Speed control method used for numerical control machine

A technology of acceleration and deceleration control and CNC machine tools, applied in the direction of digital control, computer control, general control system, etc., can solve the problems of sudden acceleration, failure to meet the real-time requirements of the CNC system, and unsmooth feed drive acceleration commands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

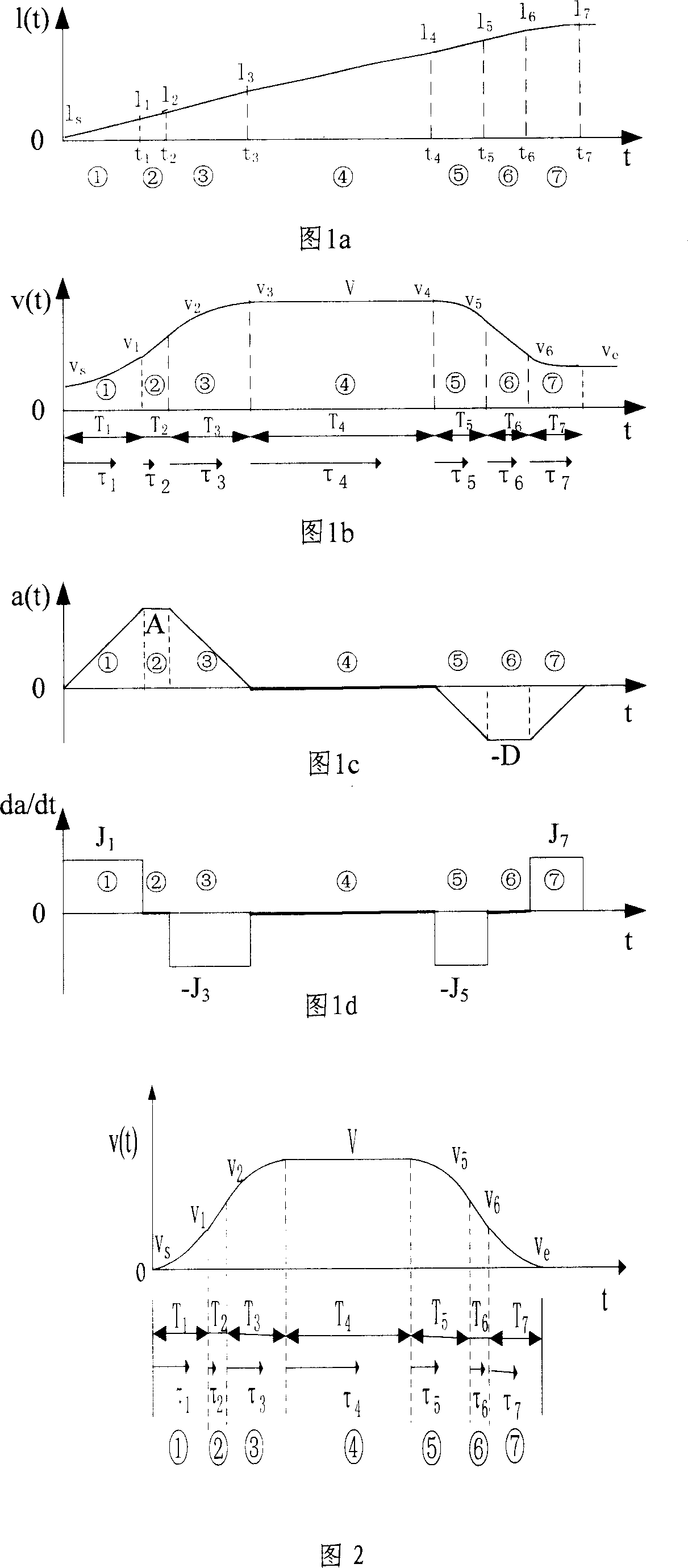

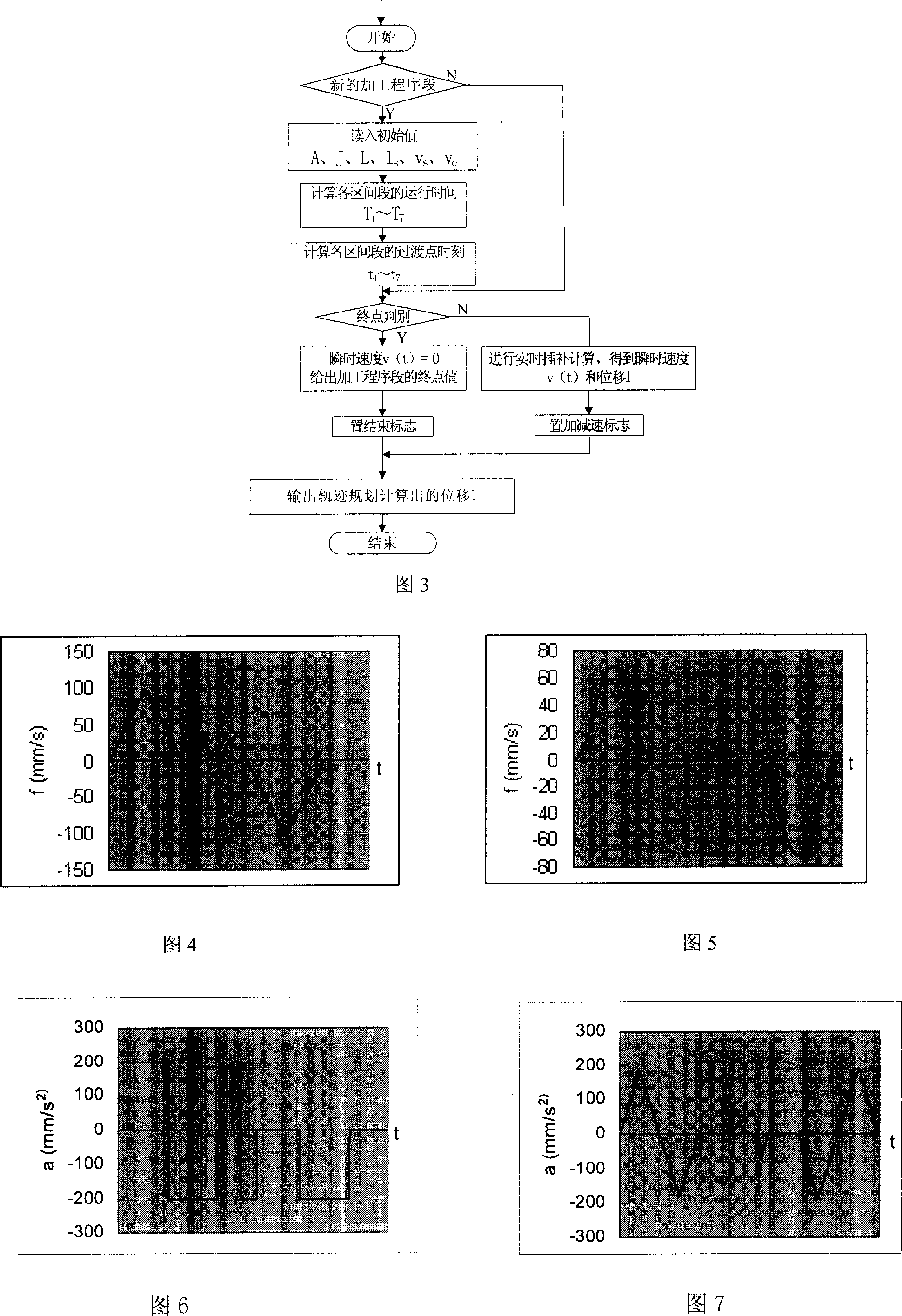

