Waterborne polyurethane surface treating agent for synthetic leather and preparation method thereof

A technology of water-based polyurethane and surface treatment agent, which is applied in the fields of matte, skin feel, solvent resistance, and scratch resistance. It can solve the problems of reducing production efficiency, production cost, no skin feel, dryness, etc. Safe, matte-increasing, easy-to-make and use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

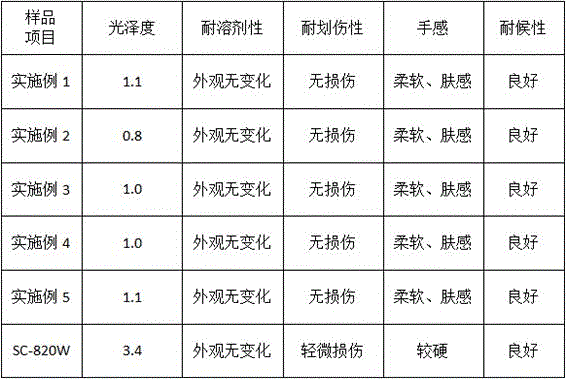

Examples

Embodiment 1

[0046] (1) Mix 45 parts of deionized water and 2 parts of silica matting powder and stir evenly;

[0047] (2) Add 55 parts of water-based polyurethane emulsion, 1.5 parts of high-slip silicone leveling agent, 2 parts of weak anionic silicone wear-resistant agent, 3 parts of non-ionic silicone hand feeling agent, and 0.2 parts of non-ionic water-based defoamer , stir evenly;

[0048] (3) Add 1 part of associative water-based polyurethane thickener, stir evenly, filter to obtain the product, solid content: 24.18%, viscosity: 1447mPa·s;

[0049] In this example, the amount of water-based polyurethane emulsion added is relatively large, and the coating feels soft and has excellent solvent resistance.

Embodiment 2

[0051] (1) Mix 47 parts of deionized water and 4 parts of silica matting powder and stir evenly;

[0052] (2) Add 45 parts of water-based polyurethane emulsion, 2 parts of high-slip silicone leveling agent, 4 parts of weak anionic silicone wear-resistant agent, 4 parts of non-ionic silicone hand feeling agent, and 0.3 parts of non-ionic water-based defoamer , stir evenly;

[0053] (3) Add 2 parts of associative water-based polyurethane thickener, stir evenly, filter to obtain the product, solid content: 26.27%, viscosity: 1629mPa·s;

[0054] In this embodiment, the amount of weak anionic silicone wear-resistant agent and silica matting powder added is relatively large, and the coating has excellent wear resistance and scratch resistance, low gloss, and delicate hand feeling.

Embodiment 3

[0056] (1) Mix 45 parts of deionized water and 3 parts of silica matting powder and stir evenly;

[0057] (2) Add 48 parts of water-based polyurethane emulsion, 1.8 parts of high-slip silicone leveling agent, 3 parts of weak anionic silicone wear-resistant agent, 5 parts of non-ionic silicone hand feeling agent, and 0.3 parts of non-ionic water-based defoamer , stir evenly;

[0058] (3) Add 2 parts of associative water-based polyurethane thickener, stir evenly, filter to obtain the product, solid content: 25.17%, viscosity: 1558mPa·s;

[0059] In this embodiment, the amount of nonionic silicone hand feeling agent added is relatively large, and the coating is relatively softer and smoother.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com