Patents

Literature

1744 results about "Thin wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

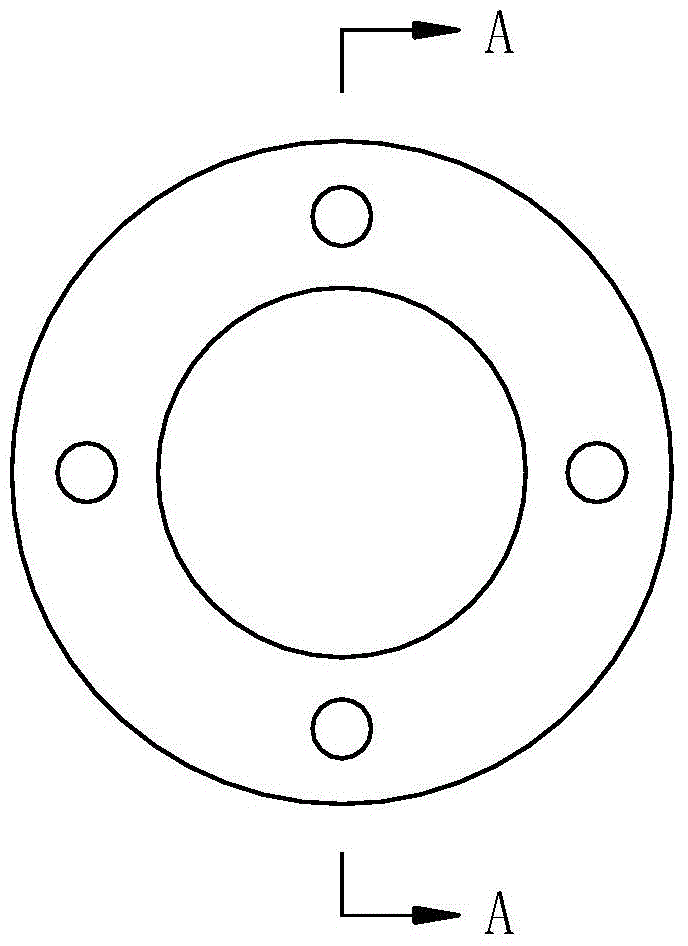

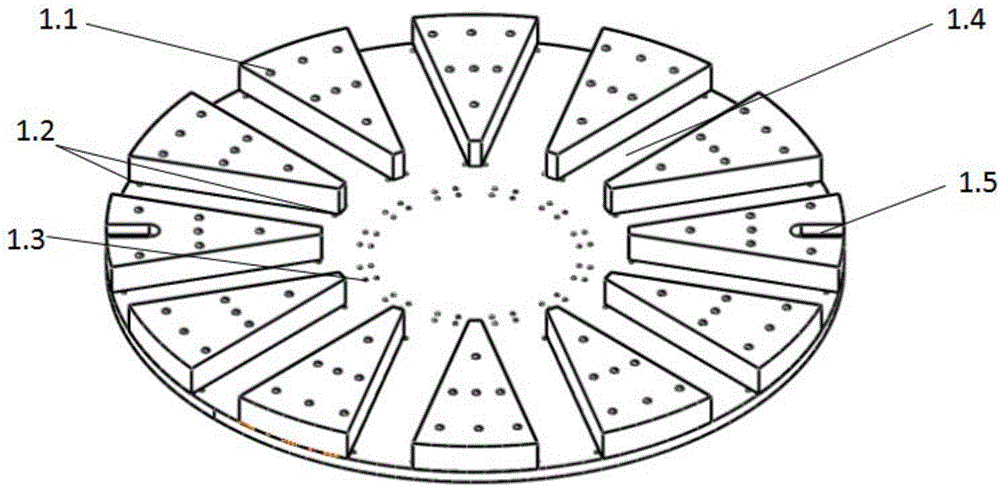

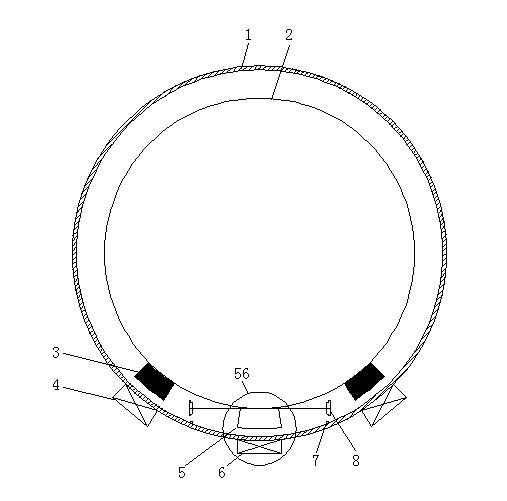

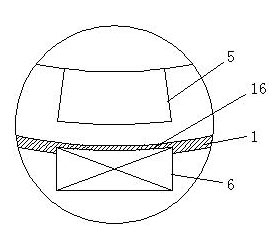

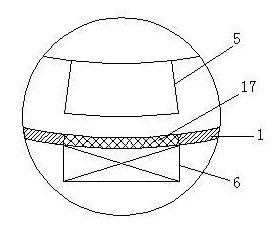

Thin-wall round pipe turning and clamping device

InactiveCN104607681AReasonable designCompact structureExpansion mandrelsEngineeringUltimate tensile strength

The invention discloses a thin-wall round pipe turning and clamping device. The thin-wall round pipe turning and clamping device comprises a slide block bracket for slidingly mounting inclined surface slide blocks, a screw rod for slidingly mounting and supporting taper sleeves, and a clamping base, wherein the slide block bracket and the screw rod are both fixedly mounted at one end of the clamping base; the taper sleeves are slidingly mounted on the screw rod; at least two inclined surface slide blocks fitting the taper sleeves to tightly eject workpieces from the inner sides are slidingly mounted on the slide block bracket; elastic cushion blocks are respectively arranged between all the inclined surface slide blocks and the workpieces; fastening nuts for tightly pressing the taper sleeves are arranged at the ends of the screw rod; and antiskid washers are arranged between the fastening nuts and the end surfaces of the taper sleeves. The thin-wall round pipe turning and clamping device has the characteristics of reasonable design, simple structure, good use effect, high machining precision, convenience for disassembly of the workpieces, low labor intensity, high production efficiency, low production cost and convenience for promotion and application.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

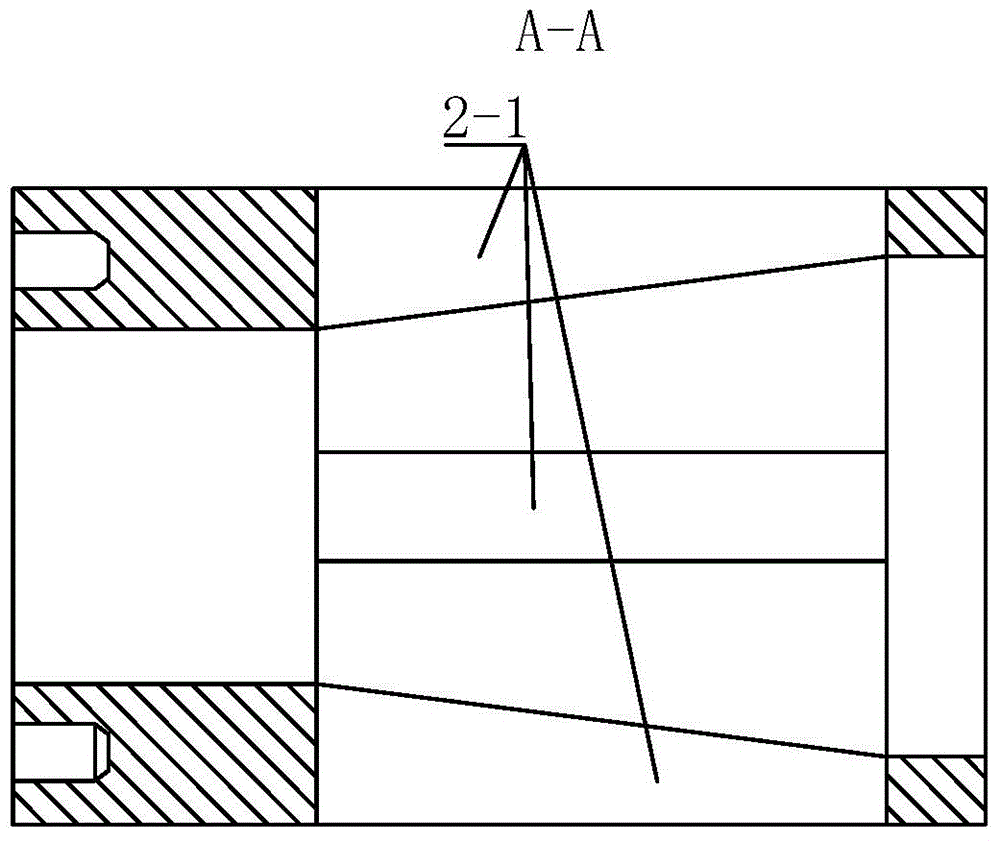

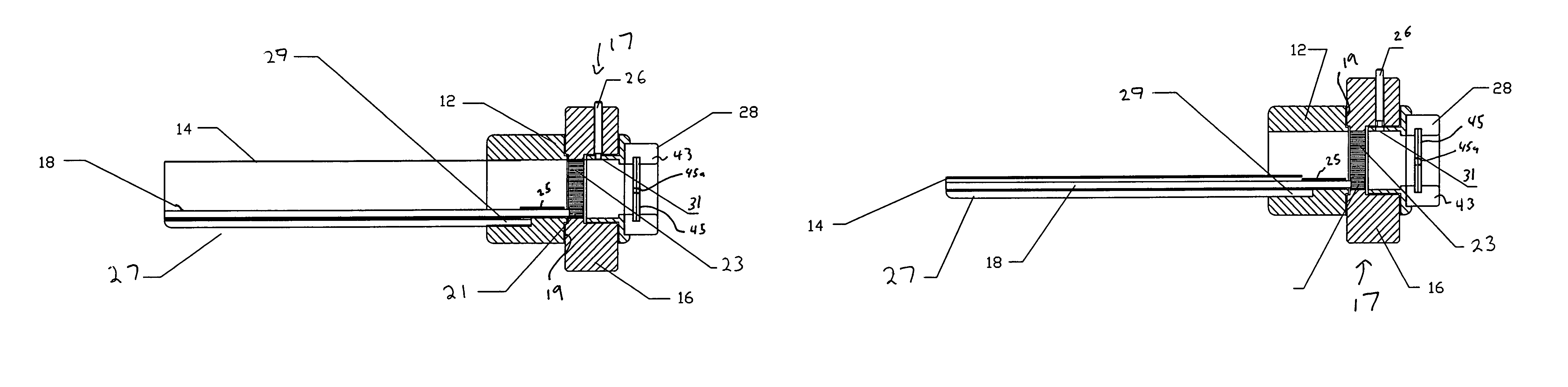

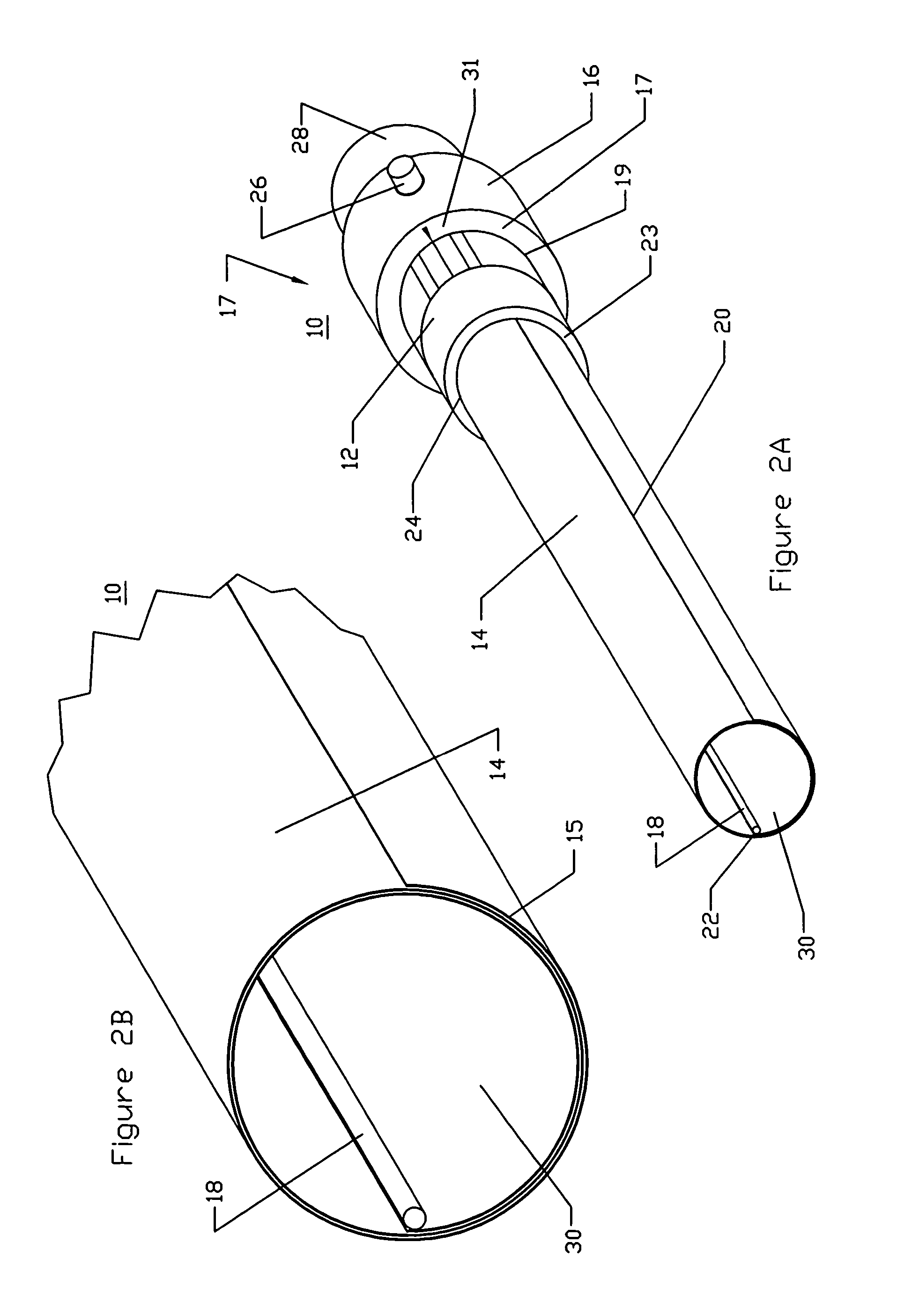

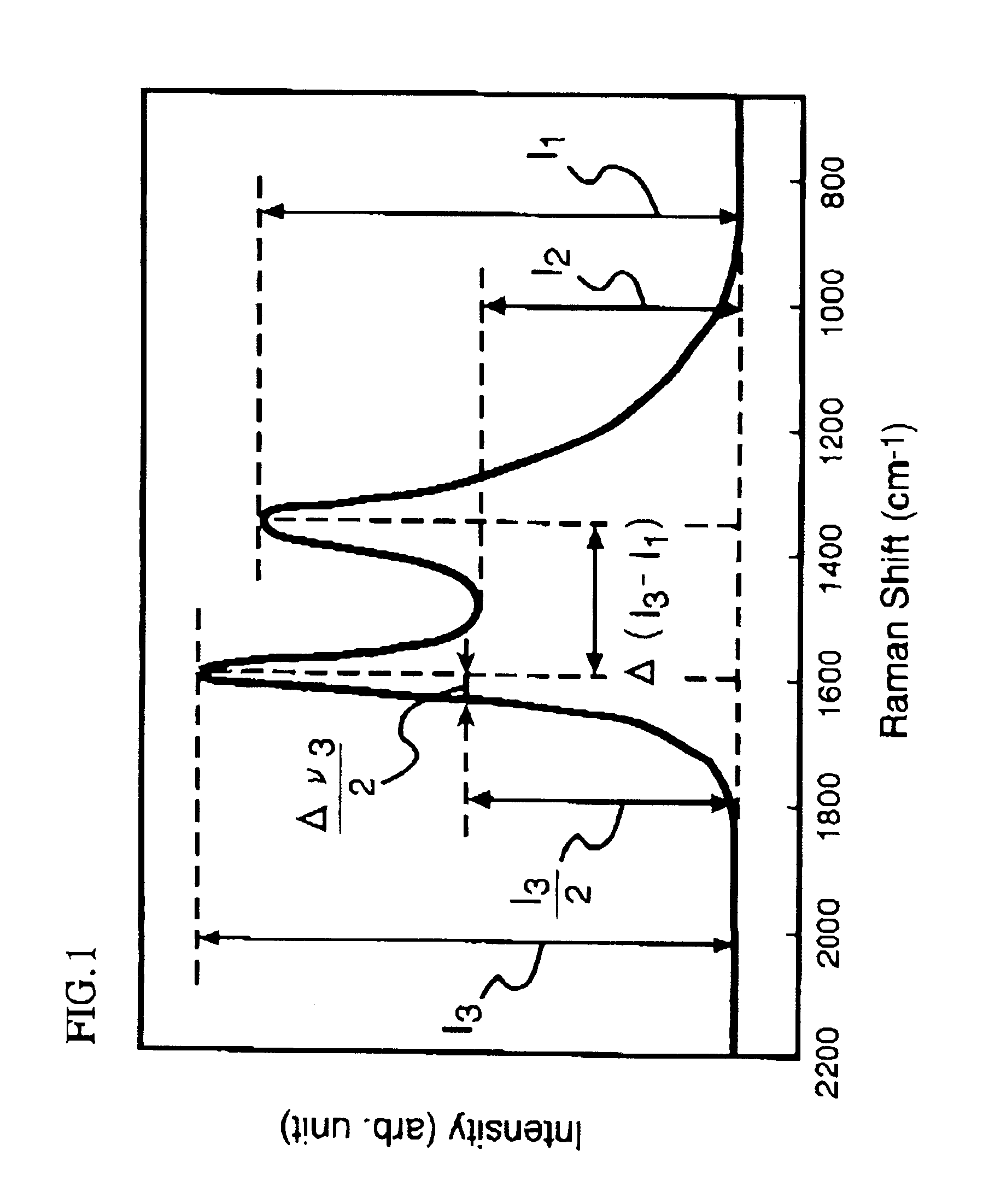

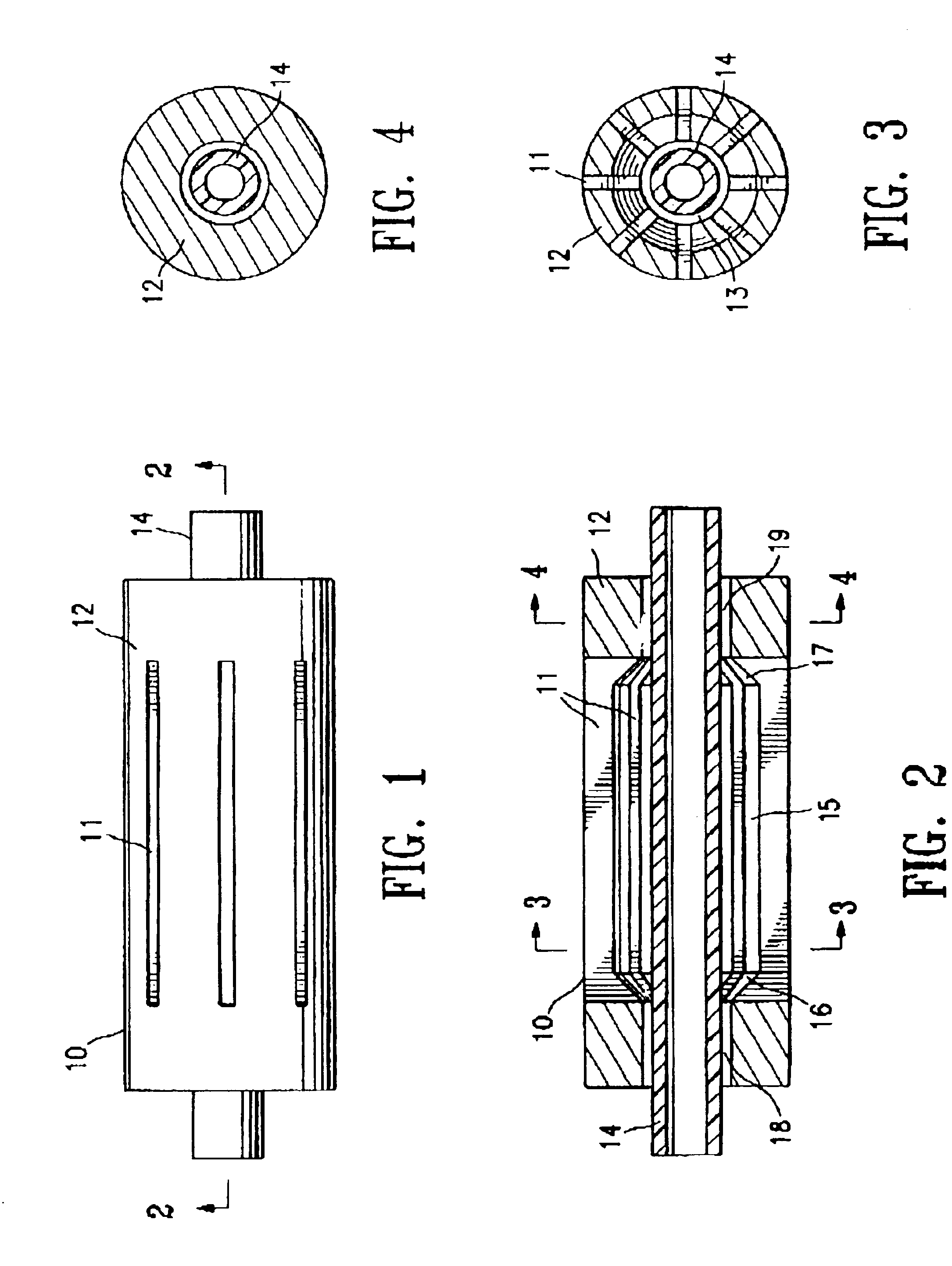

Expandable medical access device

ActiveUS7699864B2Increase the diameterPrevent minimize escapeCannulasSurgical needlesSurgical siteRotation control

An access device comprises a thin-walled sheath that is insertable into a patient through a small surgically created incision. The incision may be created using a cutdown or a percutaneous method such as that known as the Seldinger technique. Once inserted and advanced to the target surgical site, the sheath is selectively, and controllably, expanded to a desired diameter. The thin wall of the sheath is fabricated from a rectangular piece of material such as metal or plastic with two cut edges. The rectangular piece of metal or plastic is rolled tightly to create the small diameter configuration that is inserted into the patient. A cam or control member is affixed to the innermost edge of the rectangular piece of metal or plastic. The control member extends to the proximal most portion of the sheath. By rotating the control member, the operator causes the thin wall piece of rolled material to unfurl into a larger or smaller diameter, depending on the direction of rotation. A mechanical lock at the distal end of the sheath permits the control member to be selectively constrained from rotation and thus lock the sheath diameter in place.

Owner:ONSET MEDICAL CORP

Method for shielding an electronic component

Owner:PPG IND OHIO INC

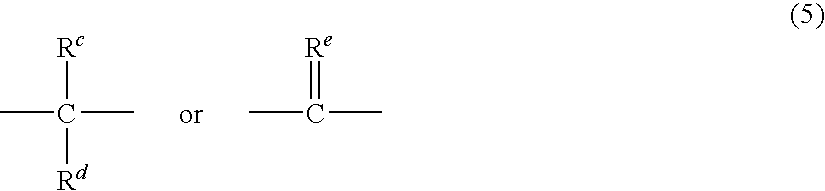

Thermoplastic resin composition, molding material, and molded article thereof

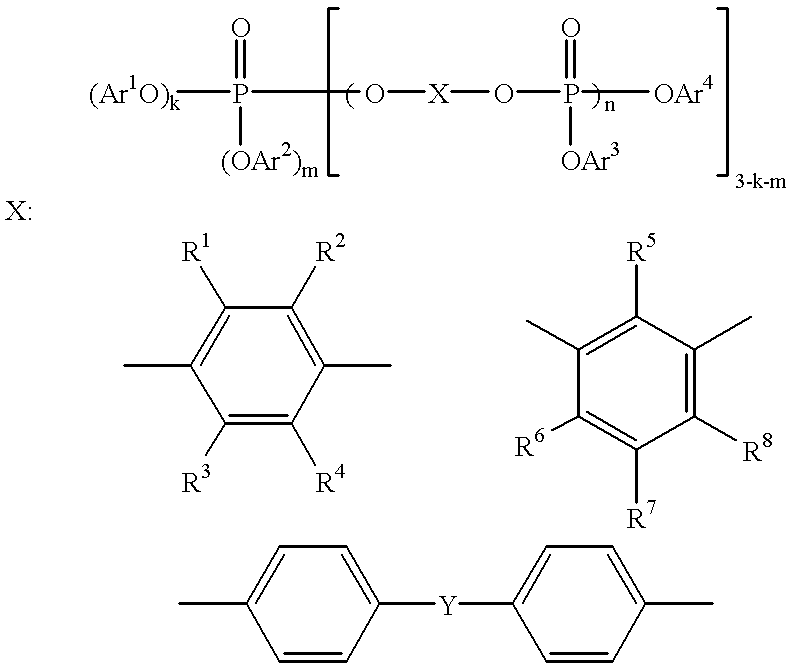

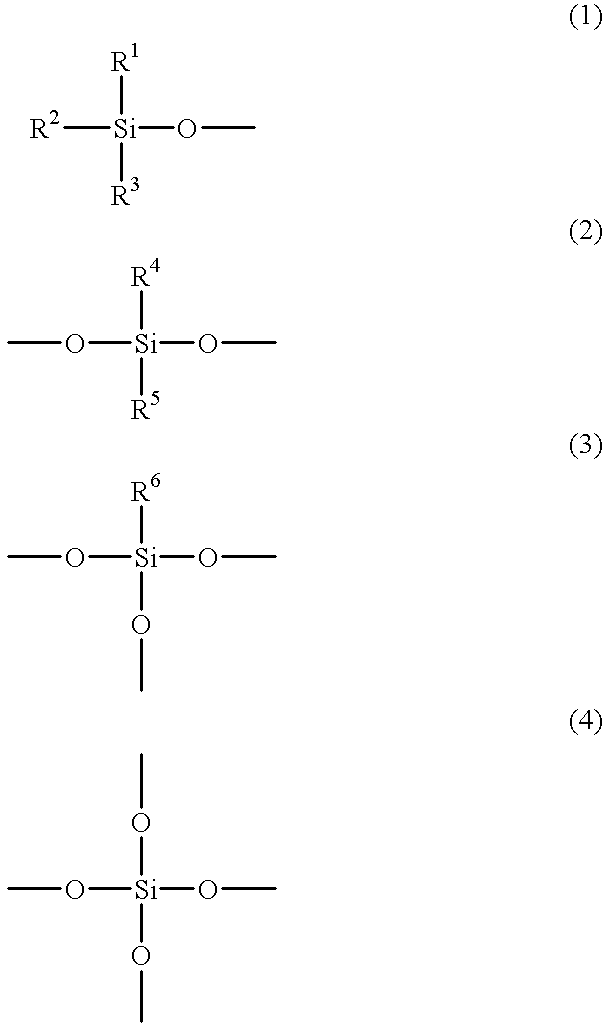

A thermoplastic resin composition capable of providing a thin walled molded article whose flame retardancy with a thickness of 1.6 mm ({fraction (1 / 16)} inch) in accordance with an UL 94 standard is V-0 or better, and which comprises the following components [A], [B] and [C], wherein the component [B] satisfies the following conditions (B1) and / or (B2):[A]: an electrically conductive fiber;[B]: a carbon powder;[C]: a thermoplastic resin;(B1): Raman scattering intensity ratio I2 / I1 is 0.55-0.8;(B2): Raman scattering intensity ratio I2 / I3 is 0.54-0.8; whereI1: local maximum value of Raman scattering intensity appearing near a Raman shift of 1360 cm-1;I2: local minimum value of the Raman scattering intensity appearing near a Raman shift of 1480 cm-1;I3: local maximum value of the Raman scattering intensity appearing neat a Raman shift of 1600 cm-1.

