Patents

Literature

291results about How to "Solvent resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled release fertilizer coated by vegetable oil based polyurethane and preparation method thereof

InactiveCN103304772AWide variety of sourcesSimple film forming processFertilizer mixturesFertilizerIsocyanate

The invention discloses a controlled release fertilizer coated by vegetable oil based polyurethane and a preparation method thereof. The preparation method of the controlled release fertilizer coated by vegetable oil based polyurethane comprises the following steps of: 1) preheating the granular fertilizer; 2) heating plant oil polyhydric alcohol containing 2-6 hydroxys and isocyanate containing at least two isocyanate groups, and uniformly mixing the ingredients to form a vegetable oil based polyurethane coating liquid; 3) spray coating the vegetable oil based polyurethane coating liquid on the surfaces of the preheated fertilizer granules, repeatedly spray coating the vegetable oil based polyurethane coating liquid for 2-10 times after the vegetable oil based polyurethane coating liquid solid is solidified to obtain the controlled release fertilizer coated by vegetable oil based polyurethane. According to the controlled release fertilizer coated by vegetable oil based polyurethane and the preparation method thereof provided by the invention, the adopted coating material is extensive in resource, cheap and liable to obtain, non-toxic, harmless, simple in production process and good in controlled release effect of fertilizer.

Owner:上海永通生态工程股份有限公司

Water-based environment-friendly finishing paint and preparation method thereof

InactiveCN101712833AGood anti-corrosion decoration effectHigh hardnessEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based environment-friendly finishing paint, which is prepared from the following compositions in part by weight: 20 to 70 parts of water borne acrylic resin solution of which the solid content is 30 to 80 percent and / or 20 to 70 parts of water borne epoxy resin solution of which the solid content is 30 to 80 percent, 4 to 10 parts of water borne amino resin solution of which the solid content is 60 to 98 percent; 1 to 5 parts of organic amine, 0.2 to 2 parts of wetting and leveling agent, 0.2 to 2 parts of thickener, 0.1 to 0.8 part of defoaming agent, 1 to 5 parts of adhesion promoter, 0.2 to 5 parts of catalyst, 10 to 30 parts of alcohol diluting solvent and / or 1 to 5 parts of nontoxic ether diluting solvent, and 20 to 50 parts of deionized water, wherein the catalyst is one or more of ammonias, alcohols and benzenesulfonic acids. The water-based environment-friendly finishing paint has the advantages of wide applicable range, high hardness, good flexibility, strong adhesion, good scratchproof performance, and environmental protection. Simultaneously, the invention also discloses a method for preparing the water-based environment-friendly finishing paint.

Owner:重庆亢石新材料科技有限公司

Aqueous environment-friendly packaging steel drum paint and preparation method thereof

InactiveCN101735703AGood anti-corrosion decoration effectHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an aqueous environment-friendly packaging steel drum paint, which is prepared by mixing the following compositions in part by weight: 20 to 70 parts of aqueous solution of acrylic resin with a solid content of 30 to 80 percent and / or aqueous solution of epoxy resin with the solid content of 30 to 80 percent, 4 to 10 parts of aqueous solution of amino resin with the solid content of 60 to 98 percent, 1 to 5 parts of organic amine, 1 to 50 parts of filling materials with the granularity of more than 2,000 meshes, 0.5 to 10 parts of color paste, 0.2 to 2 parts of wetting levelling agent, 0.2 to 2 parts of thickening agent, 0.1 to 0.8 part of antifoaming agent, 1 to 5 parts of adhesive force accelerant, 0.2 to 5 parts of catalyst, 0 to 30 parts of alcohol diluting solvent and / or 0 to 5 parts of non-toxic ether diluting solvent, and 20 to 50 parts of deionized water. The aqueous environment-friendly packaging steel drum paint has the advantages of wide application range, high rigidity, good flexibility, strong adhesive force and good anti-scraping and anti-collision properties and environmental protection; and meanwhile, the invention discloses a preparation method for the aqueous environment-friendly packaging steel drum paint.

Owner:重庆亢石新材料科技有限公司

Water soluble acrylic acid epoxy resin and preparation method thereof

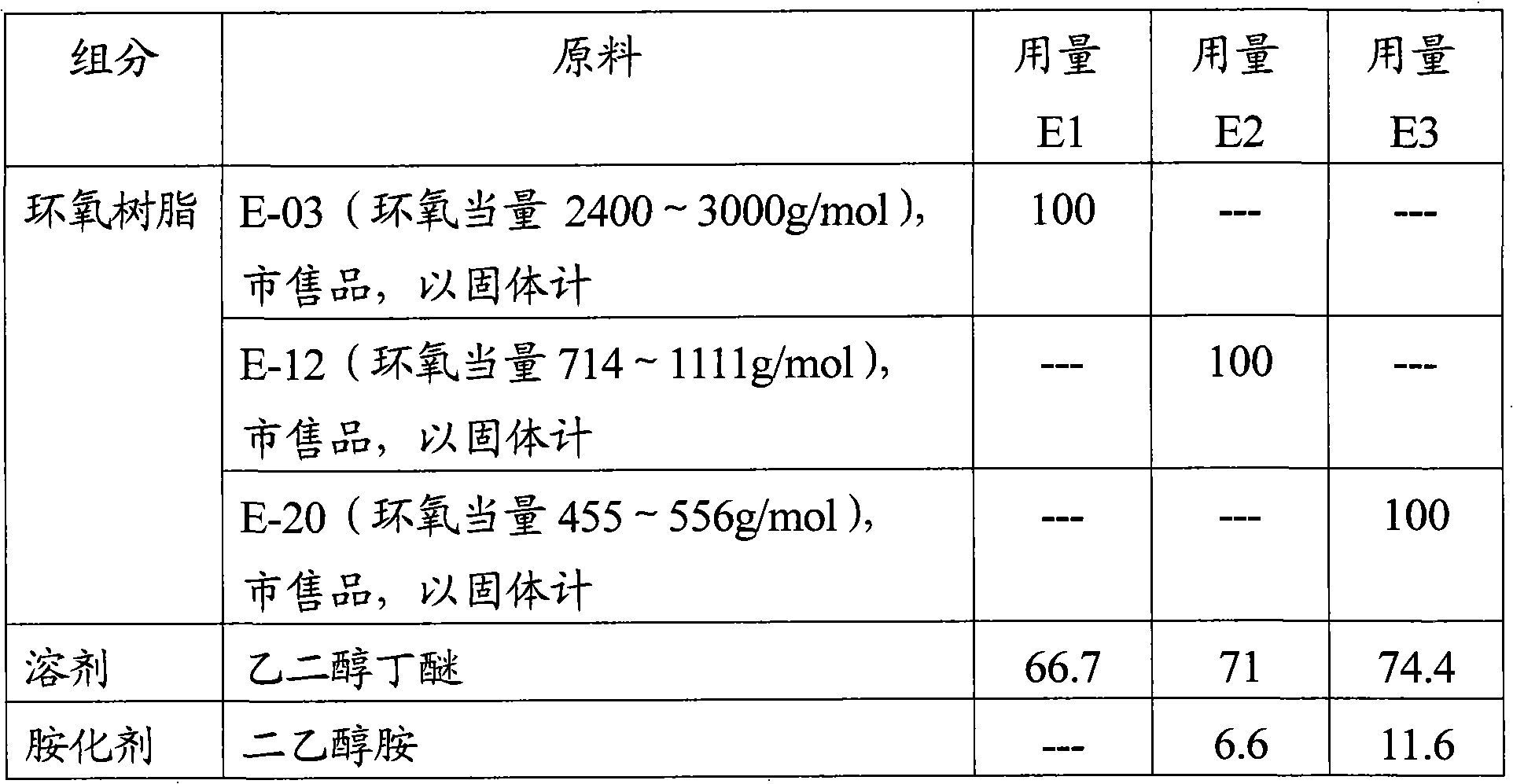

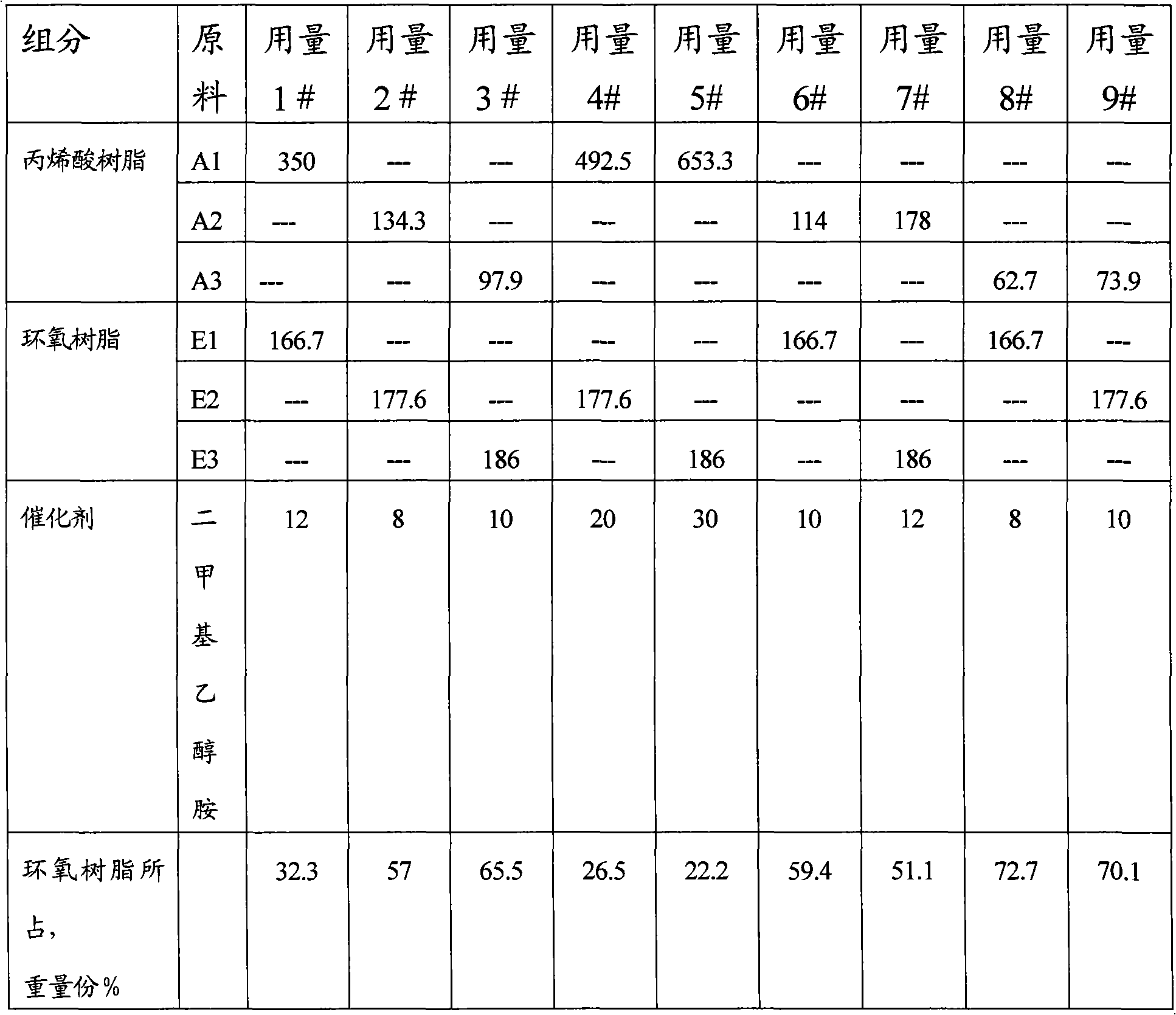

The invention relates to water soluble acrylic acid epoxy resin and a preparation method thereof. The epoxy resin is emulsion formed by neutralizing and self-emulsifying a product of a catalytic esterification reaction of acrylic acid resin and epoxy resin, and the variation of tu-4 cup viscosity of the emulsion stored for 6 months is less than 5 percent; epoxy equivalent of the epoxy resin is between 180 and 5,000g / mol, and the epoxy resin accounts for 10 to 80 percent of gross weight of the epoxy resin and the acrylic acid resin; the acrylic acid resin is polymerized from hydroxyl-containing acrylic acid, carboxyl-containing acrylic acid, other acrylic acids and styrene monomers which are initiated by peroxide, and has the acid value of between 50 and 500mgKOH / g and the number average molecular weight of between 5,000 and 60,000g / mol; and the epoxy resin with the epoxy equivalent less than 1,300g / mol does not need bisphenol A chain extension, has simple operation, and is convenient for regulating the proportion of the epoxy resin. The method can be used for preparing the water soluble acrylic acid epoxy resin with wider proportion of the epoxy resin and stable storage.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

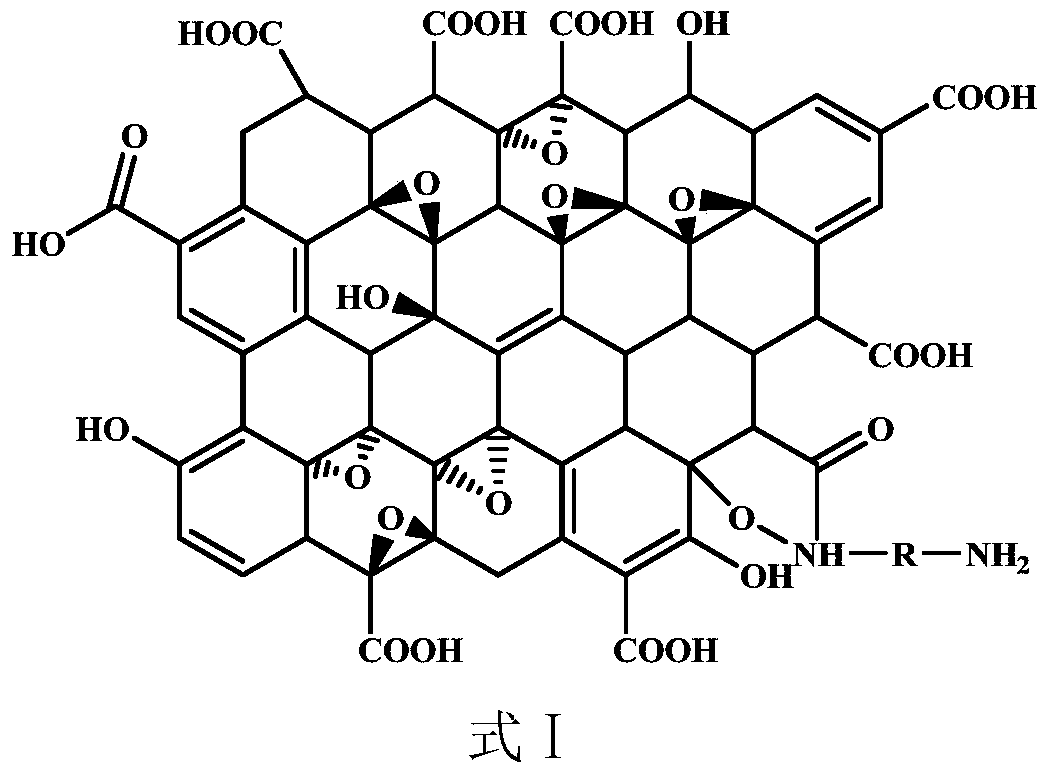

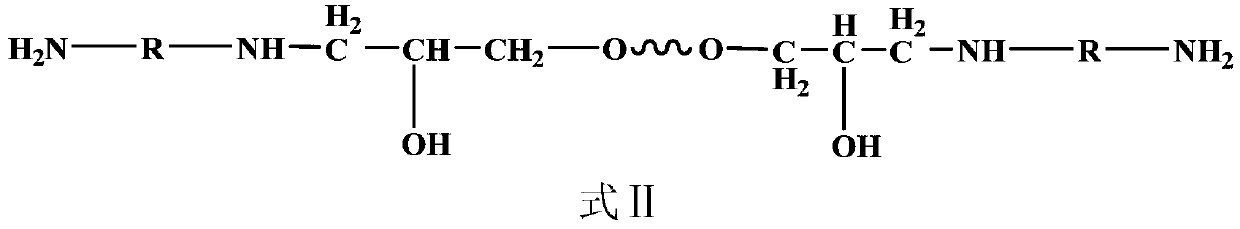

Triptycene-based VOCs (volatile organic chemicals) retained type polymer separating membrane and preparation method thereof

The invention discloses a triptycene-based VOCs (volatile organic chemicals) retained type polymer separating membrane and a preparation method thereof and relates to a gas separating membrane and a preparation method thereof. According to the preparation method of the separating membrane, a compound shown in a formula I and a compound containing active groups are taken as monomers and have a polymerization reaction for 0.5-60 h under the action of an acid-binding agent, and a membrane solution is obtained after the reaction ends; a solvent resistance basement membrane is coated with the obtained membrane solution, vacuum crosslinking drying is performed, and the triptycene-based VOCs retained type polymer separating membrane is obtained. The preparation method of the triptycene-based VOCs retained type polymer separating membrane is simple, and the prepared separating membrane can be independently used, has a good separation effect and has solvent resistance and higher separating stability.

