Patents

Literature

141 results about "Evaporation heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The evaporator is kind of heat transfer apparatuses where the heat transfer is done by forced convection or natural convection. And it’s an important component of refrigeration system and air conditioning system. Evaporation process is rejection of water (or other liquids) by concentrating the solution.

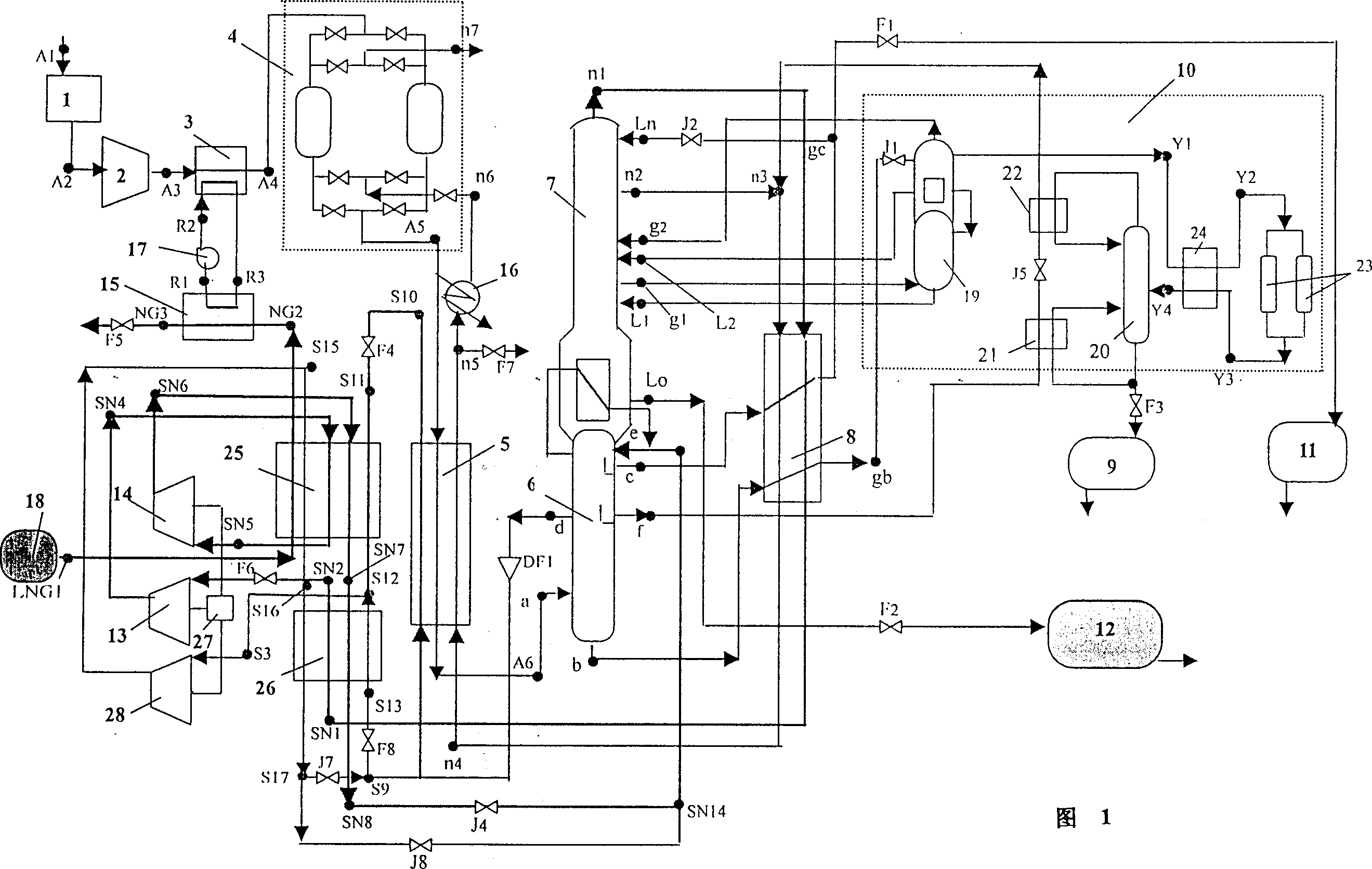

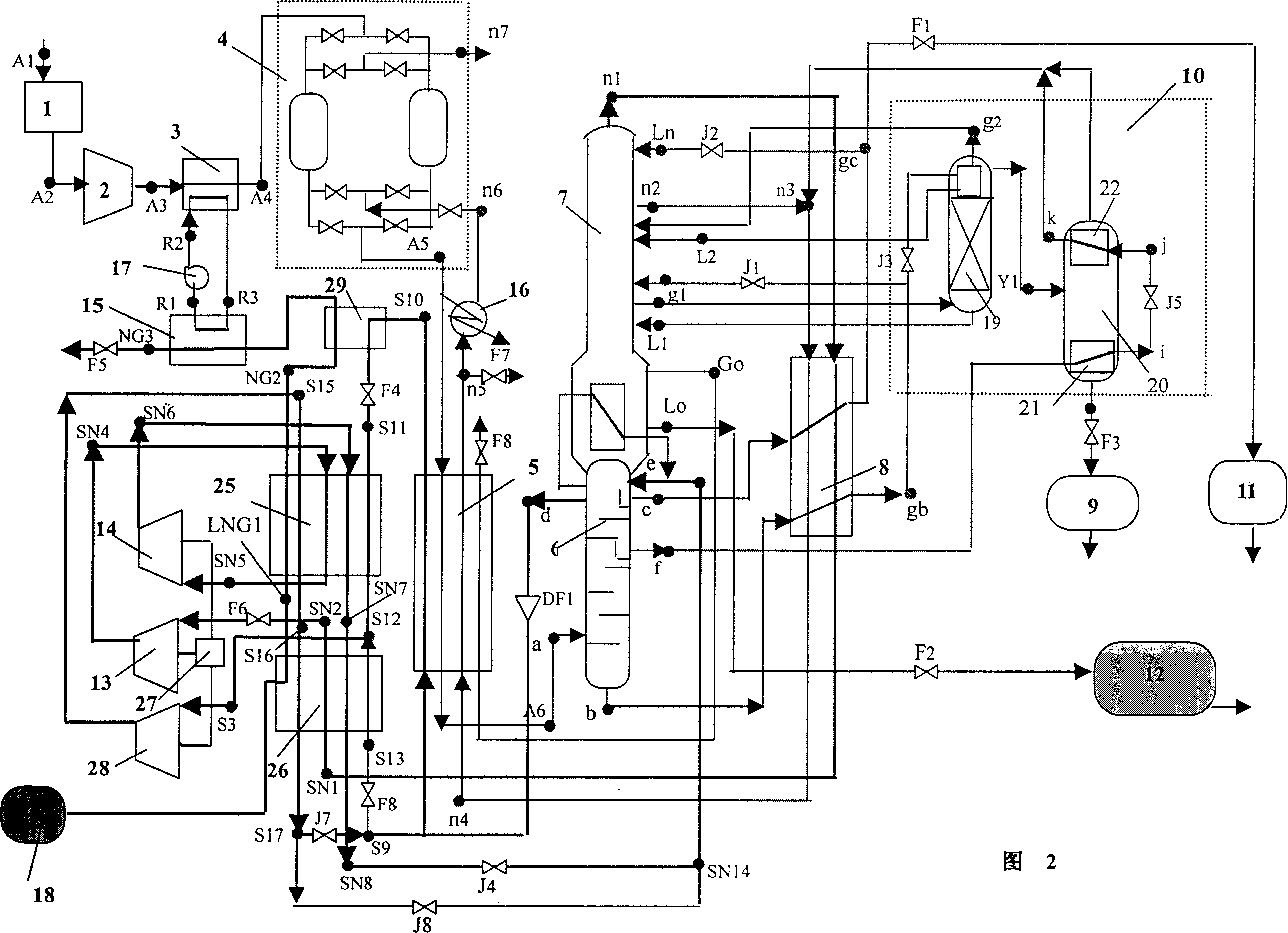

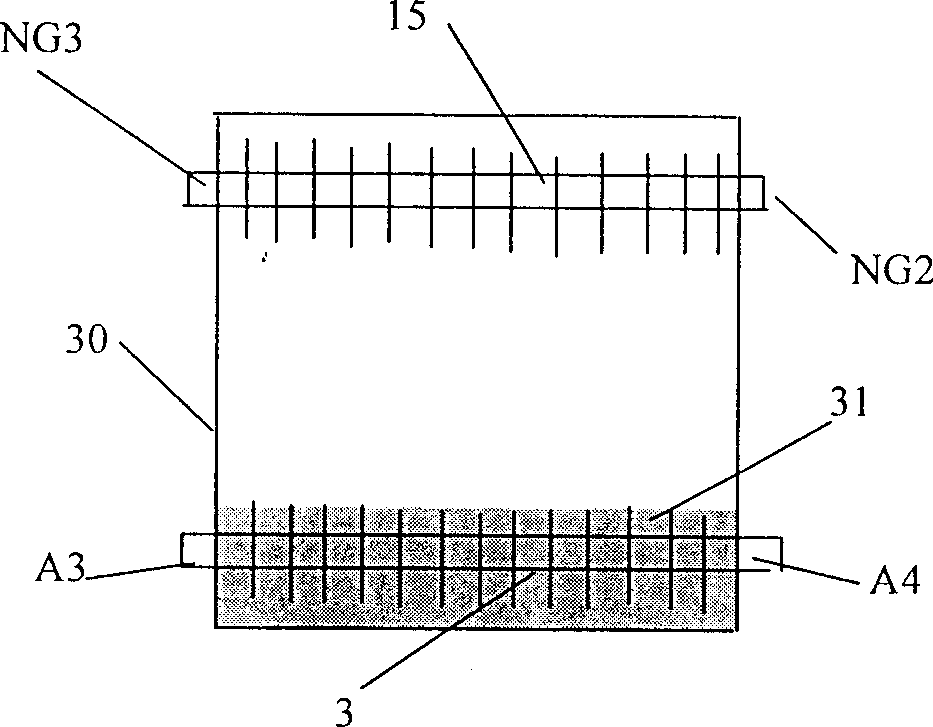

Air separator by utilizing cold energy of liquefied natural gas

InactiveCN1407303AReduce power consumptionRetrofit smallSolidificationLiquefactionEngineeringNitrogen gas

An air separator using the cold energy generated by liquefying natural gas to prepare liquefied oxygen, liquefied nitrogen and liquefied argon is based on existing air separator, and features that the multi-stage circulating nitrogen compressors, LNG heat exchanger and circulated nitrogen heat exchanger are additionally used to form a combined refrigerating system, and an air cooling system is also used.

Owner:UNIV OF SCI & TECH OF CHINA

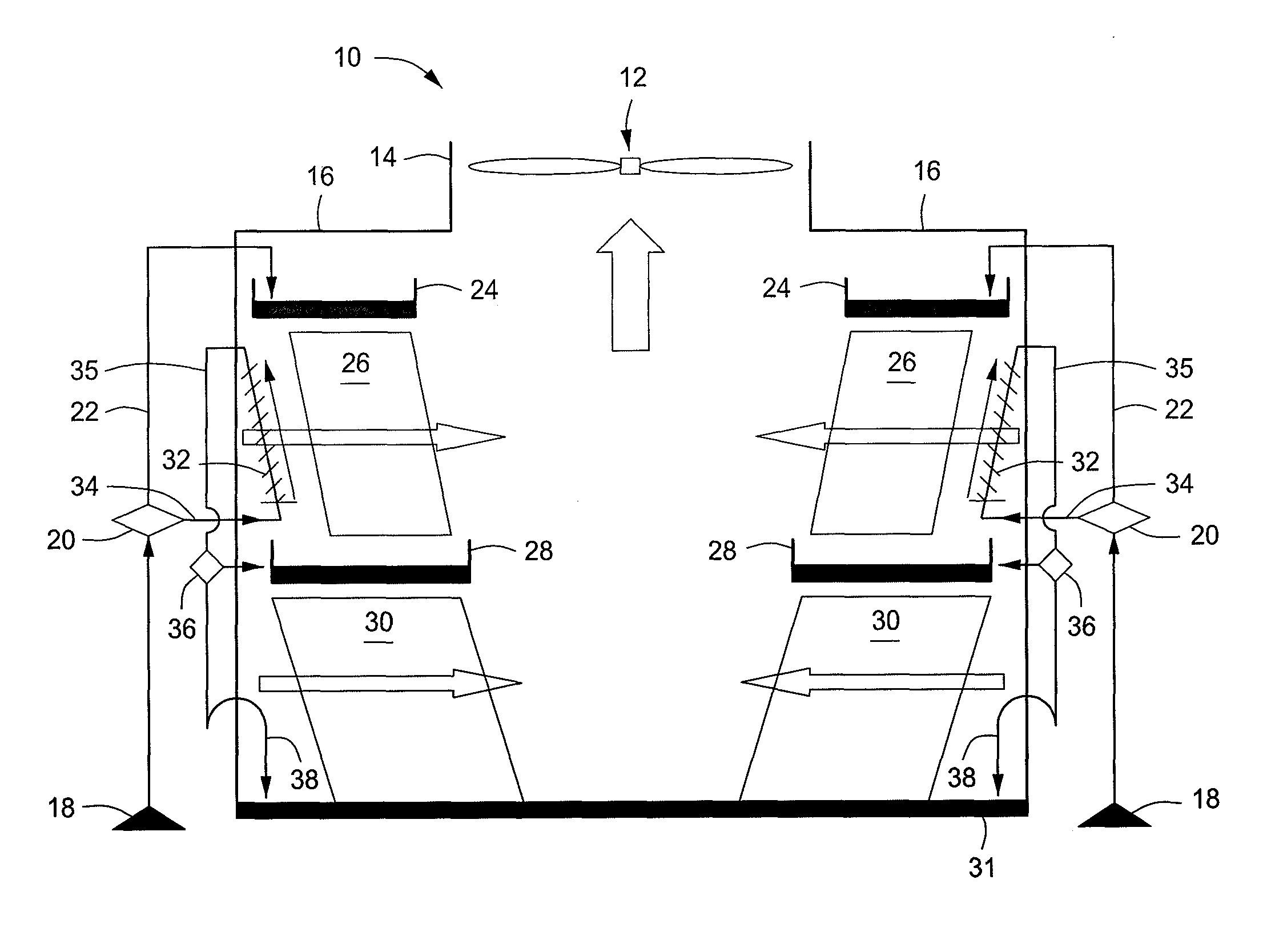

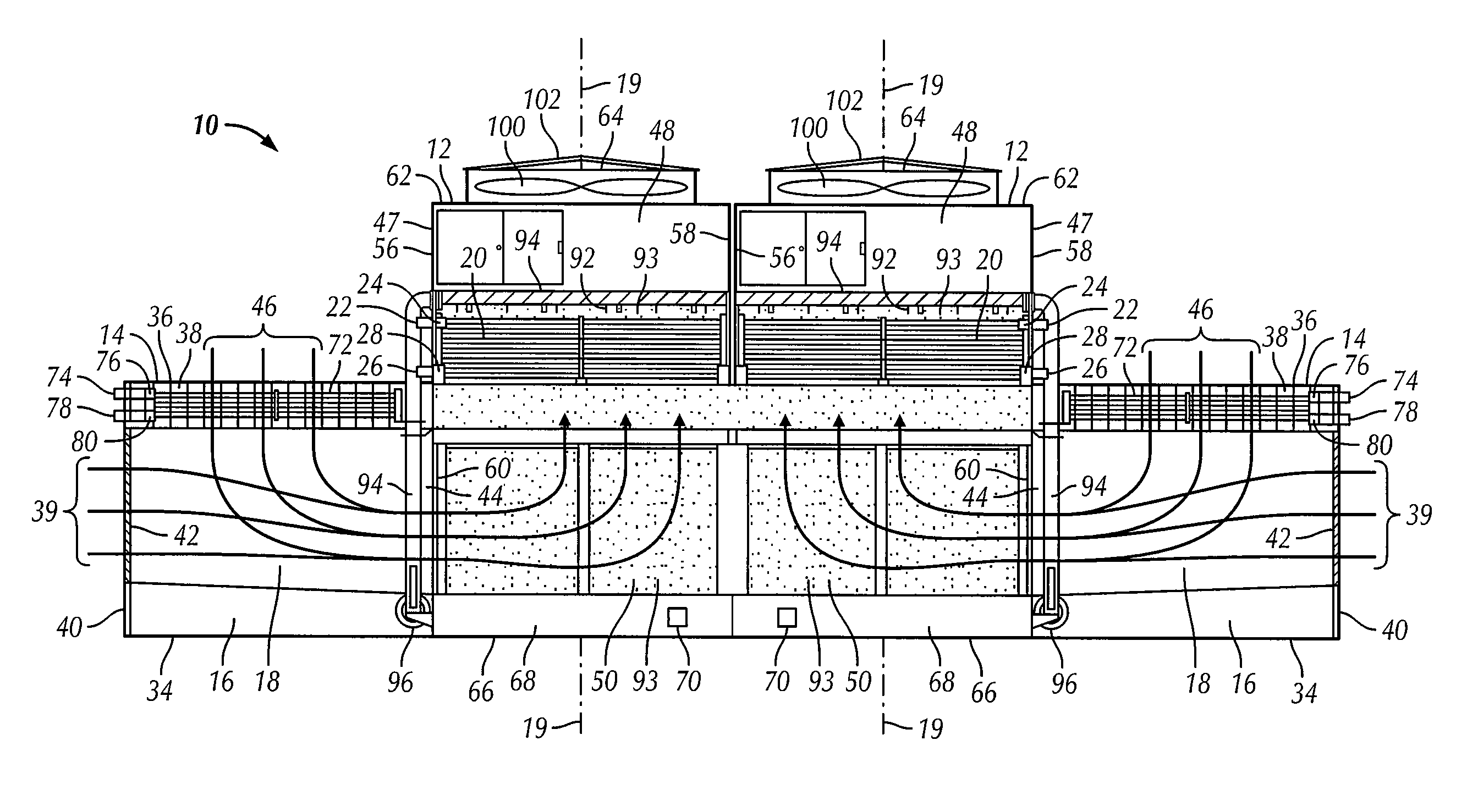

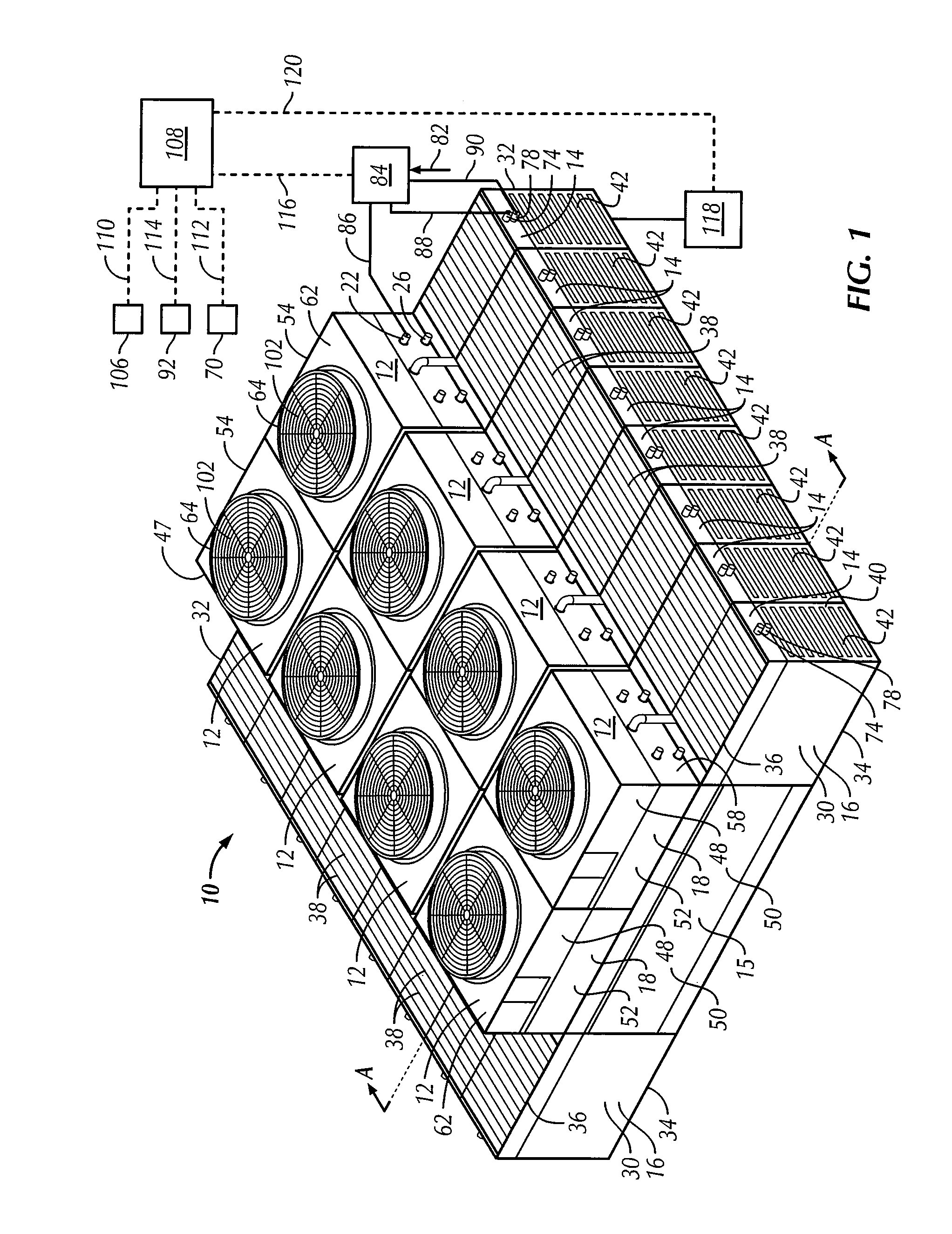

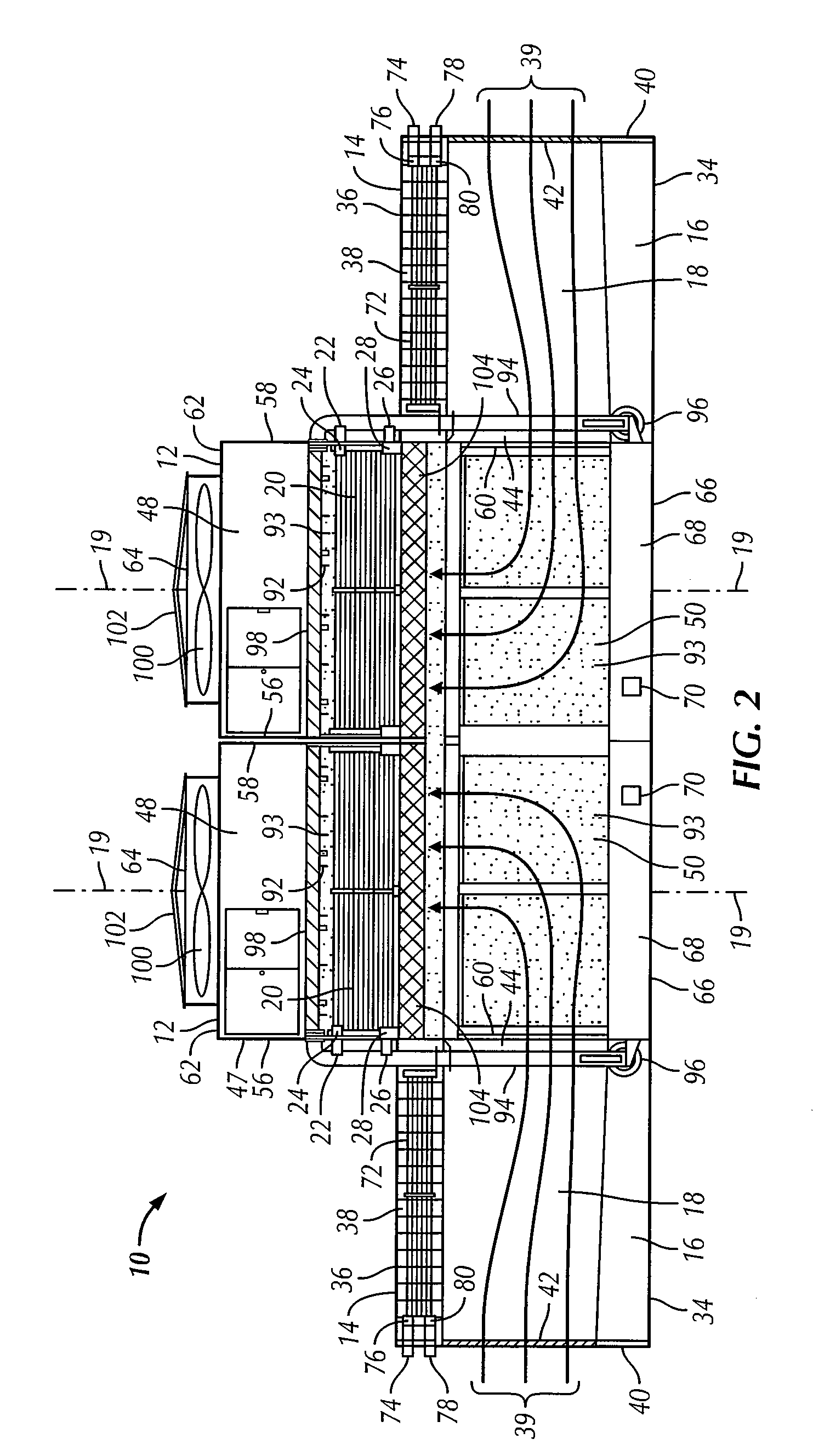

Wet/dry cooling tower and method

ActiveUS7887030B2Reducing plumeCarburetting airUsing liquid separation agentEvaporation heat transferCooling tower

