Patents

Literature

624results about How to "Few ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

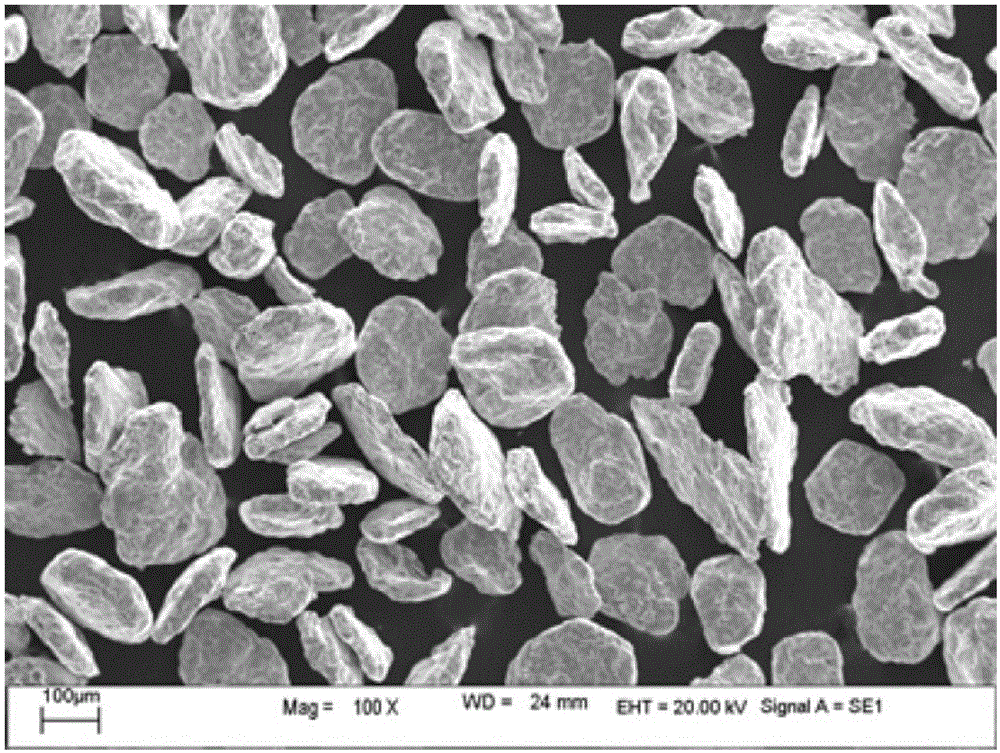

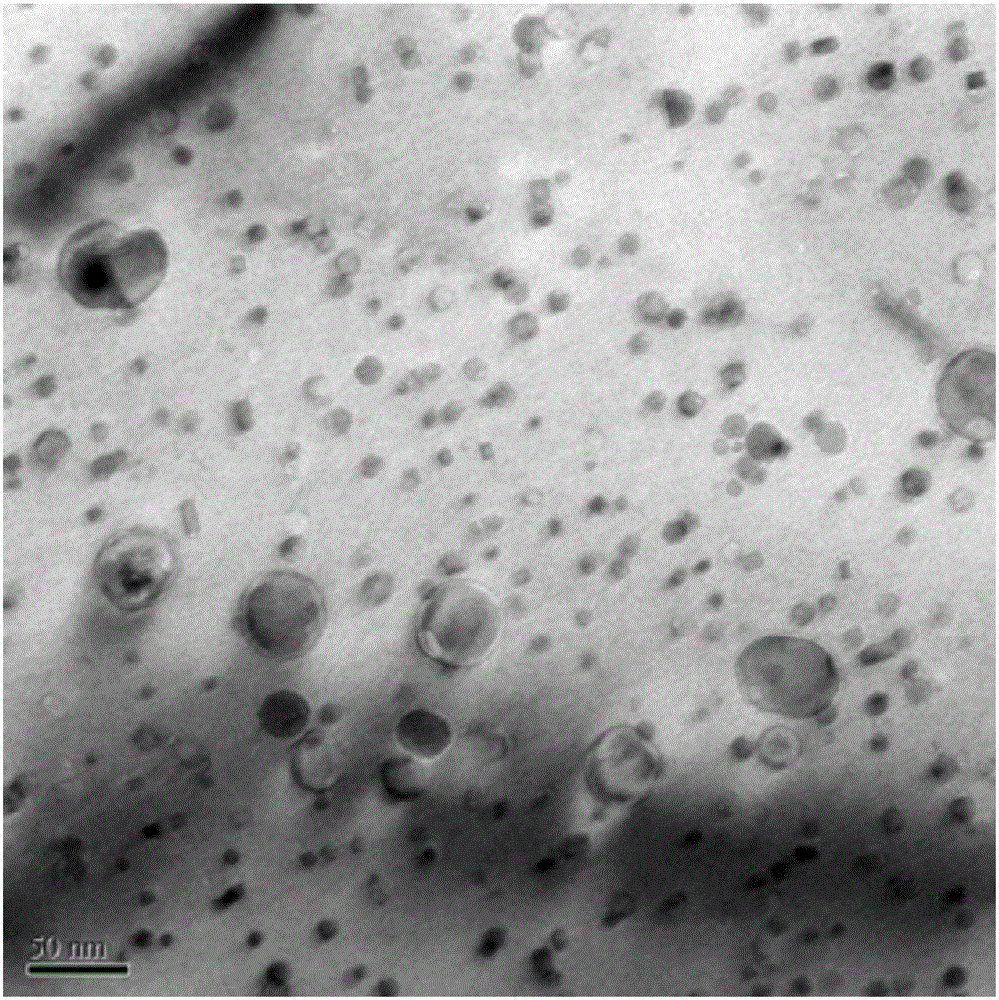

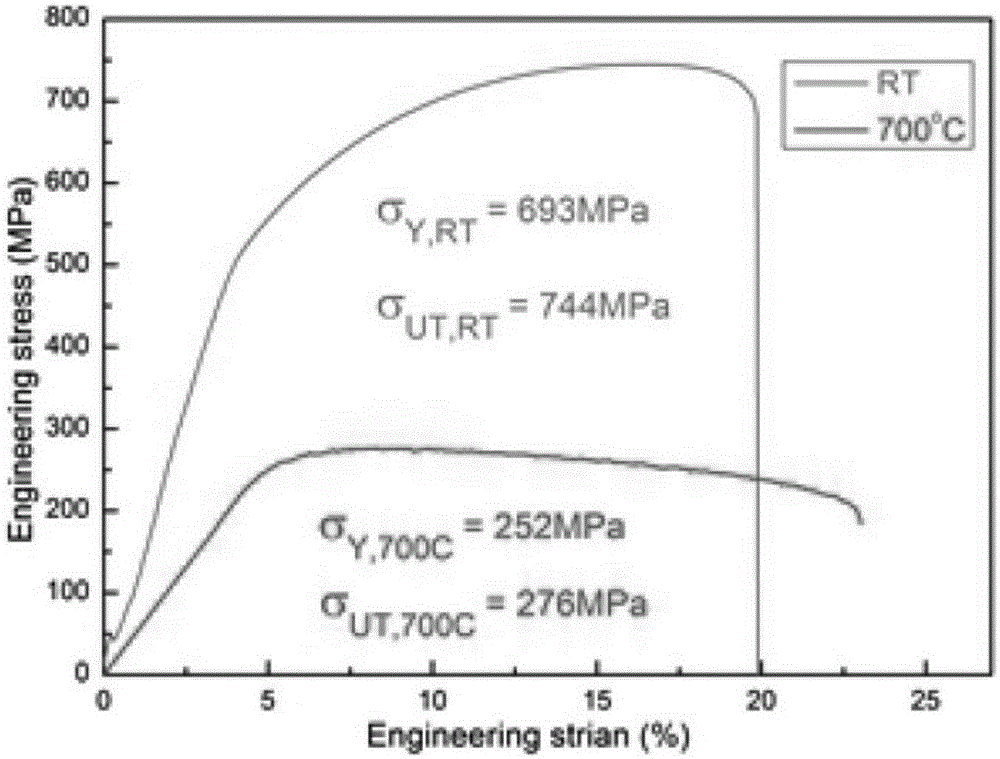

Oxide-dispersion-strengthening ferrite/martensitic steel and preparing method

The invention relates to oxide-dispersion-strengthening ferrite / martensitic steel with the excellent high-temperature strength and the good oxidation resistance and a preparing method of the oxide-dispersion-strengthening ferrite / martensitic steel. The oxide-dispersion-strengthening ferrite / martensitic steel comprises 8% to 10% of Cr, 0.5% to 2% of W, 1.5% to 5.5% of Al, 0.1% to 0.4% of V, 0.1% to 0.5% of Mn, 0% to 1.0% of Zr, 0% to 1.0% of Hf and 0.25% to 0.5% of Y2O3. The content of C and the content of N are controlled to be lower than 0.1%, and at least one kind of the Hf and the Zr is contained; the oxygen content of atomized powder is controlled to be lower than 0.05 wt.%, the atomized powder with the particle size ranging from 50 meshes to 200 meshes is selected to be mechanically alloyed with Al powder, Zr powder, Hf powder and Y2O3 powder, and the size of obtained powder ranges from 90 micrometers to 200 micrometers; silicate glass is used for wrapping, compressing and molding, the pressure is started to be boosted to 120 MPa to 180 MPa at the temperature of 850 DEG C, a two-stage sintering manner in which the temperature ranging from 850 DEG C to 950 DEG C is kept for 1 hour and the temperature ranging from 1050 DEG C to 1150 DEG C is kept for 1 hour is adopted, the tensile strength of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 250 MPa to 320 MPa, and the ductility of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 18% to 32%; and the oxidation performance of the dispersion-strengthening steel is also greatly improved on the premise that the high-temperature strength and the high-temperature plasticity are guaranteed, and after 100-h oxidation is carried out at the temperature of 850 DEG C, the oxidation weight increase only ranges from 0.0327 mg / cm<3> to 0.098 mg / cm<3>.

Owner:UNIV OF SCI & TECH BEIJING

Plating solution of magnesium alloy nickle sulfate main salt and technology of chemical plating thereof

InactiveCN1598053ALow priceReduce manufacturing costLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a plating solution of magnalium alloy Nickel sulfate and its chemical plating technique. The plating solution is made up of: (1) 5 to 40g.dm-3 of Nickel sulfate, (2) 10 to 50g.dm-3 of reducing agent of hypo-phosphite sodium; (3) one or several of the 2.5 to 30g.dm-3of the citric acid or tri-sodium citric acid, 2.5 to 30g.dm-3of the lactic acid, 2.5 to 30g.dm-3of the acetic acid, 2.5 to 30g.dm-3of the malic acid, 2.5 to 30g.dm-3 of the third acid and 2.5 to 30g.dm-3of the buta-acid; (4) one or several of the 5 to 30g.dm-3of Potassium fluoride, 5 to 30g.dm-3of sodium fluoride, 5 to 30g.dm-3of lithium fluoride and 5 to 30g.dm-3of NH4HF2; (5) 0.1 to 3g.dm-3of sulphur carbamide. The plating steps include: washing with ultrasonic->washing with alkali->washing with acid->activation->dipping it in the zinc solution->getting rid of the activation solution->secondary dipping it in the zinc solution->chemical plating->passivation and sealing the holes. The invention is featured by little pollution to the environment, low cost, uniform film and simpel technique.

Owner:HUNAN UNIV

Production method of tipping base cigarette paper with high natural air permeability

ActiveCN101935962AImprove the level ofImprove breathabilitySpecial paperWater-repelling agents additionPapermakingLeveling effect

The invention relates to a production method of tipping base paper with high natural air permeability as well as cigarette paper. The production method of the tipping base cigarette paper with the high natural air permeability comprises a pulping step, a papermaking step and a calendaring step; in the pulping step, softwood pulp, eucalyptus pulp and Spain straw pulp are respectively pulped, the softwood pulp has the pulping concentration of 3.4-3.6 percent, the beating degree / wet weight of 66-680 SR / 8-11g, the eucalyptus pulp has the pulping concentration of 3.6-3.8 percent and the beating degree of 20-220 SR, the Spain straw pulp has the beating degree of 18-220 SR; and 40-60 percent of softwood pulp, 30-40 percent of eucalyptus pulp and 10-20 percent of Spain straw pulp which are well-pulped are proportioned. The invention has higher air permeability and obvious action of diluting mainstream smoke, can greatly decrease the production cost and improve the production efficiency without static electricity or laser printing, the favorable combination strength can satisfy the requirement of a high-speed printer, the base paper is smooth and fine, has good oil print leveling effect and is fully suitable for the production requirement of a gravure printing machine.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

