Patents

Literature

6138 results about "Liquid nitrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid nitrogen—LN₂—is nitrogen in a liquid state at an extremely low temperature (−195.79 °C (77 K; −320 °F) boiling point at sea level). Nitrogen was first liquefied at the Jagiellonian University on 15 April 1883 by Polish physicists, Zygmunt Wróblewski and Karol Olszewski. It is produced industrially by fractional distillation of liquid air.

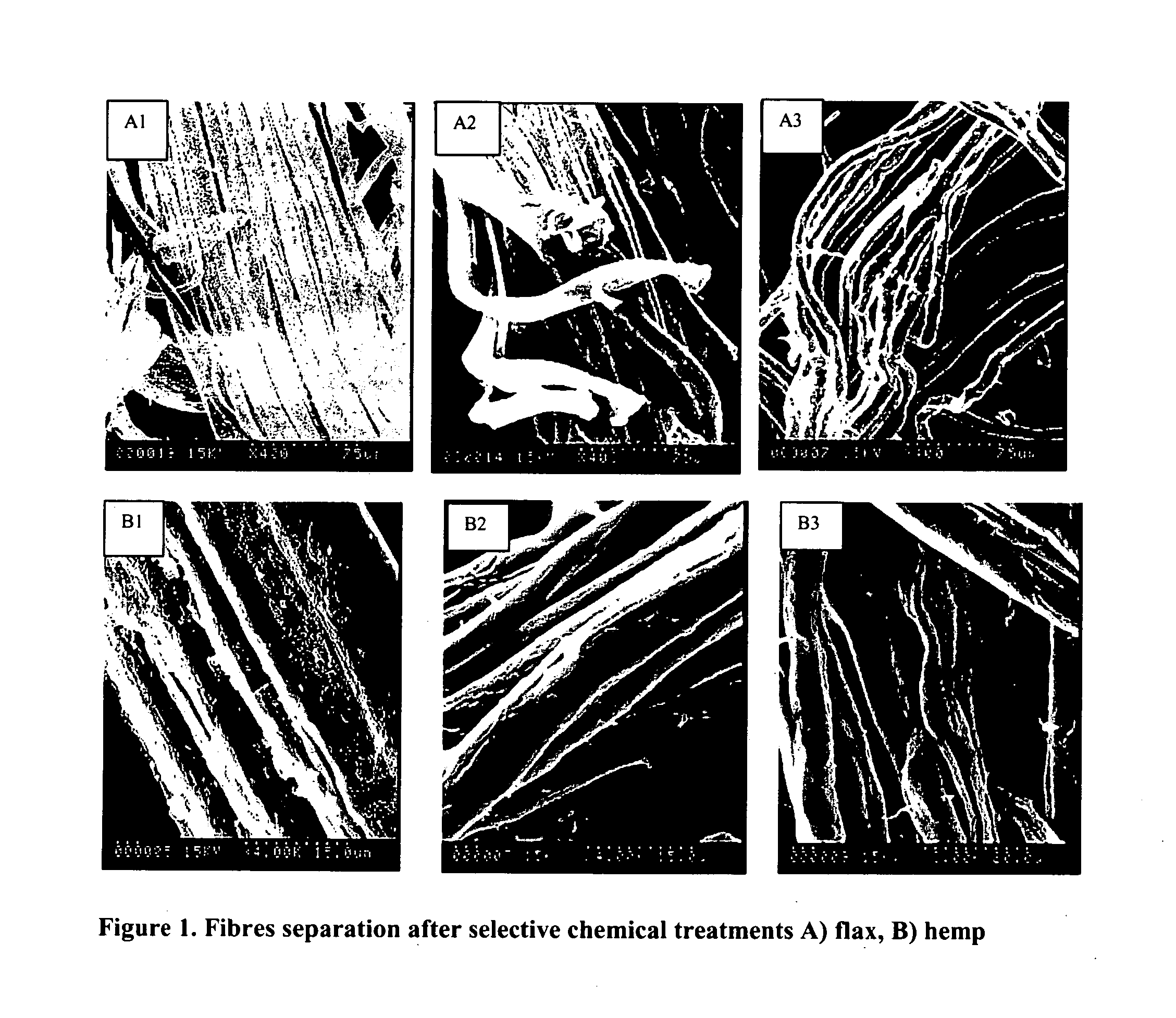

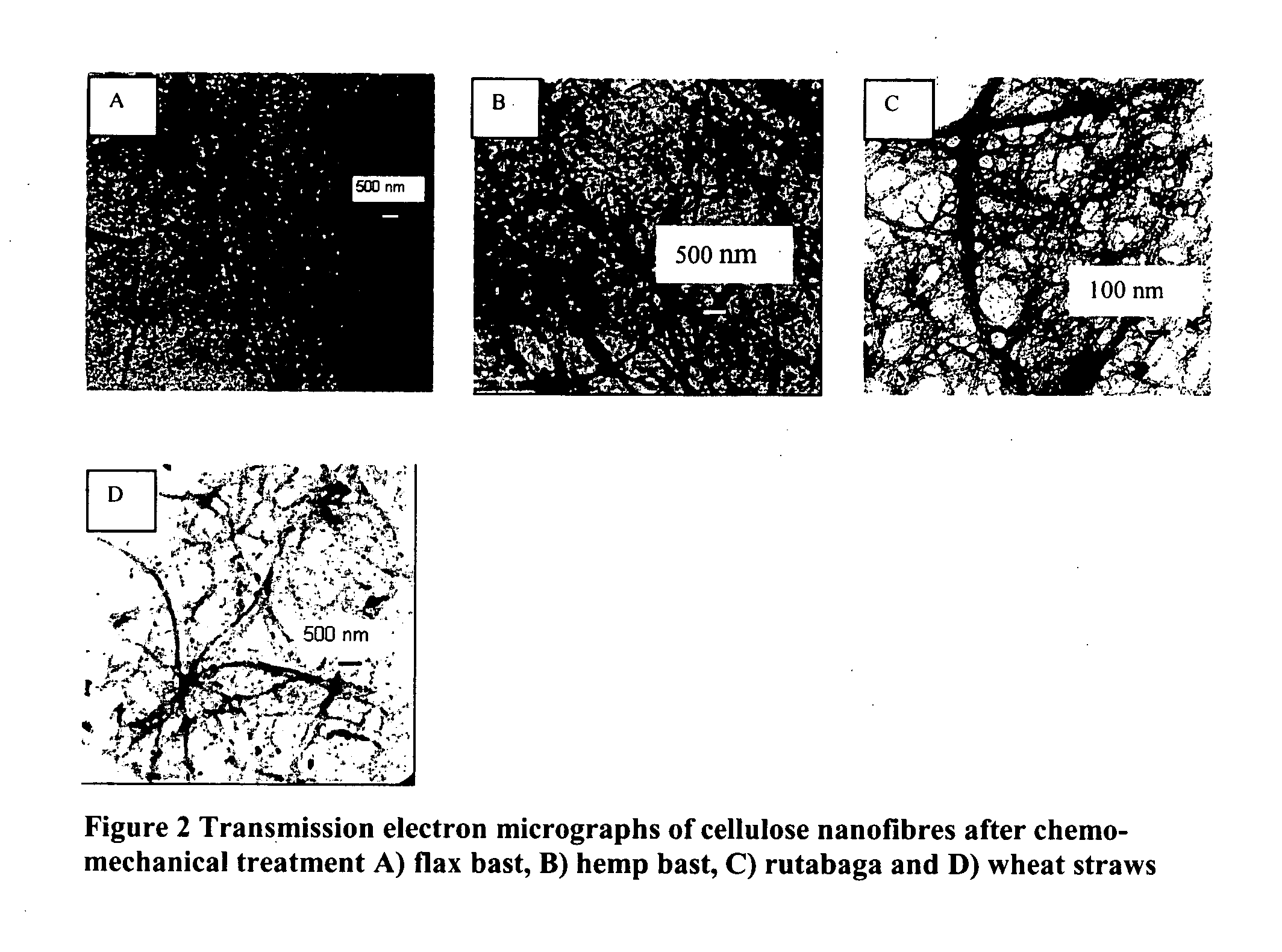

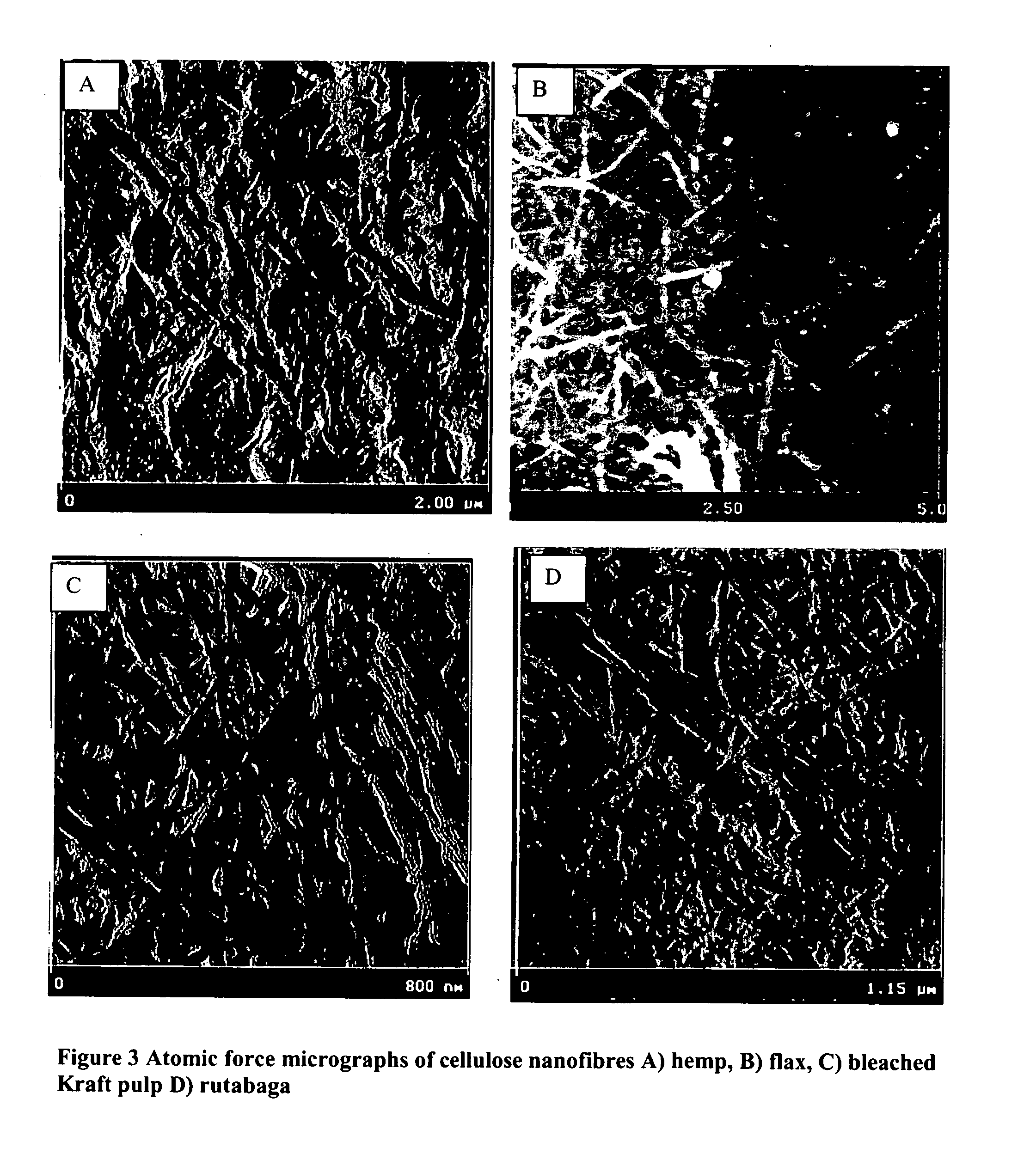

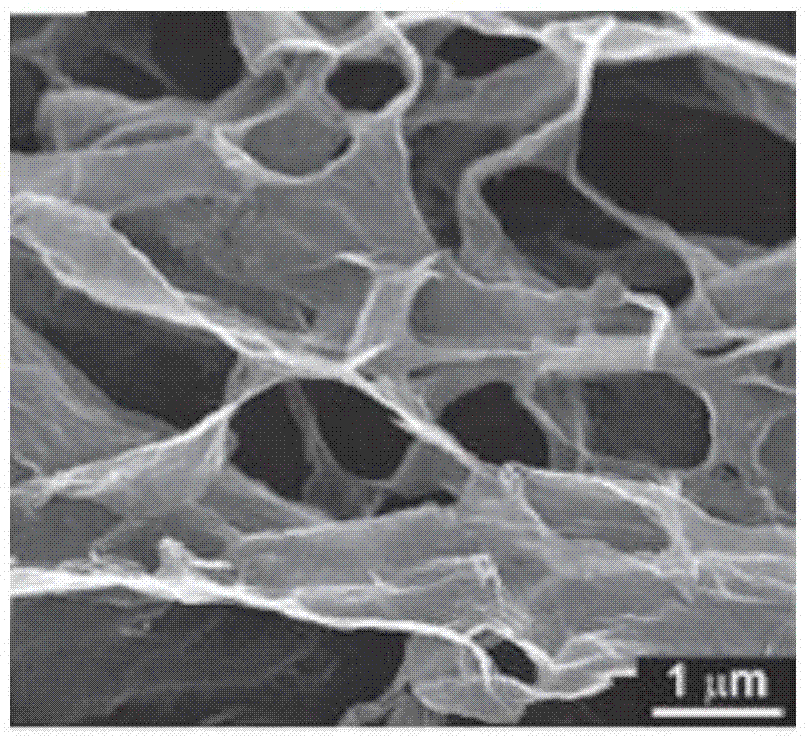

Manufacturing process of cellulose nanofibers from renewable feed stocks

InactiveUS20080146701A1High aspect ratioRaise the potentialMaterial nanotechnologyFats/resins/pitch/waxes removal in pulpCelluloseNatural fiber

Cellulose nanofibers have been processed from renewable feedstock in particularly from natural fibers, root crops and agro fibers, wherein the pulp was hydrolysed at a moderate temperature of 50 to 90 degree C., one extraction was performed using dilute acid and one extraction using alkali of concentration less than 10%; and residue was cryocrushed using liquid nitrogen, followed by individualization of the cellulose nanofibers using mechanical shear force. The nanofibers manufactured with this technique have diameters in the range of 20-60 nm and much higher aspect ratios than long fibers. Due to its lightweight and high strength its potential applications will be in aerospace industry and due to their biodegradable potential with tremendous stiffness and strength, they find application in the medical field such as blood bags, cardiac devices, valves as a reinforcing biomaterial.

