Patents

Literature

782 results about "Down feather" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The down of birds is a layer of fine feathers found under the tougher exterior feathers. Very young birds are clad only in down. Powder down is a specialized type of down found only in a few groups of birds. Down is a fine thermal insulator and padding, used in goods such as jackets, bedding (duvets), pillows and sleeping bags. The discovery of feathers trapped in ancient amber suggests that some species of dinosaur may have possessed down-like feathers.

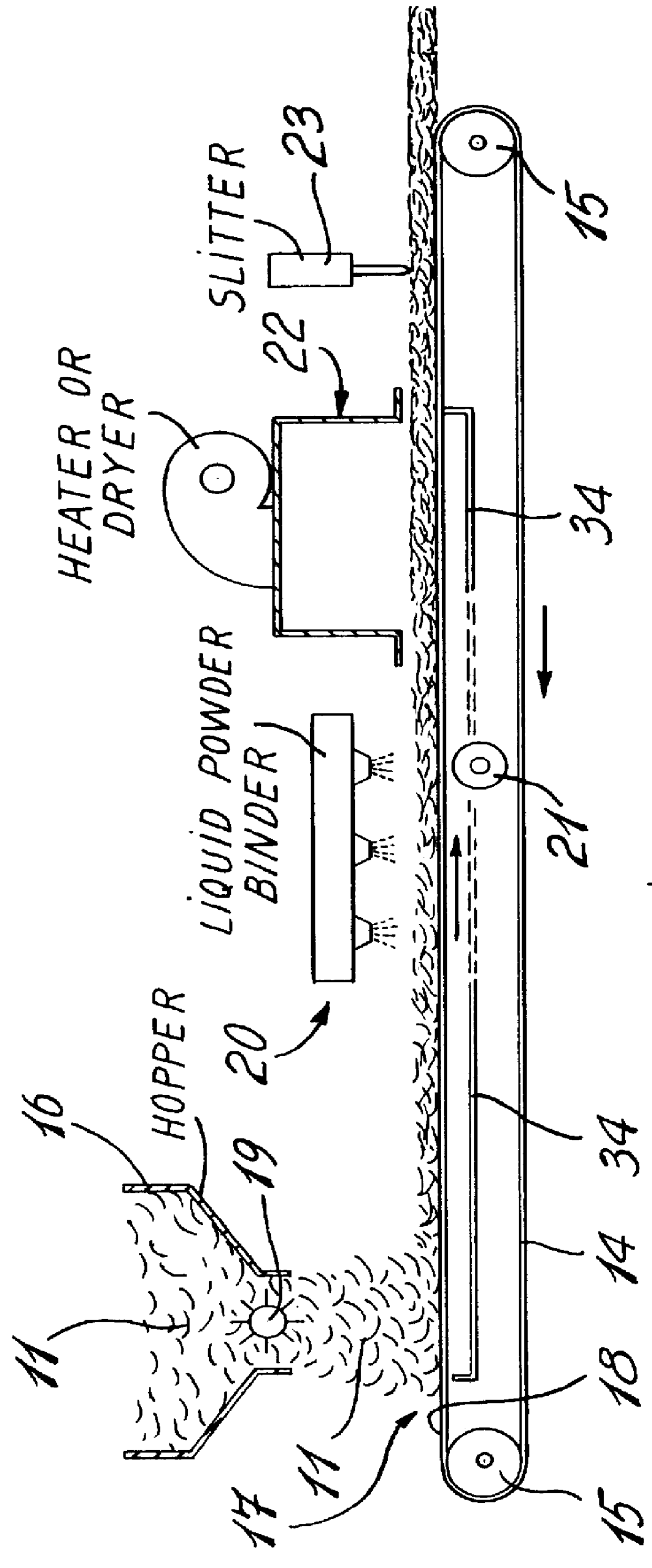

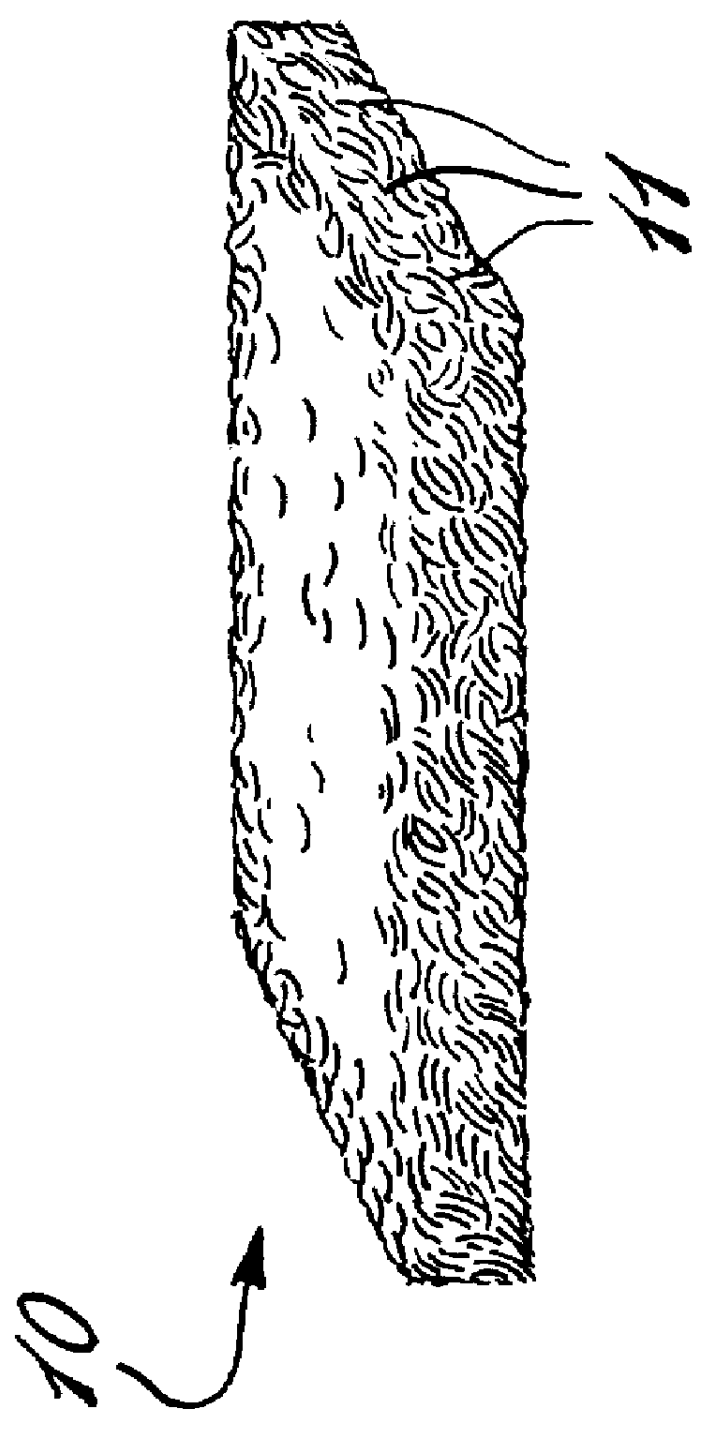

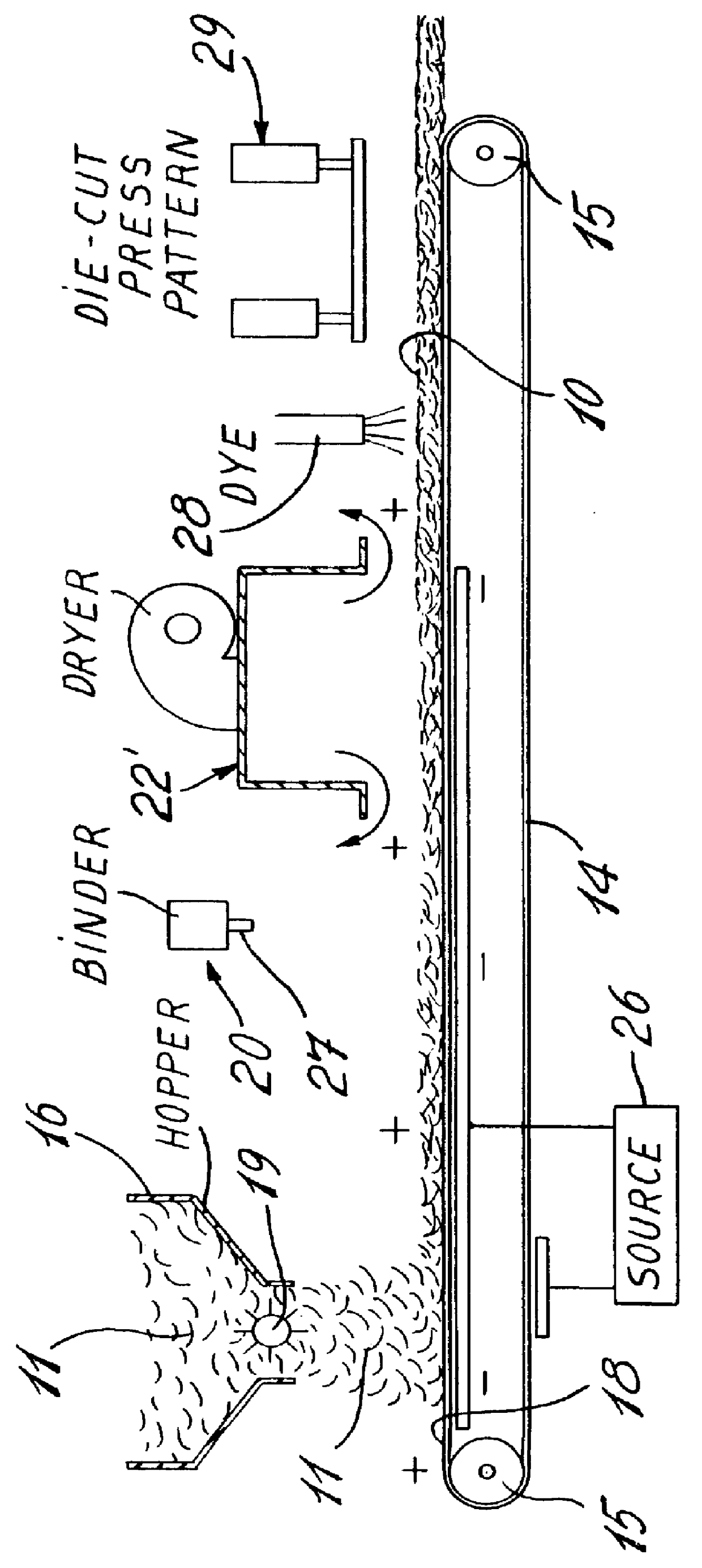

Down feather sheet

A method of fabricating a down feather sheet is described and it comprises forming a sheet of down feathers having been treated whereby to retain a homogeneous form. A binder is associated with the down feathers whereby they are retained together in sheet form. The down feather sheet product is also described.

Owner:7513194 CANADA

Antibacterial down feather and manufacturing method thereof

InactiveCN101611938APrevent mildew and insectsHigh antibacterial rateFibre treatmentDry-cleaning apparatus for textilesAntibacterial agentInflammation

The invention relates to an antibacterial down feather and a manufacturing method thereof. The manufacturing method comprises the steps of raw material stem removal, dust and sand removal, precise separation, washing, dehydration, drying, cooling and package, wherein an antibacterial agent comprises the following components in portion by weight: 6 to 10 portions of quaternary ammonium salt A, 1 to 2 portions of modified chitosan, 0.2 to 0.5 portion of silane coupling agent, 0.1 to 0.5 portion of solubilizing agent, and 0.3 to 0.6 portion of dispersing agent. The antibacterial down feather can effectively prevent mildew and attack of insects of the down feather in storage, transportation and use, and particularly when the antibacterial down feather serves as a filling material and is manufactured into articles for daily use, because of the antibacterial and bacteriostatic functions, the corresponding products have obvious functions of resisting bacteria, diminishing inflammation, deodorizing, resisting mildew, relieving itching and converging, and have no stimulation to skins, and the antibacterial rate of the obtained down feather to staphylococcus aureus bacteria reaches up to 99 percent, and after 10 times of washing, the antibacterial rate still reaches 92 percent.

