Protection film used for surface of NFC and preparation method of protection film

A technology of protective film and base material layer, applied in the field of protective film on NFC surface and its preparation, can solve the problems of affecting the service life, complex chip structure, affecting the reception of mobile phone communication signals, etc., to achieve enhanced adhesion, extended service life, Enhance the effect of the shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

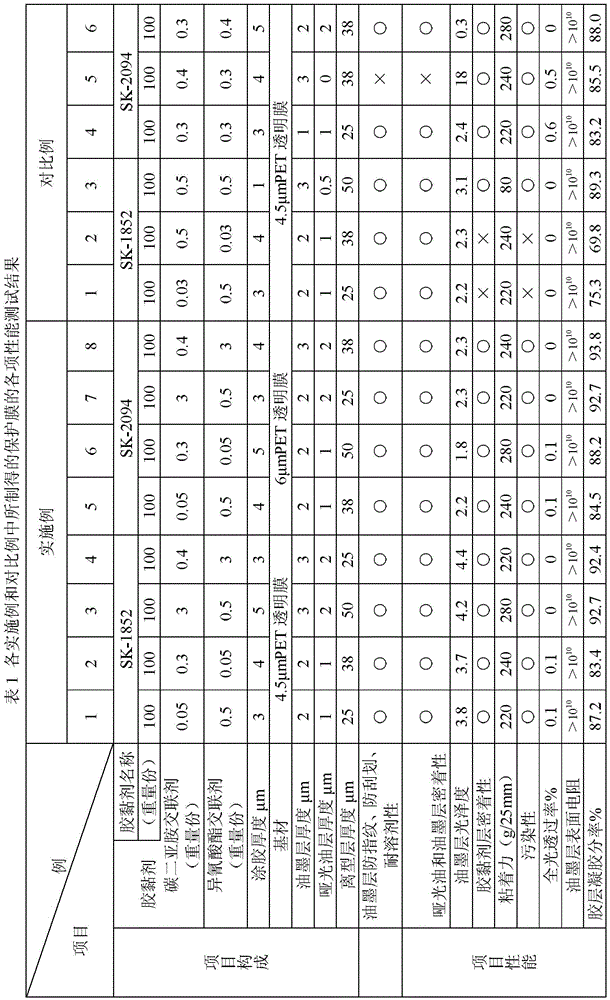

Embodiment 1

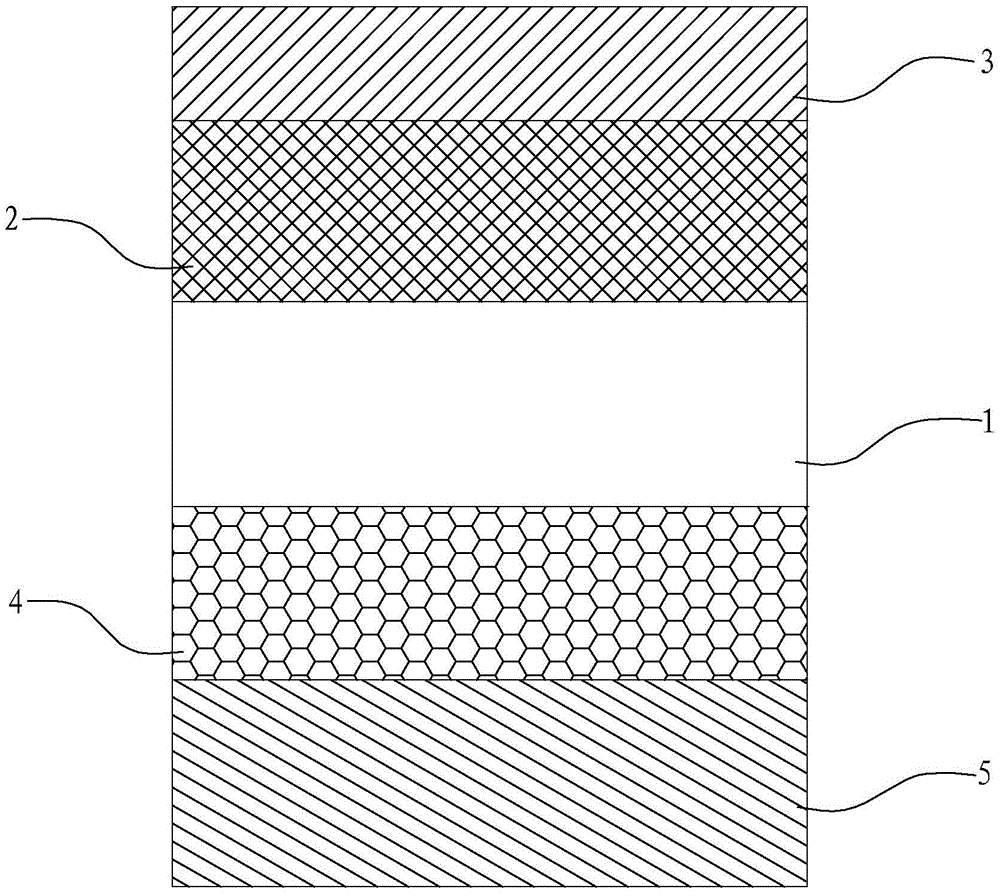

[0025] Such as figure 1 As shown, a protective film for the surface of NFC includes a PET substrate layer 1, an adhesive layer 4 provided on one side of the PET substrate 1, and a release layer attached to the adhesive layer 4 The film layer 5, the other side of the PET substrate layer 1 is provided with a black ink layer 2. The black ink layer 2 is coated with a matte oil layer 3, which is formed by forming a film of an organic matting agent, black ink The layer 2 contains aluminum compounds, the matte oil layer 3 has a thickness of 1 μm, the black ink layer has a thickness of 2 μm, the substrate layer 1 is 4.5 μm PET, the adhesive layer 4 has a thickness of 3 μm, and the release film layer 5 has a thickness of 25 μm. In the adhesive composition used in the above-mentioned adhesive layer, 100 parts of (meth)acrylic copolymer SK-1852 (produced by Soken Chemical Co., Ltd.), carbodiimide crosslinking agent XR-201 (Shanghai Xirun Chemical Technology Co., Ltd., the same below) 0.0...

Embodiment 2