Owner:NANJING UNIV OF TECH

Heat-conducting and wave-absorbing rubber material and preparation method thereof

InactiveCN106751910AHigh temperature resistantLow temperature resistanceHeat-exchange elementsCross-linkRubber material

The invention discloses a heat-conducting and wave-absorbing rubber material and a preparation method thereof. The heat-conducting and wave-absorbing rubber material is prepared from the following substances in parts by weight: 100 parts of a rubber matrix, 50-600 parts of heat-conducting powder, 50-400 parts of wave-absorbing powder, 0-2 parts of a release agent and 0.5-2 parts of a cross-linking agent. The heat-conducting and wave-absorbing rubber material has the properties of high temperature resistance, low temperature resistance, high voltage resistance, ozone aging resistance, radiation resistance, weather resistance, physiologically inert property, high permeability and solvent resistance, and especially has outstanding high temperature resistance, so that the possibility is provided for preparation of the heat-conducting and wave-absorbing material; the heat-conducting and wave-absorbing rubber material can be directly applied between a heat dissipation room and a metal housing, and heat energy can be effectively exported; and meanwhile, the heat-conducting and wave-absorbing rubber material has electromagnetic shielding and electromagnetic noise wave absorbing properties, so that a good solving scheme is provided for electronic communication products in heat conduction and electromagnetic shielding.

Owner:DALIAN DONGSHIN MICROWAVE TECH

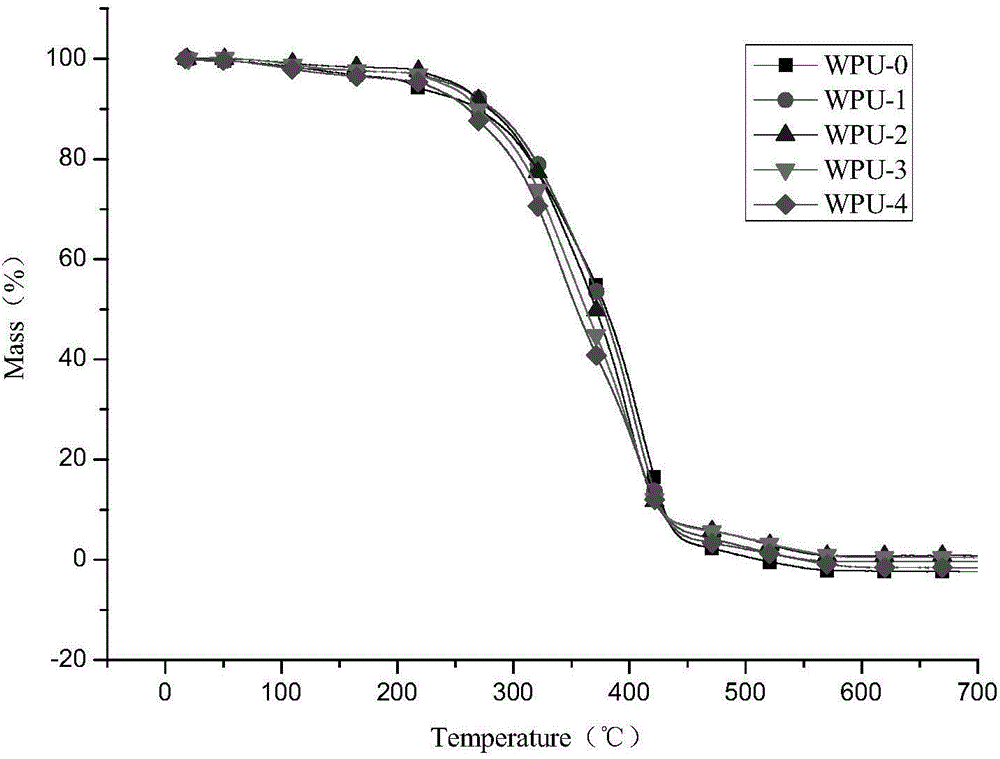

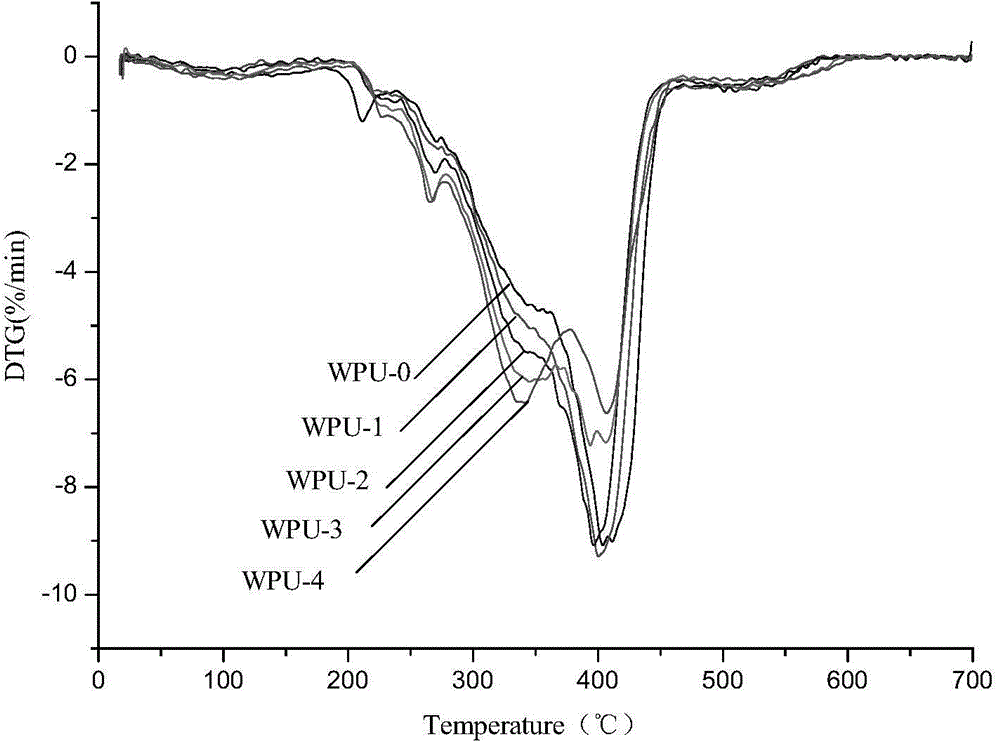

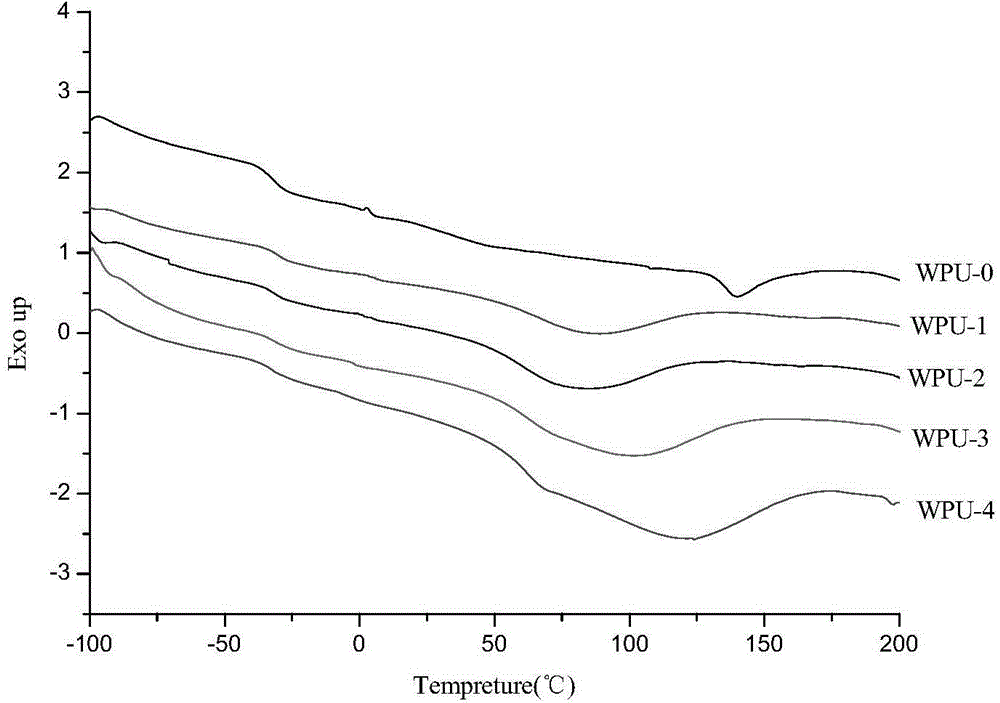

Waterborne polyurethane emulsion and preparation method thereof

InactiveCN104974327AImprove performanceKeep hydrophilicPolyurea/polyurethane coatingsLeather surface finishingPolymer scienceEmulsion

The invention discloses a waterborne polyurethane emulsion and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out vacuum dehydration on polymer polyol, a hydrophilic chain extender, isosorbide and N-methyl pyrrolidone at 90 DEG C for 1-2 hours, reducing the temperature to 80-90 DEG C, adding diisocyanate and reacting for 2.5-3 hours until NCO% reaches the theoretical value; then reducing the temperature, adding a neutralizer to an NCO-terminated polyurethane prepolymer and reacting at 60 DEG C for 0.5 hour until the neutralization degree is 95-100%; finally dispersing the polyurethane prepolymer containing isosorbide into deionized water under the high-speed shearing action of an agitator and dropwise adding a mixture of diamine and water after dispersing for a period of time, thus obtaining the waterborne polyurethane emulsion. Isosorbide is successfully introduced into the waterborne polyurethane emulsion, thus obviously improving the glossiness of waterborne polyurethane films.

Owner:JINCHUANGJING NEW MATERIAL TECH SHANGHAI

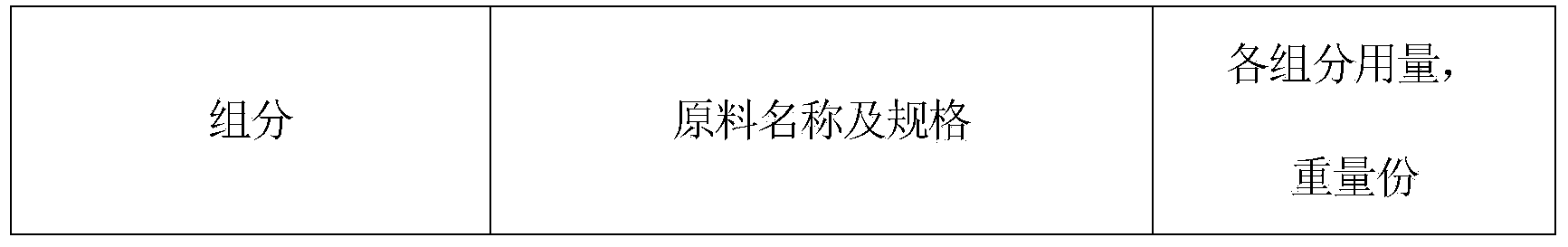

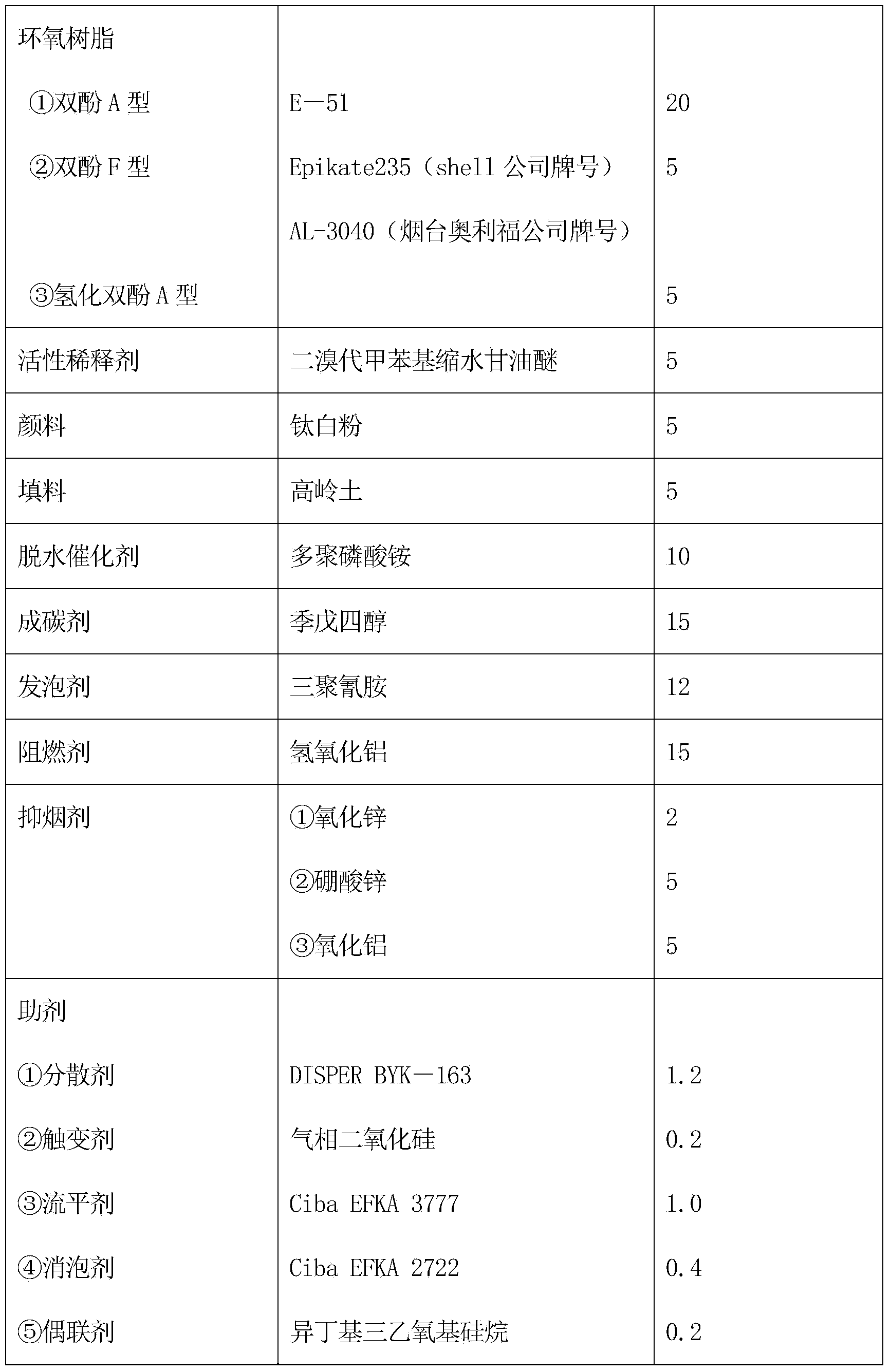

Fire retardant coating for steel structure surface of nuclear power plant

InactiveCN103709899AChemically resistantFlame retardantFireproof paintsEpoxy resin coatingsFoaming agentHyperbranched polyester