Owner:SAIN MOHINI M +1

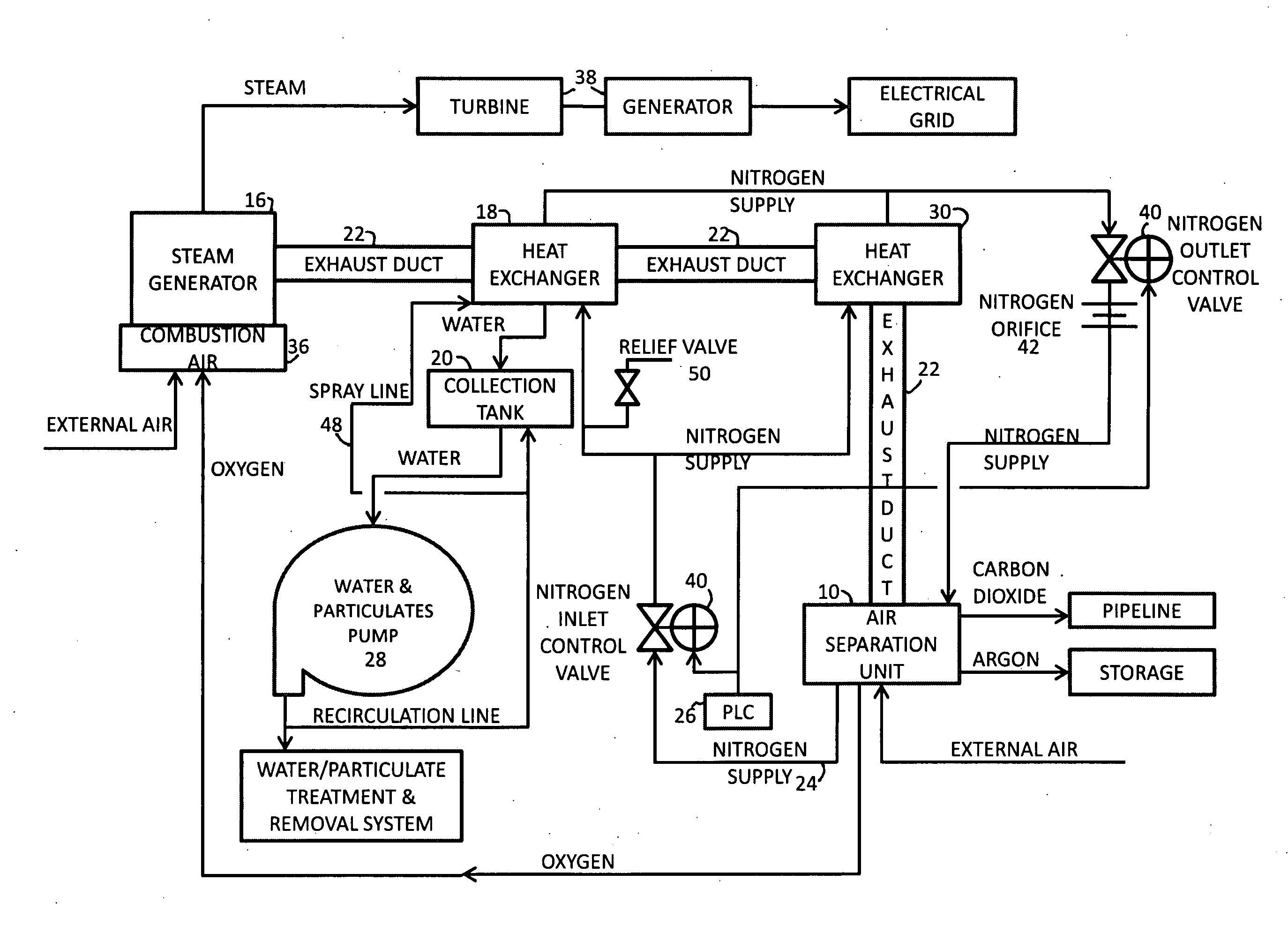

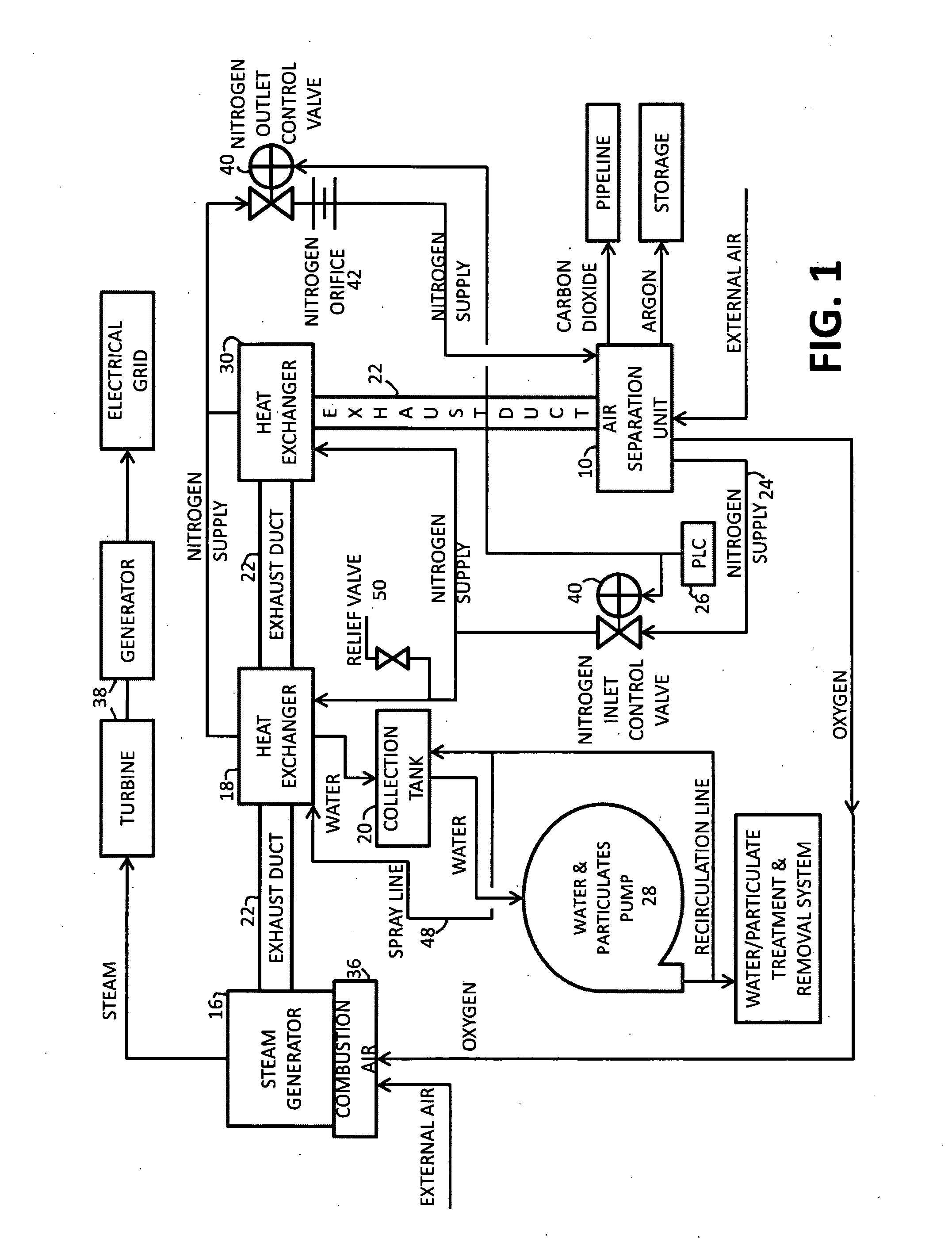

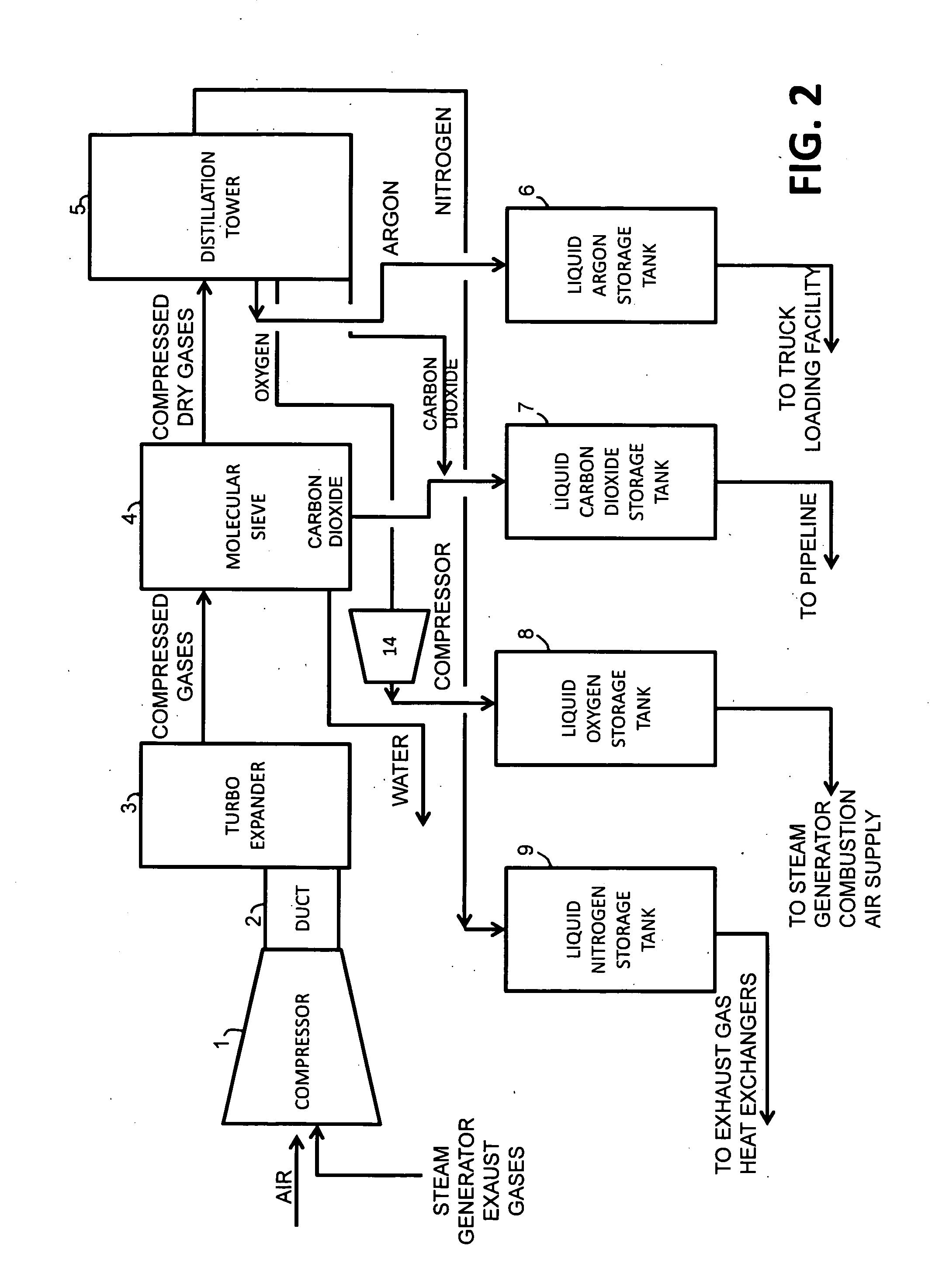

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

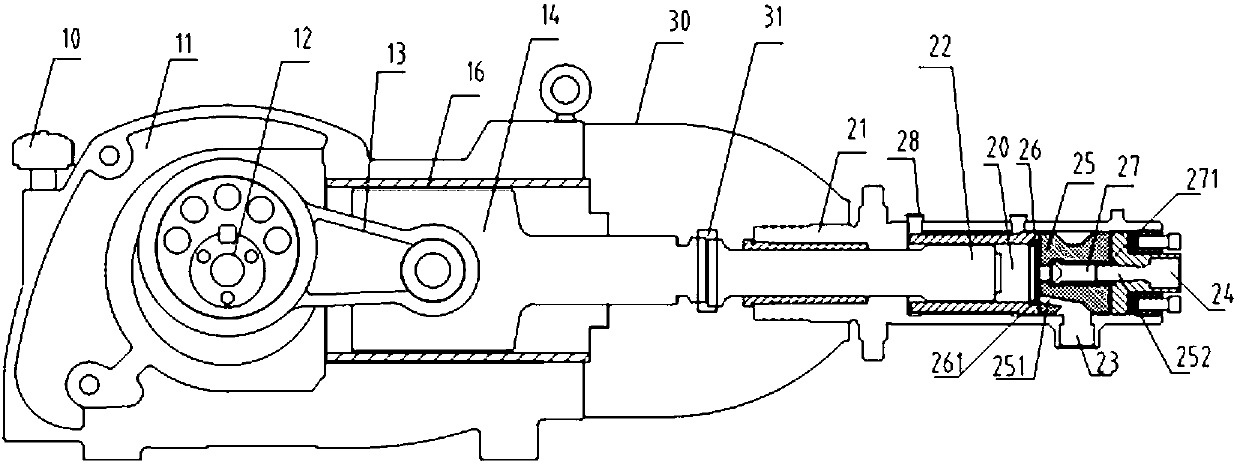

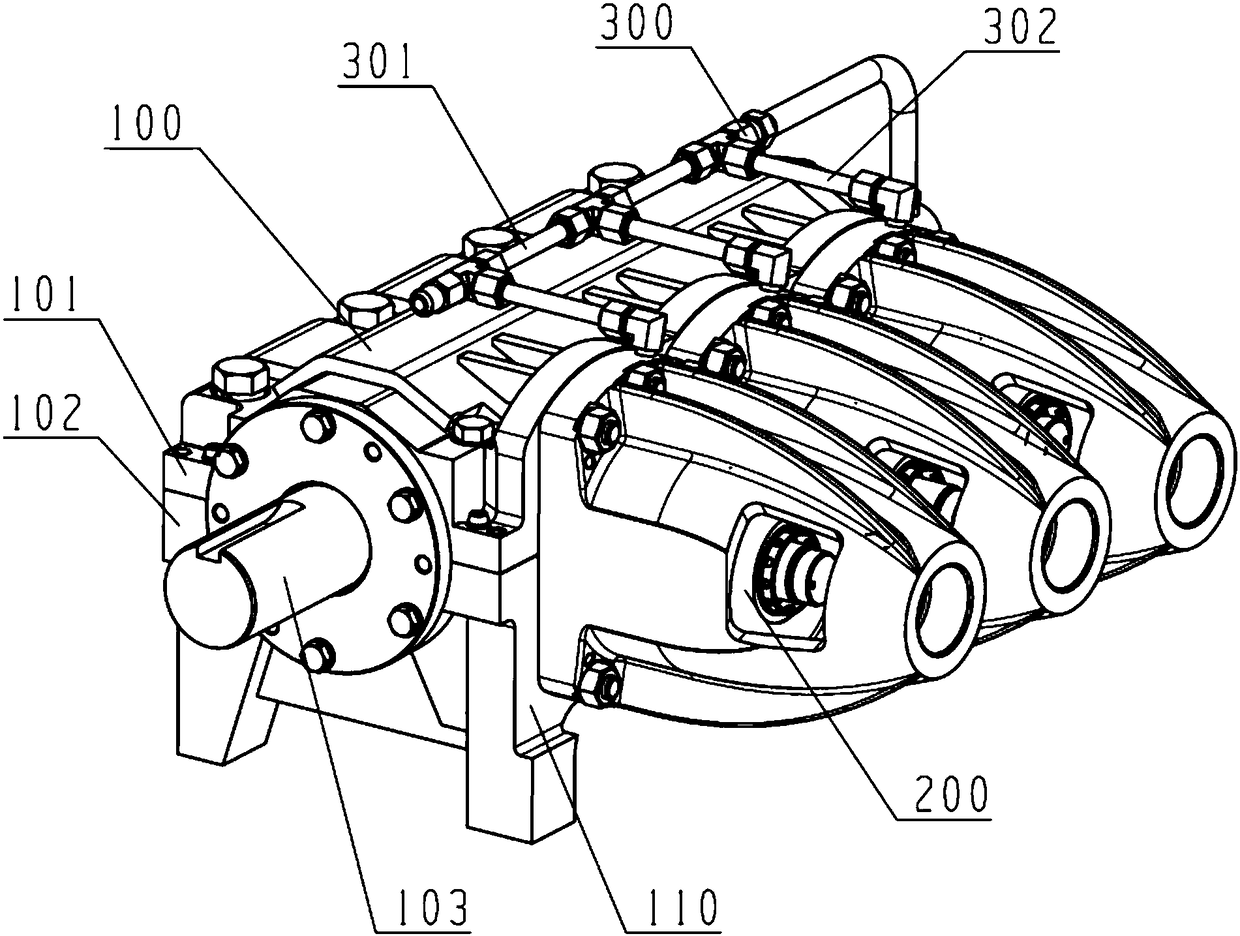

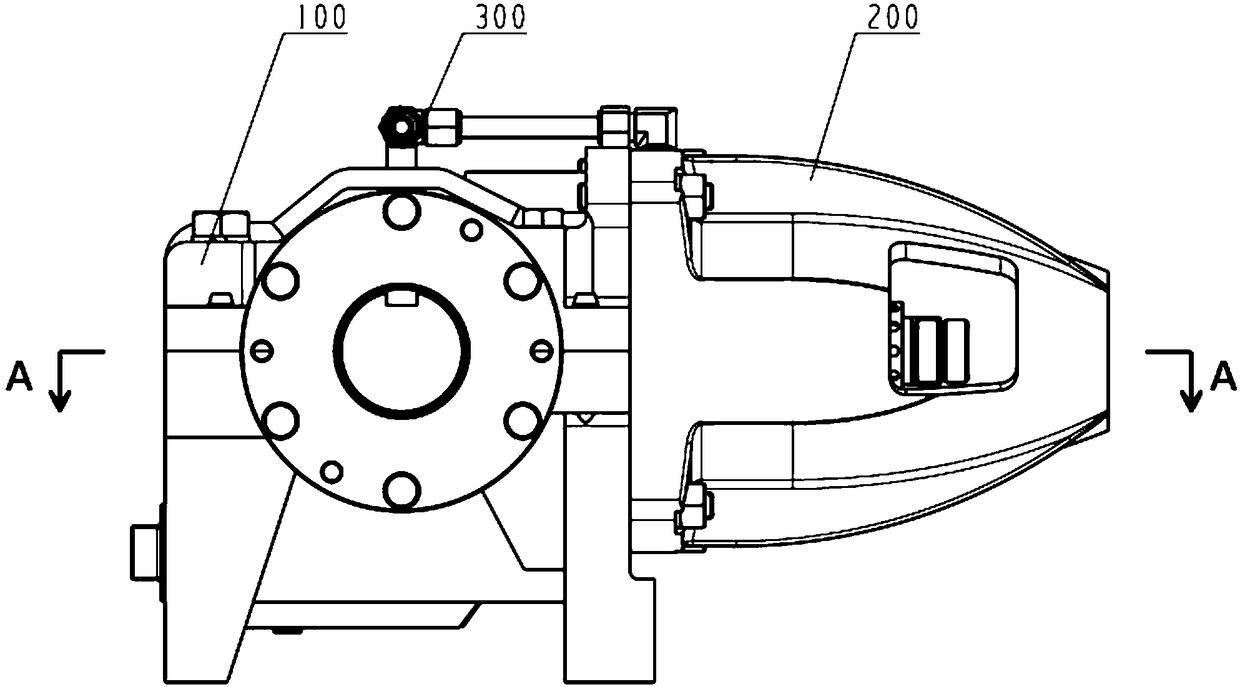

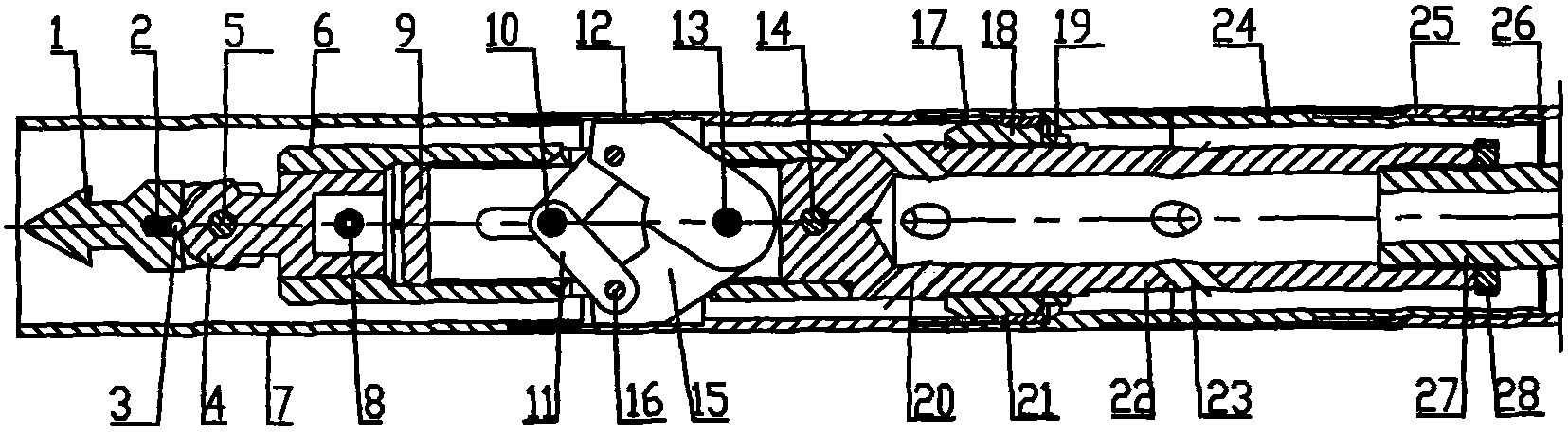

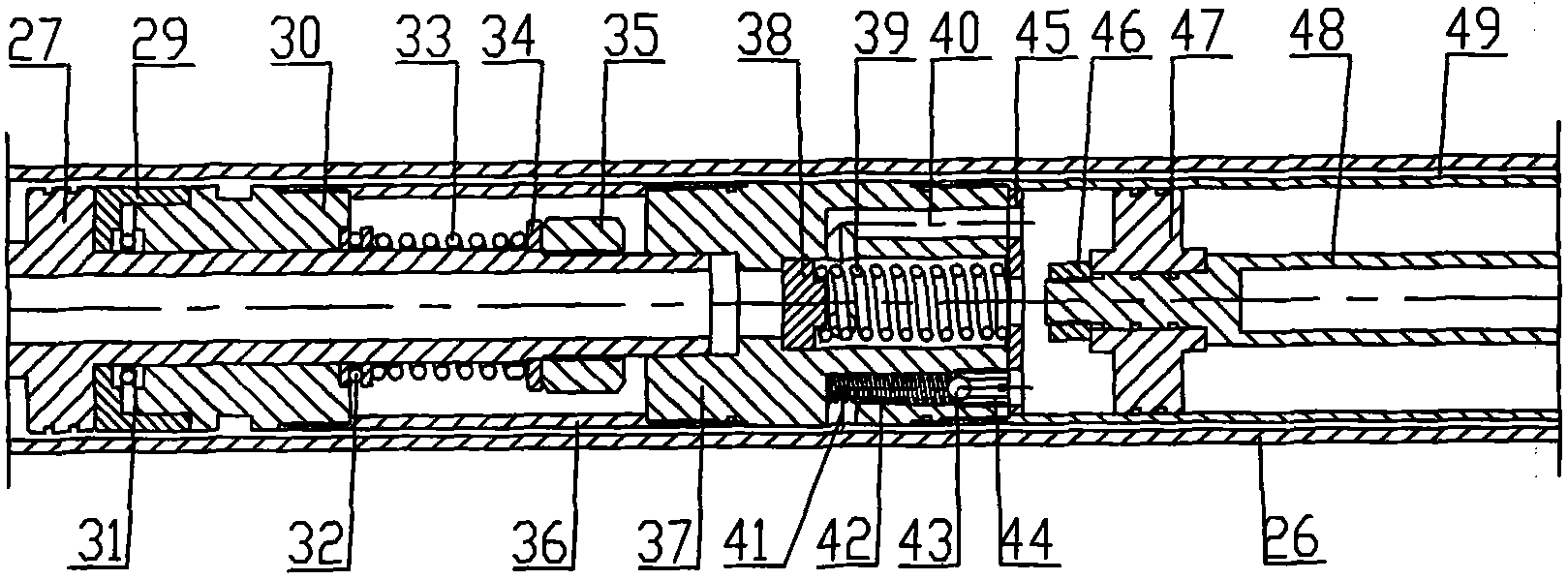

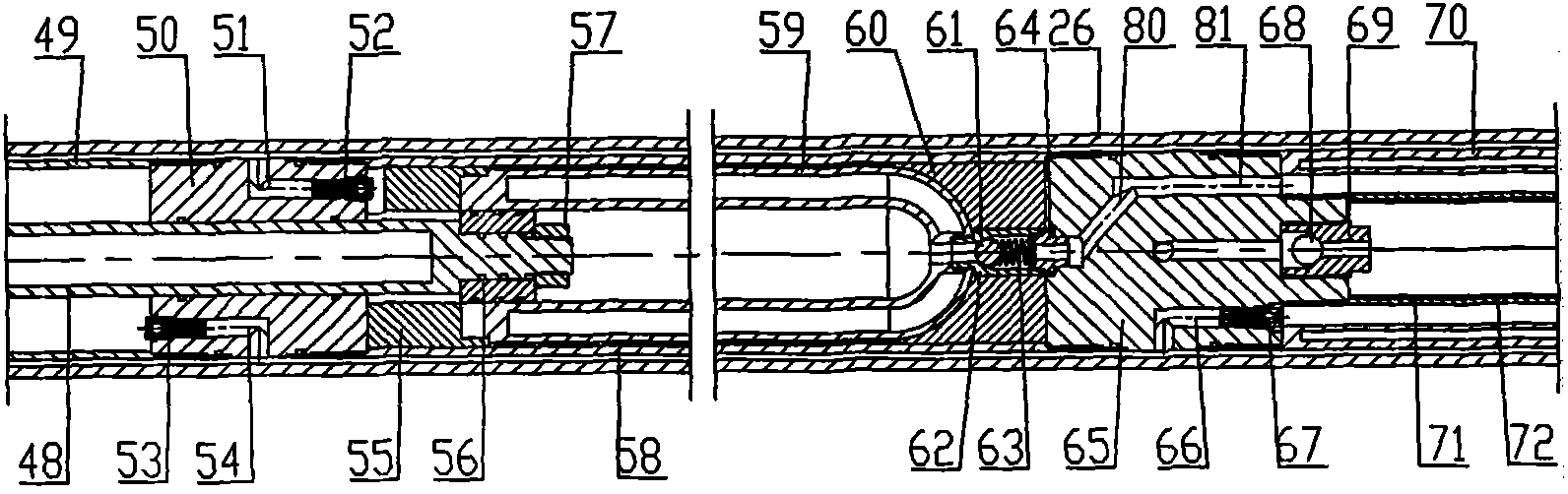

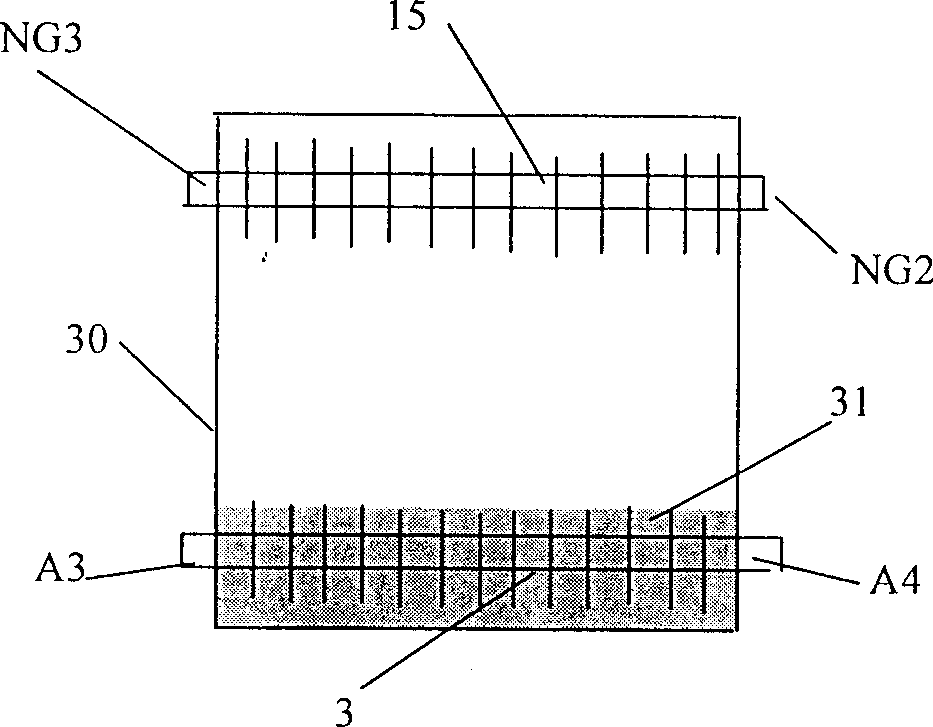

Plunger pump used for pumping ultralow-temperature liquid nitrogen

InactiveCN102889191ASolve the problem of easy heat absorption and vaporizationReduce deliveryPumpsPositive-displacement liquid enginesReciprocating motionEngineering

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

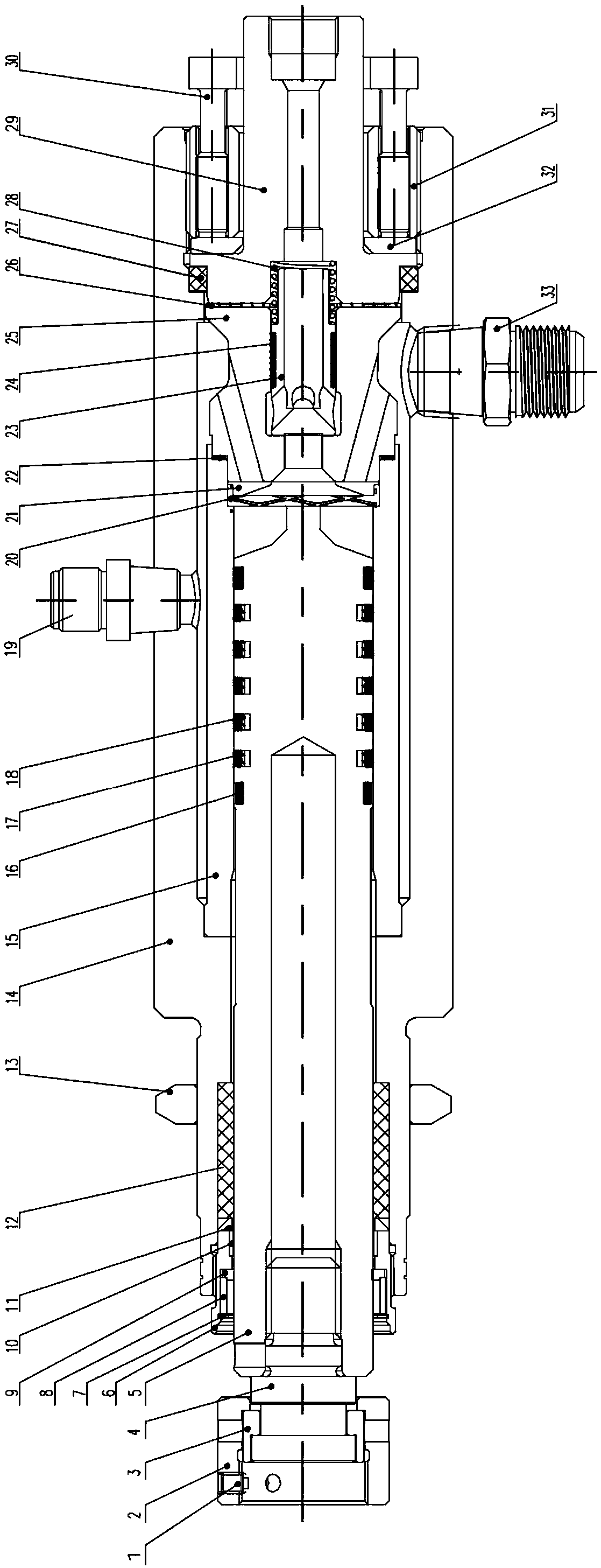

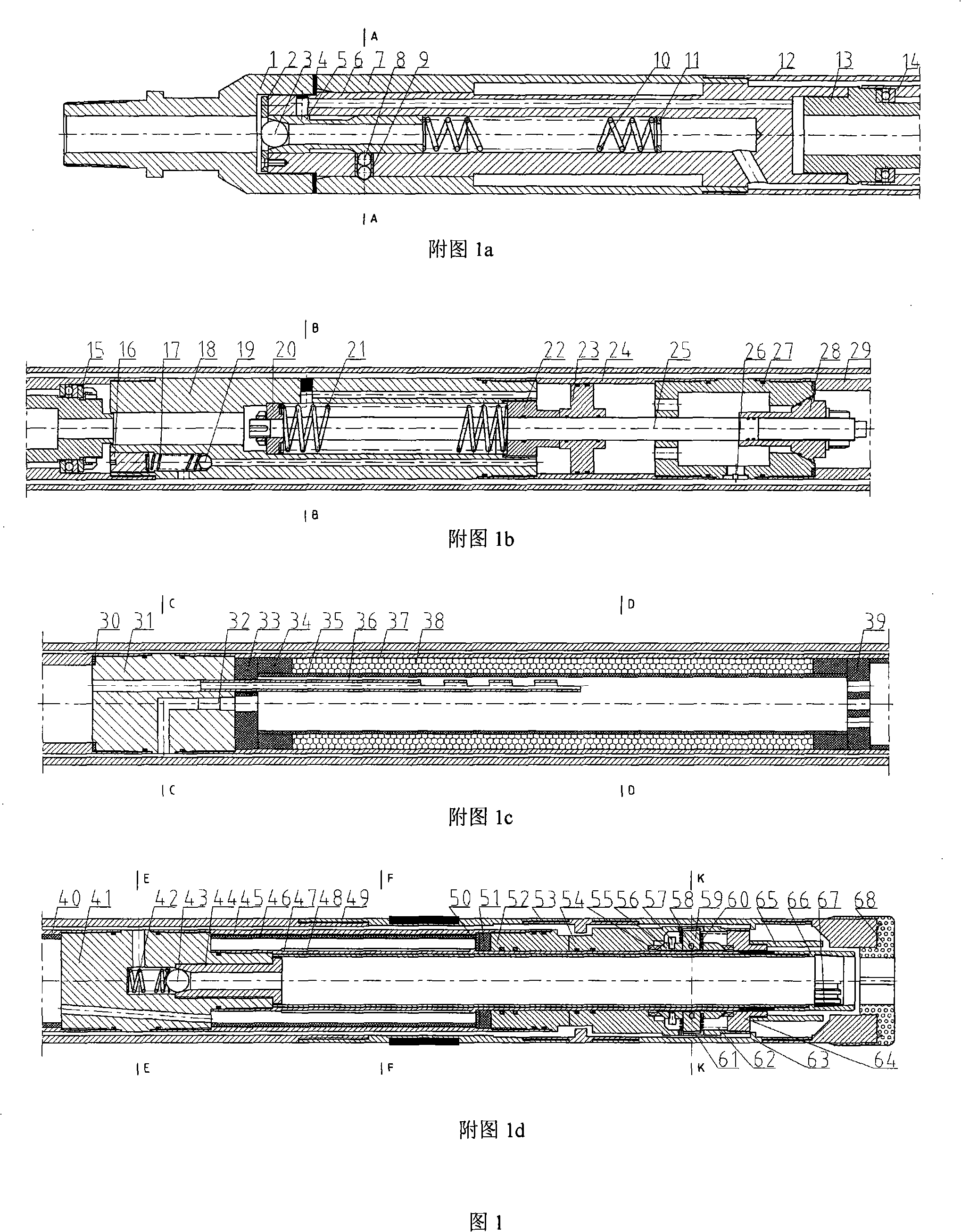

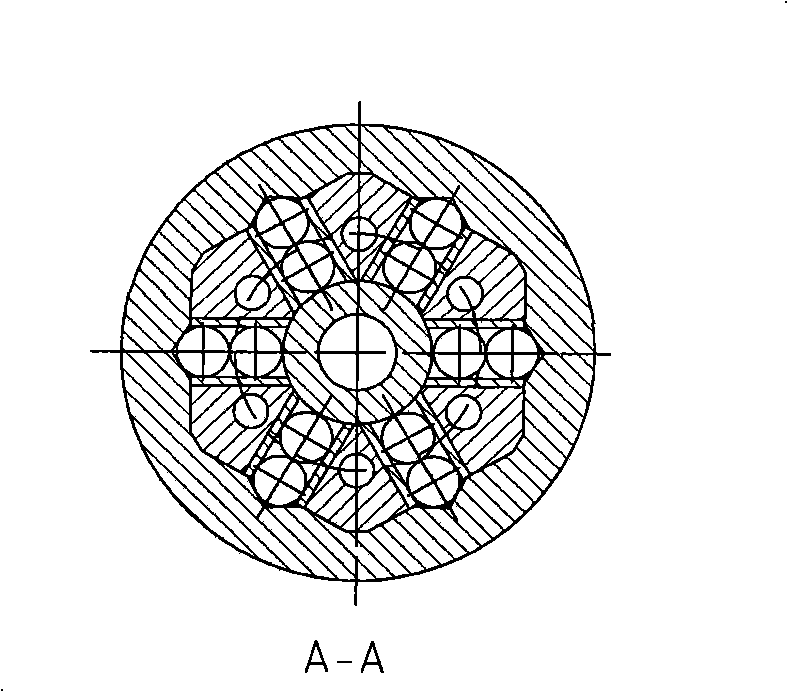

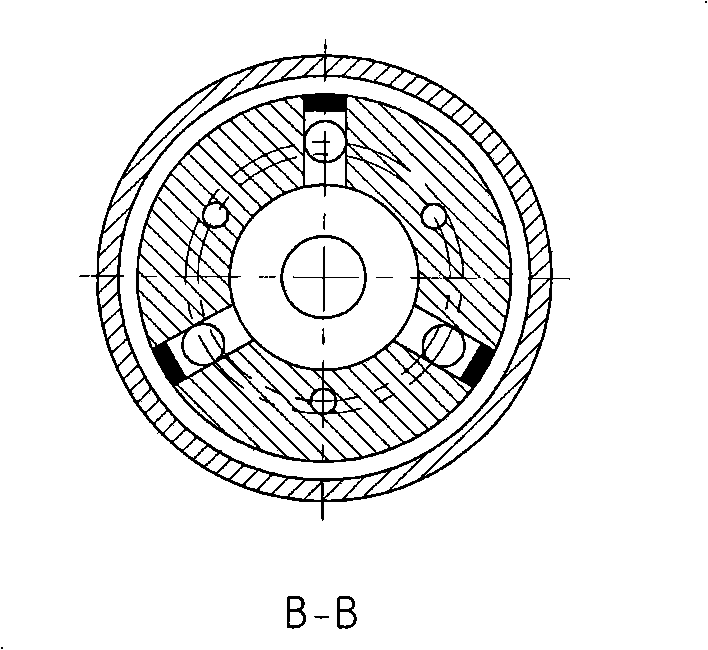

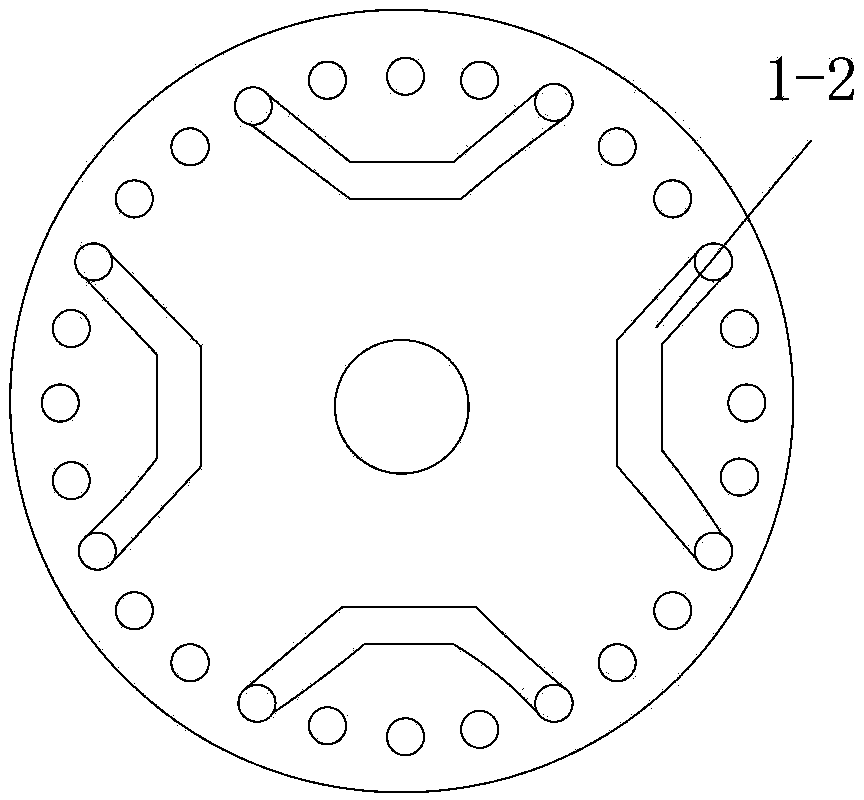

Cold end of low-temperature high-pressure plunger pump

InactiveCN109404274ASolve the problem of being unable to pump low temperature and high pressure liquid nitrogenHigh conveying medium temperaturePositive displacement pump componentsFluid removalHigh pressureLiquid nitrogen

The invention belongs to the technical field of low-temperature high-pressure plunger pumps, and particularly relates to a cold end of a low-temperature high-pressure plunger pump. The cold end comprises a cold end shell body, a plunger and a cylinder sleeve, wherein the plunger is arranged inside the cylinder sleeve, the cylinder sleeve is located inside the cold end shell body, a connecting locking device is arranged at the front end of the cold end shell body, the cold end shell body comprises a left cavity and a right cavity which communicate with each other, the right cavity internally comprises the cylinder sleeve, a valve set and a discharging flange, and the valve set comprises a valve seat, a high-pressure valve arranged in the valve seat and a low-pressure valve arranged betweenthe cylinder sleeve and the valve seat. According to the cold end of the low-temperature high-pressure plunger pump, the novel valve set structure adopts metal sealing, continuous opening and closingof the high-pressure valve and the low-pressure valve are achieved, and normal-pressure ultralow-temperature liquid nitrogen is converted into high-pressure low-temperature liquid nitrogen and is discharged so that the requirement for high-frequency opening and closing can be met, the characteristics of being low in conveying medium temperature and high in output pressure are achieved, and the problem that a common plunger pump cannot pump the low-temperature and high-pressure liquid nitrogen is solved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

