Patents

Literature

541 results about "Diaminodiphenyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

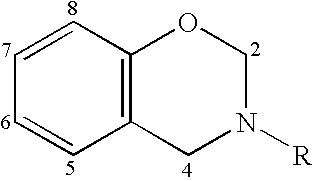

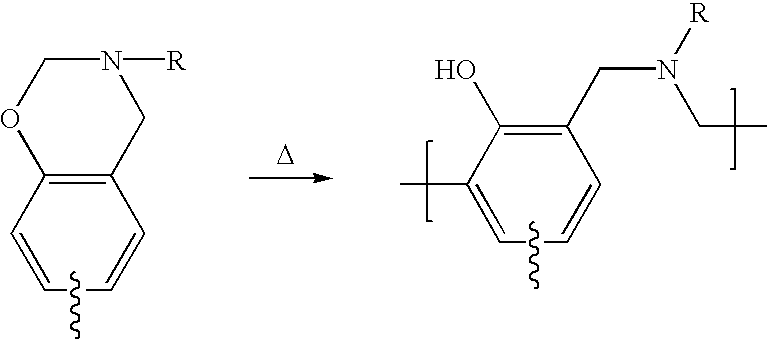

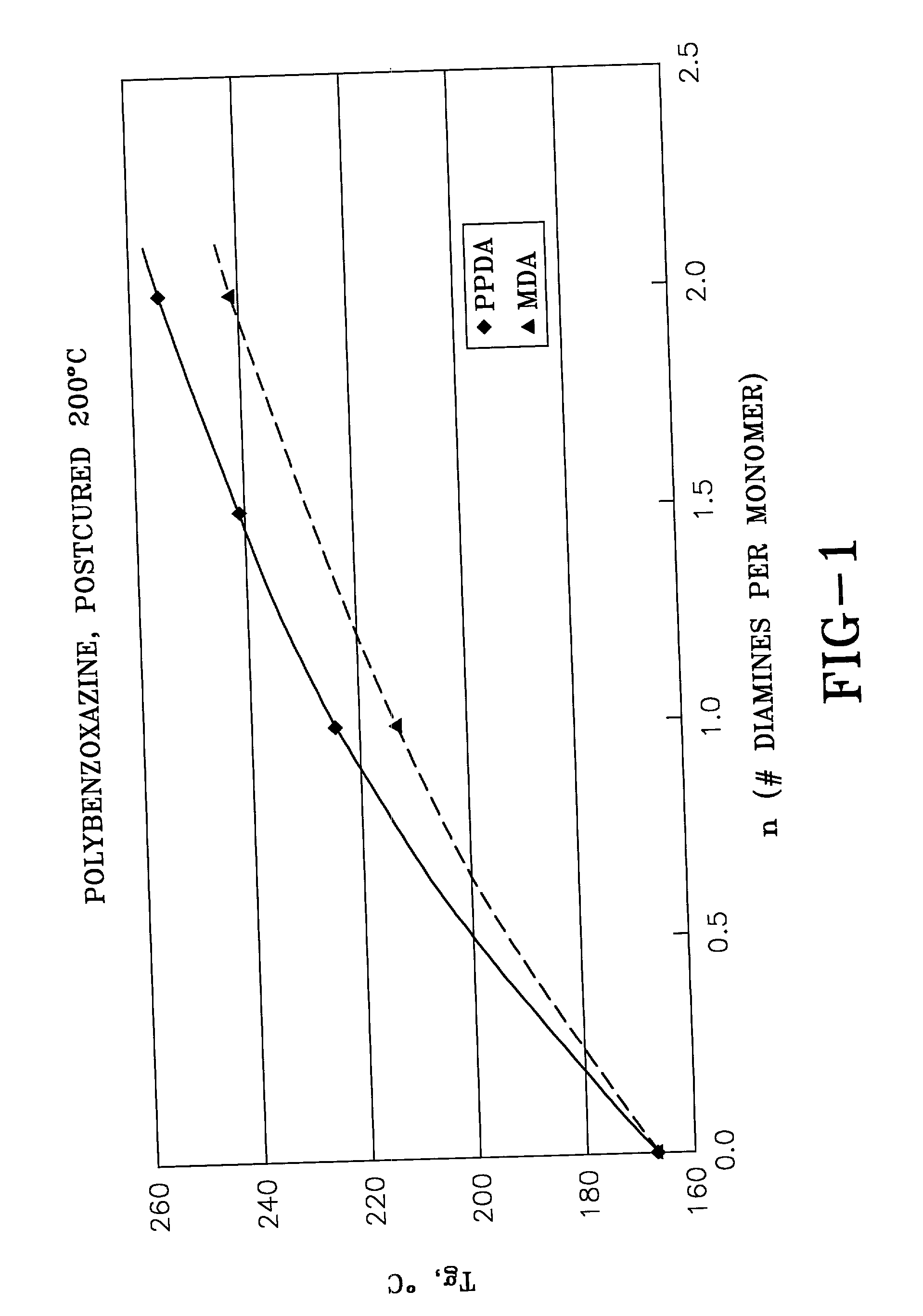

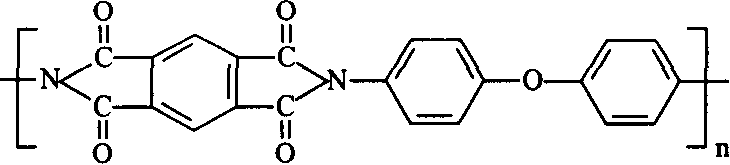

Enhancement of thermal properties of benzoxazine polymers by use of aromatic polyamines to incorporate internal benzoxazine groups within the monomer

A benzoxazine polymer having improved thermal properties. The properties are improved by inserting aromatic polyamines into the monomer, such as phenylenediamine, methylenedianiline, oxydianiline, diaminodiphenylsulfone, 2,2-bis(4-[aminophenoxy]phenyl)propane, 4,4'-oxydianiline, 4,4'-diaminodiphenyl sulfone, and diaminobenzanilide, to introduce internal benzoxazine groups that are crosslinking sites. The improved polymers can be converted into molding compounds, towpregs, and prepregs by being compounded with reinforcing fibers.

Owner:HYCOMP

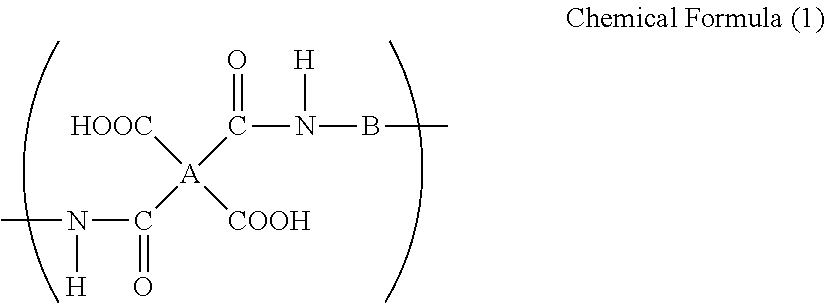

Binder resin composition for electrode, electrode mixture paste, and electrode

ActiveUS20120168688A1Small degree of swellingIncreased fracture energyHybrid capacitor electrodesElectrolytic capacitorsDiaminodiphenyl etherCarboxylic acid

The present invention relates to a binder resin composition for an electrode, including a polyamic acid and a solvent, wherein the polyamic acid is (i) a polyamic acid which includes a tetracarboxylic acid component including 10 to 100 mol % of 4,4′-oxydiphthalic acid and 90 to 0 mol % of 3,3′,4,4′-biphenyltetracarboxylic acid and / or pyromellitic acid and a diamine component including an aromatic diamine having 1 to 4 aromatic rings, (ii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 10 to 90 mol % of p-phenylene diamine and 90 to 10 mol % of 4,4′-diaminodiphenyl ether, or (iii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 40 mol % or more of a bis[4-(4-aminophenoxy)phenyl] compound.

Owner:UBE IND LTD

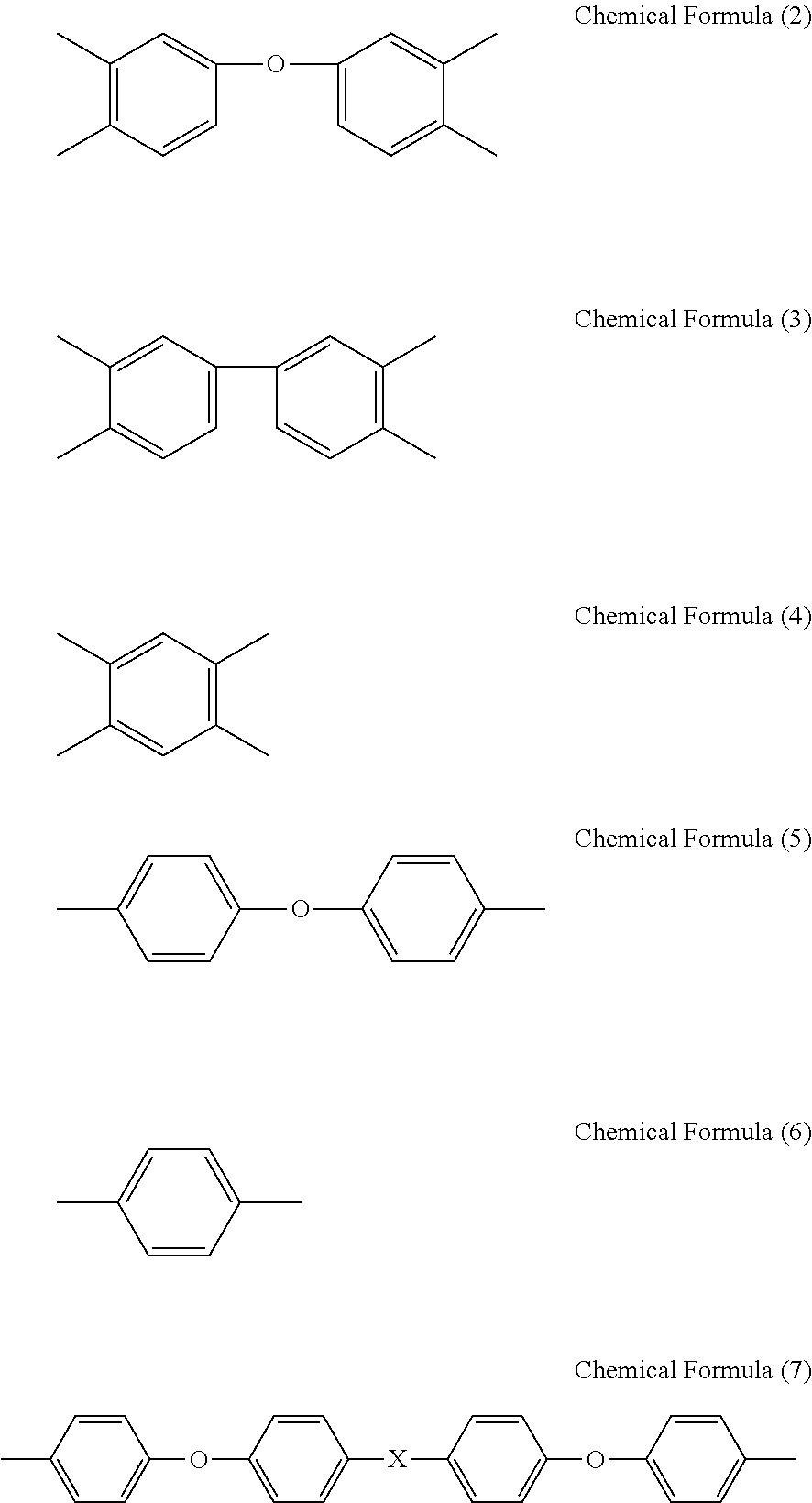

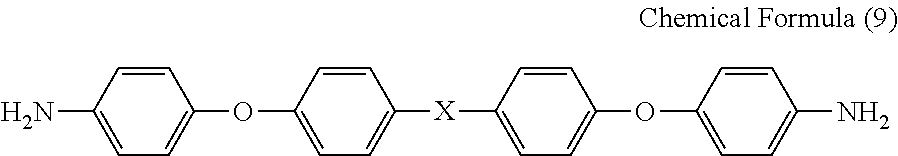

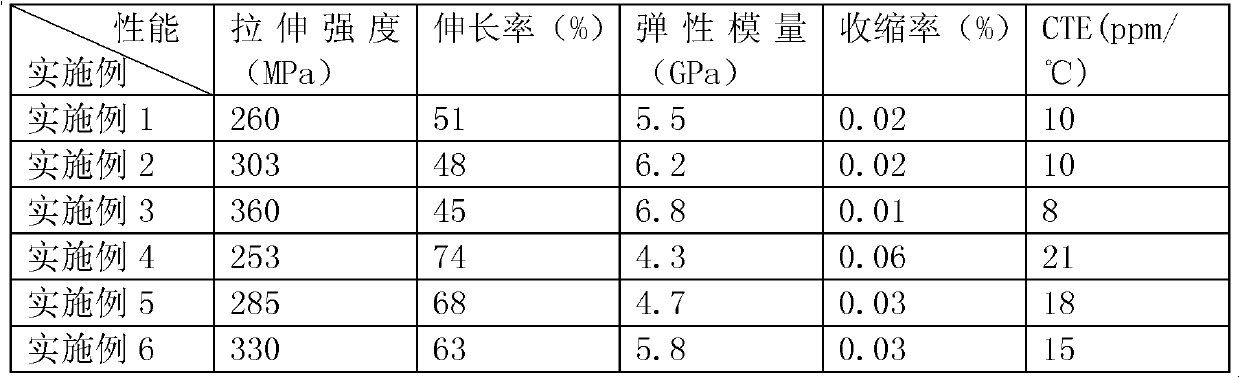

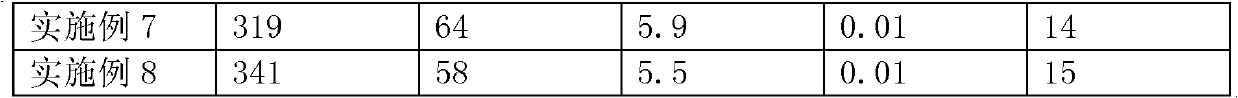

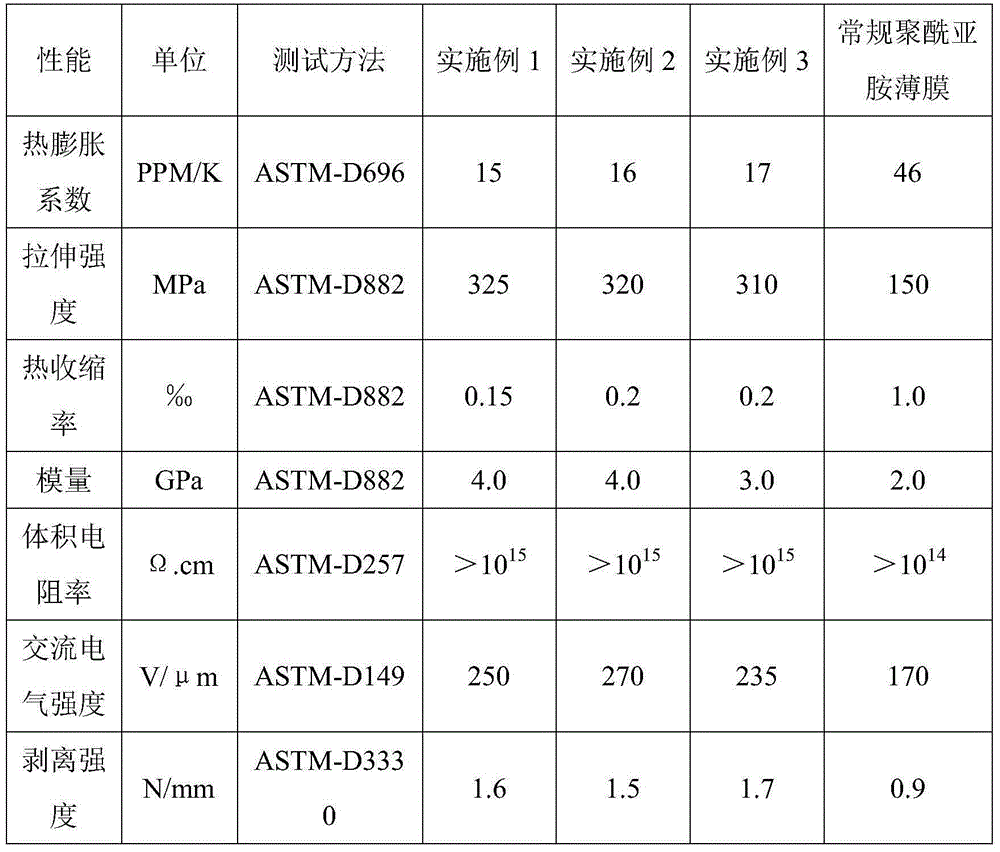

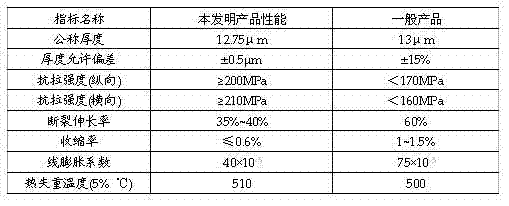

Dimensionally-stable polyimide film and preparation method thereof

ActiveCN102558860ALow heat shrinkageSmall coefficient of thermal expansionDiaminodiphenyl etherPolymer science

The invention discloses a dimensionally-stable polyimide film and a preparation method thereof. According to the weight percentage, the polyimide film is manufactured by evenly mixing 40 to 80 percent of component A, 0 to 60 percent of component B and 0 to 60 percent of component C and then conducting slobbering and imidization according to a conventional process, wherein the component A is polyamide acid resin solutions obtained after 2-(4-aminophenyl)-5-amido-benzimidazole reacts with pyromellitic dianhydride (PMDA) or biphenyltetracarboxylic acid dianhydride (BPDA); the component B is polyamide acid resin solutions obtained after p-phenylenediamine (PDA) reacts with the PMDA; and the component C is polyamide acid resin solutions obtained after 4,4'-diaminodiphenyl ether (ODA) reacts with the BPDA and the PMDA. The polyimide film provided by the invention has the advantages of lower thermal shrinkage rate, lower thermal expansion coefficient, higher elastic modulus and higher tensile strength and reflects better dimensional stability. The whole preparation method is simple and is easy to operate.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

