Patents

Literature

3890 results about "Polycondensation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

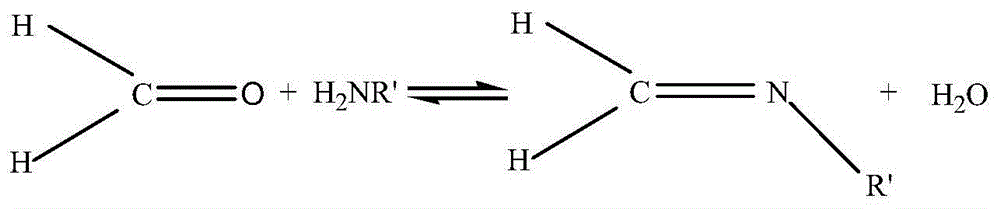

Polycondensation reactions are those chemical reactions in which the polymer is originated by successive bonds between monomers, which emit condensed molecules during the bonding process.

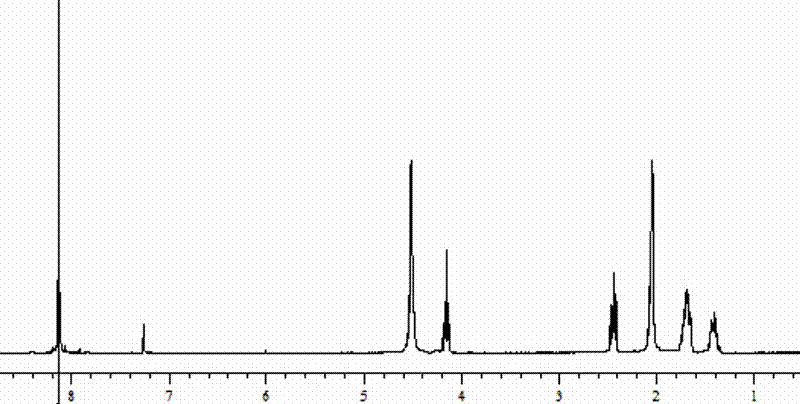

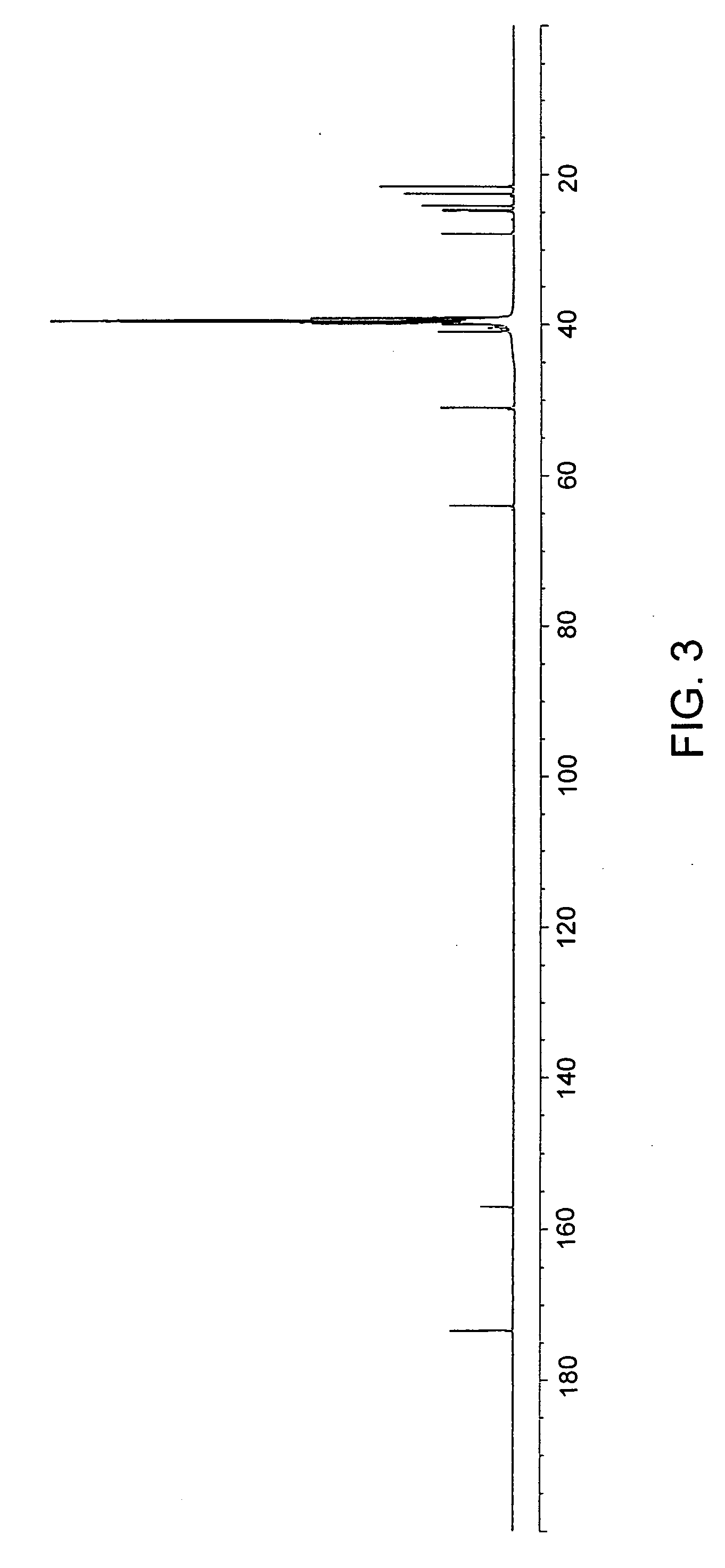

Process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and such (CO)polymers

A process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and having a number average molecular weight of at least 10,000 (as determined by GPC based on polystyrene standards) includes a first step where a prepolymer is made having the 2,5-furandicarboxylate moiety within the polymer backbone, followed in a second step by a polycondensation reaction. In the first step a 2,5-furandicarboxylate ester is transesterified with a compound or mixture of compounds containing two or more hydroxyl groups, in the presence of a tin(IV) based transesterification catalyst. In the second step at reduced pressure and under melt conditions the prepolymer prepared in the first step is polycondensed in the presence of a tin (II) based polycondensation catalyst until the polymer is obtained. This polymer may then be subjected to Solid State Polycondensation. Polymers so produced may have a 2,5-furandicarboxylate moiety within the polymer backbone, and having a number average molecular weight of at least 20,000 (as determined by GPC based on styrene standards), and an absorbance as a 5 mg / mL solution in a dichloromethane:hexafluoroisopropanol 8:2 at 400 nm of below 0.05.

Owner:FURANIX TECH BV

Addition of UV absorbers to PET process for maximum yield

InactiveUS20050008885A1Promote condensation polymerizationSynthetic resin layered productsThin material handlingUltravioletDicarboxylic acid

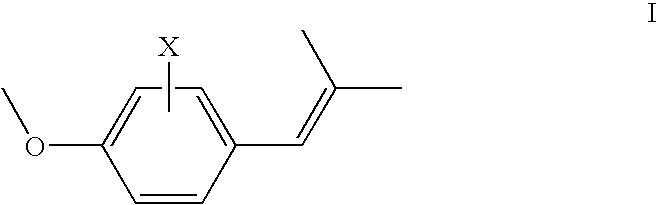

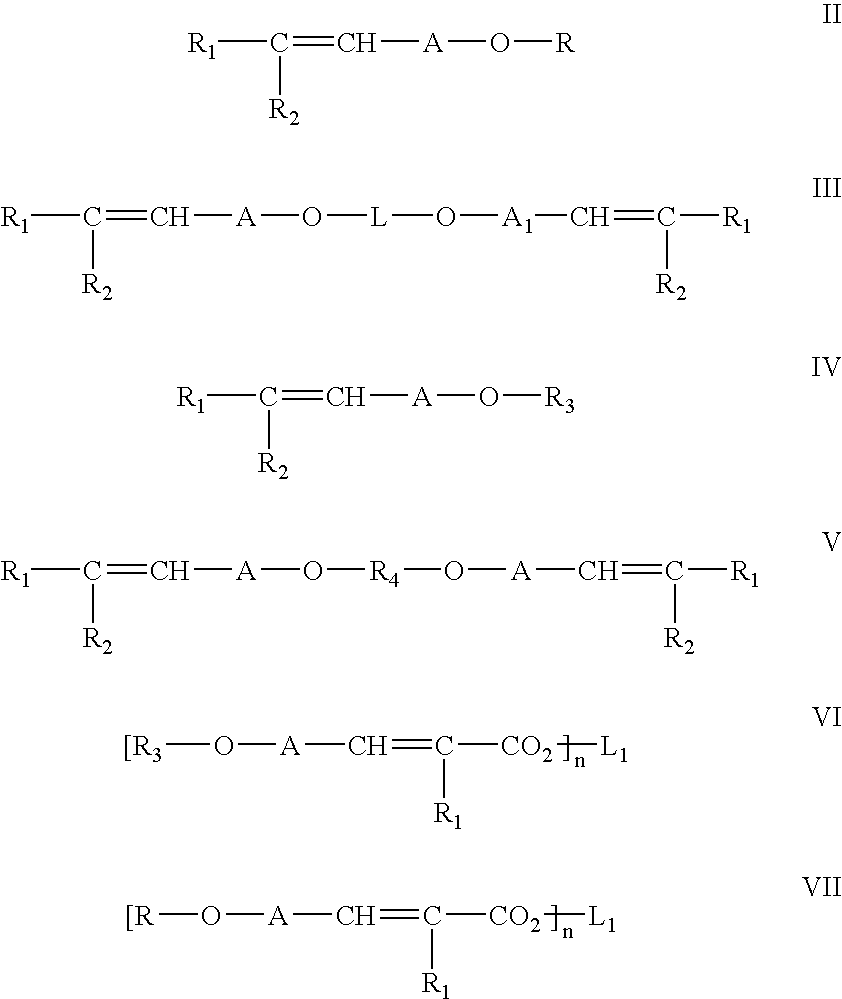

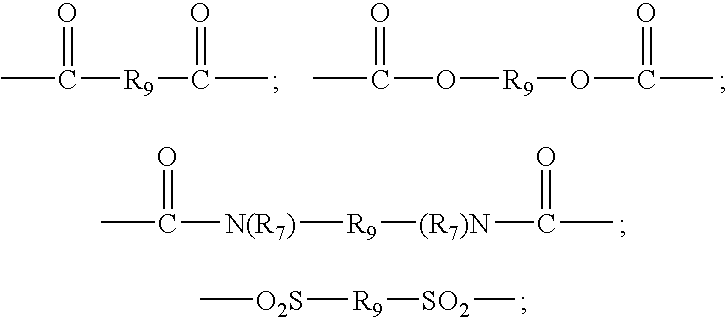

The present invention is a method for efficiently incorporating a UV absorber into a polyester resin. The method includes forming a reaction mixture comprising a diol component, a diacid component selected from the group consisting of dicarboxylic acids, dicarboxylic acid derivatives, and mixtures thereof, an antimony containing compound, a phosphorus containing compound, a metal containing compound, and a UV absorber. The reaction mixture is polymerized in a polycondensation reaction system. In another embodiment of the present invention, the UV absorber is added while the reaction products from one reactor are transferred to the next reactor in the polycondensation reaction system. A polyester composition having the UV absorber incorporated therein is also disclosed.

