Patents

Literature

530results about How to "Delicate feel" patented technology

Efficacy Topic

Property

Owner

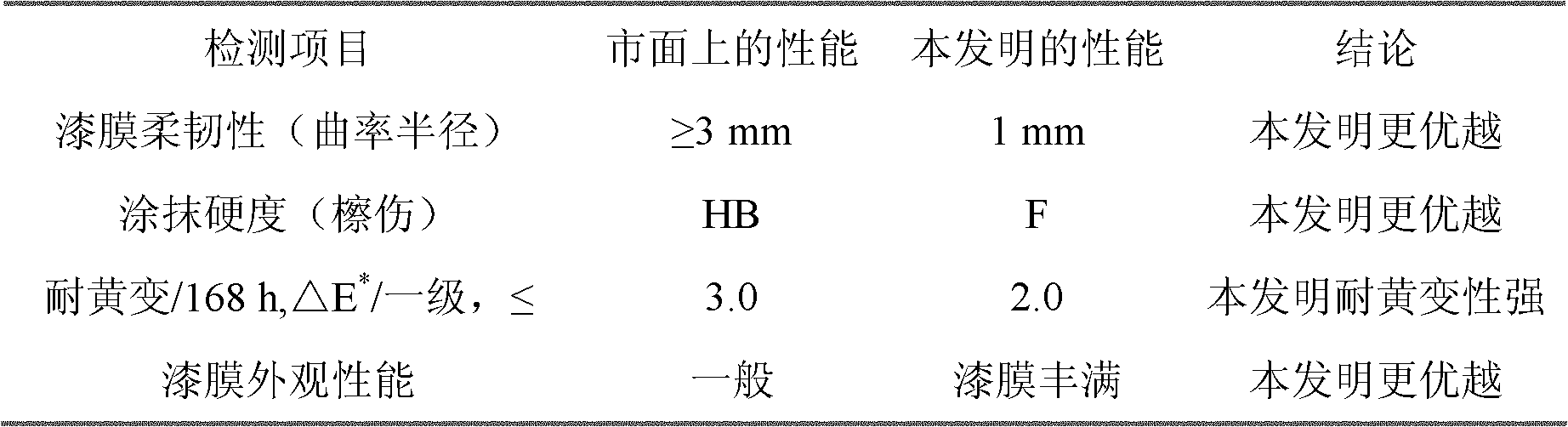

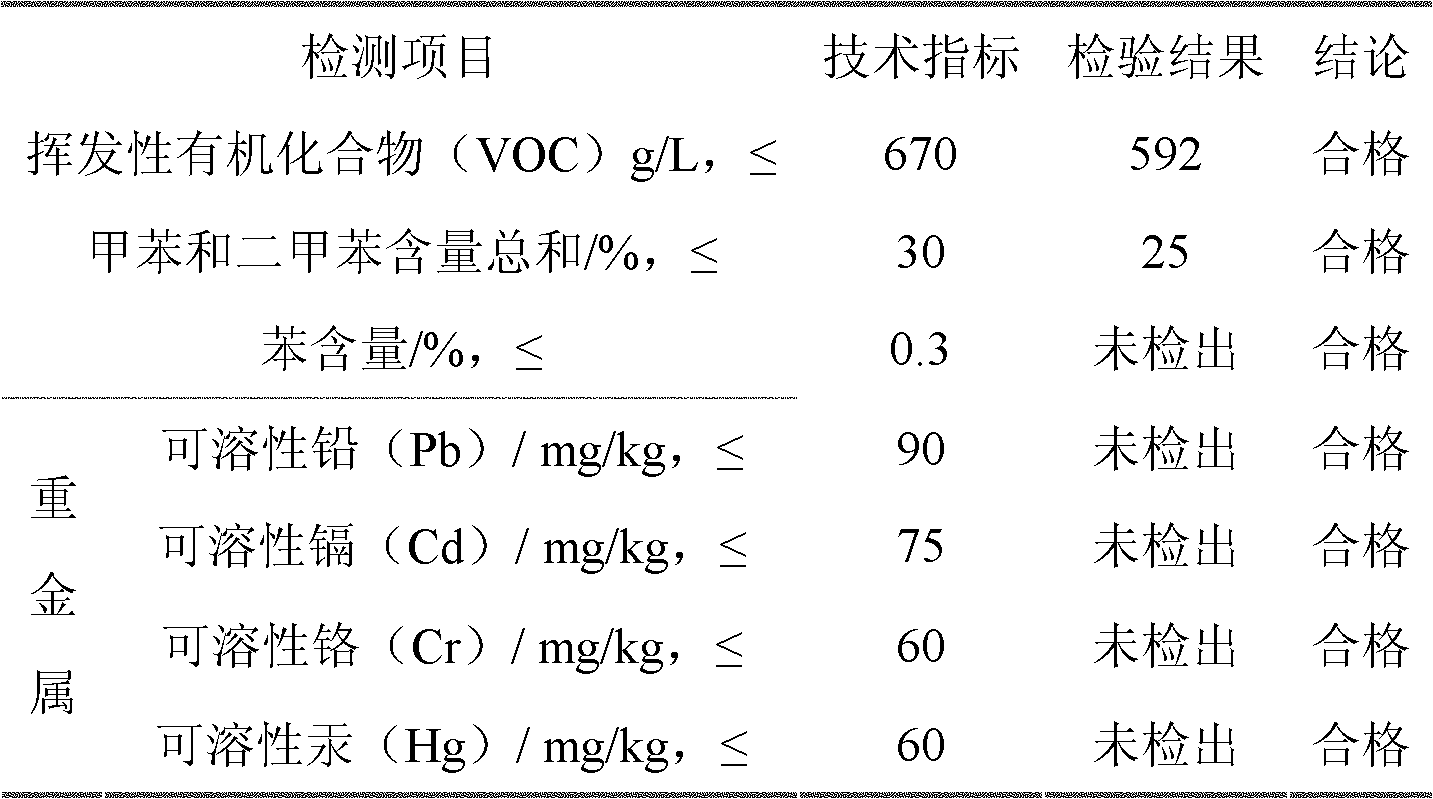

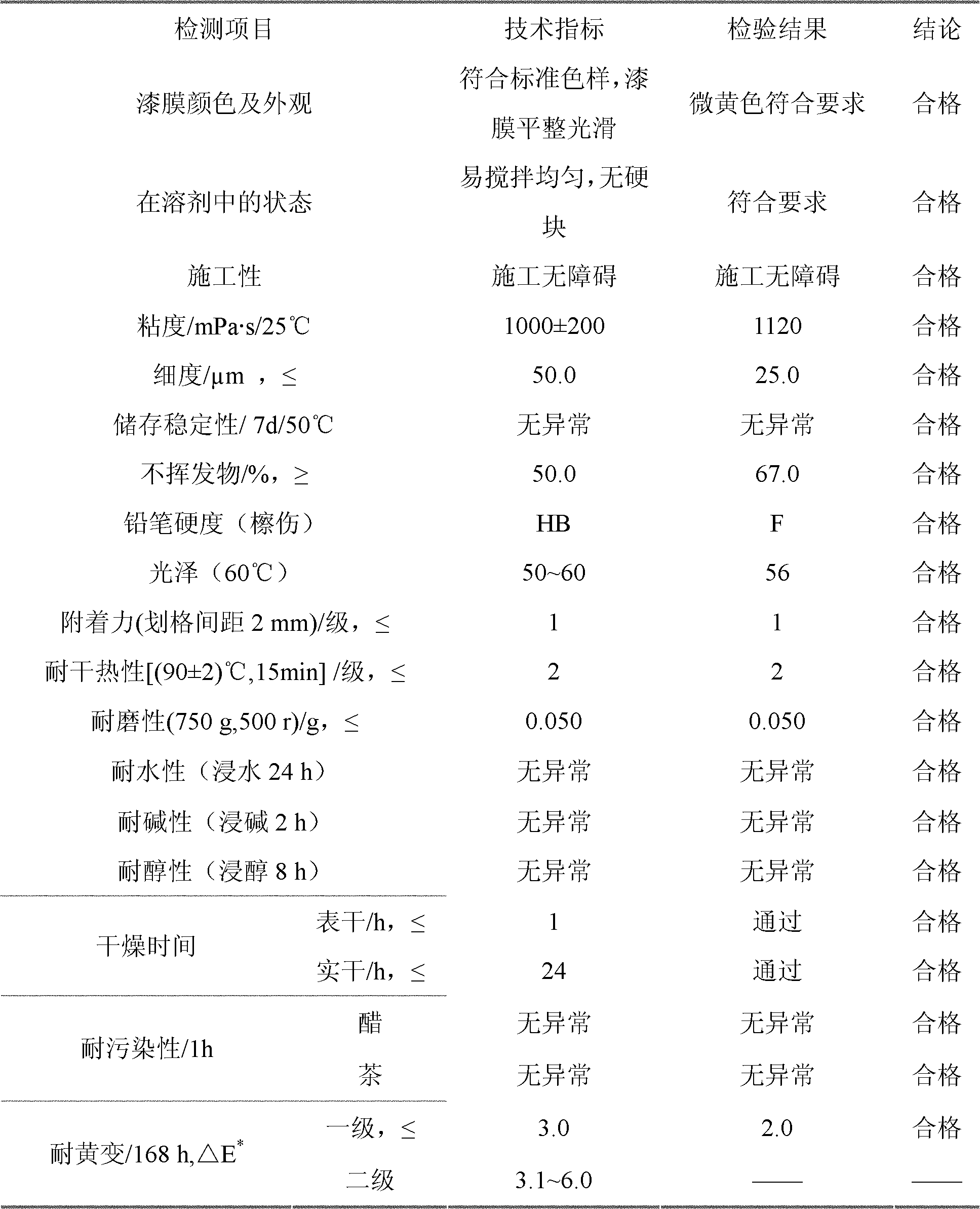

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic glaze and preparation method thereof

The invention discloses ceramic glaze prepared from the following components in weight percentages: 40 to 80% of SiO2, 8 to 20% of Al2O3, 0 to 5% of B2O3, 3 to 13% of CaO, 1 to 6% of MgO, 1 to 10% of BaO, 0 to 5% of ZnO, 1 to 4% of K2O, 1 to 4% of Na2O, 5 to 13% of ZrO2, 0 to 0.5% of Fe2O3, and 0 to 0.5% of TiO2. The invention also discloses a preparation method of the ceramic glaze. In the preparation method of the invention, some raw materials in the glaze formula are calcined at high temperature in advance, which helps to reduce defects such as bubbles and pinholes on the glaze and improves the quality of a product, meanwhile, the melting temperature of the glaze is properly reduced, the fluidity of a glaze melt at the high temperature is increased, and a flat, fine and smooth surface can be easily obtained. By adoption of the preparation method of the invention, the matte glaze with good hand feel and low glossiness can be obtained, and the high gloss glaze with a smooth surface and without pinholes or bubbles can also be obtained, so as to obtain the ceramic product with more excellent performance.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