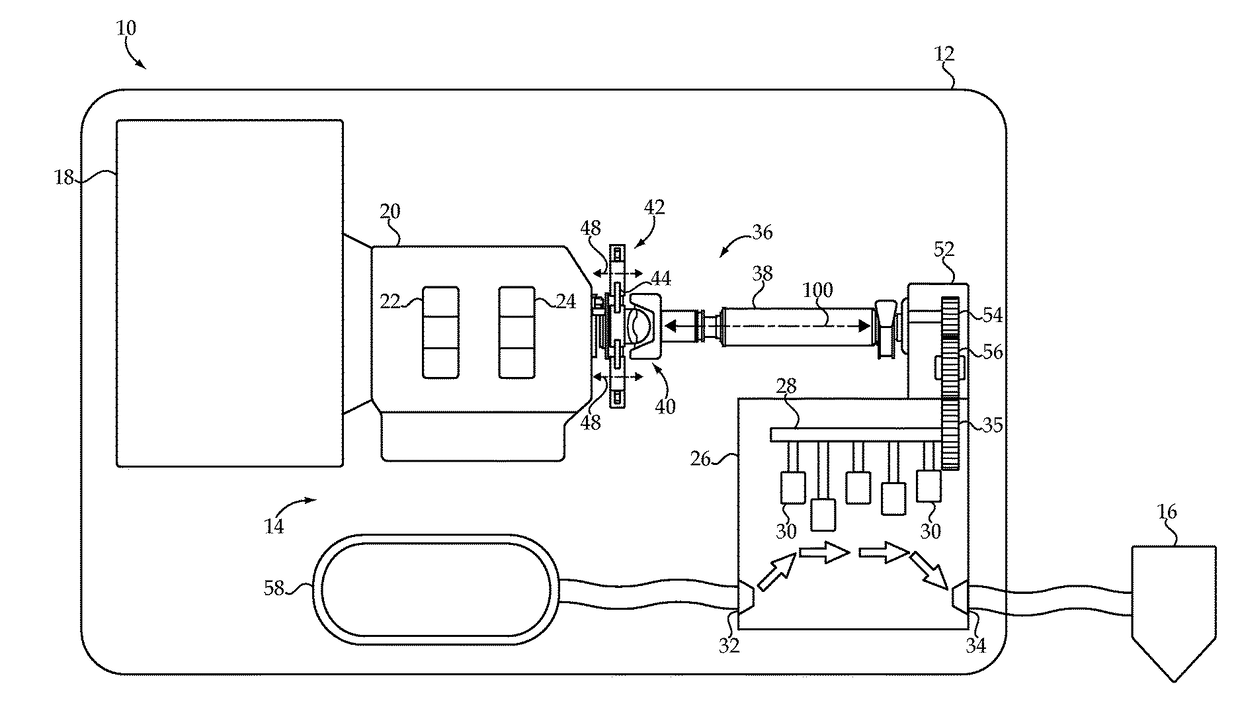

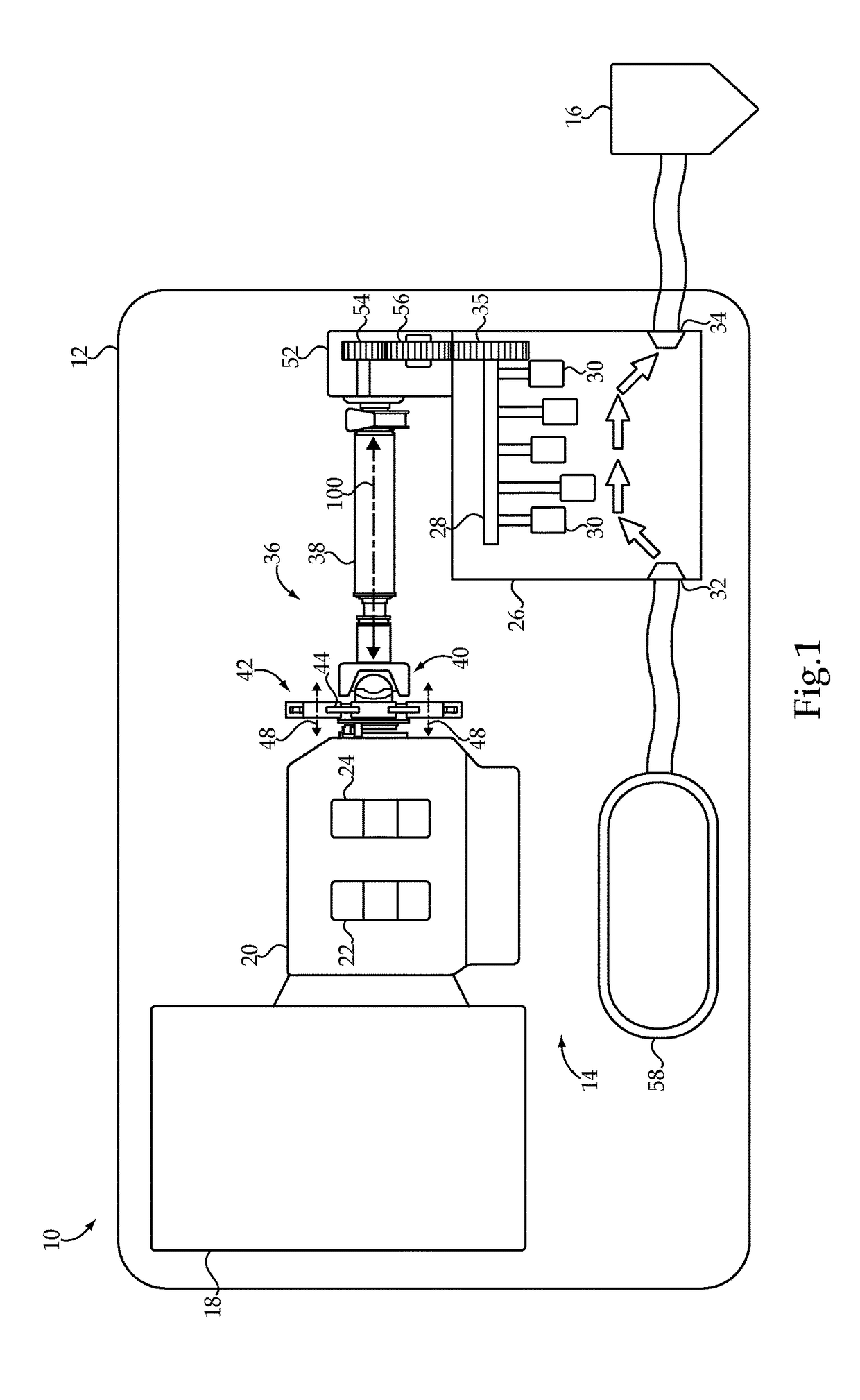

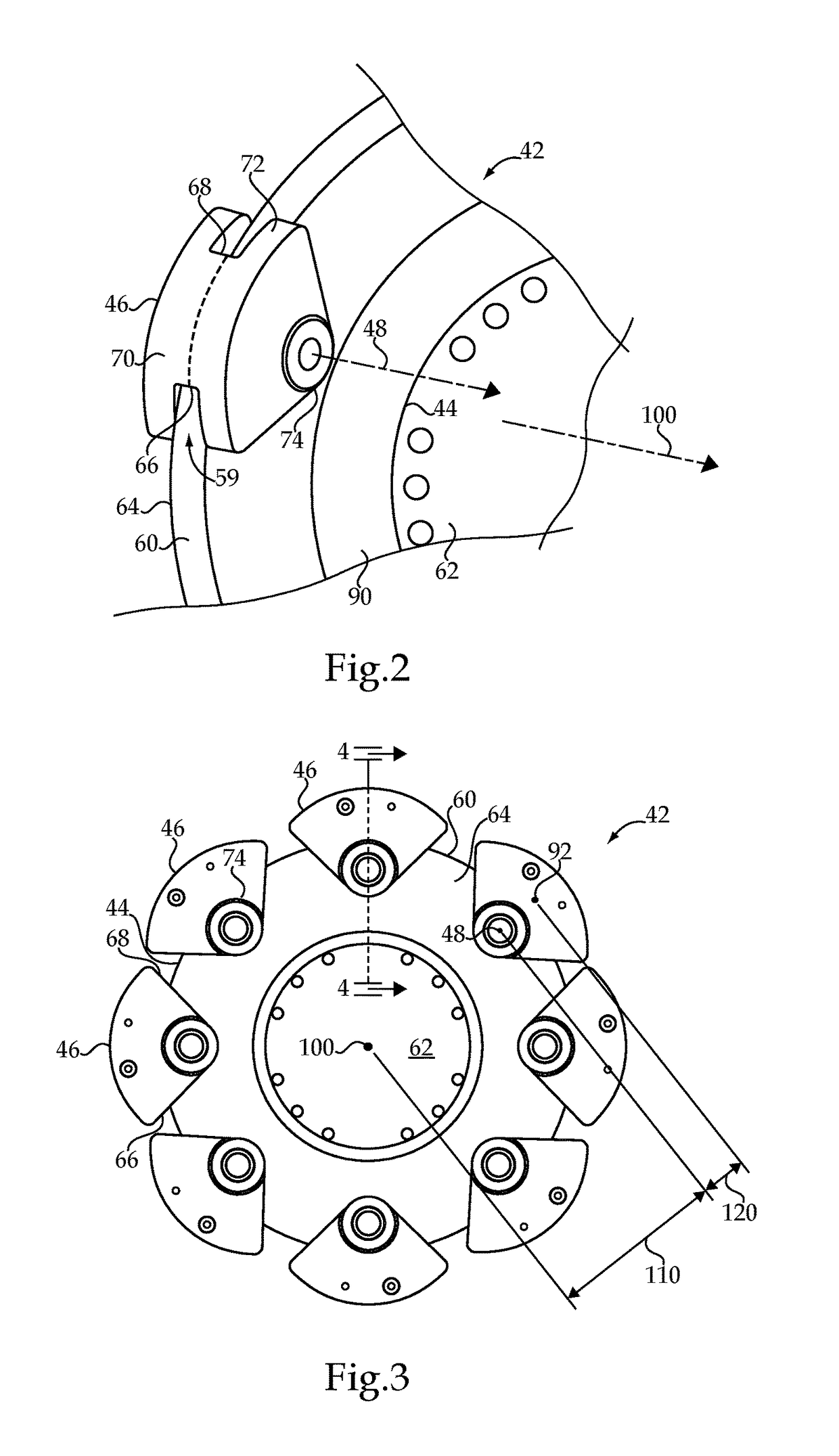

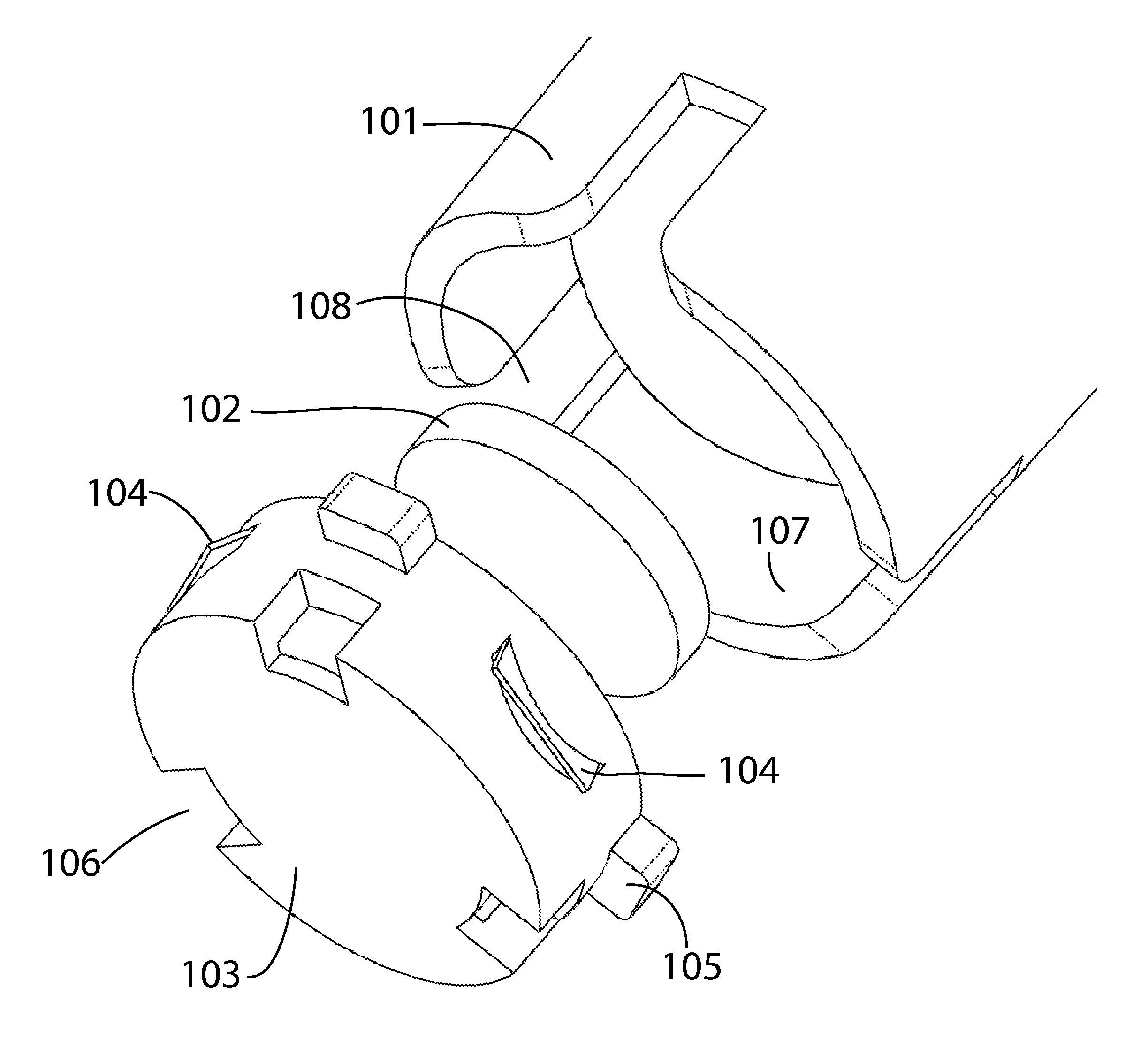

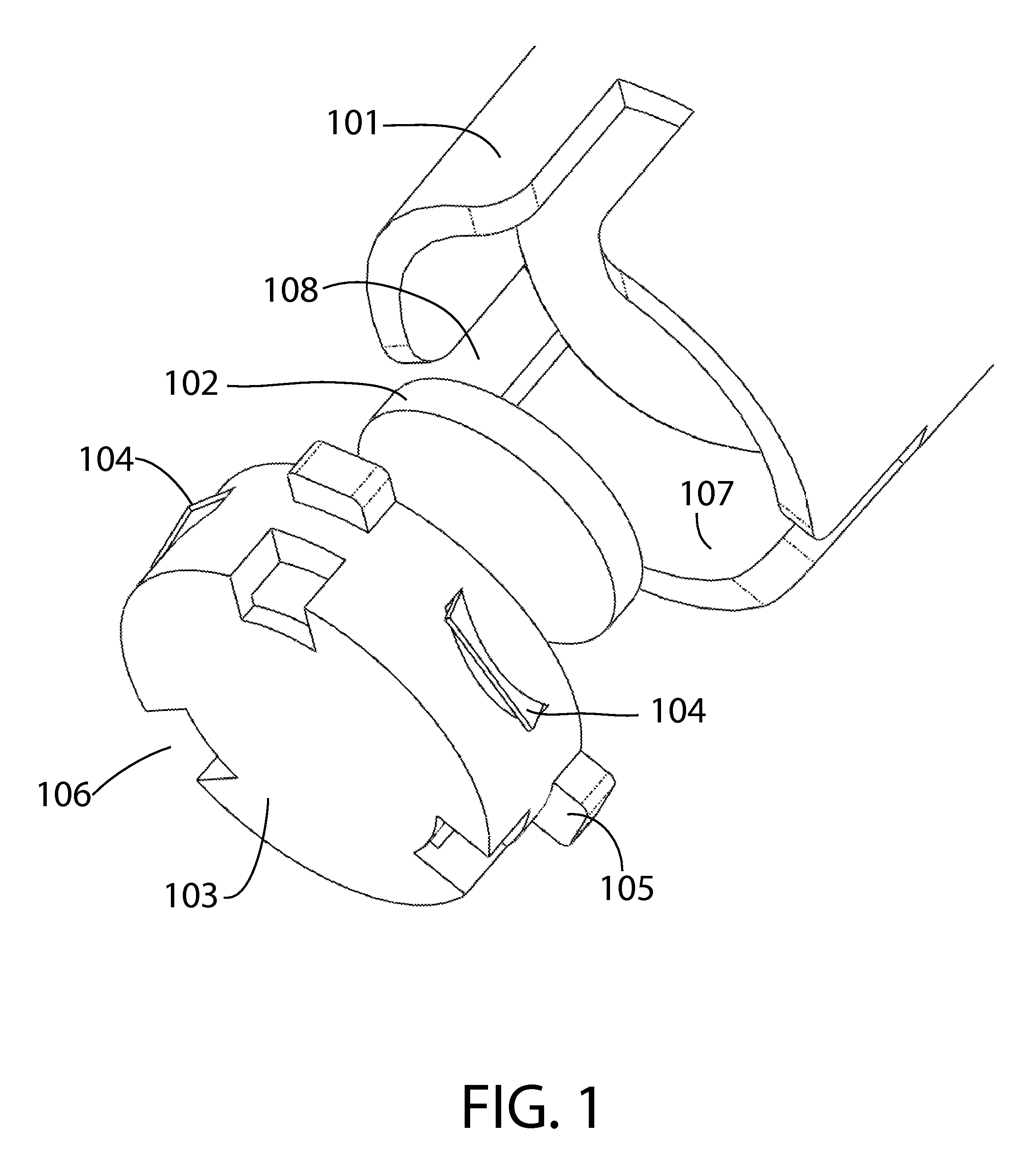

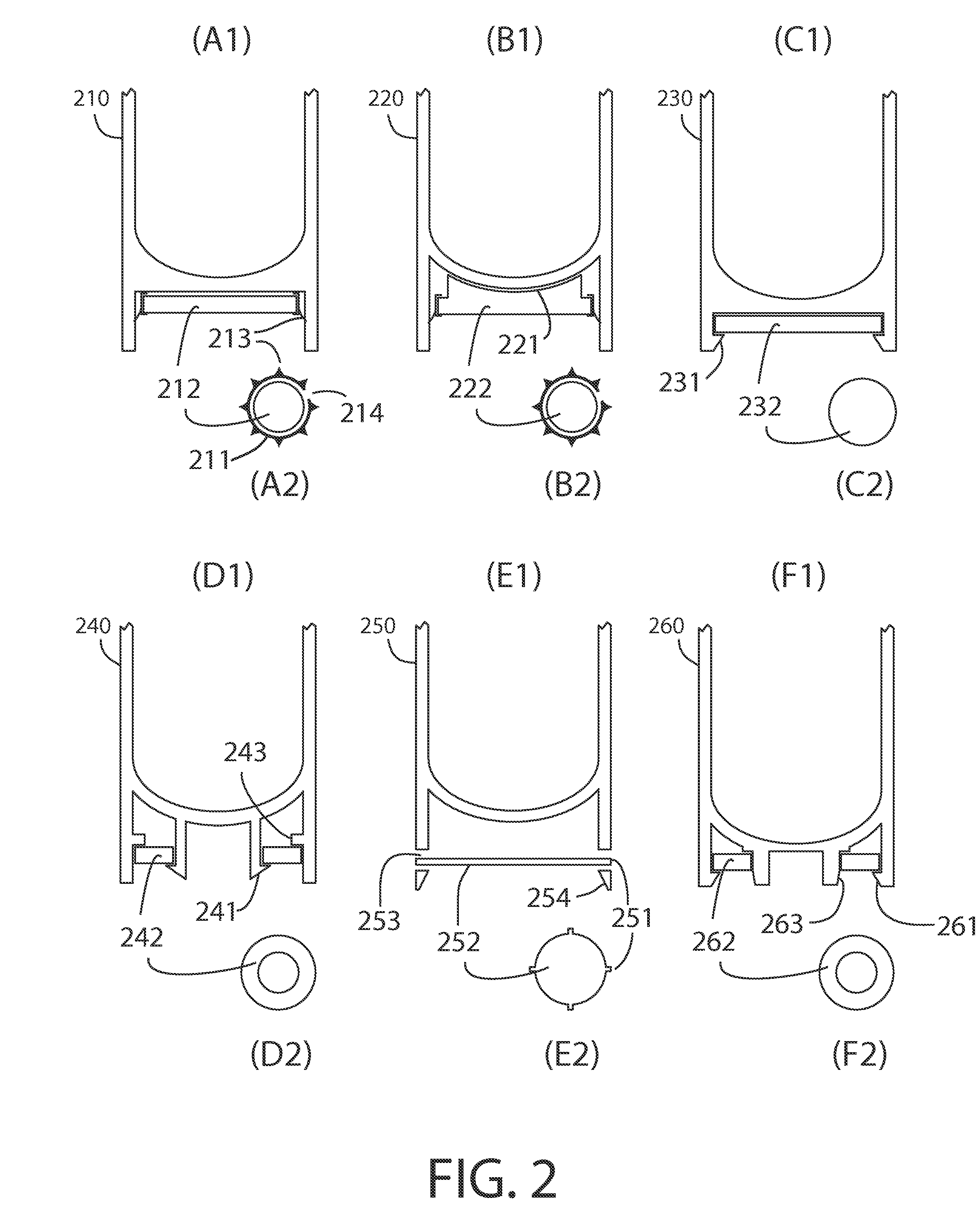

Pumping system, vibration limiting device, and method

ActiveUS20170335842A1Positive displacement pump componentsPiston pumpsVibration amplitudeEngineering

A mechanism for limiting vibration amplitudes in a pumping system includes a plurality of pendulum absorbers coupled with a carrier and each having a pivoting range. The pendulum absorbers each further include a first and a second contact surface that contacts an outer peripheral surface of the carrier at limit stop positions, and each having a shape that is conforming with a shape of the outer peripheral surface. The pumping system may be used for pumping liquid nitrogen.

Owner:CATERPILLAR INC

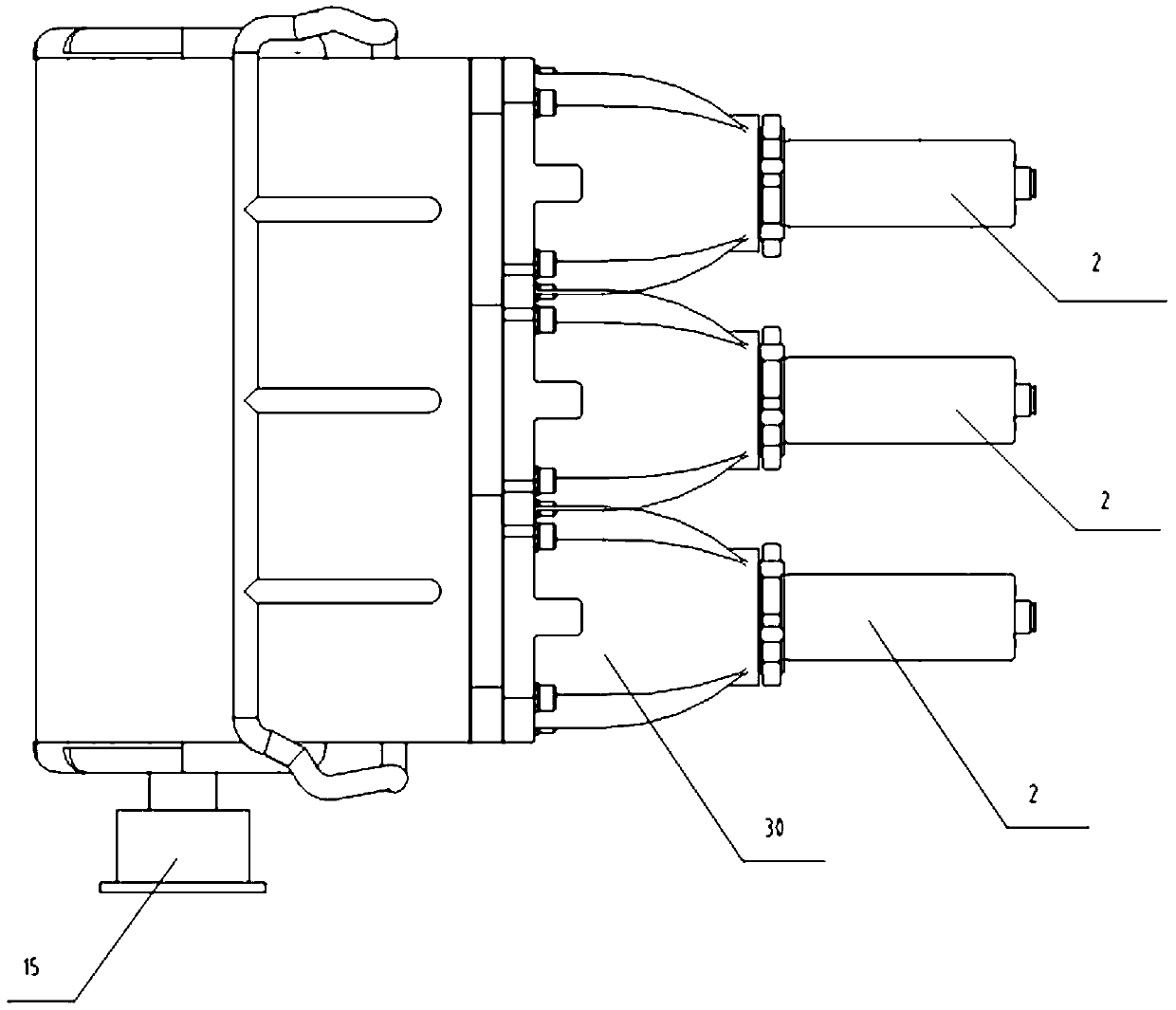

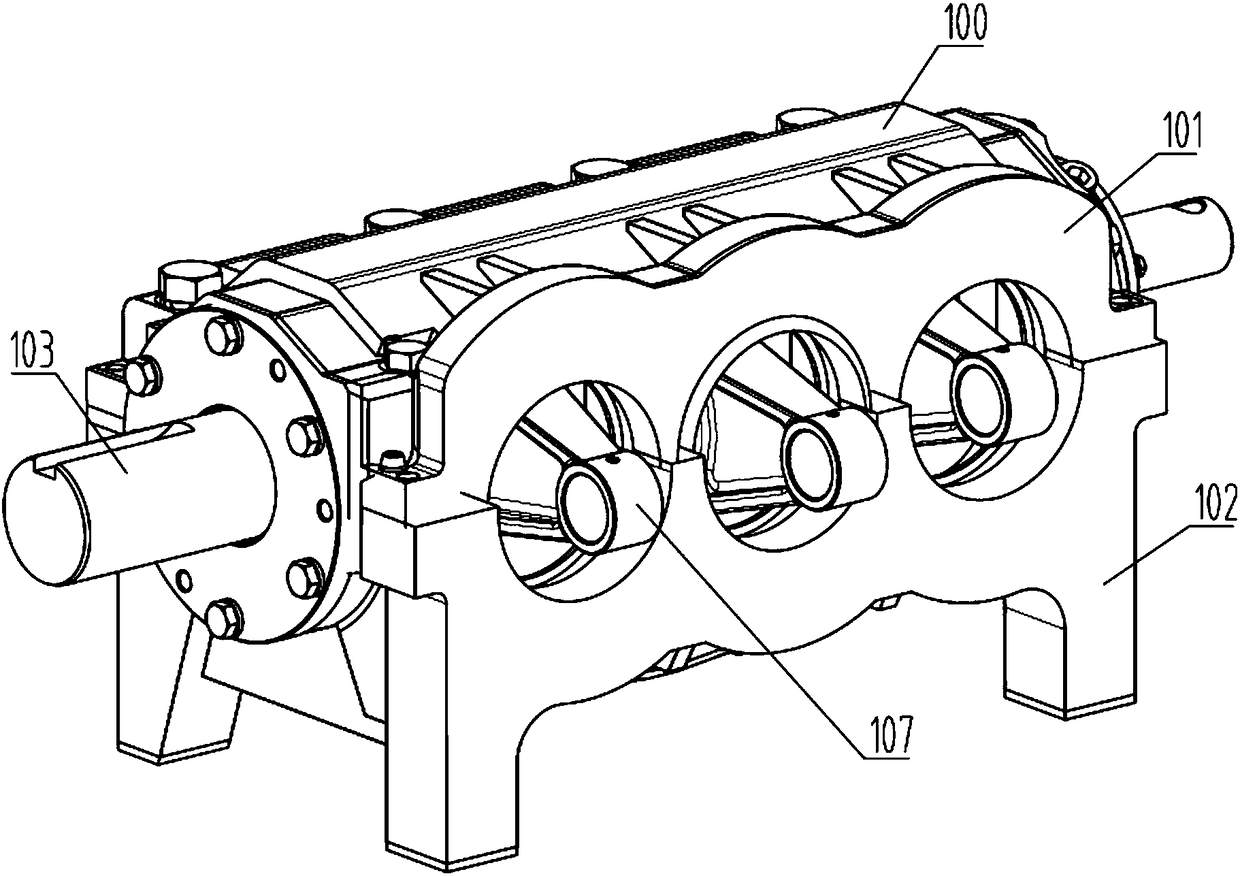

Liquid nitrogen pump power end assembly

PendingCN108547766ACompact structureEasy to processPositive displacement pump componentsPumpsTransmitted powerJackscrew

The invention provides a liquid nitrogen pump power end assembly. The liquid nitrogen pump power end assembly comprises a crankshaft box assembly. The crankshaft box assembly is correspondingly connected with crosshead shell assemblies. Lubricating systems are correspondingly arranged between the crankshaft box assembly and the crosshead shell assemblies. The liquid nitrogen pump power end assembly adopts split type module combination of the crankshaft box assembly and the crosshead shell assemblies to be assembled, a crankshaft box is designed into a welding type, crosshead shells are designed into a casting type, compared with inblock casting or overall welding, the structure is simple and compact, existing machining manners are considered, machining, manufacturing, assembling, repairingand maintaining are facilitated, crossheads are provided with threads for connection and can be connected with fluid ends with different specifications on the market to play a role in transmitting power, a crankshaft adopts a split type structure that a straight shaft and multiple eccentric wheels are connected through flat keys, the crankshaft overall machining difficulty is lowered, crosshead hinge pins are provided with jackscrew holes, by means of jackscrew fixing, axial floating of hinge pins can be eliminated, the lubricating system can protect movement members, and the service life ofeach movement member is prolonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

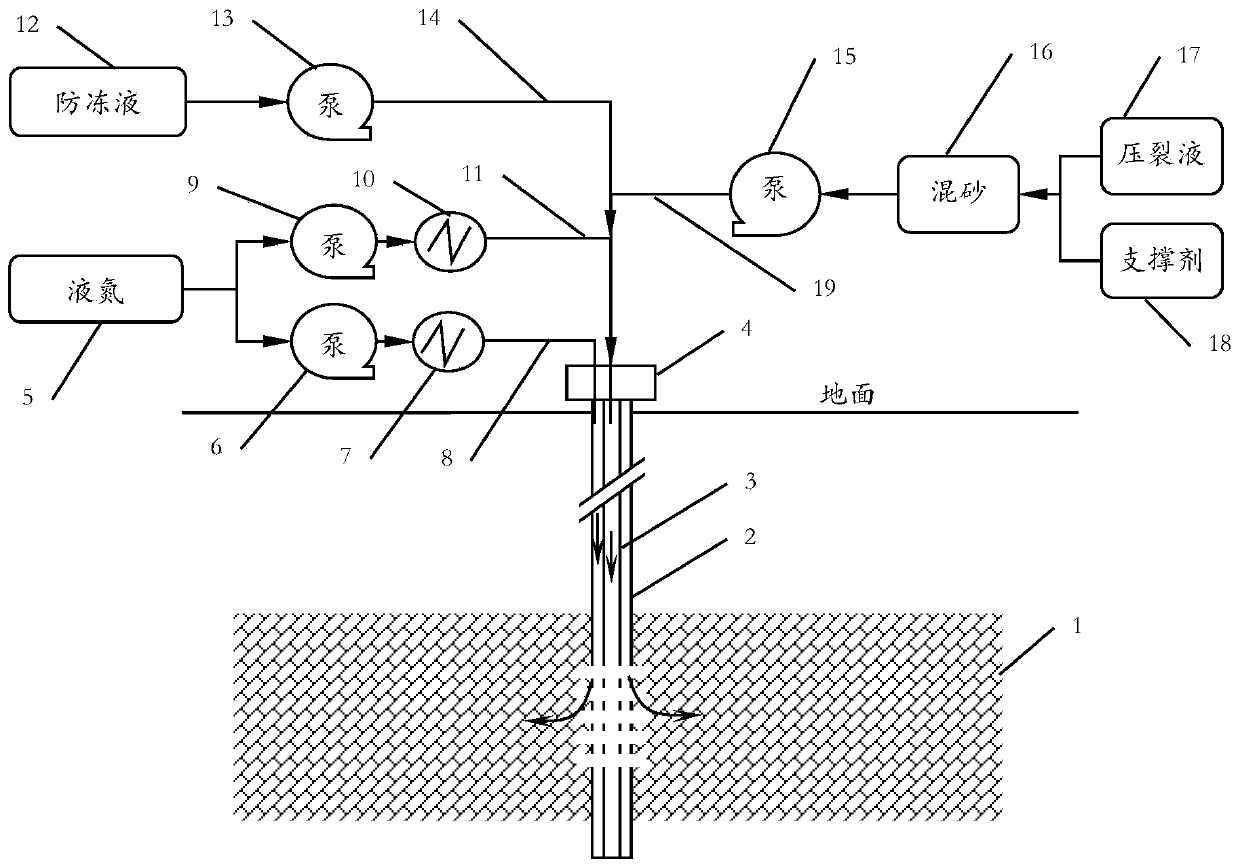

Method of low-temperature gas-assisted coalbed methane fracturing technology

InactiveCN103726819AImproved crack systemImprove mechanical propertiesInsulationFluid removalOil and natural gasIce formation

The invention relates to the field of oil and natural gas prospecting and exploitation, and provides a method of low-temperature gas-assisted coalbed methane fracturing technology. According to the method, by the aid of ultralow temperature characteristics of liquid nitrogen, cold shock transformation and ice formation are performed on a coalbed, ice blockage is caused to high-permeability channels (such as fractures), and effect of inorganic harmless dissoluble flowback fluid loss additives, even fracturing diverters and the like is achieved, so that the purpose of improving conventional coalbed methane fracturing technology is achieved. The method of the fracturing technology is suitable for primary fracturing of coalbed methane wells non-fractured or with natural fractures existing at the well bottoms, as well as refracturing of coalbed methane wells already fractured but low in productivity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

