Patents

Literature

53 results about "Polybrominated Biphenyls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biphenyl compounds which are extensively brominated. Many of these compounds are toxic environmental pollutants.

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

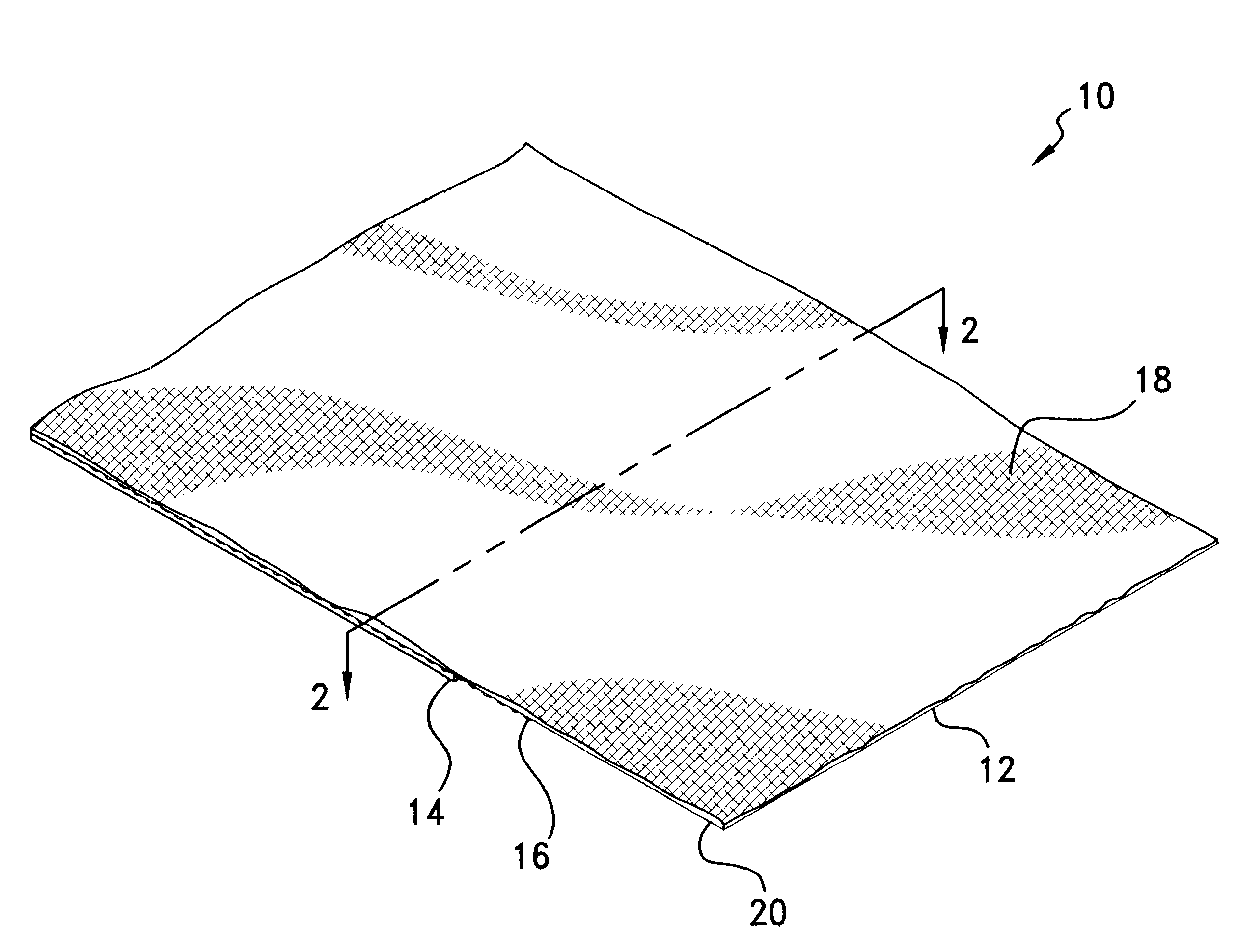

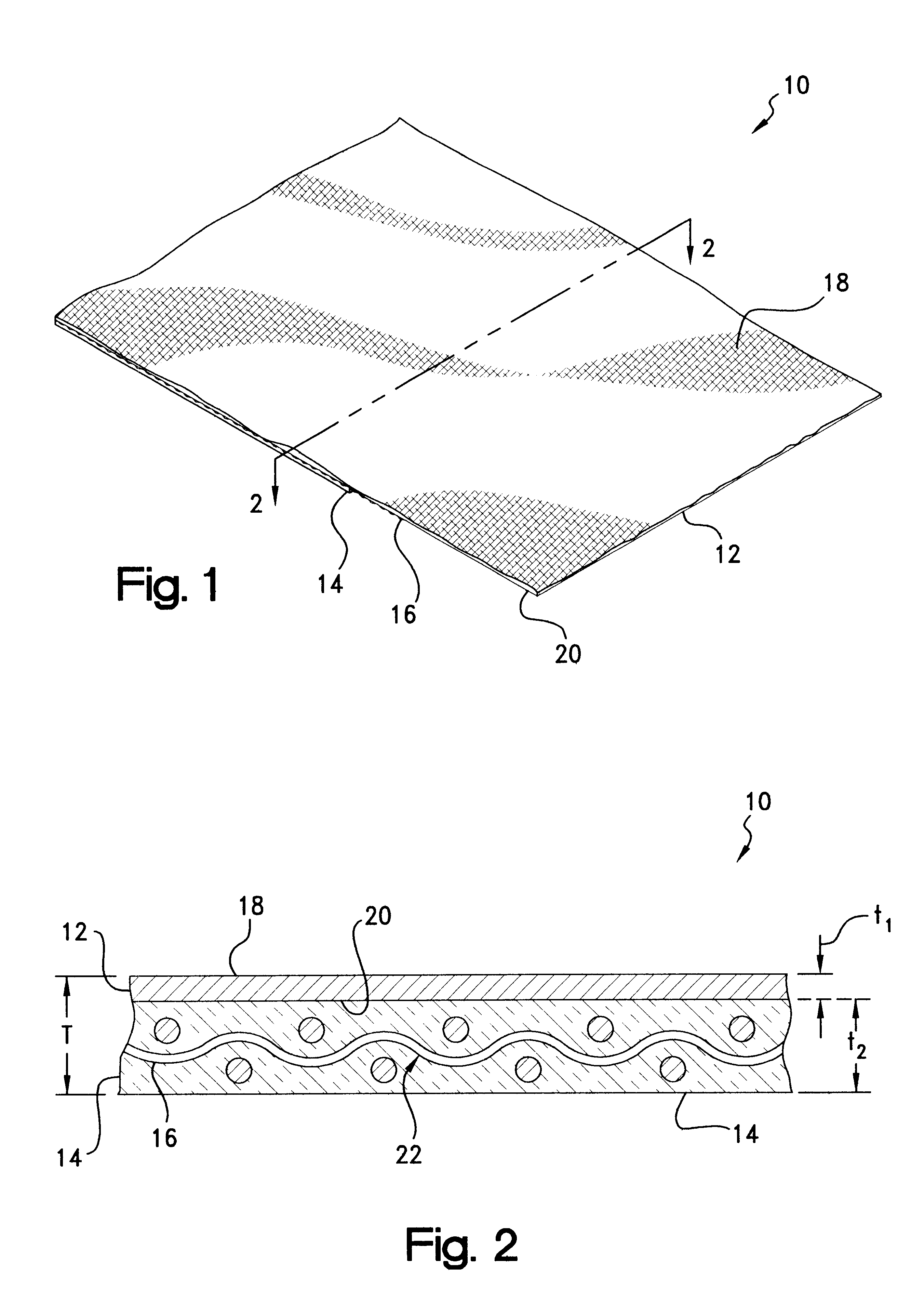

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

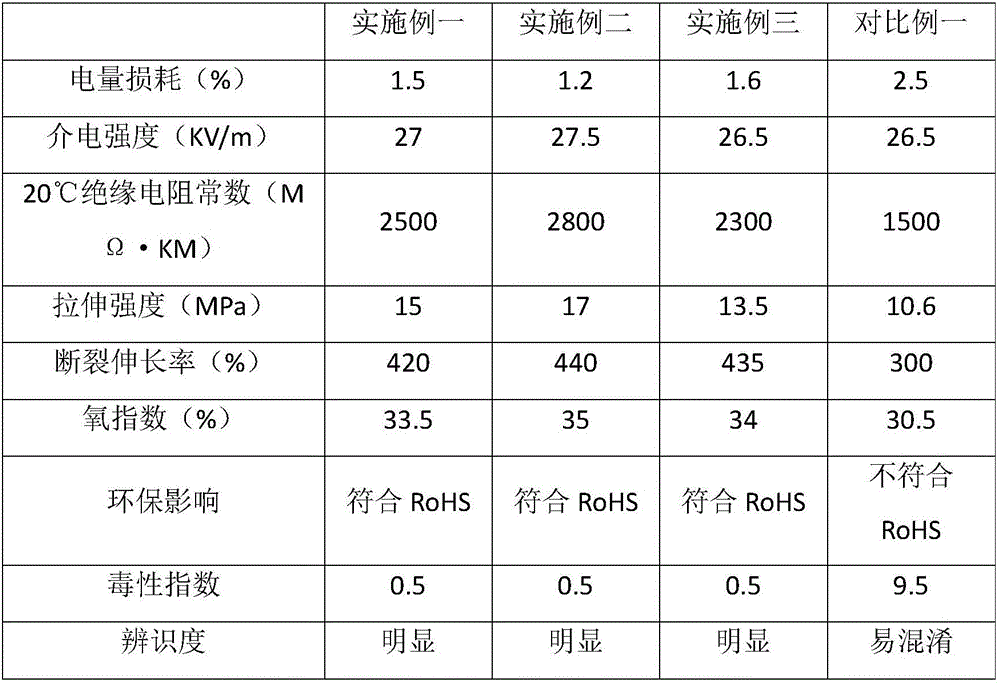

Low-temperature resistant, oil-resistant, flame-retardant and environmentally friendly CPE rubber sheath material and preparation method thereof

InactiveCN102276934ACreate pollutionRest assuredInsulated cablesInsulated conductorsSocial benefitsPolymer science

A low-temperature-resistant, oil-resistant, flame-retardant and environmentally friendly CPE rubber sheath material, comprising the following raw materials in parts by weight: 40-50 parts by weight of CPE resin, 3-6 parts of plasticizer, 14-20 parts of reinforcing agent, 10-20 parts of filler calcium carbonate, Talc powder 15~20, environmental stabilizer 2~4, hydrogen chloride absorbent 2~3, lubricant 2~5, flame retardant 4~8, vulcanizing agent 1.5~2, co-vulcanizing agent 1.5~2. The environmental protection CPE rubber sheath material of low temperature resistance and oil resistance group prepared according to the present invention can replace the rubber sheath material containing heavy metals, polybrominated biphenyls and ethers, etc. , significant social benefits, will not cause pollution to the environment; can be used for power cables and mine cables, marine cables, electrical equipment lines, etc., so that the low temperature resistance, oil resistance and flame retardancy of cables and wires are greatly improved compared with the rubber commonly used today.

Owner:ZHONGYUAN ENGINEERING COLLEGE

High electric-property high temperature resistant wearable environment protection plastic insulating material

ActiveCN101230171ACreate pollutionRest assuredPlastic/resin/waxes insulatorsWear resistantElectric cables

The invention relates to a high electrical property, high temperature resistant, wear resistant and environmental protection plastic insulating material not including substances such as heavy metal plumbum (Pb), cadmium (Cd), hydrargyrum (Hg), hexavalent chrome (Cr), polybrominated diphenyl and ether class, etc. which disobey the environmental protection requirement, and a preparation method thereof. The material is prepared by the following raw materials according to the parts by weight: 40-50 parts of PVC resin, 20-25 parts of trimellitate high temperature resistant plasticizer, 2-8 parts of bis ethylhexyl phthalate plasticizer, 3-8 parts of environmental protection stabilizer, 0.5-0.8 parts of lubricant, 5-10 parts of electrical modifier, 10-25 parts of bulking agent, and 0.6-2 parts of coloring agent; the environmental protection plastic insulating material not only can meet the environmental protection performance requirement, but also can meet the requirements of the wire and the cable to the electrical property, the high temperature performance and the wear resistant property of the plastic insulating material.

Owner:河南通达久通电缆有限公司

Environment-friendly crystalline silicon solar-cell back surface field silver-aluminium paste and preparation method thereof

InactiveCN102024856AConducive to import and exportFinal product manufactureSemiconductor devicesAdhesiveHazardous substance

The invention discloses an environment-friendly crystalline silicon solar-cell back surface field silver-aluminium paste and a preparation method thereof. The silver-aluminium paste comprises the following components in percentage by weight: 15-35% of silver powder, 30-70% of aluminium powder, 10-15% of organic carrier, 1-5% of adhesive, 3.5-13% of solvent and 0.5-2% of dispersant. The organic carrier is prepared by dissolving 10-30% of ethyl cellulose resin in 70-90% of organic solvent. In the paste, environment-friendly glass powder without harmful substances is used as the adhesive, and an environment-friendly organic reagent is used as a solvent and a diluter; and thus, the prepared silver-aluminium paste does not contain six substances (Pb, Cd, Hg, Cr(VI), polybrominated diphenyl PBB and polybrominated diphenyl ether PBDE) inhibited by European Union RoHS Instruction, completely conforms to the Instruction 2005 / 84 / EC on phthalic ester in European Union RoHS, realizes environment friendliness in deed, and is beneficial to the import and export of solar cells made in China and raw materials of the cells.