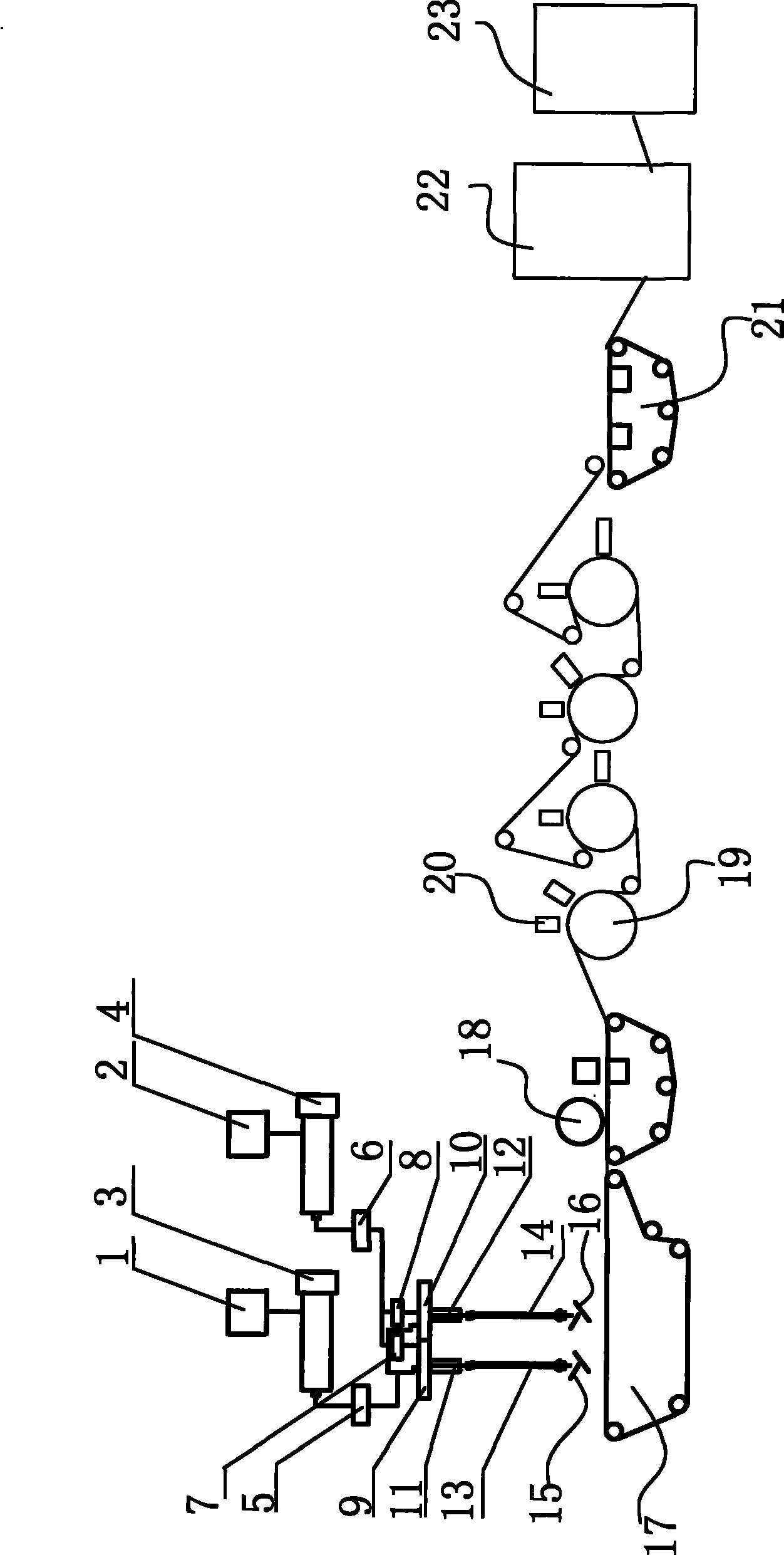

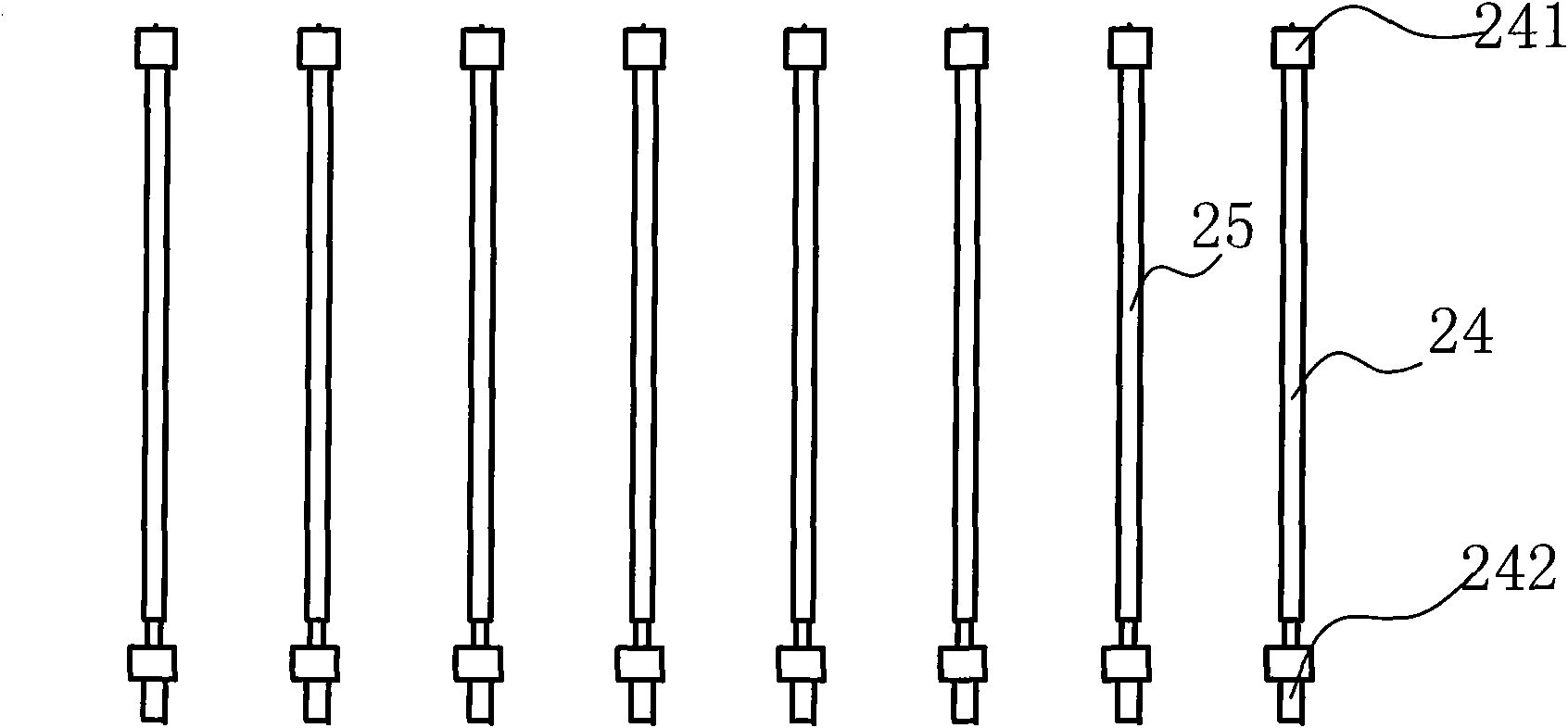

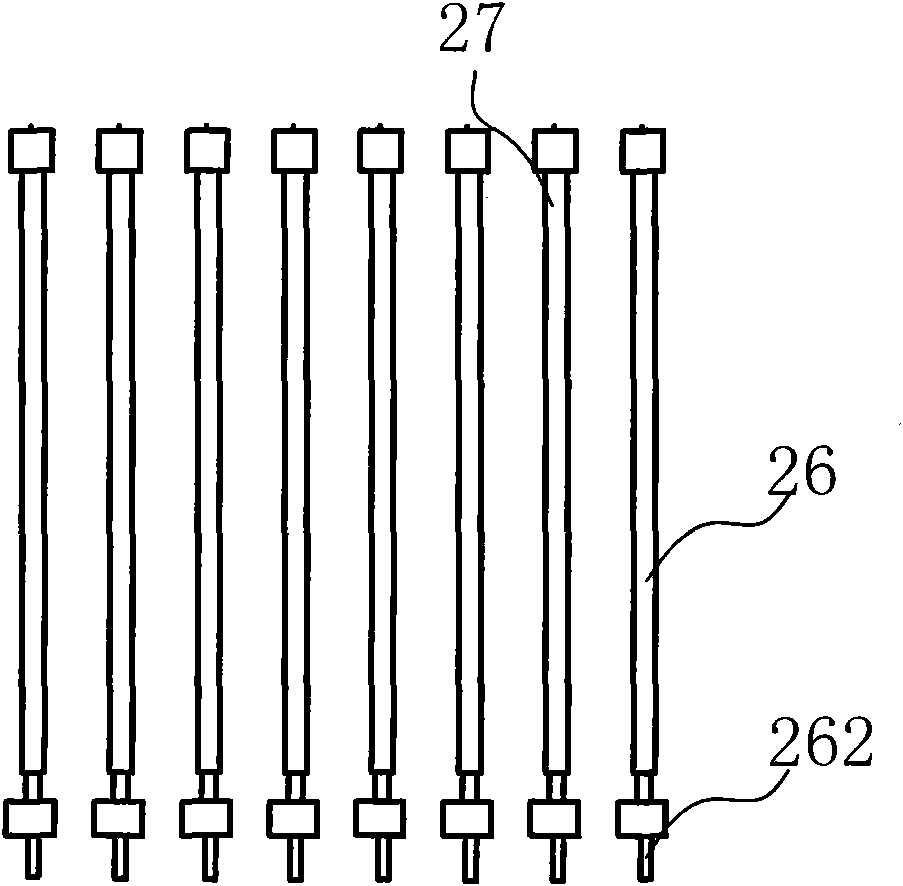

Manufacturing method and device for two-component hollow spun-bonded spunlace non-woven fabrics

InactiveCN101818413ASoft touchGood drapabilityHollow filament manufactureFilament/thread formingWoven fabricYarn

