Punch forming connecting part capable of achieving double-shaft connection

A technology of stamping and connecting parts, applied in the field of stamping parts and stamping and forming connecting parts, can solve the problems that the connecting parts cannot realize biaxial connection, the product stability is not good, and the processing accuracy is low, so as to save raw materials, improve strength, The effect of high surface machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

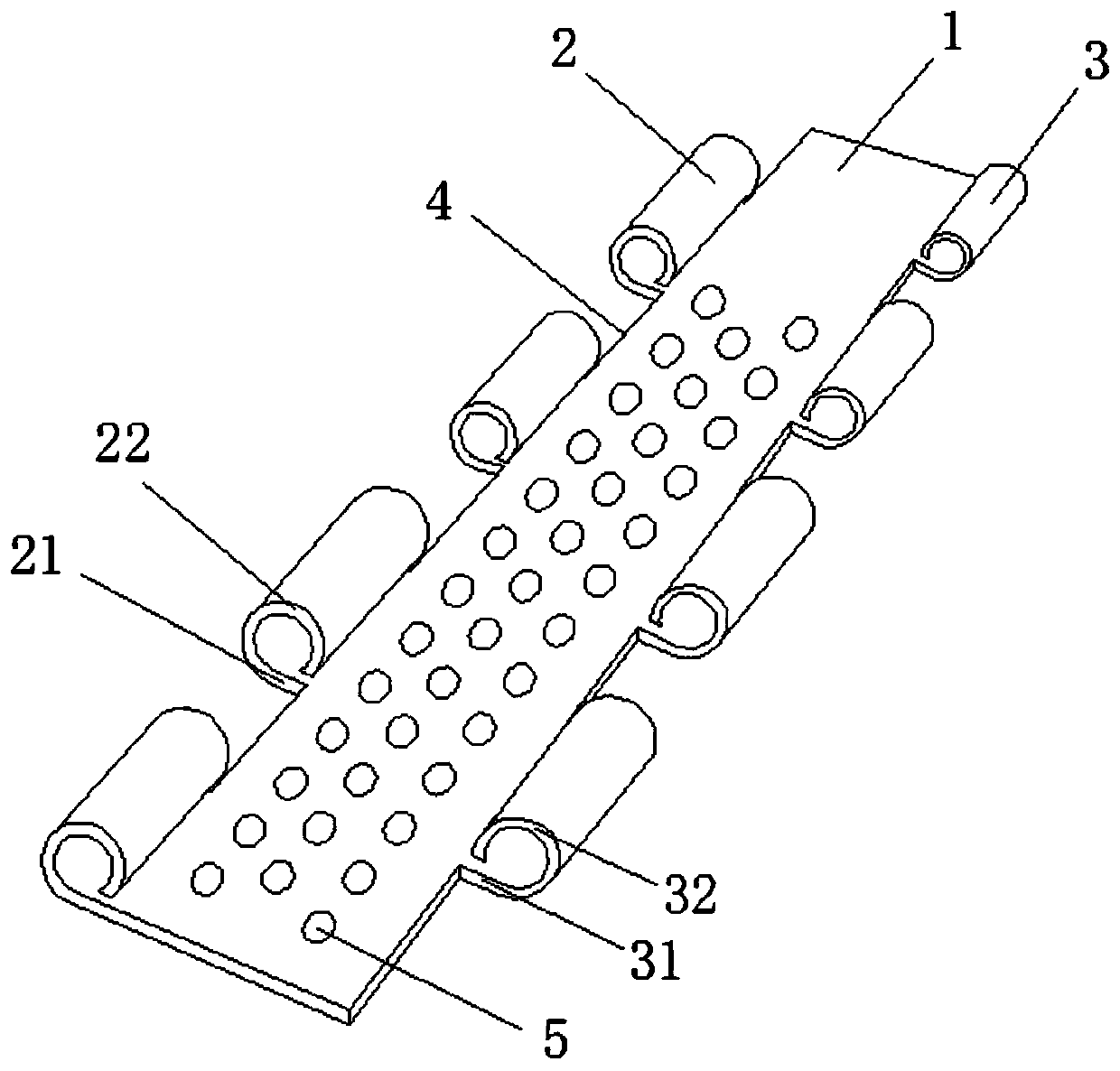

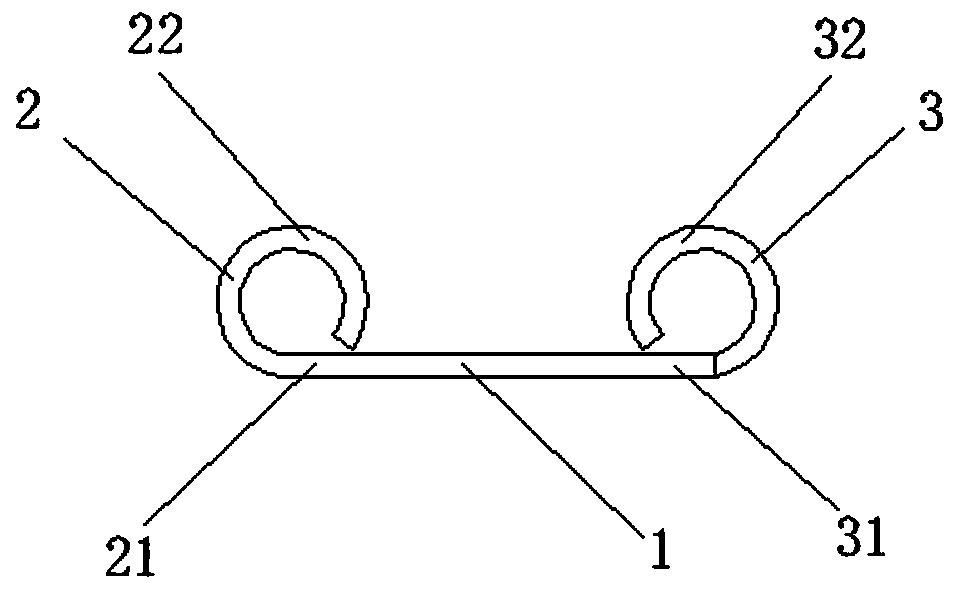

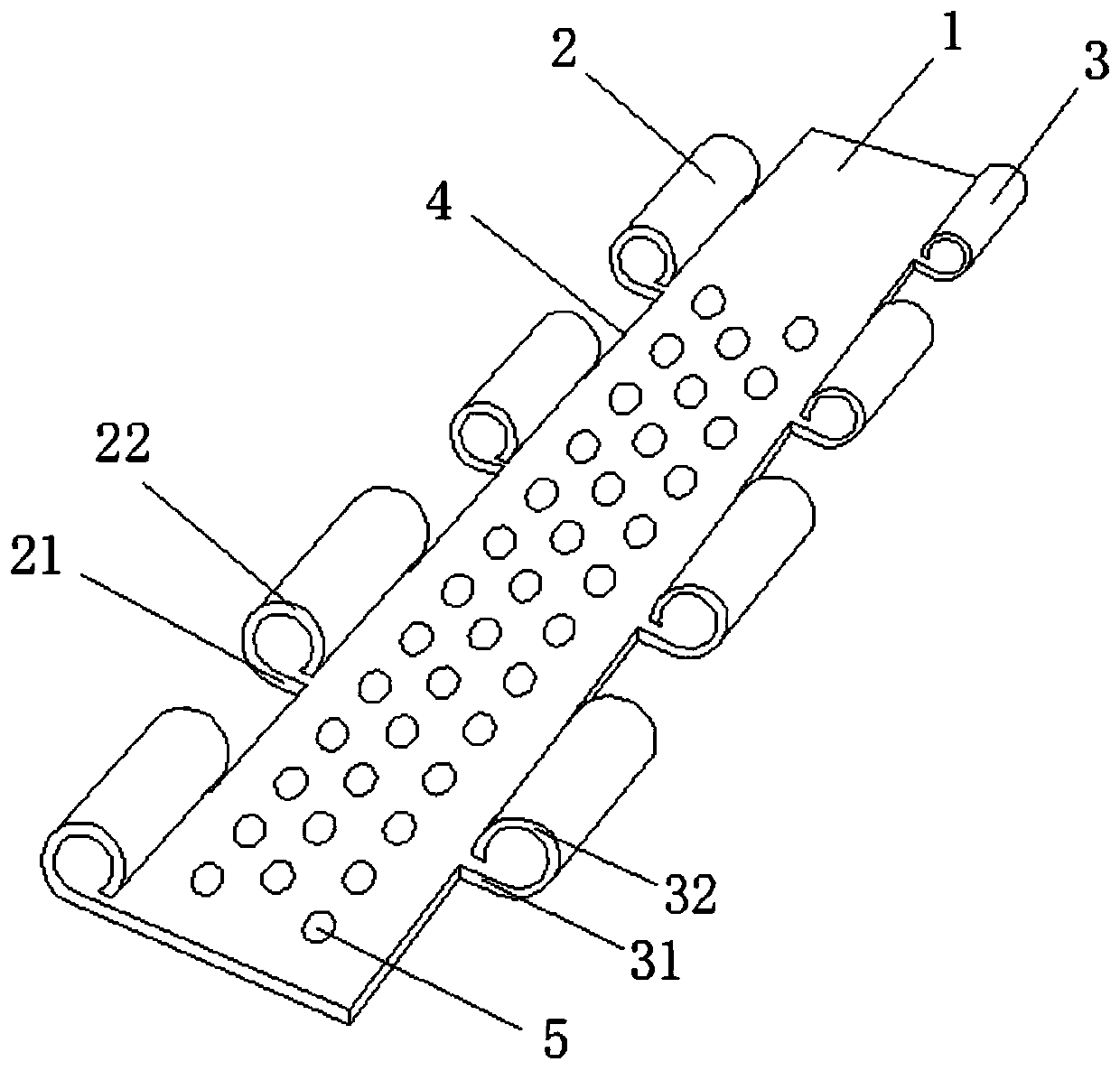

[0021] refer to figure 1 and figure 2 , the present invention is a biaxially connected stamping and forming connector, including a bottom plate 1, a first shaft frame 2, a second shaft frame 3 and a notch 4, the bottom plate 1 is a rectangular metal thin-walled plate, and one side of the bottom plate 1 is upward Punch out several first shaft frames 2 , punch out several second shaft frames 3 upwards on the other side of the bottom plate 1 , and punch out notches 4 between two adjacent first shaft frames 2 and second shaft frames 3 .

[0022] Wherein, the first shaft frame 2 is composed of a first straight section 21 and a second curved section 22, the first straight section 21 is straight, the first straight section 21 and the bottom plate 1 are located on the same plane, and the first curved section 22 is a circular arc shape, the first curved section 22 bends toward the bottom plate 1, the second shaft frame 3 has the same structure as the first shaft frame 2, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com