Patents

Literature

812 results about "Diphenylmethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diphenylmethane is an organic compound with the formula (C₆H₅)₂CH₂ (often abbreviated CH₂Ph₂). The compound consists of methane wherein two hydrogen atoms are replaced by two phenyl groups. (Or a benzyl group attached to a phenyl group.)

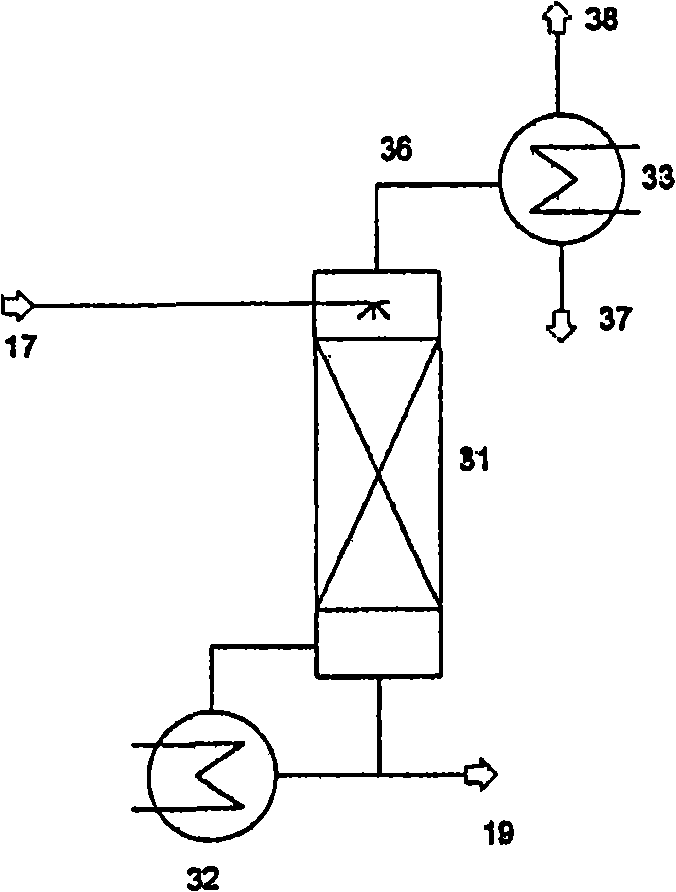

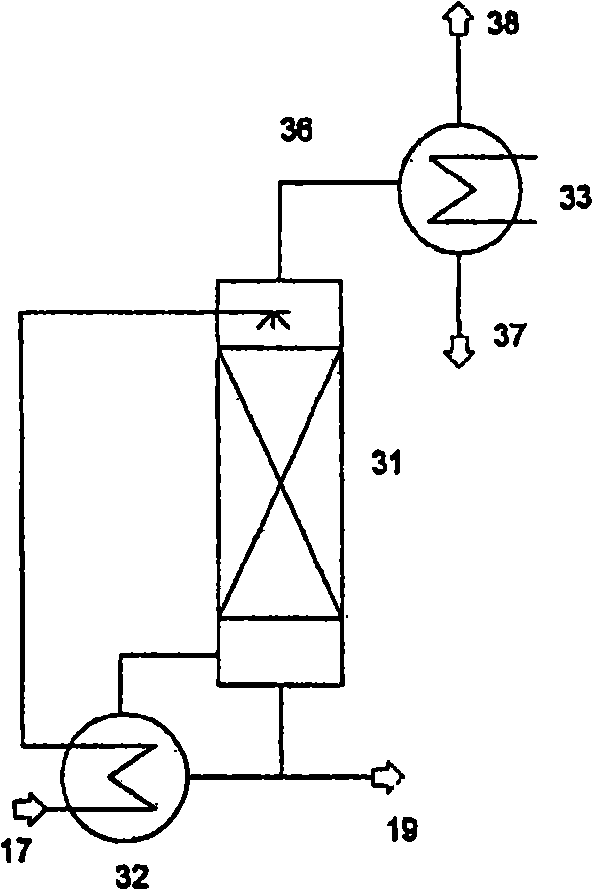

Process for the distillation of a mixture of isomeric diisocyanatodiphenylmethanes

InactiveUS7649108B2Reduce spendingReduce energy inputOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

