Patents

Literature

34results about How to "Excellent extrusion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pultrusion method for thermoplastic composite material and forming die thereof

InactiveCN1730270AImprove impregnation effectImprove mechanical propertiesPolymer scienceFiber bundle

The invention relates to a pultrusion method for thermoplastic composite, which takes fortifying fiber and matrix fiber as raw material, including the following steps: a. placing matrix fiber and fortifying fiber on the creel in the weight ratio of 95-20:5-80; b. loading the fortifying fiber and matrix fiber to demand scale into the preheat chamber by the thread wire and board and preheating them; c. loading the preheated mixed fiber tuft into the preforming die, so the tuft near to the entrance shape of the forming die; d. loading the preformed mixed fiber into the forming die. Certainly the performing die and forming die can be diad, with performing segment and forming segment in one die; e. after loading out from the forming die the section bar cooling and shaping to get products. The invention overcomes the socking problem of high molecular polymer, improving the socking effects of thermoplastic composites, and the mechanical property enhances dramatically.

Owner:SINOMA SCI & TECH

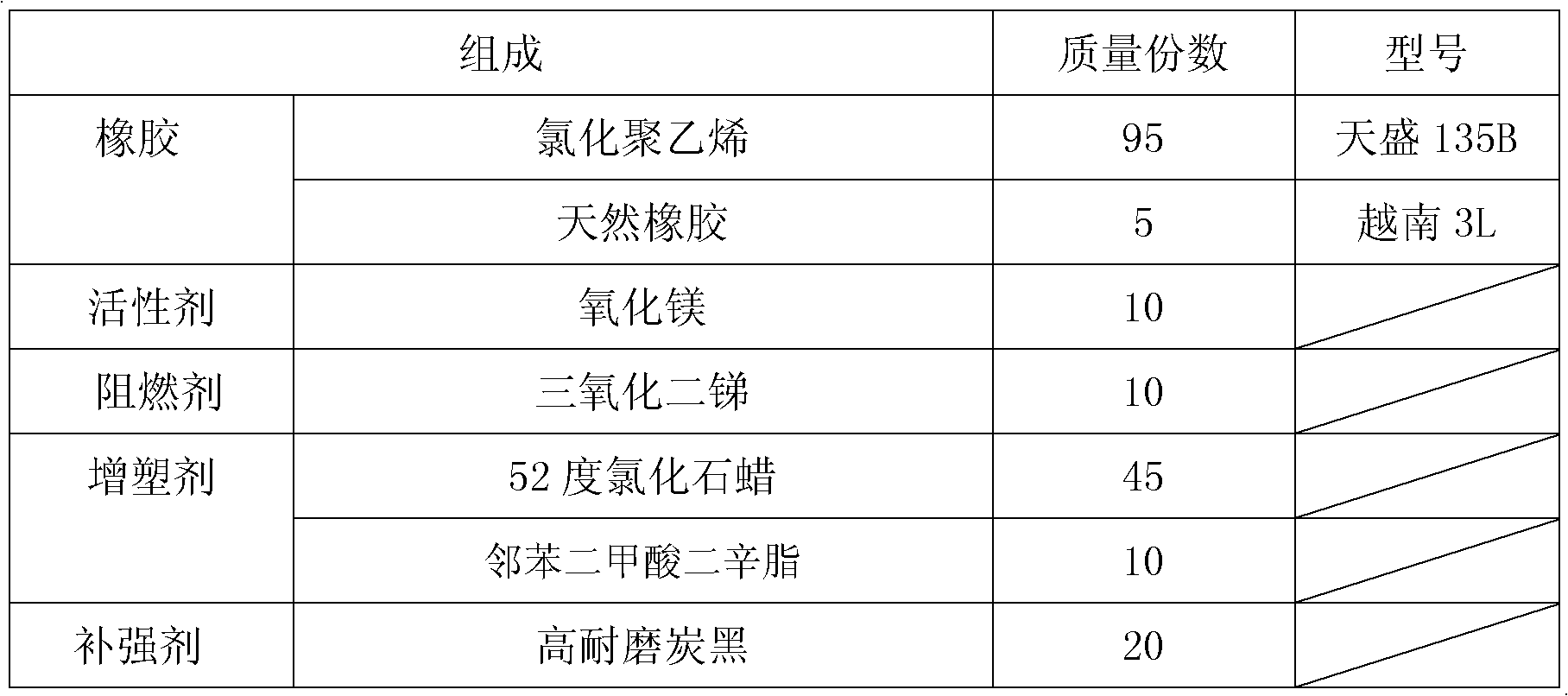

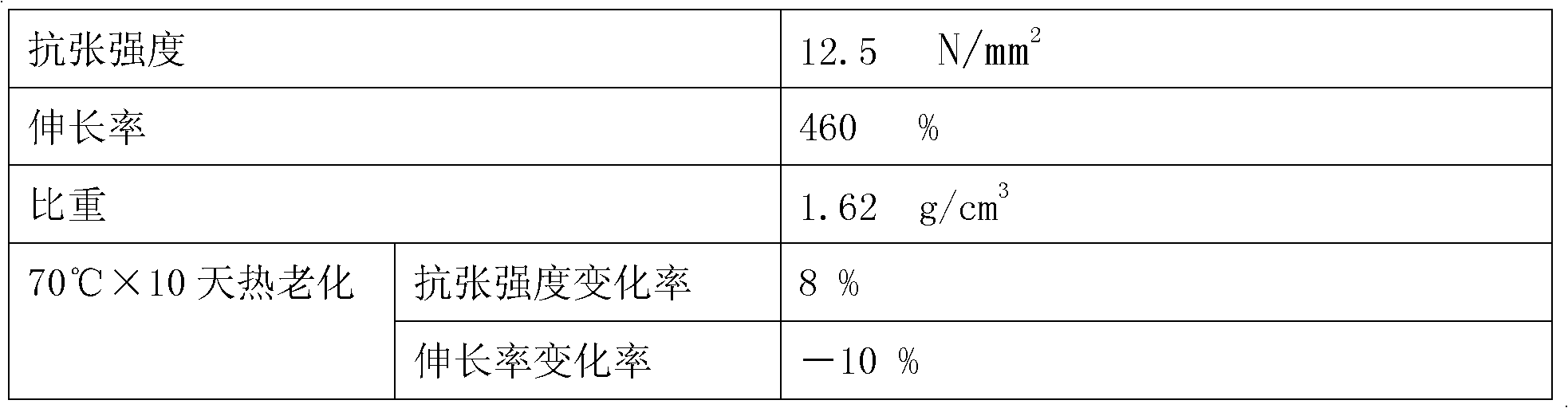

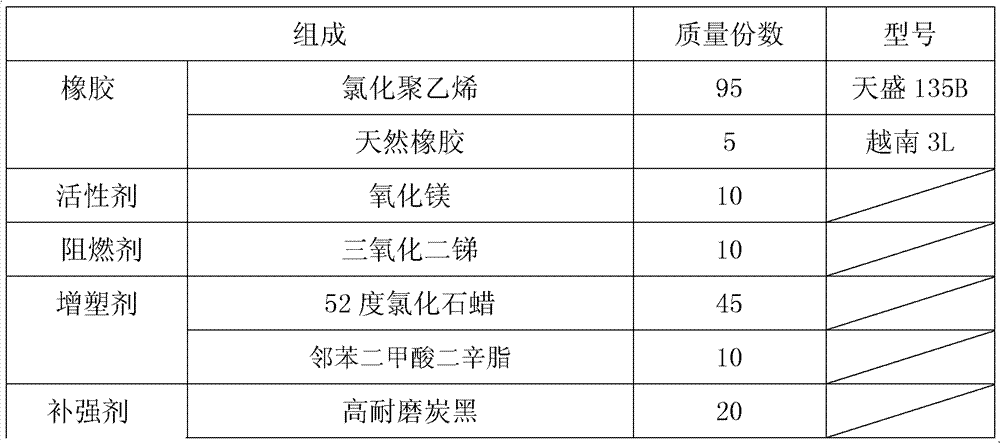

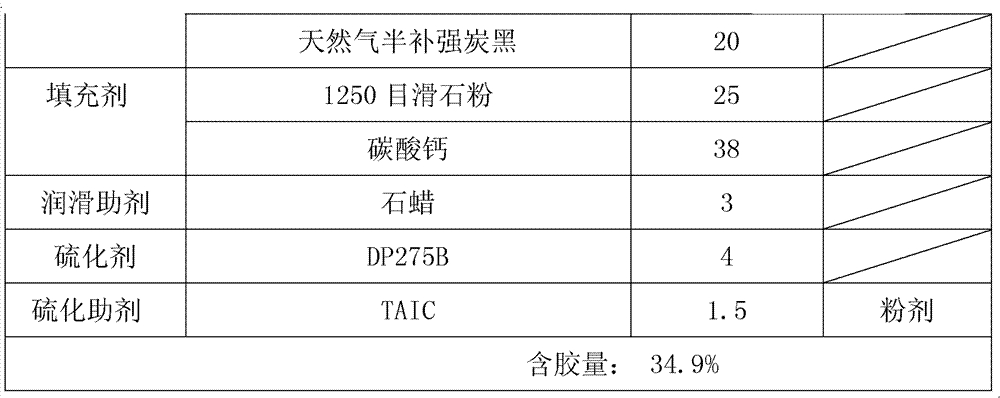

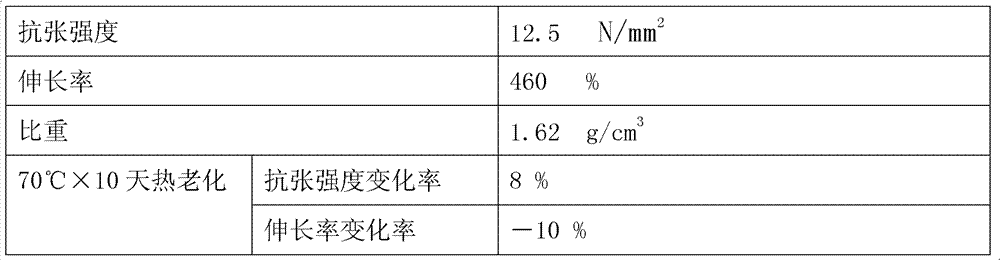

CPE and NR co-used sheath rubber for rubber sheathed flexible cables

ActiveCN102936379AExcellent extrusion performanceIncrease elasticityPlastic/resin/waxes insulatorsInsulated cablesPlasticizerActive agent

The invention relates to a CPE (chlorinated polyethylene) and NR (natural rubber) co-used sheath rubber for rubber sheathed flexible cables. The sheath rubber provided in the invention comprises the following components by mass: 95-100 parts of chlorinated polyethylene; 0-5 parts of natural rubber; 10-15 parts of an active agent; 5-10 parts of a flame retardant; 50-60 parts of a plasticizer; 40 parts of a reinforcing agent; 60-80 parts of a filling agent; 0-3 parts of a lubricating assistant; 4-5 parts of a vulcanizing agent; and 1.5-2.5 parts of a vulcanizing assistant. The sheath rubber has a rubber content of 32-36%. The sheath rubber can satisfy the performance requirements of SE4 rubber in standards GB / T 5013-2008 ''rubber insulated cables with a rated voltage of 450 / 750V and below'' and JB8735-1998 ''rubber insulated flexible cords and flexible cables with a rated voltage of 450 / 750V and below''.

