Patents

Literature

53916 results about "Machine tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A machine tool is a machine for shaping or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformation. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material.

Tool attachment

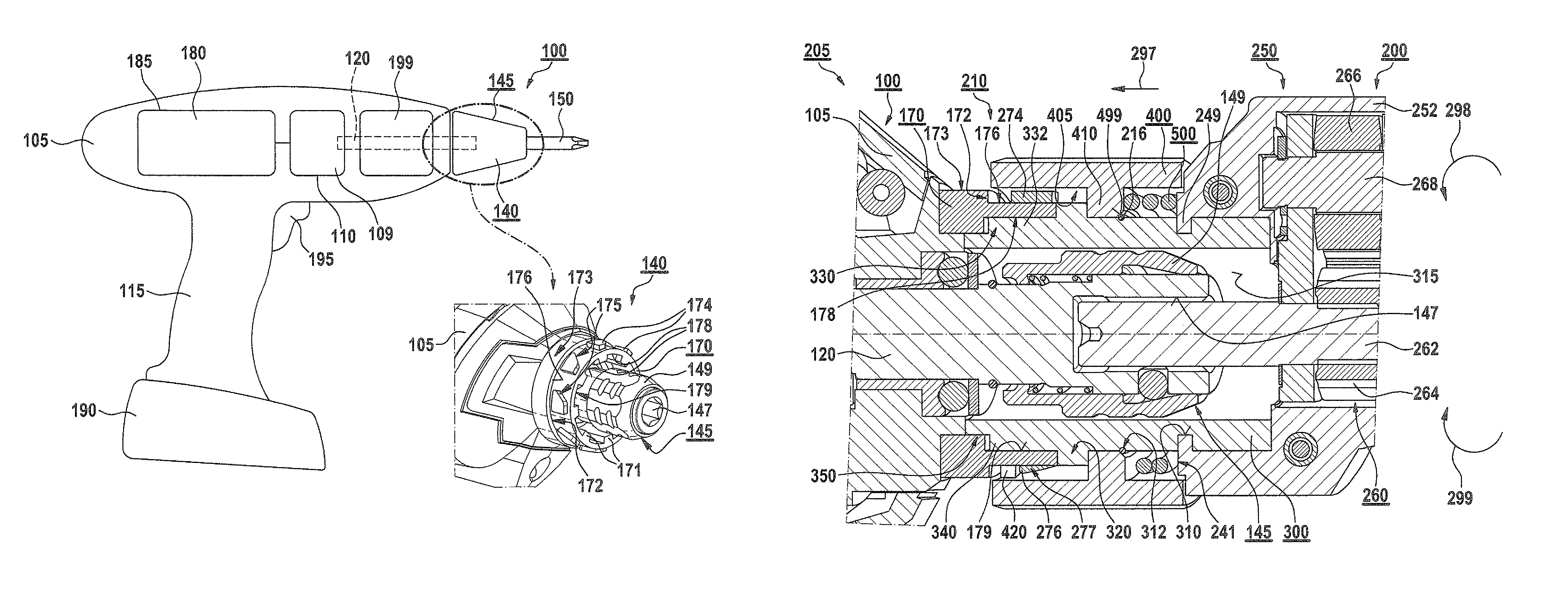

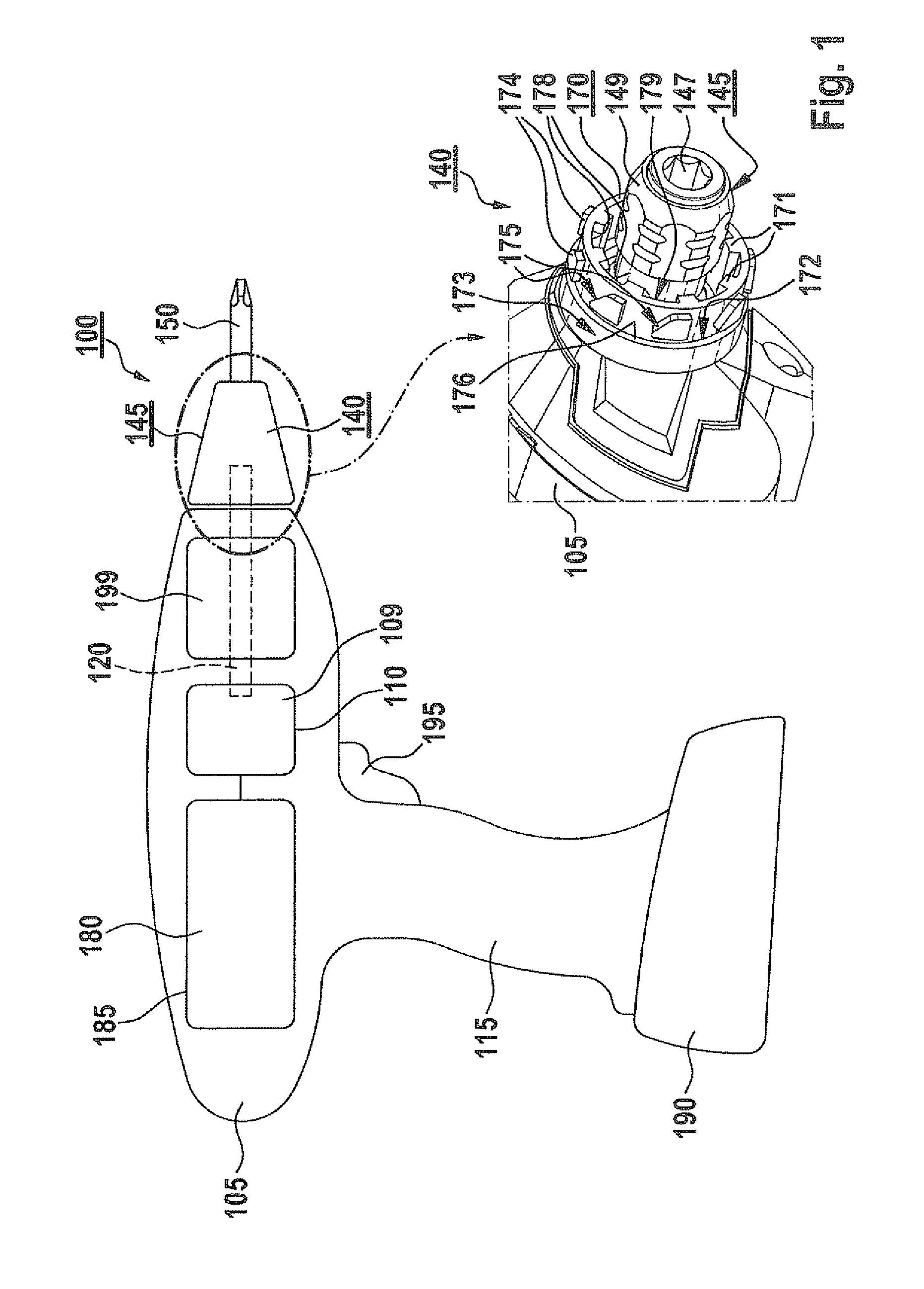

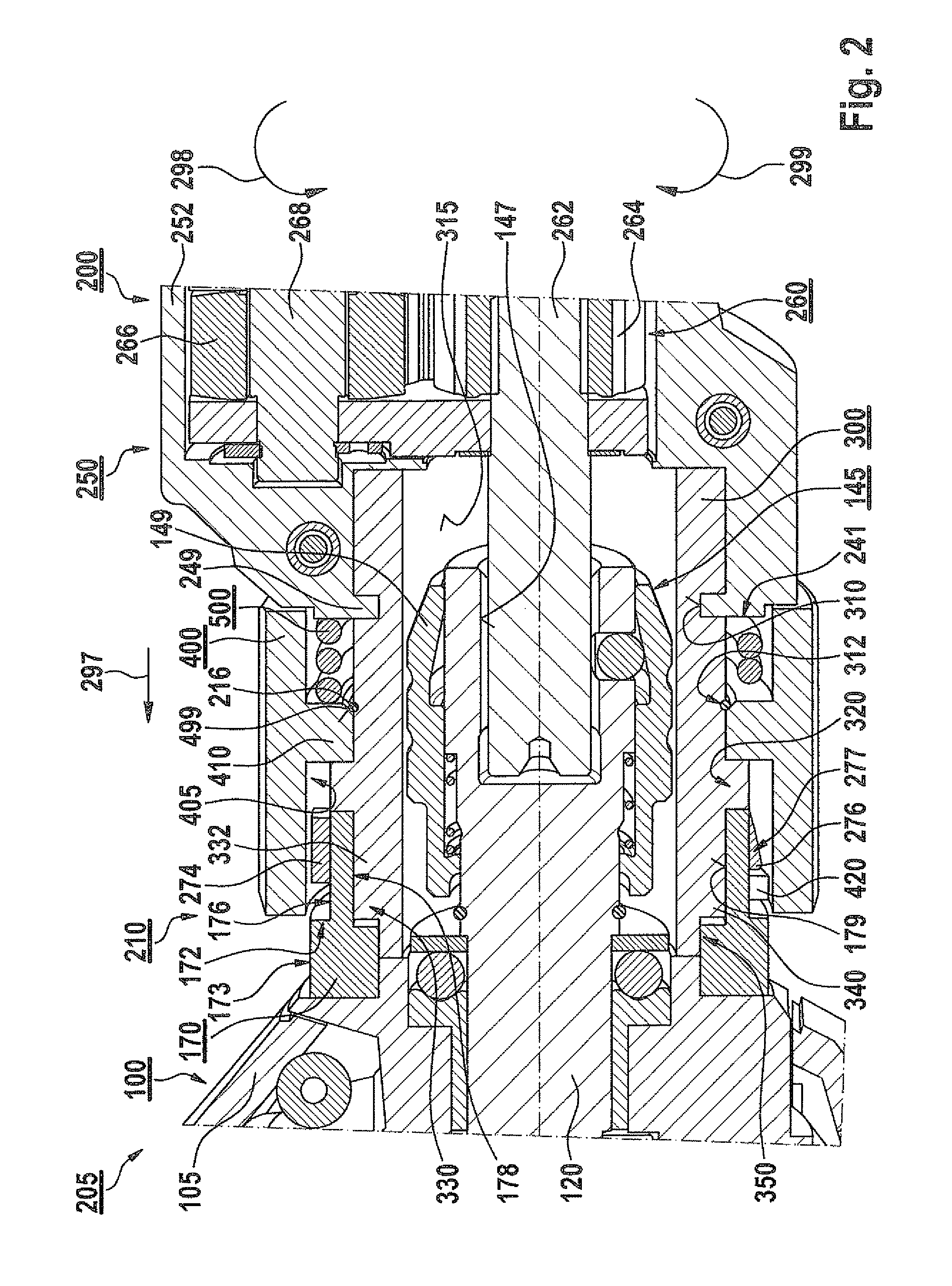

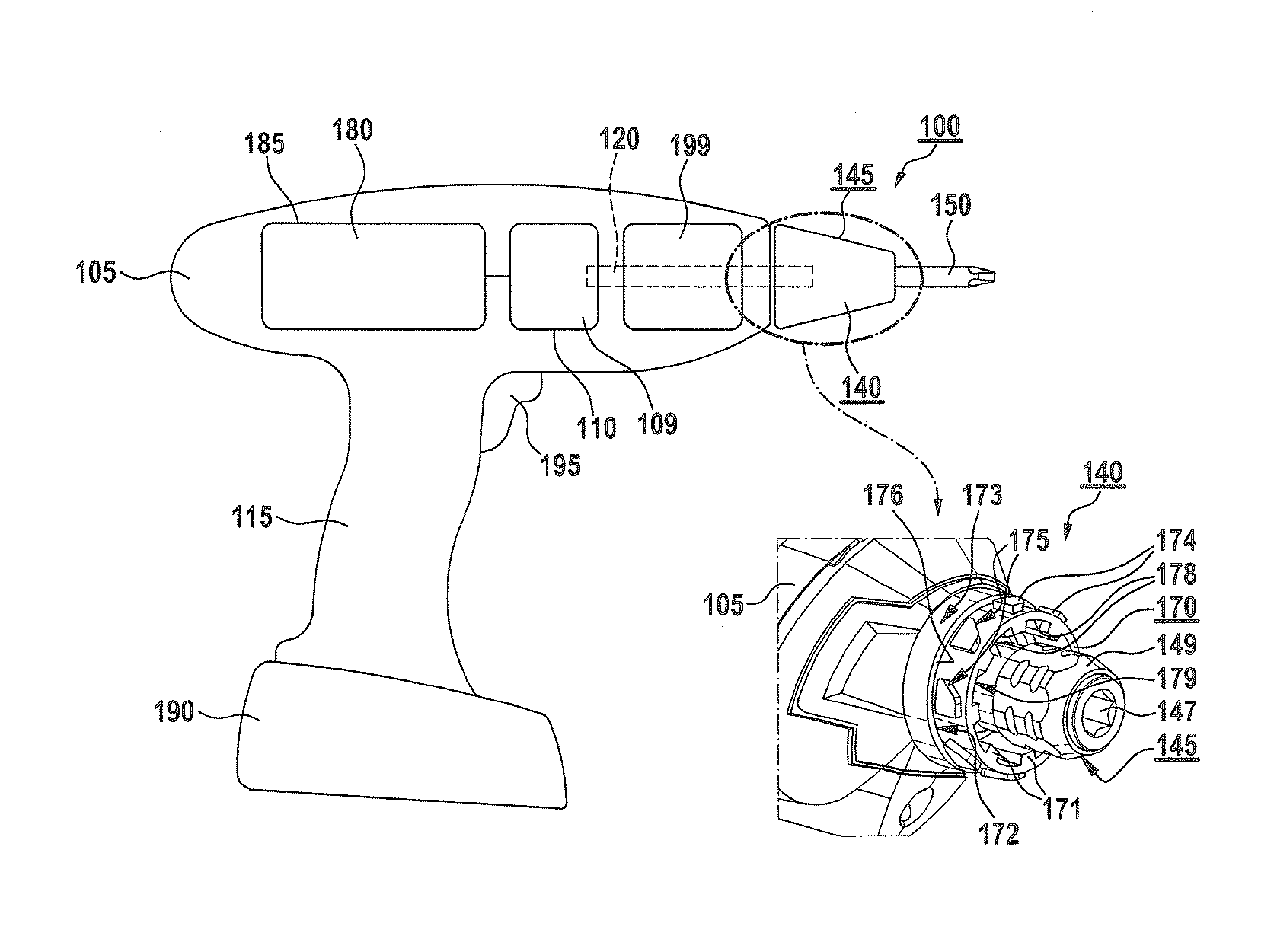

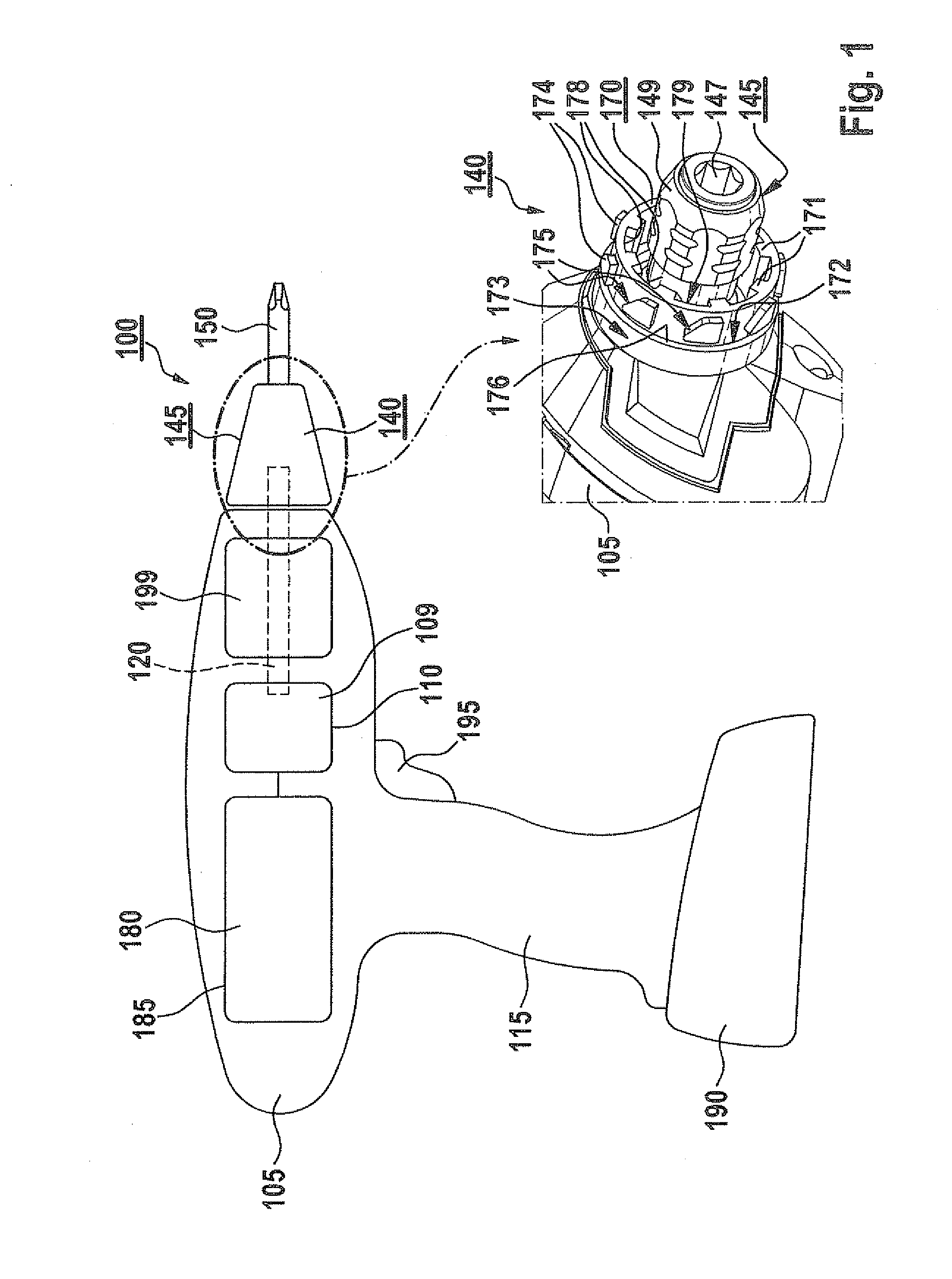

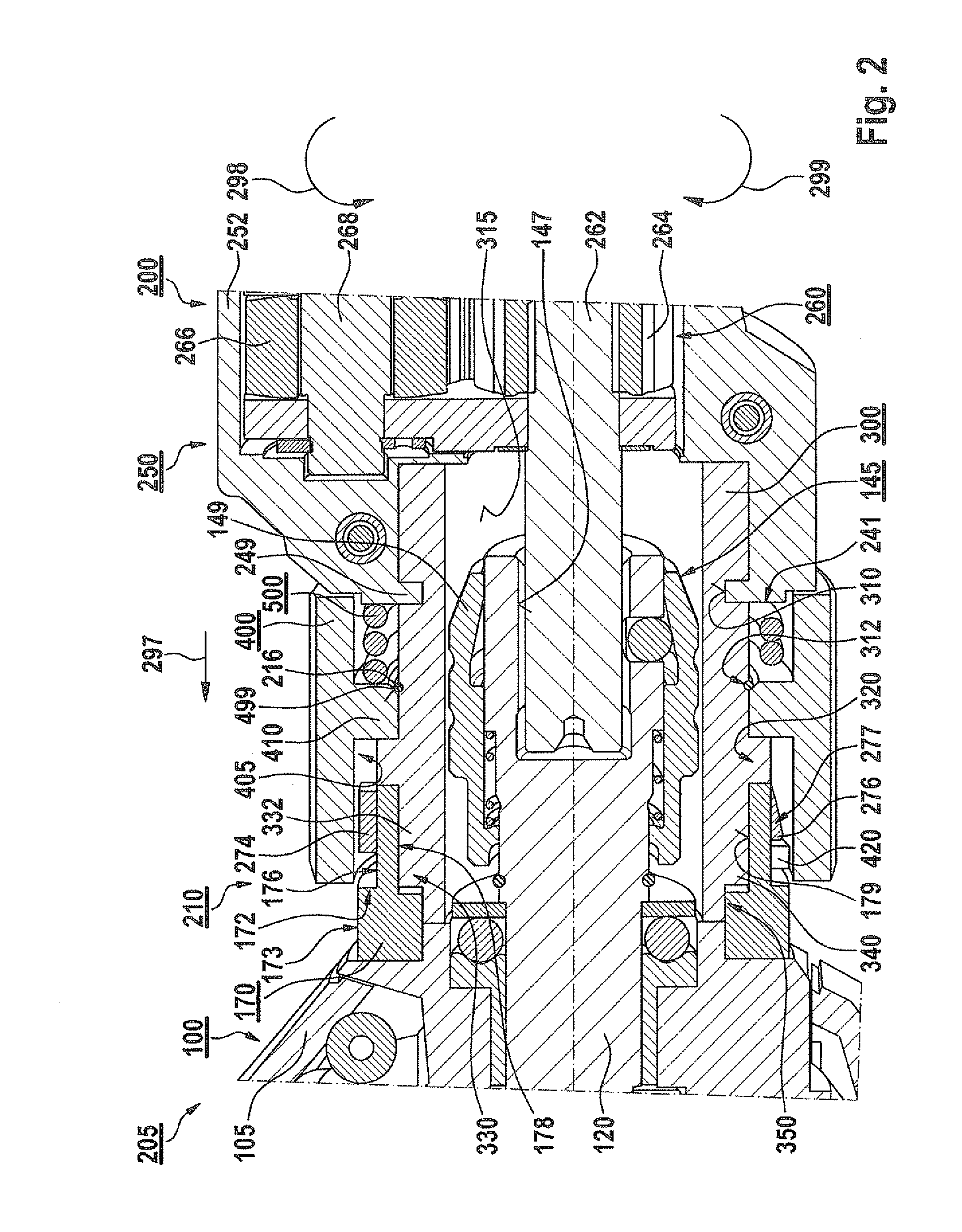

A tool attachment for mounting on a hand-held machine tool provided with a tool holder, the tool attachment having an output shaft and a base body at whose outer circumference a locking sleeve is disposed in a manner allowing it to rotate to release at least one assigned locking element; at the outer circumference of the base body, an anti-rotation unit is formed for the twist-proof mounting of the base body on a fastening unit assigned to the hand-held machine tool; on the anti-rotation unit and at an inner circumference of the fastening unit, complementary geometrical forms are provided which are configured to mesh with each other for the releasable, twist-proof mounting of the base body on the fastening unit.

Owner:ROBERT BOSCH GMBH

Tool attachment

ActiveUS20130093149A1Improve usabilitySleeve/socket jointsPortable power-driven toolsTool holderMachine tool

A tool attachment for mounting on a hand-held machine tool provided with a tool holder, the tool attachment having an output shaft and a base body at whose outer circumference a locking sleeve is disposed in a manner allowing it to rotate to release at least one assigned locking element; at the outer circumference of the base body, an anti-rotation unit is formed for the twist-proof mounting of the base body on a fastening unit assigned to the hand-held machine tool; on the anti-rotation unit and at an inner circumference of the fastening unit, complementary geometrical forms are provided which are configured to mesh with each other for the releasable, twist-proof mounting of the base body on the fastening unit.

Owner:ROBERT BOSCH GMBH

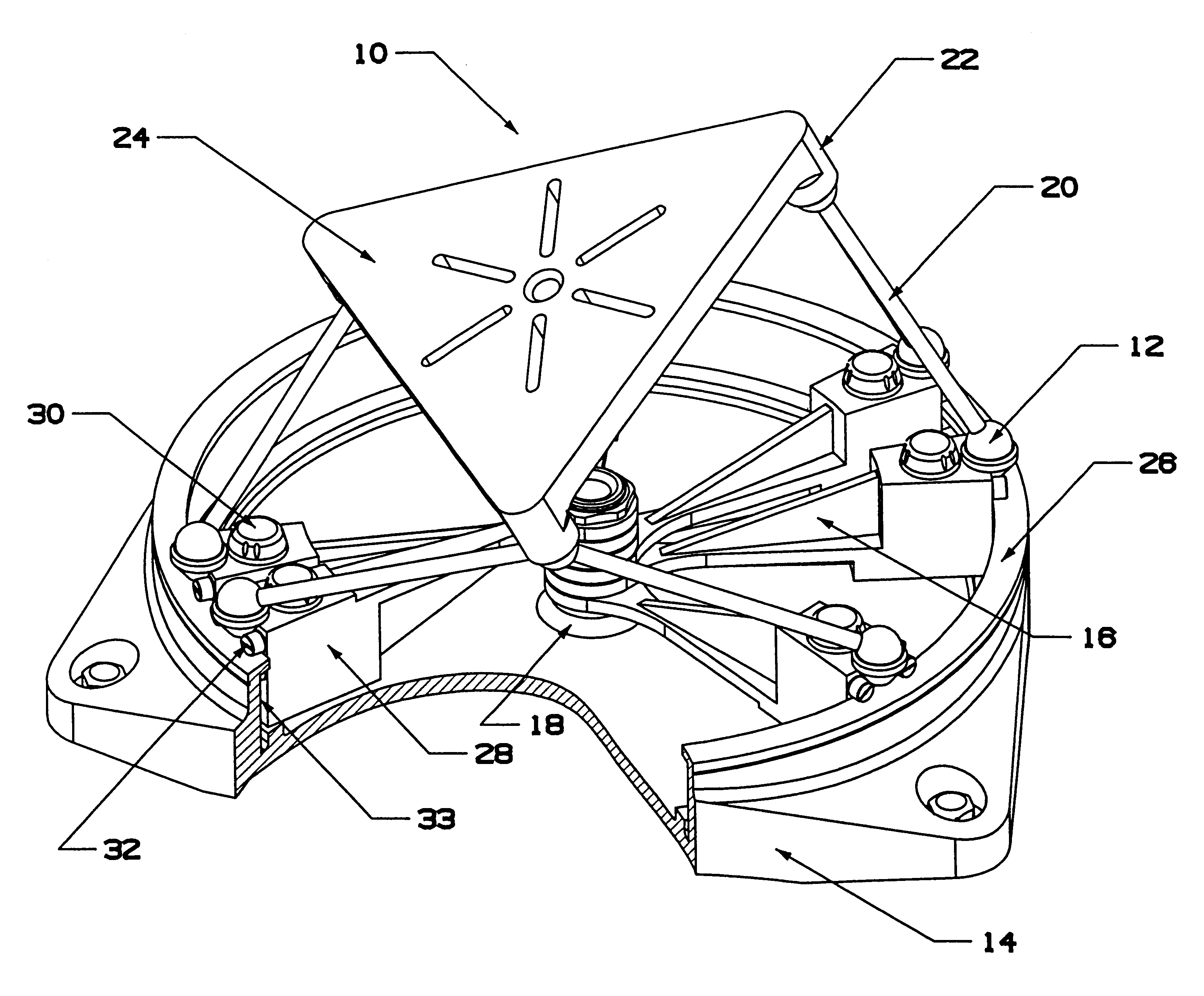

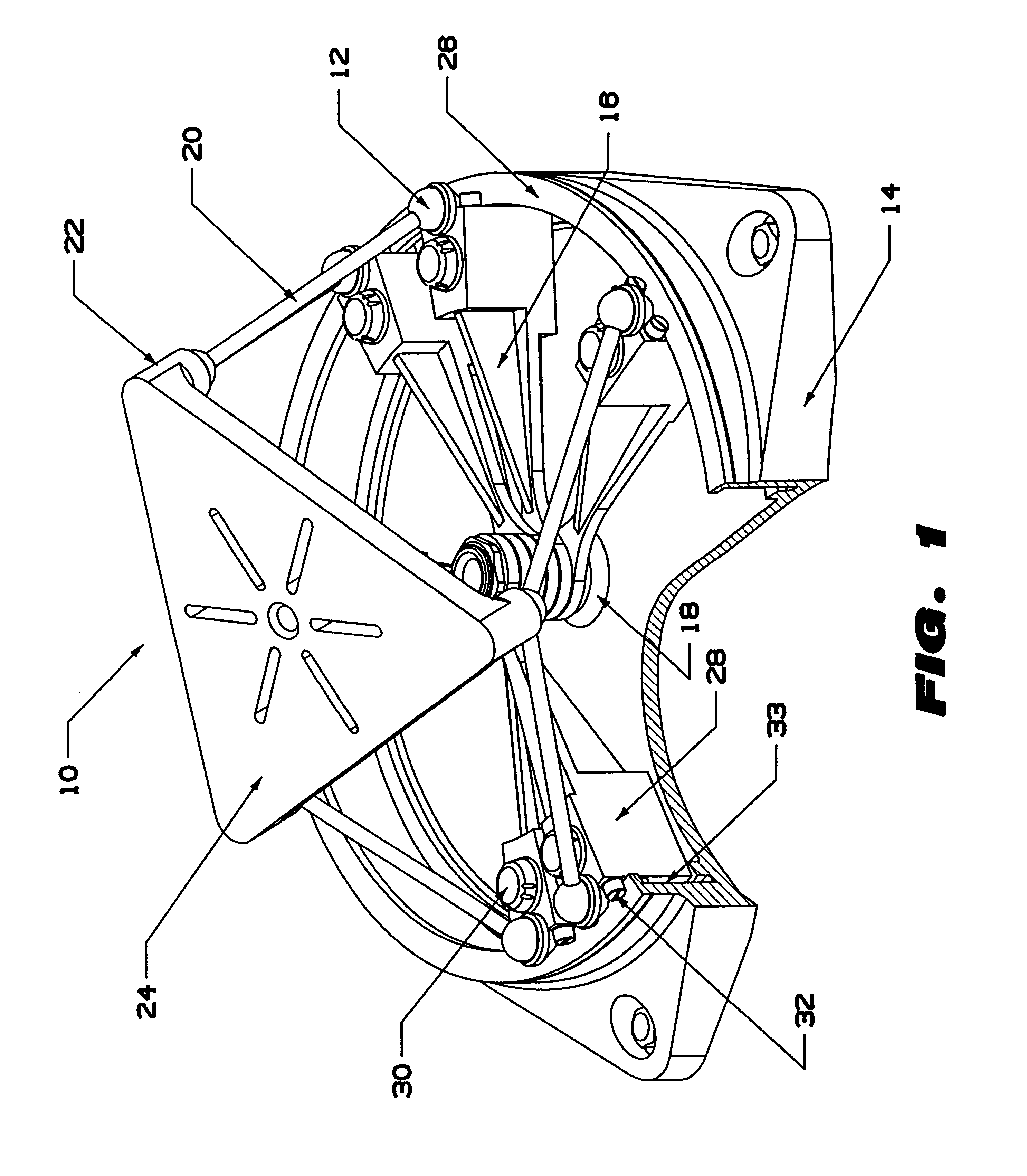

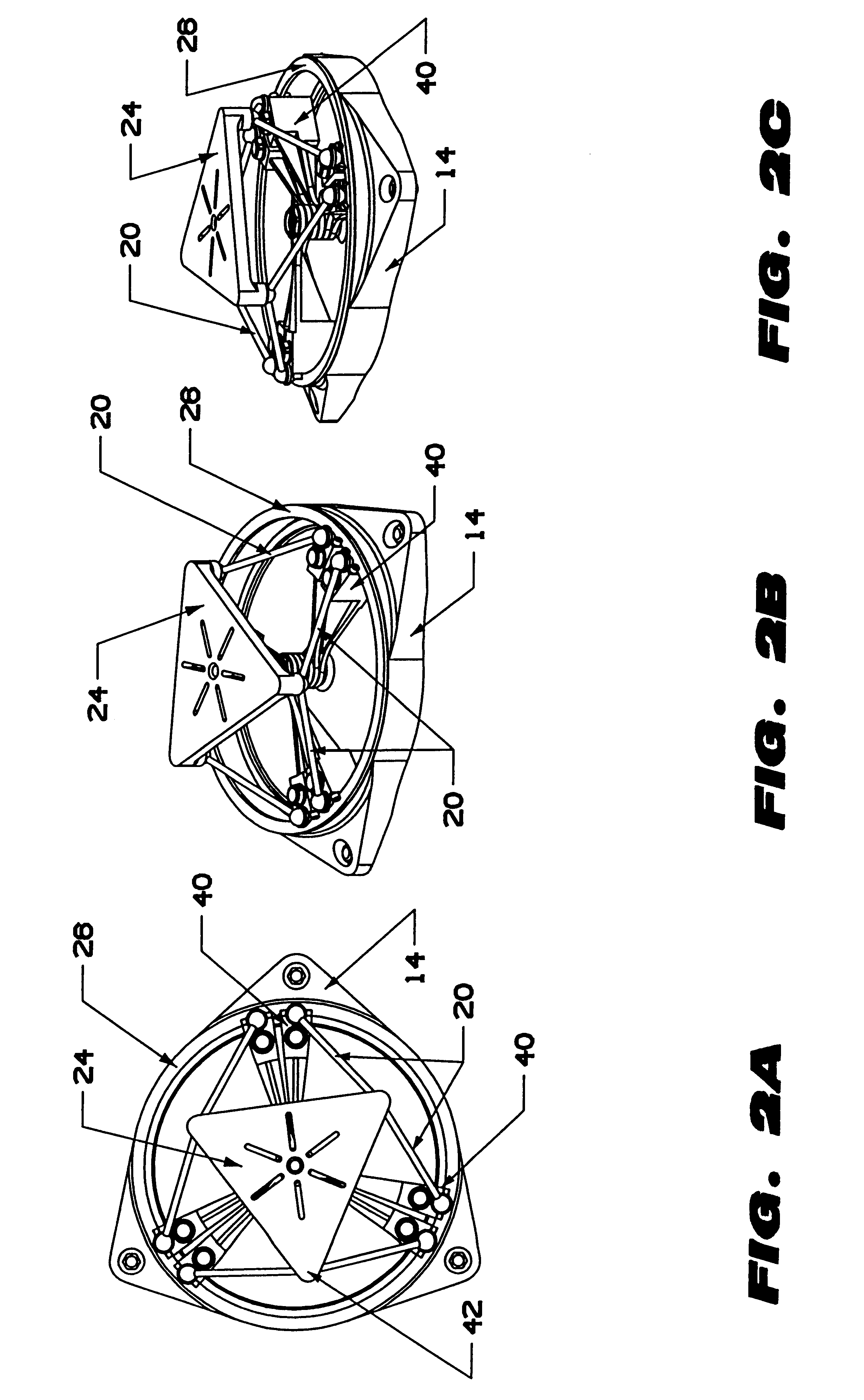

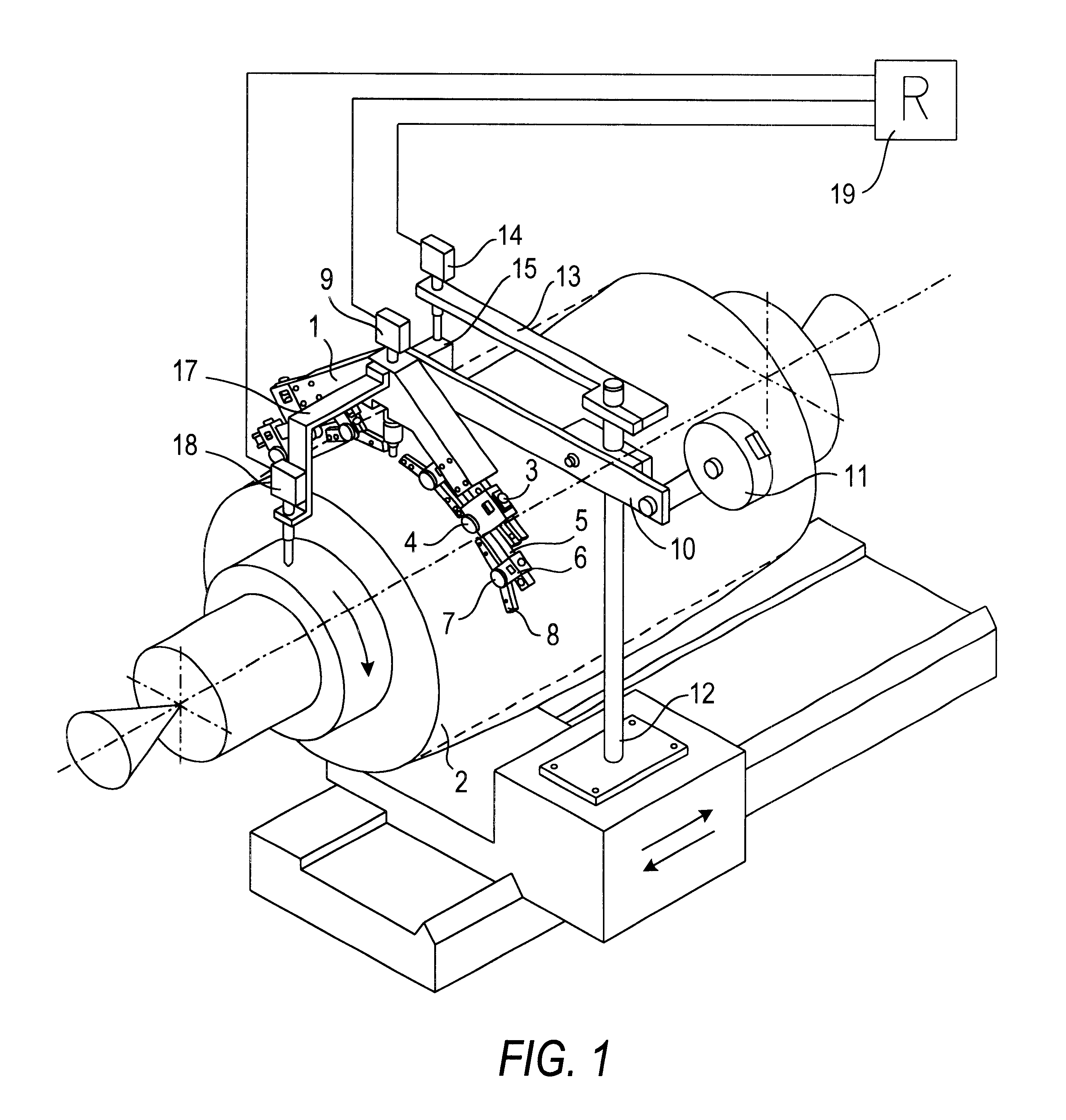

Systems and methods employing a rotary track for machining and manufacturing

InactiveUS6196081B1Low thermal expansionOptimization rangePortable framesJointsThree-dimensional spaceEngineering

The systems and methods described herein include hexapod systems, Stewart platform systems and other mechanical movement systems, in which a set of independently moveable trucks support legs that couple to a working surface capable of holding a machine tool or other end-effector, and preferably wherein the trucks travel across a reference surface, such as around the circumference of a circle or along some other pre-defined geometrical pattern or track. For example, as described herein, the systems include Stewart platform machines that have six supportive legs each of which connects to a truck that can travel independently along a track. By coordinating the movement of these six trucks, the working surface can be moved in three dimensional space and can be oriented about three axes, providing control of roll, pitch and yaw.

