Patents

Literature

1739 results about "Antimony oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony oxide may refer to any of the following: Diantimony tetroxide, Sb₂O₄ Antimony trioxide, Sb₂O₃ Antimony pentoxide, Sb₂O₅

Flat float glass

InactiveUS6846760B2High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideTransmittance

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

Flat float glass

InactiveUS20020023463A1High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideThermal expansion

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

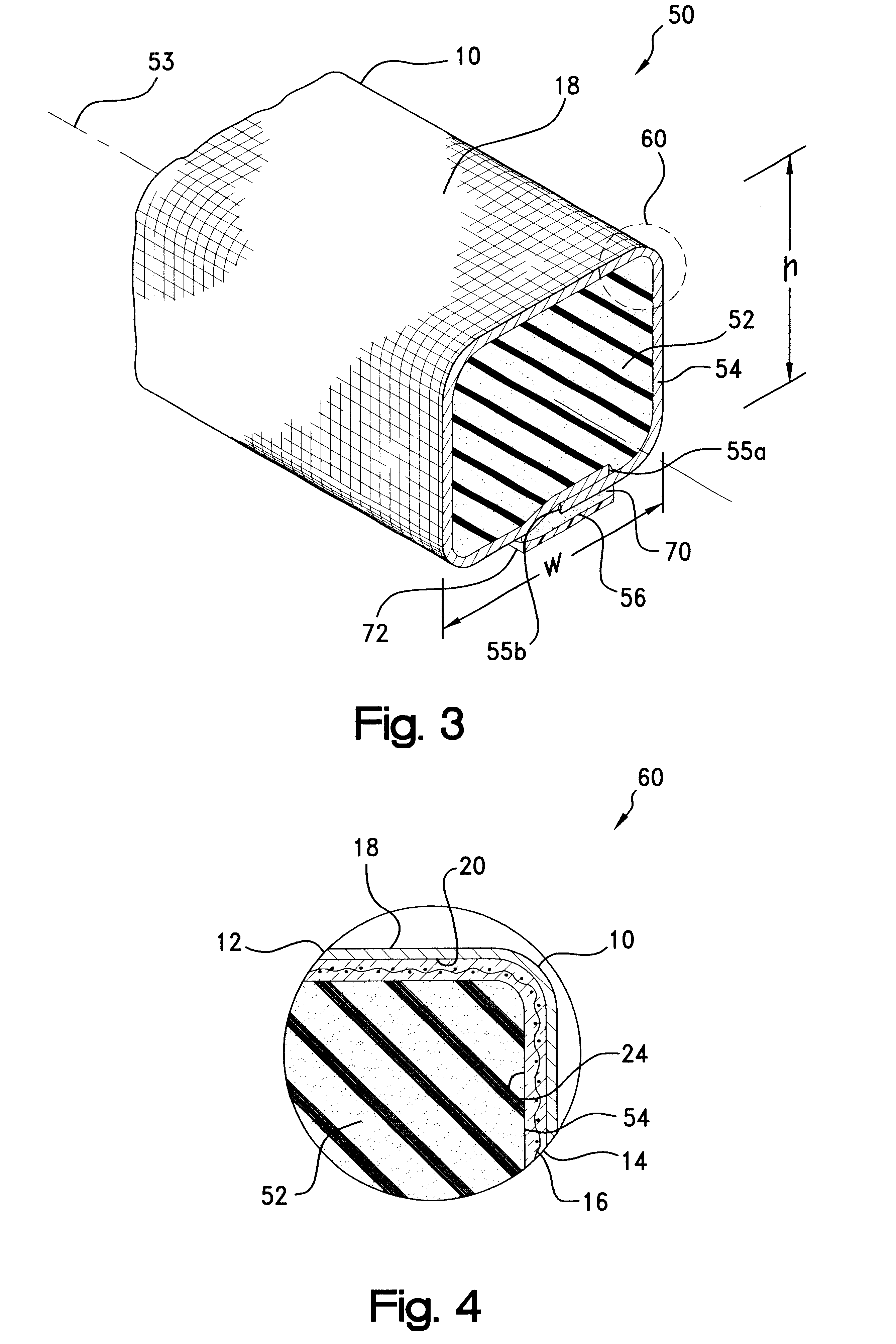

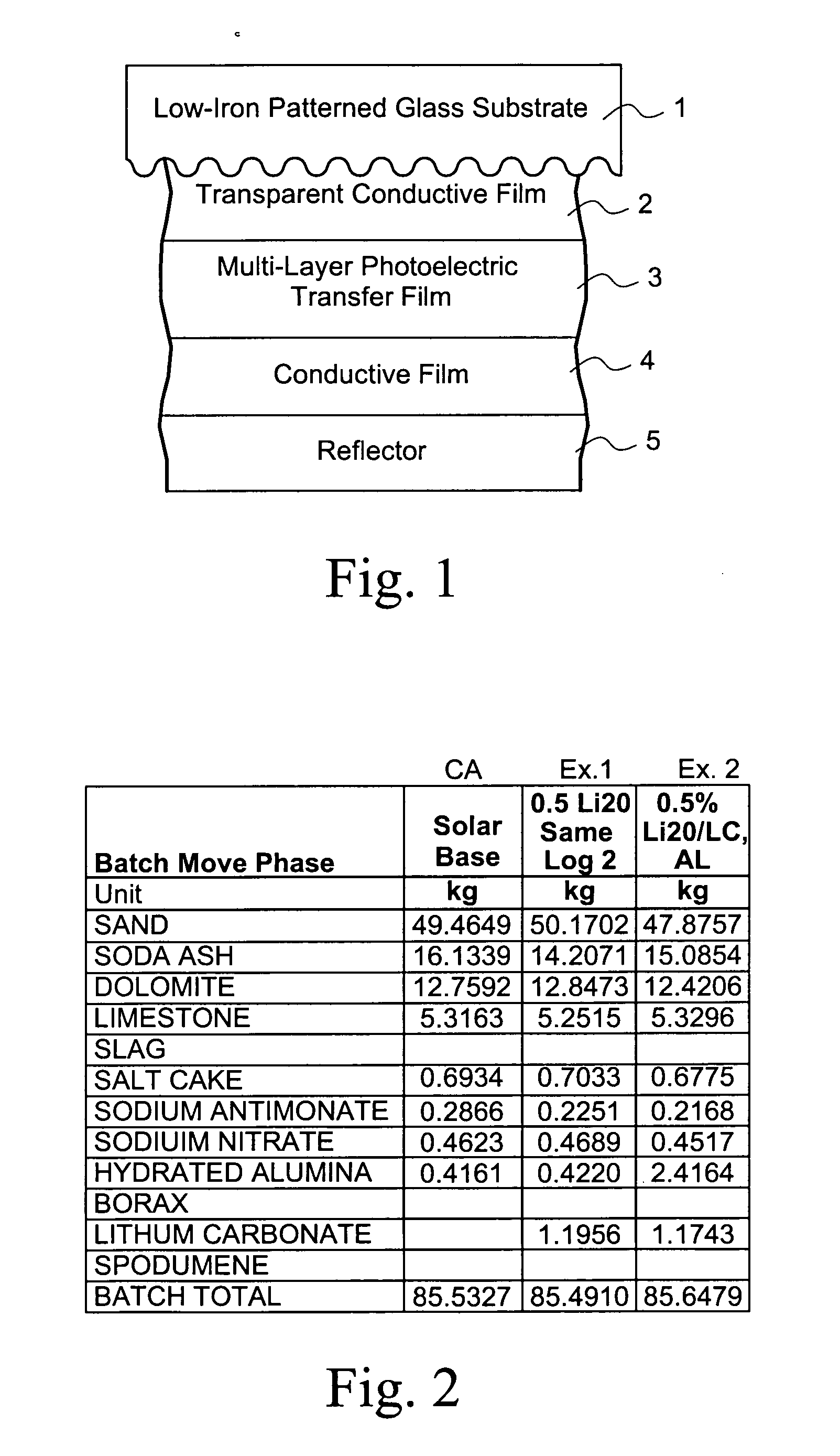

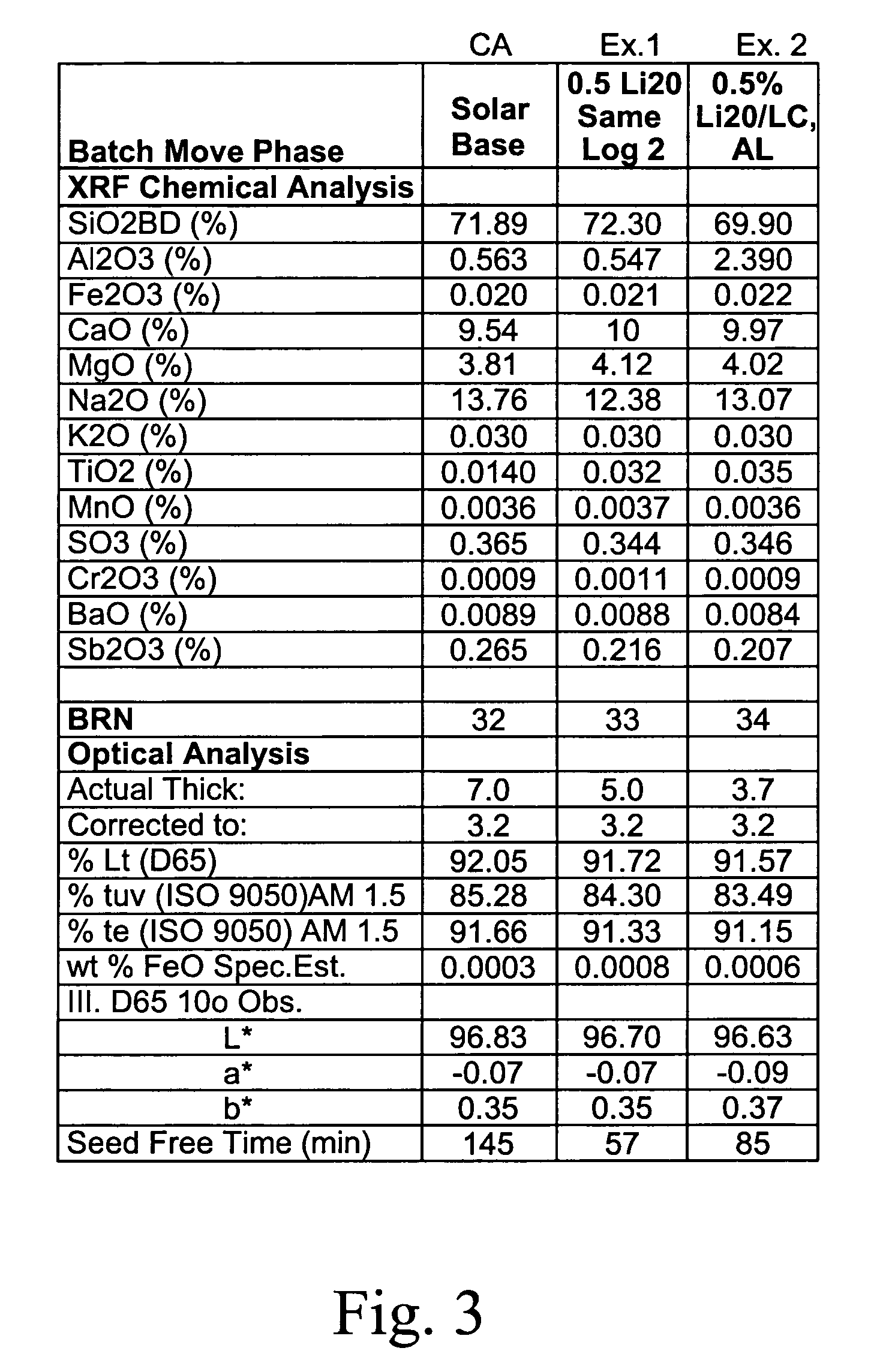

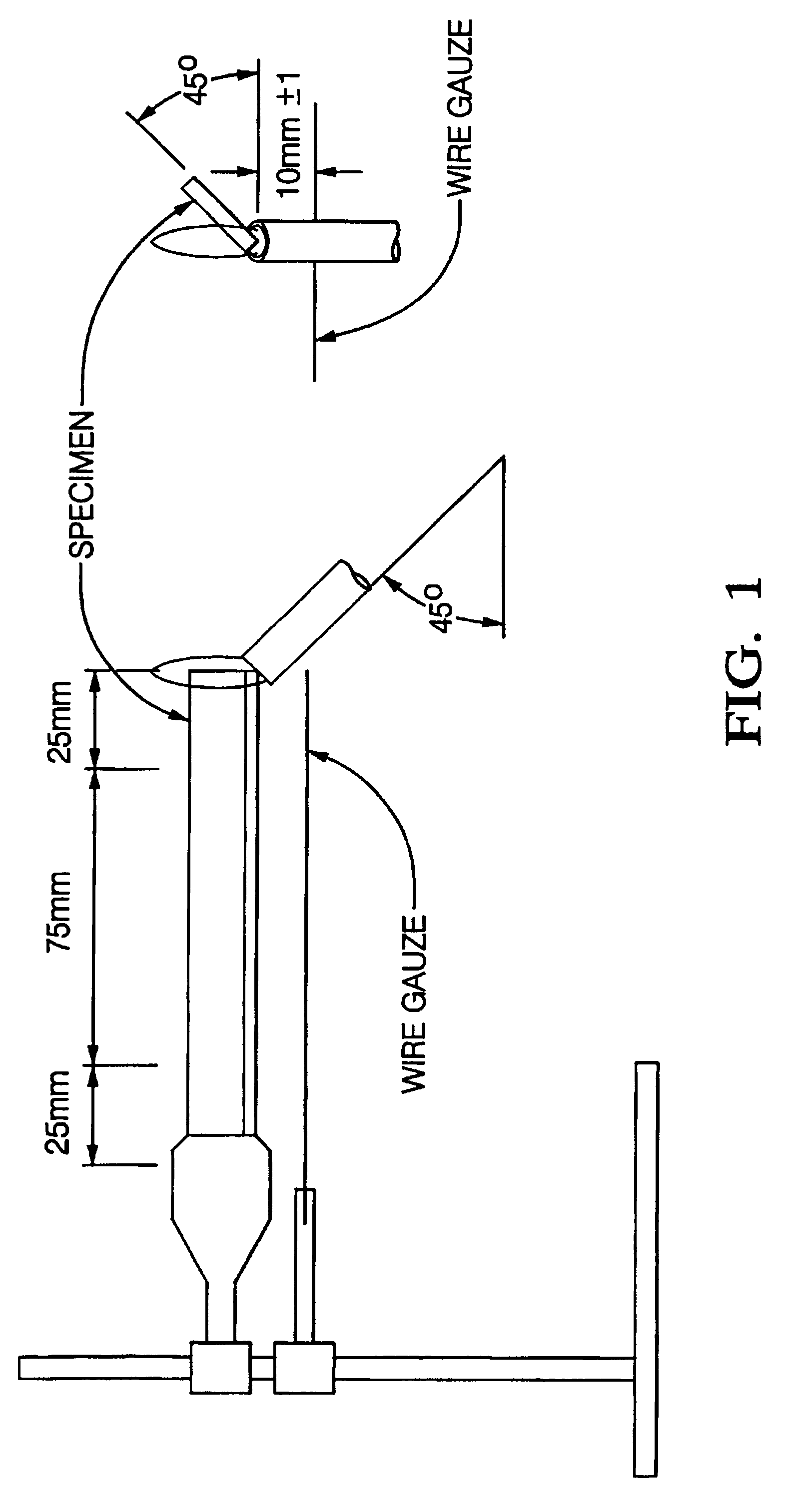

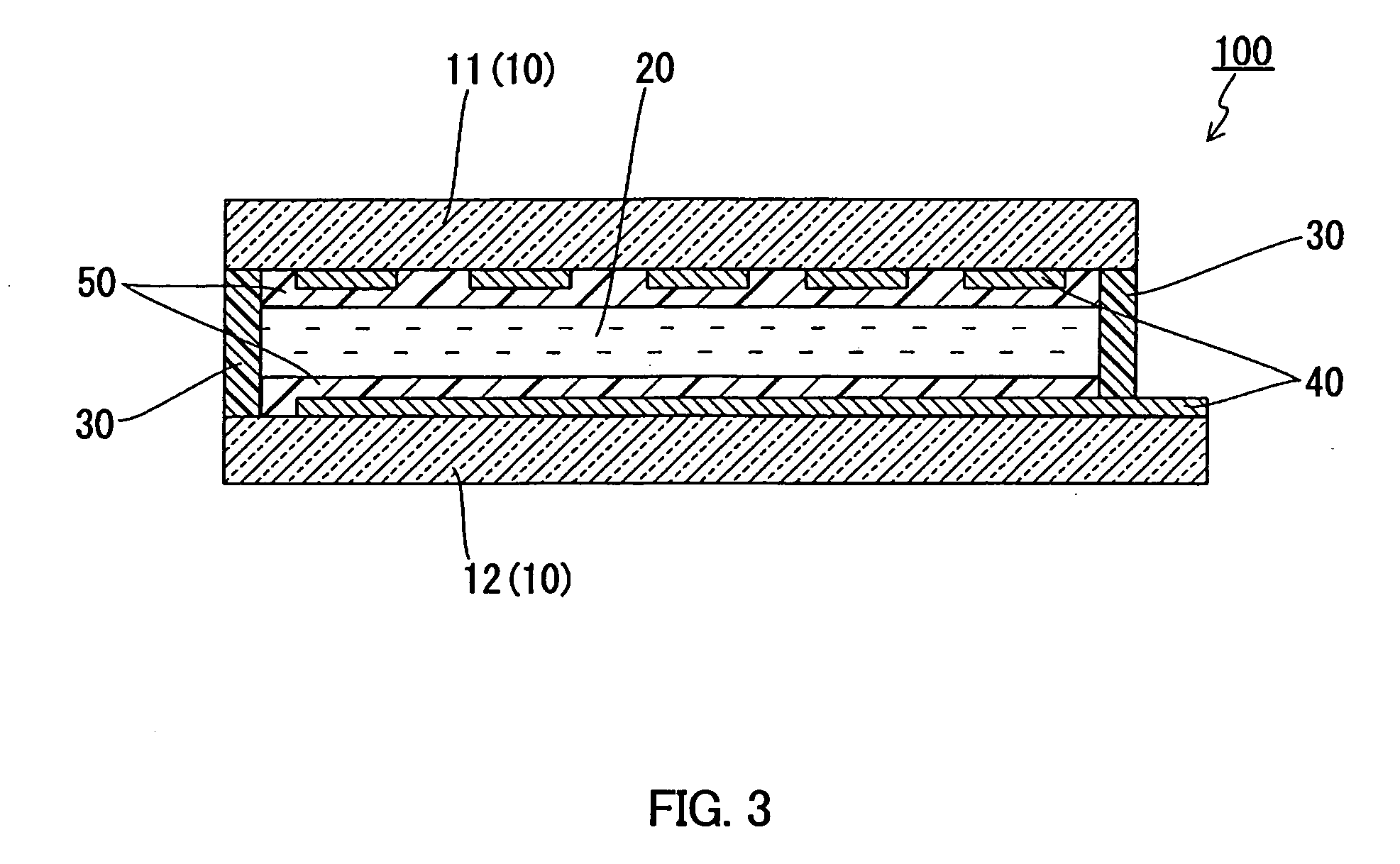

Photovoltaic device having low iron high transmission glass with lithium oxide for reducing seed free time and corresponding method

A high transmission and low iron glass is provided for use in a photovoltaic device such as a solar cell. The glass substrate may be patterned on at least one surface thereof. In certain example embodiments, a combination of lithium oxide, antimony oxide, and salt cake is used in the glass to improve the refining conditions by lowering the melting temperature of the batch, thereby resulting in a quicker seed free time in the manufacturing process.