Owner:EASTMAN CHEM CO

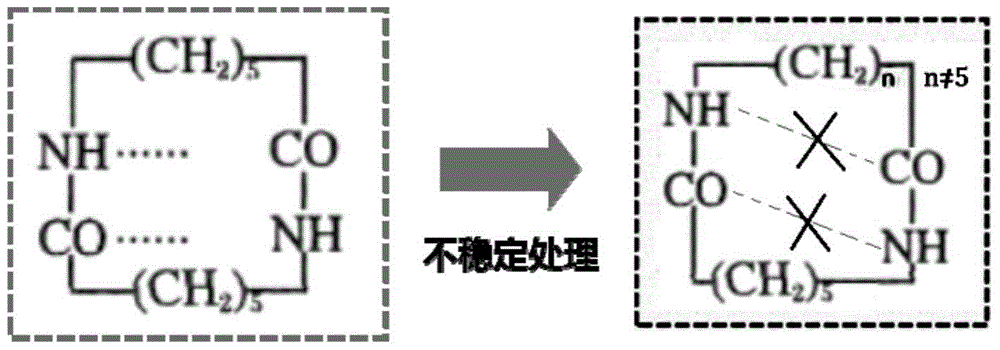

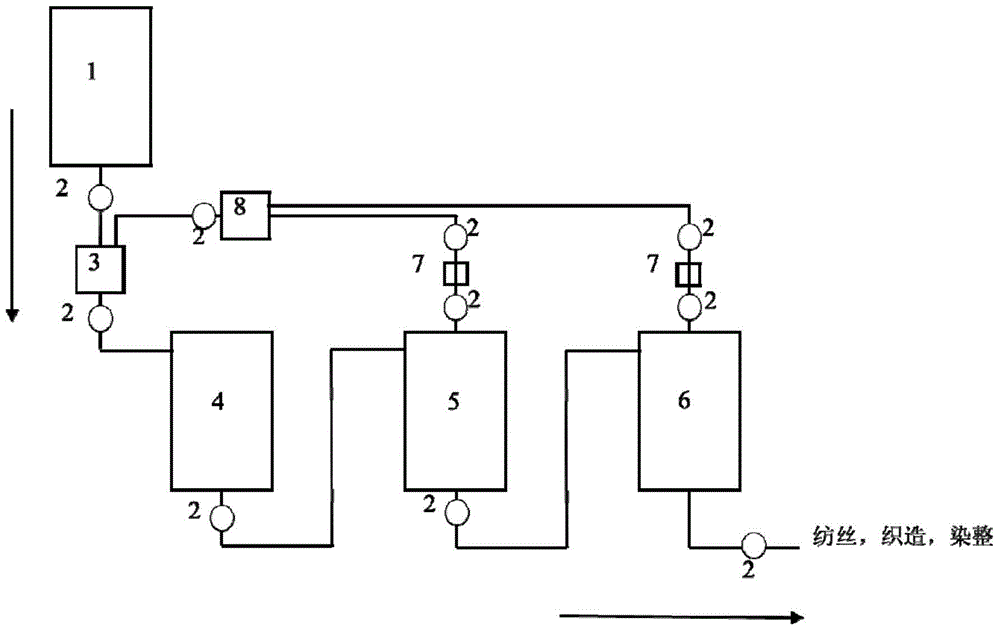

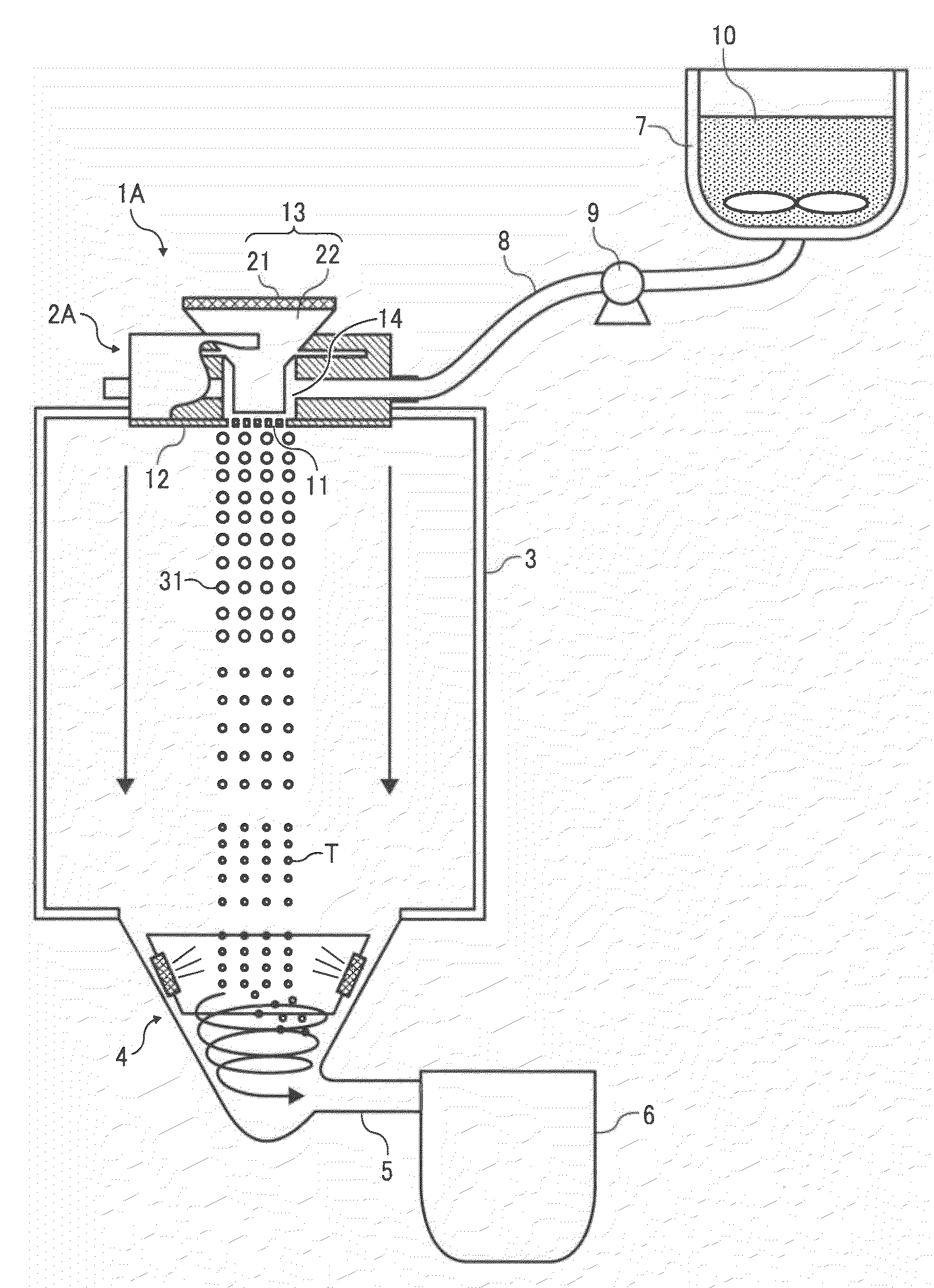

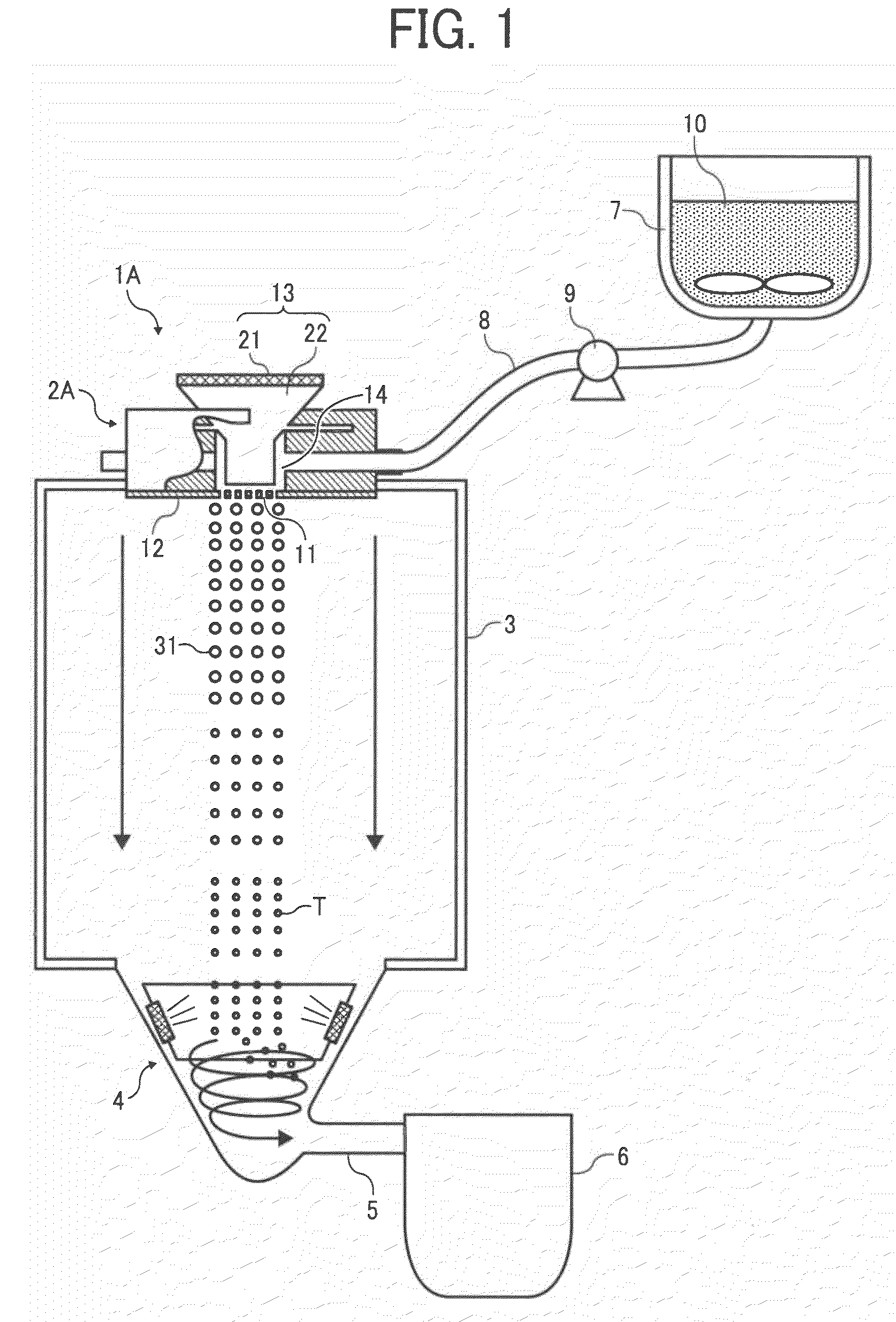

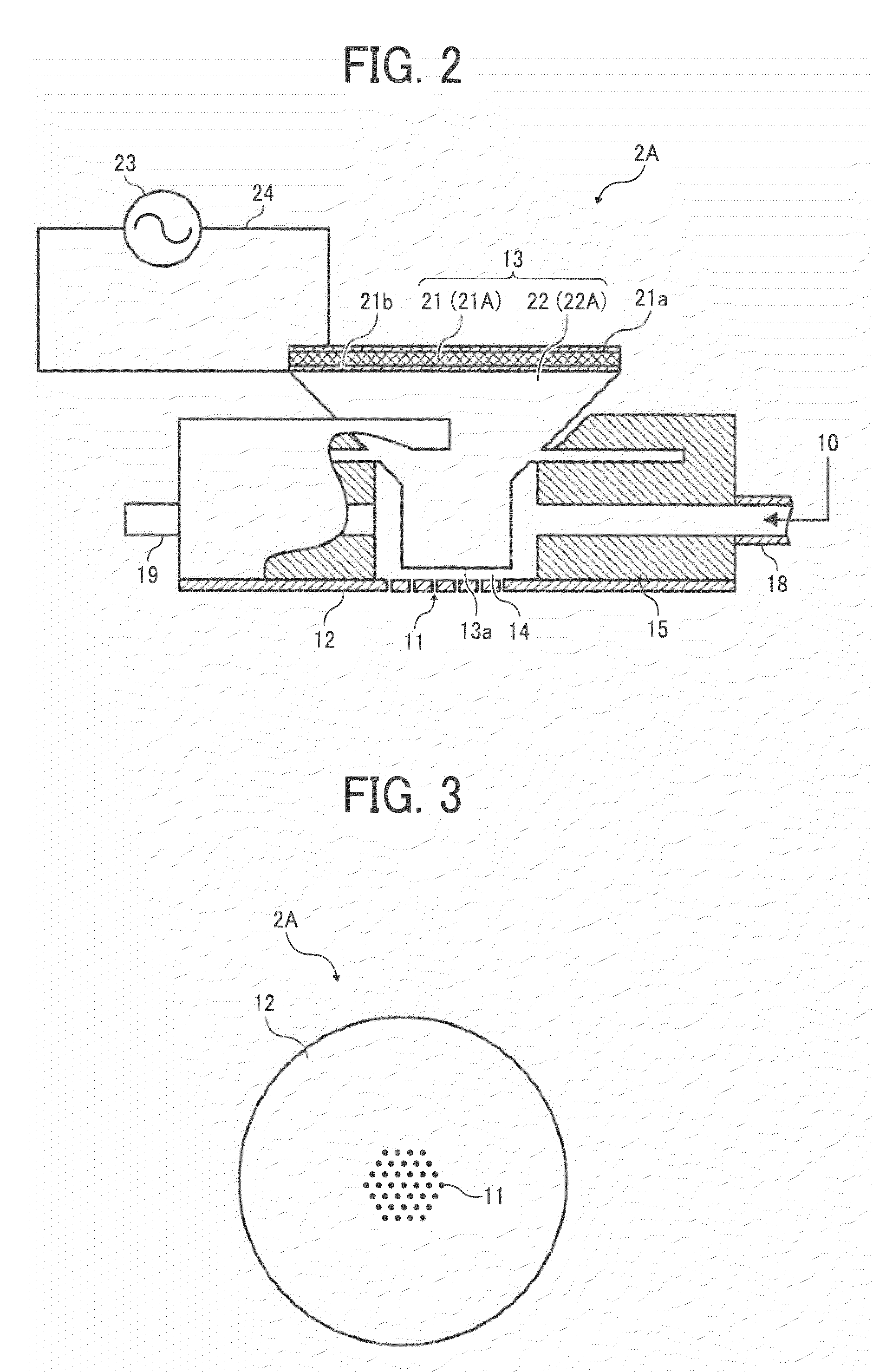

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

ActiveCN105669969AIncrease profitReduce manufacturing costFlame-proof filament manufactureHollow filament manufacturePolymer sciencePolyamide

The invention relates a nylon 6 polymerization method and a direct spinning method of a melt of a polymer obtained with the nylon 6 polymerization method. A polyamide 6 prepolymer is prepared at the low temperature, the content of oligomers in the melt is controlled in advance, polymerization is completed before a large quantity of cyclic oligomers are generated with a condensation polymerization dynamic strengthening method, a nylon 6 polymer melt with certain molecular weight is acquired, the content of extracts in the product is smaller than or equal to 1.5 wt%, and the content of cyclic dipolymers is smaller than or equal to 0.2wt%; then, direct melt spinning forming is performed after condensation polymerization dynamic strengthening ends. The process is simple, energy consumption is further reduced while the utilization rate of caprolactam is increased, the obtained melt can be directly used for melt spinning, high-capacity large-scale production is easy to realize, a modifier can be added in the polymerization process, flexible production of nylon 6 is realized, and the nylon 6 can be applied to fibers for clothes, industrial filaments, engineering plastics and other fields.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

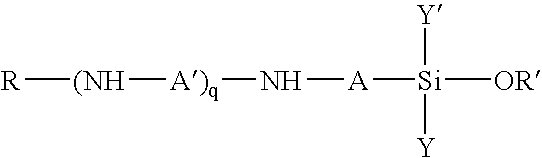

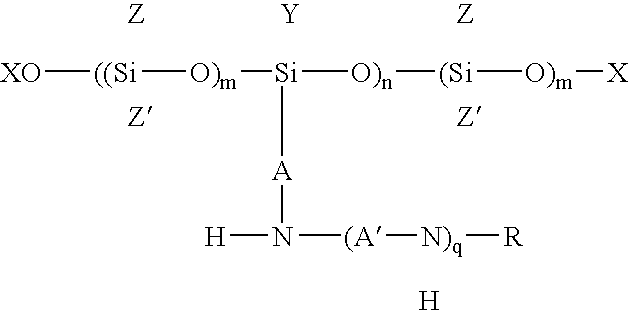

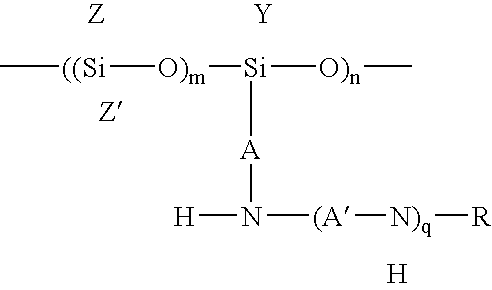

Polysiloxanes and their preparation

InactiveUS7238768B2Improve catalytic performanceCosmetic preparationsGroup 4/14 element organic compoundsPolymer sciencePtru catalyst

An amino-functional polysiloxane is prepared by reacting an aminosilane (A) which contains an aminoalkyl group and at least one alkoxy group bonded to Si with a carboxylic acid and a silanol-functional polysiloxane (B). The aminosilane (A) is partially converted into its carboxylate salt which acts as a catalyst for the siloxane condensation polymerization reaction between (A) and (B).

Owner:DOW SILICONES CORP

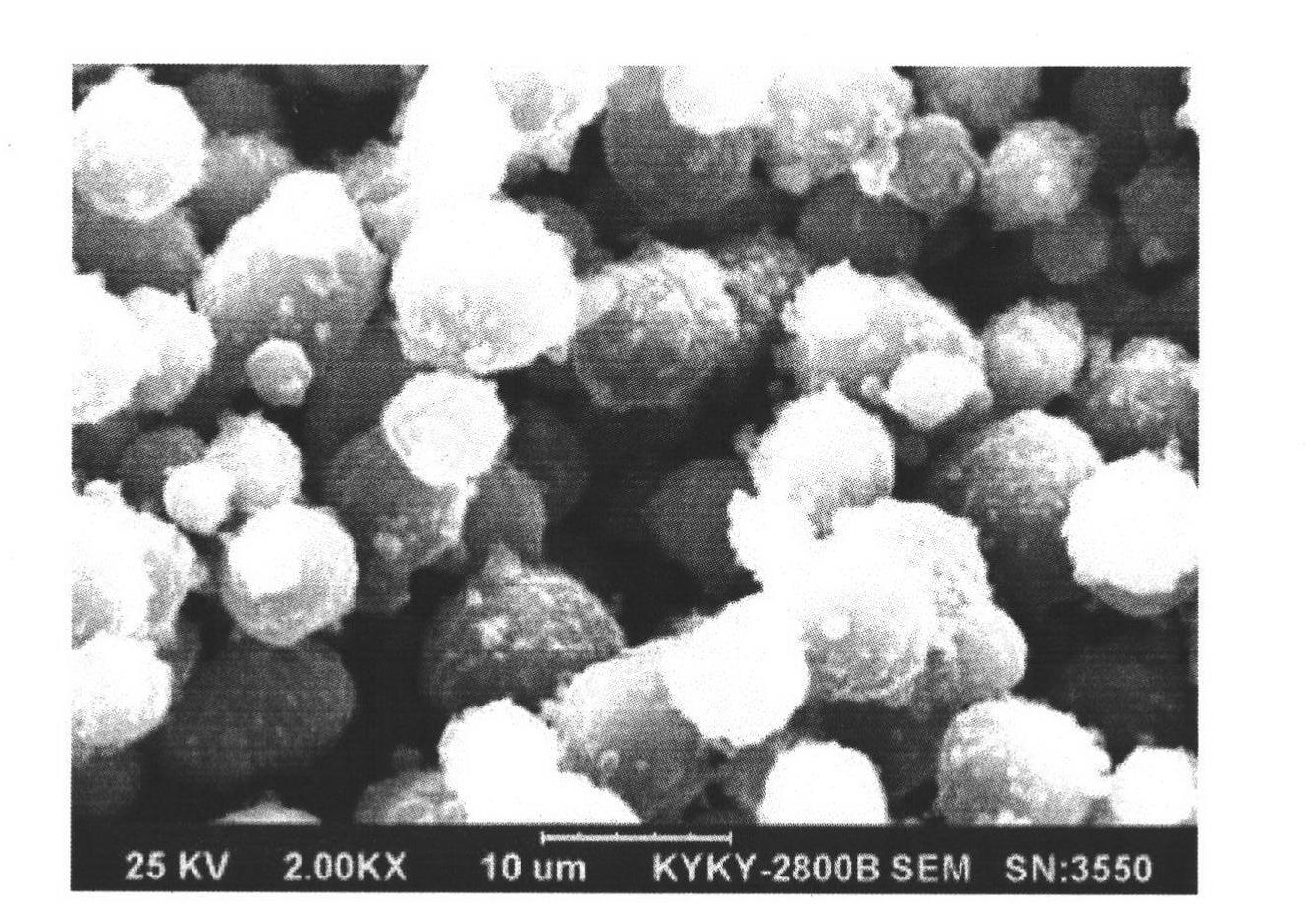

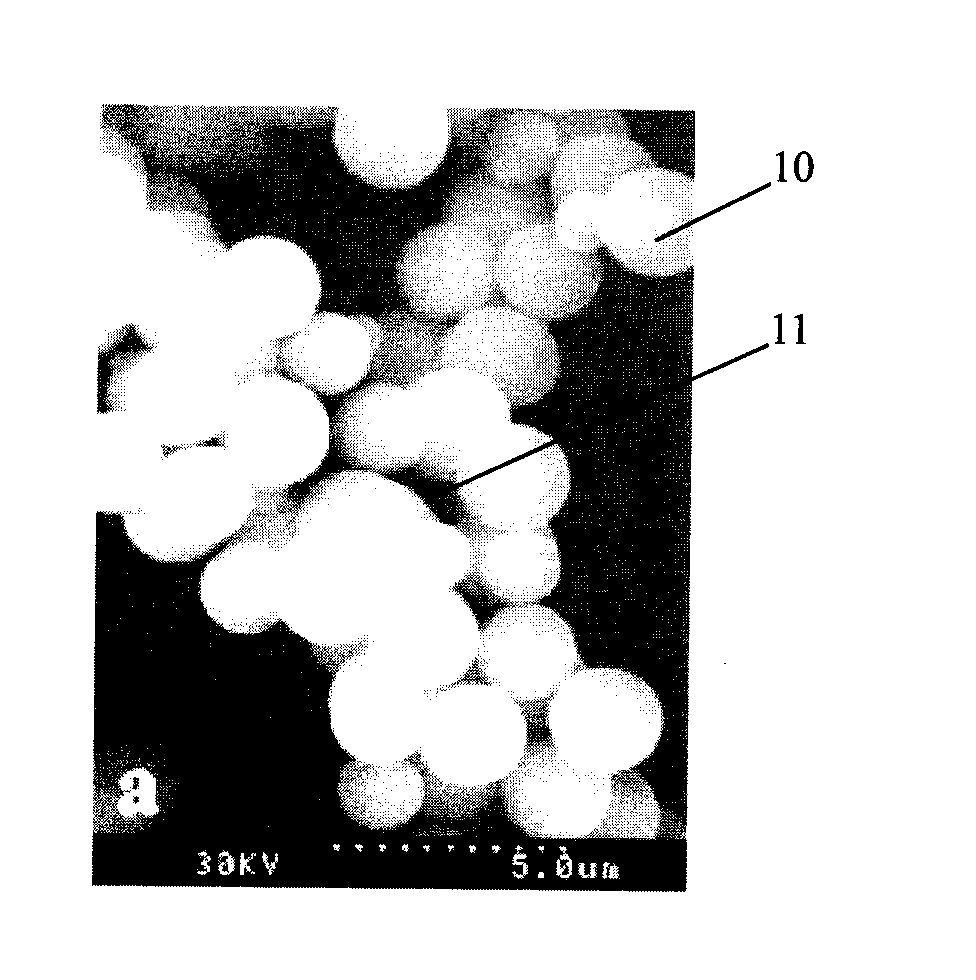

Preparation method of mesophase carbon microspheres from coal liquefaction residues

InactiveCN102225755ANarrow particle size distributionSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansMicrosphereQuinoline

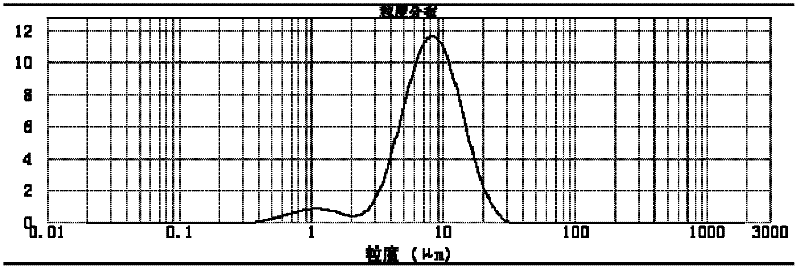

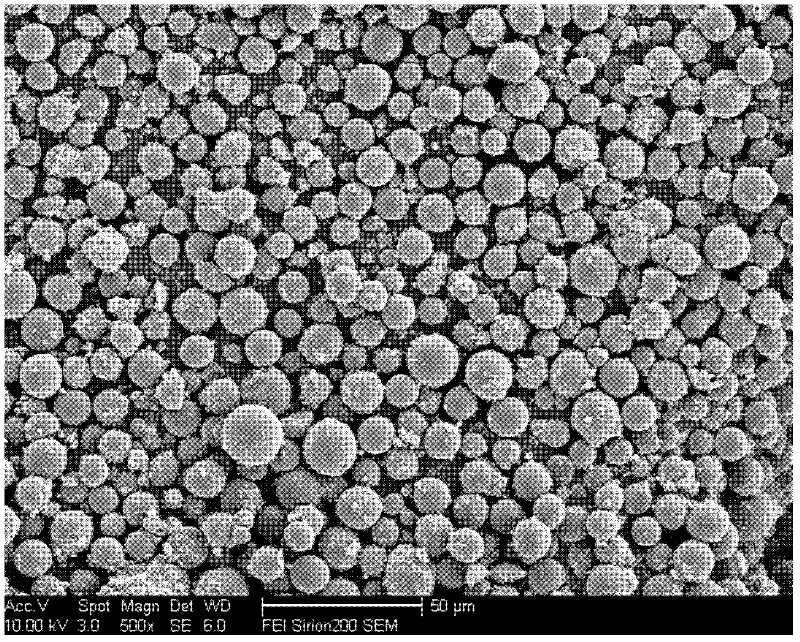

The invention discloses a preparation method of mesophase carbon microspheres from coal liquefaction residues serving as raw materials, which comprises the following steps of: firstly carrying out solvent extraction on the coal liquefaction residues, then carrying out a series of processing to obtain refined asphalt with different contents of quinoline insoluble substances, and carrying out thermal polycondensation reaction on the refined asphalt in the presence of a chemical auxiliary agent and a nucleating accelerator at the temperature of 380-450 DEG C, the pressure of 0-5 MPa and the stirring rotation speed of 40-500 r / min for 1-20 hours to obtain the mesophase microspheres. According to the invention, the chemical auxiliary agent and the nucleating accelerator can be added during theheat treatment process to improve the yield and narrow the particle size distribution of the mesophase carbon microbeads, and the mesophase carbon microspheres are prepared from the coal liquefactionresidues serving as the raw materials and have the advantages of low cost, simple preparation process, high yield (up to 35%), narrow particle size distribution, good sphericity, etc.