Owner:SPX COOLING TECH

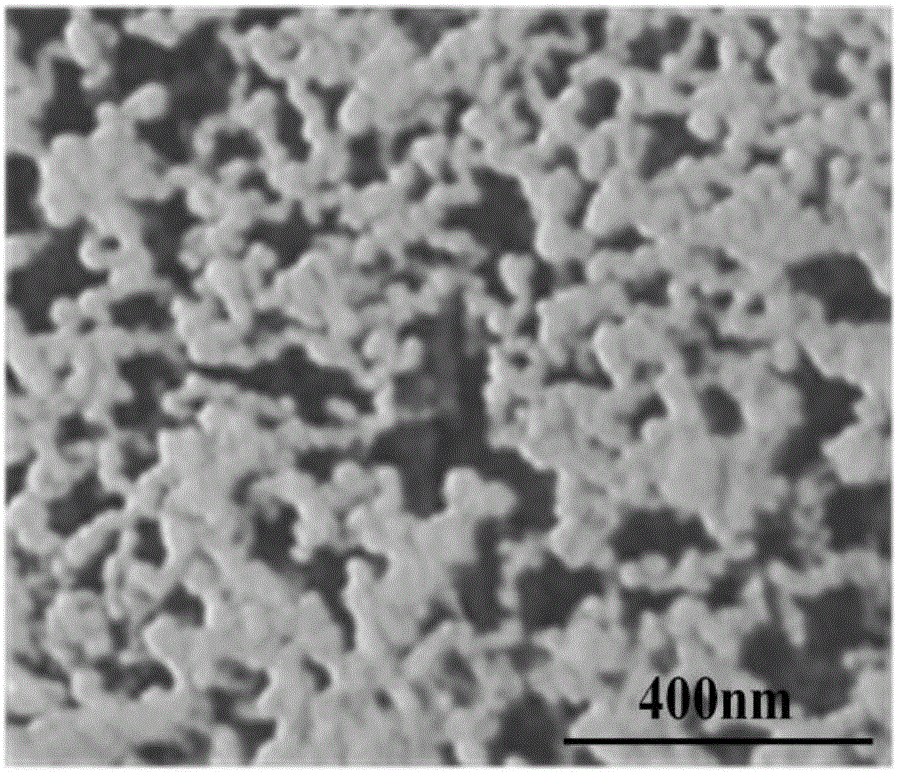

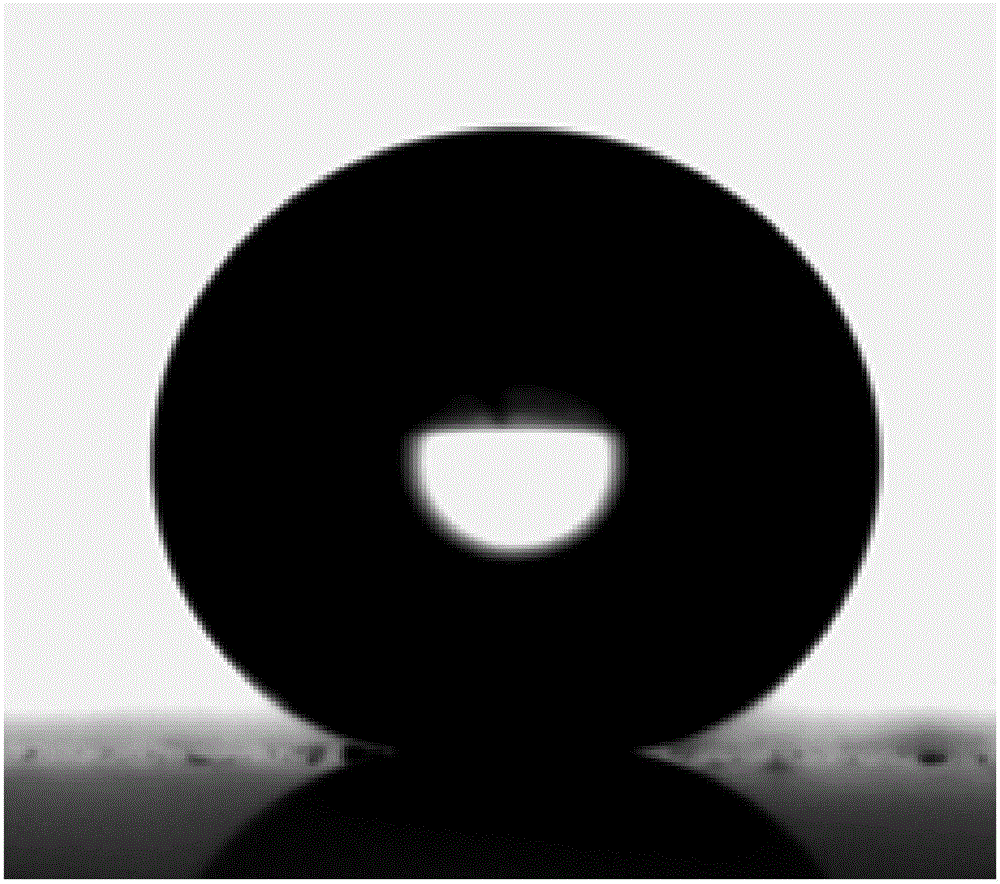

Micro-droplet self-transported wedged non-uniform wetting surface and preparation method thereof

ActiveCN105820749AReduce adhesionExcellent surface superhydrophobicityMetallic material coating processesEvaporation heat transferPolyvinyl alcohol

The invention relates to a micro-droplet self-transported wedged non-uniform ultra-wetting surface and a preparation method thereof. A super-hydrophobic surface containing titanium dioxide or zinc oxide nano-materials is constructed on the surface of a substrate by using a coating spraying or hydrothermal oxidation method, and a template method is used, ultraviolet light catalysis or oxygen plasma region selective modification is carried out to obtain a wedged super-hydrophilic region, the template method also can be used to obtain a wedged covering region, and then the coating spraying or hydrothermal oxidation method can be used again, and region selection is carried out to construct the super-hydrophobic surface, so as to obtain the wedged non-uniform ultra-wetting surface, finally, the wedged region is further modified by using polyvinyl alcohol again to obtain a bulge of the smooth super-hydrophilic wedged region, so that micro-droplets can be transported spontaneously in the wedged region without external force driving. By selecting the region of a template, the wedged super-hydrophilic region arranged in an array can be obtained on the super-hydrophobic surface, and multiple micro-droplets are in self-propelled movement by one time, so that the micro-droplet self-transported wedged non-uniform ultra-wetting surface has broad application prospects in fields of condensation heat transfer enhancement or evaporation heat transfer, fog catchment, microfluid and the like.

Owner:SOUTHEAST UNIV

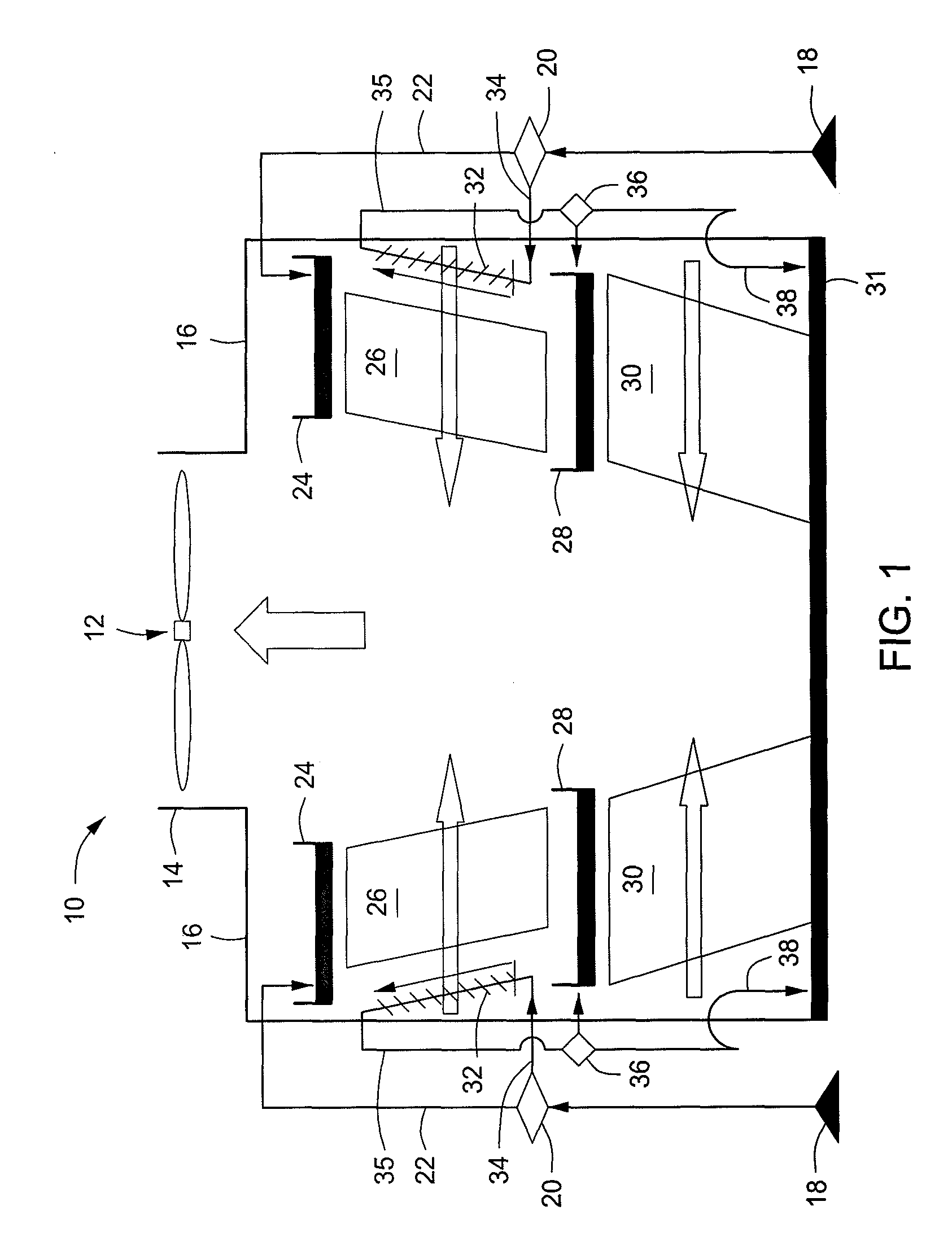

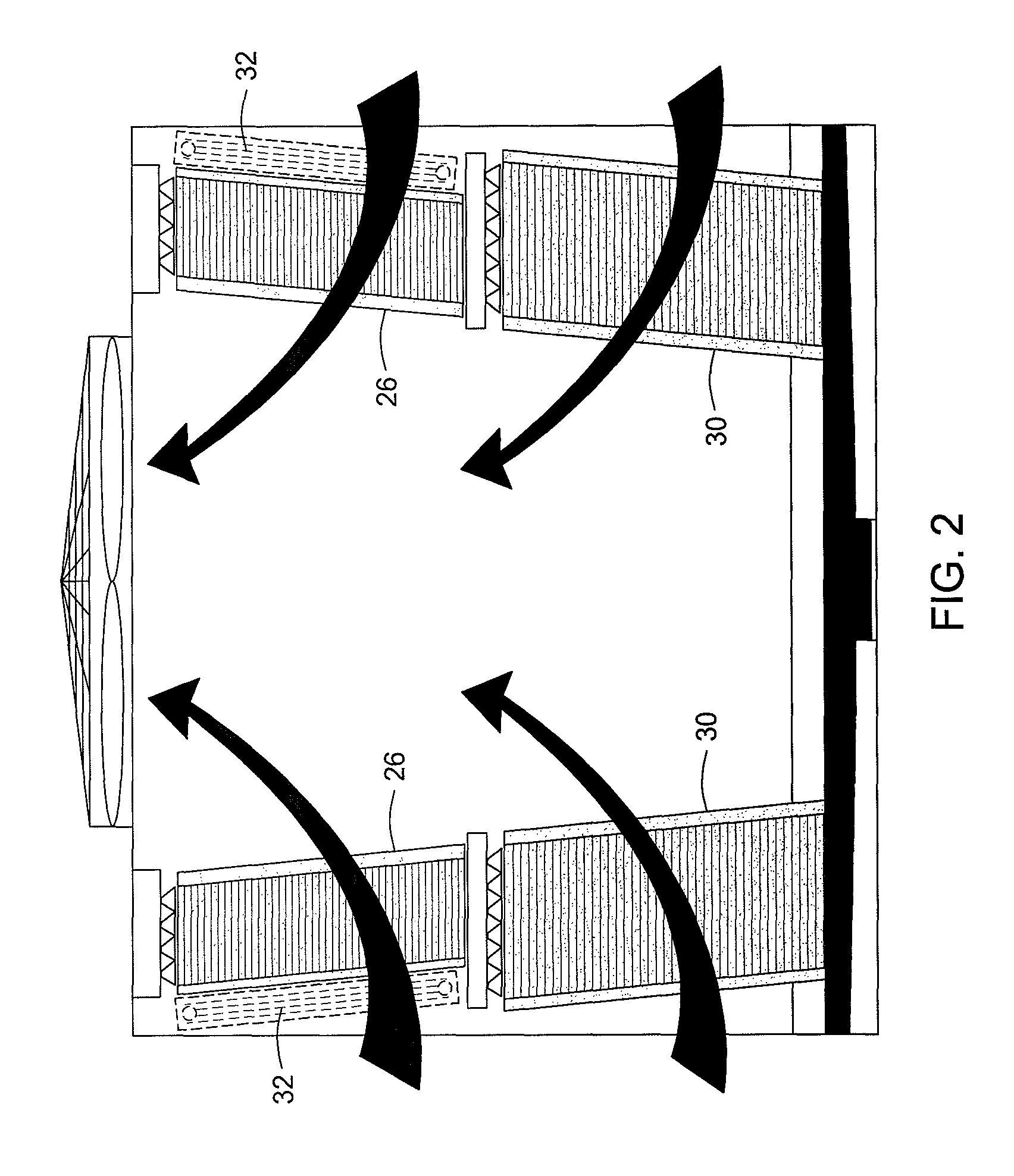

Wet/dry cooling tower and method

ActiveUS20090283245A1Reducing plumeDesirable efficiencyCarburetting airUsing liquid separation agentCooling towerEvaporation heat transfer

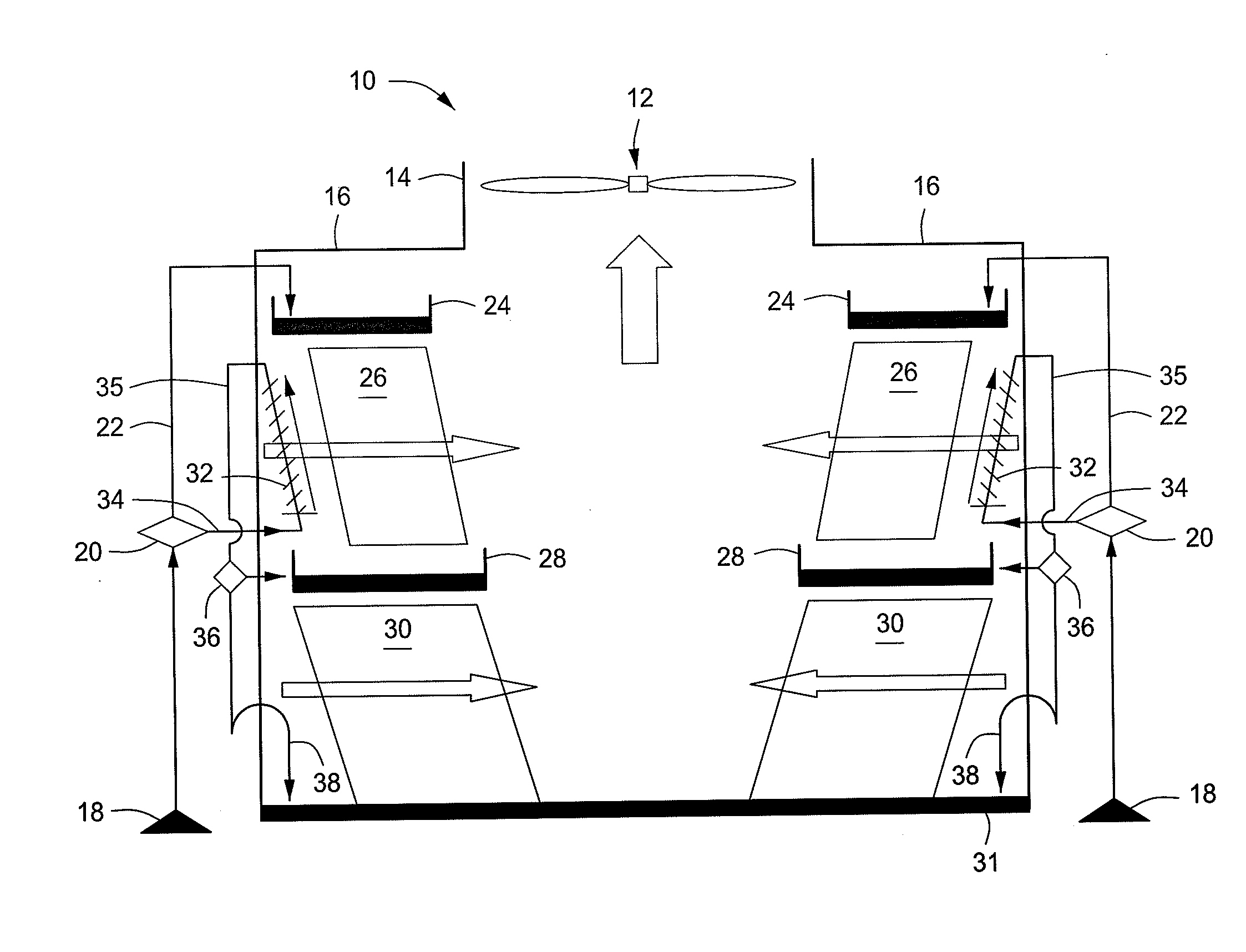

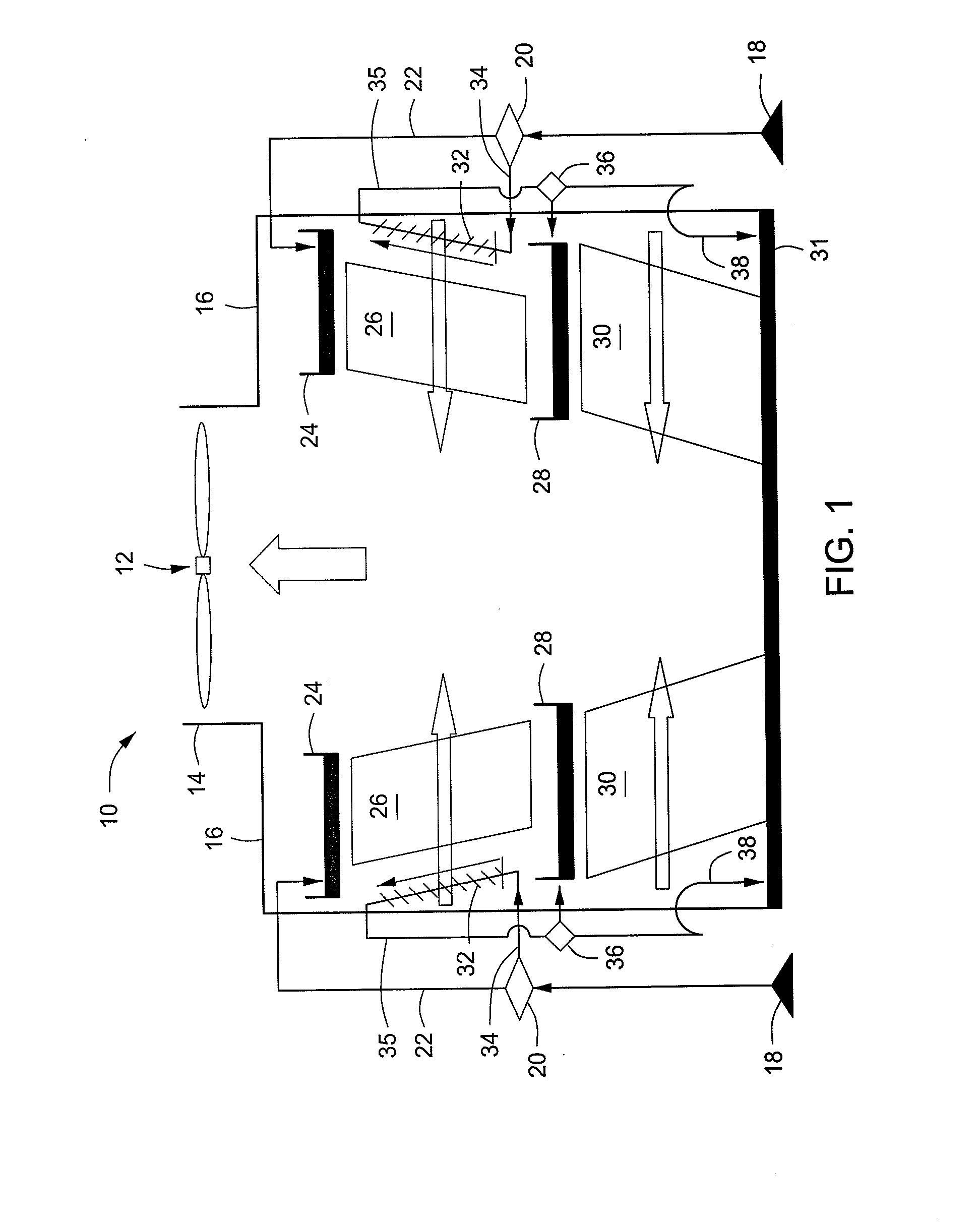

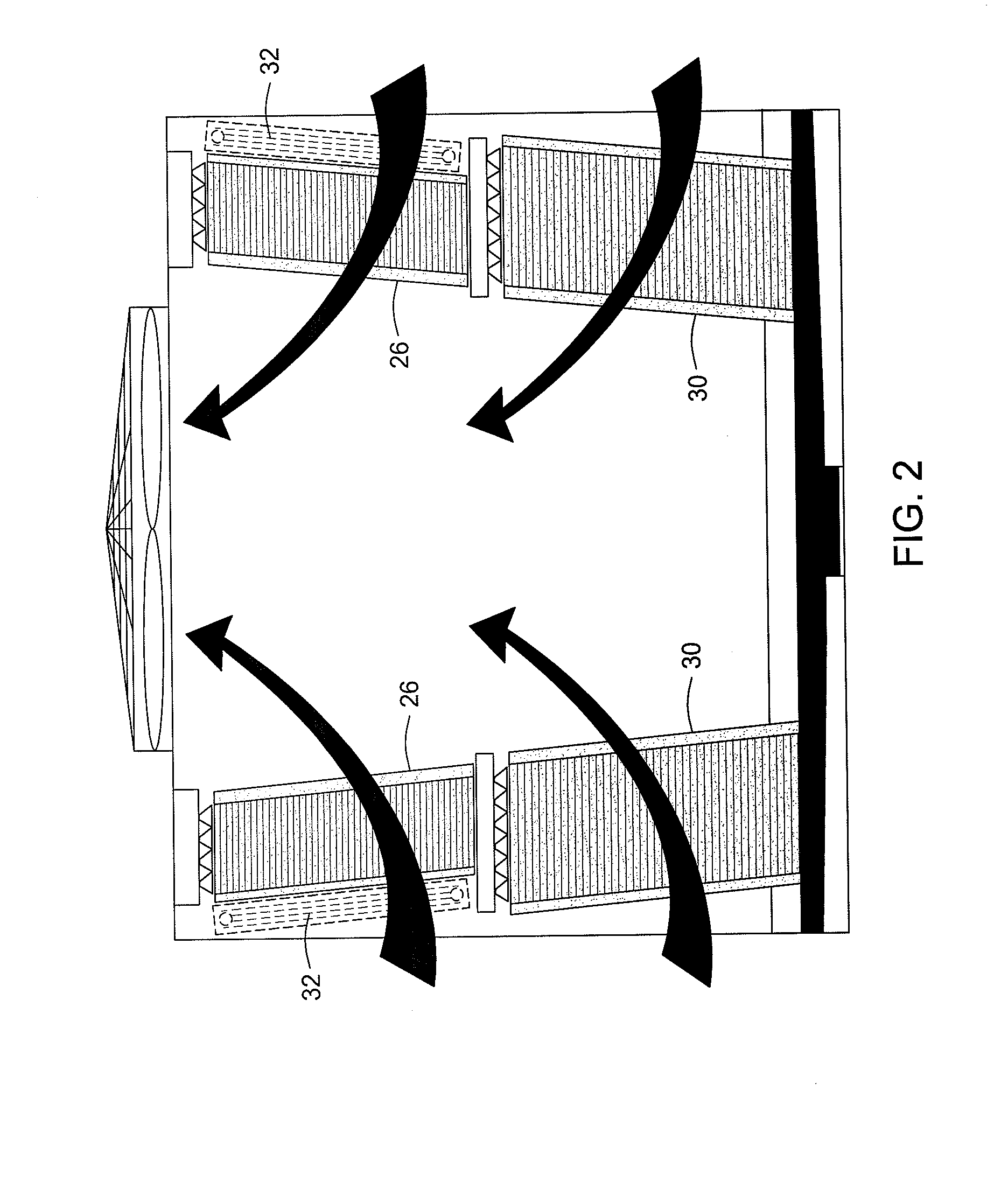

An atmospheric cooling tower apparatus includes a housing structure having an air inlet and an air outlet, a first evaporative heat transfer media disposed in the housing, and a closed coil heat transfer media disposed in the housing. A water distribution assembly is disposed above the evaporative heat transfer media and configured to distribute water onto the evaporative fill heat transfer fill media. A collection basin is disposed beneath the evaporative heat transfer media configured to collect water that has passed through the evaporative heat transfer media. A first control valve controls an inflow of water to supply water to one or both of the evaporative heat transfer media and the closed coil heat transfer media. The closed coil heat transfer media and the evaporative heat transfer media are disposed laterally next to each other.