[0029] A protective film for NFC surface, comprising a PET substrate layer, an adhesive layer arranged on one side of the PET substrate layer, a release film layer attached to the adhesive layer, and a PET substrate layer A black ink layer is provided on the other side of the black ink layer. The black ink layer is coated with a matte oil layer. The matte oil layer is made of organic matting agent. The black ink layer contains aluminum compounds. The thickness of the matte oil layer is 2μm. The thickness of the black ink layer is 2 μm, the substrate layer is 4.5 μm PET, the thickness of the adhesive layer is 4 μm, and the thickness of the release layer is 38 μm. In the adhesive composition used in the adhesive layer, 100 parts of (meth)acrylic copolymer SK-1852, carbodiimide crosslinking agent XR-2010.3 parts, isocyanate crosslinking agent L-450.05 parts, matt oil layer The organic matting agent 9000 is used, and the black ink layer is ink NB300794. The content of XCP-1002 in t...

Embodiment 3

[0033] A protective film for the surface of NFC, comprising a PET substrate layer, an adhesive layer arranged on one side of the PET substrate layer, a release film layer attached to the adhesive layer, and a PET substrate layer A black ink layer is provided on the other side of the black ink layer. The black ink layer is coated with a matte oil layer. The matte oil layer is made of organic matting agent. The black ink layer contains aluminum compounds. The thickness of the matte oil layer is 2μm. The thickness of the black ink layer is 3 μm, the substrate layer is 4.5 μm PET, the thickness of the adhesive layer is 5 μm, and the thickness of the release layer is 50 μm. In the adhesive composition used in the adhesive layer, 100 parts of (meth)acrylic copolymer SK-1852, carbodiimide crosslinking agent XR-2013 parts, and isocyanate crosslinking agent L-450.5 parts are in the adhesive composition. The black ink layer uses ink NB300794, the matte oil layer uses organic matting agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com