Patents

Literature

53results about How to "With photocatalytic function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing composite fiber material for visible light photocatalytic degradation of organic pollutants

InactiveCN101884917ASolving Recycling ProblemsReduce chance of recombinationWater/sewage treatment by irradiationDispersed particle separationTextile fiberCompound (substance)

The invention provides a composite fiber material applied to visible light photocatalytic purification of sewage and air pollutants and a preparation method thereof. The composite fiber material is synthesized by loading a visible light response type bismuth-based photocatalytic material on a textile fiber material through a green chemical synthetic route. A powdered photocatalyst is solidly loaded by the unique net-like felt structure of the textile fiber material, so that the catalyst is prevented from losing and agglomerating during sewage treatment and air purification, and the separability and reusability are improved.

Owner:于建强 +2

Micro-droplet self-transported wedged non-uniform wetting surface and preparation method thereof

ActiveCN105820749AReduce adhesionExcellent surface superhydrophobicityMetallic material coating processesEvaporation heat transferPolyvinyl alcohol

The invention relates to a micro-droplet self-transported wedged non-uniform ultra-wetting surface and a preparation method thereof. A super-hydrophobic surface containing titanium dioxide or zinc oxide nano-materials is constructed on the surface of a substrate by using a coating spraying or hydrothermal oxidation method, and a template method is used, ultraviolet light catalysis or oxygen plasma region selective modification is carried out to obtain a wedged super-hydrophilic region, the template method also can be used to obtain a wedged covering region, and then the coating spraying or hydrothermal oxidation method can be used again, and region selection is carried out to construct the super-hydrophobic surface, so as to obtain the wedged non-uniform ultra-wetting surface, finally, the wedged region is further modified by using polyvinyl alcohol again to obtain a bulge of the smooth super-hydrophilic wedged region, so that micro-droplets can be transported spontaneously in the wedged region without external force driving. By selecting the region of a template, the wedged super-hydrophilic region arranged in an array can be obtained on the super-hydrophobic surface, and multiple micro-droplets are in self-propelled movement by one time, so that the micro-droplet self-transported wedged non-uniform ultra-wetting surface has broad application prospects in fields of condensation heat transfer enhancement or evaporation heat transfer, fog catchment, microfluid and the like.

Owner:SOUTHEAST UNIV

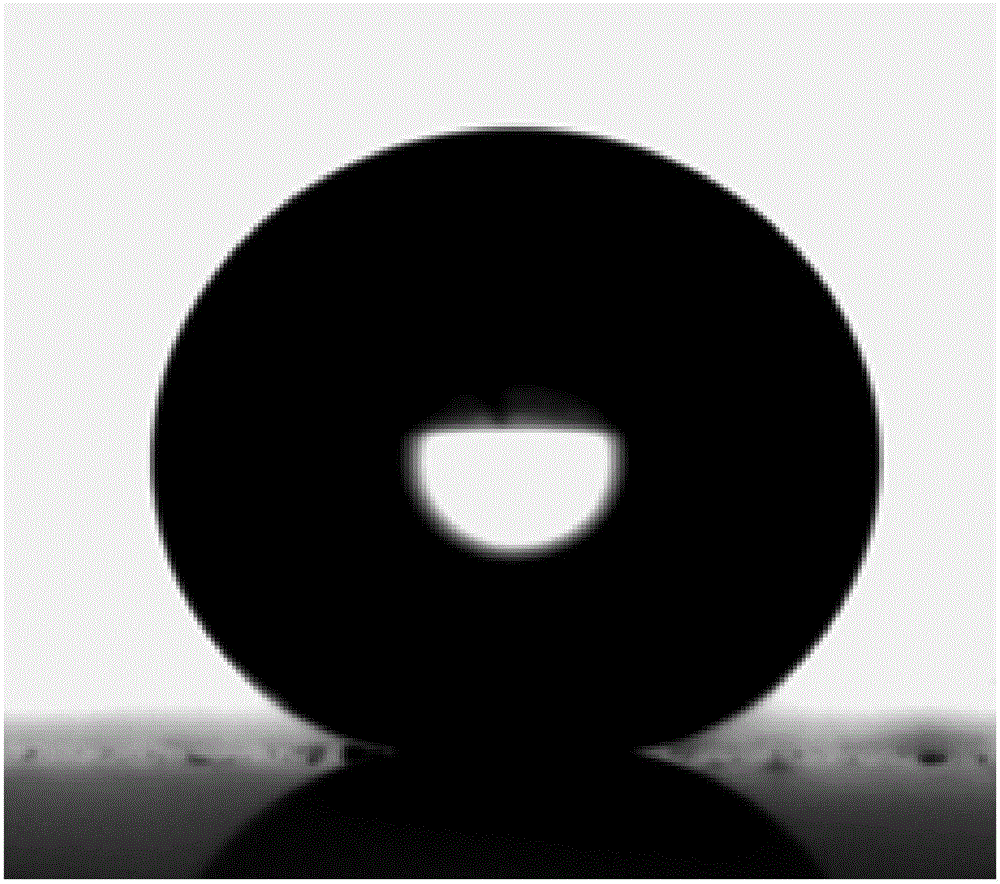

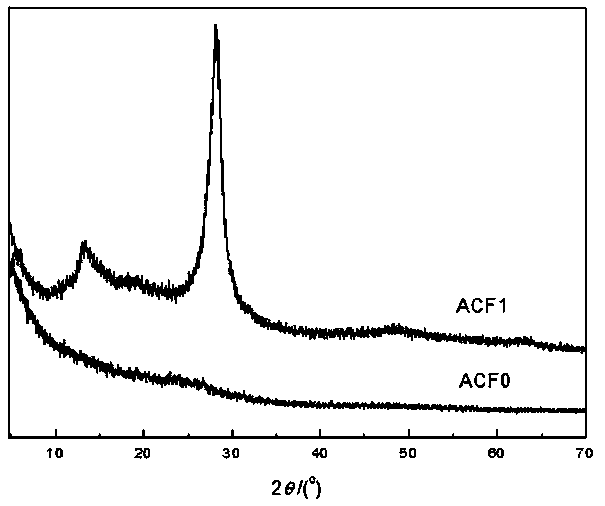

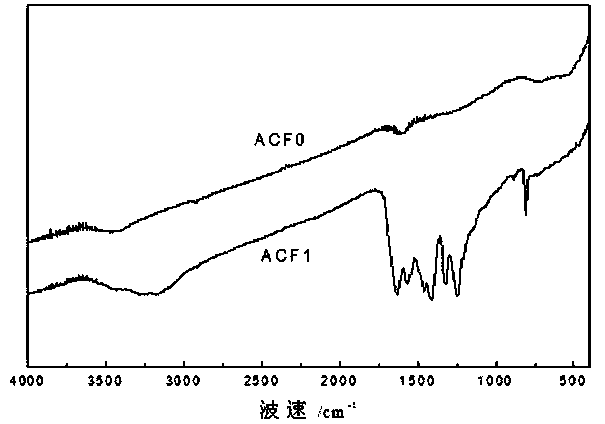

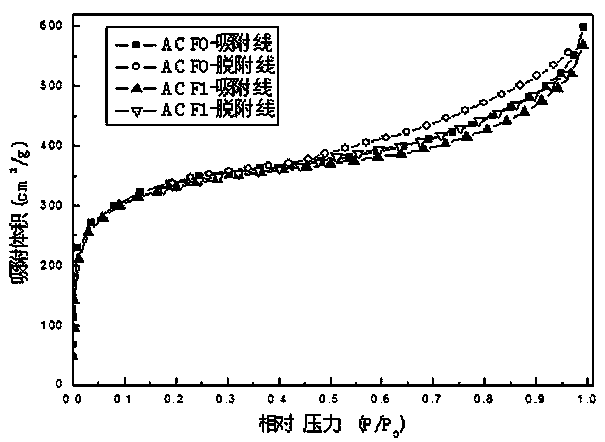

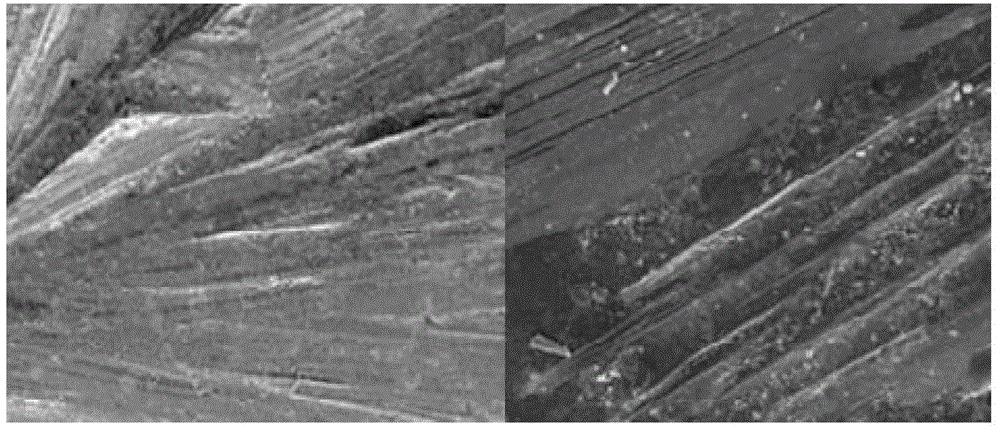

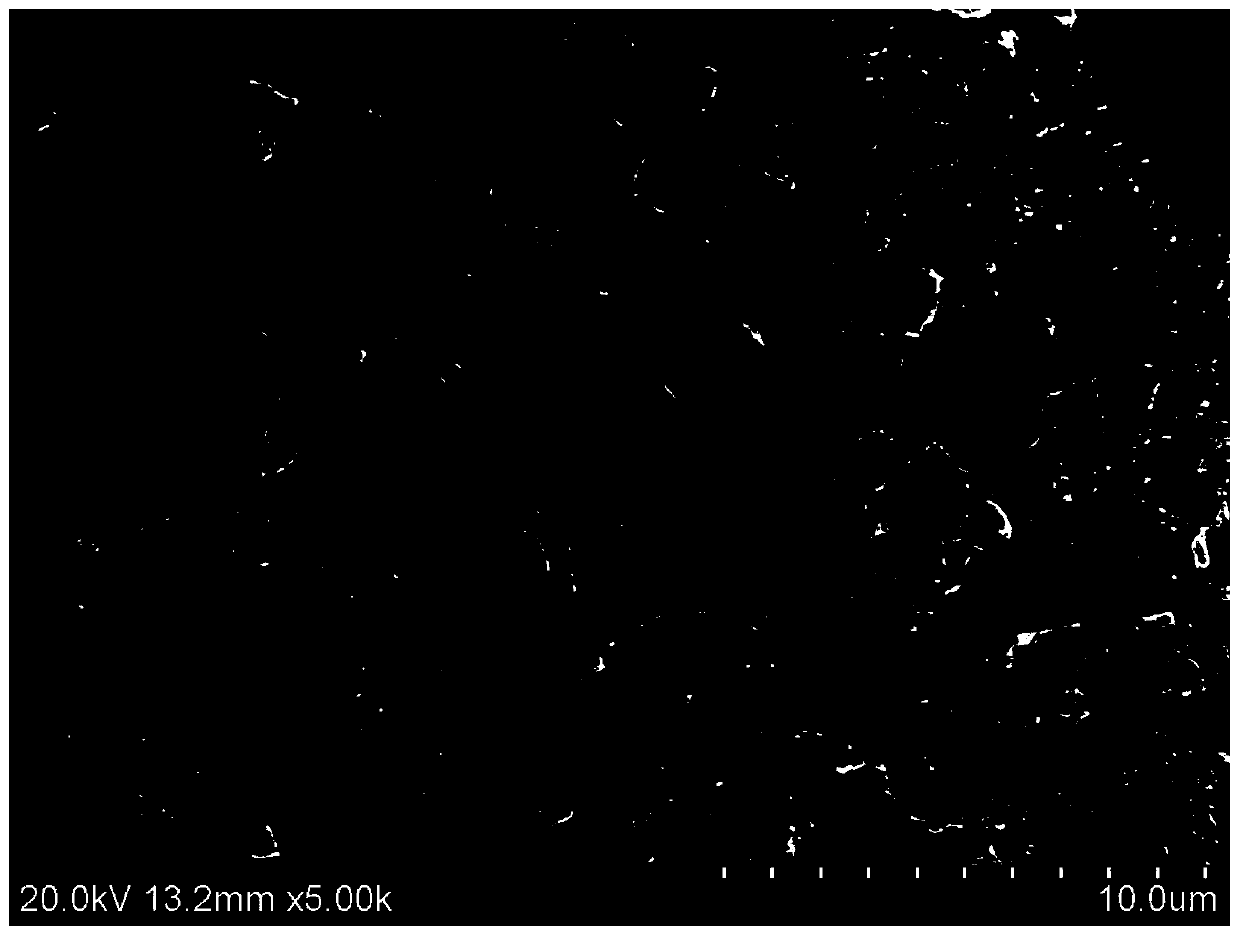

Electrochemical method for preparing activated carbon fibers with photocatalysis function

InactiveCN103769050AWith adsorption functionWith photocatalytic functionPhysical/chemical process catalystsOther chemical processesFiberActivated carbon

The invention discloses a preparation method for activated carbon fibers with a photocatalysis function. The activated carbon fibers for immobilizing graphite phase carbon nitride are prepared by an electrochemical deposition method by taking activated carbon fibers, dicyanodiamine, N,N-dimethylformamide and the like as main raw materials. The activated carbon fibers have an adsorption function and the photocatalysis function. Under a condition of darkness or insufficient light, pollutants can be purified under the adsorption function of the activated carbon fibers; under a condition of sufficient light, the pollutants can be purified under the adsorption function and the photocatalysis function; in-situ regeneration of the adsorption function of the activated carbon fibers can be realized; labor, resource and financial consumption of a regeneration process is greatly reduced. Successful research on the activated carbon fibers has an important significance for relieving of insufficience of activated carbon fiber supply in China.

Owner:FUJIAN AGRI & FORESTRY UNIV

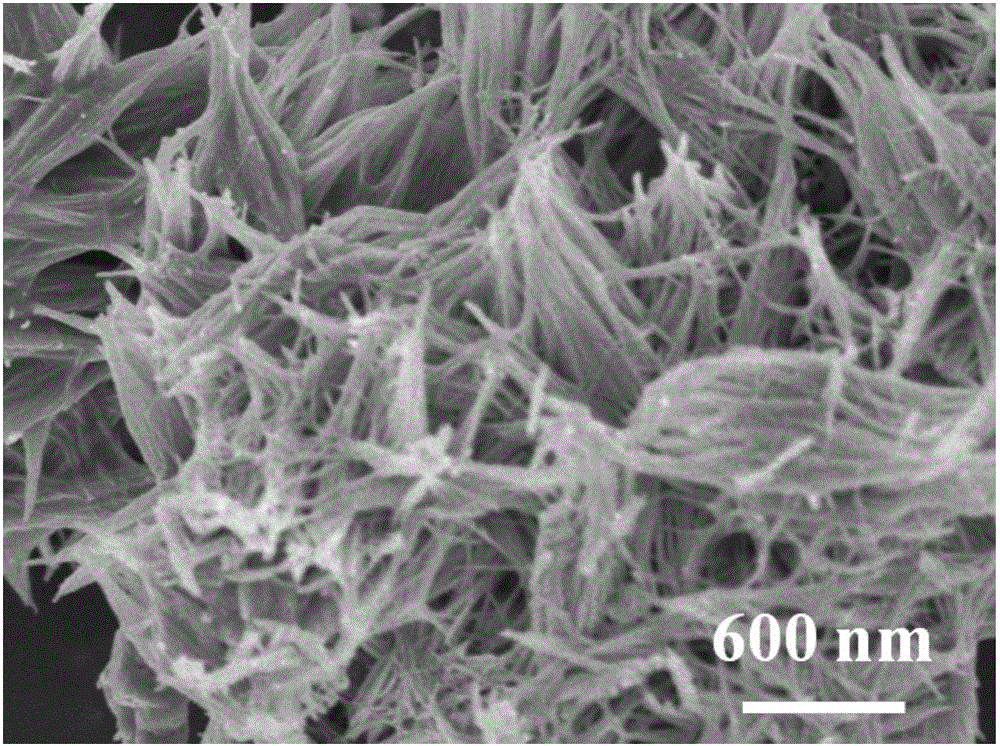

Photocatalytic material with nano TiO2 loaded on graphene-foamed nickel and preparation method of photocatalytic material

InactiveCN106334562AImprove performanceWith photocatalytic functionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickelGraphene foam

The invention discloses a photocatalytic material with nano TiO2 loaded on graphene-foamed nickel and a preparation method of the photocatalytic material. The foamed nickel is taken as a base, a graphene film layer is deposited on the foamed nickel to form a graphene-foamed nickel composite carrier, a TiO2 sol film layer is formed on the graphene-foamed nickel composite carrier, the graphene is combined with the foamed nickel to serve as an organic carrier loaded with the nano TiO2, a three-layer structure is formed, the carrier is firmly loaded with the nano TiO2, and the photocatalytic activity of the TiO2 is greatly improved. An electrophoretic deposition method is used and a polyurethane foam serves as a base to prepare the foamed nickel with high specific surface area, the foamed nickel is then loaded with the graphene through the electrophoretic deposition method, the grapheme film layer is formed, a sol-gel method is used, no binder is used, the nano TiO2 with higher photocatalytic activity is loaded on the graphene-foamed nickel composite carrier, the whole process is simple in operation, the period is short, and the manufacturing cost is low.