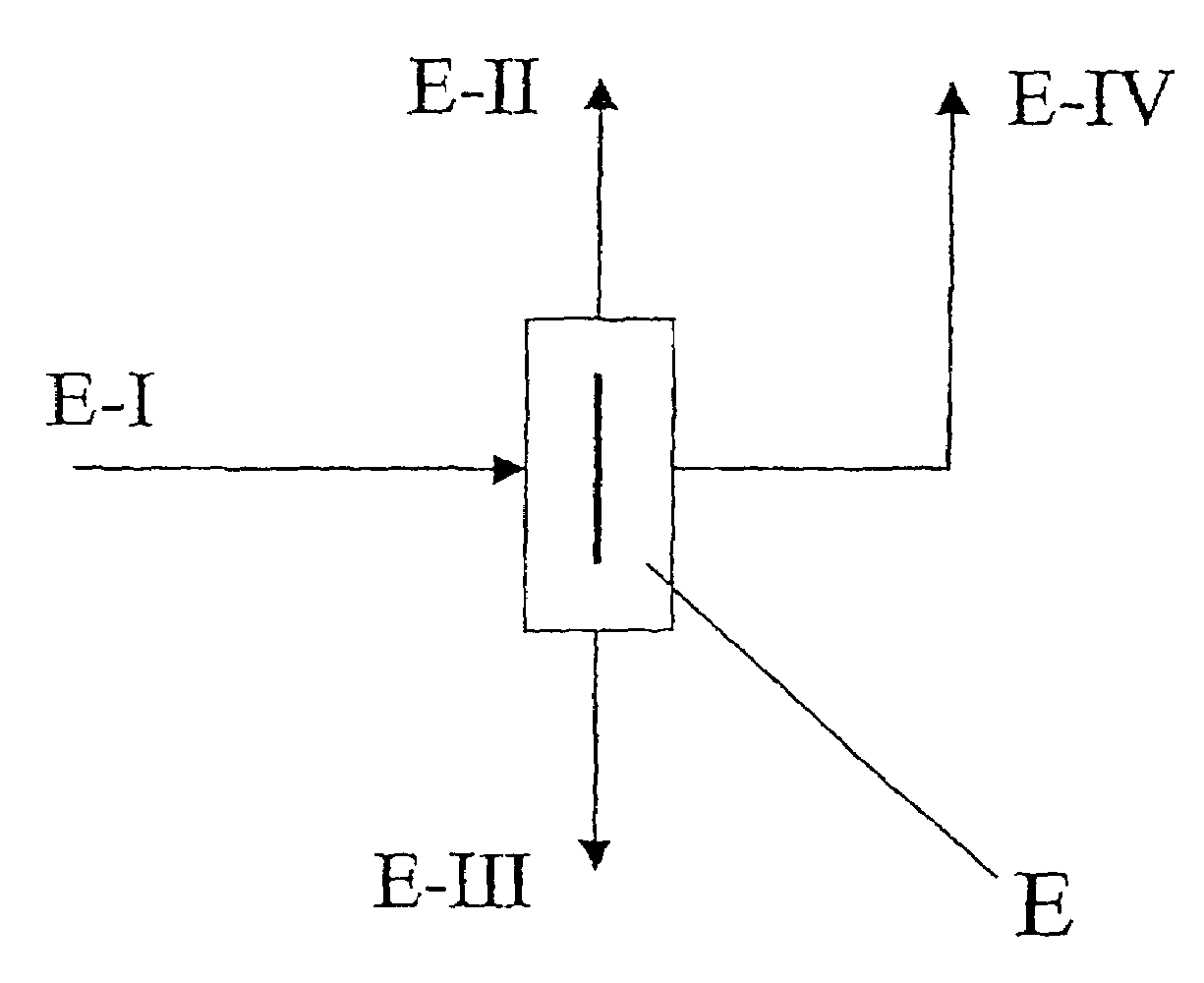

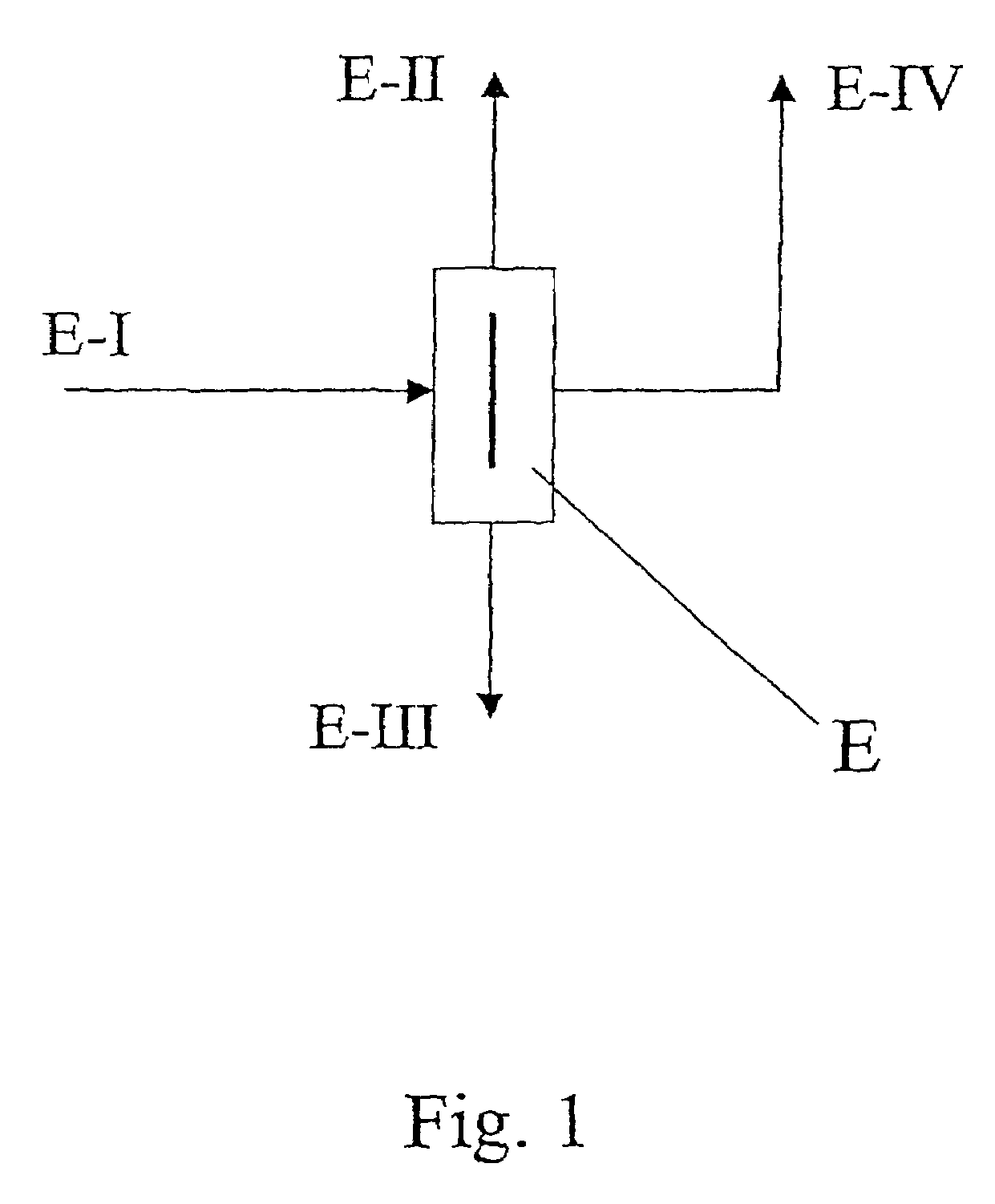

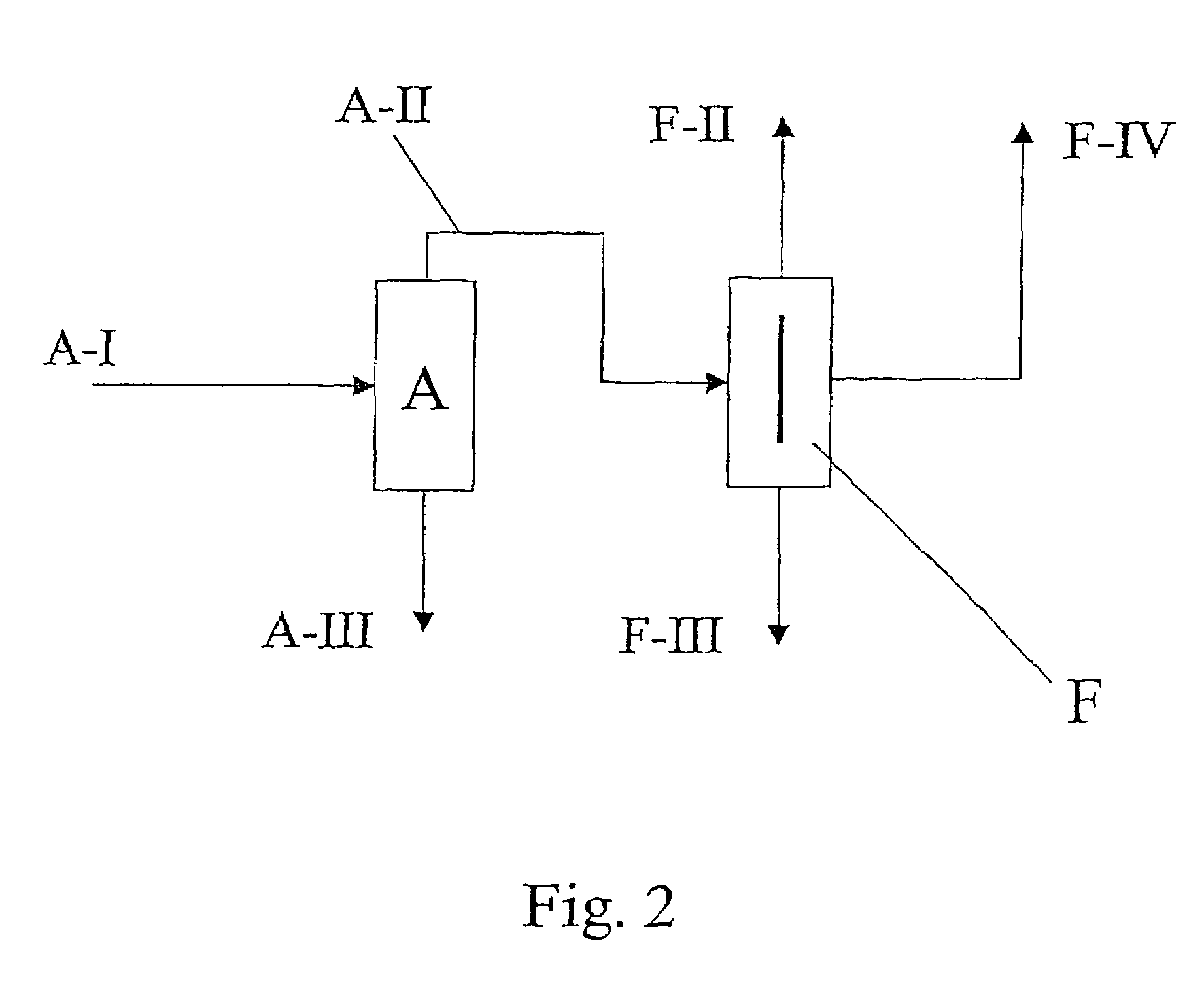

A mixture of isomeric diisocyanatodiphenylmethanes composed of at least 2,2′-diisocyanato-diphenylmethane, 2,4′-diisocyanatodiphenylmethane and 4,4′-diisocyanatodiphenyl-methane is distilled in at least one stage and a divided-wall column is used in at least one distillation stage.

Owner:BAYER MATERIALSCIENCE AG

Reactive polyurethanes having reduced diisocyanate monomer content

InactiveUS20040162385A1Other chemical processesPolyureas/polyurethane adhesivesDiphenylmethaneAlcohol

Reactive polyurethanes containing free isocyanate groups but low levels of monomeric asymmetrical diisocyanate may be obtained by reacting a monomeric asymmetrical diisocyanate such as diphenylmethane-2,4'-diisocyanate (2,4'-MDI) containing less than 5% 4,4'-MDI and 2,2'-MDI, the 2,2'-MDI content being under 0.4%, with a polyhydric alcohol such as a diol with a molecular weight of 60 g / mol to 2,000 g / mol. The ratio of isocyanate groups to hydroxyl groups may be a value of 1.05:1 to 2.0:1. The reactive polyurethanes can be used to produce one- and two-component adhesive and sealant products.

Owner:HENKEL KGAA

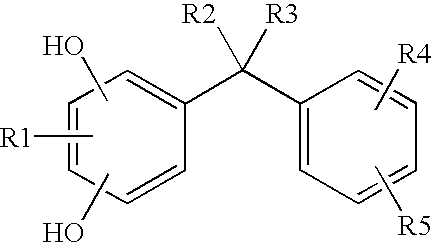

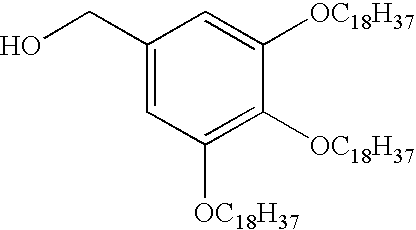

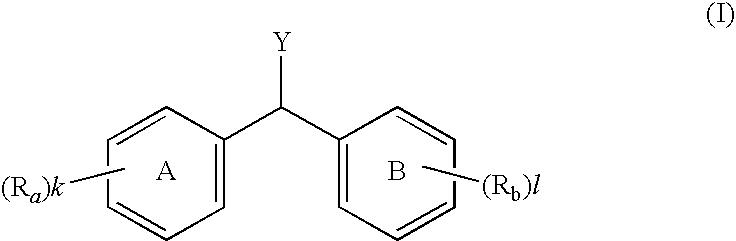

Compositions containing a hydroxylated diphenylmethane compound, methods of use

InactiveUS20070248633A1High activityEnhanced solubilizationOrganic active ingredientsCosmetic preparationsDiphenylmethaneAdditive ingredient

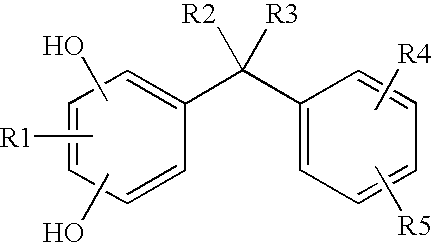

The invention relates to a composition containing, in a physiologically acceptable medium, (a) at least one hydroxylated diphenylmethane compound of formula (I)where formula variables are defined in the body of the application and claims and (b) at least one ingredient promoting the solubilization, stabilization and / or activity of the hydroxylated diphenylmethane compound of formula (I). The invention also relates to a cosmetic method for caring for or making up the skin, comprising the topical application of such a composition to the skin.

Owner:LOREAL SA

Thermoplastic polyurethane elastomer and manufacturing method thereof

The invention relates to the manufacturing field of a special extrusion grade T-die thermoplastic elastomer, in particular to a manufacturing formula and a manufacturing method thereof. The formula comprises the following components: 20-40% of 4,4'-diphenylmethane-diisocyanate, 15-70% of polybutylene adipate the molecular weight of which is 1000 or 2000, 0-50% of poly butylene glycol adipate the molecular weight of which is 2000, 5-15% of 1,4-butanediol, 0-5% of glycol, 0.1-1.0% of antioxidant, 0.1-1.0% of lubricant, 0.001-0.1% of environment-friendly catalyst, 0.1-1.0% of ultraviolet absorbent, 0.1-1.0% of light stabilizer and 0.1-1.0% of hydrolysis resistant agent. Continuous production processes are used for synthesizing TPU (thermoplastic polyurethane). The product of the invention has the advantages of stable quality, excellent performance, few T-die extrusion crystal points, good transparency (more than 4mm), stable extrusion, no occurrence of separation of additives, high hydrolysis resistance and high UV (ultraviolet) resistance, and the indexes and the performance of the product can reach the indexes of international like products. The invention provides a thermoplastic polyurethane elastomer and a manufacturing method thereof.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

Preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material

InactiveCN101445583ASolve the problem of poor flexibilityHigh bonding strengthPolyurea/polyurethane coatingsDiphenylmethaneWear resistant

The invention discloses a preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material. Polyether dihydroxy alcohol having a degree of functionality of 2 and an average relative molecular weight of 1200 to 2200 is reacted with toluene di-isocyanate or diphenylmethane-4,4'-diisocyanate prepared for preheating to synthetize polyether dihydroxy alcohol polyurethane performed polymer for reservation; one of bisphenol A E-44 and E-51 after pre-dehydration is selected for reservation; polyurethane modified epoxy is formed through polyaddition reaction in which a mass ratio of polyether dihydroxy alcohol polyurethane performed polymer to epoxide resin is 15 to 70: 100. The polyurethane modified epoxy obtained by the technology has high bonding strength, good flexibility and shock resistance with basal bodies of spare parts, totally without using plasticizers, such as dibutyl phthalate, dioctylphthalate, etc., without using or using less plasticizers, such as polysulfide rubber, liquid acrylonitrile butadiene rubber, etc., thereby not only solving the problem that general epoxide resin has bad flexibility but also saving the production cost.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