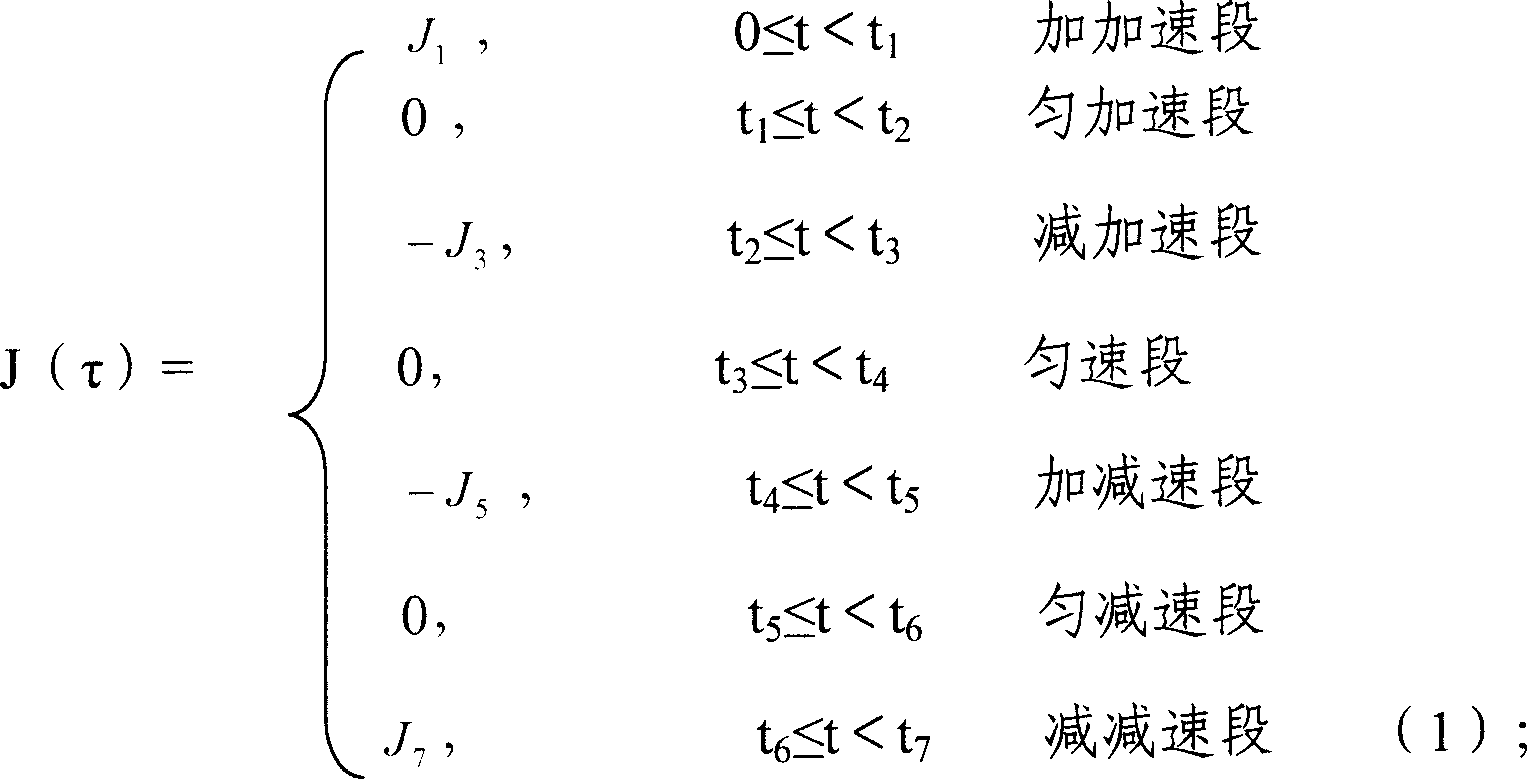

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0056] The present invention introduces the concept of "jerk" for the dynamic characteristics of the control object, makes the jerk constant during the acceleration and deceleration phase, and sets parameters for the two physical quantities of acceleration and jerk; adopts jerk section, uniform acceleration section, The subsection processing method of the seven sections of deceleration acceleration section, constant speed section, acceleration and deceleration section, uniform deceleration section and deceleration section. The real-time interpolation calculation of the segment forms an S-shaped speed curve to realize flexible acceleration and deceleration control; among them, the end point discrimination processing is performed before the real-time interpolation calculation to improve the processing accuracy of the acceleration and deceleration control; the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com