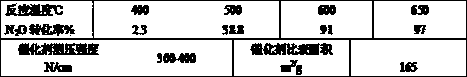

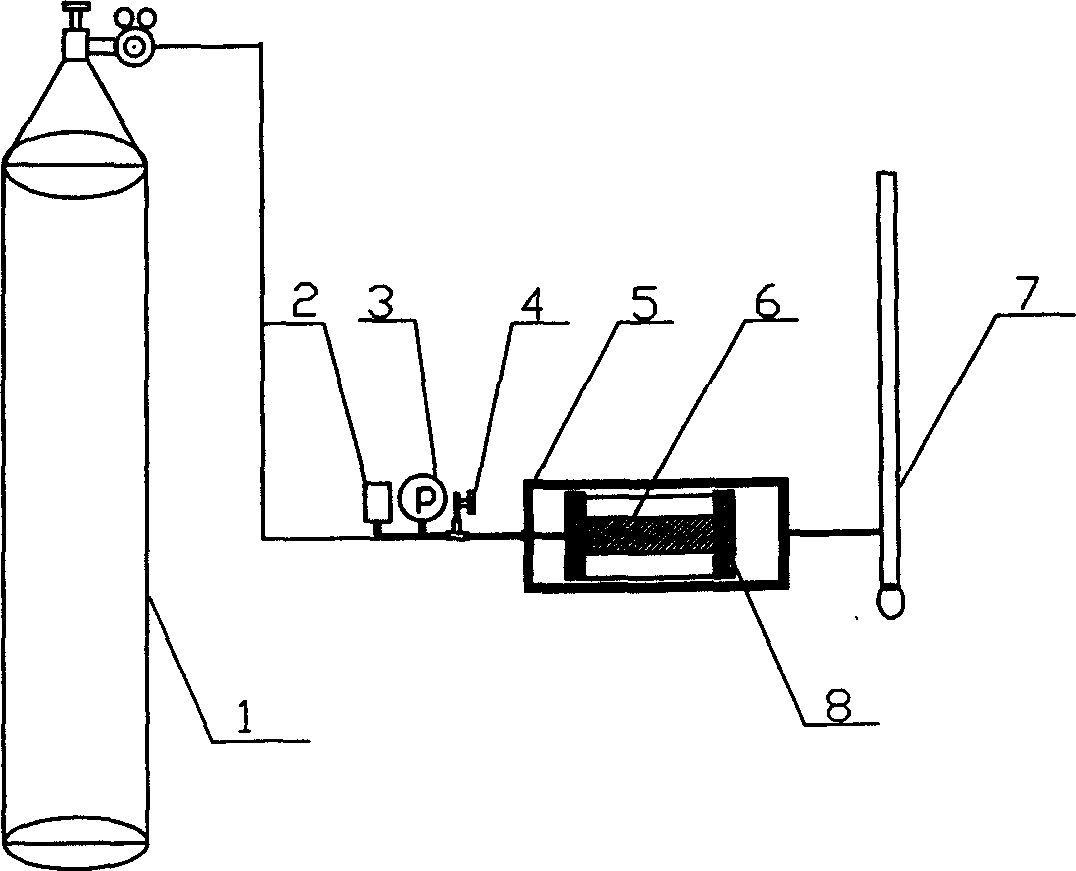

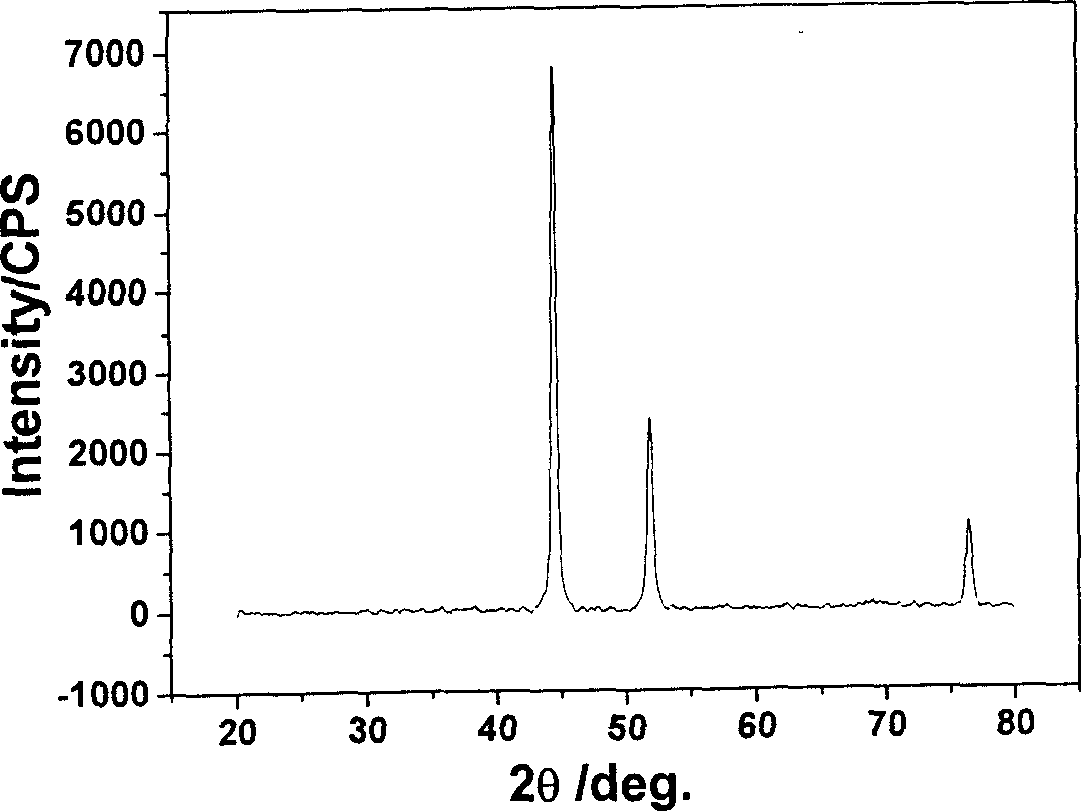

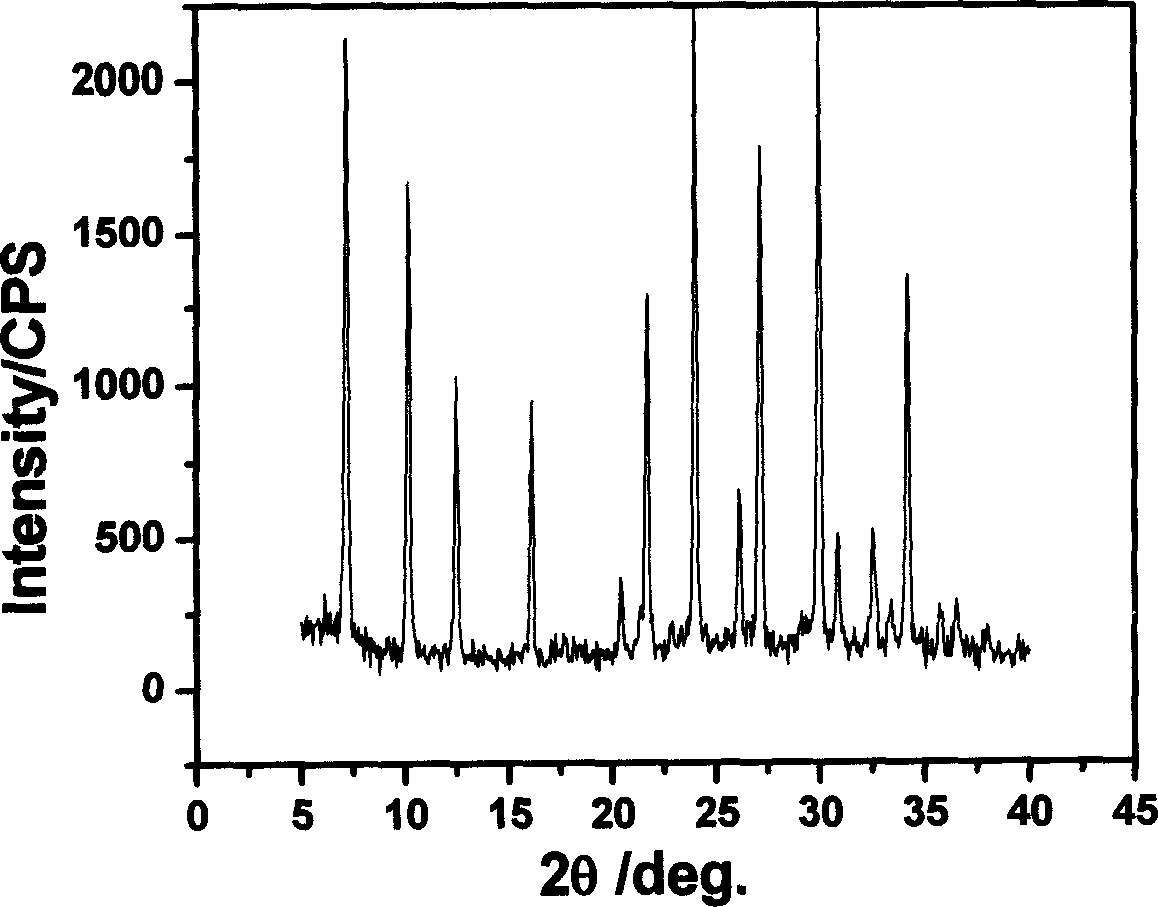

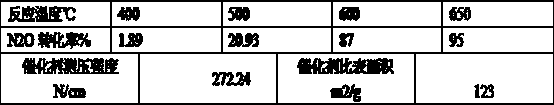

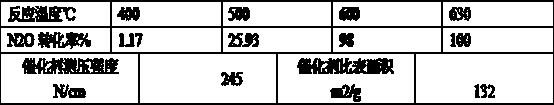

Formed catalyst for directly catalyzing N2O to decompose and manufacturing method thereof

InactiveCN103506128ASimple preparation processEasy to operateNitrous oxide captureDispersed particle separationAdipic acidChemistry

The invention relates to a preparation method for a formed catalyst for directly catalyzing N2O to decompose, and belongs to the technical field of environment protection catalytic materials and air pollution control. According to the catalyst, a compound material is used as a carrier to load metal oxide. The main active components are oxides of Zn and Ni, and one or two types from the oxides of Cu, Fe, Sr, La, Co, K, Na, Zr, Y or Ba are simultaneously loaded. The catalyst is characterized in that the compound material comprises two or more substances including clay, active carbon, bakelite powder, sesbania powder, special pseudo-boehmite powder, SiO2, TiO2, ZrO2, sandy soil and zinc oxide; the catalyst is columnar, clover-shaped or takes the shape of geranium nepalense sweet; the external diameter is 1-20 mm. The metal oxides accounts for 30-55% of the total weight of the catalyst, wherein the nickel oxide accounts for 1-5%, and the zinc oxide accounts for 30-45%. The catalyst can be widely used for removal and decomposing of N2O in a nitric plant, an adipic acid plant and other industrial process generating N2O.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

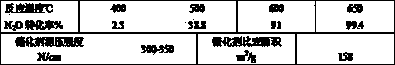

Single-film concave-convex chain clipped applying bag making machine

InactiveCN1541899AWide range of specificationsThe printing effect exceedsBox making operationsPaper-makingMicrocomputerPunching

The single-film concave-convex clip chain jointing machine is provided with upper and lower cylinders, ironing molds mounted on the pistons in the cylinders, bakelite board between the upper and lower ironing molds, and bag adhering mechanism with punching head mounted on the piston of one cylinder. The present invention has high bag making efficiency, convenient operation and stable performance, and the jointing machine is microcomputer controlled and provided with pneumatic mechanism.