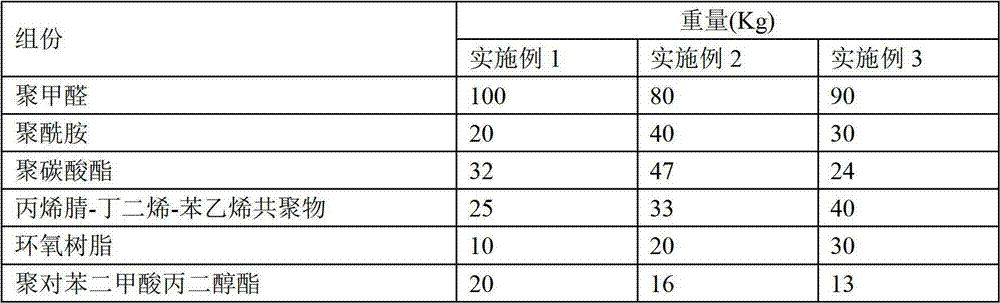

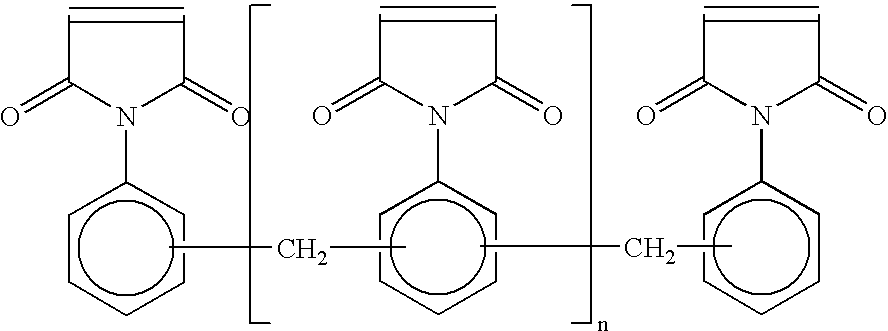

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

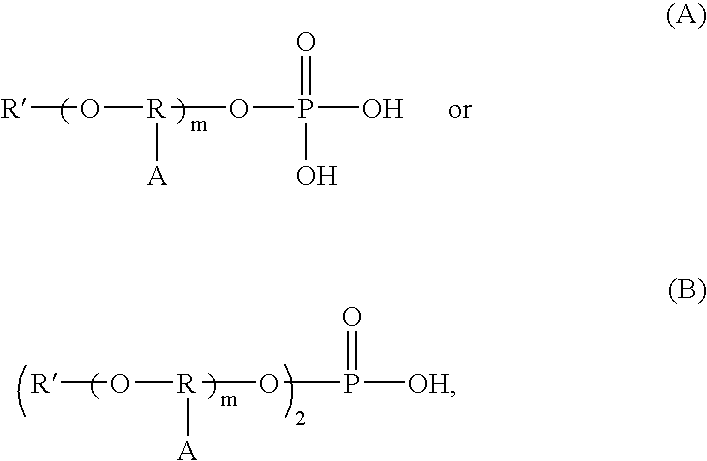

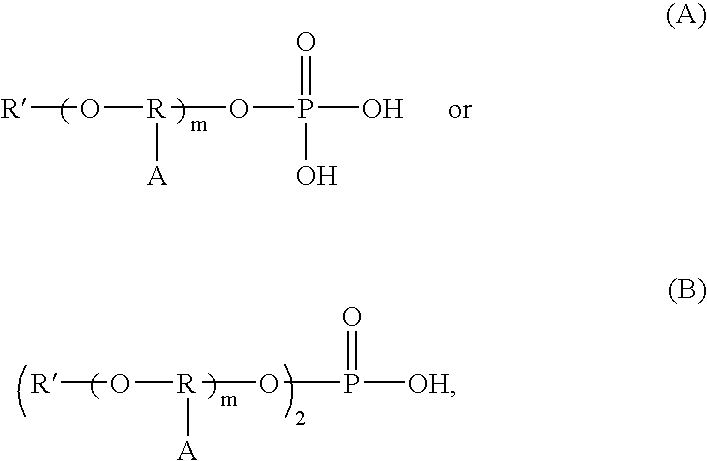

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

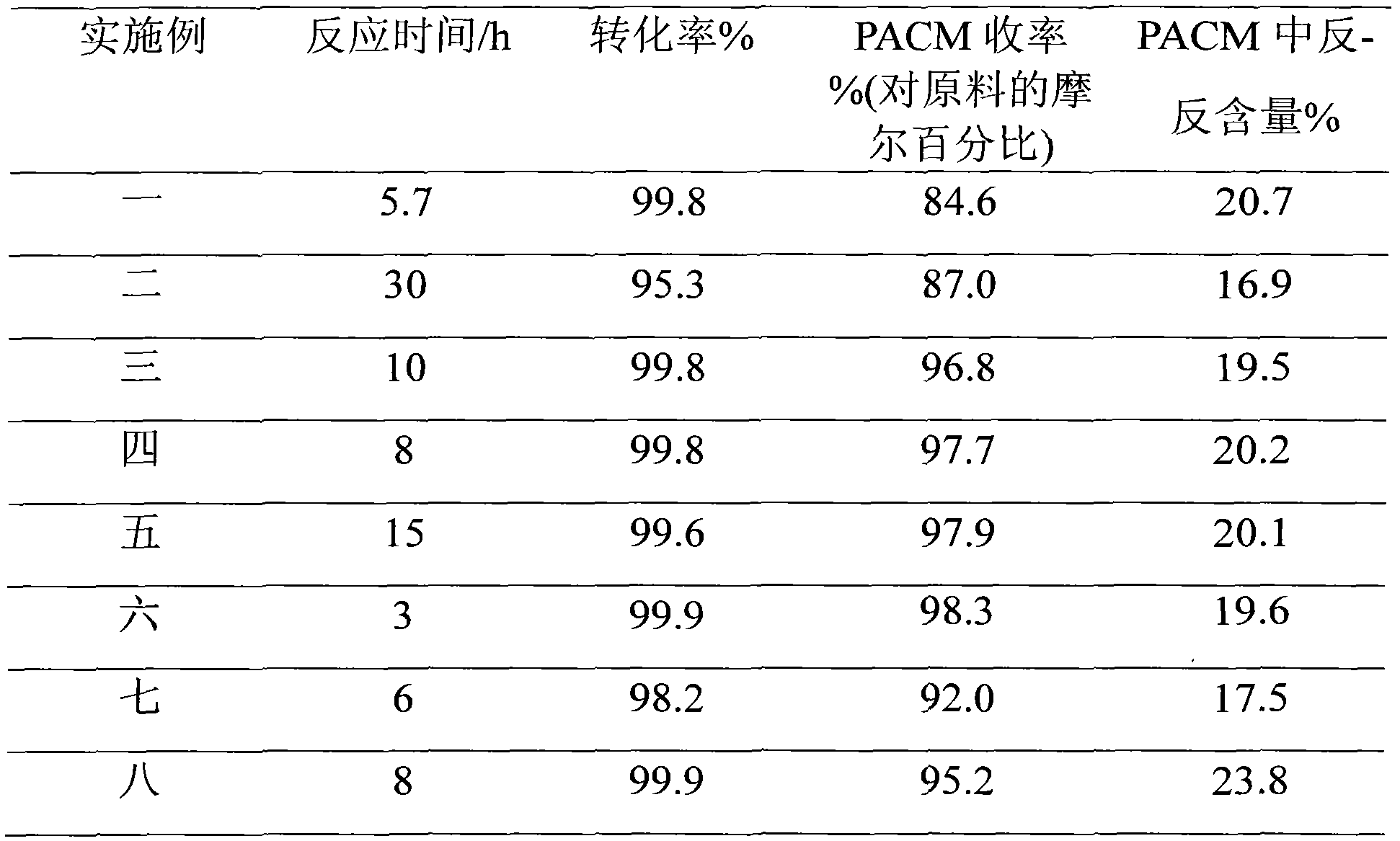

Method for producing H12MDA through hydrogenation reaction

ActiveCN101050184ALower conversion rateReduce contentOrganic compound preparationAmino compound preparationDiphenylmethaneNano catalyst

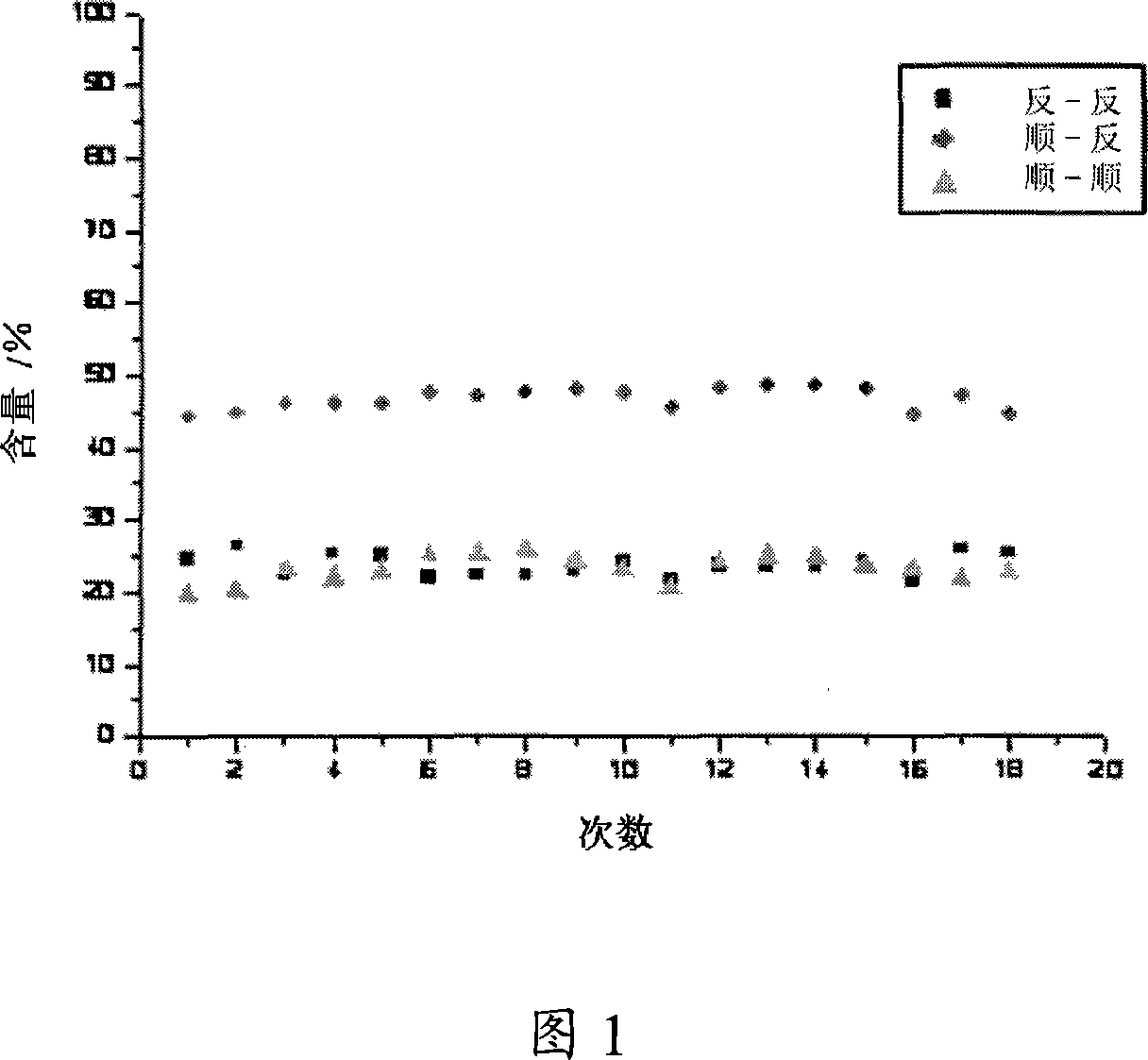

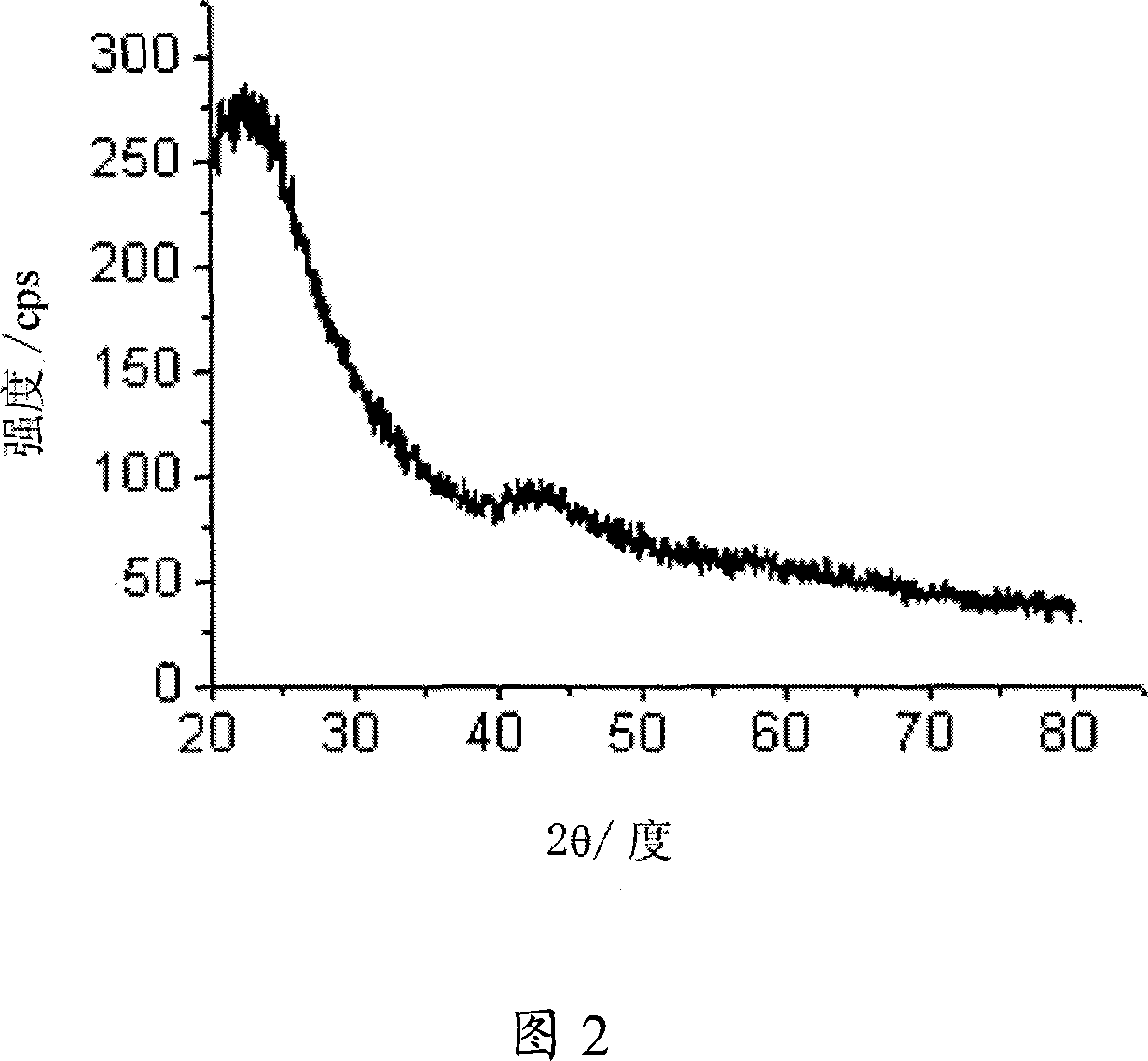

This invention discloses a method for preparing 4, 4'-diamino dicyclohexylmethane (H12MDA) from 4, 4'-diamino diphenylmethane (MDA) via hydrogenation catalyzed by supported nanoscale Ru catalyst. The method comprises: performing stereoselective hydrogenation on MDA at 100-180 deg.C and 4-10 MPa in an intermittent autoclave for 1-9 h to obtain H12MDA. The MDA conversion rate is near 100%, the H12MDA weight yield is near 100%, and the trans-H12MDA content is below 25%. After the supported nanoscale Ru catalyst is continuously reused for above 30 times without supplementation, the MDA conversion rate is still near 100%, and the trans-H12MDA content is below 27%.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

Insulated electric power cable

InactiveUS20020177638A1Maintain good propertiesOrganic chemistryPlastic/resin/waxes insulatorsCross-linkDiphenylmethane

An insulated electric power cable having an insulator layer formed by extrusion-coating and cross-linking a cross-linkable resin composition, which contains a polyolefin blended with a total of 0.05 to 0.4 parts by mass of at least one compound selected from the group of compounds such as N,N'-(4,4'-diphenylmethane)bismaleimide, based on 100 parts by mass of the polyolefin, and a prescribed amount of an organic peroxide cross-linking agent.

