Patents

Literature

416results about How to "Avoid drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

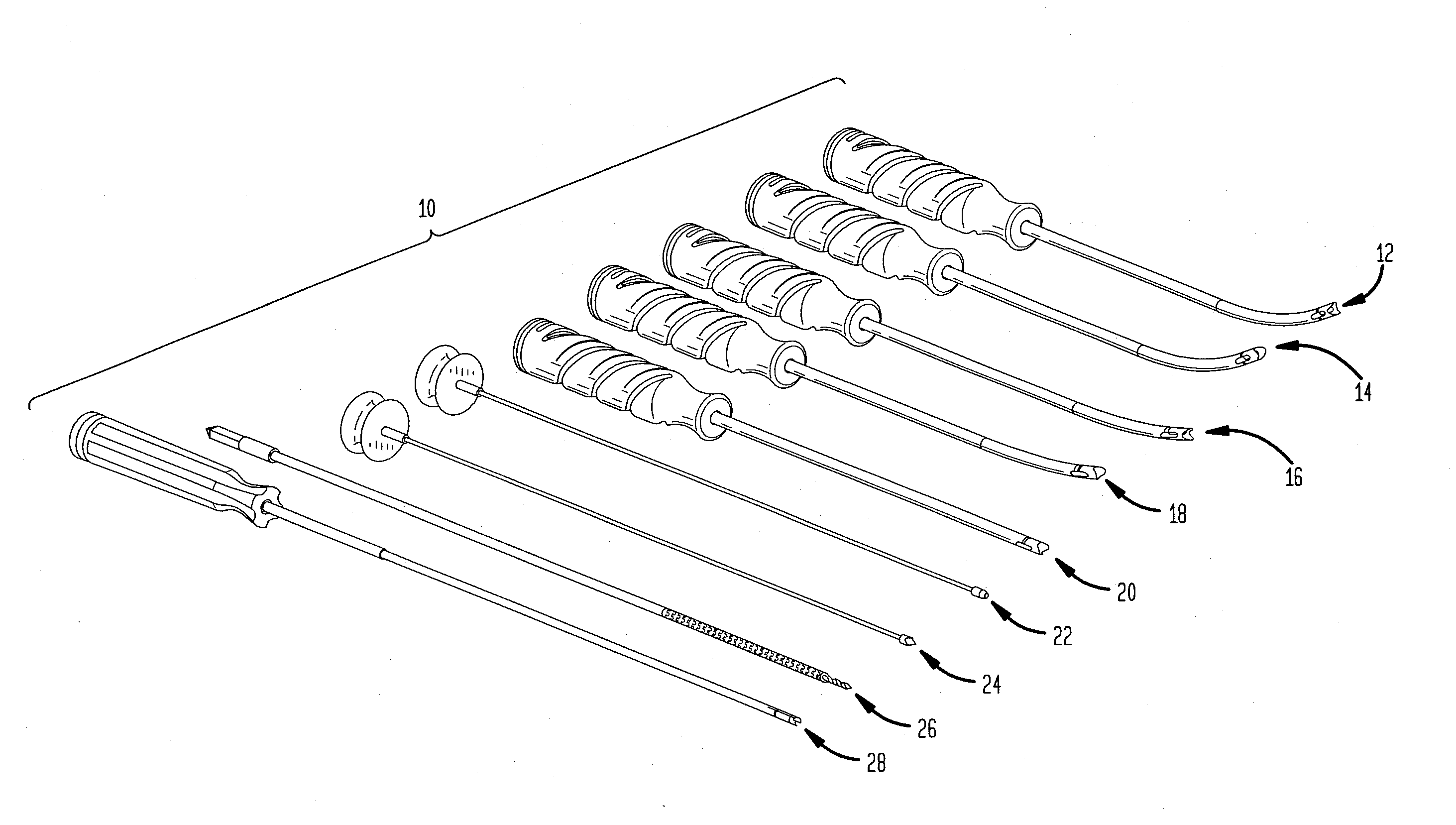

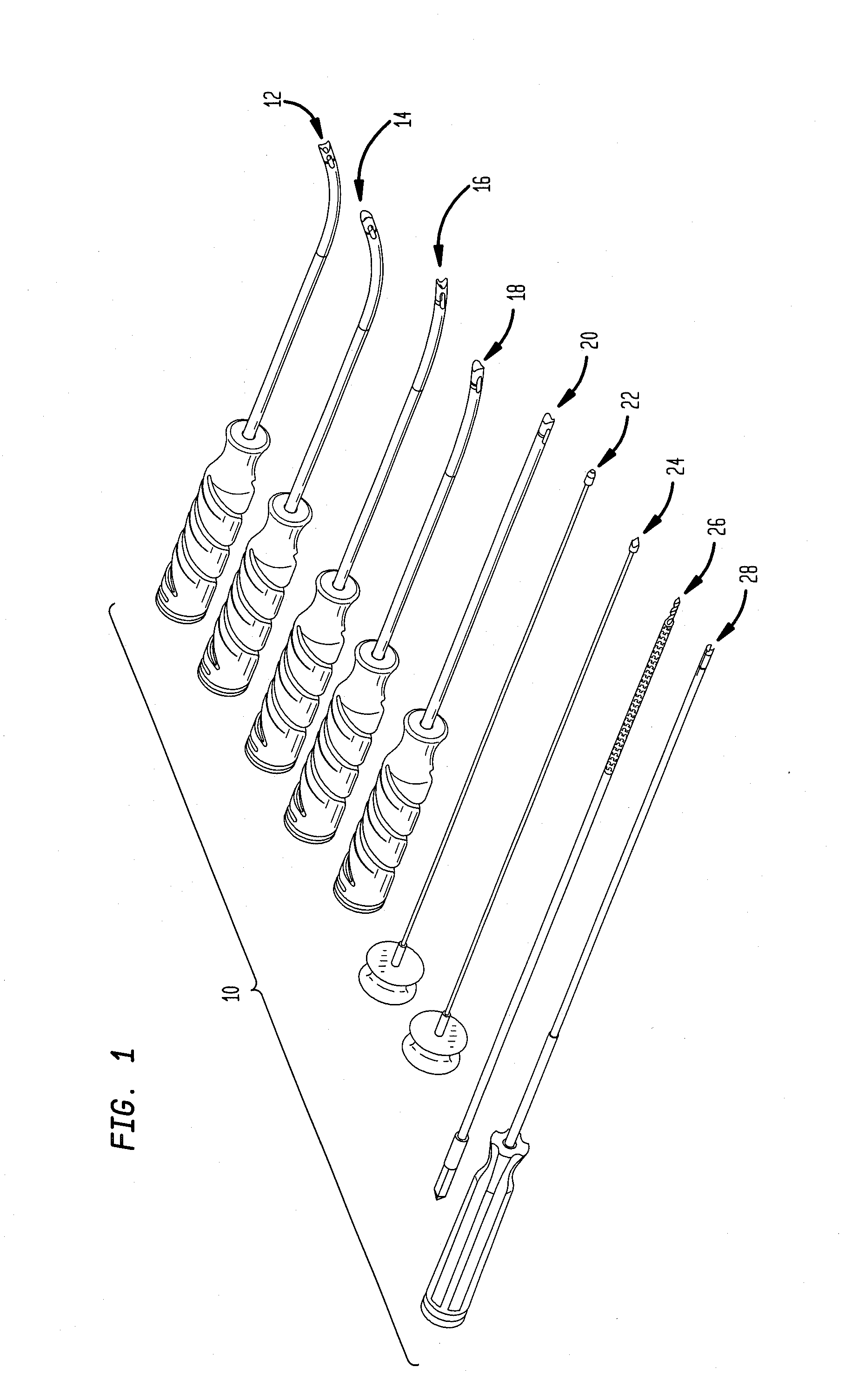

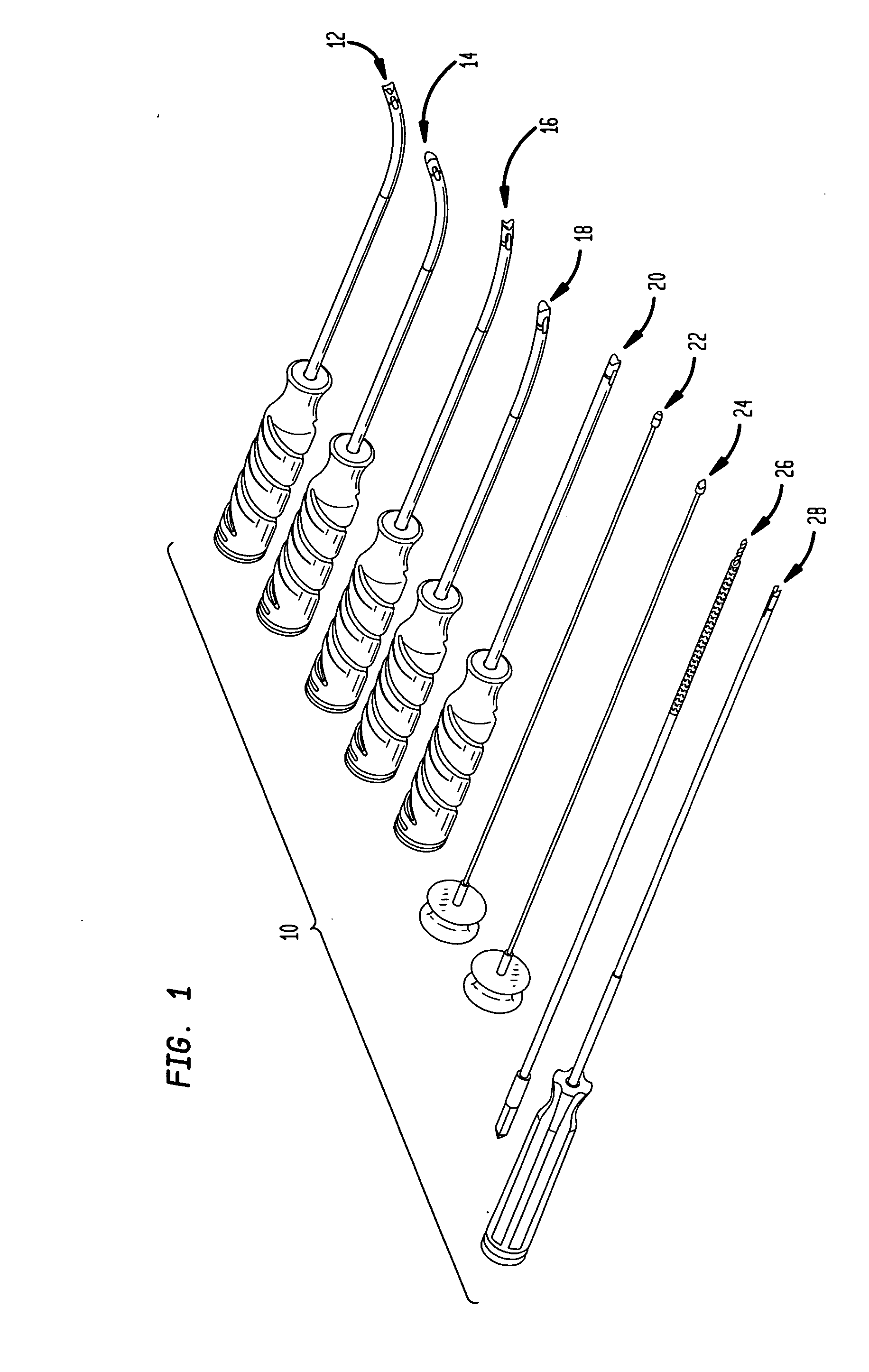

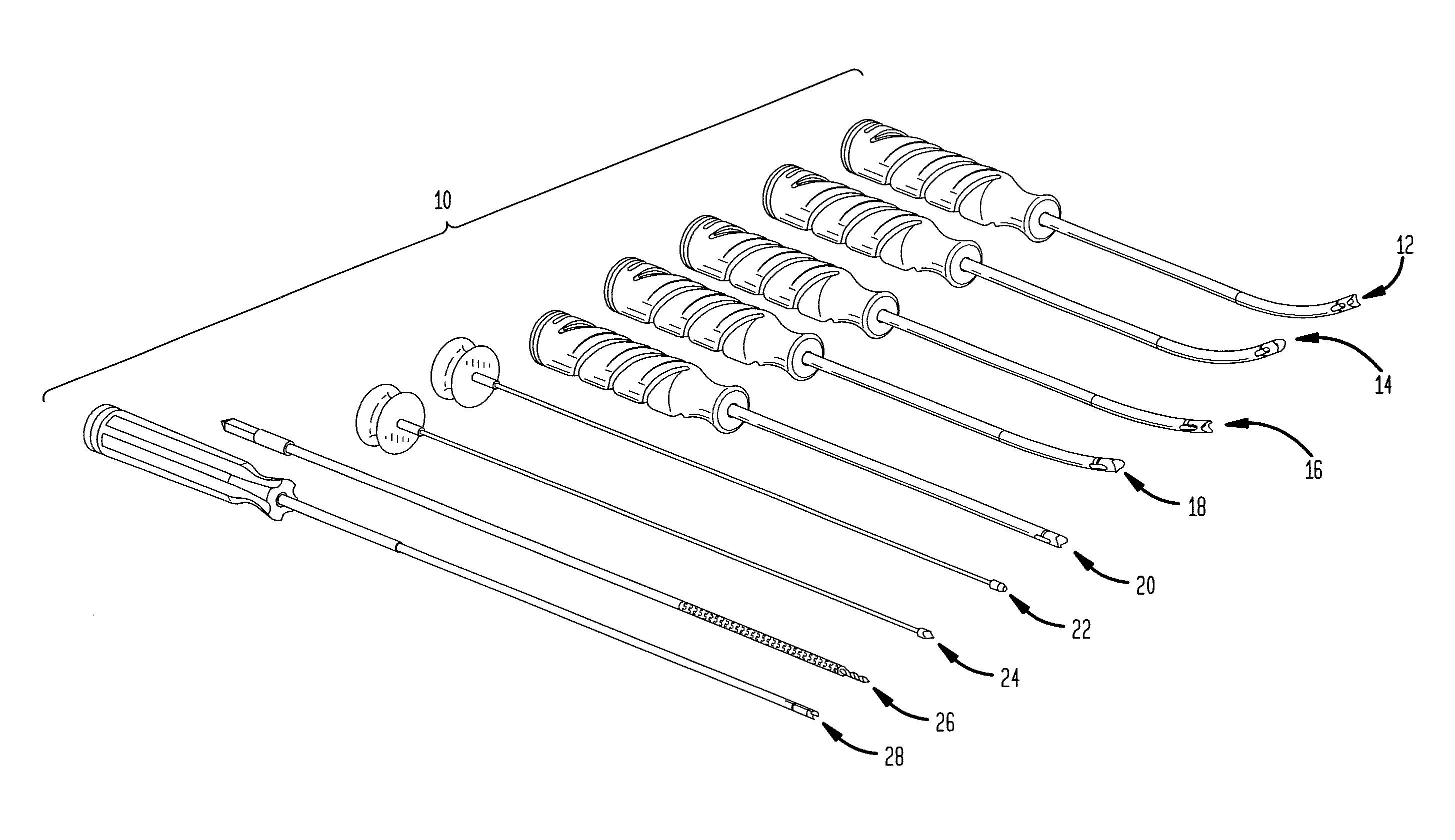

Suture anchor implantation instrumentation system

ActiveUS20110015675A1Easy to implementLarge range of motionSuture equipmentsBaby-comfortersEngineeringDrill bit

A system for implanting an anchor into bone, the system comprising a curved cannulated guide for percautaneous insertion, having a proximal end and a distal end; a flexible drill insertable through the curved guide from the proximal end to the distal end, the flexible drill having a shaft having a flexible portion; and a flexible inserter for inserting a suture anchor into a bore at the anatomical site formed by the flexible drill, the flexible inserter having a shaft having a flexible portion, wherein the flexible portions of both the flexible drill and flexible inserter include a series of discrete, interlocking segments.

Owner:HOWMEDICA OSTEONICS CORP

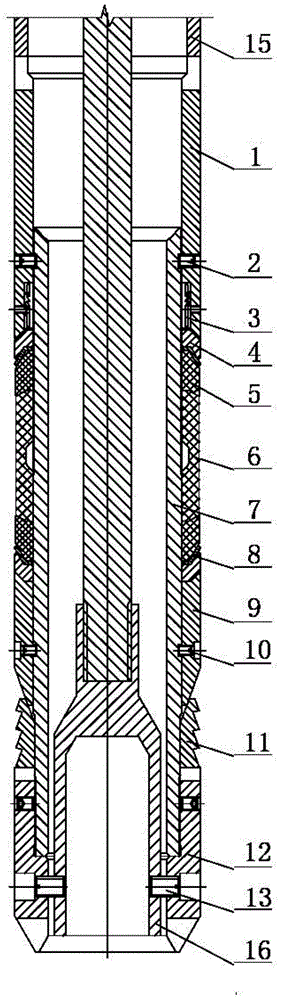

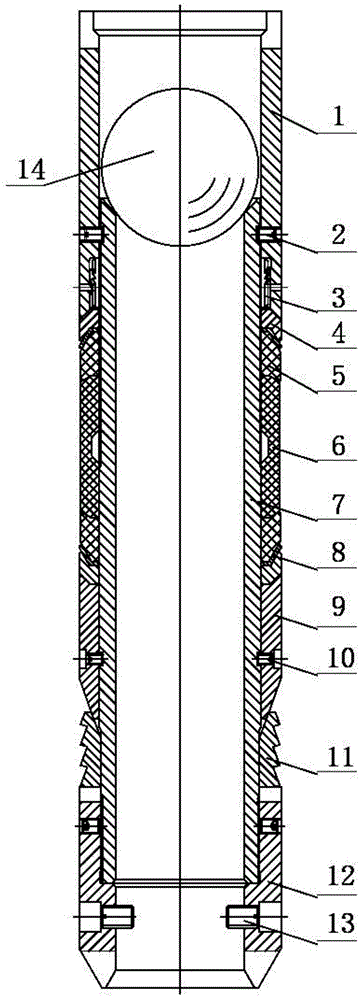

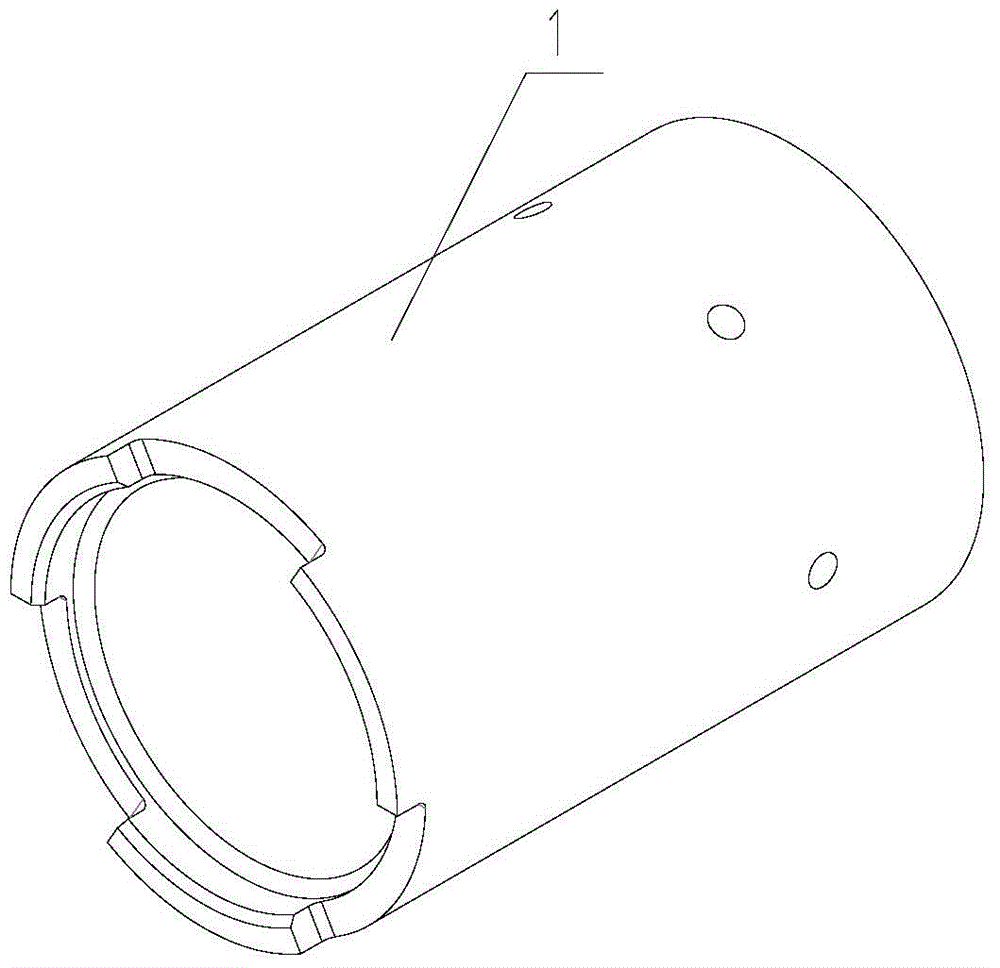

Bridge plug with large drift diameter and setting method of bridge plug

The invention discloses a bridge plug with a large drift diameter. The bridge plug comprises an upper joint, a central tube, a guiding shoe head and a bridge plug assembly; the upper joint is an annular part and is fixedly connected with the outer side of one end of the central tube in a sleeving mode; the central tube is a metal central tube, a soluble ball base is arranged at the end, close to the upper joint, of the central tube, and the central tube is a drillable metal part; the guiding shoe head is an annular part, is fixedly connected with the outer side of the other end of the central tube in a sleeving mode and is provided with a device used for being fixedly connected with a pull rod which is arranged in the bridge plug in a sleeved mode; the middle section of the central tube is sleeved with the bridge plug assembly which is located between the upper joint and the guiding shoe head. The invention further discloses a setting method of the bridge plug with the large drift diameter. The drilling polishing procedure of the bridge plug with the large drift diameter can be omitted, the problems of a long construction period, high operation cost and high construction risk brought by drilling polishing are solved, and the bridge plug is easier and more convenient to use and faster to construct.