Owner:郭明

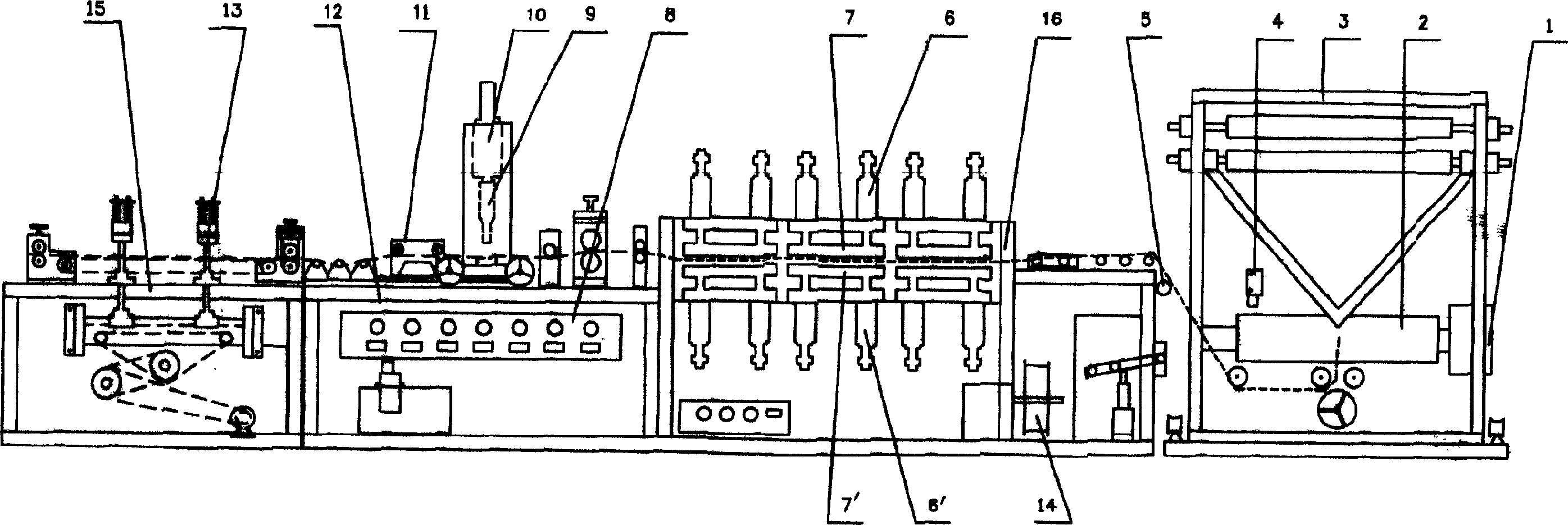

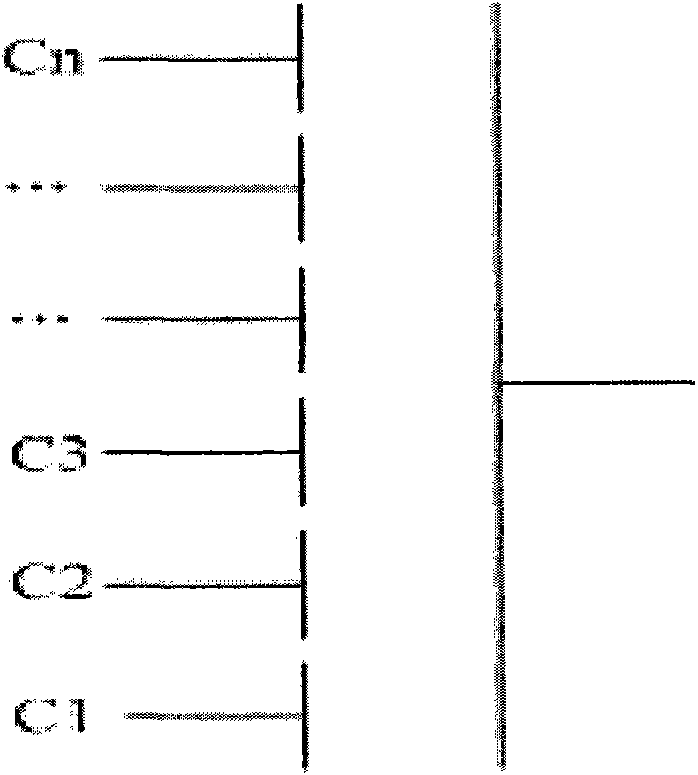

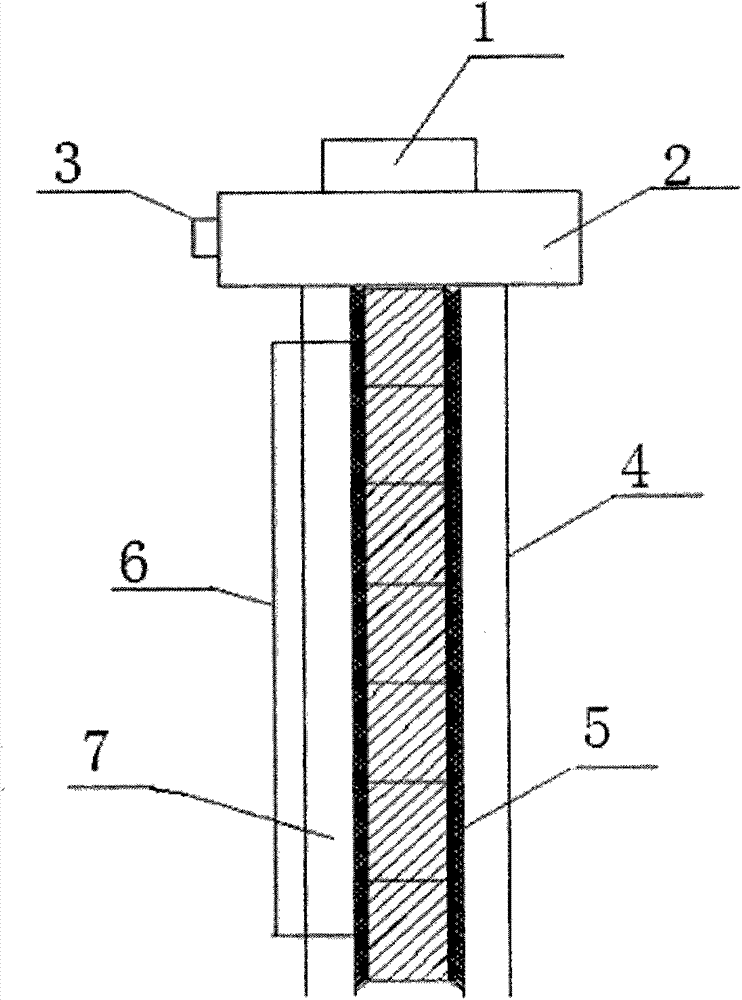

Segmented liquid level sensor based on capacitance-to-digital conversion technology

InactiveCN103900661AAvoid switchingLow failure rateLevel indicators by physical variable measurementAviationInsulation layer

The invention discloses a segmented liquid level sensor based on the capacitance-to-digital conversion technology. A seven-segment sensor inner pole cylinder is a copper foil electrode bonded onto bakelite. An outer pole cylinder is a stainless steel sensor shell, the copper foil electrode is connected with a waterproof sensor junction box through a lead, the copper foil electrode is sleeved with a polytetrafluoroethylene insulation layer, an aviation plug is arranged on one side of the waterproof sensor junction box, and the top of the waterproof sensor junction box is provided with a sensor upper cover. According to the segmented liquid level sensor, a capacitance-to-digital conversion technology chip PCAPO1 is used in the capacitance detection method, the problem of stray capacitance of capacitance measurement is solved, the problem of measurement of multiple sections of capacitance at the same time is solved, compensation calibration can be performed on the stray capacitance in the chip through a circuit and an algorithm, and the compensation result is that gain offset within a proper temperature range can be achieved. Exchange between data and a host can be performed conveniently through an SPI or IIC data serial interface. The segmented liquid level sensor is low in noise, low in power consumption and simple in peripheral circuit, and microminiaturization and integration can be achieved easily.

Owner:NORTHEAST DIANLI UNIVERSITY

Electrical insulation compound adhesive for high voltage electrical apparatus

ActiveCN101368075AImprove heat resistanceImprove toughnessPlastic/resin/waxes insulatorsAldehyde/ketone condensation polymer adhesivesEpoxyAdhesive

The invention provides a high-voltage electrical apparatus insulated adhesive, which comprises the following components by weight portion: 150 to 160 portions of bakelite, 30 to 40 portions of epoxide resin, 10 to 12 portions of methenamine, 100 to 110 portions of nitrile latex, 5 to 8 portions of 2-mercaptobenzothiazole zinc salt, 2 to 4 portions of accelerant PX, 2 to 4 portions of zinc naphthenate, 30 to 35 portions of colophony, 200 to 220 portions of benzene, 100 to 120 portions of acetone, 20 to 22 portions of toluene diisocyanate, and 50 to 80 portions of mica powder. The high-voltage electrical apparatus insulated adhesive has excellent bonding properties, ageing resistance and chemical mediator resistance as well as excellent insulating properties, which is applicable for bonding metal units, and in particular applicable for manufacturing of high-voltage electrical apparatuses and equipment.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

Graphene phenolic resin composite material and application thereof

The invention relates to the technical field of phenolic resin composite materials, in particular to a graphene phenolic resin composite material. Oxidized graphene, hydrazine hydrate, a surfactant and a formaldehyde solution are added into a reactor, stirred and heated up to 80-100 DEG C for reaction; the obtained liquid reactant is cooled down to 60-80 DEG C, then an acid catalyst and phenol are added, the temperature is increased to 85-100 DEG C for reaction, and then heating dehydration is performed. The graphene phenolic resin composite material can be applied to bakelite powder. As the proper surfactant is adopted, the problem of dispersion of graphene in resin is solved, and uniformly mixed graphene modified phenolic resin is obtained; the oxidized graphene which is not reduced can further react with phenolic resin to obtain graphene modified phenolic resin of an inorganic complexing structure; the bakelite powder prepared by resin has relatively high impact resistance and low forming shrinkage ratio.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

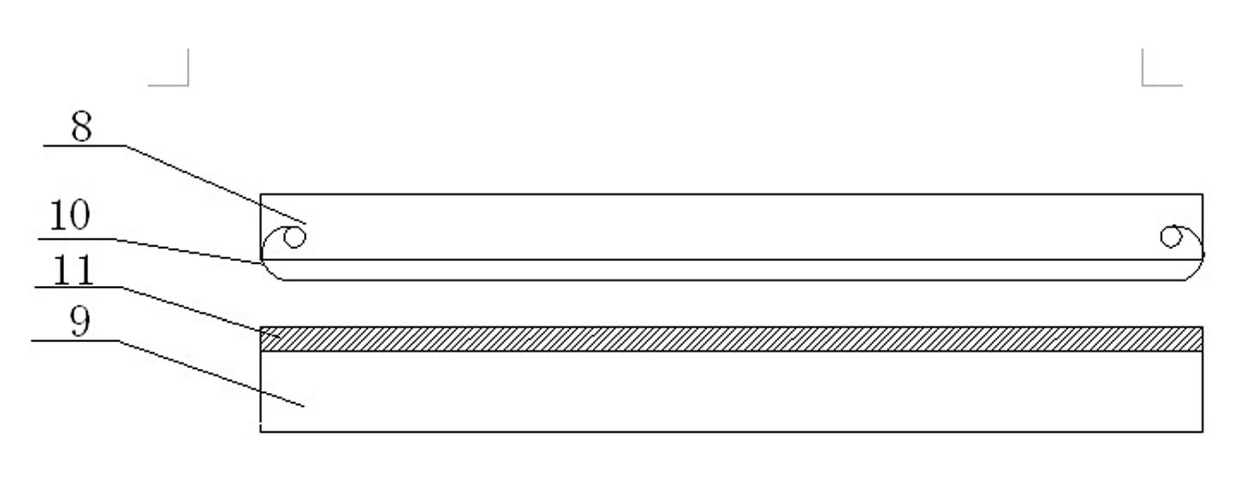

Method of processing supersonic vibration machine grinding of sapphire steel bar

InactiveCN101041227AQuality improvementEfficiently manufacture low costEdge grinding machinesOil/fat/wax adhesivesMachined surfaceSealing wax

The invention relates to an ultrasonic vibration grinding machining method for sapphire bar. After the sapphire blank workpeice is located upper and lower surfaces are grinded flat and it is bonded on bakelite by sealing wax glue; then the bakelite is fixed on the working table of machine. The ultrasonic wave is started and the frequency of ultrasonic wave is adjusted in 17kHz-23kHz to make it in resonance state. The cooling liquid is started and the workpeice is cooled by inner and outer cooling ways. The ultrasonic vibration grinding machining is carried out. After machining is accomplished the sapphire workpeice and the bakelite are set on electrical furnace together to be heated to 115deg.C-125deg.C. The sapphire workpeice is fetched from the bakelite to obtain sapphire bar with diameter of 20-140mm and length of 50-150mm. the invention is provided with good machining surface quality and low producing cost so on. It has a wide applicable prospect and can create obvious social and economical benefits.