Owner:IRICO

Coating composition and steel composite material

InactiveCN101892012AImprove appearance qualityExtended service lifeRosin coatingsAnti-corrosive paintsPolybrominated BiphenylsWater soluble

The invention provides a coating composition, which comprises maleic anhydride modified abietic resin, a water-soluble alkaline substance, a film-forming substance and a solvent. The solid content of the composition is 30 to 45 weight percent, and the pH value is 7 to 11. The invention also provides a steel composite material, which comprises a base material and an anticorrosive coating which is attached to the surface of the base material. The anticorrosive coating is a product which is cured by the provided coating composition. The coating composition can provide short-term anticorrosion for steel, in particular steel rails. Therefore, the coating composition can improve the appearance quality and service life of the steel. The coating composition does not contain Pb, Cd, Hg, Cr6+, polybrominated diphenyl ethers (PBDE) and polybrominated biphenyls (PBB) regulated in a RoHS instruction, and is environment-friendly.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

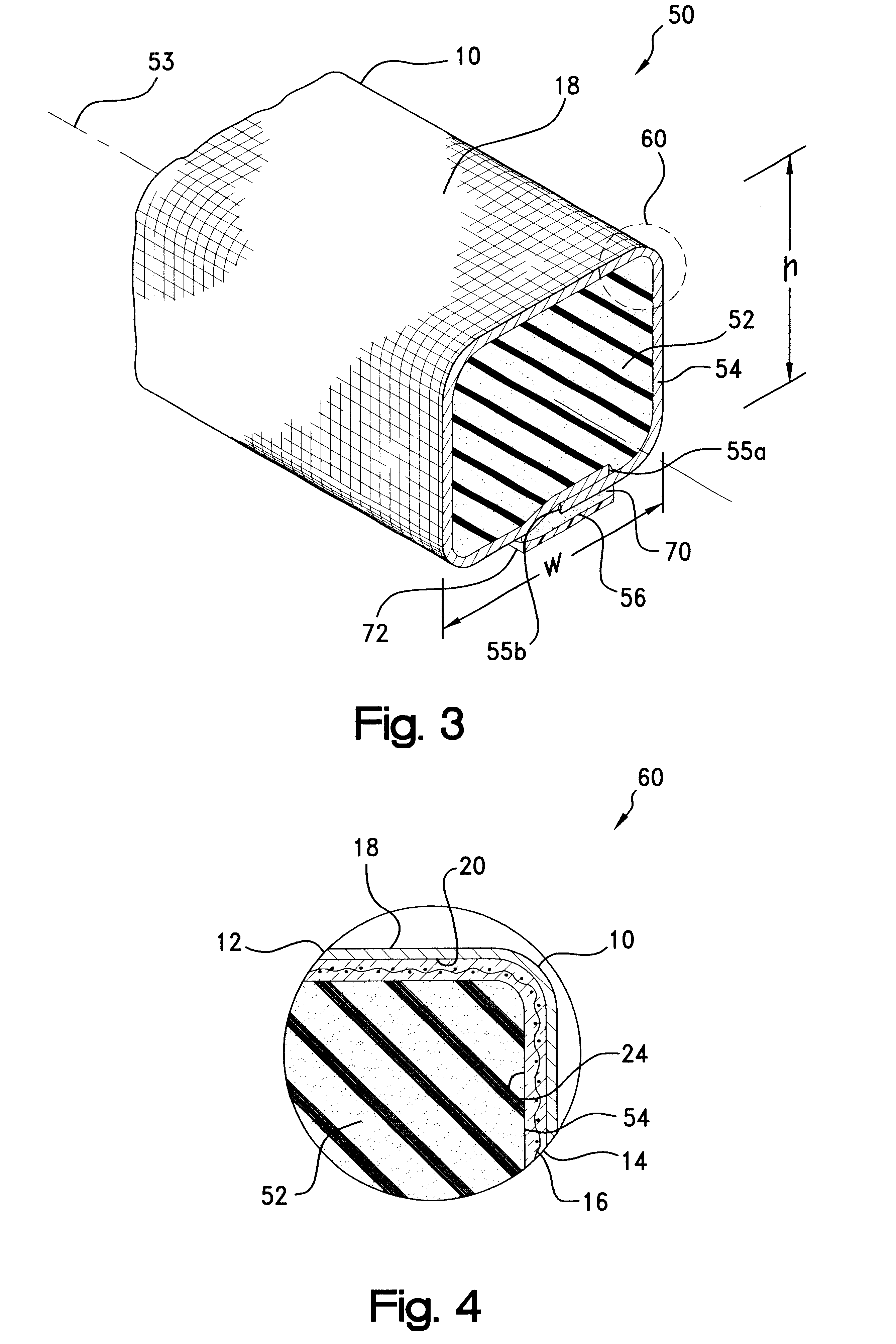

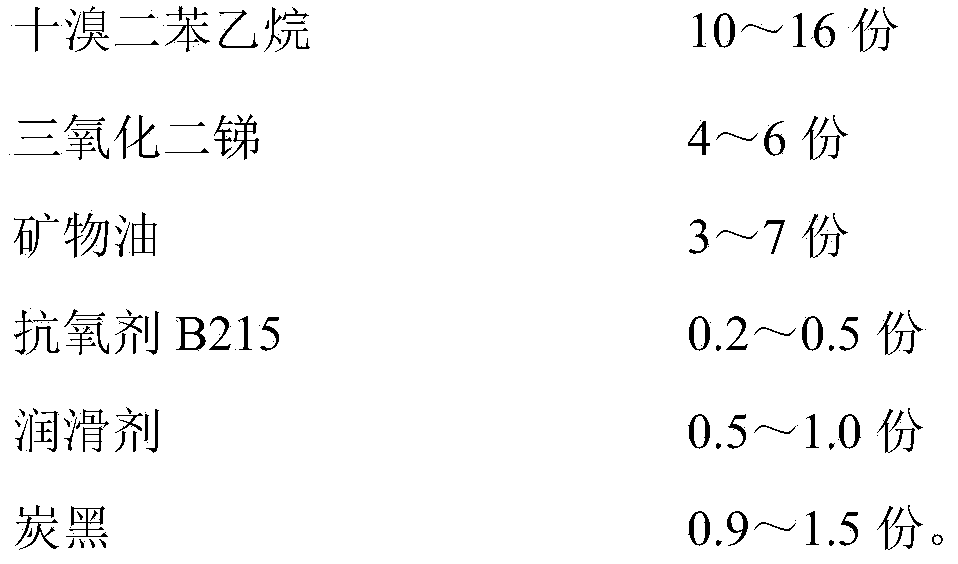

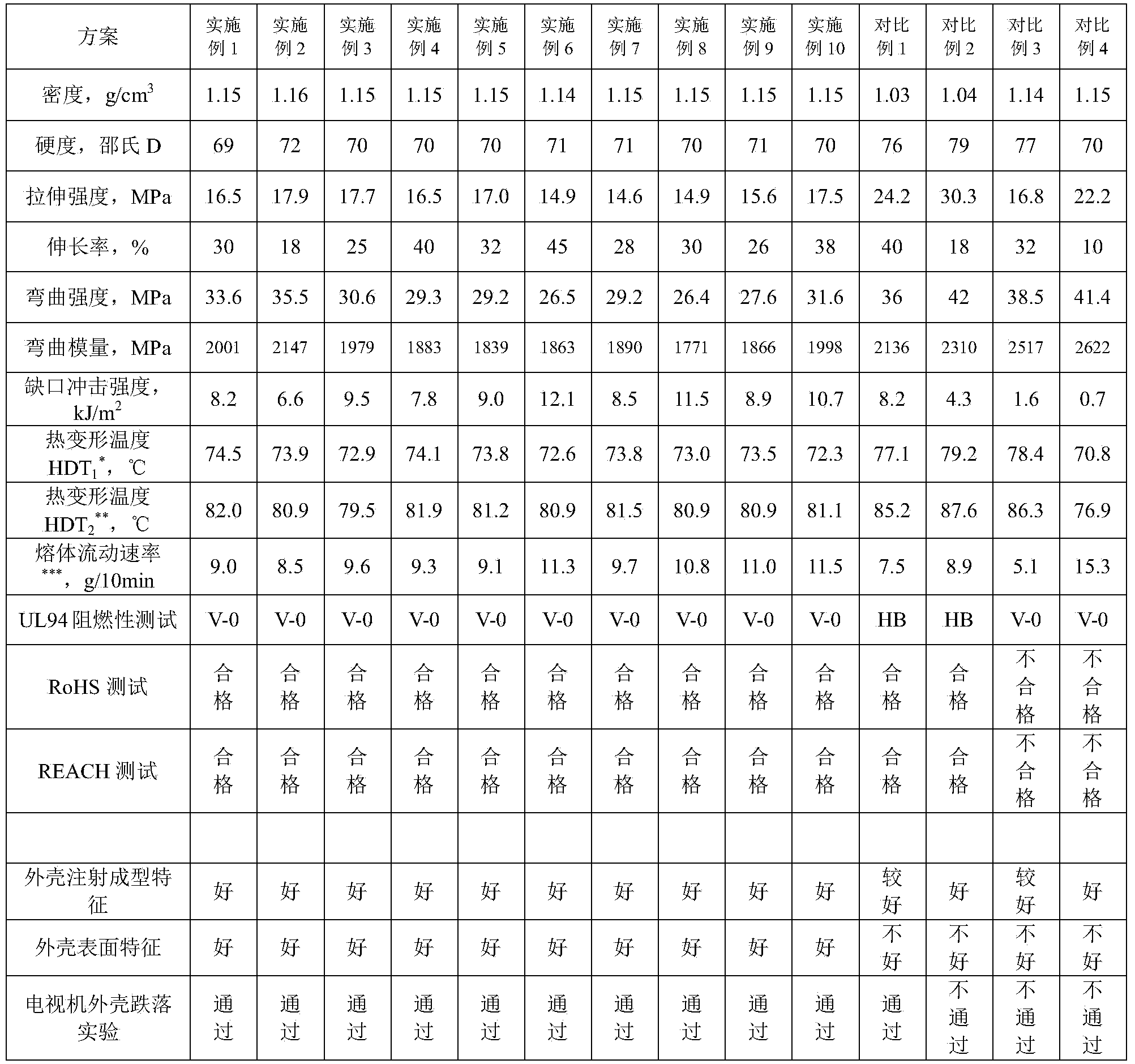

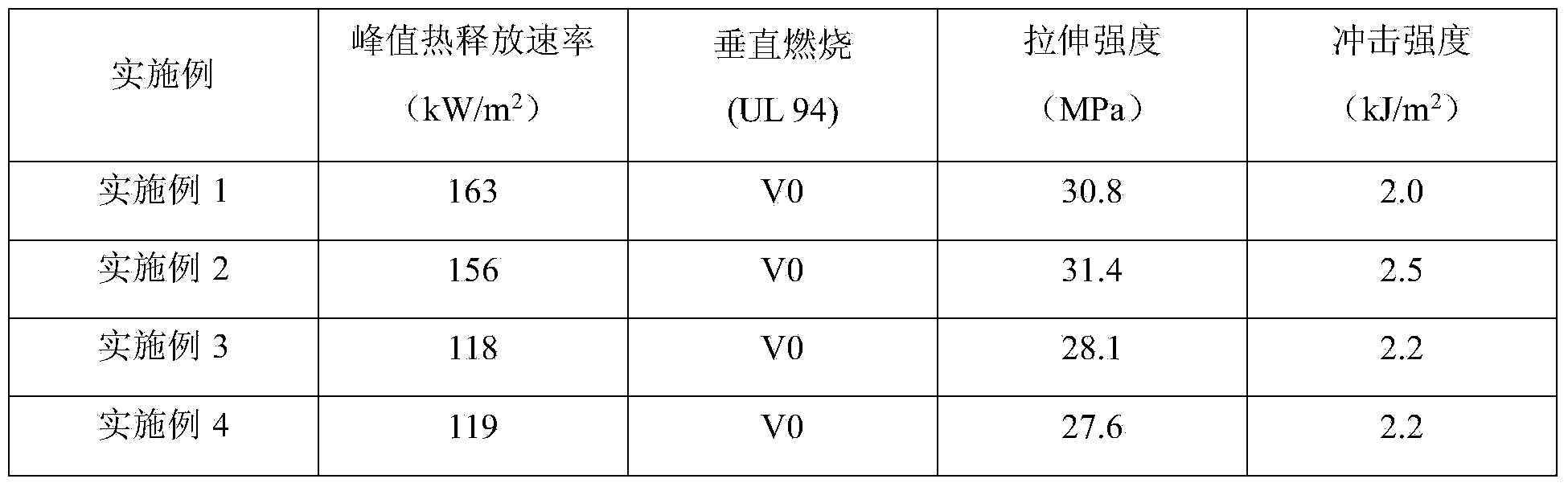

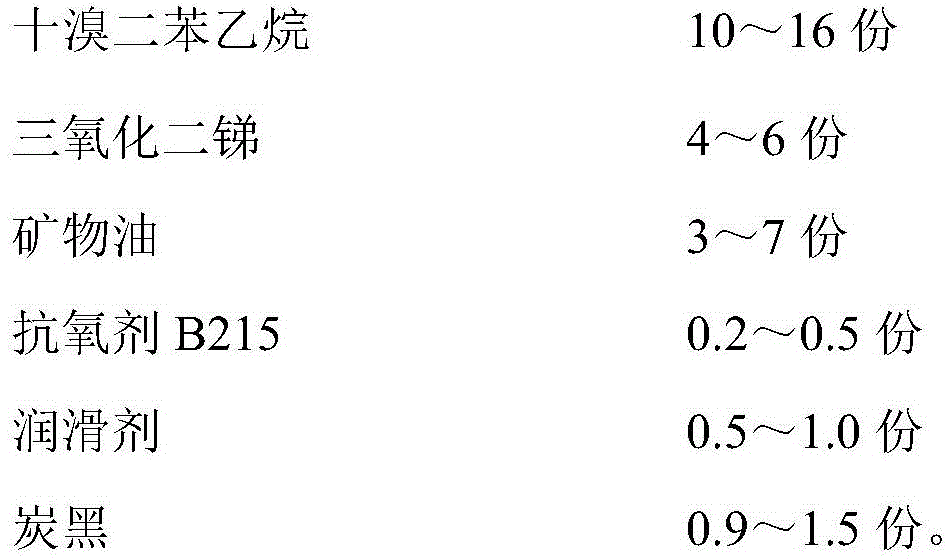

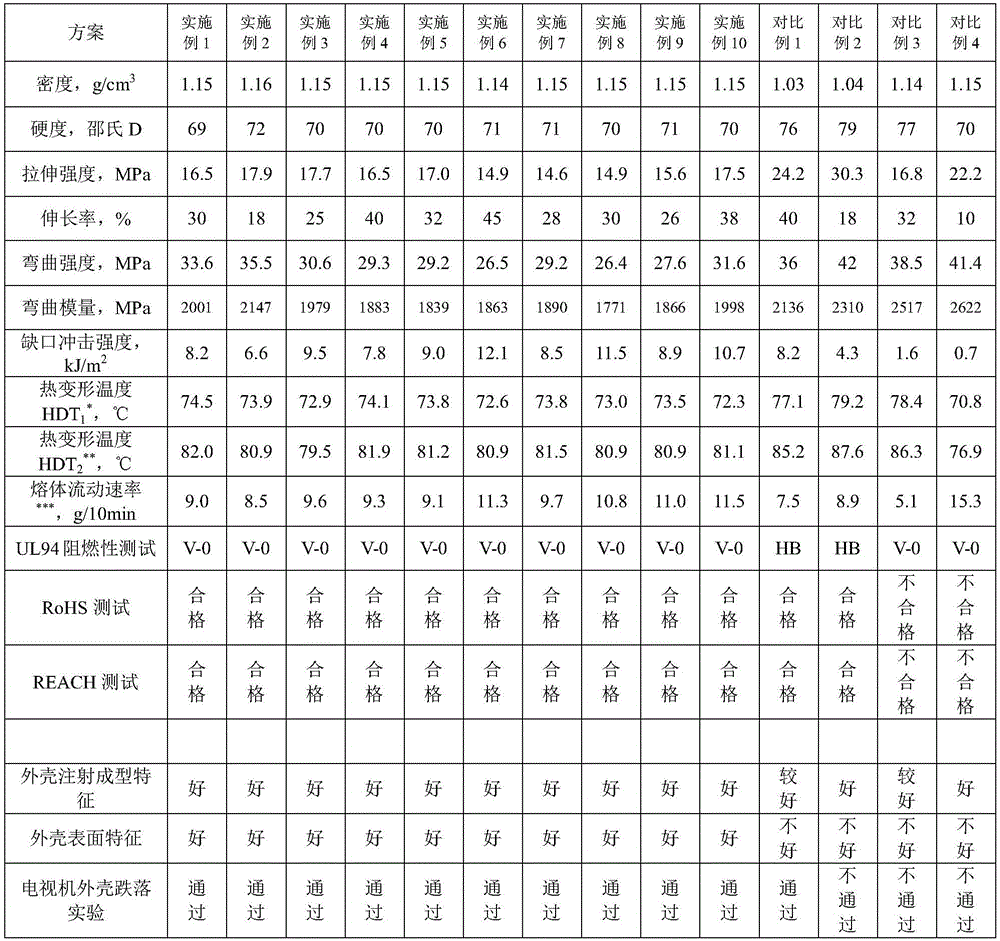

Environment-friendly flame-retardant modified HIPS (high impact polystyrene) LCDTV (liquid crystal display television) casing and preparation method thereof

ActiveCN103819865AImprove performanceBending strength balanceHazardous substanceButadiene-styrene rubber

The invention discloses an environment-friendly flame-retardant modified HIPS (high impact polystyrene) LCDTV (liquid crystal display television) casing and a preparation method thereof. The flame-retardant modified HIPS LCDTV casing contains no toxic and harmful substances such as polybrominated biphenyls, poly brominated diphenyl ethers and the like, the restriction of the use of certain hazardous substances in electrical and electronic equipment and REACH (registration, evaluation, authorization and restriction of chemicals) regulation requirements are met, and the flammability meets the UL-94V-0 grade. The environment-friendly flame-retardant modified HIPS LCDTV casing comprises raw materials by mass as follows: 45-70 parts of HIPS resin, 5-30 parts of GPPS (general purpose polystyrene) resin, 5-10 parts of thermoplastic styrene butadiene rubber SBS, 10-16 parts of decabromodiphenyl ethane, 4-6 parts of antimonous trioxide, 3-7 parts of mineral oil, 0.2-0.5 part of an antioxidant B215, 0.5-1.0 part of a lubricant and 0.9-1.5 parts of carbon black.

