Patents

Literature

43results about How to "Improve surface machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

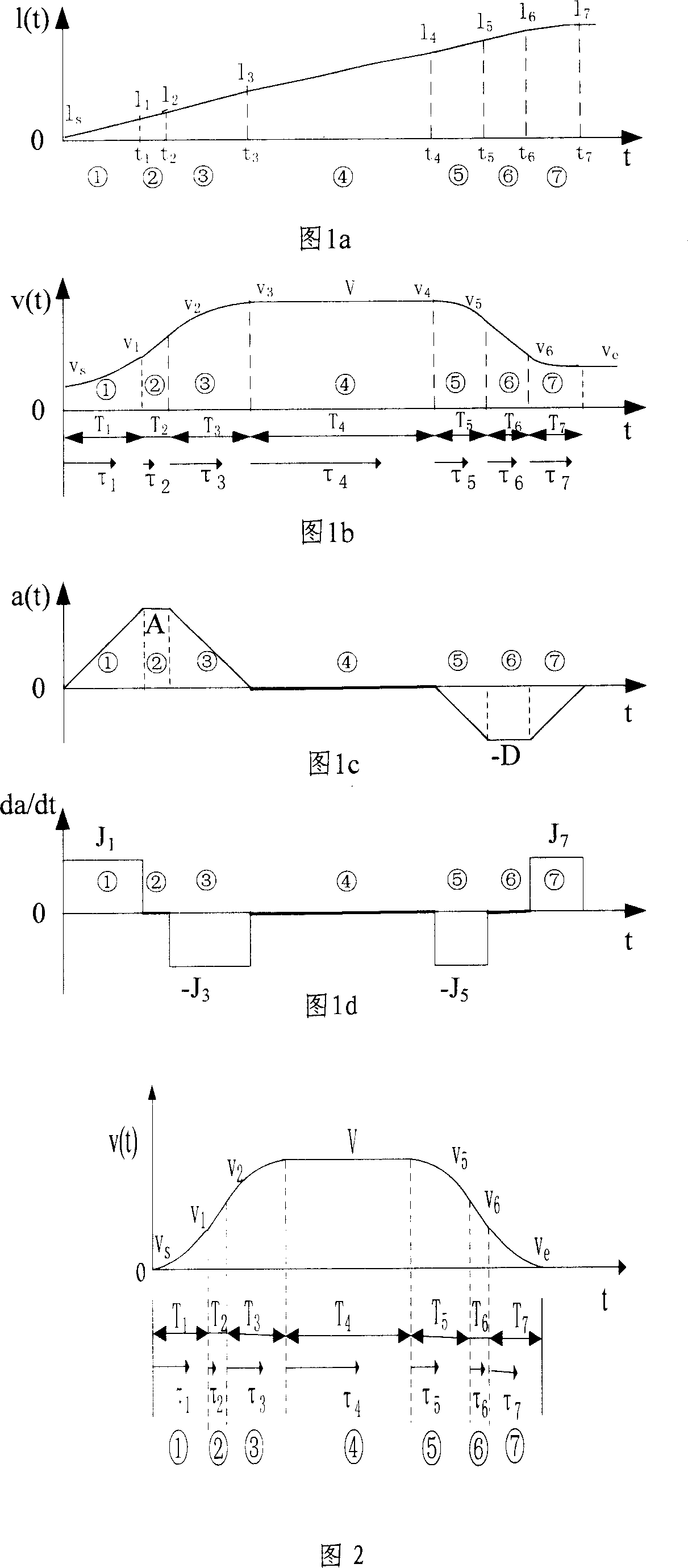

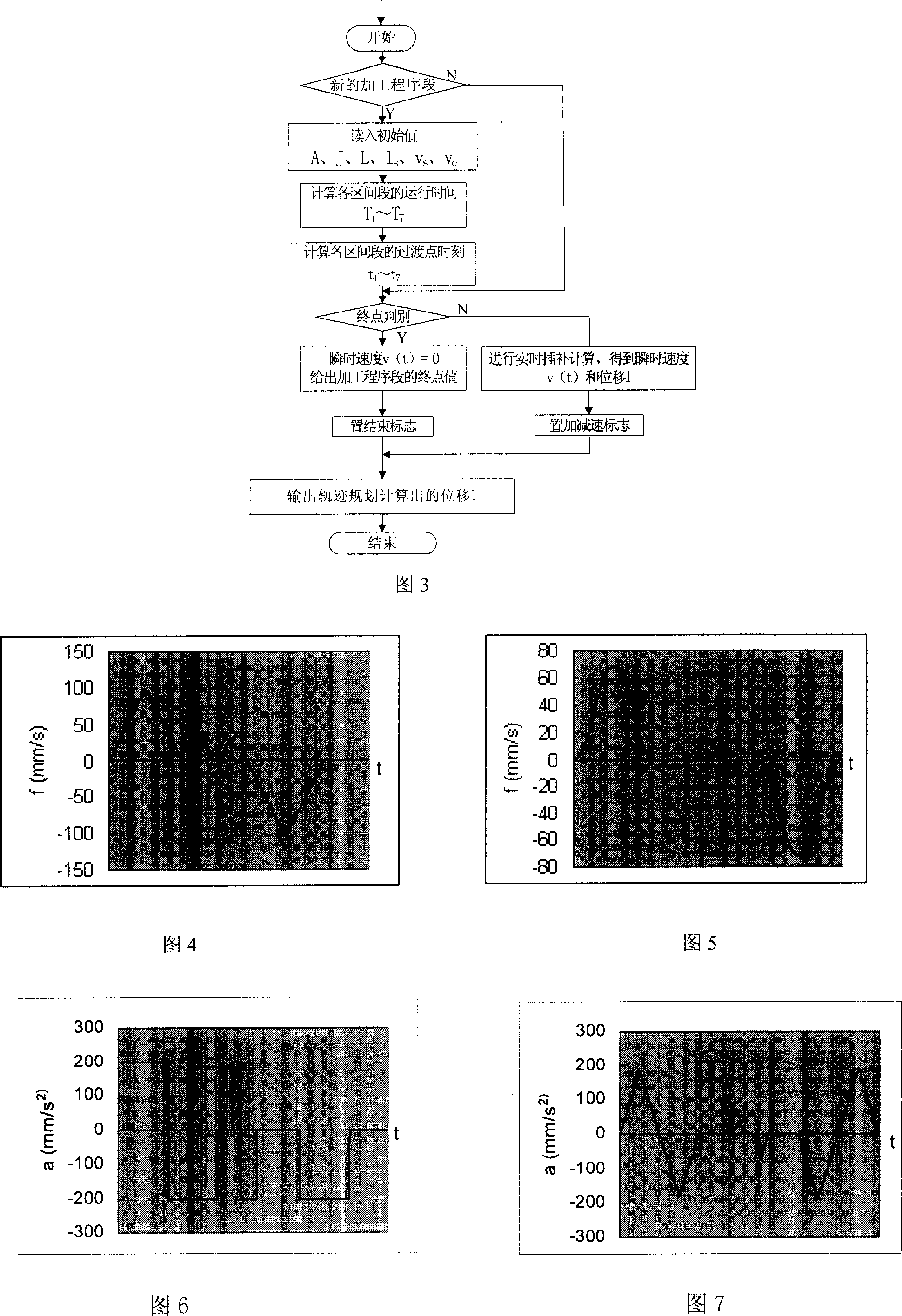

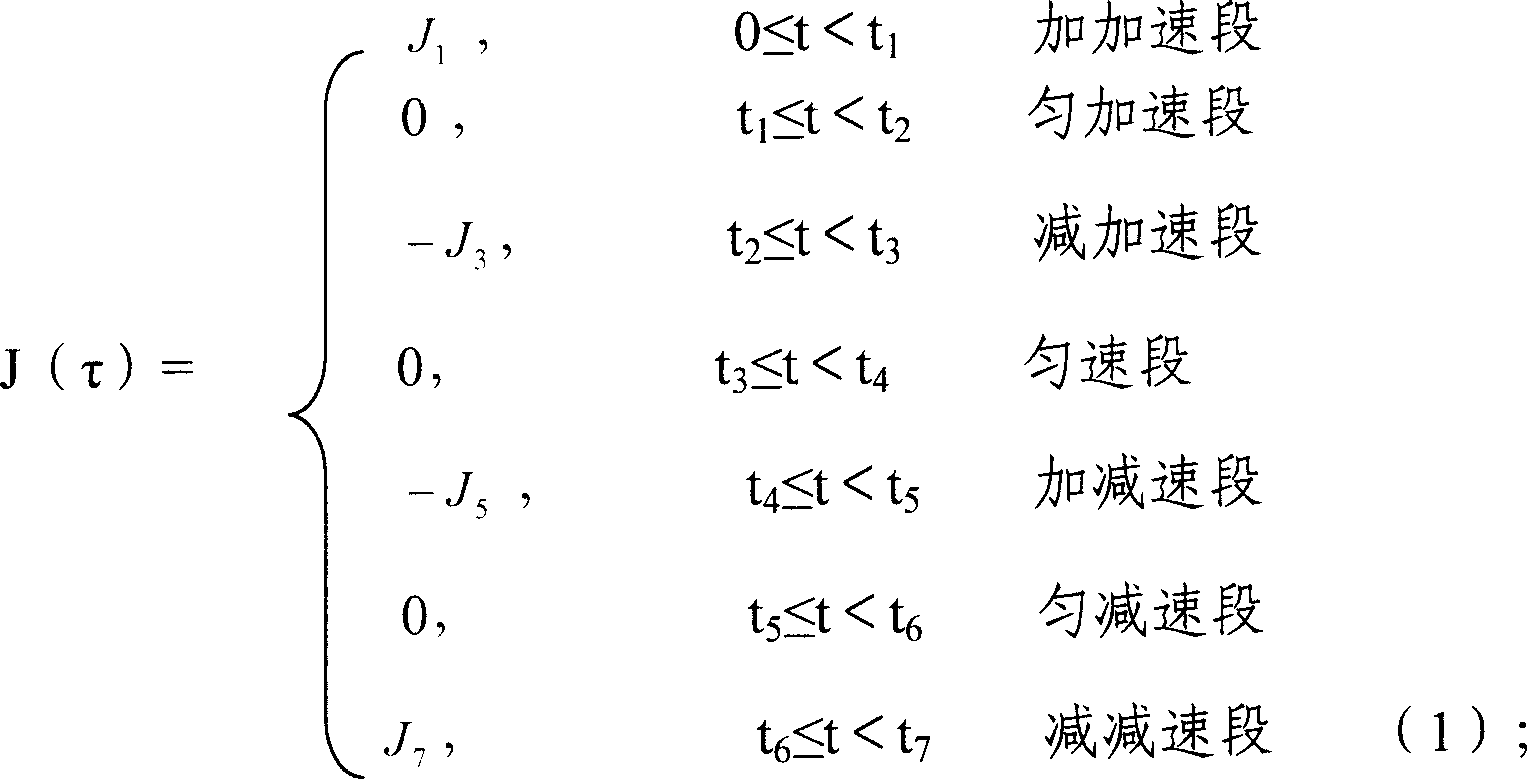

Speed control method used for numerical control machine

InactiveCN1971457AReduce shockImprove smoothnessComputer controlSimulator controlNumerical controlControl theory

The invention discloses acceleration and deceleration controlling means used in numerical control machine, the concept of 'add-acceleration' is introduced against the dynamic property of the controlled member, the add-acceleration is constant in stage of acceleration and deceleration, the two physical quantities of acceleration and add-acceleration are setting; the segmented handling method of add-accelerating sections, uniform accelerating sections, decelerated accelerating sections, uniform speed sections, add-decelerating sections, uniformly-retarded sections and decelerated deceleration sections is adopted, after the interval discrimination, the real-time interpolating calculation in every interval is exceeded based on the integral relation between the add-acceleration, acceleration, speed and displacement, the S type velocity curve is formed to realize the flexible acceleration and deceleration control; the destination discrimination process is proceeded before the interpolating calculation can increase the machining precision of the acceleration and deceleration control. The method is simple, the impact is small, the speed is smooth, the machining precision is high and the flexible control can be realized.