Owner:HARBIN INST OF TECH

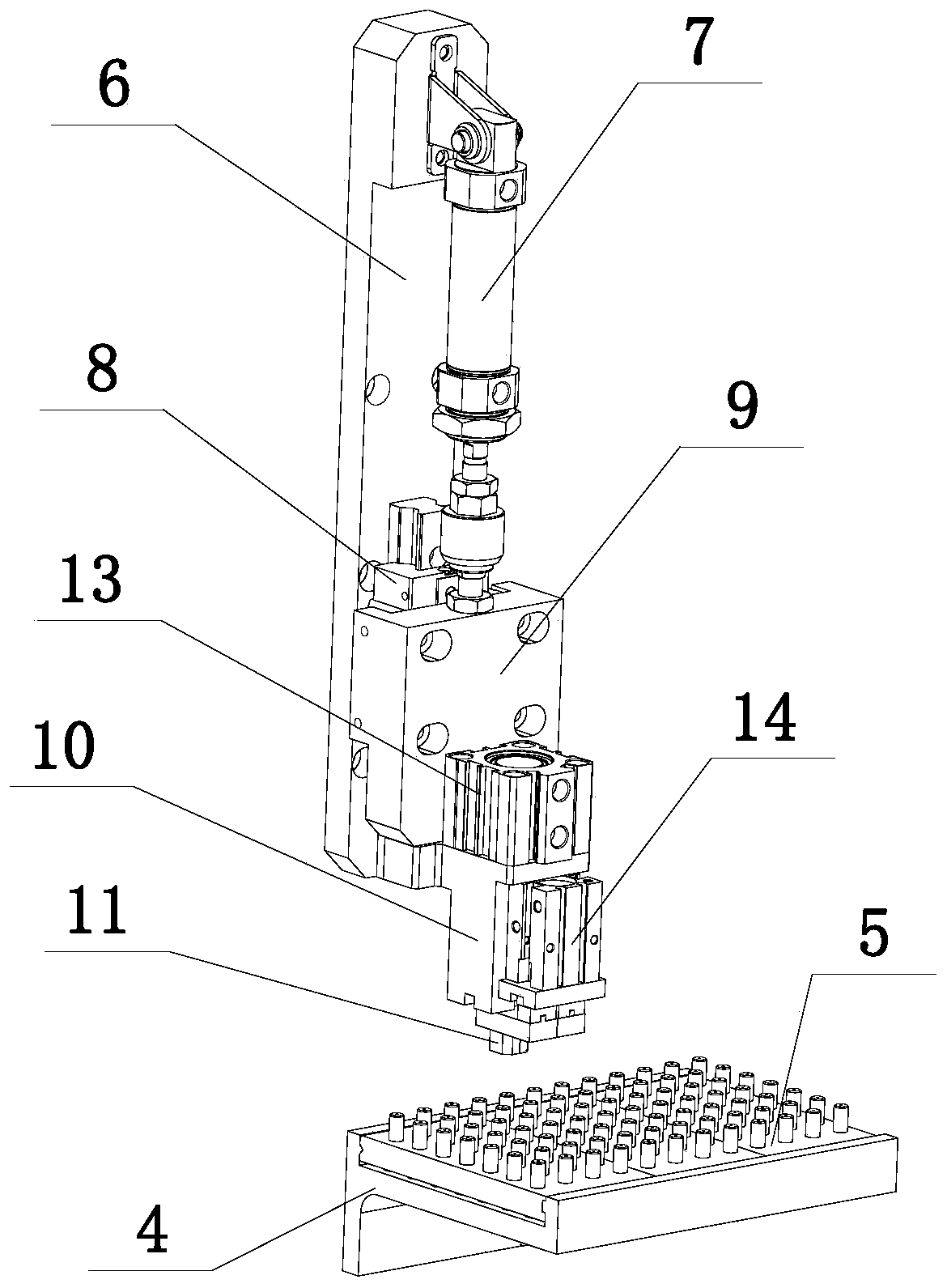

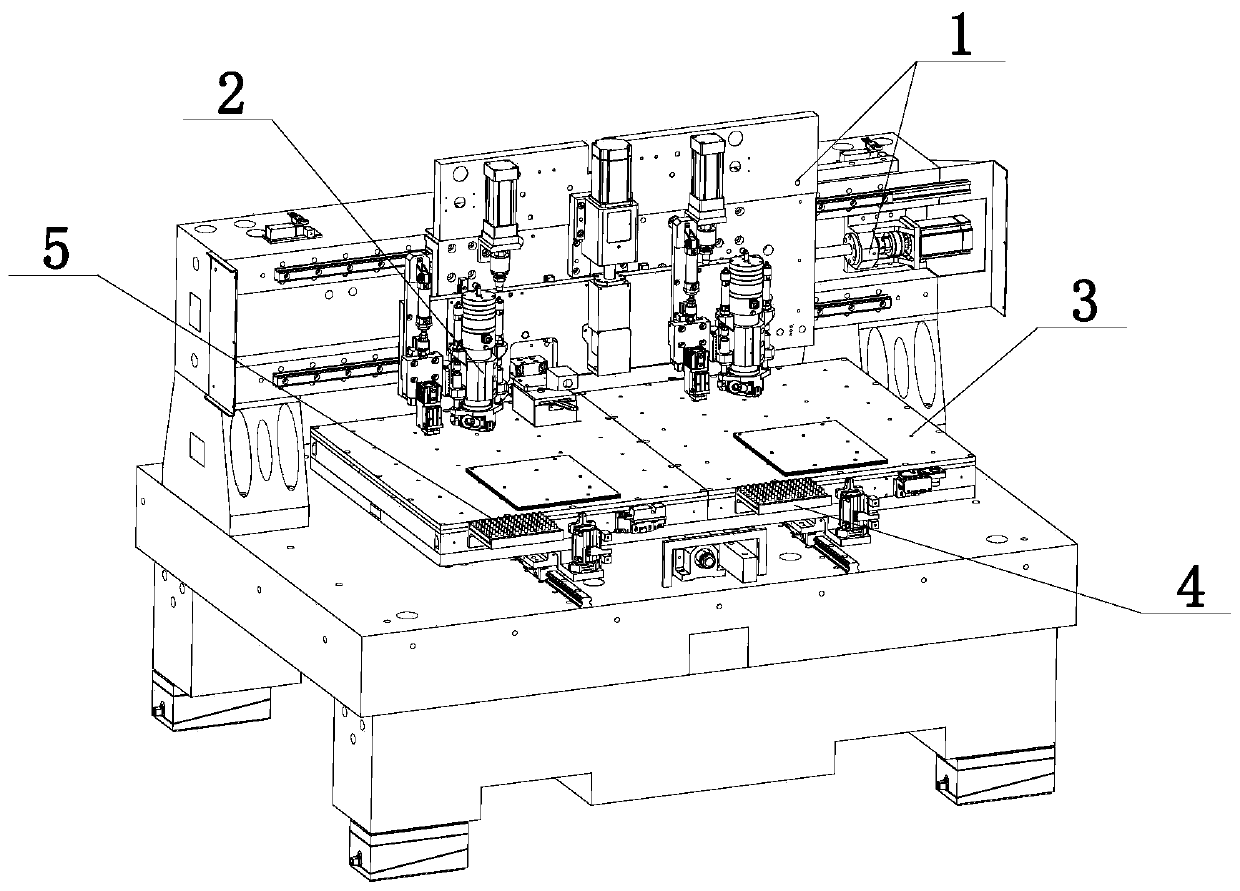

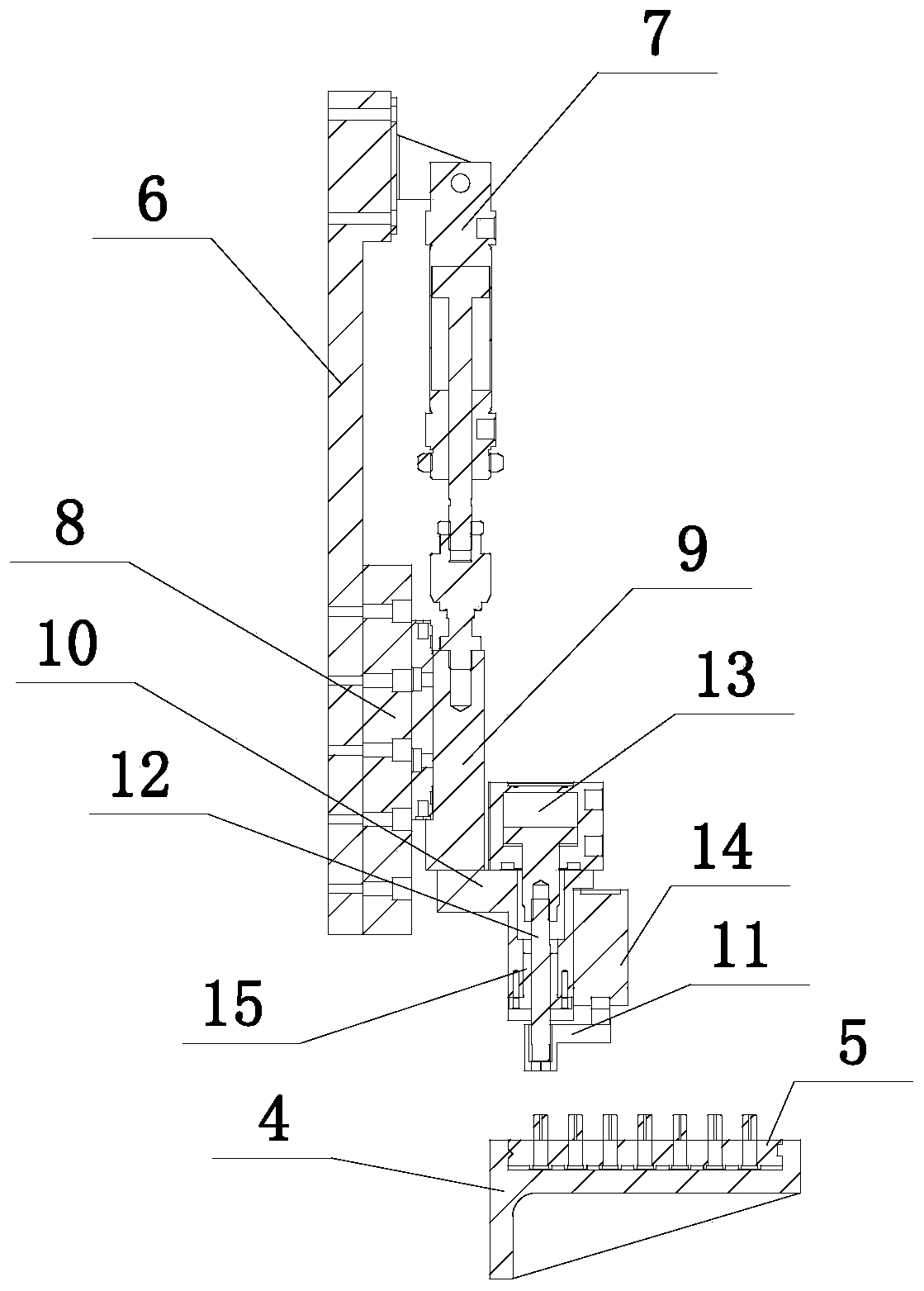

Automatic pin punching mechanism for PCB numerical control machine tool and pin punching method

PendingCN110366319AOmit timeReduce time spentCircuit board tools positioningMetal working apparatusNumerical controlPunching

The invention discloses an automatic pin punching mechanism for a PCB numerical control machine tool, which comprises a pin punching assembly, a pin box fixing seat and a pin box, wherein the pin punching assembly comprises a mechanism mounting plate; the position close to the top, close to one side of a bakelite board working table, of the mechanism mounting plate is provided with a vertical driving device; the position close to the bottom, close to one side of the bakelite board working table, of the mechanism mounting plate is provided with a sliding connection plate; and the vertical driving device is connected with the sliding connection plate and drives the sliding connection plate to move vertically along a sliding part. The invention also discloses an automatic pin punching methodfor the PCB numerical control machine tool.