Owner:SPX COOLING TECH

Hybrid heat exchange apparatus

ActiveUS9243847B2Increase temperatureSteam/vapor condensersEfficient regulation technologiesEvaporation heat transferDry heat

Heat is indirectly transferred between a process fluid and ambient air in apparatus that includes an evaporative heat transfer cell operative in a wet mode or a dry mode, a dry heat transfer cell and a fan. The air may bypass the dry heat transfer cell to flow through a first air passage or may flow through a second air passage through the dry heat transfer cell and in either event, then through the evaporative heat transfer cell. The air may partially flow through and partially bypass the dry heat transfer cell, and then through the evaporative heat transfer cell. The evaporative heat transfer cell optionally may include a direct contact evaporative heat exchanger.

Owner:EVAPCO

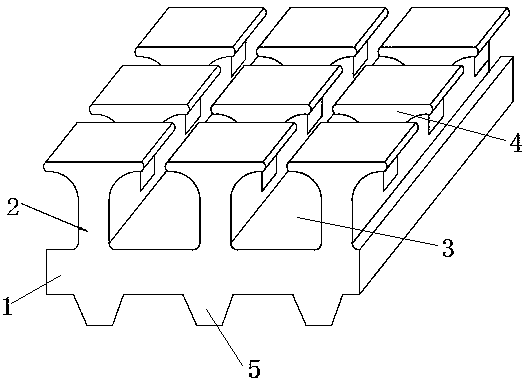

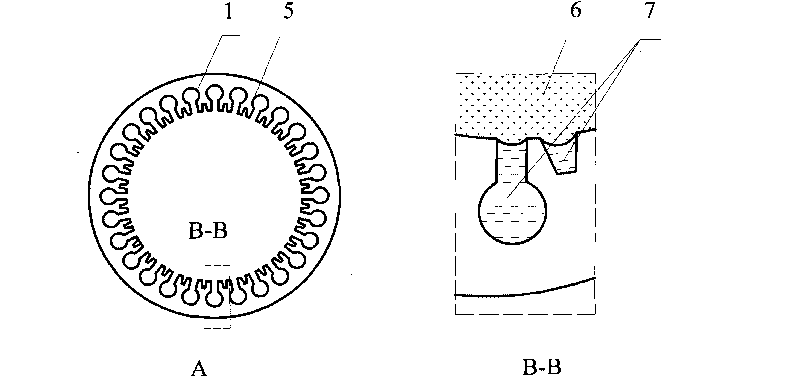

Boiling heat-exchange reinforced wall-attached orifice plate assembly shell component

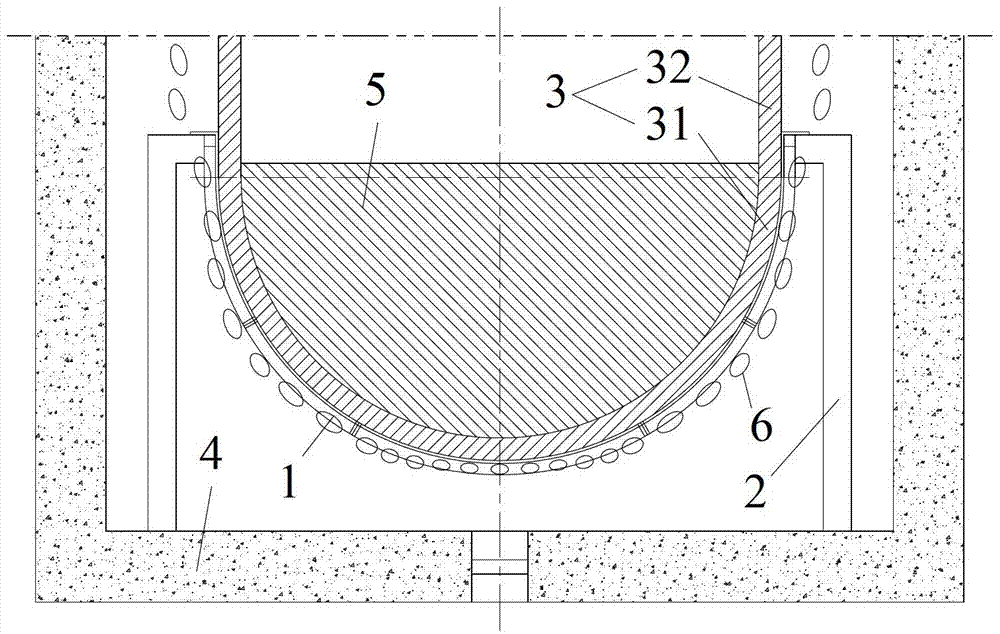

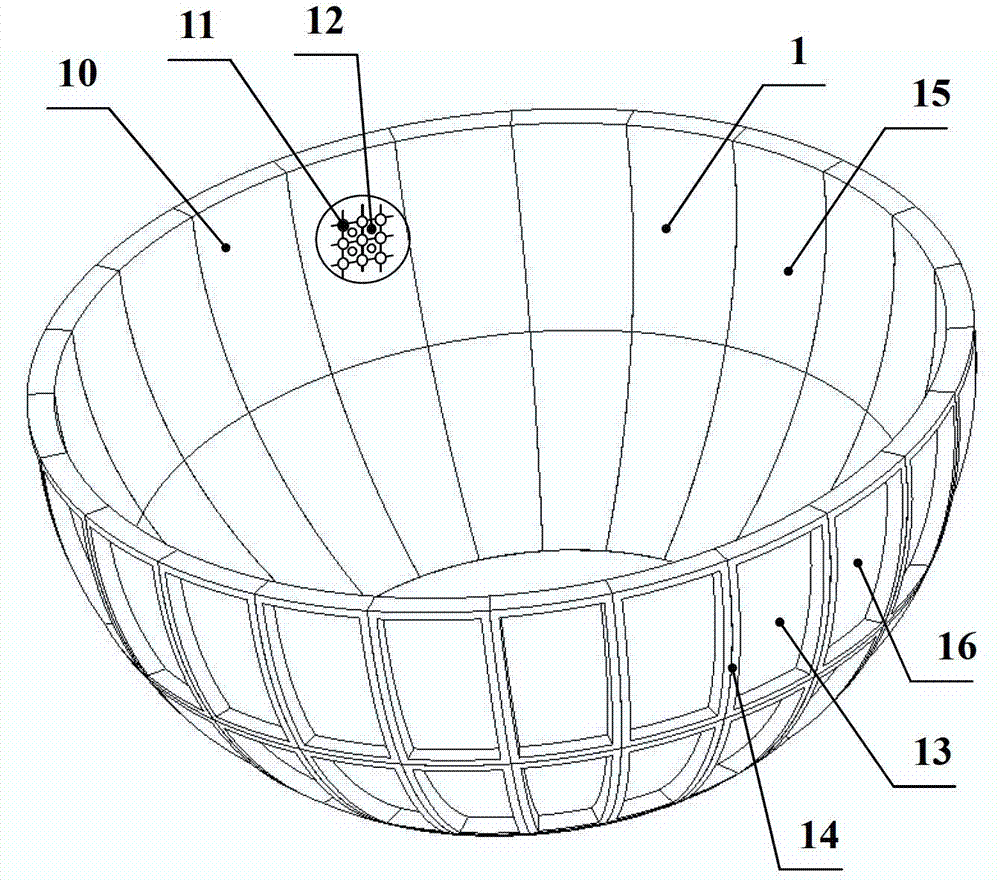

InactiveCN102969033AHigh densityEnhanced boiling heat transferNuclear energy generationCooling arrangementVena contracta diameterReactor pressure vessel

A boiling heat-exchange reinforced wall-attached orifice plate assembly shell component relates to the technical field of reinforced heat exchange. A wall-attached orifice plate assembly is mounted on an outer wall of a reactor pressure vessel and is supported and fixed by a fixing assembly, and is composed of a plurality of wall-attached orifice plate units mutually connected with each other as one. The wall-attached orifice plate units are orifice plate structure and are provided with a plurality of plate holes in an array arrangement. A plurality of wall-attached supporting members in the array arrangement are arranged at the inner side of the wall-attached orifice plate units, so that a gap is formed between part of the inner wall of the wall-attached orifice plate units except the supporting members and the outer wall of the reactor pressure vessel. The wall-attached orifice plate units are composed of orifice plates and connecting and strengthening side plates, and the connecting and strengthening side plates are arranged at edges of the orifice plates. The component can substantially reinforce boiling heat-exchange process, improve critical hot-fluid density, and thus substantially improve security; and strengthens heat exchange and improve performance stability of critical hot-fluid density.

Owner:TSINGHUA UNIV

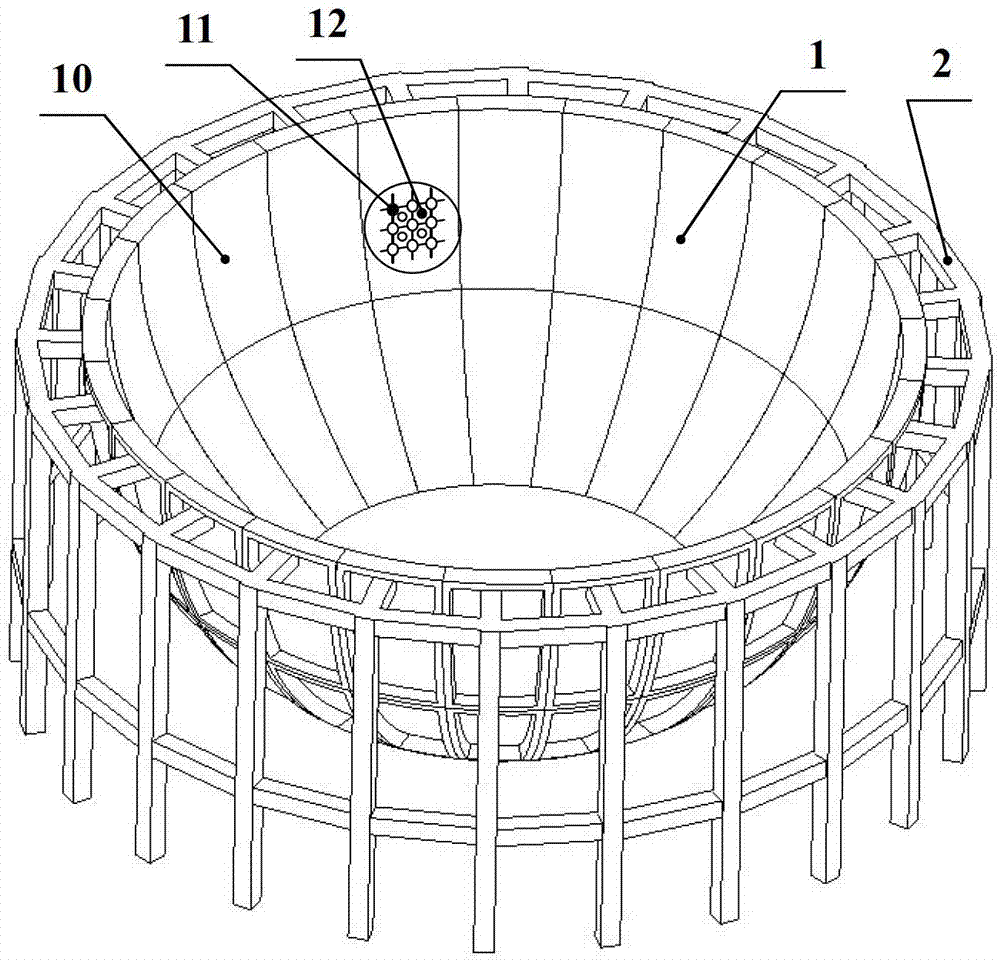

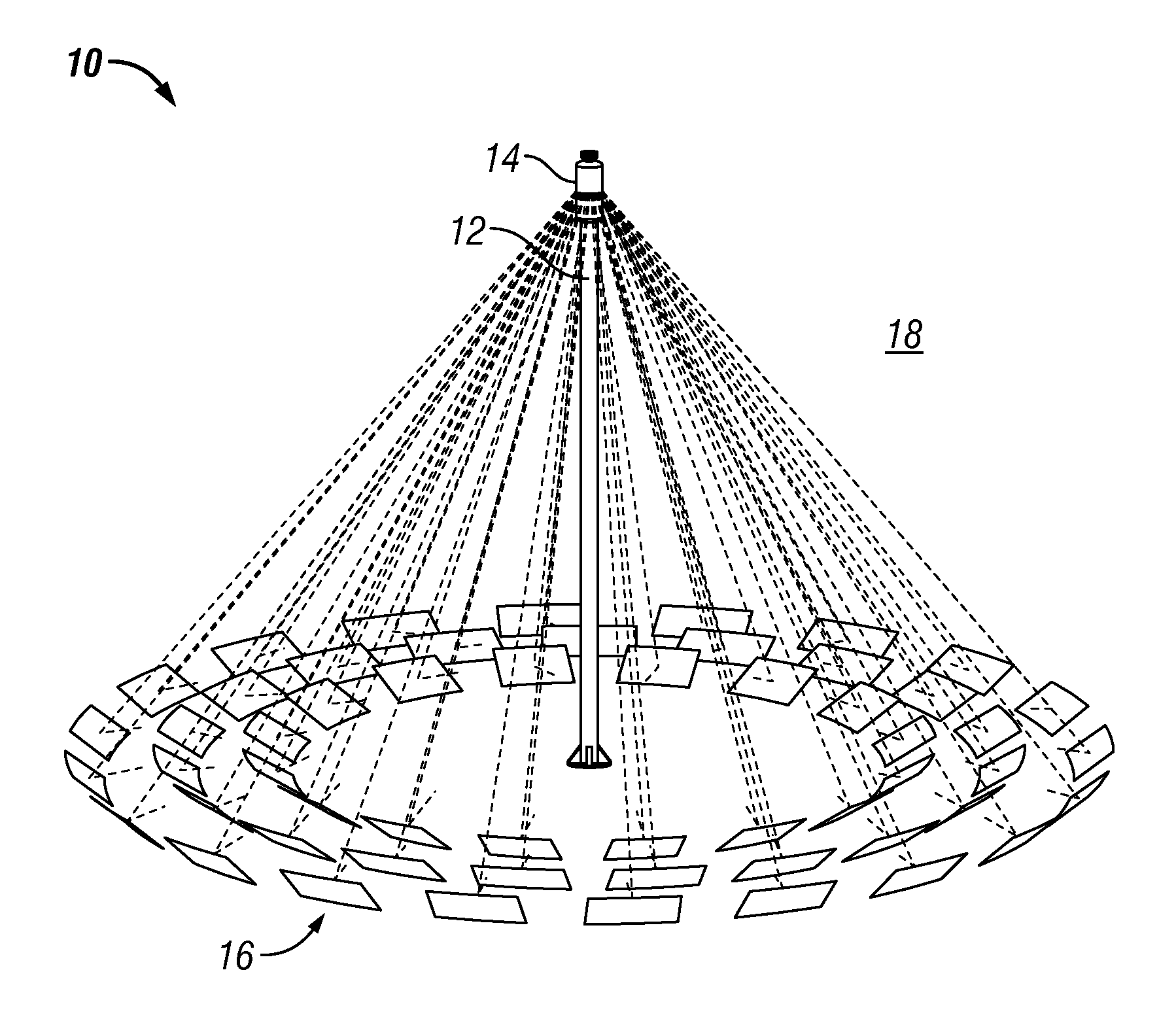

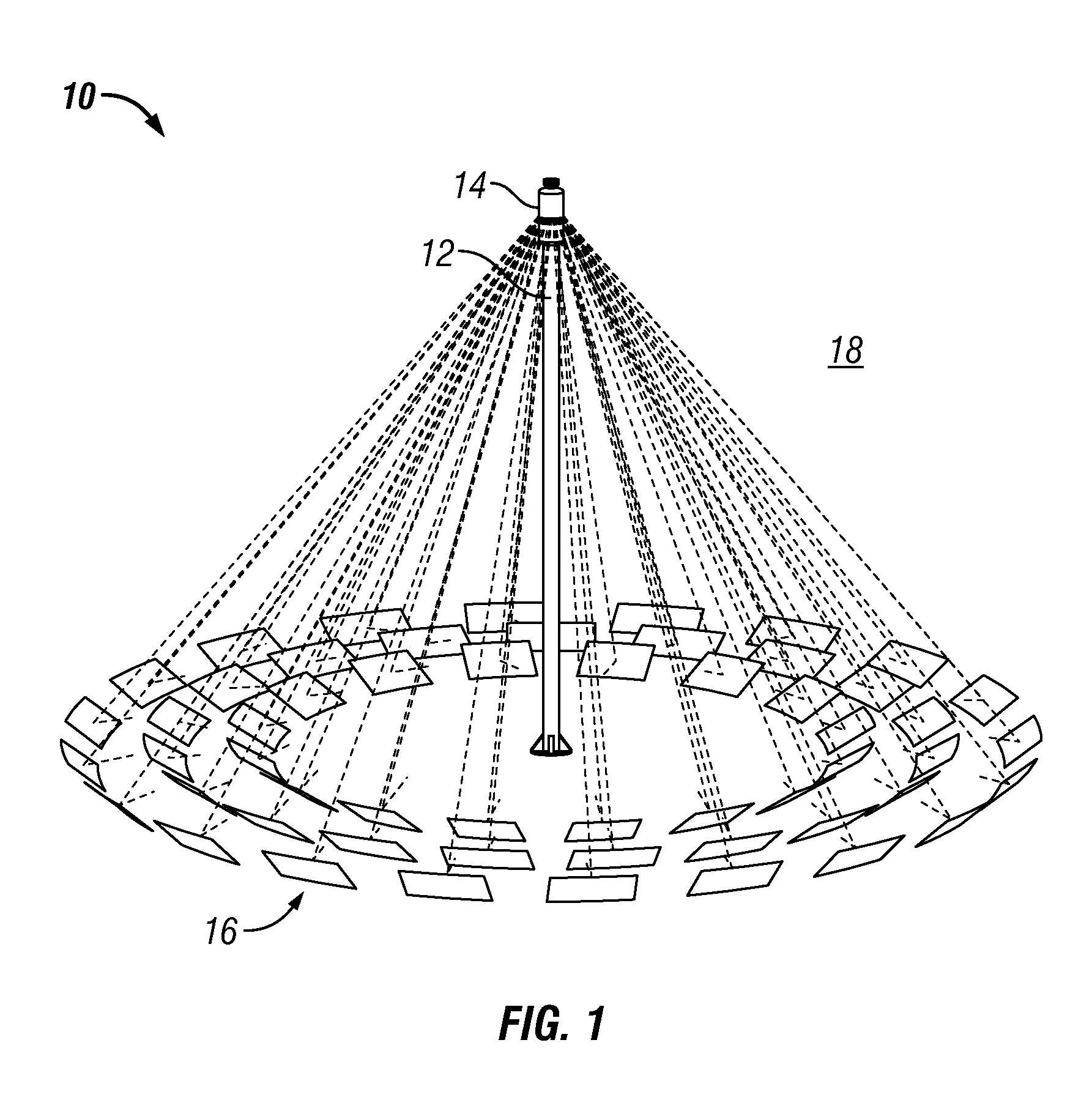

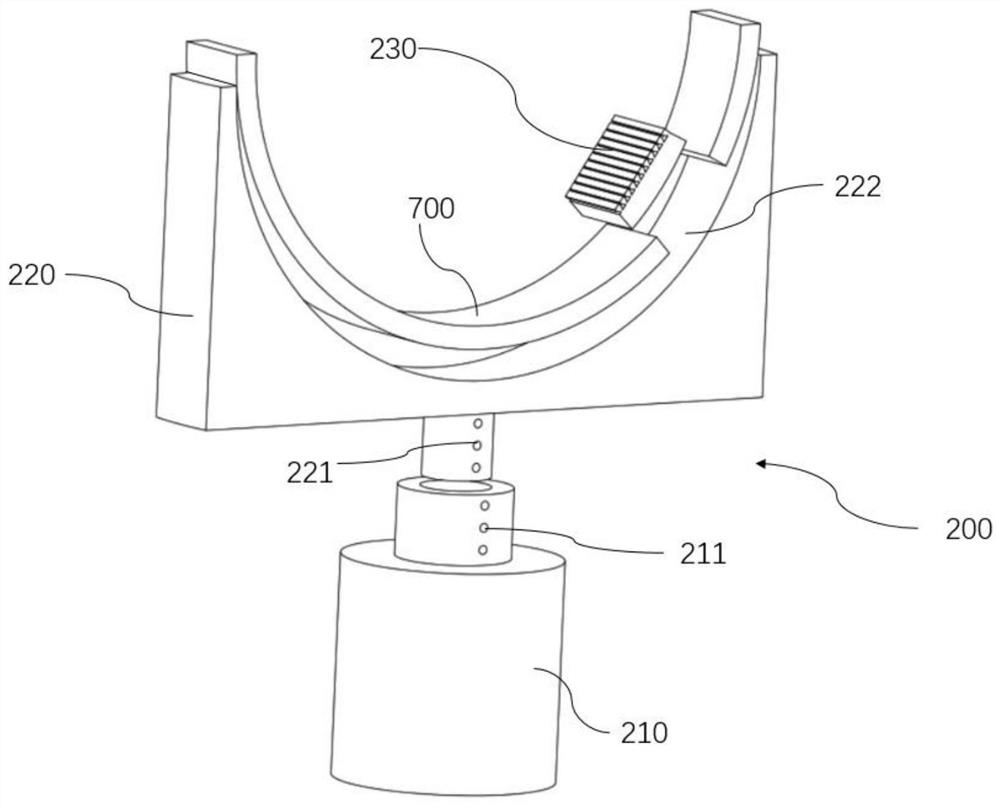

System for collecting concentrated solar radiation

InactiveUS20130047610A1Unlimited capacityLittle to no carbon dioxide emissionSolar heating energySolar heat devicesEvaporation heat transferEngineering

The present invention is directed to a solar energy system including a tower having a solar radiation receiver, the solar radiation receiver including a plurality of tubes carrying a heat-transfer medium and a drum, the drum in thermal communication with the tubes, and one or more mirrors configured to reflect solar radiation onto the receiver, wherein the receiver receives the reflected solar radiation from the mirrors, thereby heating the heat transfer medium and vaporizing the heat transfer medium.