Owner:郑州峰泰纳米材料有限公司

Method for preparing micro-arc oxidation film with photocatalysis function

The invention belongs to the field of surface treatment technologies, and particularly relates to a method for preparing a micro-arc oxidation film with a photocatalysis function. The method comprises steps of performing pretreatment, water scrubbing, configuration of micro-arc oxidation tank liquor, micro-arc oxidation, water scrubbing and the like on a matrix. By adopting the method, the film with the photocatalysis function can be directly prepared on the surface of a light alloy through a micro-arc oxidization method. The method has simple technologies, and avoids complex pretreatment and aftertreatment processes. The prepared film can be firmly combined with the matrix and has the photocatalysis function.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

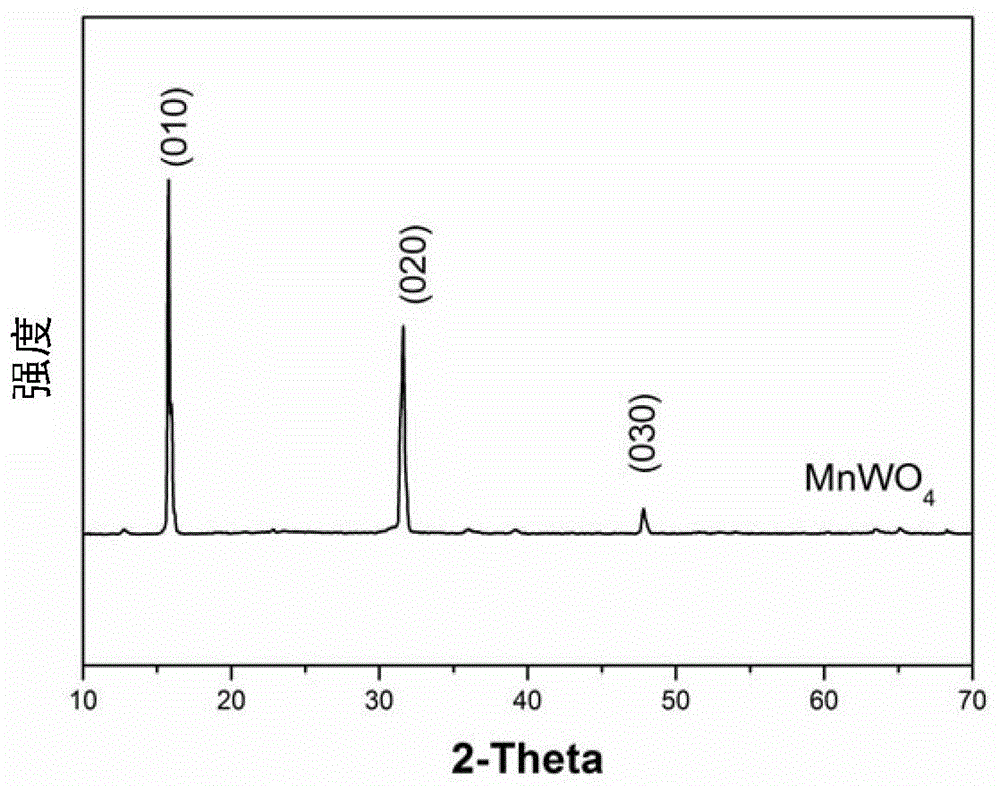

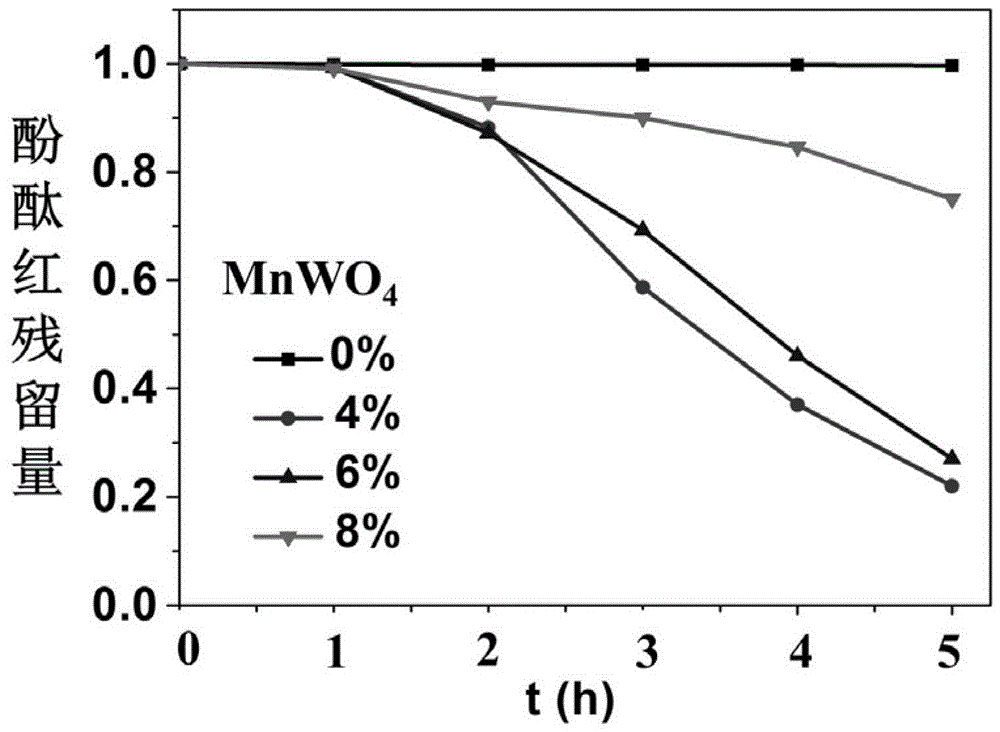

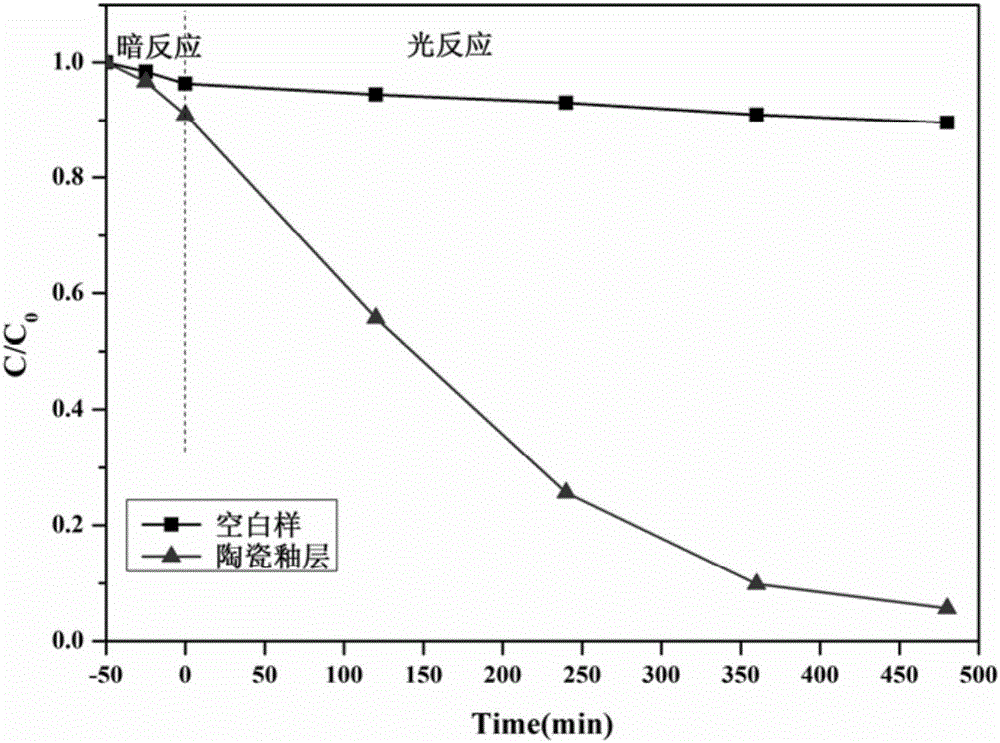

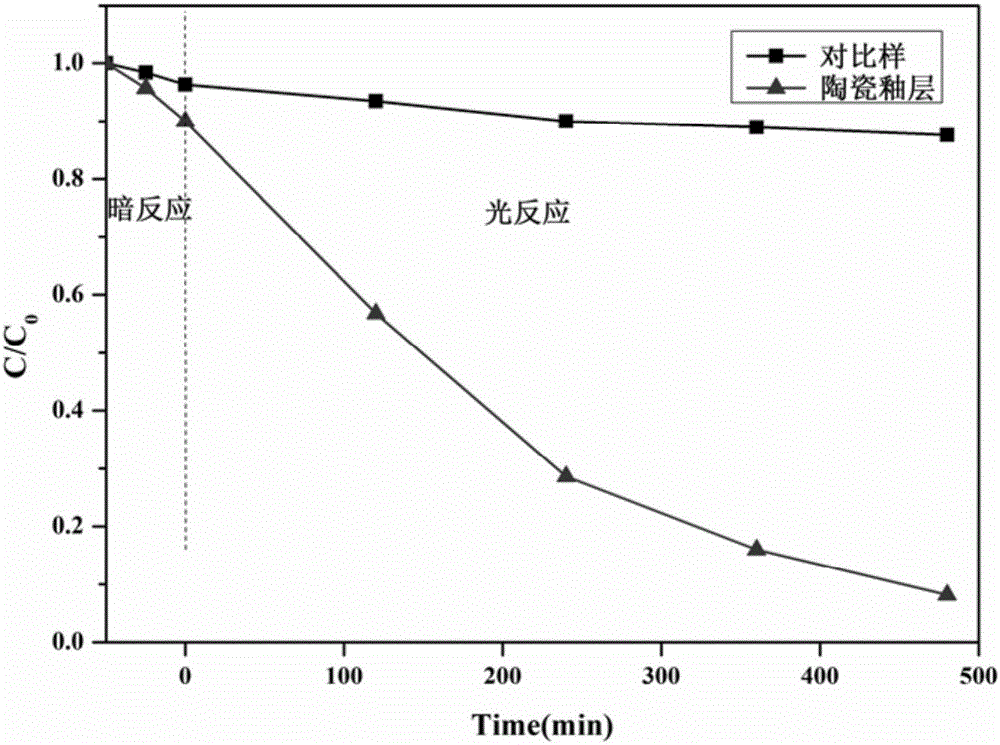

Glaze composition prepared from manganese tungstate as active material and having photocatalytic function and preparation method of glaze composition

ActiveCN106673439AHigh melting temperatureGood suspensionMetal/metal-oxides/metal-hydroxide catalystsTungstateMaterials science

The invention relates to glaze composition prepared from manganese tungstate as an active material and having a photocatalytic function and a preparation method of the glaze composition. The glaze composition is prepared from powder A, MnWO4 and kaolin, wherein the mass percentage of the powder A, MnWO4 and kaolin is (84%-88%): (4%-8%): (6%-10%); the powder A comprises raw materials by weight as follows: 20%-30% of SiO2, 5%-10% of Al2O3, 40%-50% of P2O5, 1.5%-2.5% of MnO, 12%-14% of Li2O, 6%-8% of Na2O and 12%-13% of K2O. The glaze composition contains the powder A as a main component, contains an appropriate amount of MnWO4, and has an excellent photocatalytic function on the basis of a good glaze effect.

Owner:MONALISA GRP CO LTD

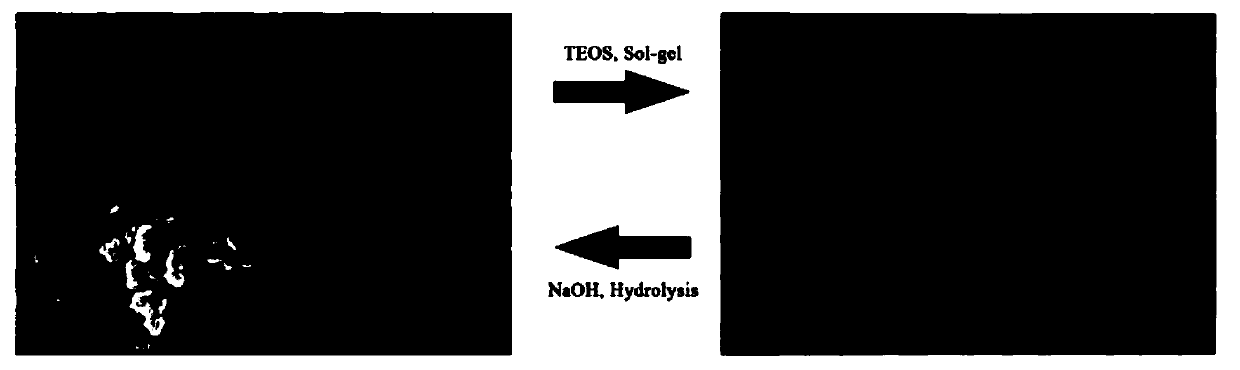

Preparation method of PAN-based oil-water separation microporous membrane with photocatalysis function

ActiveCN110860218AFunctionalWith photocatalytic functionSemi-permeable membranesWater/sewage treatment by irradiationMembrane permeabilizationSio2 nanoparticle

The invention discloses a preparation method of a PAN-based oil-water separation microporous membrane with a photocatalysis function. The preparation method comprises the following steps: firstly, introducing shell-layer SiO2 nanoparticles onto the outer surface of TiO2 by adopting a sol-gel method to realize coating of nanometer TiO2 with a photocatalysis function so as to obtain a SiO2@TiO2 additive, thereby isolating direct contact between a base membrane and photocatalysis particles and laying a foundation for migration of the photocatalysis particles to the surface of the membrane in thenext step; then blending SiO2@TiO2 and P(AN-MA) to prepare a membrane casting solution; curing the membrane casting solution containing the SiO2@TiO2 additive by using a TIPS method so as to form a membrane; then, subjecting the cured membrane to a hydrolysis reaction so as to convert cyano groups on the surface of the membrane into hydrophilic carboxyl groups; and dissolving the additive shell-layer SiO2, and allowing TiO2 in the additive to break away from constraint and migrate to the surface of the membrane so as to achieve the purpose of efficiently utilizing the photocatalysis particleswithout damaging the original performance of the base membrane, thereby obtaining the PAN-based microporous membrane with an oil-water separation function and photocatalytic degradation performance. The method has the advantages of simple process, high efficiency, no pollution and no influence on the permeability of the base membrane.