Owner:中国科学院沈阳计算技术研究所有限公司 +1

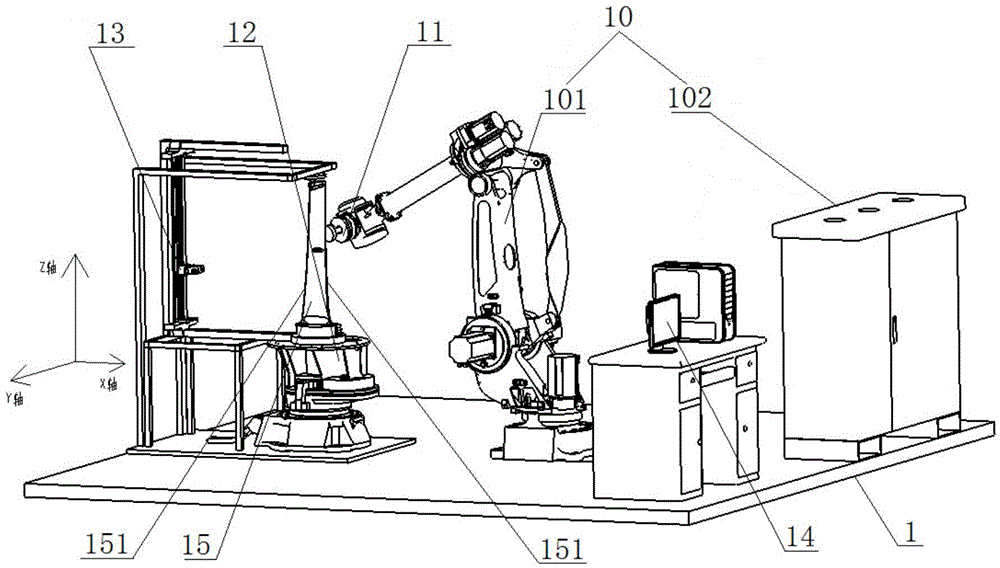

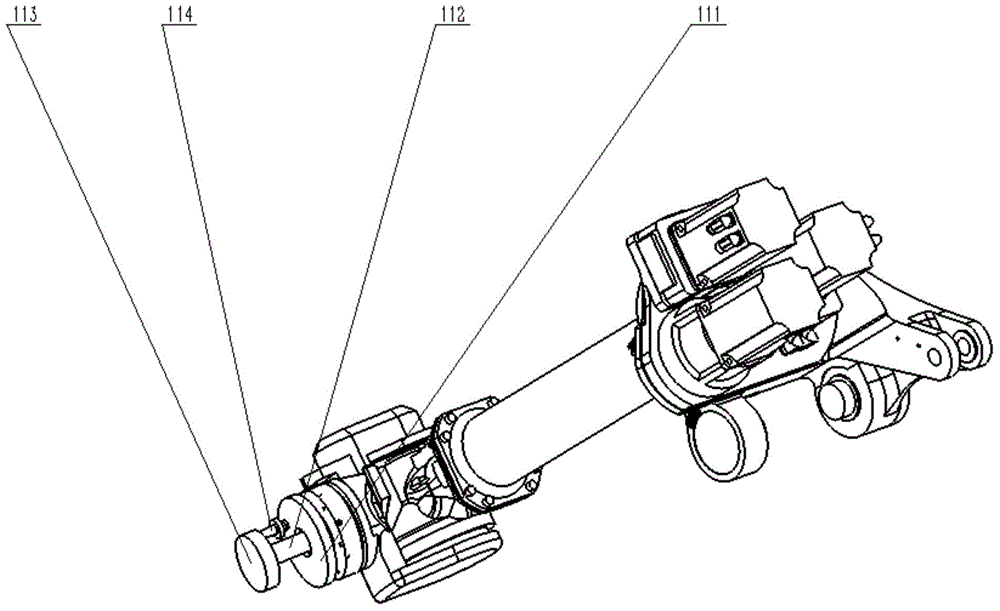

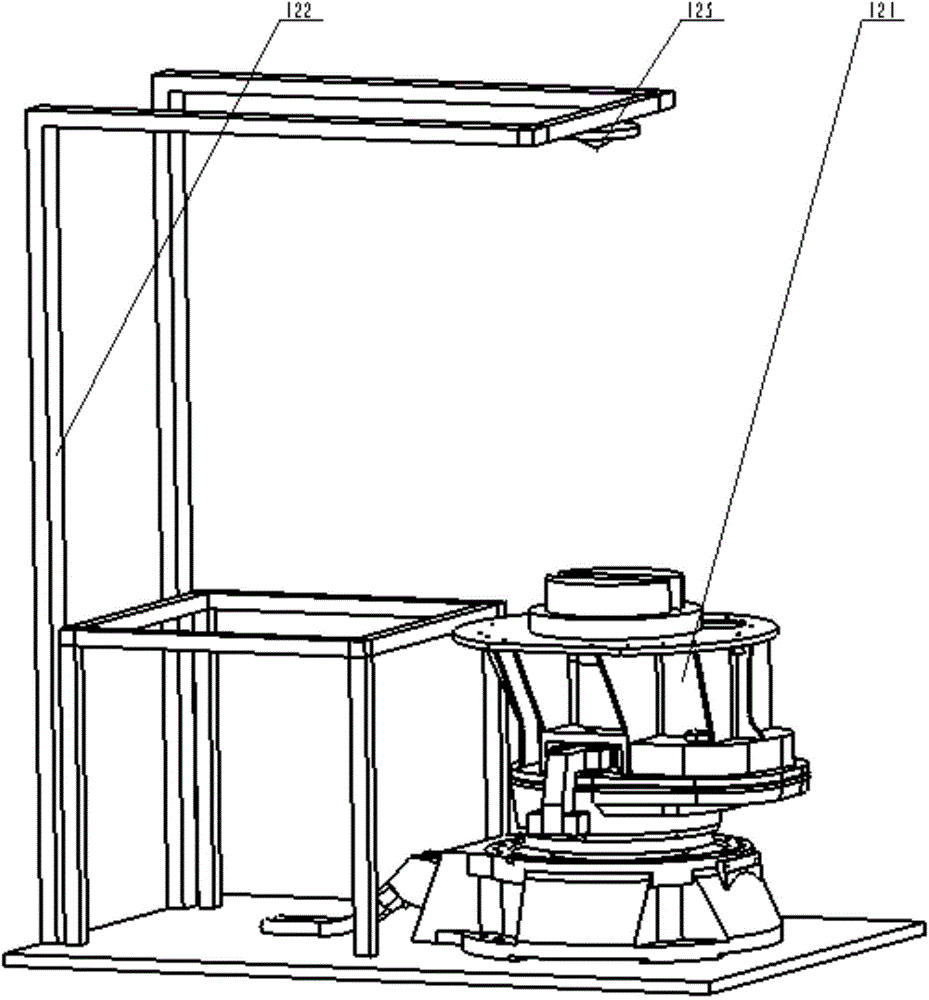

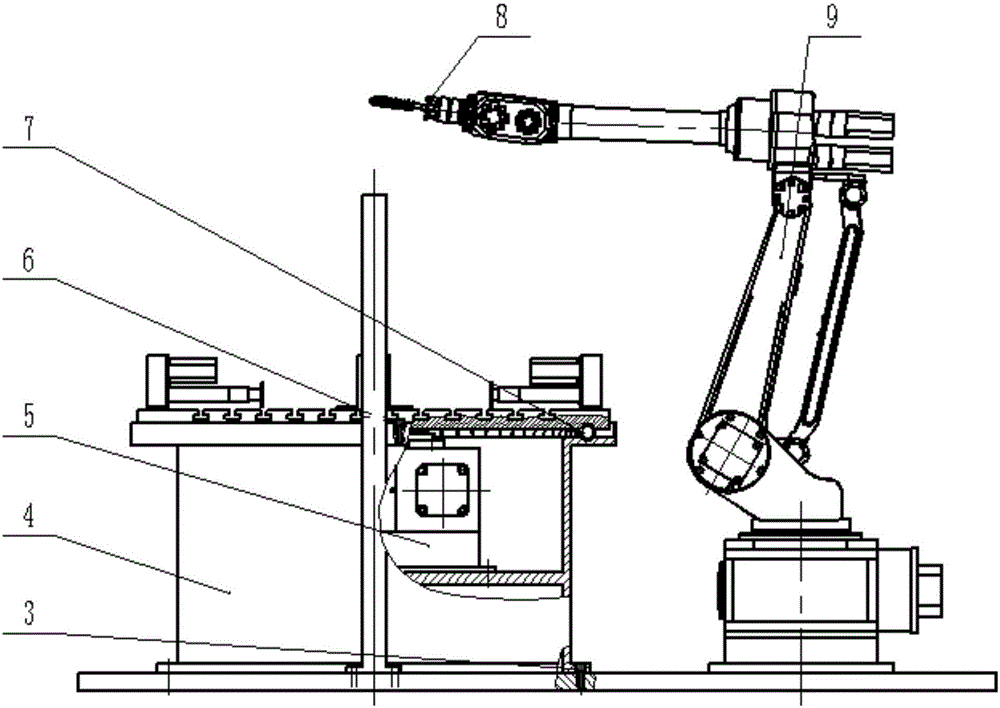

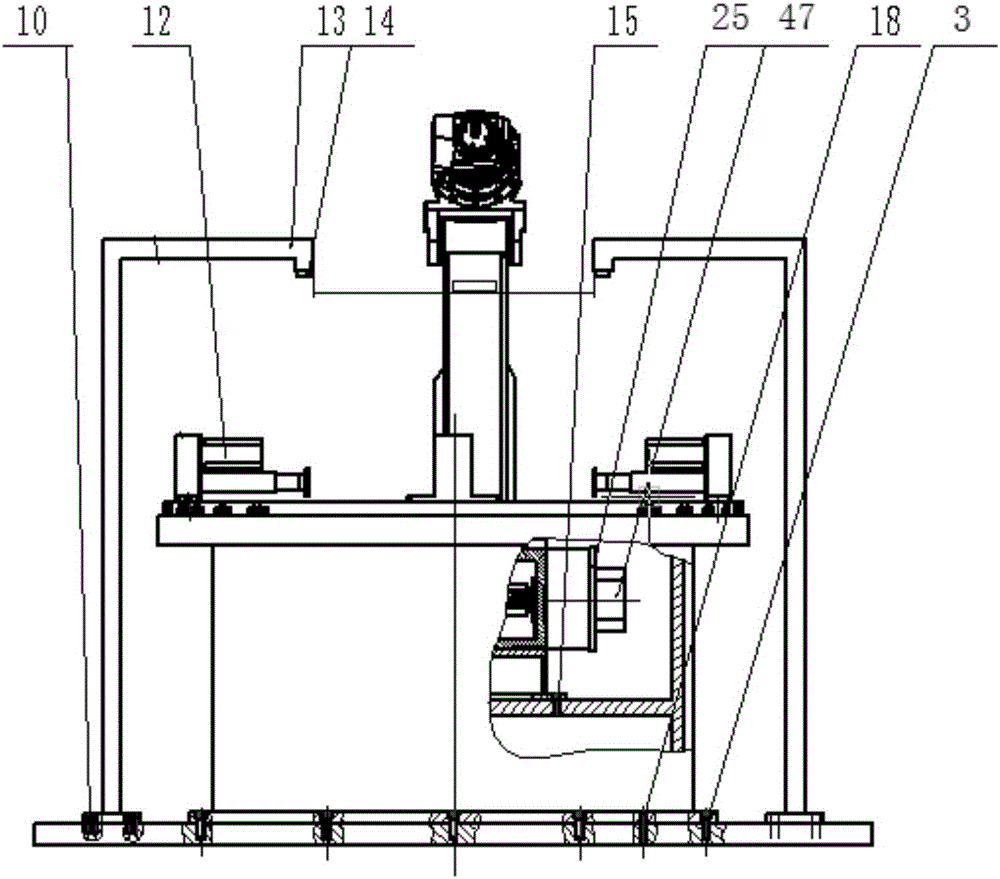

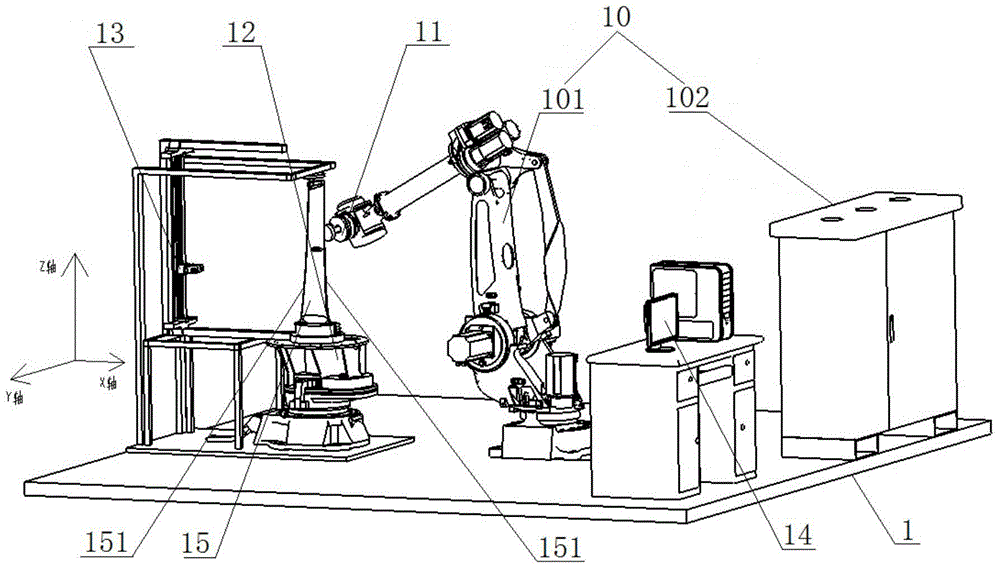

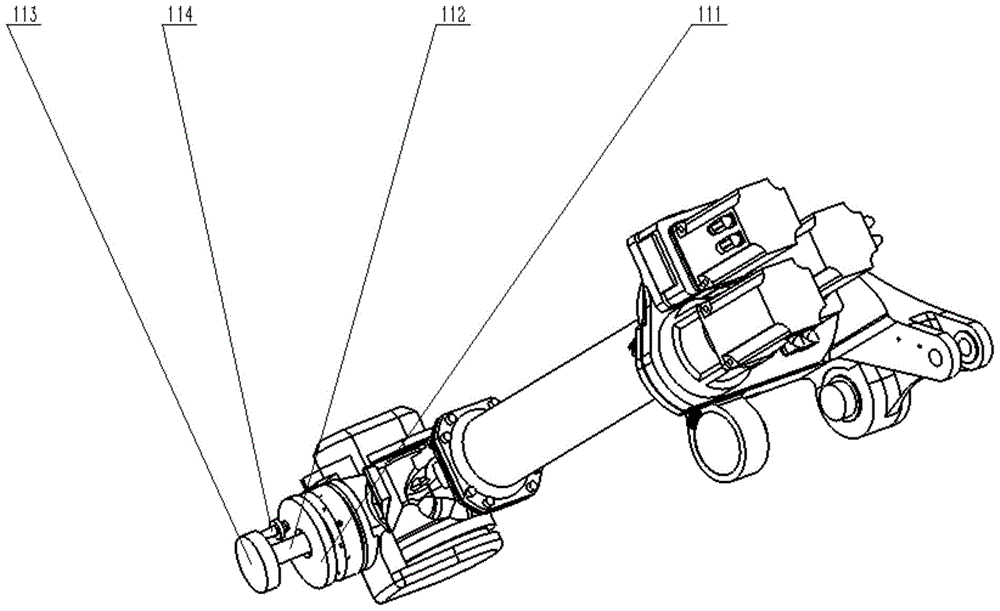

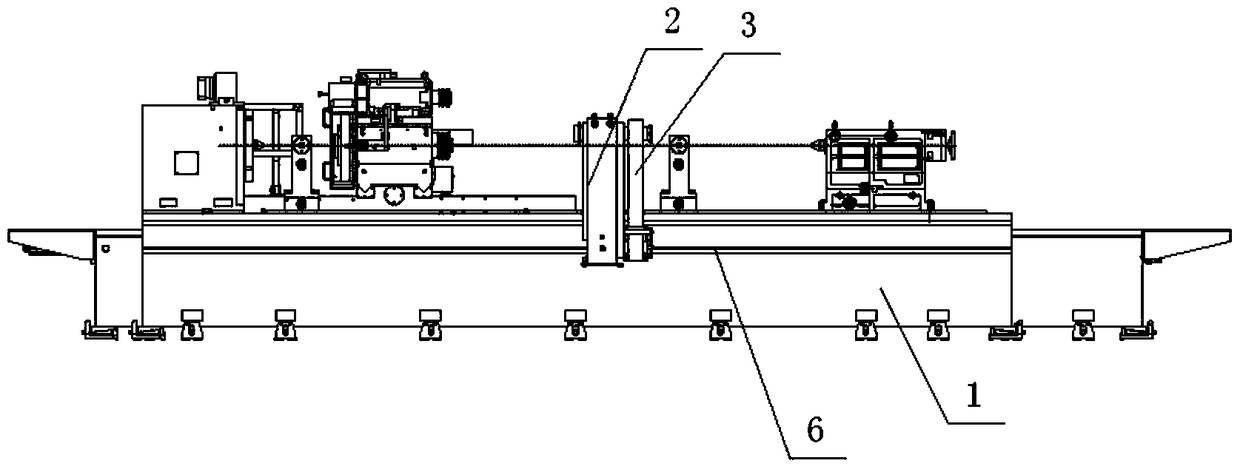

Automatic robot device for grinding air feeding and discharging edges of blade

ActiveCN104858748AGuaranteed machining accuracyGuaranteed grinding accuracyGrinding feed controlAutomatic grinding controlMeasurement deviceEngineering

The invention discloses an automatic robot device for grinding air feeding and discharging edges of a blade. The automatic robot device comprises a base station, a six-freedom-degree robot, a grinding device, a position changing machine, a three-dimensional laser measurement device and a system control host. The six-freedom-degree robot is arranged on the base station. The grinding device is used for grinding the air feeding and discharging edges of the blade. The position changing machine is arranged on the base station. The three-dimensional laser measurement device is arranged on the position changing machine and comprises a triaxial movement platform and a three-dimensional laser measurement device body. The three-dimensional laser measurement device body comprises two three-dimensional laser outline scanners. The system control host is connected with the six-freedom-degree robot and the three-dimensional laser measurement device. The system control host is used for planning the machining path of the grinding device and a moving path of the three-dimensional laser measurement device and sending the paths and commands to the six-freedom-degree robot to be executed. The automatic robot device integrates self-adaptive grinding and measurement functions, and can guarantee the machining precision of the outlines of the air feeding and discharging edges of the blade.

Owner:HUST WUXI RES INST

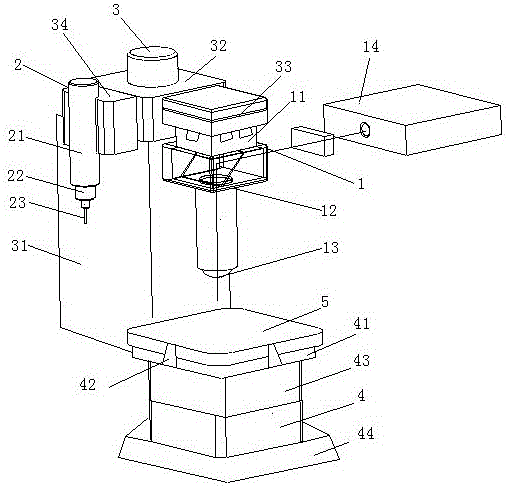

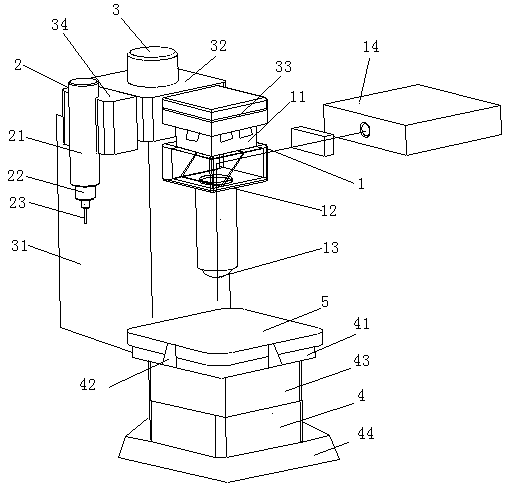

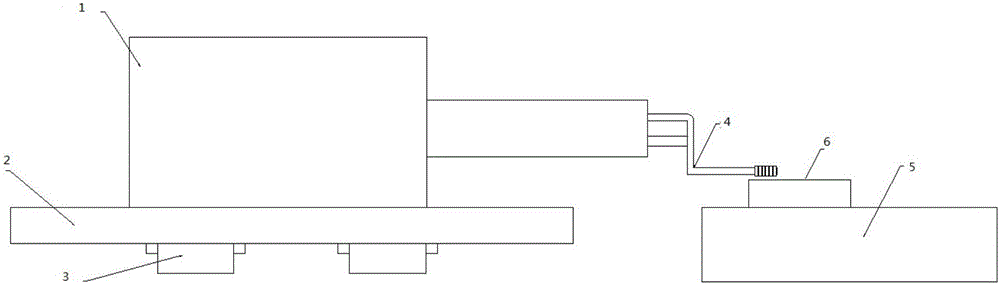

Laser and ultrasound combined type drilling system and machining method thereof

InactiveCN106513986AQuality improvementHigh precisionLaser beam welding apparatusUltrasonic machiningGravity center

The invention relates to the machining field of drilling holes in hard and brittle materials, in particular to a laser and ultrasound combined type drilling system and a machining method thereof. According to the laser and ultrasound combined type drilling system, the hard and brittle materials can be protected, high-speed machining can be realized and locating can be accurate. The laser and ultrasound combined type drilling system mainly comprises a laser machining system, an ultrasonic machining system, a precision rotating and locating mechanism and an axis aligning system, wherein the laser machining system and the ultrasonic machining system are installed on the precision rotating and locating mechanism to regulate locating. The axis aligning system mainly comprises a locating panel, locking structures, a gravity center sensor, a distance sensor, an oriented adjusting structure, a movement adjusting base and a drive control device, and the locating panel is a thin supporting panel loading work-pieces to be machined. Through a combined drilling method, the hard and brittle work-pieces can be machined at high speed and high precision. The laser machining system and the ultrasonic machining system are adopted for combined machining procedures, and therefore pre-drilling can be carried out in advance, high-speed operation can be realized, the quality of the work-pieces can be protected, and the surface machining precision can be improved.

Owner:DONGGUAN UNIV OF TECH +3

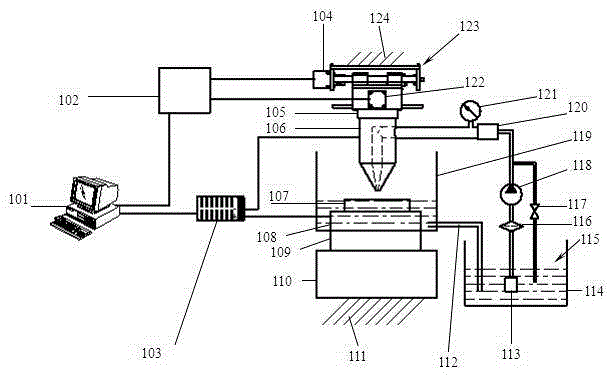

Electrochemical additive manufacturing method and device

InactiveCN104588798AImprove localizationImprove surface machining accuracyMachining working media supply/regeneration3D structure electroformingElectrochemistryEngineering

The invention discloses an electrochemical additive manufacturing method and an implementation device, namely, an electromechanical three-dimensional printing method and device. An electrochemical deposition mode is used for generating a component with the needed appearance size and a needed component. In the technology process, low-conductivity actuating media are adopted, and jet flow is adopted, or a tool electrode with an insulation shielding layer on the outer layer is adopted so as to improve the machining size precision.