Owner:CHENGDU JINDALI TECH

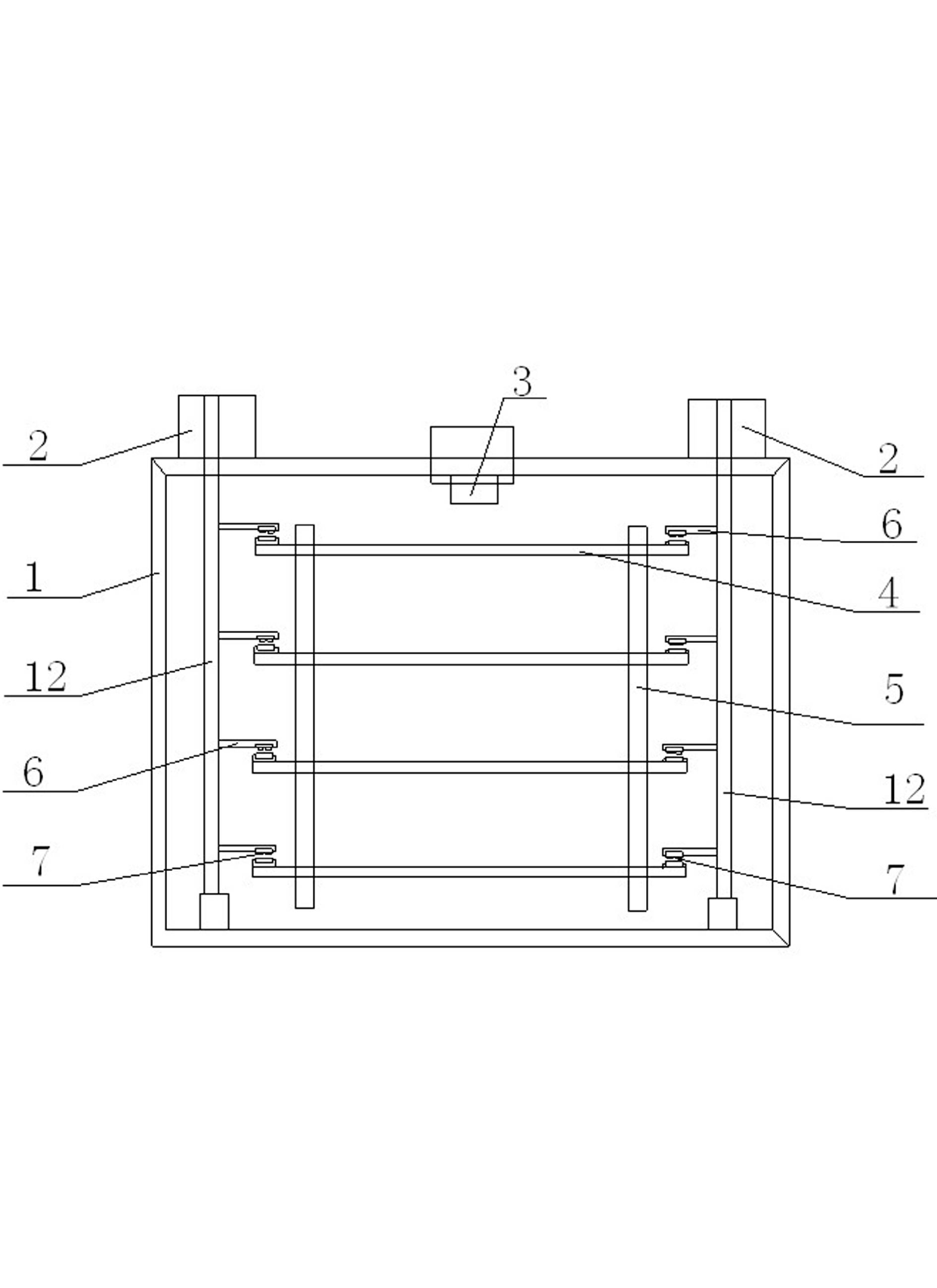

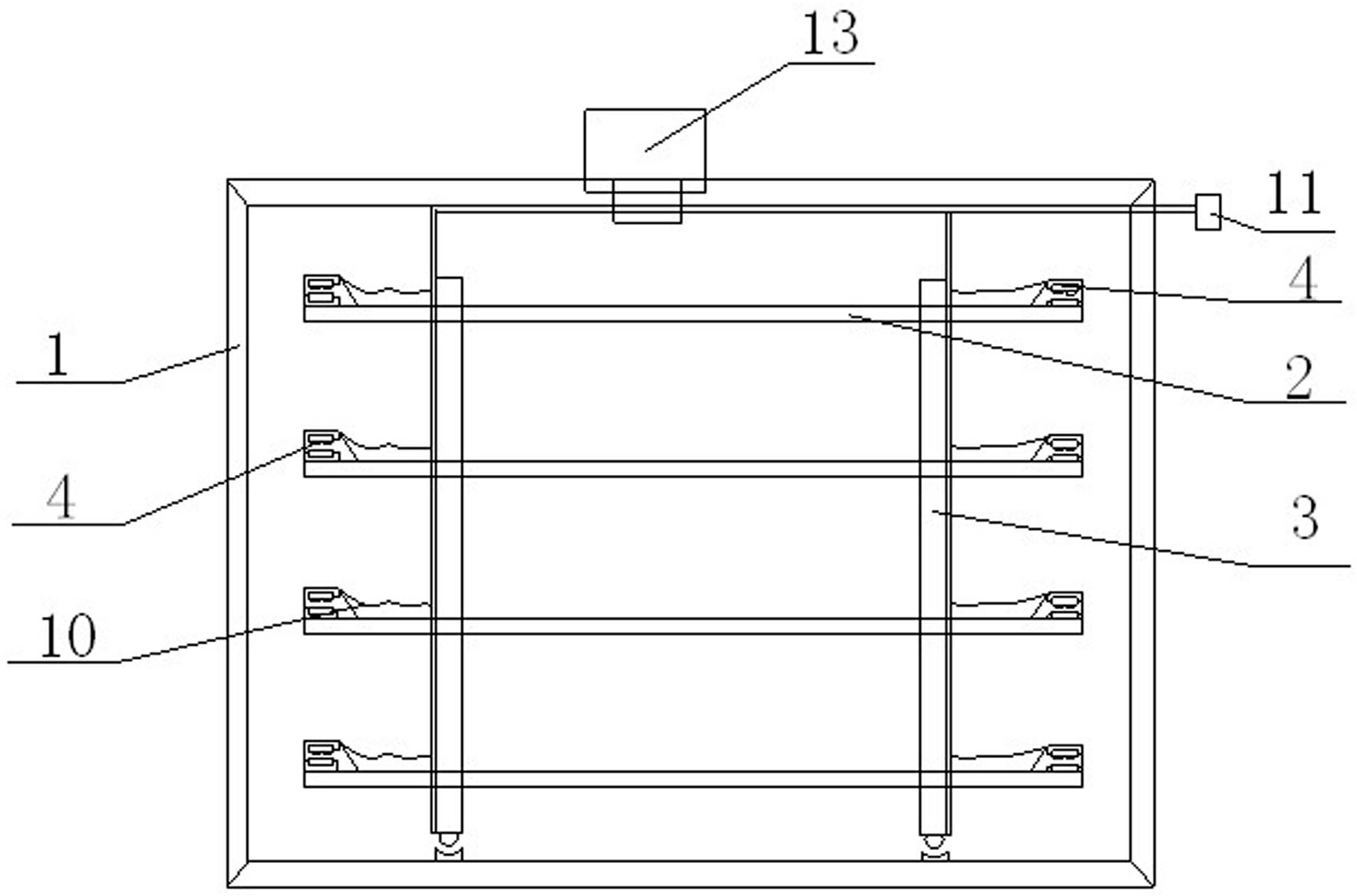

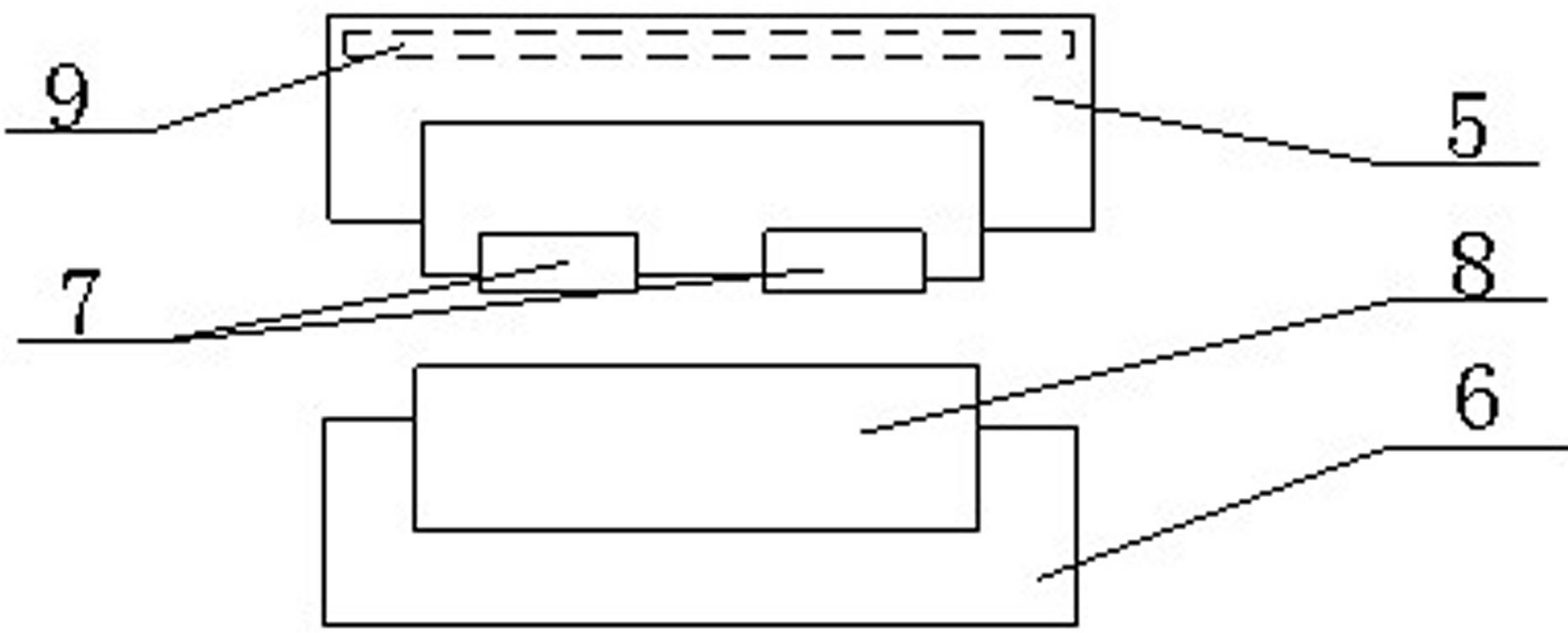

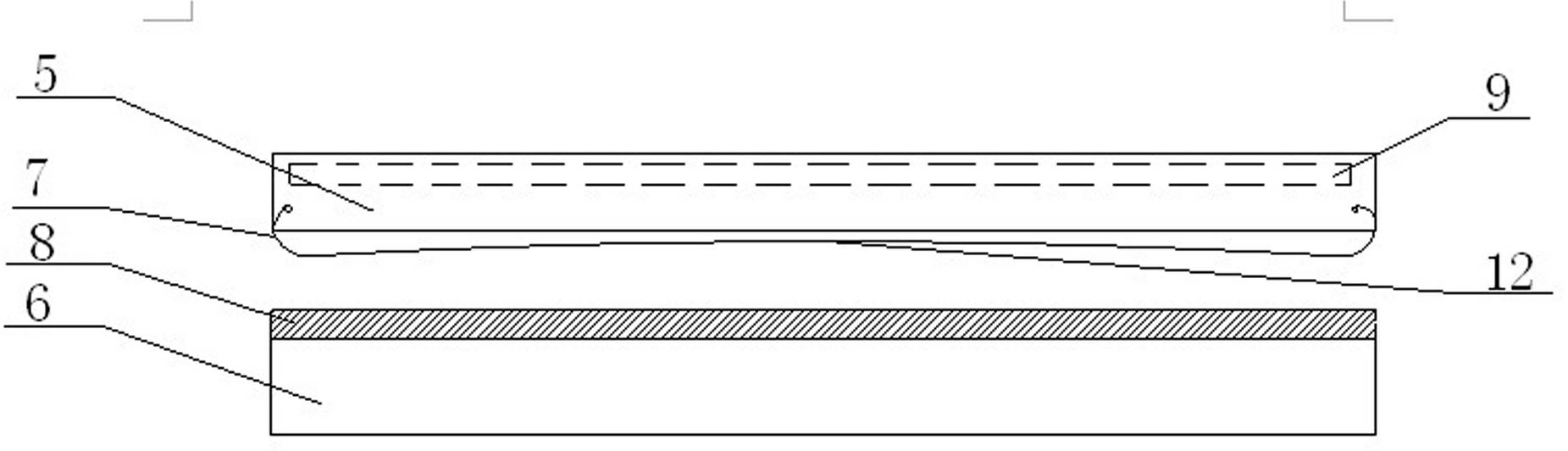

Vacuum insulation plate sealing machine and sealing process for sealing vacuum insulation plate by utilizing same

ActiveCN102168784AImprove insulation effectExtended service lifeThermal insulationPipe protection by thermal insulationEngineeringSilica gel

The invention discloses a vacuum insulation plate sealing machine and a sealing process thereof. The vacuum insulation plate sealing machine is characterized by comprising a box body, an air cylinder, a vacuumizing machine, a commodity shelf and a sealing device, wherein the sealing device comprises bakelite on an upper layer, bakelite on a lower layer and a silica gel strip attached to the bakelite on the lower layer; and two heating sealing strips are arranged below the bakelite on the upper layer. The sealing process of the vacuum insulation plate sealing machine comprises the following steps of: putting an insulation plate on the commodity shelf, starting the vacuumizing machine to vacuumize the box body, and controlling the pressure of air in the box body to be within the range of between 0.6 and 0.02 Pa; and starting the air cylinder, so that an air cylinder shaft moves downwards under the control of the air cylinder, pressing the bakelite on the upper layer to the bakelite on the lower layer to generate the pressure of between 2 and 4 Pa, allowing the two heating sealing strips to perform heating seal on an aluminum foil barrier bag simultaneously, forming at a time, and taking the sealed vacuum insulation plate out, wherein the time of the heating seal is controlled to be 1 to 3 seconds. The vacuum insulation plate sealing machine has the advantages of reasonable structure, simplicity of operation and high quality of products.

Owner:启东市恒怡电源有限公司

Tubular supporting carbon molecular sieve membrance and its preparing method

InactiveCN1709560AGood effectPermeate flux decreaseSemi-permeable membranesMolecular sieveProduct gas

The present invention relates to char molecule sieve membrane and its method especially the cannular backstop char sieve membrane. It is a new Nami material -char sieve membrane filled Nami material in char sieve membrane. The preparation method is adding Nami material in no water ethanol of bakelite colophony. Nami materials are Nami nickel, Nami NaA molecule, Nami titanium dioxide. The ultrasonic makes Nano material decentralize in the membrane liquid and dip cannular backstop. Nami material has different adsorption ability to some gas. According this, char molecule can permeate or remain some gas. So it can increase or decrease the selectivity of the gas to other gas.

Owner:NANJING UNIV OF TECH

Preparation method of direct N2O catalytic decomposition catalyst

InactiveCN103506129ASimple preparation processGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsActivated carbonCatalytic decomposition

The invention relates to a preparation method of a direct N2O catalytic decomposition catalyst, and belongs to the technical field of environment-friendly catalytic materials and atmospheric pollution control. The catalyst uses a composite as a carrier and loads two layers of metal oxide by twice or multiple times of impregnation. The composite is the molded product of two or more of clay, activated carbon, bakelite powder, sesbania powder, special pseudo-boehmite powder, SiO2, TiO2, ZrO2, sandy soil or high alumina cement; the first layer of metal oxide is the composite oxide of Cu, Zn and Ni, and the second layer of metal oxide is an oxide of Ba, Ca, Mg, Y, Cr, Mo, Co, La, Pr or Nd; the catalyst takes the shape of a column, a clover or a five-leaf grass, and the outer diameter is 1-20 nm. The catalyst can be widely used in decomposition of N2O in a nitric plant, an adipic acid plant or other N2O-producing industrial processes.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

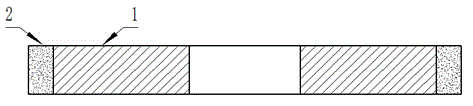

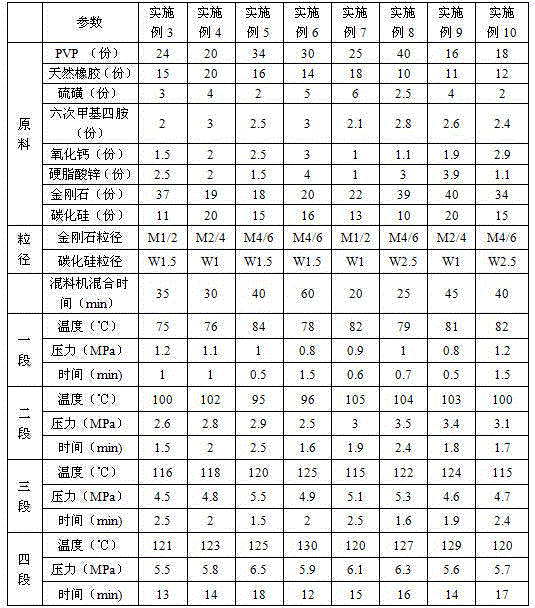

Resin and rubber combined binding agent grinding wheel for polishing of ceramic materials

ActiveCN105058249AObvious flexibilityObvious elasticityAbrasion apparatusGrinding devicesCarbide siliconVulcanization

A resin and rubber combined binding agent grinding wheel for polishing of ceramic materials comprises a grinding wheel base body and a grinding material layer stuck to the outer side of the base body; the base body is a bakelite base body; the grinding material layer is formed by mixing combined binding agents and grinding materials; the combined binding agents are composed of polyvinyl butyral resin, natural rubber, vulcanizing agents, vulcanization accelerators and vulcanizing activators; the grinding materials are composed of diamond and silicon carbide; the grinding material layer is composed of, by volume percentage, 15-40 parts of the polyvinyl butyral resin, 10-20 parts of the natural rubber, 2-6 parts of the vulcanizing agents, 3-6 parts of the vulcanization accelerators, 1-4 parts of the vulcanizing activators, 18-40 parts of diamond micro powder and 10-20 parts of silicon carbide micro powder. The prepared grinding wheel can meet the machining requirements for high precision and high surface quality of the fine ceramic materials.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Graphene phenolic resin composite material, and preparation method and application thereof