Owner:JEREH ENERGY SERVICES

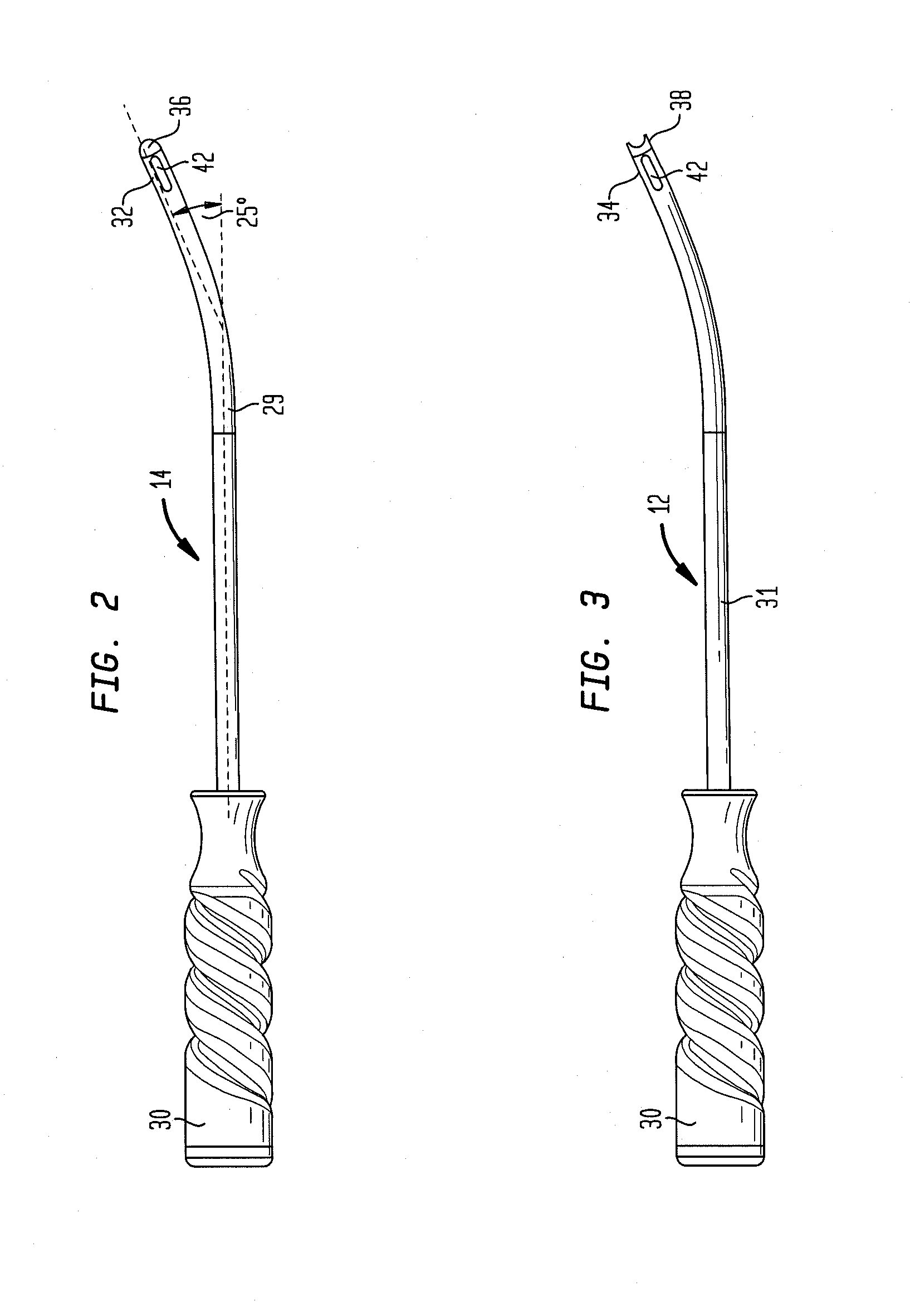

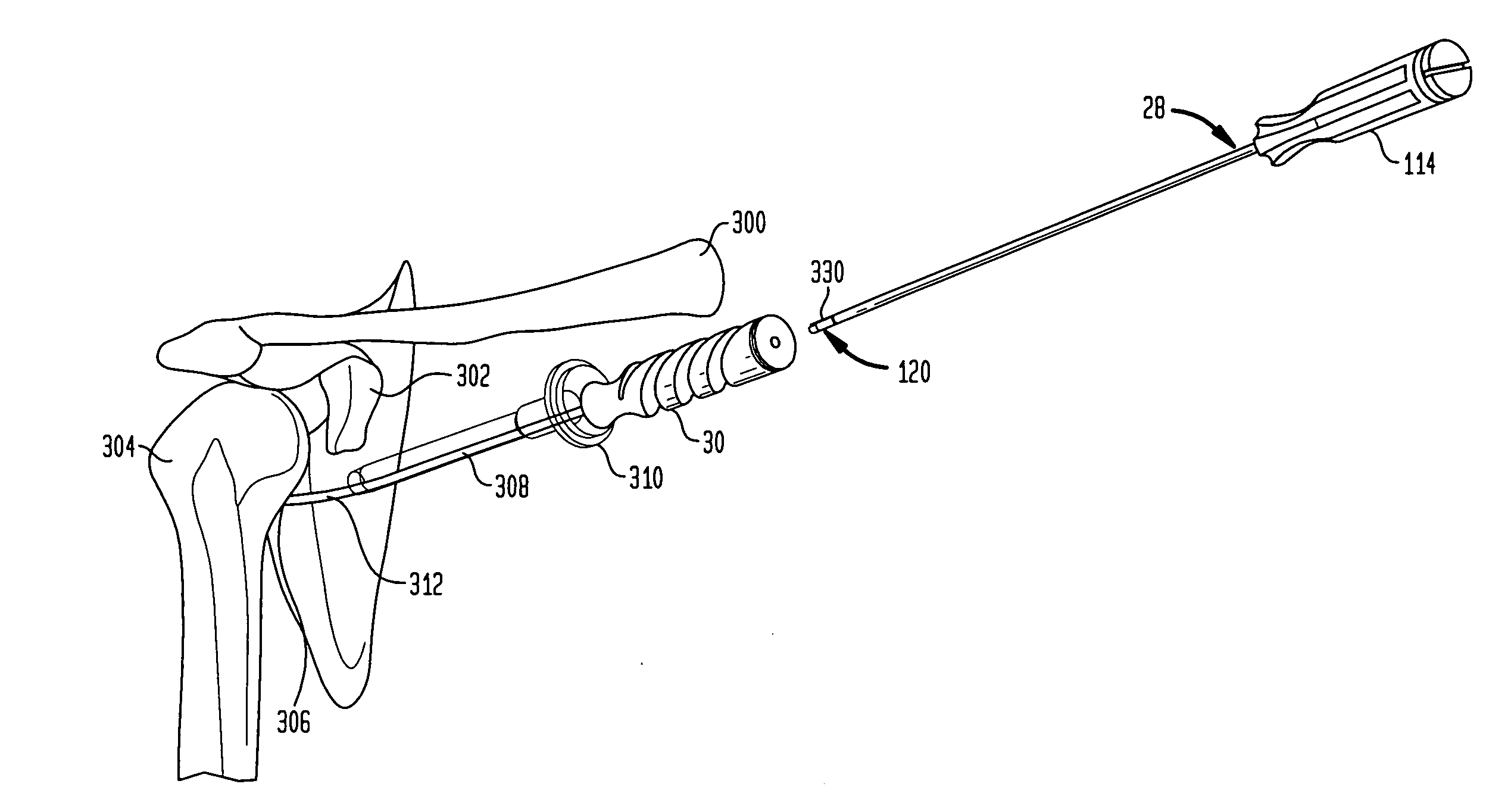

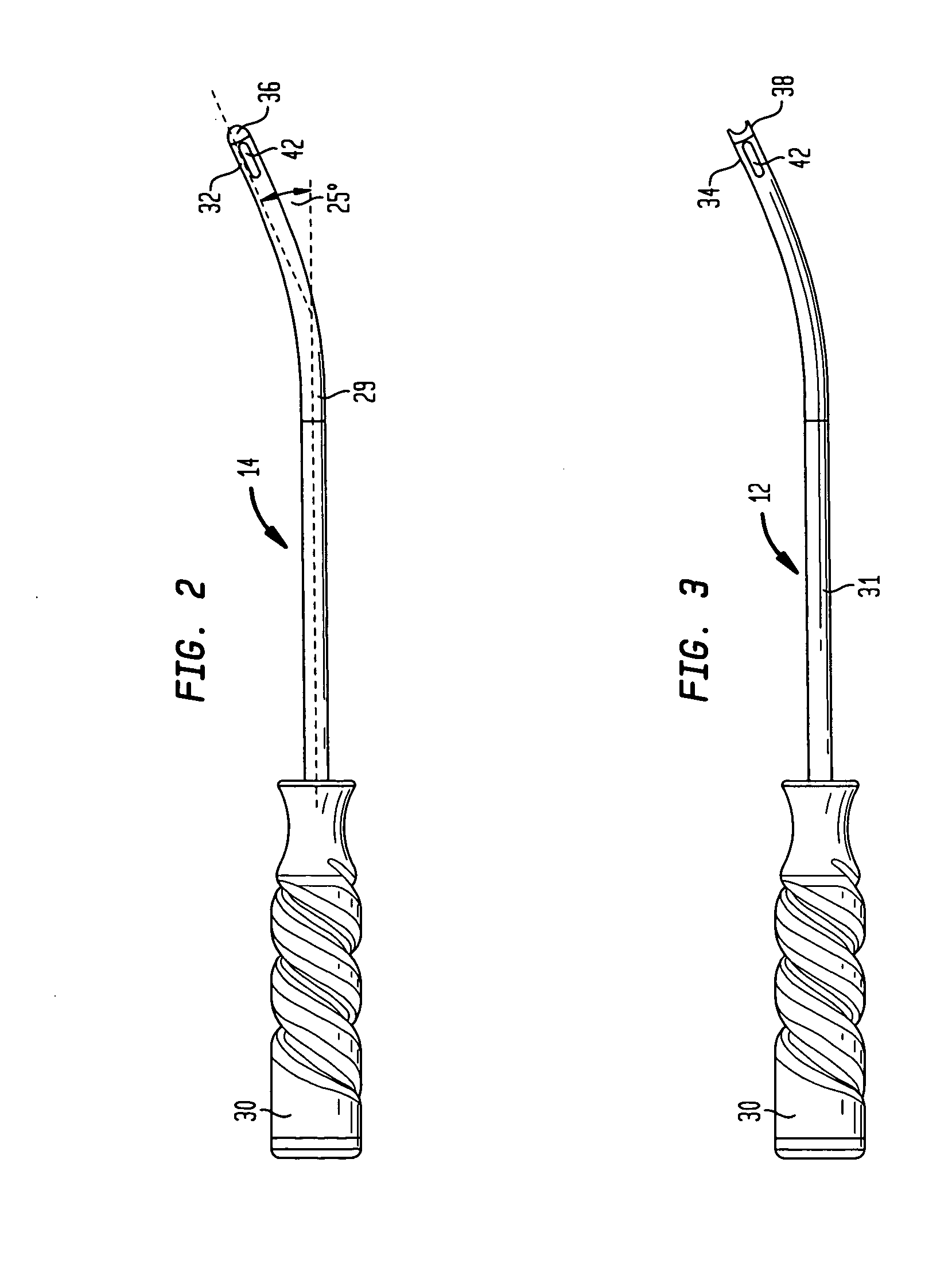

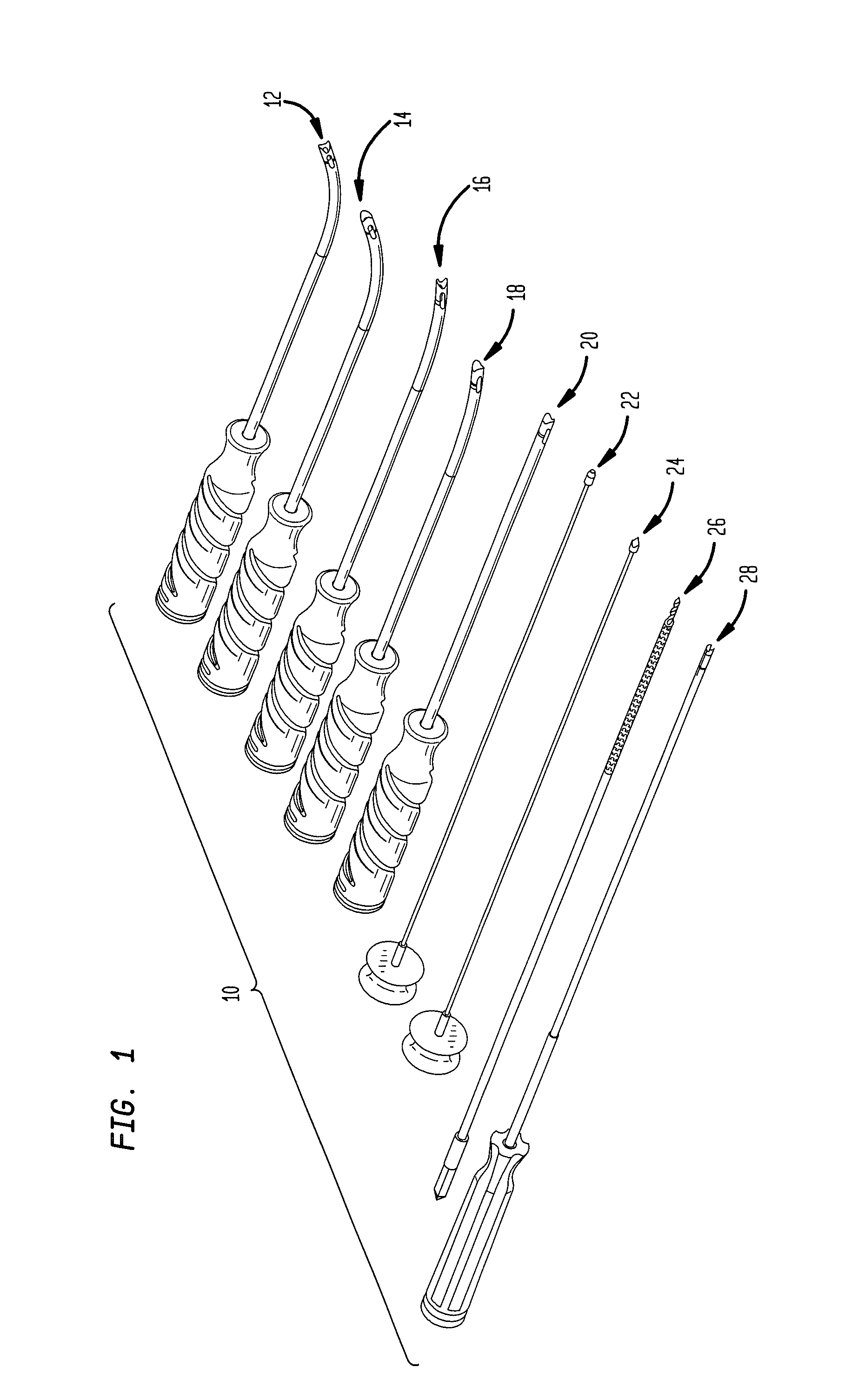

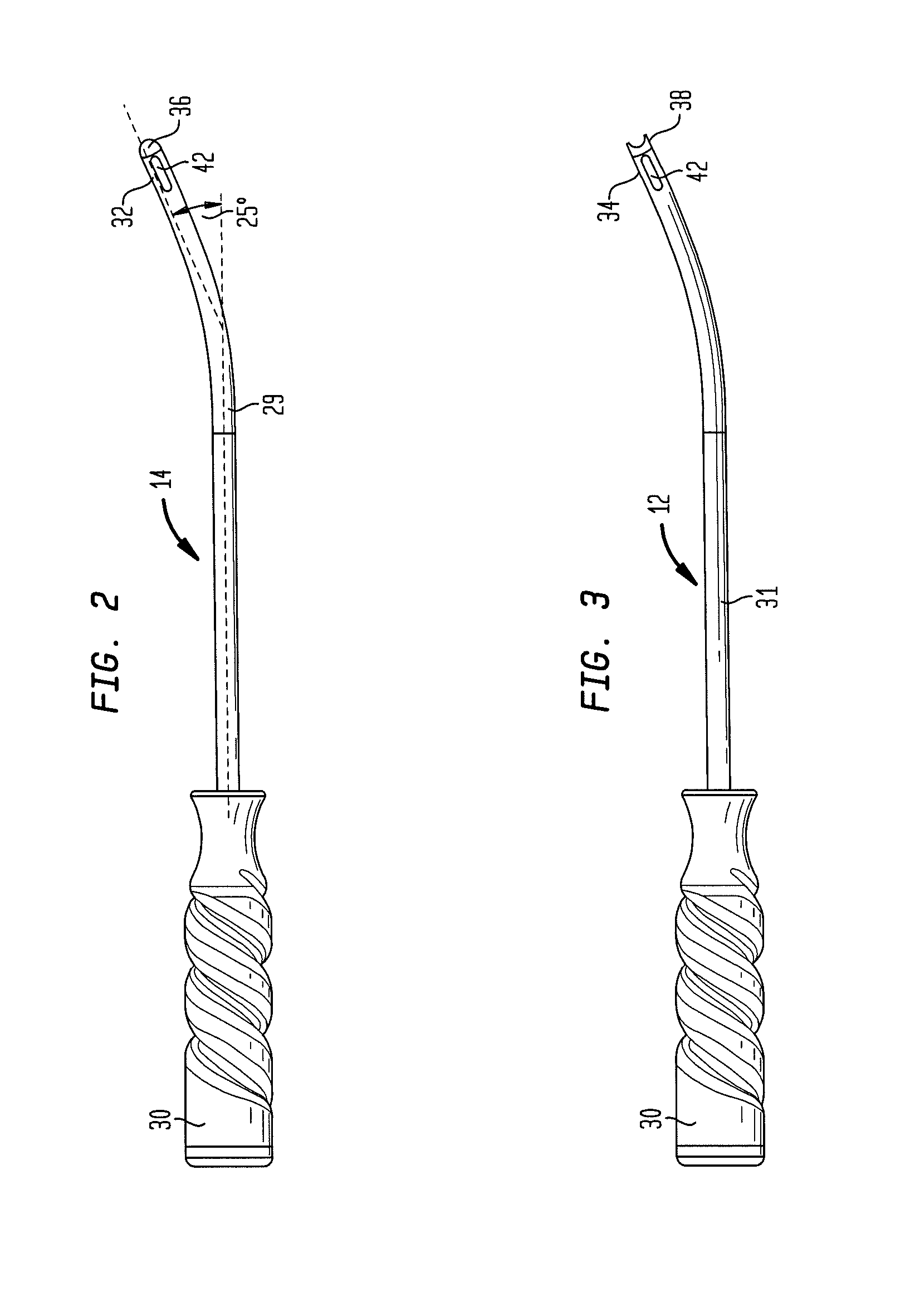

Suture anchor implantation instrumentation system

ActiveUS20110015674A1Large range of motionEasy to implementSuture equipmentsBone drill guidesSuture anchorsAnatomical sites

An apparatus for inserting a suture anchor into an internal anatomical site through a cannula, or percutaneously, has a curved hollow guide for insertion into the cannula and / or tissue. The guide has a proximal end and a distal end. The distal end has a “parabolic ” shape for engaging the intended anatomical site such as a glenoid. A flexible obturator is insertable through the curved guide from the proximal end to the distal end to facilitate insertion of the guide through the cannula. A flexible drill is insertable through the curved guide from the proximal to the distal end once the guide is in place. A flexible inserter is provided for inserting a suture anchor into a bore at the anatomical site formed by the flexible drill.

Owner:HOWMEDICA OSTEONICS CORP

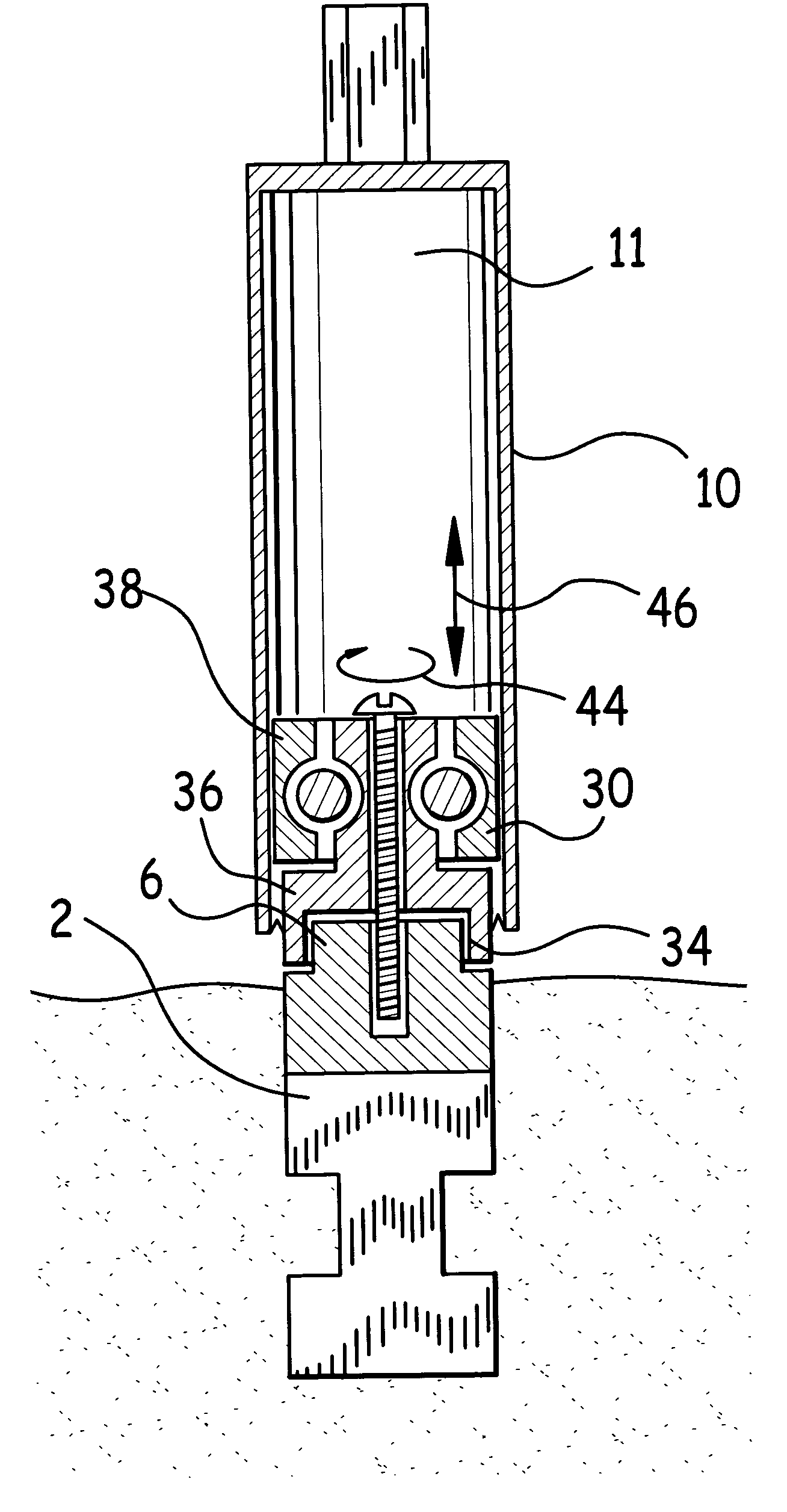

Apparatus and method to remove dental implant

InactiveUS7179084B1Reduce drillingImprove efficiencyDental implantsDental toolsImplanted deviceBone trephine

A method and apparatus to remove dental implant. The apparatus comprises a guide ring rotatably attached to a base, means to rotatably attach the guide ring to the base, means to attach the apparatus to an implant, and apparatus to remove dental implant indexing means sized to mate with implant indexing means when the apparatus is attached to the implant. Where an abutment is mounted to the implant, means of attaching the base to the abutment is taught. The method includes the steps of attaching the apparatus to an implant or abutment, sliding a trephine burr bore over the guide ring, and using the guide ring to guide the trephine while drilling into bone in which the implant is implanted, without drilling into the implant or abutment.

Owner:KOMETAS ATHAS N

Suture anchor implantation instrumentation system

ActiveUS8439947B2Large range of motionEasy to implementSuture equipmentsBaby-comfortersSuture anchorsEngineering

A system for implanting an anchor into bone, the system comprising a curved cannulated guide for percautaneous insertion, having a proximal end and a distal end; a flexible drill insertable through the curved guide from the proximal end to the distal end, the flexible drill having a shaft having a flexible portion; and a flexible inserter for inserting a suture anchor into a bore at the anatomical site formed by the flexible drill, the flexible inserter having a shaft having a flexible portion, wherein the flexible portions of both the flexible drill and flexible inserter include a series of discrete, interlocking segments.

Owner:HOWMEDICA OSTEONICS CORP

Anticollision device for rear of truck

The invention discloses an anticollision device for the rear of a truck, which comprises a collision cross bar and a pair of screw shearing energy absorbers arranged on both sides of the rear of a truck, wherein the thread shear energy absorbers respectively comprise a crank, a connecting rod, an energy absorbing screw and a shear slide block. The energy absorbing screws are arranged on a frame of the truck, the shear slide blocks are sleeved on the energy absorbing screws, the upper ends of the cranks are hinged to the frame, the upper ends of the connecting rods are hinged to the shear slide blocks, the lower ends of the connecting rods are hinged to the lower ends of the cranks, and the collision cross bar is connected with the lower ends of the connecting rods or the cranks of the thread shear energy absorbers. The anticollsion device for the rear of a truck has the advantages of simple structure, simple disassembly and assembly and stable absorption of collision energy, and prevents a rear-ended car from entering space below a truck.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

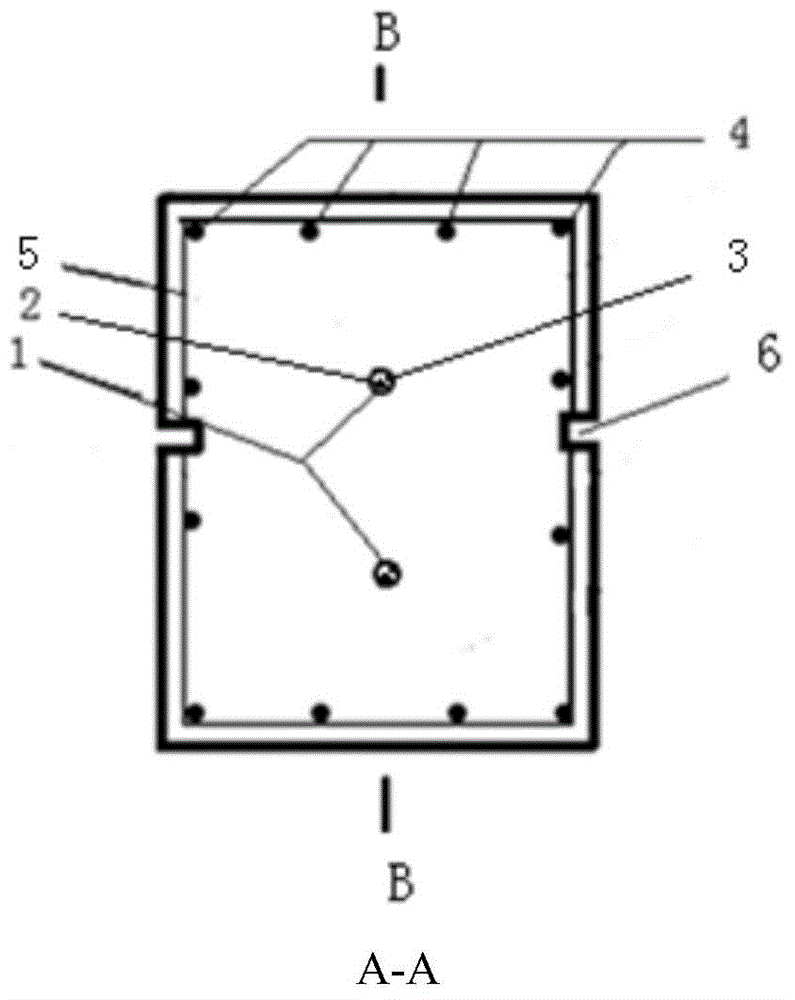

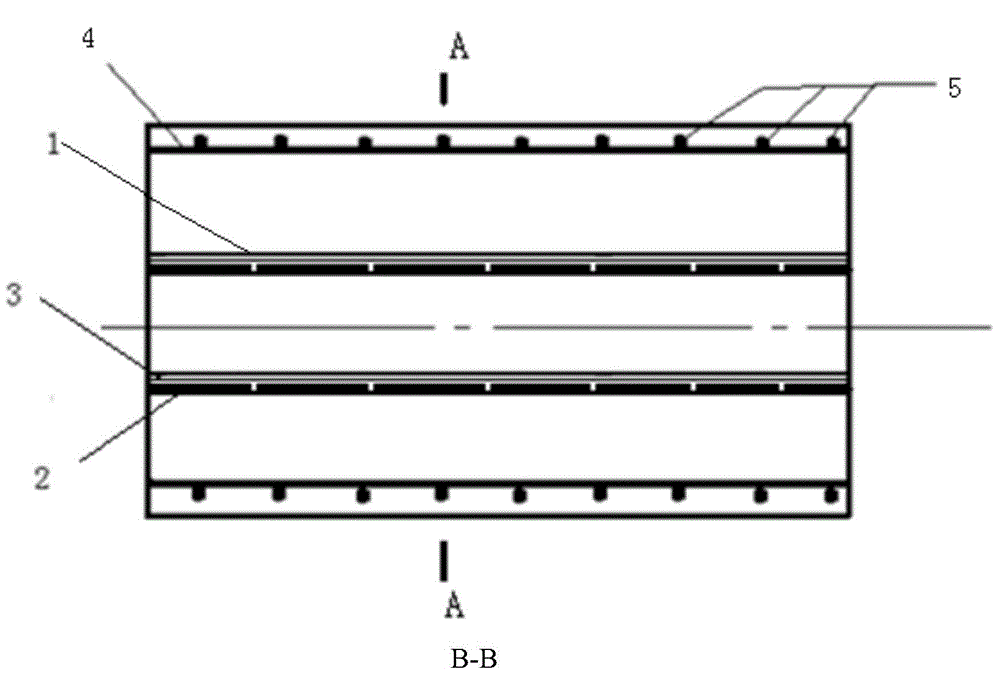

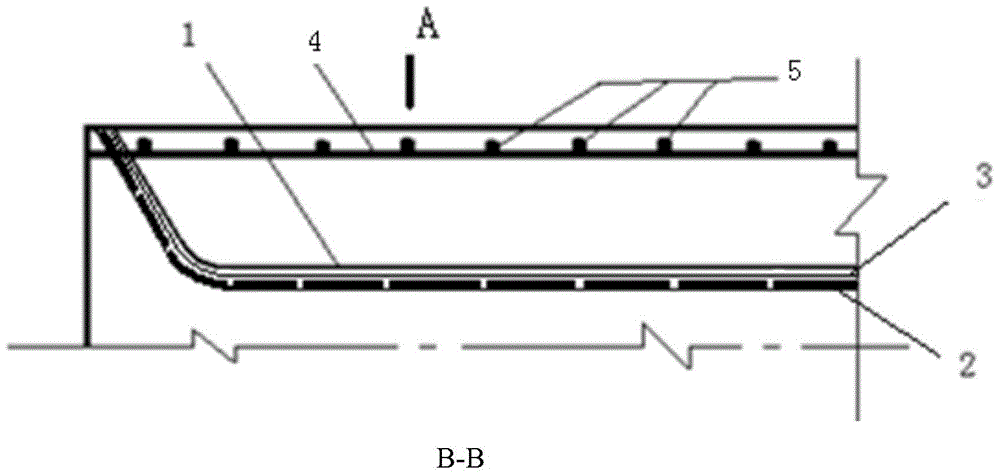

Axial embedded blast hole of reinforced concrete beam and blasting demolition method

The invention provides an axial embedded blast hole of a reinforced concrete beam and a blasting demolition method. The blast hole is formed in the mode that a pipe is embedded in the beam in the axial direction, continuous or discontinuous charging is adopted in the blast hole, a detonating fuse is arranged in the blast hole in an overall-length mode, a stirrup is cut off, and other technical means are taken. In this way, drilling operation is avoided, the number of blast holes and the number of detonators are reduced, consumption of explosive and the detonators is reduced, the smashing effect on reinforced concrete is improved, and the damage of explosion to the environment is reduced. The axial embedded blast hole of the reinforced concrete beam and the blasting demolition method can bring remarkable economic and social benefits.

Owner:HUBEI UNIV OF TECH +1

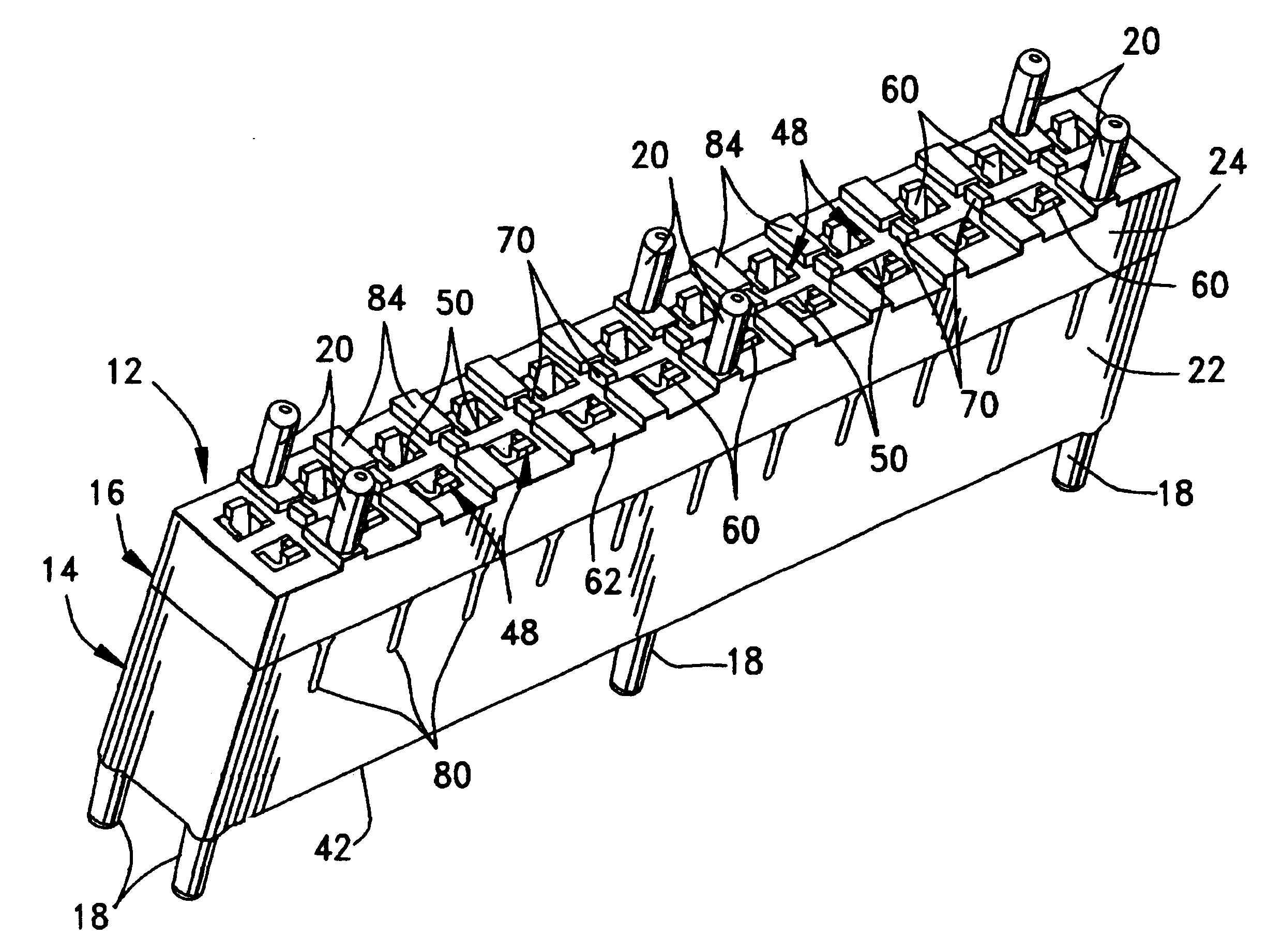

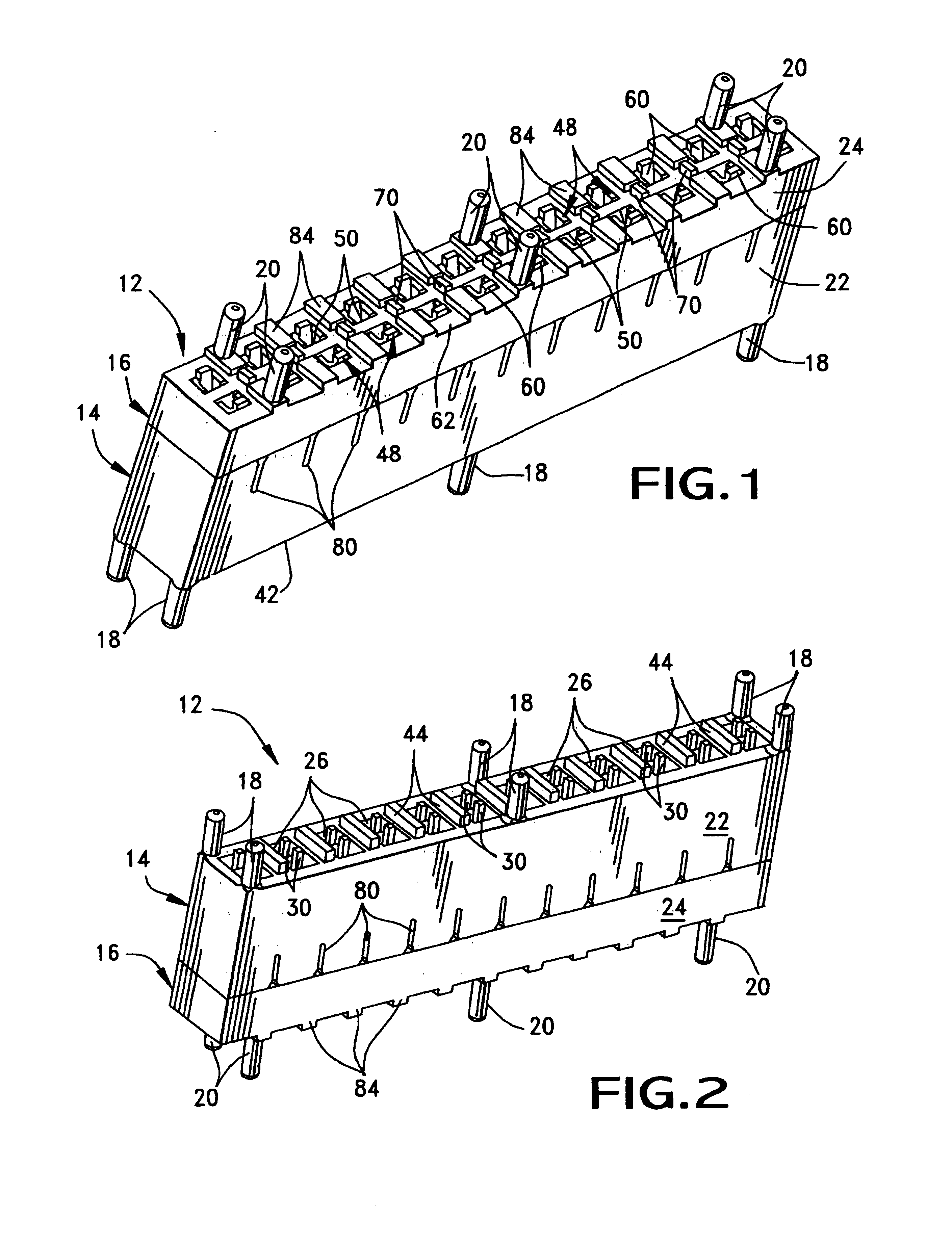

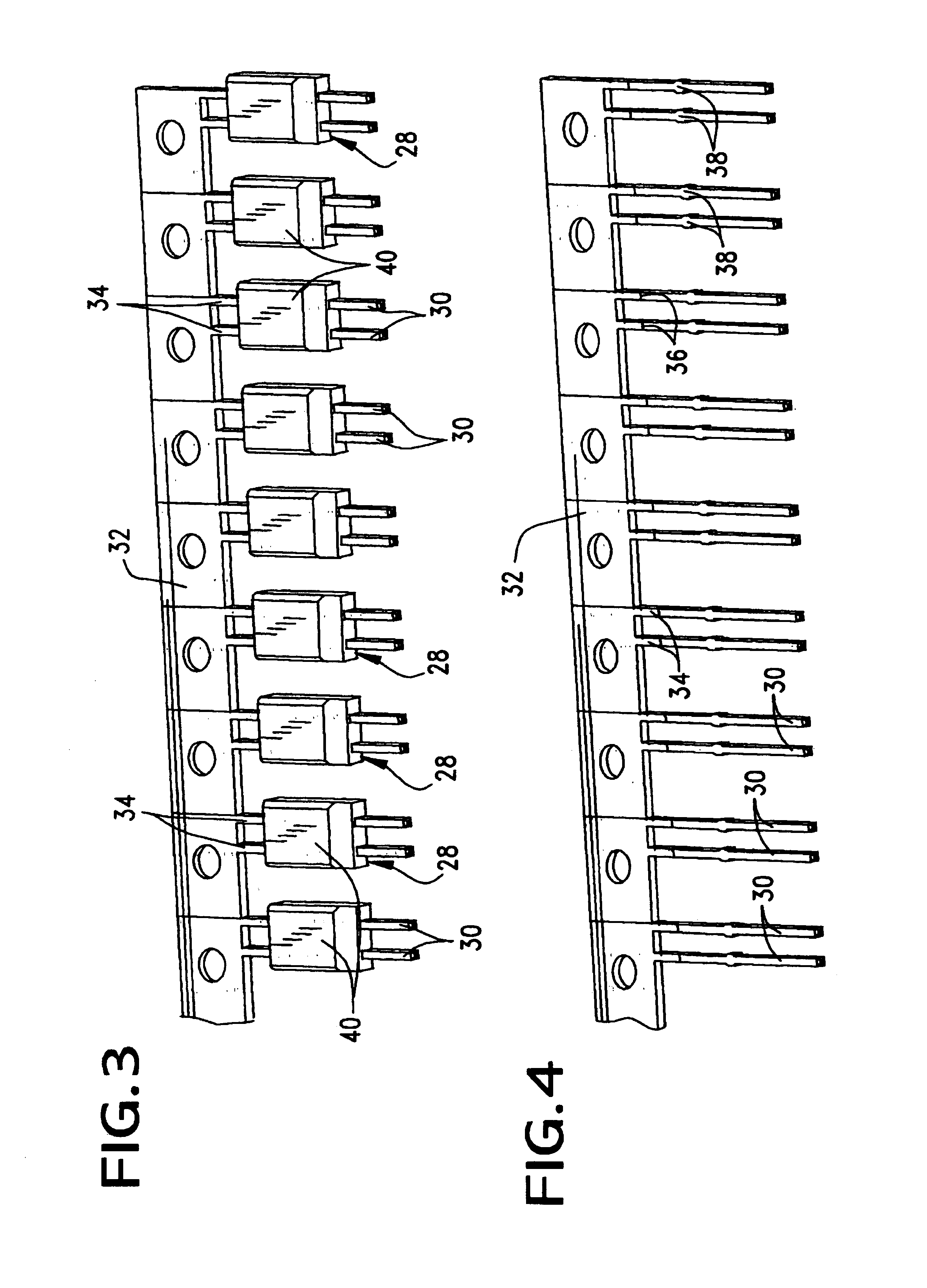

Shielded electrical connector

InactiveUS7018239B2Avoid drillingElectrically conductive connectionsCoupling protective earth/shielding arrangementsEngineeringElectrical connector

A shielded electrical connector is provided for mounting on a printed circuit board. The connector includes a dielectric housing having a plurality of terminal-receiving cavities and a plurality of board-engaging pads projecting from the bottom of the housing. A plurality of terminals are received in the cavities. Portions of the housing between the terminals are plated with conductive metal material to electrically shield the terminals from each other and to provide a controlled impedance. The plating is continuous onto the pads for connection to appropriate ground circuit means on the printed circuit board. In an alternative embodiment, a shielded electrical connector assembly includes a pair of connectors both of which have plated housings with interengaging plated portions.

