Air separator by utilizing cold energy of liquefied natural gas

A technology for the separation of liquefied natural gas and air, applied in the direction of cold treatment separation, liquefaction, refrigeration and liquefaction, etc., can solve the problem of waste of cold energy, and achieve the effects of ensuring equipment safety, compact structure, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

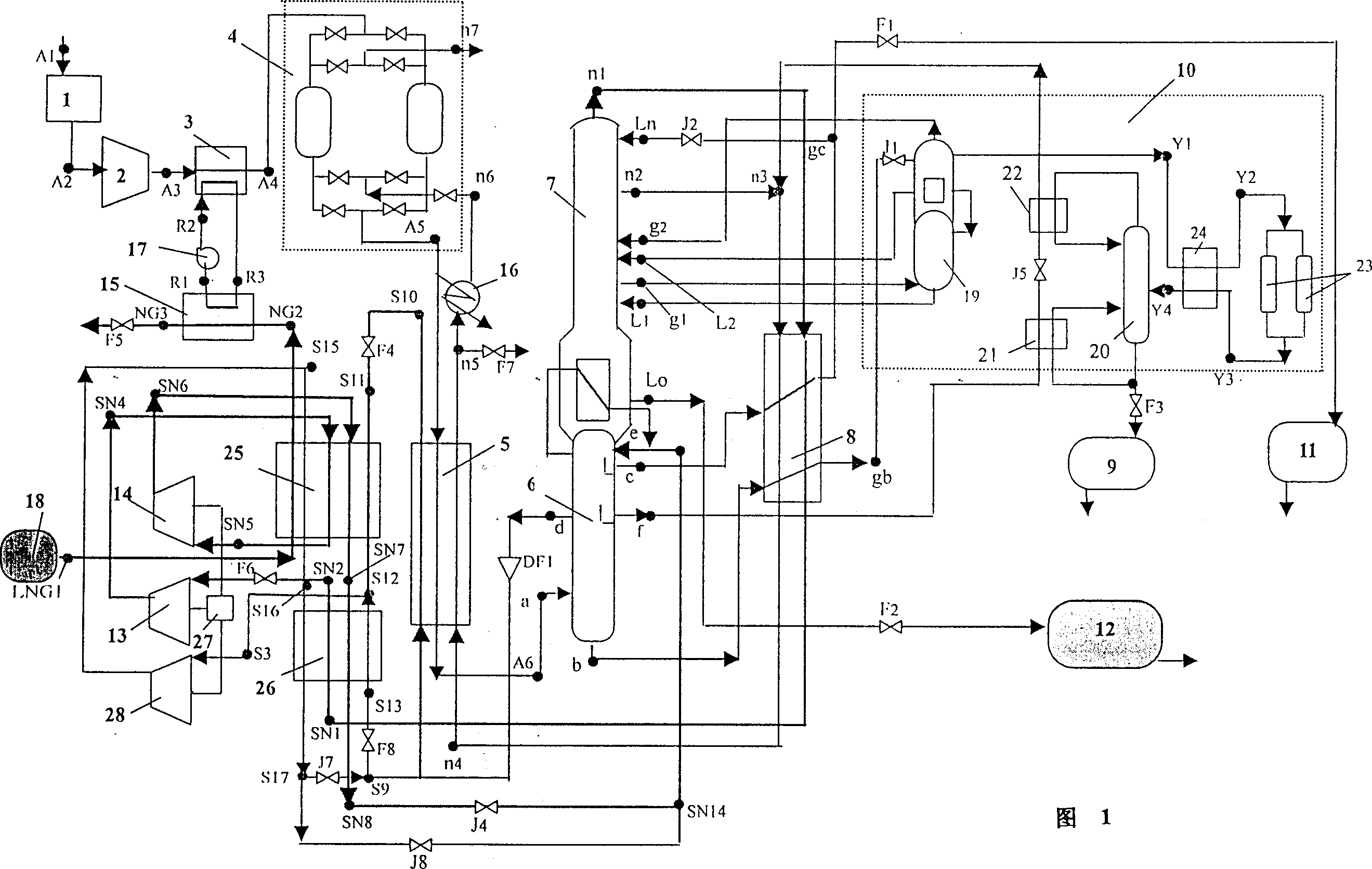

[0019] The equipment that the air separation plant of embodiment 1 adopts and connection route thereof are (seeing as shown in accompanying drawing 1):