The invention relates to the technical field of phenolic resin composite materials, in particular to a graphene phenolic resin composite material. Oxidized graphene, hydrazine hydrate, a surfactant and a formaldehyde solution are added into a reactor, stirred and heated up to 80-100 DEG C for reaction; the obtained liquid reactant is cooled down to 60-80 DEG C, then an acid catalyst and phenol are added, the temperature is increased to 85-100 DEG C for reaction, and then heating dehydration is performed. The graphene phenolic resin composite material can be applied to bakelite powder. As the proper surfactant is adopted, the problem of dispersion of graphene in resin is solved, and uniformly mixed graphene modified phenolic resin is obtained; the oxidized graphene which is not reduced can further react with phenolic resin to obtain graphene modified phenolic resin of an inorganic complexing structure; the bakelite powder prepared by resin has relatively high impact resistance and low forming shrinkage ratio.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Vacuum heat insulation panel air pressure sealing machine and sealing process for sealing vacuum heat insulation panel utilizing same

ActiveCN102147042AAvoid wrinklesAvoid convectionThermal insulationPipe protection by thermal insulationSilica gelAluminum foil

The invention discloses a vacuum heat insulation panel air pressure sealing machine which comprises a box body, a vacuumizer, a commodity shelf and a rack, wherein two ends of the commodity shelf are provided with sealing devices; each sealing device comprises an upper layer of bakelite, a lower layer of bakelite and a silica gel bar which is adhered on the lower layer of bakelite; an arc-shaped supporting frame is arranged below the upper layer bakelite; the arc-shaped supporting frame is provided with two heating seal bars; the upper layer of bakelite is provided with an air bag internally; and the air bag is connected with a circumscribed air source. The sealing process of the vacuum heat insulation panel air pressure sealing machine comprises the following steps: placing a heat insulation panel on the commodity shelf; starting the vacuumizer; carrying out vacuumizing treatment for the box body; controlling the pressure of air in the box body within the range from 0.6 to.002Pa; inflating the air bag in the upper layer bakelite; pressing the upper layer of bakelite on the lower layer of bakelite, wherein 2-4Pa pressure is generated; heating the seal bars and simultaneously heating and sealing an aluminum foil blocking bag and molding for one time; controlling the time of the heating and sealing to be 1-3 seconds; and taking the sealed vacuum heat insulation panel from the box body of the sealing machine.

Owner:启东市恒怡电源有限公司

Molecular structure modified rigid polyurethane foam thermal insulation material

The invention discloses a molecular structure modified rigid polyurethane foam thermal insulation material and relates to the field of thermal insulation materials. The molecular structure modified rigid polyurethane foam thermal insulation material is prepared from polymerization polyisocyanates, bakelite, brominated epoxy resin, catalysts, a halogen-free flame retardant, cyclopentane, methylsilicone oil and polyether polyol. The molecular structure modified rigid polyurethane foam thermal insulation material has high mechanical strength and thermostability, and is safe and free of pollution.

Owner:吴婷婷

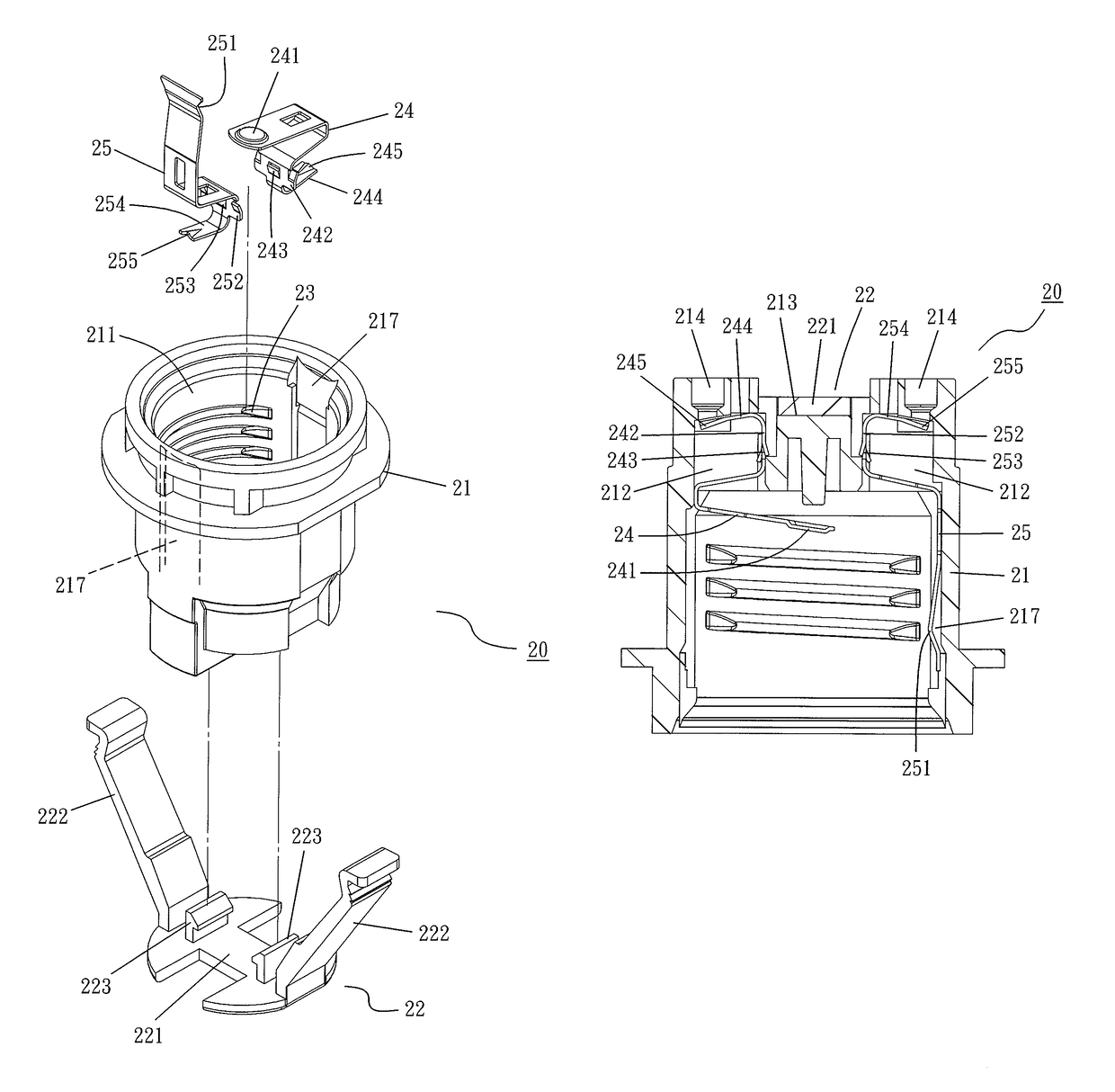

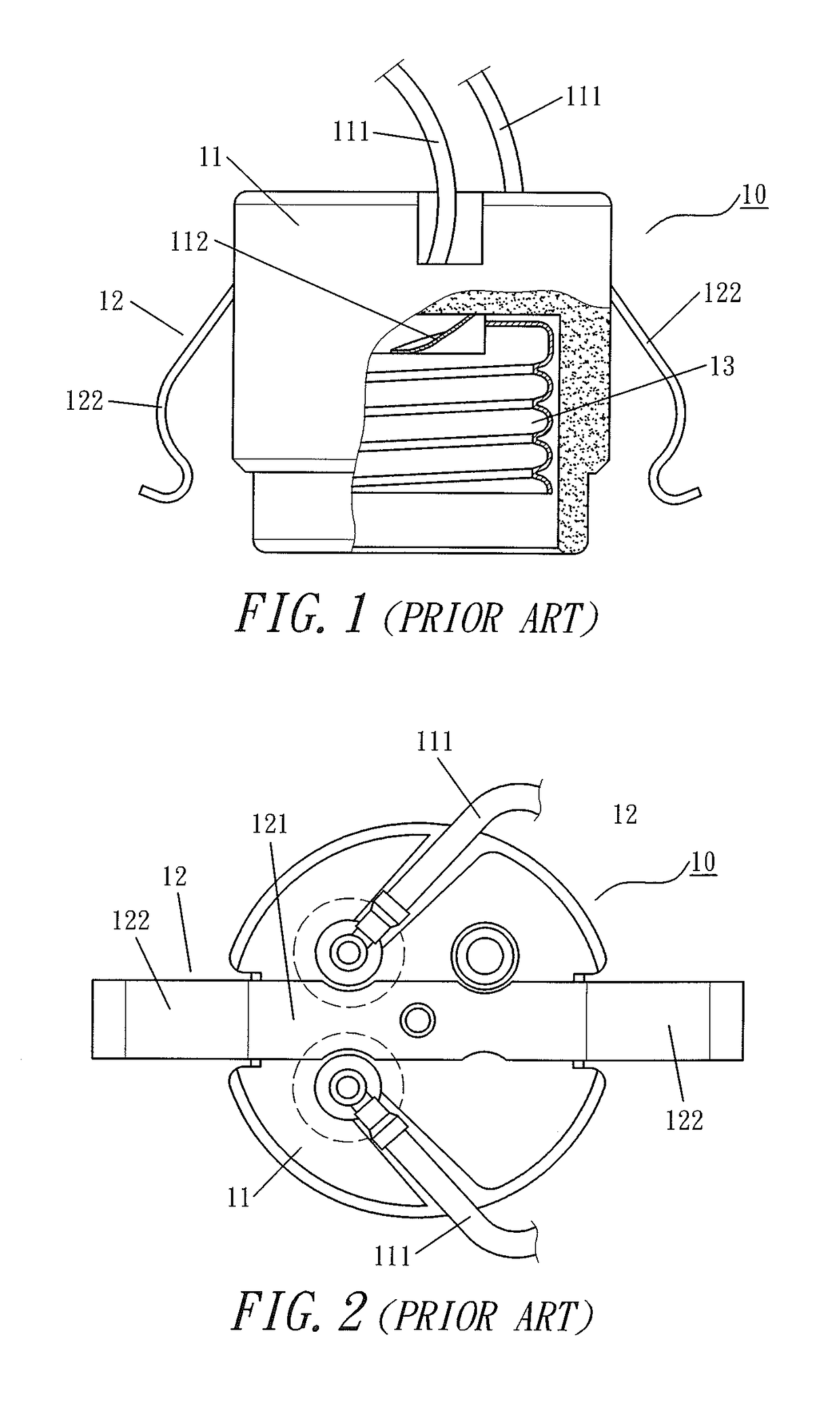

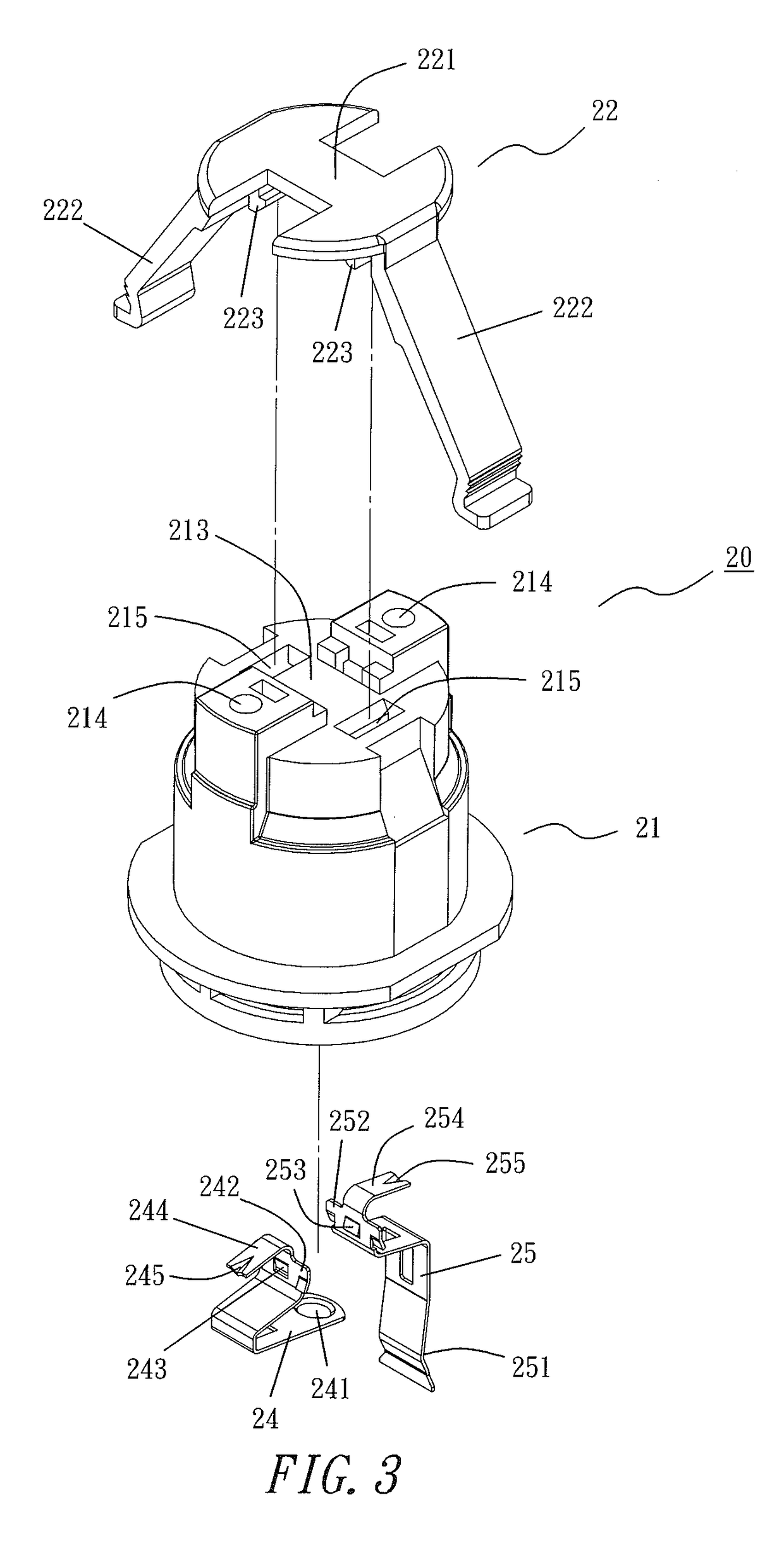

E26 wire-plugged bakelite lampholder

ActiveUS9768571B1Firmly connectedEasy to processElectric discharge tubesElectric circuit arrangementsEngineeringBakelite

An E26 wire-plugged bakelite lampholder is composed of a housing, an joint bracket, a threaded ring, a positive electrode plate and a negative electrode plate and installed to a downlight. The lampholder has two wire plug slots for plugging two electrodes of a power line by a bare line section, so that a power source is introduced with a convenient operation. The joint bracket and the housing of the E26 wire-plugged bakelite lampholder are made of a bakelite material, and a combining groove is reserved on the housing to provide for installing and positioning the joint bracket, and further inserting into the combining groove of the housing to engage via the combining latch rod of the joint bracket. In the meantime, the threaded ring of the E26 wire-plugged bakelite lampholder is integrally formed in the housing, so as to facilitate the manufacturing and assembling processes.