Owner:WUXI HUAZHEN NEW ENERGY TECH

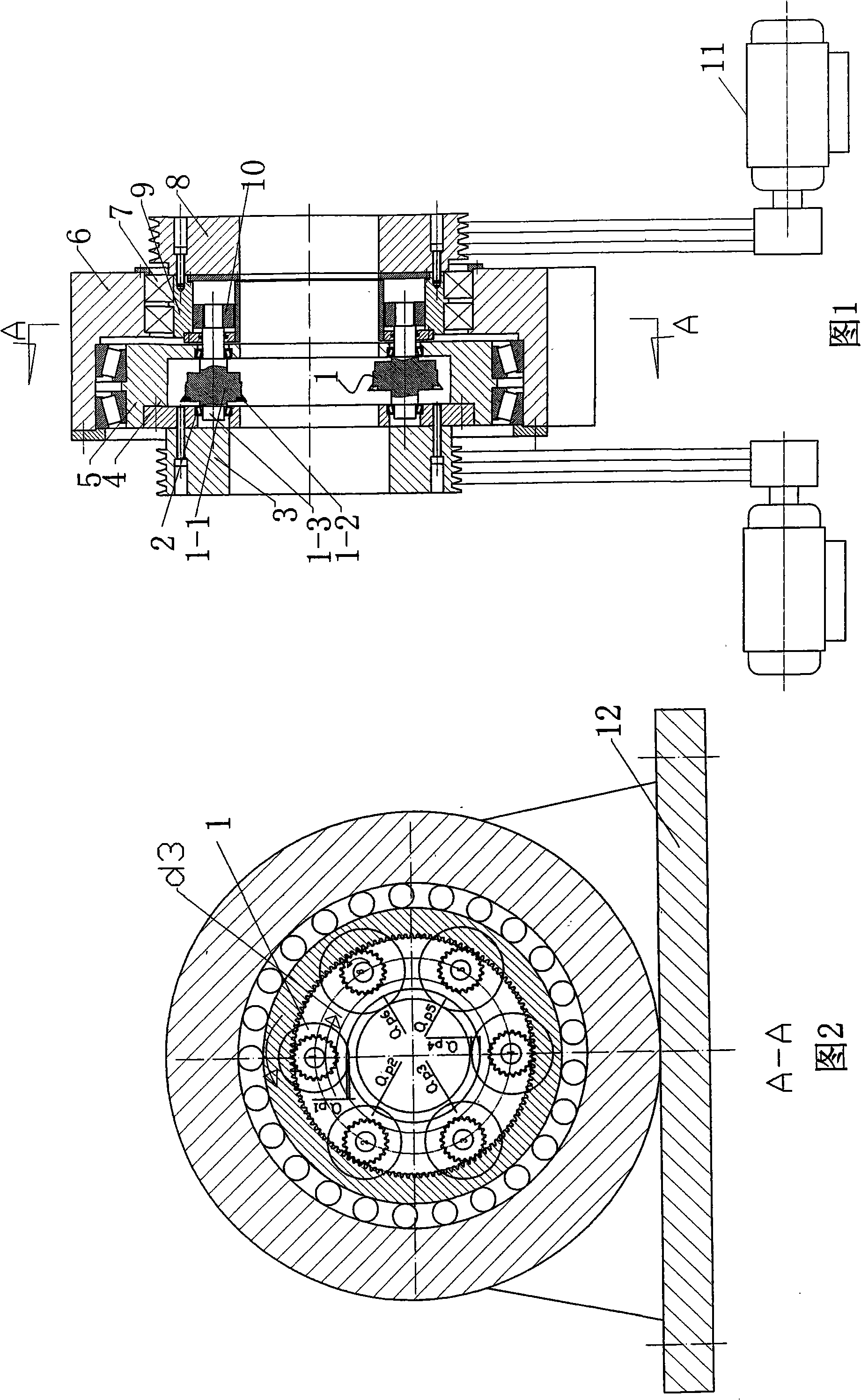

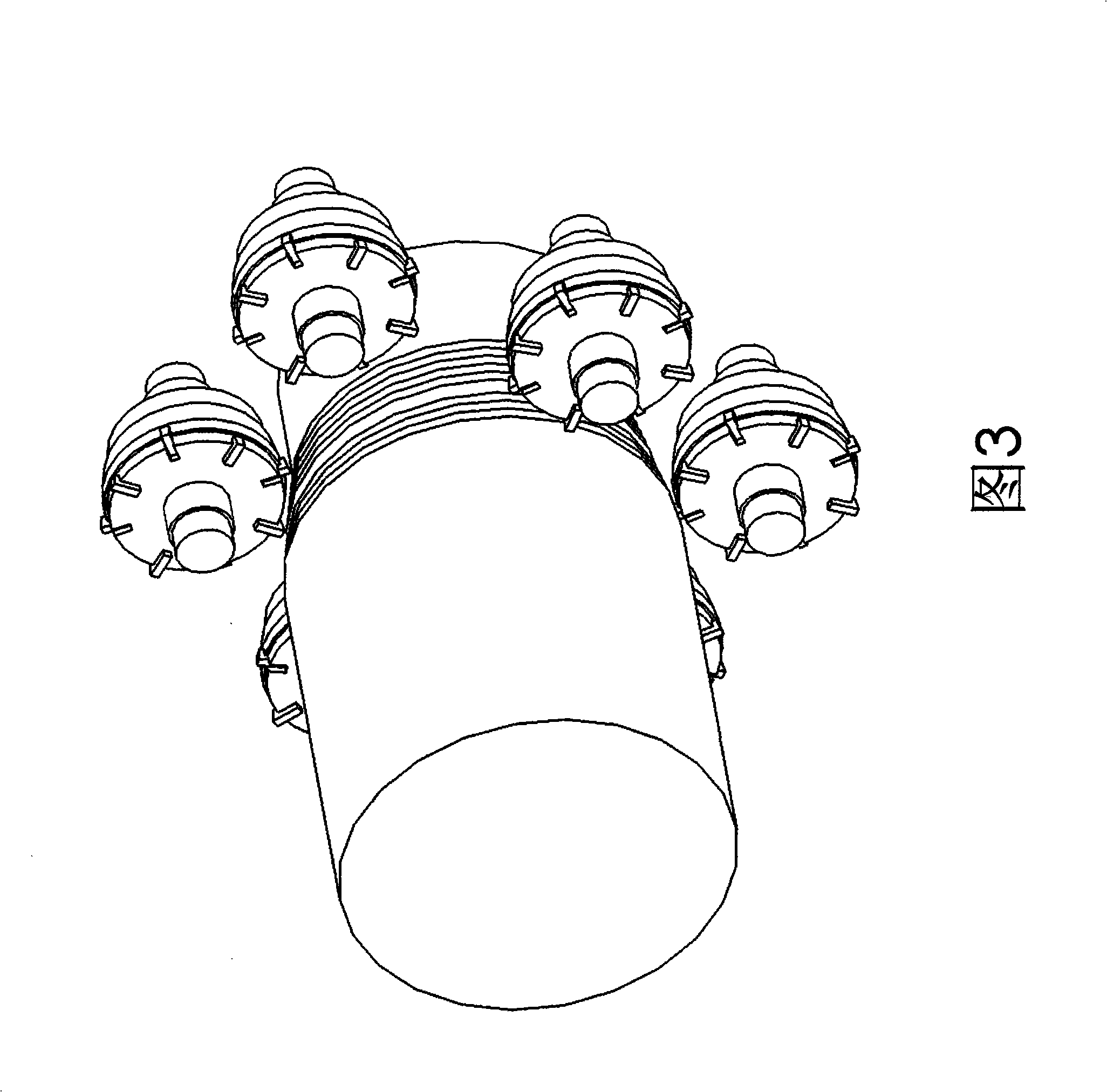

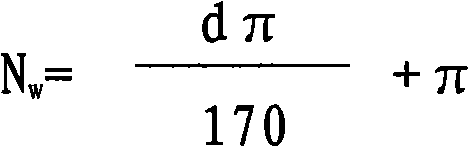

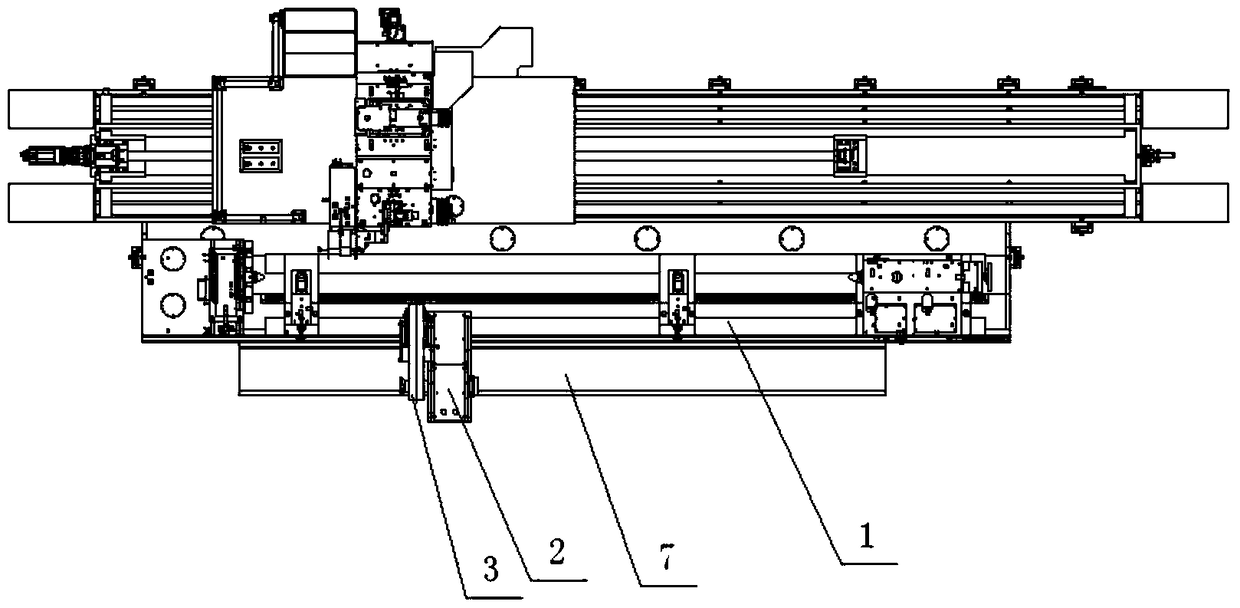

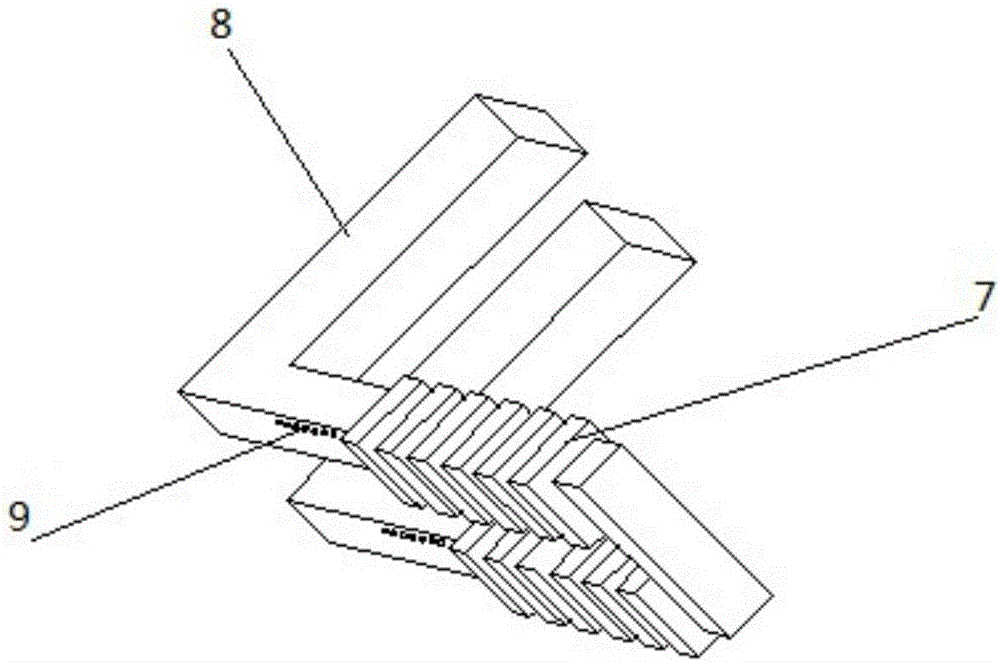

Multi-cutter complex cyclone milling processing method and special topping mechanism thereof

InactiveCN101284316AImprove cutting resistanceImprove efficacyMilling cuttersMilling equipment detailsEngineeringWhirlwind

The invention relates to a multi-cutter combined whirlwind milling method and a dedicated cutting device thereof. The multi-cutter combined whirlwind milling method is adopted for processing shaft-type products. The dedicated cutting device is characterized in that the shaft of the cutter body is supported on a revolving body through a bearing; at least a cutter body is distributed and connected on the concentric circumference of the revolving body; each cutter body is connected with a transmission mechanism for enabling the cutter body to rotate; the revolving body is connected with a fixed sleeve support through a bearing and driven by a motor and a transmission mechanism. The method has the advantages that a plurality of cutter bodies revolving along the revolving body as well as rotating automatically are fixed on the concentric circumference of the revolving body, and each cutter performs high-speed cutting on different processing diameters, thus improving the cutting resistance. By the method, the purpose of saving energy, improving effect and surface machining precision can be fulfilled. The production efficiency of the cutting device is improved a plurality of times compared to an ordinary whirlwind milling machine, and dozens of times compared to turning efficiency. Under the same cutting condition, the power output is greatly reduced.

Owner:张永康 +2

View screen self-guiding type machined part burr removing machine

InactiveCN105945669AReduce cutting timePrecise and controllable movementEdge grinding machinesGrinding drivesMachine partsEngineering

The invention relates to a view screen self-guiding type machined part burr removing machine. A rotation component is fixedly connected in a base. A magnetic needle cutter assembly is installed on a mechanical arm. The upper end and the lower end of a spindle are installed in a rotation base through a bearing and a blind flange correspondingly. A worm gear is connected to the spindle and connected with a worm in a meshing mode. One end of the worm is fixedly connected with an output shaft of a rotary motor. The other end of the worm is connected with the rotation base through a bearing and a blind flange. The rotary motor is fixed to the side face of the rotation base. The upper end of the spindle is fixedly connected with a workbench assembly. A sensor support rod is fixed to the ground. A visual sensor is embedded into the upper end of the sensor support rod. According to the view screen self-guiding type machined part burr removing machine, through the visual sensor, a machined part can be scanned and a burr position of the part can be detected, comparison with a three-dimensional model is made through system software, a cutting path of a burr cutter is generated automatically, the mechanical arm conducts burr removing operation through the burr removing cutter according to the cutting path, and thus intelligent, efficient and mechanized burr removing operation is achieved on a workpiece.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Laser direct writing pre-forming photocatalysis plating preparing method for material surface metal pattern

ActiveCN108441843AReduce manufacturing costShort processLiquid/solution decomposition chemical coatingSemiconductorMetal

The invention discloses a laser direct writing pre-forming photocatalysis plating preparing method for a material surface metal pattern, and belongs to the technical field of material surface treatment. The laser direct writing technology and the photocatalysis plating technology are combined, and on the basis of a laser direct writing etched pre-formed high-precision nano semiconductor film pattern, photocatalysis plating is conducted for preparing the high-quality metal pattern. The laser direct writing pre-forming photocatalysis plating preparing method for the material surface metal pattern is environment-friendly, short in process, capable of saving metal, efficient and low in cost and has universality and high stability; and the prepared metal pattern is high in size precision, goodin clad layer surface quality and excellent in performance, and the bonding strength between the prepared metal pattern and a base body is high.

Owner:UNIV OF SCI & TECH BEIJING

Environment-friendly water-based metal working fluid and preparation method thereof

InactiveCN104357204AImprove cooling effectGuaranteed hardnessLubricant compositionMetalworking fluidDioxyethylene Ether

Owner:QINGDAO BAIZHONG CHEM TECH

Environment-friendly metal cutting fluid and preparation method thereof

InactiveCN104293465AImprove cooling effectGuaranteed hardnessLubricant compositionPhosphateAlkylphenol

The invention relates to an environment-friendly metal cutting fluid and a preparation method thereof. The environment-friendly metal cutting fluid is composed of the following components in parts by weight: 15-20 parts of alkylphenol polyoxyethylene, 15-20 parts of cocoanut fatty acid diethanolamide, 15-20 parts of glycerylmonoricinoleate, 3-6 parts of rosin alcohol solution, 2-5 parts of synthetic rust inhibitor, 0.1-0.2 part of defoaming agent, 0.3-0.5 part of octadecylamine isooctyl acidic sulfur phosphate and the balance of water. The water-based metal cutting fluid has the advantages of favorable lubricating property, high rust resistance, high antibacterial property, high stability, long service life, no environmental pollution and no harm to the human body, and comprehensively satisfies the demands from some highly difficult processing for cutting.

Owner:QINGDAO BAIZHONG CHEM TECH

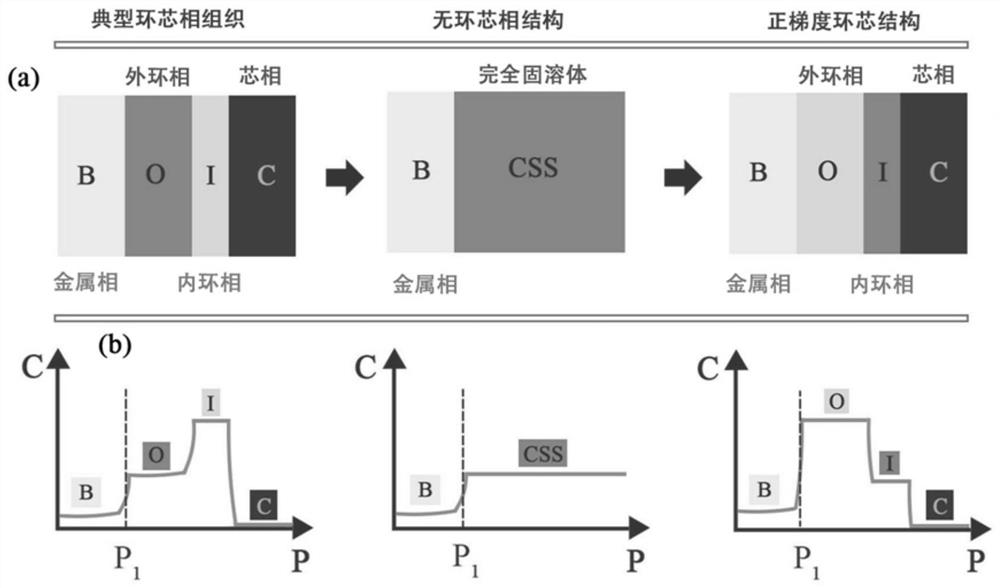

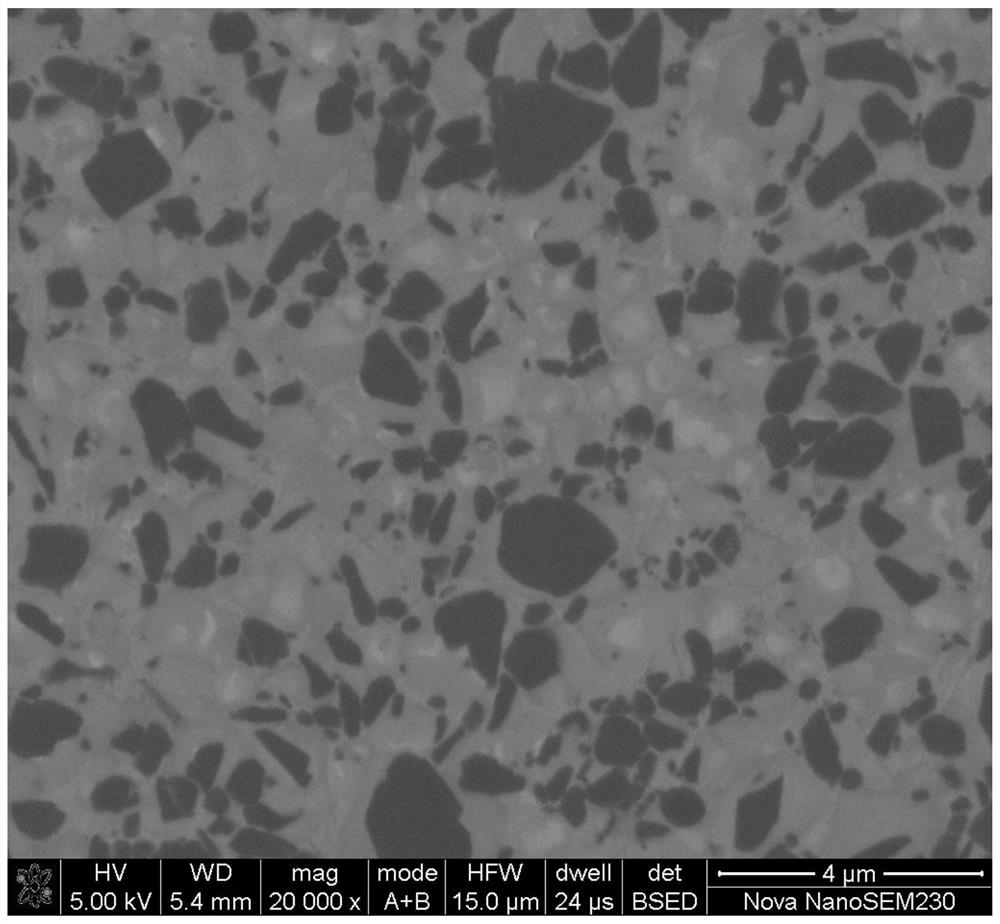

Ti (C, N)-based metal ceramic with positive gradient ring core phase and preparation method thereof

The invention discloses a Ti (C, N)-based metal ceramic with a positive gradient ring core phase and a preparation method thereof. The outer ring phase of a metal ceramic ring core structure is rich in W / Mo and poor in N compared with the inner ring phase, a solid solution metal element W / Mo in a ring core phase is distributed in a positive gradient mode from the core part to the outer ring, and the metal ceramic ring core structure is of a positive gradient structure opposite to a conventional ring core phase in composition. Compared with a conventional ring core phase Ti (C, N)-based metal ceramic, a positive gradient ring core phase structure can improve the interface wetting and bonding strength of a ceramic phase and a binding phase, reduce the lattice mismatch degree of the interface in a ring core, and effectively improve the strength and thermal shock resistance of the Ti (C, N)-based metal ceramic. On the basis of keeping good obdurability, the metal ceramic has higher obdurability and thermal shock resistance compared with conventional metal ceramic, can improve the surface machining precision of a tool and prolong the service life of the tool, and is widely applied to the fields of bearing materials, cutting tools, mold materials and the like.