Owner:CHEVROU USA INC

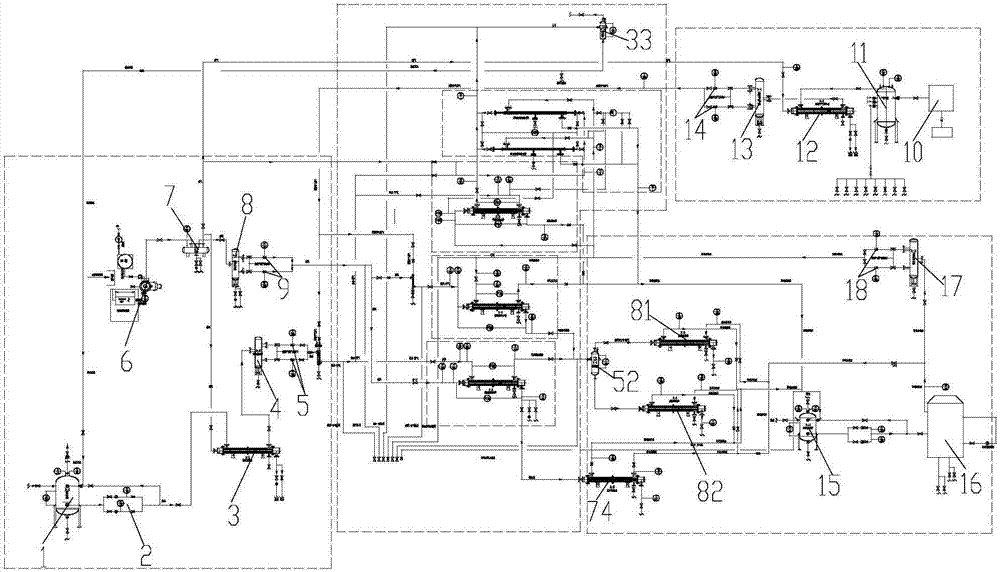

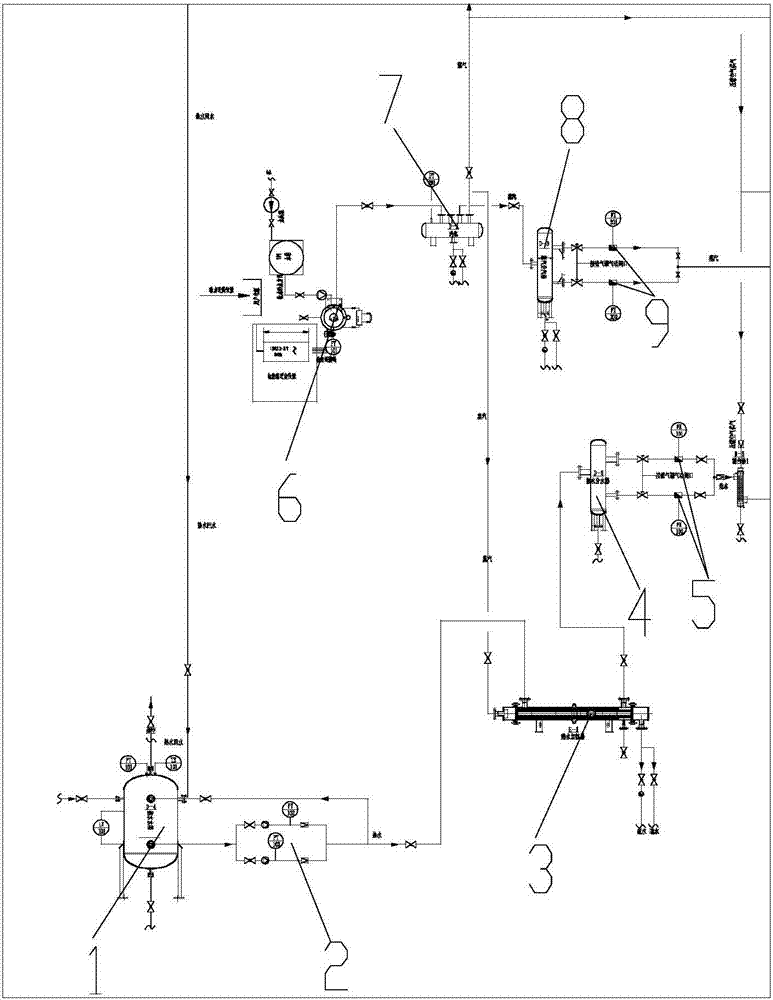

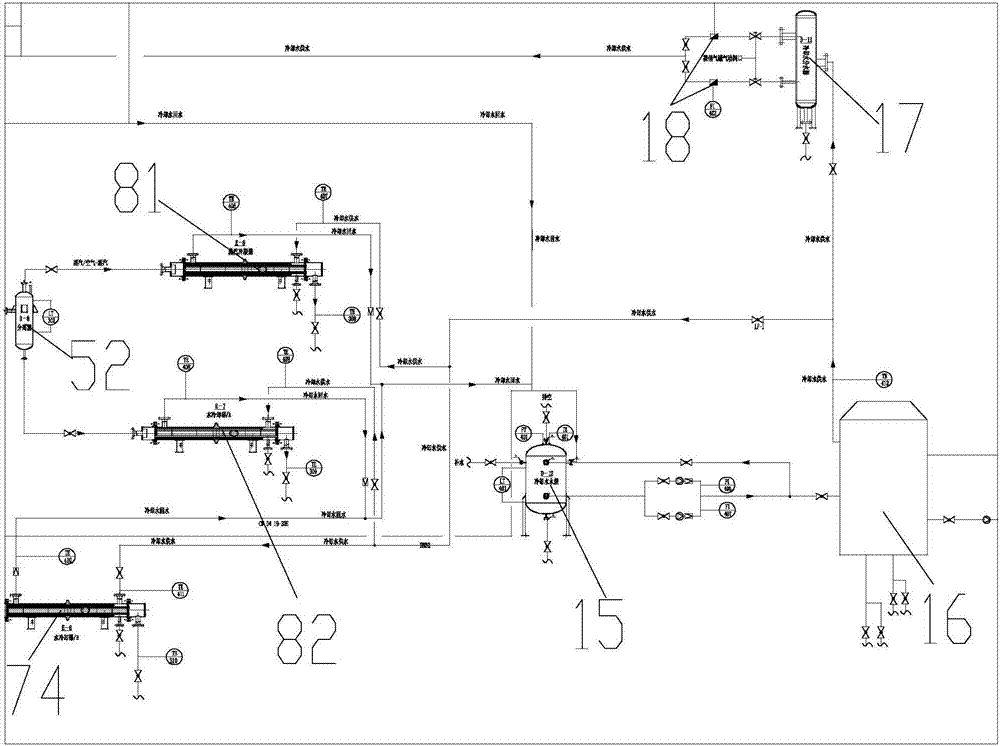

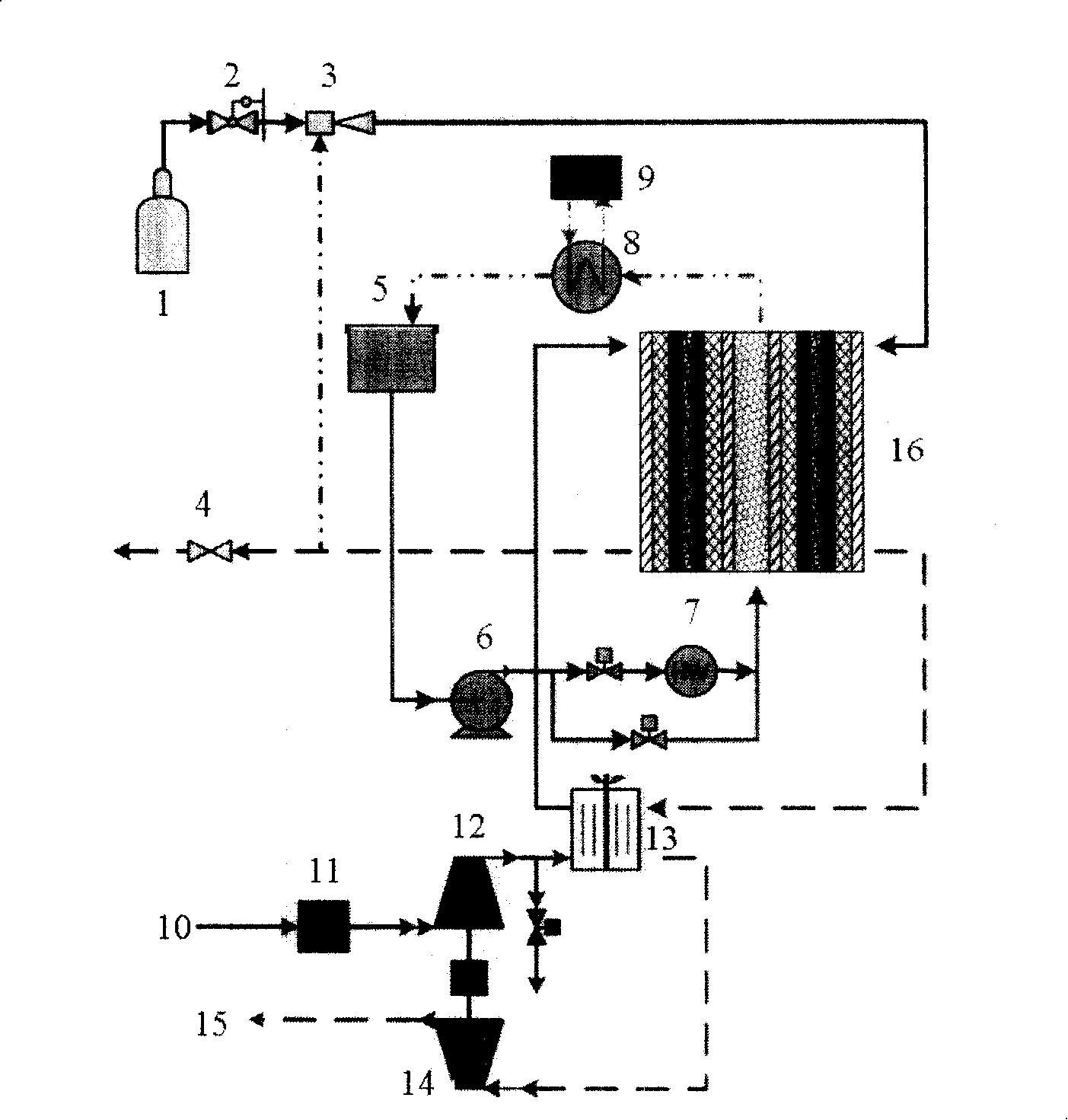

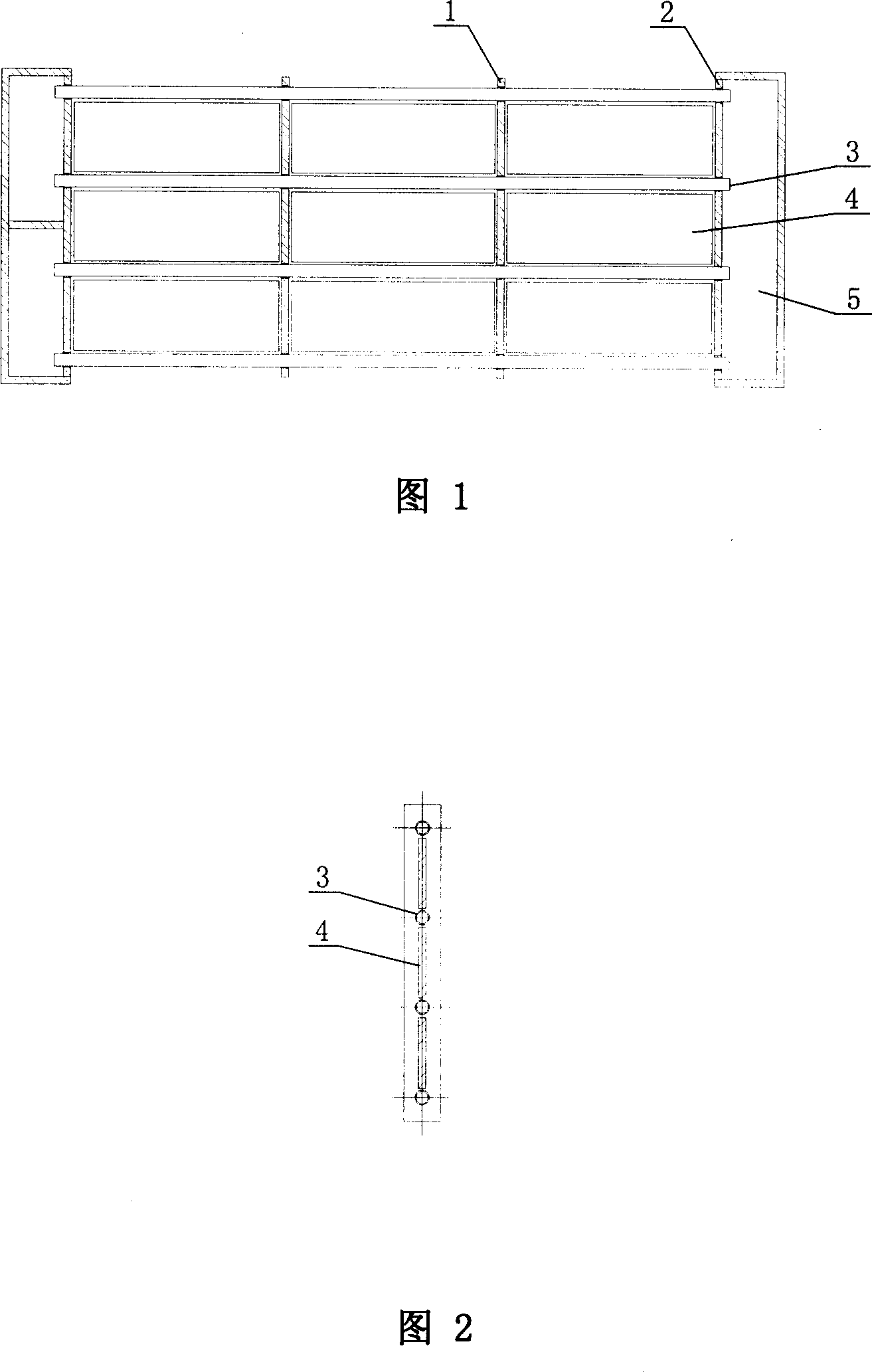

Performance and efficacy testing platform of heat exchanger

PendingCN106932214AReduce manufacturing costThe test data is reliableMaterial heat developmentHydrodynamic testingSteam condensationTest bench

The invention relates to a performance and efficacy testing platform of a heat exchanger. The platform comprises a heat source part, a vapor source part, first and second mixers, an air source part, a shell-and-tube heat exchanger, first and second separators, a shell-and-tube type double-tube heat exchanger testing assembly, a condensation heat exchanger, a boiling heat exchanger, first and second water cooling devices and a steam condenser. The platform can test heat transfer properties and fluid flowing resistances of the shell-and-tube type heat exchanger, the double-tube heat exchangers, the condensation heat exchanger and the boiling heat exchanger respectively, does not occupy much space, reduces the production cost, satisfies practical measurement requirements and has good application and development prospects, and test data is stable and reliable.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