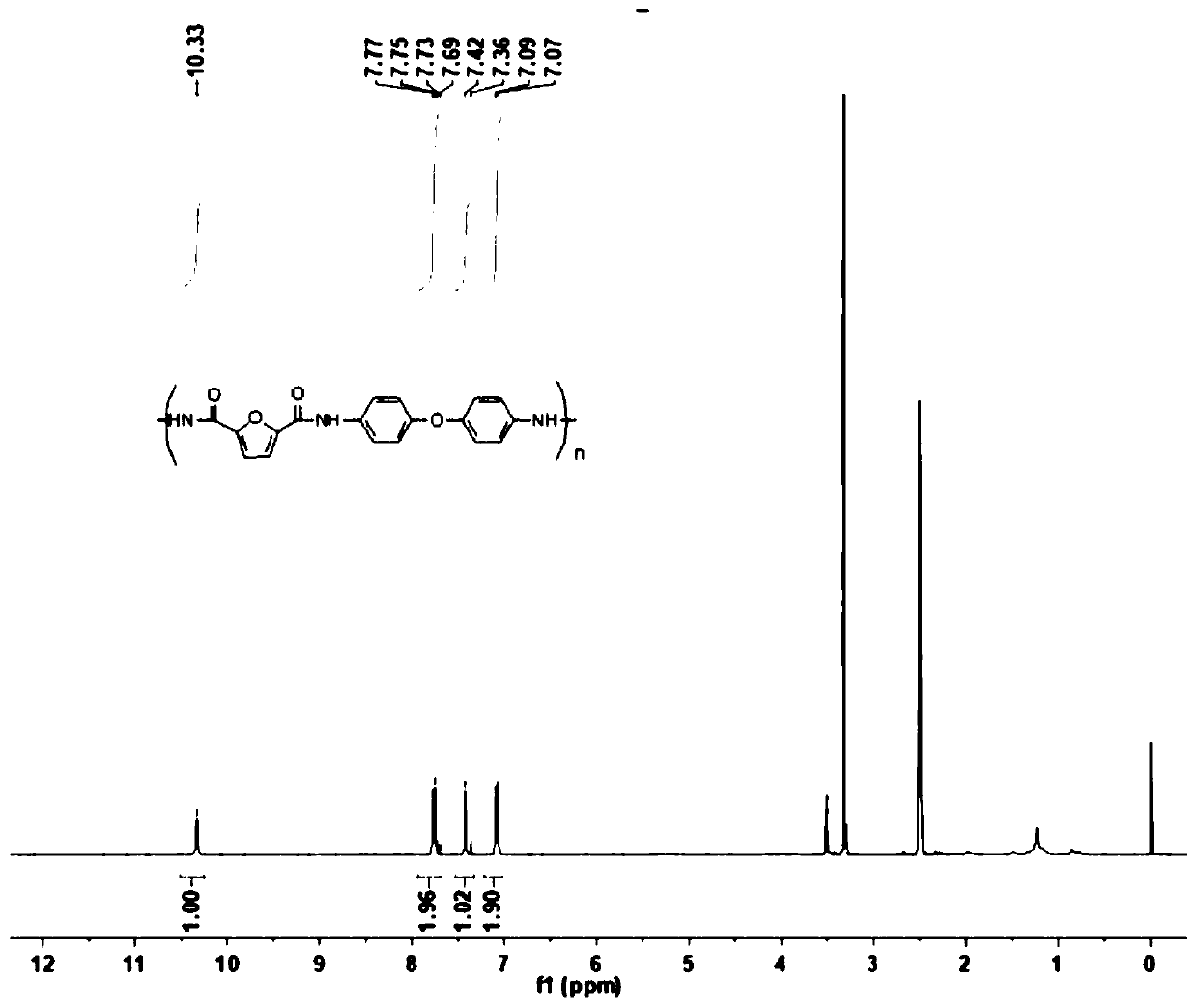

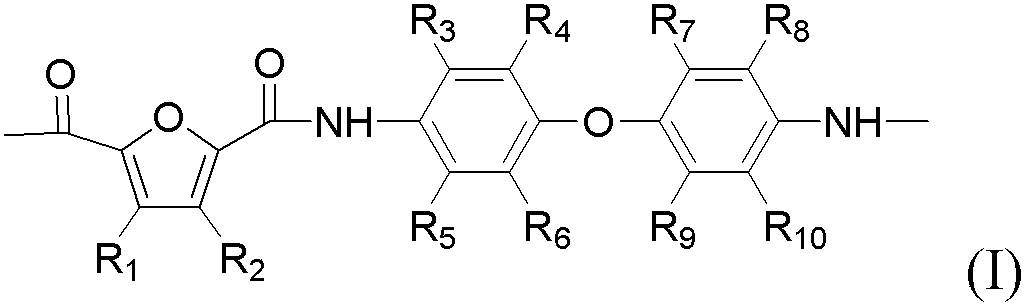

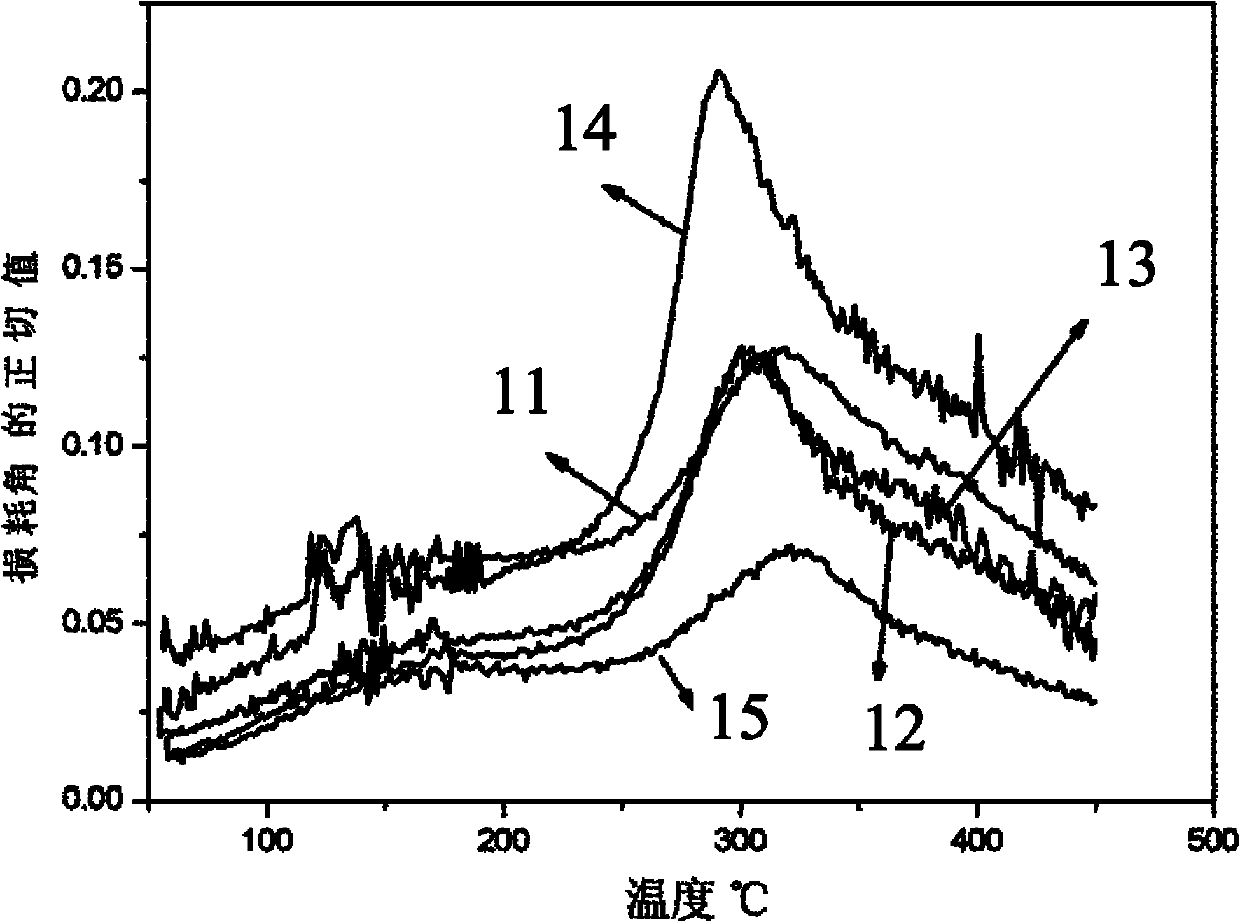

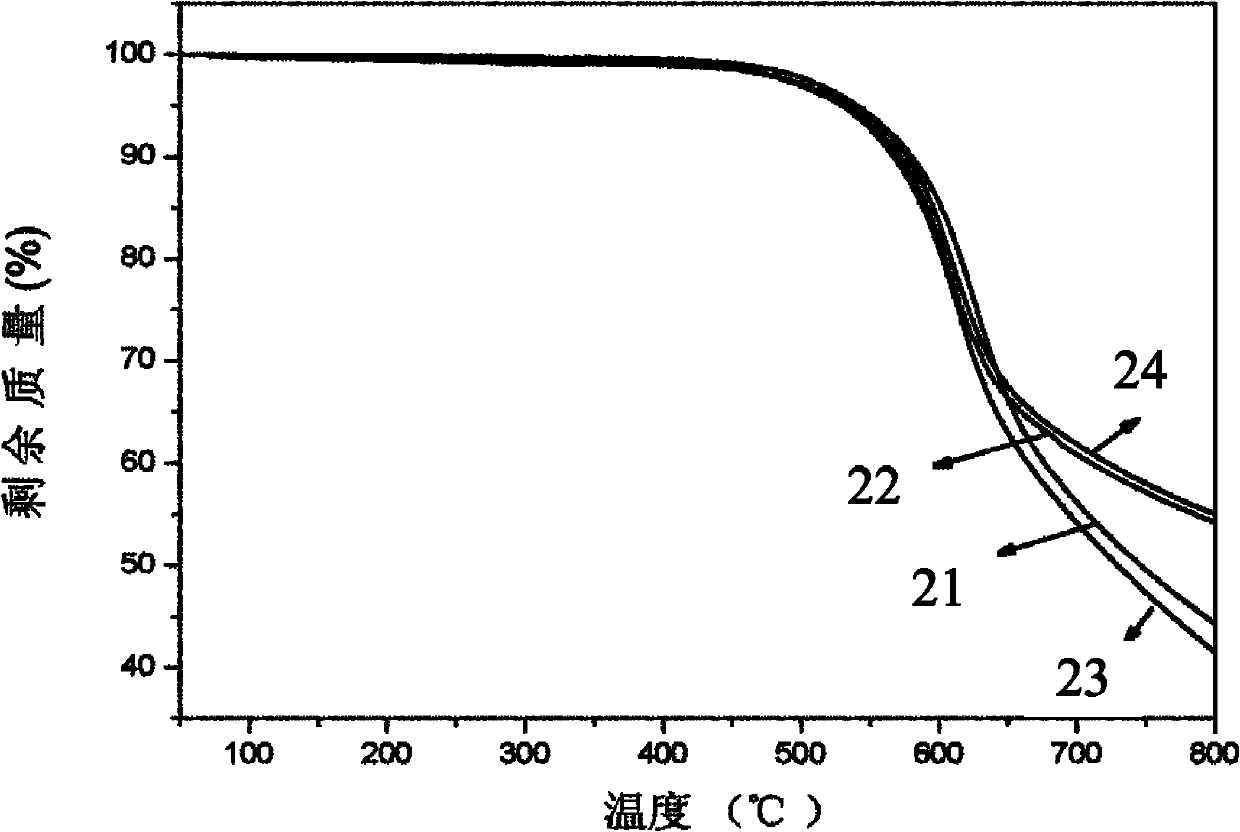

High-molecular-weight furyl aromatic polyamide, preparation method and application thereof

ActiveCN110256668AImprove mechanical propertiesImprove thermal stabilityWet spinning methodsMonocomponent polyamides artificial filamentFuranDiaminodiphenyl ether

Owner:UNIV OF SCI & TECH OF CHINA

Polyimide fiber and preparation method thereof

ActiveCN102041577AImprove mechanical propertiesGood mechanical propertiesArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberOrganic solvent

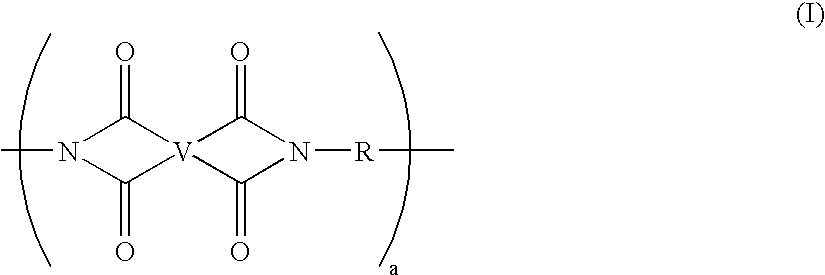

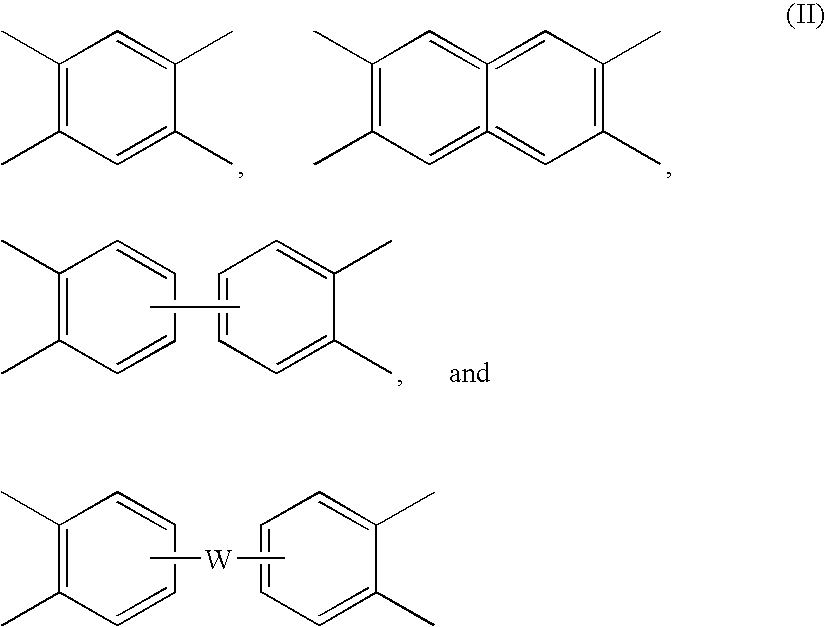

The invention provides a polyimide fiber comprising a polymer with a structure shown in a formula (I) in the specification, wherein m is the proportion of a repeat unit with a structure shown in a formula (II), in the structure of the polymer, and is more than and equal to 0.8 and less than and equal to 0.95. The invention also provides a preparation method of the polyimide fiber, comprising the following steps of: mixing p-phenylenediamine, 4,4'-diaminodiphenyl ether and 3,3',4,4-biphenyltetracarboxylic dianhydride in an organic solvent to carry out condensation polymerization so as to obtain a polyamic acid spinning solution, wherein proportion of the mole number of the p-phenylenediamine to the total mole number of the p-phenylenediamine and the 4,4'-diaminodiphenyl ether is 0.8-0.95; spinning to obtain polyamic acid protofilaments by using the polyamic acid spinning solution; carrying out imidization processing on the polyamic acid protofilaments to obtain polyimide nascent fibers; and carrying out hot stretching processing on the polyimide nascent fibers to obtain the polyimide fiber.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Graphene modified polyimide-based composite and preparation method thereof

ActiveCN102911360AImprove conductivityImprove mechanical propertiesDiaminodiphenyl etherComposite film

The invention discloses a graphene modified polyimide-based composite which is characterized in that the graphene modified polyimide-based composite comprises the following components in parts by weight: 95-105 parts of 4,4'-diaminodiphenyl ether, 110-120 parts of pyromellitic dianhydride and 1-25 parts of graphene. A preparation method comprises the steps of weighing ODA (octyl decyl adipate) and the graphene in proportion, measuring a DMAC (dimethylacetamide) solvent, adding the ODA, the graphene and the DMAC solvent to a reaction vessel, using ultrasonic till the ODA is dissolved sufficiently and the graphene is dispersed completely in the DMAC to obtain a graphene suspension, adding PMDA (pyromellitic dianhydride) in batches under high-speed stirring conditions till weak pole climbing appears, continuing to stir to allow diamine to react with dianhydride completely, and flattening an obtained graphene / PAA (poly acrylic acid) complex to obtain a composite film with uniform thickness so as to obtain a graphene polyimide composite film. The composite is 0.5 g / cm<3>-1.5 g / cm<3> in density and 60-170 KJ / m<2> in tensile strength.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