Owner:凌颖

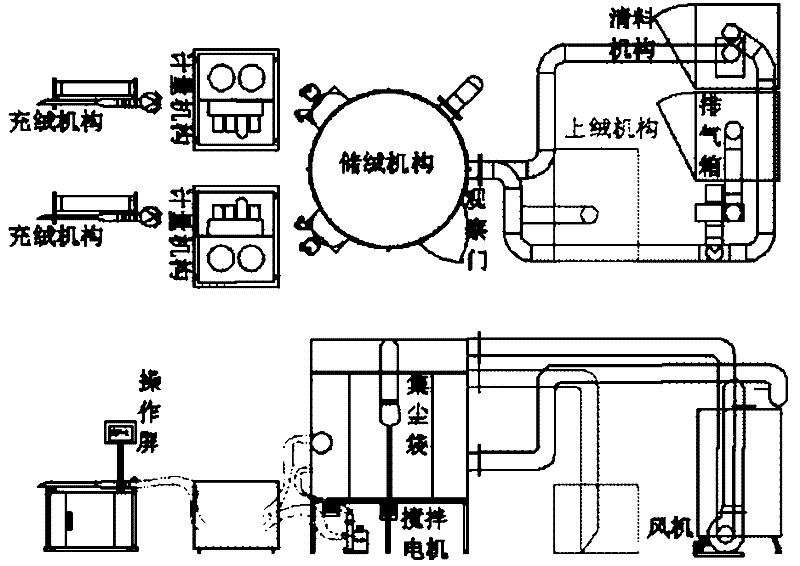

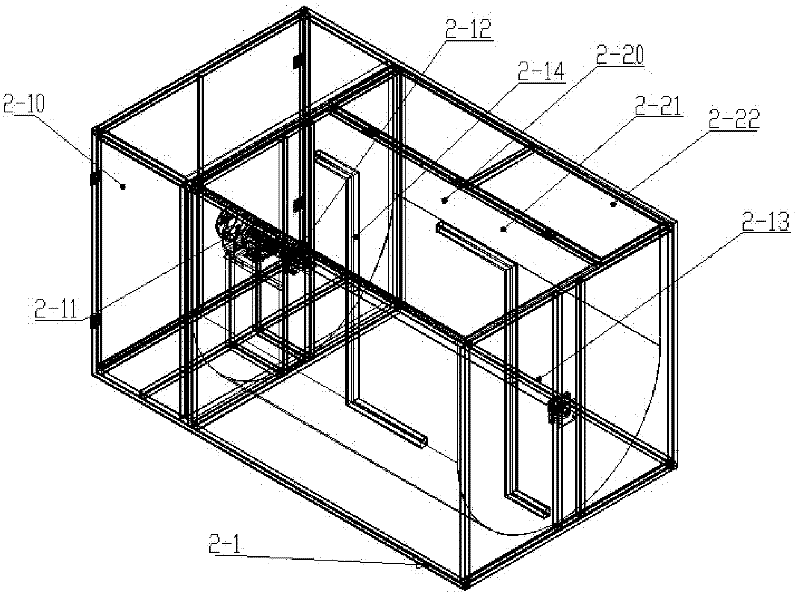

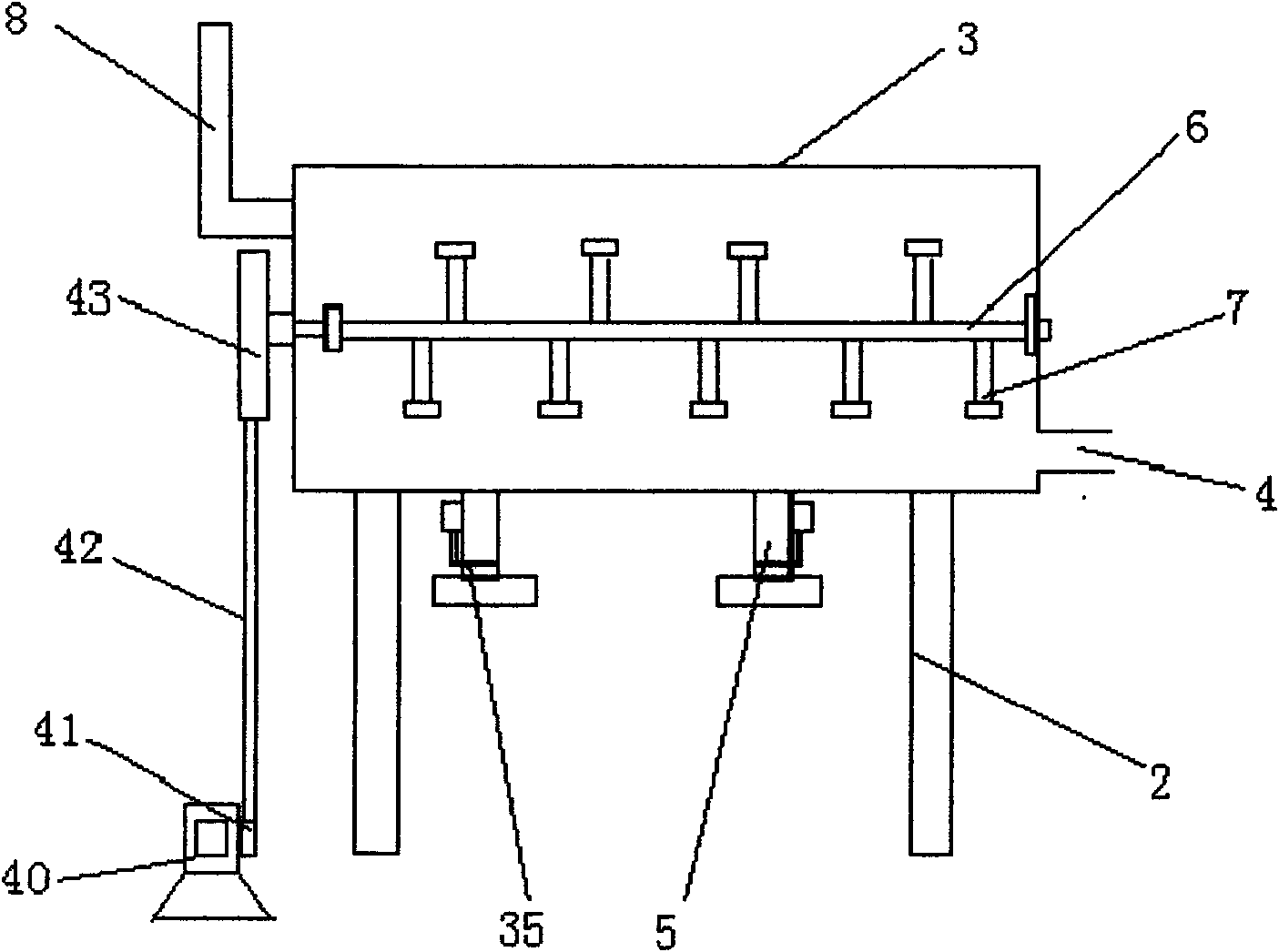

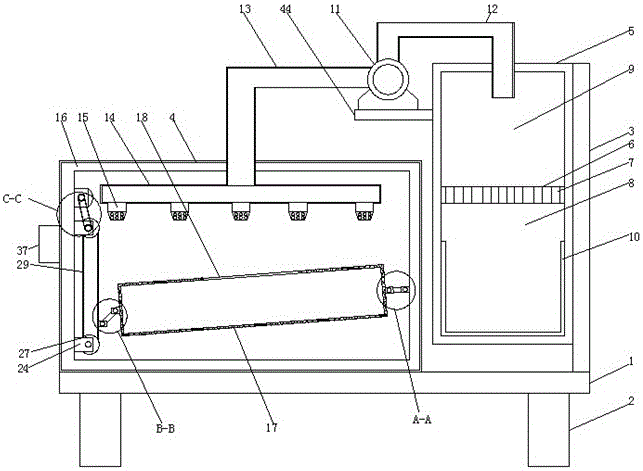

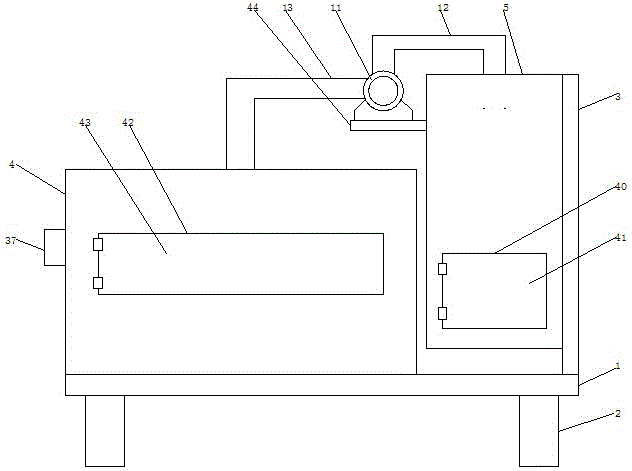

Full-automatic down feather filling machine

InactiveCN102303838AReduce wasteImprove working environmentUpholstery manufactureUpholstery fillingWorking environmentEngineering

The invention discloses a full-automatic down feather filling machine, which consists of a fan, a material loading mechanism, a down feather storage mechanism, a metering mechanism, a down feather filling mechanism and a material cleaning mechanism. The air inlet of the fan is connected with the material loading mechanism, the material loading mechanism is connected with the down feather storage mechanism, the down feather storage mechanism is connected with the metering mechanism, the metering mechanism is connected with the down feather filling mechanism, the down feather filling mechanism is connected with the material cleaning mechanism, and the material cleaning mechanism is connected with the air outlet of the fan. The working mode of manually filling down feather is replaced by the full-automatic down feather filling machine with the structure, and the down feather flows in a full-enclosed environment in the overall process, so that the working environment of staff is improved, labor intensity is lowered, the waste of the down feather is reduced, and working efficiency is improved. In addition, the full-automatic down feather filling machine has the advantages that: the machine has a simple structure and a rational design and is convenient to use.

Owner:天津艾瑞克机械设备有限公司

Down feather composite fiber modified by polypropylene fiber and preparation method of down feather composite fiber

InactiveCN104195664AThe ratio is scientific and reasonableDelicate feelMonocomponent protein artificial filamentArtifical filament manufactureSucrosePhosphoric acid

The invention discloses a down feather composite fiber modified by polypropylene fiber. The down feather composite fiber modified by polypropylene fiber is prepared from the following raw materials in parts by weight: 18-20 parts of superfine duck down powder, 25-30 parts of puffed goose feather powder, 12-15 parts of polypropylene fiber, 3-5 parts of kaolin, 0.3-0.6 part of calcium saccharate, 1-2 parts of wolfberry fruit, 2-4 parts of fruit of Chinese magnoliavine, 1-3 parts of radix rehmanniae, 3-5 parts of cucumber juice, 0.1-0.3 part of ammonium dihydrogen phosphate, 120-130 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 110-140 parts of 1-ethyl-3-diethyl methyl imidazole phosphoric acid, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber modified by polypropylene fiber, the components such as the polypropylene fiber, the wolfberry fruit, the fruit of Chinese magnoliavine and the radix rehmanniae are added; the prepared product is soft and smooth in hand feeling, has the characteristics of the down feather, also has the characteristics of being light, soft, warm, breathable, moisture permeable, mildew-proof, mothproof and washable, and is wide in application prospect and further and more competitive in the market.

Owner:ANHUI LION GOOSE PROD

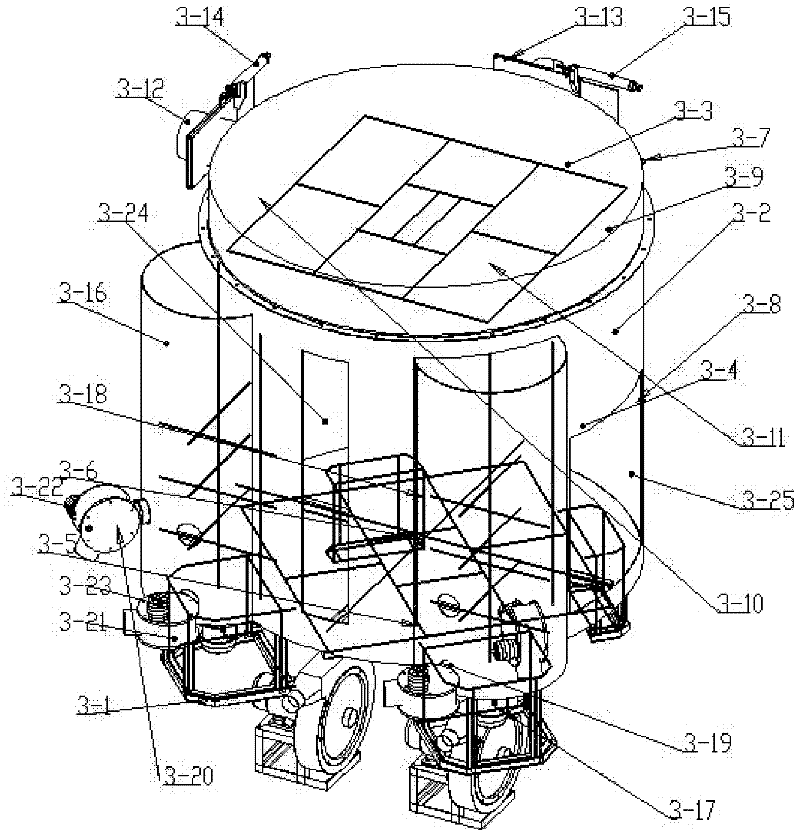

Method for processing and collecting down feather from feather and rinsing down feather

The invention discloses a method for processing and extracting eiderdown from feathers and washing eiderdown. The method comprises the steps of carrying out feeding, extracting, dust removal, stem absorption, washing, rinsing, dehydrating, drying, cooling, impurity removal and packing on the feathers. The eiderdown extraction comprises: adopting an eiderdown extracting tower, throwing the feathers into the eiderdown extracting tower, and making the rotation speed of a stirring device in the chenille eiderdown extracting tower be 40-50 turns / min; the washing procedure comprises: putting the feathers into water added with a washing agent, stirring and cleaning the feathers; the rinsing procedure comprises: cleaning the washed feather slurry repeatedly by water; and the drying procedure comprises: drying the dehydrated feathers to 50 to 70 percent of dryness through steam, dampening the feathers, drying the feathers by the steam, and repeating the procedure frequently. The method reduces the down loss rate to 1 percent from 5 percent, and improves the high value contents of down in a feather sheet from 82 percent to 98 percent so as to reduce down mechanical loss and achieve the effects of improving quality and reducing loss. The fluffy degree of the 90 percent eiderdown is improved from 13 cm to 18 cm.

Owner:ANHUI LION GOOSE PROD

Preparation method of antibacterial and deodorant down feather and its product

The invention discloses a preparation method of an antibacterial and deodorant down feather and its product, the preparation method comprises the following steps: a)immersing the washed clean down feather in 1-2.5% (owf) of a silver-loaded nano antiseptic aqueous solution for leaching, wherein the leaching rate is 60-80%; and b)predrying, stoving, flushing, dehydrating, and drying the leached down feather, and naturally cooling to obtain the antibacterial and deodorant down feather. The antibacterial and deodorant down feather can effectively prevent milden, rot and moth eating in the process of storage, transportation and use, and the corresponded product has obvious functions for preventing bacteria and deodorization.

Owner:LUOLAI LIFESTYLE TECH CO LTD

Down feather processing production technique

InactiveCN104172633ARealize the purpose of deodorization and disinfectionWash thoroughlyApparelMicrowavePulp and paper industry

The invention provides a down feather processing production technique. The down feather processing production technique includes steps of presorting, dedusting, separating, washing and drying of the down feather, soaking, secondary dewatering and drying, cooling, checking and packaging. The separating step includes separating dedusted down feather into nap, large, medium and small feather and large and small feather shafts; the washing step includes washing the feather more than five times by a feather washing machine by adding down feather detergent; the dewatering step includes dewatering until water content of the down feather is lower than 30%; the drying step includes drying the dewatered down feather at the temperature of 120 DEG C by a drying machine or microwaves, and deodorizing and disinfecting; the soaking step includes soaking the down feather in clean water added with natural essential oil; the secondary dewatering and drying step includes dewatering the down feather by a centrifugal machine and drying the dewatered down feather. By the down feather processing production technique, after presorting, dedusting and separating, the down feather is washed, and different kinds of down feathers can be thoroughly cleaned and disinfected; after washing, drying and disinfecting, via secondary soaking in the clean water with natural essential oil, the processed down feather has faint scent and a nerve soothing function.

Owner:江苏欣隆羽绒有限公司

Down feather screening device

ActiveCN107587209ASpray evenlyAvoid enteringFibre cleaning/opening machinesTextile treatment machine arrangementsAir pumpAir compressor

The invention discloses a down feather screening device. The device comprises an air pump, a motor, a pneumatic retractable rod, a bracket, atomizing nozzles, a fixing rod, a vibration motor, a vibration box, a sieve net, a water tank, a drying box, an air compressor, a stirring motor, a water pump, a winch board, an air heater, a connecting frame, a miniature motor, a first screw rod, a fixture and a second screw rod; the motor and the second screw rod are utilized to control the movement of the fixture in the horizontal direction to make the fixture enter the drying box; down feathers are introduced into the drying box, a stirring motor, a stirring stick and the winch board are utilized to prevent the down feathers from accumulating at the bottom of the drying device, and drying is conducted more fully; a pressure gauge and a safety valve are utilized to control the safety of the drying box, and a filter net is utilized to prevent the down feather or impurities from entering the equipment. The down feather screening device is easy to operate, the down feathers can be screened to remove impurities and dust particles and then cleaned and dried, the production efficiency is improved, the resources are saved, and the cost is reduced.