Owner:TORAY IND INC

Thin wall, high pressure, volume compensator

Accumulators / compensators for pressurized fluent material systems are provided, in which a continuous substantially non-permeable, flexible membrane (like a bellows) surrounds or is surrounded by a non-gaseous support medium, all within a surrounding housing. Various combinations of support media, which may include internal gas-filled cavities, are described and illustrated.

Owner:SENIOR ENG INVESTMENTS

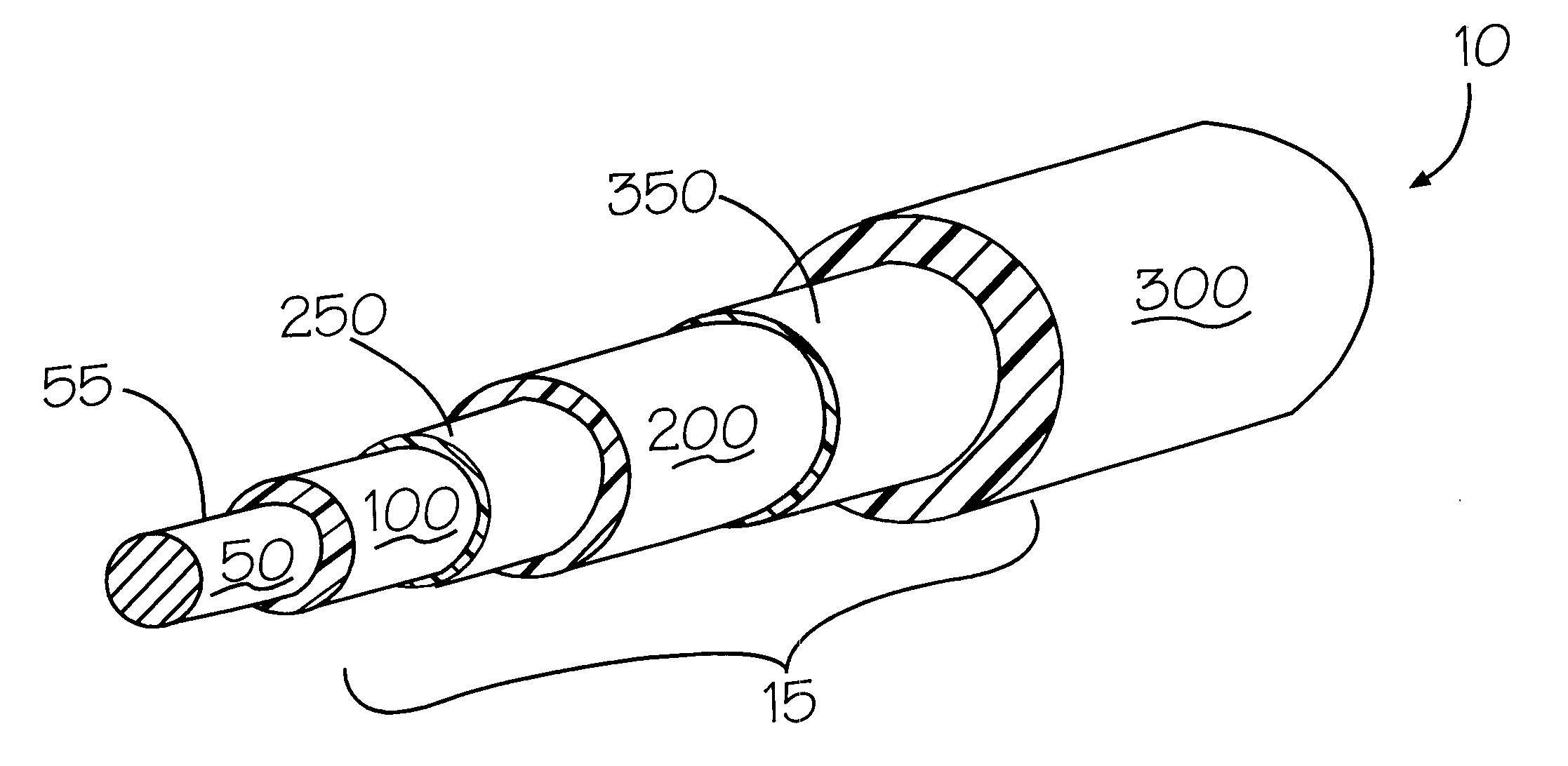

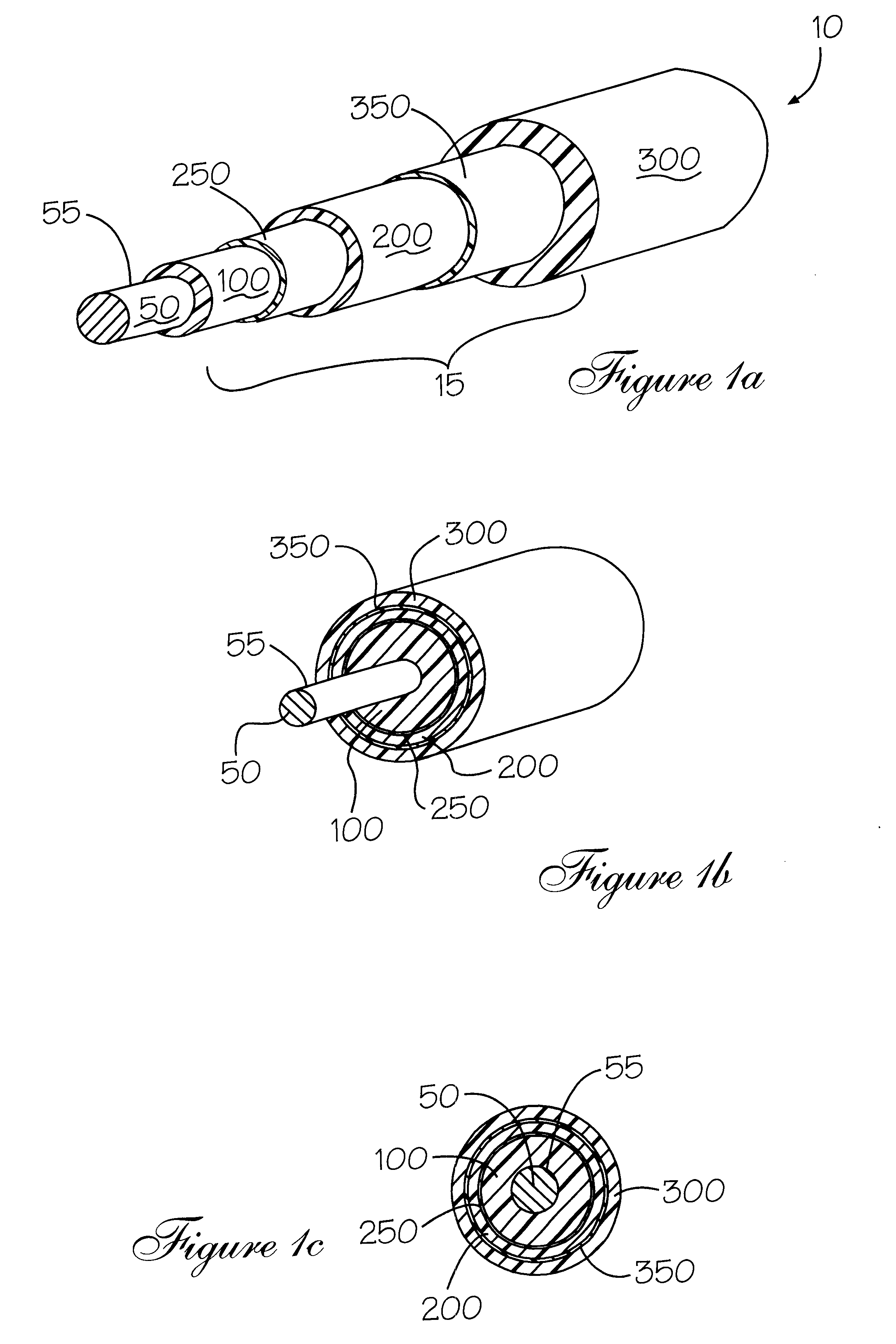

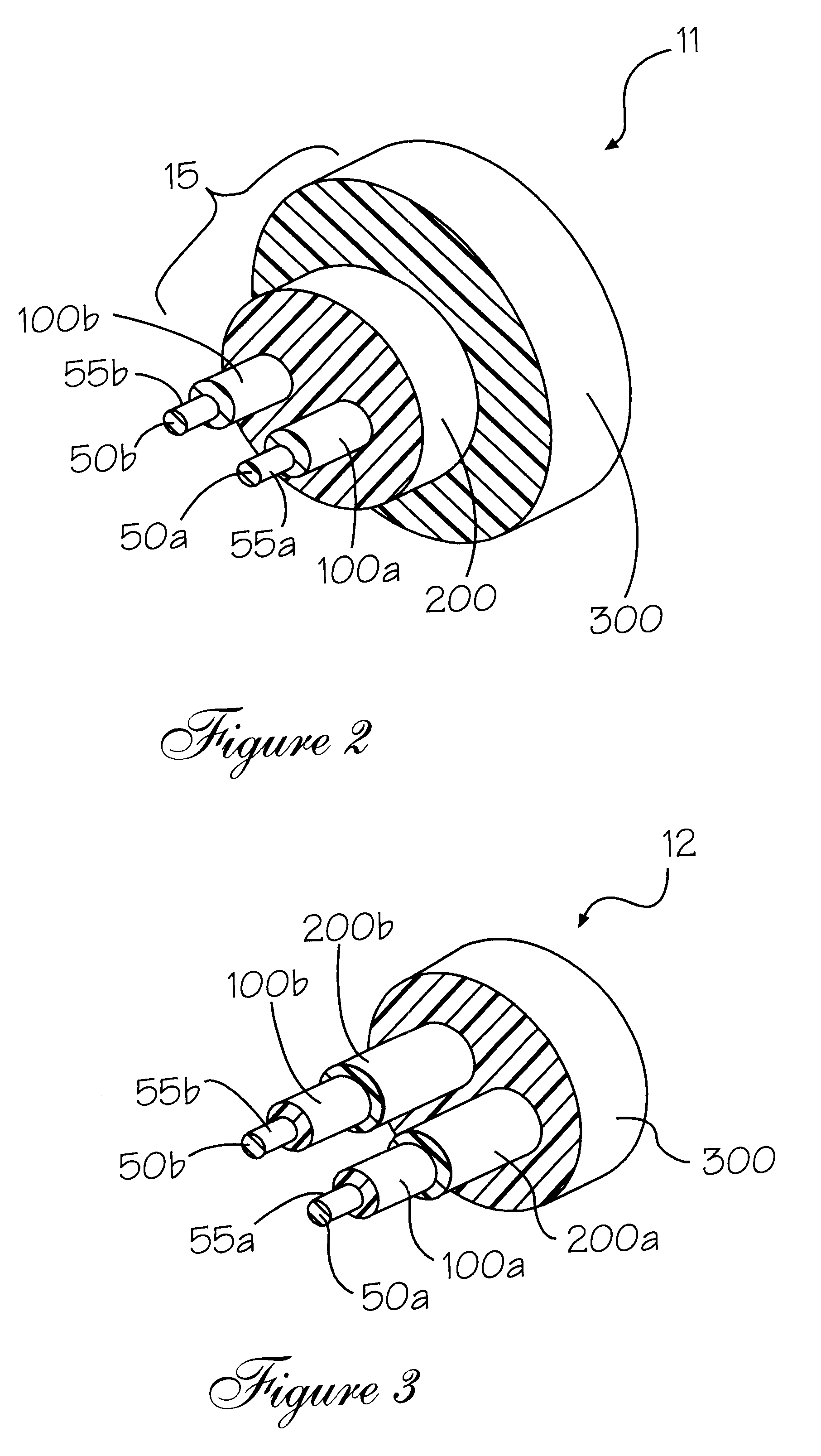

Automotive-wire insulation

InactiveUS6359230B1Excellent physical toughnessResistant to oxidationPlastic/resin/waxes insulatorsInsulated cablesPolyesterInter layer

The invention pertains to multi-layer polymeric formulations for protecting or insulating metallic objects, and, more particularly, to an integrated, tri-layer, thin-wall insulation composite, for use in a high temperature, automotive-wire article. The tri-layer design comprises an inner layer of a fluoropolymer, polyether sulfone, polyether-ketone, polyetherimide, or thermoplastic polyester; a middle layer comprising a polyolefin; and an outer layer comprising a fluoropolymer. The inner and outer layers serve to protect the middle polyolefinic layer from degradation.

Owner:CHAMPLAIN CABLE CORP

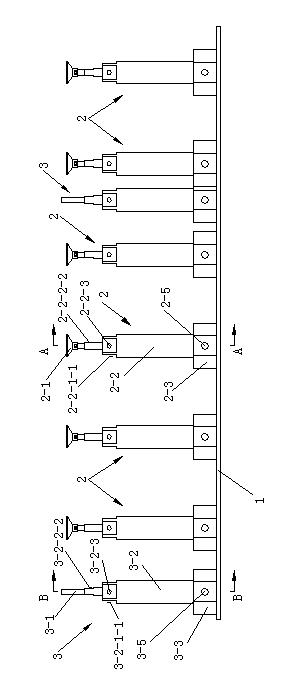

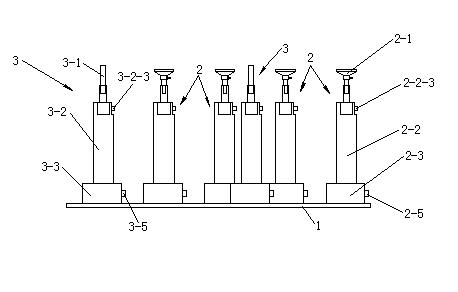

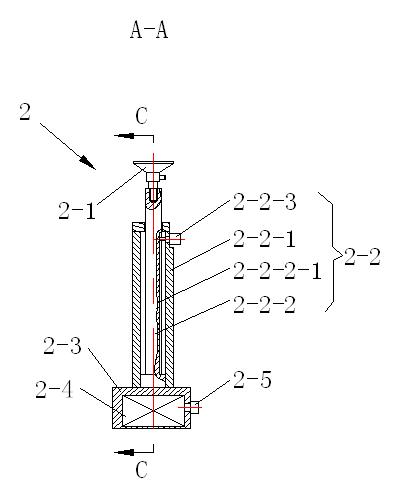

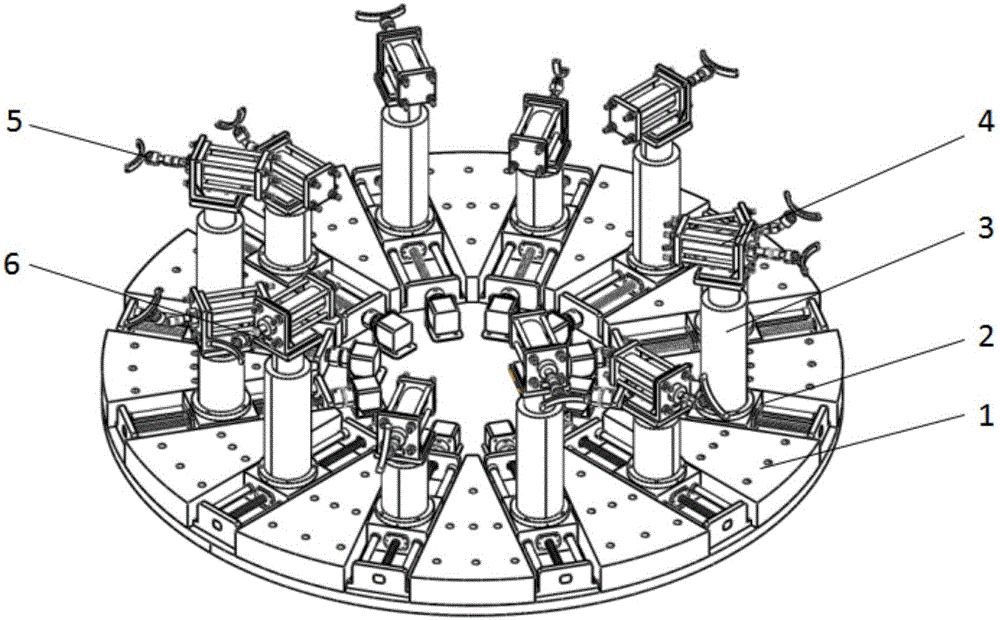

Flexible multipoint tool set for positioning and supporting thin-walled curved surface parts

The invention discloses a flexible multipoint tool set for positioning and supporting thin-walled curved surface parts, which comprises an operating platform and at least three supporting / fixing units, wherein the supporting / fixing units are all arranged on the operating platform, and each supporting / fixing unit comprises a spherical hinge side draught vacuum chuck, a first hoisting assembly and a fixed base, the spherical hinge side draught vacuum chuck is arranged at the upper part of the first hoisting assembly, and the lower part of the first hoisting assembly is arranged on the fixed base; the fixed base of each supporting / fixing unit is provided with a first electromagnet, and the first electromagnet is in magnetic suction with the upper surface of the operating platform; and the operating platform is also provided with at least two positioning units, each positioning unit comprises a positioning pin, a second hoisting assembly and a positioning base, the positioning pin is arranged at the upper end part of the second hoisting assembly, the lower end part of the second hoisting assembly is arranged on the positioning base, and the positioning base is connected with the operating platform. The flexible multipoint tool set disclosed by the invention not only can accurately position thin-walled curved surface parts, but also can conveniently move above the operating platform and adjust the distance between every two supporting / fixing units.

Owner:HOHAI UNIV CHANGZHOU

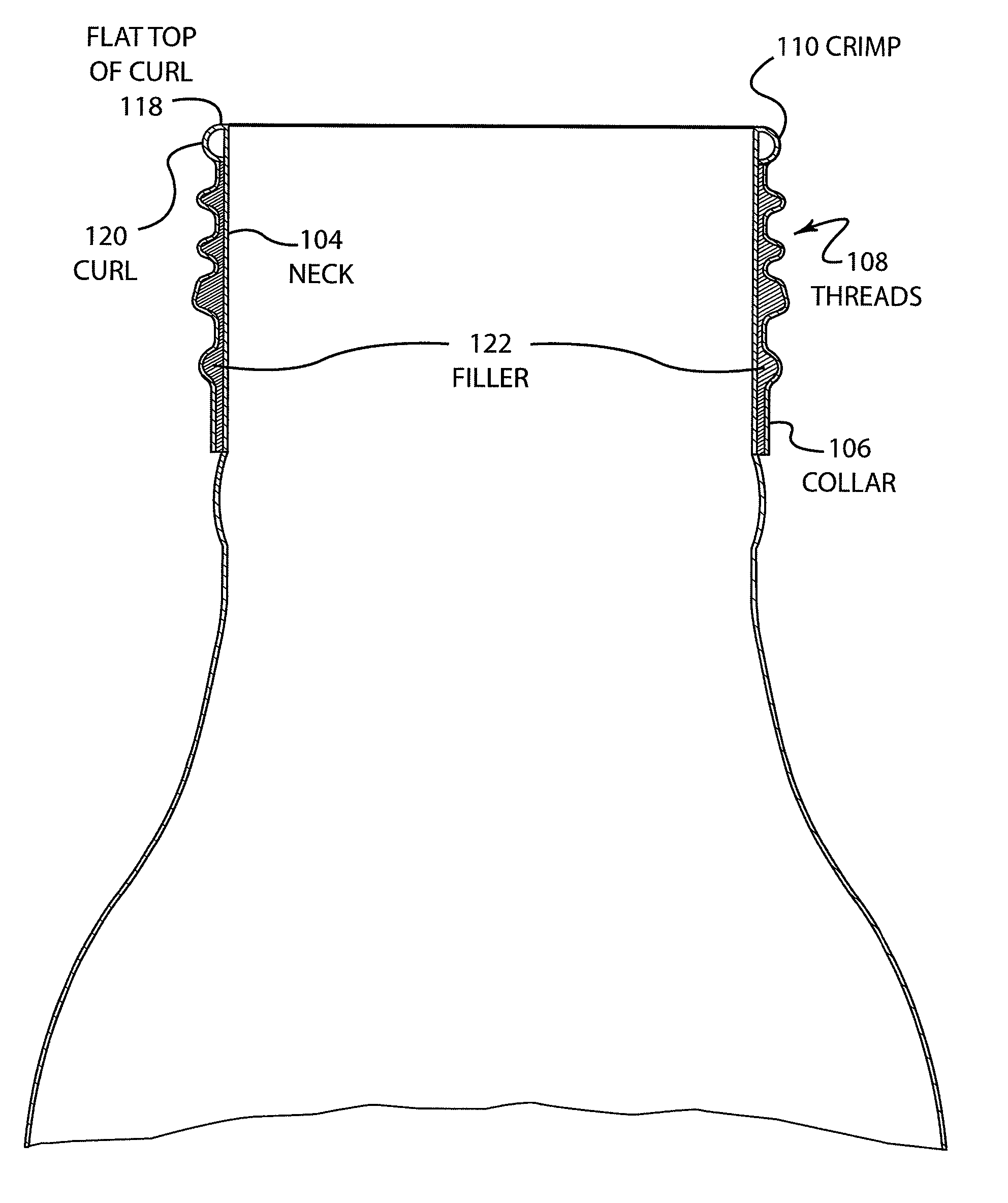

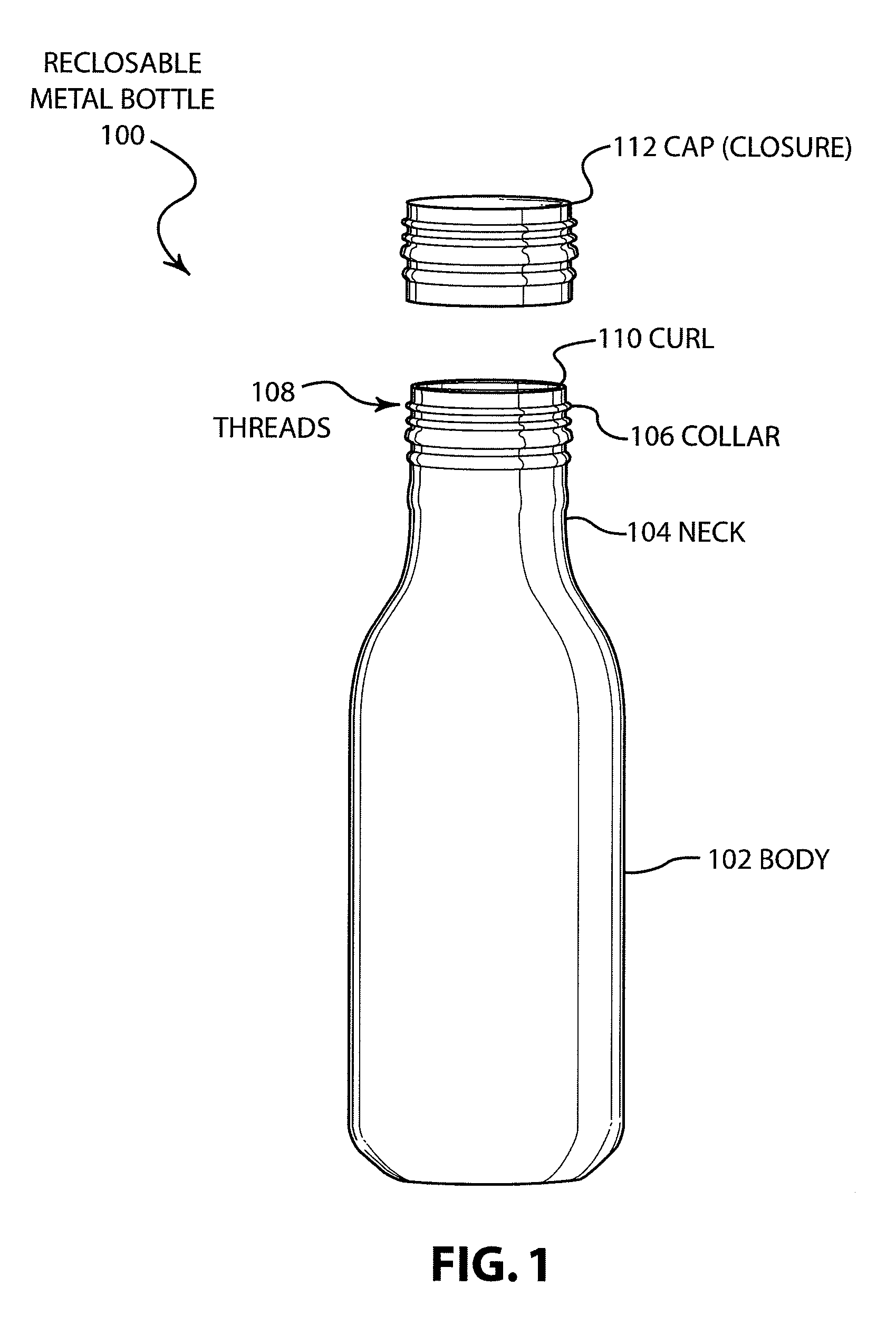

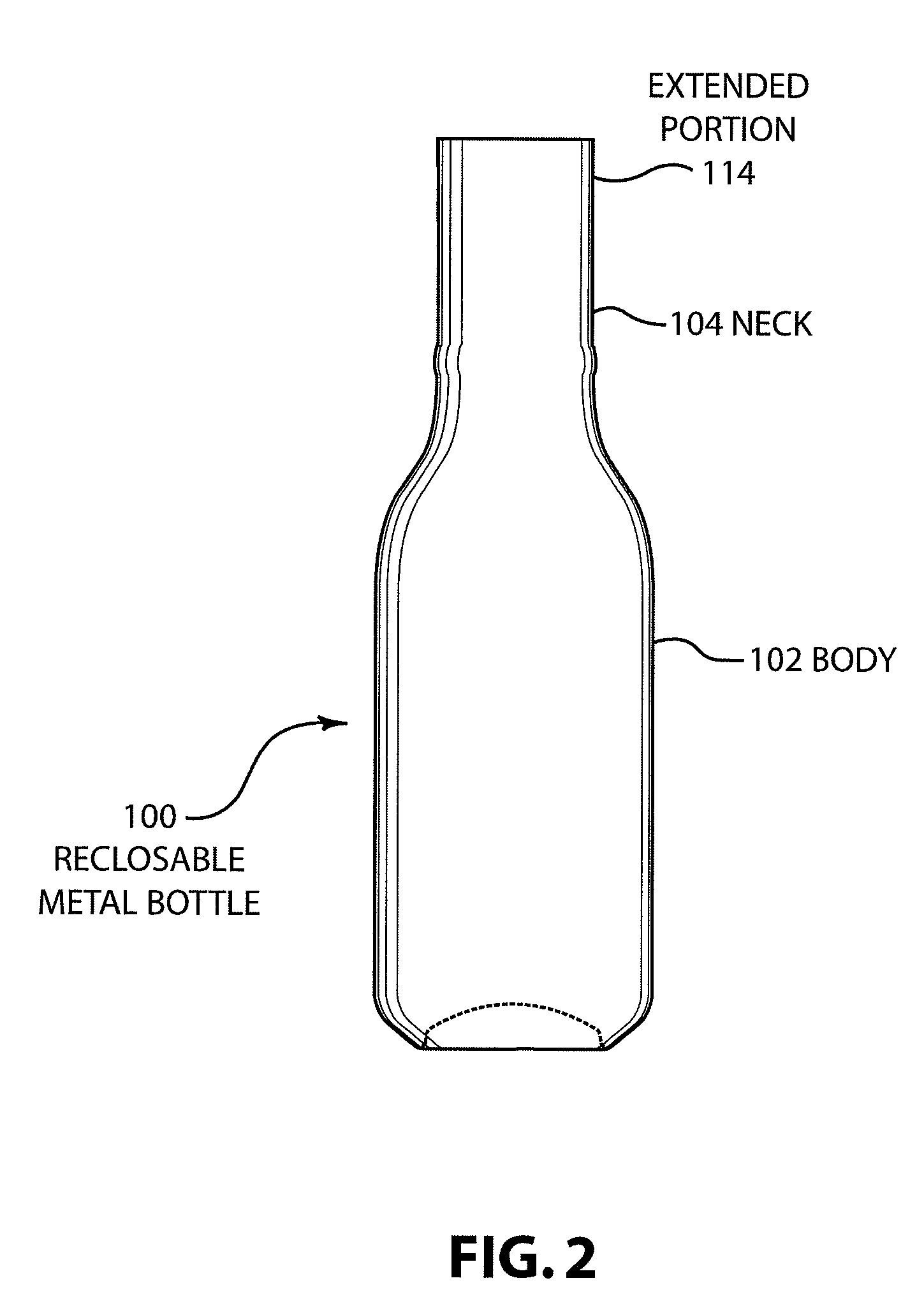

Reclosable metal bottle

InactiveUS20070051687A1Provide rigidityProvide strengthClosure capsRigid containersEngineeringBottle

Disclosed is an unique reclosable metal bottle in which a trim portion of the neck can be reused and mounted on the neck as a collar, or a separate collar provided, that has the structural rigidity necessary to form threads or lugs for recloseability. Thin wall metal bottles, having thicknesses on the order of thin wall metal cans currently in use, can be made using this process with minimal material waste since the trim neck portion is reused as a threaded collar. Structural rigidity and strength can be added by using fillers to backfill the indentations of the threads in the collar. Threads or lugs can be used, including pressure release lugs, that add both safety and convenience. Since the reclosable metal bottle is an all-metal container, the bottle can be recycled without introducing contaminants.