Owner:HEXEL CORP

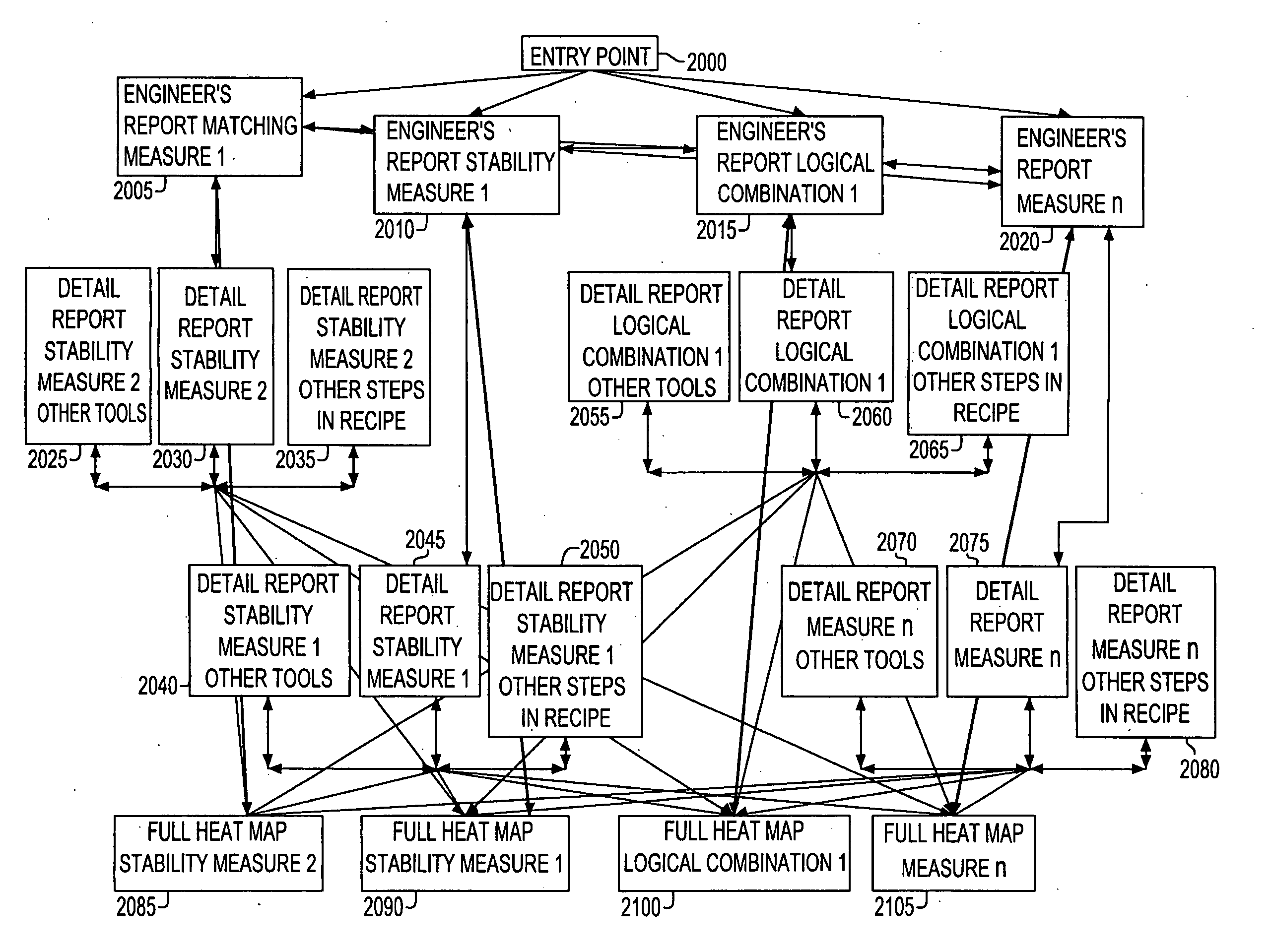

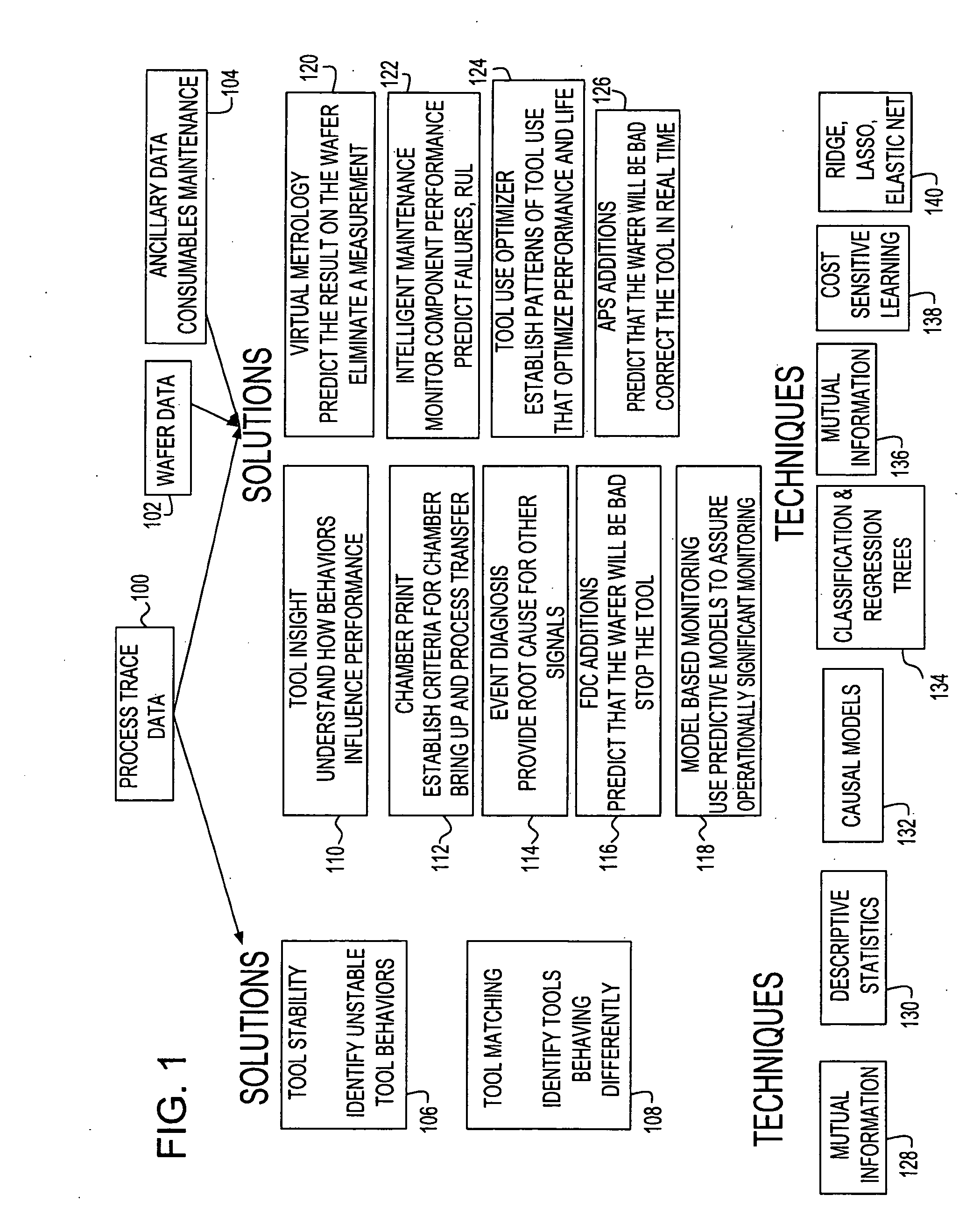

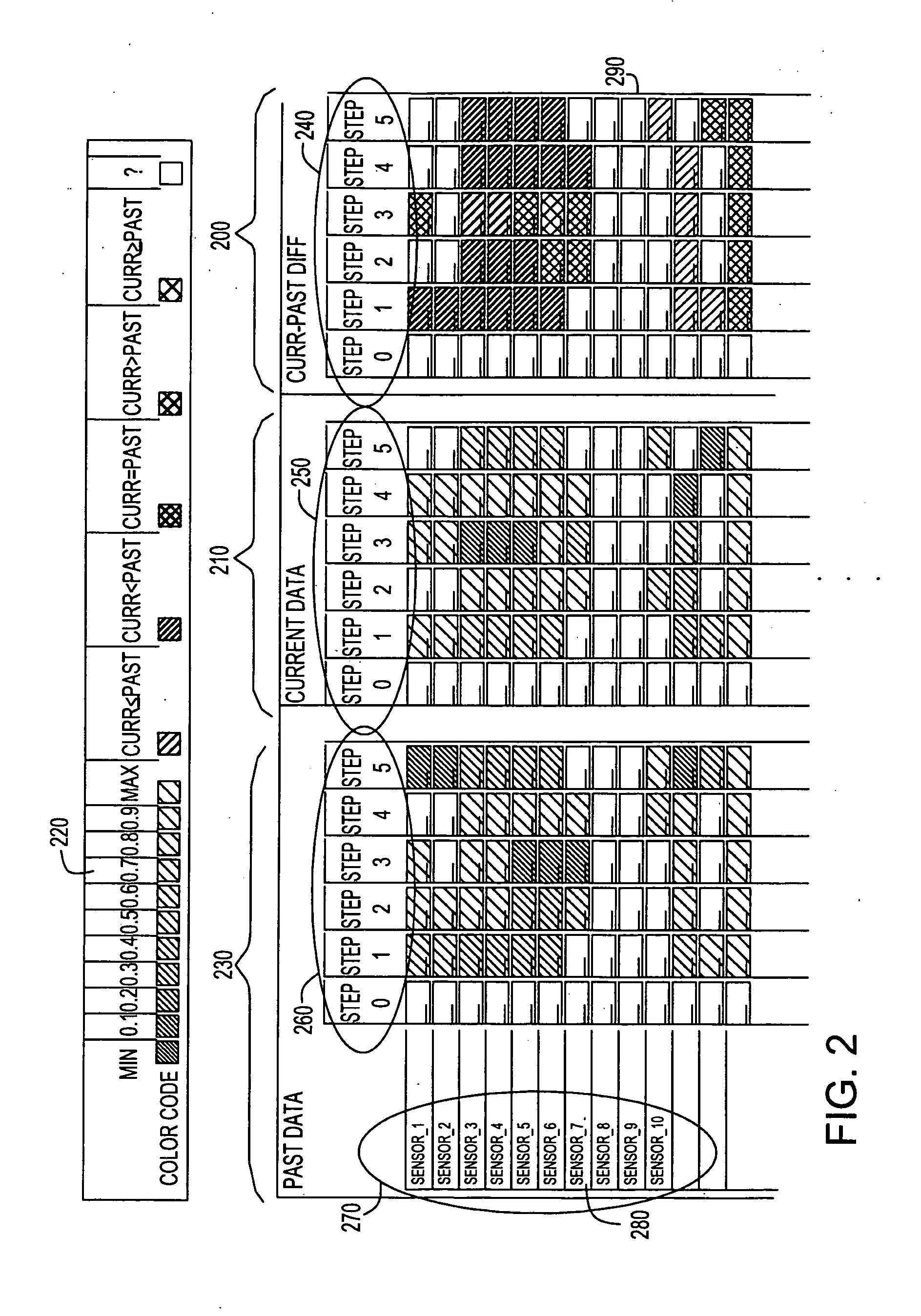

Method and system for evaluating a machine tool operating characteristics

A method and system for evaluating a performance of a semiconductor manufacturing tool while manufacturing microelectronic devices are disclosed. At least one report is generated based on executions of at least one statistical test. The report includes at least one heat map having rows that correspond to sensors, columns that correspond to trace data obtained during recipe steps, and cells at the intersection of the rows and the columns. At least one sensor in the tool obtains trace data of a recipe step while manufacturing at least one microelectronic device. A computing device analyzes the obtained trace data to determine a level of operational significance found in the data and assigns a score to the trace data that indicates a level of operational significance. Then, the computing device places the score in a corresponding cell of the heat map. A user uses the cell for evaluating the tool performance.

Owner:GLOBALFOUNDRIES INC

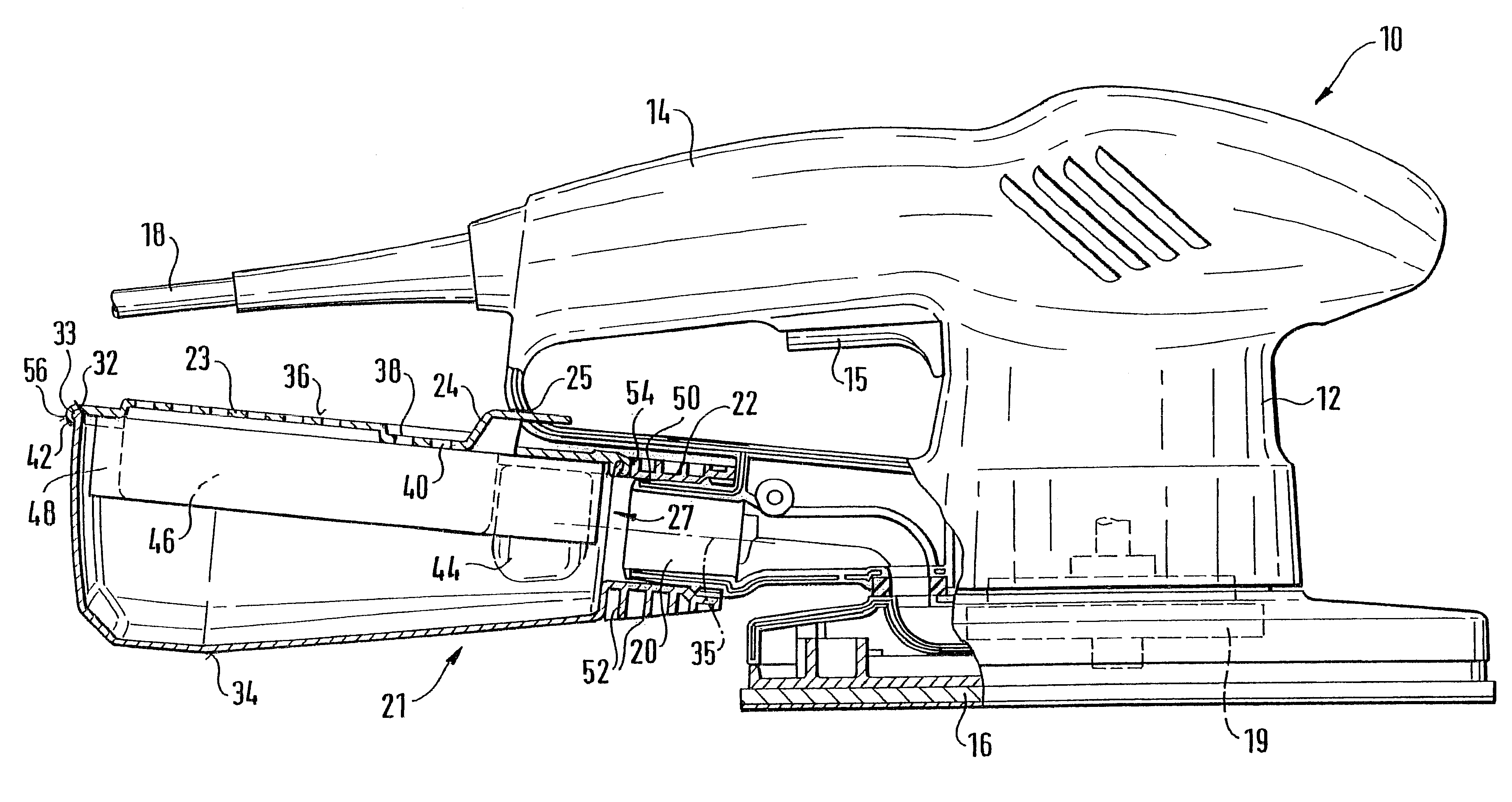

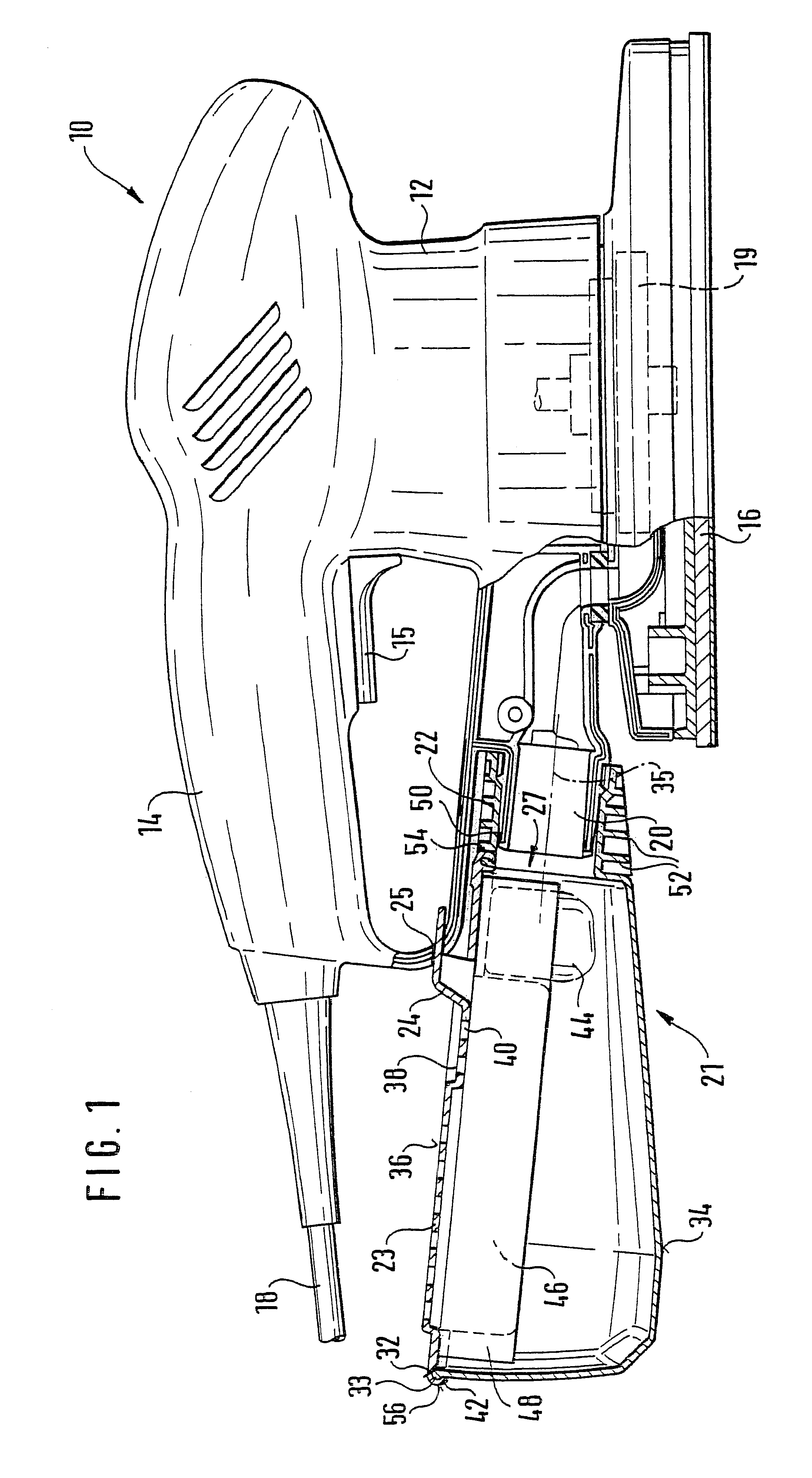

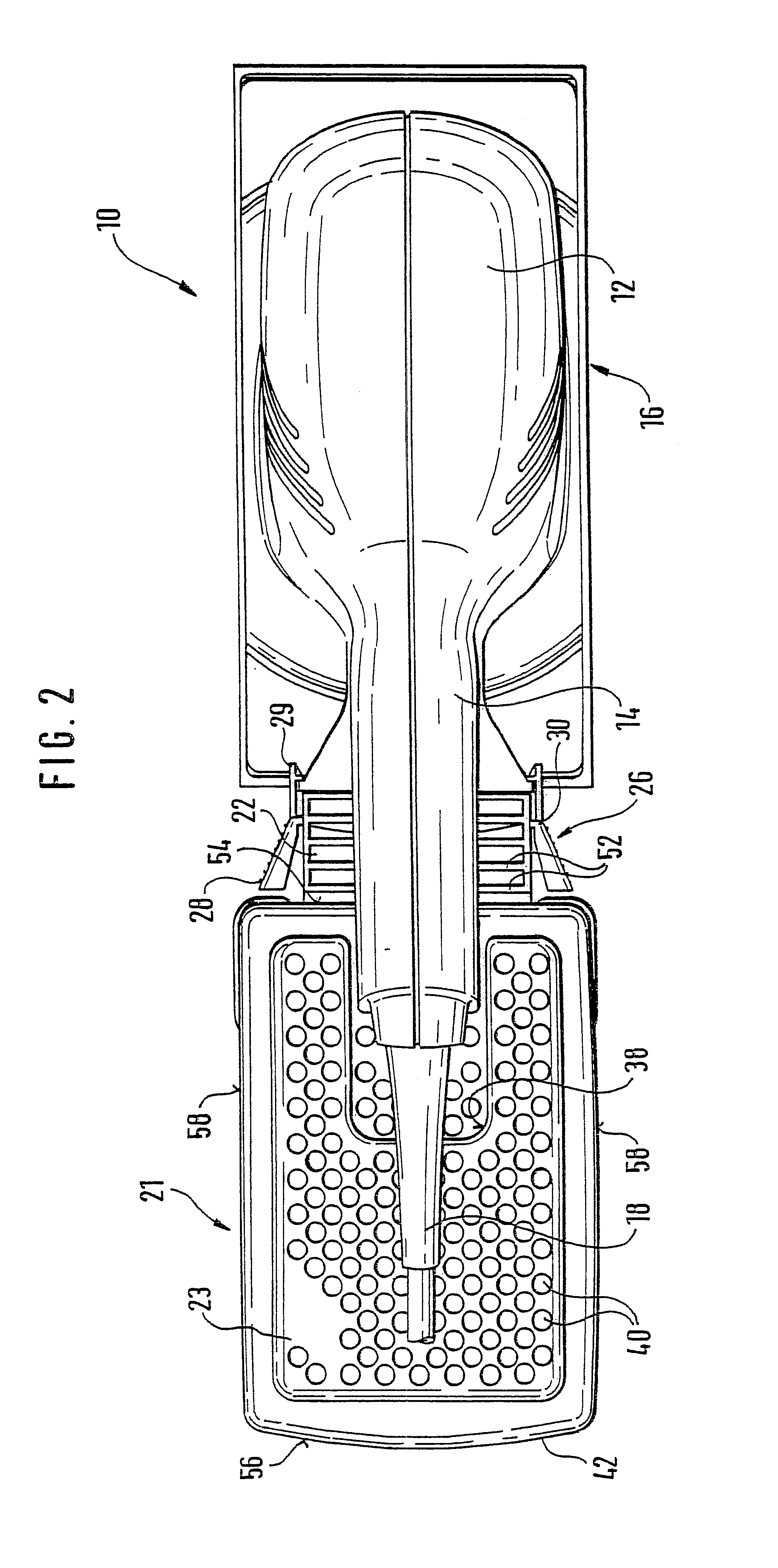

Hand-held machine tool with dust extraction

InactiveUS6514131B1Large filter areaHigh degreePortable grinding machinesMaintainance and safety accessoriesHand heldPower tool

A power tool (10) having a dust suction device (19) integrated into its housing (12) and having an ejection fitting (20) which is connected to the dust suction device (19) and can be detachably fastened with its injection fitting (22) to a dustproof dust box (21) is particularly suitable for containing sanding dust because of a number of side walls (34) of the dust box (21) have air openings (40) and on the inside, support at least one filter element (48), in particular a folded filter, which overlaps the air openings (40).

Owner:ROBERT BOSCH GMBH

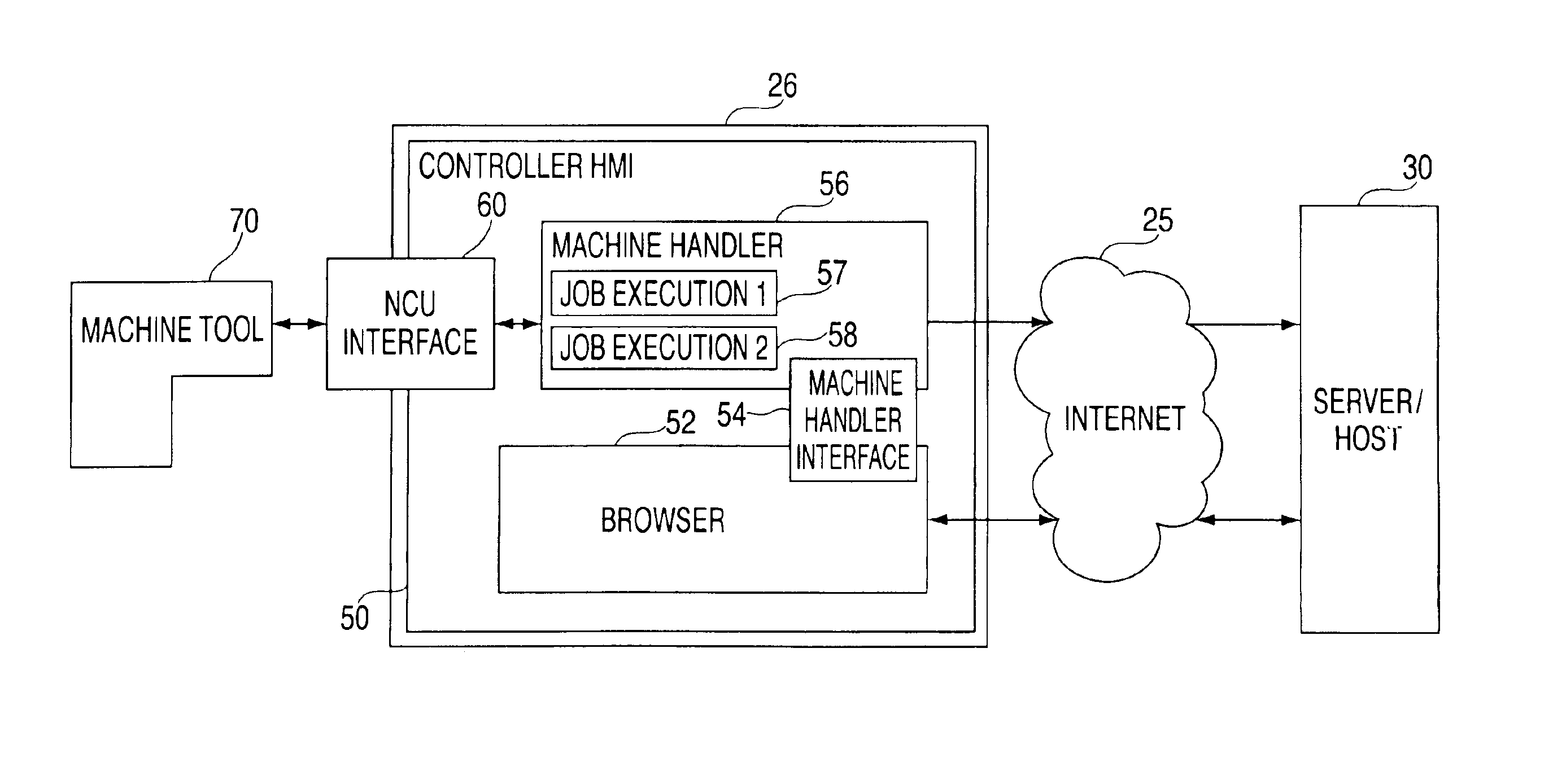

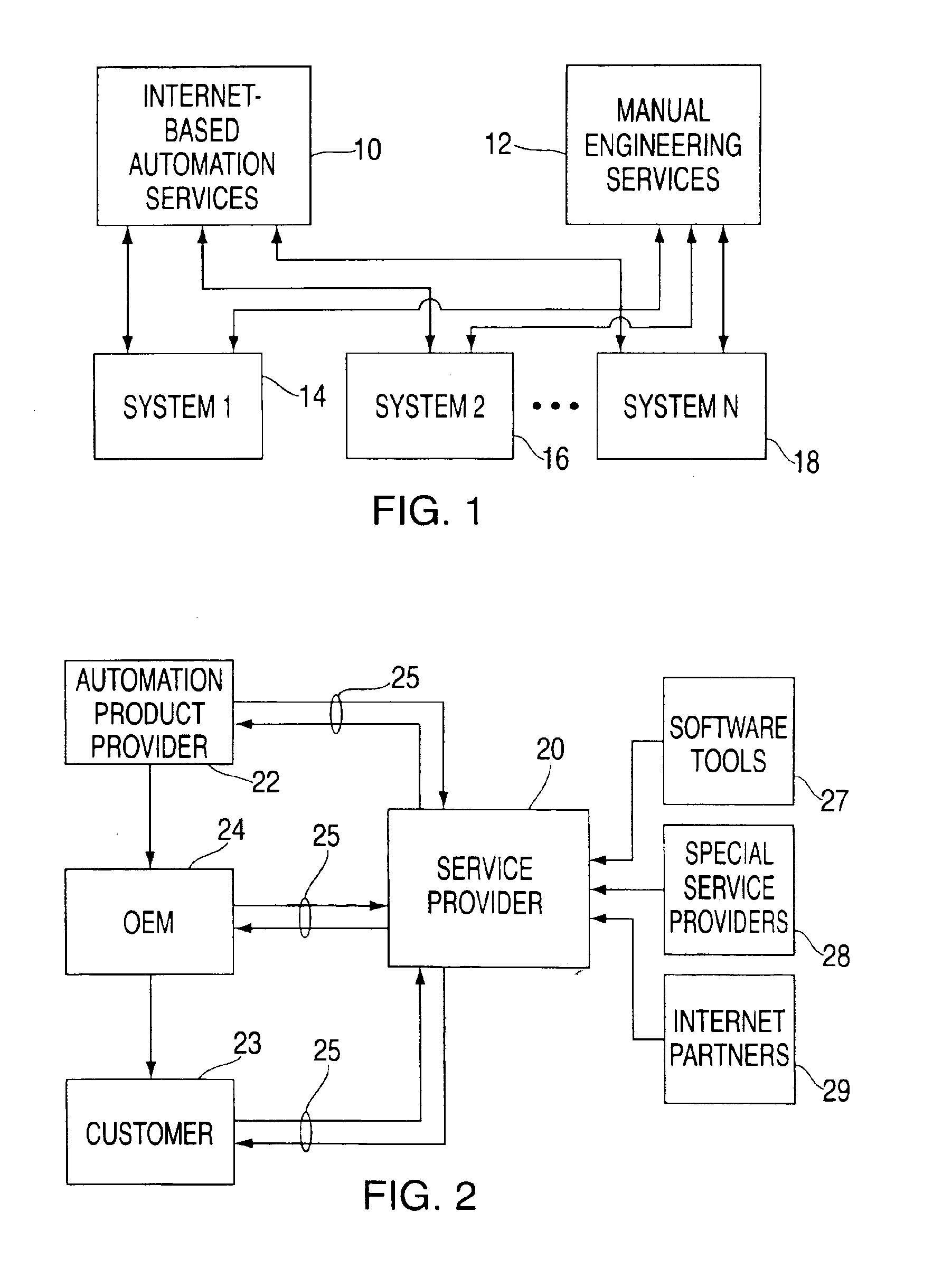

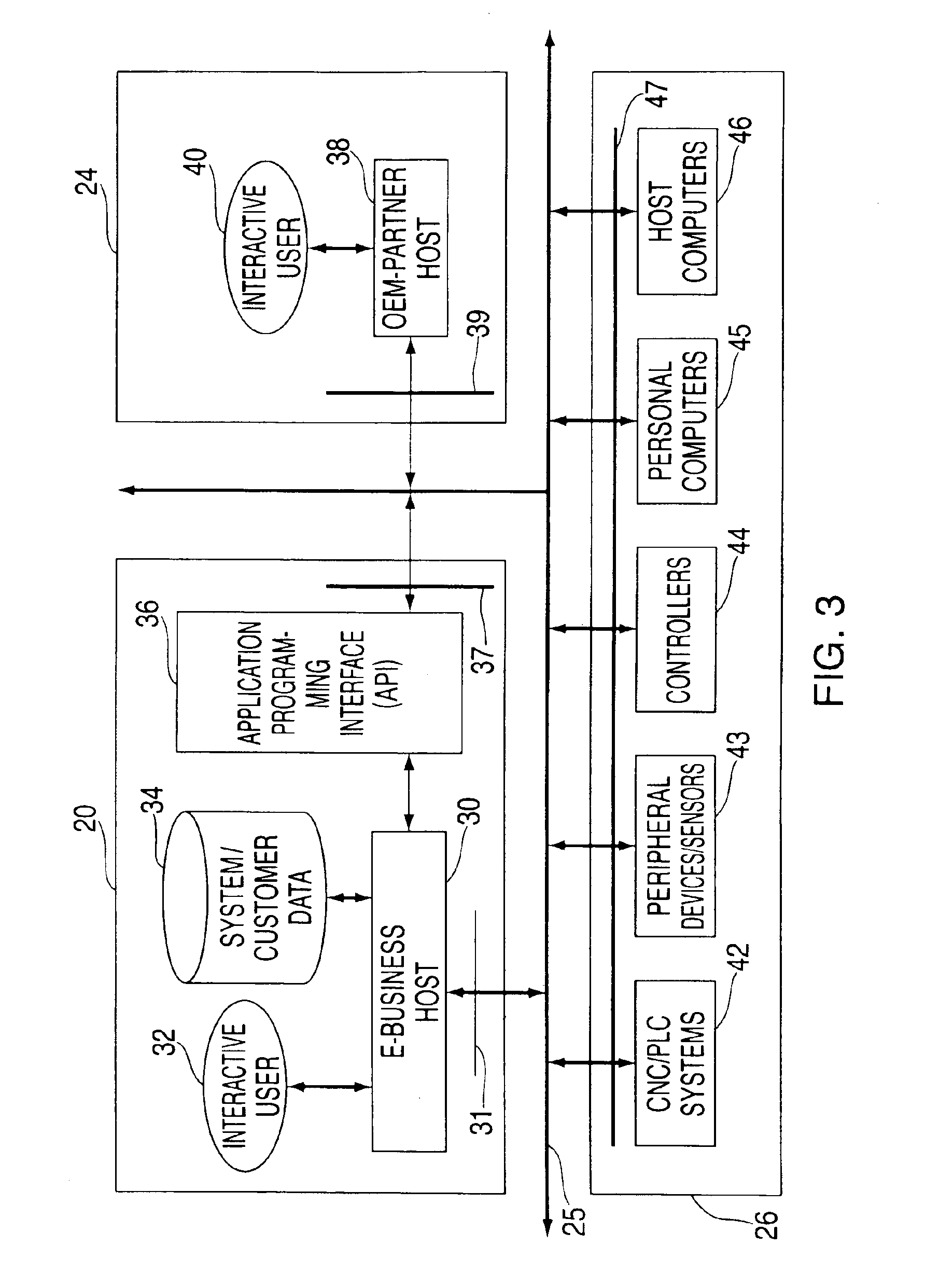

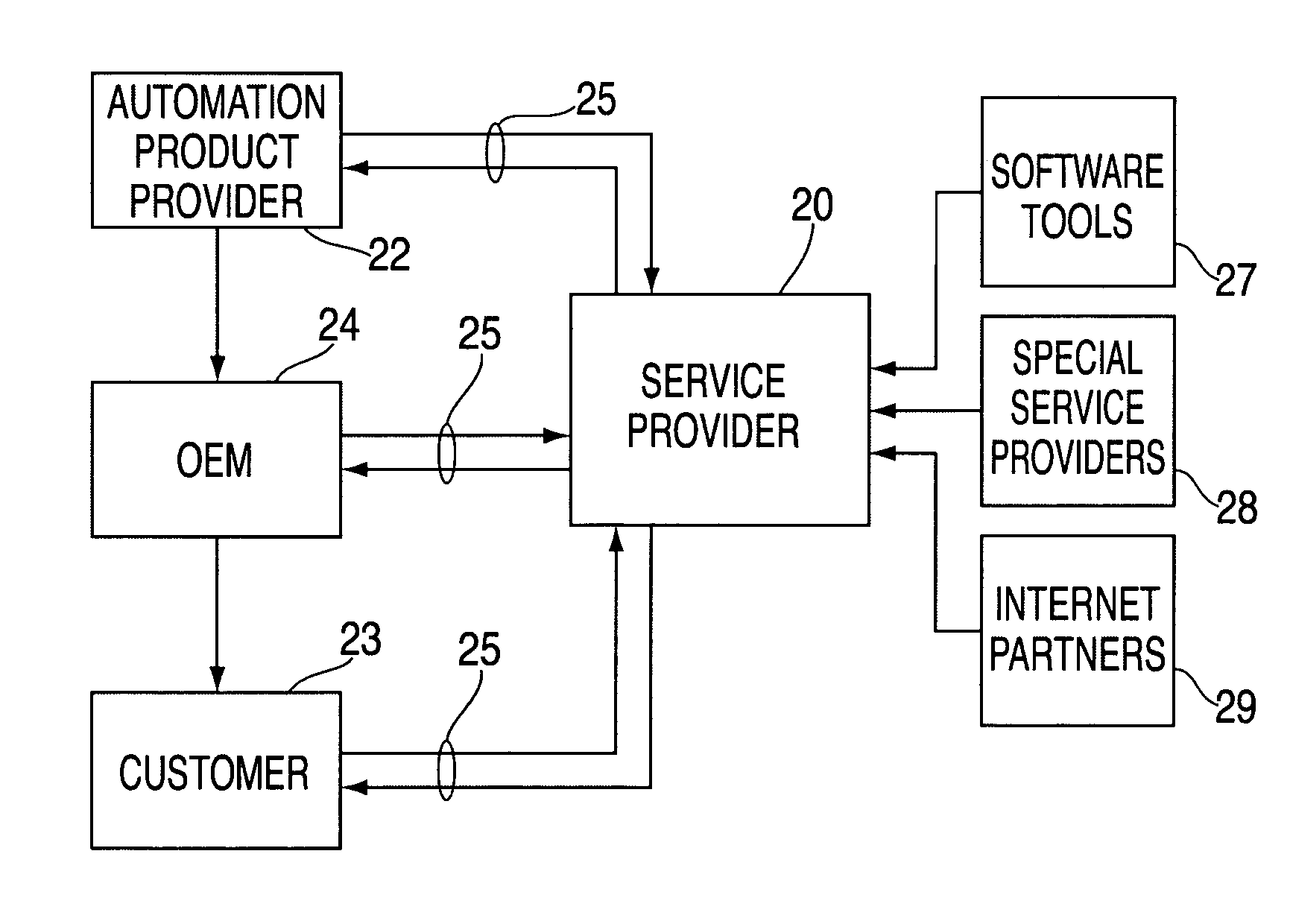

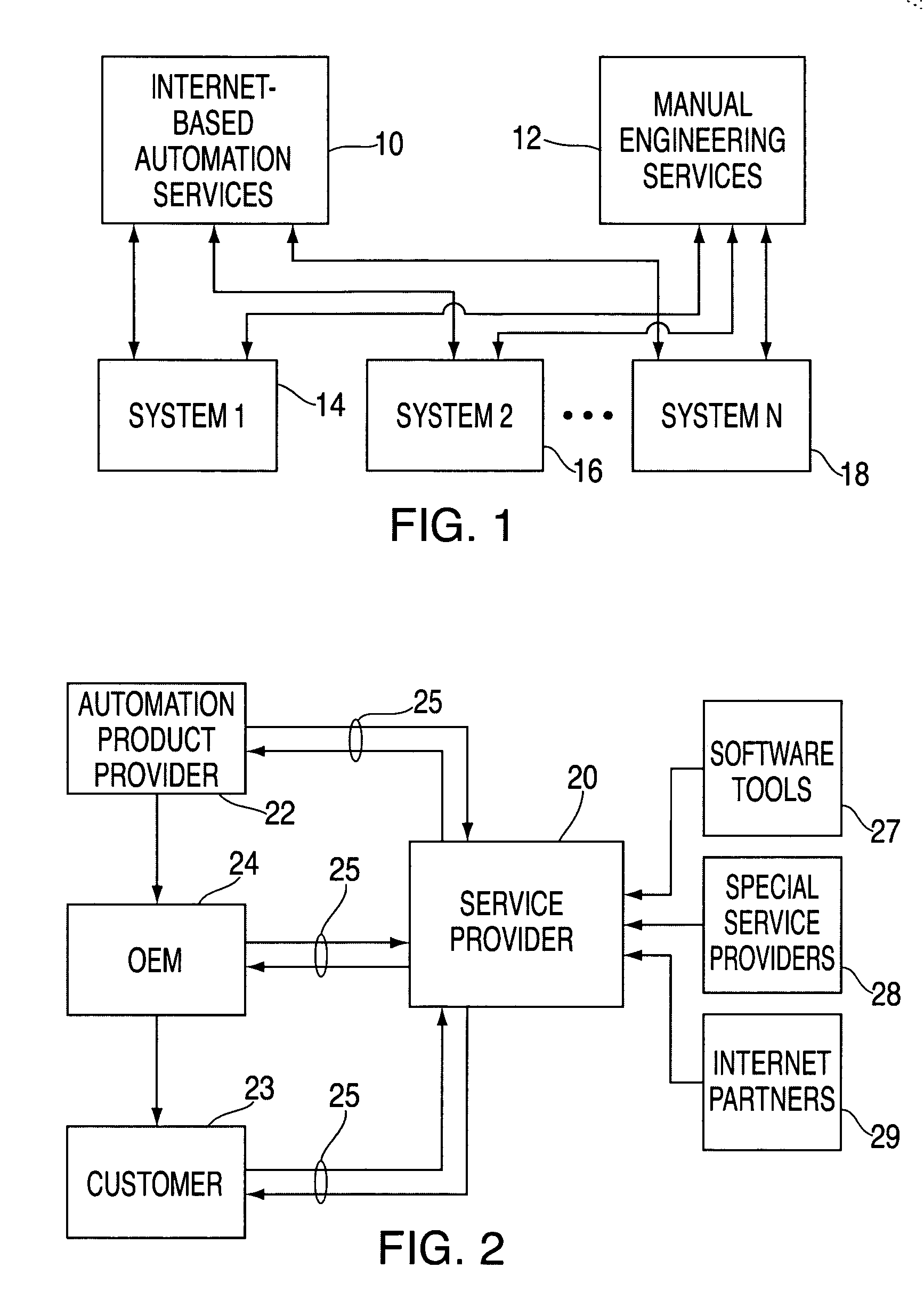

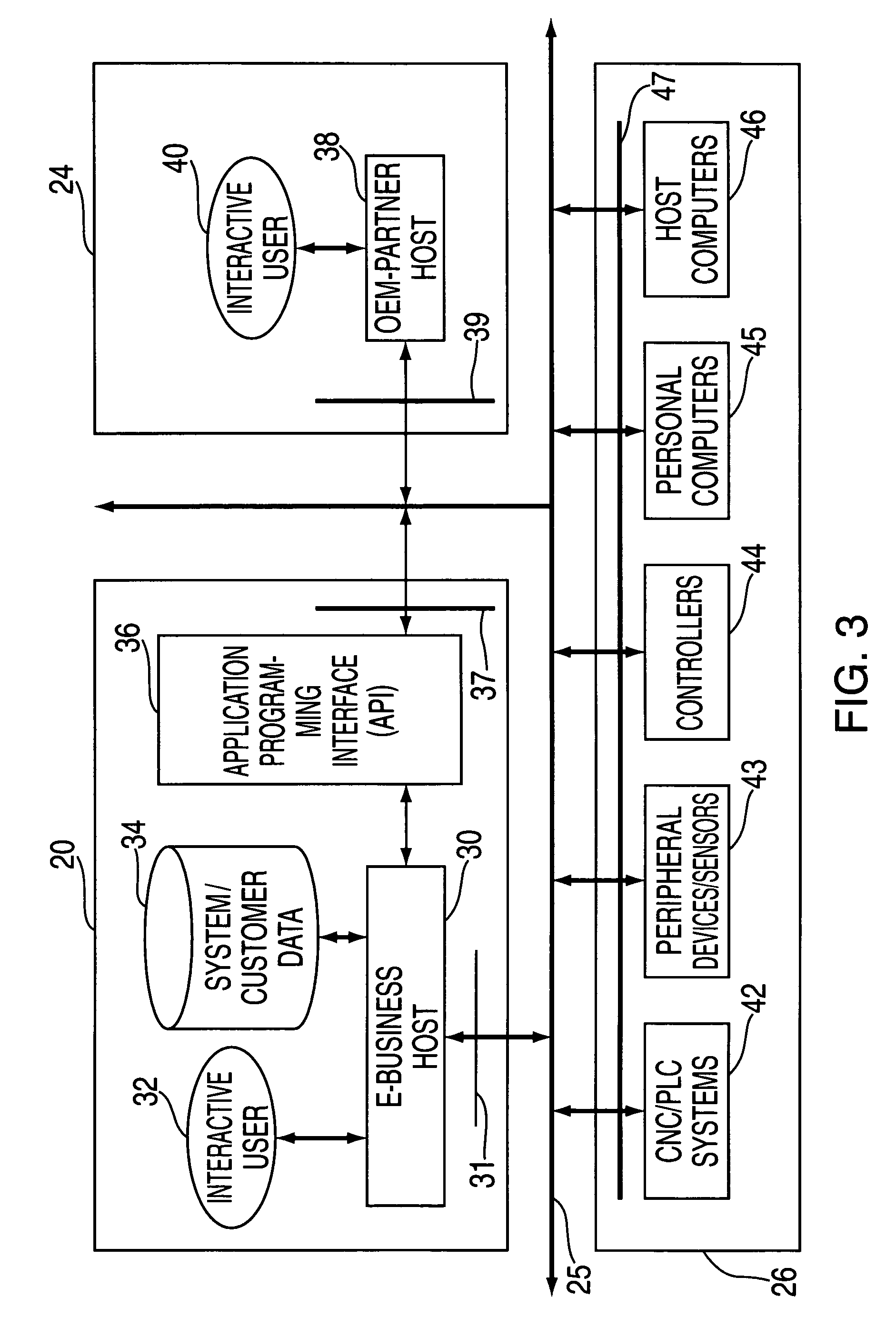

Database system and method for industrial automation services

InactiveUS6975913B2Improve data securityProvide informationComputer controlSimulator controlReal-time dataOriginal equipment manufacturer

A host system generates and manages databases incorporating data gathered from a plurality of client automation systems, such as CNC machine tools. The data may include real-time data, and is captured from the client systems under supervision of software downloaded over a network from the host system to the client systems. The captured data is transmitted over the network to the host, which creates the databases. The databases preferably include a commercial database comprising data associated with customer owners or operators of the client automation system, as well as a technical database, comprising captured data, administrative and other data, organized by customer and client system. Captured data is preferably associated with the date of capture, providing for the creation of a historical database for given client equipment. With customer authorization, others, such as original equipment manufacturers, may access the captured data, for which they may be charged a fee.

