Patents

Literature

123results about How to "Moderate adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

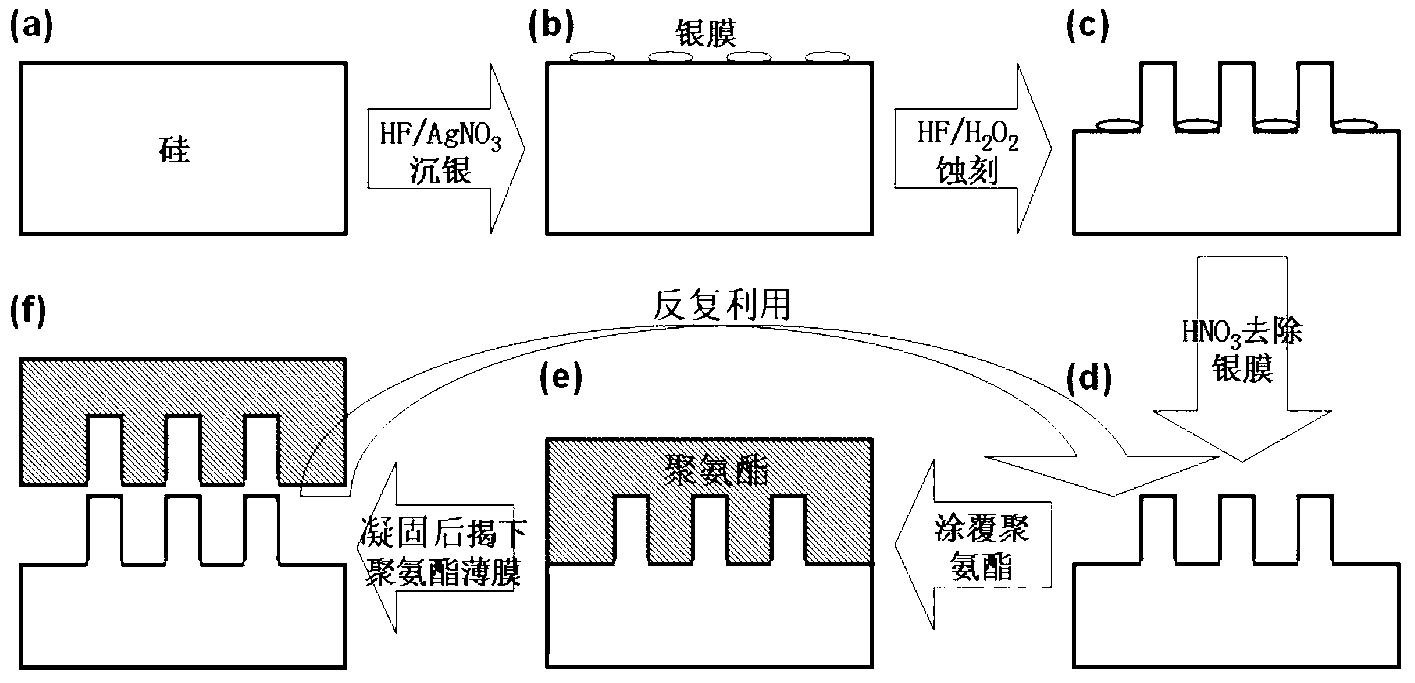

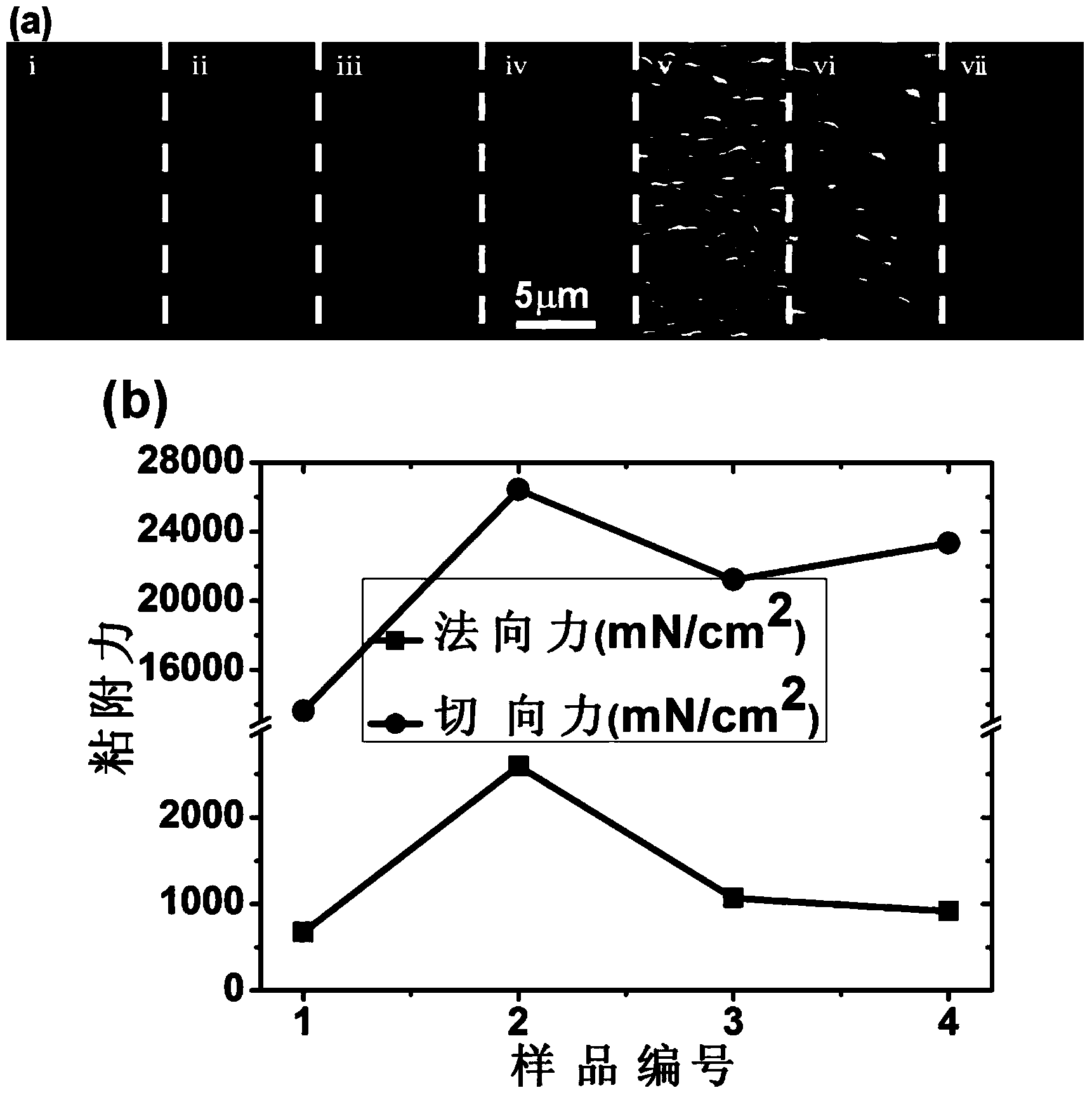

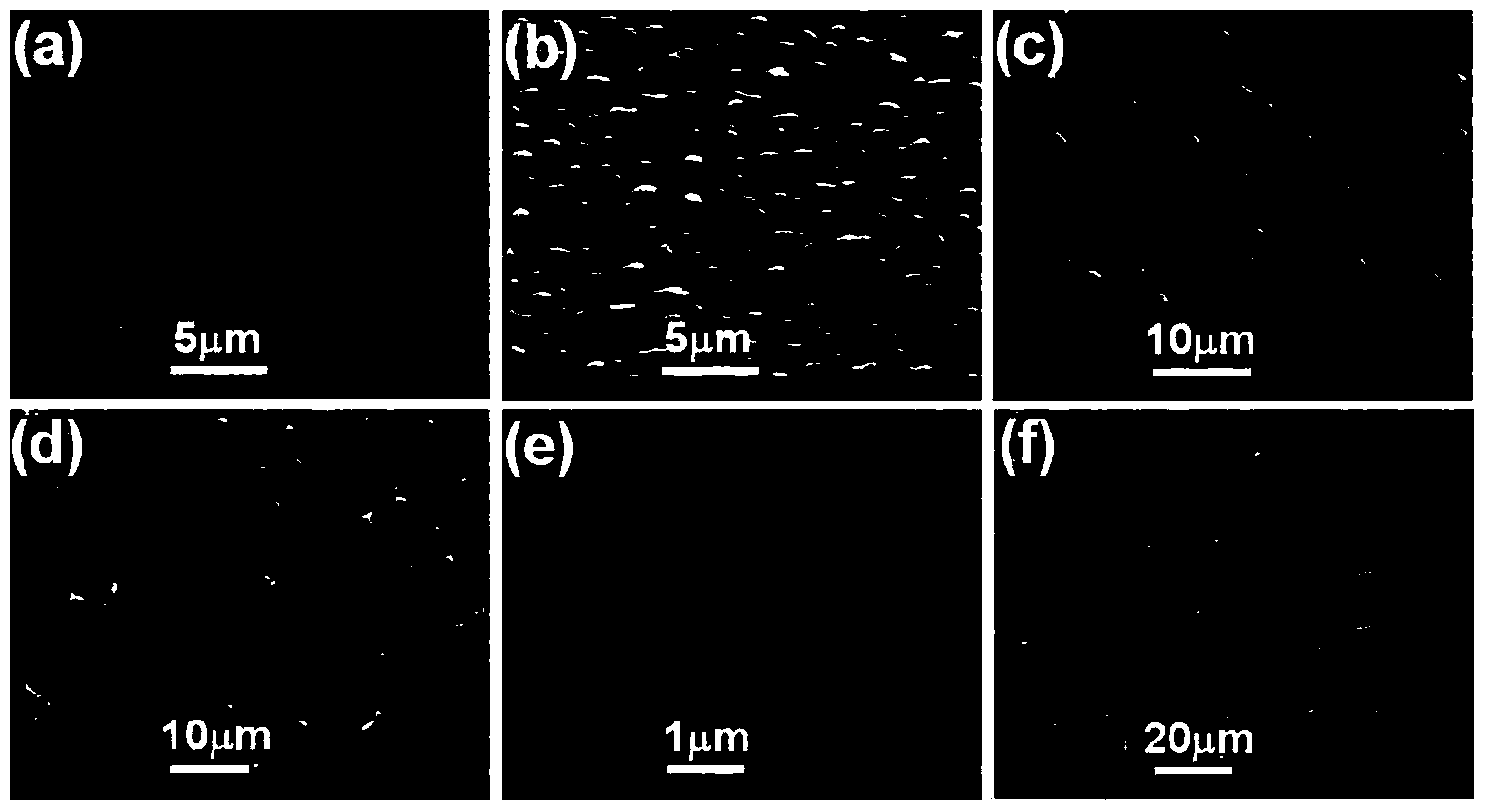

Method for preparing high-adhesion micro-nano array structure film through wet etching and reverse transfer printing

InactiveCN104045054ARaise the ratioGood repeatabilityDecorative surface effectsChemical vapor deposition coatingMicro nanoPotassium hydroxide

The invention discloses a method for preparing a high-adhesion micro-nano array structure film through wet etching and reverse transfer printing. The method comprises the following steps: with a silver nitrate / hydrofluoric acid solution as a silver deposition solution, depositing a layer of porous silver film on a silicon chip so as to obtain an etching catalytic metal and etching a desired micro-nano array structure in a hydrofluoric acid / hydrogen peroxide solution or potassium hydroxide / isopropanol solution; carrying out soaking with concentrated nitric acid so as to remove the silver film, carrying out air drying and using the treated silicon chip as a template silicon chip; uniformly coating the template silicon chip with organic matter colloid and standing the template silicon chip for a period of time; and placing the template silicon chip on a heating plate after precipitation and uniform distribution of bubbles, heating the template silicon chip at a certain temperature for a period of time, stripping off a colloid film when the colloid completely solidifies and printing a reversed structure of the prepared micro-nano array structure on the colloid film through transfer printing so as to realize preparation of the high-adhesion micro-nano array structure film. The method is simple to operate, has low cost, is not restricted by a preparation area and can be extensively applied to the field of bionic adhesion.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