Owner:FAR EAST CABLE +2

Low-smoke halogen-free flame retardant cable material

InactiveCN104387645AExcellent extrusion performanceHigh LOI valuePlastic/resin/waxes insulatorsLow-density polyethyleneCross-link

The invention discloses a low-smoke halogen-free flame retardant cable material which is prepared from the following raw materials in parts by weight: 15-25 parts of low-density polyethylene, 15-25 parts of an ethylene-vinyl acetate copolymer, 12-18 parts of EVA resin, 40-60 parts of magnesium hydrate, 5-6 parts of nano silicon carbide, 0.2-0.4 part of aluminum nitride nano powder, 1-2 parts of a cross-linking agent, 1-2 parts of calcium stearate, 0.5-1.0 part of stearic acid, 0.2-0.4 part of an ultraviolet absorbent UV-531, 8-15 parts of a smoke inhibitor, 20-40 parts of a compatilizer, 150-240 parts of a flame retardant, 6-12 parts of a flame retardant additive, 7-10 parts of a processing aid, 3-6 parts of antioxidant and 1-3 parts of a termite preventing agent. The low-smoke halogen-free flame retardant cable material is excellent in flame retardancy and secondary combustion prevention property, generates little smoke, no toxic gas or corrosive gas when combusted and has good low-temperature resistance and ultraviolet resistance.

Owner:ANHUI TIANYUAN CABLE

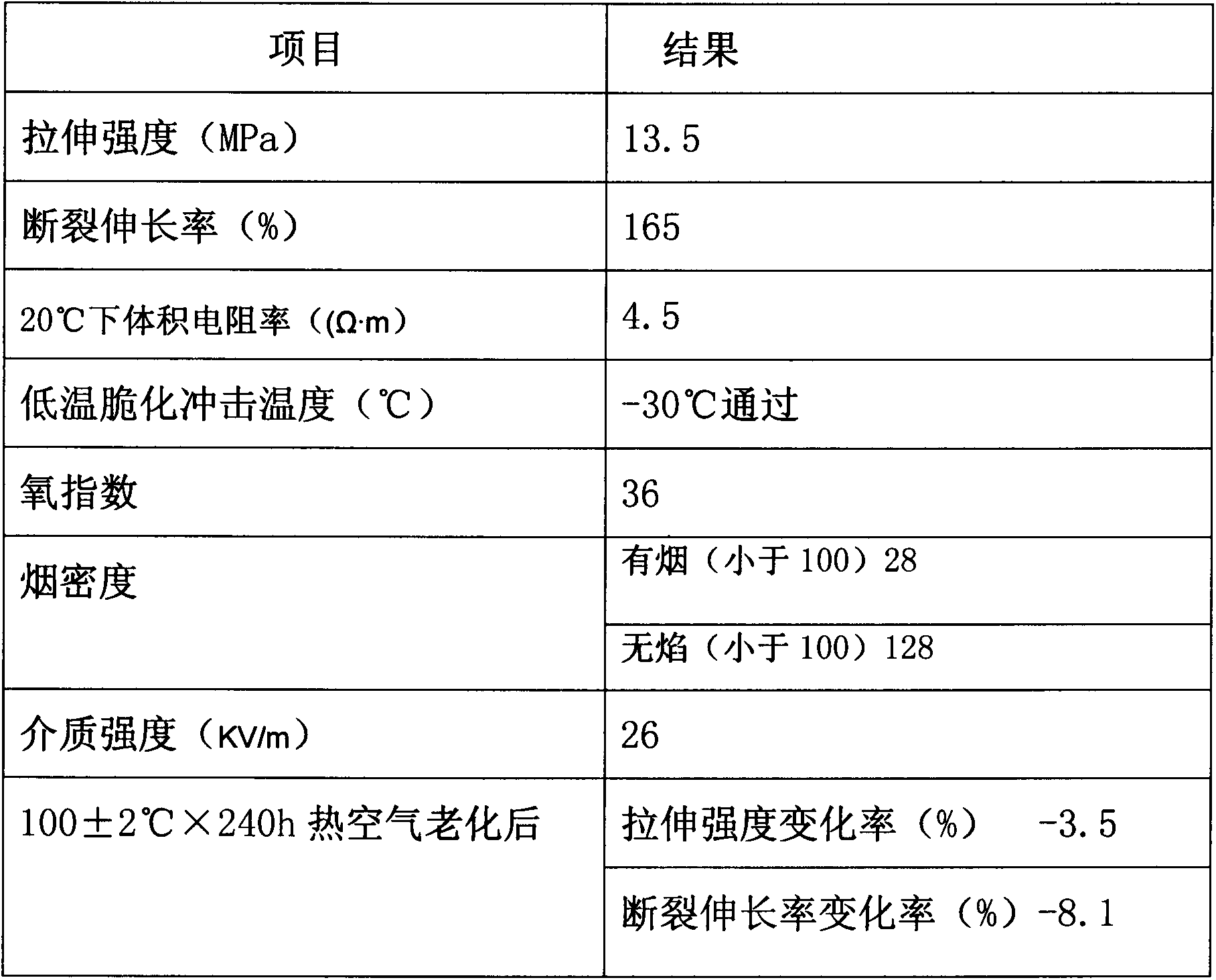

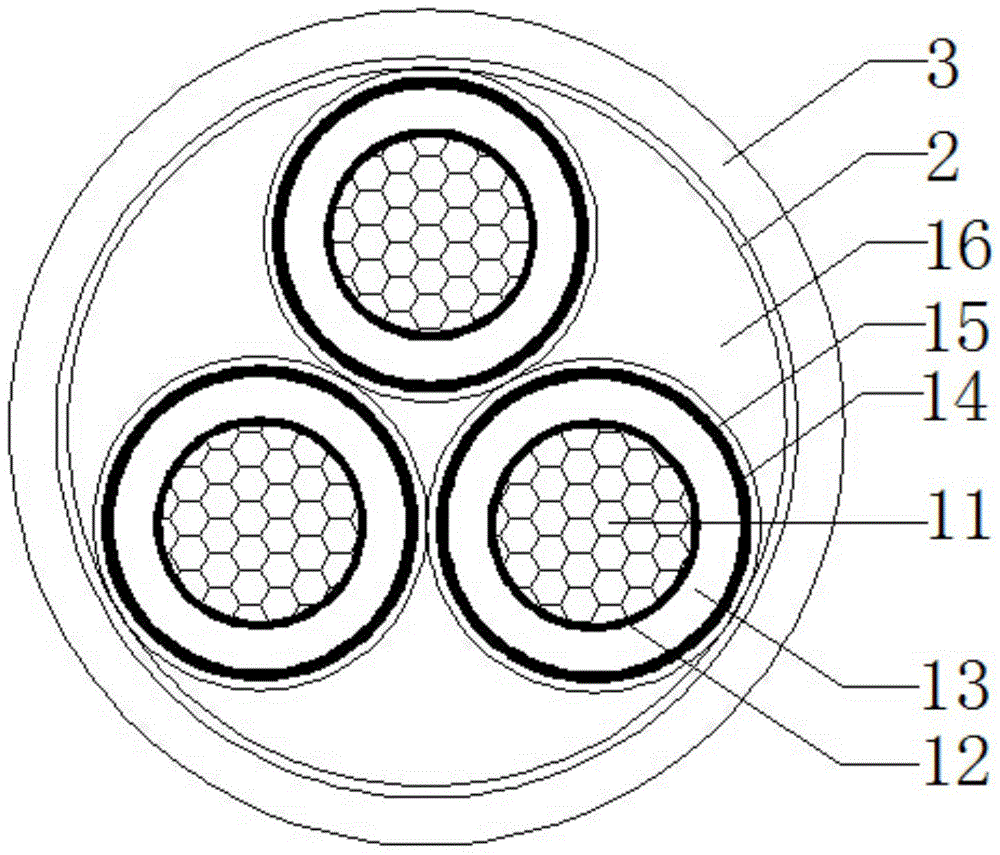

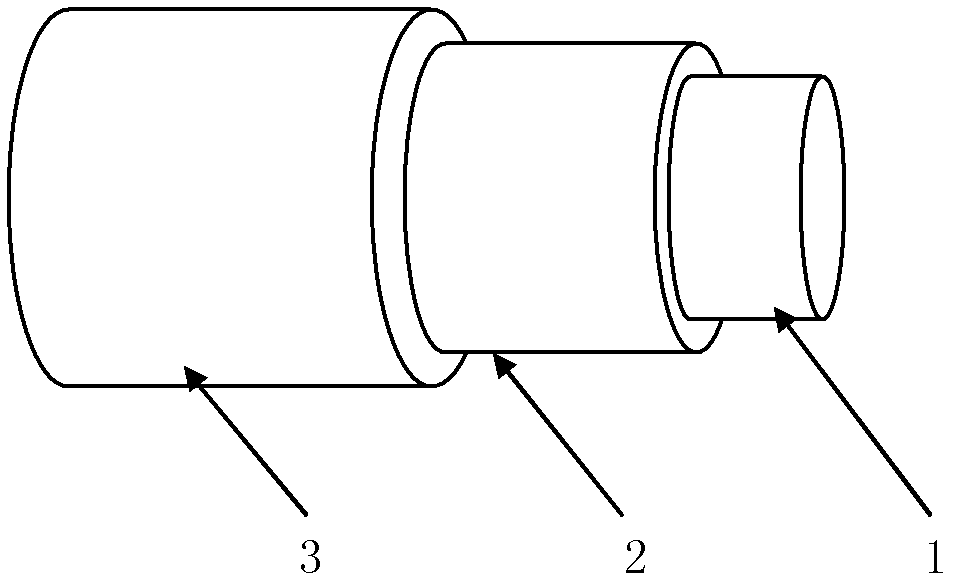

End chain functional graphene modified intelligent energy cable, shielding material and manufacturing method thereof

InactiveCN104356502AGood dispersionImprove safe operationPower cables with screens/conductive layersInsulated cablesElectrical conductorCo extrusion

The invention discloses an end chain functional graphene modified intelligent energy cable, a shielding material and a manufacturing method thereof. The cable sequentially comprises a cable core, a wrapping tape and an outer sheath from interior to exterior, wherein the cable core comprises one or three insulated cable cores; each insulated cable core sequentially comprises a conductor, an end chain functional graphene modified conductor shielding layer, an insulating layer, an end chain functional graphene modified insulated shielding layer and a copper strip shielding layer from interior to exterior; and the end chain functional graphene modified conductor shielding layer, the insulating layer and the end chain functional graphene modified insulated shielding layer are of a three-layer co-extrusion structure. According to the cable disclosed by the invention, the conductor shielding and insulating and smooth and gap-free conductor shielding effects are achieved, so that the safety operation capacity of the cable is improved. Meanwhile, the end chain functional graphene can be uniformly and stably dispersed in a composite material, so that the long-time safety operating stability is further improved.