Owner:TIANJIN POLYTECHNIC UNIV

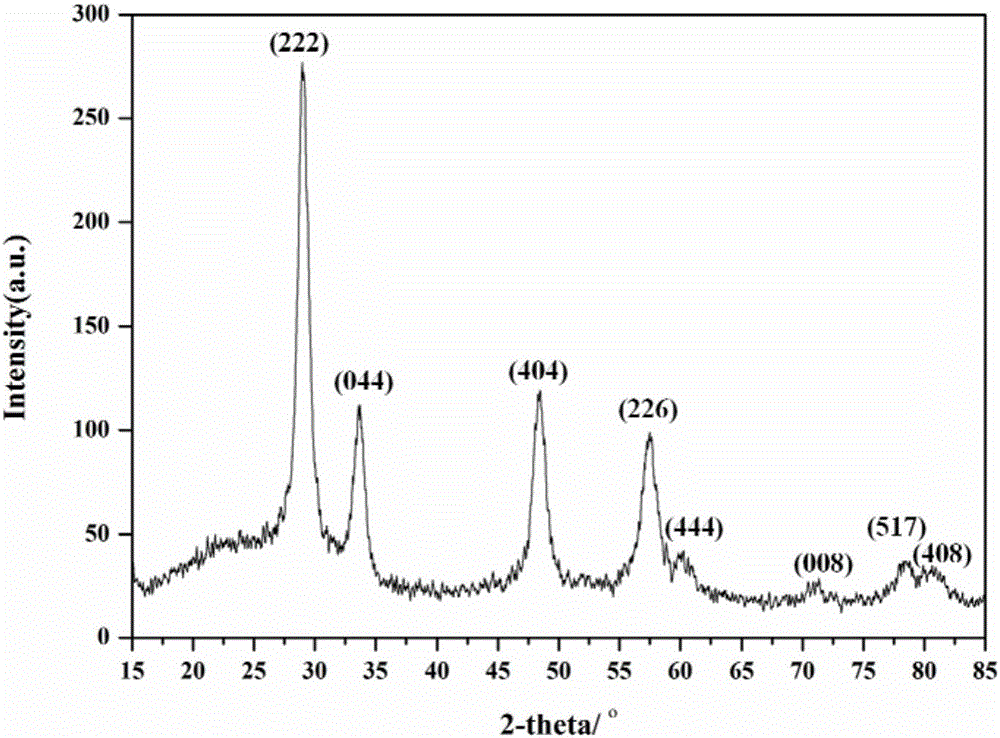

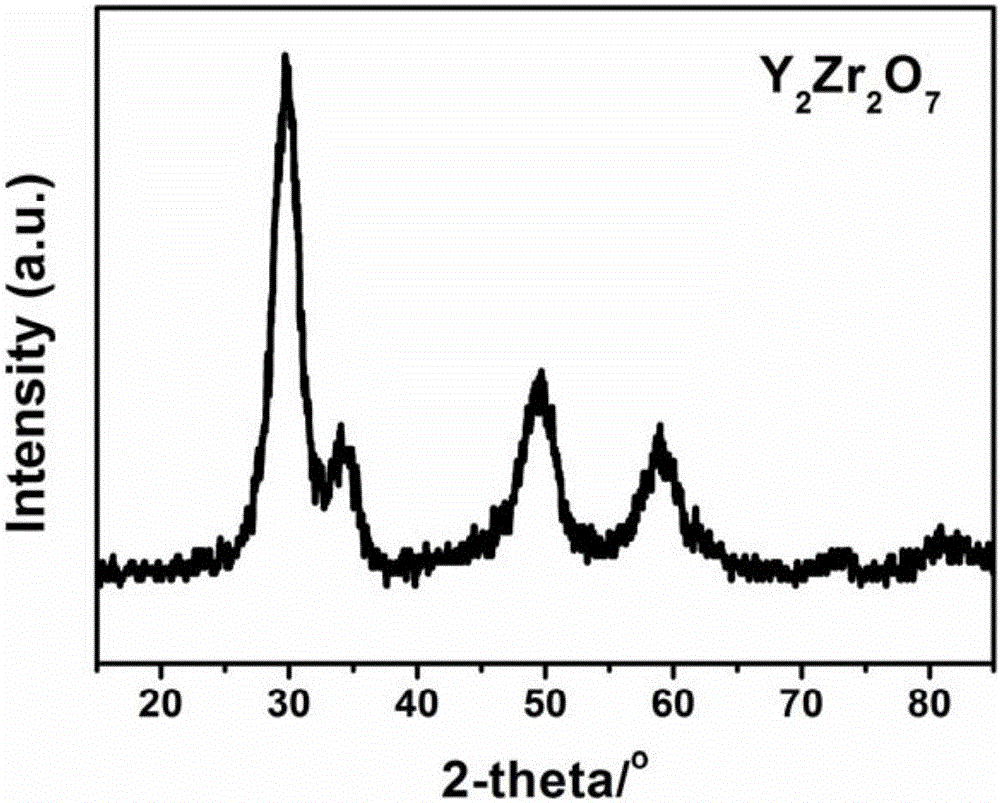

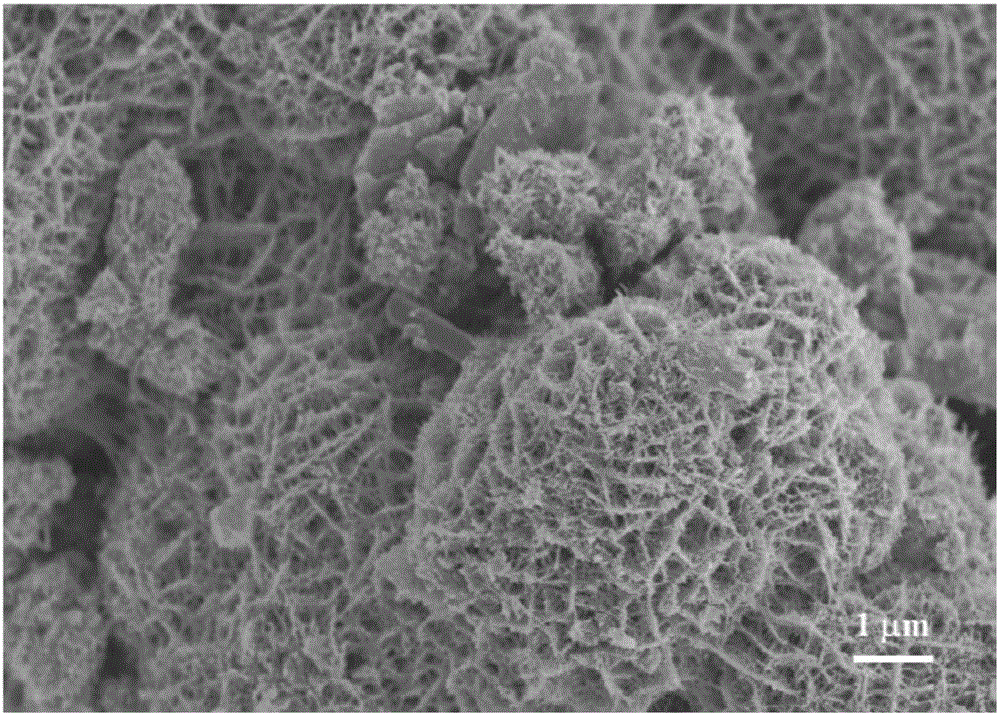

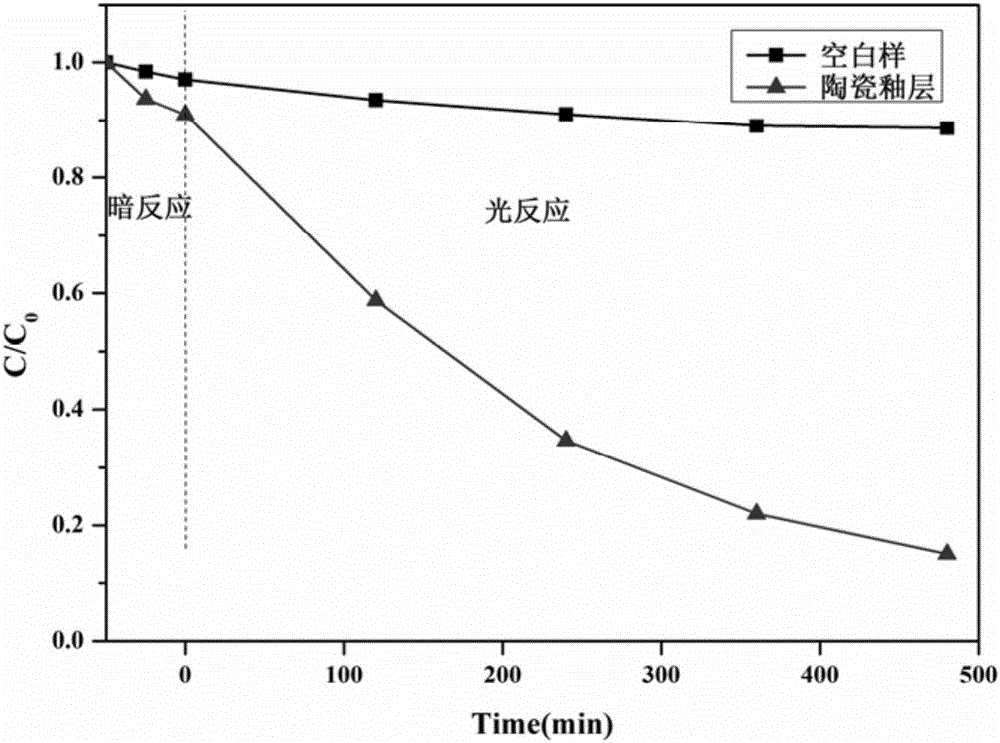

Preparation method of yttrium zirconate ceramic glaze material having photocatalytic function

The invention relates to a preparation method of a yttrium zirconate ceramic glaze material having a photocatalytic function. The preparation method comprises the following steps: preparing quartz, potash feldspar, albite, borax, Y2O3, Suzhou clay and lithium carbonate, keeping the temperature at 1270-1290 DEG C for 20-40 minutes, taking out, pouring into water, quenching to prepare a fusion cake, and grinding the fusion cake to obtain a material A; preparing the material A, Y2O3, ZrO2 and Suzhou clay, and grinding to obtain a material B; adding the material B and dispersing agent into water, and uniformly stirring and mixing to prepare a glaze slip; and applying the glaze slip to the surface of ceramics in a glaze spray manner, and firing to obtain the yttrium zirconate ceramic glaze material having a photocatalytic function. According to the invention, the ceramic glaze is prepared through a firing process and does not need coating, so that the prepared functional ceramic glaze material can be tightly combined with a ceramic matrix; and the photocatalyst yttrium zirconate generated in the sintering process of Y2O3 and ZrO2 is uniformly distributed in the glaze material, thereby avoiding influencing the aesthetic property of the glaze material due to a rainbow effect.

Owner:广西艾陶新型材料科技有限公司

Anti-aging coating for power device and preparation method thereof

InactiveCN107189674AWear-resistantWaterproof and anti-agingFireproof paintsAntifouling/underwater paintsGas phaseMicrosphere

The invention discloses an anti-aging coating for a power device and a preparation method thereof and relates to the technical field of coatings. The anti-aging coating is prepared from 55-65 parts of polyamide resin, 55-60 parts of organic silicone modified epoxy resin, 20-25 parts of thermoplastic expansion hollow microspheres, 18-20 parts of hydrophobic gas-phase silica, 15-17 parts of nano titanium dioxide, 13-15 parts of aluminum nitride, 13-15 parts of talcum powder, 20-25 parts of additive and 55-65 parts of water. The anti-aging coating has abrasion-resisting, waterproof, anti-aging, acid and alkali resistance properties, the preparation method is simple, the power device is effectively protected, and the service life is prolonged.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

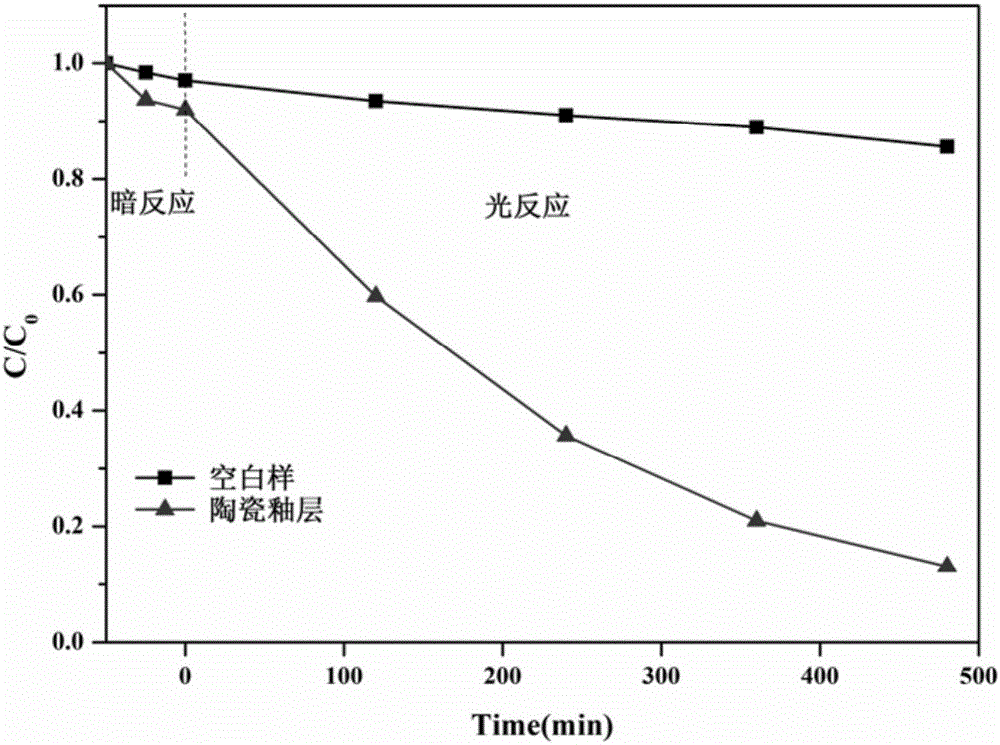

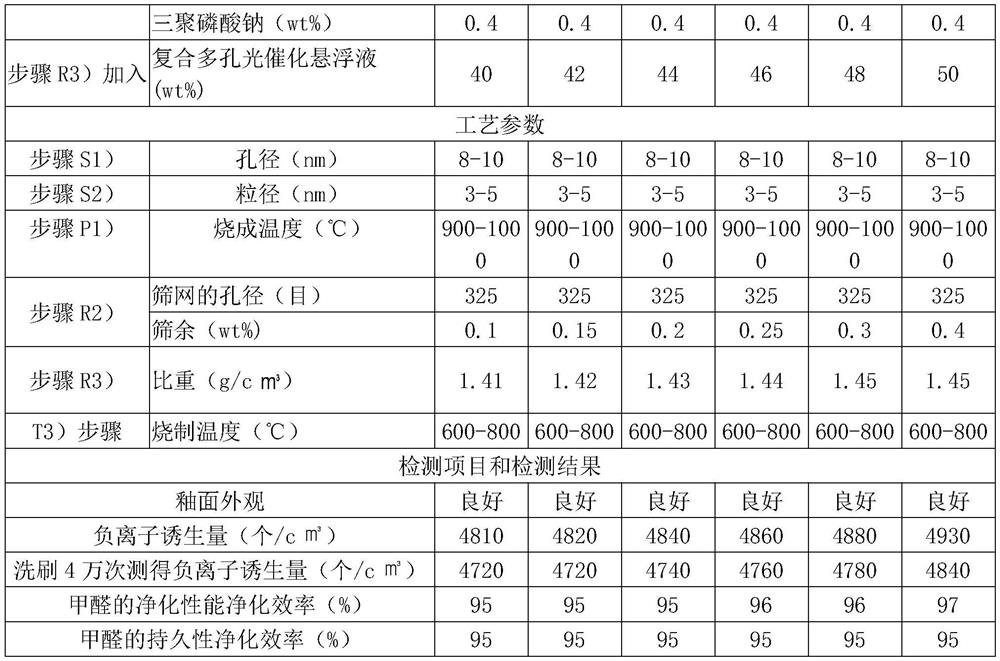

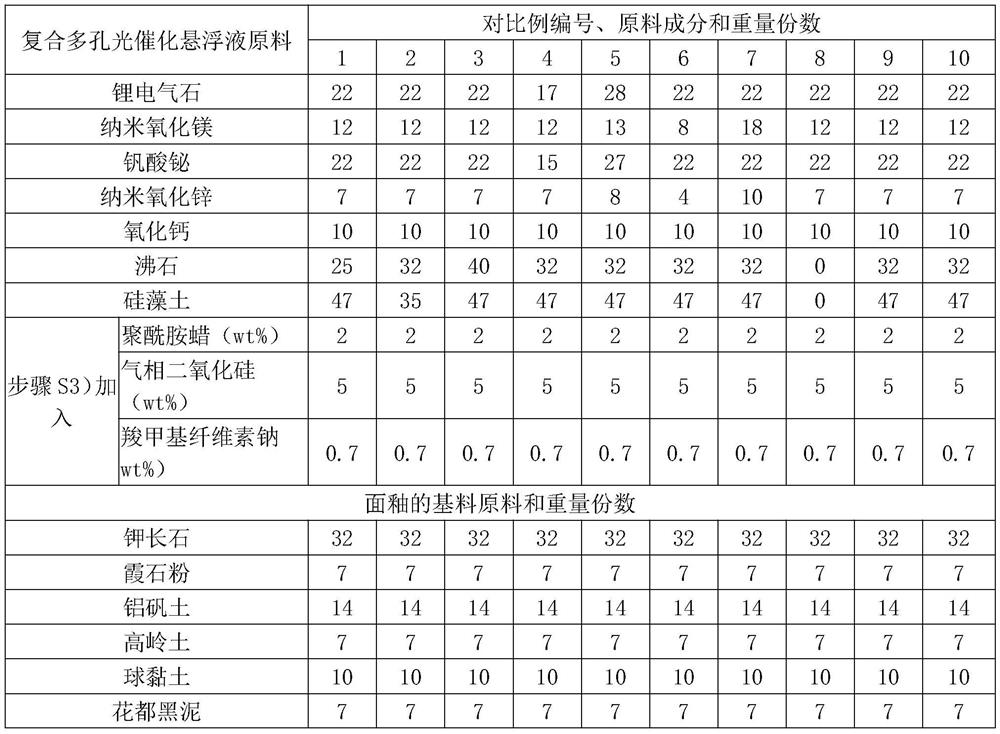

Photocatalytic negative ion ceramic tile containing modified porous material and preparation process of ceramic tile

PendingCN112321270AEfficient harmful gas purification efficiencyWith photocatalytic functionCeramic materials productionClaywaresNano zinc oxidePhoto catalysis

The invention relates to the technical field of ceramics and functional decorative materials, in particular to a photocatalytic negative ion ceramic tile containing a modified porous material and a preparation process of the ceramic tile. The ceramic tile comprises a ceramic tile blank and cover glaze, raw materials of the cover glaze comprise a composite porous photocatalytic suspension and a base material, wherein the composite porous photocatalytic suspension accounts for 40-50 wt% of the weight of the base material, the composite porous photocatalytic suspension is prepared from the following raw materials: a porous material, elbaite, nano magnesium oxide, bismuth vanadate, nano zinc oxide and calcium oxide, the porous material is prepared from zeolite and diatomite, and the particle sizes of the elbaite, the nano magnesium oxide, the bismuth vanadate, the nano zinc oxide and the calcium oxide are all smaller than the pore diameters of micropores of the porous material. The prepared photocatalytic negative ion ceramic tile cover glaze contains a porous material, micropores of the porous material can absorb harmful gas in air, and harmful gas is purified through negative ions, photocatalysis, far infrared rays and other materials.

Owner:FOSHAN DONGPENG CERAMIC +2

Protective bird dispersing composition for outdoor equipment of electric power network and preparation method thereof

InactiveCN105295716AWith photocatalytic functionImprove wear resistanceWax coatingsWear resistantPhosphate

The invention discloses a protective bird dispersing composition for outdoor equipment of an electric power network and a preparation method thereof. Nano silicon oxide, nano titanium dioxide, pulverized asbestos, epoxy modified silicone resin, emulsified silicone oil, multi-walled carbon nano tubes, aluminum silicate fiber, FeCuMnO3.5, ammonium bicarbonate, acrylic acid, 2,4,6-tris(dimethylaminomethyl)phenol, dibutyltin dilaurate, styrene-acrylic emulsion, ammonium polyphosphate, chlorinated paraffin wax, diphenyl isopropylphenyl phosphate, ethyl cellulose, xylene, folium artemisiae argyi, scirpoides holoschoenus, musk and eucalyptus oil are used as raw materials to prepare a corrosion-resistant, wear-resistant and self-cleaning protective bird dispersing composition for the outdoor equipment of the electric power network through a distributed mixing method.