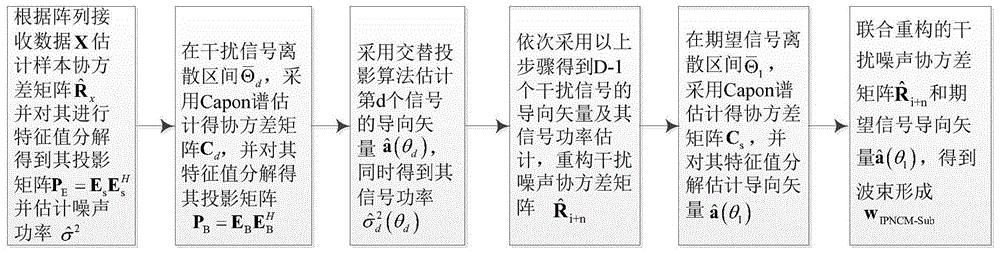

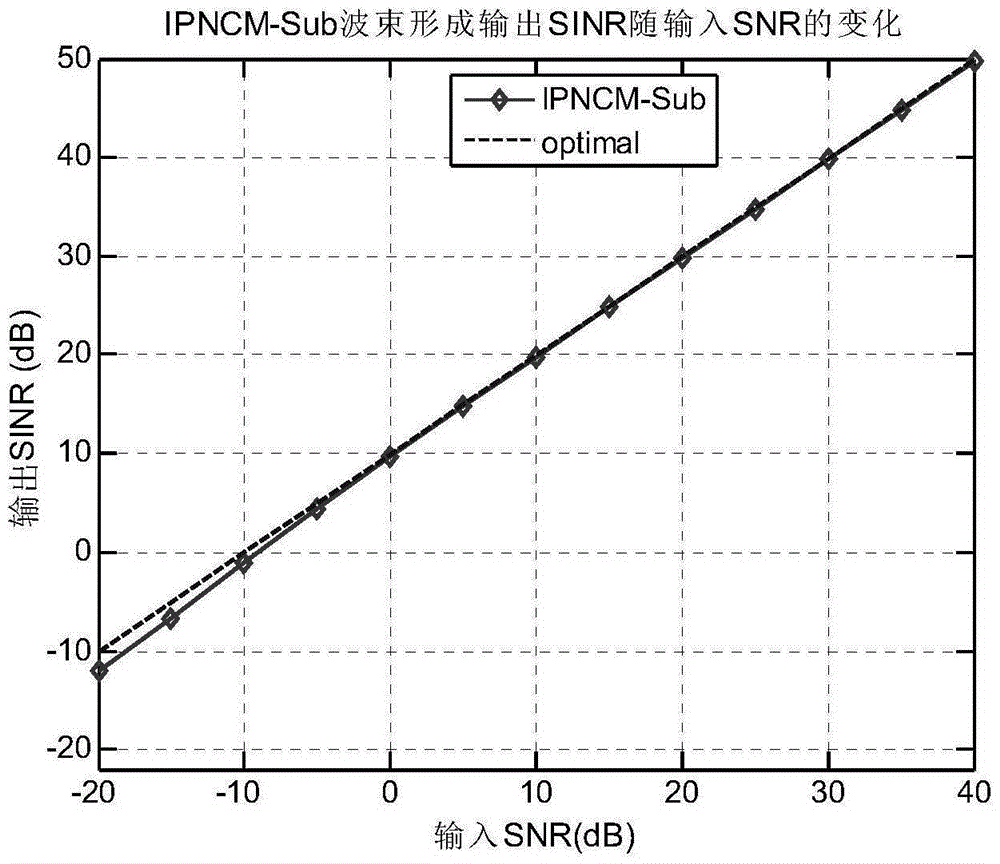

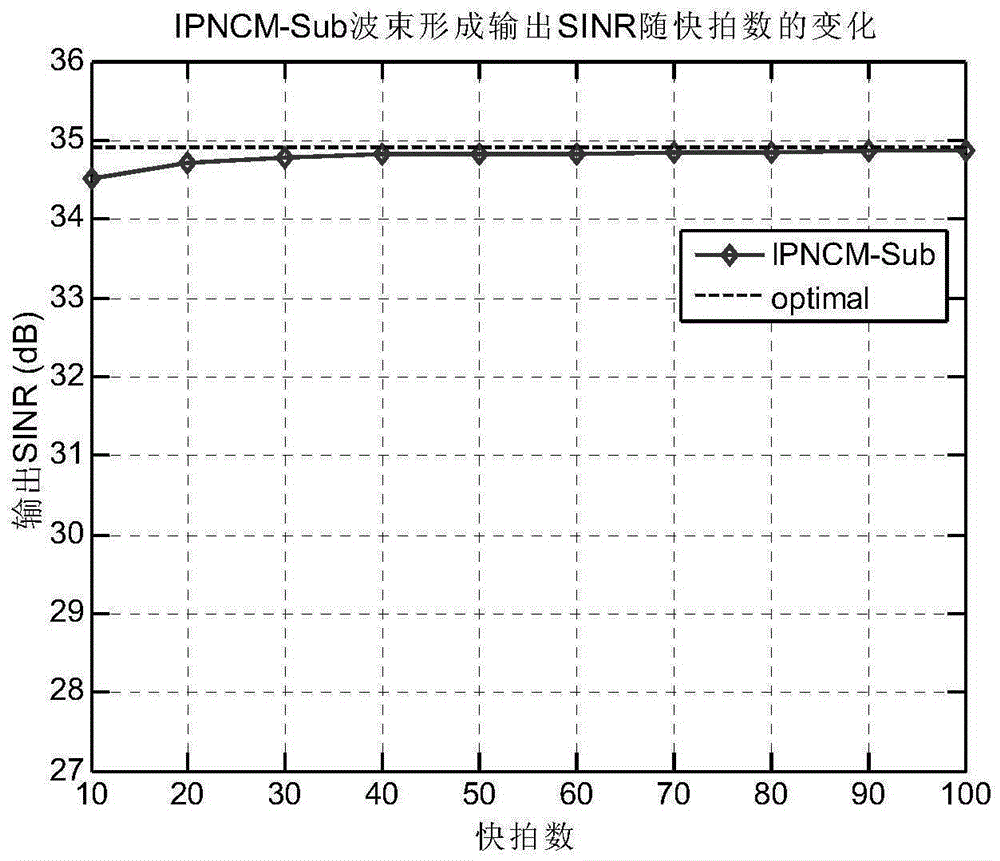

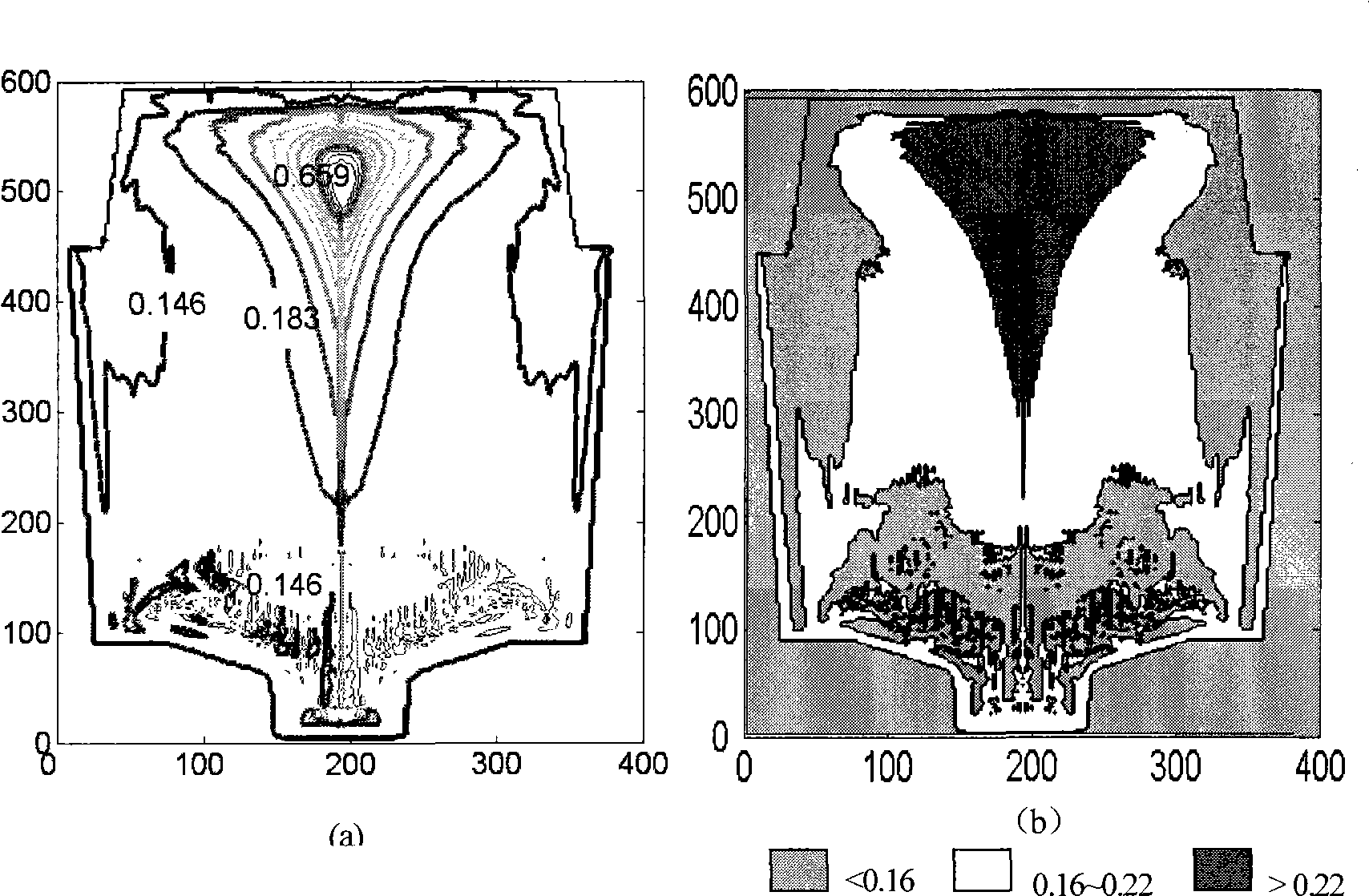

Beam forming method based on subspace interference-plus-noise covariance matrix reconstruction

InactiveCN105204006AImprove estimation accuracyFew ingredientsWave based measurement systemsSpecial data processing applicationsFeature vectorAlgorithm

The invention belongs to the field of array signal processing and mainly relates to robustness of a standard Capon self-adaptive beam forming algorithm based on covariance matrix reconstruction to interference signal steering vector errors. The beam forming algorithm based on subspace interference-plus-noise covariance matrix reconstruction comprises the following steps: at first, utilizing matrix received data to estimate the steering vector a(theta d), d=2,3,...,D and the power sigma<2> d(theta d) of all D-1 interference signals and meanwhile estimate the noise power sigma<2>, wherein d=2,3,...,D; then reconstructing an interference-plus-noise covariance matrix R' according to the definition R of the interference-plus-noise covariance matrix; finally, constructing a signal covariance matrix in a relatively small angle range 1; taking the dominant eigenvector of the signal covariance matrix as a desired signal steering vector to estimate a(theta 1); together with the reconstructed R', obtaining a novel beam forming weighing vector W, wherein the formulas of R, R' and W are shown in the description. The beam forming method provided by the invention overcomes the defects of the conventional beam forming algorithm, thereby having good robustness to interference signal steering vector errors.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

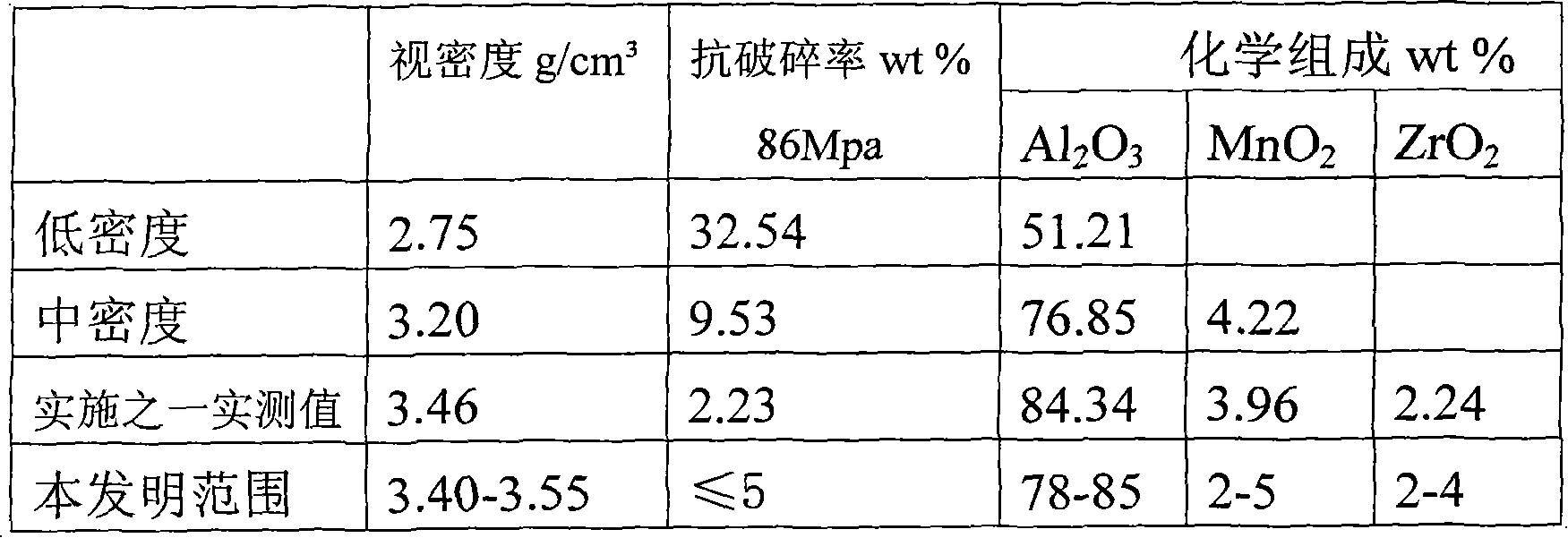

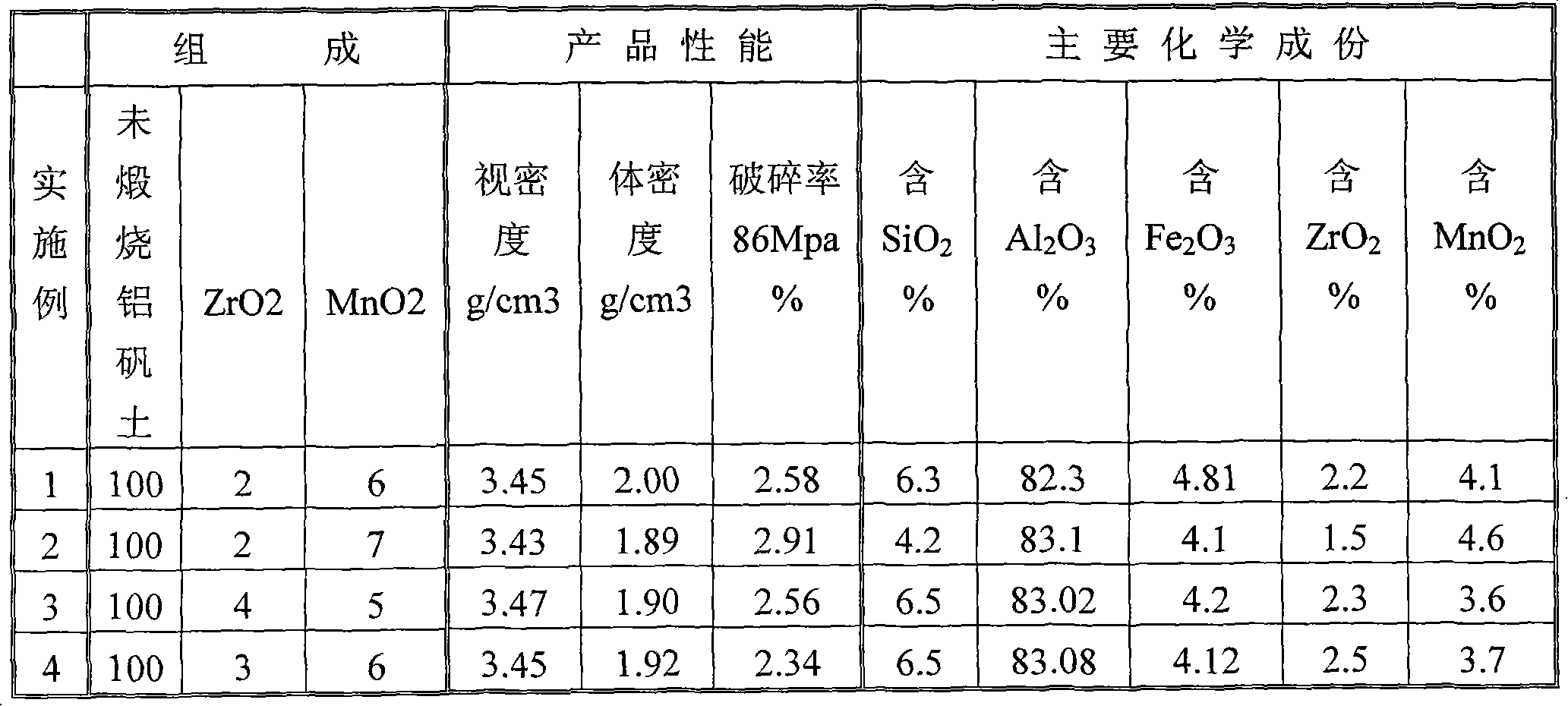

High-density high-strength pressure crack proppant

InactiveCN101168660ASatisfied with fracturing floodingHigh densityFluid removalApparent densityChemical composition

The invention relates to a high closing pressure extra-deep oil well and an extra-deep gas well, and pressing crack driving adopts high density and high strength pressing crack propping agent. The invention is characterized in that the composition is as follows: 100 parts of non-annealing bauxite with more than or equal to 75 percent of Al2O3, and 3 to 8 parts of MnO2, and 1 to 5 parts of ZrO2, the apparent density after balling is fired is 3.40-3.55 kg / cm <3>, the anti- fragmentation capacity under 86 MP pressure is more than or less than 5 percent (20 / 40 meshes), the main chemical composition is 78 to 85 wt percent of Al2O3, 2 to 5 wt percent of MnO2, 78 to 85 wt percent of Al2O3, 2 to 5 wt percent of MnO2, and 2 to 4 wt percent of ZrO2. The propping agent of the invention has small composition material, simple preparation, low cost and good economical efficiency, the apparent density reaches the density limiting of 3.40 to 3.55 g / cm <3>, the compressive strength is high, the propping agent has 20 / 40 meshes of grain size, the anti-fragmentation capacity is (SY / T5108-2007) 86 MPa which is more than or less that 5 percent, the maximum can reach 100 MPa which is more than and less than 8 percent, the invention can satisfy the pressing crack driving of the high pressure extra-deep oil well and the extra-deep gas well under the formation closing pressure more than and equal to 86 MPa, the formation crack is supported under the high pressure, and the flow conductivity can be greatly improved.

Owner:宜兴东方石油支撑剂有限公司

Xylem filber-polyvinyl chloride composite material and method for producing the same

A wood fiber-polyvinyl chloride composite material and a preparation method thereof, which relate to a composite material and a preparation method thereof. It solves the problem that the wood fiber-polyvinyl chloride composite material has high flammability and produces a large amount of black smoke and toxic gas when burned. The wood fiber-polyvinyl chloride composite material is mainly composed of 100-600 parts of polyvinyl chloride resin, 30-700 parts of wood fiber material, 3-145 parts of intumescent flame retardant, 1-55 parts of copper oxide, 6 ~75 parts of heat stabilizer, 4~60 parts of plasticizer and 4~65 parts of compatibilizer. Preparation method: 1. premixed material; 2. extrusion molding. According to the GB / T8924-2005 standard test of the wood fiber-polyvinyl chloride composite material of the present invention, the oxygen index of the wood fiber-polyvinyl chloride composite material of the present invention is greater than 35%, the ignition time is long, no melting drops occur, and it belongs to the flame retardant grade Material. The preparation method of the wood fiber-polyvinyl chloride composite material of the invention is simple, easy to operate, has low requirements on equipment, and is convenient for popularization and application.

Owner:NORTHEAST FORESTRY UNIVERSITY

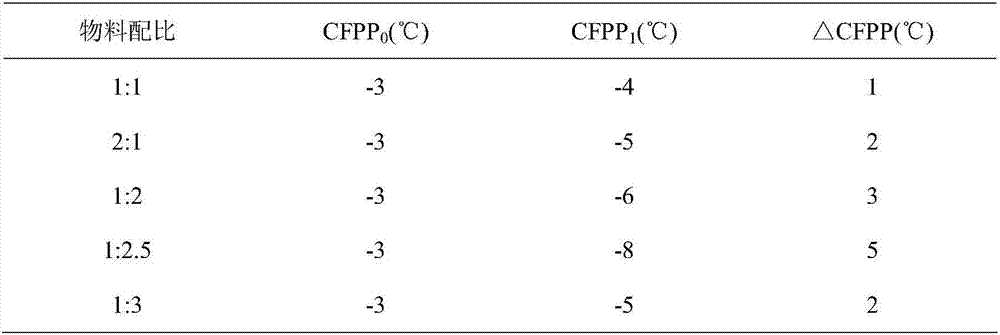

Clean diesel pour point depressant and preparation method thereof

InactiveCN106947556ARaise the ratioLow costOrganic compound preparationCarboxylic acid esters preparationRotary evaporatorDiesel combustion

The invention relates to a clean diesel pour point depressant and a preparation method thereof. The clean diesel pour point depressant is composed of long carbon chain fatty acid, low-carbon alcohol and low-carbon acid. The preparation method comprises the following concrete steps: weighing oleic acid by weight; adding glycerol, and carrying out heating under stirring until the oleic acid and the glycerol are dissolved; measuring the rate of esterification through an acid-base titration method; after a period of time, adding methacrylic acid, carrying out caustic washing and alcohol washing, then removing water through a rotary evaporator, and carrying out drying in an oven so as to obtain a target product namely methacrylic acid-glyceryl monooleate. According to the invention, by adopting an additive-free solvent and a catalyst, materials are economical, and cleanness and environment protection are realized. The pour point depressant provided by the invention has a formula applicable to good improvement of fluidity of diesel at a low temperature, and specifically meets the requirements of a diesel engine for clean and environment-friendly combustion tail gas emission in the process of diesel combustion.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Mixed feed for sea-bass fish and preparation method thereof

The invention discloses a mixed feed for sea-bass fish and a preparation method thereof. The mixed feed is made from the following raw materials in parts by weight: 35 to 45 of insect powders, 20 to 30 of a compound fermented material, 0.5 to 1 of fish oil, 10 to 20 of flour, 1.5 of calcium dihydrogen phosphate, 2 of a vitamin-mineral salt mixture, and 0.5 of choline chloride, wherein the compound fermented material is a fermented product of castor cake, rape cake and cotton cake with compound dry microbial inocula. The mixed feed is prepared by the steps as follows: mixing castor cake, rape cake and cotton cake according to a weight ratio of 1:1:1, and adding the compound dry microbial inocula composed of at least two of lactic acid bacteria, saccharomycetes, bacillus and geotrichum candidumlink strain for fermentation 2-24h, wherein the additive amount of the compound dry microbial inocula is 1% of the total weight of the fermentation raw material; and thoroughly mixing the raw materials, compounding, pelletizing and oven-drying to obtain the final product. The preparation method is simple and low in cost. The mixed feed for sea-bass fish is good in palatability and nutrition and can enhance disease resistance and stress resistance of sea-bass fish.