Owner:FURUKAWA ELECTRIC CO LTD

Diphenylmethane compound

ActiveUS20100249374A1Superior in broad utilityImprove stabilityOrganic compound preparationDiaryl/thriaryl methane dyesDiphenylmethaneOrganic synthesis

Compounds having a diphenylmethane skeleton are superior in broad utility and stability, and are useful as a protecting reagent (anchor) of amino acid and / or peptide in the liquid phase synthesis and the like of a peptide having a C-terminal etc., which are of a carboxamide(-CONHR)-type, and in organic synthetic reaction methods (particularly peptide liquid phase synthetic methods), and may be contained in a kit for peptide liquid phase synthesis.

Owner:AJINOMOTO CO INC

Aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material

InactiveCN104610663AHigh strengthGood air aging resistanceRubber insulatorsPlastic/resin/waxes insulatorsCalcium silicateElastomer

The invention discloses an aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material. The material comprises raw materials as follows: EPDM rubber, natural rubber, an ethylene-butene elastomer, superfine talc powder, nano calcium carbonate, modified superfine desulfurization ash, active calcium silicate, zinc methacrylate modified nano silicon nitride, pre-dispersed hollow phenolic microspheres, reinforcing fibers, zinc oxide, stearic acid, dicumyl peroxide, sulfur, N,N'-meta phenylene bismaleimide, diphenylmethane bismaleimide, DIPDIS, coumarone-indene resin, APP (ammonium polyphosphate), ADP, an MPE (metallocene polyethylene) elastomer, N-(4-anilino phenyl maleimide and 2-mercapto benzimidazole. The aging-resistant and low-temperature-resistant EPDM rubber cable material is high in strength, good in aging resistance and low-temperature resistance, excellent in insulating property and flame retardation and long in service life.

Owner:无为县华祥电缆材料有限公司

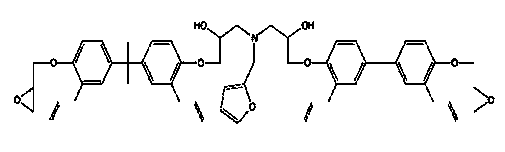

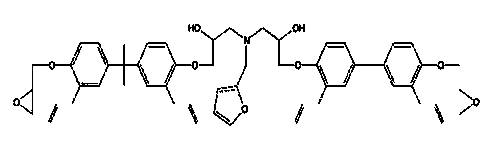

Reversible repair functional matrix resin for pultrusion and preparation method of matrix resin

InactiveCN104194269AMeet the requirements of pultrusion processImprove axial tensile strengthEpoxyDiphenylmethane

The invention discloses a reversible repair functional matrix resin for pultrusion and a preparation method of the matrix resin. The matrix resin is prepared from the following raw materials in parts by weight: 30-60 parts of 4,4'-diallylbisphenol A diglycidyl ether epoxy resin, 20-35 parts of furfuryl amine, 15-30 parts of 4,4'-bismaleimide diphenylmethane, 0-25 parts of liquid epoxy resin and 5-15 parts of curing agent. The preparation method comprises the following steps: dissolving the 4,4'-diallylbisphenol A diglycidyl ether epoxy resin in a formula amount into a solvent, slowly adding the furfuryl amine into a reaction container for reacting, adding the 4,4'-bismaleimide diphenylmethane, liquid epoxy resin and curing agent, reacting and mixing for a hour, performing reduced pressure distillation to remove the solvent, and cooling. The reversible repair functional matrix resin for pultrusion and the preparation method of the matrix resin disclosed by the invention have the beneficial effects that the matrix resin has good molding manufacturability, the molecular structure contains furan and imide structures, the heating and repairing functions of the prepared composite material can be realized by virtue of a Diels-Alder reversible reaction, and the matrix resin also has the advantages of high strength and high heat resistance.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

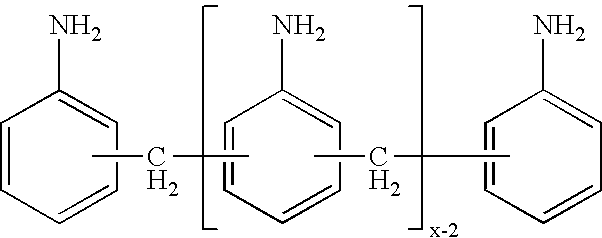

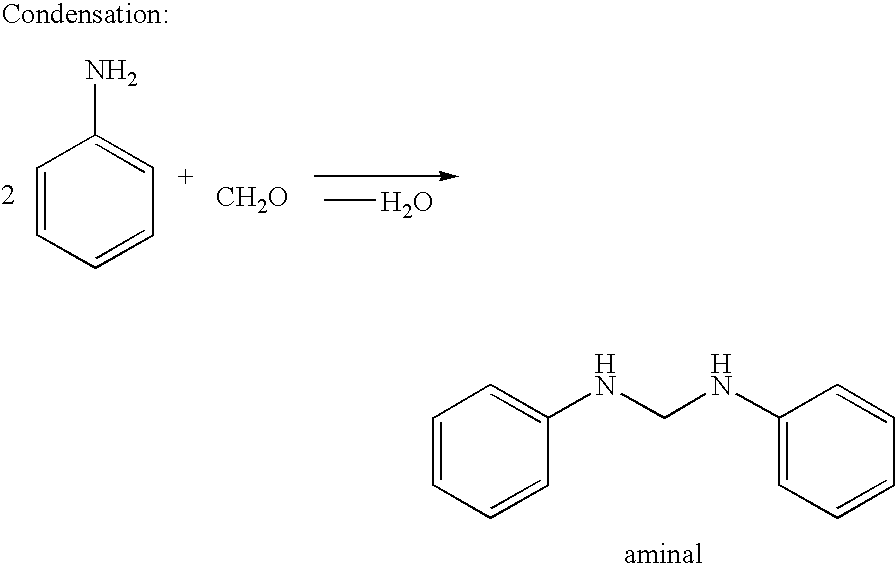

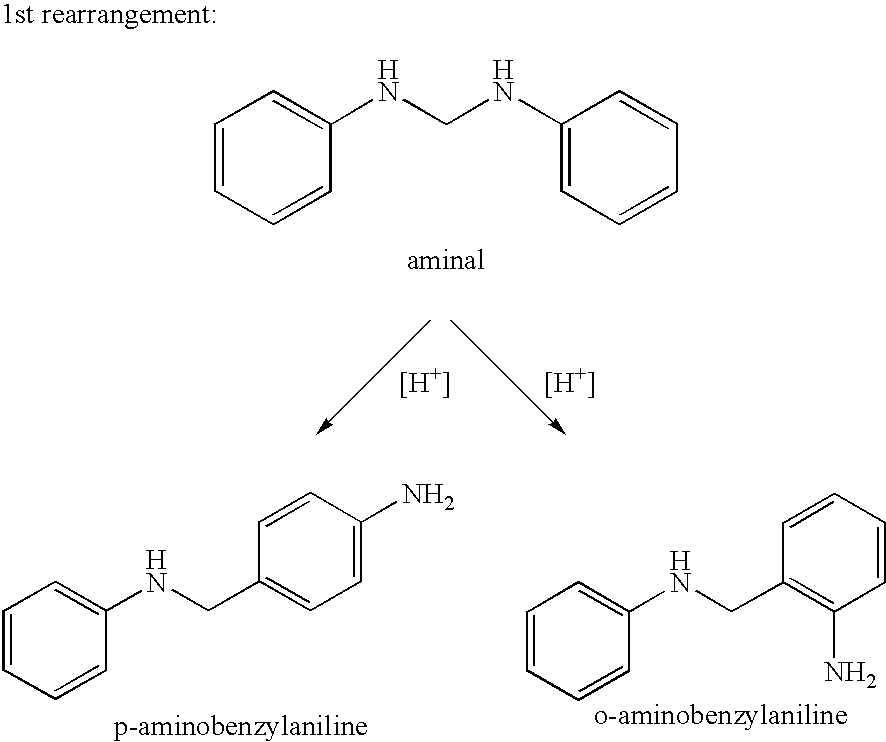

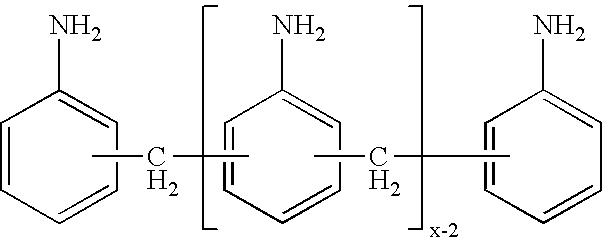

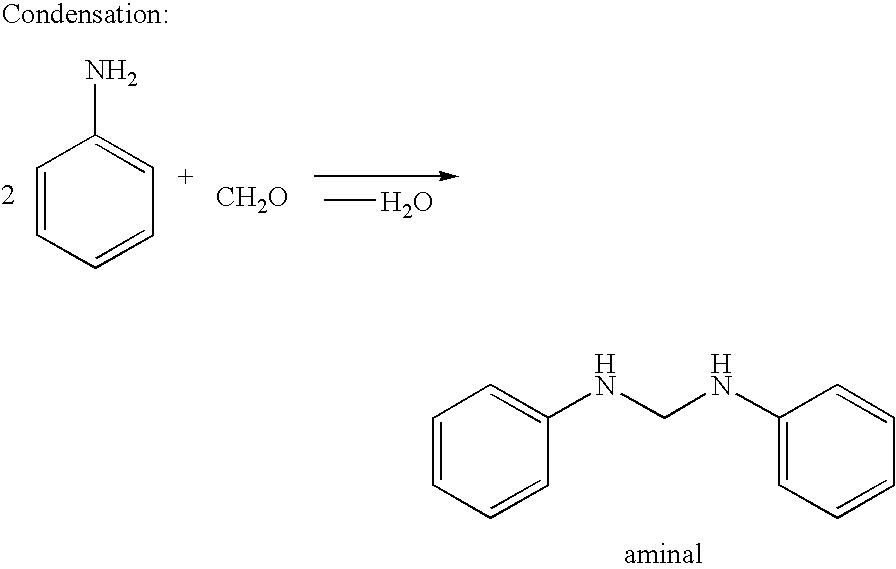

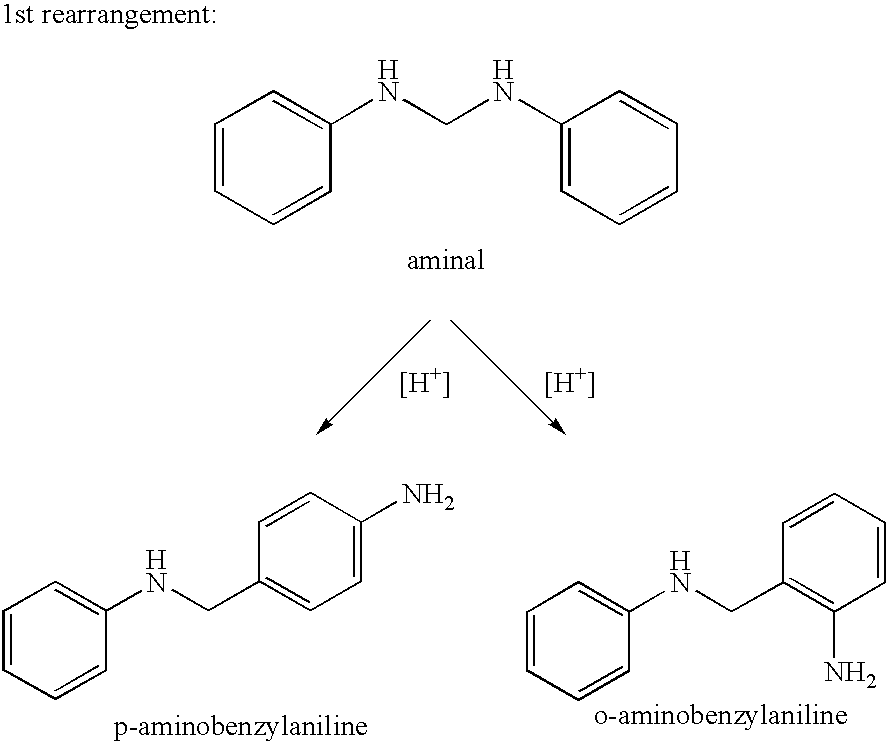

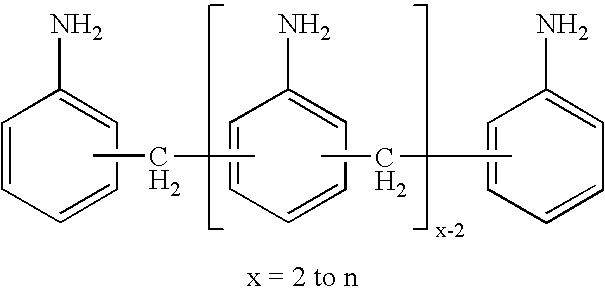

Process for the preparation of polyamines of the diphenylmethane series at a low degree of protonation

ActiveUS20060287555A1Reduce the probability of reactionLong dwell timeIsocyanic acid derivatives preparationOrganic compound preparationDiphenylmethaneProtonation

The invention provides a process for the preparation of polyamines of the diphenylmethane series. This process comprises a) reacting aniline and formaldehyde in a molar ratio of 1.5:1 to 6:1, in the presence of an acid catalyst at temperatures of 20° C. to 100° C., in which the water content in the acid reaction mixture is <20 wt. % and a degree of protonation of <15% is established, and b) increasing the temperature of the reaction to a temperature of 110° C. to 250° C. when the ratio of the weight contents of p-aminobenzylaniline to 4,4′-MDA in the reaction mixture falls below a value of 1.00.