Owner:CENT SOUTH UNIV +1

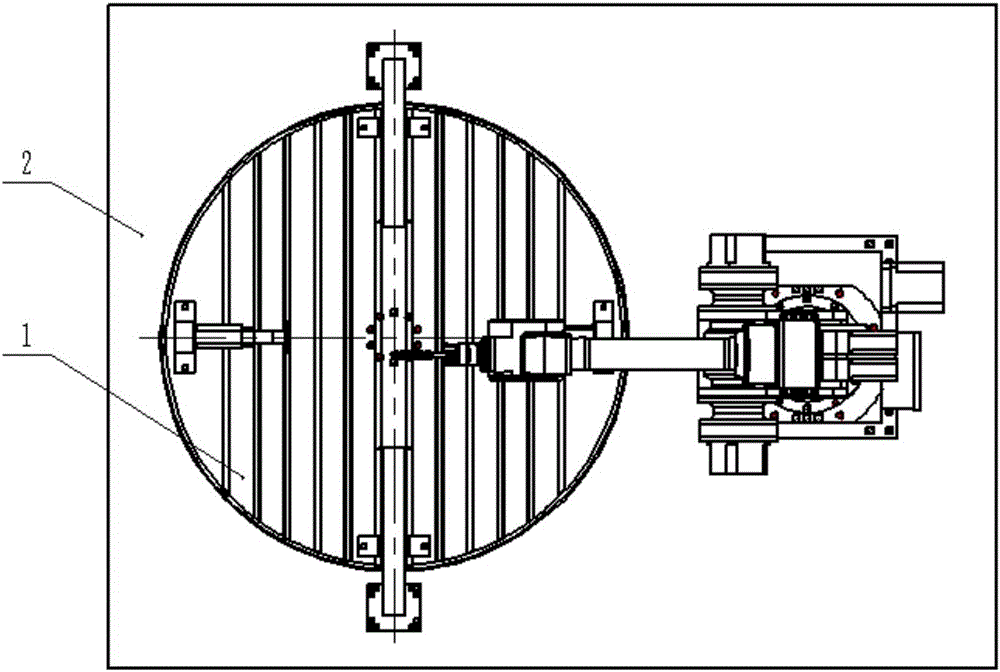

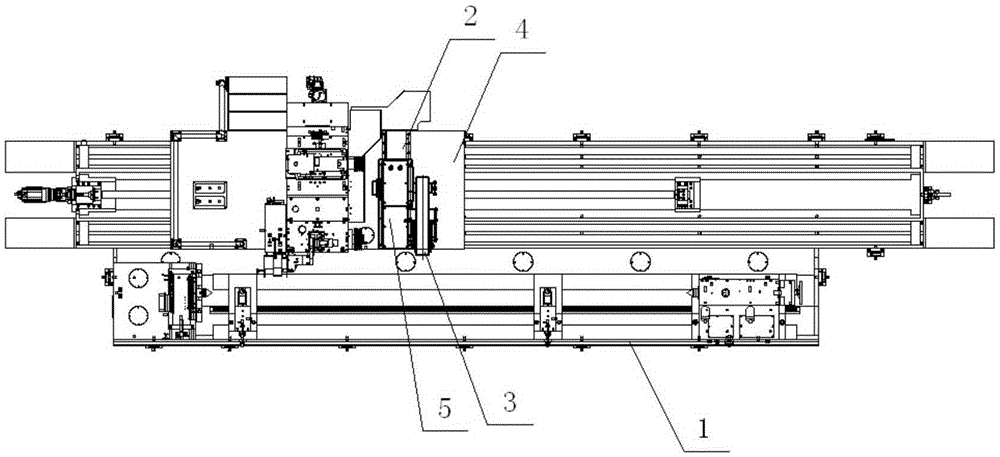

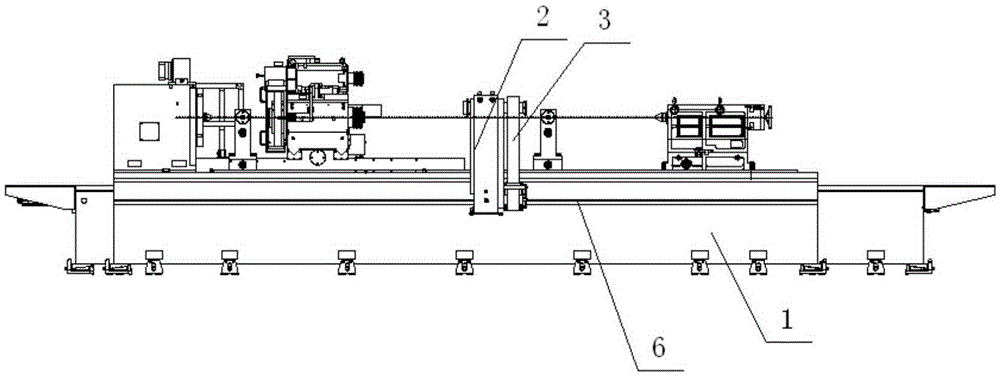

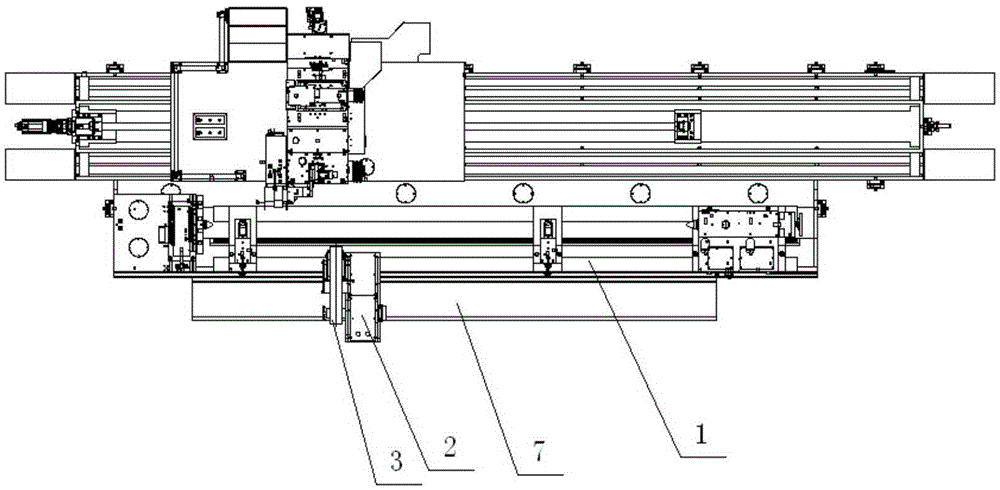

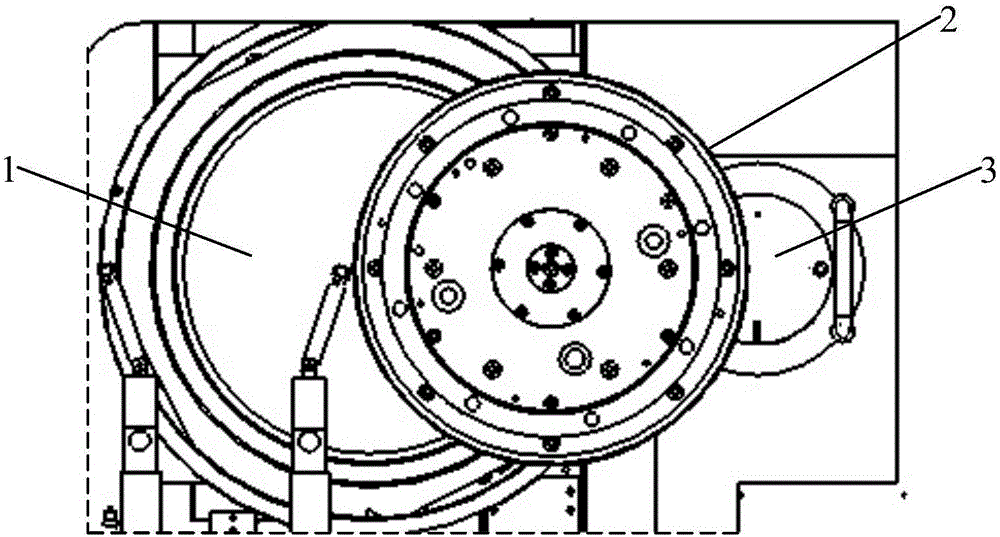

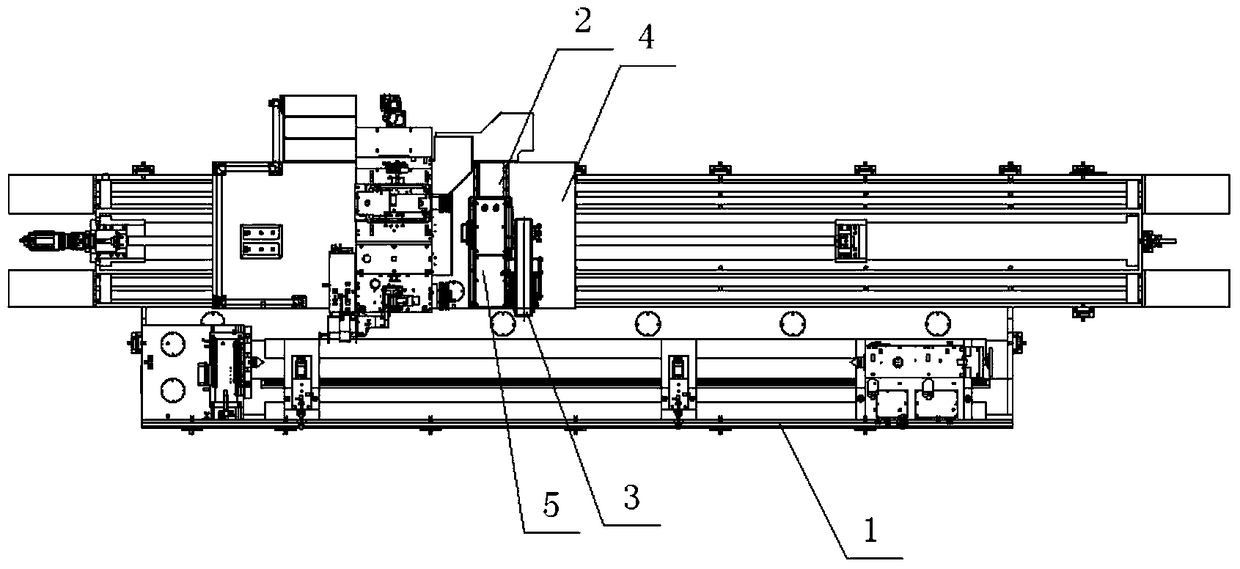

Roll workpiece surface grinding and polishing all-in-one machine

ActiveCN105382641AAvoid disassemblyAvoid secondary liftingGrinding carriagesPolishing machinesEngineeringUltimate tensile strength

The invention discloses a roll workpiece surface grinding and polishing all-in-one machine which comprises a roll grinder, a polishing device, an axial driving device and a radial driving device. The polishing device is mounted on one side of the roll grinder; the axial driving device can drive the polishing device to move in the axial direction of a roll; the radial driving device can drive the polishing device to be fed in the radial direction of the roll; at least one polishing head is arranged on the polishing device; the polishing head can make contact with the surface of the roll on the roll grinder. According to the roll workpiece surface grinding and polishing all-in-one machine, the roll is ground and polished through the roll grinder, the roll can be lifted and polished at a time, and disassembling, secondary lifting and secondary positioning of the roll are avoided; positioning errors are lowered, the surface machining precision is improved, the machining efficiency is improved, and the labor intensity of workers is lowered. Compared with original polishing equipment, the polishing device is simple in structure, equipment cost is greatly lowered, equipment energy consumption is lowered, the space occupied by the equipment is reduced, and the roll machining cost is lowered.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

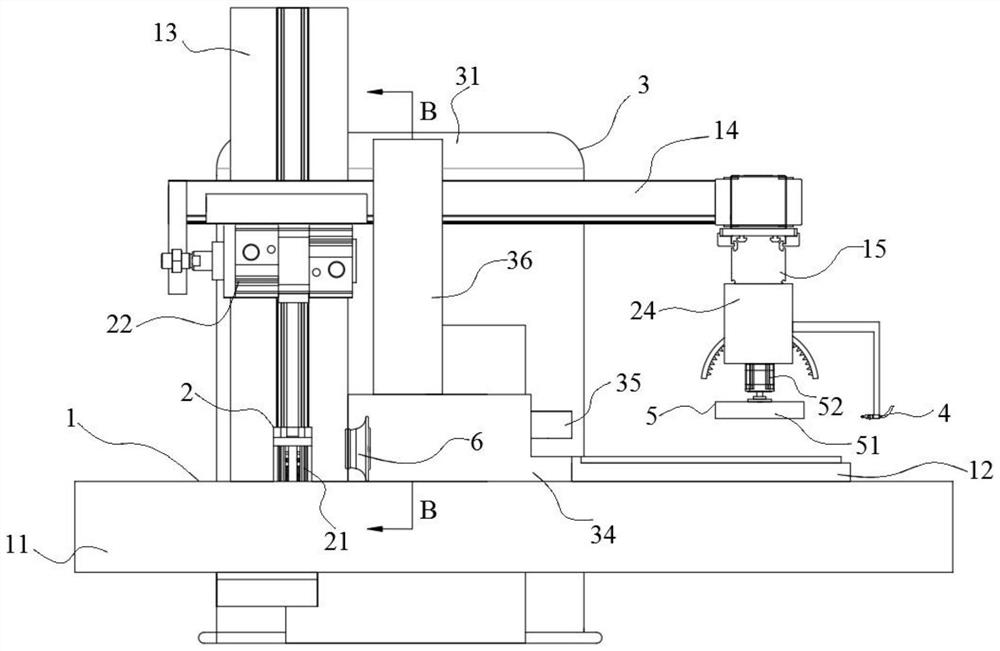

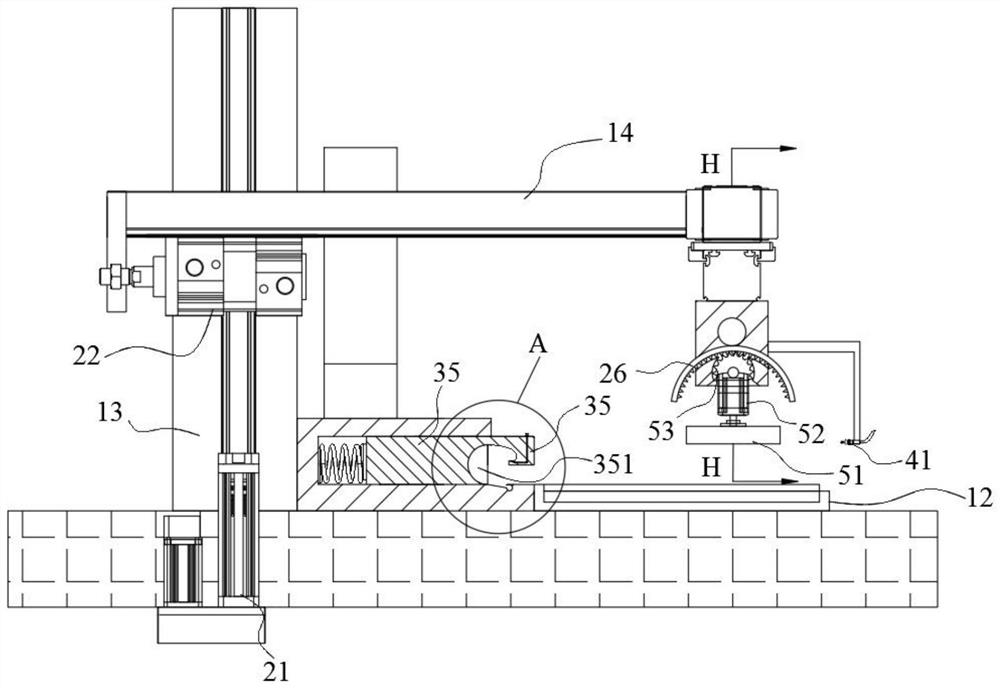

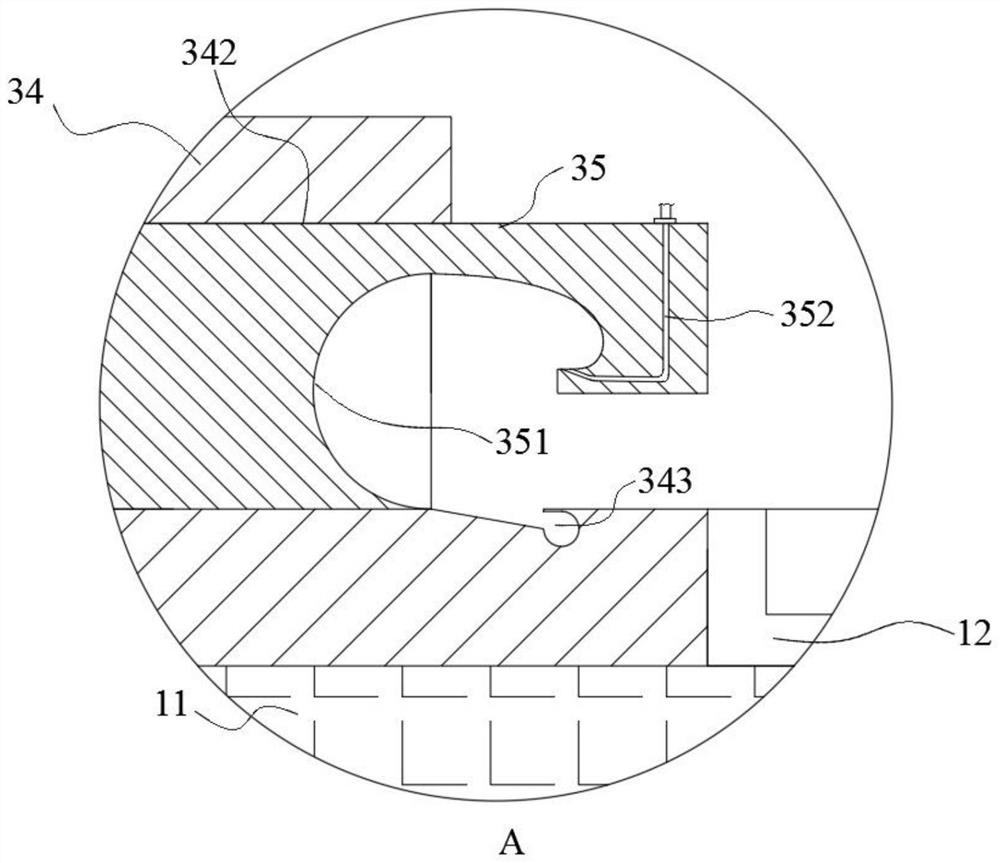

Machining method for profile detection test sheet of diamond roller

ActiveCN105382663AImprove surface machining accuracyImprove detection accuracyGrinding machinesEngineeringMachining