The invention relates to a fire retardant coating for a steel structure surface of a nuclear power plant. The fire retardant coating consists of components A, B and C at a weight ratio of (4-6): 1: 1, wherein the component A is a mixture composed of 15-35 parts of epoxy resin, 2-10 parts of reactive diluent, 5-15 parts of dehydration catalyst, 10-30 parts of carbonizing agent, 5-20 parts of foaming agent, 15-35 parts of fire retardant, 5-15 parts of smoke inhibitor, 10-30 parts of pigment and filler and 2-10 parts of auxiliaries; the component B is a mixture composed of 10-50 parts of toughened resin, 10-30 parts of pigment and filler and 2-10 parts of auxiliaries; the C component is an amine curing agent; and the toughened resin in the component B is hyper-branched polyester resin with a terminal carboxyl group. The fire retardant coating disclosed by the invention is more excellent than a normal intumescence fire retardant coating in binding strength, freezing and thawing cycle resistance, acid and base resistance, and fire retardant limit, and is specifically up to fire resistance requirements of the steel structure surface of the nuclear power plant.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Fluorine water-base paint

The present invention relates to paint industry technology, and is especially one kind of fluoric water-base paint. The fluoric water-base paint consists of fluorocarbon emulsion 20-90 wt%, supplementary emulsion 1-25 wt%, pigment 5-20 wt%, stuffing 1-31 wt%, dispersant 0.1-1.4 wt%, defoaming agent 0.1-0.3 wt%, wetting agent 0.3-0.5 wt%, bactericidal anti-mildew agent 0.1-0.3 wt%, filming assistant 0.01-13.5 wt%, thickener 0.01-1.1 wt% and multifunctional assistant 0.3-0.5 wt% except water. The paint has high weather resistance, high chemical corrosion resistance, antifouling property, high performance / cost ratio and other advantages.

Owner:SHANGHAI HENGFENG FLUOROCARBON MATERIAL

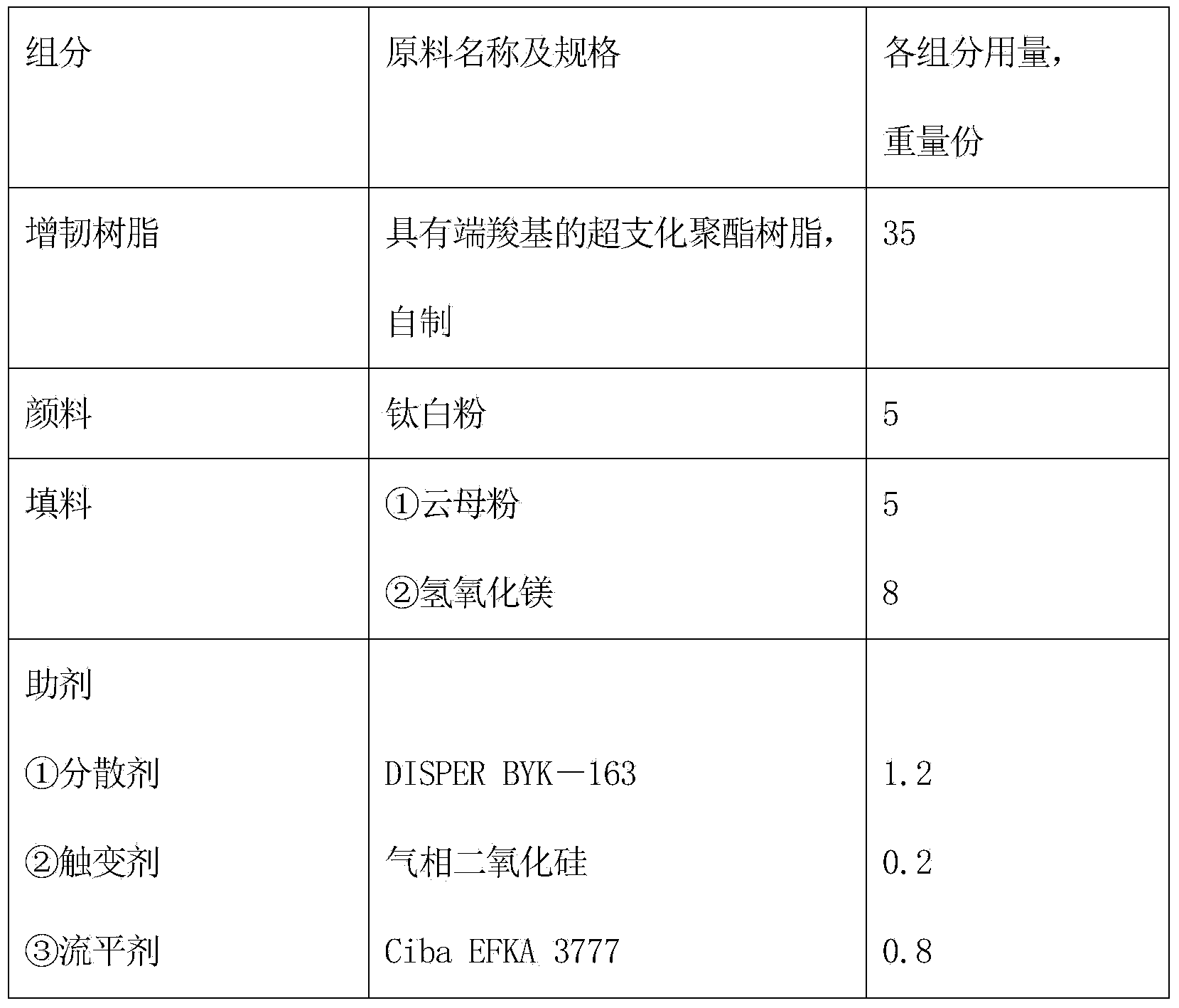

Waterborne polyurethane surface treating agent for synthetic leather and preparation method thereof

InactiveCN106634524AGood dispersionGood matte effectPolyurea/polyurethane coatingsTextiles and paperEmulsionWear resistant

The invention relates to a waterborne polyurethane surface treating agent for synthetic leather and a preparation method thereof. The waterborne polyurethane surface treating agent for the synthetic leather is formed by compounding, by weight, 40-50 parts of deionized water, 2-4 parts of silicon dioxide matting powder, 45-55 parts of waterborne polyurethane emulsion, 1.5-2.0 parts of highly-smooth organosilicon flatting agent, 2-4 parts of weak anion organosilicone wear-resistant agent, 3-5 parts of nonionic organosilicone feeling agent, 0.2-0.3 part of non-ionic waterborne defoamer and 1-2 parts of associative waterborne polyurethane thickening agent. The waterborne polyurethane surface treating agent has functional advantages of having skin touch and being matt and resistant to scratching and solvents.

Owner:LIAONING FIXED STAR FINE CHEM

Water-based expoxy antiquing coating, preparation method and application as well as using method thereof

The invention relates to a water-based expoxy antiquing coating, a preparation method and application as well as using method thereof. The antiquing coating is composed of a water-based sealing primer, a middle coating, a coloring agent and a water-based finishing coat, wherein the water-based sealing primer, the middle coating and the water-based finishing coat are composed of two components; the antiquing coating is suitable for various new and old cement floors and new and old wall surfaces; pain films have the performances such as water resistance, medicine resistance, solvent resistance, corrosion resistance and moisture proofing; the water-based expoxy antiquing coating can meet the requirements of modern industrial terraces and has the advantages which a solvent type expoxy terrace coating does not have; the coating effect and the color of the water-based expoxy antiquing coating are three-dimensional; the flower color of the water-based expoxy antiquing coating is various; and the water-based expoxy antiquing coating is safe, non-toxic and pollution-free in the construction process, breaks through the situation that a solvent based coating occupies the leading market, broadens and meets the market requirement.

Owner:刘娜

Coating composition for solar cell protective covers

InactiveCN101317274ADoes not compromise transparencyRoom temperature processabilitySynthetic resin layered productsPolyurea/polyurethane coatingsWeather resistanceRoom temperature