Owner:GUARDIAN GLASS LLC

Coating composition, process for preparing coating composition and process for preparing dispersing component of inorganic oxide sol

InactiveUS6022919AGood weather resistanceLow appearance requirementsSpecial tyresMixingMeth-Acrylonitrile

A coating composition which comprises (A) a resin having a glass transition temperature of 50 to 120 DEG C., a number average molecular weight of 2,000 to 100,000, a hydroxyl value of 50 to 150 mgKOH / g and an acid value of 1 to 25 mgKOH / g, which is produced by copolymerizing 10 to 90 percent by weight of (a) a (meth)acrylic acid ester of a C1 to C12 alkyl alcohol, 10 to 50 weight % of (b) a first polymerizable double bond-containing and hydroxyl group-containing monomer, 0.1 to 10 weight % of (c) a polymerizable double bond-containing and carboxyl group-containing monomer, 0 to 20 weight % of (d) styrene, 0 to 20 weight % of (e) acrylonitrile and 0 to 10 weight of (f) a second polymerizable double bond-containing monomer, (B) at least one compound selected from the group consisting of a polyisocyanate compound having two or more unblocked isocyanate groups and / or blocked isocyanate groups in the molecule and an aminoplast resin, (C) a dispersing component of at least one inorganic oxide sol selected from the group consisting of an aluminum oxide sol, a silica sol, a zirconium oxide sol and an antimony oxide sol, wherein an amount of a nonvolatile matter of component (C) is 5 to 60 percent by weight based on a total amount of nonvolatile matter of resin (A), compound (B) and component (C). The coating composition provides cured films having excellent weathering resistance, light resistance, stain resistance, stain-removing property, chemical resistance, moisture resistance and appearance and is environmentally friendly and safe.

Owner:BASF NOF COATINGS CO LTD

Intumescent fire retardant composition and method of manufacture thereof

InactiveUS6706793B2Improve flame retardant performanceHigh impact strengthFireproof paintsSpecial tyresGraphiteFire retardant

Owner:APTIV TECH LTD

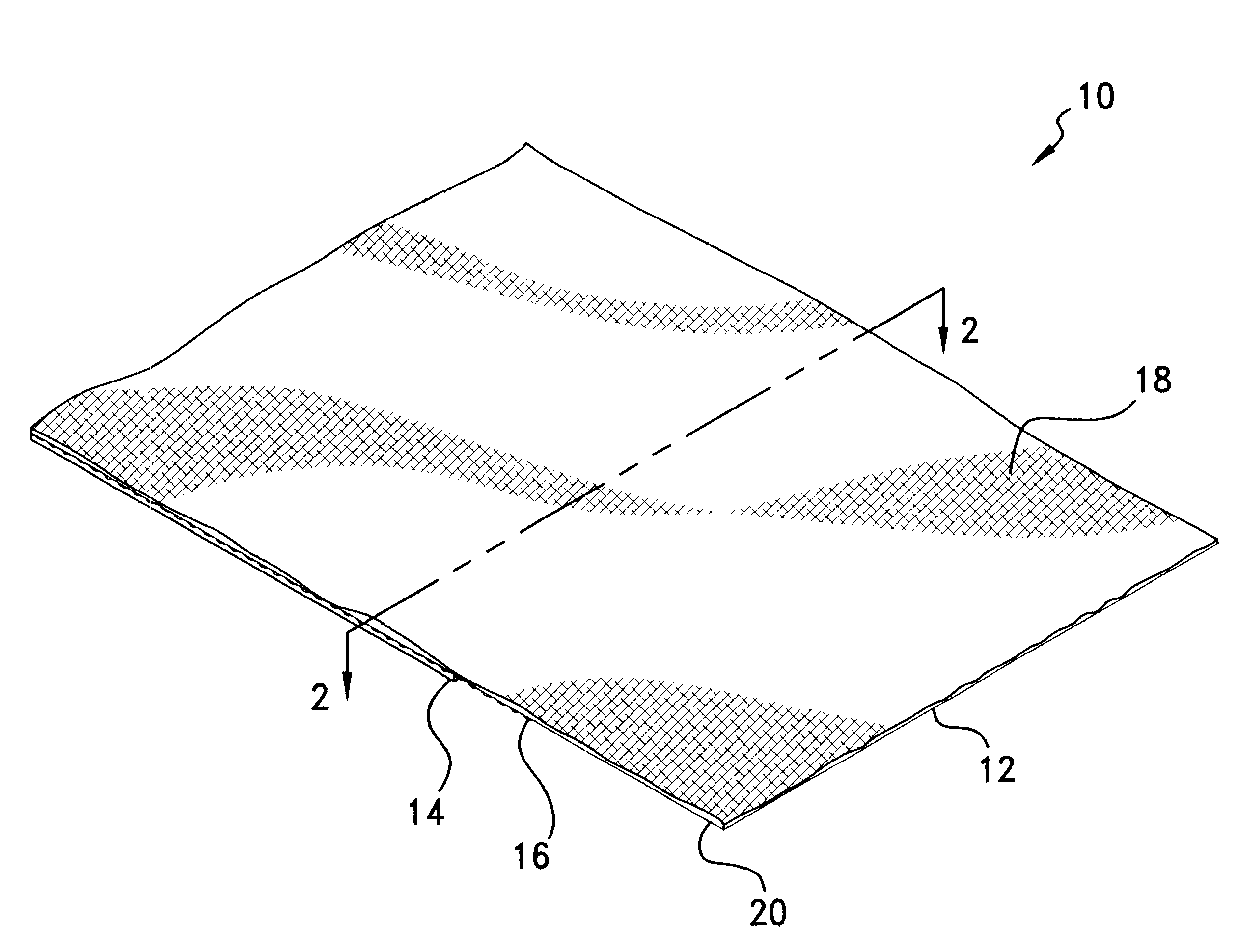

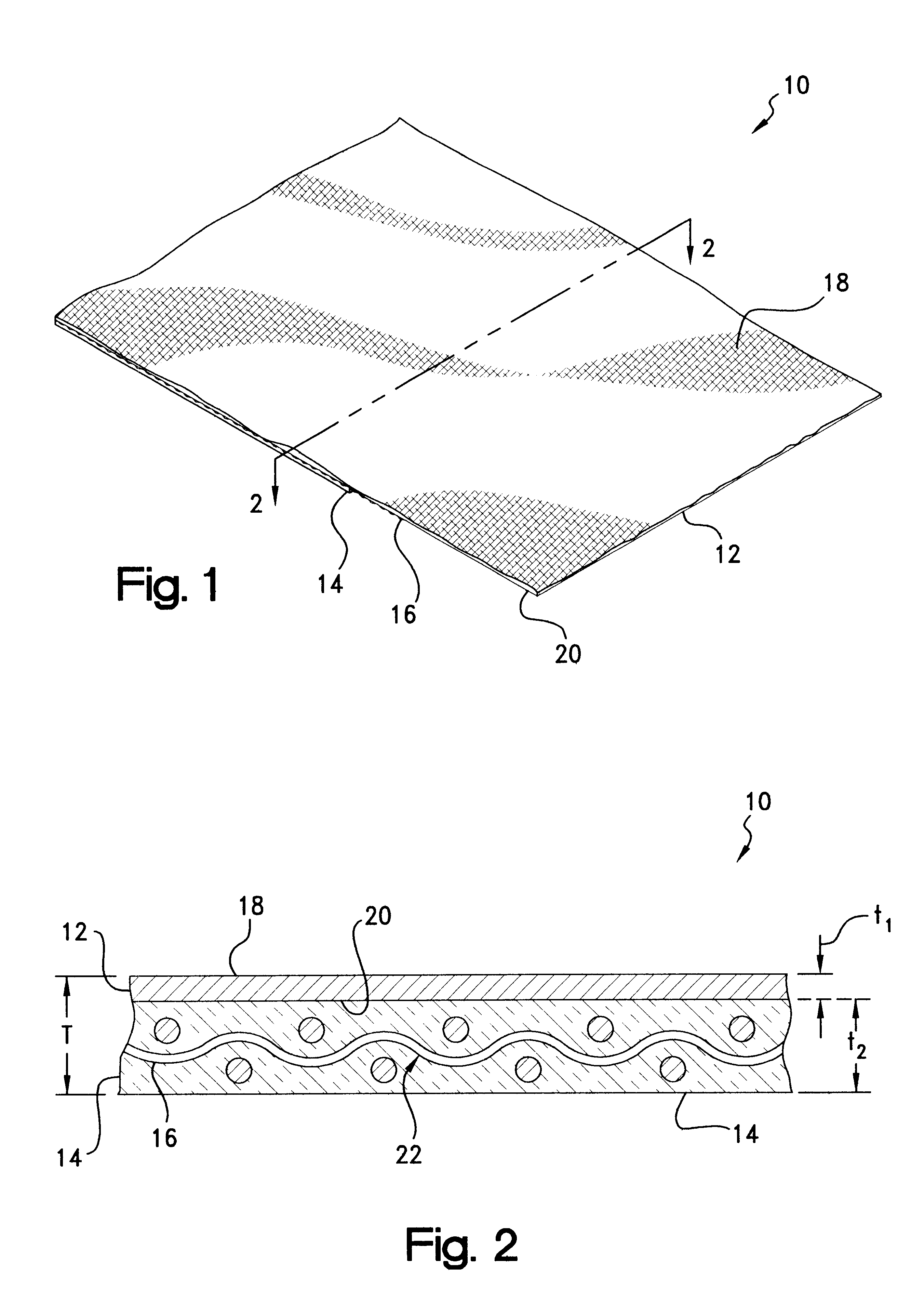

Solar control laminate

InactiveUS20070048519A1Synthetic resin layered productsCellulosic plastic layered productsControl layerNanoparticle

Provided are solar control laminates comprising a solar control film and a polymeric sheet. The solar control film comprises a polymeric film coated with a coating comprising inorganic infrared absorbing nanoparticles. Preferably, inorganic infrared absorbing nanoparticles comprise nanoparticles of antimony tin oxide (ATO), indium tin oxide (ITO), lanthanum hexaboride (LaB6) or mixtures thereof. Optionally, the solar control laminate also comprises a rigid sheet, such as a glass sheet.

Owner:KURARAY AMERICA INC

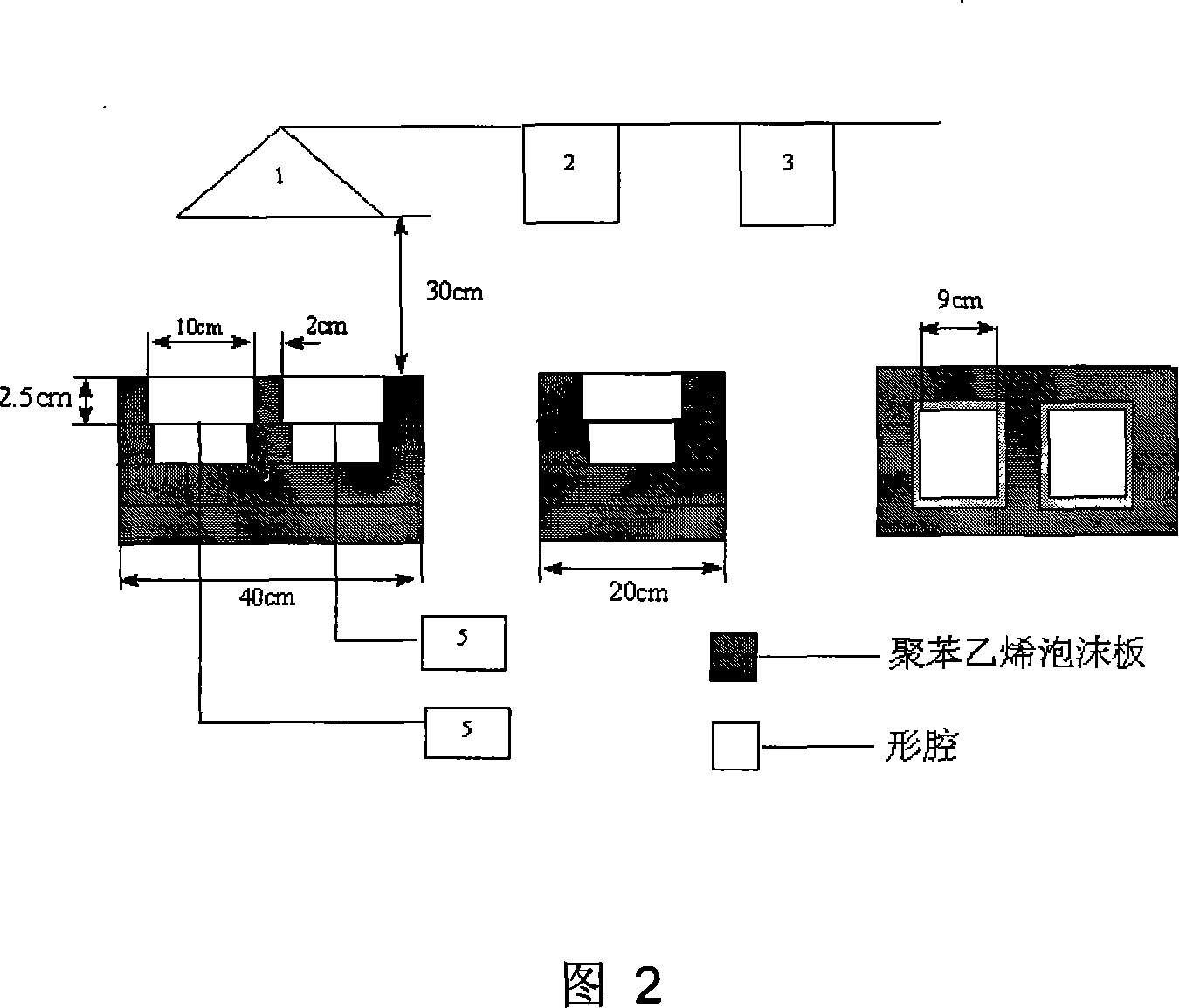

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

High capacity electrode and methods for its fabrication and use

InactiveUS20070099084A1Improve cycle lifeMinimised mechanical strainElectrode manufacturing processesSecondary cellsAlloyBuffering agent

A battery electrode comprises an electrically conductive substrate having an electrochemically active electrode composition supported thereupon. The composition includes an active material capable of reversibly alloying with lithium, which material shows a volume change upon such reversible alloying. The composition includes a buffering agent which accommodates the volume change in the active material and minimizes mechanical strain in the composition. The active composition may further include materials such as carbon. The active material may comprise silicon, aluminum, antimony, antimony oxides, bismuth, bismuth oxides, tin, tin oxides, chromium, chromium oxides, tungsten, and tungsten oxides or lithium alloys of the foregoing. The buffering agent may comprise a metal or a metal oxide or lithium alloys of the foregoing. Also disclosed are batteries which incorporate these electrodes, methods for the fabrication of the electrodes and methods for the fabrication and operation of the batteries.

Owner:A123 SYSTEMS LLC

Thick-film conductive paste

InactiveUS20060001009A1Conductive materialNon-conductive material with dispersed conductive materialConductive pasteCompound (substance)

A thick-film composition comprising: (a) conductive metal; (b) one or more inorganic binders; (c) antimony, antimony oxide, antimony-containing compound capable of forming an antimony oxide upon firing, or mixtures thereof; dispersed in (d) organic medium. The windshield defogger element and a method of forming a windshield defogger element comprising: (a) providing the thick film composition as above; (b) providing a glass substrate; (c) printing the composition of (a) onto said glass substrate; and (d) firing said composition and substrate. A vehicle having as the conductive element in the windshield defroster system a windshield defogger element comprising an antimony oxide containing layer as a protective layer. A windshield defogger element comprising an antimony oxide containing layer as a protective layer.

Owner:EI DU PONT DE NEMOURS & CO

Leadless electronic slurry composition for solar silicon photovoltaic cell and preparation method thereof

InactiveCN101345263AHigh electrical conductivityRefined nanocrystalline structureFinal product manufactureSemiconductor devicesAdhesiveSlurry

The invention discloses a compounding and a preparation method for lead-free electronic slurry used for a solar silicon photocell; according to the mass percentage, the slurry is obtained by preparing 70 to 75 percent of aluminium powders, 20 to 25 percent of organic adhesive, 1 to 5 percent of inorganic glass powders and 1 to 5 percent of additives; the aluminium powder is ball-shaped aluminium powder with the surface covered by an aluminium nitride protection layer, with the purity not less than 99.9 percent and the average grain size of 2 to 6 microns; simultaneously, organic adhesives consisting of ethyl cellulose, resin, hexadecanol, diethyleneglycol monomethyl ether, diethyleneglycol monobutyl ether, terpineol and n-butyl alcohol are added into the aluminium powder; the inorganic glass powder is silicon dioxide, boracic acid, alumina, antimony oxide and zirconia; the additive consists of Span and pump oil. The product prepared by the method of the invention has no dust generation or aluminium peeling phenomenon and achieves the requirement of no lead and environmental protection.