The invention provides a machining method for a profile detection test sheet of a diamond roller. The method includes the steps that a two-column jig boring machine is selected as a machining device, the diamond roller is installed in a boring head of the two-column jig boring machine through a self-made locating mandrel, the profile detection test sheet is installed on the machine face of the two-column jig boring machine through a pair of flat tongs, the machine face is moved, the profile detection test sheet is moved to and makes contact with the diamond roller, the two-column jig boring machine is started, and the diamond roller rotates at a high speed and is controlled to be fed towards the profile detection test sheet till the profile detection test sheet is ground by the diamond roller to be in a complete profile contour. By the adoption of the method, the two-column jig boring machine is introduced to grinding of the profile detection test sheet of the diamond roller for the first time, the machining task can be finished only through one device, the possibility of clamping and aligning errors and manual operation errors is reduced to the lowest extent, the profile machining accuracy of the profile detection test sheet is effectively improved, and meanwhile the detection accuracy of the size of the profile of the diamond roller is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Porous silicon nitride capillary core for a loop heat pipe

ActiveCN106066131BGood chemical stabilityImprove acid and alkali corrosion resistanceIndirect heat exchangersDecompositionChemical stability

A porous silicon nitride capillary core for a loop heat pipe is formed by firing raw materials including silicon nitride powder, a sintering aid and a pore forming agent, wherein the content of silicon nitride is not smaller than 90% by weight. The average grain size of the silicon nitride powder ranges from 0.1 micrometer to 10 micrometers, and the proportion of the alpha-phase silicon nitride is larger than 90%. Micropores included in the porous silicon nitride capillary core communicate with one another, the pore diameter of the micropores ranges from 0.5 micrometer to 5 micrometers, and the open porosity is larger than 50%. The porous silicon nitride capillary core is formed by sintering the silicon nitride powder, has good chemical stability and is resistant to corrosion of acid and alkali, decomposition of working media in the loop heat pipe can be effectively restrained, and the service life of the loop heat pipe is prolonged. Meanwhile, the porous silicon nitride capillary core is high in brittleness and good in machining performance, the surface micropores cannot be closed during outer wall finish machining, and the high open porosity of the capillary core is guaranteed.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

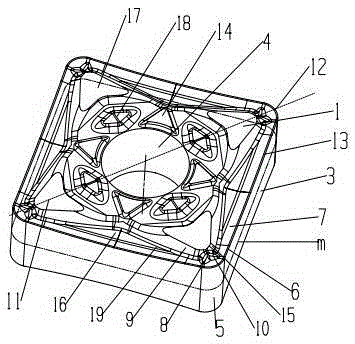

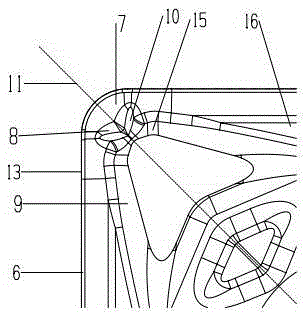

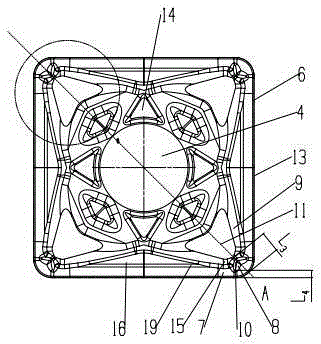

Indexable double-sided cutting inserts

ActiveCN103551615BImprove impact resistanceHigh strengthTurning toolsUltimate tensile strengthMechanical engineering

The invention provides a double-sided cutting blade capable of transferring. The double-sided cutting blade comprises a blade body which has a polygon shape and is symmetrical up and down; the blade body comprises an upper end surface, a lower end surface and side surfaces; a mounting through hole is arranged at the geometric center of the blade body; every two adjacent side surfaces are connected with each other by an arc surface; a cutting unit is arranged at the included angle between every two adjacent side surfaces; each cutting unit comprises an auxiliary cutting edge, a main cutting edge, a chamfered edge plane, a front cutter surface, a bottom surface of a concave surface and a chip breaking table body, wherein the front cutter surface is connected with the bottom surface of the concave surface and the chip breaking table body into a whole; each chip breaking table body is provided with a plurality of bosses which are respectively adjacent to each main cutting edge; the bosses are symmetrically arranged about the angular bisector; the surfaces of the bosses are gradually heightened, so that a first chip breaking table and a second chip breaking table can be formed. The double-sided cutting blade capable of transferring improves the surface quality of the processed parts, the chip breaking capability of the blade and the whole performance of the blade on the premise of guaranteeing the strength of the cutting edge of the blade.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

Environment-friendly waterborne cutting fluid

The invention discloses an environment-friendly waterborne cutting fluid. The cutting fluid is prepared from, by mass, 5-15 parts of sodium dodecyl sulfate, 11-20 parts of barium petroleum sulfonate, 17-23 parts of anti-wear reagent at extreme pressure, 6-9 parts of tween, 6-10 parts of triethanolamine, 3-5 parts of fungicide, 30-45 parts of water, 9-12 parts of sodium molybdate, 0.3-1 part of coconut oil, 0.5-0.8 part of organic boron, 1-3 parts of sodium cumenesulfonate, 0.2-0.6 part of mercaptopropyl trimethoxy silane and 0.5-1.5 parts of laurylene succinic acid diethanolamide. The invention further discloses a preparation method of the environment-friendly waterborne cutting fluid. The cutting fluid has the cooling property, lubricating property and anti-rusting property and is capable of preventing corrosion and easy to dilute, the problems that a traditional soap-based emulsifying liquid is prone to smelliness in summer, difficult to dilute in winter and poor in anti-rusting effect are avoided, and the cutting fluid has no bad influence on lathe paint and is suitable for cutting and grinding machining of ferrous metal.

Owner:全椒县兴盛化工厂

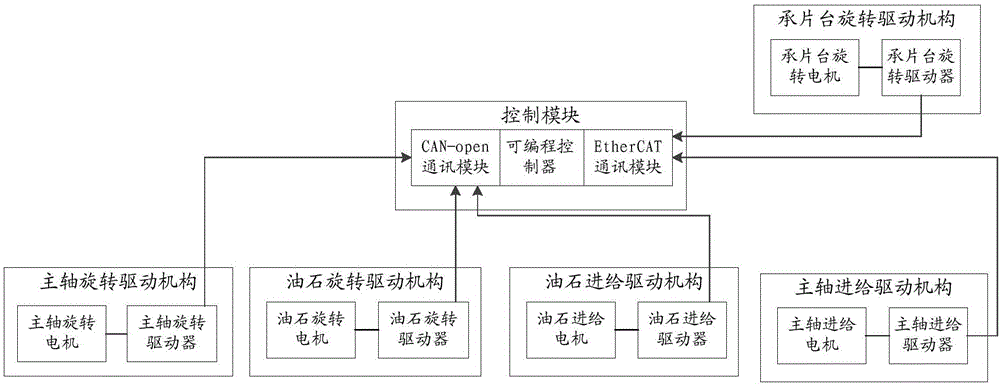

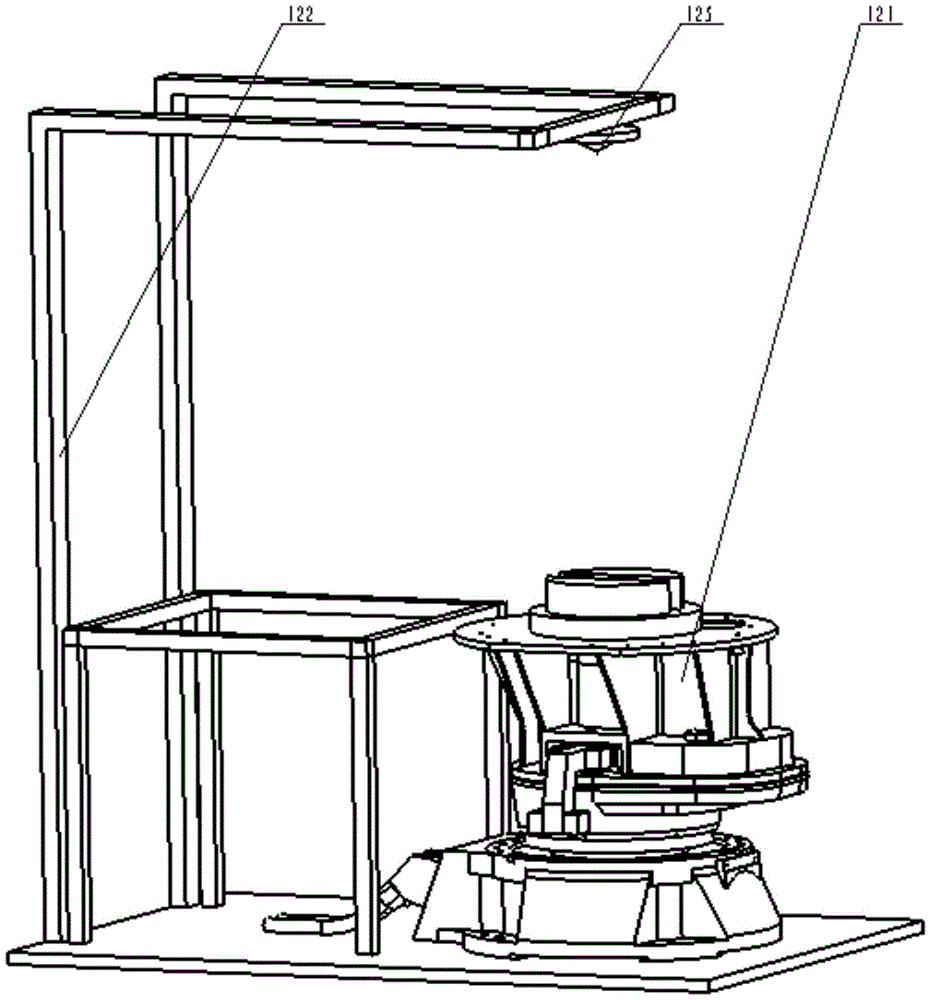

Dressing control system and method for grinding wheel

ActiveCN106392884ALarge amount of removalImprove machining efficiency and surface machining accuracyAbrasive surface conditioning devicesAutomatic grinding controlFeed driveMechanical engineering

The invention provides a dressing control system and a dressing control method for a grinding wheel. The system comprises a wafer bearing platform mechanism, a main shaft grinding mechanism, an oilstone dressing mechanism, a main shaft rotating driving mechanism, a main shaft feeding driving mechanism, a wafer bearing platform rotating driving mechanism, an oilstone rotating driving mechanism, an oilstone feeding driving mechanism and a control module; the control module is connected with each of the oilstone rotating driving mechanism, the oilstone feeding driving mechanism, the main shaft rotating driving mechanism, the main shaft feeding driving mechanism and the wafer bearing platform rotating driving mechanism, wherein when the main shaft grinding mechanism moves to a first preset position relative to the wafer bearing platform mechanism, and the oilstone dressing mechanism moves to a second preset position relative to the main shaft grinding mechanism, the surface of a main shaft grinding is in contact with each of the surface of oilstone and the surface of the wafer bearing platform. According to the dressing control system and the dressing control method for the grinding wheel, the purposes of grinding a substrate material and dressing the sand wheel simultaneously can be achieved; the removal amount of the substrate material is increased; the machining efficiency and the surface machining precision of the substrate material are improved; meanwhile, the grinding capacity of the sand wheel is ensured.

Owner:CETC BEIJING ELECTRONICS EQUIP

A laser and ultrasonic composite drilling processing system and processing method thereof

InactiveCN106513986BQuality improvementHigh precisionLaser beam welding apparatusLaser processingUltrasonic machining

The invention relates to the machining field of drilling holes in hard and brittle materials, in particular to a laser and ultrasound combined type drilling system and a machining method thereof. According to the laser and ultrasound combined type drilling system, the hard and brittle materials can be protected, high-speed machining can be realized and locating can be accurate. The laser and ultrasound combined type drilling system mainly comprises a laser machining system, an ultrasonic machining system, a precision rotating and locating mechanism and an axis aligning system, wherein the laser machining system and the ultrasonic machining system are installed on the precision rotating and locating mechanism to regulate locating. The axis aligning system mainly comprises a locating panel, locking structures, a gravity center sensor, a distance sensor, an oriented adjusting structure, a movement adjusting base and a drive control device, and the locating panel is a thin supporting panel loading work-pieces to be machined. Through a combined drilling method, the hard and brittle work-pieces can be machined at high speed and high precision. The laser machining system and the ultrasonic machining system are adopted for combined machining procedures, and therefore pre-drilling can be carried out in advance, high-speed operation can be realized, the quality of the work-pieces can be protected, and the surface machining precision can be improved.

Owner:DONGGUAN UNIV OF TECH +3

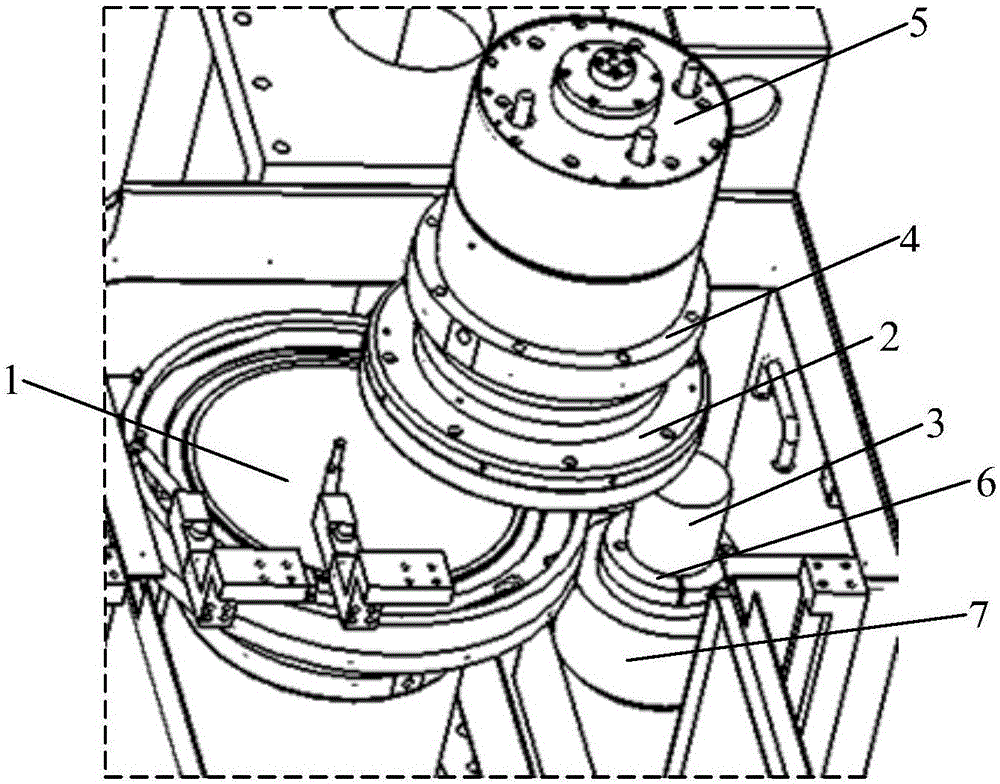

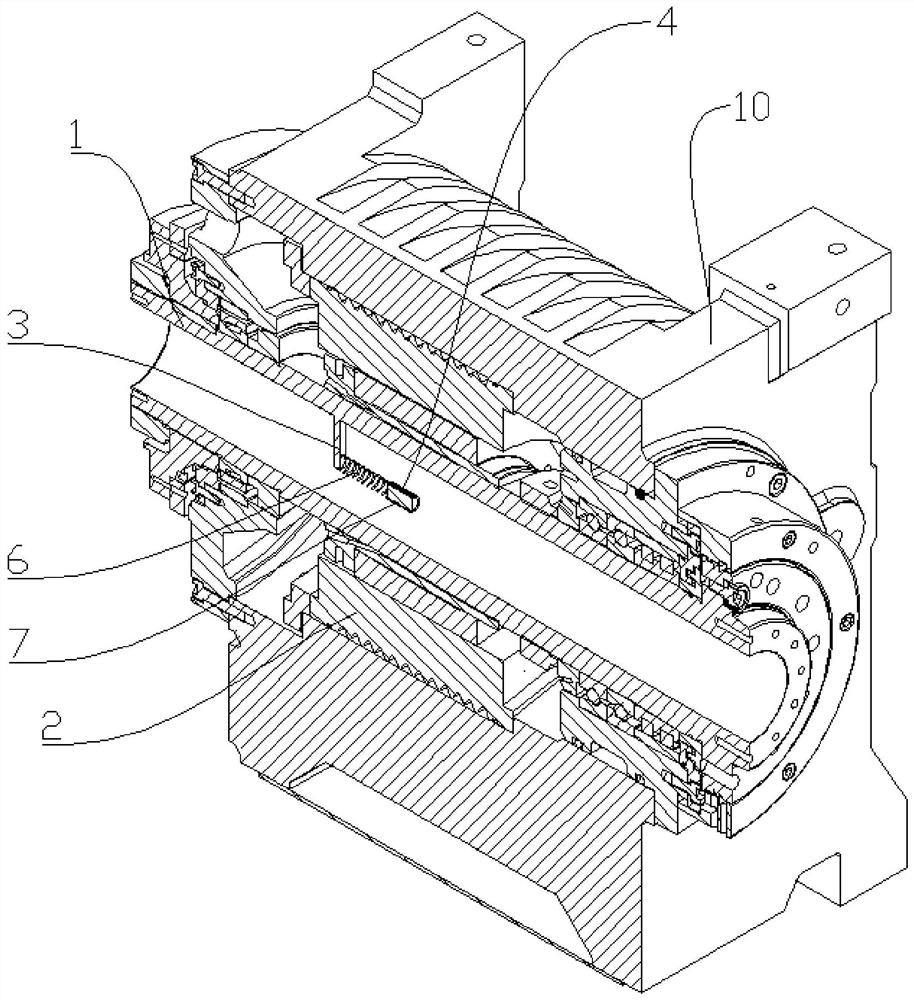

A robot automation equipment for blade intake and exhaust edge grinding

ActiveCN104858748BGuaranteed machining accuracyGuaranteed grinding accuracyGrinding feed controlAutomatic grinding controlEngineeringSix degrees of freedom

The invention discloses a robot automation equipment for blade intake and exhaust edge grinding, which includes a base, a six-degree-of-freedom robot, a grinding device, a positioner, a three-dimensional laser measuring device, and a system control host. The six-degree-of-freedom robot is installed on the base on the platform; the grinding device is used to grind the inlet and exhaust edges of the blade; the positioner is installed on the base platform; the three-dimensional laser measurement device is installed on the positioner, which includes a three-axis motion platform and a three-dimensional laser measurement device; three-dimensional laser measurement The device includes two 3D laser profile scanners; the system control host is connected with the six-degree-of-freedom robot and the 3D laser measuring device to plan the processing path of the grinding device and the moving path of the 3D laser measuring device, and send the path and instructions to Six degrees of freedom robot execution. The invention integrates self-adaptive grinding and measurement, and can ensure the machining accuracy of the profile of the intake and exhaust edges of the blades.