Owner:FAR EAST CABLE +2

Halogen-free flame-retardant cable material

ActiveCN104017261AExcellent extrusion performanceHigh LOI valuePlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxidePolymer chemistry

A halogen-free flame-retardant cable material is disclosed. The cable material comprises following raw materials by weight: 60-80 parts of LDPE resin, 15-25 parts of EPDM resin, 5-15 parts of EVA resin, 70-90 parts of aluminium hydroxide, and 6-8 parts of red phosphorus. The cable material is excellent in extrusion process property, high in LOI value and good in flame retardant property.

Owner:ANHUI MEITENG SPECIAL ELECTRIC CABLE MATERIALS

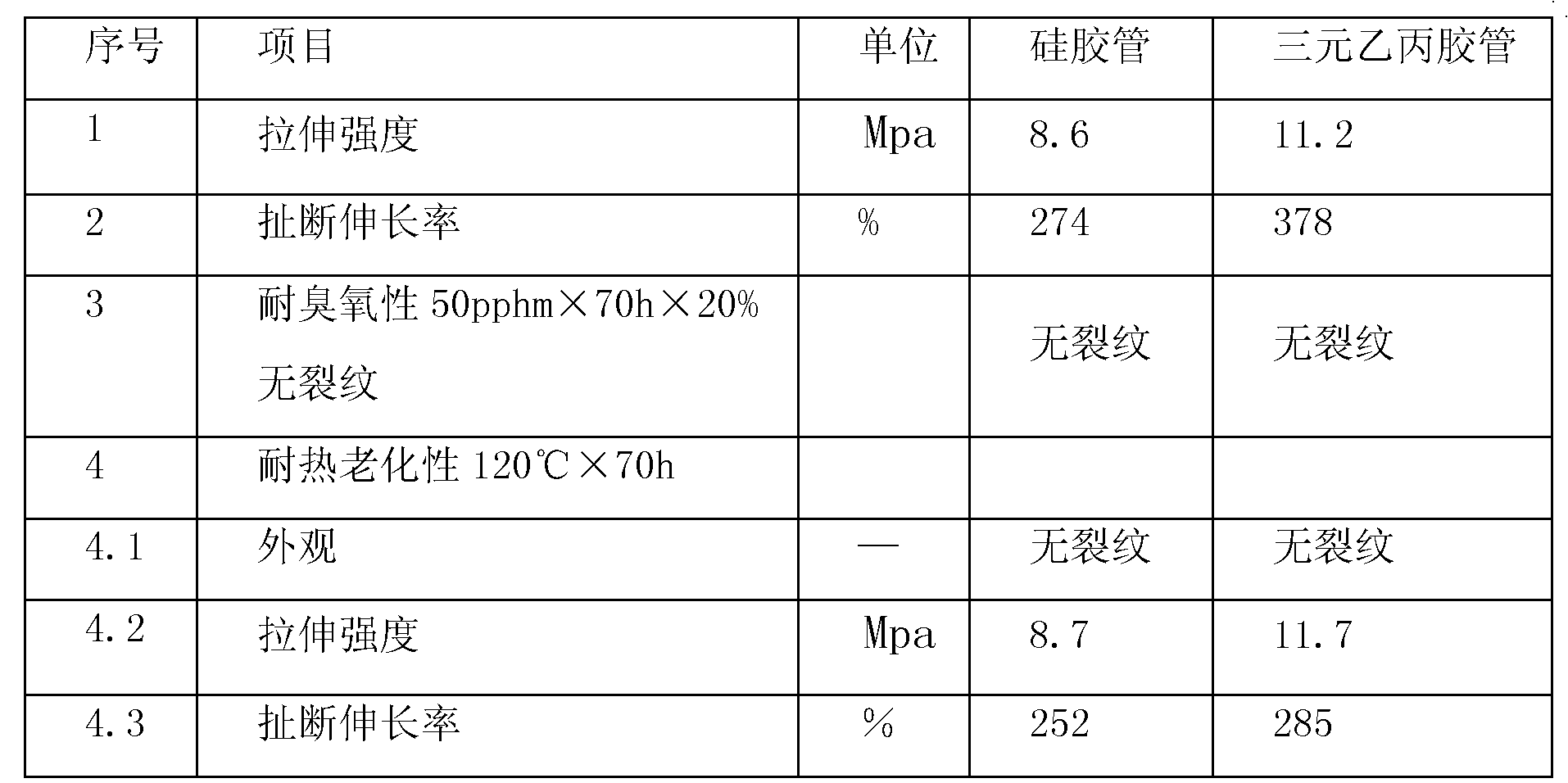

Ethylene propylene diene rubber composition for air outlet pipe of intercooler and preparation method thereof

InactiveCN102627809AExcellent extrusion performanceGood heat aging resistanceFlexible pipesIntercoolerCoumarones

The invention relates to an ethylene propylene diene rubber for an air outlet pipe of an intercooler. The rubber composition consists of ethylene propylene diene rubber, zinc oxide, polyethylene glycol, an anti-ageing agent RD, coumarone, carbon black, paraffin oil, an accelerating agent and sulfur. A preparation method of the rubber composition comprises the following steps of: selecting a rubber extruder, controlling the length-diameter ratio of a screw rod at 11-15, and controlling the temperature at each stage of the extruder, wherein the temperature of a handpiece is 60-80 DEG C, the temperature of an extruding section is 50-70 DEG C, the temperature of a plasticizing section is 50-70 DEG C, and the temperature of a feeding section is 50-60 DEG C; controlling the temperature of circulating water at 15+ / -5 DEG C, cooling and sizing a rubber pipe, cutting length, and standing for later use; and sleeving a semi-finished product on a mandrel of a fixed specification, and entering a steam vulcanizing tank for vulcanizing at the vulcanizing temperature of 150-170 DEG C for 15-40 minutes. An air outlet rubber pipe of the intercooler processed by using gross rubber produced with the method has the advantages of low price, appropriate performance, simple production process, high efficiency, excellent ageing resistance and high ozone resistance, and better meets the current use requirements.

Owner:TIANJIN PENGYI GRP CO LTD

Dealcoholization sealant for photovoltaic assembly and preparation method thereof

InactiveCN109666448AGood storage stabilityImproved cross-linking functionNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkFire retardant

The invention belongs to the technical field of sealing materials, and particularly relates to dealcoholization sealant for a photovoltaic assembly and a preparation method thereof. The dealcoholization sealant for the photovoltaic assembly is prepared from the following raw materials in parts by weight: 80 to 100 parts of polyalkoxy silicon base-terminated polydimethylsiloxane, 20 to 30 parts offiller, 4 to 6 parts of flame-retardant agent, 3 to 5 parts of titanium dioxide color paste, 1.5 to 2.5 parts of water removal agent, 2 to 4 parts of cross0linking agent, 0.4 to 0.6 part of organic tin chelate catalyst and 0.8 to 1.2 parts of compound coupling agent. The preaparation method of the dealcoholization sealant for the photovoltaic assembly comprises the following steps: (1) measuring all raw materials according to the weight ratio; (2) adding the polyalkoxy silicon base-terminated polydimethylsiloxane, the filler, the flame-retardant agent and the titanium dioxide color paste intoa vacuum kneading machine, dehydrating, blending, kneading for 4 to 6 hours, and cooling to the room temperature; and (3) adding a dewatering agent, a cross-linking agent, organic tin chelate catalystand a compound coupling agent, and sufficiently mixing, so as to obtain the dealcoholization sealant for the photovoltaic assembly. The dealcoholization sealant for the photovoltaic assembly has thecharacteristics of short curing time, high adhesion strength and good aging resistance.