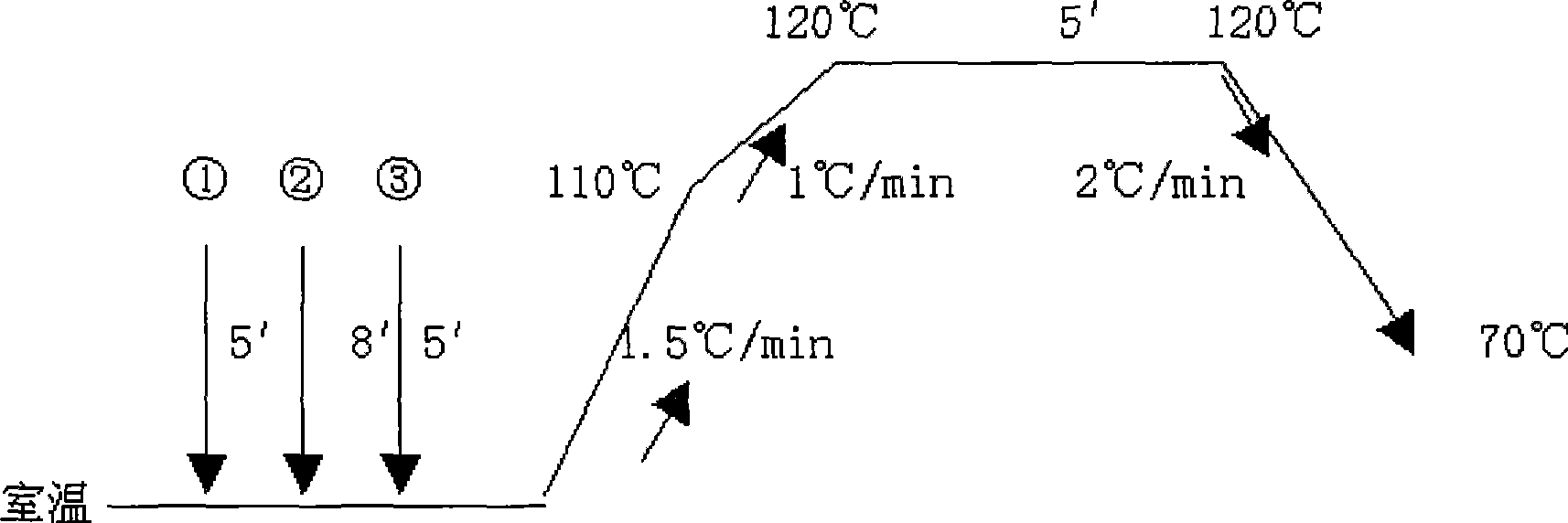

The invention belongs to the technical field of spun-bonded nonwovens manufacturing. The manufacturing method comprises the following steps: a. respectively drying, extruding, melting and filtering the two slices made of different materials according to a ratio; b. precisely measuring the two melts with a metric pump to enter into a main box for conjugate composition, spinning the composite melts at the condition of air cooling to obtain hollow as-spun fibers; c. air-drafting and spinning the as-spun fibers; d. spreading and lapping the obtained spinning; e. carrying out spunlace solidifying and splitting on the fiber nets obtained by spreading and lapping; and f. drying and shaping to form clothes. The device comprises a slice device, a conjugate composition device, a spinning device, an air drafting device, a swaying yarn and web forming device, a spunlace device and a sari forming device which are arranged in turn, and also comprises a central control desk which can manipulate the devices. The invention has the advantages of less labor room buildings, short processing flow, high production efficiency and the like. And the produced non-woven fabrics have better hand feeling, better softness and thinner single fiber fineness, have improved filtering property and developed application of the non-woven fabrics in health care.

Owner:JIAN CITY SANJIANG SUPERFINE FIBER NONWOVEN

Nanometer particles-containing cold accumulating material for cooling pad

InactiveCN102703034AReduce the degree of phase separationDelicate feelHeat-exchange elementsFiberCompressive strength

The invention discloses a nanometer particles-containing cold accumulating material for a cooling pad, containing 80-90% of sodium sulfafe decahydrate, 2-6% of halogenating salt or halogenating salt hydrate, 2-6% of supercooling-resisting agent, 1-3% of nanometer particles, 1-5% of thickener and the balance of de-ionized water according to weight percentage, wherein the sum of the weight percentage of the components is 100%. Because the nanometer particles are uniformly dispersed in the cold accumulating material containing thickener, the compressive strength of the cooling pad is increased; the crystal form of the sodium sulfafe decahydrate is improved and the mould-proofing and sterilizing function is realized. The cold accumulating material disclosed by the invention is white cotton fiber, has the advantages of low phase separation degree, exquisite hand feeling, environment protection and no toxicity, is easy to obtain raw materials and is easy to perform.

Owner:范忠娟

Terylene DTY fiber soft cotton velvet and technique for producing the same

InactiveCN101424006AUnique performanceShortening dyeing and finishingWarp knittingDyeing processDyeingFiber

The invention relates to a terylene DTY fibre cotton flannel blanket and a production process thereof, wherein wool silk adopts terylene DTY fibre as a raw material; the specification of the terylene DTY fibre is between 100D / 96F and 300D / 432F; bottom silk adopts two raw materials, namely terylene DTY fibre with specification of between 50D / 24F and 200D / 144F and semi-dull terylene FDY fibre with specification of between 50D / 24F and 200D / 144F; and the production process comprises material ordering, greige cloth weaving, greige cloth inspection, cylinder separation, combing and presetting, dyeing(printing), softening rolling (softening), dewatering, drying, carding, combing and shearing, luster finishing, ring baking, molding, inspection and packaging. The production process has low cost; and the obtained product is light as cocoon silk and warm as eiderdown, and offers unique cordial feeling and full feel in the contact with skin.

Owner:苏州市恒信针织印染有限责任公司

High whiteness and strength adhesive short fiber and process for making same

ActiveCN1632189AImprove qualityHigh whitenessArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceAdhesive

The invention relates to a viscose staple fiber with high white strength and fine denier and a production process thereof, which belong to the viscose staple fiber and the production method of the textile spinning industry and the non-woven fabric industry. Its raw materials and weight percent content are: 86.7-92 percent of cellulose fiber, 7.7-13 percent of water, and 0.15-0.30 percent of oil agent. The raw materials are impregnated, squeezed, yellowed, spun, drawn, bundled, scoured, bleached twice with hydrogen peroxide, and dried to make finished products. The product of the present invention has finer denier, higher strength, higher yarn count and higher strength, and the garment fabric has higher strength, strong abrasion resistance, delicate hand feeling, wrinkle resistance and resistance to multiple deformations than ordinary viscose of the same process. Short fiber processing clothing fabrics and other advantages. High-count yarn products have thinner fabrics and lower grammage. The area of fabrics processed from raw materials of the same weight is increased and the cost is reduced.

Owner:唐山三友集团兴达化纤有限公司

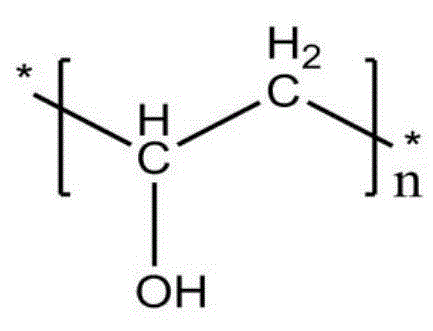

Active packaging film based on essential oil/beta-cyclodextrin inclusion compound and preparation method for active packaging film

InactiveCN102585412AConsistent thicknessDelicate feelFlexible coversWrappersAntibacterial actionBroad spectrum

The invention relates to a novel active packaging film. The active packaging film is characterized in that a film-forming base material is polyvinyl alcohol; a film-forming assistant contains ethylene glycol and lauryl sodium sulfate. The novel active packaging film contains broad-spectrum long-acting antibacterial beta-cyclodextrin inclusion compound particles. The inclusion compound particles account for 4-24 percent of the weight of the active antibacterial film. The particles are 1-100 nanometers in particle size; through the slow release of essential oil in the inclusion compound and the migration in the film, an antibacterial action is performed on surfaces of foods finally. The active packaging film provided by the invention is a colorless transparent film which is light in spice smell, consistent in thickness, fine and smooth in hand feeling and better in mechanical property, is not obvious in bubbles, is complete, bright and clean, and is capable of meeting the mechanical requirement of food packaging. The transparency is good, so that content held in the active packaging film can be clearly seen when the active packaging film is used for packaging the foods.

Owner:邓靖 +1

Wax-containing composition for leather and its product surface coating

ActiveCN1611560AGood miscibilityHigh affinityLiquid surface applicatorsCoatingsSolubilityCarbon chain

The invention relates to a kind of waxy combination for surface coating of leather and its products, which is mainly composed with wax, high molecular polymer cream, long carbon-chain fatty alcohol, fatty amide, surface-active agent, and water, but its components doesn't contain organic solvent, water solubility organic alcohol, and mineral oil. Use fatty amide as cosolvent of coating combination system; fatty amide has fine intersolubility with wax, fatty alcohol, high molecular polymer, and other solid constituents; so it can improve stability of coating combination system, can guarantee continuation and compactness of coating film, and also can avoid the disadvantages of containing mineral oil and low molecular water solubility alcohol in the components. When using for surface coating of leather and its products, it has natural gloss, excellent abilities of water-resistant, antidusting, drying proof, and wet proof, and fine frictional property. So it has convenient usage that is safe, and can decline pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