Owner:SIEMENS AG

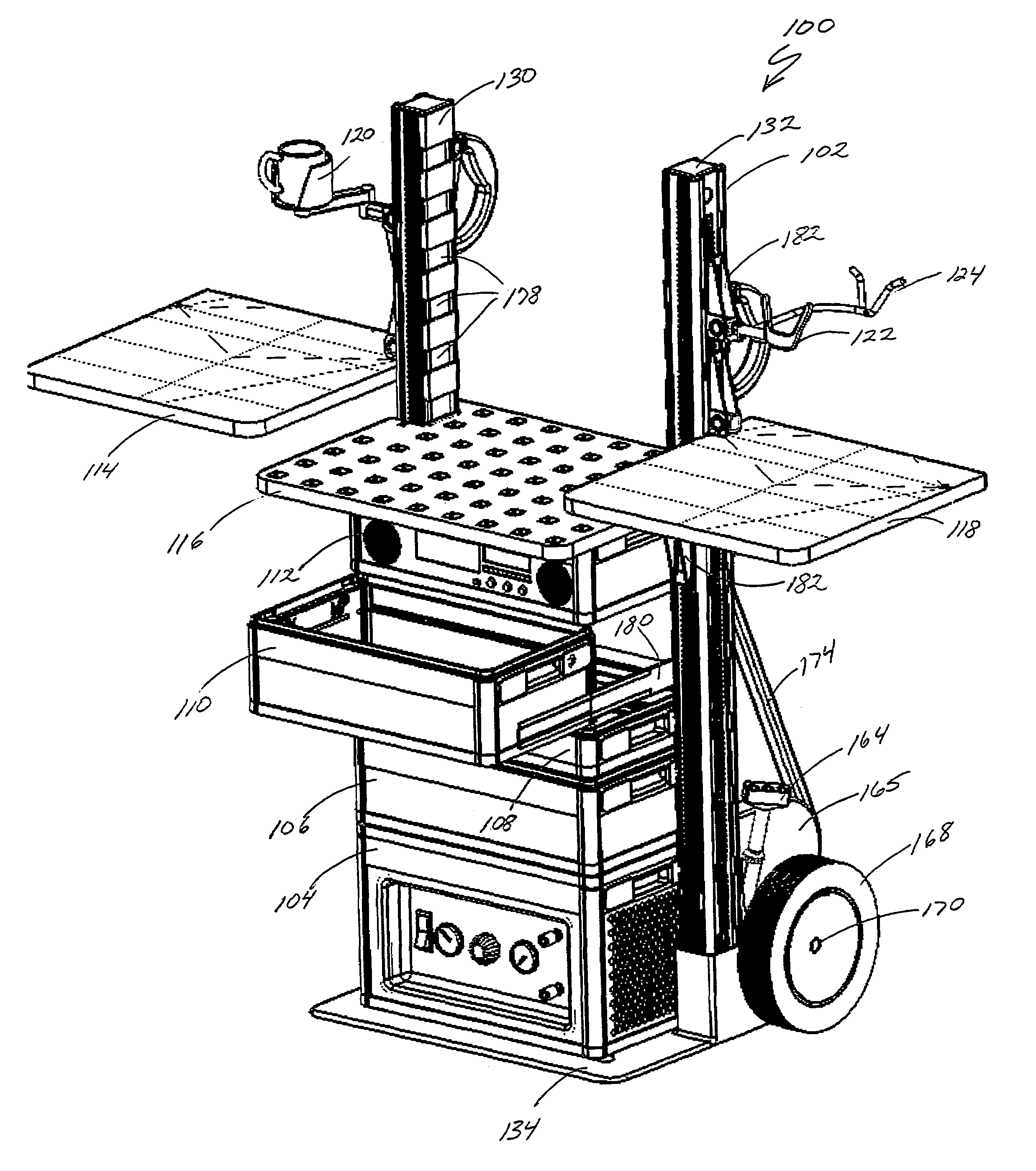

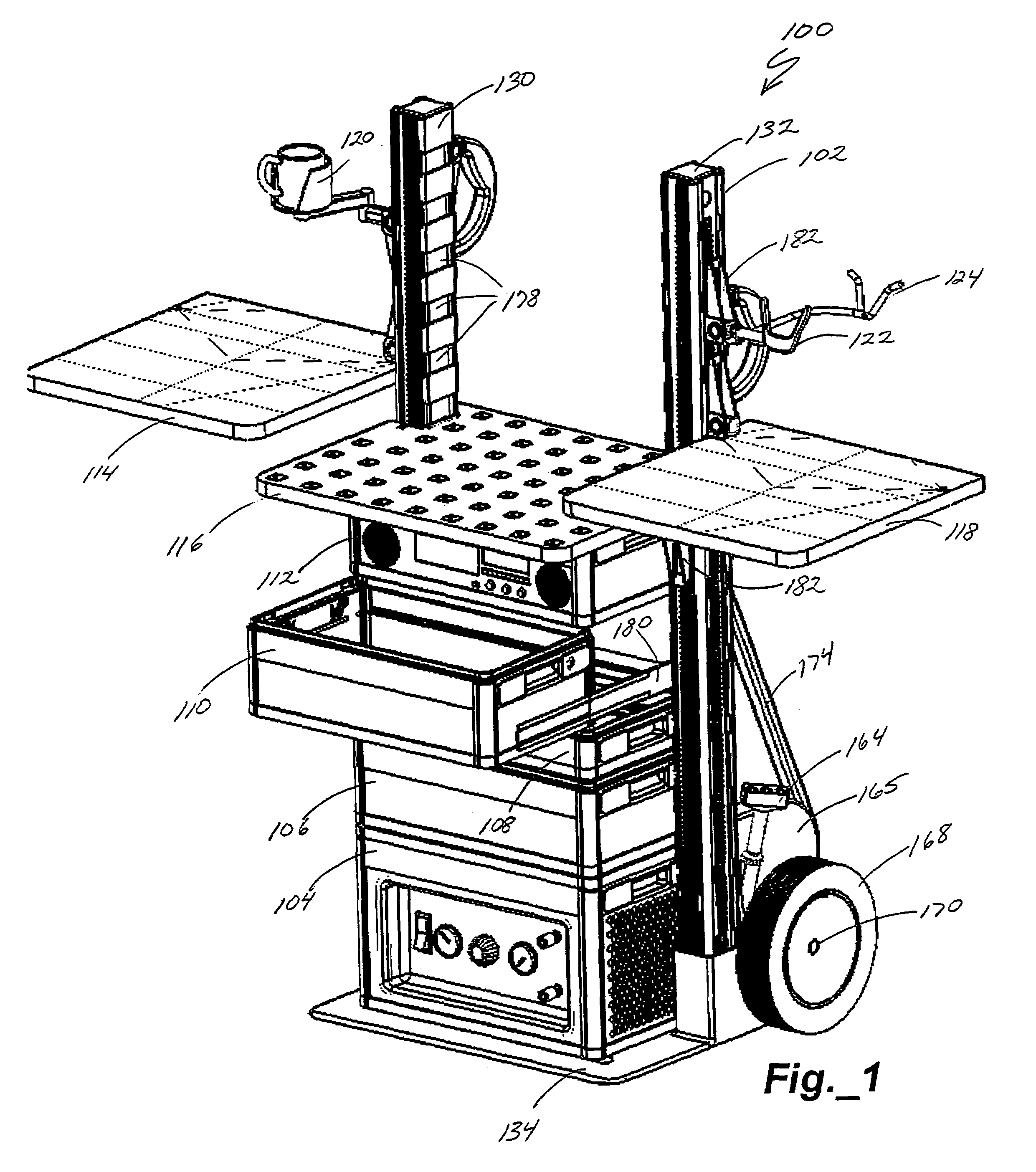

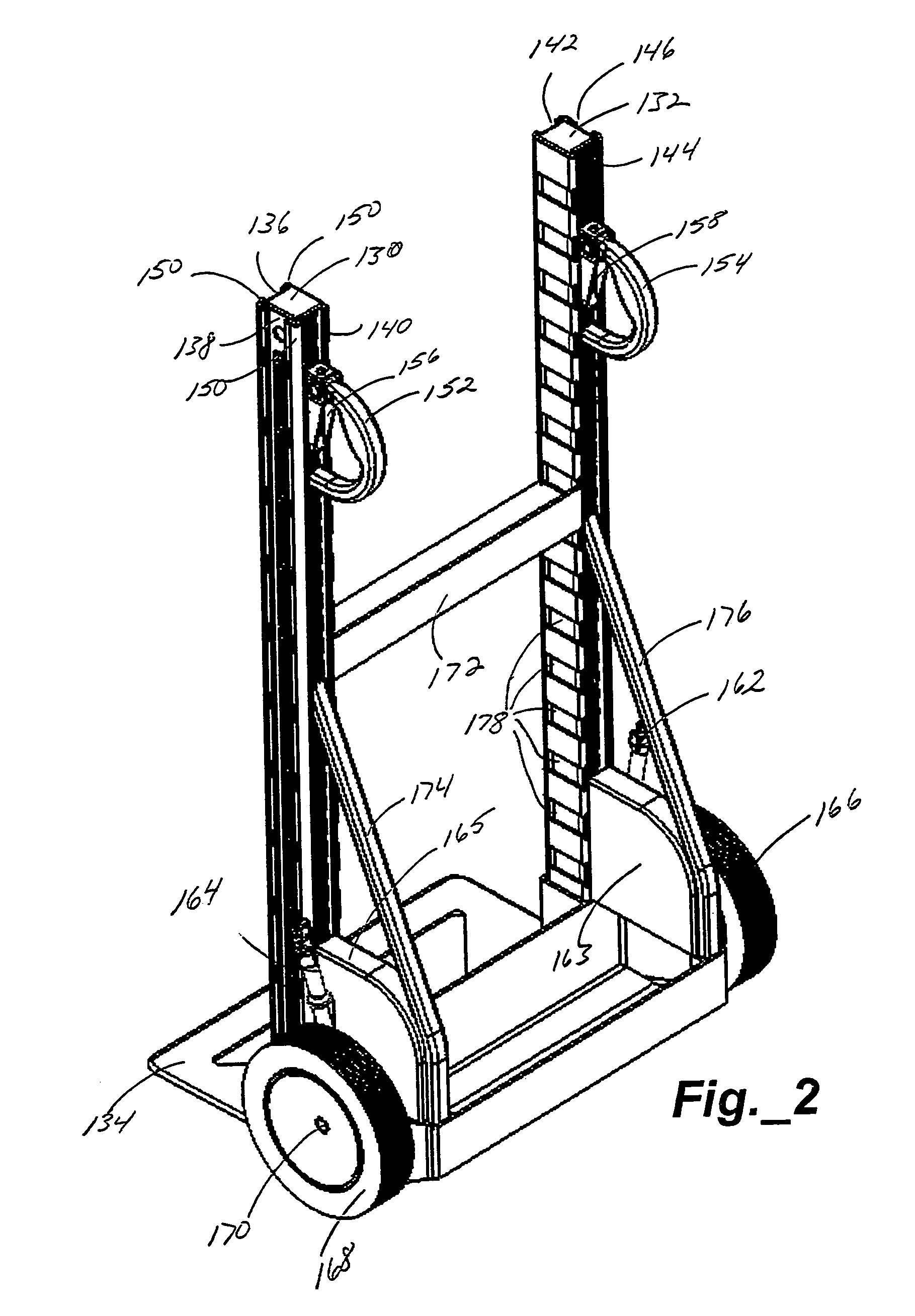

Tool and task box storage, transport, and workbench system

InactiveUS7367571B1Easy to liftCarriage/perambulator with single axisWork benchesMachine toolWorkbench

A machine tool stand and / or workbench, electrical outlet panel, light supply, and modular task box system, combined into an integrated system that includes a support structure having a support base on wheels and side rails disposed on the surface of the support base. The side rails include structure for attaching tool holders, work pieces holders, work surfaces, and the like.

Owner:STAINBROOK & STAINBROOK

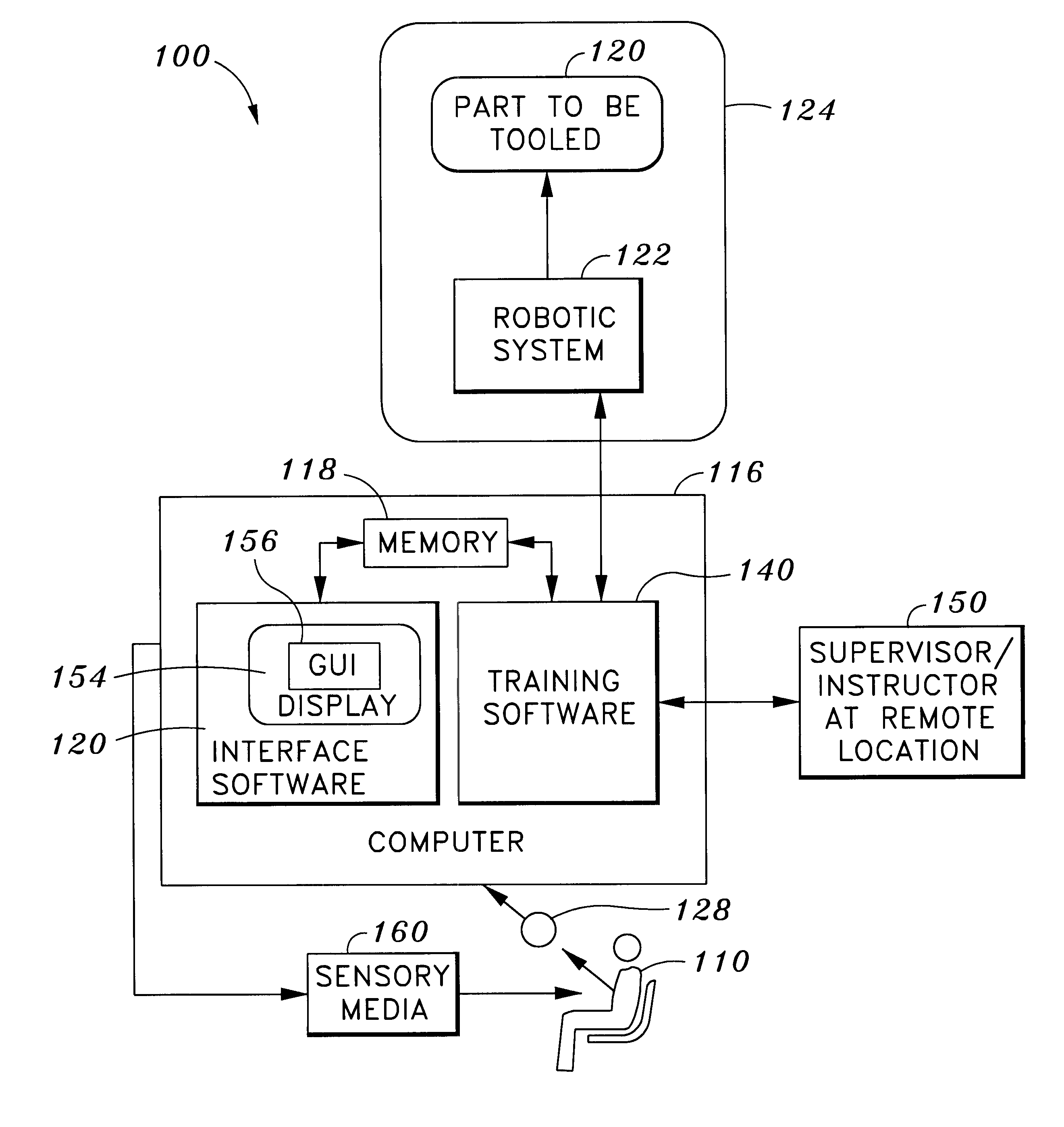

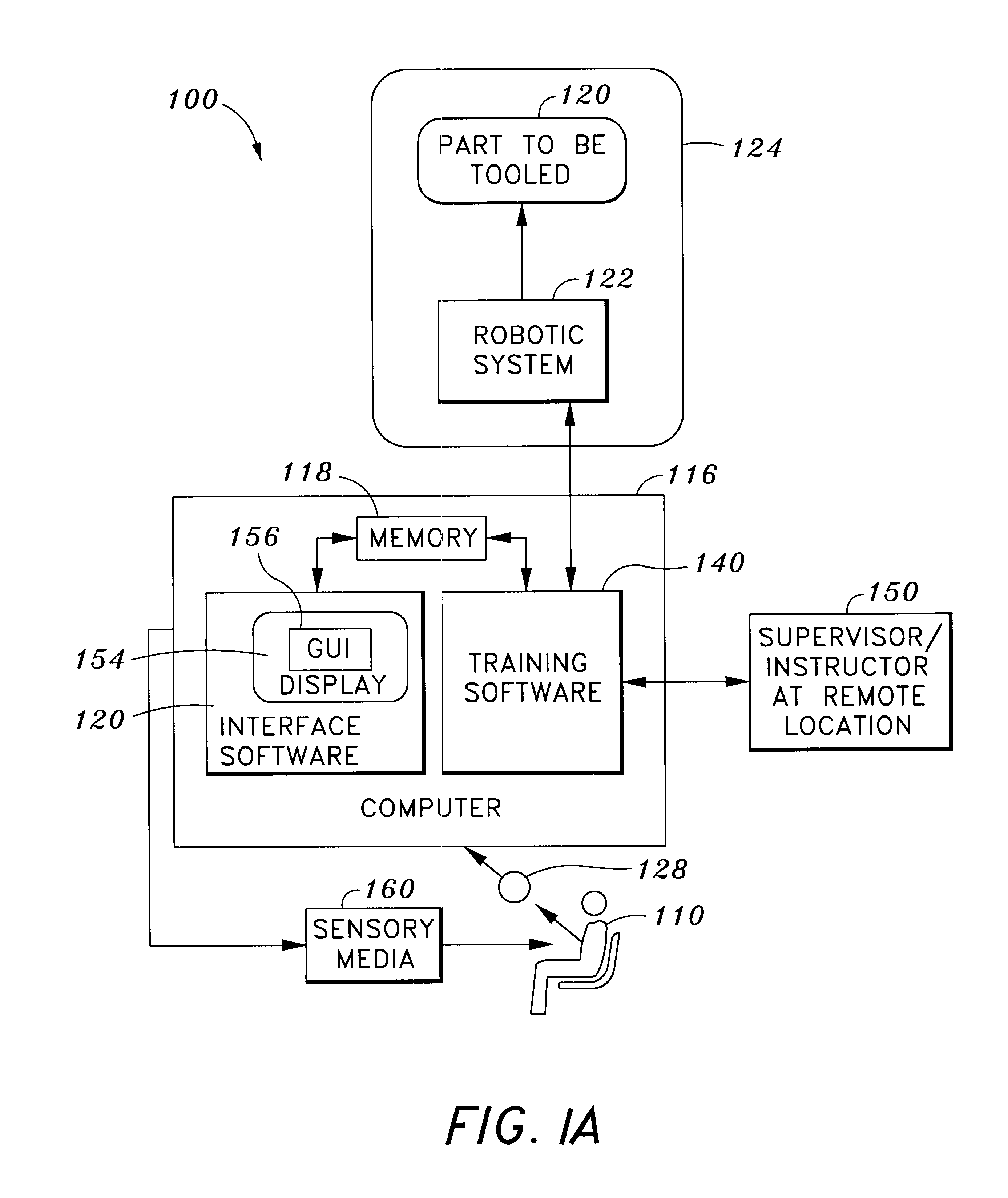

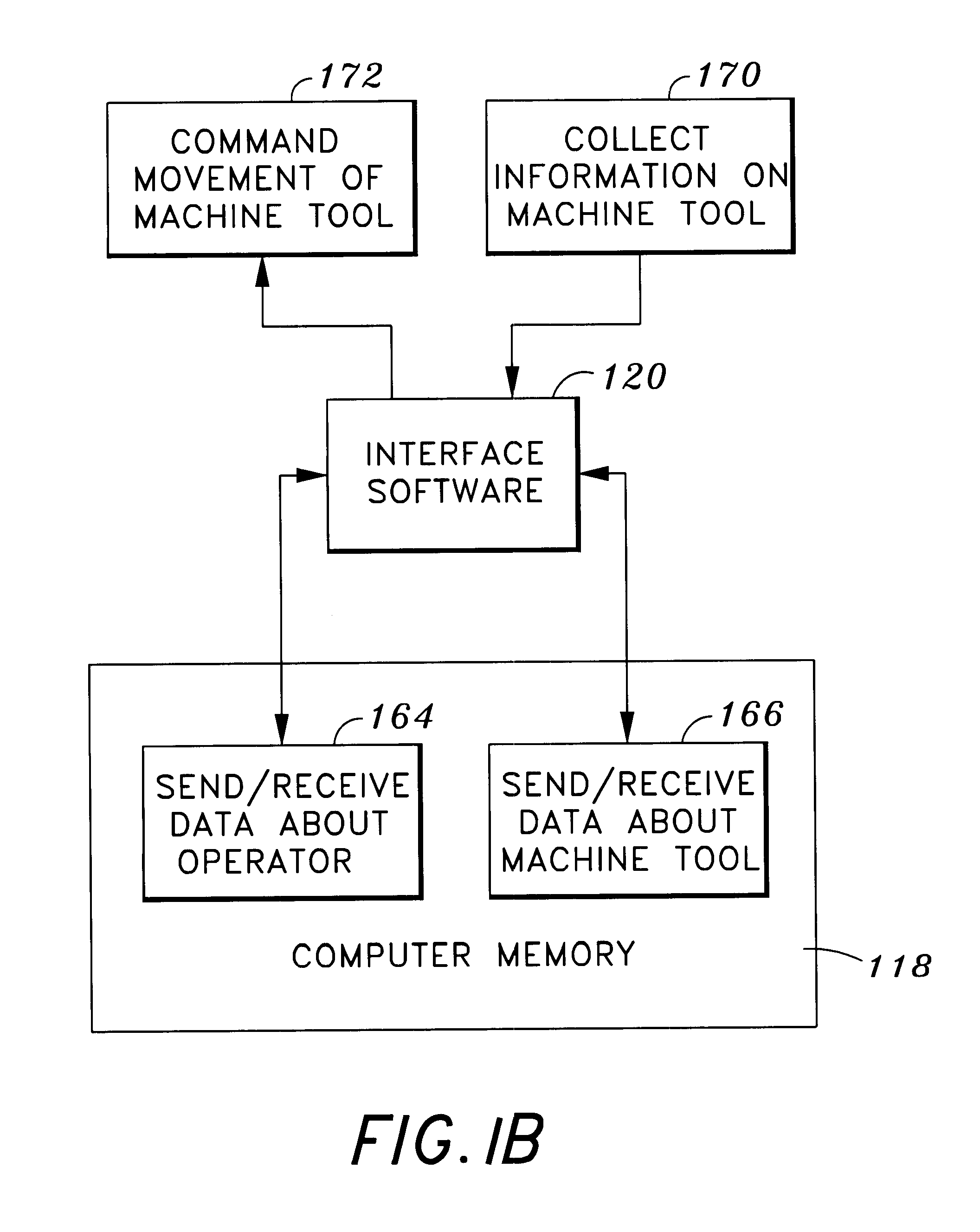

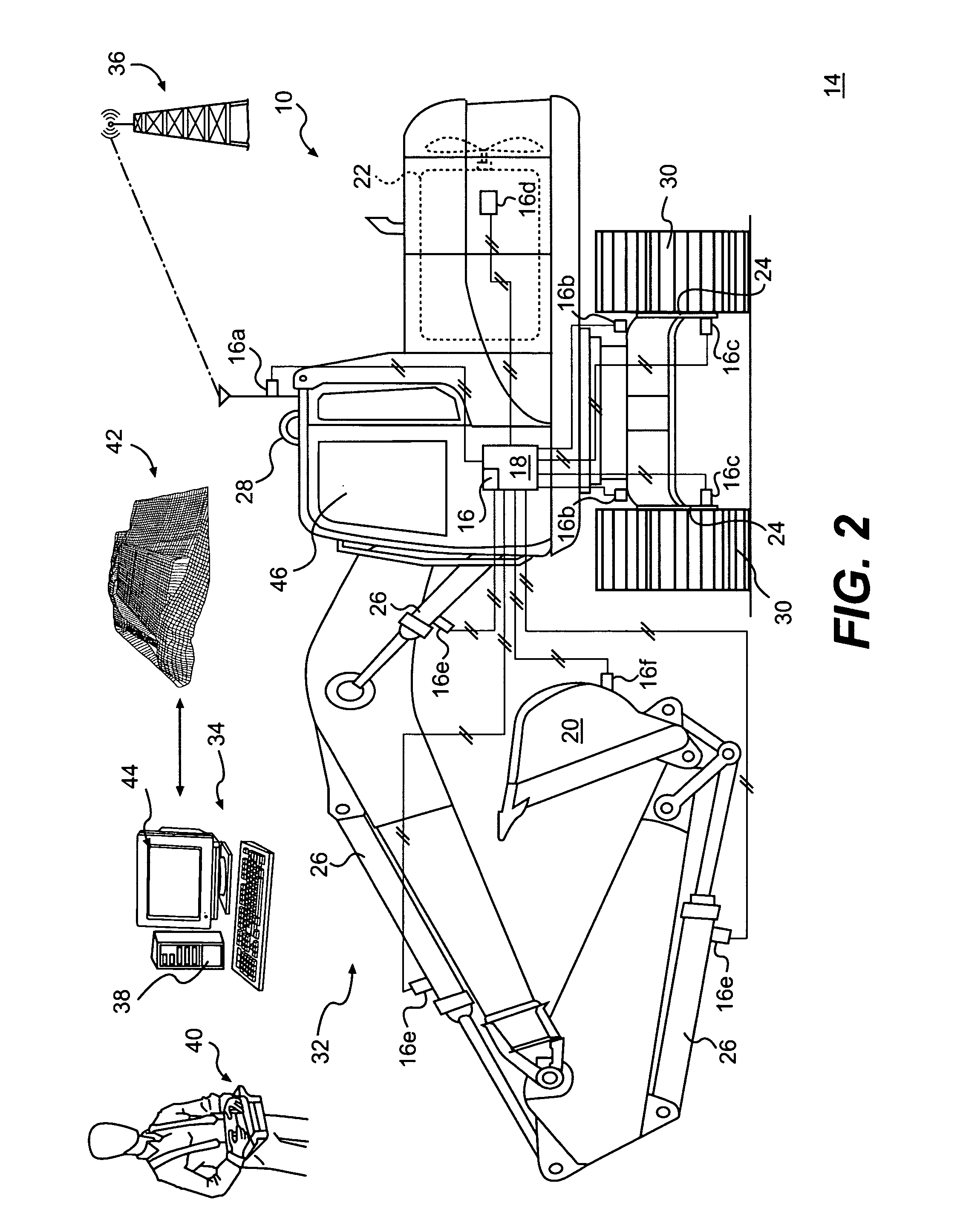

Computer interface system for a robotic system

InactiveUS6292712B1Reduce amountEasy to operateProgramme controlComputer controlPointing deviceWorkstation

The present invention is an interactive multi-media interface system which incorporates text, audio, and video graphics animation and other tools to interface a user with a device in an outside environment, such as a robotic device, machining or other tool. The interface system includes a computer workstation to allow inputs from a user, such as a machine operator, computer memory, and an interface computer program operating on the computer. The computer has a graphical user interface for interfacing the operator with the workstation and to allow interactive operation and control of the machine tool. The operator can provide inputs to the interface system by various input devices such as a keyboard, cursor, mouse, a stylus pointing device or a touch sensitive screen. The interface software shares access to and exchanges data with the computer memory.

Owner:NORTHROP GRUMMAN SYST CORP

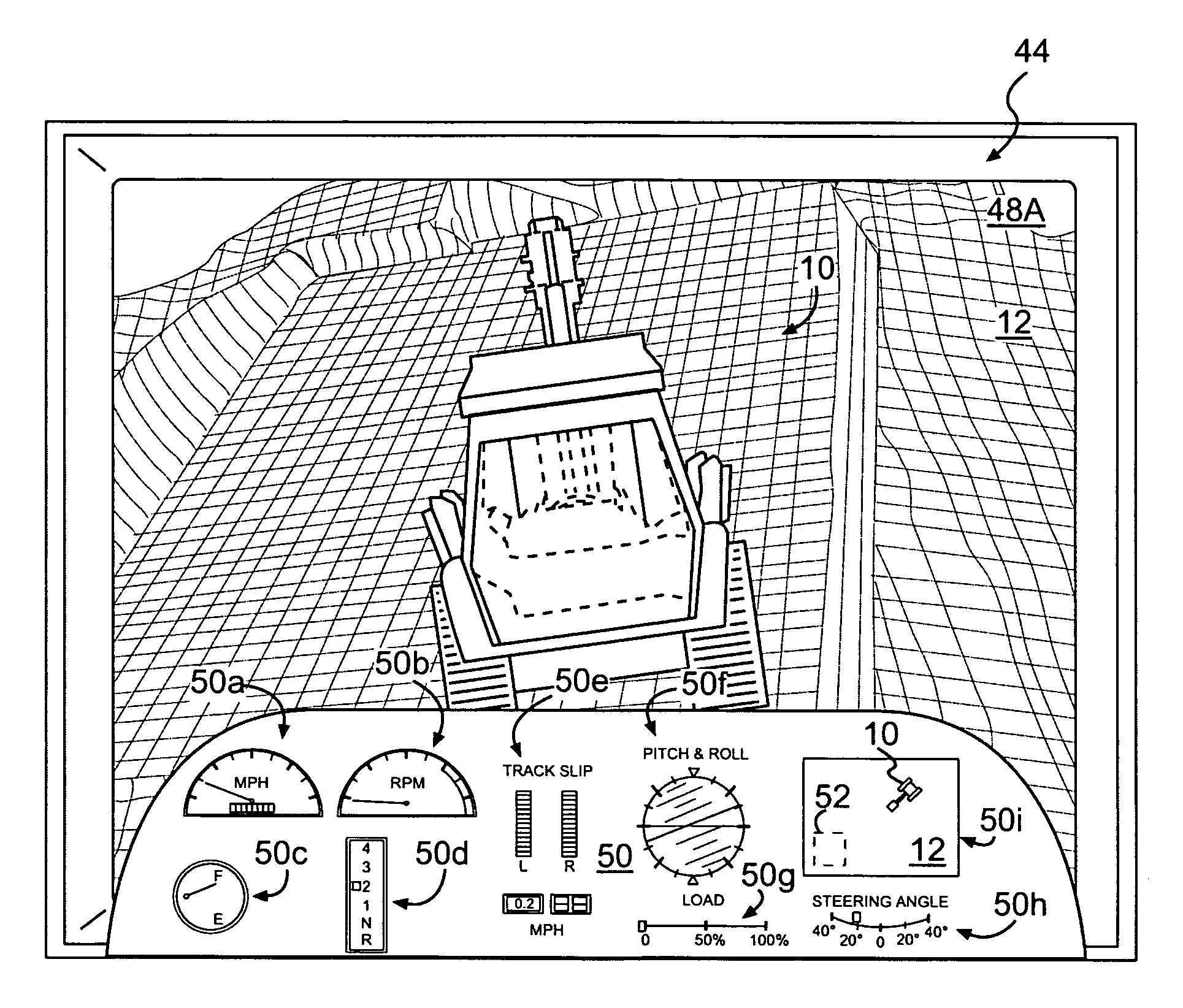

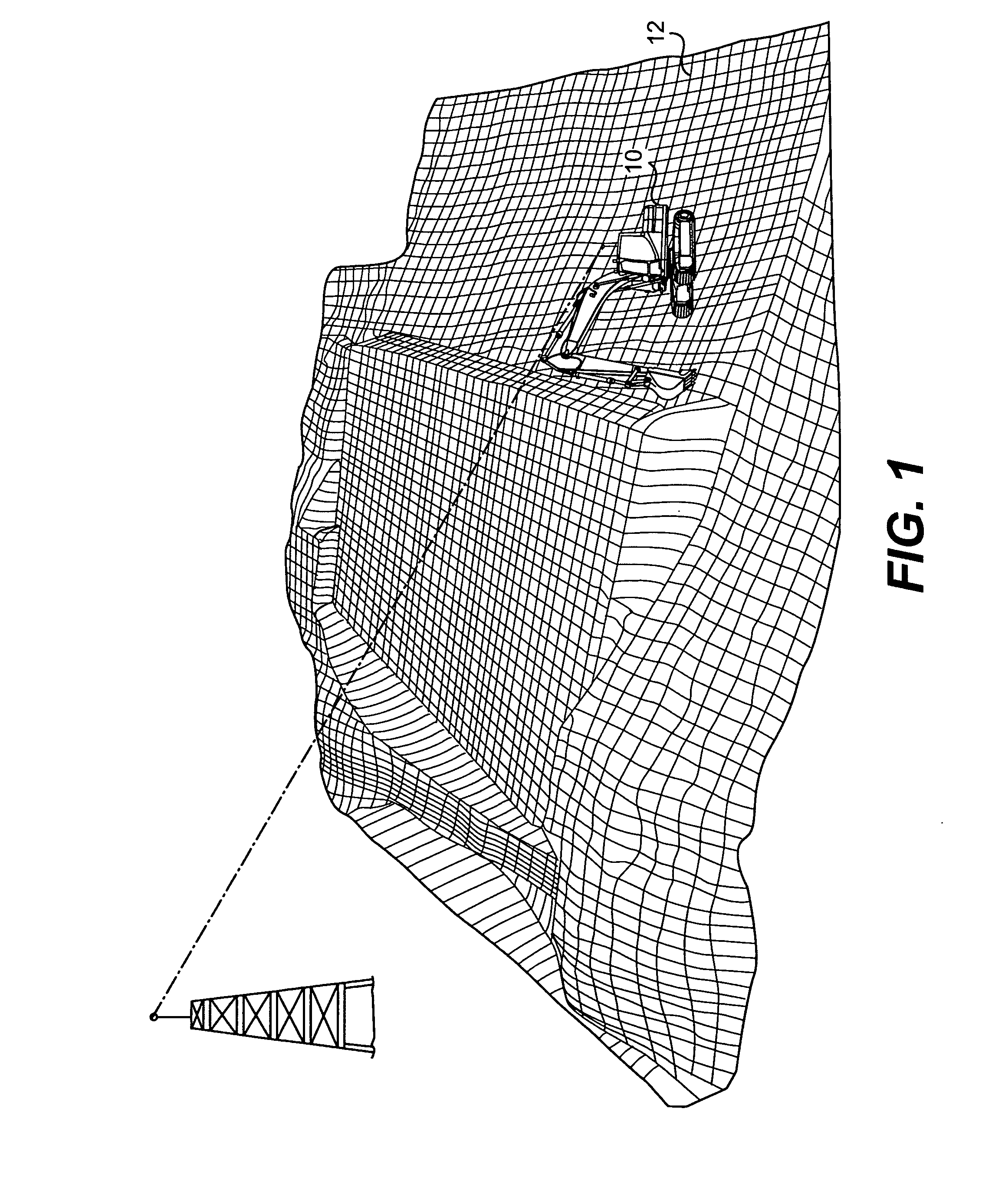

Simulation system implementing real-time machine data

ActiveUS20080180523A1Affect operationCosmonautic condition simulationsColor television detailsTime informationControl system

A simulation and control system for a machine is disclosed. The simulation and control system may have a user interface configured to display a simulated environment. The machine simulation and control system may also have a controller in communication with the user interface and a remotely located machine. The controller may be configured to receive from the machine real-time information related to operation of the machine at a worksite. The controller may also be configured to simulate the worksite, operation of the machine, and movement of a machine tool based on the received information. The controller may further be configured to provide to the user interface the simulated worksite, operation, and movement in the simulated environment.