Owner:HUST WUXI RES INST

Polyaniline cutting fluid

The invention discloses a polyaniline cutting fluid. The polyaniline cutting fluid is prepared from, by mass, 12-30 parts of water soluble polyaniline, 22-42 parts of polyacrylamide, 5-9 parts of polyether polyol, 18-33 parts of triethanolamine, 11-18 parts of di-n-butyl phosphite, 5-13 parts of sodium molybdate, 17-24 parts of petroleum barium sulfonate, 7-16 parts of boracic acid, 10-25 parts of emulsified silicone oil and 33-48 parts of water. The invention further discloses a preparation method of the polyaniline cutting fluid. The product not only has good anti-corrosion and mildew-preventing properties, also has good lubricity and extreme pressure resistance and meanwhile is safe, environmentally friendly and free of environmental pollution.

Owner:全椒县兴盛化工厂

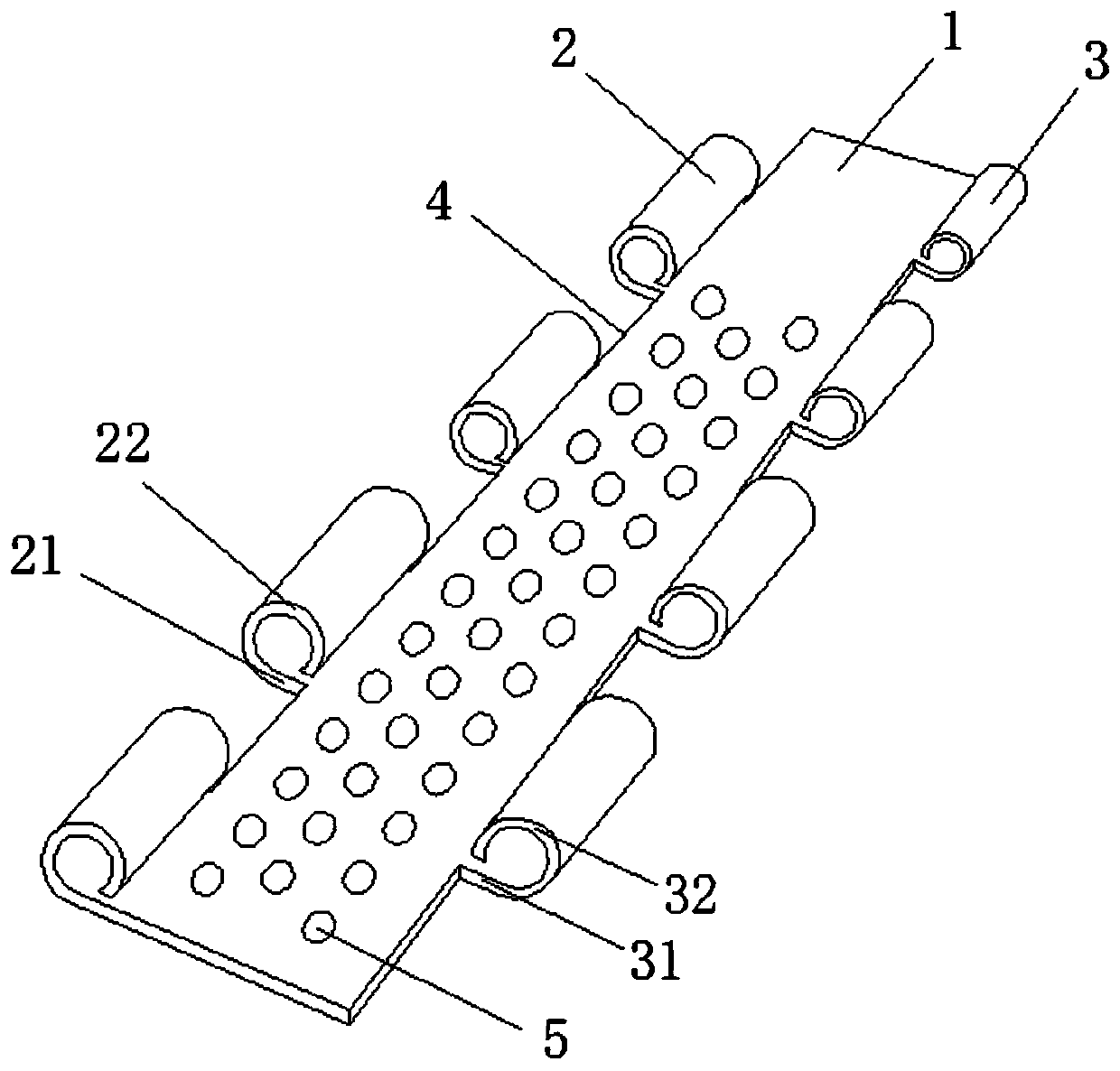

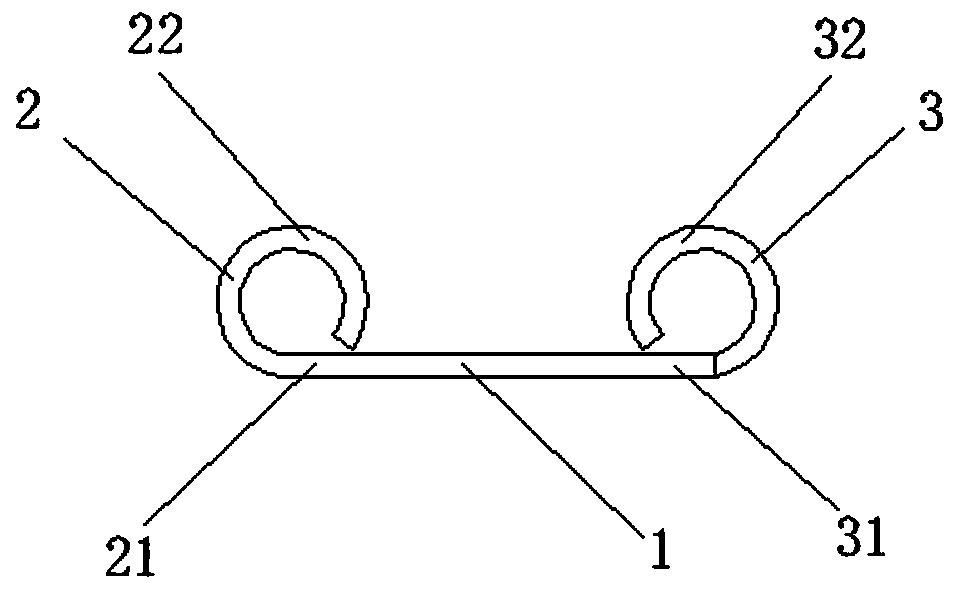

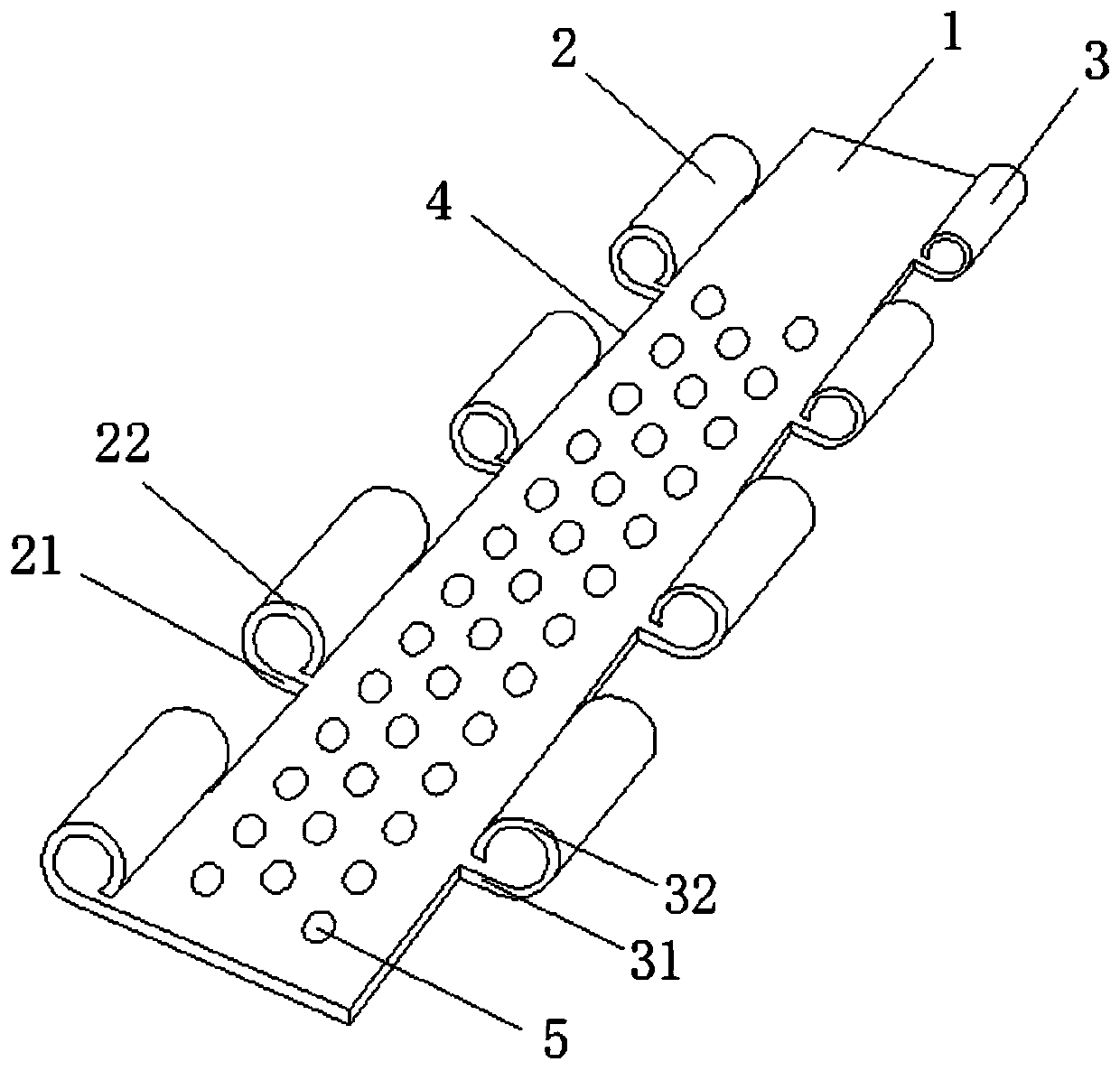

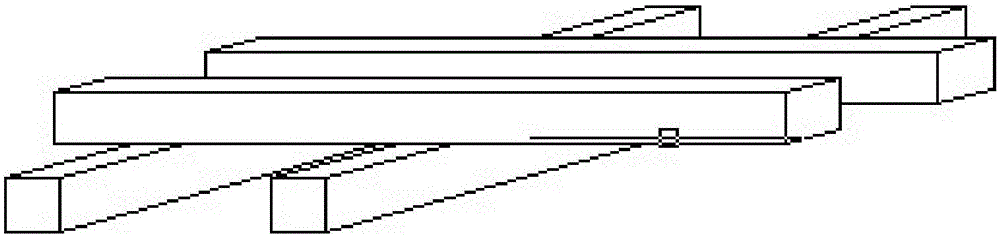

Punch forming connecting part capable of achieving double-shaft connection

PendingCN110005696AHigh strengthAchieve dual-axis connectionPivotal connectionsEngineeringUltimate tensile strength

The invention discloses a punch forming connecting part capable of achieving biaxial connection. The connecting part comprises a bottom plate, first shaft frames, second shaft frames and groove openings. The bottom plate is rectangular metal thin wall plate, the multiple first shaft frames are punched on one side of the bottom plate upwards, the second shaft frames are punched on the other side ofthe bottom plate upwards, groove openings are punched between two adjacent first shaft frames and second shaft frames, each first shaft frame is composed of a first straight line segment and a secondbending segment, the first straight line segments are in straight line shapes, the first straight line segments and the bottom plate are located on the same plane, the first bending segments are arc,the first bending segments are bent towards the bottom plate, the second shaft frames and the first shaft frames are the same in structure, each second shaft frame is composed of a second straight line segment and a second bending segment, the second bending segments and the first bending segments are opposite in bending direction, multiple rows of grooves are punched in the top face of the bottom plate, two adjacent rows of grooves are staggered, and the distances between two adjacent grooves in the same row are same. Production efficiency can be improved, raw materials are saved, and the strength and surface machining precision can be improved.