Owner:NANJING UNIV OF TECH +1

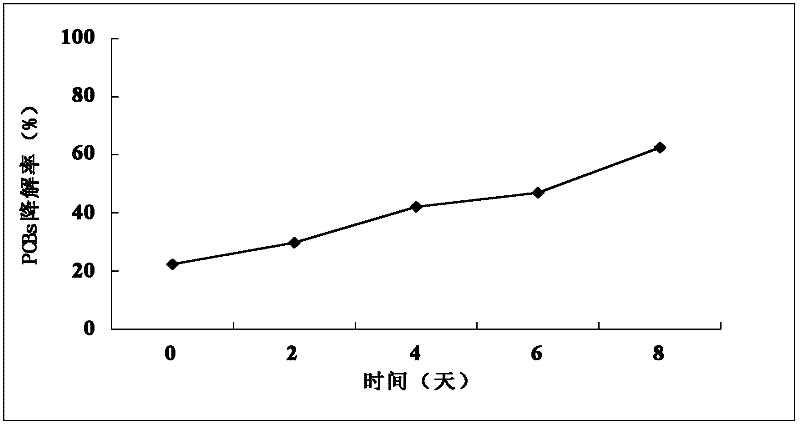

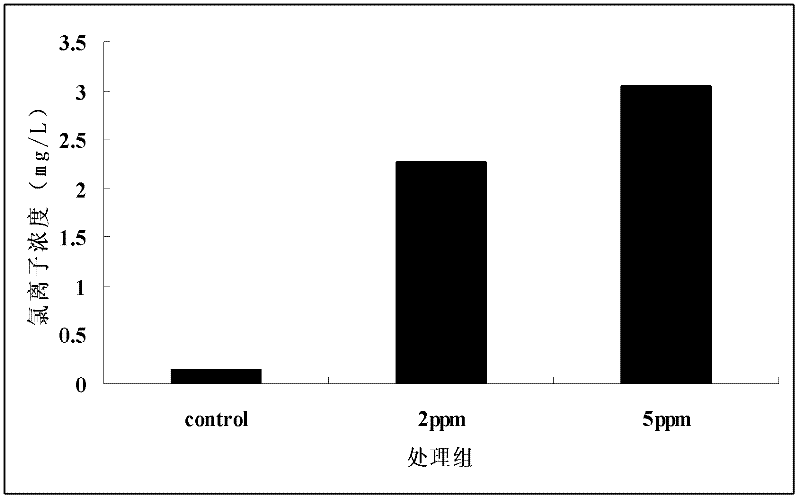

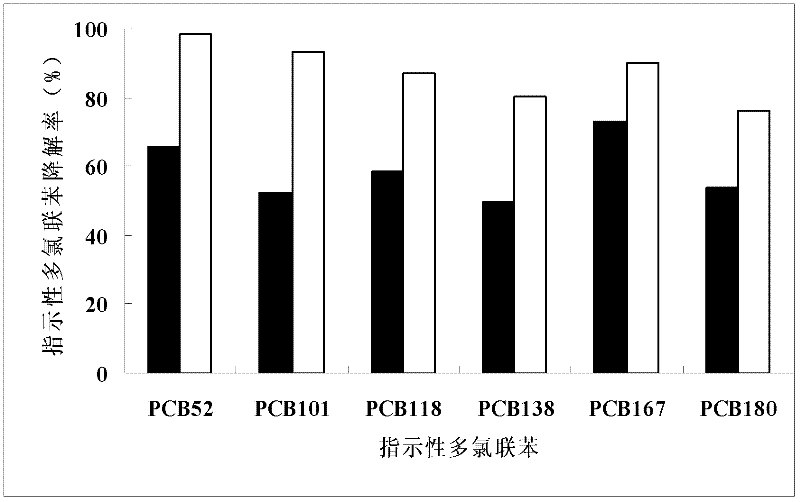

Nostoc capable of degrading polychlorinated biphenyls and application thereof

The invention provides nostoc capable of degrading polychlorinated biphenyls. A frond of the nostoc is multicellular protonema, has algal filaments and a colloid sheath, and can fix inorganic nitrogen. The nostoc can degrade polychlorinated biphenyl (PCB) 1254 efficiently; after the nostoc is exposed for a week, the degradation efficiency of the nostoc on the PCB1254 is over 60 percent, and the content of residual chlorine ions tested in a culture medium after the degradation and dechloridation of the PCB1254 is 2.26mg / L and 3.01mg / L; the one-month degradation efficiency of the nostoc on six typical indicative polychlorinated biphenyl (PCB52, PCB101, PCB118, PCB138, PCB137 and PCB180) in environment is more than 70 percent, wherein the degradation rate of the PCB52 is 98.7 percent; and after the PCB1254 is degraded for one month, the residual amount of the PCB1254 in the culture medium is only 15.65 percent. Therefore, the nostoc can be widely applied to the degradation of the PCBs insoil environment.

Owner:HANGZHOU NORMAL UNIVERSITY

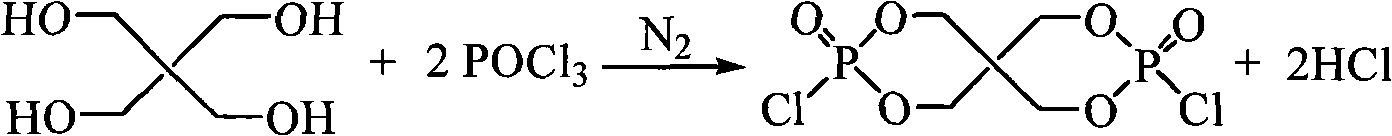

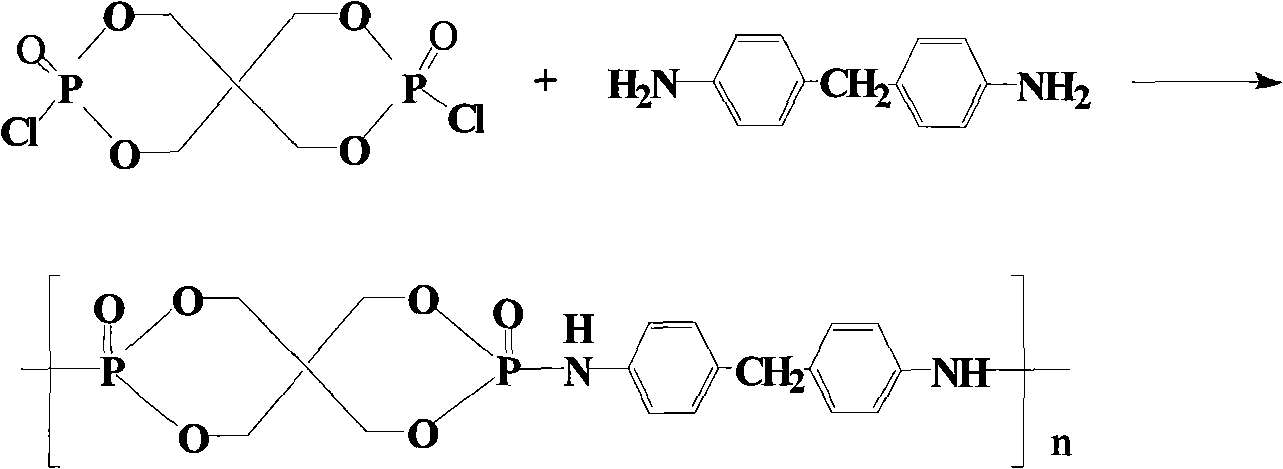

Environment-friendly flame-resistant ABS resin

The invention discloses an environment-friendly flame-resistant ABS resin, which comprises the following components by weight percentage: 72 percent to 84 percent of ABS resin granules, 15 percent to 22 percent of PDSPB expanding type flame retardant, 0.7 percent to 4.5 percent of montmorillonite, 0.1 percent to 0.5 percent of anti-oxidant agent, 0.1 percent to 0.5 percent of anti-dripping agent and 0.1 percent to 0.5 percent of lubricant. The flame-resistant ABS resin does not contain harmful substances of lead, mercury, cadmium, hexavalent chrome, polybrominated biphenyls, polybrominated diphenyl ethers and the like, and meets the requirements of RoHS instruction about innocuity and environmental protection. The montmorillonite / PDSPB synergistic flame-resistant ABS resin not only can guarantee the flame-resistant performance, but also can keep good mechanical performance, can completely or partially replace the flame-resistant ABS resin of the traditional halogenated flame retardant and has wide market prospect.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