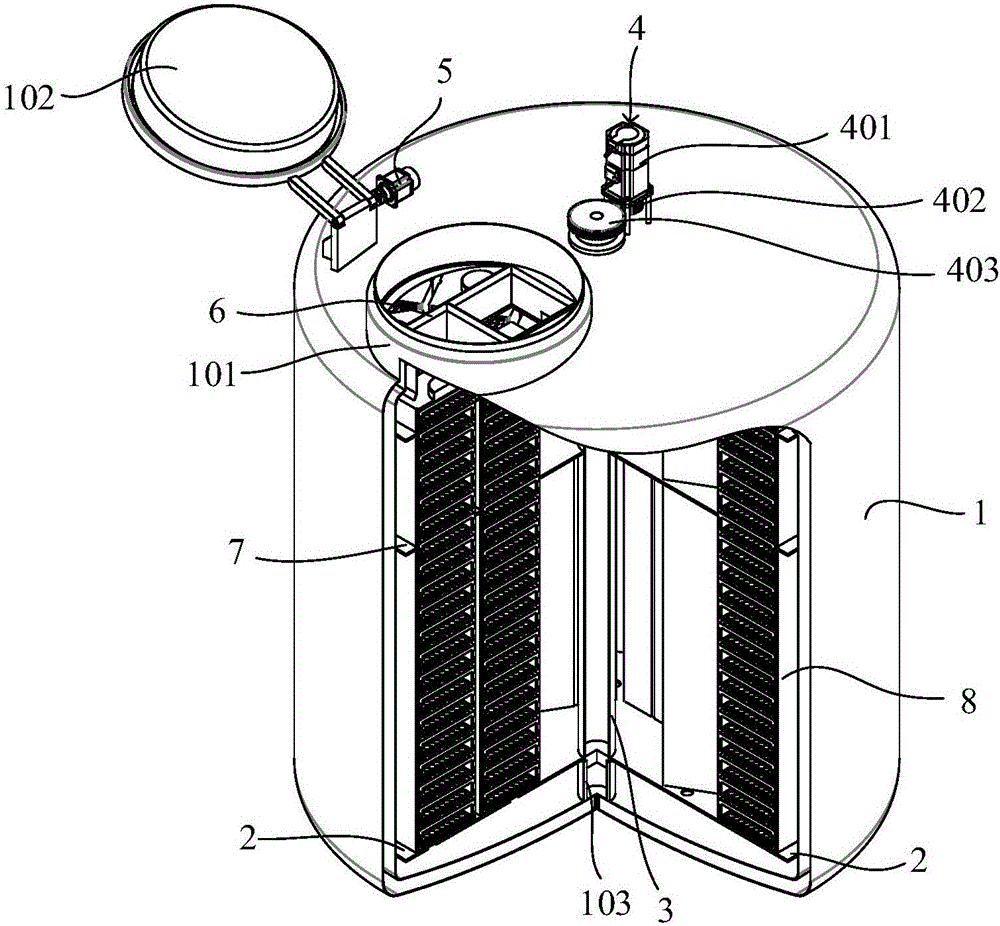

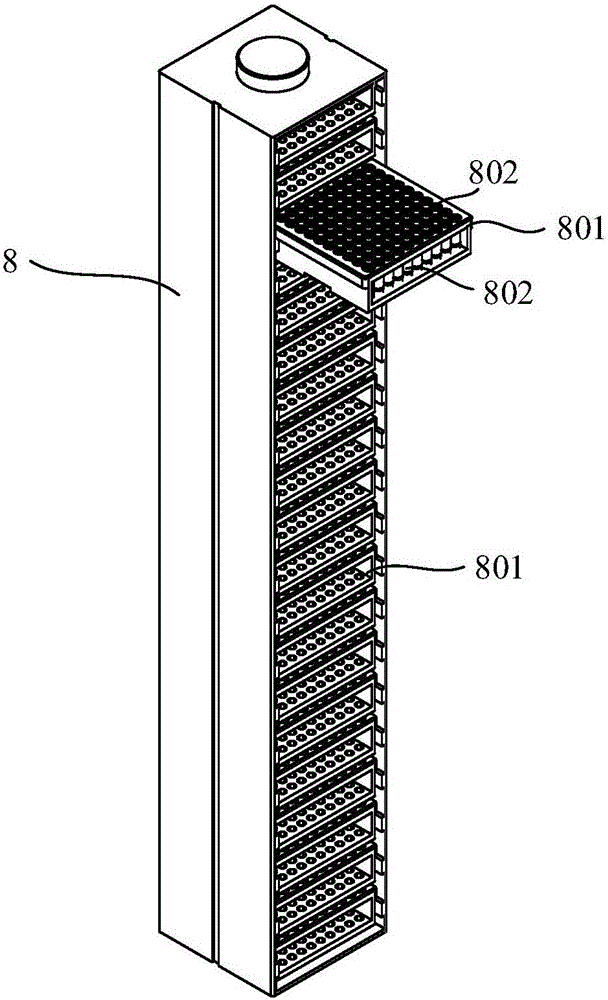

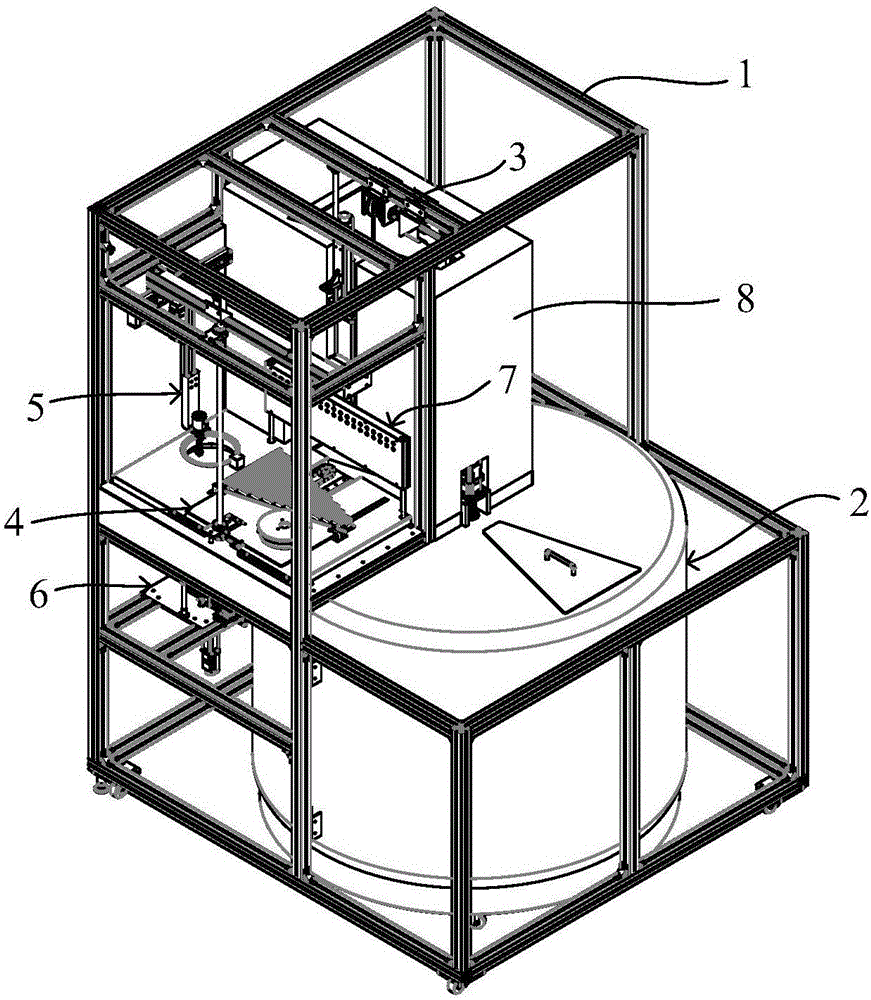

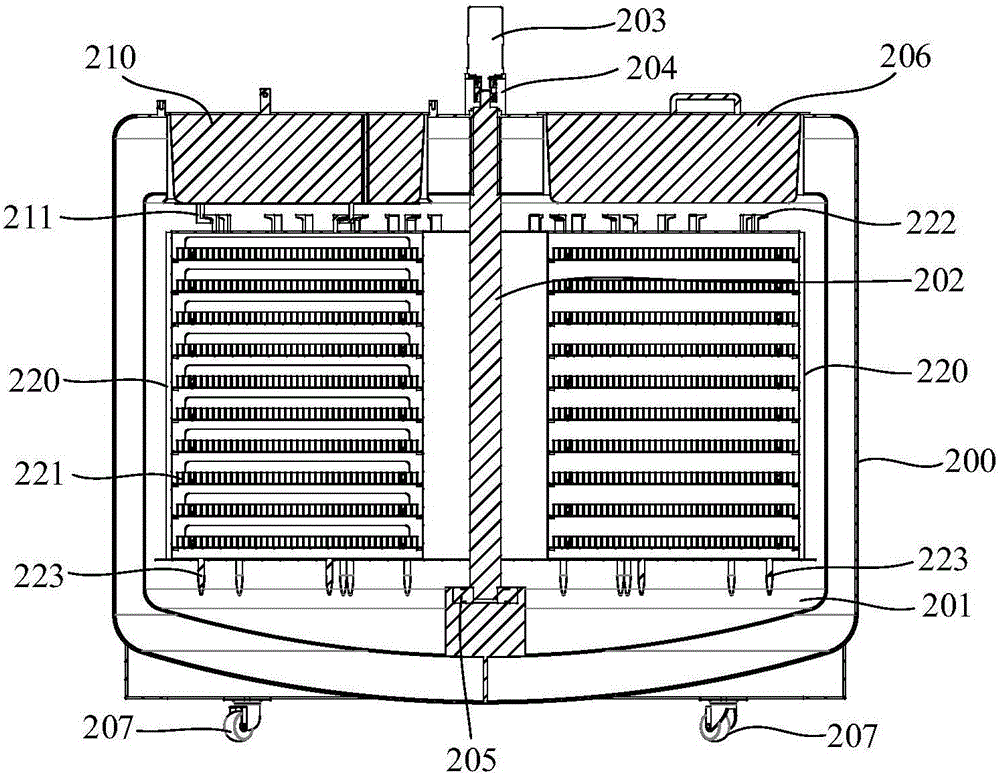

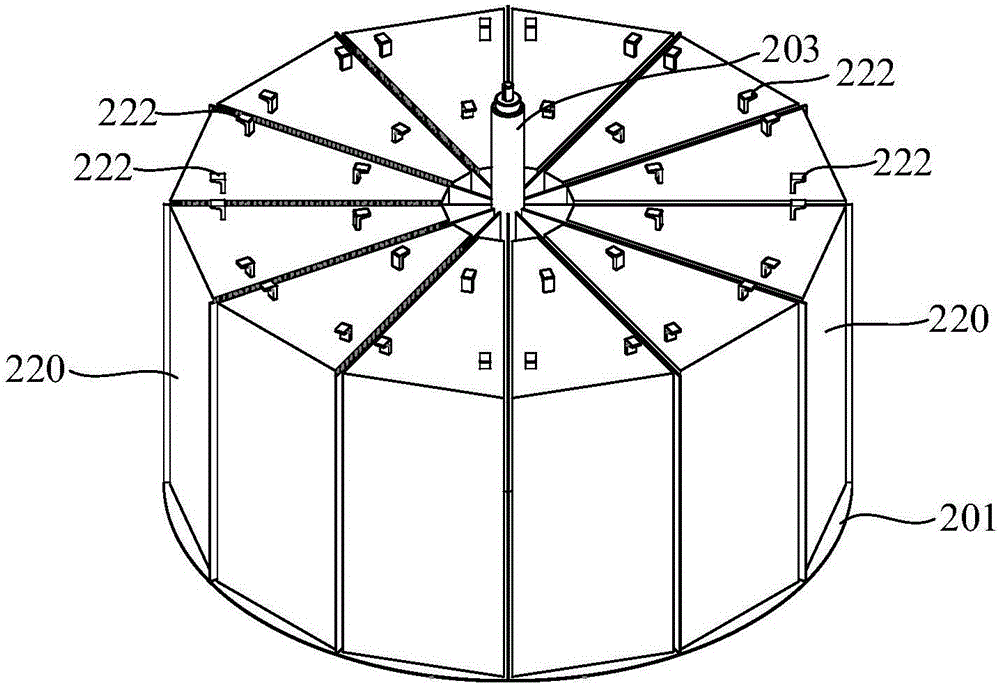

Liquid nitrogen cylinder, cryogenic vial storing and fetching device and liquid nitrogen cylinder storing and fetching system

ActiveCN105857937AReduce error rateAvoid safety hazardsLarge containersControl devices for conveyorsEngineeringLiquid nitrogen

The invention discloses a liquid nitrogen cylinder, a cryogenic vial storing and fetching device and a liquid nitrogen cylinder storing and fetching system. The liquid nitrogen cylinder comprises a cylinder body, wherein the cylinder body is provided with a sealed opening; the liquid nitrogen cylinder further comprises a bracket tray; the bracket tray is arranged in the cylinder body; the bracket tray is used for bearing cryogenic baskets; a central shaft is vertical to the bracket tray and is fixedly connected with the bracket tray; a driving component is electrically connected with the central shaft; the driving component is used for driving the central shaft to rotate; and the central shaft is used for driving the cryogenic baskets to rotate through the bracket tray and conveying the cryogenic baskets to the opening. By adopting the liquid nitrogen cylinder, the error rate of manual cryogenic vial selecting is reduced; and meanwhile, safety hazards for operation personnel during a manual bracket tray rotation process are avoided. By adopting the cryogenic vial storing and fetching device, the process for selecting a single target cryogenic vial for biological samples is realized; and during the whole selecting process, the cryogenic vials are all in a liquid nitrogen environment, so that non-target cryogenic vials are prevented from being exposed at environment temperature. The liquid nitrogen cylinder storing and fetching system is applicable to vial picking work for large biological sample banks.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

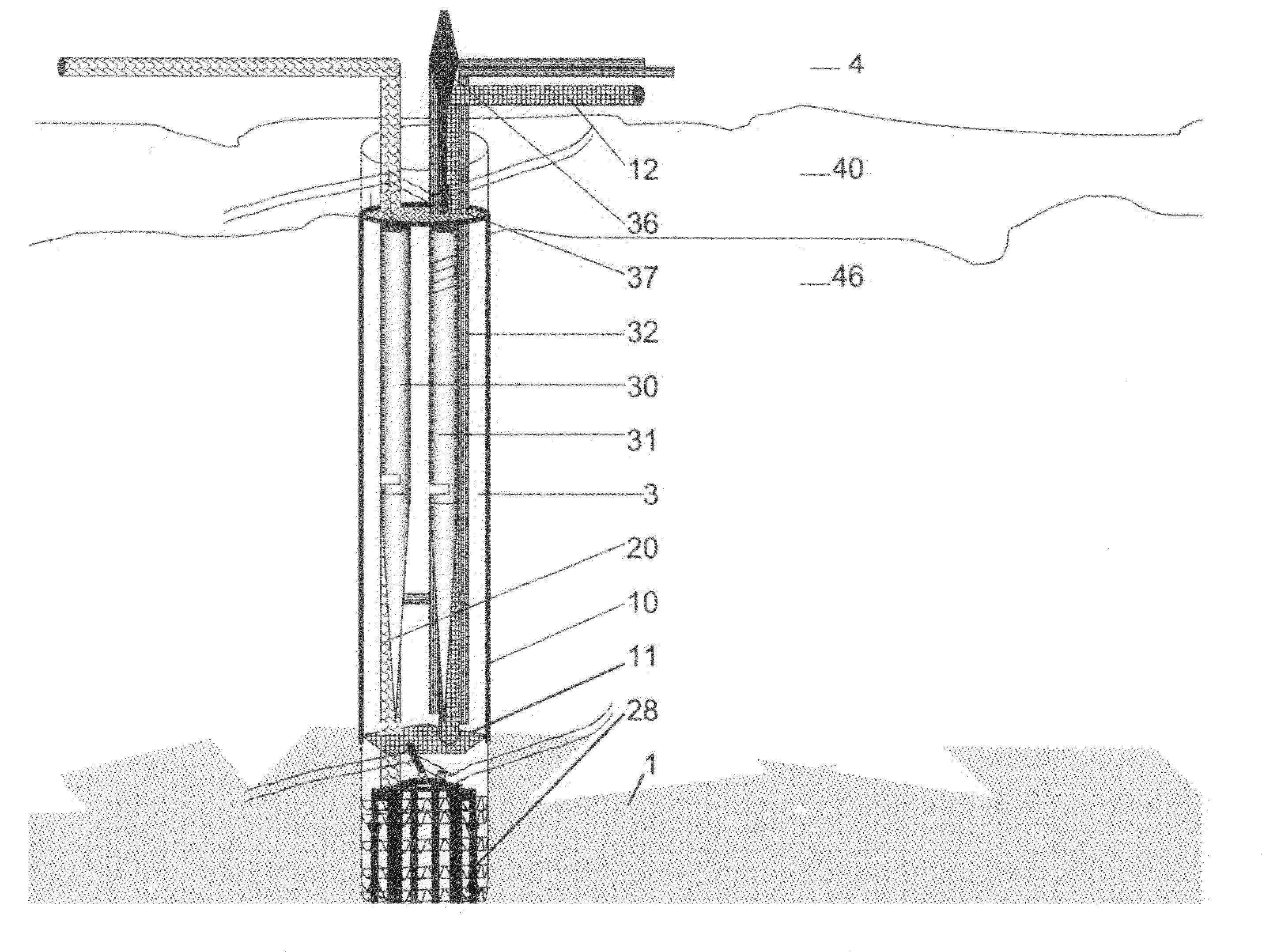

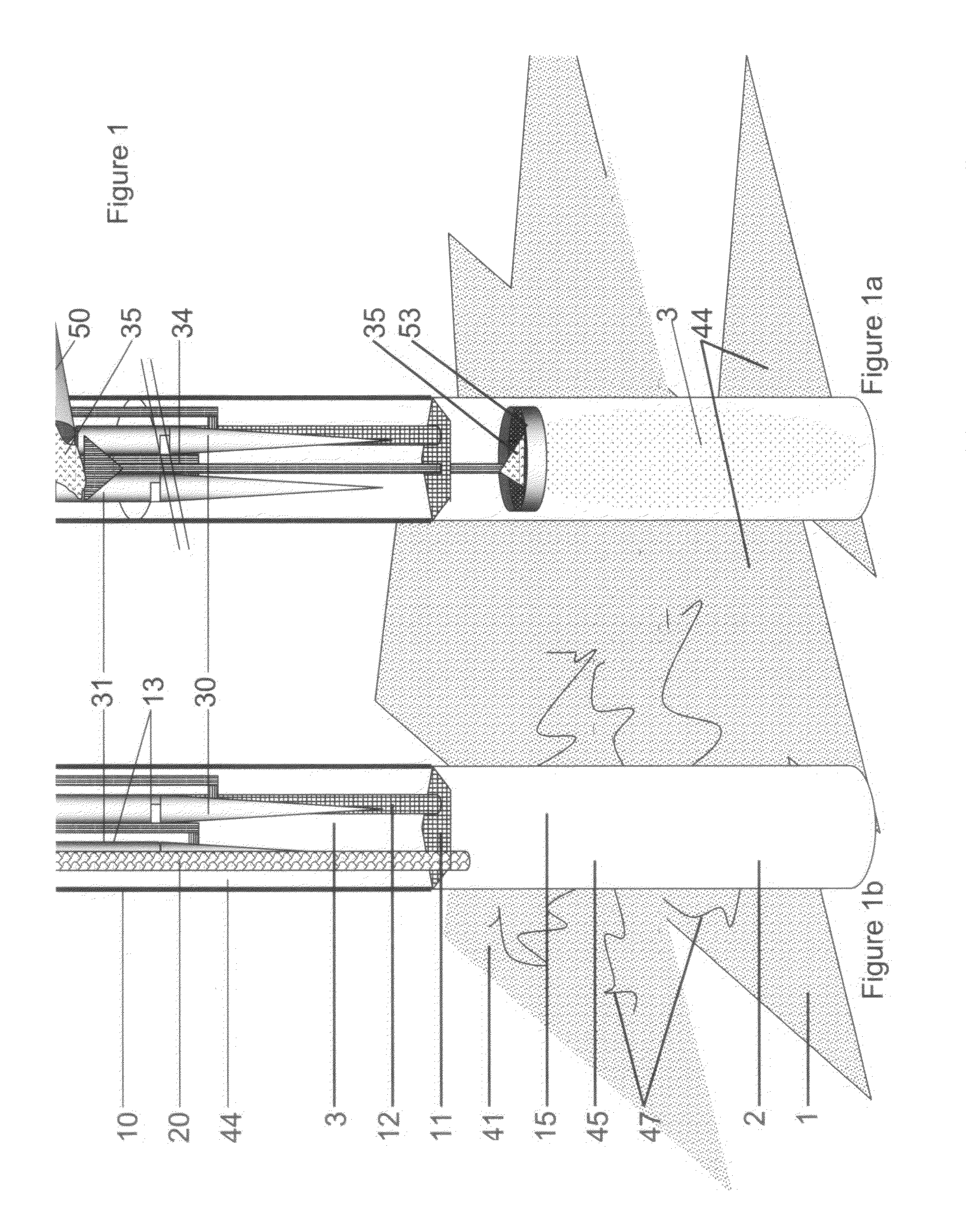

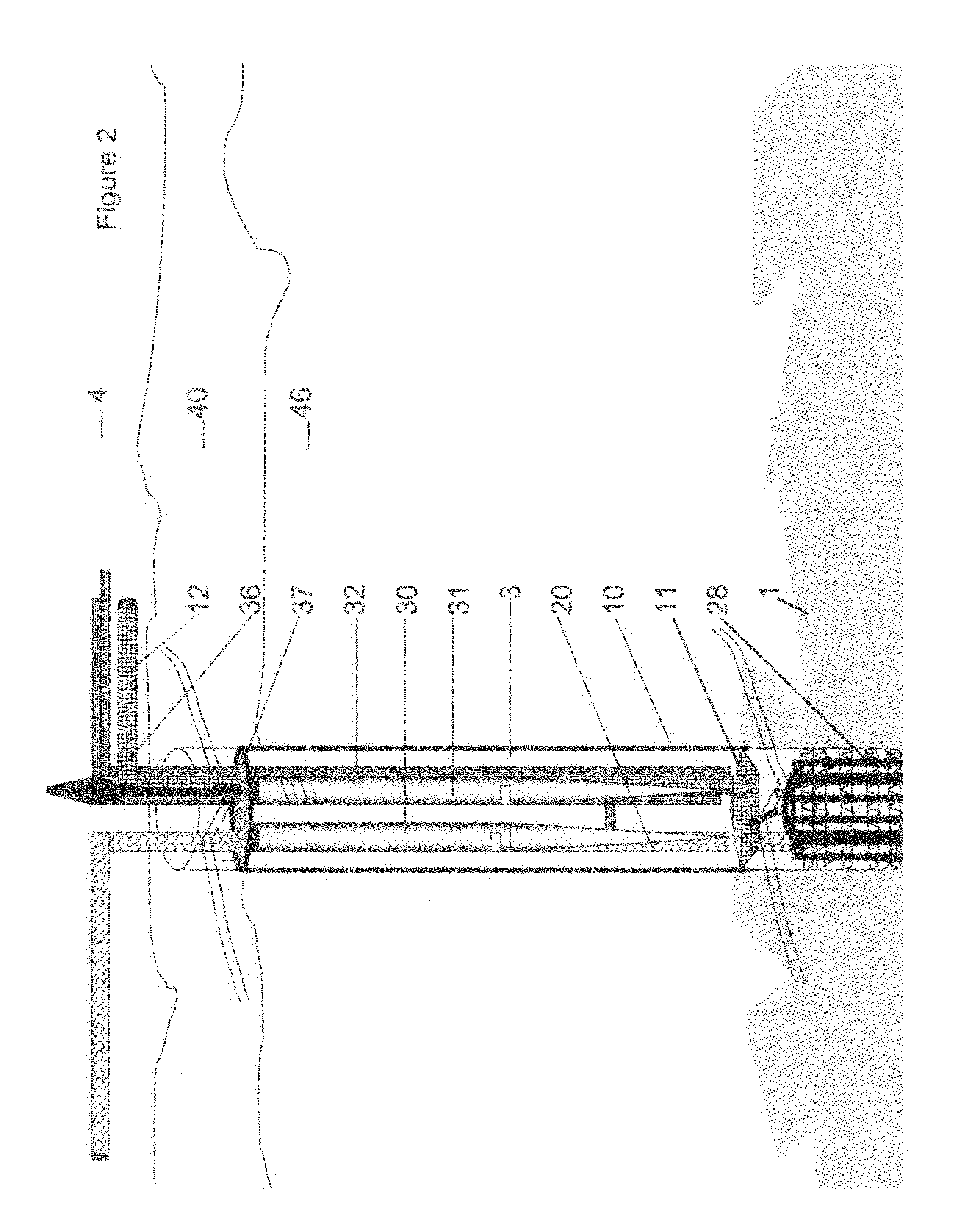

Harvesting hydrocarbons and water from methane hydrate deposits and shale seams

InactiveUS20100006281A1Low extraction temperatureLess waterConstructionsMultiple-effect/fractional condensationNoble gasKerosene

A method of extraction of fuels, organic pollutants, and elements from Methane hydrate deposits, shale seams and the soil is described which freezes the zone and heats the center carrying the fuel, chemicals and water in these deposits and seams from where they are found, be it deep in the sea or on land, and carries them into the condensing unit in inert Nitrogen gas. Required drilling on the surface or sea bottom includes a main shaft and with auxiliary narrow drillings widely spaced from the shaft. The extraction zone, which is first cooled to brittle cold using the evaporation of Liquid Nitrogen and fractured with vibrations, is heated to the highest temperature of the hydrocarbon fraction desired to be extracted. The evaporating hydrocarbons are extracted in a Nitrogen gas carrier, a recognized fire suppressant (NFPA Code 2000). To speed the extraction rate, tonal input from two or more sounding units vibrates the seam structure freeing the evaporated hydrocarbons allowing more rapid escape into the shaft. To prevent air loss in aquifers, ice barriers seal the zone periphery. These hydrocarbons are separated into the hydrocarbons fractions, into fuel fractions as heating oil, kerosene, gasoline, ethers, and fuel gas including methane, Argon / Oxygen and rare gas segments, or, if pollutants, into the separate chemicals by boiling point. The thermal gradient of the extraction pipe is implemented by sourcing the Nitrogen from Liquid Nitrogen and bundling those pipes with the extraction pipe condensing its contents by hydrocarbon fractions into vessels and gas drums depending on boiling points of fractions. Water is separated from the gasoline segment and purified first by separation and then by freezing. The extraction of deep deposits layer the extraction zones as well as work neighboring extraction zones covering many acres. Fuel gases can be liquefied or burned in an on-site electric generating plant.