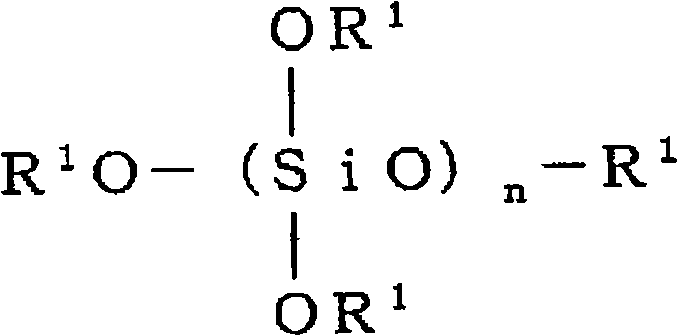

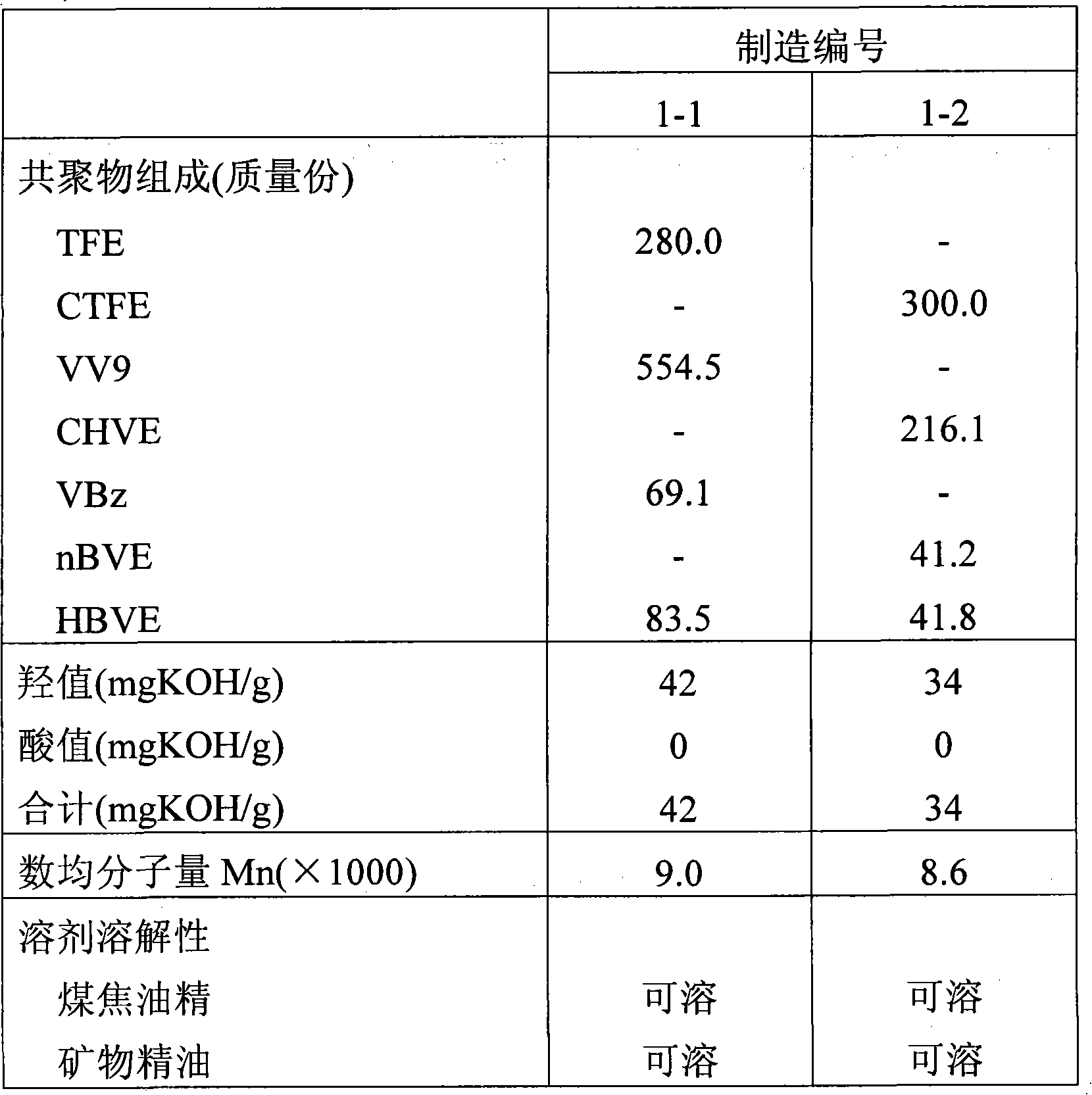

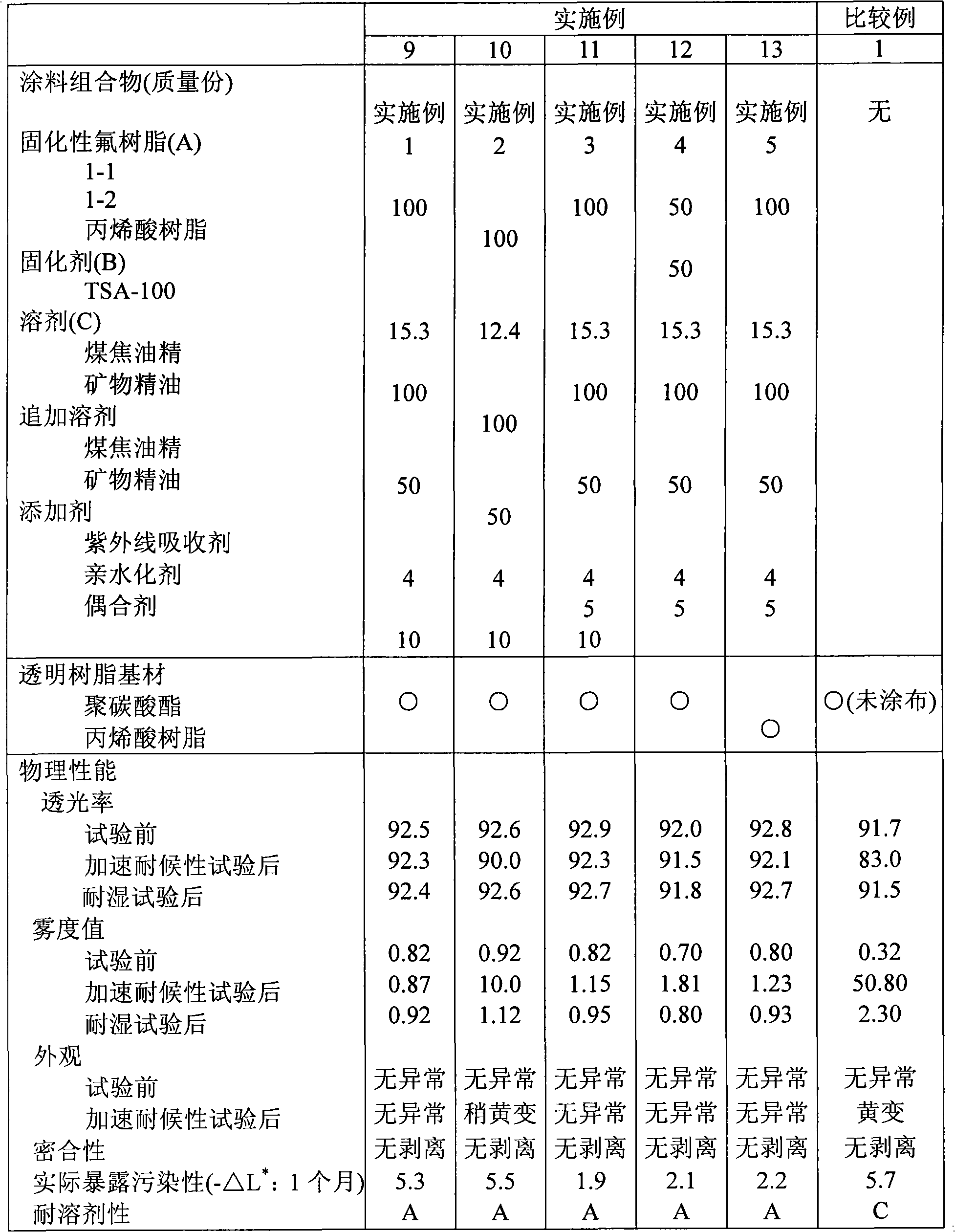

The invention provides a solar cell protective cover which is not impaired in the transparency satisfactory for the protective cover for solar cells and has excellent room-temperature workability, solvent resistance, weather resistance and endurance; and a curable fluororesin coating composition capable of forming the cover. A curable fluororesin coating composition for solar cell protective covers comprising (A) a curable fluororesin, (B) a curing agent, and (C) a solvent, which is to be applied either directly to a transparent resin layer (II) formed on the side of a solar cell module (I) to be irradiated with sun rays or to a primer layer (IV) previously formed on the layer (II) and thus form a top coat layer (III) made of a cured fluororesin.

Owner:DAIKIN IND LTD

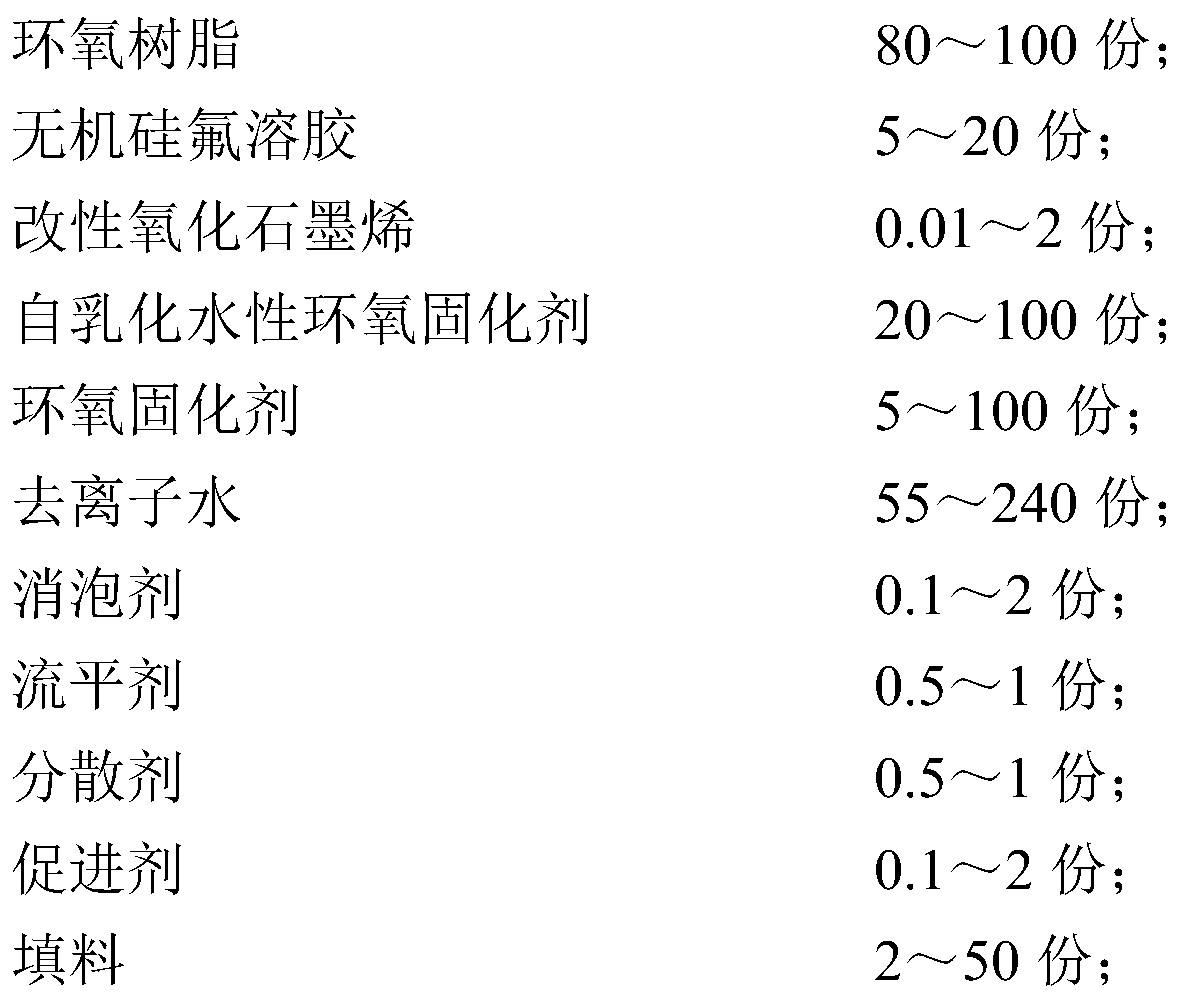

Low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof

ActiveCN110330862AWear-resistantLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceFluorographene

The invention discloses a low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof. The molecular structure of the coating contains structures such as epoxy groups, polyether, silicon fluoride and graphene; in the stage of emulsifying epoxy resin of the coating, the coating has excellent aqueous property and high emulsifying capability owing to a self-emulsifying aqueous epoxy curing agent, the coating has good compatibility with the epoxy resin, and the stability of emulsion is improved. In a curing stage of modification of a graphene oxide modified coating, it is ensured that the self-emulsifying water-based epoxy curing agent does not separate out from a coating layer to form a stable coating layer; a flexible micro-region is formed by flexiblelong-chain polyether in the coating layer, so that the mechanical property of a coating film is improved; by silicon-fluorine sol, the surface energy of the coating film is reduced; graphene is grafted into the molecular structure through chemical bonds, after the dispersion performance is improved, the graphene can cover a metal surface efficiently, and the corrosion resistance of the coating layer is improved. Therefore, the coating provided by the invention has excellent properties of adhesion, hardness, acid and alkali resistance, water resistance and the like after film formation, variouscomponents are compatible well, and the coating can be used for metal parts and the like.

Owner:中科广化(重庆)新材料研究院有限公司 +2

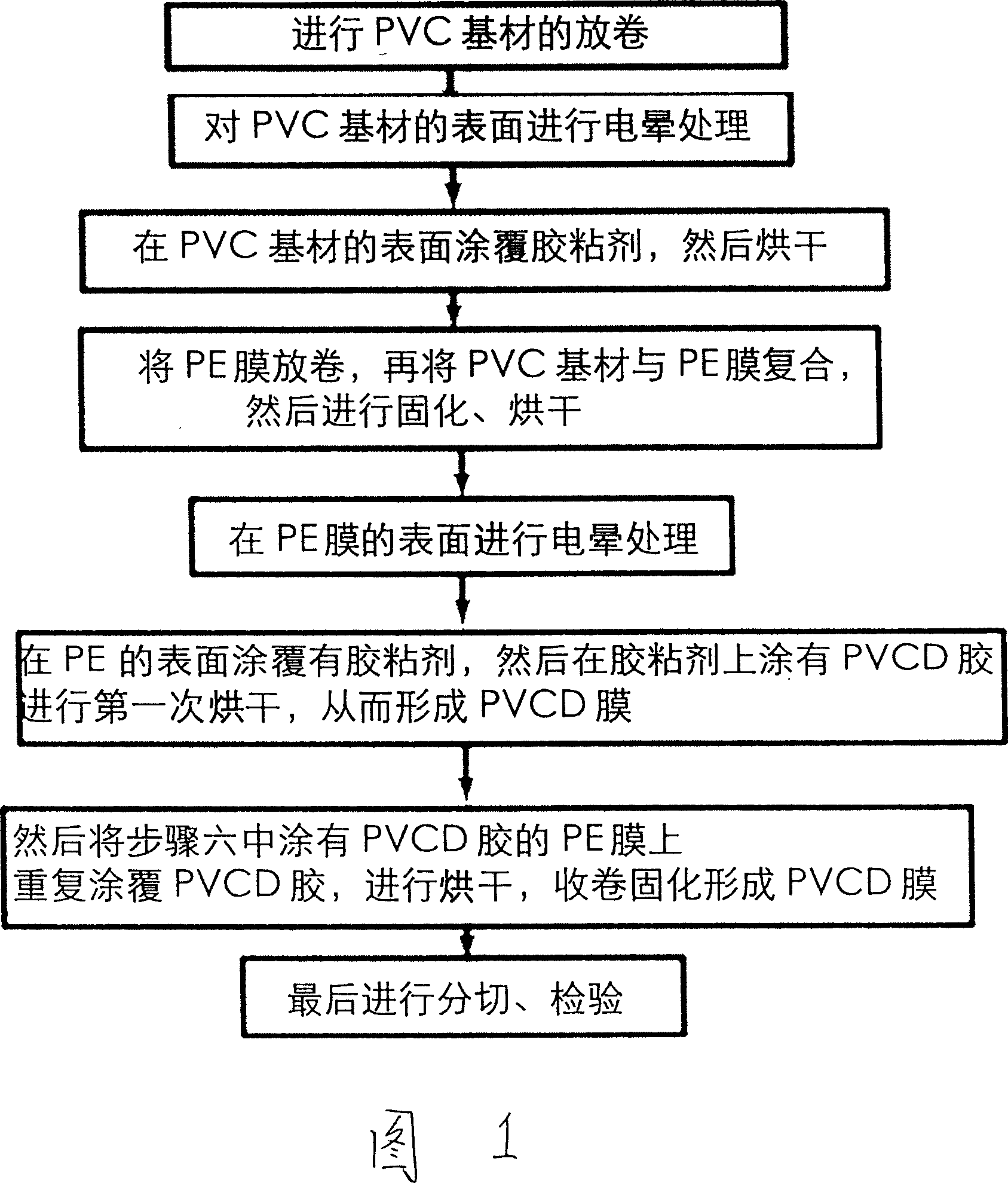

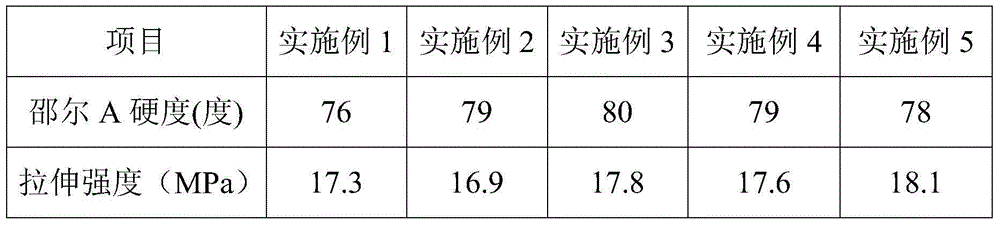

Technology for preparing high-separation, low solvent residue and low resolving-out matter PVC/PE/PVCD solid medicinal composite hard sheet

InactiveCN101024325ASolvent resistantUV resistantLamination ancillary operationsSynthetic resin layered productsManufacturing technologyAdhesive

The invention discloses PVC / PE / PVCD solid medicine using composite hard sheet manufacturing technology. It includes the following steps: unreeling for PVC basis material; corona treatment for its surface; coating adhesive; drying; unreeling for PE film; compositing the PVE basis material and PE film; solidifying; dying; corona treatment for the PE film surface; coating adhesive; coating PVCD glue; drying to form PVCD film; repeating coating the PVCD glue on the PE film; drying; rolling, solidifying to form PVCD film again; patting cut and detecting.