Owner:COVESTRO DEUTSCHLAND AG

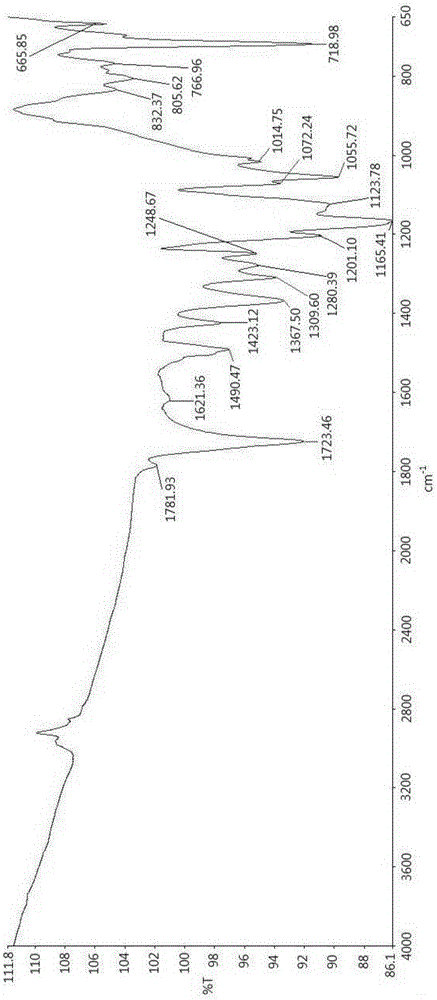

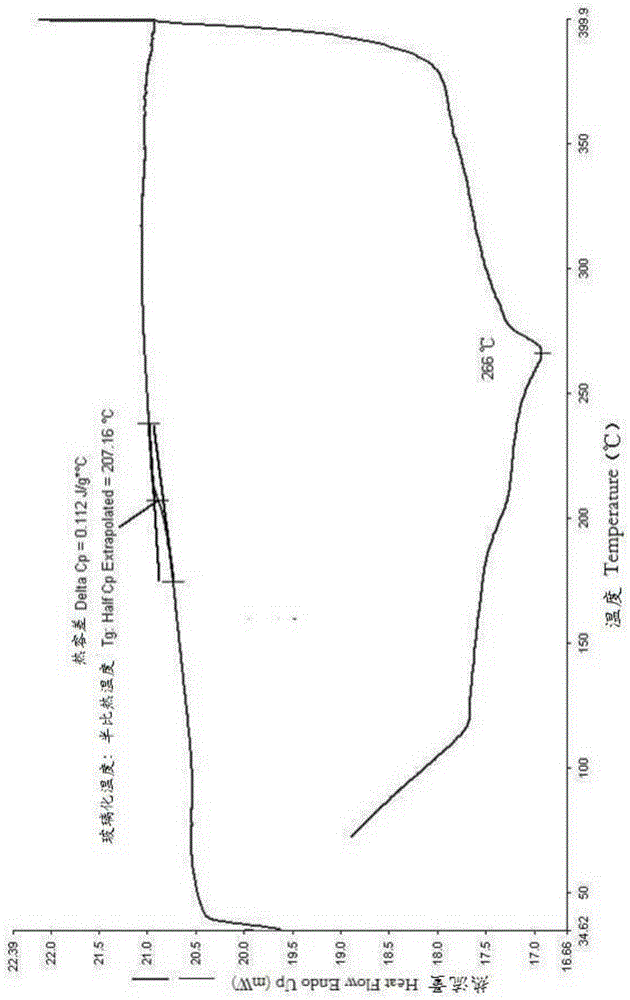

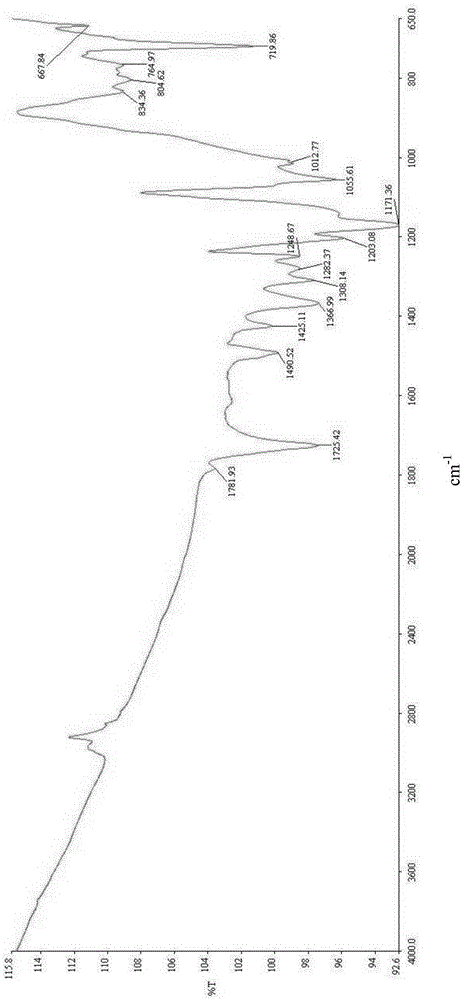

Polymide resin, method for manufacturing the same and thin film thereof

The invention discloses a polymide resin, a method for manufacturing the same and thin film thereof. The polyimide resin is derived from at least two dianhydrides and at least two diamines. The dianhyride is selected from a group consisting of p-phenylenebis (trimellitate anhydride), 4,4'-(hexafluoroisopropylidene)-diphthalic anhydride, and 4,4'-(4,4' -isopropylidenediphenoxy)bis(phthalic anhydride). One of the diamine monomers is 2,2' -bis(trifluoromethyl)benzidine, and the molar ratio of the 2,2'-bis(trifluoromethyl)benzidine to the diamine monomers is between 70% and 90%; and the other diamine monomers are selected from a group consisting of 4,4'-diaminobenzanilide, 4,4'-methylenedianiline, 2,2-bis[4-(4-aminophenoxy)phenyl, 4,4'-diaminodiphenyl-sulfone, 1,3-bis(4-aminophenoxy)benzene, 4,4'-oxydianiline, p-phenylenediamine, 4,4'-diamino-2,2'-dimethyl-1,1'-biphenyl and 2,2-bis[4-(4-aminophenoxy)phenyl]-1,1,1,3,3,3-hexafluoropropane.

Owner:MICROCOSM TECH

4,4'-diamido diphenylmethane direct preparation method

InactiveCN101007767AHigh activityHigh stereoselectivityPreparation by reductive alkylationDiphenylmethaneMolecular sieve

The invention discloses a catalytic synthesizing technique of 4, 4'-diamino diphenylmethane, which comprises the following steps: adopting phenylamine and formaldehyde as raw material to do one-step condensed reaction intervally acted by solid acid catalyst; setting the molar rate of phenylamine and formaldehyde at 10 / 1-2 / 1 under 100-200 deg.c for 1-8h; circulating diamino diphenylmethane; recycling USY to synthesize the product with high activity.

Owner:ZHEJIANG UNIV

Process for the preparation of polyamines of the diphenylmethane series at a low degree of protonation

ActiveUS7253321B2Reduce the probability of reactionLong dwell timeIsocyanic acid derivatives preparationOrganic compound preparationDiphenylmethaneMethylaniline

The invention provides a process for the preparation of polyamines of the diphenylmethane series. This process comprisesa) reacting aniline and formaldehyde in a molar ratio of 1.5:1 to 6:1, in the presence of an acid catalyst at temperatures of 20° C. to 100° C., in which the water content in the acid reaction mixture is <20 wt. % and a degree of protonation of <15% is established, andb) increasing the temperature of the reaction to a temperature of 110° C. to 250° C. when the ratio of the weight contents of p-aminobenzylaniline to 4,4′-MDA in the reaction mixture falls below a value of 1.00.

Owner:COVESTRO DEUTSCHLAND AG

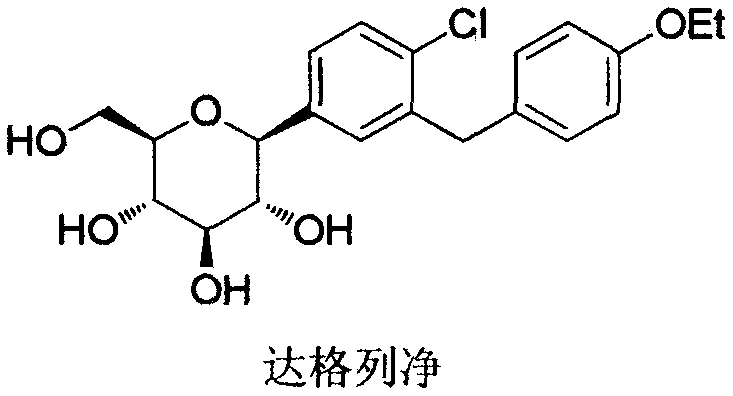

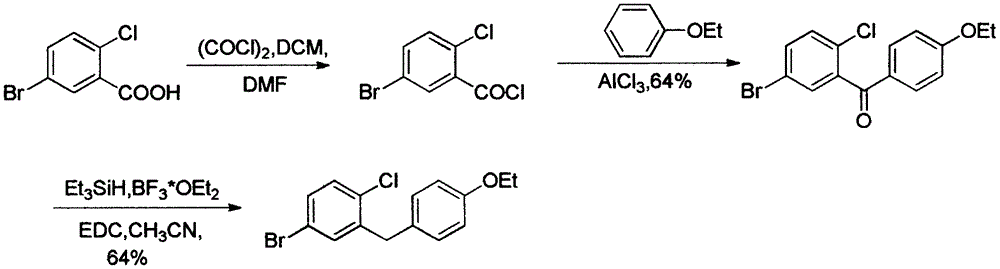

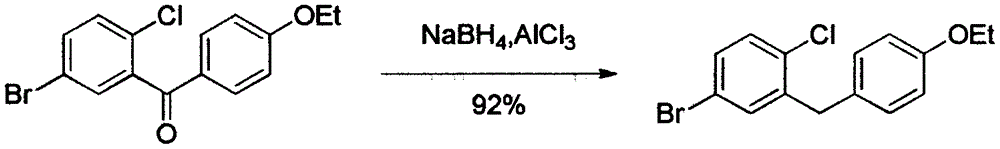

Preparation method of 5-bromine-2-chlorine-4'-ethyoxyl diphenylmethane

InactiveCN104478670ALow water requirementMild reaction conditionsOrganic chemistryOrganic compound preparationDiphenylmethaneAlkyl transfer

The invention relates to the chemical field and particularly relates to a novel synthesis method for preparing a key intermediate 5-bromine-2-chlorine-4'-ethyoxyl diphenylmethane of a drug dapagliflozin for treating diabetes mellitus II. The preparation method comprises the following steps: enabling a starting raw material ortho-toluidine to firstly perform bromization and then perform chlorination after diazotization on a benzene ring with N-bromo-succinimide; then, in the presence of a halogenating agent, performing halogenating reaction of beta-position; and finally, performing Friedel-Crafts alkylation synthesis with phenetole, thereby obtaining the key intermediate. The preparation method is simple and convenient, economical and relatively high in reaction yield in each step, and suitable for industrial production.