Owner:MOLEX INC

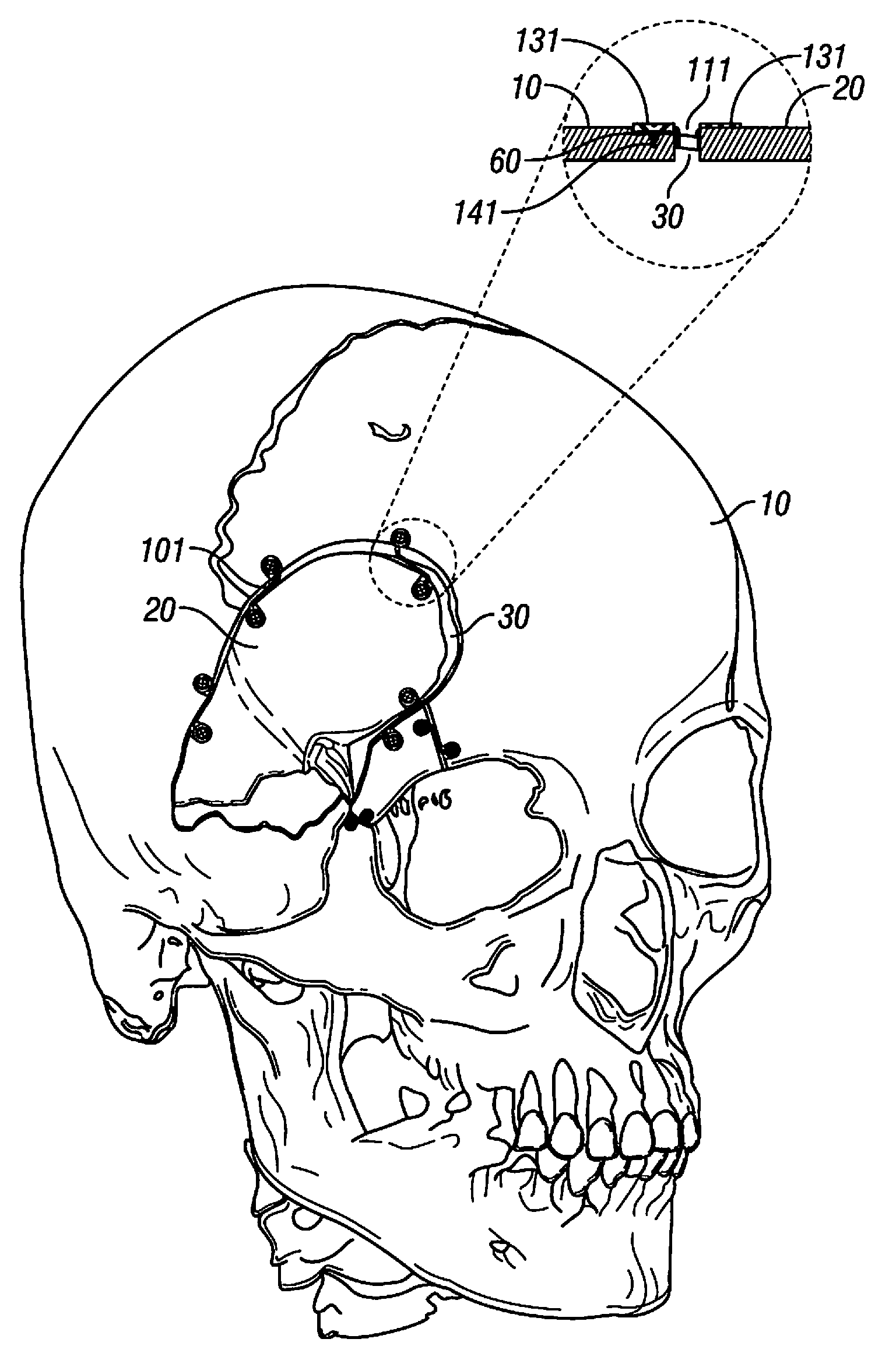

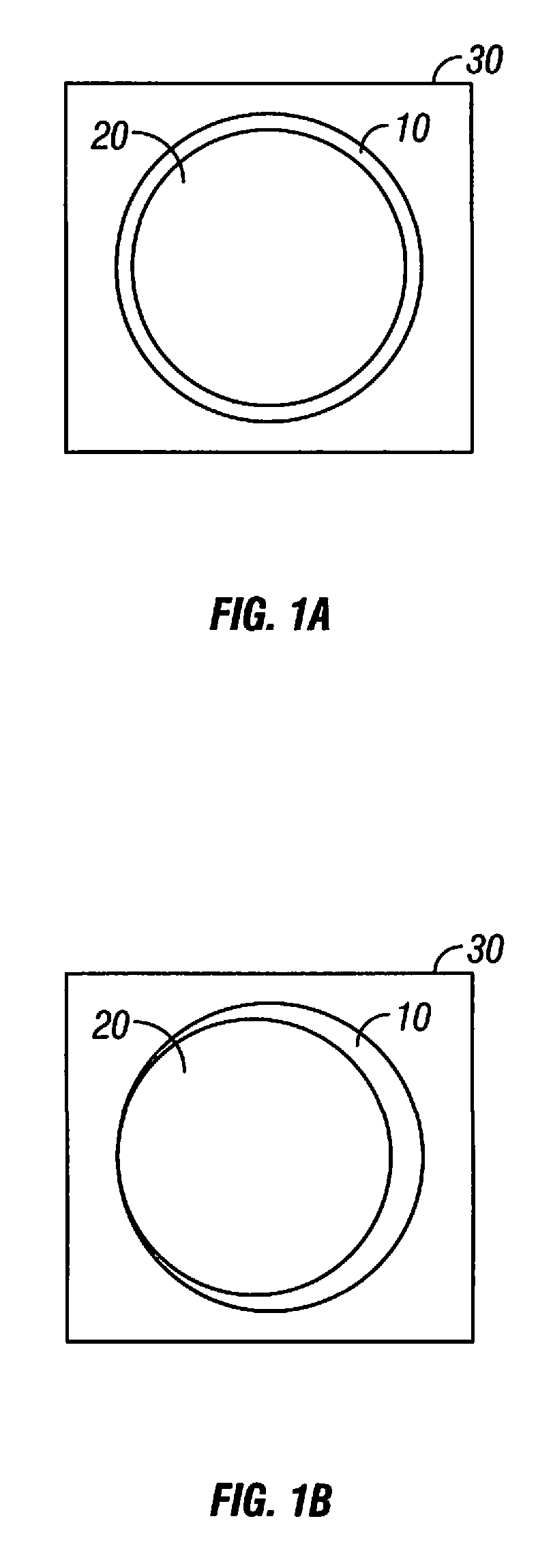

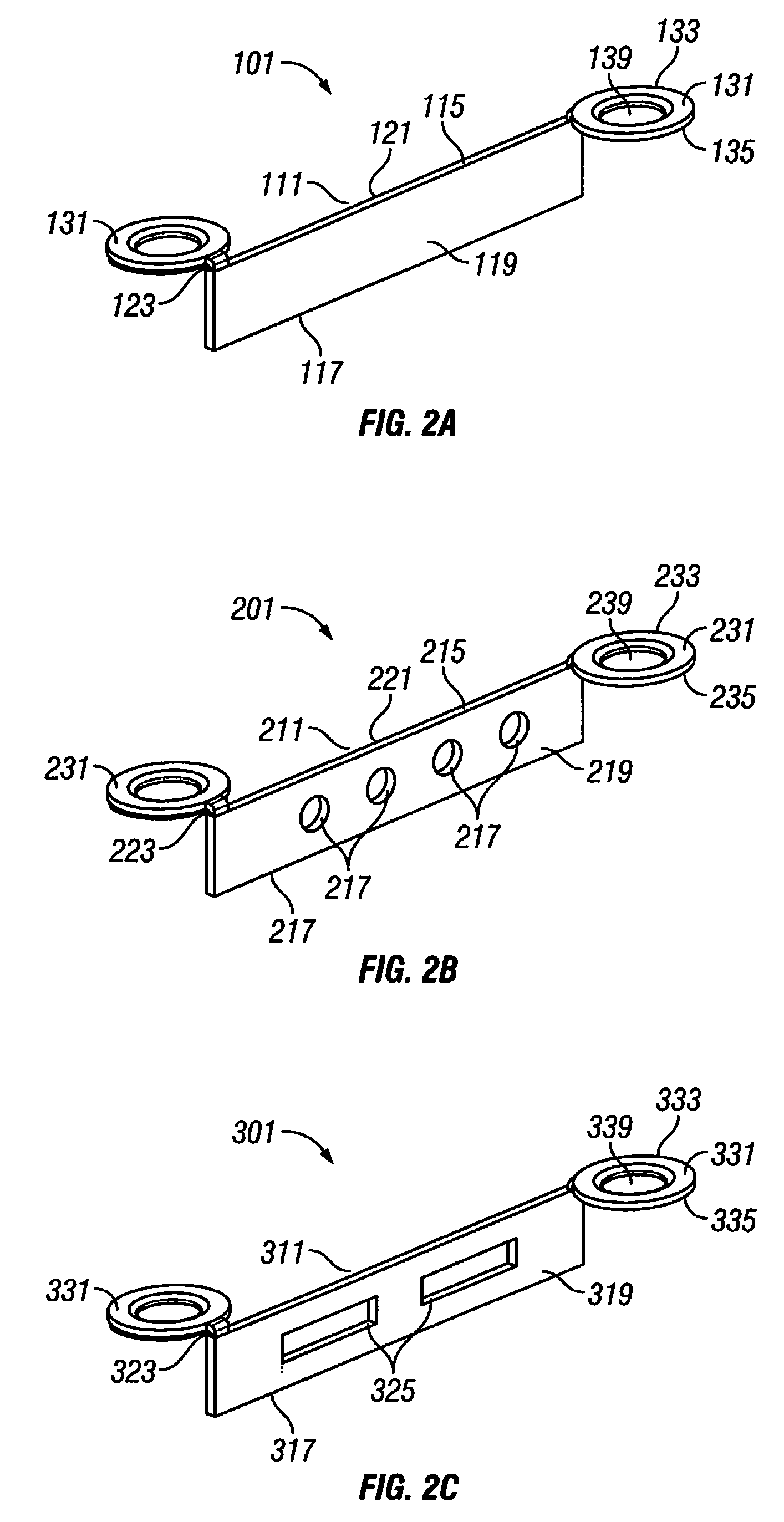

Cranial plating and bur hole cover system and methods of use

InactiveUS20120289964A1Reduce protrusionAddress bad outcomesInternal osteosythesisBone platesCovering systemCranial surface

The present disclosure is for a device, tooling, methods of use and kits containing the cranial plates and bur hole covers used for resecuring a cranial flap after a craniotomy. The cranial repair system is meant to reduce the profile of cranial plates or bur hole covers on the external surface of the cranium after a craniotomy is performed. The embodied devices of present disclosure are designed to reside substantially within the kerf or bur holes and thus minimize the surface area of devices resides on the external surface of the cranium. Additional embodiments include kits, tooling and methods to further reduce and / or eliminate the external profile of the cranial plate on the external cranial surface.