Owner:AIR WARS DEFENSE

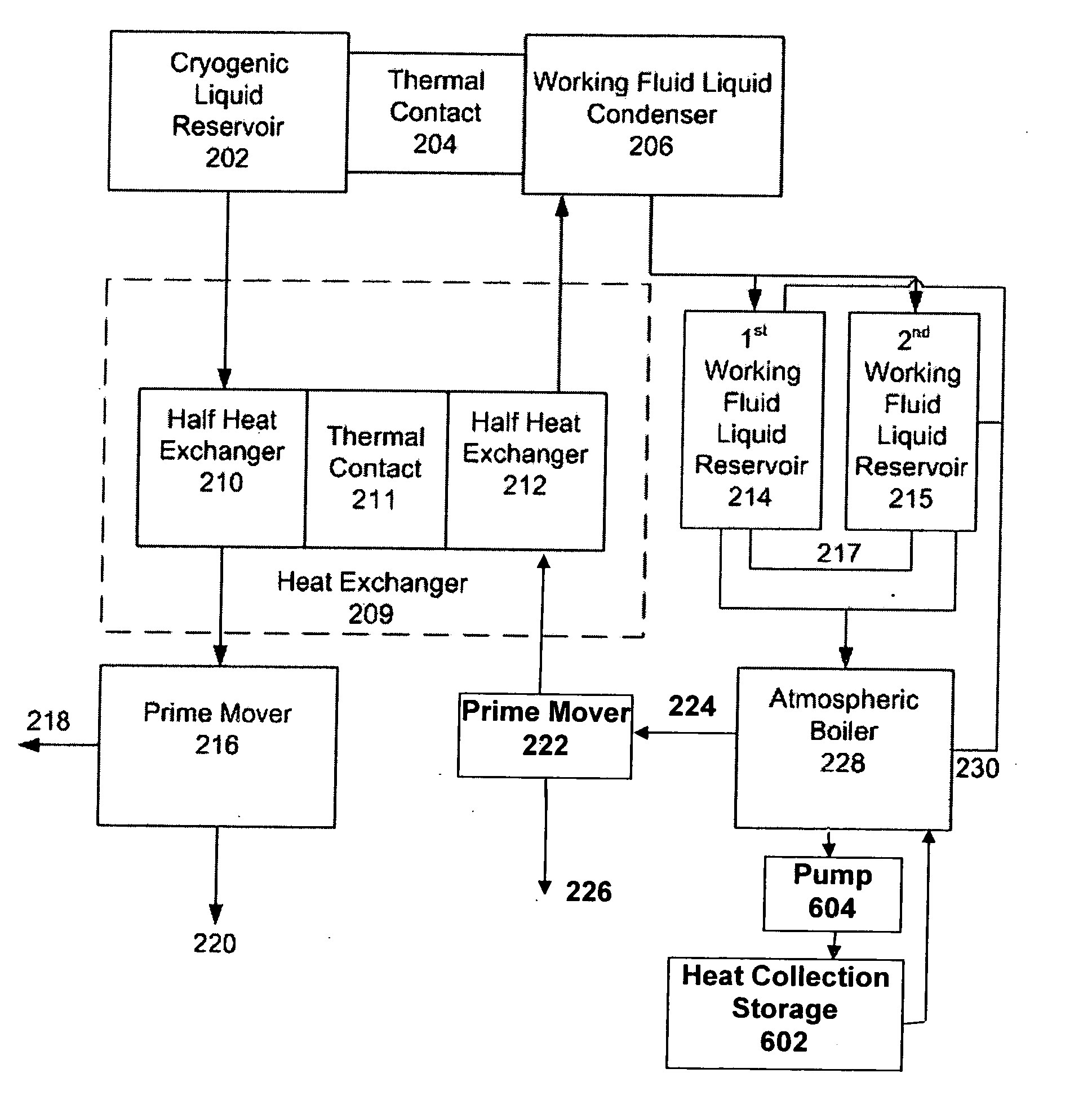

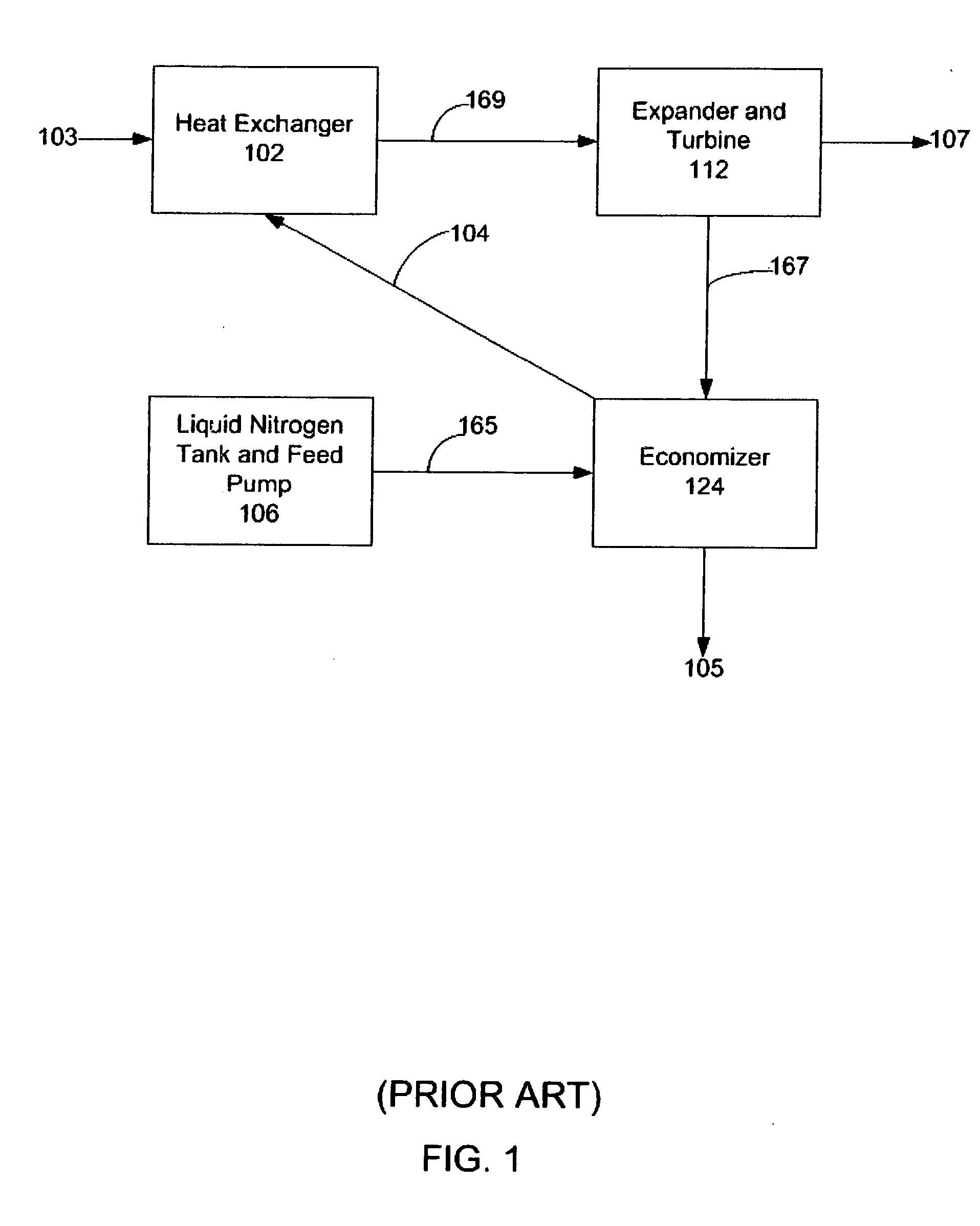

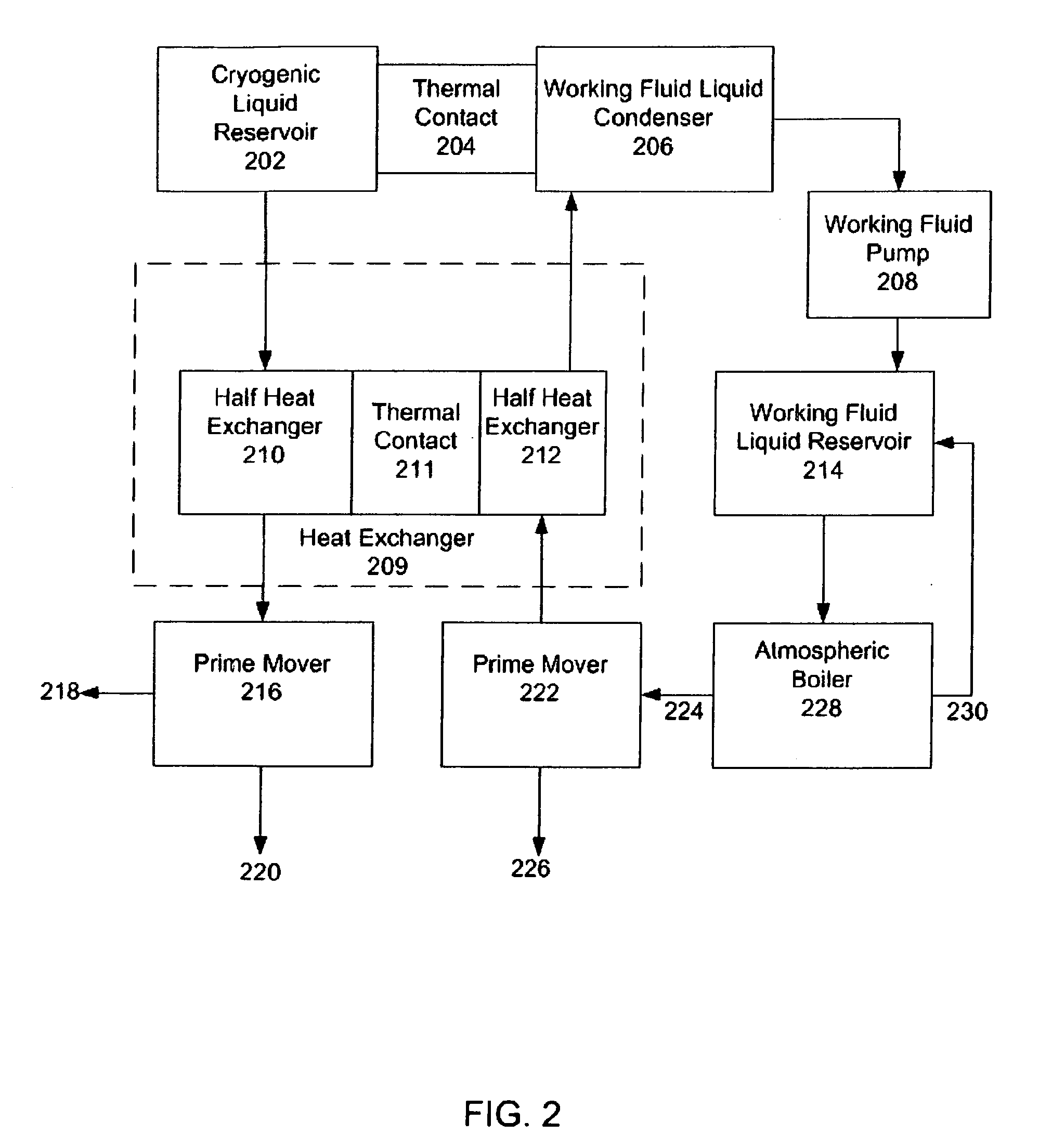

Dual thermodynamic cycle cryogenically fueled systems

Systems and methods for converting thermal energy, such as solar energy, from a localized thermal energy source to another form of energy or work comprise dual thermodynamic cycle systems that utilize the liquid-to-gas phase transitions of a cryogenic fluid such as liquid nitrogen and a working fluid such as sulfur hexafluoride to drive prime movers. Heat transfer between the fluids as they undergo the phase transitions is used to increase the energy in the system and its work output, and improve system efficiency.

Owner:MEV TECH

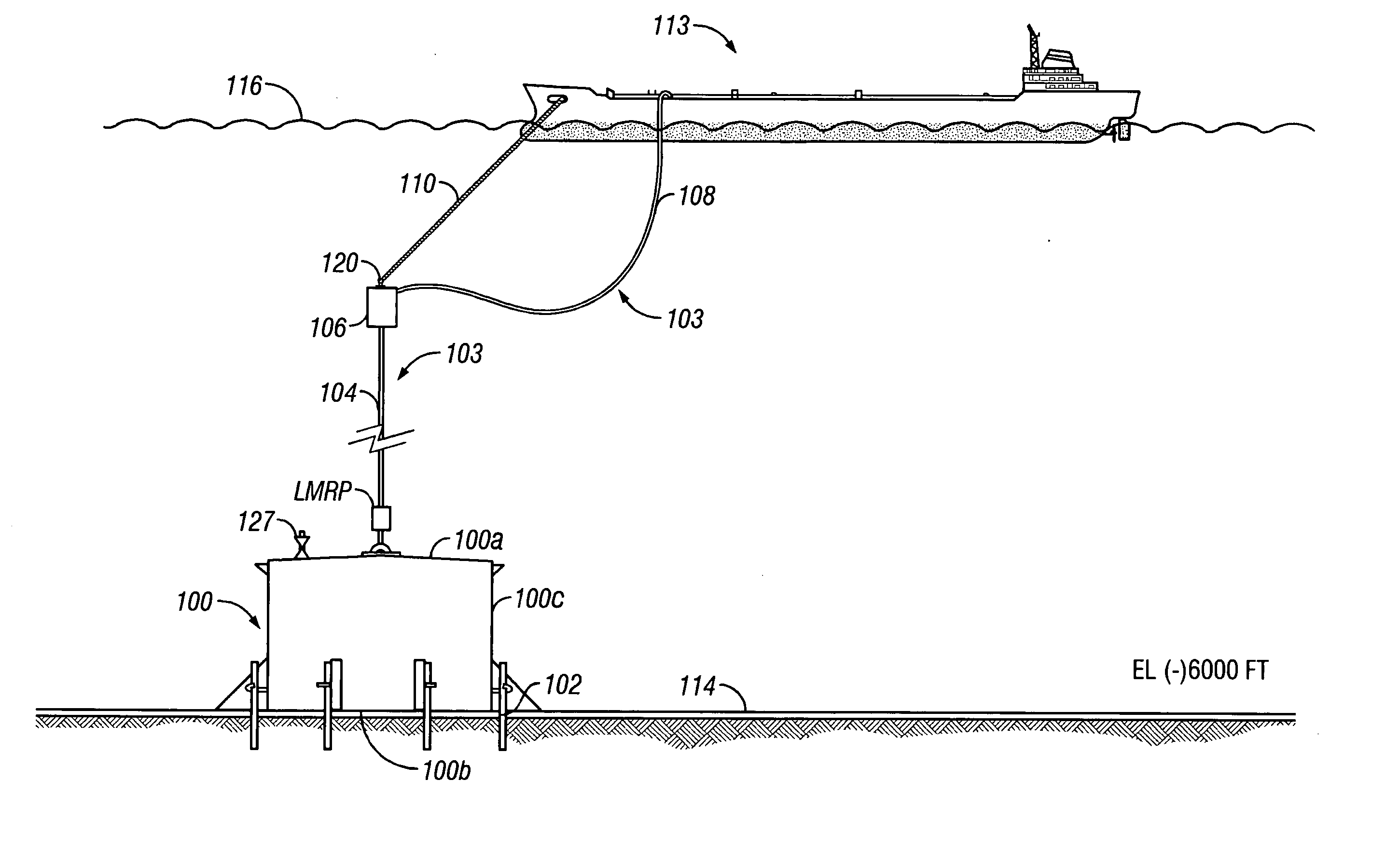

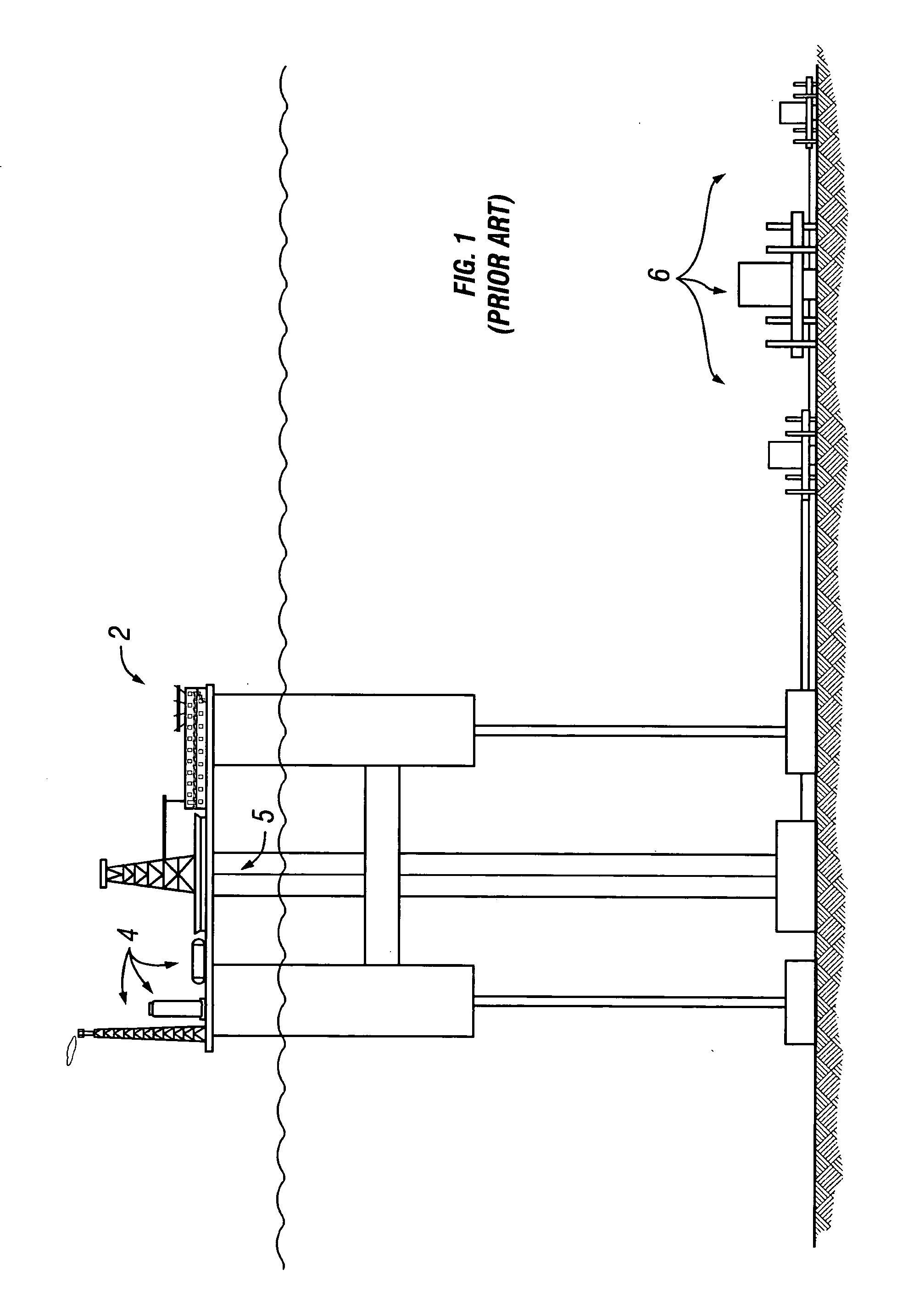

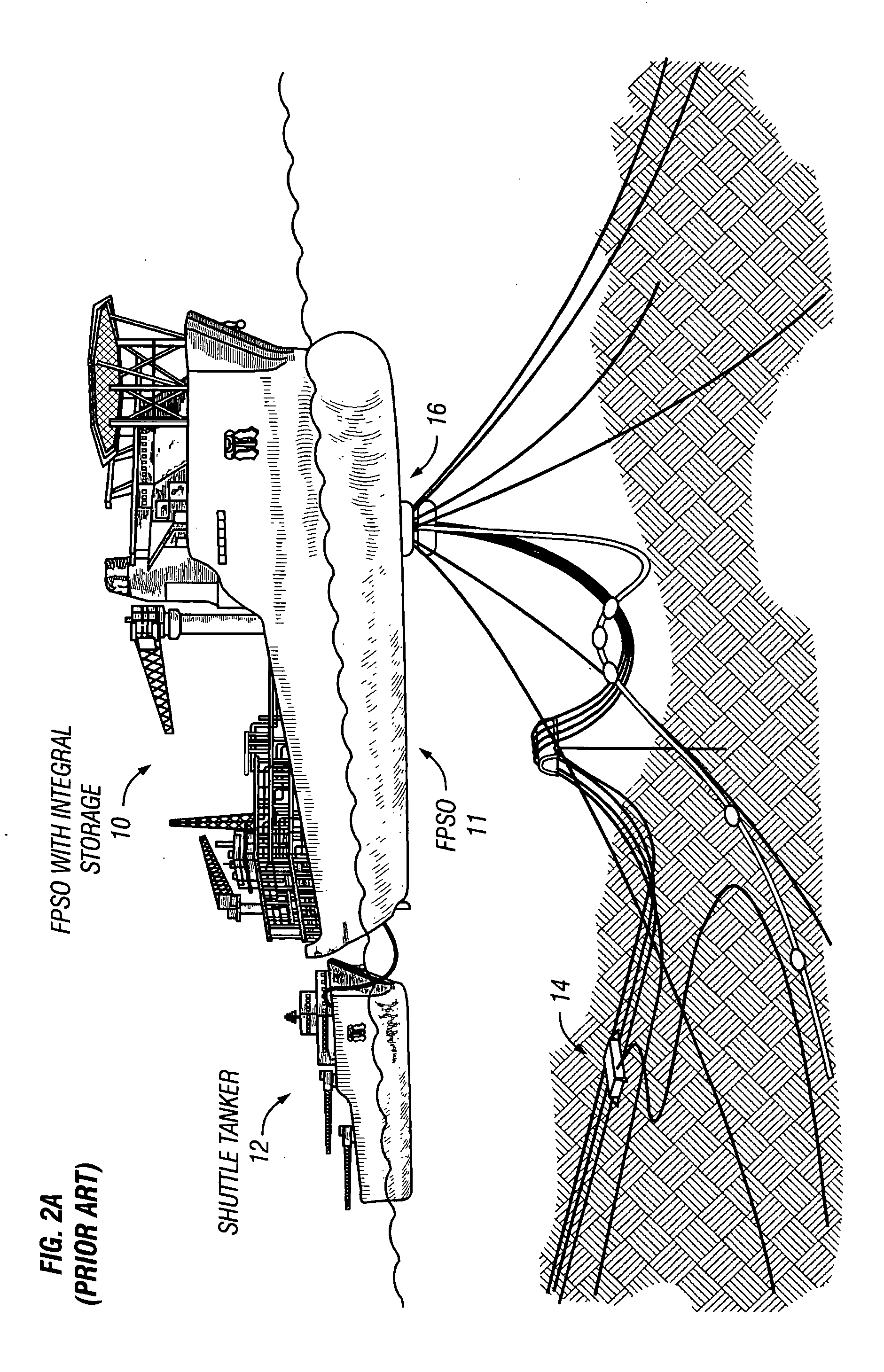

Infrastructure-independent deepwater oil field development concept

A method for developing a sub-sea hydrocarbons field includes sub-sea wells, sub-sea oil / gas separation, storing the degassed oil in a storage tank located or the seabed, liquefying natural gas aboard a vessel using liquid nitrogen aboard the vessel to obtain liquefied natural gas, transporting the liquefied natural gas to an onshore terminal, re-gasifying the liquefied natural gas, and obtaining a new batch of liquid nitrogen using energy recovered from the re-gasifying the liquefied natural gas.