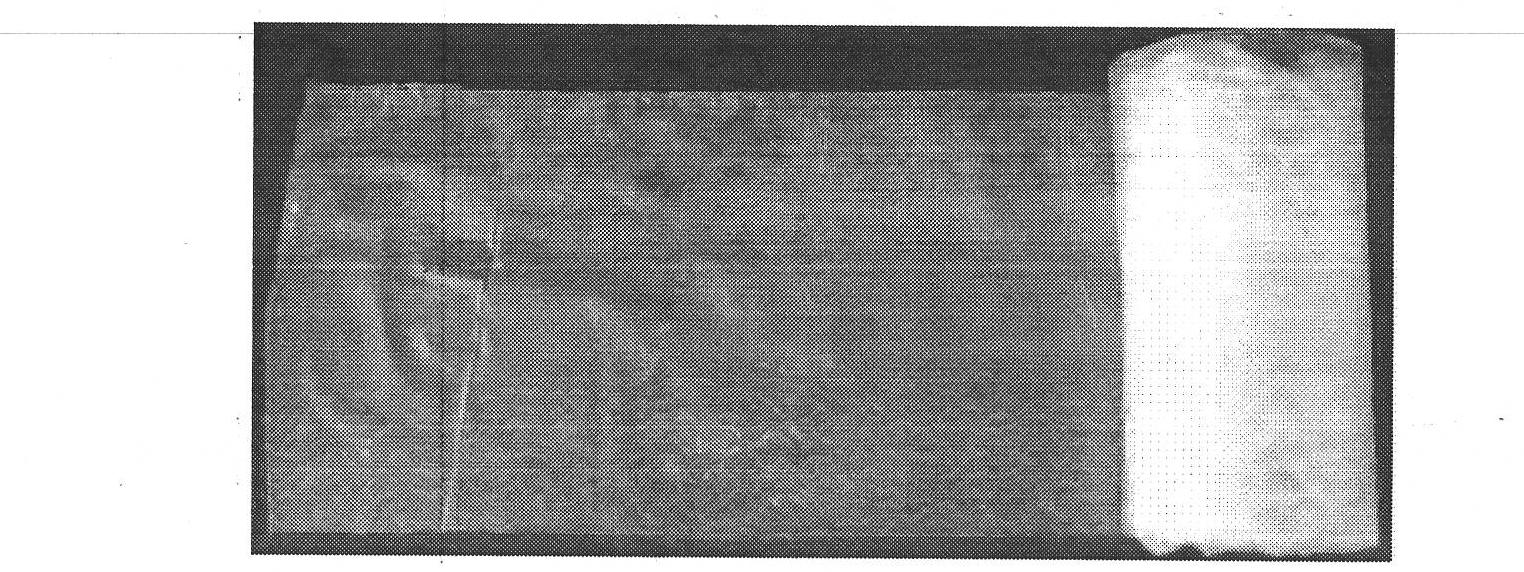

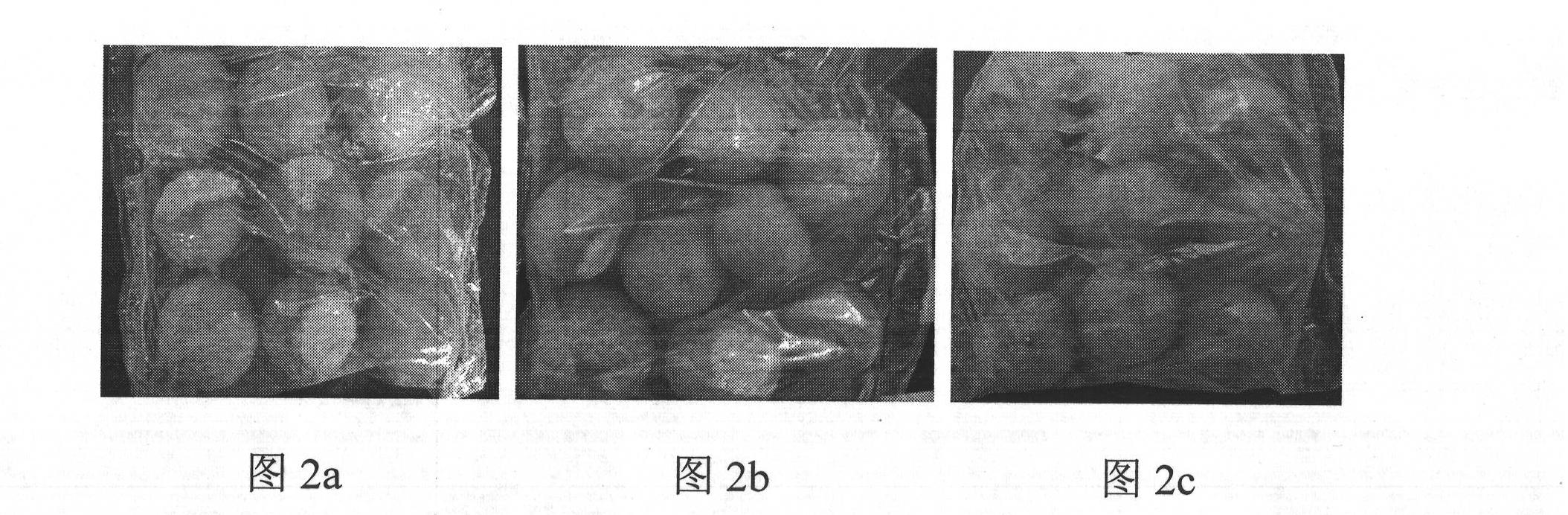

Active packaging film for chilled meat and preparation method of the active packaging film

ActiveCN102604292AConsistent thicknessDelicate feelFlexible coversMeat/fish preservationChemistryPolylactic acid

The invention relates to an active packaging film for chilled meat and a preparation method of the active packaging film. The active packaging film employs polyvinyl acetate (PVA) and polylactic acid (PLA) as film-forming materials and sustained-release microcapsules as an active antimicrobial agent. The natural antimicrobial agent is slowly released from the microcapsules, migrates in the film and finally reaches the surface of the chilled meat to achieve antimicrobial and fresh-keeping effects. Meanwhile, as PVA has a good gas barrier property, good chilled meat packaging atmosphere conditions can be kept. PLA has a good water vapor barrier property, and can effectively reduce the moisture loss of the chilled meat during storage. The active packaging film for the chilled meat provided by the invention is a colorless transparent film with a smooth and uniform surface without visible air bubbles, and mechanical properties of the film can meet the mechanical requirements of chilled meat packaging.

Owner:HUNAN NEW WELLFUL CO LTD +1

Down feather composite fiber modified by polypropylene fiber and preparation method of down feather composite fiber

InactiveCN104195664AThe ratio is scientific and reasonableDelicate feelMonocomponent protein artificial filamentArtifical filament manufactureSucrosePhosphoric acid

The invention discloses a down feather composite fiber modified by polypropylene fiber. The down feather composite fiber modified by polypropylene fiber is prepared from the following raw materials in parts by weight: 18-20 parts of superfine duck down powder, 25-30 parts of puffed goose feather powder, 12-15 parts of polypropylene fiber, 3-5 parts of kaolin, 0.3-0.6 part of calcium saccharate, 1-2 parts of wolfberry fruit, 2-4 parts of fruit of Chinese magnoliavine, 1-3 parts of radix rehmanniae, 3-5 parts of cucumber juice, 0.1-0.3 part of ammonium dihydrogen phosphate, 120-130 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 110-140 parts of 1-ethyl-3-diethyl methyl imidazole phosphoric acid, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber modified by polypropylene fiber, the components such as the polypropylene fiber, the wolfberry fruit, the fruit of Chinese magnoliavine and the radix rehmanniae are added; the prepared product is soft and smooth in hand feeling, has the characteristics of the down feather, also has the characteristics of being light, soft, warm, breathable, moisture permeable, mildew-proof, mothproof and washable, and is wide in application prospect and further and more competitive in the market.

Owner:ANHUI LION GOOSE PROD

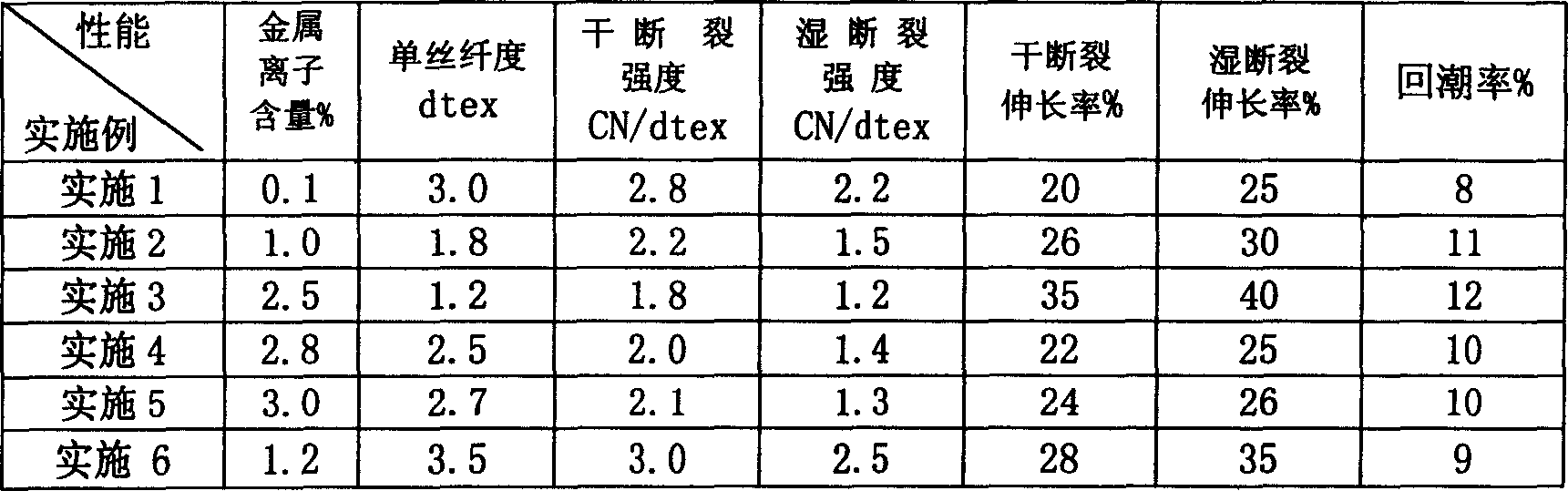

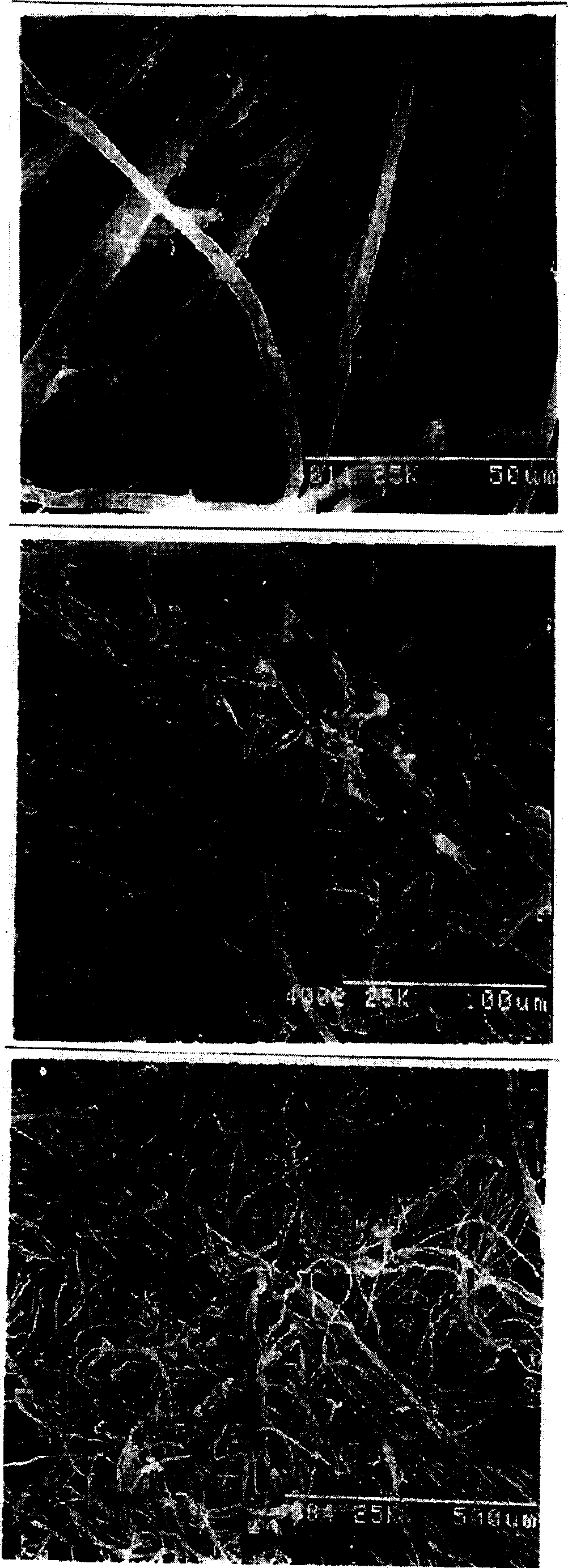

Collagen-polyvinyl alcohol composite fiber modified by metallic ion, and preparation method

InactiveCN1696362AImprove stabilityHigh strengthConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberPolyvinyl alcohol

The invention relates to a metal ion modified collagen protein-polyvinyl alcohol composite fibre. On the basis containing collagen protein and polyvinyl alcohol it also contains metal ions capable of producing chelation crosslinking action. Said invention also relates the preparation method of said composite fibre, and said method includes the following steps: adding metal salt into the collagen protein-polyvinyl alcohol mixed solution to make chelation crosslinking modification to obtain spinning solution, and adopting a series of after processes so as to obtain the new type collagen protein-polyvinyl alcohol composite fibre.

Owner:SICHUAN UNIV

Process for production of ultra-fine wool worsted face fabric

The invention relates to a manufacturing method for superfine wool worsted fabric. It selects superfine wool with the diameter of 14.5um and produces superfine wool worsted fabric by stripe dyeing, spinning, weaving and after-treatment. Merits of the invention are that the high quality of superfine wool worsted fabric is outstanding; the fabric is provided with good quality, exquisite handle feeling and good spring-back; it is also provided with high-grade quality, high added value and it has higher social and economical benefits.