Owner:NANTONG UNIVERSITY

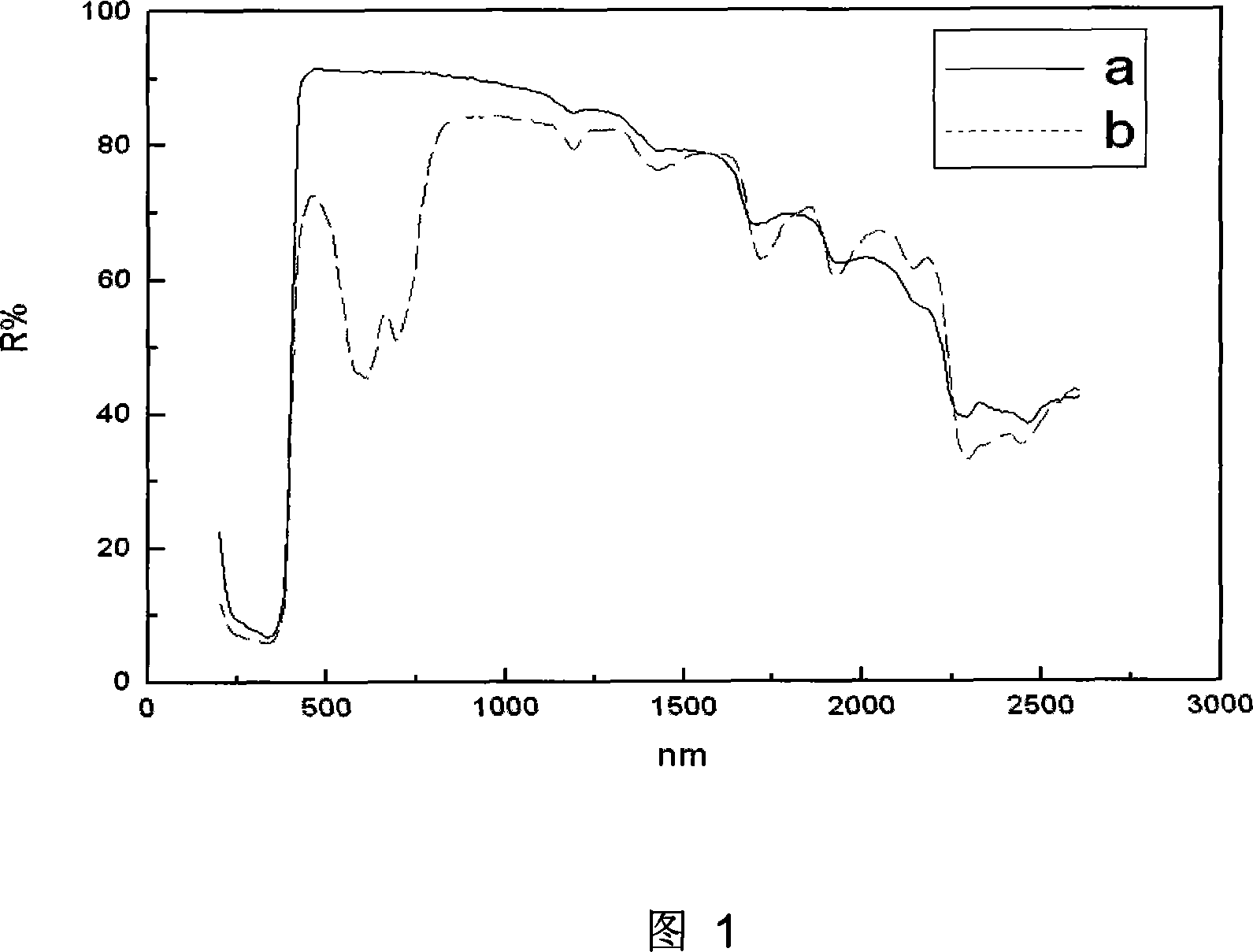

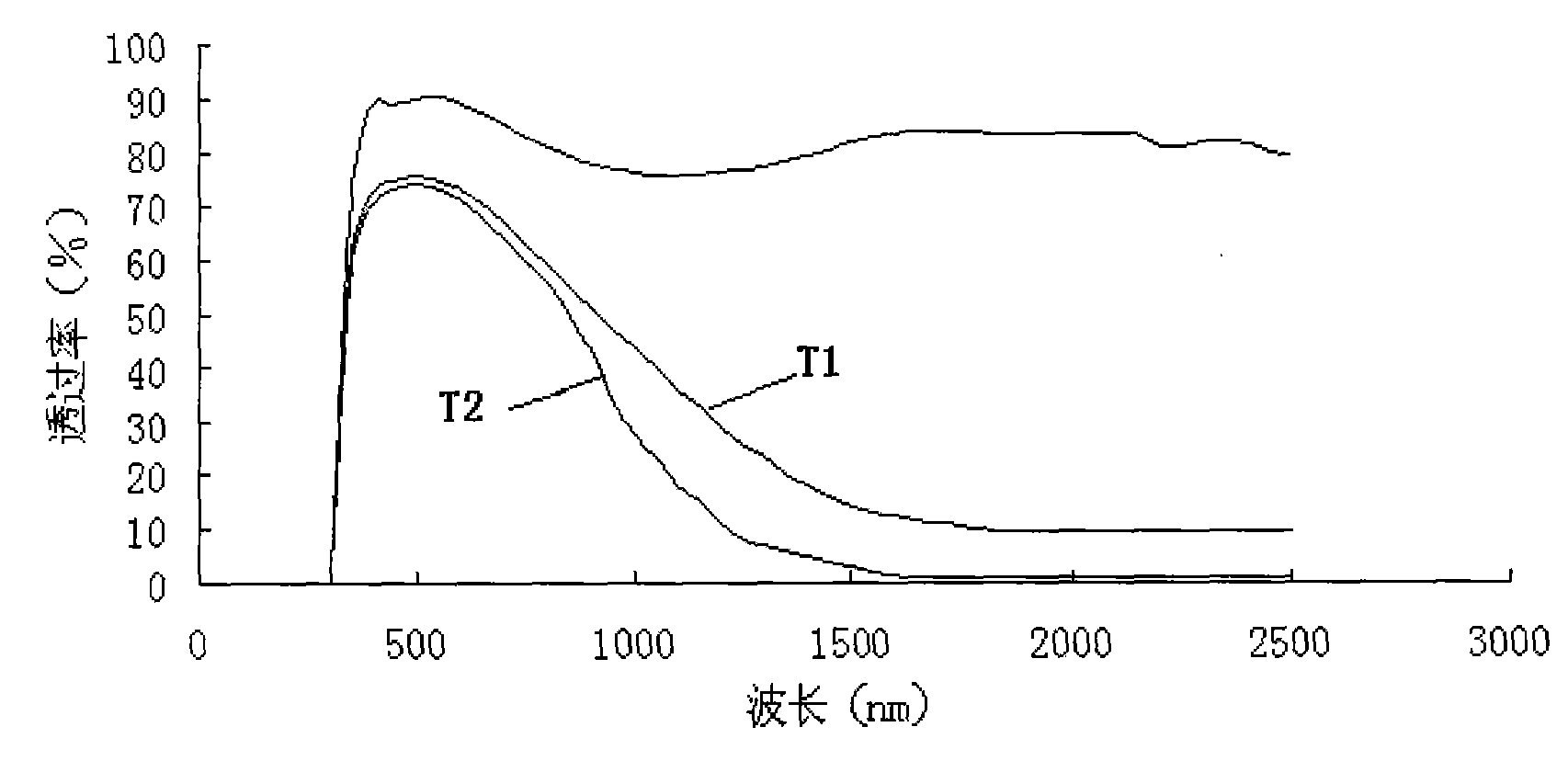

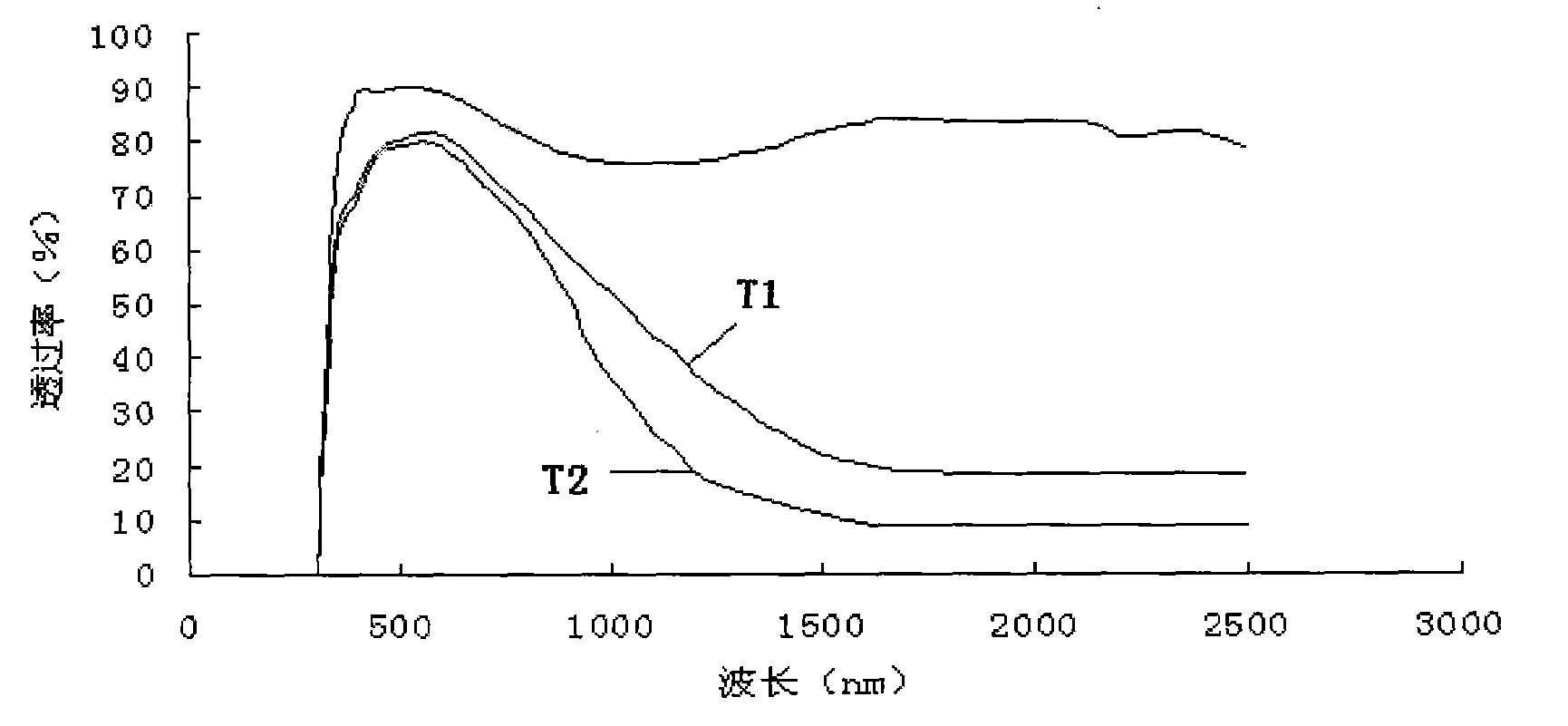

Transparent heat insulation coating material, preparation method and application thereof

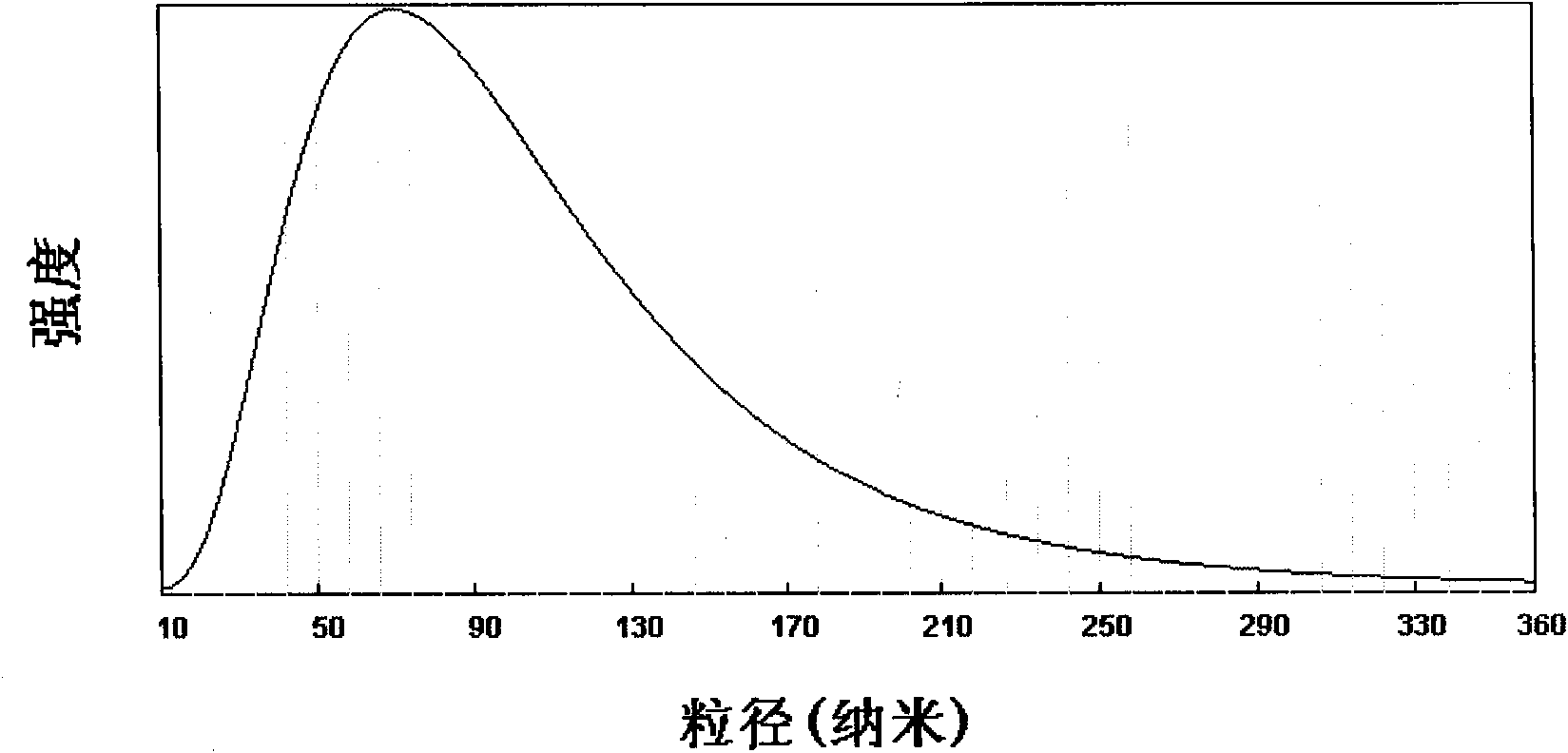

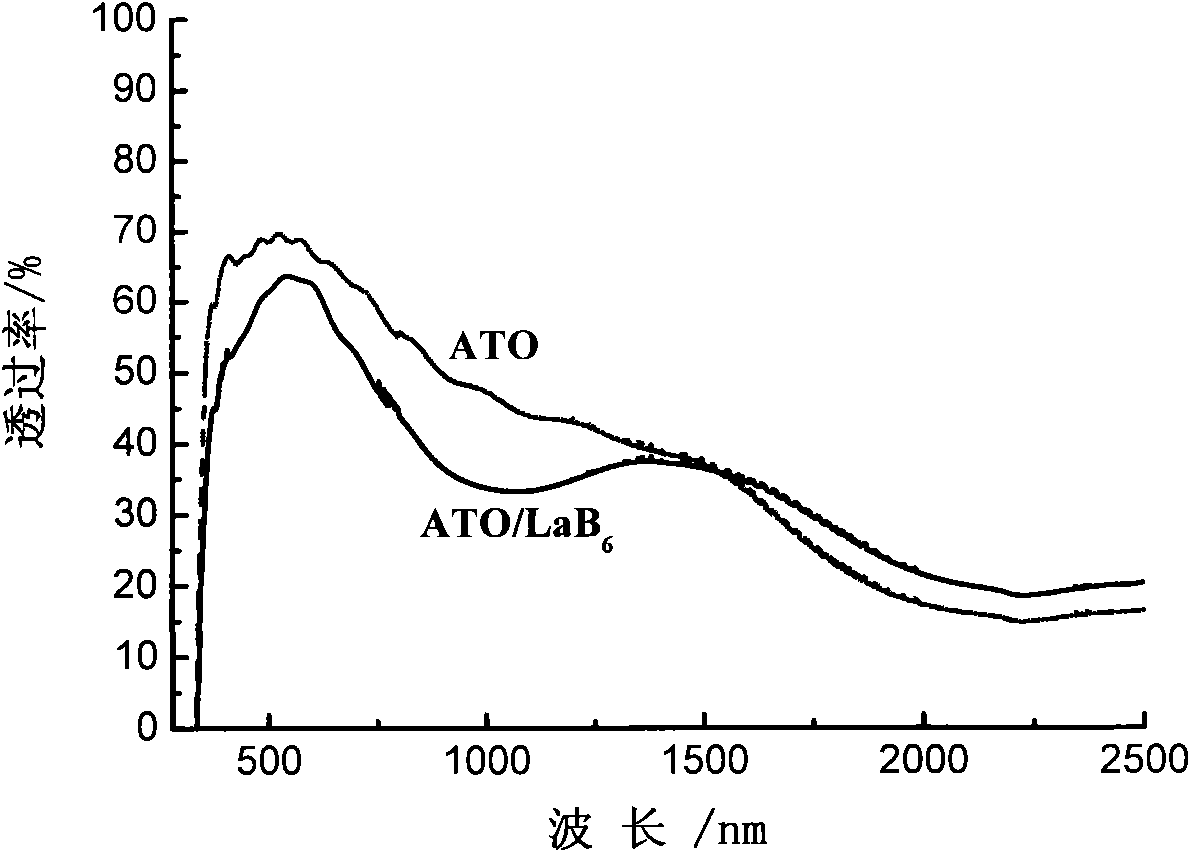

InactiveCN101550307AImprove adhesionGood infrared blocking performancePolyurea/polyurethane coatingsPolyester coatingsDispersion stabilityPolyester

The invention relates to a transparent heat insulation coating material, the preparation method and the application thereof. The material is made from the raw material of lanthanum hexaboride / tin indium oxide or lanthanum hexaboride / tin antimony oxide, by the steps of pretreating by ultrasonic dispersion, and grinding to prepare nanometer slurry with heat insulation function, wherein the nanometer slurry has particle sizes mainly between 10nm and 200nm, the average particle size between 50nm and 120nm, and superior dispersion stability; mixing the nanometer slurry with film forming substance, auxiliary agent and solvent, to obtain the transparent heat insulation coating material. The coating material can obstruct more than 80% of infrared light, has a visible light transmittance above 60%, achieves excellent transparency and sunshine energy shielding effect; can be directly coated on transparent glass, polycarbonate, synthetic glass and polyester; and achieves the aims of energy conservation and heat insulation.