Owner:宁波天邦饲料科技有限公司

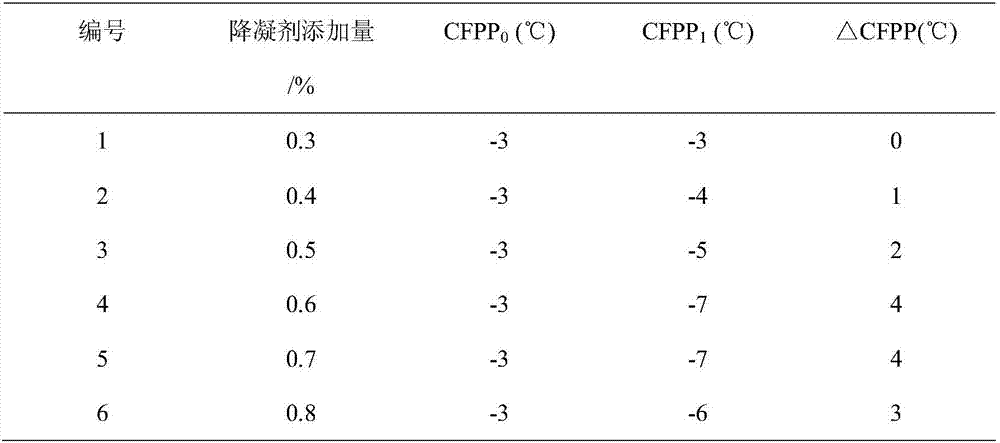

Secondarily-curable polyurethane modified epoxy asphalt mixture, preparation method therefor and application thereof

The present invention provides a secondarily-curable polyurethane modified epoxy asphalt mixture which is prepared by mixing 2-8 parts by mass of polyurethane modified epoxy asphalt with 92-98 parts by mass of mineral aggregates; the polyurethane modified epoxy asphalt consists of a component A, a component B, and a component C, wherein the component A is 100 parts of polyurethane modified epoxy resin; the component B consists of the following substances in parts by mass: 70-150 parts of a curing agent and 0-0.02 parts of an accelerator; and the component C is 50-200 parts of asphalt. The secondarily-curable polyurethane modified epoxy asphalt mixture provided by the present invention is suitable for paving a steel bridge deck and a cement concrete bridge deck and paving and repairing an asphalt pavement, and is used for special road sections such as an intersection and a bus stop.

Owner:中路交建(北京)工程材料技术有限公司

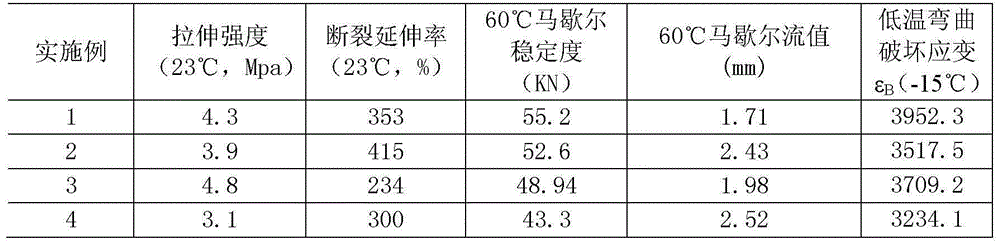

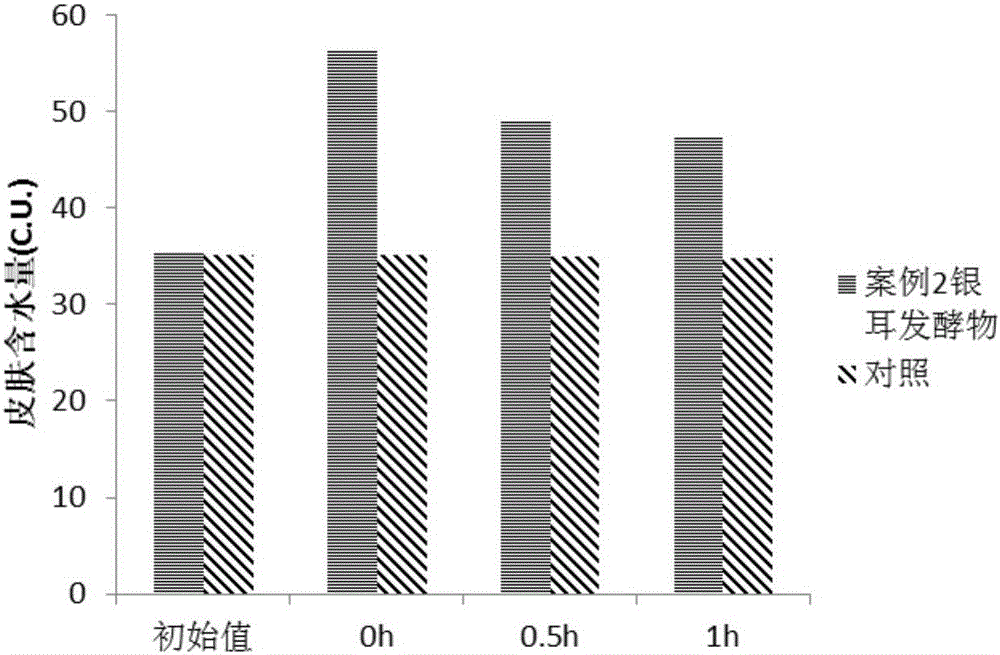

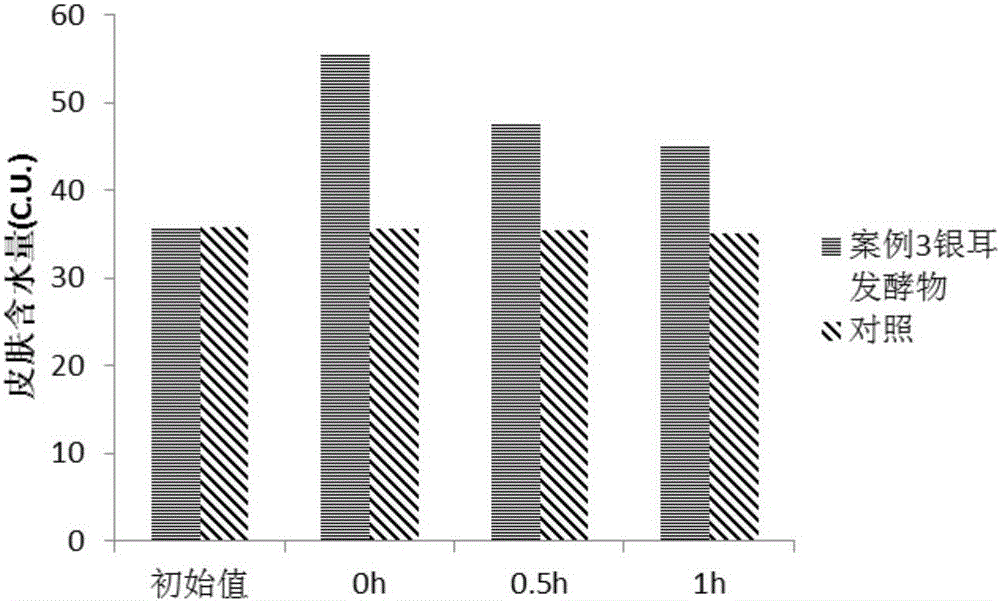

Preparation method and application of tremella fermentation extract

ActiveCN105002254AFully absorbedCause negative effectsCosmetic preparationsToilet preparationsTremellaZygosaccharomyces

The invention discloses a preparation method of a tremella fermentation extract and its application. The preparation method of the tremella fermentation extract comprises the following step: tremella undergoes fermentation cultivation by the use of a strain or its culture solution or its suspension so as to obtain a fermentation product, namely the tremella fermentation extract. The strain is at least one of the following strains: zygosaccharomyces rouxii, pasteur yeast, brewer's yeast, wine yeast, acetobacter xylinum, Lactobacillus delbrueckii subsp. Bulgaricus, Streptococcus thermophilus, Bifidobacterium bifidum, lactococcus lactis and enterococcus faecalis. Through experiments, it proves that the tremella fermentation extract prepared by the method contains no chemical components, can be directly used as a finished product of facial mask or essence or toner, is more natural than other existing products in the market and will not have any negative effect on the skin. In addition, smaller components can be obtained by the preparation method in comparison with a common extraction method and the extract is easier to fully absorb by the skin.

Owner:SHANGHAI BIOTRULY BIOTECH CO LTD

Production method of cold-rolled steel strip for flux cored wire

InactiveCN102755992ASimple production processLow costWork treatment devicesRollsExtensibilityCarbide

The invention provides a production method of a cold-rolled steel strip for a flux cored wire. The production method comprises the following steps of: (1) selecting a raw material, to be specific, selecting an SPCE hot-rolled acid-washed raw material with thickness of 2.2-3.0 mm and width of 300-850 mm, wherein the raw material comprises the following components in percentage by weight: 0.01-0.025 percent of C, 0.002-0.010 percent of Si, 0.150-0.350 percent of Mn, not greater than 0.01 percent of S, not greater than 0.015 percent of P, not greater than 0.003 percent of N, not greater than 0.05 percent of Alt and the balance of iron element and inevitable impurities; (2) cold-rolling, to be specific, performing cold-rolling on the acid-washed raw material to be 0.5-1.2 mm and controlling total screw-down rate to be 700-85 percent; (3) performing recrystallization annealing, to be specific, holding a rolled steel strip in a forced circulation hood type annealing furnace, heating, preserving heat and cooling, wherein the holding temperature is 610-660 DEG C and the holding time is controlled to be 9-12 hours; (4) leveling; and (5) cutting to obtain the cold-rolled steel strip for the flux cored wire. The produced flux cored wire steel strip has a simple production process and is low in cost. The produced flux cored wire steel strip has stable performance; solid solution carbide is fully separated through staged slow cooling in the process of the hood type annealing furnace; the influence of time limitation on subsequent drawing is avoided; the hardness of the product is HV 90-110; and the extensibility A reaches 42-50 percent.

Owner:武钢集团有限公司

Method for extracting vanadic anhydride from stone coal vanadium ore

InactiveCN101182596AReduced drying processFew ingredientsVanadium oxidesProcess efficiency improvementCelsius DegreeDesorption

The invention relates to a method for extracting vanadic oxide from bone coal vanadium mine; the method comprises the following steps that the bone coal vanadium mine is selected to be delivered into a kiln for baking and the kiln temperature is controlled between 750 to 1100 Celsius degrees and the discharge temperature of the baked material is 750 to 1000 Celsius degrees; and then the materials are delivered into a heat-preservation warehouse to be kept still for 24 to 120 hours; and then the material is extracted and the pH value of the obtained extraction liquid is adjusted to be 2.5; the liquid is absorbed and desorbed to obtain the desorption liquid and then the desorption liquid is purified and the silicon and phosphor in the desorption liquid is removed; ammonium chloride is added to precipitate vanadium and obtain ammonium meta-vanadate; the ammonium meta-vanadate is implemented with the process of pyrolysis to obtain the vanadic oxide. The beneficial effect of the invention is that the bone coal vanadium mine is directly baked which reduces the working procedures of baking, proportioning, ball grinding and balling; the invention adopts the heat-preserving warehouse for preserving heat and the extraction rate can reach more than 90 percent if the temperature is kept between 750 to 1100 Celsius degrees for more than 72 hours; the extraction rate is higher if the heat-preserving time is longer; moreover, the mechanization degree is high and no dust pollution exists.

Owner:杨秋良

Method for repairing large-scale roller

InactiveCN1796602ALow technical requirementsReduces the possibility of crackingMetallic material coating processesMaterials scienceRepair method

This invention publishes a repair method for large casting rollers. In this method, surface welding technology and laser cladding technology are well combined so that respective drawbacks are avoided and advantages are further exerted. Generally speaking, it is a low-risk and reliable repair method.

Owner:李贞

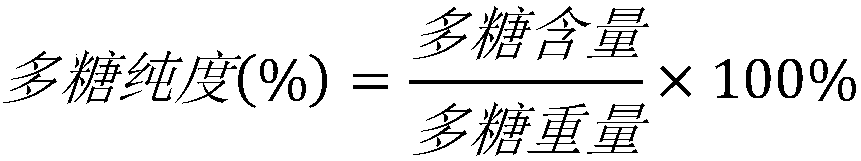

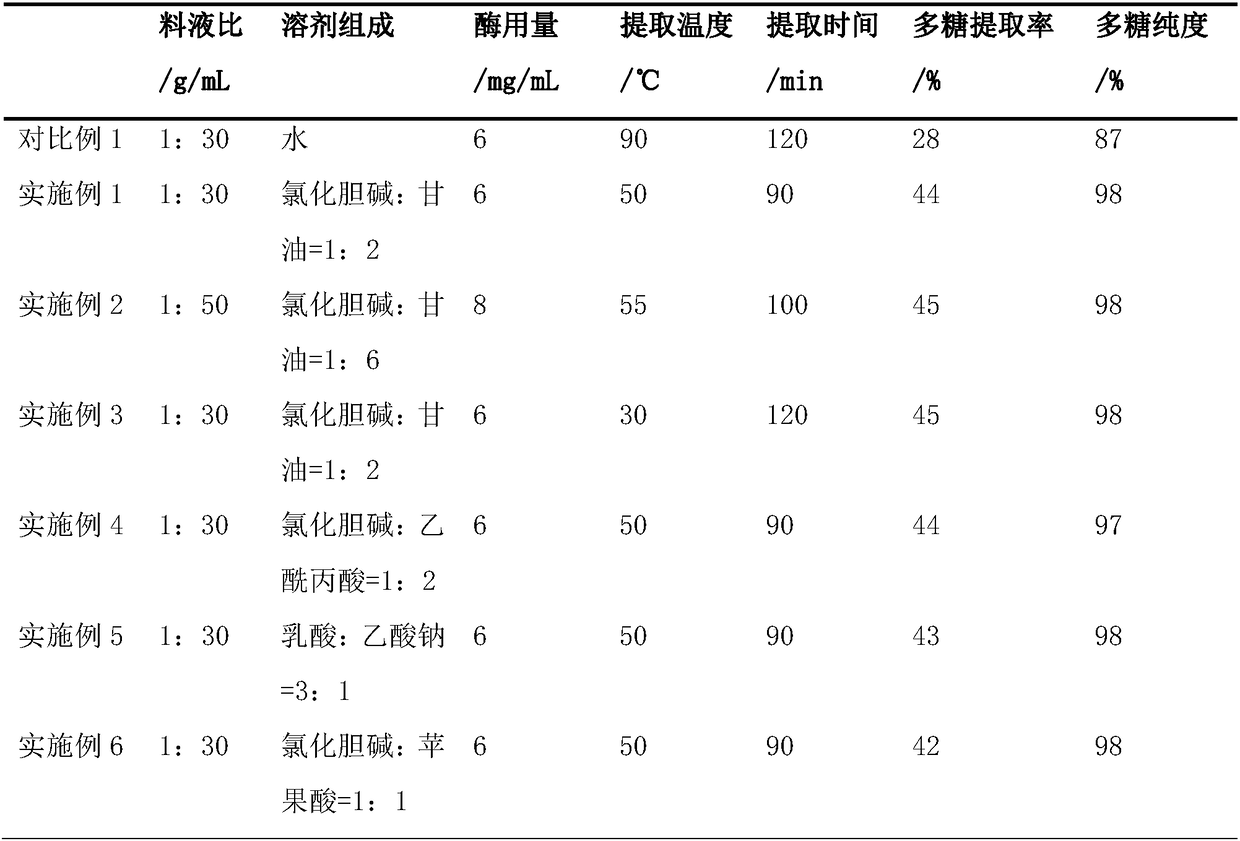

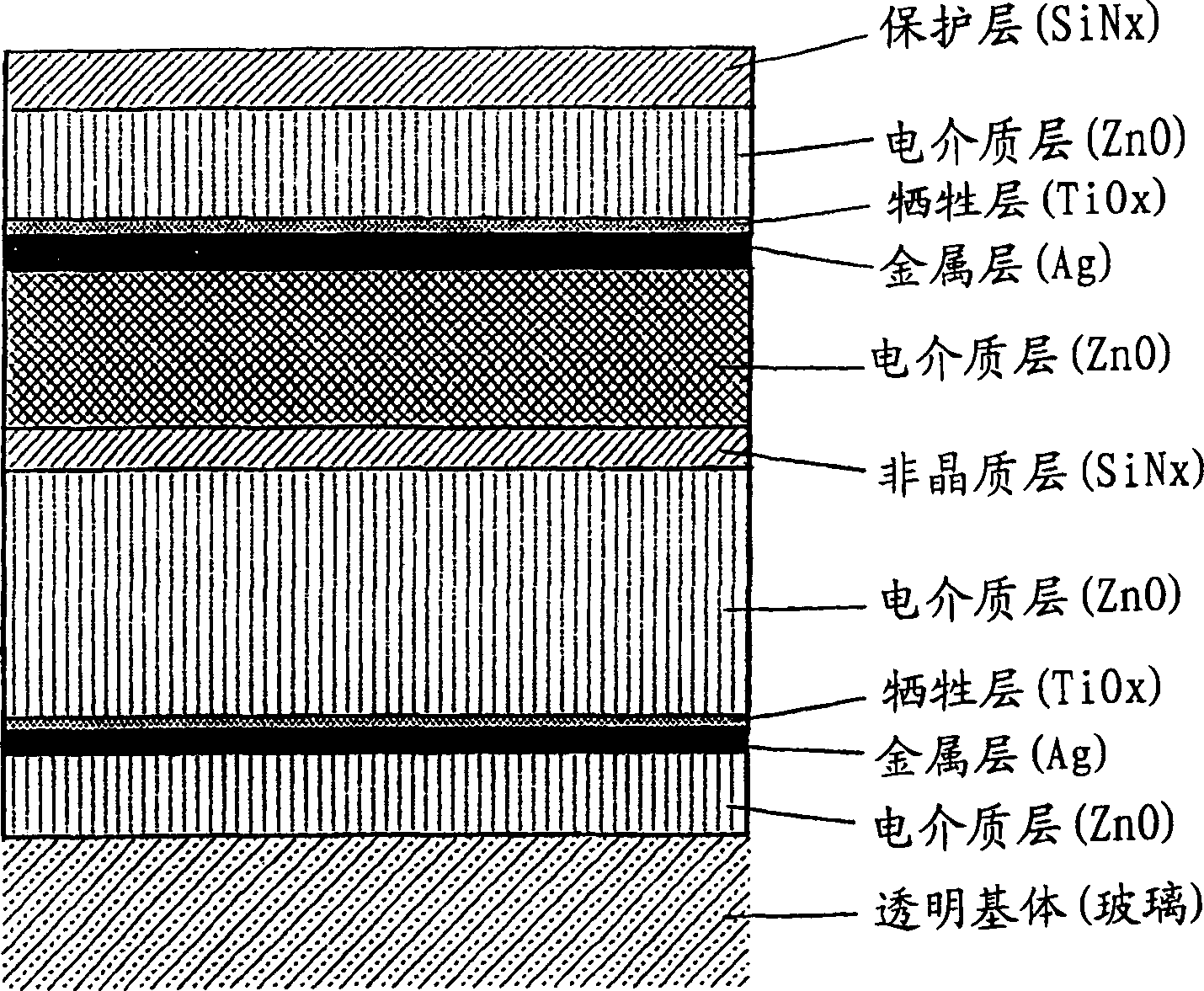

Method for extracting polysaccharide of dendrobium officinale

The invention discloses a method for extracting polysaccharide of dendrobium officinale. The method specifically comprises the following steps of uniformly mixing dendrobium officinale powder and a deep eutectic solvent according to a material and liquid ratio of 1g to (30 to 50)mL, wherein the ratio of hydrogen bond receptor to hydrogen bond donor is 3 to (1 to 18)mol / mol; adding 4 to 8mg / mL of at least one of cellulase and pectinase; extracting for 90 to 120min at the temperature of 30 to 60 DEG C; separating and purifying the extracting solution, so as to obtain the polysaccharide of dendrobium officinale. Compared with the traditional enzyme type water extracting method, the method has the advantages that by using the enzyme-assisted deep eutectic solvent to extract, the volatility islow, the stability is high, and the reaction system is mild; the content of impurities in the extracting solution is reduced, the loss of the solvent is reduced, the purifying burden is decreased, theextracting rate of polysaccharide is increased by 10% or above, and the content of polysaccharide is increased by 10% or above.