Owner:安徽芙芮雅羽绒有限公司

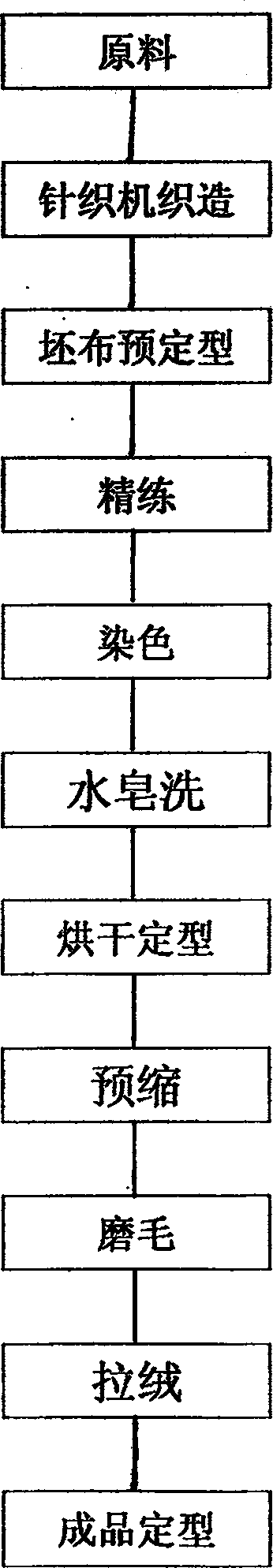

Technique for producing knitting face fabric of blended yarn of down feather

InactiveCN1873072ASolve the problem of irritating the human bodySolve thin and lightWeft knittingWarp knittingYarnRaw material

A production process for preparing knitted shell fabric of eiderdown blended yarn includes raw material-weaving by knitting machine-presetting of fabric-refining-dyeing-soap water washing-drying and setting- preshrinking- napping- teasing- product setting. The said knitted shell fabric is prepared by three-layer fabric of surface fabric, middle fabric and lining fabric as middle fabric being used as connection layer to connect the other two layers and being structure by material of eiderdown blended yarn.

Owner:高德康

Method for compounding functional nano particles on surfaces of down feather fibers

InactiveCN103556477AStable dispersion solutionIncrease production valueFibre treatmentFiberEcological environment

The invention relates to a method for compounding functional nano particles on the surfaces of down feather fibers and belongs to the technical field of textile materials. According to the method provided by the invention, the functional nano particles are compounded on the surfaces of the down feather fibers by preparing a down feather fiber / sodium polystyrenesulfonate dispersed solution, preparing a functional nano particle solution and compounding the surfaces of the down feather fibers. The dispersed functional nano particles are firmly compounded on the surfaces of the down feather fibers by the effects of molecules layer upon layer through sodium polystyrenesulfonate, a sulfo group dispersing agent and the functional nano particles, so that the down feather fibers have various functions. The method for compounding the functional nano particles on the surfaces of the down feather fibers effectively utilizes a lot of waste down feather fibers, improves the additional value of the down feather fibers and explores applications of the down feather fibers in the other fields; furthermore, the whole process equipment is simple, the cost is low, pollution to the ecological environment is not caused and the application prospect is very great.

Owner:WUHAN TEXTILE UNIV

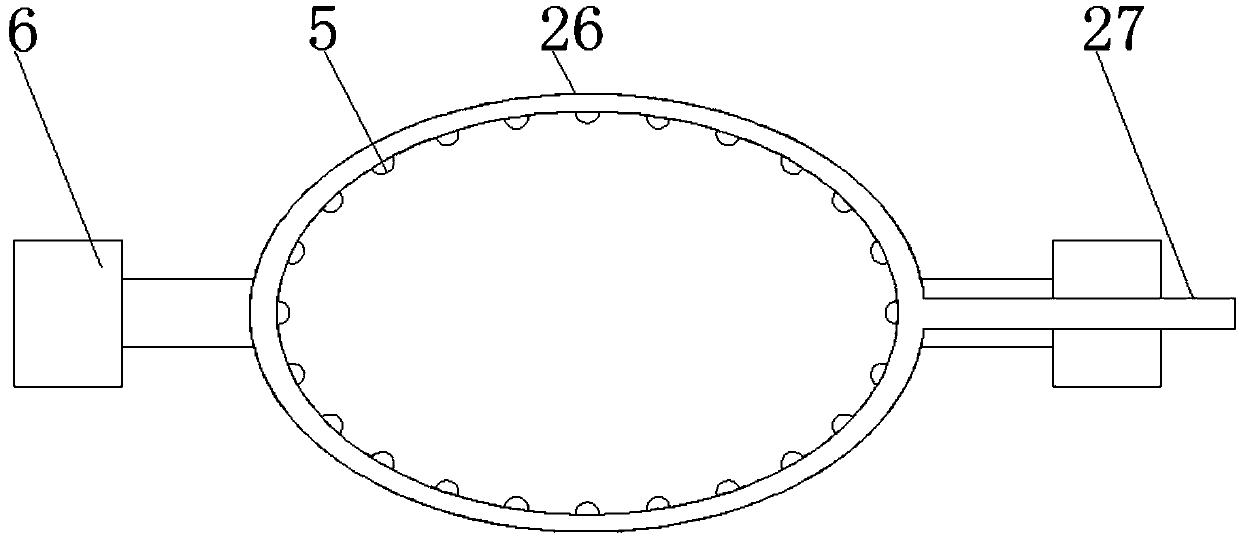

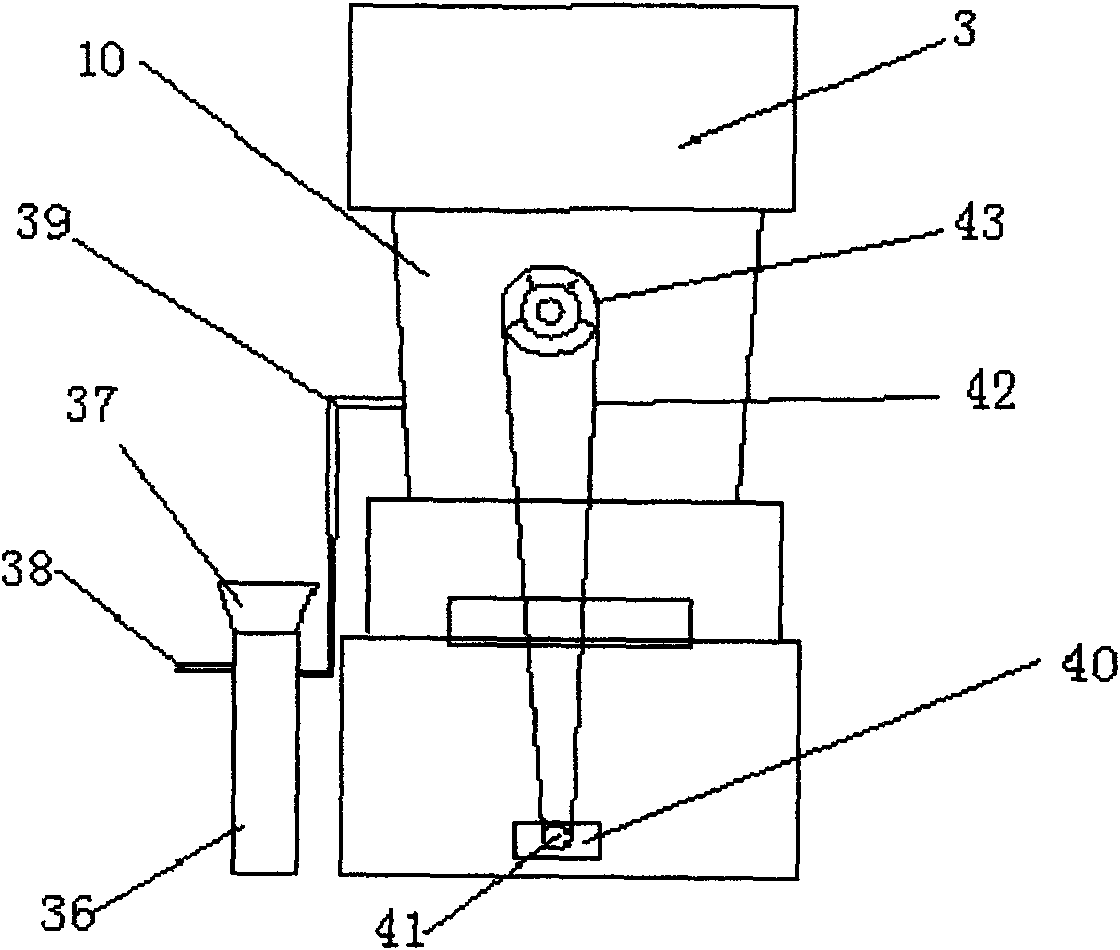

Production technology of the best down feather hanging down feather and hanging down feather screening device

The invention belongs to the technical field of down feather deep processing and particularly relates to a production technology of the best down feather hanging down feather and a hanging down feather screening device. The hanging down feather screening device is provided with a screening box body, a roller screen is arranged inside the screening box body, a blowing leakage tube is arranged in the middle of the roller screen, two ends of the roller screen are connected with a drive motor through a rolling shaft, at least one of two ends of the blowing leakage tube is connected with an air blower, screening holes are evenly formed in the surface of the roller screen, and air leakage holes are evenly formed in the surface of the blowing leakage tube. The feather and down feather row materials are sequentially processed by a preliminary classification process, a dust removing process, a water washing process, a drying process and a hanging down feather screening process. On the basis of the existing down feather processing technology, technological innovation is conducted to be combined with the hanging down feather screening technology, the down feather produced by white gooses in western Anhui is used as raw materials, and thereby down feather content of the screened hanging down feather is close to 100%, wherein the down feather has unique qualities such as big down feather flower, high bulkiness and extremely good quality.

Owner:六安皖智知识产权运营有限公司

Down feather composite fiber compounded by waste down feather fiber and acrylic staple fiber and preparation method of down feather composite fiber

ActiveCN104195665AEfficient use ofPrevent mildew and insectsMonocomponent protein artificial filamentSpinning solutions preparationPerilla frutescensMaterials science

The invention discloses a down feather composite fiber compounded by waste down feather fiber and acrylic staple fiber. The down feather composite fiber compounded by the waste down feather fiber and the acrylic staple fiber is prepared from the following raw materials in parts by weight: 10-15 parts of superfine goose down powder, 20-25 parts of waste down feather fiber, 25-30 parts of nano goose feather powder, 18-20 parts of acrylic staple fiber, 14-17 parts of collagen fiber, 7-9 parts of nano bamboo charcoal powder, 17-21 parts of coconut shell, 0.3-0.6 part of magnesium oxide, 1-3 parts of perilla frutescens bark, 2-4 parts of rhizoma smilacis glabrae, 13-15 parts of rice straw pulp fiber, 100-120 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 120-140 parts of 1,3-dimethyl imidazole dimethyl phosphate, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber compounded by the waste down feather fiber and the acrylic staple fiber, the waste down feather fiber is effectively used; the cost is reduced; meanwhile, perilla frutescens bark and rhizoma smilacis glabrae are added in the down feather composite fiber, so that the mildew and moth of the down feather composite fiber during the storage, transportation and utilization of the down feather composite fiber can be effectively avoided; especially, after the down feather composite fiber is used as a filler and made into articles of daily use, due to the bacteria resistance and bacteriostasis of the down feather composite fiber, the corresponding products have the obvious antibacterial, anti-inflammatory, deodorant, mildew-proof, anit-pruritic and astringent functions, have no stimulation to the skin and are well received by consumers.

Owner:ANHUI LION GOOSE PROD

Down products with penetration resistance and manufacturing method thereof and manufacturing method of down jacket

InactiveCN101669688AAvoid drillingHigh densityOvergarmentsProtective garmentMechanical engineeringDown feather

The invention discloses down products with penetration resistance and a manufacturing method thereof and a manufacturing method of a down jacket. The manufacturing method of the down products with penetration resistance comprises the following steps: cutting out terylene cloth and inviscid non-woven interlining; sewing up the terylene cloth and the inviscid non-woven interlining together to form abag-shaped composition body of the terylene cloth and the inviscid non-woven interlining; filling down feathers to the bag-shaped composition body of the terylene cloth and the inviscid non-woven interlining; completely sewing up the bag-shaped composition body of the terylene cloth and the inviscid non-woven interlining to manufacture into the down products with penetration resistance. In the manufactured down products with penetration resistance, the terylene cloth completely wraps up the down feathers and is between the down feathers and the inviscid non-woven interlining; and the inviscidnon-woven interlining completely wraps up the terylene cloth. The invention can effectively realize the function of penetration resistance.