Owner:OMNITECH INT +1

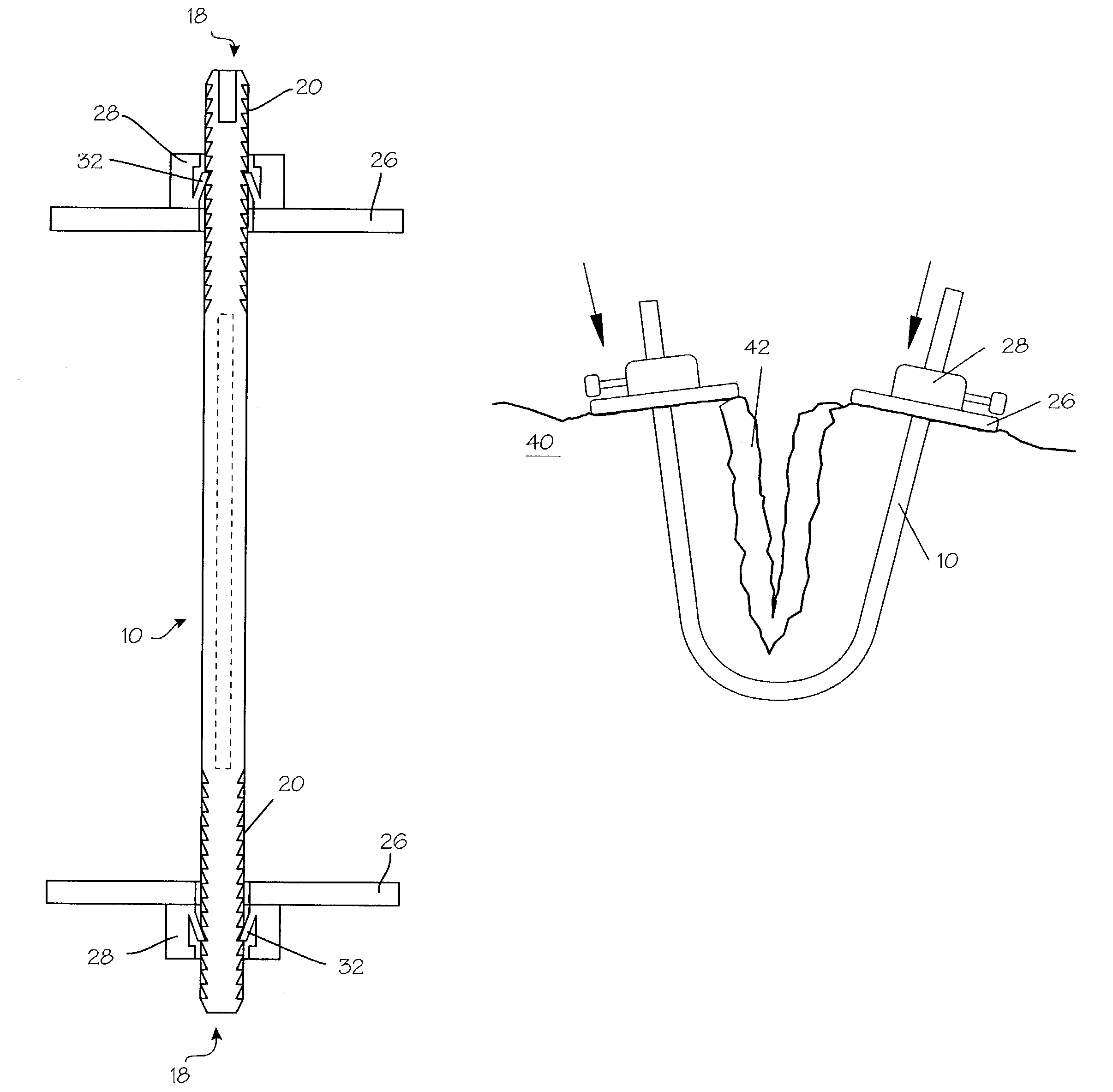

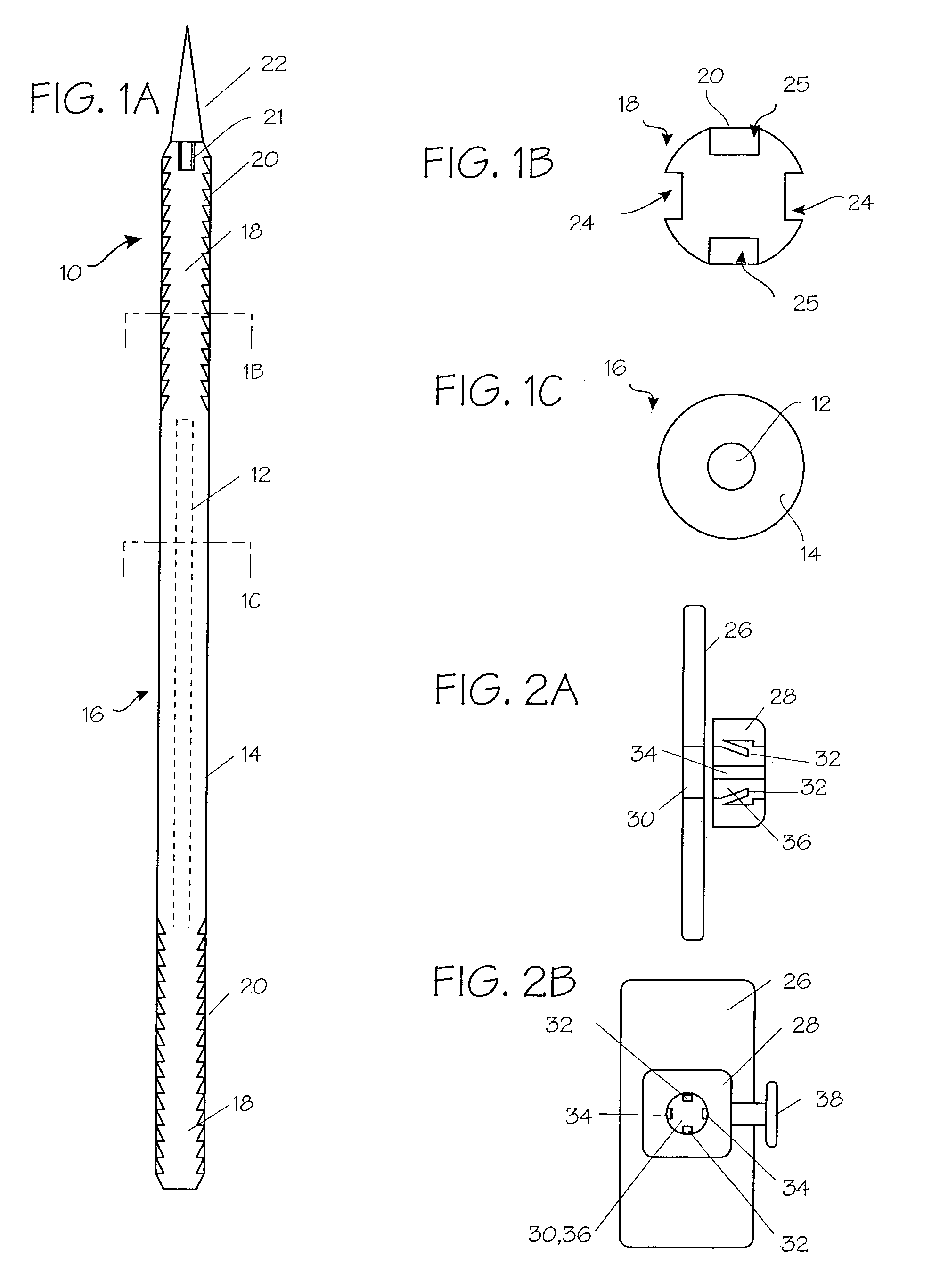

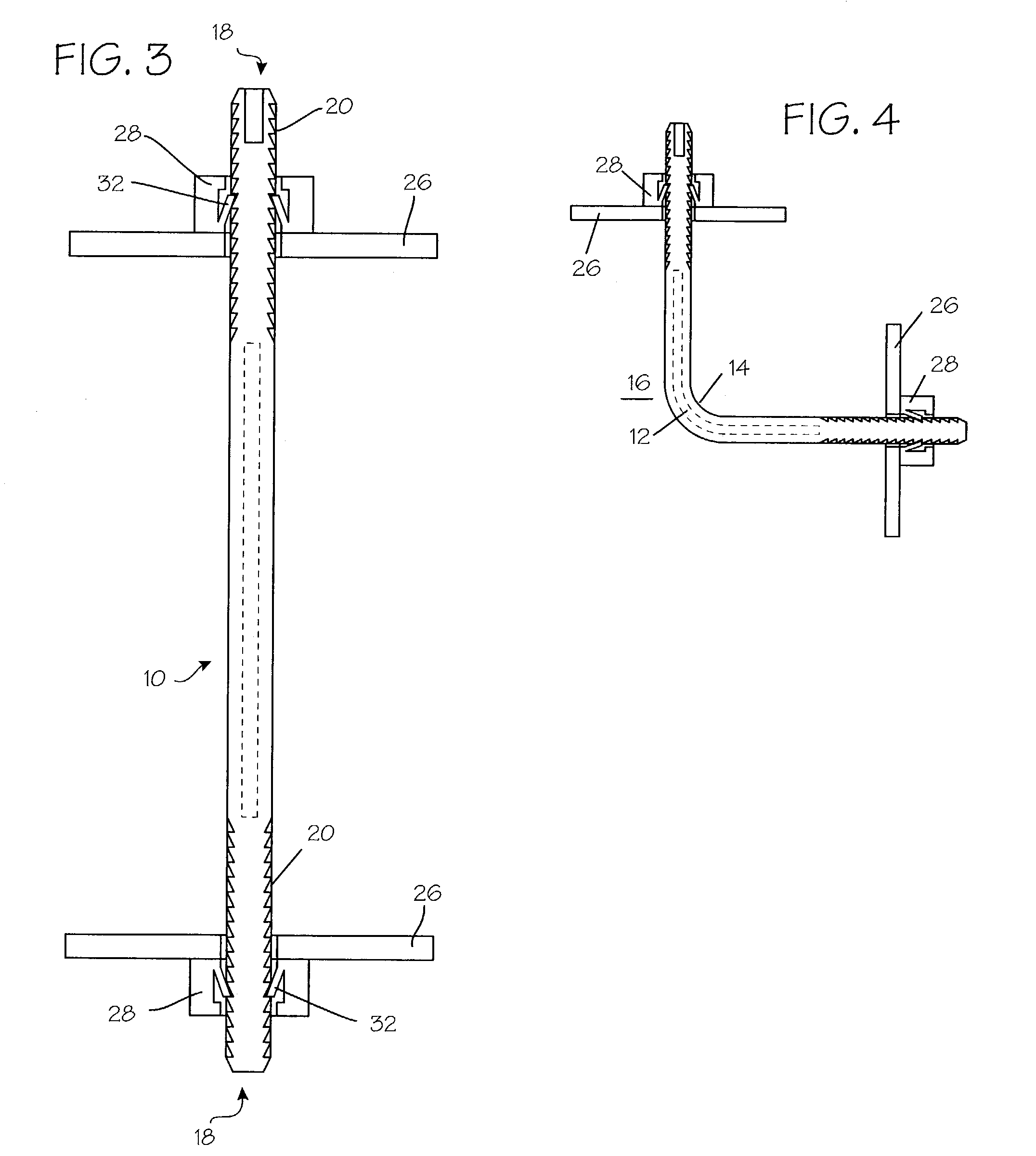

Method and apparatus for solid organ tissue approximation

InactiveUS7235090B2Improved haemostatic tissue appositionEasy and fast applicationIntravenous devicesSurgical veterinaryTrauma surgeryParenchyma

Devices and methods are disclosed for achieving hemostasis in solid visceral wounds. Such devices and methods are especially useful in the emergency, trauma surgery or military setting. In such cases, the patient may have received trauma to the abdominal viscera. The devices utilize flexible, variable depth transfixing bolts that penetrate the viscera. These bolts are pulled tight to bring the tissue into apposition and hold said tissue in apposition while the wound heals. These bolts overcome the limitations of sutures that are currently used for the same purposes. The bolts come in a variety of lengths and diameters. Since the bolts are flexible, the curvature may be adjusted by the surgeon. The devices are flexible, bendable, and conformable in their wet or dry state. They can be used either straight or through a broad range of curvatures to suit the needs of various pathologies. The bolts include pressure plates that are capable of exerting compressive pressure over broad areas of visceral wounds without causing tearing of the friable parenchyma. The bolts may be placed and removed by open surgery or laparoscopic access.