Owner:CONOCOPHILLIPS CO

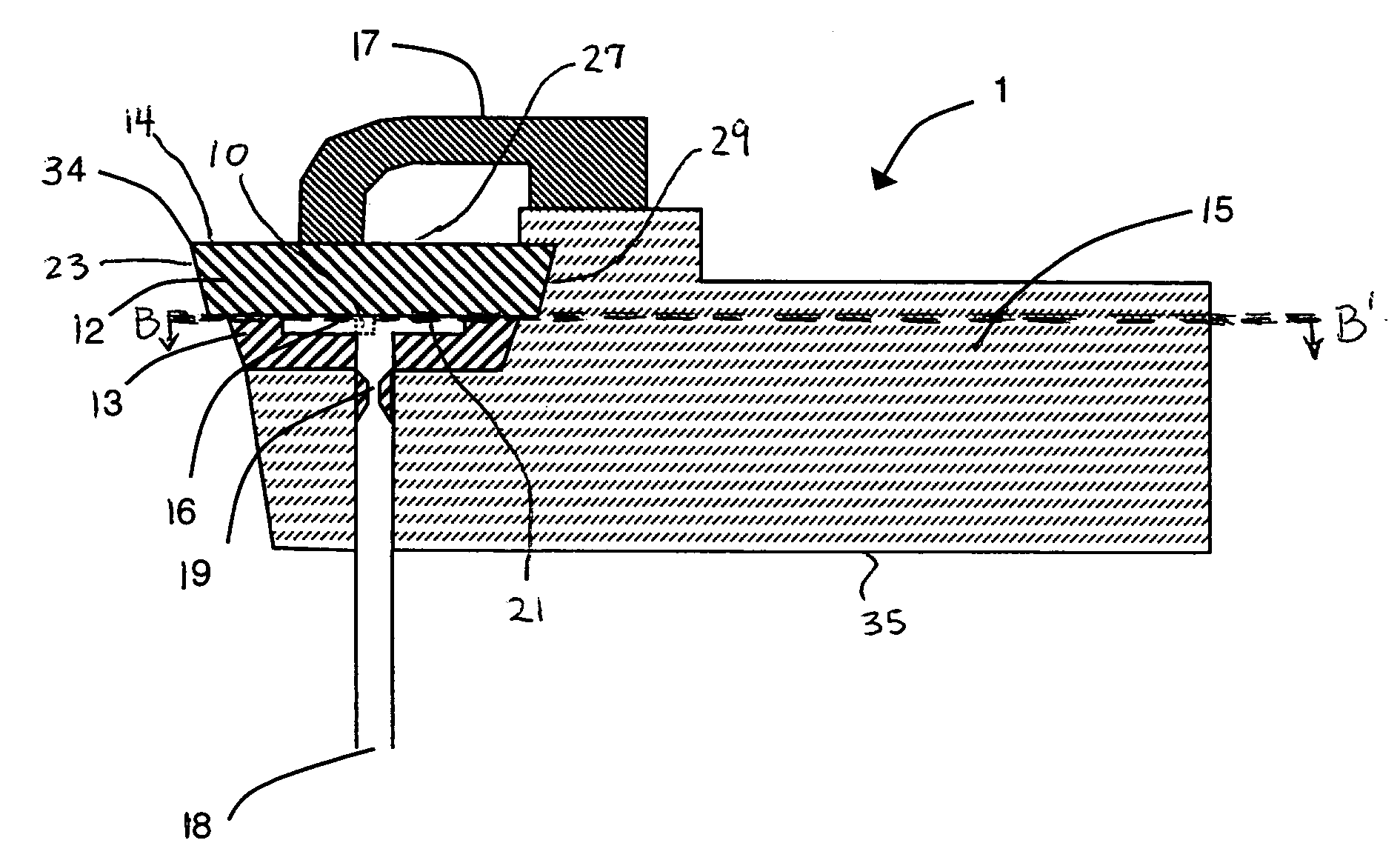

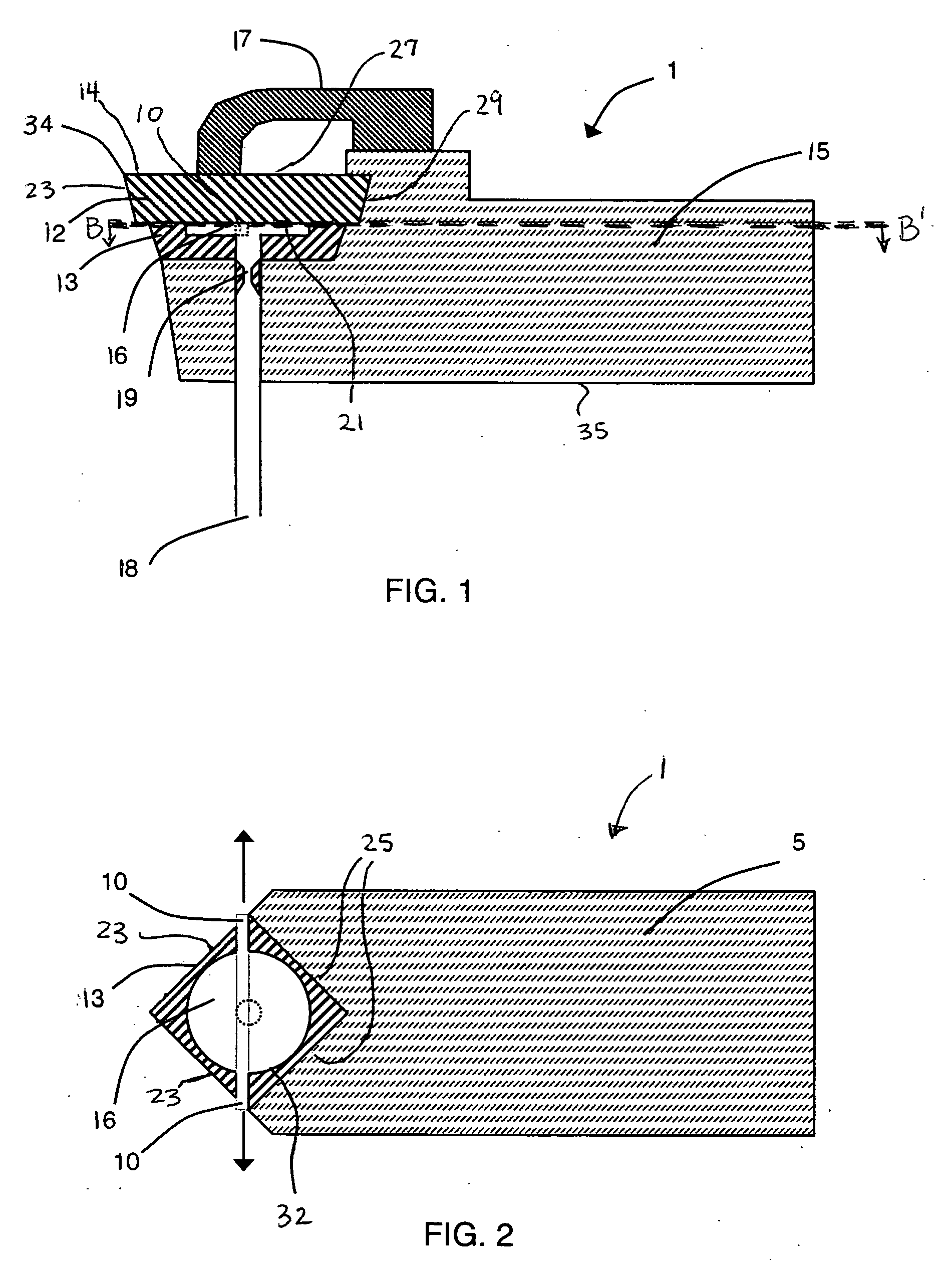

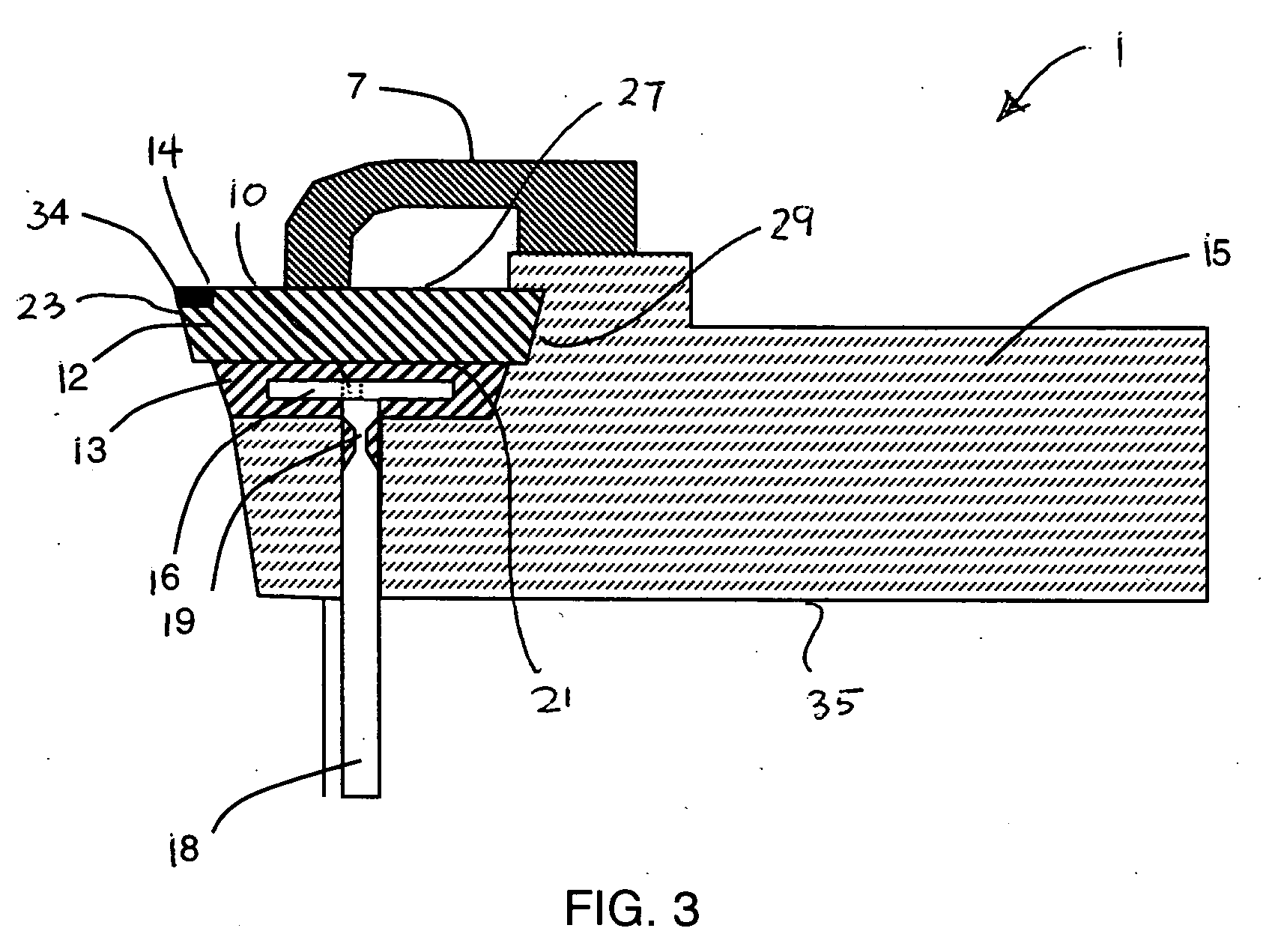

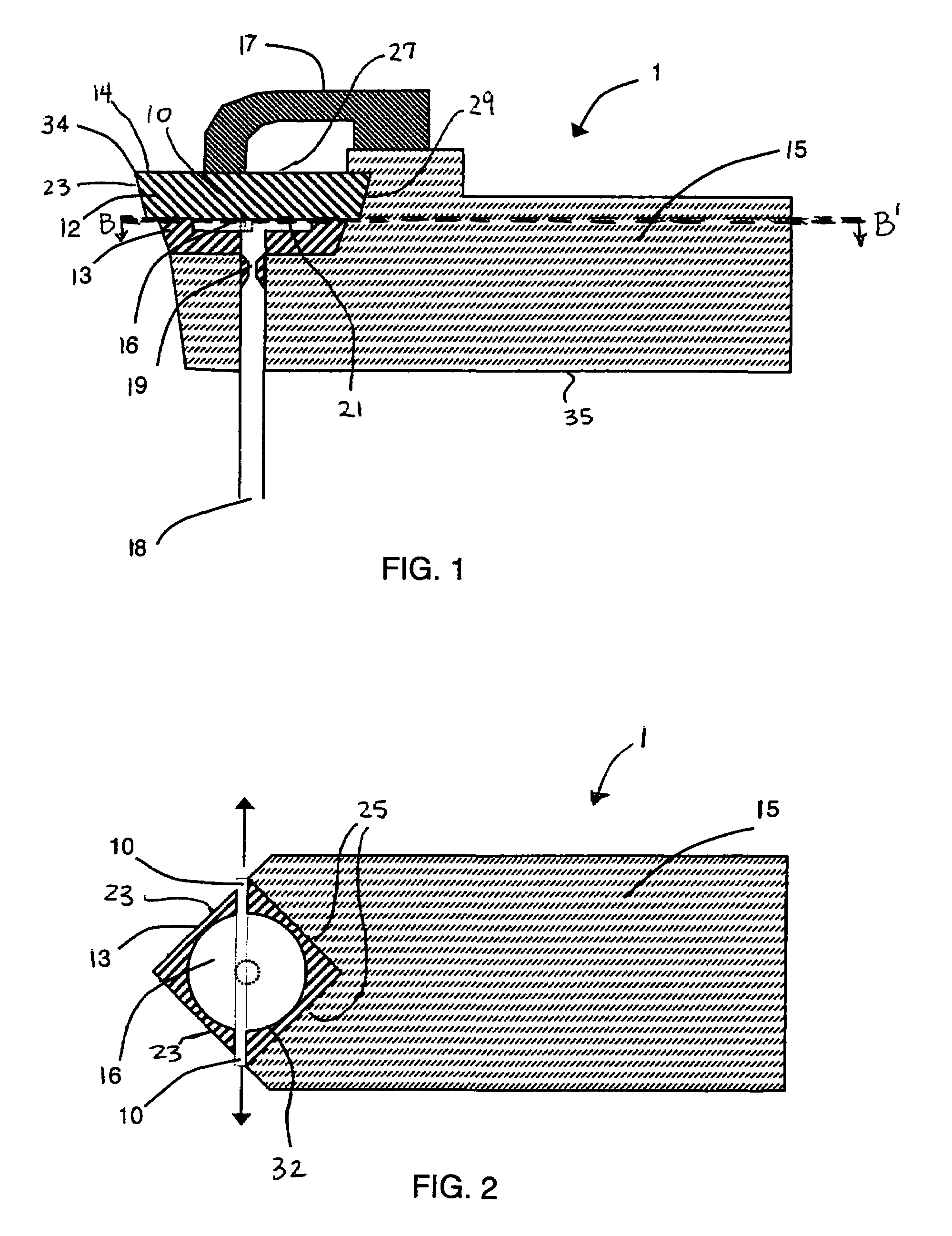

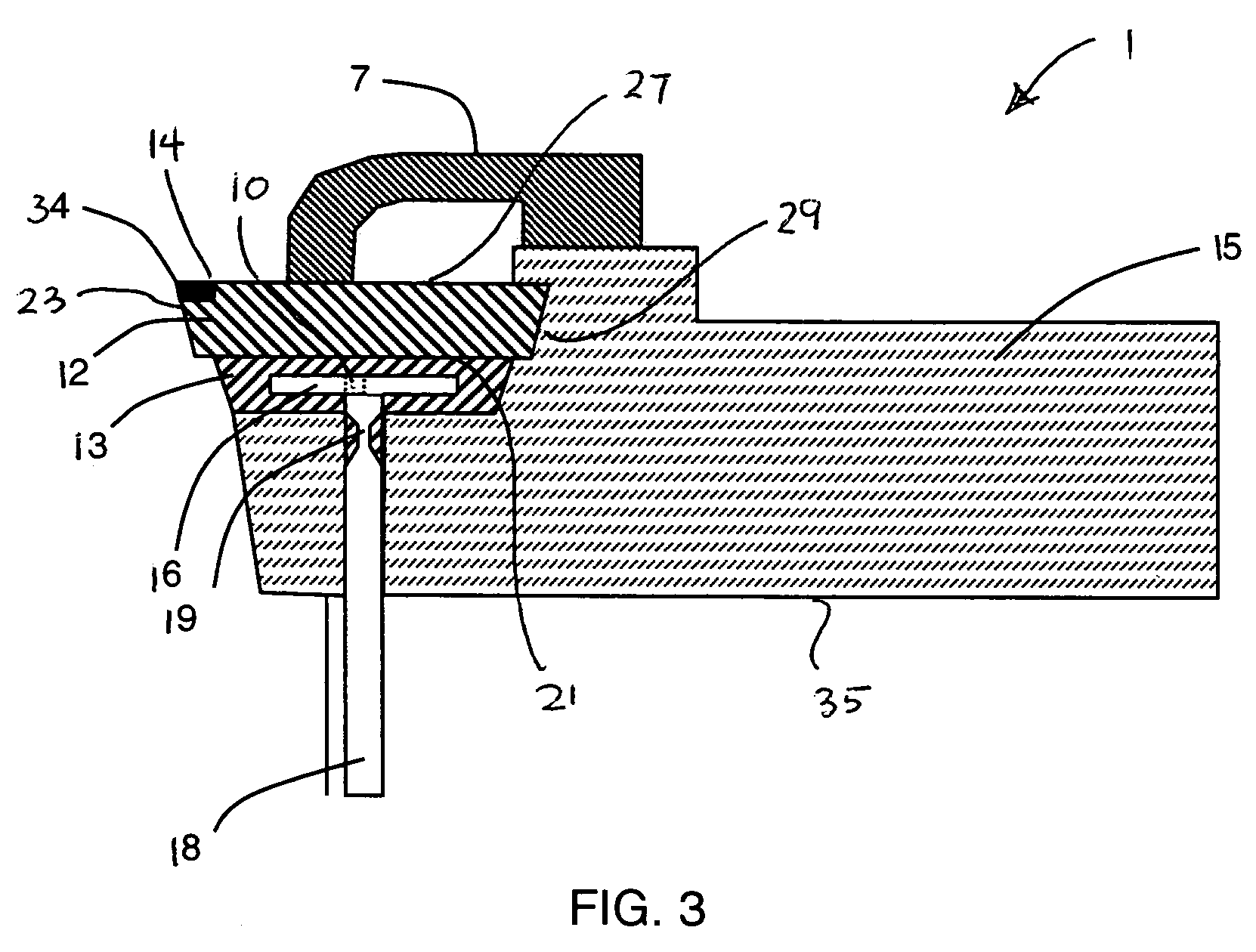

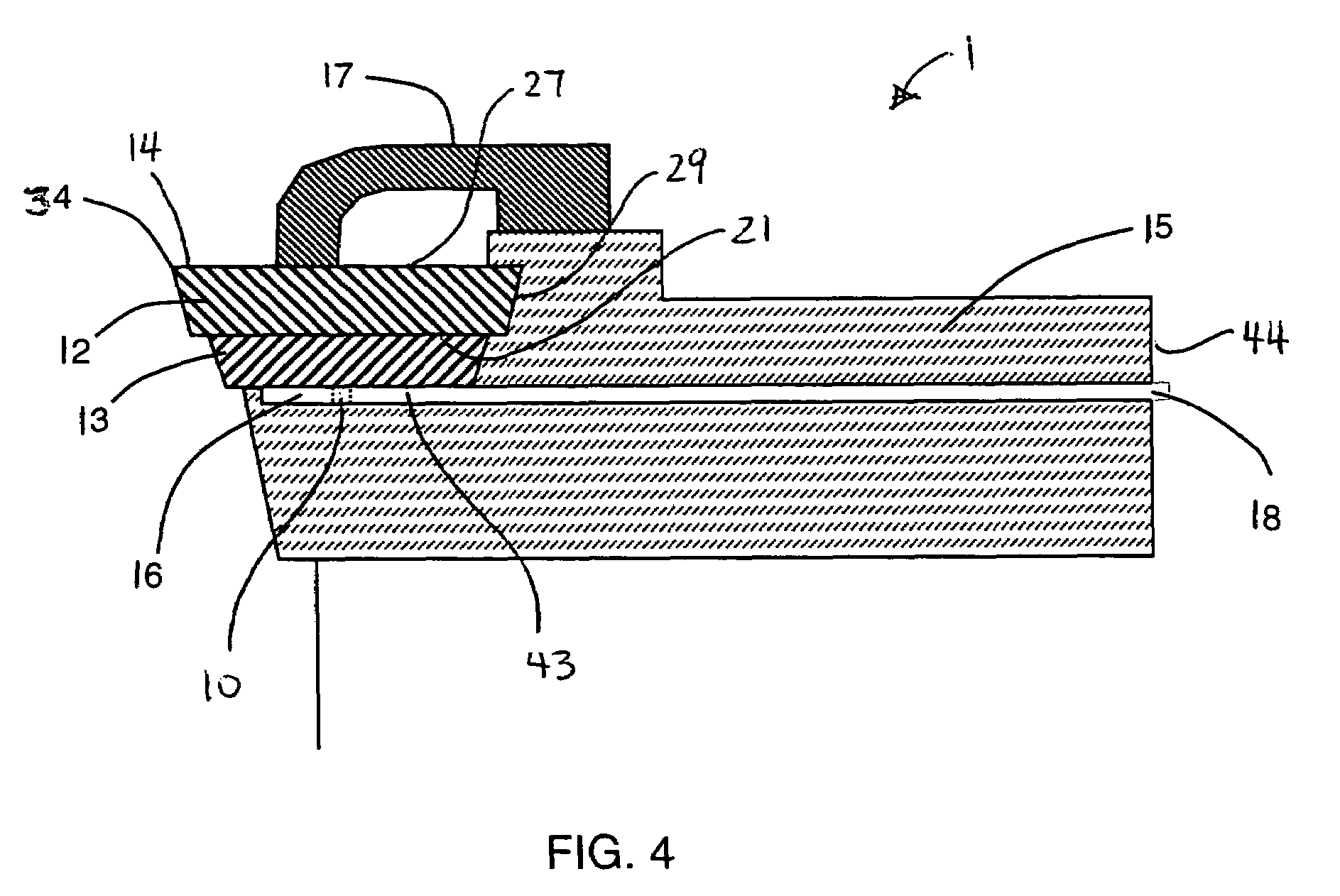

Method and apparatus for machining workpieces having interruptions

This invention is a method and apparatus for cutting a workpiece which may have interruptions, with a cutting insert having a cutting edge, where the cutting insert is held in a tool holder and is optionally supported by a shim. Coolant, which may contain liquid nitrogen, is introduced through a passageway to a cooling passage located near the cutting edge. The cooling passage may be located either under, behind, or under and behind the cutting edge. Coolant impacts the wall surfaces of the cooling passage near the cutting edge where it is partly evaporated thereby cooling the cutting insert.

Owner:AIR PROD & CHEM INC

Tracking Biological and Other Samples Using RFID Tags

RFID tags are affixed to vials used to store samples, such as biological samples stored in liquid nitrogen dewars or mechanical freezers. In one set of embodiments, an RFID tag is inserted into a recess at the bottom of a vial and held in place by an insert that engages with vial structure. In another set of embodiments, the RFID tag is retained in the recess by directly engaging with the vial structure and without using a separate insert. Mechanisms for keeping the insert and / or tag in place include tabs that gouge into the vial material, clips that allow the insert / tag to be inserted, but not removed, and holes in the side wall of the vial recess that receive tabs extending from the insert / tag. Tag-insertion techniques enable tags to be affixed to vials either before or after insertion of the sample, thereby enabling retrofitting of existing sample-storing vials with tags.

Owner:BIOTILLION

Stabilizing Composition for Biological Materials

Dry stabilizing compositions for bioactive materials include sugars and hydrolyzed proteins, and may be formed into tablets or other forms providing enhanced stability for the bioactive material. Compositions containing the bioactive materials may be produced by a method that includes (a) combining the bioactive material with other ingredients in an aqueous solvent to form a viscous slurry; (b) snap-freezing the slurry in liquid nitrogen to form solid frozen particles, beads, droplets or strings; (c) primary drying by water removal under vacuum of the product of step (b) while maintaining it at a temperature above its freezing temperature; and (d) secondary drying of the product of step (c) at maximum vacuum and a temperature of 20° C. or higher for a time sufficient to reduce the water activity to below 0.3 Aw.

Owner:ADVANCED BIONUTRITION CORP

Human placenta, umbilical cord mesenchyma stemcell stock and its construction method

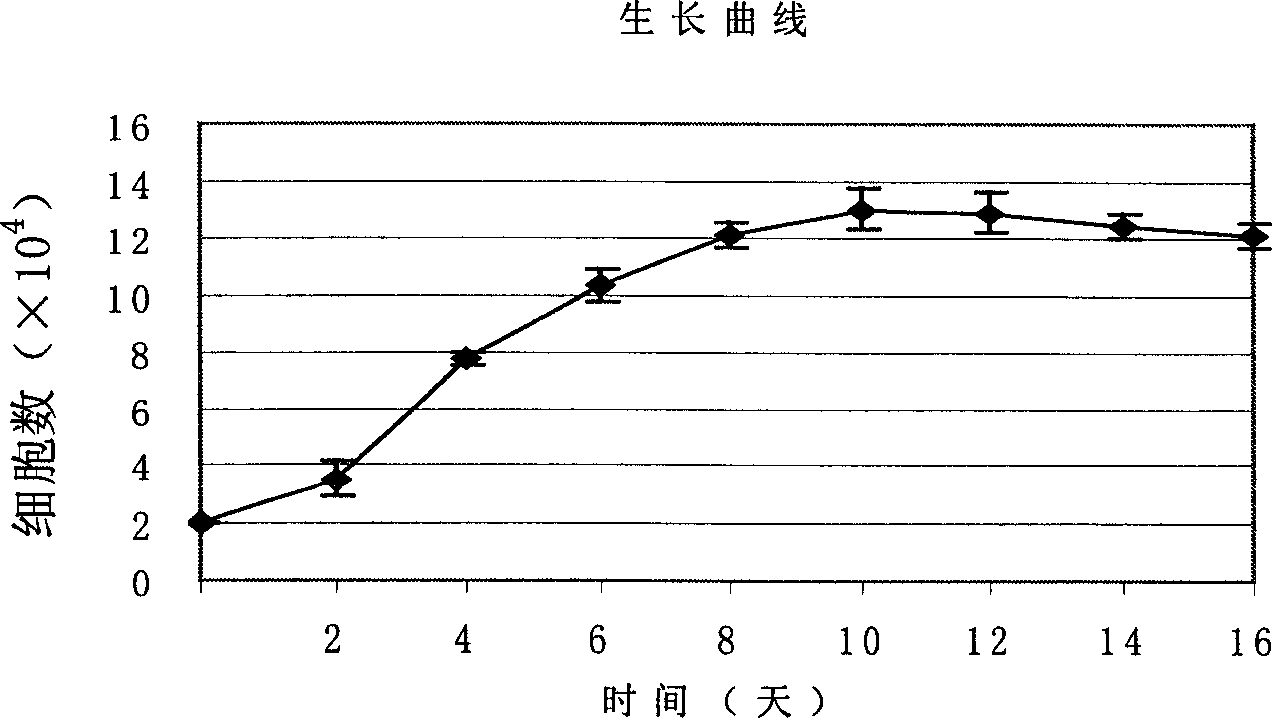

ActiveCN1786154AActivity without lossEasy to operateSkeletal/connective tissue cellsDiseaseMesenchyme

The invention discloses a human placenta, umbilical cord mesenchyme stem cell bank and its making method. The method includes the following steps: the first is taking human placenta, umbilical cord to test; smashing after cleaning by phosphate buffer; adding phosphate buffer to dilute; the second is adding collagenase to digest; the third is adding phosphate buffer; the fourth is adding trypsinization; the fifth is mixing the cell from the second and fourth, centrifuging, removing supernatant, cleaning by the phosphate buffer, centrifuging, and removing supernatant; the mesenchyme stem cell are gained; the sixth is freezing them in liquid nitrogen; saving by ABO / Rh subtype and HLA subtype; setting recallable cell information file. The invention is newborn storage placenta and umbilical cord mesenchyme stem cell. It can offer mesenchyme stem cell to treat the disease for personal, family and others.

Owner:TIANJIN AMCELLGENE ENG

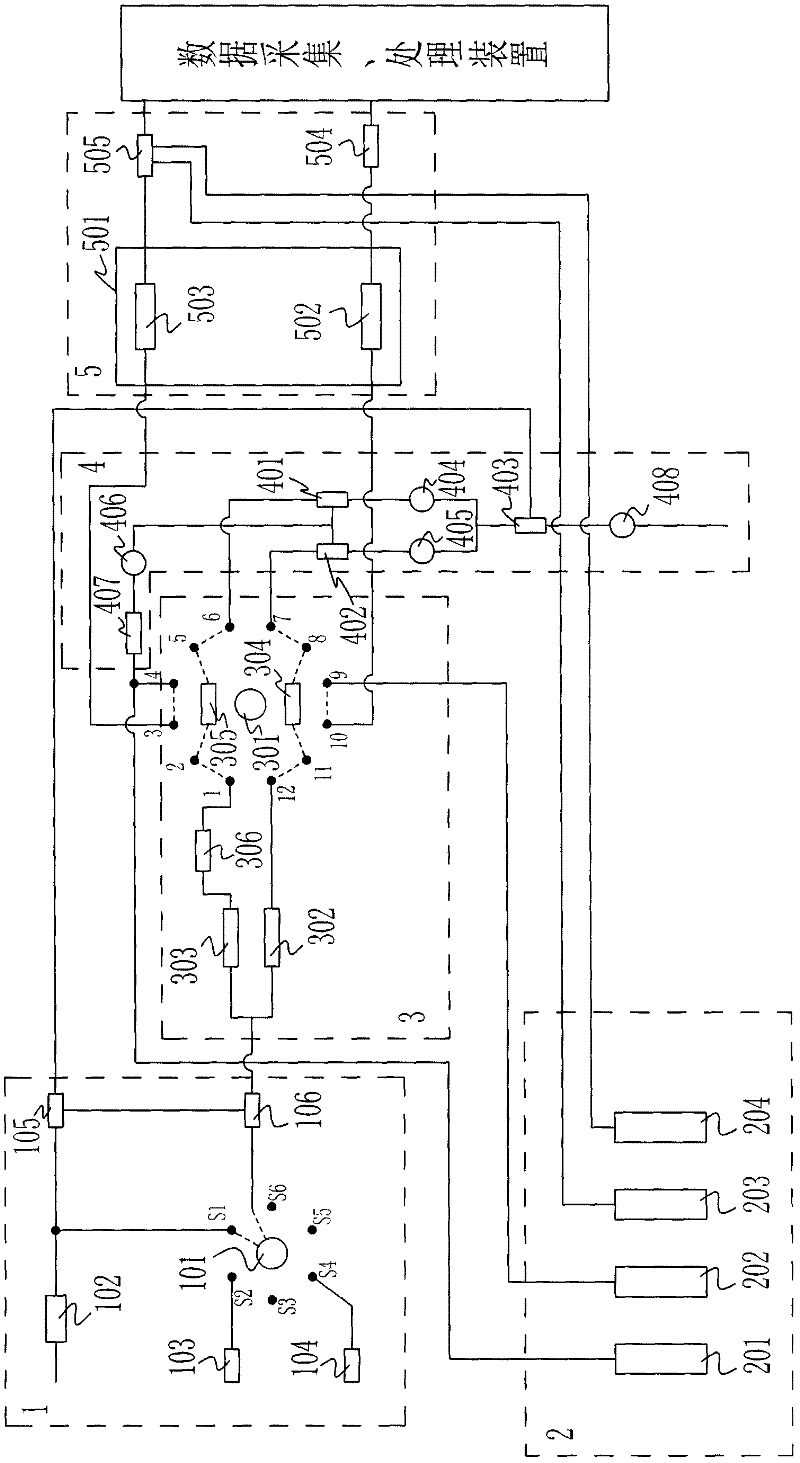

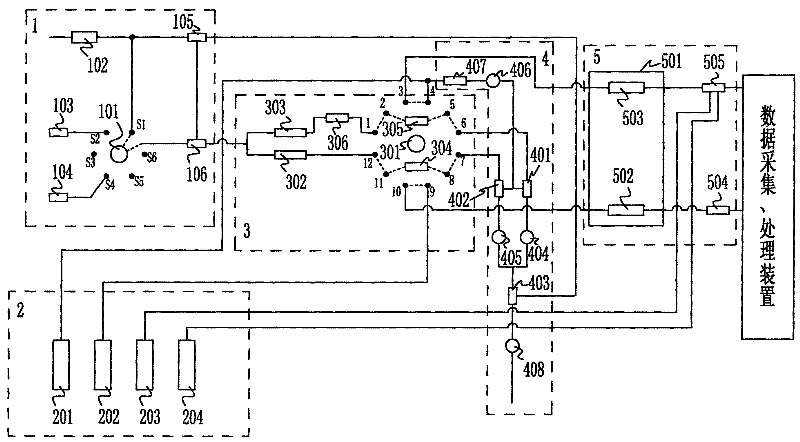

Online volatile organic matter analyzer and using method thereof

ActiveCN102375041AImprove qualitative analysisImprove the ability of quantitative analysisComponent separationWithdrawing sample devicesData acquisitionProduct gas

The invention relates to an online gas volatile organic matter analyzer and a using method thereof. The analyzer comprises a sampling device (1), a gas supplying device (2) and a refrigerating device (3), wherein the refrigerating device (3) is connected with the sampling device (1) and the gas supplying device (2) respectively. A double-hollow-pipe cold enriching double-detector gas online volatile organic matter analyzer further comprises a gas flow control device (4), an analysis device (5) and a data acquiring and processing device, wherein the gas flow control device (4) is connected with the sampling device (1) and the gas supplying device (2) respectively; the analysis device (5) is connected with the gas flow control device (4); and the data acquiring and processing device is connected with the analysis device (5). The invention has the advantages: ultralow temperature refrigeration is realized by adopting an electronic refrigerating technology, so that the defects of frequent addition of liquid nitrogen during refrigeration with liquid nitrogen and limit on the application conditions are overcome, the analyzer can run automatically continuously for a long time, and automatic operation is convenient.

Owner:WUHAN TIANHONG INSTR

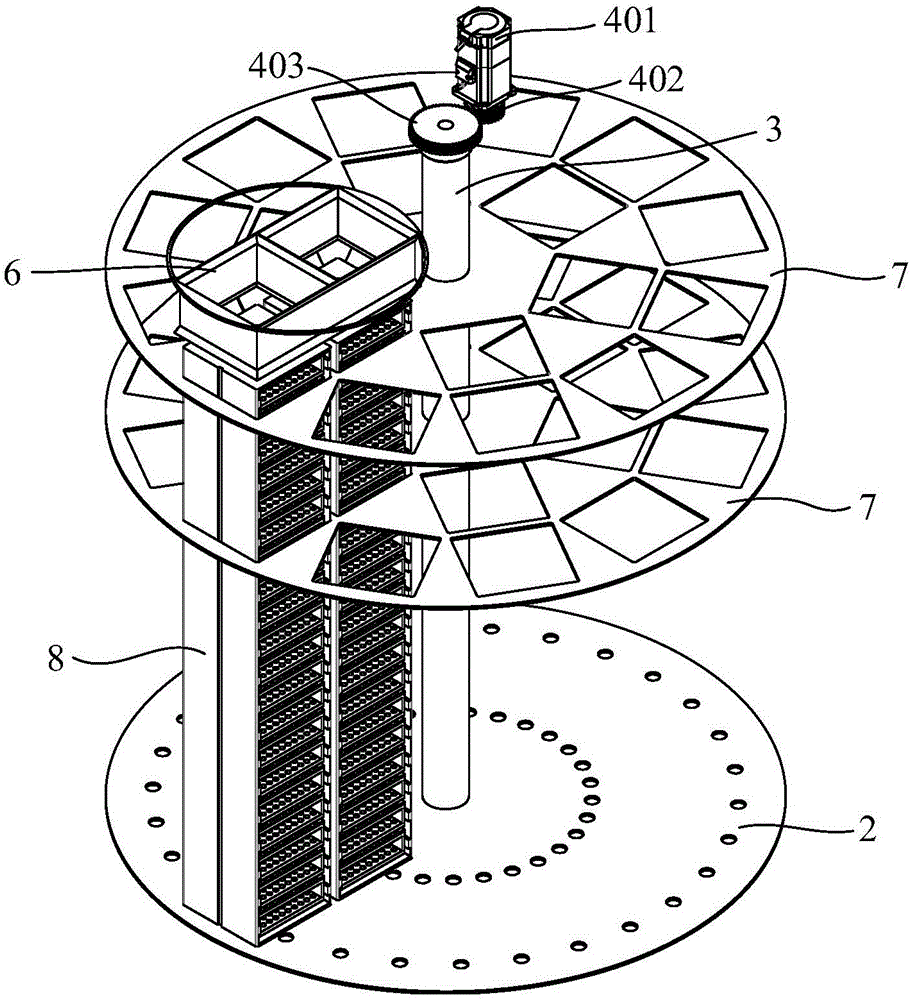

Cryogenic vial storing and fetching device

ActiveCN105857941AAchieve strict controlKeep aliveDomestic cooling apparatusLighting and heating apparatusThermal insulationHanging basket

The invention discloses a cryogenic vial storing and fetching device. The cryogenic vial storing and fetching device comprises a frame and a liquid nitrogen cylinder, wherein the liquid nitrogen cylinder is located in the frame; the liquid nitrogen cylinder comprises a cylinder body and a moving mechanism; the cylinder body is provided with a sealed opening; the sealed opening is provided with a first thermal insulation shell; the moving mechanism is arranged in the cylinder body and is used for moving hanging baskets in the liquid nitrogen cylinder to the opening; the cryogenic vial storing and fetching device further comprises a hoisting mechanism, a tray shoveling mechanism and a vial selecting mechanism; the hoisting mechanism is used for hoisting a hanging basket at the opening into the first thermal insulation shell; the tray shoveling mechanism is used for storing or fetching a cryogenic tray from the hanging basket which is hoisted by the hoisting mechanism; and the vial selecting mechanism is used for storing or fetching a cryogenic vial from the cryogenic tray which is fetched by the tray shoveling mechanism. By adopting the cryogenic vial storing and fetching device, the process for selecting a single target cryogenic vial for biological samples is realized; and during the whole selecting process, the cryogenic vials are all in a liquid nitrogen environment, and non-target cryogenic vials are prevented from being exposed at environment temperature, so that the activity of the biological samples is ensured.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

Dry ice sublimation hole bottom refrigerating and pressure keeping sampler and sampling method

InactiveCN101514614AAvoid destructionIncrease adoption rateWell/borehole valve arrangementsSealing/packingRock coreDry ice

The invention relates to a dry ice sublimation hole bottom refrigerating and pressure keeping sampler and a sampling method. The device is mainly composed of a suspension differential action mechanism, a single action mechanism, a control mechanism, a refrigerating mechanism and a pressure keeping mechanism. The method comprises: using dry ice as refrigerant, alcohol as refrigeration assisting catalyst and secondary refrigerant, and applying low temperature alcohol to the hole bottom to refrigerate the rock core; closing a ball valve to keep pressure of the rock sample so as to inhibite the decomposition of the hydrate rock core; dismounting a blocking tube and a drill bit when sampling, dismounting a clamp spring and a clamp spring seat, pulling out a half combining tube and the rock core from the rock core tube, and using a liquid nitrogen holdup vessel or a high pressure container to keep the rock core sample. When drilling for sampling the rock core, the external tube and the drill bit gyre, but the internal tube assembly does not gyre, thus avoiding the damage of mechanical force to the rock core caused by the gyrus of the drilling tool to a larger degree, improving the rock core sampling rate, integrity and representativeness more effectively, and realizing pure refrigeration sampling as well as a combination of refrigeration sampling and rock core pressure keeping; compared with the prior art, the invention has simple process, convenient operation and greatly reduces the cost.

Owner:JILIN UNIV

Method for freezing and reviving umbilical cord tissues and for separating and increasing stem cells

ActiveCN102660497AEfficient in vitro expansionAvoid churnDead animal preservationArtificial cell constructsMedicineUmbilical cord tissue

The invention relates to a method for freezing and reviving umbilical cord tissues and for separating and increasing stem cells after reviving the umbilical cord, and the step comprises the following steps of preparing umbilical cord tissue freezing liquid; sterilizing and washing the umbilical cord tissues; cutting the tissues into blocks; placing the tissue blocks and the freezing liquid into afreezing tube, cold storing the tissue blocks for 0.5 hour under the temperature condition of 4 DEG C and then storing the tissue blocks for one day under the temperature condition of minus 80 DEG C,and then freezing the tissue blocks in liquefied nitrogen; and taking the umbilical cord tissues out of the liquefied nitrogen to use, thawing the umbilical cord tissues in constant-temperature waterbath, utilizing mesenchymal stem cell culture base to washing the umbilical cord tissues through a drop method, and separating and increasing the mesenchymal stem cells of the revived umbilical cord tissues through a tissue attachment method. The method can effectively protect the frozen umbilical cord tissue, so that the umbilical cord tissues can be revived to use, and the method is particularly suitable for separating and increasing the mesenchymal stem cells after the umbilical cord tissue is revived.