Owner:SOUTH CHINA UNIV OF TECH

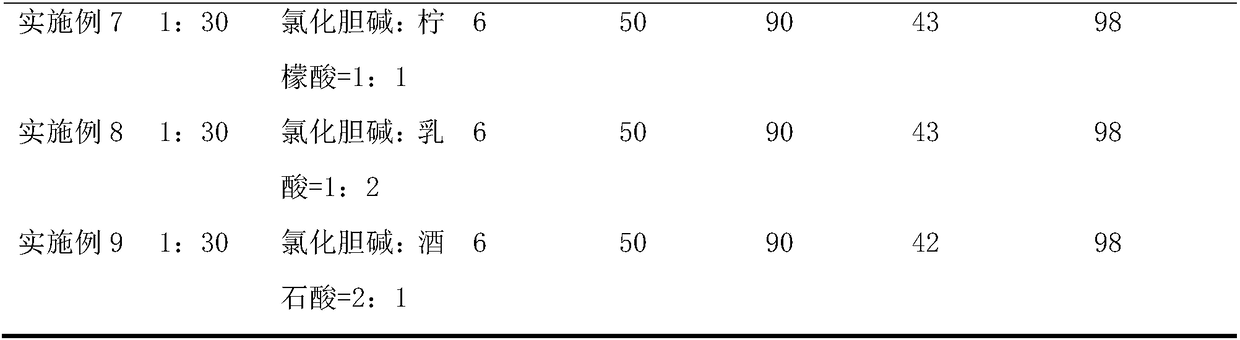

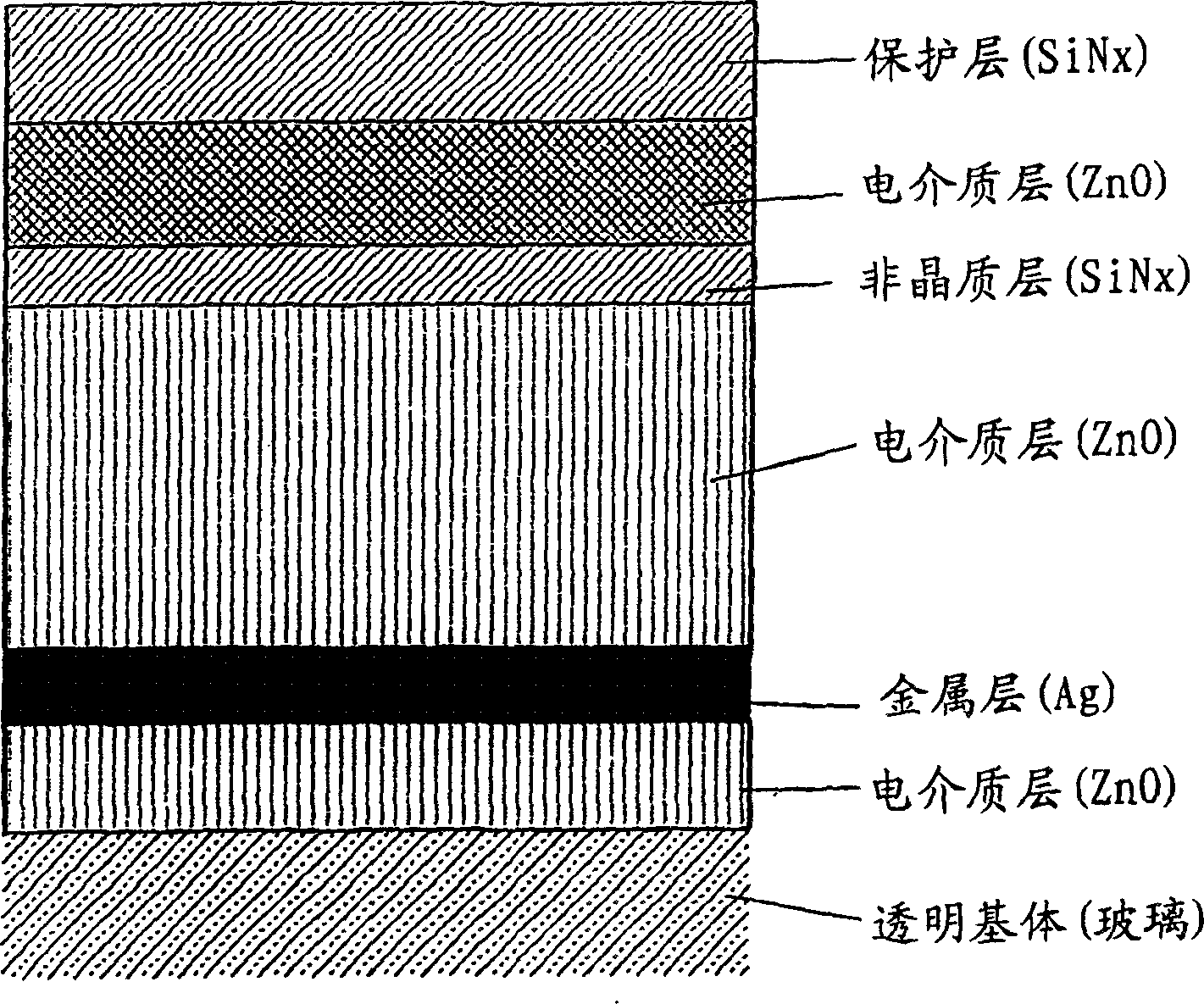

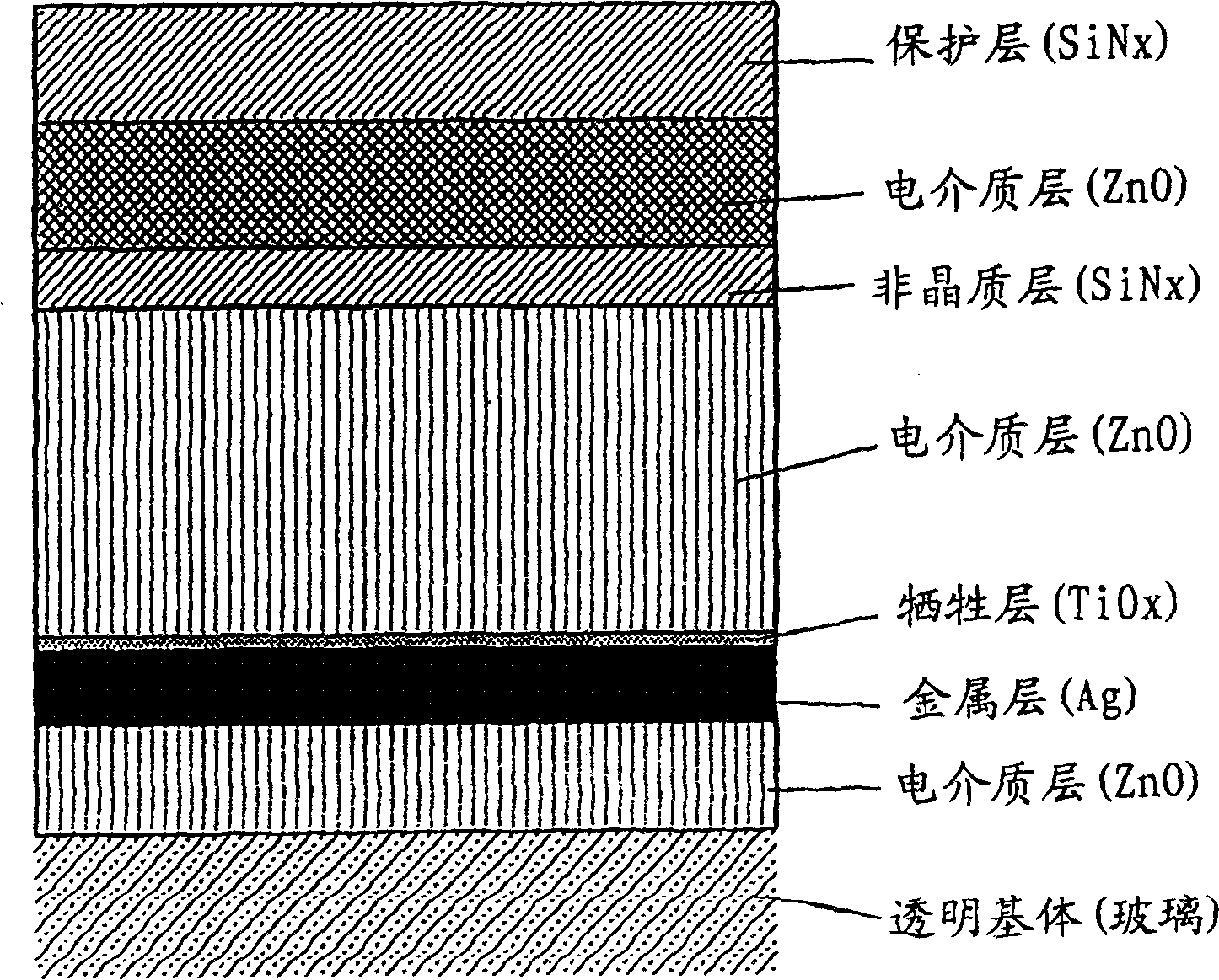

Transparent laminate having low emissivity

InactiveCN1476379AInhibit crystallizationImprove wear resistance and durabilityVacuum evaporation coatingSputtering coatingLow emissivityZinc

A transparent laminate having low emissivity which has one or more dielectric layers such as a zinc oxide (ZnO) film and one or more metal layers such as a silver (Ag) film being laminated on one another, characterized in that at least one dielectric layer is divided in the direction of film thickness by at least one amorphous layer. The transparent laminate having low emissivity exhibits improved durability of the metal layer, since the formation of a zinc oxide film as a dielectric layer on an amorphous layer causes the collapse of the columnar crystal structure of zinc oxide and, as a result, not only the amorphous layer but also the dielectric layer act also as a barrier preventing the entry of moisture or a gas.