Owner:DAMAGE CONTROL SURGICAL TECH

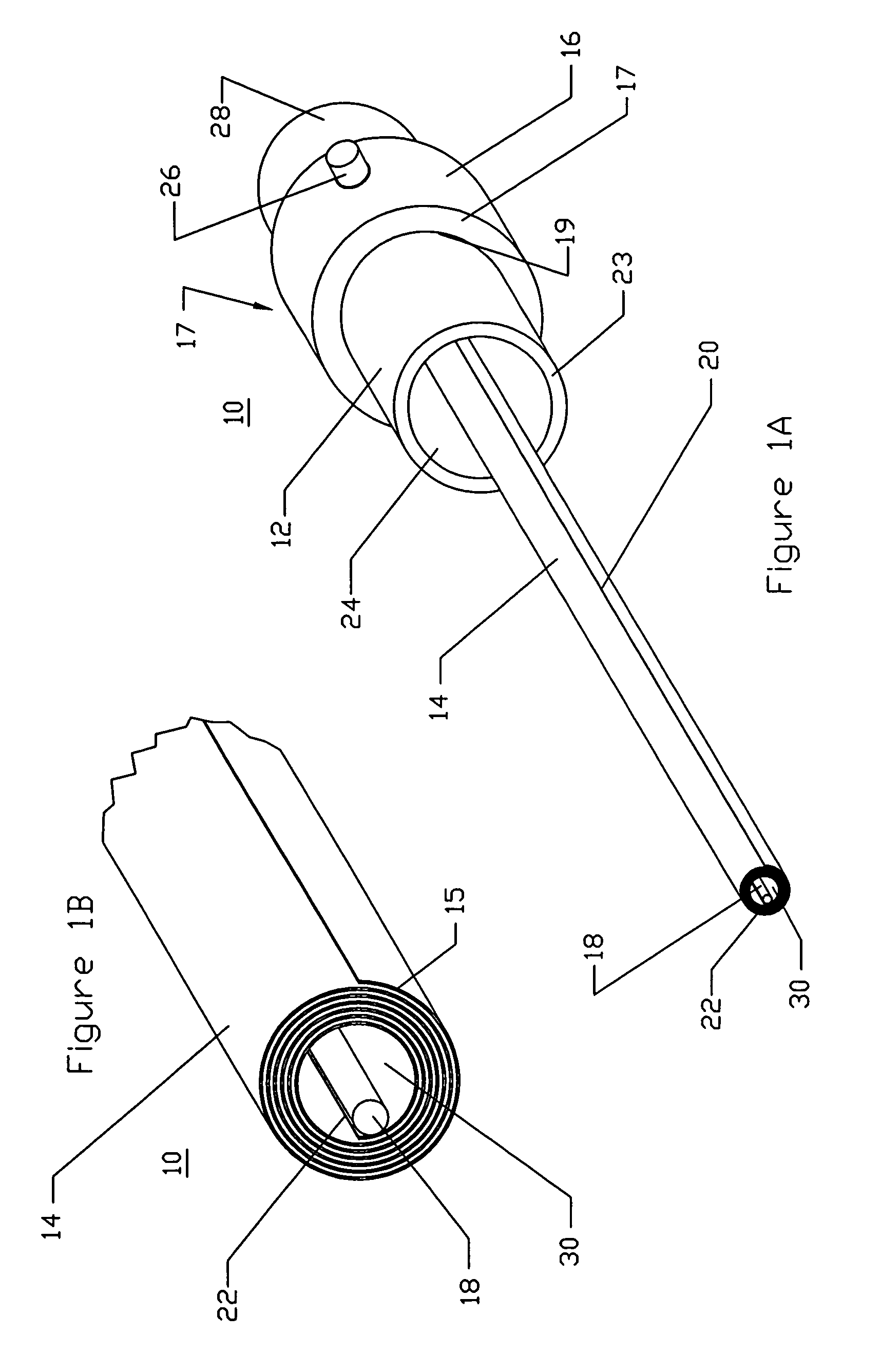

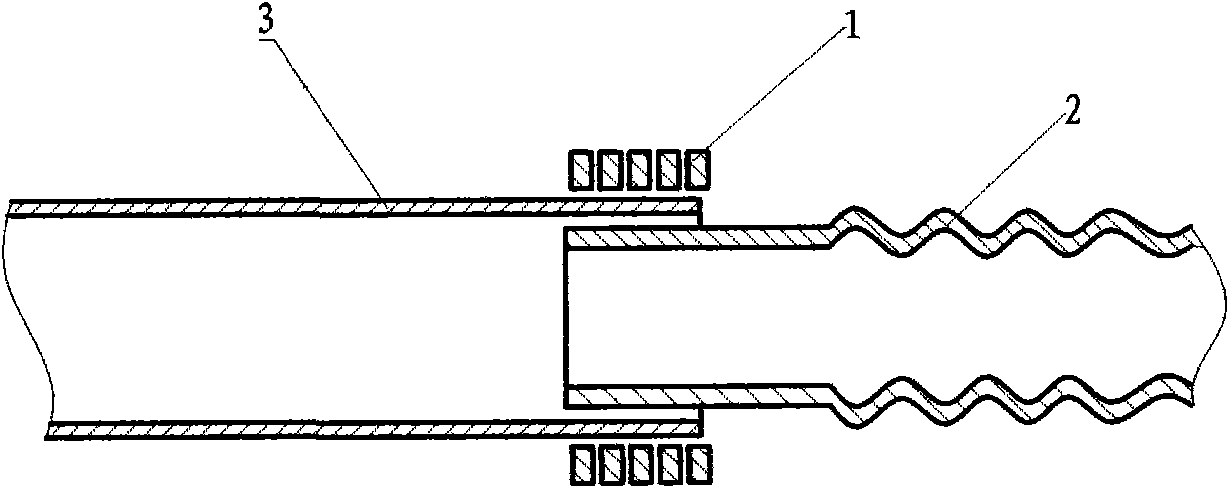

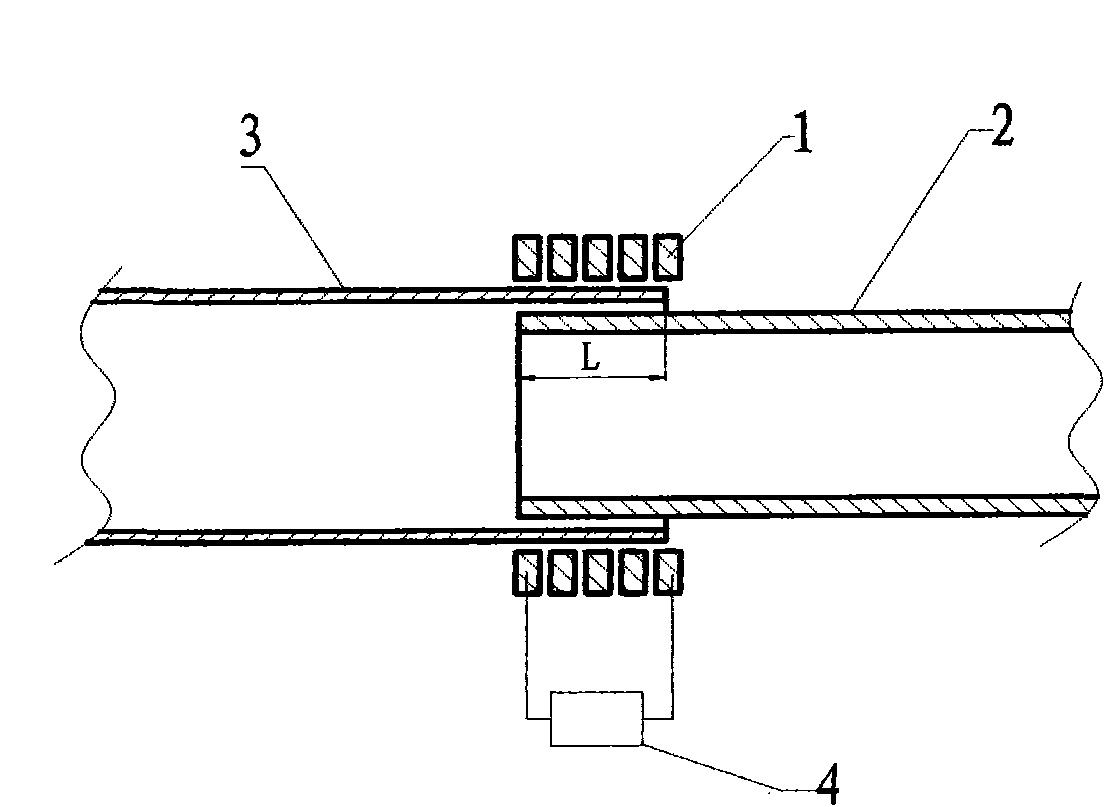

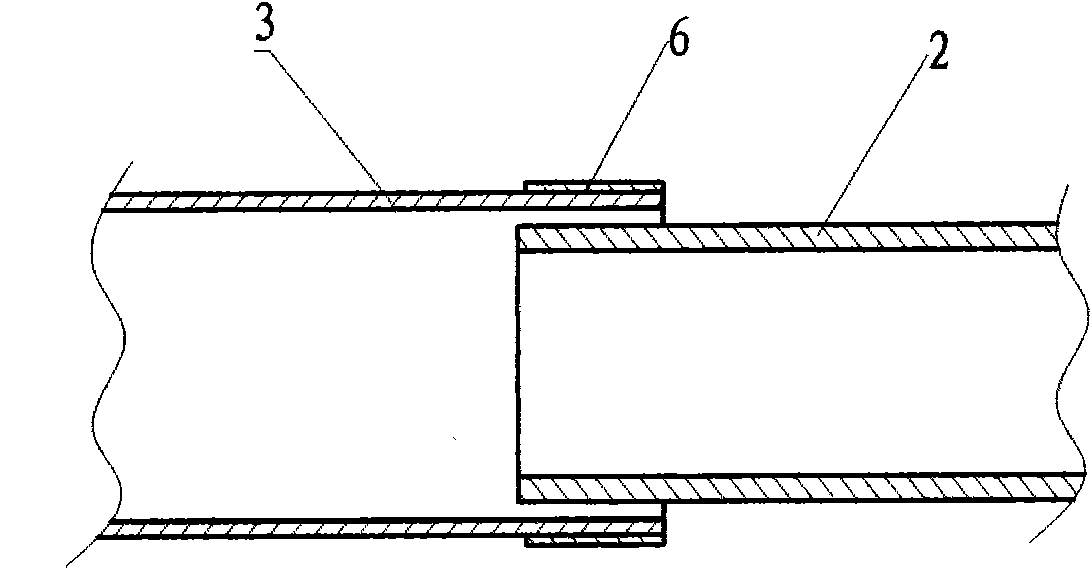

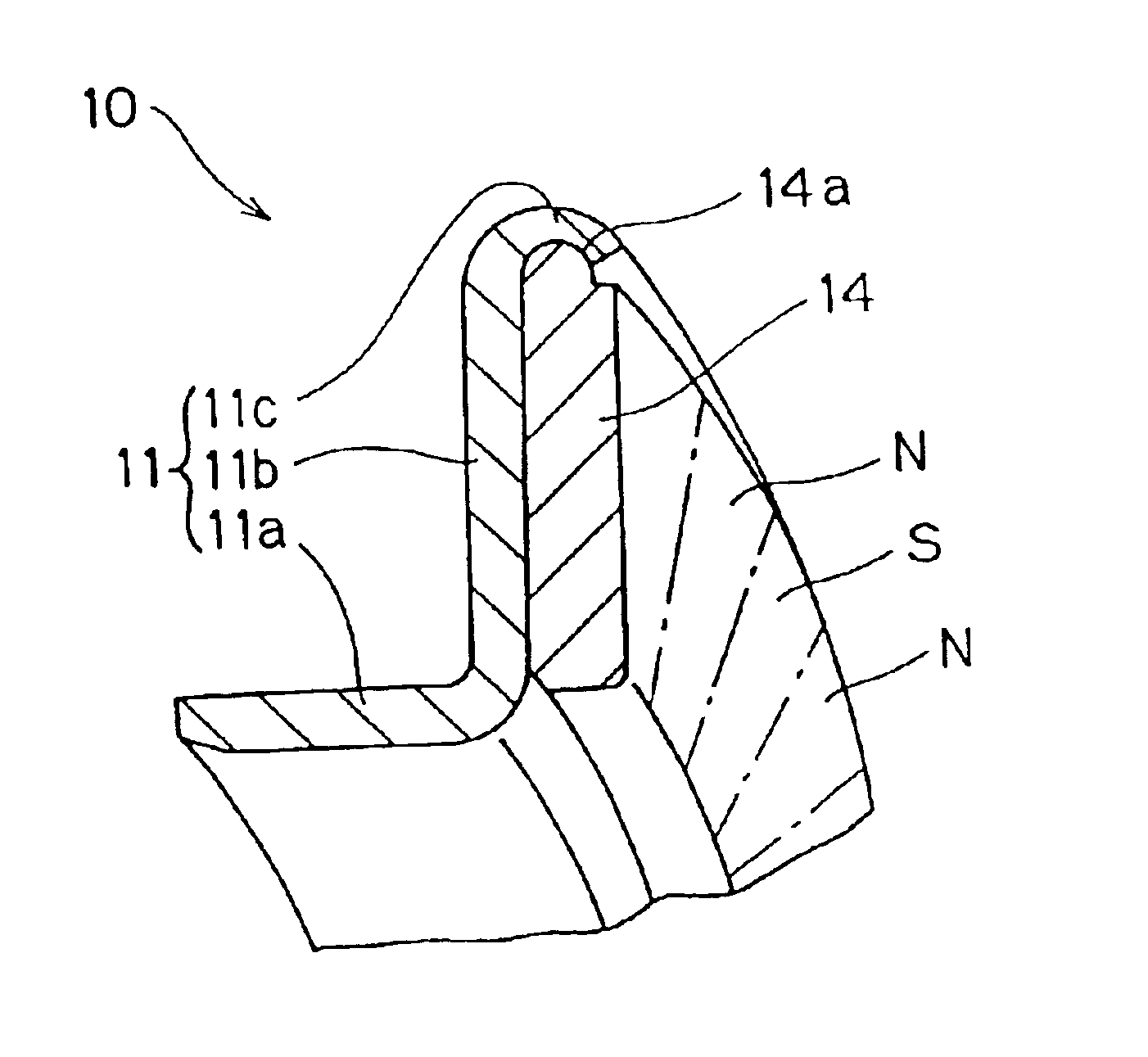

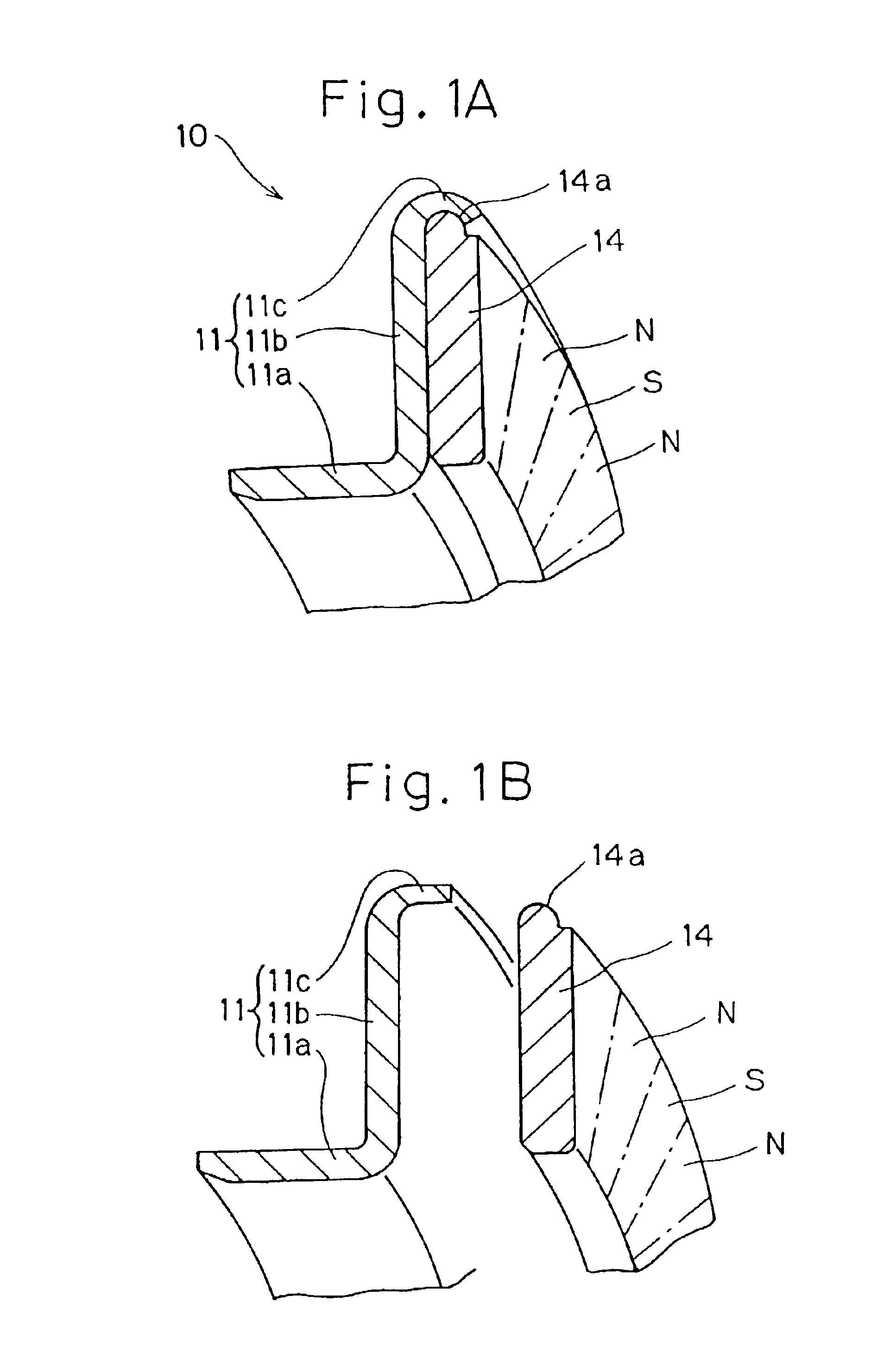

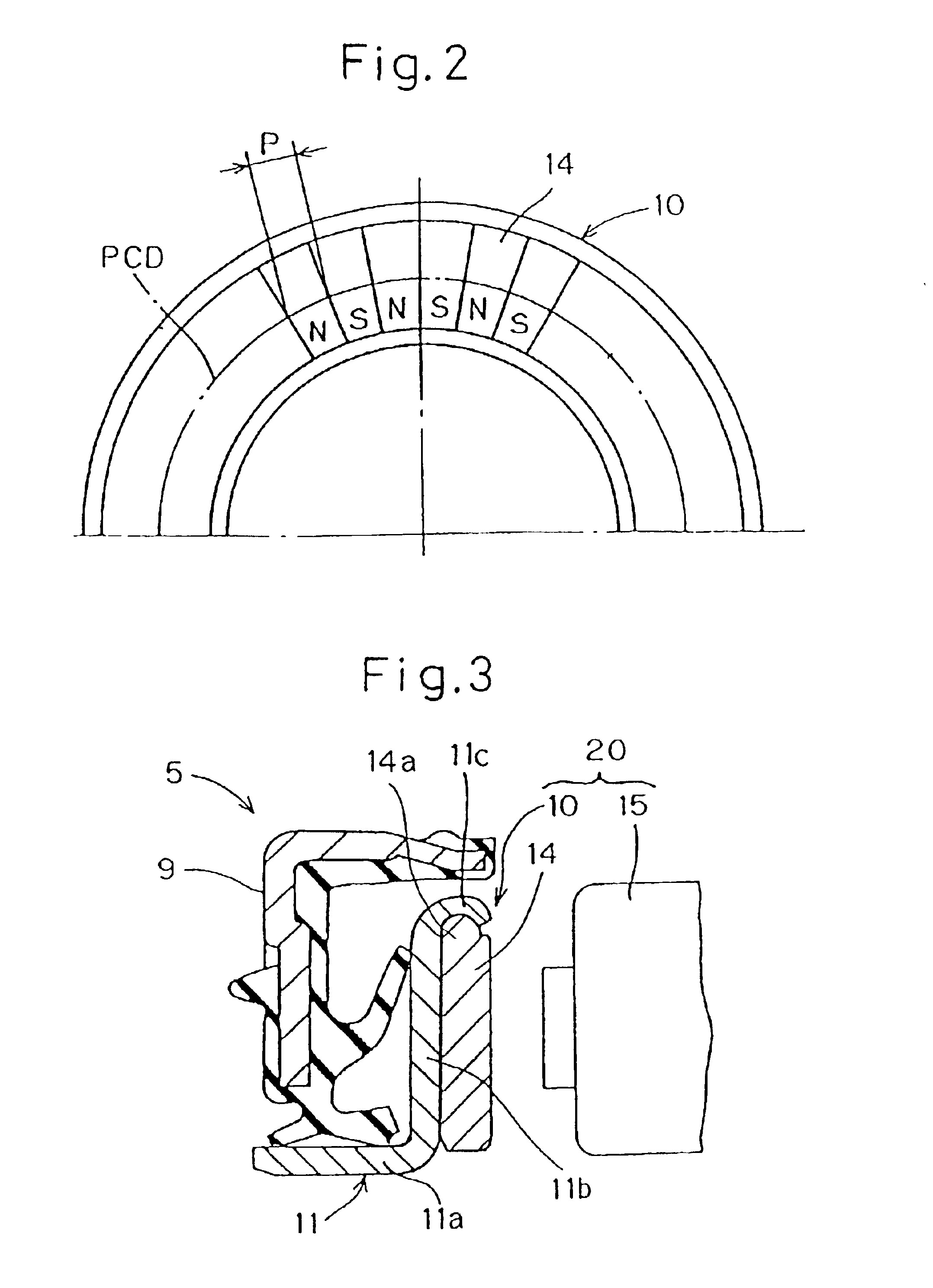

Magnetic pulse connecting method and joint structure for thin-wall metal pipelines

InactiveCN101905375AIncreased processing flexibilityHigh strengthNon-electric welding apparatusHeat-affected zoneEngineering

The invention discloses a magnetic pulse connecting method and a joint structure for thin-wall metal pipelines and provides a safe and high-efficiency magnetic pulse connecting method and a magnetic pulse connecting joint structure for similar and dissimilar thin-wall metal pipelines. A coil-magnetic concentrator composite inductor or a coil inductor is connected with electromagnetic pulse forming equipment so that the pipelines of various metal materials or various structure shapes can be connected in a magnetic pulse way. The transition area of the joint connecting interface is small, the brittle phase or intermetallic compound almost cannot be generated, and the joint almost has no heat affected area and torsion deformation and has high strength and corrosion-resistance property; the tension strength and torsion strength of the joint are respectively higher than those of weak base metal; the subsequent cleaning procedure and post-weld heat treatment are not needed; and the connected pipeline satisfies certain rigidity requirement, cannot be subjected to the plastic deformation in the magnetic pulse connecting process and has high process flexibility.

Owner:HARBIN INST OF TECH

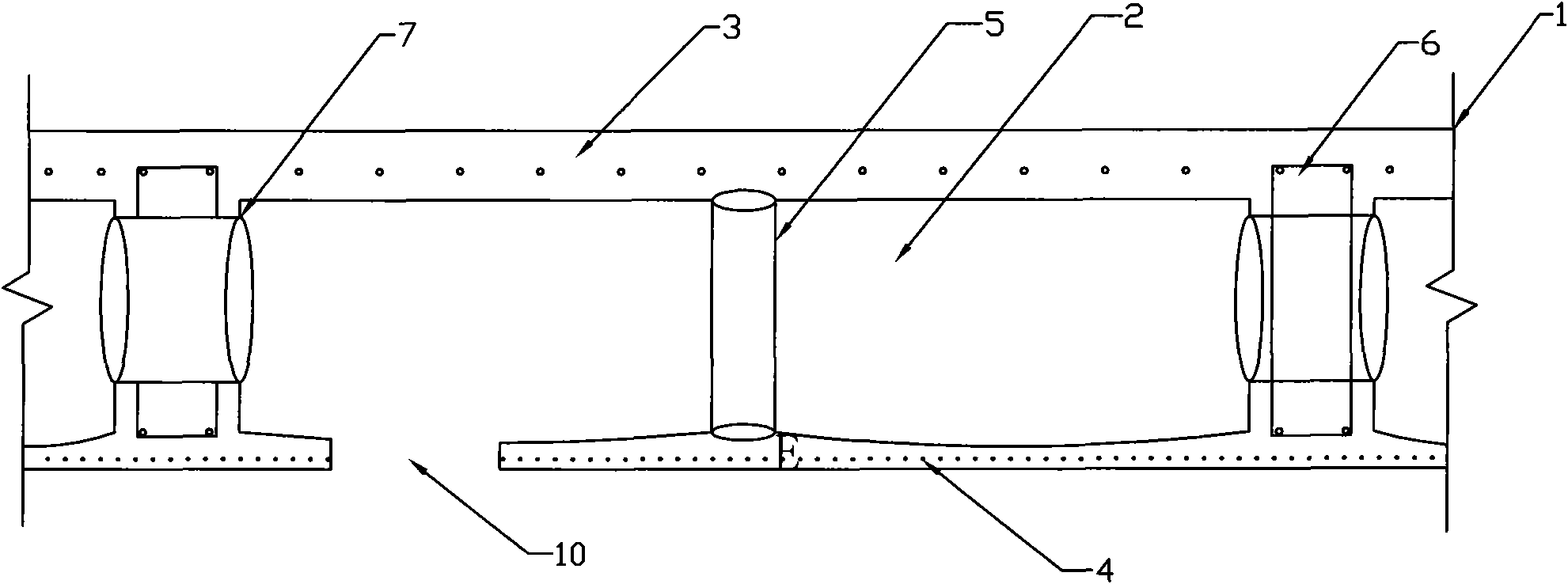

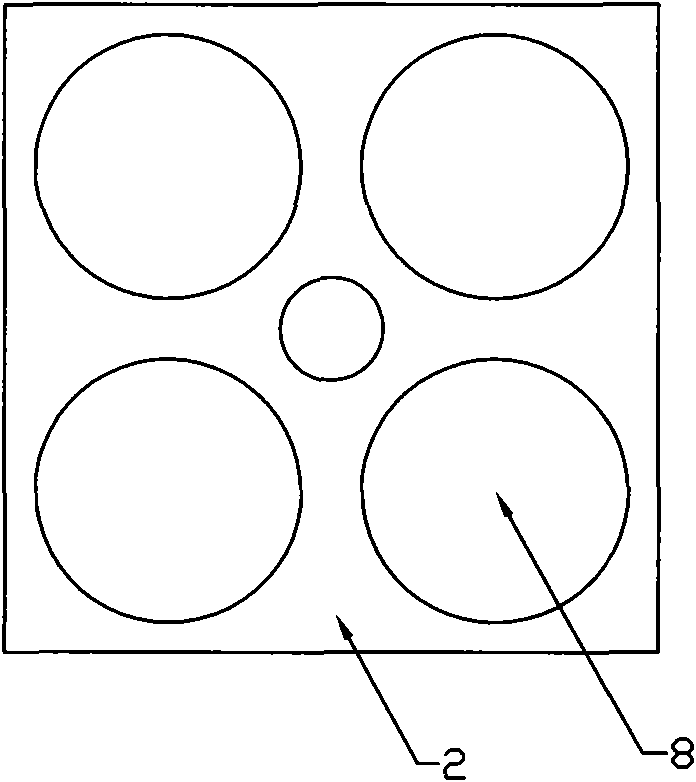

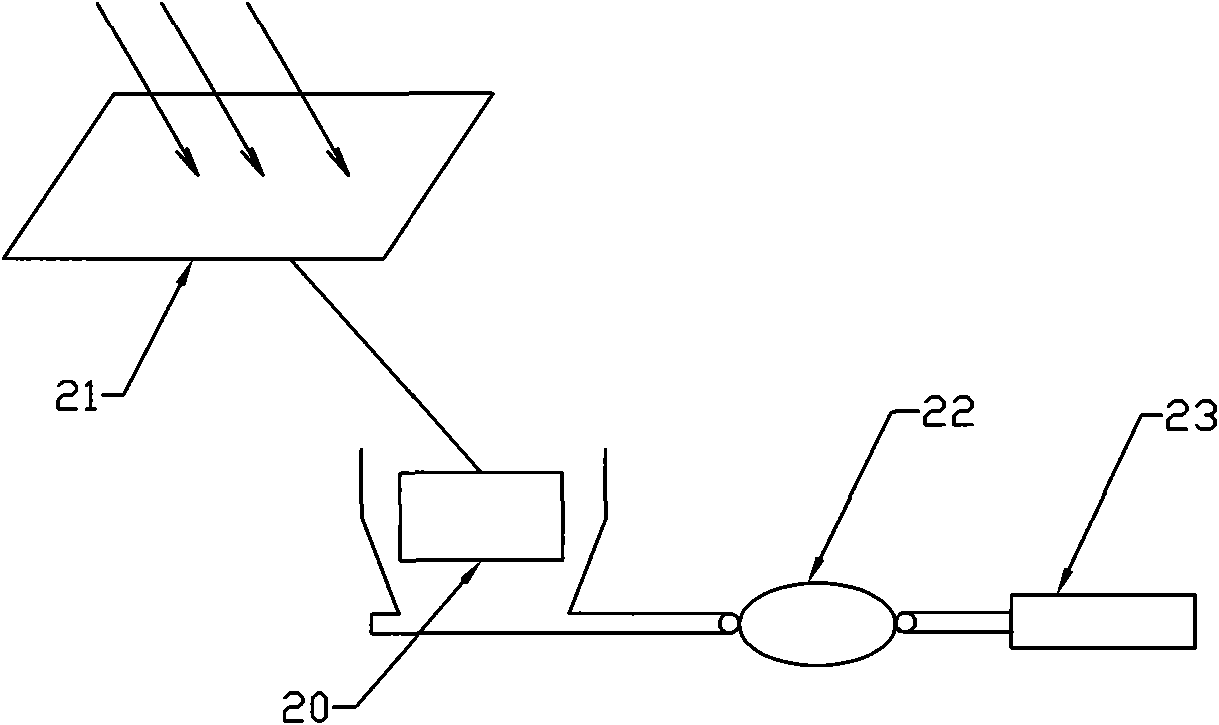

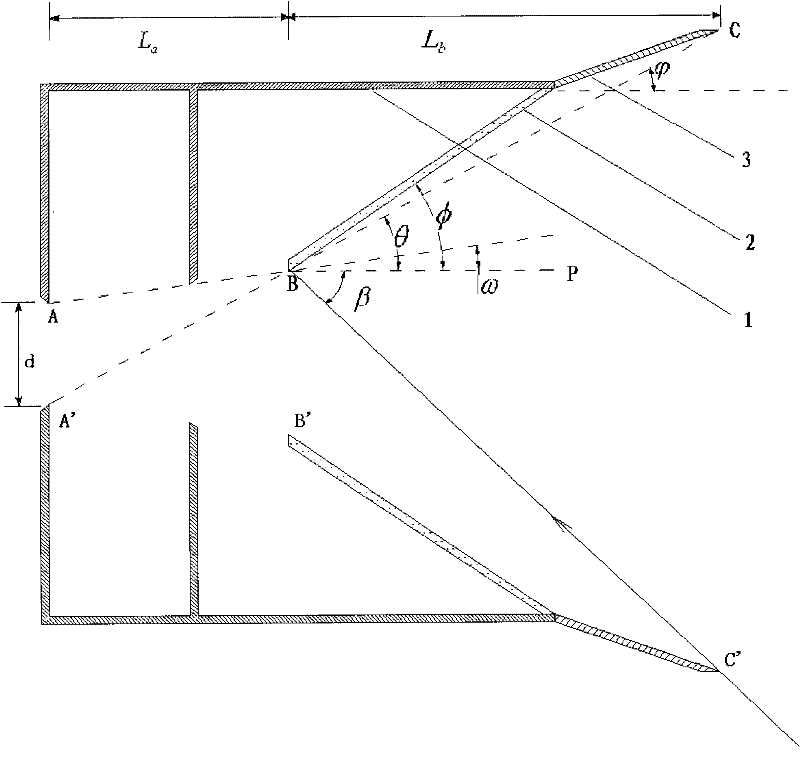

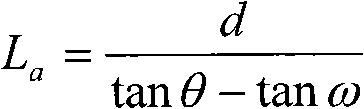

Solar heating system for building with cast-in-situ open-web floor

InactiveCN101603698AImprove efficiencyLow costSolar heating energyHot-air central heatingAir cycleThermal energy

The invention relates to a solar heating system for a building with a cast-in-situ open-web floor, which belongs to a system for providing heat for the building by using solar energy. In the proposal, sunlight is focused on a heat energy receiver by a concentration chip, and then hot air generated by the heat energy receiver is blown to the floor by a fan. The floor is formed by cast-in-situ of thin-walled box bodies; the thin-walled box bodies form a hot air cycle channel in the floor by using connecting channels; the hot air heats the floor after entering the floor, so the entire floor becomes a heat dissipating integration. The lower part of the thin-walled box bodies is provided with an air outlet leading to a room; when the air outlet is opened, the hot air is discharged to the room directly to heat the room quickly. The proposal makes use of the energy of the nature, so the solar heating system is clean and environment-friendly and saves cost and power; besides, the proposal makes full use of own structural characteristics of the building to avoid the problems of installation of additional devices and space occupation.