Owner:报喜鸟控股股份有限公司

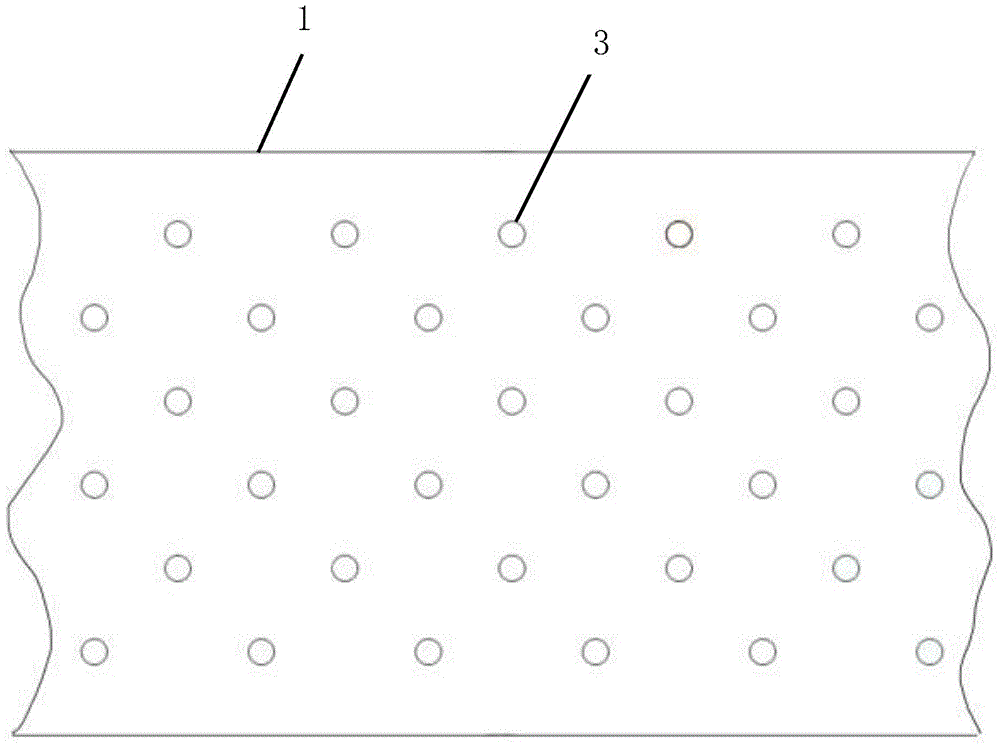

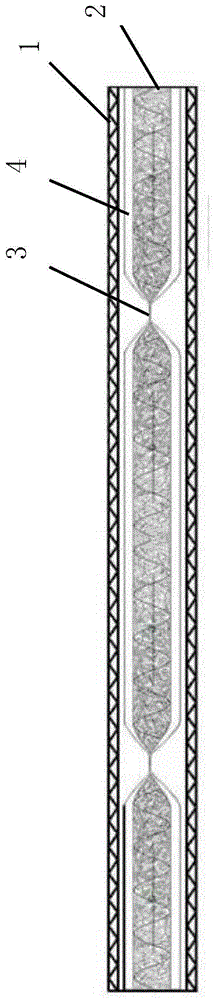

Structure capable of preventing down feather displacement and penetration and maintaining fabric elasticity and manufacturing technology thereof

InactiveCN105128442ADoes not damage the elasticityEvenly distributedSynthetic resin layered productsClothingsManufacturing technologyEngineering

The invention provides a structure capable of preventing down feather displacement and penetration and maintaining fabric elasticity and a manufacturing technology thereof. The structure comprises two fabric layers and down feathers, the down feathers are filled into the space between the two fabric layers, the structure further comprises multiple connection points which are used for positioning the down feathers and making the down feathers distributed in a netted mode, the two fabric layers both adopt extended elastic fabric, and the down feathers are wrapped with elastic air-permeable films. According to the technical scheme, by means of the structure, the fabric elasticity of down feather products is maintained to the maximum extent, distribution of the down feathers is always kept even, the downproofness is achieved, and displacement caused by the exogenic action such as gravity cannot happen.

Owner:SHANGHAI YIQI GARMENT CO LTD

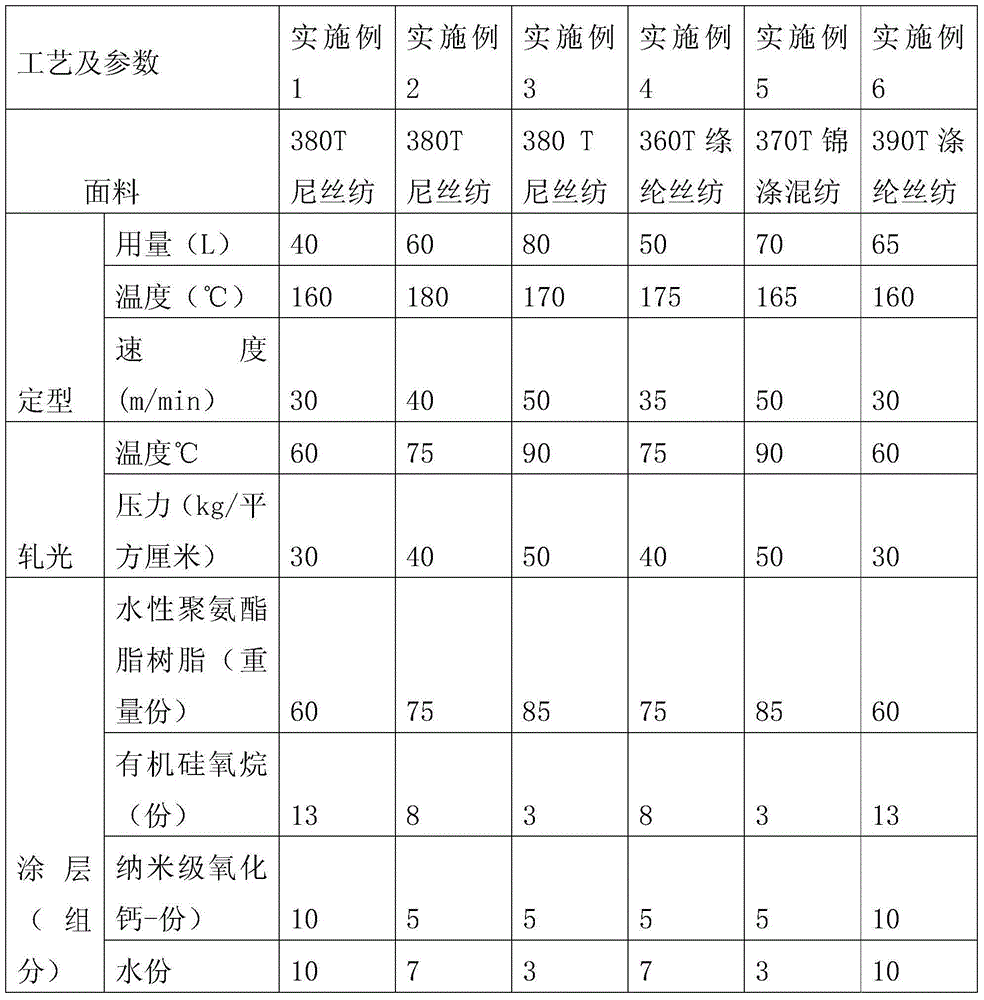

Water-based highly down-proof finishing agent, preparation method thereof and down-proof fabric after-treatment method

InactiveCN104358129ANo pollution in the processEnvironmental protection is goodFibre typesCross-linkWater based

The invention aims to solve the problems in the prior art that during fabric after-treatment of a down-proof finishing agent and a down-proof finishing method, the environmental friendliness and the fabric strength are low, the water resistance is poor and the down-proof performance is low, and provides a water-based highly down-proof finishing agent, a preparation method thereof and a down-proof fabric after-treatment method. The water-based highly down-proof finishing agent comprises 60-85 parts of polyurethane resin, 3-13 parts of organosilicone, 5-10 parts of nanoscale calcium oxide, 3-10 parts of water, 3-6 parts of a bridging agent, and 1-2 parts of a cross-linking agent. As water serves as the solvent, no pollution and good environmental friendliness are realized in the treatment process; the water-based polyurethane resin, the organosilicone and the nanoscale calcium oxide serve as main components, so that an integral protecting film is formed on the fabric surface, the weave clearances between fabric warps and wefts can be made up while down feather is prevented from getting out of the fabric surface, and the anti-tearing capability of the fabric cannot be reduced.