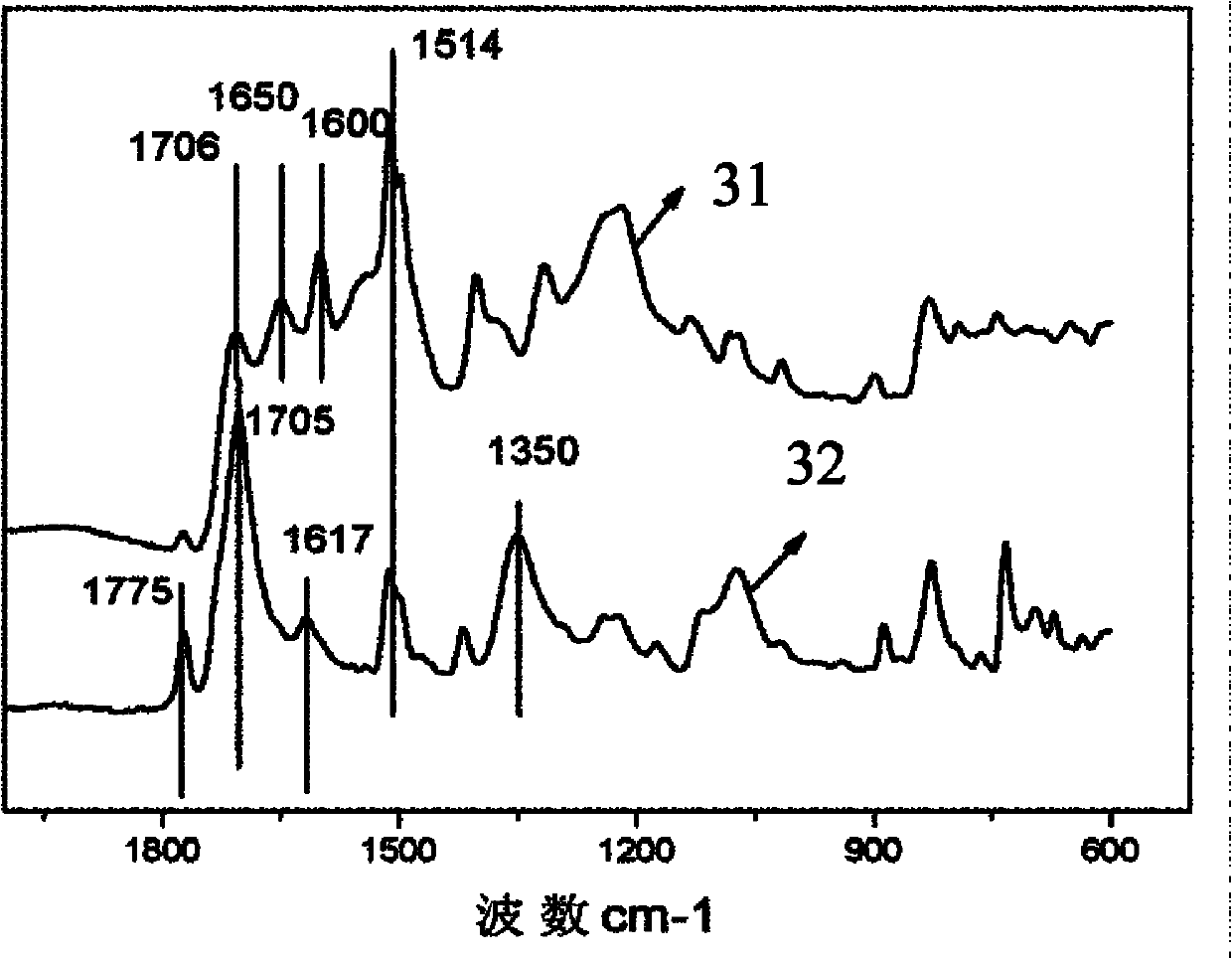

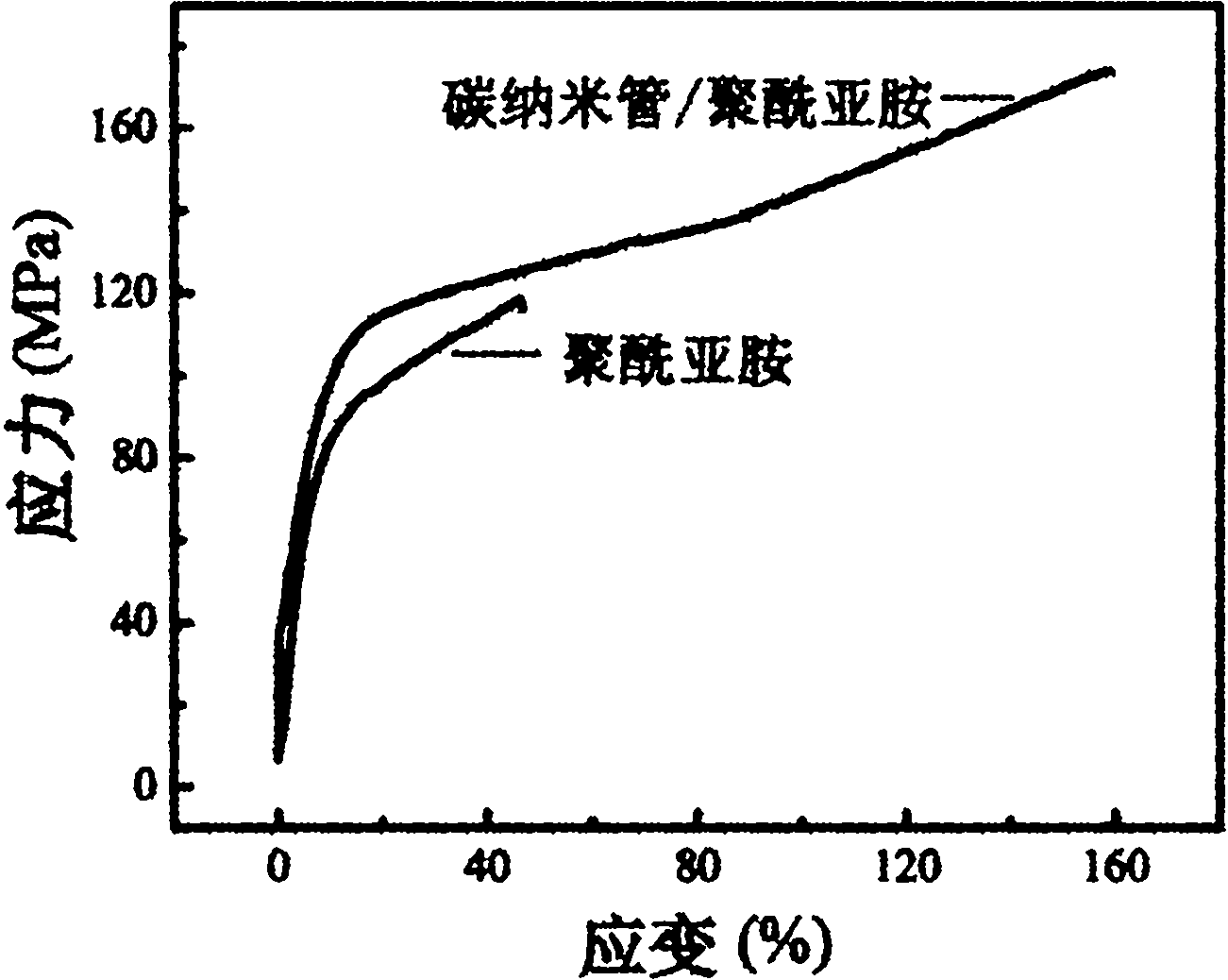

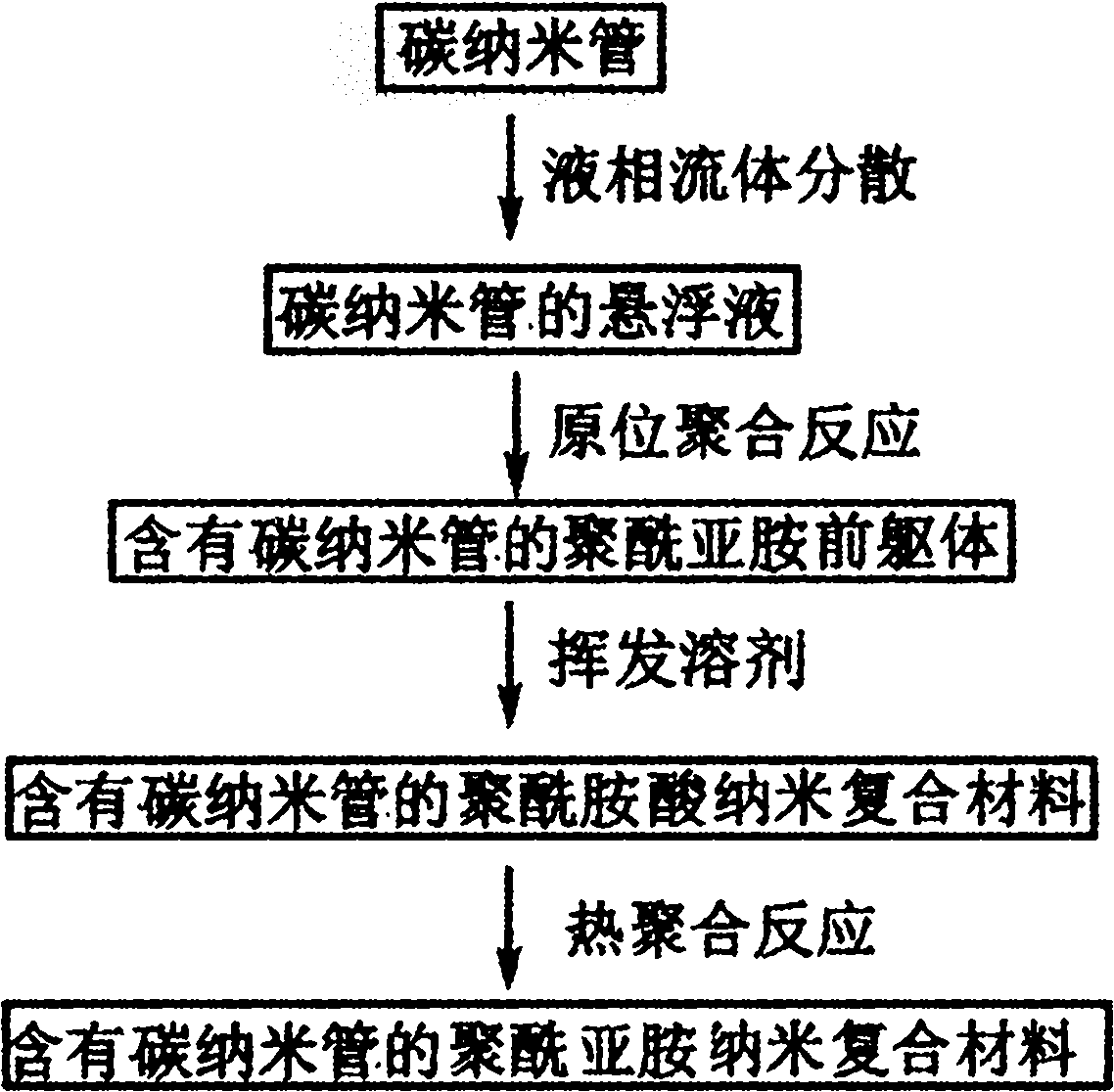

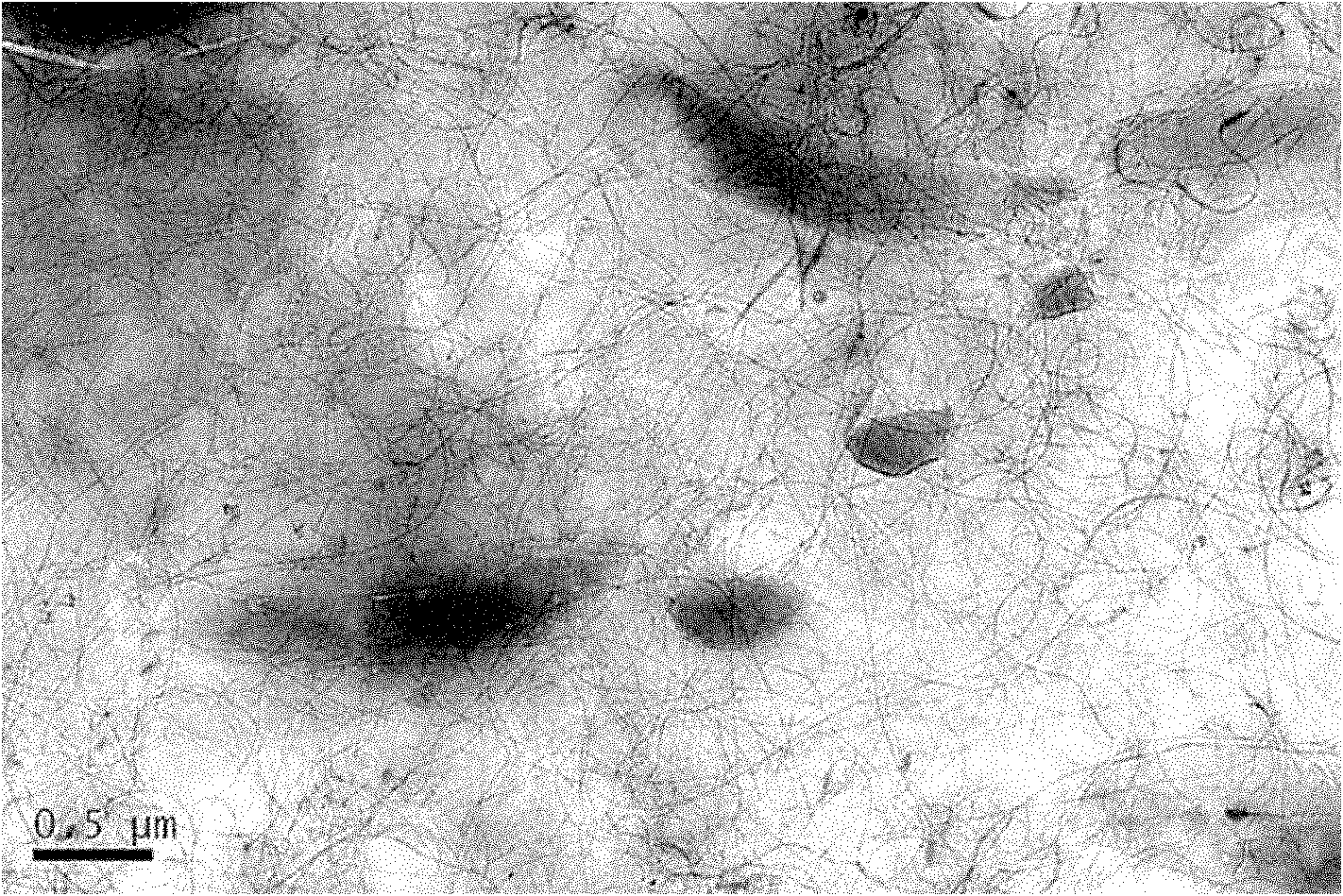

Preparation method of carbon nanotube reinforced polyimide nano composite material

ActiveCN102093715AImprove thermal stabilityIncrease contentMonocomponent synthetic polymer artificial filamentFiberImide

The invention relates to a preparation method of a carbon nanotube reinforced polyimide nano composite material, which comprises the following steps: carrying out liquid-phase shearing dispersion on 10-10000 micrometer long carbon nanotubes in an organic solvent; adding 4,4-diaminodiphenyl ether and pyromellitic dianhydride into the dispersed carbon nanotube slurry to carry out an in-situ polymerization reaction; and carrying out vacuum degasification to obtain a thin film or fibers, volatilizing the solvent, and carrying out heat treatment to obtain the carbon nanotube / polyimide nano composite material. By using the high-length-diameter ratio carbon nanotubes to provide interfaces for adequate slip of polyimide molecules and favorable interface combination, the composite material has excellent mechanical properties, thereby being hopefully applied to fields such as aerospace, automobiles, flexible substrates and the like.

Owner:TSINGHUA UNIV

TGDADPE type epoxy matrix resin for advanced composite material and preparation method thereof

InactiveCN103483553AConvenient sourceSimple preparation processSynthetic resin layered productsGlass fiberDiaminodiphenyl ether

The invention relates to a TGDADPE type epoxy matrix resin for an advanced composite material and a preparation method of the TGDADPE type epoxy matrix resin for the advanced composite material. The TGDADPE type epoxy matrix resin for the advanced composite material is prepared from N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, aromatic diamine, aromatic binary anhydride, a curing agent and organic solvent, wherein the mass ratio of the N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, the aromatic diamine, the aromatic binary anhydride, the curing agent and the organic solvent is 100:5-10:10-20:1-5:80-200. The preparation method of the TGDADPE type epoxy matrix resin is simple in operation technology, the prepared matrix resin is excellent in overall performance and good in wettability to glass fiber, carbon fiber, quartz fiber, basalt fiber and aramid fiber and can be used for preparing the advanced composite material good in overall performance, and the preparation method of the TGDADPE type epoxy matrix resin is suitable for industrial production and has broad application prospects.