Owner:王本淼 +1

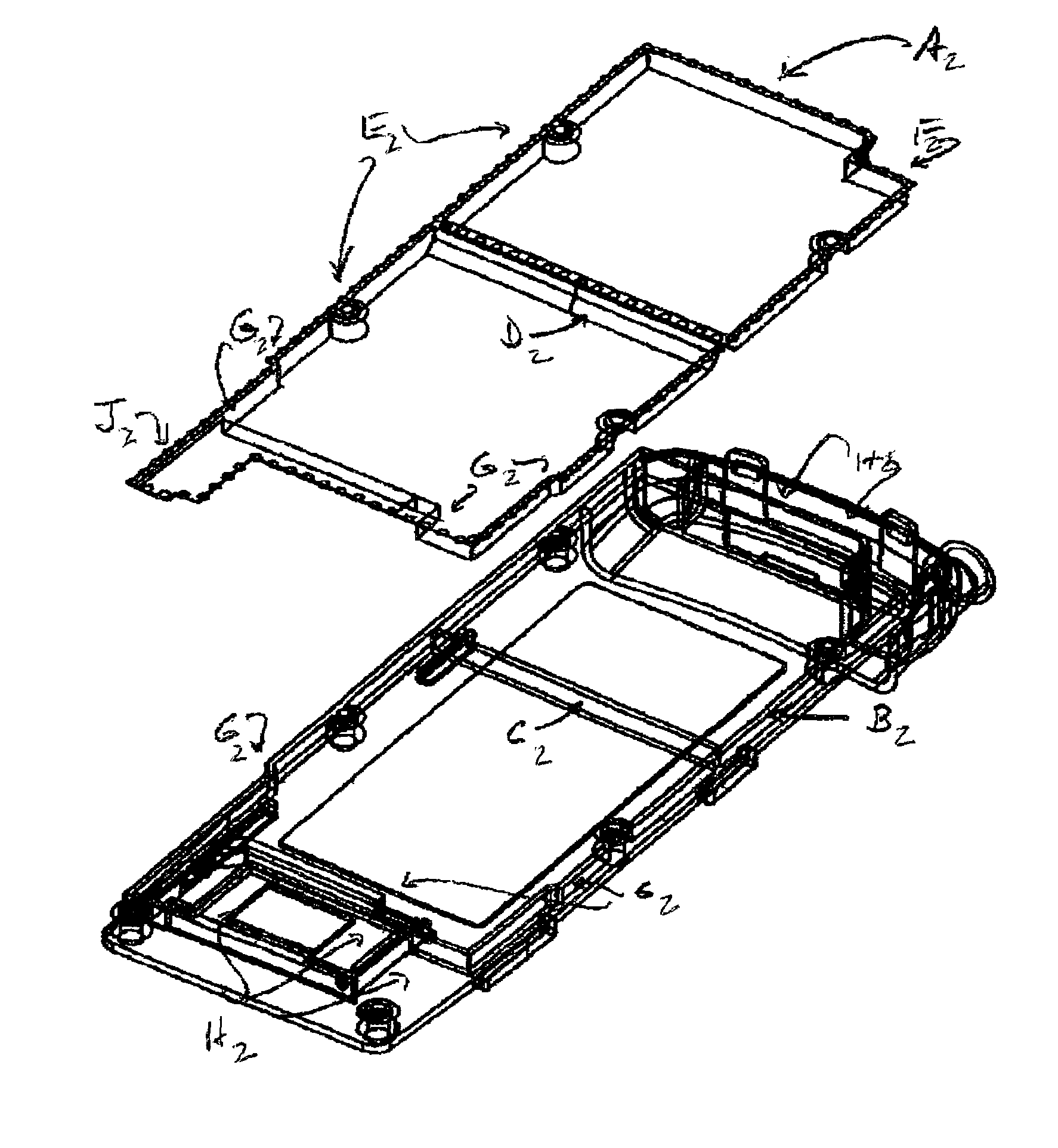

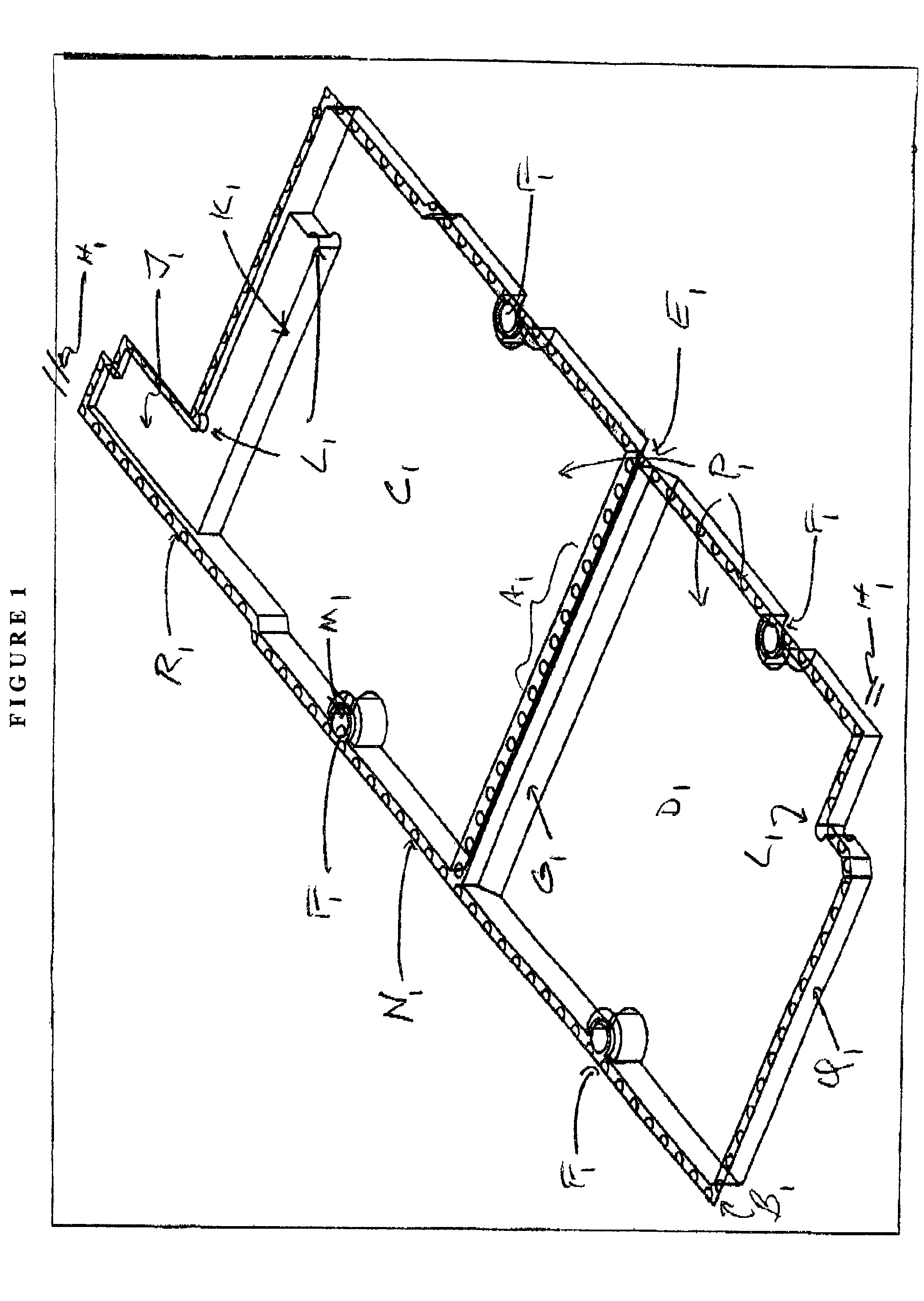

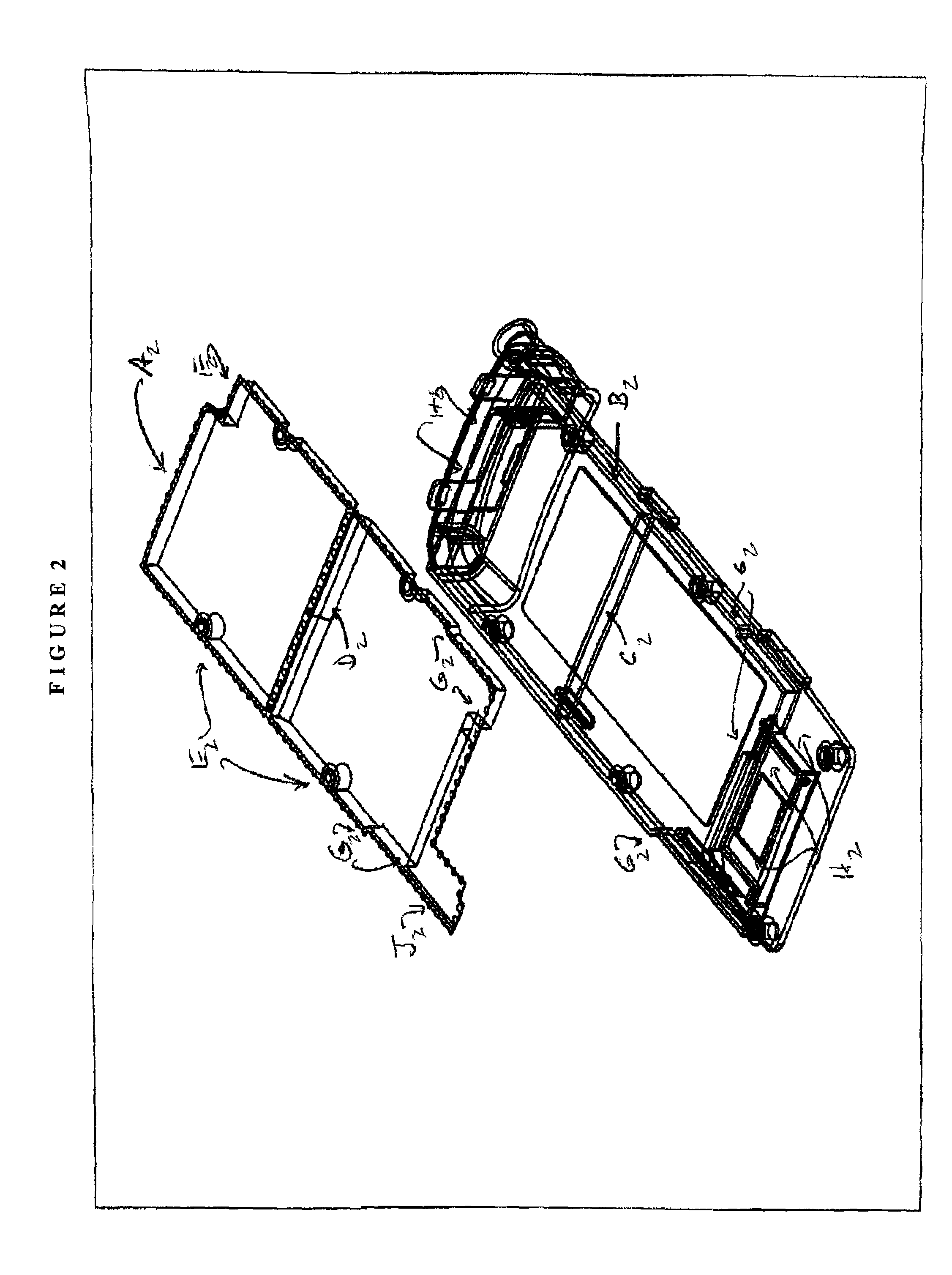

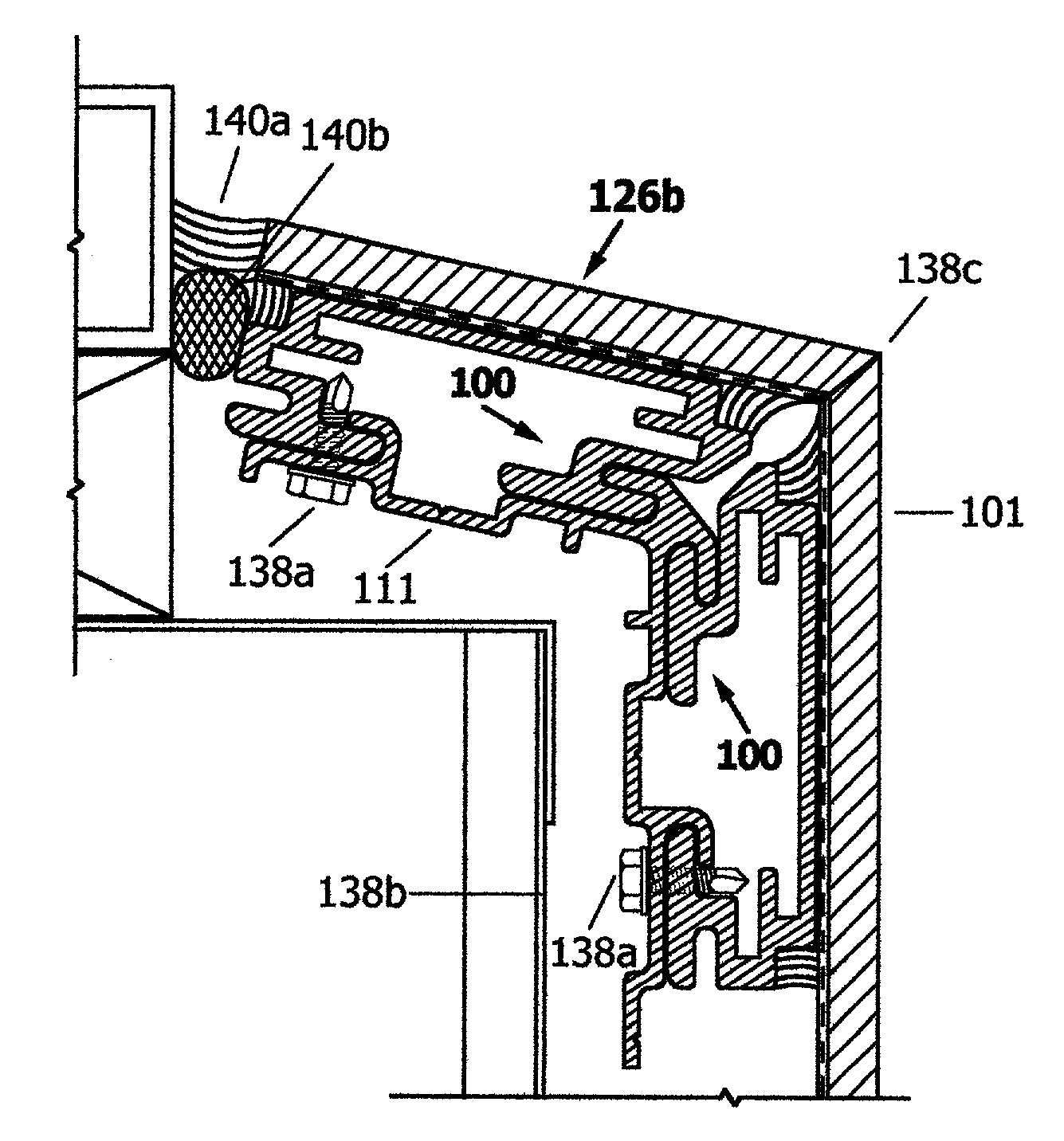

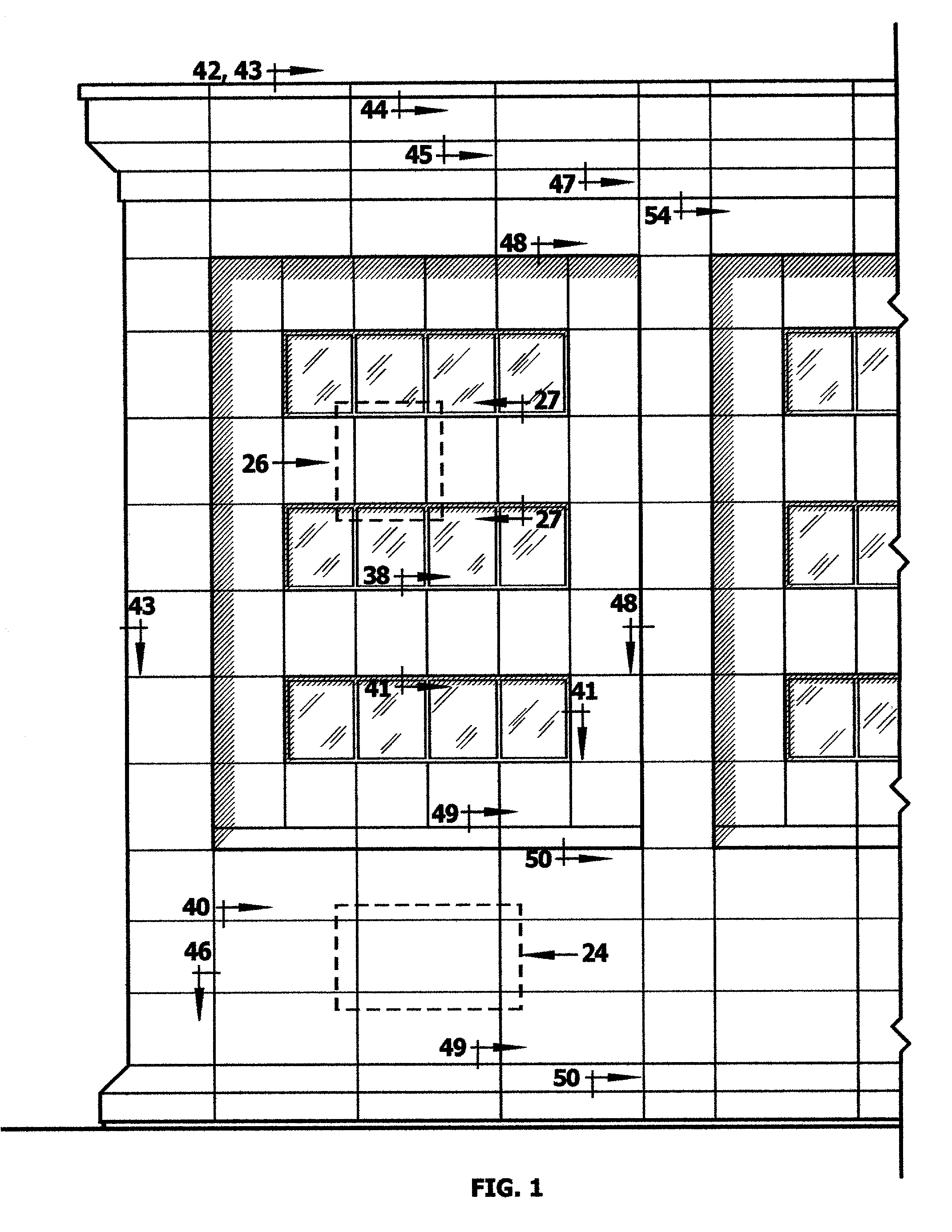

Exterior wall cladding system for panels of thin reinforced natural stone

An installation system designed specifically for thin reinforced natural stone panels used as exterior cladding, re-cladding, or over-cladding of buildings is comprised of a series of extruded aluminum shapes which, when properly applied to the back side of the thin reinforced stone panels, provide structural support for the thin panels and facilitate their installation and will also provide the means for the panels to be pre-assembled in order to obtain desired shapes or profiles and to be easily installed on the building. The series, or family, of extruded aluminum shapes are designed to mate or interlock to perform a variety of tasks such as perimeter frames, structural stiffeners, corner angle supports, interlocking sleeves, runner clips which facilitate attachment to various substrates of a building such as steel stud framing, aluminum curtain wall frames, brick or concrete walls or plywood sheathing.

Owner:THIN STONE SYST

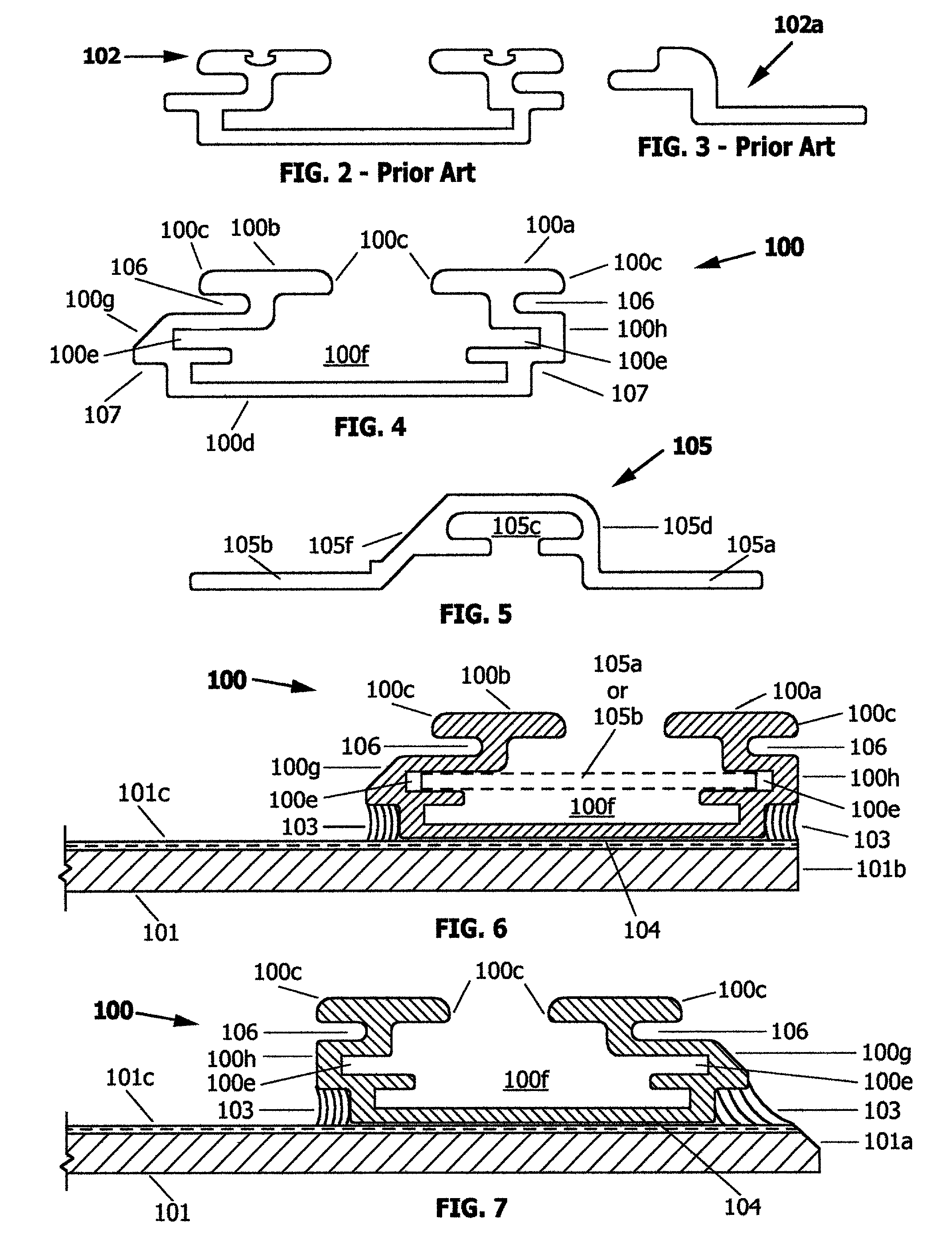

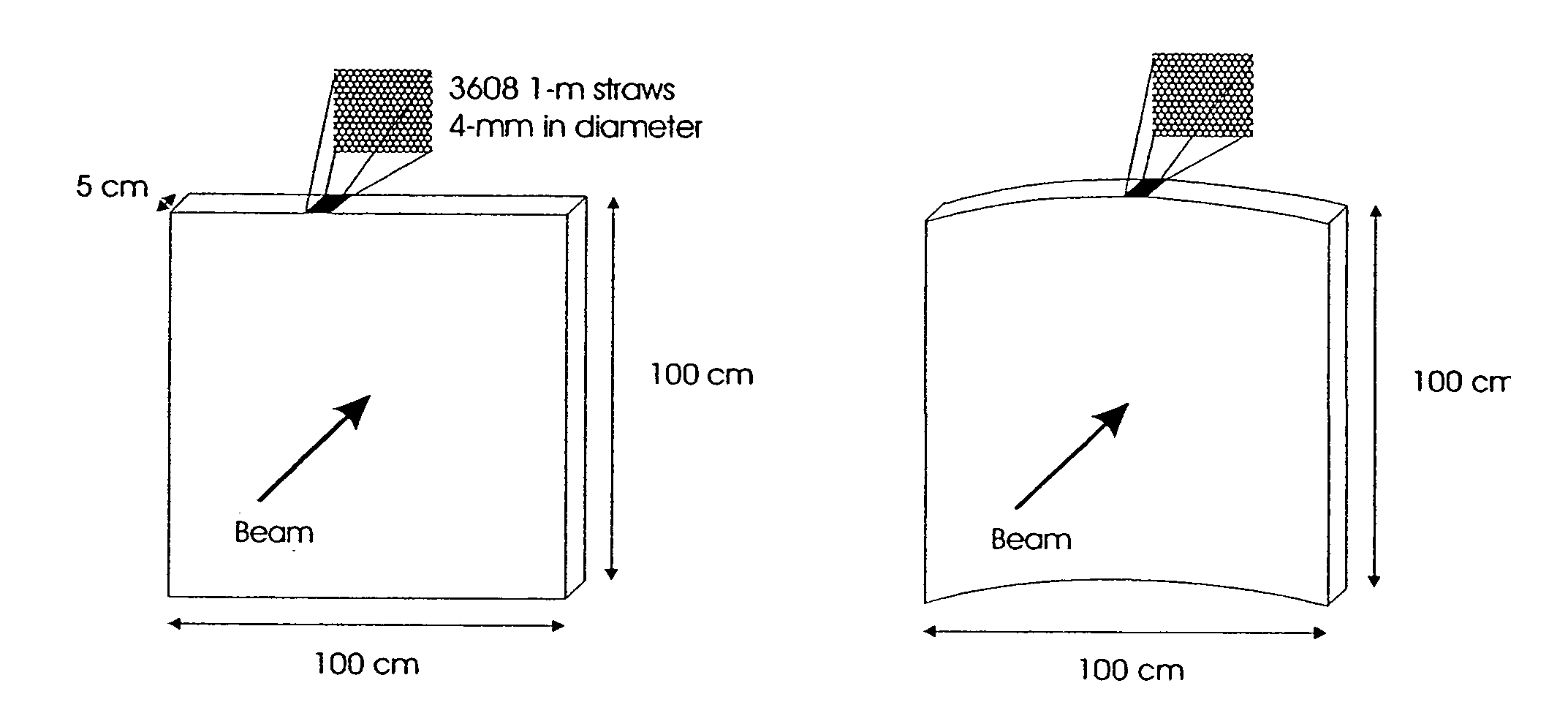

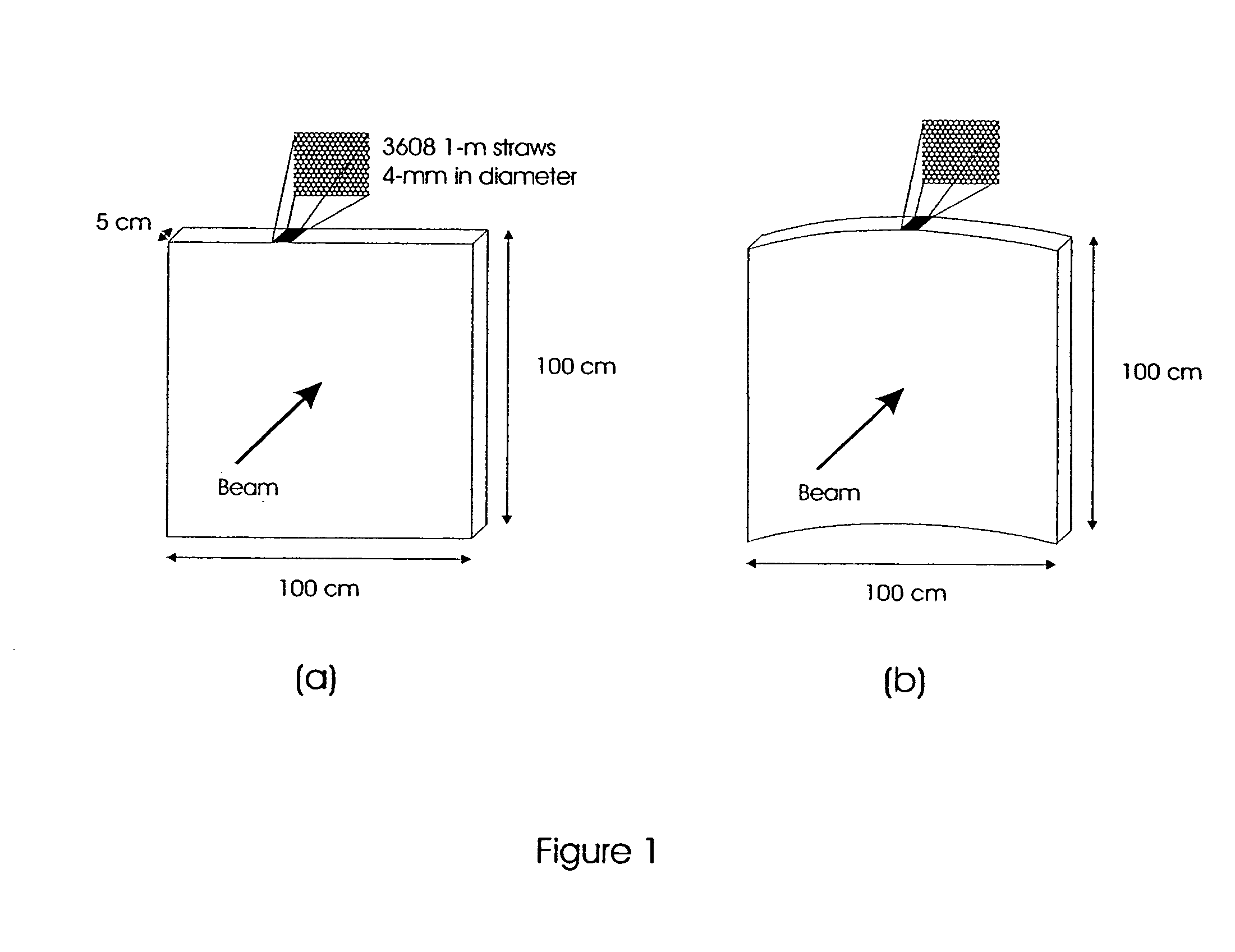

Boron coated straw neutron detector

ActiveUS7002159B2Sensitive to radiationImpression capsElectric discharge tubesElectronCharge division

A neutron detector technology based on 10B thin film conversion of neutrons and detection of neutron capture reaction products in a counter gas within a thin straw tube detector body is described. This neutron detector is based on gas-filled thin wall straw tubes, modified for the conversion of neutrons in a very thin coating, or layer, of 10B, applied for example as a sputter-coated film of 10B4C, that lines the interior, or inside of the straw tube surface; and the subsequent detection of the neutron reaction products in the counter gas. One embodiment of this invention employs a closely-packed array of 10B4C-lined straw tubes employing a very thin and therefore high efficiency 10B4C layer, hence removing the barrier to efficient neutron capture reaction product escape while still providing for efficient neutron capture by providing a plurality of very thin 10B converters, each individual converter element providing efficient reaction product escape. Using such densely packed straw tube detectors of small diameter, a reasonable stack depth allows a high neutron detection efficiency to be achieved on the 1–10Å wavelength range of thermal neutrons. The position of each interacting neutron can be accurately obtained with for example, resistive charge division readout combined with straw decoding electronics to determine the identity of the struck straw.

Owner:PROPORTIONAL TECH

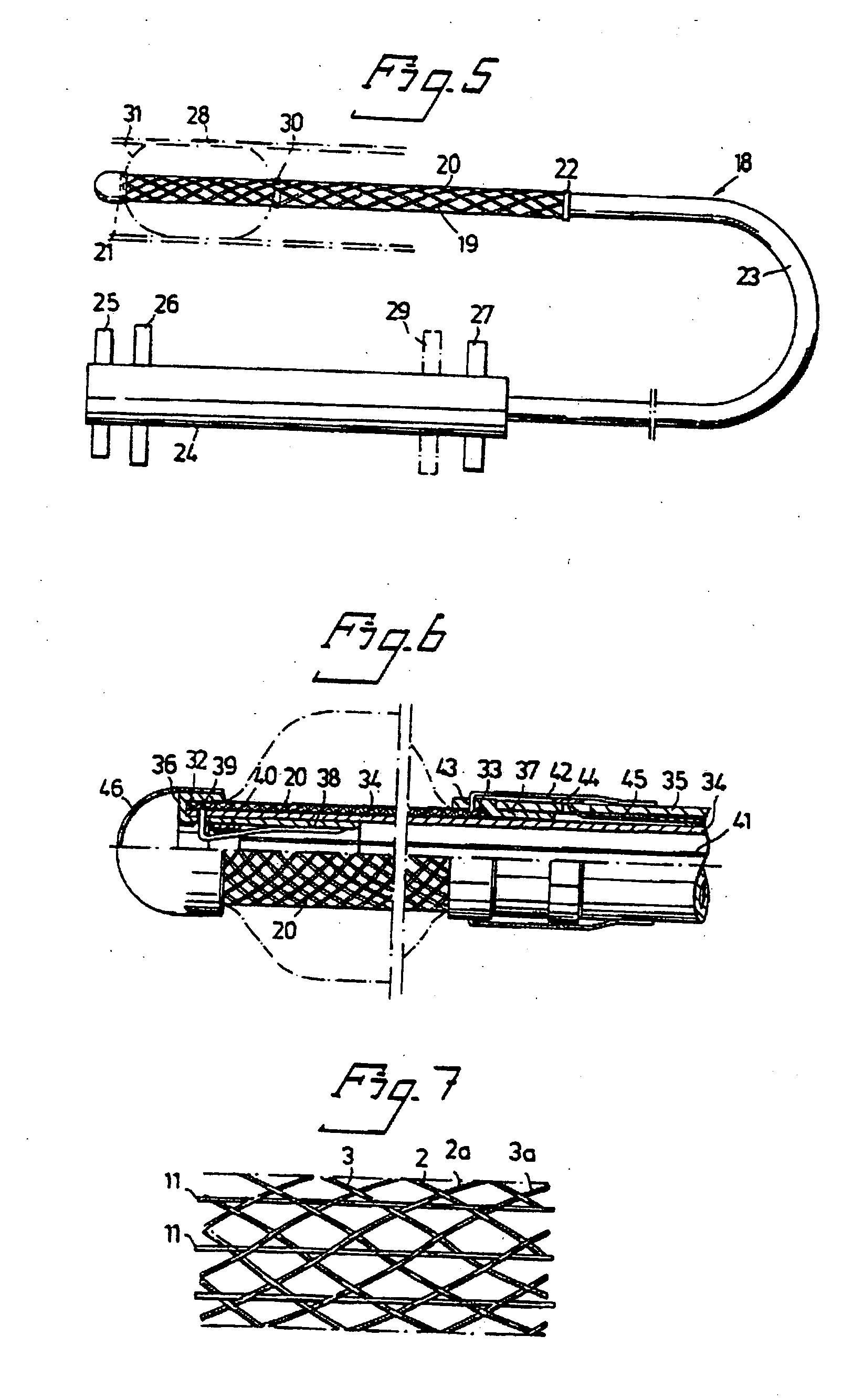

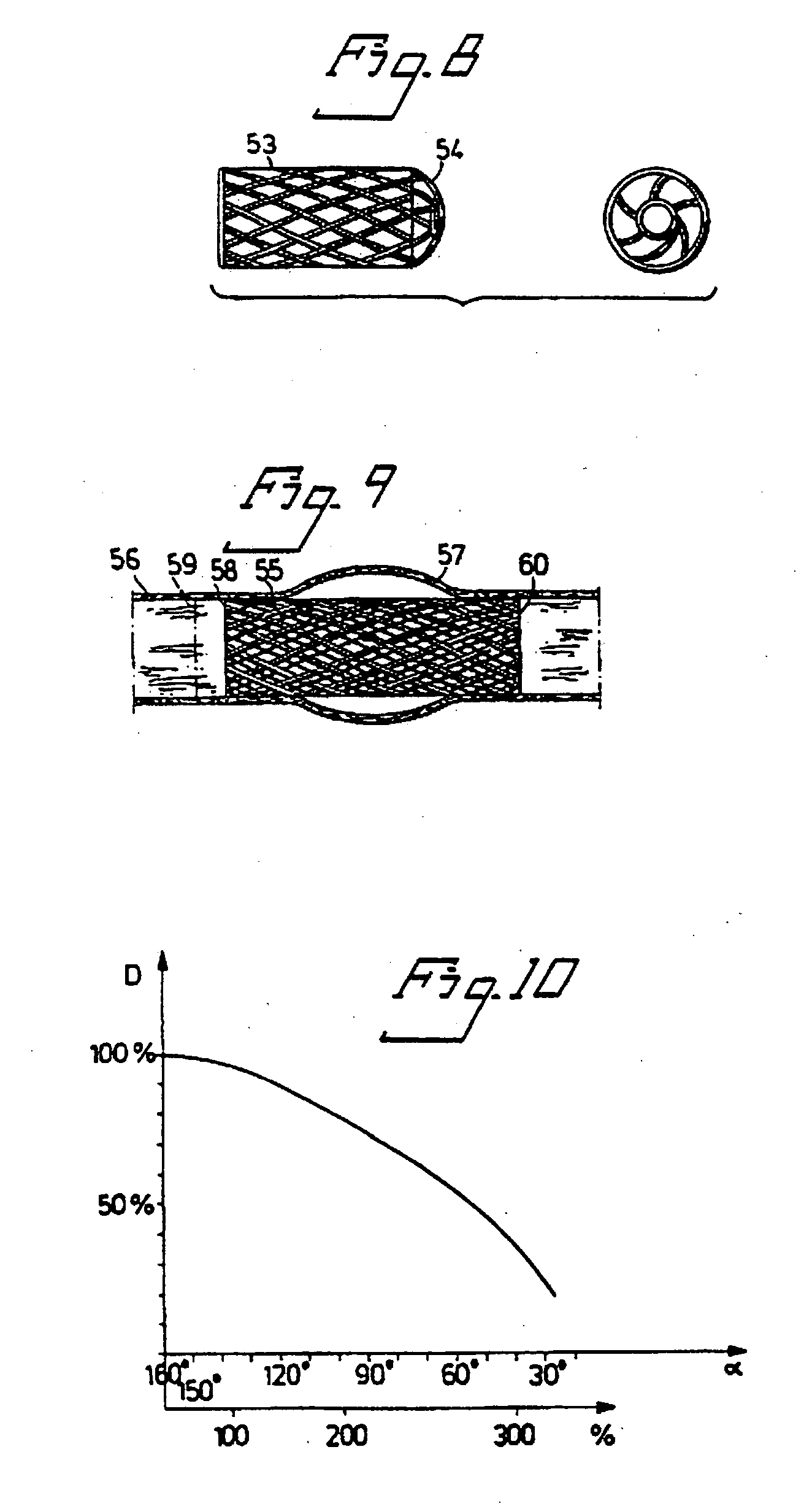

Cell-loaded prostheses for regenerative intraluminal applications

Cell-loaded devices or prostheses having various applications such as insertion into body passages are disclosed. The prostheses include cell carrier portions which are compatible with living tissue and which are loaded with therapeutic cell populations, and the prostheses can be applied within or replace one or more of narrow segments, environments which may be difficult to access or luminal areas of the body such as parts of blood vessels. In the context of blood vessels, the cell-loaded devices or prostheses can line or otherwise treat with therapeutic cell populations inner walls of damaged blood vessels and surrounding parenchyma or other organs.