Owner:CATERPILLAR INC

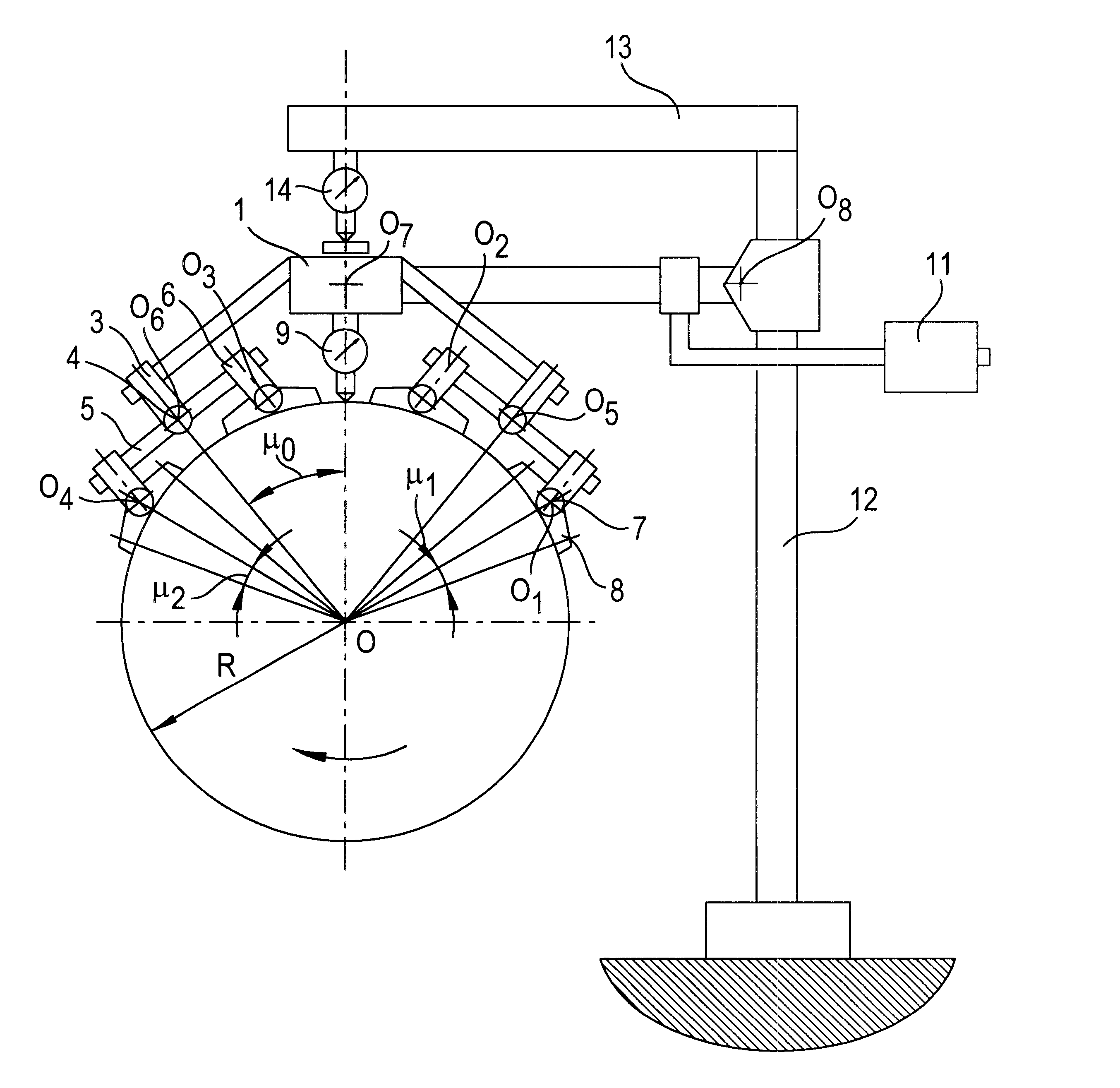

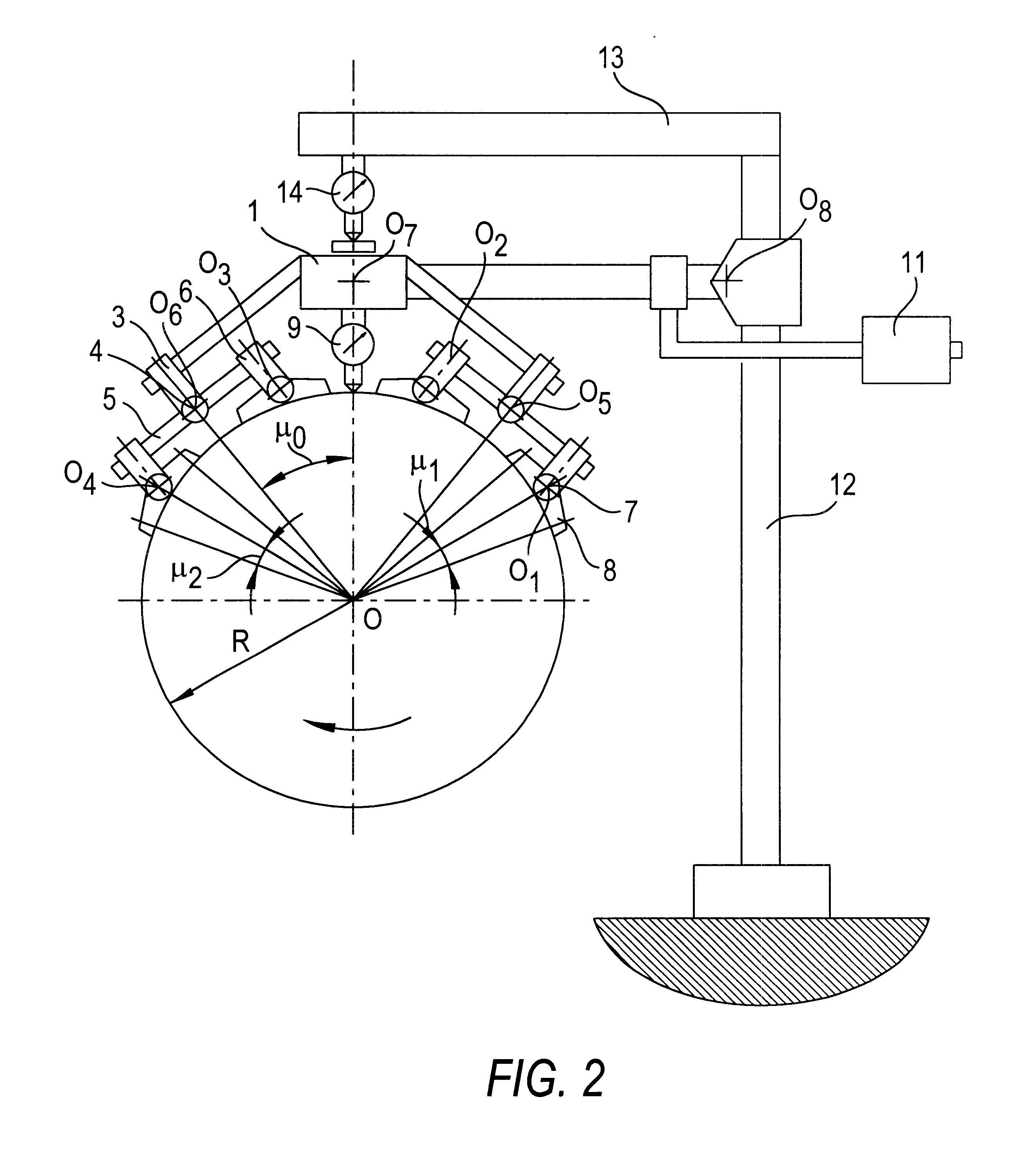

Device and method for measuring shape deviations of a cylindrical workpiece and correcting steadying element and correcting follower for use therewith

InactiveUS6568096B1Accurate measurementPrecise processingLathesAngles/taper measurementsShape deviationEngineering

A device and method for measuring deviations in shape of a generally cylindrical workpiece is disclosed. The device enables measurement of a number of shape-defining parameters while the workpiece is positioned in a machine tool, so that the workpiece does not have to be removed from the machine tool in order for the measurements to be taken. A steadying rest, for use on machine tools to hold a workpiece, especially one having a longitudinal central axis that is rotationally unsymmetrical or unstable with respect to the machining tool, in position to enable measurement of the shape defining parameters and shape deviations while the workpiece is mounted on the machine tool, is also disclosed.

Owner:OBSCHESTVO S OGRANICHENNOI OTVETABTVENNOSTIJU TEKHNOMASH

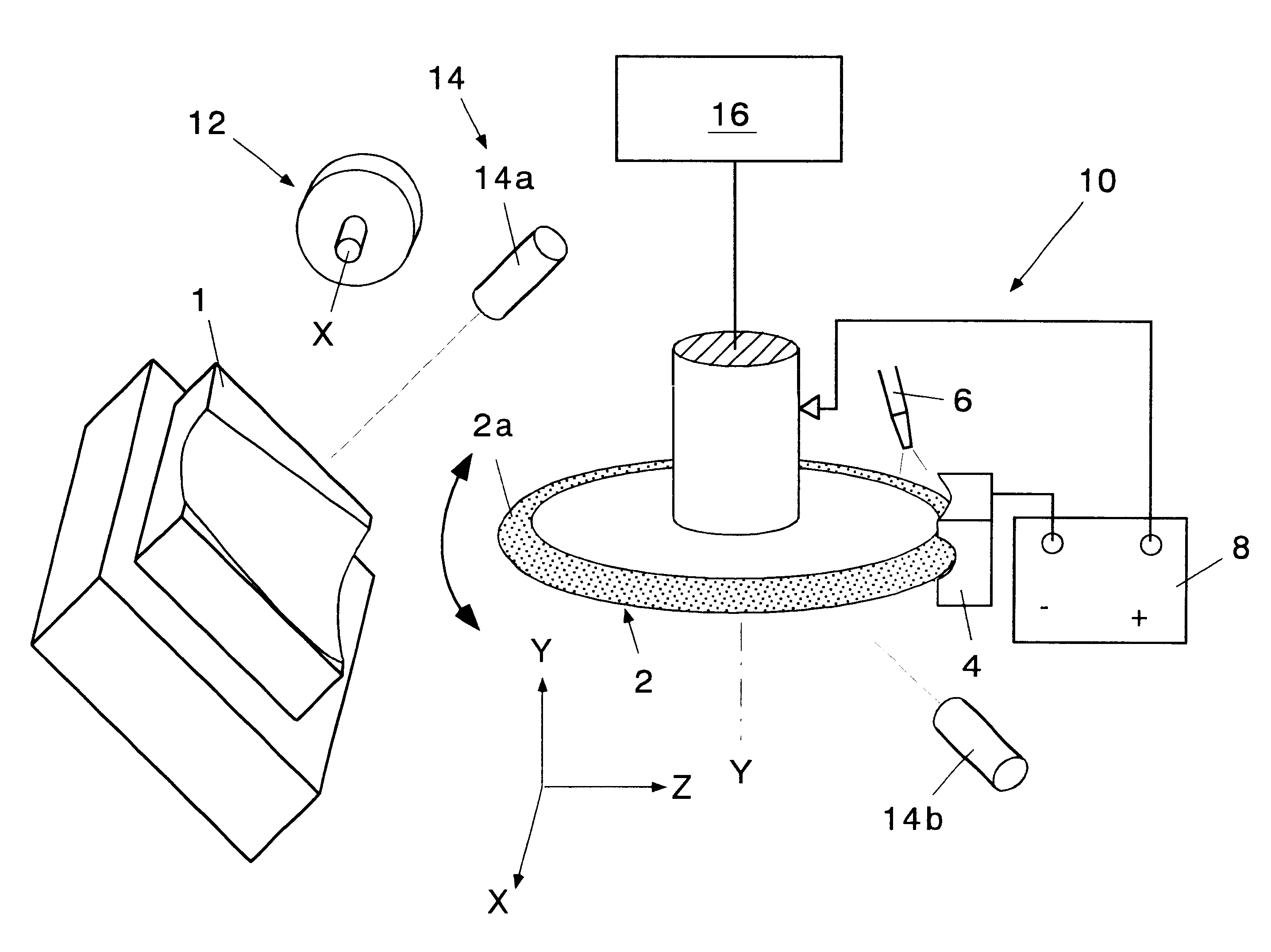

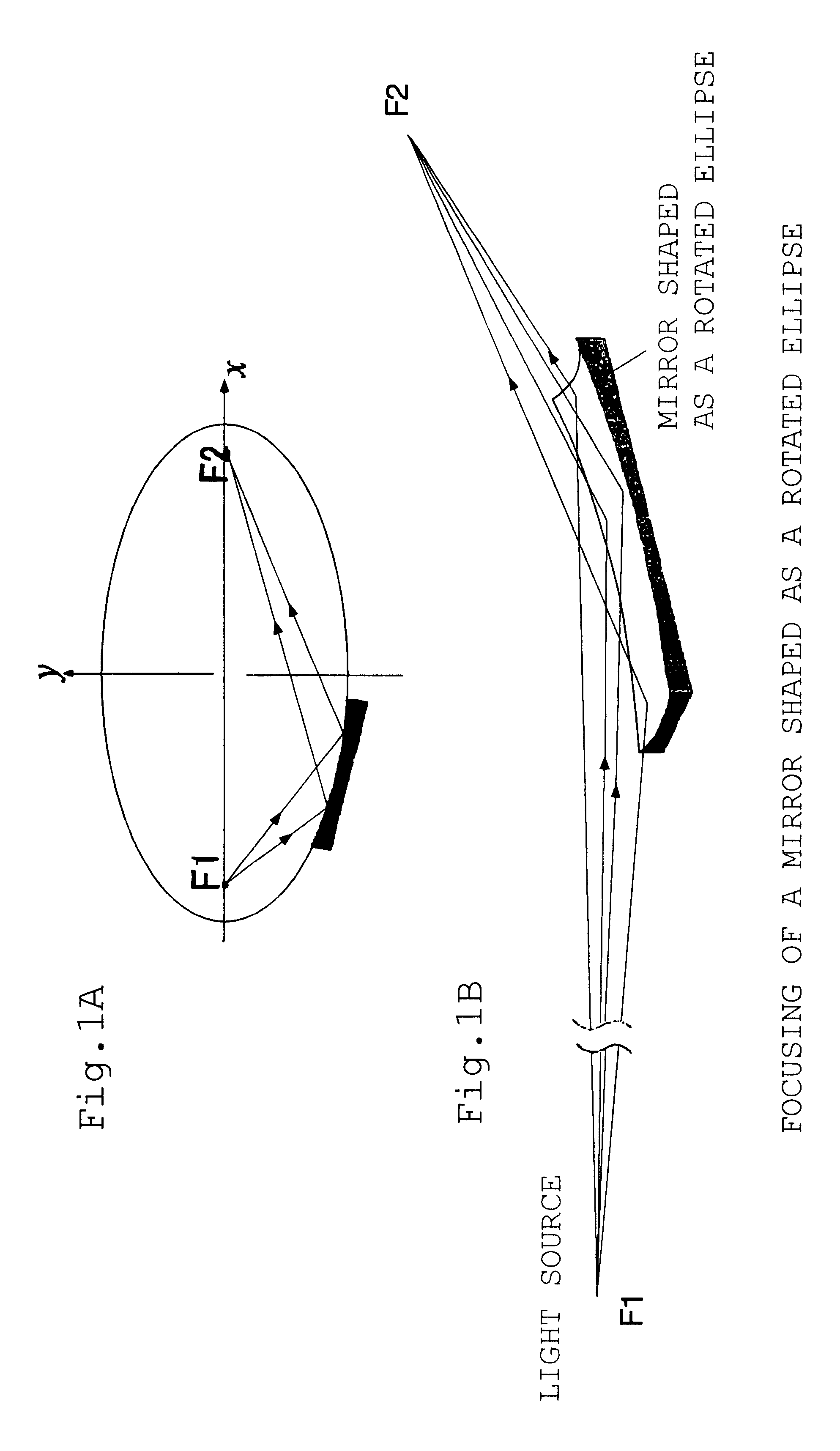

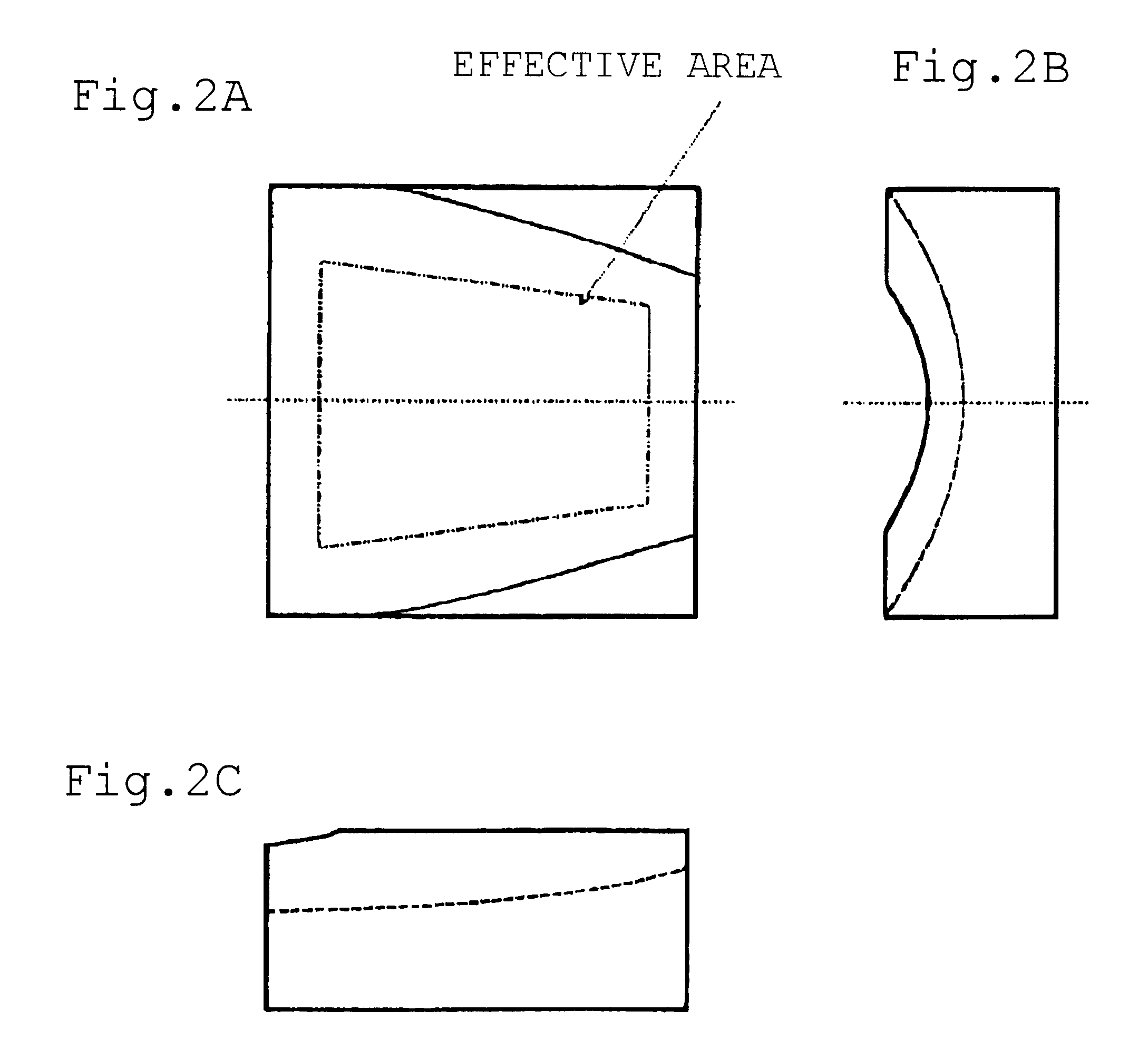

Method of grinding an axially asymmetric aspherical mirror

InactiveUS6537138B2Improve accuracyReliably madeEdge grinding machinesOptical surface grinding machinesNumerical controlSurface roughness

An electrolytic in-process dressing device 10 is provided with a disk-shaped metal-bonded grindstone 2 with a surface 2a with a circular arc shape with a radius R at its outer periphery and a numerical control device 16. The disk-shaped metal-bonded grindstone 2 rotates around an axis Y, and the grindstone is dressed electrolytically while the device 10 grinds the workpiece 1. The numerical control device 16 is provided with a rotary truing device 12 that rotates around the X axis that orthogonally crosses the axis of rotation Y and trues the circular arc surface 2a, a shape measuring device 14 for measuring the shape of the circular arc surface of the grindstone and the shape of the processed surface of workpiece 1 on the machine, and controls the grindstone numerically in the three directions along the axes X, Y and Z. The numerical control device 16 moves the grindstone in three axial directions and repeats the operations of truing, grinding and measurements on-line. Thus, an axially asymmetrical aspheric mirror with a highly accurate shape and extremely low surface roughness, that can precisely reflect or converge light can be manufactured within a short time with a high accuracy.

Owner:RIKEN +1

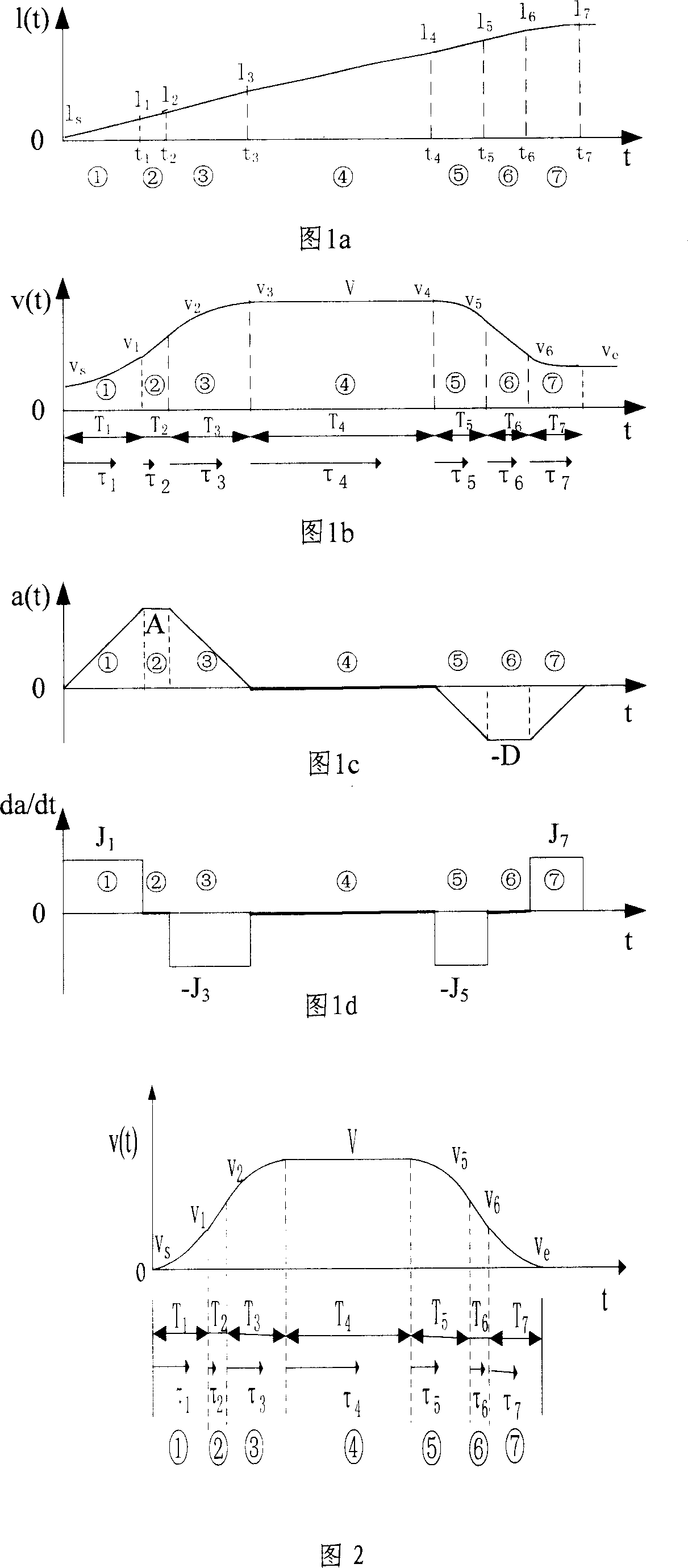

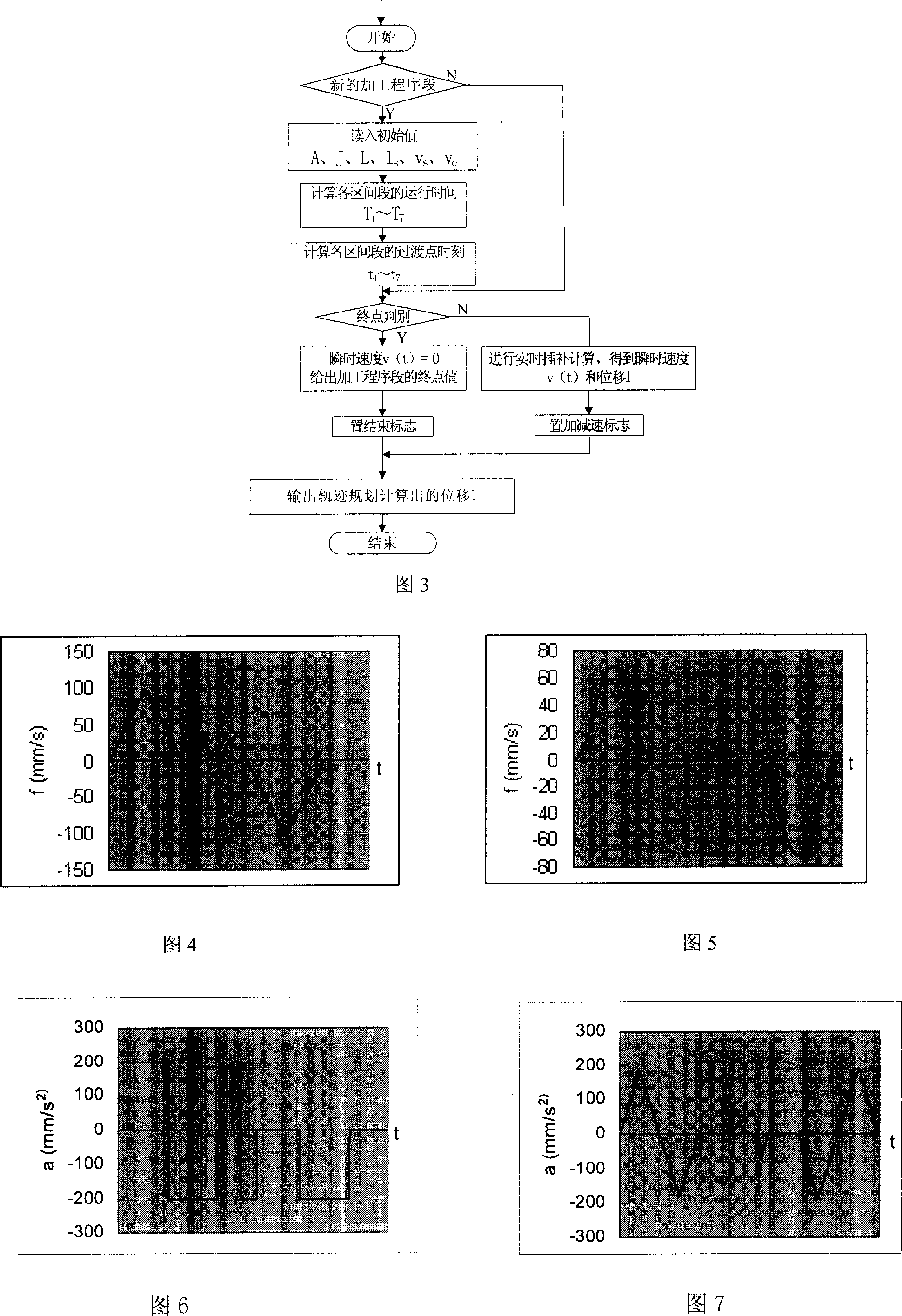

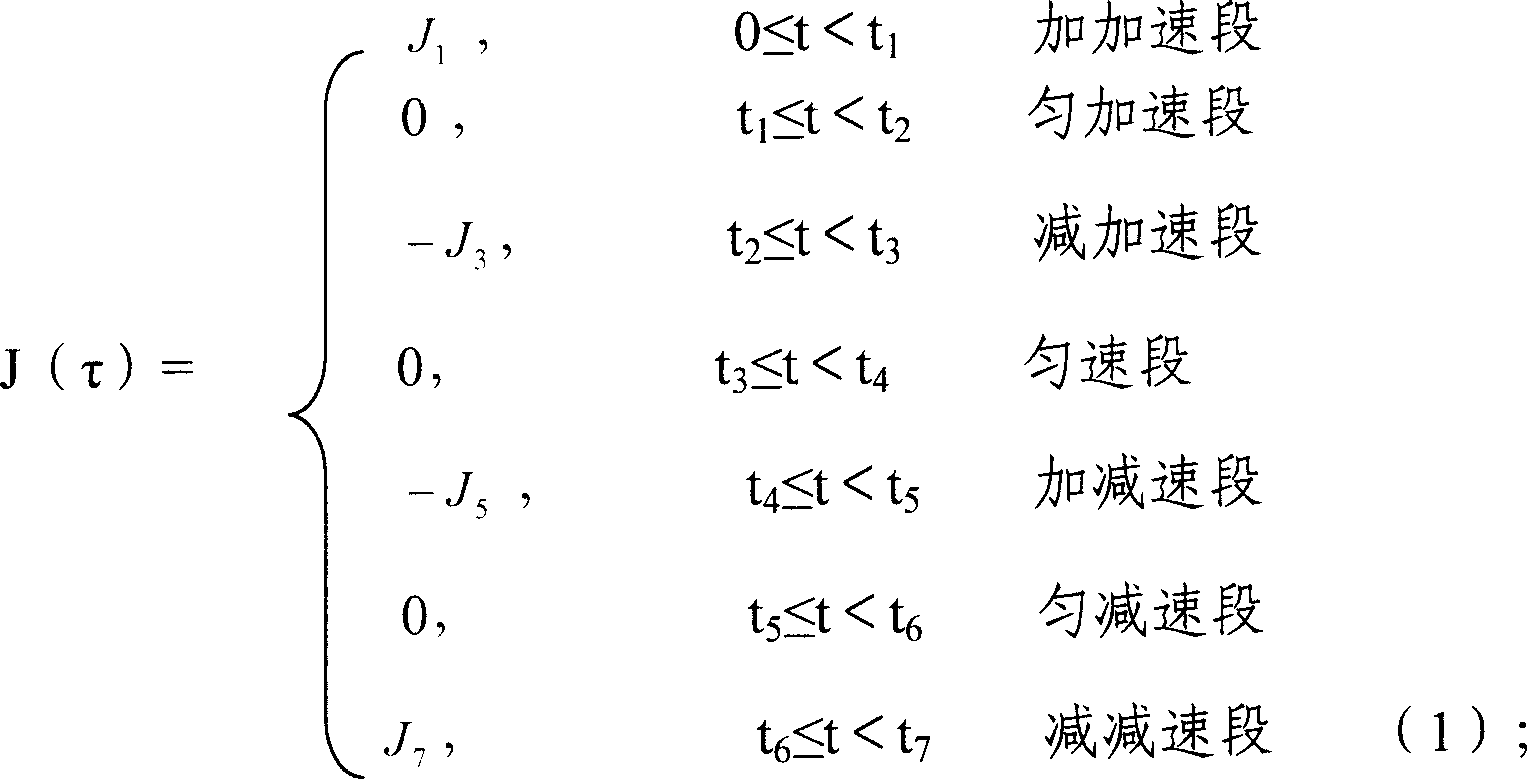

Speed control method used for numerical control machine

InactiveCN1971457AReduce shockImprove smoothnessComputer controlSimulator controlNumerical controlControl theory

The invention discloses acceleration and deceleration controlling means used in numerical control machine, the concept of 'add-acceleration' is introduced against the dynamic property of the controlled member, the add-acceleration is constant in stage of acceleration and deceleration, the two physical quantities of acceleration and add-acceleration are setting; the segmented handling method of add-accelerating sections, uniform accelerating sections, decelerated accelerating sections, uniform speed sections, add-decelerating sections, uniformly-retarded sections and decelerated deceleration sections is adopted, after the interval discrimination, the real-time interpolating calculation in every interval is exceeded based on the integral relation between the add-acceleration, acceleration, speed and displacement, the S type velocity curve is formed to realize the flexible acceleration and deceleration control; the destination discrimination process is proceeded before the interpolating calculation can increase the machining precision of the acceleration and deceleration control. The method is simple, the impact is small, the speed is smooth, the machining precision is high and the flexible control can be realized.

Owner:中国科学院沈阳计算技术研究所有限公司 +1

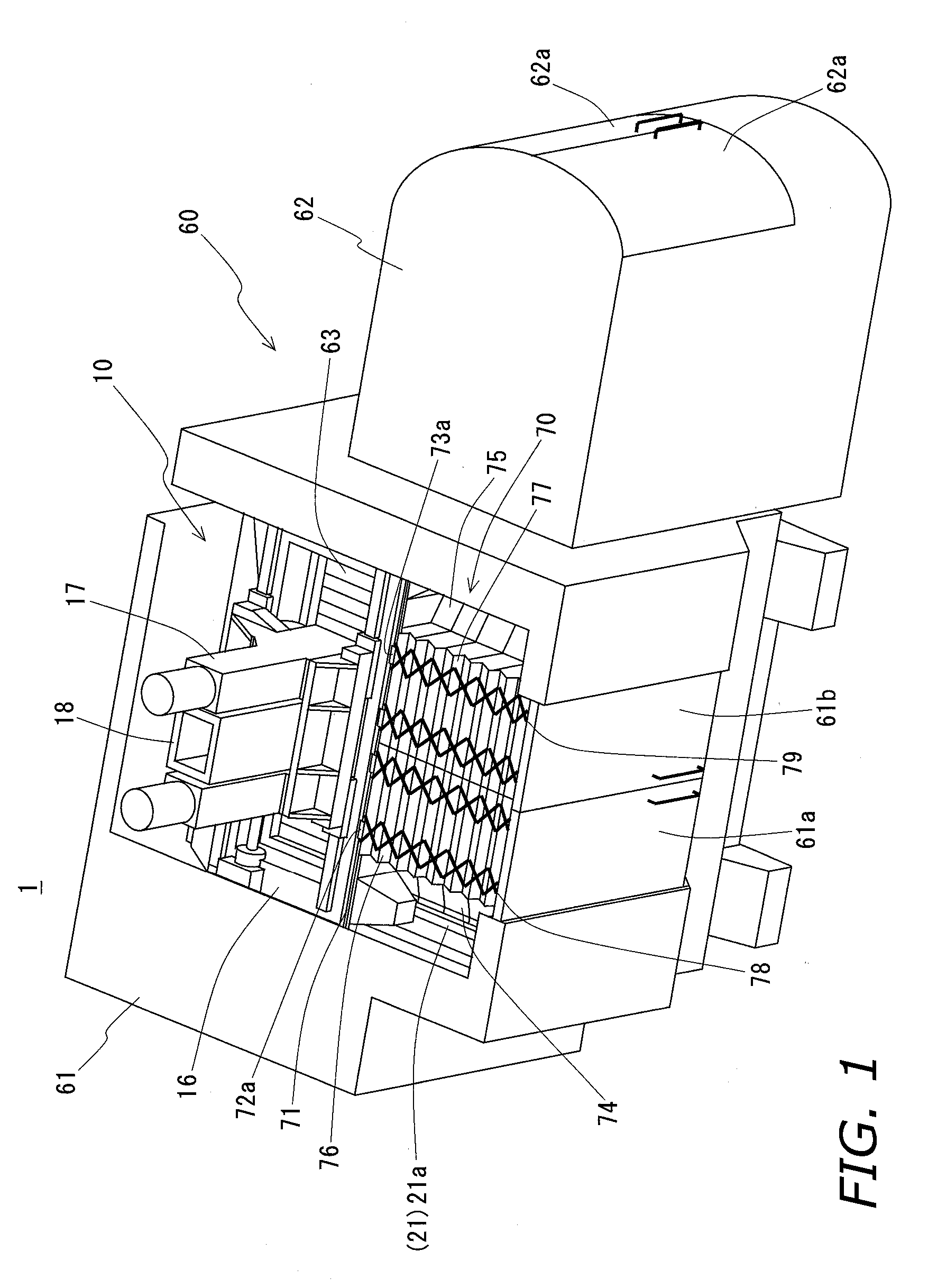

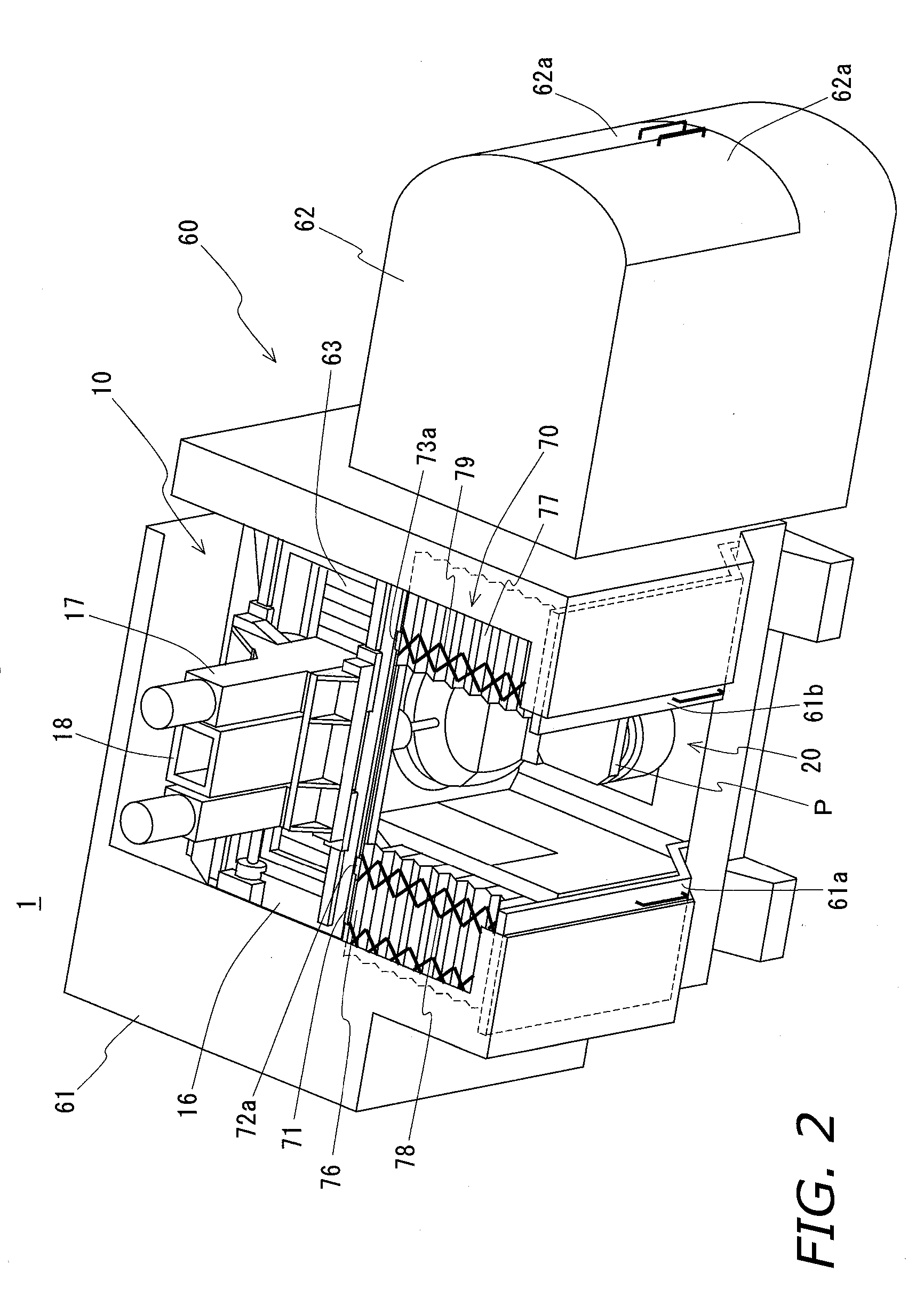

Machine Tool

ActiveUS20060270540A1Easy maintenanceReduce manufacturing costPlaning/slotting machinesMilling machinesFree rotationSaddle shape

Machine tool simplifying maintenance, reducing manufacturing costs, and enabling high precision machining. The machine tool is equipped with: a bed furnished with a rectangular base, right and left sidewalls provided standing either side of the base, and a rear sidewall provided standing along the back of the base; a table disposed in the space surrounded by the three sidewalls; a first saddle shaped in the form of a rectangular frame shape, provided free to shift back and forth supported on the tops of the left and right sidewalls; a second saddle penetrated by a perpendicular through-hole and arranged free to shift sideways inside the first saddle frame; and a spindle head arranged free to shift perpendicularly inside the through-hole in the second saddle; and a main spindle arranged over the table and supported by the spindle head free to rotate centered on its axis.