Owner:安徽兆拓新能源科技有限公司

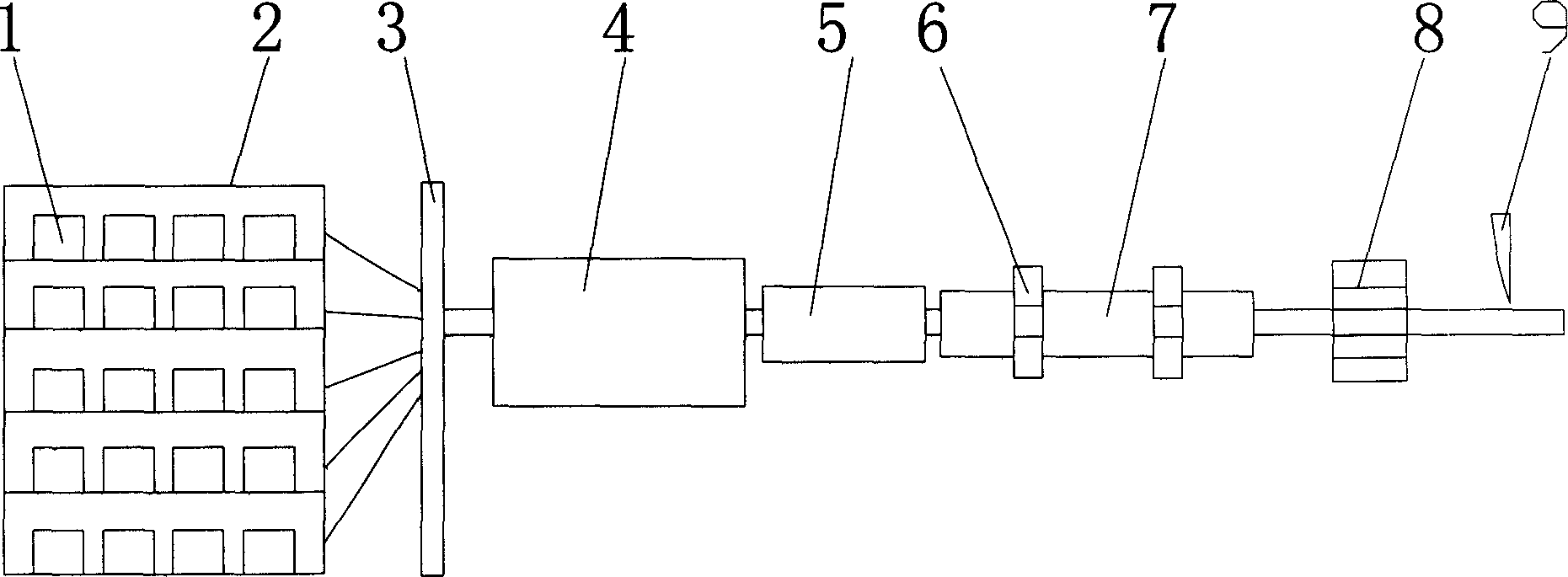

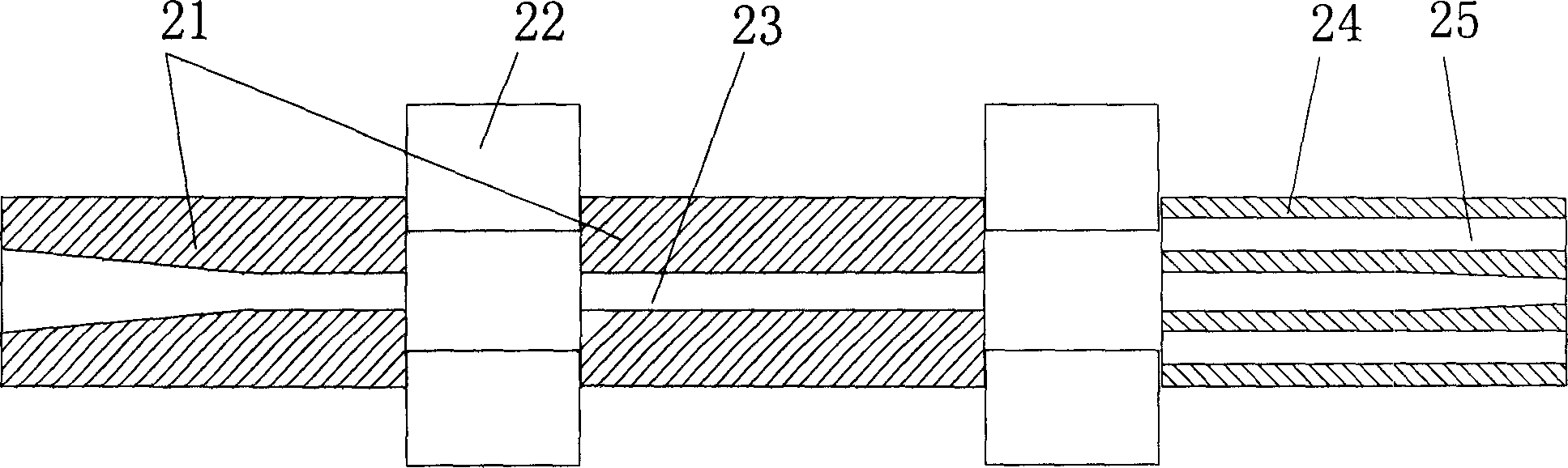

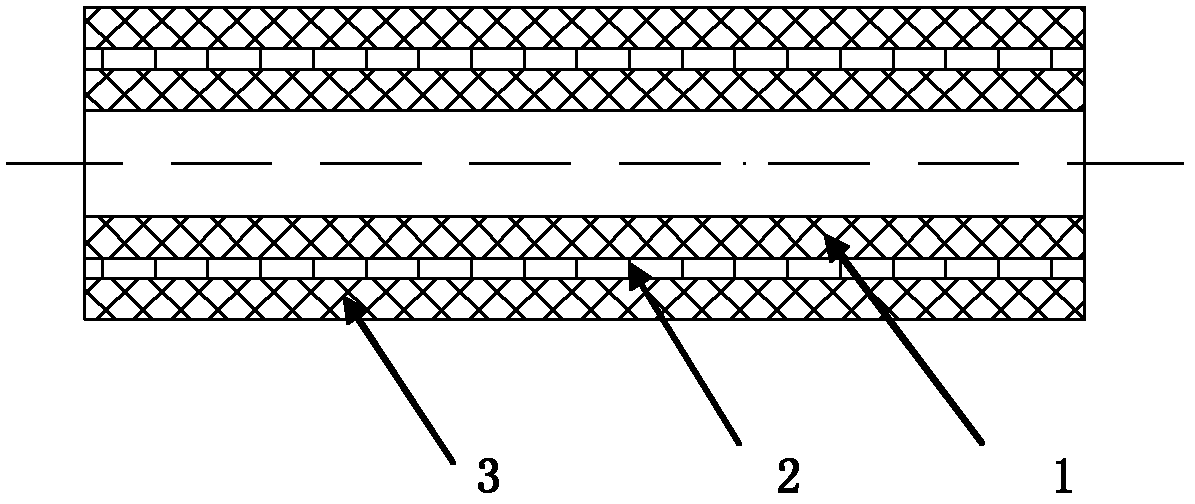

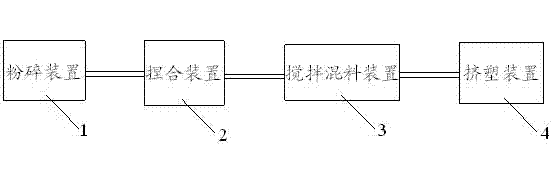

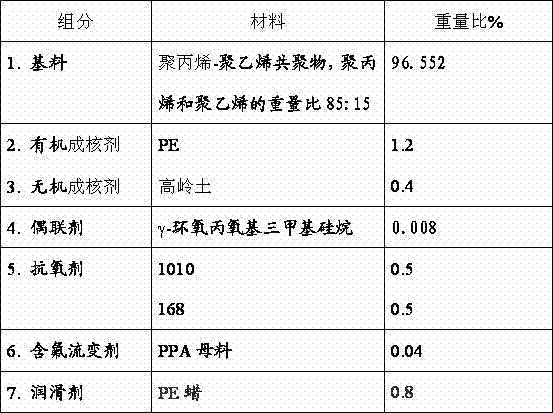

Modified polypropylene for manufacturing optical fiber buffer tube, manufacturing process and production system thereof

ActiveCN102850665AGood impact resistanceImprove bending resistanceFibre mechanical structuresAntioxidantPolypropylene

The present invention discloses modified polypropylene for manufacturing an optical fiber buffer tube, a manufacturing process and a production system thereof. The modified polypropylene comprises the following components, by weight, 96.0-97.5% of a polypropylene-polyethylene copolymer base material, 0.5-2.5% of a nucleating agent, 0.001-0.05% of a coupling agent, 0.4-2.0% of an antioxidant, and 0.5-3.0% of an additive. The manufacturing process comprises: making a rheological agent into master batch by using a polypropylene-polyethylene copolymer base material; carrying out a surface treatment on an inorganic nucleating agent by using a coupling agent; adding the polypropylene-polyethylene copolymer base material, the prepared master batch, an organic nucleating agent, the surface-treated inorganic nucleating agent, an antioxidant and a lubricant to a stirring mixing apparatus to mix to prepare a mixture; adding the mixture to a plastic extruding apparatus to carry out mastication and extrusion, and then carrying out cooling and pelletizing; and carrying out weighing and packaging. The modified polypropylene of the present invention has good impact resistance, and has mechanical and processing properties of the optical fiber buffer tube.

Owner:JIANGSU NANFANG COMM TECH

Environmental-friendly ratproof glue stock formula

InactiveCN101619153AExcellent extrusion performanceImprove low temperature resistancePolybrominated BiphenylsDioctyl terephthalate

The invention relates to a glue stock formula, in particular to an environmental-friendly ratproof glue stock formula with ratproof functionality. The environmental-friendly ratproof glue stock formula contains PVC resin which is XS-2 type or XS-3 type resin and also contains the following components: 100.0 phr of the PVC resin, 8.0 phr of Ca / Zn compound stabilizing agents, 40.0 phr of di-iso-decylphthalate, 10.0 phr of dioctyl terephthalate and 35.0 phr of heavy CaCO. The whole formula system does not contain heavy metal, i.e. Pb, Cd, Hg, Cr6+, and the like, polybrominated biphenyls and ethers thereof which are harmful to human and environment, the property of jacket materials completely meets the standard property requirement of environmental-friendly PVC jacket materials with temperature of 90 DEG C, the extrusion technology property is good, the low temperature resistant property is greatly improved, the flame retardant property more accords with the environmental-friendly standard and meets the requirement for the PVC jacket materials with temperature of 90 DEG C in the standard national standard GB8815-2002, an oxygen index is more than 30, and the property accords with related regulations.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

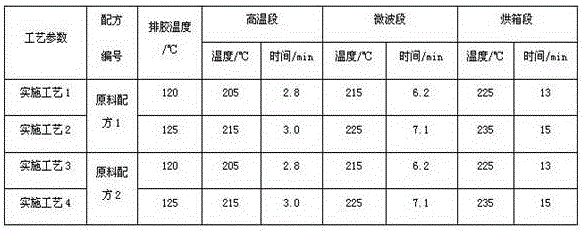

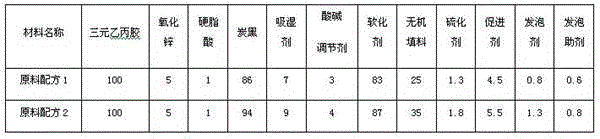

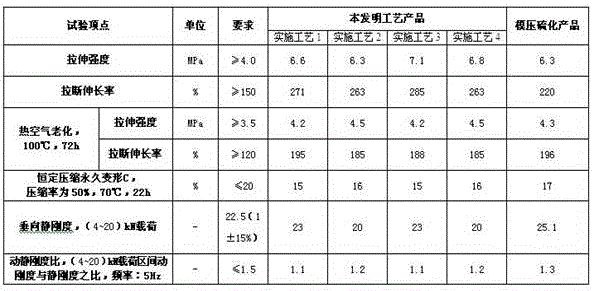

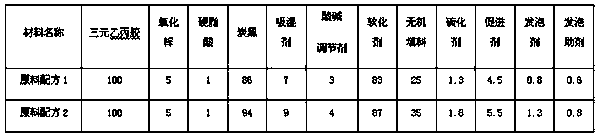

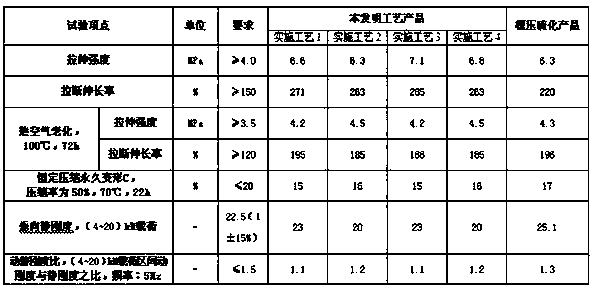

Production process for ethylene propylene diene monomer microporous base plate and product produced by production process