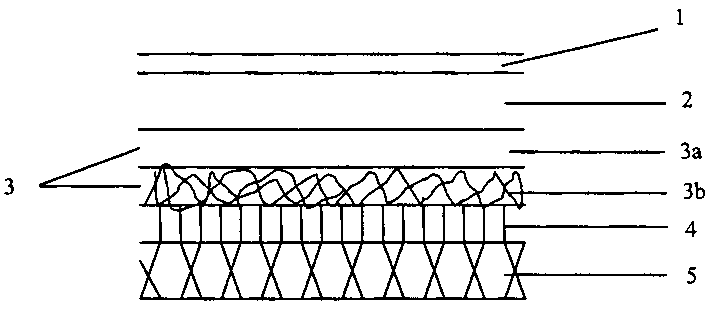

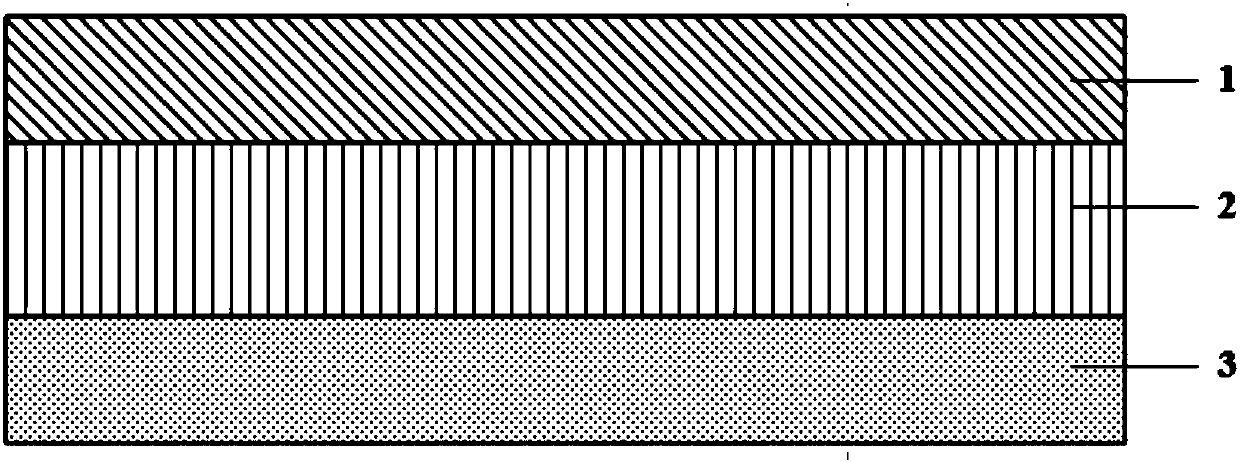

Composite substrate for fabricating flexible display, fabrication method of composite substrate and fabrication method of active matrix/organic light emitting diode (AMOLED)

InactiveCN105789440AFacilitate strippingAvoid connectionSolid-state devicesSemiconductor/solid-state device manufacturingComposite substrateDisplay device

The invention provides a composite substrate for fabrication of flexible display. The composite substrate comprises a hard substrate, wherein a high-temperature resistant flexible substrate layer is arranged on the surface of the hard substrate, a high-temperature resistant thin film layer is arranged between the high-temperature resistant flexible substrate layer and the hard substrate, and the bonding force between the high-temperature resistant thin film layer and the hard substrate is larger than that between the high-temperature resistant thin film layer and the high-temperature resistant flexible substrate layer. In a flexible display thin film transistor (TFT) process of the composite substrate, a flexible substrate and the hard substrate are connected by the high-temperature resistant thin film layer on the hard substrate and a composite layer structure of the high-temperature resistant flexible substrate layer without the adoption of a binding agent, and the bonding force between layers is moderate; the material selects a high-temperature resistant material, so that the mass production of a flexible active matrix / organic light emitting diode (AMOLED) display device by a high-temperature FTF process is achieved; and moreover, the difference of the binding force between layers can be used for facilitating the striping of the flexible substrate after a high temperature.

Owner:SHENZHEN TCL IND RES INST

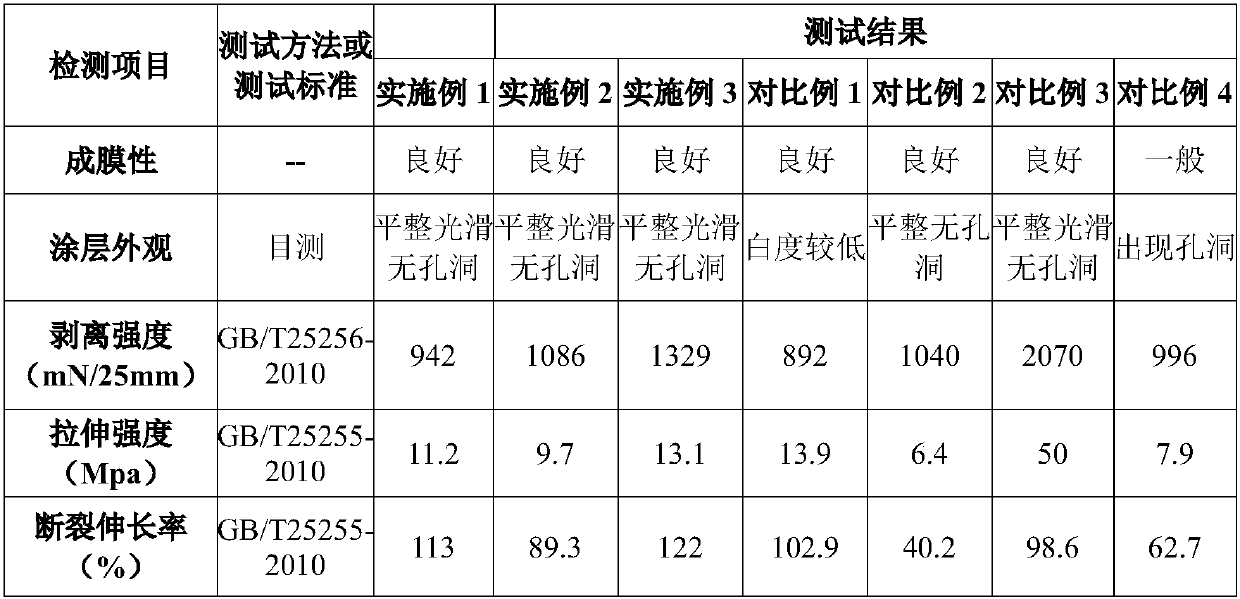

Self-adhesive EVA (Ethylene-Vinyl Acetate) protective film and manufacturing process thereof

ActiveCN103640288AModerate adhesionEasy to pasteSynthetic resin layered productsForeign matterPolymer science

The invention relates to the technical field of protective films and particularly relates to a self-adhesive EVA (Ethylene-Vinyl Acetate) protective film and a manufacturing process thereof. The self-adhesive EVA protective film is formed by a film which is coextruded and adhered by a base film layer, a middle layer and a self-adhesive layer. Especially, due to the self-adhesive layer, adhesive force of the EVA self-adhesive protective film is moderate, so that the self-adhesive EVA protective film is easily stuck and torn; after the film is stuck, the change of the adhesive force along with the time is small, the self-adhesive EVA protective film can be stuck repeatedly without adhesive failure and residual foreign matters, and can be used in special and large-corner surfaces with a radian and without upwarping; since the specific material combination of the base film layer, the middle layer and the self-adhesive layer is adopted, the impact resistance is also greatly improved; the manufacturing process of the self-adhesive EVA protective film is low in cost and is simple.

Owner:东莞市尼的科技股份有限公司

Protection film used for surface of NFC and preparation method of protection film

ActiveCN105482731AReduce surface glossSolvent resistantFilm/foil adhesivesInksTectorial membraneEngineering

The invention relates to a protection film used for the surface of NFC. The protection film comprises a PET base material layer, an adhesive layer arranged on one side of the PET base material layer and a release film layer attached to the adhesive layer. A black ink layer is arranged on the other side of the PET base material layer, the black ink layer is coated with a matte oil layer which is formed by film formation of an organic delustering agent, the black ink layer contains 0.5%-0.8% of aluminum compound, and the mean grain size of the aluminum compound ranges from 0.2 mm to 0.5 mm. The invention further relates to a preparation method of the protection film. The matte oil layer prevents fingerprints and scratches, meanwhile, the protection film has the functions of resisting solvents, achieving heat radiation and the like, and the service life of an NFC chip can be effectively prolonged. In addition, the aluminum compound is added to the black ink layer, waves, interfering with communication message receiving of a mobile phone, sent by the NFC chip can be shielded, it is guaranteed that the adhesive force of the adhesive layer of the protection film is moderate, the protection film can be completely attached to the surface of NFC, and adhesive residues or other pollution cannot be caused to the surface of NFC after the protection film is removed.

Owner:NINGBO SOKEN CHEM

UV photocuring blue nail polish

InactiveCN104027261AModerate adhesionMeet the attachment effectCosmetic preparationsToilet preparationsOrganic solventNail lacquer

The invention relates to the technical field of printing ink and particularly relates to UV photocuring blue nail polish. The UV photocuring blue nail polish comprises the following components in percentage by weight: 35-55% of polyurethane acrylate, 20-35% of trimethylolpropane triacrylate, 15-20% of epoxy acrylate, 3-5% of a photoinitiator, 1-5% of an indigo dye and 0.5-1% of a flatting agent. The UV photocuring blue nail polish provided by the invention is moderate in adhesive force, can satisfy the adhering effect on nails and can be easily stripped from the nails, and assistant stripping due to addition of an organic solvent is avoided, so that the damage of a stripping solution on the nails is effectively prevented.