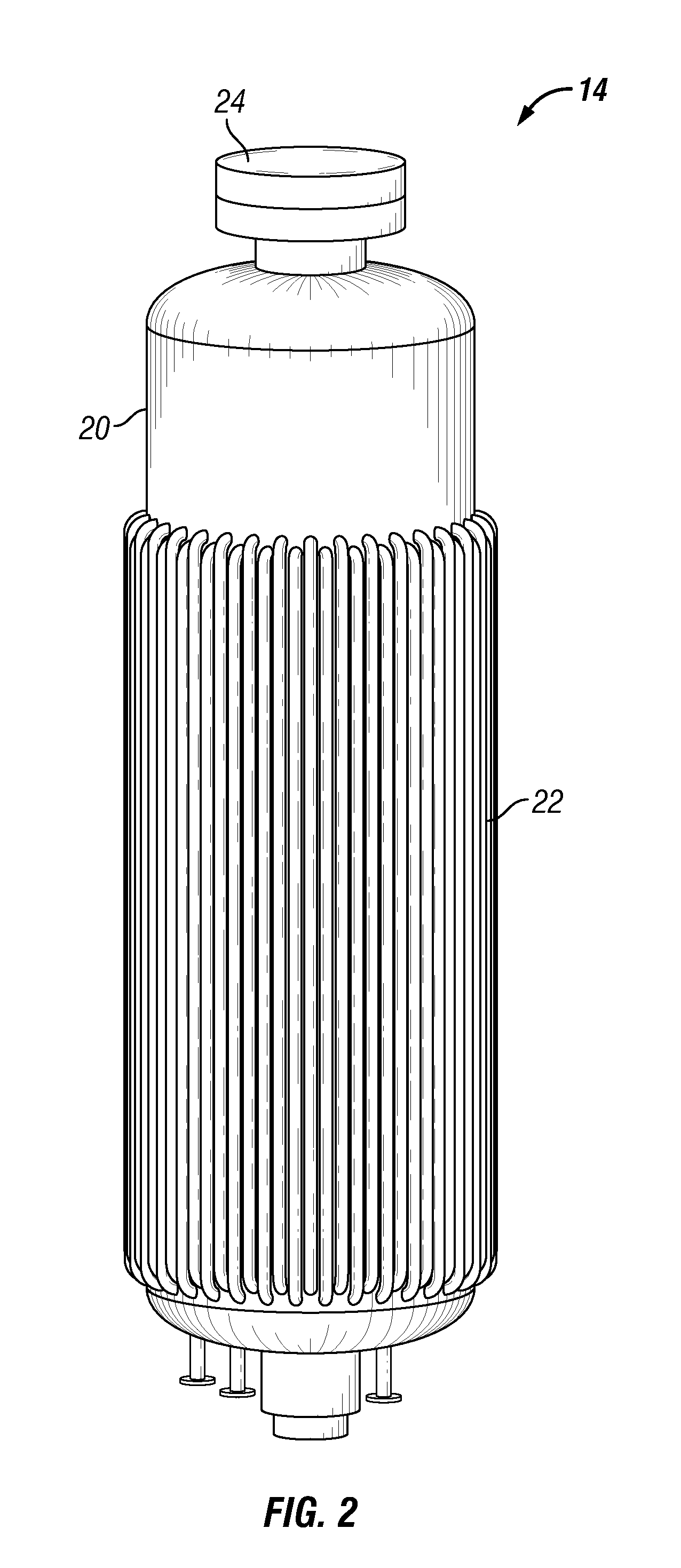

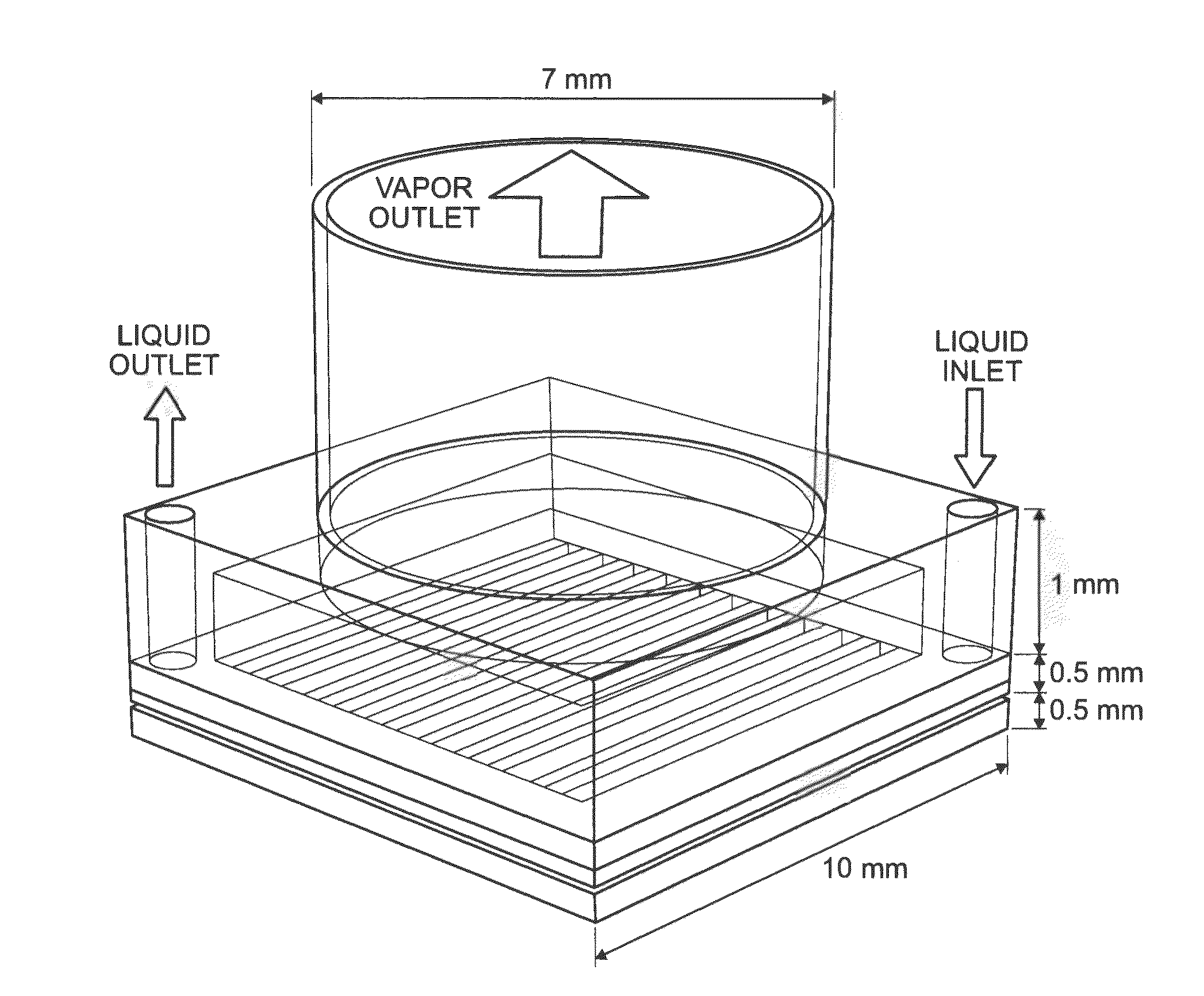

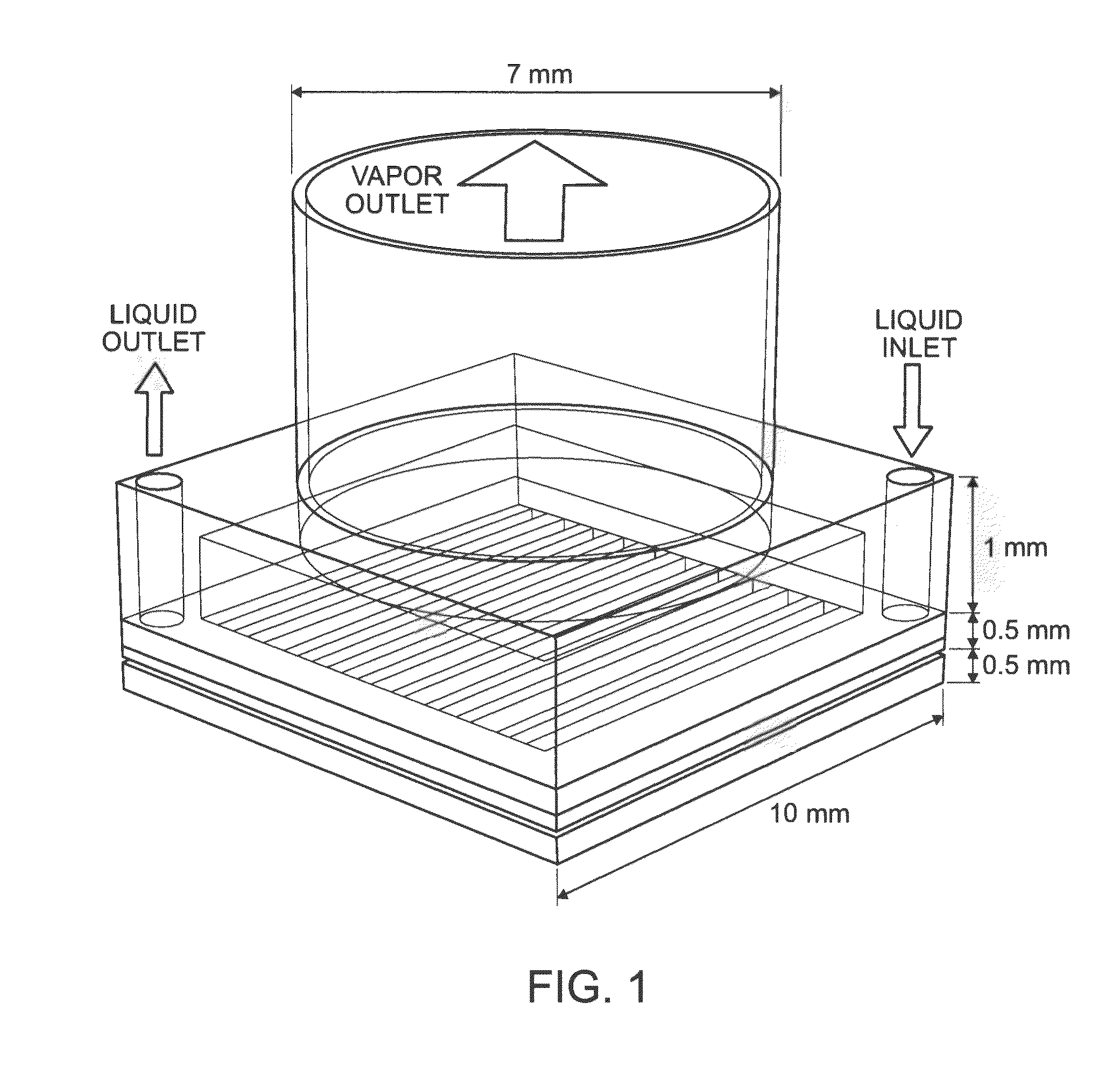

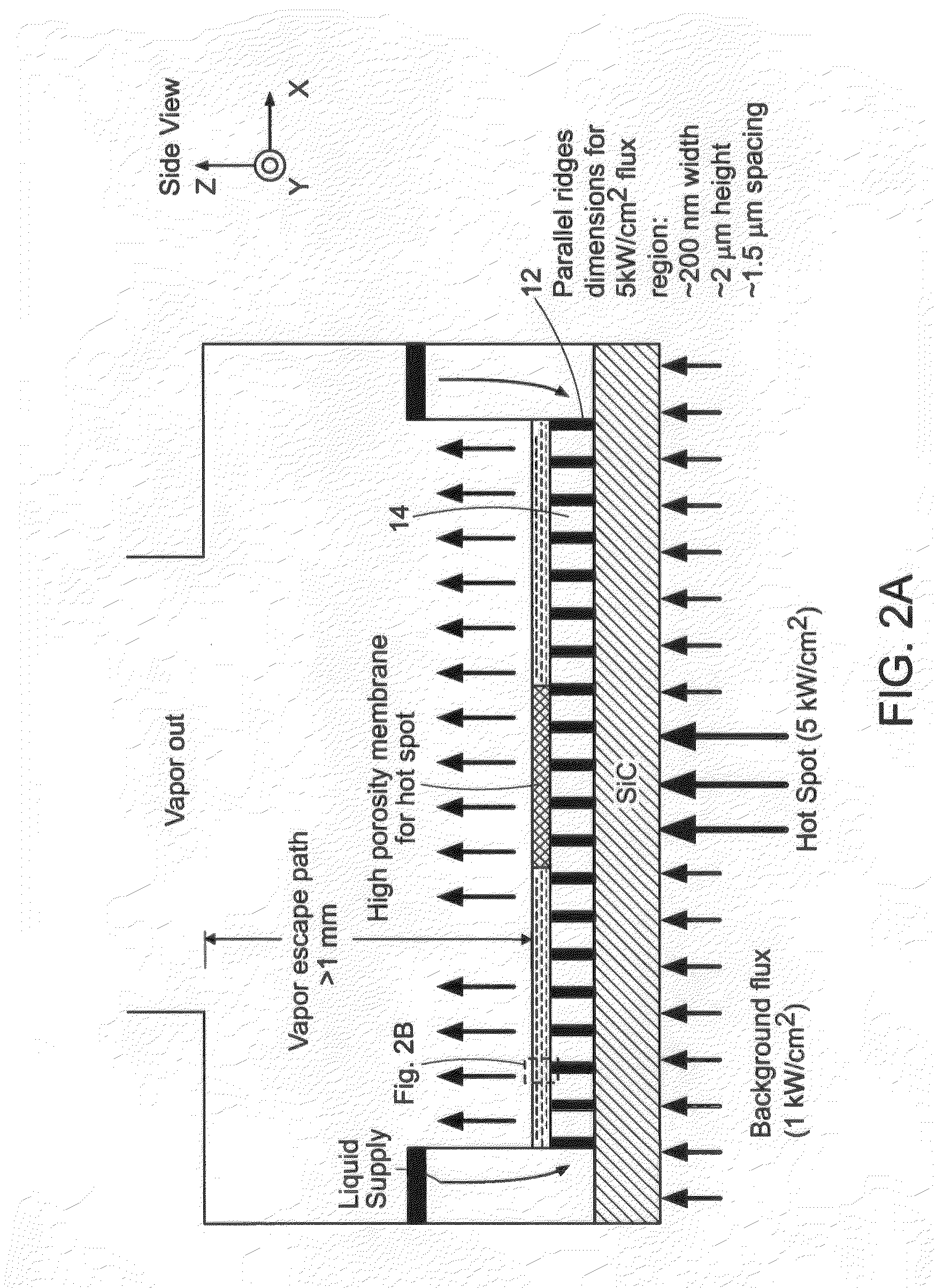

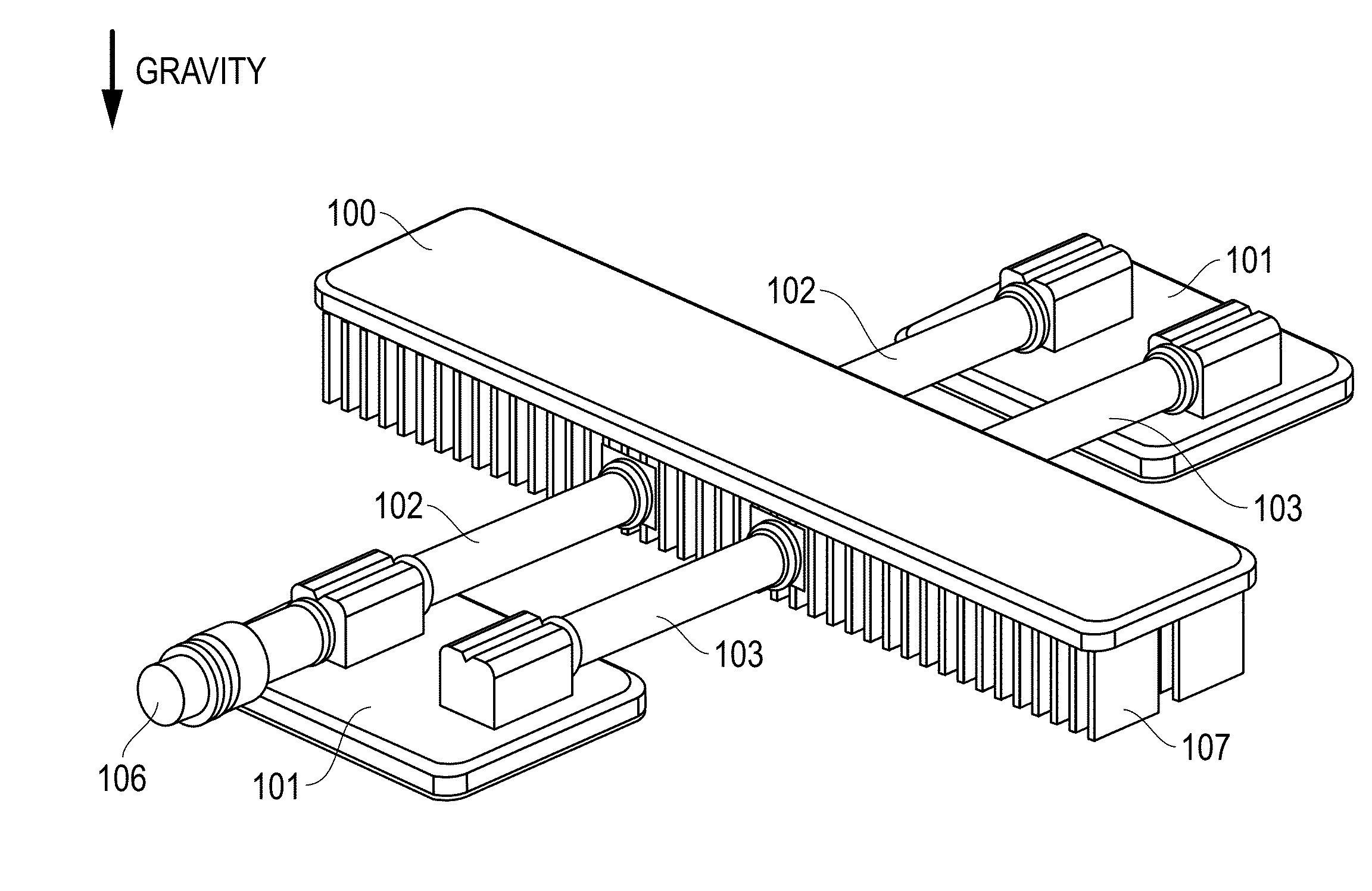

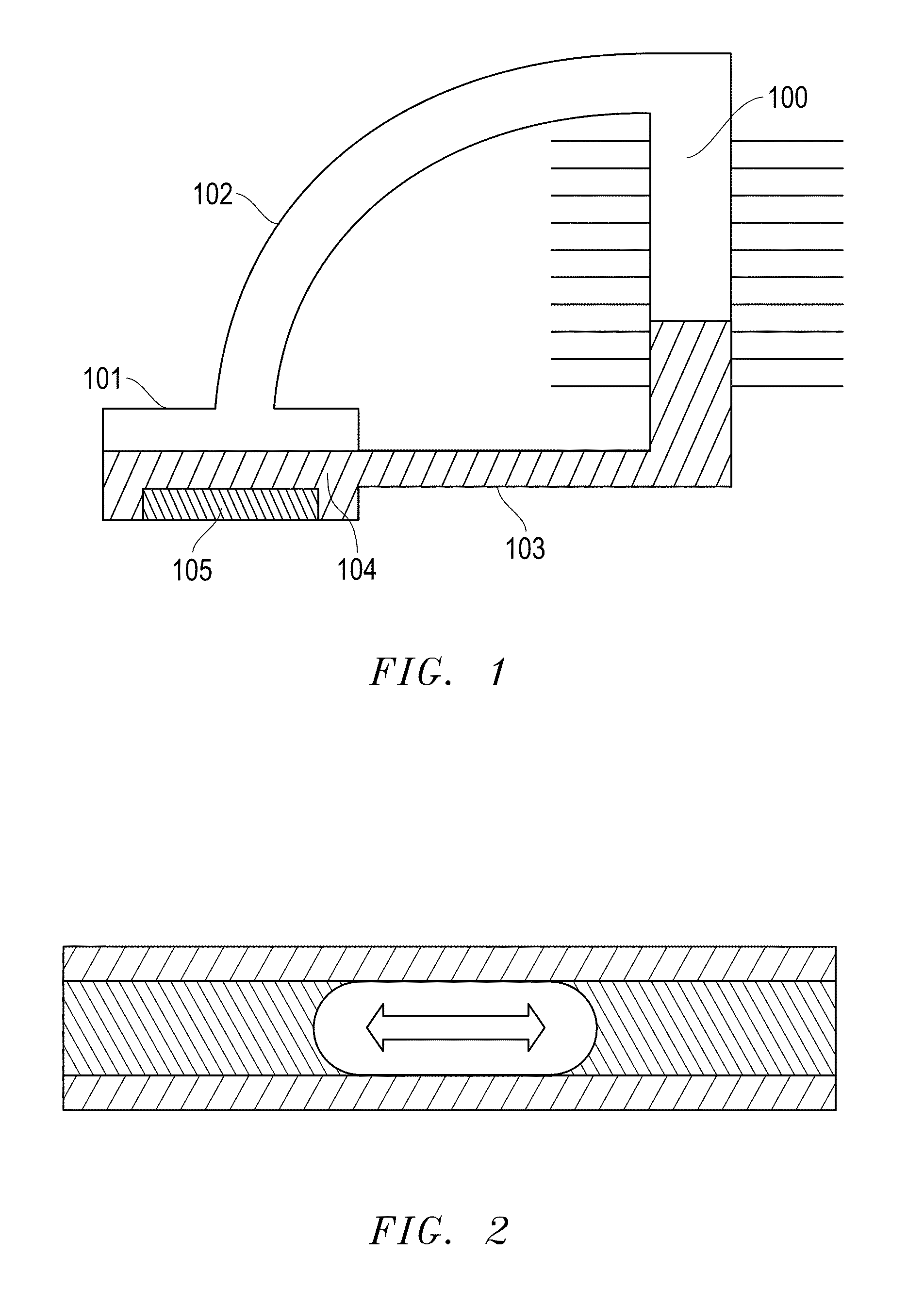

Evaporative Heat Transfer System

ActiveUS20140196498A1High capillary pressureHeat dissipationSemiconductor/solid-state device detailsEvaporators/condensersEvaporation heat transferNanoporous membrane

Evaporative heat transfer system. The system includes a substrate and a plurality of substantially parallel, spaced-apart ridges extending from the substrate forming vertical liquid manifolds therebetween. A nanoporous membrane is supported on the ridges and a pump delivers a dielectric fluid across the ridges. The fluid is drawn through the liquid manifolds via capillarity provided by the nanoporous membrane and evaporates to dissipate heat flux through the substrate. A preferred dielectric fluid is pentane. It is preferred that membrane porosity vary across the membrane to tailor thermal resistances to limit temperature rises.

Owner:MASSACHUSETTS INST OF TECH

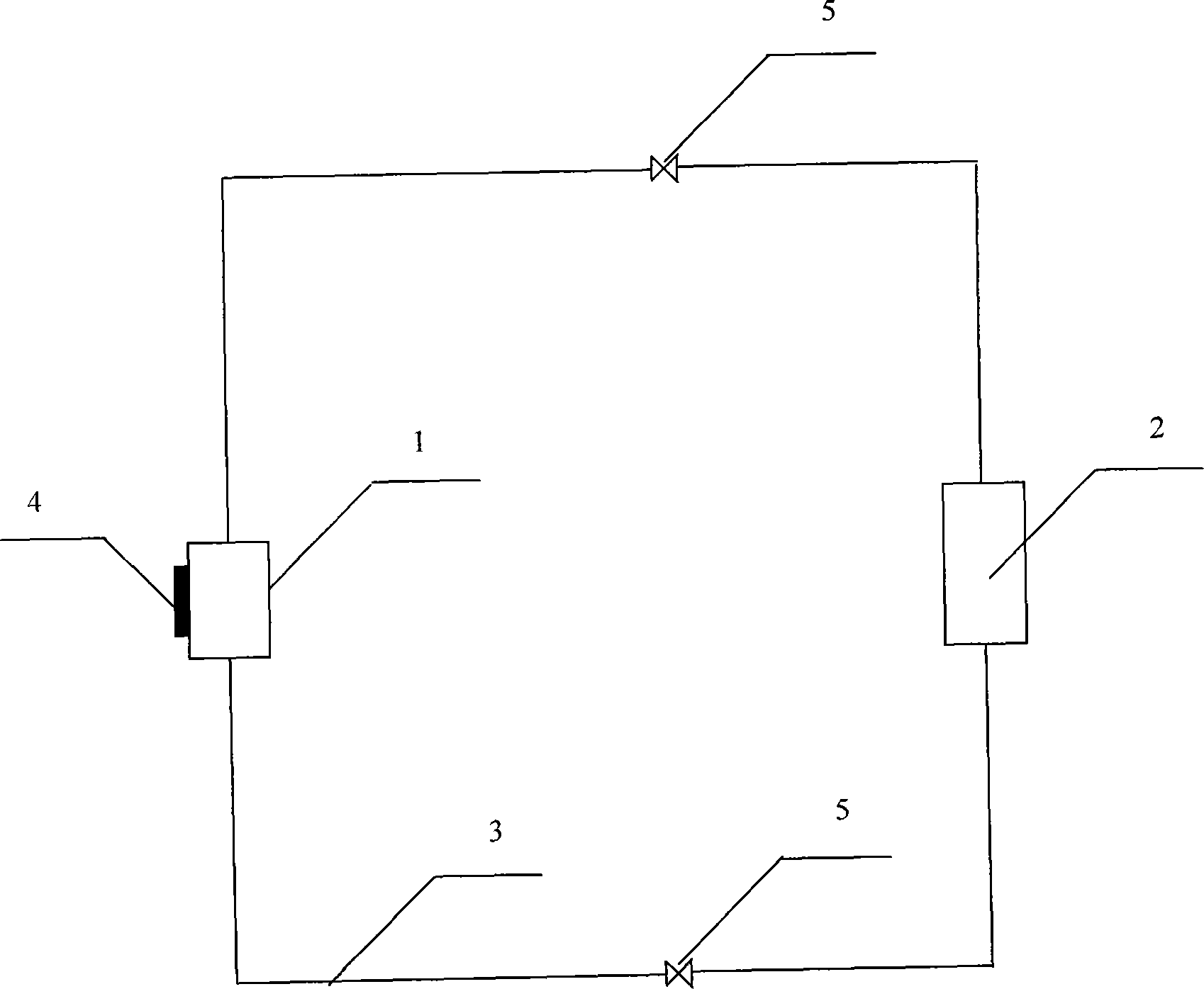

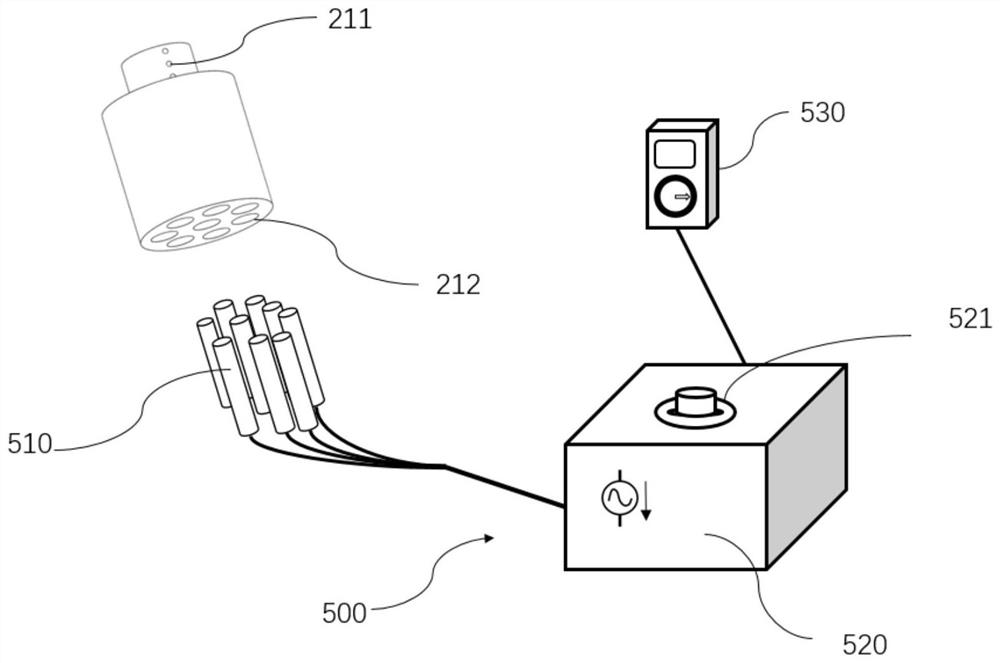

EHD intensification minitype heat radiating device

InactiveCN101252822AImprove heat transfer performanceIncrease capillary driveSemiconductor/solid-state device detailsSolid-state devicesVolumetric Mass DensityEngineering

The invention relates to a heat sink cooling device of an electronic device, in particular to miniature heat sink intensified through the EHD and used for the electronic device under the condition of high heat-flow density. The miniature heat sink comprises an evaporator, a condenser (2), a soft plastic capillary pipe (3), and high voltage electrodes (9) which are distributed at the both sides of the capillary in the evaporator and are parallel with the evaporating surface of the evaporator. The evaporator, the soft plastic capillary pipe (3) and the condenser (2) are connected in series to form a one-way circulating loop. The capillary core of the evaporator adopts a combined capillary core fixed on a base plate (6), and comprises inner and outer layers, the aperture of the inner layer capillary core is layer, and the aperture of the outer layer capillary core is smaller. The high voltage electrodes can intensify the vaporization and the heat transfer of the evaporator. Through adopting the heat sink, real-time sufficient cooling can be performed to the electronic device with high heat-flow density, therefore, the requirements of heat emission of the computer chips with high performance, the high energy laser and the other electronic devices.

Owner:BEIJING UNIV OF TECH

Intermittent Thermosyphon

ActiveUS20160245593A1High heat transfer rateEnhanced solid/liquid/vaporIndirect heat exchangersHeat transfer modificationEvaporation heat transferStreaming instability

The device and methods described herein relate to the isothermal heat transport through an intermittent liquid supply to an evaporator device, thereby enabling high evaporative heat transfer coefficients. A liquid and vapor mixture flows through miniature and micro-channels in an evaporator and addresses flow instabilities encountered in these channels as bubbles rapidly expand. Additionally, a high percentage of the fins are exposed to vapor and limit the required charge of refrigerant within the system due to effective condensate removal in the condenser.

Owner:J R THERMAL LLC

Air energy heat pump cold-warm-hot integrated equipment

InactiveCN102478324ASatisfied with the effectReduce indoor temperatureEnergy recovery in ventilation and heatingFluid heatersWater storage tankEngineering

The invention discloses air energy heat pump cold-warm-hot integrated equipment. The equipment absorbs heat around an evaporator to evaporate a heat transfer working medium; the steam of the working medium is compressed by a compressor, and then the temperature and pressure thereof are increased; when the high-temperature steam is condensed into liquid by the condenser, heat is released and transferred to the water in a water storage tank; and the condensed heat transfer working medium returns to an evaporator through an expansion valve and then is evaporated again to finish a heating cycle. Comparatively, a low-temperature low-pressure liquid refrigerant firstly absorbs heat from a low-temperature heat source in the evaporator and is gasified; then a compressor extracts the gasified refrigerant gas in the evaporator and compresses the refrigerant gas in the condenser, and the refrigerant gas turns into high-temperature high-pressure gas; the high-temperature high-pressure gas is condensed into liquid in the condenser and turns into a high-temperature high-pressure liquid refrigerant; and the high-temperature high-pressure liquid refrigerant is throttled by the expansion valve to become a low-temperature low-pressure liquid refrigerant to finish a refrigeration cycle. The system can meet all requirements of domestic heating, hot water supply and refrigeration.

Owner:张耀中

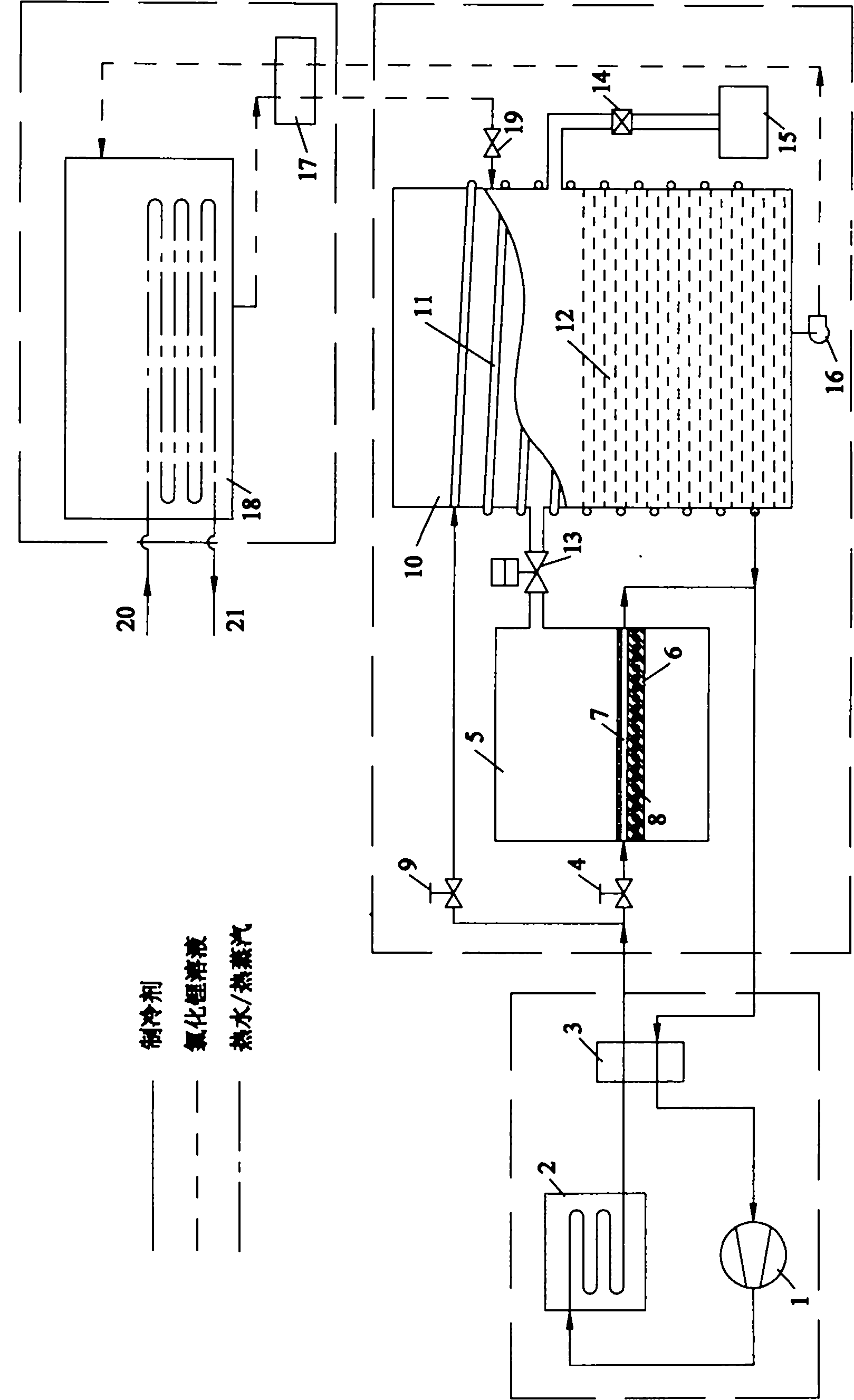

Freeze drier capable of self-recirculating and regenerating of cold trap

InactiveCN102095305AReduce consumptionIncrease productivityDrying solid materials without heatLithium chlorideWater vapor

The invention discloses a freeze drier capable of self-recirculating and regenerating of a cold trap. The freeze drier comprises a refrigerating system, a vacuum freezing and drying system and a lithium chloride liquid regenerative system, wherein the a freezing and drying tank is internally provided with a shelf, and the shelf is internally provided with an evaporation heat transferring coil and an electric heating strip; the cold trap is externally provided with a cooling coil, and the cold trap is filled with a lithium chloride solution; a single-level compression refrigerating system is adopted as the refrigerating system; and a freezing and drying tank vacuumizing opening, a vacuum diaphragm valve, the cold trap, an electromagnetic air-release valve and a vacuum pump are connected sequentially; and a cold trap solution outlet, a lithium chloride solution pump, a lithium chloride solution regenerator dilute solution channel, a regenerator, a lithium chloride solution regenerator concentrated solution channel, a throttling valve and a cold trap solution are connected sequentially. The invention has the following beneficial effects: in the cold trap, a concentrated lithium chloride solution is adopted for absorbing vapor without an over-low refrigeration temperature, and the ordinary single-level compression refrigerating circulation can be reached; and the lithium chloride solution can be regenerated continuously, and the production efficiency can be improved without a frost removing step and an ice-melting step.