Owner:DMG MORI SEIKI CO LTD

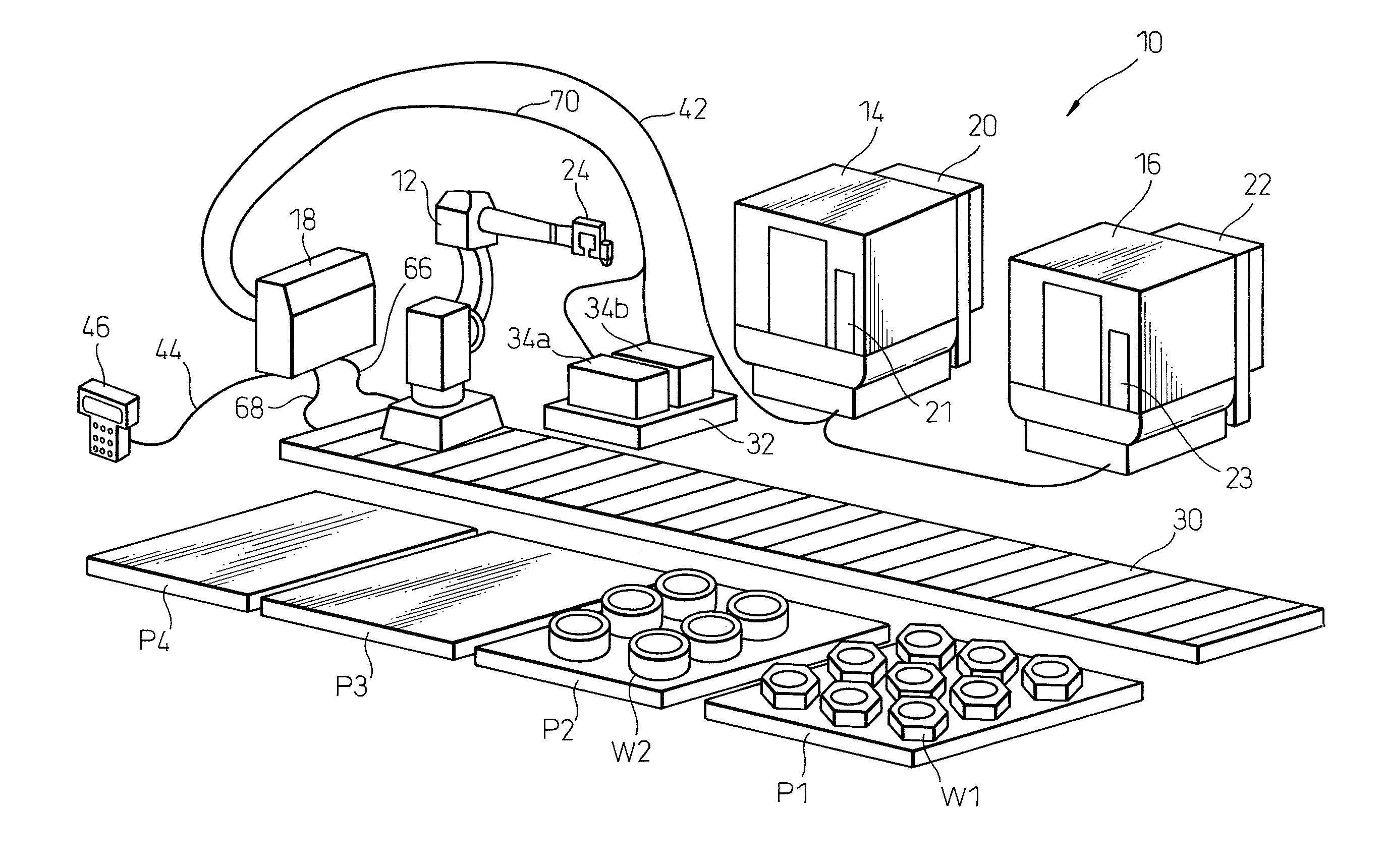

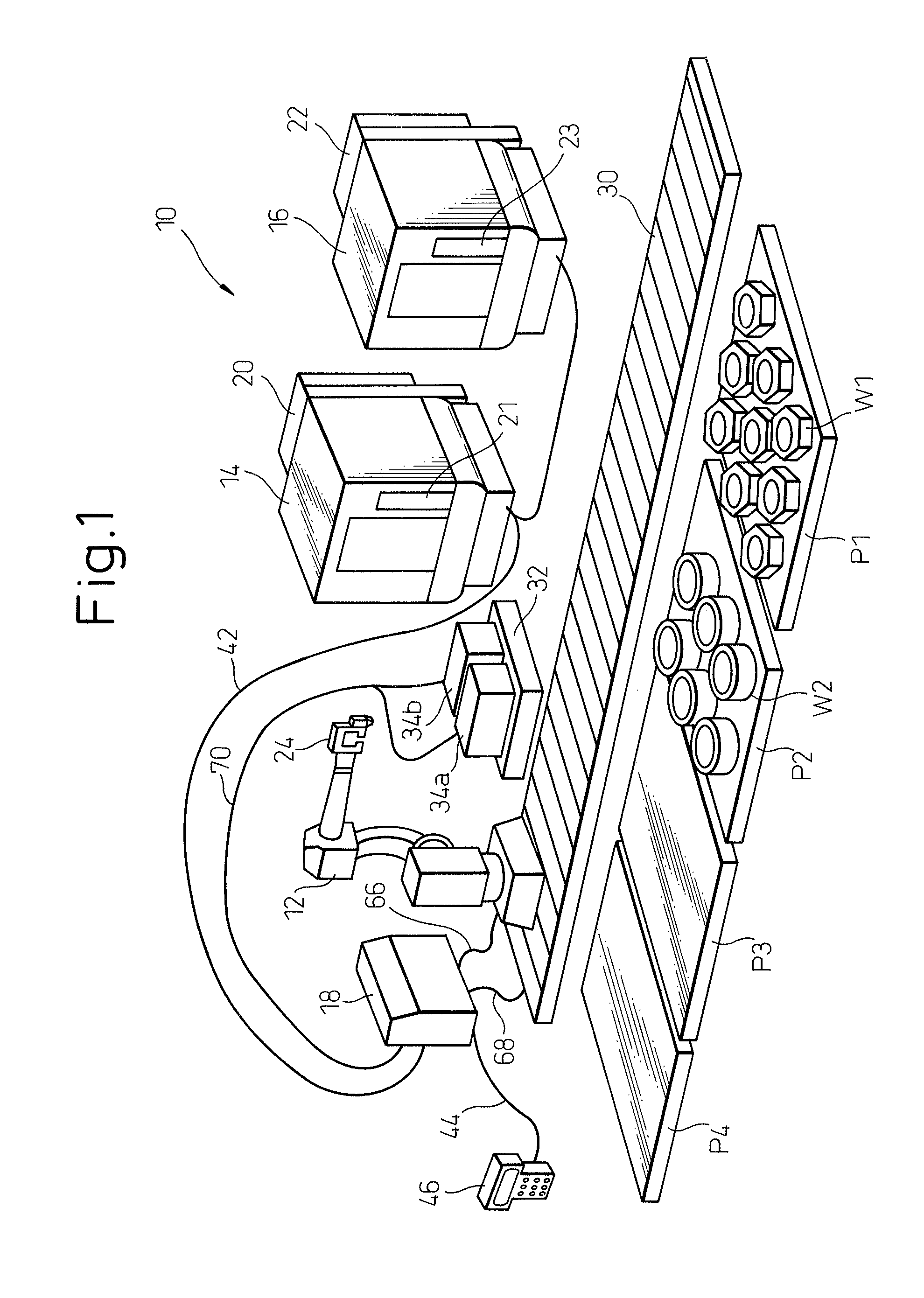

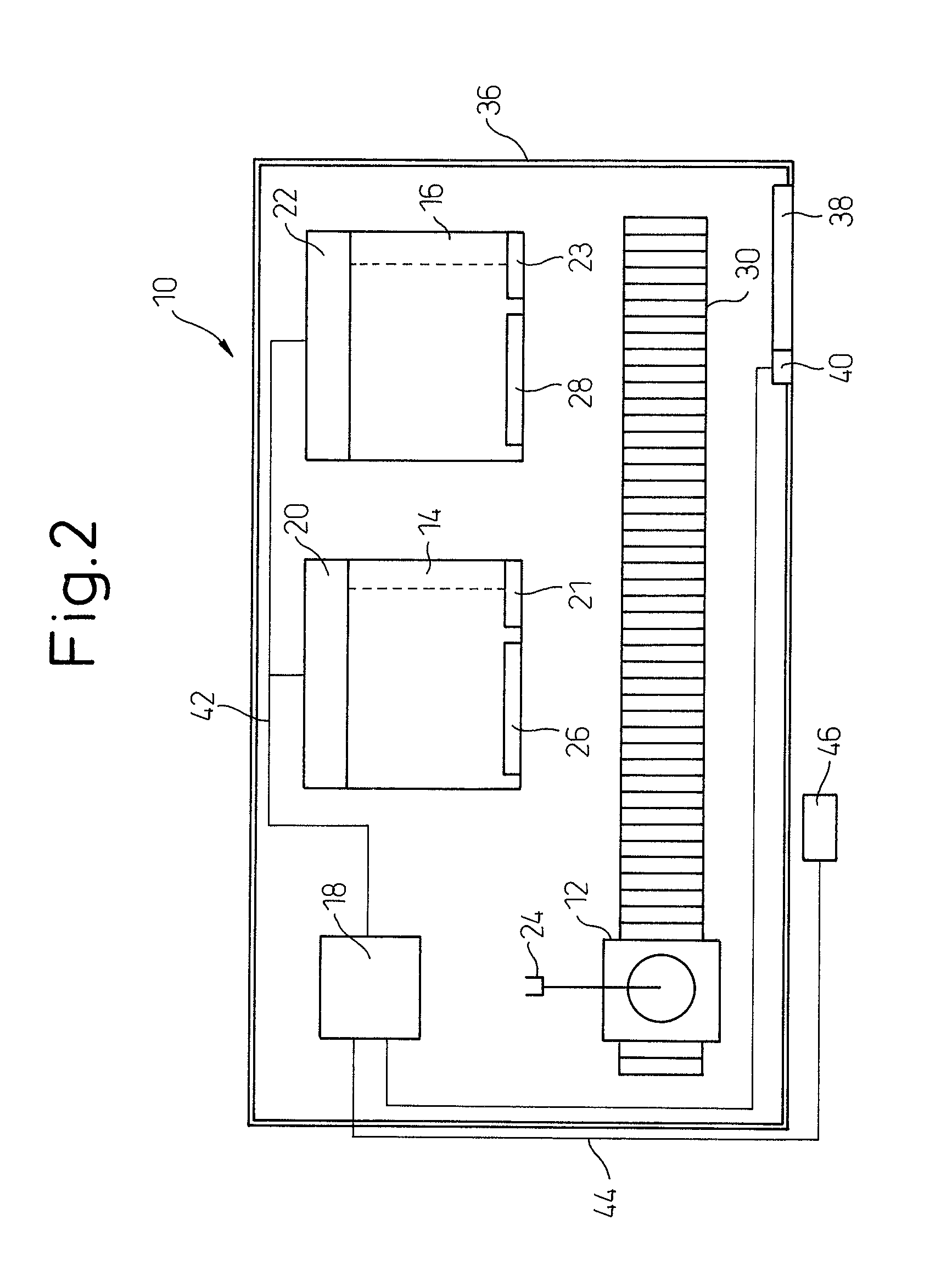

Robot control system provided in machining system including robot and machine tool

ActiveUS20100305758A1Stoppage of operation can be reducedReduce needProgramme-controlled manipulatorComputer controlControl systemMachining system

A robot control system provided in a machining system including a robot and a machine tool. The robot control system includes a robot controller controlling the robot, a portable teach pendant connected to the robot controller, and a communication network adapted to connect the robot controller to a machine tool controller controlling the machine tool. The teach pendant includes a display section configured to display information relating to the robot and the machine tool. The robot controller includes a processing section configured to obtain information relating to the machine tool from the machine tool controller through the communication network, make the display section of the teach pendant display a machine tool-related screen in accordance with a given screen program, and make the machine tool-related screen of the display section of the teach pendant display the information, as obtained, relating to the machine tool.

Owner:FANUC LTD

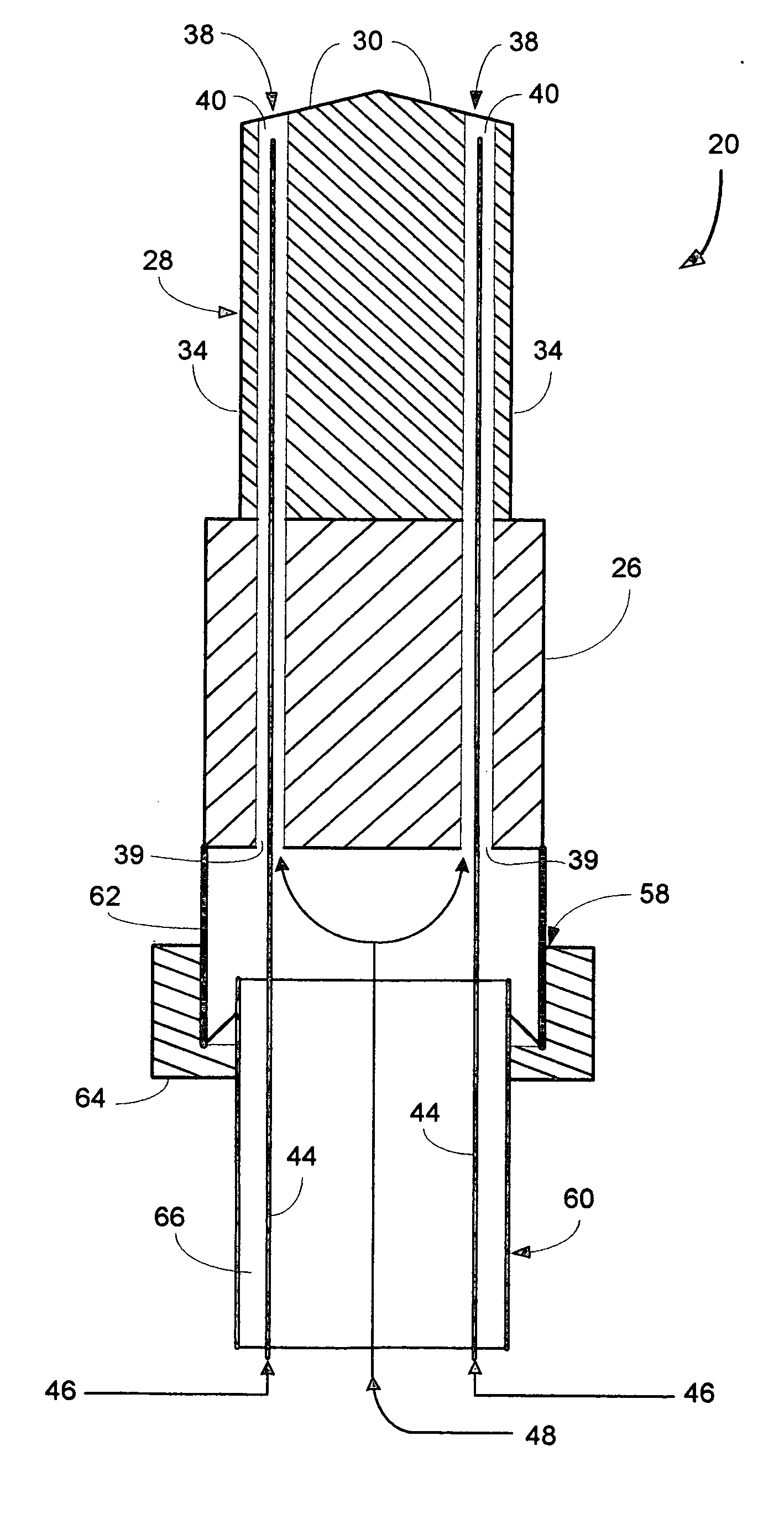

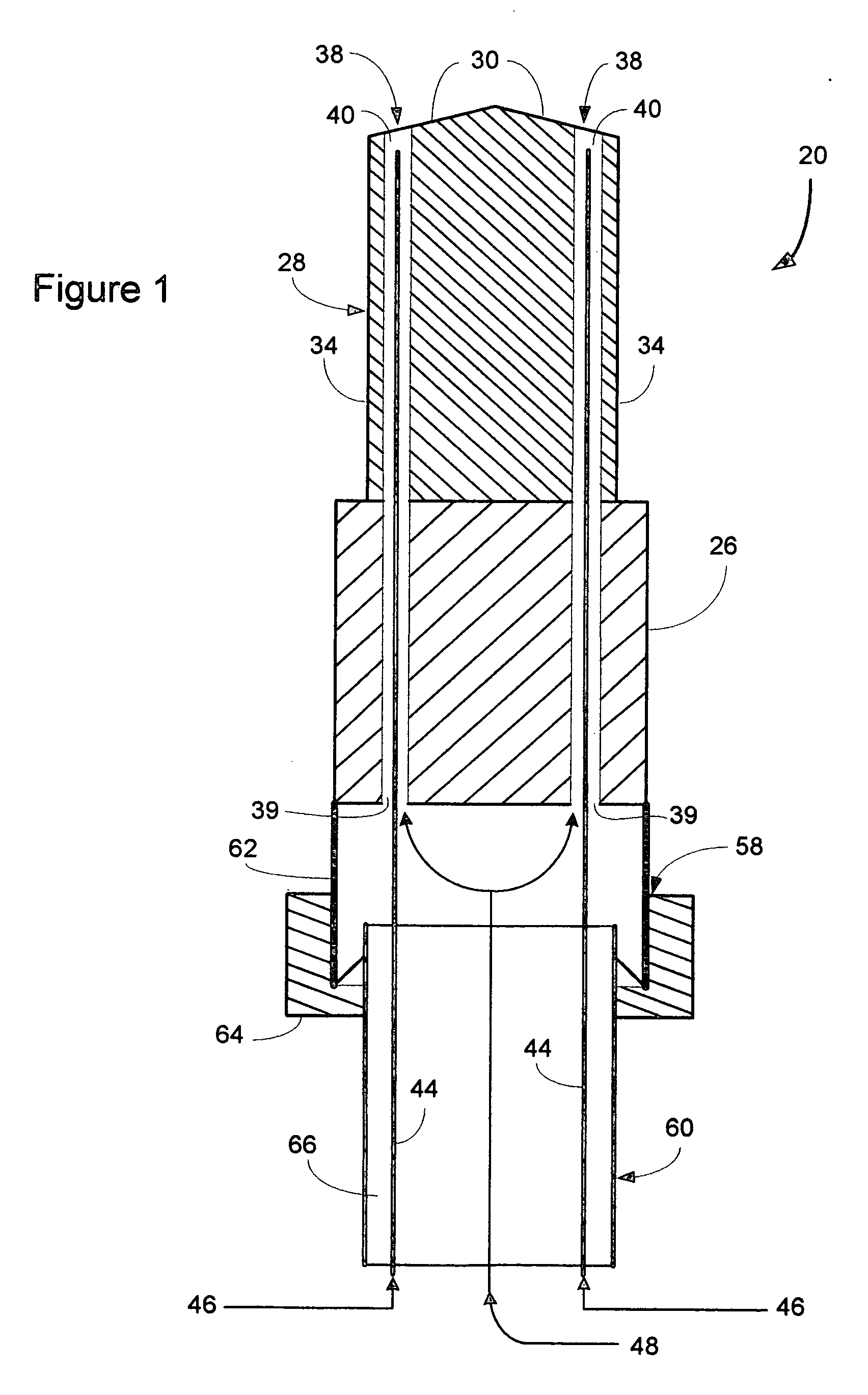

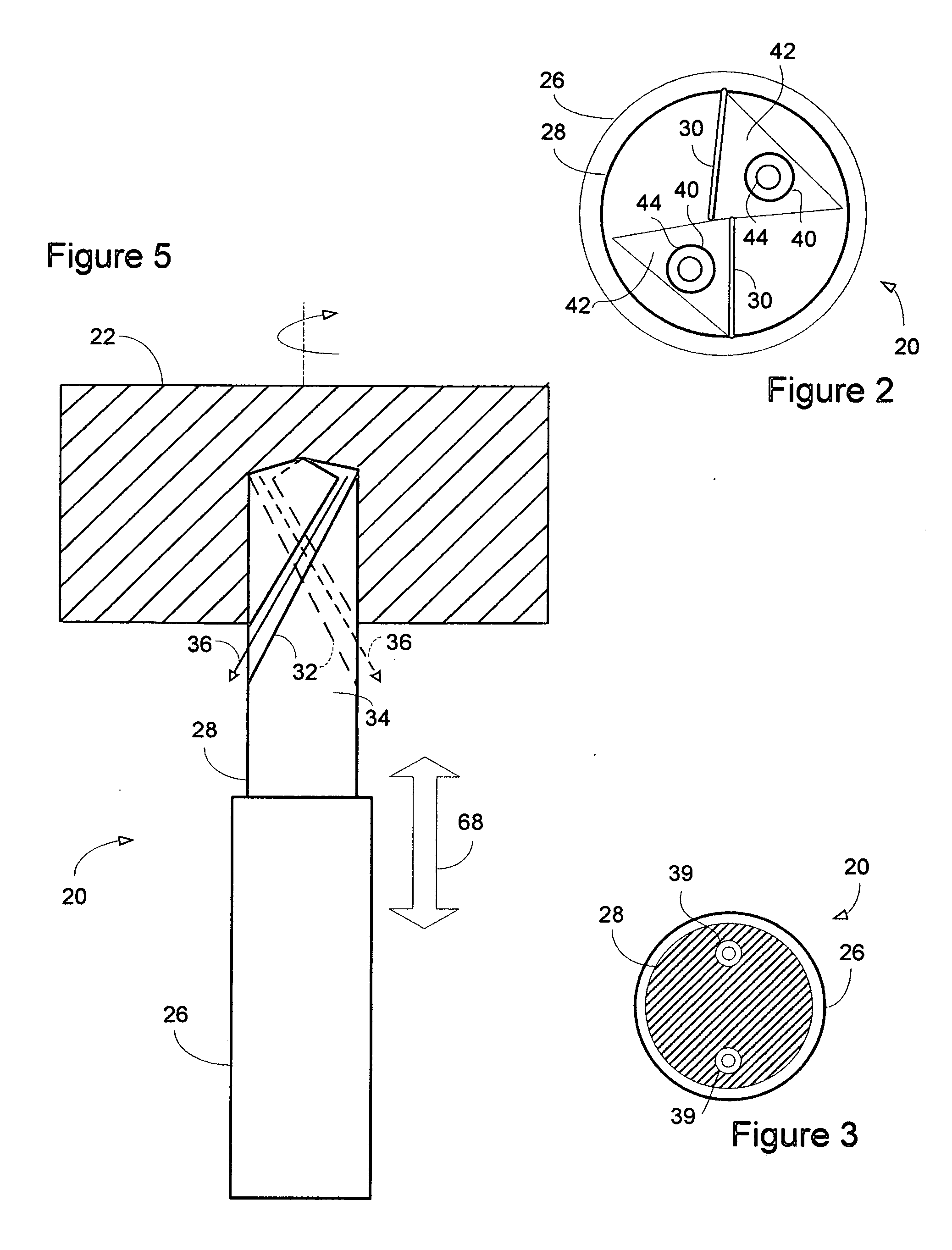

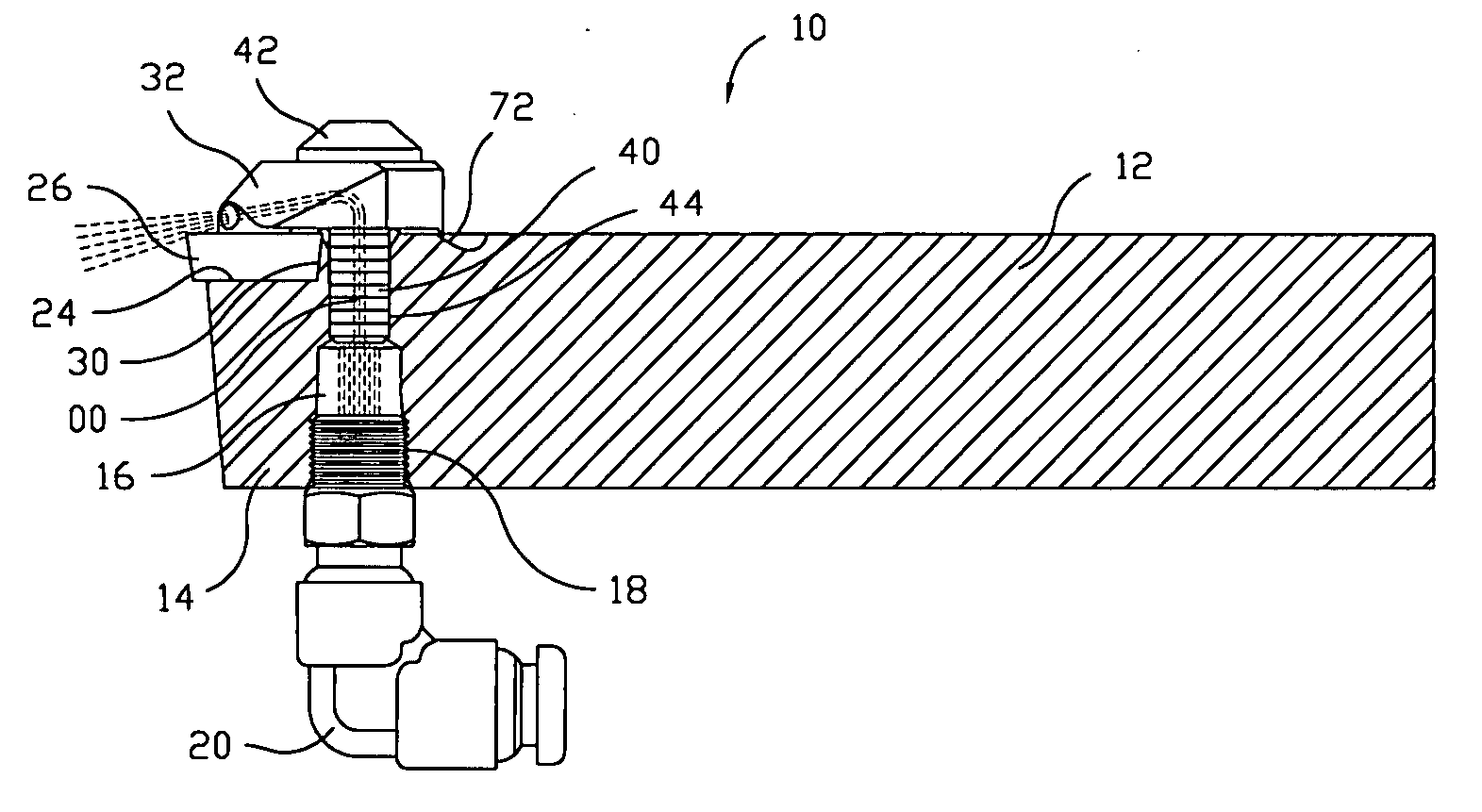

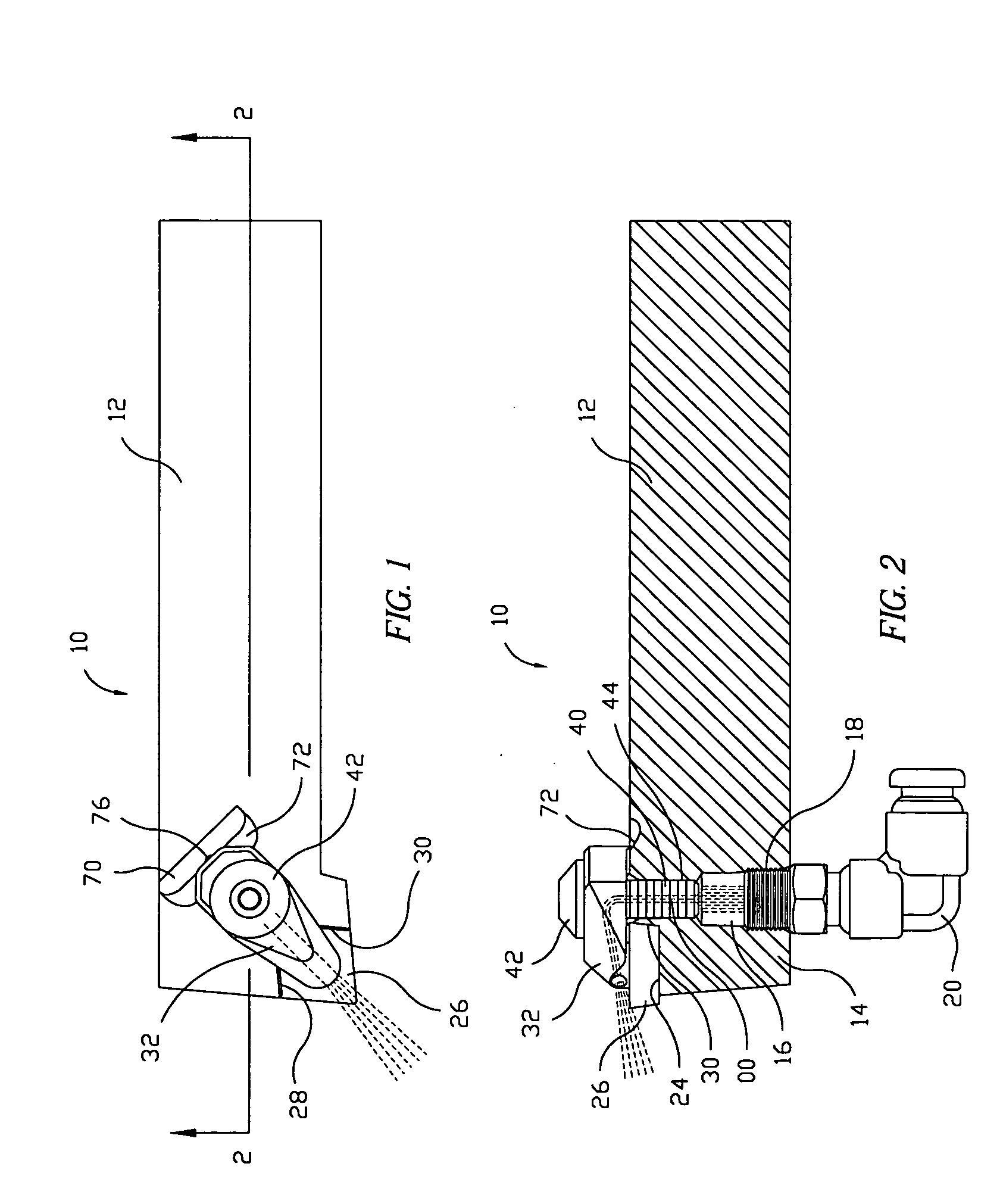

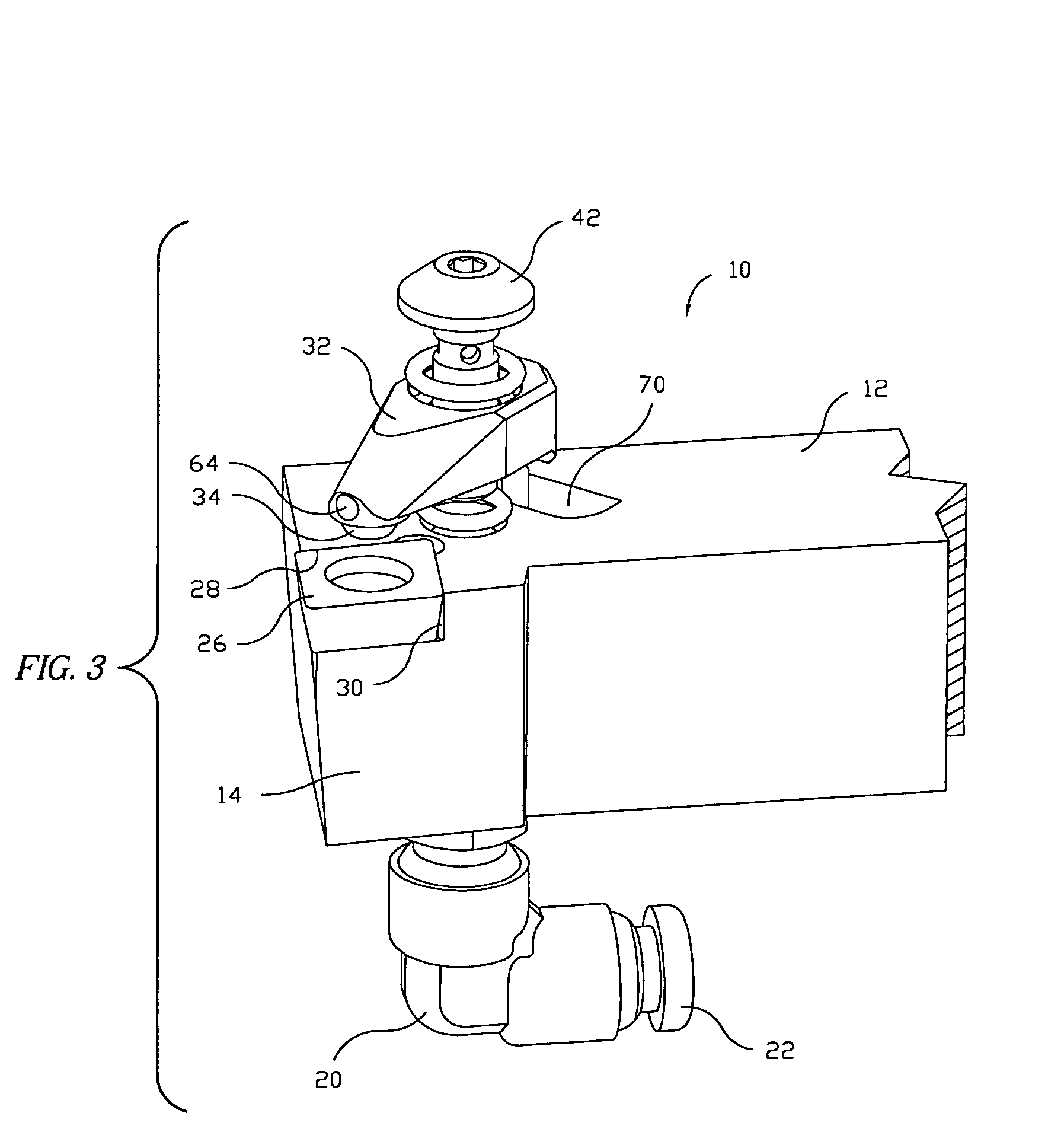

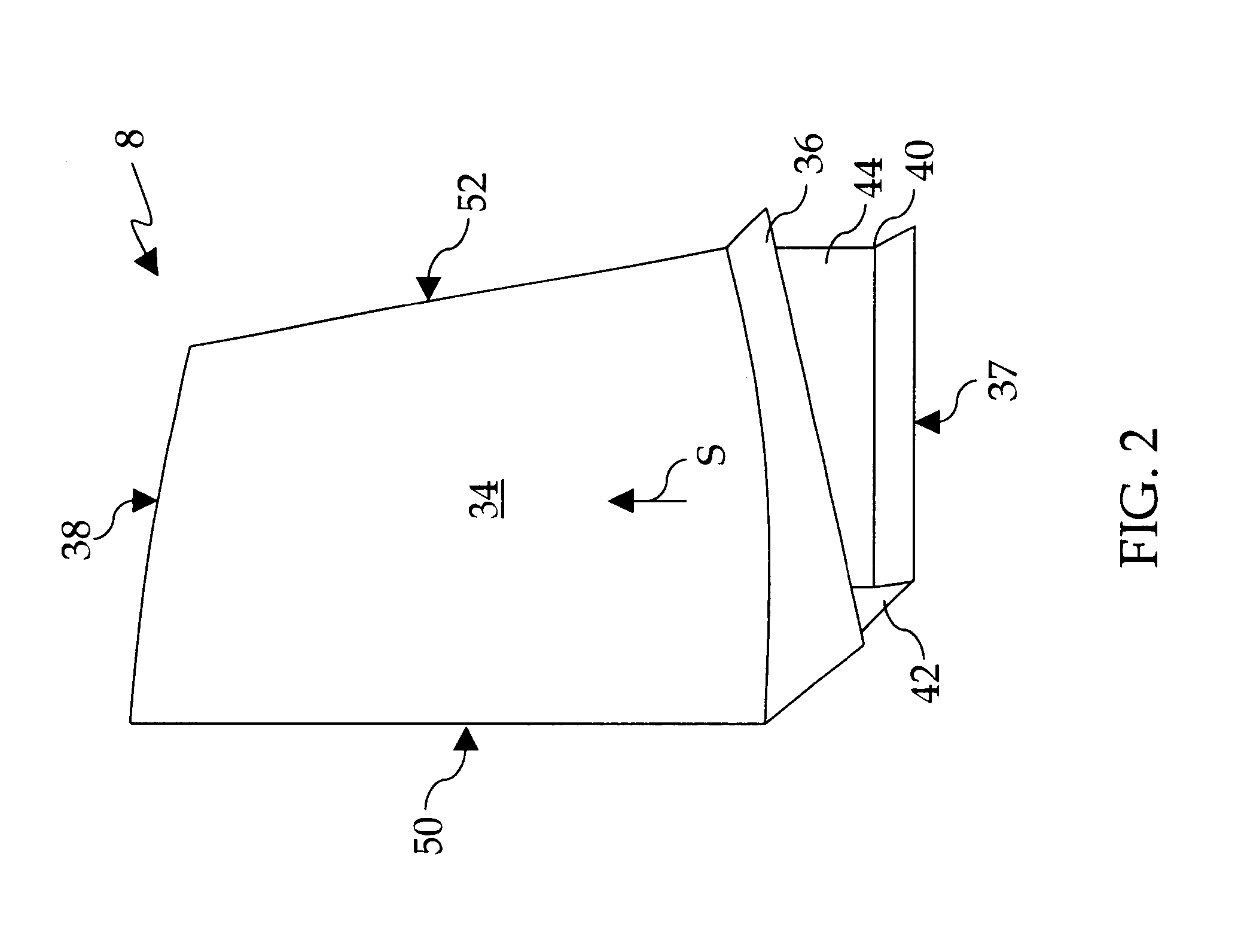

Device for applying cryogenic composition and method of using same

A device of the present invention for applying a cryogenic composition includes a machining tool or tool holder having a channel positioned therethrough and a capillary tube positioned within the channel. A dense cryogenic fluid is passed through the capillary tube while a diluent or propellant fluid is passed through the channel. The diluent or propellant fluid flows within the channel and about the capillary tube. Upon exiting the capillary tube, the dense fluid admixes with the diluent or propellant fluid to form a cryogenic composite fluid or spray. The cryogenic composite fluid or spray is selectively directed onto a substrate for cooling or lubrication purposes, or onto the machining tool for cooling purposes.

Owner:COOL CLEAN TECH

Data capture for electronically delivered automation services

InactiveUS7395122B2Improve data securityImprove securityProgramme controlComputer controlReal-time dataControl system

Content is generated on a host system based on real-time data from a controlled process collected over an internet from a customer's client machine tool control system. The real-time data is captured from the client machine tool by downloading software that manipulates controller functionality to perform a data capture trace predefined events and triggers. The captured data is retrieved by the host, which may generate content based on the data, or provide selective, authorized access to the data by others.

Owner:SIEMENS AG

Machine tool holder having internal coolant supply and cutter retaining and coolant distribution cutter insert retaining clamp assembly

InactiveUS20070283794A1Minimizes heat induced wear and deteriorationExtended service lifeLathesCutting insertsCooling fluidMachine tool

A boring bar has a shank having a cutter support head at one end. A flow passage extends to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp screw defines an internal or external passage that communicates with the internal coolant fluid passage and completes a coolant distribution circuit. The clamp defines an internal coolant fluid passage having a discharge opening located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The cutter support head also has a passage and chip removal jet nozzle that orients a jet of coolant fluid adjacent the cutter insert for remove metal chips during machining.