Owner:国网山东莒南县供电公司 +1

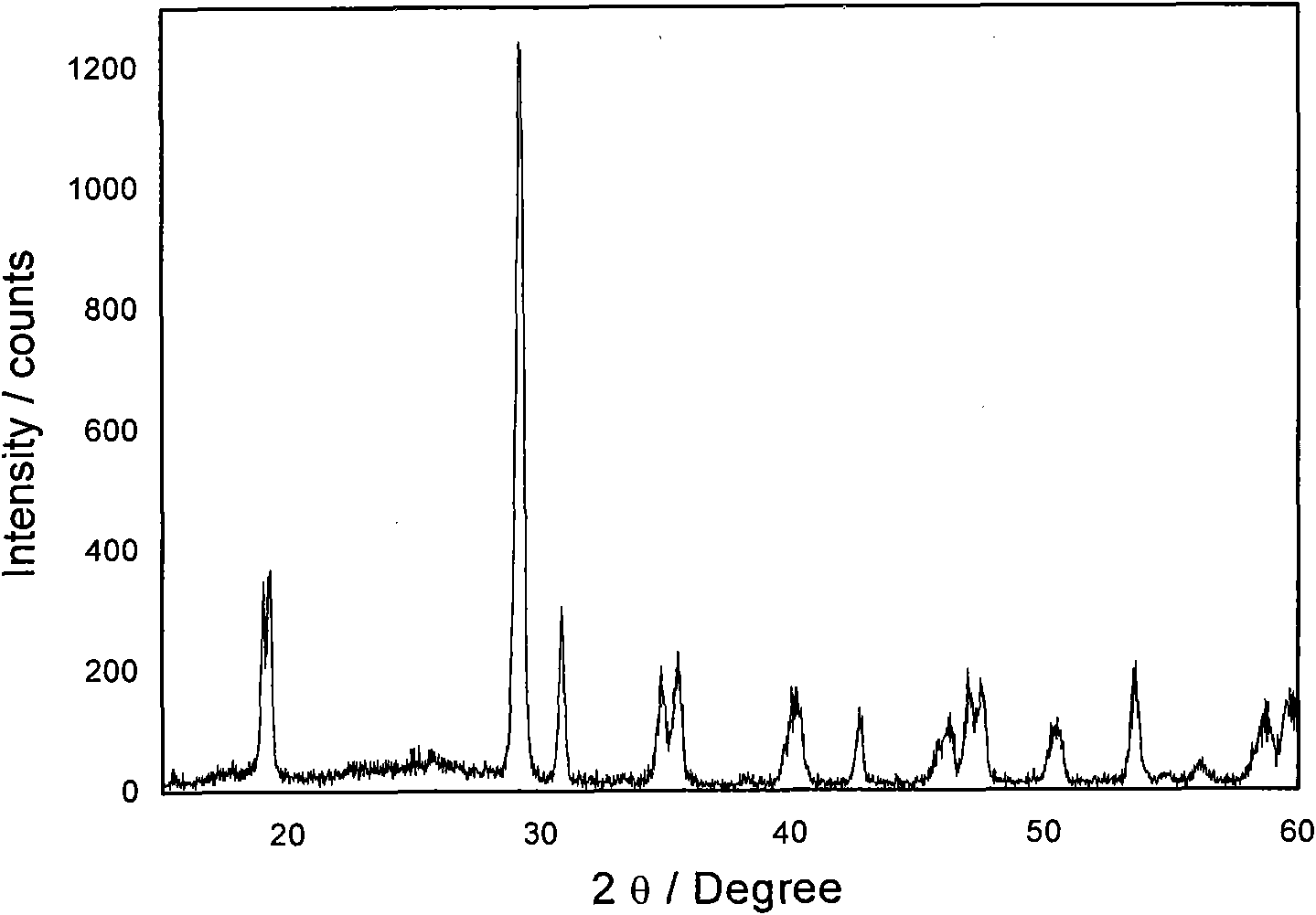

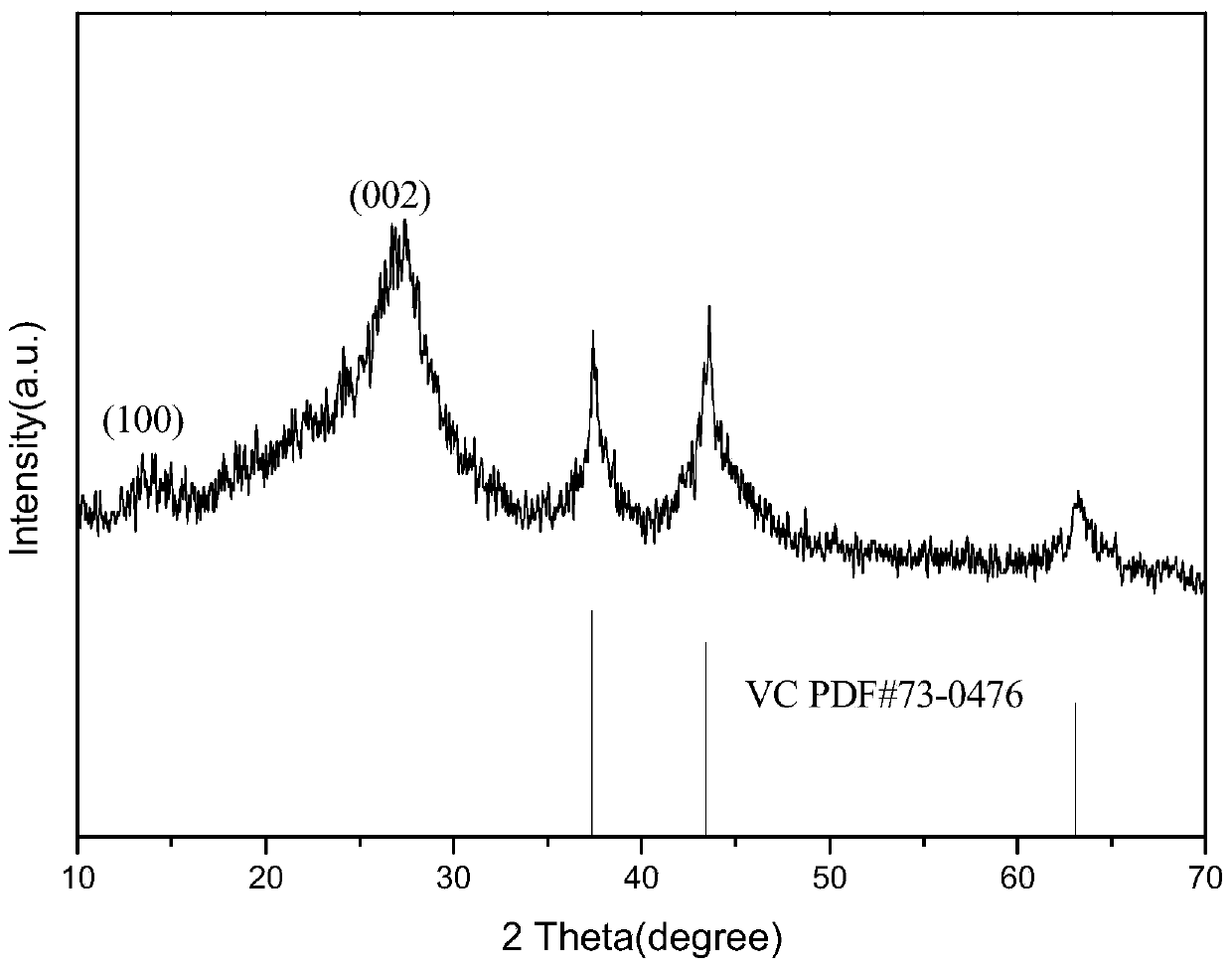

VC/g-C3N4 photocatalyst preparation method

InactiveCN110652995ASimple preparation processEase of industrial productionPhysical/chemical process catalystsHydrogen productionPtru catalystPhysical chemistry

The invention relates to a VC / g-C3N4 photocatalyst preparation method, which comprises: uniformly mixing and grinding dicyandiamide, ammonium bicarbonate and ammonium metavanadate, calcining in a tubular furnace, and carrying out ball milling to obtain VC powder; mixing and grinding the VC powder, citric acid, glucose and dicyandiamide, and calcining in a tubular furnace; and after calcining, carrying out ball milling to obtain the VC / g-C3N4 photocatalyst. According to the invention, raw materials are calcined by a tubular furnace to form a g-C3N4 matrix, and VC is uniformly attached to the matrix to form a nano-scale photocatalytic phase VC / g-C3N4 composite material; the preparation process is simple, the conditions are easy to control, the production cost is low, and the method is suitable for industrial production; and the introduced VC cocatalyst can be used for increasingactive sites during photocatalytic hydrogen production and improving the hydrogen production efficiency.

Owner:SHAANXI UNIV OF SCI & TECH

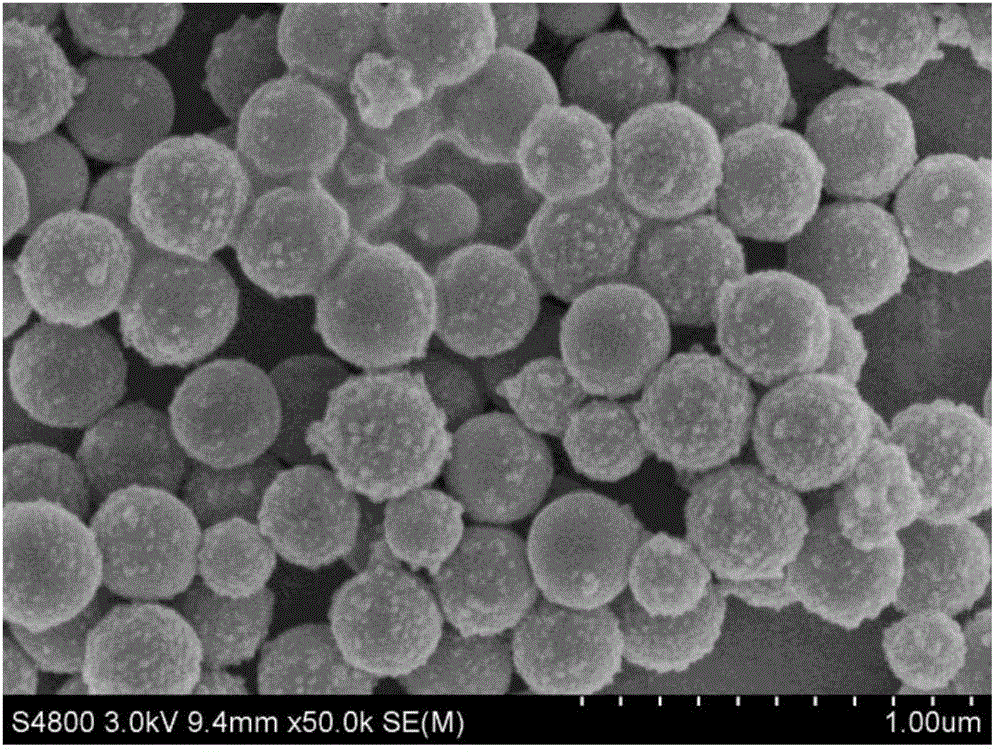

Preparation method of orange-yellow photonic crystal structure color thin film with photo-catalytic effect

InactiveCN104817281AWith photocatalytic functionIncrease the effective refractive indexMicroballoon preparationMetal/metal-oxides/metal-hydroxide catalystsZinc Acetate DihydrateEmulsion

The invention discloses a preparation method of an orange-yellow photonic crystal structure color thin film with a photo-catalytic effect. The method comprises the following steps: firstly mixing SiO2 microsphere powder with particle diameter of 252+ / -5 nm and polyvinylpyrrolidone and then adding water to prepare PVP (Polyvinyl Pyrrolidone)-modified SiO2 microspheres; then adding into absolute ethyl alcohol to perform ultrasonic treatment to obtain emulsion containing SiO2 microspheres; then preparing mixed solution of lithium hydroxide-ethanol and zinc acetate-ethanol; dropwise adding the emulsion containing SiO2 microspheres into the mixed solution, reacting and then filtering, washing, centrifuging, drying and thermally treating precipitate to prepare the SiO2@ZnO core-shell structure microspheres with the photo-catalytic effect; next adding ethanol into the SiO2@ZnO core-shell structure microspheres to perform ultrasonic dispersion to prepare emulsion; finally vertically inserting a glass substrate into the emulsion by using a vertical deposition method to generate the orange-yellow photonic crystal structure color thin film with the photo-catalytic effect. The method is simple and easy, causes no pollution to environment, can realize large-scale industrial production and has broad application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

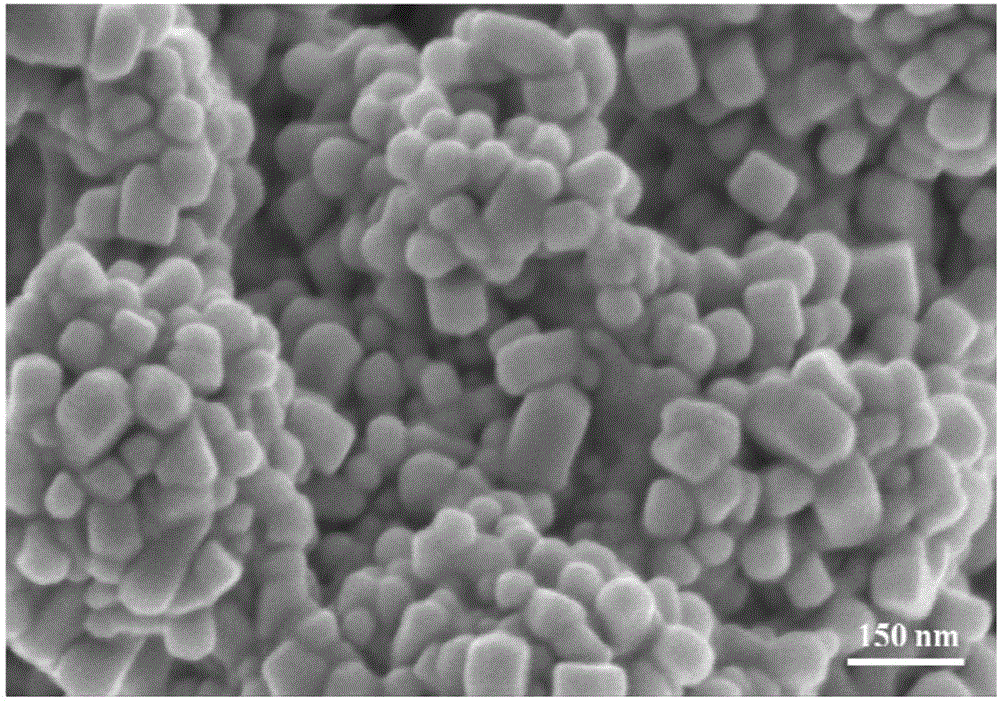

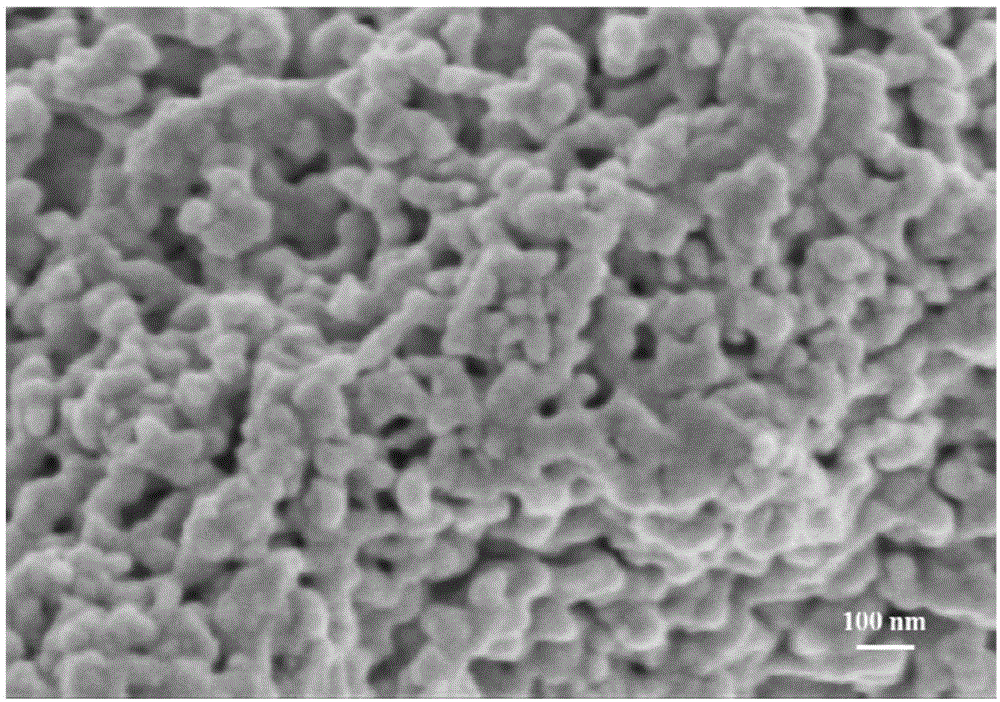

Preparation method of bismuth zirconate microcrystal ceramic glaze with photocatalytic function

ActiveCN106630621ATightly boundAffect aestheticsMetal/metal-oxides/metal-hydroxide catalystsZirconatePotassium

The invention relates to a preparation method of bismuth zirconate microcrystal ceramic glaze with a photocatalytic function. The preparation method includes: blending quartz, potassium feldspar, albite, borax, Bi2O3, Suzhou kaolin and lithium carbonate according to the mass ratio, performing heat preservation at 1270-1290 DEG C for 20-40 minutes, taking out, pouring into water for quenching, and grinding to obtain a material A; blending the material A, the Bi2O3, ZrO2 and the Suzhou kaolin according to the mass ratio to obtain a material B; adding the material B and a dispersing agent into water, and evenly stirring to prepare glaze slip; glazing the surface of ceramic with the glaze slip, and sintering to obtain the bismuth zirconate microcrystal ceramic glaze with the photocatalytic function. The preparation method has the advantages that the ceramic glaze is prepared by the sintering process, coating is not needed, the prepared functional glaze can be tightly combined with a ceramic matrix, the photocatalyst generated during the sintering of the Bi2O3 and the ZrO2 is evenly distributed in the glaze, and the 'rainbow effect' which affects glaze attractiveness is not generated.

Owner:SHAANXI UNIV OF SCI & TECH

Oil-based rock debris cement paste and preparation method thereof

The invention discloses oil-based rock debris cement paste which comprises the following raw materials in parts by weight: 90-100 parts of cement, 10-15 parts of oil-based rock debris, 30-40 parts of metal powder, 1-3 parts of an anti-freezing agent, 1-3 parts of an antibacterial agent, 1-3 parts of a defoaming agent, 15-35 parts of gypsum powder and 30-35 parts of water. The preparation method of the oil-based rock debris cement slurry comprises the following steps: weighing the raw materials, crushing and sieving the raw materials, uniformly mixing the raw materials, calcining and cooling the raw materials, and stirring the raw materials to prepare slurry. The main component of the oil-based rock debris subjected to thermal desorption treatment is a siliceous material, so that the cement component is reduced, the cost is reduced, and the waste utilization rate is high; wherein the metal powder are slags, so that the compression resistance of the cement is enhanced; due to the anti-freezing agent, the cement paste is good in use state under the low-temperature condition; moreover, the antibacterial agent endows the cement with a good antibacterial effect, wherein the nano titanium dioxide has a photocatalytic function, can generate hydroxyl radicals with high oxidability in water after absorbing light, and plays a role in sterilization.