Owner:徐小圣

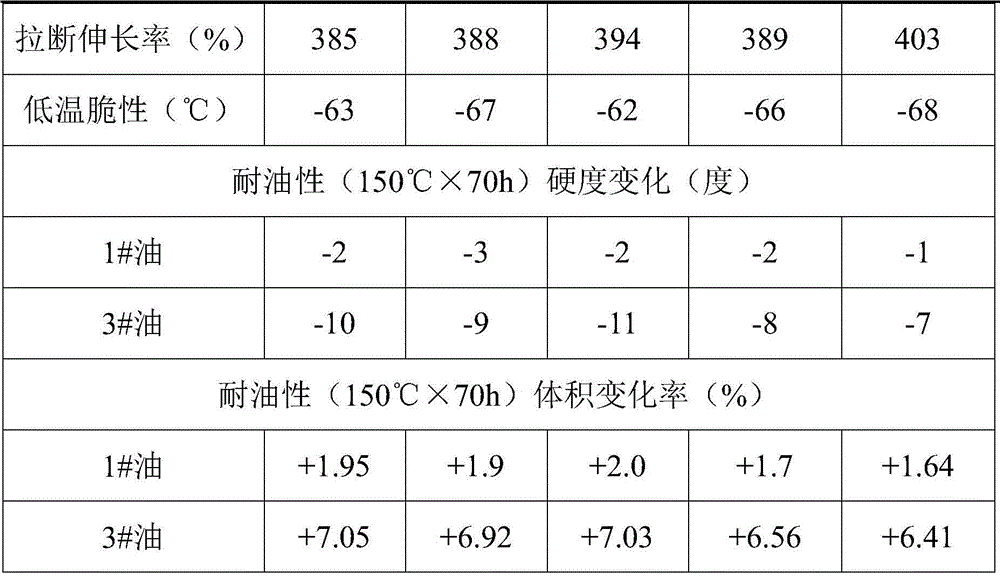

Cold-resisting oil-resisting modified fluorine rubber cable sheath material

The invention discloses a cold-resisting oil-resisting modified fluorine rubber cable sheath material which comprises the following components in parts by weight: 50-70 parts of fluorine rubber, 15-30 parts of silica rubber, 15-20 parts of fluorine silica rubber, 10-25 parts of pre-swelled organic clay, 15-25 parts of white carbon black, 5-13 parts of ternary nylon, 1-2.5 parts of stearic acid, 3-10 parts of active magnesium oxide, 3-9 parts of rare earth complex, 5-12 parts of calcium hydroxide, 0.5-1.8 parts of polyethylene glycol, 1-5 parts of epoxy octyl stearate, 1-2.5 parts of epoxy triglyceride fatty acid, 4-8 parts of a bisphenol vulcanizing agent, 1-3 parts of an accelerant, 0.5-2 parts of an anti-aging agent MB and 0.8-1.5 parts of an anti-aging agent 4010NA. The cold-resisting oil-resisting modified fluorine rubber cable sheath material disclosed by the invention is excellent in cold resistance and oil resistance and is good in comprehensive property and long in service life when used for manufacturing a cable sheath.

Owner:安徽华峰电缆集团有限公司

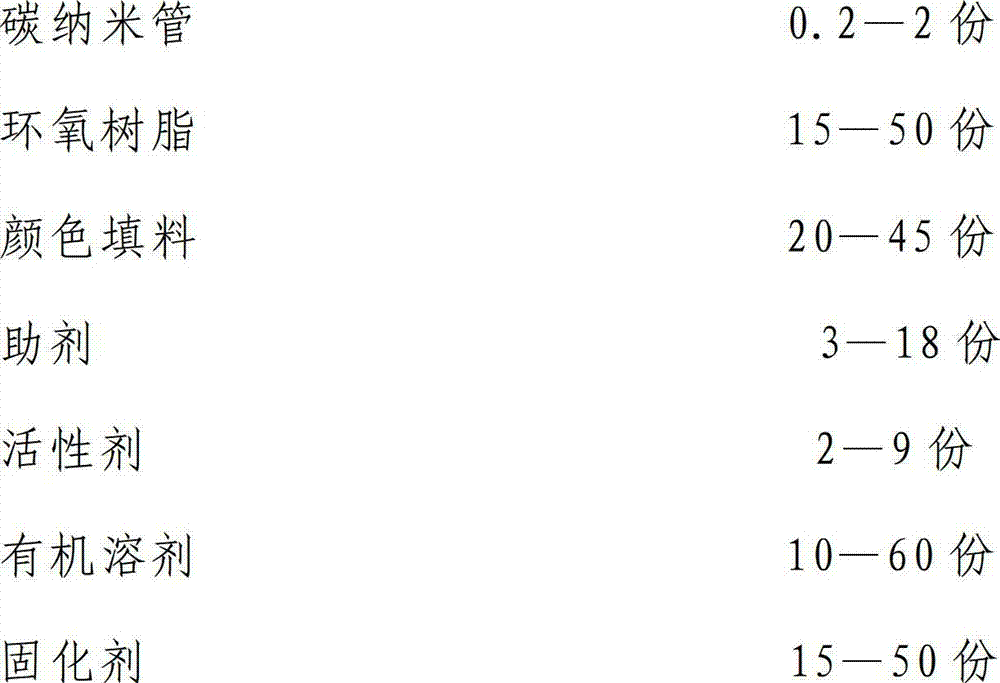

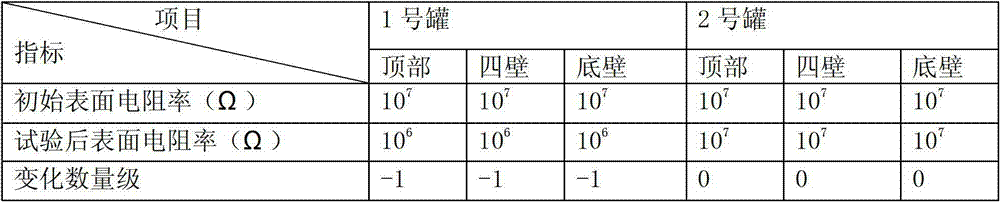

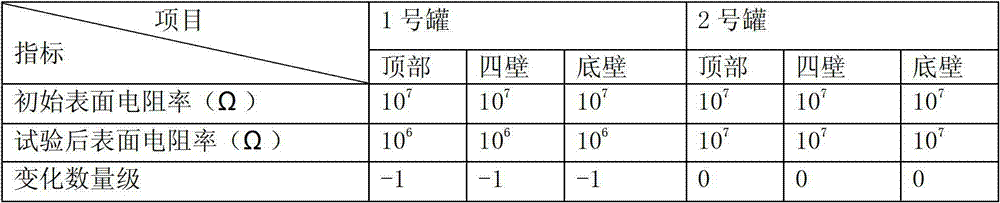

Carbon nanotube epoxy resin static conductive coating material and fabrication method thereof

InactiveCN103031039AGood stabilityWater resistantEpoxy resin coatingsElectrically-conductive paintsSolventSpecial effects

The invention discloses a carbon nanotube epoxy resin composited static conductive coating material and a fabrication method thereof. As a carbon nanotube with a special effect is adopted as a static conductive body, the carbon nanotube epoxy resin composited static conductive coating material is good in electrical conductivity; as the carbon nanotube is subjected to chemical and mechanical dispersion and complex treatment, the carbon nanotube is adaptable to an anti-corrosive paint system; a static conductive coating formed by the carbon nanotube epoxy resin composited static conductive coating material has comprehensive properties of durable oil resistance, water resistance, heat resistance, corrosion resistance, solvent resistance, no pollution to an oil product, no influence on regeneration of storage tank steel and the like; and the static conductive coating meets relevant requirements of GB6950-2001'Safe Rest Conductivity of Light Fuel Oil' in a standard exceeding manner, and is very good in stability.

Owner:HUNAN WEIERSI CHEM IND

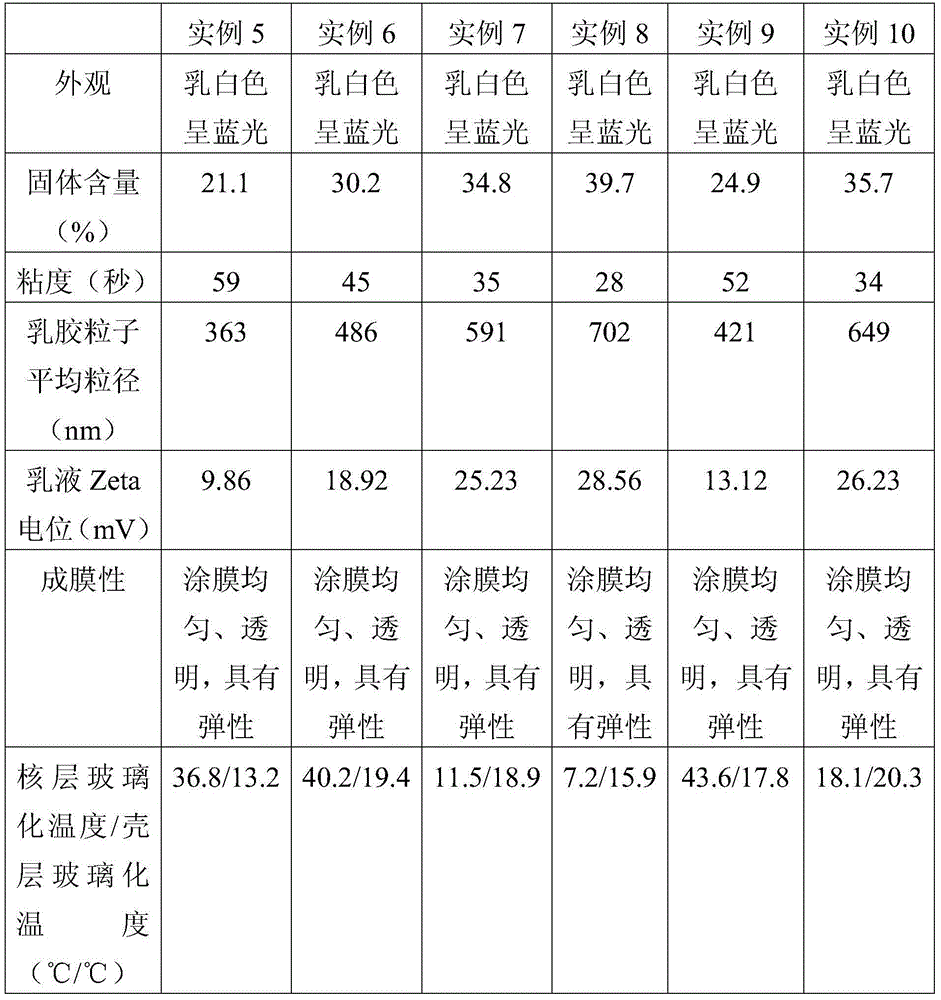

Nuclear shell type long-acting antibacterial emulsion and preparation method thereof

ActiveCN104592459ANot easy to scrub and dissolveLow film forming temperatureAntifouling/underwater paintsPaints with biocidesEmulsionChemistry

The invention relates to a nuclear shell type long-acting antibacterial emulsion. The nuclear shell type long-acting antibacterial emulsion comprises the following raw material components: water, n-butyl acrylate, isobutyl acrylate, isooctyl acrylate, styrene, methyl methacrylate, vinyl acetate, guanidinium oligomer macromonomers, an emulsifying agent, an initiating agent, a cross-linking agent and sodium bicarbonate. The preparation method comprises the following steps: preparing each raw material component; adding water, the emulsifying agent and isooctyl acrylate into a reactor, stirring, heating to 60-70 DEG C, adding the initiating agent to initiate reaction, and after the emulsion becomes blue, maintaining for 60-120 minutes, so as to obtain a nuclear layer emulsion; maintaining the temperature at 70-80 DEG C, adding n-butyl acrylate, heating to 81-85 DEG C, maintaining the temperature, cooling, and discharging, so as to obtain the nuclear shell type long-acting antibacterial emulsion. According to the preparation method, guanidinium and guazatine oligomers are taken as antibacterial functional groups, and guanidyl serves as a main antimicrobial group, has an obvious antibacterial effect and is very safe to human bodies. The preparation method for the nuclear shell type long-acting antibacterial emulsion is simple, rapid, environmentally friendly and suitable for industrial production, and the operation is easy.

Owner:GUANGXI UNIV

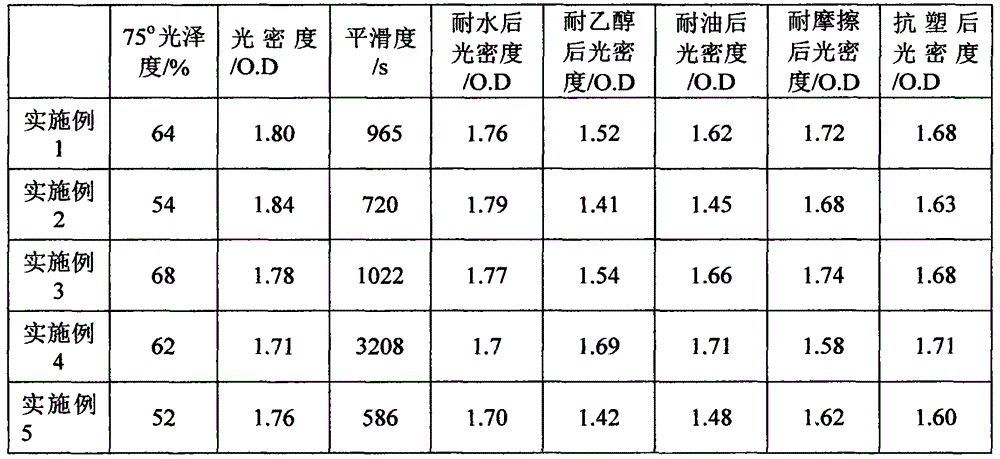

High-gloss multi-proof thermo-sensitive recording material and preparation method thereof

InactiveCN105040521AHigh glossImprove smoothnessCoatings with pigmentsSpecial paperCompound aUltraviolet

The invention relates to a thermo-sensitive recording material, in particular relates to a multi-proof thermo-sensitive recording material, and discloses a high-gloss multi-proof thermo-sensitive recording material and a preparation method thereof. A precoating layer, a thermo-sensitive top coat and a pre-coating protective layer sequentially coat the front surface of a base material; and a back coating coats the back surface of the base material. The top coating technology comprises the following steps: compounding a film material coated with a top paint and the base material coated with a thermo-sensitive paint; and drying and then stripping, so as to obtain the high-gloss multi-proof thermo-sensitive paper, wherein calendaring is not needed. The high-gloss multi-proof thermo-sensitive recording material is excellent in performance, and lower in cost in comparison with the high-gloss thermo-sensitive paper which is obtained by ultraviolet (UV) top coating and solidifying.