Owner:OSTEOMED

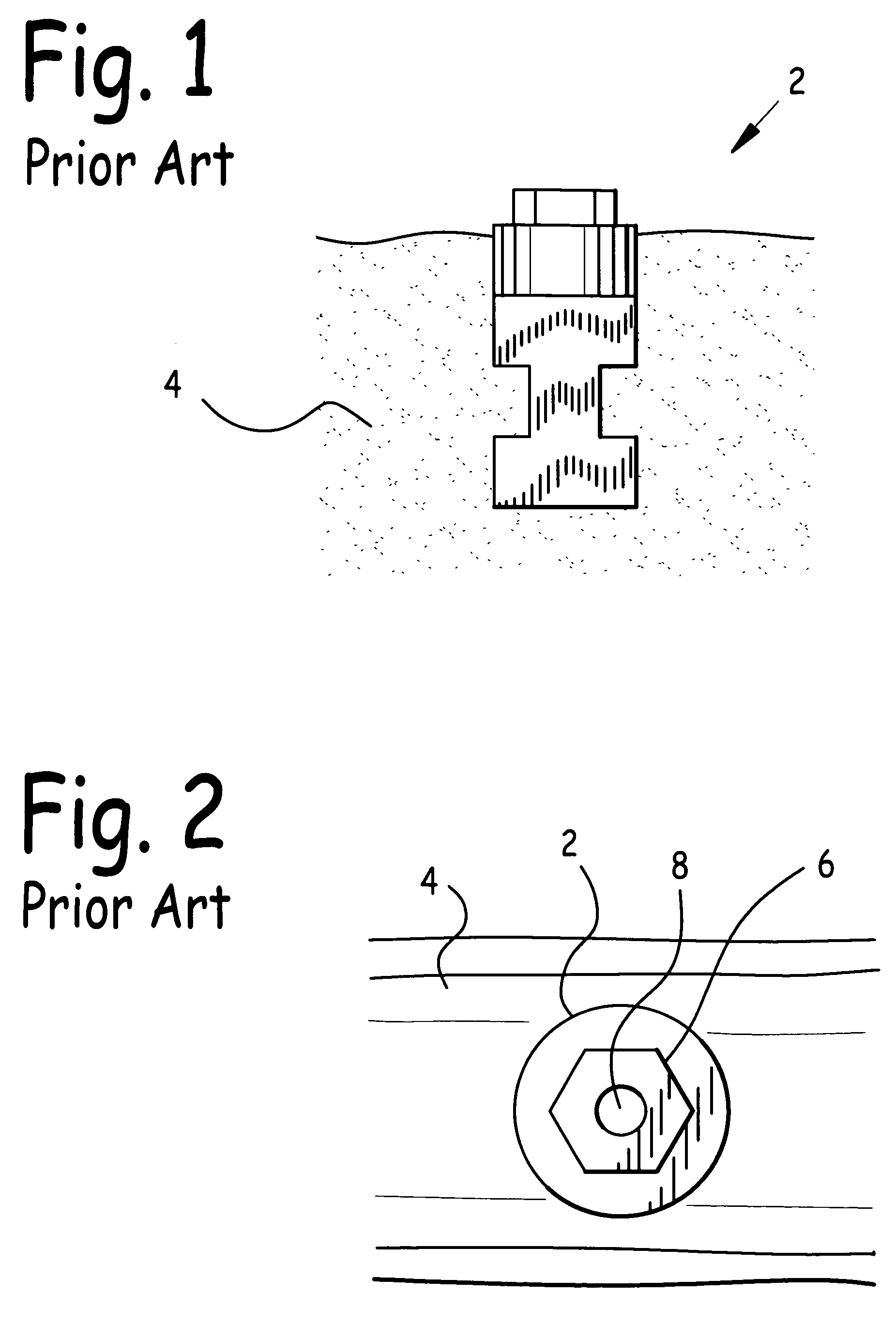

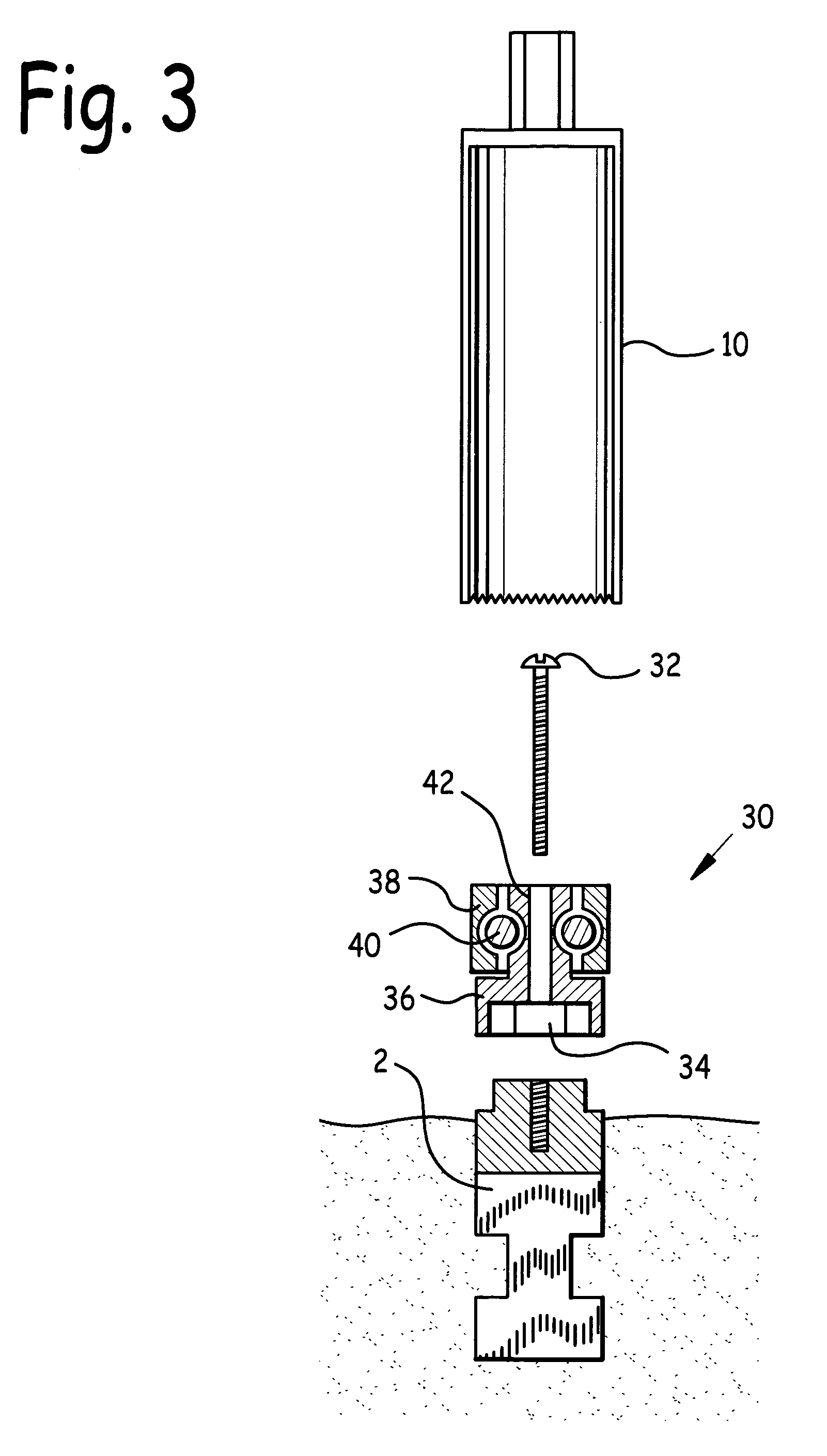

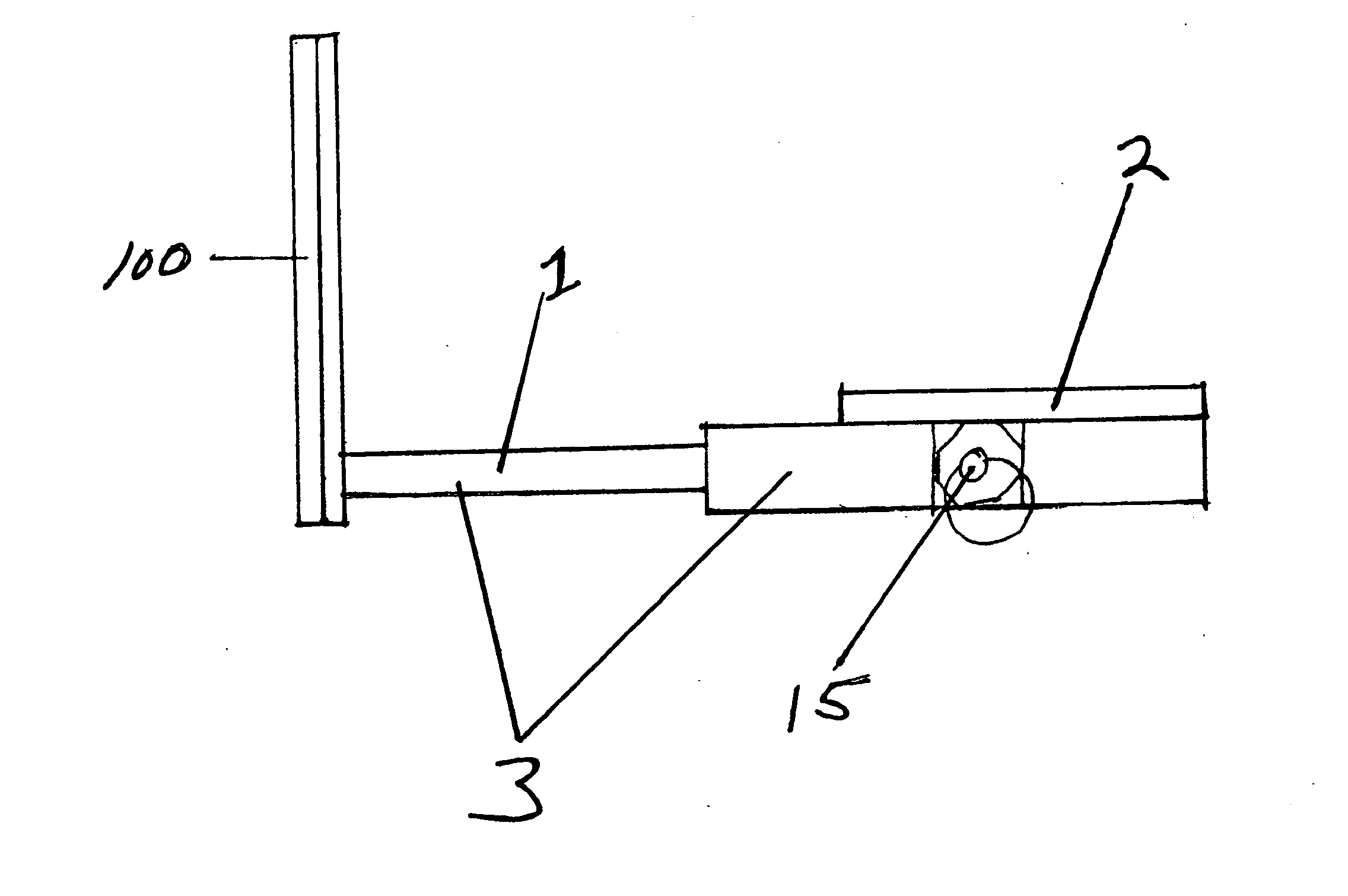

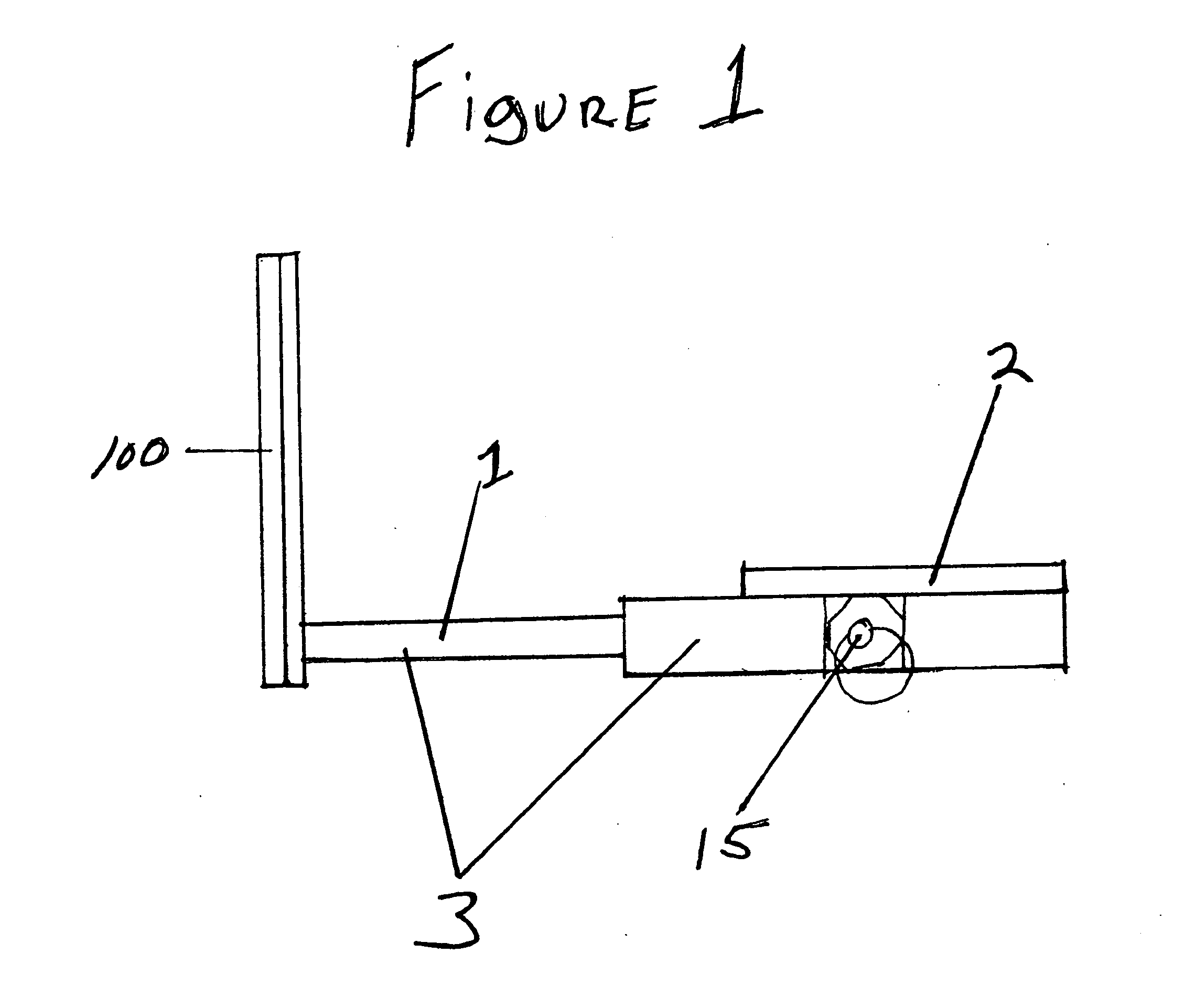

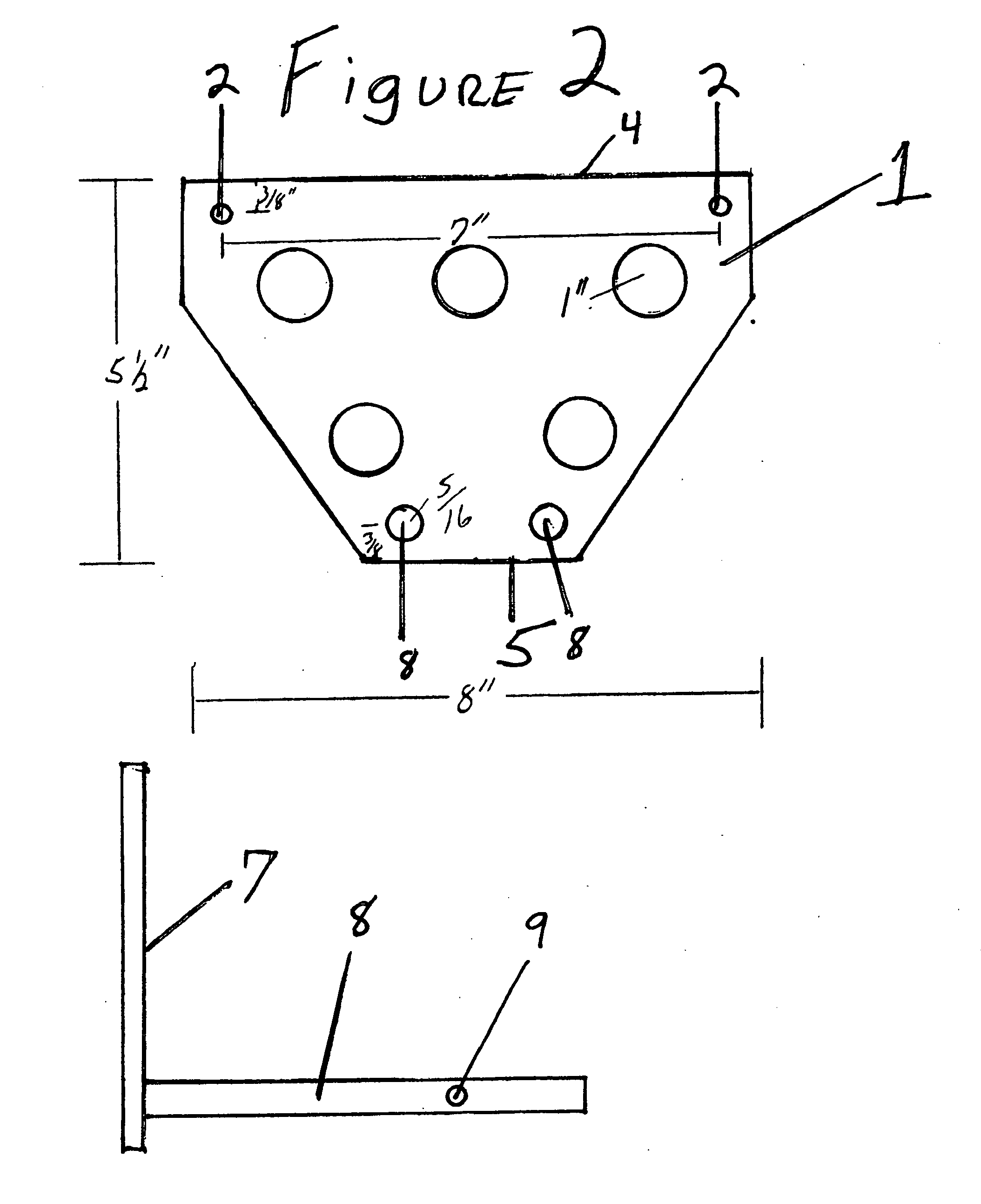

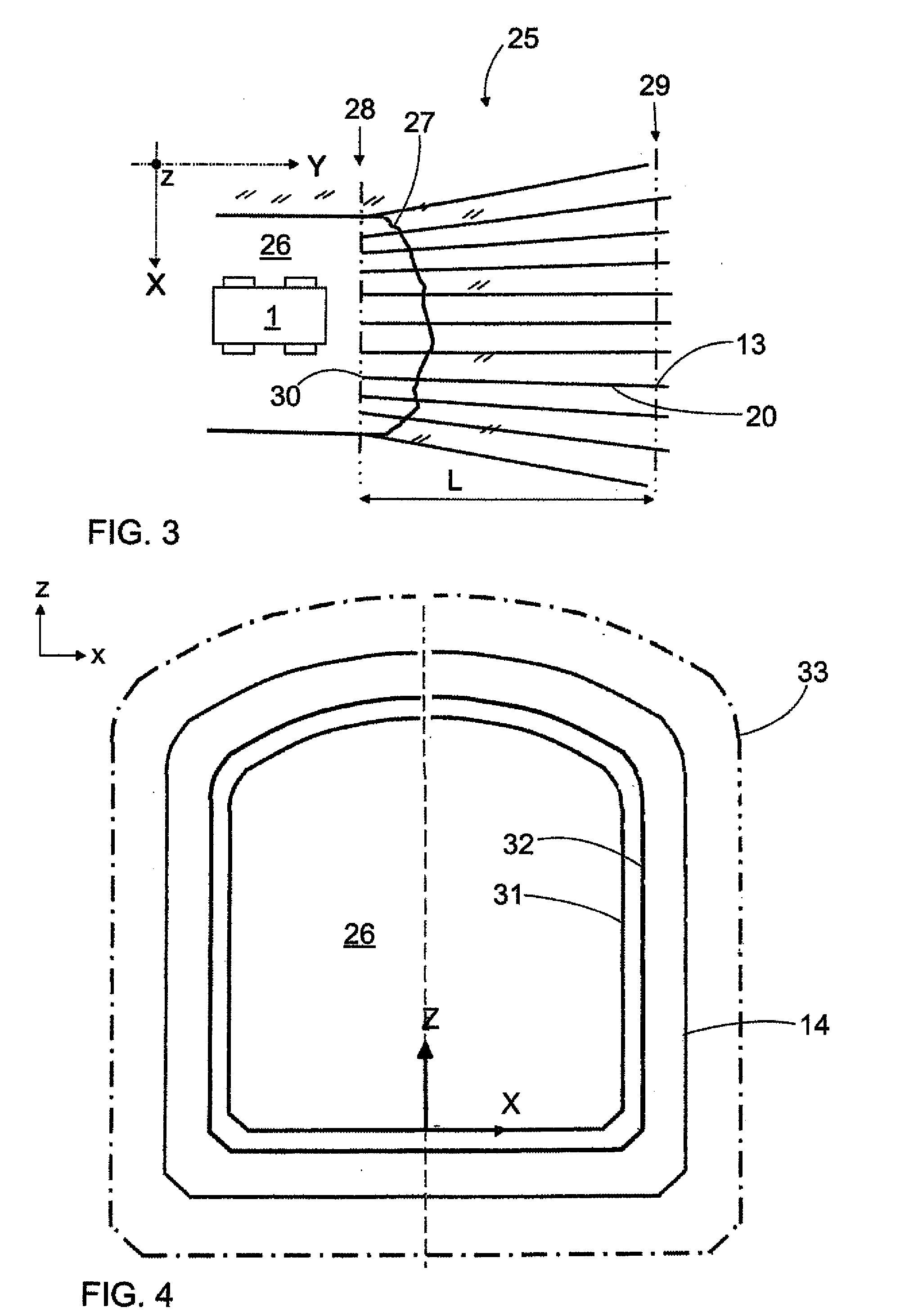

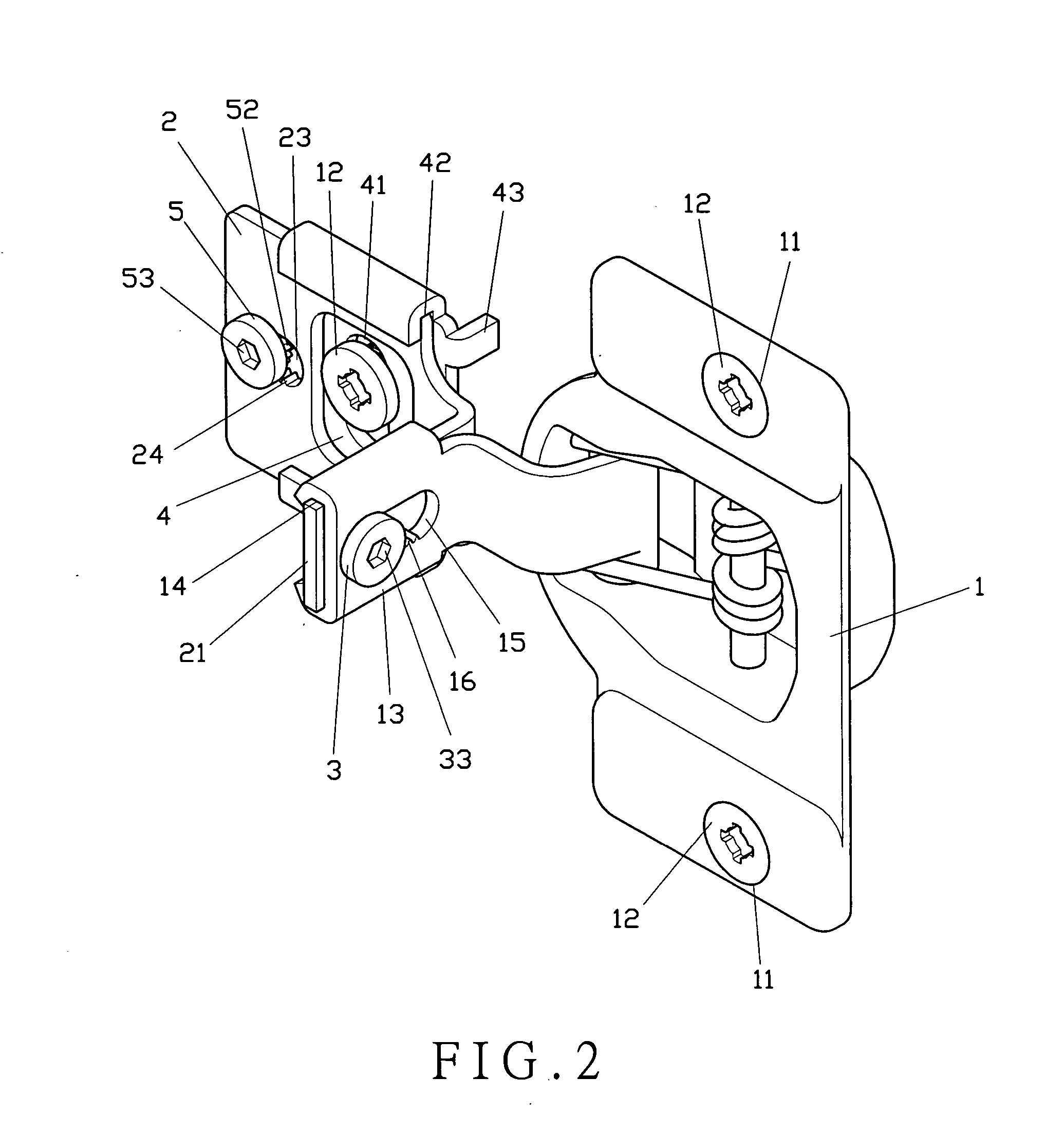

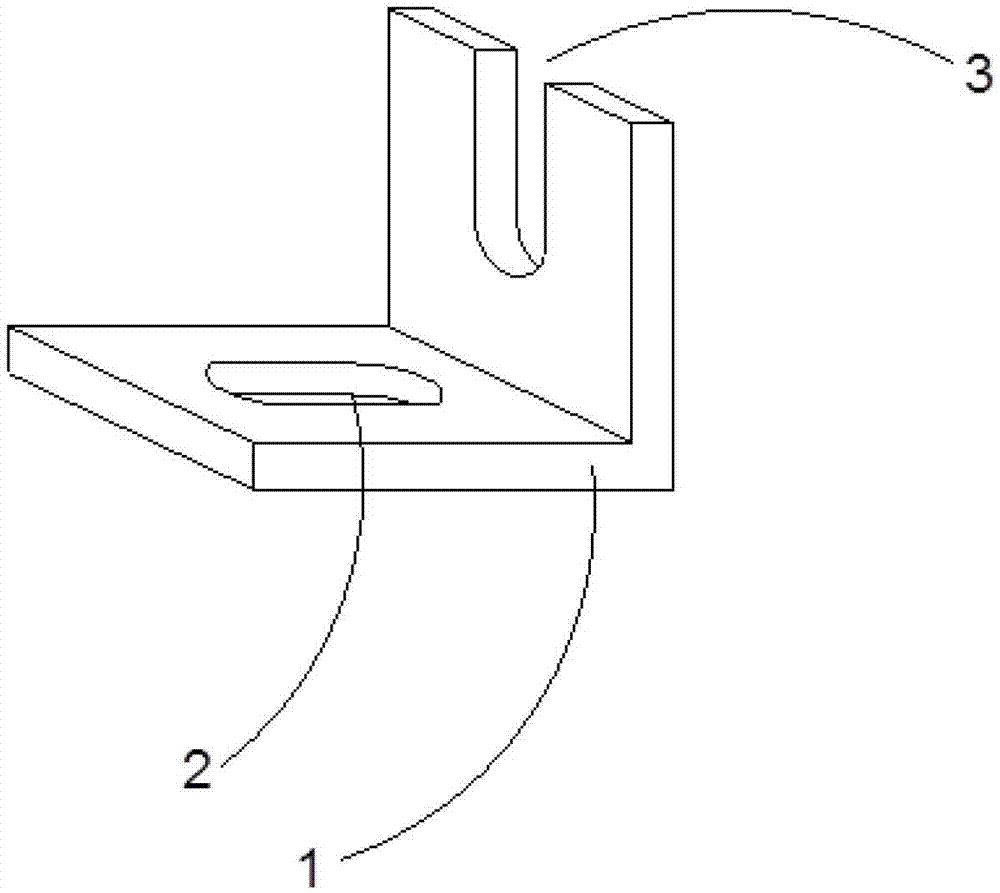

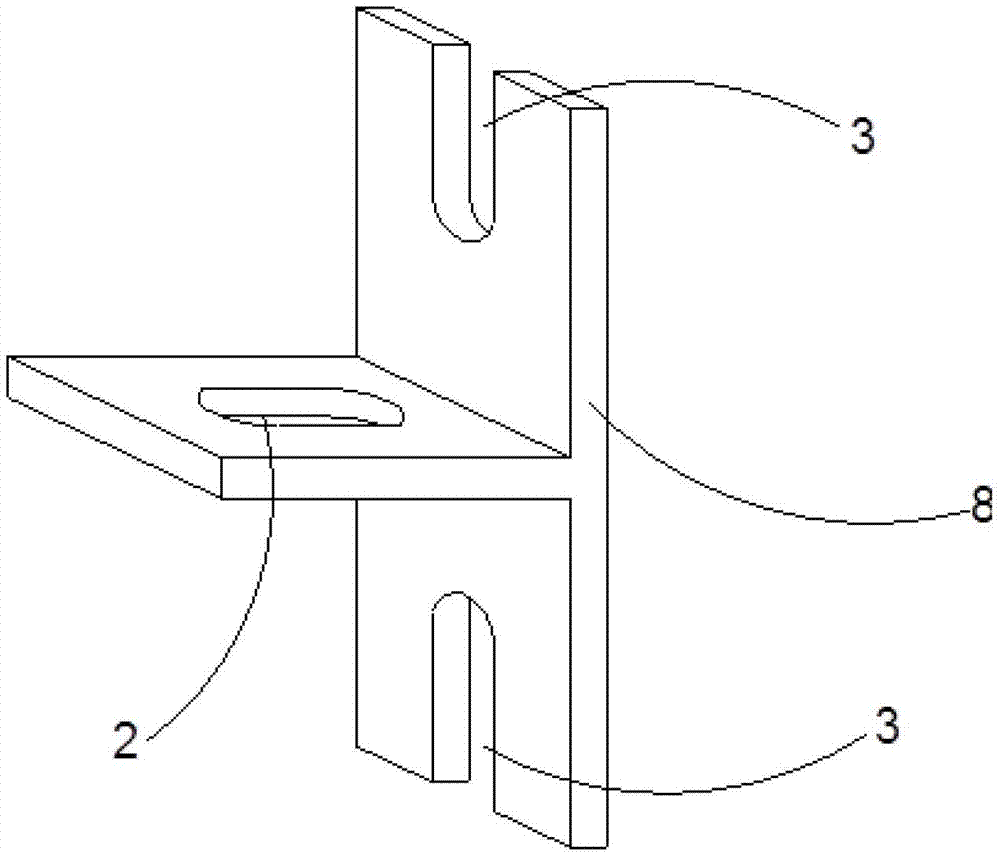

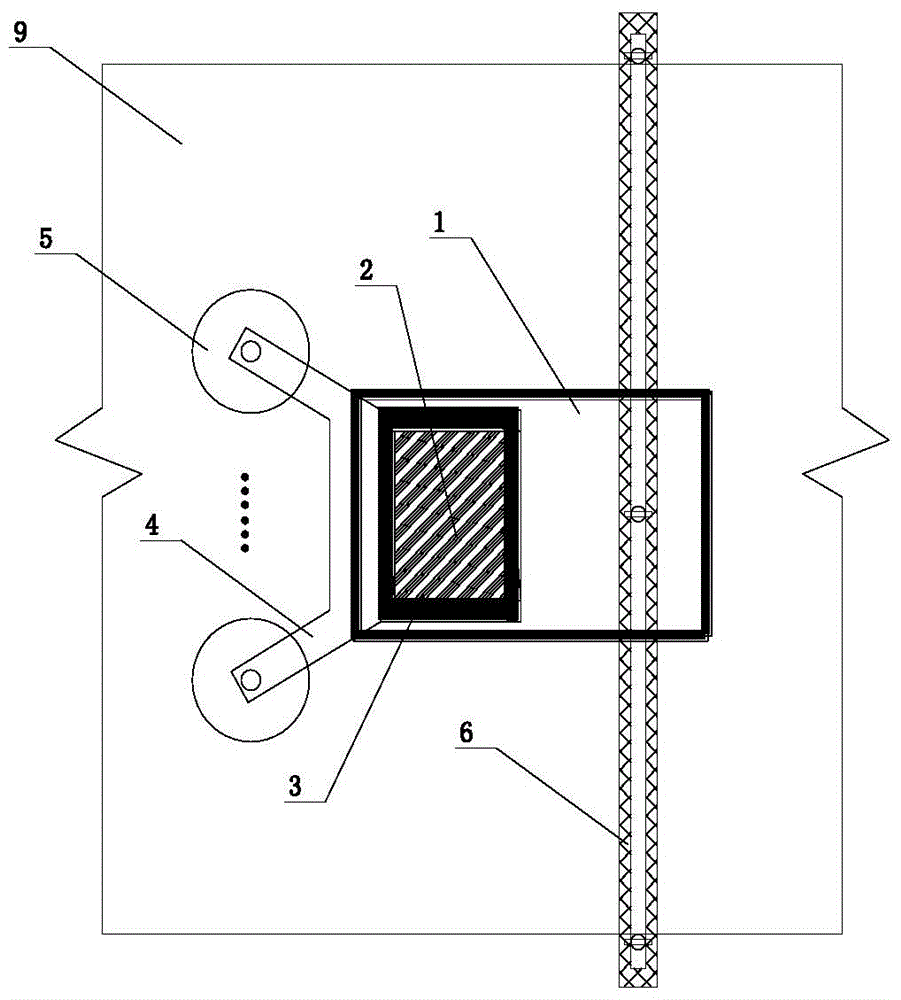

Detachable Front License Plate Mounting System (Sto n Sho)

InactiveUS20140263923A1Avoid drillingGood adhesionPicture framesDomestic mirrorsEngineeringMechanical engineering

One bracket assembly constructed of aluminum; however any metal, modern plastic or composite material may be substituted. Bracket assembly consists of a front mounting plate (FIG. 2) and a base mounting assembly or plate (FIG. 3). The base mounting assembly or plate contains a pull pin (FIG. 3, 15) locking device, which is attached to the base plate by square aluminum nut (FIG. 3, 17) welded to the tube. The front mounting plate consists of a notch (FIG. 2, 9) in the rod (8) that the pull pin (FIG. 3, 15) locks in to. This allows for assembly of the bracket and quick removal of the front mounting plate (FIG. 2) when desired. Other embodiments are described and shown.

Owner:MCKINNEY MICHAEL PATRICK

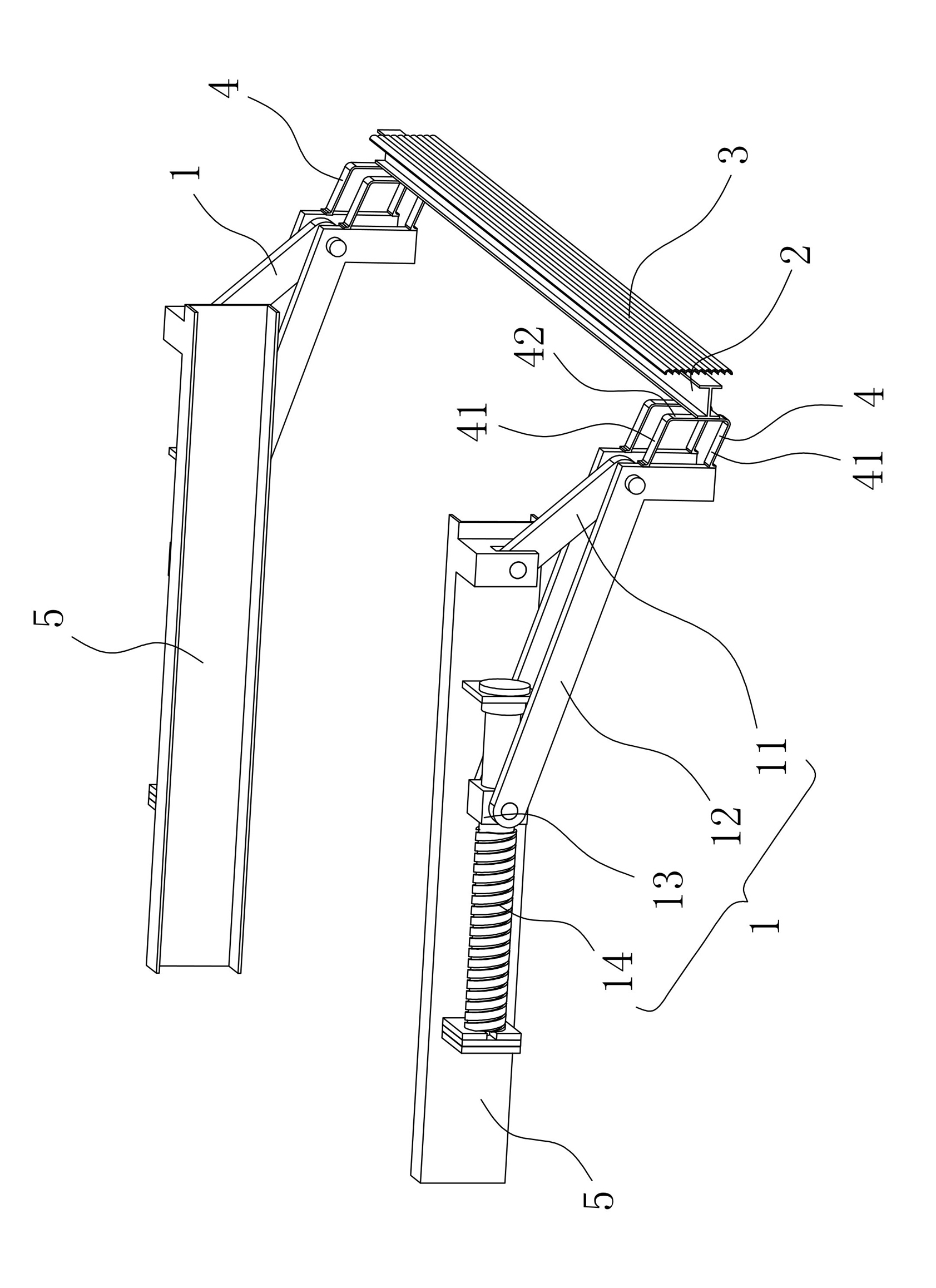

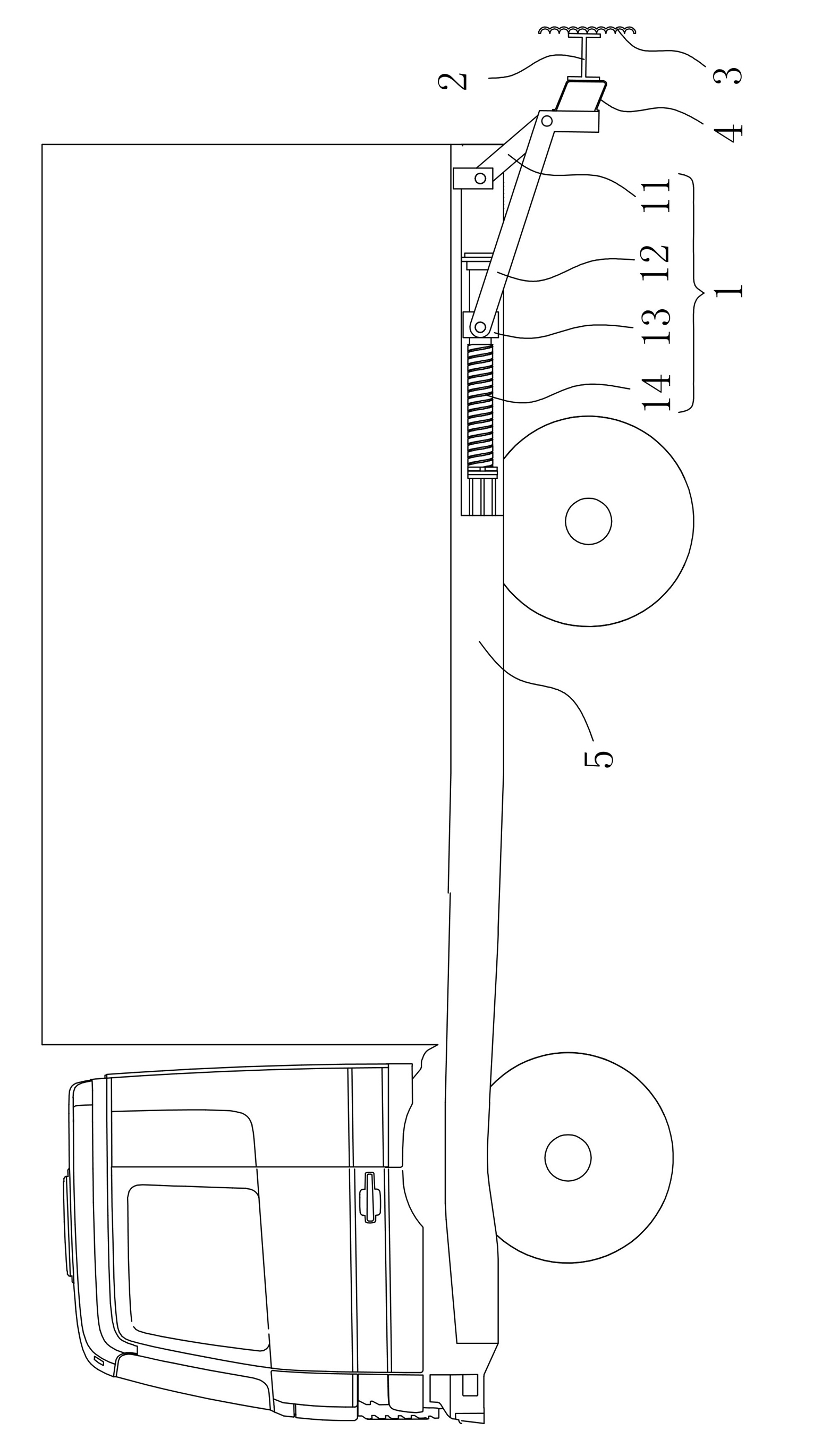

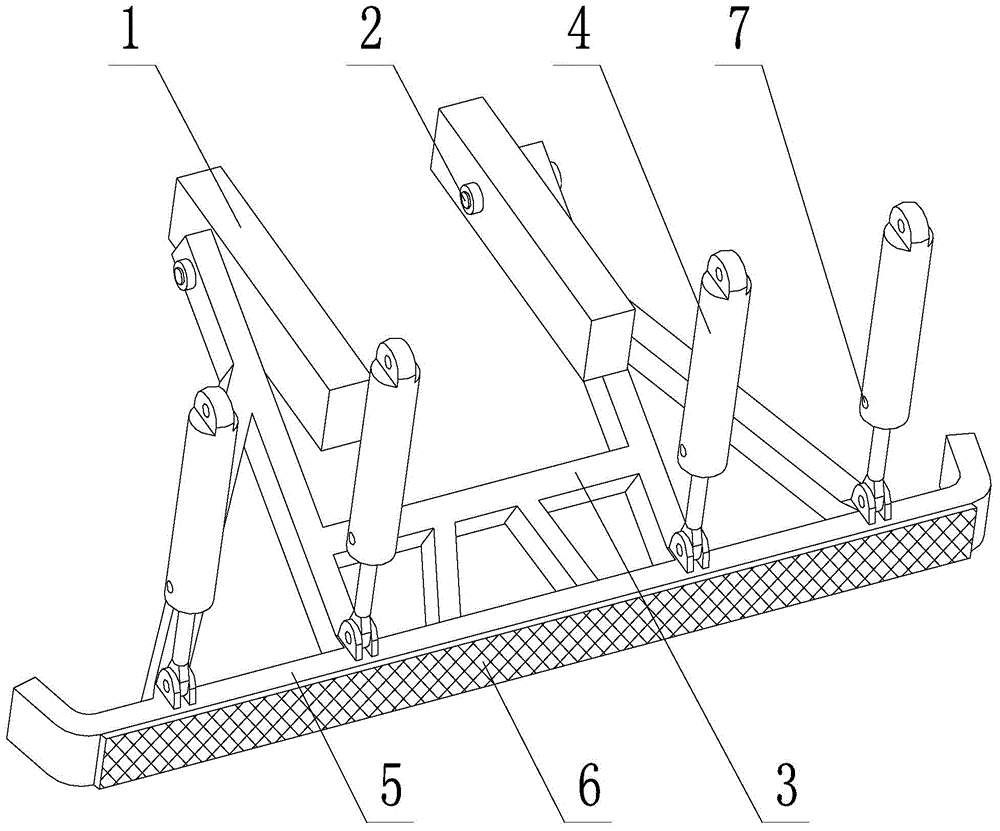

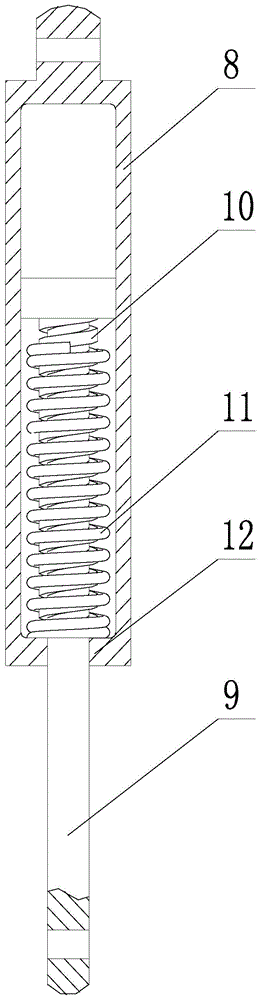

Multistage-buffering and height-adjustable truck tail collision avoiding device

The invention belongs to the technical field of truck tail bumper collision avoiding devices and discloses a multistage-buffering and height-adjustable truck tail collision avoiding device which comprises a rigid swing frame, a bumper and a plurality of energy-absorbing buffering and height-adjusting hydraulic cylinders, one end of the rigid swing frame is hinged on crossbeams of a truck while the other end of the same is fixedly connected with the bumper, one ends of the energy-absorbing buffering and height-adjusting hydraulic cylinders are hinged on the bumper while the other ends of the same are hinged at the bottom of a compartment of the truck, and oil incoming holes in the energy-absorbing buffering and height-adjusting hydraulic cylinders are connected with a vehicle-mounted hydraulic system of the truck; each energy-absorbing buffering and height-adjusting hydraulic cylinder comprises a cylinder body and a piston rod positioned in the cylinder body, a sealed side of each cylinder body is hinged to the bottom of the compartment of the truck while an open side of the same is in sealed sliding fit with the corresponding piston rod, the end portion of a rod body of an extending section of each piston rod is hinged to the bumper, an energy-absorbing thread is formed on the rod body of each piston rod positioned in the corresponding cylinder body and is in shear fit with the open side of the corresponding cylinder body, and an opening of each cylinder body is a shear opening; a buffering spring is mounted on the piston rod in each cylinder body in a sleeved manner, and a high-elasticity rubber pad is additionally mounted on an impact face of the bumper.