Owner:FUDAN UNIV +1

Chemically and thermally pre-stressable lithium aluminosilicate float glass of high temperature resistance

ActiveCN1693247AGood quality bubblesImprove heat resistanceBase layers for recording layersGlass tempering apparatusArsenic oxideTemperature resistance

The invention provides a lithium aluminosilicate flat float glass with a high thermal stability which can be chemically and thermally tempered and is suitable for economical and environmentally friendly production. The lithium aluminosilicate flat float glass which can be chemically and thermally tempered, is refined without using a standard refining agent such as arsenic oxide and / or antimony oxide and has excellent thermal stability is constituted so as to contain 2.5-6.0 wt.% Li2O, 0<4 wt.% in total of Na2O+K2O, 0-4 wt.% B2O3, 15-30 wt.% Al2O3, 55-75 wt.% SiO2and <2 wt.% in total of TiO2+ZrO2(the undesirable crystallization of [beta]-quartz and / or keatite solid solution is prevented) as main components per the weight of the total compositions.

Owner:SCHOTT AG

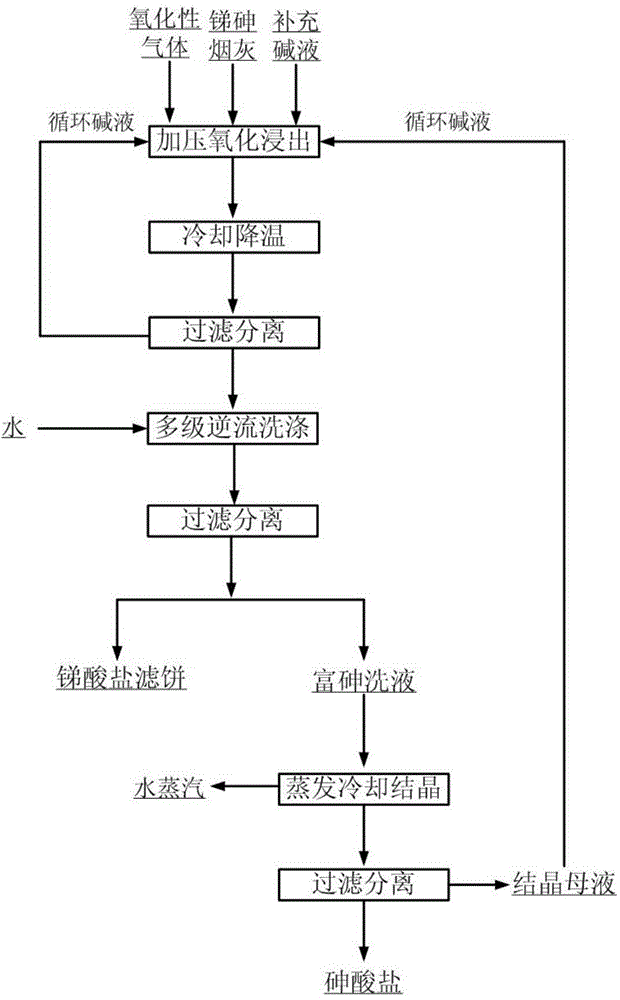

Method for separating antimony and arsenic from antimony and arsenic-containing ash through oxidation and alkaline leaching

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Polyester polycondensation with catalyst and a catalyst enhancer

InactiveUS20020032300A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyesterPotassium

The present invention is based upon the discovery that nontitanyl oxalates can enhance the catalytic functionality of titanyl oxalate catalysts. This invention provides a novel catalytic composition containing a titanyl oxalate catalyst and a metallic oxalate catalyst enhancer and optionally containing a metallic cocatalyst such as an antimony based catalyst. A synergistic relationship has been discovered between titanyl oxalate catalyst and the catalyst enhancer. A synergistic relationship has also been discovered between the titanyl oxalate catalyst, catalyst enhancer and a metallic cocatalyst such as antimony oxide or antimony triacetate. Also provided is an improved process of producing polyester by the polycondensation of polyester forming reactants in the presence of a catalytically effective amount of a polycondensation catalyst, wherein the improvement comprises utilizing, as the polycondensation catalyst, the novel catalyst composition containing a titanyl oxalate such as lithium titanyl oxalate and a catalyst enhancer such as a nontitanyl metallic oxalate like lithium oxalate and optionally containing a metallic catalyst such as antimony oxide or antimony triacetate. The improved process produces an improved polyester having lower acetaldehyde numbers and good color. The titanyl oxalate / catalyst enhancer composition can be used as a polycondensation catalyst in combination with other catalysts to achieve synergistic catalytic activity. Preferred is a combination of lithium or potassium titanyl oxalate, Li2 or K2TiO(C2O4)2, lithium or potassium oxalate, Li2 or K2(C2O4)2 with antimony oxide or antimony triacetate or antimony trisglycoxide.

Owner:ARKEMA INC

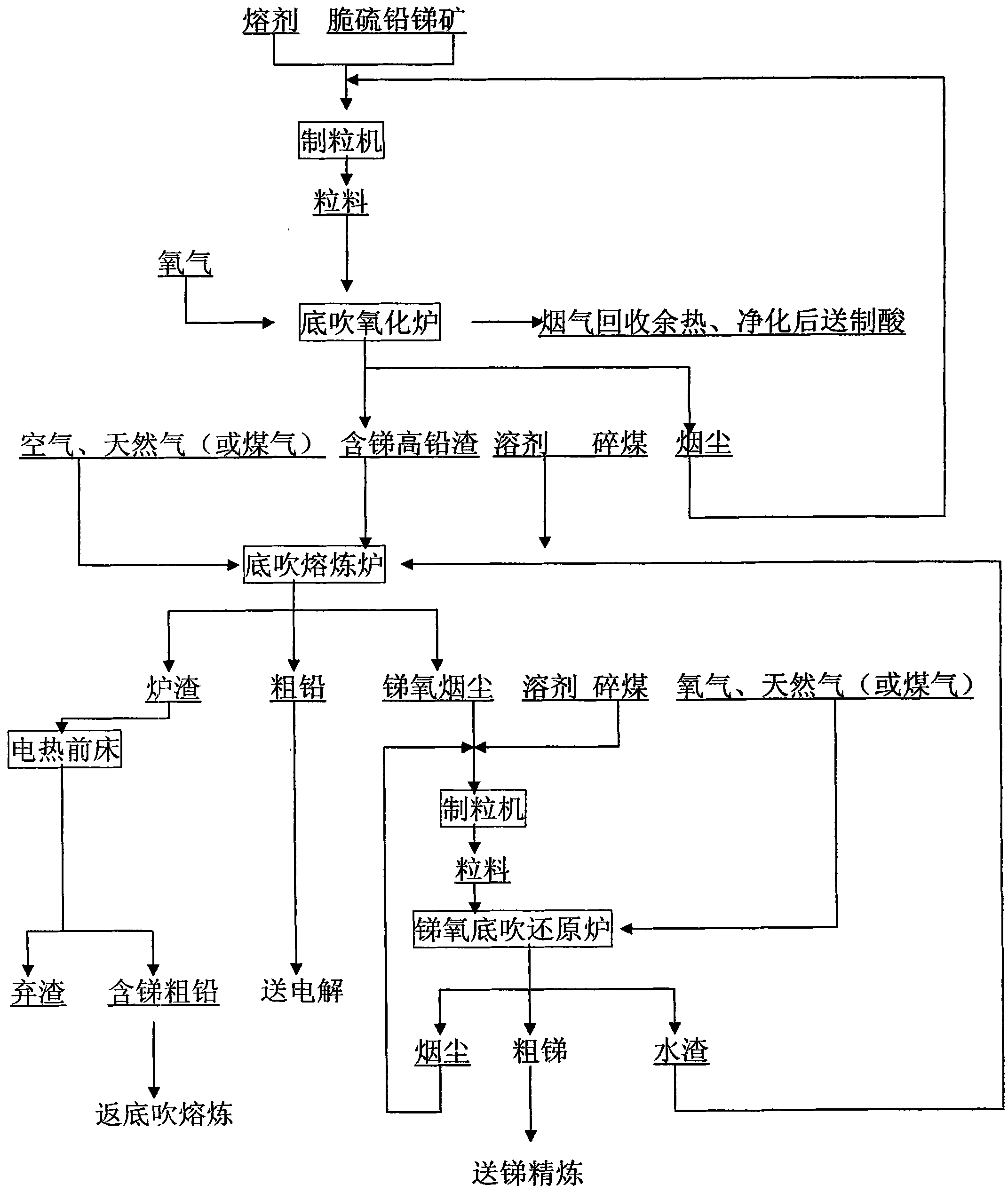

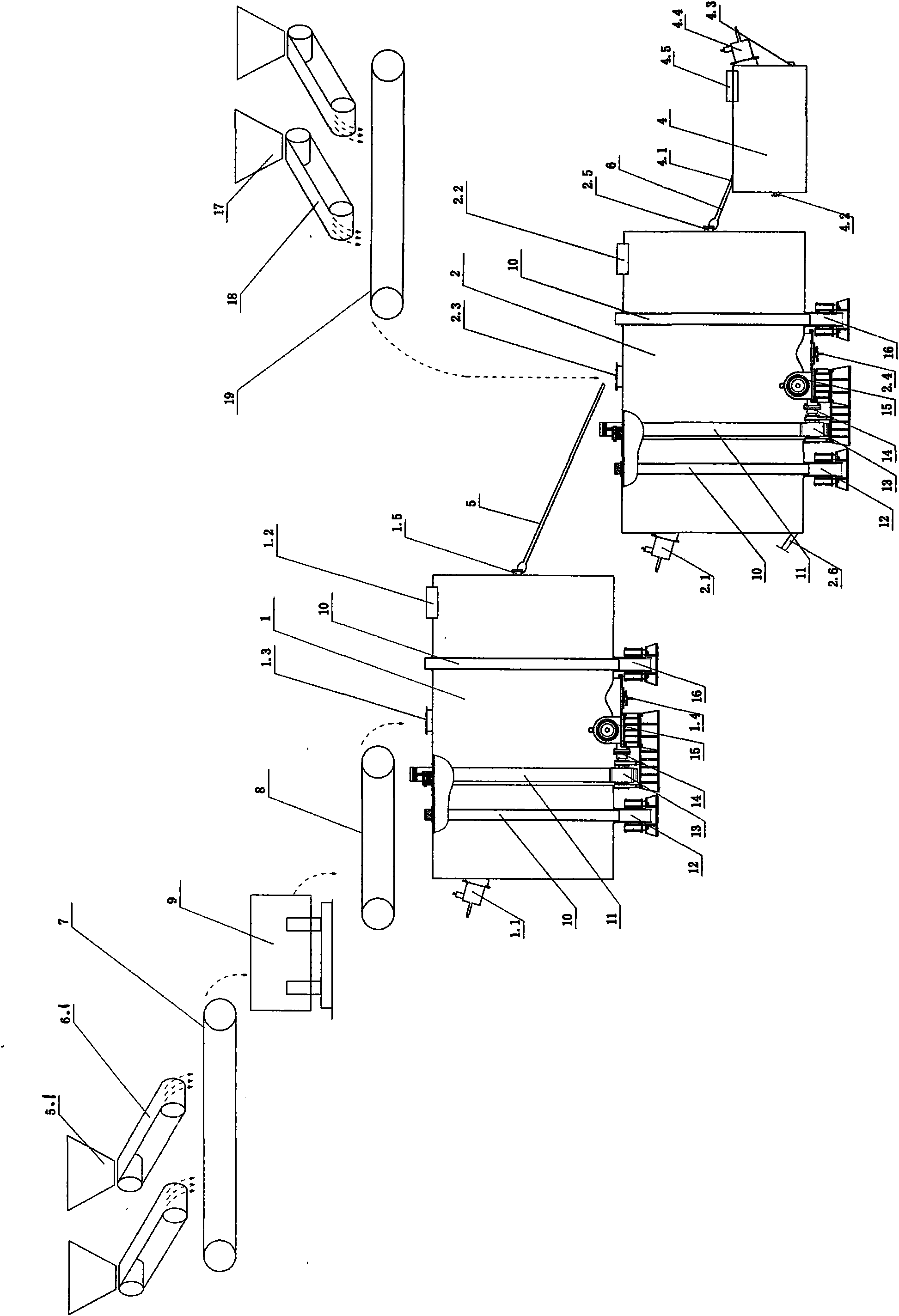

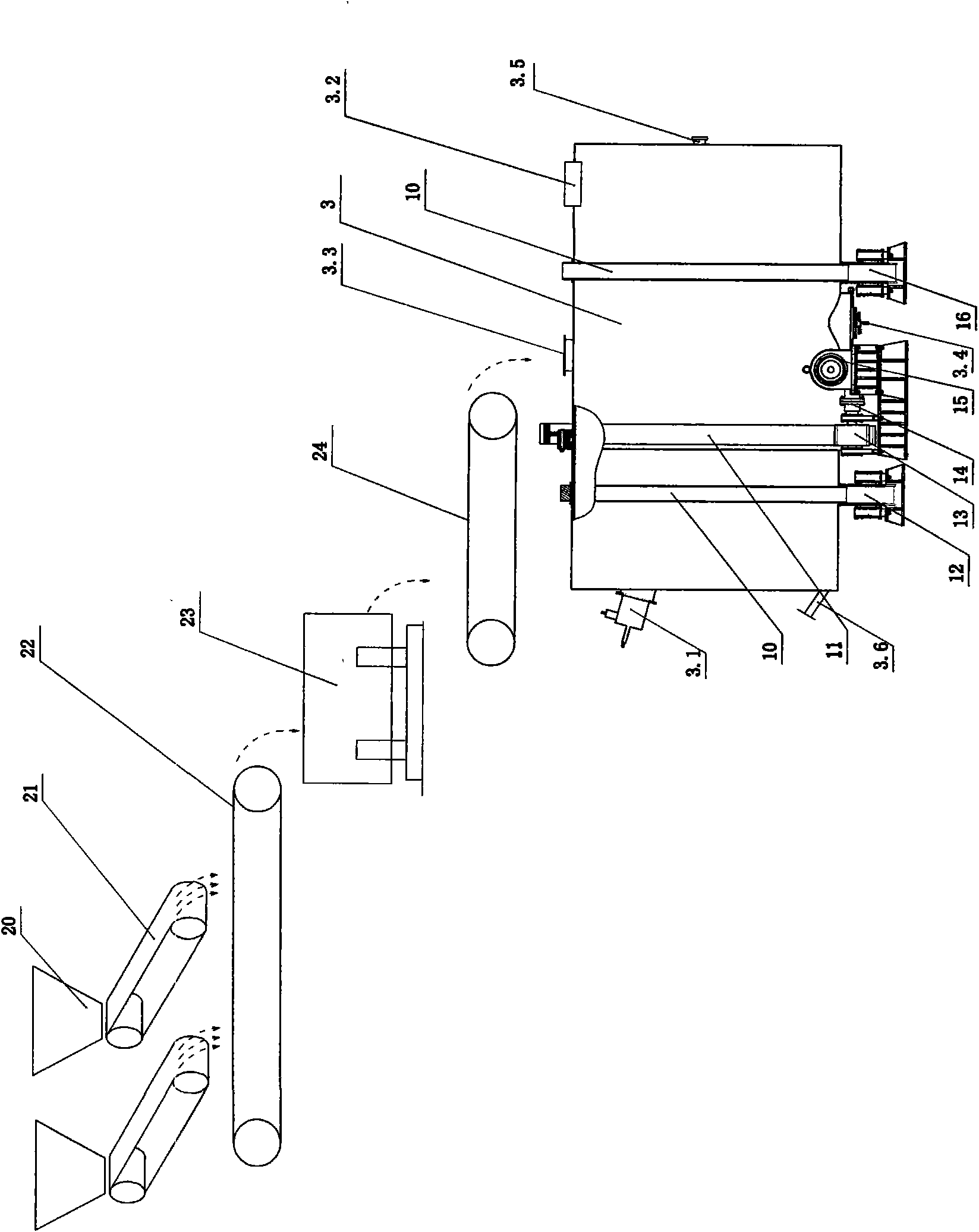

Method and device for smelting jamesonite by bottom-blowing pool

The invention relates to a method and a device for smelting jamesonite by a bottom-blowing pool. The method comprises the following steps of: performing pool smelting, oxidation and desulfurization on the jamesonite by using a bottom-blowing oxidation furnace to produce antimony-containing high-lead slag, a lead-antimony alloy and flue gases suitable for acid preparation; reducing the antimony-containing high-lead slag and blowing the lead-antimony alloy by using a bottom-blowing smelting furnace to produce antimony oxides and lead bullion capable of being used for electrolysis; and reducing the antimony oxides by using a bottom-blowing reduction furnace to produce needle antimony. In the smelting method of the invention, the three bottom-blowing furnaces and an electrically-heated settler are adopted to treat the jamesonite to produce the lead bullion, the needle antimony and the slag; therefore, compared with the prior art, the method has the advantages of short flow, good lead-antimony separation effect, fewer intermediate products, less revert, high resource utilization rate and production continuity; and the bottom-blowing oxidation furnace can realize spontaneous heating balance by sulfide combustion with low energy consumption and high recovery rate and can greatly reduce the cost.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

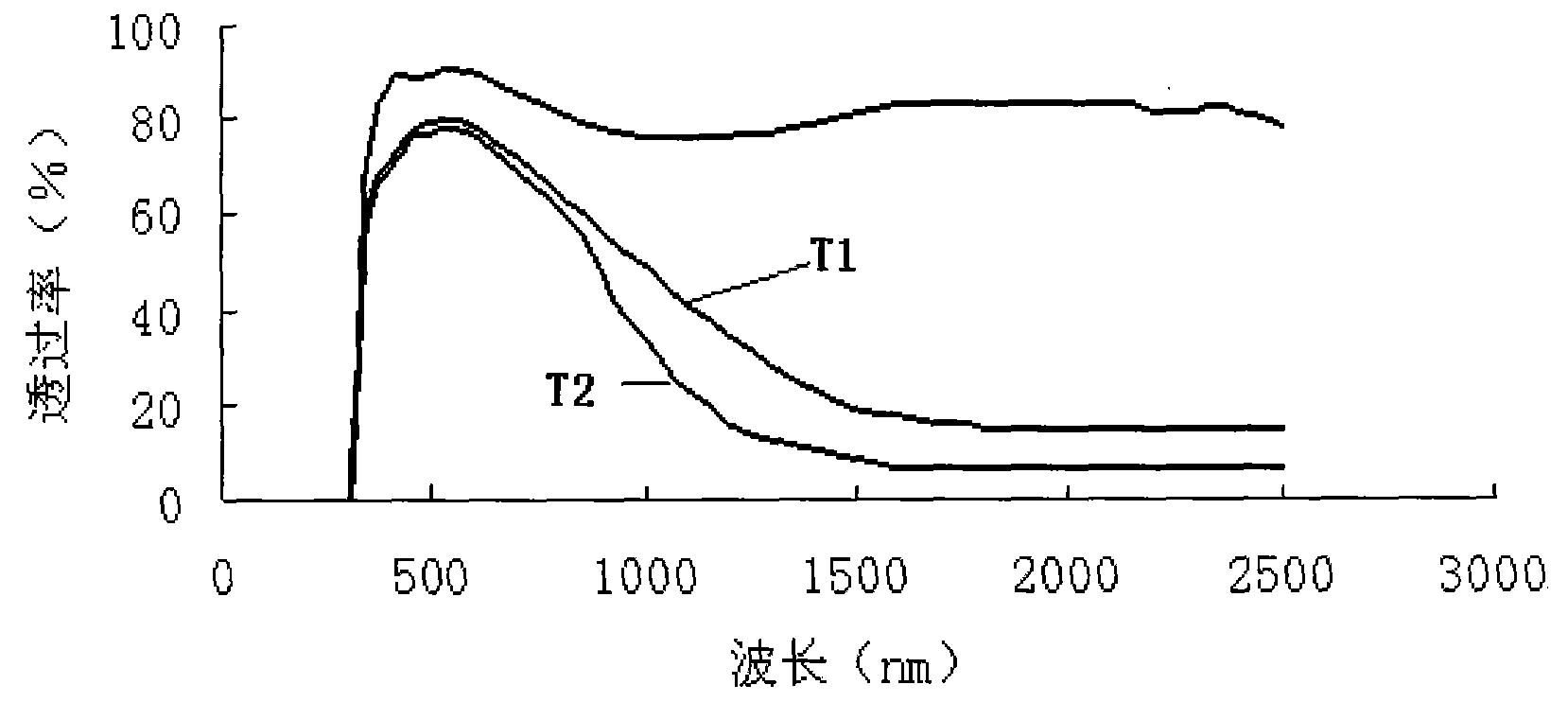

Intelligent nano transparent insulating glass coating

InactiveCN101993657AOvercome the disadvantage of needing to dryGood weather resistanceCoatingsVanadium dioxideIndium

