Automatic pin punching mechanism for PCB numerical control machine tool and pin punching method

A CNC machine tool, automatic technology, applied in the direction of circuit board tool positioning, electrical components, printed circuit manufacturing, etc., can solve the problems of not finding pin holes, time-consuming, time-consuming and efficient, and achieving the effect of reducing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

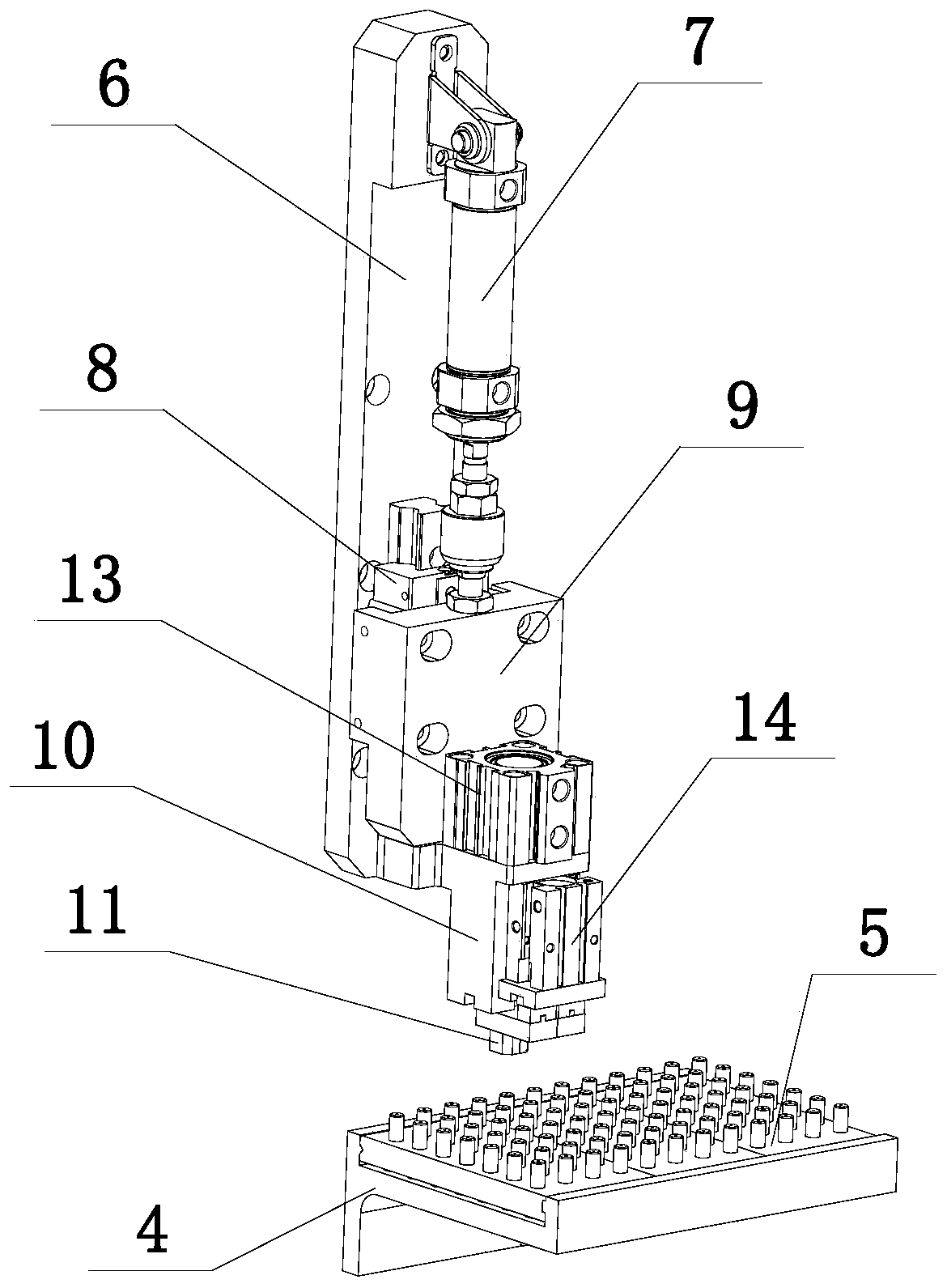