Owner:ZHANGJIAGANG MAOAN TRADING

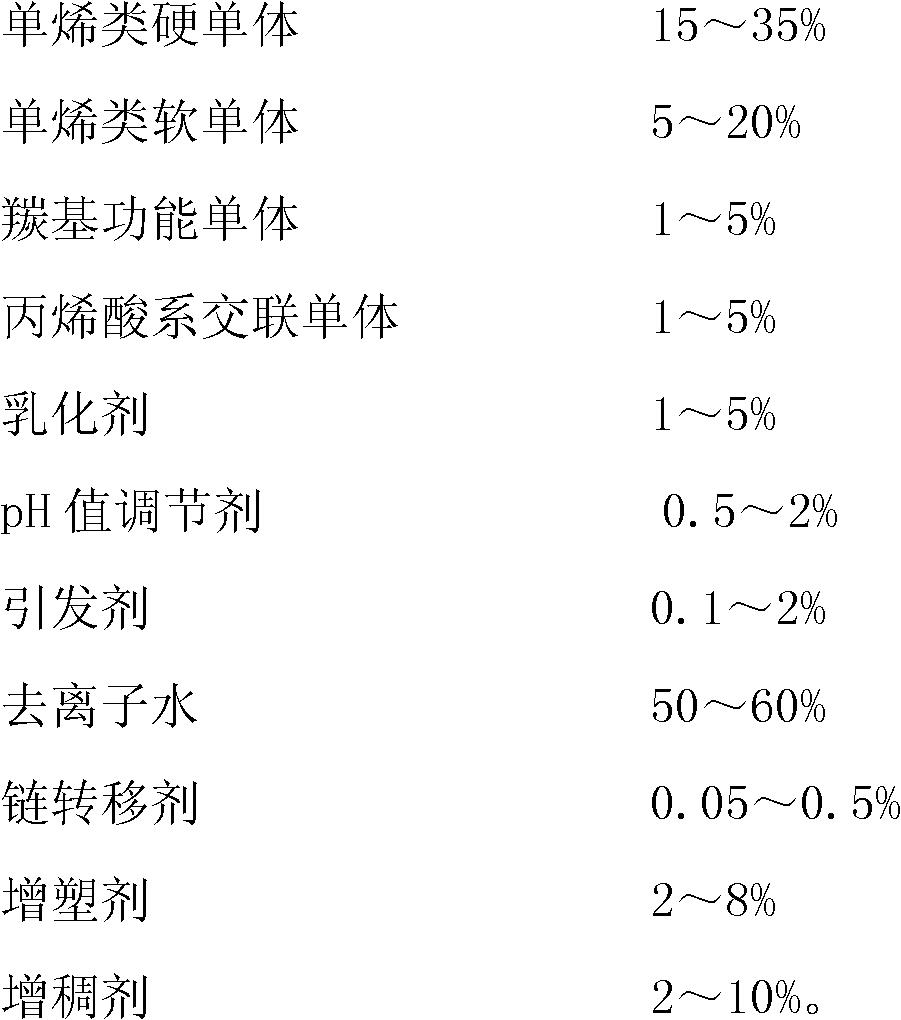

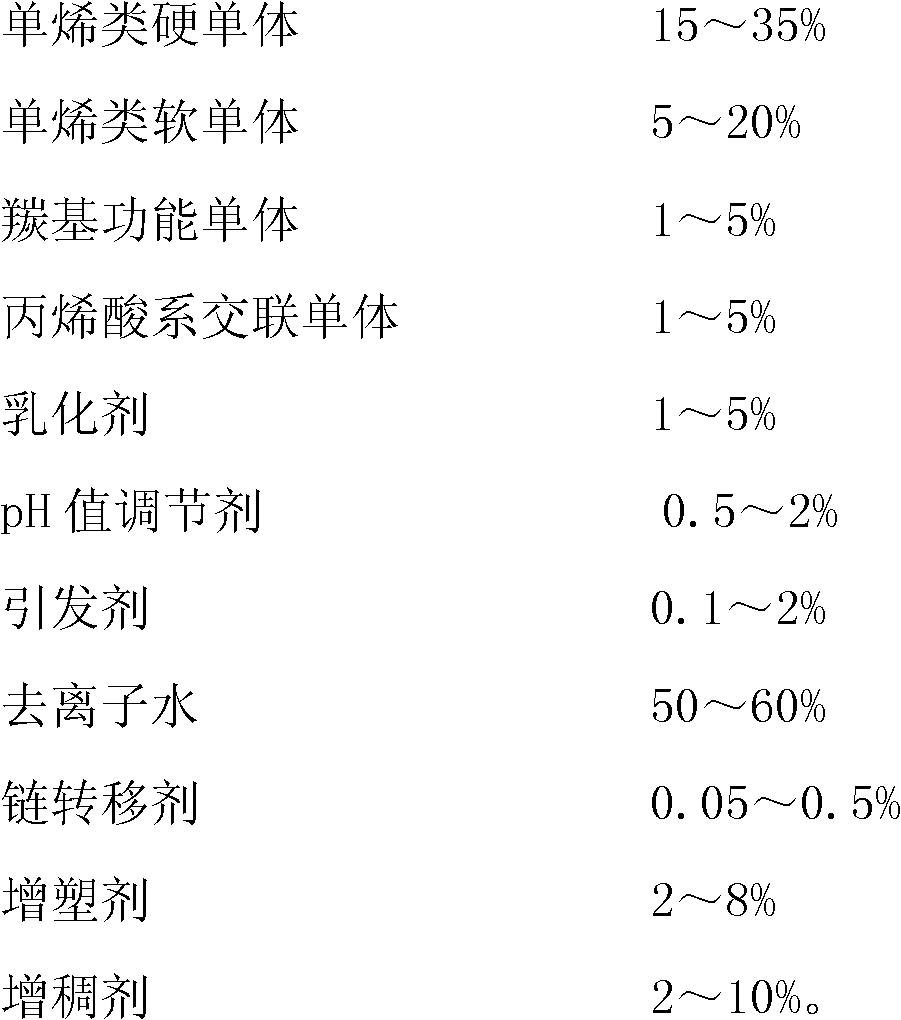

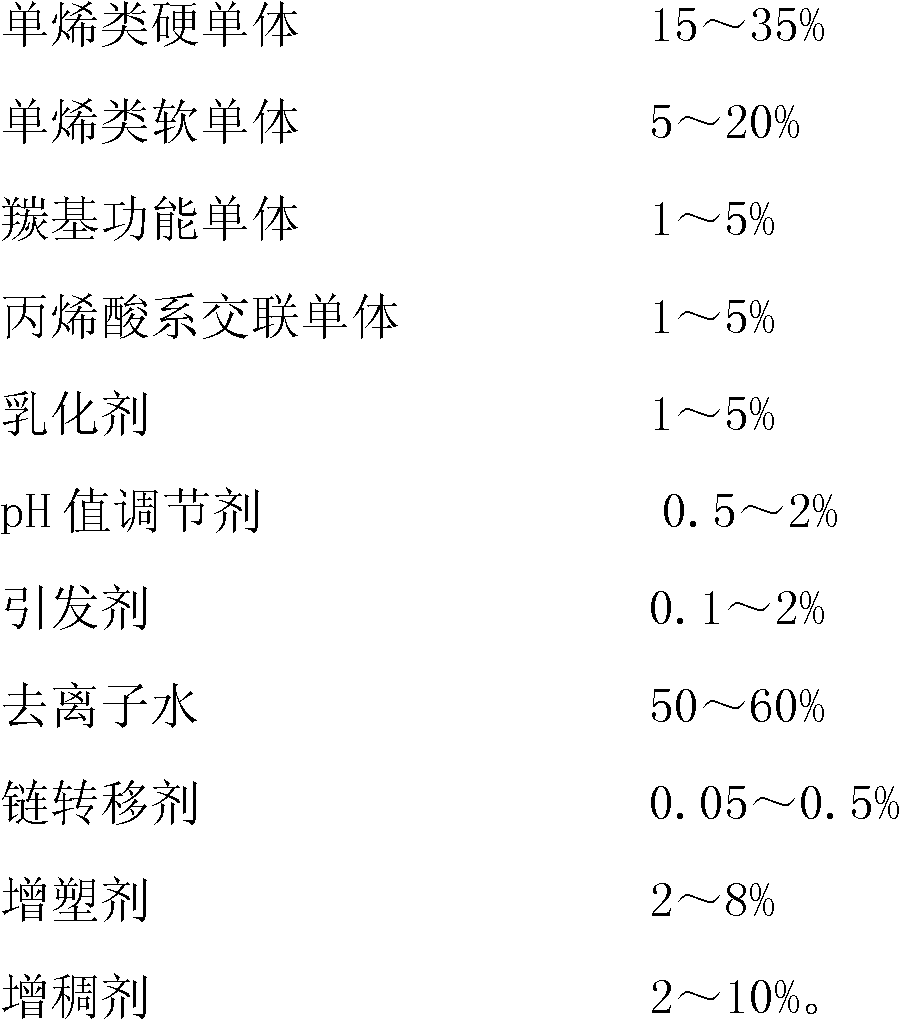

Water-emulsion plant adhesive and its preparation method

InactiveCN102433093AEliminate pollutionModerate adhesionEster polymer adhesivesFunctional monomerEmulsion

Belonging to the field of adhesive preparation, the invention discloses a water-emulsion plant adhesive and its preparation method. The adhesive is formed through polymerization of a monoene hard monomer, a monoene soft monomer, a carbonyl functional monomer, an acrylic crosslinking monomer, an emulsifier, a pH value conditioning agent, an initiator, deionized water, a chain transferring agent, aplasticizing agent and a thickening agent. The vitrification temperature Tg of the adhesive is 15-65DEG C. Compared with current solvent type bicomponent plant adhesives, the adhesive provided in theinvention has the advantages of safety and environmental protection, as well as higher microbead transfer rate.

Owner:NANTONG GAOMENG NEW MATERIAL

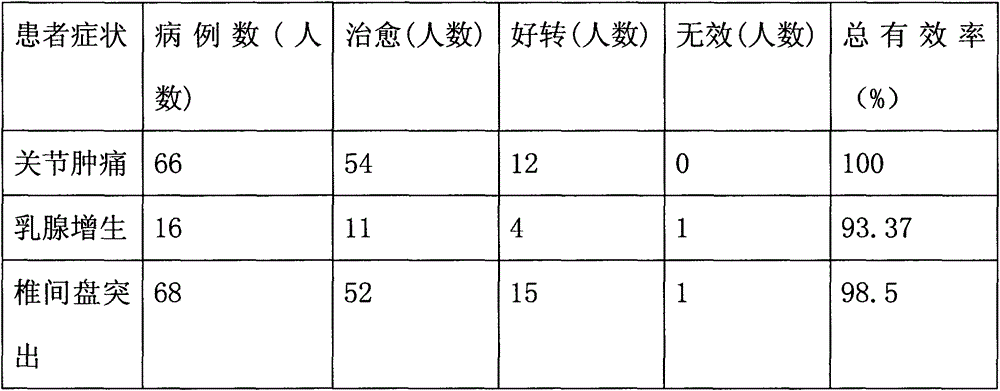

External rheumatalgia-relieving bone penetrating plaster and preparation method thereof

InactiveCN104436103AAvoid side effectsImprove permeabilityHeavy metal active ingredientsNervous disorderDiseaseSide effect

The invention discloses an external rheumatalgia-relieving bone penetrating plaster, consisting of an A group of crude medicament prescription, a B group of crude medicament prescription, a C group of crude medicament prescription and a novel modified plaster matrix, wherein the ratio of the A group of crude medicament prescription, the B group of crude medicament prescription to the novel modified plaster matrix is 1: 1: (3-4). The external rheumatalgia-relieving bone penetrating plaster has the advantages that the plaster can also be made into a wet application plaster and a powder plaster; the rheumatalgia-relieving bone penetrating plaster treats diseases when being externally applied to a local part or an acupuncture point; the plaster has good slow-release property, strong penetrability, good softness and moderate adhesive force, does not have toxic or side effect, and can be applied for 3 to 6 days; and the preparation method of the plaster is simple, low in labor intensity, short in man-hour and low in cost.

Owner:王全文

Strippable semi-conductive shielding material for ethylene propylene rubber cable

InactiveCN102558660AExcellent performance indexSemi-conductive and stableInsulated cablesInsulated conductorsVulcanizationPolymer science

The invention discloses a strippable semi-conductive shielding material for an ethylene propylene rubber cable. The shielding material is prepared by mixing the following raw materials in part by weight: 70 parts of ethylene vinyl acetate, 30 parts of chlorinated polyethylene, 50 to 70 parts of conductive carbon black, 5 to 15 parts of coarse-particle carbon black, 5 to 10 parts of metal oxide, 20 to 40 parts of mineral filler, 3 to 20 parts of dispersing agent, 2 to 6 parts of cross-linking agent, 4 to 6 parts of cross-linking aid, 2 to 5 parts of anti-ageing agent and 15 to 20 parts of plasticizer. The defects that the shielding material has overhigh volume resistivity, and insufficient adhesion with an ethylene propylene insulation layer, and is difficult to strip, the shielding material and the ethylene propylene insulation layer cannot be synchronously vulcanized, and the like in the prior art are overcome, and the strippable semi-conductive shielding material for the ethylene propylene rubber cable has high semi-conductivity, high extrusion processability, and moderate adhesion with the insulation layer, is easy to strip and has a vulcanization rate equivalent to that of ethylene propylene rubber.