Owner:嘉兴联心汽车零部件有限公司

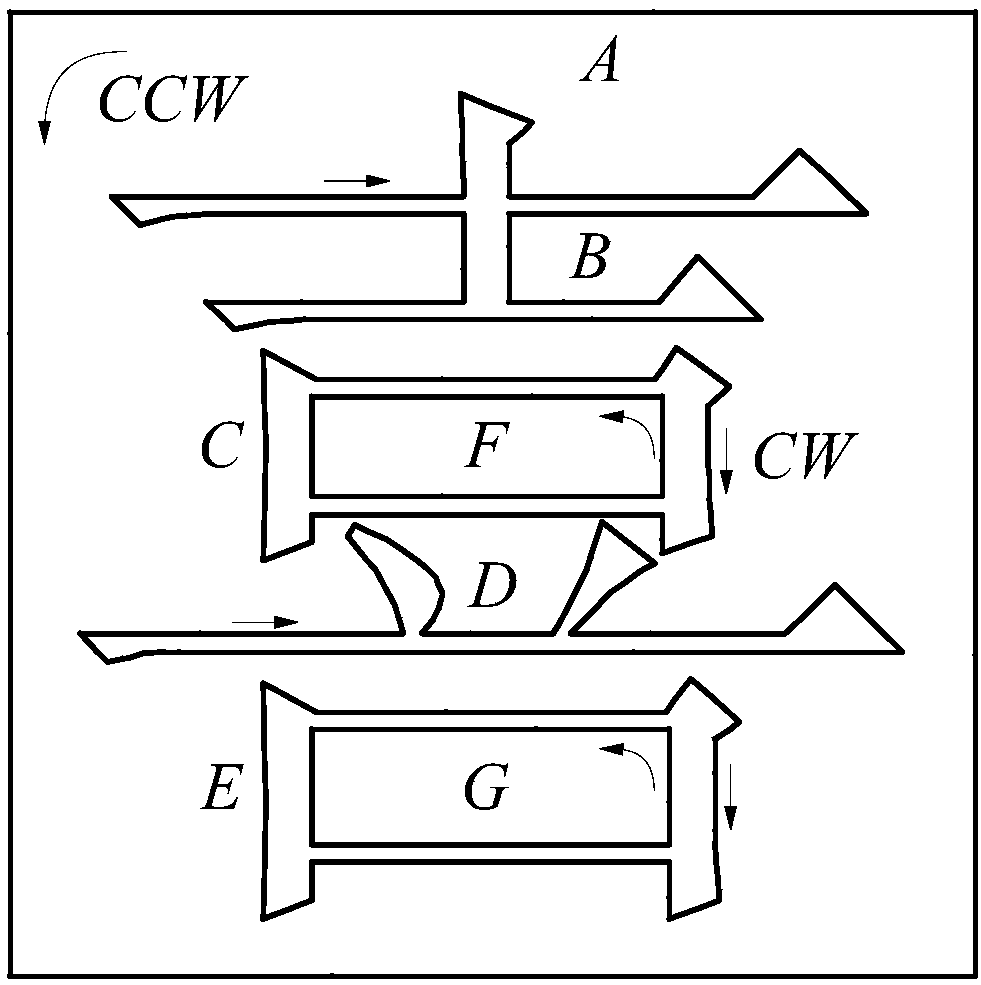

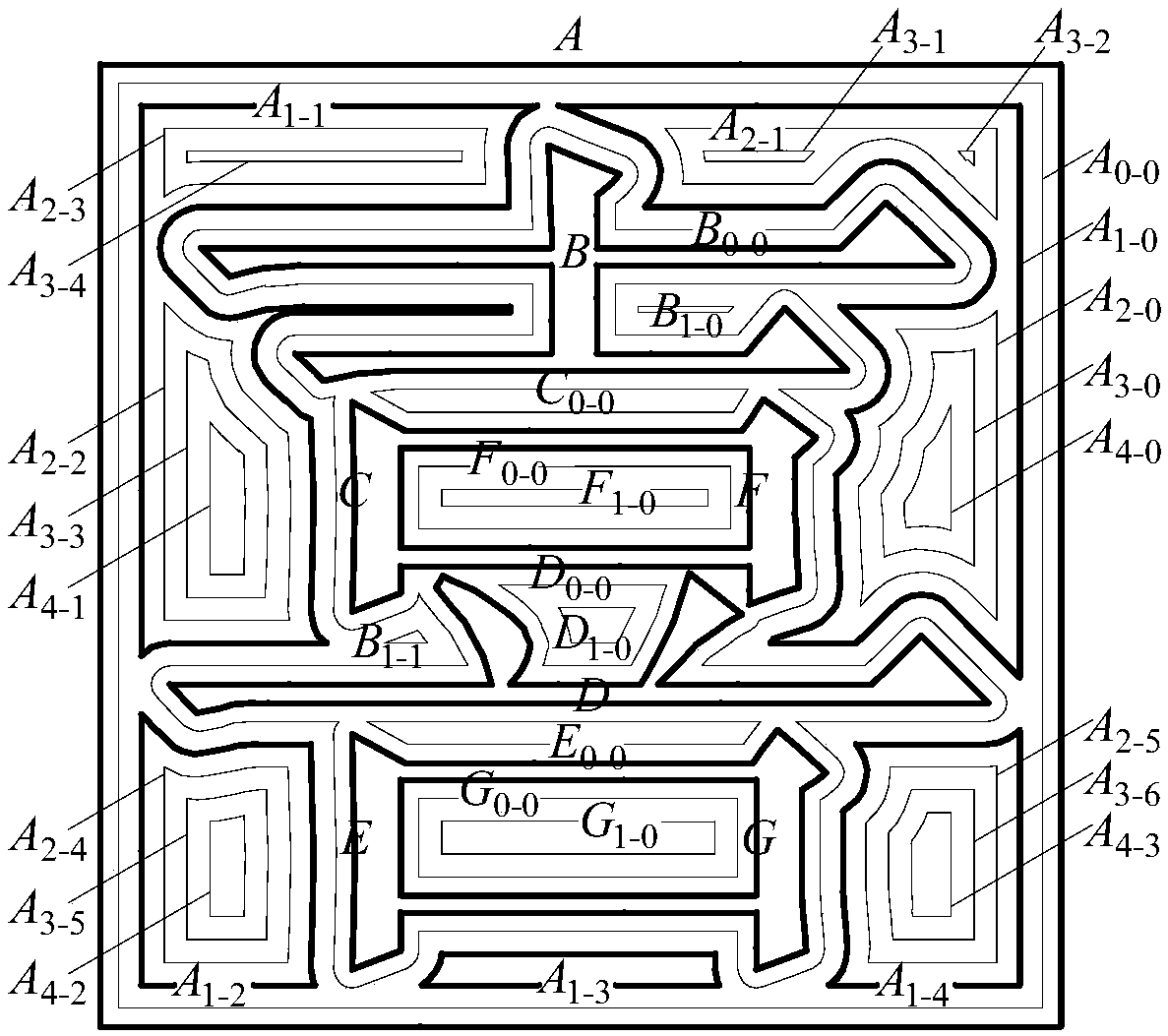

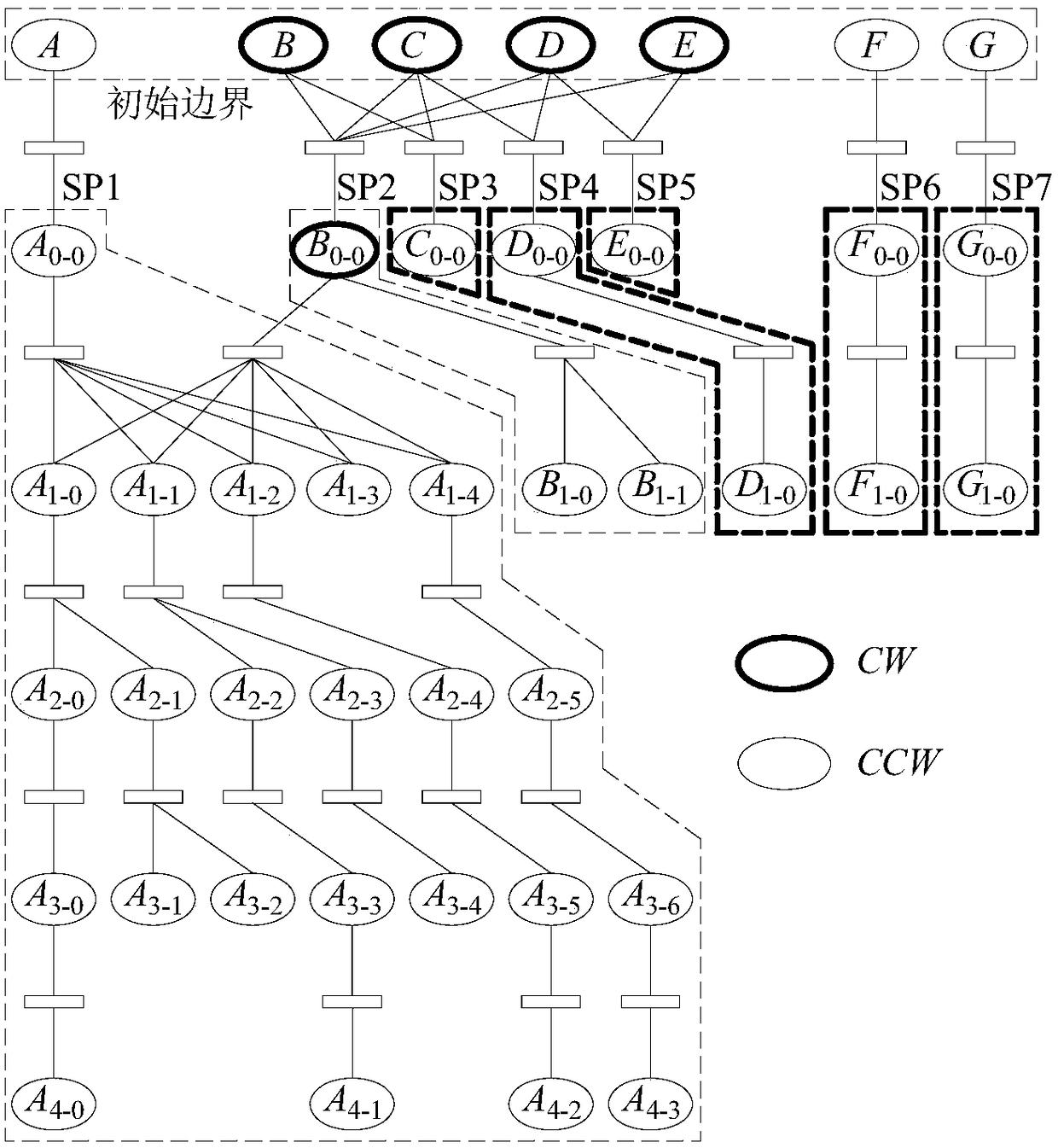

A circular cutting knife-rail connection method with a lake-shaped section in an island

ActiveCN105843163BAvoid frequent knife jumpsStable processingNumerical controlInclusion relationMachining process

The invention discloses a contour-parallel offset tool path linking method of double-ring-shaped sections. Offset rings are divided into CW (clockwise) type offset rings, CCW (counter clockwise) I type offset rings and CCW (counter clockwise) II type offset rings; these three kinds of offset rings are searched based on inclusion relations, so that longest main links and a plurality of branch links are obtained; intersecting points are recorded, transitional connection points on the offset rings are solved one link by one link; a tool cuts in from the main link of the CCW I type offset rings, and performs counter clockwise machining from inner layers to outer edges; when meeting CCW I type local branch links, the tool firstly cuts into the innermost layer of the branch links and performs machining from inside to outside; the main link and branch links of the CCW II type offset rings are machined in a tool-retraction manner; and the main link and branch links of the CW type offset rings are machined in a tool-retraction manner along the clockwise direction of the rings from outer layers to inner layers. According to the method of the invention, the intersecting points of the branch links and main link are recorded repeatedly, and time when the main link and the branch links are connected together can be determined correspondingly. With the method adopted, the defect of frequent tool retraction in traditional line cutting machining can be effectively avoided, and a machining process more tends to be stable, and surface machining accuracy can be improved.

Owner:ZHEJIANG UNIV

Semi-solid machining process for automobile hub

The invention discloses a semi-solid machining process for an automobile hub. The semi-solid machining process is characterized by comprising the following steps: selecting an aluminum alloy as a raw material for the automobile hub; adopting semi-solid forging preparation, that is, mainly conducting compressive deformation on a blank to be heated into a semi-solid state in a forging die, so as to obtain a product with a required shape and required properties. A novel automobile hub prepared according to the semi-solid machining process is high in specific strength. The semi-solid machining process has the characteristics that the aluminum alloy is high in corrosion resistance and malleability, and the novel automobile hub can be made of the aluminum alloy with high specific strength; compared with a casting, the aluminum alloy automobile hub manufactured by utilizing a semi-solid machining technology is low in porosity degree, fine in structure, higher in strength, accuracy of part sizes, and surface machining precision, and lower in cost.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

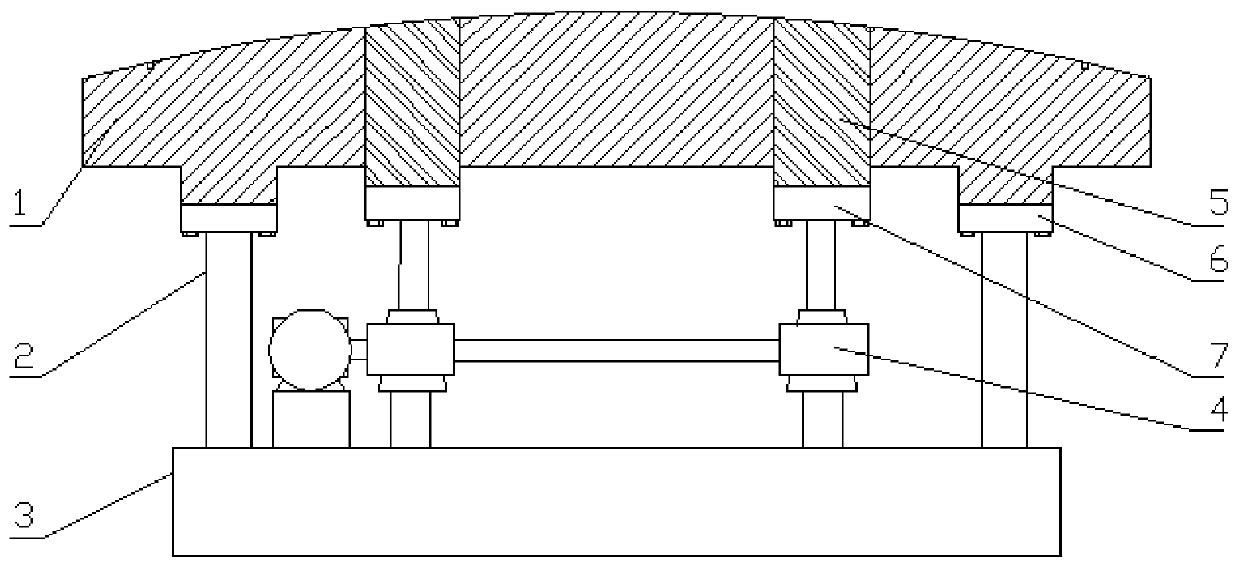

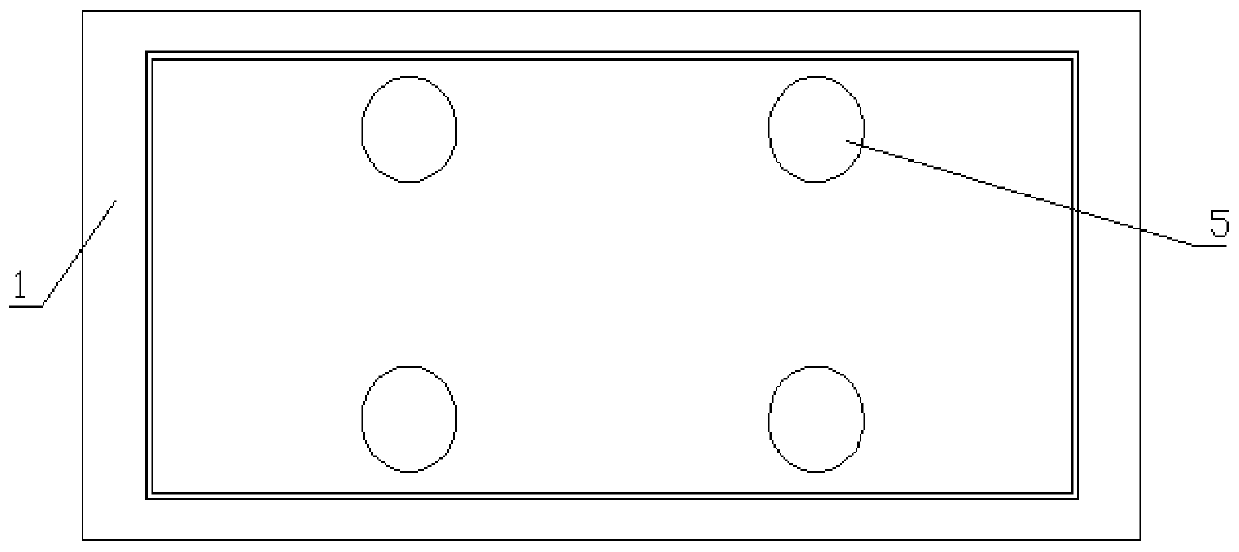

A kind of mechanical material preparation mold

InactiveCN108394118BSmall coefficient of thermal expansionHigh specific strengthPressesMaterials preparationEngineering

The invention relates to a mechanical material preparation mold. The mold comprises a seat body, supporting columns are arranged at four corners of the upper surface of the seat body correspondingly,damping devices are arranged inside the supporting columns, and first connecting plates are arranged at the upper ends of the supporting columns; a female mold is arranged on the upper surfaces of thefirst connecting plates, a plurality of evenly-distributed mounting holes I are formed in the female mold, and filling bodies matched with the mounting holes I are arranged in the mounting holes I; and second connecting plates are arranged at the lower ends of the filling bodies, and lifting devices are arranged below the second connecting plates. According to the mold, the female mold is small in thermal expansion coefficient, high in specific strength and light in weight, the surface machining precision is high, the overall structure is reasonable, the stability is good, the machining period of the mold is short, the machining economic cost is low, the stress is uniform during demolding, the operation is convenient, the damage is not easy to occur, labor is saved, working efficiency isimproved, practicability is high, and popularization is achieved.

Owner:SHANGQIU INST OF TECH

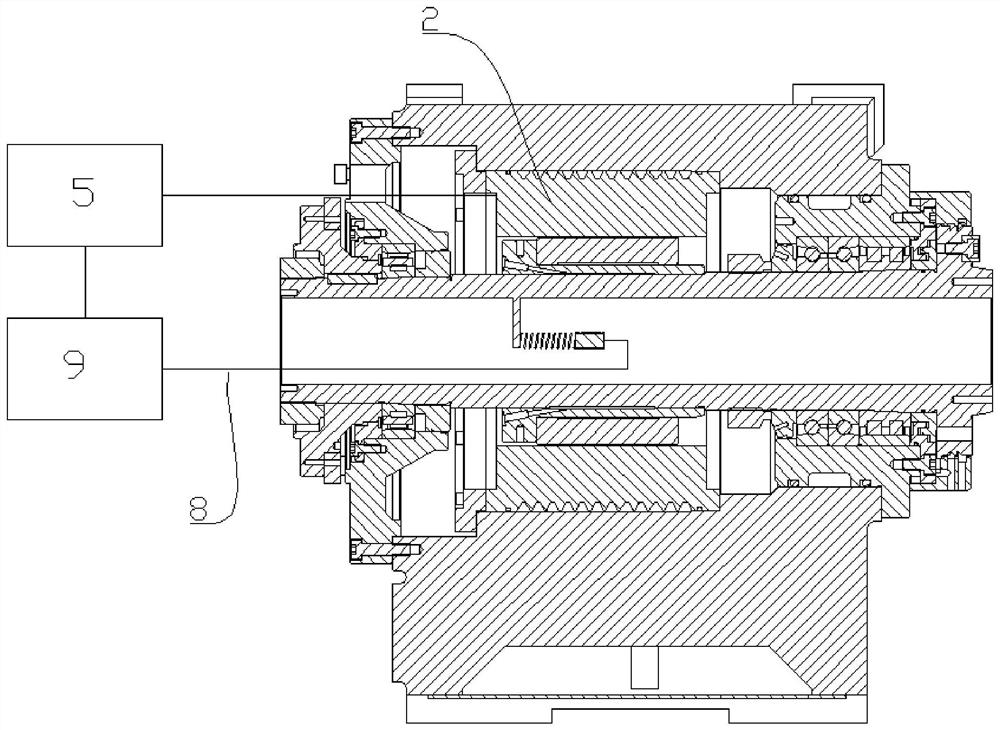

Machining electric spindle and numerical control machine tool

ActiveCN113878134AImprove surface machining accuracyHigh precisionLarge fixed membersProcess engineeringDirect control

The invention relates to the technical field of numerical control machine tools, in particular to a machining electric spindle and a numerical control machine tool. The machining electric spindle comprises a main shaft, a stator and rotor excitation winding, a fixing support, an induction coil and a controller, and the main shaft is of a hollow structure; the stator and rotor excitation winding is arranged outside the main shaft in a surrounding manner and is used for driving the main shaft to rotate around the axis of the main shaft; the first end of the fixing support is connected with the inner wall of the main shaft, and the second end of the fixing support is suspended in the main shaft; the induction coil is arranged at the second end of the fixed bracket; and the controller is in communication connection with the induction coil and the stator and rotor excitation winding, and can control the stator and rotor excitation winding to adjust the rotating speed when the current generated in the induction coil is greater than a preset value. The induction coil is arranged in the main shaft, is not influenced by the external environment, is high in precision and long in service life, and the controller directly controls the stator and rotor excitation winding to finely adjust the rotating speed of the main shaft when generating current in the induction coil, so that the efficiency is greatly improved, and complicated wiring is not needed.

Owner:ZHUHAI GREE INTELLIGENT EQUIP TECH RES INST CO LTD +2

Preparation method of laser direct writing preformed photocatalytic plating of metal pattern on material surface

ActiveCN108441843BReduce manufacturing costShort processLiquid/solution decomposition chemical coatingThin membranePhoto catalysis

The invention discloses a laser direct writing pre-forming photocatalysis plating preparing method for a material surface metal pattern, and belongs to the technical field of material surface treatment. The laser direct writing technology and the photocatalysis plating technology are combined, and on the basis of a laser direct writing etched pre-formed high-precision nano semiconductor film pattern, photocatalysis plating is conducted for preparing the high-quality metal pattern. The laser direct writing pre-forming photocatalysis plating preparing method for the material surface metal pattern is environment-friendly, short in process, capable of saving metal, efficient and low in cost and has universality and high stability; and the prepared metal pattern is high in size precision, goodin clad layer surface quality and excellent in performance, and the bonding strength between the prepared metal pattern and a base body is high.