Owner:CARDINAL CG +1

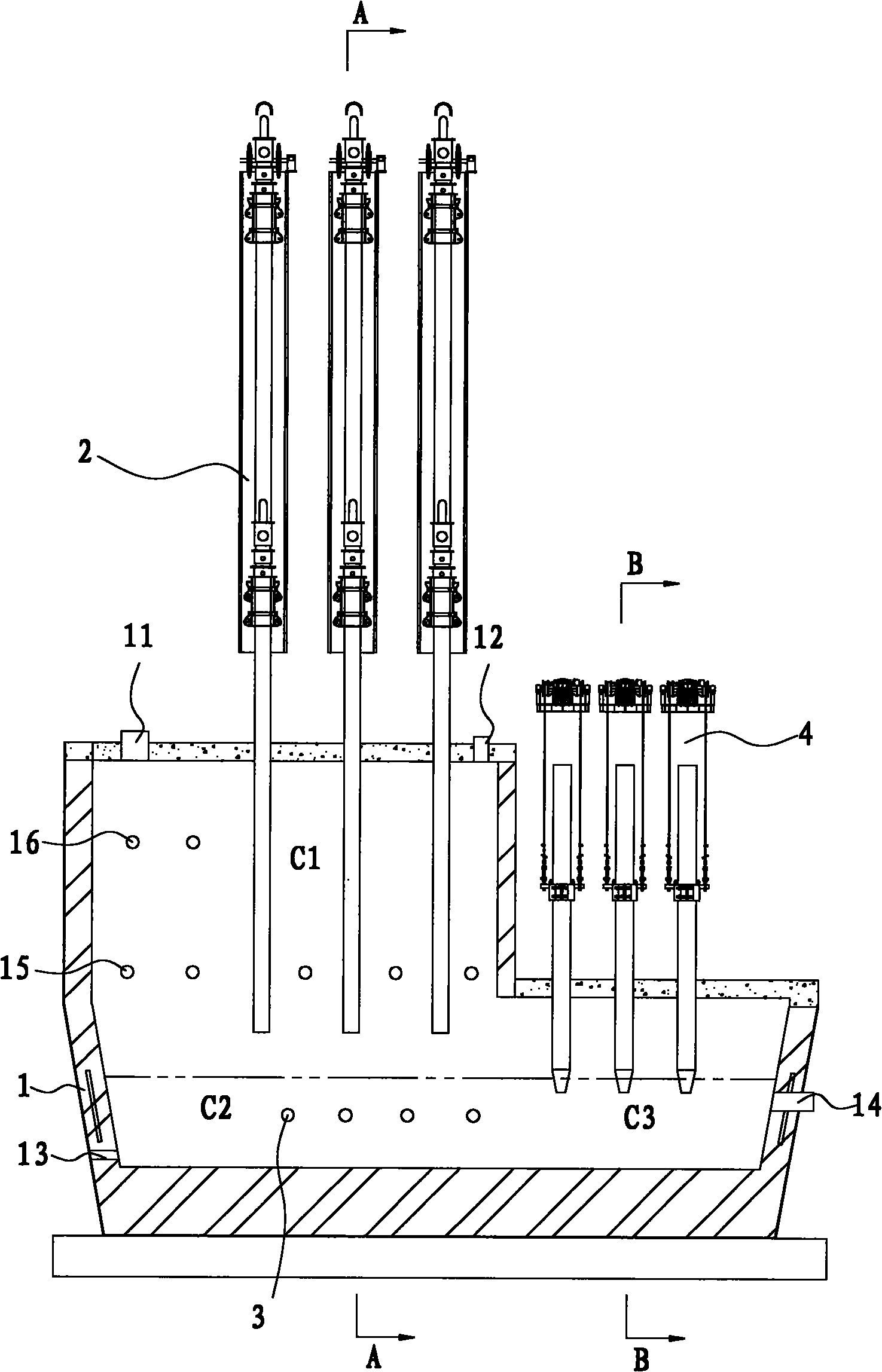

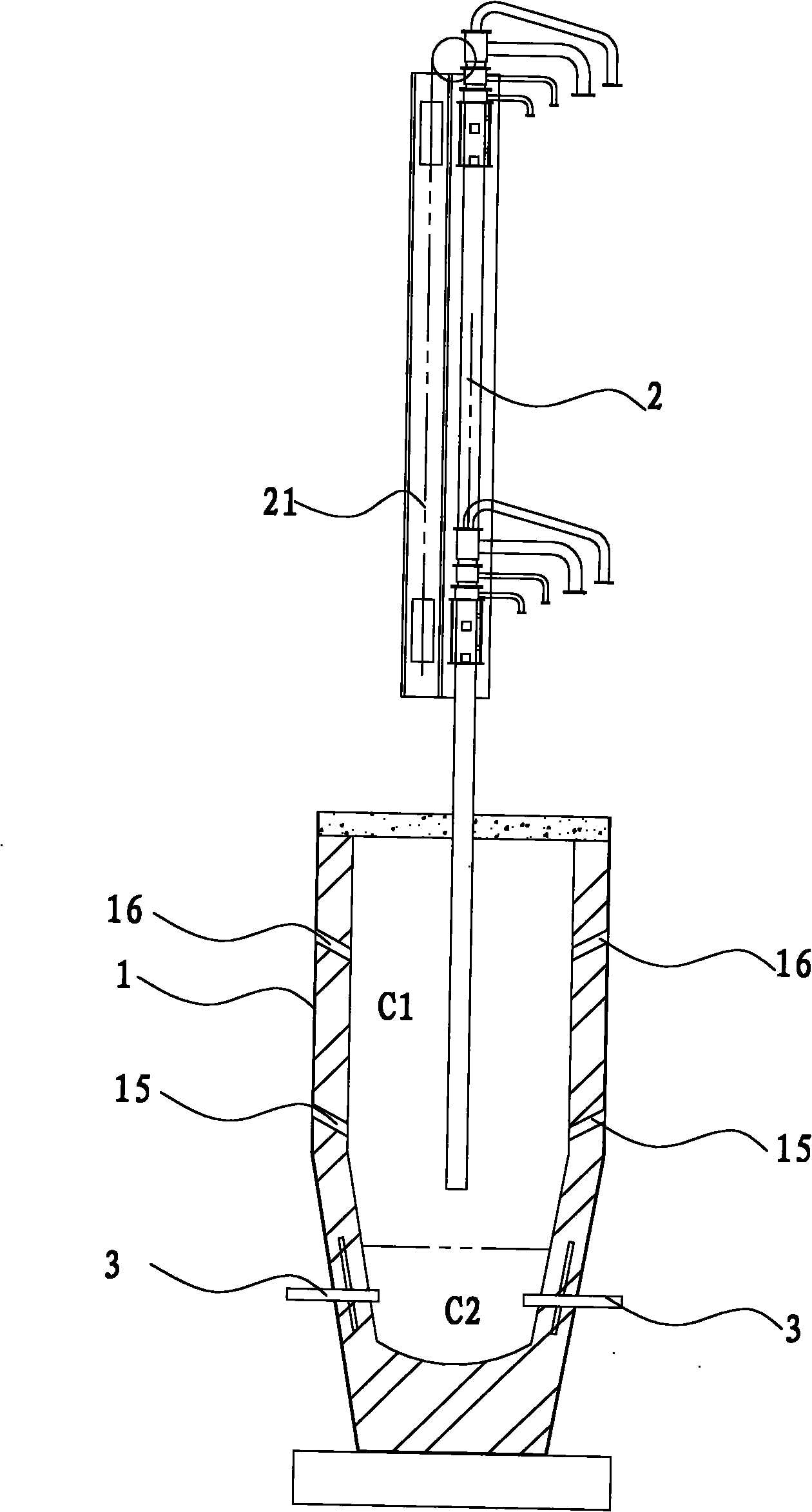

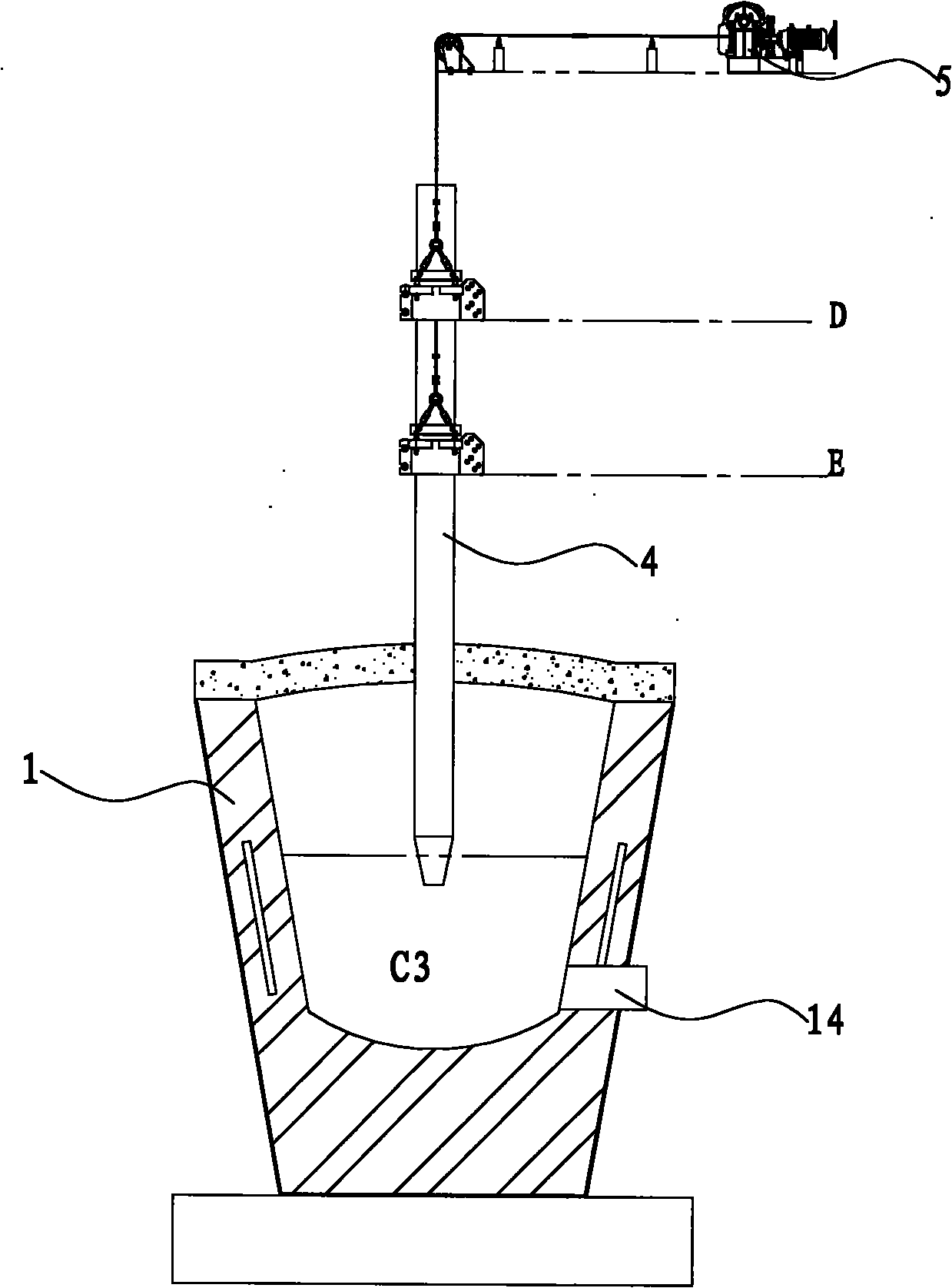

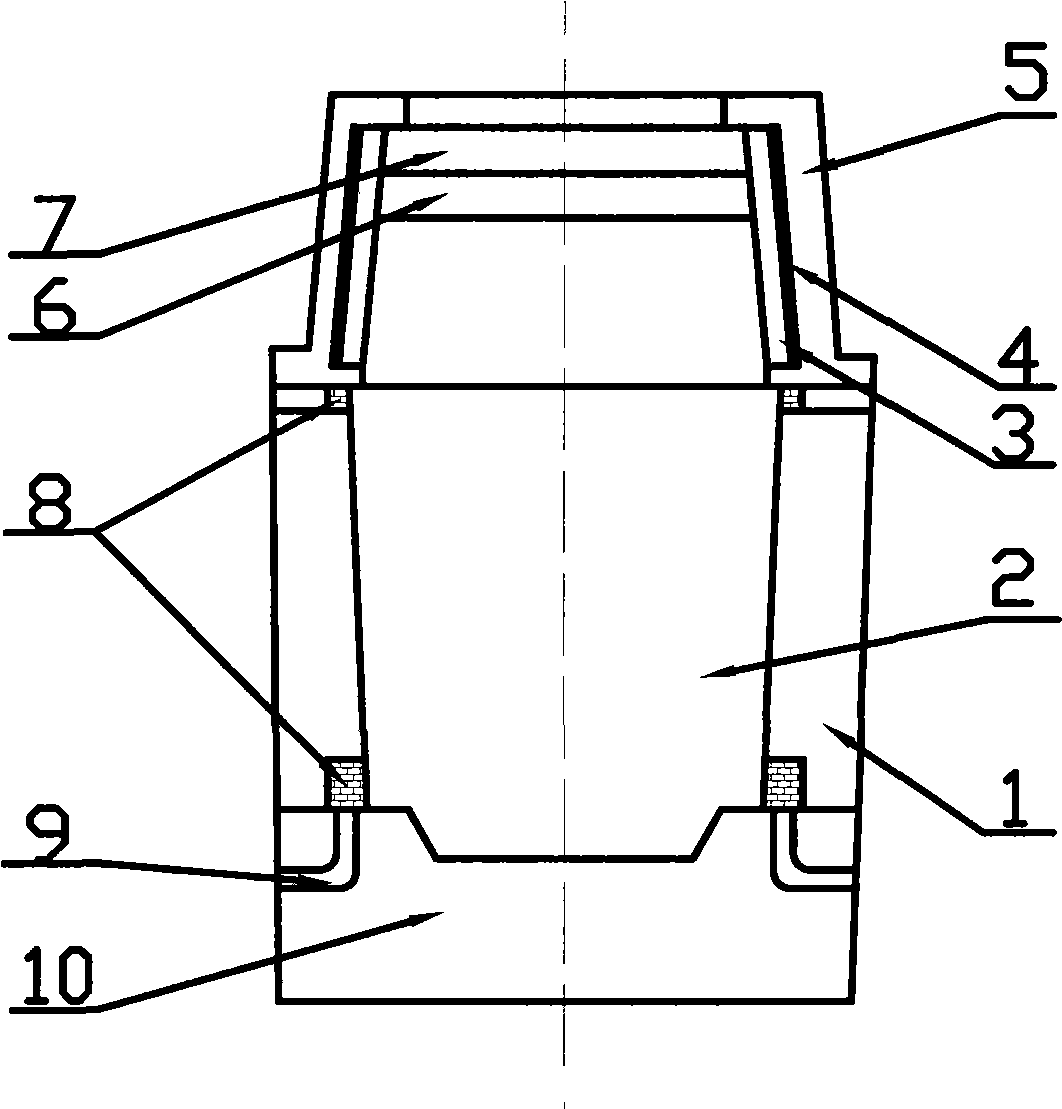

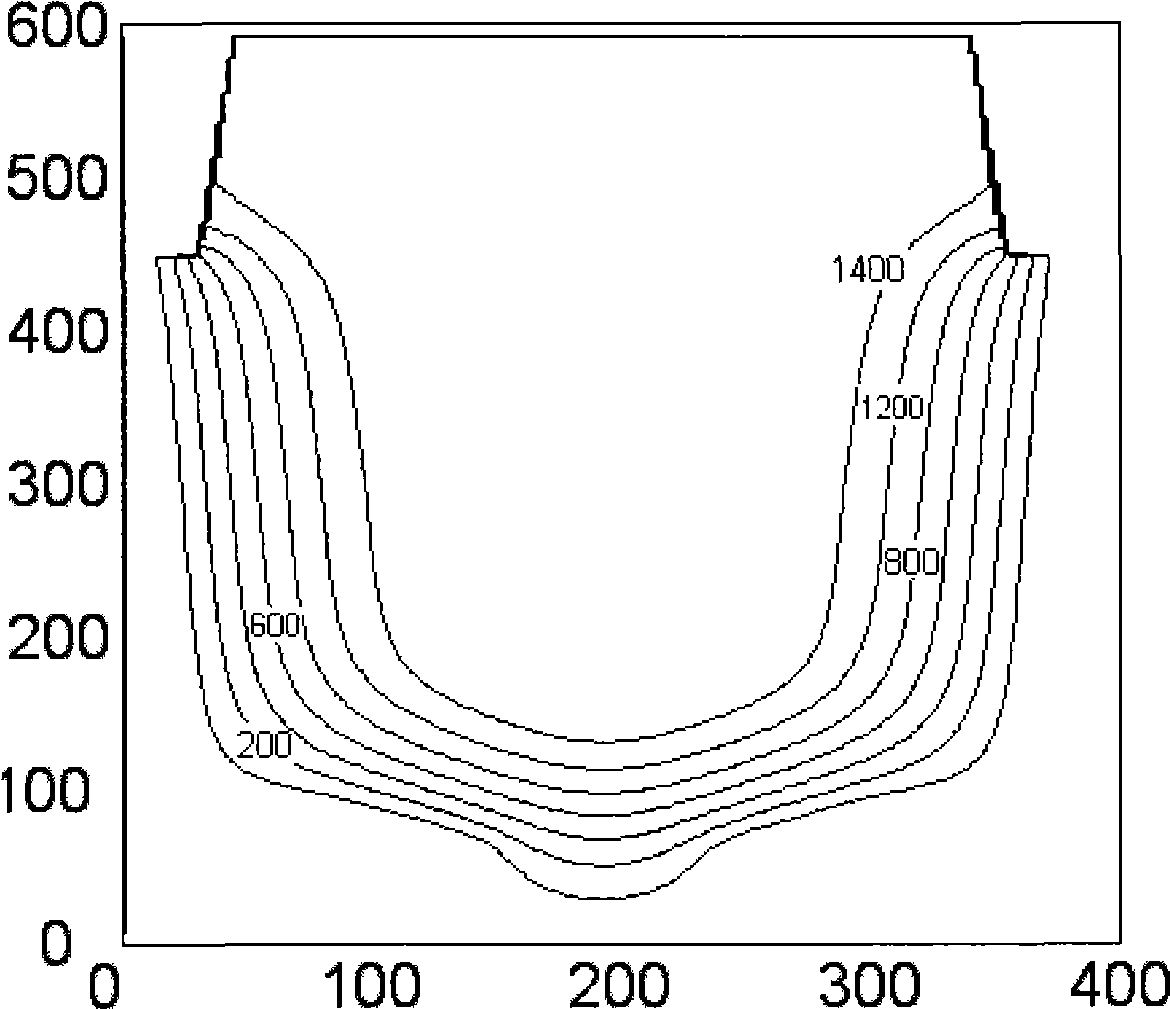

Smelting furnace for nickel-bearing laterite ore

The invention discloses a smelting furnace for nickel-bearing laterite ore, comprising a furnace body, a gunjet for top combustion, a side-blown jugjet and an electrode. A hearth is limited in the furnace body; a smelting bath is arranged at the lower part of the hearth, and the furnace body is provided with a charging hole for adding materials to the hearth, a smoke outlet, a nickel outlet and a dreg outlet; the lower end of the gunjet for top combustion extends from the top of the furnace body to the hearth and is located at the upper side of the smelting bath and sprays pulverized coal and oxygen to the upper part of the hearth towards the smelting bath; the side-blown gunjet extends from the lateral side of the furnace body to the smelting bath to spray the pulverized coal and oxygen; and the lower end of the electrode extends to the smelting bath to heat the melt in the smelting bath and clarify and separate dregs from nickel and ferrum. The smelting furnace for the nickel-bearing laterite ore has the advantages of low cost and energy consumption, good operating environment, low pollution and simple process.