Owner:CHINA PHARM UNIV

Lignocellulosic composite material and method for preparing the same

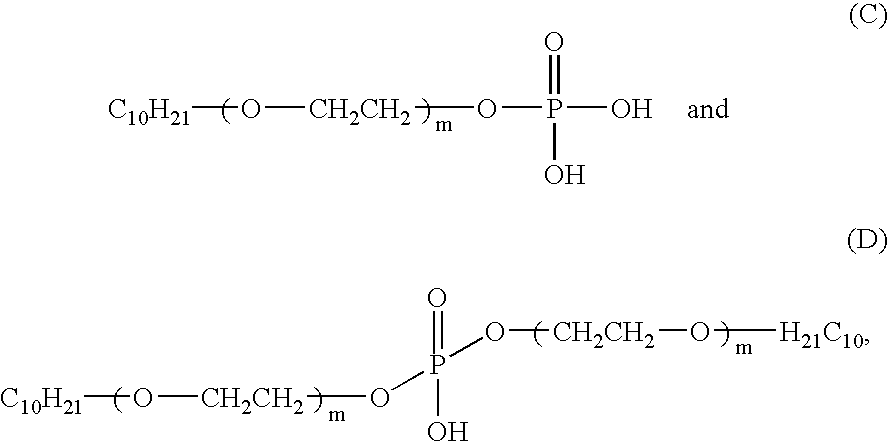

InactiveUS20050242459A1Improved stability and storage lifeWood working apparatusDomestic articlesCelluloseDiphenylmethane

A lignocellulosic composite material and a method for preparing the lignocellulosic composite material are disclosed. The composite material includes lignocellulosic particles and a binder resin being a mixture of a polyisocyanate component and a release agent. The release agent is formed from a first component having hydroxyl groups and a second component having isocyanate groups in excess of the hydroxyl groups. The first component is selected from at least one of i) an acid phosphate and ii) pyrophosphates represented by those derived from the acid phosphates (i) and mixtures of the acid phosphates (i). The first component is passivated by mixing it with the second component which is preferably monomeric diphenylmethane diisocyanate selected from at least one of diphenylmethane-4,4′-diisocyanate, diphenylmethane-2,4′-diisocyanate, and diphenylmethane-2,2′-diisocyanate.

Owner:BASF CORP

Process for making a flexible polyurethane foam

Process for preparing a flexible polyurethane foam comprising reacting at an isocyanate index of 70 to 130, 1) 40-65 parts by weight of a polyisocyanate composition comprising a) 80-100% by weight of a diphenylmethane diisocyanate component comprising, based on 100 parts by weight of the diphenylmethane diisocyanate component, i) 75-100 parts by weight of diphenylmethane diisocyanate comprising 15-75 parts by weight of 4,4′-diphenylmethane diisocyanate, and 25 to 85 parts by weight of 2,4′-diphenylmethane diisocyanate, and 2,2′-diphenylmethane diisocyanate and / or a liquid variant of such diphenylmethane diisocyanate, and ii) 0 to 25 parts by weight of homologues of diphenylmethane diisocyanates having an isocyanate functionality of 3 or more; and b) 20-0% by weight of toluene diisocyanate; 2) 20 to 45 parts by weight of a polyether polyol having an average molecular weight of 4500-10000, an average nominal functionality of 2-6 and comprising oxypropylene and optionally oxyethylene groups, the amount of oxypropylene groups being at least 70% by weight calculated on the weight of this polyol; 3) 3 to 20 parts by weight of a polyether polyol having an average molecular weight of 700-4000, an average nominal functionality of 2-6 and an hydroxyl value of at most 225 mg KOH / g and comprising oxyethylene and optionally oxypropylene groups, the amount of oxyethylene groups being at least 70% by weight calculated on the weight of this polyol; and 4) 2-6 parts by weight of water, wherein the amount of the polyisocyanate composition, polyol 2), polyol 3), and water being 100 parts by weight.

Owner:HUNTSMAN INT LLC +1

Preparation of CFC-free, highly resilient, flexible polyurethane foams, and diphenylmethane diisocyanate-based polyisocyanate mixtures modified by means of urethane groups which can be used for this purpose

InactiveUS6096238AIncrease elasticityEasy to processOther chemical processesDiphenylmethaneCarbamate

The present invention relates to a process for the preparation of CFC-free, flexible polyurethane (molded) foams by reacting A) liquid polyisocyanate mixtures containing bonded urethane groups having a content of NCO groups of from 22 to 30% by weight which are themselves prepared by reacting a mixture of diphenylmethane diisocyanates and polyphenyl-polymethylene polyisocyanates having a content of diphenylmethane diisocyanate isomers of from 55 to 99% by weight, based on the total weight, with at least one trifunctional polyoxypropylene-polyol having a hydroxyl number of from 20 to 60, with B) relatively high-molecular-weight polyhydroxyl compounds and, if desired, C) low-molecular-weight chain extenders and / or crosslinking agents, in the presence of D) blowing agents, E) catalysts and, if desired, F) auxiliaries and / or additives, and to the polyisocyanate mixtures (A) modified by means of urethane groups which can be used according to the invention.

Owner:BASF AG

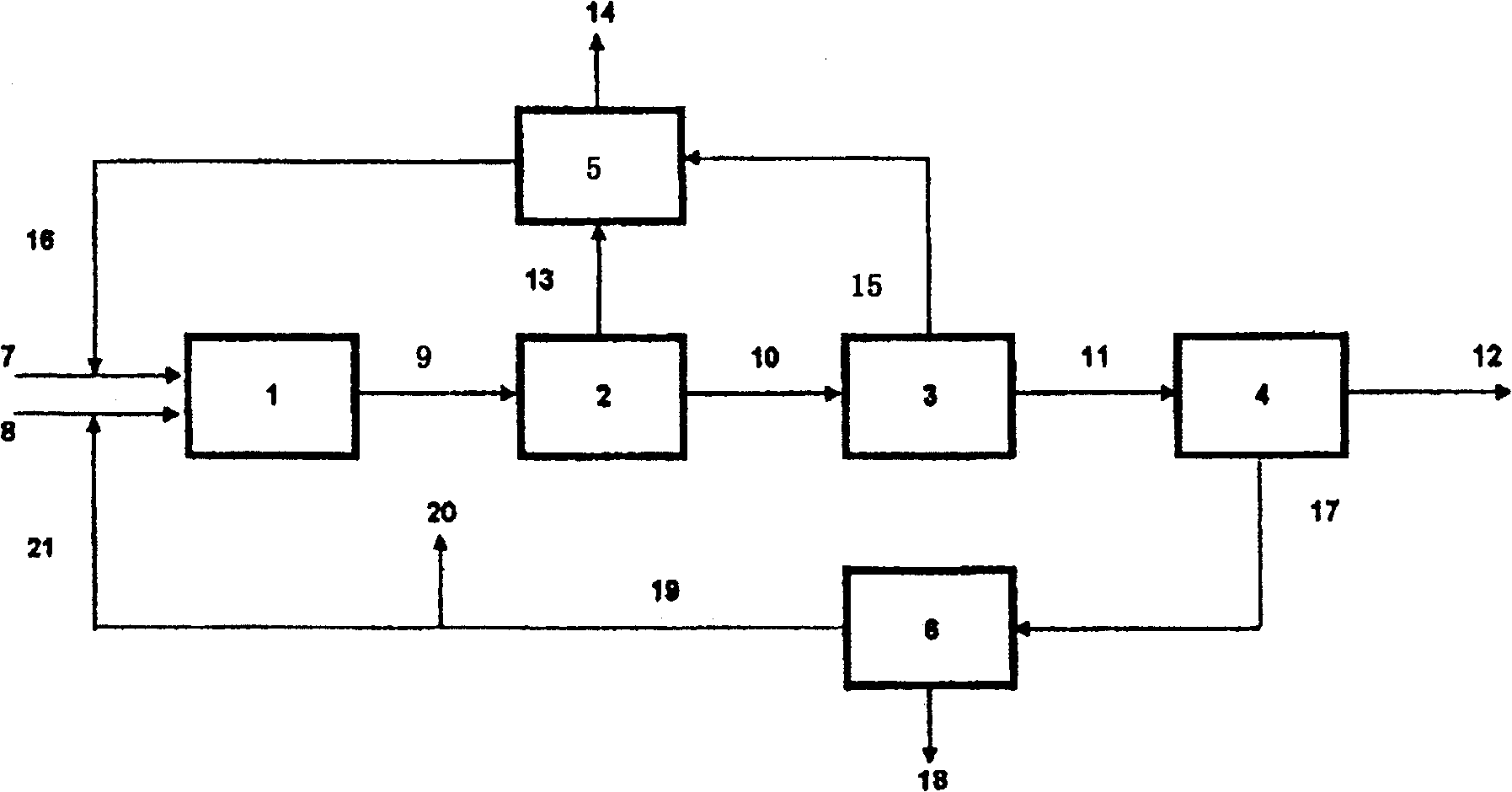

Process for the production of 4,4'-diphenylmethane diisocyanate

InactiveUS20070117997A1Simple processOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

The present invention relates to a process for the production of 4,4′-diphenylmethane diisocyanate (4,4′-MDI) by acid-catalyzed condensation of aniline with formaldehyde, reaction of the mixtures of di- and polyamines obtained with phosgene to form the corresponding mixture of MDI isomers and homologues (di- and polyisocyanates of the diphenylmethane series) and subsequent separation of the mixture by distillation to form 4,4′-MDI and polymeric MDI.