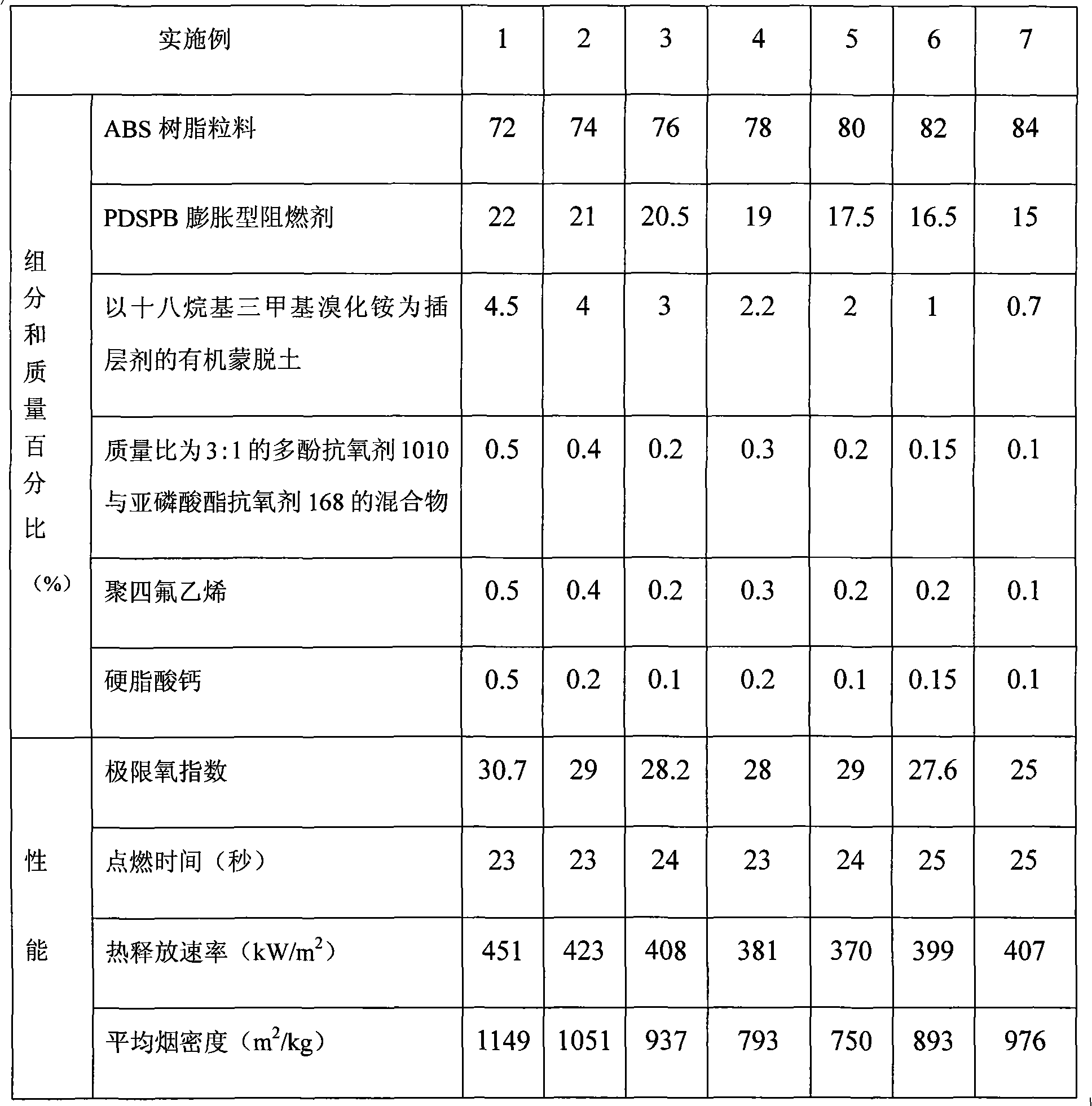

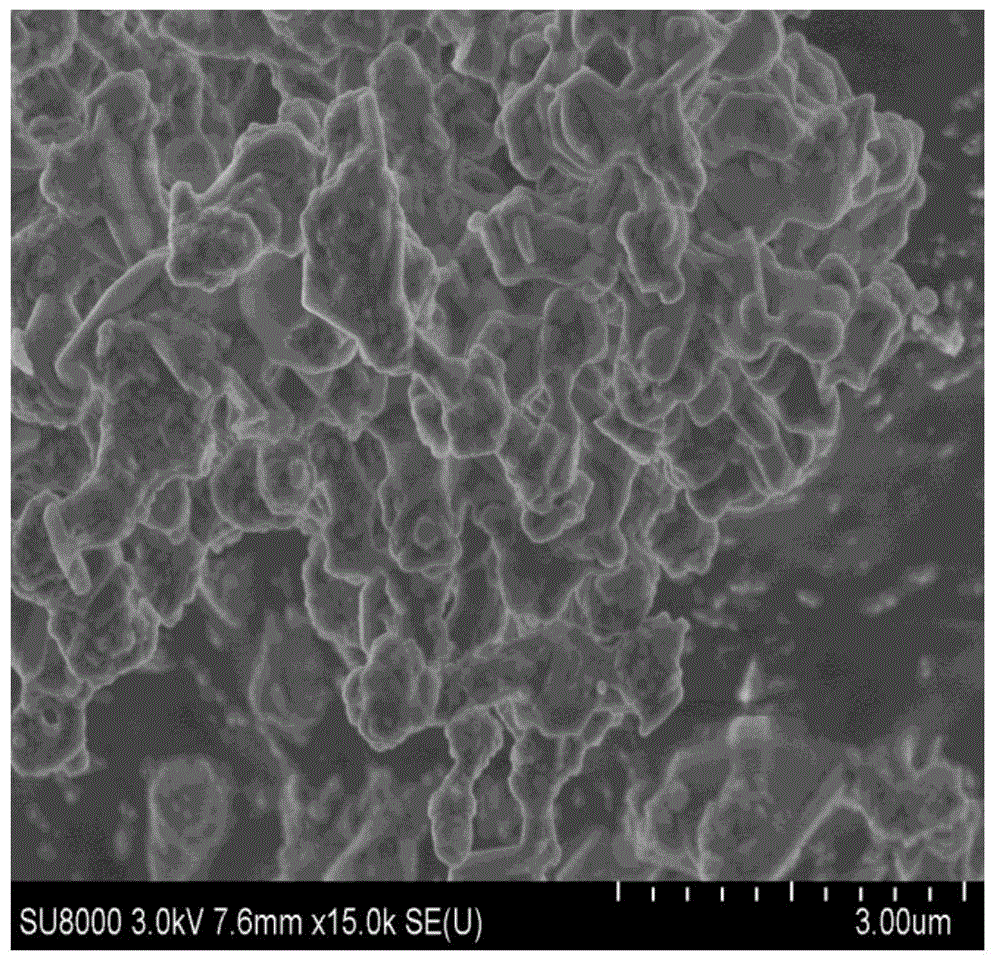

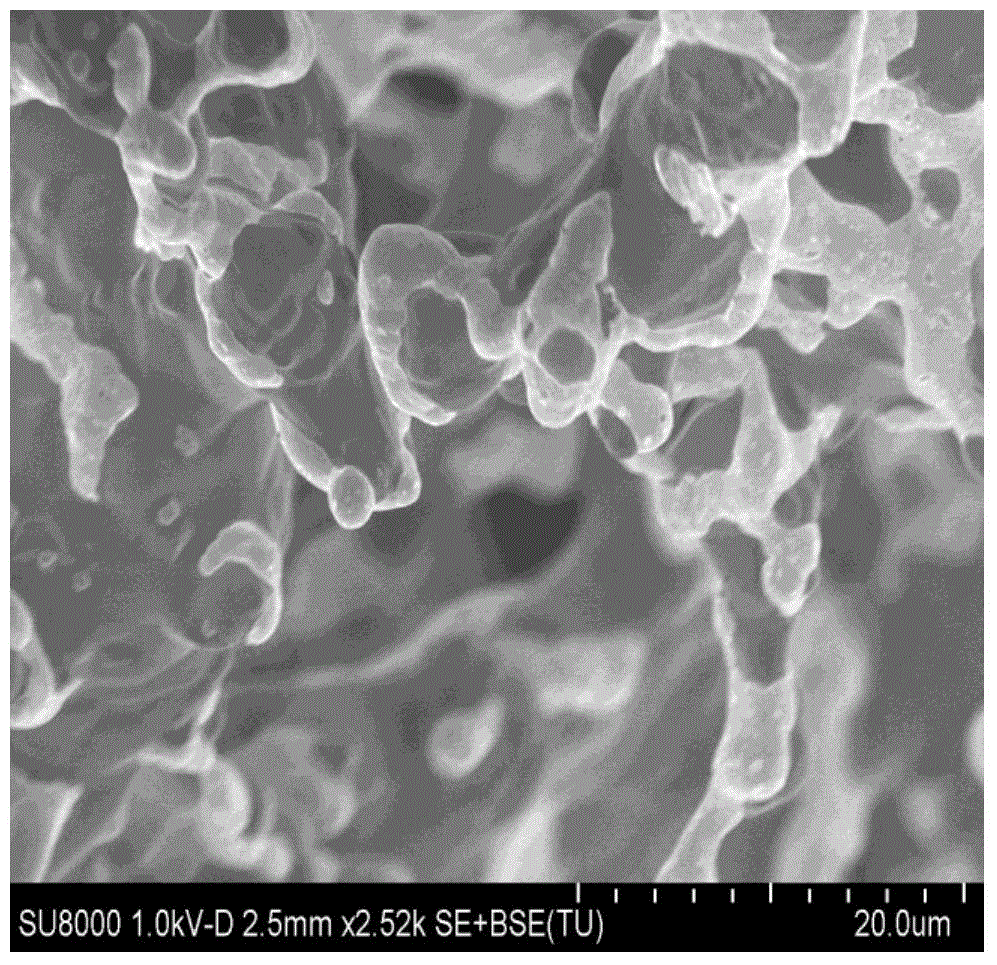

Screening and application of polybrominated diphenyl ethers (PBDEs) degrading bacterium