Owner:SICHUAN XINGCHUANCHENG CEMENT CO LTD

Bird repelling composition used for power network lines

InactiveCN105368313AGood wear resistanceImprove acid and alkali resistanceCoatingsAluminium silicateParaffin oils

The invention discloses a bird repelling composition used for power network lines. The bird repelling composition is prepared by taking nano silicon dioxide, nano titanium dioxide, asbestos powder, epoxy modified silicon resin, emulsified silicone oil, multiwalled carbon nanotube, aluminium silicate fibre, FeCuMnO3.5, ammonium hydrogen carbonate, acrylic acid, 2,4,6-tris(dimethylaminomethyl)phenol, dibutyltin dilaurate, styrene-acrylic emulsion, ammonium polyphosphate, chlorinated paraffin, isopropyl phenyl diphenyl phosphate, ethyecellulose, xylene, folium artemisiae argyi, scirpoides holoschoenus, musk, and eucalyptus oil as raw materials, via distribution mixing. The bird repelling composition possesses corrosion resistance and wear resistance, and is capable of realizing self cleaning.

Owner:国网山东莒南县供电公司 +1

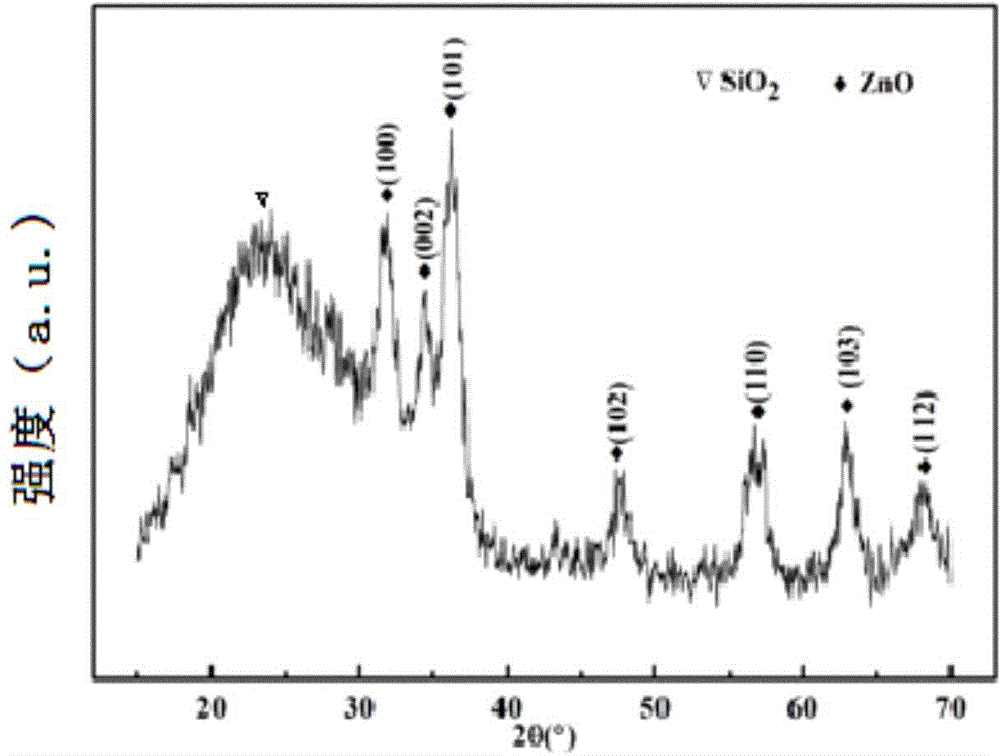

Preparation method of bismuth zirconate microcrystalline ceramic glaze with photocatalysis function

ActiveCN106630632AWith photocatalytic functionHigh glossMetal/metal-oxides/metal-hydroxide catalystsPotassiumZirconate

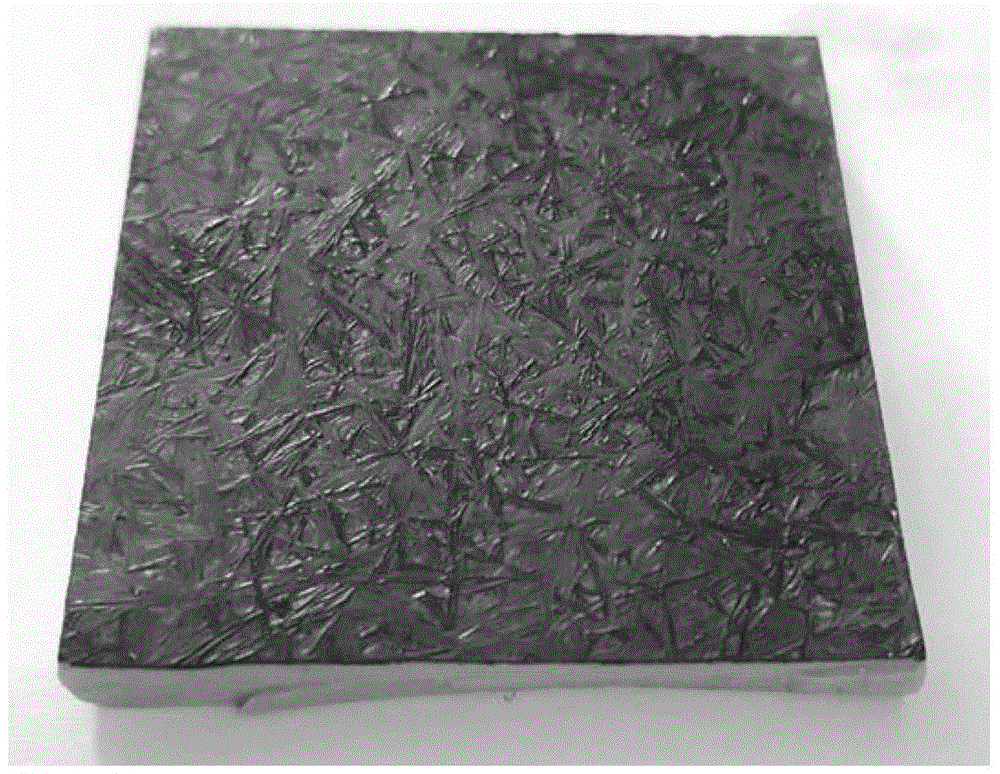

The invention discloses a preparation method of bismuth zirconate microcrystalline ceramic glaze with a photocatalysis function. The preparation method comprises the following steps: blending quartz, potassium feldspar, albite, borax, Bi2O3, Suzhou soil and lithium carbonate; preserving heat at 1,270-1,290 DEG C for 20-40min; taking out and pouring into water for quenching to obtain a frit; grinding the frit to obtain a material A; blending the material A with Bi2O3, ZrO2 and Suzhou soil to obtain a material B; adding the material B and a dispersing agent into water, stirring and uniformly mixing to obtain glaze slip; glazing the ceramic surface with the glaze slip; and firing to obtain a bismuth zirconate ceramic glaze with a photocatalysis function. The glaze prepared According to the invention has good gloss and stable chemical property. According to the invention, the ceramic glaze is prepared by adopting a firing technology, coating is not needed, and thus the prepared functional ceramic glaze is tightly combined with a ceramic base and does not fall off easily; and moreover, crystal flowers of special morphology can be quickly formed on the glaze surface, and the surface decoration effect is good.

Owner:SHAANXI UNIV OF SCI & TECH

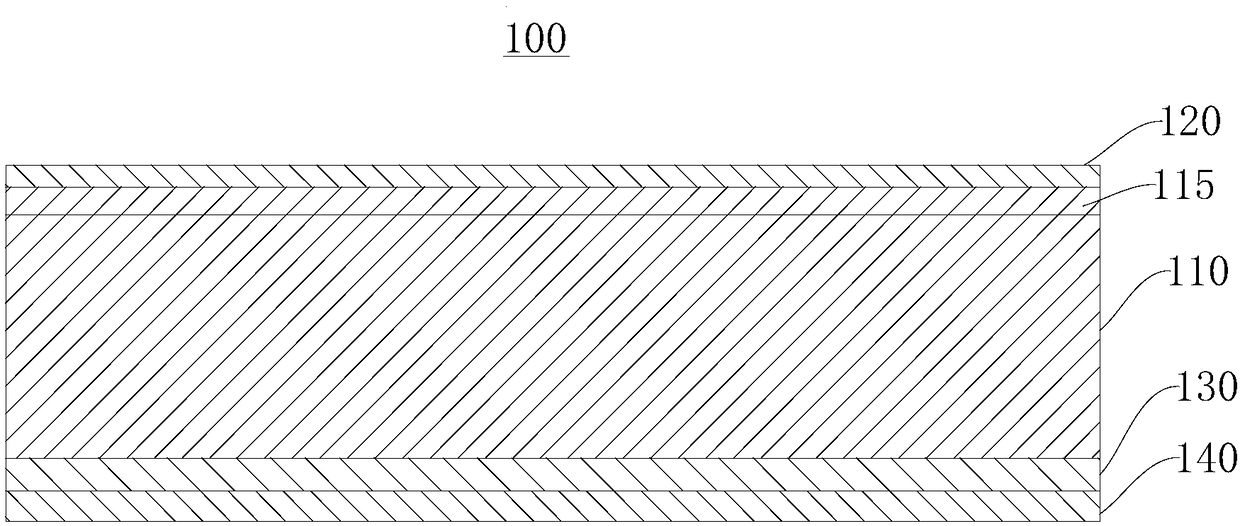

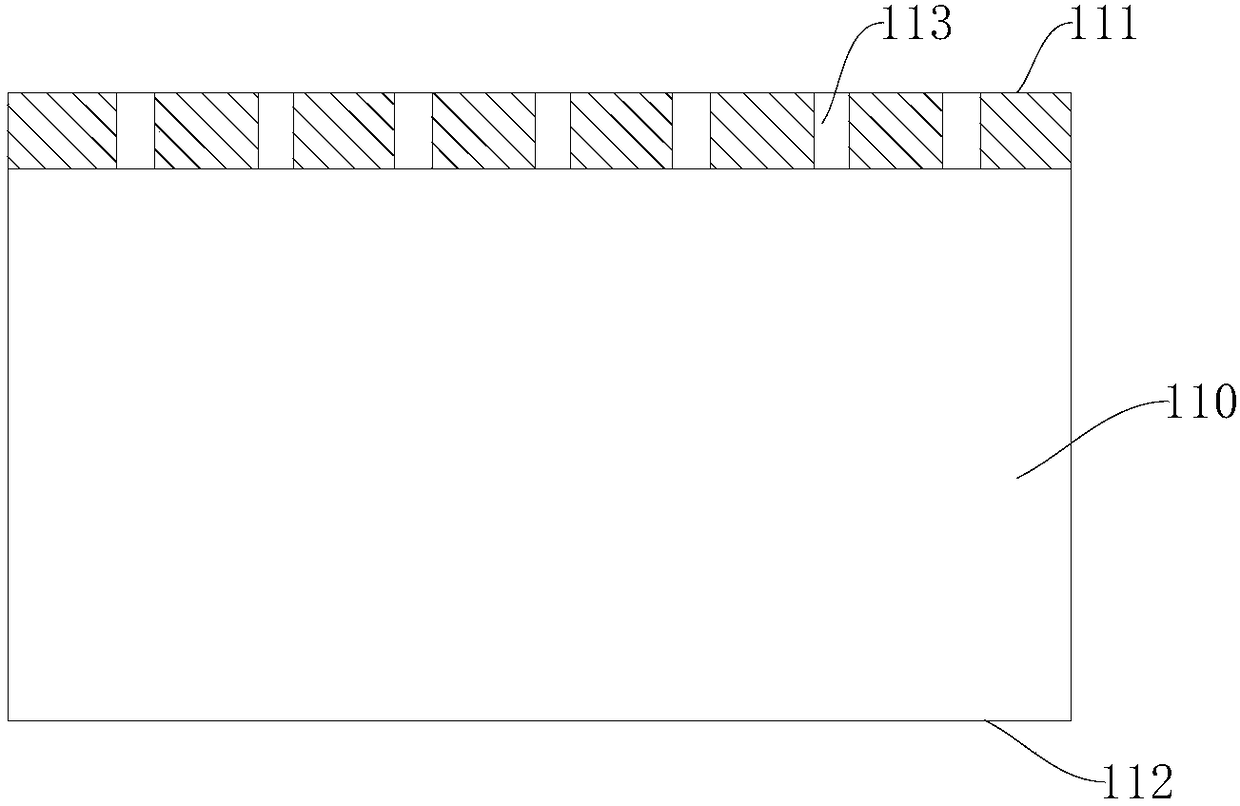

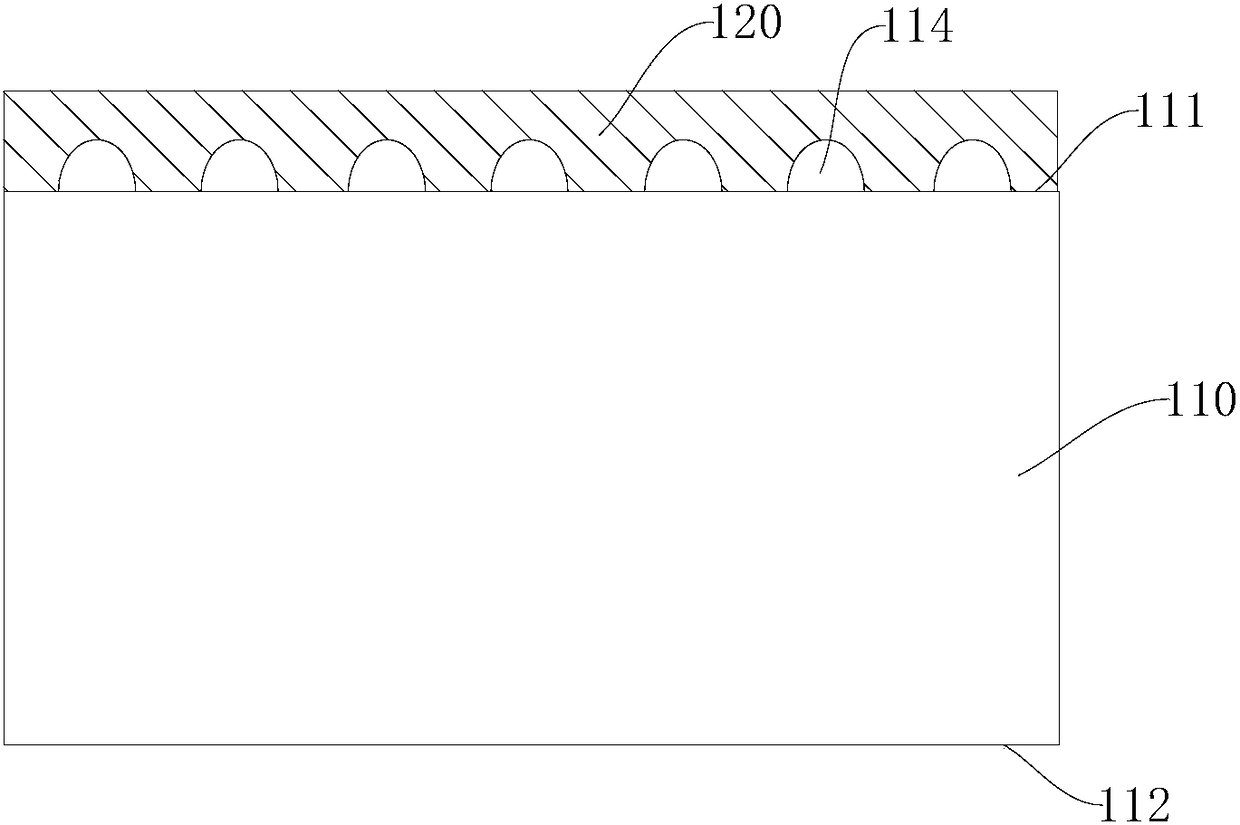

Projection glass screen

PendingCN108169994AWith photocatalytic functionWith self-cleaning abilityProjectorsOptoelectronicsNanometre

The invention provides a projection glass screen and relates to the field of imaging. The projection glass screen is in a layered structure and comprises a transparent glass substrate, a nanometer self-cleaning coating layer and a spectral absorption coating layer. The transparent glass substrate ahs a first surface and a second surface, which are opposite. The nanometer self-cleaning coating layer is contacted with the first surface; and the spectral absorption coating layer is contacted with the second surface. The first surface is a rough plane, and the roughness of the first surface is 0.05-1.5 microns. The projection glass screen can effectively reduce the intensity of reflected light, reduce dazzle light and improve imaging definition.