Owner:重庆鸽牌电线电缆有限公司

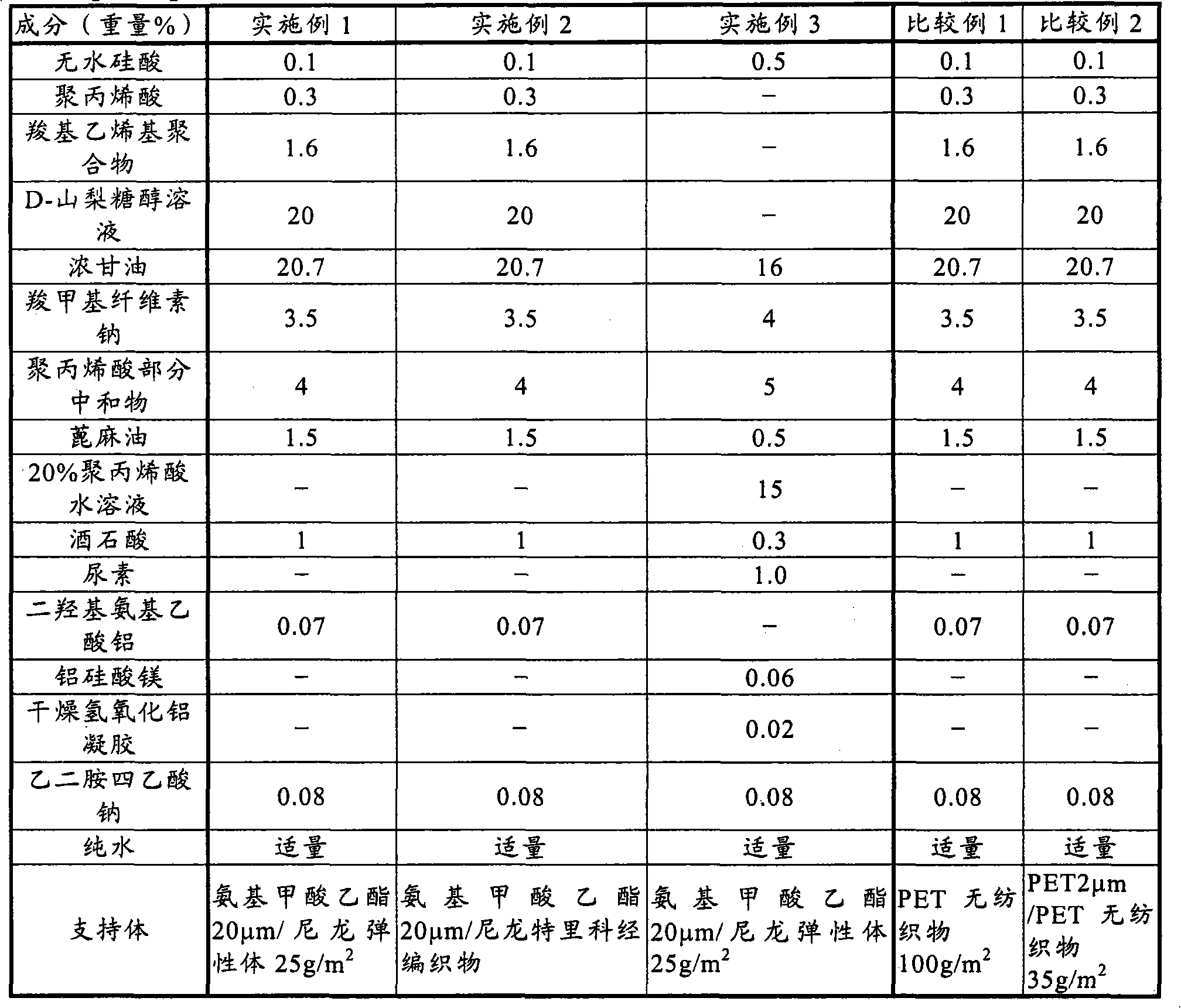

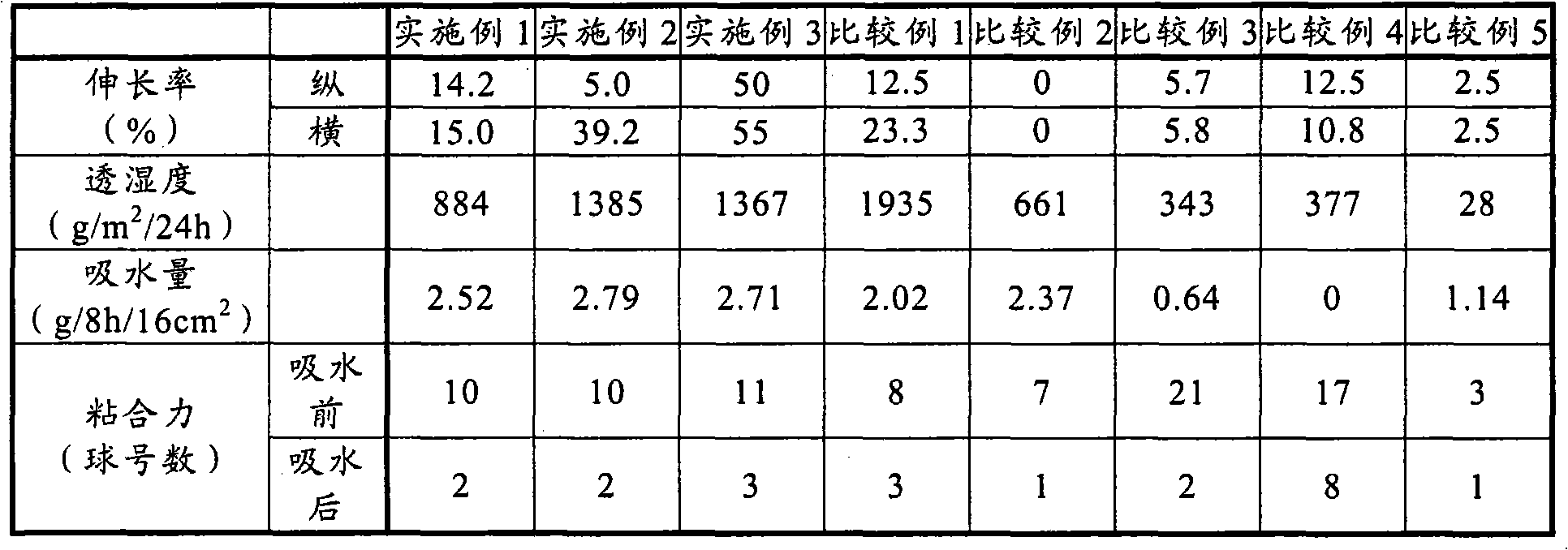

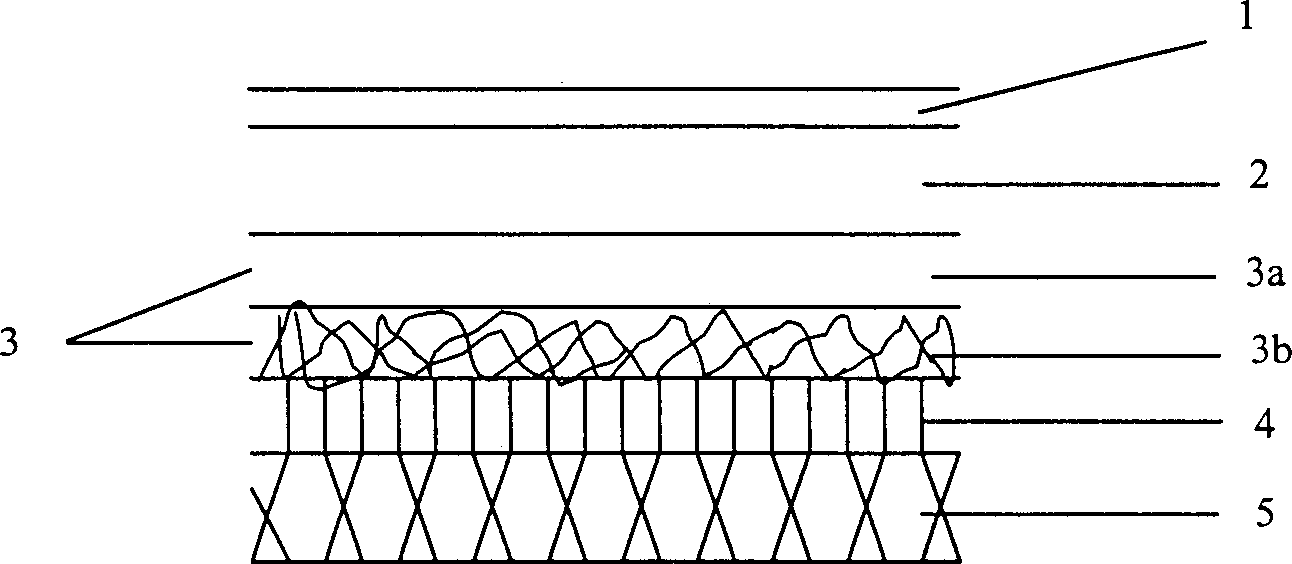

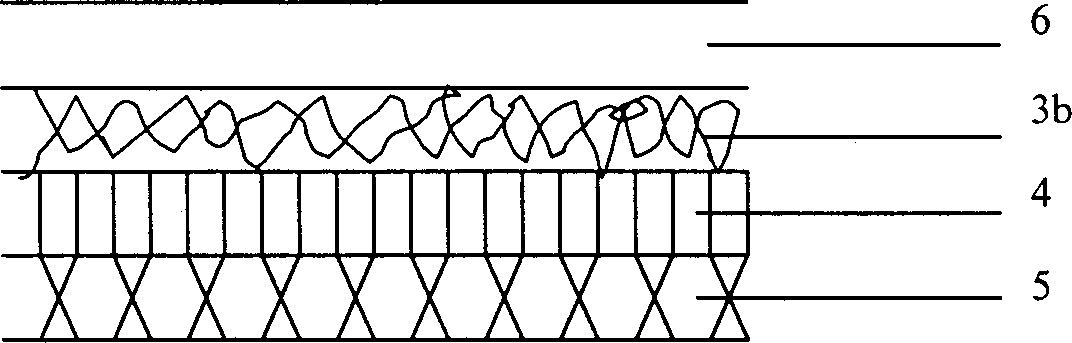

Wound-covering hydrogel material

A wound-covering hydrogel material which has excellent stretchability and absorbs exudates from wounds. It can maintain over long a wet environment which is suitable for accelerating the healing of wounds. There is no fear of causing pain or damaging the regenerated skin when the wound-covering hydrogel material is replaced with a fresh one. The wound-covering hydrogel material comprises: a laminated two-layer film composed of a polyurethane film and hydrophobic fibers; and a hydrogel spread on the laminated film, the hydrogel comprising a water-soluble (semi)synthetic polymer, glycerol, and water. The covering material has a moisture permeability as measured by the cup method in accordance with JIS Z0208 of 500-2,000 (g / m2 / 24h).

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD

Tree spraying agent for offshore dredger fill

InactiveCN104497769AReduce usageModerate adhesionAntifouling/underwater paintsPaints with biocidesFrostEmulsion

The invention provides a tree spraying agent for offshore dredger fill, which comprises 10-25% of calcium carbonate, 10-20% of lithopone, 5-10% of titanium white, 10-20% of cationic mixed emulsion, 0.1-1% of emulsifier, 0.5-1.5% of dispersing agent, 2-5% of bactericide and / or pesticide, 0.5-5% of pearl essence, 0.5-5% of reflective powder and the balance of water. On the premise of ensuring the effects of preventing pests and plant diseases, preventing sunburn and frost damage and the like in the original whitening agent, the spraying agent can adapt to garden trees in offshore dredger fill and other alkaline regions, and has the effect of beautifying.

Owner:天津港海湾园林绿化有限公司

Adherable and peelable plastic printing ink and comprehensive antiforge mark made of said printing ink

An ink able to be adhered to and torn from plastic film is disclosed, which can be used to prepare antiforge marker by gravure printing on plastic film. It features that its antiforge pattern can be torn from plastic film, but not produce, so having high antiforge effect.

Owner:TSINGHUA UNIV

Ultraviolet curing in-situ polymerization reworkable water-proof sealant

InactiveCN110358493AModerate adhesionSimple construction processOther chemical processesPolyureas/polyurethane adhesivesAdhesiveIn situ polymerization

The invention discloses an ultraviolet curing in-situ polymerization reworkable water-proof sealant and relates to the field of photocuring adhesives. The water-proof sealant comprises the following raw materials: an acrylate resin prepolymer, a reactive diluent, a photoinitiator, filling, a thixotropic agent, wax and a stabilizing agent. The ultraviolet curing in-situ polymerization reworkable water-proof sealant is suitable for various plastic substrates and various irregularly shaped sample pieces and can substitute a silica gel sealing material. At the same time, the ultraviolet curing sealant can be polymerized in situ; a construction process is simple and easy to operate; and full curing can be achieved only within tens of seconds. The cured sealant has moderate adhesive strength tothe substrates and can be reworked easily. After curing, the hardness is Shore A20-80; rupture strength is 2-10Mpa; and breaking elongation is 100-500%.

Owner:上海汉司实业有限公司

Sinlmenine hydrochloride plaster and its preparation method

InactiveCN1557310AModerate adhesionIncreased matrix strengthOrganic active ingredientsSheet deliveryWater soluble polymersIrritation

The coculine hydrochloride cataplasma with raised patient compliance includes coculine hydrochloride as medicine component; matrix comprising water soluble polymer skeleton, stuffing, cross-linking agent, cross-linking regulator, humectant and transdermal promoter; and non-woven fabric as lining layer. The preparation process includes dispersing water soluble polymer in glycerin to obtain phase A; mixing cross-linking agent, cross-linking regulator and small amount of deionized water to obtain phase B; adding transdermal promoter, medicine and sufficient deionized water to obtain phase C; mixing phase an and phase B and adding gradually phase C to obtain mixture; painting the mixture onto the lining layer and covering with anti-sticking layer. The present invention has good skin hydrolyzing effect, proper skin affinity, no pain produced during taking off, no irritation on skin and obvious slowly releasing effect.

Owner:SHENYANG PHARMA UNIVERSITY

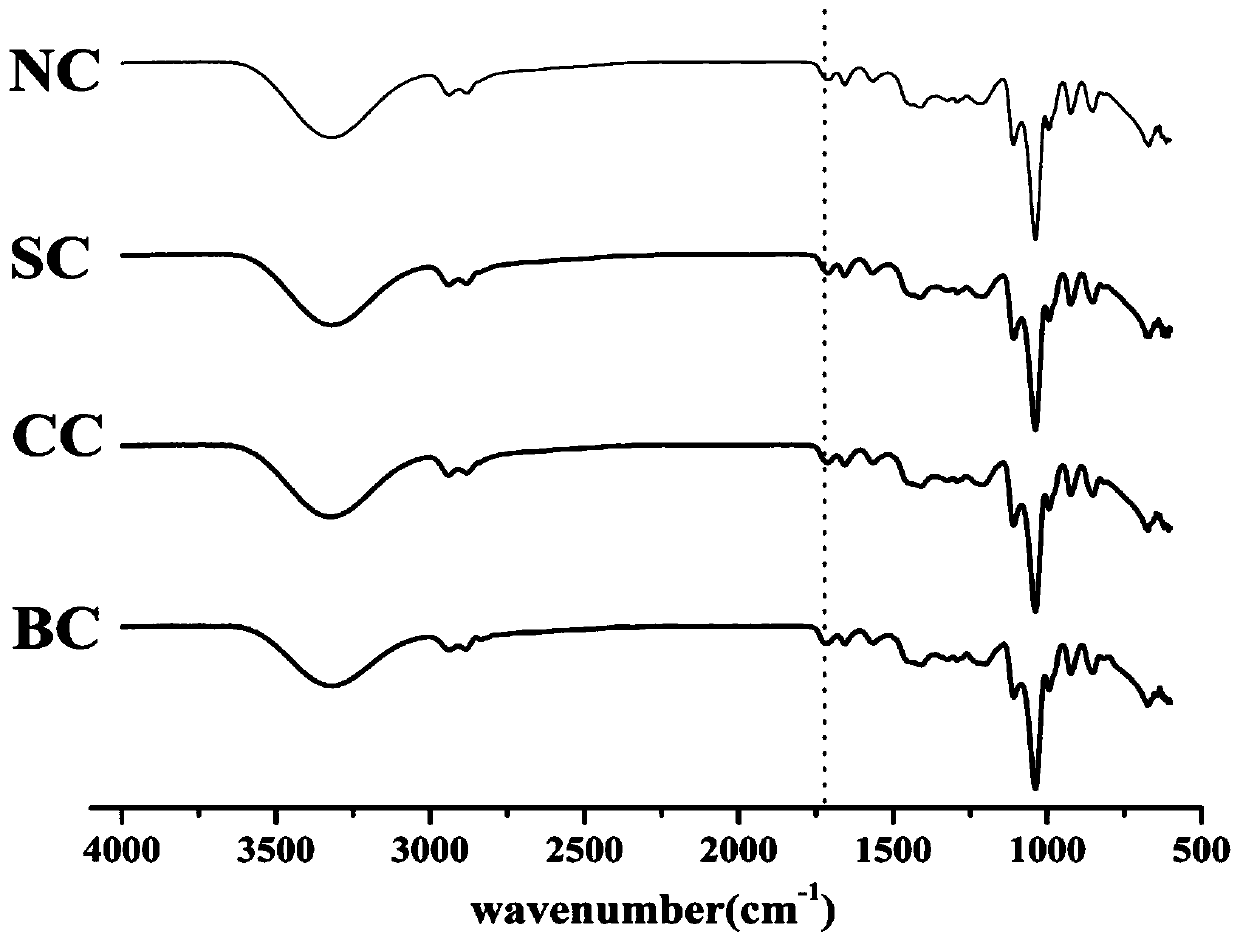

Environment-friendly repeated-writing paper and preparation method therefor

ActiveCN107227651AEasy to wipeImprove writing effectNatural cellulose pulp/paperWater-repelling agents additionCleansers skinHandwriting