Owner:BAYER MATERIALSCIENCE AG

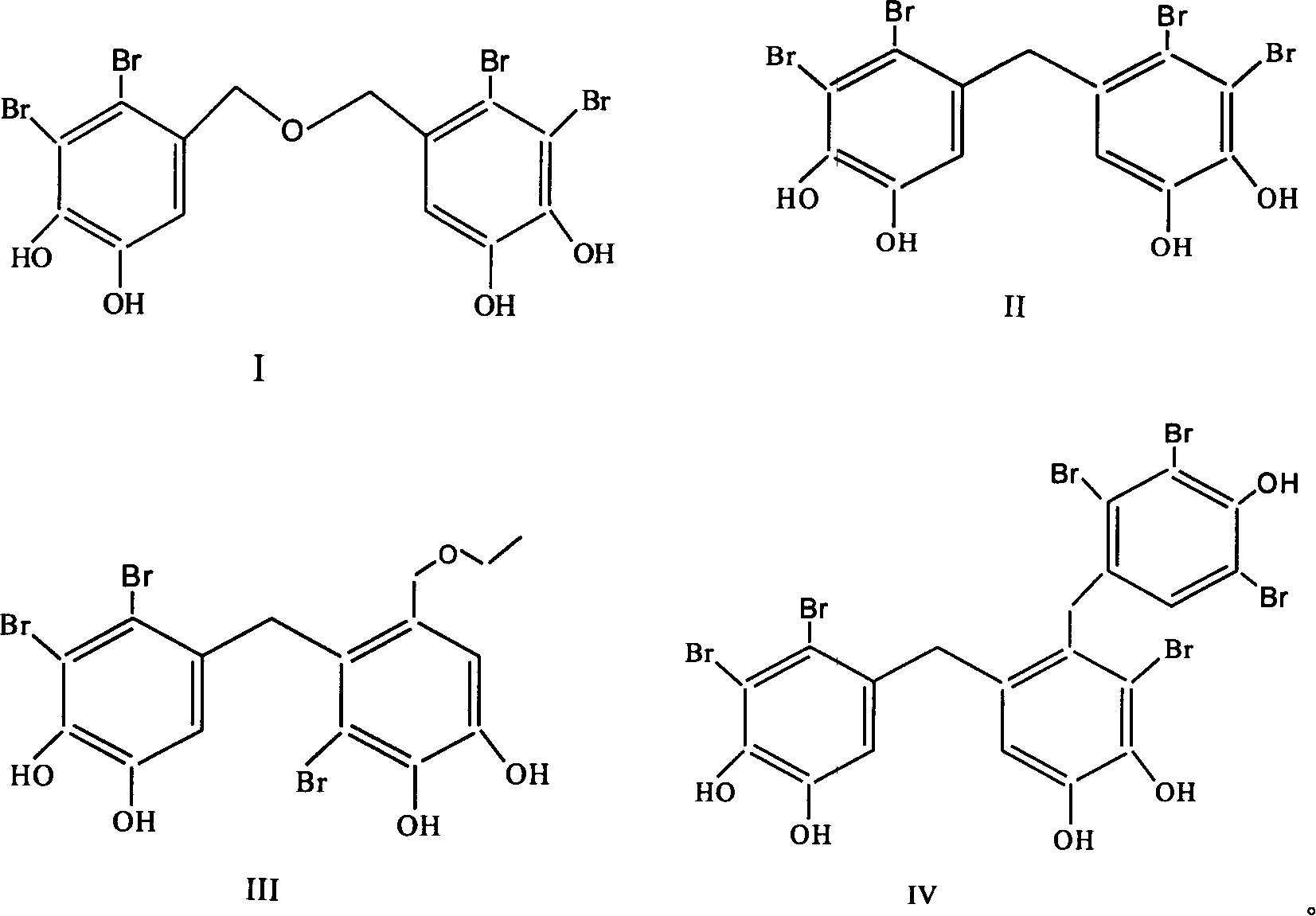

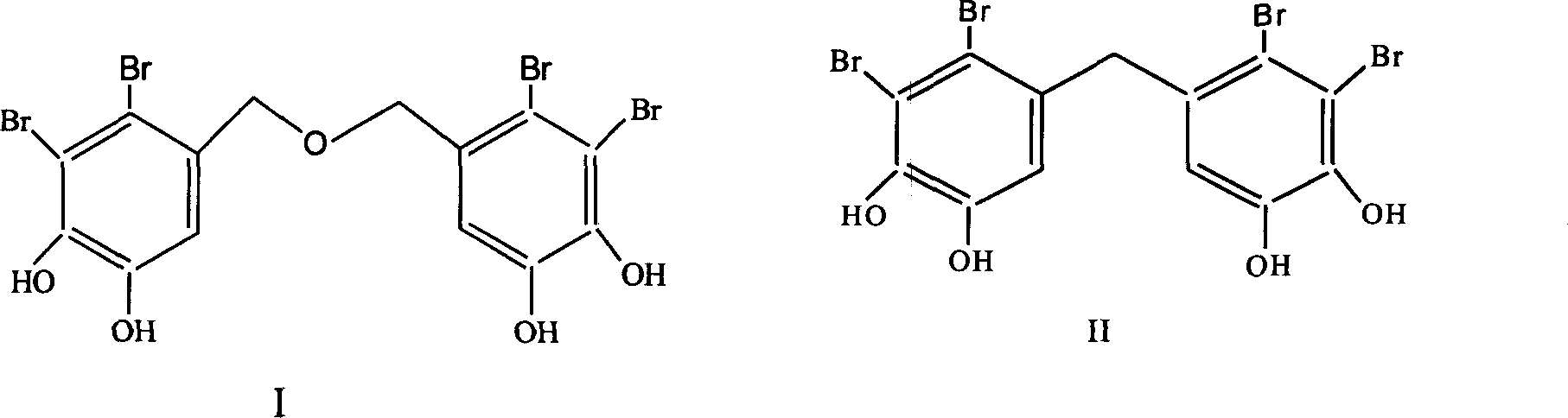

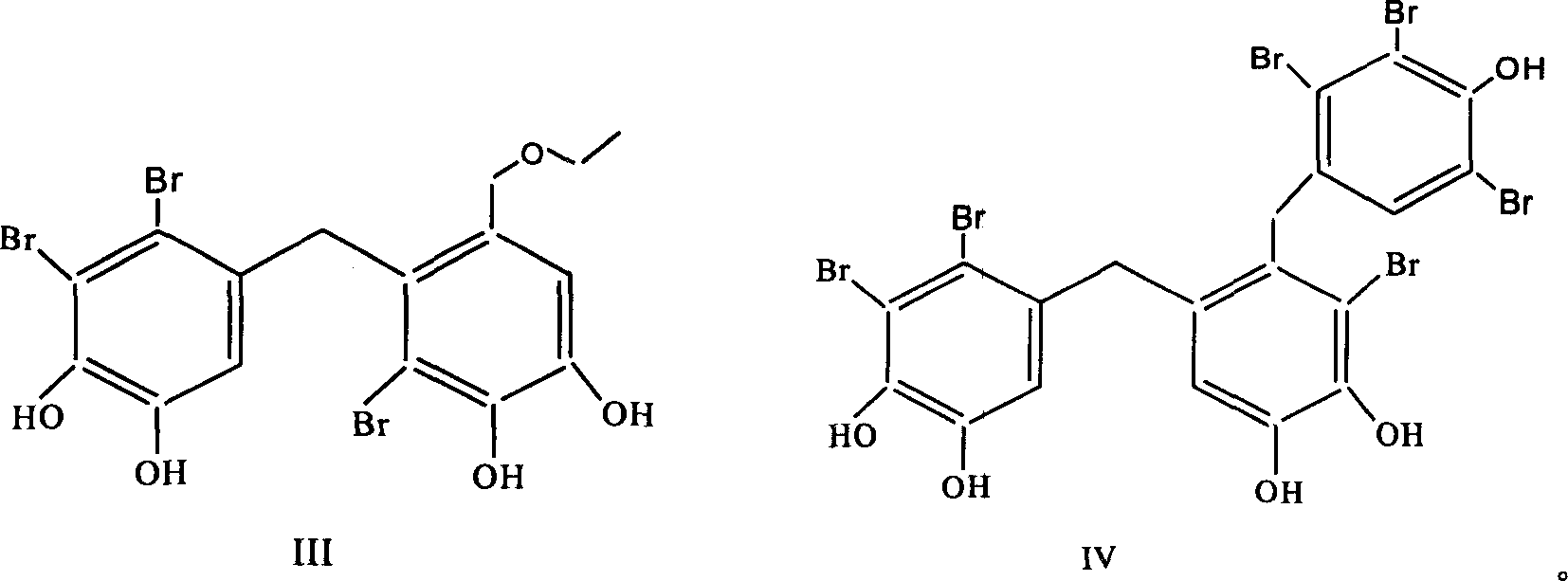

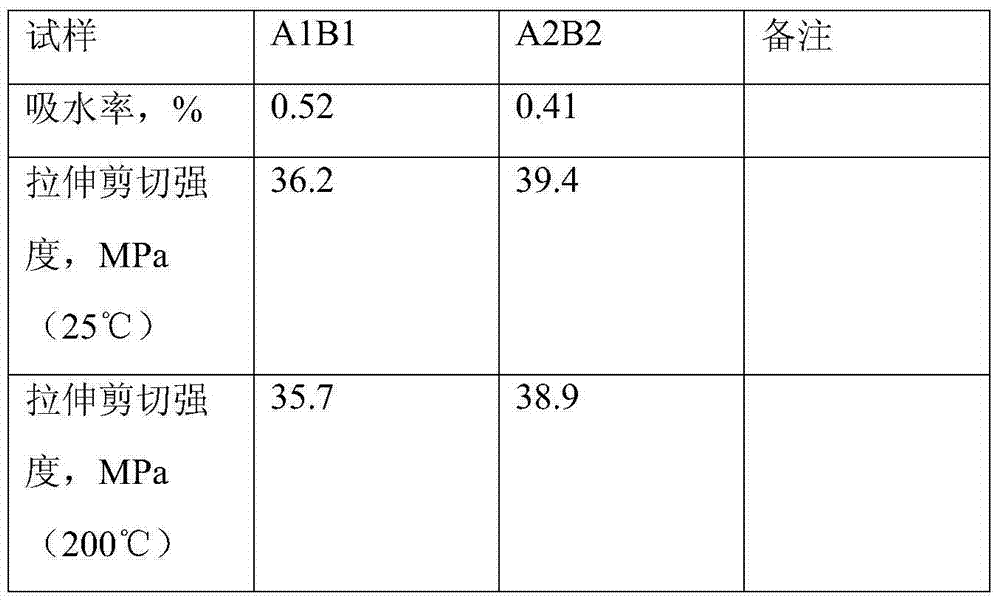

Use of bromphenol compound in protein-tyrosine phosphonatease inhibitor

InactiveCN1853618ALower blood sugar levelsPrevent diabetesOrganic active ingredientsMetabolism disorderDiabetes mellitusDiphenylmethane

An application of the bromophenol compounds chosen from bis-(2,3-bibromo-4,5- dihydroxybenzyl)-ether, 2,2',3,3'-tetrabromo-4,4',5,5'-tetrahydroxydiphenyl methane, 2,2',3- tribromo-3',4,4',5-tetrahydroxy-6'-ethoxymethyl diphenylmethane, 3-bromo-4,5-bis-(2,3-dibromo -4,5-dihydroxybenzyl)-catechol, their pharmacologically acceptable derivatives, and their mixture in preparing the depressant of protein tyrosine phosphatase for treating diabetes and obesity is disclosed.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Liquid partially trimerized and allophanized polyisocyanates based on toluene diisocyanate and diphenylmethane diisocyanate

InactiveUS7553963B2Urea derivatives preparationIsocyanic acid derivatives preparationPrenylationToluene diisocyanate

This invention relates to storage-stable, liquid, partially trimerized and allophanized polyisocyanates having an NCO group content of 15 to 41% by weight, and comprising 5 to 85% by weight of toluene diisocyanate, 5 to 85% by weight of a polyisocyanate of the diphenyl-methane series and an organic compound or mixture thereof. The present invention also relates to a process for the preparation of the storage-stable, liquid, partially trimerized and allophanized polyisocyanates; to storage-stable, liquid urethane prepolymers of these partially trimerized and allophanized polyisocyanates; and to a process for the production of these storage-stable, liquid, urethane prepolymers.

Owner:BAYER MATERIALSCIENCE AG

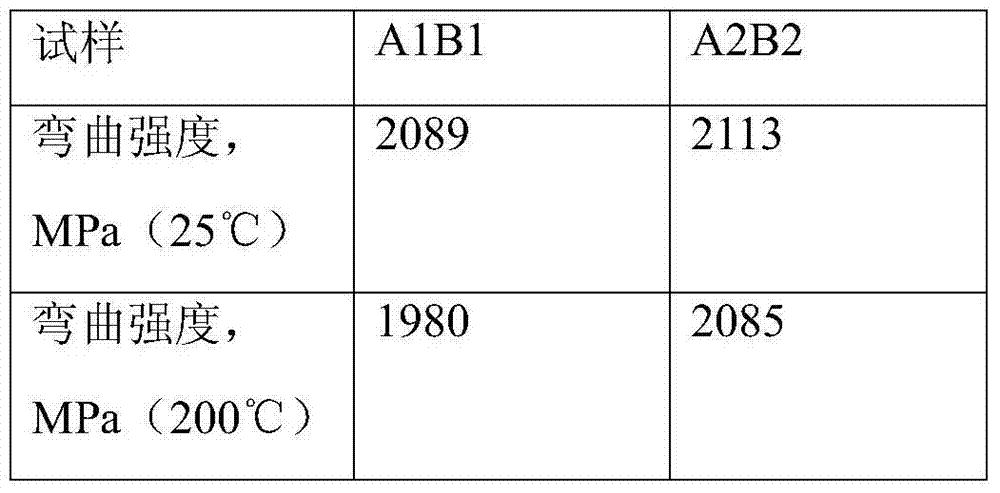

Matrix resin for carbon fiber composite material and preparation method of matrix resin

The invention relates to matrix resin for a carbon fiber composite material and a preparation method of the matrix resin. The matrix resin comprises N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, ES216 epoxy resin, 2,2-bi[4-(2-trifluoromethyl-4-maleimido phenoxy)phenyl]propane, 3,3'-dimethyl-4,4'-bi(4-carboxyl phthalimido)diphenylmethane, a curing agent and an organic solvent based on a mass ratio of 100 to (50-100) to (10-50) to (5-20) to (50-100) to (300-600). According to the matrix resin, the preparation process is simple; the raw materials are convenient to get; the obtained matrix resin is excellent in integral performance, can be used for preparing the high-performance carbon fiber composite material, can be applied to structure materials in the fields of sports equipment, aerospace, autos, electronics, micro-electronics and the like, is suitable for industrial production, and has a very high commercial prospect.