The invention provides a preparation method of intelligent nano transparent insulating glass coating comprising organic silicon resin, nano-tin indium oxide or nano-tin antimony oxide pulp, nano-silica or nano-aluminium oxide pulp, doped nano-vanadium dioxide pulp, a diluent and an addition agent. The preparation method comprises the following steps of: mixing the pulp, respectively dripping the pulp, the diluent and the addition agent into the organic silicon resin, and stirring for 10-30 minutes to obtain synthetic intelligent nano transparent insulating glass coating. The test shows that after the intelligent nano transparent insulating glass coating is coated on a white glass with thickness of 5mm, the heat-insulating property of the white glass is greatly increased, and the corresponding transmittance of visible light is higher; after the intelligent nano transparent insulating glass coating is coated on the glass, the transmission of near infrared rays of the glass can be reduced at the temperature above 35DEG C, and the transmission of near infrared rays of the glass can be increased at the temperature below 35DEG C, thereby the automatic regulation of the near infrared ray transmission of the glass along with the temperature variation can be realized and the contradiction of heating in winter and shading in summer is overcome so that the thermal property of the energy-saving glass can be intelligently regulated along with climatic change. The intelligent nano transparent insulating glass coating realizes the functions of insulating heat in winter and shading, lighting and insulting in summer and has higher energy-saving effect.

Owner:BEIJING BUILDING TECH DEV

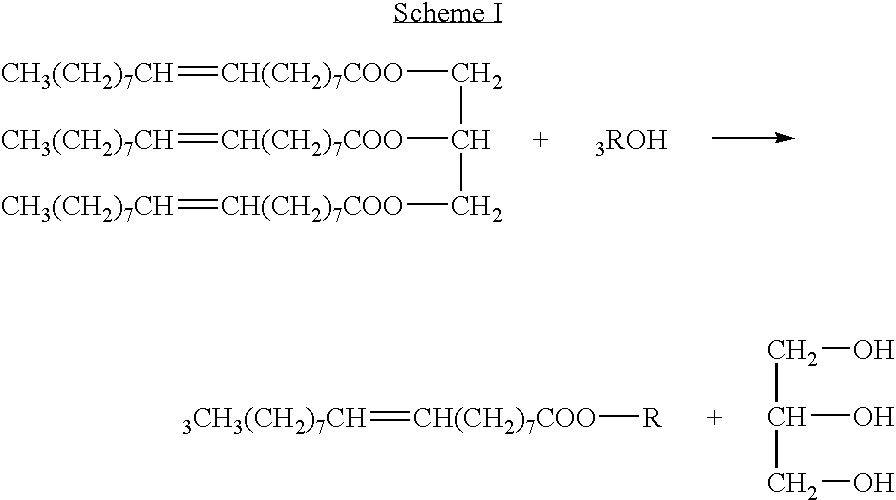

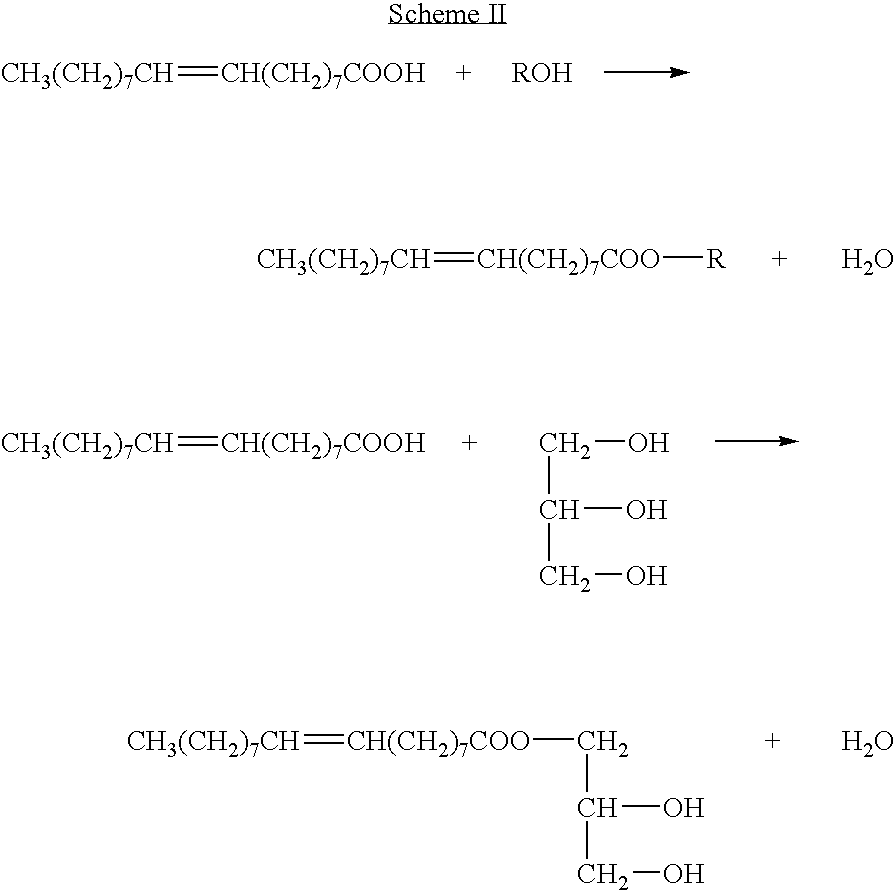

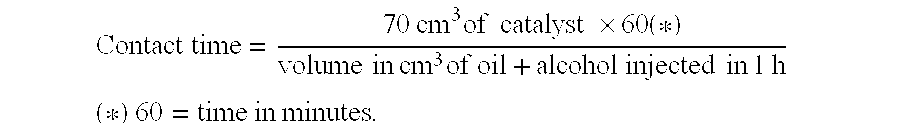

Process for transesterification of vegetable or animal oils using heterogeneous catalysts based on titanium, zirconium or antimony and aluminium

InactiveUS20050266139A1Possible formFatty acid esterificationPreparation by ester-hydroxy reactionHomogeneous catalysisTitanium oxide

A novel process is described for producing esters of linear monocarboxylic acids containing 6 to 26 carbon atoms, by reacting vegetable or animal oils, neutral or otherwise, with monoalcohols containing 1 to 18 carbon atoms in the presence of a catalyst selected from: mixtures of titanium oxide and alumina having formula: (TiOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y, representing the weight ratio of the two oxides, has a value of 0.005 to 0.995; mixtures of zirconium oxide and alumina having formula: (ZrOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y has a value of 0.005 to 0.995; and mixtures of antimony oxide and alumina having formula: (SbOx)y(Al2O3)1-y where x has the value 1.2 to 2.6 and y has a value of 0.005 to 0.995, in order to directly produce, in one or more steps, an ester for use as a fuel and a pure glycerin.