Owner:LIAONING TECHNICAL UNIVERSITY

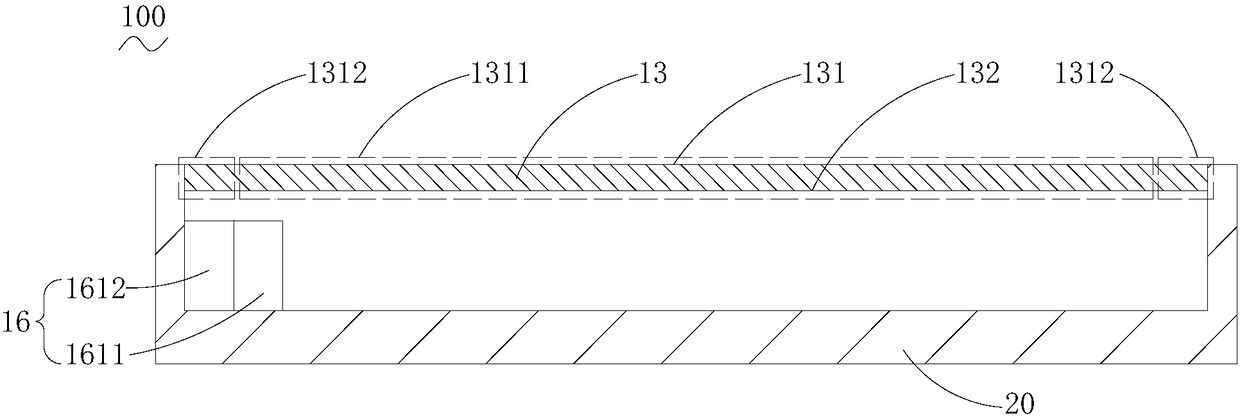

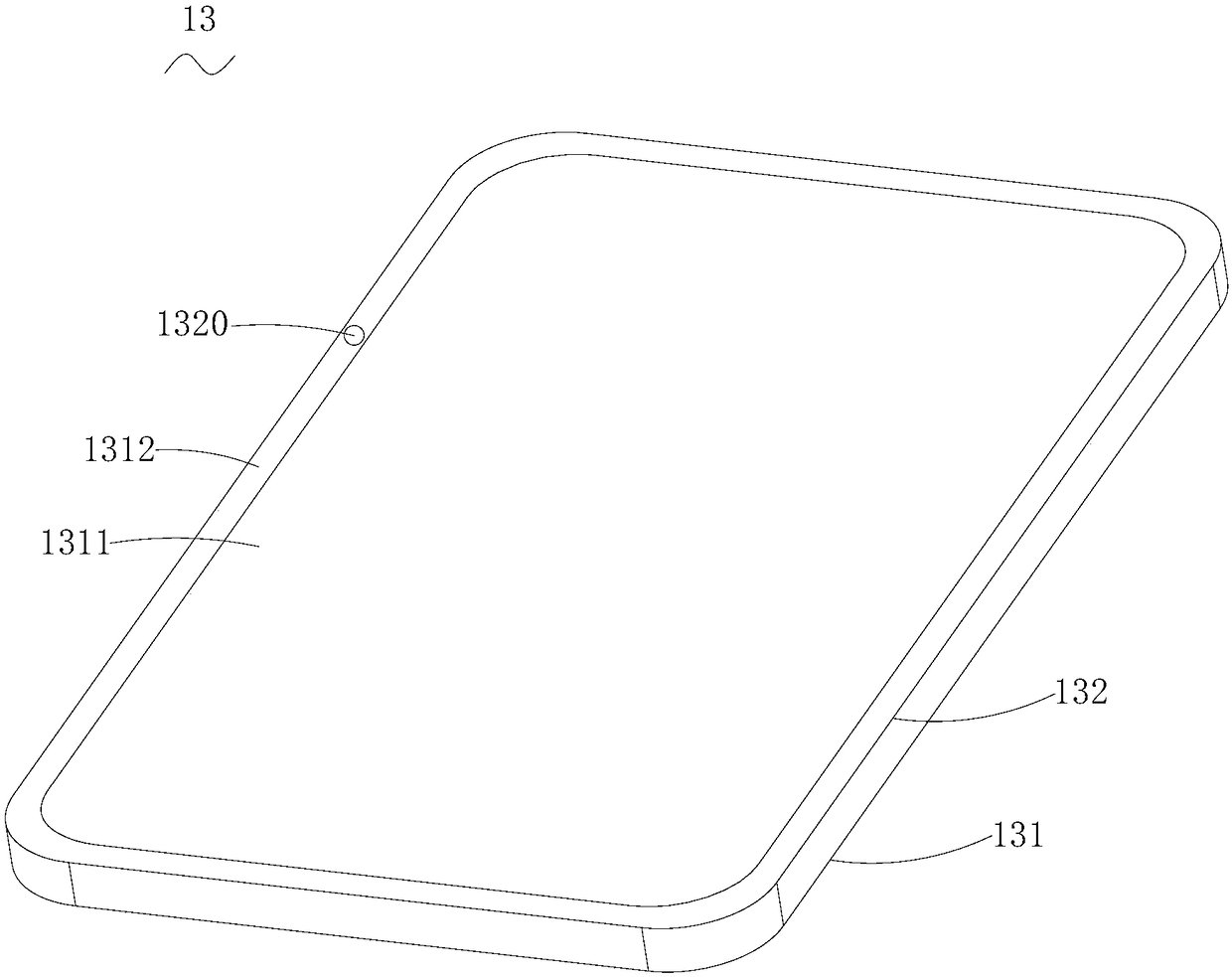

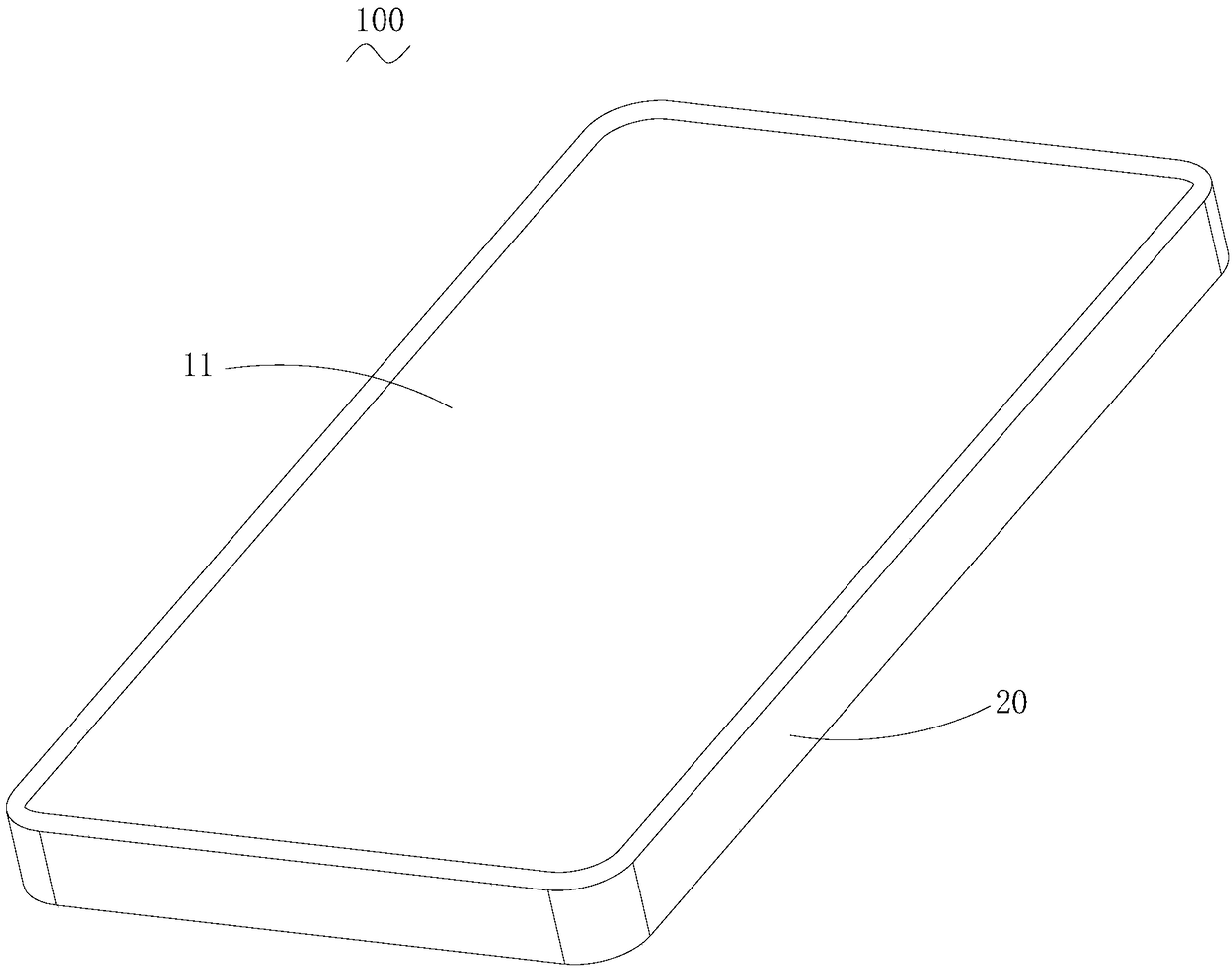

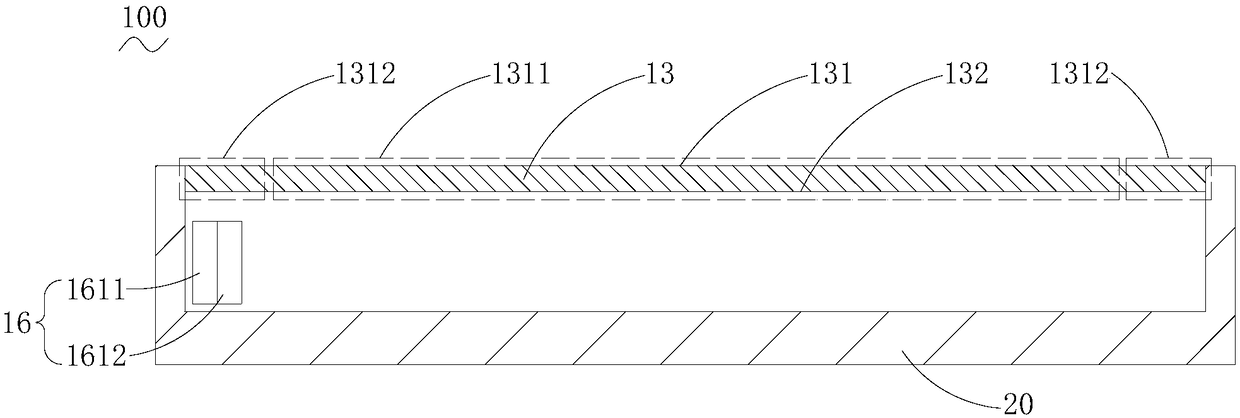

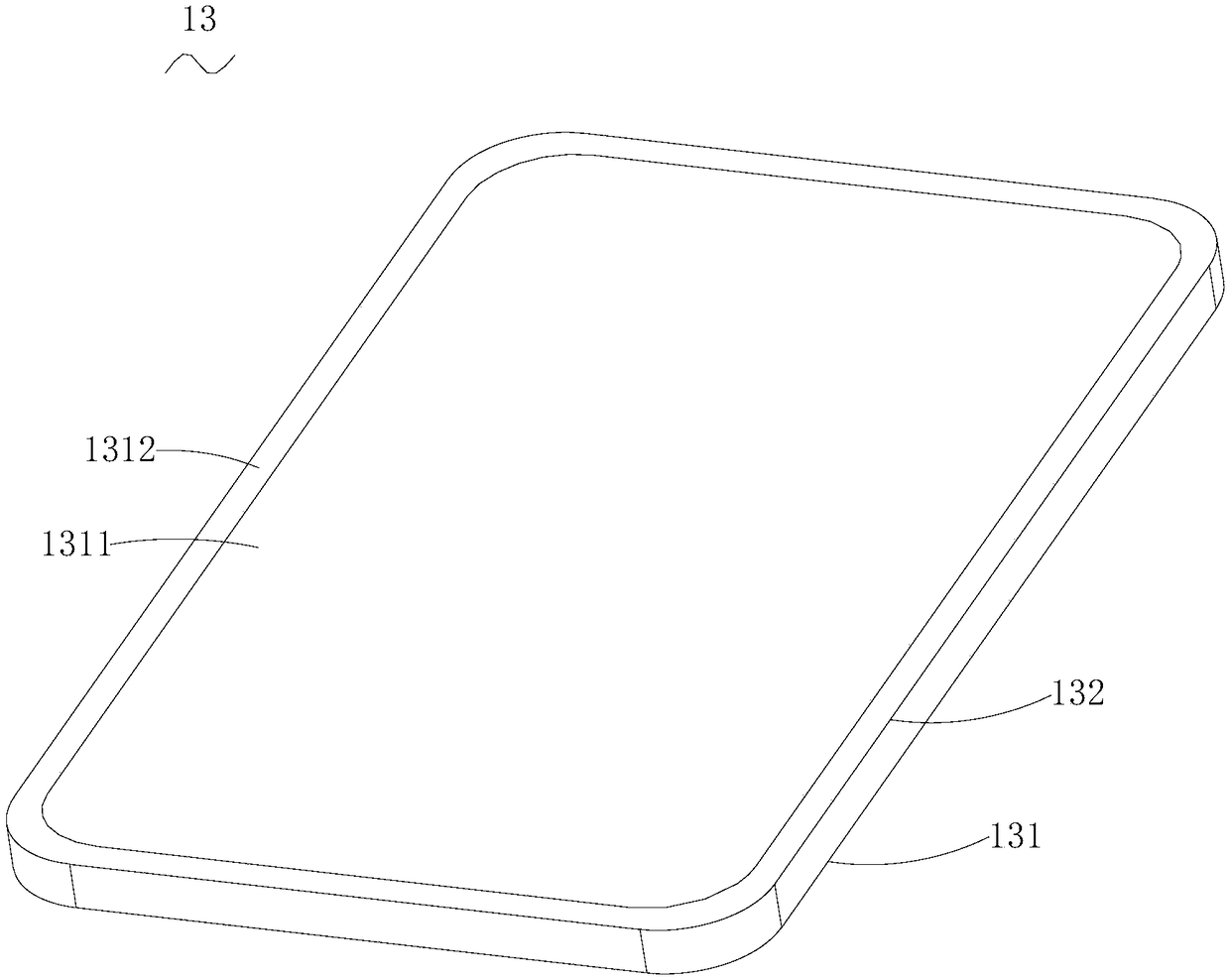

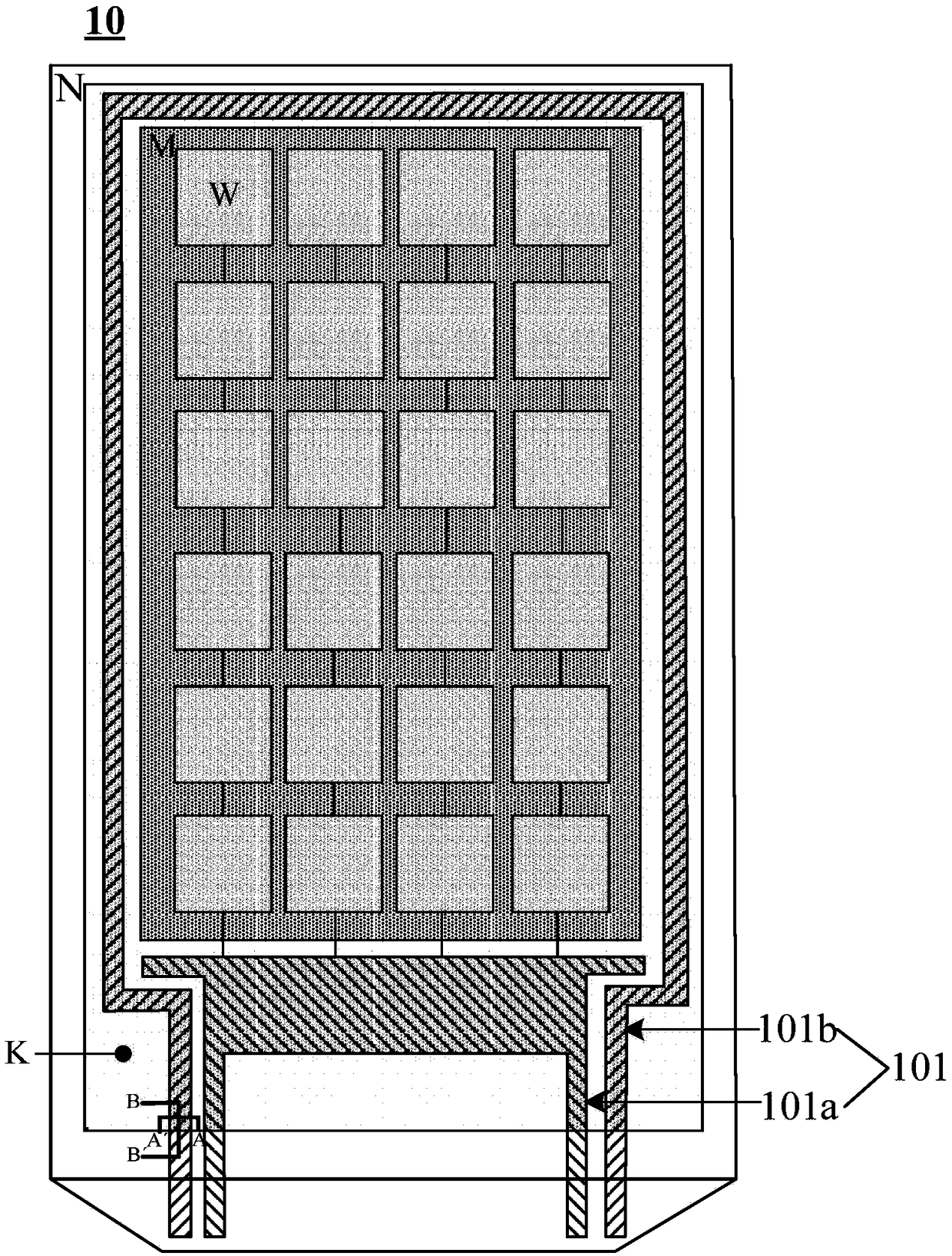

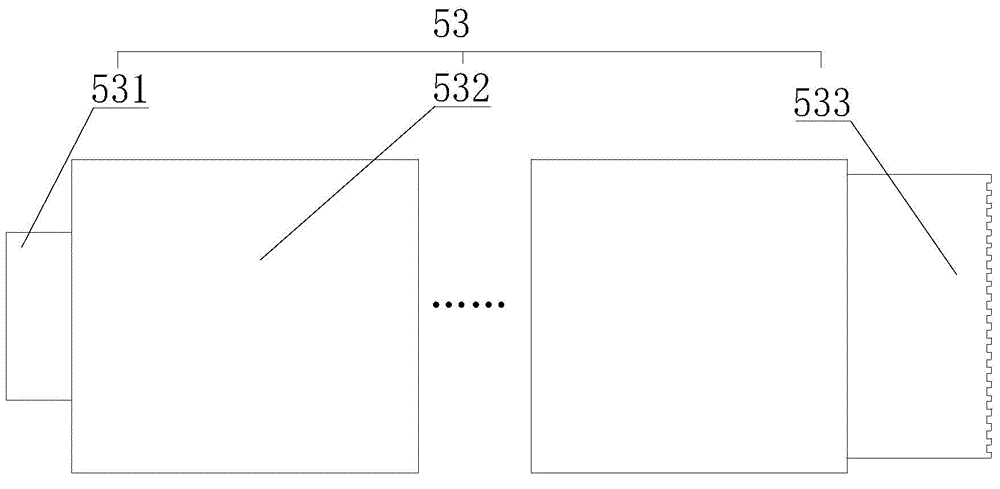

Electronic device and manufacturing method thereof

InactiveCN108600419AIncrease the screen ratioGuaranteed reliabilityMagnetic/electric field screeningStatic indicating devicesComputer scienceTransmitter

The invention discloses an electronic device and a manufacturing method thereof. The electronic device includes a light transmitting display screen and a light sensor. The light transmitting display screen includes an upper surface and a lower surface which is opposite to the upper surface. The light transmitting display screen is used for luminous display through the upper surface. The lower surface includes a display area and a frame area surrounding the display area. The frame area includes a first window area. The light sensor includes a transmitter for transmitting infrared light throughthe first window area and a receiver for receiving infrared and / or visible light through the lower surface. According to the invention, the light sensor can be arranged below the light transmitting display screen in a full screen condition. Moreover, the transmitter of the light sensor is arranged in the frame area, thereby preventing infrared light emitted by the transmitter from affecting the work stability of a TFT in the display area and making the light transmitting display screen and the light sensor realize respective functions without interfering with each other.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Production method of down proof fabric

InactiveCN103535950AImprove breathabilityImprove wear resistanceDry-cleaning apparatus for textilesDyeing processPolyesterFiber

The invention relates to a preparation method of textiles, in particular to a production method of a down proof fabric. The production method of the down proof fabric sequentially includes the steps of selecting of a gray fabric, wherein the gray fabric is elastic tribute silk formed by cotton, polyester, bamboo fibers and spandex, the tribute silk is blended yarns formed by cotton fibers and the bamboo fibers in the warp direction, the cotton fibers account for 50-70%, the bamboo fibers account for 30-50%, and the tribute silk is low-elasticity network yarns and spandex core-spun yarns, sanding, rolling of wind-proof agents, wherein the vehicle speed is 60-80m / min when the wind-proof agents are rolled, specifically, the fabric after sanding processing is placed into a wind-proof agent solution at the temperature of 40-55 DEG C, the liquor detention rate is 45-65%, the wind-proof agents comprise starch composite catalysts and compounds, and the compounds are formed by compositing acrylic acid amide compounds and hydrophilia softening agents KF-896 according to the mass ratio of 2-5:1, calendaring, wherein the calendaring temperature is controlled to be at 105-115DEG C, and the vehicle speed is 30-50m / min, preshrinking and after-finishing. The down proof fabric prepared in the method has excellent air permeability and the effect of preventing down from coming out.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

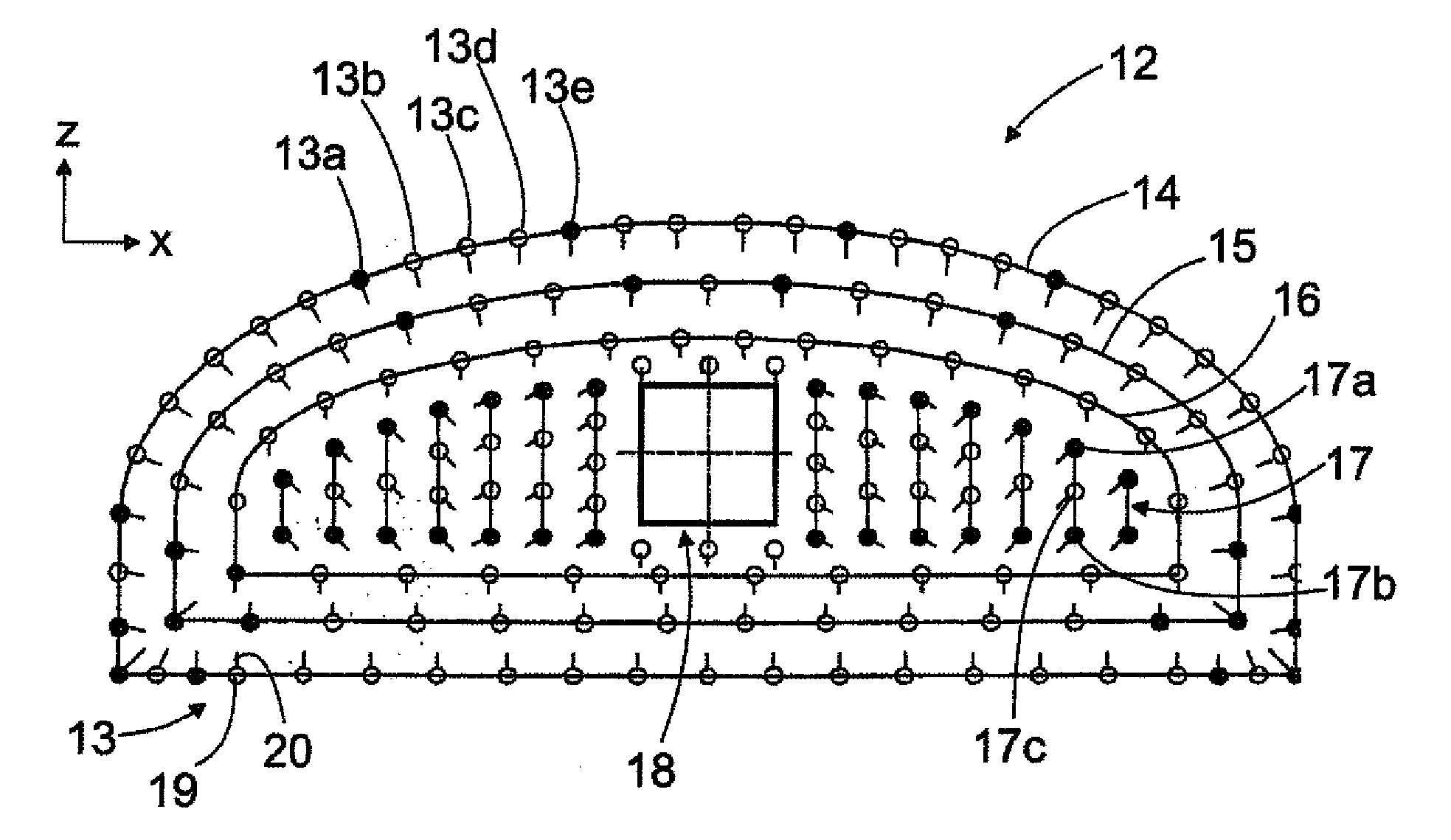

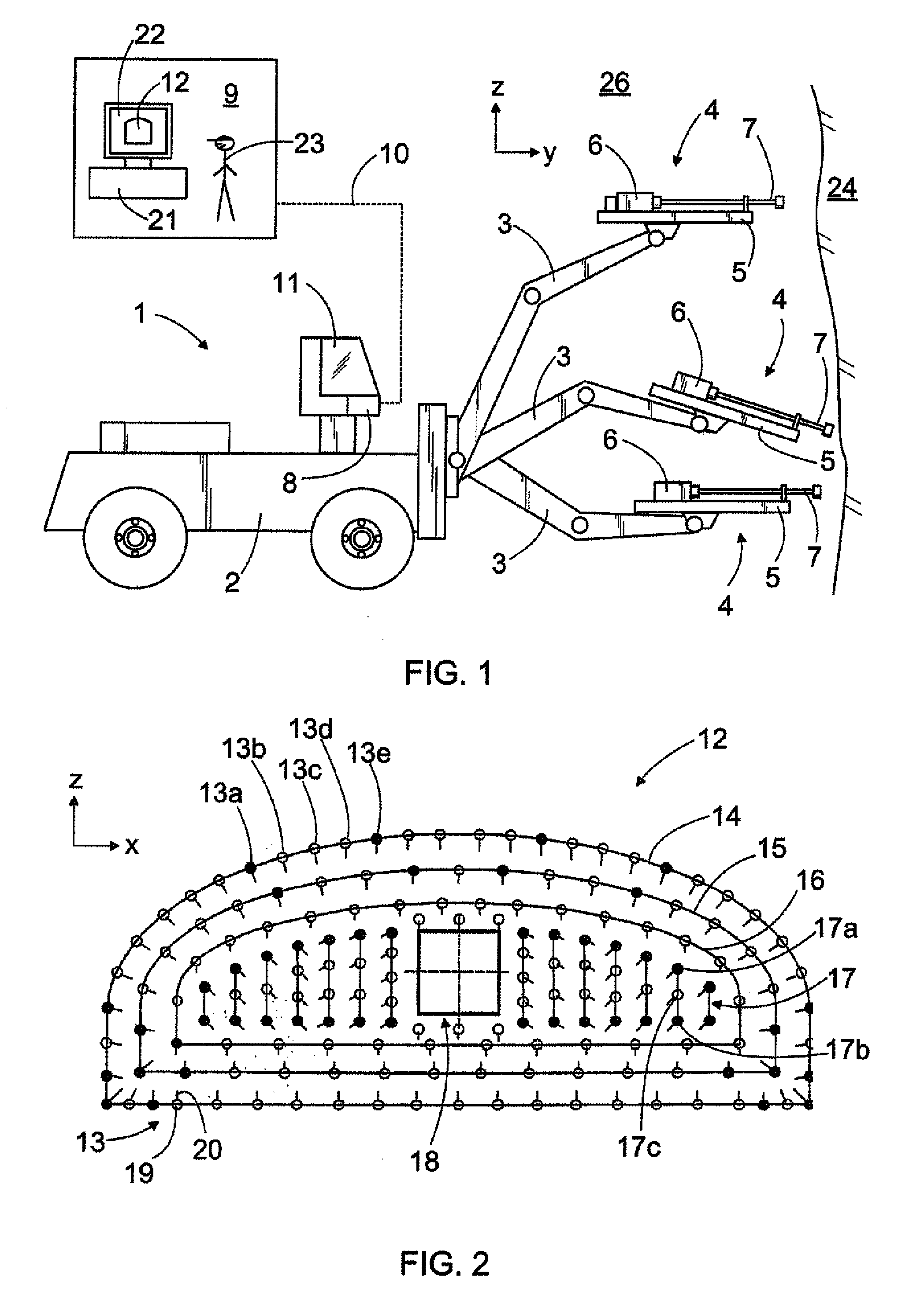

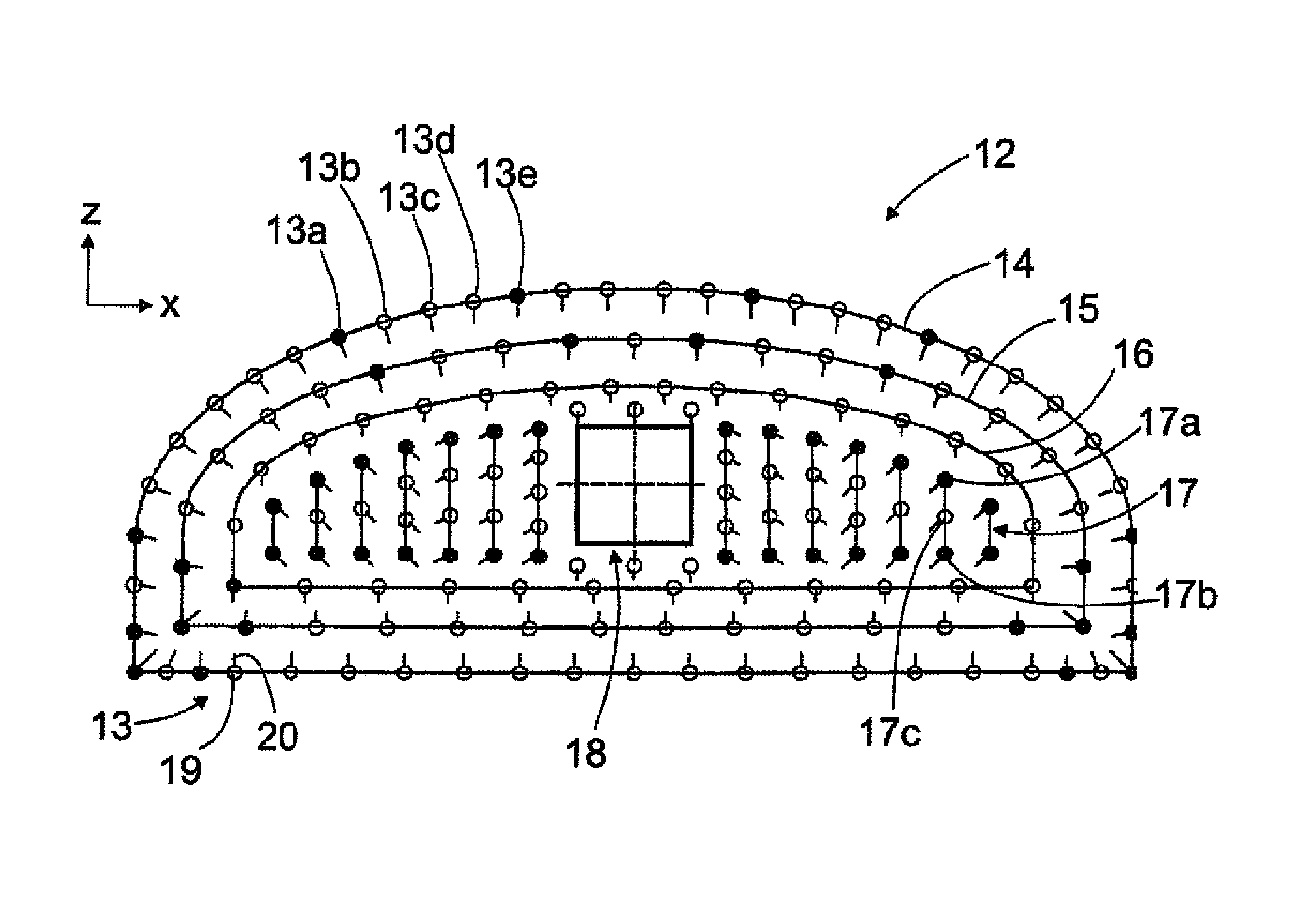

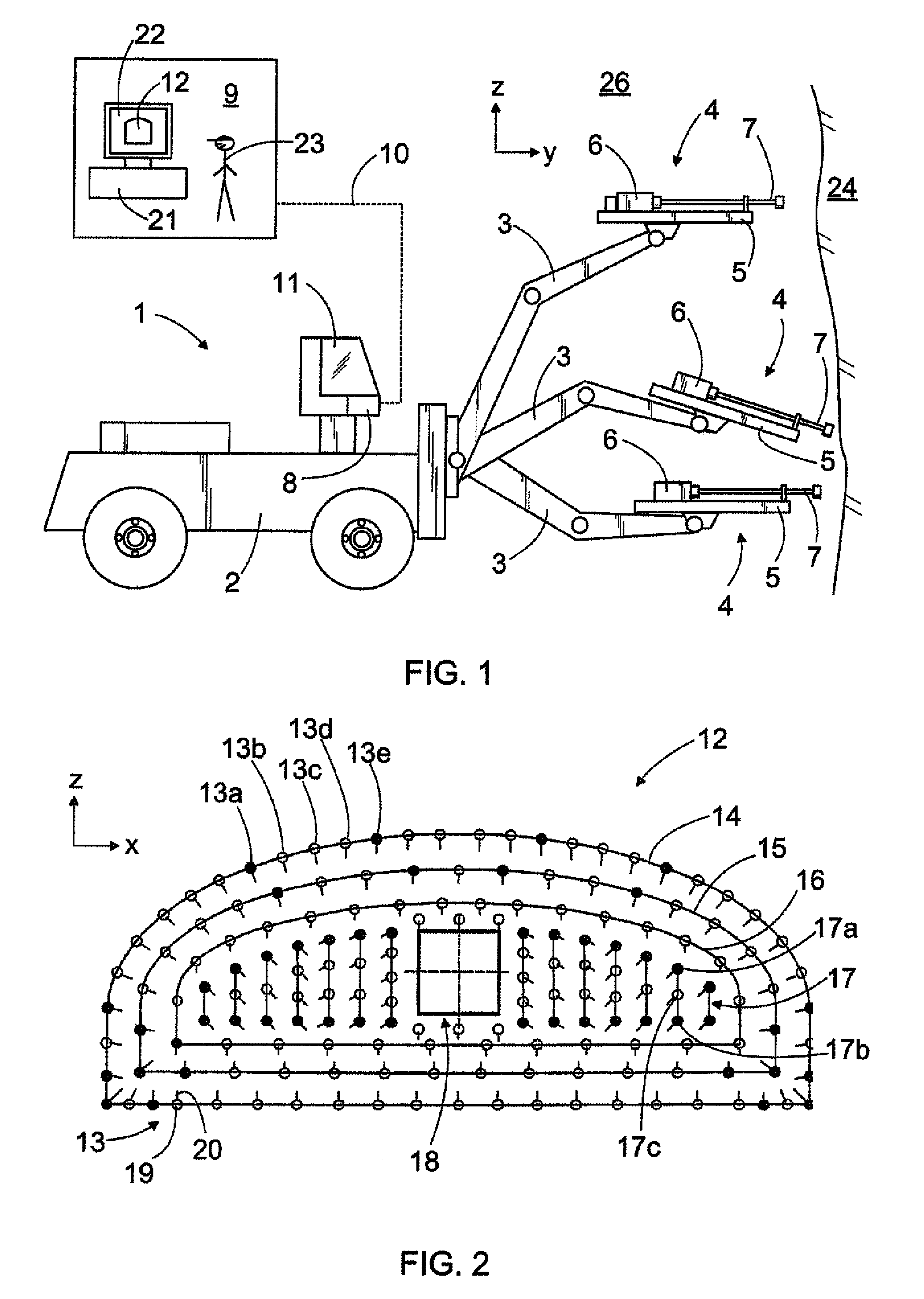

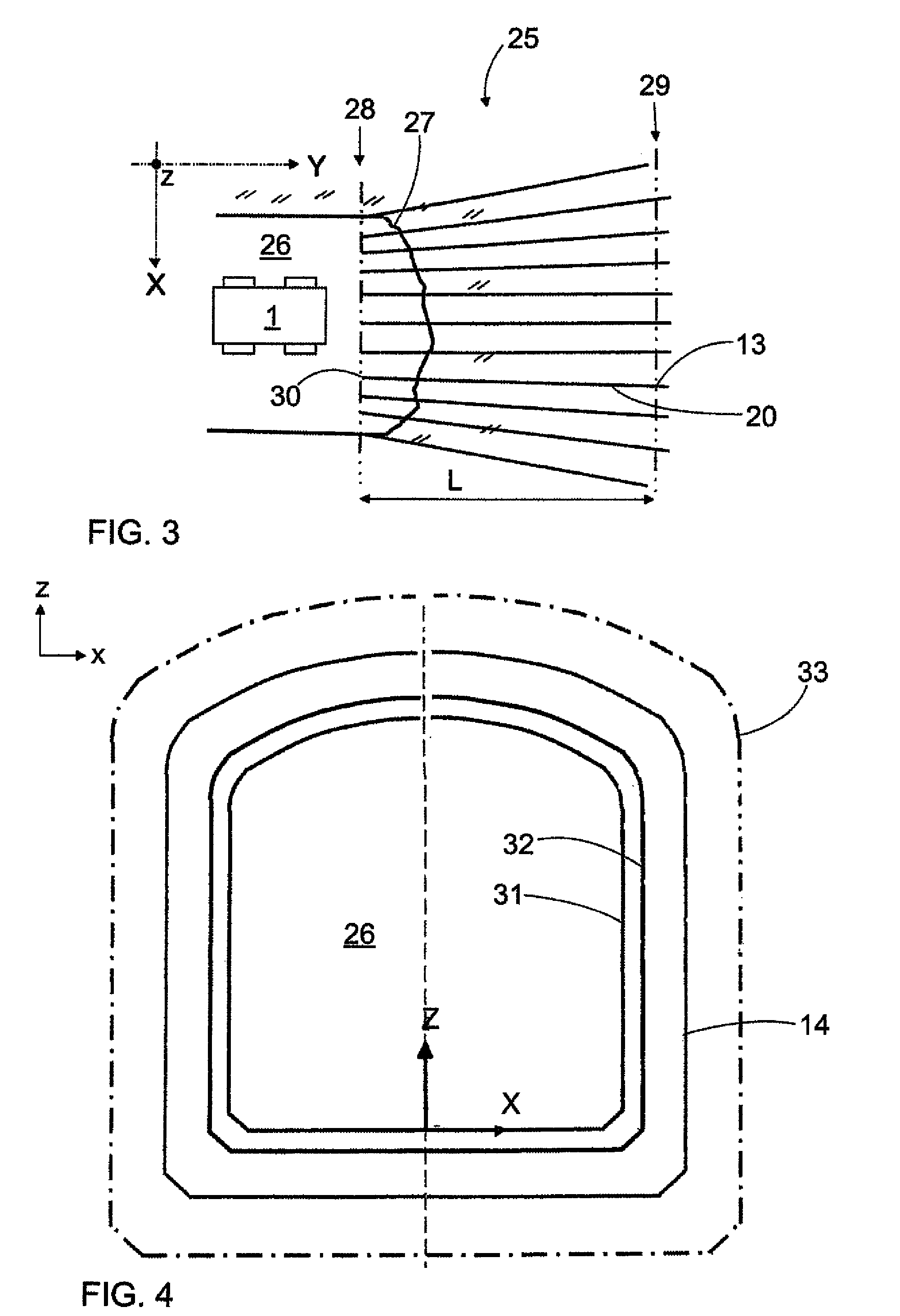

Designing drilling pattern for excavating rock cavern

ActiveUS20100044107A1Efficient detachmentEasy to determineComputer controlBlastingMarine navigationSoftware

The invention relates to a method and a software product for designing a drilling pattern for excavating a rock cavern. The invention further relates to a rock-drilling rig, in whose control unit the software product and the method are executable. During designing of the drilling pattern, drill hole bottom locations are placed at a blast plane at the bottom of a round. A drilling pattern design program determines the missing properties of the drill holes viewed from the bottom of the round towards a navigation plane. The program is able to determine a starting location for a drill hole based on the location and the direction of the bottom. The program also performs blasting calculation on the drill holes positioned.