The invention discloses a production process for an ethylene propylene diene monomer microporous base plate. The production process comprises the following steps: adding ethylene propylene diene monomer into a kneading machine to knead, and then adding zinc oxide, stearic acid, carbon black, a moisture absorbent, an acid and alkali regulator, a softening agent and an inorganic filler into the kneading machine to knead, thereby preparing a master batch; adding the prepared master batch into an open mixing machine, adding a vulcanizing agent, a promoter, a foaming agent and a foaming aid, uniformly mixing, regulating roll spacing to 0.8-1.3 millimeters for thin-passing, carrying out triangular packaging for 3-4 times, regulating the roll spacing to 5-6 millimeters for discharging, so as to prepare a rubber compound, and standing the rubber compound for not smaller than 16 hours; putting the rubber compound on a cutter for cutting; feeding prepared rubber strips into a cold feeding extruder to extrude; sequentially feeding the prepared rubber strips into a high-temperature section, a microwave section and an oven section to carry out continuous vulcanizing until complete vulcanizing; and pulling the prepared vulcanized rubber into the cutter through a pulling machine, and cutting the prepared vulcanized rubber into a needed dimension, thereby obtaining a microporous base plate finished product. The invention further provides an ethylene propylene diene monomer microporous base plate.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Cable material with high expansion force

InactiveCN105462106AExtended service lifeReduced service lifePlastic/resin/waxes insulatorsChemical structureBenzoyl peroxide

The invention discloses a cable material with high expansion force, and is characterized in that the cable material comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 40-50 parts of PVC resin, 15-20 parts of PBT resin, 15-18 parts of dibutyl phthalate, 10-12 parts of benzoyl peroxide, 7-10 parts of dipentaerythritol hexaacrylate, 2-4 parts of a silane coupling agent, 0.6-0.8 part of an antibacterial agent, 10-15 parts of straw ash, 3-5 parts of graphite, 3-5 parts of an anti-aging agent, 16-18 parts of a filling material, and 4-6 parts of silicone rubber. The cable material extends the aging resistance of the cable material, the filling material has the advantages of stable chemical structure, good gelation ability and high expansion ability, prolongs the service life of a cable, and saves the resources; a copper body is protected from avoiding oxidation, the copper body cannot be damaged, the service life is extended, the cost is saved, and the efficacy is improved; the addition of the straw ash, the requirements of the standards on environmental protection are met; and the extrusion process performance is excellent.

Owner:王威淞

Flame-retardant fatigue-resistant cable material

InactiveCN106317672AExcellent extrusion performanceHigh LOI valuePlastic/resin/waxes insulatorsLow-density polyethylenePolyvinyl chloride

The object of the invention is to provide a flame-retardant fatigue-resistant cable material and belongs to the technical field of cable manufacture. The flame-retardant fatigue-resistant cable material is prepared from the following raw materials in parts by weight: 50-75 parts of low-density polyethylene (LDPE) resin, 10-20 parts of ethylene propylene diene monomer (EPDM) resin, 5-10 parts of ethylene-vinylacetate copolymer (EVA) resin, 90-110 parts of polyvinyl chloride (PVC) resin, 70-80 parts of aluminum hydroxide, 8-10 parts of red phosphorus, 60-80 parts of dioctyl phthalate, 0.5-1.0 part of erucyl amide, 3-5 parts of zinc stearate and 50-60 parts of heavy calcium carbonate. The flame-retardant fatigue-resistant cable material is excellent in extrusion property, has good flame retardance and good fatigue resistance and is long in service life and easy to produce and manufacture.

Owner:孙宽林

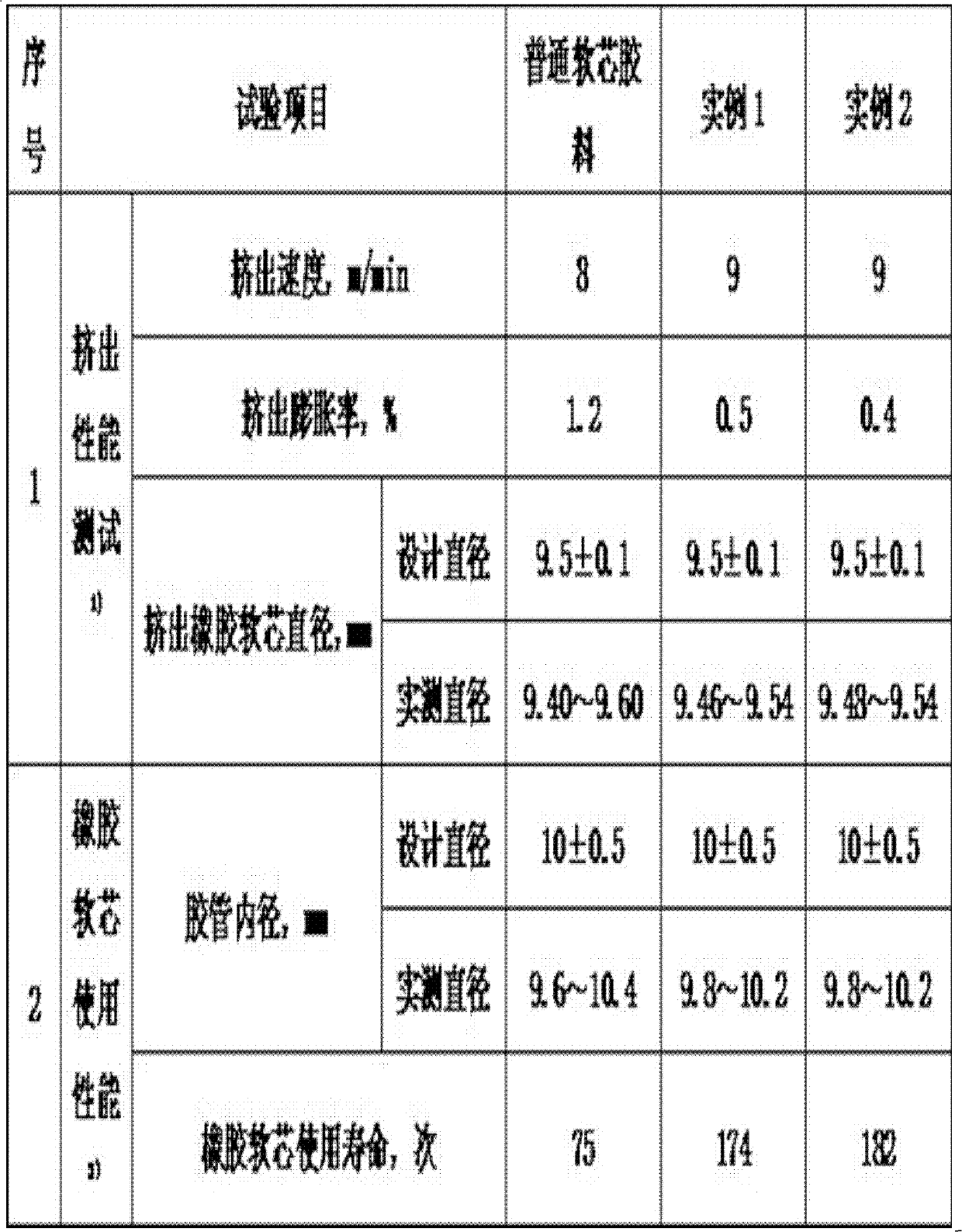

Preparation raw material for rubber soft core of rubber pipe

InactiveCN102585382AImprove aging resistanceExtended service lifeFlexible pipesRubber materialPolymer science

The invention discloses a preparation raw material for a rubber soft core of a rubber pipe. The preparation raw material is characterized by comprising the following components in part by mass: 100 parts of ethylene propylene diene monomer (EPDM) rubber, 5 to 10 parts of zinc oxide, 0.5 to 2 parts of stearic acid, 1 to 3 parts of antioxidant RD, 0.5 to 2.5 parts of antioxidant 4010NA, 2 to 4 parts of paraffin, 1 to 4 parts of tackifier A-90, 40 to 100 parts of paraffin oil 2280, 40 to 80 parts of carbon black N550, 40 to 80 parts of carbon black N774, 1 to 3.5 parts of dicumyl peroxide (DCP), 2 to 4 parts of accelerator triallyl isocyanurate (TAIC) and 0.1 to 0.5 part of accelerator tetrabenzylthiuram disulfide (TBzTD). The special preparation raw material has the advantages that 1) the rubber material has high ageing resistance, so that the service life of the soft core is greatly prolonged; 2) the rubber material is tightly bonded with a steel wire and is not separated; and 3) the soft core has high extrusion processing property and dimensional stability, and product dimensions are easy to ensure.

Owner:SHANDONG MEICHEN ECOLOGY & ENVIRONMENT CO LTD

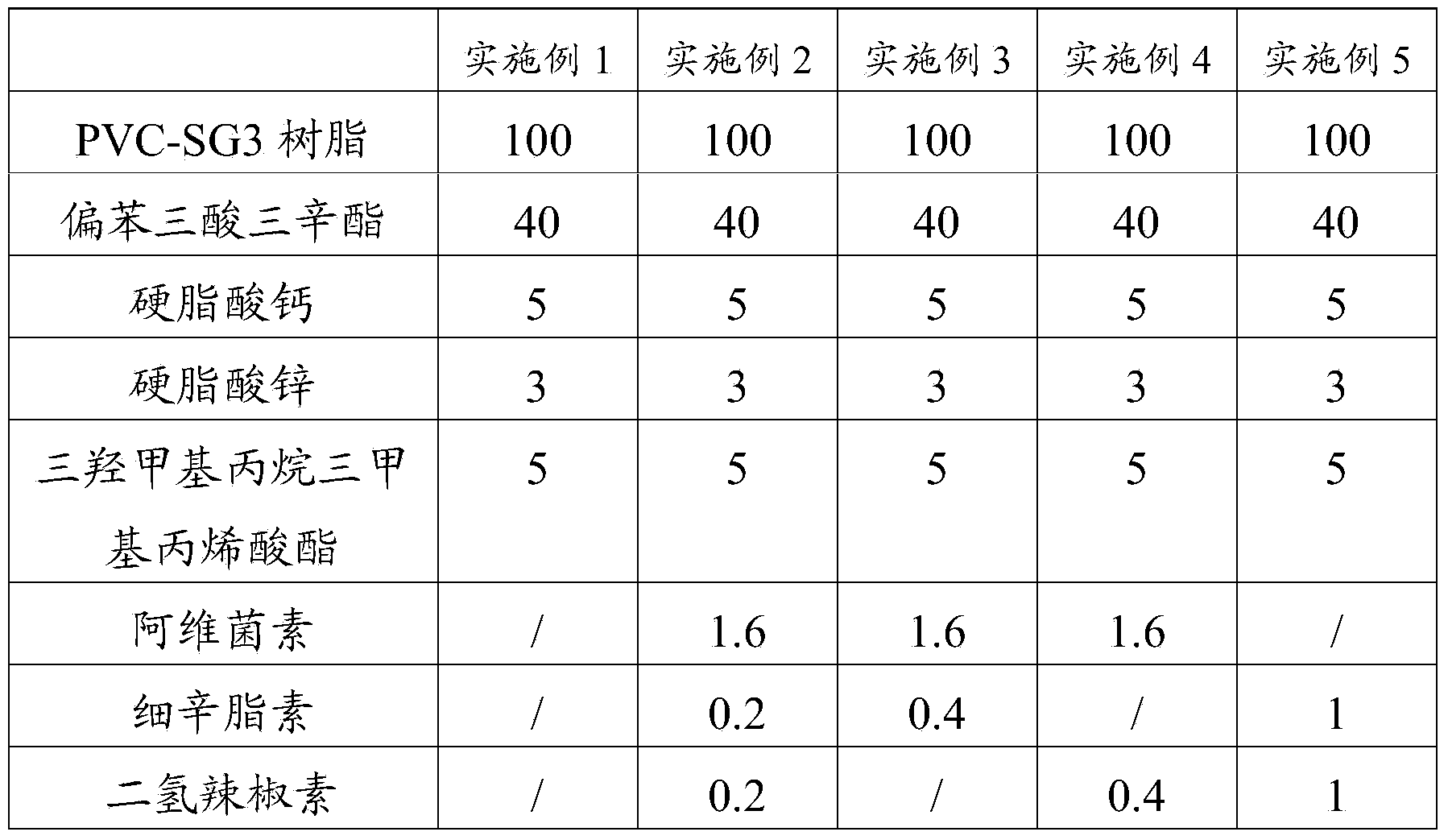

Wear-resistant PVC cable material

InactiveCN104017305AExcellent extrusion performanceImprove wear resistancePlastic/resin/waxes insulatorsWear resistantZinc