Owner:INST FR DU PETROLE

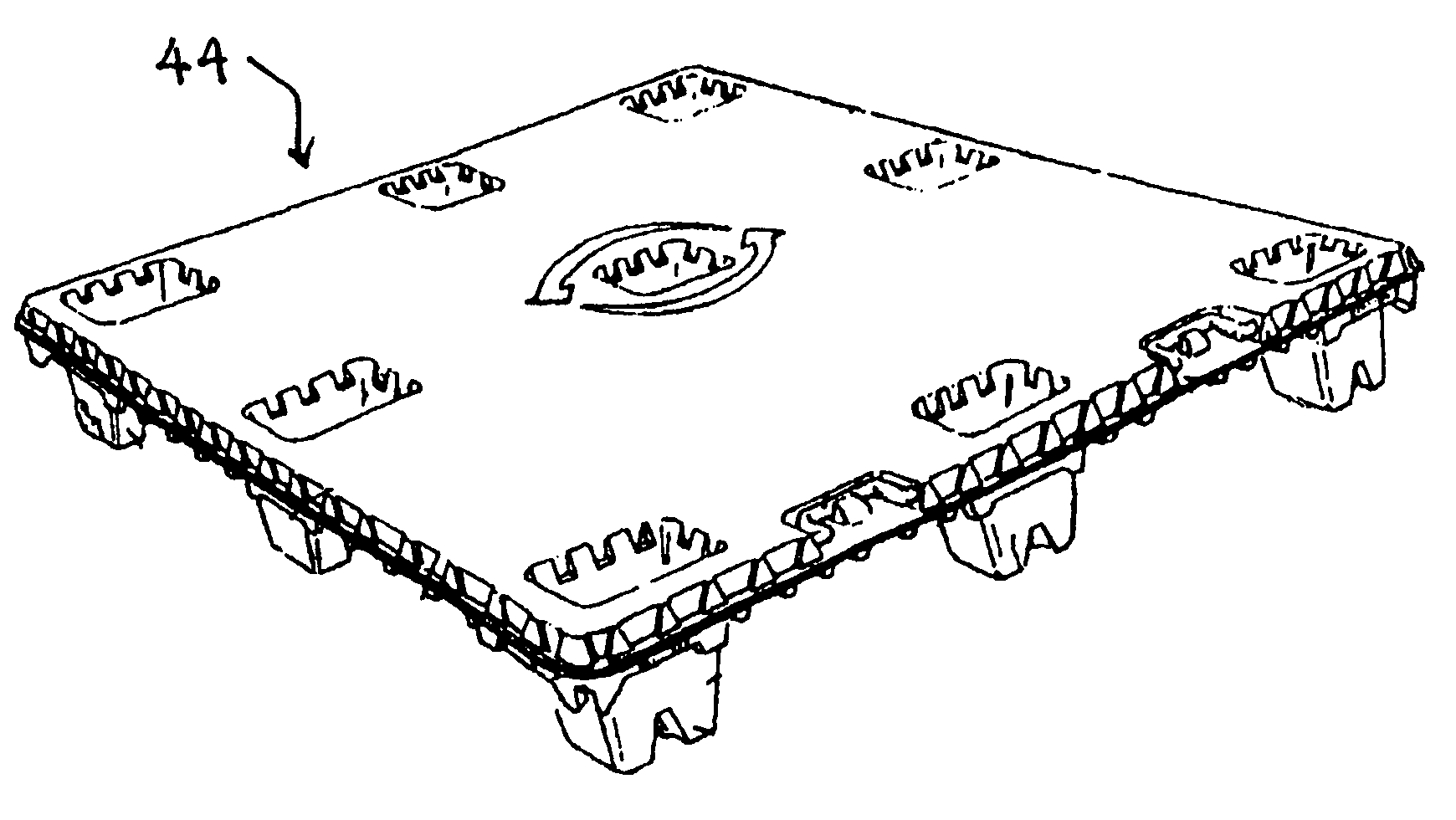

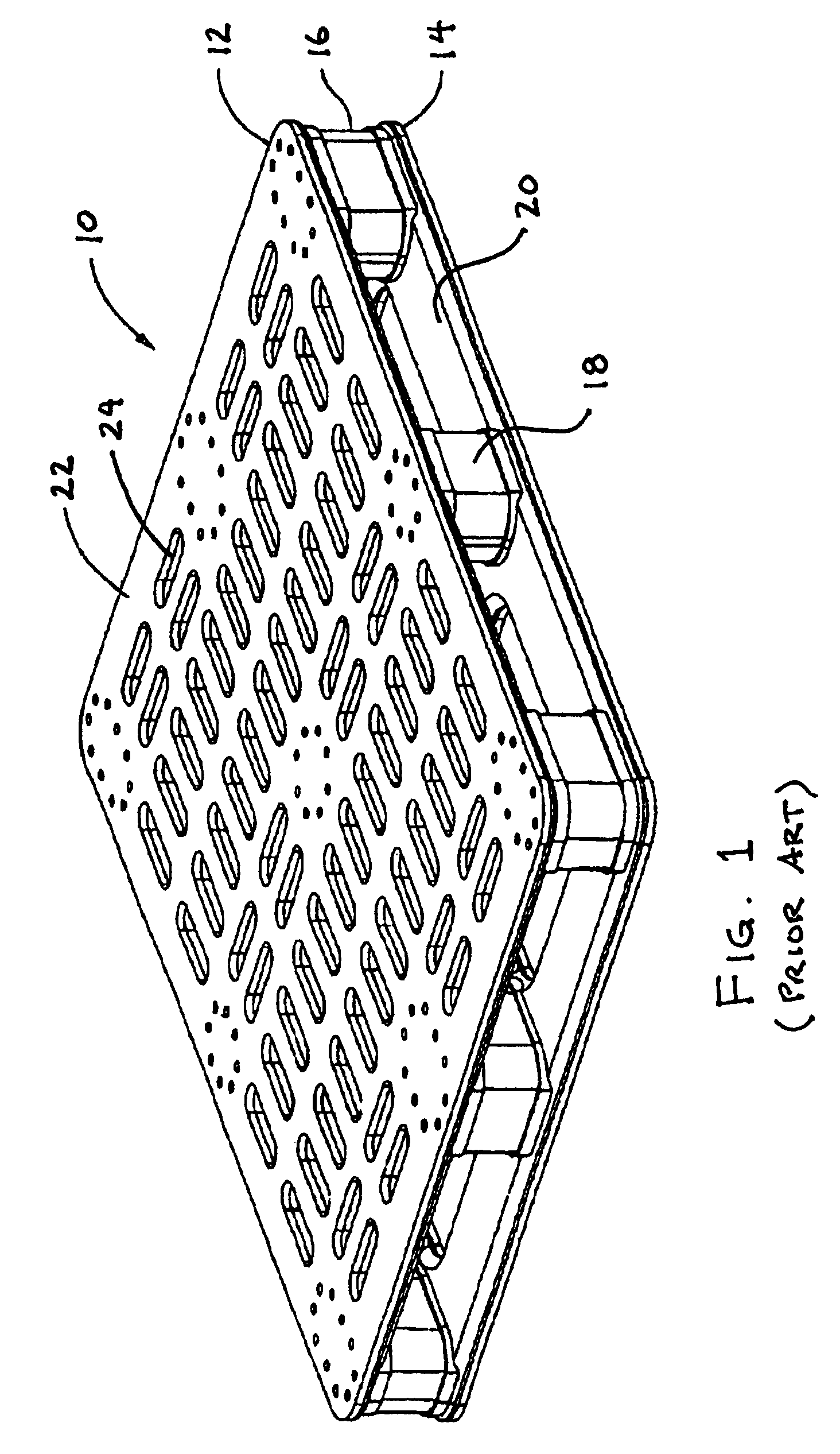

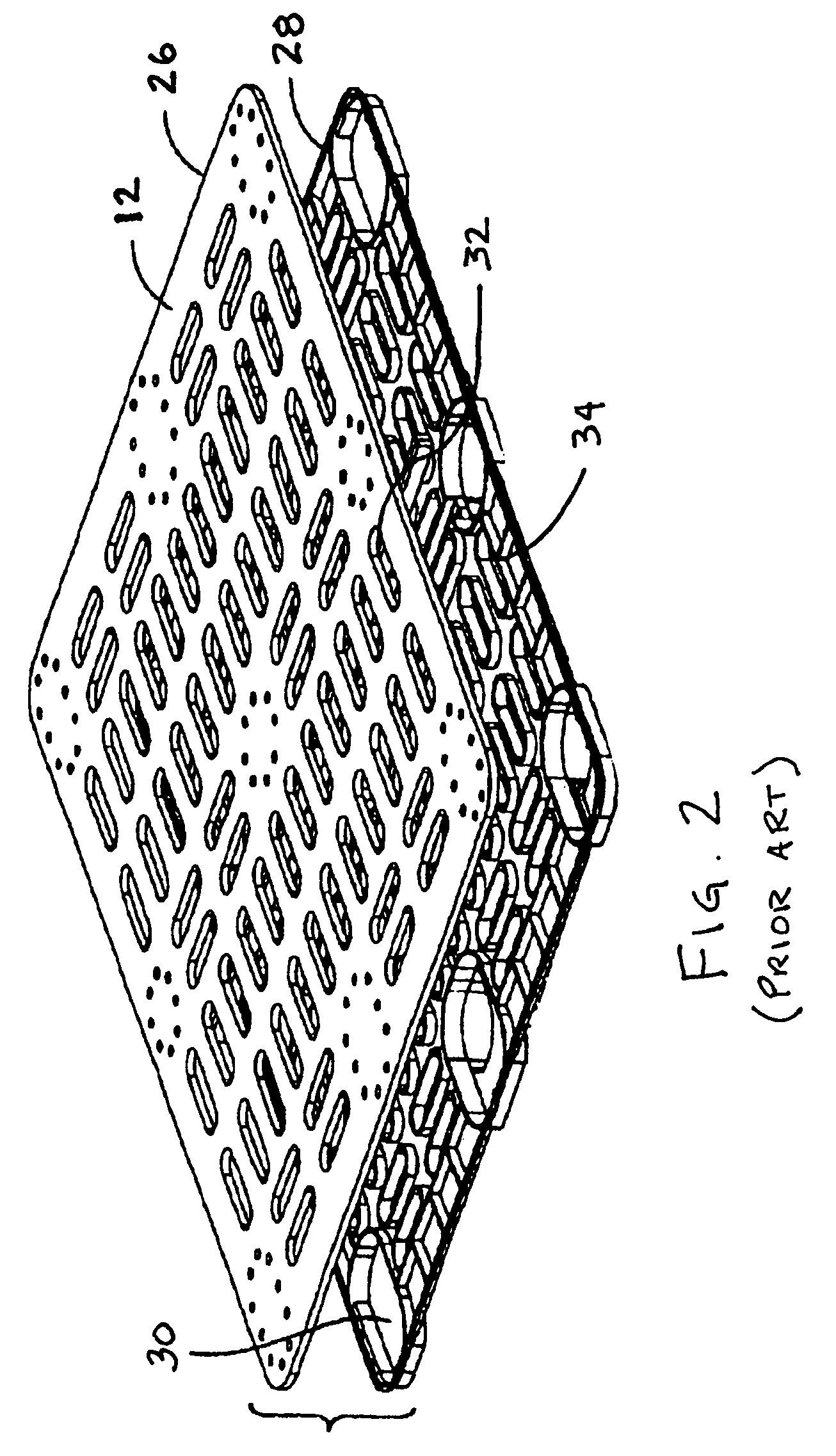

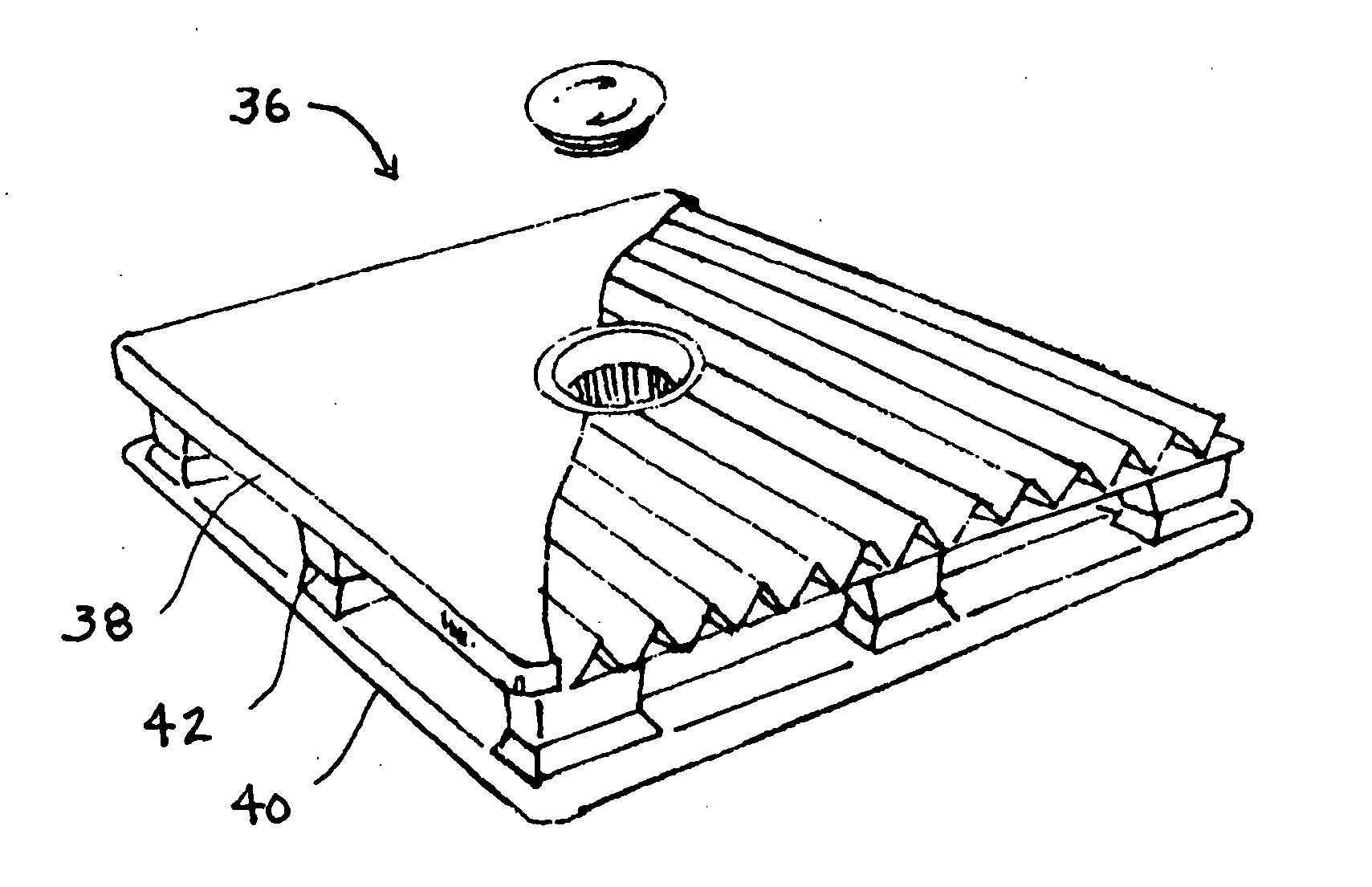

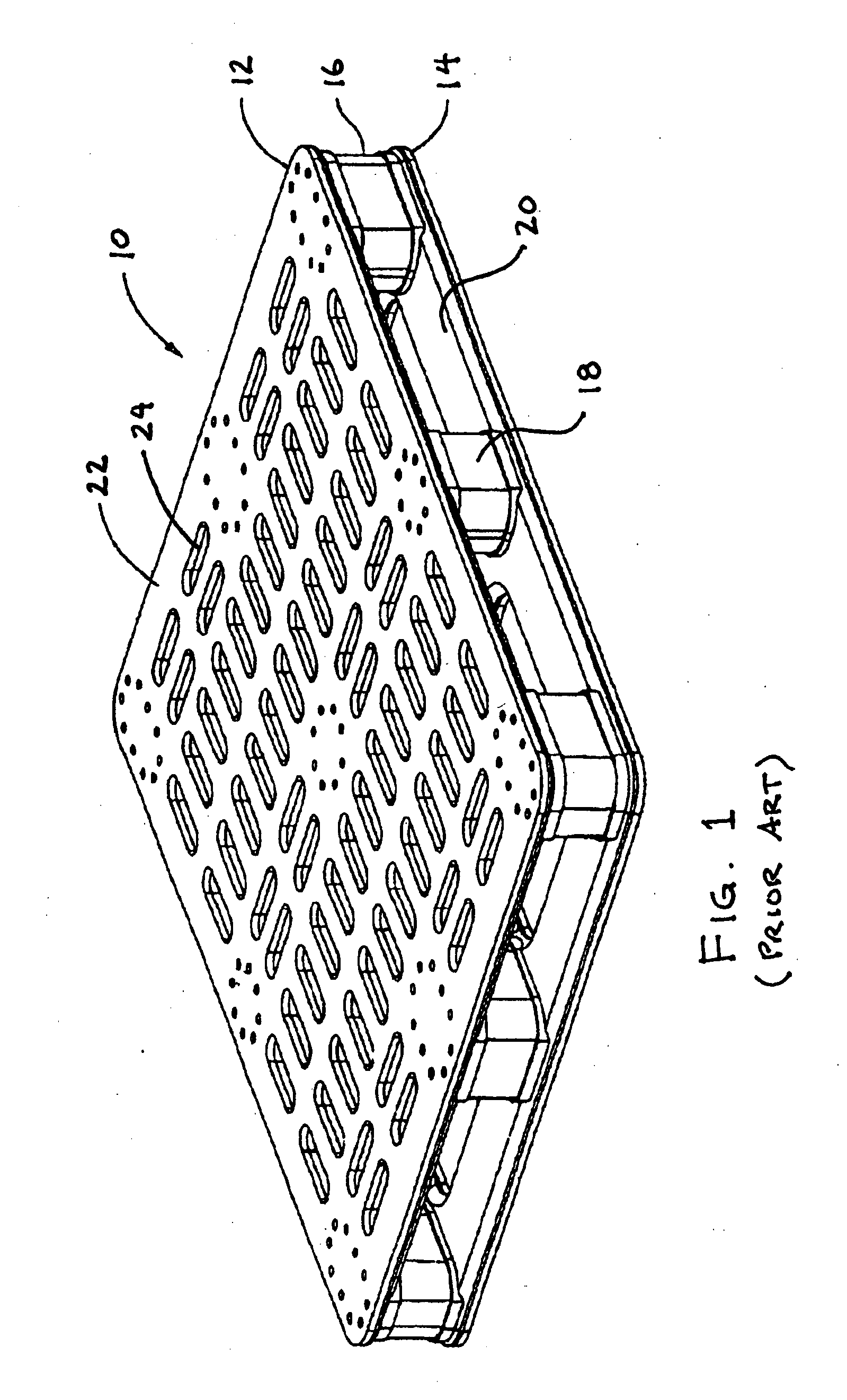

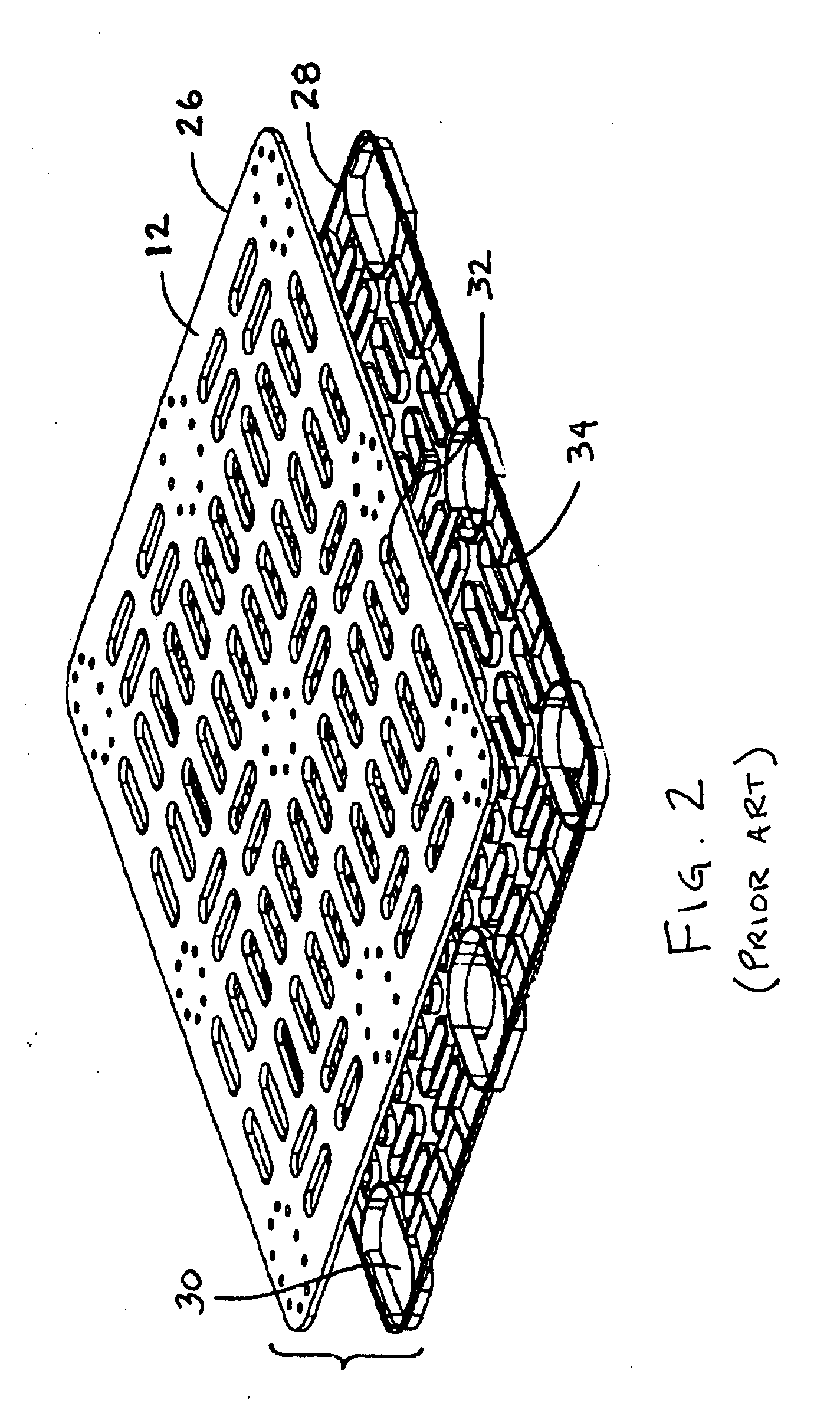

Fire resistant plastic pallet with low radio frequency resistivity

A halogen free fire resistant RF transparent polymer pallet has attenuated electrical resistance. A pallet body has a fire resistant layer and a substrate supporting the fire resistant layer. The fire resistant layer includes fire retardant materials, such as Al(OH)3, Mg(OH)2, intercalated graphite, zinc borate, and antimony oxide. The substrate is substantially free of the fire retardant materials to reduce the density and the electrical resistance of the pallet body. The fire resistant layer is substantially thinner than the substrate to lower RF distortion effects on RF transponder communications from additives and the conductive materials within an RF tracking system.

Owner:NEXTREME

Inorganic thermal insulation material and preparation method thereof

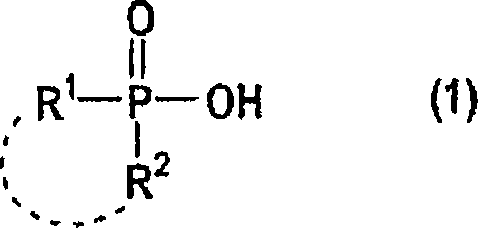

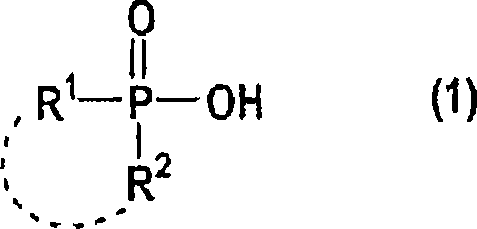

The invention provides an inorganic thermal insulation material and a preparation method thereof. The material is obtained through the following steps of: mixing silica aerogel, soluble silicate, compound of structural formula (I), tin antimony oxide and hollow glass bead, adding a coupling agent into the above mixture for modification, mixing the resulting mixture with water, causing the resulting solution to infiltrate a glass fiber mat, and obtaining the material by processing the infiltrated glass fiber mat by means of hot-press forming. Compared with the prior art, the invention has the following advantages: firstly, hydrophobic treatment by modification is carried out, hydrophobic groups in a material nanometer microporous reticulated structure is exposed due to the action of the coupling agent so that the inorganic material has good water resistance, supercritical fluid drying is not needed and production cost is reduced; secondly, inorganic nanometer materials and inorganic fibers are adopted so that the compressive strength, tensile strength and rupture strength of the inorganic thermal insulation material are all pretty high, the bonding strength of the inorganic thermal insulation material with a base course is also pretty high, and the structure is stable; and finally, the silica aerogel causes the inorganic thermal insulation material to have a nanometer grade micro-closed-hole reticulated structure so that the heat conductivity coefficient of the inorganic thermal insulation material is reduced and thermal insulation performance is improved.