Owner:GIANNETTI ENRICO R

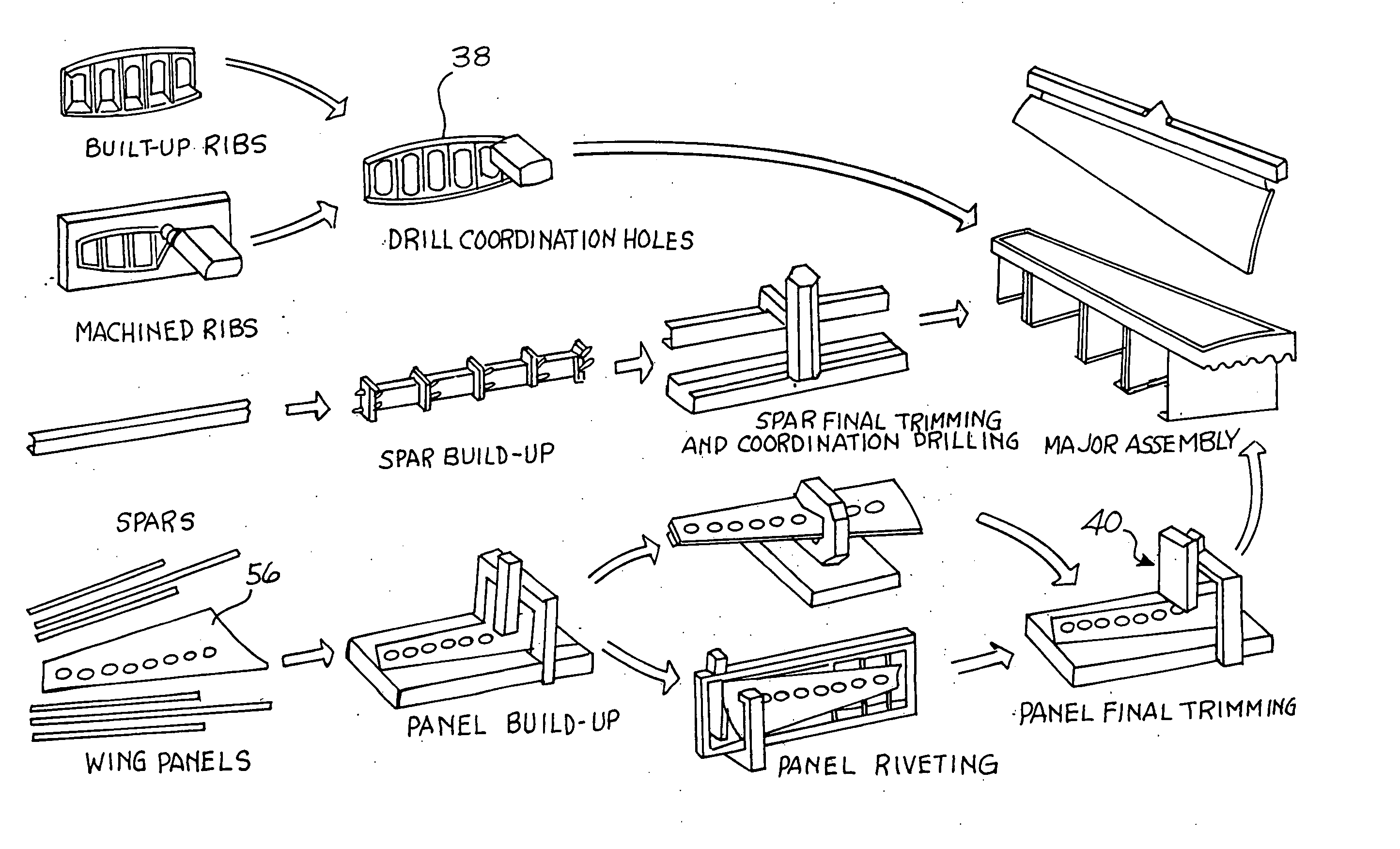

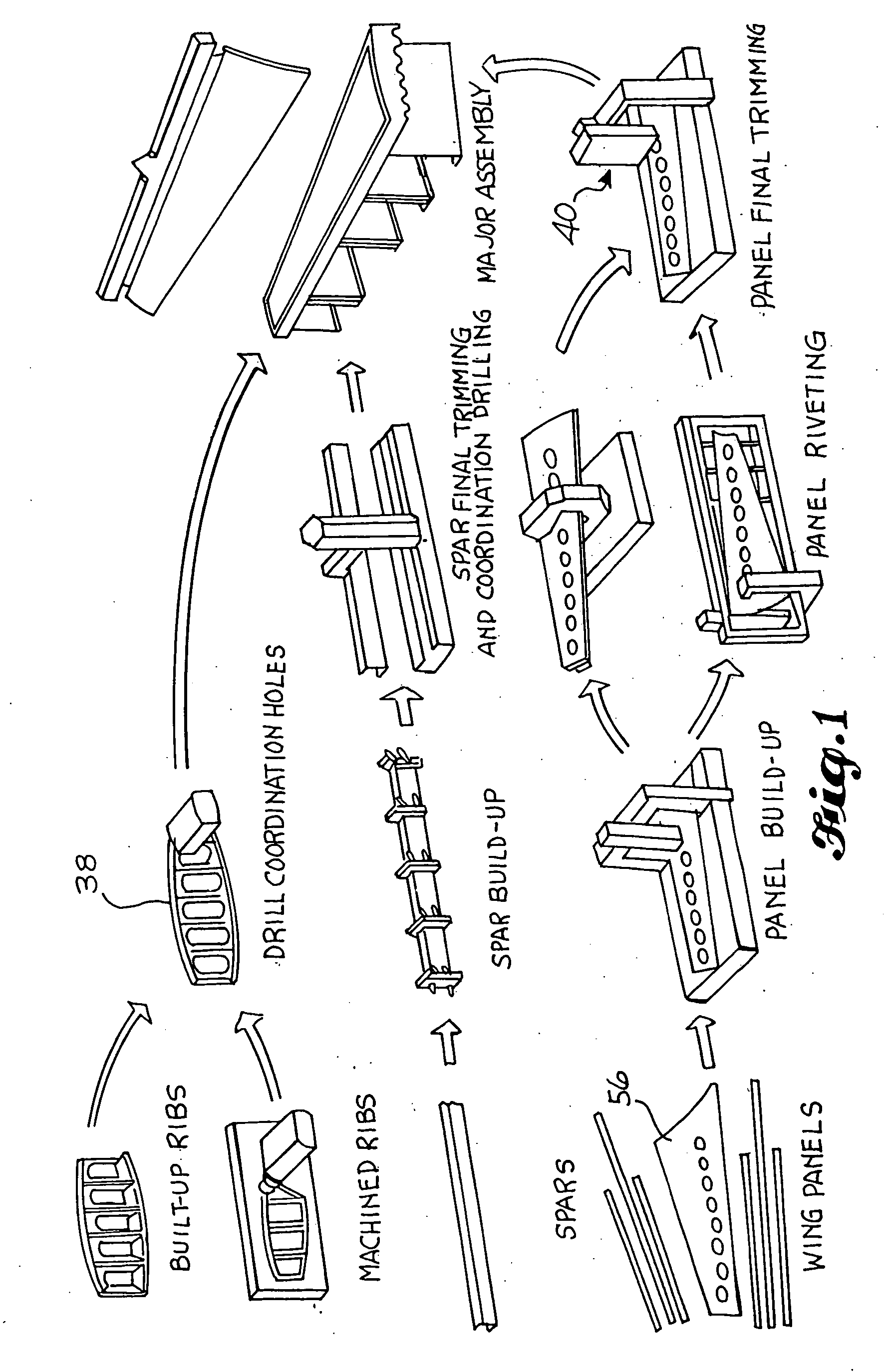

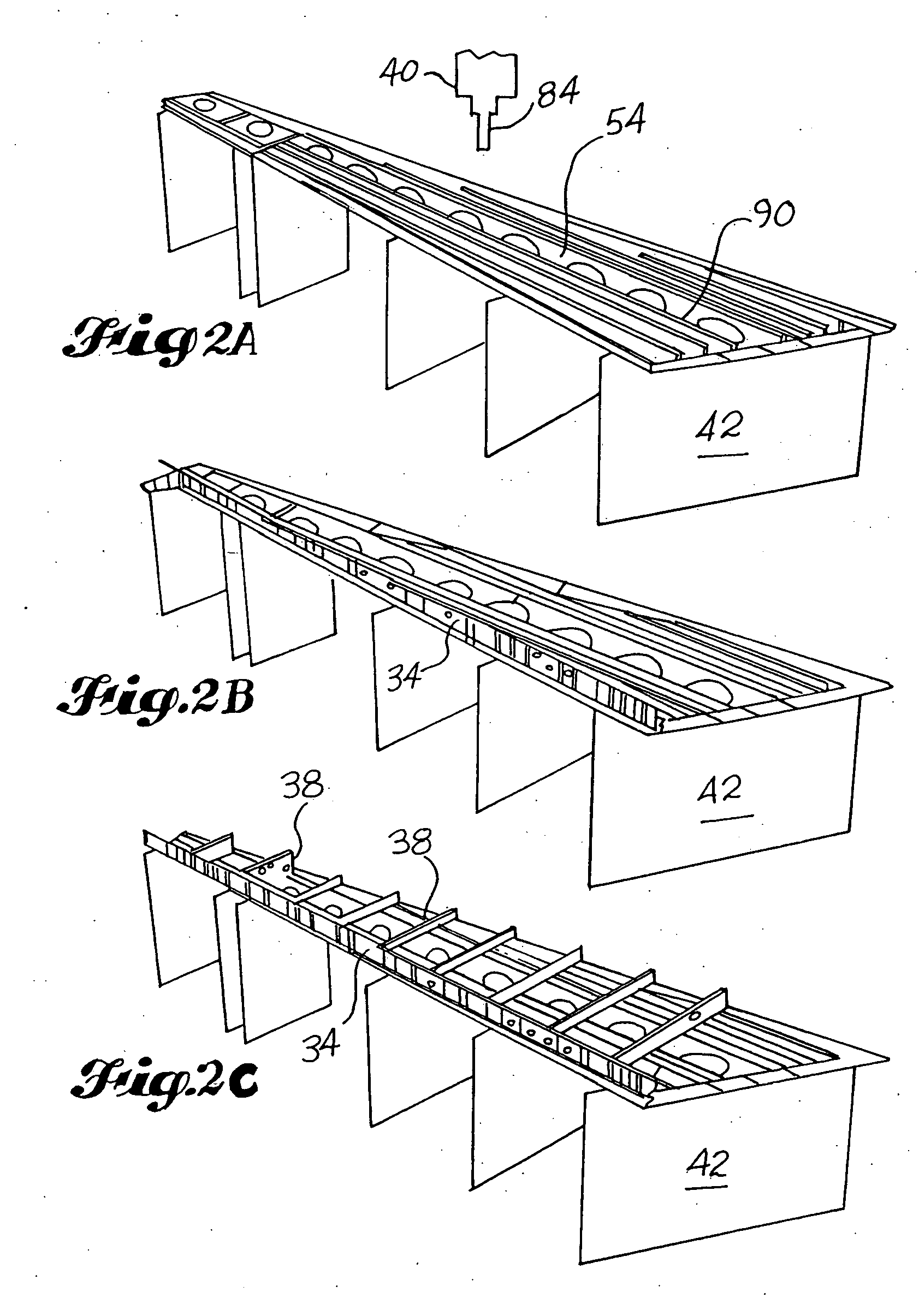

Determinant wing assembly

InactiveUS20050116105A1Accurate locationEasy to manufactureAircraft stabilisationWingsNumerical controlMachine tool

A method and apparatus for manufacturing wings includes a fixture that holds wing panels for drilling and edge trimming by accurate numerically controlled machine tools using original numerical part definition records, utilizing spatial relationships between key features of detail parts or subassemblies as represented by coordination features machined into the parts and subassemblies, thereby making the parts and subassemblies intrinsically determinant of the dimensions and contour of the wing. Spars are attached to the wing panel using the coordination holes to locate the spars accurately on the panel in accordance with the original engineering design, and in-spar ribs are attached to rib posts on the spar using accurately drilled coordination holes in the ends of the rib and in the rib post. The wing contour is determined by the configuration of the spars and ribs rather than by any conventional hard tooling which determines the wing contour in conventional processes.

Owner:THE BOEING CO

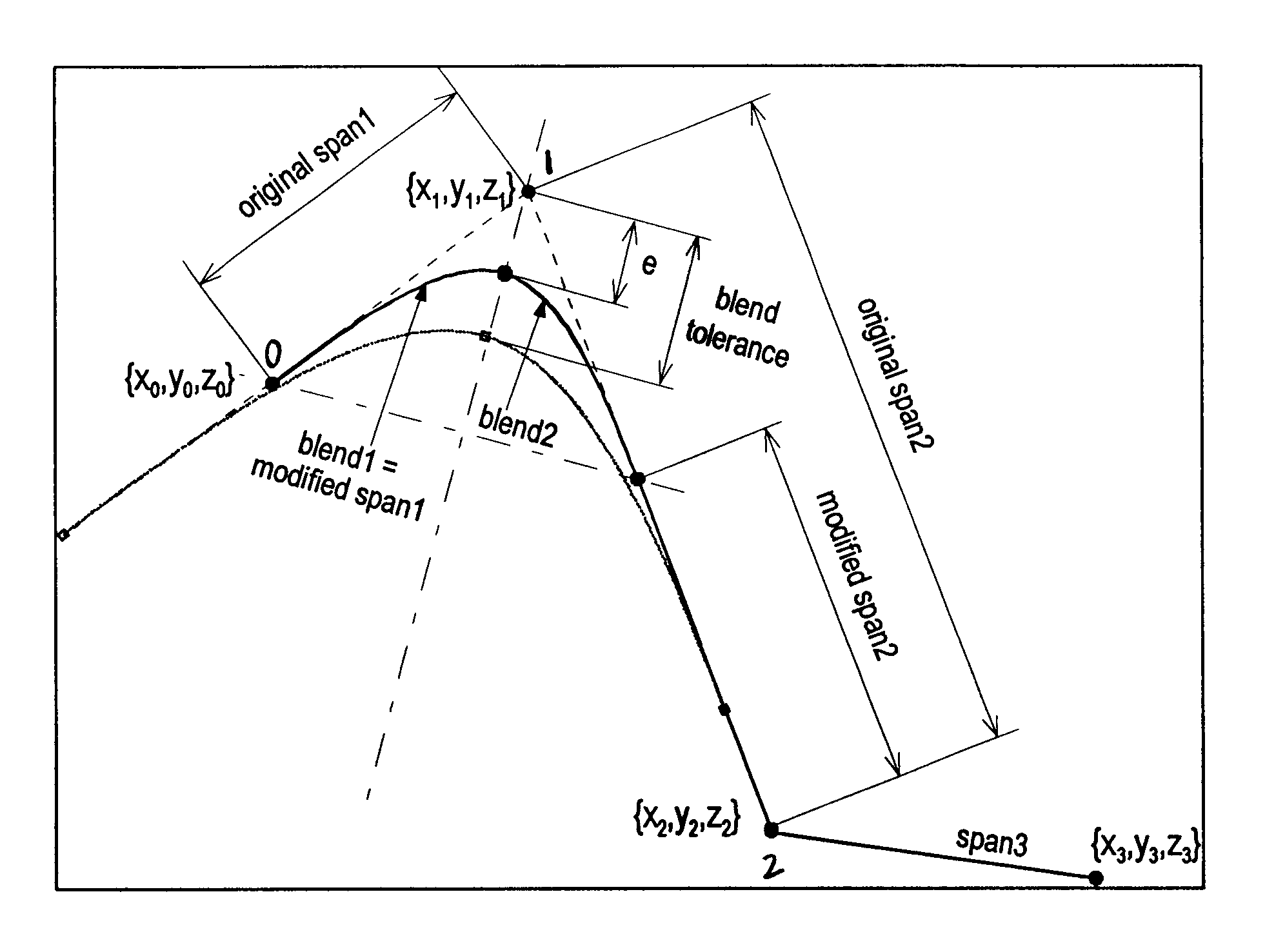

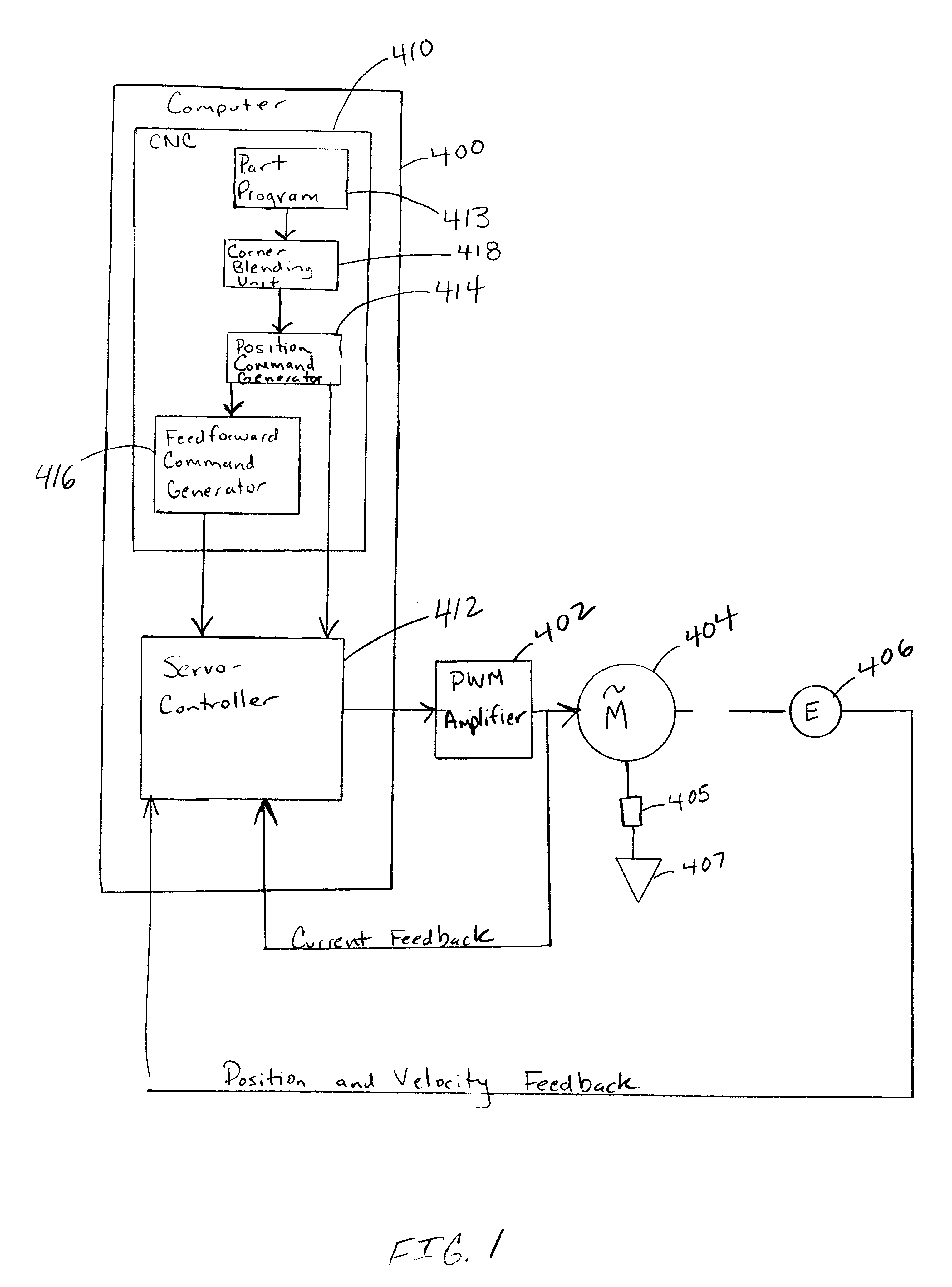

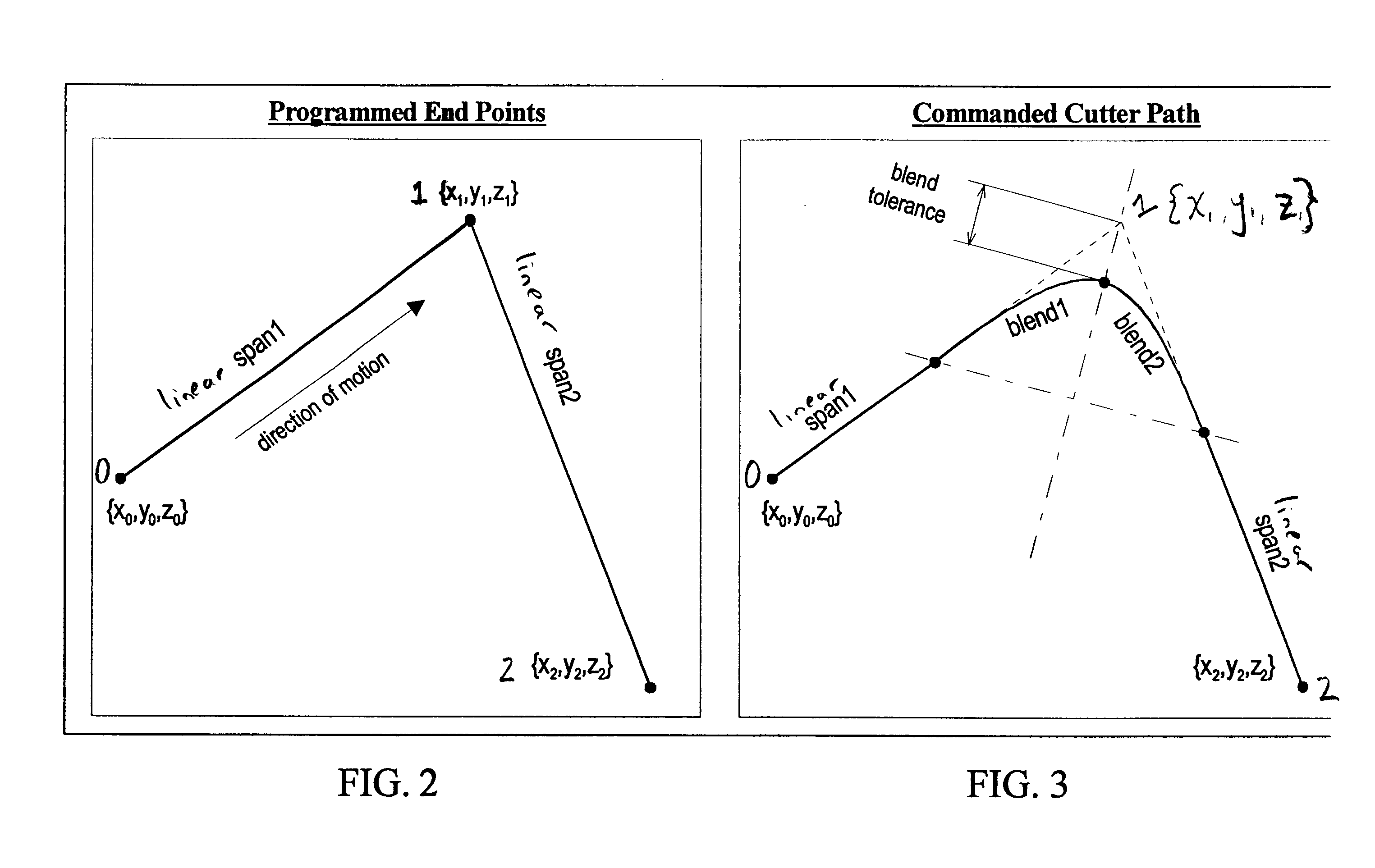

Apparatus and method for smooth cornering in a motion control system

InactiveUS6922606B1Effective controlReducing eliminating step discontinuityComputer controlSimulator controlControl systemMovement control

A method and apparatus for controlling motion through consecutive linear spans that define a corner in a desired motion path, such as a motion path in a machine tool system for example, is disclosed. In one embodiment, a plurality of data points that define a desired motion path is provided, and the plurality of data points define a plurality of consecutive spans. It is determined whether two consecutive linear spans define a corner having an angle within a predetermined range, and if so, a non-linear path is determined which connects to the two consecutive linear spans with continuity in curvature. An actuator is then controlled according to the non-linear path.

Owner:SIEMENS ENERGY & AUTOMATION INC

Position control apparatus and method of the same, numerical control program preparation apparatus and method of the same, and methods of controlling numerical control machine tool

InactiveUS6097168AEasy to controlPrecise positioningProgramme-controlled manipulatorComputer controlNumerical controlTarget setting

Owner:TOSHIBA MASCH CO LTD

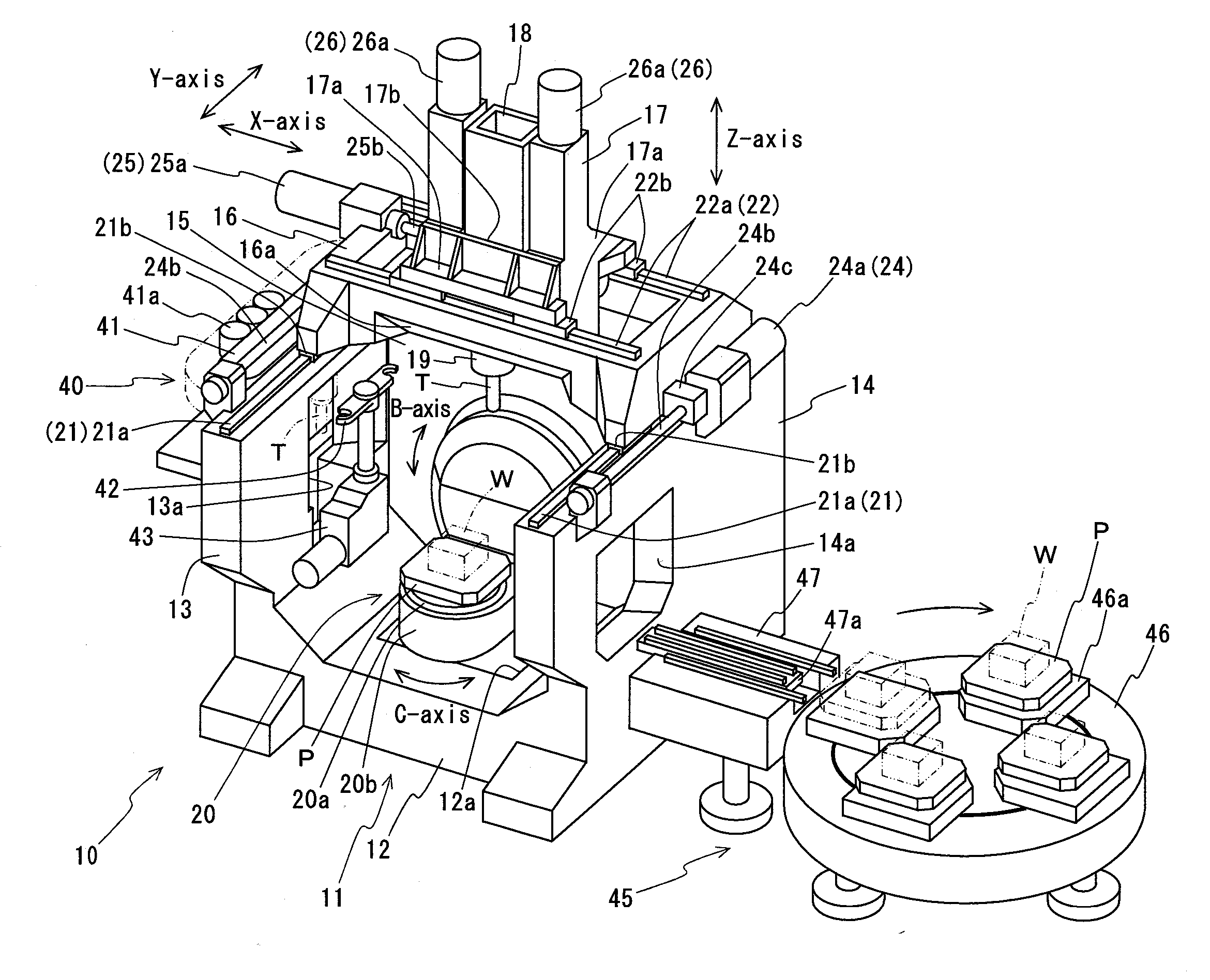

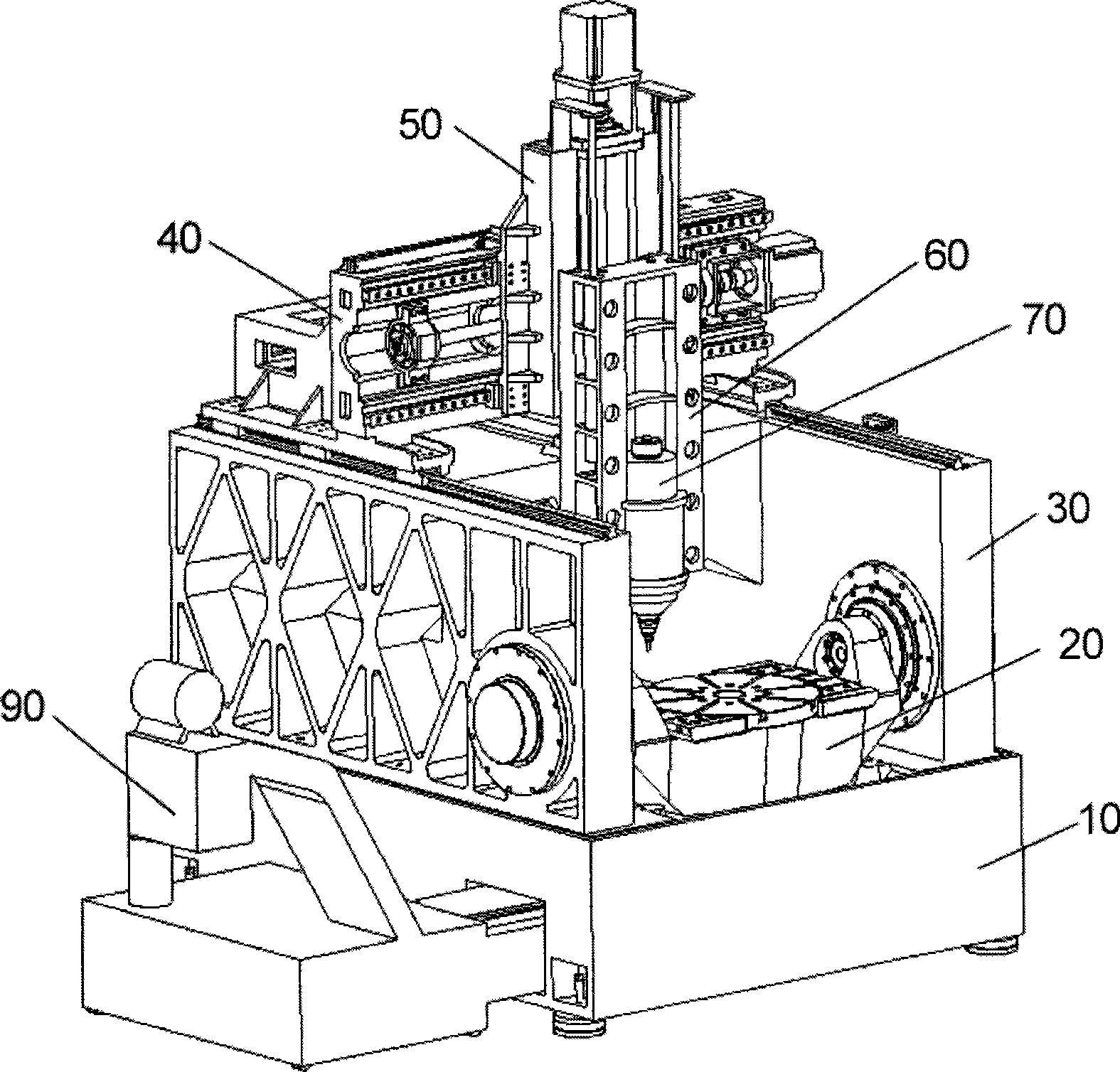

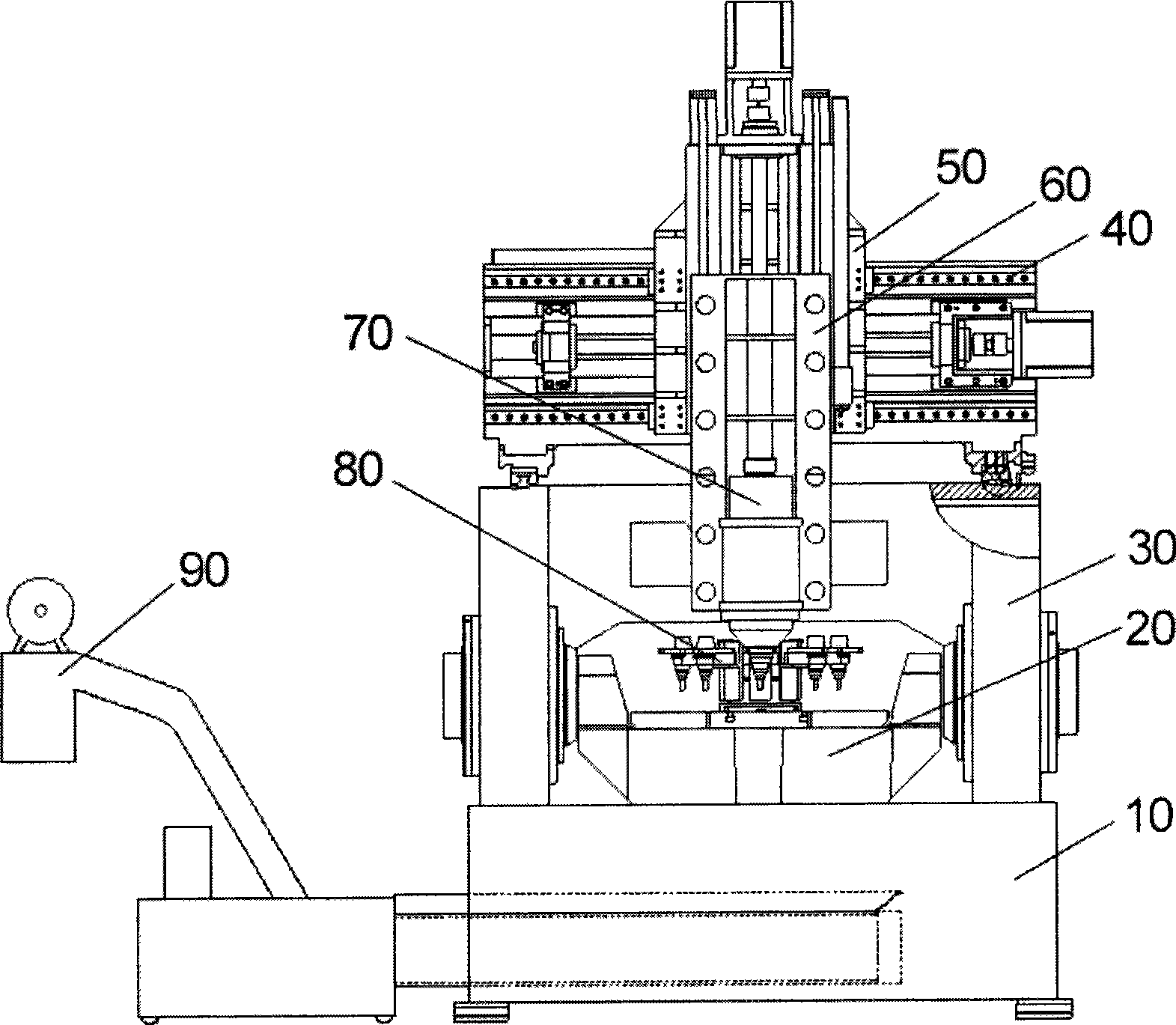

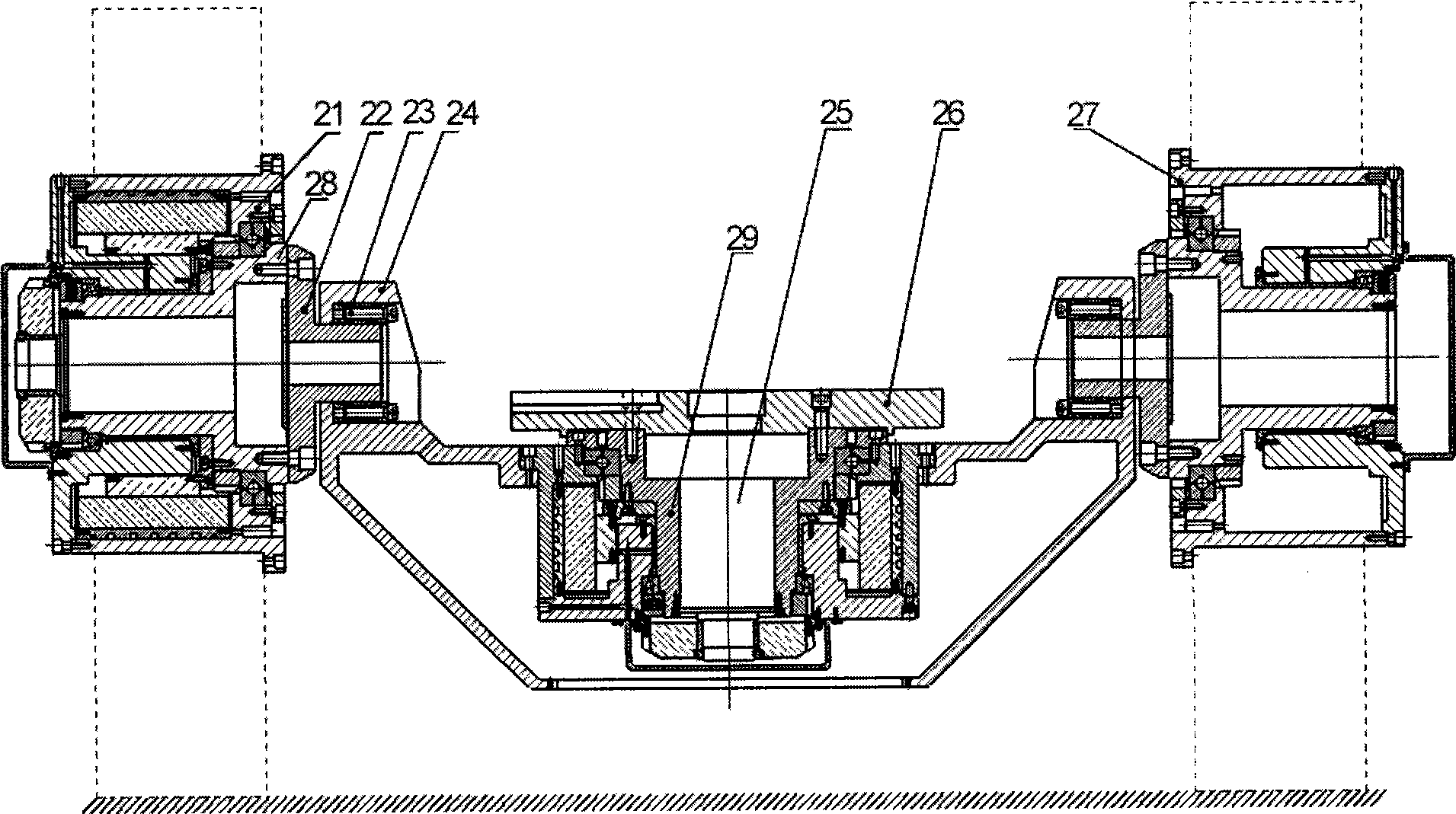

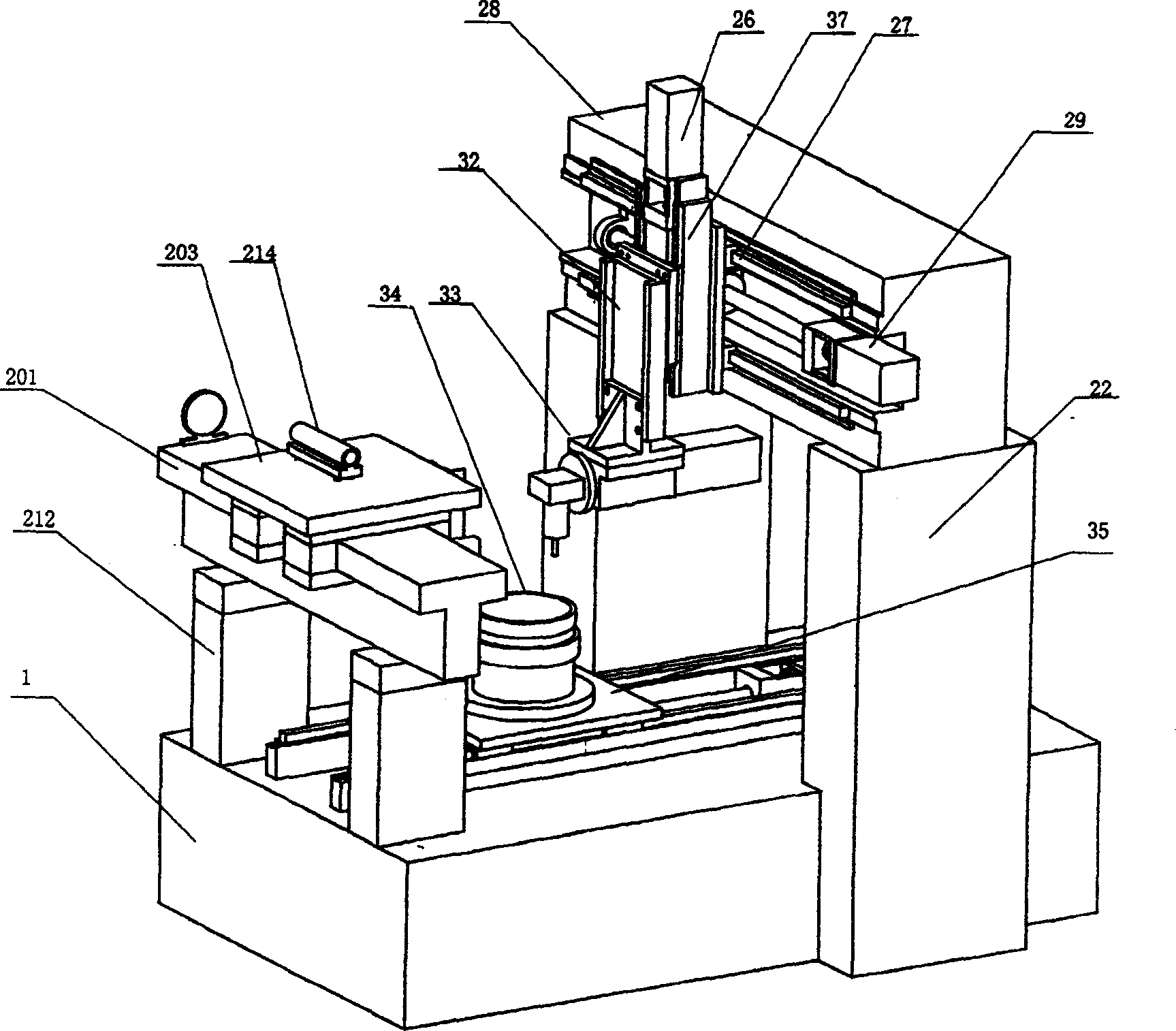

Five-shaft linkage numerical control machining center

InactiveCN101480777ANovel structureSmall footprintLarge fixed membersPositioning apparatusNumerical controlPortal frame

The invention discloses a five-axle linkage digital-control processing centre which comprises a lathe bed (10) and a portal frame (30), wherein the portal frame (30) comprises a left portal upright post (32), a right portal upright post (32) and a fixing portal crossbeam (35), and the front part of each portal upright post (32) is provided with a direct driving type double-shaft precise rotating table (20) which enables a working table (26) to simultaneously rotate round an A shaft and a C shaft. Furthermore, the portal frame (30) is provided with a crossbeam (40) which can move along the Y direction, the front part of the crossbeam (40) is provided with a slide carriage (50) which can move along the X direction, the front part of the slide carriage (50) is provided with a main shaft box (60) which can move along the Z direction, the main shaft box (60) is provided with a main shaft installing hole (66) used for installing a main shaft (70), and a tool magazine (80) is arranged in a cavity positioned between the lathe bed (10) and the portal frame (30). The invention has novel structure, small occupied area, space saving, low cost and stable operation and property. Besides, a motion shaft of a machine tool has high dynamic property, regulating property, positioning precision and repeated positioning precision.