Owner:UNIV OF SCI & TECH BEIJING

Roll workpiece surface grinding and polishing machine

ActiveCN105382641BAvoid disassemblyAvoid Positioning EffectsGrinding carriagesPolishing machinesSurface grindingEnergy consumption

The invention discloses a roll workpiece surface grinding and polishing all-in-one machine which comprises a roll grinder, a polishing device, an axial driving device and a radial driving device. The polishing device is mounted on one side of the roll grinder; the axial driving device can drive the polishing device to move in the axial direction of a roll; the radial driving device can drive the polishing device to be fed in the radial direction of the roll; at least one polishing head is arranged on the polishing device; the polishing head can make contact with the surface of the roll on the roll grinder. According to the roll workpiece surface grinding and polishing all-in-one machine, the roll is ground and polished through the roll grinder, the roll can be lifted and polished at a time, and disassembling, secondary lifting and secondary positioning of the roll are avoided; positioning errors are lowered, the surface machining precision is improved, the machining efficiency is improved, and the labor intensity of workers is lowered. Compared with original polishing equipment, the polishing device is simple in structure, equipment cost is greatly lowered, equipment energy consumption is lowered, the space occupied by the equipment is reduced, and the roll machining cost is lowered.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

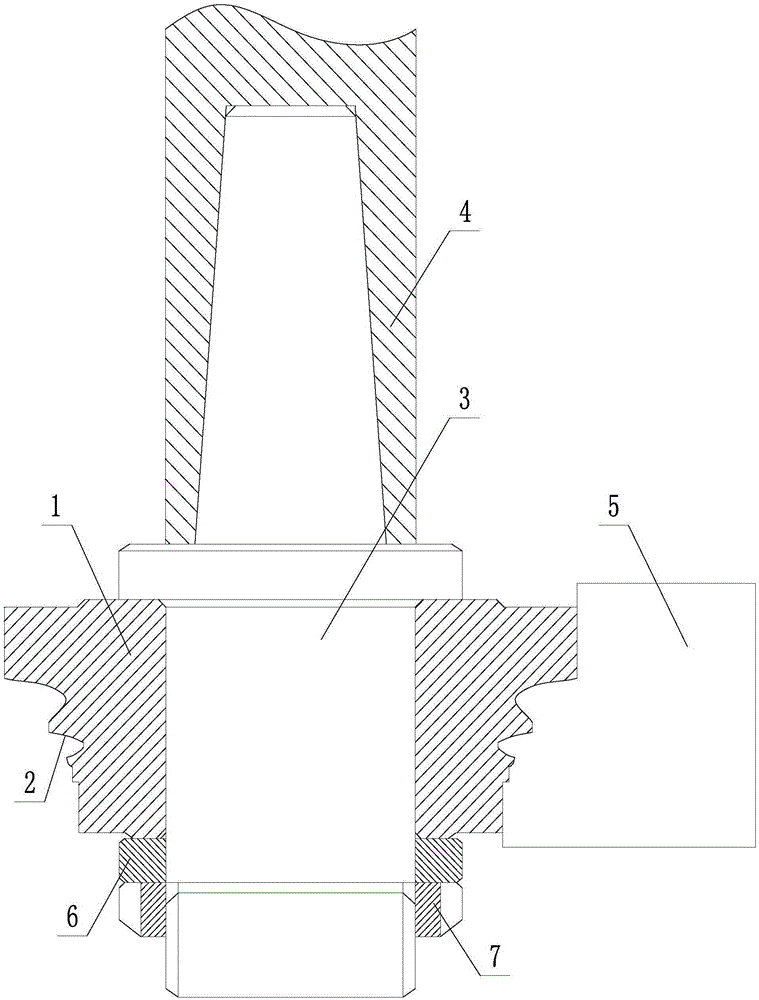

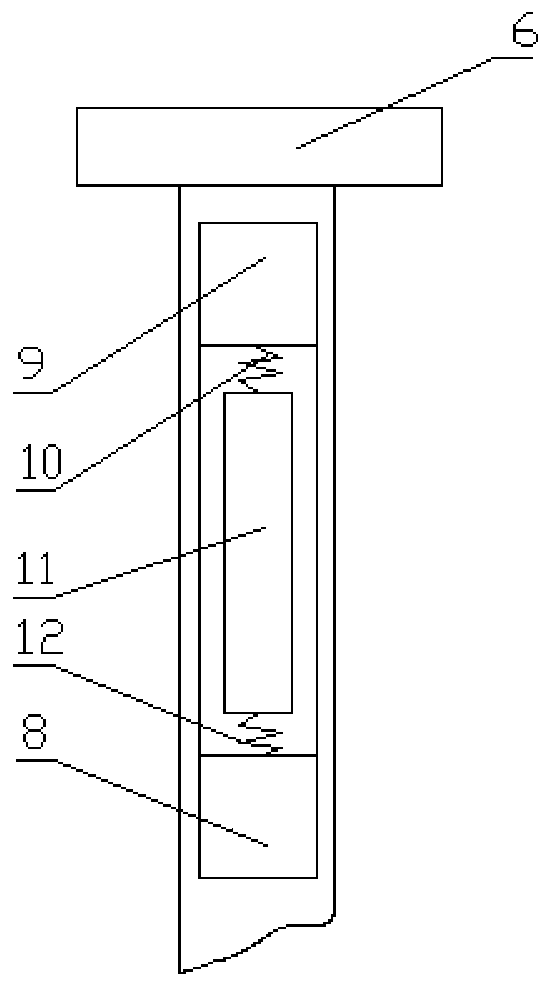

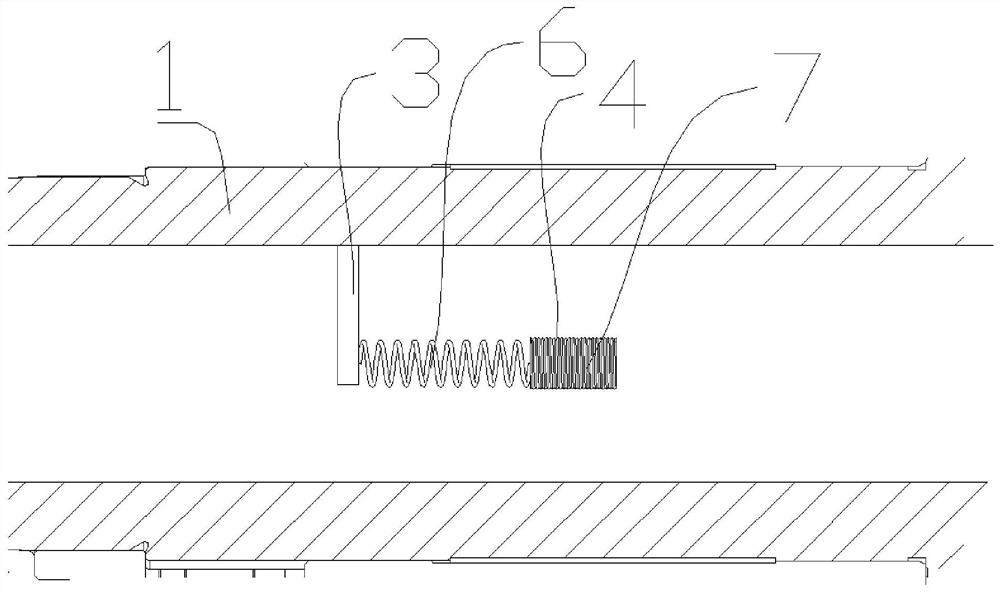

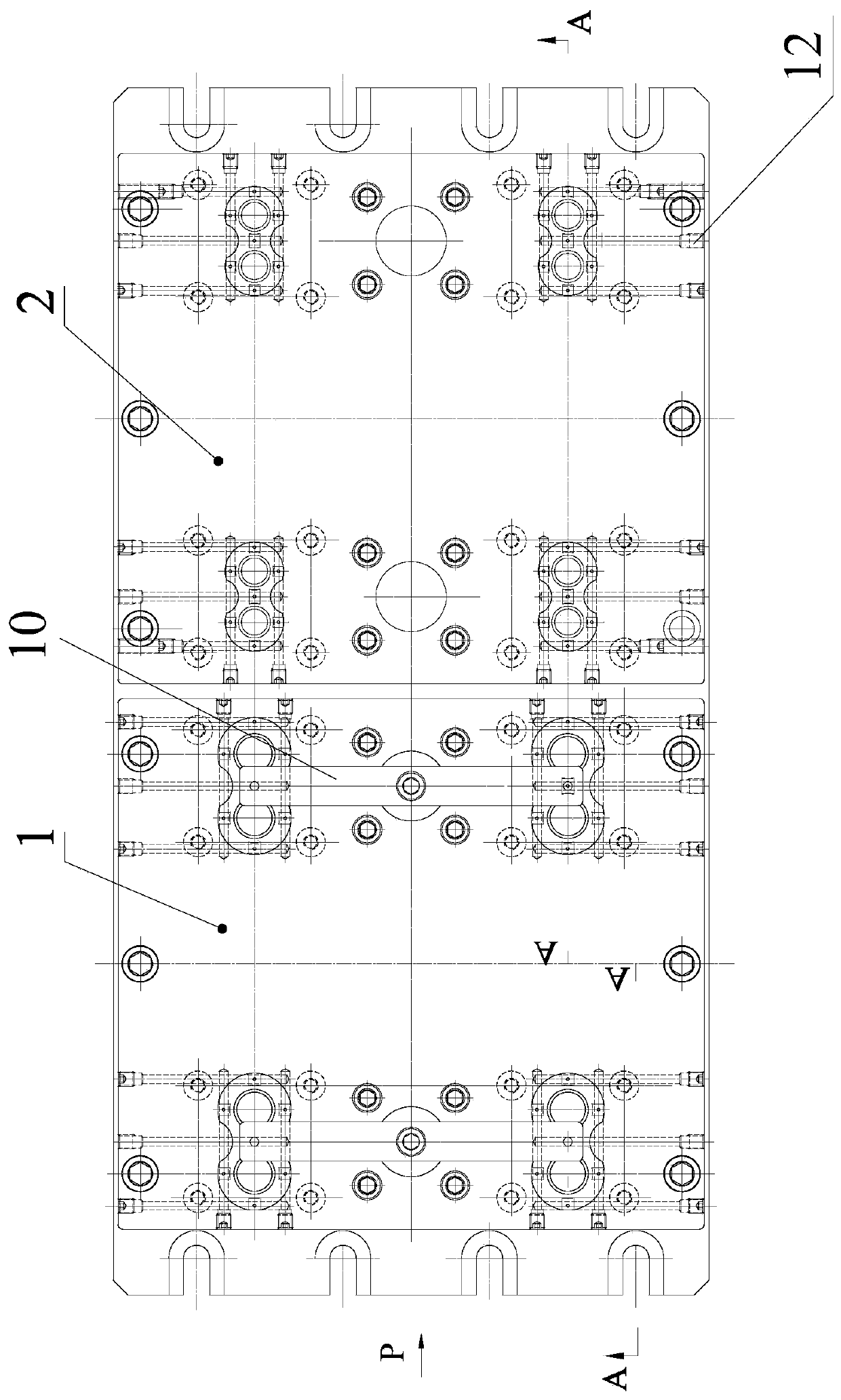

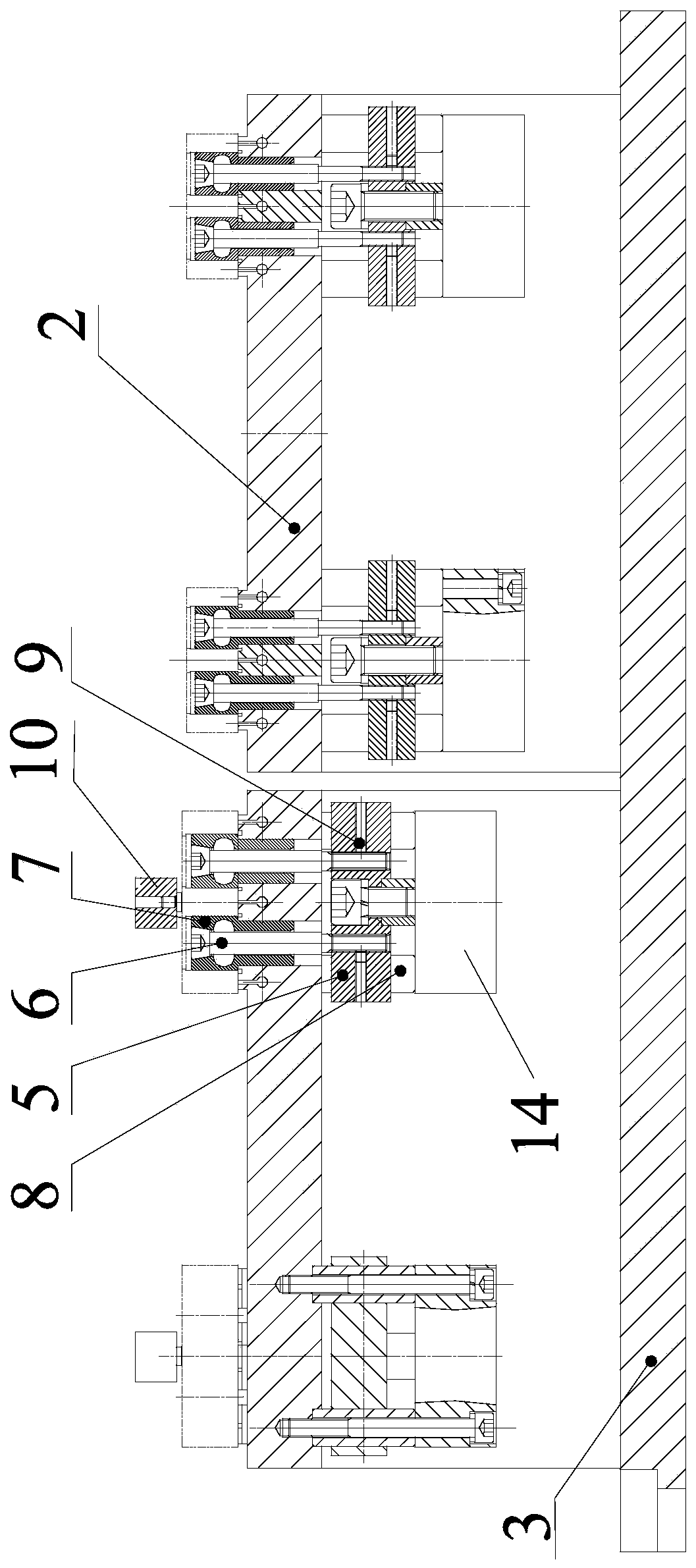

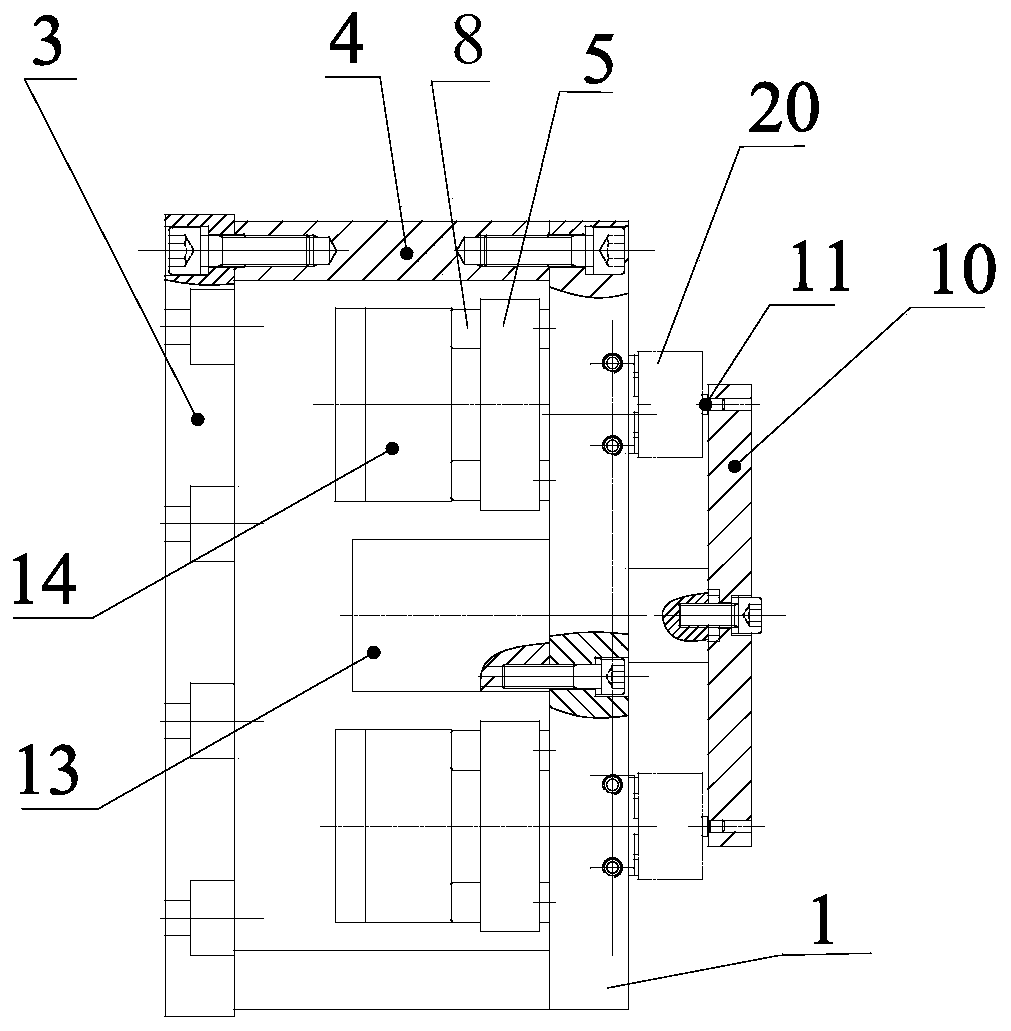

Combined pneumatic machining fixture suitable for various shaft sleeves

PendingCN110000585AHigh shape precisionImprove surface machining accuracyWork clamping meansPositioning apparatusEngineeringMachining

The invention discloses a combined pneumatic machining fixture suitable for various shaft sleeves. The shaft sleeves are double-hole shaft sleeves of a gear oil pump. The combined pneumatic machiningfixture comprises a top panel, expanding sleeves arranged on the top panel, a pull rod which is arranged internally, a tensioning cylinder arranged at the lower end of the top panel, a guide plate which is positioned between the tensioning cylinder and the top panel and is connected with the cylinder rod and the pull rod of the tensioning cylinder, and a guide column which passes through a cylindrical through hole in the guide plate and is connected with the top panel, wherein the cylinder body of the tensioning cylinder is connected with the top panel, the expanding sleeves with various sizesare installed on the top panel for clamping various types of shaft sleeves. According to the fixture, expanding sleeves with different sizes are installed on the top panel to be suitable for combinedmachining of various shaft sleeves; and through a pressing plate, the shaft sleeves can undergo positioned adjustment before clamping is completed, so that the appearance and surface machining precision of the shaft sleeves is high.

Owner:HEFEI CHANGYUAN HYDRAULICS

Multi-axis linkage type water pressure intelligent adjusting type deburring equipment

ActiveCN114406839AImprove sanding suitabilityHigh strengthEdge grinding machinesBlast gunsWater resourcesEngineering

The invention discloses multi-axis linkage type water pressure intelligent adjusting type deburring equipment which comprises a supporting device, a power device, a circulating device, an adjusting device, a grinding device and an industrial camera, the supporting device is connected with the power device, the power device is in transmission connection with the circulating device, the circulating device is connected with the supporting device, and the adjusting device is in transmission connection with the grinding device. The adjusting device is communicated with the circulating device through a pipeline, the grinding device is in transmission connection with the power device, the industrial camera is fixedly connected with the supporting device, the supporting device comprises a supporting plate, a vertical plate, a first cross arm and a second cross arm, an objective table is arranged on the supporting plate, the industrial camera faces the objective table, and the lower end of the vertical plate is fixedly connected with the supporting plate. The first cross arm is slidably connected with the vertical plate, the second cross arm is movably connected with the first cross arm, the first cross arm, the second cross arm and the vertical plate are vertically arranged, when a large workpiece is polished, step-by-step polishing is carried out, cooling water is circulated through the circulating device, and waste of water resources is reduced.

Owner:哈工大机器人(中山)无人装备与人工智能研究院

A kind of microemulsion cutting fluid for aluminum alloy and preparation method thereof

Owner:江苏悠谷未来科技有限公司

Quenching device

InactiveCN106381369AEasy to moveImprove surface machining accuracyIncreasing energy efficiencyQuenching devicesQuenchingEngineering

The invention relates to a quenching device. The quenching device comprises a first guide rail part, a second guide rail part, a control box, a quenching die and a product table, wherein the second guide rail part is arranged on the first guide rail part, the control box is arranged on the second guide rail part, the first guide rail part is arranged so that the second guide rail part and the control box move along an extension direction of the first guide rail part, and the second guide rail part is arranged so that the control box moves along an extension direction of the second guide rail part; one end of the control box extends to a space above the product table, and is connected with the quenching die; and the quenching die quenches a workpiece arranged on the product table. The quenching device provided by the invention is capable of improving machining accuracy and increasing working efficiency.

Owner:苏州金凡球墨铸铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com