Water-based highly down-proof finishing agent, preparation method thereof and down-proof fabric after-treatment method

A finishing agent and anti-velvet technology, which is applied in fiber treatment, textiles and papermaking, fiber types, etc. It can solve the problems of low anti-drilling down performance, poor washing resistance, and low strength of fabrics, etc., and achieve good anti-velvet effect and environmental protection performance Good, good glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

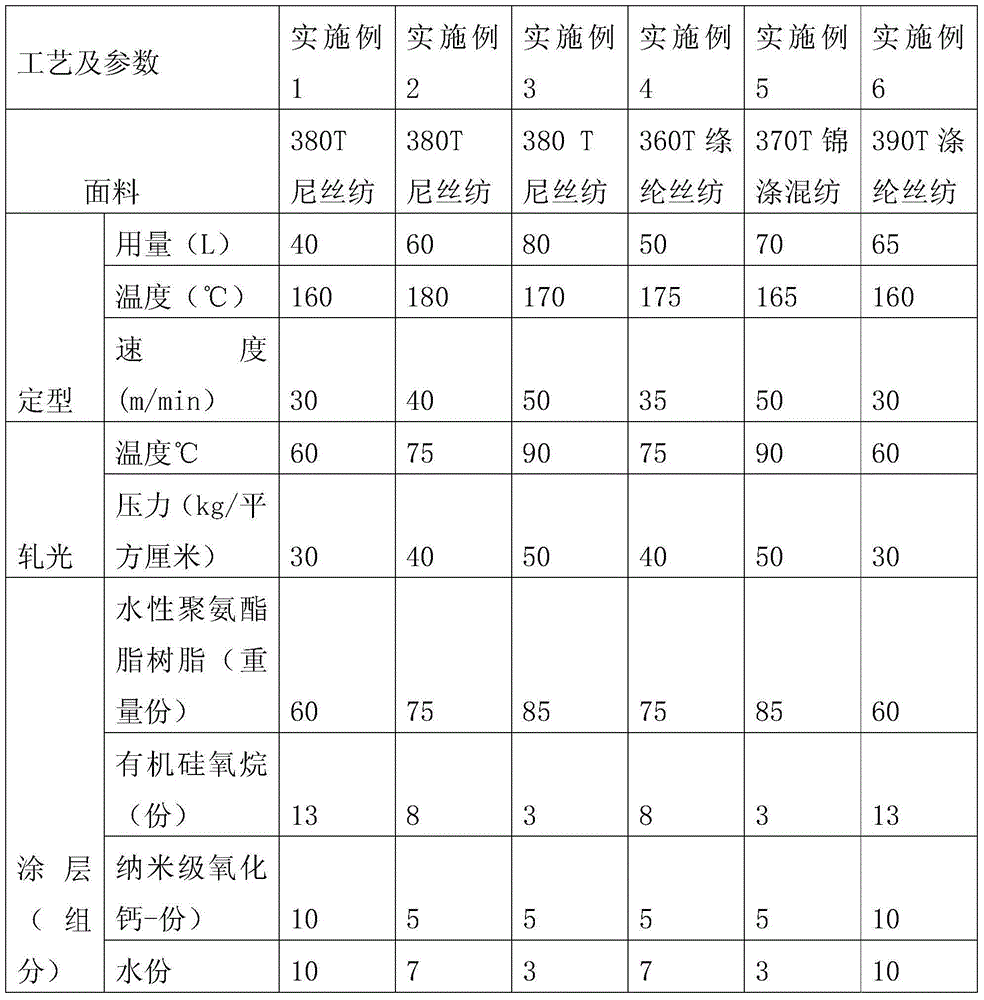

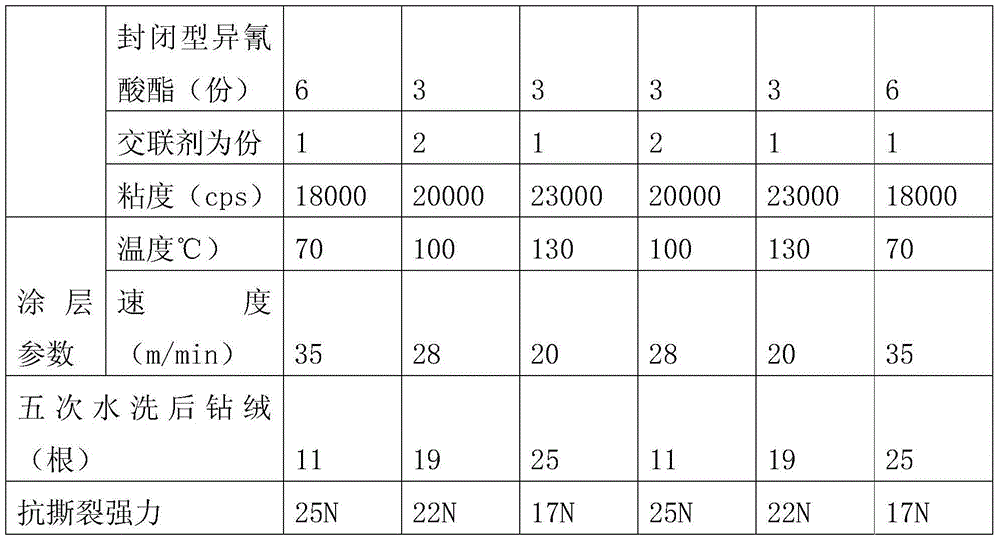

[0021] The preparation method of the water-based high anti-velvet finishing agent of the present invention is as follows, first add calcium oxide to 3-4 parts of water, stir evenly, then add water-based polyurethane resin, add organosiloxane to 3-4 parts of water, stir well and then Add the mixture of calcium oxide, water-based polyurethane resin and water that is stirred evenly, and finally add bridging agent and crosslinking agent to the mixed solution in turn, after stirring evenly, add 2-4 parts of water to adjust the viscosity of the mixed solution to 18000cps -23000cps. Adding calcium oxide into water for hydrolysis and then adding water-based polyurethane resin can prevent calcium oxide from being directly added to water-based polyurethane resin with too high viscosity to cause agglomeration, ensure water-resistant performance and reduce drilling wool. Stir the water and organosiloxane evenly first, the purpose is to disperse the organosiloxane evenly in the water-based...

Embodiment 1

[0033] Fabric: 380T ultra-light nylon spinning down fabric.

[0034] With liquid cooling reactor: the pH value is 10-12, and the cooling time is 12-24h;

[0035] Dyeing: Acid dye dyeing. PH is 3.5-6.5;

[0036] Shaping: hot air shaping. The shaping formula adopts conventional fluorocarbon resin, the dosage is 40-80g / L, citric acid is 1-2g / L, the temperature is 160°C, and the speed is 30m / min.

[0037] Calendering: calendering temperature 60°C, pressure 30kg / cm2

[0038] Coating: Adopt a conventional floating knife coating machine, the knife type is 0.1-0.5#, the distance between the knife and the bottom plate is 1-3cm, the knife height is 1-4cm, the temperature is 700°C, and the coating speed is 20m / min . The finishing agent components are: 60 parts of water-based polyurethane resin, 13 parts of organosiloxane, 10 parts of nano calcium oxide, 10 parts of water, 6 parts of bridging agent, 1 part of triethylenediamine, and the viscosity of the liquid mixture is 18000 cps. ...

Embodiment 2

[0040] Linking agent adopts dibutyltin dilaurate, and all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com