The invention discloses environment-friendly repeated-writing paper and a preparation method therefor. According to the environment-friendly repeated-writing paper and the preparation method therefor, a hydroxyl protective group is added into a nano bacterial cellulose suspension with excellent characteristics such as high water absorptivity and water retention ability and good water and air permeability, so as to lower hydrophilicity; a staged reaction is carried out under strong base conditions, so that bacterial cellulose reaches moderate water absorptivity and water retention ability, ink can only be present in a surface layer and be clear in writing while the ink is absorbed, and thus, writing, reading and subsequent handwriting wiping are facilitated; then, a scientifically-compounded dispersant is added, and ultrasonic and high-voltage pulse electric field combined dispersion is carried out, so that a stable and uniform modified bacterial cellulose suspension is obtained; finally, the surface of raw paper is coated with the suspension so as to obtain the writing paper with appropriate ink absorbing uniformity and adhesive power and a dense structure, thus, the writing property of the writing paper can be enhanced, and the clearness of writing is enhanced; and waterproofing and oil-proofing actions can be achieved, most importantly, ink marks on the paper can be erased with a cleanser and the paper can be reused for 40 to 100 times under the condition that the performance of the paper is not affected.

Owner:BEIJING GUANLAN TECH

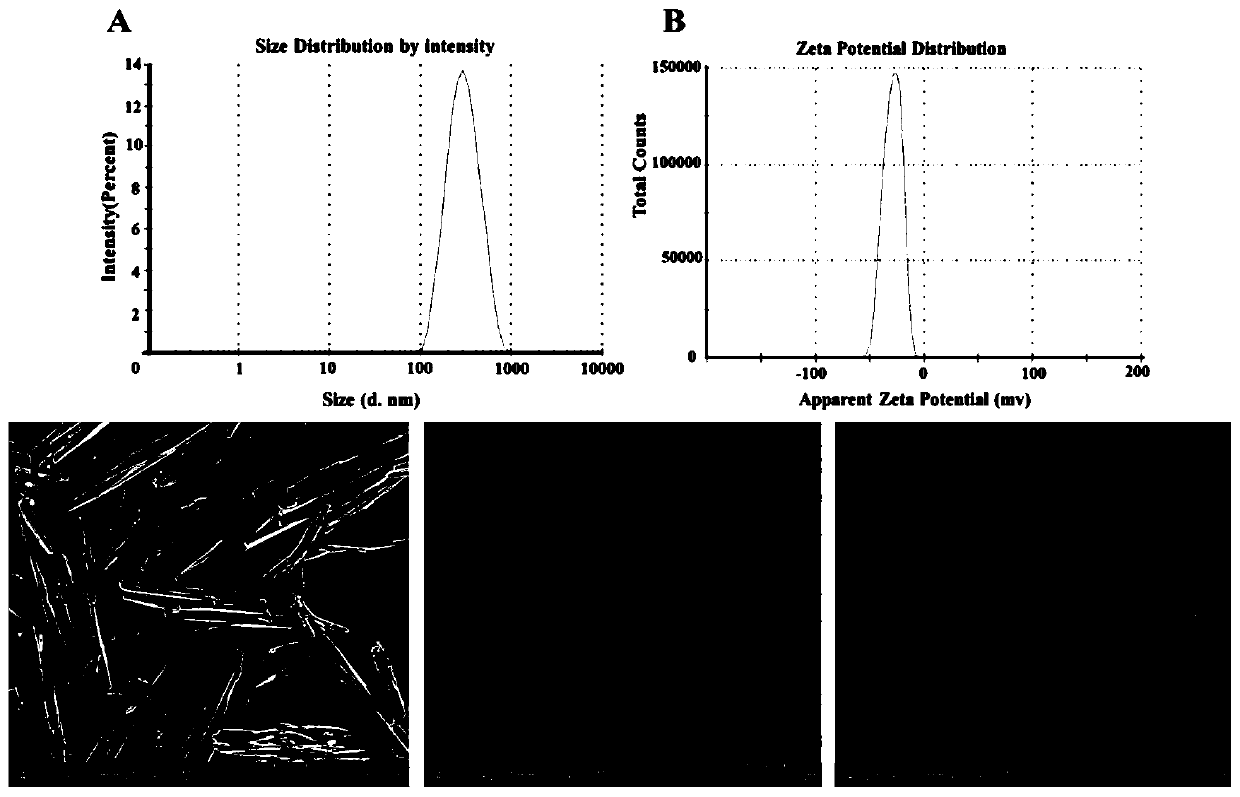

Transdermal gel patch for promoting drugs with low skin absorption ability and preparation method of transdermal gel patch

PendingCN110787152AEasy to prepareFew excipientsPowder deliveryOrganic active ingredientsBiomedical engineeringTransdermal absorption

The present invention relates to the technical field of medicines and particularly to a transdermal gel patch for promoting drugs with low skin absorption ability and a preparation method of the transdermal gel patch. The transdermal gel patch comprises (1) an outward-facing backing layer; (2) a gel layer applied on the backing layer; and (3) a removable anti-adhesion layer; and the gel layer contains nano-drugs or drug-loaded mesoporous silica dispersion drugs. Nano drug crystals reduce drug particle size to a nanometer level, surface area is increased, while the drug-loaded mesoporous silicadispersion mainly increases concentration difference between a preparation and a skin layer by amorphously transforming the drugs to increase infiltration capacity, and higher drug utilization rate for transdermal drug administration can be realized. The prepared gel patch is free of skin irritation, has a function of softening stratum corneum, has suitable peeling strength and rheological properties, further promotes transdermal absorption of the drugs, provides new ideas for development of traditional drugs and provides a reference for an application of a modern preparation technology in atransdermal drug administration system.

Owner:NINGXIA MEDICAL UNIV

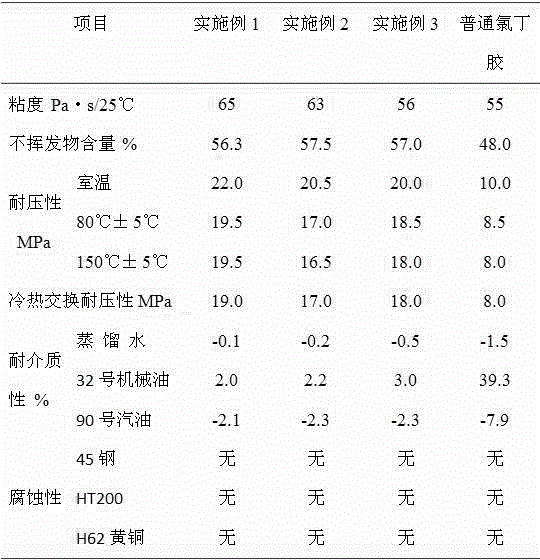

Oil-resistant liquid sealant and preparation method thereof

ActiveCN103602285AGood oil resistanceExcellent medium resistanceNon-macromolecular adhesive additivesOther chemical processesPolymer scienceNitrile rubber

The invention belongs to a sealant, and particularly relates to a solvent type oil-resistant liquid sealant and a preparation method thereof. The solvent type oil-resistant liquid sealant comprises the following components: 15-30% of nitrile rubber, 2-5% of tackifying resin, 20-45% of reinforcing filler, 0-5% of pigment, 0.5-2% of antiager and 0-60% of solvent. The preparation method comprises the following steps: firstly putting the nitrile rubber into a rubber refining machine, plasticizing so as to form a thin film and cutting the thin film into pieces for standby application; putting the weighed solvent, filler and pigment into a reaction kettle in proportions, stirring for about 1 hour at a high speed, then putting the tackifying resin and the antiager into the reaction kettle, stirring, putting the treated nitrile rubber into the reaction kettle, stirring for about 4-5 hours at a high speed, after dissolving materials into a bright white uniform viscous glue solution, cooling and carrying out vacuum defoaming so as to obtain the oil-resistant liquid sealant. The oil-resistant liquid sealant is convenient to use and has excellent pressure-resistant property, medium-resistant property and endurance property.

Owner:GLEIHOW NEW MATERIALS CO LTD

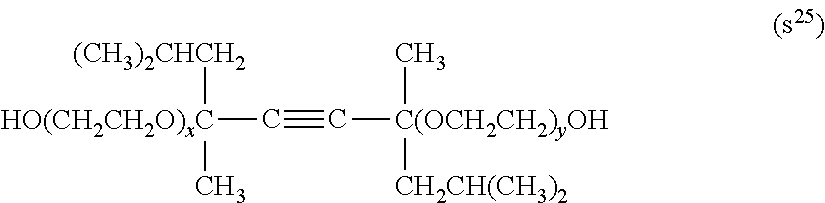

Release agent composition

The present invention provides a release agent composition which can impart moderate adhesion and releasability to the surface of articles such as protective materials for adhesive face of repositional notes, pressure-sensitive adhesive sheets and tapes, release films and release paper, and which has a low environmental burden, and its production process.The release agent composition of the present invention is characterized by comprising a fluorocopolymer having structural units based on a monomer (a) having a C1-6 polyfluoroalkyl group and structural units based on a (meth)acrylate (b) having a C18-30 alkyl group, and a medium.