Owner:LOREM VASCULAR PTE LTD

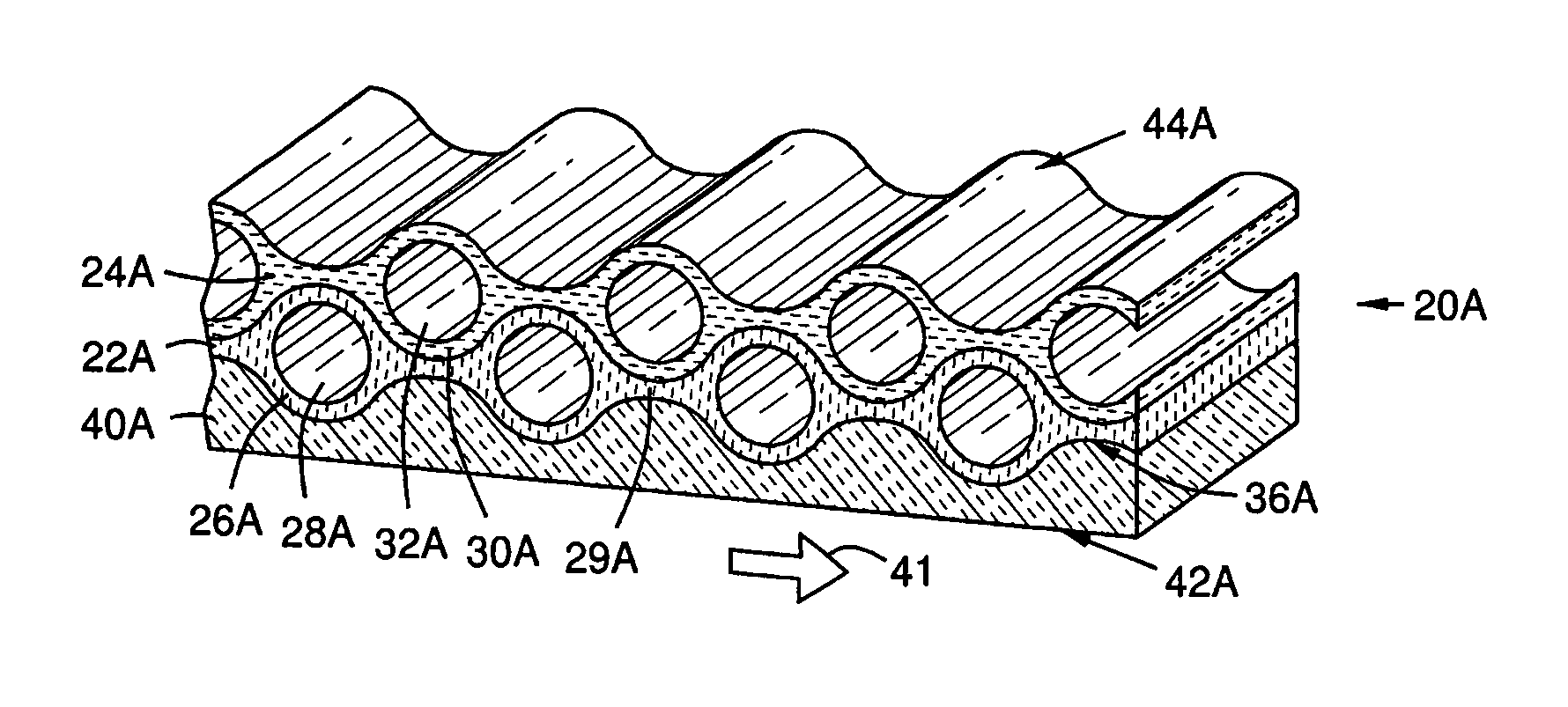

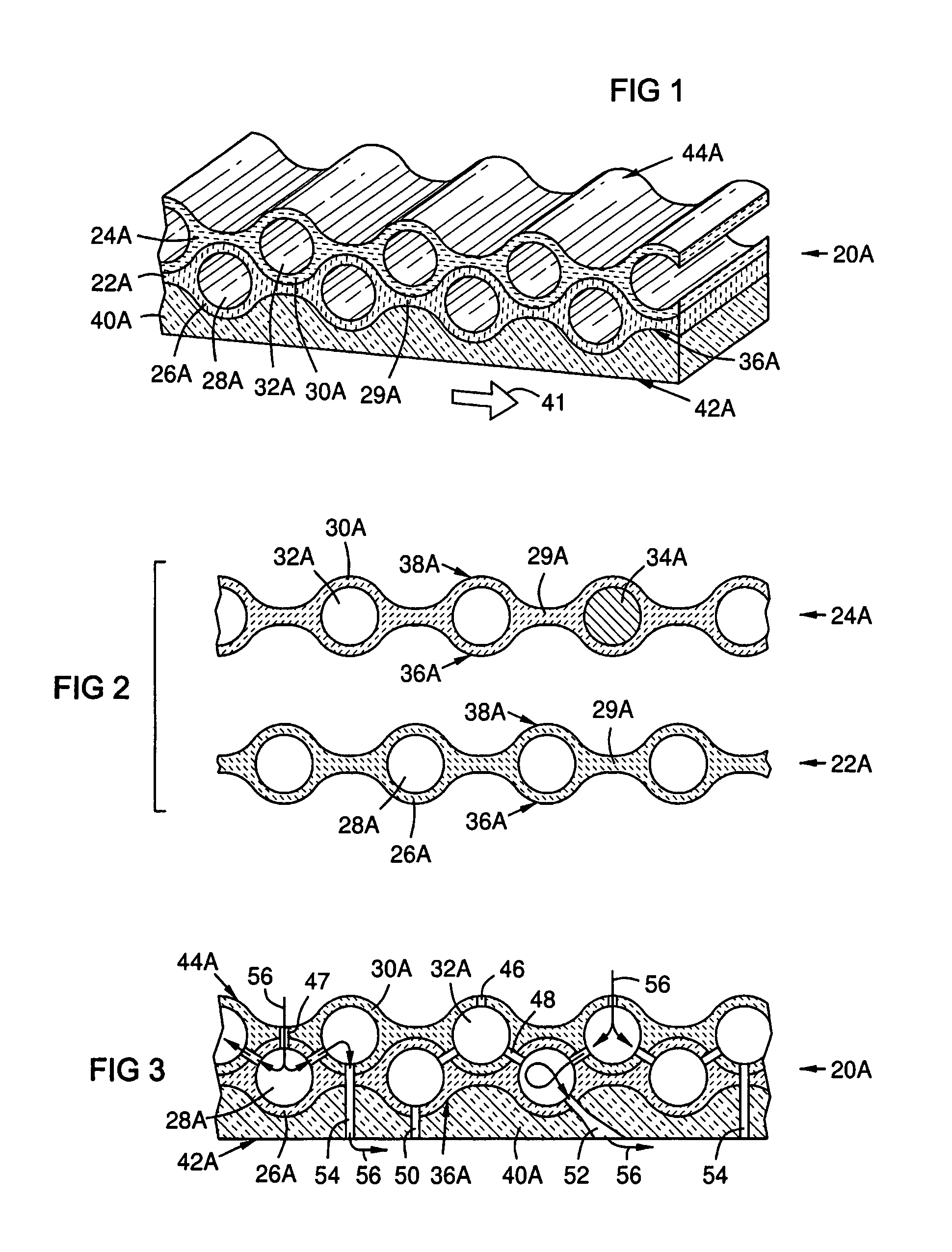

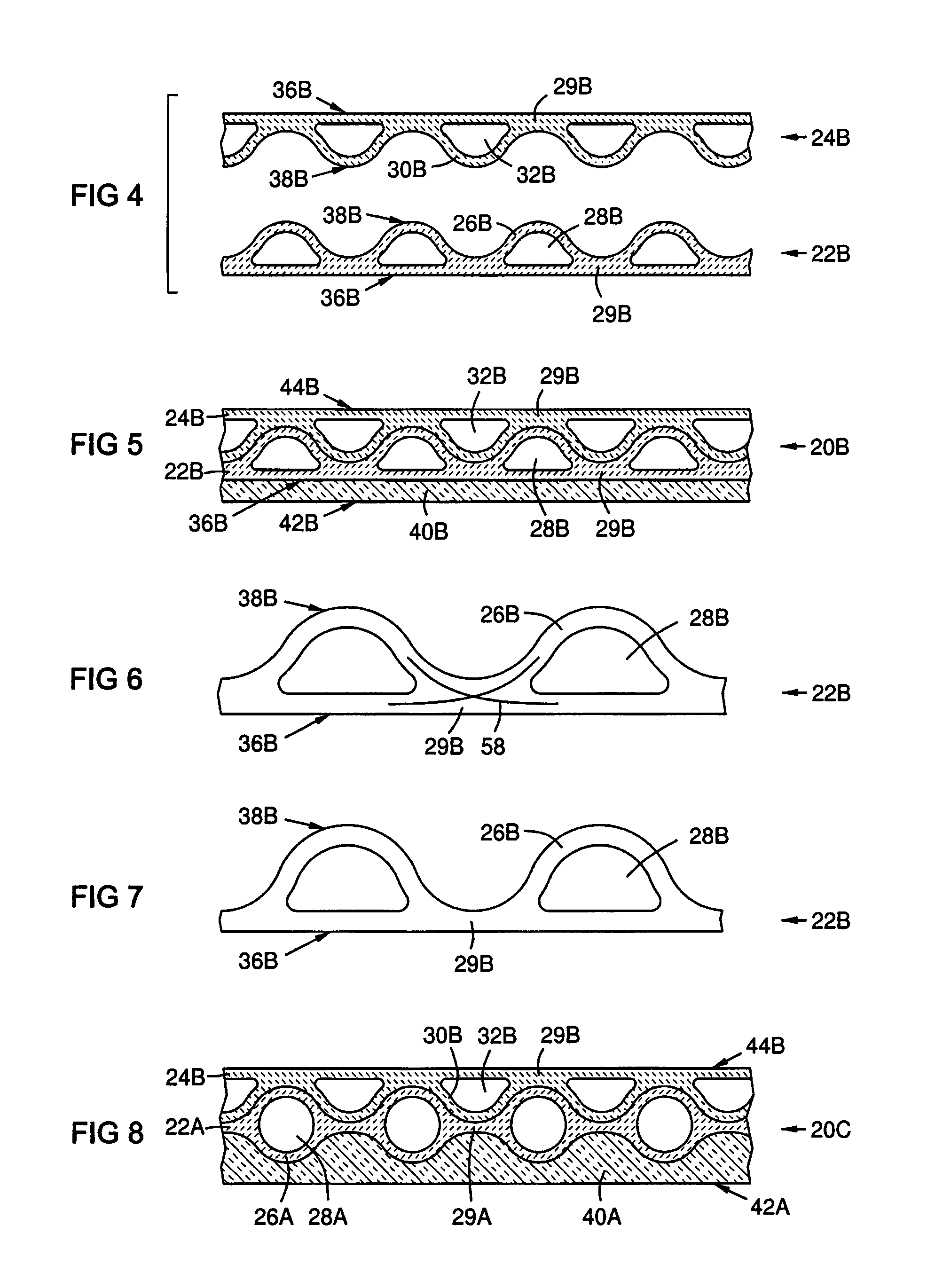

CMC wall structure with integral cooling channels

A ceramic matrix composite wall structure (20A) constructed of interlocking layers (22A, 24A) of woven material with integral cooling channels (28A, 32A). The CMC layer closest to the hot gas path (41) contains internal cooling tubes (26A, 30A) protruding into a ceramic insulating layer (40A). This construction provides a cooled CMC lamellate wall structure with an interlocking truss core.