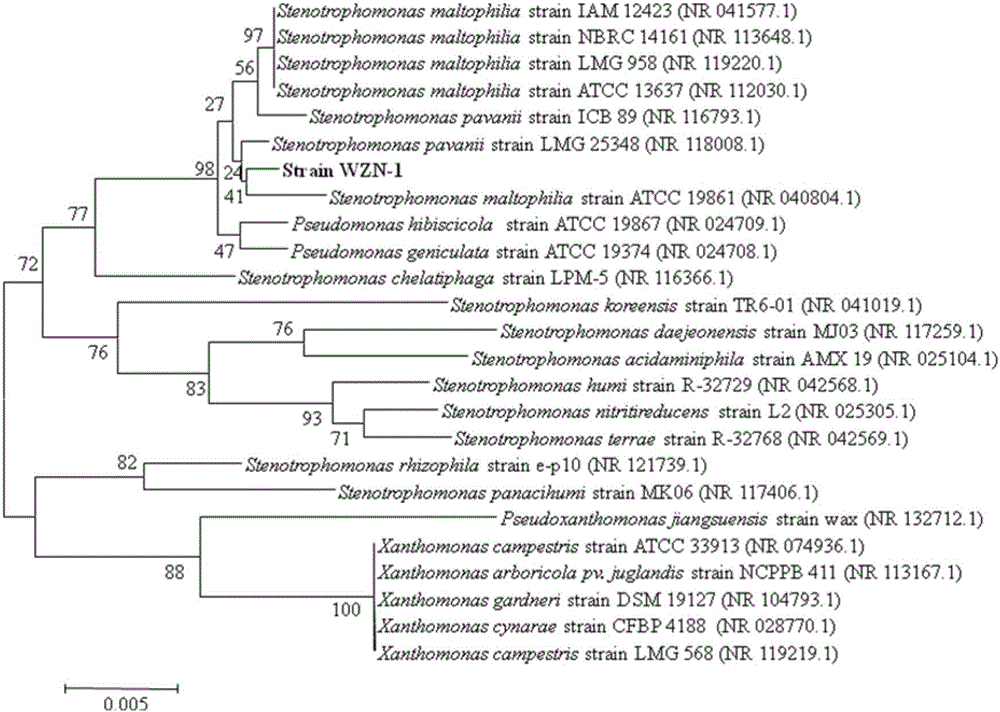

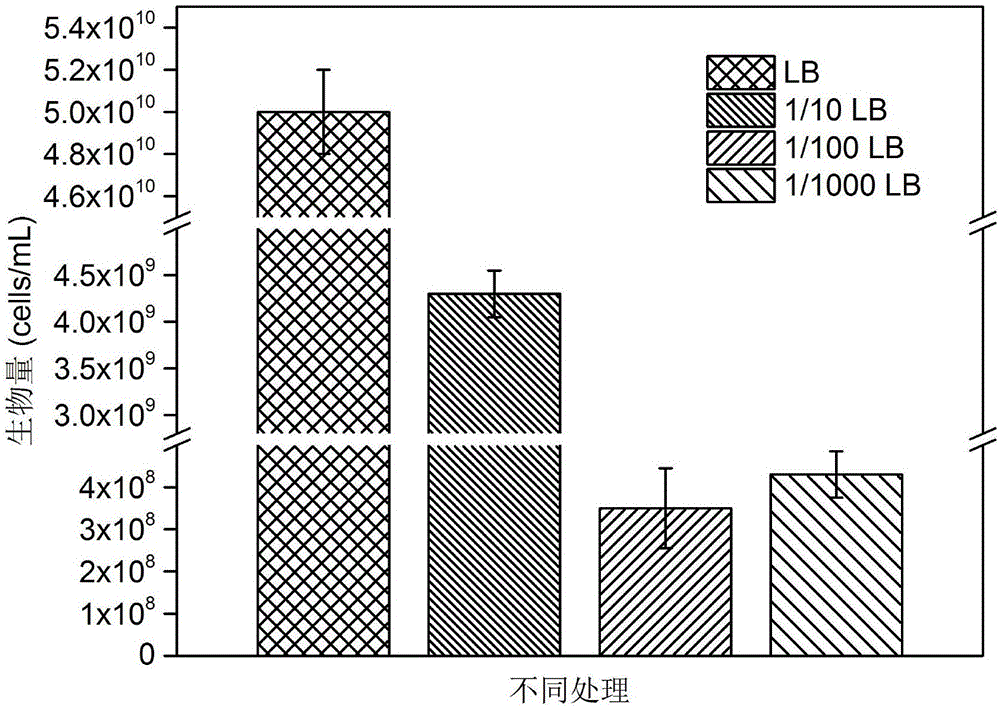

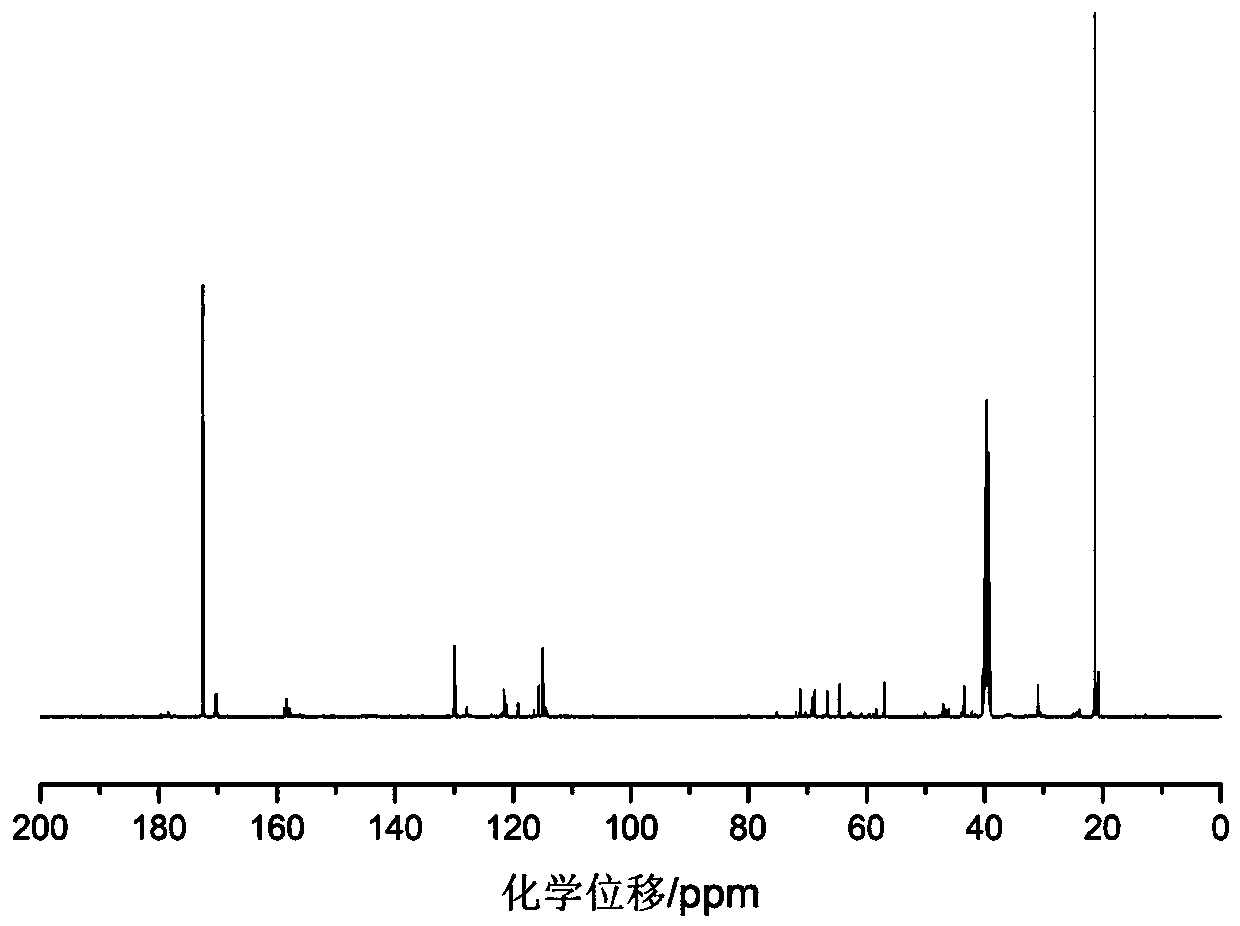

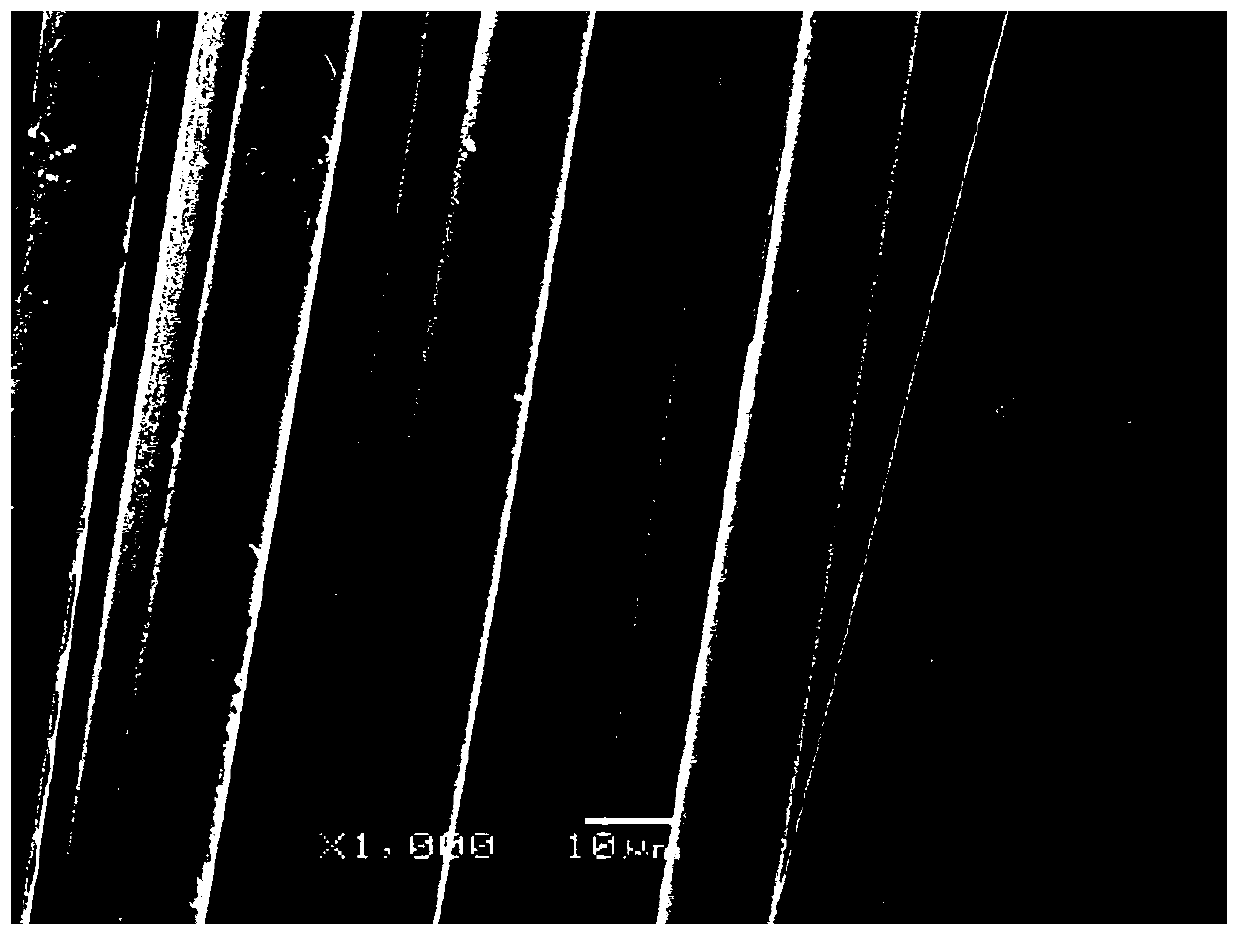

ActiveCN106282070APromote degradationNo secondary pollutionBacteriaWater contaminantsStenotrophomonas pavaniiDecabromobiphenyl ether

The invention discloses screening and application of a polybrominated diphenyl ethers (PBDEs) degrading bacterium, and belongs to the technical field of biological treatment of environmental pollutants. The PBDEs degrading bacterium comes from soil contaminated by PBDEs and is obtained through artificial enrichment, separation and purification. The strain is a stenotrophomonas pavanii strain WZN-1 and is preserved in the China General Microbiological Culture Collection Center, the preservation date is August 30, 2016, and the preservation serial number is CGMCC No.12918. The WZN-1 strain is a Gram-negative bacterium, is faint yellow and presents a milk white and non-transparent circular bacterial colony with the surface raised; in a scanning electron microscope, the bacterium is in a rod shape, and the diameter is (0.5-0.7) micrometer*(1-2) micrometer. In a liquid culture medium, the strain has the good degrading capability on both decabromodiphenyl ether (BDE 209) and tetrabromodiphenyl ether (BDE 47).

Owner:NANKAI UNIV

Two-step all-component recycling method of waste circuit boards

InactiveCN110757682AGood swelling propertiesCatalytic degradationSolid waste disposalTransportation and packagingEpoxyPtru catalyst

The invention belongs to the field of recycling and resource recovery of electronic solid wastes and particularly relates to a two-step all-component recycling method of waste circuit boards. The method includes the steps that (1) the waste circuit boards are cut, a non-proton organic swelling agent is added so that epoxy resin-glass fiber composite materials in substrates of the circuit boards can be subjected to swelling, the epoxy resin-glass fiber composite materials are swelled and become fluffy, and meanwhile the interface portions between the epoxy resin-glass fiber composite materialsand copper foils on copper-clad plates are separated; and (2) the swelled circuit board substrates are immersed in a proper catalyst-solvent system, then the epoxy resin-glass fiber composite materials are degraded, the epoxy resins are degraded into soluble low polymers, the epoxy resin low polymers are dissolved through the non-proton organic solvent, and glass fibers, polybrominated biphenyls,the copper foils and other metal components in the waste circuit boards can be recycled. By means of the two-step all-component recycling method of the waste circuit boards, all-component recycling ofthe waste circuit boards is achieved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

High-flame-retardancy chlorinated polyethylene cable material

InactiveCN105585785AImprove insulation performanceImproves Structural IntegrityPlastic/resin/waxes insulatorsMicrocrystalline waxModified carbon

The invention discloses a high-flame-retardancy chlorinated polyethylene cable material which is prepared from the following raw materials in parts by weight: 100 parts of chlorinated polyethylene, 20-35 parts of ethylene propylene diene monomer rubber, 2-8 parts of magnesium oxide, 1-3 parts of stearic acid, 1-2.5 parts of dicumyl peroxide, 2-5 parts of 1,3,5-trimercapto-2,4,6-sym-triazine, 5-10 parts of white carbon black, 2-5 parts of magnesium hydroxide, 10-18 parts of aluminum hydroxide, 5-20 parts of modified carbon nanotube, 10-18 parts of talcum powder, 1-3 parts of anti-aging agent, 2-4 parts of accelerator, 3-10 parts of polybrominated diphenyl ether, 3-15 parts of trioctyl trimellitate, 1-5 parts of microcrystalline wax and 2-5 parts of rosin-polythylene oxide ester. The high-flame-retardancy chlorinated polyethylene cable material disclosed by the invention has the advantages of favorable flame retardancy, excellent processability, excellent mechanical properties and long service life, and can adapt to the operating requirements for multiple environments.