Owner:DONGGUAN JINZHUN ELECTRICAL

Heavy wood with mildew-prevention function and preparing method thereof

ActiveCN107584622AMildew-resistant long-lastingExpanded bactericidal spectrumWood treatment detailsFlat articlesIsothiazolinonePreservative

The invention discloses heavy wood with a mildew-prevention function and a preparing method thereof. An efficient mildew preservative and low-molecular-weight bakelite are added into bamboo bunches, and the mildew resistance of the heavy wood is effectively improved. The mildew preservative is composed of three preservatives of azoles, isothiazolinone and pyrethroid, an auxiliary is composed of water, emulgator, dispersing agent, penetrant and cross-linking agent, a main agent and the auxiliary are prepared through the procedures of emulsification, crosslinking, dispersion, compounding and thelike, and through the synergistic effect of azoles, isothiazolinone and pyrethroid, the mildew preservative expands a bacteriocidal spectrum and reduces the dosage. The purpose that the heavy wood does not go mildewed under an outdoor environment of processed bamboo woods for 6 months can be achieved, and long-acting mildew prevention of the heavy wood can be achieved. After bakelite is adopted to make the wood recombined and glued, the preservative is sealed in bakelite and does not run off, and compared with common mildew-prevention wood, the heavy wood is more environmentally friendly.