Owner:ASAHI GLASS CO LTD

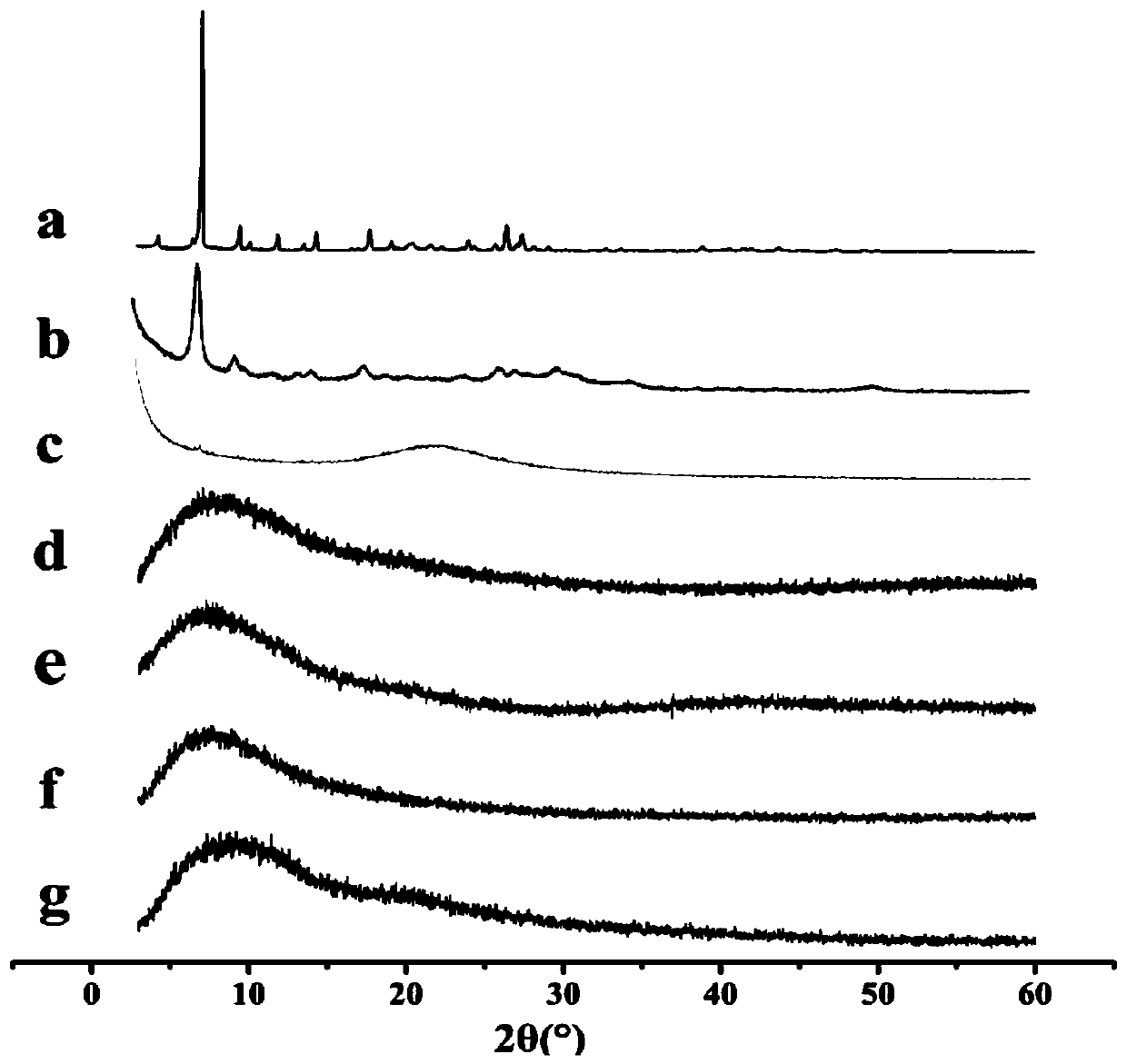

Preparation method of layered nickel cobalt lithium manganate cathode material

InactiveCN105789614AEvenly embeddedImprove electrochemical performanceSecondary cellsPositive electrodesManganateMixed materials

The invention relates to a nickel cobalt lithium manganate cathode material, in particular to a preparation method of a layered nickel cobalt lithium manganate cathode material. The preparation method comprises the following steps: feeding a mixture of solid-state Mn(NO3)2, CoCO3, Ni(NO3)2.6H2O and Li2CO3 into an inner cavity of a rotating drum according to a stoichiometric ratio; throwing out the mixture from the inner cavity by using the rotating drum under the action of centrifugal force, and feeding the mixture into the inner cavity of the drum again to obtain a uniform mixture; adding a dispersant to the uniform mixture for ball milling; placing ball-milled slurry in a drying oven for drying to obtain a precursor; presintering the precursor in a resistance furnace; grinding the presintered precursor, and placing the ground materials in a rotary roaster for roasting. According to the preparation method of the invention, the centrifugal force and a fan are used to enable the mixed materials to achieve irregular circulating motion, so as to achieve the purpose of mixing the materials uniformly without dead corner; the nickel cobalt lithium manganate cathode material with excellent electrochemical properties is obtained through presintering and roasting.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

UV cured modified thiol resin nail polish and preparation method thereof

PendingCN111035575AFast curingModerate adhesionCosmetic preparationsToilet preparationsPolymer scienceOrganic solvent

The invention provides UV cured modified thiol resin nail polish which comprises the following components in parts by weight: 35-55 parts of modified thiol resin, 30-50 parts of an acrylate compound,3-5 parts of a photoinitiator, 1-5 parts of color paste, 0.3-6 parts of a nanometer oxide, 0.1-0.3 part of an essence and 0.5-1 part of a leveling agent. The UV light-cured red nail polish prepared from the components according to the specific ratio is moderate in adhesive force, good in toughness, not prone to brittle fracture, capable of being rapidly cured under UV light irradiation, convenientto use, free of organic solvents and environmentally friendly.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Tripterygium wilfordii hook extract cataplasm and preparation method thereof

ActiveCN102008536AImprove securityIncrease drug concentrationAntipyreticAnalgesicsBlood concentrationSide effect

The invention discloses a tripterygium wilfordii hook extract cataplasm and a preparation method thereof. The tripterygium wilfordii hook extract cataplasm provided by the invention contains tripterygium wilfordii hook extract and a substrate, wherein the weight ratio of the tripterygium wilfordii hook extract to the substrate is 1:3-12. The tripterygium wilfordii hook extract cataplasm provided by the invention improves the clinical medication security of the tripterygium wilfordii hook, increases the medicament concentration of the tripterygium wilfordii hook at inflammatory joints, reduces adverse reaction and toxic or side effect caused by medicaments, and has enhanced anti-inflammatory action and reduced blood concentration fluctuation.