Owner:金隽

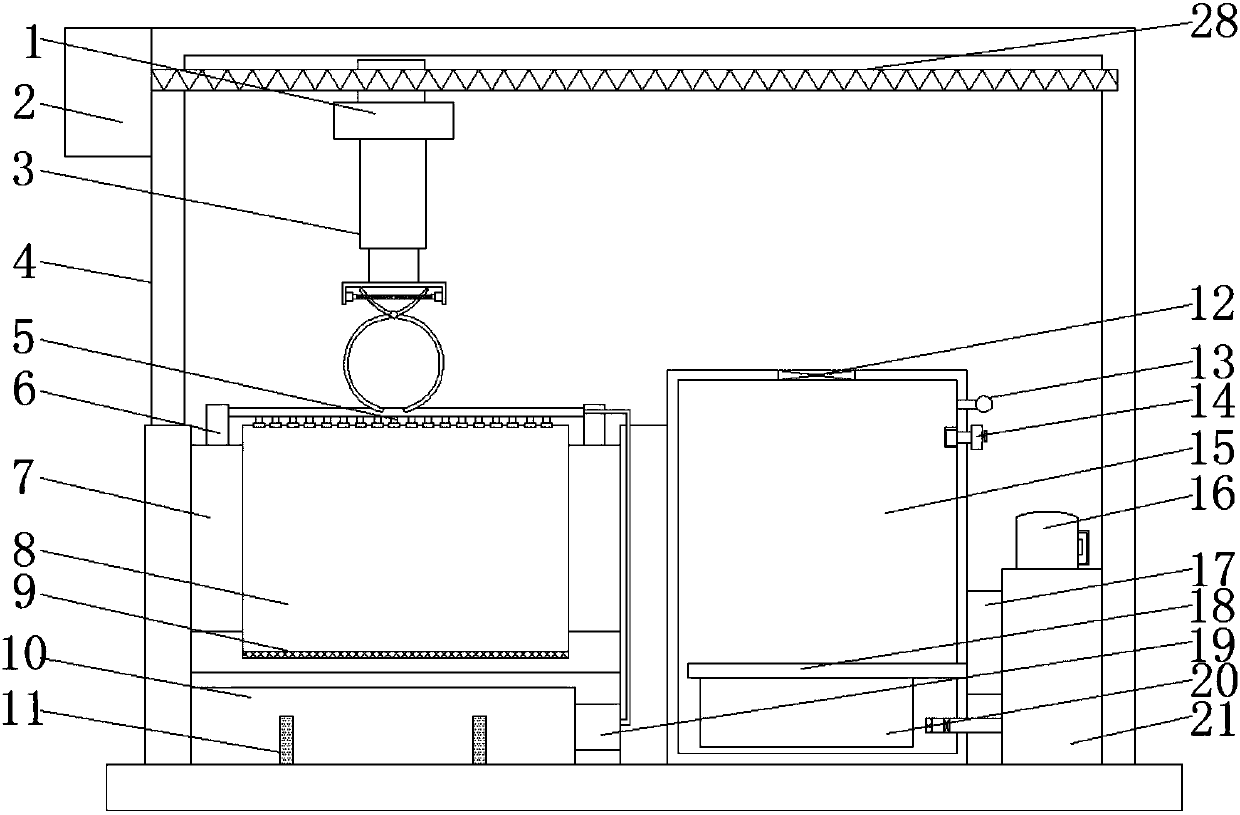

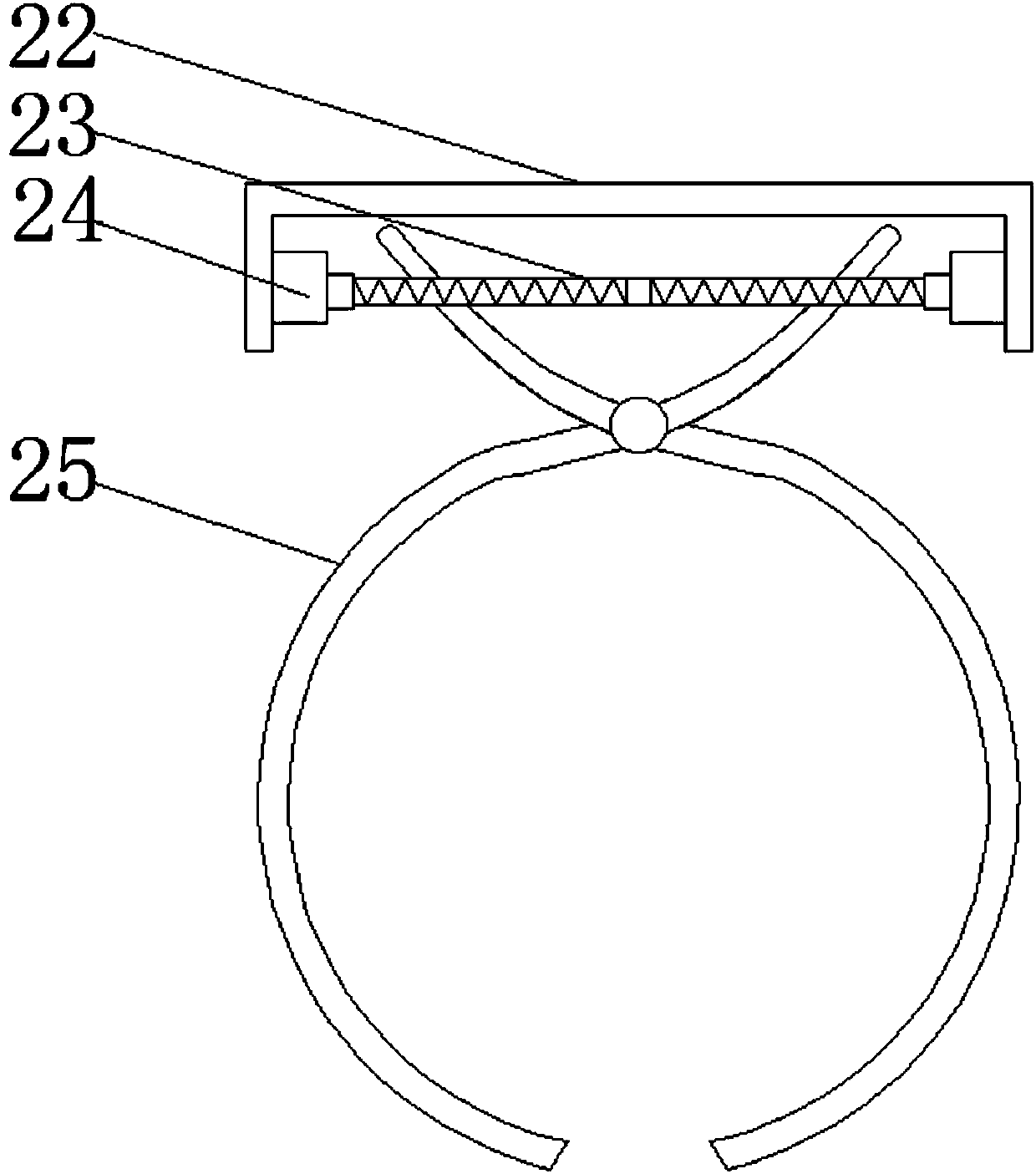

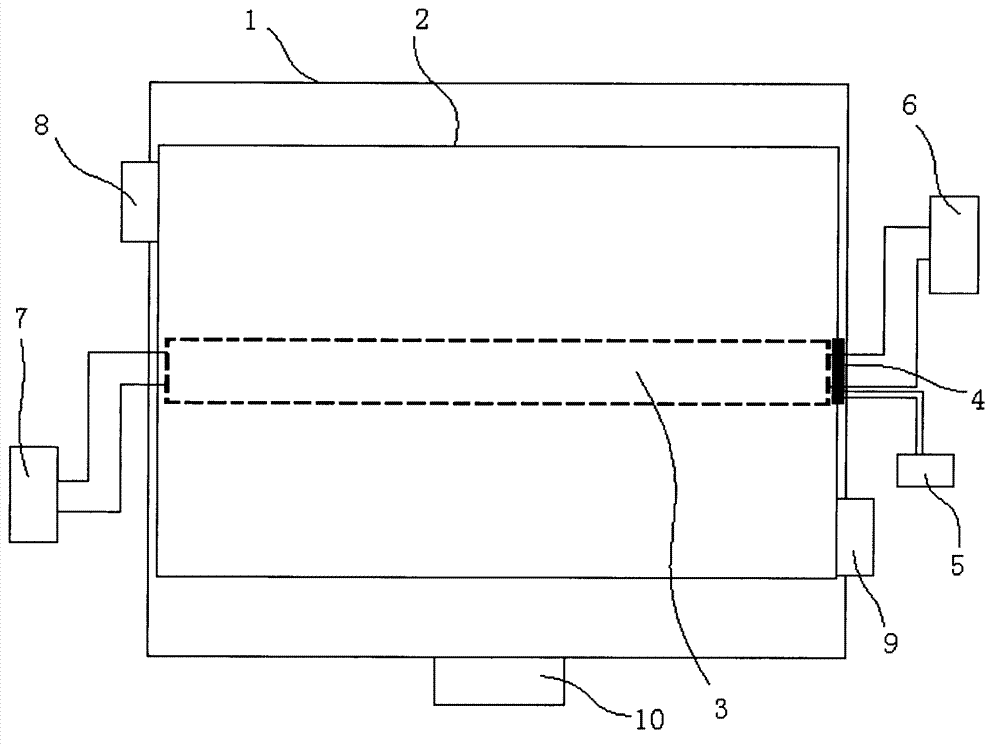

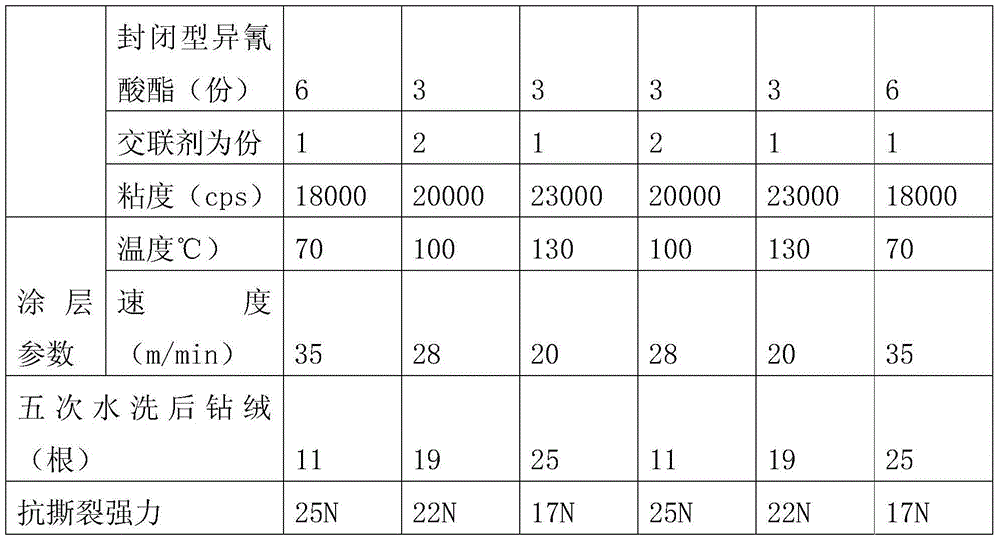

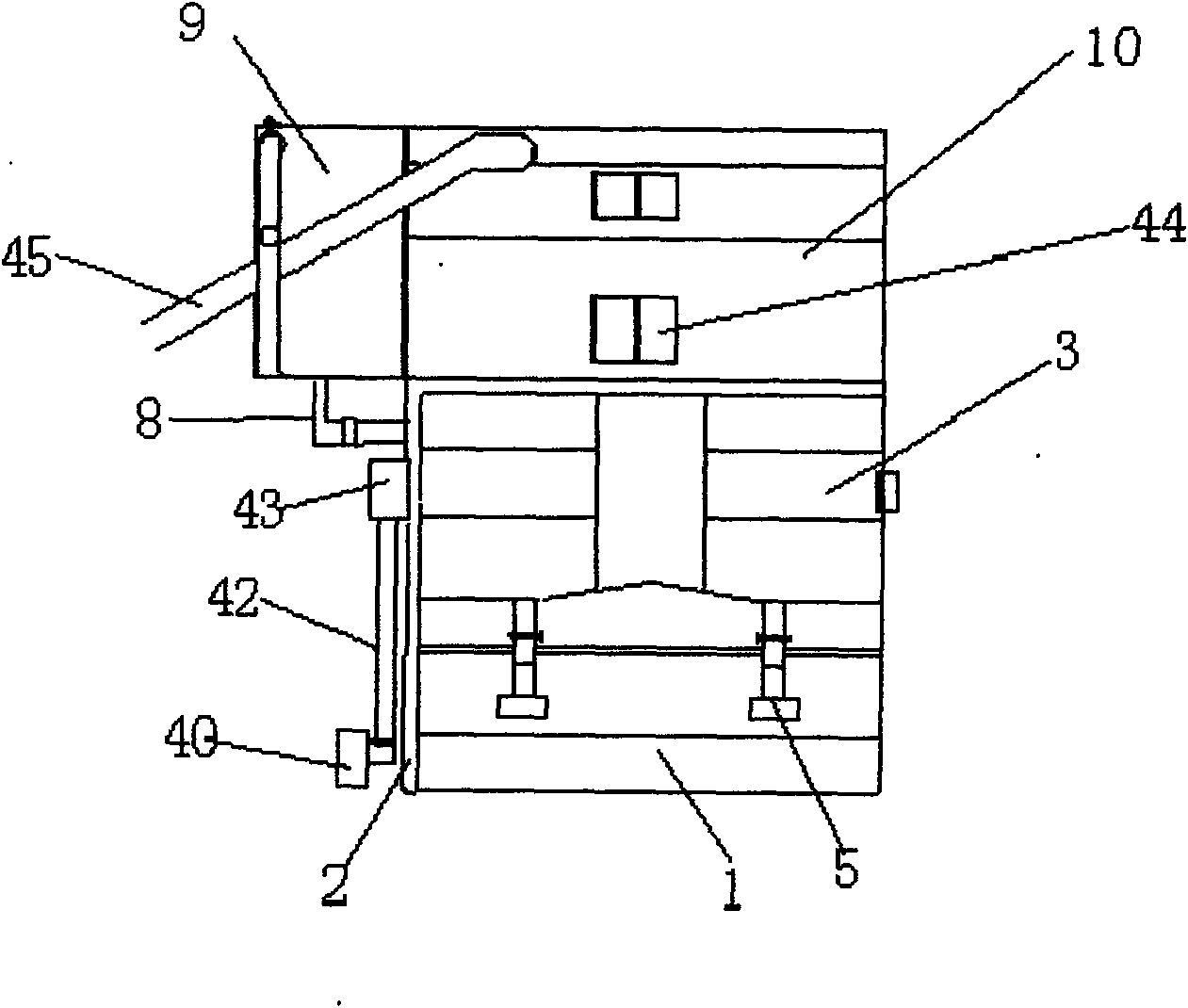

Metering system of automatic down filling machine

InactiveCN103397411AImprove reliabilityImprove stabilityOakum treatmentWeighing apparatus for materials with special property/formGramDisplay device

The invention discloses a metering system of an automatic down filling machine. The metering system comprises at least two weighing sensors, a transmitter, a controller and a terminal display. The weighing sensors are respectively in communication connection with the transmitter, the transmitter, the controller and the terminal display are sequentially in communication connection with one another, and weighing metering hoppers are further placed at the upper ends of the weighing sensors. Owing to the mode, the metering system of the automatic down filling machine has the advantages that the weighing sensors can simultaneously weigh down feather at various positions before the down feather is filled, the metering system has a simultaneous weighing function, is good in reliability and stability and low in error rate and is applied to quantitatively filling products such as down jackets, down sleeping bags, down cushion, down mattresses and down quilts, the requirement on filling different gram weights of down feather at different positions of the same product can be met, and the production efficiency is improved.

Owner:CHANGSHU SHIBO MACHINERY

Down proof fabric

InactiveCN103541222AImprove breathabilityImprove wear resistanceFibre treatmentWoven fabricsAqueous solutionSodium sulphide

The invention relates to a textile and in particular relates to a down proof fabric. The down proof fabric is prepared by the following steps: selecting a gray fabric; sanding; rolling a down proof finishing agent at the processing speed of 60-80 m / min, namely ensuring that a sanded fabric passes through a down proof finishing agent aqueous solution at the temperature of 40-55 DEG C with the pick-up of 45%-65%, wherein the down proof finishing agent comprises a starch composite catalyst and a compound, and the compound is formed by compounding an acrylic acid acrylamide compound with a hydrophilic softening agent KF-896 in a mass ratio of (2-5):1; dyeing, namely immersing in a dye liquor, reducing and steaming, washing, oxidizing, washing, soaping, washing, drying and rolling up, wherein the dye liquor comprises dye, sodium sulphide, a wetting agent and sodium carbonate, and the thickness pick-up of the dye liquor is 60%-70%, a reducing and steaming temperature is 90-100 DEG C, and reducing and steaming time is 40-50 seconds; printing at the temperature of 100-115 DEG C; calendaring at the temperature of 105-115 DEG C and at the processing speed of 30-50 m / min; preshrinking; and after finishing. The prepared down proof fabric has excellent air permeability and an excellent effect of preventing down feather from unthreading.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

High-density waterproof coated fabric

ActiveCN103790024AIncrease elasticityImprove waterproof performanceWoven fabricsAnimal fibresPolyesterCross-link

The invention relates to a high-density waterproof coated fabric. The high-density waterproof coated fabric comprises a base cloth layer and at least one coating, wherein the base cloth layer is formed by weaving of warp yarns and weft yarns, the warp yarns and the weft yarns are formed by polyester fibers and silk fibers through blending respectively, the silk fibers account for 20-35%, the warp density of the base cloth layer is 150-250 / cm, and the weft density of the base cloth layer is 180-300 / cm; the base cloth layer is coated with a sizing agent coating which is prepared from the following components in parts by mass: 50-70 parts of modified polyurethane resin, 6-10 parts of a silane coupling agent, 7-15 parts of a cross-linking agent, 0.5-1.5 parts of pigment, and 12-18 parts of solvent. The high-density waterproof coated fabric provided according to the technical scheme has the characteristics of lightness, thinness, excellent elasticity, good waterproof effect and stable coating performances, can well protect a down feather interlayer and is very suitable for serving as the coating fabric of the down garments.