Owner:DONGHUA UNIV +1

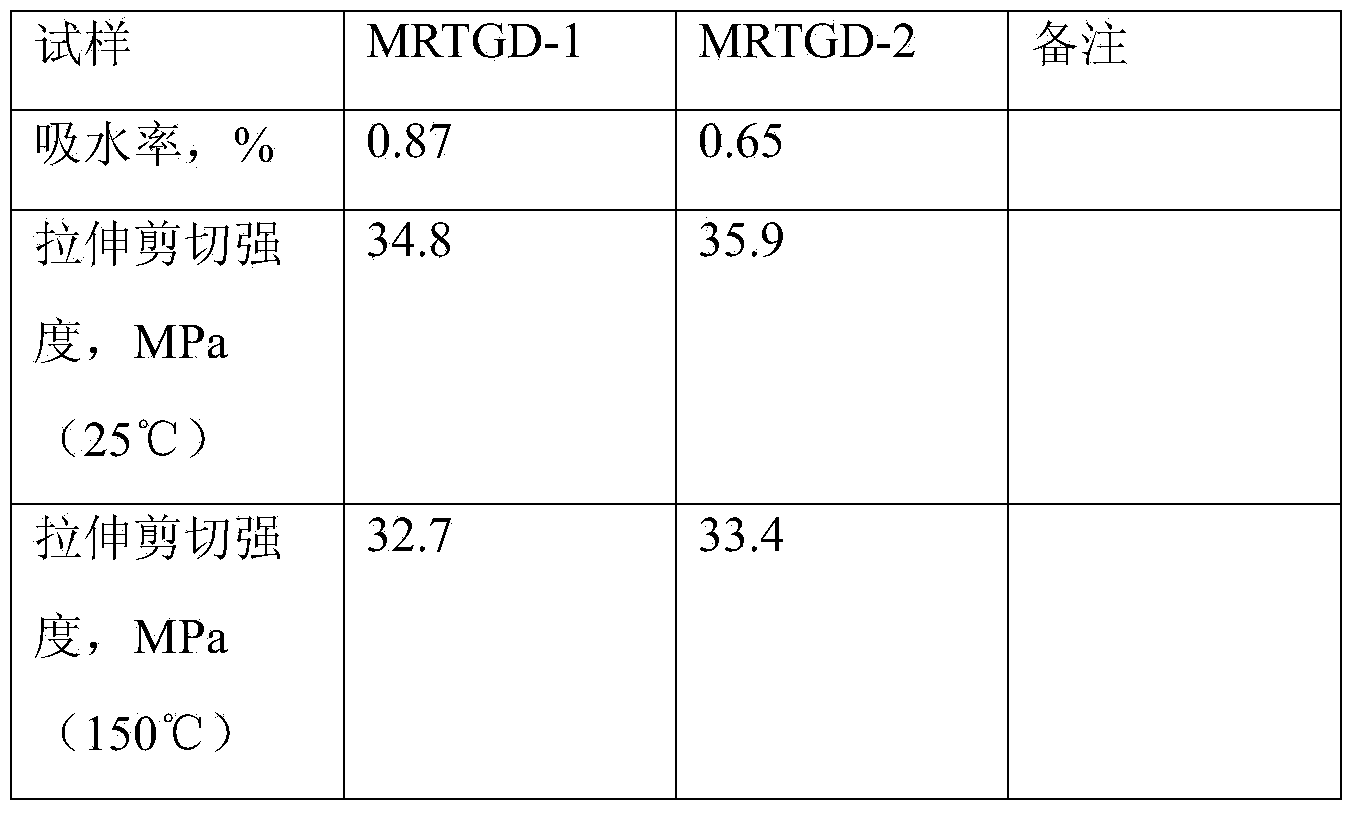

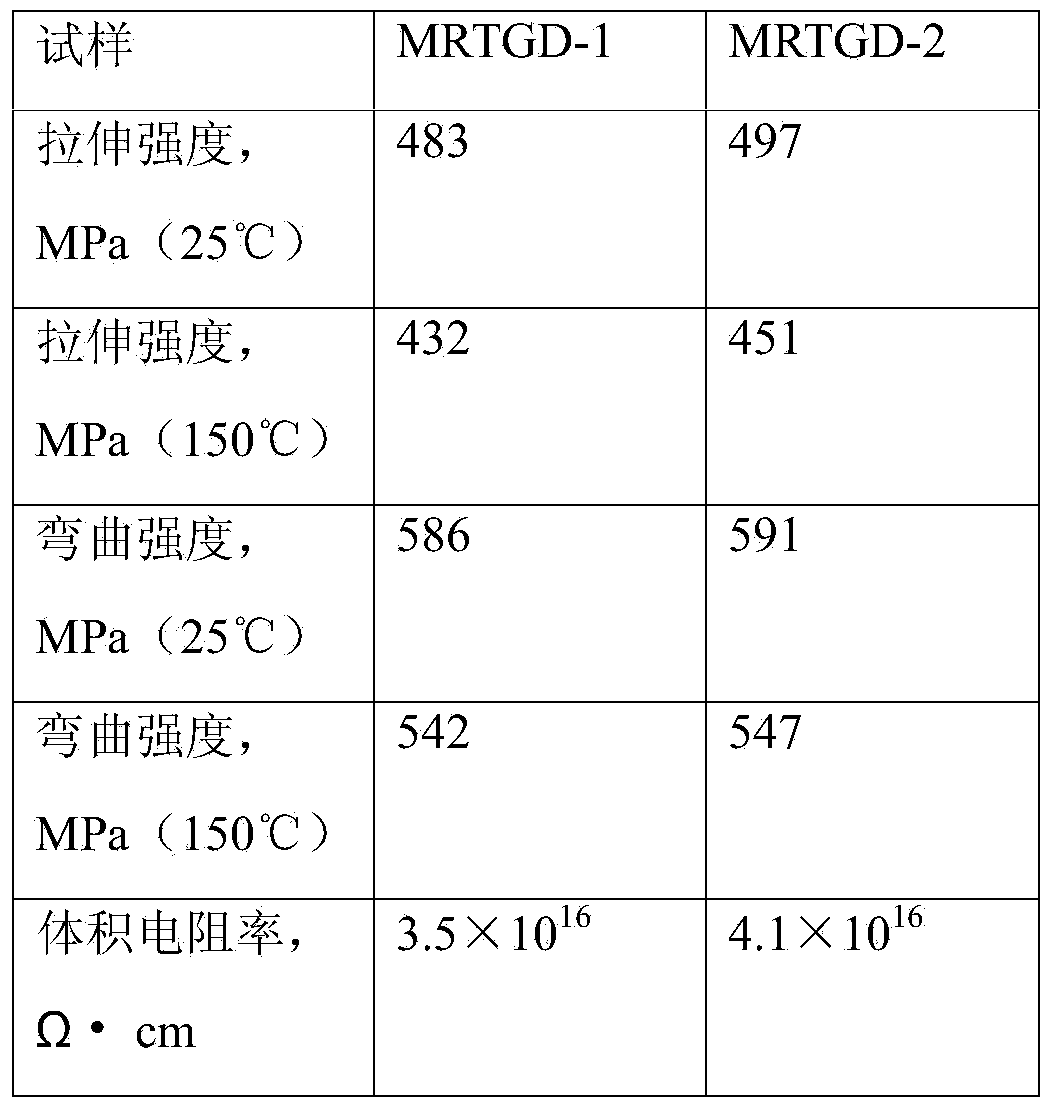

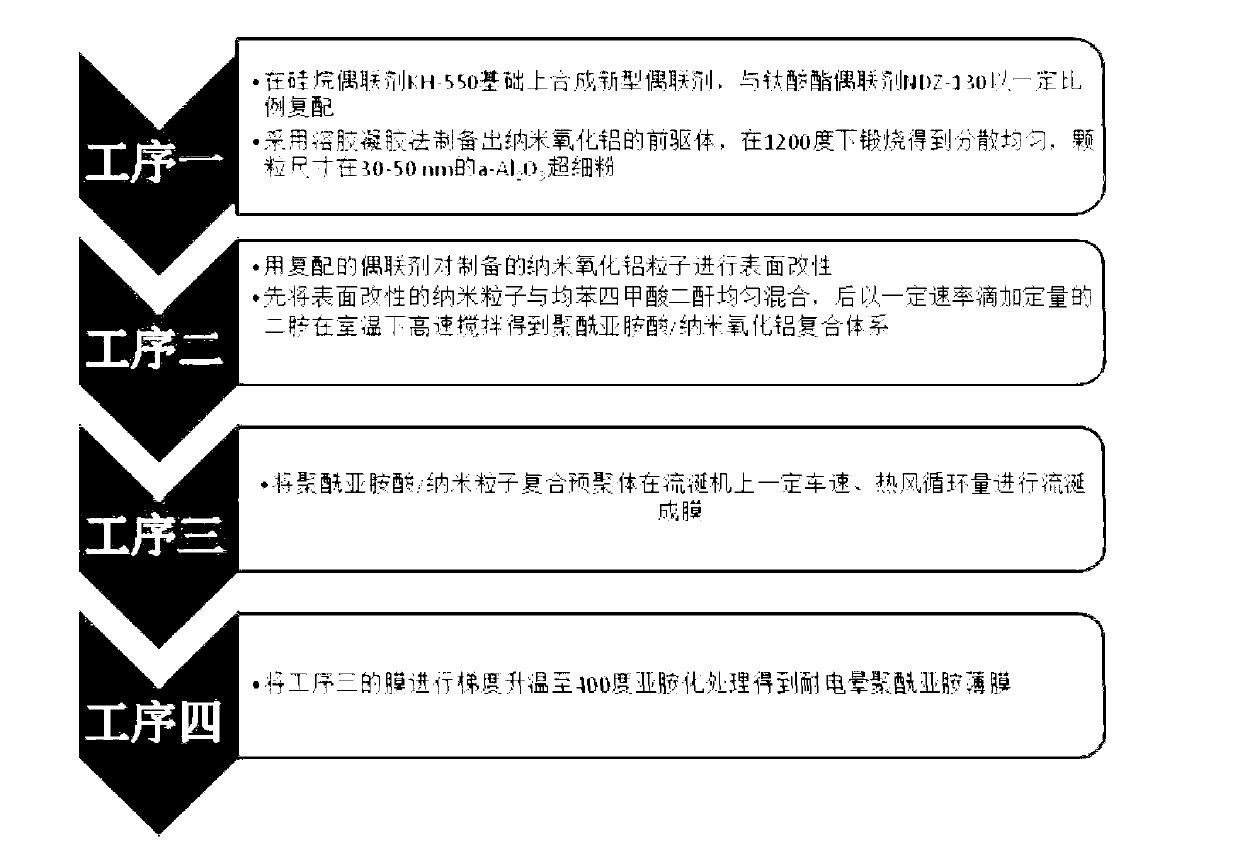

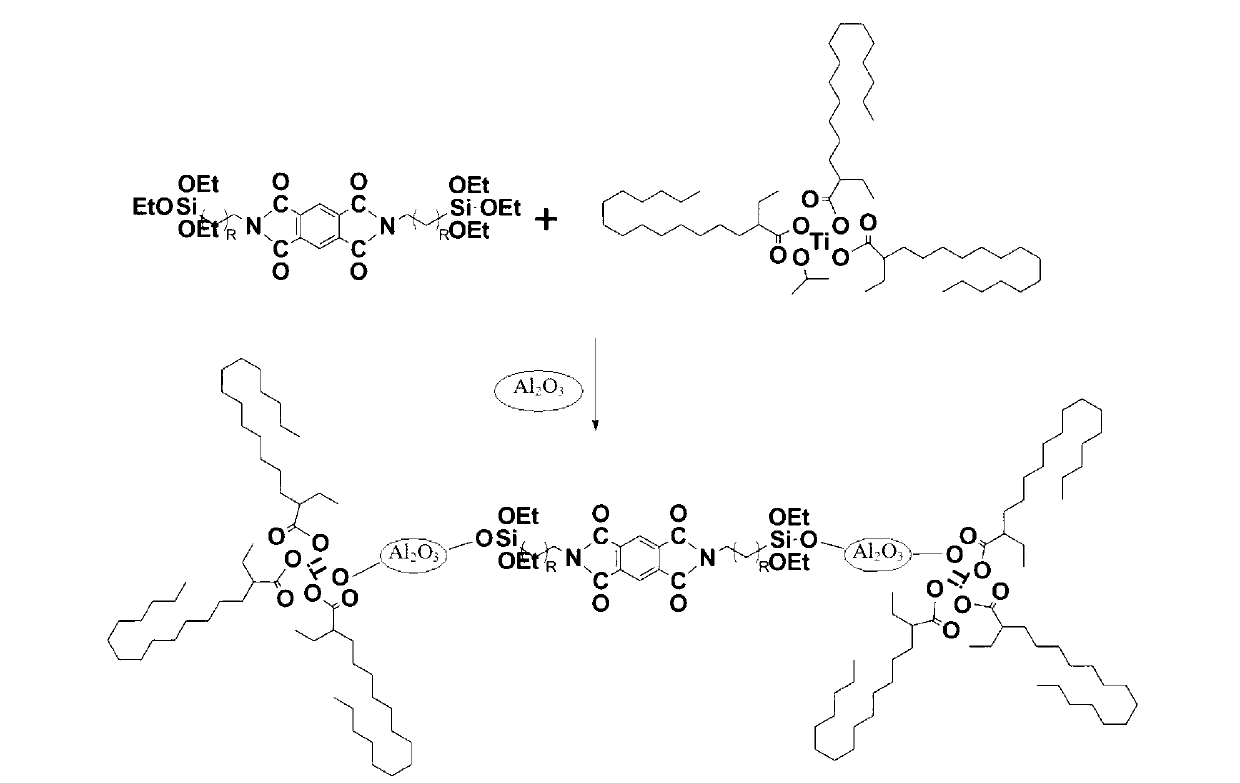

Nano Al2O3 composite corona-resistant polyimide film

The invention relates to a corona-resistant polyimide film containing high-concentration nano metal oxide, which comprises the following main components: benzenetetracarboxylic anhydride, 4, 4'-diamino diphenyl ether and nano-scale aluminum oxide, wherein the particle size of the nano-scale metal oxide is in the range from 30nm to 50nm. The film provided by the invention has the following outstanding advantages that a novel coupling agent is synthesized and is compounded with titanate coupling agent NDZ-130 to conduct surface modification on prepared alpha-Al2O3, thus the modified nano-particles can be steadily and uniformly dispersed in the substrate polyimide film with relatively high mass percentage (can reach 30wt%). By adoption of the above novel technical scheme of the invention, the technical problem that high-concentration nano-metal oxide is very difficultly doped uniformly in the corona resistant polyimide film according to the prior art is solved well, and meanwhile the mechanical strength of the film is kept from dropping.

Owner:UNIV OF SCI & TECH BEIJING

Corona resistant enamel-covered wire paint for variable frequency motor and preparing process thereof

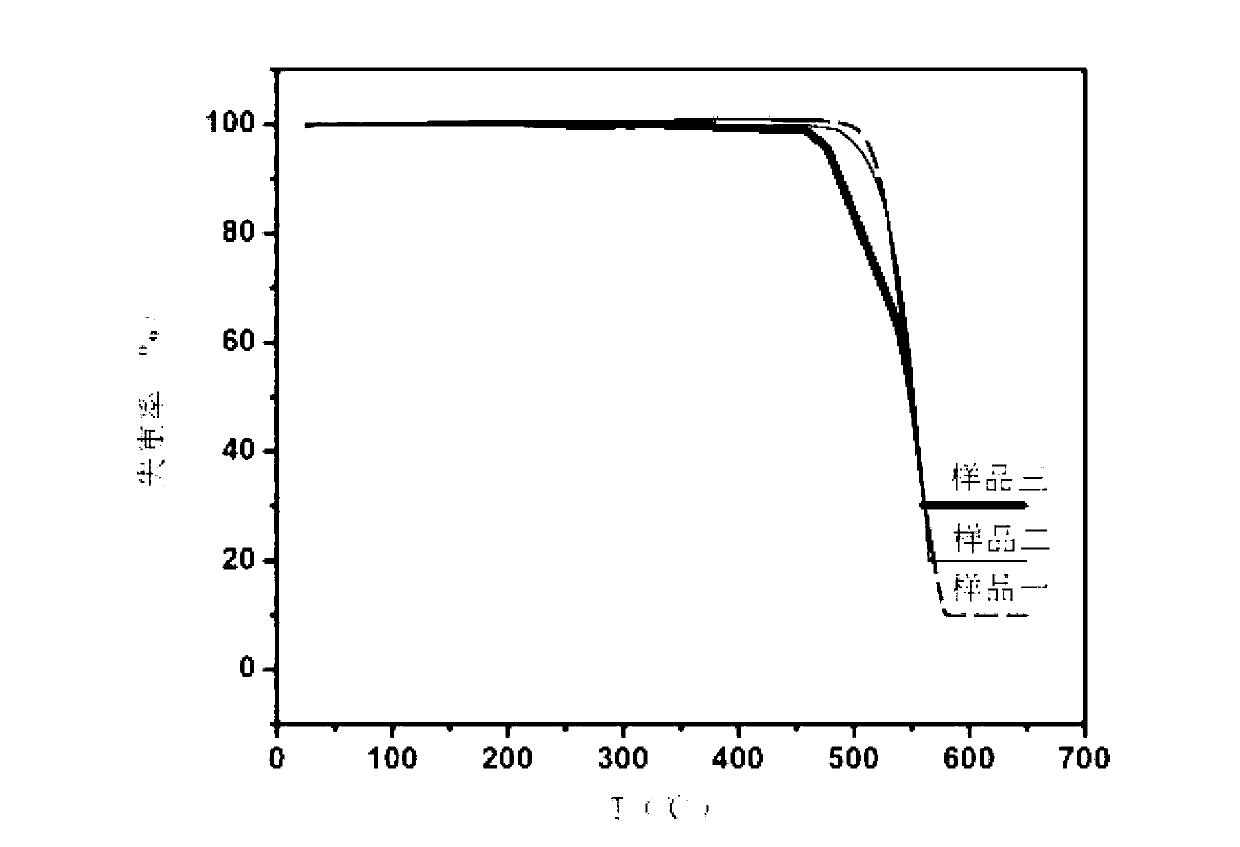

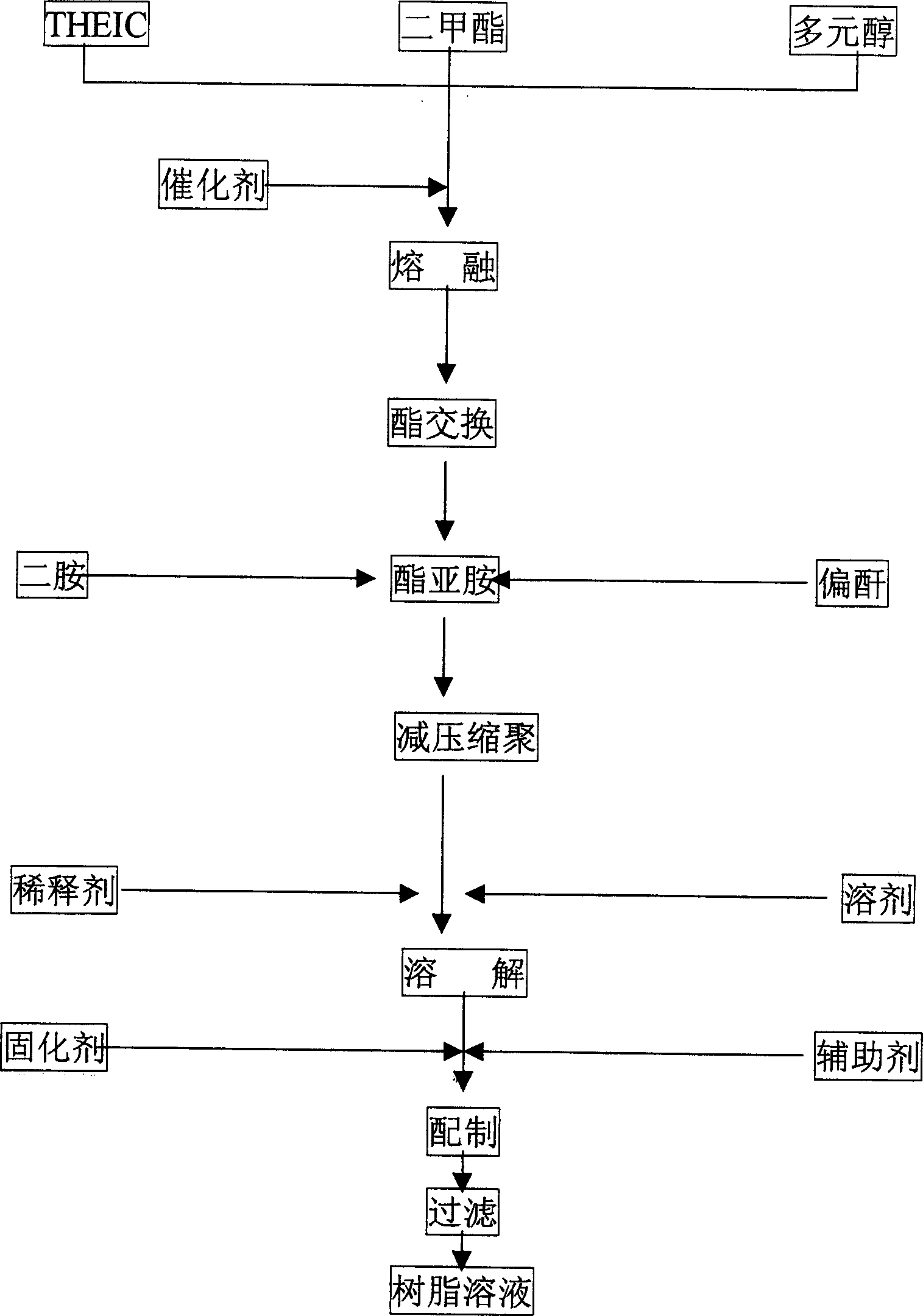

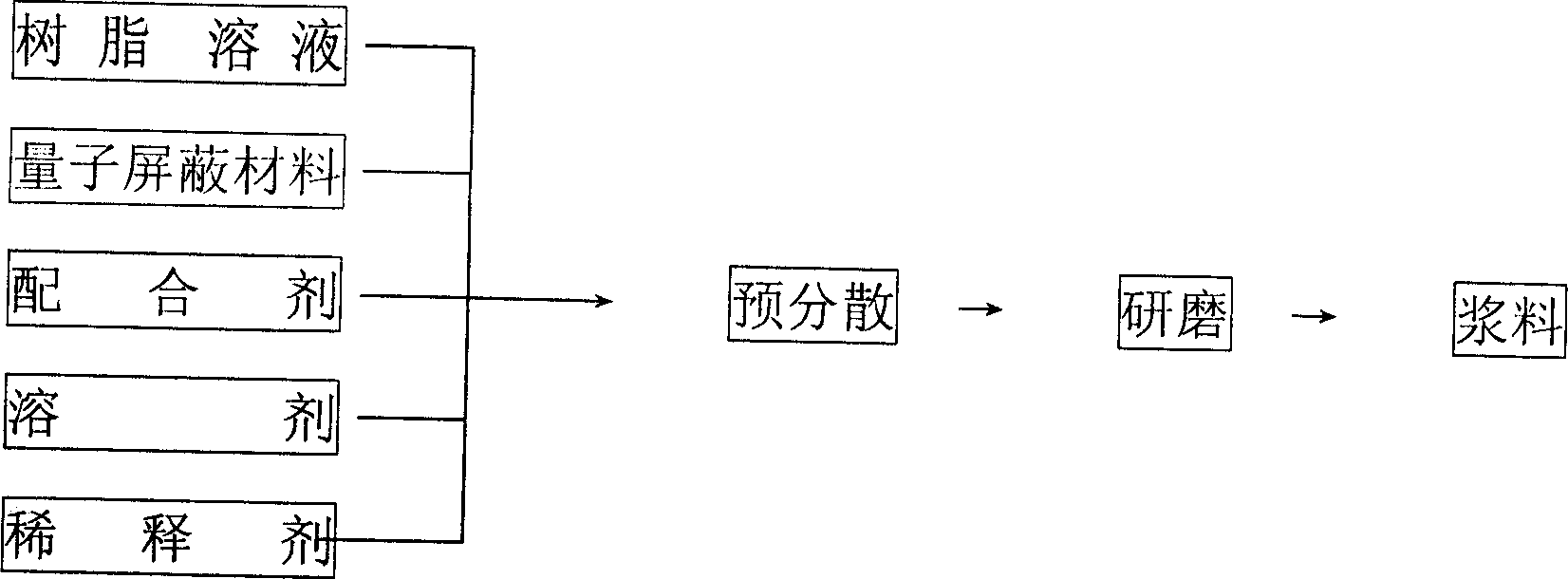

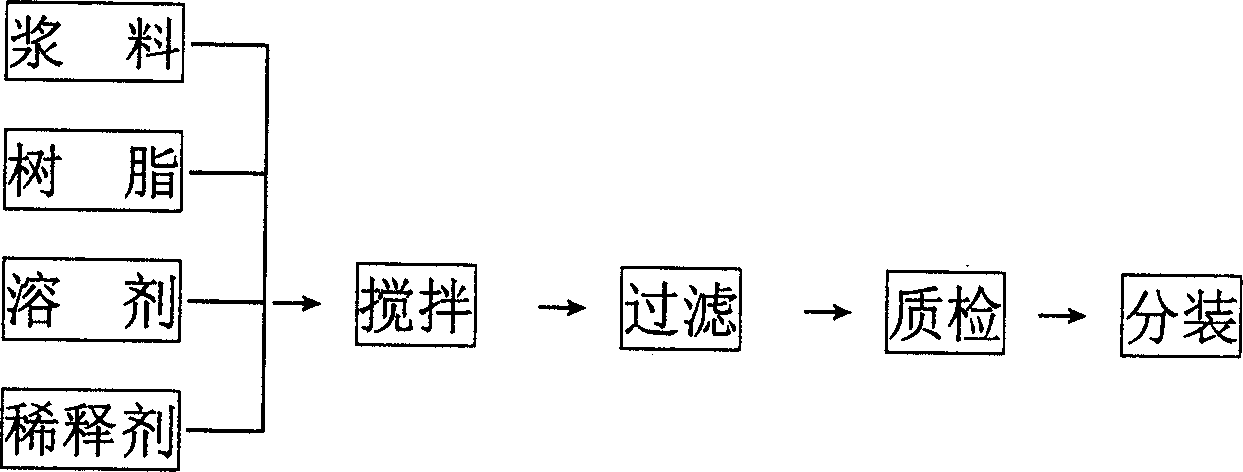

InactiveCN1488697AImprove insulation performanceImprove performanceChemical industryInsulated cablesDimethyl terephthalatePolyester

Owner:上海汉邦化工有限公司

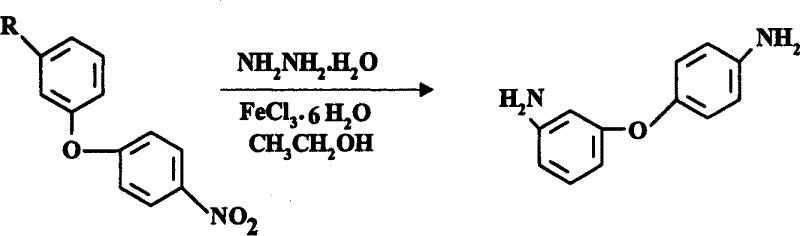

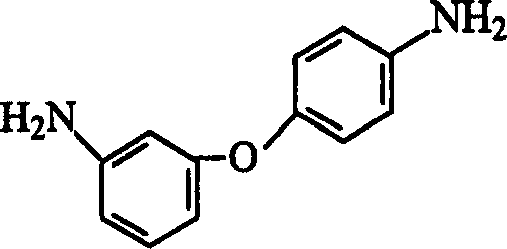

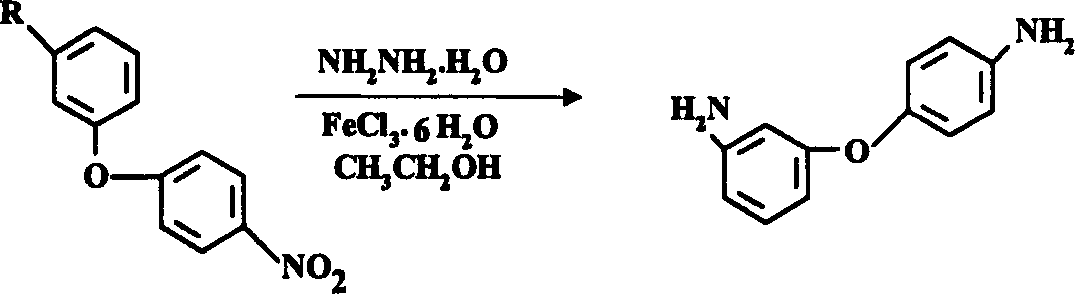

Process for preparing 3,4-diaminodiphenyl ether

InactiveCN1485315AAvoid unsafe factorsEliminate high vacuum distillation stepsOrganic compound preparationAmino-hyroxy compound preparationDiphenyl etherDiaminodiphenyl ether

A process of preparing 3ú¼4'-diamino diphenyl ether. It comprises: taking nitrodiphenyl ether as the raw material, hydrazine hydrate as the reducing agent, reducing in the presence of a catalyst, obtaining 3ú¼4'-diamino diphenyl ether at a low pressure. The invention overcomes unsafe factors in the method of high-pressure hydrogenation, avoid the step of highpressure distillation, and has mild reactive conditions. The product has good purity. So the invention is suitable for industrial production.

Owner:SHANGHAI CHEM REAGENT RES INST

Polyimide fiber and its preparing method

InactiveCN1821457AOptimize synthesis conditionsGood mechanical propertiesMonocomponent synthetic polymer artificial filamentDiphenyl etherFiber

The present invention discloses a kind of polyimide fiber and its preparation process. The preparation process includes the following steps: 1. reacting 4, 4í»-diamino diphenyl ether and pyromellitic dianhydride in the weight ratio of 1 to 1.02 with N, N-dimethyl acetylamide solution of 15-20 % concentration at 0-5 deg.c to obtain polyamic acid solution; 2. wet spinning the polyamic acid solution and imidation reaction of the polyamic acid fiber to obtain polyimide fiber through dewatering and cyclization; and 3. mixing the polyimide fiber with acetic anhydride and triethylamide, flushing with acetone, soaking and drying to obtain the polyimide fiber. The present invention has positive effects of optimized synthesis condition of spinning solution, prolonged solidification period of initially formed fiber in the solidification bath, and fiber with ideal mechanical performance.