Owner:深圳市鸿益源科技有限公司

Environment-friendly anti-formaldehyde acid and alkali resistant industrial coating

InactiveCN114149716AWith photocatalytic functionLarge specific surface areaAnti-corrosive paintsAcrylic resinTitanium oxide

The invention provides an environment-friendly anti-formaldehyde acid and alkali resistant industrial coating which comprises the following components in parts by weight: 40-60 parts of acrylic resin, 5-15 parts of a chitosan-titanium dioxide-carbon nanotube compound, 0.5-1 part of a dispersing agent, 0.5-3 parts of a film-forming agent, 0.1-0.5 part of a wetting agent, 0.1-0.5 part of a defoaming agent, 0.1-1 part of a flatting agent, 0.5-2 parts of an adhesion promoter and 0.1-0.5 part of a mildew preventive, the chitosan-titanium dioxide-carbon nano tube compound is prepared from a chitosan-titanium dioxide compound and a carbon nano tube. The coating can effectively absorb formaldehyde and convert the formaldehyde into non-toxic substances, and has excellent acid and alkali corrosion resistance.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

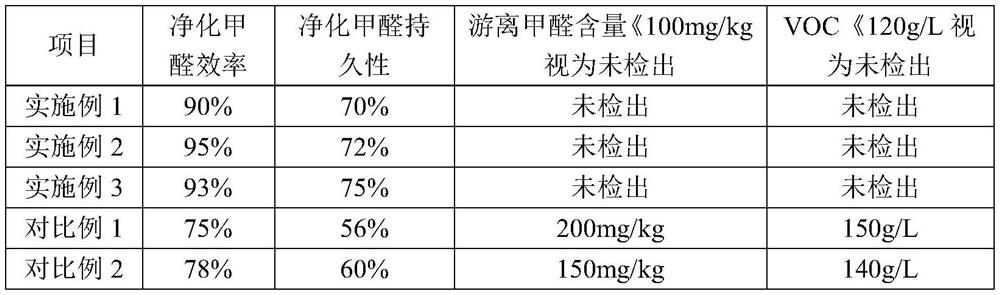

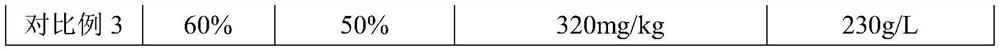

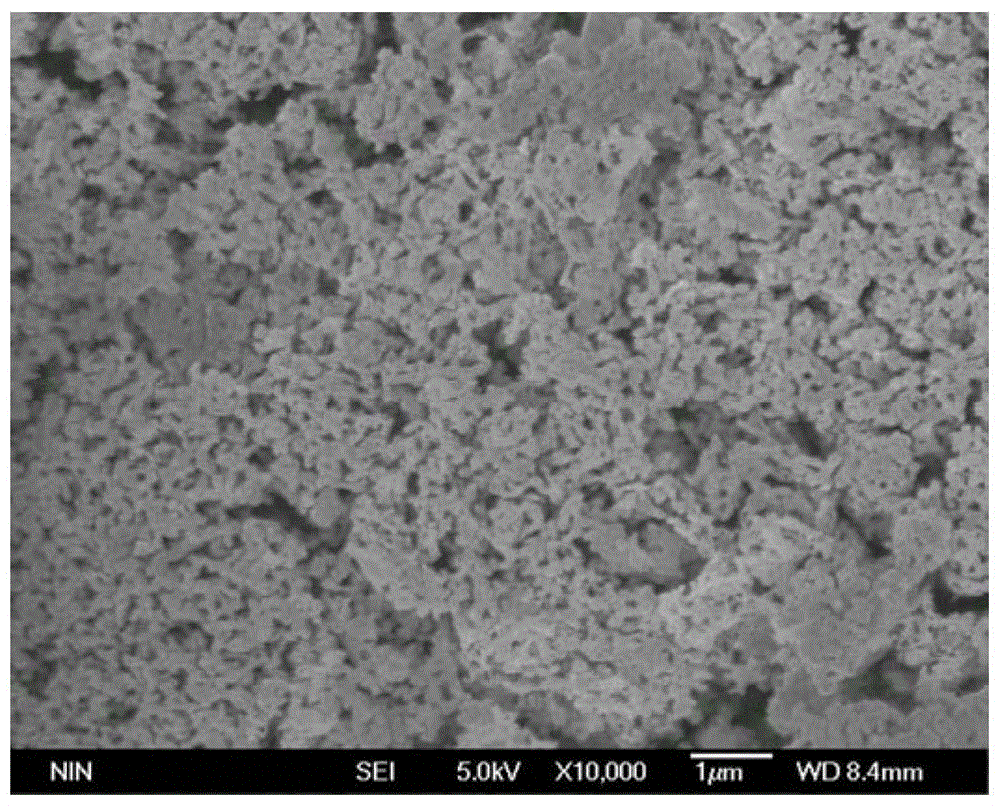

WP2O7 crystalline glaze composition with photocatalysis function and preparation method thereof

The invention relates to a WP2O7 crystalline glaze composition with a photocatalysis function and a preparation method thereof. The WP2O7 crystalline glaze composition is prepared from the following constituents by mass percent: 84% to 88% of powder material A, 7% to 9% of WP2O7 and 5% to 7% of kaolin, wherein the chemical composition mass ratio of SiO2 to Al2O3 to P2O5 to MgO to Li2O to Na2O to K2O of the powder material A is (10 to 14) to (3 to 5) to (45 to 49) to (1 to 3) to (8 to 12) to (8 to 12) to (4 to 6). The WP2O7 crystalline glaze composition has the advantages that the WP2O7 is introduced into the preparation of the glaze for the first time, not only is the decorative effect on the obtained glaze layer surface crystallization good, but also the performance in photocatalysis degradation on toxic gas and organic pollutant is excellent.

Owner:MONALISA GRP CO LTD

Preparation method of protective coating for power grid outdoor equipment

InactiveCN105349030AWith photocatalytic functionWith self-cleaning functionAnti-corrosive paintsParaffin oilsPhenols

The invention discloses a preparation method of a protective coating for power grid outdoor equipment. Nano silica, nano titanium dioxide, asbestos powder, epoxy modified silicon resin, silicone emulsion, multi-walled carbon nanotubes, alumina silicate fibers, FeCuMnO3.5, ammonium bicarbonate, acrylic acid, 2,4,6-tris(dimethyl aminomethyl)phenol, dibutyltin dilaurate, styrene-acrylic emulsion, ammonium polyphosphate, chlorinated paraffin, isopropyl phenyl diphenyl phosphate, ethyecellulose and xylene are adopted as raw materials, and the protective coating for the power grid outdoor equipment is prepared through a distribution and mixing method, wherein the protective coating is resistant to corrosion and abrasion and can achieve the self-cleaning function.

Owner:国网山东莒南县供电公司 +1

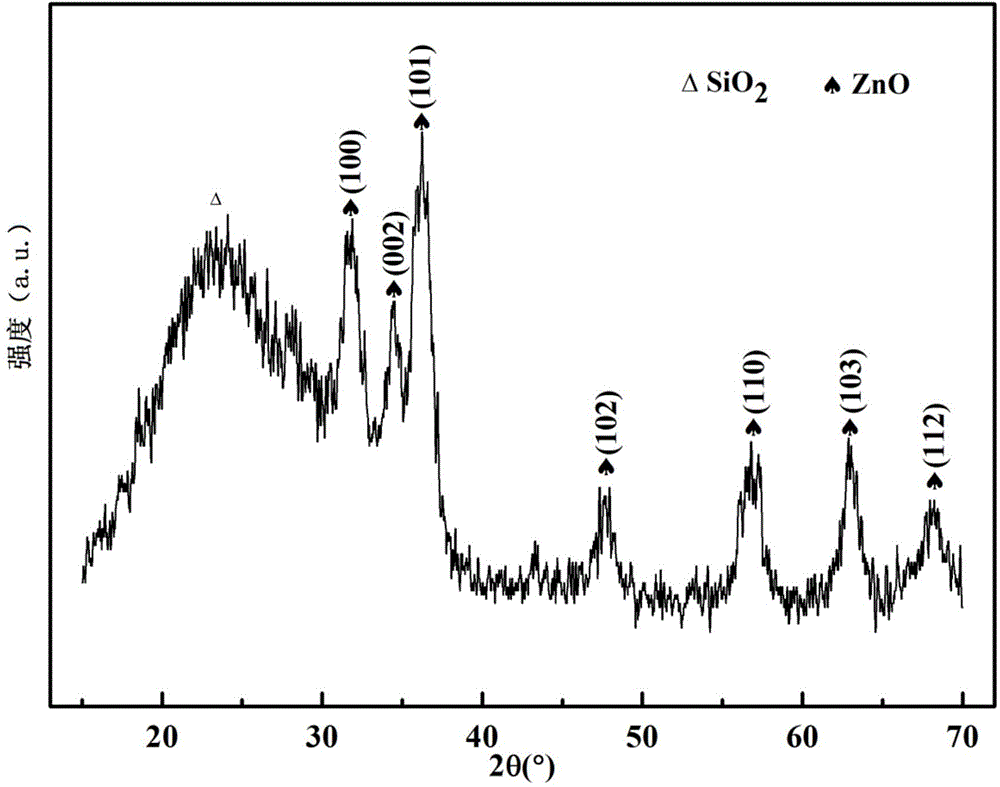

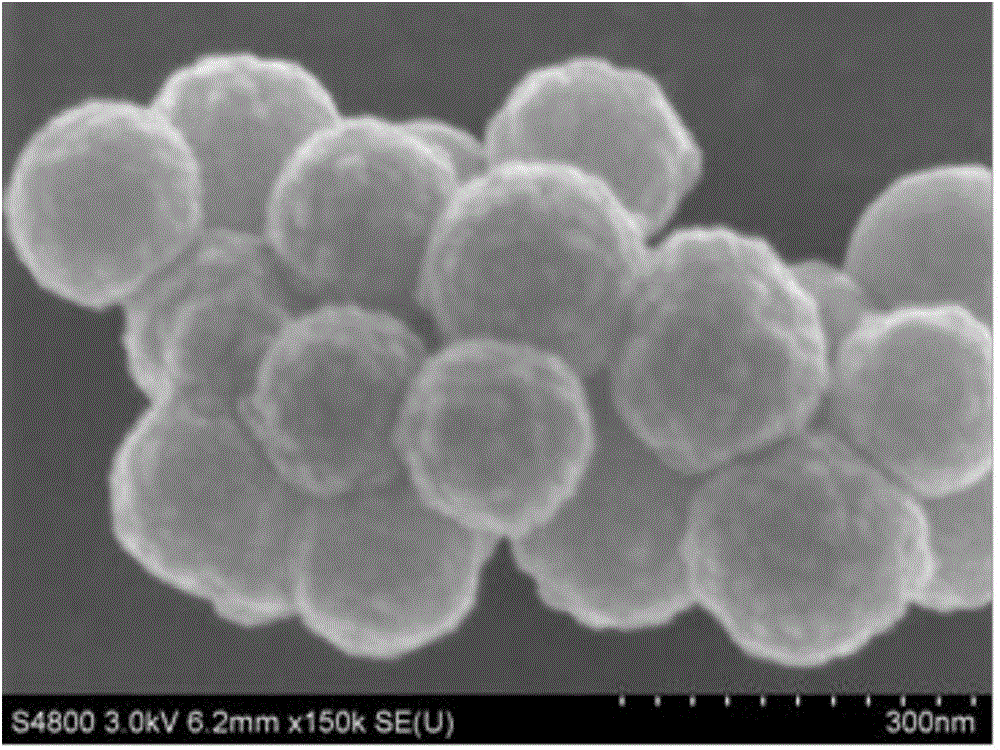

Preparation method of ianthinus photonic crystal structure colored film with photocatalysis effects

InactiveCN104829141AWith photocatalytic functionIncrease the effective refractive indexMetal/metal-oxides/metal-hydroxide catalystsLithium hydroxideMicrosphere

The invention discloses a preparation method of an ianthinus photonic crystal structure colored film with photocatalysis effects. The preparation method comprises 1, blending SiO2 microsphere powder with particle sizes of 180+ / -5nm and polyvinylpyrrolidone, adding water into the mixture and preparing PVP-modified SiO2 microspheres, 2, adding the PVP-modified SiO2 microspheres into anhydrous ethanol and carrying out ultrasonic treatment to obtain a SiO2 microsphere-containing emulsion, 3, preparing lithium hydroxide-ethanol and zinc acetate-ethanol mixed solutions, dropwisely adding the SiO2 microsphere-containing emulsion into the mixed solution, carrying out a reaction process, filtering the reaction product, carrying out washing, centrifugation and drying on the precipitates, and carrying out heat treatment to obtain SiO2@ZnO core-shell structure microspheres with photocatalysis functions, 4, adding ethanol into the SiO2@ZnO core-shell structure microspheres, and carrying out ultrasonic dispersion to obtain an emulsion, and 5, vertically inserting a glass substrate into the emulsion by a vertical sedimentation method so that the ianthinus photonic crystal structure colored film with photocatalysis effects is produced. The preparation method has the advantages of simple and easy processes, no pollution on the environment, large scale industrial production and wide application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of yttrium zirconate microcrystal ceramic glaze having photocatalytic function

The invention relates to a preparation method of a yttrium zirconate microcrystal ceramic glaze having a photocatalytic function. The preparation method comprises the following steps: preparing quartz, potash feldspar, albite, borax, Y2O3, Suzhou clay and lithium carbonate, keeping the above raw materialsat 1270-1290 DEG C for 20-40 minutes, taking out, pouring into water, quenching to prepare a fusion cake, and grinding the fusion cake to obtain a material A; preparing the material A, Y2O3, ZrO2 and Suzhou clay to obtain a material B; adding the material B and dispersing agent into water, and uniformly stirring and mixing to prepare a glaze slip; and applying the glaze slip to the surface of ceramics, and firing to obtain the yttrium zirconate microcrystal ceramic glaze having a photocatalytic function. According to the invention, the ceramic glaze is prepared through a firing process and does not need coating, so that the prepared functional ceramic glaze material can be tightly combined with a ceramic matrix; and the photocatalyst Y2Zr2O7 generated in the sintering process of Y2O3 and ZrO2 is uniformly distributed in the glaze material, thereby avoiding the condition that the aesthetic property of the glaze material is influenced due to a rainbow effect.

Owner:SHAANXI UNIV OF SCI & TECH

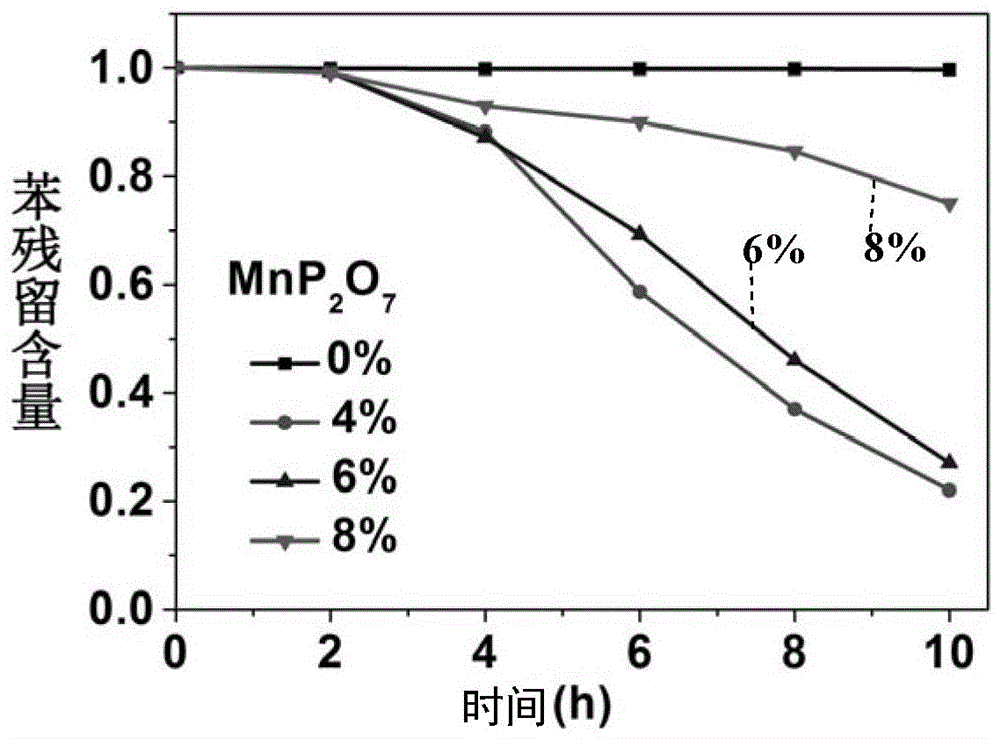

MnP2O7 microcrystalline opacified matt glaze material composition having photocatalysis function and preparation method thereof

The invention relates to a MnP2O7 microcrystalline opacified matt glaze material composition having photocatalysis function and a preparation method thereof. The MnP2O7 microcrystalline opacified matt glaze material composition comprises the following components by mass percentage: 88-92% of powder A, 4-6% of MnP2O7 and 4-6% of kaolin; wherein the powder A comprises the following components by weight: 12-14% of SiO2, 4-6% of Al2O3, 47-49% of P2O5, 1.5-2.5% of MnO, 12-14% of Li2O, 6-8% of Na2O, and 11-13% of K2O. According to the invention, MnP2O7 is firstly introduced in preparation of a glaze material, the surface crystallization and decorative effect of a glaze layer are good, and the toxic gas degradation through photocatalysis is excellent.