Owner:苏州迪星生物医药科技有限公司

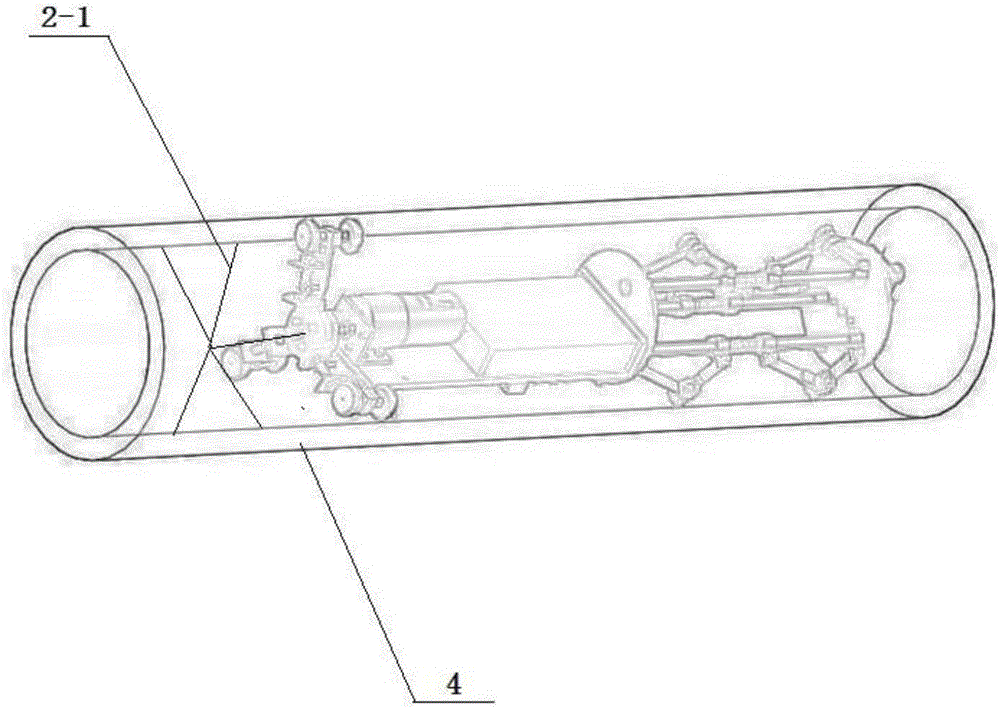

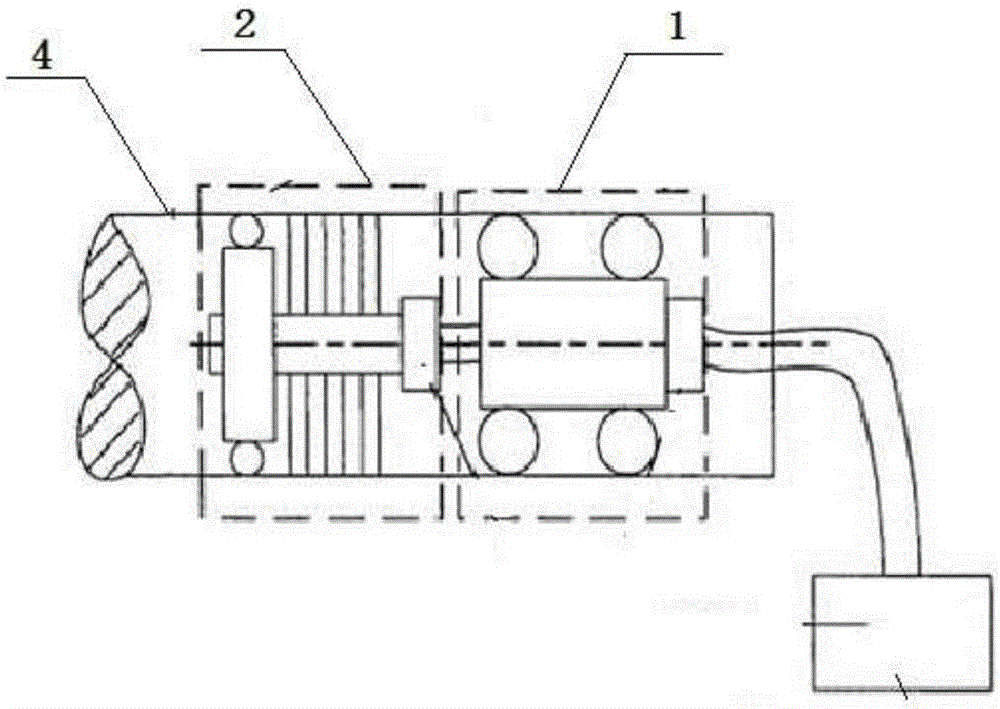

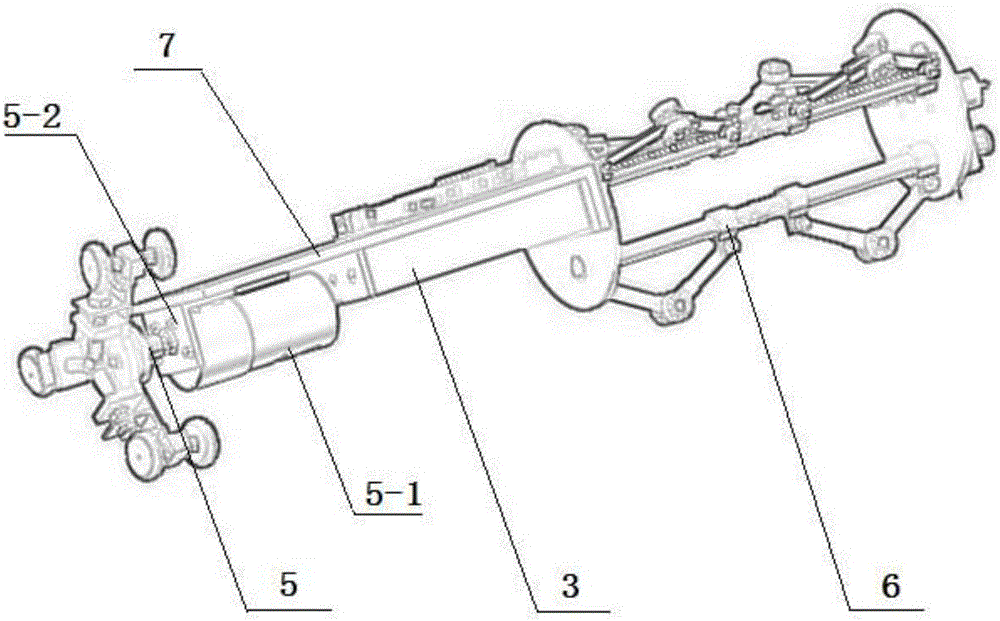

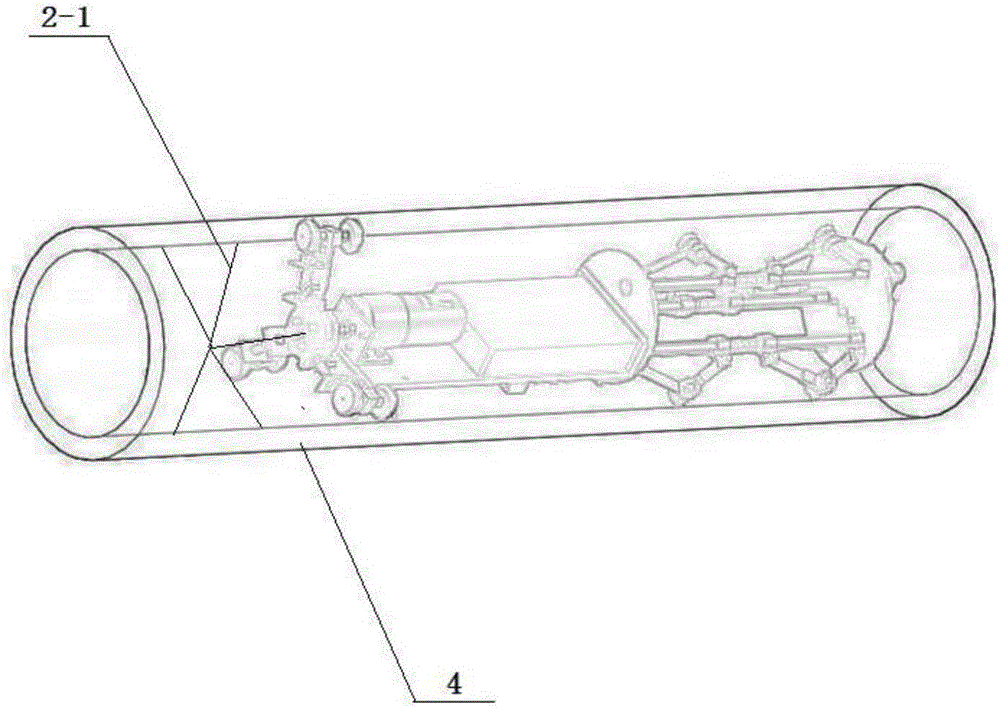

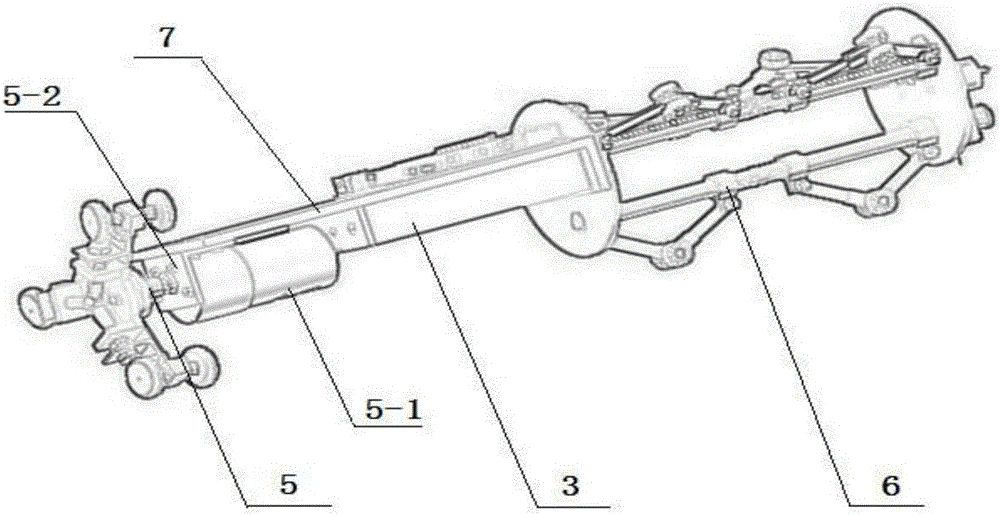

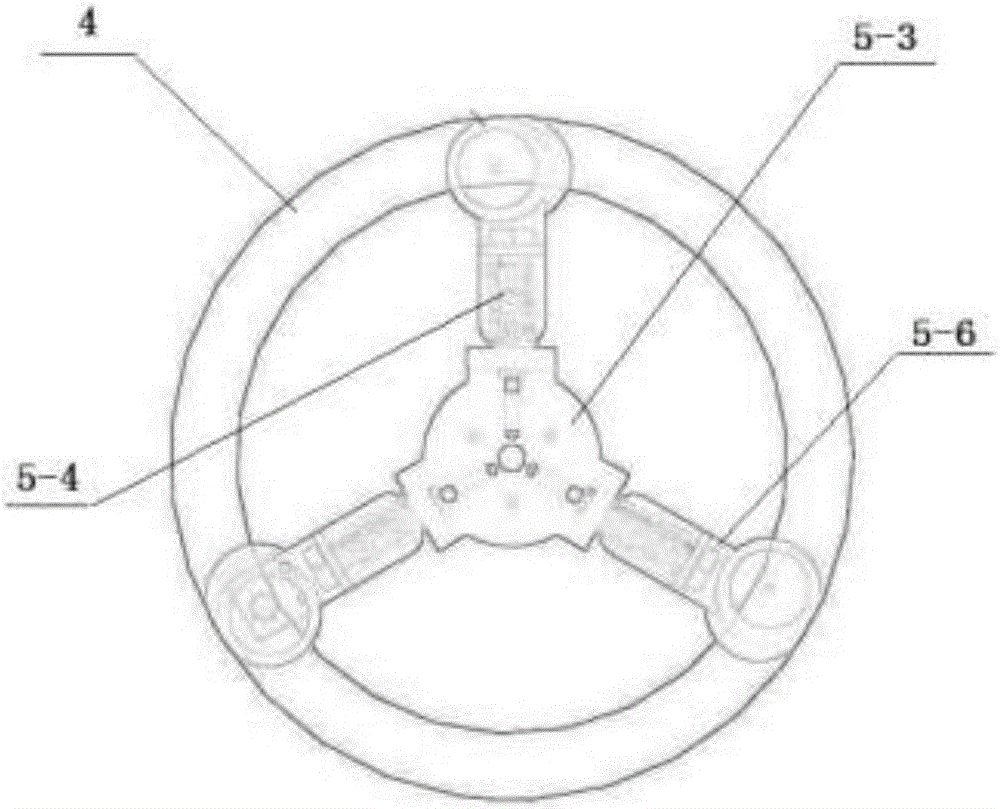

Pipeline robot for cleaning gun barrels

The invention discloses a pipeline robot for cleaning gun barrels. The pipeline robot consists of a spiral driving structure, a cleaning module, a control module and an auxiliary camera module, wherein the spiral driving structure consists of a support plate, a driving motor, a spiral driving execution head and a movement retainer; the spiral driving execution head consists of a trisection flange disk, an L-shaped driving wheel bracket, a wheel set and a compression spring; the movement retainer consists of a first disk, a second disk, a fixed support rod, a front support guide wheel mechanism, a rear support guide wheel mechanism and a retainer compression spring; the cleaning module consists of a special cleaning brush and a cleaning fluid spray mechanism; the control module is used for controlling the driving motor and the cleaning fluid spray mechanism to execute a power source and the auxiliary camera module. The pipeline robot for cleaning gun barrels is simple in structure and can be suitable for continuous and smooth movement under working conditions with different inner diameters.

Owner:严松法

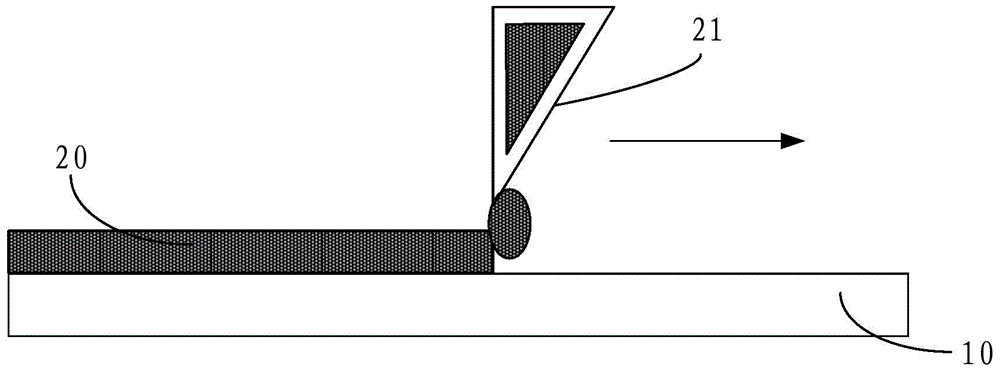

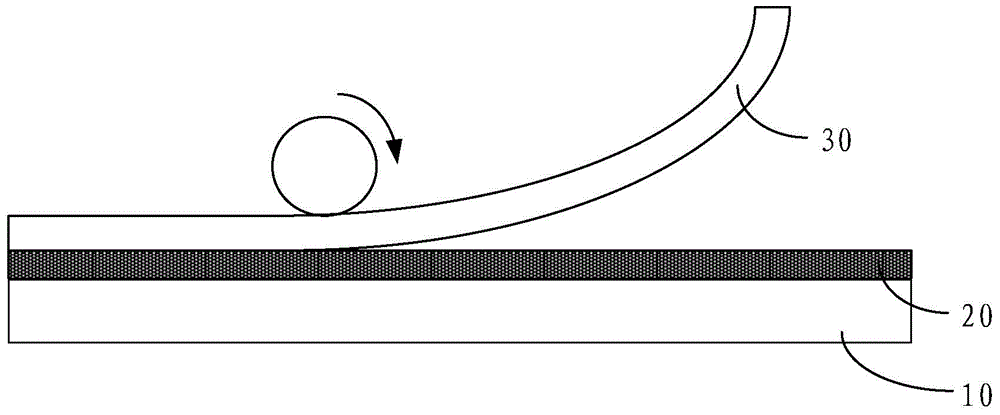

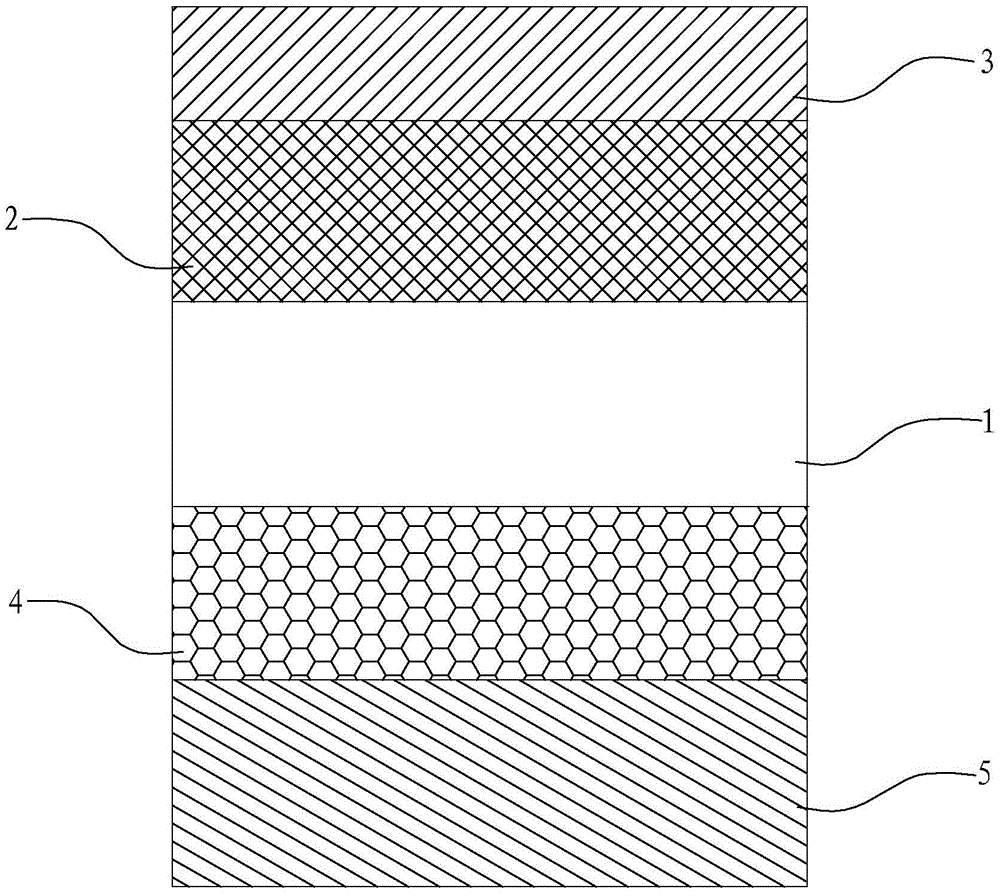

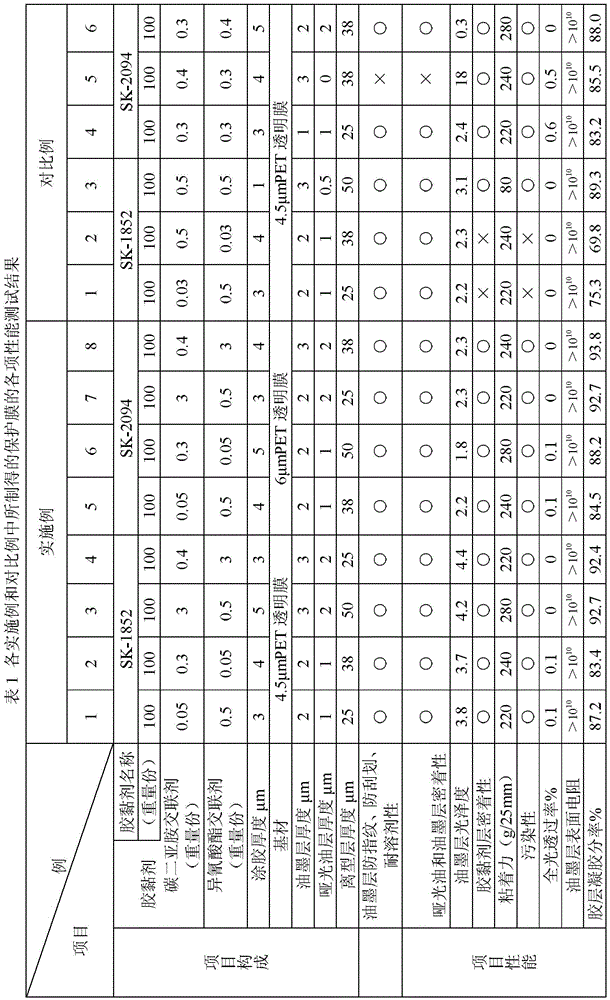

Release agent, release film, composite film and ink-jet printing medium, preparation methods of release agent, release film, composite film and ink-jet printing medium, and application of ink-jet printing medium