Owner:杨毅方

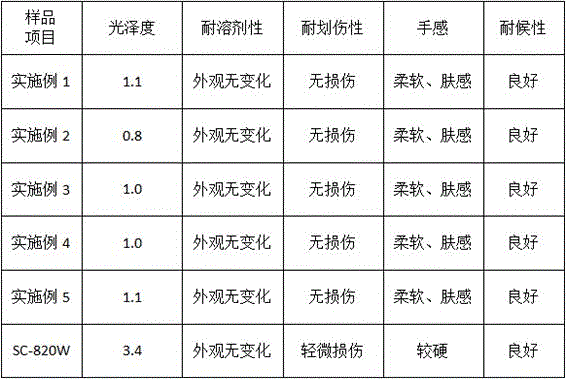

Waterborne polyurethane surface treating agent for synthetic leather and preparation method thereof

InactiveCN106634524AGood dispersionGood matte effectPolyurea/polyurethane coatingsTextiles and paperEmulsionWear resistant

The invention relates to a waterborne polyurethane surface treating agent for synthetic leather and a preparation method thereof. The waterborne polyurethane surface treating agent for the synthetic leather is formed by compounding, by weight, 40-50 parts of deionized water, 2-4 parts of silicon dioxide matting powder, 45-55 parts of waterborne polyurethane emulsion, 1.5-2.0 parts of highly-smooth organosilicon flatting agent, 2-4 parts of weak anion organosilicone wear-resistant agent, 3-5 parts of nonionic organosilicone feeling agent, 0.2-0.3 part of non-ionic waterborne defoamer and 1-2 parts of associative waterborne polyurethane thickening agent. The waterborne polyurethane surface treating agent has functional advantages of having skin touch and being matt and resistant to scratching and solvents.

Owner:LIAONING FIXED STAR FINE CHEM

Method for producing pure pashm worsted plus material

The invention relates to a producing method for a pure wool spinning lining by using wool as raw material, comprising steps of top dyeing, spinning, weaving and finishing. The advantages of the invention are that the produced lining has good quality, delicate hand feeling, good flexibility, high added value and is provided with good social benefit and economic effectiveness.

Owner:杨毅方

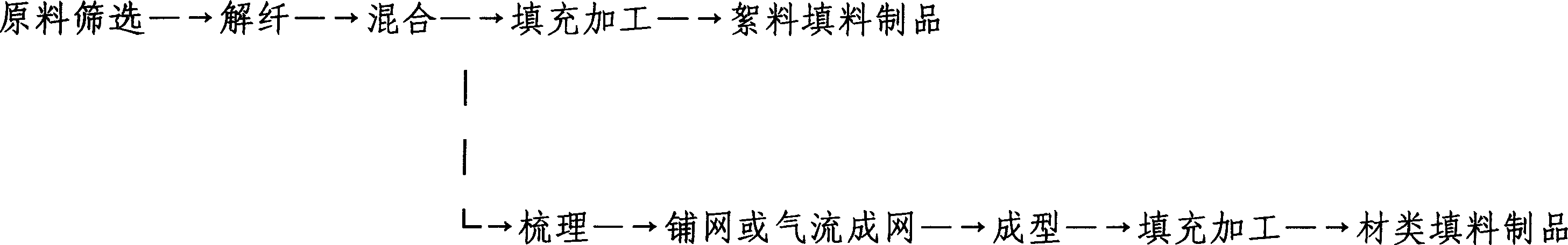

Collagen fiber stuffing product and processing method thereof

ActiveCN1730376AHigh heat retention rateHigh static stabilityMonocomponent protein artificial filamentUpholstery fillingTextile fiberEngineering

The invention provides a collagen fiber stuffing product which comprises 50%-100% collagen fiber in the stuffing and its Process for preparing. The said stuffing is oakum stuffing mixed collagen fiber deliberating from animal hide with at least another textile fiber; or materials stuffing arise from teasing, bedding web and modeling. The stuffing product in the invention is provided with advantages of well puffy, well rebound, well warming, flameproof and sound absorbing which the current stuffing can not get because it uses collagen fiber as main stuffing. The stuffing produced in the process provided in the invention has no peculiar smell, without putrefaction, without mouldy, and can be used in practice. The product is low cost and settles the problem of leftover bits and pieces of industrial material, so it is environment friendly.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Aqueous crackle coating

The present invention relates to an aqueous crackle coating characterized by comprising: a primer and a topcoat, wherein the primer comprises the following components, by weight: water-dispersible cationic epoxy resin 40-95%, an aqueous sterilizing agent 0.1-0.4%, an aqueous antifoaming agent 0.03-0.2%, a water-based color paste 0-10%, and the balance water; and the topcoat comprises the following components, by weight: water 30-45%, an aqueous multifunctional additive 0.05-0.3%, an aqueous dispersant 0.2-0.4%, an aqueous wetting agent 0.1-0.2%, the aqueous antifoaming agent 0.05-0. 4%, an aqueous matte powder 8-15%, titanium dioxide 0-20%, a room temperature self-crosslinking acrylic emulsion 27-45%, dipropylene glycol butyl ether 0.6-1.5%, an aqueous sterilizing agent 0.1 -0.4%, a water-based color paste 0-10%, and the balance water. The aqueous crackle coating of the present invention is environmentally friendly, safe and no hidden trouble, and has a good adhesion to various substrates, and a good flexibility; the film feels fine and smooth, and by adopting the aqueous crackle coating of the invention, one can choose whether a finish coat is needed or not according to the actual situation.

Owner:SKSHU PAINT

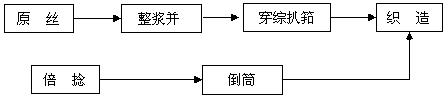

Rayon three-dimensional lattice shell fabric and production process thereof

The invention discloses a rayon three-dimensional lattice shell fabric and a production process thereof. The shell fabric comprises organzine and tram. The organzine is dacron black silk. The tram comprises first tram and second tram. The first tram is superfine denier fiber and the second tram is lustrous dacron filament. The rayon three-dimensional lattice shell fabric production process comprises organzine processing, tram processing and weaving, wherein organzine process steps comprises beam warping, starching, warp rebeaming and drafting scrabbling reed; and tram process steps comprises spooling, two-for-one twisting and rewinding. The process combines a specific fabric style and a novel type fiber advantage, product property is optimized, and stability of the product quality is improved. Products which are produced by the process are smooth, light in weight, exquisite in handle, good in air permeability, good in drapability and capable of being used as high-grade garment materials.

