Preparation method for polymide film with low thermal expansion coefficient

A polyimide film, low thermal expansion coefficient technology, applied in the field of polyimide film preparation, can solve problems such as unfavorable dimensional stability, and achieve the effects of balanced performance, high stability, electrical strength, and high electrical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

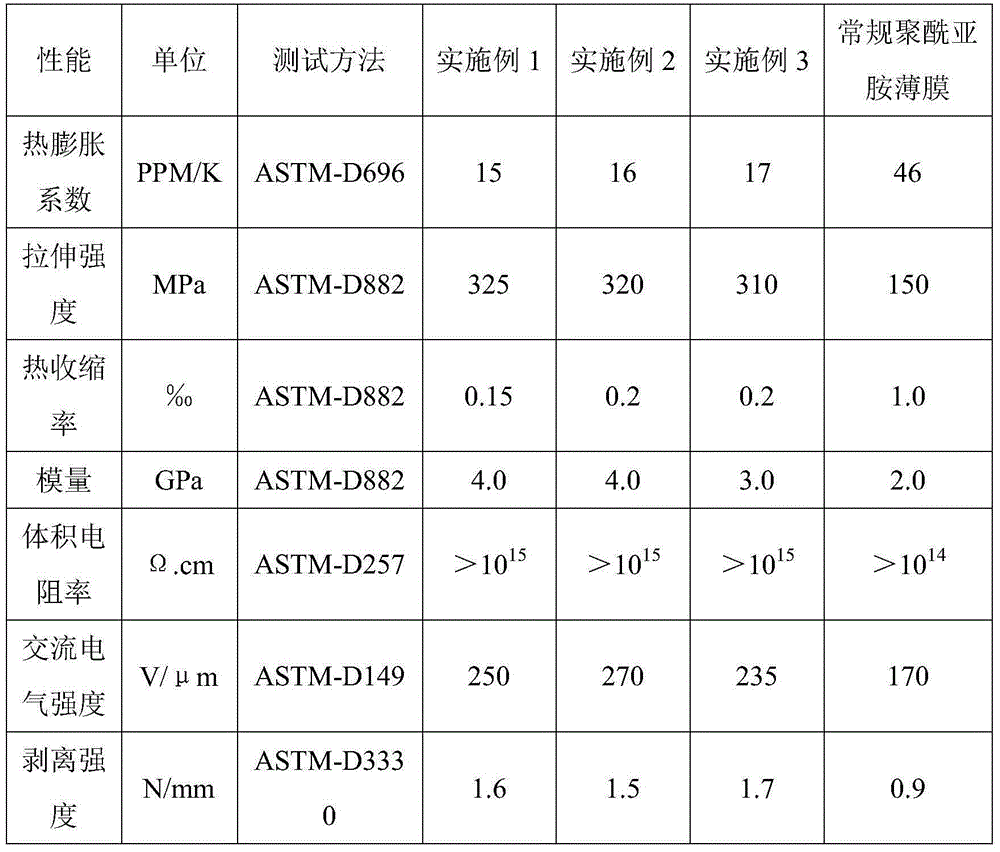

Examples

Embodiment 1

[0019] The preparation method of low thermal expansion coefficient polyimide film comprises the following steps:

[0020] (1) under the normal pressure condition of being full of nitrogen in the still body of 45 ℃, place pyromellitic dianhydride and p-phenylenediamine in dimethylacetamide solvent to carry out polycondensation reaction, pyromellitic dianhydride and p-phenylenediamine The molar ratio of phenylenediamine is 1:1.005. When carrying out the polycondensation reaction, first dissolve p-phenylenediamine in dimethylacetamide solvent (stirring speed 70r / min, time not less than 2h), then add it in 4 times Pymellitic dianhydride (stirring speed 115r / min), and in the process of adding pyromellitic dianhydride, the time interval between two adjacent times is 60 minutes, and the amount of each addition in the first three times accounts for 54% of the remainder. %, after the addition of pyromellitic dianhydride, react for 180 minutes to obtain polyamic acid glue A with a solid...

Embodiment 2

[0025] The preparation method of low thermal expansion coefficient polyimide film comprises the following steps:

[0026] (1) Under the normal pressure condition of being full of nitrogen in the still body of 35 ℃, place pyromellitic dianhydride and p-phenylenediamine in dimethylacetamide solvent to carry out polycondensation reaction, pyromellitic dianhydride and p-phenylenediamine The molar ratio of phenylenediamine is 1:1.002. When carrying out the polycondensation reaction, first dissolve p-phenylenediamine in dimethylacetamide solvent (stirring speed is 70r / min, and the time is not less than 2h), and then add it in 4 times. Pyromellitic dianhydride (stirring speed 115r / min), and in the process of adding pyromellitic dianhydride, the time interval between two adjacent times is 40 minutes, and the amount of each addition in the first three times accounts for 45% of the remainder. %, after adding the pyromellitic dianhydride, react for 200 minutes to obtain polyamic acid glu...

Embodiment 3

[0031] The preparation method of low thermal expansion coefficient polyimide film comprises the following steps:

[0032] (1) under the normal pressure condition of being full of nitrogen in the still body of 55 ℃, place pyromellitic dianhydride and p-phenylenediamine in dimethylacetamide solvent to carry out polycondensation reaction, pyromellitic dianhydride and p-phenylenediamine The molar ratio of phenylenediamine is 1:1.008. When carrying out the polycondensation reaction, first dissolve p-phenylenediamine in dimethylacetamide solvent (stirring speed 70r / min, time not less than 2h), then add 4 times Pyromellitic dianhydride (stirring speed 115r / min), and in the process of adding pyromellitic dianhydride, the time interval between two adjacent times is 80 minutes, and the amount of each addition in the first three times accounts for the remaining wt. %, after the addition of pyromellitic dianhydride, the reaction was continued for 160 minutes to obtain polyamic acid glue A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com