External thin-wall vacuum duct maglev traffic system of power system

A vacuum pipeline and power system technology, applied in sliding/floating railway systems, tunnel systems, tracks, etc., can solve problems such as increasing pipeline wall loads, occupying effective pipeline space, and heat accumulation in pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

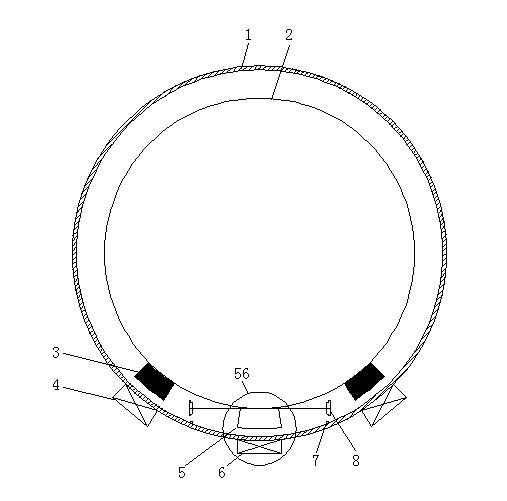

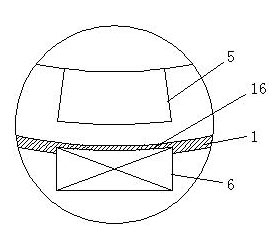

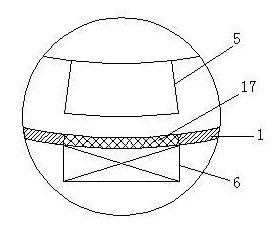

[0025] For repulsive levitation, electric levitation and high temperature superconducting magnetic levitation, the layout of linear motor and levitation system can be adopted as figure 1 structure shown. For example, when high-temperature superconducting maglev is used, the vehicle-mounted levitation mechanism (3) is a low-temperature Dewar containing superconducting blocks and liquid nitrogen, and the levitation mechanism (4) fixed outside the tube wall is a permanent magnet guide rail.

[0026] The support wheels (8) and rails that provide support and walking for the vehicle (2) can also be arranged on both sides of the lower half of the vehicle / pipe, such as Figure 4 shown.

[0027] The linear motor can also be arranged on the top, that is, the mover (3) is installed on the top of the vehicle, and the stator (4) is installed on the top of the pipe, such as Figure 5 shown.

Embodiment approach 2

[0029] For suction suspension, the suspension mechanism should be set near the top of the vehicle (2) and pipeline (1), such as Figure 6 shown.

[0030] It is also possible to adopt a mixed suspension method, arrange the suspension mechanism that provides repulsion at the bottom, and arrange the suspension mechanism that provides suction at the top, such as Figure 7 shown. Figure 7 Middle (65) can be linear motor, also can be suspension mechanism.

Embodiment approach 3

[0032] The superconducting maglev vehicle of the Yamanashi test line in Japan belongs to electric suspension, and the suspension and driving devices are on both sides of the vehicle and the line. For this suspension mode, it is enough to arrange the suspension mechanism and the drive mechanism on both sides of the vehicle and the pipeline accordingly. Such as Figure 8 As shown, the vehicle-mounted suspension mechanism and the driving mechanism (11) are arranged on both sides of the vehicle (2), and the suspension mechanism and the driving mechanism (12) fixed on the pipeline are arranged outside the pipeline wall.

[0033] In this suspension mode, the pipeline can also be designed as an arch, such as Figure 9 shown. Figure 9 Middle (18) is the vehicle-mounted suspension and drive device / linear motor, and (19) is the fixed suspension and drive device / linear motor belonging to the track component. The pipe wall at the place where the suspension and driving device (19) is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com