Owner:SANDVIK MINING & CONSTR OY

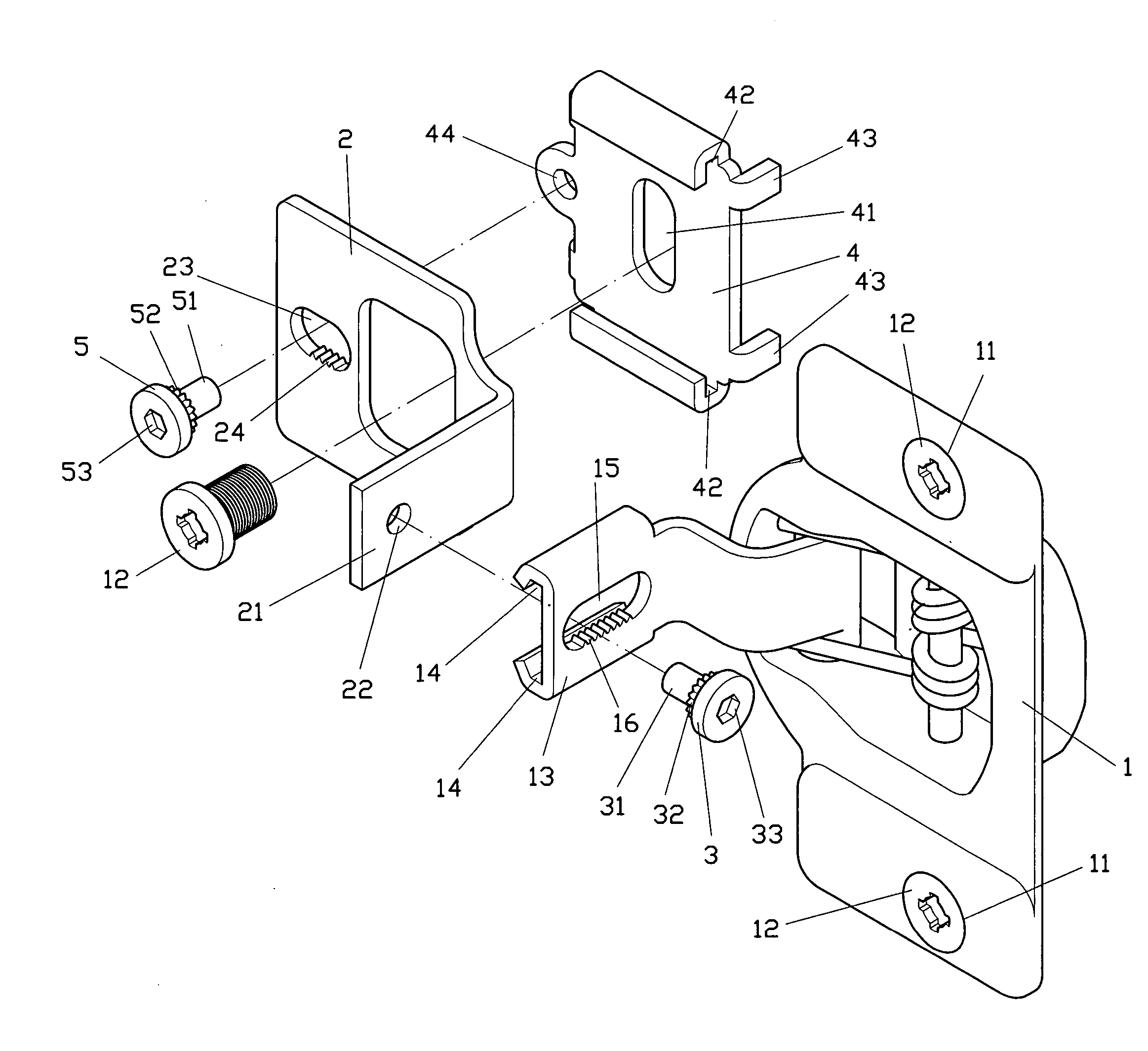

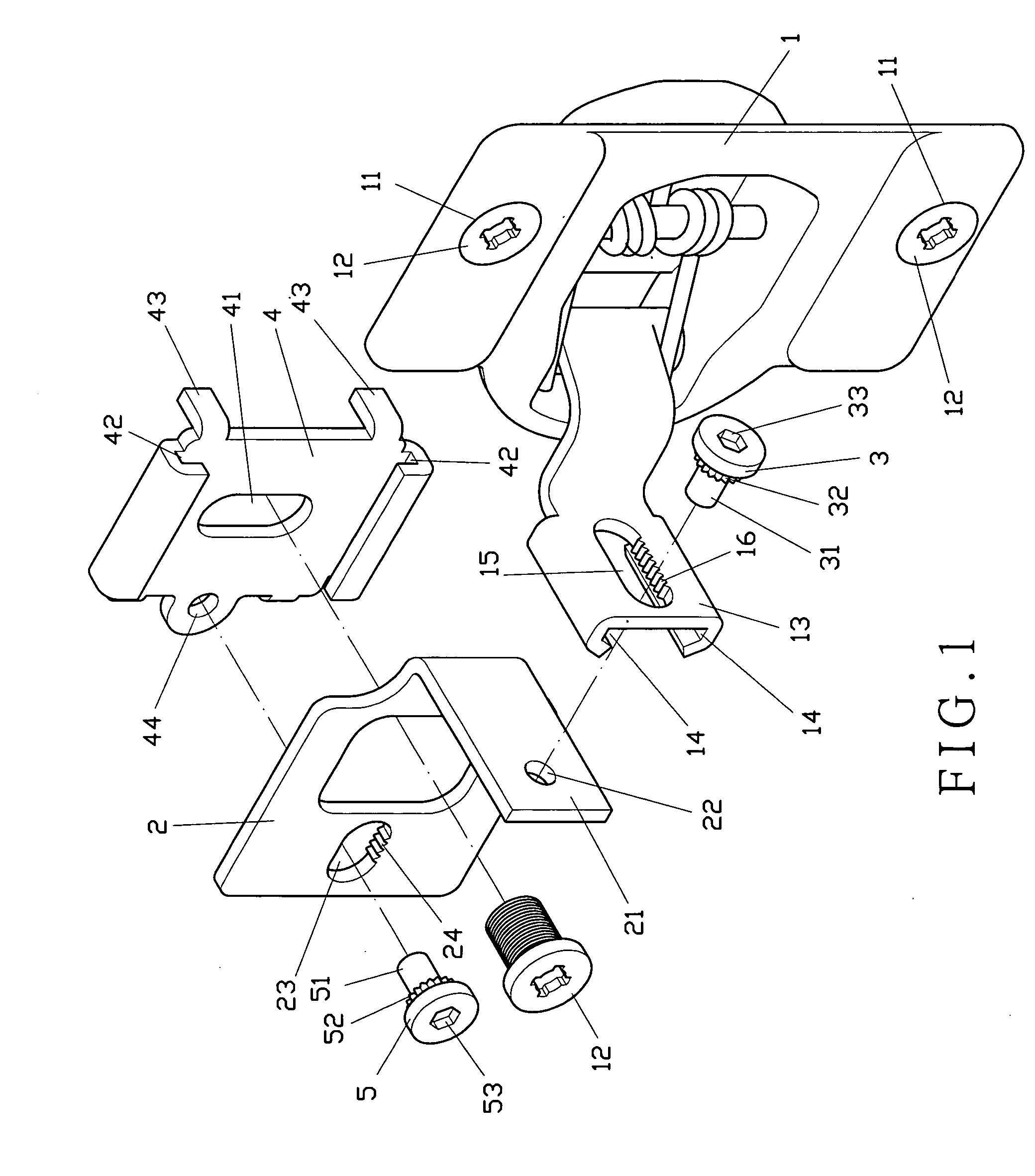

Adjustable hinge structure

InactiveUS20050251961A1Easy to adjustAvoid drillingPortable framesPin hingesEngineeringMechanical engineering

Owner:LIU HSU NAN

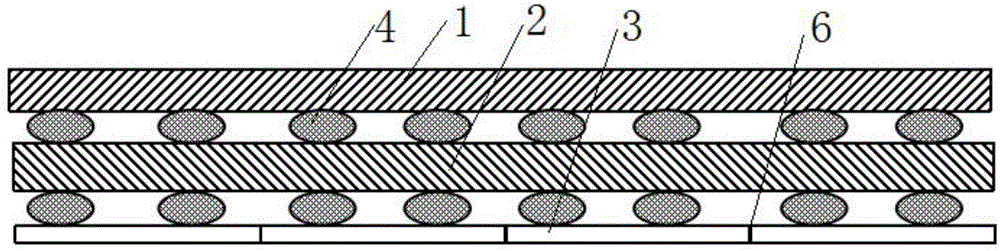

Heat-storing waterproof moisture-permeable outdoor down cotton-wadded garment fabric and preparation method thereof

ActiveCN106042538AImprove comfortFluffy goodSynthetic resin layered productsLaminationThree-dimensional spaceCompound structure

The invention discloses a heat-storing waterproof moisture-permeable outdoor down cotton-wadded garment fabric and a preparation method thereof and belongs to the field of textile garments. The fabric comprises a waterproof layer, a waterproof moisture-permeable heat-storing PU (polyurethane) film and a nylon fabric layer sequentially from outside to inside, and both the side of the waterproof layer contacted with the waterproof moisture-permeable heat-storing PU film and the side of the waterproof moisture-permeable heat-storing PU film contacted with the nylon fabric layer are laminated by using spot hot-melt PU adhesive. The invention has the advantages that the hot-melt adhesive is used to laminate the waterproof fabric, the waterproof moisture-permeable heat-storing PU film and bilayer quilting-free 20D nylon fabric to form the multilayer composite fabric so that a down garment fabric obtained has good puffy effect and reasonable three-dimensional space structure and comfort of a down garment to wear is improved.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Electronic device and manufacturing method thereof

ActiveCN108540595AIncrease the screen ratioGuaranteed reliabilityPower managementTelephone set constructionsEngineeringElectron

The invention discloses an electronic device and a manufacturing method thereof. The electronic device comprises a light-transmitting display screen and an infrared sensor, wherein the light-transmitting display screen comprises an upper surface and a lower surface backed to the upper surface; the light-transmitting display screen is used for emitting light to display through the upper surface; the lower surface comprises a display region and a border region surrounding the display region; and the infrared sensor is used for transmitting and / or receiving infrared light through the border region. According to the electronic device and the manufacturing method thereof, which are disclosed by the invention, the light-transmitting display screen is adopted, and the infrared sensor can be arranged in the border region of the lower surface of the light-transmitting display screen in a case of a full screen, so that influence of the infrared light emitted by the infrared sensor on working stability of a TFT of the display region can be avoided, thereby enabling the light-transmitting display screen and the infrared sensor to achieve respective functions in a case of mutual noninterference.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

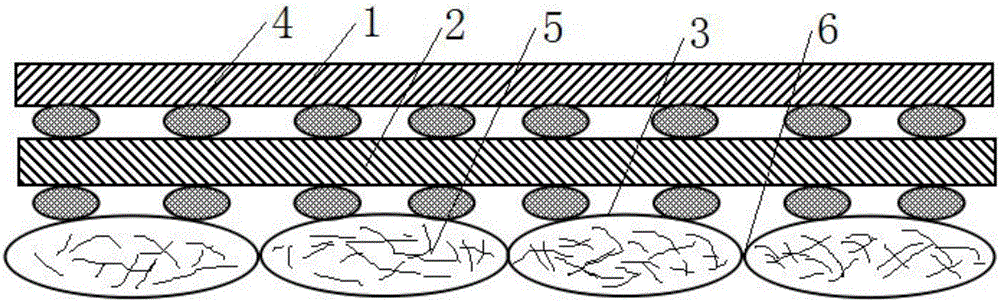

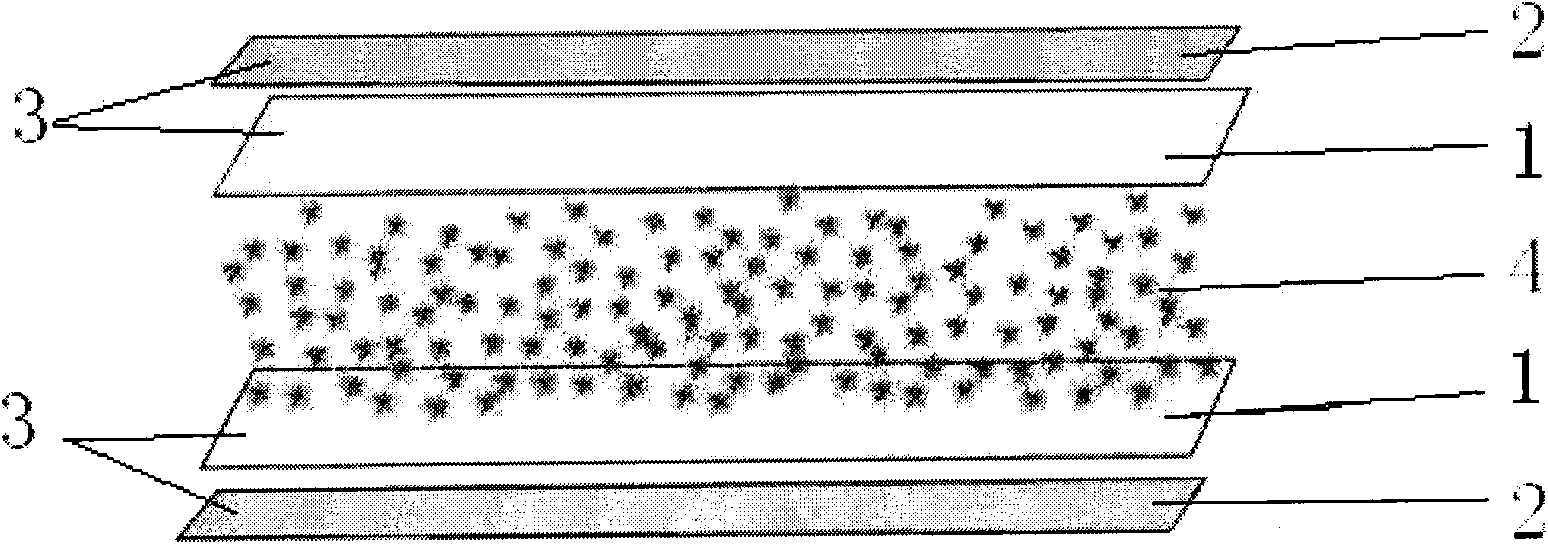

Down products with penetration resistance and manufacturing method thereof and manufacturing method of down jacket

InactiveCN101669688AAvoid drillingHigh densityOvergarmentsProtective garmentMechanical engineeringDown feather

The invention discloses down products with penetration resistance and a manufacturing method thereof and a manufacturing method of a down jacket. The manufacturing method of the down products with penetration resistance comprises the following steps: cutting out terylene cloth and inviscid non-woven interlining; sewing up the terylene cloth and the inviscid non-woven interlining together to form abag-shaped composition body of the terylene cloth and the inviscid non-woven interlining; filling down feathers to the bag-shaped composition body of the terylene cloth and the inviscid non-woven interlining; completely sewing up the bag-shaped composition body of the terylene cloth and the inviscid non-woven interlining to manufacture into the down products with penetration resistance. In the manufactured down products with penetration resistance, the terylene cloth completely wraps up the down feathers and is between the down feathers and the inviscid non-woven interlining; and the inviscidnon-woven interlining completely wraps up the terylene cloth. The invention can effectively realize the function of penetration resistance.

Owner:报喜鸟控股股份有限公司

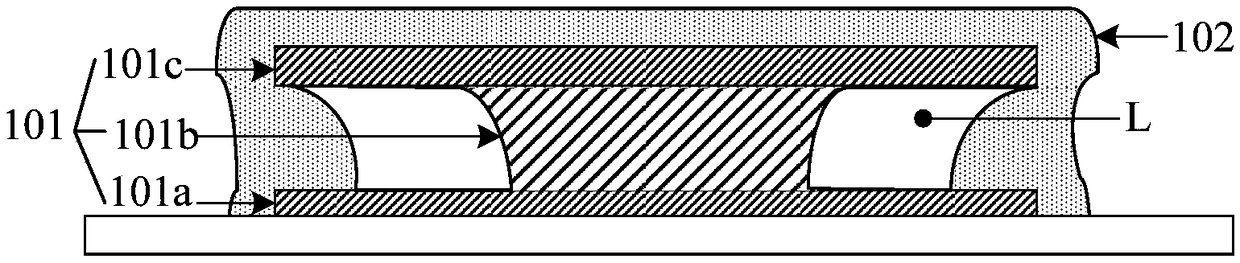

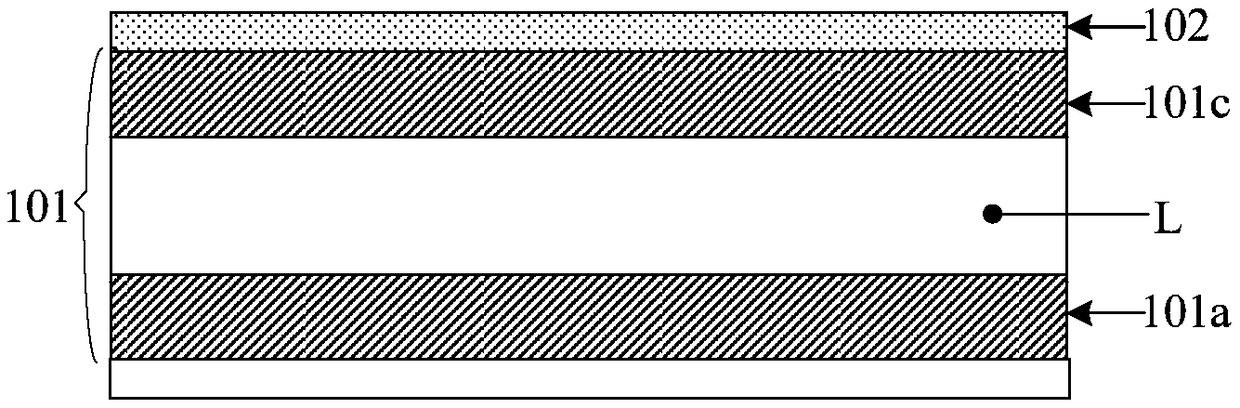

Display substrate, manufacturing method thereof and display device

InactiveCN109449182AImprove package reliabilityInhibitionSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDisplay device

The invention discloses a display substrate, a manufacturing method thereof and a display device, and belongs to the technical field of displaying. The display substrate comprises a substrate, a thinfilm transistor, a light-emitting device and a package structure, wherein the thin film transistor, the light-emitting device and the package structure are sequentially arranged on the substrate, thethin film transistor comprises a gate pattern, a gate insulation layer, an active layer and a source-drain pattern, the source-drain pattern comprises a source, a drain and at least one power signal line, the source and the drain are arranged in the display region, the at least one power signal line is arranged in a non-display region, at least one side edge of each power signal is coated with anelectrode block, the light-emitting device comprises a first electrode, a light-emitting layer and a second electrode which are laminated along a direction far away from the substrate, and the electrode block and the first electrode are obtained by fabrication at the same layer. By coating the side edge of the power signal line arranged in the non-display region with the electrode block, the sideedge, coated with the electrode block, of the power signal line can be prevented from being drilled, and the package reliability of the display substrate is improved.

Owner:BOE TECH GRP CO LTD

Down proof fabric

InactiveCN103541222AImprove breathabilityImprove wear resistanceFibre treatmentWoven fabricsAqueous solutionSodium sulphide

The invention relates to a textile and in particular relates to a down proof fabric. The down proof fabric is prepared by the following steps: selecting a gray fabric; sanding; rolling a down proof finishing agent at the processing speed of 60-80 m / min, namely ensuring that a sanded fabric passes through a down proof finishing agent aqueous solution at the temperature of 40-55 DEG C with the pick-up of 45%-65%, wherein the down proof finishing agent comprises a starch composite catalyst and a compound, and the compound is formed by compounding an acrylic acid acrylamide compound with a hydrophilic softening agent KF-896 in a mass ratio of (2-5):1; dyeing, namely immersing in a dye liquor, reducing and steaming, washing, oxidizing, washing, soaping, washing, drying and rolling up, wherein the dye liquor comprises dye, sodium sulphide, a wetting agent and sodium carbonate, and the thickness pick-up of the dye liquor is 60%-70%, a reducing and steaming temperature is 90-100 DEG C, and reducing and steaming time is 40-50 seconds; printing at the temperature of 100-115 DEG C; calendaring at the temperature of 105-115 DEG C and at the processing speed of 30-50 m / min; preshrinking; and after finishing. The prepared down proof fabric has excellent air permeability and an excellent effect of preventing down feather from unthreading.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

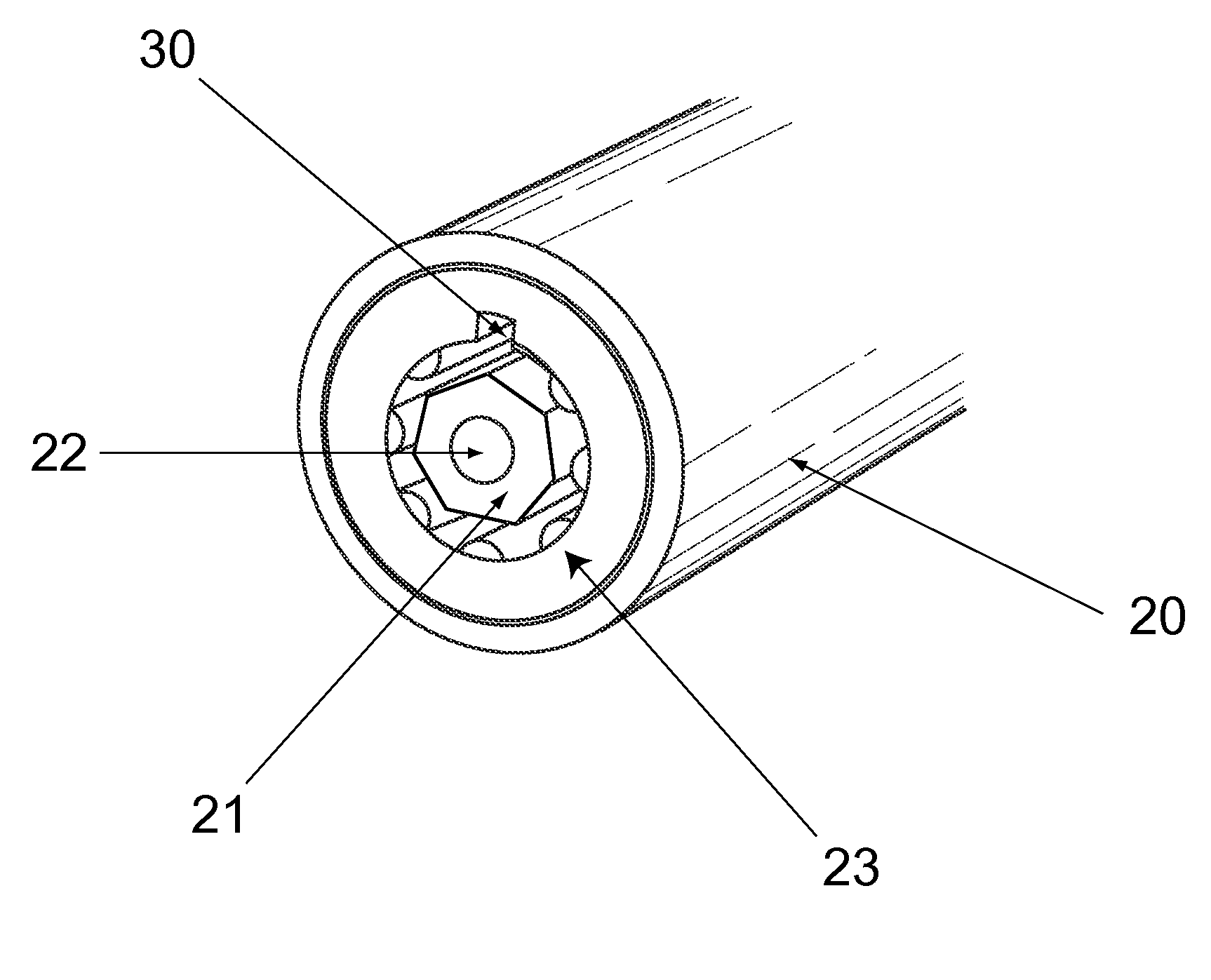

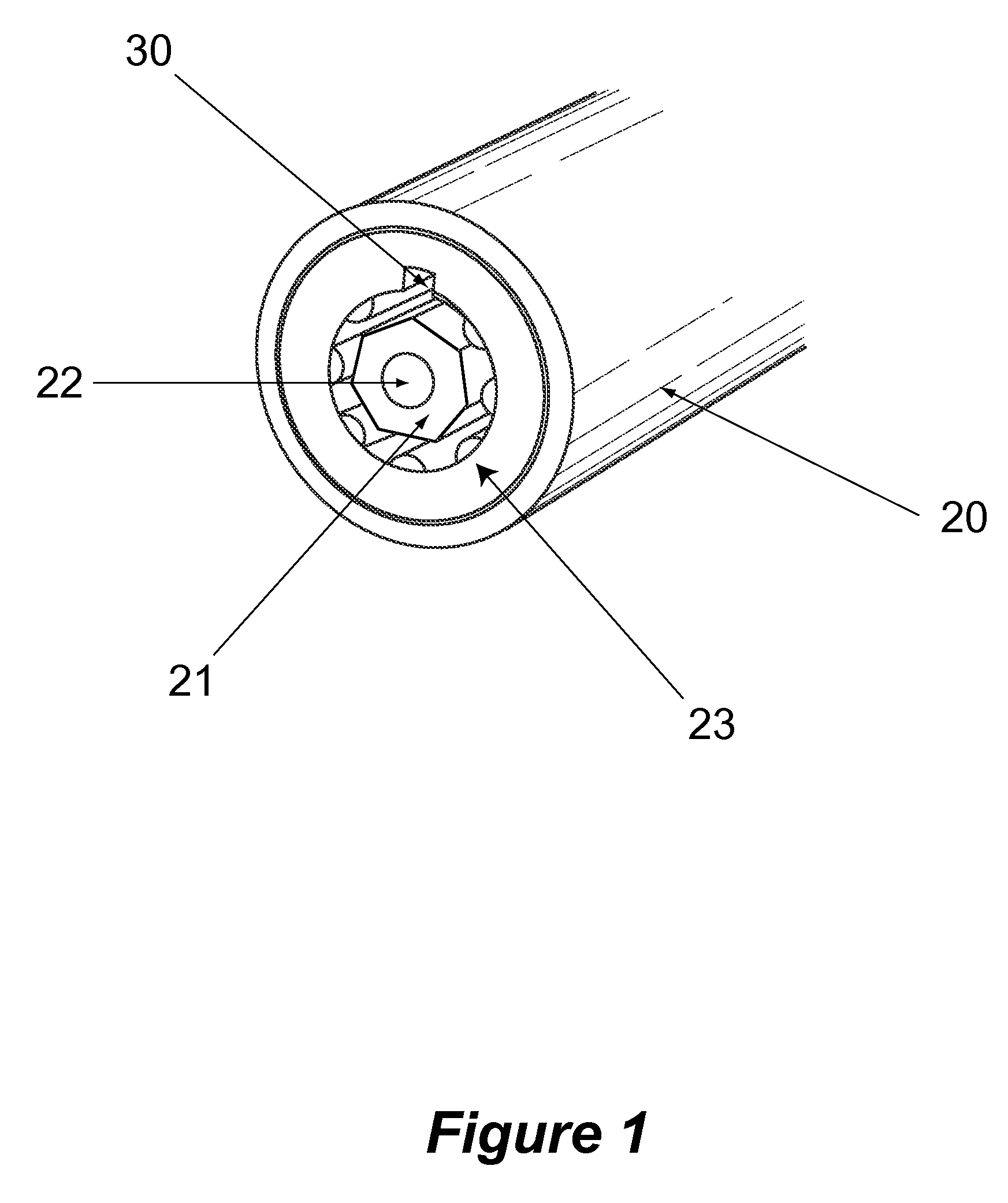

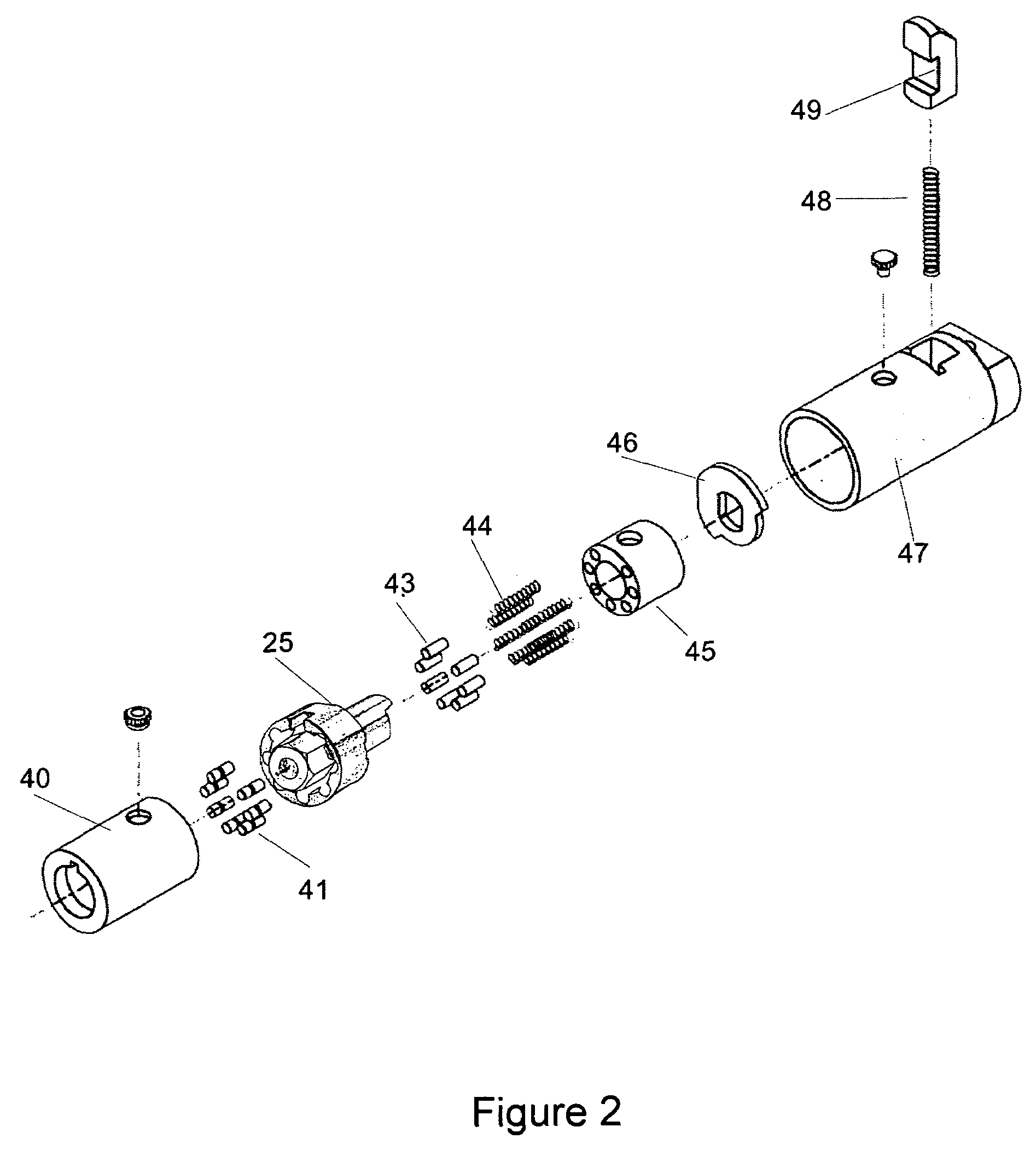

Tubular radial pin tumbler lock

Owner:LOCKING SYST INT

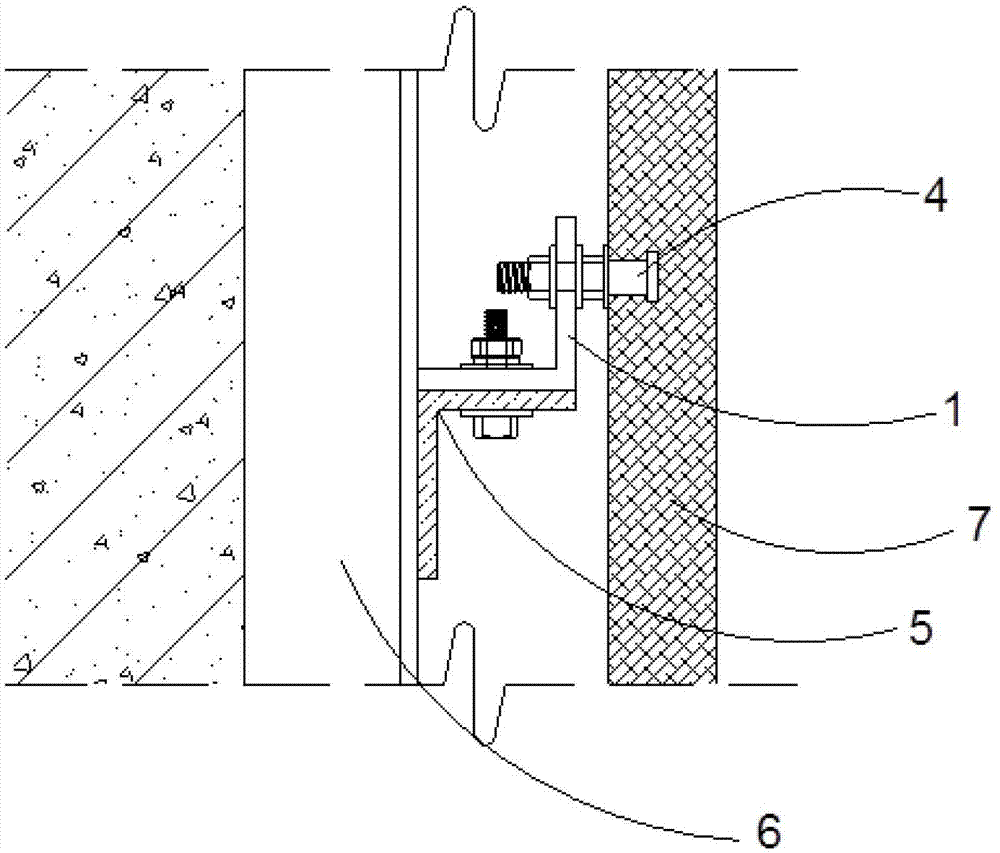

Metal hanger of stone curtain wall

InactiveCN102733521ADoes not destroy strengthAvoid drillingWallsArchitectural engineeringCurtain wall

The invention discloses a metal hanger of a stone curtain wall. The metal hanger consists of a horizontal wing and a vertical wing. The horizontal wing and the vertical wing are respectively provided with a hole or a slot. According to the metal hanger of the stone curtain wall, the end part of stone is prevented from slotted or drilled, whereas the mode that the back part of the stone is drilled to install a back plug is adopted, and thus, the strength of the stone cannot be broken, and the safe reliability is high. Meanwhile, based on the metal hanger of the stone curtain wall, the horizontal position of the stone is regulated through a screw nut, the vertical position of the stone is regulated through a metallic gasket between the hanger and a rear steel structural part, and the left and right position of the stone is regulated through a strip hole of the screw nut in the hanger, therefore, four-dimensional regulation can be realized on the stone curtain wall. The metal hanger of the stone curtain wall has the advantages that the structure is simple, steel is saved, the installation is convenient, and the construction efficiency is high.

