Micro-droplet self-transported wedged non-uniform wetting surface and preparation method thereof

A self-transporting, non-uniform technology, applied in the coating, metal material coating process, etc., to achieve the effect of promoting rapid desorption, improving water collection efficiency and microfluidic efficiency, and easy to roll off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The method for preparing a wedge-shaped non-uniform super-wetting surface capable of self-transporting microdroplets is characterized in that the super-hydrophobic coating contains 1-5mg / mL titanium dioxide or zinc oxide nanoparticles, 2-20mg / mL Silica nano chain particles, 1-10mg / mL hydrophobic silicone or fluororesin, 0.1-1mg / mL trimethoxy fluorine-containing silane with a carbon chain length of 5-10, are obtained by uniformly mixing in the presence of an organic solvent.

[0057] The method for preparing a wedge-shaped non-uniform super-wetting surface capable of self-transporting microdroplets is characterized in that the organic solvent includes any one of ethanol, acetone, butyl acetate, and toluene.

[0058] The method for preparing a self-transporting wedge-shaped non-uniform super-wetting surface of microdroplets is characterized in that, the hydrothermal oxidation method uses KOH and Zn(NO 3 ) 2 Formulated Zn(OH) 4 2- The aqueous solution reacts to build a ...

Embodiment 1

[0062] (1) Pretreatment: The slides were ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 15 minutes in order to remove oil and dust on the surface, then rinsed with absolute ethanol, dried with cold air, and set aside.

[0063] (2) Superhydrophobic coating preparation: the coating contains 5mg / mL titanium dioxide or zinc oxide nanoparticles, 10mg / mL hydrophobic silicon dioxide nano chain particles, 4mg / mL hydrophobic silicone or fluororesin, 1mg / mL carbon chain Trimethoxy fluorine-containing silane with a length of 10 is mixed with ethanol, acetone, butyl acetate, toluene and other volatile miscible liquids as solvents, and mixed with ultrasonic or mechanical stirring for 5 hours. When in use, the super-hydrophobic paint is sprayed on the surface of the substrate, and after drying, blowing or drying, a super-hydrophobic surface is obtained.

[0064] (3) Construction of wedge-shaped non-uniform wetting surface: Expose the substrate through photore...

Embodiment 2

[0069] (1) Pre-treatment: ultrasonically clean a 1mm thick copper sheet (25mm*25mm, copper element content 99.5%) with acetone, absolute ethanol and deionized water for 15 minutes to remove oil and dust on the surface, and then clean it with absolute ethanol Rinse, dry with cold air, and set aside;