Owner:DONGHUA UNIV

Epoxide resin curing agent, epoxide resin embedding glue and confecting method thereof

ActiveCN101225156AImprove heat resistanceImprove mechanical propertiesOther chemical processesEpoxy resin adhesivesVitrificationEpoxy

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

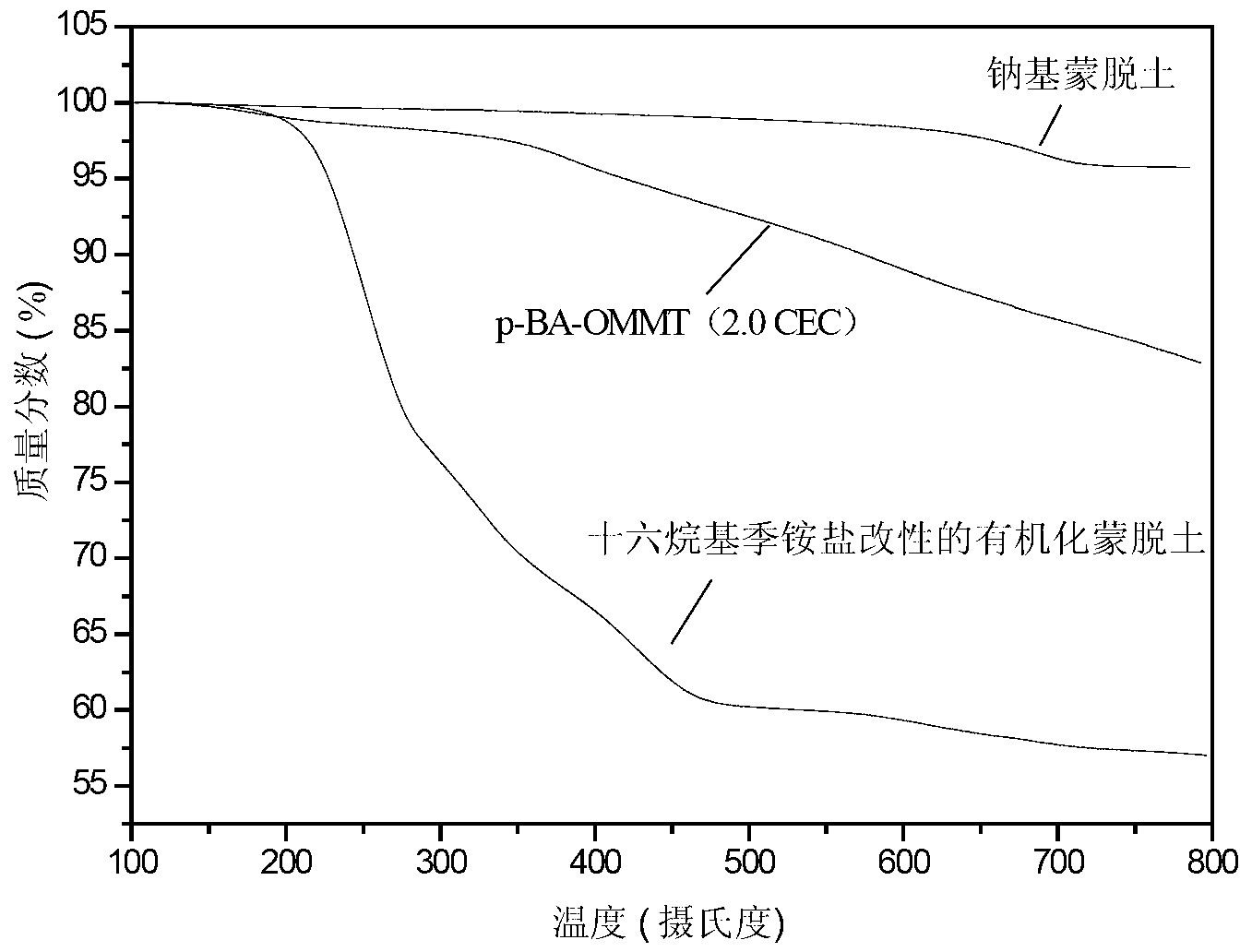

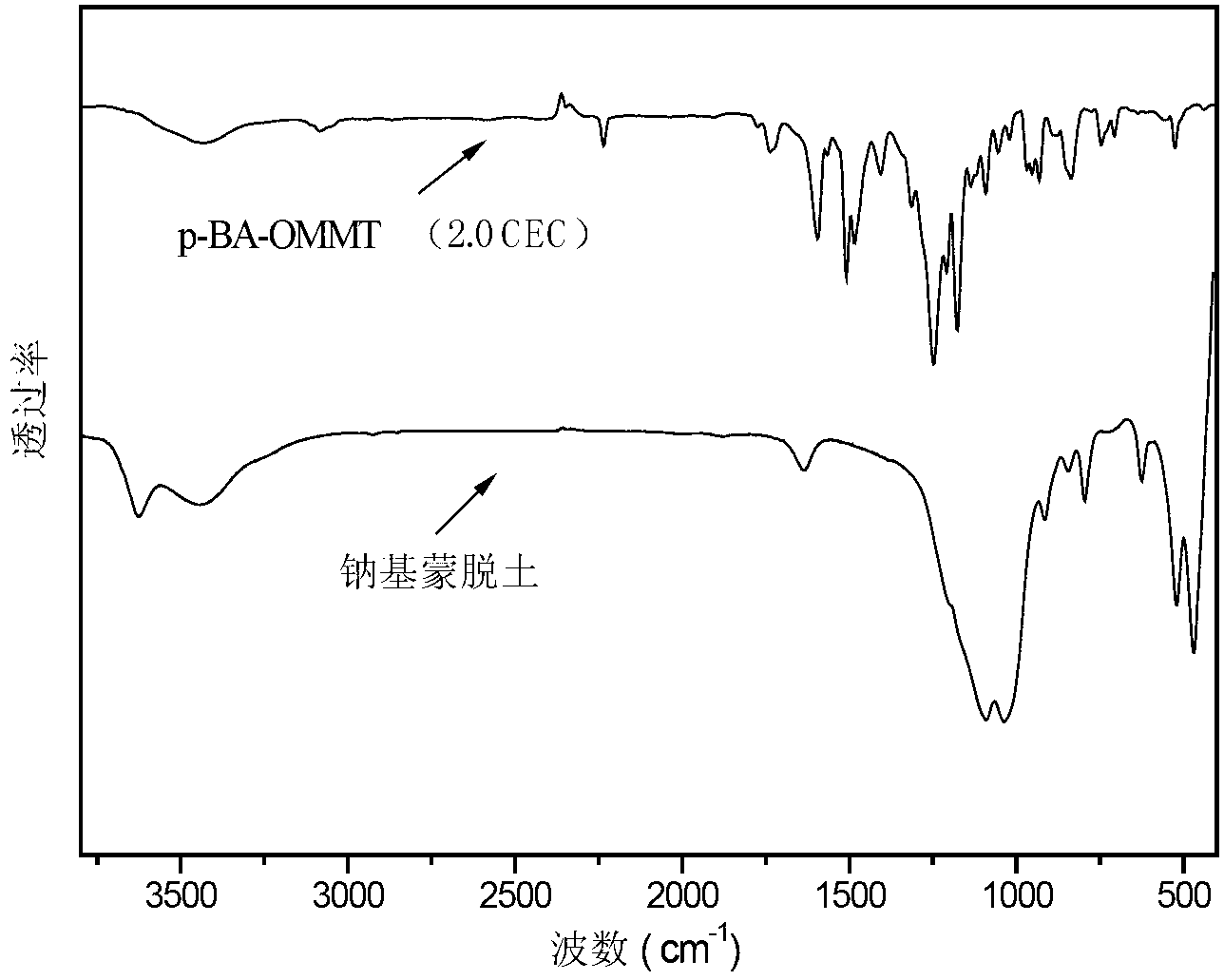

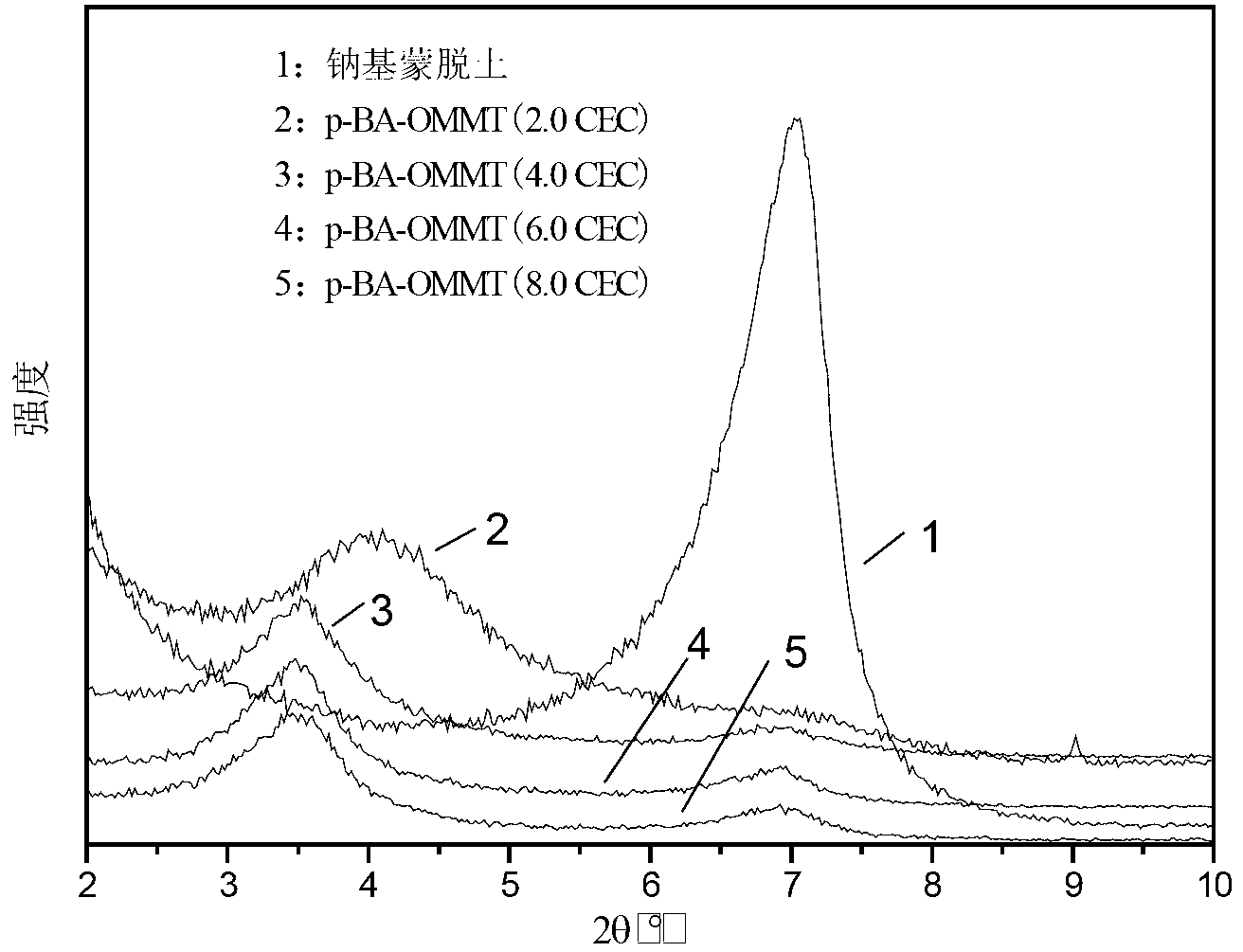

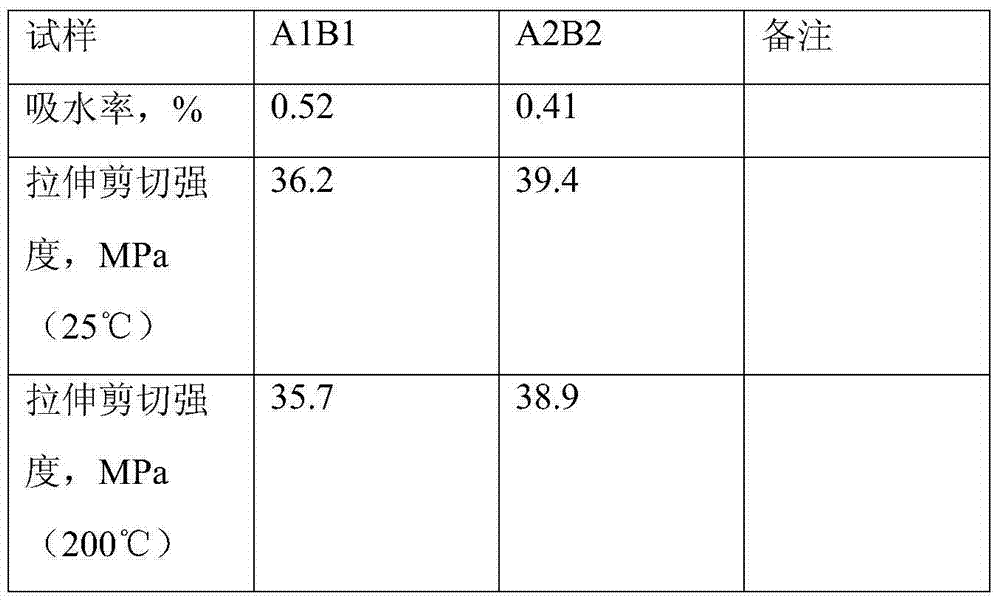

Bisphthalonitrile resin/aromatic amine organic montmorillonite nano composite material and preparation method thereof

The invention relates to a bisphthalonitrile resin / aromatic amine organic montmorillonite nano composite material and a preparation method thereof, belonging to the technical field of thermosetting resin composite materials. The bisphthalonitrile resin / aromatic amine organic montmorillonite (p-BA-OMMT) nano composite material comprises the components in parts by mass: 100 parts of bisphthalonitrile monomer, 0.5-5 parts of p-BA-OMMT, and 3 parts of curing agent of 4,4'-Bisaminophenoxyphenylsulfone (p-BAPS). The method comprises the steps of montmorillonite organic treatment and composite material preparation. The bisphthalonitrile resin / p-BA-OMMT nano composite material, prepared by the preparation method, has excellent mechanical property and thermal stability, is lower in preparation cost, satisfies the application requirement of industrial production, and has broad application prospect in the fields, such as vehicles, mechanicals, aviation, aerospace and submarines.

Owner:JILIN UNIV

Matrix resin for carbon fiber composite material and preparation method of matrix resin

The invention relates to matrix resin for a carbon fiber composite material and a preparation method of the matrix resin. The matrix resin comprises N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, ES216 epoxy resin, 2,2-bi[4-(2-trifluoromethyl-4-maleimido phenoxy)phenyl]propane, 3,3'-dimethyl-4,4'-bi(4-carboxyl phthalimido)diphenylmethane, a curing agent and an organic solvent based on a mass ratio of 100 to (50-100) to (10-50) to (5-20) to (50-100) to (300-600). According to the matrix resin, the preparation process is simple; the raw materials are convenient to get; the obtained matrix resin is excellent in integral performance, can be used for preparing the high-performance carbon fiber composite material, can be applied to structure materials in the fields of sports equipment, aerospace, autos, electronics, micro-electronics and the like, is suitable for industrial production, and has a very high commercial prospect.

Owner:DONGHUA UNIV +1

Method for preparing polyimide multilayer complex films containing inorganic nanometer powder

InactiveCN101812183AImprove mechanical propertiesSolve the shortcomings of insufficient mechanical propertiesDiaminodiphenyl etherPolyamic acid

The invention relates to a method for preparing polyimide multilayer complex films containing inorganic nanometer powder. Polyimide multilayer complex materials containing inorganic nanometer powder often reduce the mechanical property of films, and obviously reduce the property of the films especially when the nanometer powder is unevenly distributed. The method comprises the following steps of: (1) pre-processing the inorganic nanometer powder; (2) dissolving 4, 4'- diaminodiphenyl ether and pyromellitic dianhydride as raw material monomers into a solvent, and polymerizing to generate polyamic acid solution; (3) dispersing the pre-processed inorganic nanometer powder to the solvent through an ultrasound, and adding the solvent to the polyamic acid solution to prepare the polyamic acid solution containing the inorganic nanometer powder; (4) sequentially paving films on the polyamic acid solution containing the inorganic nanometer powder and the pure polyamic acid solution; and (5) putting the films in an oven for hot-imidization treatment at the temperature of 50 to 400 DEG C to obtain the polyimide hybrid multilayer complex films containing the inorganic nanometer powder. The invention is used for preparing the polyimide multilayer complex films containing the inorganic nanometer powder.

Owner:HARBIN UNIV OF SCI & TECH +1

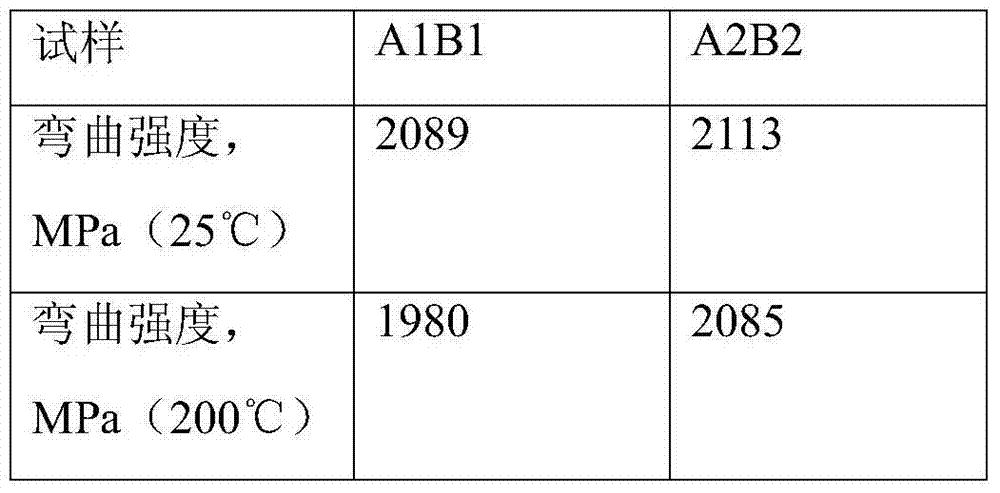

Preparation method for polymide film with low thermal expansion coefficient

The invention provides a preparation method for a polymide film with the low thermal expansion coefficient. The method comprises the following steps that 1, pyromellitic anhydride and ursol are placed into a dimethylacetamide solvent for condensation polymerization to obtain a polyamide acid glue solution A; 2, 2, 3',3,4'- biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether are placed into the dimethylacetamide solvent for condensation polymerization to obtain a polyamide acid glue solution B; 3, the polyamide acid glue solution A and the polyamide acid glue solution B are mixed for a high-speed stirring reaction to obtain a polyamide acid glue solution C; 4, the tape casting technology is adopted on the polyamide acid glue solution C to obtain a film, and finally the film is fed into an imidization furnace to be processed to obtain the polymide film with the low thermal expansion coefficient. The CTE of the polymide film with the low thermal expansion coefficient is 15-17 ppm / K, and the polymide film further has the advantages of being high in strength, stability, electrical strength and the like.

Owner:安徽统唯新材料科技股份有限公司

Easily workable high-performance polyimide material and its preparation method

InactiveCN1428361AEasy to processEasy to withstand high temperatureDiphenyl etherDiaminodiphenyl ether

The present invention uses 4,4-diphenyl ether tetrahydric dianhydride and 4,4'-diaminodiphyl ether as polymerization monomer, and adopts the solution polycondensation method combining chemical imidation process and thermal imidation process to synthesize the high-temp.-resistant and solvent-resistant polyimide resin. Said invented polyimide resin possesses good working property, the polyimide plate material die-moulded by using said polyimide resin possesses high strength and fire resistance, its glas-stransition temperature is 267.7 deg.C, 5% thermal weight loss temperature is 543.1 deg.c, tensile strength is 145 MPa, impact strength is 192 KJ / sq.m, compressive strength is 1635 MP and oxygen index is 46.2.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