Owner:ZIBO MINING GRP

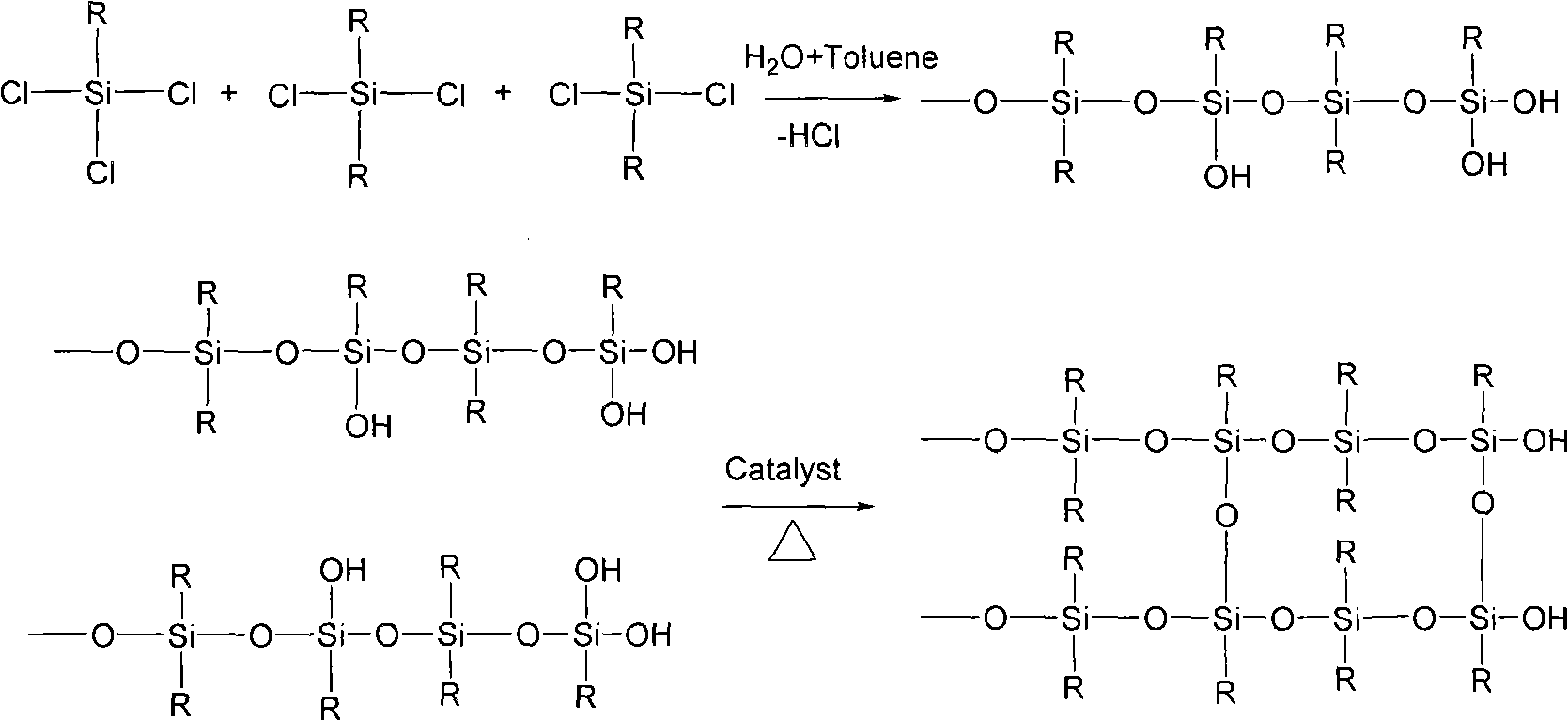

Preparation method for methyl phenyl vinyl polysiloxane for packaging LED

The invention discloses a preparation method for organosilicon, in particular relates to a preparation method of methyl-phenyl-vinyl silicone resin with high refractive index and high light transmission rate for packaging LED. The preparation method adopts the steps that the mixture of chlorosilane and toluene is added into the solvent which is composed of water and the toluene, the hydrolysis reaction is performed, then an amount of catalyzer is added into the silanol-toluene solution as hysrolysis product, the polycondensation reaction is performed, end capping reagent is finally added to perform the reaction, thus the objective product is obtained. The methyl-phenyl-vinyl silicone resin prepared by utilizing the method has the advantages of high refractive index, transparent clarification, radiation resistance, and high and low temperature resistance and weather resistance, thereby being especially suitable for the high modular basic glue in the packaging material for LED and expected to be applied in organosilicon material such as elastomeric sealant, pouring sealant, elastomoric adhesive and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

Composite semipermeable membrane and method for producing same

ActiveUS20120248027A1Improve performanceGood removal effectSemi-permeable membranesMembranesOrganic solventPolyamide

A composite semipermeable membrane comprising a porous support membrane on which a separating functional polyamide layer resulting from the polycondensation reaction of polyfunctional aromatic amines with polyfunctional acid halides is formed, wherein the separating functional polyamide layer has carboxy groups, amino groups, phenolic hydroxyl groups, and azo groups, wherein XA, the ratio of the amino groups (molar equivalent of the amino groups / (molar equivalent of the azo groups+molar equivalent of the phenolic hydroxyl groups+molar equivalent of the amino groups)) on a feed water contact surface of the separating functional polyamide layer (an A surface), is in the range 0.5 or less, and XB, the ratio of the amino groups (molar equivalent of the amino groups / (molar equivalent of the azo groups+molar equivalent of the phenolic hydroxyl groups+molar equivalent of the amino groups)) on a permeate-side surface of the separating functional polyamide layer (a B surface), i.e., the opposite side to the A surface, is in the range of 0.5 to 1. The present invention provides a composite semipermeable membrane that achieves a balance between high solute removal properties and a high permeate flow rate and has high organic-solvent resistance, and a method for producing same.

Owner:TORAY IND INC

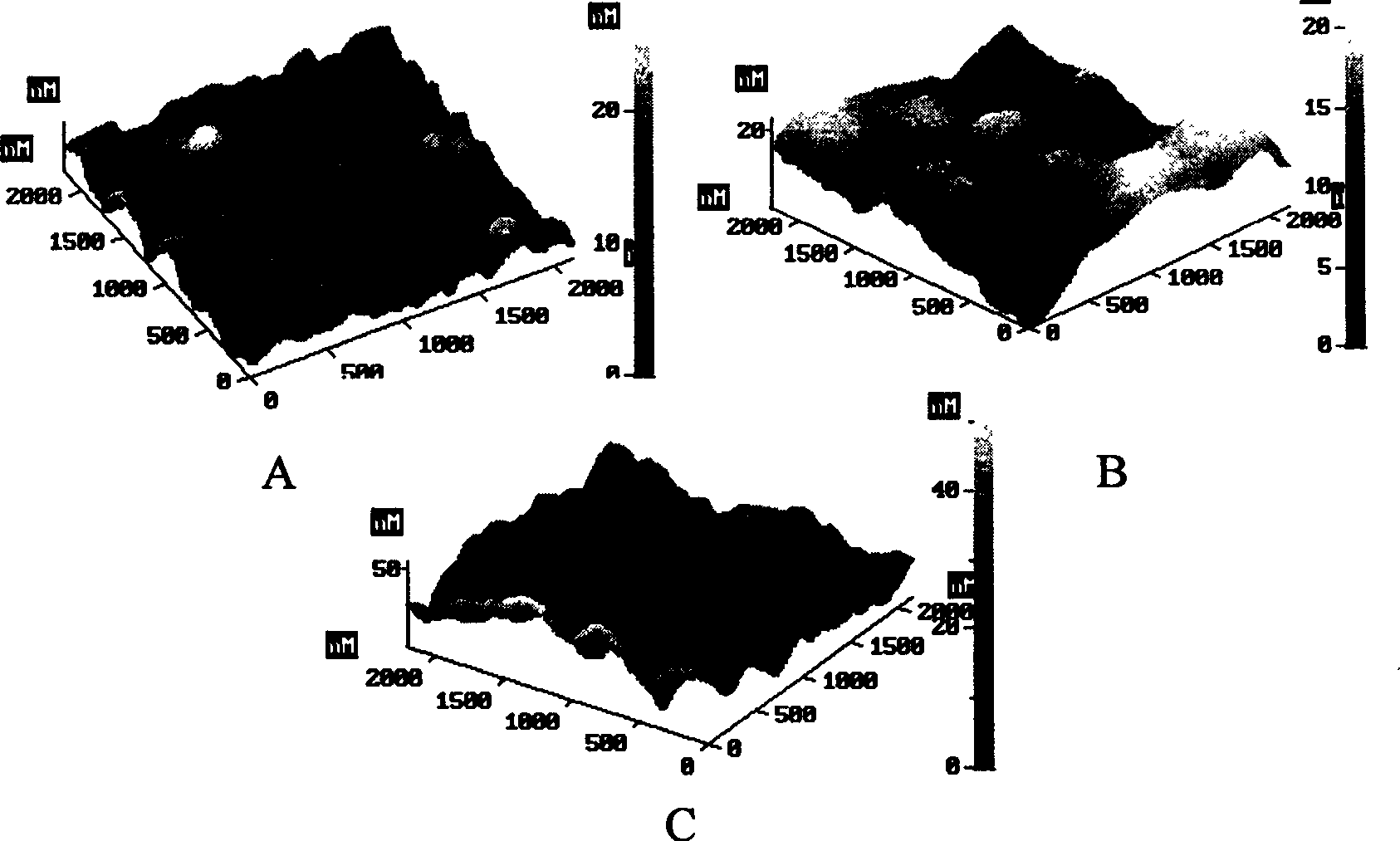

Preparing method for nanometer porous silica thin-membrane

InactiveCN1553219AHigh refractive indexLow refractive indexOptical elementsPtru catalystSilicic acid

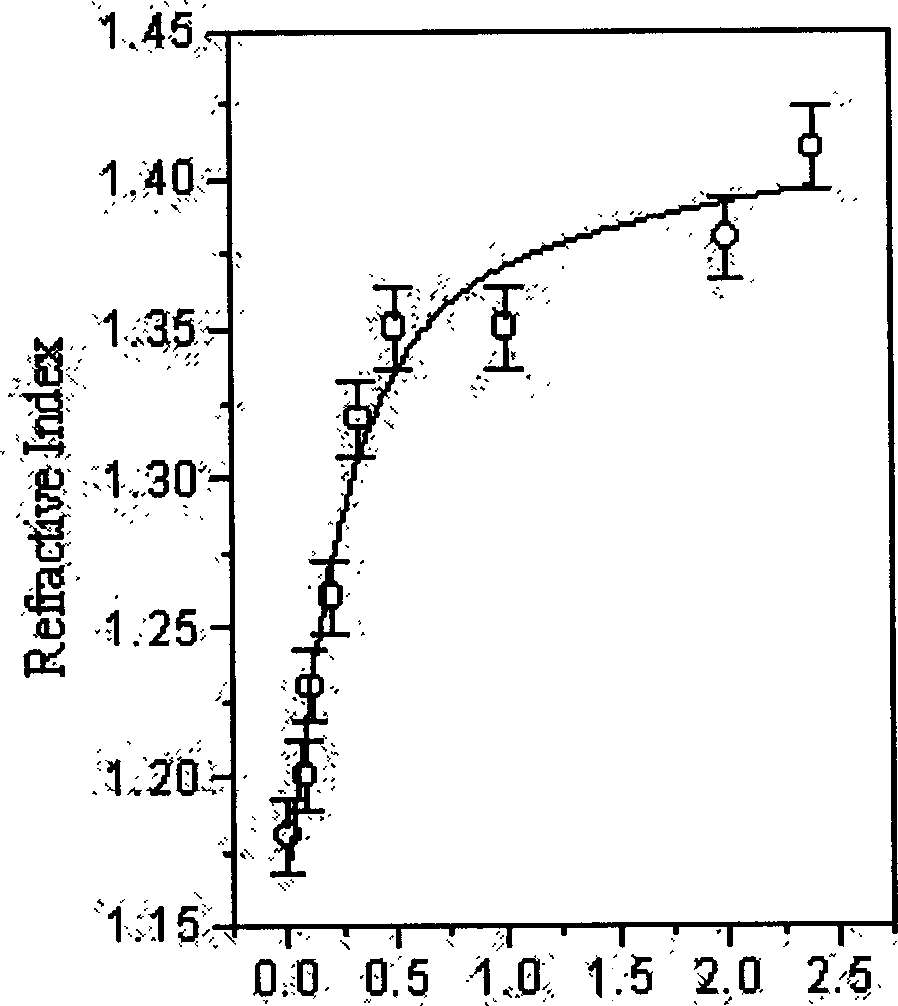

The preparing method is as the follows, positive silester is used as presoma alcohol as solvent and ammonia water as well as hydrochloric acid as catalysts, they are become basic and acidic soliquid after hydrolyzation and polycondensation are carried out silica soliquid can be obtained by further polycondensation and hydrolyzation after basic silica soliquid is agitated in some acidic soliquid, a complete nanomultihole network structure which is not simply piled up can be formed by closely combining particles to be film when using acidic soliquid as coupling agent to link basic soliquid particles together.