Owner:NANTONG QUANJI TEXTILE COATING

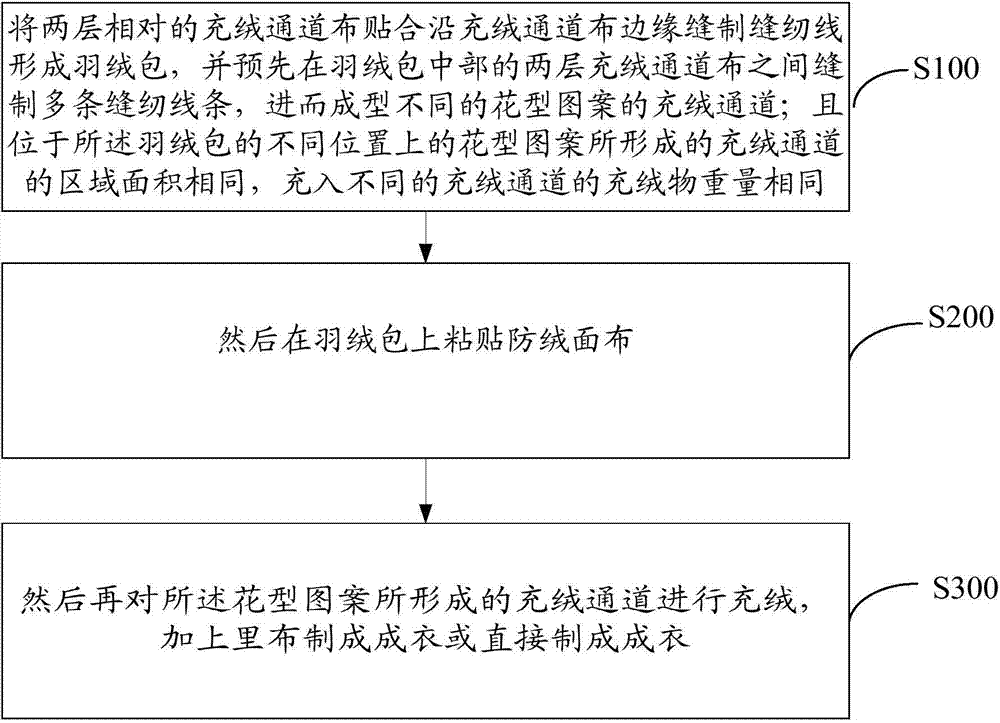

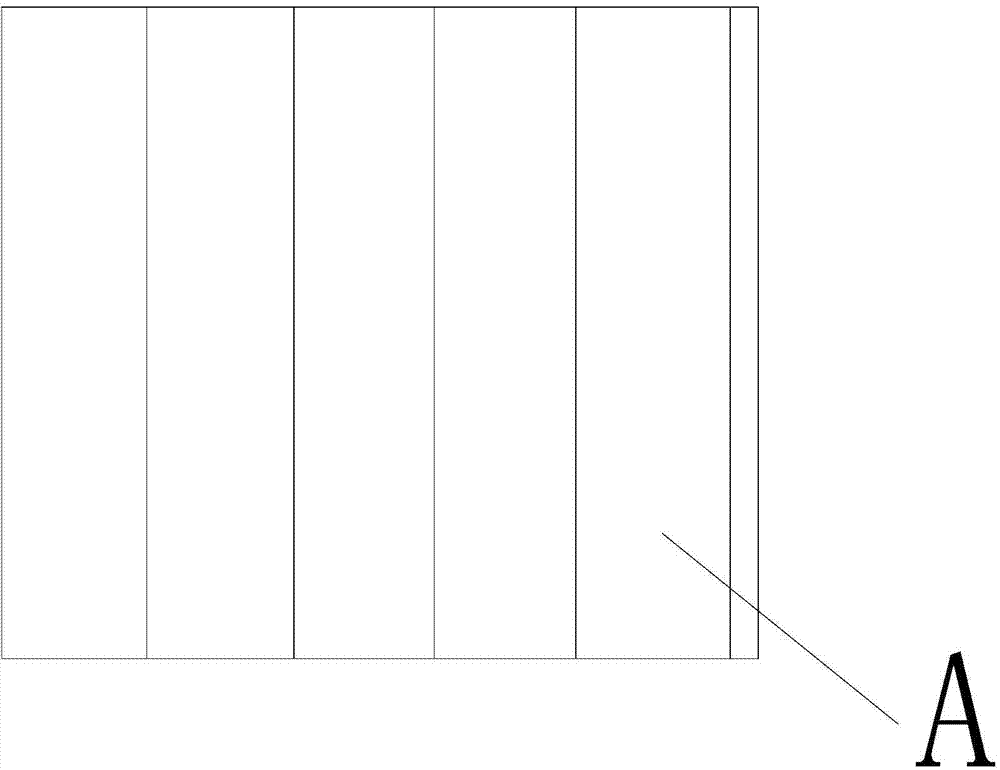

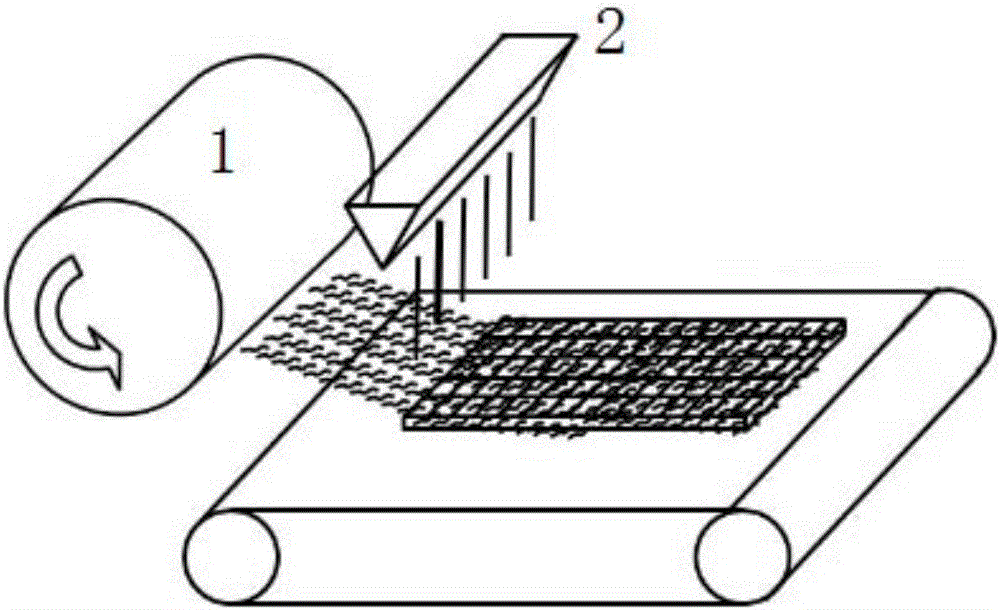

Manufacturing method of down feather escape-free down jacket and down feather escape-free down jacket

InactiveCN104705880AAvoid uneven thicknessWon't run outOvergarmentsProtective garmentEngineeringMechanical engineering

The invention discloses a manufacturing method of a down feather escape-free down jacket and the down feather escape-free down jacket. The manufacturing method comprises the following steps: pre-sewing a plurality of sewing threads between two pieces of down feather filling channel cloth in the middle of a down feather bag so as to mould down feather filling channels with different patterns; then adhering down feather resisting shell cloth on the down feather bag; and then filling down feather into the down feather filling channels formed by the patterns and adding liner cloth to prepare product clothes or directly preparing product clothes. The manufacturing method of the down feather escape-free down jacket and the down feather escape-free down jacket disclosed by the invention can be used for mainly solving the problems that down feather of a conventional down jacket in the market escapes, is pressed and split in a nonuniform manner and the like.

Owner:江志宏

Composite accompanying environment-friendly imitation goose down thermal material and method for producing same

ActiveCN105780297ANot easy to drill downHas a warming effectMelt spinning methodsNon-woven fabricsCamel hairMelt blowing

The invention discloses a composite accompanying environment-friendly imitation goose down thermal material and a method for producing the same.The composite accompanying environment-friendly imitation goose down thermal material is prepared from PLA (polylactic acid) melt-blown superfine short fibers and a type or a plurality of types of cashmere, camel hair, alpaca wool and rabbit hair fibers.The surface density of the composite accompanying environment-friendly imitation goose down thermal material is 50-300 g / m<2>, the thickness of the composite accompanying environment-friendly imitation goose down thermal material is 3-30 mm, a CLO value of the composite accompanying environment-friendly imitation goose down thermal material is 0.8-3, the warmth retention rate of the composite accompanying environment-friendly imitation goose down thermal material is 50-85%, and a thermal resistance value R of the composite accompanying environment-friendly imitation goose down thermal material is 0.5-3.The composite accompanying environment-friendly imitation goose down thermal material and the method have the advantages that shortcomings of bulkiness, easiness in deformation due to water washing, down piercing and the like of the traditional down feather can be effectively overcome; existing melt-blowing equipment is modified, so that the light, thin, environment-friendly and efficient imitation goose down thermal material can be developed and is wide in service range, and development of the thermal material industry can be effectively promoted.

Owner:吉祥三宝高科纺织有限公司

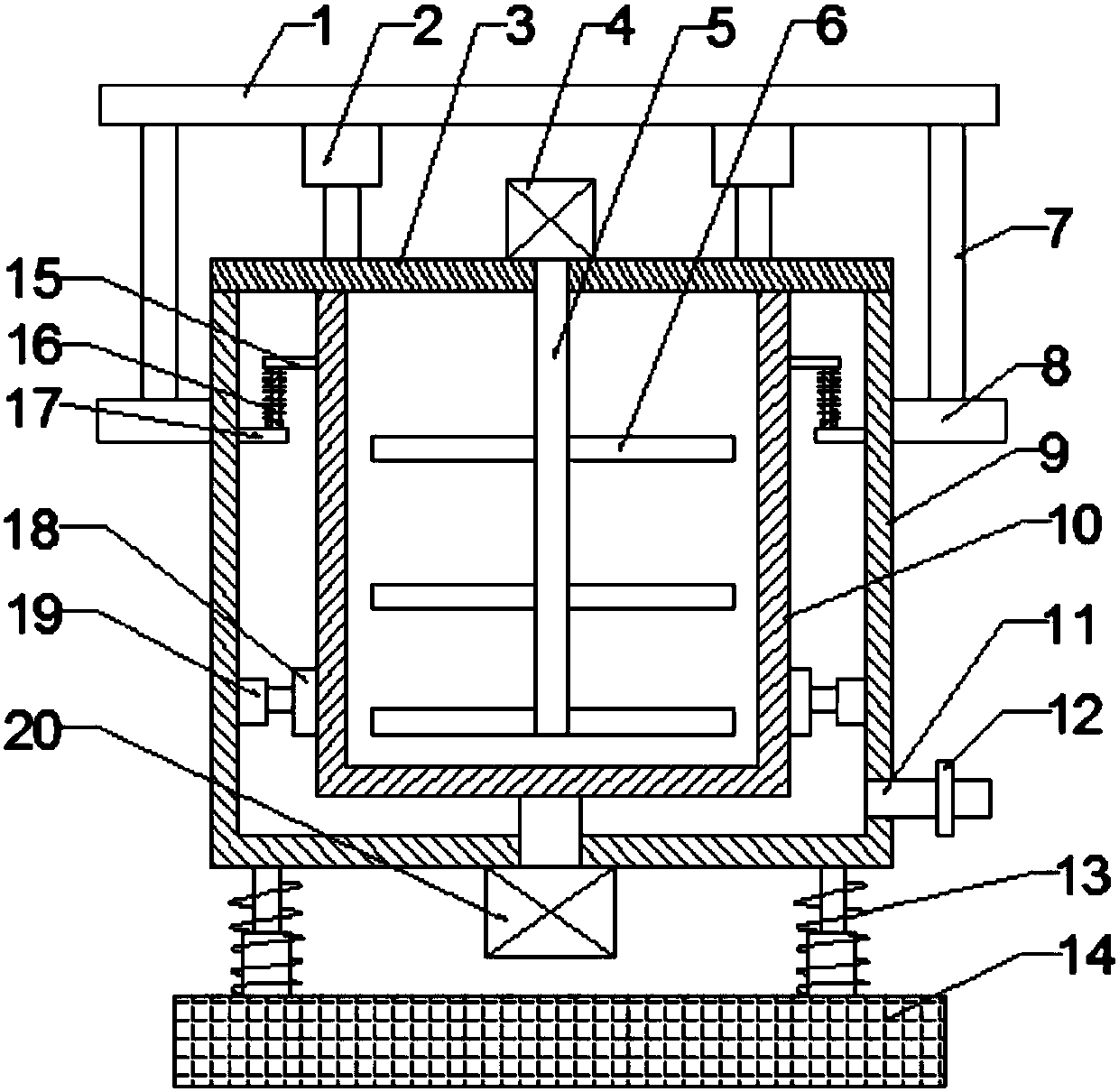

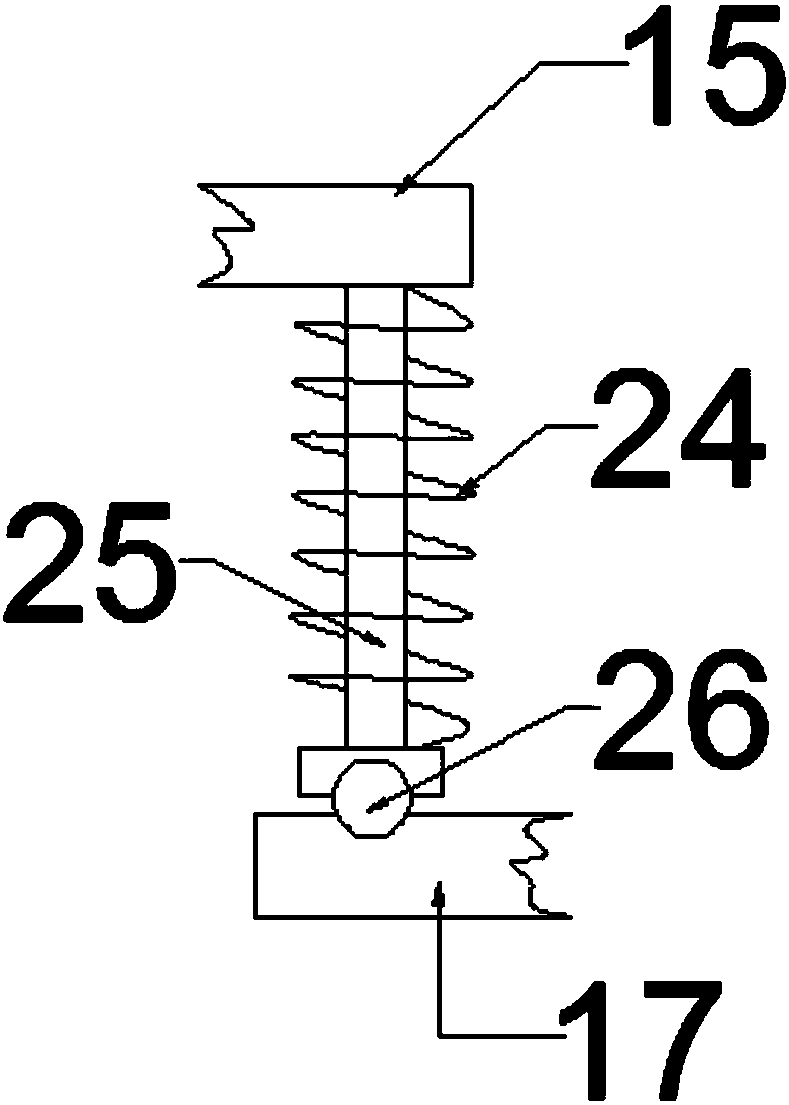

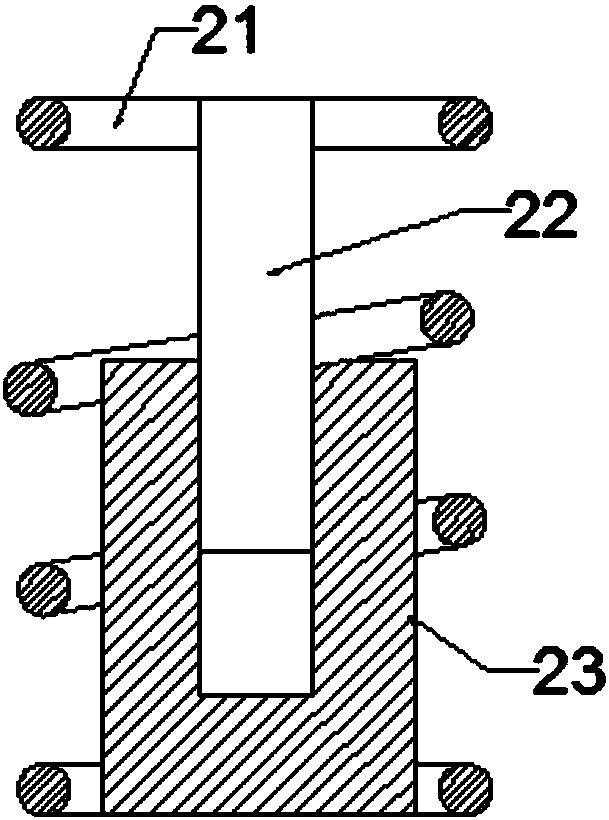

Cleaning equipment capable of dewatering for down feather processing

InactiveCN107841794AImprove efficiencyReduce labor intensityWool fibre washing/scouringBiochemical engineeringDown feather

The invention discloses cleaning equipment capable of dewatering for down feather processing, and belongs to the field of down feather processing equipment. The cleaning equipment capable of dewatering for down feather processing comprises an outer barrel and an inner barrel, wherein the inner barrel is arranged in the outer barrel; an end cap is arranged on the top of the outer barrel; an elasticsupporting device is arranged on the lower side of the outer end of the guide rod; a throw-drying motor is arranged in the center of the bottom end of the outer barrel; an output shaft of the throw-drying motor penetrates through the outer barrel and is fixedly connected with the center of the bottom end of the inner barrel; a stirring motor is fixedly arranged in the center of the upper end surface of the end cap; an output shaft of the stirring motor is connected with a stirring shaft; the stirring shaft is vertically arranged in the inner barrel; stirring blades are arranged on the stirring shaft; mounting plates are symmetrically arranged on the outer side of the outer barrel in the left-right direction; a supporting rod is vertically arranged on the upper side of each mounting plate;a water outlet tube is arranged in the right lower direction of the outer barrel; and a water outlet valve is arranged on the water outlet tube. The cleaning equipment is reasonable in structure andconvenient to operate; cleaning and throw-drying can be integrated; and the cleaning efficiency is high.