Owner:合肥市再德高分子材料有限公司

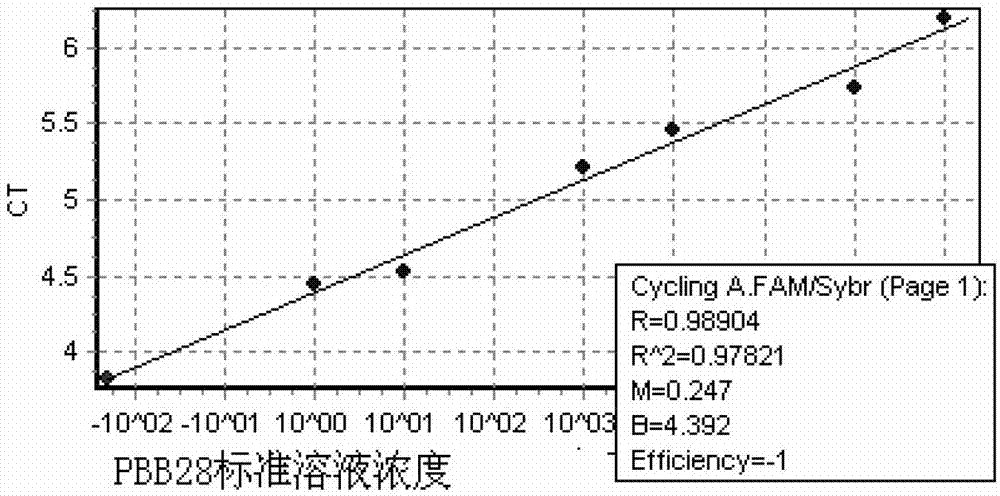

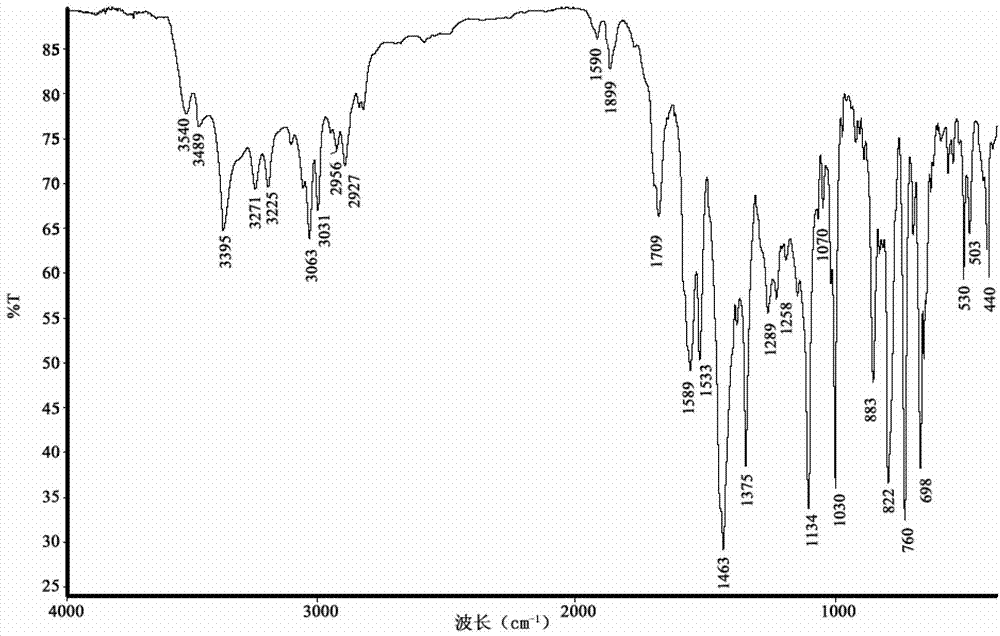

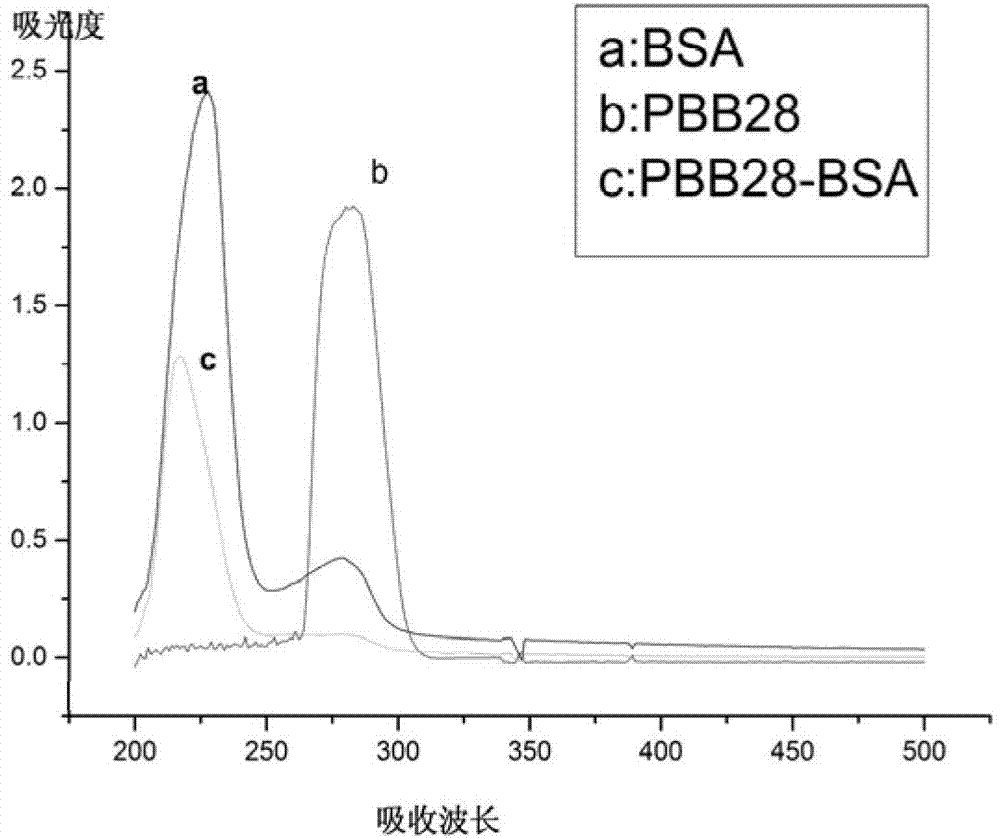

Polybrominated biphenyls homologue immunogen and preparation method

The invention relates to a polybrominated biphenyls homologue immunogen and a preparation method, which comprises the following steps: dissolving succinic anhydride and 4,4'-dibromobiphenyl in dichloromethane, stirring in ice bath, feeding anhydrous aluminum trichloride under the condition of ice water-bath, stirring in a seal mode and adding dilute hydrochloric acid for completing a reaction, processing to obtain PBB28 semiantigen 4-(4,4'-dibromobiphenyl)-4oxygen-butyric acid, then mixing N-hydroxy succinimide and N,N'-dicyclohexylcarbodiimide, adding bovine serum protein for stirring and reacting and then transferring to a semi-permeable membrane, dialyzing in a phosphatic buffer solution, centrifuging to obtain a supernatant to obtain a PBB28 artificial immunogen PBB-BSA conjugate. The method of the invention has the advantages of simple preparation method, low cost and easy industrial production; the polybrominated biphenyls artificial immunogen PBB28-BSA can prepare a specific antibody having an immunization reaction characteristic on a polybrominated biphenyls monomer through immunization animals, and the polybrominated biphenyls homologue immunogen can be used for on-site detection of the polybrominated biphenyls monomer with trace amount in water, soil and atmosphere.

Owner:SHANGHAI JIAO TONG UNIV

Environment-friendly ink paste for automobile glass and preparation method thereof

The invention relates to an environment-friendly ink paste for automobile glass and a preparation method thereof. The ink paste is characterized by comprising 8-45wt% of a carbon black powder with average particle size in the range of 0.2-8 mum, 3-15wt% of a carrier, 2-15wt% of a solvent, 0.5-2wt% of a dispersing agent and the balance of a binder. The ink paste for automotive glass provided by the invention uses an environment-friendly glass powder as the binder, and an environment-friendly organic reagent as the solvent and a diluent; the prepared paste does not contain the six substances prohibited by the EU RoHS directive (Pb, Cd, Hg, Cr (VI), polybrominated biphenyls PBB and poly brominated diphenyl ethers PBDE) and is in line with the EU RoHS directive 2005 / 84 / EC concerning phthalate, so as to achieve a true sense of environmental protection, and benefit import and export of domestic ink for automobile glass.

Owner:IRICO

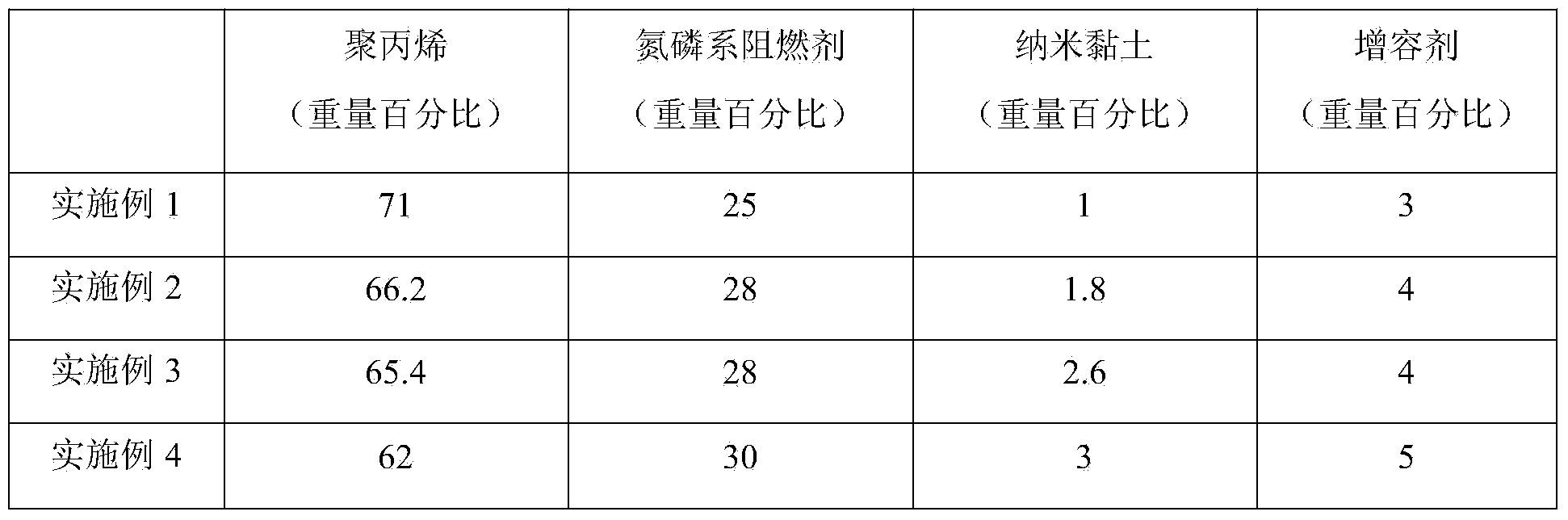

Nano-clay and nitrogen phosphorus flame retardant synergistic flame retardant polypropylene material and preparation method thereof

ActiveCN103642125AHarm reductionLow heat generation and smoke generationPolymer sciencePolybrominated Biphenyls

The invention discloses a nano-clay and nitrogen phosphorus flame retardant synergistic flame retardant polypropylene material and a preparation method thereof. The nano-clay and nitrogen phosphorus flame retardant synergistic flame retardant polypropylene material comprises the following components: by weight, 62%-71% of polypropylene, 25% - 30% of a nitrogen and phosphorus flame retardant, 1%-3% of nano-clay and 3%-5% of a compatibilizer. The nano-clay and nitrogen phosphorus flame retardant synergistic flame retardant polypropylene material does not contain lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls and poly brominated diphenyl ethers and other harmful substances, is low in heat producing quantity and producing smoke quantity in the process of burning, is less in damages to the environment and the human body, the nano-clay is dispersed evenly in the material, and while improvement of flame retardant properties, physical and mechanical properties and processability of the material can be maximumly maintained.

Owner:NINGBO LISI HOUSEWARE CO LTD

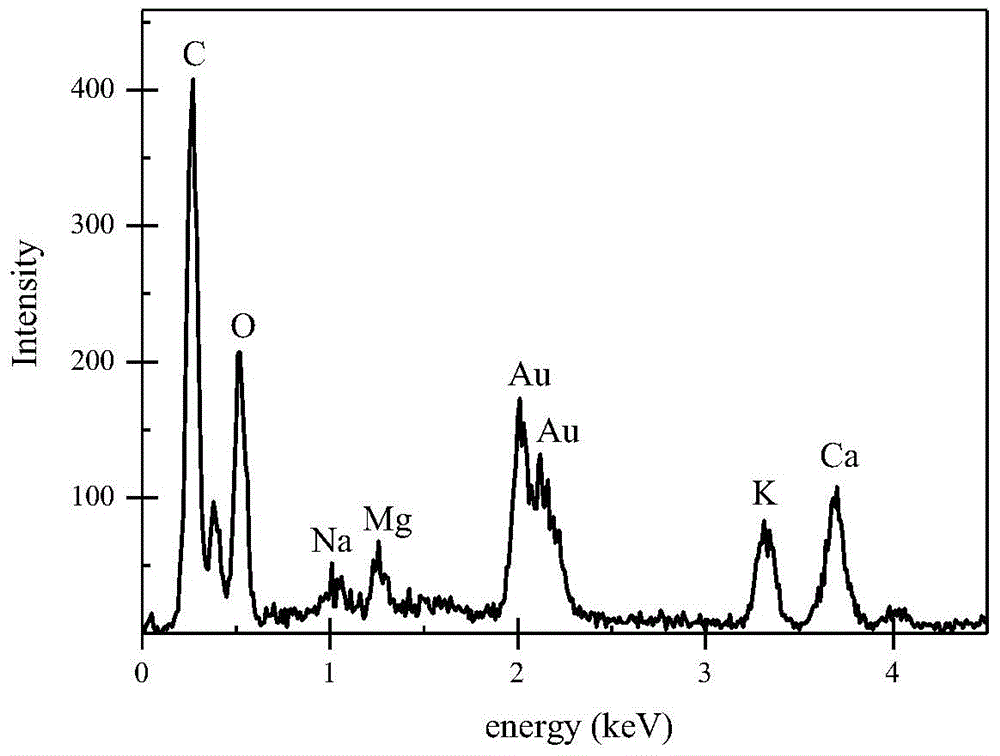

Quick analysis method for PBDEs (polybrominated diphenyl ethers)

InactiveCN105136774AQuick checkSimple and fast operationRaman scatteringPolybrominated BiphenylsEther

The invention provides a gold solid substrate synthesized with a high-temperature method and supported by a carbon skeleton, PBDEs (polybrominated diphenyl ethers) are adsorbed on the surface of the substrate, and Raman characteristic peaks of BDE-47 (2,2',4,4'-tetrabromodiphenyl ether) are observed through a portable Raman spectrometer. A series of experiments prove that a sample preparation method and a target pollutant analysis method are simple and convenient to operate, and PBDEs in an environment substrate can be quickly detected.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Regeneration method of waste plastic containing polybrominated biphenyls and poly brominated diphenyl ethers

ActiveCN105237799ARealize resource reuseAchieve regenerationPlastic recyclingDecabromobiphenyl etherResource utilization

The invention relates to a regeneration method of waste plastic containing polybrominated biphenyls and poly brominated diphenyl ethers, and discloses a method for separating and regenerating flame-retardant styrene plastic containing bromine. The method comprises the steps that the waste flame-retardant styrene plastic containing the bromine is added to solvent A, and the styrene plastic of the waste flame-retardant styrene plastic containing the bromine is dissolved; a dissolved plastic solution passes through a screen sieve, an obtained plastic solution is heated, decabromodiphenyl ether is dissolved, and antimonous oxide and the like are removed through heat filtration; the solution obtained through heat filtration is decreased to 0 DEG C; solvent B is added; aging is conducted on the solution at 0 DEG C; small-granule crystals are eliminated; separation is conducted through a centrifuge, and decabromodiphenyl ether granules are obtained; the solution is increased to range from 20 DEG C to 50 DEG C, the solvent B is added, the plastic is precipitated out, and separation of the plastic and toxic flame retardants is achieved; obtained sediments are sent to an extruder, residual solvent in the sediments is removed, and a regenerated plastic product is obtained. According to the regeneration method of the waste plastic containing the polybrominated biphenyls and the poly brominated diphenyl ethers, separation of the toxic brominated flame retardants and non-toxic brominated flame retardants is achieved, and meanwhile the purpose of resource utilization of the waste electronic plastic and brominated flame retardants is achieved.