The invention discloses a wear-resistant cable material. The wear-resistant cable material comprises following raw materials by weight: 100 parts of PVC resin, 35-45 parts of trioctyl trimellitate, 3-7 parts of calcium stearate, 2-4 parts of zinc stearate and 2-8 parts of trimethylolpropane trimethacrylate. The wear-resistant PVC cable material is excellent in extrusion process performance and high in wear resistance.

Owner:广东领航新材料有限公司

Modified attapulgite reinforced cable sheath material

InactiveCN105542262AGood high and low temperature resistanceGood oil resistanceRubber insulatorsInsulated cablesEmulsionAcrylonitrile

The invention discloses a modified attapulgite reinforced cable sheath material. The modified attapulgite reinforced cable sheath material is prepared from, by weight, 30-50 parts of NBR-2707 type butadiene-acrylonitrile rubber, 50-70 parts of SBR-1502 type emulsion polymerized butadiene styrene rubber, 1-2 parts of stearic acid, 2-4 parts of N, N-meta phenylene bismaleimide, 0.5-2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1-2 parts of zinc diethyldithiocarbamic acid, 2-6 parts of paraffin, 0.5-1.5 parts of antiager DPPD, 3-8 parts of nano-hydroxyapatite powder, 4-8 parts of enhancer DH-2, 15-25 parts of semi-reinforcement carbon black and 10-20 parts of modified attapulgite. The modified attapulgite reinforced cable sheath material has excellent processability and mechanical strength, and is simple in processing process, high in practicality and easy to popularize.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Halogen-free flame retardant cable compound

ActiveCN104017261BExcellent extrusion performanceHigh LOI valuePlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxideEngineering

Owner:ANHUI MEITENG SPECIAL ELECTRIC CABLE MATERIALS

Environment-friendly halogen-free flame-retarding cable material

The invention discloses an environment-friendly halogen-free flame-retardant cable material, which comprises the following raw materials in parts by weight: 90-100 parts of LDPE resin, 30-50 parts of EPDM resin, 20-30 parts of EVA resin, 5-10 parts of PVC resin, hydrogen 100-120 parts of alumina, 20-24 parts of red phosphorus, 2-6 parts of anti-termite agent, 2-4 parts of stabilizer. The invention has excellent extrusion process performance, high LOI value, good flame retardancy, environmental protection and halogen-free.

Owner:李志博

Semi-steel radial tire cap strip rubber material suitable for extrusion method and preparation process thereof

ActiveCN111944213AImprove driving safetyModerate adhesionTyresPneumatic tyre reinforcementsRubber materialPolymer science

The invention belongs to the technical field of tire rubber, and particularly relates to a formula, a mixing process and an extrusion process of a semi-steel radial tire cap strip rubber material which is suitable for an extrusion method, low in heat generation and moderate in adhesiveness. The rubber material formula comprises standard particulate rubber, trans-polycyclooctene rubber, styrene butadiene rubber, low-structure high-wear-resistance carbon black, zinc oxide, stearic acid, an anti-aging agent 4020, a resorcinol or resorcinol formaldehyde adhesive, a methylene donor adhesive, a plasticizer A, a peptizer, insoluble sulfur with high thermal stability, an anti-scorching agent CTP and a sulfonamide accelerator. The cap strip rubber material prepared by the preparation process provided by the invention has the characteristics of low heat generation, moderate bonding performance with nylon cords, suitability for production of nylon cap strips by an extrusion method and the like, is few in use personnel and high in production efficiency, is directly used during molding, is easy to unwind in a rolling manner, is not easy to adhere, and is suitable for large-scale production. Thedefects that in the using process of the nylon cap strip cord fabric roll produced through a calendering method, the viscosity between layers is large, and separation is not easy can be effectively overcome.

Owner:QINGDAO LIYANG RUBBER TECH CO LTD

CPE and NR co-used sheath rubber for rubber sheathed flexible cables

ActiveCN102936379BExcellent extrusion performanceIncrease elasticityPlastic/resin/waxes insulatorsInsulated cablesPlasticizerActive agent

The invention relates to a CPE (chlorinated polyethylene) and NR (natural rubber) co-used sheath rubber for rubber sheathed flexible cables. The sheath rubber provided in the invention comprises the following components by mass: 95-100 parts of chlorinated polyethylene; 0-5 parts of natural rubber; 10-15 parts of an active agent; 5-10 parts of a flame retardant; 50-60 parts of a plasticizer; 40 parts of a reinforcing agent; 60-80 parts of a filling agent; 0-3 parts of a lubricating assistant; 4-5 parts of a vulcanizing agent; and 1.5-2.5 parts of a vulcanizing assistant. The sheath rubber has a rubber content of 32-36%. The sheath rubber can satisfy the performance requirements of SE4 rubber in standards GB / T 5013-2008 ''rubber insulated cables with a rated voltage of 450 / 750V and below'' and JB8735-1998 ''rubber insulated flexible cords and flexible cables with a rated voltage of 450 / 750V and below''.

Owner:FAR EAST CABLE +2

Low-smoke halogen-free flame-retardant rubber for cables and method thereof

InactiveCN105985609AExcellent extrusion performanceHigh LOI valueLow-density polyethyleneAntioxidant

The invention discloses a low-smoke halogen-free flame-retardant rubber for cables and a preparation method thereof. The material is made of the following raw materials in parts by weight: 20-25 parts of low-density polyethylene, 15-25 parts of ethylene-vinyl acetate copolymer 20 parts, 12-18 parts of TPU thermoplastic elastomer, 45-55 parts of mixed thermoplastic phenolic resin, 45-55 parts of modified nano-magnesium hydroxide, 45-55 parts of microencapsulated red phosphorus, 1-2 parts of cross-linking agent, 1~2 parts of calcium stearate, 1~2 parts of stearic acid, 0.2~0.4 parts of ultraviolet absorber UV~531, 8~15 parts of smoke suppressant, 20~40 parts of compatibilizer, 7~10 parts of processing aid 3-6 parts of antioxidant, 1-3 parts of anti-termite agent, appropriate amount of deionized water. The invention has excellent flame retardancy and non-flammability; when burning, the amount of smoke is very small, no toxic gas is produced, no corrosive gas is produced, and at the same time it has good low temperature resistance and ultraviolet resistance.

Owner:ANHUI TIANYUAN CABLE

Cable material for outdoor charging piles and preparation method thereof

InactiveCN105985608AExcellent extrusion performanceHigh LOI valuePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneAntioxidant

The invention discloses a cable material for outdoor charging piles and a preparation method thereof. The material is made of the following raw materials in parts by weight: 20-25 parts of low-density polyethylene, 45-55 parts of mixed thermoplastic phenolic resin, TPU thermoplastic 15-20 parts of elastomer, 0.2-0.4 parts of nano-aluminum nitride powder, 1-2 parts of cross-linking agent, 1-2 parts of calcium stearate, 1-2 parts of stearic acid, UV-531 0.2- 0.4 parts, 3-5 parts of light stabilizer, 20-40 parts of compatibilizer, 7-10 parts of processing aid, 3-6 parts of antioxidant, 1-3 parts of anti-termite agent, appropriate amount of deionized water. The invention has excellent flame retardancy and non-flammability; when burning, the amount of smoke is very small, no toxic gas is produced, no corrosive gas is produced, and at the same time it has good low temperature resistance and ultraviolet resistance, and is very suitable for electric piles Use cable materials.

Owner:ANHUI TIANYUAN CABLE

Cold-resistant halogen-free cable material for electric automobile

InactiveCN107286448AExcellent extrusion performanceImprove cold resistancePlastic/resin/waxes insulatorsLinear low-density polyethyleneSesquioxide

The invention relates to a cable material, in particular to a cold-resistant halogen-free cable material for an electric vehicle, and belongs to the technical field of cable manufacturing. A cold-resistant halogen-free cable material for electric vehicles, comprising the following components in parts by weight: 30-50 parts of linear low-density polyethylene, 20-30 parts of polystyrene, 2-5 parts of tributyl citrate, 2-5 parts of isocyanate 4 parts, 5-8 parts of iron oxide, 3-5 parts of molybdenum trioxide, 1-2 parts of tetraphenylethylene, 1-5 parts of ethylene-vinyl acetate copolymer, 5-7 parts of diundecyl phthalate , 1-3 parts of chlorinated paraffin. The cold-resistant halogen-free cable material for electric vehicles of the invention has excellent extrusion performance, is halogen-free and environmentally friendly, has good cold resistance performance, good fatigue resistance performance, long service life, and is easy to manufacture.

Owner:孙宽林

Flame retardant cable material comprising tetraphenyl ethylene and high-density polyethylene

InactiveCN107286418AExcellent extrusion performanceHigh LOI valuePlastic/resin/waxes insulatorsInsulated cablesEpoxyTetraisopropyl titanate

The invention relates to a cable material, in particular to a flame retardant cable material comprising tetraphenyl ethylene and high-density polyethylene, and belongs to the technical field of cable manufacturing. The flame retardant cable material comprising the tetraphenyl ethylene and high density polyethylene comprises the following components in parts by weight: 40 to 60 parts of tetraphenyl ethylene, 20 to 30 parts of high-density polyethylene, 10 to 20 parts of linear high-density polyethylene, 10 to 15 parts of magnesium hydrate, 10 to 15 parts of aluminium hydroxide, 0.5 to 1 part of tetraisopropyl titanate, 0.5 to 1 part of polyhexamethylene adipamide, 1 to 5 parts of soybean oil, 1 to 5 parts of polyvinyl acid, and 1 to 2 parts of epoxy butyl oleate. The flame retardant cable material disclosed by the invention is excellent in extrusion performances, good in flame retardant properties, excellent in fatigue resistance, long in service life and easy to produce and manufacture.