Owner:BEIJING BOTIANZIRUI TECH CO LTD

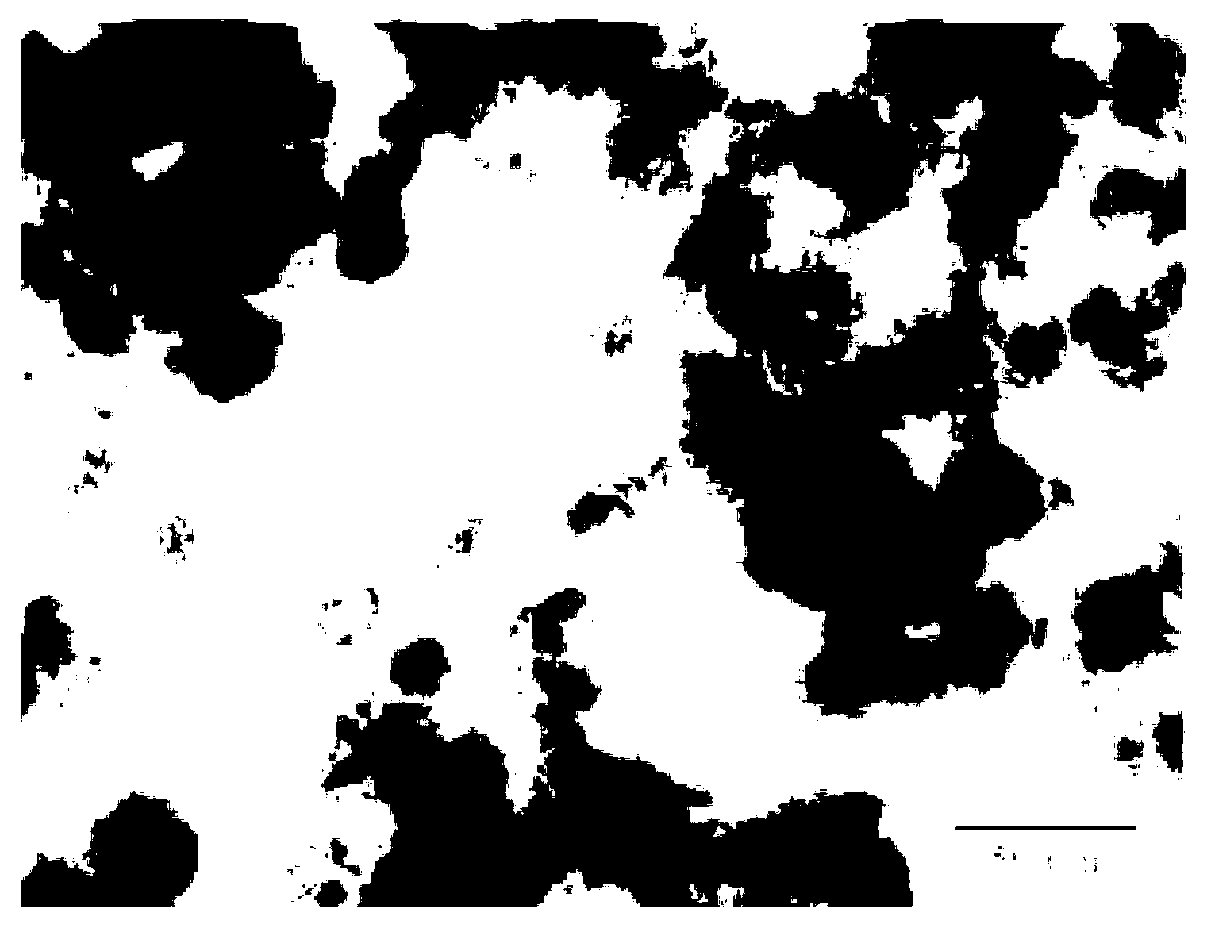

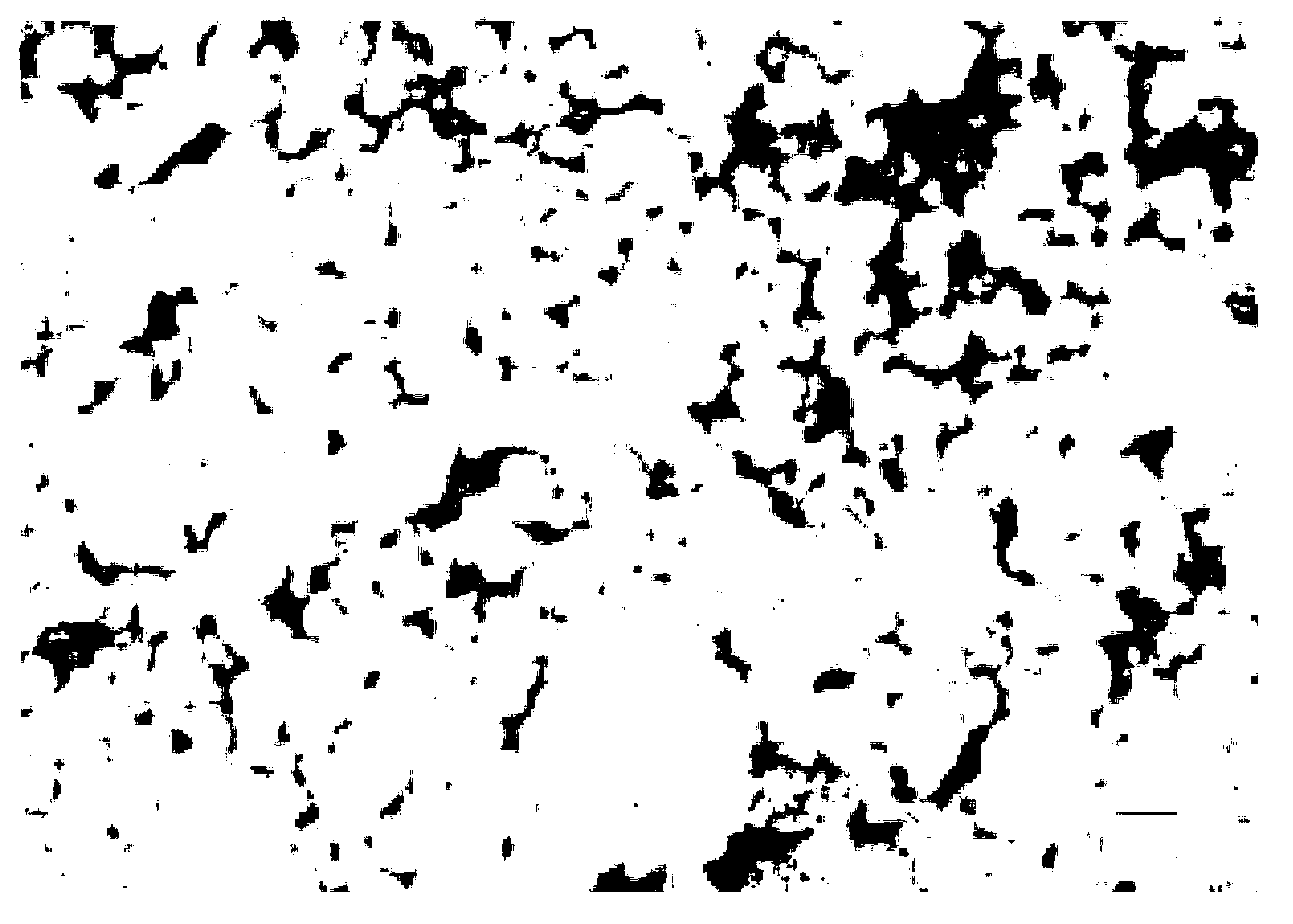

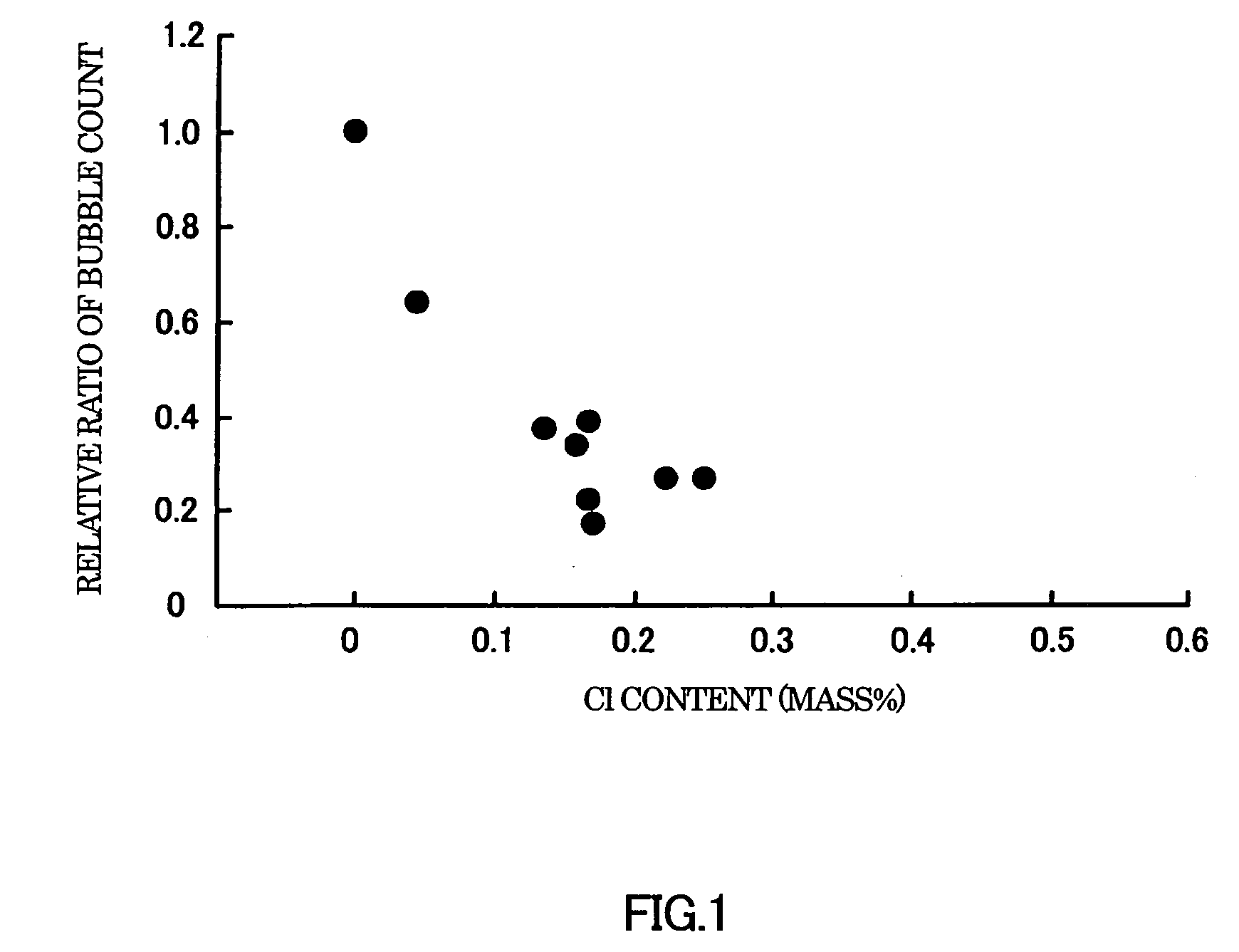

Glass composition

ActiveUS20090143214A1Improve glass fining effectSufficient fining effectNon-linear opticsIdentification meansArsenic oxideChemistry

A glass composition which is reduced in the amount of residual bubbles and is produced using smaller amounts of an environmentally unfriendly component such as arsenic oxide and antimony oxide. This glass composition comprises, in terms of mass %: 40-70% SiO2; 5-20% B2O3; 10-25% Al2O3; 0-10% MgO; 0-20% CaO; 0-20% SrO; 0-10% BaO; 0.001-0.5% Li2O; 0.01-0.5% Na2O; 0.002-0.5% K2O; and 0-1.0%, excluding 0%, Cl

Owner:AVANSTRATE INC

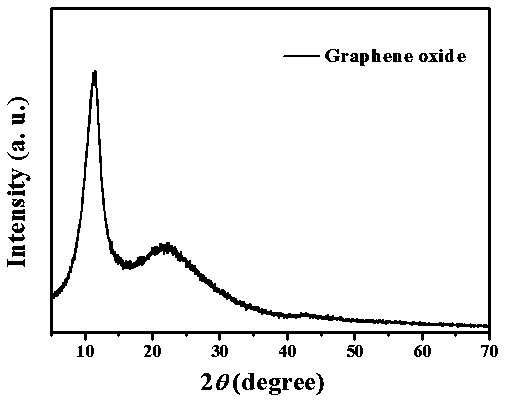

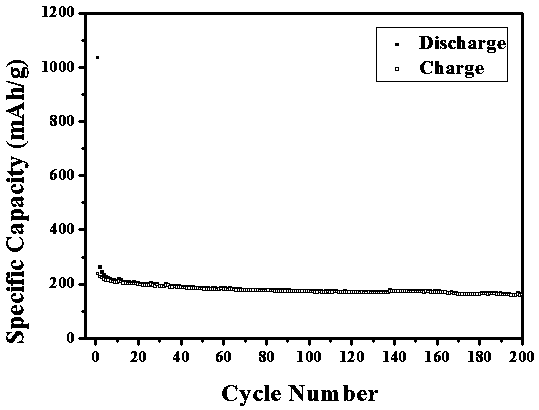

Preparation method of graphene oxide and graphene oxide composite material and use of graphene oxide and graphene oxide composite material in sodium-ion battery

InactiveCN104269534AEasy to embedPromote prolapseSecondary cellsNegative electrodesOxide compositeCopper oxide

The invention discloses a preparation method of graphene oxide and a graphene oxide composite material and a use of the graphene oxide and the graphene oxide composite material in a sodium-ion battery. The graphene oxide and the graphene oxide composite material can be used as sodium-ion battery cathode materials. The graphene oxide composite material is prepared from the graphene oxide and metals or metal oxides by a compounding method, wherein the metals comprise Ag, Au, Cu, Fe, Sn, Si, Ni and Sb, the metal oxides comprise nickel oxide, copper oxide, tin oxide, antimony oxide, cobalt oxide, iron oxide and manganese oxide and a mass percentage of the graphene oxide is in a range of 10-80%. The graphene oxide and the graphene oxide composite material prepared by a plurality of effective processes can be used as sodium-ion battery cathode materials, have the advantages of high specific capacity and good cycling stability, have a low manufacturing cost and are suitable for sodium-ion battery large-scale exploitation and application.

Owner:ZHEJIANG UNIV

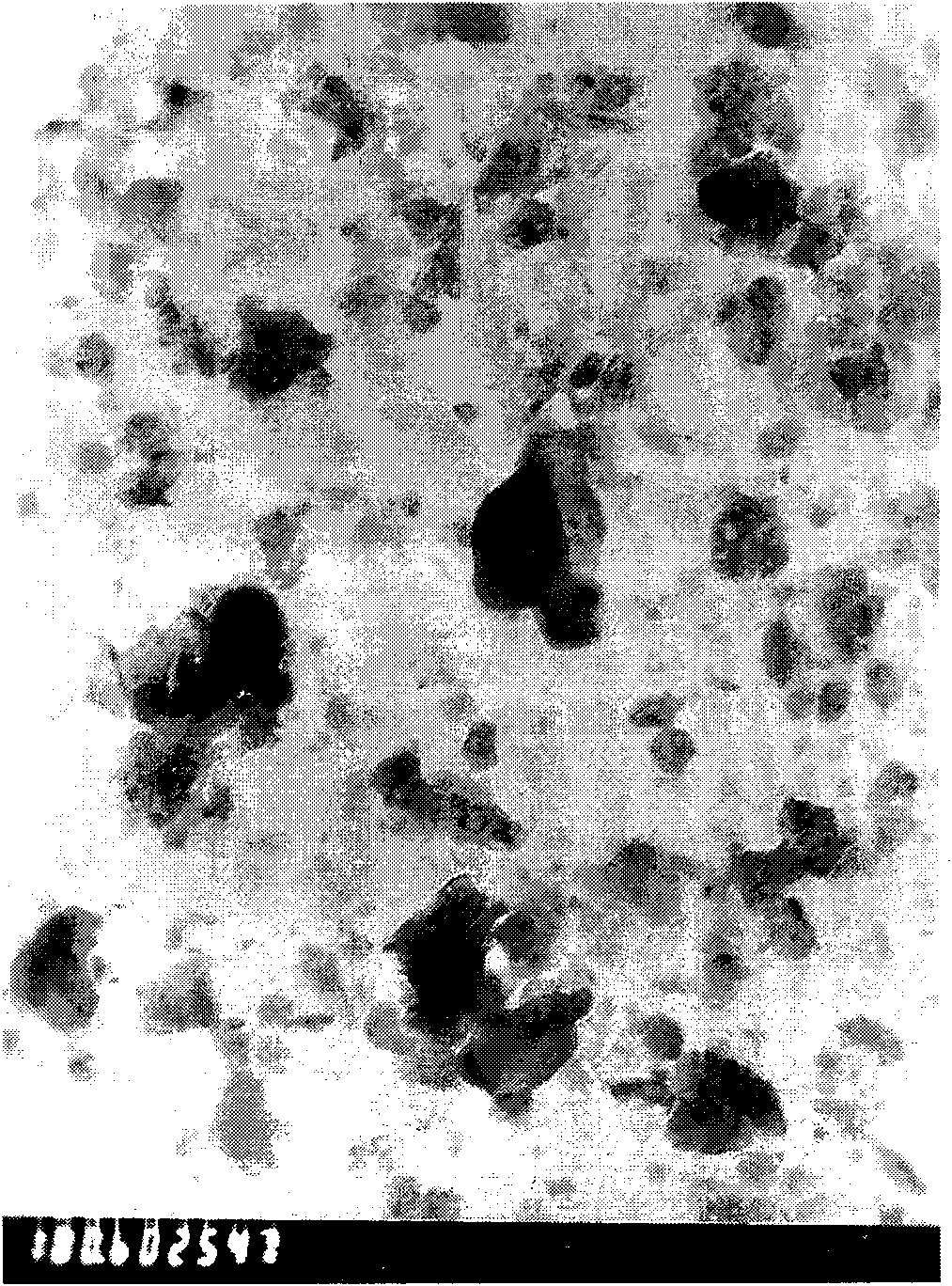

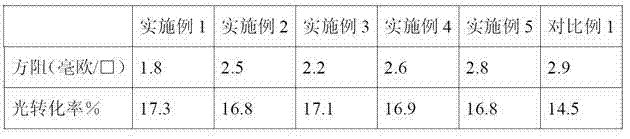

Glass powder and its preparation method and conductive paste for solar cell

ActiveCN102476919AConvenient sourceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesEngineeringSelenium Oxide

The invention provides glass powder, which comprises bismuth oxide 30wt%-70wt%, titanium oxide 1wt%-20wt%, zinc oxide 5wt%-40wt%, antimony oxide 5wt%-30wt% optional tellurium oxide 0wt%-30wt%, optional molybdenum oxide 0wt%-10wt% and selenium oxide 0wt%-15wt%. The invention also relates to a preparation method of the glass powder and conductive paste for solar cell prepared from the glass powder. The inventive glass powder contains no lead and boron, does no harm to the environment and can be used for preparing conductive paste for solar cell with high photoelectric conversion efficiency.

Owner:BYD CO LTD

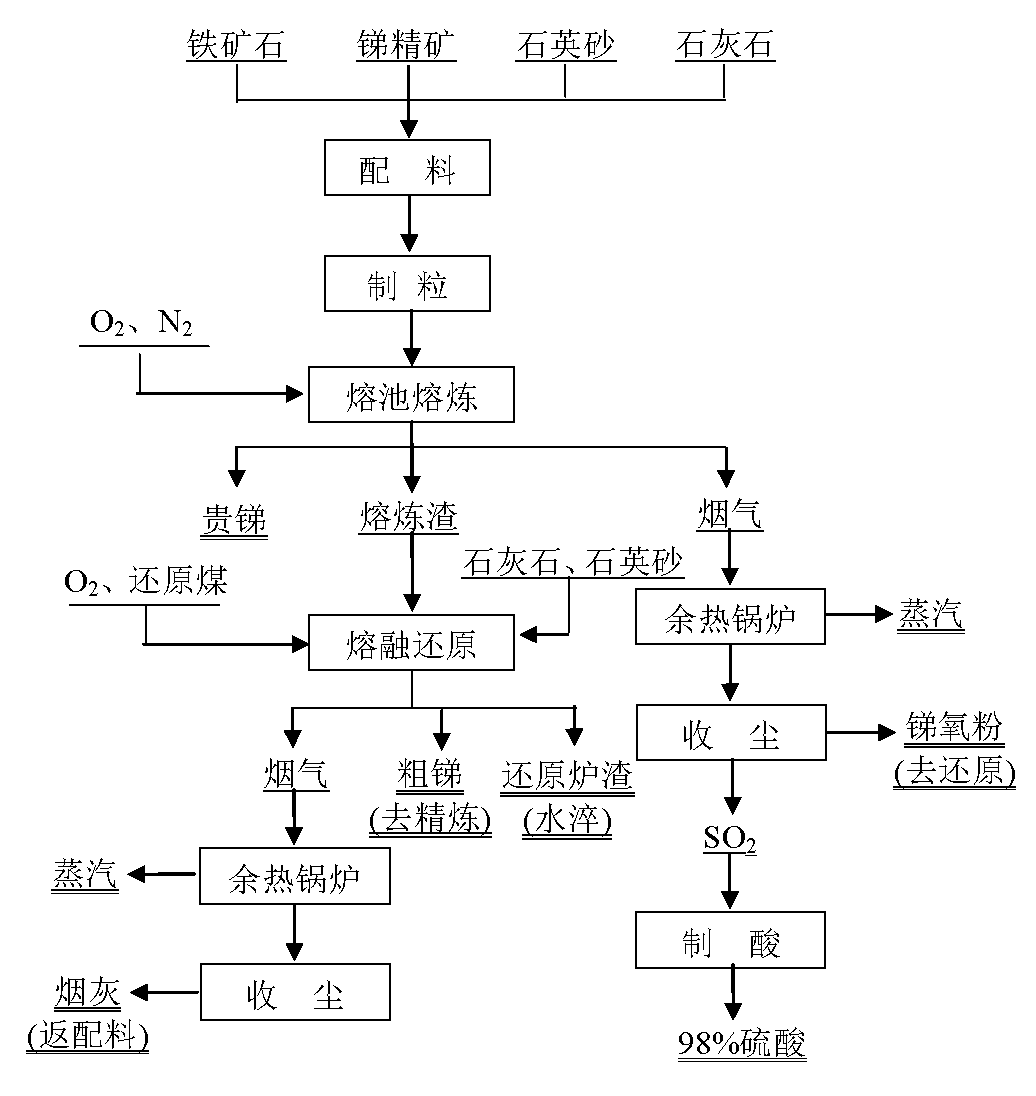

Antimony sulfide concentrate oxygen-enriched melting tank melting method

The invention discloses an antimony sulfide concentrate oxygen-enriched melting tank melting method. For solving problems of high pollution and high energy consumption of existing blast furnace volatilization melting technologies, and the impossibility of practical industrialization of existing oxygen-enriched melting tank melting technologies, the antimony sulfide concentrate oxygen-enriched melting tank melting method provided by the invention comprises the steps that: (1) material blending is carried out, wherein antimony concentrate limestone, quartz sand and iron ore are blended; (2) the blended material is granulated; (3) melting is carried out, wherein antimony sulfide is subjected to a volatilization or oxidation reaction and enters flue gas, and partial antimony sulfide enters melting slag through the oxidation reaction; (4) smoke dust recovery is carried out; (5) antimony oxide in the melting slag is reduced into metal antimony; (6) crude antimony and reduction slag are discharged in a stratified manner; wherein the crude antimony is used to be refined into refined antimony, and precious metal is recovered. With the method provided by the invention, antimony sulfide concentrate self-heat melting is realized, energy saving and consumption reducing are realized, and antimony and gold recovery rates are greatly improved. Antimony white has good quality, and can be directly subjected to reduction melting to produce refined antimony.