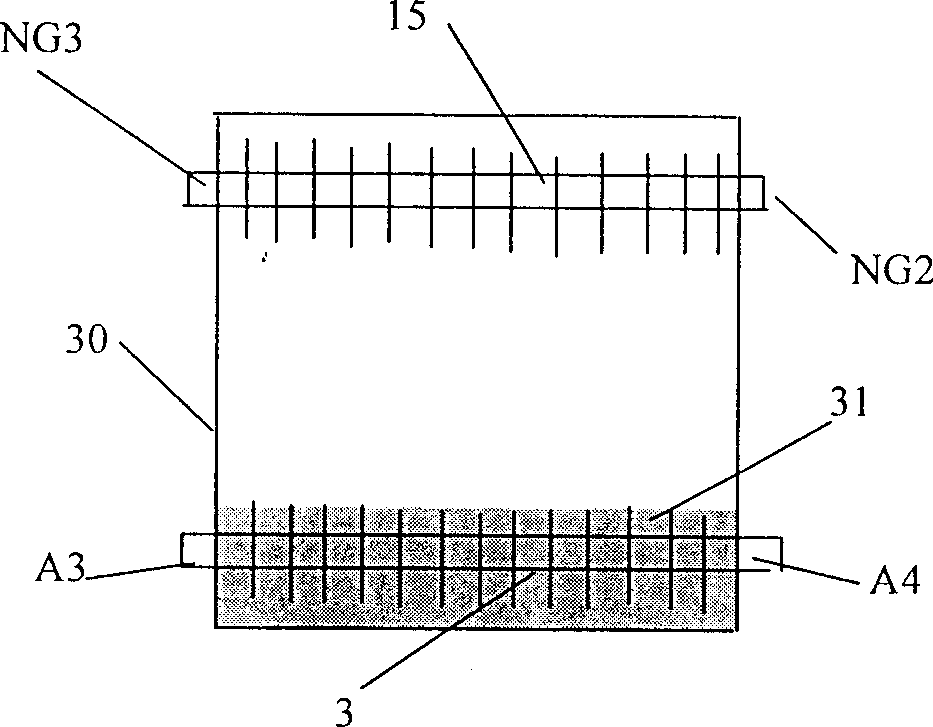

[0020] The air filter 1 has an air inlet A1, and its outlet is connected to the inlet A2 of the air compressor 2; the outlet of the air compressor 2 is connected to the air inlet A of the air cooler 3 3The air outlet of the air cooler 3 is connected to the air inlet of the molecular sieve adsorption system 4, connection point A4; the air outlet of the molecular sieve adsorption system 4 is connected to the inlet of the high-pressure air heat exchange tube at the top of the hot end of the main heat exchanger 5, connection point A5; The outlet A6 of the high-pressure air heat exchange tube of the main heat exchanger 5 is located at the bottom, and it is connected with the high-pressure air inlet a of the high-pressure fractionation tower 6; the liquid air outlet b of the high-pressure fractionation tower 6 is connected to the su...