Owner:CHINA ENFI ENGINEERING CORPORATION

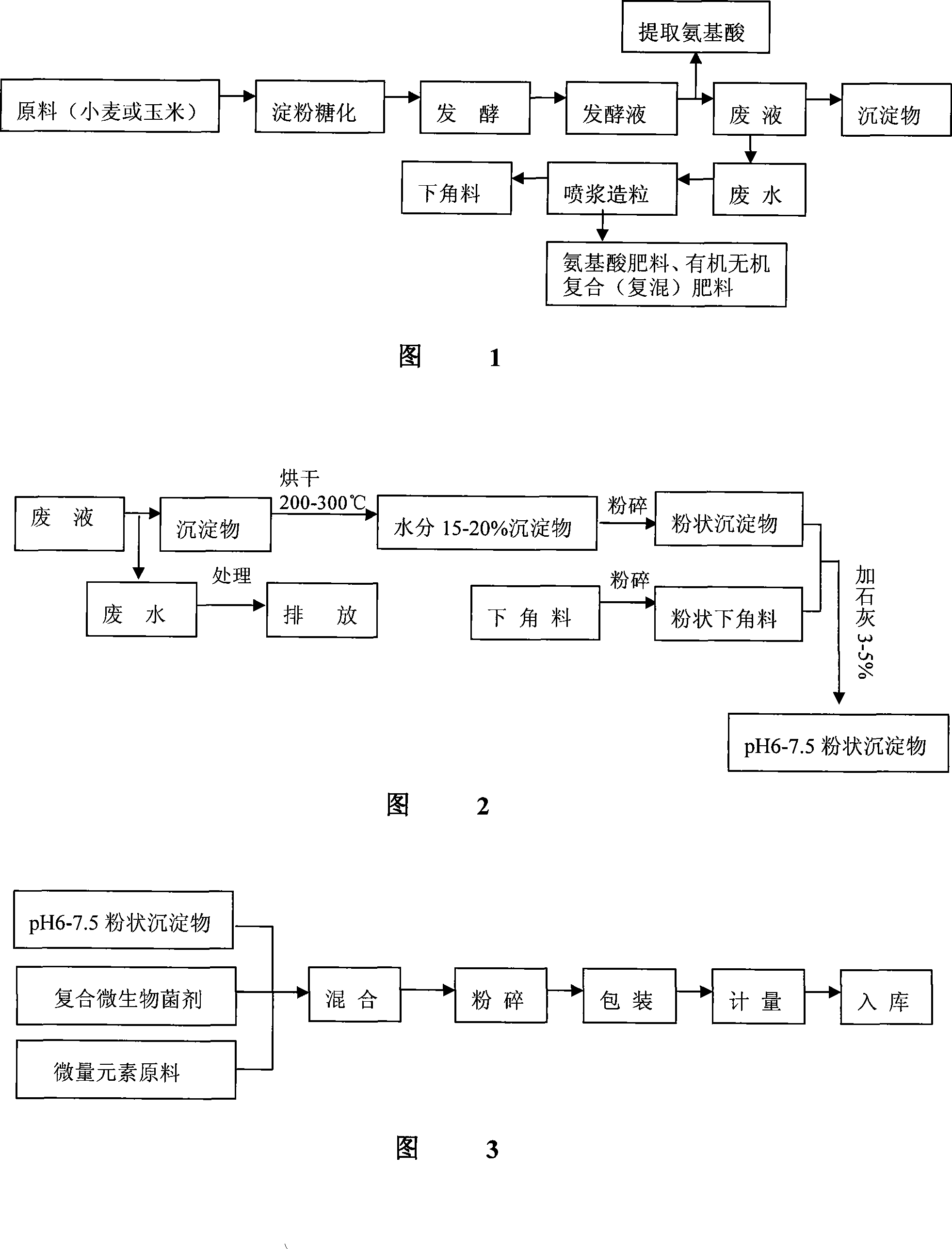

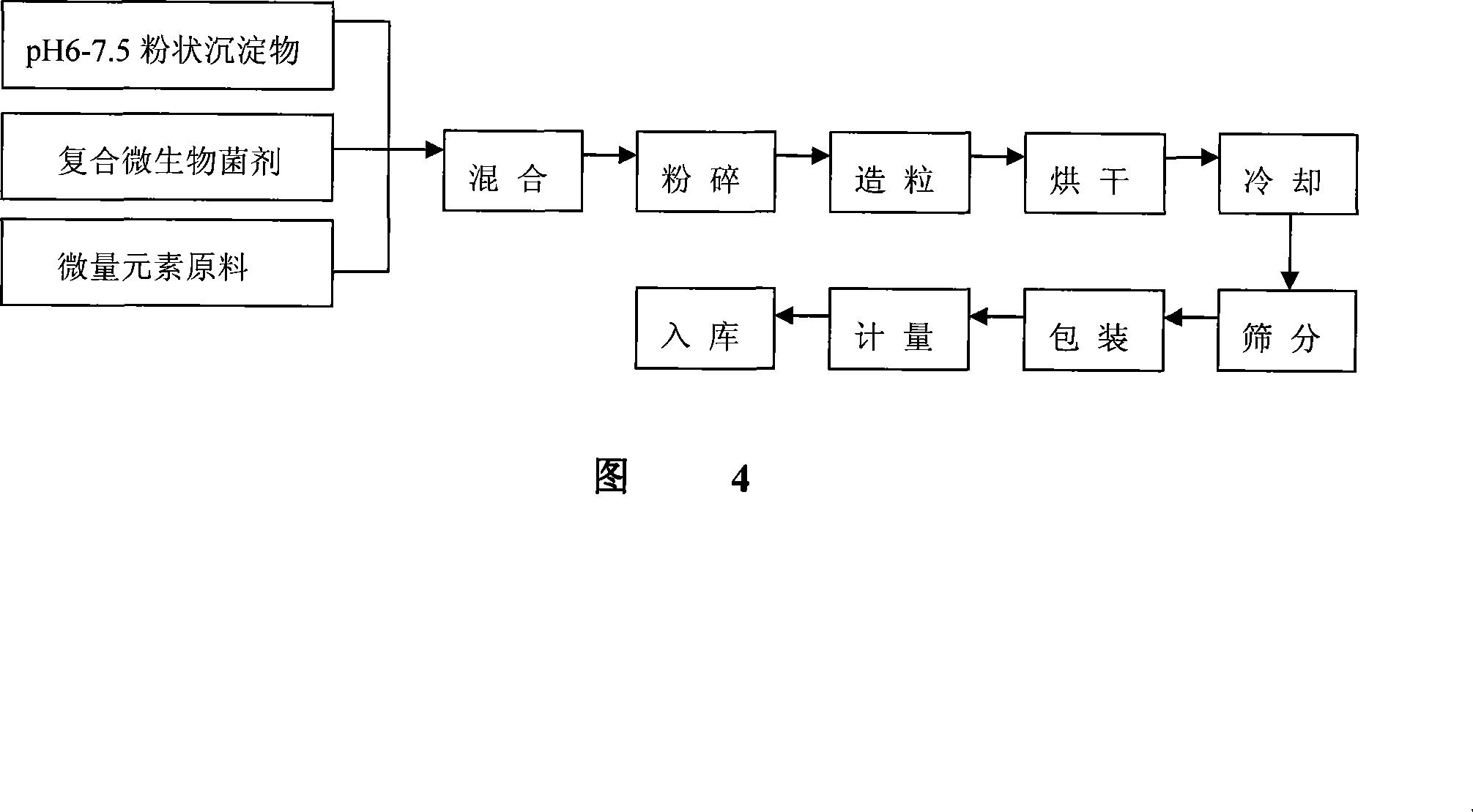

Method for producing soluble composite microorganism fertilizer

InactiveCN101195542AIncrease added valueReduce manufacturing costClimate change adaptationSewage/sludge fertilisersMicroorganismBacillus megaterium

The invention provides a method for preparing soluble compound microbe fertilizer. The technical project of the invention comprises fermenting bacillus subtilis, bacillus megaterium and bacillus mucilagimosus krassilm individually. The fermented bacterial liquid is adsorbed by turf separately. Three adsorbed single microbial inoculum is blended and grinded according to the proportion of 1:0.9-1.2:0.9-1.2 to obtain the compound microbial inoculum. The used liquid sediment in the production procedure of gourment powder factory and amino acids manufacturers as lysine plant and the like is disposed to charge trace element raw material and 6%-8% compound microbial inoculum with relative to total weight to obtain the needed compound microbe fertilizer which is easy to dissolve in the water and facilitates to adsorb and utilize plants.

Owner:SHANGHAI LVLE BIO TECH

Process for preparing needle coke raw material by using medium and low temperature coal tar and high temperature pitch

ActiveCN102786979AHigh yieldImprove qualityWorking-up pitch/asphalt/bitumen by chemical meansTreatment with hydrotreatment processesChemistryProcess engineering

The invention relates to a process for preparing a needle coke raw material by using medium and low temperature coal tar and high temperature pitch, which comprises the following steps: 1) distilling the medium and low temperature coal tar, separating to obtain heavy distillate with the temperature more than 350DEG C; 2) sending the heavy distillate of the medium and low temperature coal tar in a reactor, under the existence of a catalyst, introducing hydrogen in the reactor, performing hydropyrolysis on the heavy distillate, wherein the catalyst is a Fe catalyst and the mass of the catalyst accounts for 0.01-3% of mass of the heavy distillate; the pressure during the hydropyrolysis is 7-12 MPa and the temperature is 350-550 DEG C; 3) sending the products after hydropyrolysis in the step 2) in a separator, and separating to obtain lower oil and higher oil; and 4) performing physical separation on the higher oil, and removing the catalyst. According to the hydropyrolysis treatment of the medium and low temperature coal tar, the content of condensed polycyclic aromatic hydrocarbons can be greatly increased and the raw material suitable for preparing needle coke can be obtained.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

High-temperature wear-resisting ceramic composite fiber brake block

InactiveCN103122959AInhibition of devitrification changesImprove adhesionOther chemical processesFriction liningCeramic compositeBarium titanate

The invention relates to a high-temperature wear-resisting ceramic composite fiber brake block which is manufactured by processing framework materials and auxiliary materials through material mixing, mould pressing, hot press molding and solidification procedures, wherein the framework materials comprise bismaleimide modified phenolic resin, short aramid fiber, high-purity ceramic fiber, potassium titanate fiber, mineral fiber, barium titanate and nickel; the auxiliary materials comprise molybdenum sulfide and / or tin sulfide, graphite and / or coke, acrylonitrile-butadiene rubber, mica, zinc oxide, stearic acid, barium sulfate and 4010-type antiager. The high-temperature wear-resisting ceramic composite fiber brake block solves the problems existing in the prior brake blocks, can well avoid high-speed decay and high-temperature decay, has the advantages of being good in staibility and long in service life, and is a high-temperature wear-resisting ceramic composite fiber brake block which is low in noise, high in intensity and low in pollution.

Owner:山东金山汽配有限公司

Method for preventing heavy steel ingot from liquating by different pouring ladles

InactiveCN101508018AReasonable process designMitigate top negative segregationMolten metal pouring equipmentsCarbon steelCast iron

The invention discloses a method for restraining the liquation of a large-sized steel ingot through multi-ladle composite casting, relates to a casting process for large-sized steel ingots of metal molds of all grades below 600t, is applied to a casting process for carbon steel and alloy steel ingots under vacuum and non-vacuum conditions, and has restraint function on the liquation of all components of steel ingots made of various metal materials. The method comprises that: 1) a steel ingot mold is made of grey cast iron; 2) a riser head adopts a heat insulating riser head, and the taper thereof is between 8 and 16 percent; 3) the ratio of the height to the diameter of the steel ingot is 1:1-3:1; 4) the steel ingot is made of carbon steel or alloy steel; 5) different pouring ladles adopt different component ratios; and 6) the pouring process of different pouring ladles adopt different time intervals. The method designs the multi-ladle pouring technical proposal of the large-sized steel ingot, has good restraint function on the liquation of the large-sized steel ingots, and solves the prior problem of the liquation of the large-sized steel ingots in factories.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for extracting beryllium oxide from low-grade beryllium ore

InactiveCN102168184AIncrease concentrationLow firing temperatureProcess efficiency improvementKeroseneSlag

The invention discloses a method for extracting beryllium oxide from low-grade beryllium ore. The method is characterized by comprising the following steps of: grinding the low-grade beryllium ore, pelletizing, drying, roasting, and crushing to obtain a roasted material; adding concentrated sulfuric acid, stirring, leaching, and separating to obtain acidified liquid and acidified slag; adding the acidified liquid into the other roasted material, and stirring and leaching to obtain primary steep and primary leaching residue; adding concentrated sulfuric acid into the primary leaching residue, adding water, and stirring and leaching to obtain secondary steep and secondary leaching residue, wherein the acidified liquid is replaced by the secondary steep for recycling; extracting the primary steep by adopting an extracting agent in a volume ratio of phosphors extracting agents: alkanol: kerosene of (25-45):(5-1):(50-70) to obtain a beryllium-loaded organic phase and raffinate; washing the beryllium-loaded organic phase by adopting solution of oxalic acid, and performing back extraction by using solution of NaOH to obtain a blank organic phase and stripping solution; and regulating the concentration of hydroxyl ions in the stripping solution to ensure that beryllium is hydrolyzed and precipitated, and calcining a precipitate to obtain the beryllium oxide. The method is easy to operate, the cost is low, the beryllium oxide with the content of over 97 percent is obtained, and the recovery rate of the beryllium is about 80 percent. The method is suitable for extracting the beryllium oxide from low-grade beryllium ore with low BeO content and high CaF2 content.

Owner:广东省资源综合利用研究所

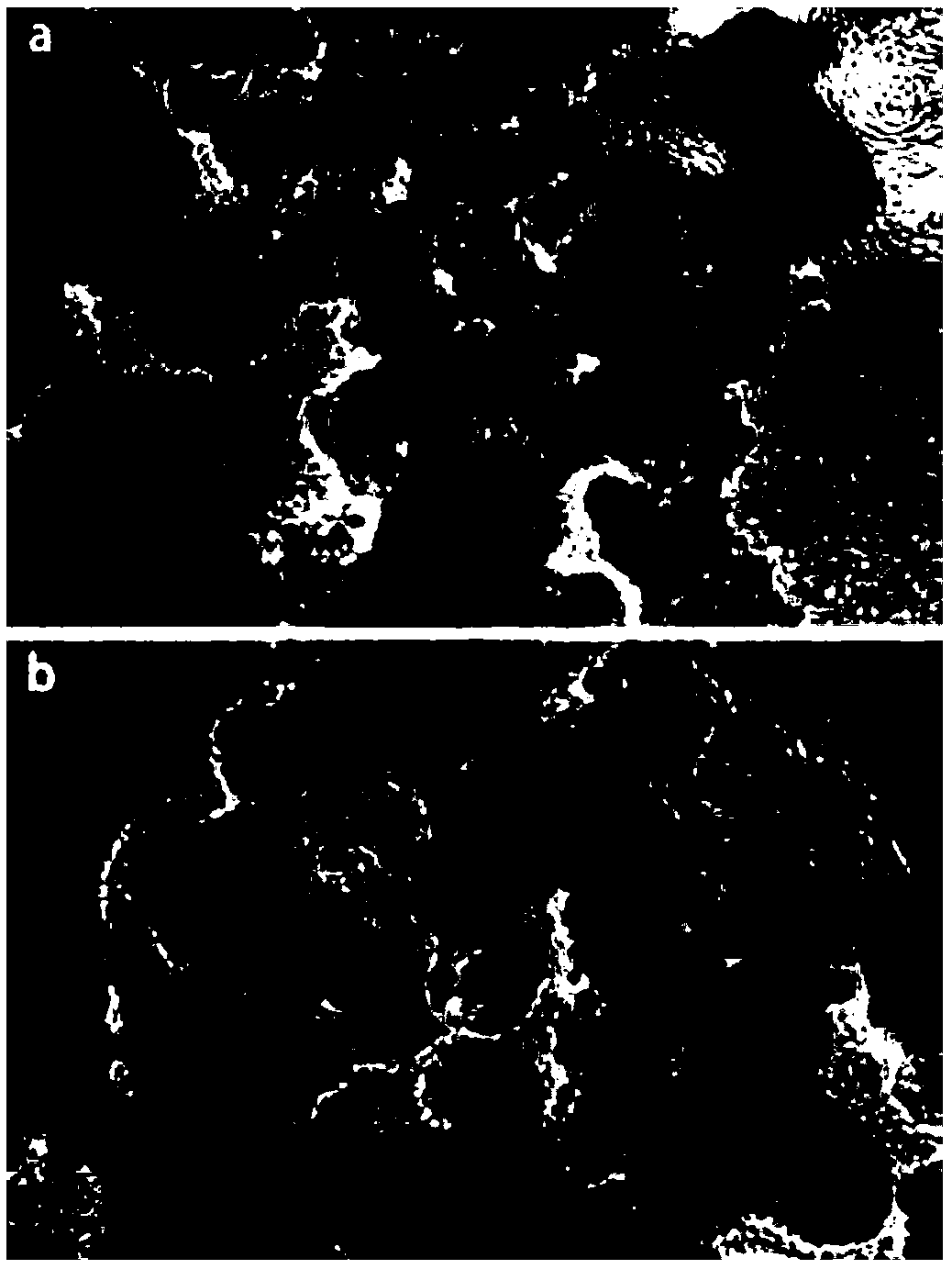

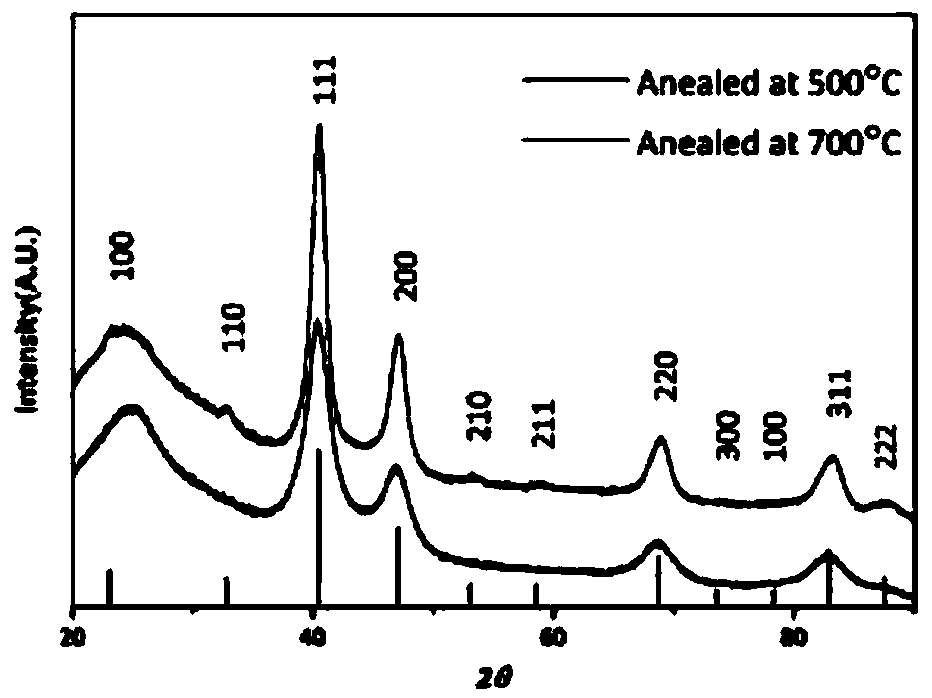

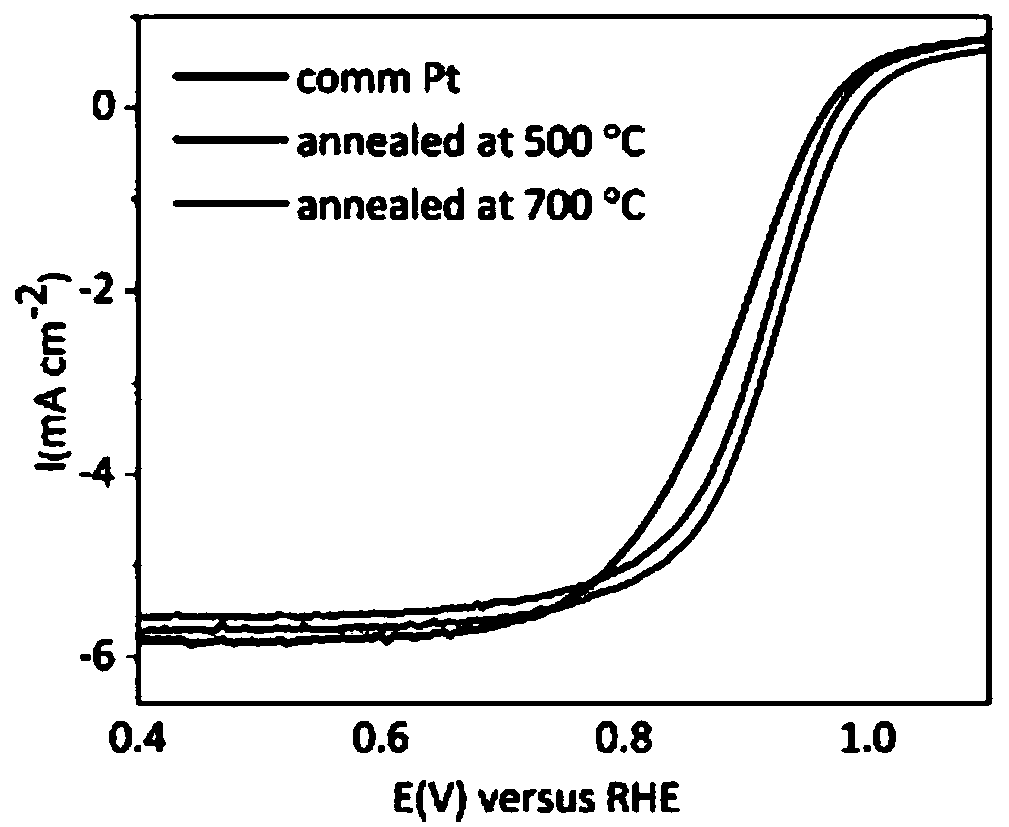

Preparation method of precious metal alloy/carbon material supported catalyst

InactiveCN108745373AFew ingredientsUniform composition of fine precious metal alloy nanoparticlesMetal/metal-oxides/metal-hydroxide catalystsNanoparticleMetal alloy

A preparation method of a precious metal alloy / carbon material supported catalyst comprises the steps that 1, a mixed solution of at least one precious metal salt or acid, at least one transition metal salt or acid, a carbon material and a dispersing agent is prepared; 2, the obtained mixed solution is prepared into compound powder by a method of spraying the solution to the surface of a high-temperature solid and performing quick drying; 3, the compound powder obtained in the step 2 is annealed in the reducing atmosphere, and metal alloying is performed to obtain the precious metal alloy / carbon material supported catalyst. The mixed solution of the precious metal salt or acid, the transition metal salt or acid, the carbon material and the dispersing agent contains the precious metal saltor acid, the transition metal salt or acid, the carbon material, the dispersing agent and a solvent. By utilizing rapid evaporation of water when the solution is sprayed to the surface of the high-temperature solid and is rapidly dried and separation of the precious metal alloy by carbon material powder, alloy particles do not grow in the annealing process, and small-sized precious metal alloy nano-particles are uniformly supported on the surface of a carbon material.