Owner:季元吉

Washable wrinkle-proof compound silk floss material

InactiveCN105088404AAdd new usesGood antibacterialFibre treatmentConjugated cellulose/protein artificial filamentsFiberWrinkle skin

The invention discloses a washable wrinkle-proof compound silk floss material. The washable wrinkle-proof compound silk floss material is characterized by being prepared by, by weight, 40-60 parts of poultry feathers, 14-17 parts of down feathers, 1-3 parts of silane coupling agents KH550, 1-2 parts of nano silica, 1-2 parts of nano-silver, 14-20 parts of chitosan, 30-50 parts of polypropylene, 4-6 parts of soybean protein fibers, 2-5 parts of waterborne polyurethane and an appropriate amount of water. The soybean protein fibers and the waterborne polyurethane interact with each other to improve strength and elongation and the properties of good acid and alkali resistance, good moisture absorption and moisture conductivity and others of the compound silk floss material, and the compound silk floss material is free of washing, achieves a good wrinkle-proof effect, brings noble and comfortable feeling and is high in cost performance, abandoned feathers are utilized, the number of effective utilization paths is increased, and the compound silk floss material saves energy, is environmentally friendly and has broad application prospects.

Owner:安徽咏鹅家纺股份有限公司

Down feather cleaning machine

InactiveCN102115916AEasy to collectWool fibre washing/scouringApparelEngineeringMechanical engineering

The invention discloses a down feather cleaning machine, comprising a down feather cleaning device fixedly arranged on a draining pool. The down feather cleaning device comprises a cleaning cavity arranged on a support of the draining pool, the upper part of the cleaning cavity is provided with a discharge opening, a feed opening is communicated with a feed pipe, the lower part of the cleaning cavity is provided with a water outlet, the cleaning cavity is internally provided a rotation shaft rotating under the drive of a driving device, stirring rods are uniformly distributed on the rotation shaft, and the upper part of the cleaning cavity is further provided with a water inlet connected with a water tank on one side of the cleaning cavity. The down feather cleaning machine is characterized in that the upper part of the cleaning cavity is further connected with a feed device. A down feather loosening device is arranged below distribution openings of an outer cavity, the outer cavity is internally provided with a down feather hair loosening device, and the lower part of an air compartment is connected with an oscillating mechanism. The down feather cleaning machine can be used for evenly and smoothly conveying down feathers inside a feed conveying pipeline into processing equipment as required and also can be used for removing impurities and dust inside the down feathers so as to enable the down feather to be cleaner.

Owner:广东羽顺羽绒制品有限公司

Down feather dryer capable of preventing down feathers from being stacked

ActiveCN106500468AAvoid accumulationEvenly distributedDrying gas arrangementsDrying solid materialsCombustion chamberAir pump

The invention provides a down feather dryer capable of preventing down feathers from being stacked and relates to the field of down feather processing. The down feather dryer capable of preventing the down feathers from being stacked comprises an operating table. Supporting legs are fixedly connected with the four corners of the bottom of the operating table. A fixing column and a machine body are fixedly connected to the top of the operating table from right to left in sequence. The left side of the fixing column is fixedly connected with a heat supply box. A partition plate is arranged in the heat supply box. Air holes are formed in the surface of the partition plate. The interior of the heat supply box is partitioned into a combustion chamber and a hot gas chamber through the partition plate. The combustion chamber is located at the bottom of the hot gas chamber. A combustion box is arranged in the combustion chamber. The bottom of the combustion chamber is fixedly connected with the bottom of the inner wall of the heat supply box. A gas pump is arranged on the left side of the heat supply box. An air inlet of the gas pump communicates with a U-shaped exhaust tube. Through the down feather dryer capable of preventing the down feathers from being stacked, the problem of uneven heating due to the fact that the down feathers are stacked is solved, and the drying speed is increased.