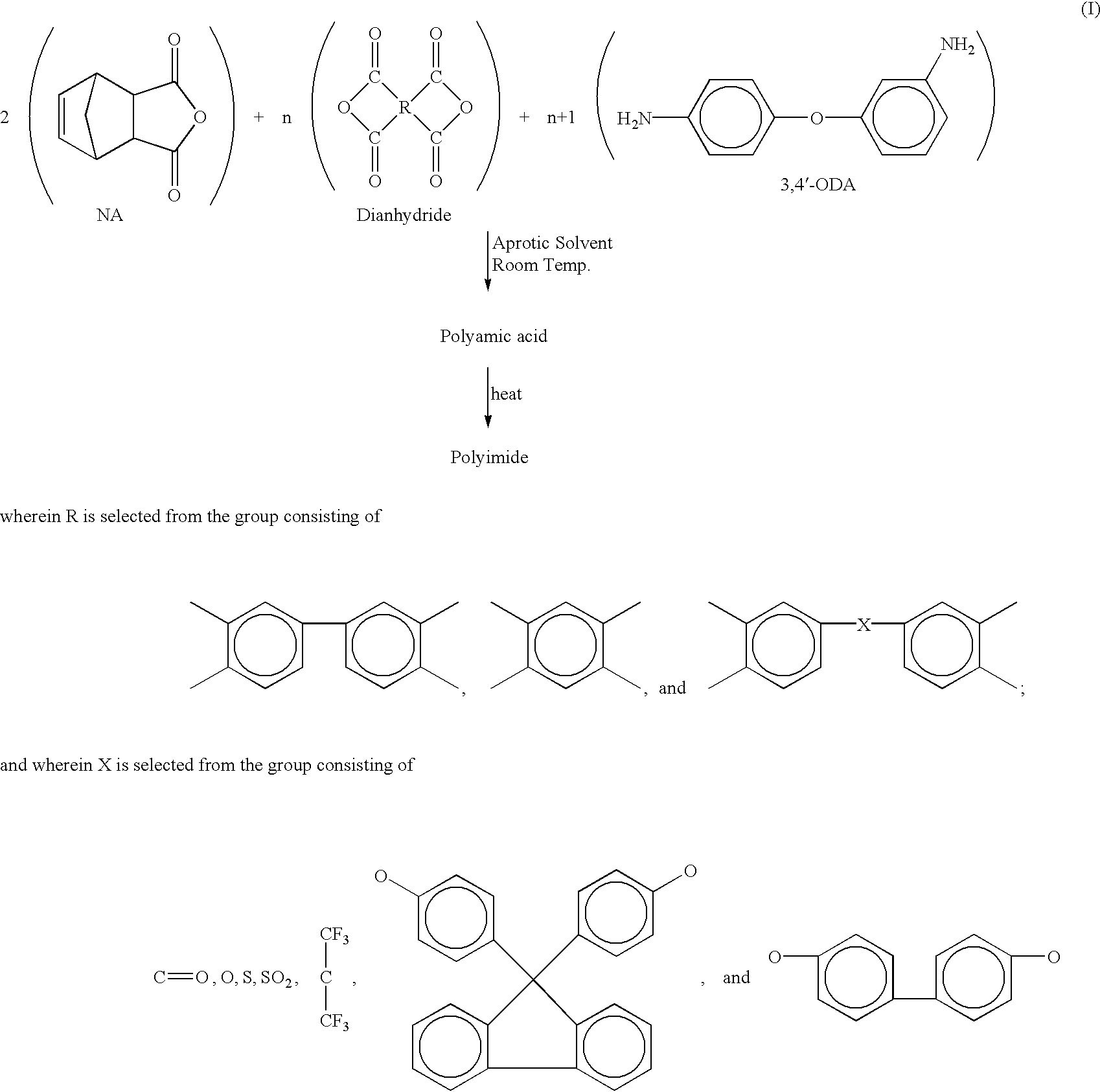

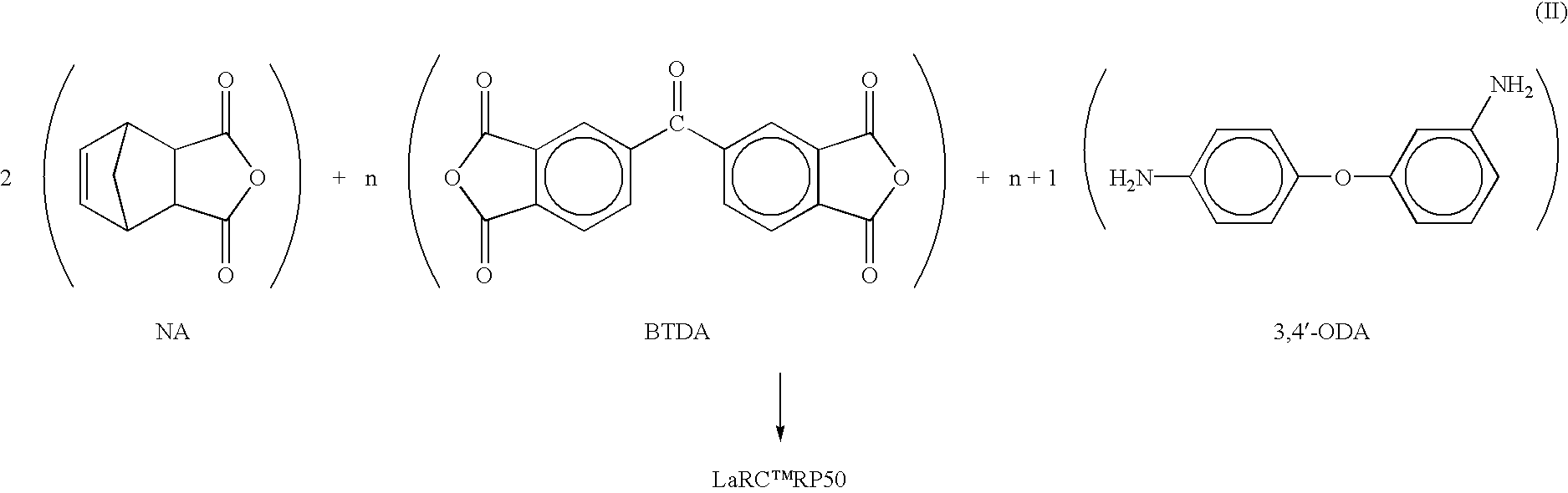

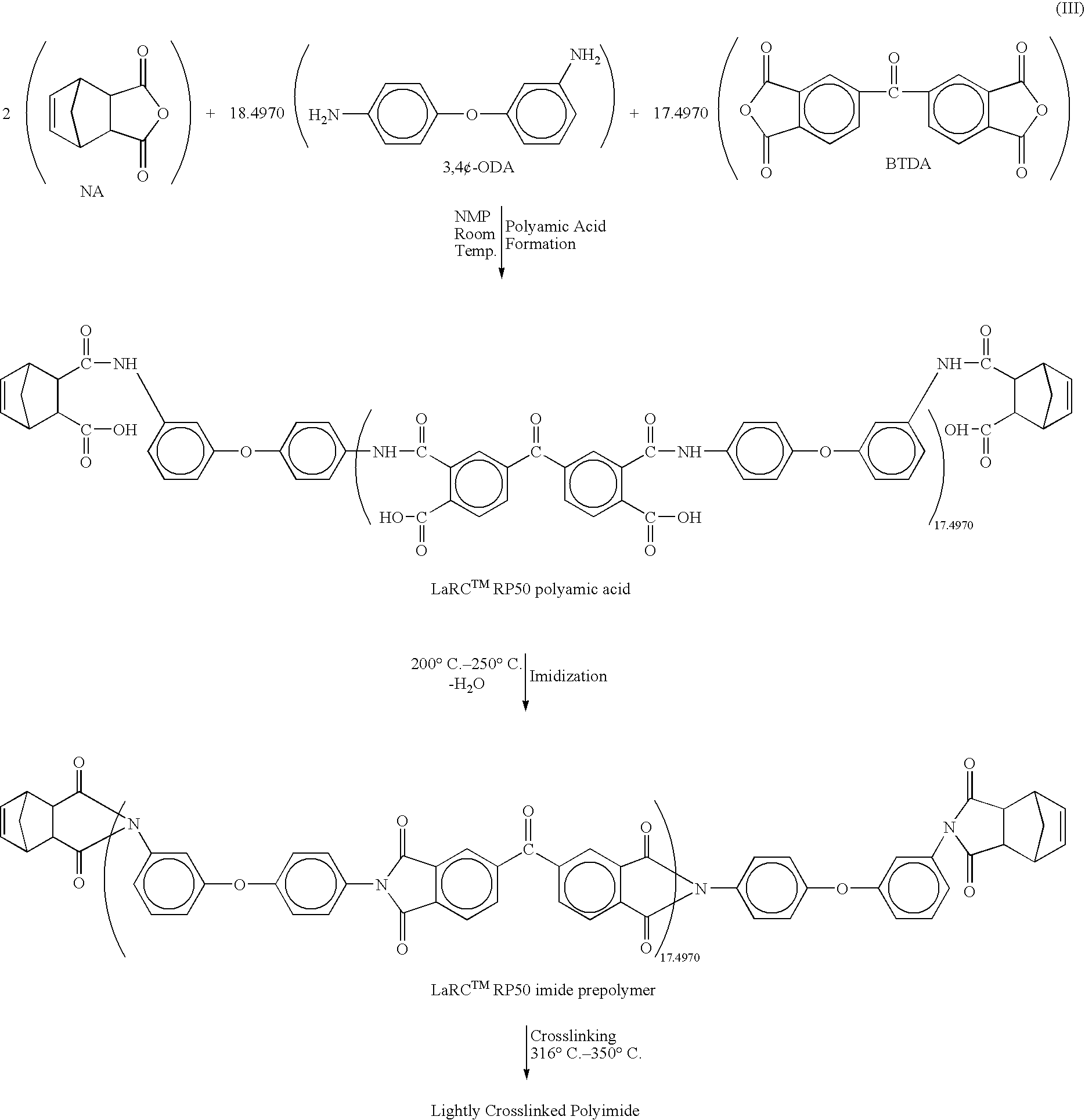

Heat, moisture, and chemical resistant polyimide compositions and methods for making and using them

InactiveUS6777525B2Improve mechanical propertiesGood thermal propertiesEngine sealsSynthetic resin layered productsDiaminodiphenyl etherBoiling point

Polyimides having a desired combination of high thermo-oxidative stability, low moisture absorption and excellent chemical and corrosion resistance are prepared by reacting a mixture of compounds including (a) 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA), (b) 3,4'-oxydianiline (3,4'-ODA), and (c) 5-norbornene-2,3-dicarboxylic anhydride (NA) in a high boiling, aprotic solvent to give 5 to 35% by weight of polyamic acid solution. The ratio of (a), (b), and (c) is selected to afford a family of polyimides having different molecular weights and properties. The mixture first forms a polyamic acid precursor. Upon heating at or above 300° C., the polyamic acids form polyimides, which are particularly suitable for use as a high temperature coating, adhesive, thin film, or composite matrix resin.

Owner:NASA

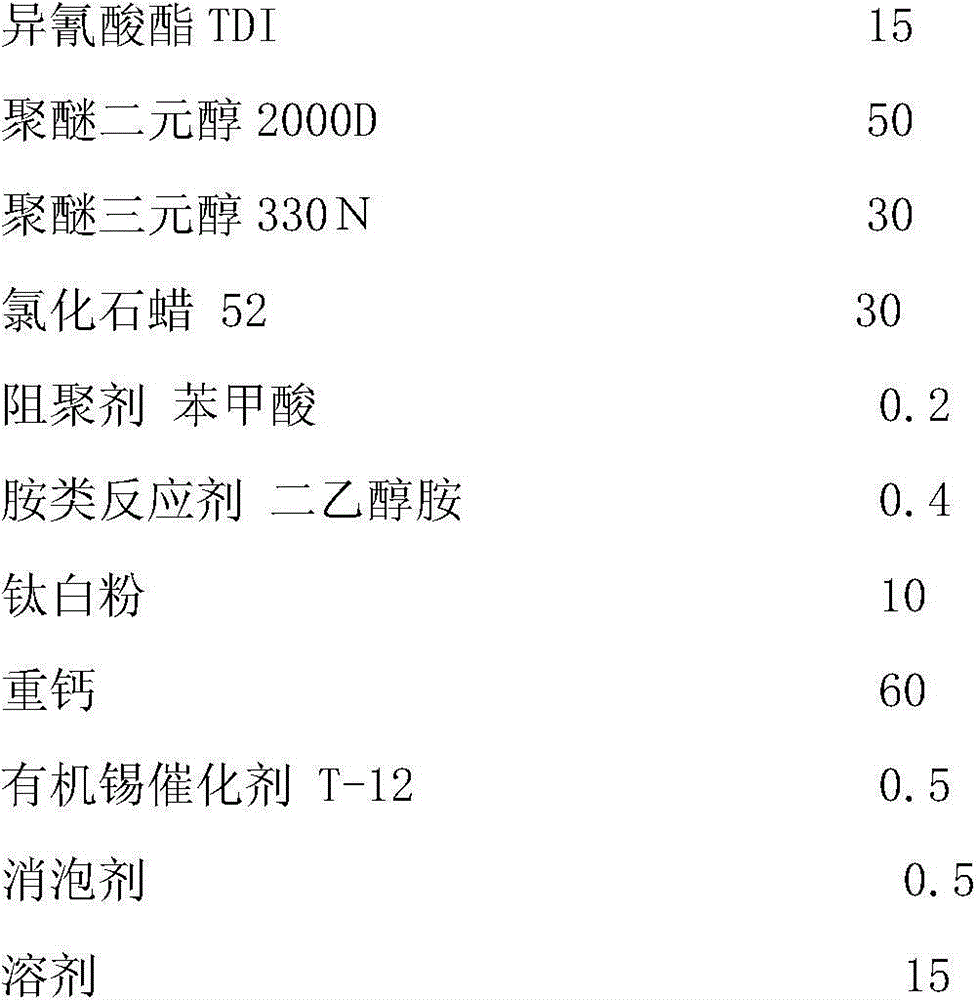

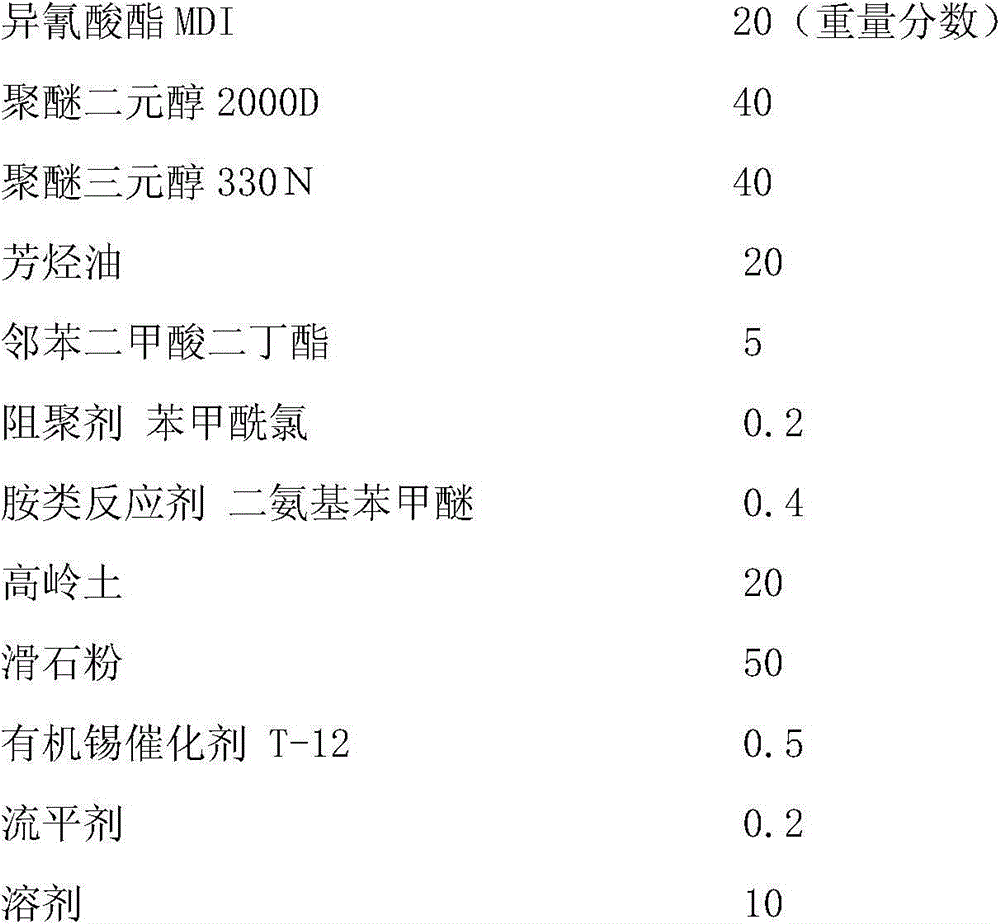

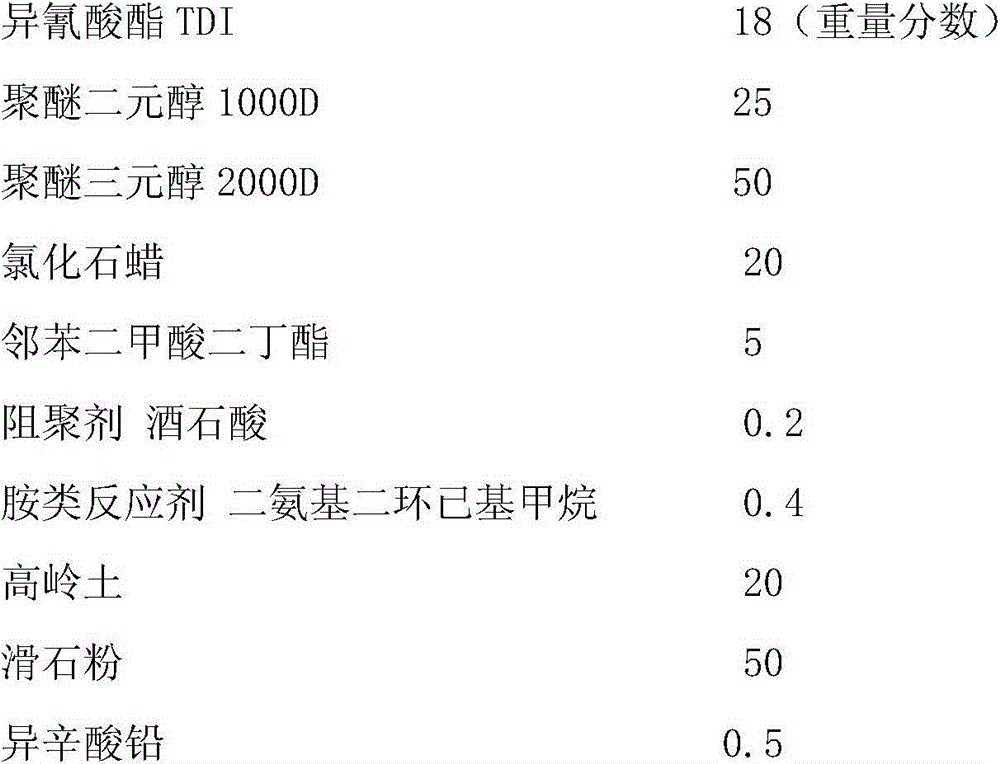

Single-component reactive thixotropic polyurethane waterproof paint and preparation method thereof

ActiveCN104559735ASolve the problem of particularly serious flowImprove constructabilityPolyurea/polyurethane coatingsDiaminodiphenyl etherPlasticizer

The invention discloses a single-component reactive thixotropic polyurethane waterproof paint which comprises the following components in parts by weight: 10-25 parts of isocyanate, 60-100 parts of polyether, 20-40 parts of plasticizer, 0.1-1 part of polymerization inhibitor, 0.1-1 part of amine reactant, 0.2-1 part of catalyst, 20-80 parts of pigment and filler, 5-20 parts of solvent and 0.1-1 part of high-performance assistant. The amine reactant is one or mixture of more of diaminodiphenyl ether, diamidodicyclohexyl methane, dialkylol amine and the like. The polyurethane waterproof paint has favorable thixotropic properties, and basically does not flow when being applied 2-3 times into a 1.5-2 mm coating in facade construction, thereby solving the problems of severe flow and difficulty in thickness increase in facade construction of the existing single-component polyurethane waterproof paint, effectively reducing the waste of materials and enhancing the operating efficiency and operating quality.

Owner:XUZHOU WONIUSHAN NEW WATERPROOF MATERIALS

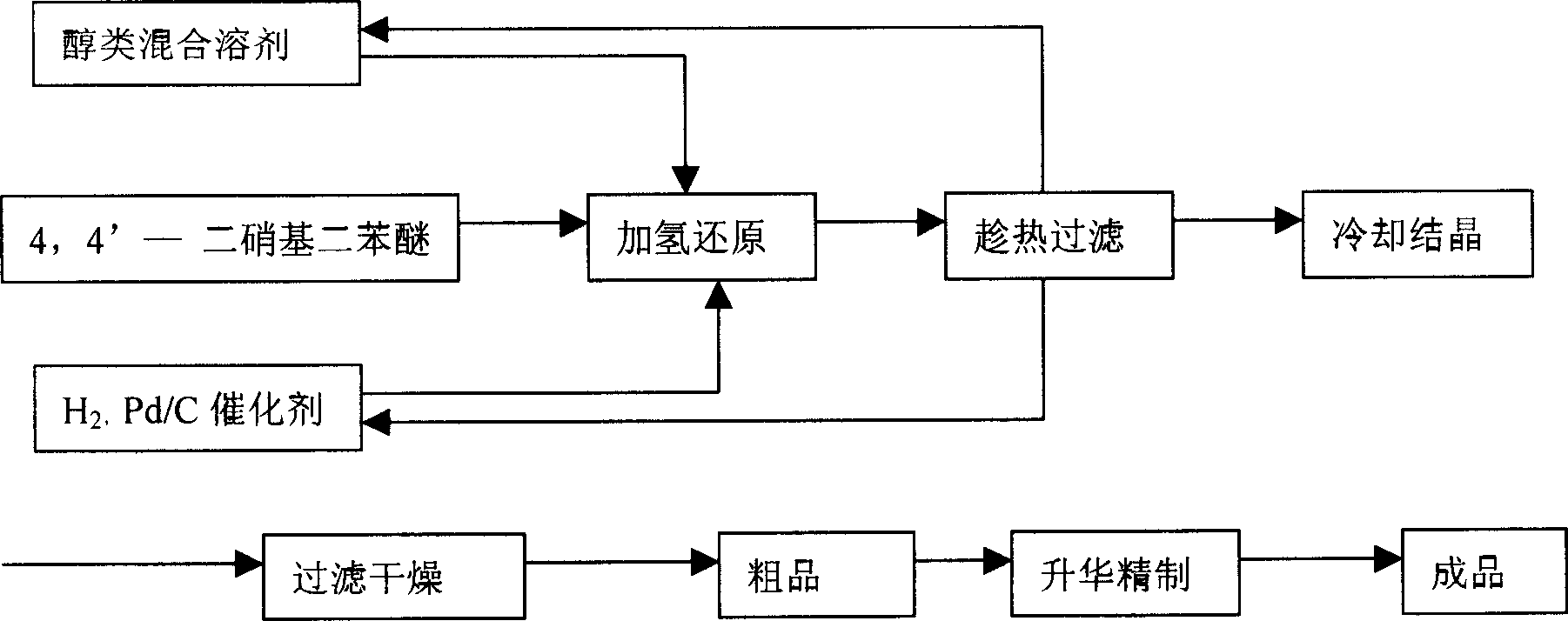

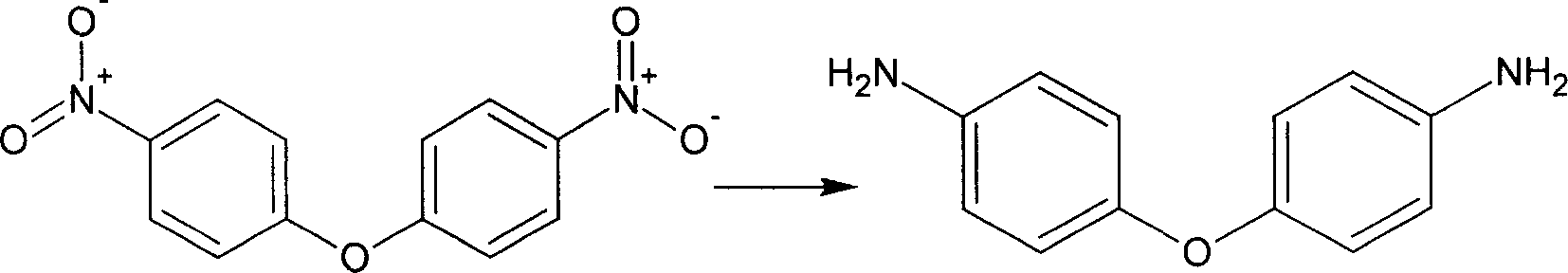

Method for preparing 4,4'-diaminodiphenyl ether

InactiveCN1807399AReduce manufacturing costReduce pollutionOrganic compound preparationAmino-hyroxy compound preparationDiphenyl etherDiaminodiphenyl ether

The invention relates to a preparation method for 4, 4'-diamino diphenyl ether, which comprises: taking catalytic hydrogenation reduction reaction to the 4, 4'-dinitro diphenyl ether in alcohol solvent; crystallizing to obtain the coarse product; reducing pressure to sublimate and refine the coarse product for final product. This invention has well product quality and no pollution with low cost, and more fit to spread than the traditional ferrous powder-chlorhydric acid reduction method.