Owner:TONGJI UNIV

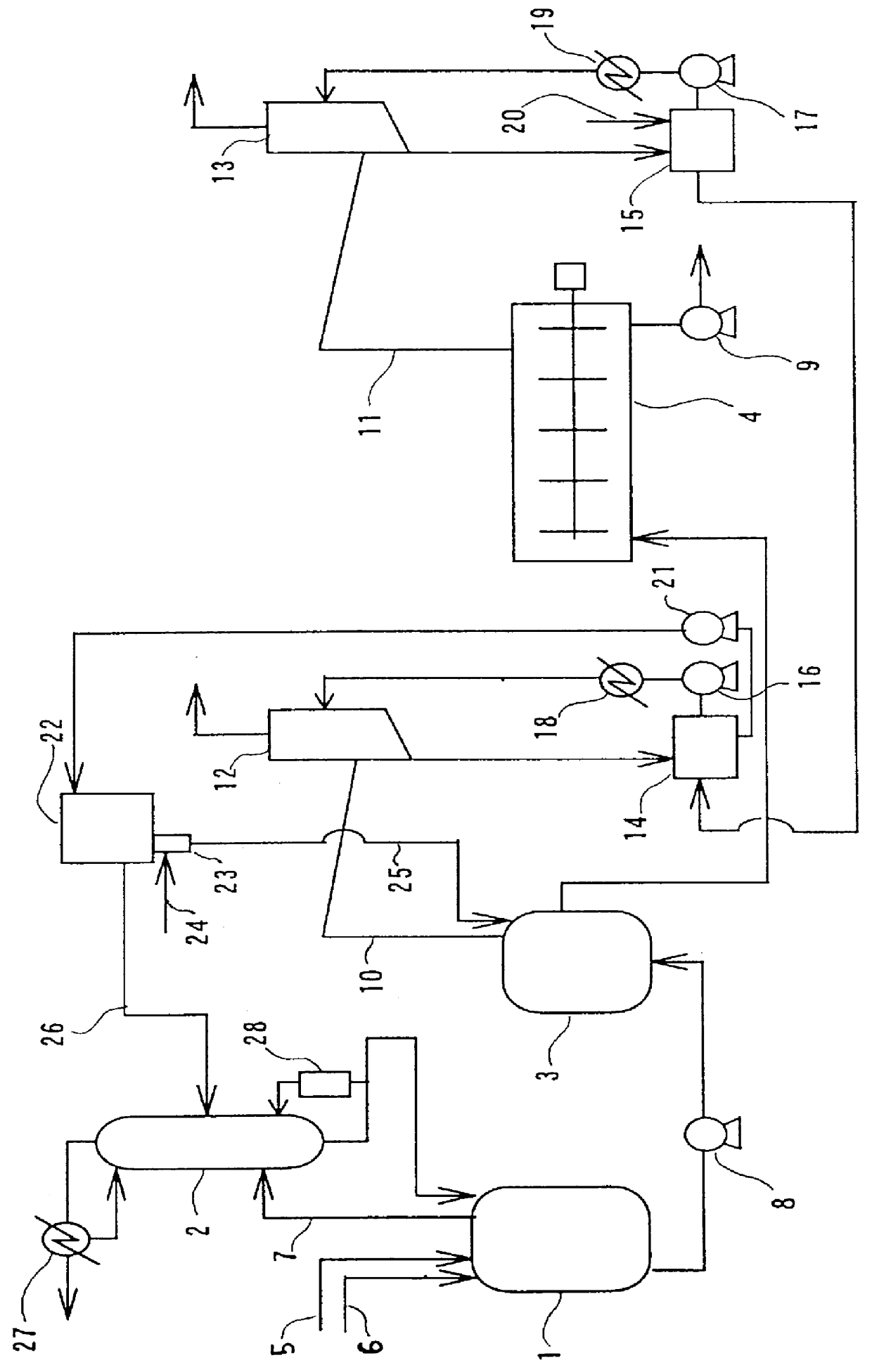

Process for continuously producing polyesters

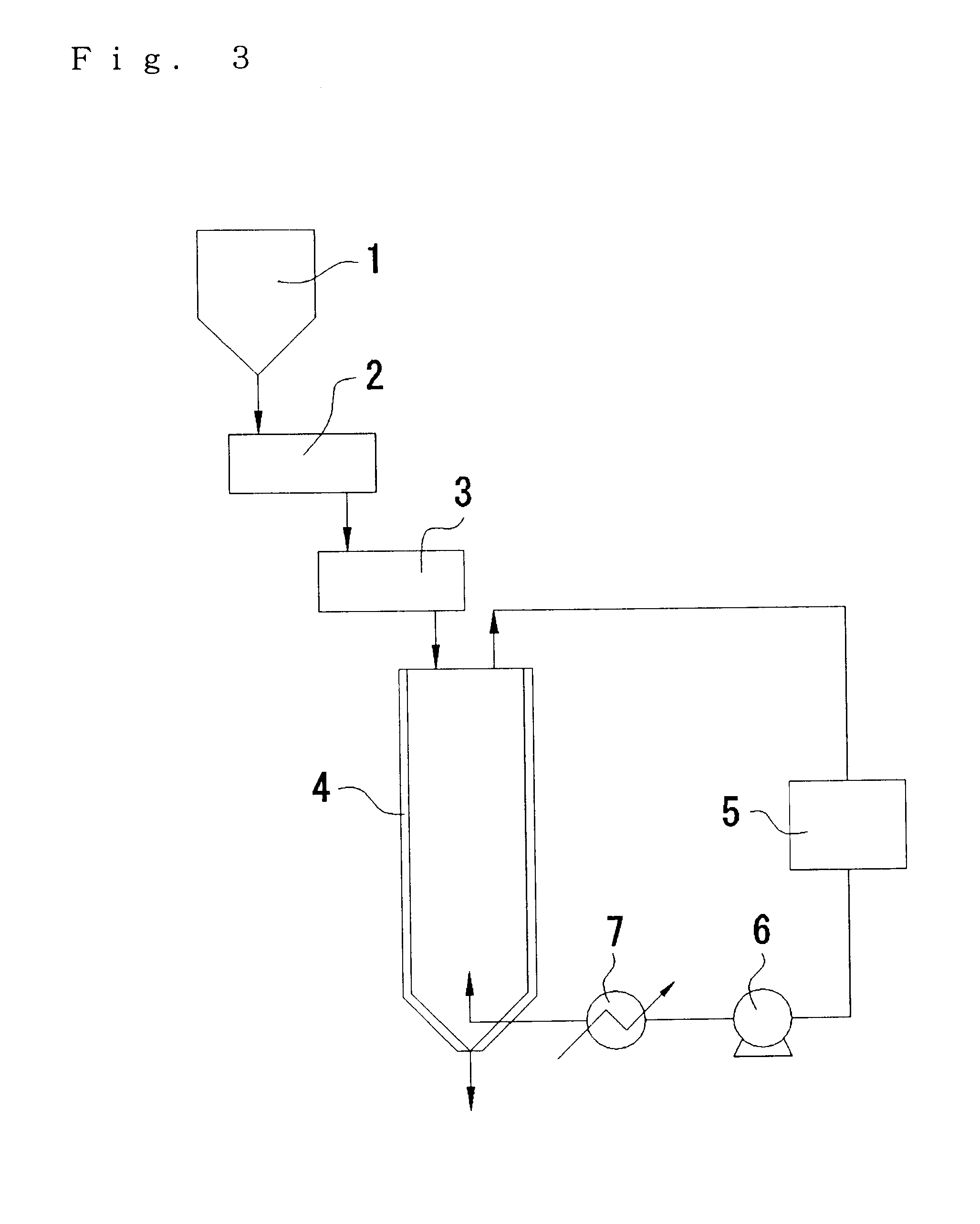

PCT No. PCT / JP98 / 01977 Sec. 371 Date Dec. 21, 1998 Sec. 102(e) Date Dec. 21, 1998 PCT Filed Apr. 30, 1998 PCT Pub. No. WO98 / 50448 PCT Pub. Date Nov. 12, 1998A method for continuously producing a polyester by continuously melt-polymerizing a raw material consisting of a dicarboxylic acid component composed of mainly an aromatic dicarboxylic acid and containing an alicyclic dicarboxylic acid or an aliphatic dicarboxylic acid, or their ester-forming derivatives with a diol component, characterized in that said diol component as a distillate in the polycondensation reaction, including an adhering material, is condensed, said adhering material is separated centrifugally, and then the residual diol component, after distillation, is supplied to an esterification reaction or an ester interchange reaction.

Owner:TEIJIN LTD

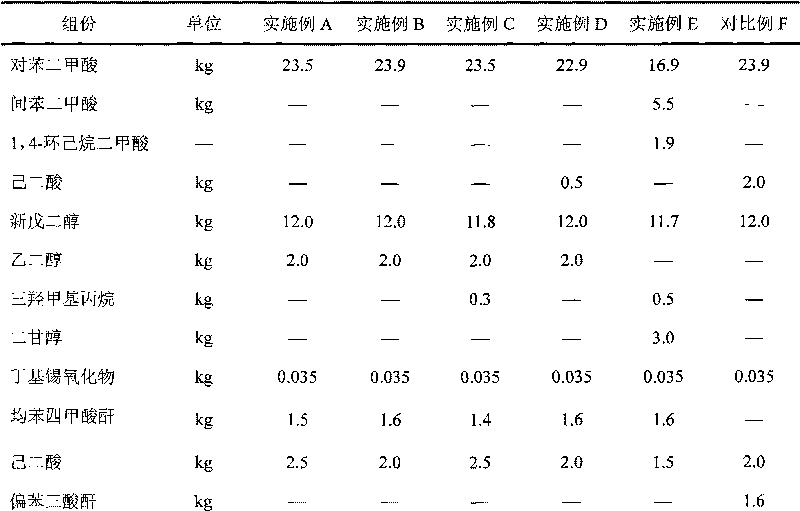

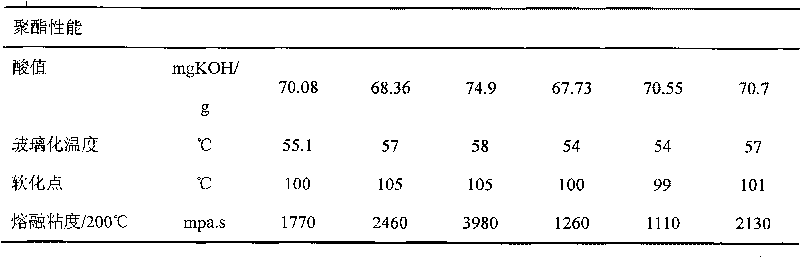

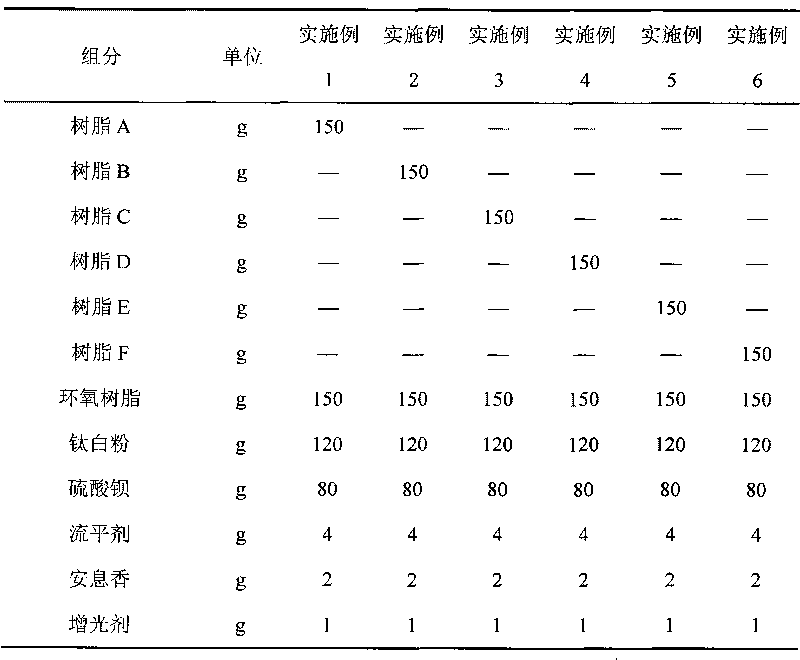

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432ASuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsHybrid typeEpoxy

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

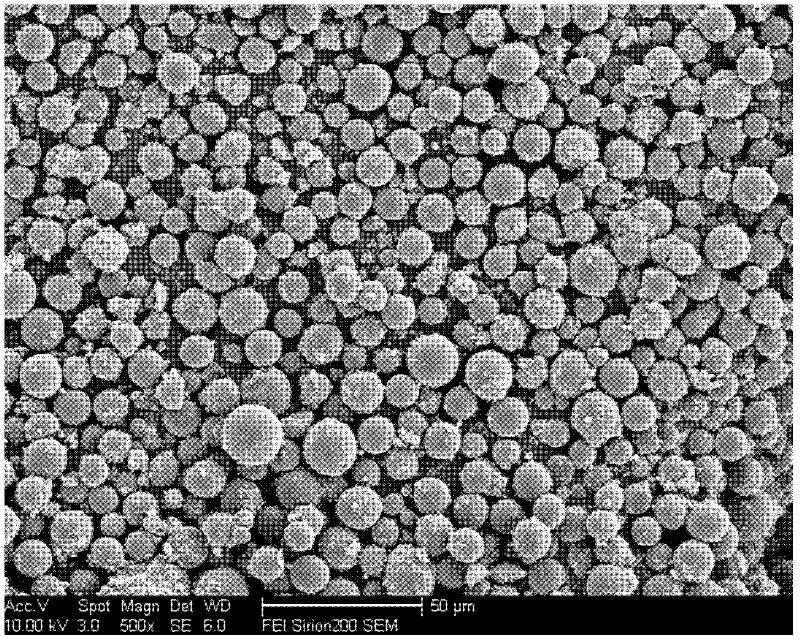

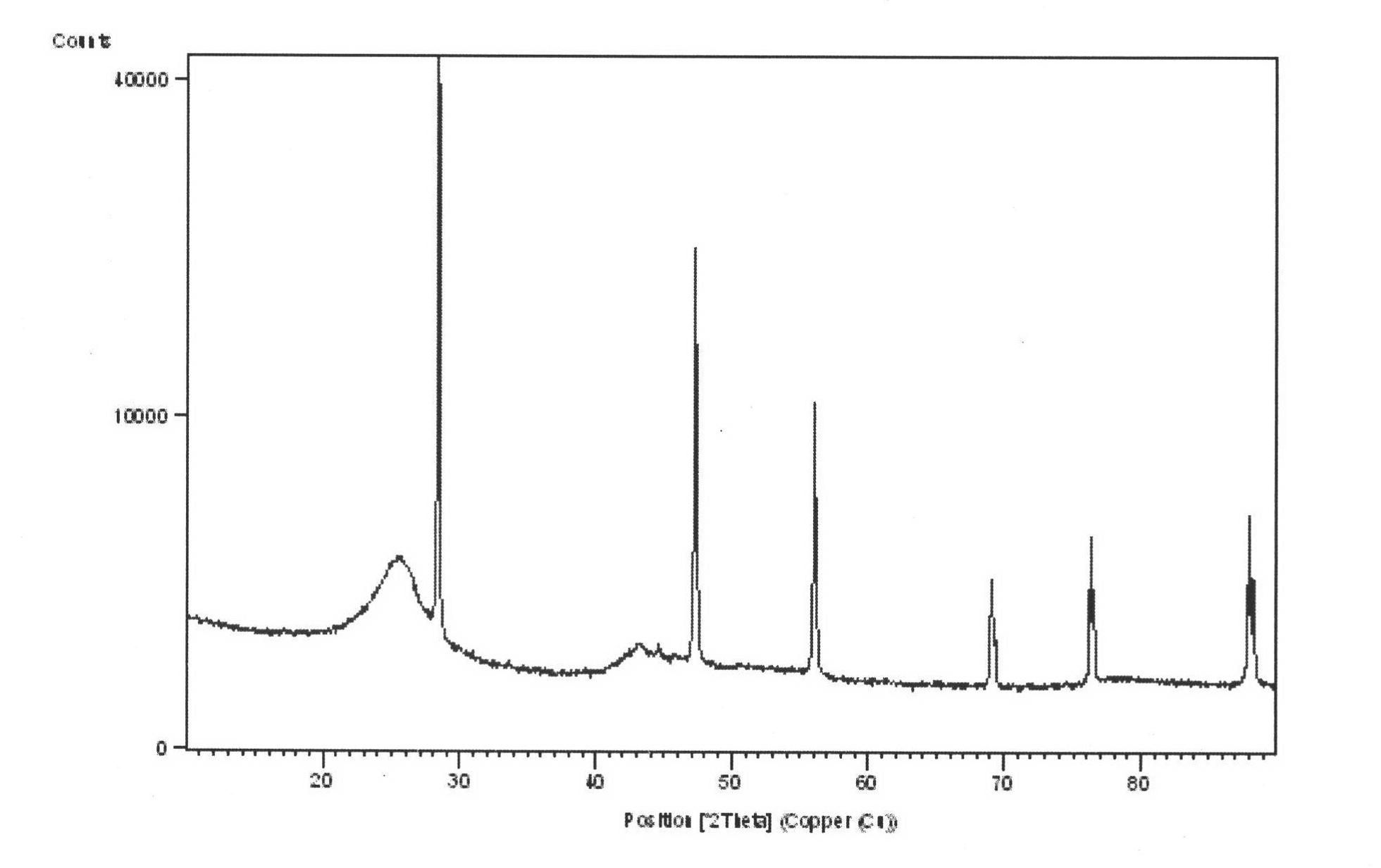

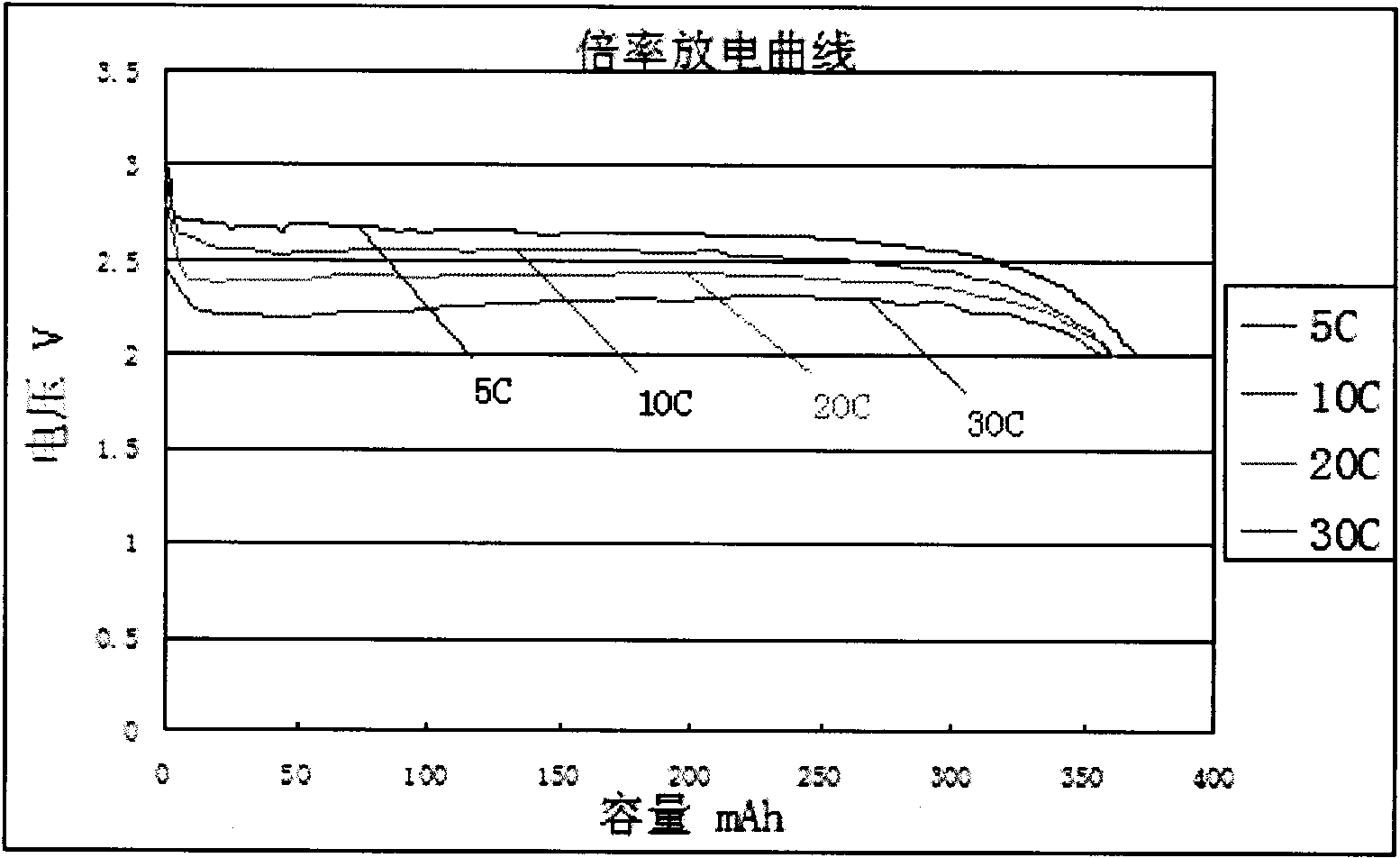

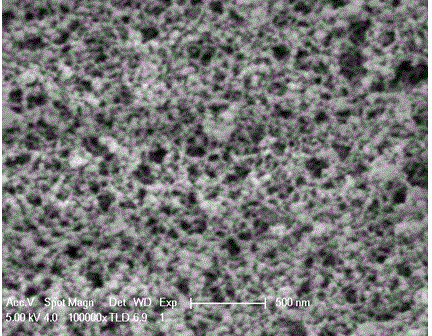

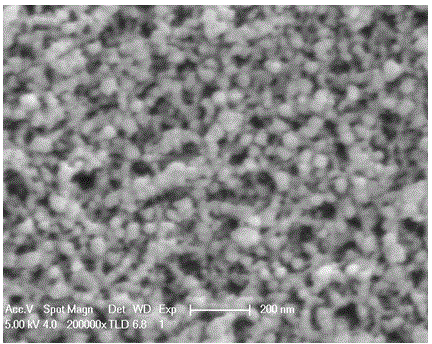

Cathode material for lithium-ion power and energy storage battery and preparation method thereof

The invention discloses a cathode material for a lithium-ion power and energy storage battery and a preparation method thereof, aiming to solve the problem on how to improve the high-magnification charge-discharge property of the battery and how to enable the battery to have good cycle property. The cathode material is obtained by carbonizing asphalt containing a catalyst at 500-1,300 DEG C. The preparation method comprises the following steps of: raising the temperature and the pressure to have a carbonized thermal polycondensation reaction; washing, extracting and then washing; drying to obtain mesophase microbead precursors; and then carbonizing to obtain the cathode material for the lithium-ion power and energy storage battery. Compared with the prior art, the invention reduces the production cost; because the mesophase soft carbon materials obtained by low-temperature carbonization are adopted, the interior of the cathode material is in a turbostratic structure capable of charging and discharging with high power and high current; and the main raw material of the mesophase soft carbon material is asphalt, so that compared with other hard carbons such as the resin type, the plant, and the like, the cathode material has yield improved by 3-5 times, low cost and higher specific capacity.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

Method for preparing silicon dioxide aerogel with low density and large specific surface area at ordinary pressure

The invention discloses a method for preparing silicon dioxide aerogel with low density and large specific surface area at ordinary pressure. The method comprises the steps of taking cheap industrial water glass as a precursor and absolute ethyl alcohol as a solvent, performing hydrolysis and polycondensation reaction by the catalysis of acid and alkali respectively to form wet gel, performing water bath drying and aging, performing solvent exchange for many times, and performing graded drying at the ordinary pressure after surface modification to form the silicon dioxide aerogel with the low density. According to the method, the completely modified super hydrophobic silicon dioxide aerogel is obtained by using the least amount of modifier; the cheap industrial water glass is adopted as a silicon source, so that the production cost is greatly lowered; and the energy source is greatly saved for drying at the ordinary pressure in comparison with supercritical drying.