ActiveCN107699067AImprove toughnessHigh opacityWax coatingsPolyurea/polyurethane coatingsComposite filmPolyvinyl alcohol

The invention discloses a release agent, a release film, a composite film and an ink-jet printing medium, preparation methods of the release agent, the release film, the composite film and the ink-jetprinting medium, and an application of the ink-jet printing medium. The release agent comprises the following components in parts by weight: 5-7 parts of polyvinyl alcohol, 1-2 parts of silicon dioxide, 4-8 parts of titanium dioxide, 5-10 parts of waterborne polyurethane, 5-10 parts of emulsion wax, 0.5-1.5 parts of a wetting agent, and water, wherein the solid content of the release agent is 15-30%. The preparation method of the release agent comprises the following steps: preparing 8-12% of polyvinyl alcohol water solution, 10-15% of a silicon dioxide dispersion liquid and 20-40% of a titanium dioxide dispersion liquid, and then performing uniform mixing with other components to obtain the release agent. The release film is obtained by coating the release agent on a base material, and performing drying, cooling and stripping, wherein the usage amount of the release agent is 100-130 g / m<2>. The composite film comprises a polymer base film and a release film. The ink-jet printing medium comprises a composite film and a transparent ink-absorbing coating. The release film and the polymer base film have moderate adhesive force, the release effect is good, and the ink-jet printing medium can be identified during printing.

Owner:SHANGHAI ALLECARD IMAGE MATERIAL

Sintering method for precious metal layer on surface of ceramic or glass

The invention discloses a sintering method for a precious metal layer on the surface of ceramic or glass. The sintering method adopts three slurries, i.e., a bottom slurry, a body slurry and a surfaceslurry. The sintering method comprises the following steps: coating the bottom slurry onto the surface of the ceramic or the glass, carrying out drying in the air, and carrying out sintering; then coating the body slurry, carrying out drying in the air, and carrying out sintering; and coating the surface slurry, carrying out drying in the air, and carrying out sintering so as to form the preciousmetal layer on the surface of the ceramic or the glass, wherein the bottom slurry comprises the following components in parts by weight: 50 to 70 parts of precious metal powder, 3 to 5 parts of glasspowder, 1 to 5 parts of borax, 1 to 5 parts of a wetting agent, 10 to 20 parts of polyethylene glycol and 15 to 20 parts of water; the body slurry comprises the following components in parts by weight: 70 to 80 parts of precious metal powder, 1 to 3 parts of glass powder, 1 to 5 parts of a wetting agent, 5 to 10 parts of polyethylene glycol and 15 to 20 parts of water; and the surface slurry comprises the following components in parts by weight: 80 to 90 parts of precious metal powder, 0.5 to 1.5 parts of glass powder, 1 to 5 parts of a wetting agent, 5 to 10 parts of polyethylene glycol and2 to 20 parts of water. The method provided by the invention can firmly attach the precious metal layer onto porcelain, has controllable and uniform thickness, and is friendly to the environment.

Owner:HANDAN COLLEGE

Adhesive sheet

InactiveCN101484545AModerate adhesionLittle change over timeNon-macromolecular adhesive additivesFilm/foil adhesivesVitrificationPolymer science

An adhesive sheet comprising a substrate and an adhesive layer formed on at least one side of the substrate, characterized in that an adhesive agent contained in the adhesive layer comprises an acrylic ester copolymer and a citrate plasticizer; the acrylic ester copolymer has a glass transition temperature of -45 DEG C or less; the citrate plasticizer is contained in an amount of 1.0 to 50.0 parts by mass (solid content), with respect to 100 parts by mass (solid content) of the acrylic ester copolymer; and a rate of a gel content in the adhesive agent in the adhesive layer is 70% or more, is disclosed. The adhesive sheet according to the present invention has a slightly-adhesive property and a removable property, and can be suitably used, for example, as a carrier sheet.

Owner:LINTEC CORP

Composite strippable emulsion, strippable protective coating and application thereof

The invention relates to the technical field of protective products, in particular to a composite strippable emulsion, a strippable protective coating and application thereof. The composite strippableemulsion is prepared from the following raw materials: acrylic acid self-film-forming emulsion and acrylic acid self-crosslinking emulsion in a weight ratio of (65-85): (10-25). The composite strippable emulsion has relatively strong cohesion, the protective coating is not liable to break in the stripping process and has no residue on the base material; in addition, the adhesive force between thecomposite strippable emulsion and a base material is moderate, good adhesion of a coating film to a base material can be ensured, a product is effectively protected from being damaged in the transportation process, the product can be easily stripped off when stripping is needed, the glossiness of the surface of the base material such as woodware, metal, glass, plastic and concrete is not reduced,and the comprehensive performance of the base material is not influenced. In addition, the composite strippable emulsion can be independently used, and can also be compounded with a surface coating for use.

Owner:广州市首牵化工有限公司 +1

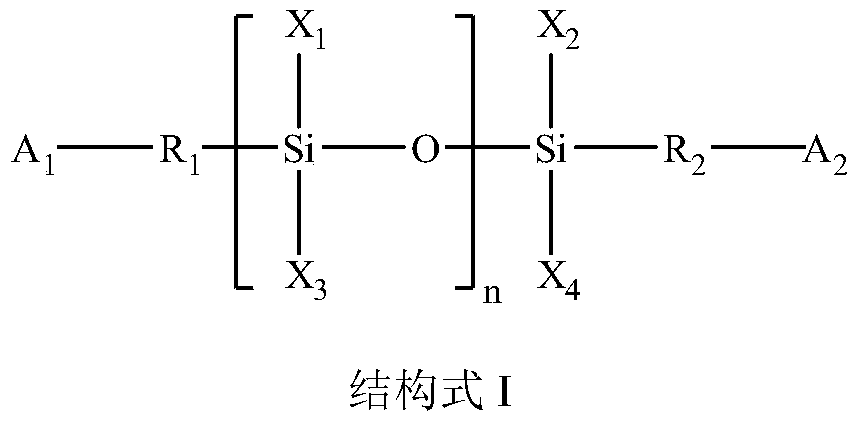

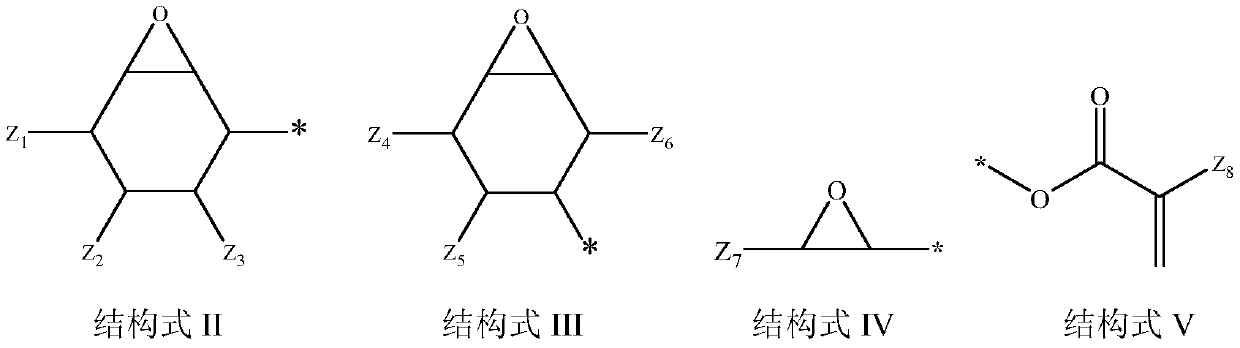

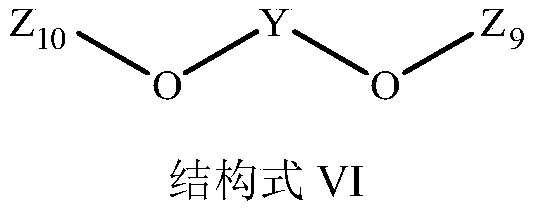

Ink composition, package structure and semiconductor device

PendingCN110982346AImprove light curing rateImprove curing shrinkageSemiconductor/solid-state device detailsSolid-state devicesEpoxyPolymer science

The invention provides an ink composition, a package structure and a semiconductor device. The ink composition comprises a photocurable silicon-containing monomer component, an active diluent component and a photoinitiator component, wherein the photocurable silicon-containing monomer component is a photocurable silicon-containing monomer or a combination of a plurality of photocurable silicon-containing monomers; each photocurable silicon-containing monomer has a structural formula as shown in the specification; and in the structural formula, at least one of A1 and A2 is an acrylate group, and at least one of A1 and A2 is an epoxy group. Monomers containing two functional groups, i.e., acrylate and epoxy, are mixed for use, so a free radical-cation hybrid curing system can be formed; andthe material integrating the advantages of the acrylate and epoxy photocurable silicon-containing monomers is obtained, and an organic barrier layer with a high photocuring rate, a low curing shrinkage rate and moderate base material adhesive force and hardness is achieved. Therefore, requirements on a packaging film in the prior art are better met.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

Spraying type ceramic surface-sintered silver paste and preparation method thereof

The invention discloses a spraying type ceramic surface-sintered silver paste which contains the following components: 50-60 parts of nanometer silver powder, 1-3 parts of glass powder, 5-10 parts of twain, 5-10 parts of polyvinylpyrrolidone, 5-10 parts of dimeticone, 3-5 parts of sweet almond oil and 15-20 parts of water. A preparation method comprises the following steps: adding water into a container; adding polyvinylpyrrolidone and stirring till dissolving; adding twain, dimeticone and sweet almond oil and stirring for 0.5-1 hour at 500-600rpm; lastly, adding the nanometer silver powder and the glass powder and stirring for 20-30min at 500-600rpm. According to the invention, the preparation process of the silver paste is simple, the silver layer is firm after the sintering and is difficult to fall off; the silver paste is nontoxic and harmless and contains no other heavy metal; when the silver paste is applied to the food container, the silver paste has disinfecting and bactericidal effects; the silver paste is wide in application prospect.

Owner:河北银瓷天成文化传播有限公司

Helical driving structure for gun barrel duct cleaning robot

The invention discloses a helical driving structure for a gun barrel duct cleaning robot. The helical driving structure consists of a support plate, a driving motor, a spiral driving actuating head and a motion cage, wherein the driving motor is arranged on the support plate through a motor fixing seat; the spiral driving actuating head is fixed on an output shaft of the driving motor; the spiral driving actuating head consists of a trisection flange disc, an L-type driving wheel bracket, a wheel set and a compression spring; the motion cage consists of a first disc, a second disc, a fixed support rod, a front support guide wheel mechanism, a rear support guide wheel mechanism and a cage compression spring. The helical driving structure for the gun barrel duct cleaning robot is simple in structure, and can continuously move stably under different inner diameter conditions.

Owner:严松法

Polystyrene-polyacrylate-polyurethane-unsaturated polyester copolymer and preparation method thereof

ActiveCN104710586ABalance complianceGood compatibilityPolyurea/polyurethane coatingsPolyesterPolystyrene

The invention relates to a polystyrene-polyacrylate-polyurethane-unsaturated polyester copolymer and a preparation method thereof. The copolymer comprises residues of methyl-(4-hydromethycyclohexyl) methyl acrylate; the number average molecular weight of the copolymer is 5,000-70,000; the molecular weight is distributed below 3. The polystyrene-polyacrylate-polyurethane-unsaturated polyester copolymer can be used for forming a peelable protective material; the peelable protective material can be quickly peeled off in a whole piece, and is free of residues after being peeled, particularly remarkable in shrinkage resistance and high temperature resistance, non-sticky, free of fogging, and high in chemical reagent resistance.

Owner:SHENZHEN GLITER PRINTING MATERIALS & EQUIP

Laminated film comprising ethylene copolymer

ActiveCN108779304AGood optical performanceImprove adhesionSynthetic resin layered productsGlass/slag layered productsSilanesCopolymer

The invention is a polymer composition for film layer comprising less than 50 wt% of a copolymer of ethylene with silane group(s) containing units and at least 50 wt% of a thermoplastic polyolefine free from silane group(s) wherein the polymer composition has creep of less than l mm at 90 DC, and an adhesion above 20 N / cm. The invention relates to a laminated article with at least one film layer of the polymer composition and a substrate.

Owner:BOREALIS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com