Owner:CHANGZHOU SUNLIGHT PHARMA

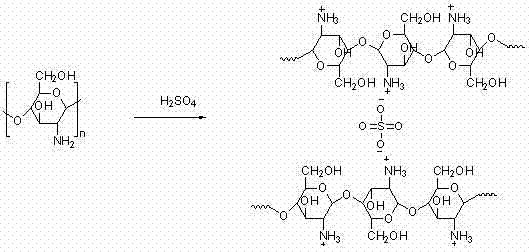

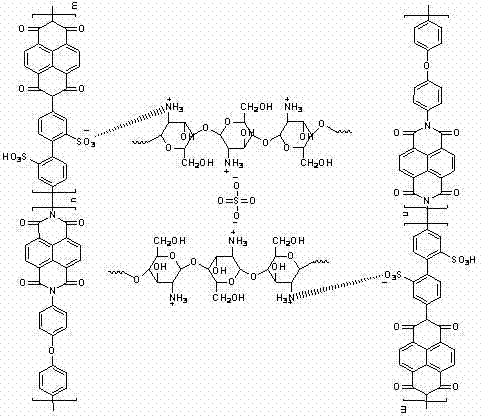

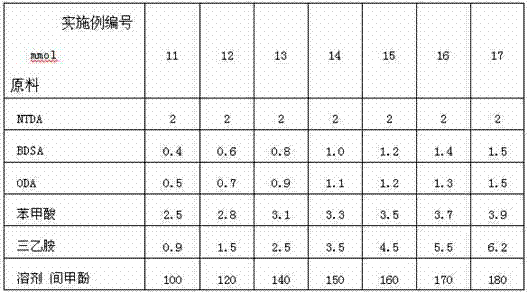

Preparation method of sulfonated polyimide/chitosan composite proton conducting film

The invention discloses a preparation method of a sulfonated polyimide / chitosan composite proton conducting film. The preparation method is characterized by comprising the following steps of: feeding 2,2'-disulfobenzidine, m-cresol and triethylamine into a reactor under the condition of nitrogen protection, and stirring until solid substances are dissolved; adding 1,4,5,8-naphthalene tetracarboxylic dianhydride, benzoic acid and 4,4'-diamido diphenyl ether, heating and reacting, and cooling to below 80 DEG C; pouring into acetone for precipitation, filtering, washing precipitate with acetone,and drying to obtain triethylamine salt type sulfonated polyimide; dissolving triethylamine salt type sulfonated polyimide in an organic solvent, casting and filming, soaking, washing and drying to obtain a protonated sulfonated polyimide film; and preparing the sulfonated polyimide / chitosan composite proton conducting film by using soaking and self-assembly chitosan solution crosslinking methods. The sulfonated polyimide / chitosan composite proton conducting film prepared by using the preparation method has good application prospect in the aspects of a full-vanadium redox liquid flow battery and a fuel battery.

Owner:SOUTHWEAT UNIV OF SCI & TECH

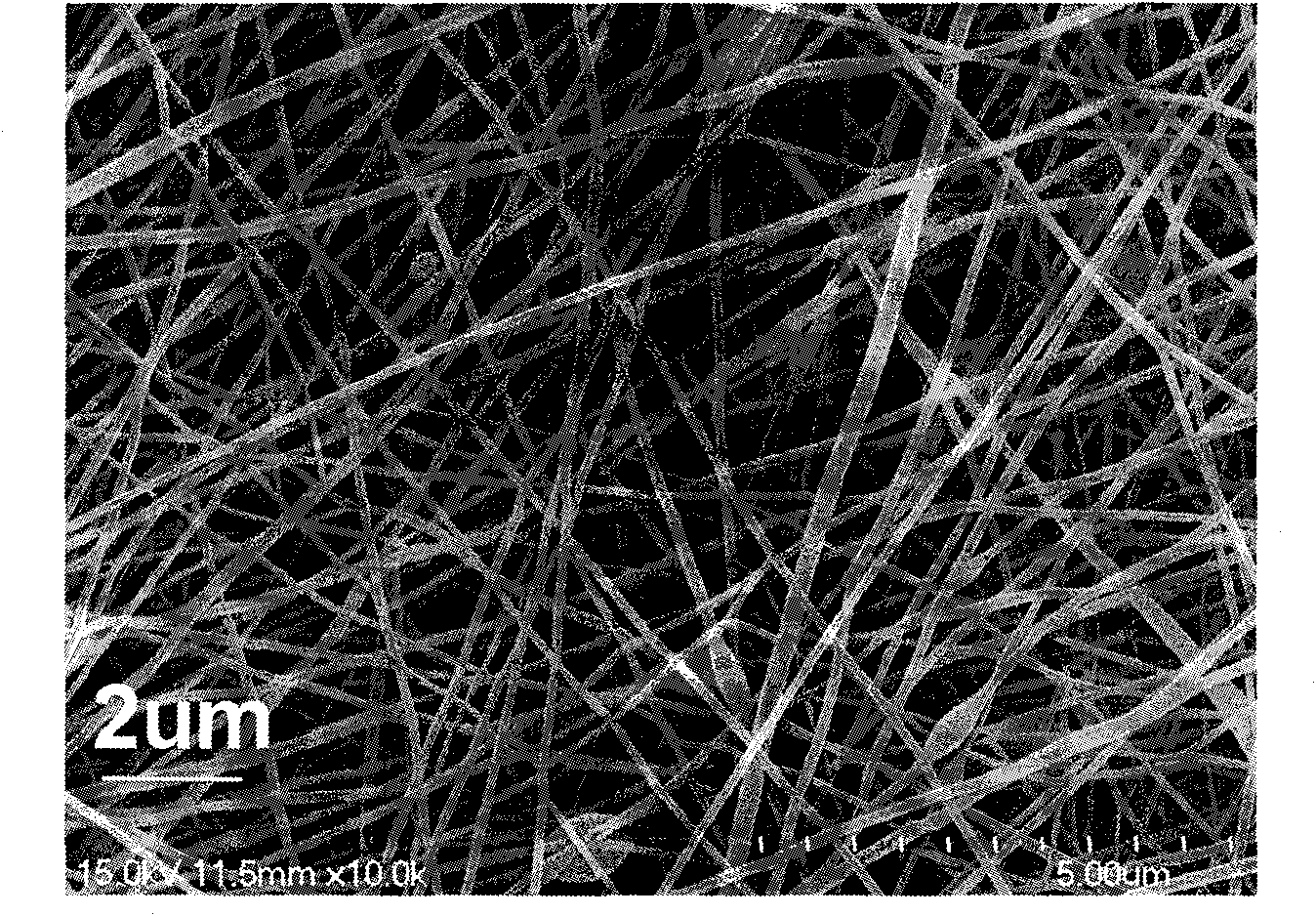

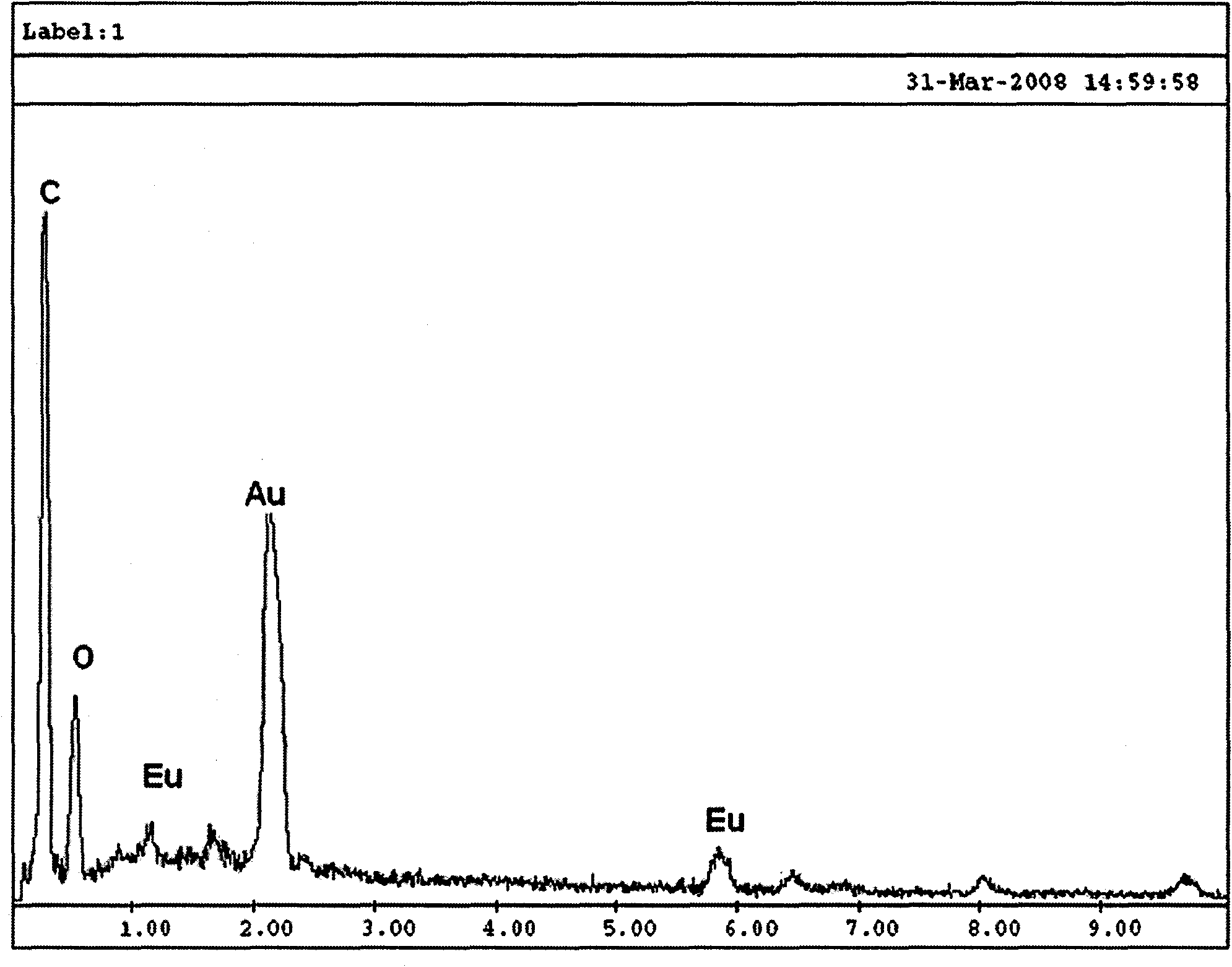

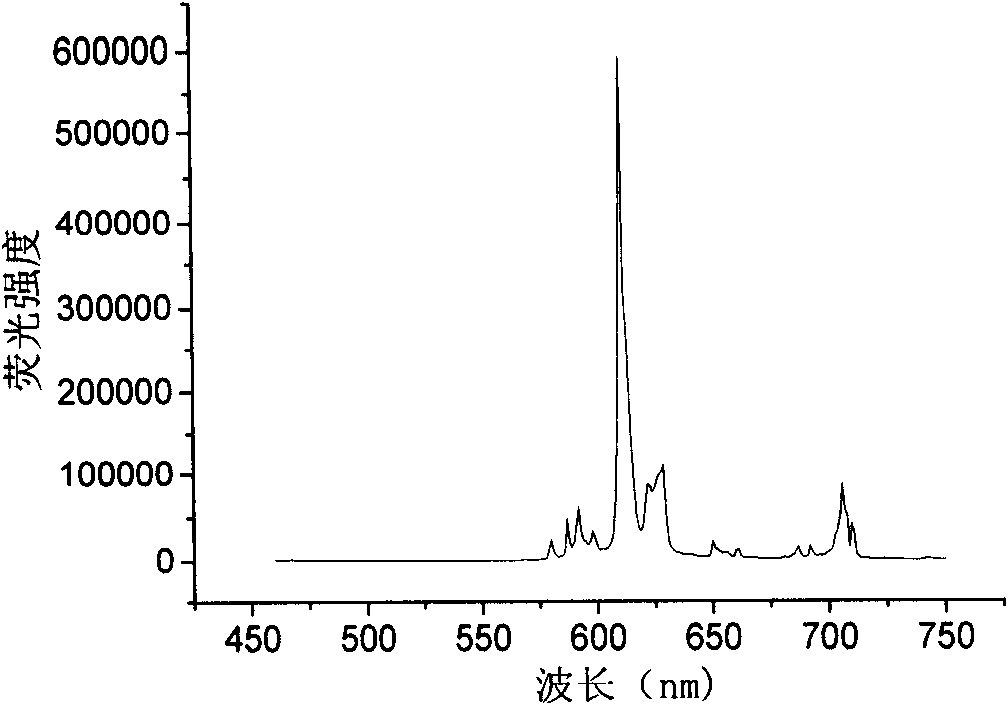

Polyimide nano-fiber and preparation method thereof

InactiveCN101603213AExcellent fluorescence effectImprove heat stabilityFilament/thread formingMonocomponent synthetic polymer artificial filamentDiaminodiphenyl etherFluorescence

The invention relates to a polyimide nano-fiber and a preparation method thereof. The invention adopts the technical scheme that 4,4'-oxydianiline (ODA) and pyromellitic dianhydride (PMDA) are used as polycondensation monomers to synthesize a polyamic acid (PAA) solution; in the reaction process, europium oxide which is processed by a coupling agent and has fluorescent effect is added, and then, the PAA / europium oxide nano-fiber is prepared by using the electrostatic spinning technology, wherein the fiber diameter can be controlled to be between 50 and 200nm; and then, the PAA / europium oxide nano-fiber is put in an oven to be heated gradually for imidization to enable the PPA / europium oxide to carry out polycondensation, thereby generating the polyimide nano-fiber with the fluorescent effect. The application of the polyimide in the high-technology fields, such as anti-falsification certificates, bills, aerospace, microelectronics and the like is extended.

Owner:SUZHOU UNIV

Biaxially oriented polyimide film for flexible printed circuit board base material and preparation method of biaxially oriented polyimide film

ActiveCN102391532AGood chemical propertiesMeet the requirementsCoatingsDiaminodiphenyl etherEngineering

The invention relates to a biaxially oriented polyimide film for flexible printed circuit board base material and a preparation method of the biaxially oriented polyimide film. The method is characterized by mainly comprising the following steps of: (1) polymerizing: preparing a basic solution of polyimide acid according to the following proportions: 1-5% of p-phenylenediamine, 2-8% of biphenyltetracarboxylic dianhydride, 5-10% of diaminodiphenyl ether, 8-15% of pyromellitic dianhydride and 62-84% of dimethylacetylamide; (2) salivating the solution into a film; (3) longitudinally stretching the film according to the stretching ratio of 1:1.02-1.15; (4) transversely stretching the film according to the stretching ratio of 1:1.05-1.2 and carrying out imidization; (5) cutting the edge and rolling up the film; (6) postprocessing the film; and (7) cutting and packaging the film. The special biaxially oriented polyimide film material conforming to the flexible printed circuit board base material can be obtained by using the preparation method provided by the invention.

Owner:朱宏清

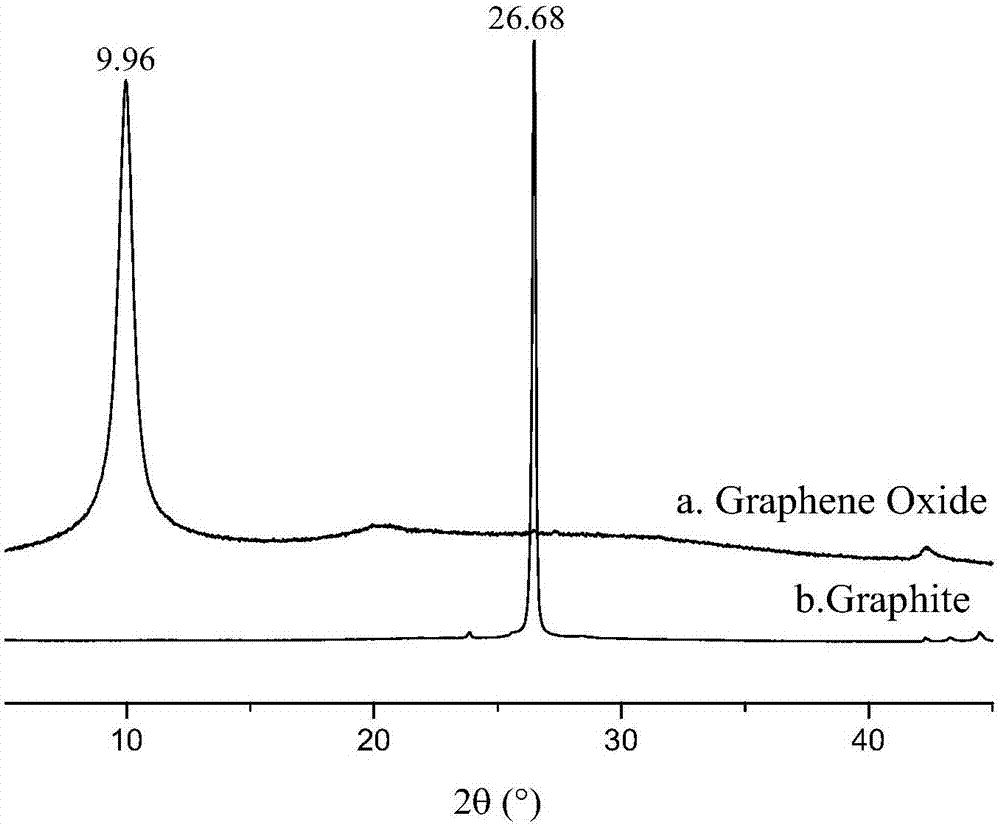

Preparation method of modified graphene oxide/PMMA composite material

ActiveCN107141680AGood dispersionImprove thermal performanceDiaminodiphenyl etherPolymethyl methacrylate

The invention discloses a preparation method of a modified graphene oxide / PMMA composite material. The preparation method of the modified graphene oxide / PMMA composite material comprises the following steps: preparing graphene oxide; performing reaction on the graphene oxide and 4,4-diaminodiphenyl ether to prepare aminated graphene oxide; mixing the aminated graphene oxide with a methyl methacrylate monomer, adding a toluene solution of dibenzoyl peroxide to obtain graphene oxide grafted polymethyl methacrylate, drying the graphene oxide grafted polymethyl methacrylate and dispersing the graphene oxide grafted polymethyl methacrylate into tetrahydrofuran; and blending the solution with a pure polymethyl methacrylate solution, and casting a film to obtain the modified graphene oxide / PMMA composite material. A redox initiation system is used for successfully initiating polymerization of methyl methacrylate on the surface of the graphene oxide, and simple solutions are blended to prepare the modified graphene oxide / PMMA composite material; and the modified graphene oxide has high dispersibility in the composite material, and the thermal performance of the material is improved to a certain extent under the condition of low adding amount.

Owner:CHANGZHOU UNIV

Biaxially oriented film, laminates made therefrom, and method

InactiveUS20080118730A1Overcome limitationsSynthetic resin layered productsPrinted circuit aspectsDiaminodiphenyl etherStructural unit

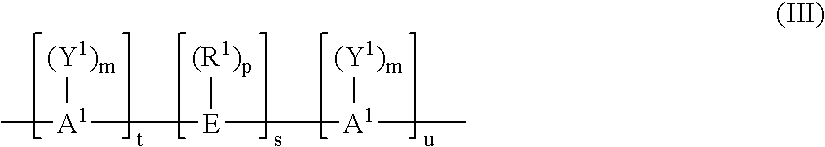

Disclosed is a biaxially oriented multilayer film comprising at least two layers A-B, wherein A and B represent separate layers at least one of which layers comprises a polyimide having a Tg of greater than about 200° C., wherein the film has a CTE of less than 35 ppm / ° C., and wherein A comprises 60 wt. %-100 wt. % of amorphous polymer with 0 wt. %-40 wt. % of crystallizable polymer, and B comprises 60 wt. %-100 wt. % crystallizable polymer with 0 wt. %-40 wt. % amorphous polymer, the relative thicknesses of layer A to layer B are in a ratio in a range of between 1:5 and 1:100, and the thickness of the film is in a range of between 5 μm and 125 μm. Also disclosed is a biaxially oriented monolithic film comprising a polyimide with structural units formally derived from 3,4-diaminodiphenylether and 4,4-oxydiphthalic anhydride. Laminates comprising the films and methods for making film and laminate are also disclosed. Articles comprising a film or laminate of the invention are also disclosed.