Owner:BOYALIFE

Hole bottom freezing cord coring drill and coring method thereof

Owner:JILIN UNIV

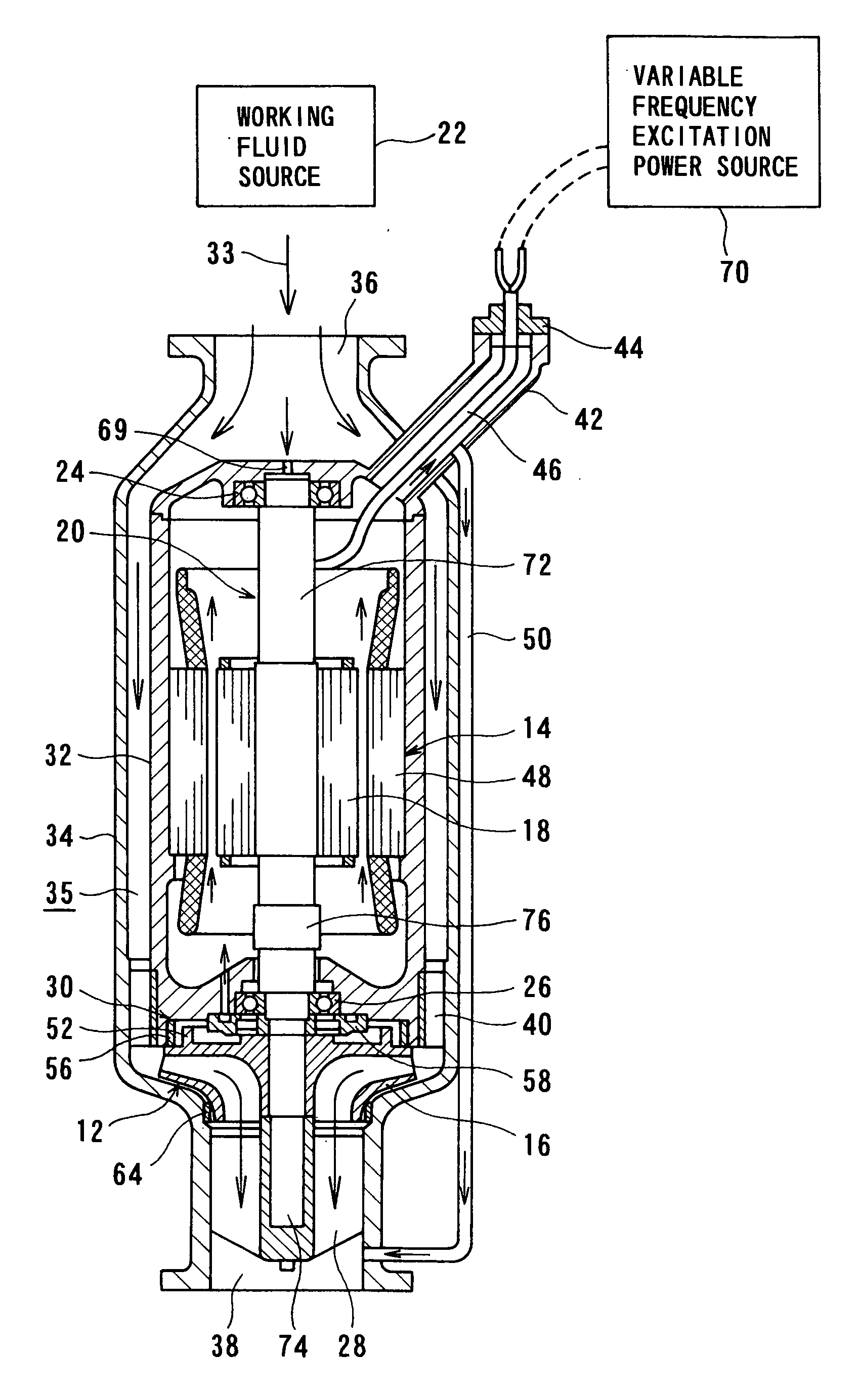

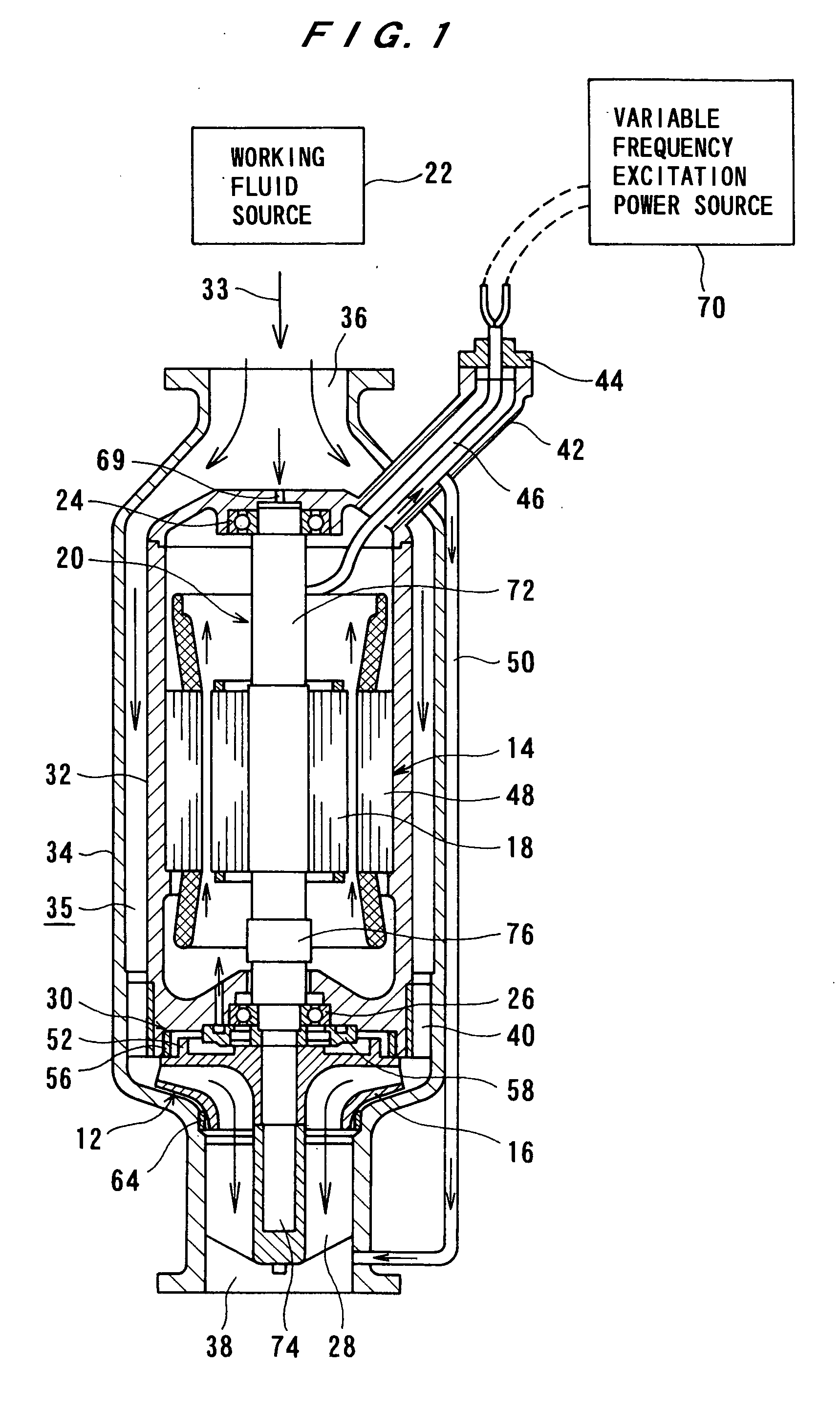

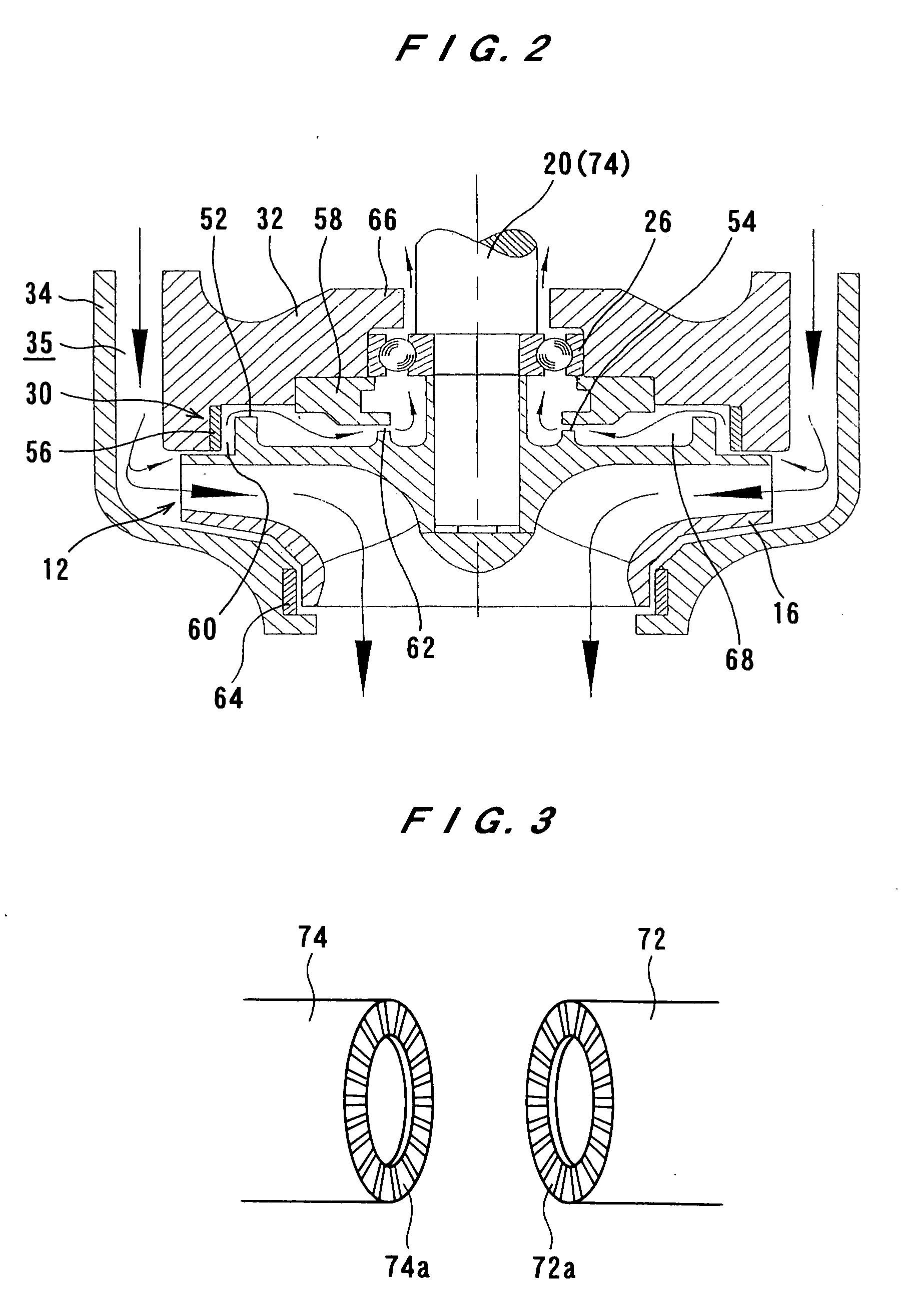

Submerged turbine generator

InactiveUS20060186671A1Minimal lossImprove performanceWorking fluid for enginesMachines/enginesWorking fluidEngineering

A submerged turbine generator is operated by a working fluid, such as liquid nitrogen, liquefied natural gas, or liquid ethylene, to generate electric power. The submerged turbine generator includes a shaft, a casing, a turbine having a runner fixed to the shaft, a generator having a rotor fixed to the shaft and a stator surrounding the rotor, and bearings for rotatably supporting the shaft. The runner is rotated integrally with the shaft by the pressure of the working fluid introduced into the casing. The shaft includes at least two members.

Owner:EBARA CORP

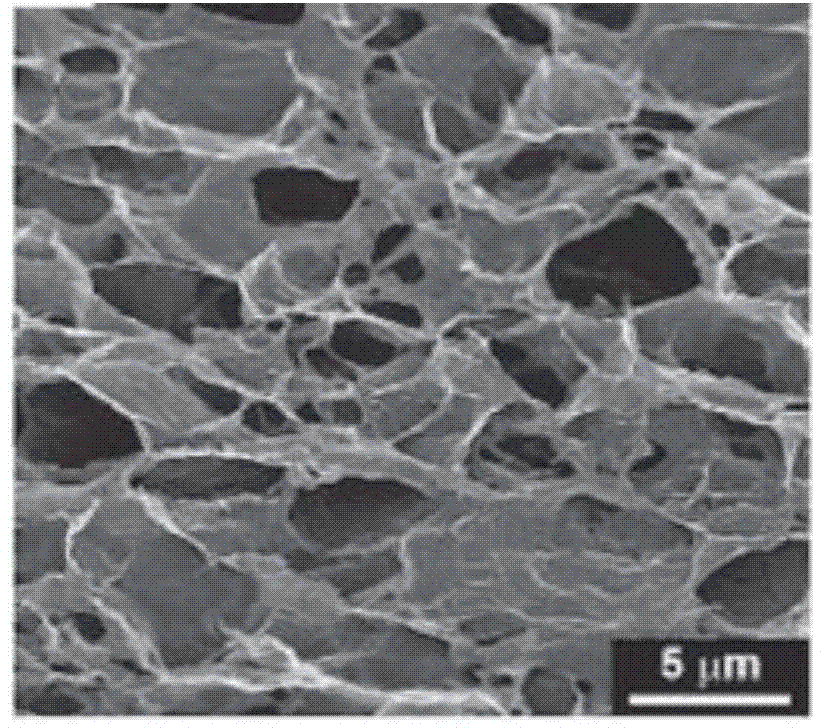

Preparation method for graphene aerogel

The invention discloses a preparation method for graphene aerogel. The method comprises the following steps: preparing an aqueous polyvinyl alcohol solution containing graphene oxide so as to obtain a graphene oxide dispersion liquid with a concentration of 1 to 10 mg / cm<3>; subjecting the graphene oxide dispersion liquid to freezing in the condition of no higher than minus 196 DEG C so as to obtain a frozen sample; subjecting the frozen sample to freezing and drying so as to obtain a frozen-dried sample; and subjecting the frozen-dried sample in an argon-hydrogen mixed gas environment to high-temperature reduction so as to obtain the required graphene aerogel, wherein the high-temperature reduction comprises the steps of burning at 350 to 450 DEG C for 2 to 3 hours and burning again at 900 to 1100 DEG C for 2 to 3 hours. The preparation method for the graphene aerogel provided by the invention adopts a liquid nitrogen freezing manner to obtain a graphene oxide aerogel precursor, the subsequent segmented high-temperature reduction process is combined, the frozen-dried sample undergoes high-temperature burning at different temperatures, polyvinyl alcohol is removed and graphene oxide is reduced at high temperature, so the graphene aerogel is finally obtained; meanwhile, the graphene aerogel obtained by using the method in the invention has stable structure, good homogeneity and stable material performance.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Method and apparatus for machining workpieces having interruptions

This invention is a method and apparatus for cutting a workpiece which may have interruptions, with a cutting insert having a cutting edge, where the cutting insert is held in a tool holder and is optionally supported by a shim. Coolant, which may contain liquid nitrogen, is introduced through a passageway to a cooling passage located near the cutting edge. The cooling passage may be located either under, behind, or under and behind the cutting edge. Coolant impacts the wall surfaces of the cooling passage near the cutting edge where it is partly evaporated thereby cooling the cutting insert.

Owner:AIR PROD & CHEM INC

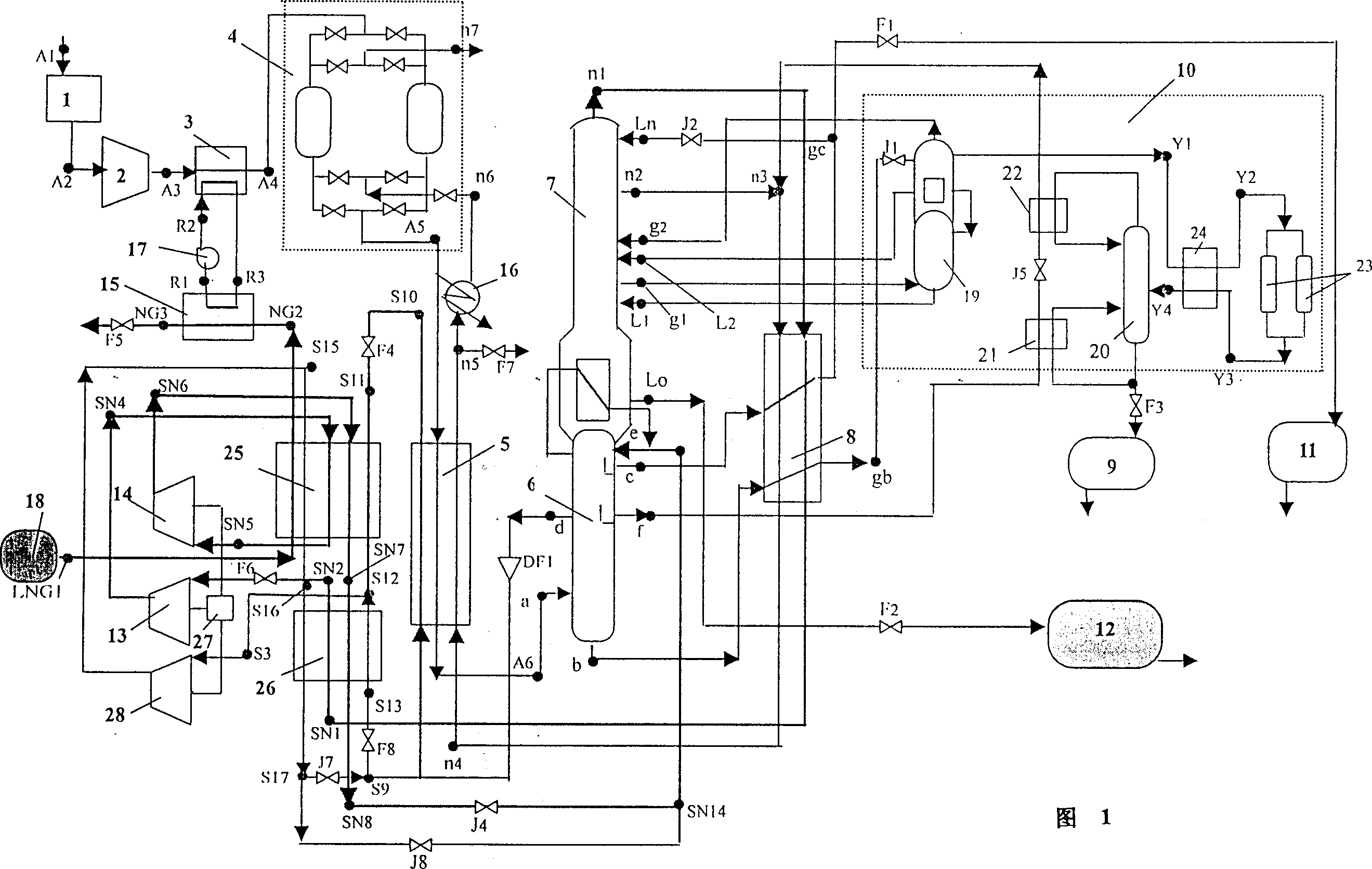

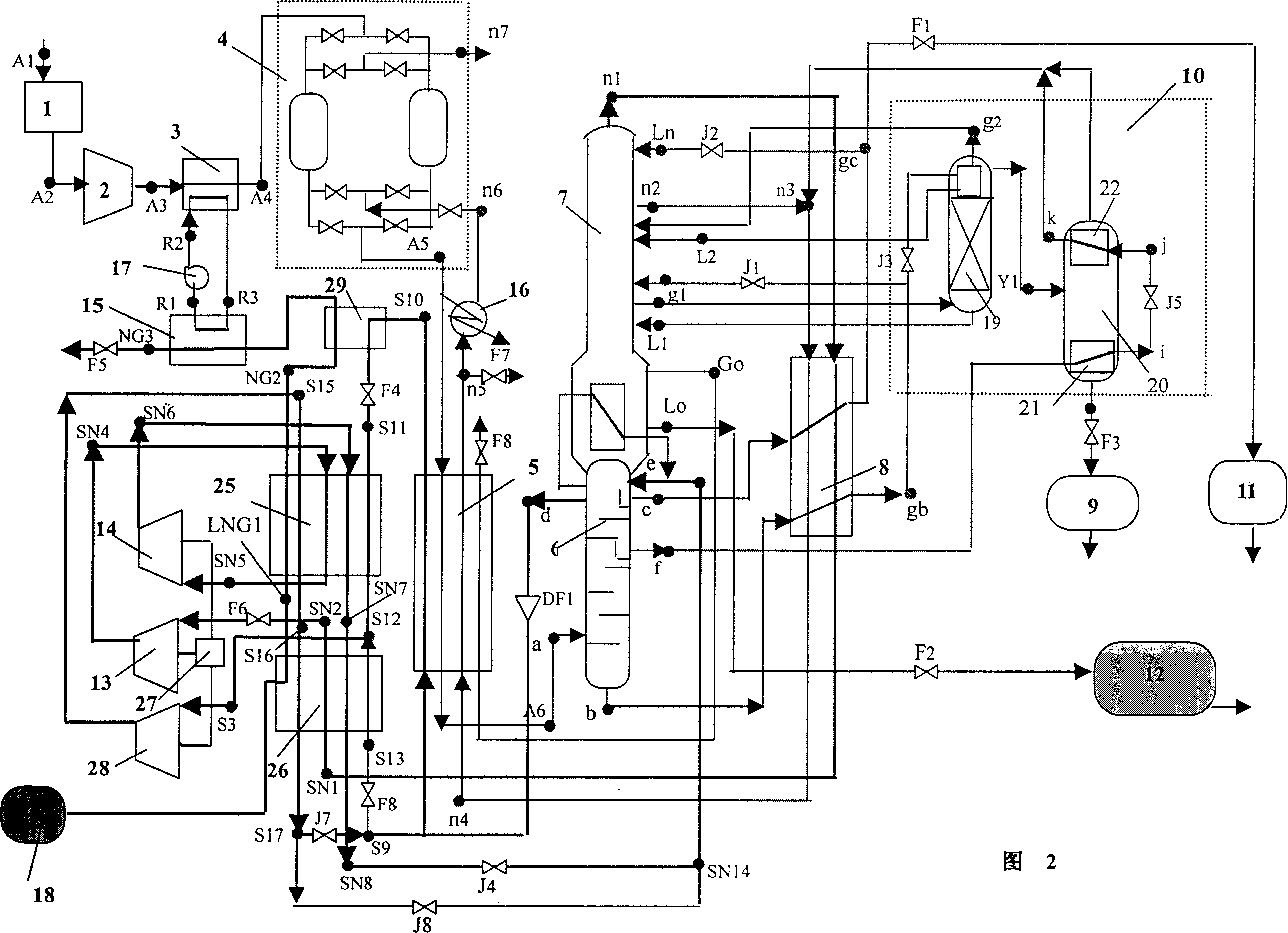

Air separation system for generating liquid oxygen and liquid nitrogen

This kind of air separation system obtaining liquid oxygen and liquid nitrogen at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; oxygen is drawn out from the underpart of the upper column on the fractionating tower, and cools and liquefied in the liquid-oxygen heat exchanger as the liquid oxygen products; after nitrogen from the top of the upper column passes through a liquid-nitrogen liquid air subcooler and is reheated by main heat exchanger, some nitrogen enters into liquefied-natural-gas heat exchanger to recool and exchange heat to become high pressure nitrogen through primary compression and pressurization at least. And through throttling expansion and air-liquid separator, nitrogen and liquid nitrogen participate in recycling and other nitrogen as liquid-nitrogen products; energy consumption is reduced notably after using actually, power consumption which produces liquid oxygen of 1kg is 0.39kwh, while the power consumption of the traditional equal air separator is 1.0 to 1.25kwh, which is 2.4 to 3 times than the separator. And it is easy to popularize and apply.

Owner:HANGZHOU HANGYANG

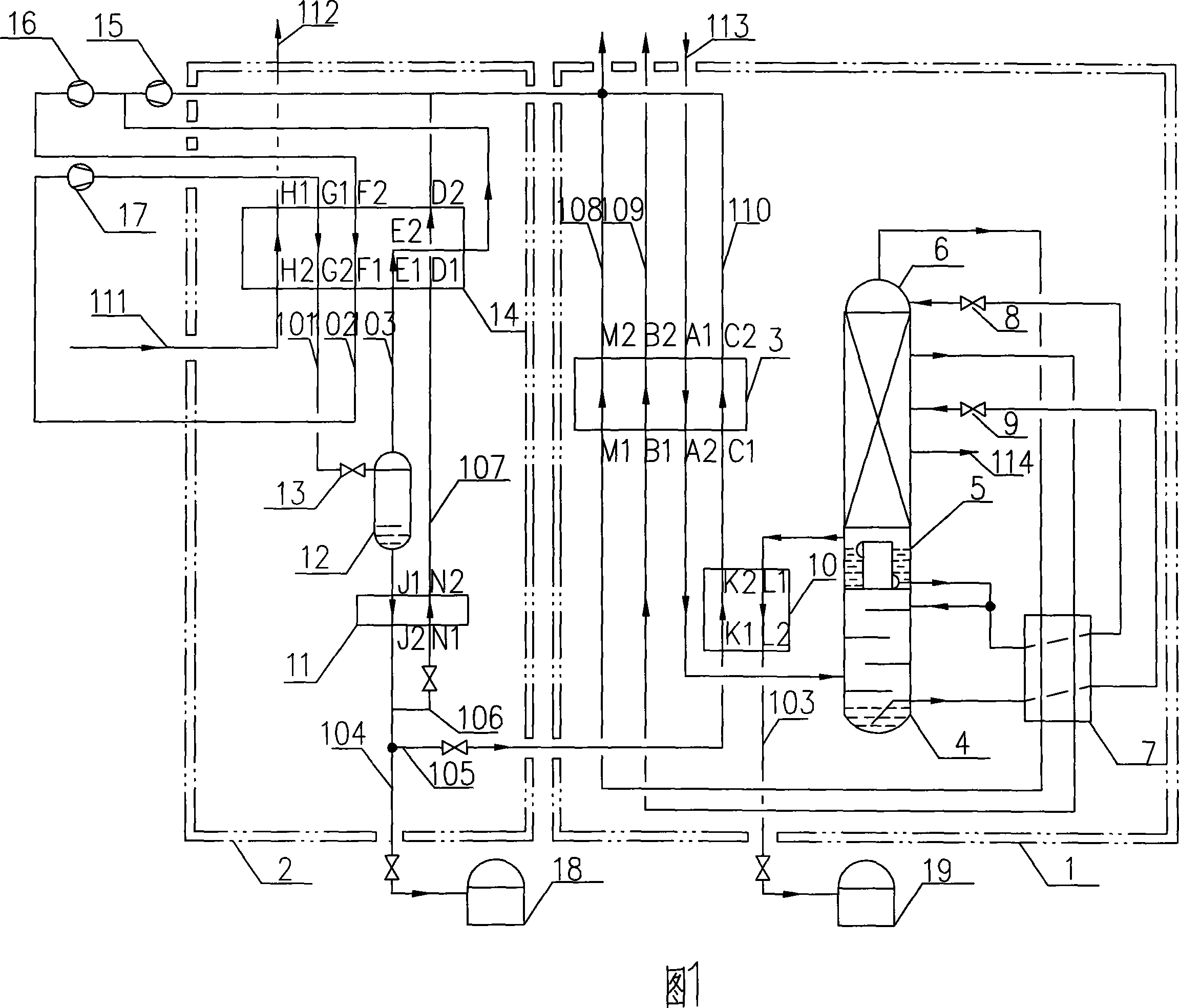

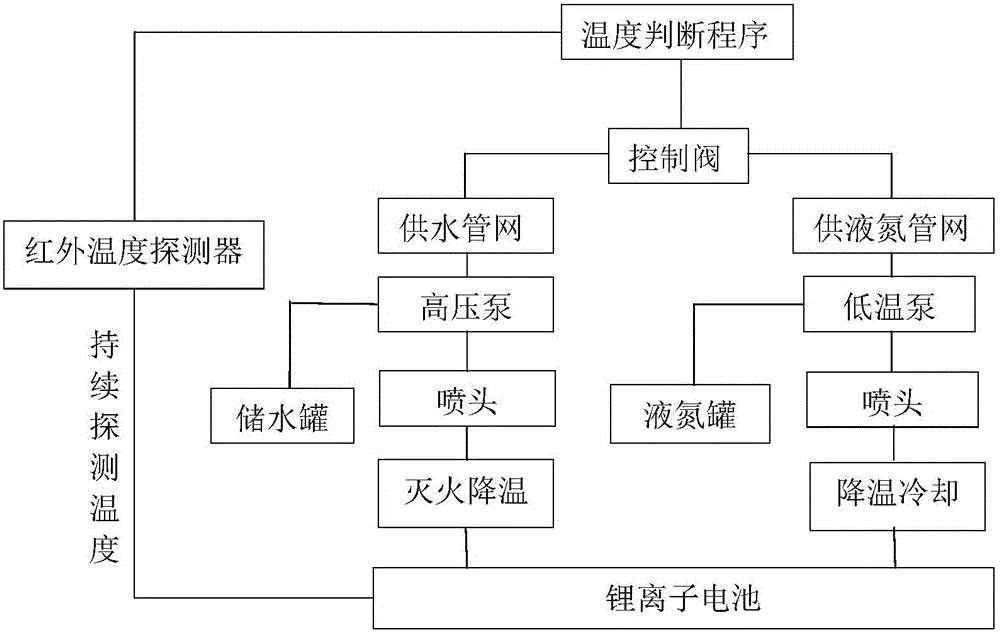

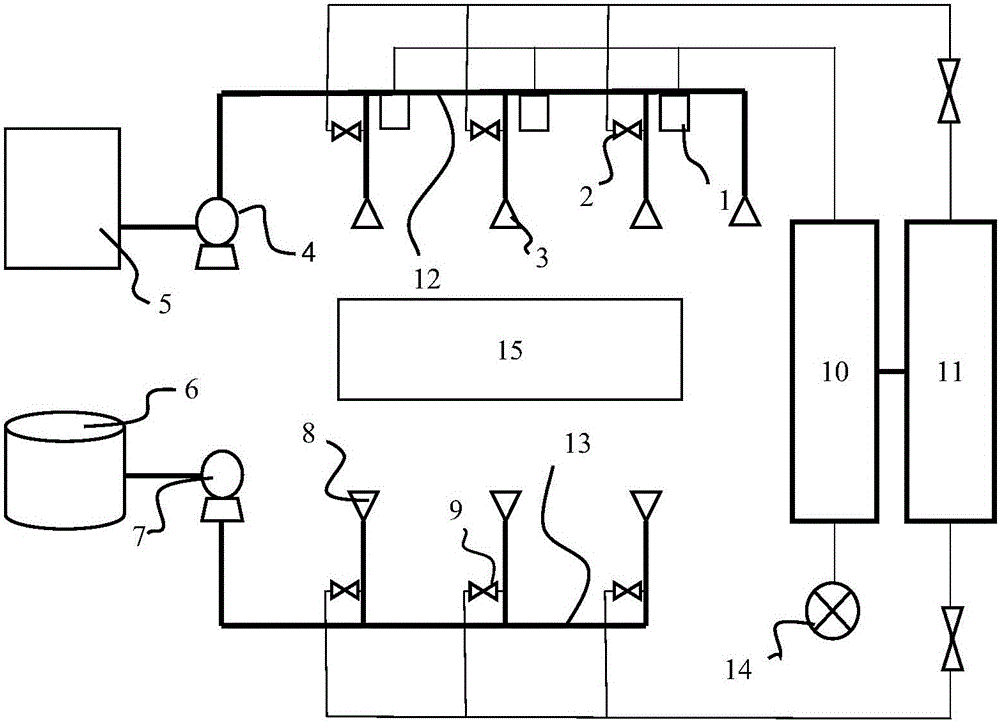

Cooling fire extinguishing device and fire extinguishing method specific to stored lithium ion battery thermal runaway

InactiveCN106110537AEnsure safetyGuaranteed reliabilityFire rescueSecondary cells servicing/maintenanceWater storage tankElectrical battery

The invention relates to a cooling fire extinguishing device specific to stored lithium ion battery thermal runaway. The cooling fire extinguishing device is composed of a control part, a water supply device and a liquid nitrogen supply device. The control part is composed of infrared temperature detectors (1), a temperature judgment program (10), a control valve (11), water control valves (2), liquid nitrogen control valves (9) and an electrical circuit connected with the infrared temperature detectors (1), the temperature judgment program (10), the control valve (11), the water control valves (2) and the liquid nitrogen control valves (9). The water supply device is composed of a water storage tank (5), a high-pressure pump (4), a water supply pipe network (12) and fine water mist spray nozzles (3). The liquid nitrogen supply device is composed of a liquid nitrogen tank (6), a low-temperature pump (7), a liquid nitrogen supply pipe network (13) and liquid nitrogen spray nozzles (8). The cooling fire extinguishing device is mainly suitable for storage places of lithium ion battery packs and can provide safety insurance for application, storage and transportation of lithium ion batteries. The fire extinguishing device can conduct targeted cooling in the initial stage of lithium ion battery pack thermal runaway, and meanwhile, timely fire extinguishment can be conducted after the battery pack is integrally on fire.