Owner:HEFEI KESIFU SAFETY TECH

Process for manufacture of polytrimethylene ether glycol

A process of manufacture of polytrimethylene ether glycol comprising:(a) polycondensing reactant comprising diol selected from the group consisting of 1,3-propanediol, 1,3-propanediol dimer and 1,3-propanediol trimer or mixtures thereof in the presence of acid polycondensation catalyst to form polytrimethylene ether glycol;(b) adding water to the polytrimethylene ether glycol and hydrolyzing the acid esters formed during the polycondensation to form a hydrolyzed mixture containing the polytrimethylene ether glycol and the hydrolyzed acid esters;(c) adding organic solvent that is miscible with water to the hydrolyzed mixture to form an aqueous-organic mixture comprising (i) organic phase containing polytrimethylene ether glycol and residual acid polycondensation catalyst from the polycondensing and (ii) water phase;(d) separating the water phase and the organic phase;(e) adding base to the separated organic phase to neutralize the residual acid polycondensation catalyst by forming salts of the residual acid polycondensation catalyst;(f) separating the organic phase into (i) liquid phase comprising the polytrimethylene ether glycol, the organic solvent and any residual water, and (ii) solid phase comprising the salts of the residual acid polycondensation catalyst and the base which is unreacted; and(g) removing the organic solvent and the residual water from the organic phase to obtain polytrimethylene ether glycol.

Owner:EI DU PONT DE NEMOURS & CO

Graphene oxide/unsaturated polyester composite material and preparation method thereof

The invention discloses a graphene oxide / unsaturated polyester composite material and a preparation method of the composite material. The composite material comprises the raw materials: dihydric alcohol, graphene oxide, saturated binary acid or acid anhydride, unsaturated binary acid or acid anhydride, vinyl monomer, and normal polymerization inhibitor, initiator and accelerant, wherein the content of the graphene oxide is 0.06-0.5wt%. The preparation method of the graphene oxide / unsaturated polyester composite material comprises the following steps of: adding the graphene oxide into the dihydric alcohol to directly and ultrasonically disperse, or adding the dihydric alcohol into graphene oxide water solution to ultrasonically disperse and remove water in a fractional distillation way so as to obtain graphene oxide / dihydric alcohol solution which is evenly dispersed; performing polycondensation between the obtained graphene oxide / dihydric alcohol solution and the saturated binary acidor acid anhydride, unsaturated binary acid or acid anhydride and polymerization inhibitor with metering ratio, and diluting by adding the vinyl monomer after the polymerization so as to prepare graphene oxide / unsaturated polyester resin; and adding the initiator and the accelerant, and curing and crosslinking to prepare the graphene oxide / unsaturated polyester composite material.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Polyester polycondensation with catalyst and a catalyst enhancer

InactiveUS20020032300A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyesterPotassium

The present invention is based upon the discovery that nontitanyl oxalates can enhance the catalytic functionality of titanyl oxalate catalysts. This invention provides a novel catalytic composition containing a titanyl oxalate catalyst and a metallic oxalate catalyst enhancer and optionally containing a metallic cocatalyst such as an antimony based catalyst. A synergistic relationship has been discovered between titanyl oxalate catalyst and the catalyst enhancer. A synergistic relationship has also been discovered between the titanyl oxalate catalyst, catalyst enhancer and a metallic cocatalyst such as antimony oxide or antimony triacetate. Also provided is an improved process of producing polyester by the polycondensation of polyester forming reactants in the presence of a catalytically effective amount of a polycondensation catalyst, wherein the improvement comprises utilizing, as the polycondensation catalyst, the novel catalyst composition containing a titanyl oxalate such as lithium titanyl oxalate and a catalyst enhancer such as a nontitanyl metallic oxalate like lithium oxalate and optionally containing a metallic catalyst such as antimony oxide or antimony triacetate. The improved process produces an improved polyester having lower acetaldehyde numbers and good color. The titanyl oxalate / catalyst enhancer composition can be used as a polycondensation catalyst in combination with other catalysts to achieve synergistic catalytic activity. Preferred is a combination of lithium or potassium titanyl oxalate, Li2 or K2TiO(C2O4)2, lithium or potassium oxalate, Li2 or K2(C2O4)2 with antimony oxide or antimony triacetate or antimony trisglycoxide.

Owner:ARKEMA INC

Toner, developer, and image forming apparatus

InactiveUS20100021209A1Fast chargingEasy to disassembleElectrographic process apparatusDevelopersOrganic solventGas phase

A toner produced by dissolving or dispersing toner components comprising a binder resin, a colorant, and a charge controlling agent in an organic solvent to prepare a toner components liquid, forming liquid droplets of the toner components liquid in a gas phase, and solidifying the liquid droplets into toner particles of the toner. The charge controlling agent includes a polycondensation reaction product of a phenol with an aldehyde.

Owner:RICOH KK

Method for preparing polyester-polyester blocked copolyester

The invention discloses a method for preparing polyester-polyester blocked copolyester, which comprises the following steps: (1) synthesizing an aromatic polyester hard segment to obtain a prepolymer P1 with a number-average molecular weight in the range of 500-10,000g / mol; (2) synthesizing an aliphatic polyester soft segment to obtain a prepolymer P2, wherein the prepolymer P2 can also be obtained by ring-opening polymerization of caprolactone monomer, and the number-average molecular weight of the prepolymer P2 is in the range of 500-10,000g / mol; (3) carrying out polycondensation reaction of the aromatic polyester oligomer and the aliphatic polyester oligomer: mixing the esterified product P1 and the esterified product P2, adding antioxidant, catalyst, passsivator and chain expander, allowing reaction at 220-260 DEG C to obtain a polyester-polyester block polyester elastomer. The catalysts used in the steps (1) and (2) are selected from titanium-containing organic substances. The method disclosed by the invention has the following advantages: (1) because the aliphatic polyester soft segment is introduced, the product has both the mechanical properties of the rigid aromatic polyester hard segment and the flexibility of the soft segment; and (2) because a number of assistants are added, the good chain expansion effect is achieved, and the reaction conditions are controlled.

Owner:KINGFA SCI & TECH CO LTD +2

Low-melting-point copolyester and method for preparing same

InactiveCN101338023AIncrease exerciseLow melting pointMonocomponent copolyesters artificial filamentFiberPolymer science

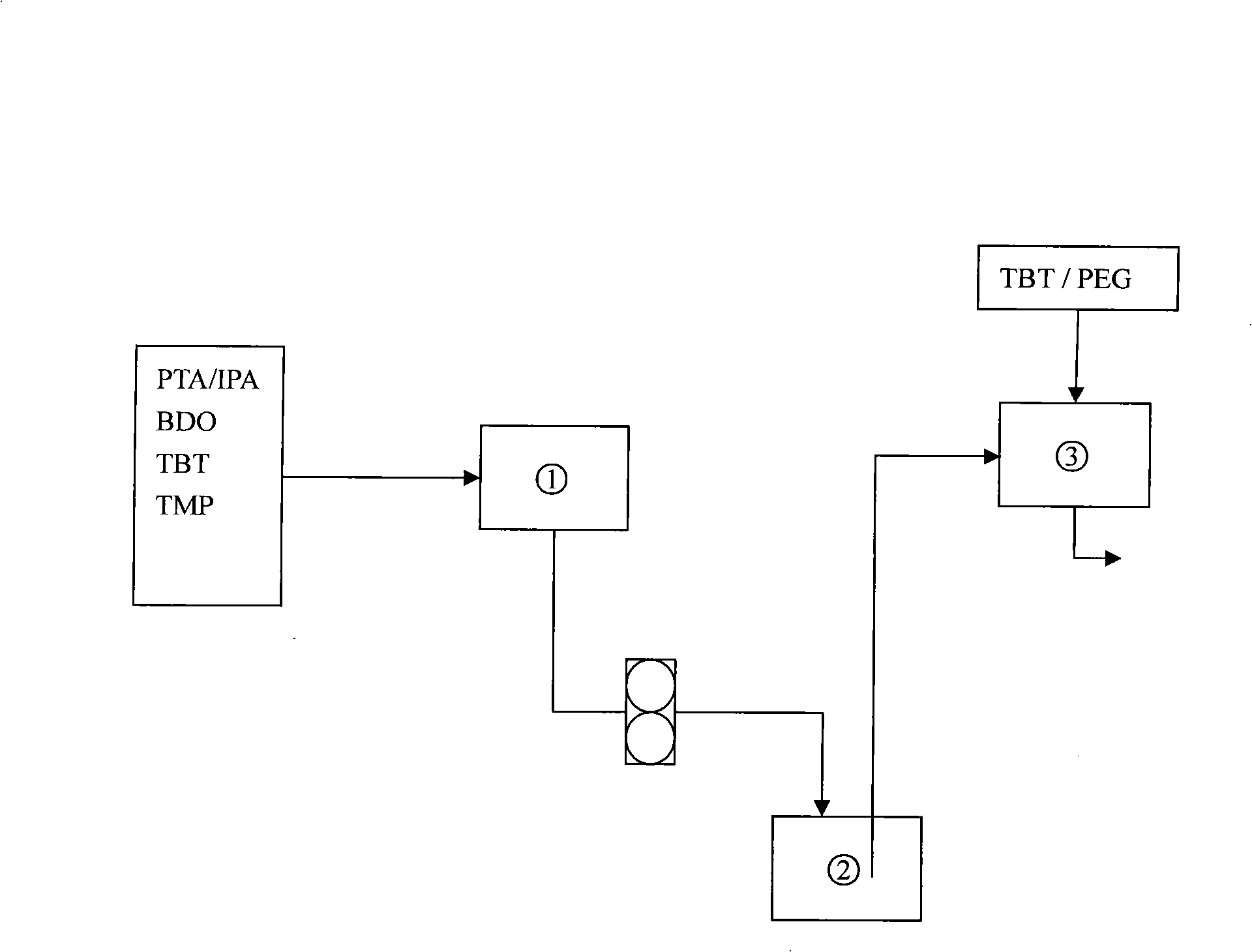

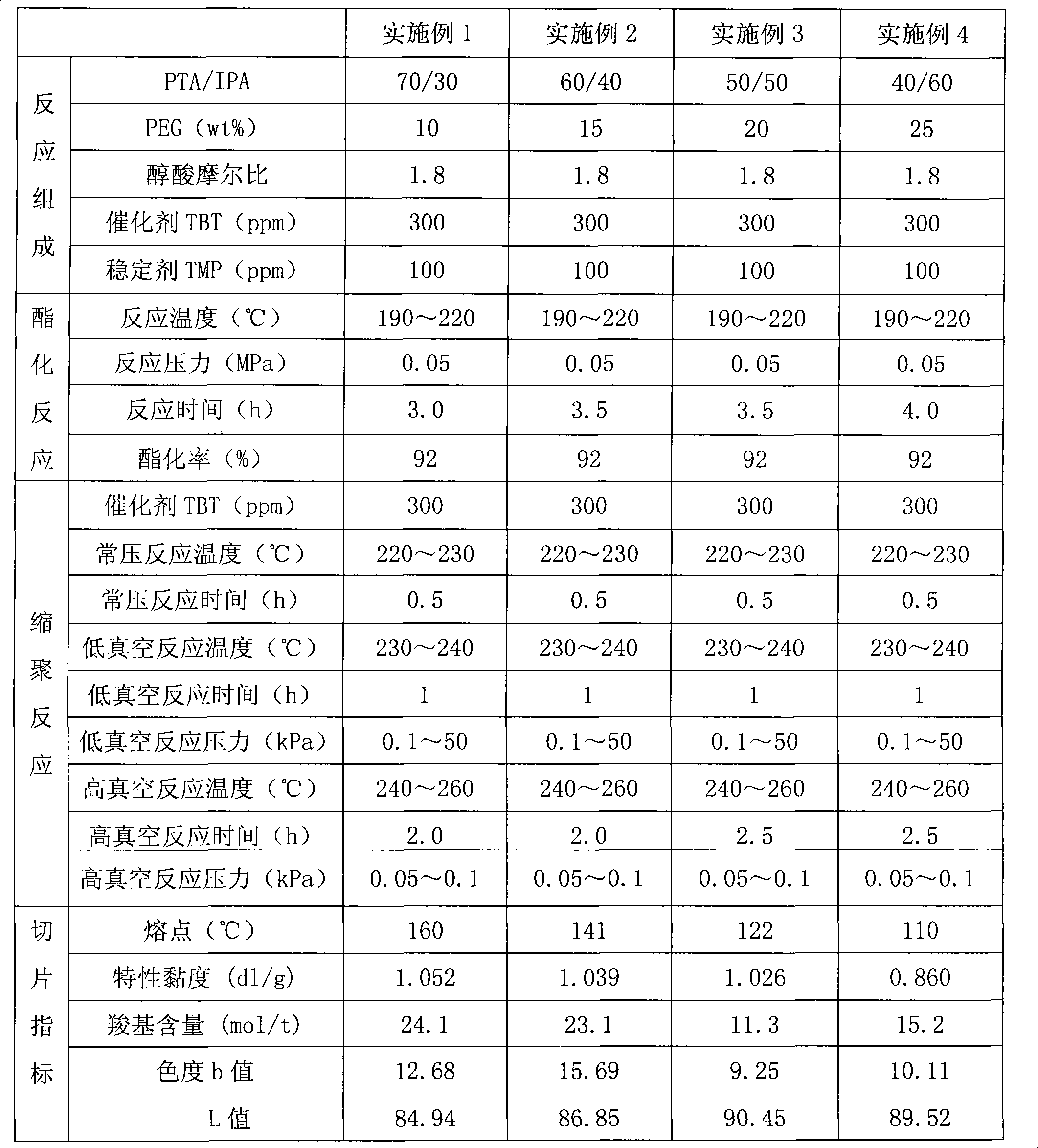

The invention relates to low melting point copolyester and a preparation method thereof. The low melting point copolyester is made from the following monomers followed by the esterification reaction and the polycondensation reaction: (a) terephthalic acid (PTA) and isophthalic acid (IPA), (b) 1, 4- butanediol (BDO) and (c) polyethylene glycol 600 to 6000 (PEG); wherein, in the a component, the feeding mass ratio of the terephthalic acid and the isophthalic acid is between 80 to 20 : 20 to 80; in the c component, the feeding weight ratio of polyethylene glycol is 1 to 30 percent based on the a; the molar ratio of the a and the b is 1:1.5 to 2.3. The preparation method comprises an esterifcation stage and a polycondensation stage. The copolyester has the characteristics of low melting point, good crystallization property, high intrinsic viscosity and difficult adhesion of particles, and is suitable for spinning the filament, the staple fibers and the non-woven fabrics.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of functional polyester fiber

ActiveCN103789868AAdequate responseHigh apparent viscosityArtificial filament heat treatmentMelt spinning methodsPolymer scienceMoisture absorption

The invention relates to a preparation method of a functional polyester fiber. The preparation method comprises the following steps: performing esterification by stages, wherein dihydric alcohols, polyhydric alcohols and functional inorganic powder are mixed according to a certain mole ratio, in the first esterification stage, acid is slightly excess to ensure that monomers with low capability of participating in esterification reaction in the polyhydric alcohols fully react and are grafted into polyester molecular chains, and in the second esterification stage, the dihydric alcohols are replenished to control the terminal carboxyl group of copolyester. The preparation method has the advantages that polyhydric functional groups can improve the apparent viscosity of a system and play a role in wrapping the introduced functional inorganic powder (such as far infrared ceramic inorganic powder, titanium dioxide powder and zinc oxide antibacterial powder), thus improving the dispersion uniformity of particles; settlement is unlikely to happen in the polymerization process and then functional polyester is prepared through condensation polymerization; the functional polyester fiber is finally prepared by carrying out melt spinning on the prepared polyester, has good moisture absorption property and flexibility and can be widely used for preparing far-infrared moisture absorbing and sweat releasing antistatic and antibacterial fabrics next to the skin.