Owner:HUNAN HENGHAN HIGH TECH CO LTD

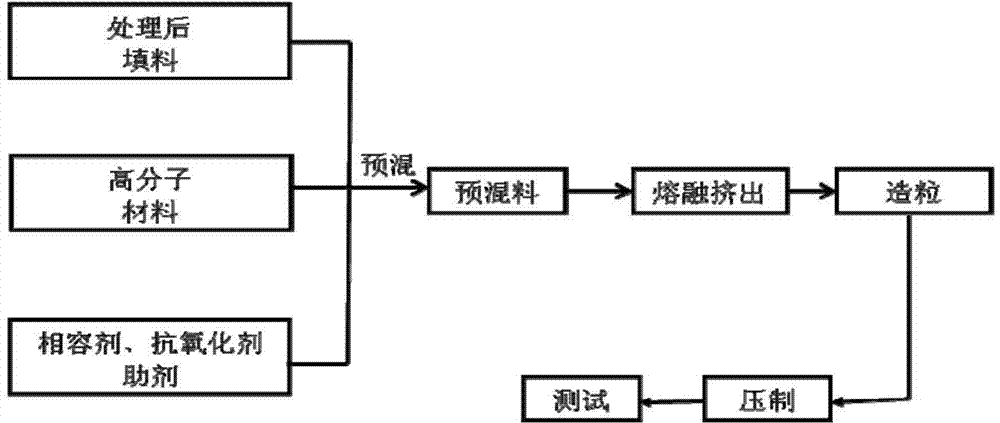

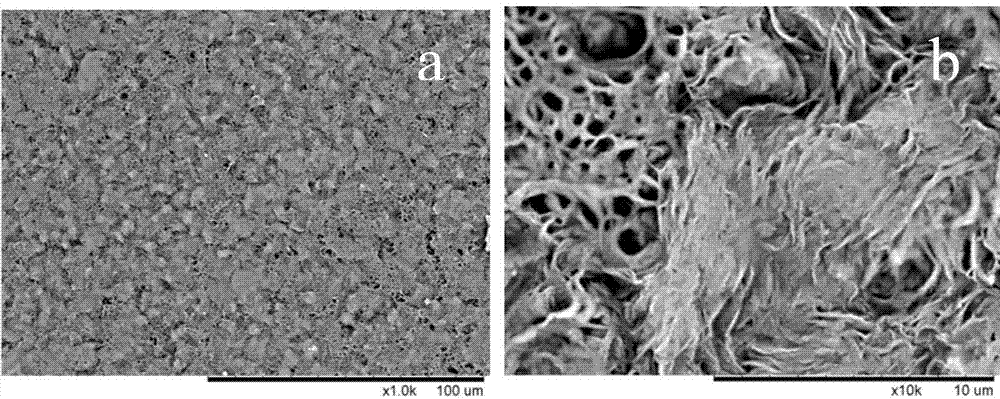

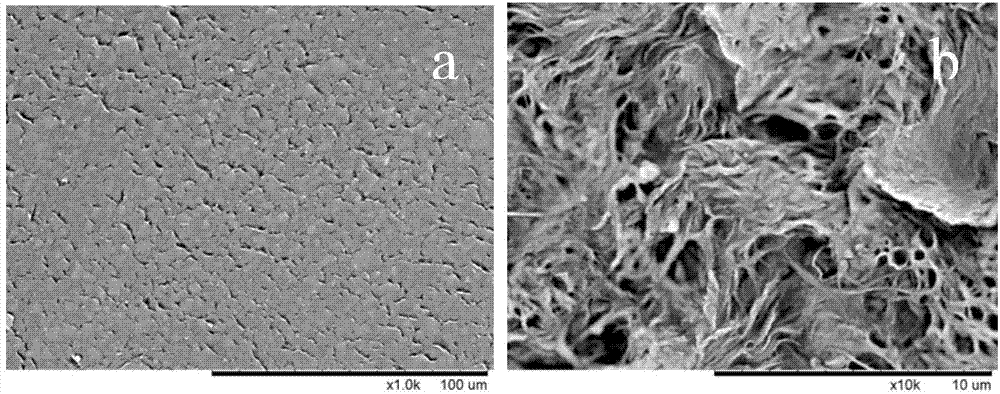

Method for preparing synthetic paper based on ultrahigh-molecular weight polyethylene

The invention relates to a method for preparing synthetic paper based on ultrahigh-molecular weight polyethylene. The method comprises the following steps: modifying an inorganic filler to obtain a modified filler, then uniformly premixing the modified filler with the ultrahigh-molecular weight polyethylene, a compatilizer, an antioxidant and an additive, performing melt-extrusion, and pelleting to obtain master batches; flatly laying the master batches on a hollow mold, melting and hot-pressing the master batches in the shape of a membrane, cold-rolling, and extracting to obtain the synthetic paper. The synthetic paper prepared by the method disclosed by the invention has excellent performances of good mechanical properties, light weight, solvent resistance, micro-porosity and the like.

Owner:DONGHUA UNIV +1

Fluorosilicate self-cleaning glass nanophase material and producing method thereof

The invention discloses a silicon fluoride self-cleaning glass nano-material, which is composed of solvent and active ingredients; the active ingredients are fluorinated modified silicone nano-particles, and the reaction raw materials comprise ortho-silicon ester and fluorine modified alkyl silane, with the ratio volume and dosage reaching 1.5-3:0.15-1.8. The invention also discloses a manufacturing method for the silicon fluoride self-cleaning glass nano-material, comprising two steps: synthesizing the surface modification of silica nano-particles, silica nano-particles; the ratio between volume and dosage for each added reactant is as follows: solvent: water: ortho-silicon ester: fluorine modified alkyl silane equals to 100: 1.5-3: 1.5-3: 0.15-1.8. The invention has simple production process, stable product performance, higher storage stability, excellent chemical properties, low surface energy and good tolerance against pollution, which is used for glass surface treatment; the contact angle between water and coating is greater than 110 degrees.

Owner:GUANGZHOU BAIYUN CHEM IND

Butyl blending emulsion chemical protective glove and preparation method thereof

ActiveCN103965554AKeep airtightCorrosion resistance hasGlovesProtective garmentPolymer scienceVulcanization

The invention discloses a butyl blending emulsion chemical protective glove and a preparation method thereof. The butyl blending emulsion chemical protective glove comprises a glove liner and a macromolecule blending emulsion material outer gumming layer, wherein the macromolecule blending emulsion material outer gumming layer comprises the components of a macromolecule blending alloy material main body, a vulcanizer, a promoter and a vulcanization activator according to the mass ratio of 100 to 0.5-5 to 0-2 to 1-3; the macromolecule blending alloy material main body comprises 60 to 100 percent of butyl rubber and 0 to 40 percent of other high polymer materials; the high polymer materials are PVC, PE, phenolic aldehyde or nitrile rubber. The butyl blending emulsion chemical protective glove overcomes defects in binding power and tear resistance, has excellent performances of chemical corrosion prevention, solvent resistance and oil resistance, has an excellent water resisting property and an electrical insulating property, and also has wear resisting, cut preventing and puncture resisting properties and the like; the preparation process is accomplished through mechanized linkage and flow production; the production is feasible, the technology is reasonable, the cost is reasonable, and the butyl blending emulsion chemical protective glove and the preparation method are applicable to industrialized scale production.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

Local anodic oxidation method for surface of workpiece

The invention discloses a local anodic oxidation method for the surface of a workpiece. The method comprises the following steps of: putting the workpiece into a pretreatment solution, and treating the workpiece for 20 to 30 seconds; washing and drying the pretreated workpiece; firmly sticking a polyimide adhesive tape to the oxidation-free surface of the workpiece, and removing bubbles on the adhesive tape and the surface of the workpiece; performing anodic oxidation treatment according to the conventional oxidation flow; and tearing down the adhesive tape on the surface of the oxidized workpiece, and wiping the residual adhesive on the surface of the workpiece by using an organic solvent. The local anodic oxidation method has the advantages of reducing the machining frequency, reducing the machining cost of the workpiece and avoiding the defects of poor repeated positioning precision and low product qualification rate; and the oxidation-free surface of the workpiece is effectively shielded by the polyimide adhesive tape.

Owner:SHANGHAI REAL INDAL

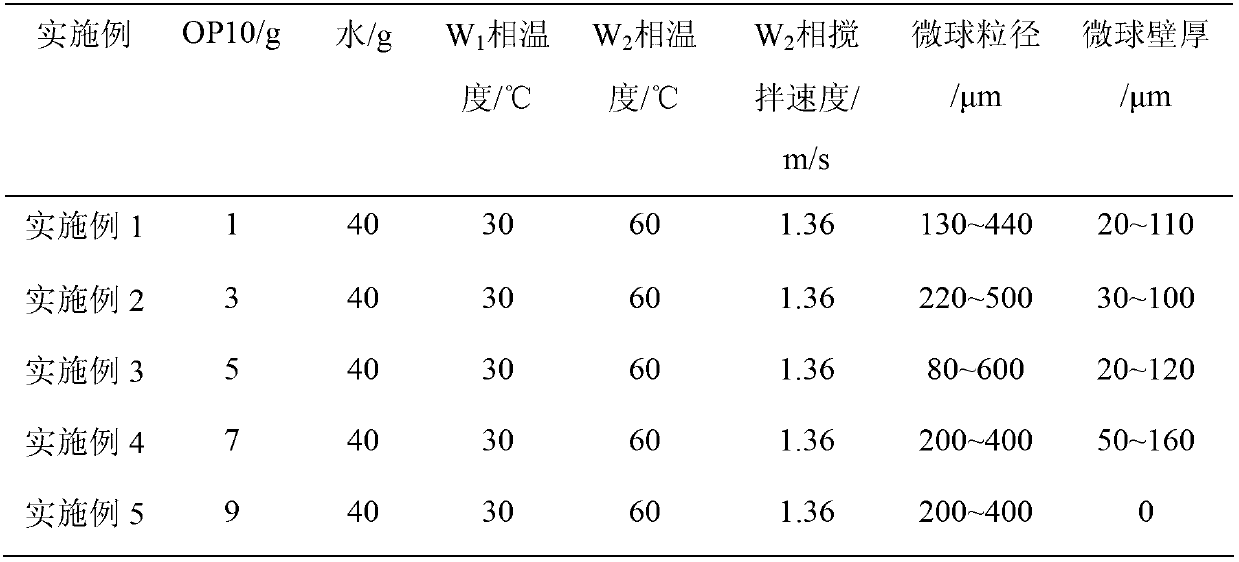

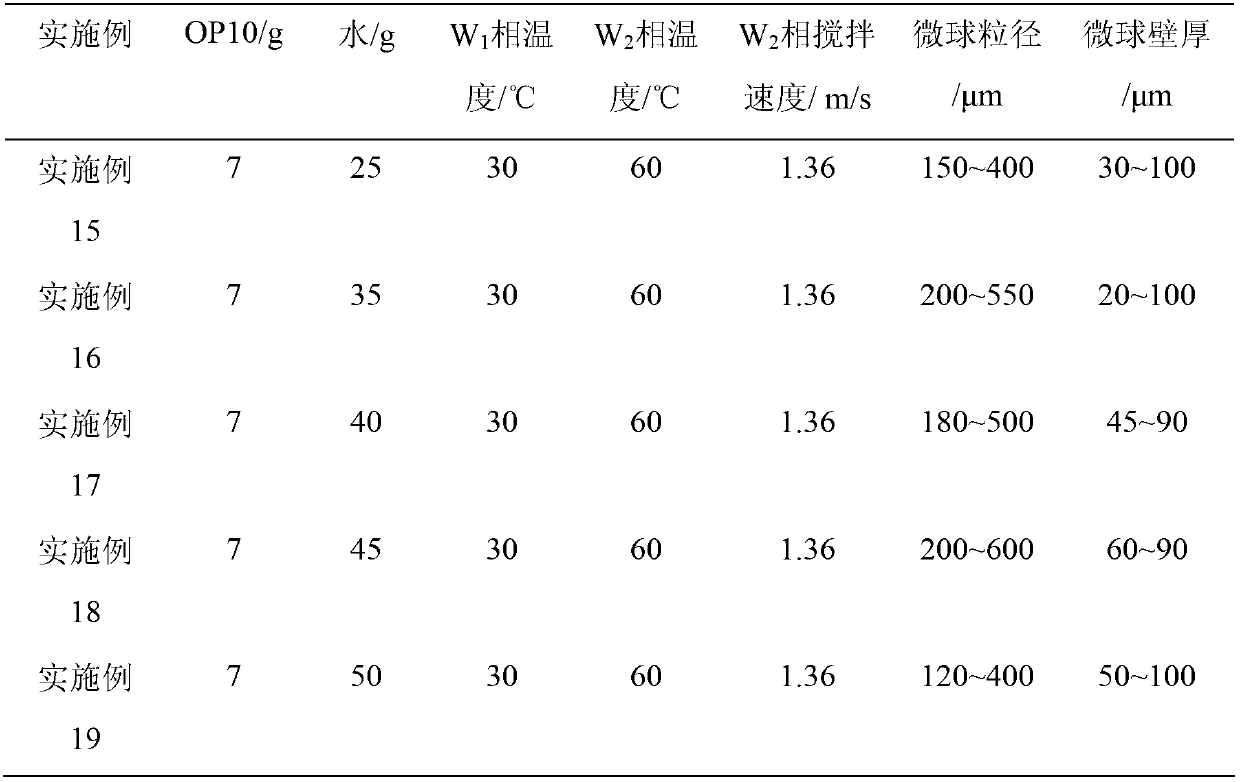

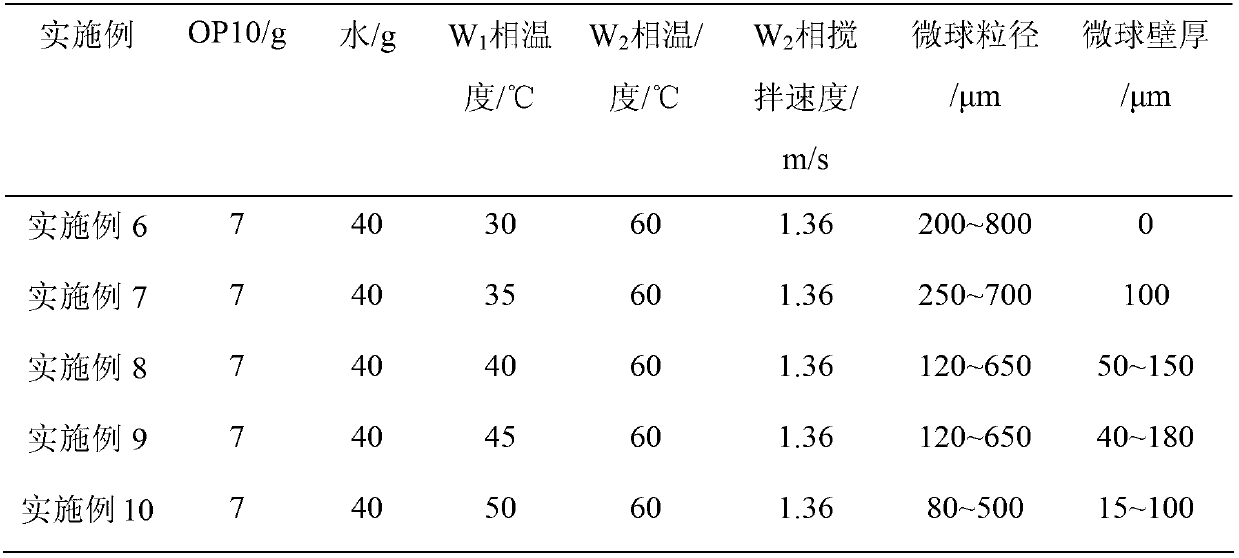

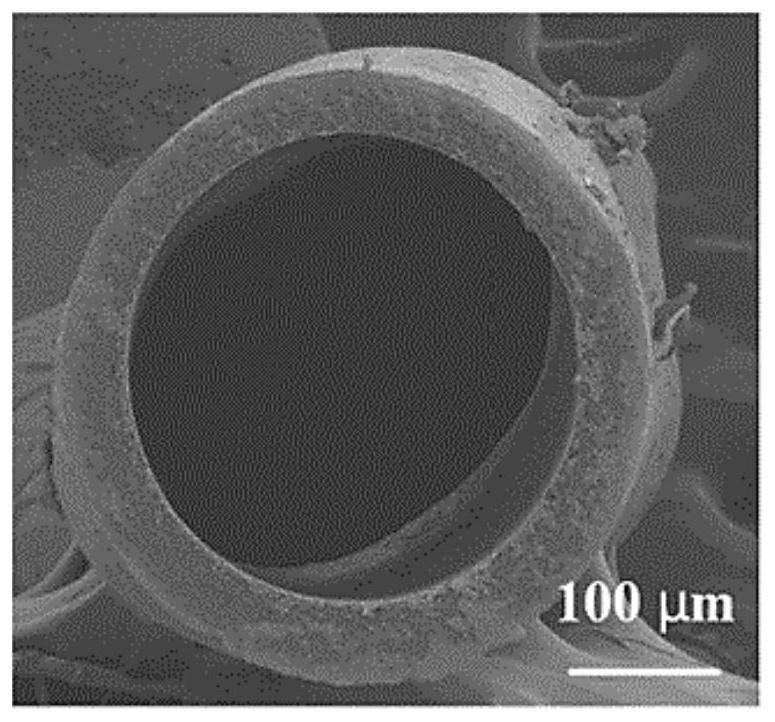

Preparation method of epoxy resin hollow microsphere

InactiveCN102850521AHeat resistantSolvent resistantMicroballoon preparationMicrocapsule preparationEpoxyPolymer science