Owner:GUANGDONG ACAD OF FORESTRY

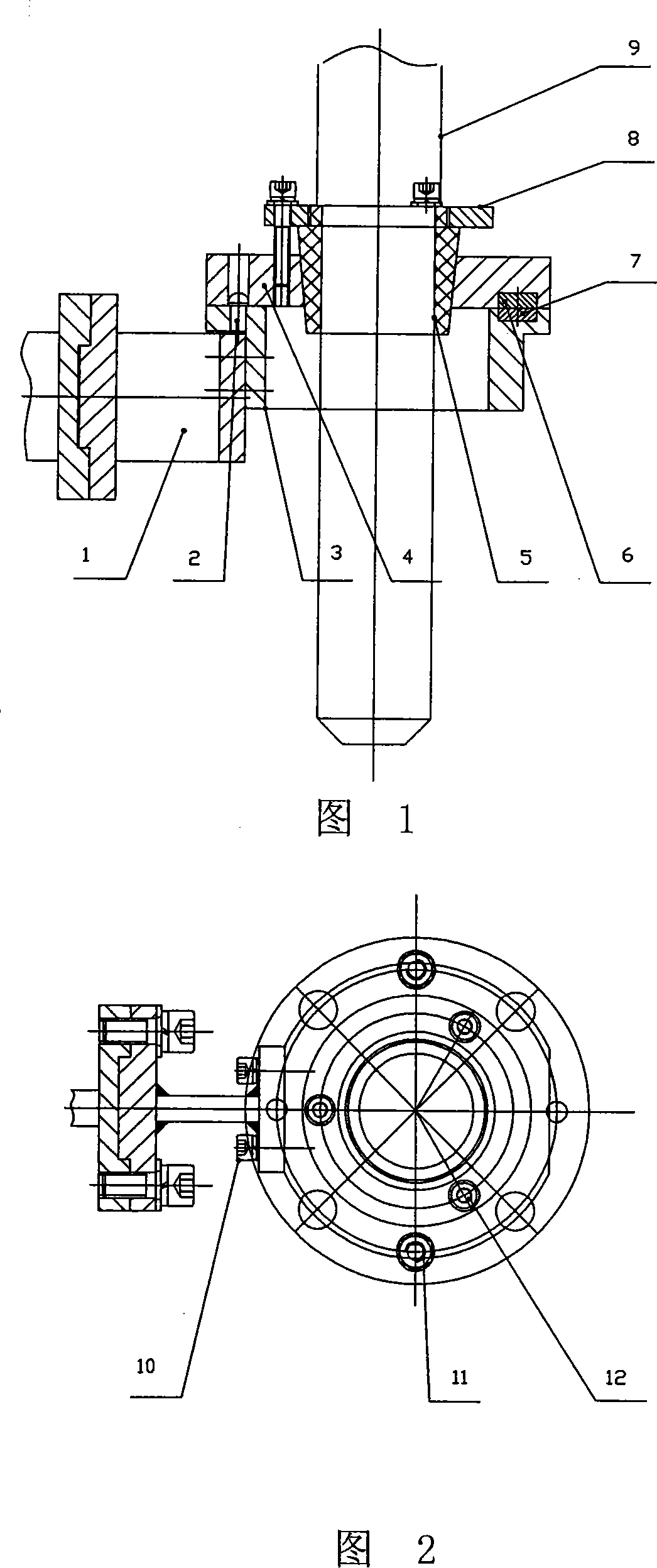

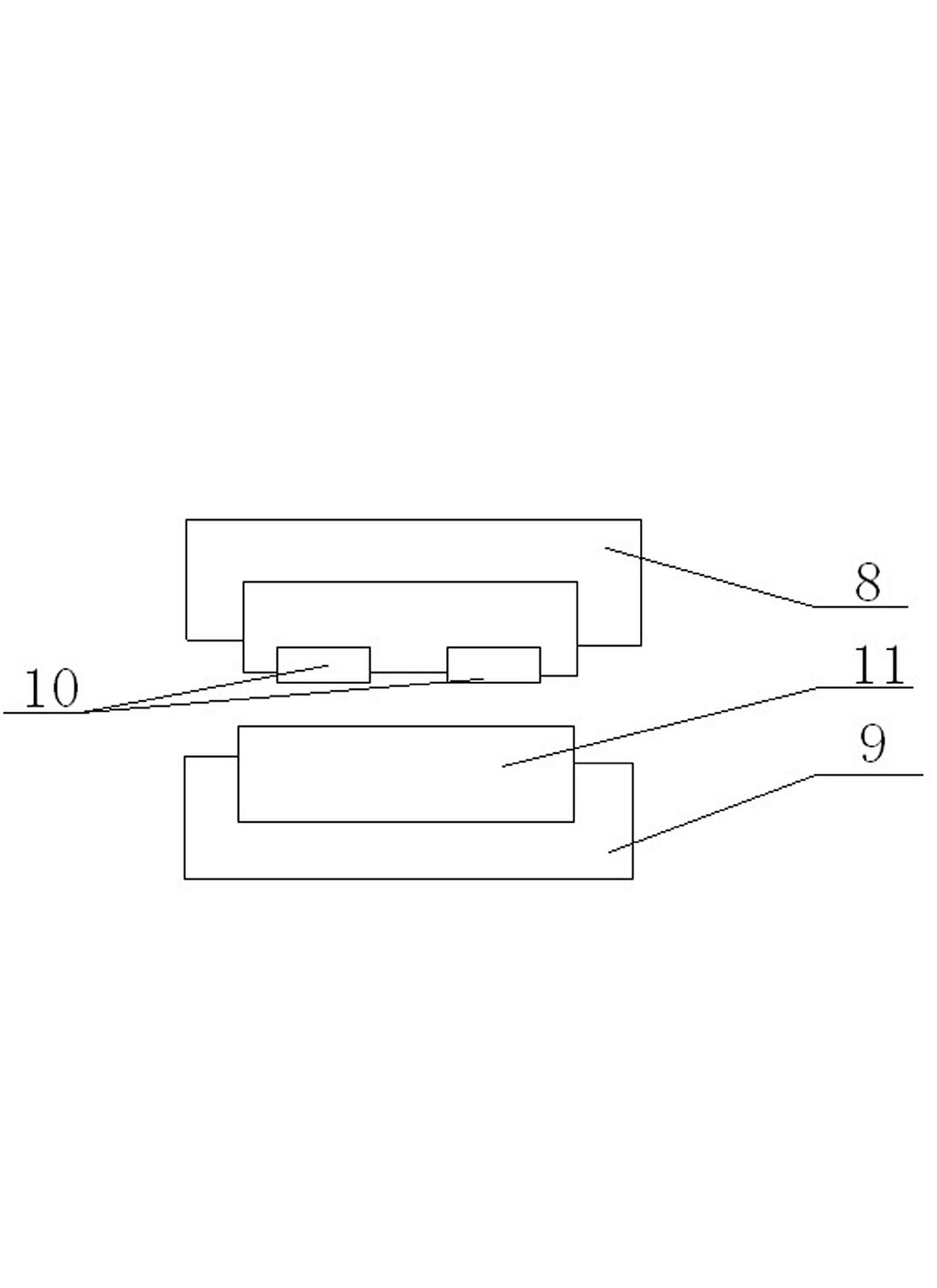

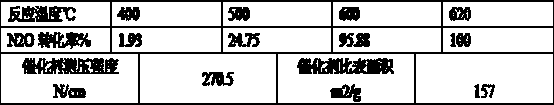

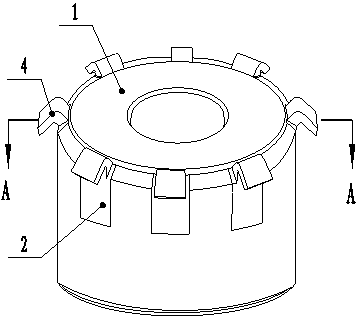

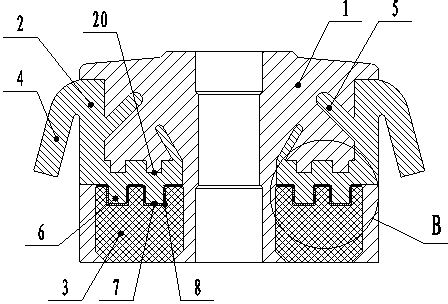

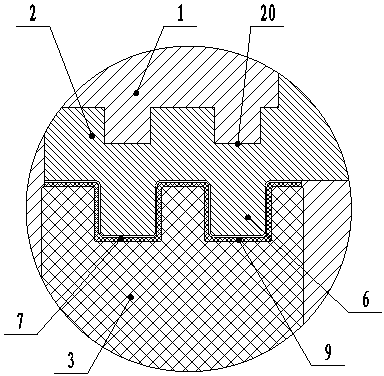

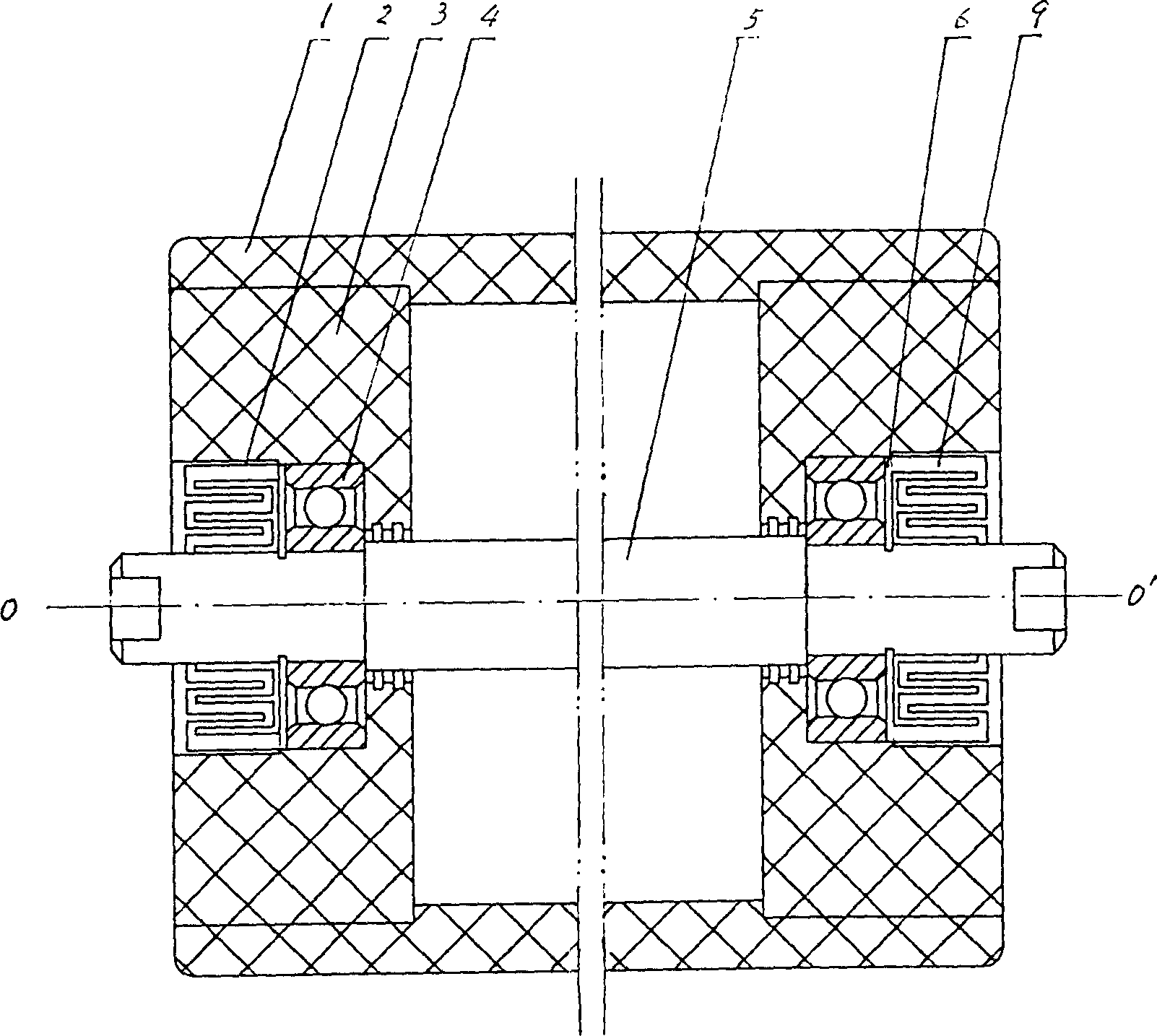

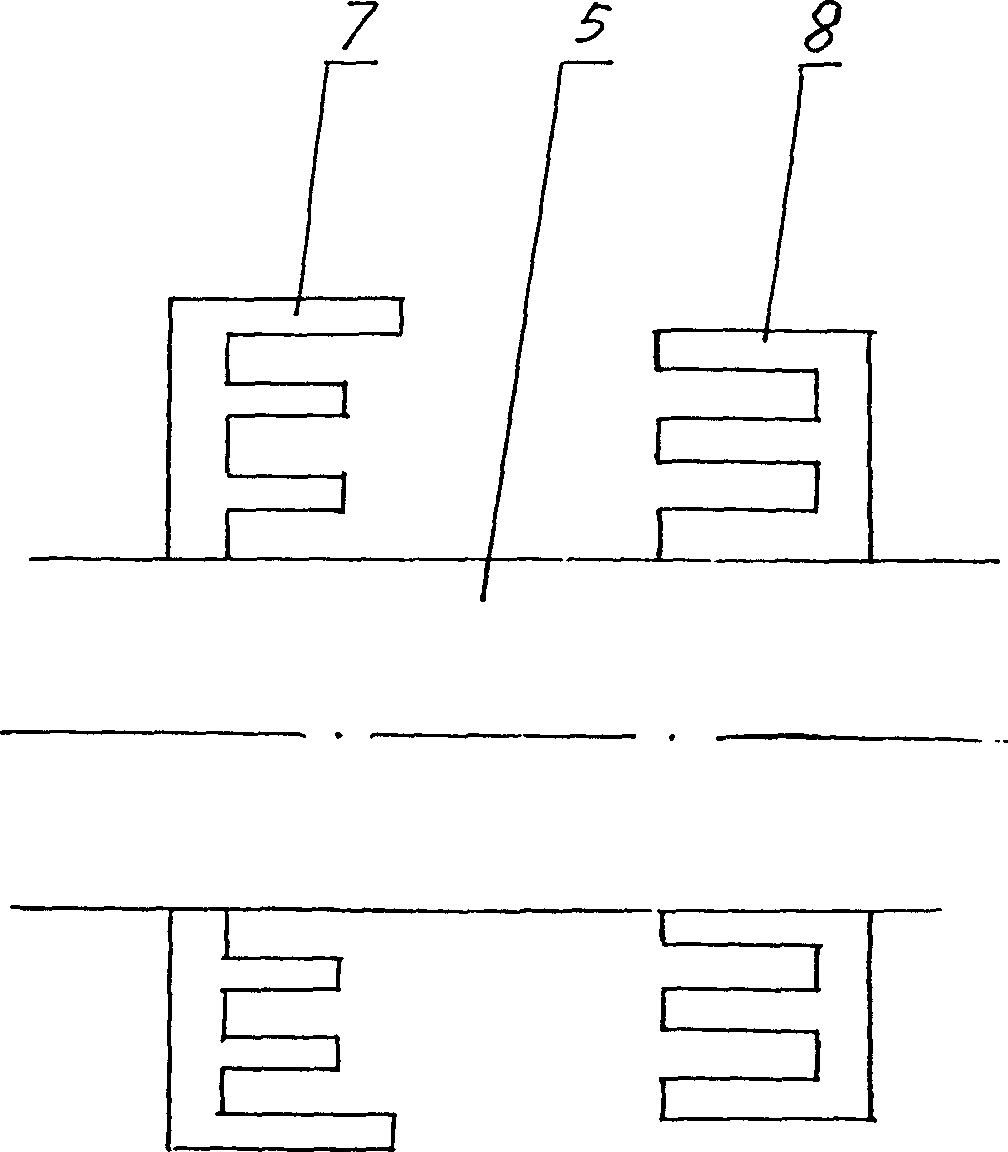

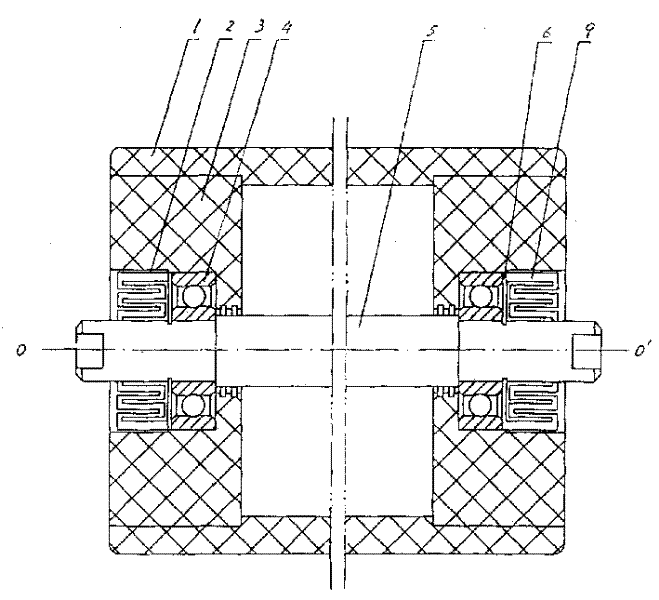

Graphite commutator

The invention discloses a graphite commutator, which comprises bakelite (1), commutator bars (2) and graphite sheets (3), and is characterized in that the bakelite (1), the commutator bars (2) and the graphite sheets (3) are injected and molded integrally; each commutator bar (2) is of an L-shaped structure; a projected bolt (5) is arranged on an inner side of each commutator bar (2); a flanging hooked pin (4) is arranged on an upper end of each commutator bar (2); an inserted pin (6) is arranged on a lower end of each commutator bar (2); the graphite sheets (3) are totally surrounded by the bakelite (1), and fixed with the commutator bars (2) to form an integral structure; and compact first grooves (7) are arranged on the graphite sheets (3), and are consistent with the inserted pins (6) in shape. According to the invention, through combination innovation of structures of the commutator bars and the graphite sheets and a connection relationship thereof, the graphite commutator with low cost, uneasy-to-damage graphite sheets, long service life, and strong effective grasping force among the graphite sheets, the commutator bars and the bakelite after forming is provided.

Owner:HUARUI ELECTRICAL APPLIANCE

Food-grade anticorrosion liner rubber plate

A food-grade anticorrosion liner rubber plate comprises, by weight, 60-70 parts of natural rubber 3L, 25-35 parts of styrene butadiene rubber 2000, 2-3 parts of magnesium oxide, 3-8 parts of carbon black N330, 60-70 parts of M-grade bakelite powder, 2-5 parts of third line oil, 30-36 parts of sulfur and 1-2 parts of an accelerant. The food-grade anticorrosion liner rubber plate has the advantages of corrosion resistance, no heavy metal pollution and reduced production cost, and is specially used in food production apparatuses and biological pharmacy industry production apparatuses.