Owner:孙宽林

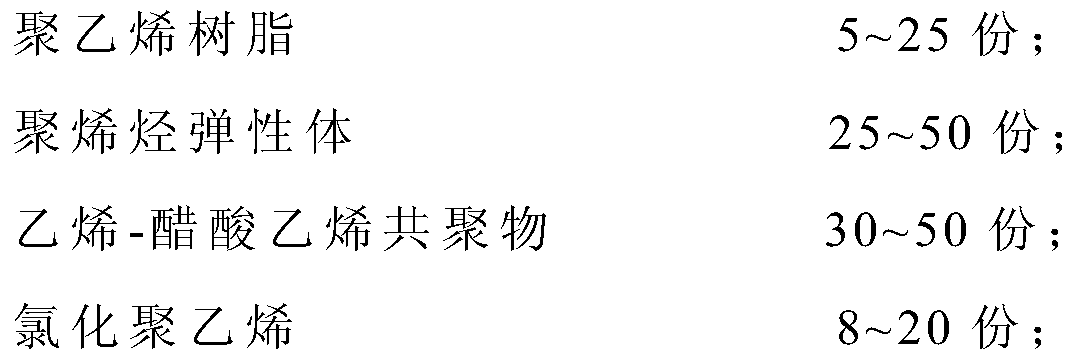

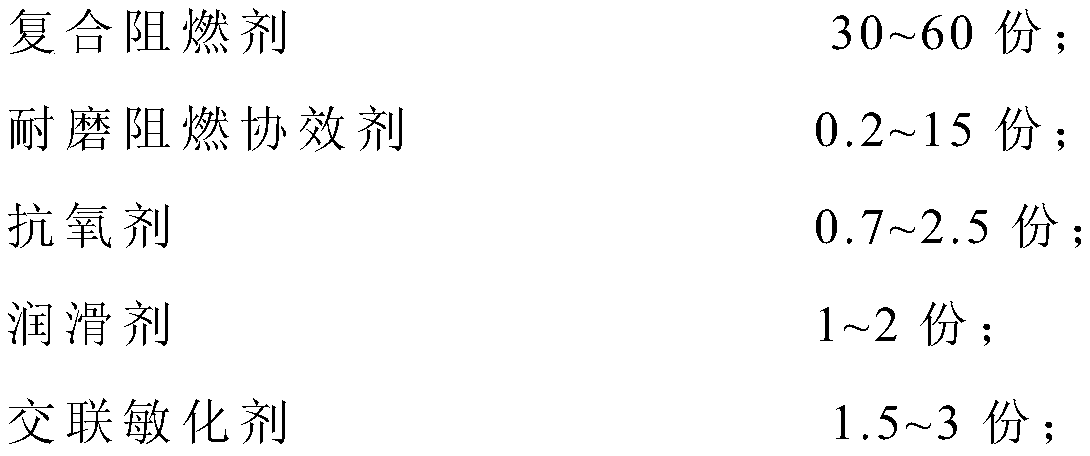

A kind of high flame-retardant composite material for new energy high-voltage line and preparation method thereof

ActiveCN107200917BImprove flame retardant performanceRetain softnessPlastic/resin/waxes insulatorsElastomerPolymer science

The present invention relates to a high flame retardancy composite material for a high voltage cable of a new energy automobile, the high flame retardancy composite material comprising the following raw materials in parts by weight: 5-25 parts of polyethylene resin; 25-50 parts of polyolefin elastomer; 30-50 parts of ethylene-vinyl acetate copolymer; 8-20 parts of chlorinated polyethylene; 30-60 parts of composite flame retardant; 0.2-15 parts of wear-resistant flame retardant synergist; 0.7-2.5 parts of antioxidant; 1-2 parts of lubricant; and 1.5-3 parts of cross-linking sensitising agent. The formulation of the present invention is improved, for example by using a mixture of bimodal polyethylene and high melt index high density polyethylene as a polyethylene resin and chlorinated polyethylene as a modifier, adding polyolefin elastomer and ethylene-vinyl acetate copolymer, and additionally adding a composite flame retardant, a flame retardant synergist, and an antioxidant, such that the composite material of the present invention has better flame retardancy properties and burns at a UL94 V0 grade whilst retaining the flexibility, high temperature resistance, oil resistance, and flame retardancy of high voltage cable material for use in a new energy automobile, and having excellent extrusion processing properties.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Abrasion-resistant and fatigue-resistant cable material containing styrene thermoplastic elastomer

InactiveCN107286490AExcellent extrusion performanceHigh LOI valuePlastic/resin/waxes insulatorsZinc hydroxideThermoplastic elastomer

The invention relates to a cable material, in particular to a wear-resistant and fatigue-resistant cable material containing styrene thermoplastic elastomer, which belongs to the technical field of cable manufacturing. A wear-resistant and fatigue-resistant cable material containing styrene-based thermoplastic elastomer, comprising the following components in parts by weight: 50-60 parts of styrene-based thermoplastic elastomer, 25-35 parts of EPDM rubber, polyethylene masterbatch 5-10 parts, 4-8 parts of zinc oxide, 2-5 parts of monoalkoxy titanate, 5-15 parts of SG-3 polyvinyl chloride, 0.2-0.6 parts of silane coupling agent, 2-4 parts of ferrocene 10-20 parts of zinc hydroxide, 1-5 parts of compatibilizer. The invention has excellent extrusion performance, good wear resistance, good fatigue resistance, long service life and easy production.