Owner:无锡锡东新农村投资发展有限公司

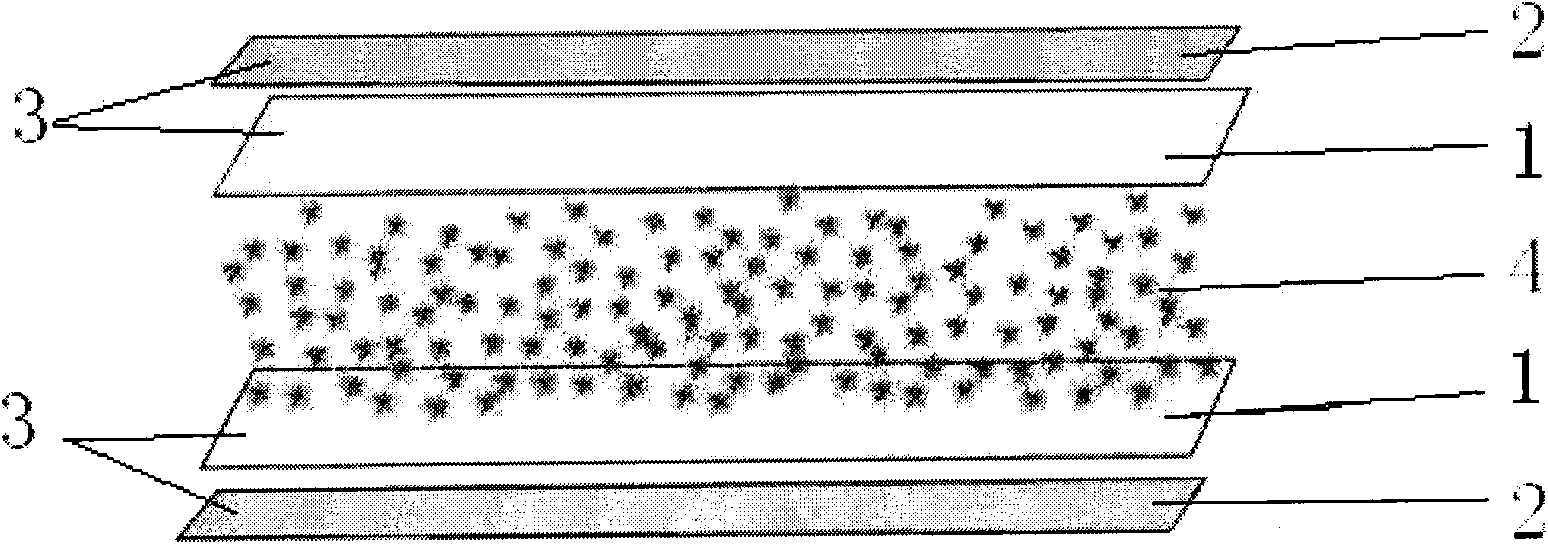

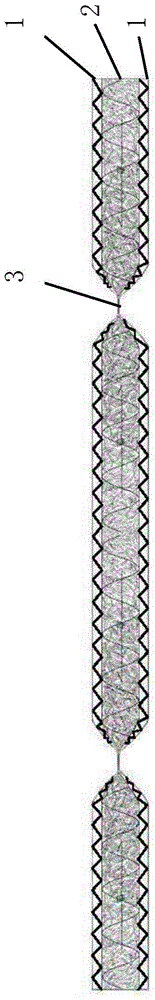

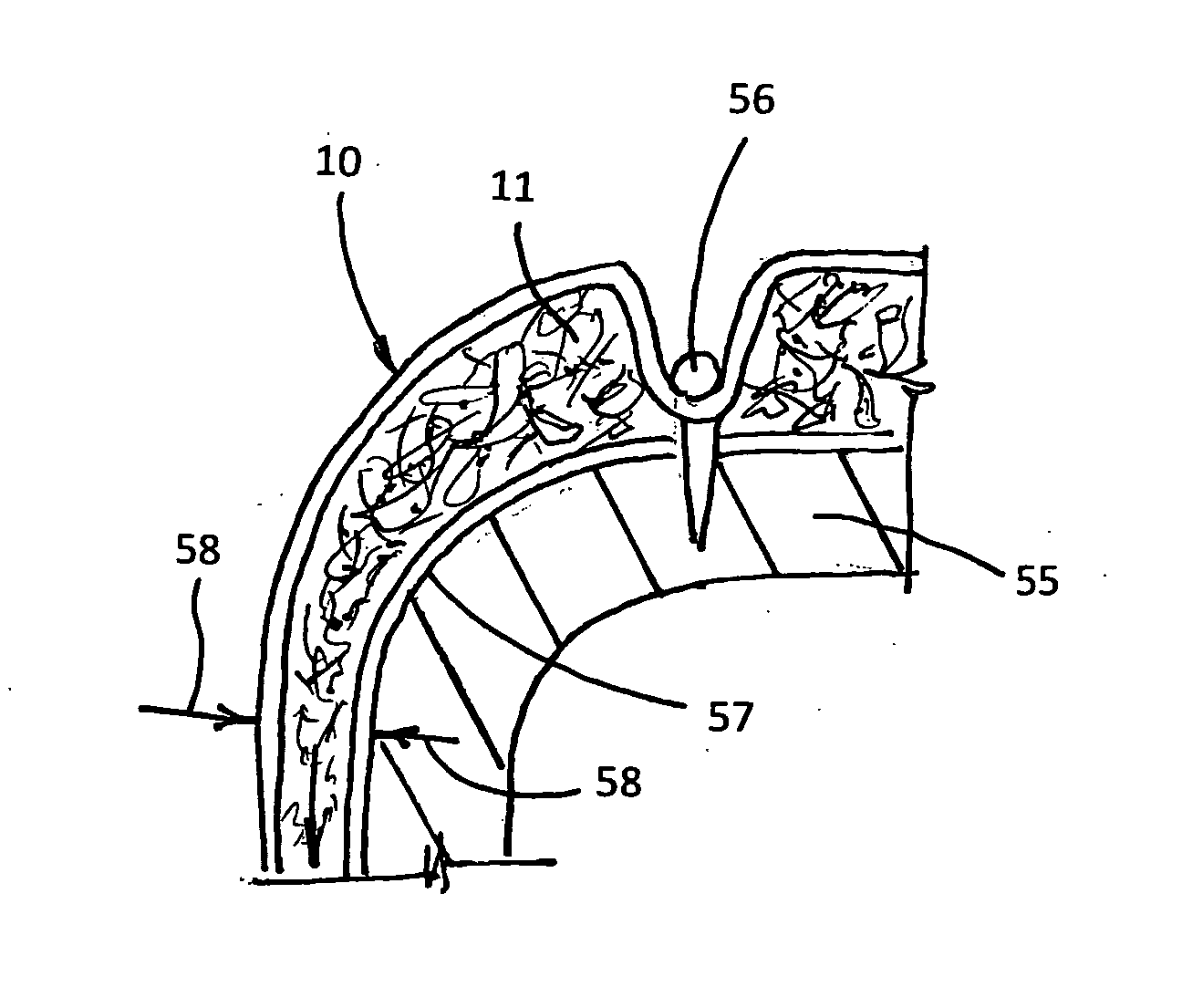

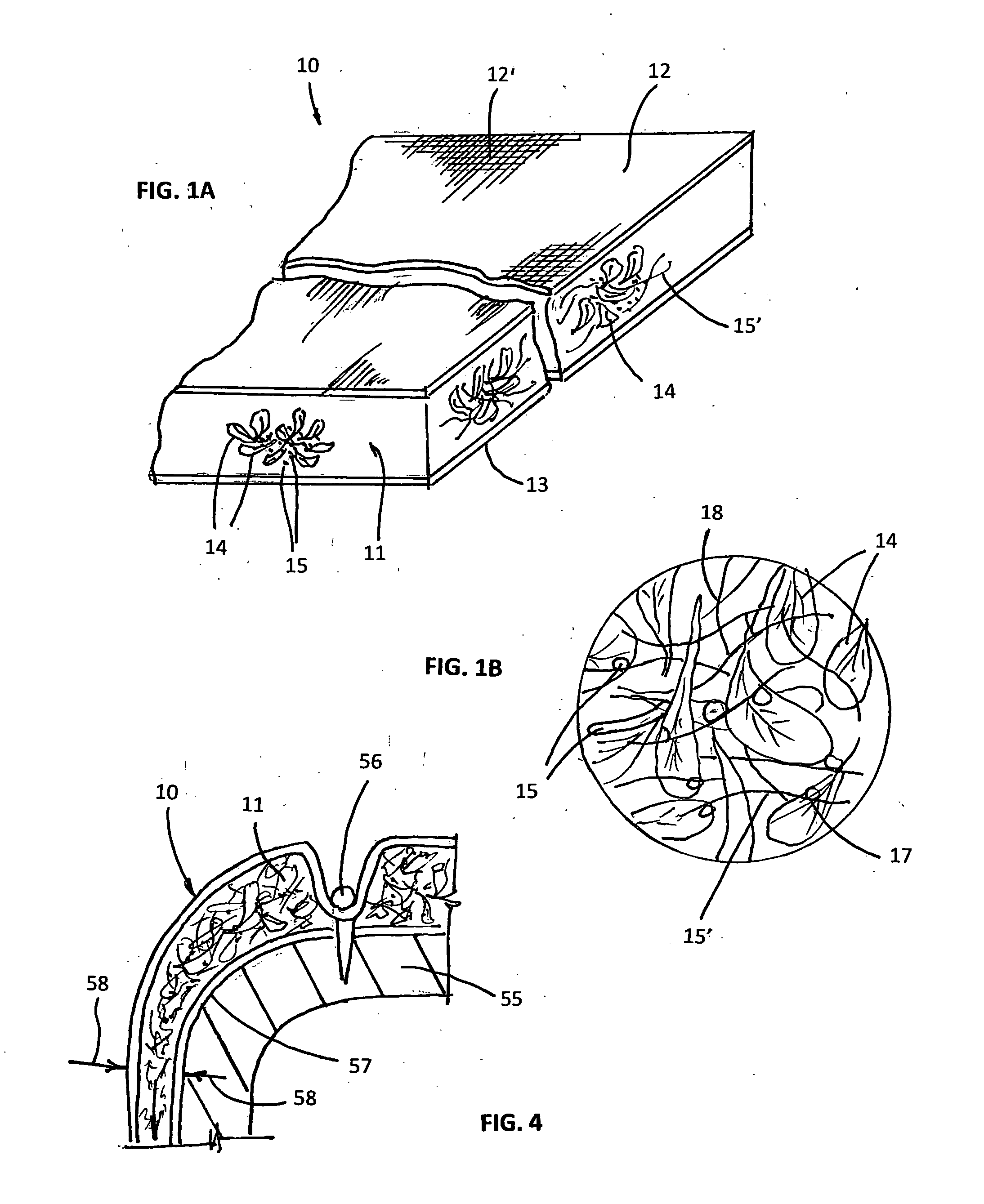

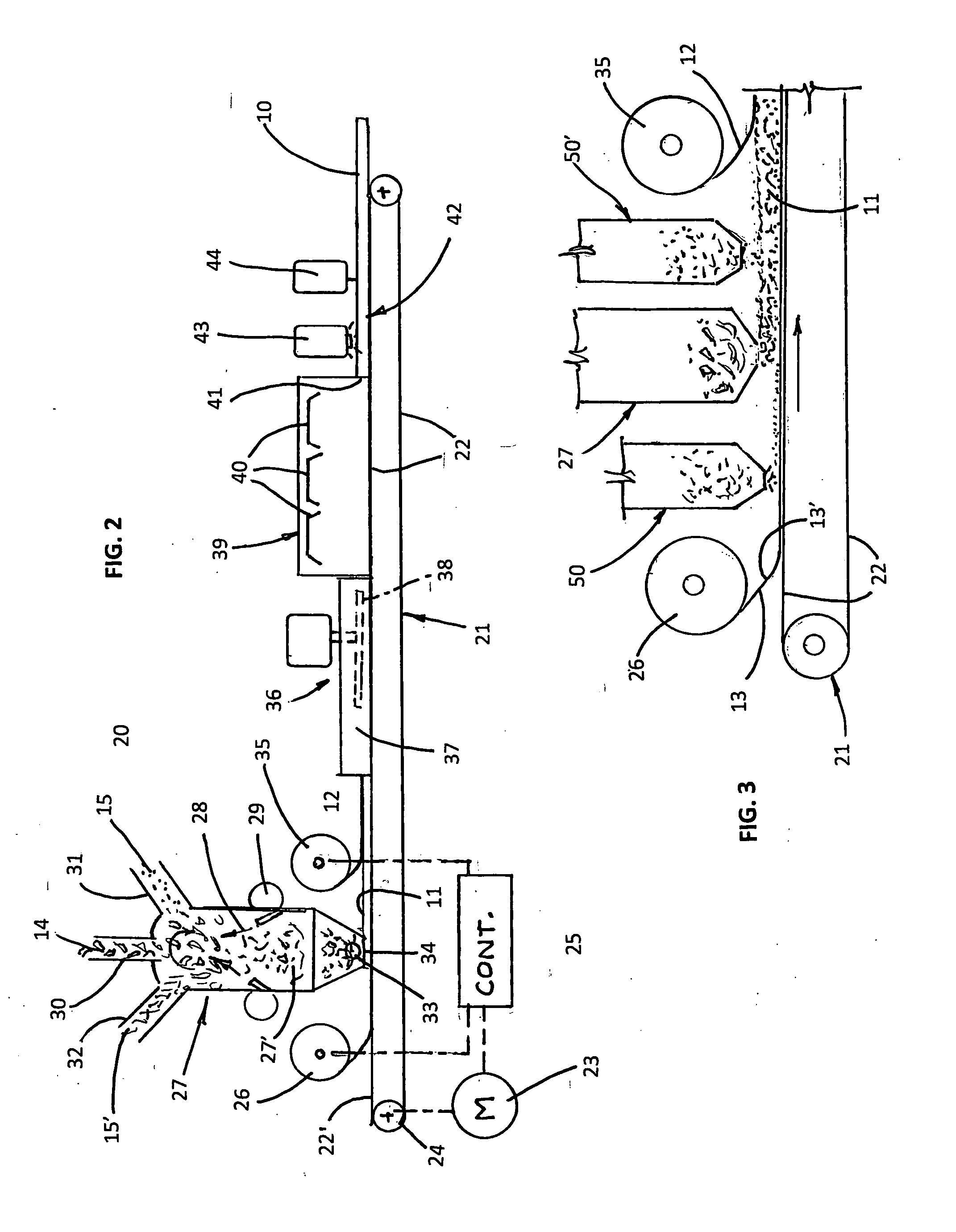

Thermally Insulating Stretchable Down Feather Sheet and Method of Fabrication

A thermally insulating stretchable down feather sheet and its method of manufacture is described. The core of the sheet is comprised of down feathers mixed with a binder which exhibits elastic properties. The core is sandwiched between a top and bottom stretchable elastomeric sheet having multi-directional stretchability. The core down feathers and the binder as well as the elastomeric sheet and bound together by heat treatment to provide a down feather insulating sheet which is stretchable in all directions without fractioning the sheet.

Owner:7513194 CANADA

Woven fabric with sound insulation and warm keeping properties and manufacturing method thereof

InactiveCN104652017AImprove spinnabilityImprove spinning qualityConjugated cellulose/protein artificial filamentsWoven fabricsFiberLophatherum

The invention discloses a woven fabric with sound insulation and warm keeping properties. The woven fabric is formed by weaving warp yarns and weft yarns through an air jet loom; the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30-34 parts of isotatic polypropylene, 1-3 parts of hargil, 3-7 parts of rock wool, 20-25 parts of modal fibers, 22-26 parts of fireproof fiber cotton, 25-28 parts of waste down feather fibers, 16-19 parts of bambusa texlitis pulp, 0.6-0.9 part of sodium hexametaphosphate, 8-10 parts of methyl methacrylate, 2-4 parts of eucalyptus oil, 12-15 parts of butyl glycidyl ether, 1-3 parts of jasmine, 2-5 parts of herba cepbalanoplosis segeti, 3-4 parts of lophatherum gracile, 85-95 parts of 1-butyl-3-methyl imidazole acetate, 95-110 parts of 1-allyl-3-methyl imidazole chlorine salt, proper amount of water and 5-8 parts of an auxiliary agent. The woven fabric has the sound insulation and warm keeping properties, and antibacterial and mould-proof, and inflaming retarding properties, is applied to automotive trims, and has the properties of low cost, high cost performance and good shape keeping performance and the like; the prospect is wide.

Owner:章云

Mothproof down feather composite fiber and preparation method thereof

InactiveCN104264277AAntibacterial and mothproofLightweight and high strengthConjugated cellulose/protein artificial filamentsArtifical filament manufactureAluminium silicateGluconates

The invention discloses a mothproof down feather composite fiber. The mothproof down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-18 parts of duck's down, 15-19 parts of chicken feather, 11-13 parts of mercerized wool fibers, 12-14 parts of mercerization cotton fibers, 4-7 parts of copper ammonia fibers, 15-19 parts of straw stalk, 4-6 parts of closed cell perlite powder, 1-3 parts of angelica sinensis, 2-4 parts of gastrodia elata, 2-3 parts of ligusticum wallichii, 0.2-0.4 part of zinc gluconate, 0.3-0.6 part of aluminium silicate, 100-105 parts of 1-butyl-3-methyl imidazole acetate, 110-115 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 2-4 parts of additives and a proper amount of water. The down feather composite fiber prepared by the invention has the advantages of sterilization, moth prevention, light weight, high intensity, thermal preservation, flame retardance and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Down feather washing technology

The invention discloses a down feather washing technology. The down feather washing technology comprises the following steps that first, dedusting is performed; second, feather is separated; third, pre-washing is performed, and some dust and impurities are removed, wherein every 0.5 KG to 1 KG of down feather is washed through 45 KG to 55 KG of clean water, and the cleaning time ranges from 4 min to 8 min; fourth, deep cleaning is performed, wherein pre-washed down feather is thrown into 25 KG to 35 KG of warm water with the temperature ranging from 30 DEG C to 40 DEG C, and special down feather detergent with the concentration being 1.5% to 3.5% and deodorant with the concentration being 0.2% to 0.4% are added; fifth, rinsing is performed, 25 KG to 35 KG of clean water is added for rinsing for 4 min to 5 min at each time, then sewage is drained, clean water is added for rinsing, and rinsing is performed for 10 times to 13 times; sixth, dewatering is performed, the rinsed down feather enters a centrifugal to be dewatered; seventh, half drying is performed; eighth, drying is performed; ninth, cooling is performed. The down feather washing technology has the advantages that adhering substances between down feather fibers are reduced, the fluffy degree of down feather is improved, the amount of static air in the down feather is increased, and the thermal insulating performance of the down feather is greatly improved.

Owner:江苏欣隆羽绒有限公司

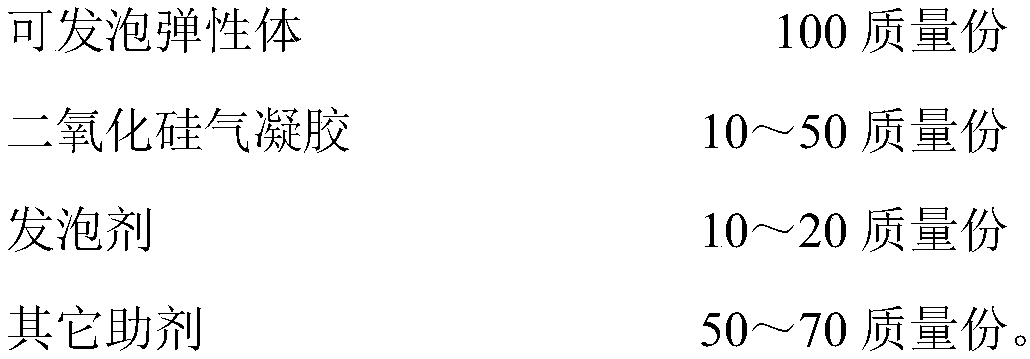

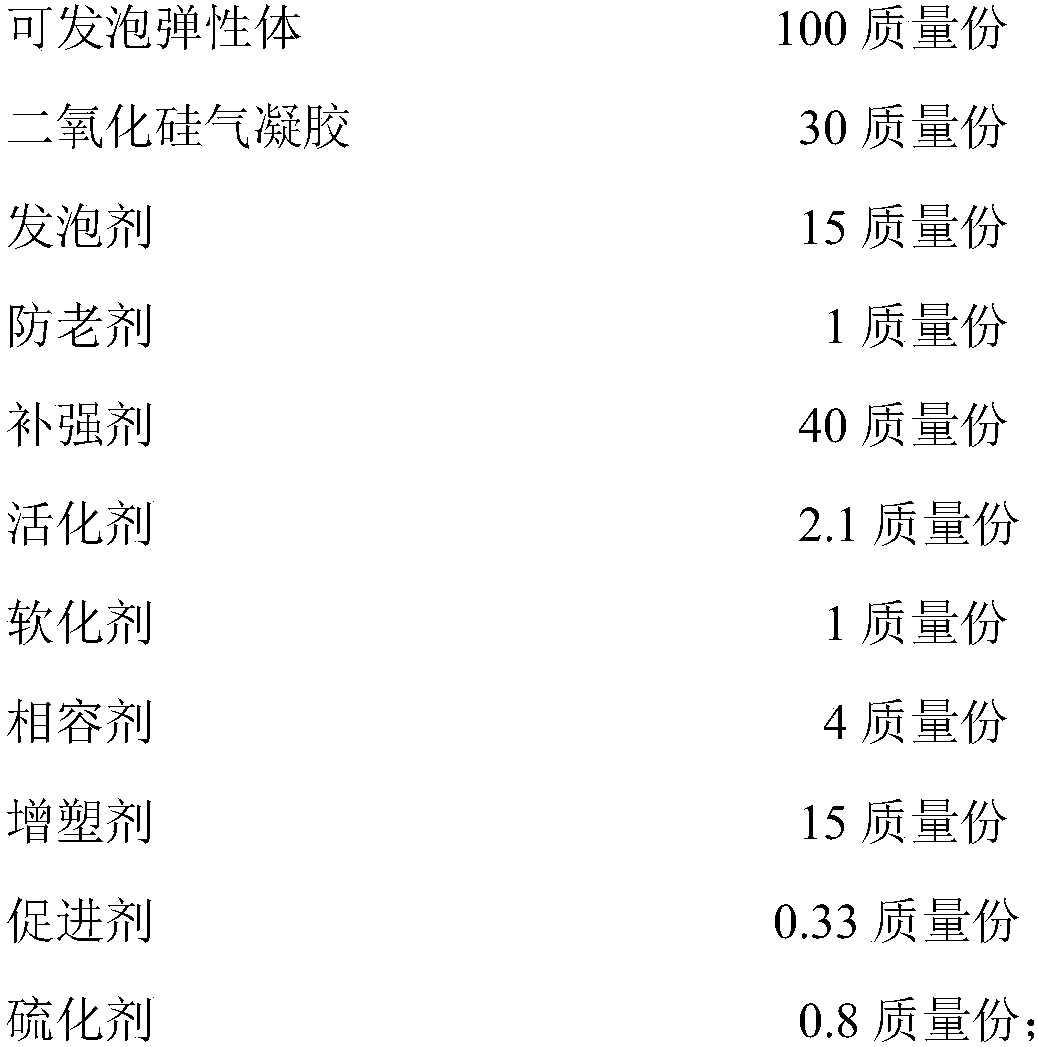

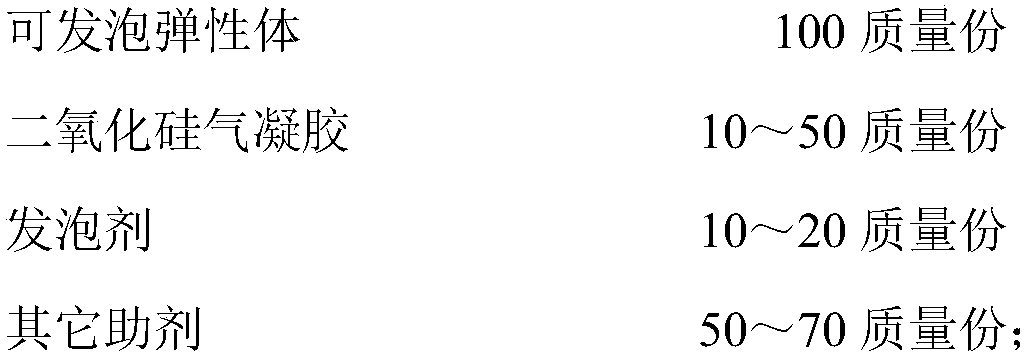

Cold-defending insulating composite material and preparation method and application thereof

The invention discloses a cold-defending insulating composite material and a preparation method and an application thereof. The composite material is prepared by blending and foaming a foamable elastomer and a silicon dioxide aerogel in a mass ratio of 2: (1-10):1. The composition material is excellent in cold-defending insulating performance, and the compression cold-resistant coefficient at 30 DEG C below zero can reach 0.50. Experiments verify that in a same condition, clothes prepared by the 3mm thick composition is equivalent to the clothes prepared by a 40mm thick down feather material in cold-defending insulating effect. The composite material provided by the invention has the advantages of being light, not too fat, comfortable, attractive and the like if being prepared to garmentsor bedding. In addition, the cold-defending insulating composite material provided by the invention also has the advantages of being flexible, low in cost, energy-saving and environment-friendly and the like, the preparation process is simple, raw materials are easily available, special equipment and severe conditions are not needed, scaled production is implemented easily, and the cold-defendinginsulating composite material has extremely strong industrial value.

Owner:蔡晨灿

Down feather mildew-proof nursing agent

InactiveCN103741494AGood conditionConvenient careFibre treatmentSurface-active non-soap compounds and soap mixture detergentsPediatricsDown feather

The invention discloses a down feather mildew-proof nursing agent. The down feather mildew-proof nursing agent is capable of removing stains on down feather effectively, is high in mildew resistance, and possesses excellent adjusting and nursing effects on down feather; original elasticity and bulkiness of down feather are recovered; and original heat retention performance is maintained.

Owner:常熟市爱博尔服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com