Owner:JIANGSU DESHUN TEXTILES

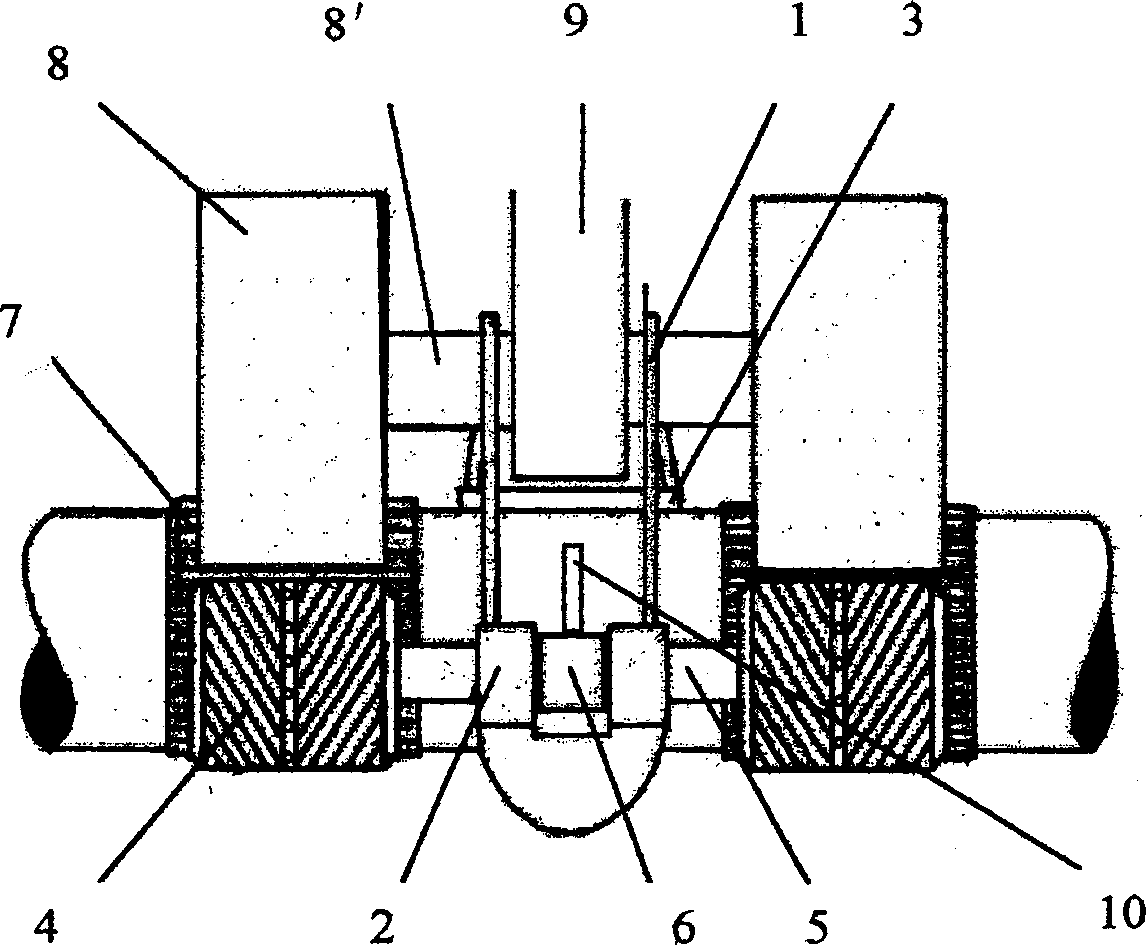

Fiber strand aggregating device for air slide

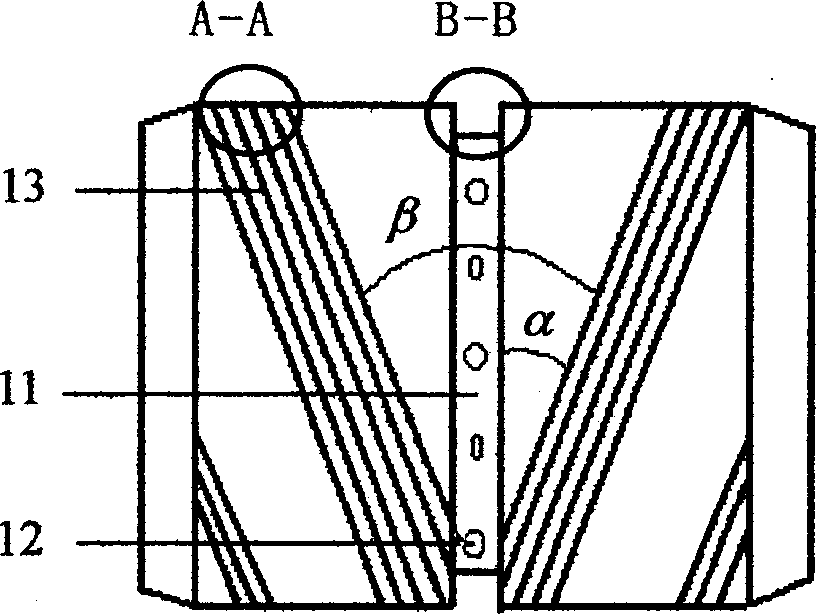

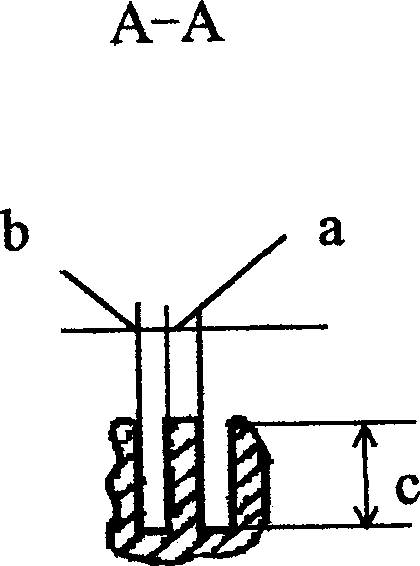

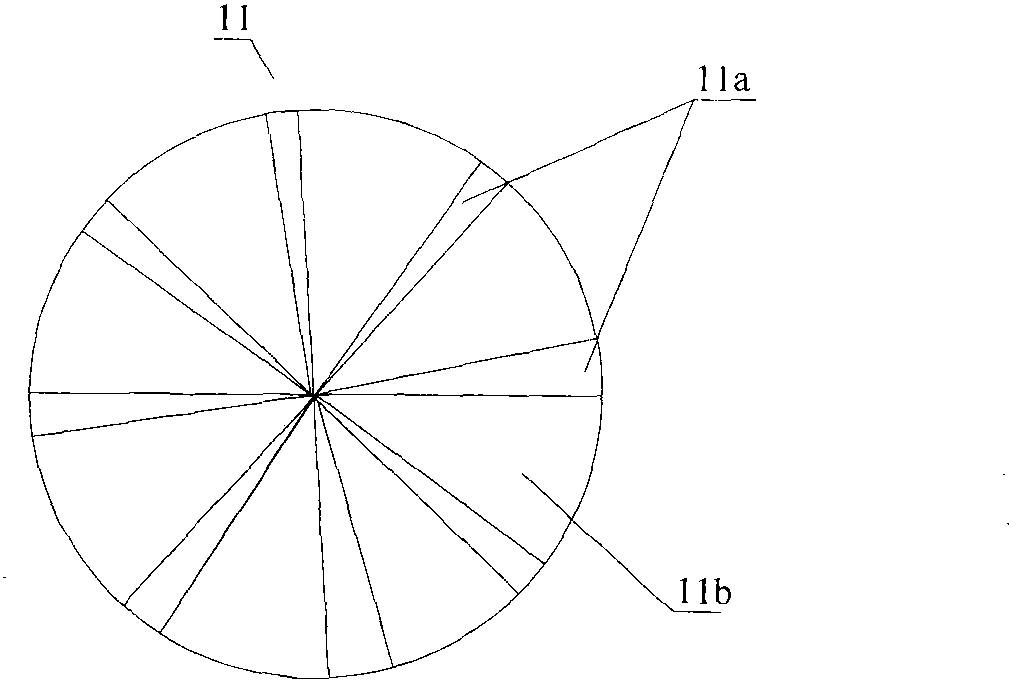

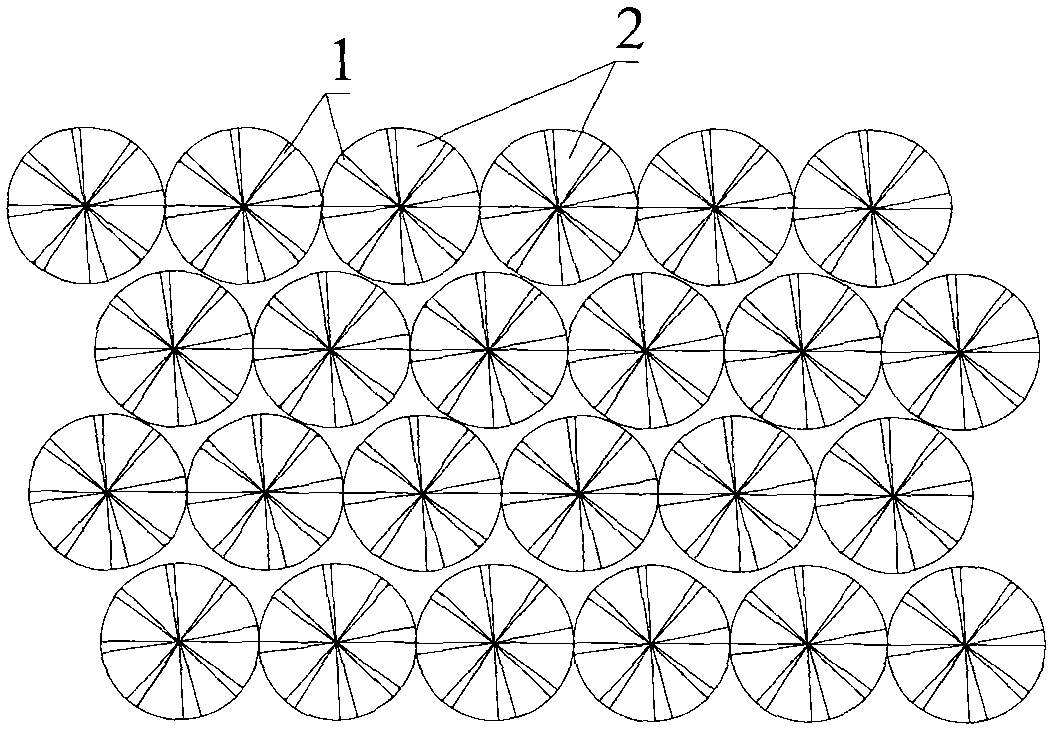

InactiveCN1388279AHigh glossImprove wear resistanceDrafting machinesContinuous wound-up machinesEngineeringHigh intensity

The present invention is fiber strand aggregating device for air slide, and its novel design is its aggregating roller with new splitting guide flute and porous aggregating flute. It is installed between the front jaw and the spinning section in the drawing area of spinnin frame, and the air slide fiber strand aggregating device and the front roller form one fiber jaw. By means of the additional aggregating air flows, one flow field for fiber inside the guide flute and the aggregating flute is provided. By means of splitting and guide of the guide flute and the aggregating flute and the aggregation of fiber strand in the aggregating flute, the fiber strand is twisted closely in the aggregating flute. The yarn of the present invention has improved axial parallel degree, decreased hairy feather amount outside the yarn and raised yarn strength.

Owner:DONGHUA UNIV

Mutton fat matt white glaze for ceramic decoration and preparation method of white glaze

The invention discloses mutton fat matt white glaze for a ceramic decoration and a preparation method of the white glaze. The white glaze is prepared from, by mass percentage, 15-25% of feldspar powder, 10-17% of calcium carbonate, 5-7% of dolomite, 6-12% of talc, 3-8% of barium carbonate, 15-20% of zirconium silicate, 10-15% of zirconium white frit, 0-6% of zinc oxide, 5-7% of aluminum oxide and 0-12% of kaolin. The components are weighed according to the formula, fully mixed and added into a grinding tank, water with the weight 45-50% that of dry powder is added for grinding for 10-15 h, then glaze slurry obtained after ball milling is subjected to iron removal and screening, and the concentration is adjusted till the true specific gravity is 50-54 degrees. A ceramic product is coated with the white glaze in a spraying mode or a soaking mode or other decoration modes. After drying, the ceramic product enters a kiln to be oxidized and fired for 8-11 h at the temperature of 1200-1235 DEG C, and the ceramic product is taken out of the kiln after being naturally cooled. The prepared mutton fat matt white glaze has the advantages of being high in processing property, high in operability and not prone to cracking.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

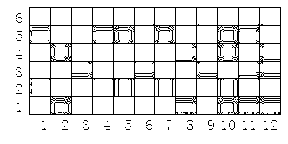

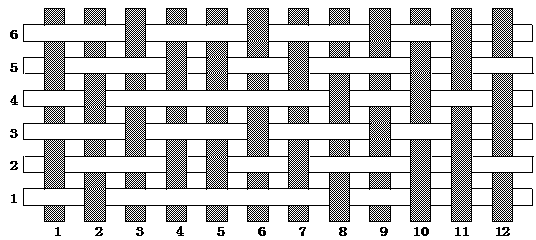

Weaving of elastic waffle weave double-layer cloth

InactiveCN101177825ARaise the gradeImprove the three-dimensional effectFibre treatmentWoven fabricsYarnFiber

The invention provides a novel weaving concept of an elastic honeycomb weave two-layered cloth and a weaving method thereof: the structure of two layered cloth is utilized; cotton spandex covered yarn is adopted as warp; blended yarn or covered yarn with wet permeability and infrared function is adopted as weft; the lining is basket weave structure; the surface of the textile is honeycomb weave; the invention has fine and yielding texture and meanwhile elastic covered yarn is adopted as weft, thereby enhancing stereoscopic impression due to dimensional shrinkage after being put into the machine; the cloth surface style is full; at the same time, two-layered fiber with infrared function is adopted, thus leading the whole warming effect of the fabric to be improved and the production value of the product to be increased.

Owner:SHENGHONG GRP CO LTD

Solid glue stick and method for producing the same

InactiveCN101220252AImprove mechanical propertiesImprove performancePolyureas/polyurethane adhesivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePolyurethane adhesive

The invention discloses a solid glue stick, and is prepared with watercraft polyurethane latex as a major glue component, water as solvent, sodium stearate as gel, and polyvinyl alcohol and polyethylene pyrrole azululanone as accessory ingredients, and moderate glycerol added as humectant, wherein a self-emulsion method is adopted for the preparation of the watercraft polyurethane latex. The invention has the advantages that coated surface of the watercraft polyurethane adhesive adopted in preparing the solid glue stick is not easy to be damaged; the mechanical property is excellent; the modification is easy; the compatibility with paint is good; the prepared solid glue stick has obvious advantages in properties of assigned model, hardness, coating, and splicing, etc.; the exterior is pure white; the feeling is subtle; the splicing property is good; the drying speed is high; time for paper tearing is less than one minute; the hydrating period is as long as one year; the reserve property is fine.

Owner:ZHONGBEI UNIV +1

Novel blended fabrics

InactiveCN103205838AImproved breathability and comfort zoneDelicate feelWoven fabricsFilling materialsNatural fiber

The invention discloses novel blended fabrics comprising following raw materials: by mass, 5-25 parts of dacron, 10-20 parts of nylon, 15-40 parts of polypropylene fibers, 5-15 parts of spandex, 10-30 parts of vinylon, 10-40 parts of polyacrylic fibers, 2-10 parts of plumetis, 4-10 parts of plush, 8-15 parts of gabardine, 5-15 parts of poplin, 5-8 parts of corduroy, 5-12 parts of synthetic fibers, 4-16 parts of natural fibers, 7-17 parts of eiderdown, 3-12 parts of bamboo fibers and 4-10 parts of filling materials. By the arrangement, breathability of the fabrics can be improved, the comfort zones of the fabrics are enlarged, hand feel is good, and manufacturing costs are low.

Owner:YANGZHOU GUANGHONG STEEL STRUCTURE METAL IND

Pure natural plant children shampoo

InactiveCN102379836ABacteriostaticAnti-dandruffCosmetic preparationsHair cosmeticsUltravioletMushroom

The invention provides a pure natural plant children shampoo, which is mainly prepared by soaking soapberry, honey, mushroom and Pu'er tea, extracting, mixing and the like. The pure natural plant children shampoo has the advantages of adoption of a pure natural formula, mildness, no stimulation, a plenty of foam, fine handfeel, high cleaning and moistening capabilities, and capability of preventing ultraviolet from injuring hair.