A preparation method of epoxy resin hollow microspheres belongs to the field of polymer material. The preparation method provided by the invention comprises the following steps: (a) preparation of water / epoxy emulsion: mixing epoxy resin monomers, triethylene tetramine, an emulsifier OP10 at 30-50 DEG C, and stirring while adding deionized water, so as to obtain a water / epoxy emulsion, wherein a mass ratio of epoxy resin monomer to triethylene tetramine to OP10 to deionized water equals to A: B: C: D, and A equals to 100, and B equals to 12.9, and C equals to 1-9, and D equals to 25-40; (b) dropwise adding the water / epoxy emulsion prepared in the step (a) at a stirring speed of 0.68-1.70 m / s into ethylene glycol of 30-70 DEG C; (c) heating the water / epoxy / ethylene glycol emulsion prepared in the step ( b ) to 100 DEG C for reaction for 1h; and (d) drying the water-containing epoxy resin microspheres prepared in the step (c) in vacuum. The epoxy resin microsphere prepared by the invention has high heat resistance, solvent resistance and mechanical strength.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Self-delustering soft waterborne polyurethane leather finishing agent and preparation method thereof

ActiveCN106432667ASelf-dullingHigh wear resistancePolyurea/polyurethane coatingsLeather surface finishingPolyethylene oxideDiol

The invention discloses self-delustering soft waterborne polyurethane leather finishing agent and a preparation method thereof. Raw materials are matched by weight: (1) adding 30-50 parts of 4, 4'-dicyclohexylmthane diisocyanate, 5-20 parts of hexamethylene diisocyanate, 5-20 parts of linear double hydroxyalkyl siloxane, 30-60 parts of poly propylene carbonate diol, 30-50 parts of polyethylene oxide diol, 3-5 parts of 2, 2, 4-trimethyl-1, 3 pentanediol and 2-4 parts of dimethylolbutyric acid into a reaction kettle, heating to 70-90 DEG C and reacting for 4-6 hours; (2) cooling to 50-60 DEG C, adding 1-3 parts of triethylamine and reacting for 25-35 minutes; (3) adding 430-850 parts of deionized water, adding 4-6 parts of hydrazine hydrate after high-speed dispersion, stirring, heating to 50-60 DEG C and reacting for 1-2 hours. The product not only has good delustering and softness, but also has excellent abrasion resistance and solvent resistance.

Owner:LIAONING FIXED STAR FINE CHEM

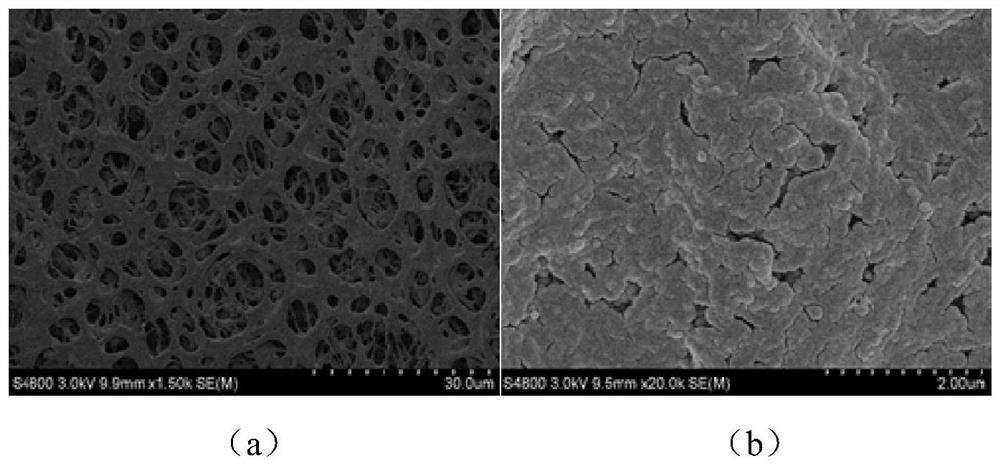

Portable photo-thermal seawater desalination hollow fiber membrane, preparation method, device and application

ActiveCN113230903AWatered down realizationSolvent resistantSemi-permeable membranesGeneral water supply conservationHydrophilic polymersEnvironmental engineering

The invention discloses a portable photo-thermal seawater desalination hollow fiber membrane, a preparation method, a device and application. The preparation method comprises the following steps: 1) dispersing and dissolving a hydrophilic polymer and nano-particles in a buffer solution with the pH value of 8.5 to prepare a uniform solution, circularly washing the hollow fiber membrane with the uniform solution for 1-24 hours, and conducting cleaning and drying for later use to prepare the hollow fiber membrane with the super-hydrophilic inner surface, wherein the ratio of the hydrophilic polymer to the nano-particles is (1-20):(0-20); and (2) putting the hollow fiber membrane with the super-hydrophilic inner surface obtained in the step (1) in 0.1-20wt% photo-thermal modified material solution atmosphere, and conducting treating for 1-24 hours in manners of surface adsorption, surface vapor deposition, surface cross-linking fixation, suction filtration and / or coating modification, so as to prepare the hollow fiber membrane with the super-hydrophilic inner surface and the photo-thermal outer surface. The three-dimensional hollow fiber membrane is selected as a base material, and the photo-thermal seawater desalination hollow fiber membrane obtained through inner / outer surface modification can realize photo-thermal seawater desalination.

Owner:ZHEJIANG UNIV

Preparation method of electrode sheet including PTC coating layer and lithium ion battery

ActiveCN110137426AImprove compatibilityGood processing performanceElectrode thermal treatmentFinal product manufactureSolventIon

The invention provides a preparation method of an electrode sheet including a PTC coating layer and a lithium ion battery including the electrode sheet, and belongs to the technical field of lithium ion batteries. The preparation method comprises the following steps: step 1: according to the number of parts by weight, 400-1000 parts of solvent, 50-100 parts of high-molecular polymer and 0. 5-3 parts of conductive agent are uniformly stirred and then 0. 1-5 parts of mixed reagent of high-voltage-resistant crosslink agent and initiator are added, wherein the mass fraction of the initiator in thehigh-voltage-resistant crosslinking agent is 0. 1-2%, and the mixture is stirred for 2-8 hours so as to obtain a coating slurry; step 2: the coating slurry is coated on a current collector and driedat 80-120 DEG C for 2-6h so as to obtain the current collector coated with the PTC coating layer; and step 3, the electrode sheet slurry is uniformly coated on the current collector and dried, rolledand pressed and sliced so as to obtain the lithium ion battery electrode sheet including the PTC coating layer. The molecular design method is used and the high-voltage-resistant crosslink structure system is introduced so as to effectively improve the compatibility and the processing performance of the PTC coating layer and the electrode sheet.