Owner:JIANGSU HENGZE COMPOSITE MATERIALS TECH

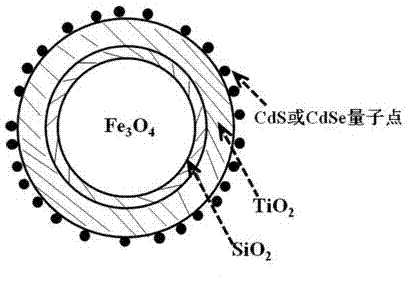

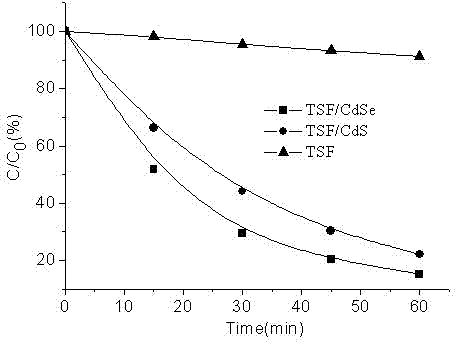

Magnetic Fe3O4/SiO2/TiO2/quantum dot compounded nanometer photocatalyst and preparation method and application thereof

InactiveCN102921435AHigh visible light photocatalytic performancePromote degradationPhysical/chemical process catalystsWater/sewage treatment by irradiationNano catalystVisible light photocatalytic

The invention belongs to the technical field of treatment and application of nanometer materials and industrial and agricultural wastewater, and provides a magnetic Fe3O4 / SiO2 / TiO2 / quantum dot compounded nanometer photocatalyst and a preparation method and application thereof. The preparation method comprises the following steps of: synthesizing an Fe3O4 magnetic nucleus by a coprecipitation method; preparing an SiO2 protective layer by virtue of hydrolysis reaction and polycondensation reaction of TEOS (Tetraethyl Orthosilicate); then preparing a TiO2 layer on the surface of the SiO2 protective layer by a sol-gel method; and finally modifying Fe3O4 / SiO2 / TiO2 nanoparticles by CdS and CdSe quantum dots. The obtained magnetic Fe3O4 / SiO2 / TiO2 / quantum dot compounded nanometer photocatalyst has very good visible-light photocatalytic capability, can be conveniently and fast recovered and reused by an external magnetic field, and can be used for removing organic pollutants of azo dyes contained in the industrial wastewater.

Owner:HUBEI UNIV

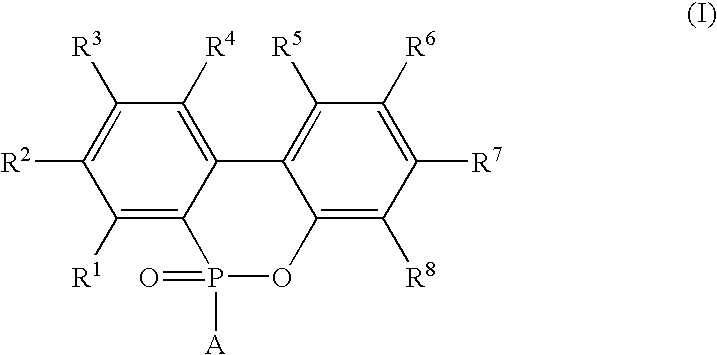

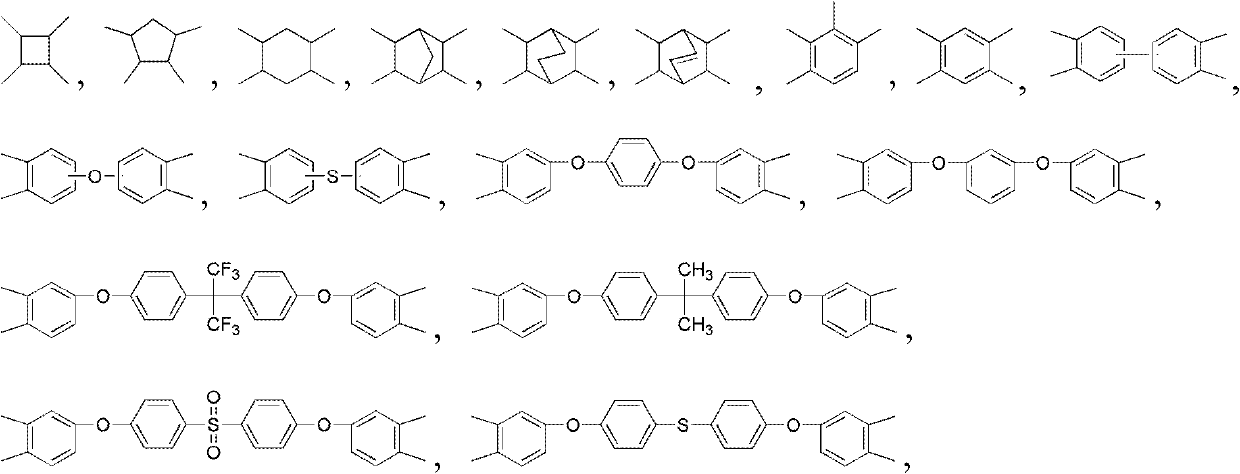

Water-soluble flame-retardant polyester resin, resin composition containing the resin, and fiber product treated with the resin composition

InactiveUS7358323B2Improve flame retardant performanceEliminate the problemSynthetic resin layered productsHeat resistant fibresSolubilityFiber

A water-soluble, flame retardant polyester resin is obtained by a condensation reaction or a polycondensation reaction of a dicarboxylic-acid component, a glycol component, a water-solubility imparting component and a reactive phosphorus-containing compound such that a ratio of the water-solubility imparting component in a total of the dicarboxylic-acid component and the water-solubility imparting component is in a range of 1 to 60 mol %. Since this polyester resin can be dissolved in a solvent by allowing a halogen-free, phosphorus-containing polyester with excellent flame resistance to have water solubility, it is possible to improve applicability and eliminate problems of working environment and environmental destruction resulting from organic solvents. In addition, even when treating substrates such as fibers and PET films with the polyester resin, there is no deterioration of these substrates.

Owner:GOO CHEM IND

Binary titanium alkoxide (VI) compound and its preparing process and application

InactiveCN1327985AHas photocatalytic propertiesImprove catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsTitanium organic compoundsPolyesterDiol

A binary titanium (VI) alkoxide compound is disclosed, which can be used as high-activity catalyst in esterification, ester exchange and polycondensation reactions. Said compound is prepared from easily hydrolytic Ti (VI) compounds or their hydrolyzed products and diol or hydrous diol through direct reaction to generate gel, regulating temp and pressure of reaction system or introducing inert gasto gradually remove the low-molecular resultants in reaction system, decolouring and drying. Its advantages include simple preparing process, low cost, and the high catalytic activity, optical catalytic performance and anti-hydrolysis nature of said product.

Owner:济南齐鲁化纤集团有限责任公司

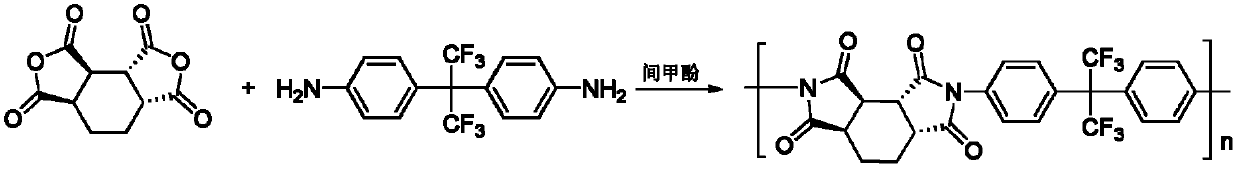

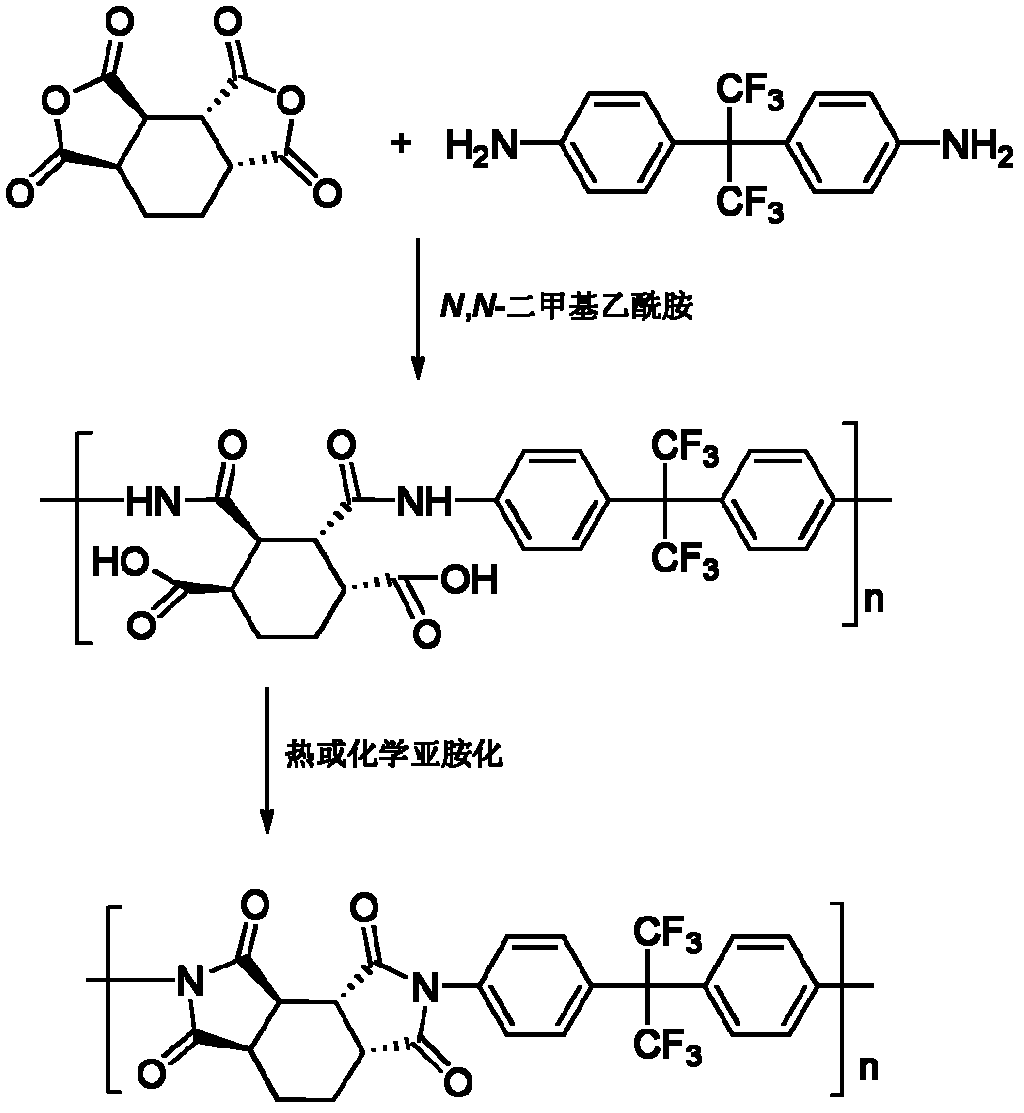

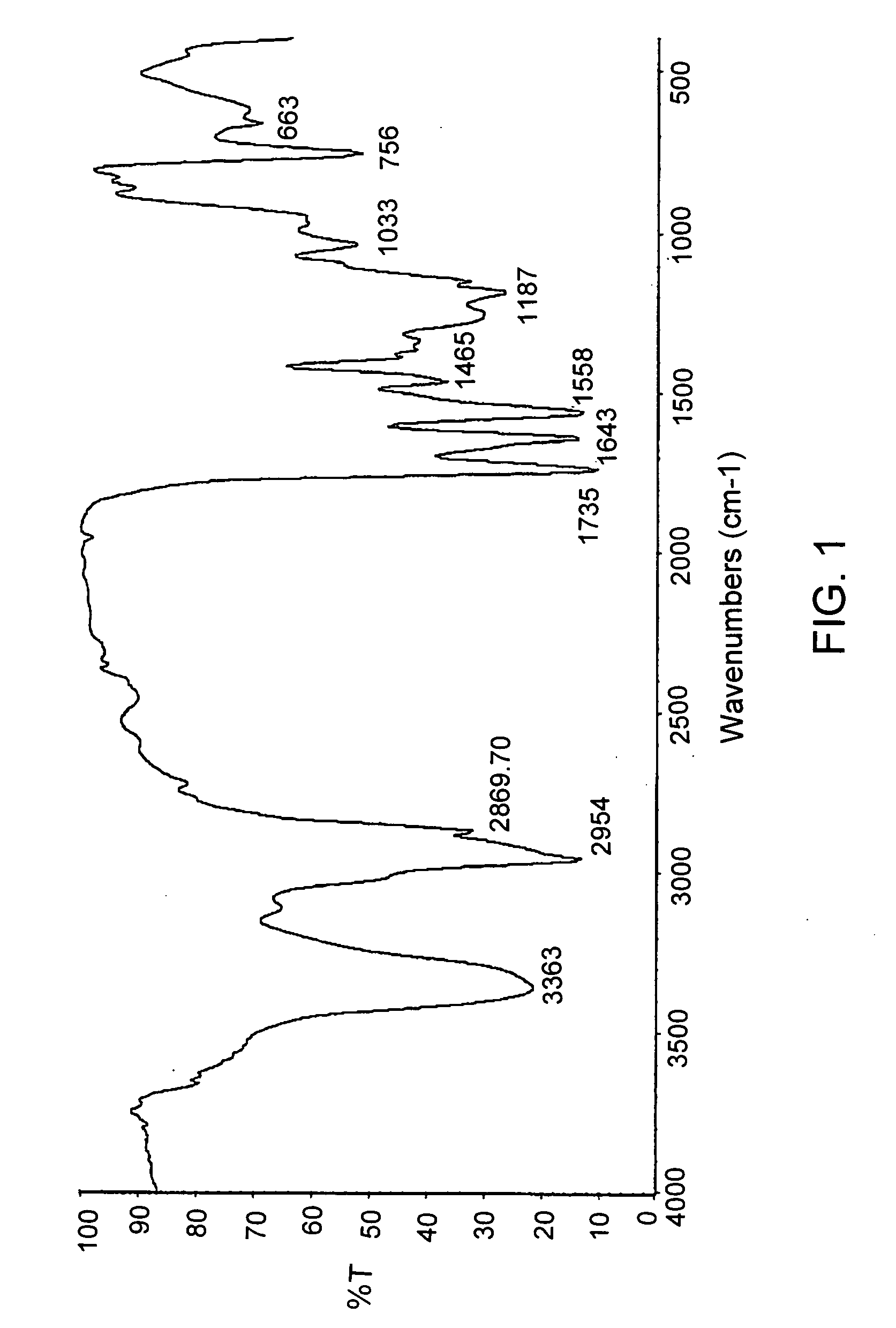

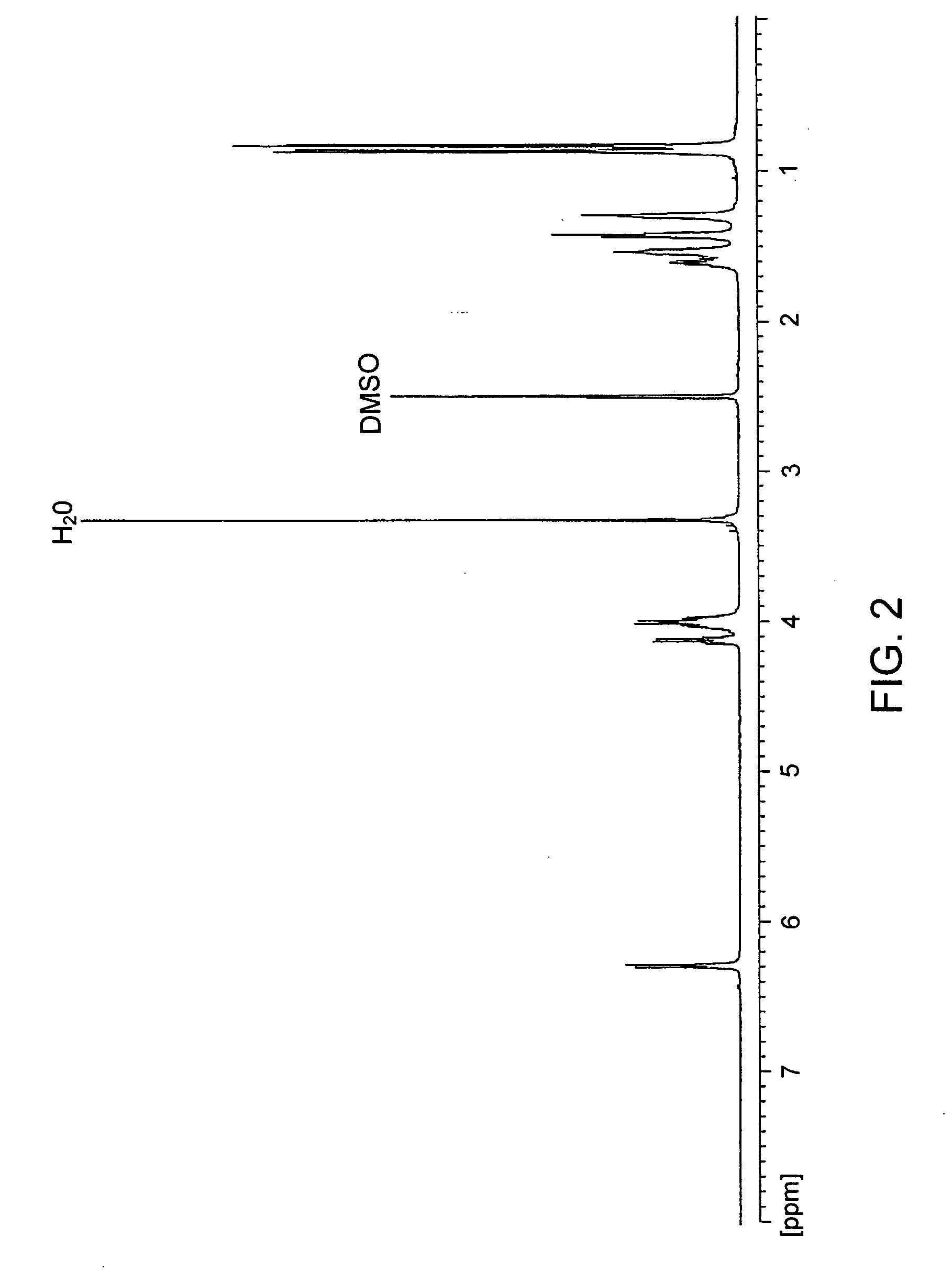

Colorless and transparent polyimide resin material and preparation method thereof

ActiveCN102382303AHigh transparencyHigh glass transition temperatureCharge-transfer complexUltraviolet lights

The invention discloses a colorless and transparent polyimide resin material. 1,2,3,4-cyclohexanetetracarboxylic dianhydride is chosen as dianhydride monomer or comonomer to carry out polycondensation reaction with primary diamine, so that the polyimide resin material is prepared. Because the 1,2,3,4-cyclohexanetetracarboxylic dianhydride comonomer has a distorted molecular structure, a large free volume exists between polymer molecular chains, and thereby the formation of charge transfer complex (CTC) in and between polyimide molecules is inhibited; and meanwhile, because of the introductionof a lipid structure, the electron-stimulated transition mode in the polyimide molecular chains is changed, the absorption of the aromatic polyimide in the visible light region is remarkably weakened, and thereby the transparency of the polymer is greatly increased. The ultraviolet light transmission cutoff wavelength of a produced polyimide film is 280nm to 380nm, the light transmissivity at 450nm is 86 to 94 percent, moreover, the glass-transition temperature is 250 DEG C to 400 DEG C, and the polyimide resin material has a good application prospect in the fields of flexible substrate materials for solar cells, flexible transparent conducting film substrate materials, liquid crystal display materials and the like.