Owner:NANJING UNIV

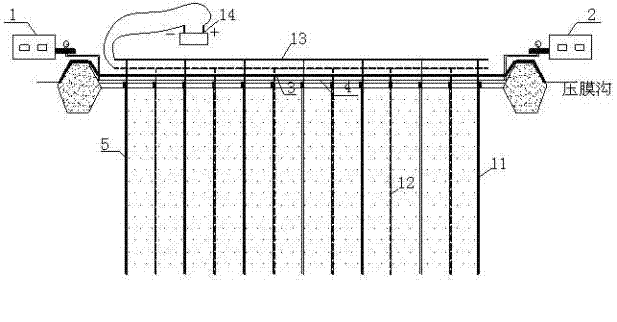

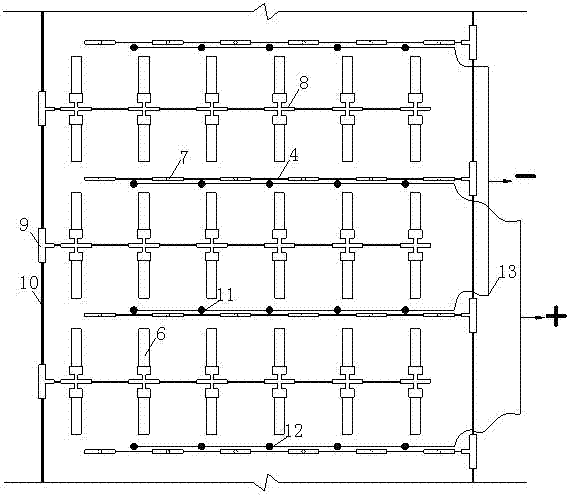

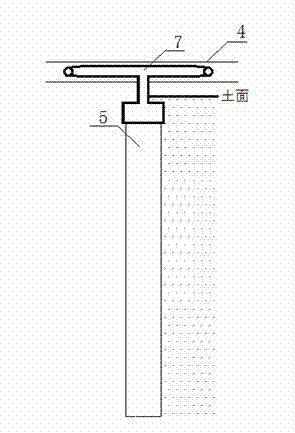

Processing method for reinforcing soft clay ground through vacuum preloading in combination with electro-osmosis method

The invention discloses a processing method for reinforcing a soft clay ground through vacuum preloading in combination with electro osmosis. According to the method, solid airtight separate vacuum preloading in combination with electric osmosis in which reinforcing steel bars are taken as the electro osmosis electrodes are adopted for reinforcing the ground. During the arrangement of vacuum preloading systems, by using a separate seal joint, a sealed water pipe, a sealed main pipe and a vacuumizing device, plastic water drainage plates which are inserted into the soil and plastic water drainage plates which are paved on the surface of the soil form two sets of separate airtight vacuum systems which can be separately controlled to turn on or off, and the vacuum degrees of the two vacuum systems can be separately regulated. After the vacuum systems are arranged, rebar electrodes are inserted in rows in the gaps between the plastic water drainage plates inserted in the soil, and then the perforations between the rebar electrodes and the vacuum preloading airtight systems are sealed. With the processing method, the vacuum transfer and utilization efficiency is improved, the water drainage effect of deep-layer soil is improved, the soil processing uniformity is remarkably improved, the overall soil reinforcing effect is improved, and fast, efficient and energy-saving hybrid reinforcement construction is realized.

Owner:SHANGHAI UNIV

Magnesium alloy chromium-free fluorine-free phosphorization solution and phosphorization method

InactiveCN101851755AProcess stabilityFew ingredientsMetallic material coating processesChromium freeSal ammoniac

The invention relates to magnesium alloy chromium-free fluorine-free phosphorization solution and a phosphorization method. Each liter of the magnesium alloy chromium-free fluorine-free phosphorization solution comprises 1 to 50 g of dihydric phosphate, 0 to 30 g of nitrate and 0.1 to 5 g of additive. The processed magnesium alloy workpiece is soaked and stood in the phosphorization solution of which the pH value is adjusted to be 2.0 to 5.0 by using phosphoric acid and ammonia water and is subjected to phosphating treatment at the temperature of between 30 and 100 DEG C for 1 to 60 minutes to form a phosphate coating. The magnesium alloy is phosphated by the phosphorization solution and the process, a uniform phosphate conversion coating with high corrosion resistance can be obtained on the surface of the magnesium alloy and the phosphate coating can effectively improve the adhesion and the protective property of the subsequent coatings. The phosphorization solution on the surface ofthe magnesium alloy has the advantages of few components and simple preparation. The phosphorization method of the phosphorization solution has the advantages of easy control, stable process, low cost and little sediment.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

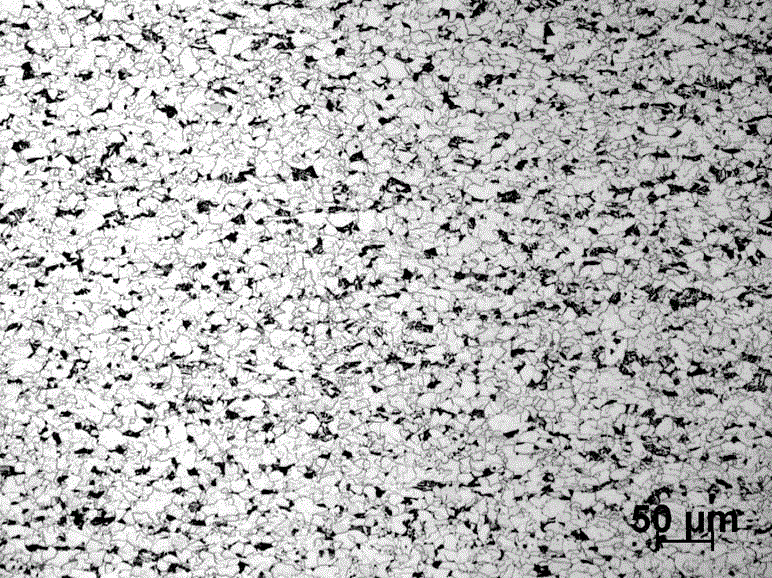

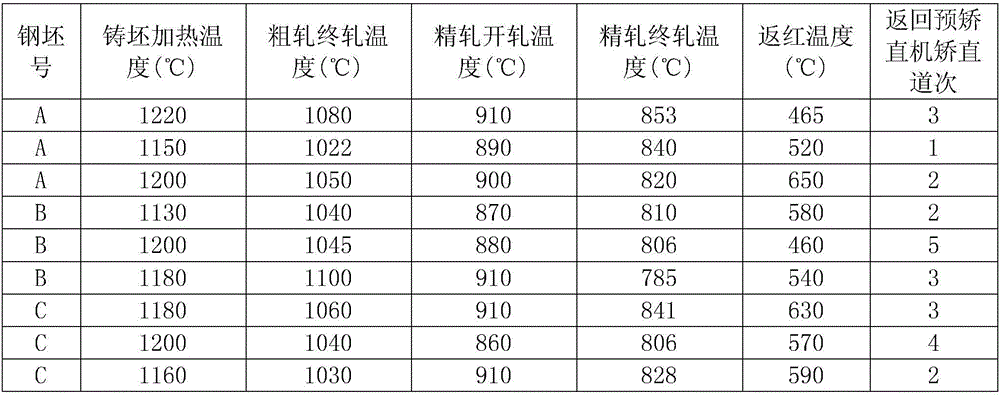

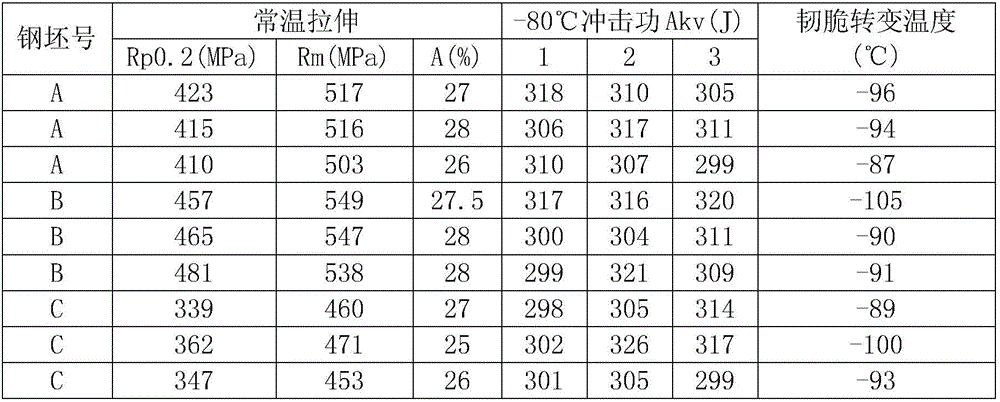

Carbon manganese low-temperature steel for liquefied gas boat and manufacturing method of carbon manganese low-temperature steel

The invention discloses carbon manganese low-temperature steel for a liquefied gas boat and a manufacturing method of the carbon manganese low-temperature steel. The carbon manganese low-temperature steel comprises, by weight, 0.03%-0.08% of C, 0.10%-0.30% of Si, 0.60%-1.30% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.010%-0.080% of Nb, 0.010%-0.060% of Al and the balance Fe and inevitable impurities. The clean steel smelting-continuous casting process is adopted in the method, and a high-purity homogenous continuous casting slab is manufactured; and through two-stage control rolling and control cooling, a wee ferrite and pearlitic structure is obtained. The carbon manganese low-temperature steel for the liquefied gas boat has the beneficial effects that the steel is pure, the texture is even, the grain size is in the 10.0 level to 13.5 level, and the ductile-brittle transition temperature is lower than -80 DEG C; building requirements of a cargo tank and a boat body structure of the liquefied gas boat are met; and meanwhile, the carbon manganese low-temperature steel has the beneficial effects of being simple in chemical component and low in cost.

Owner:NANJING IRON & STEEL CO LTD

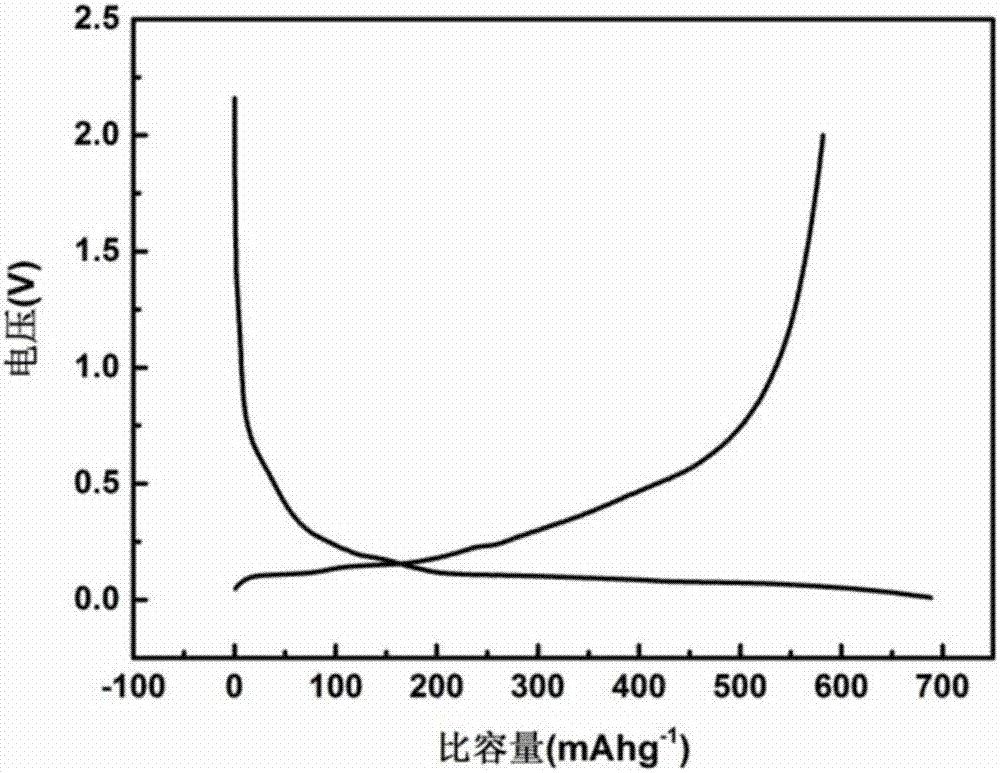

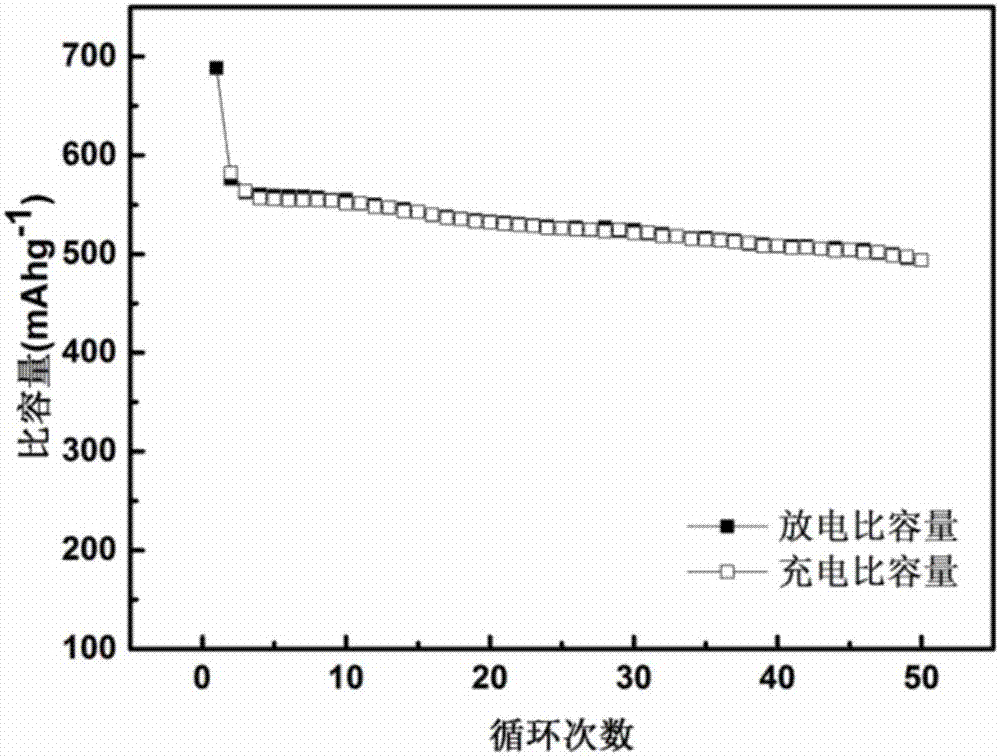

Silicon-carbon composite material as well as preparation method and application thereof

ActiveCN107170965AImprove conductivityImprove cycle stabilityMaterial nanotechnologyCell electrodesCarbon compositesLithium carbonate

The invention discloses a silicon-carbon composite material as well as a preparation method and application thereof. The silicon-carbon composite material comprises nanometer silicon, graphite and lithium carbonate. The nanometer silicon, graphite and lithium carbonate are encapsulated by polymers and carbonized so as to obtain the silicon-carbon composite material. The preparation method comprises the following steps: mixing graphite, lithium carbonate and nanometer silicon so as to obtain a lithium carbonate / silicon / graphite mixture; dispersing the lithium carbonate / silicon / graphite mixture into a polymer solution, and drying to obtain a precursor material; carbonizing the precursor material, thereby obtaining the silicon-carbon composite material. The silicon-carbon composite material disclosed by the invention has high electrical conductivity and excellent cycling stability and can be applied to preparing lithium ion batteries.

