Secondarily-curable polyurethane modified epoxy asphalt mixture, preparation method therefor and application thereof

A technology of polyurethane modified and epoxy asphalt, which is applied to thermosetting high-performance polyurethane modified epoxy asphalt mixture, the preparation of the above mixture, and the application field of the above mixture, which can solve the complex compatibilizer preparation method and heat resistance. Poor performance, poor fatigue resistance and other problems, to achieve the effect of high temperature and low temperature secondary curing, reduce the restrictions of construction conditions, improve strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

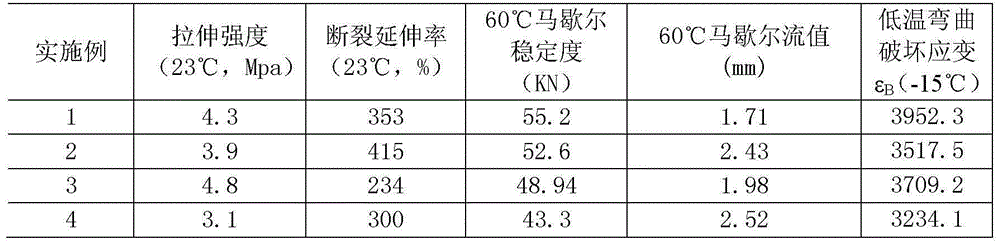

Examples

preparation example Construction

[0061] The preparation method of tung oil modified amine curing agent is as follows: mix tung oil, phenols and acidic catalyst, heat up to 50-110°C, react for 0.5-3h, then cool down to 30-60°C, add amines, stir and heat up to 70- At 90°C, after mixing evenly, add aldehydes dropwise, react for 2-5 hours and then dehydrate to obtain tung oil modified amine.

[0062] The long-chain curing agent is synthesized from tung oil and maleic anhydride.

[0063] The preparation method of the long-chain curing agent is as follows: mix tung oil and maleic anhydride, pass nitrogen into the container for protection, raise the temperature to 180-210°C, and react for 1-5 hours to obtain the long-chain curing agent.

[0064] Accelerators for component B are tertiary amines or imidazoles. The tertiary amine accelerator is one or more of benzyldimethylamine, N,N-dimethylaniline, diethylaminopropylamine, 2,4,6-tris(dimethylaminomethyl)phenol kind. The imidazole accelerator is one or more of imid...

Embodiment 1

[0077] (1) Vacuum dehydrate 5 parts of polyoxypropylene diol at 120°C for 1 hour, add 4 parts of diphenylmethane diisocyanate, stir and raise the temperature to 80°C for 2 hours to obtain a polyurethane prepolymer.

[0078] (2) Add 100 parts of epoxy resin to the polyurethane prepolymer, continue to stir and react at 80° C. for 2 hours, and perform vacuum defoaming treatment to obtain component A polyurethane modified epoxy resin.

[0079] (3) Add 60 parts of polyamide 650 curing agent with heat preservation at 60 degrees to the reaction kettle, add 60 parts of long-chain curing agent, 0.005g of N,N-dimethylaniline accelerator, mix and stir for 20 minutes, and complete the preparation of component B. preparation;

[0080] (4) Mix 100 parts of component A polyether type polyurethane modified epoxy resin with component B, and stir at room temperature for 5 minutes;

[0081] (5) Mix components A and B with 110 parts of 70# petroleum asphalt kept at 120°C for 10 minutes to obtain...

Embodiment 2

[0084] (1) Vacuum dehydrate 6 parts of polyoxypropylene triol at 110° C. for 1.5 h, add 6 parts of hexamethylene diisocyanate, stir and heat up to 85° C. for 2 h to obtain a polyurethane prepolymer.

[0085] (2) Add 100 parts of epoxy resin to the polyurethane prepolymer, continue to stir and react at 80° C. for 3 hours, and perform vacuum defoaming treatment to obtain component A polyurethane modified epoxy resin.

[0086] (3) Add 50 parts of polyamide 650 curing agent at a temperature of 60 degrees to the reaction kettle, add 75 parts of long-chain curing agent, 0.00625 g of benzyldimethylamine accelerator, mix and stir for 20 minutes, and complete the preparation of component B;

[0087] (4) Mix 100 parts of component A polyether type polyurethane modified epoxy resin with component B, and stir at room temperature for 5 minutes;

[0088] (5) Mix the material mixed in step 4, 112.5 parts of 70# petroleum asphalt with heat preservation at 110°C into the stone, and stir at 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com