Owner:ZHUHAI COSMX BATTERY CO LTD

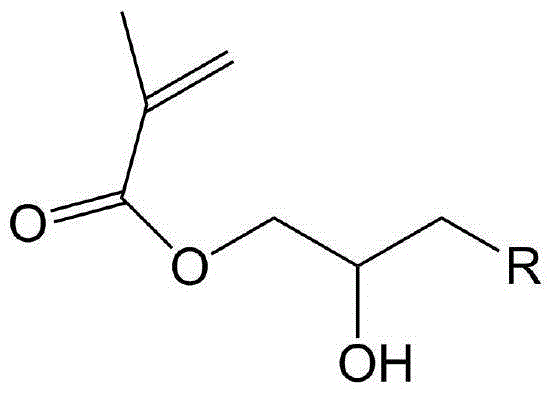

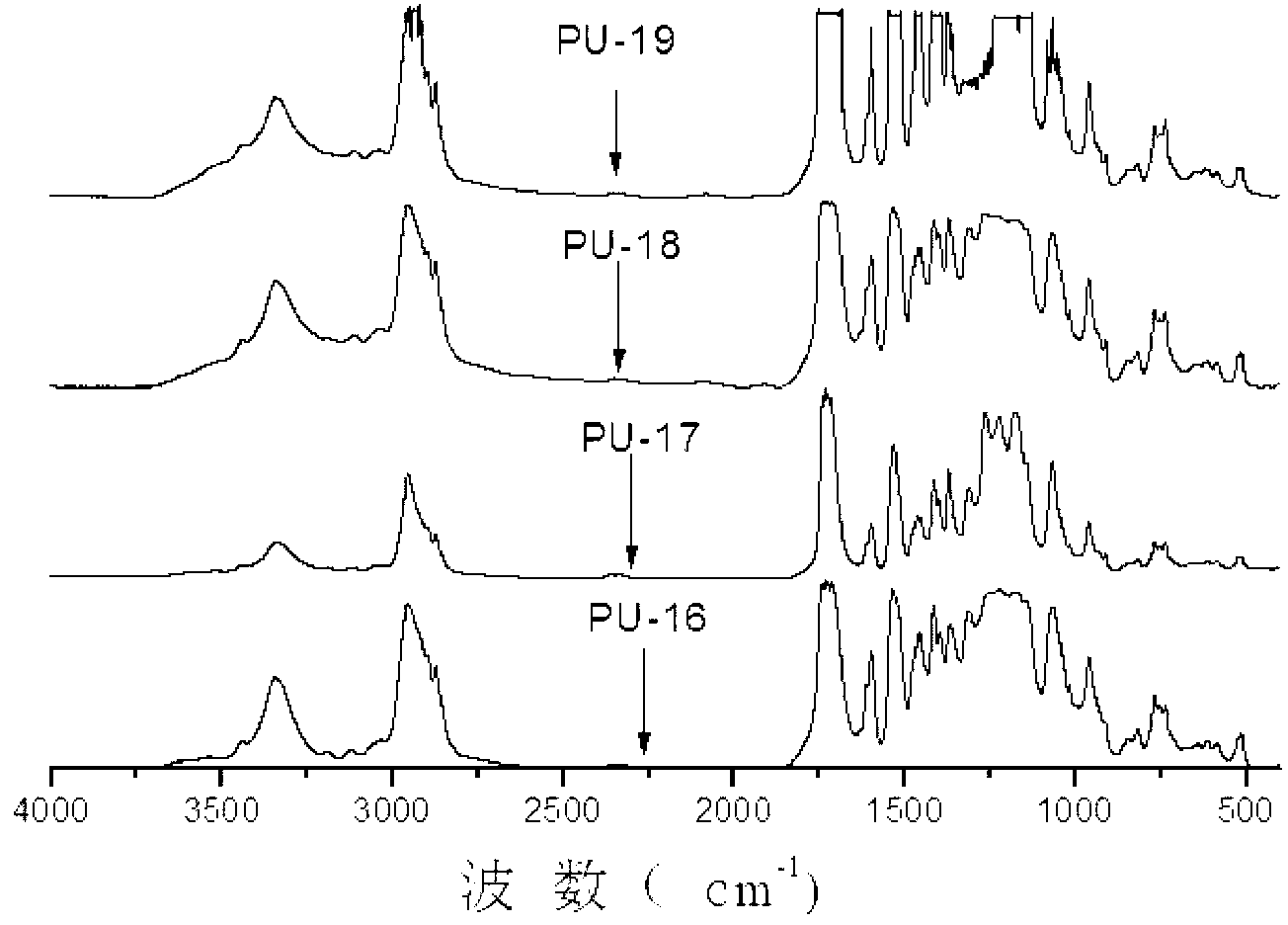

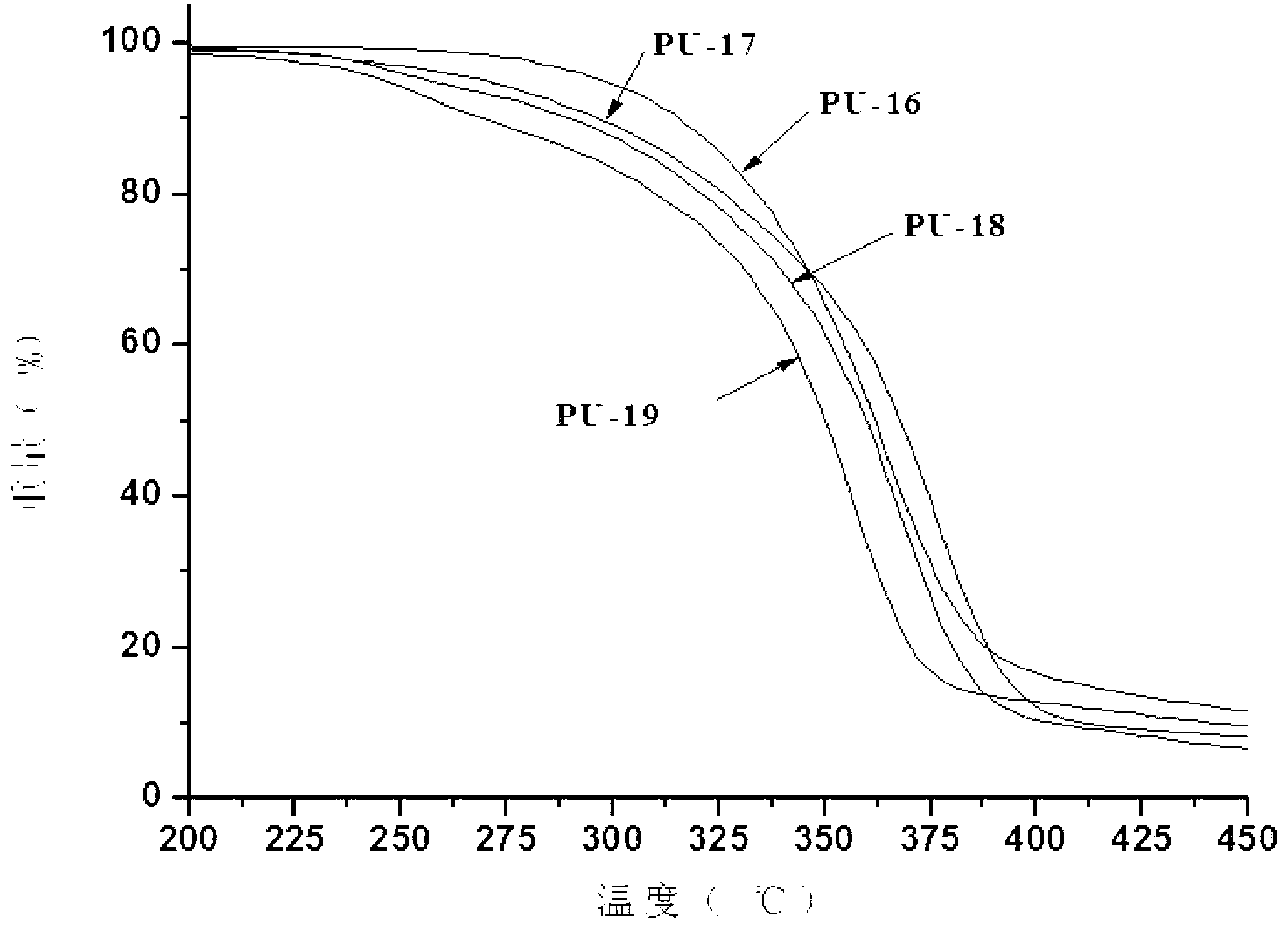

Preparation method of imidazole-containing cationic antistatic polyurethane

The invention discloses a preparation method of imidazole-containing cationic antistatic polyurethane. The preparation method provided by the invention is characterized by comprising the following steps: carrying out a reaction between imidazole and an acrylic acid ester compound at the mole ratio of 1:1-5 to obtain an esterified imidazole derivative; carrying out a reaction between the imidazole ester derivative and 2-bromoethanol at the mole ratio of 1:1-5 to obtain a hydroxyl-terminated imidazole ionic liquid, performing ester interchange between the hydroxyl-terminated imidazole ionic liquid and polyester or polyether glycol so as to obtain dihydroxy-terminiated imidazole cationic polyester or polyether glycol; and finally carrying out a reaction between 1-10 mol of dihydric alcohol with the molecular weight being 90-2000, 1-10 mol of dihydroxy-terminiated imidazole cationic antistatic long-chain dihydric alcohol and 1-20 mol of diisocyanate in a solvent in the presence of a catalyst so as to obtain the cationic antistatic polyurethane with the main chain containing imidazole. The imidazole-containing cationic polyurethane is prepared in the invention. The polyurethane has excellent antistatic performance. Electric property of the polyurethane will not be damaged by alkalinity or acidity, and electroconductibility of the polyurethane is not dependent on environment humidity. Thus, the polyurethane has a wider application field.

Owner:SICHUAN UNIV

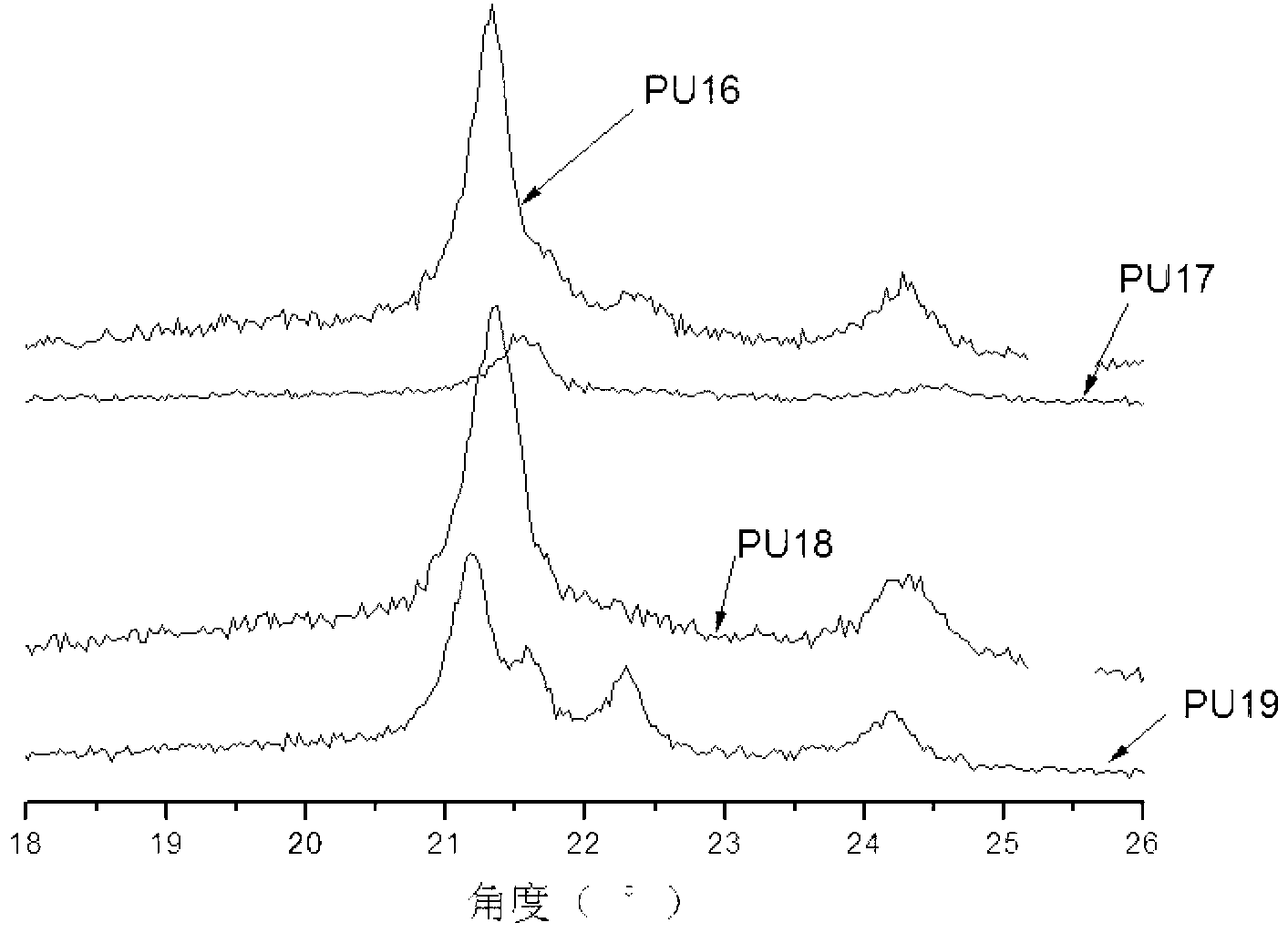

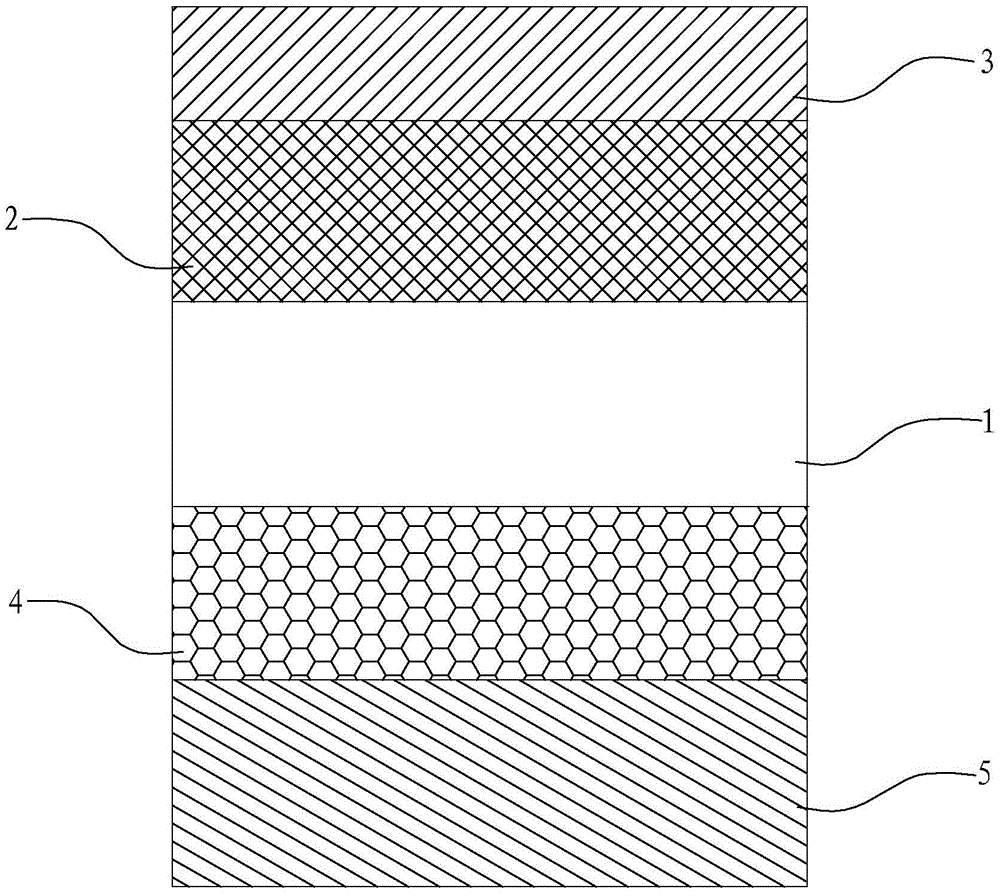

Highly heatproof polyurethane hot melt adhesive and three layer heat-sealing adhesive tape

InactiveCN107384289AMaintain propertiesImprove stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterAlcohol

The invention discloses a highly heatproof polyurethane hot melt adhesive, a three layer heat-sealing adhesive tape, and a preparation method thereof. The highly heatproof polyurethane hot melt adhesive comprises the following raw materials in parts by weight: 70 to 80 parts of polyester polyol, 10 to 20 parts of diisocyanate, 5 to 10 parts of chain extender, and 0.1 to 2 parts of nano filling material, wherein the hydroxyl value of polyester polyol is 10-200 mgKOH / g, the acid value is 0.1-3 mgKOH / g, and the chain extender is a mixture of an alcohol amine chain extender and a polyol chain extender according to a mole ratio of 1:0.5-1.5. The three layer heat-sealing adhesive tape comprises a basic material layer (1), polyurethane hot melt adhesive (2), and a basic material layer (3), which are laminated in sequence, wherein the polyurethane hot melt adhesive is the abovementioned highly heatproof polyurethane hot melt adhesive. The adhesive property, high temperature boiling resistant performance, water absorbing performance, and dyeing property of heat-sealing adhesive tape are largely improved by the highly heatproof polyurethane hot melt adhesive; at the same time, the characteristics of polyurethane, such as excellent medium resistant stability, electric properties, and the like, are maintained, and the application range of the heat-sealing adhesive tape is largely enlarged.

Owner:江门市衣美贴科技有限公司

Premix formulation for parenteral use and packaging thereof

InactiveUS20170128421A1Minimizes extractables/leachablesEasy to storeOrganic active ingredientsPharmaceutical containersPerioperative careMedicine

The present invention relates to stable premix formulations for parenteral use and packaging for such formulations. The present invention relates to use of a single layer or multilayer film bags comprising polypropylene for packing premixed injectable formulations which remain stable during the storage period.The present invention relates to use of a single layer or multilayer film bags comprising polypropylene for packing dexmedetomidine premixed formulations. Such stable premixed formulations packed into a single layer or multilayer film bags comprising polypropylene are highly advantageous since they are ready-to-use, for example, in perioperative care of a subject in need thereof for sedation.

Owner:SURA SIVA PRASAD REDDY +5

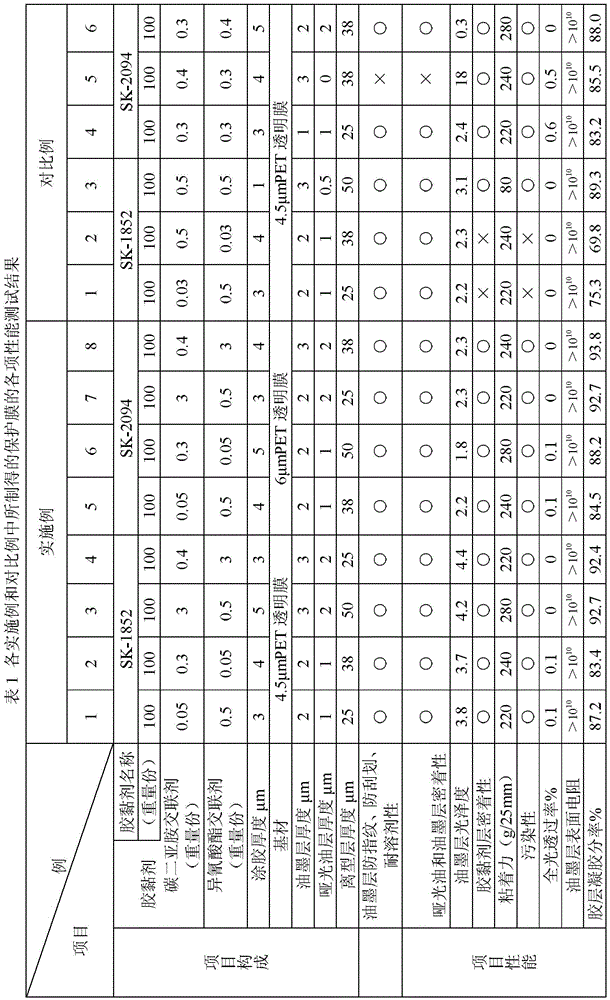

Protection film used for surface of NFC and preparation method of protection film

ActiveCN105482731AReduce surface glossSolvent resistantFilm/foil adhesivesInksTectorial membraneEngineering

The invention relates to a protection film used for the surface of NFC. The protection film comprises a PET base material layer, an adhesive layer arranged on one side of the PET base material layer and a release film layer attached to the adhesive layer. A black ink layer is arranged on the other side of the PET base material layer, the black ink layer is coated with a matte oil layer which is formed by film formation of an organic delustering agent, the black ink layer contains 0.5%-0.8% of aluminum compound, and the mean grain size of the aluminum compound ranges from 0.2 mm to 0.5 mm. The invention further relates to a preparation method of the protection film. The matte oil layer prevents fingerprints and scratches, meanwhile, the protection film has the functions of resisting solvents, achieving heat radiation and the like, and the service life of an NFC chip can be effectively prolonged. In addition, the aluminum compound is added to the black ink layer, waves, interfering with communication message receiving of a mobile phone, sent by the NFC chip can be shielded, it is guaranteed that the adhesive force of the adhesive layer of the protection film is moderate, the protection film can be completely attached to the surface of NFC, and adhesive residues or other pollution cannot be caused to the surface of NFC after the protection film is removed.

Owner:NINGBO SOKEN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com