Owner:CENT SOUTH UNIV

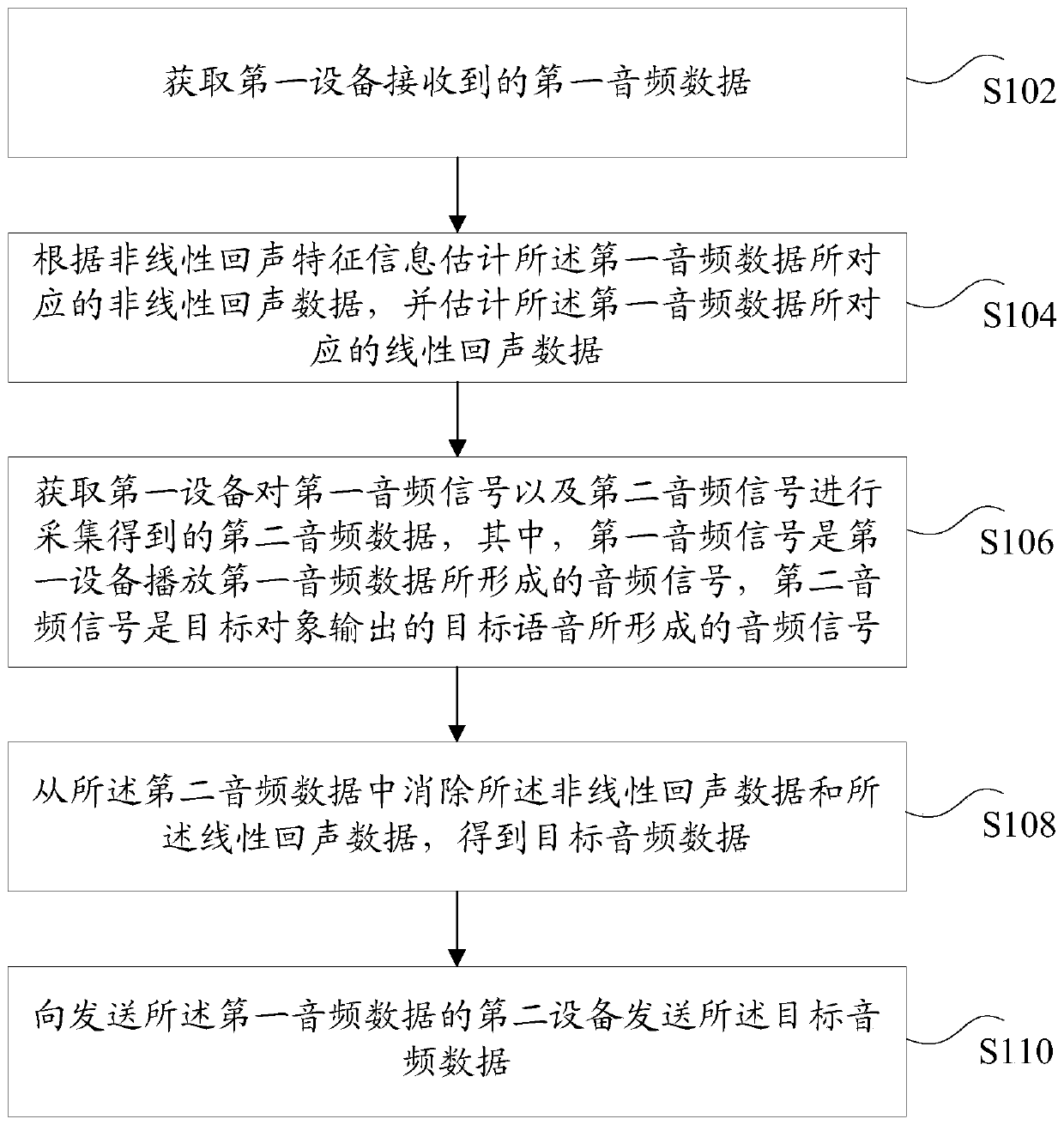

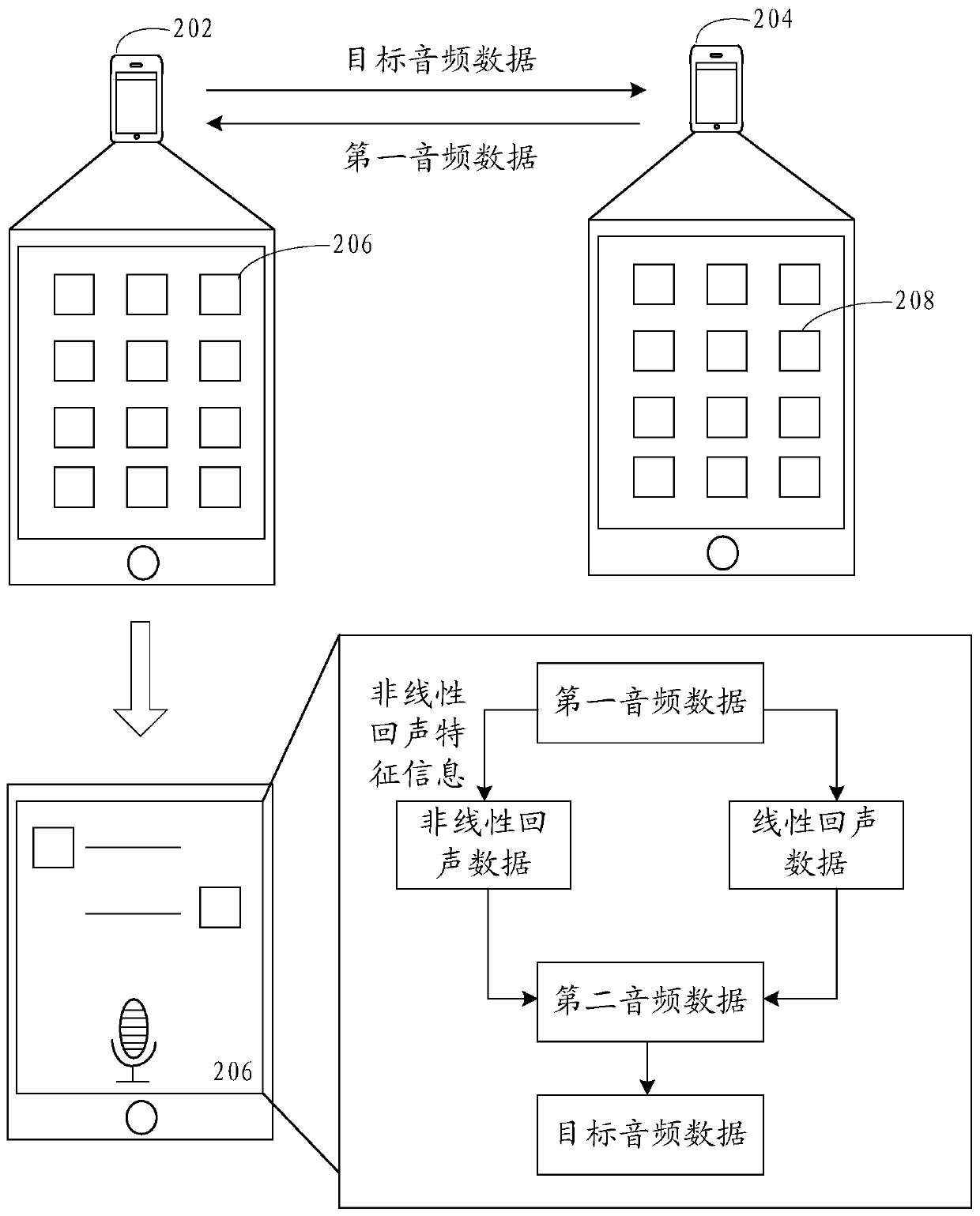

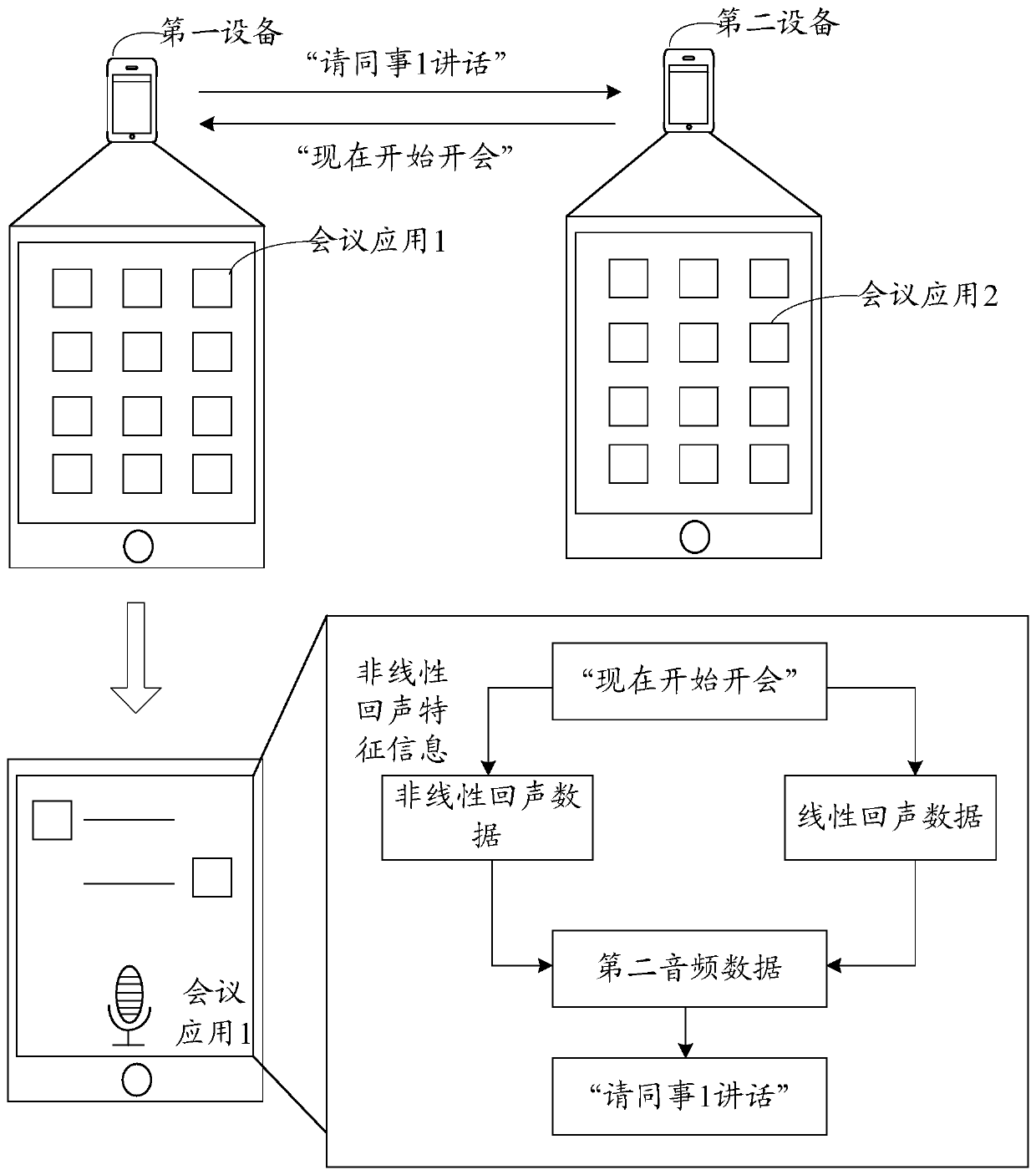

Elimination method and device of echo, storage medium and electronic device

PendingCN110246515AFew ingredientsSolve the technical problem of less efficient echo cancellationTwo-way loud-speaking telephone systemsSpeech analysisElimination methodAudio signal

The invention discloses an elimination method and device of echo, a storage medium and an electronic device. The elimination method comprises the steps that first audio data received by first equipment are obtained; non-linear echo data corresponding to the first audio data are estimated according to the non-linear echo characteristic information, linear echo data corresponding to the first audio data is estimated, and wherein the non-linear echo characteristic information is used for indicating non-linear echo characteristics of the first equipment; a first audio signal and a second audio signal are acquired by the first equipment to obtain second audio data; the non-linear echo data and the linear echo data are eliminated from the second audio data, and target audio data is obtained; and the target audio data is transmitted to second equipment transmitting the first audio data. According to the elimination method, the technical problem of low efficiency of eliminating the echo is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Process for preparing needle coke raw material by using medium and low temperature coal tar

ActiveCN102786984AGuaranteed catalytic effectLow costTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonPtru catalyst

The invention relates to a process for preparing a needle coke raw material by using medium and low temperature coal tar, which comprises the following steps: 1) distilling the medium and low temperature coal tar, separating to obtain heavy distillate with the temperature more than 350DEG C; 2) sending the heavy distillate of the medium and low temperature coal tar to a reactor, under the existence of a catalyst, introducing hydrogen into the reactor, performing hydropyrolysis on the heavy distillate, wherein the catalyst is a Fe catalyst and the mass of the catalyst accounts for 0.01-3% of mass of the heavy distillate; the pressure during the hydropyrolysis is 7-12 MPa and the temperature is 350-550 DEG C; 3) sending the products after hydropyrolysis in the step 2) to a separator, and separating to obtain lower oil and higher oil; and 4) performing physical separation on the higher oil, and removing the catalyst. According to the hydropyrolysis treatment of the medium and low temperature coal tar, the content of condensed polycyclic aromatic hydrocarbons can be greatly increased and the raw material suitable for preparing needle coke can be obtained.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

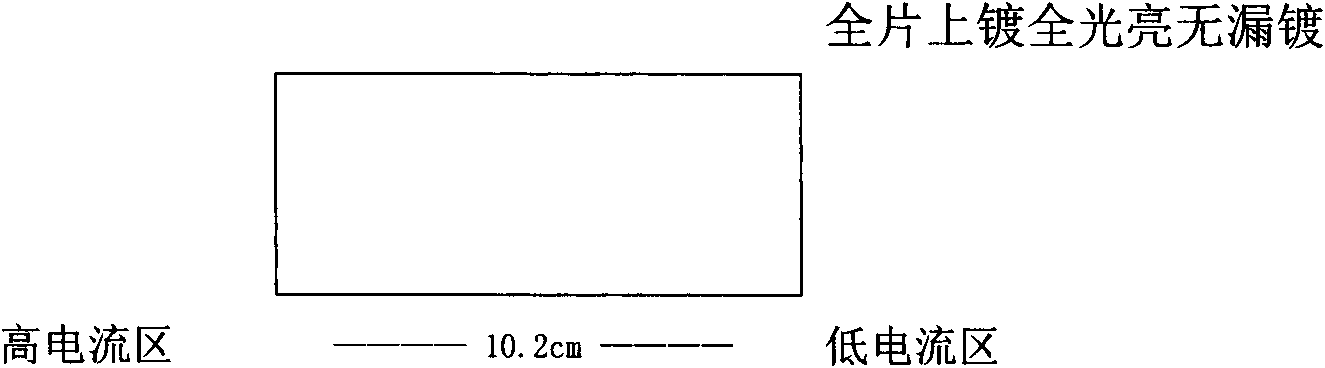

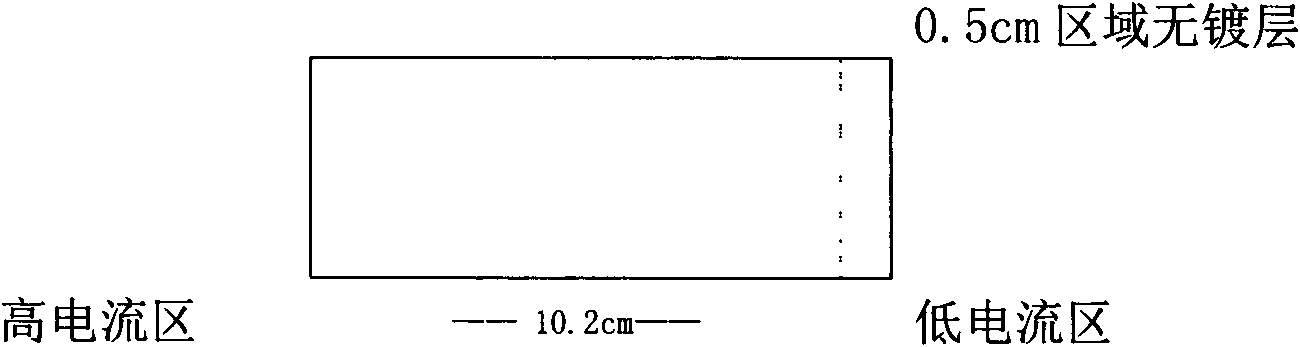

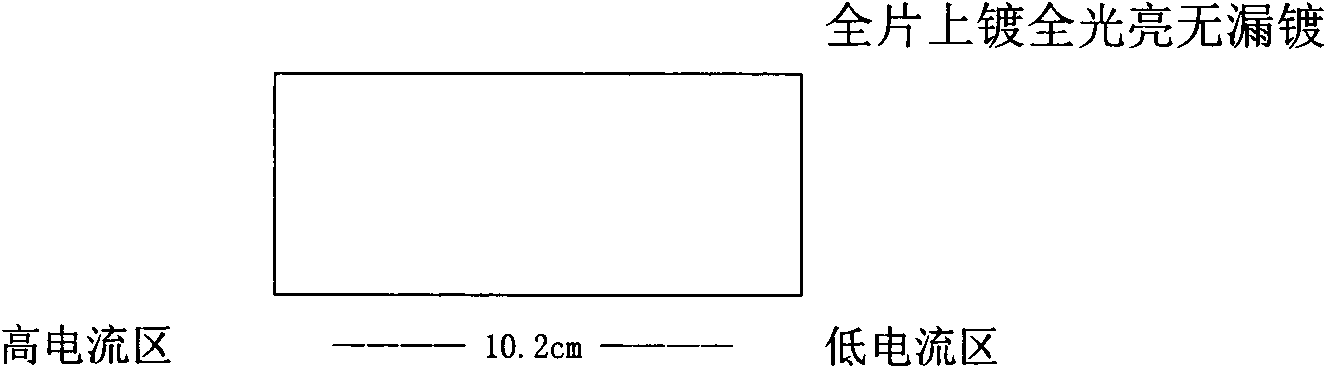

Electronickelling alloy solution for improving corrosion resistance of coating

The invention discloses an electronickelling solution for improving the corrosion resistance of a coating. The electronickelling solution comprises nickel salt, phosphorous acid, boric acid, organic carboxylic acid or salts thereof, and hydroxycarboxylic acid of unsaturated hydrocarbon. The electronickelling solution has good stability, no self decomposition and excellent corrosion resistance. The electronickelling solution solves the problem of poor dispersibility of a nickel-phosphorus alloy coating (namely the problem of skip plating in a region with low current density) in the prior art. Compared with a common nickel coating with the same thickness, no matter whether chromium is plated on the coating obtained by an optimal formula of the plating solution or not, the salt fog test time is prolonged by 3 times.

Owner:GUANGZHOU JINHUI CHEM SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com