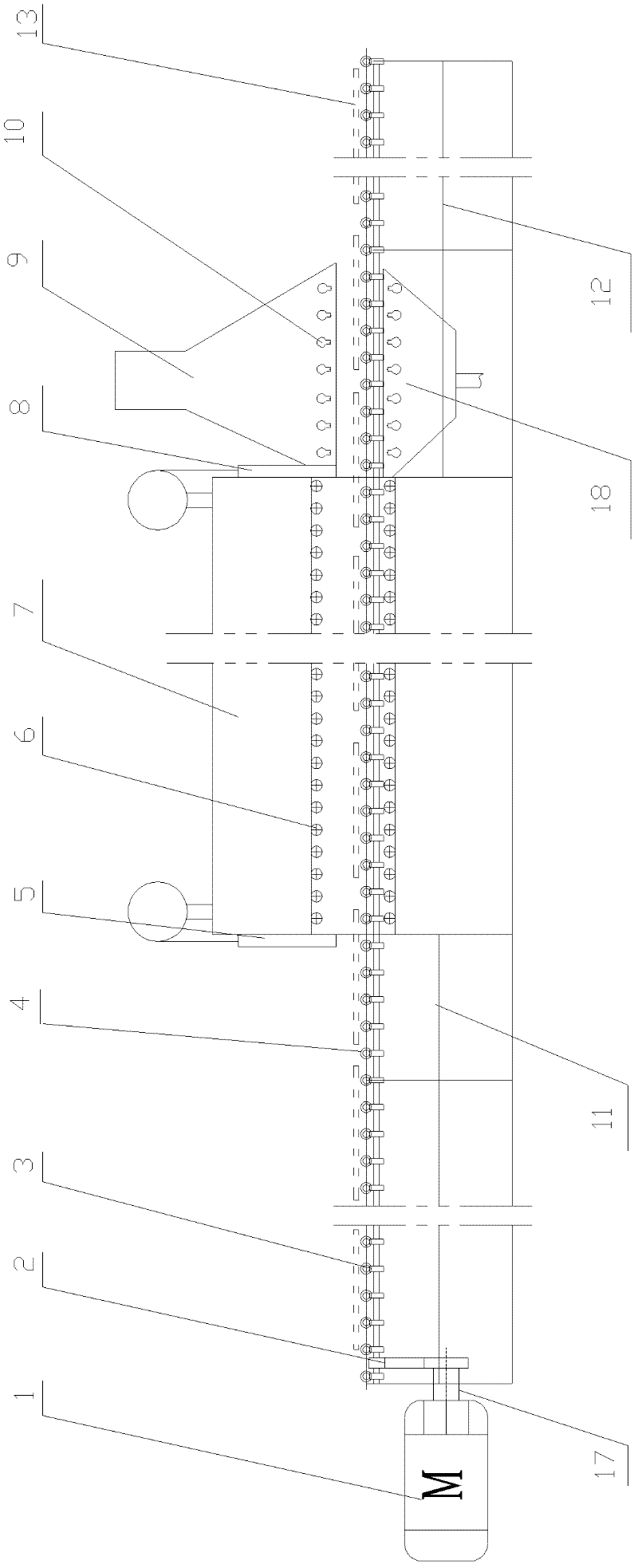

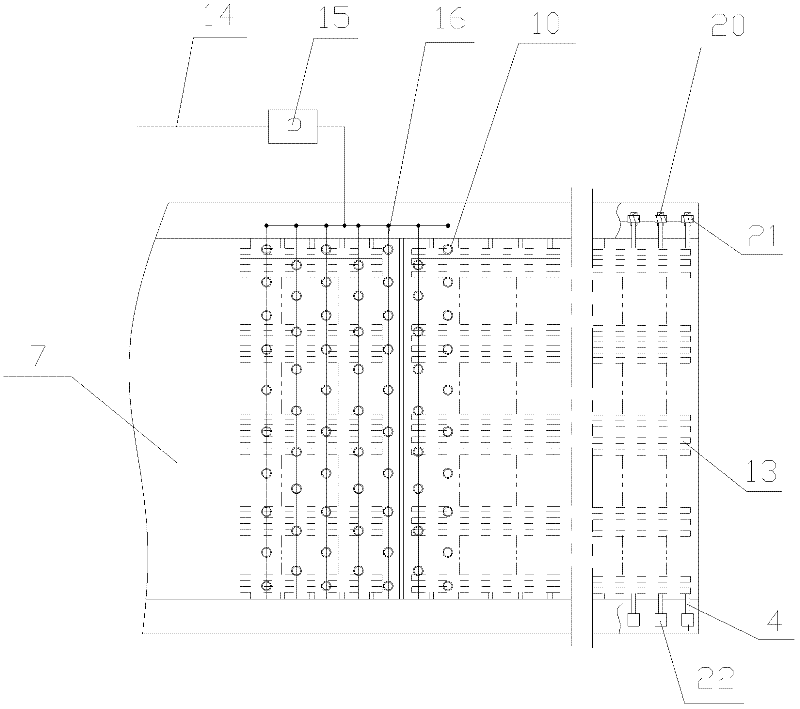

Quenching equipment for Al-Mg-Si system aluminum alloy cold drawn pipes, and quenching method thereof

A quenching equipment, aluminum alloy technology, applied in the direction of quenching device, heat treatment equipment, furnace type, etc., can solve the problems of inability to meet customer surface requirements, affecting production efficiency and yield, and large volume of vertical quenching furnaces to shorten production. effect of cycle, improved corrosion resistance, improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

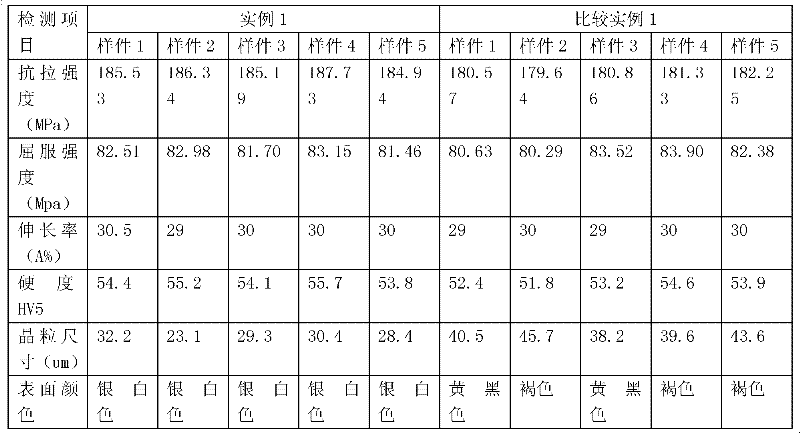

Embodiment 1

[0034] The drawn pipe of material 6063 and specification φ12*1.5*1000 is quenched by the quenching method of the present invention,

[0035] Heat treatment parameters: set temperature 520°C, heating time 12.3 minutes.

[0036] Sampling Quantity: 5

Embodiment 2

[0044] Quenching the drawn pipe with material 6061 and specification φ20*1.8*1000 using the quenching method of the present invention;

[0045] Heat treatment parameters: heating temperature 535°C, heating time 15.6 minutes.

[0046] Sampling Quantity: 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com