Owner:韶关鑫山塑料有限公司

Environmental-friendly ratproof glue stock formula

InactiveCN101619153AExcellent extrusion performanceImprove low temperature resistancePolybrominated BiphenylsDioctyl terephthalate

The invention relates to a glue stock formula, in particular to an environmental-friendly ratproof glue stock formula with ratproof functionality. The environmental-friendly ratproof glue stock formula contains PVC resin which is XS-2 type or XS-3 type resin and also contains the following components: 100.0 phr of the PVC resin, 8.0 phr of Ca / Zn compound stabilizing agents, 40.0 phr of di-iso-decylphthalate, 10.0 phr of dioctyl terephthalate and 35.0 phr of heavy CaCO. The whole formula system does not contain heavy metal, i.e. Pb, Cd, Hg, Cr6+, and the like, polybrominated biphenyls and ethers thereof which are harmful to human and environment, the property of jacket materials completely meets the standard property requirement of environmental-friendly PVC jacket materials with temperature of 90 DEG C, the extrusion technology property is good, the low temperature resistant property is greatly improved, the flame retardant property more accords with the environmental-friendly standard and meets the requirement for the PVC jacket materials with temperature of 90 DEG C in the standard national standard GB8815-2002, an oxygen index is more than 30, and the property accords with related regulations.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

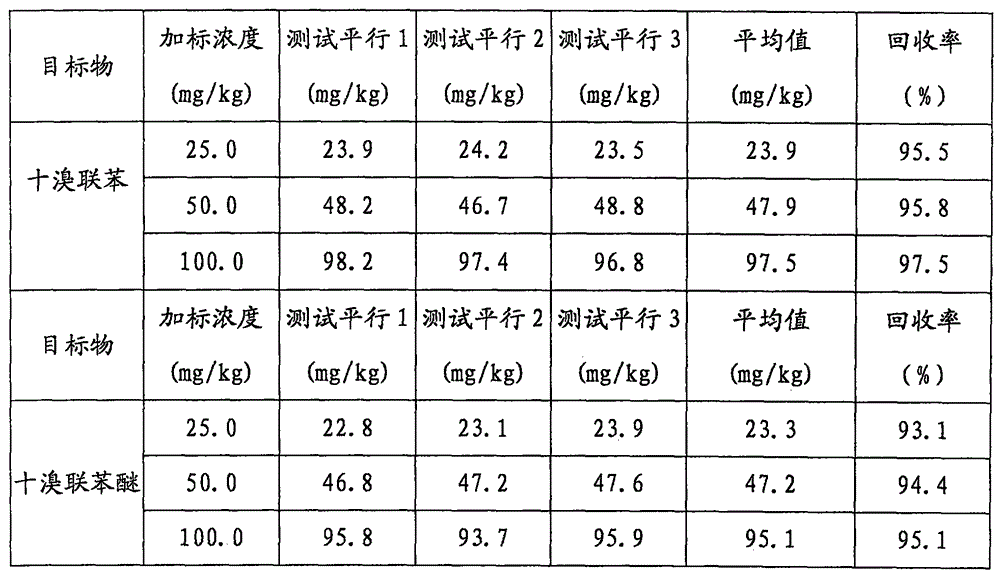

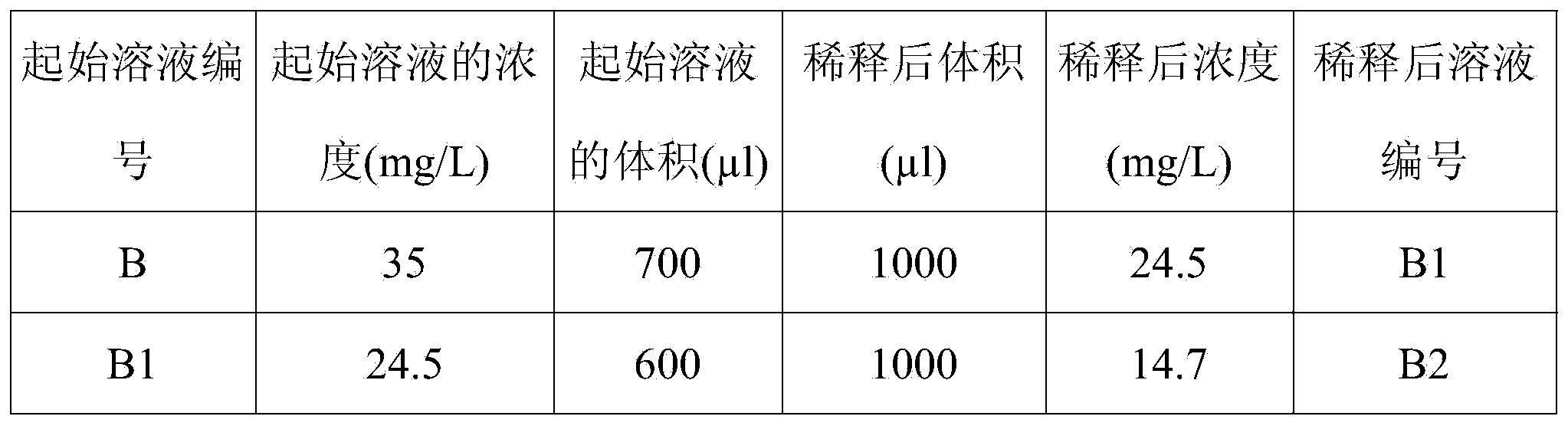

Pretreatment method of polybrominated biphenyls and poly brominated diphenyl ethers in nylon resin and nylon resin products

InactiveCN105116077AAvoiding Disadvantages of DecompositionHigh recovery rateComponent separationPretreatment methodPolybrominated Biphenyls

The invention belongs to the field of analytic chemistry, and relates to a pretreatment method of polybrominated biphenyls and poly brominated diphenyl ethers in nylon resin and nylon resin products. In hazardous substance determination of nylon resin, especially brominated flame retardant determination, flame retardant recovery rate obtained via a standard pretreatment method is extremely low because of the properties of nylon resin; Soxhlet extraction recovery rate in eight hours is lower than 70%; and recovery rate of conventional ultrasonic extraction is even lower. The pretreatment method is capable of reducing sample pretreatment time to about 30min, and recovery rate is 93% or higher. The pretreatment method is simple and convenient; both labour and time are saved; and environmental protection is realized.

Owner:URUMCHI PONY TESTING TECH CO LTD

Environment-friendly flame-retardant modified hips LCD TV shell and preparation method thereof

The invention discloses an environment-friendly flame-retardant modified HIPS (high impact polystyrene) LCDTV (liquid crystal display television) casing and a preparation method thereof. The flame-retardant modified HIPS LCDTV casing contains no toxic and harmful substances such as polybrominated biphenyls, poly brominated diphenyl ethers and the like, the restriction of the use of certain hazardous substances in electrical and electronic equipment and REACH (registration, evaluation, authorization and restriction of chemicals) regulation requirements are met, and the flammability meets the UL-94V-0 grade. The environment-friendly flame-retardant modified HIPS LCDTV casing comprises raw materials by mass as follows: 45-70 parts of HIPS resin, 5-30 parts of GPPS (general purpose polystyrene) resin, 5-10 parts of thermoplastic styrene butadiene rubber SBS, 10-16 parts of decabromodiphenyl ethane, 4-6 parts of antimonous trioxide, 3-7 parts of mineral oil, 0.2-0.5 part of an antioxidant B215, 0.5-1.0 part of a lubricant and 0.9-1.5 parts of carbon black.

Owner:NANJING TECH UNIV +1

Environment-friendly plastic for athletic tracks and preparation method thereof

Owner:黑龙江全模块体育科技有限公司

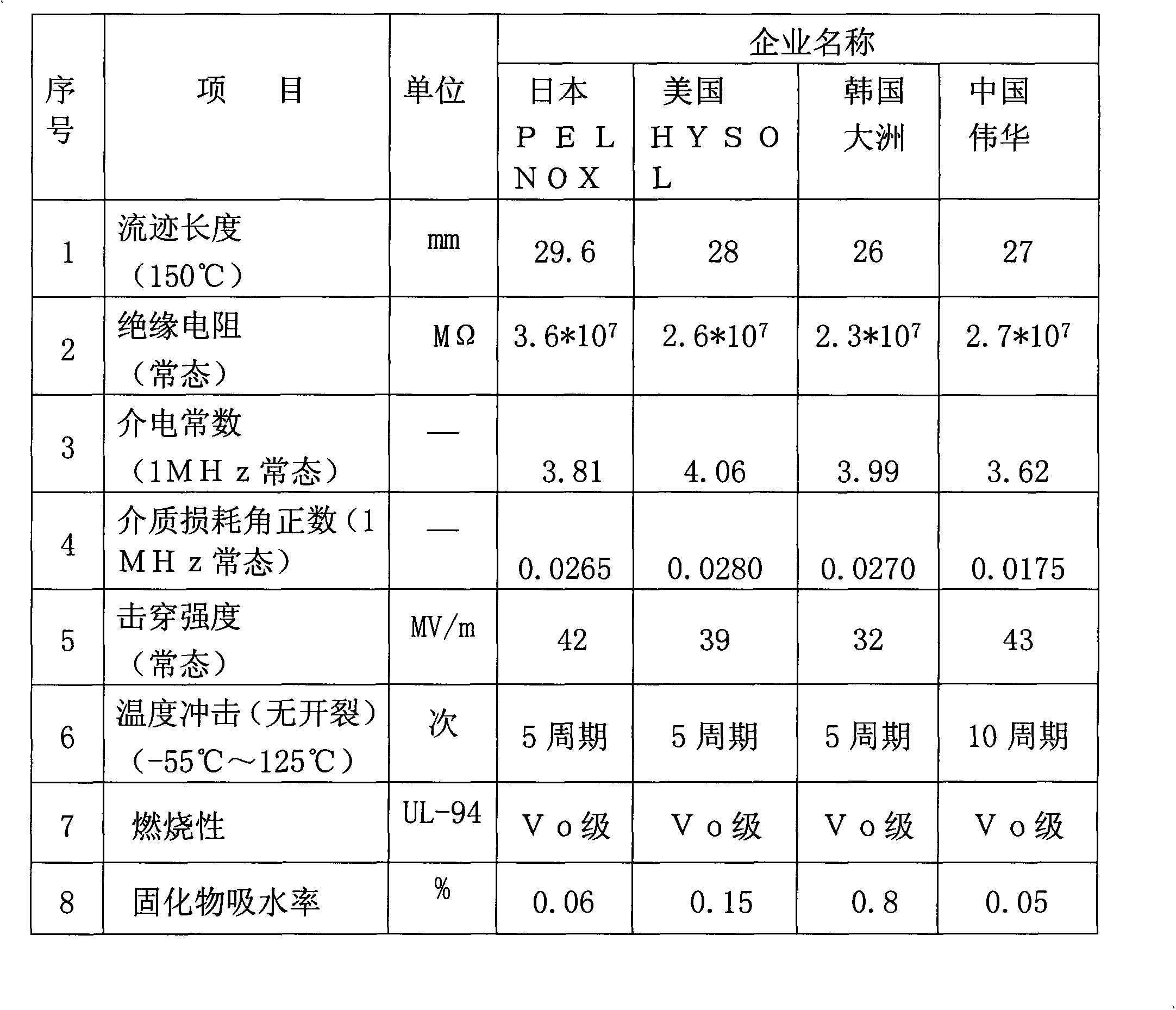

Halogen-free flame-retardant environment-friendly epoxy electronic encapsulating material

InactiveCN104072945AImprove flame retardant performanceImprove moisture resistanceMeth-Firming agent

The invention provides a halogen-free flame-retardant environment-friendly epoxy electronic encapsulating material. The encapsulating material mainly comprises epoxy resin, microsilica, a curing agent, 2-methylimidazole, a halogen-free flame retardant, a leveling agent, a pigment and cupric oxalate in a weight ratio of 40-43:40-42:5:0.2:3-4:1:2:2.8. The encapsulating material has characteristics of good flame retardance, moisture proofness and laser developing effects. The encapsulating material is free of lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls and polybromodiphenyl ether which are the six toxic and harmful compounds forbidden by directives of the European Union, and meets the newest international halogen-free antimony-free environment protection requirements of the European Union, the International Electrotechnical Commission and the Interconnecting and Packaging Electronic Circuits. The encapsulating material has excellent flame retardance, electric properties, mechanical properties, resistance to temperature shock, and good process using properties, plays roles of moisture proofness, insulation, mechanical protection, and the like, and reaches the level of similar products at abroad.

Owner:XIANYANG WEIHUA INSULATION MATERIALS

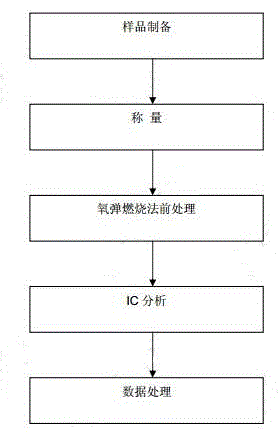

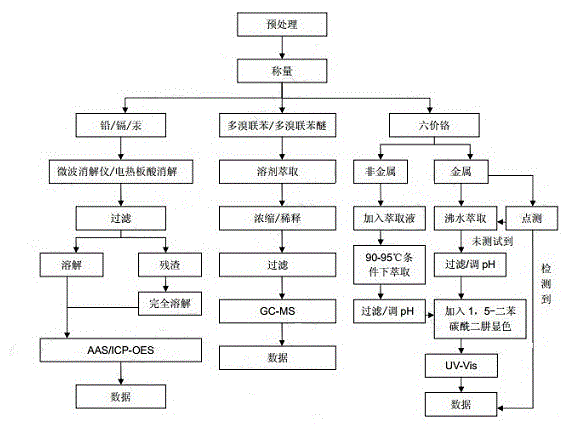

Halogen-free material testing method

InactiveCN105021750AThe detection method is simpleImprove work efficiencyComponent separationHalogenPolybrominated Biphenyls

The present invention provides a halogen-free material testing method, which comprises complete digestion testing and halogen testing, wherein the systematic detection is performed on lead, cadmium, mercury, polybrominated biphenyls, polybrominated diphenyl ethers, hexavalent chromium and halogen in the halogen-free material through the complete digestion testing and the halogen testing. According to the present invention, the operation process is provided so as to optimize the halogen-free material detection method, improve the work efficiency, and achieve the accurate testing result.