Owner:NANJING UNIV OF TECH

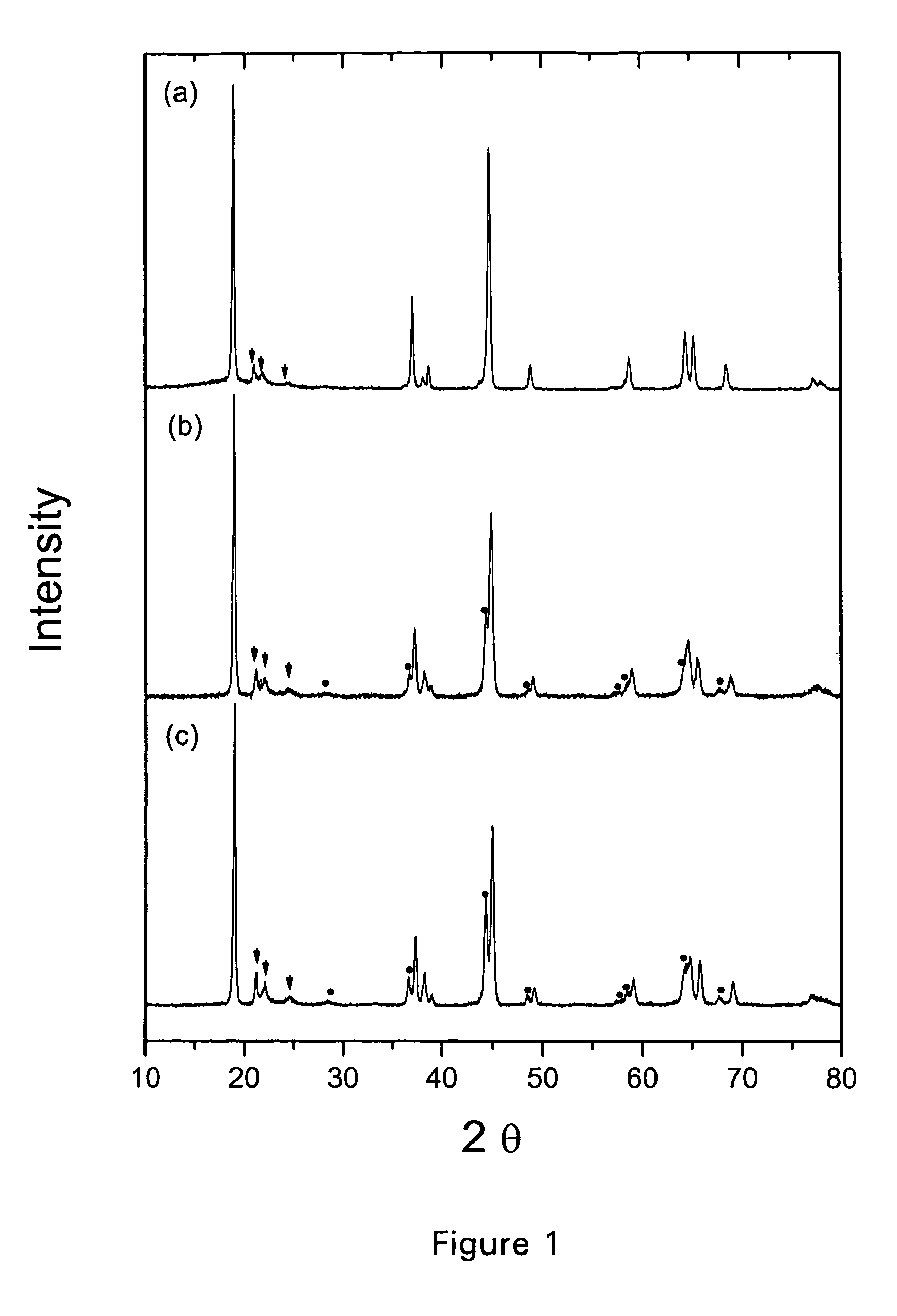

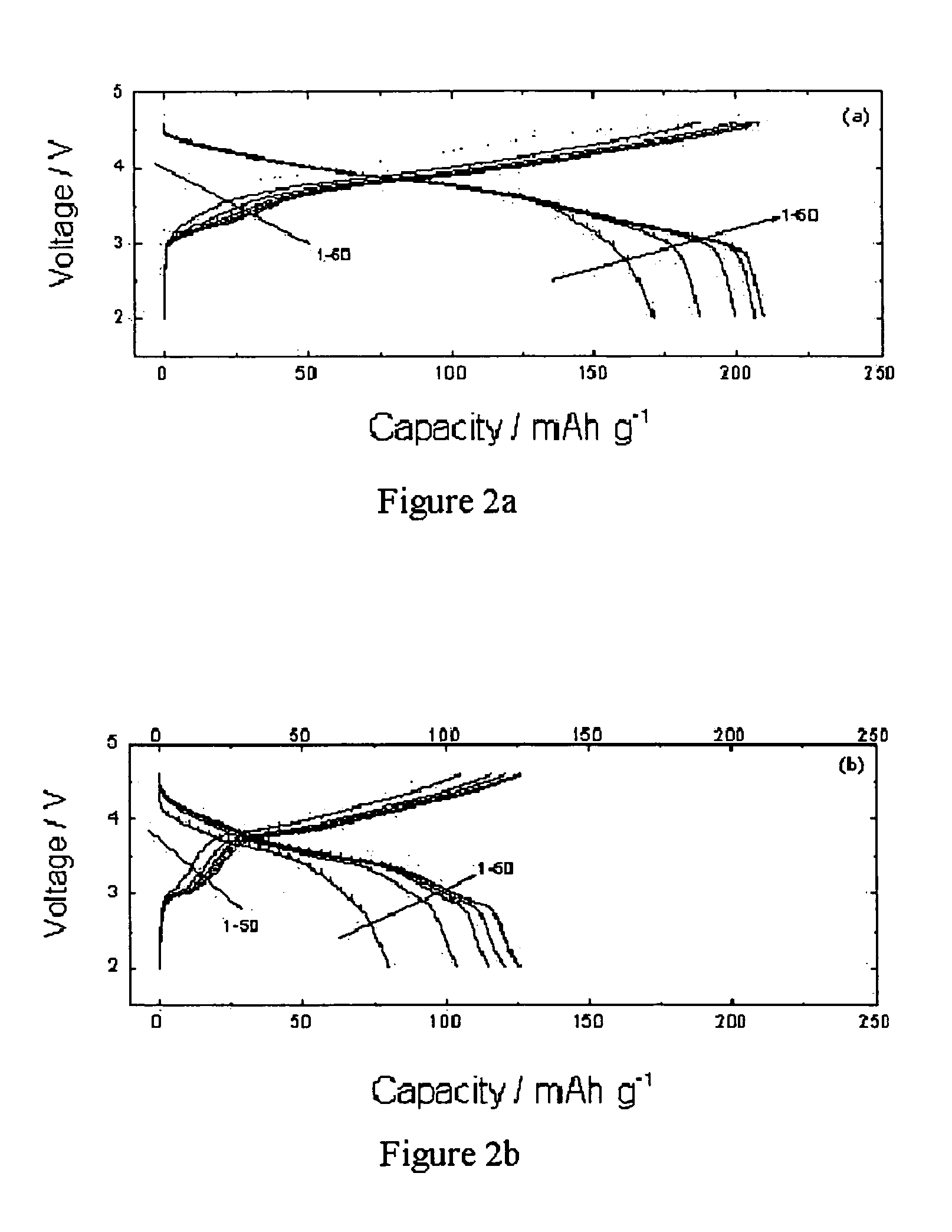

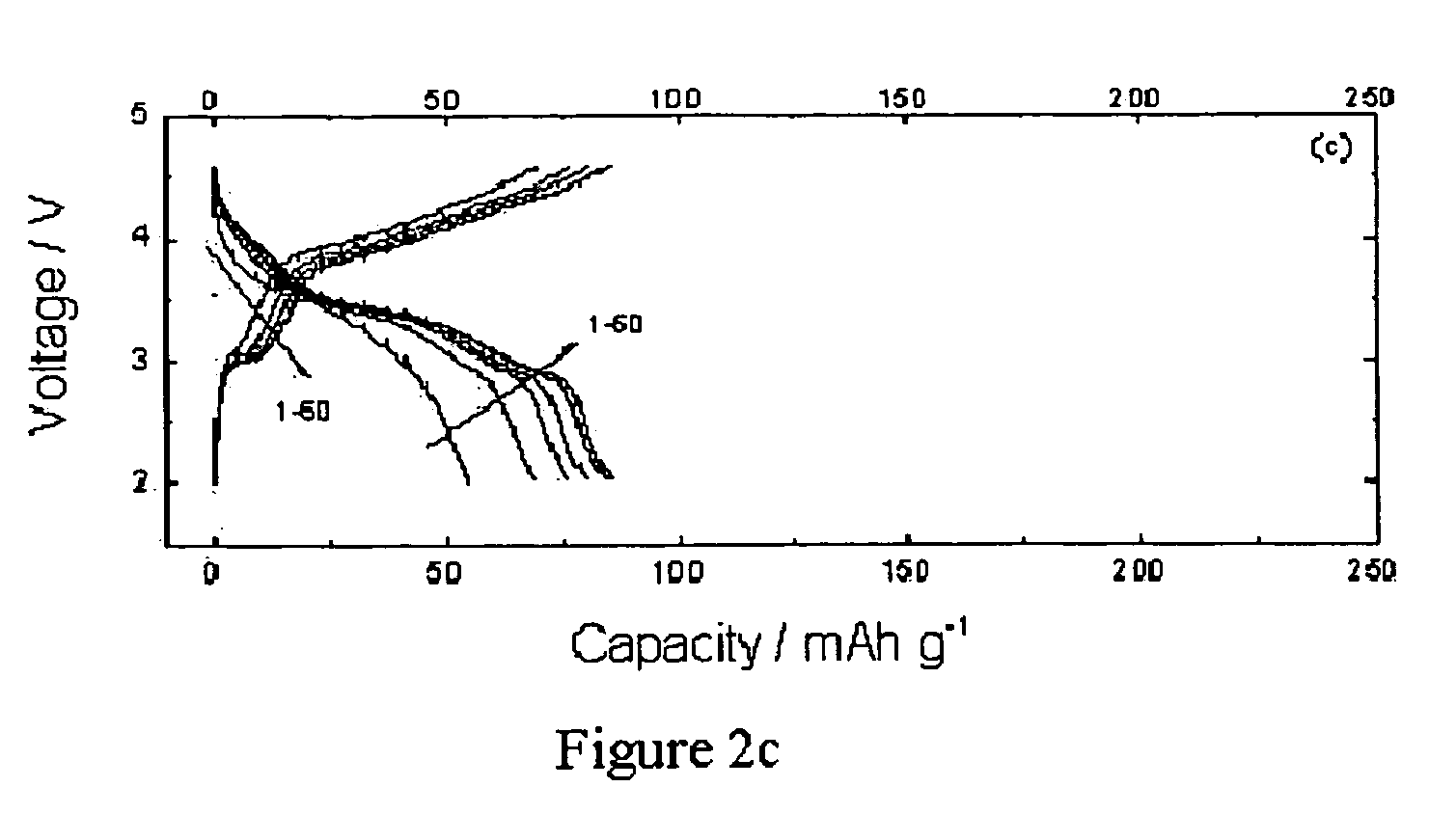

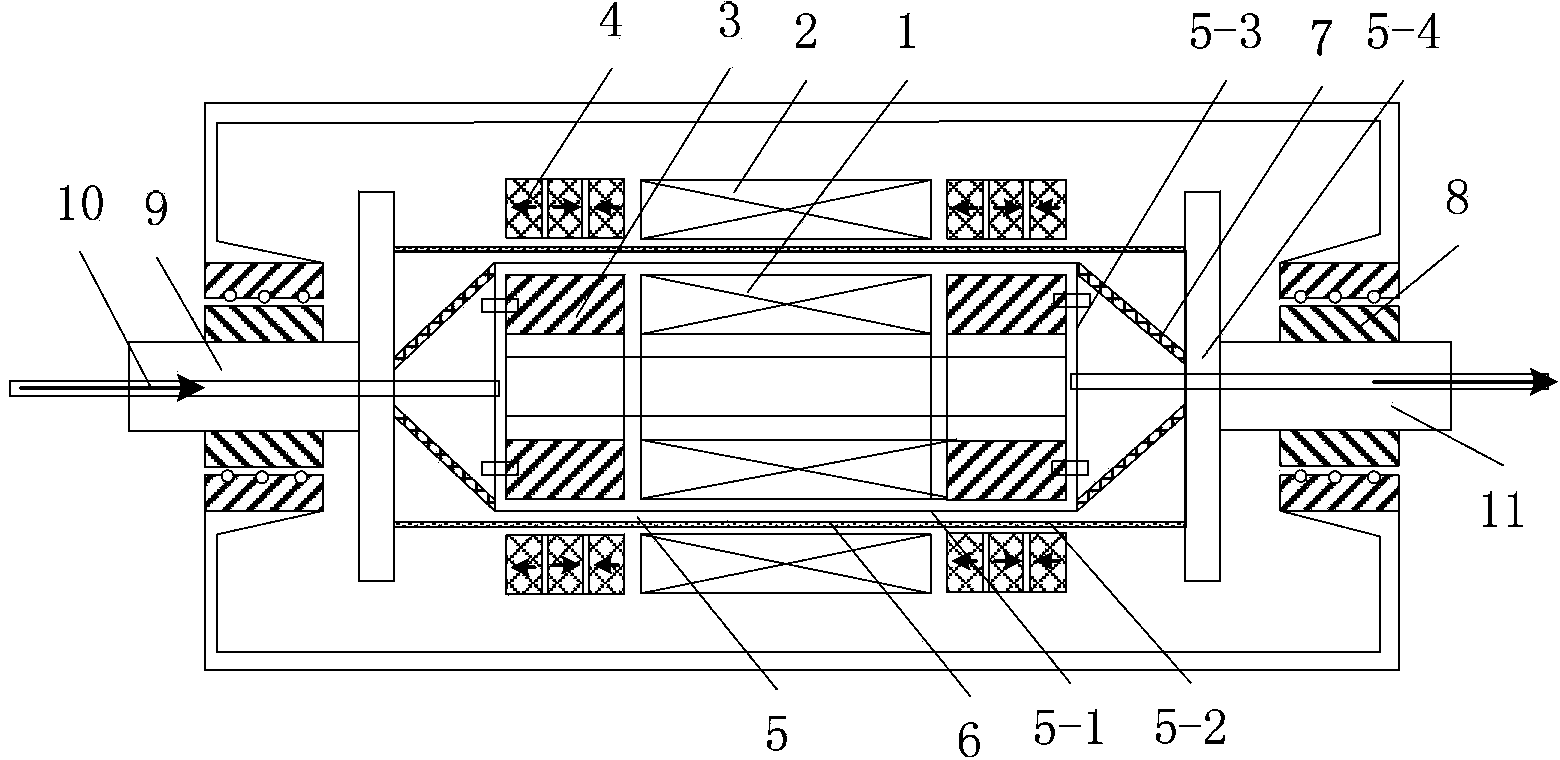

Layer cathode methods of manufacturing and materials for Li-ion rechargeable batteries

ActiveUS7314684B2Lower performance requirementsRapid coolingSecondary cellsAlkali metal oxidesLithiumSolid state reaction method

A positive electrode active material for lithium-ion rechargeable batteries of general formula Li1+xNiαMnβAγO2 and further wherein A is Mg, Zn, Al, Co, Ga, B, Zr, or Ti and 0<x<0.2, 0.1≦α≦0.5, 0.4≦β≦0.6, 0≦γ≦0.1 and a method of manufacturing the same. Such an active material is manufactured by employing either a solid state reaction method or an aqueous solution method or a sol-gel method which is followed by a rapid quenching from high temperatures into liquid nitrogen or liquid helium.

Owner:CHICAGO UNIV OF THE +1

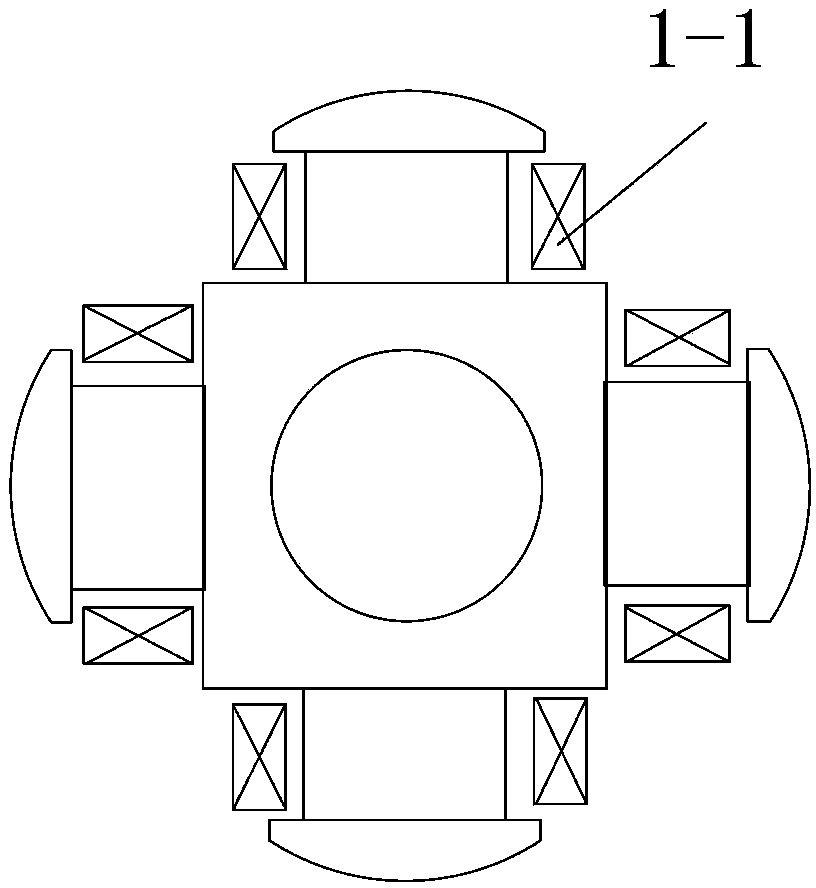

High-temperature superconducting magnetic levitation motor

InactiveCN103441648AReduce weightIncrease speedDynamo-electric machinesMagnetic holding devicesMagnetic bearingSuperconducting electric machine

A high-temperature superconducting magnetic levitation motor is formed by a superconducting motor rotor (1), a motor stator (2), superconducting bearing rotors (3), permanent magnetic bearing stators (4), a rotary dewar (5), an electromagnetic screen (6), torque tubes (7), mechanical protection bearings (8), a main shaft (9), a low-temperature liquid (gas) inlet pipeline (10) and a low-temperature liquid (gas) outlet pipeline (11). The superconducting motor rotor (1) and the superconducting bearing rotors (3) are arranged in the rotary dewar (5) and are cooled by liquid nitrogen or liquid neon or liquid helium or cold helium, the motor stator (2) and the permanent magnetic bearing stators (4) are arranged outside the rotary dewar (5) and are coaxial with the rotary dewar (5), and the two mechanical protection bearings (8) are used in a left and right mode in the radial direction for protecting against the influence brought by the failure of superconducting bearings.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

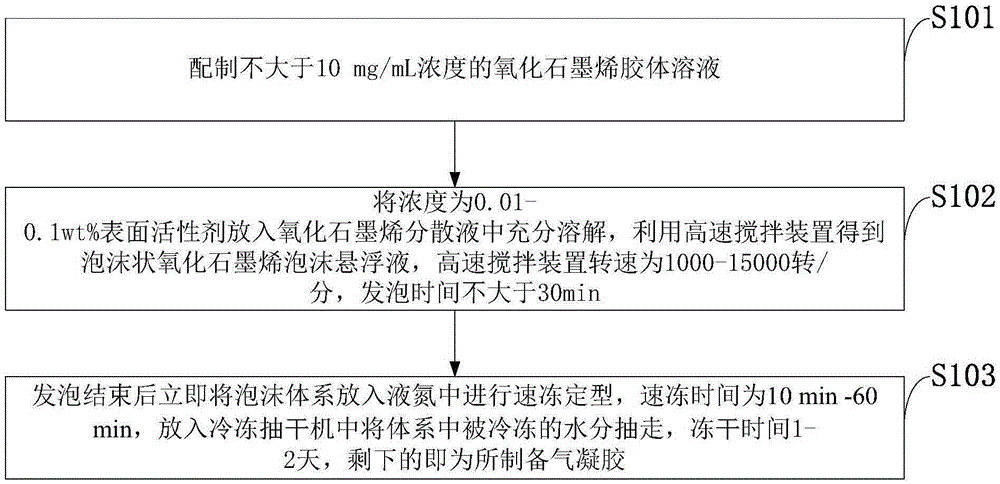

Spongy-like lightweight graphene aerogel preparation method

The present invention discloses a spongy-like lightweight graphene aerogel preparation method, which comprises: preparing a graphene oxide colloid solution with a concentration of not more than 10 mg / mL; adding a surfactant with a concentration of 0.01-0.1 wt% into the graphene oxide dispersion, and completely dissolving to obtain a foam-like graphene oxide foam suspension; and immediately placing the foam system into liquid nitrogen after completing the foaming, carrying out rapid freezing shaping, carrying out freeze drying, and removing the water to obtain the graphene aerogel material. According to the spongy-like lightweight graphene aerogel of the present invention, the solution system surface tension is reduced, and the dispersion property of the graphene oxide in the solvent is improved while the specific surface area of the aerogel material is further increased so as to improve the adsorption property on dyes, organic solvents and other substances; and the prepared spongy-like lightweight graphene aerogel material has characteristics of simple process, low cost, stable structure, excellent performance, and maximal maintaining of the excellent properties of the graphene material.

Owner:CAPITAL NORMAL UNIVERSITY

Air separator by utilizing cold energy of liquefied natural gas

InactiveCN1407303AReduce power consumptionRetrofit smallSolidificationLiquefactionEngineeringNitrogen gas

An air separator using the cold energy generated by liquefying natural gas to prepare liquefied oxygen, liquefied nitrogen and liquefied argon is based on existing air separator, and features that the multi-stage circulating nitrogen compressors, LNG heat exchanger and circulated nitrogen heat exchanger are additionally used to form a combined refrigerating system, and an air cooling system is also used.

Owner:UNIV OF SCI & TECH OF CHINA

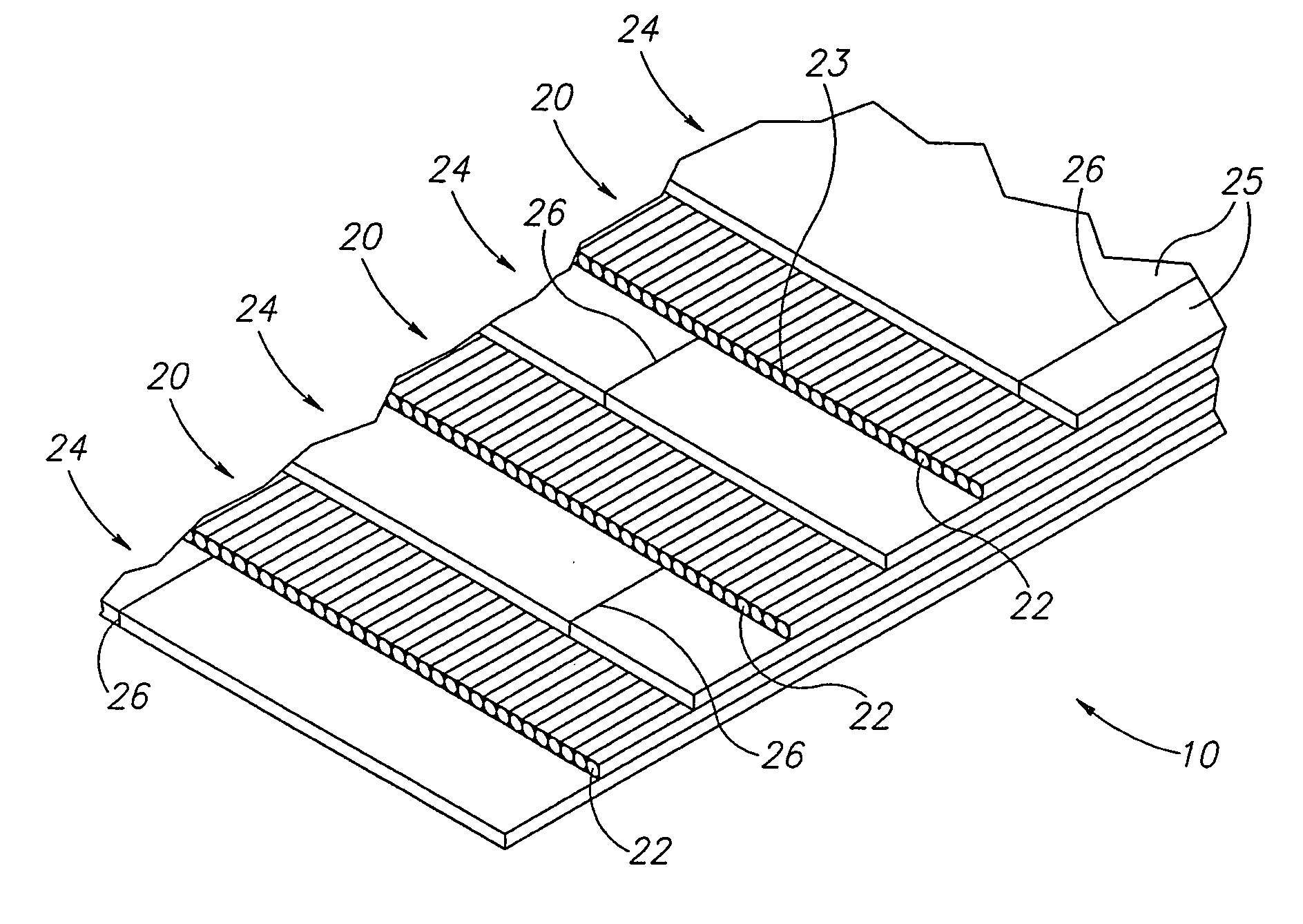

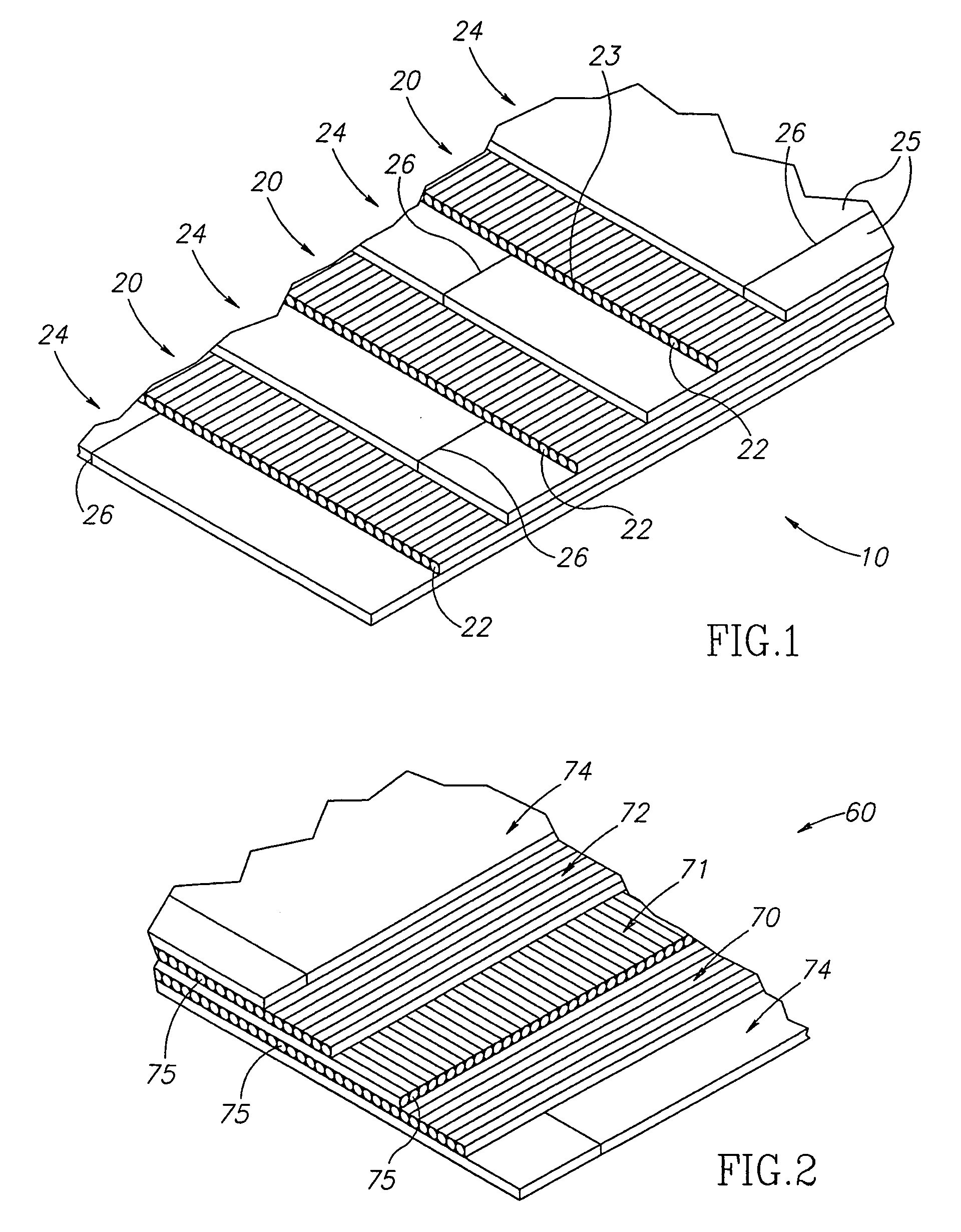

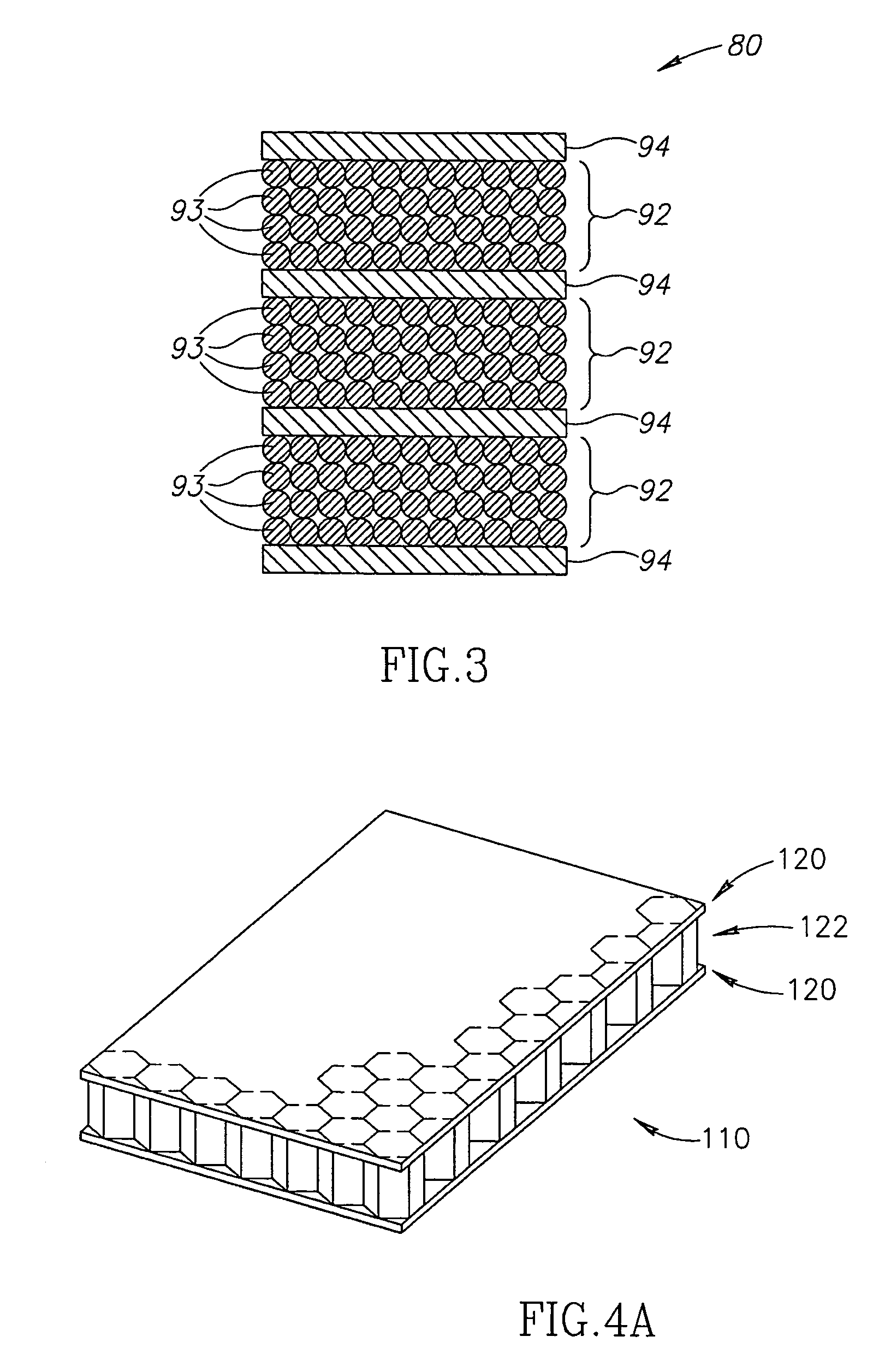

Nanostructure aluminum fiber metal laminates

InactiveUS20050271859A1Reduce property damageEffective solution to strength character issuesVehicle componentsThin material handlingFiber metal laminateAluminum metal

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com