Owner:MONALISA GRP CO LTD

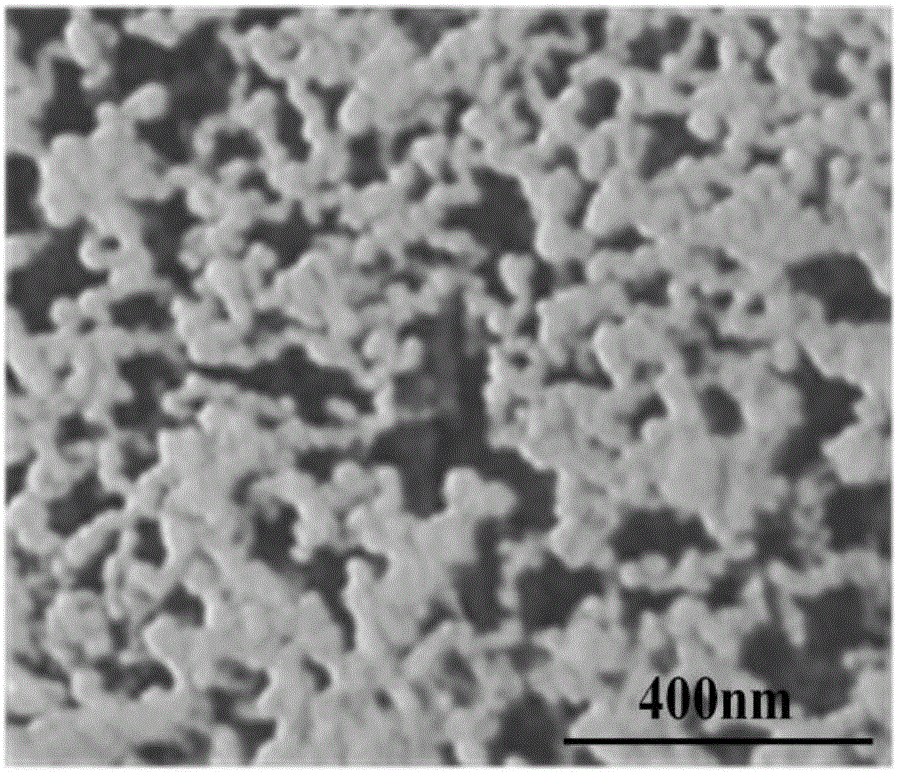

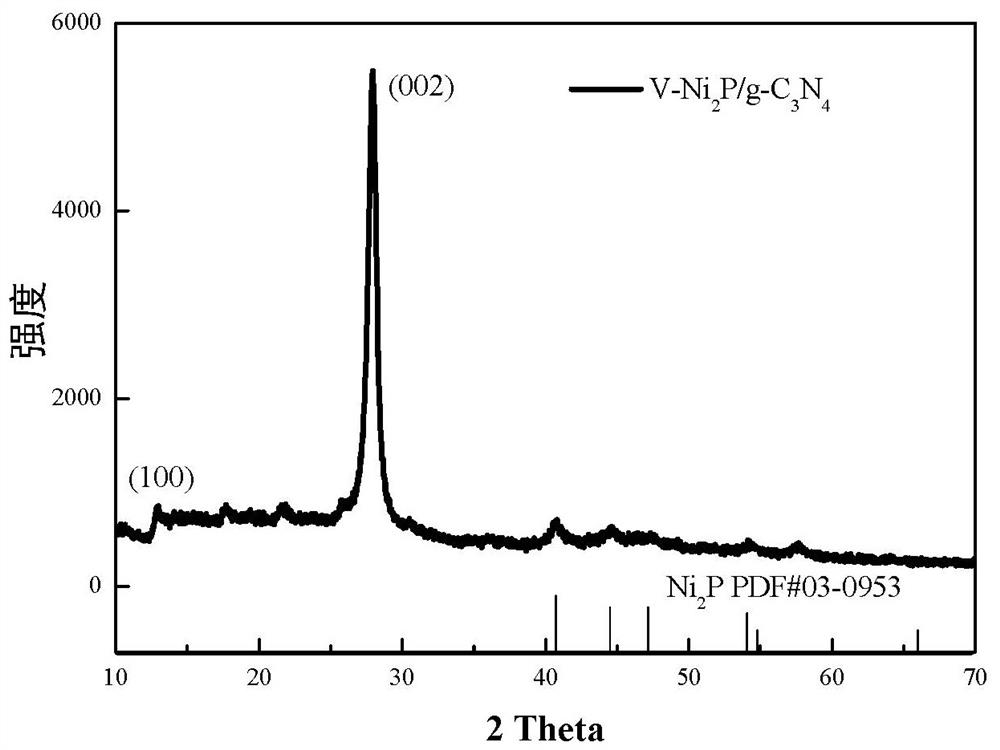

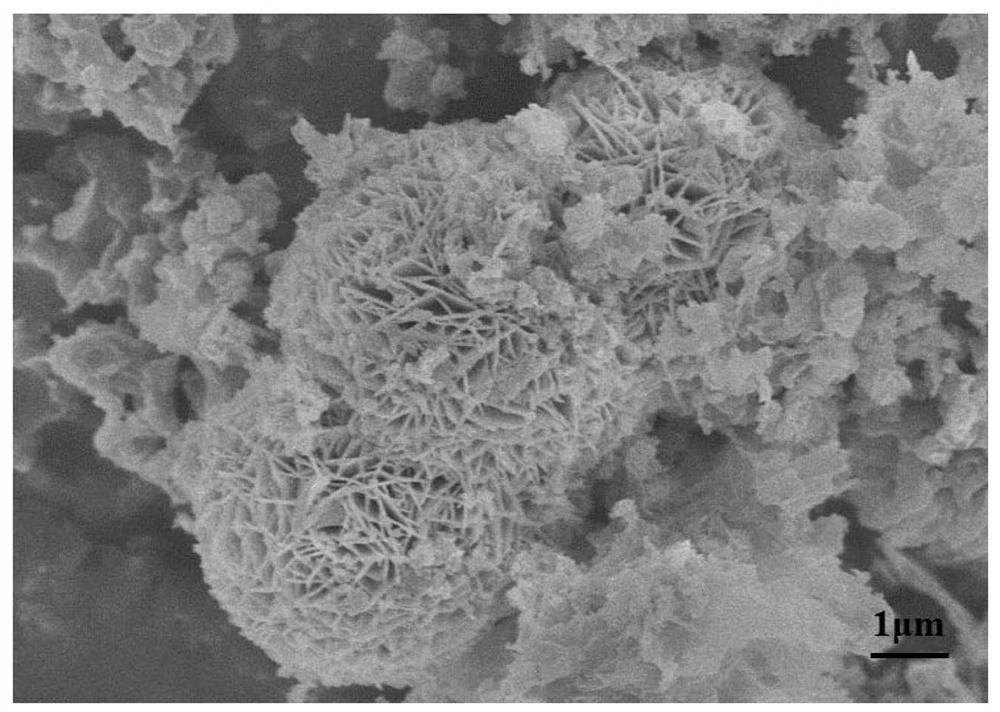

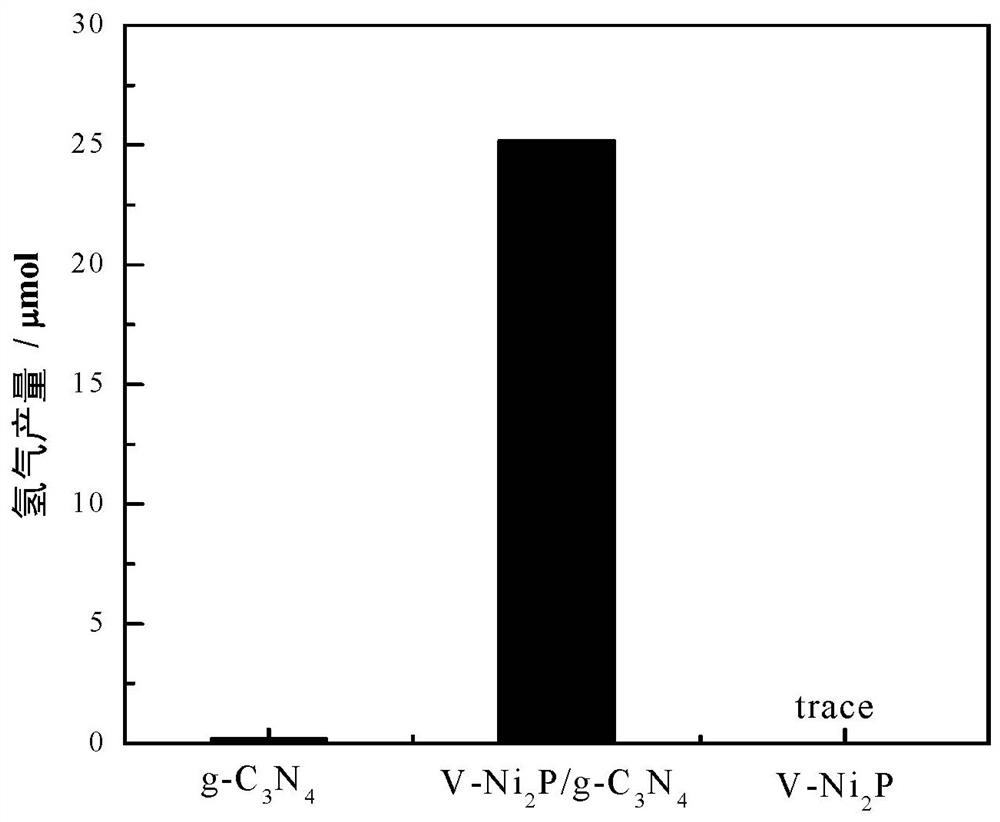

V-Ni2P/g-C3N4 photocatalyst as well as preparation method and application thereof

PendingCN114130411AAvoid introducingEase of industrial productionCatalyst activation/preparationHydrogen productionPhysical chemistryPhoto catalysis

The invention relates to a V-Ni2P / g-C3N4 photocatalyst as well as a preparation method and application thereof, the V-Ni2P / g-C3N4 photocatalyst is a composite material of V-Ni2P and g-C3N4, and the V-Ni2P has a spherical structure formed by nanosheets; the mass ratio of the V-Ni2P to the g-C3N4 is (0.01 to 0.2): 1.

Owner:SHAANXI UNIV OF SCI & TECH

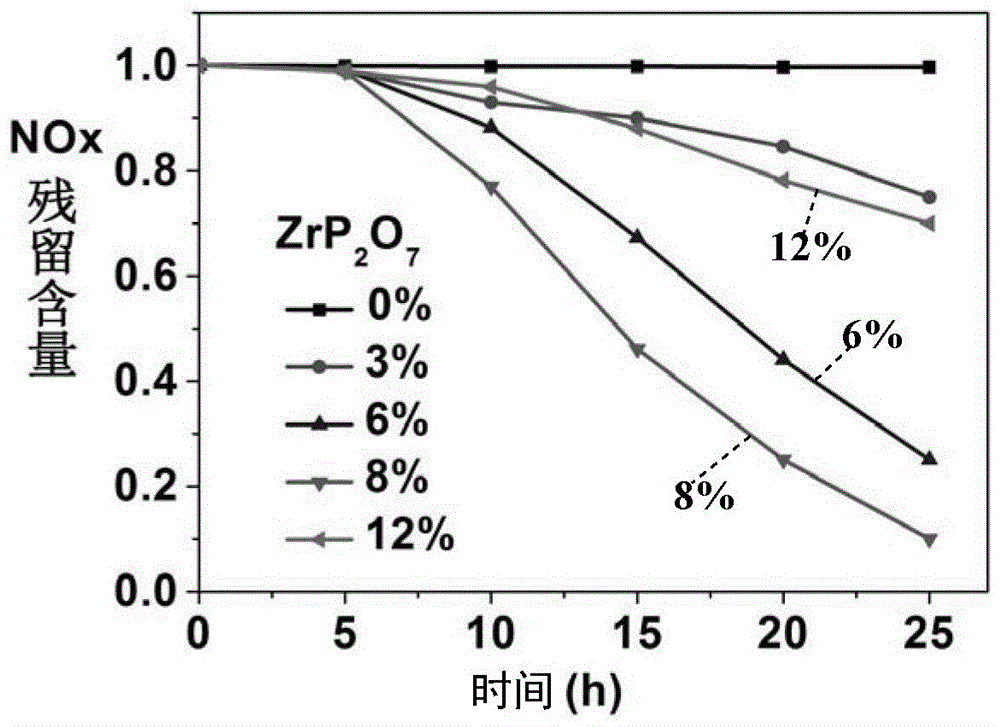

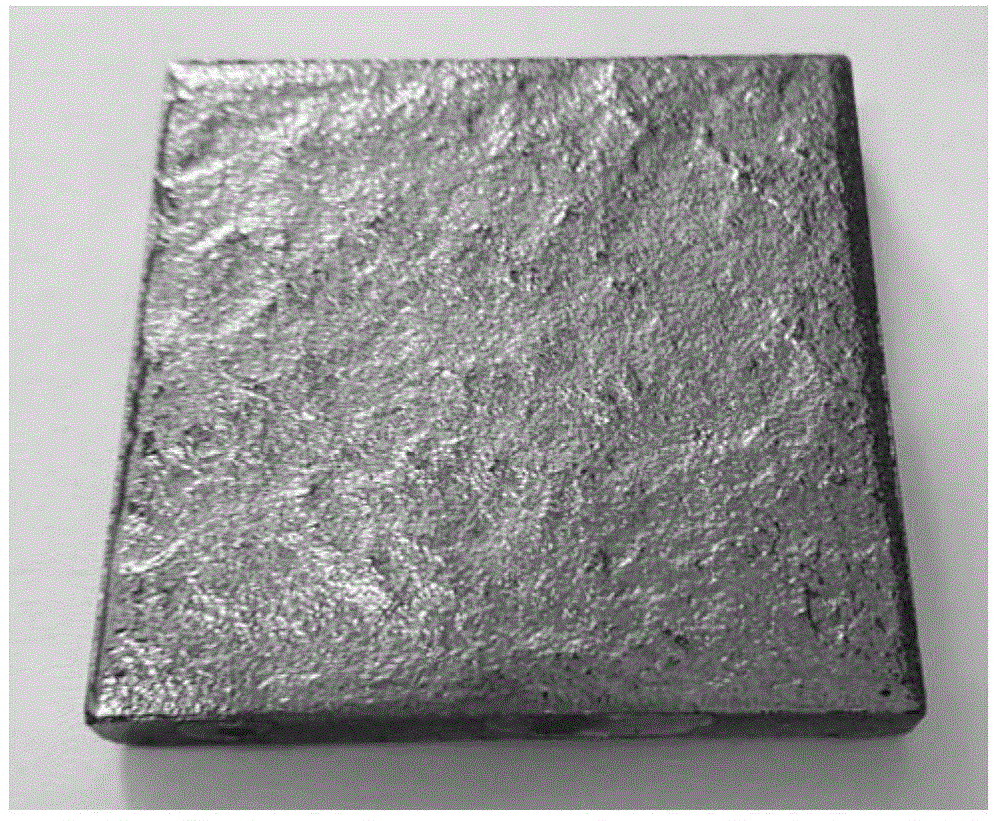

Photocatalytic function ZrP2O7 microcrystalline opaque glaze composition and preparation method thereof

ActiveCN106517794AGood opacity decorative effectImprove performancePhotocatalytic degradationMaterials science

The invention relates to a photocatalytic function ZrP2O7 microcrystalline opaque glaze composition and a preparation method thereof. The microcrystalline opaque glaze composition includes the following components by mass percentage: 86-90% of powder A, 6-8% of ZrP2O7 and 4-6% of kaolin. Specifically, the powder A comprises, by weight, 12-16% of SiO2, 2-4% of Al2O3, 51-55% of P2O5, 2-4% of MgO, 8-10% of Li2O, 8-10% of Na2O and 8-10% of K2O. According to the invention, ZrP2O7 is introduced into the preparation of glaze for the first time, the obtained glaze layer has good opacifying decorative effect, but also has excellent performance of photocatalytic degradation of toxic gas.

Owner:MONALISA GRP CO LTD

Usemethod of nanometer titanium dioxide on ceramics, leather, cloth and furniture

InactiveCN110655866AWith photocatalytic functionWith self-cleaning functionCoatingsResin coatingTitanium oxide

The invention discloses a use method of nanometer titanium dioxide on ceramics, leather, cloth and furniture, and relates to the technical field of materials. The use method comprises: S1, adding a Ti<4+> salt solution into hydrogen peroxide, and carrying out a flocculation reaction on the Ti <4+> salt solution and the hydrogen peroxide to prepare a titanium peroxide complex; S2, adding a crystalform control agent into the titanium peroxide complex, carrying out a reaction on the crystal form control agent and the titanium peroxide complex, heating to 300-500 DEG C, and keeping for 5-10 hto obtain a titanium oxide blocky gel; and S6, adding a silane coupling agent into the nanometer titanium dioxide sol, and adding the mixed solution into a water-based glass baking varnish resin accordingto the adding amount of 0.5-1.5% of the nanometer titanium dioxide. According to the invention, the resin coating material is mixed and processed into glass, furniture and ceramic finished products,so that the glass, furniture and ceramic finished products have photocatalysis function, can catalyze and photolyze various organic matters such as formaldehyde and the like and part of inorganic matters attached to the surface of objects, have a self-cleaning function, improve automatic cleaning effect and are convenient to clean.

Owner:广东绿驰科技有限公司

A kind of thermoplastic composite film and its production process

ActiveCN111389690BSolve the problem of thermoplastic not addingImprove toughnessFlat articlesCoatingsPolypropylene compositesPolymer science

The invention discloses a thermoplastic composite film. The thermoplastic composite film sequentially comprises a nanoscale titanium dioxide layer, a polyethylene terephthalate layer, a modified polypropylene layer, a polyethylene terephthalate layer, and a polyethylene terephthalate layer from outside to inside. Glycol ester layer and nanoscale titanium dioxide layer, the thickness of two nanoscale nanoscale titanium dioxide layers is 10-15 μm, and the thickness of two described polyethylene terephthalate layers is 15-18 μm, described The thickness of the modified polypropylene layer is 25-50 μm, and the modified polypropylene layer is obtained by casting the modified polypropylene through a tape casting machine, and the modified polypropylene is made of a high-density material with a weight of 15-25 Polyethylene and polypropylene with a weight fraction of 75-85 are mixed and extruded through a twin-screw extruder to solve the problem of poor thermoplasticity of the existing polypropylene composite film and long-term exposure of the polypropylene composite film to the air. Aging problem.