Owner:SIEMENS ENERGY INC

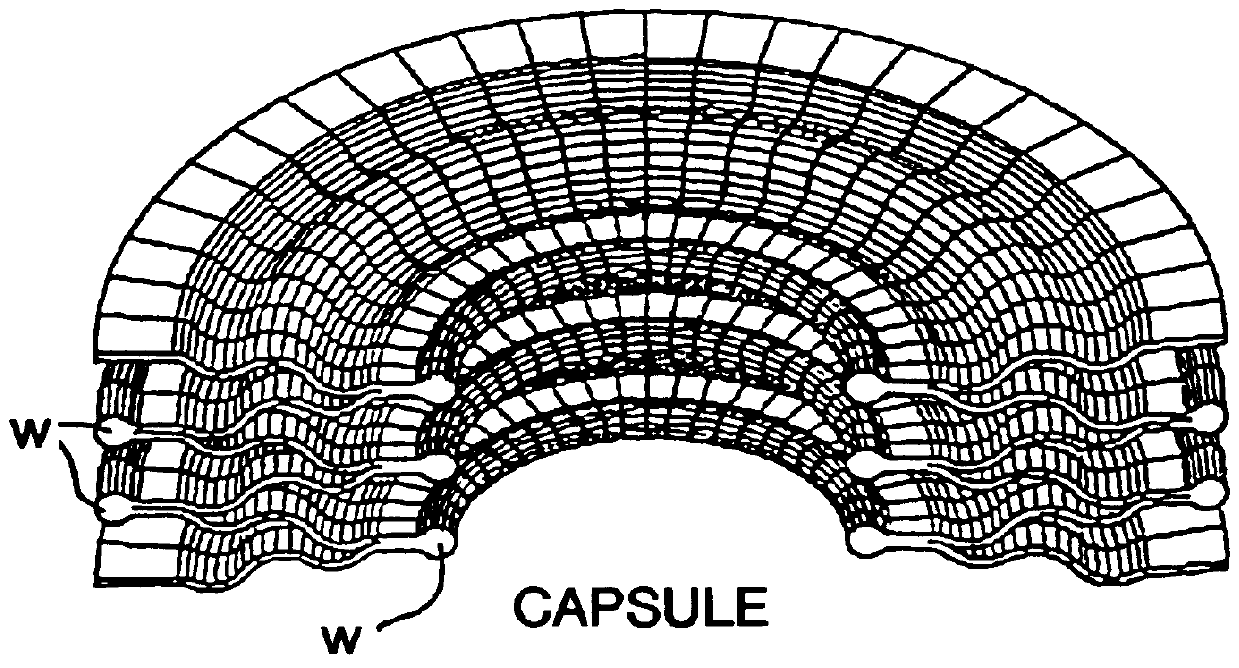

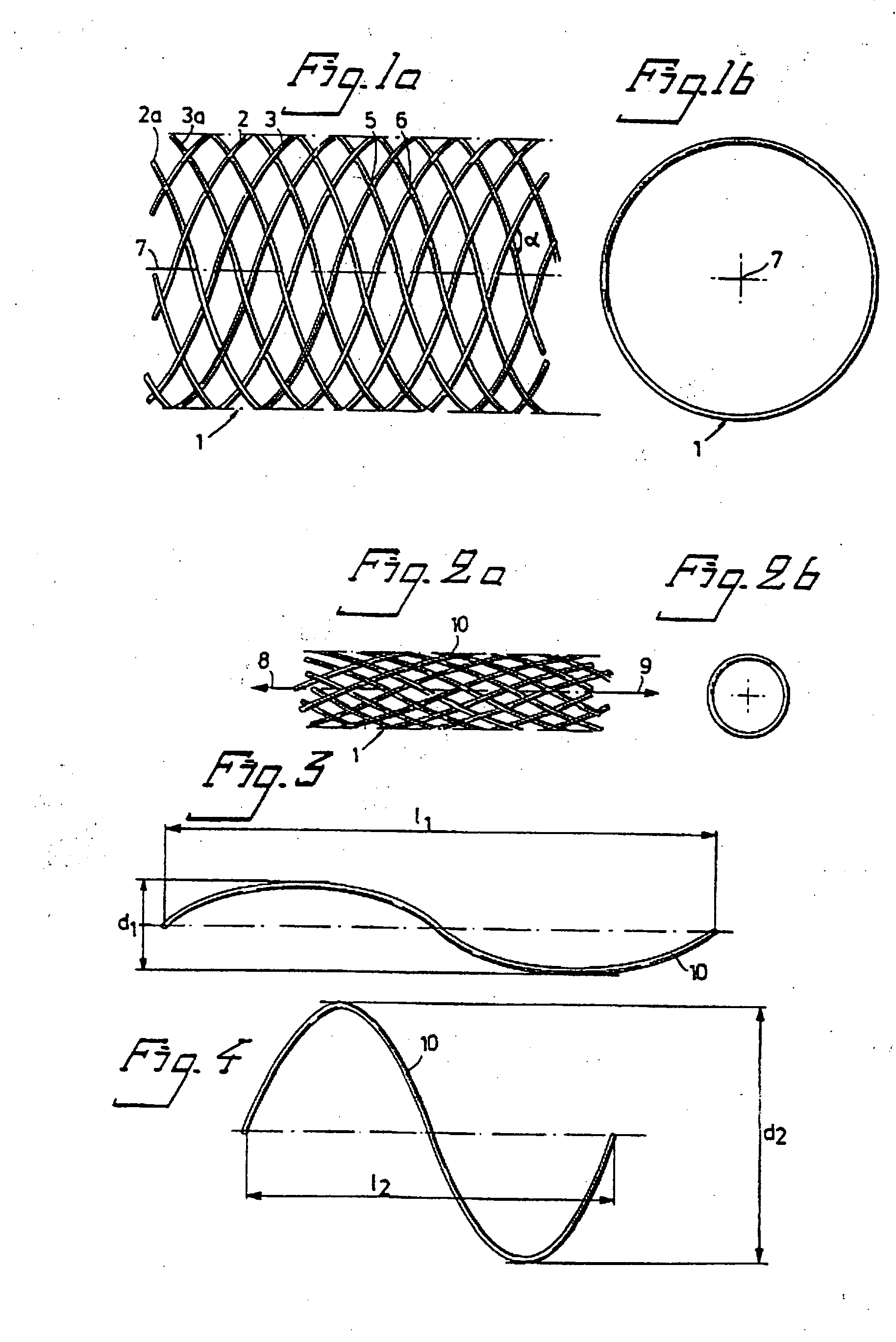

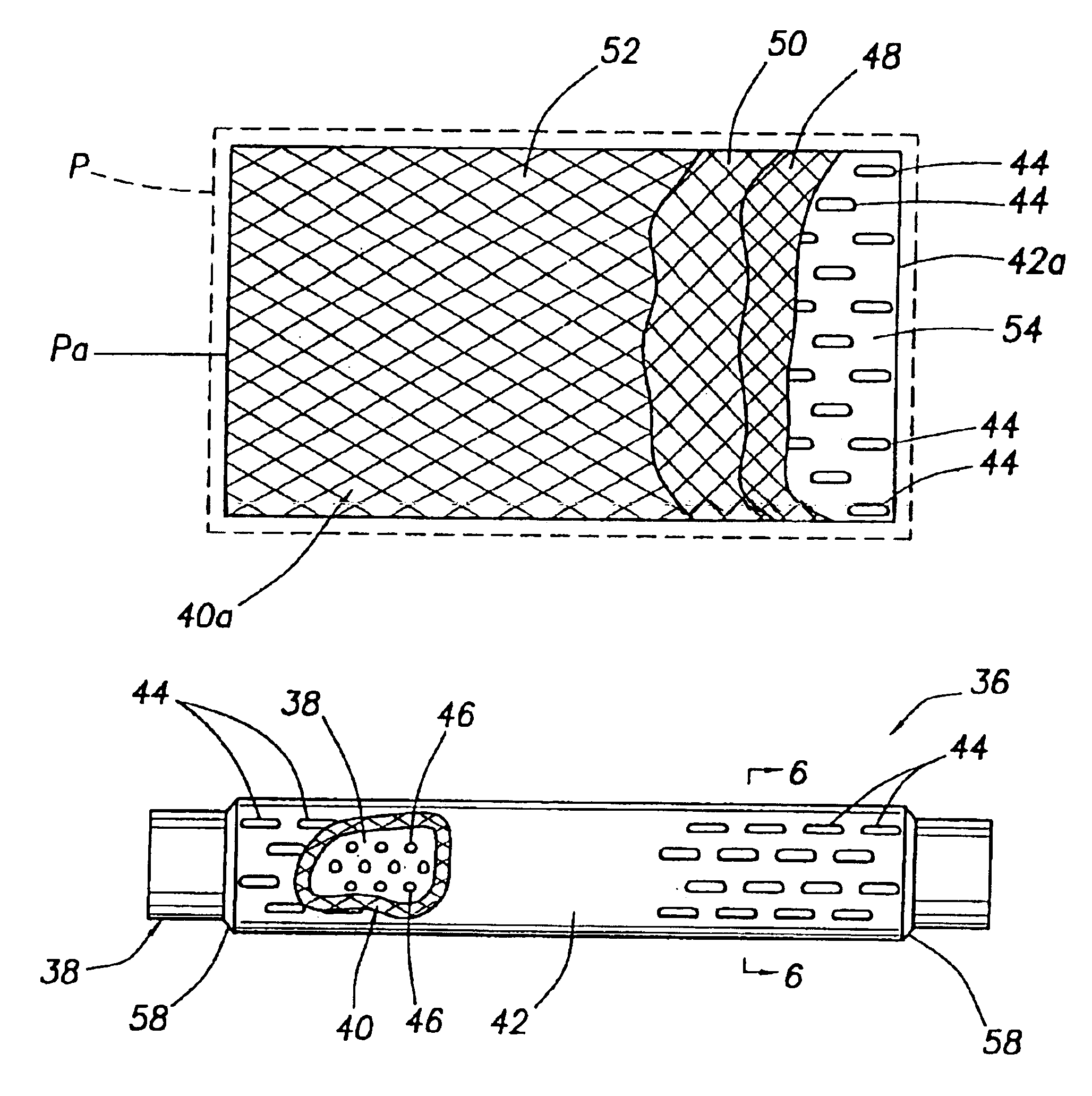

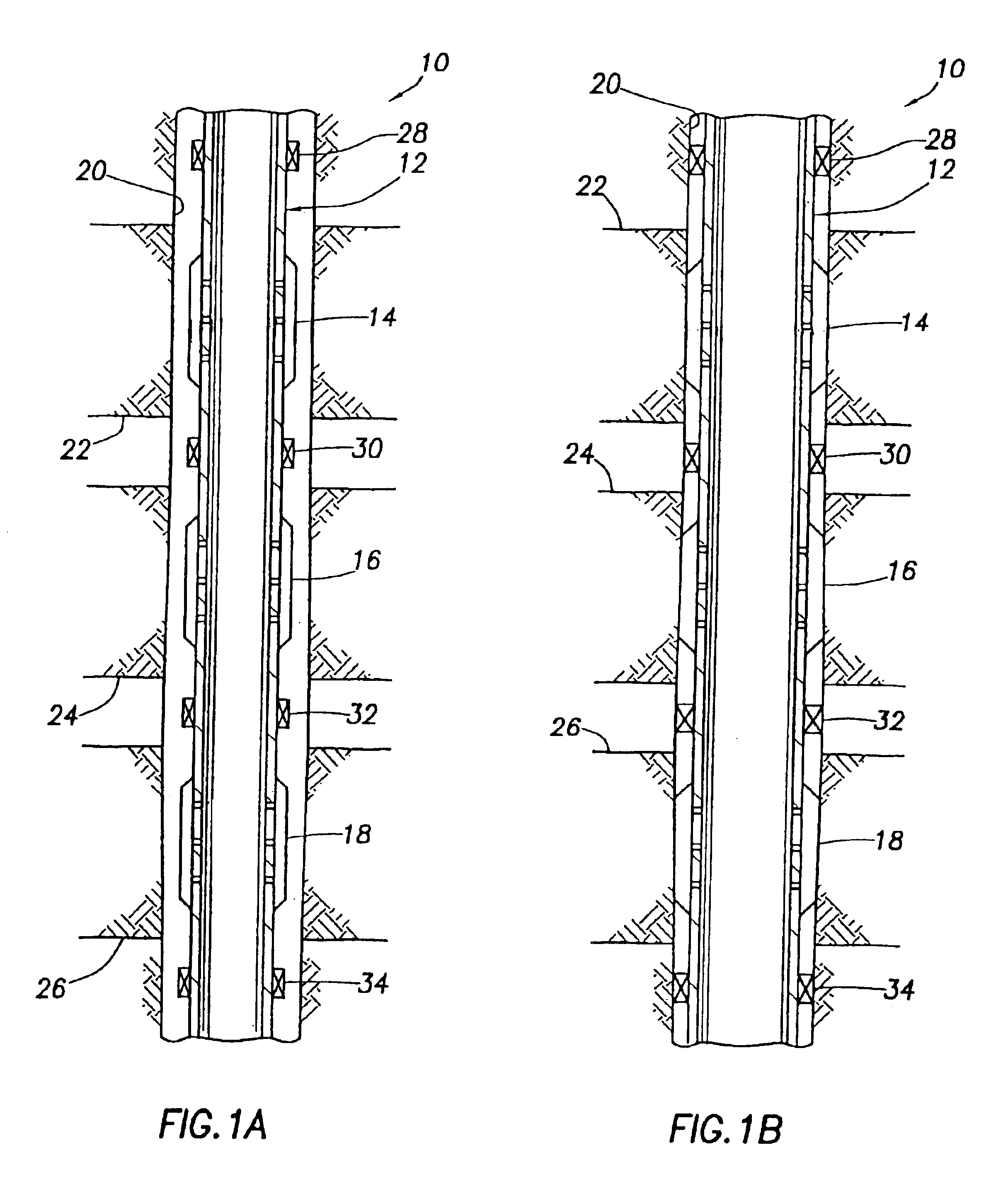

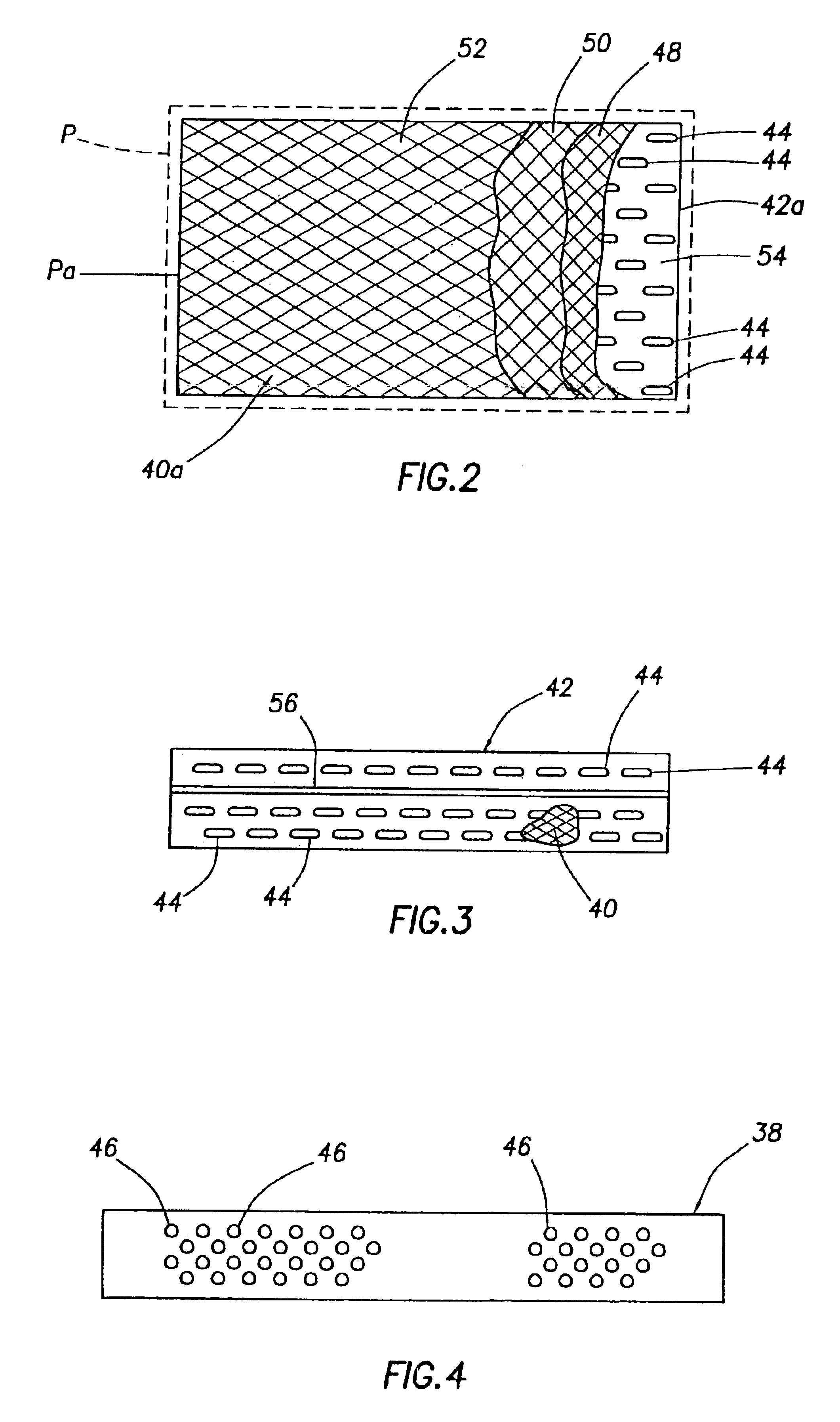

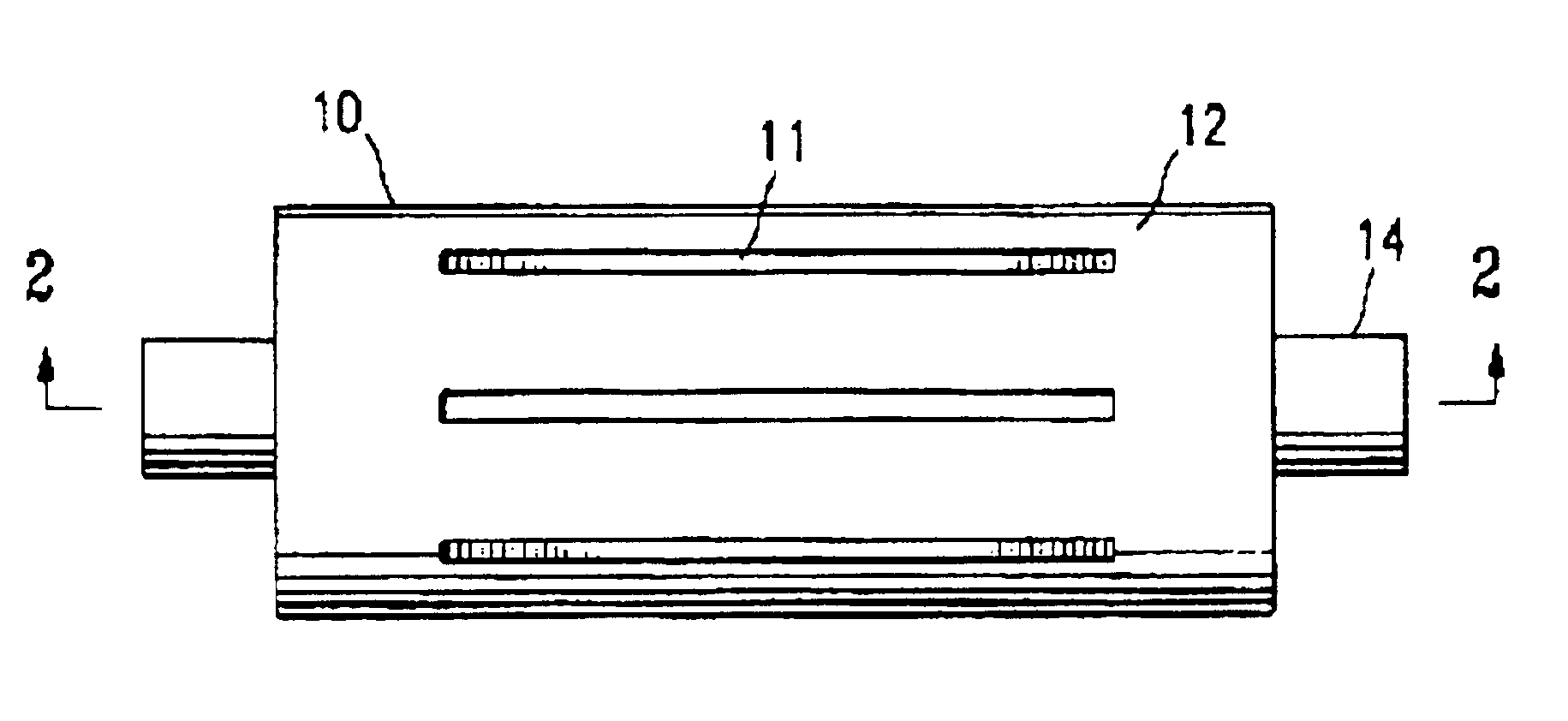

Methods of fabricating a thin-wall expandable well screen assembly

InactiveUS6941652B2Facilitates radial expansionGreat central flow areaDrilling rodsAssembly machinesFilter mediaEngineering

An expandable well screen has a desirable thin-wall construction together with a simplified fabrication method. In fabricating the screen, a flexible sheet of metal mesh filter media is diffusion bonded to an inner side of a perforated metal sheet which is then deformed to a tubular shape to form a filter structure having an outer perforated tubular shroud interiorly lined with the filter media. The tubular filter structure is telescoped onto a perforated base pipe and has its opposite ends sealingly secured thereto to complete the expandable well screen.

Owner:HALLIBURTON ENERGY SERVICES INC

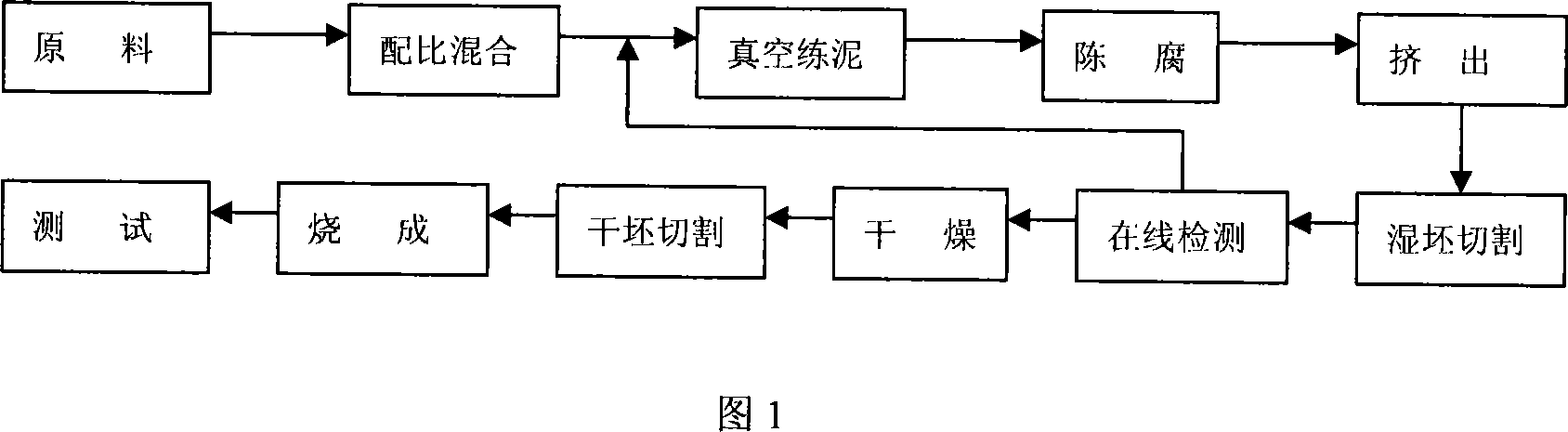

Reflective star sensor light shield

InactiveCN102243414AEnhanced inhibitory effectSmall sizeAircraft componentsCosmonautic vehiclesCamera lensBlack paint

A reflective star sensor light shield comprises three thin-wall cone barrels, wherein the three thin-wall cone barrels are successively connected. Inner walls of two cone barrels which are far from a lens are smooth clean surfaces and are sprayed with black paint or black films with high reflectivity and a low scattering rate. The inner wall of the cone barrel which is close to the lens is a baffle vane or a barrel type structure of eliminating veiling glare threads and is sprayed with black paint or black films with low reflectivity and the low scattering rate. The whole light shield can possess a optimal length through setting an algebraic relation of cone angles of each cone barrel. The reflective star sensor light shield of the invention has a short length and light weight, and is convenient for processing and manufacturing. The reflective star sensor light shield possesses strong inhibition capability for stray light, such as sunlight and ground gas light, which is a strong light source out of field of view. The invention can be used for the star sensor to shade light and be used for optical remote sensors to explore deep space, such as a star camera and the like.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

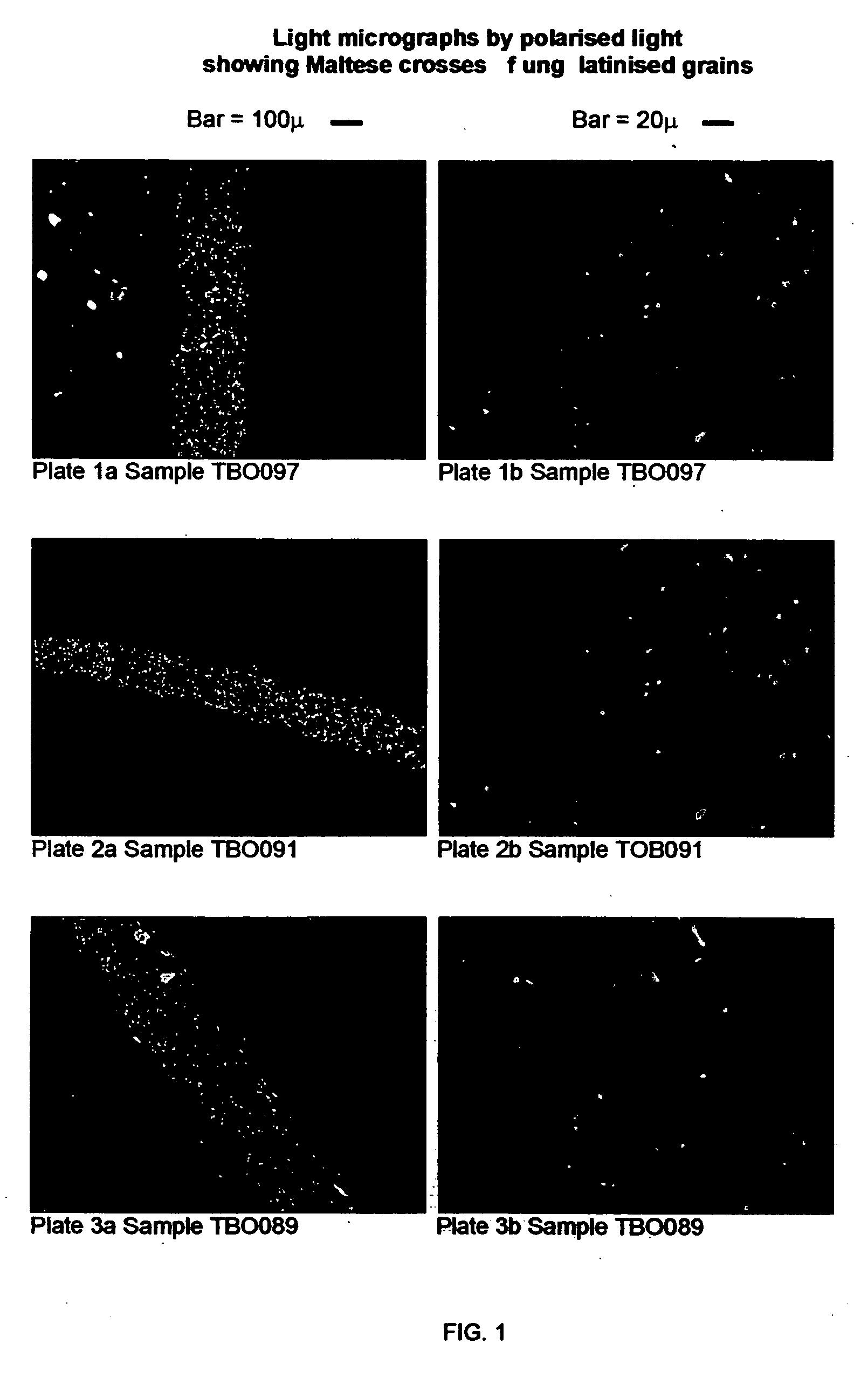

Chewable soft capsules containing ungelatinized starch

A soft chewable capsule film suitable for medicament or foodstuff encapsulation, and a method of fabricating capsules from such a film. Such capsules demonstrate fast rupture in the oral cavity, good mouth feel and chewability, and rapid dissolution of the shell components. In particular, the modified starch is substantially ungelatinized, due at least in part to the processing temperature, and may act as a water retention agent to promote hydration. Additionally, gelatins are selected for bloom strengths that result in a robust capsules that may be fabricated at a thinner wall thickness than previously experienced in the art. Accordingly, such thin capsules have a smaller mass than traditional capsules of the same size and dissolve more quickly than chewable capsules having greater thicknesses. The capsules may be fabricated by a rotary die process at speeds greater than those generally known for soft chewable capsules.

Owner:R P SCHERER TECH INC

Thin and thermal insulation inner wall paint, preparation method and construction method thereof

ActiveCN101085892AImprove the decorative effectLow costFireproof paintsEmulsion paintsPolymer scienceMicrosphere

The invention discloses a kind of thin thermal insulating inner wall paint. The comprised components and their weight proportion are as follows: styrene-acrylic emulsion 28- 35%, titanium dioxide 8- 13%, fillings 10- 18%, borosilicate hollow microsphere 6- 12%, water- brone nanometer anti- pollution agent 0.5- 2%, defoaming agent 0.3- 0.5%. Said hollow microsphere is hollow white spherical powder with thin wall, the main component is silicon dioxide and diboron trioxide, the real density is small and heat conductive coefficient is 0.04- 0.08 w / m.k. The invention aslo discloses the preparation and construction method for said paint. It employs high pressure airless painting process for construction, the aperture of employed gunjet nozzle is 0.6- 0.8 mm, atomization pressure is 15- 18 Mpa, and when the coating layer is 0.3- 1.0 mm, the coating layer is homogeneous and tight, and the thermal insulating effect is good. The paint is especially suitable for building inner wall and ceiling painting.

Owner:上海秀珀化工有限公司

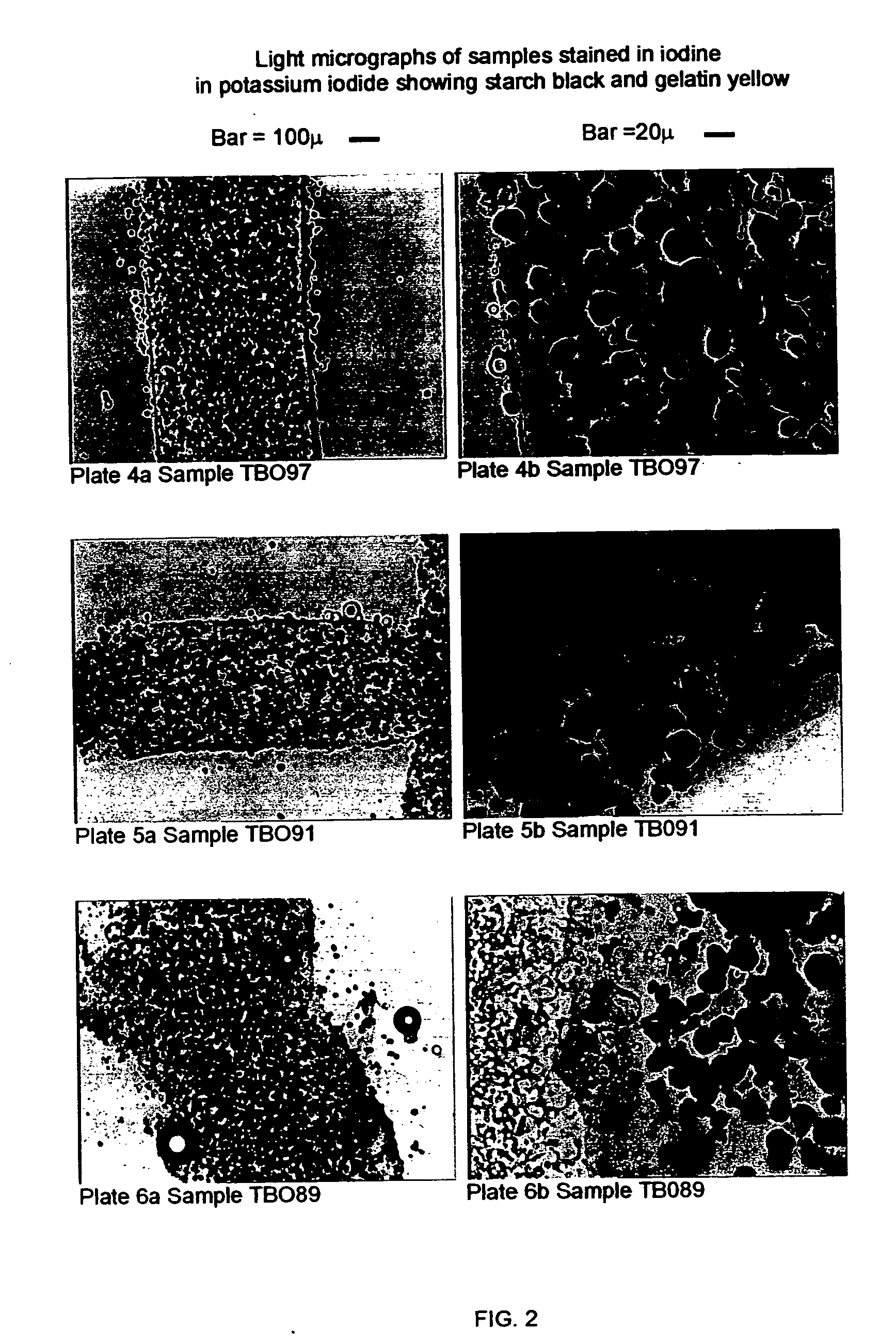

Iolite cellular ceramic and preparation method

A high-porosity thin-wall cordierite-type cellular ceramics is prepared proportionally from LiO2, talc, kaolinite, calcined kaolinite, alpha-AlO, aluminum hydroxide, silicon powder, solid adhesive, and the liquid organic additive prepared from water, propanetriol, liquid adhesive, surfactant and lubricant. Its preparing process is also disclosed.

Owner:JIANGSU GAOCHUN CERAMICS +1

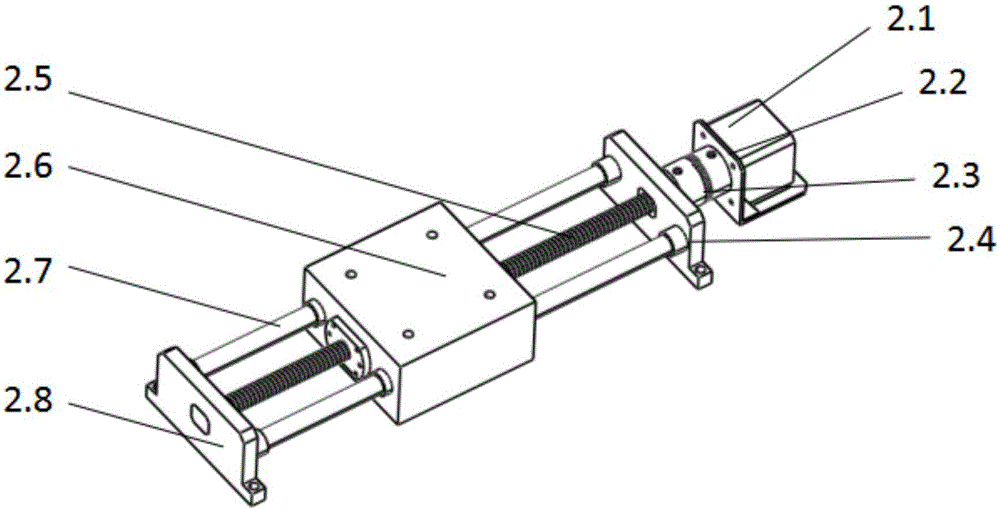

Thin-wall ring part machining method and automatic auxiliary supporting device thereof

ActiveCN106808246AImprove rigidityHigh precisionPositioning apparatusMetal-working holdersContact forceBearing surface

The invention discloses a thin-wall ring part machining method and an automatic auxiliary supporting device thereof. According to the allowance of a workpiece bearing surface, the corresponding machining method can be adopted. In the manufacturing procedure that the workpiece bearing surface has allowance, according to the change of contact force between the workpiece bearing surface and the automatic auxiliary supporting device after a certain number of materials of workpieces are removed, the automatic auxiliary supporting device can automatically adjust radial auxiliary supporting space positions, and workpiece deformation in the machining process can be released. In the manufacturing procedure that the workpiece bearing surface does not have allowance, the automatic auxiliary supporting device is controlled to support the workpiece bearing surface to be of an ideal shape, and then machining is performed. In order to implement the machining method, the automatic auxiliary supporting device is invented, and the device can adjust the radial auxiliary supporting space positions automatically. By means of the thin-wall ring part machining method and the automatic auxiliary supporting device thereof, the effect that part deformation is small after unloading is guaranteed, wall thickness precision can meet the requirements, and meanwhile automation of the auxiliary supporting device is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