Embodiment 2

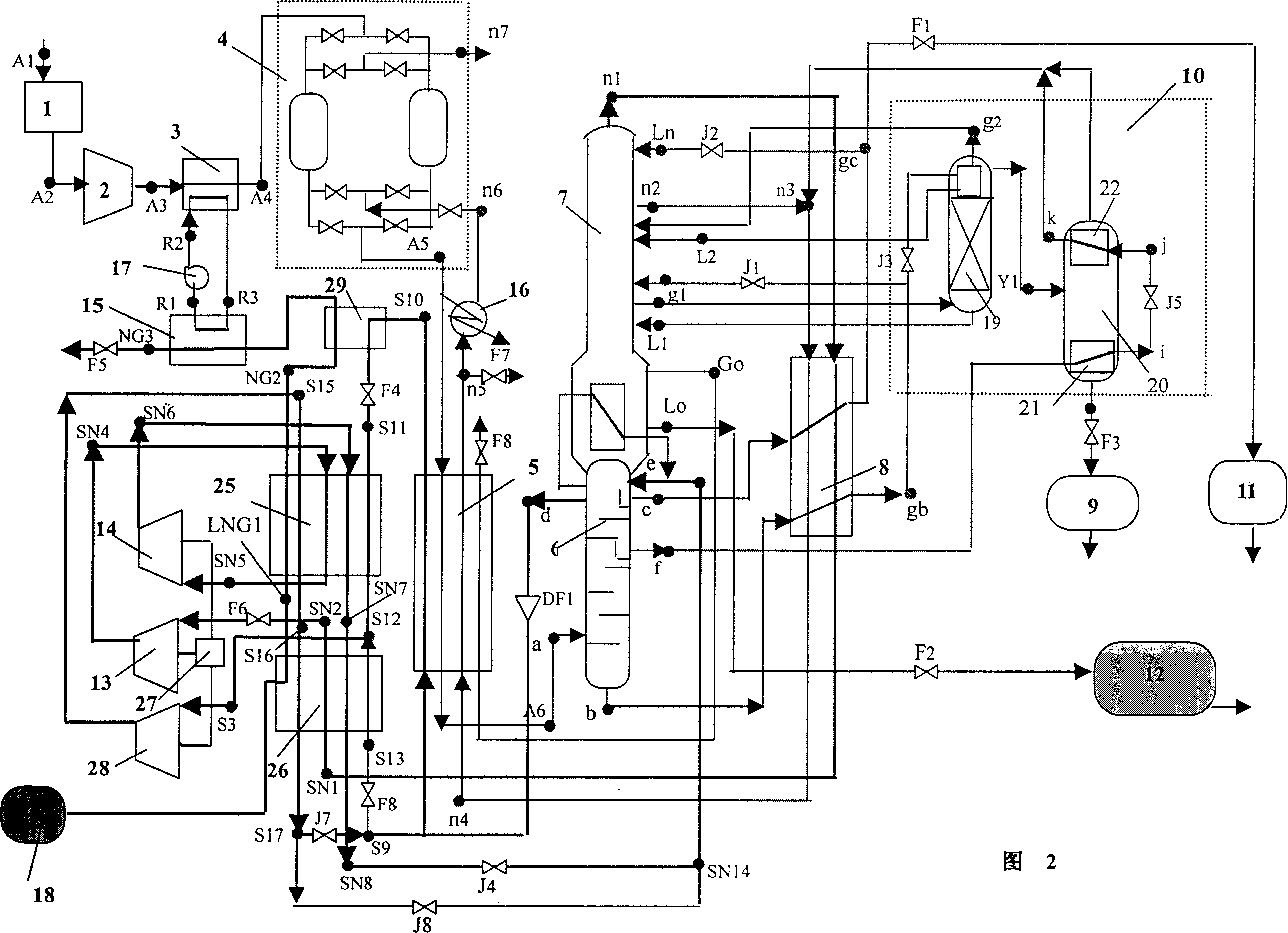

[0041] The air separation plant of embodiment 2 and the different equipment of embodiment 1 and connection route thereof are (seeing accompanying drawing 2 shown):

[0042] A pre-external nitrogen pre-cooler 29 is added on the top of the LNG heat exchanger 25, wherein only two heat exchange passages for liquefied natural gas and circulating nitrogen from the main heat exchanger 5 are provided, and the heat exchange of the liquefied natural gas The inlet of the flow channel is connected to the outlet of the liquefied natural gas heat absorbing pipe LNG1→NG2 of the LNG heat exchanger 25, and the outlet of the liquefied natural gas heat exchange flow channel is connected to the inlet of the natural gas channel of the natural gas reheating heat exchanger 15, and its circulating nitrogen gas exchange The inlet of the hot runner is connected to the outlet S10 of the circulating nitrogen heat recovery channel of the main heat exchanger 5, and its outlet is connected to the regulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com