Owner:ZHEJIANG UNIV

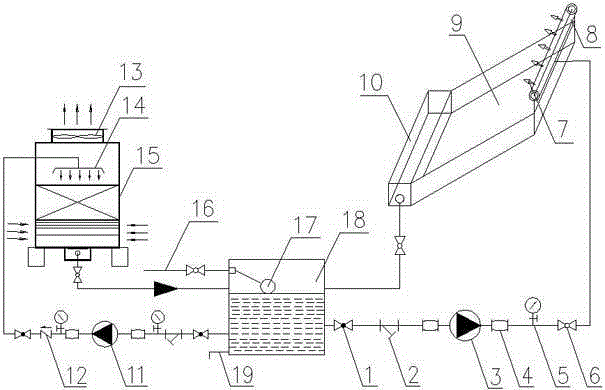

Solar power generation circulating cooling system and control method thereof

InactiveCN104811132ASimple structureEasy to assemblePhotovoltaicsPhotovoltaic energy generationEvaporation heat transferCooling tower

The invention relates to the technical field of solar power generation, and particularly relates to a solar power generation circulating cooling system and a control method thereof. During a process in which water is sprayed on the surface of a PV module for temperature reduction and efficiency improvement, a circulating water pump is started, cooling water in a water tank is fed to sprayers uniformly distributed on the solar PV module via the circulating water pump, and spraying water flows across the surface of the PV module, brings heat, flows in a water receiving tank and returns to the water tank. When temperature of water in the water tank meets a certain condition as heat of the PV module is absorbed, countercurrent evaporation heat transfer is carried out between air pumped from around the bottom part of a cooling tower by a fan and the high-temperature water in the water tank to bring heat in the high-temperature water, low-temperature water is obtained and flows back to the water tank, and thus, low-temperature water can be ensured to continuously sprayed on the surface of the PV module for cooling. According to the solar power generation circulating cooling system and the control method thereof, the working temperature of a solar cell can be reduced, the problem of dirt on the surface of the solar PV module can be solved, and the power generation efficiency is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

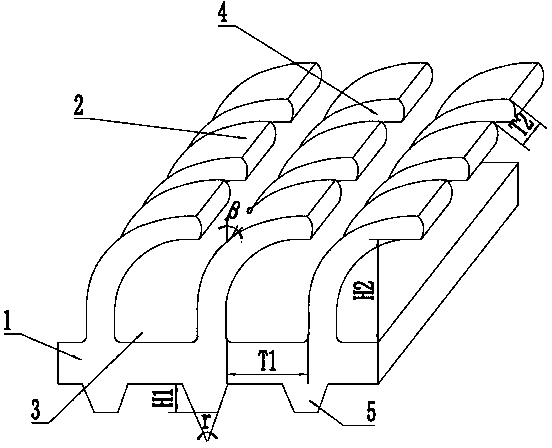

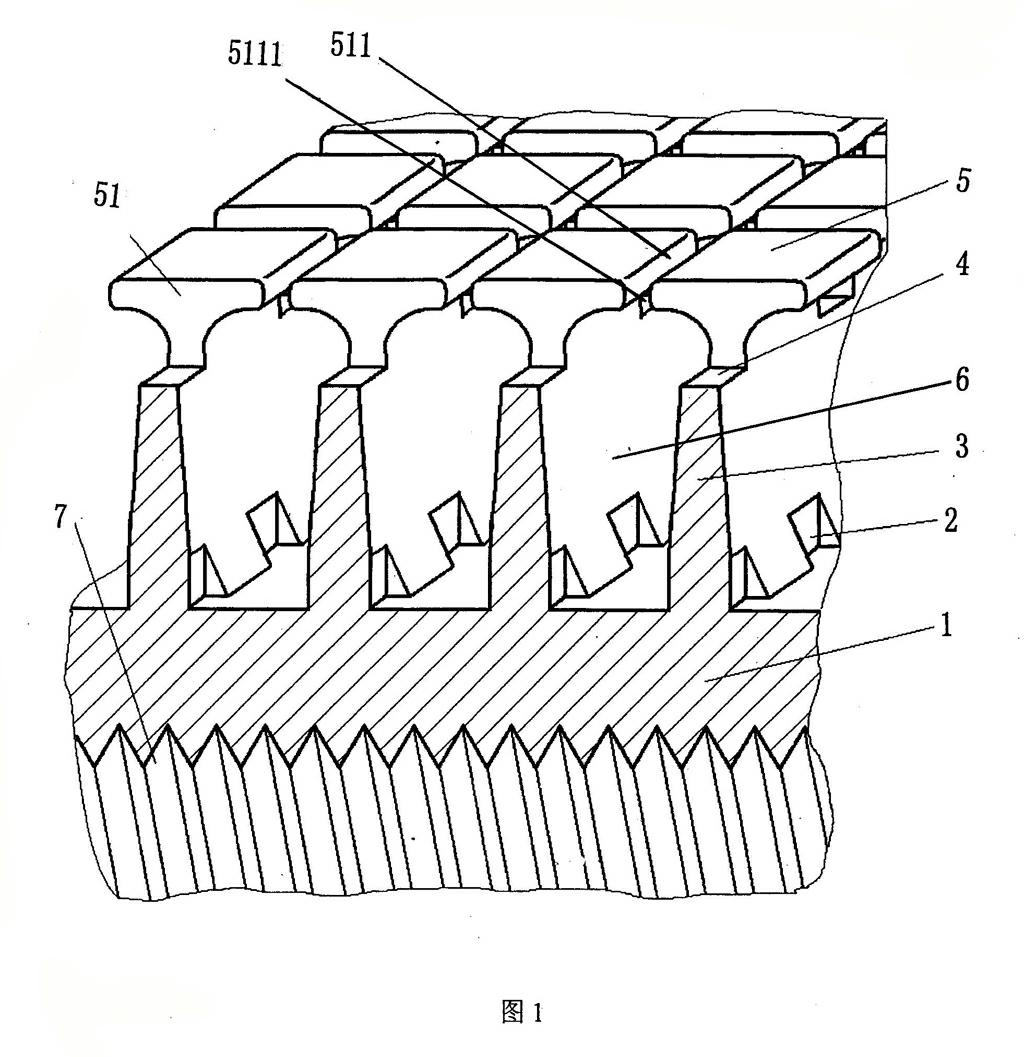

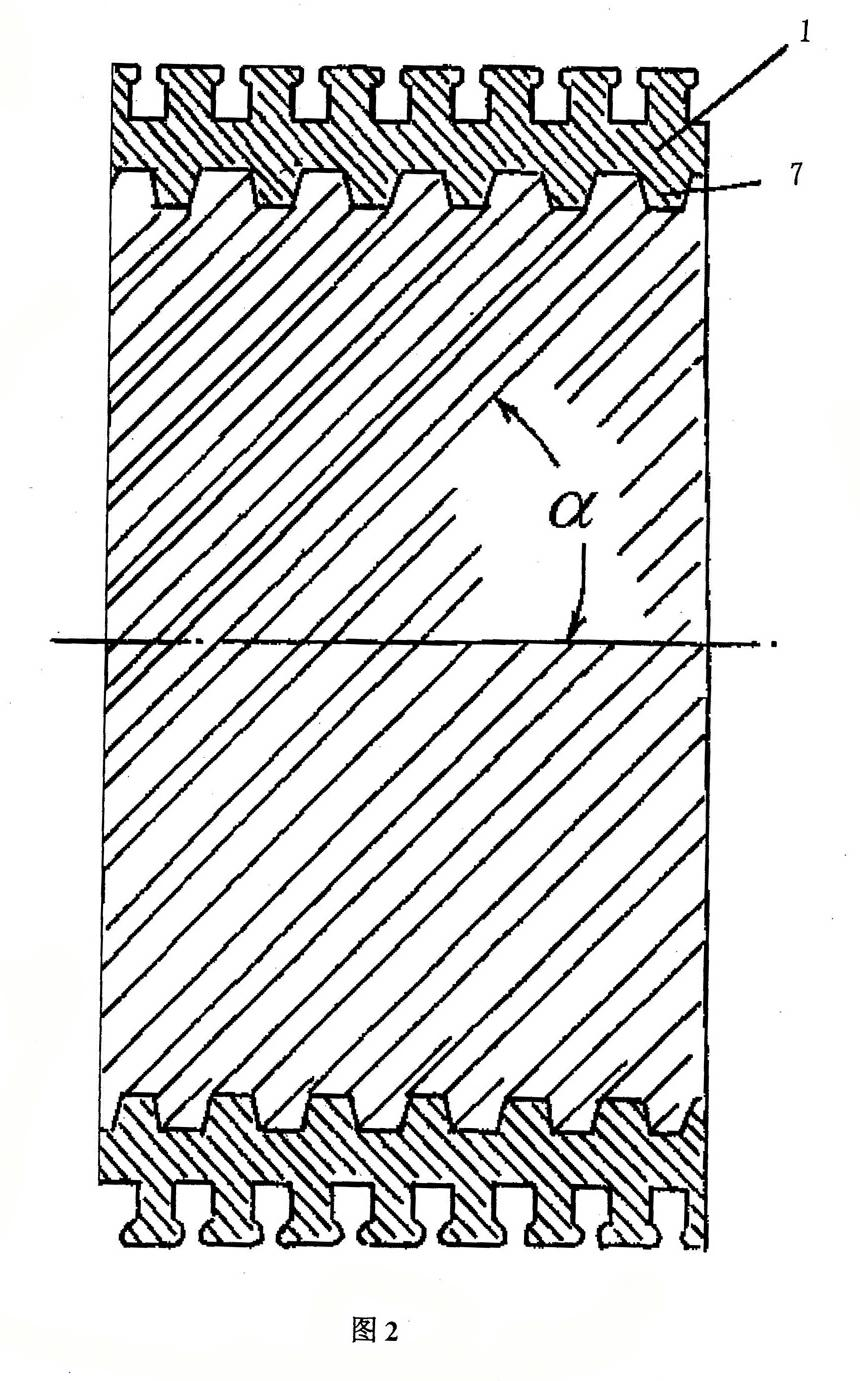

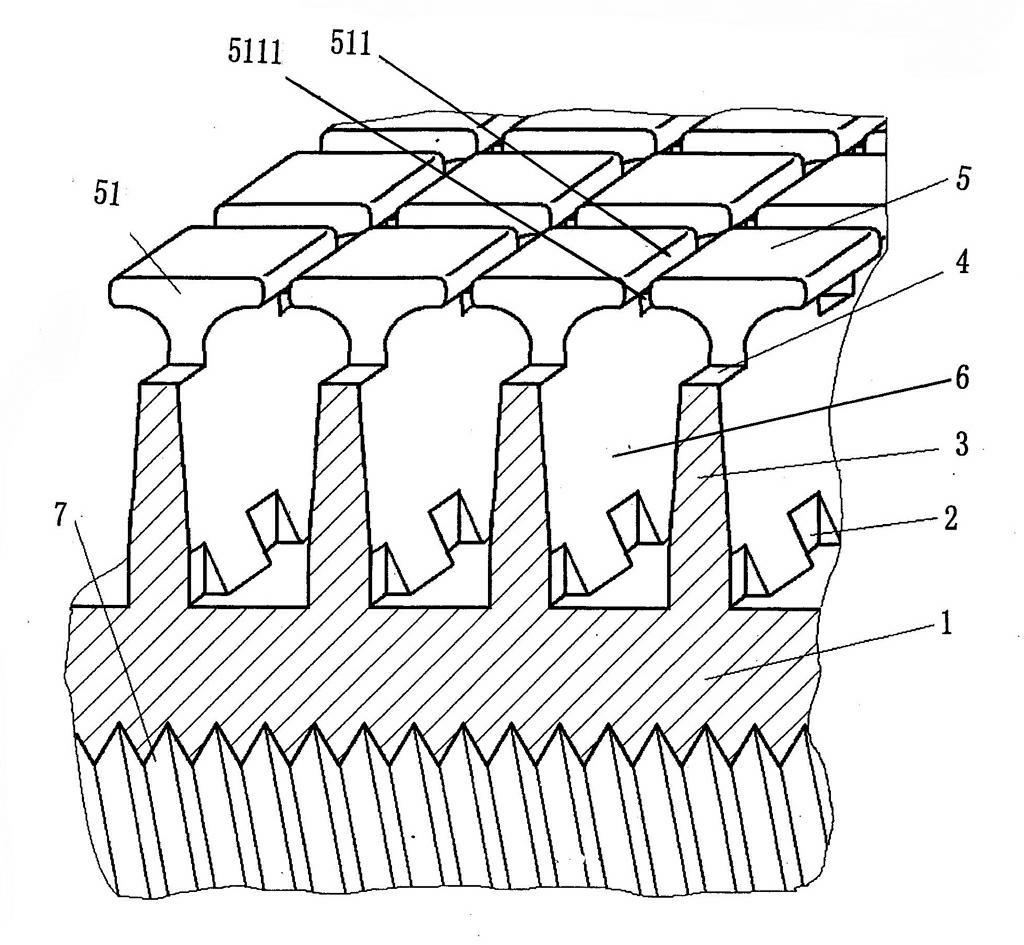

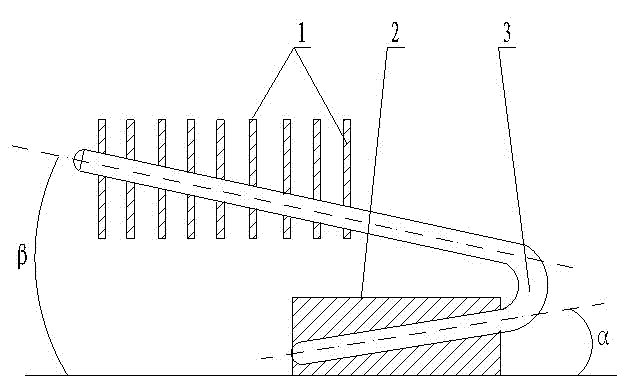

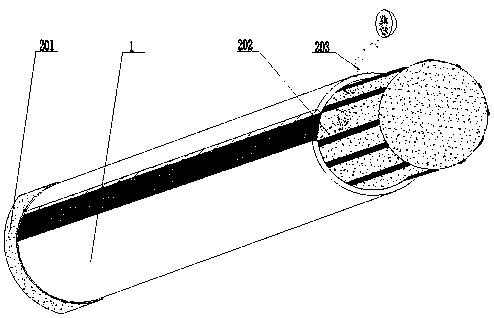

Strengthened evaporation heat transferring tube

InactiveCN104374224AImprove heat transfer efficiencyStable evaporation performanceEvaporators/condensersTubular elementsEvaporation heat transferSteering wheel

The invention provides a strengthened evaporation heat transferring tube comprising a tube body and fins, the tube body and the fins are integrally formed, the fins are wound around the surface of the outer circumference of the tube body in the spiral direction, the fins are uniformly bent and inclined in the axial direction of the tube body through a tool, gaps between the fins and the tube body form evaporation cavities, a plurality of fin grooves are formed in the fins in the circumferential direction of the tube body, and the fin grooves divide the cavities into multiple small holes. According to the strengthened evaporation heat transferring tube, the fins are uniformly bent and inclined through the tool and will not twist or deform, and the structural shapes of the cavities are uniform, so that bubbles are uniform in the formation and growth processes, the evaporation performance of the heat transferring tube is stabilized, and the heat exchange efficiency of the heat transferring tube is improved.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

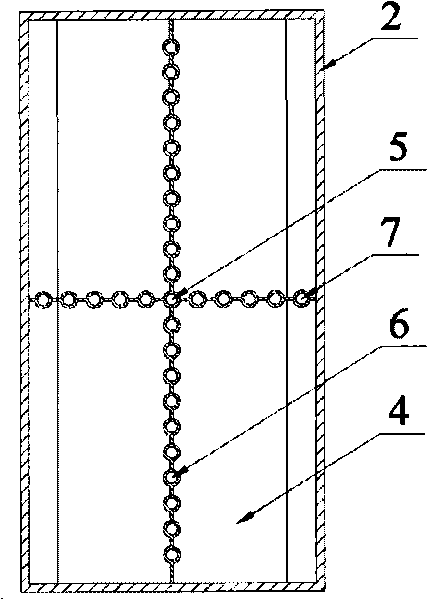

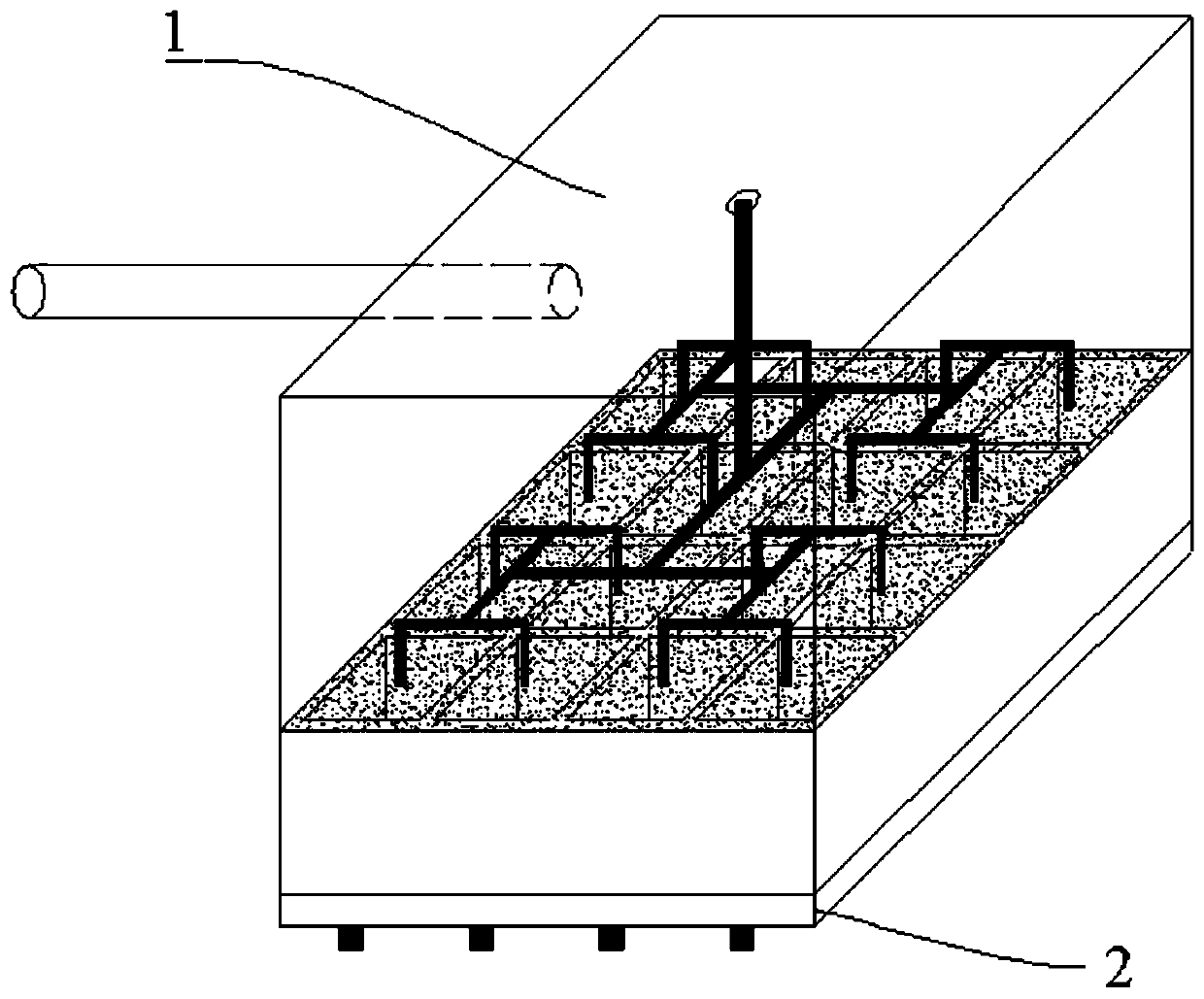

Circulating fluidized bed boiler hearth with grand-cross penetrating middle wall structure

InactiveCN101749697AReduce shockReduce wearFluidized bed combustionSteam boilersAmbient waterEvaporation heat transfer

The invention discloses a circulating fluidized bed boiler hearth with a grand-cross penetrating middle wall structure, comprising an air distributing board, a water cooled wall, a ceiling and a circulating fluidized bed boiler hearth, wherein the water cooled wall is arranged around the circulating fluidized bed boiler hearth, the upper end of which is provided with the ceiling, the lower end of the circulating fluidized bed boiler hearth is provided with the air distributing board, and a grand-cross penetrating middle wall is arranged in the circulating fluidized bed boiler hearth and comprises a middle wall vertically arranged in the width direction and a middle wall vertically arranged in the depth direction. The grand-cross penetrating middle wall is arranged in the hearth and has the heated condition similar to that of the ambient water cooled wall so that large enough evaporating and heat-transferring area can be provided, and meanwhile, a membrane wall or a light tube is selected as required so that the concentration, the temperature and the heat-transferring uniformity of materials in the hearth are ensured.

Owner:ZHEJIANG UNIV

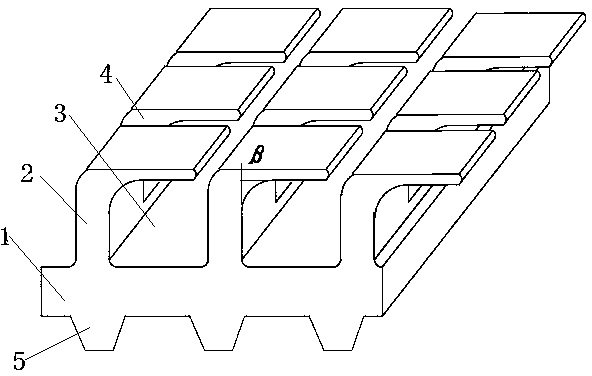

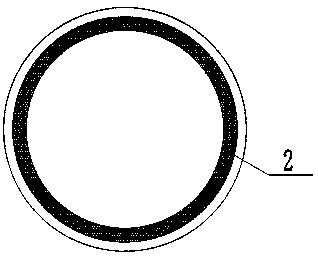

Heat exchanger tube used for evaporator

InactiveCN102305569AHigh activityIncrease boiling heat transfer coefficientHeat transfer modificationTubular elementsEvaporation heat transferEngineering

The invention relates to a heat exchanger tube used for an evaporator, belonging to the technical field of heat exchange parts. The heat exchanger tube comprises a tube body and an external fin formed on the external wall surface of the tube body, wherein at least one side of the root of the external fin is provided with grooves which are used for retaining residue steam and is of small-scale hollow cavity structures at intervals. The heat exchanger tube provided by the invention has the advantages that the grooves with small-scale hollow cavity structures are formed on the side surface of at least one side of the root of the external fin at intervals, thus the grooves with small-scale hollow cavity structures are provided for a chamber with a large-scale hollow cavity structure in the existing technology so as to retain the residue steam which is used as the gasifying center for generating the next bubble, thereby improving the activity of the chamber with the large-scale hollow cavity structure and obviously improving the boiling heat transfer coefficient; and the weight of the tube body is reduced because the grooves with the small-scale hollow cavity structures are designed, which is in favor of saving materials and dose not cause the reduction of the strength of the tube body.

Owner:JIANGSU CUILONG PRECISION COPPER TUBE CORP

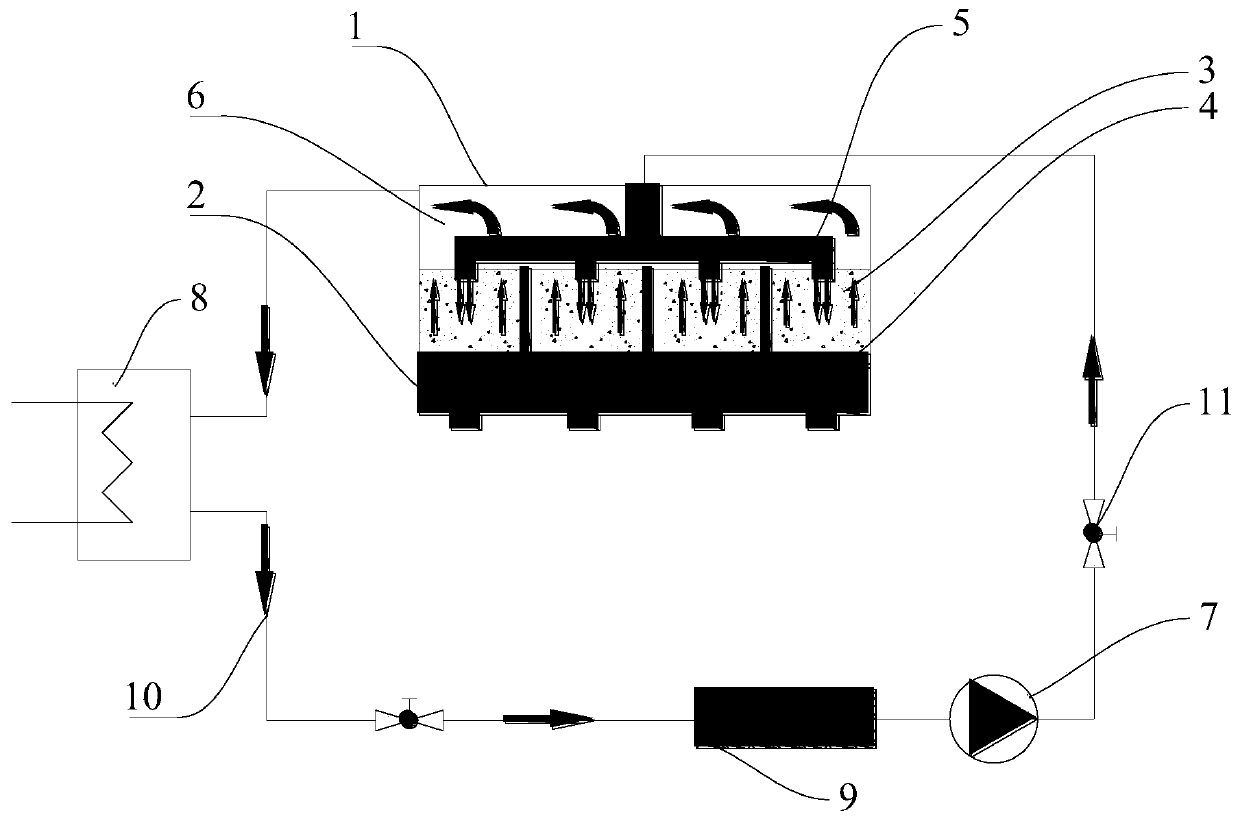

Cooling method and system for high temperature proton exchange membrane fuel cell battery

ActiveCN101212059AReduce energy consumptionTo achieve the purpose of evaporative heat transferFuel cell heat exchangeSolid electrolyte fuel cellsEvaporationEngineering

The invention relates to a fuel cell, in particular to a method applicable to cooling a fuel cell stack having a high-temperature proton exchange membrane and a system thereof. Under normal pressure, water with temperature more than 90 DEG C while less than 100 DGE C is filled in a cooling cavity of the fuel cell stack having the proton exchange membrane; generated heat of water and the cell is used for heat exchange, and the water is gasified to bring away waste heat of the battery. The system adopts the cooling method of water evaporation, which takes water as cooling medium and applies the latent heat of evaporation required in the process of water phase change to bring away the waste heat of the cell. Compared with the traditional fuel cell having a proton exchange membrane operating under 80 DEG C, the latent heat process of water cycle can greatly increase the heat transfer efficiency compared with the process of sensible heat transfer. By adjusting the output power and automatic coupling of the amount of cooled water, the target of evaporation and heat transfer is reached. Compared with the system which takes ethanol and other organics as evaporation and cooling medium, the invention has no potential harm on important components such as an electrode and the proton exchange membrane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

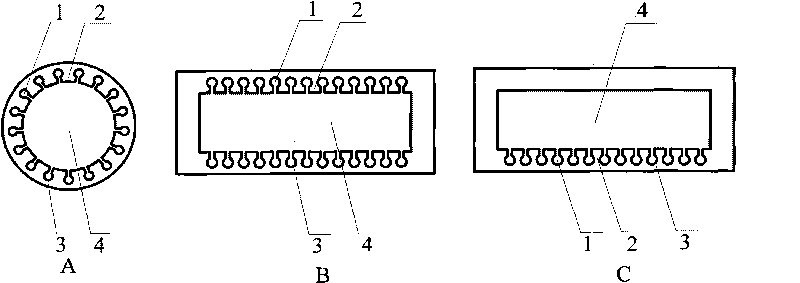

Liquid absorbing core for embedded channels of heat pipe

InactiveCN101738119AReduce weightEliminate thermal short circuitIndirect heat exchangersHeat flowEvaporation heat transfer

The invention discloses a liquid absorbing core for embedded channels of a heat pipe, which comprises a heat pipe wall, a steam chamber, common channels and ribs, wherein the common channels are arranged on the heat pipe wall; the common channels are separated by the ribs; embedded channels are formed on the ribs; the depth of each embedded channel is smaller than the depth of each common channel; and each embedded channel is in a triangular shape or an inverted trapezoidal shape. The novel capillary core heat pipe which has optimal combination of omega-shaped common channels and inverted trapezoidal or triangular embedded channels can eliminate the short circuit phenomenon so that the heat flow can smoothly reach an evaporative thin liquid film region to greatly increase the evaporative heat transfer area, thereby improving the heat transfer capacity of the heat pipe; and the space above the ribs among the common channels can be more effectively utilized to relieve the weight of the heat pipe. In addition, because gas-liquid interfaces can move inside and outside the channels freely, the liquid can be filled more conveniently and flexibly.