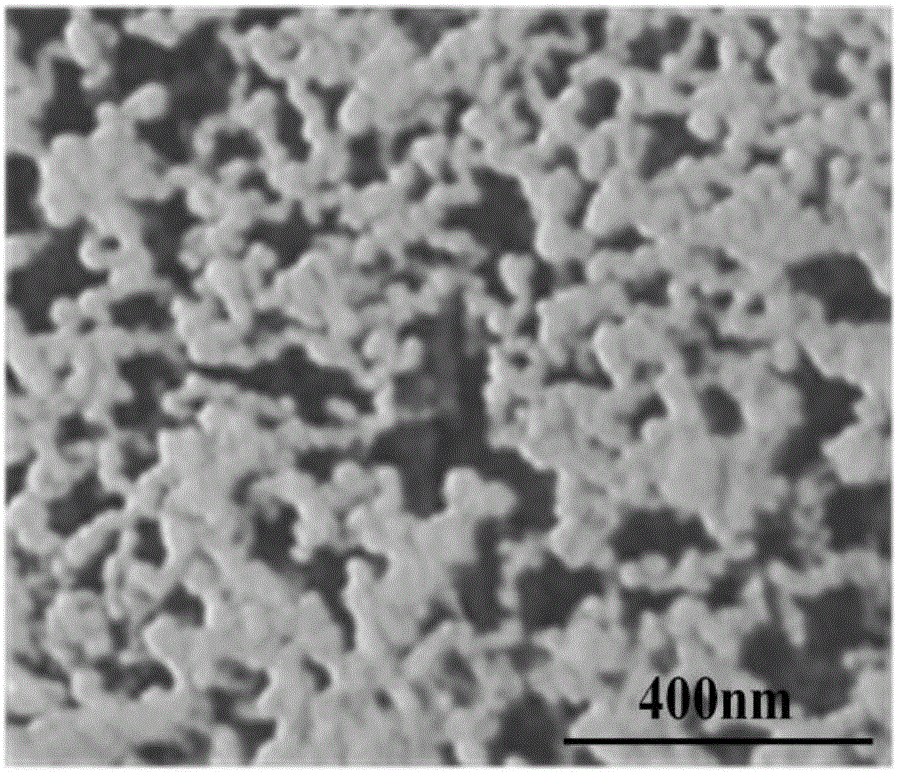

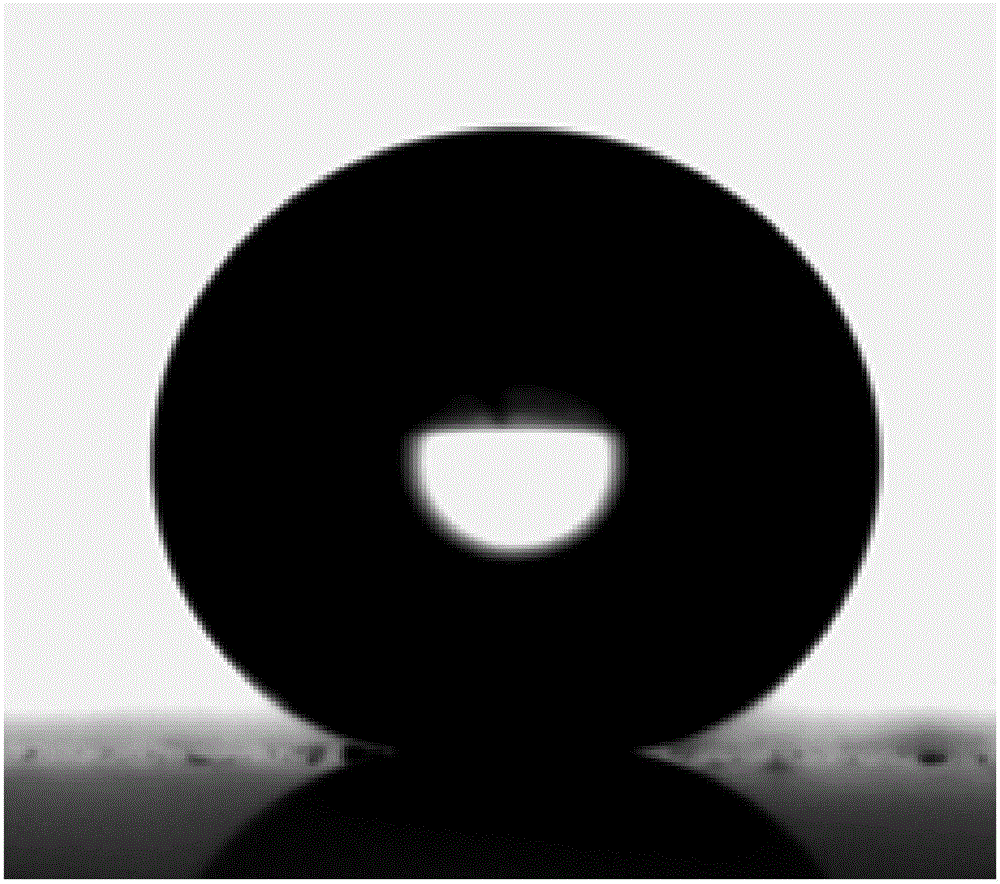

[0070] (2) Preparation of superhydrophobic surface: using hydrothermal oxidation method, the copper sheet is reversed or vertically inserted with KOH and Zn(NO 3 ) 2 The prepared concentration is 0.1MZn(OH) 4 2- Aqueous solution, 90°C constant temperature water bath for 30min, grow zinc oxide nano-arrays on the surface of copper sheet, such as Figure 8 As shown, the superhydrophobic surface was obtained after fluorosilane modification;

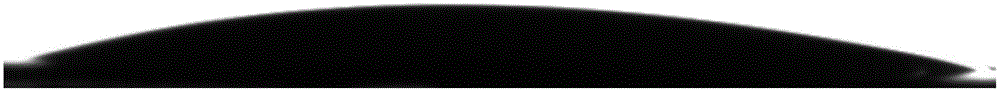

[0071] (3) Construction of wedge-shaped superhydrophilic region: place a polydimethylsiloxane soft template with wedge-shaped through holes on the superhydrophobic surface of the substrate, irradiate with 500w ultraviolet light for 10 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com