Owner:WUHAN YIMAIDE NEW MATERIALS TECH CO LTD

Poly(ester urea) polymers and methods of use

InactiveUS20070128250A1Easy to produceImprove mechanical propertiesOrganic active ingredientsSurgeryAntibiotic YHard tissue

The invention provides high molecular weight, crystalline or semi crystalline biodegradable and biocompatible poly(ester urea) (PEU) polymers useful for making vascular stents and hard tissue replacement implants, such as bone substitutes. The PEU polymers are based on α amino acids and are made by a polycondensation reaction. PEU polymer compositions can contain a therapeutic diol incorporated into the polymer backbone that is released from such an implant in situ. Bioactive agents, such as analgesics, antibiotics, and the like, can also be covalently attached to certain PEU polymers for release into tissue surrounding an implant during biodegradation of the polymer.

Owner:MEDIVAS LLC

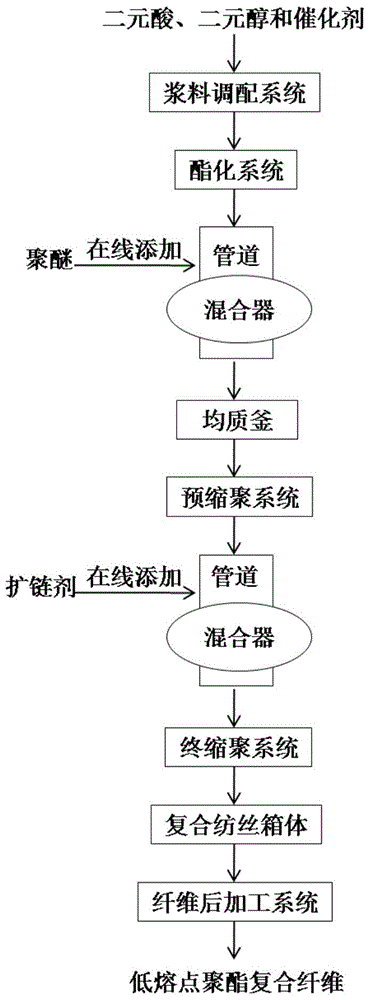

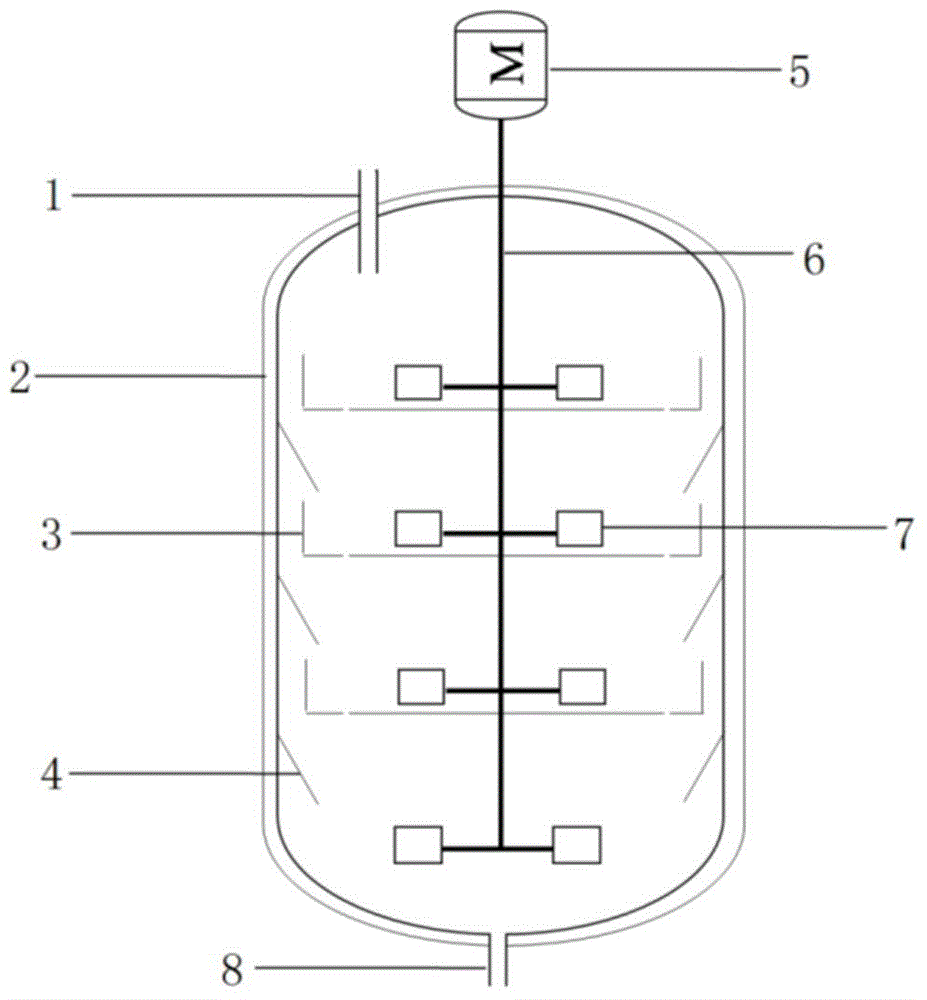

Method for preparing low-melting-point polyester composite fiber by adopting continuous polymerization and melt direct-spinning

ActiveCN105063797AImprove thermal stabilitySuppress thermal degradation side reactionsArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsOligomerTransesterification

The invention relates to a method for preparing a modified copolyester composite fiber, in particular to a method for preparing a low-melting-point polyester composite fiber by adopting continuous polymerization and melt direct-spinning. The method comprises the following steps: slurry is prepared from raw materials in proportion and added continuously into an esterification system for an esterification reaction, an obtained oligomer is uniformly mixed with polyether, the mixture enters a homogenizing kettle for transesterification and pre-polycondensation, a product is uniformly mixed with a chain extender for final polycondensation, and an obtained low-melting-point polyester melt and a common polyester melt enter a composite spinning assembly to prepare the low-melting-point polyester composite fiber which comprises a common polyester core layer and a low-melting-point polyester cortex layer. The method has the advantages as follows: a side reaction of thermal degradation of polyether components is inhibited effectively, and the color and spinnability of the low-melting-point polyester melt are improved; the problem of poor performance of composite spinning of the low-melting-point polyester on the cortex layer and the common polyester on the core layer due to large dynamic viscosity difference of the melt is solved, and the composite fiber is well formed; the production efficiency of the low-melting-point polyester composite fiber is improved.

Owner:CHINESE TEXTILE ACAD

High-activity catalyst and its application in synthesizing polyester

A high-activity catalyst for both esterification and polycondensation contains anti-hydrolytic high-activity glycol titanium, the acetate, carbonate or oxalate of (1-4)-valence metal ions, and at least one of alkoxyl compound, organic acid and phosphorous compound. Its advantages are high activity, short reaction period, and no environmental pollution. Its resultant polyester has high photochemical performance and whiteness.

Owner:济南齐鲁化纤集团有限责任公司

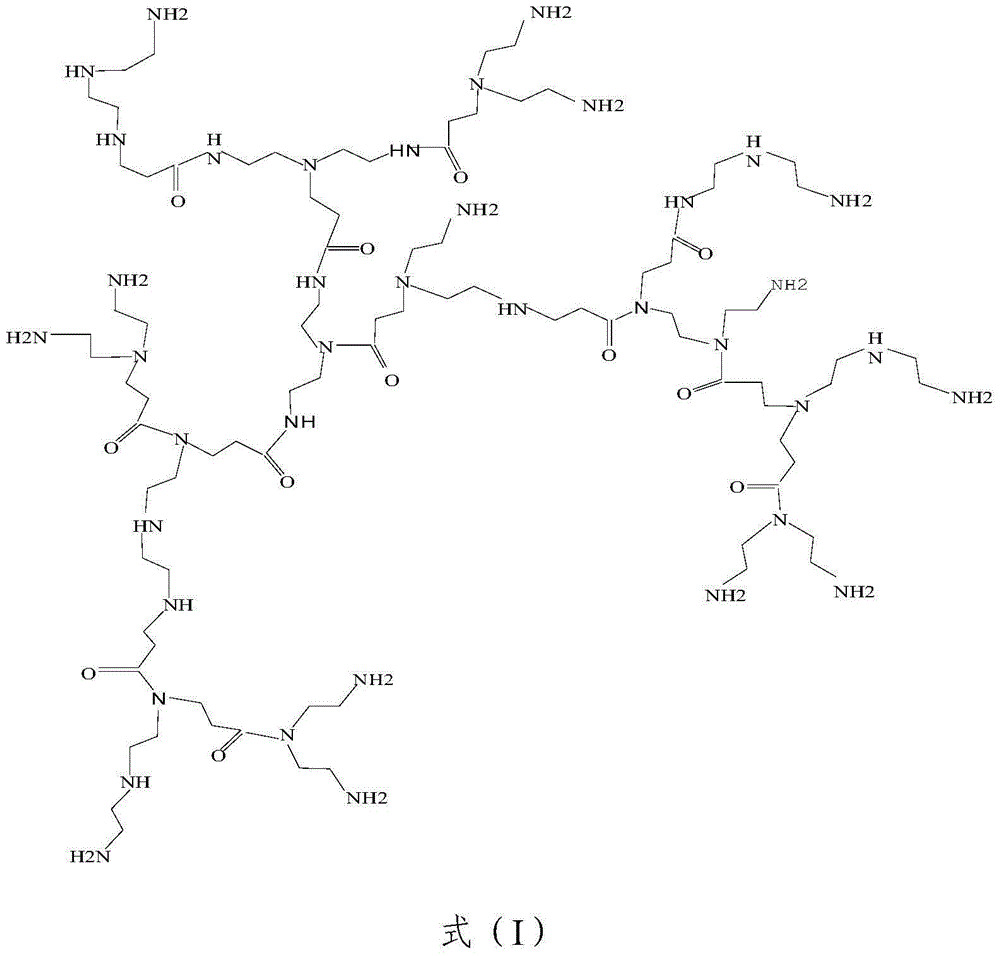

Formaldehyde catching agent and preparation method thereof

ActiveCN104645800ANon-volatileNo irritating smellDispersed particle separationPolyamine CompoundMethyl acrylate

The invention provides a formaldehyde catching agent. An efficient macromolecular type formaldehyde catching agent is synthesized by performing addition polycondensation reaction on a methyl acrylate monomer and a polyamine compound to generate an amino-group-enriched hyperbranched polymer and adding corresponding auxiliaries. According to the catching agent, formaldehyde is caught by using an amino group of the hyperbranched polymer and film forming fixing is implemented by using a carbon framework of an acrylate type substance; modification is realized by the corresponding various auxiliaries, so that the physical performance and the formaldehyde elimination effect are improved. The formaldehyde catching agent has the characteristics of no toxicity, no volatility and no irritating odor, and secondary harm to a human body is avoided; the formaldehyde catching agent can be limitlessly dissolved in water, is mild in property, free from corrosion, easy to add and spray, high in film forming property and durable.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

SiO2 nanoscale porous material with aerogel property prepared by microwave reaction and preparation method thereof

InactiveCN101633505ALarge specific surface areaHigh strengthNanostructure manufactureSilicaSupercritical dryingOrganic solvent