Owner:三六零安全科技股份有限公司 +2

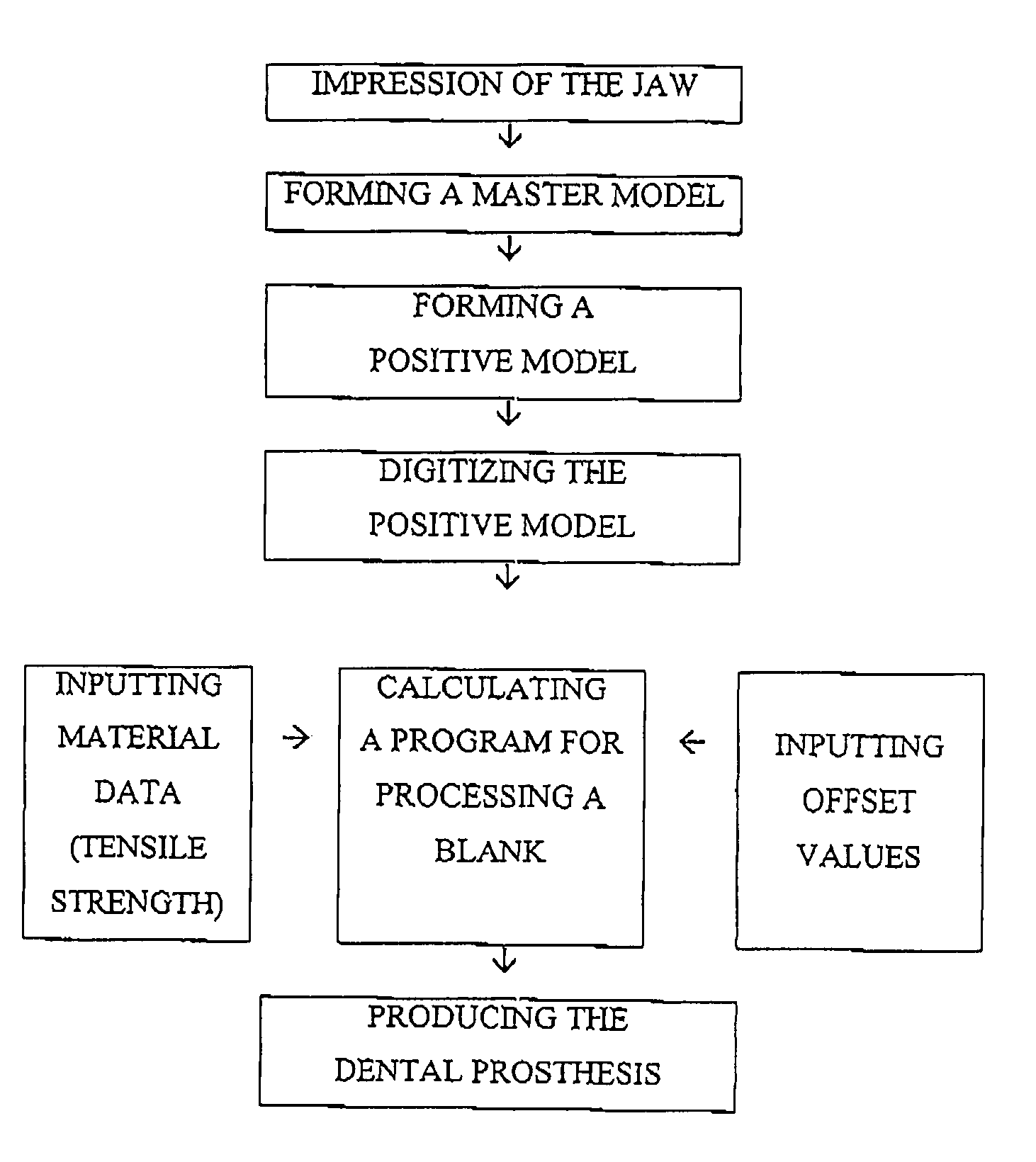

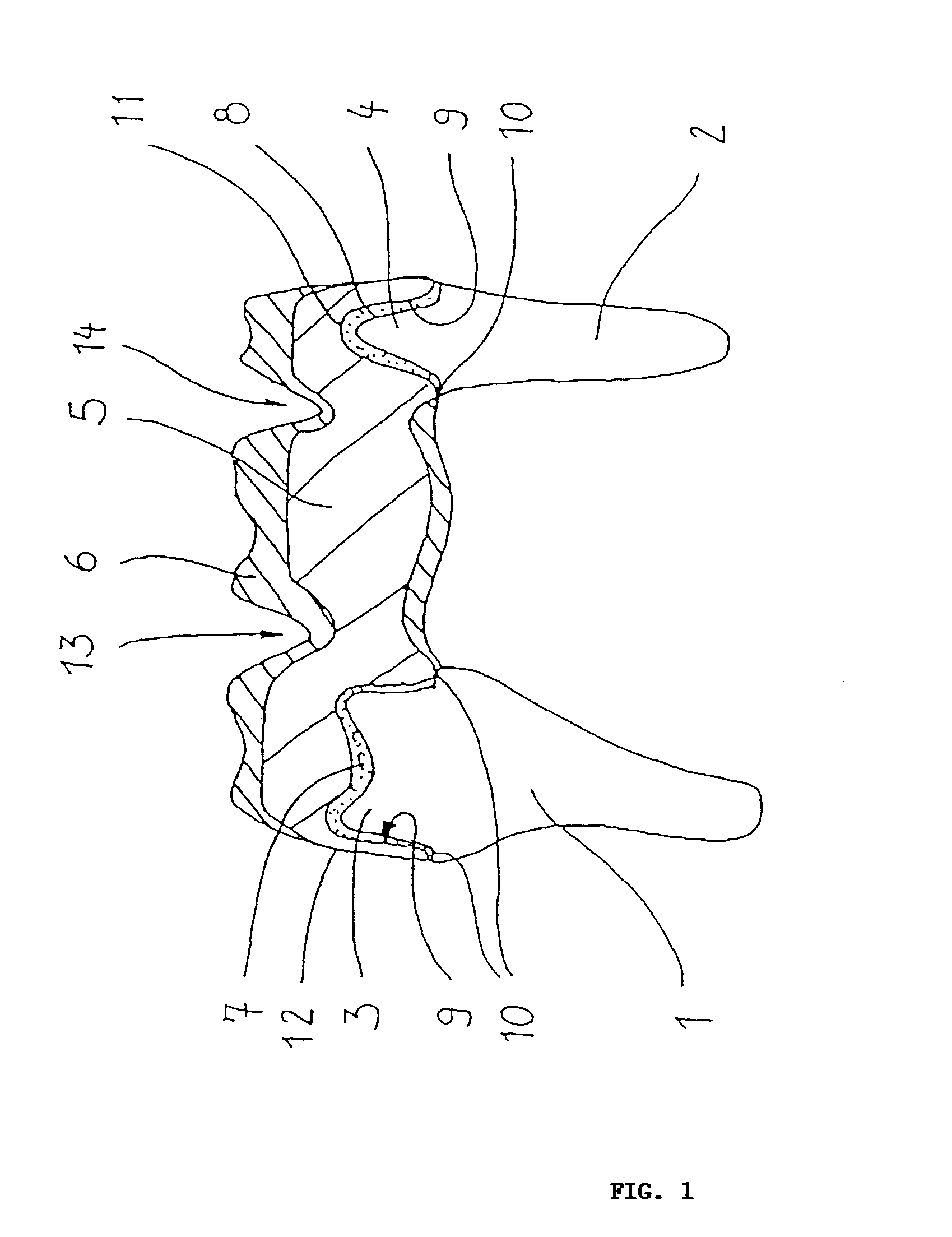

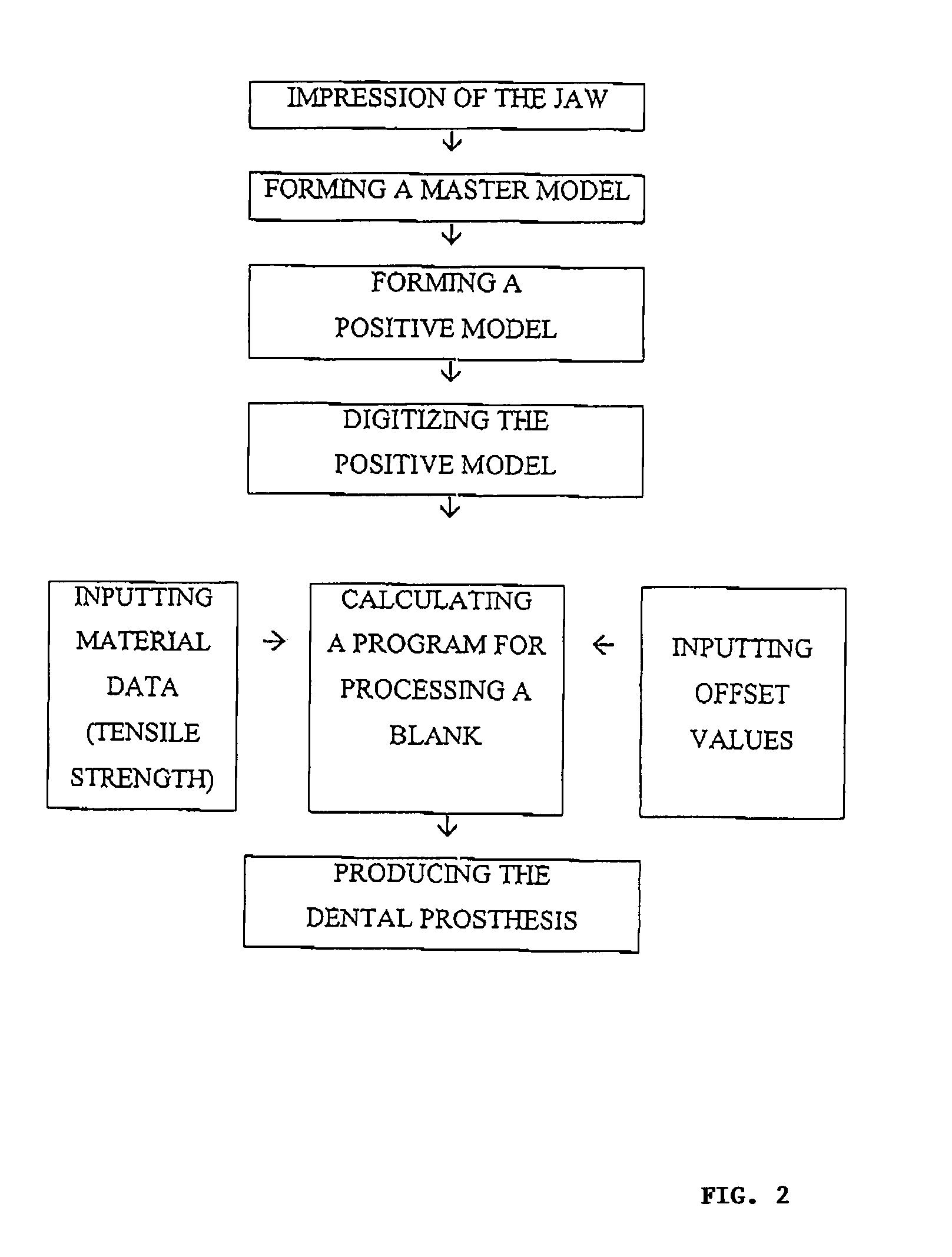

Production of replacement teeth from a three-dimensionally determined and digitized positive model

InactiveUS6970760B2High strengthSufficient aesthetic effectImpression capsDental articulatorsMachine toolOrthodontics

A method for the production of replacement teeth (5) from a three-dimensionally determined and digitized model, whereby for improved handling, cost and quality of the produced replacement tooth (5) a method including the following steps is carried out: inputting the data for the digitized model, treating the inner surface (9) of the surface model with a given offset value to generate a cement gap (7, 8) between the tooth replacement (5) to be made and tooth stump (1, 2) and calculation of a program for machining the blank or a mold by means of a machine tool.

Owner:DEGUDENT

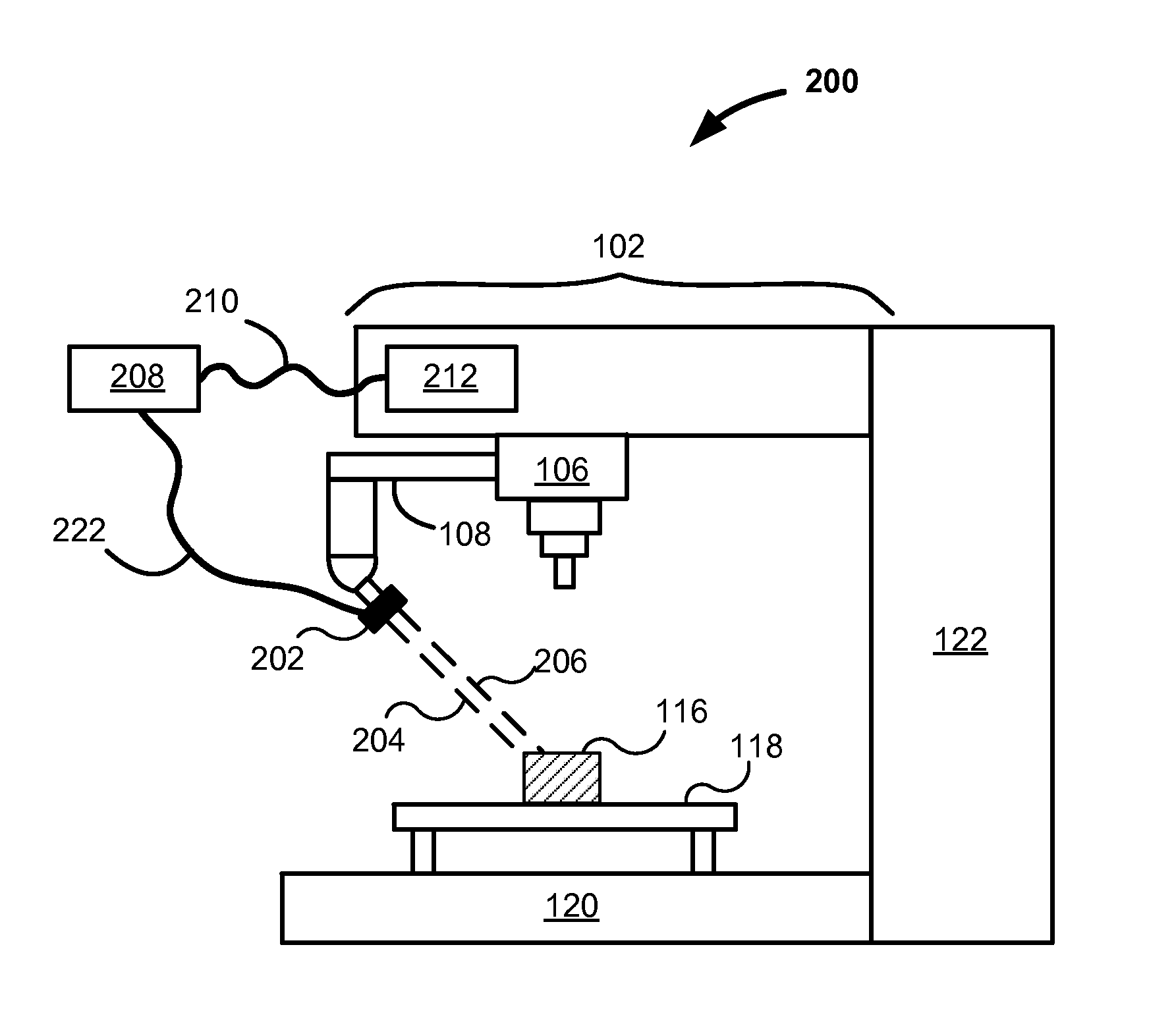

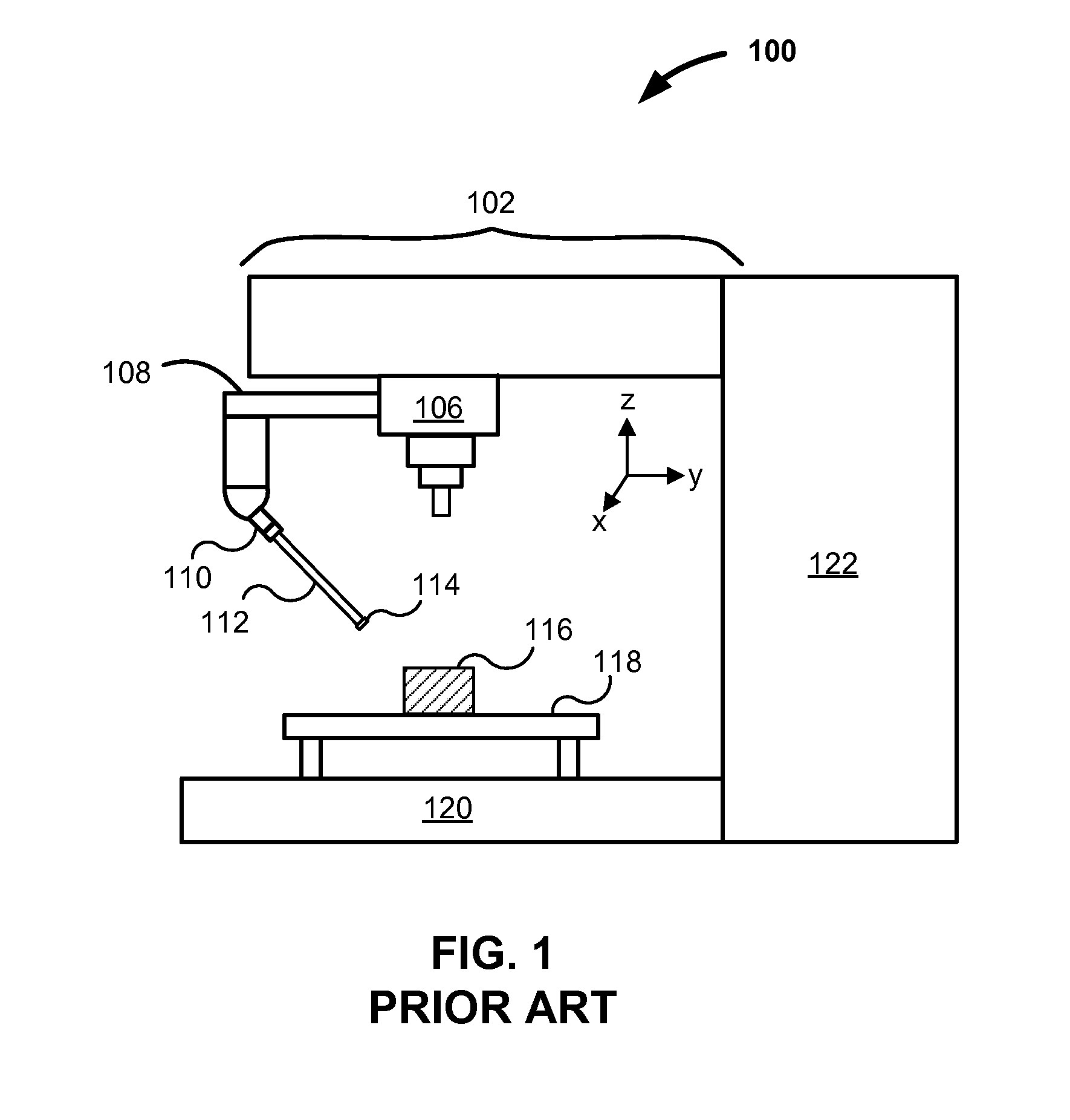

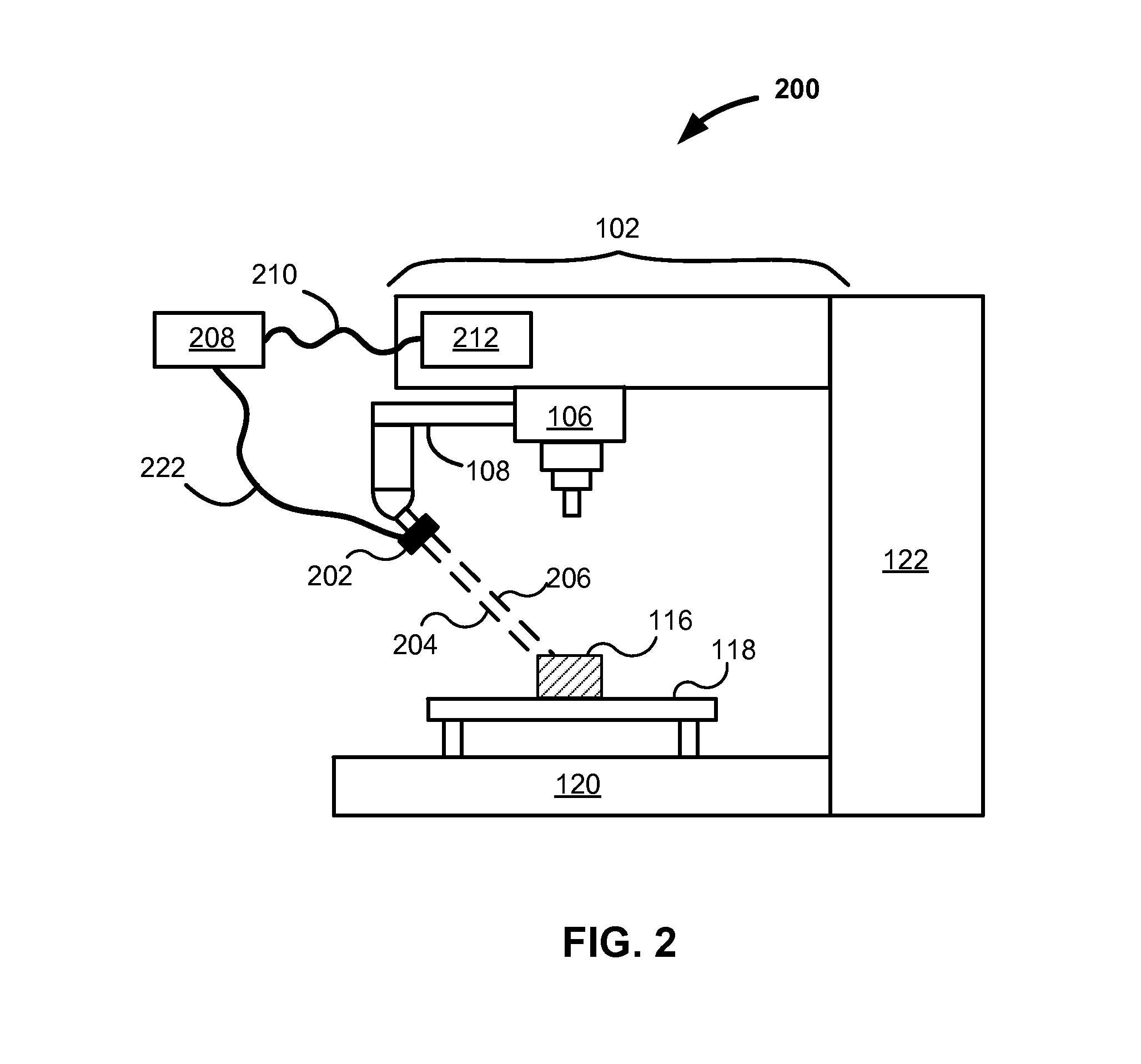

High Speed Metrology with Numerically Controlled Machines

ActiveUS20140157610A1Accurate verificationTight stack-up toleranceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNumerical controlMetrology

Systems, apparatuses and methods are described for integrating an electronic metrology sensor with precision production equipment such as computer numerically controlled (CNC) machines. For example, a laser distance measuring sensor is used. Measurements are taken at a relatively high sample rate and converted into a format compatible with other data generated or accepted by the CNC machine. Measurements from the sensor are synchronized with the position of the arm of the machine such as through the use of offsets. Processing yields a detailed and highly accurate three-dimensional map of a workpiece in the machine. Applicable metrology instruments include other near continuously reading non-destructive characterization instruments such as contact and non-contact dimensional, eddy current, ultra-sound, and X-Ray Fluorescence (XRF) sensors. Various uses of measurements include: multiple component matching, correction of machine drift, closed loop control of machines, and verification of product tolerances via substantially complete serialized dimensional quality control.

Owner:GRALE TECH

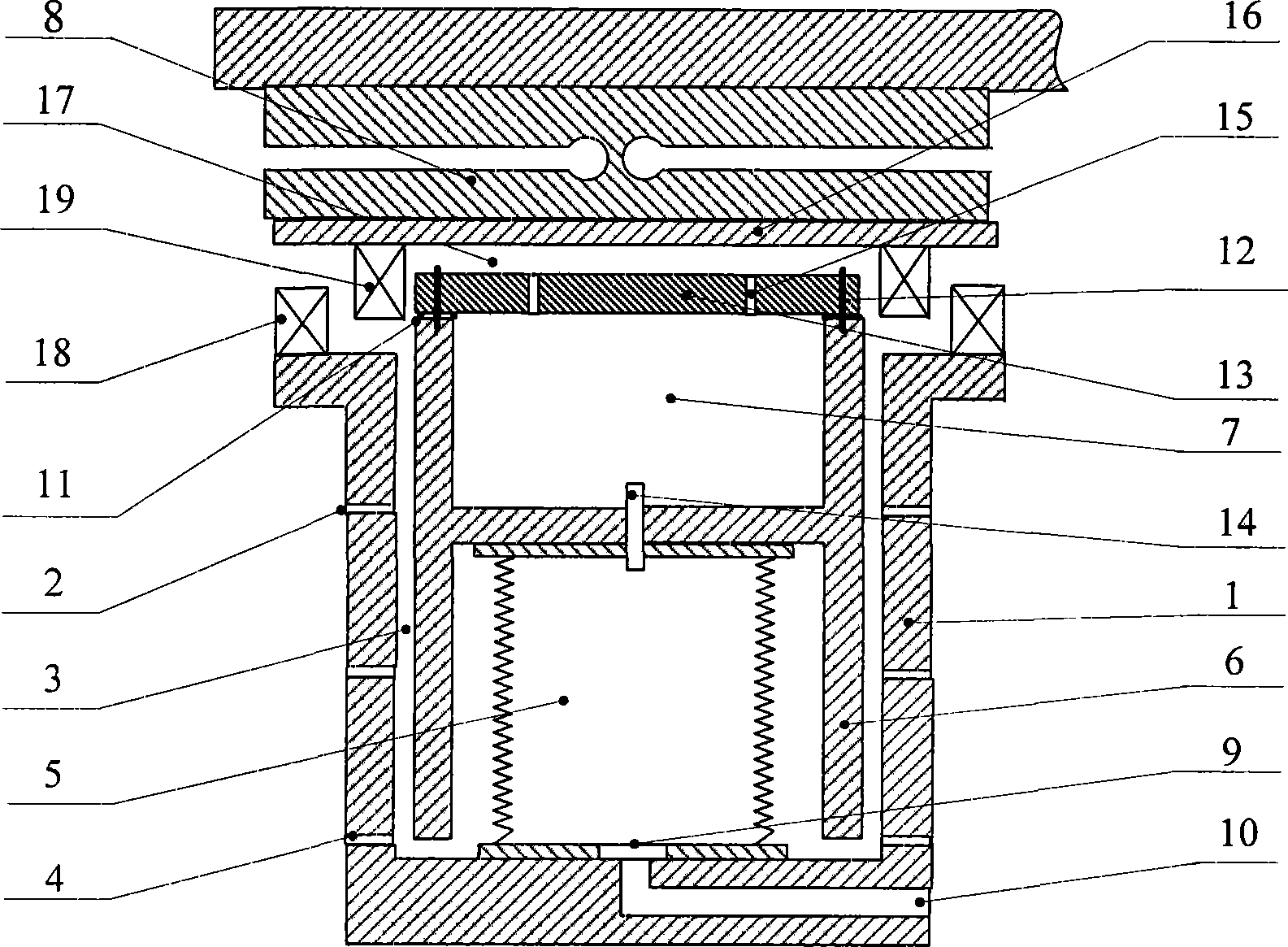

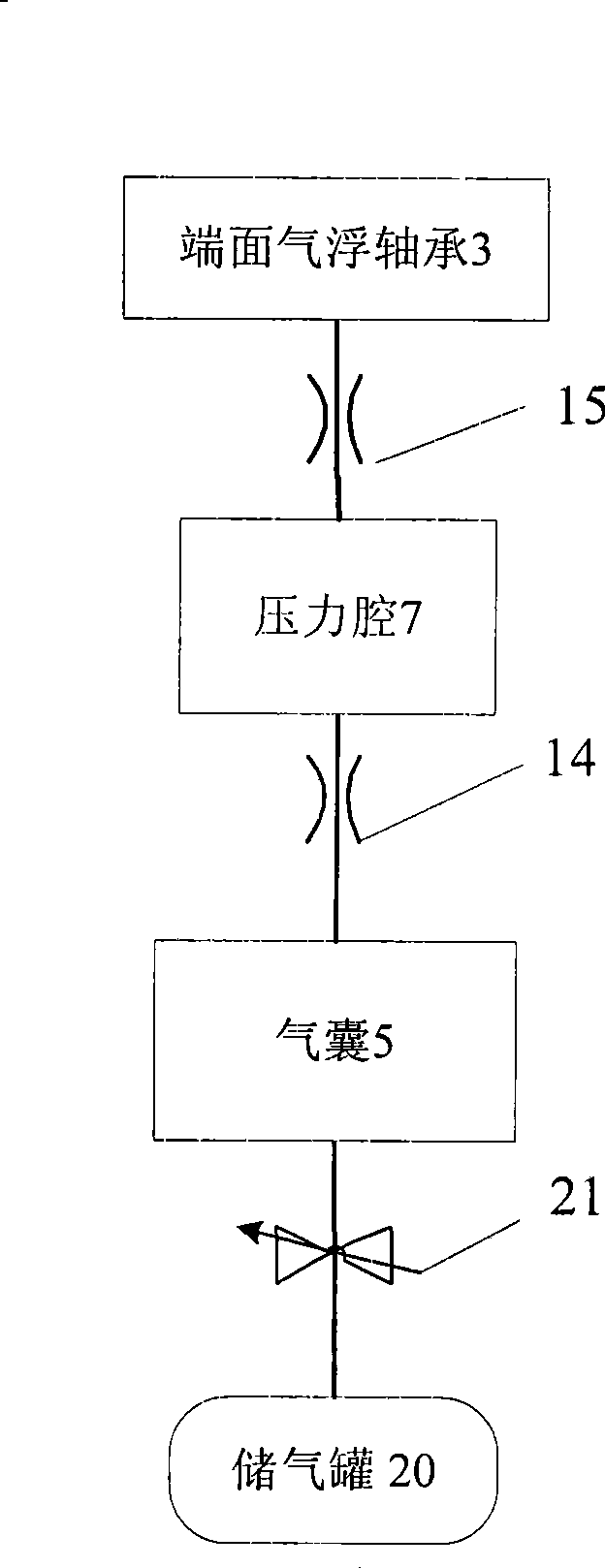

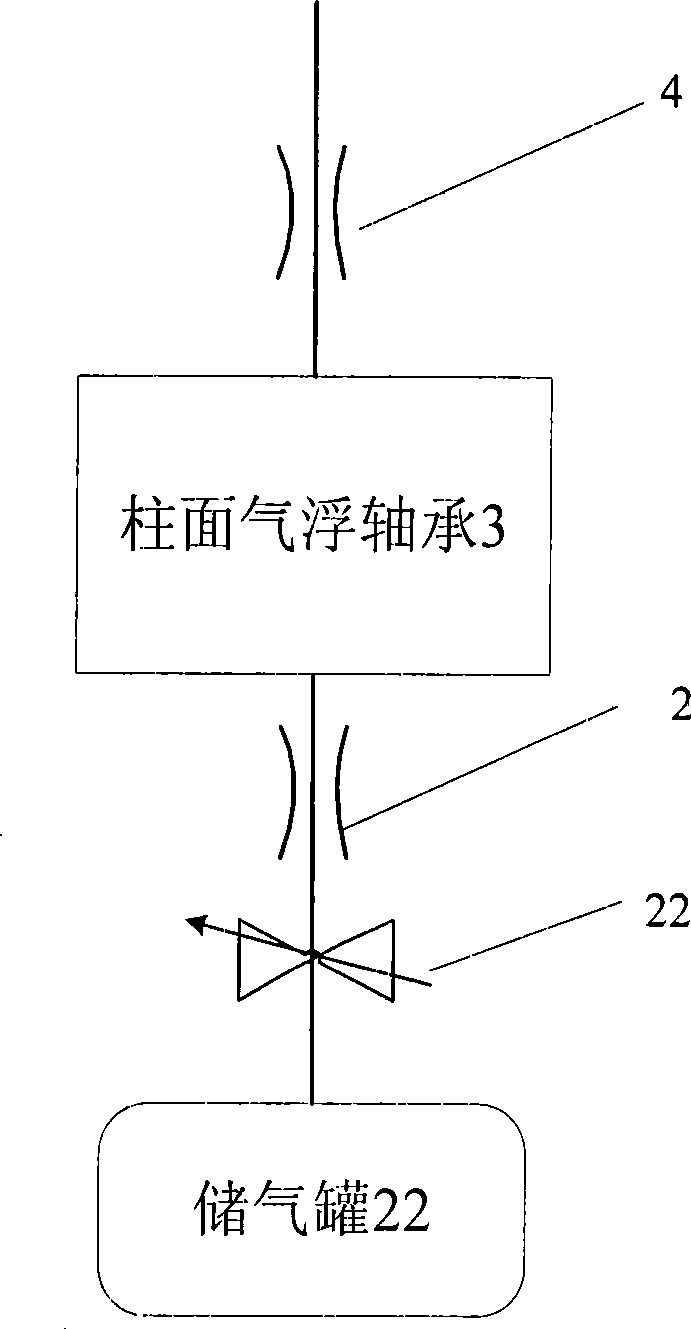

Precision vibration damping assembly and vibration damping platform composed of the assembly

InactiveCN101398636AAchieve precise positioningWith leveling and positioning functionPhotomechanical exposure apparatusMicrolithography exposure apparatusUltrasound attenuationDamping function

The invention discloses a precision damping component and a damping platform composed of the precision damping component, and the damping platform has damping function and positioning function along a Z direction. The precision damping component comprises a passive damping part, an active damping actuator and an external frame. The passive damping part is a piston rod with a structure of double cavities, an air pocket and a pressure cavity are respectively positioned in the two cavities, and the air pocket has larger longitudinal bracing power and lower rigidity, and can isolate the vibration of attenuation high frequency. The active damping actuator is a linear voice coil motor connected in parallel with the passive damping part, and applies acting force to a passive object according to the vibration condition and location information of the controlled object, so as to drive the controlled object to move to a designated position and compensate the vibration. The damping platform composed of at least three precision damping components has the functions of vibration damping with a plurality of degrees of freedom, accurately positioning along the Z direction, focusing and leveling. The precision damping component and the damping platform can be used in the apparatus with precision damping requirements such as mask aligners, ultra-precision numerically-controlled machine tools, biochip scanners and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

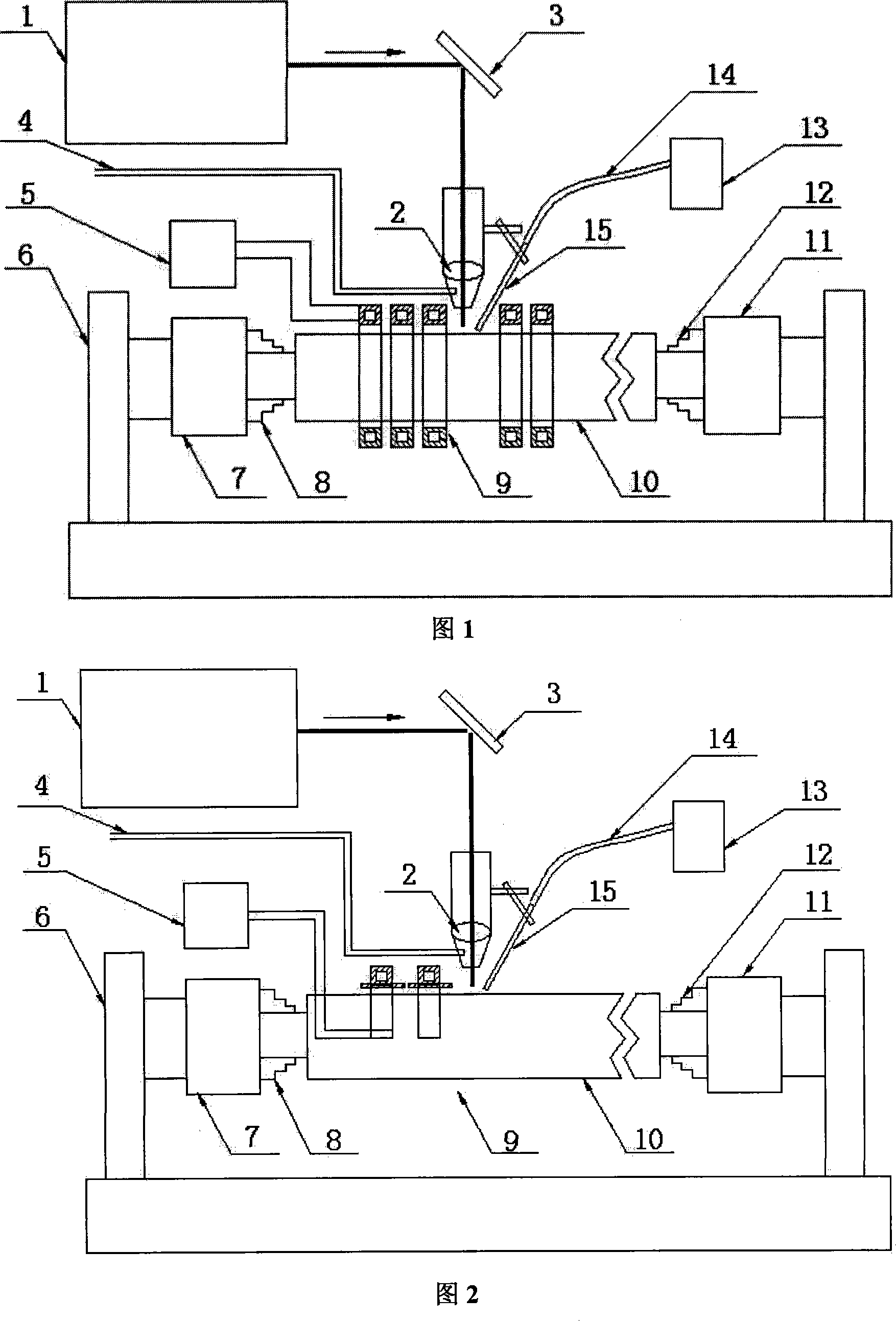

Laser machining method and device applicable for complicated curved surface

ActiveCN102151984AReduce the overall heightImprove energy consumptionLaser beam welding apparatusLaser etchingLaser processing

The invention provides a laser machining method applicable for a complicated curved surface. By adopting processing steps of dividing the complicated curved surface into curved surface sheets and establishing a coordinate system of each curved surface sheet, the subsequent processing steps of dividing sub blocks and machining pattern parallel projection can be implemented according to the coordinates of the curved surface sheets respectively, so the limit that a machining molded surface backing to a laser incident direction or a steep surface parallel to an optical axis direction cannot be machined because only one coordinate system is adopted to perform whole injection in the prior art can be overcome, the machining efficiency is improved and the machining applicable range is extended. The invention also provides a laser machining device. The laser machining device has a three-axis laser machining head structure provided with a two-axis laser polarization mirror and a Z-axis mobile mechanism, so the problem that the conventional system depends on a three-axis lathe is solved; therefore, a machining unit is independent and compact, and is easy to assemble and disassemble; the conventional five-axis linkage milling machine can be changed into a laser-etching machining lathe so that the functions are compatible; and the laser machining device has a significant practical value.