Owner:CENT SOUTH UNIV +1

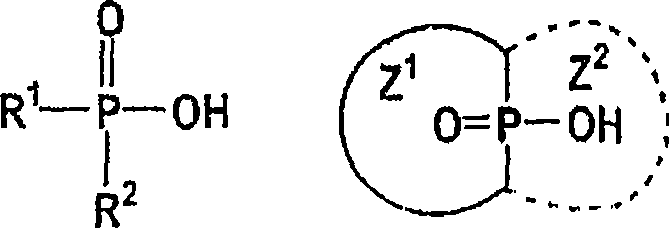

Flame retardant resin composition

InactiveCN101128541AImprove flame retardant performanceExcellent electrical propertiesMeth-Phosphate

Disclosed is a resin composition improved in flame retardance and electrical characteristics. Specifically disclosed is a flame retardant resin composition which is improved in electrical characteristics and composed of a base resin, a halogen flame retardant (namely, a bromine-containing flame retardant such as a brominated polybenzyl (meth)acrylate resin or brominated styrene resin), an organic phosphinic acid (such as dialkylphosphinic acid, alkylenephosphinic acid or cycloalkylenephosphinic acid) or a salt thereof (such as a metal salt or a salt with a nitrogen-containing compound having an amino group), and a flame retardant assistant which are different from the base resin (namely, an antimony-containing compound such as an antimony oxide or an antimonate, a fluorine-containing resin, a silicon-containing compound, an aromatic resin and / or a phosphorus-containing compound except for (fused) aminotriazine phosphates). This resin composition may further contain an olefin resin and an electrical characteristics improver assistant. Per 100 parts by weight of the base resin, there may be contained 3-30 parts by weight of a halogen flame retardant, 1-30 parts by weight of an organic phosphinic acid or a salt thereof, and 0.1-30 parts by weight of a flame retardant assistant.

Owner:POLYPLASTICS CO LTD

Fire resistant plastic pallet with low frequency resistivity

InactiveUS20080053342A1Low costReduce distortionContainer decorationsLevel indicationsEngineeringConductive materials

A halogen free fire resistant RF transparent polymer pallet has attenuated electrical resistance. A pallet body has a fire resistant layer and a substrate supporting the fire resistant layer. The fire resistant layer includes fire retardant materials, such as Al(OH)3, Mg(OH)2, intercalated graphite, zinc borate, and antimony oxide. The substrate is substantially free of the fire retardant materials to reduce the density and the electrical resistance of the pallet body. The fire resistant layer is substantially thinner than the substrate to lower RF distortion effects on RF transponder communications from additives and the conductive materials within an RF tracking system.

Owner:NEXTREME

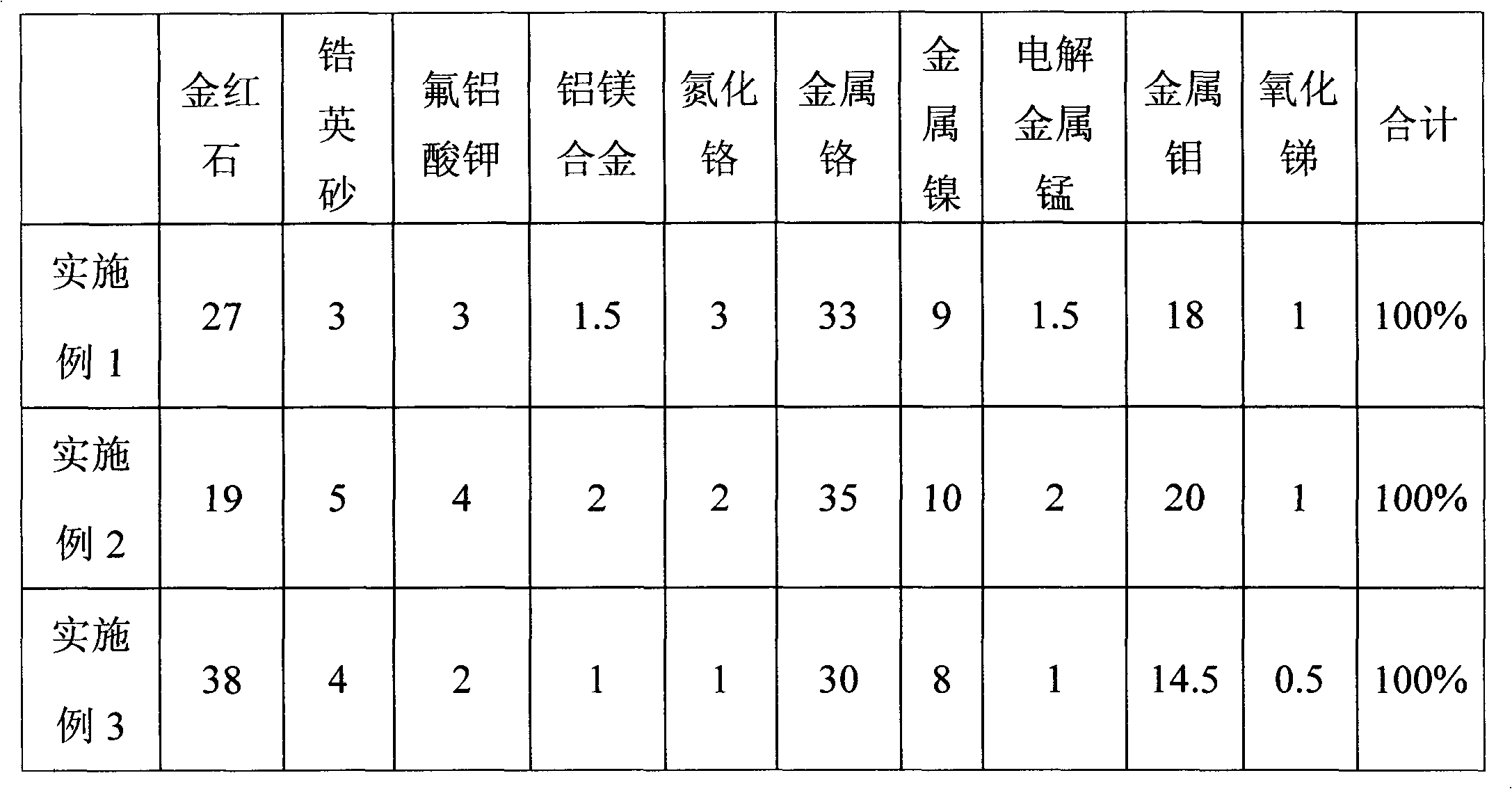

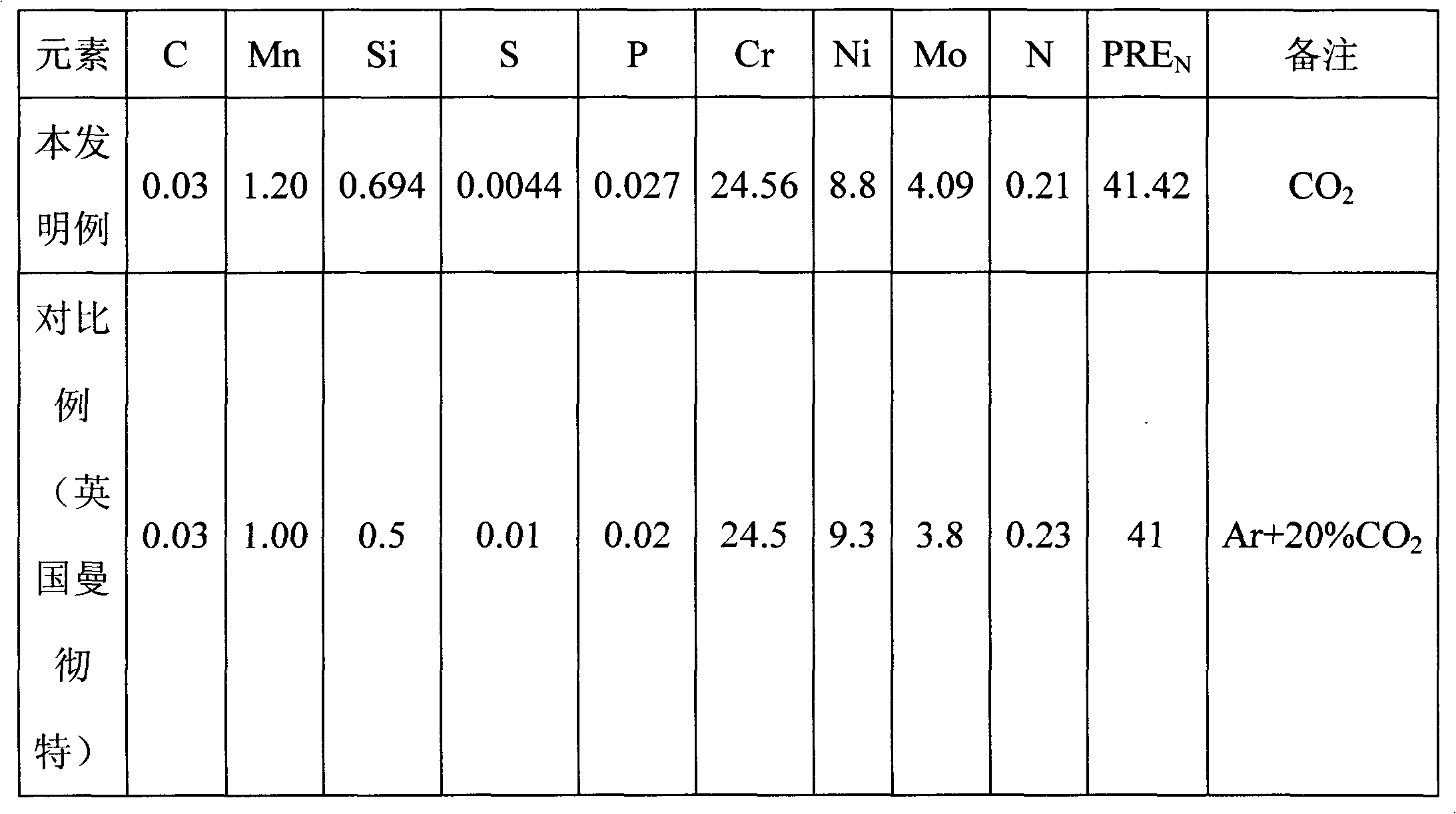

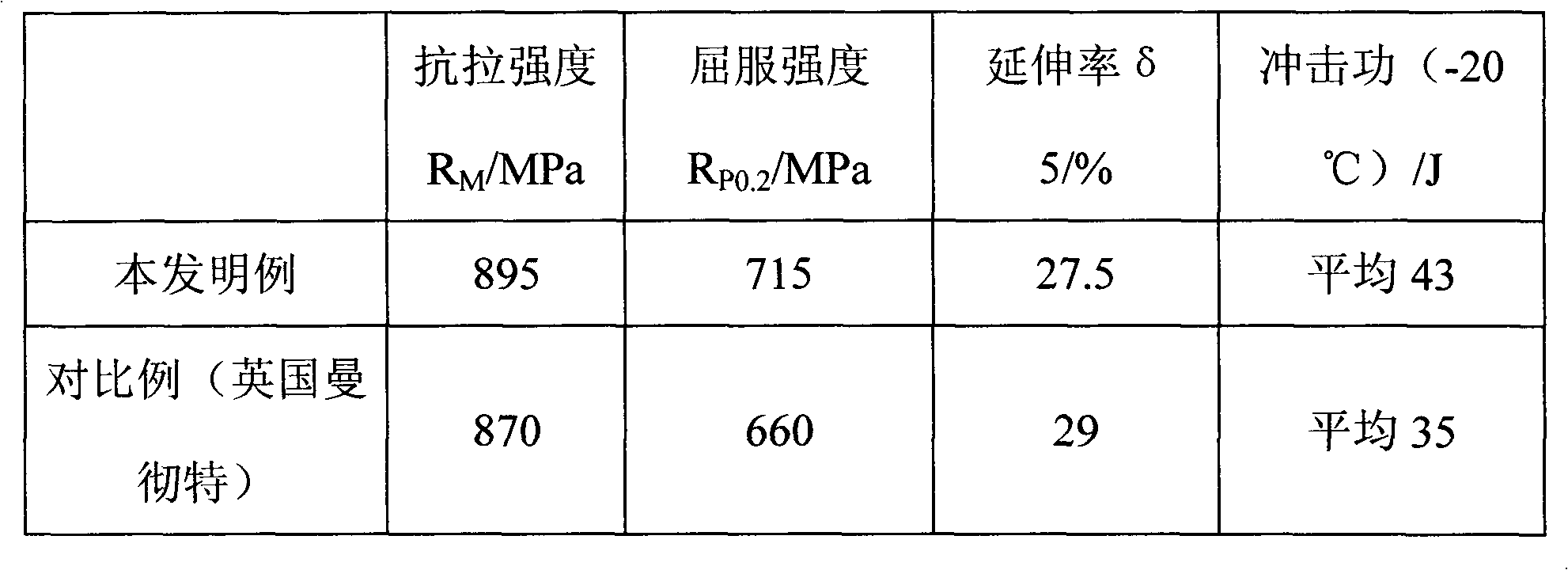

Chemical powder components of 2507 type super double-phase stainless steel flux-cored wire

InactiveCN101966628AGood performance in welding operationBeautiful weld shapeWelding/cutting media/materialsSoldering mediaElectrolysisDouble phase

The invention belongs to the field of welding materials and discloses chemical powder components of a 2507 type super double-phase stainless steel flux-cored wire. A common 304L stainless steel metal strip is used as an outer skin; the chemical powder components are filled inside the common 304L stainless steel metal strip to be rolled into a flux-cored wire. The chemical powder components of the 2507 type super double-phase stainless steel flux-cored wire are characterized by comprising the following components in percent by mass: 19 percent-38 percent of rutile, 3 percent-5 percent of zircon sand, 2 percent-4 percent of potassium fluoroaluminate, 1 percent-2 percent of aluminium magnesium alloy, 1 percent-3 percent of chromium nitride, 30 percent-35 percent of metallic chrome, 8 percent-10 percent of metallic nickel, 1 percent-2 percent of electrolytic manganese metal, 14.5 percent-20 percent of metallic molybdenum and 0.5 percent-1 percent of antimony oxide. In the invention, the steel pipe made from the 304L stainless steel strip (with the specification of 10*0.4mm) filled with the chemical powder is manufactured into the super double-phase stainless steel flux-cored wire according to the general production process. CO2 is used as welding protection gas for the flux-cored wire, and the flux-cored wire has the characteristics of good welding operation process performance, attractive welding line moulding, excellent welding process performance, favorable balance of welding tissue austenite and ferrite and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Thermosetting compositions, methods of coating and coated articles

InactiveUS6103387AGood lookingSynthetic resin layered productsPretreated surfacesVinyl etherDouble bond

PCT No. PCT / JP96 / 02971 Sec. 371 Date Jun. 10, 1997 Sec. 102(e) Date Jun. 10, 1997 PCT Filed Oct. 14, 1996 PCT Pub. No. WO97 / 13809 PCT Pub. Date Apr. 17, 1997A thermosetting composition comprises (A) a compound having in the molecule two or more carboxyl groups blocked by a vinyl ether compound, a vinyl thioether compound or a hetero compound having a vinyl type double bond and oxygen or sulfur as the hetero atom, (B) a compound having in the molecule two or more reactive functional groups which can form chemical bonds with the blocked carboxyl groups, and (C) a dispersing component of at least one inorganic oxide sol selected from the group consisting of aluminium oxide sol, silica sol, zirconium oxide sol and antimony oxide sol, and optionally (D) a thermal latent acid catalyst which is activated during curing the composition by heating. A method of coating and a coated article comprise applying the composition. The obtained paint film has excellent weathering resistance, stain resistance, stain-removing property, chemical resistance, moisture resistance and excellent appearance.

Owner:NOF CORP

Polyester polycondensation with catalyst and a catalyst enhancer

InactiveUS6372879B1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyesterPotassium

Owner:ARKEMA INC

Toughness reinforcing flame-proof reinforced polybutylene terephthalate complex and method for producing the same

The invention discloses a toughening flame-retardant reinforcing polybutylene terephthalate compound and a relative production method, while the compound is prepared from PBT, glass fiber, bromide, antimony oxide, toughening agent, anti-oxidant and anti-drop agent. The production method comprises weighting materials according to a certain ratio, mixing the PBT, bromide, antimony oxide, toughening agent, anti-oxidant and anti-drop agent at a certain mass ratio in a high-speed mixer uniformly, arranging the uniform mixture in bucket, using a feeder to feed the mixture into a twin-screw extruder, to obtain flame-retardant reinforcing PBT compound with good toughness. The bromines reinforcing flame retardant PBT compound has good toughness and performance price ratio, with simple preparation and low cost.

Owner:南通市旺茂实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com