Owner:赵斌

Raising method of artificial leather

InactiveCN101798737AGuaranteed performanceDelicate feelFilament/thread formingRougheningPolyesterPolymer science

The invention provides a raising method of artificial leather, comprising: providing superfine fibre polyurethane leather composed of superfine fibre non-woven fabric and polyurethane impregnated in the superfine fibre non-woven fabric, wherein superfine fibre non-woven fabric contains bi-component superfine fibre of which double components are respectively polyester superfine fibre and polyamide superfine fibre; the single surface or double surfaces of the superfine fibre polyurethane synthetic leather are carried out peached finish; the polyester superfine fibre and the polyamide superfine fibre on the surface are curled up to form polyester fluff and polyamide fluff so as to prepare two types of superfine fibre PU synthetic leather of which the average fluff length is 10-200 mu m. The raising method of the invention realizes the evenly raise of two types of superfine fibre, and the combination property of two types of superfine fibre is simultaneously kept, so that finally prepared raising superfine fibre PU synthetic leather has terylene stiffness, nylon flexibility and fine hand feel at the same time.

Owner:厦门象屿兴泓超细材料有限公司

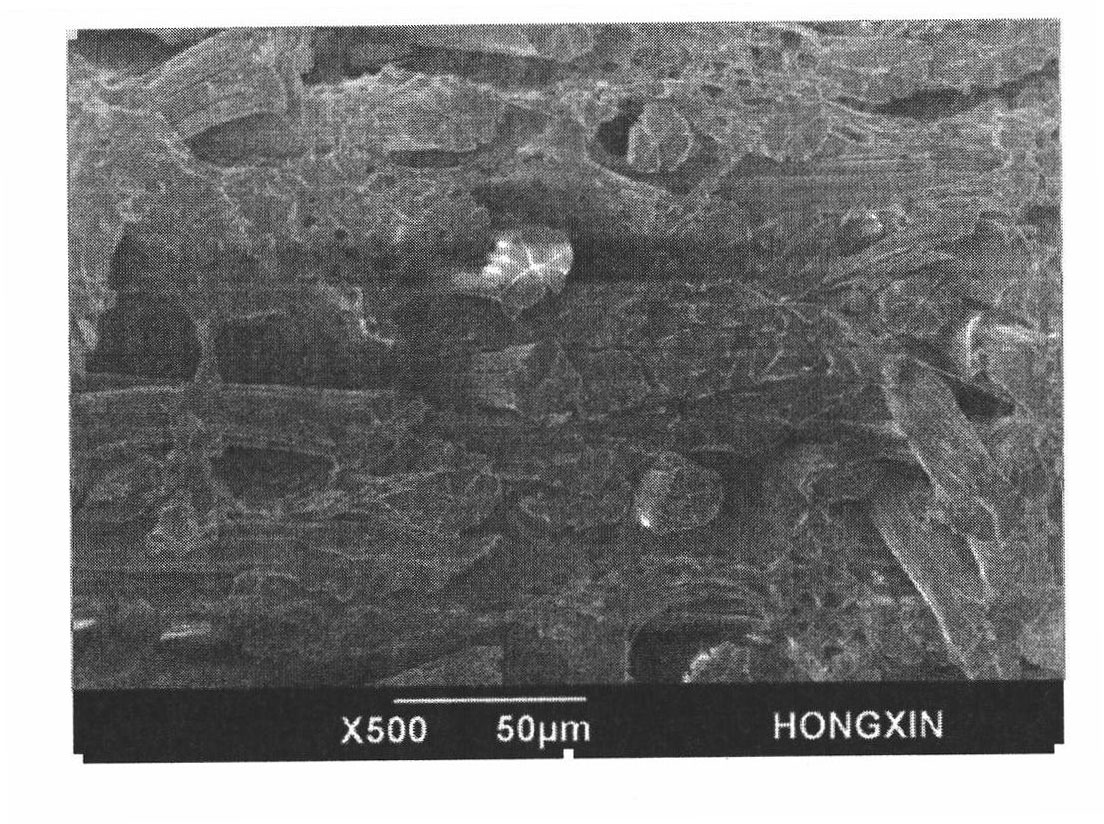

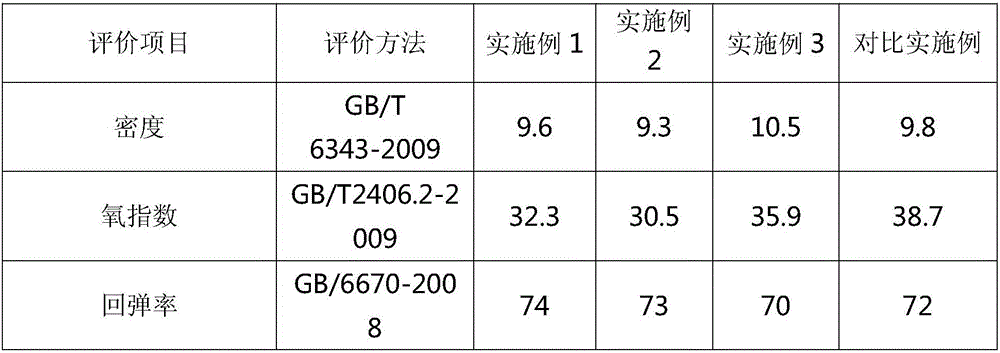

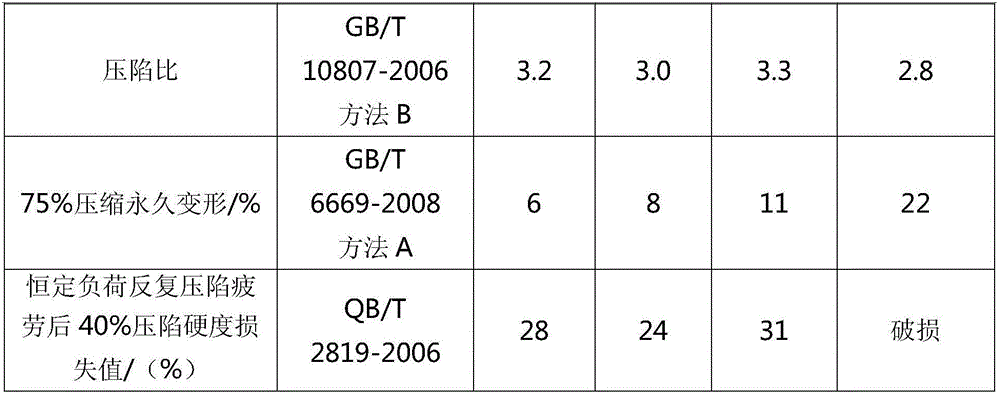

Novel high-resilience load-bearing foam material and preparation method thereof

The invention discloses a novel high-resilience load-bearing foam material. The novel high-resilience load-bearing foam material is prepared from raw materials as follows: expandable melamino-formaldehyde resin, elastomer rubber or resin, a surfactant, a nucleating agent, a foaming agent and a vulcanizing agent. The invention further discloses a preparation method of the novel high-resilience load-bearing foam material. The preparation method comprises the following steps: the expandable melamino-formaldehyde resin is prepared; the elastomer rubber or resin, the surfactant, the vulcanizing agent and the nucleating agent are added, and an expandable melamino-formaldehyde resin-elastomer emulsion is prepared; the foaming agent and an acid catalyst are added, and a foaming solution is prepared; micorwave foaming and crosslinking are performed; high-temperature drying and curing are performed; quenching is performed at the normal temperature, and the novel high-resilience load-bearing foam material is obtained. The novel high-resilience load-bearing foam material has good flame retardancy, thermal stability, shock resistance and flexibility, high resilience and high indentation ratio, high porosity, high elasticity and better compression set resistance and repeated indentation fatigue performance than common melamine foam and touches fine.

Owner:成都美讷敏新材料科技有限公司

Formula of putty coated on gypsum inner wall

The invention discloses a formula of putty coated on a gypsum inner wall. The putty comprises the following raw materials in parts by weight: 100 parts of desulfurized gypsum, 5-20 parts of French chalk, 0.3-5 parts of methyl cellulose, 0.1-1 part of polyvinyl alcohol, 0.01-1 part of sodium citrate and 0.01-1 part of redispersable gelatine powder. The raw materials are uniformly mixed and stirred to obtain the product. The initial setting time is 30-110 minutes, the final setting time is 45-125 minutes, the folding strength is 1.76-2.34 MPa, the compression strength is 3.55-5.05 MPa, and the bonding strength is 0.30-0.38 MPa. The invention has the advantages of strong adhesive force, high bonding strength, favorable air permeability, high water resistance, delicate hand feel of the wall surface, soft appearance and favorable tactile sensation.

Owner:河南省翔宇建材科技有限公司

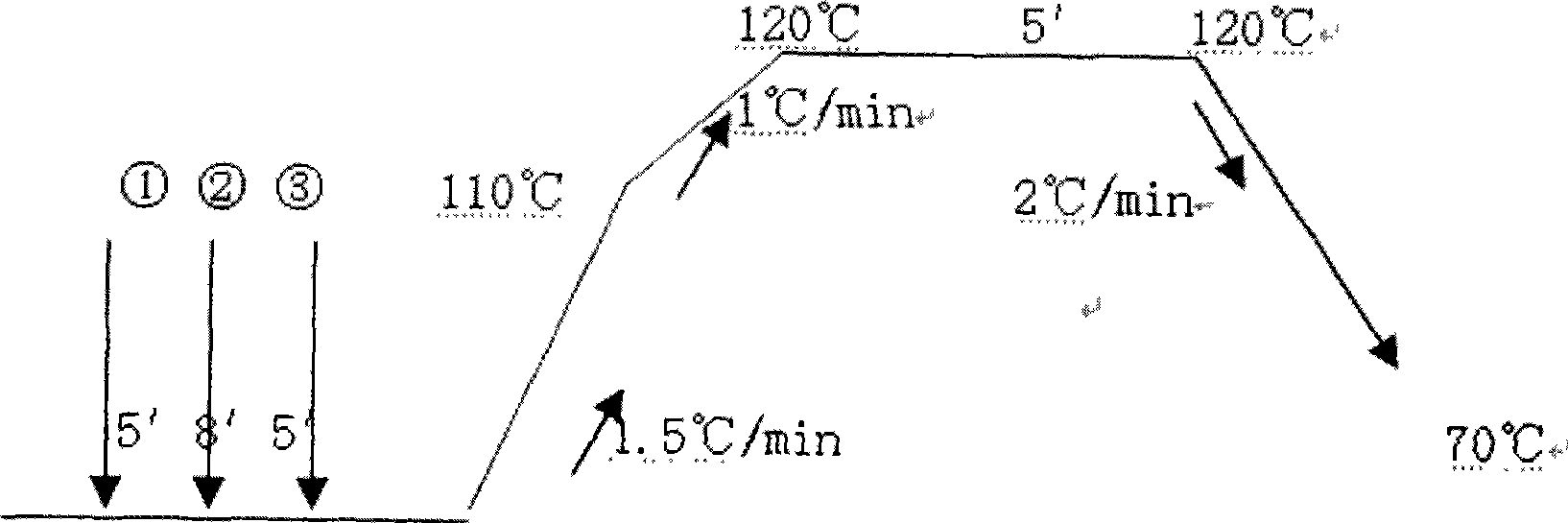

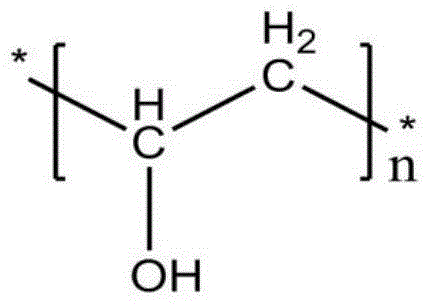

Polyvinyl alcohol spongy material and production method thereof

The present invention discloses a polyvinyl alcohol spongy material, which has a three-dimensional perforated structure, average bubble diameter size of 2-3 mm, porosity of 70-98% and a degree of acetalization of 50-85%. The invention also discloses a production method of the polyvinyl alcohol sponge material. The method comprises the steps of: preparing an aqueous solution of polyvinyl alcohol; stirring the polyvinyl alcohol solution, or adding a foaming agent or a pore-forming agent in the aqueous solution of polyvinyl alcohol to obtain a foaming solution; adding aldehyde as a crosslinking agent into the foaming solution to obtain a slurry, curing the slurry, rinsing and drying after forming to obtain a polyvinyl alcohol sponge material, wherein at least one of the slurry acquisition, curing, rinsing and drying processes comprises a process of rising the temperature to 90-150 DEG C and insulating for 10-900 s. Through heat treatment on the foaming system, the polyvinyl alcohol sponge material with larger aperture, high opening rate, good water absorption, high water absorption capacity and high value of application is prepared.