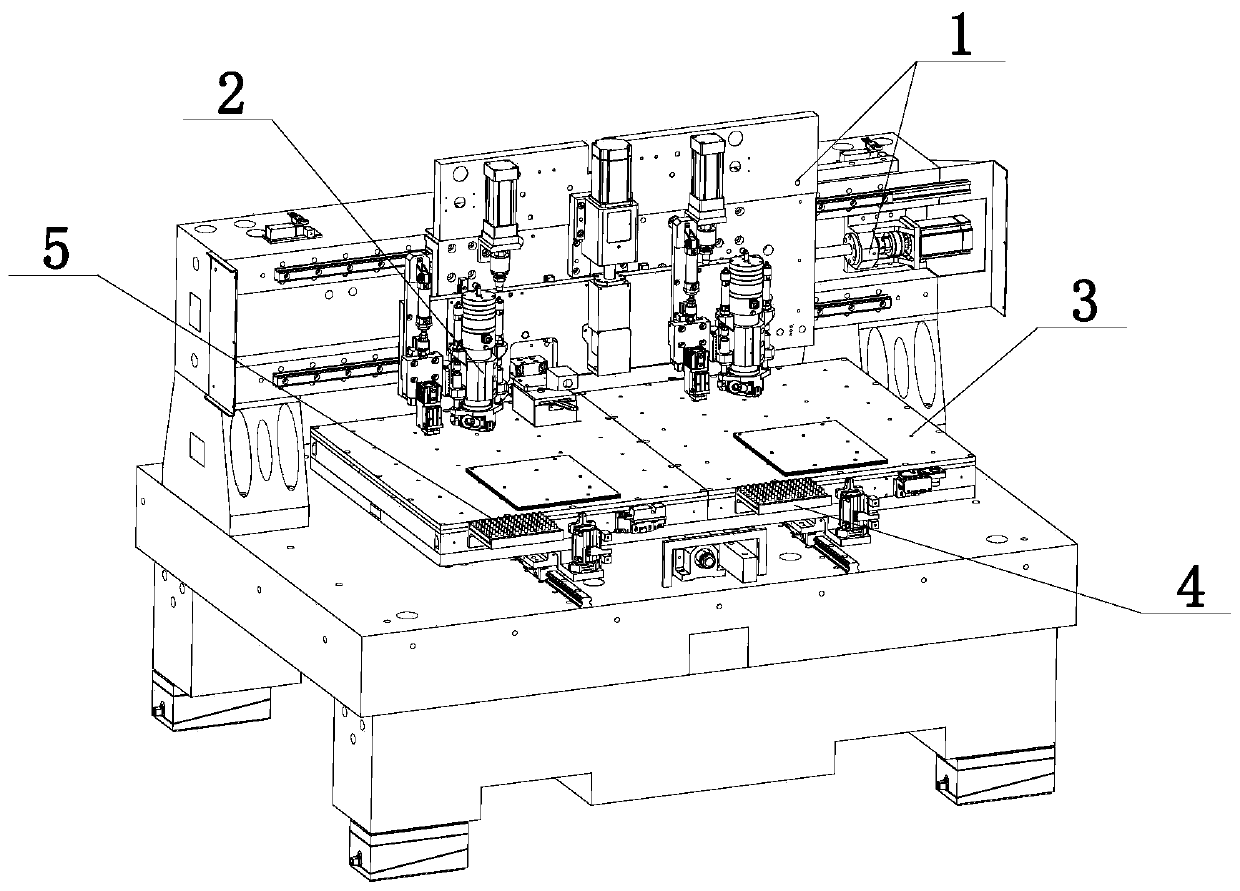

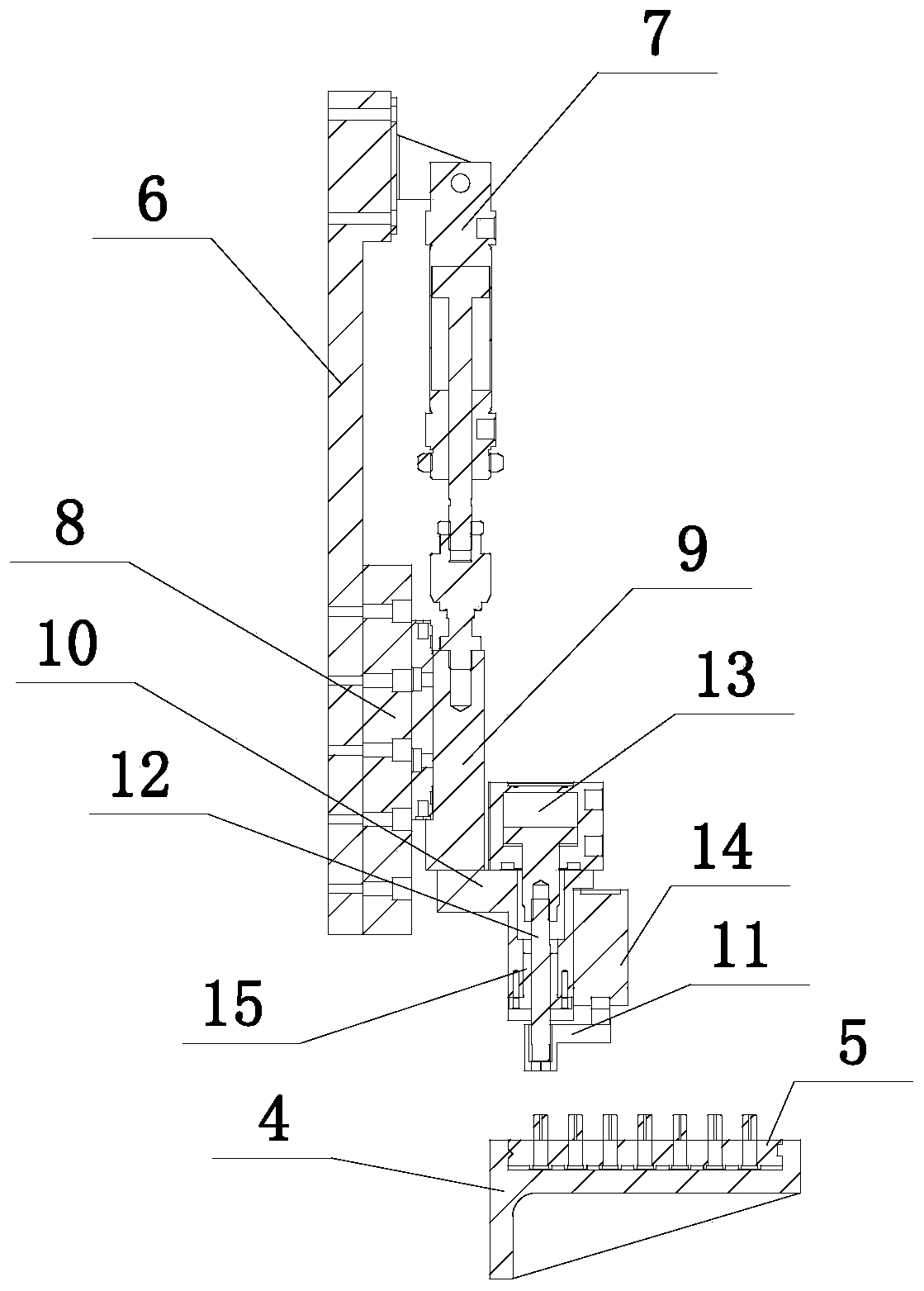

[0034] Such as Figure 1-Figure 10 As shown, an automatic pinning mechanism for a PCB numerical control machine tool includes several pinning assemblies, a number of which are arranged at the position where the mobile assembly 1 of the PCB numerical control machine tool is close to the drilling assembly 2 and can move horizontally with the mobile assembly 1 of the PCB numerical control machine tool. A bakelite workbench 3 arranged on the PCB numerical control machine tool is away from one end of the moving assembly 1 and corresponds to several pin box fixing seats 4 of the pinning components and a pin box arranged on the top of each pin box fixing seat 4 5. The pinning assembly includes a mechanism installation plate 6 connected to the mobile assembly 1 of the PCB CNC machine tool, and the side of the mechanism installation plate 6 cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com