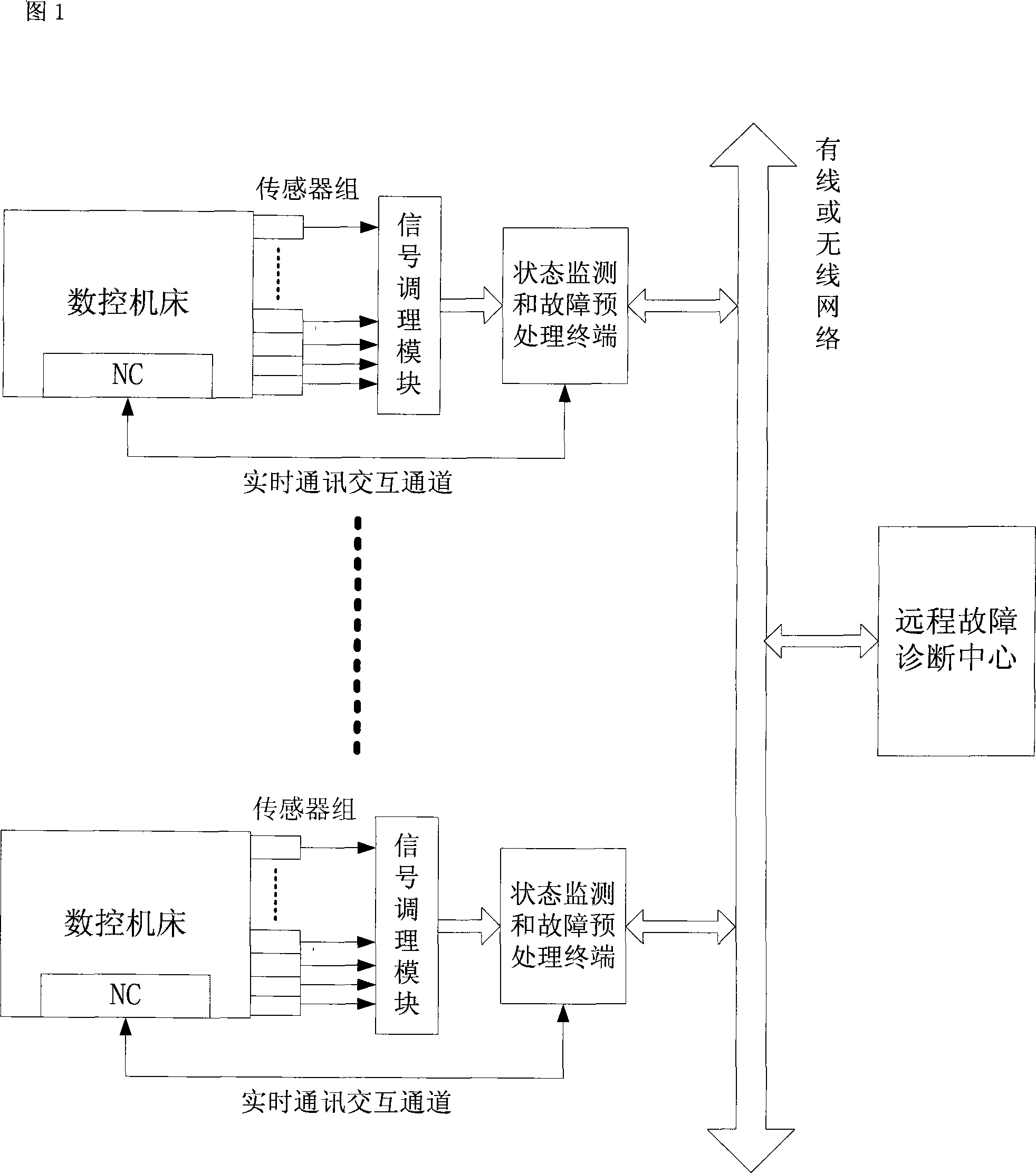

New style numerically controlled machine remote condition monitoring and failure diagnosis system realizing method

A fault diagnosis system and CNC machine tool technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of cumbersome debugging operations, prolonging the downtime of faults, increasing the cost of after-sales service, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] 1) CNC machine tool status monitoring and fault preprocessing terminal

[0011] The CNC machine tool state monitoring and fault preprocessing terminal mainly completes the functions of four parts, namely monitoring function, information communication function with the CNC system, status data and fault data preprocessing function, and remote communication function.

[0012] The first function is to monitor the main signals that can reflect the movement status and processing status of CNC machine tools. The monitoring objects are mostly spindles, feed axes, hydraulic and pneumatic equipment, etc. The status monitoring signals are mainly divided into power, vibration, pressure, flow and temperature etc.

[0013] Power signal monitoring is to monitor the state of the machining process by monitoring the input voltage and current parameters of the CNC machine tool. These parameters reflect the working status of the spindle motor, feed motor, transmission components, and cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com