Owner:SOUTHEAST UNIV

Liquid-evaporation-type heat radiator and manufacturing method thereof

InactiveCN102345993AEfficient heat dissipationSmall thermal inertiaIndirect heat exchangersHeat exchange apparatusEvaporation heat transferEvaporation

The invention discloses a manufacturing method of a liquid-evaporation-type heat radiator. The method provided by the invention comprises the following steps: setting a heat radiation plate and a heat conduction block which conducts the temperature of objects emitting heat to be separated; simultaneously arranging a heat conduction pipeline in the heat conduction block, wherein one section of the heat conduction pipeline is embedded in the heat conduction block, and the other section of the heat conduction pipeline extends out of the heat conduction block and is higher than the top end of the heat conduction block; adding and pouring liquids which can be evaporated into the enclosed containing chamber of the heat conduction pipeline; and then mounting the heat radiation plate on the heat conduction pipeline which is higher than the top end of the heat conduction block. According to the invention, the temperature of the objects emitting heat is utilized for heating the liquids which can be evaporated in the heat conduction pipeline, thus the liquids which can be evaporated are heated rapidly into evaporation gases and radiate through the heat radiation plate, and after the evaporation gases are changed into liquids which can be evaporated after the evaporation gases are cooled, and flow back to the lower part of the heat conduction pipeline for the next evaporation and heat transfer circulation. The method provided by the invention has the advantages of good heat radiation effect, small volume, lighter weight, easiness in manufacturing, lower manufacturing cost and the like.

Owner:陈志明 +2

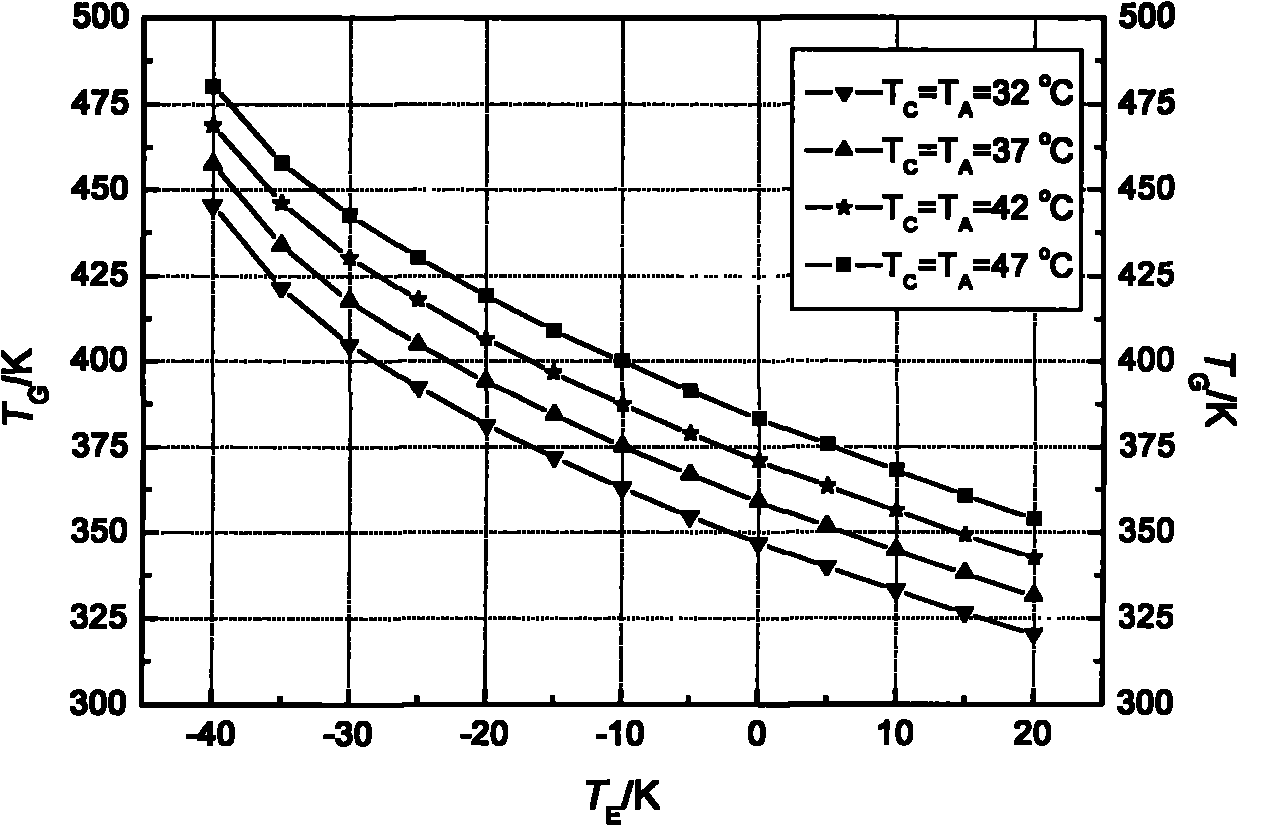

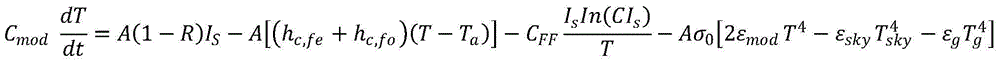

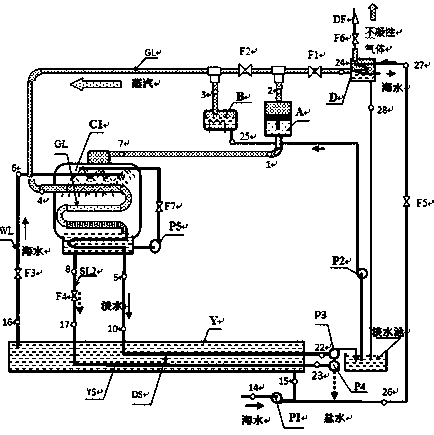

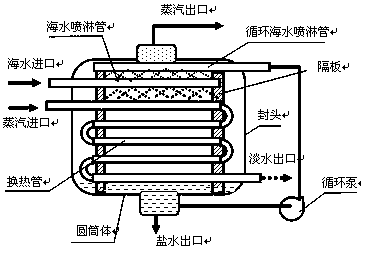

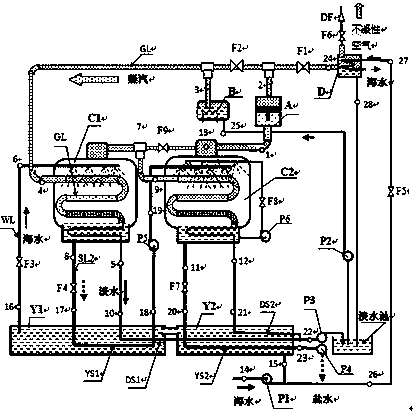

Seawater desalination method using heat supplied by steam heat pump, and system thereof

InactiveCN107804886ANo wasteIncrease the spray sea water flow rateWater treatment parameter controlGeneral water supply conservationDistillationEngineering

The invention provides a seawater desalination method using heat supplied by a steam heat pump, and a system thereof. A steam booster is used to compress seawater vaporization steam, and pressurized and heated hot steam is used to heat seawater, and then is condensed to form distilled water freshwater; and the heated seawater vaporization steam is compressed again and then is condensed to form thedistilled water freshwater, and above processes are cycled. The theory of the method is characterized in that electric energy consumed during the compression of the steam booster firstly increases the effective energy of the pressurized steam and then is used for offsetting the effective energy consumed in the seawater preheating and seawater evaporation heat transfer processes. The system includes the steam booster, a boiler, an evaporation-condensation heat exchanger, a seawater feed water preheater, a seawater cooler, a seawater booster pump, a brine pump, a freshwater pump, a boiler waterfeeding pump, a circulating pump, and a signal test and control systems; and initial hot steam in the initial running stage of the system is supplied by the boiler. The running cost is several timeslower than that of multi-effect distillation seawater desalination methods using a self-contained boiler to generate steam in the whole course.

Owner:陈则韶

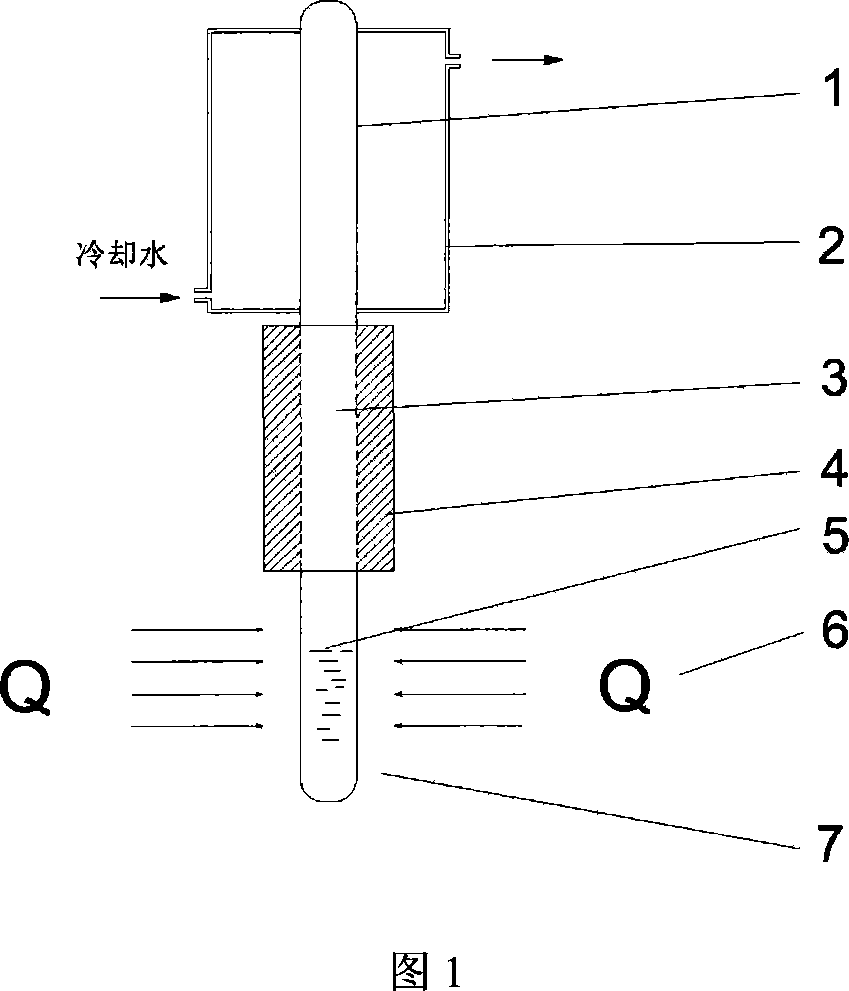

Axial round tube type silk net heat-tube using cupric oxide nano particle suspending liquid as working medium

InactiveCN101251348AEnhanced heat transfer propertiesInfluence of heat transfer characteristicsIndirect heat exchangersWater basedThermal insulation

The invention relates to an axial circular pipe type screen heat pipe taking copper oxide nanoparticle suspension as working substance, which consists of an evaporation section, a thermal insulation section and a cooling section, wherein, the thermal insulation section is externally covered with a Teflon stick to make thermal insulation, the cooling section is externally welded with a cooling water jacket, the inner wall of the evaporation section is provided with a screen liquid-absorbing core structure, the working substance filled inside the screen liquid-absorbing core structure is copper oxide nanoparticle suspension, and the fluid filling rate is 40 to 60 percent of the volume of the evaporation section. The copper oxide nanoparticle suspension is the mixing liquid of de-ionized water and copper oxide nanoparticles, and the mass concentration of the copper oxide nanoparticles in the suspension is between 0.5 and 2 percent. During the use, the element which needs to make a heat radiation is pasted on the lower end of the heat pipe, the heat of the element which needs to make a heat radiation is transferred to the cooling section depend on the evaporation heat transfer of the working substance inside the grooved heat pipe, the working substance in the cooling section condenses the heat transfer to transfer the heat into condensed water. After the invention uses the water based copper oxide nanoparticle suspension as the working substance, the heat exchange performance is improved, and the total heat resistance of the heat pipe is decreased.

Owner:SHANGHAI JIAO TONG UNIV

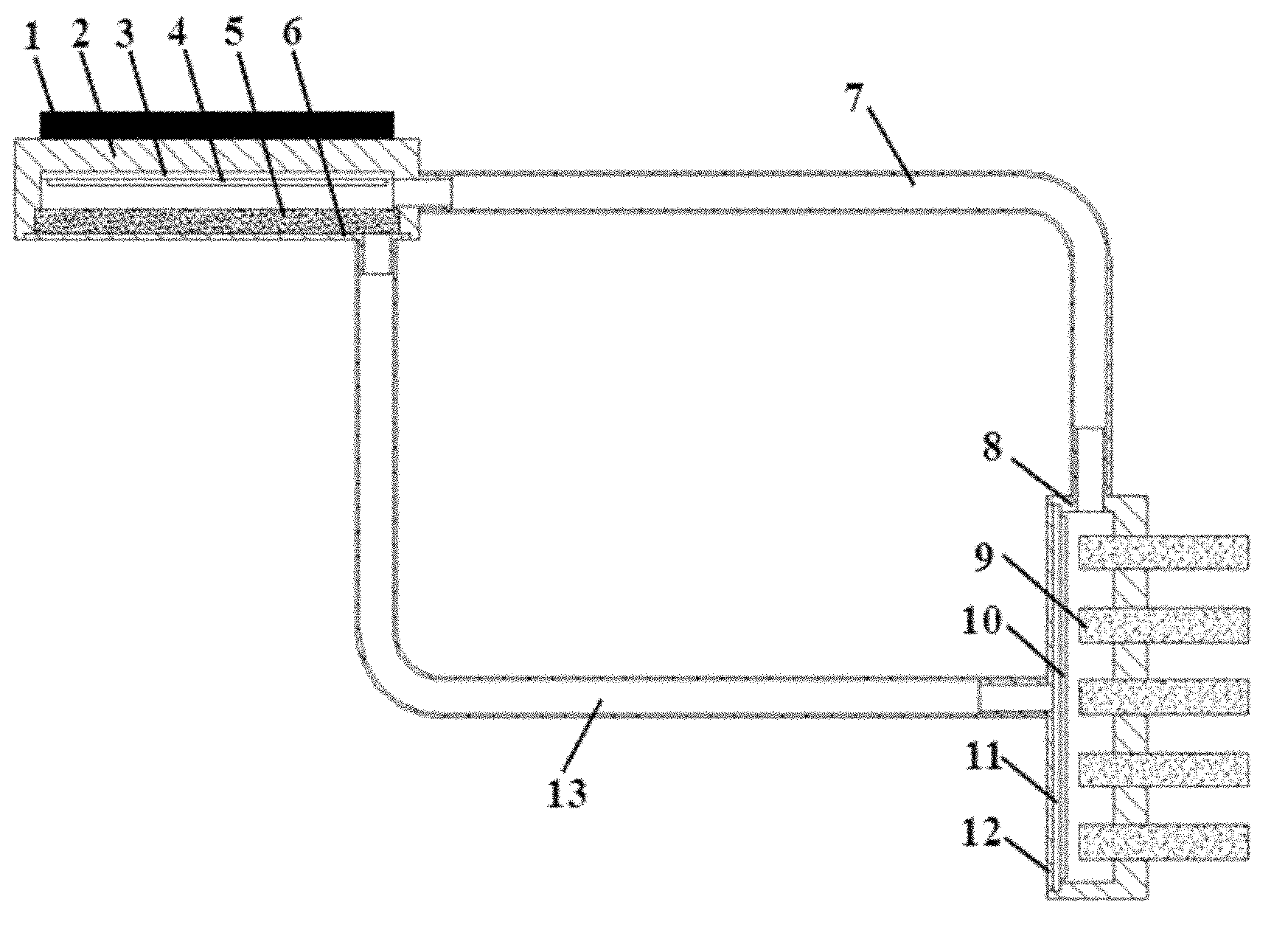

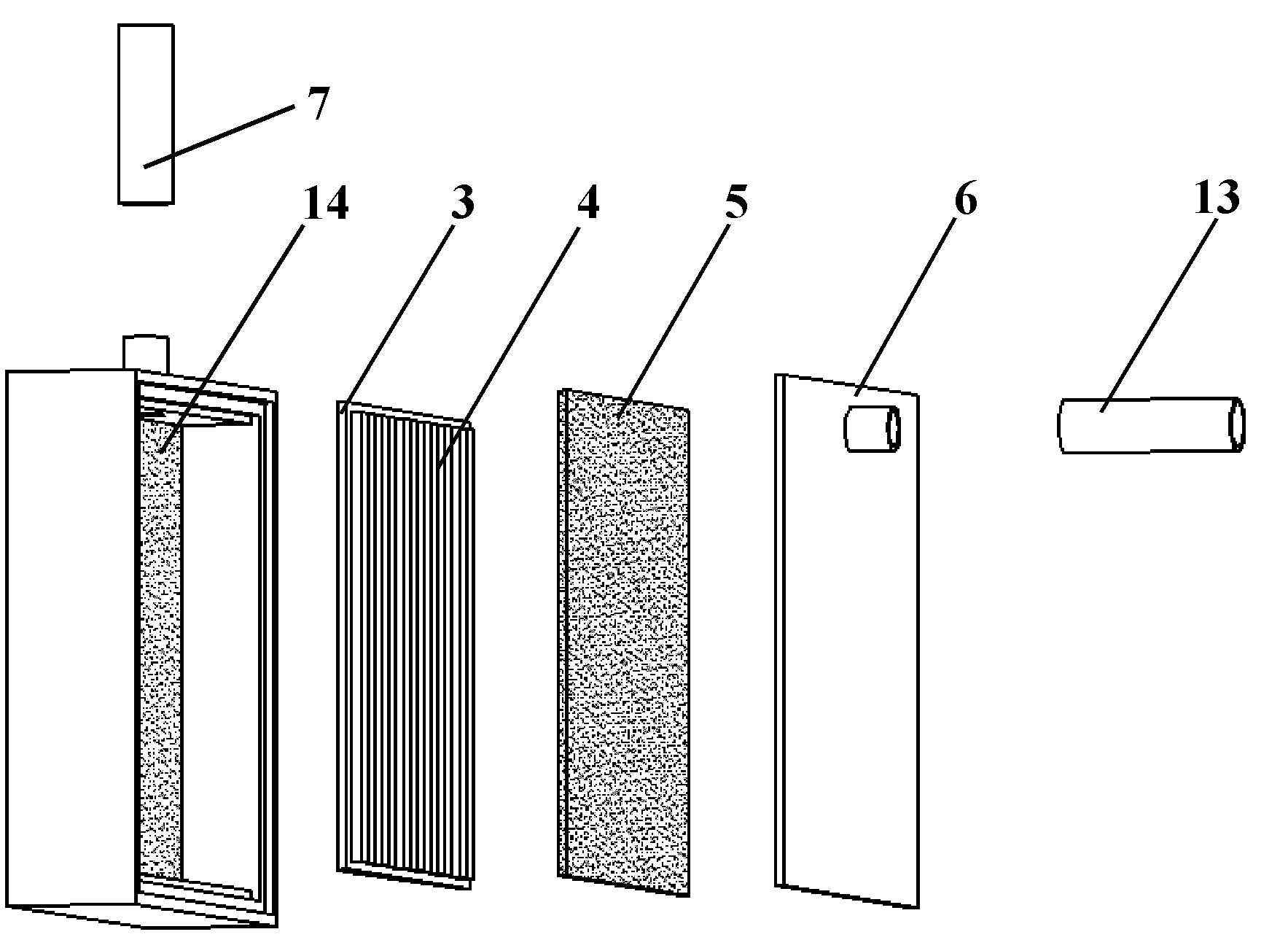

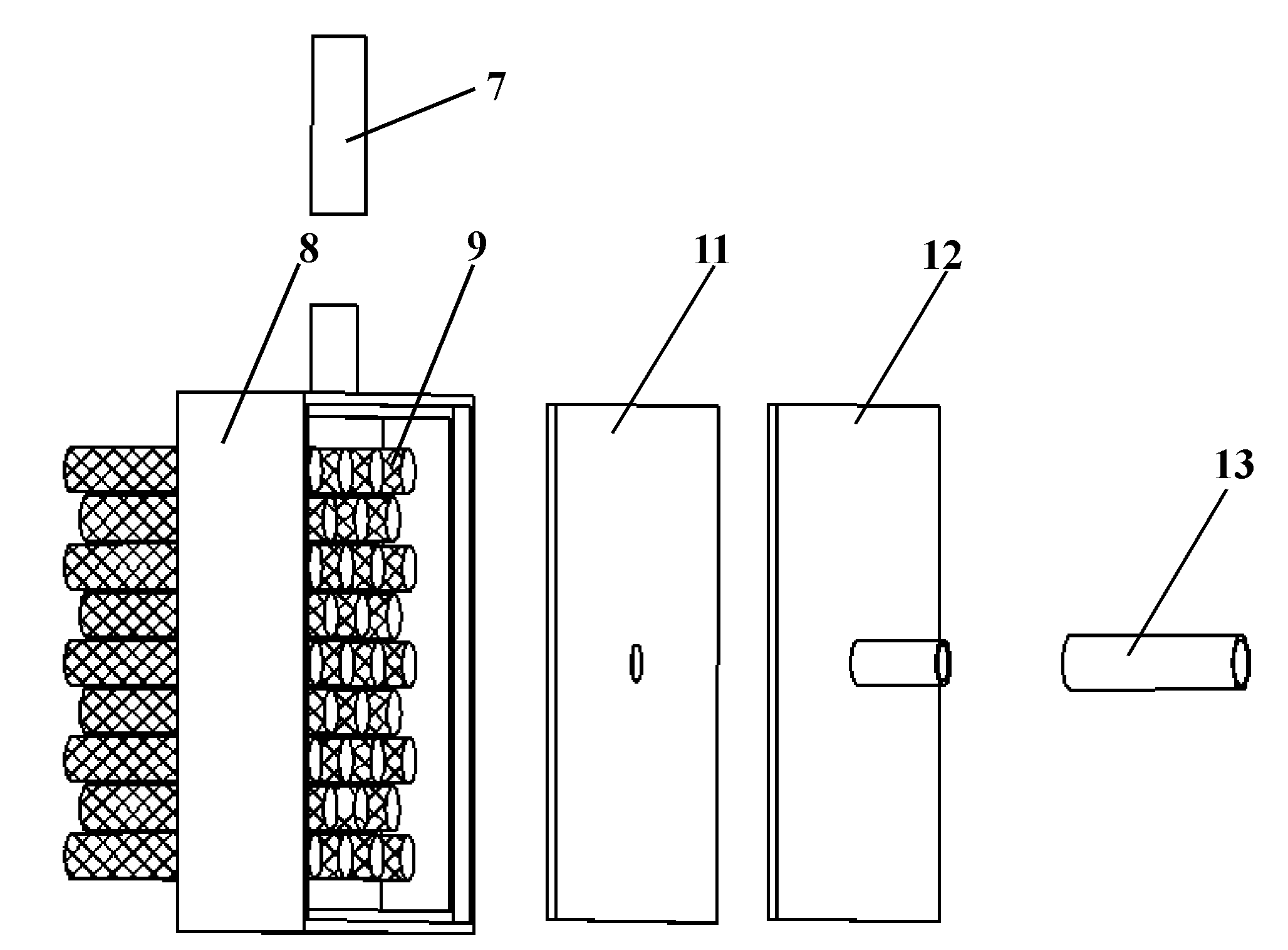

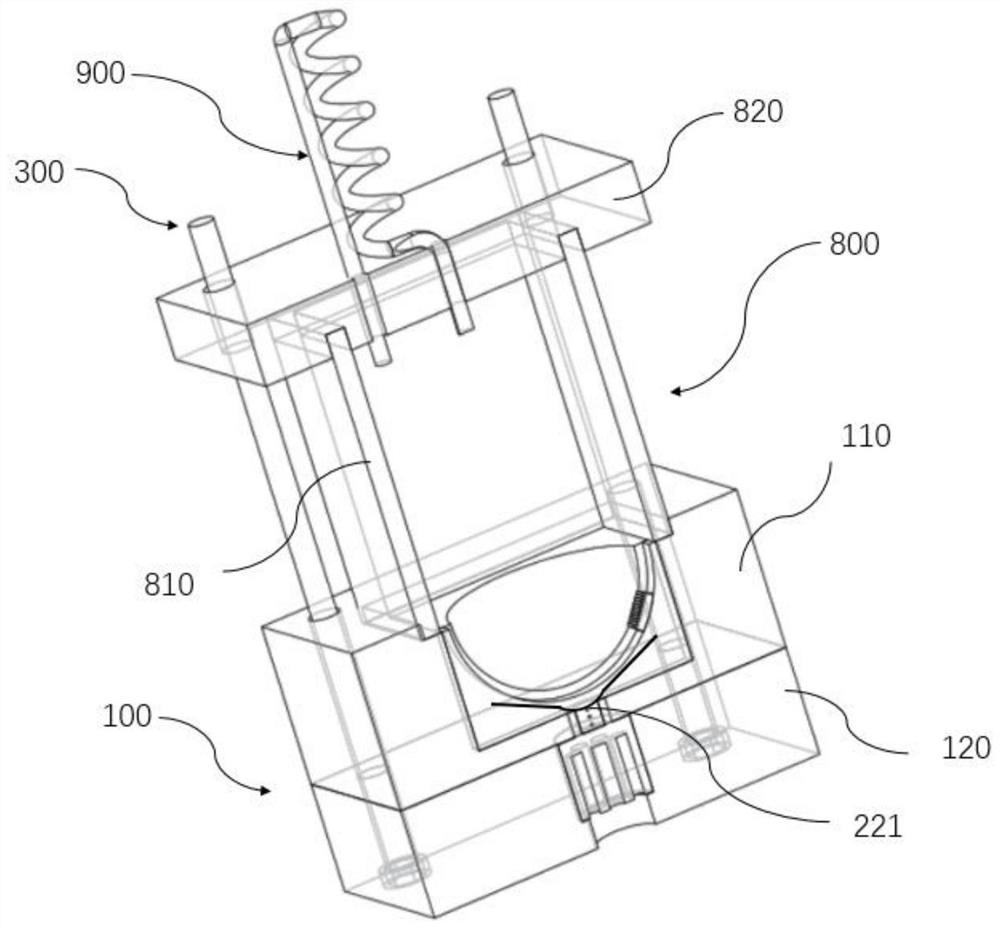

Micro LHP radiating system for integrated electrofluid power pump

InactiveCN102157470AImprove heat transfer efficiencySpeed up overflowSemiconductor/solid-state device detailsSolid-state devicesEvaporationEngineering