Owner:武汉飞能达激光技术有限公司

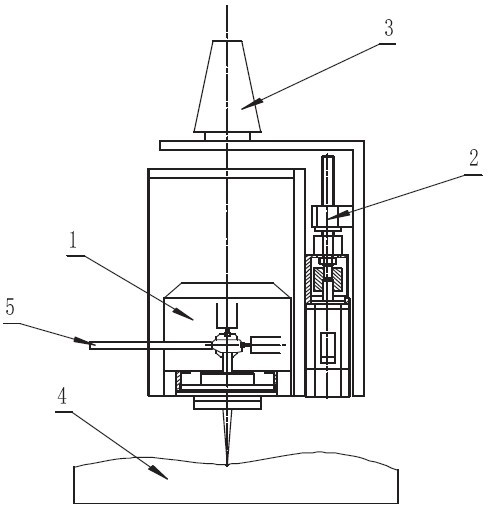

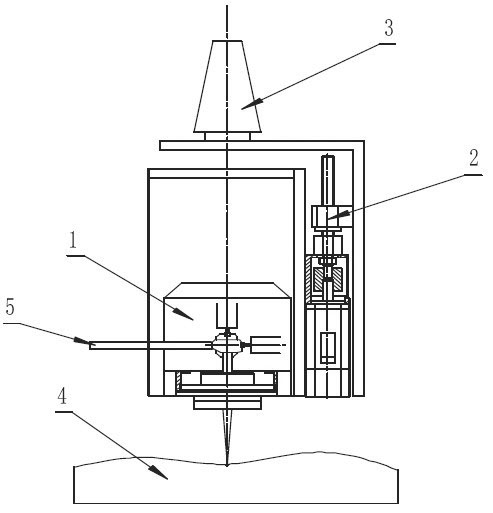

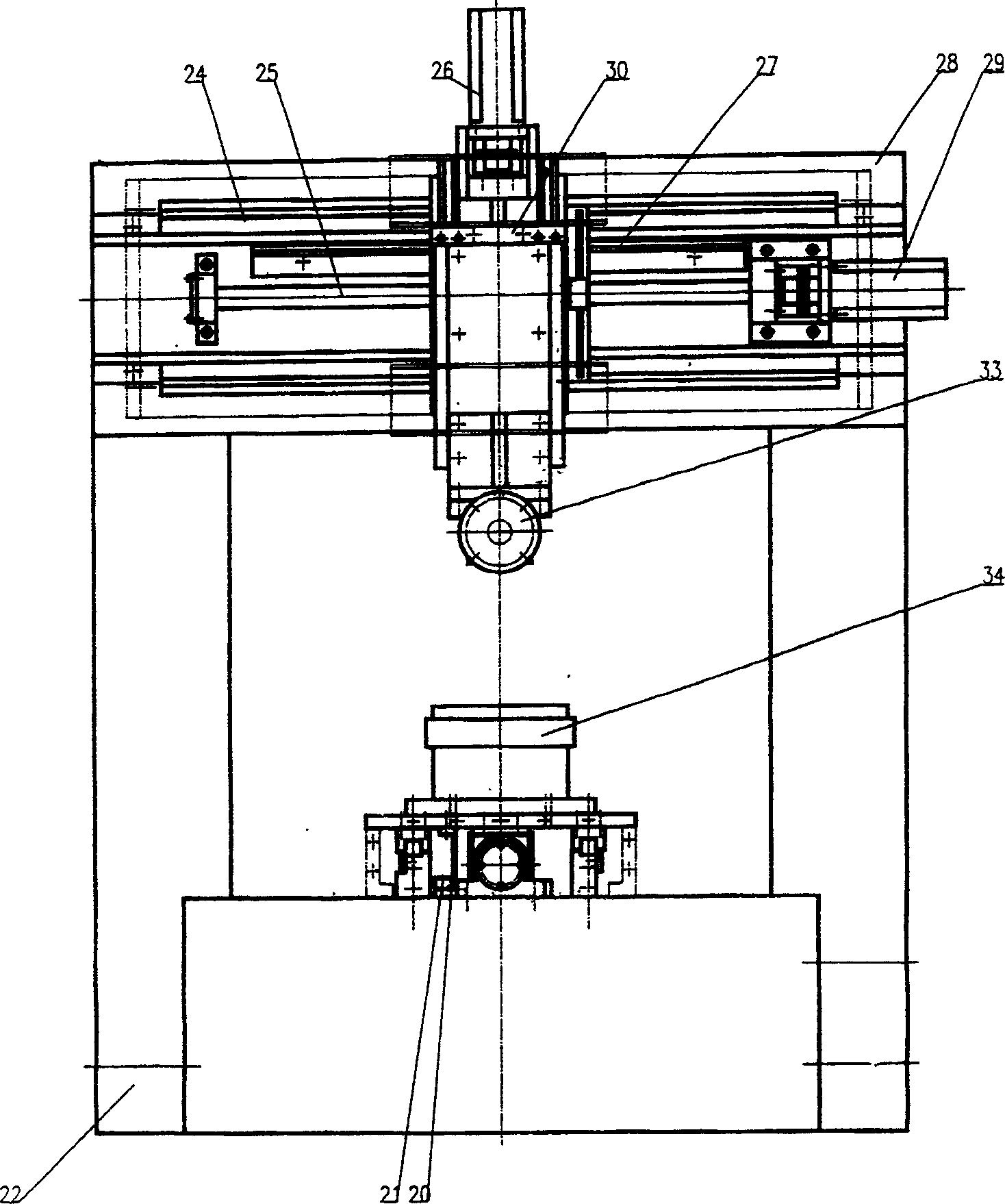

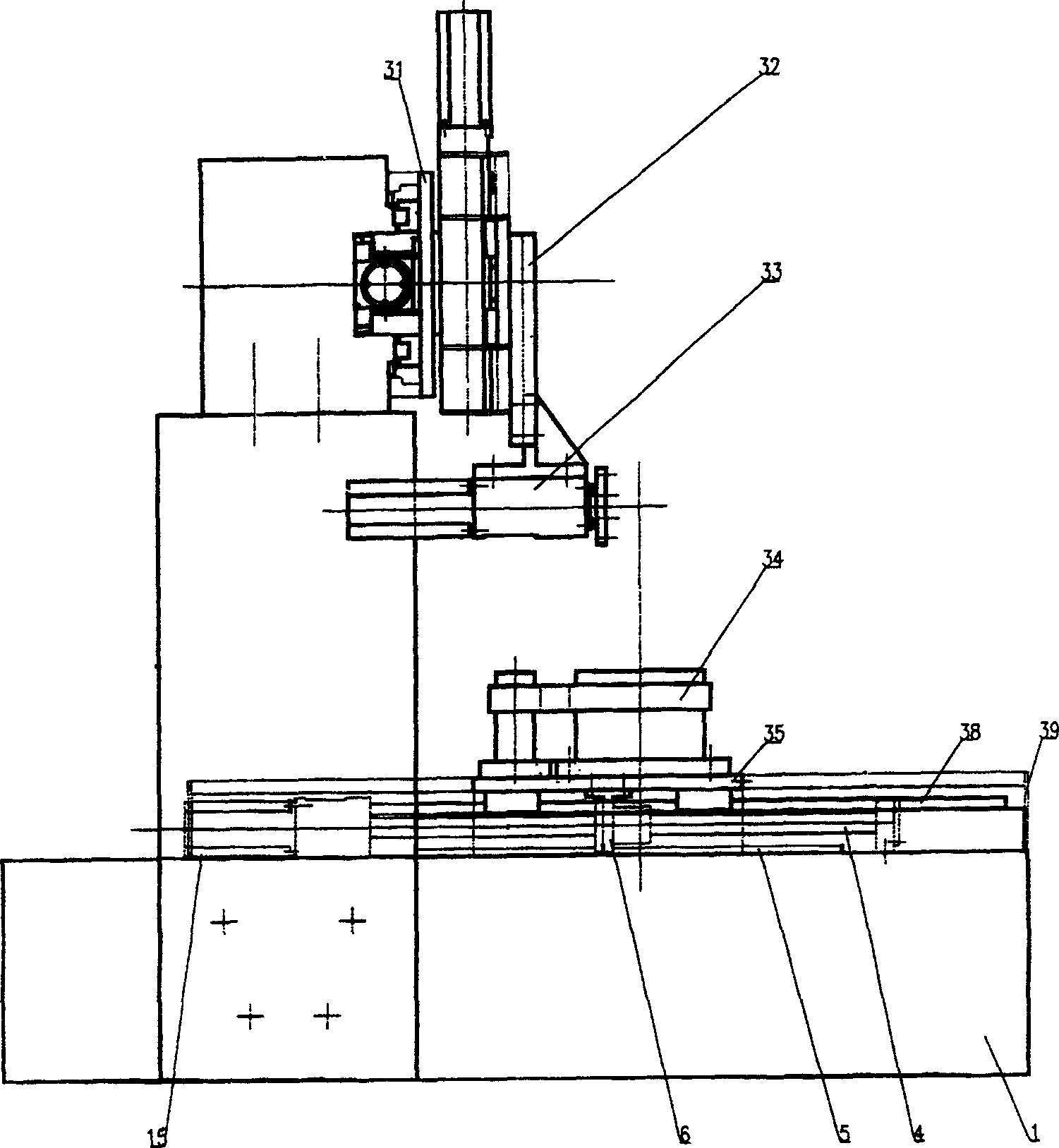

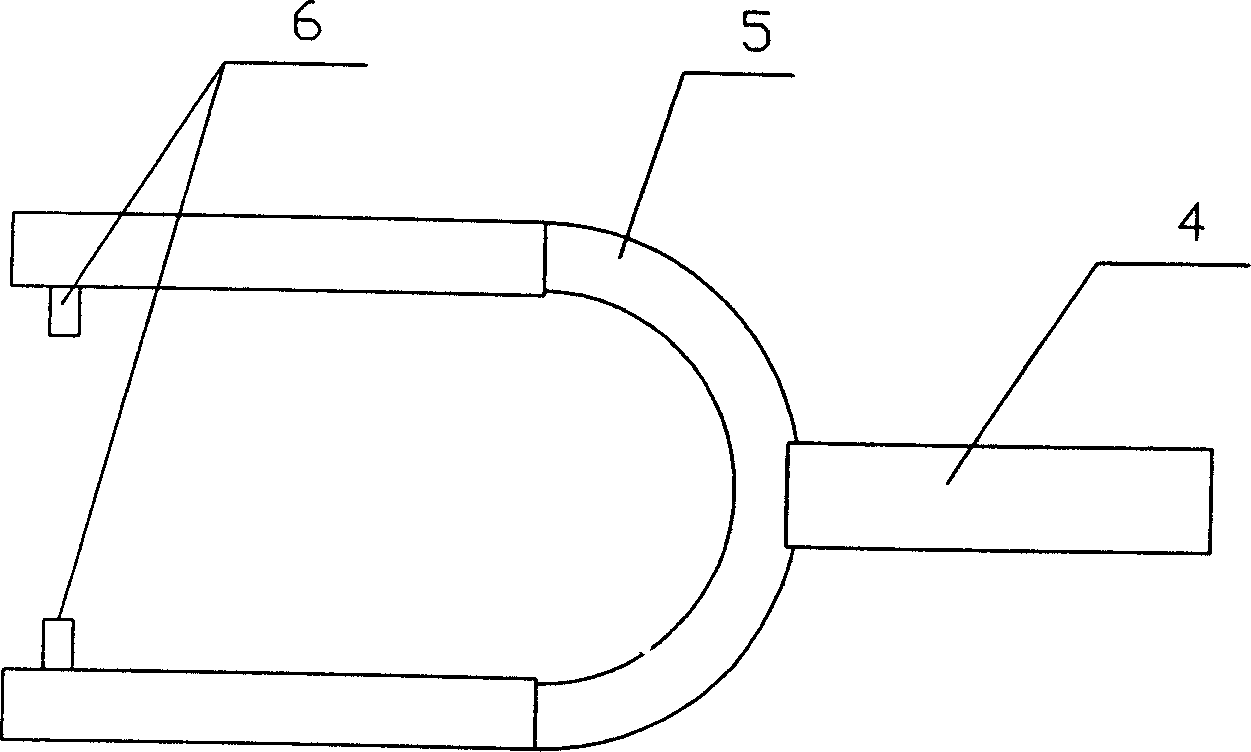

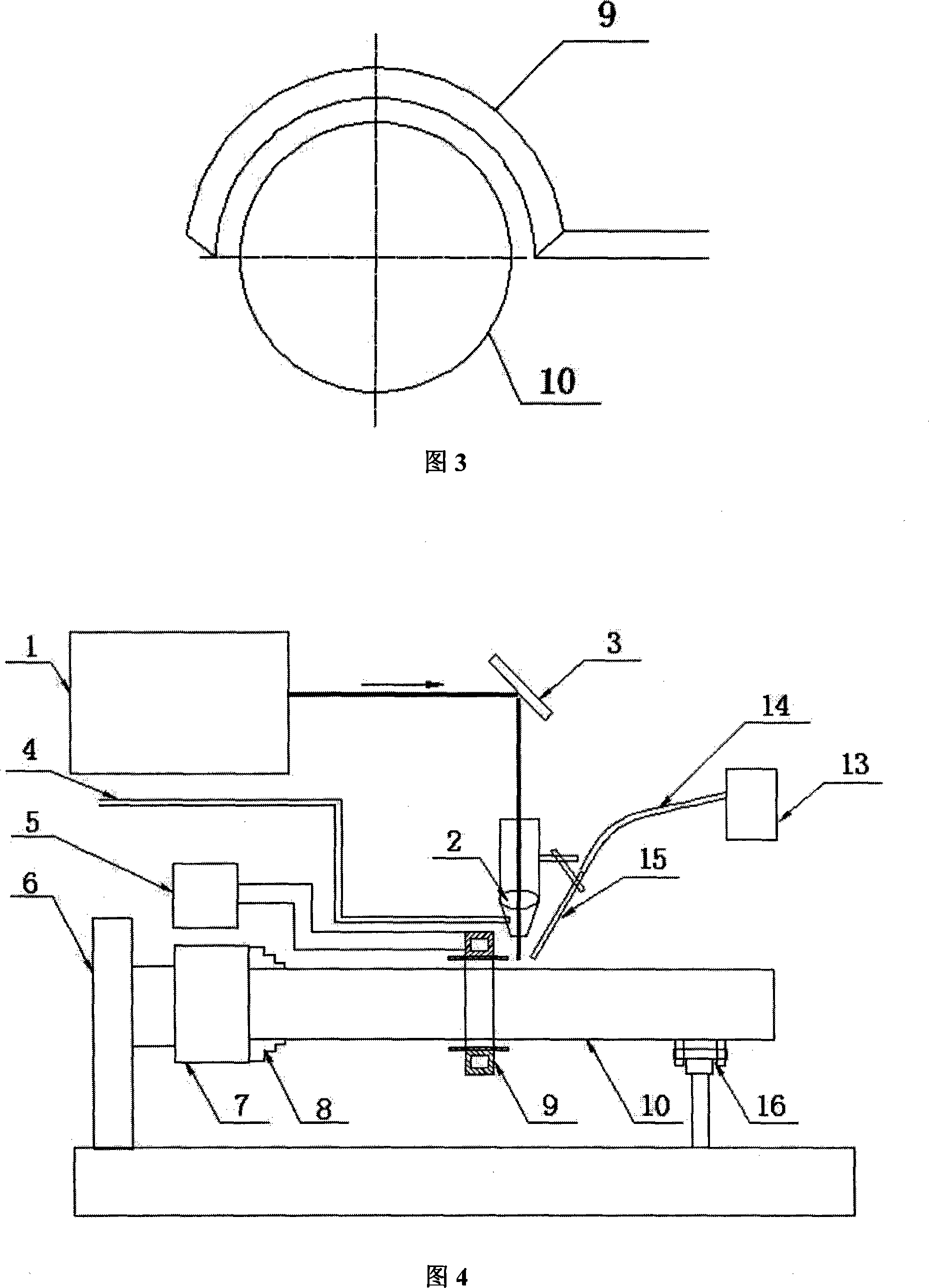

Non-spherical optical component composite machining and testing machine tools

InactiveCN1490125AImprove processing efficiencyOvercome the disadvantage that the revolution speed is difficult to increaseAutomatic control devicesFeeding apparatusEngineeringFloating platform

A machine tool for machining and testing the non-spherical optical part features that its main body has the symmetrical gantry frame structure with X, Y, Z and C axises designed modularly, the milling head or polishing mechanism is installed to the Z-axis bench, and the floating platform equipped with the in-line measuring and error-measuring unit for plane and parallel to Y axis is arranged on main body. Its advantage is high machining precision.

Owner:NAT UNIV OF DEFENSE TECH

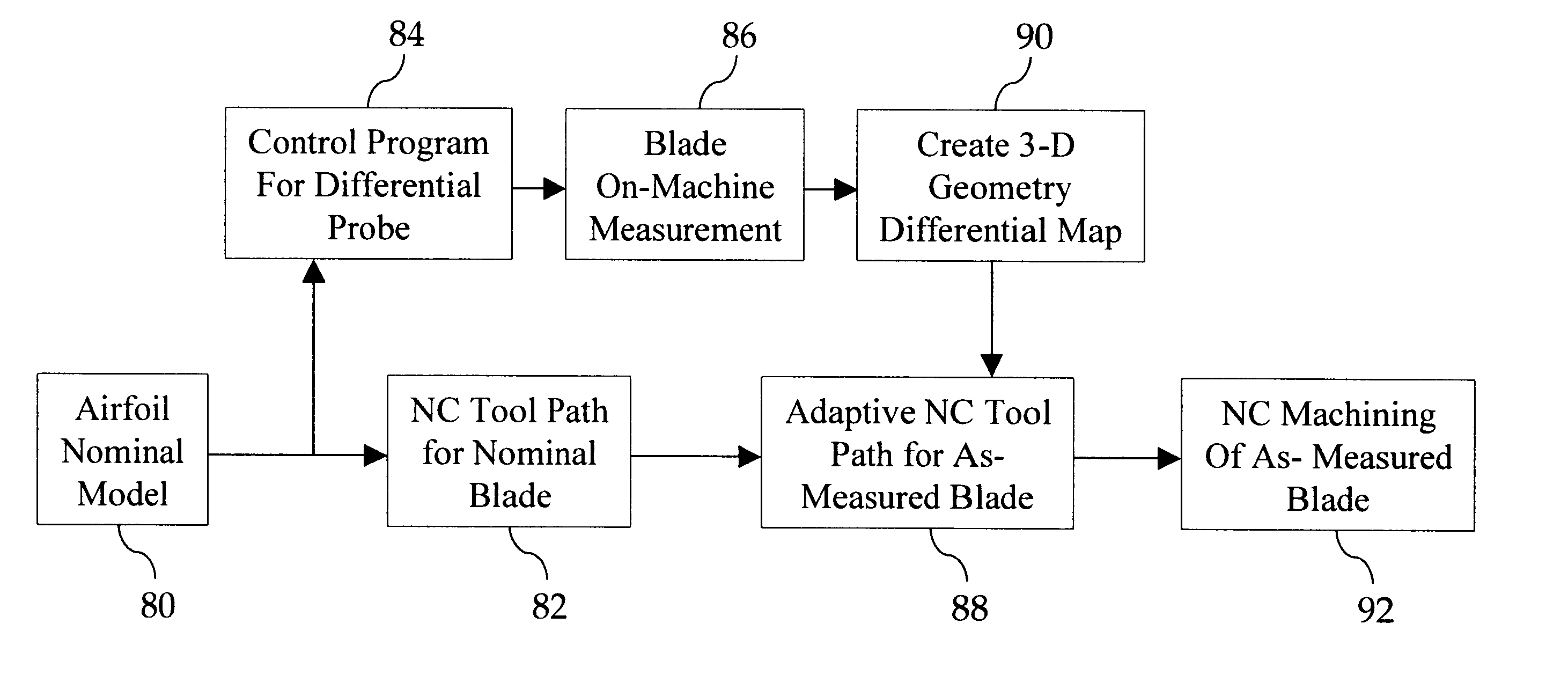

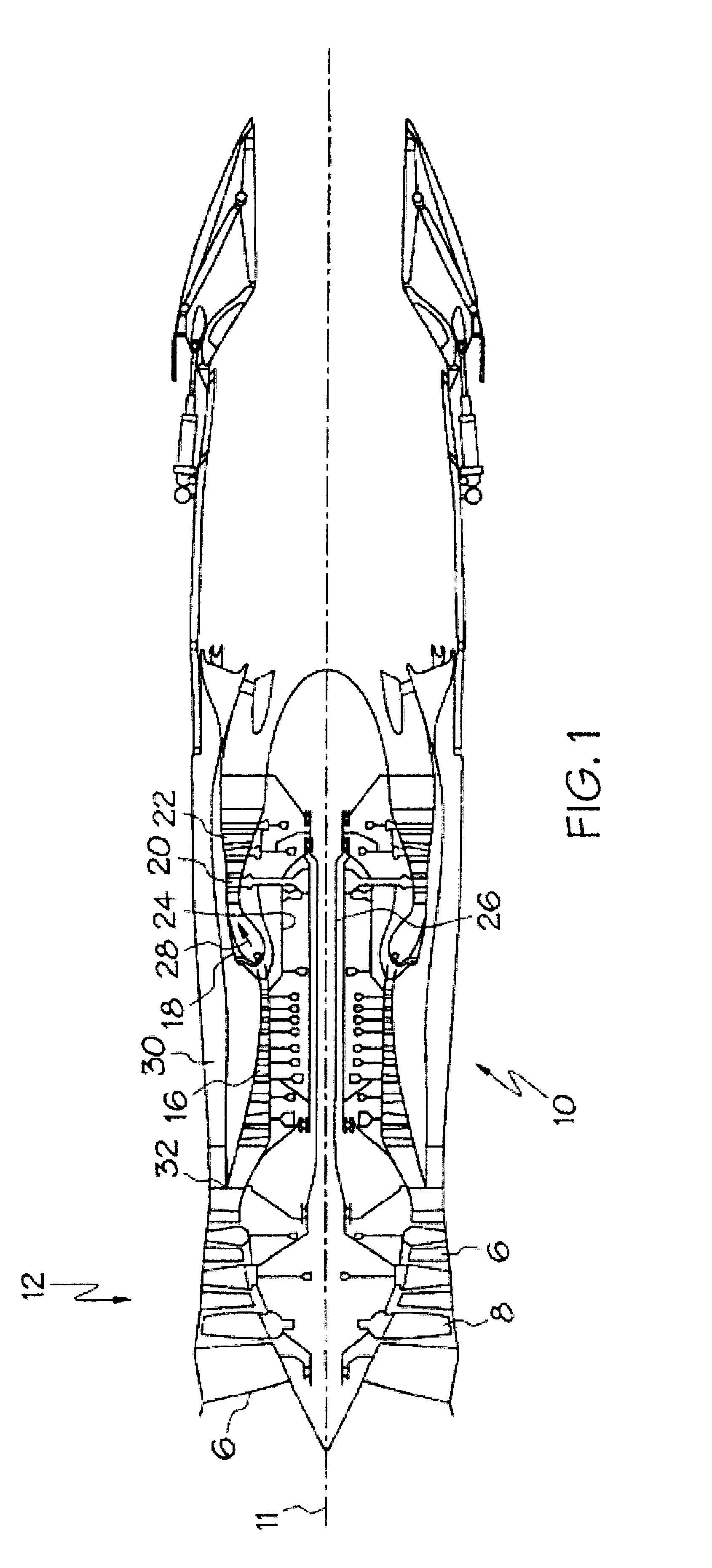

Systems and methods for automated sensing and machining for repairing airfoils of blades

InactiveUS6912446B2AdaptableEasy maintenanceProgramme controlTurbinesNumerical controlData acquisition

A method for repairing an airfoil comprising creating a nominal numerically-controlled tool path based on a nominal shape of the airfoil, measuring the airfoil using a displacement sensor, capturing differences in the airfoil shape as compared to the nominal shape, creating a three-dimensional map by synchronizing x, y and z coordinates and readings from the sensor, modifying the tool path based on the three-dimensional map, and machining the airfoil. A system for measuring and machining an airfoil comprising a computer operable for data acquisition and numerically-controlled tool path generation, a numerically-controlled machine, a cutting tool holder comprising a plurality of cutting tools, and a displacement-sensing probe.

Owner:GENERAL ELECTRIC CO

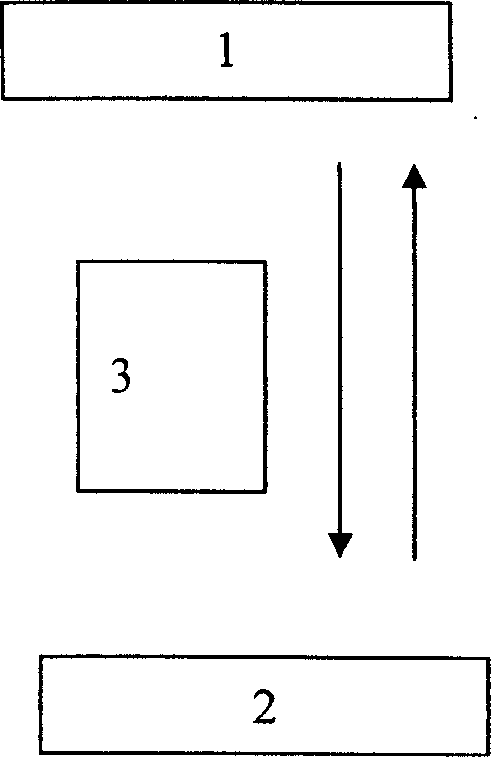

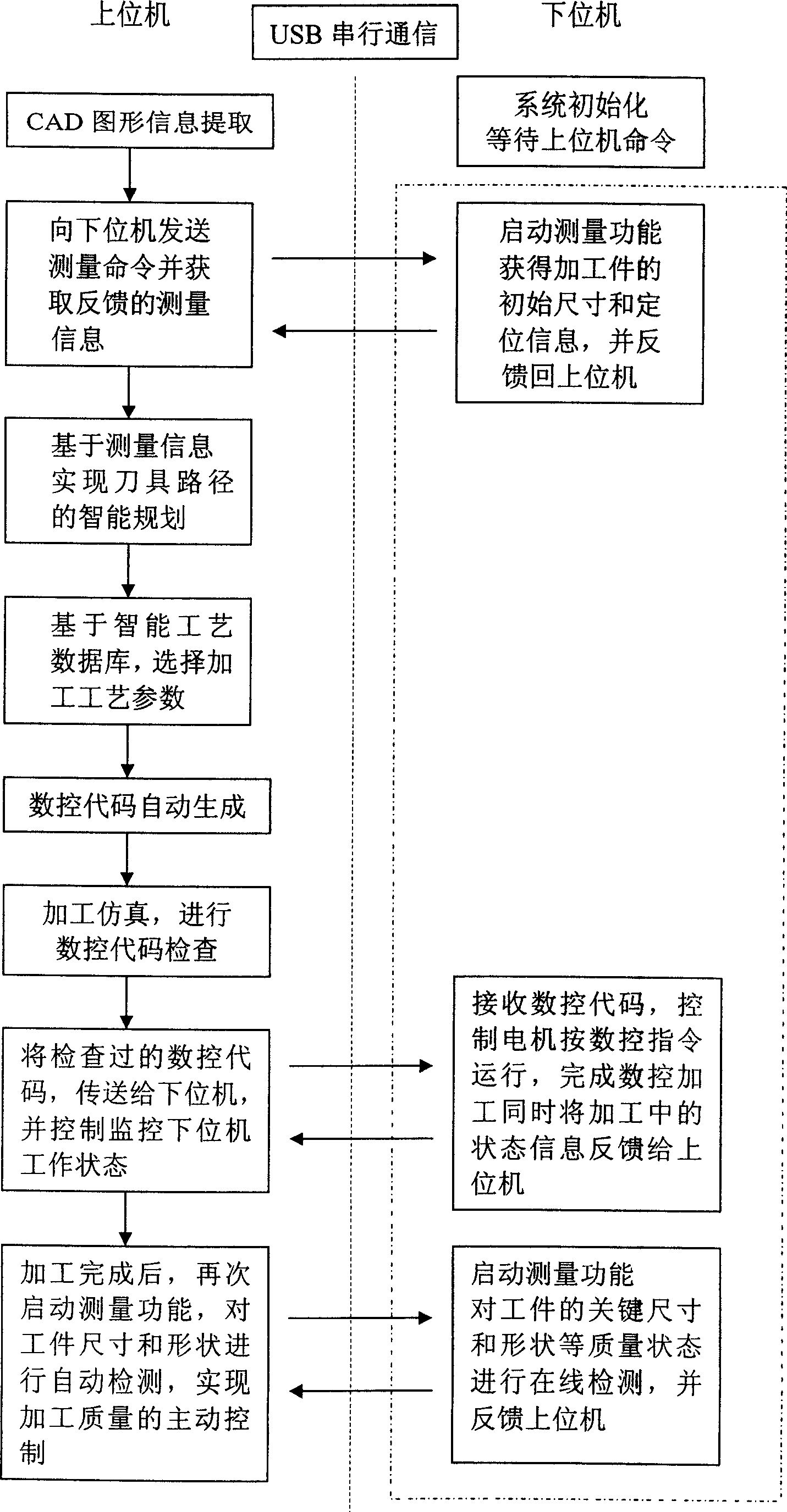

Intelligent control system for digital control machine tool and control method thereof

InactiveCN1740932ARealize real-time controlEasy to detectComputer controlSimulator controlUSBDigital control

The intelligent control system of NC machine tool is formed from NC machine tool, upper position machine and lower position machine. The upper position machine and lower position machine are formed into open control system, between upper position machine and lower position machine it utilizes USB to make serial communication, on the NC machine tool a photoelectric detection device is mounted and connected with lower position machine. Said system can implement on-line detection.

Owner:SHANDONG UNIV

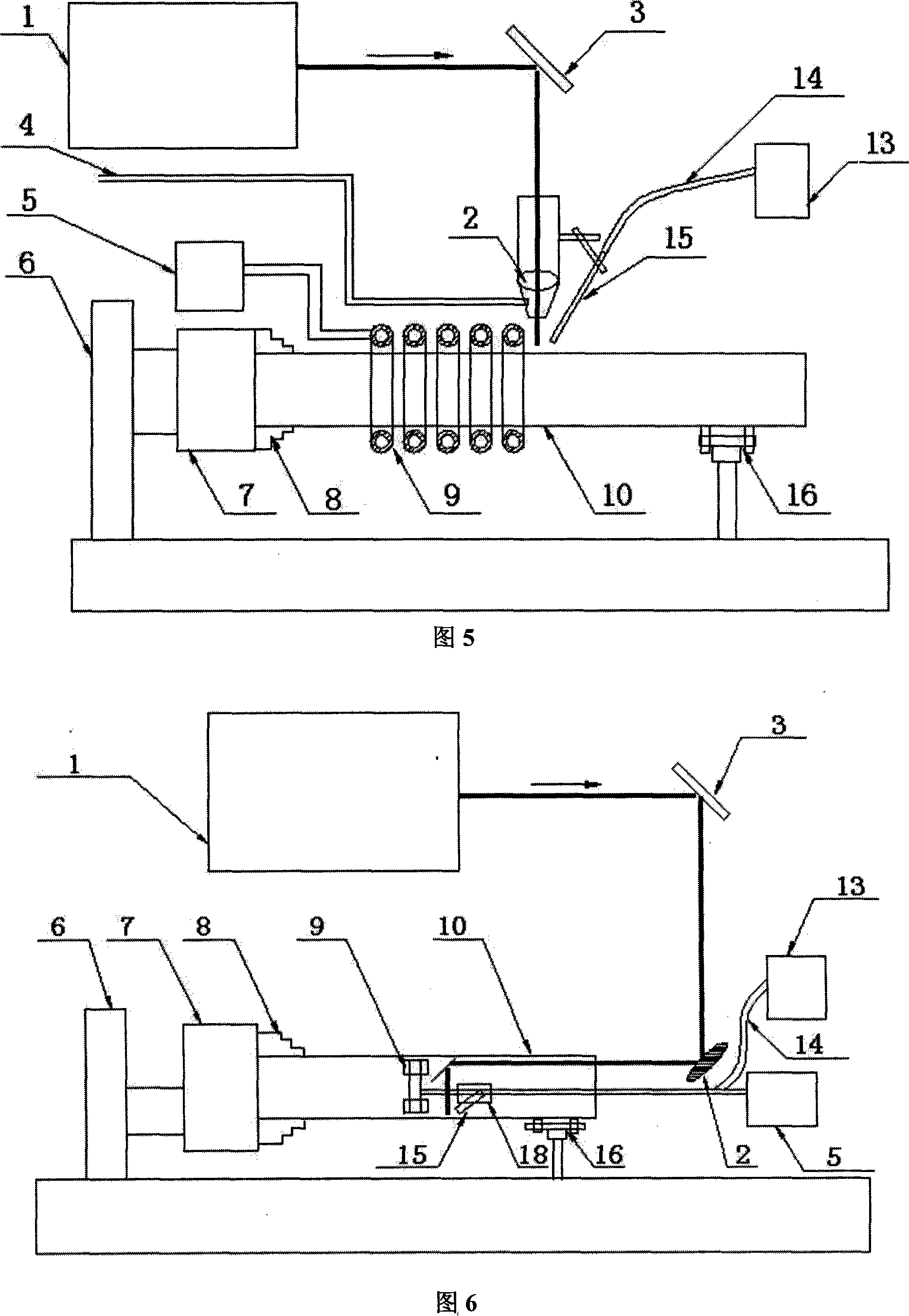

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

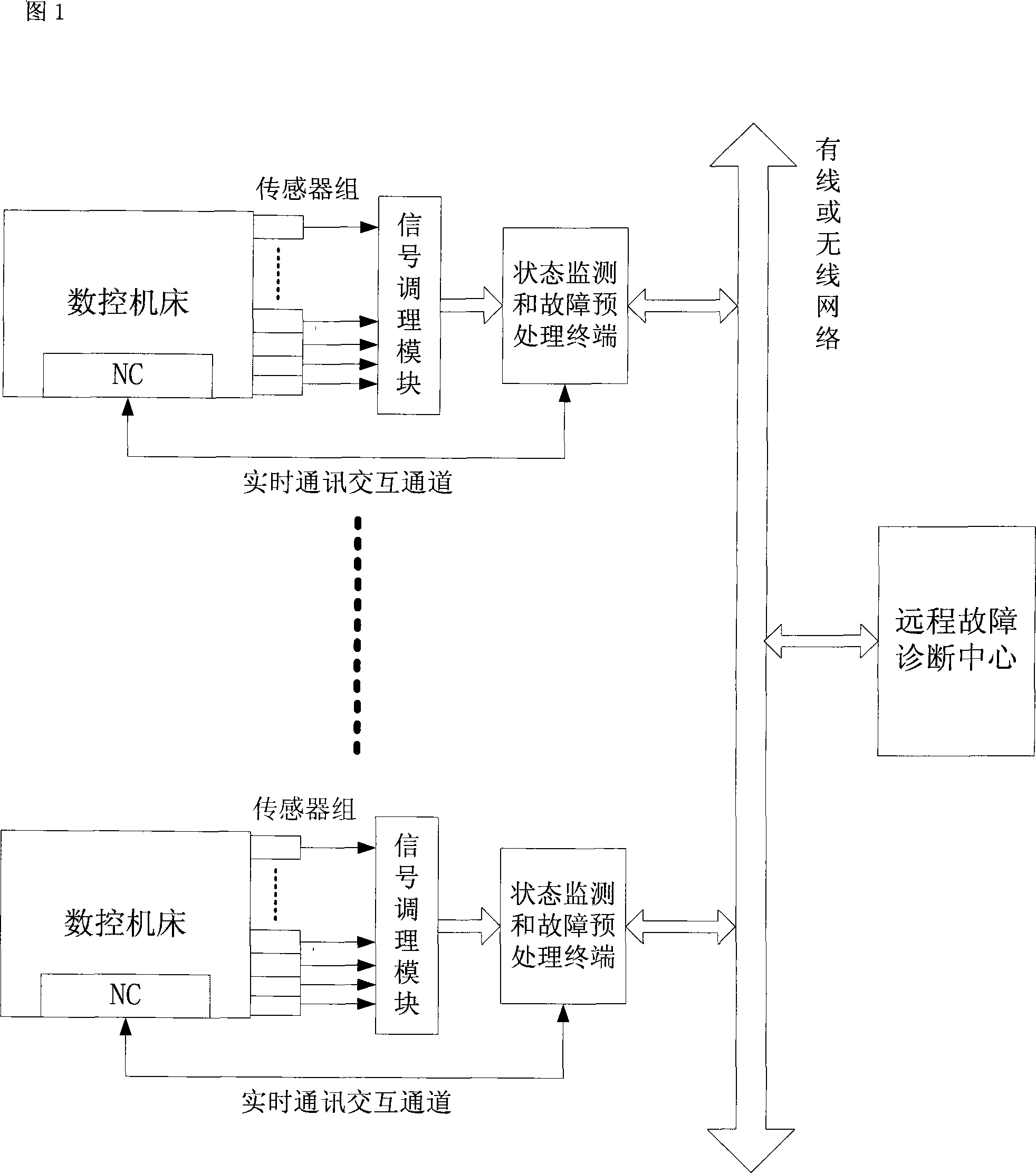

New style numerically controlled machine remote condition monitoring and failure diagnosis system realizing method

The present invention discloses an implementation method of a long-distance state monitor and failure diagnosis system of a novel numerical control machine, and belongs to the numerical control machine, information processing, network technology, industrial control technology fields, and relates to the digital control technology, long-distance telemetry tracking and command, failure diagnosis, network communication, automatic control and signal processing, and mainly makes the use of the modern long-distance telemetry tracking and command technology and the failure diagnosis analysis technology, and combines the characteristics of the state monitor and failure diagnosis of the numerical control machine, and builds the method of the state monitor and failure diagnosis system of the novel numerical control machine based on the wired and the wireless internet.

Owner:石毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com