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

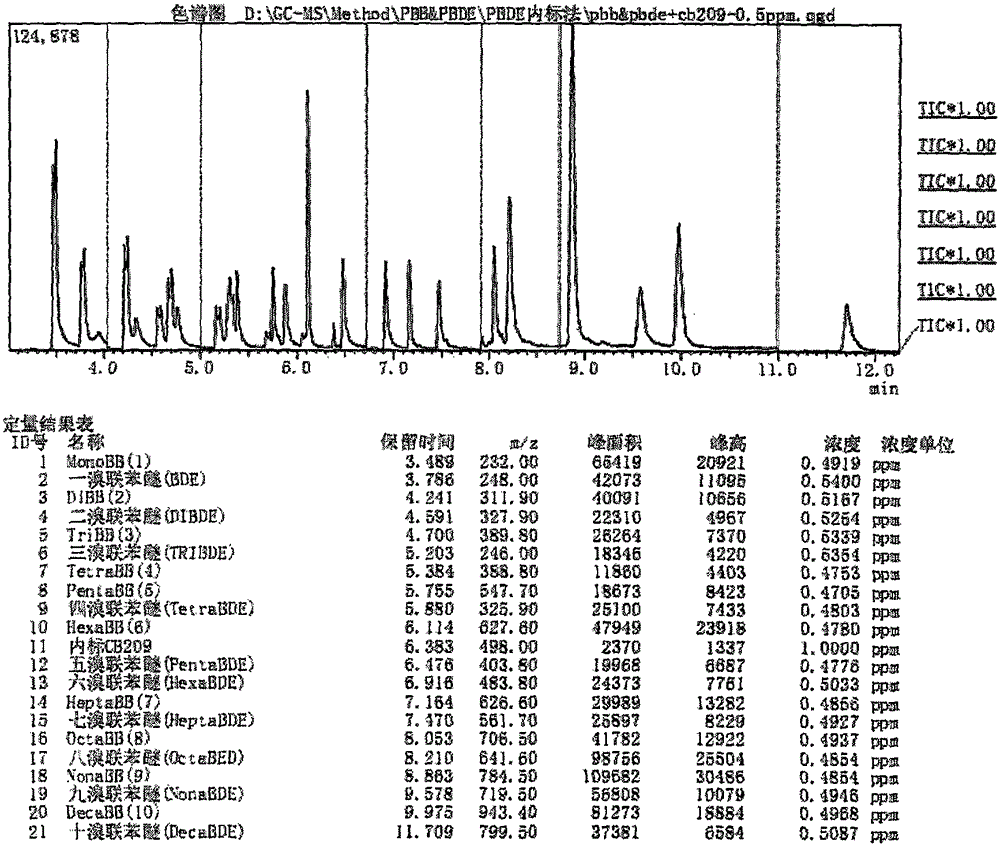

Detecting method for PBBs (polybrominated biphenyls) in plastic component of electronic element

InactiveCN103852538AGet content reliablyEasy extractionComponent separationMicrowavePolybrominated Biphenyls

The invention discloses a detecting method for PBBs (polybrominated biphenyls) in a plastic component of an electronic element. The detecting method comprises the following steps of (a) treating a sample to form particles, wherein the mass of each particle is less than or equal to 0.2g; (b) placing the sample treated in the step (a) into a hexane and acetone mixed solution to carry out microwave extraction, wherein the ratio of the sample to a solvent for extraction is 1: (5-20)g / mL; (c) analyzing the solution extracted in the step (b) by using a GC-MS (Gas Chromatography-Mass Spectrometer), and setting a special chromatographic condition. The analysis method provided by the invention is rapid, high in accuracy and good in repeatability and reproducibility.

Owner:昆山洛丹伦生物科技有限公司

Efficient degradation method for polybrominated diphenyl ethers fire retardant

The invention discloses an efficient degradation method for a polybrominated diphenyl ethers fire retardant. The degradation method comprises the specific steps that a surfactant is added into the fire retardant, then the mixture is added into a microwave reactor, non-pulse microwave continuous heating is conducted at the temperature of 250-300 DEG C for 1-2 h, and ctivation and enrichment of polybrominated diphenyl ethers are facilitated; then the microwave reactor is put in an ultrasonic environment, and sponge iron / Ag bimetallic catalysts are added, hydrogen is led in; and then strong light with the intensity of 50000 lux irradiates the microwave reactor, and the polybrominated diphenyl ethers fire retardant is degraded through reduction reaction. According to the efficient degradation method, the sponge iron / Ag bimetallic catalysts are combined with the surfactant, the polybrominated diphenyl ethers can be degraded efficiently through reduction reaction, the efficient degradation method is simple, and the degradation efficiency is high.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

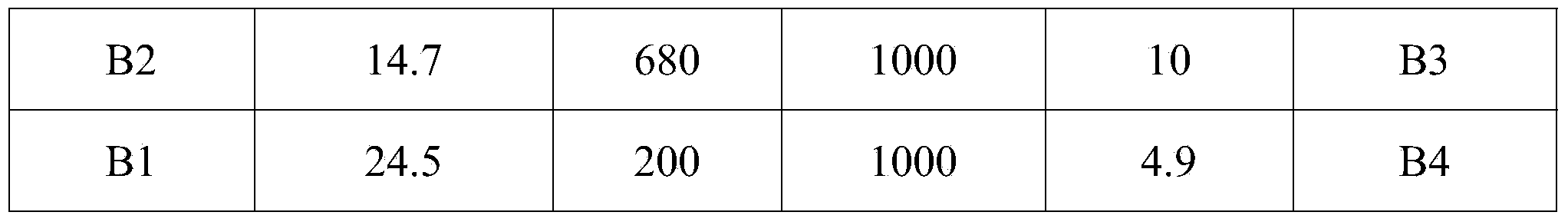

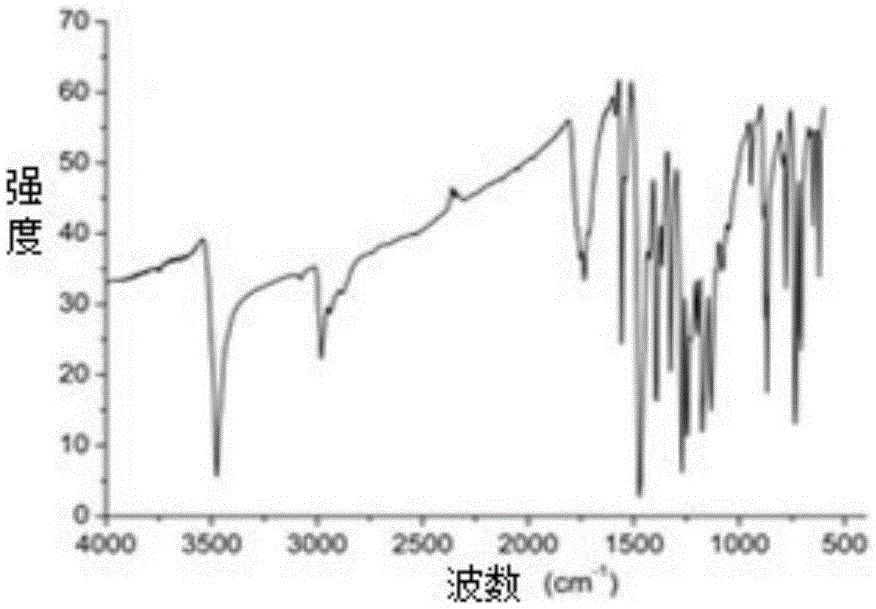

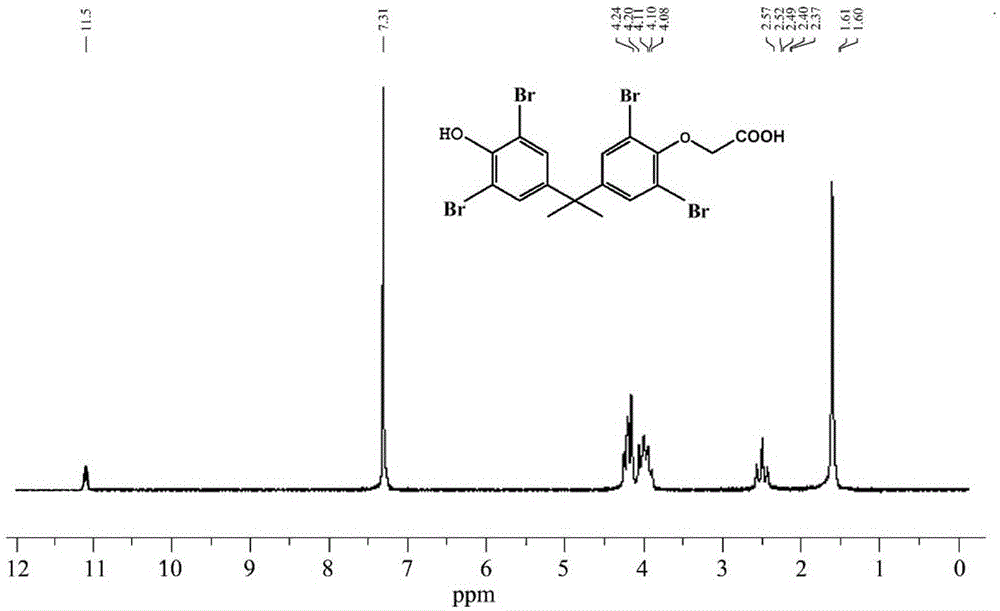

Poly-brominated biphenyl homolog semi-antigen and preparation method thereof

InactiveCN105130787APracticalStrong specificityOrganic compound preparationOvalbuminAntigenImmuno pcr

The invention provides a poly-brominated biphenyl homolog semi-antigen and a preparation method thereof. The structural formula of the semi-antigen is represented in the description. The preparation method comprises a step of reacting TBBPA with bromo-acetic acid in an alkaline environment to introduce a carboxyl group into the terminal end of the phenolic hydroxyl group of TBBPA so as to obtain the semi-antigen. The provided semi-antigen preparation method has the advantages of simpleness, high stability, low cost, and easiness for industrial production. TBBPA semi-antigen can be coupled to carrier protein to prepare TBBPA artificial holoantigen through a carbodiimide method, a mixed acid anhydride method, or an activated ester method. The holoantigen can be used to prepare antibody having the advantages of high specificity and high titer and establish an immuno-PCR biological bar-code method.

Owner:SHANGHAI JIAO TONG UNIV

Manufacturing method of high-performance environment-friendly domestic wire

ActiveCN106847425AHigh purityImprove overload capacityConductive materialInsulated cablesEnvironmental resistanceElectricity

The invention discloses a manufacturing method of a high-performance environment-friendly domestic wire. The method comprises the steps of wiredrawing, twisting, co-extruding, detecting, looping, warehousing, and the like. A high purity copper single wire is adopted as a core material, and the core material, an inner-layer uncolored insulating material and an outer-layer colorful insulating material are formed through co-extruding in a mode that three extruders share one machine head after wiredrawing, twisting and forming. The insulating materials adopt a PVC insulating material, the inner and outer layer materials are manufactured through a new raw material ratio and heat stabilizer, and hazardous substances of lead (Pb), cadmium (Cd), mercury (Hg), hexavalent chromium (Cr<6+>), polybrominated diphenyl ethers (PBDE), polybrominated biphenyls (PBB) and the like are not contained, which is more environmentally friendly. According to the manufacturing method of the high-performance environment-friendly domestic wire, the formed wire core material is high in purity, high in overload capacity, low in electricity consumption, good in integrity of the double-layer co-extruding insulating material, good in overall performance, good in insulating performance and free from hazardous substances of lead, chromium and the like, and the requirements of the European Union RoHS environmental directive are met in the environmental protection aspect.

Owner:重庆鸽牌电线电缆有限公司

Polyurethane and preparation process thereof

The invention relates to the technical filed of foam production, in particular to polyurethane and a preparation process thereof. In the preparation process, the water of combined polyether reacts with isocyanate to produce carbon dioxide, the carbon dioxide is not an ozone-depleting substance (ODS), and a catalyst promotes the isocyanate and polyether to form a polymer, so that the pore forming performance of the polyurethane is formed, the polyurethane does not produce a bulge phenomenon after being subjected to high temperature, and high temperature resistant performance is formed. The polyurethane has the enough pore-forming performance, the density of the polyurethane can be lower, and accordingly the dimensional stability of the polyurethane is improved. The polyurethane is resistant to high temperature and has good dimensional stability. When the preparation process does not adopt CFCs and HCFCs foaming agents, no ODS or ODP is used for the raw materials and is not used in the production process, an ozone layer in the atmosphere is not damaged, the environment is effectively protected, and the polyurethane meets the limiting value requirements of revised directive 2011 / 65 / EU appendix II of EU RoHS directives 2008 / 95 / E, does not contain cadmium, lead, mercury, hexavalent chromium, polybrominated biphenyls (PBBs), polybrominated diphenyl ethers (PBDEs) and other harmful substances and is an environmentally-friendly product.

Owner:GUANGZHOU JOYKO POLYURETHANES CO LTD

Multifunctional metal surface composite treatment agent and preparation method and use method thereof

ActiveCN106048622AReduce labor costsReduce equipment costsMetallic material coating processesSodium phosphatesNuclear chemistry

The invention provides a multifunctional metal surface composite treatment agent and a preparation method and a use method thereof. The multifunctional metal surface composite treatment agent comprises the following ingredients: water, manganese phosphate, magnesium chloride, sodium chloride, sodium alkyl benzene sulfonate, sodium tripolyphosphate, vegetable tannin, ethylene glycol, hydroxy acid, tartaric acid, methyl acid, polybrominated biphenyls, polybrominated diphenyl ethers, veratrole, sodium phosphate and peregal. Traditional metal surface treatment needs to adopt such processes as deoiling, dedusting and passivating, however, by use of the multifunctional metal surface composite treatment agent, only one process is needed, that is, effects of the multiple processes of the traditional metal surface treatment method can be achieved so long as metal to be treated is immersed into a soaking pool in which the multifunctional metal surface composite treatment agent is placed to be soaked for a period of time, so that the manual cost and the equipment cost are greatly lowered, and the working efficiency is improved.

Owner:三明市爱绿地节能环保有限公司

Environment-friendly plastic containing modified starch

The invention discloses an environment-friendly plastic containing modified starch. The environment-friendly plastic is composed of the following components in parts by weight: 45-60 parts of modified starch, 15-20 parts of polypropylene, 14-25 parts of acrylic resin, 20-28 parts of methylcyclohexane, 19-30 parts of propanediol butyl ether and 18-26 parts of diatomite, wherein the weight ratio of the modified starch to the polypropylene is 3: 1. The environment-friendly plastic is reasonable in formula, free of pungent smell and toxicity, hardly generates smoke in combustion, can be optically degradable after being discarded, and thus is environment-friendly; through detection, the environment-friendly plastic contains no lead, cadmium, polybrominated biphenyls or poly brominated diphenyl ethers, and has the mercury content of 500-800ppm and the hexavalent chromium content of 500-600ppm.

Owner:SUZHOU YUFAN NEW MATERIAL TECH

Environment-friendly flexible PVC (polyvinyl chloride) cable material

The invention discloses an environment-friendly flexible PVC (polyvinyl chloride) cable material and belongs to the field of semiconductive shielding materials. The environment-friendly flexible PVC cable material is prepared from raw materials in parts by weight as follows: 100 parts of PVC, 15-40 parts of a calcium / zinc compound stabilizer, 40-60 parts of a plasticizer, 10-15 parts of epoxidized soybean oil, 5-10 parts of epoxidized butyl oleate, 20-30 parts of calcium carbonate, 10-20 parts of calcined clay and 1-5 parts of a lubricating agent. The cable material does not contain heavy metal such as cadmium, chromium, mercury and the like harmful to a human body and the environment or hazardous substances of PBBs (polybrominated biphenyls) and PBDEs (poly brominated diphenyl ethers).

Owner:STATE GRID SHANDONG TANCHENG POWER SUPPLY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com