Owner:DONGHUA UNIV +1

Processing method of effluent brine produced in MDI production process

ActiveCN101665302ARemove completelyReduce pollutionMultistage water/sewage treatmentNature of treatment waterDiphenylmethaneSaline water

The invention discloses a processing method of effluent brine produced in MDI production process, comprising the following steps: (1) effluent brine containing phenylamine, diphenylmethane toluene diamine and polyamine, which is produced in MDI production process, carries out super-gravity extraction, and then tower-type extraction is carried out; (2) effluent brine discharged by the step (1) is fed to a stripping tower to carry out steam stripping; (3) effluent brine discharged from the stripping tower in step (2) and chemical oxidants are conveyed to an oxidation reactor, and air is vented to carry out aeration; (4) the effluent brine processed by the step (3) is transported to an adsorption tower to carry out adsorption. The effluent brine processed by the method of the invention has less than 8ppm of TOC, less than 2.5 ppm of TN (total nitrogen); sodium chloride and water and the other resources in effluent brine are realized, so as to carry out circulating utilization.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

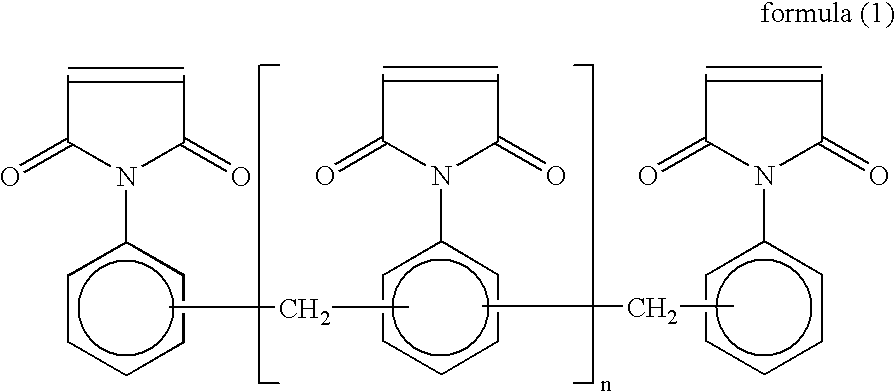

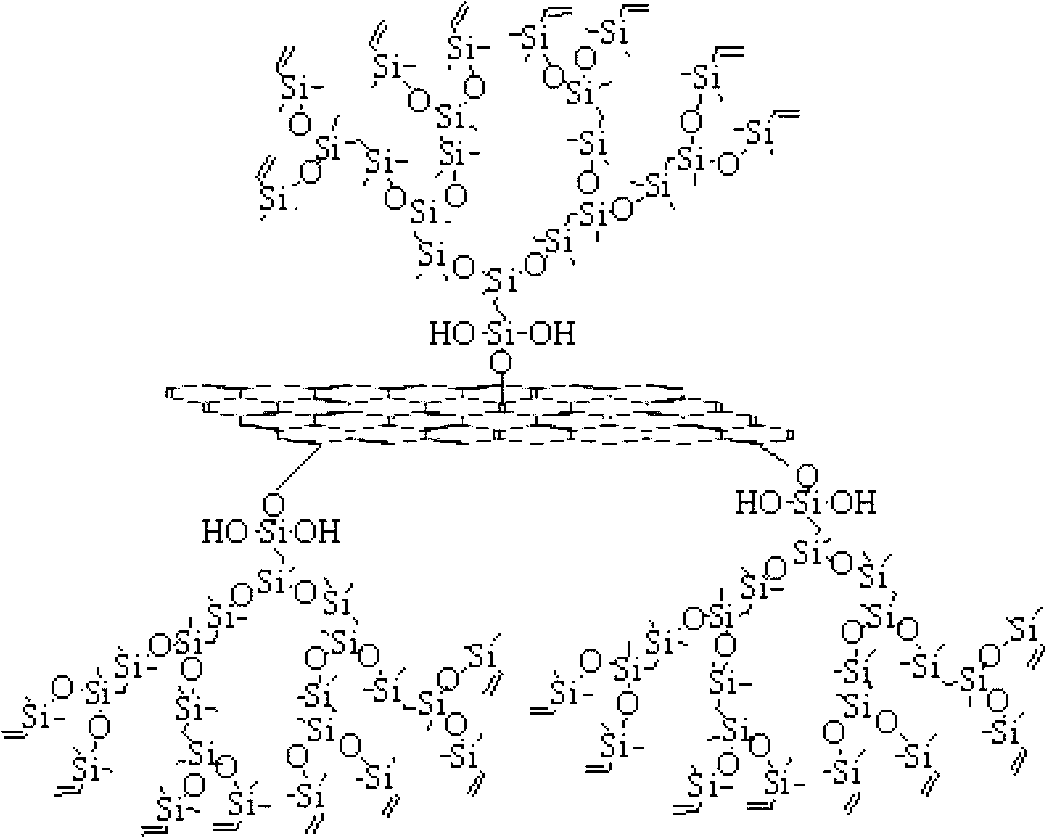

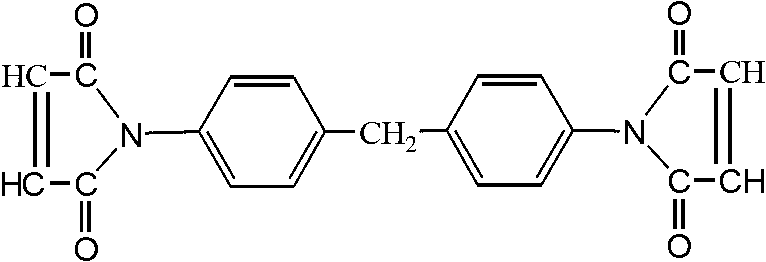

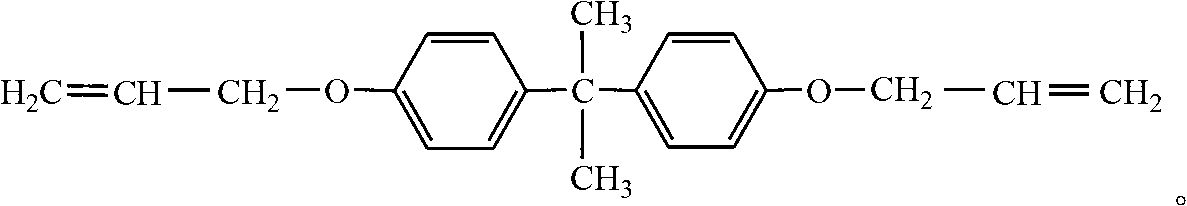

Hyperbranched polysiloxane grafted graphene/bismaleimide composite material and preparation method thereof

The invention relates to a hyperbranched polysiloxane grafted graphene / bismaleimide composite material and a preparation method thereof. The composite material is prepared by casting for forming and comprises 0.1-10 weight parts of graphene modified by hyperbranched polysiloxane, 100 weight parts of diphenylmethane bismaleimide and 10-100 weight parts of bisphenol A diene propyl ether, wherein for further raising the dispersibility of graphene in resins and the interface bonding strength between the graphene and resins, the graphene is modified by conducting silicon-hydrogen addition polymerization; according to the bisphenol A diene propyl ether included in the resins, the prepolymer has low viscosity in a wide temperature range, thus the dispersibility of graphene in benefited; the bisphenol A diene propyl ether can be rearranged into 2,2'-diallyl bisphenol A at a high temperature to react with the diphenylmethane bismaleimide, thus the strength of the resins is guaranteed. The prepared composite material has good mechanical properties and excellent friction properties, and can be used as slide plates of non-lubricated water pumps or dynamic seal coatings of engines, etc.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process for the preparation of di- and polyamines of the diphenylmethane series

InactiveUS20060094897A1Organic compound preparationDiaryl/thriaryl methane dyesDiphenylmethaneAniline

The present invention relates to a process for the preparation of di- and polyamines of the diphenylmethane series, and to the preparation of di- and polyisocyanates of the diphenylmethane series from these di- and poly-amines. The di- and poly-amines of the diphenylmethane series are prepared by the reaction of aniline and formaldehyde in the presence of hydrochloric acid. In with the present invention, the hydrochloric acid employed contains less than 0.001 wt. % of metal ions which are divalent and / or more than divalent.

Owner:BAYER MATERIALSCIENCE AG

Method for producing isocyanate

ActiveCN101302174AOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

Isocyanates, preferably diisocyanates and polyisocyanates of the diphenylmethane series (MDI), are produced by reaction of amines dissolved in a solvent with phosgene in the same solvent to form the corresponding isocyanates. Hydrogen chloride and excess phosgene are subsequently removed from the reaction mixture to obtain a crude isocyanate-containing solution. Subsequently, the crude isocyanate-containing solution is separated by distillation into isocyanates and solvent. The solvent is recycled and used for the production of solutions of the amines and of phosgene. The solvent being recycled is treated to reduce the phosgene and diisocyanate contents before being used for the production of the solution of the amine.

Owner:COVESTRO DEUTSCHLAND AG

Hydrogenation catalyst and preparation method of 4,4'-diamino-dicyclohexyl methane

InactiveCN101966456ALow costEasy to prepareOrganic compound preparationAmino compound preparationDiphenylmethaneActive component

The invention discloses a hydrogenation catalyst and a preparation method of 4,4'-diamino-dicyclohexyl methane. The hydrogenation catalyst comprises a carrier used as mesoporous carbon and an active component used as ruthenium, wherein the load capacity of the active component is 0.5-10 percent by mass of the hydrogenation catalyst. in the preparation method of low transisomer 4,4'-diamino-dicyclohexyl methane, the catalyst of the invention is adopted to selectively hydrogenate and generate a target product under the conditions of solvents and hydrogenation. In the invention, the catalyst and the method reduce the generation of byproducts while the higher conversion ratio of the 4,4'-diamino-diphenylmethane is remained, and decrease the content of the transisomer of the 4,4'-diamino-dicyclohexyl methane. Meanwhile, the catalyst is low in cost and simple and convenient in preparation and is suitable for industrial application.

Owner:CHANGZHOU UNIV +1

Silicon rubber/ethylene propylene terpolymer blending material and processing method

The invention discloses a silicon rubber / ethylene propylene terpolymer blending material and a processing method of the silicon rubber / ethylene propylene terpolymer blending material. The silicon rubber / ethylene propylene terpolymer blending material comprises silicon rubber raw rubber, ethylene propylene terpolymer raw rubber, diphenylmethane bismaleimide and an organic peroxide vulcanizing agent. In the silicon rubber / ethylene propylene terpolymer blending material vulcanized by peroxide, the vulcanizing speed of the ethylene propylene terpolymer component is improved by diphenylmethane bismaleimide, so that the vulcanizing speed of the ethylene propylene terpolymer component and the vulcanizing speed of the silicon rubber component trend to be close, and the purpose of co-vulcanization of all rubber components can be achieved. According to the invention, the silicon rubber / ethylene propylene terpolymer blending material is mixed and processed by an open two-roll rubber mixing mill and a sealed rubber mixing mill, and the rubber compound containing diphenylmethane bismaleimide is heated and vulcanized to obtain the silicon rubber / ethylene propylene terpolymer rubber compound with excellent properties.

Owner:SOUTH CHINA UNIV OF TECH

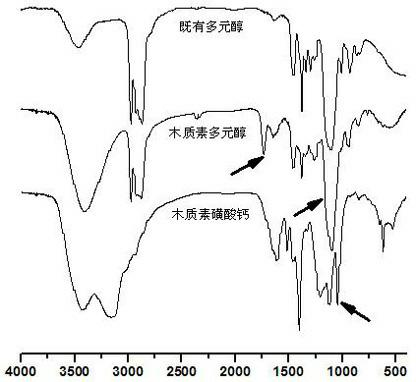

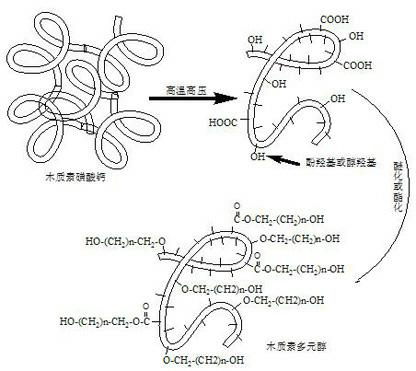

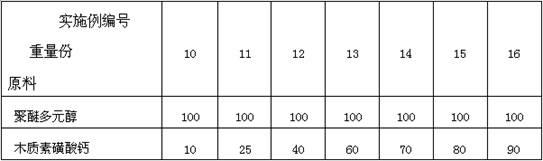

Preparation method of polyurethane foam materials based on liquefied lignin calcium sulfonate polyalcohol

The invention discloses a preparation method of polyurethane foam materials based on liquefied lignin calcium sulfonate polyalcohol. The preparation method is characterized in that through being metered in parts by weight, 100 parts of polyether polyol is added into a reaction kettle, 5 to 100 parts of lignin calcium sulfonate is added, the reaction lasts 1 to 5 hours at the temperature being 150 to 190 DEG C and the pressure being 1 to 3 MPa, and liquefied lignin polyalcohol is obtained; 100 parts of liquefied lignin polyalcohol is respectively mixed and stirred with 2.5 to 5 parts of foaming agent water, 0.8 to 1.2 parts of foam stabilizers, 0.2 to 0.6 part of triethylene diamine, then, 0.3 to 0.5 part of stannous octoate is added, the stirring is carried out, and ingredients A are obtained; and crude diphenylmethane-4,4'-diisocyanate is taken as ingredients B, the ingredients A and the ingredients B are mixed according to a weight ratio being (0.95-1.1):1 and take reaction for foaming and curing by a high-pressure foaming machine, and the polyurethane foam materials are prepared. The preparation method has the advantages that the process is simple, green and clean effects are realized, and good market prospects are realized.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com