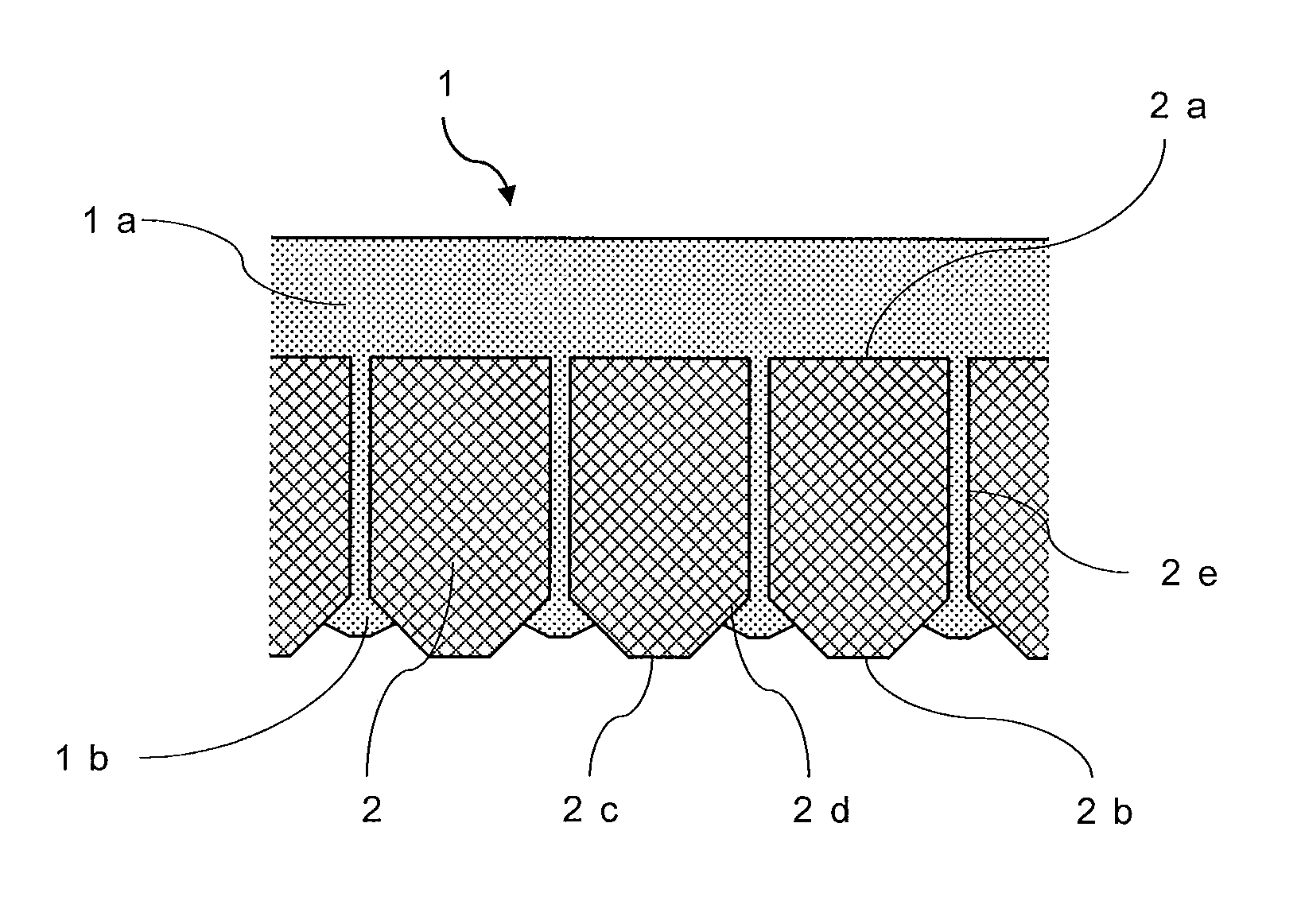

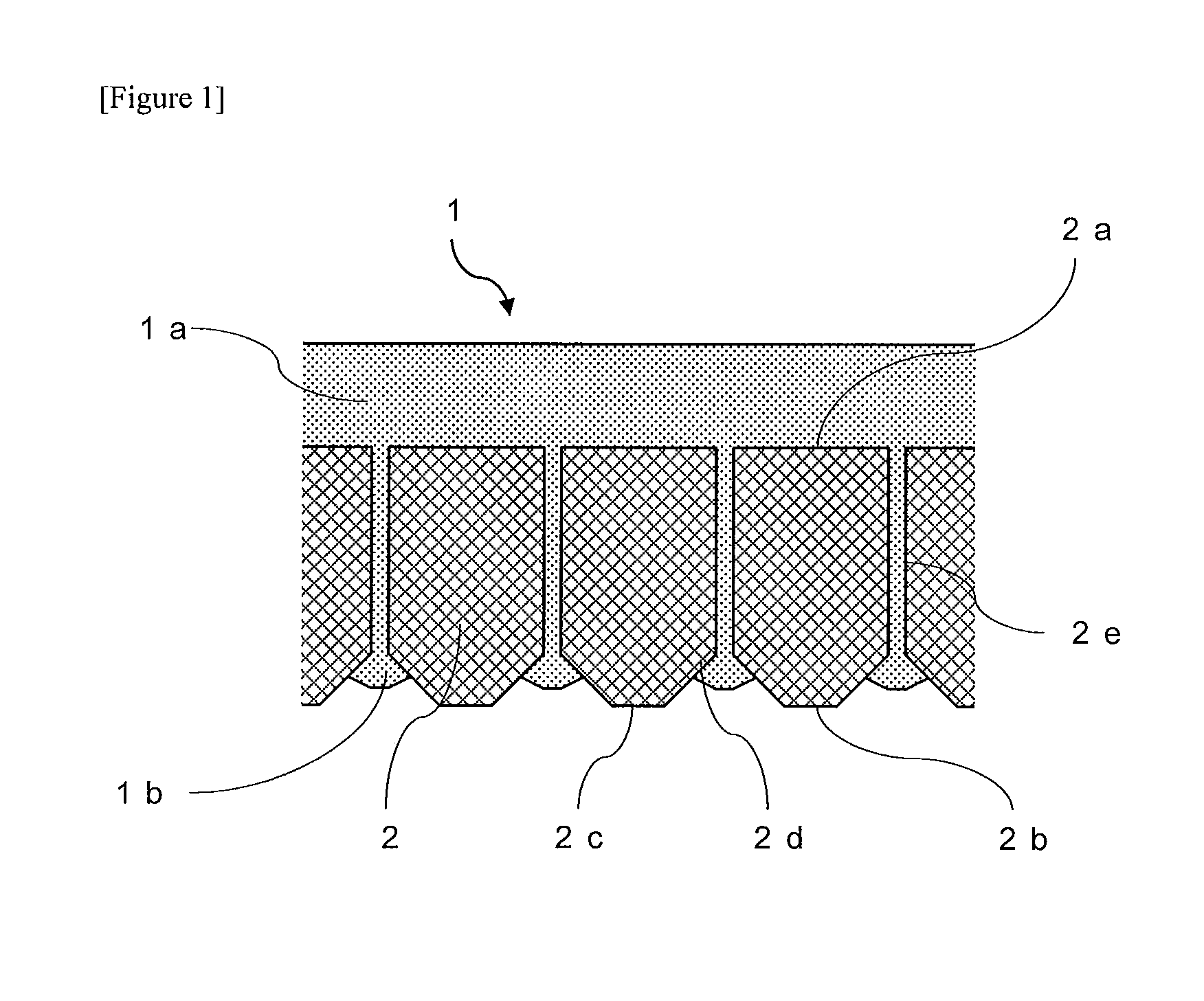

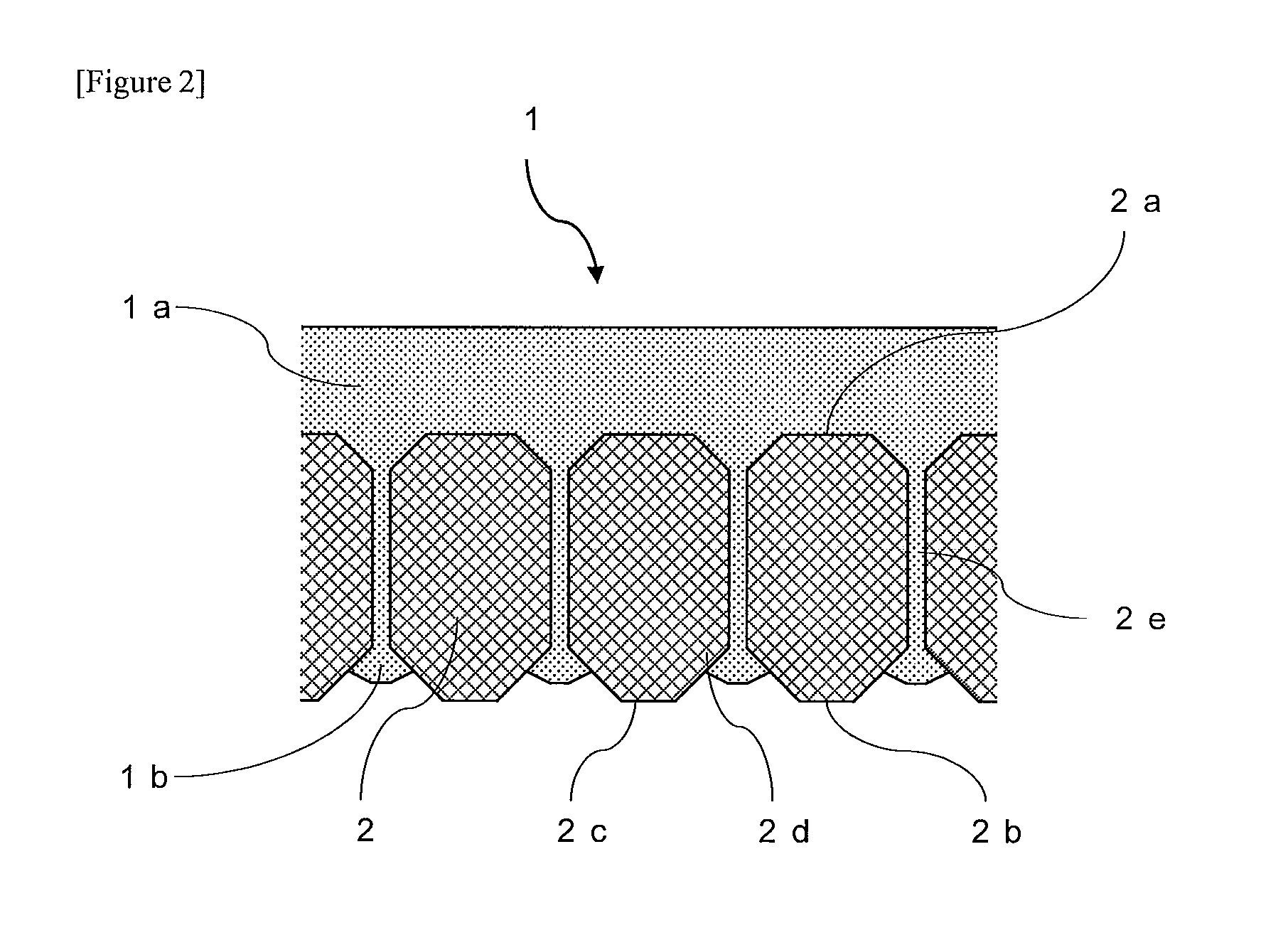

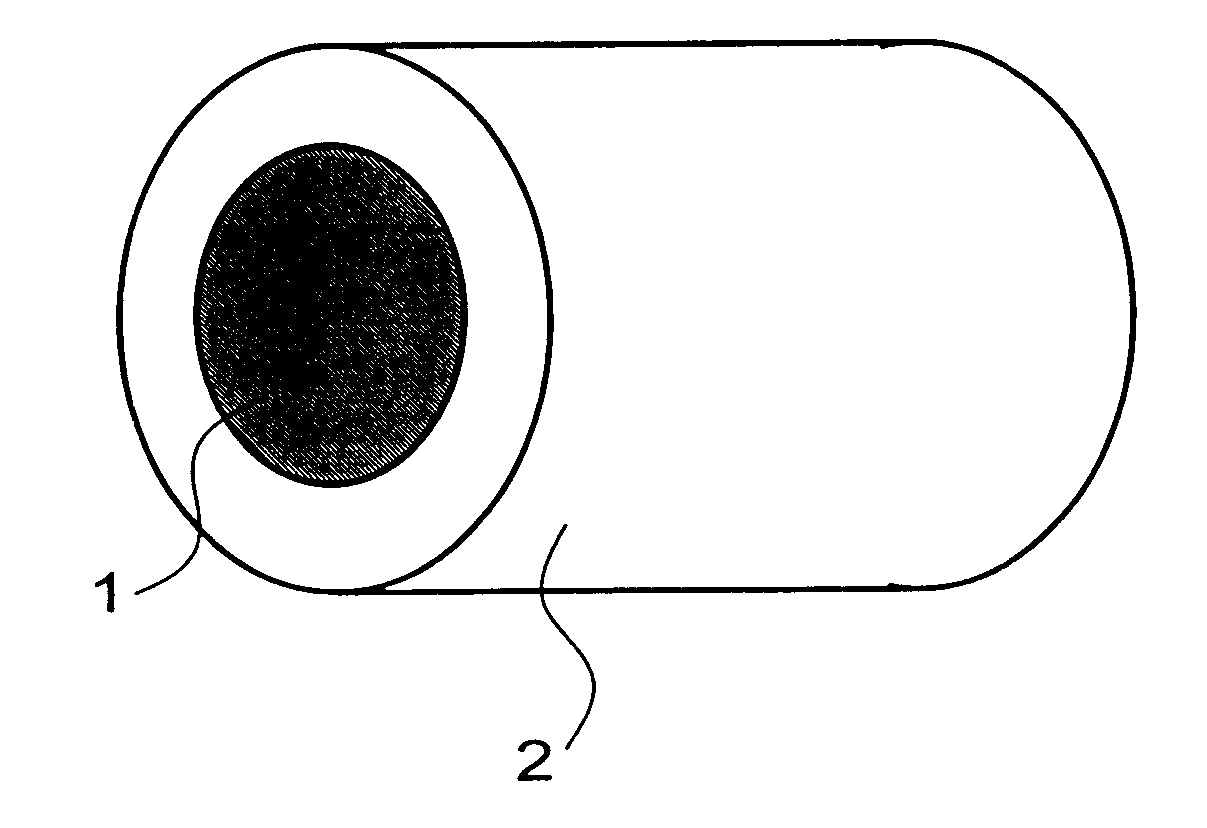

The invention provides a SiO2 nanoscale porous material with aerogel property prepared by microwave reaction and a preparation method thereof; the nanoscale porous material comprises silicon dioxide skeletons (1) and bubble-shaped nanoscale pores (2), wherein the foam-shaped nanoscale pores (2) are arranged among the silicon dioxide skeletons (1). The preparation method comprises four steps, namely preparation of silicon dioxide sol, preparation of wet gel, aging of mother solution and drying at normal pressure and the preparation of silicon dioxide sol comprises the following steps: adopting organosiloxane, organic solvent, water and acid catalysis as raw materials; mixing each components in a defined ratio in a container while adopting microwave radiation to perform hydrolytic polycondensation reaction or adopting microwave radiation to perform hydrolytic polycondensation reaction after mixing the components. Owning to adopting microwave radiation technology, a lot of bubbles are generated in silicon dioxide sol, a large quantity of nanoscale bubble-shaped pores are formed on the silicon dioxide substrate, and meanwhile silicon dioxide space skeletons are retained so that silicon dioxide porous material with extremely large specific area and higher intensity can be obtained. In addition, because carbon dioxide supercritical drying process is not needed, the production cost is greatly reduced.

Owner:郑文芝 +2

Process for preparing polyhydroxycarboxylic acid

InactiveUS6429280B1High molecular weightEfficient preparationCoatingsVitrificationReaction temperature

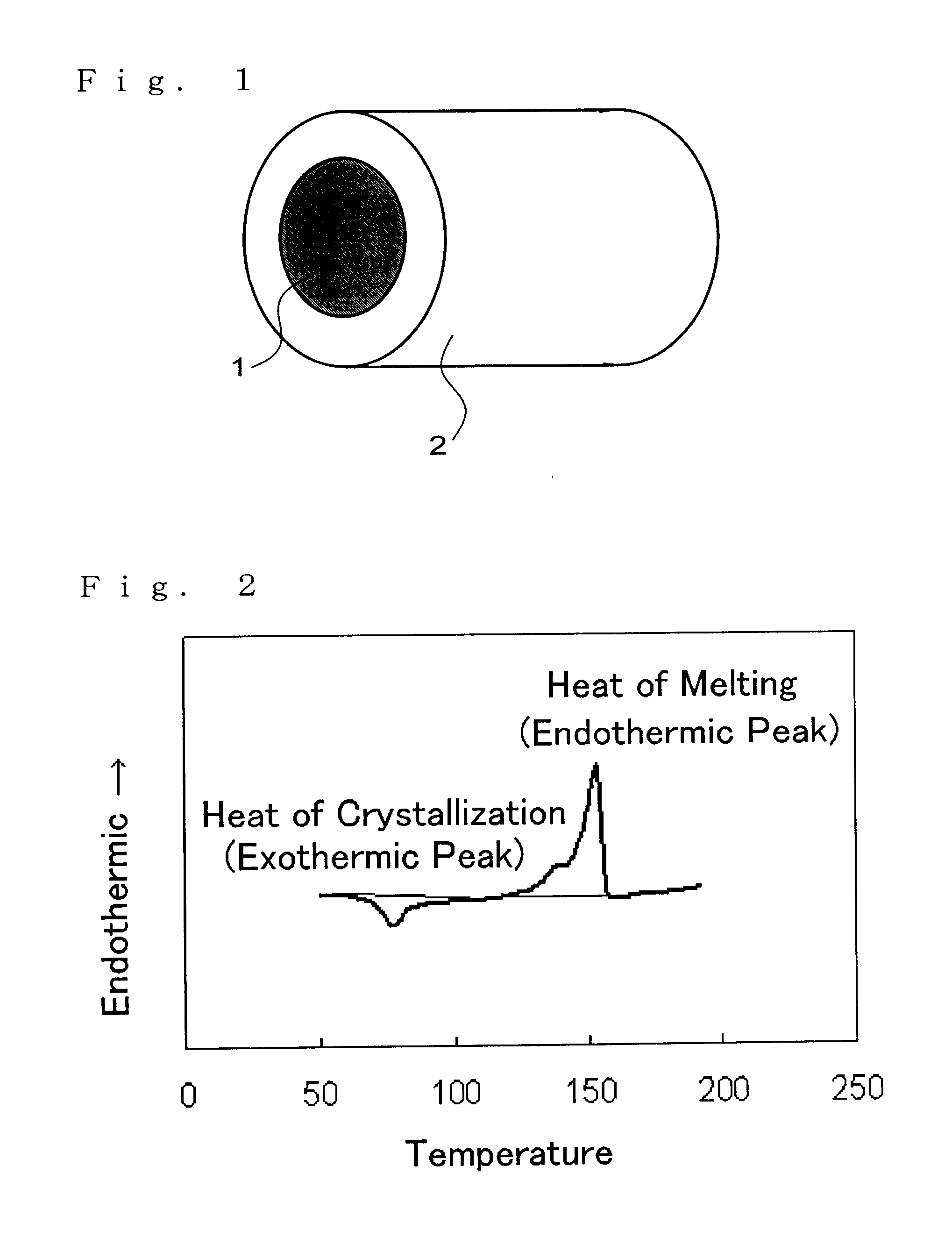

A process for preparing a polyhydroxycarboxylic acid having a weight average molecular weight of 50,000 to 1,000,000, which comprises a crystallizing step comprising (A) a step of heating pellets of a polyhydroxycarboxylic acid having a weight average molecular weight of 2,000 to 100,000 under stirring to a temperature from glass transition point or higher to a melting point or lower and heating until a defined result is attained, and (B) a step of heating the polyhydroxycarboxylic acid to a temperature of solid phase polycondensation reaction temperature, and a solid phase polycondensation reaction step of reacting the crystallized polyhydroxycarboxylic acid at an endothermic start temperature or lower of an endothermic peak as recognized upon temperature elevation analysis of the crystallized polyhydroxycarboxylic acid by using a differential scanning calorimeter.

Owner:MITSUI CHEM INC

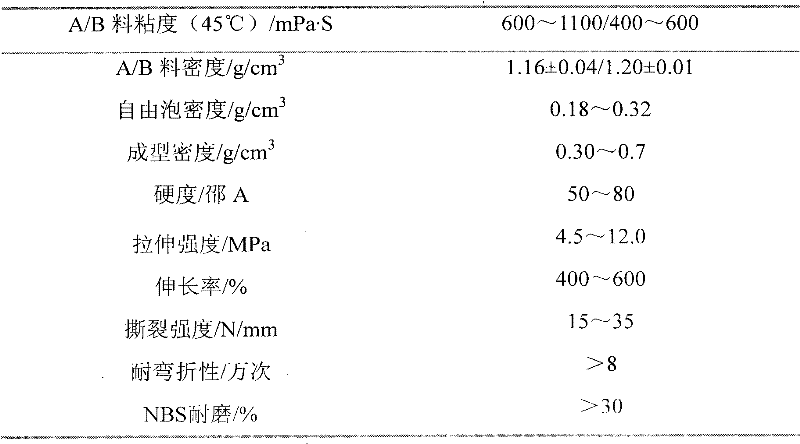

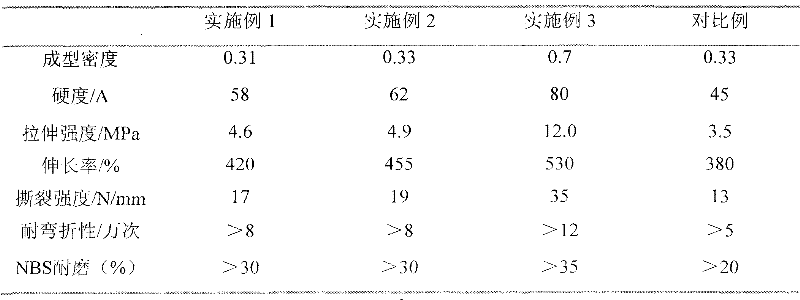

Microcellular polyurethane elastomer and preparation method thereof

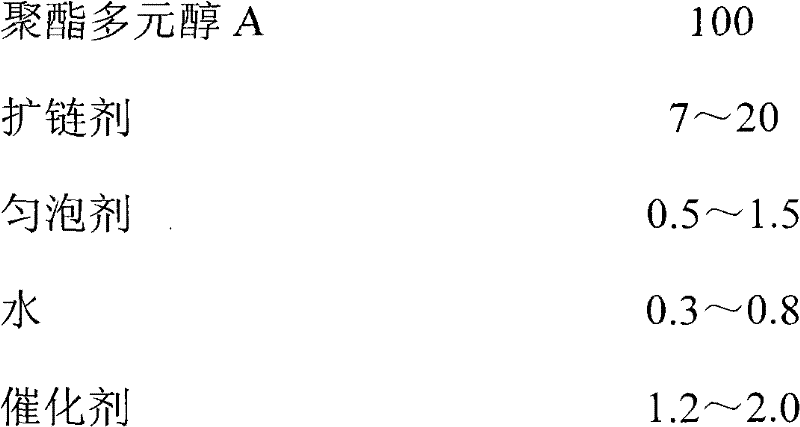

The invention discloses a microcellular polyurethane elastomer and a preparation method thereof. The elastomer contains two components, i.e., a polyol component and a prepolymer component, wherein the polyol component comprises polyester polyol, a chain extender, a foam stabilizer, water, a catalyst and the like; and the prepolymer component comprises polyester polyol, isocyanate and the like. The polyester polyol in the polyol component is prepared from a mixture of aromatic dibasic acid and aliphatic diacid and a mixture of diethylene glycol and other dihydric alcohols by means of polycondensation reaction. Compared with common microcellular polyester-type elastomers, the prepared elastomer has higher hardness and mechanical properties as well as better abrasive and bending resistances, besides, the flowability of materials is good. The material can be used in the fields like soles, solid tires, buffer blocks and the like. The preparation method is simple and feasible.

Owner:LIMING RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com