Owner:徐禄贵

High whiteness and strength adhesive short fiber and process for making same

ActiveCN100359050CHigh strengthHigh yarn countArtificial filament washing/dryingArtificial filaments from viscoseYarnPolymer science

A high whiteness and strength adhesive short fiber and a process for producing same belong to an adhesive short fiber of spinning industry but not a weaving industry, and a producing process thereof. Materials and respective percent content are: cellulose fiber 86.7-92%, water 7.7-13%, oil solution 0.15-0.30%. The material is produced to a product by dipping, pressing, etiolation, spinning, drafting, beaming, refining, oxydol secondary albifaction and drying. The product of the invention has fine denier, high strength, yarns of the product have high counts and high strength, thereby cloth face fabric has advantages of high strength, strong abradability, exquisite hand feeling, and pleat resistance and multi-deformation resistance higher than that of cloth face fabric machined by common adhesive short fiber and by a same process. The high counts product has thin cloth face fabric, light weight, area of a same weight mateiral machining face fabric in creased and cost is reduced.

Owner:唐山三友集团兴达化纤有限公司

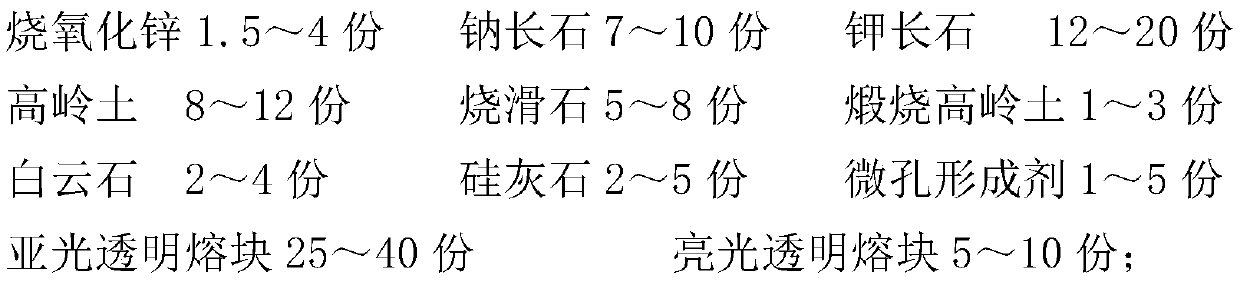

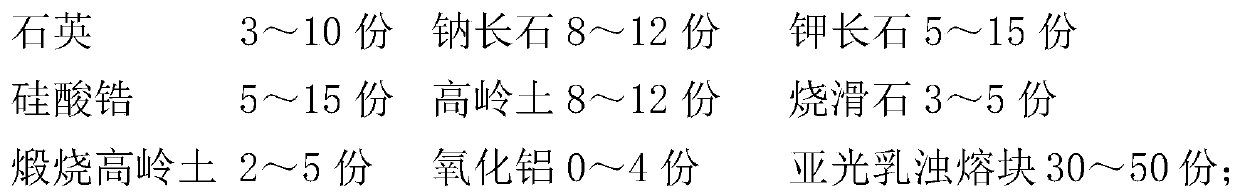

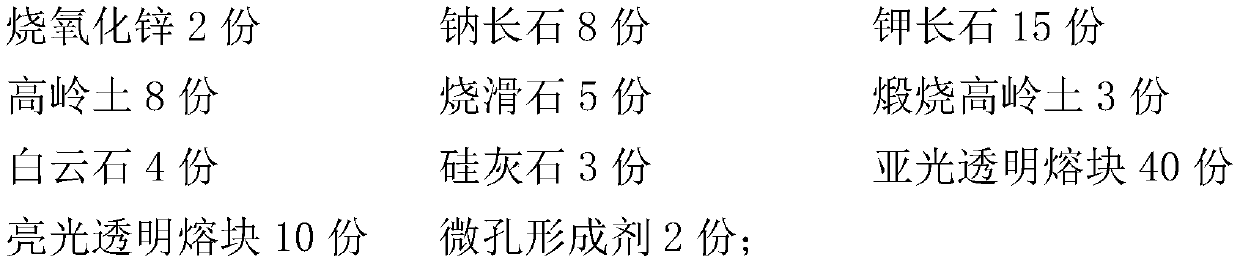

Anti-skid matte ceramic tile

The invention relates to an anti-skid matte ceramic tile. A microporous forming agent is introduced to overglaze of the ceramic tile. Micropores in the glaze layer on the surface of the ceramic tile are formed in a firing process. The microporous forming agent is composed of one or more of fluorite, cryolite and fluorapatite. The ceramic tile is composed of a blank, bottom glaze and surface glazeattached to two faces, separately, and the microporous forming agent introduced into the glaze. The bottom glaze is prepared from the following components: quartz, albite, potash feldspar, calcined talc, zirconium silicate, kaolin, calcined kaolin, aluminum oxide and a matte opacified melt block. The surface glaze is prepared from the following components: calcined zinc oxide, albite, potash feldspar, kaolin, calcined talc, calcined kaolin, dolomite, wollastonite, a matte transparent melt, a bright and transparent melt and the microporous forming agent.

Owner:JIANGXI HEMEI CERAMICS +4

Novel polyurethane semi-matte white finish for woodware protection

InactiveCN101967340AHigh glass transition temperatureSmall steric hindrancePolyurea/polyurethane coatingsWaxDeodorant

The invention discloses novel polyurethane semi-matte white finish for woodware protection. The finish is prepared by mixing the following components: stearic acid modified alkyd resin, polyketone resin solution, an antifoaming agent, an anti-settling agent, a dispersing agent, white slurry, handfeel wax powder, aerosol extinction powder, 20 percent hydroxyl modified vinyl acetate (VAGH) resin, a leveling agent, an anti-yellowing auxiliary agent, a deodorant and butyl ester. A film prepared from the novel polyurethane semi-matte white finish has the advantages of fullness, moderate hardness, high flexibility, high water resistance, yellowing resistance and environmental protection; and the semi-matte white finish has high comprehensive performance.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

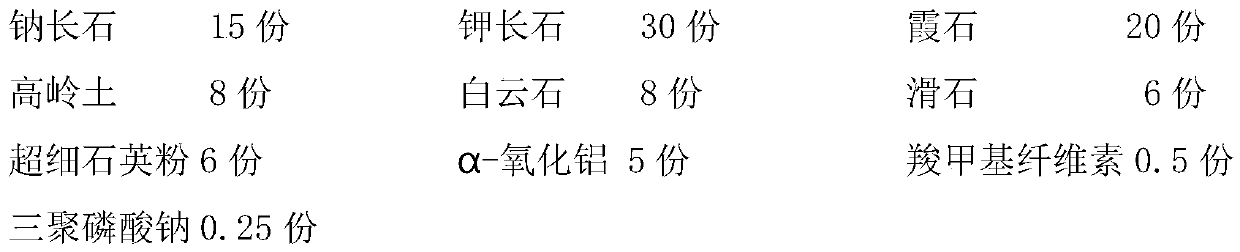

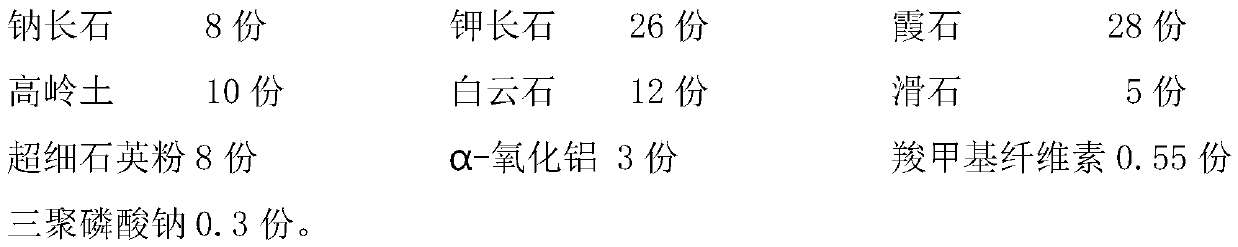

Anti-skid glaze and anti-skid ceramic tile

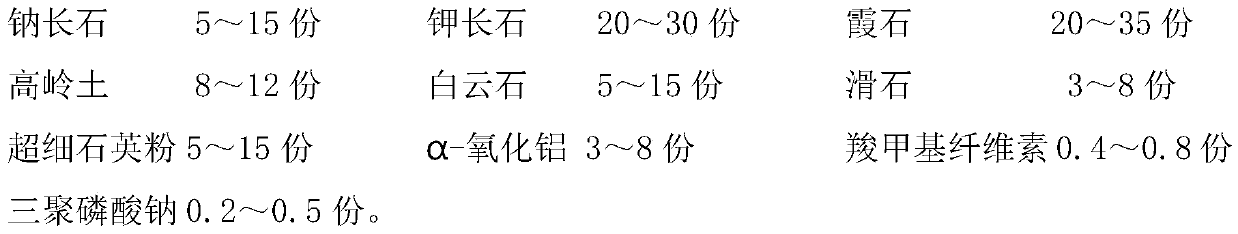

The invention relates to an anti-skid glaze and an anti-skid ceramic tile, wherein the anti-skid ceramic tile consists of a blank layer, a surface glaze layer, an ink jet layer and an anti-skid glazelayer. The anti-skid glaze comprises 5 to 15 parts of albite, 20 to 30 parts of potash feldspar, 20 to 35 parts of nepheline, 8 to 12 parts of kaolin, 5 to 15 parts of dolomite, 3 to 8 parts of talc,5 to 15 parts of superfine quartz powder, 3 to 8 parts of alpha alumina, 0.4 to 0.8 part of carboxymethyl cellulose and 0.2 to 0.5 part of sodium tripolyphosphate.

Owner:JIANGXI HEMEI CERAMICS +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com