Owner:GENERAL ELECTRIC CO

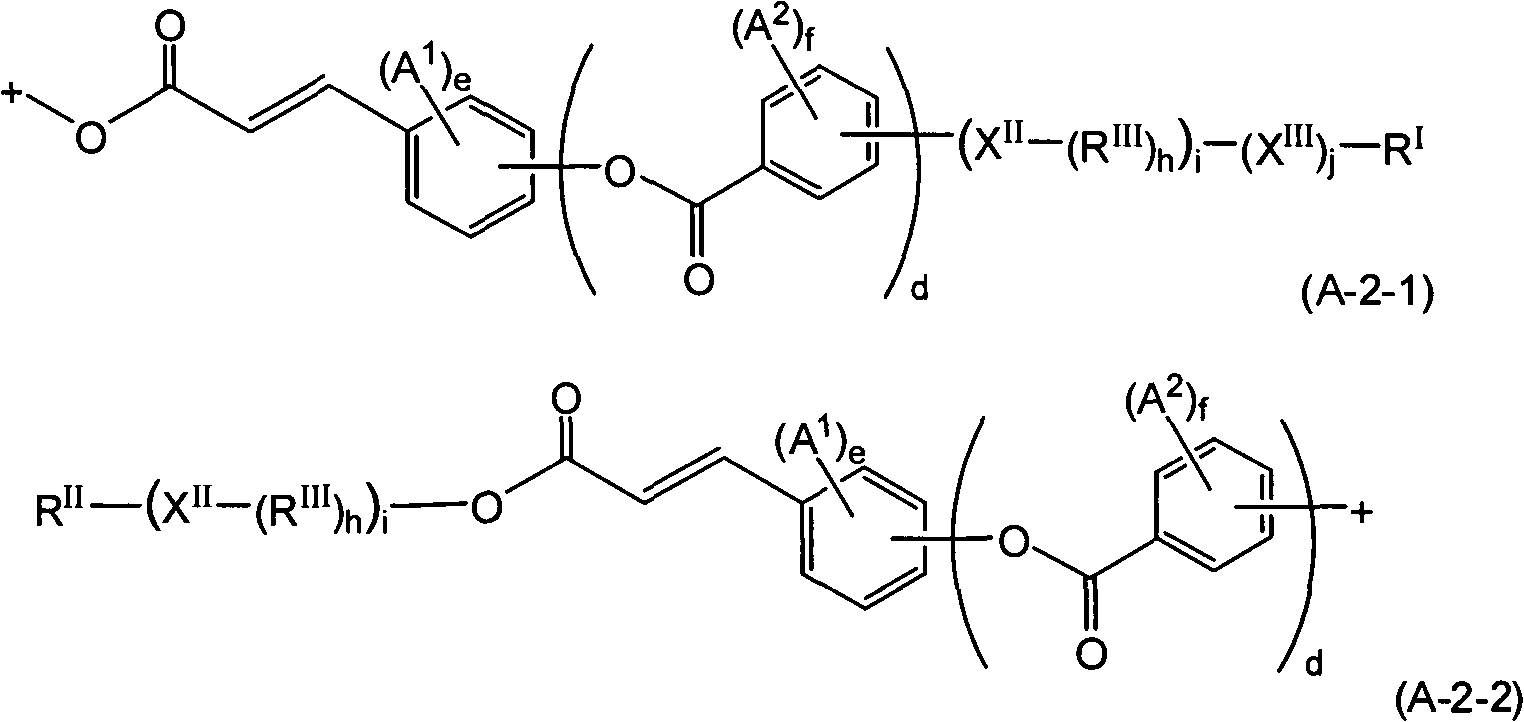

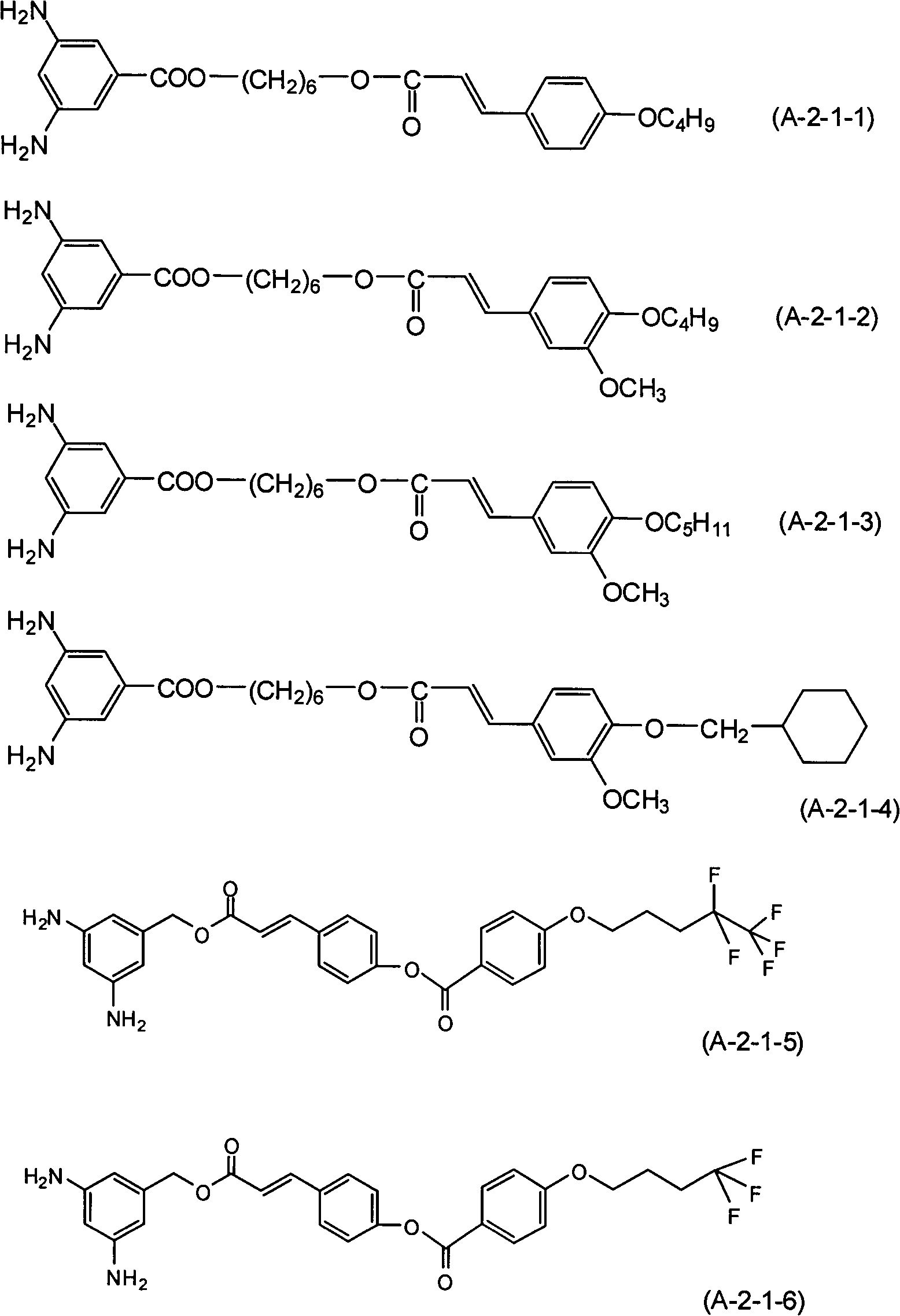

Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element

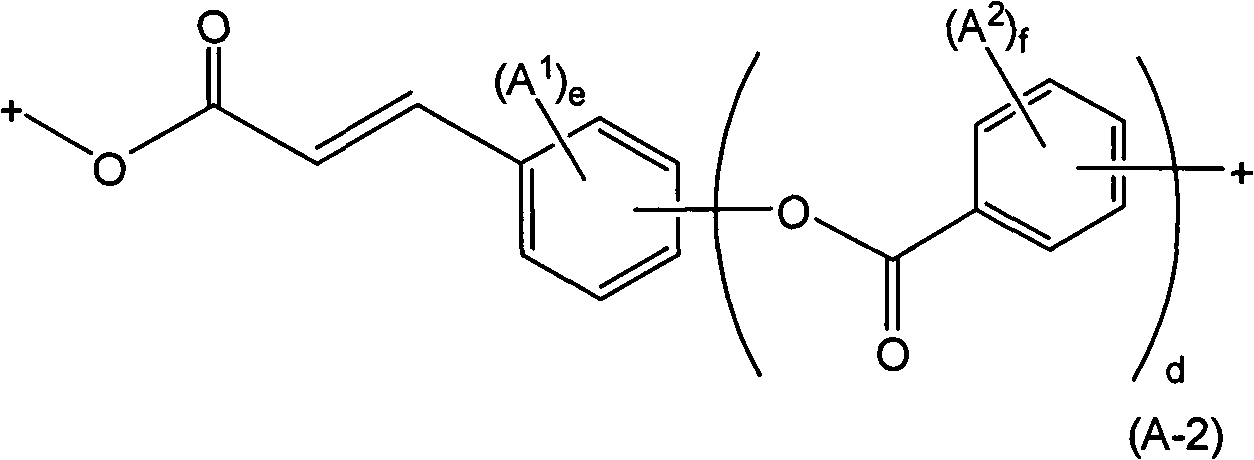

InactiveCN102140352ANo degradation in display performanceGood printabilityLiquid crystal compositionsNon-linear opticsDiaminodiphenyl etherLiquid-crystal display

The invention relates to a liquid crystal aligning agent, a liquid crystal aligning film and a liquid crystal display element. The invention provides a liquid crystal aligning agent which is provided with an excellent pretilt angle property by an optical alignment method, and can form a liquit crystal aligning film which does not result in poor display performance even when drived continuously for a long time. The liquit crystal aligning agent contains: (A) polyamide acid A, which is obtained by allowing tetracarboxylic dianhydride to react with diamines containing a diamine with a photoreactive structure; (B) polyamide acid B, which is obtained by allowing at least one tetracarboxylic dianhydride selected from a group composed of 1, 2, 3, 4-cyclobutane tetracarboxylic dianhydride, pyromellitic dianhydride to react with at least one diamine selected from a group composed of 2, 2'-dimethyl-4, 4'-diaminobiphenyl, p-phenylenediamine, 4, 4'-diaminodiphenylmethane, 4, 4'-diaminodiphenyl ether (with the polyamide acid A excluded).

Owner:JSR CORPORATIOON

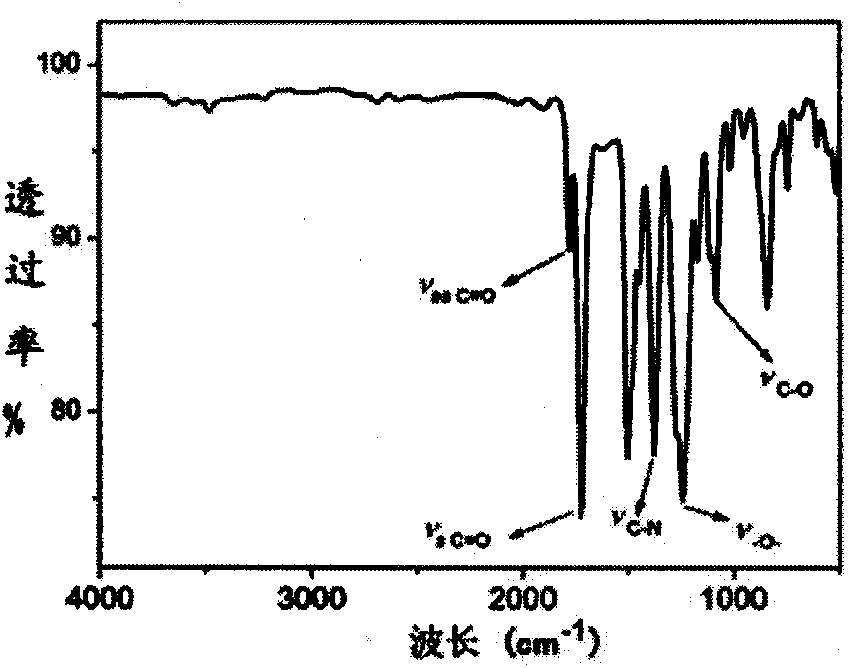

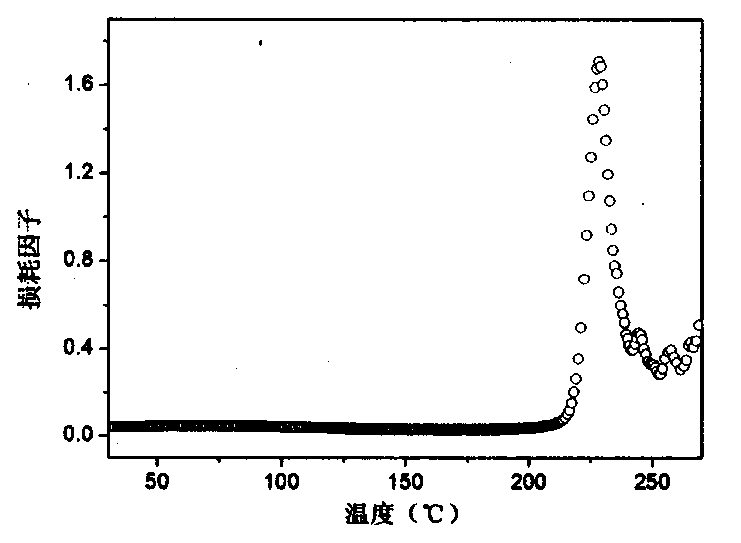

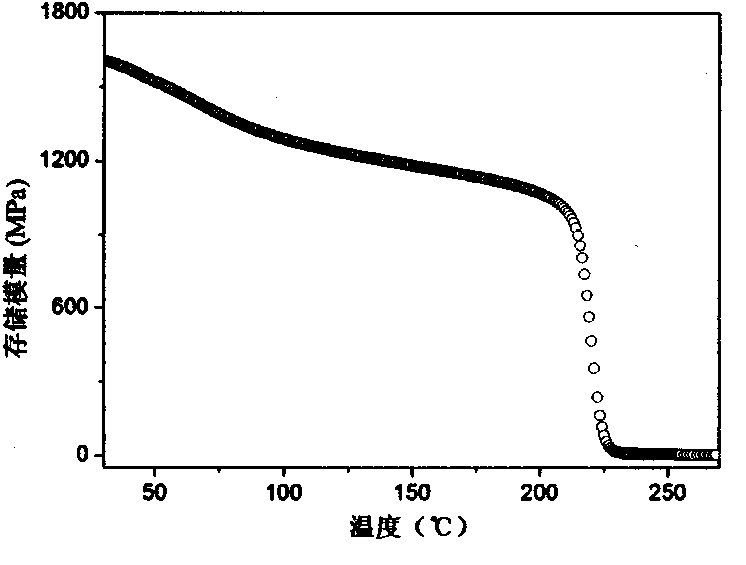

Shape memory polyimide prepared by virtue of chemical imidization and preparation method thereof

The invention discloses a shape memory polyimide prepared by virtue of chemical imidization and a preparation method thereof. The preparation method is used for preparing the thermoplastic shape memory polyimide by synthesizing a polyamide acid prepolymer from reaction monomers 4,4'-diaminodiphenyl ether and bisphenol A dianhydride and then carrying out chemical imidization under the action of acetic anhydride, triethylamine and pyridine. The glass-transition temperature of the thermoplastic shape memory polyimide exceeds 220 DEG C, and therefore, the thermoplastic shape memory polyimide can be applied to the field of the high-temperature shape memory polymers; and the thermoplastic shape memory polyimide has excellent processability, thermal stability, mechanical properties and shape memory properties.

Owner:冷劲松

Preparation method of graphene/polyimide composite material

InactiveCN105820569AEnhanced interface bindingImprove mechanical propertiesCell component detailsMeth-Diaminodiphenyl ether

The invention discloses a preparation method of a graphene / polyimide composite material, belonging to the technical field of composite materials. The preparation method comprises the following steps: performing ultrasonic dispersion of graphene oxide in a dimethyl sulfoxide solvent to obtain graphene oxide dispersion; crosslinking and coupling the graphene with 2-vinyl-5-aminothiophenol under the effect of a coupling agent vinyldimethoxysilane and a crosslinking agent N,N-methylene bisacrylamide to obtain modified graphene containing mercapto, carbon-carbon double bond and amino cross-linkable groups; condensing 4,4-diaminodiphenyl ether and pyromellitic dianhydride to obtain polyamide acid; and crosslinking the modified graphene containing different cross-linkable groups with polyamide acid to obtain a modified graphene / polyimide composite material. In the invention, the interface bonding between graphene and polyimide matrix is strong, the compatibility with a polymer is good, and the mechanical properties of the material are improved.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

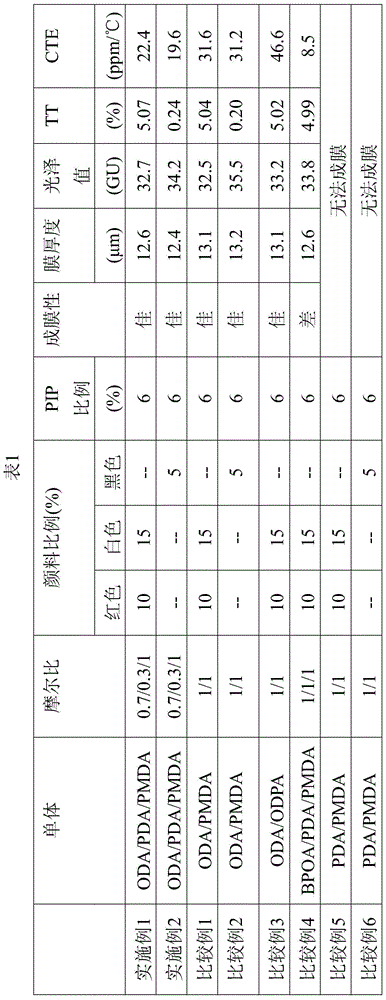

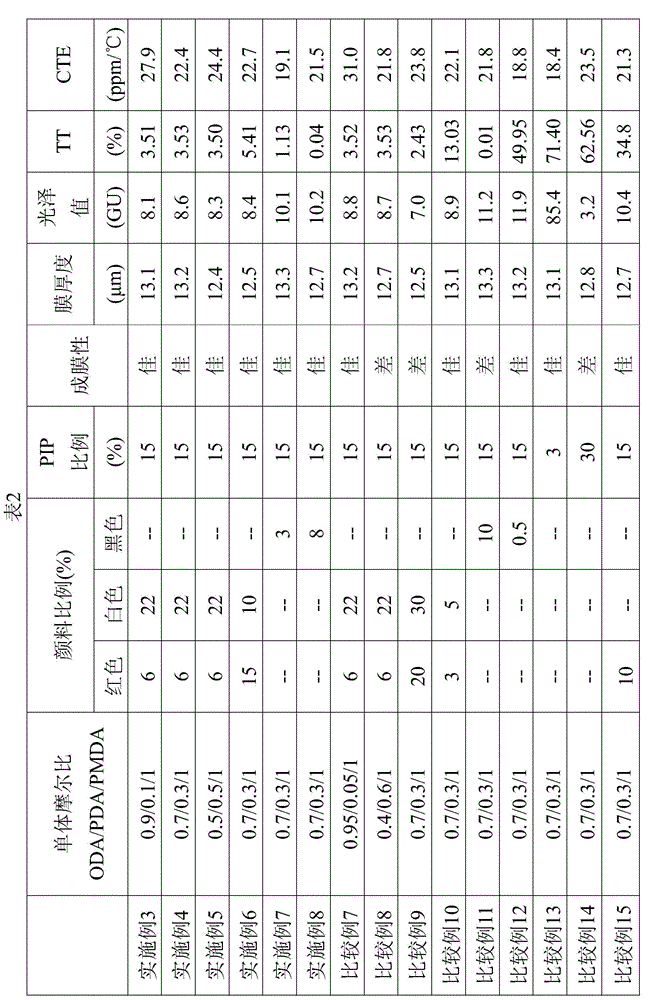

Colored polyimide film

A colored polyimide film includes a polyimide polymer obtained by reacting diamine monomers with dianhydride monomers, wherein the diamine monomers are oxydianiline (ODA) and phenylene diamine (PDA) monomers, and the dianhydride monomers are pyromellitic dianhydride (PMDA); a matting agent comprised of polyimide particles; and one or more color pigment. The polyimide films described herein have low gloss, low transparency, and low coefficient of thermal expansion.

Owner:TAIMIDE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com