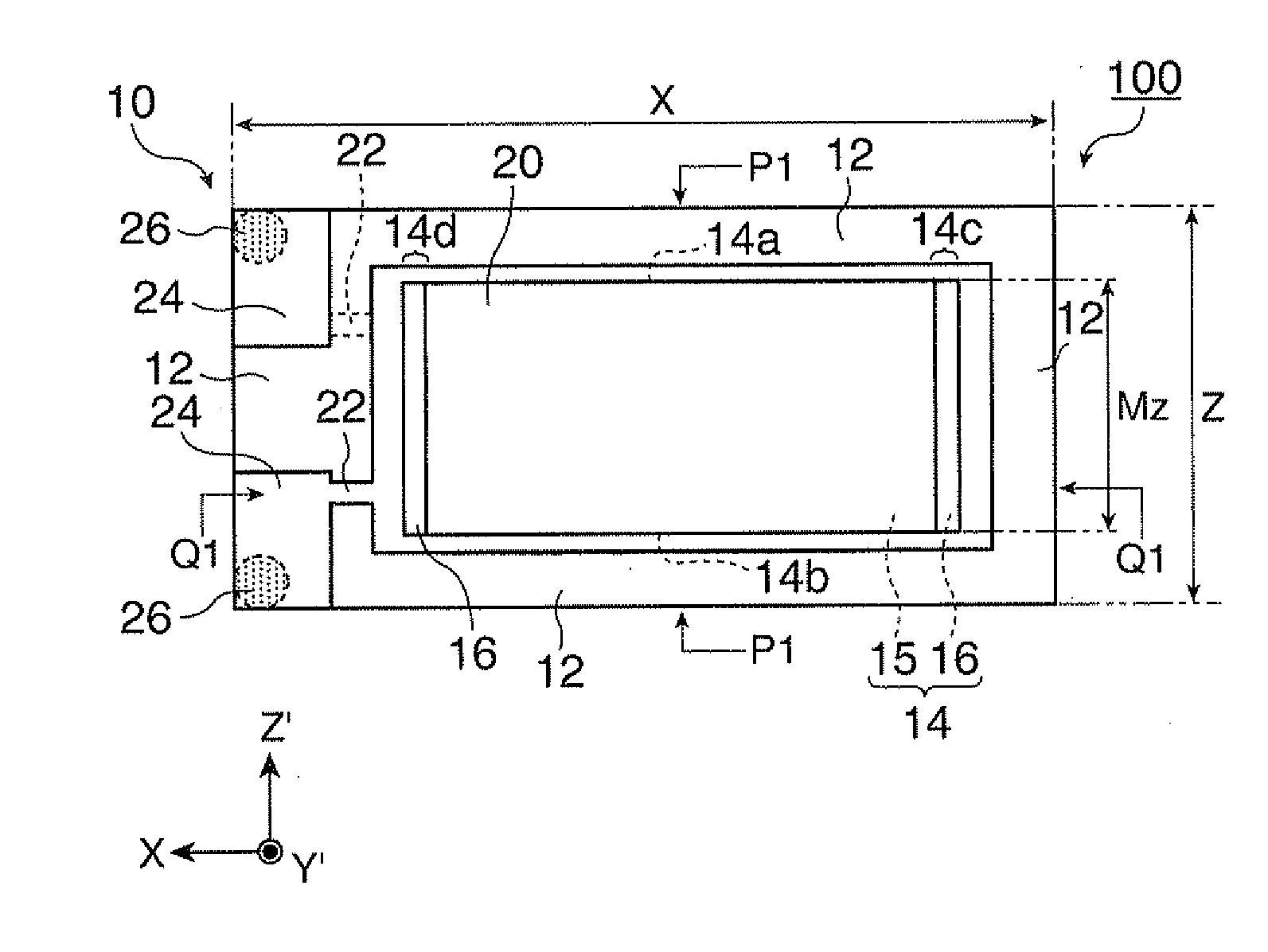

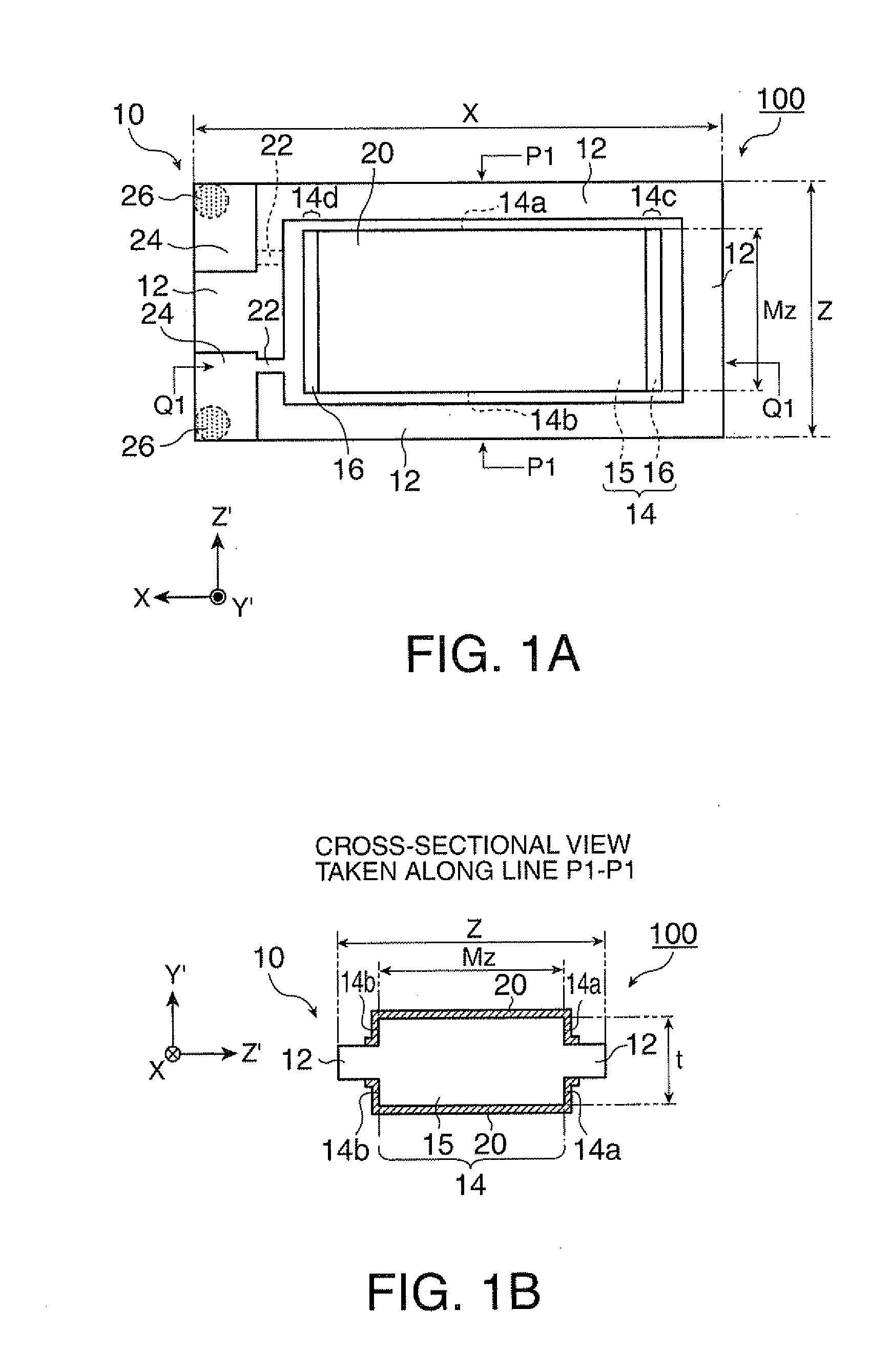

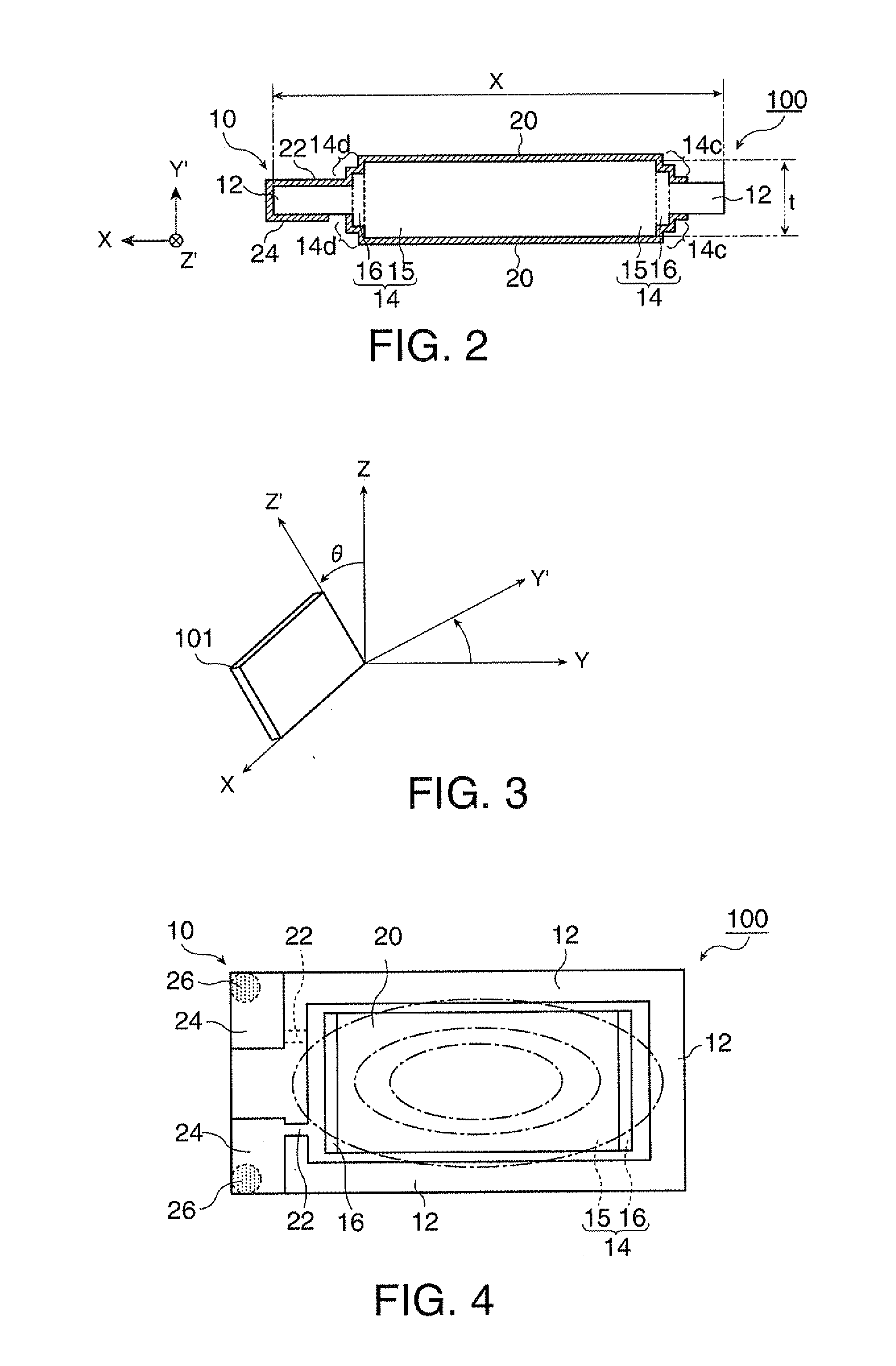

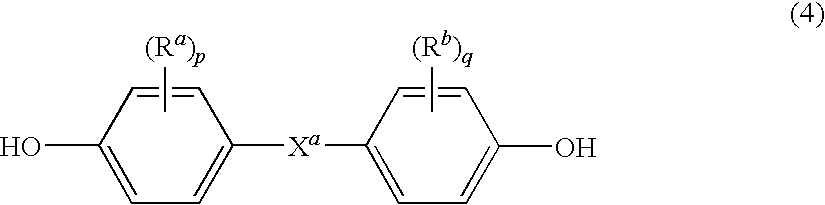

Piezoelectric vibration element, piezoelectric vibrator, piezoelectric oscillator, and electronic device

InactiveUS20120235762A1Configuring an electronic devicePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPiezoelectric actuatorsElectron

A piezoelectric vibration element includes: a piezoelectric substrate; excitation electrodes that are arranged so as to face each other on both principal faces of the piezoelectric substrate; drawn-out electrodes; and pads. The piezoelectric substrate includes an excitation portion that is located at the center and a peripheral portion that is thin-walled to be thinner than the thickness of the excitation portion and is disposed on a peripheral edge thereof. The pads have support areas that fix the piezoelectric substrate to a support member at positions of the piezoelectric substrate corresponding to corner portions. The excitation electrodes are formed over the excitation portion and a vibration area that is at least a part of the peripheral portion.

Owner:SEIKO EPSON CORP

Flame retardant thermoplastic polycarbonate compositions

Polycarbonate compositions are disclosed. The compositions comprise an optional polycarbonate polymer (A); a polycarbonate-polysiloxane copolymer (B); a phosphorous-containing flame retardant (C); and a reinforcing agent (D). The resulting compositions have an improved combination of properties, particularly Vicat softening temperature and high flame retardance in thin walls.

Owner:SHPP GLOBAL TECH BV

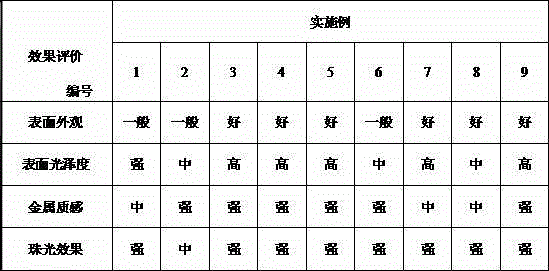

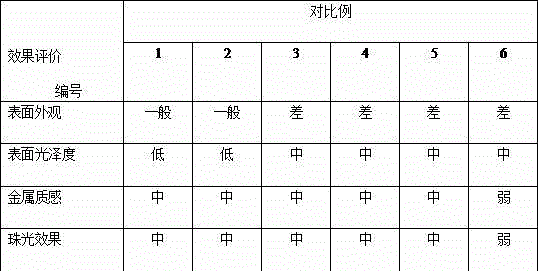

High-flowability high-glossiness no-surface-defect colored metallic-pearl-effect spraying-free polypropylene automobile material and preparation method thereof

The invention discloses a high-flowability high-glossiness no-surface-defect colored metallic-pearl-effect spraying-free polypropylene automobile material and a preparation method thereof. The material is composed of the following components in percentage by weight: 40.8-74.4% of polypropylene, 2-4% of toughener, 5-20% of mineral master batch, 5-10% of compatilizer, 0.4-0.6% of antioxidant, 0.4-0.6% of light stabilizer, 0.8-2% of lubricant, 6-10% of surface modifier, 3-6% of colored metallic pigment master batch and 3-6% of pearl color master batch. By using the high-melt-flow-rate polypropylene resin, compatilizer, surface modifier, mineral master batch, colored metallic pigment master batch and pearl color master batch, all the components can be uniformly dispersed, so that the material has the advantages of favorable glossiness, favorable pearl effect, favorable metallic sensation and no surface defect, and the appearance effect is infinitely approximate to the painting effect. The material can solve the problem of surface flow mark, tiger skin or fusion wire in the thin-wall complex-structure large-size product without especially customizing the ultrahigh-glossiness mirror surface mold or harsh injection molding technique, and can implement direct color-bearing injection molding of the part.

Owner:蔡勤勤

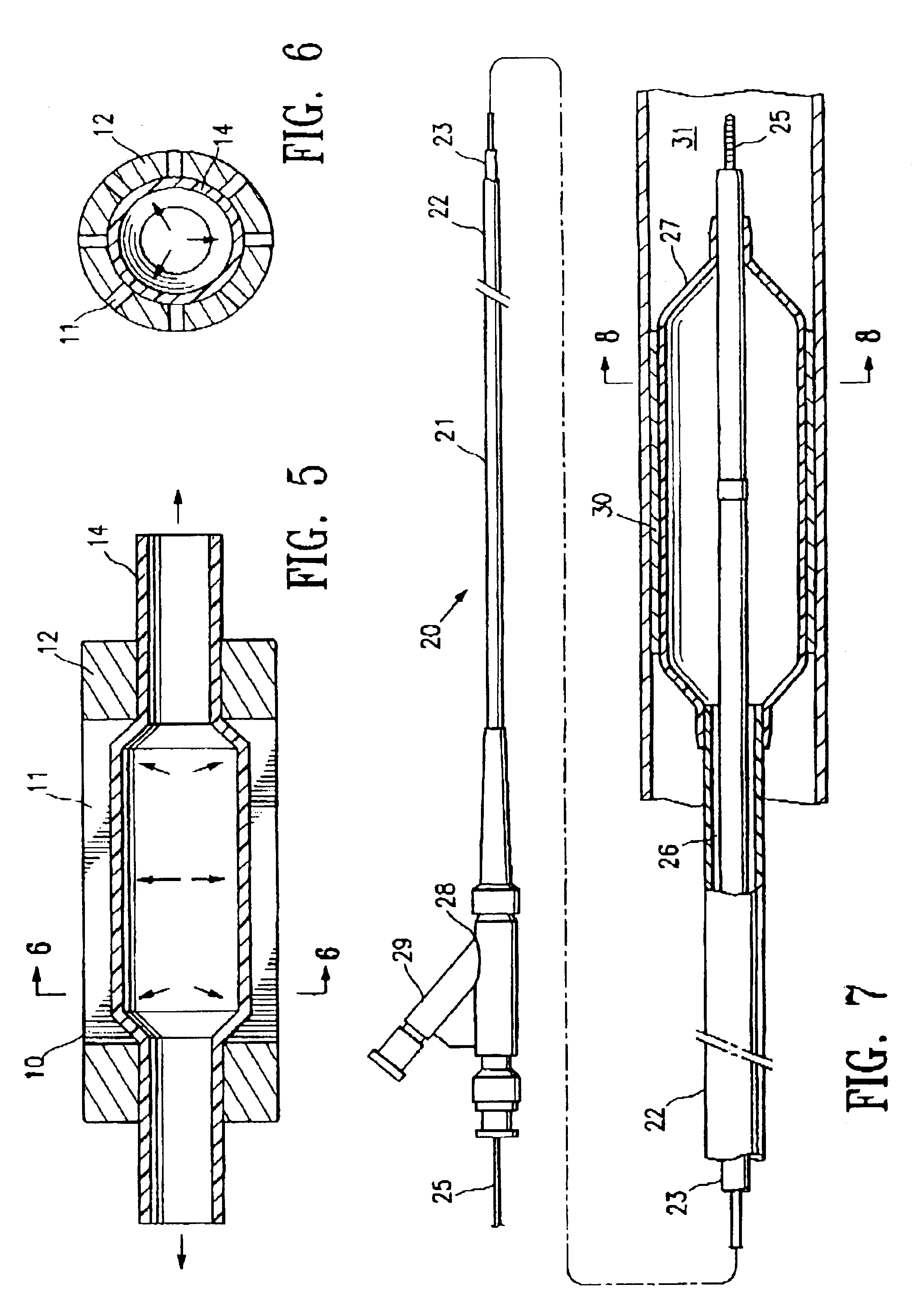

Slotted mold for making a catheter balloon

InactiveUS6863856B1Increase heatIncrease frictional resistanceTyresCeramic shaping apparatusBlow moldingMaterials science

A method of making a catheter balloon, and a balloon formed thereby, in which a polymeric tube is radially expanded in a mold having a wall with an outer surface and an inner surface defining a chamber, and having at least a section with one or more channels in the wall. The channels result in improved transfer of heat to the polymeric tube within the chamber of the mold during blow molding of the tube to form a balloon, so that the tube is heated more quickly and evenly. One aspect of the invention is directed to a balloon having sections with improved thin walls.

Owner:ABBOTT CARDIOVASCULAR

External thin-wall vacuum duct maglev traffic system of power system

The invention provides an external thin-wall vacuum duct maglev traffic system of a power system. A vacuum duct with small wall thickness is adopted, a linear motor coil, a track levitation mechanism and other communication, detecting and control devices are arranged outside the duct and provide power, levitation force and control to vehicles in the duct in the state that one thin duct wall is used for separation. The material of the duct wall is required to have no effect on the electromagnetic field of a linear motor and the levitation magnetic field of a levitation device, for example, non-magnetized stainless steel, carbon alloy, glass fiber reinforced plastics or high-strength organic materials are adopted, or the duct is made of a composite material. The arrangement has the advantages that the installation construction of a linear motor stator and the levitation mechanism can be conveniently performed outside the duct; routine maintenance and repair during operation can also be performed outside the duct; mechatronic systems can be well cooled, and heat aggregation in the vacuum duct is avoided; and the space in the duct is not occupied; and the construction, maintenance and system operation costs of the vacuum duct high-speed maglev traffic system can be lowered.

Owner:张耀平

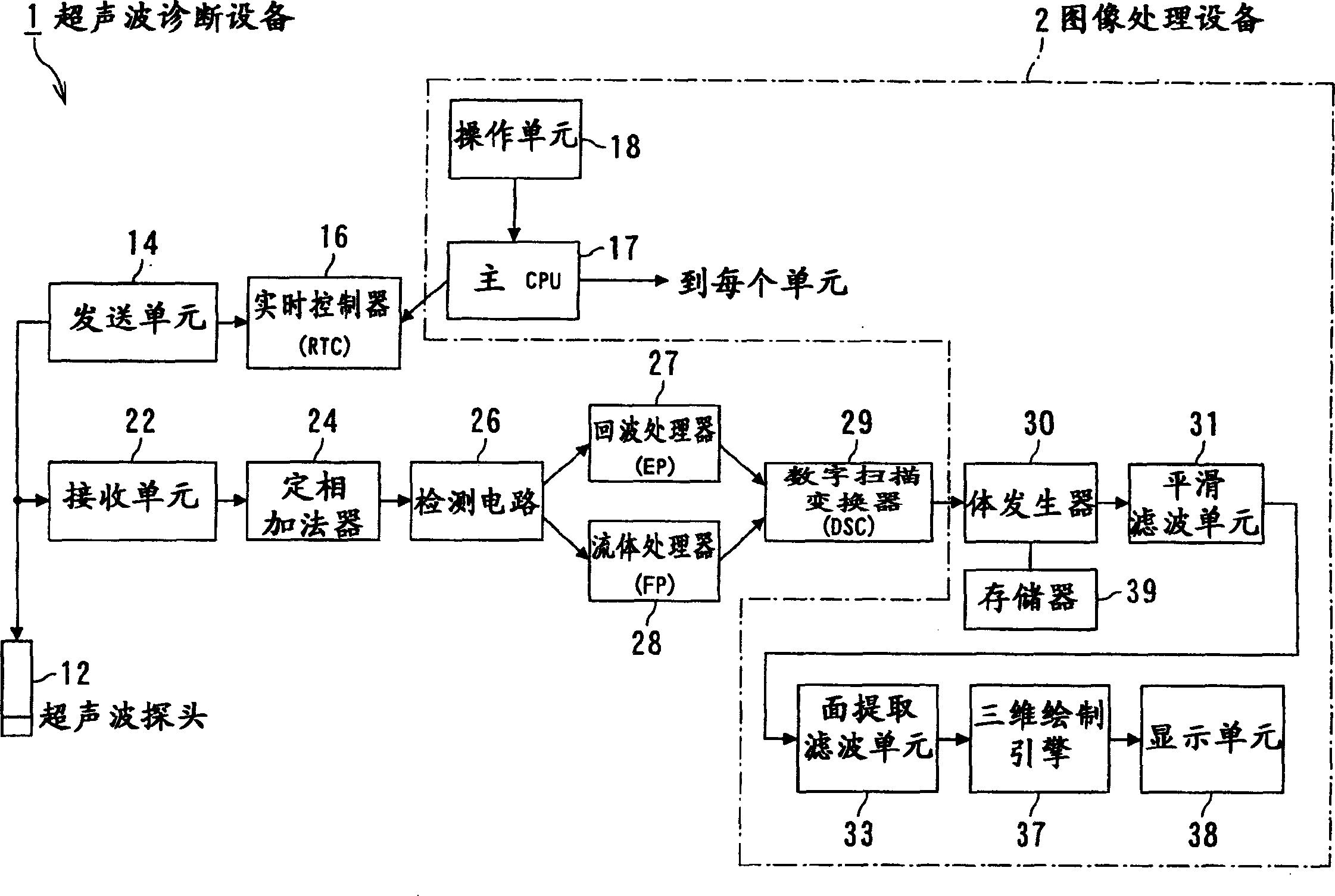

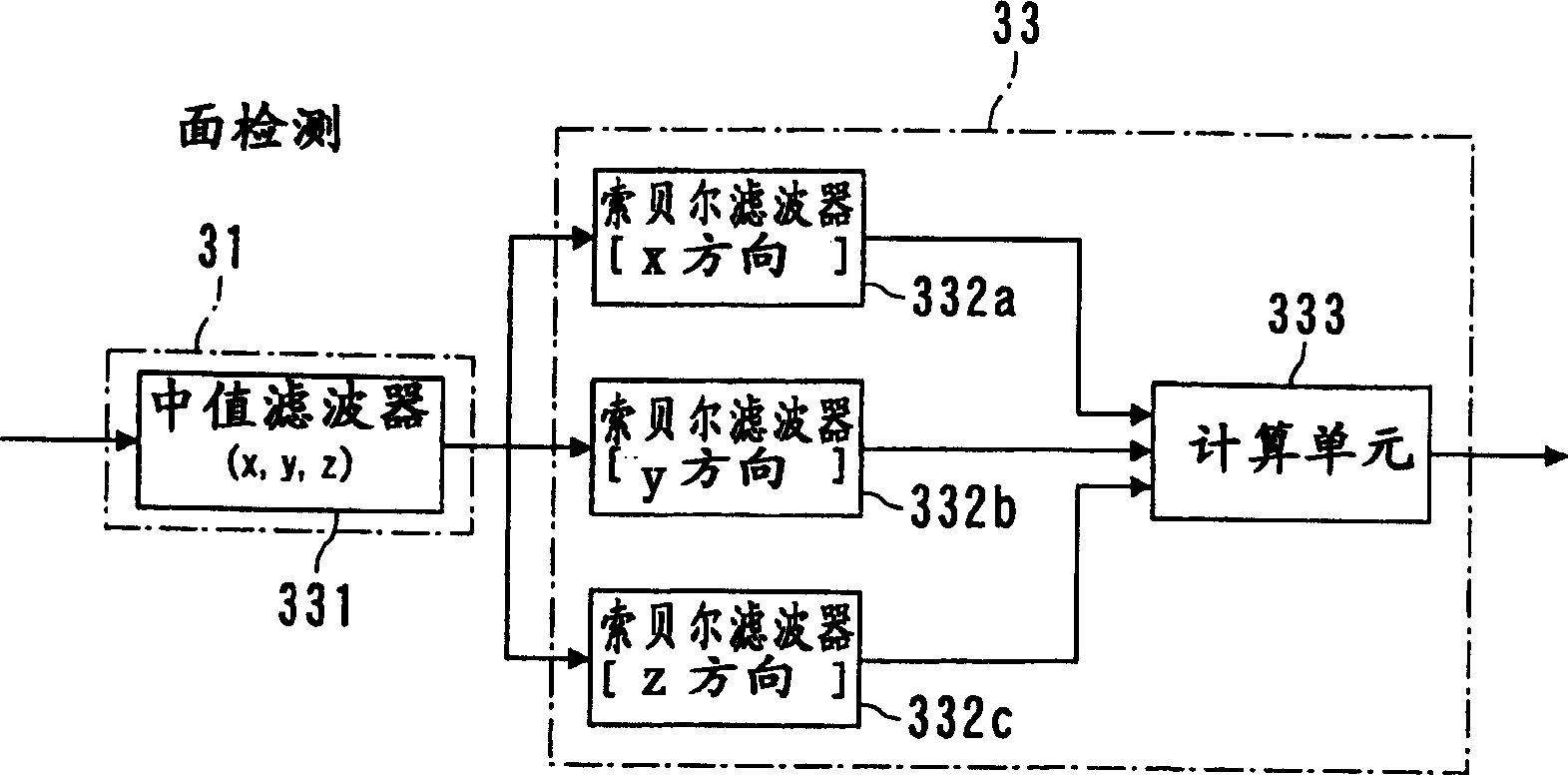

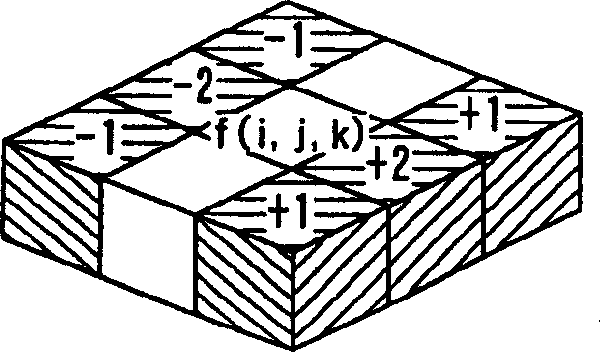

Image processing apparatus and ultrasonic wave diagnosis apparatus

InactiveCN1493258AOrgan movement/changes detectionInfrasonic diagnosticsVoxel volumeImaging processing

An acquired volume data from a subject, which is allocated in points constituting three-dimensional space and forming a group of data representing a physical property of the subject, is recorded in a recording means, a characteristic quantity computed from values of the physical property held by the volume data at each point is extracted by a characteristic quantity extracting means, and three-dimensional image is generated by providing opacity to the characteristic quantity by three-dimensional image generating means, whichever the volume data is voxel volume data or polar-coordinate ultrasound volume data, so that the internal structure of parenchymatous organs, especially internal blood vessels and cavitary structures can be displayed three dimensionally.

Owner:KK TOSHIBA

Preparation method of large quartz ceramic crucible

The invention discloses a preparation method of a large quartz ceramic crucible, which is formed based on the method of gel casting molding, and particularly comprises the following steps: a) taking fused quartz with purity of 99.0-99.9% according to the mass percent as a raw material, and carrying out granular grading on the grains of the fused quartz; b) uniformly mixing the raw material proportioned by the step a), adding gel solution, preparing into pulp in a ball mill or a blender; c) injecting or pressure-injecting the prepared pulp prepared by the step b) into a preheated metal mold, and taking out from the metal mold after the pulp is solidified into green bodies; d) naturally drying the green bodies; and e) putting the dried green bodies into a high-temperature furnace, baking toobtian the large quartz ceramic crucible. Raw material grain proportioning and the preparation method, optimized by the invention, can product the quartz ceramic crucible with larger overall dimension and thin wall for fusion of special glass, casting of polycrystalline and calcining of rear earth material.

Owner:洛阳北苑新材料技术有限公司

3D printing mould-free injection forming method through metal sizing agents

The invention provides a 3D printing mould-free injection forming method through metal sizing agents. According to the method, a 3D printing technology and an injection forming technology are combined, an injection forming process is utilized for evenly mixing metal powder and organic binding agents to form the metal sizing agents, the sizing agents are adopted as the raw materials of 3D printing, layered printing is carried out through 3D printing equipment according to a data model, layer-by-layer accumulation is carried out to obtain a metal blank, and a metal part product in a complex shape is obtained through degreasing and sintering. The method can be used for manufacturing a part including a sealed cavity, a complex inner cavity and the like, the part cannot be manufactured through a traditional injection forming mode, the metal blank is directly formed through the 3D printing technology, a mould is not needed, the cost of single part and small scale production is low, requirements for powder materials are low, process reliability is high, repeatability is high, efficiency is high, and the industrialization of manufacturing the small thin-wall metal part in the complex shape through the 3D printing technology is easy to achieve.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com