Owner:ANHUI JIE CHENG PACKAGING PROD CO LTD

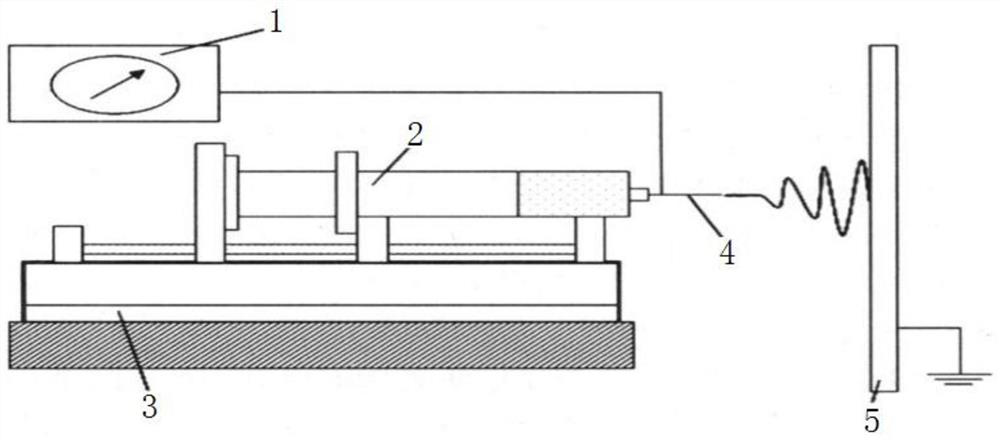

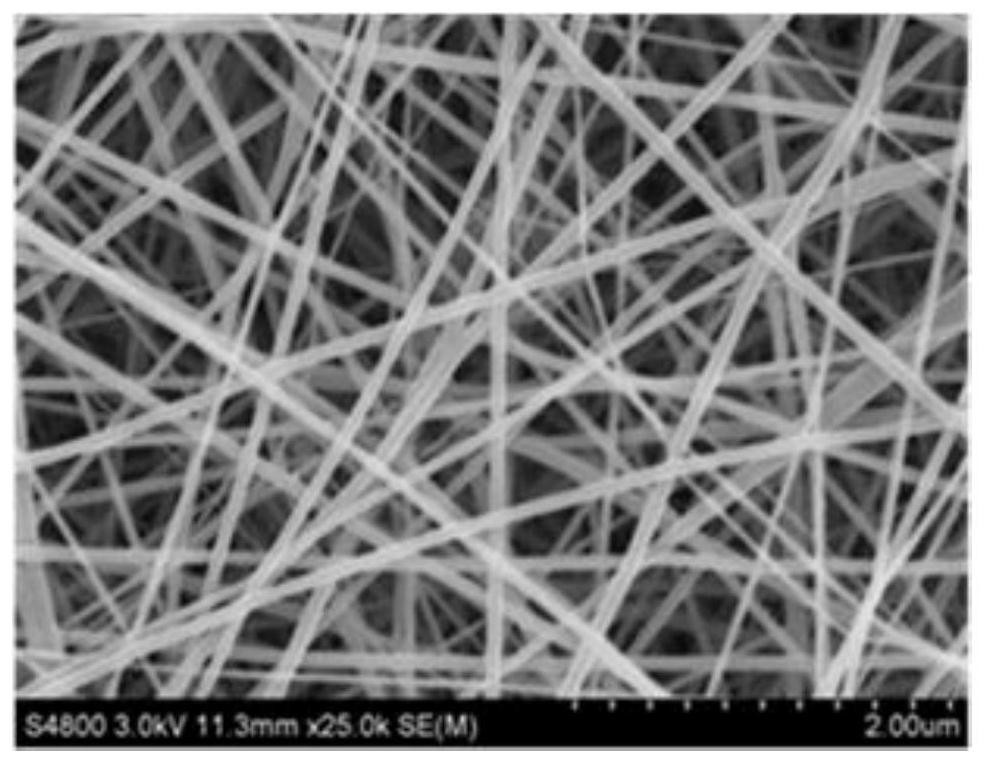

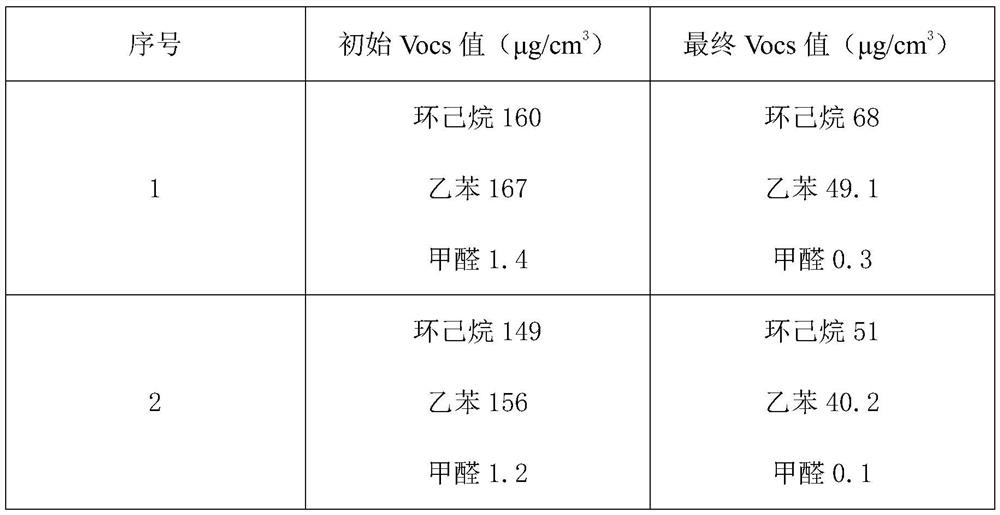

A kind of transparent pm2.5 filter film with photocatalysis and preparation method thereof

ActiveCN107754493BAvoid accessWith photocatalytic functionSemi-permeable membranesDispersed particle filtrationPolyamideNanofiber

The invention discloses a transparent PM2.5 filter membrane with photocatalysis and a preparation method thereof. The PM2.5 filter membrane is a composite nanofiber membrane with a sandwich-like structure, including polyacrylonitrile@TiO 2 and polyamide-6, the nanofiber diameter distribution of the composite nanofiber membrane is 60 to 100nm. The composite membrane is tightly cross-linked and has photocatalytic function, high transparency and efficient PM2.5 filtration performance. When used in anti-nano screen windows, it can not only effectively block outdoor PM2.5 from entering the room, but also effectively prevent outdoor PM2.5 from entering the room under the influence of sunlight. Photocatalyzes low-concentration harmful gases in the atmosphere while maintaining good lighting and ventilation effects.

Owner:SHAANXI UNIV OF SCI & TECH

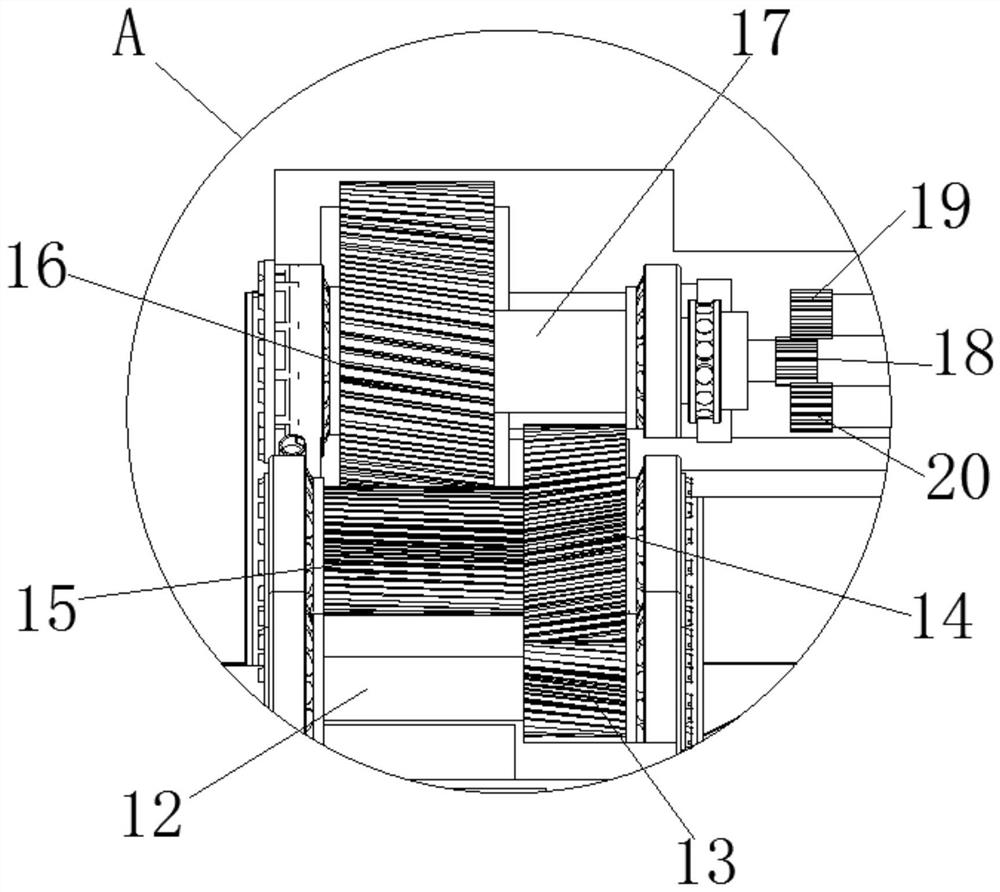

Sputtering apparatus

InactiveCN1528946AWith photocatalytic functionPhysical/chemical process catalystsDispersed particle separationSputteringUltraviolet

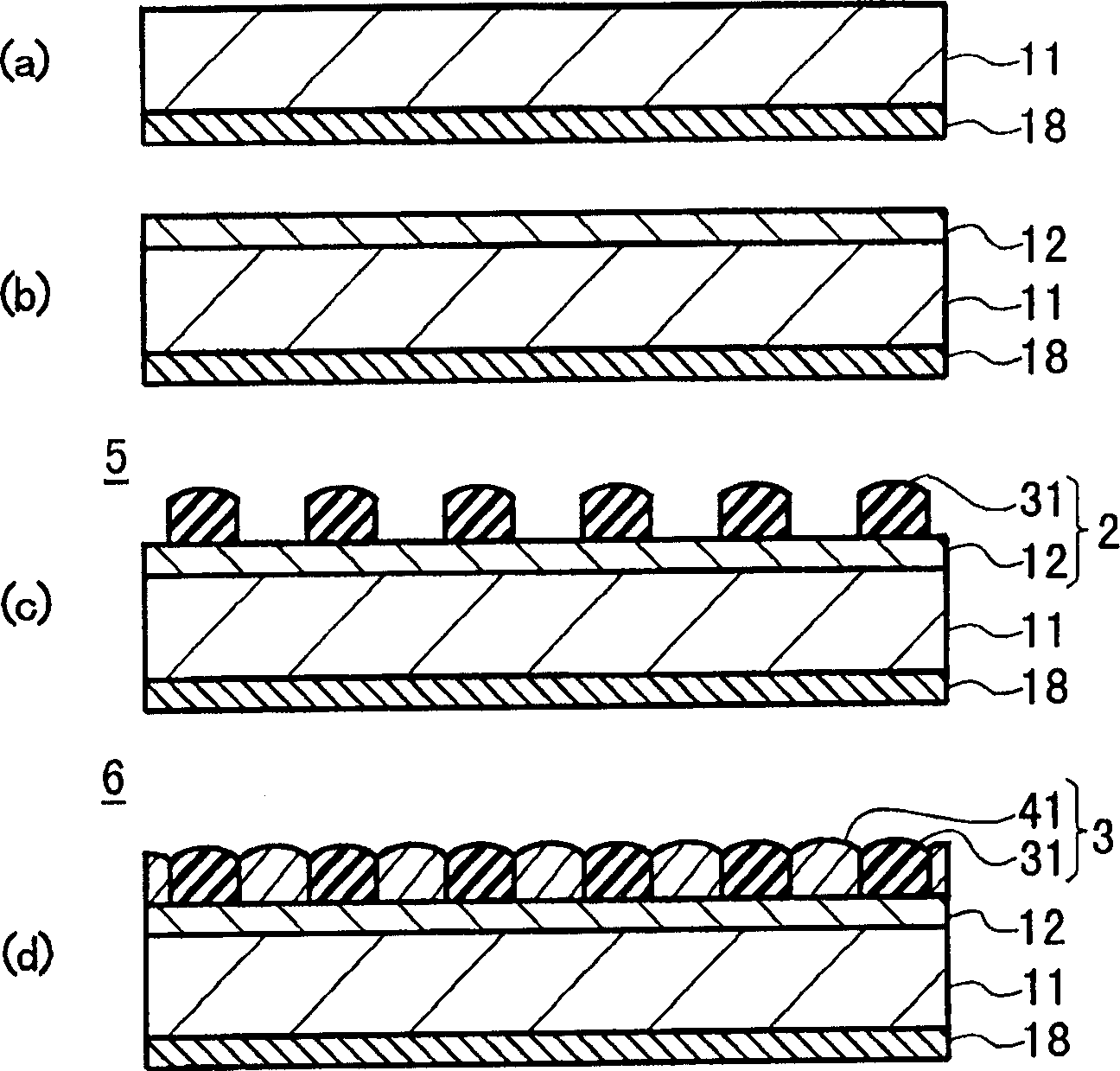

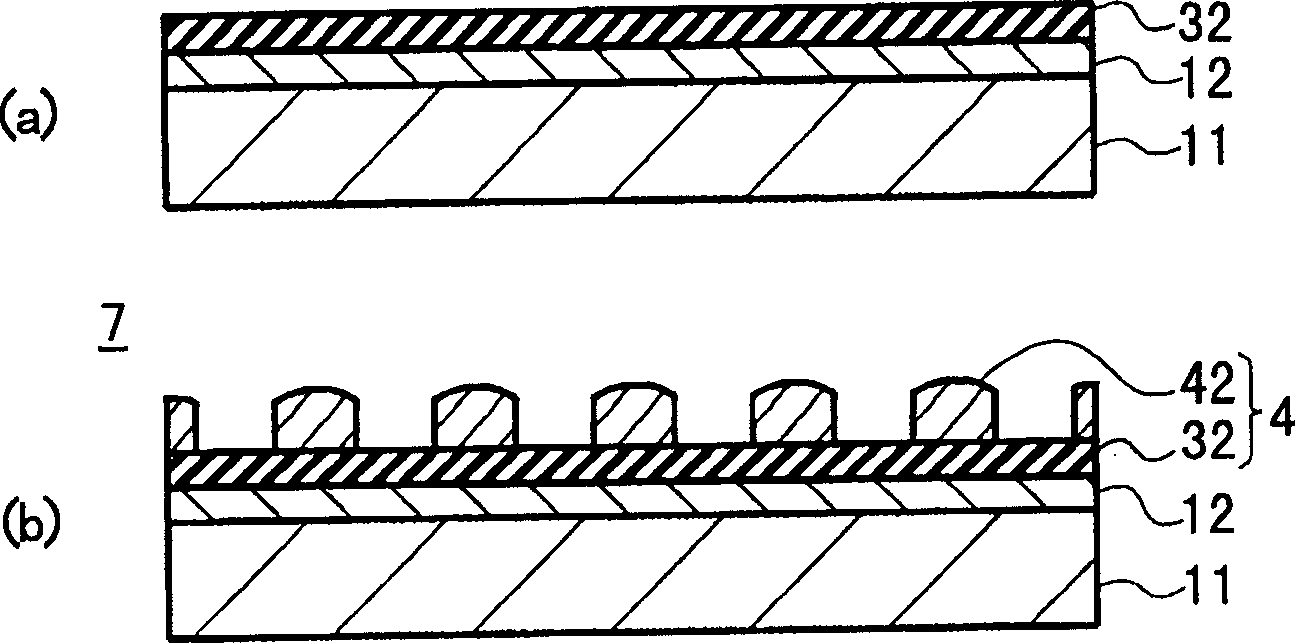

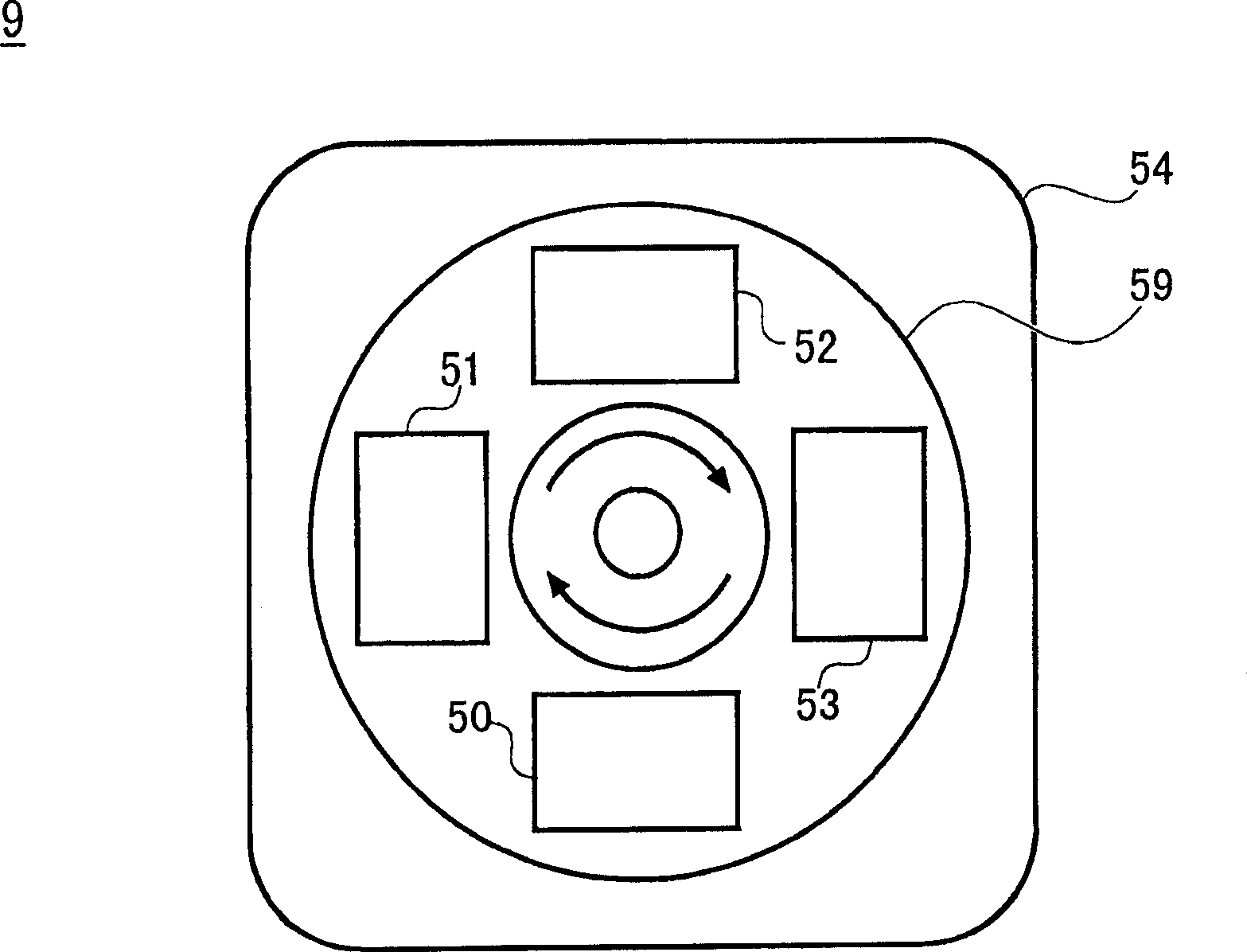

To obtain a titanium oxide thin film having high durability and photocatalytic function. Titanium oxide thin films 31 are made to exist at intervals on the surface of a barrier thin film 12, hydrophilic thin films 41 are formed between the titanium thin films to constitute a functional thin film 3. Since both parts to which the titanium oxide thin films 31 are exposed and parts to which the hydrophilic thin films 41 are exposed exist together on the surface of the functional thin film 31, functions of both the thin films can be obtained. Consequently a self cleaning effect and superhydrophilic nature are developed under an environment of irradiation with ultraviolet rays and a hydrophilicity of a certain degree is obtained even at a dark place. When a titanium oxide target in the titanium oxide thin films 31 is sputtered with a sputtering gas containing an oxygen gas, deficient oxygen in the titanium oxide thin film to be formed can be supplied with oxygen to form the titanium oxide thin films 31 having a photocatalytic function.

Owner:ULVAC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com