Owner:江苏开源环保技术工程有限公司

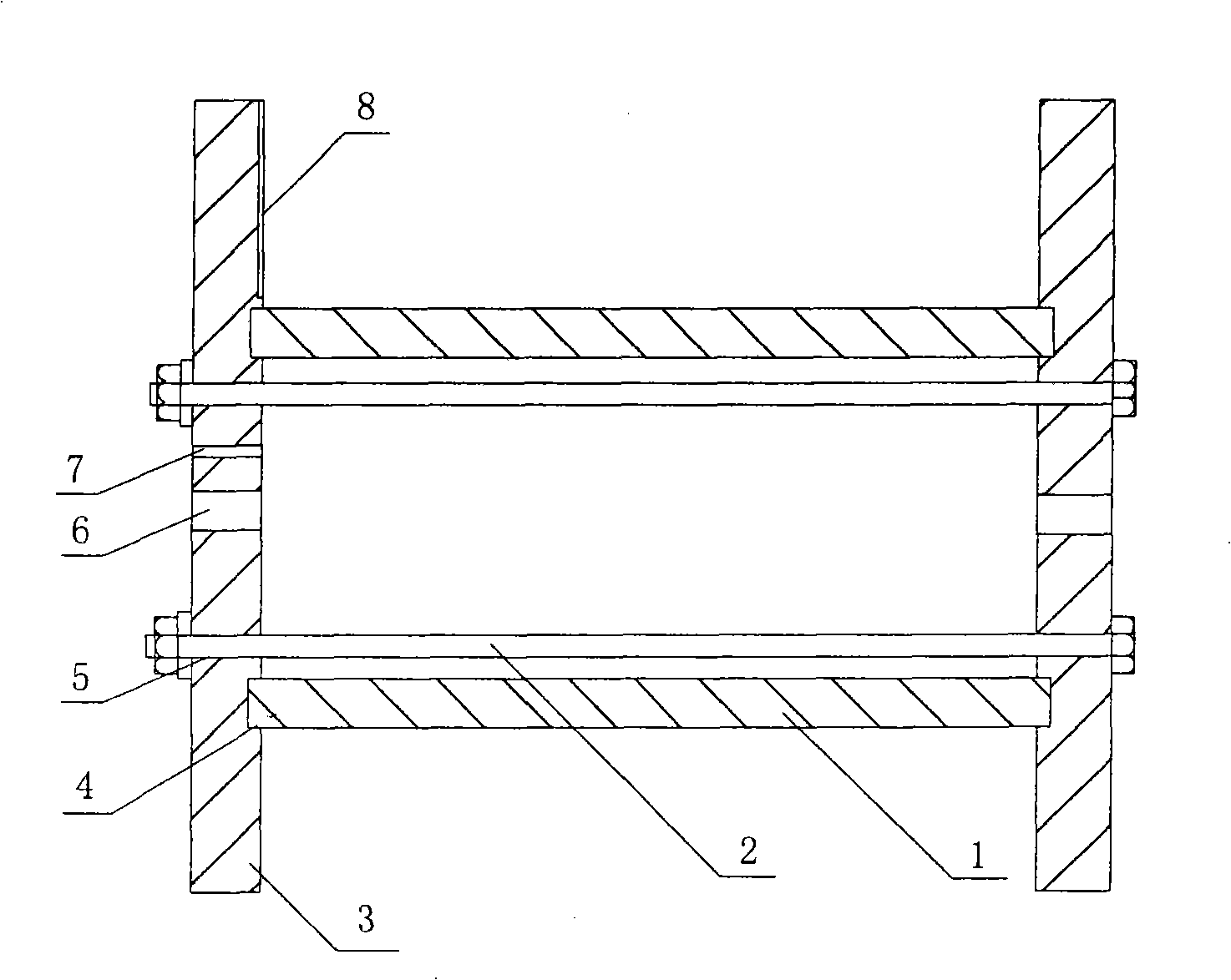

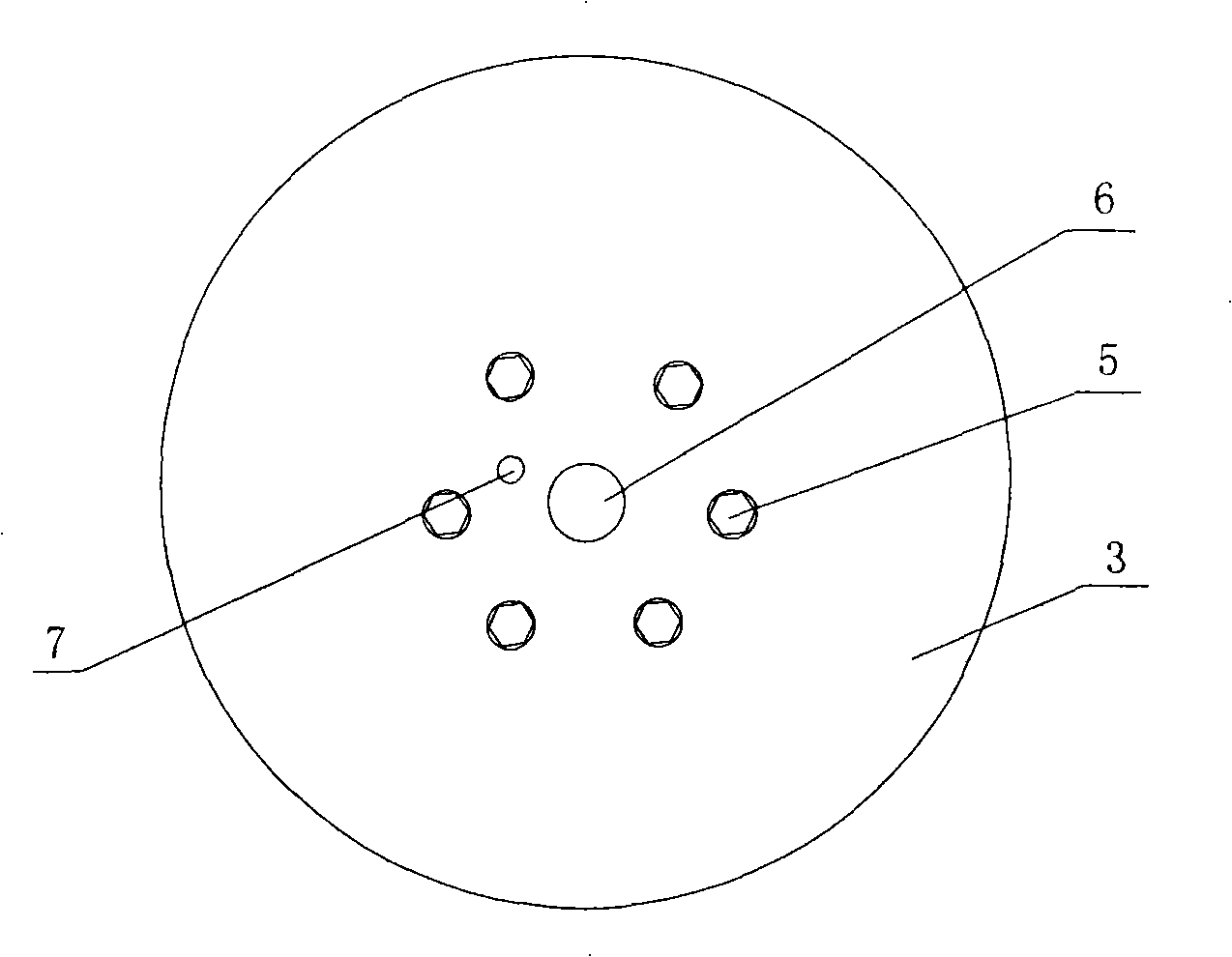

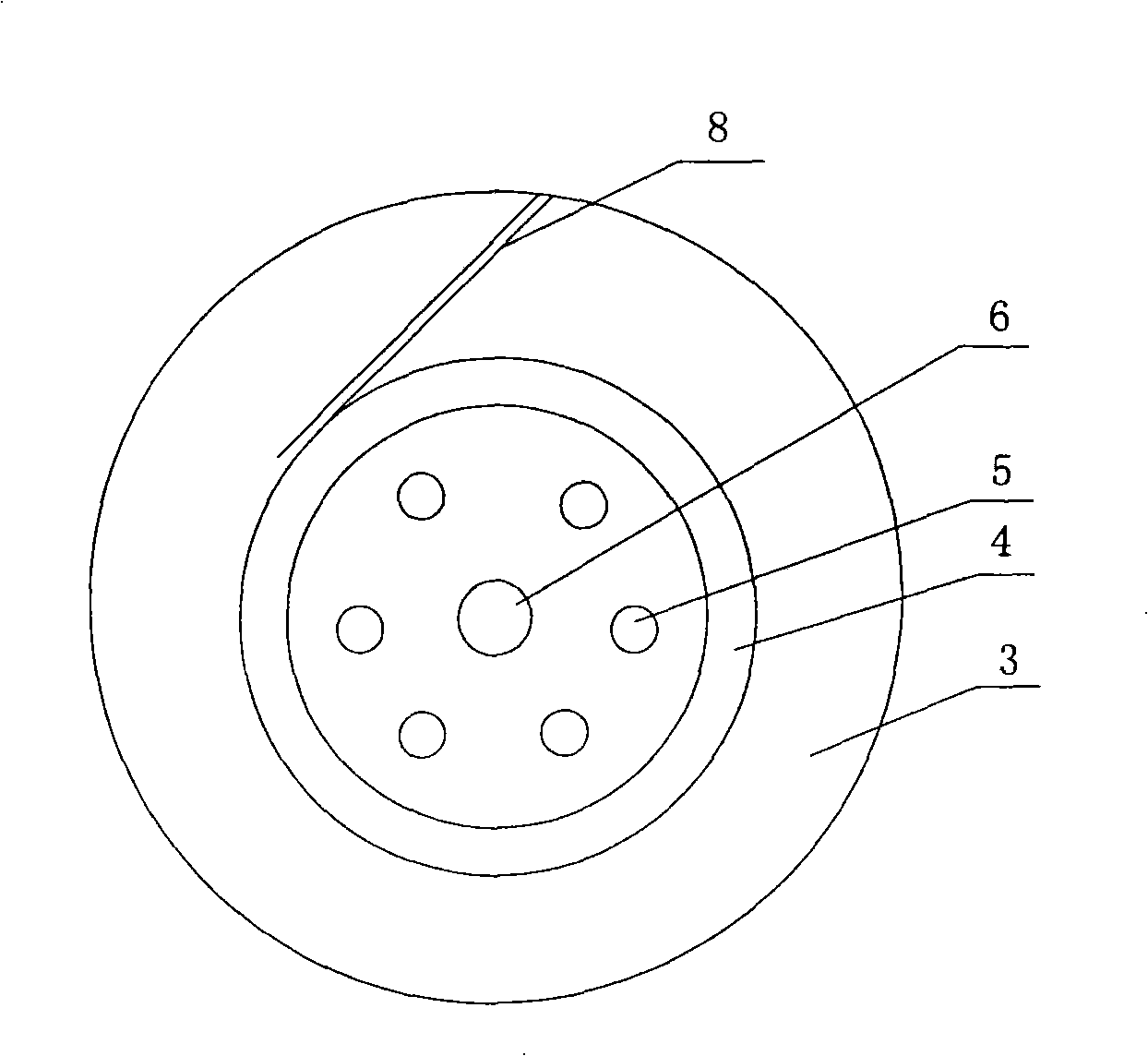

Bakelite structural optic cable and cable delivery hank and preparation thereof

InactiveCN101337630AReasonable designSave resourcesFlat articlesDomestic articlesAdhesiveWood machining

The invention discloses a bakelite-structured optical and electrical cable delivery pallet and a preparation method thereof, and relates to a bakelite-structured optical and electrical cable delivery pallet, particularly an all-wood structured optical and electrical cable delivery pallet, which is characterized in that fixing grooves for cable extending out of the front end of the optical and electrical cable are formed on the inner sides of discs, and a preparation method thereof. The structure comprises discs, a central cylinder body and a plurality of disc fixing bolts; the discs are mounted at the two ends of the central cylinder body; a plurality of disc fixing bolts for connecting and fixing the central cylinder body are mounted inside the central cylinder body; the discs are mounted at the two ends of the central cylinder body; disc fixing bolts are mounted inside the central cylinder body; fixing grooves for cable extending out of the front end of the optical and electrical cable are formed on the inner sides of the discs; and central shaft holes and holes for disc fixing bolts are formed on the discs. The preparation method comprises the following steps: preparing the discs by crushing the off-cuts of lumber from a wood-working factory, churning with waterproof adhesive, placing into a die, and compressing by using a compressor to obtain the discs; arranging fixing grooves for cable extending out of the front end of the optical and electrical cable on the inner side plates of the discs; preparing the central cylinder body; and assembling the bakelite-structured optical and electrical cable delivery pallet.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

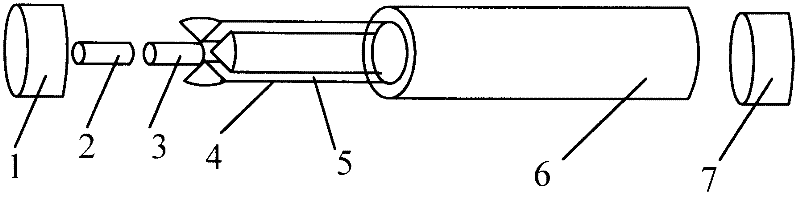

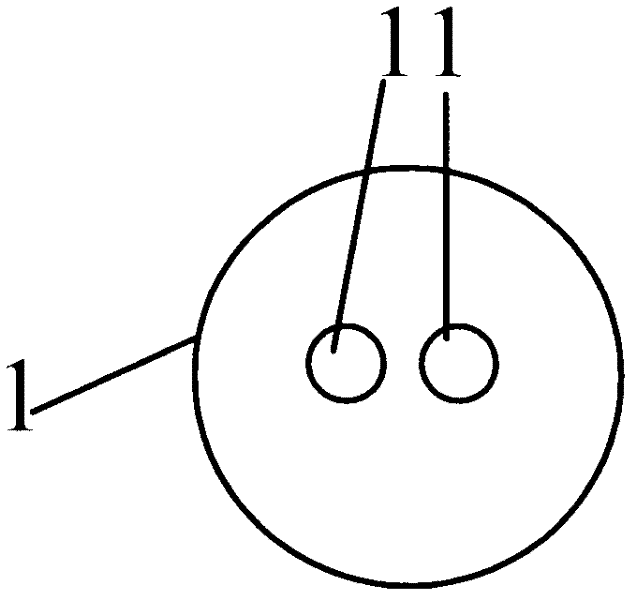

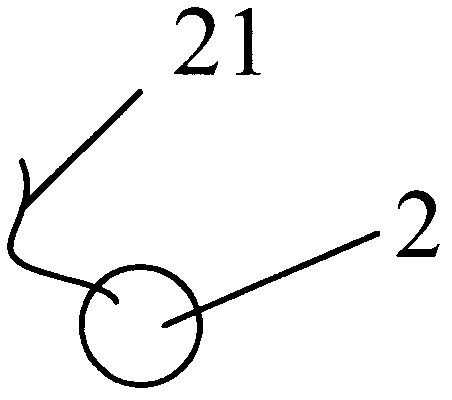

Micro-fracture explosion propagation device for interlayer explosion laboratory study

The invention discloses a micro-fracture explosion propagation device for interlayer explosion laboratory study. The device comprises first bakelite, a detonator, an explosion propagation explosive, an aluminum inner core, an aluminum inner core groove, a bakelite pipe body and second bakelite, wherein the detonator is fixed on the first bakelite; the first bakelite is adhered at one end of the bakelite pipe body; the aluminum inner core is provided with a central hole; the explosion propagation explosive is filled in the central hole of the aluminum inner core; the aluminum inner core groove is formed on the aluminum inner core; the aluminum inner core is sleeved in the bakelite pipe body; and the second bakelite is adhered at the other end of the bakelite pipe body. The device is convenient to use, has a smaller volume, saves materials and can be used for accurately measuring explosion propagation data of a suspension explosive and a liquid explosive in an underground micro-fracture in the process of imitating underground perforation fracturing operation and interlayer explosion and indirectly measuring pressure and temperature variation numerical values from a wellhead to an operation layer.

Owner:XI'AN PETROLEUM UNIVERSITY +1

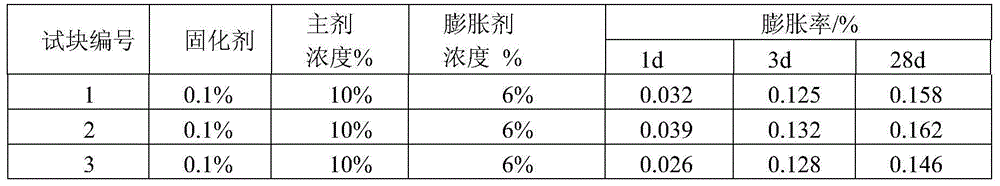

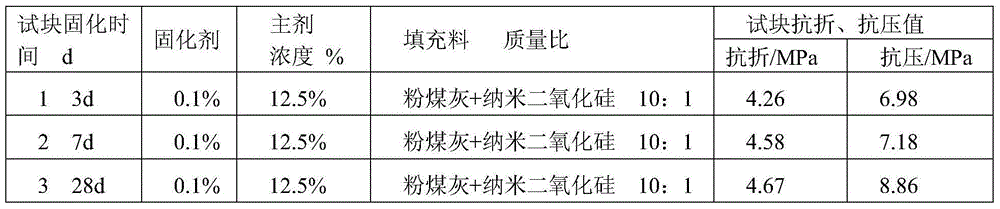

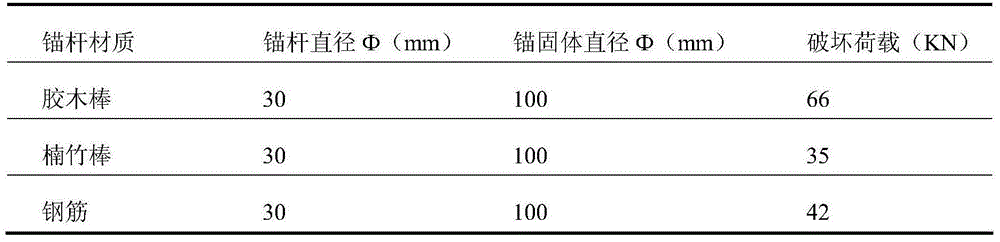

Earthen site grouting material of fiber bakelite rod grouted rock bolt based on water-based fluorine

The invention discloses an earthen site grouting material of a fiber bakelite rod grouted rock bolt based on water-based fluorine. The earthen site grouting material is prepared from the following raw materials at the ratio of (8-10) to (8-10) to (0.5-1.5) to (0.7-1) to (8-10) to (1.5-2.5) to (4-5), wherein the ratio is mass ratio. The earthen site grouting material has consistency with a surrounding soil material in ingredient, physical and chemical property and mechanical property, can be fused into a whole under the action of a curing agent water-based fluorine and inserted bar glue, and has compatibility with a surrounding rammed earth layer; meanwhile, the material contains the water-based fluorine, the inserted bar glue and the like, is close to cotton and bast fiber and phenolic resin in the bakelite rock bolt in property, and has relatively good compatibility; the curing time can be shortened; and filling and anchoring are facilitated.

Owner:SHAANXI NORMAL UNIV

Bakelite idler and its making process

The present invention is bakelite idler and its making process. The bakelite idler includes outer pipe, bearing seats on two ends, rotating shaft in the center, inner ball bearings and outer sealing parts between the bearing seats and rotating shaft and clamping spring to separate bearing seats from rotating shaft. The present invention features that the outer pipe and the bearing seats are made of bakelite comprising glass fiber fabric and mixture of epoxy resin and phenolic resin. The making process of the bakelite idler includes mixing and heating epoxy resin in 60-80 wt% and phenolic resin in 20-40 wt% as well as proper amount of triethanolamine to form glue, gluing glass fiber fabric, stoving, winding to form pipe, heating inside mold to form, cooling, demolding, and machining. The present invention has the advantages of high wear resistance, anticorrosion, long service life, light weight, etc.

Owner:刘明书

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com