Owner:孙宽林

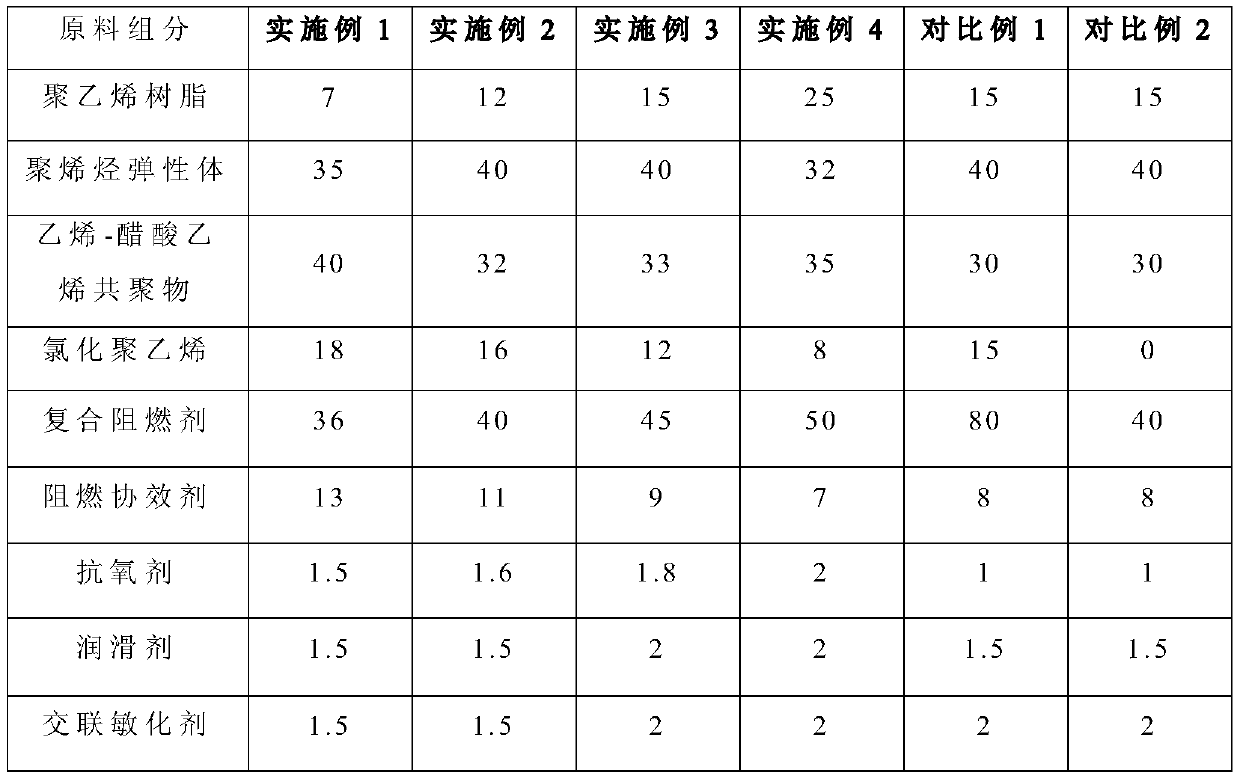

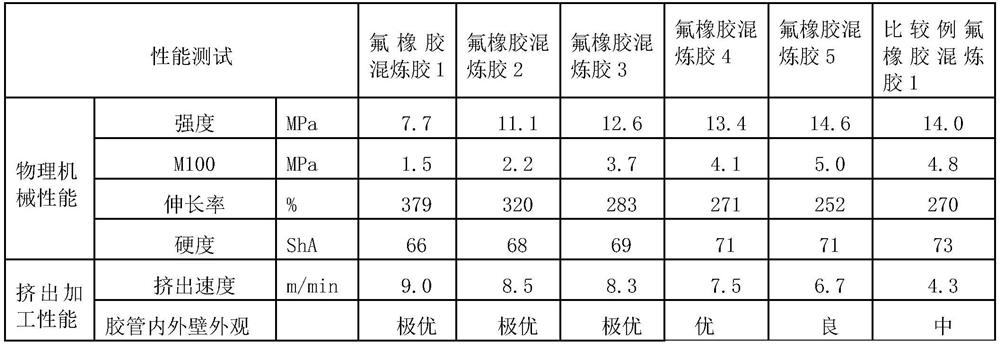

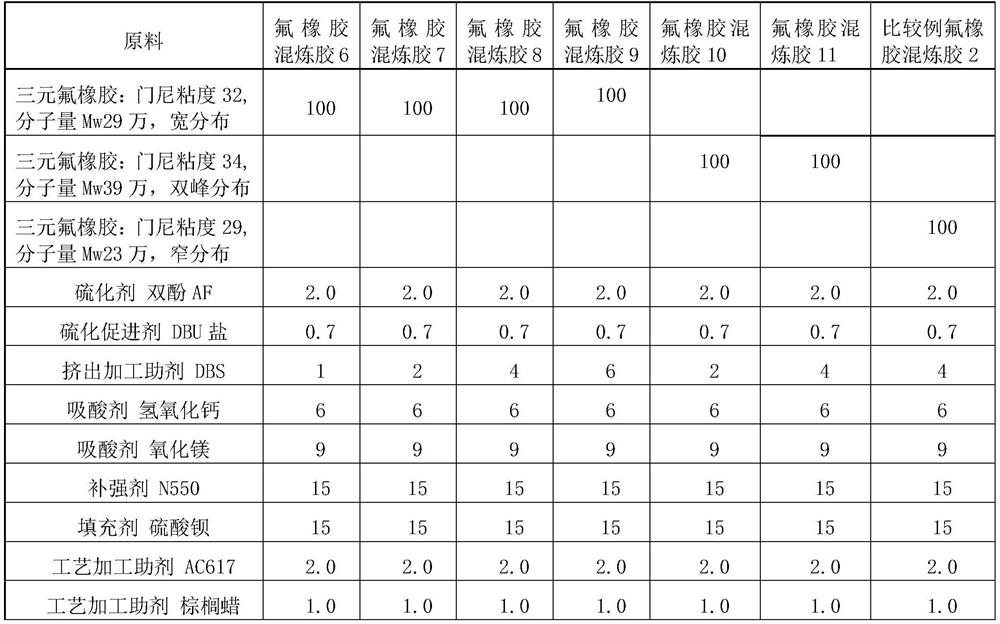

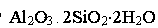

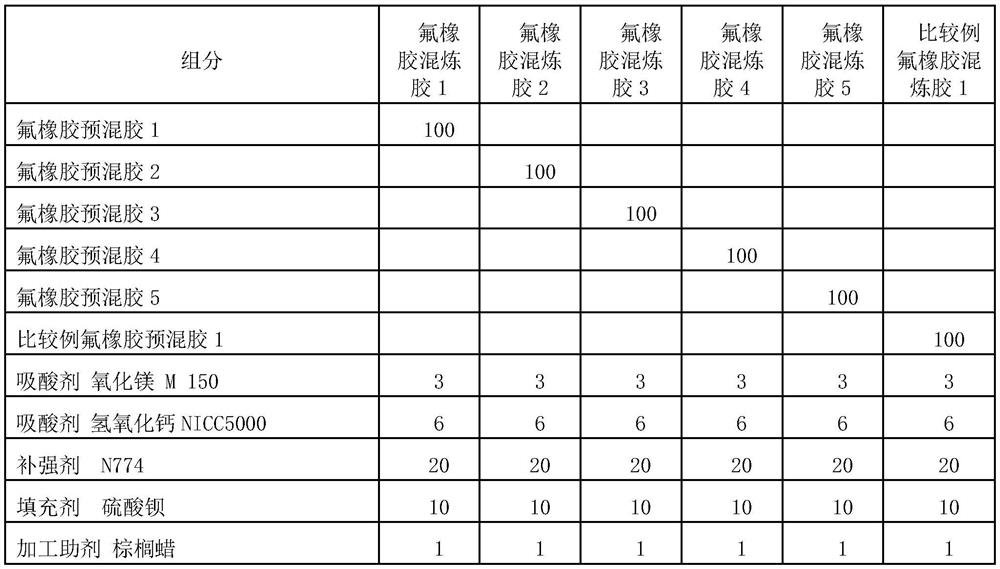

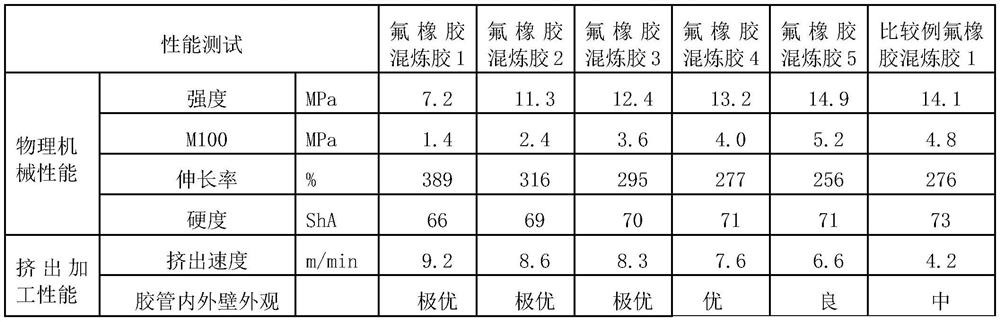

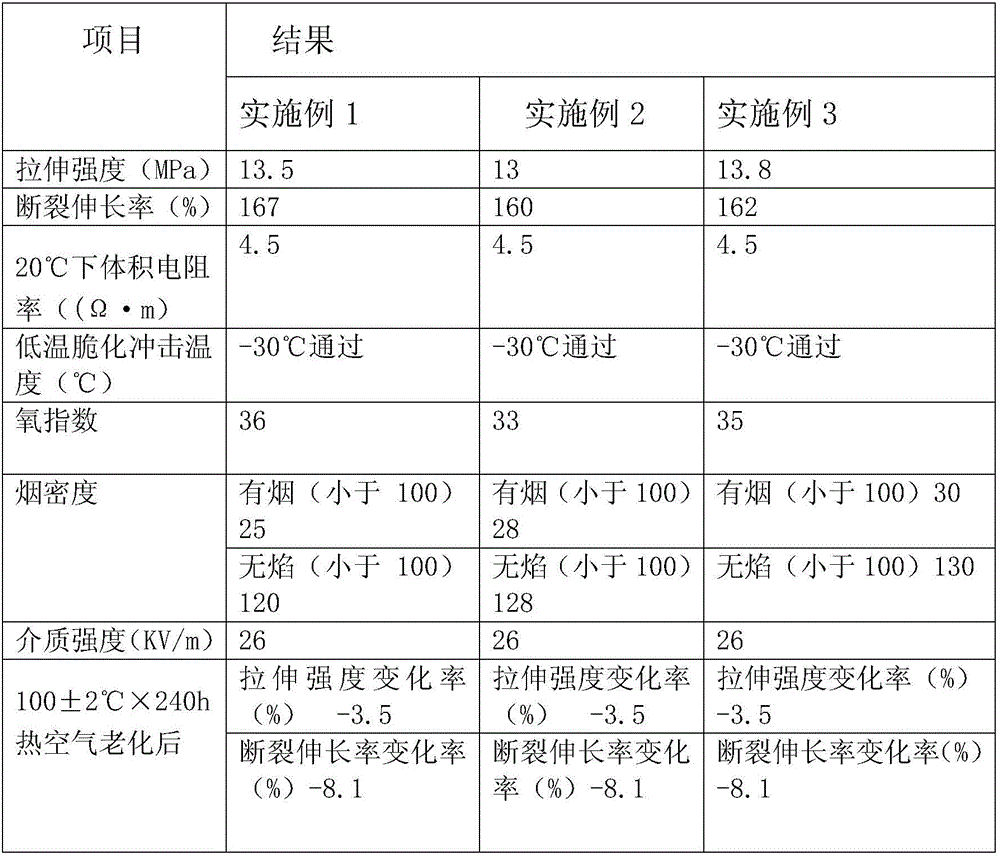

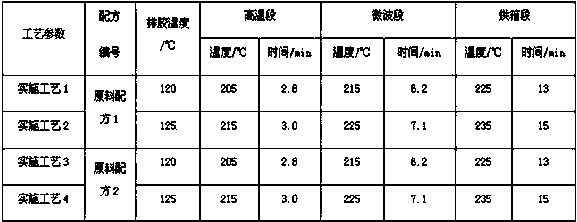

Extrusion-grade fluororubber compound with low fuel oil permeability and preparation method thereof

Owner:成都道弘氟橡胶有限公司

Modified polypropylene for manufacturing optical fiber buffer tube, manufacturing process and production system thereof

ActiveCN102850665BGood impact resistanceImprove bending resistanceFibre mechanical structuresAntioxidantPolypropylene

The present invention discloses modified polypropylene for manufacturing an optical fiber buffer tube, a manufacturing process and a production system thereof. The modified polypropylene comprises the following components, by weight, 96.0-97.5% of a polypropylene-polyethylene copolymer base material, 0.5-2.5% of a nucleating agent, 0.001-0.05% of a coupling agent, 0.4-2.0% of an antioxidant, and 0.5-3.0% of an additive. The manufacturing process comprises: making a rheological agent into master batch by using a polypropylene-polyethylene copolymer base material; carrying out a surface treatment on an inorganic nucleating agent by using a coupling agent; adding the polypropylene-polyethylene copolymer base material, the prepared master batch, an organic nucleating agent, the surface-treated inorganic nucleating agent, an antioxidant and a lubricant to a stirring mixing apparatus to mix to prepare a mixture; adding the mixture to a plastic extruding apparatus to carry out mastication and extrusion, and then carrying out cooling and pelletizing; and carrying out weighing and packaging. The modified polypropylene of the present invention has good impact resistance, and has mechanical and processing properties of the optical fiber buffer tube.

Owner:JIANGSU NANFANG COMM TECH

Extrusion-grade fluororubber premix with low fuel oil permeability and preparation method thereof

The invention provides an extrusion-grade fluororubber premix with low fuel oil permeability and a preparation method thereof, and solves the technical problems of high fuel oil permeability, poor extrusion processability and poor composite bonding performance with other rubber of an automobile fuel oil rubber hose prepared from an existing fluororubber material. The fluororubber premix is prepared from the following raw materials in parts by weight: 100 parts of fluororubber raw rubber, 1.2 to 2.5 parts of a vulcanizing agent, 0.2 to 1.0 part of a vulcanization accelerator, 1-6 parts of an extrusion processing aid, and 0.5-3 parts of a technological processing aid. The fuel oil permeability is improved by selecting the fluorine content of the fluororubber raw rubber; the composite bondingperformance with other rubber is improved by selecting a vulcanization accelerator; the extrusion processability is improved by selecting fluororubber raw rubber with wide distribution and bimodal distribution and an extrusion processing aid. The environment emission standard is met, so that the method is widely applied to the rubber pipe industry with more strict requirements.

Owner:成都道弘氟橡胶有限公司

Low-smoke flame-retardant cable material and preparing method thereof

The invention discloses a low-smoke flame-retardant cable material and a preparing method thereof. The material is prepared from, by weight, 20-25 parts of low-density polyethylene, 15-20 parts of ethylene-vinyl acetate copolymer, 12-18 parts of EVA resin, 45-55 parts of modified nano-magnesium hydroxide, 0.2-0.4 part of nano aluminum nitride powder, 1-2 parts of a cross-linking agent, 1-2 parts of calcium stearate, 1-2 parts of stearic acid, 0.2-0.4 part of ultraviolet light absorber UV-531, 8-15 parts of smoke inhibitor, 20-40 parts of compatilizer, 7-10 parts of a processing agent, 3-6 parts of antioxidant, 1-3 parts of a temite resisting agent and an appropriate amount of deionized water. The low-smoke flame-retardant cable material has excellent flame retardance and non-combustion-delay performance, fuming amount is small during combustion, toxic gas and corrosive gas are not generated, and the low-smoke flame-retardant cable material is good in low temperature resistance and ultraviolet resistance.

Owner:ANHUI TIANYUAN CABLE

Production process and products of EPDM microporous backing plate

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com