Owner:曾红

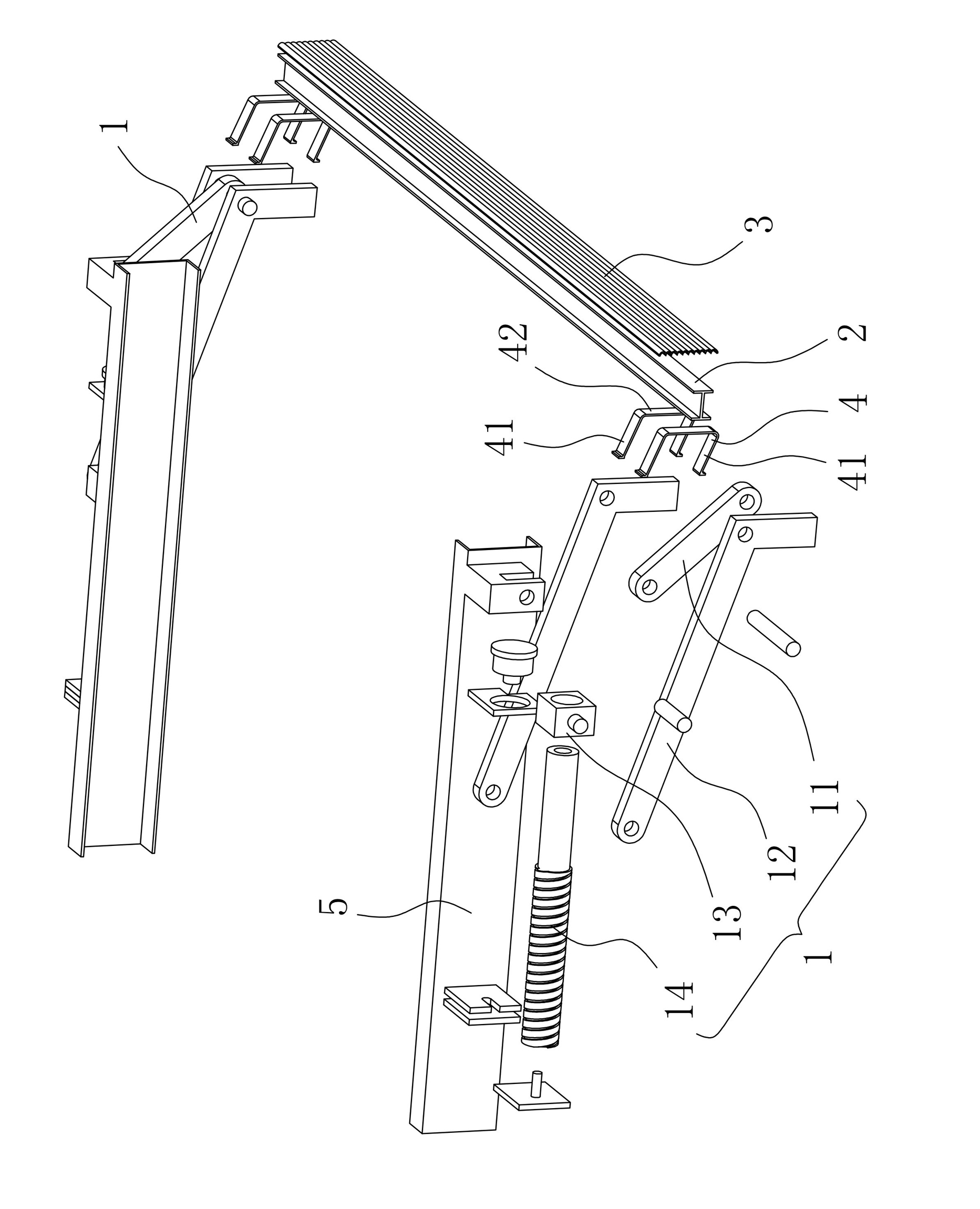

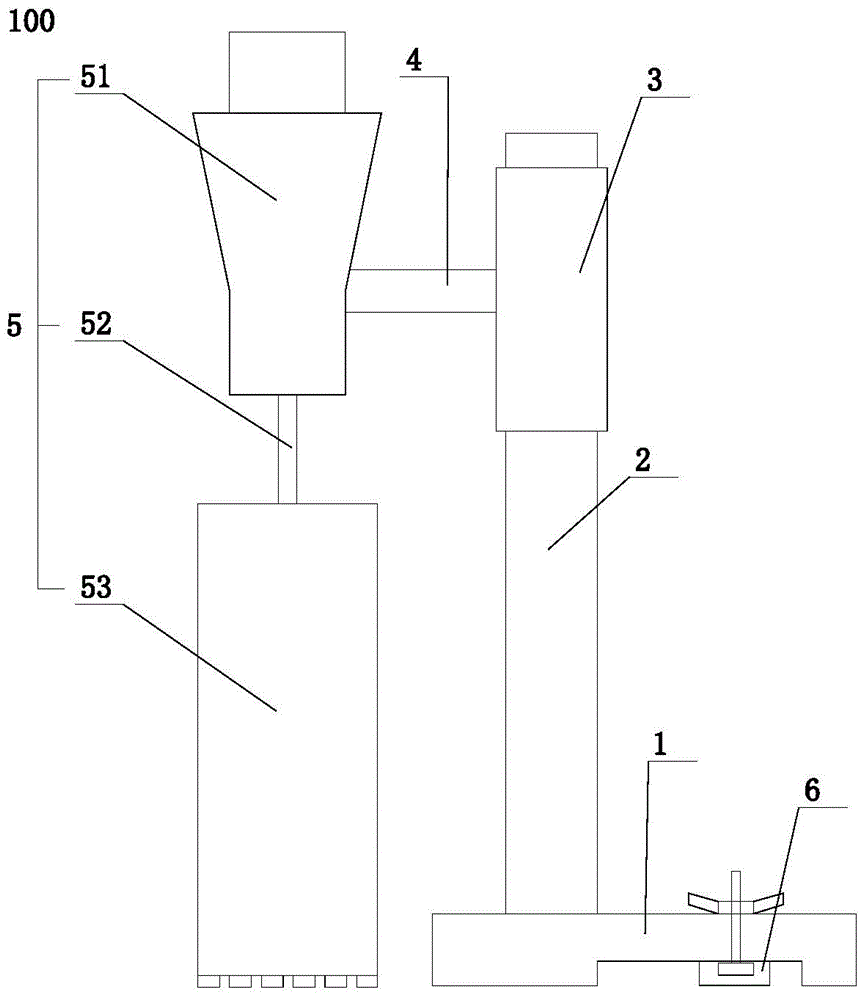

Drilling device and method for cutting reinforced concrete supporting beam

ActiveCN104669449AImprove work efficiencyShorten the construction periodWorking accessoriesExcavationsReinforced concreteRebar

The invention provides a drilling device, comprising a base, a machine body, a drill bit lifting device, a connecting rod drilling machine, at least two drill bits and a guide rail, wherein the drill bits can be controlled independently; the drilling device can drill a plurality of holes in one step, so that the drilling efficiency can be improved exponentially, and repeated work is prevented. Meanwhile, the invention further provides a method for cutting a reinforced concrete supporting beam. According to the drilling device and the method for cutting the reinforced concrete supporting beam, the drilling device is arranged on the surface of the reinforced concrete supporting beam, so that a plurality of holes can be drilled at intervals in one step, and the working efficiency for drilling and cutting the reinforced concrete supporting beam is greatly improved.

Owner:SHANGHAI CONSTRUCTION GROUP

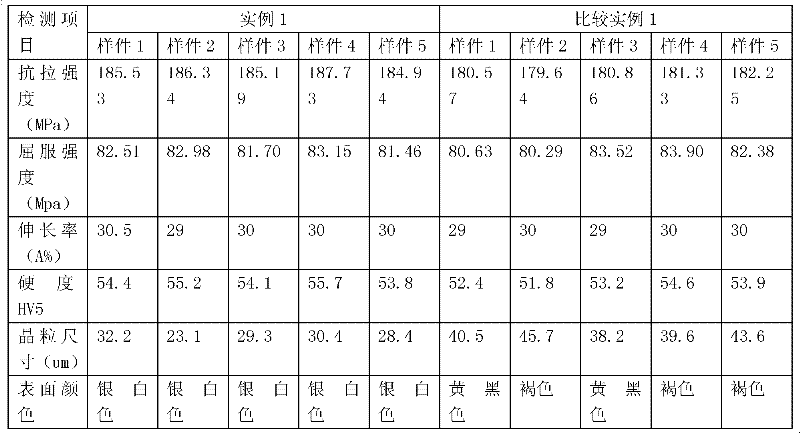

Preparation method of molybdenum metal grille

ActiveCN109014230AHigh sphericityIncrease heatAdditive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strength3d printer

The invention discloses a preparation method of a molybdenum metal grille. The preparation method comprises the steps of 1, conducting cold isostatic pressing, high-temperature sintering, hot fine forging and straightening treatment on molybdenum powder to obtain a molybdenum rod; 2, machining the molybdenum rod into spherical molybdenum powder through plasma rotating electrode powder manufacturing equipment; and 3, preparing a molybdenum metal grille molded part with the spherical molybdenum powder as a raw material through a powder bed electron beam 3D printer and then conducting annealing,hot isostatic pressing and alkaline washing in sequence to obtain the molybdenum metal grille. According to the preparation method, the molybdenum powder is prepared into the spherical molybdenum powder; the molybdenum metal grille is prepared through the powder bed electron beam 3D printer; according to the characteristics that the spherical molybdenum powder is good in fluidity, compact and uniform in particle and tight in combination after quick melting and the heat of electron beams is high, the defects that molybdenum metal is high in strength, low in plasticity, very easy to oxidize andpoor in formability and is not likely to be machined into complex structural parts and functional parts are overcome, the specification and using properties of the molybdenum metal grille are improved, and the preparation cost is saved.

Owner:JINDUICHENG MOLYBDENUM CO LTD

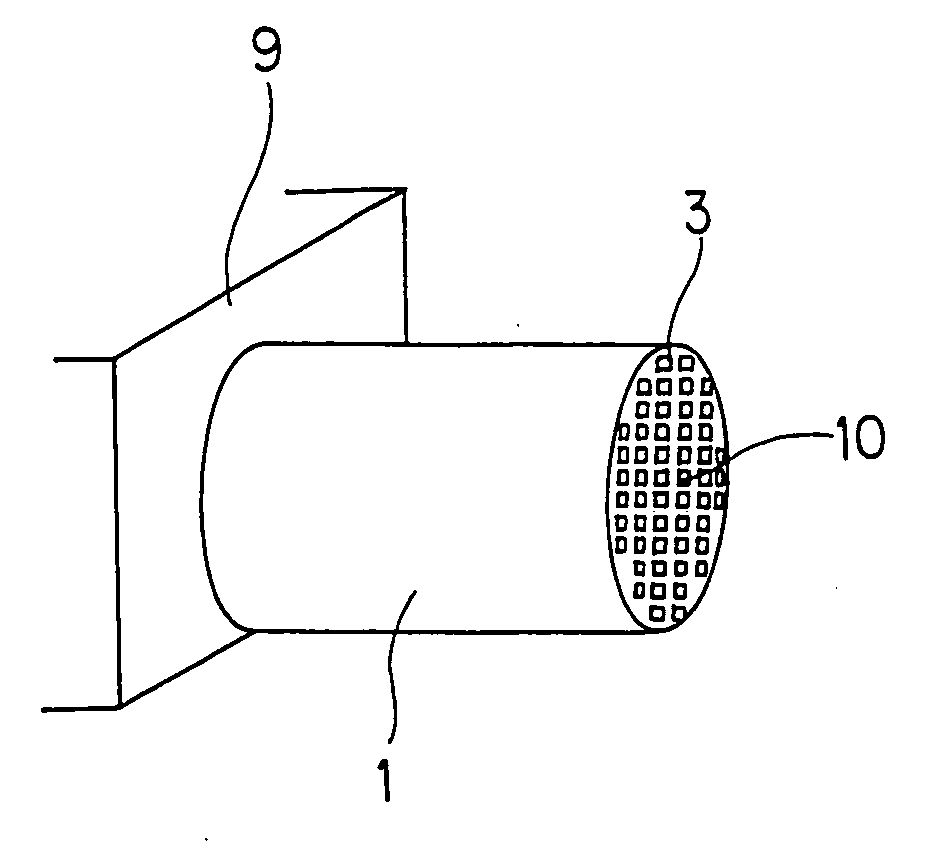

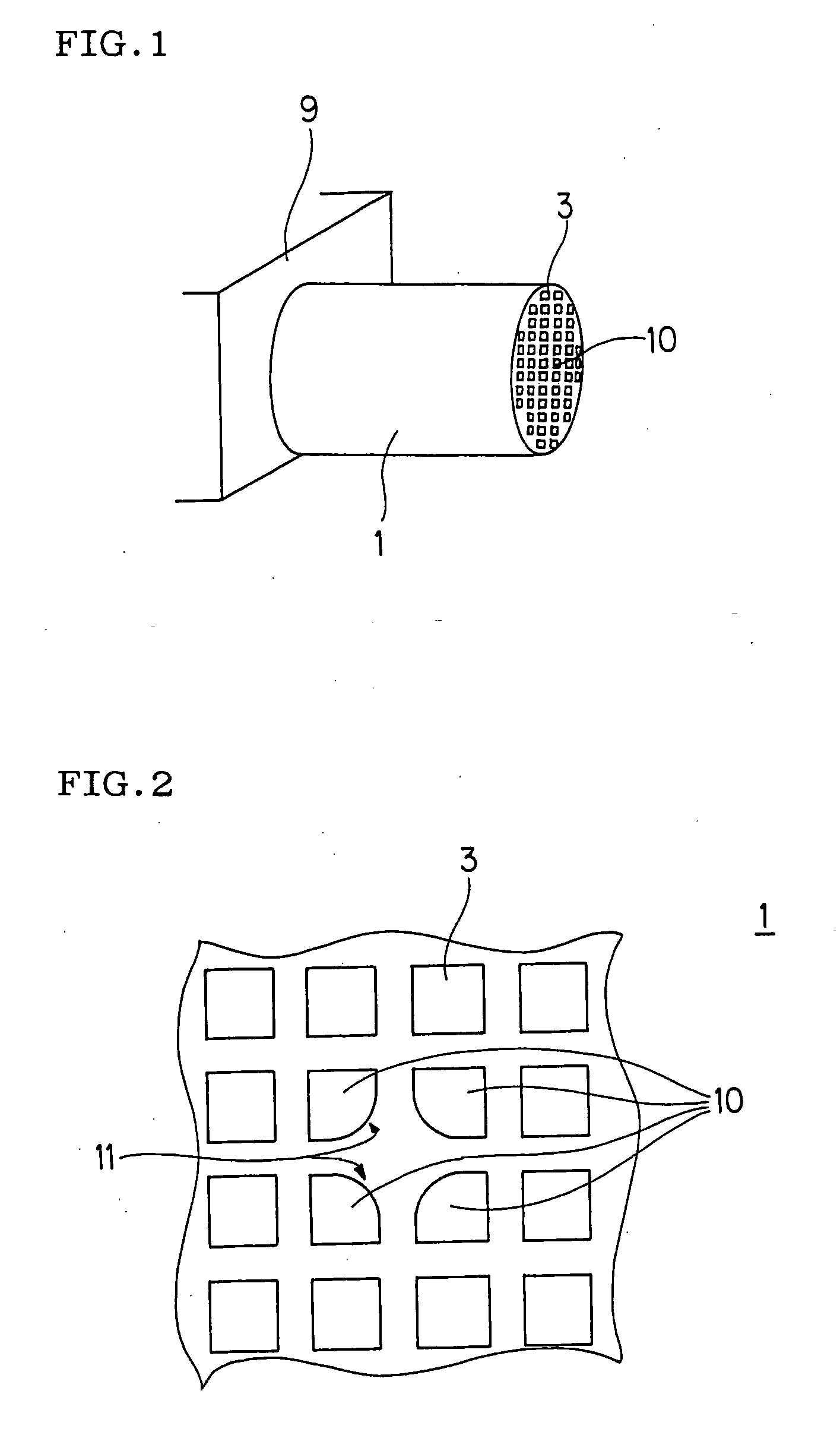

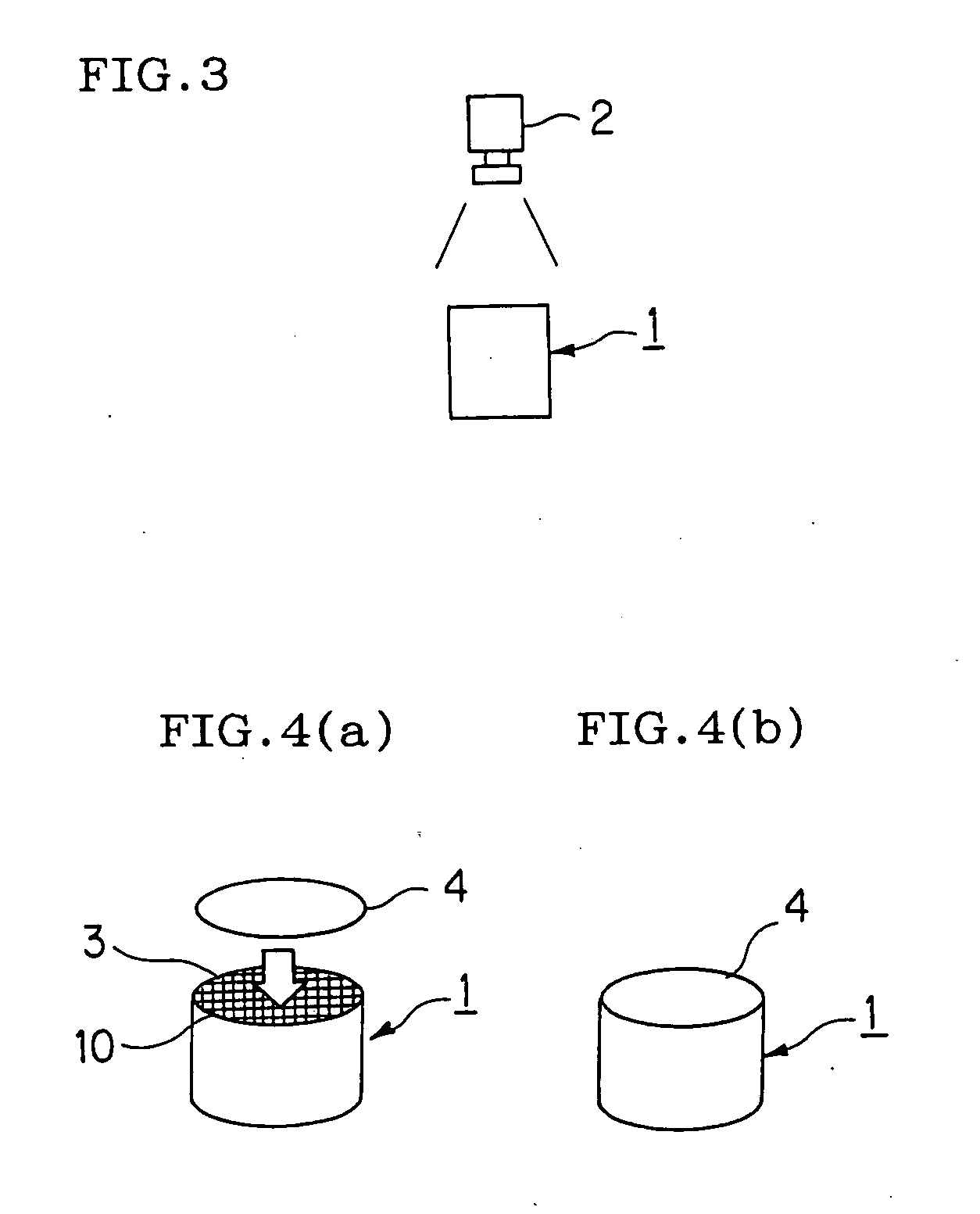

Method of manufacturing ceramic honeycomb structural body, and ceramic honeycomb structural body

InactiveUS20050161148A1Simple stepsAvoid drillingButtonsDispersed particle filtrationMetallurgySlurry

A method of manufacturing a ceramic honeycomb structure of the present invention, comprising the steps of: stamping sheets onto opposite end faces of a ceramic honeycomb body having a plurality of cells and formed into a honeycomb shape; drilling holes in the sheets at positions corresponding to opening parts of the cells; filling, through the holes, a slurry for sealing into the opening parts of the cells in the opposite end faces of the ceramic honeycomb body; firing the body; and alternately sealing the opening parts of the cells, characterized by comprising the steps of: forming the ceramic honeycomb body into a shape having at least one reference cell different in the shape of the opening part in the end face from the other cells; and drilling the holes in the sheets at the positions corresponding to the opening parts of the reference cell and the other cells with the reference cell taken as a reference point, whereby the ceramic honeycomb structure thus obtained can be manufactured at a low cost, since the cells to be sealed can be easily distinguished, and the holes can be quickly positioned in the drilling step.

Owner:NGK INSULATORS LTD

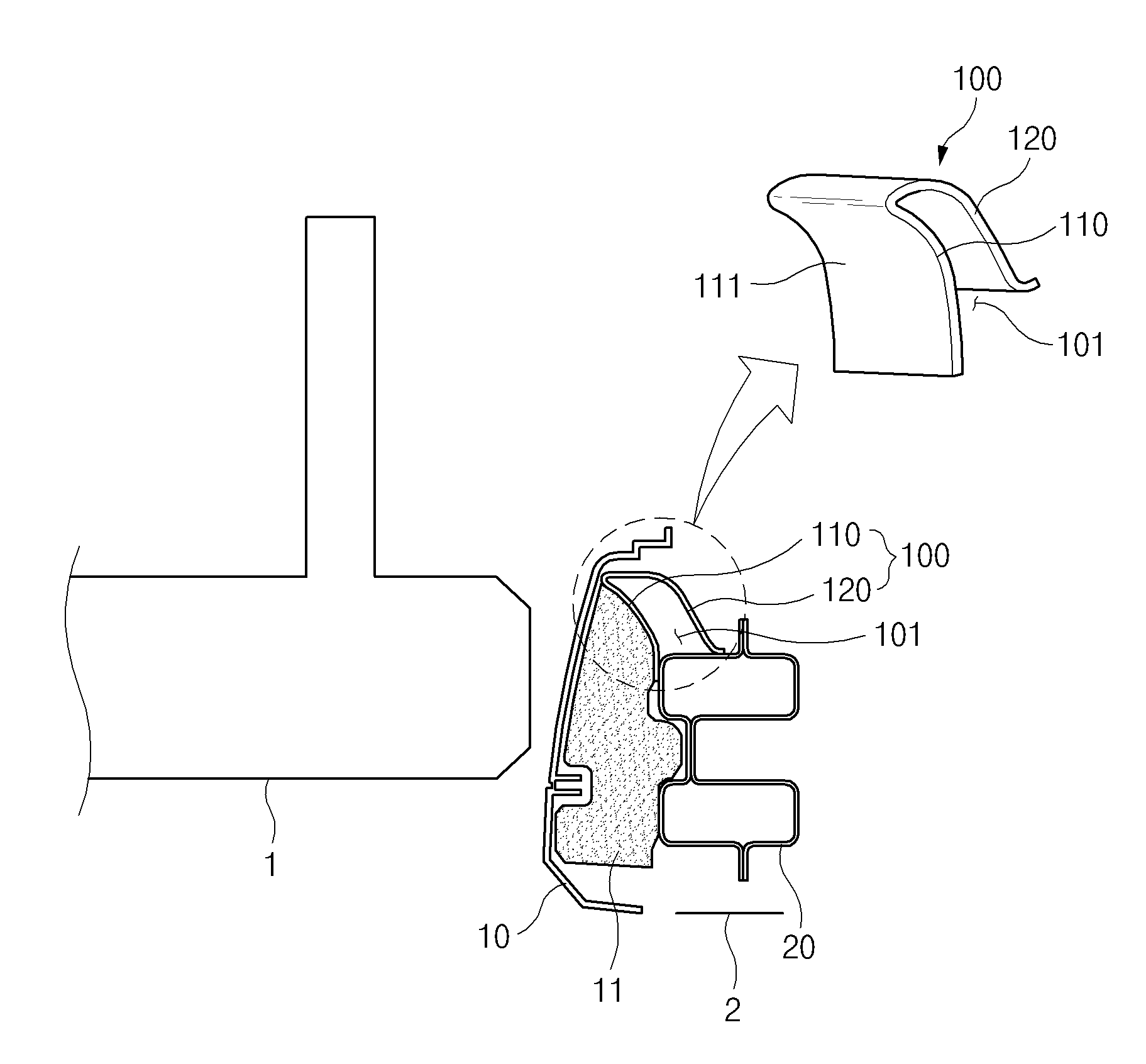

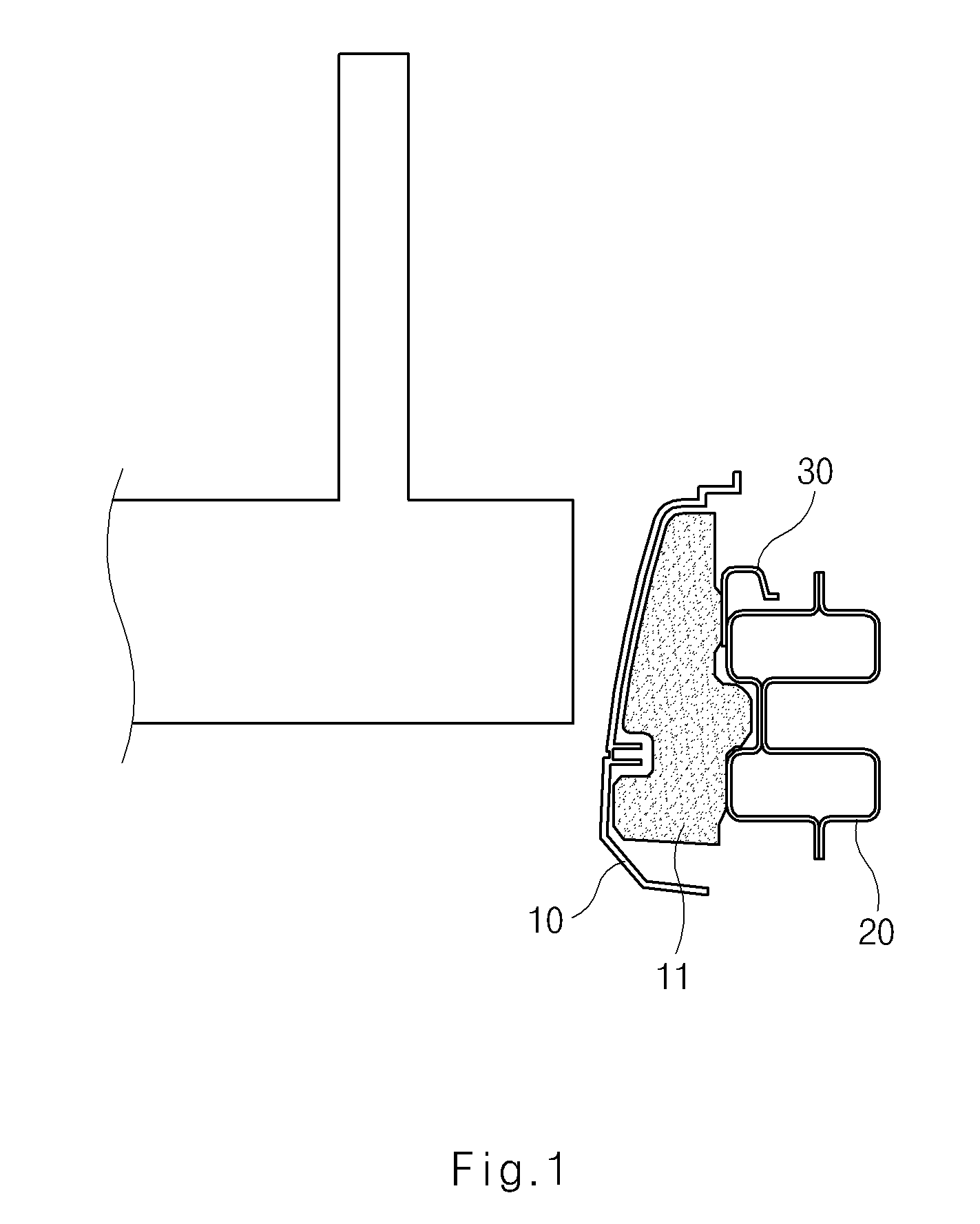

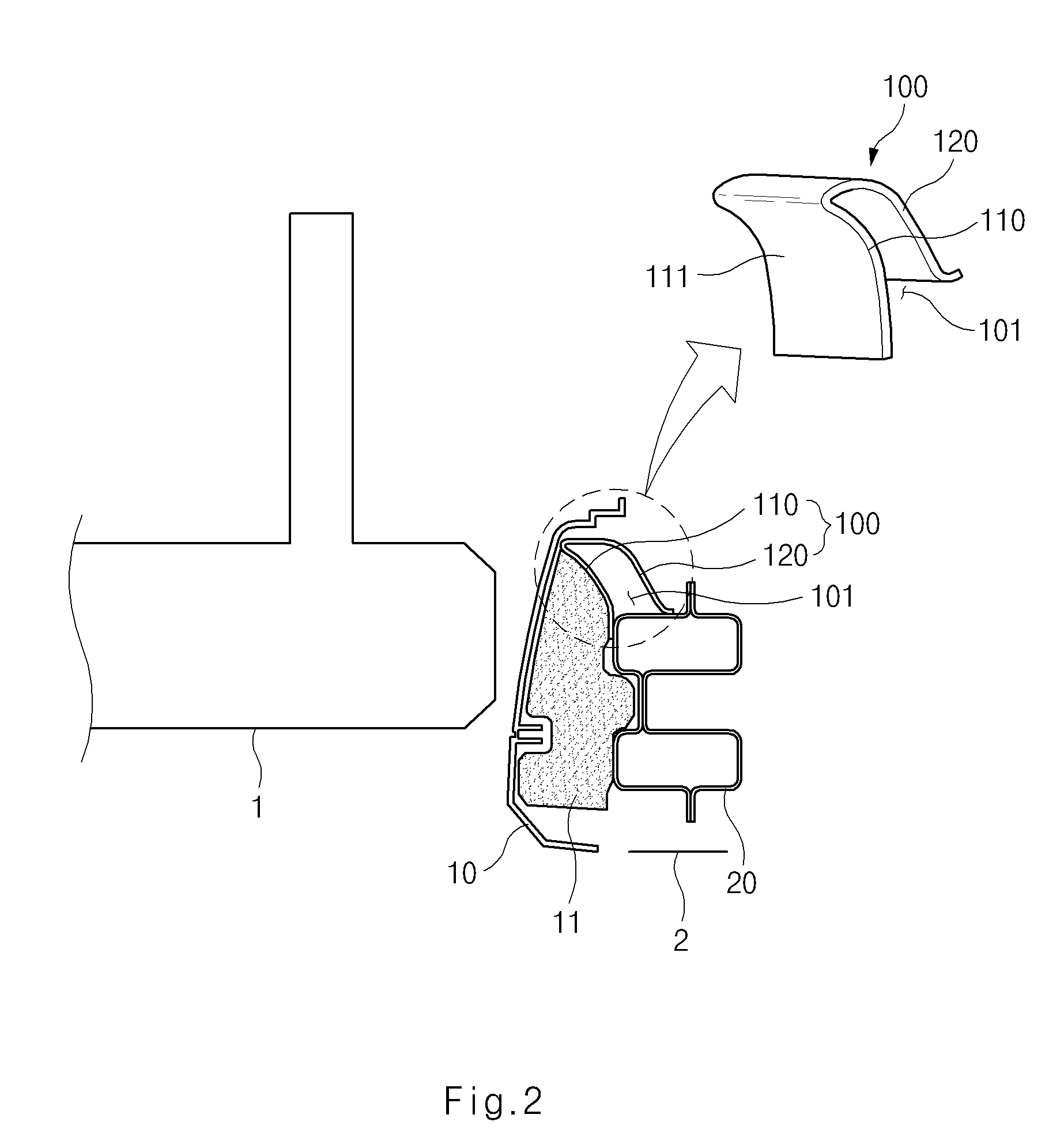

Automobile Bumper Back Beam Structure

An automobile bumper back beam structure provided in a bumper cover comprises a guide member for preventing under-riding from being generated when vehicles collide. The guide member comprises a guide part which is concavely curved with an arc-shape and fixed at the bumper back beam in the bottom end of the guide part and a supporting part which is extended from the top end of the guide part and fixed at the bumper back beam in the bottom end of the guide part. The guide member for adjusting a height difference of bumpers prevents under-riding of the bumpers when automobiles collide at a low speed, and minimizes a damaged area, thereby reducing repair cost and alleviating shock to obtain stability and silence.