The invention discloses a micro loop heat pipe (LHP) radiating system for an integrated electrofluid power pump. The system comprises an electrohydrodynamic (EHD) evaporator, an EHD condensator, a steam pipeline, a liquid pipeline and the like. A high-voltage electrode and a porous metal sintering plate which are separated by using an insulating partition plate and are parallel to an evaporation plane are arranged in the EHD evaporator, wherein the high-voltage electrode is used for reinforcing the evaporation and the heat transfer of the evaporator; and the porous metal sintering plate can improve the reflowing speed of a liquid working medium. The evaporator has the advantages of small size, compact structure, no mechanical power and the like. A machining column with a roughened surfaceand a high-voltage electrode are arranged in the EHD condensator, wherein the machining column can accelerate the condensing speed of steam; and the high-voltage electrode improves the pumping efficiency of the liquid working medium. Therefore, the condensation and heat exchange efficiency of the micro LHP is greatly improved. The radiating system can fully and immediately cool electronic components and parts with high-heat flux density, thereby meeting radiating requirements on high-performance micro electronic components and parts.

Owner:SOUTH CHINA UNIV OF TECH

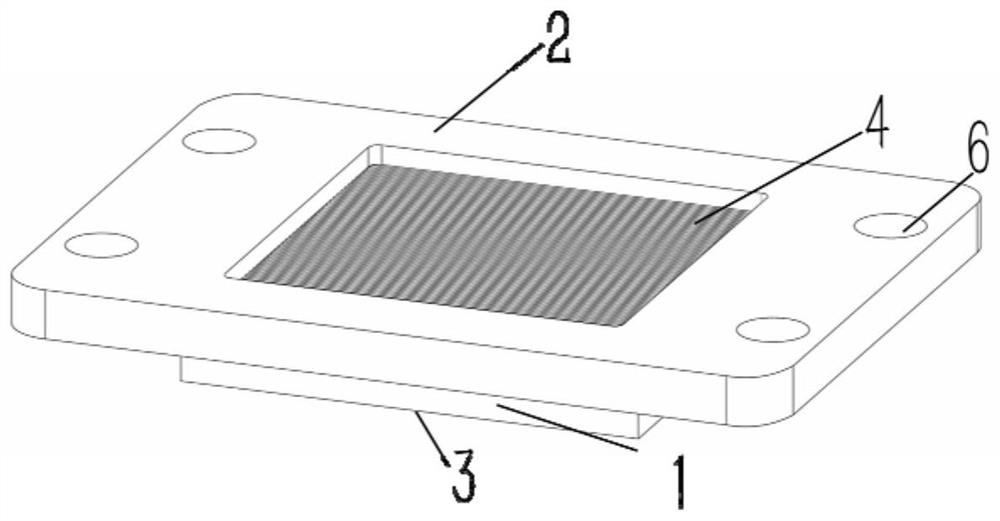

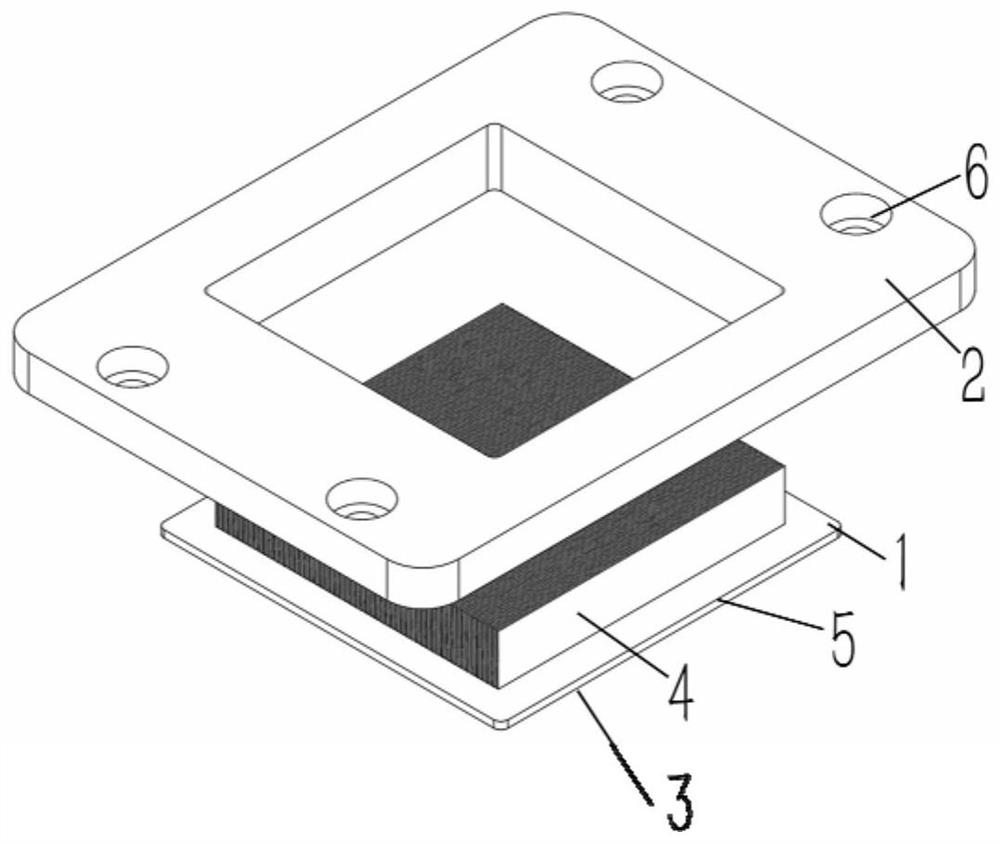

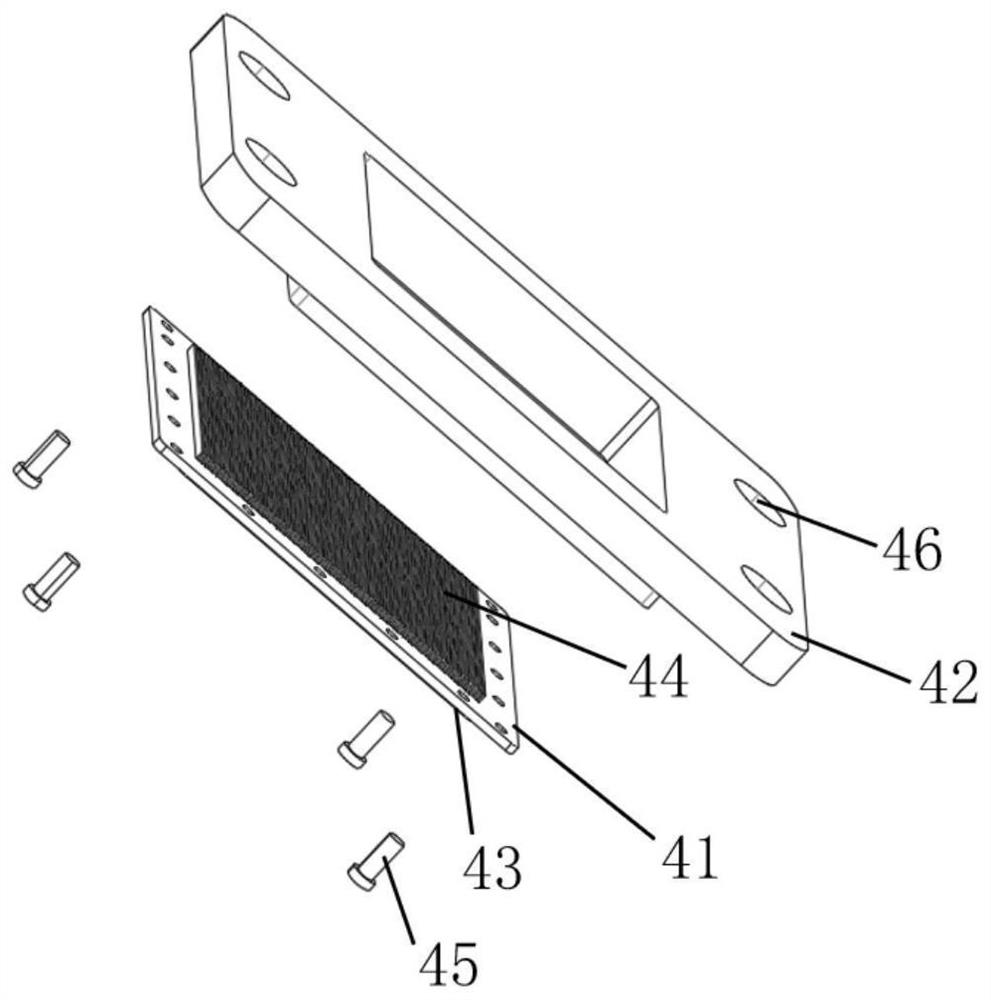

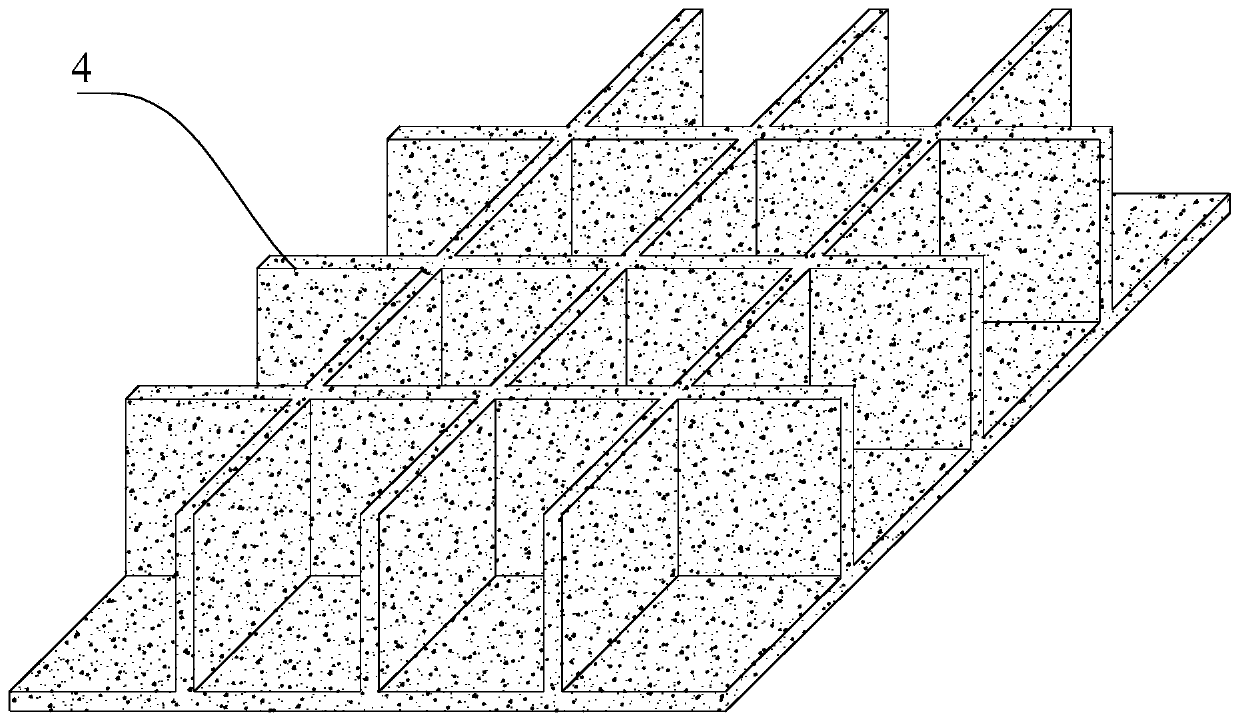

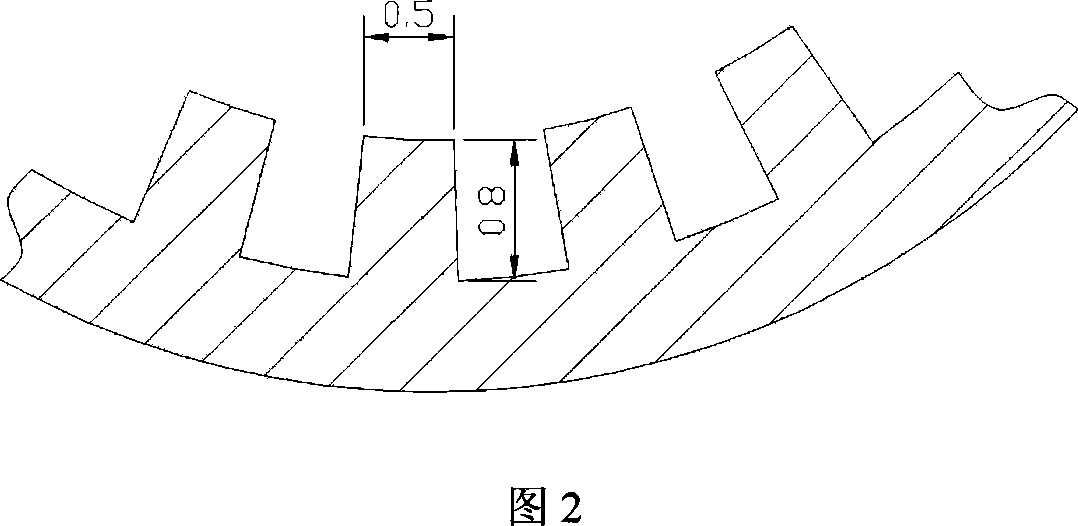

Immersion cooling heat dissipation structure, radiator, heat dissipation system and manufacturing method of immersion cooling heat dissipation structure

PendingCN112071817AAvoid the defect of high contact thermal resistanceIncrease the heat exchange areaSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyThermodynamics

The invention discloses an immersion cooling heat dissipation structure, a radiator, a heat dissipation system and a manufacturing method of the immersion cooling heat dissipation structure. The immersion cooling heat dissipation structure comprises a boiling heat exchange unit, and the boiling heat exchange unit comprises a first surface and a second surface which are arranged back to back; a microstructure composed of a plurality of opposite convex parts and / or a plurality of opposite concave parts is distributed on the first surface, and the first surface is at least used for making contactwith an electrically insulating immersion cooling medium; the second surface is a smooth face and used for being attached to a heating element, or the second surface and the heating element are integrally arranged. The immersion cooling heat dissipation structure provided by the invention has the advantages of higher heat exchange area, more nucleation sites, stronger capillary fluid infusion capability, excellent boiling heat exchange performance, high heat transfer coefficient and critical heat flux density, low superheat degree of a nucleation boiling starting point and great advantages ina small-space high-heat-flux heat dissipation application scene; meanwhile, the manufacturing process is relatively flexible and controllable, the cost is low, industrial large-scale application canbe achieved, and the market competitiveness is high.

Owner:SUGON DATAENERGYBEIJING CO LTD

Impact jet array phase change cooling device combined with foam metal

InactiveCN111076587AIncrease independenceEfficient separationIndirect heat exchangersEvaporation heat transferHeat flow

The invention discloses an impact jet array phase change cooling device combined with foam metal. The impact jet array phase change cooling device combined with the foam metal comprises a heat sink chamber, a substrate with a heat source, a foam metal capillary core, a flow divider, a pressure pump, a condenser, a drying filter and a cooling working medium. The heat sink chamber comprises a lowerworking chamber and an upper steam chamber; the surface of the foam metal capillary core is provided with a plurality of columnar porous ribs, and the flow divider evenly distributes the liquid cooling working medium to a working chamber unit. Aiming at an ultra-high heat flow density device, an electronic chip of the high heat flow density electronic device is cooled by combining the impact jet flow boiling mode with the foam metal capillary core with the fins, on one hand, the sufficiency of liquid supply can be guaranteed, on the other hand, the smooth discharge of steam can be guaranteed,the good separation of gas and liquid phases can be realized, the gas flow structure of jet flow boiling heat exchange is optimized, and the CHF and the cooling performance can be greatly improved.

Owner:JIANGSU UNIV OF SCI & TECH

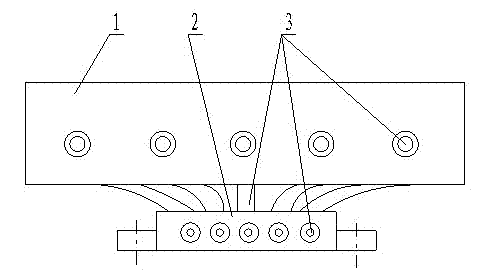

Surface evaporation air cooler heat transfer pipe bundle having membrane expanding plate

InactiveCN101013005AIncrease the areaImprove heat transfer performanceStationary conduit assembliesHeat exchanger casingsEvaporation heat transferHeat transmission

A surface evaporating air cooler heat exchange tube with membrane plate can improve the water membrane area and improve the evaporation heat transmission, without significant wind resistance. The invention comprises a tubular box, a tubular plate, a support plate and a heat exchange light tube, wherein, the heat exchange light tube is through the tubular hole of support plate, to be fixed on the tubular plate at the side of tubular box; the support plates, the support plate and the tubular plate have membrane plates fixed between them; the membrane plate is under the upper heat exchange light tube; and above the lower heat exchange light tube, the central line of long edge of membrane plate is parallel with the axles of upper and lower relative heat exchange light tubes. The invention can improve the area of water membrane, strengthen the evaporation, and transmit energy outwards quickly.

Owner:HUAZHONG UNIV OF SCI & TECH

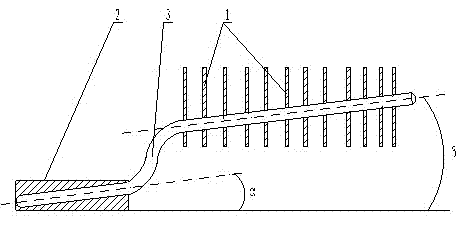

Heated part for multi-angle detection of boiling heat transfer, and experimental device and experimental method thereof

ActiveCN112798645ALow costEasy to operateNuclear energy generationMaterial heat developmentEvaporation heat transferEngineering

The invention relates to the field of phase-change heat exchange, and concretely relates to a heated part for multi-angle detection of boiling heat exchange, and an experimental device and an experimental method thereof. The heated part for multi-angle detection of boiling heat transfer comprises a to-be-detected modified surface part and a to-be-detected heated column, the to-be-detected modified surface part is arranged at the top of the to-be-detected heated column, and the to-be-detected modified surface part is mounted on the to-be-detected heated column at a variable angle. According to the heated part for multi-angle detection of boiling heat exchange, and the experimental device and the experimental method thereof, the to-be-detected modified surface part can be fixed in a multi-angle manner relative to the heated part, namely the to-be-detected heated column, so that the angle of a boiling surface is changed, and the technical problem that only upward boiling performance of a horizontal surface can be tested and experimental performance of different placement angles of a modified surface cannot be detected in the prior art is solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Two-phase closed type hot siphon tube using water-based carbon nanotube suspension liquid as working fluid

InactiveCN101078600ASmall total thermal resistanceDecrease the tilt angleIndirect heat exchangersHeat-exchange elementsSiphonWater based

The invention relates to a two-phase closed thermosyphon with water-based carbon nano-tube suspension, comprising vaporizing segment, thermal insulation segment and condensing segment. Axial micro grooves arranged evenly are set on the inner wall of condensing segment to increase the area of heat transferring face. Carbon nano-tube suspension, as working fluid is filled in the vaporizing segment. Fluid-loaded rate is 40-60% of vaporizing segment cubage. The carbon nano-tube suspension is mixed solution of de-ionized water and carbon nano-tube. Mass concentration of carbon nano-tube in suspension is 1-2.5%. In using, required heat dispersing elements are attached on the lower end of heat pipe. Depending on evaporation of working fluid in the vaporizing segment of thermosyphon heat is transferred so that heat quantity of required heat dispersing elements is transferred to cooling water in the condensing segment. The invention uses water-based carbon nano-tube suspension as working fluid. Not only heat exchanging performance is improved but also total heat resistance of heat pipe is decreased. Oblique angle of heat pipe is decreased greatly and when the oblique angle of heat achieves horizontal 15 degrees heat exchanging performance is still good.

Owner:SHANGHAI JIAO TONG UNIV

Method for improving surface pool boiling heat transfer performance based on femtosecond laser joint processing technology

The invention relates to a method for improving the surface pool boiling heat transfer performance based on a femtosecond laser joint processing technology and belongs to the technical field of heat transfer enhancement. With top-speed development of economy, stable heat dissipation under high heat flow becomes an urgently-achieved aim, and more and more researches have been made on boiling heat transfer as an efficient and stable heat transfer mode. Micro-nano improvement on the heat transfer surface has become an application technology for heat transfer enhancement. But the problem that theheat transfer performance (CHF and HTC) cannot be synchronously improved hasn't been solved yet. The method for improving the surface pool boiling heat transfer performance based on the femtosecond laser joint processing technology can synchronously improve the surface heat transfer performance.

Owner:CHANGCHUN UNIV OF SCI & TECH

Efficient boiling enhanced heat exchange tube and manufacturing method thereof

ActiveCN111207619AIncrease supplementImprove wettabilityHeat transfer modificationEvaporation heat transferProcess engineering

The invention discloses an efficient boiling enhanced heat exchange tube and a manufacturing method thereof, and belongs to the technical field of heat exchangers. The efficient boiling enhanced heatexchange tube is structurally composed of an external base tube and a tube inner wall sintered layer, wherein the tube inner wall sintered layer is a heterogeneous super-hydrophilic copper powder particle layer, and is distributed along the cross section of the base tube in a space mode that particles on the upper wall surface are thin and dense, particles on the lower wall surface are thick and sparse, and the side wall surface is uniformly changed, so that the anti-gravity migration of liquid at the bottom of the tube can be effectively realized, and the flow pattern in the tube is improved.The tube inner wall sintered layer can provide a large number of stable vaporization cores, meanwhile, tiny holes in the tube can provide large capillary force to promote liquid supplement, the dynamic behavior of steam bubbles is changed, the steam bubble separation period is shortened, the distribution in the base tube is regulated and controlled, and boiling heat exchange is effectively enhanced. The efficient boiling enhanced heat exchange tube can be applied to a medium-low temperature waste heat power generation system, an air conditioner evaporator, a groove type solar heat collectingtube and a boiler water wall, and has wide application value and social value.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com