Owner:HYUNDAI MOTOR CO LTD

Designing drilling pattern for excavating rock cavern

ActiveUS8214073B2Efficient detachmentEasy to determineComputer controlBlastingRock cuttingSoftware product line

The invention relates to a method and a software product for designing a drilling pattern for excavating a rock cavern. The invention further relates to a rock-drilling rig, in whose control unit the software product and the method are executable. During designing of the drilling pattern, drill hole bottom locations are placed at a blast plane at the bottom of a round. A drilling pattern design program determines the missing properties of the drill holes viewed from the bottom of the round towards a navigation plane. The program is able to determine a starting location for a drill hole based on the location and the direction of the bottom. The program also performs blasting calculation on the drill holes positioned.

Owner:SANDVIK MINING & CONSTR OY

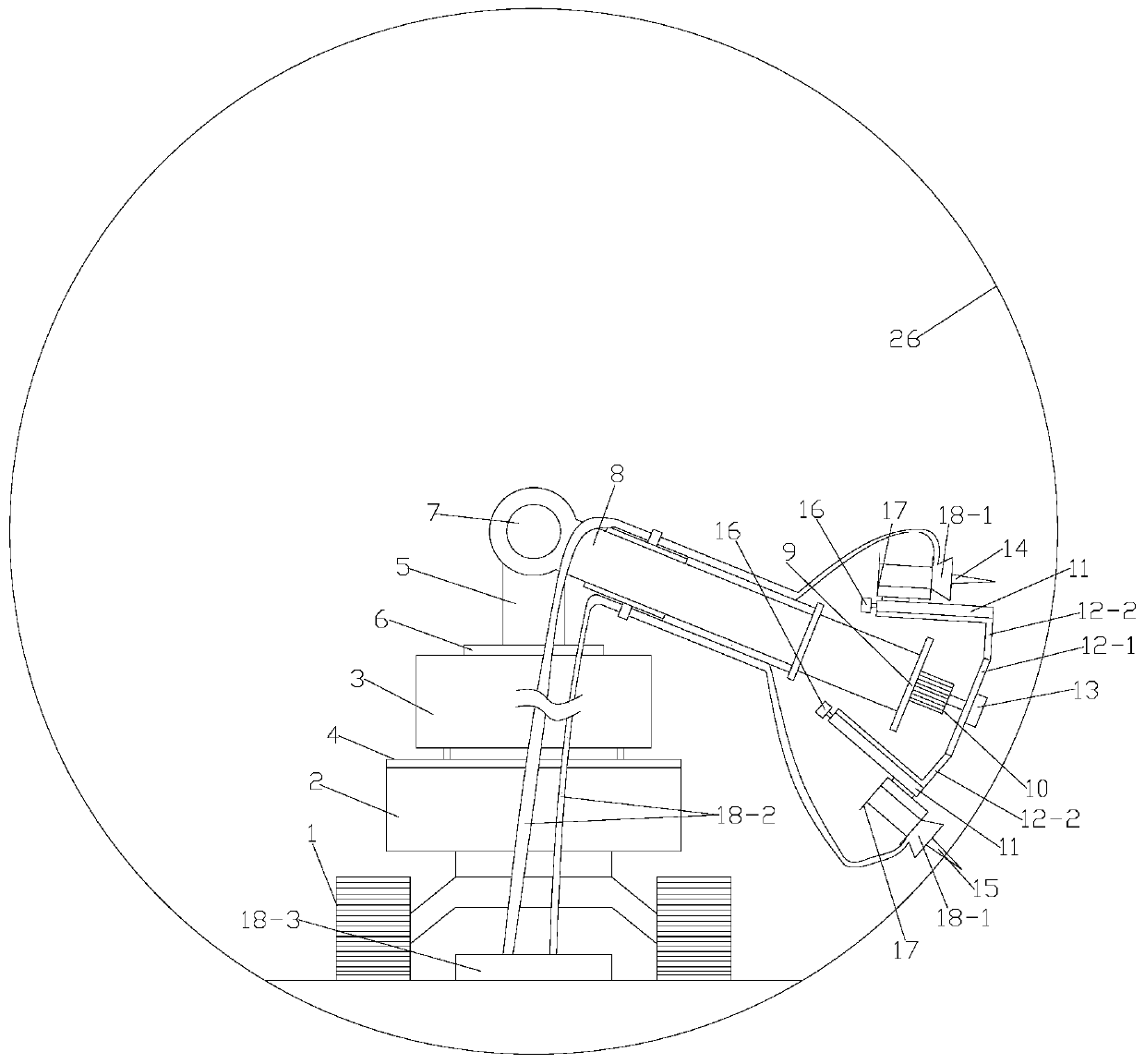

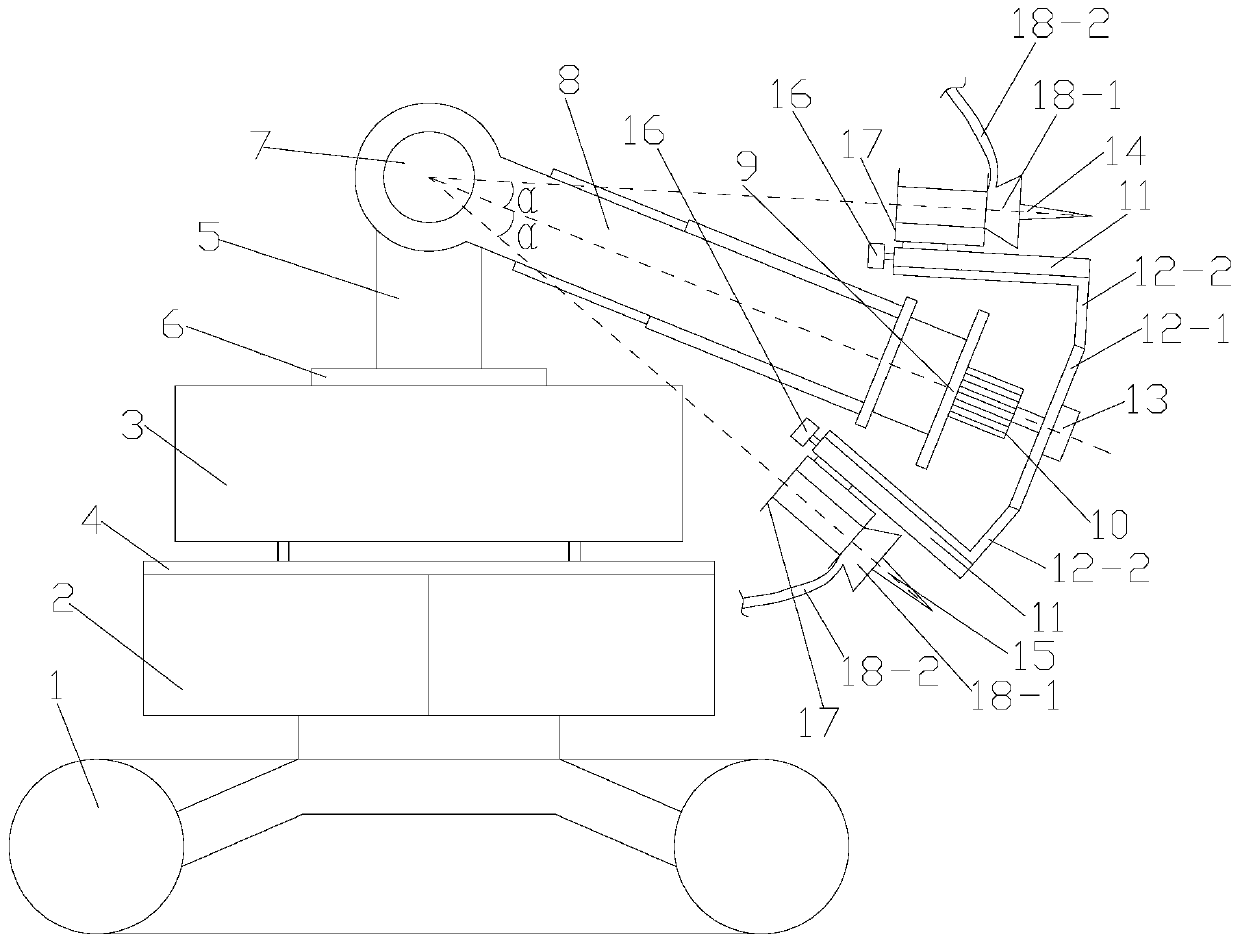

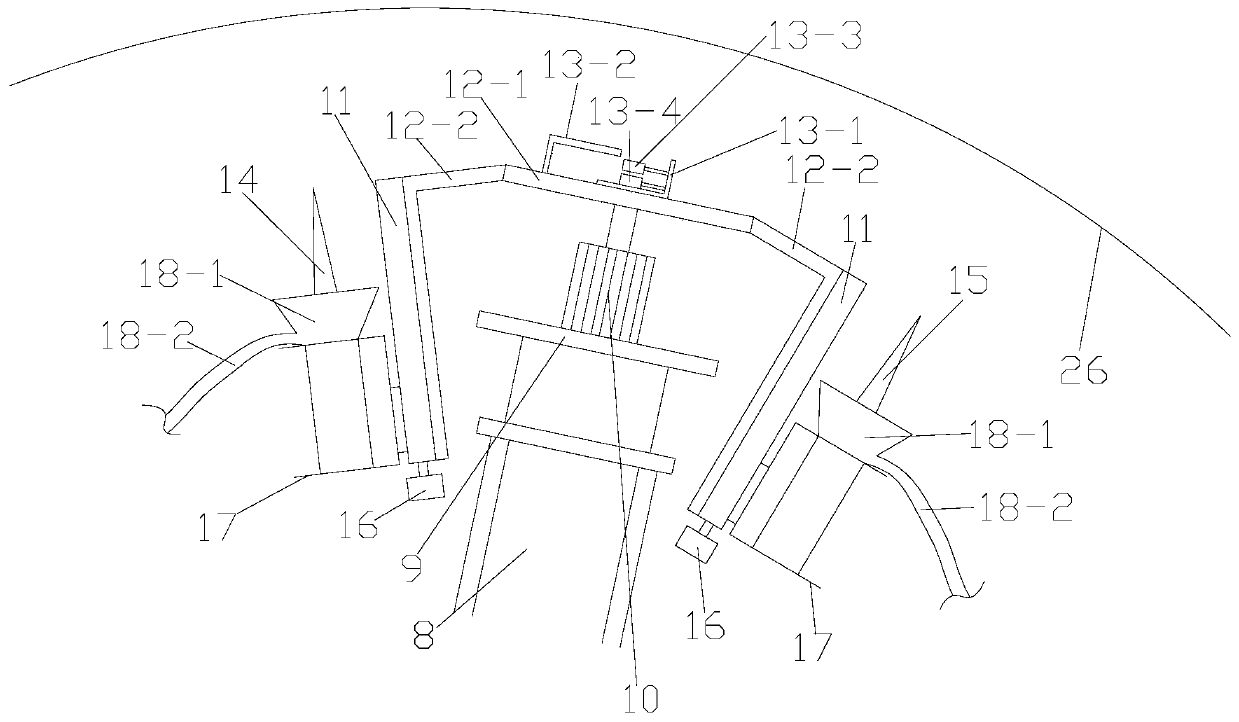

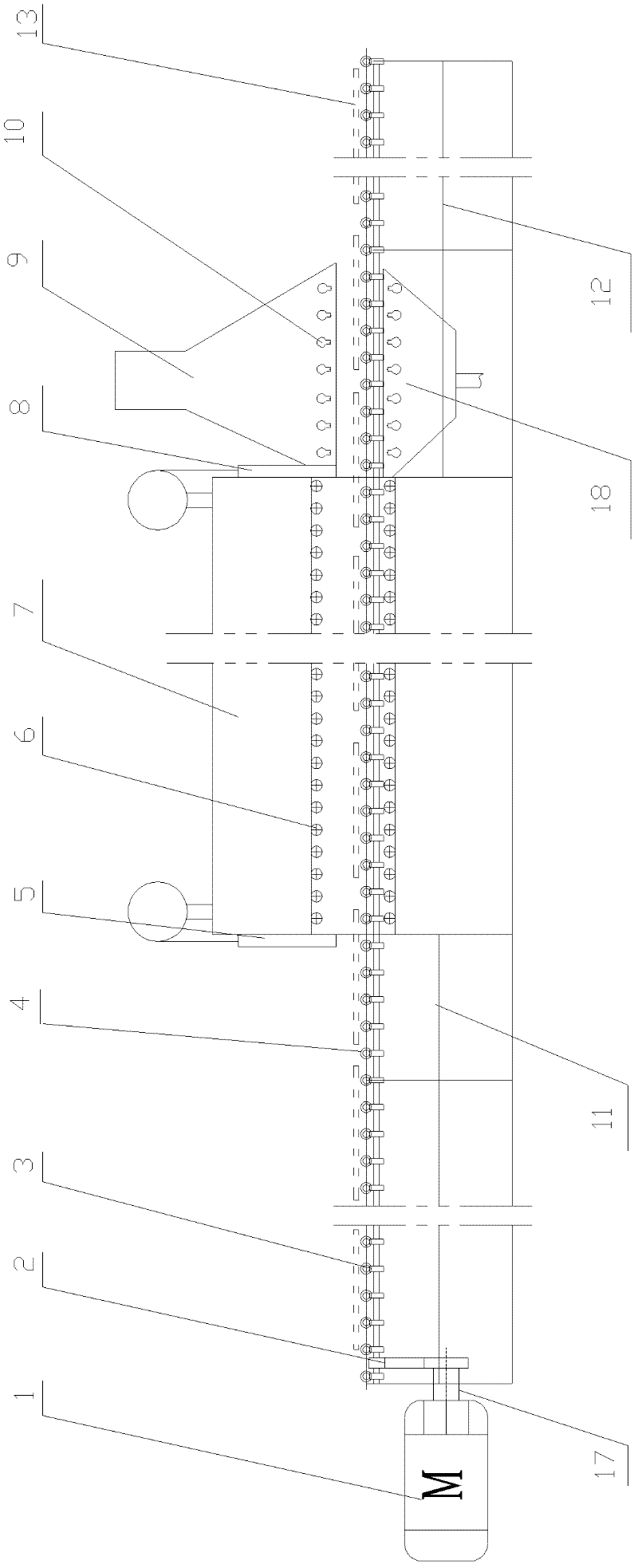

Double-drill bit tunnel automatic drilling machine and method

The invention discloses a double-drill bit tunnel automatic drilling machine and a method. The drilling machine comprises a crawler chassis, a control supporting box, a hydraulic control box, a centersupporting shaft, a transverse shaft, a main oil cylinder, a motor and a double-drill bit mechanism. The method comprises the following steps that 1, a hole position mark is arranged; 2, the drillingmachine carries out automatic drilling in a tunnel section by; 3, the drilling machine carries out tunnel automatic drilling; 4, percussion drill trouble shooting is carried out; and 5, steel bar drill trouble hunting is carried out. According to the double-drill bit tunnel automatic drilling machine and the method, by arranging the double-drill bit mechanism, unnecessary abrasion to a steel bardrill is reduced, and the production cost is reduced; and the working state of the drilling machine is identified through the drilling depth and the drilling speed, whether a steel bar is encounteredor not in the drilling process is detected in time, the drilling is continuously carried out by timely switching the drill bit when the steel bar is encountered, the drilling machine is prevented fromworking in an abnormal state or drilling a non-normal hole, the working reliability is high, and the drilling machine is convenient to popularize and use.

Owner:CCCC MECHANICAL & ELECTRICAL ENG

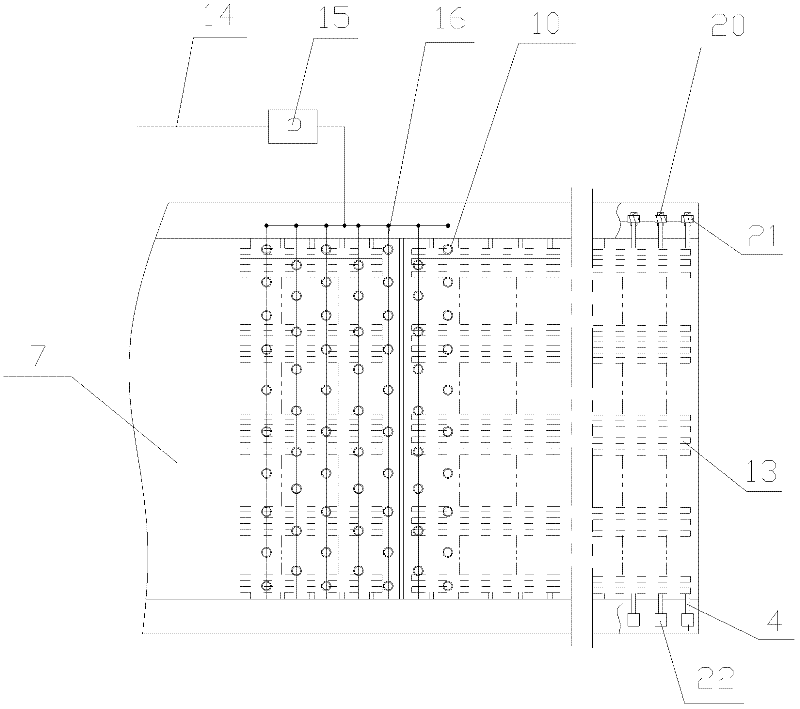

Quenching equipment for Al-Mg-Si system aluminum alloy cold drawn pipes, and quenching method thereof

InactiveCN102418056ADoes not affect normal operationAvoid drillingFurnace typesHeat treatment furnacesHeating furnaceFriction force

The invention discloses quenching equipment for Al-Mg-Si system aluminum alloy cold drawn pipes, and a quenching method employing the equipment. The equipment comprises a transmission system, and orderly connected components of a feeding stage, a horizontal heating furnace, a quenching system, and a discharging stage. The transmission system comprises a motor, a transmission mechanism and a carrier roller transmission chain. The carrier roller transmission chain sequentially penetrates the feeding stage, the horizontal heating furnace, the quenching system, and the discharging stage. Electric heating tubes are symmetrically arranged above and below the carrier roller transmission chain in the horizontal heating furnace. The electric heating tubes are arranged in parallel with carrier rollers. A loading zone, a heating zone, a quenching zone and a fetching zone of the aluminum pipes are positioned on a same horizontal straight line. The aluminum pipes are always in a moving state. With the friction forces between the aluminum pipes and the carrier rollers on the rotary carrier roller transmission chain, the aluminum pipes move forward. During the moving process, heating and quenching are completed, and the aluminum pipes are finally delivered to the fetching zone. Therefore, hole-drilling on the end of an aluminum pipe is avoided, and a purpose of continuous feeding and quenching can be realized. With the equipment and the method, the operations of loading and fetching are simple and convenient, and the energy consumption during a quenching process is low.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

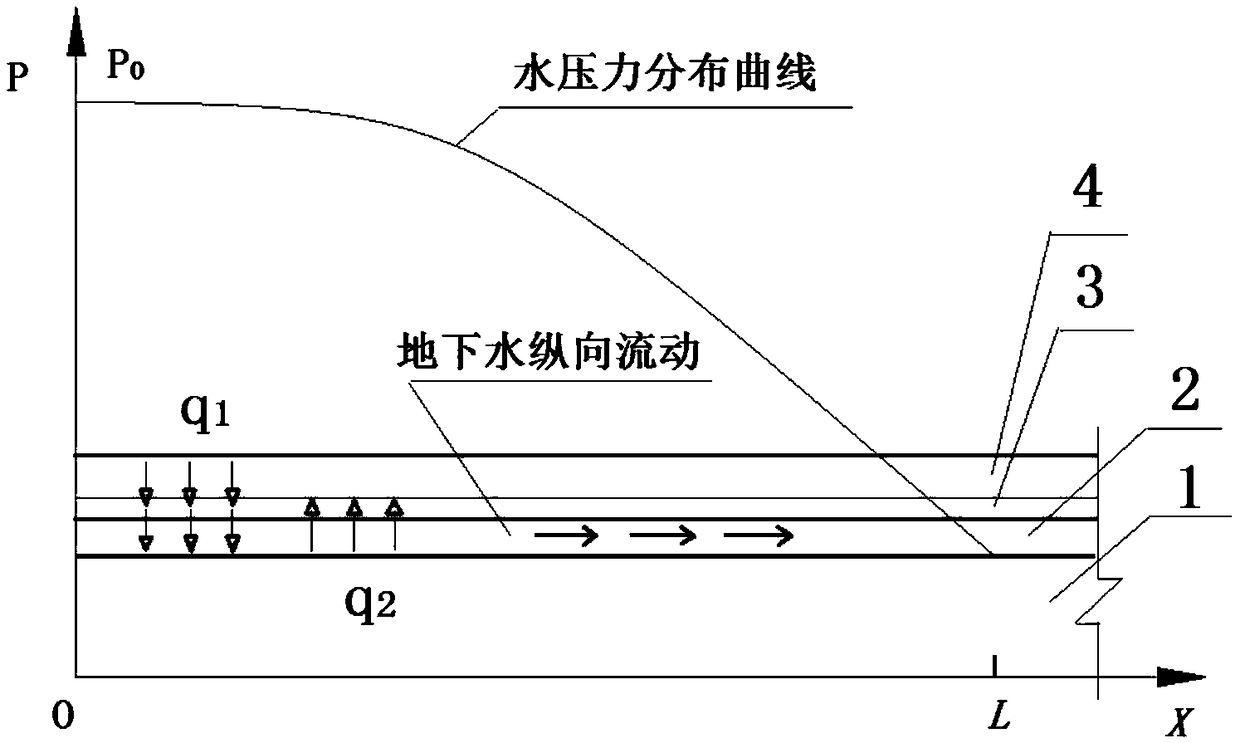

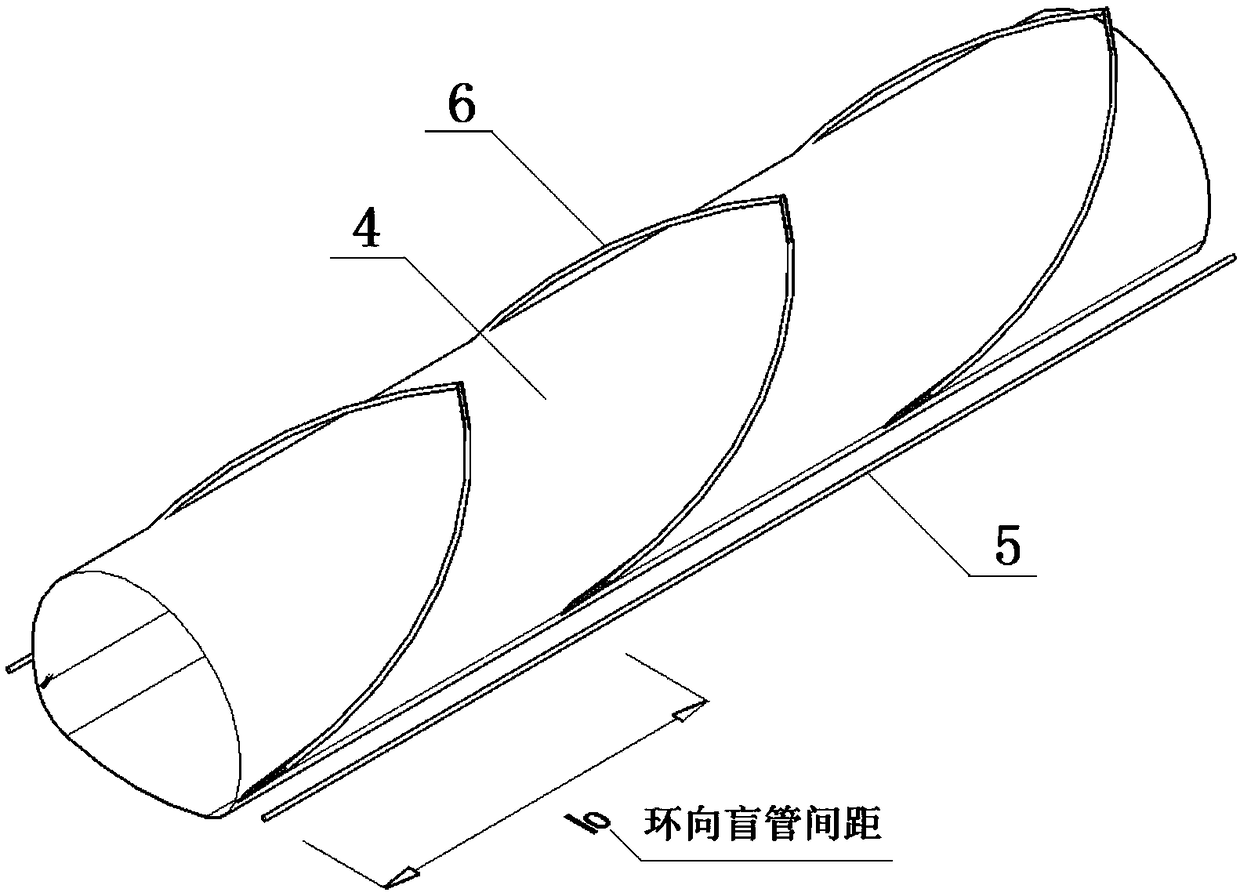

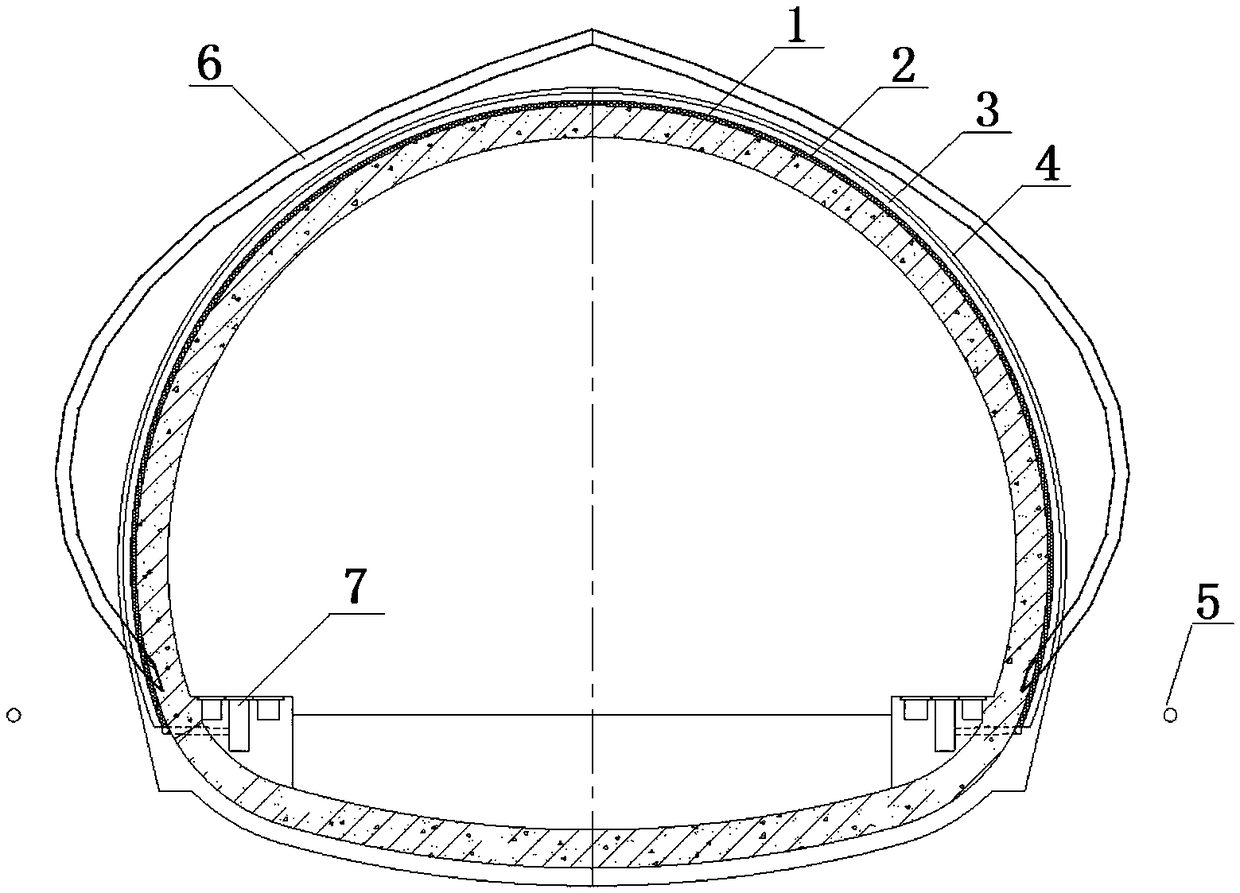

Tunnel drainage disease prevention processing method and system

ActiveCN109184754AEnsure safetyEnsure structural safetyUnderground chambersDrainageEngineeringHigh pressure

The invention discloses a tunnel drainage disease prevention processing method, which comprises the steps of obtaining the water pressure at each point on the outer surface of a secondary lining in ablocking section in consideration of the actual longitudinal flow of underground water along the space between an initial support and the secondary lining, determining the drainage amount of a circumferential blind pipe, further determining the diameter and spacing of a newly laid longitudinal blind pipe (5) and a newly laid circumferential blind pipe (6), and finally laying the newly laid longitudinal blind pipe (5) and the newly laid circumferential blind pipe (6) in surrounding rocks at the outer side of the initial support of the tunnel, and leading the underground water outside the tunnellining to a ditch at the inner side of the tunnel by using the blind pipes, thereby fundamentally reducing the external water pressure of the lining. The invention further discloses an existing tunnel drainage disease prevention processing system, which comprises an existing tunnel main body and a novel drainage system, wherein the novel drainage system includes a newly laid longitudinal blind pipe (5) and a newly laid circumferential blind pipe (6), thereby solving a problem that the lining bears high water pressure after the blockage caused by small diameter of the original drainage blind pipe and the aging of materials, and ensuring the structural safety of the tunnel.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com